Membrane distillation concentration method for hydrogen peroxide solution

A hydrogen peroxide solution, membrane distillation technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of large product loss , The equipment is large in size and the operating cost is high, so as to achieve the effect of simple process, avoiding high temperature decomposition and avoiding decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

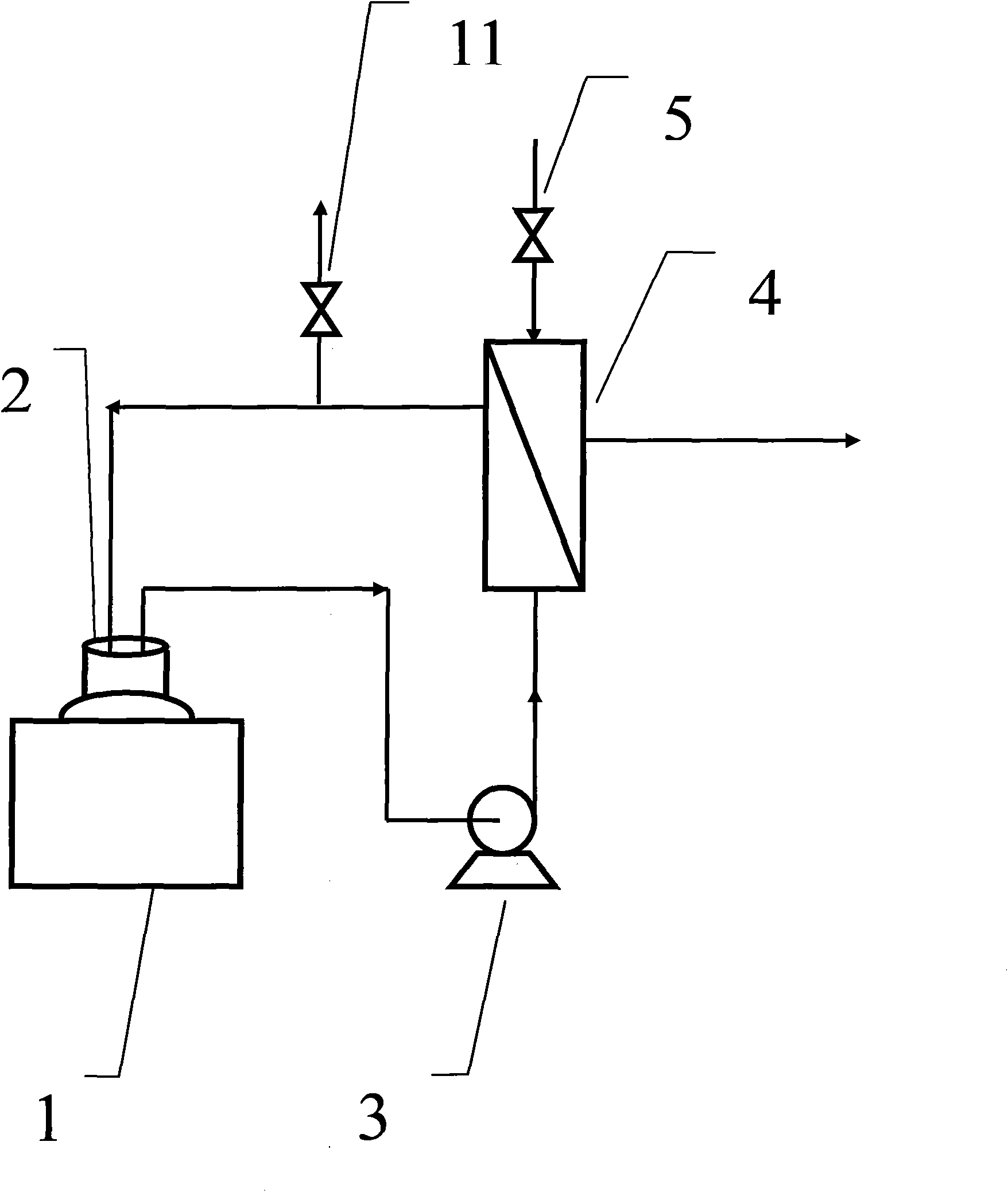

[0026] The flat-plate membrane distillation component is selected, and the membrane distillation is realized in the form of direct contact, and the device is as attached figure 1 , using a hydrophobic polyvinylidene fluoride microporous membrane. The raw material liquid is 20.05wt.% hydrogen peroxide solution, and the cold fluid is tap water at 0-3°C.

[0027] Add 250ml of this hydrogen peroxide solution into the raw material tank 2 as a raw material solution, heat it to a constant temperature of about 30°C by the heat source 1, turn on the raw material pump 3, and open the valve 5 to introduce cooled tap water on the permeation side of the membrane module 4, and the constant temperature raw material solution It is pumped into the raw material side of the membrane module 4 through the raw material pump 3 . The raw material liquid flows through the flat membrane module at a flow rate of 20L / h, and the water and a small amount of hydrogen peroxide in it pass through the membran...

Embodiment 2

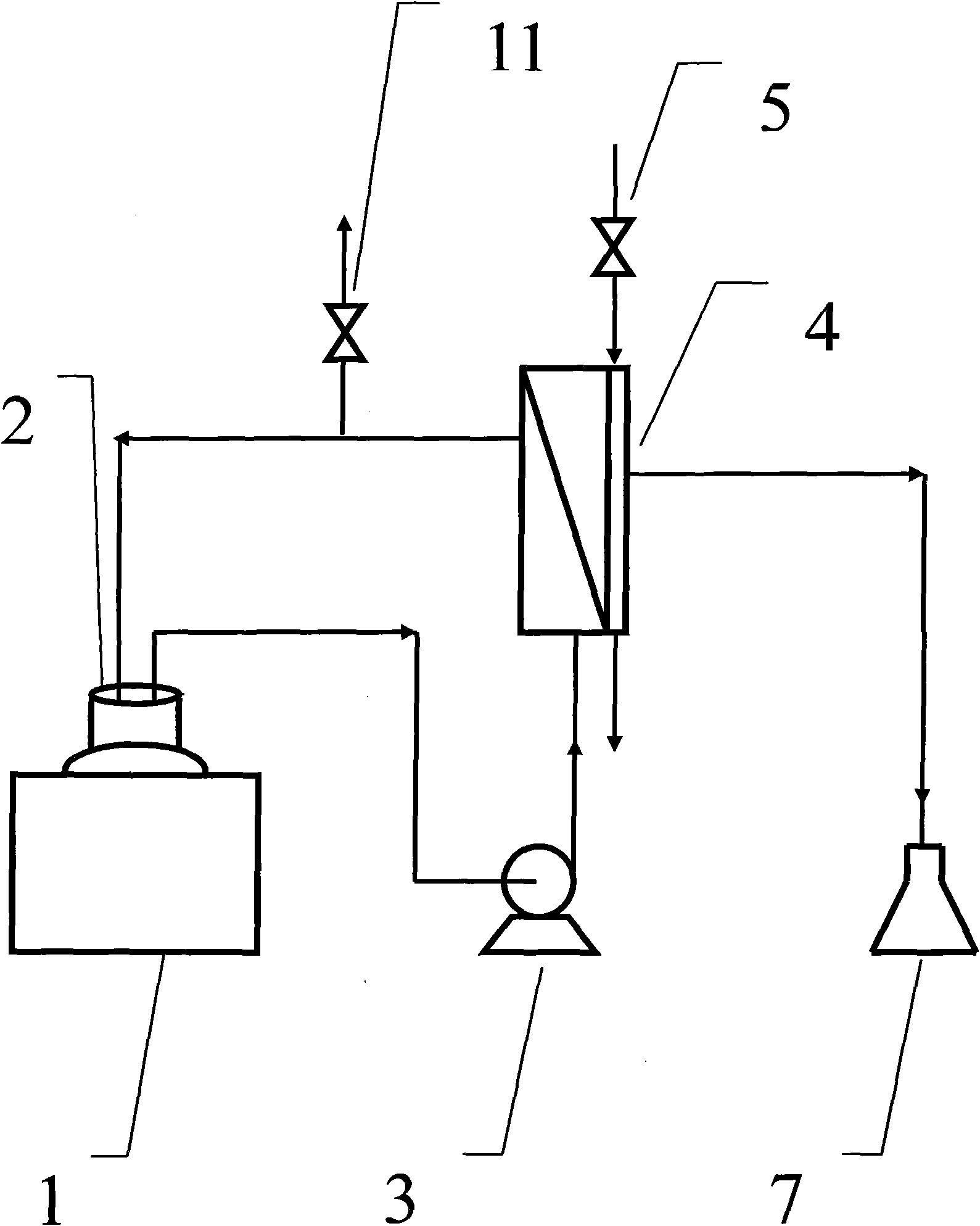

[0030] The flat-plate membrane distillation component is selected, and the membrane distillation is realized in the air-gap type, and the device is as attached figure 2 , using hydrophobic polytetrafluoroethylene microporous membrane. The raw material liquid is 20.05wt.% hydrogen peroxide solution, and the temperature of the cooling plate is obtained by cooling an aqueous solution of ethylene glycol at -5 to -1°C.

[0031]Add 250ml of the hydrogen peroxide solution as a raw material solution into the raw material tank 2, heat it to a constant temperature of about 40°C by the heat source 1, open the valve 5 and let the cooled ethylene glycol aqueous solution lower the temperature of the cooling plate in the membrane module 4, and open Raw material pump 3, the constant temperature raw material solution is pumped into the raw material side of the membrane module 4 through the raw material pump 3. The raw material liquid flows through the flat membrane module at a flow rate of 2...

Embodiment 3

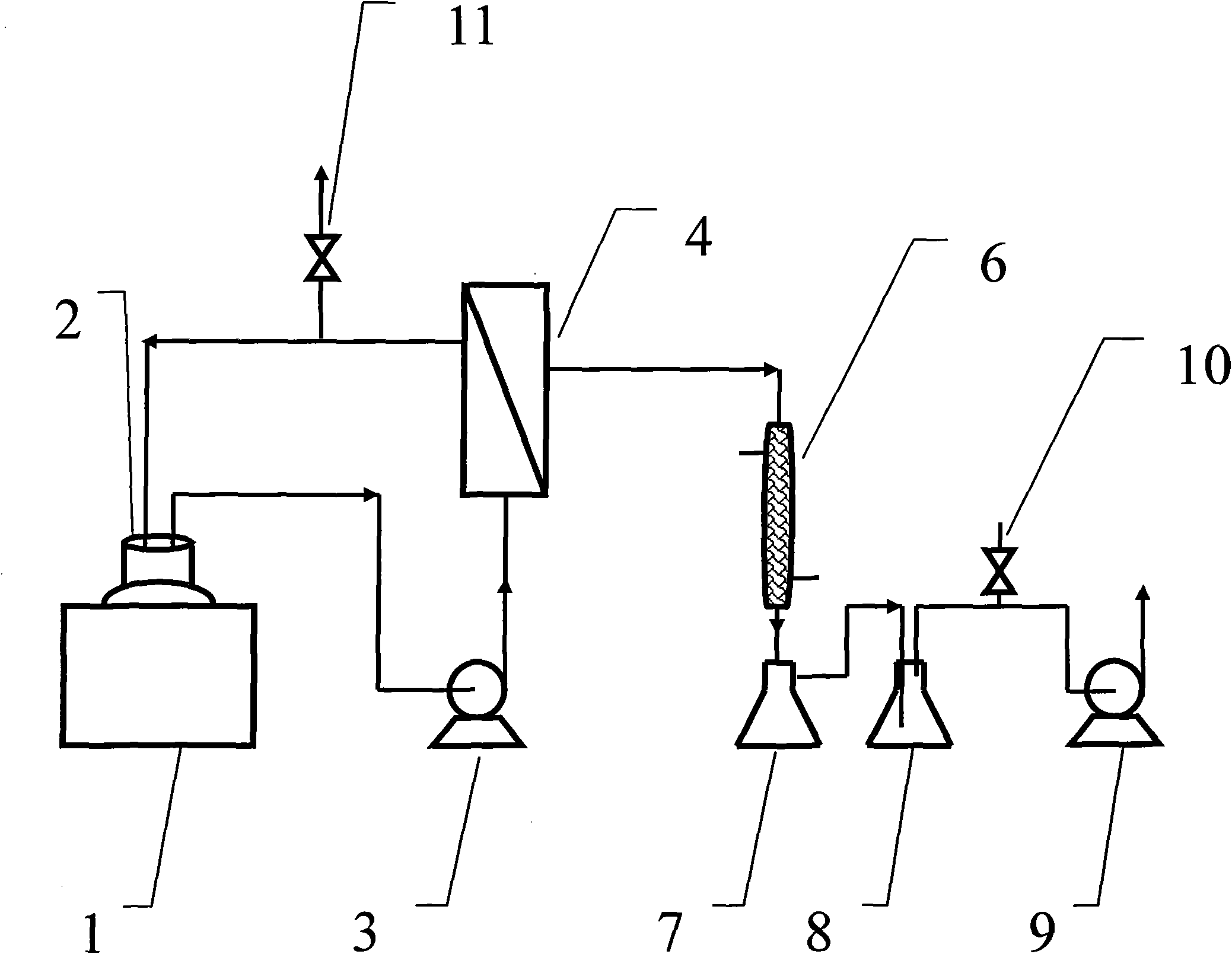

[0034] The flat-plate membrane distillation component is selected, and the membrane distillation is realized in the form of vacuum, and the device is as attached image 3 , using hydrophobic polypropylene microporous membrane. The raw material liquid is 29.95wt.% hydrogen peroxide solution, and the cooling liquid circulating in the condensing system is an aqueous solution of ethylene glycol at -5 to -1°C.

[0035] Add 250ml of the hydrogen peroxide solution as a raw material solution into the raw material tank 2, heat it from the heat source 1 to a constant temperature of about 50°C, turn on the raw material pump 3, the condensing system 6 and the vacuum pump 9 successively, and the constant temperature raw material solution enters the membrane through the raw material pump 3 Component 4 raw side. The raw material liquid flows through the flat membrane module at a flow rate of 20L / h, and the water and a small amount of hydrogen peroxide in it pass through the membrane pores t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com