Vehicle-mounted DPF on-line regeneration system and control method

A regeneration system and DPF technology, which is applied to the electronic control of exhaust treatment devices, exhaust treatment, mechanical equipment, etc., can solve the problems of large space occupation and inability to realize full-flow online regeneration, so as to inhibit pyrolysis and prolong retention Time, the effect of improving the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

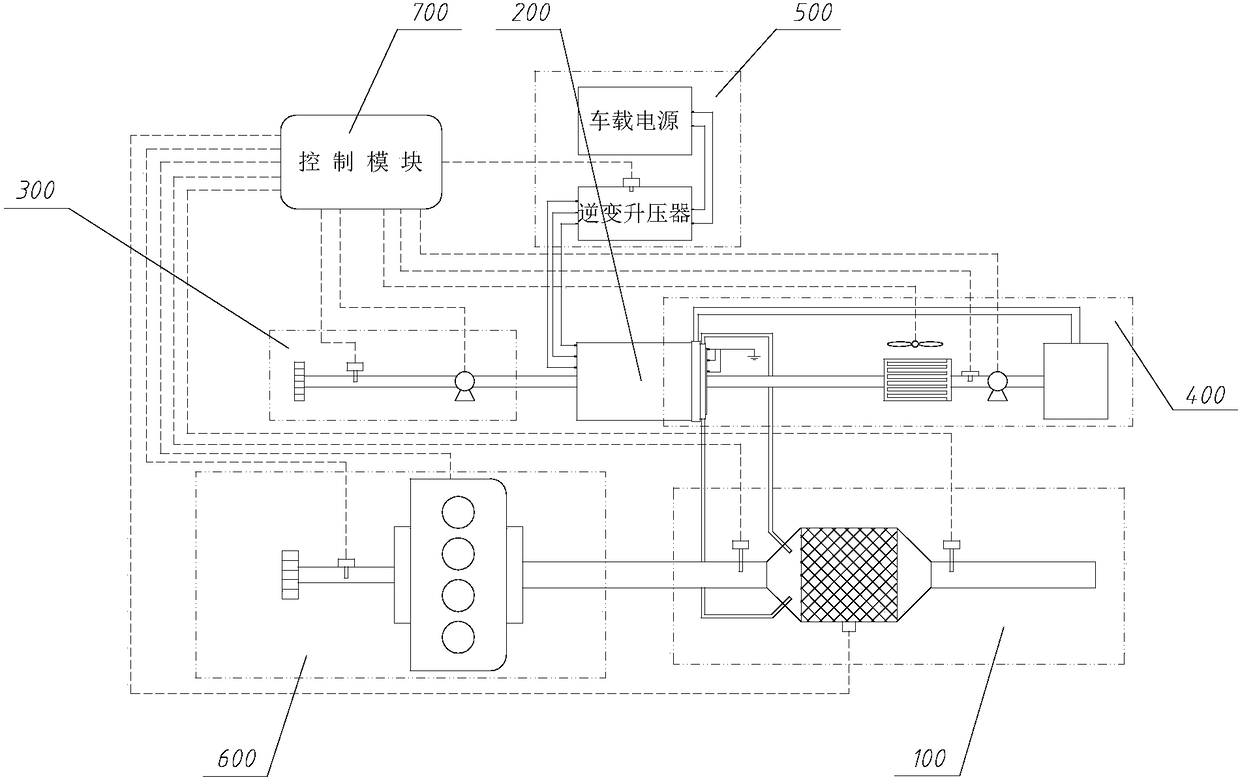

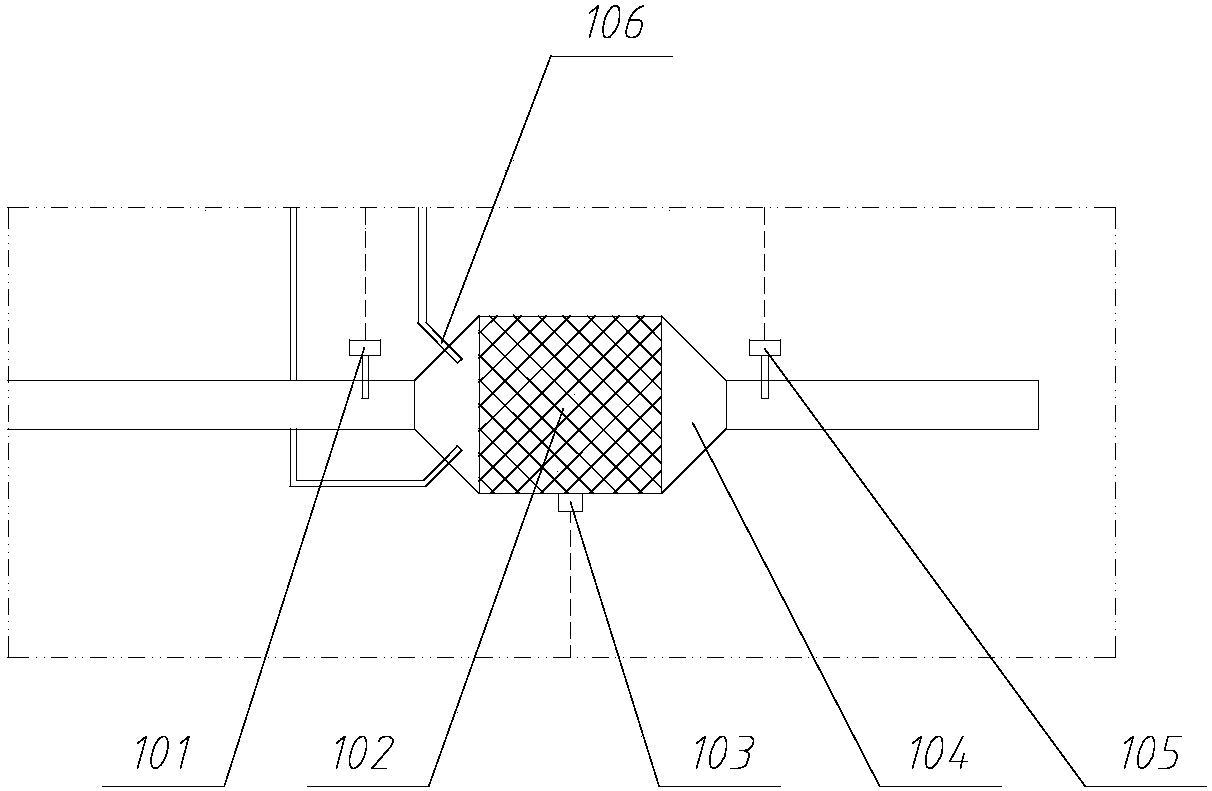

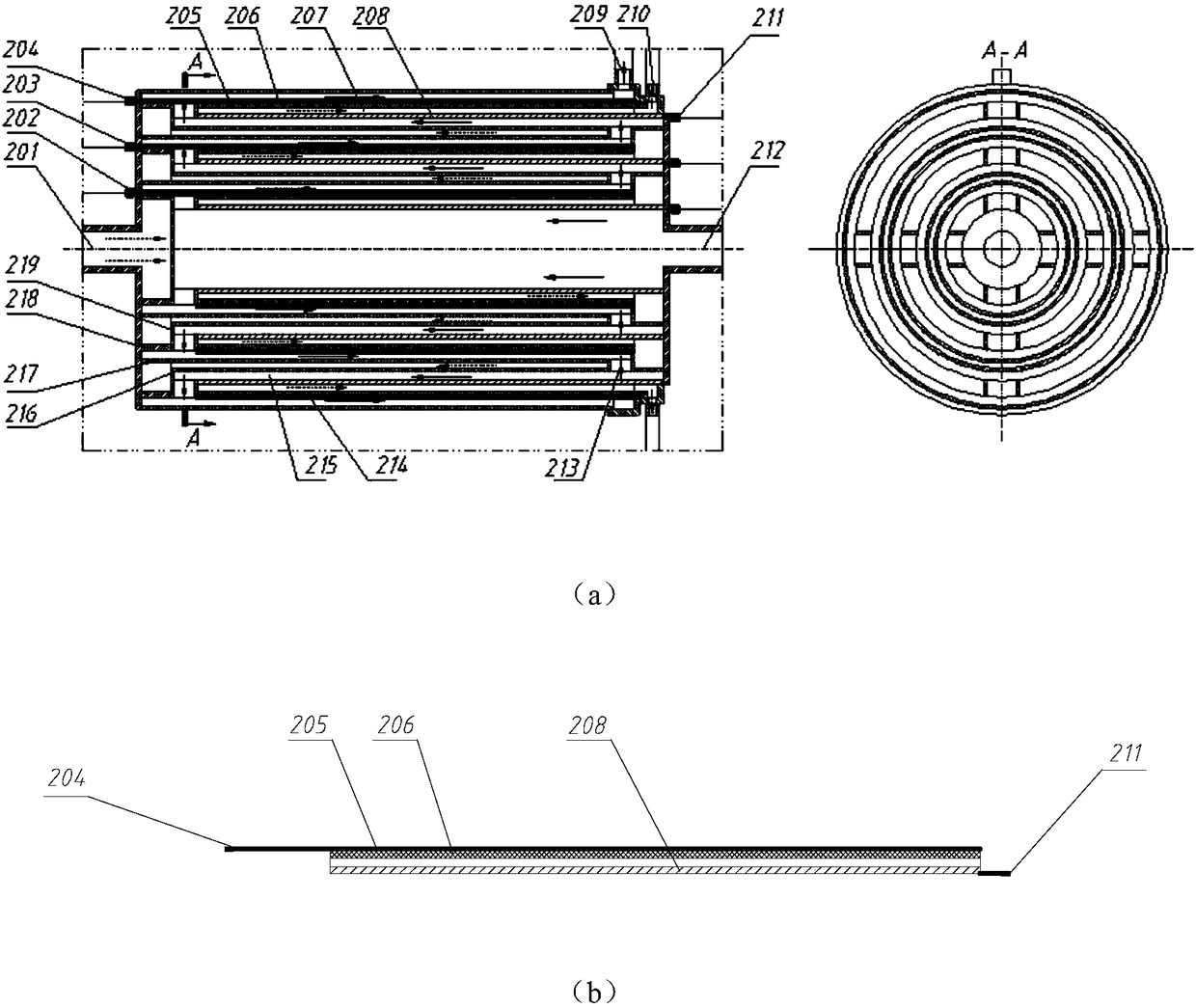

[0047] Such as figure 1 As shown, the vehicle-mounted DPF regeneration system of the present invention includes: an aftertreatment system 100 , an NTP generation system 200 , an air intake system 300 , a cooling system 400 , a power supply device 500 , a diesel engine system 600 and a control module 700 . The aftertreatment system 100 is connected to the diesel engine system 600 through the diesel engine exhaust pipe 604 , and the NTP generation system 200 provides NTP active substances to the aftertreatment system 100 through the NTP nozzle 106 . The intake system 300 supplies reactant gas to the NTP generation system 200 through the intake pipe 304 , and the cooling system 400 provides cooling water to the NTP generation system 200 through the cooling water pipe 404 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com