Carbon dioxide subcritical extraction, recycling and reusing method for electrolyte of waste lithium ion battery

A lithium-ion battery, carbon dioxide technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of separation, secondary pollution of solvents, etc., to avoid pollution, high resource utilization, and conducive to large-scale applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

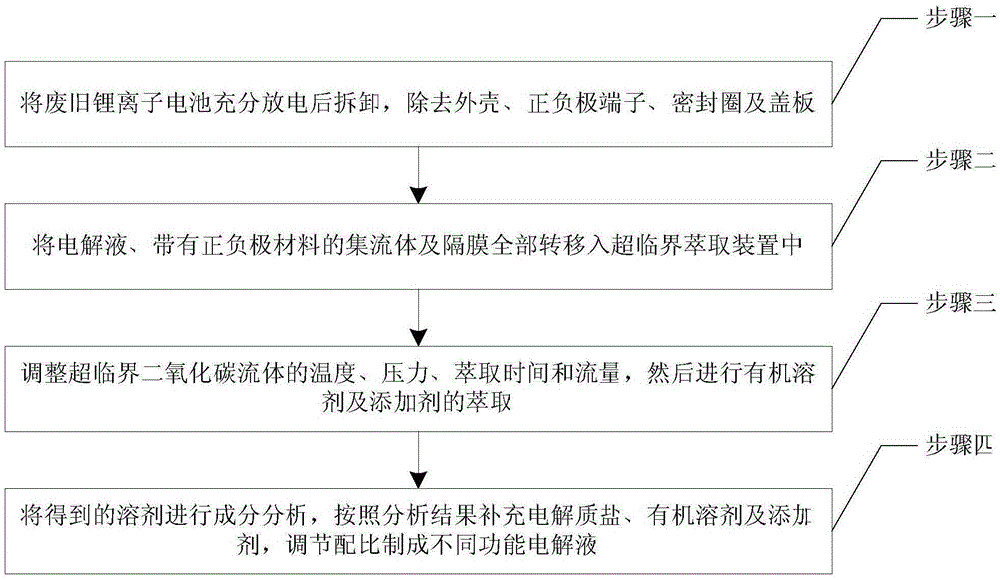

[0014] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, the carbon dioxide subcritical extraction recycling method of the waste lithium-ion battery electrolyte described in this specific embodiment is realized by the following steps:

[0015] Step 1. Disassemble the used lithium-ion battery after fully discharging, and remove the shell, positive and negative terminals, sealing ring and cover plate;

[0016] Step 2. Transfer the electrolyte, current collectors with positive and negative materials, and diaphragms into a supercritical extraction device;

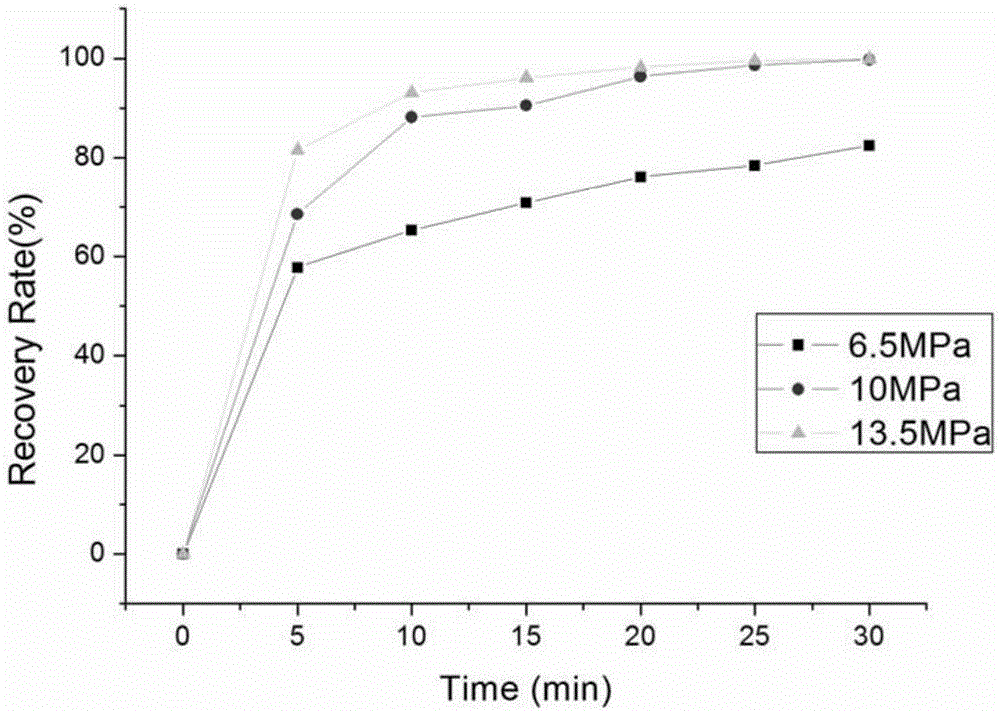

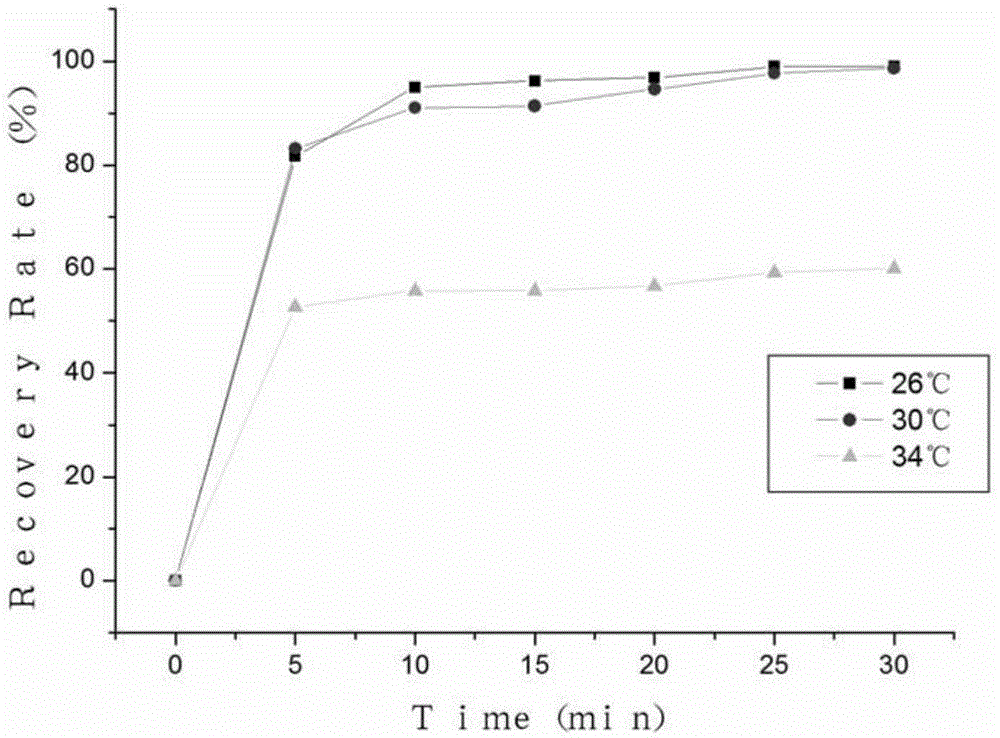

[0017] Step 3, adjusting the temperature, pressure, extraction time and flow rate of the supercritical carbon dioxide fluid, and then extracting the organic solvent and additives;

[0018] Step 4: Analyze the components of the obtained solvent, supplement electrolyte salt, organic solvent and additives according to the analysis results, and adjust the ratio to prepare electrolytes with dif...

specific Embodiment approach 2

[0020] Embodiment 2. The difference between this embodiment and the carbon dioxide subcritical extraction and recycling method of a waste lithium-ion battery electrolyte described in Embodiment 1 is that the waste lithium-ion battery described in step 1 is a buckle One or a combination of formula batteries, cylindrical batteries, square batteries or power batteries.

specific Embodiment approach 3

[0021] Embodiment 3. The difference between this embodiment and the carbon dioxide subcritical extraction and recycling method of a waste lithium-ion battery electrolyte described in Embodiment 1 is that the waste lithium-ion battery described in step 1 is fully The discharge method is one or a combination of liquid nitrogen freezing method, graphite powder short circuit method or charging and discharging motor discharge method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com