Patents

Literature

36results about How to "Mild operating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

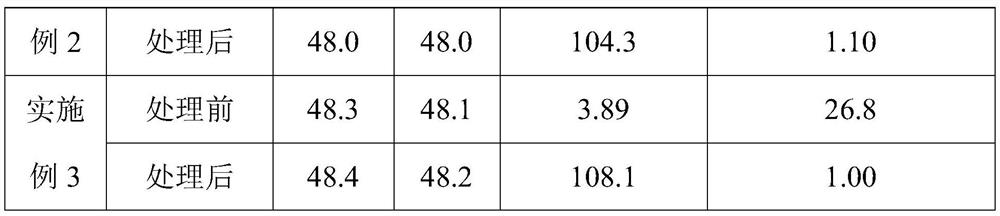

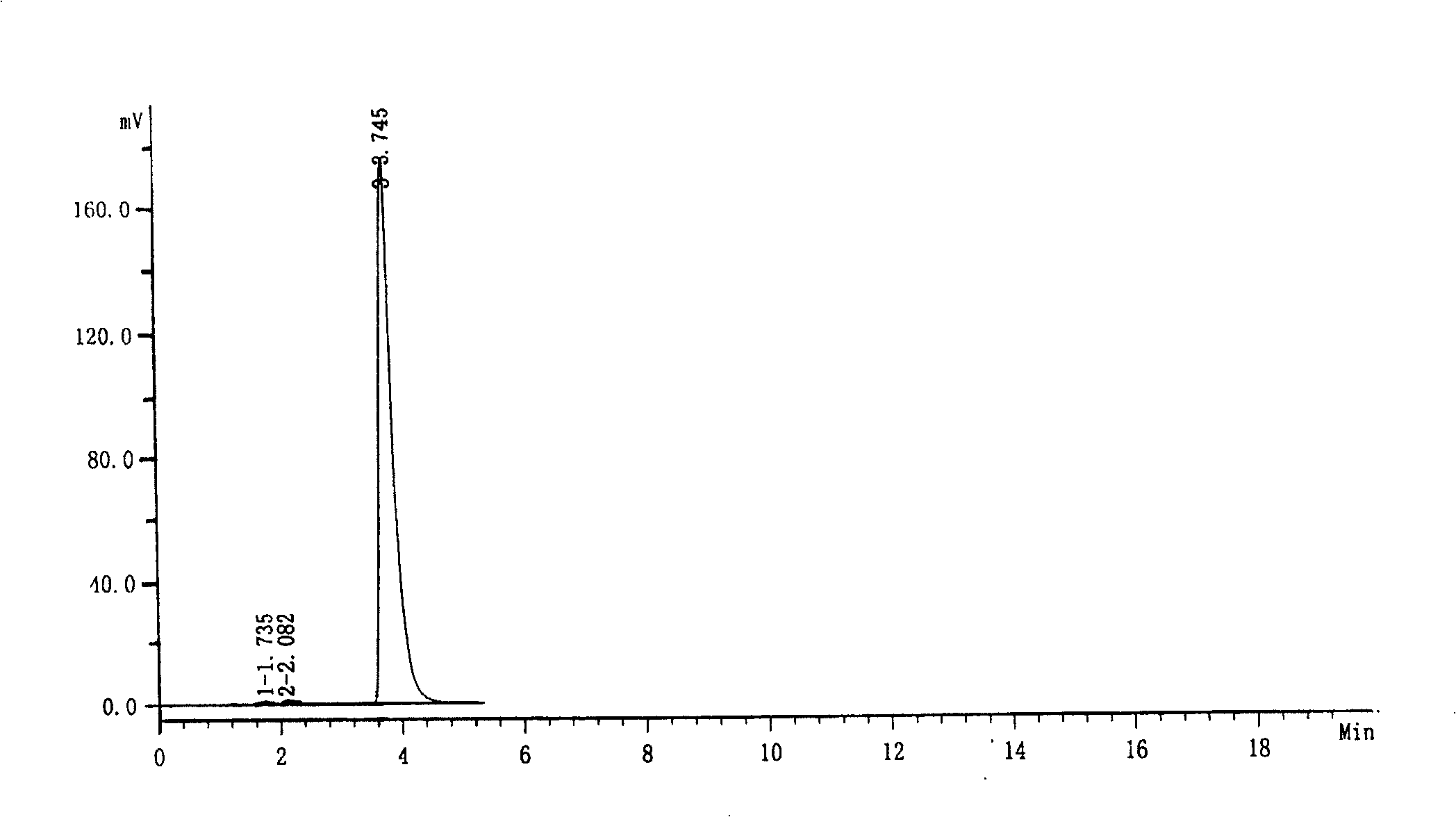

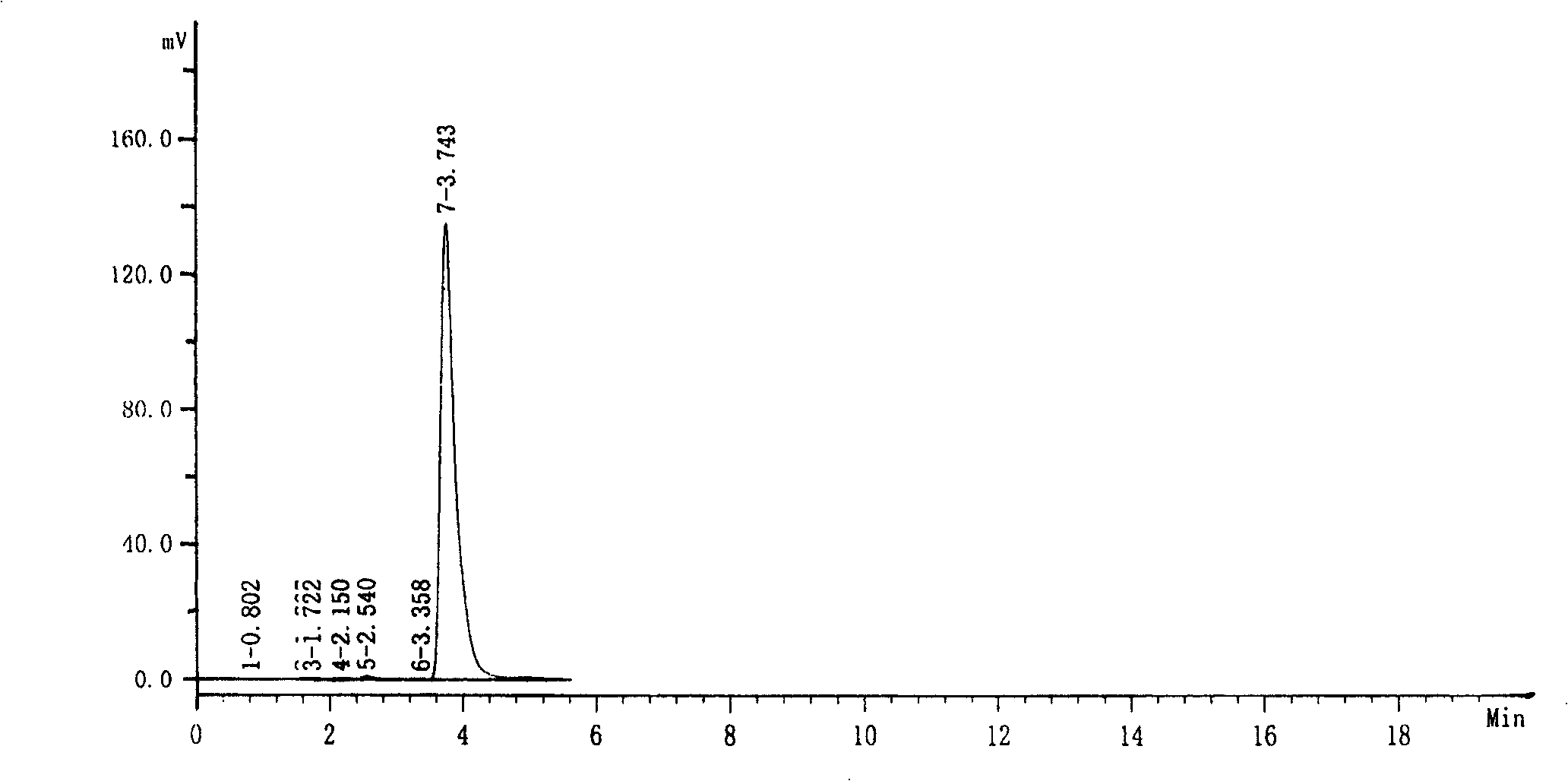

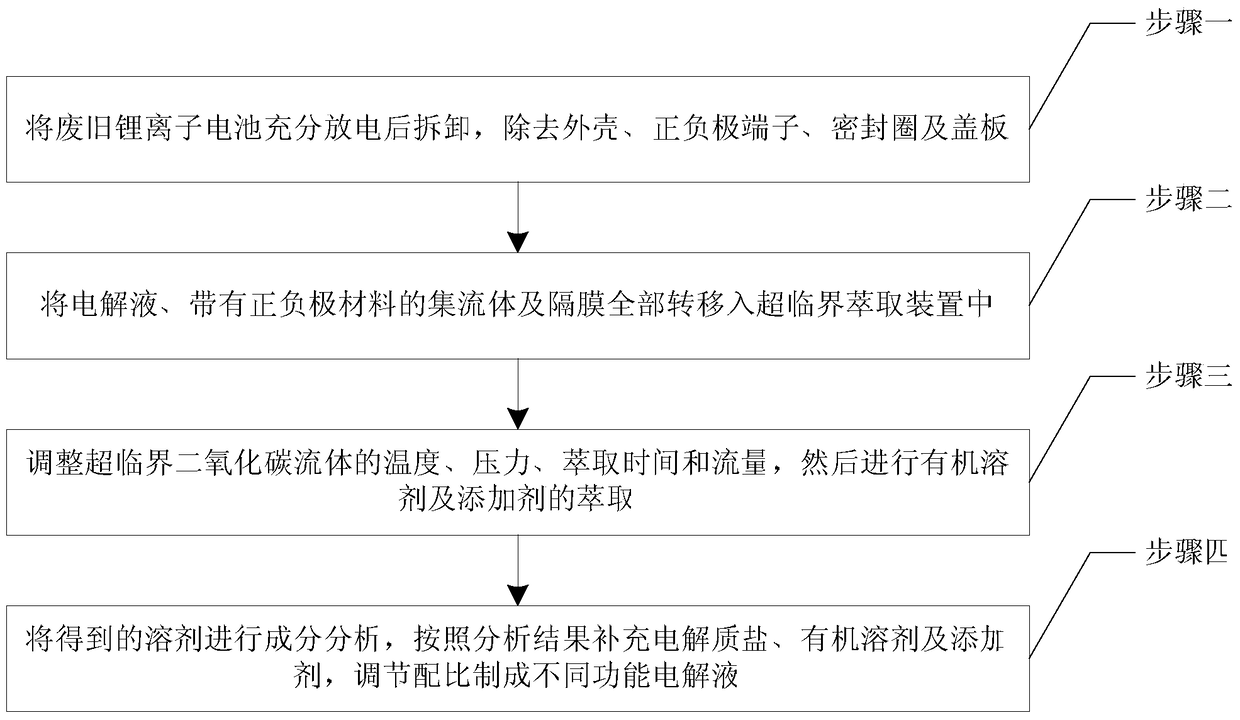

Carbon dioxide subcritical extraction, recycling and reusing method for electrolyte of waste lithium ion battery

ActiveCN105406146AAvoid pollutionAvoid degradationWaste accumulators reclaimingBattery recyclingOrganic solventResource utilization

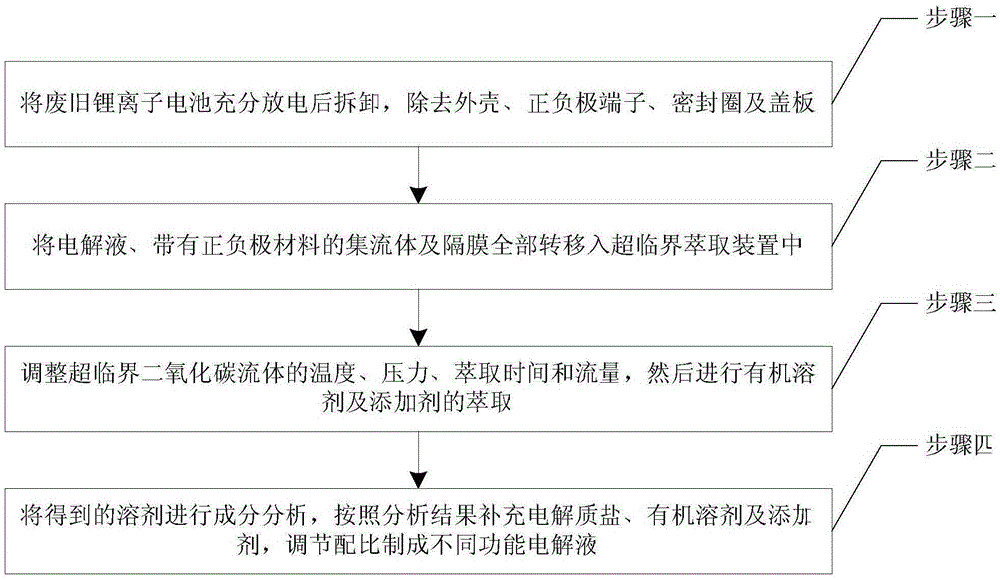

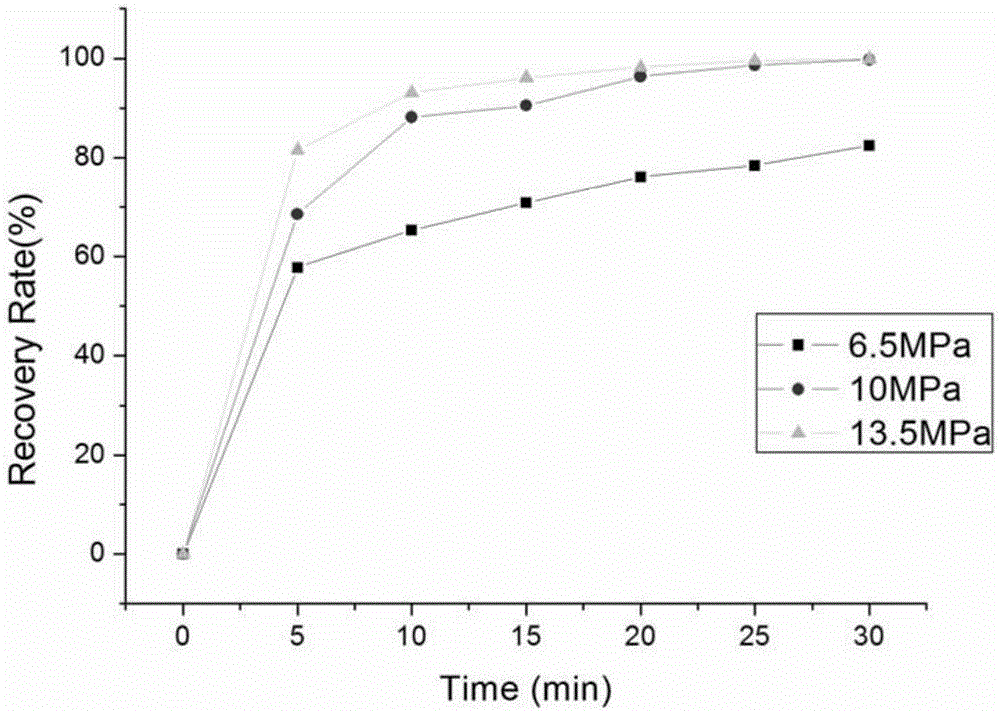

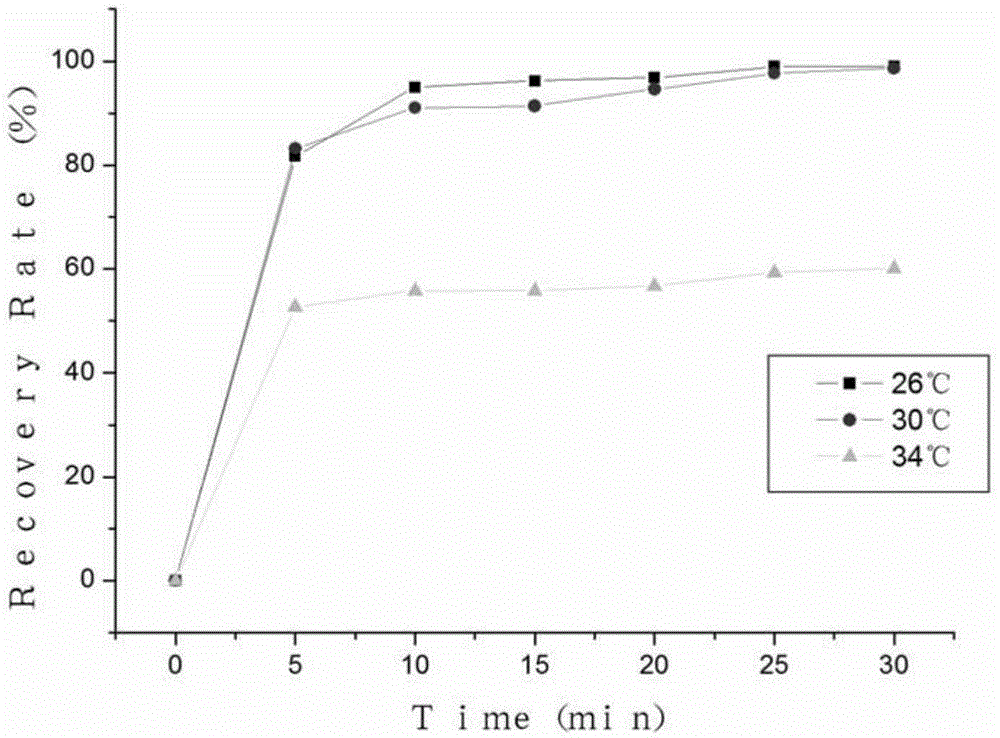

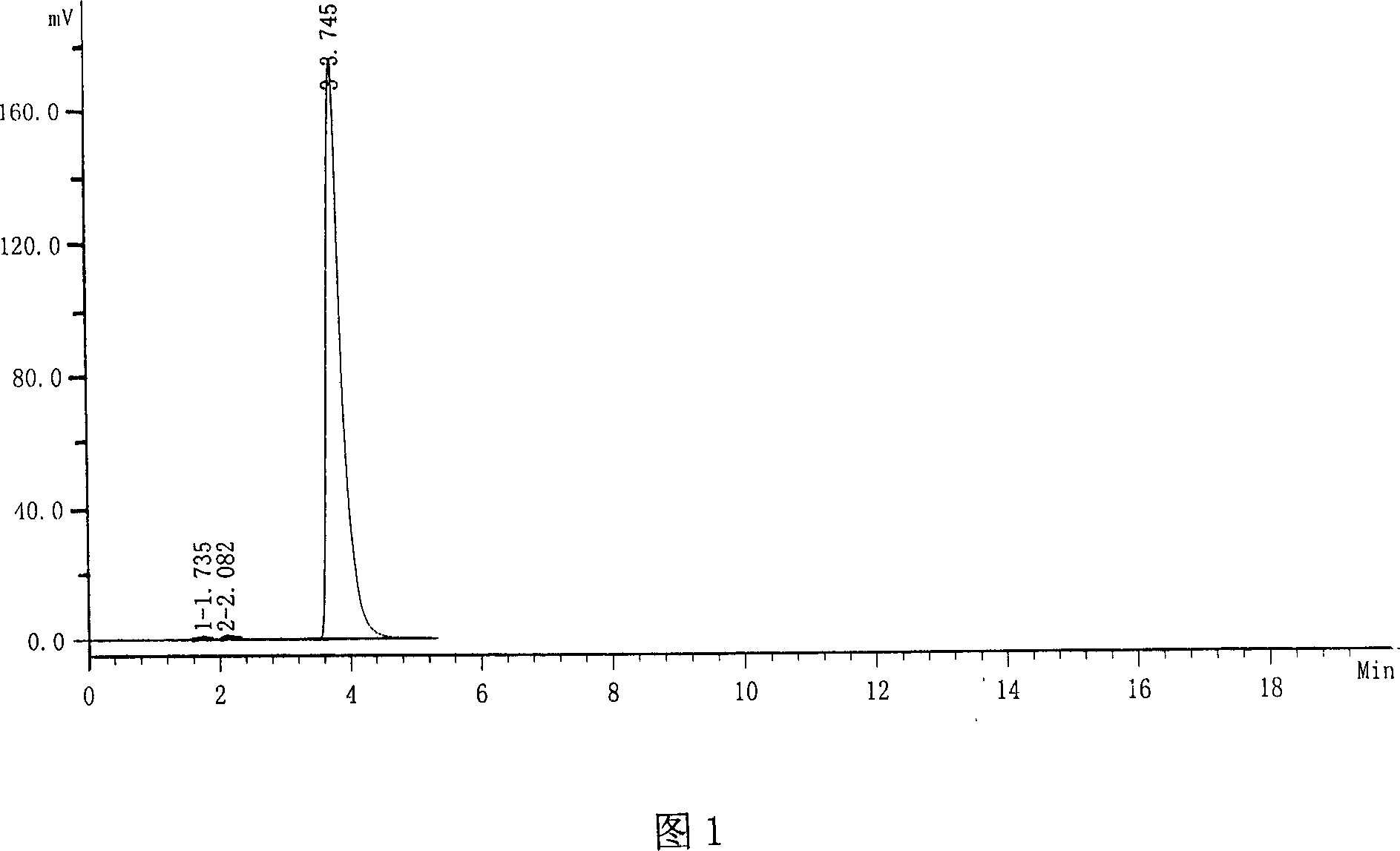

The invention provides a carbon dioxide subcritical extraction, recycling and reusing method for the electrolyte of a waste lithium ion battery, belonging to the field of recycling and reusing of solid waste. The method comprises the following steps: after complete discharging of the waste lithium ion battery, dismounting the waste lithium ion battery and removing a shell, positive and negative terminals, sealing rings and cover plates; transferring the electrolyte, current collectors with positive and negative electrode materials and a diaphragm into a supercritical extraction apparatus; adjusting the temperature, pressure, extraction time and flow of a supercritical carbon dioxide fluid and extracting an organic solvent and an additive; and subjecting the obtained solvent to component analysis, supplementing electrolyte salt, the organic solvent and the additive according to analysis results and adjusting a ratio to prepare electrolytes with different functions. The method effectively prevents degradation and dissipation of heat-sensitive substances; operation parameters are easy to control; extraction, separation and recovery are integrated together; later complicated treating procedures are omitted; and the utilization rate of resources is higher.

Owner:HARBIN INST OF TECH

Technology of extracting adenosin phosphoric acid from date

InactiveCN1948329AImprove extraction efficiencyStable in natureSugar derivativesSugar derivatives preparationAlcoholIon exchange

The present invention relates to a technological process for extracting cyclophosphoadenosine from jujube. Said technological process includes the following steps: breaking, soaking, filtering soaking liquor, using ultrasonic technique to extract filter residue, combining extracts to obtain clear jujube juice; making the clear jujube juice be passed through ion exchange column, then making the eluent be again passed through ion exchange column, making the obtained secondary eluent be passed through chromatographic column, collecting solution containing cyclophosphoadenosine concentrating and crystallizing in ethyl alcohol so as to obtain high-purity cyclophosphoadenosine.

Owner:常月梅

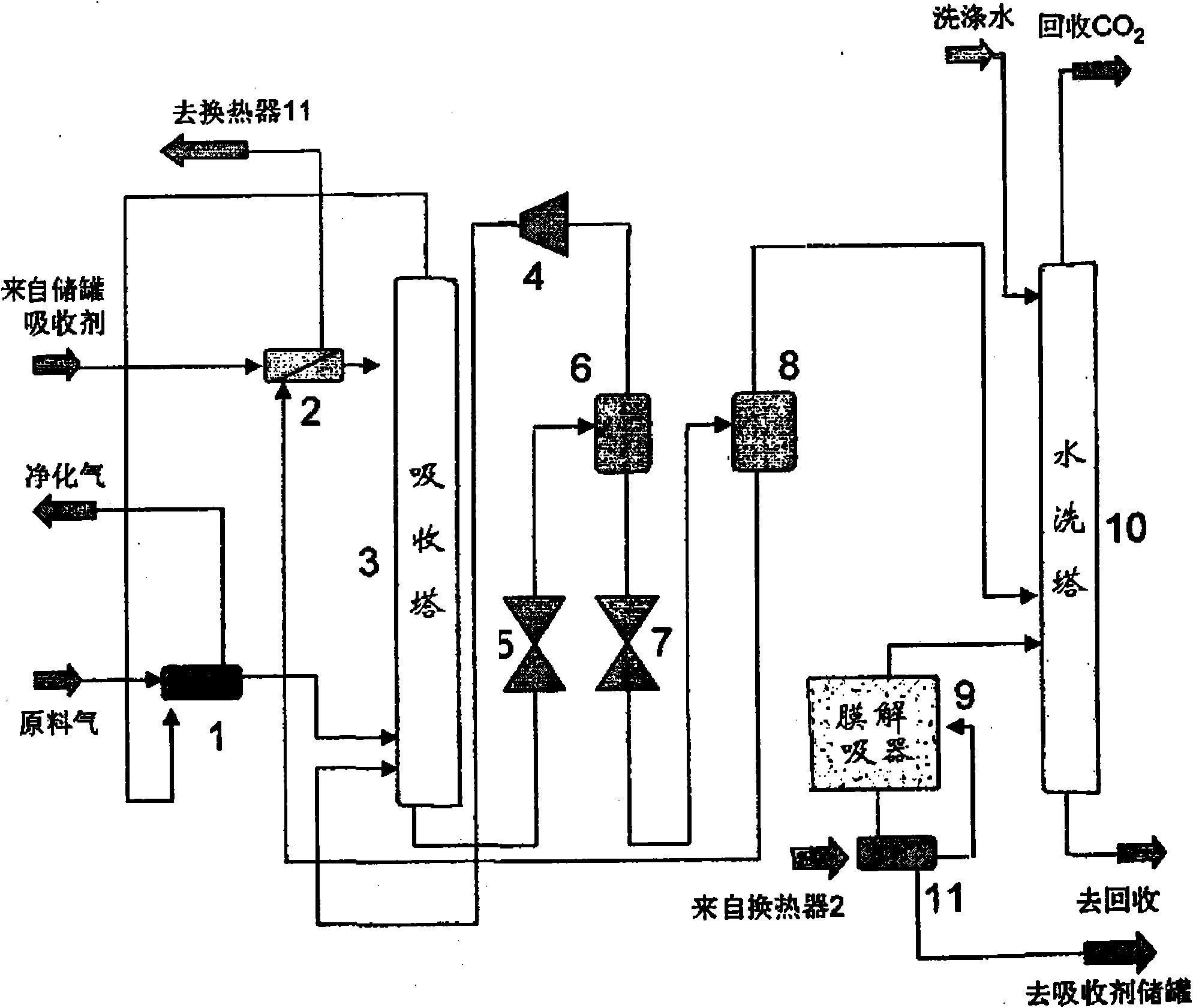

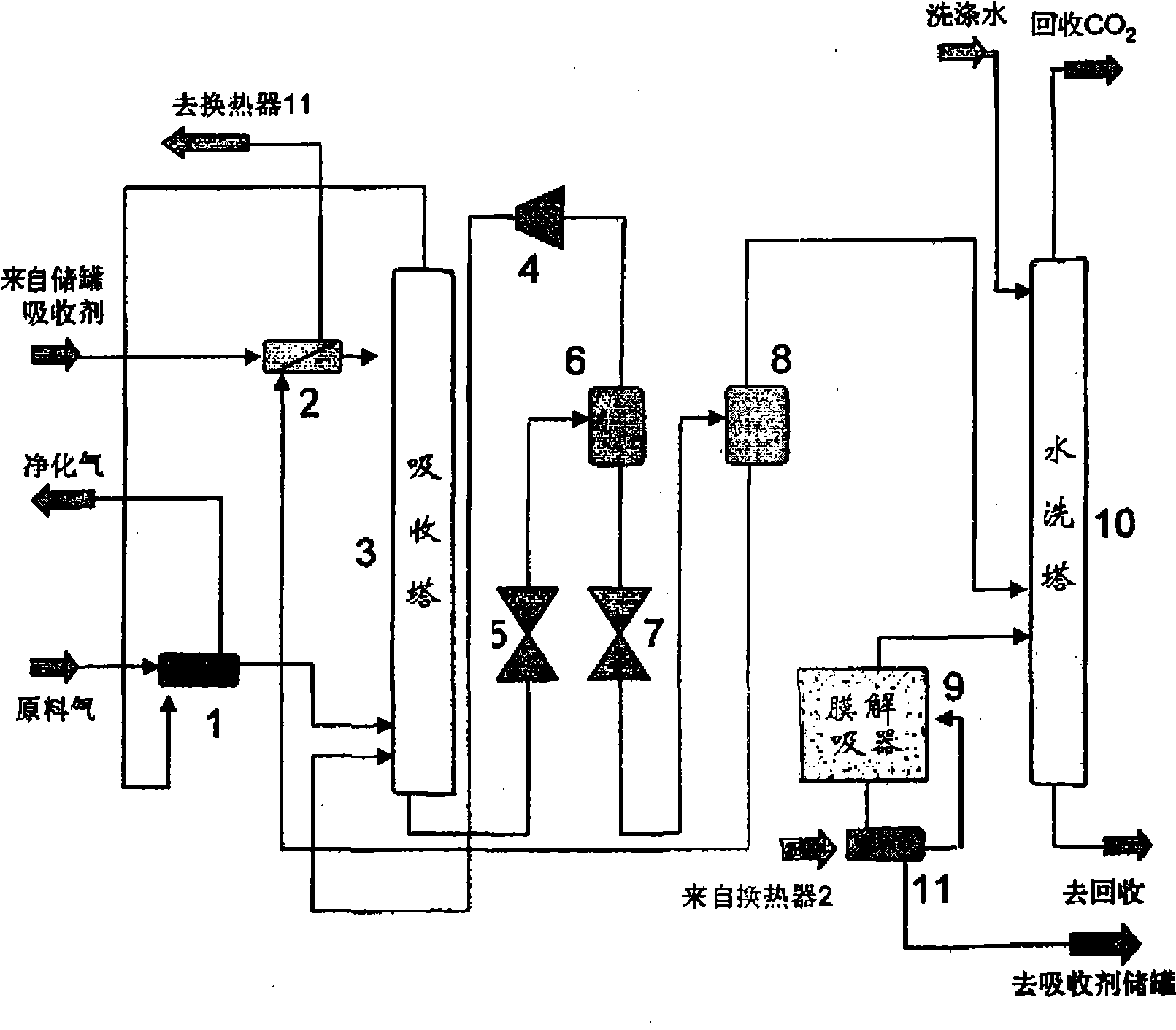

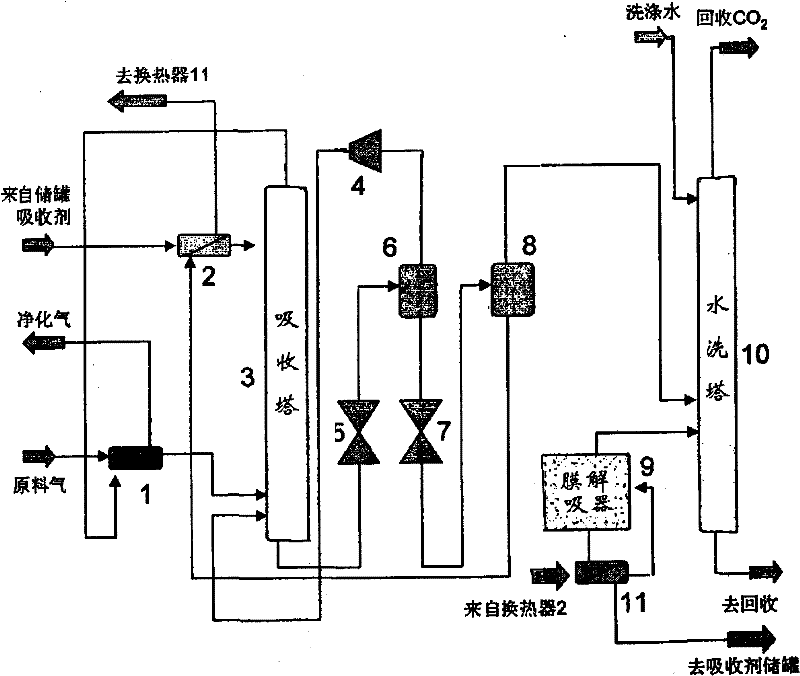

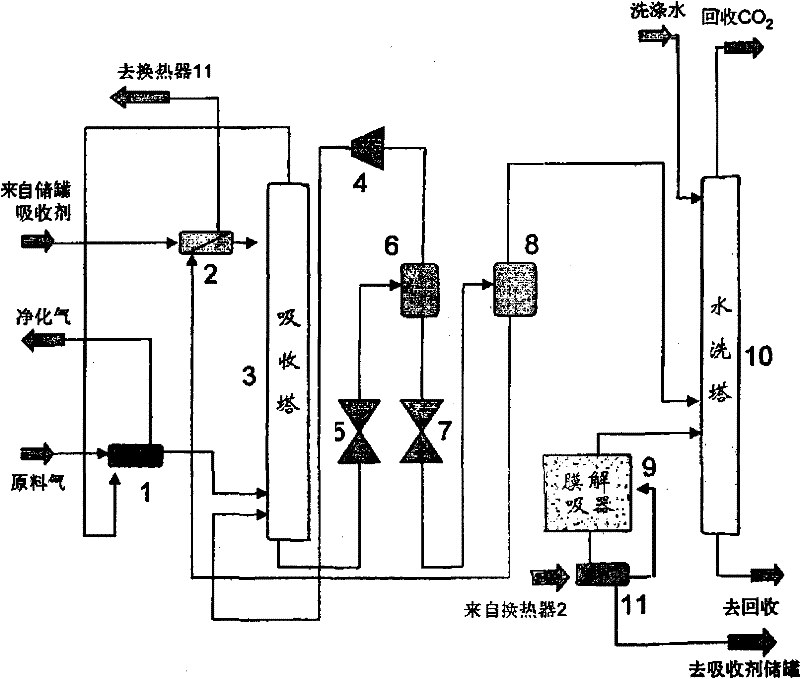

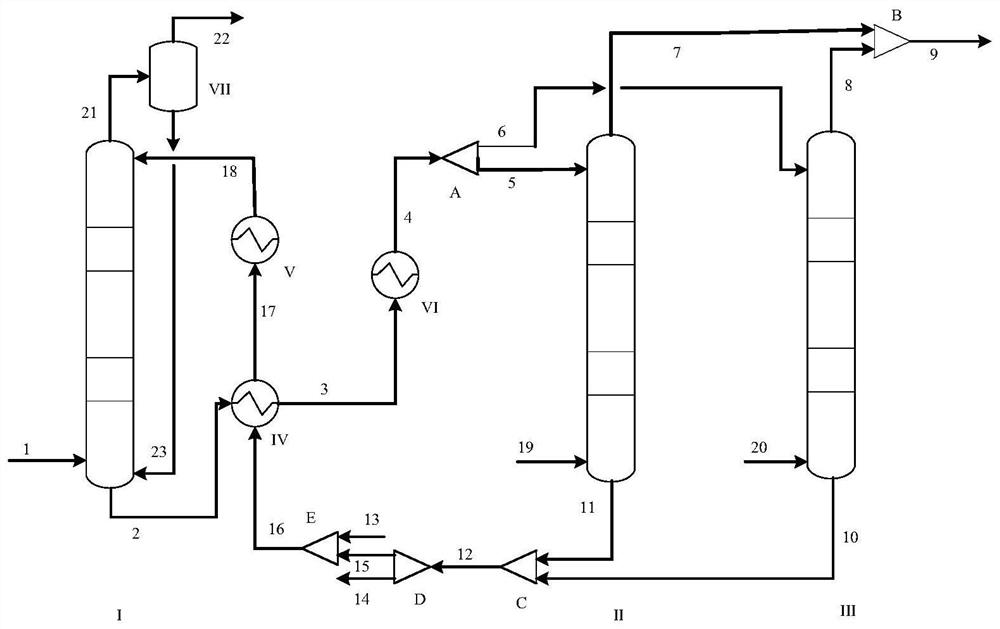

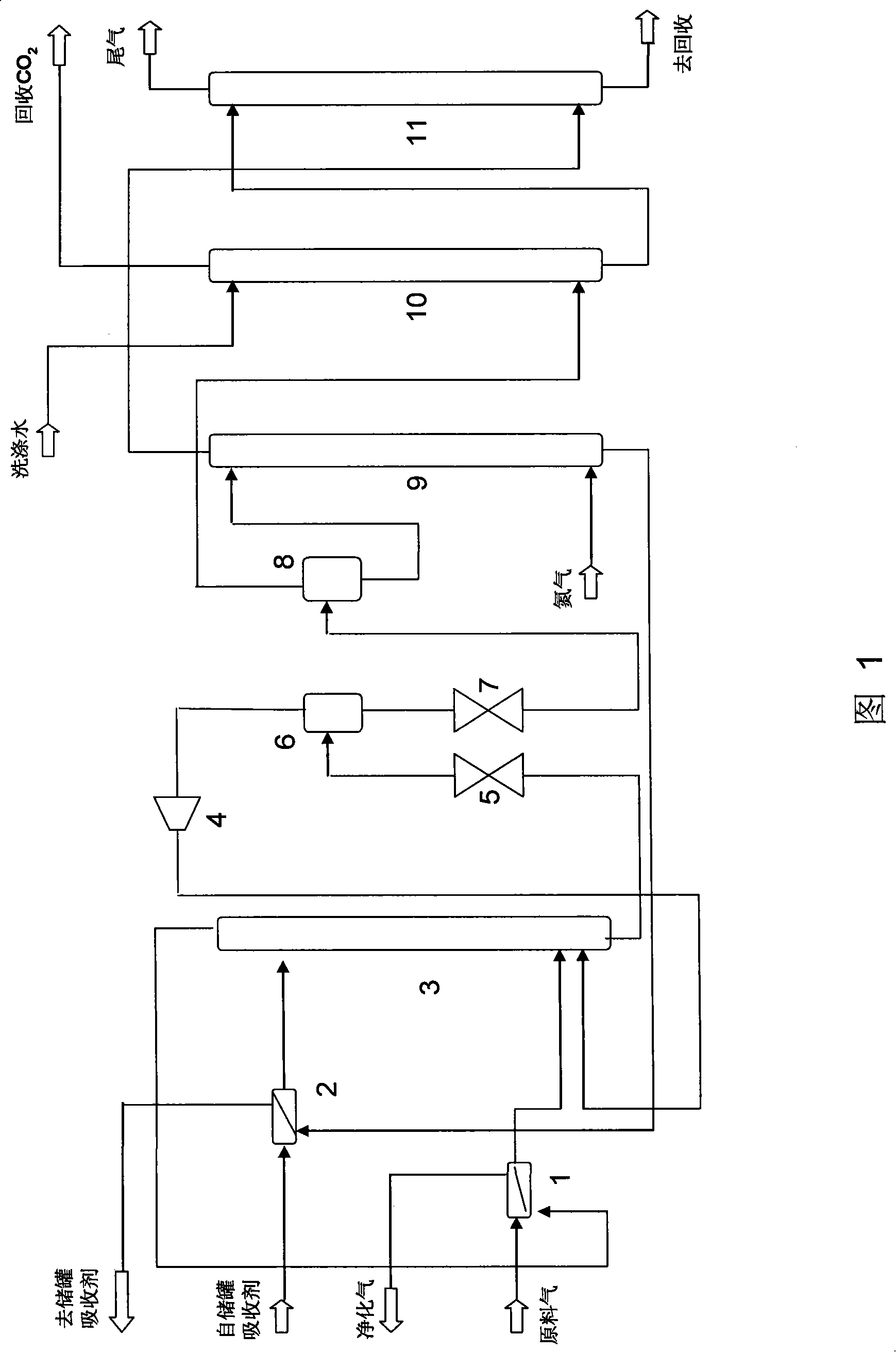

CO2 trapping method combining dimethyl carbonate absorption and membrane desorption

InactiveCN101830462ALow priceReduce energy consumptionProductsCarbon compoundsPoly(ethylene glycol) dimethyl etherDesorption

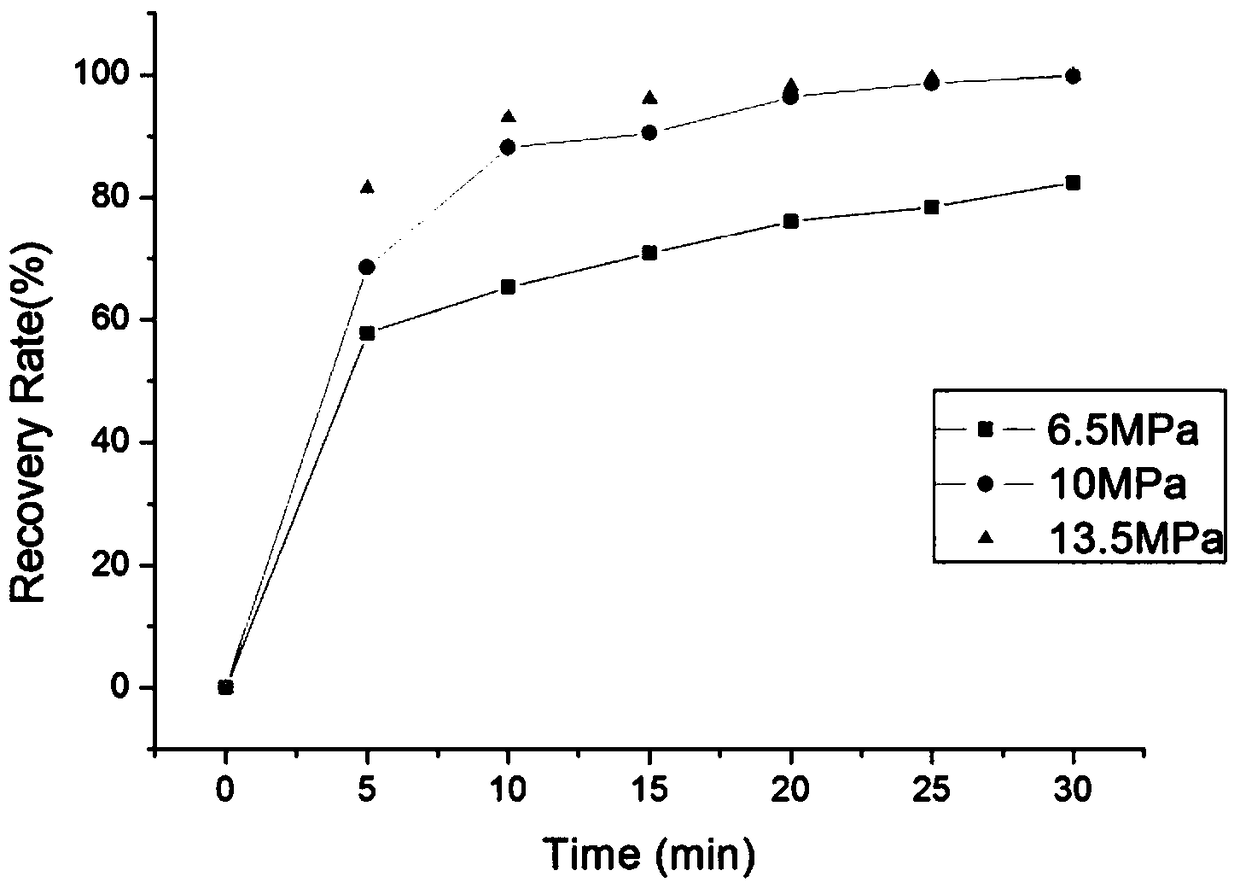

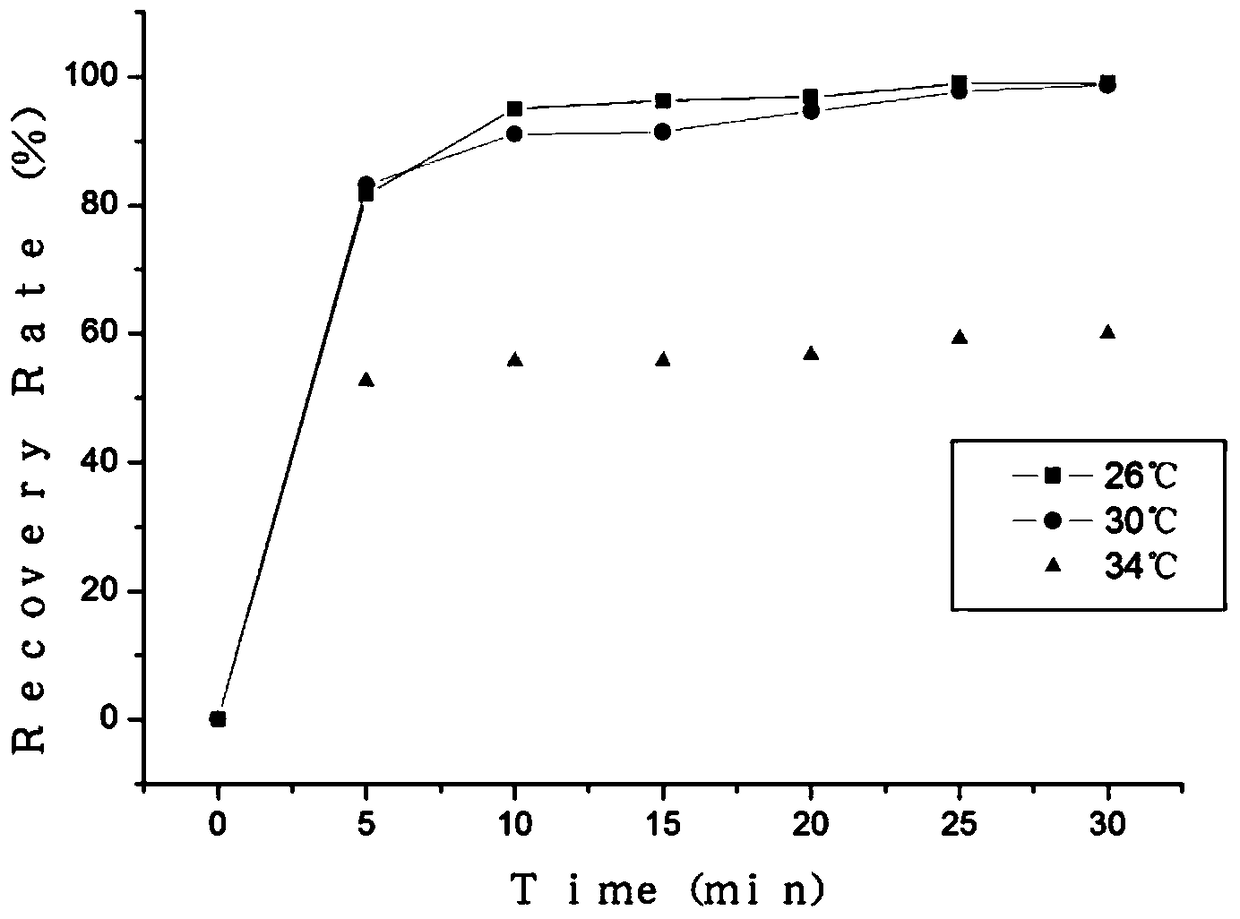

The invention discloses a CO2 trapping method combining dimethyl carbonate absorption and membrane desorption, belonging to the technical field of chemical engineering. The method comprises the following steps of: decarbonizing feed gas containing CO2 by dimethyl carbonate absorption; then carrying out two-stage throttling expansion and membrane desorption regeneration on CO2-absorbed absorbent rich liquor, and discharging CO2 gas generated by the throttling expansion and the membrane desorption out of the battery limit. Compared with a decarbonizing process of the inventor, which adopts the dimethyl carbonate as the absorbent, the new process of the dimethyl carbonate decarburization and the membrane desorption can reduce the comprehensive energy consumption by 5-20 percent. Compared with the propylene carbonate method maturely applied in industry at present, the energy consumption can be reduced by 30-40 percent; compared with the polyethylene glycol dimethyl ether method, the price of a solvent is lower, and polymerization losses are reduced by 40-60 percent; and compared with the low-temperature methane swabbing process, the operating temperature is milder, and the equipment investment is reduced by 30-40 percent. The CO2 removing efficiency can reach 95 percent or above.

Owner:TSINGHUA UNIV

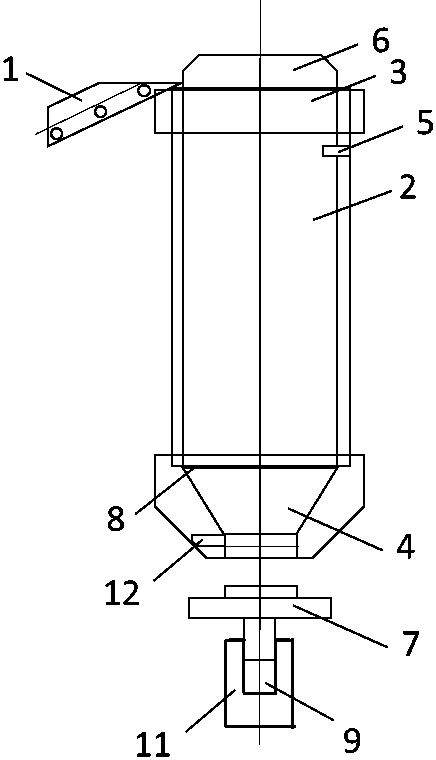

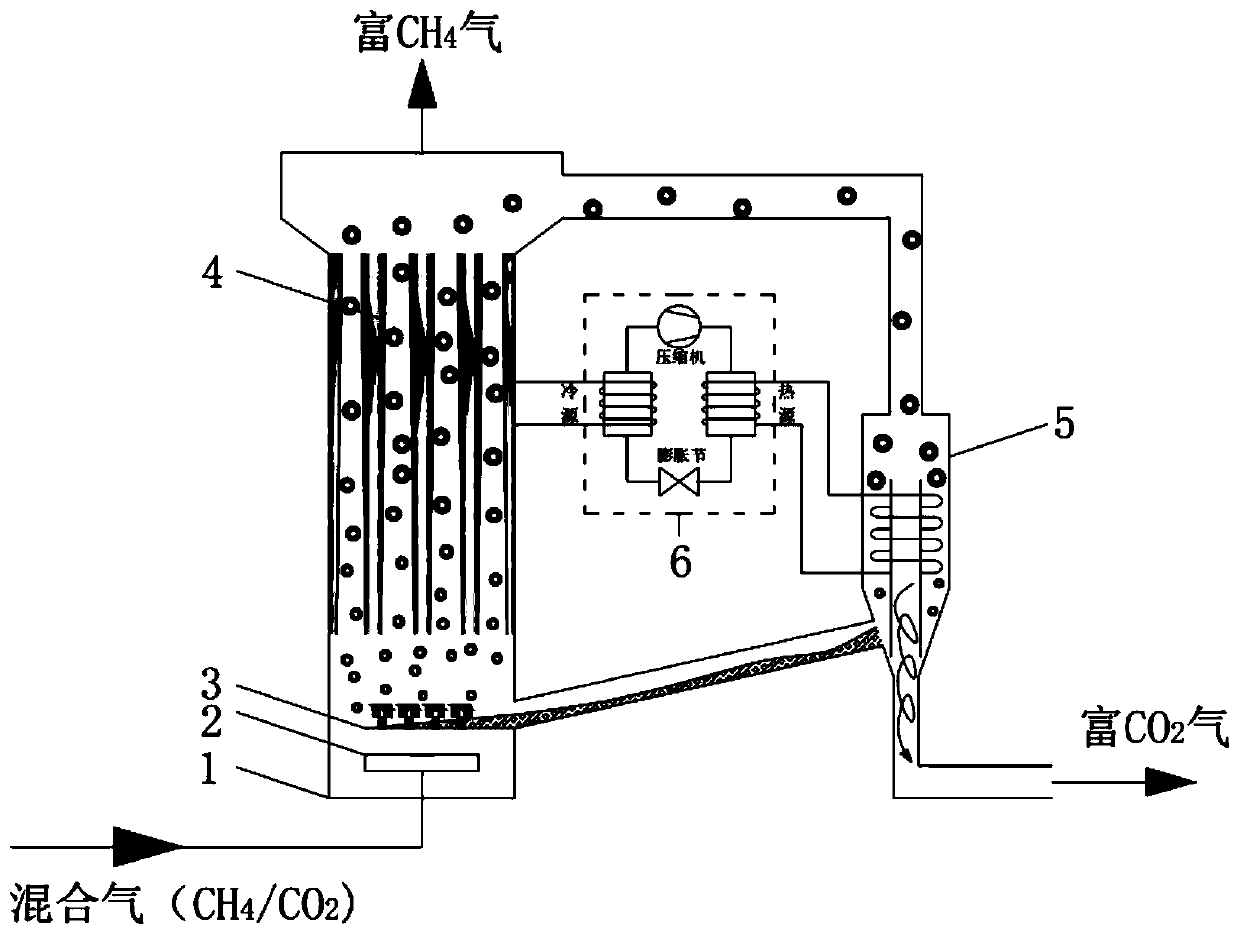

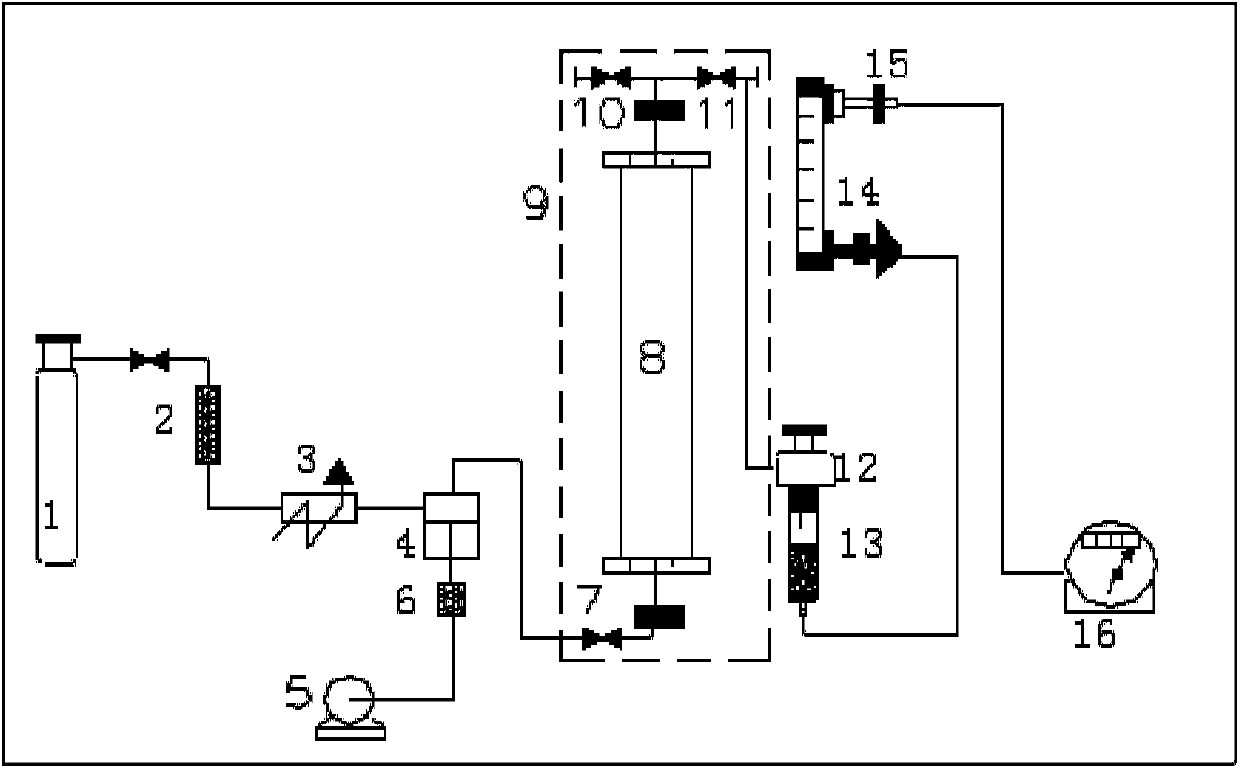

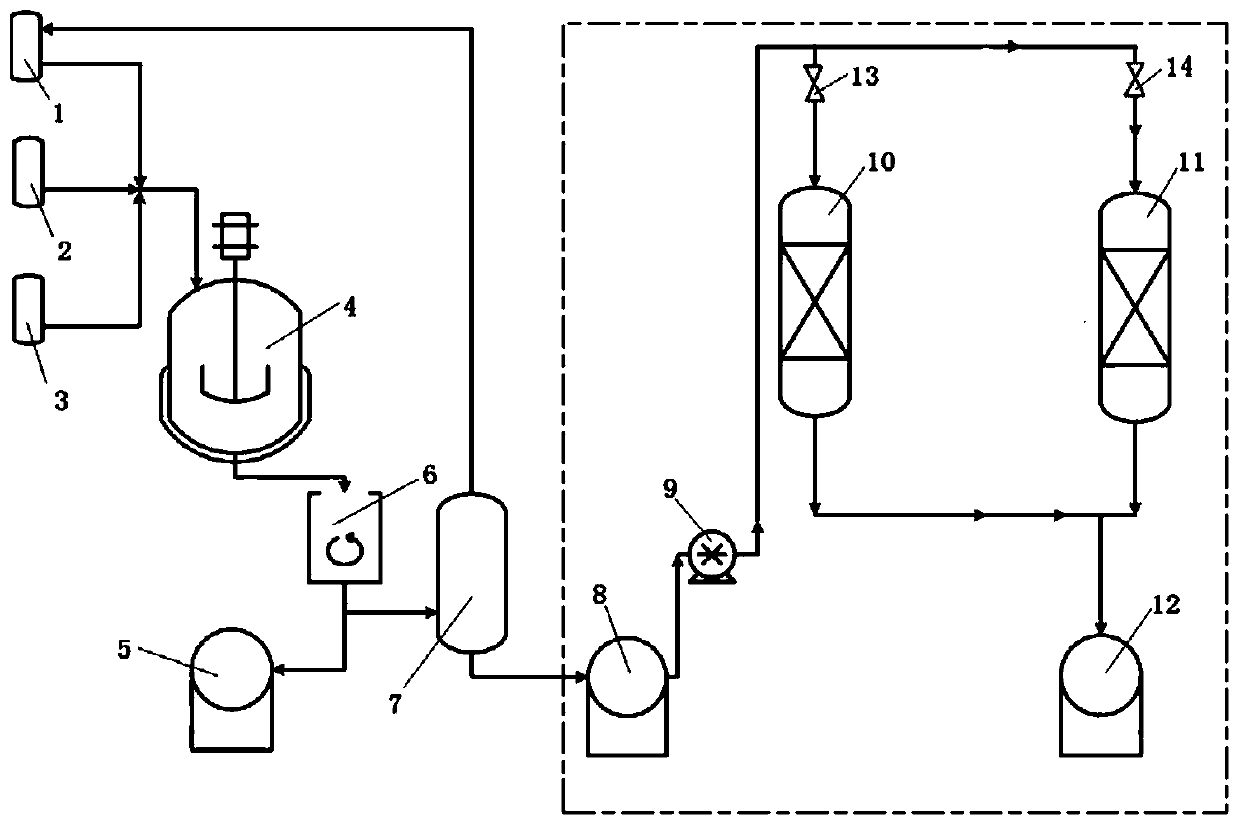

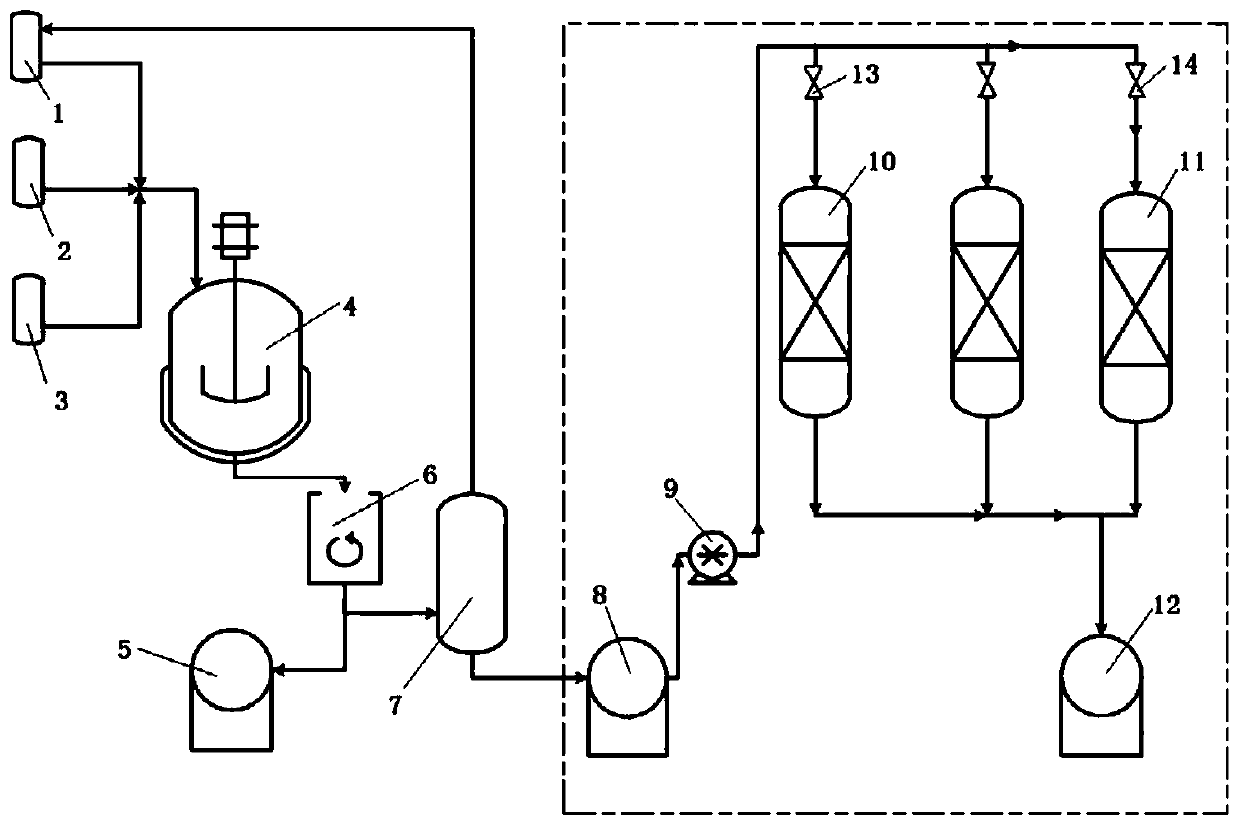

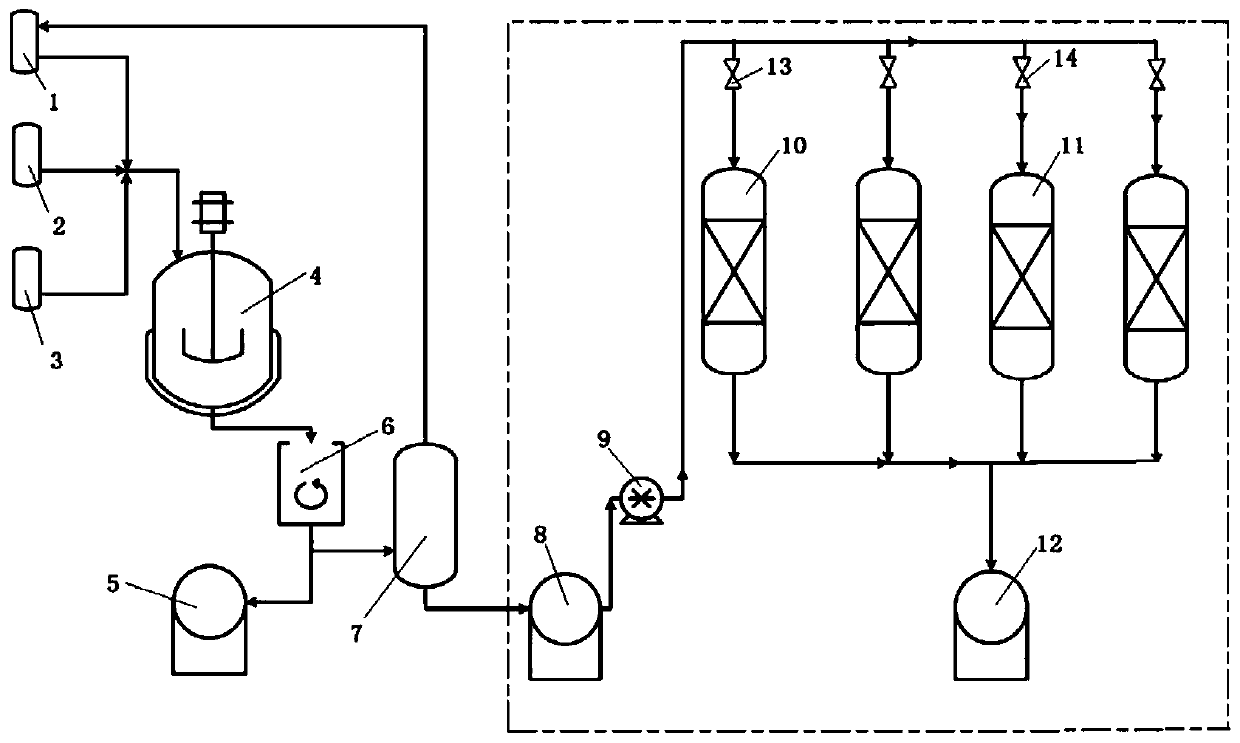

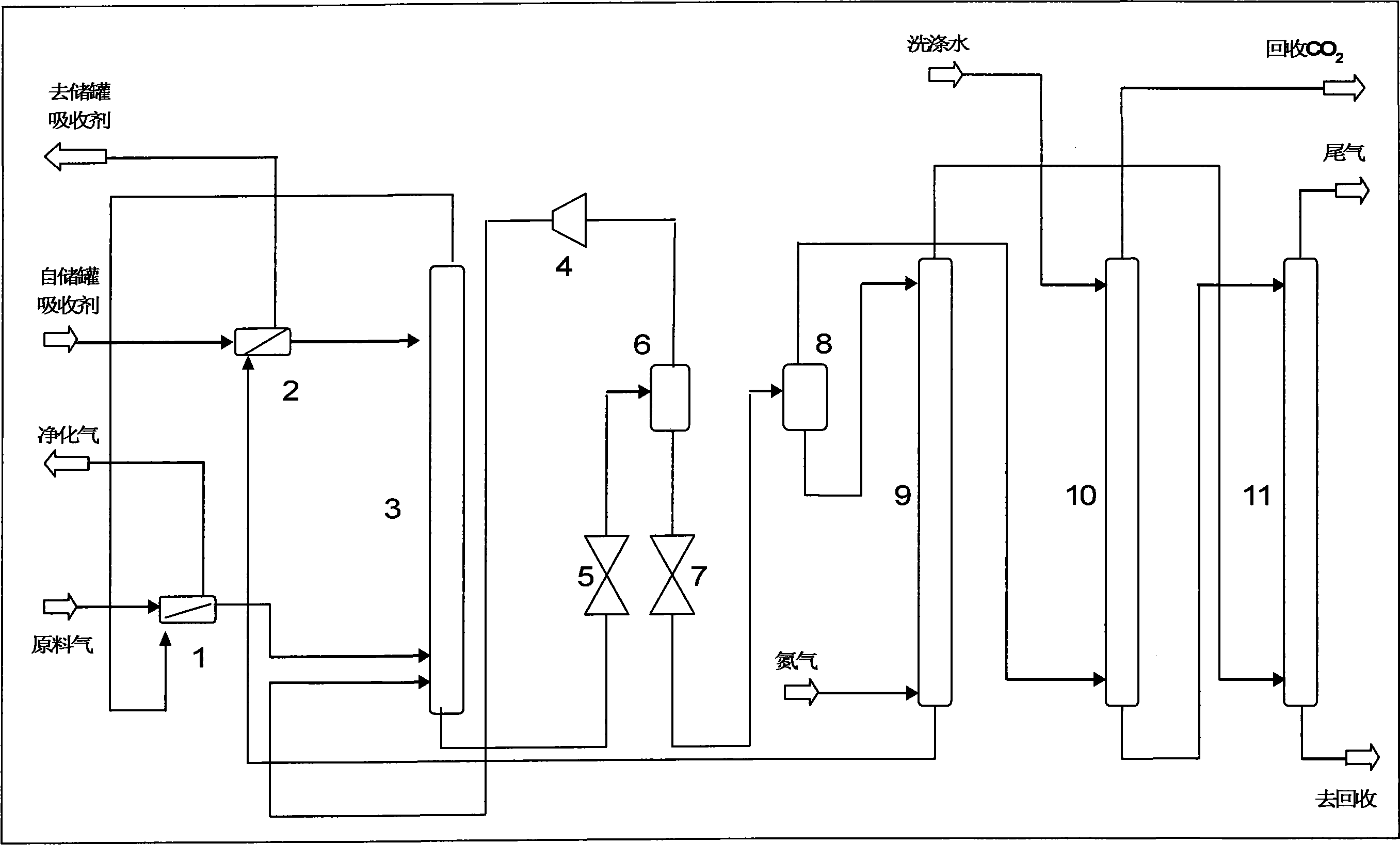

Spent lithium-ion battery electrolyte supercritical carbon dioxide extraction process and device

InactiveCN108079617AEfficient clean separationAvoid pollutionWaste accumulators reclaimingSolid solvent extractionOrganic solventProcess engineering

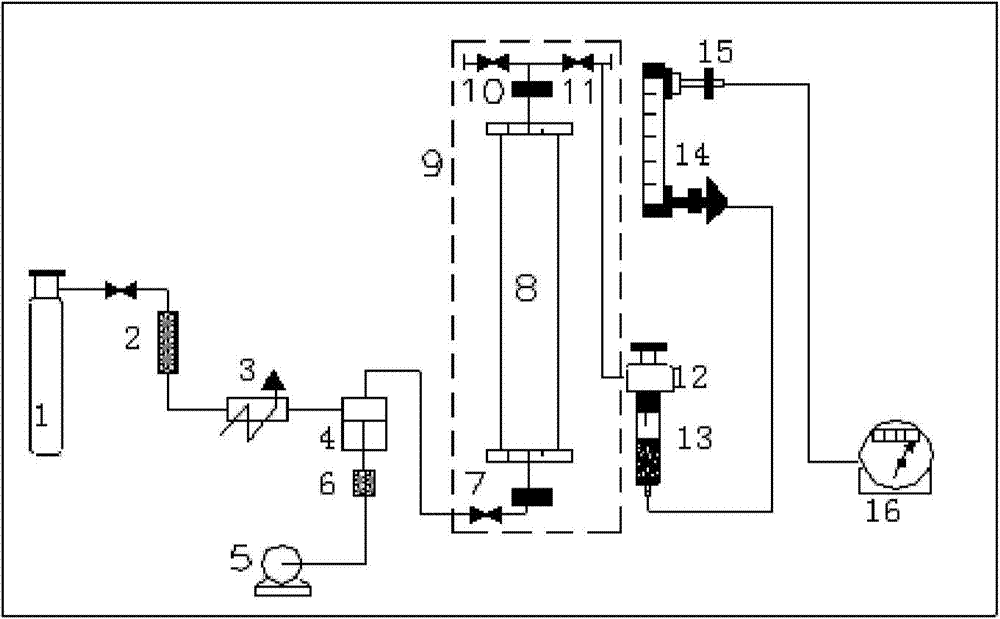

The invention discloses a spent lithium-ion battery electrolyte supercritical carbon dioxide extraction process and device. The process comprises the process steps of charging, extracting and separating. A reaction kettle is changed into an up feeding and bottom discharging mode, a full-sealed conveying belt is used, up lifting and charging of a basket are omitted in charging, crushed spent lithium-ion batteries are conveyed to the top of the reaction kettle by the full-sealed conveying belt and charged, the requirement for the space height of a factory building is reduced, and safety in the production process is improved. Raffinate is sucked out and discharged by negative pressure after extraction, and production efficiency is improved. By taking the advantage of high cleaning and separating efficiency of supercritical carbon dioxide, and body poison and environmental pollution caused by residual solvents in solvent extraction are avoided. According to the process, operation temperature and pressure conditions are mild, degradation and dissipation of thermosensitive substances are effectively prevented, the recovery rate of the electrolyte is higher than 80%, and zero organic solvent discharge and high production efficiency are realized.

Owner:CAMEL GRP WUHAN OPTICS VALLEY R&D CENT CO LTD

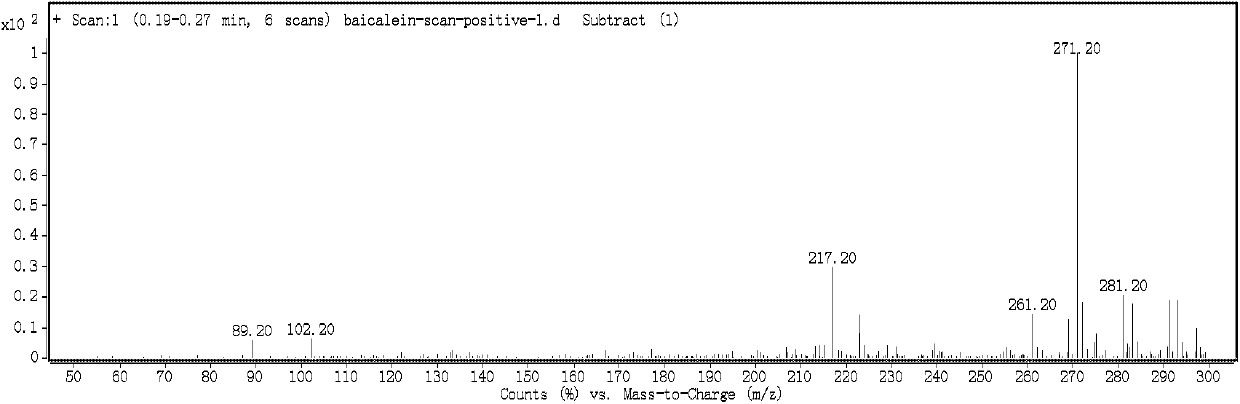

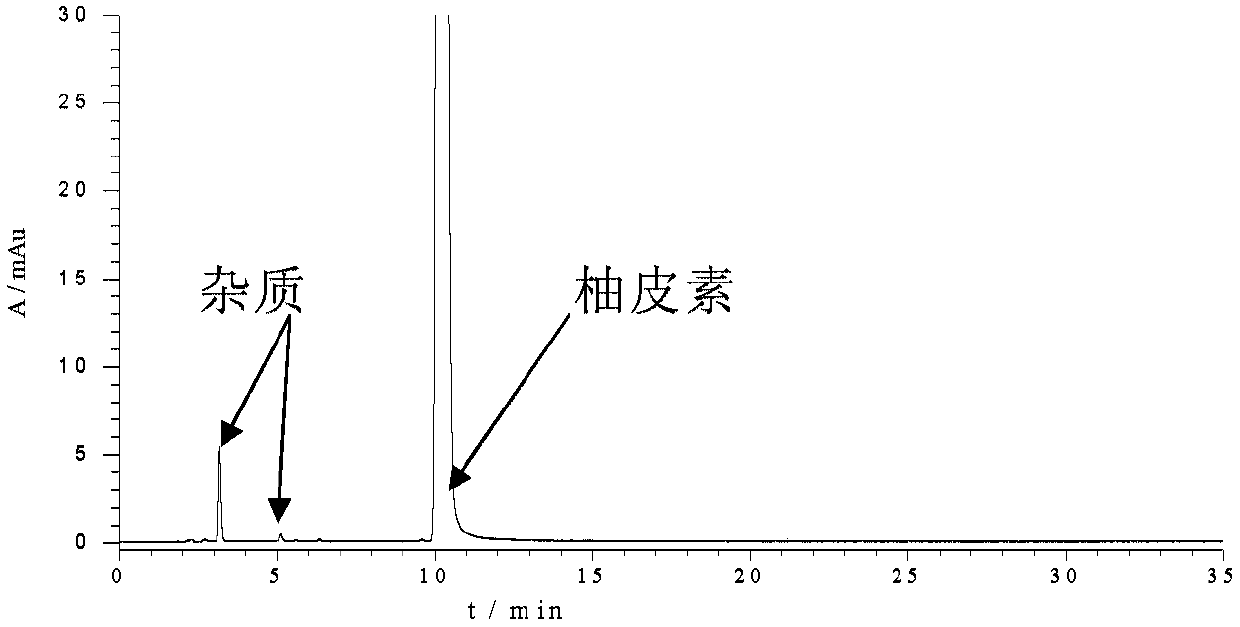

Naringenin standard substance as well as preparation and application thereof

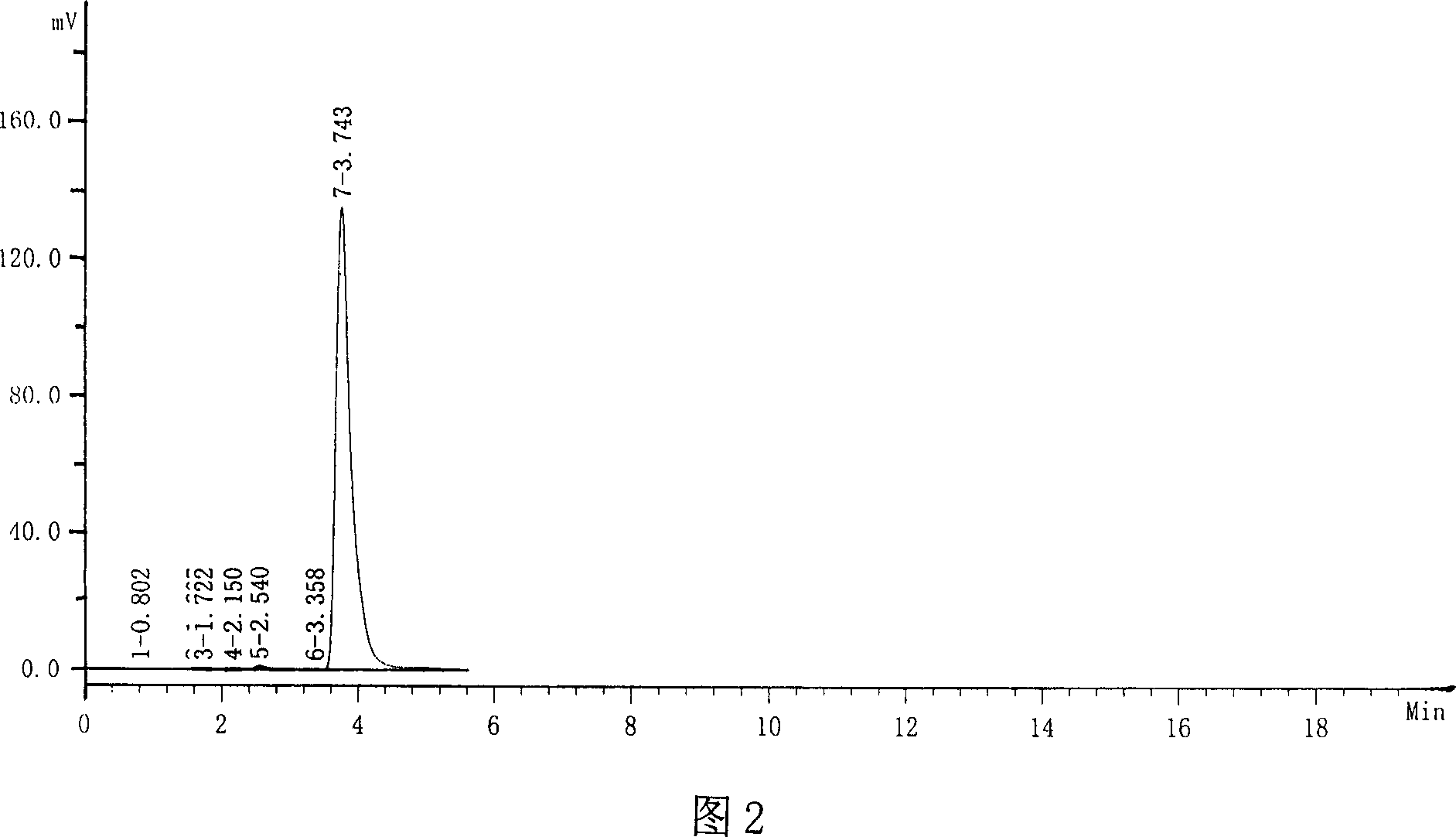

InactiveCN103896898AHigh selectivityImprove mass transfer coefficientOrganic chemistryComponent separationNaringeninHigh-performance liquid chromatography

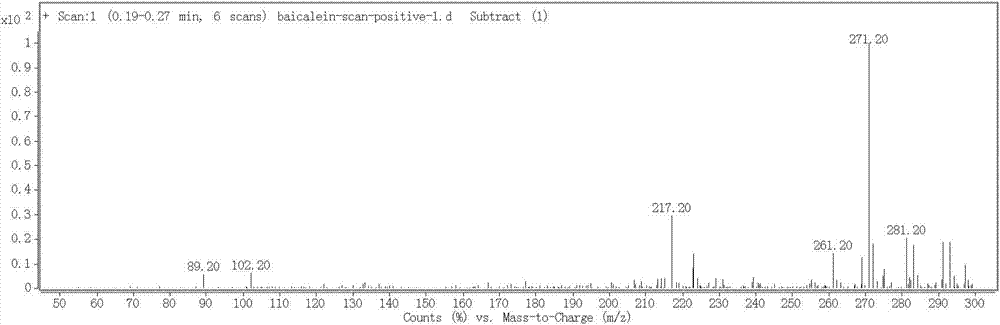

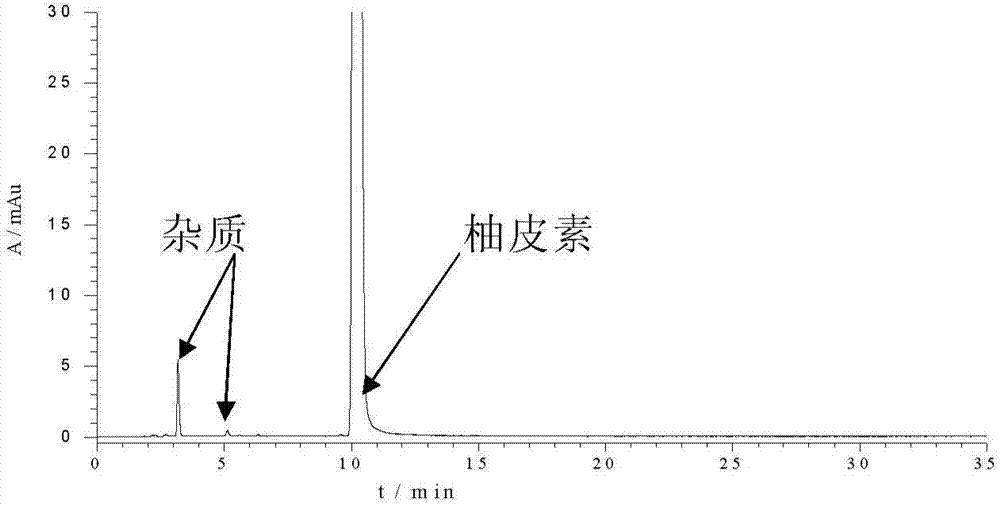

The invention provides a method for extracting and separating high-purity naringenin from citrus peel. According to the method, the high-purity naringenin product with the purity reaching up to 99.5% can be prepared by a supercritical fluid extraction technique and a preparative high performance liquid chromatography, and the preparation requirements of a standard substance can be met.

Owner:NAT INST OF METROLOGY CHINA

Chemical coarsening and metallizing process for calcium magnesium titanate ceramic

PendingCN112500193AStrong adhesionEfficient removalLiquid/solution decomposition chemical coatingSuperimposed coating processSurface roughnessMetallizing

The invention discloses a chemical coarsening and metallizing process for calcium magnesium titanate ceramic, belonging to the technical field of ceramic surface treatment. The invention aims to solvethe problem of poor adhesive force of a subsequent coating due to the fact that an effective coarsening process for the calcium magnesium titanate ceramic has not been reported in the industry at present. According to main points of a technical scheme in the invention, the process is characterized by specifically comprising the following steps of oil removing, roughening, adjusting, activating, peptizing, chemical copper plating and electroplating. With the process, the surface of the calcium magnesium titanate ceramic can be effectively roughened; the surface roughness of a ceramic sample before roughening is 0.4-0.5 micrometer, and the surface roughness of the sample after roughening is 0.8-1.0 micrometer, so good adhesive force is provided for a subsequent metal plating layer; technological operation is convenient, the whole process is a wet process, operation temperature is relatively mild, and risks are relatively low; and in addition, requirements on equipment are reduced, and the production cost of a product is also reduced.

Owner:麦德美科技(苏州)有限公司

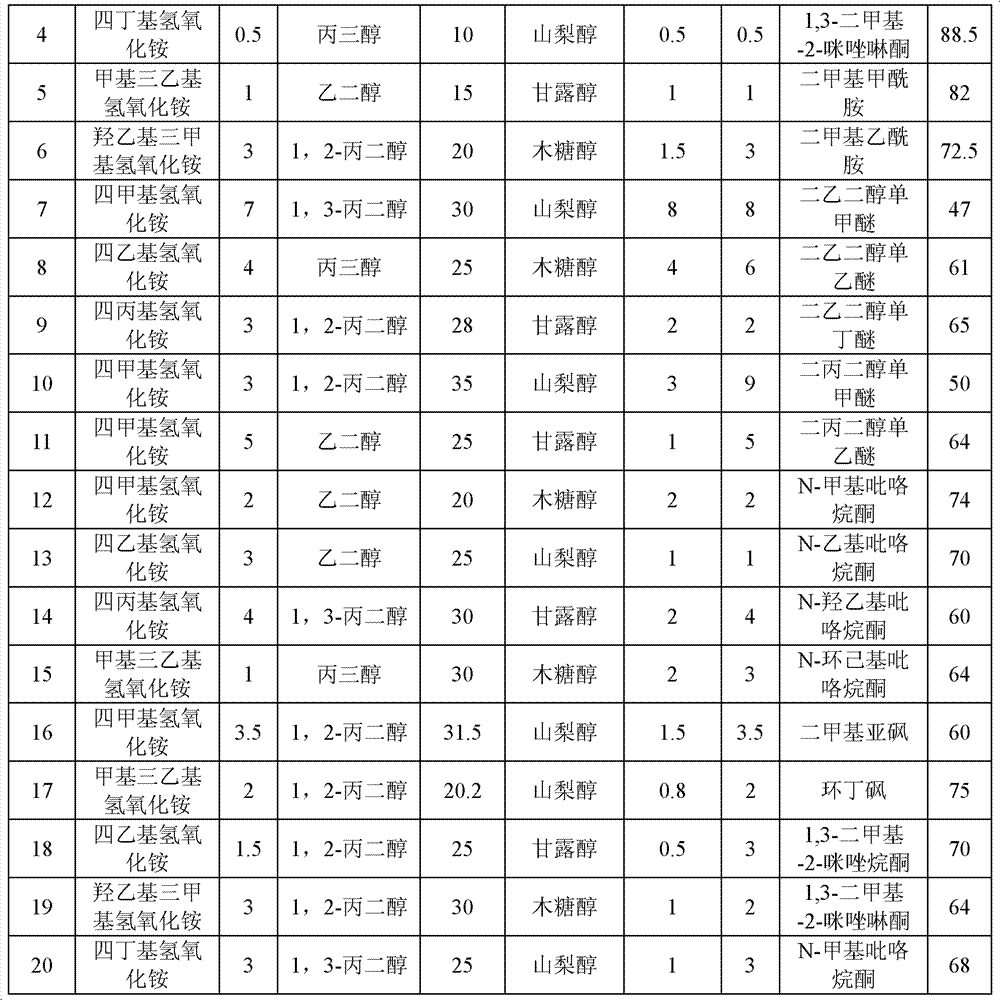

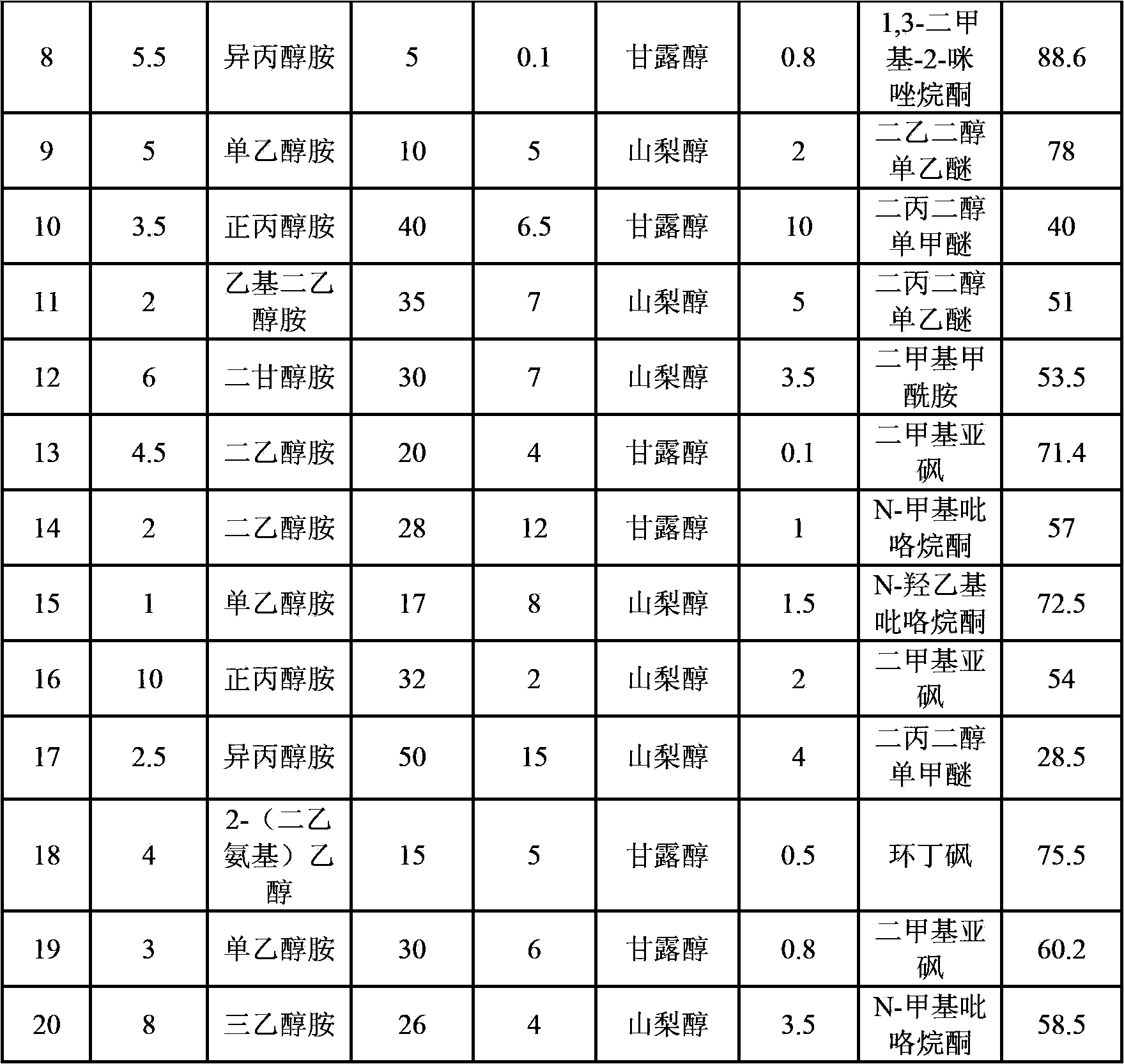

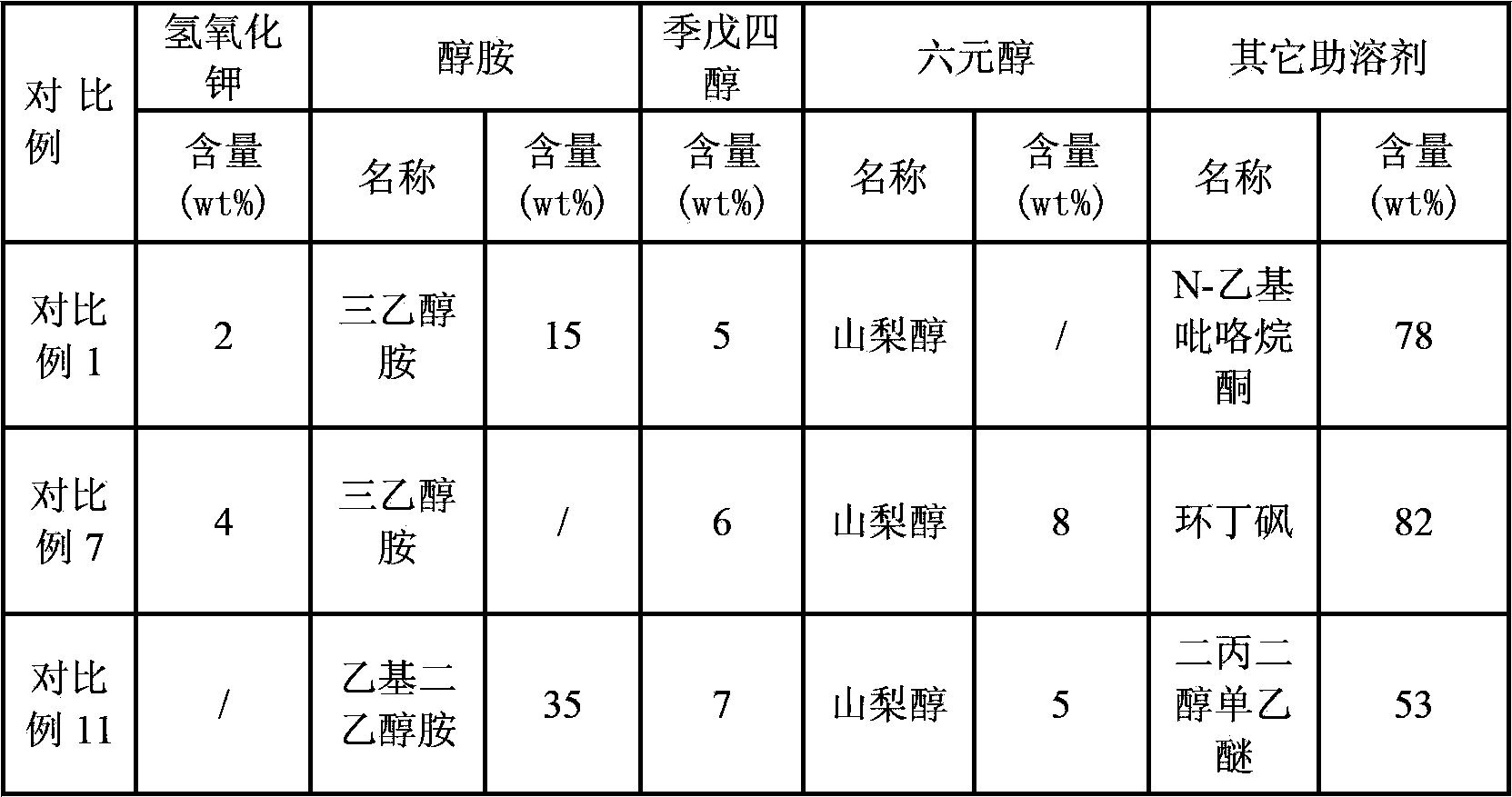

Low-etch cleaning fluid for photoresist

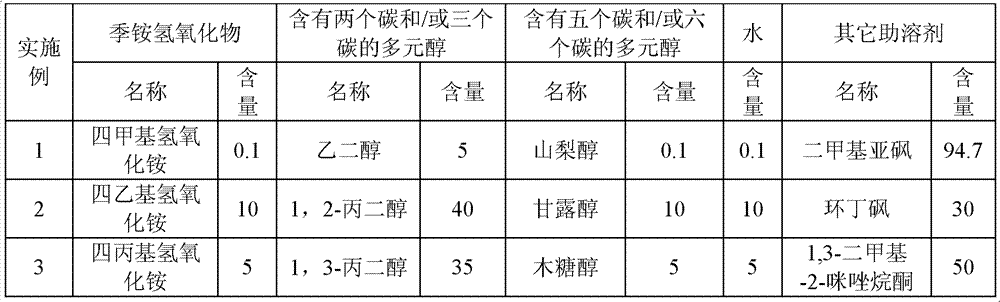

InactiveCN102955380AStrong corrosion inhibition abilityGood removal effectPhotosensitive material processingPolyolAmmonium hydroxide

The invention discloses a low-etch cleaning fluid for photoresist and compositions thereof. The low-etch cleaning fluid for the photoresist comprises (a) quaternary ammonium hydroxide, (b) polyol containing two or three carbons, (c) polyol containing five or six carbons, (d) water, and (e) other cosolvents. The low-etch cleaning fluid for the photoresist can highly-efficiently remove the photoresist on semiconductor wafers, basically has no attack to base materials such as aluminium, copper, etc., and has good application prospect in the fields of semiconductor wafer cleaning and the like.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

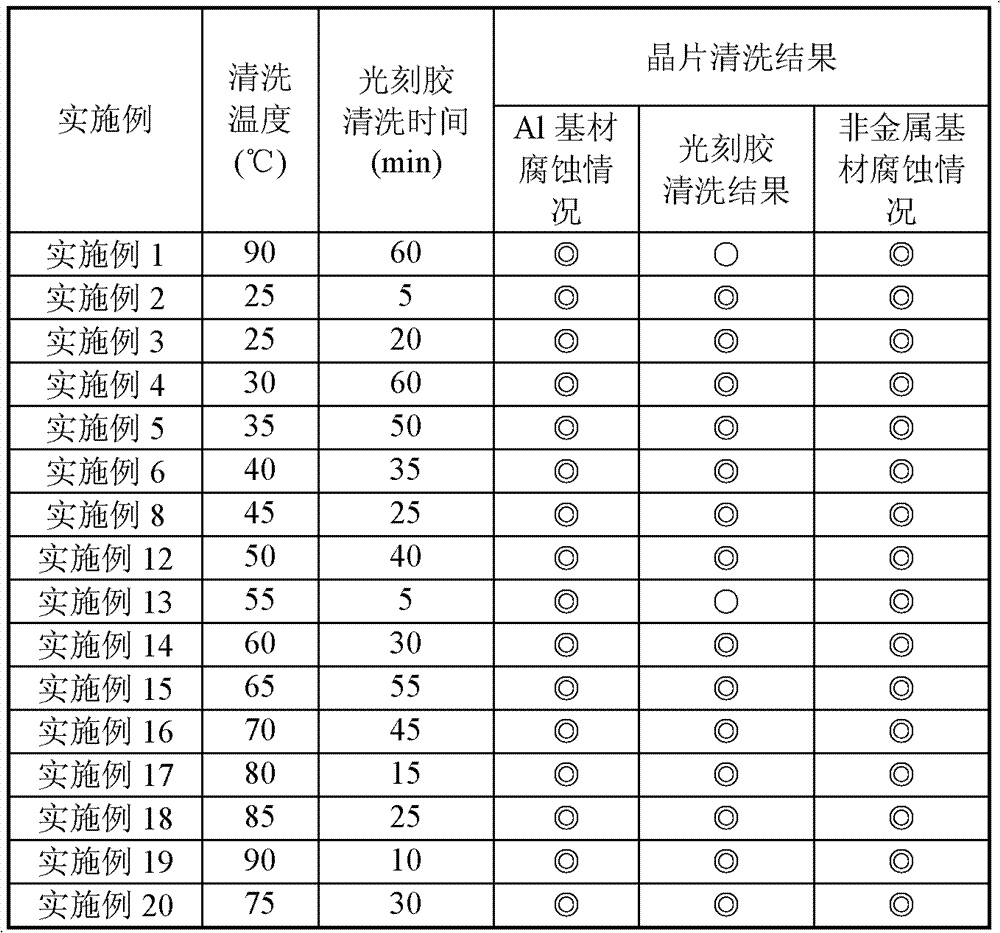

Method for continuously separating CH4/CO2 by using fluidized bed

ActiveCN110090543AImprove thermal conductivityPromotes hydrationGas treatmentDispersed particle separationGas phaseDecomposition

A method for continuously separating CH4 / CO2 by using a fluidized bed is achieved by a significant difference among pressures needed by different guest molecules to form hydrates at the same temperature. The mixed gas forms a hydrate in a fluidized bed reactor, the increasing mass and the arrangement of a variable diameter conduit for changing the flow rate push hydrate particles to move upwards,the temperature of the fluidized bed reactor is controlled to make CO2 in the mixed gas continuously form hydrate, and CH4 is enriched in the gas phase and flows out from the top of the fluidized bedto achieve the separation purpose. A heat pump technology is combined with the formation and decomposition of the hydrate to increase the energy utilization efficiency. A cold source is provided for the fluidized bed reactor to form the hydrate and produce a CH4-rich gas; and a heat source is provided for the cyclone separator to decompose the hydrate and produce a CO2-rich gas. The method forms aclean, efficient and environmentally-friendly separation method for the CH4 / CO2 mixed gas.

Owner:SOUTH CHINA UNIV OF TECH +1

Catalyst for preparing 3-pentanol through 3-pentanone hydrogenation and preparation method of catalyst for preparing 3-pentanol through 3-pentanone hydrogenation

InactiveCN104368359AMild operating temperatureMild operating pressureOrganic compound preparationHydroxy compound preparationHydrogenation process3-Pentanol

The invention discloses a catalyst for preparing 3-pentanol through 3-pentanone hydrogenation. The catalyst comprises a carbon-based carrier and a multi-metal component recorded as M1-M2-M3 / C, wherein M1 is selected from one of Ru, Mn and Ag; M2 is selected from one of Ir, Au and Cu; and M3 is selected from one of La, Ce and Y. The catalyst is applied to the liquid phase 3-pentanone hydrogenation process. The conversion rate of 3-pentanone can be 100 percent within a short time, and the selectivity of the 3-pentanol is 100 percent. The invention also provides a method for preparing the catalyst, and the industrial preparation is easily realized.

Owner:XIAMEN UNIV

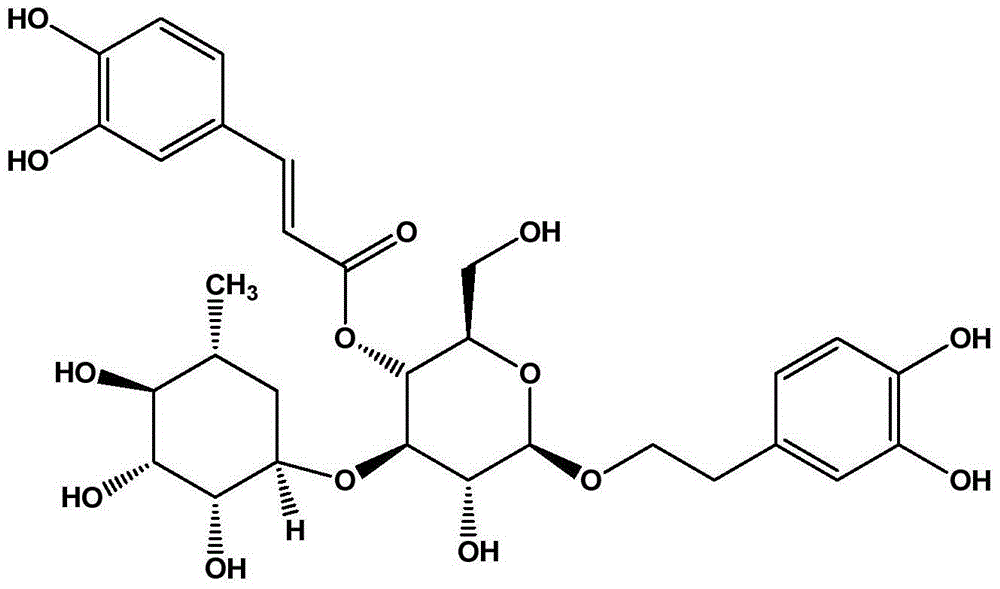

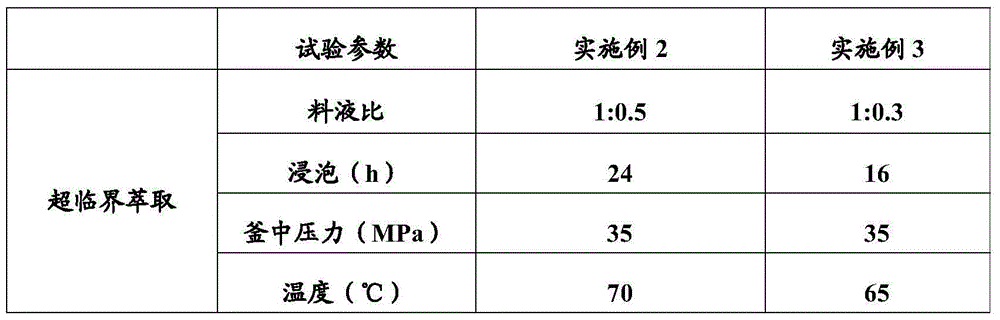

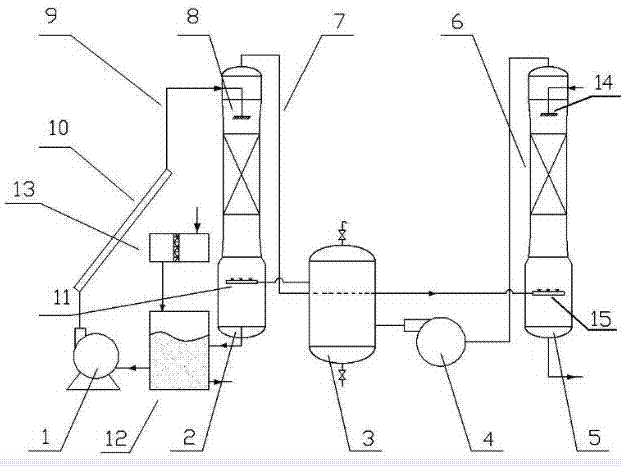

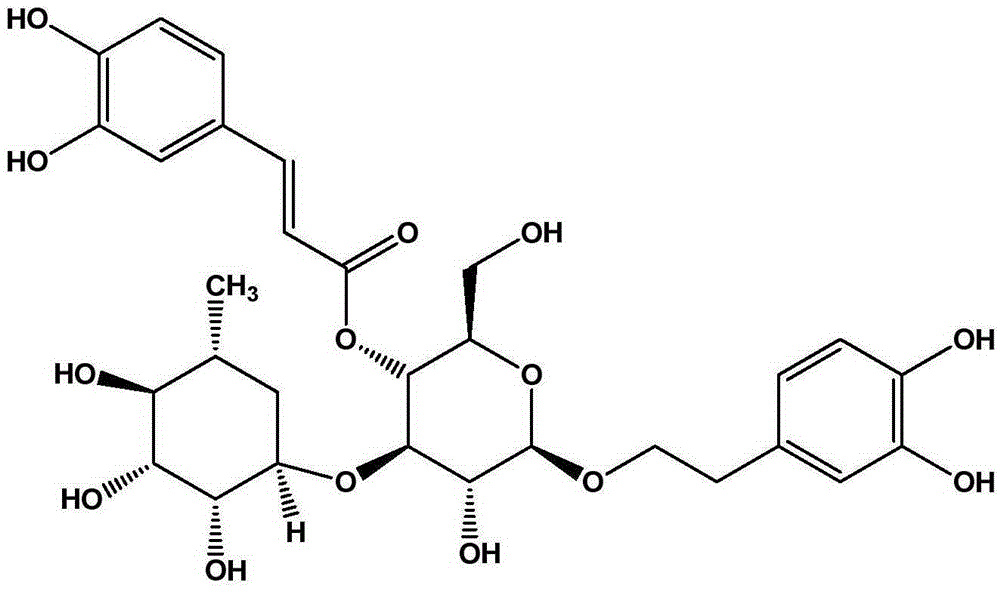

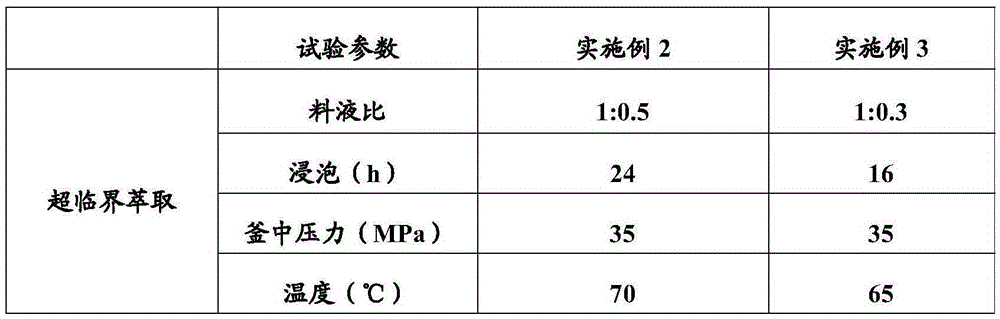

Method for preparing verbascoside standard product from callicarpa nudiflora leaf

ActiveCN104530147AHigh selectivityImprove mass transfer coefficientSugar derivativesSugar derivatives preparationCallicarpa nudifloraAmmonia

The invention relates to a preparation method of verbascoside, particularly relates to a method for preparing a high-pure verbascoside product from callicarpa nudiflora by adopting a supercritical fluid extraction technique, and a use of the verbascoside product obtained by the preparation method as a standard substance. The supercritical fluid extraction technique adopts the following extraction conditions: the amount of an entrainer is 0.2-0.5 time of the raw material mass, soaking is carried out for 12-24 h, under the conditions of the pressure of 35 MPa and the temperature of 60-70 DEG C, static extraction is carried out for 0.1-0.5 h, and then dynamic extraction is carried out for 1.5-2 h at the speed of 0.1-1.0 L / min. The entrainer is composed of water, methanol, n-hexane and ammonia water with the volume percentage ratio of 55%:15%:25%:5%.

Owner:JIANGXI POZIN PHARMA

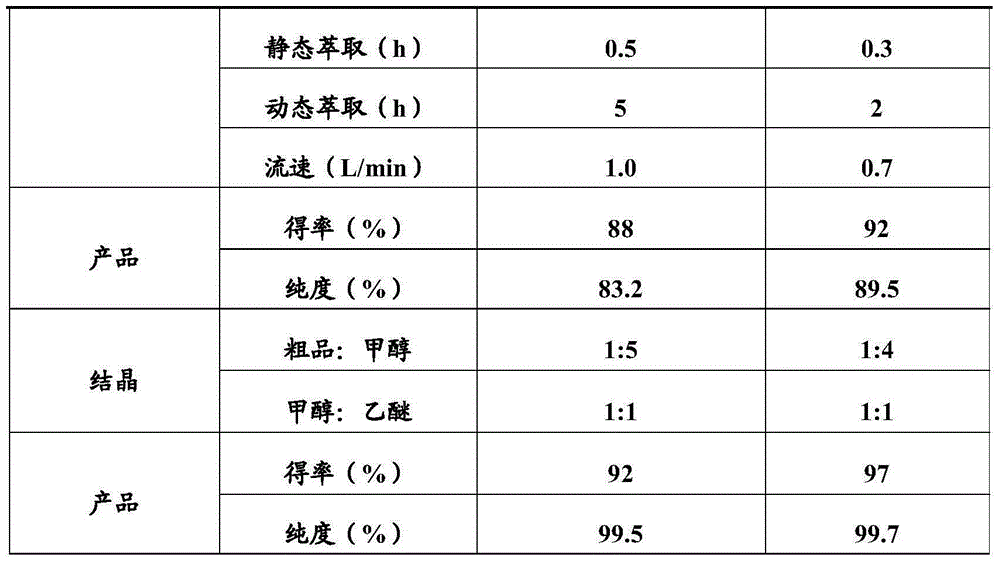

Photoresist cleaning liquid

InactiveCN103389627AStrong removal abilityMild operating temperaturePhotosensitive material processingSolventPhotoresist

The invention provides a photoresist cleaning liquid comprising potassium hydroxide, hydramine, pentaerythritol, hexol, and a cosolvent. The cleaning agent has high cleaning capacity, and low corrosion to semiconductor wafer patterns and substrates.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

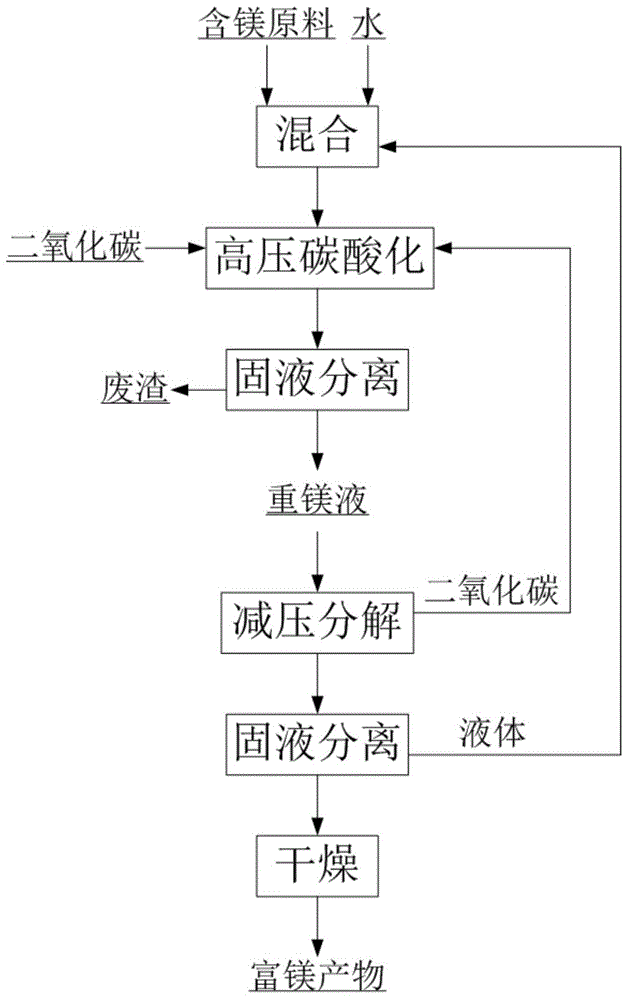

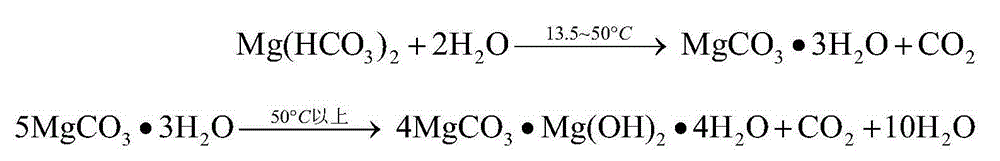

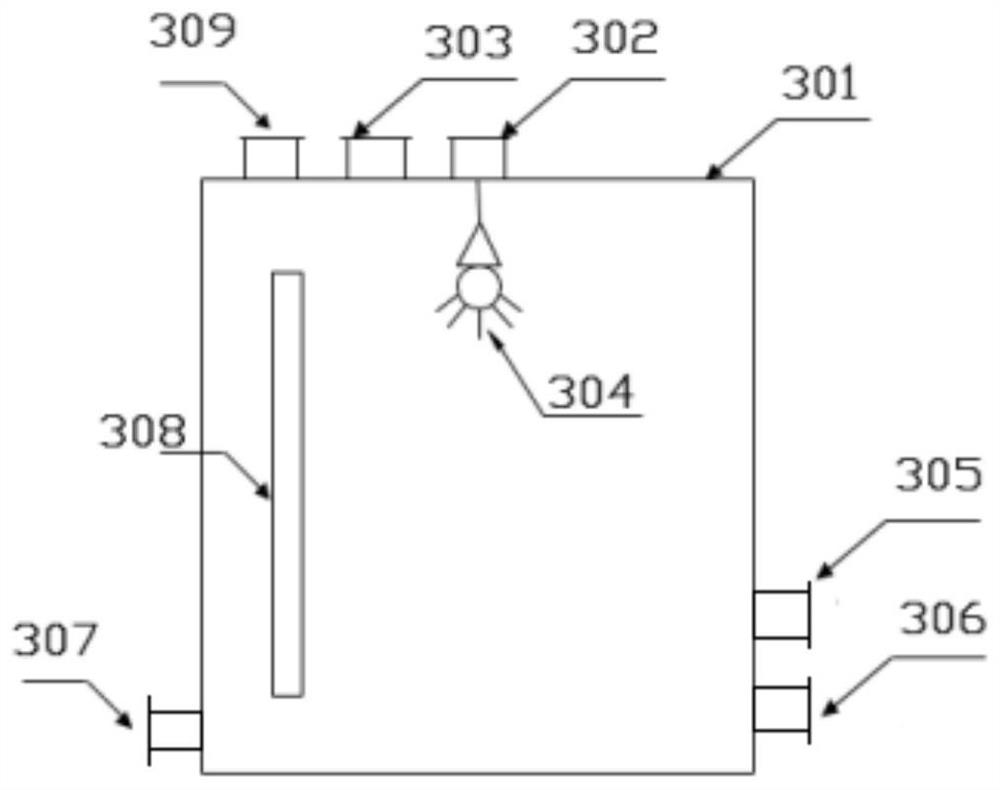

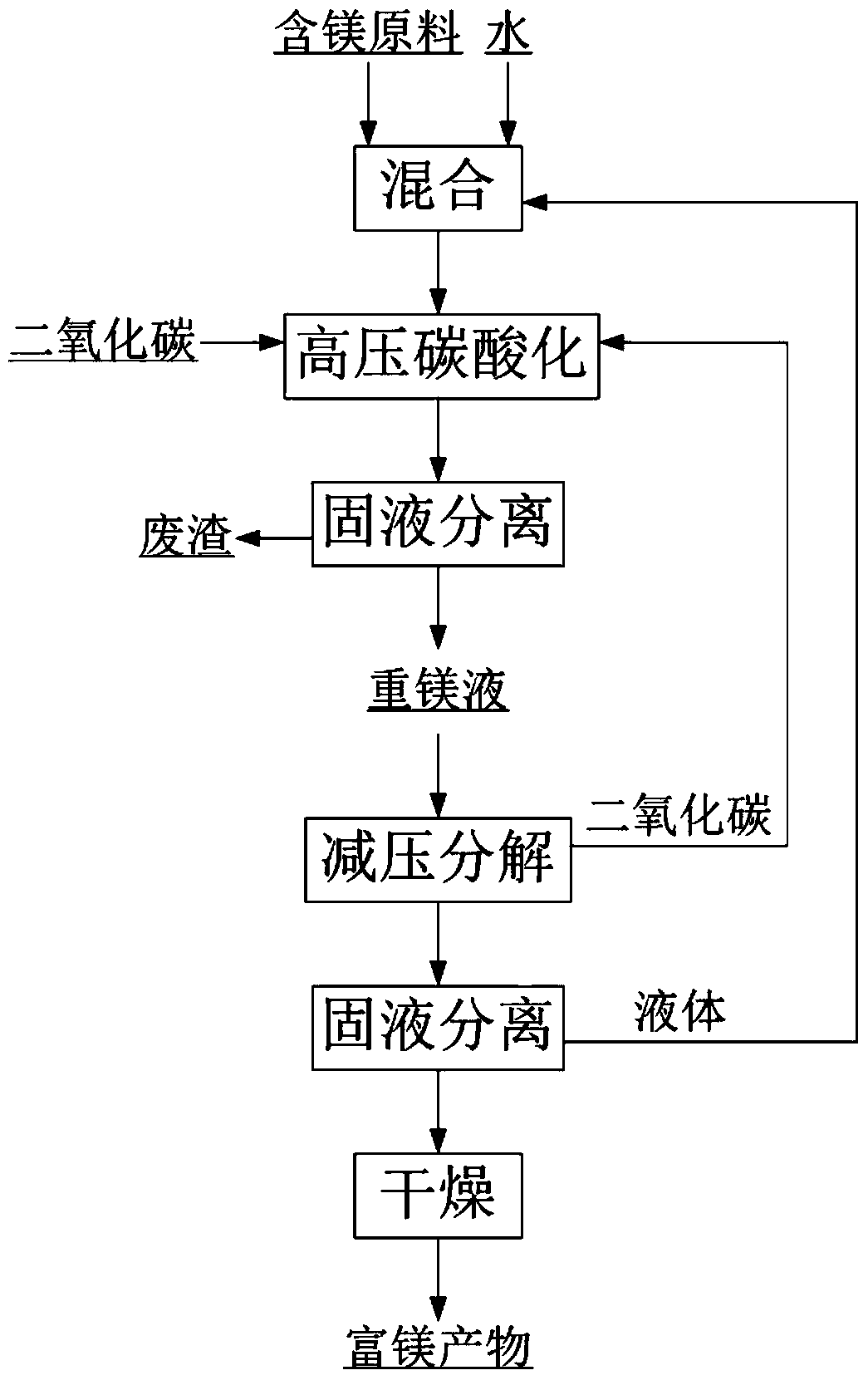

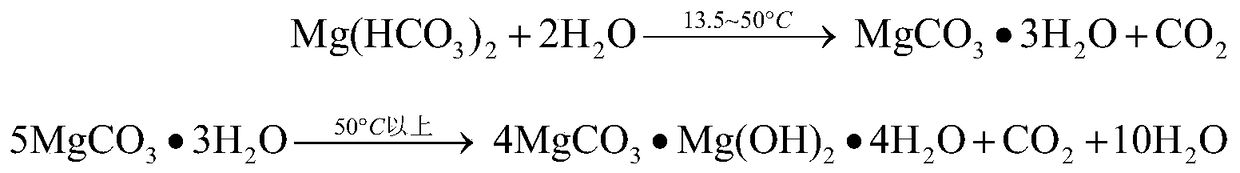

Method for extracting magnesium by means of high-pressure carbonization

The invention provides a method for extracting magnesium by means of high-pressure carbonization.The method includes steps of uniformly mixing water with raw materials with magnesium to obtain reaction slurry; carrying out carbonization reaction on the reaction slurry and carbon dioxide gas under the condition of gauge pressures of 1-5 MPa to obtain serous fluid; keeping the reaction pressures and separating solid from fluid in the serous fluid to obtain fluid with heavy magnesium; reducing the pressures and decomposing the fluid with the heavy magnesium to obtain decomposed serous slurry; separating solid from fluid in the decomposed serous fluid to obtain solid and drying the solid to obtain magnesium-rich products.The method has the advantages that the method can be applied to utilizing magnesium-rich minerals such as magnesite and magnesium-rich solid waste such as boric sludge, the carbonization magnesium extraction efficiency and the calcium and magnesium separation efficiency can be improved, and energy consumption and the economic cost can be reduced to a great extent; as compared with existing processes for extracting magnesium, the method is mild in operation temperature, little in variation, low in energy consumption and heat exchange difficulty and easy to implement, required equipment is small, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

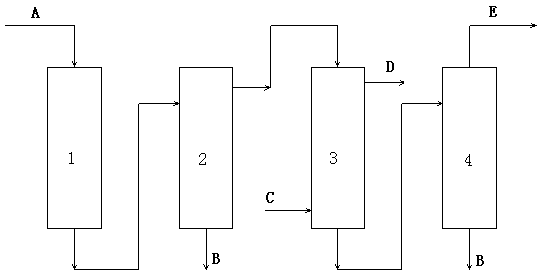

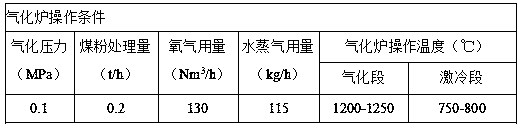

Process for gasification production of synthesis gas through low temperature entrained-flow bed by using ultrafine powder

InactiveCN110257105AMild operating temperatureReduce erosionEnergy inputGasification processes detailsLow activityChemistry

The invention discloses a process for gasification production of synthesis gas through a low temperature entrained-flow bed by using ultrafine powder. The process comprises the steps: spraying an ultrafine gasified raw material which is pulverized to less than 75 [mu]m and a gasification agent into a gasification furnace from the top of the gasification furnace of the entrained-flow bed, performing a reaction on the gasified raw material and the gasification agent so as to generate the synthesis gas containing carbon monoxide and hydrogen at a gasification temperature of lower than 1300 DEG C, spraying chilled water during downward flow of the synthesis gas, and reducing the temperature of the gas so as to meet requirements for the entrance temperature of a cyclone separator, wherein the entrance temperature of the cyclone separator is generally lower than 900 DEG C; discharging the gas with ash slag from a lower outlet of the gasification furnace after cooling, introducing the gas directly into the cyclone separator, removing most of coarse particles and a part of fine ash which are carried by the gas, then introducing the obtained gas into a waste heat boiler for further cooling of the gas, generating steam at the same time, finally introducing the gas into a filter so as to remove fine dust entrained in the gas, and sending the obtained gas to a subsequent section. In the gasification process, the ash slag does not have to reach a melt flow state, and the process is particularly suitable for production processes of low-activity coal and gasification of coal with a high-ash fusion point.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

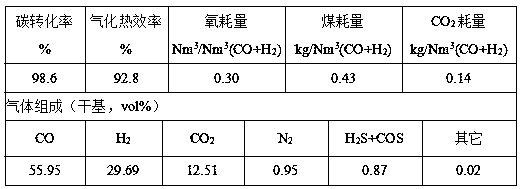

Uvioresistant polyethylene non-woven fabric and preparation method thereof

PendingCN112726206AImprove mechanical propertiesNot easy to fall offBiochemical fibre treatmentLight resistant fibresPolymer scienceNonwoven fabric

The invention discloses a uvioresistant polyethylene non-woven fabric. A polydopamine layer and a titanium dioxide layer are sequentially adhered to the surface of the polyethylene non-woven fabric. The invention also discloses a preparation method of the uvioresistant polyethylene non-woven fabric, which comprises the following steps of S1, soaking the polyethylene non-woven fabric in a dopamine solution, washing, and drying to obtain an intermediate fabric; and S2, soaking the intermediate fabric in the titanium dioxide dispersion liquid, washing and drying to obtain the uvioresistant polyethylene non-woven fabric. The uvioresistant polyethylene non-woven fabric provided by the invention has high ultraviolet resistance and antibacterial performance, and good mechanical properties.

Owner:安徽省临泉县万隆塑料包装有限公司

Technology of extracting adenosin phosphoric acid from date

InactiveCN100425620CImprove extraction efficiencyStable in natureSugar derivativesSugar derivatives preparationAlcoholIon exchange

The present invention relates to a technological process for extracting cyclophosphoadenosine from jujube. Said technological process includes the following steps: breaking, soaking, filtering soaking liquor, using ultrasonic technique to extract filter residue, combining extracts to obtain clear jujube juice; making the clear jujube juice be passed through ion exchange column, then making the eluent be again passed through ion exchange column, making the obtained secondary eluent be passed through chromatographic column, collecting solution containing cyclophosphoadenosine concentrating and crystallizing in ethyl alcohol so as to obtain high-purity cyclophosphoadenosine.

Owner:常月梅

Carbon dioxide subcritical extraction and recycling method of waste lithium-ion battery electrolyte

ActiveCN105406146BAvoid pollutionAvoid degradationWaste accumulators reclaimingBattery recyclingOrganic solventResource utilization

The invention provides a carbon dioxide subcritical extraction, recycling and reusing method for the electrolyte of a waste lithium ion battery, belonging to the field of recycling and reusing of solid waste. The method comprises the following steps: after complete discharging of the waste lithium ion battery, dismounting the waste lithium ion battery and removing a shell, positive and negative terminals, sealing rings and cover plates; transferring the electrolyte, current collectors with positive and negative electrode materials and a diaphragm into a supercritical extraction apparatus; adjusting the temperature, pressure, extraction time and flow of a supercritical carbon dioxide fluid and extracting an organic solvent and an additive; and subjecting the obtained solvent to component analysis, supplementing electrolyte salt, the organic solvent and the additive according to analysis results and adjusting a ratio to prepare electrolytes with different functions. The method effectively prevents degradation and dissipation of heat-sensitive substances; operation parameters are easy to control; extraction, separation and recovery are integrated together; later complicated treating procedures are omitted; and the utilization rate of resources is higher.

Owner:HARBIN INST OF TECH

CO2 trapping method combining dimethyl carbonate absorption and membrane desorption

InactiveCN101830462BLow priceReduce energy consumptionProductsReagentsPoly(ethylene glycol) dimethyl etherTrapping

The invention discloses a CO2 trapping method combining dimethyl carbonate absorption and membrane desorption, belonging to the technical field of chemical engineering. The method comprises the following steps of: decarbonizing feed gas containing CO2 by dimethyl carbonate absorption; then carrying out two-stage throttling expansion and membrane desorption regeneration on CO2-absorbed absorbent rich liquor, and discharging CO2 gas generated by the throttling expansion and the membrane desorption out of the battery limit. Compared with a decarbonizing process of the inventor, which adopts the dimethyl carbonate as the absorbent, the new process of the dimethyl carbonate decarburization and the membrane desorption can reduce the comprehensive energy consumption by 5-20 percent. Compared with the propylene carbonate method maturely applied in industry at present, the energy consumption can be reduced by 30-40 percent; compared with the polyethylene glycol dimethyl ether method, the priceof a solvent is lower, and polymerization losses are reduced by 40-60 percent; and compared with the low-temperature methane swabbing process, the operating temperature is milder, and the equipment investment is reduced by 30-40 percent. The CO2 removing efficiency can reach 95 percent or above.

Owner:TSINGHUA UNIV

A secondary metallization process of high temperature co-fired ceramics

ActiveCN112323049BEfficient removalReduce tensionLiquid/solution decomposition chemical coatingMetal coatingPtru catalyst

The invention discloses a secondary metallization process of high-temperature co-fired ceramics, comprising the following steps: (1) degreasing, (2) deoxidizing: the degreasing substrate obtained in step (1) is heated at a temperature of 80-85 ℃ oxidizing solution for 10-20min; obtain the deoxidized film substrate; (3) neutralization, (4) activation, (5) electroless nickel plating and (6) electroless gold plating. The secondary metallization process of high-temperature co-fired ceramics of the present invention can effectively remove the oxide film produced on the surface of the metallized substrate due to high-temperature baking by using potassium permanganate and sodium hydroxide, and form a uniform metallization on the surface of the primary metallized substrate. The pores are conducive to the adsorption of subsequent catalysts, provide reliable adhesion for subsequent coatings, and solve the technical problem of poor adhesion of metal coatings caused by oxides produced in tungsten metallization.

Owner:麦德美科技(苏州)有限公司

A kind of naringenin standard substance and its preparation and application

InactiveCN103896898BHigh selectivityImprove mass transfer coefficientOrganic chemistryComponent separationStandard PreparationsNaringenin

The invention provides a method for extracting and separating high-purity naringenin from citrus peel. According to the method, the high-purity naringenin product with the purity reaching up to 99.5% can be prepared by a supercritical fluid extraction technique and a preparative high performance liquid chromatography, and the preparation requirements of a standard substance can be met.

Owner:NAT INST OF METROLOGY CHINA

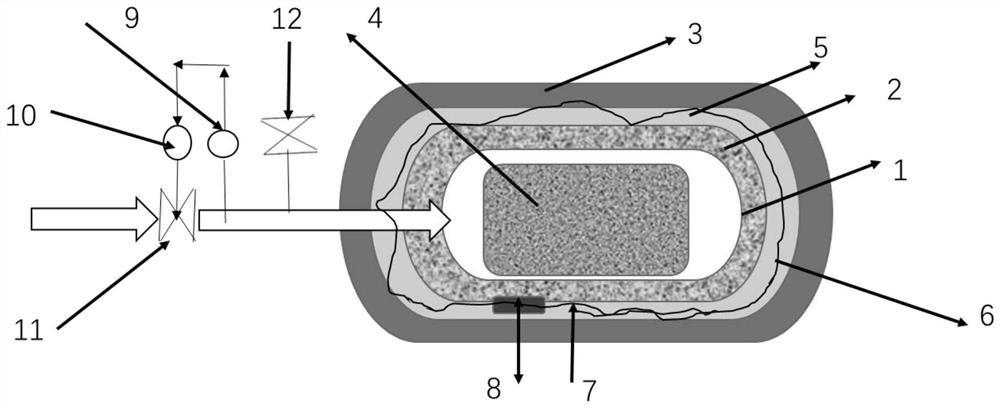

Efficient hydrogen storage device

PendingCN112833323AMild operating temperatureLow hydrogen storage pressureVessel geometry/arrangement/sizeContainer filling methodsSheet structureGraphene

Owner:CNOOC GAS & POWER GRP

Purifying method of biodiesel

ActiveCN109810735ARich capillary channelsRich pore size range distributionBiofuelsFatty-oils/fats refiningBiodieselPurification methods

The invention discloses a purifying method of biodiesel. The purifying method is characterized by purifying crude biodiesel by adopting a percolation system, thus obtaining the biodiesel, wherein thepercolation system at least comprises one percolation tower taking thermal activated bauxite as filler. According to the purifying method disclosed by the invention, the percolation tower taking the thermal activated bauxite as the filler is adopted for percolating and purifying the crude biodiesel, and the adsorption ability on impurities such as polar molecular water, methanol, sterol, glycerinum, phospholipid, acid-base catalyst residue and free fatty acid in the crude biodiesel is increased by utilizing strong adsorption and filtering functions and high purifying resolution of the thermalactivated bauxite on the impurities, so that the biodiesel with higher quality and higher purity is obtained; meanwhile, the acid value of the biodiesel is reduced, mixing of poor impurities is avoided, the quality of the biodiesel is increased, and the purifying efficiency is high.

Owner:CHANGAN UNIV

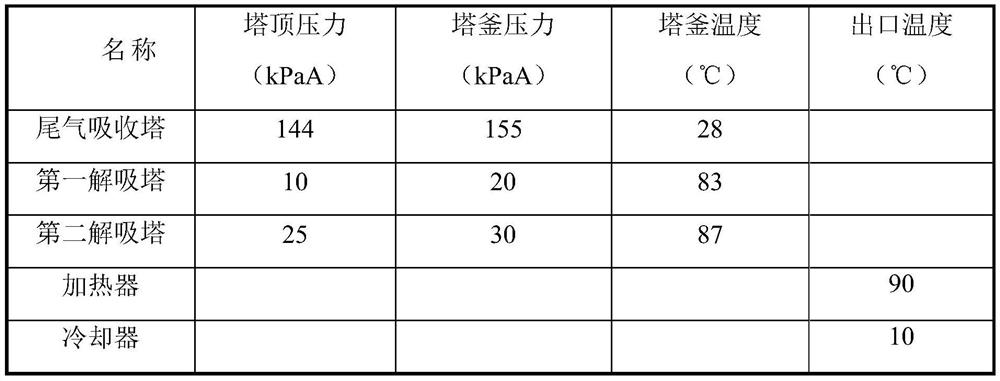

Treatment system and treatment method for divinyl benzene production tail gas

ActiveCN114515497AImprove recycling efficiencyMild operating temperatureGas treatmentChemical industryEngineeringMechanical engineering

The invention provides a treatment system for divinyl benzene production tail gas. The treatment system comprises a tail gas absorption tower, a first desorption tower and a second desorption tower, wherein the first desorption tower and the second desorption tower are respectively connected with the tail gas absorption tower. By means of the absorption tower and the two desorption towers connected with the absorption tower in parallel, a good recovery effect is achieved, and meanwhile the device has the advantages of being easy to operate and easy to control.

Owner:CHINA PETROLEUM & CHEM CORP +1

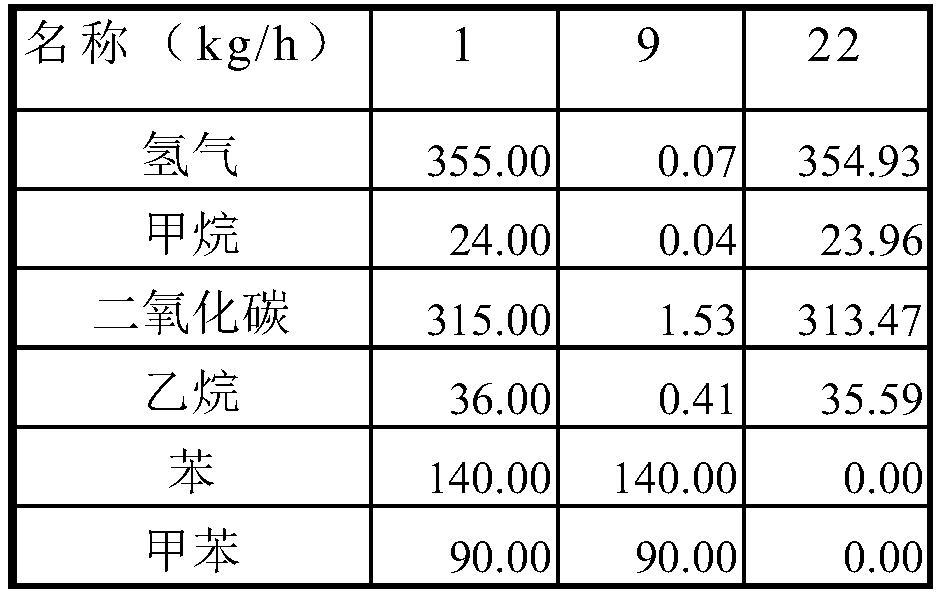

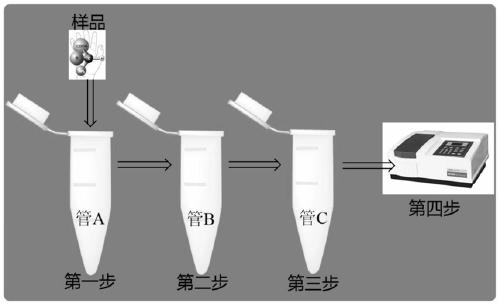

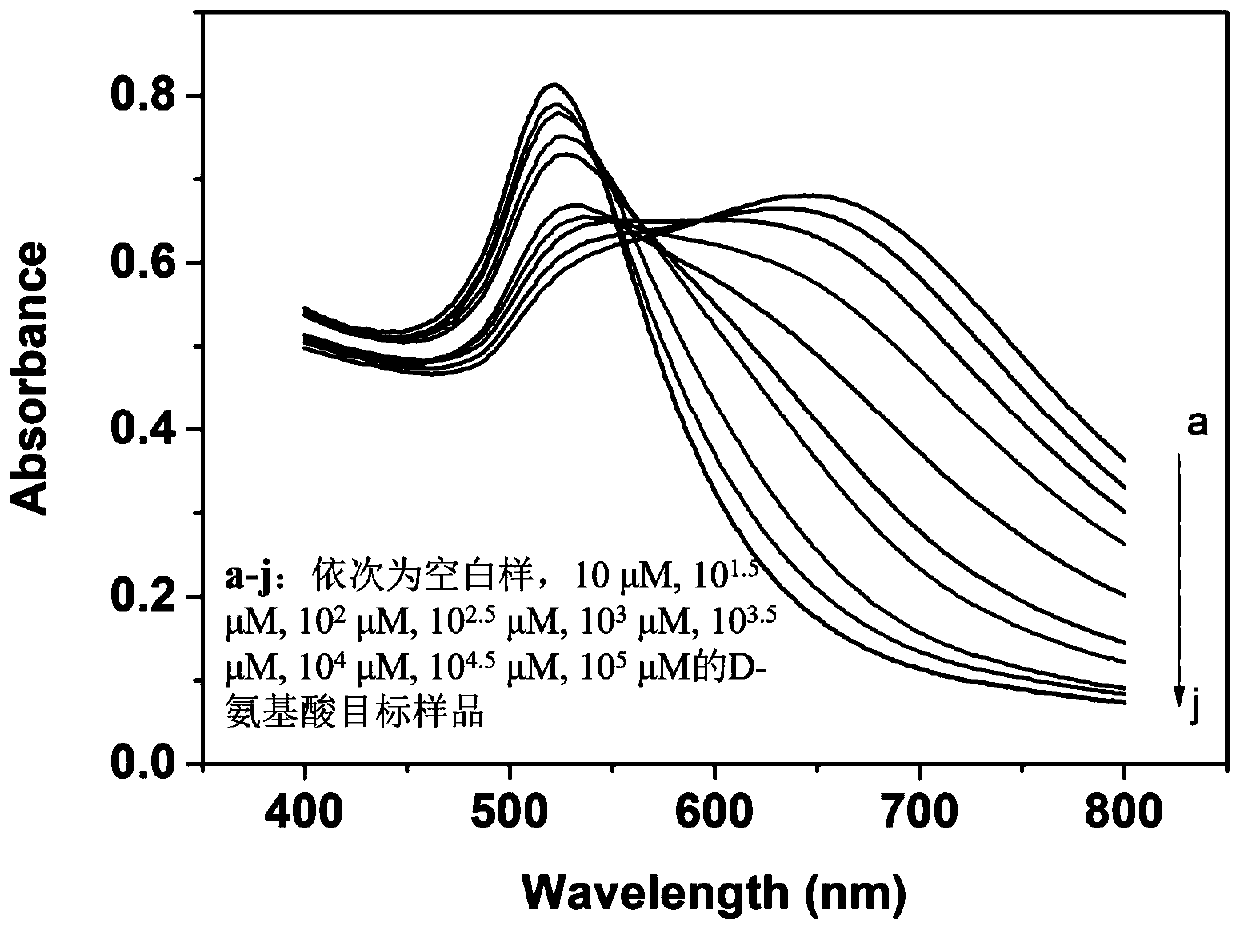

D-amino acid detection kit and detection method thereof

InactiveCN111272945AMild operating temperatureReduce dosageChemical analysis using catalysisColor/spectral properties measurementsNanoparticleEnzyme

The invention relates to synthesis of kits, in particular to a D-amino acid detection kit and a detection method thereof. The kit contains D-amino acid enzyme, a 1, 4-benzeneboronic acid solution anda gold nanoparticle solution, wherein the volume ratio is 1: (1-5): (10-20). The kit is simple and easy to operate, can realize green and pollution-free D-amino acid detection, and has potential application value in the research fields of molecular biology, bioanalytical chemistry, marine science, tumor science and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

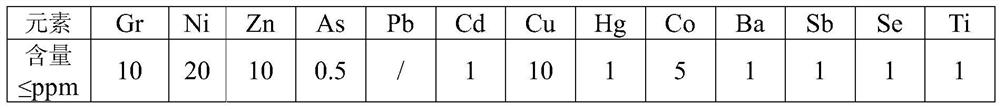

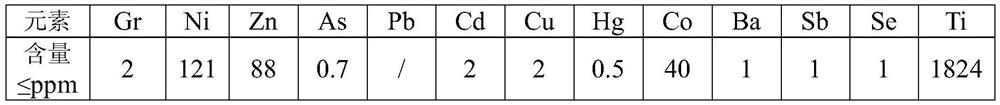

A kind of refining method of electronic grade ferrous sulfate solution and electronic grade ferrous sulfate

The invention discloses a method for refining an electronic-grade ferrous sulfate solution, which comprises the following steps: (1) taking the by-product ferrous sulfate solution of titanium dioxide, adjusting the pH to 4.5-5, stirring for 0.1-3 hours, separating and precipitating, and removing Titanium ferrous sulfate solution; (2), control the temperature of the ferrous sulfate solution for titanium removal at 20-50°C, adjust the pH to 6.5-7, and then add an appropriate amount of ferrous sulfate solution to ionize S 2‑ sulfide solid, or drop an appropriate amount of sulfide aqueous solution, then continue to stir for 0.5 to 3 hours, adjust the pH to 6.5 to 7, continue to stir for 0.1 to 3 hours, separate and precipitate, and obtain a ferrous sulfate refined solution; (3), Adjust the pH of the ferrous sulfate refining solution to 2.5-2.8. The refining method of the present invention has cheap and easy-to-obtain raw materials, and by controlling the pH and temperature within an appropriate range, the heavy metal content in the titanium dioxide by-product ferrous sulfate can be effectively removed to meet the requirements of electronic grade ferrous sulfate, and the production cost is significantly reduced .

Owner:YIXING HUAYI COLORING TECH CO LTD

Carbon elimination technique using dimethyl carbonate as absorbing agent

InactiveCN101254388BLow priceReduce energy consumptionDispersed particle separationBy absorptionCo2 removalPoly(ethylene glycol) dimethyl ether

Owner:TSINGHUA UNIV

A humidifying-dehumidifying seawater or brackish water desalination device and method

InactiveCN105036220BIncrease heat and mass transfer rateLow vaporization temperatureGeneral water supply conservationSeawater treatmentWater desalinationWater vapor

The present invention belongs to a humidification-dehumidification desalination method and apparatus for sea water or brackish water, and the apparatus includes pretreatment system and a humidification-dehumidification system. The pretreated seawater or brackish water is introduced into a storage tank, preheated by a heater, pumped into a humidification tower; and then the seawater or brackish water passes through an overhead liquid distributor and directly contacts with the bottom-up carrier gas flowing through a packed column, so as to humidify the carrier gas; and the carrier gas with high humidity is introduced to dehumidification tower bottom via a pipeline, and direct contacts with the top-down cooling water, and the water vapor is condensed and discharged with cooling water, so as to obtain fresh water. The method uses the characteristics of large specific surface area and small resistance of the filler, realizes gas-liquid interphase faster heat and mass transfer, and is applicable to sea island, desert and thermal power plants. Compared with the prior desalination technology, the apparatus has the characteristics of simple equipment, easy operation, easy treatment and cleaning, small investment, and easy operation and maintenance.

Owner:ZHEJIANG UNIV

A method for extracting and preparing verbascoside standard substance from the leaves of Auranthus nudiflora

ActiveCN104530147BHigh selectivityImprove mass transfer coefficientSugar derivativesSugar derivatives preparationBiotechnologyCallicarpa nudiflora

The invention relates to a preparation method of verbascoside, particularly relates to a method for preparing a high-pure verbascoside product from callicarpa nudiflora by adopting a supercritical fluid extraction technique, and a use of the verbascoside product obtained by the preparation method as a standard substance. The supercritical fluid extraction technique adopts the following extraction conditions: the amount of an entrainer is 0.2-0.5 time of the raw material mass, soaking is carried out for 12-24 h, under the conditions of the pressure of 35 MPa and the temperature of 60-70 DEG C, static extraction is carried out for 0.1-0.5 h, and then dynamic extraction is carried out for 1.5-2 h at the speed of 0.1-1.0 L / min. The entrainer is composed of water, methanol, n-hexane and ammonia water with the volume percentage ratio of 55%:15%:25%:5%.

Owner:JIANGXI POZIN PHARMA

Catalyst for preparing 3-pentanol by hydrogenation of 3-pentanone and preparation method thereof

InactiveCN104368359BMild operating temperatureReduce energy consumptionOrganic compound preparationHydroxy compound preparationHydrogenation process3-Pentanol

The invention discloses a catalyst for preparing 3-pentanol through 3-pentanone hydrogenation. The catalyst comprises a carbon-based carrier and a multi-metal component recorded as M1-M2-M3 / C, wherein M1 is selected from one of Ru, Mn and Ag; M2 is selected from one of Ir, Au and Cu; and M3 is selected from one of La, Ce and Y. The catalyst is applied to the liquid phase 3-pentanone hydrogenation process. The conversion rate of 3-pentanone can be 100 percent within a short time, and the selectivity of the 3-pentanol is 100 percent. The invention also provides a method for preparing the catalyst, and the industrial preparation is easily realized.

Owner:XIAMEN UNIV

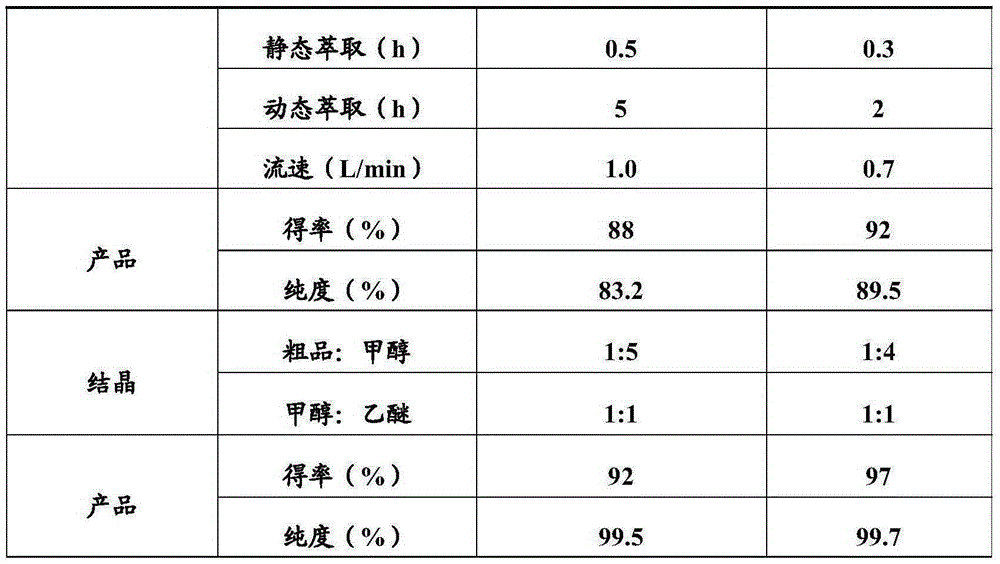

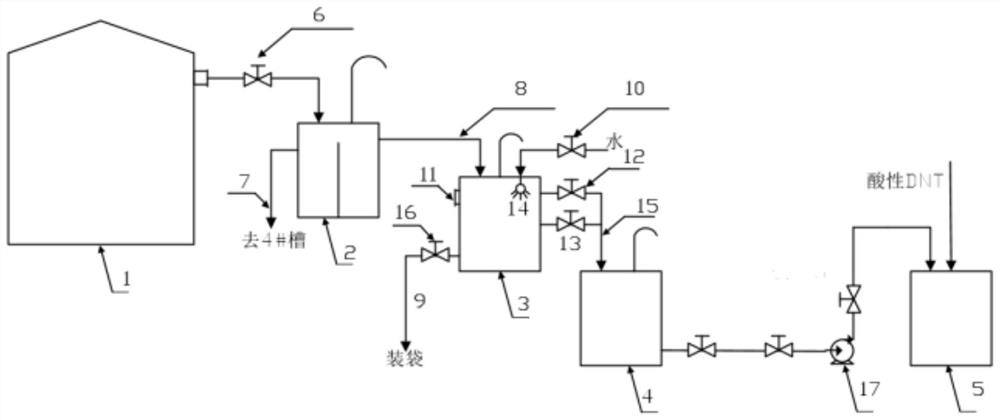

TNT waste acid-residual liquid recovery process and device

ActiveCN113371768ALess quantityReduce the amount of destructionWater contaminantsNature of treatment waterNitrobenzeneEnvironmental engineering

The invention discloses a TNT waste acid-residual liquid recovery process and device. The production process comprises the following steps of: (1) enabling waste acid-residual liquid to stand, and separating the waste acid at the lower layer and the residual liquid at the upper layer according to the specific gravity difference; (2) separating MNT at the upper layer and a polymer at the lower layer according to the difference of the specific gravity of components in the residual liquid; and (3) mixing the separated MNT and DNT acid liquor for reproduction of TNT. According to the method disclosed by the invention, the treatment capacity of the polymer is reduced, and meanwhile, full recycling of waste acid and MNT is realized; the recovered MNT is mixed with the acidic DNT generated by a polynitrobenzene production chain, so that the melting point of the DNT can be effectively reduced, and the DNT can be better stored and reproduced; and therefore, comprehensive recovery of waste acid-residual liquid is realized on the whole, and energy conservation, emission reduction and cyclic utilization are realized.

Owner:HUBEI DONGFANG CHEM IND

A kind of method for extracting magnesium by high-pressure carbonization

The invention provides a method for extracting magnesium by means of high-pressure carbonization.The method includes steps of uniformly mixing water with raw materials with magnesium to obtain reaction slurry; carrying out carbonization reaction on the reaction slurry and carbon dioxide gas under the condition of gauge pressures of 1-5 MPa to obtain serous fluid; keeping the reaction pressures and separating solid from fluid in the serous fluid to obtain fluid with heavy magnesium; reducing the pressures and decomposing the fluid with the heavy magnesium to obtain decomposed serous slurry; separating solid from fluid in the decomposed serous fluid to obtain solid and drying the solid to obtain magnesium-rich products.The method has the advantages that the method can be applied to utilizing magnesium-rich minerals such as magnesite and magnesium-rich solid waste such as boric sludge, the carbonization magnesium extraction efficiency and the calcium and magnesium separation efficiency can be improved, and energy consumption and the economic cost can be reduced to a great extent; as compared with existing processes for extracting magnesium, the method is mild in operation temperature, little in variation, low in energy consumption and heat exchange difficulty and easy to implement, required equipment is small, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com