Method for continuously separating CH4/CO2 by using fluidized bed

A CO2 and fluidized bed technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low mass transfer and heat transfer efficiency, long separation time, etc., and achieve easy control, uniform temperature, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

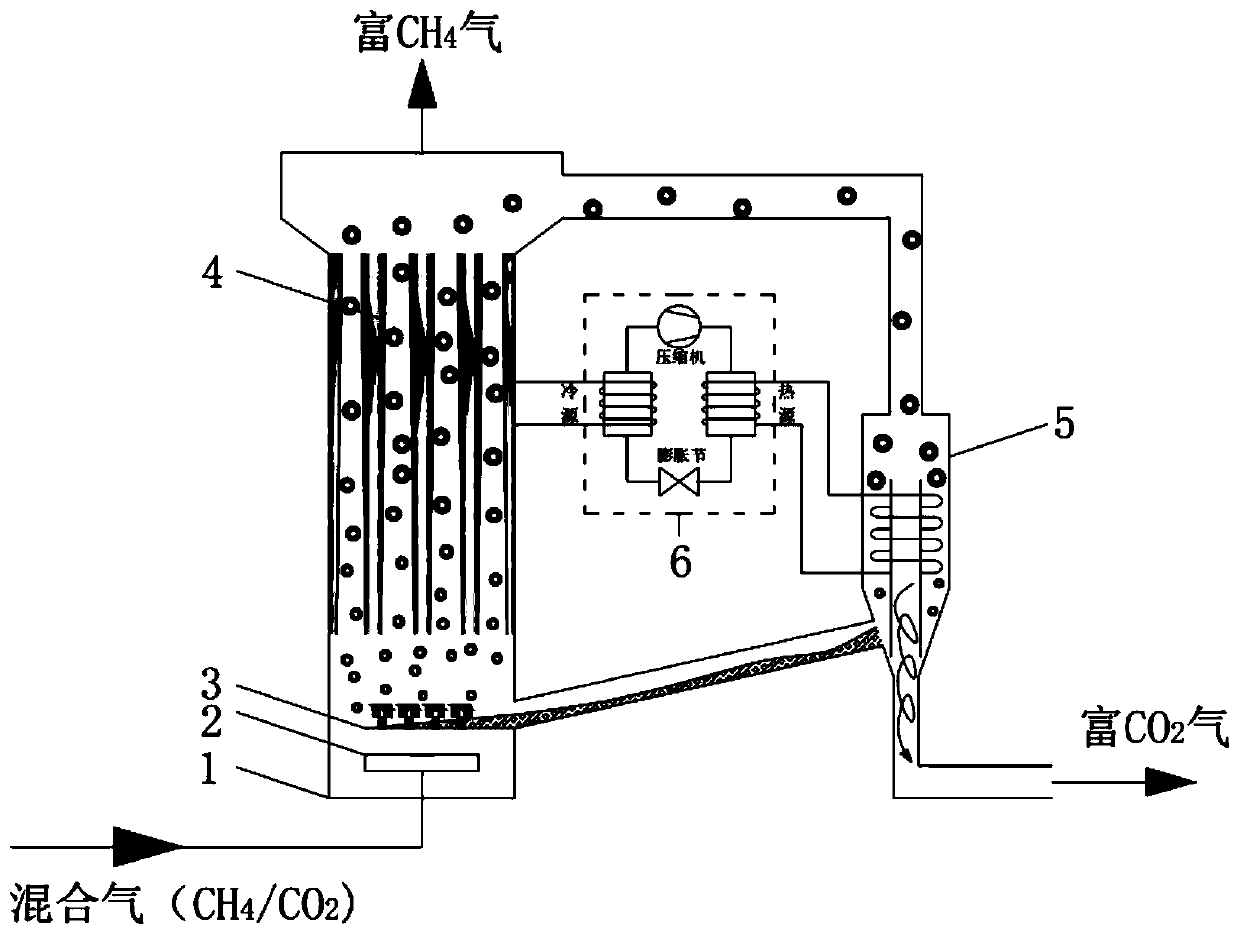

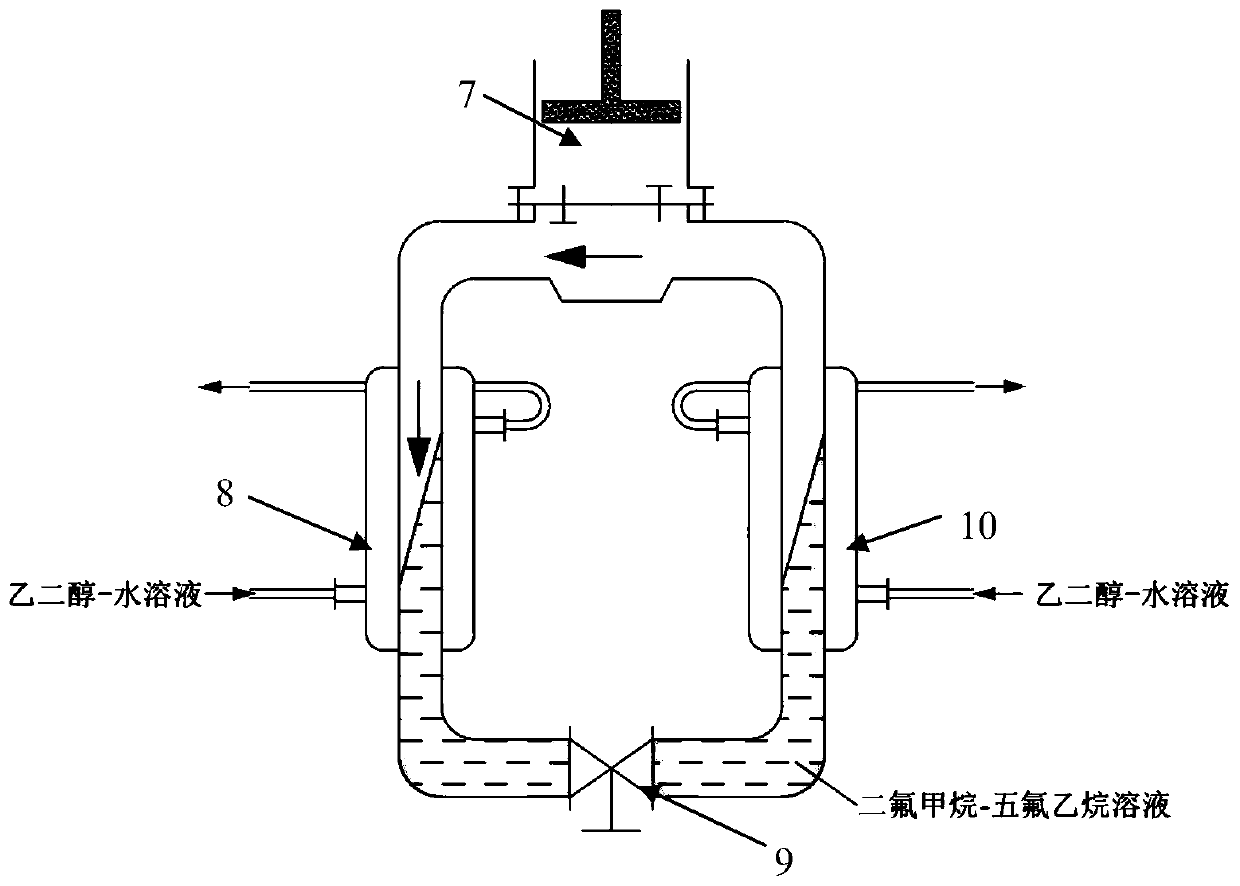

Method used

Image

Examples

Embodiment 1

[0033] In this example, CH is carried out through the formation and decomposition of hydrate 4 / CO 2 Separation of mixture. Select 1.76wt% tetrabutylammonium bromide solution to separate CH 4 (67.00 mol%) / CO 2 (33.00 mol%), first set the operating temperature in the fluidized bed to 281.3K, where the mixed gas feed pressure is 1.14MPa, the flow rate is 1.5m / s, the working fluid flow rate is 0.3m / s, CH 4 Enriched in the fluidized bed gas phase. Using a heat pump to control the inner surface temperature of the cone of the cyclone separator to 298.15K, the hydrate decomposes, and the CO 2 It is enriched in the gas phase, while the working fluid flows into the fluidized bed reactor for recycling. It is calculated that under the above conditions, 90.38% CH can be produced continuously 4 and 71.51% CO 2 .

Embodiment 2

[0035] In this example, CH is carried out through the formation and decomposition of hydrate 4 / CO 2 Separation of mixture. Select pure aqueous solution to separate CH 4 (67.00 mol%) / CO 2 (33.00 mol%), first set the operating temperature in the fluidized bed to 278.15K, where the mixed gas feed pressure is 3MPa, the flow rate is 1.4m / s, the working fluid flow rate is 0.3m / s, CH 4 Enriched in the fluidized bed gas phase. Using a heat pump to control the inner surface temperature of the cone of the cyclone separator to 298.15K, the hydrate decomposes, and the CO 2 It is enriched in the gas phase, while the working fluid flows into the fluidized bed reactor for recycling. It is calculated that under the above conditions, 78.66% CH can be produced continuously 4 and 51.53% CO 2 .

Embodiment 3

[0037] In this example, CH is carried out through the formation and decomposition of hydrate 4 / CO 2 Separation of gas mixture. Select 0.293mol% tetrabutylammonium fluoride solution to separate CH 4 (50mol%) / CO 2 (50.00 mol%), first set the operating temperature in the fluidized bed to 278.15K, where the mixed gas feed pressure is 3MPa, the flow rate is 1.8m / s, the working fluid flow rate is 0.3m / s, CH 4 Enriched in the fluidized bed gas phase. Using a heat pump to control the inner surface temperature of the cone of the cyclone separator to 298.15K, the hydrate decomposes, and the CO 2 It is enriched in the gas phase, while the working fluid flows into the fluidized bed reactor for recycling. It is calculated that under the above conditions, 80.57% CH can be produced continuously 4 and 56.9% CO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com