Patents

Literature

151 results about "Tetrabutylammonium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetra-n-butylammonium fluoride, commonly abbreviated to TBAF and n-Bu4NF, is a quaternary ammonium salt with the chemical formula (CH3CH2CH2CH2)4N+F−. It is commercially available as the white solid trihydrate and as a solution in tetrahydrofuran. TBAF is used as a source of fluoride ion in organic solvents.

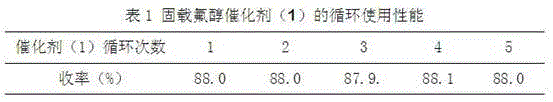

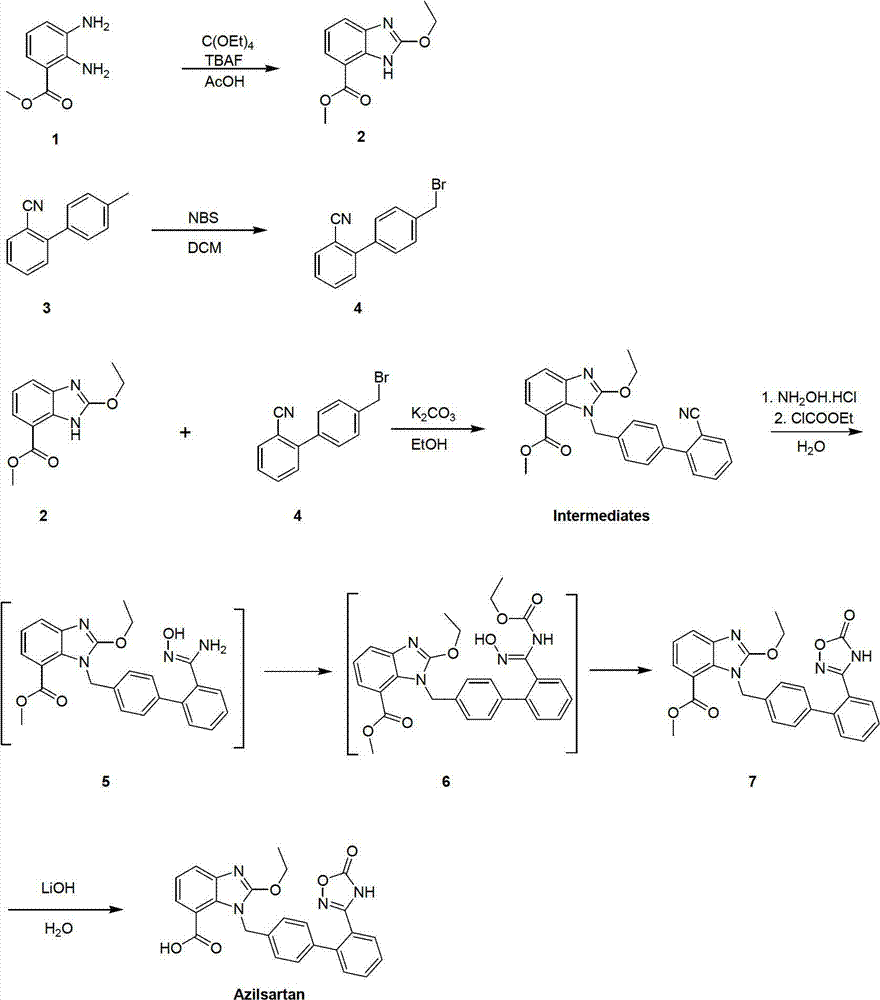

Preparation method of azilsartan

InactiveCN102766138AReduce usageEmission reductionOrganic chemistryEthyl chloroformateCarboxylic salt

The invention relates to a preparation method of azilsartan, comprising the following steps of: (1) preparing ethoxybenzimidazole-7-methyl carboxylate; (2) preparing 2-cyan-4'-bromomethyl biphenyl; (3) dissolving the ethoxybenzimidazole-7-methyl carboxylate and the 2-cyan-4'-bromomethyl biphenyl into ethanol; adding potassium carbonate to react to obtain 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate; (4) suspending the 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate in water; adding hydroxylamine hydrochloride, sodium hydroxide and tetrabutylammonium fluoride; heating and reflowing, and then cooling; adding the sodium hydroxide and ethyl chloroformate, heating and reflowing to obtain azilsartan methyl ester; and (5) hydrolyzing the azilsartan methyl ester to obtain a product. The preparation method of the azilsartan, disclosed by the invention, has the advantages of being short in process route, high in yield, and safe and reliable; and the purity of the azilsartan obtained by using the method is high.

Owner:WENZHOU PEOPLES HOSPITAL

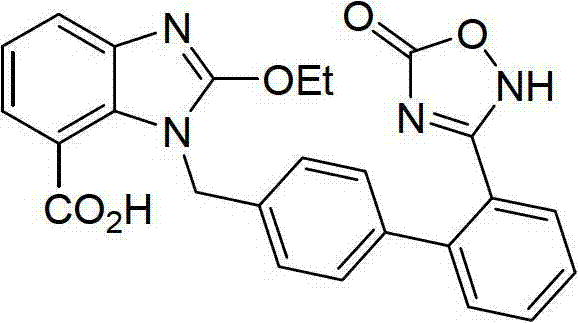

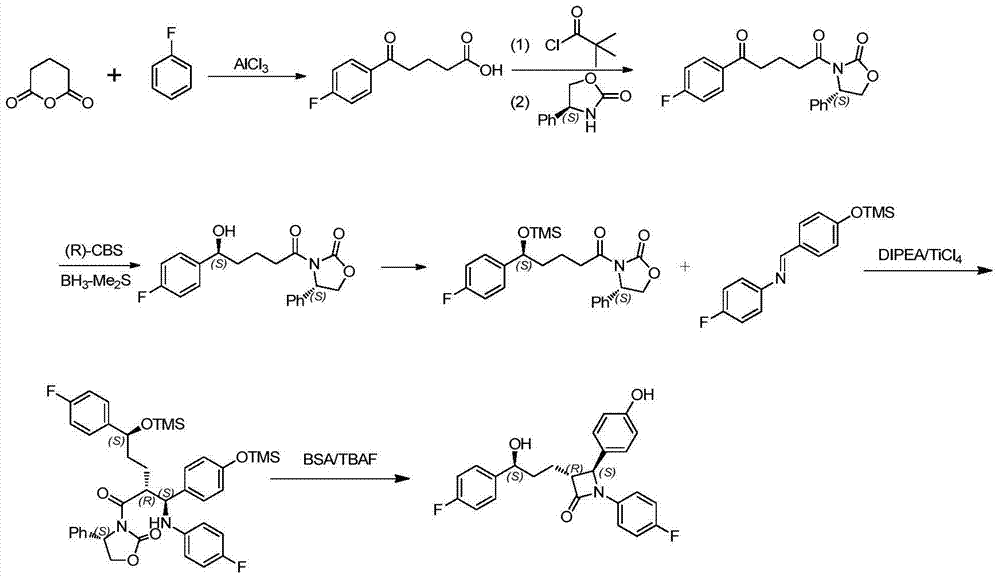

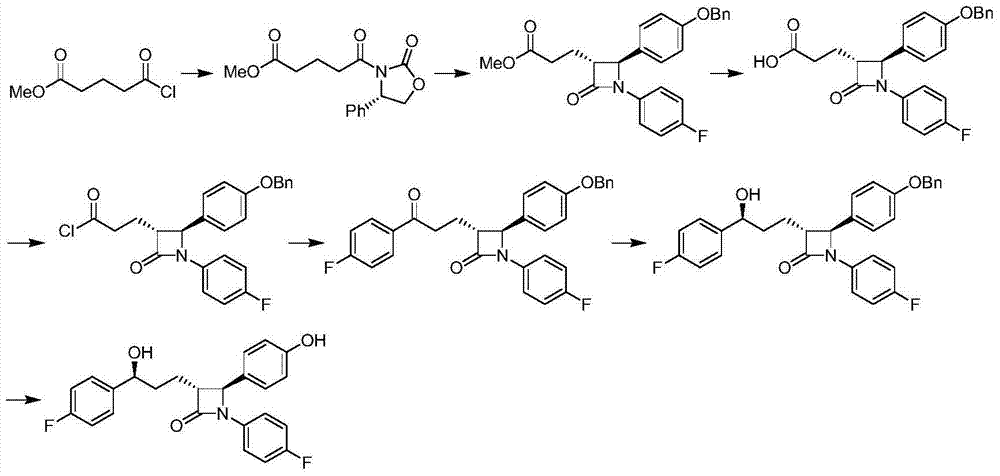

Ezetimibe synthesis method and Ezetimibe intermediate synthesis method

ActiveCN104513187AReduce usageStarting materials are cheap and readily availableGroup 4/14 element organic compoundsTert-butyldimethylsilyl chlorideOrganic solvent

The invention provides an Ezetimibe synthesis method comprising the following steps: (a) a compound (5) is subjected to asymmetric reduction reaction to obtain a compound (6), and the compound (6) and tert-butyldimethylsilyl chloride react in an organic solution under the action of alkali to obtain a compound (7); (b) the compound (7) and diisopropylethylamine are dissolved in the organic solution, titanium tetrachloride is added in the organic solution to react at 20-50 DEG C, and a compound (3) is added in the organic solution at minus 20 to minus 60 DEG C to react to obtain a compound (8); (c) the compound (8) and N,O-bis(trimethylsilyl) acetamide react in the organic solution at 20-80 DEG C, tetrabutylammonium fluoride trihydrate is added into the organic solution to react at 20-80 DEG C to obtain a compound (9); (d) the compound (9) is subjected to off-protection reaction to obtain Ezetimibe, wherein R is equal to TBS, Ac or COOCH2CCl3. The invention further provides an Ezetimibe intermediate and a preparation method thereof.

Owner:ARROMAX PHARMATECH

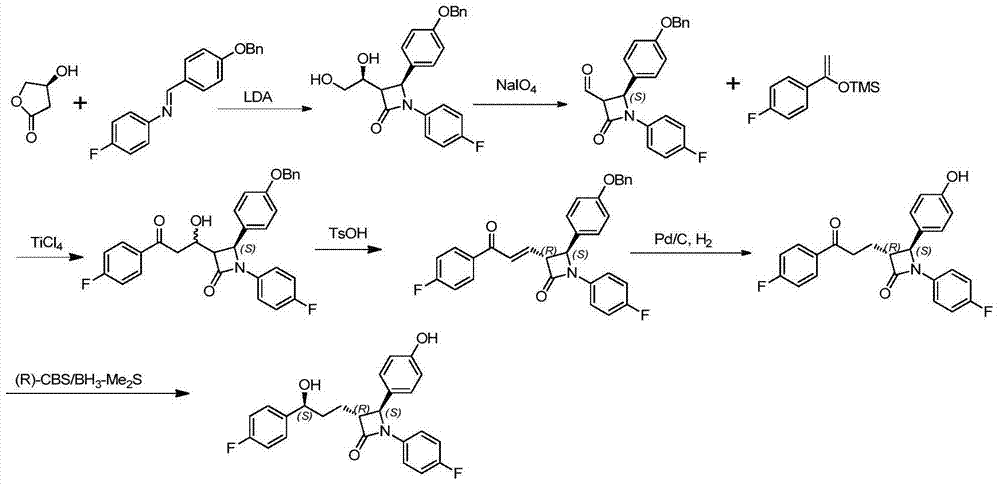

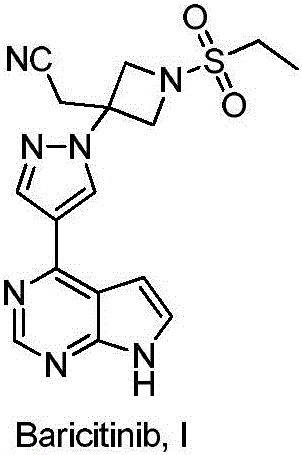

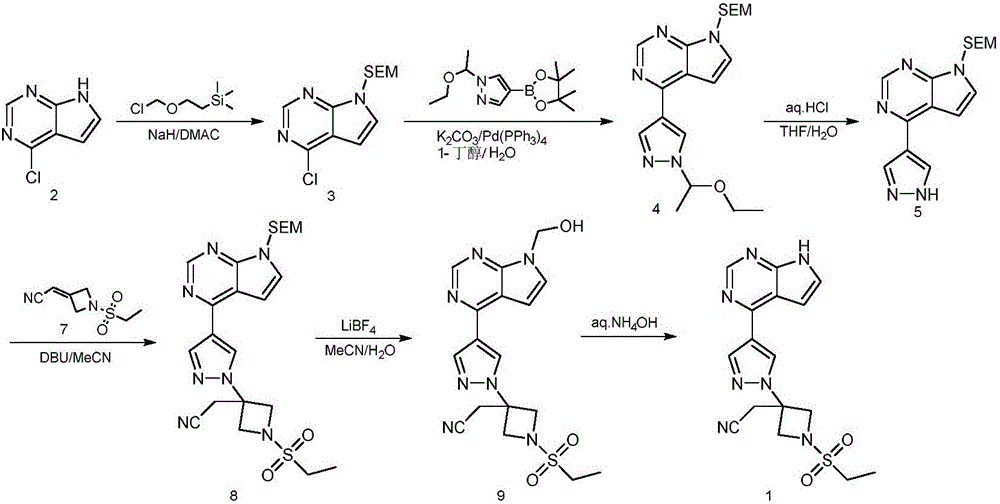

Preparation method of baricitinib

ActiveCN107176955ARaw materials are easy to getSimple processOrganic chemistrySulfonyl chlorideBoronic acid

The invention discloses a preparation method of baricitinib. The method comprises the following steps: performing a substitution reaction on 4-chloro-7H-pyrrolo[2,3-d]pyrimidine (II) serving as a raw material and benzene sulfonyl chloride in the presence of an alkali to obtain an intermediate III; then, performing a Suzuki coupling reaction on the intermediate III and 4-pyrazole-4-boronic acid pinacol ester in the presence of a palladium catalytic system and an alkali to obtain an intermediate V; then performing a Michael addition reaction on the intermediate V and 3-(cyanomethylene)azetidine-1-tert-butyl formate in the presence of a catalyst to obtain an intermediate VII; then removing Boc protection from the intermediate VII under the action of hydrochloric acid to obtain an intermediate VIII; then performing a sulfoamidate reaction on the intermediate VIII and ethyl sulfonyl chloride in an organic solvent in the presence of an alkali to obtain an intermediate IX; lastly, removing benzenesulfonyl protection from the intermediate IX under the action of tetramethylammonium fluoride or tetrabutylammonium fluoride or a trihydrate of the tetramethylammonium fluoride or the tetrabutylammonium fluoride to obtain baricitinib (I). Compared with the prior art, the method has the advantages of adoption of readily-available raw materials, low cost, high product yield and easiness for industrial production.

Owner:NANJING YOKO PHARMA +2

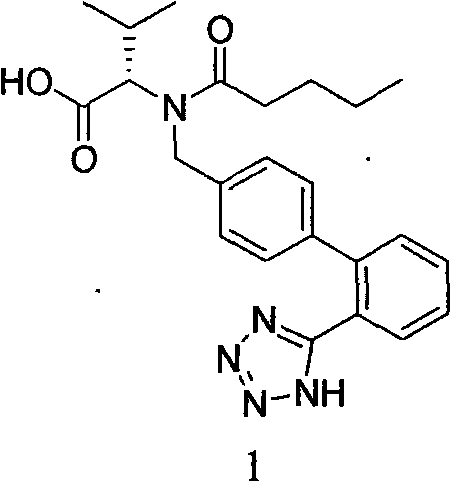

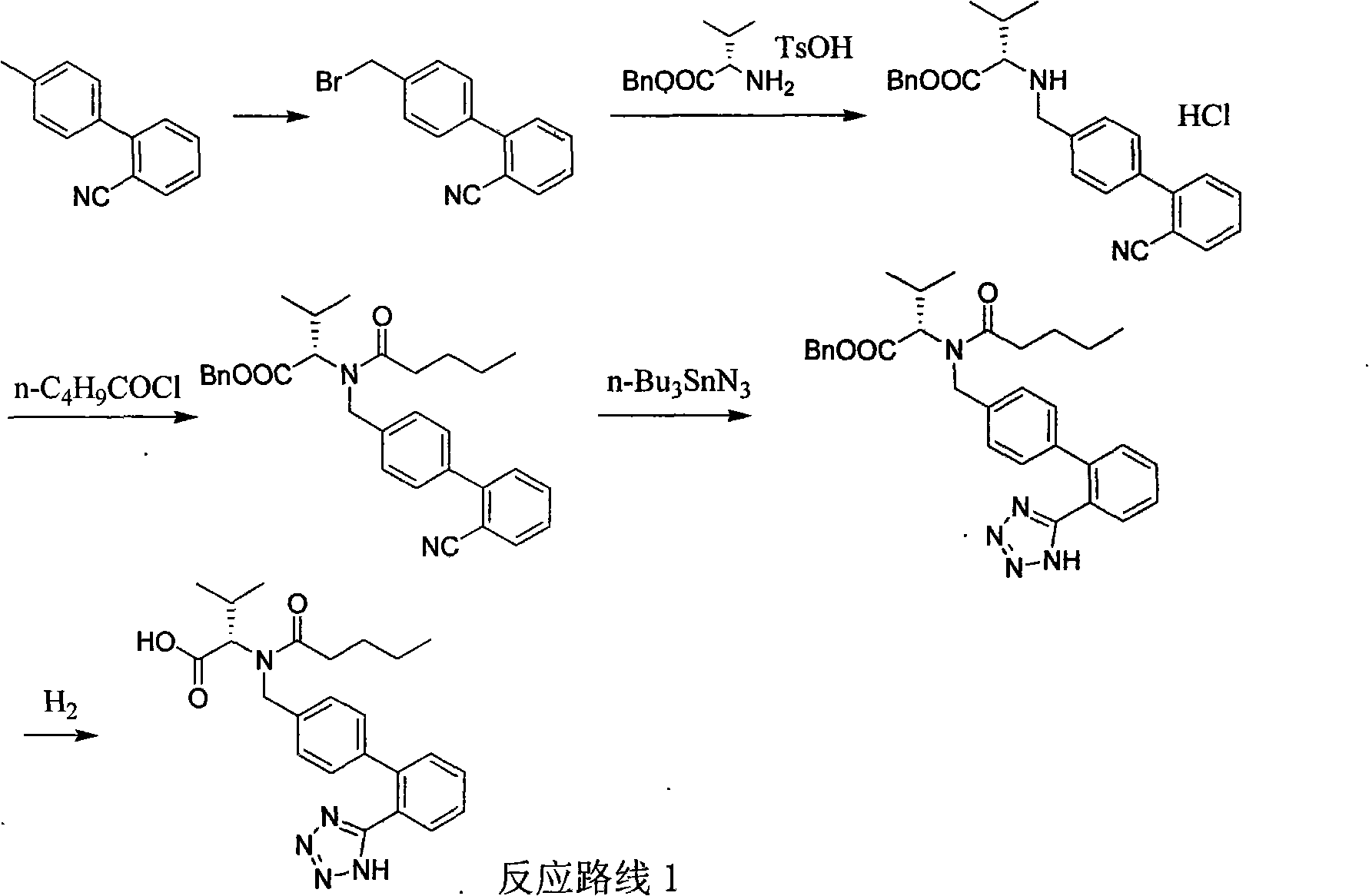

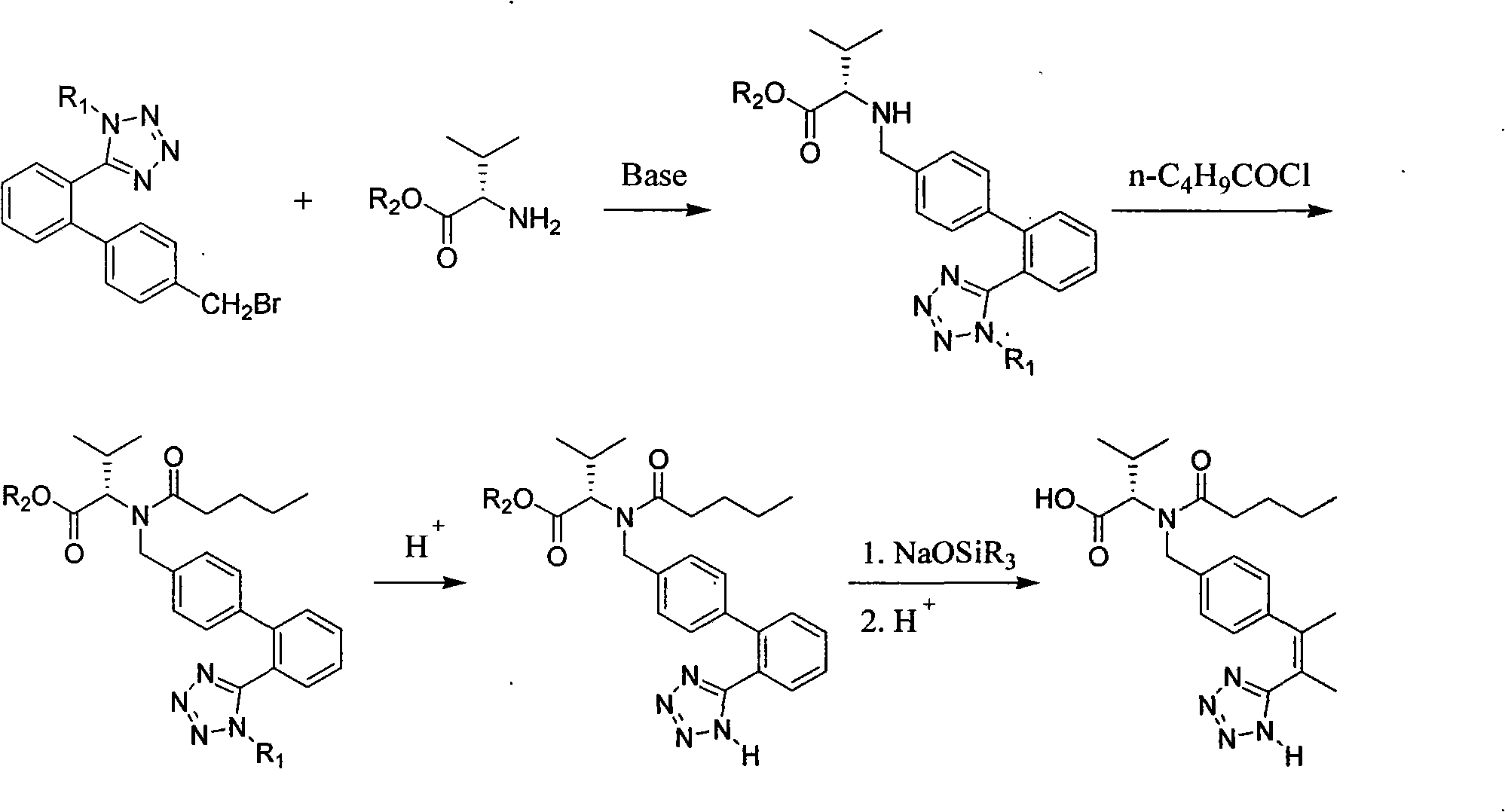

Improved preparation method of valsartan

ActiveCN102010381AOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAzirineValsartan

The invention provides an improved preparation method of valsartan, which is characterized in that triazo trimethylsilane is replaced with a triazo tin compound to be used as a source of triazo to ensure that the toxicity is greatly reduced, tetrazole is introduced by adopting a solvent-free reaction method when tetrabutylammonium fluoride is used as a catalyst, thus the operation is simplified, and the yield is improved and reaches above 80 percent.

Owner:鲁南新时代生物技术有限公司

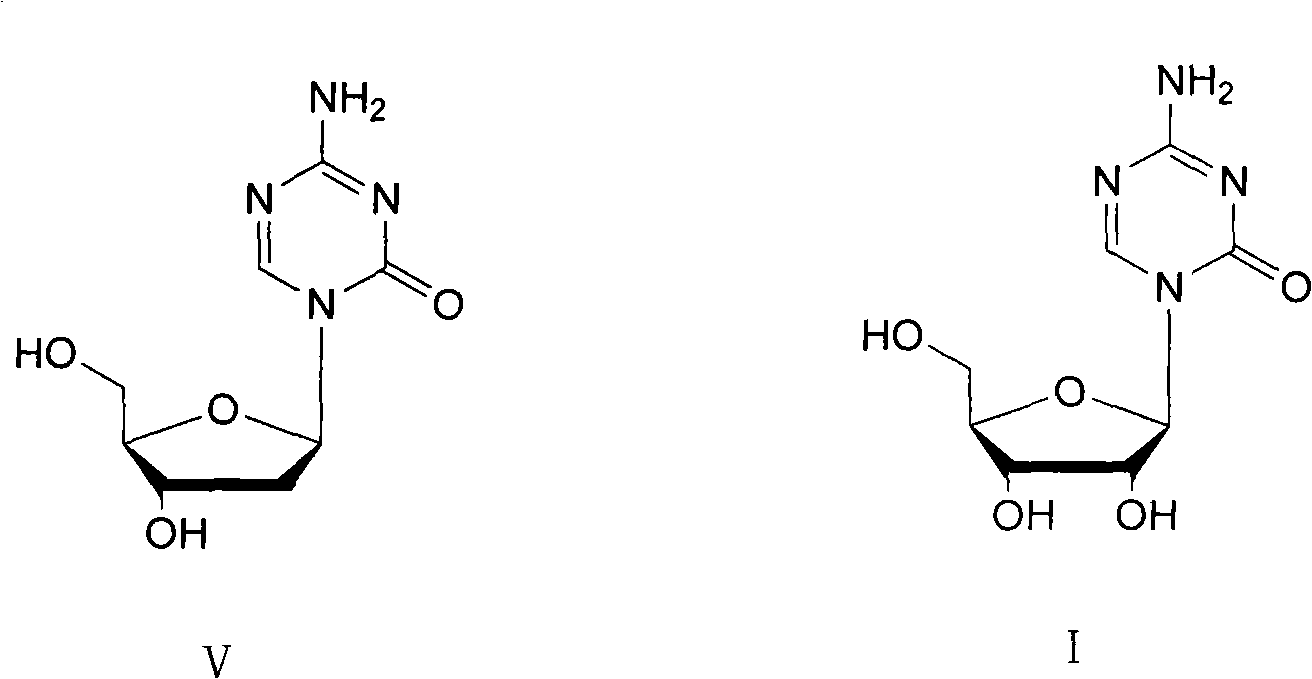

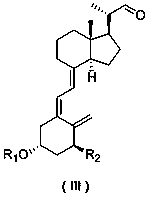

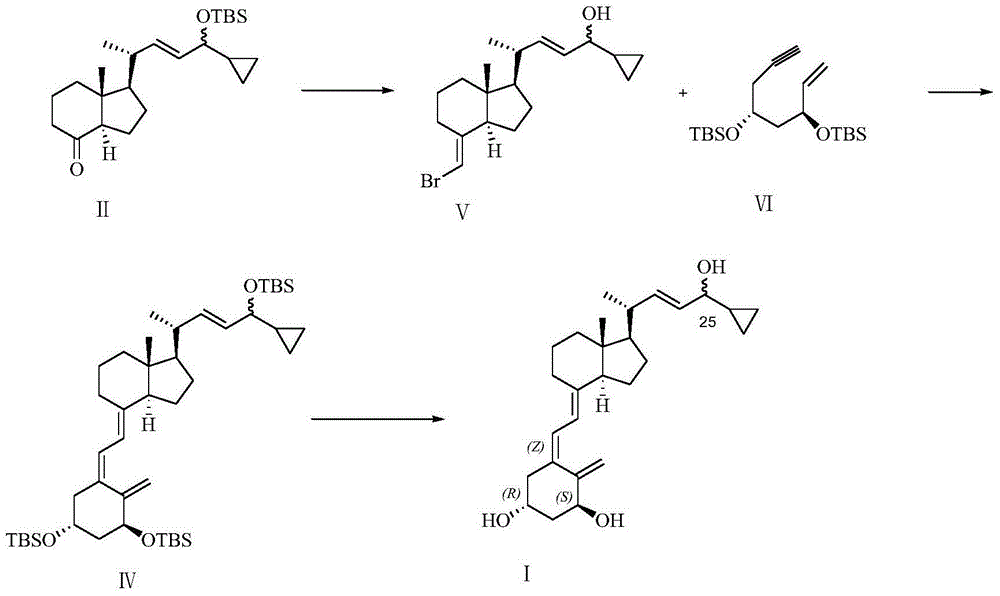

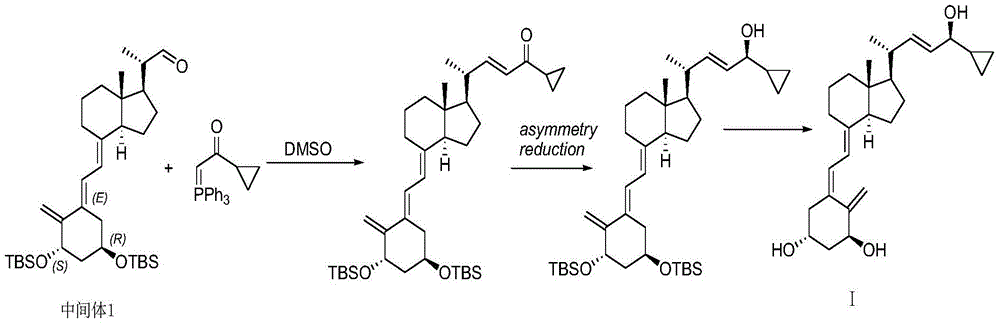

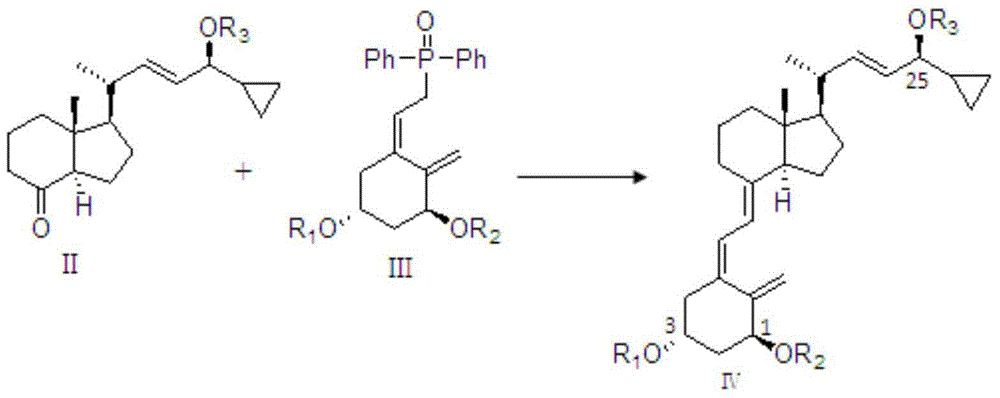

Novel preparation method for vitamin D class drug

InactiveCN104402922ALow costHigh purityGroup 4/14 element organic compoundsBulk chemical productionDrugDouble bond

The invention discloses a novel synthesis method for a vitamin D class drug, namely a calcipotriol (formula I) compound. The novel synthesis method comprises the following steps: using a compound shown as a formula II and a compound shown as a formula III as raw materials, carrying out double-bond coupling reaction under a strong base action to obtain a compound shown as a formula IV, and then removing the compound shown as the formula IV from the protection of hydroxyl silyl ethers under the action of tetrabutyl ammonium fluoride to obtain the compound shown as the formula I. The operation is simple, the yield is high and the novel preparation method is suitable for industrialization.

Owner:CHONGQING HUAPONT PHARMA

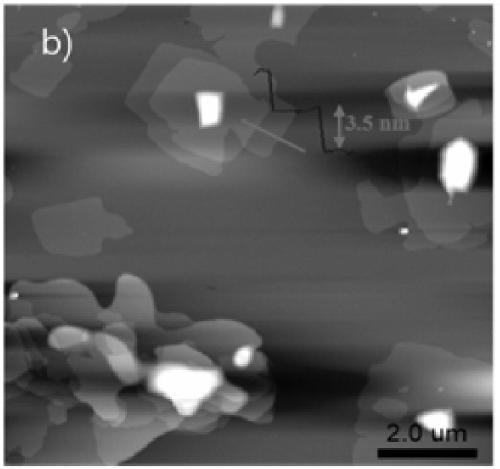

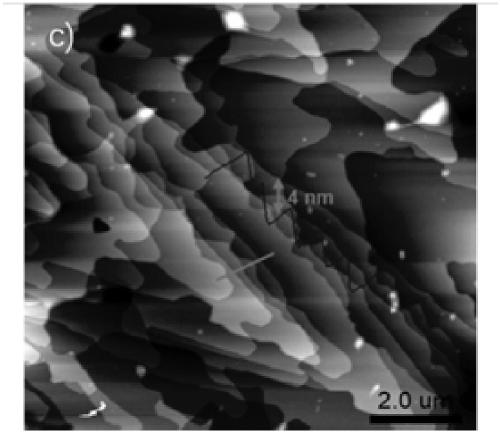

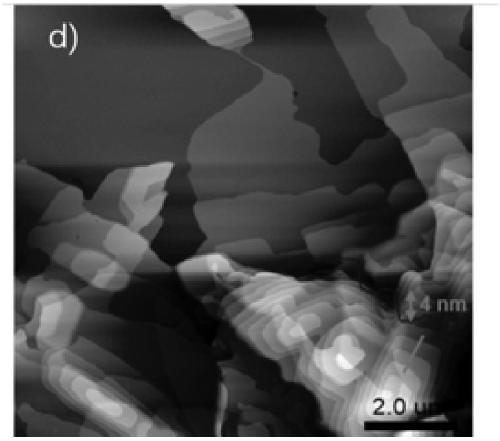

Preparation method of graphdiyne film and graphdiyne film

The invention discloses a preparation method of a graphdiyne film and the graphdiyne film prepared by the method. The method comprises the following steps: (1) mixing a catalyst with water to obtain acatalyst solution; (2) mixing a monomer with an organic solvent to obtain a monomer solution, and adding tetrabutylammonium fluoride into the monomer solution to obtain a hexaalkynyl benzene solution; (3) mixing the hexaalkynyl benzene solution, the catalyst solution and water, and uniformly mixing in an inert gas atmosphere under the action of stirring to obtain a mixed solution; and (4) reacting the mixed solution, and separating from the reaction product to obtain the graphdiyne film. Through the method, the graphdiyne film with high yield can be simply and efficiently obtained, and industrial production is easy.

Owner:QINGDAO UNIV OF SCI & TECH

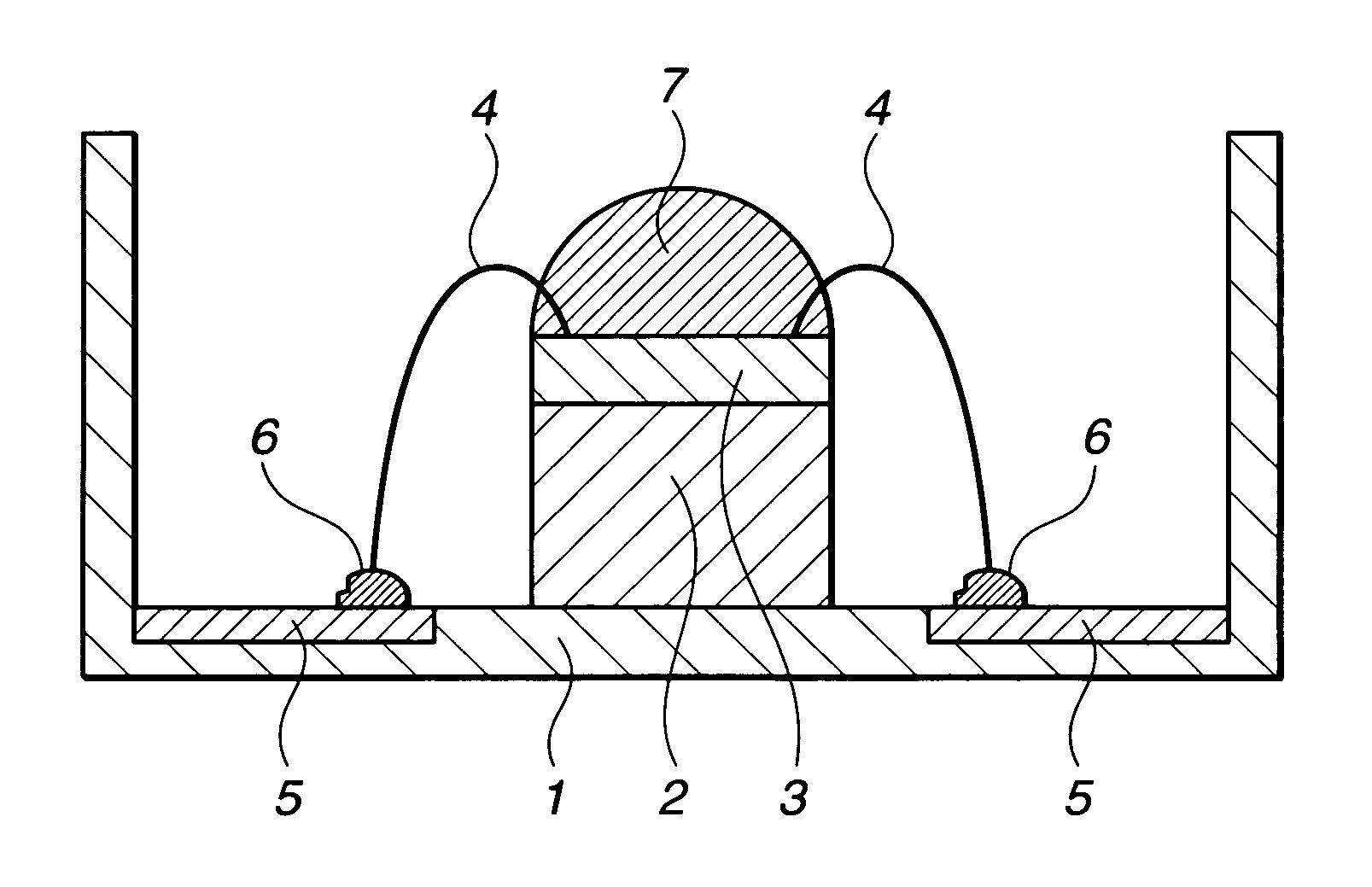

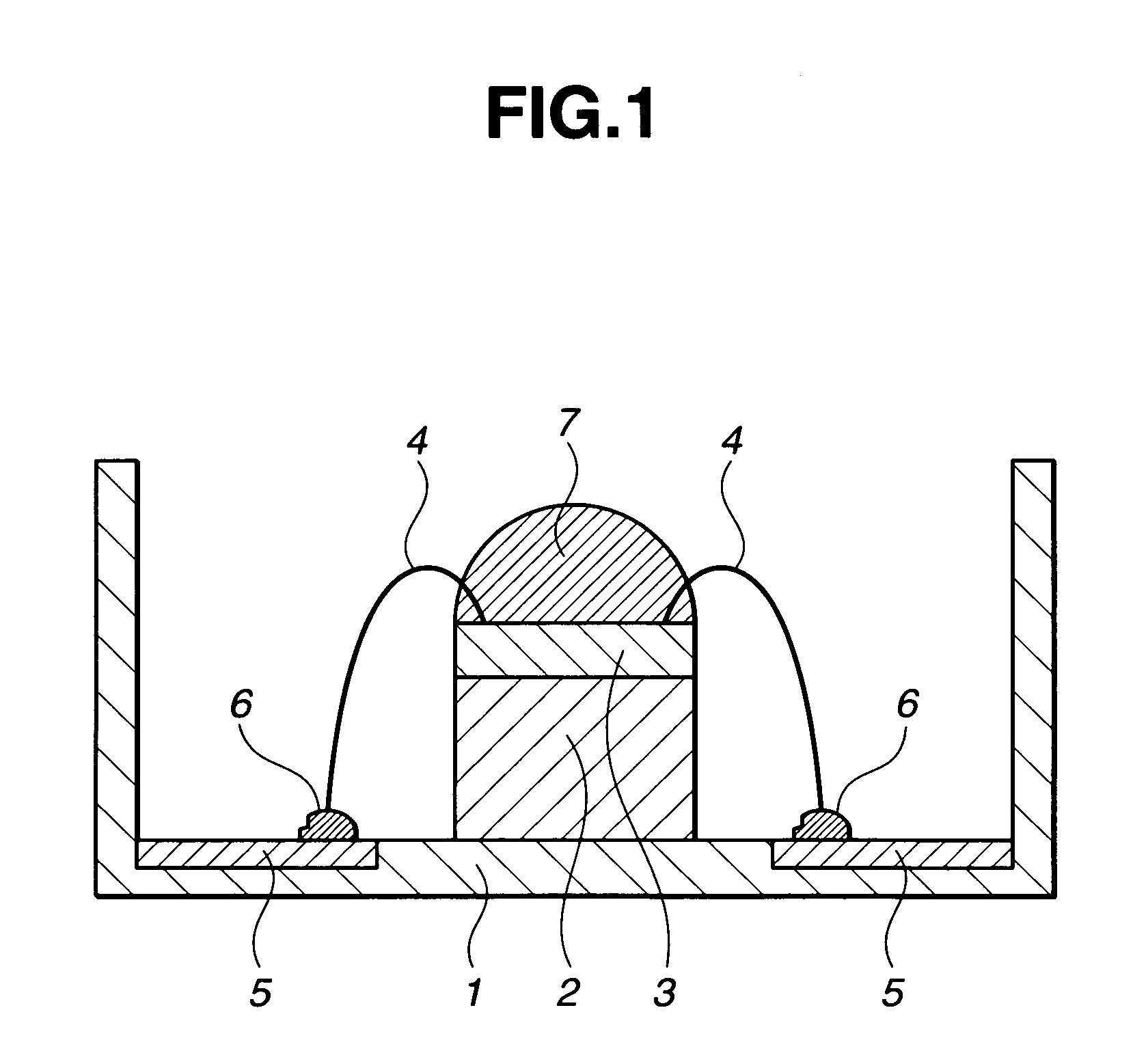

Method of removing sealant used for the protection of electric or electronic part

InactiveUS7083684B2Solid-state devicesElectrical testingTetramethylammonium hydroxidePolymer science

A sealant used for the protection of an electric or electronic part is removed by contacting the sealant with tetramethylammonium hydroxide, tetrabutylammonium fluoride or the like for thereby dissolving the sealant. The method is capable of removing only the protective sealant from the electric or electronic part without causing damage to other components of the part.

Owner:SHIN ETSU CHEM IND CO LTD

Cyano-containing resveratrol analogue and preparation method and purpose thereof

InactiveCN105503652AReduce harmAvoid harmCarboxylic acid nitrile preparationOrganic compound preparationBenzoic acidPotassium cyanide

The invention provides a cyano-containing resveratrol analogue and a preparation method and application thereof, and relates to the field of medical compounds. A structure of the cyano-containing resveratrol analogue is shown in the formula of the description; 3,5-dihydroxy-benzoic acid is mainly used as a raw material, and the cyano-containing resveratrol analogue is prepared by the following steps of methylation, reduction, brominating, Abozove rearrangement, Wittig-Hornor reaction and Knoevenegal reaction; in the preparation process of the cyano-containing resveratrol analogue, the chemical substances with lower toxicity, such as trimethylsilyl cyanide and tetrabutylammonium fluoride, are used for replacing chemicals with higher toxicity, such as sodium cyanide or potassium cyanide, to introduce cyano, so that the damage to the health of an operator is greatly decreased, and the serious harm to environments is avoided. The preparation method has the advantages that the yield is higher, the environment-friendly effect is good, and multiple types of cyano-containing resveratrol analogue with anti-cancer activity on cells can be obtained.

Owner:YANBIAN UNIV

Cleaning hairbrush for rotary screen

InactiveCN107254721AGood mechanical propertiesImprove wear resistanceBristleMonocomponent polyolefin artificial filamentBetelSebacic acid

The invention discloses a cleaning hairbrush for a rotary screen. The cleaning hairbrush for the rotary screen comprises a hairbrush body and brush hairs. The brush hairs are prepared by the following components by weight: 80-90 parts of a thermoplastic resin, 10-14 parts of betel nut shell powder, 2-4 parts of silica powder, 1-3 parts of carbon powder, 6-8 parts of tetrabutylammonium fluoride, 2-4 parts of sebacic acid disodium salt, and 3-6 parts of hydrogenation poly-1-decene. The brush hairs prepared by the provided method have the excellent mechanical properties, good abrasive resistance, and excellent acid-base and corrosion resistance. The quality of the cleaning hairbrush is greatly improved.

Owner:马鞍山起劲磁塑科技有限公司

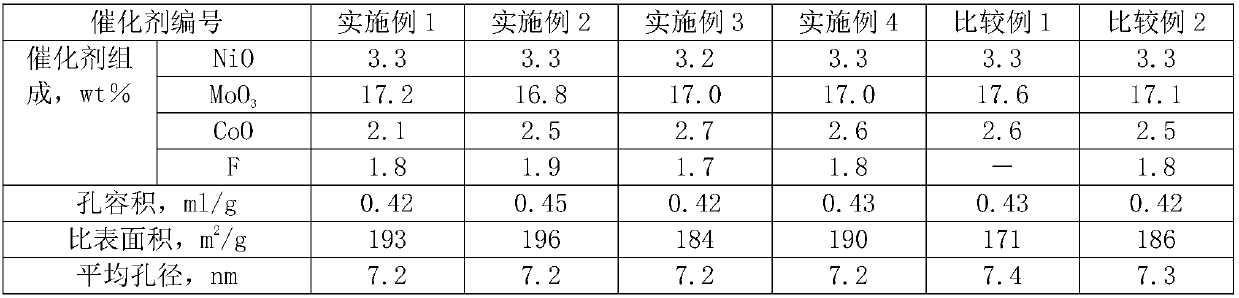

Hydrogenation catalyst and preparation method thereof

InactiveCN107597152AGood dispersionHigh catalytic activityPhysical/chemical process catalystsHydrodesulfurizationKerosene

The invention discloses a hydrogenation catalyst and a preparation method thereof. The preparation method of the catalyst comprises the following steps: (1) first, preparing a gamma-Al2O3 carrier; (2)loading the gamma-Al2O3 carrier by a Co metal component and a F-containing assistant component, and performing drying and roasting; and (3) performing impregnation on the carrier obtained in the step(2) by adopting a solution containing a Ni-containing compound and a W-containing and / or Mo-containing compound, and performing drying and roasting to obtain the catalyst. The catalyst is prepared byloading the gamma-Al2O3 with active components of Co, Ni and W / Mo, and simultaneously the F-containing compound is used as an auxiliary agent, wherein the F-containing compound is at least one selected from a group consisting of tetrabutylammonium fluoride, trifluoroacetic acid, hexafluoroacetone and hexafluoroisopropanol. The catalyst can be used for hydrofining of light distillate oil such as gasoline fraction, kerosene fraction and diesel fraction, has high hydrogenation desulfurization activity and aromatic saturation activity.

Owner:PETROCHINA CO LTD

Hydrophobic group-containing Anti-corrosion reinforced concrete water discharge pipe and preparation method thereof

The invention discloses a hydrophobic group-containing anti-corrosion reinforced concrete water discharge pipe and a preparation method thereof. The anti-corrosion reinforced concrete water discharge pipe is characterized by using flyash, ore slag powder, metakaolin, gypsum, sodium sulfate, a naphthalene-based superplasticizer, sand, gravels, bisphenol-a epoxy resin E-44, benzo peroxide, acrylic acid, N,N-dimethylethanolamine, organic montmorillonite, cement, steel fiber, calcined diatomite, steel bars, tetrabutylammonium fluoride, cationic polyacrylamide and the like as raw materials. Water-borne epoxy resin is prepared by a graft copolymerization method; a network structure with mutually penetrating polymers and cement base materials is obtained; the organic montmorillonite is used as a filing material; a polymer solution intercalation method is used for adding the organic montmorillonite into a water-borne epoxy resin base body; a water-borne epoxy resin / montmorillonite nanometer composite material is prepared; uniform magnetic field is exerted on a steel fiber concrete mixture; steel fiber concrete in unidirectional distribution is prepared; the fiber utilization rate is high; the enhancement effect is good.

Owner:阜阳市华顺水泥制品有限公司

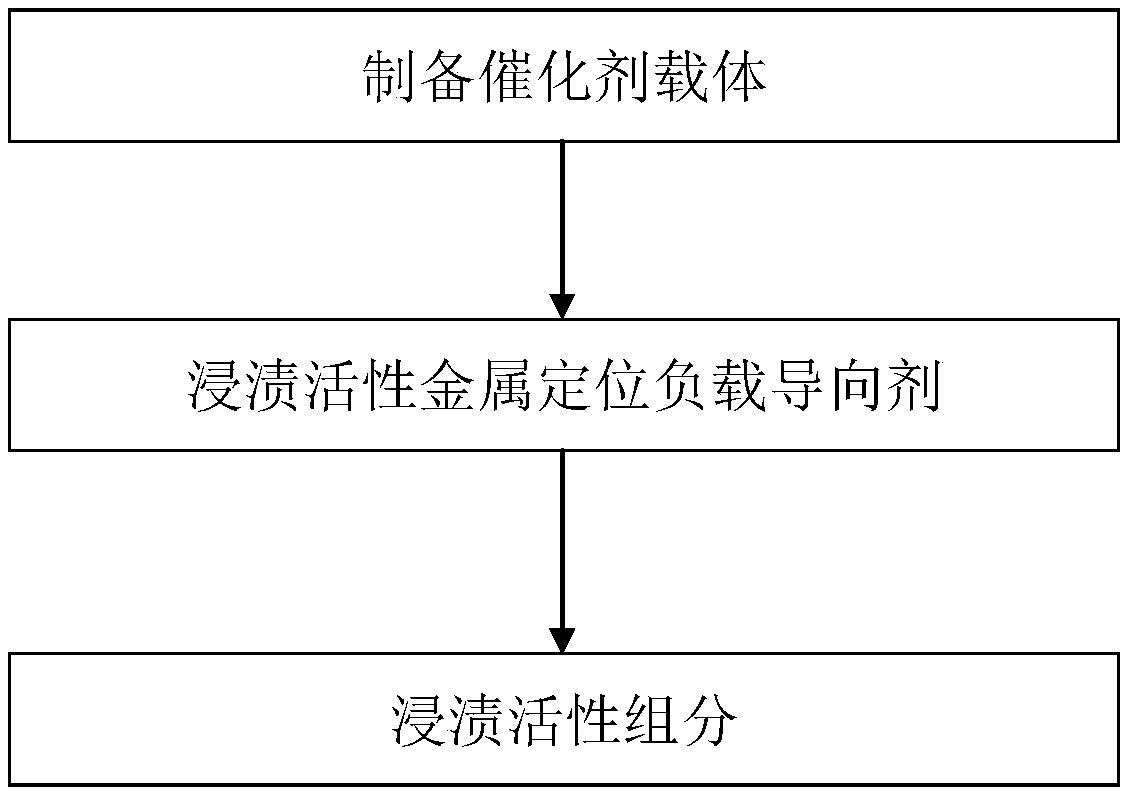

Supported hydrogenation catalyst and preparation method thereof

ActiveCN111250103AImprove orderAvoid the problem that the utilization rate is not high and the synergy cannot be fully exertedHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystHydrodesulfurization

The invention discloses a preparation method of a supported hydrogenation catalyst. The preparation method comprises the following steps: 1, preparing a gamma-Al2O3 carrier; 2, dipping the gamma-Al2O3carrier in a solution of an active metal positioning and loading guiding agent, and drying the gamma-Al2O3 carrier; and 3, impregnating the gamma-Al2O3 carrier obtained in the step 2 with an impregnation liquid containing an active component, and carrying out drying and roasting to obtain the supported hydrogenation catalyst, wherein the active metal positioning and load guiding agent is one or more of a group consisting of ethylenediamine tetramethylene sodium phosphate, tetrabutylammonium fluoride and tartaric acid. The catalyst prepared by the invention can be used for hydrofining distillate oil such as gasoline distillate, kerosene distillate, diesel distillate and the like, and has high hydrodesulfurization and denitrification activity and aromatic hydrocarbon saturation activity.

Owner:PETROCHINA CO LTD

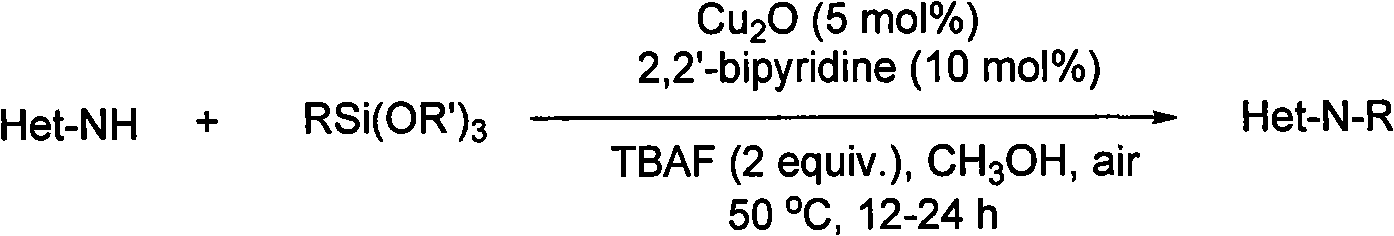

Preparation method for N-arylazoles compounds

The invention discloses a preparation method for an N-aryl azole compound. 0.5 mmol of azole compound, 1 to 2 mmol of aryl siloxane, 1 to 2ml of tetrahydrofuran solution (1M) of tetrabutylammonium fluoride (TBAF), 5 to 10 mol percent of cuprous oxide, and 10 to 20 mol percent of 2, 2-bipyridyl are added with 3 to 6 ml of methanol in a reactor, are made a magnetic stirring, and are reacted for 12 to 48 hours in the air with the temperature of 25 to 50 DEG C, the solvent is dried, and the product is obtained through the silica gel column chromatography. The preparation method has the advantages that: 1) the reaction conditions are mild, the reaction can be finished within 12 to 48 hours in the methanol with the temperature of 25 to 50 DEG C, and the yield is high. 2) the reaction is made in the air, is steady to the water and the air, and does not need the water-free oxygen-free operation; the methanol is taken as the solvent, has low boiling point, is easy to handle and has simple and convenient operation. 3) catalyst and ligand are economic and easily obtained. 4) reaction raw material, aryl siloxane, has low cost, and the industrial production is easily realized.

Owner:ZHEJIANG UNIV

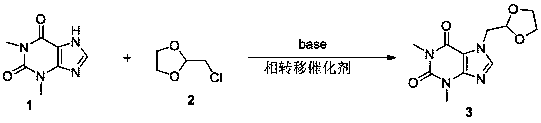

Synthetic method of doxofylline

InactiveCN108840872AEase of industrial productionShort reaction timeOrganic chemistryDoxofyllineOrganic synthesis

The invention discloses a synthetic method of doxofylline and belongs to the technical field of organic synthesis. The method comprises the following step: theophylline and 2-chloromethyl-1,3-dioxolane are subjected to a reaction at 60-110 DEG C in an aprotic solvent under the action of alkali and a phase transfer catalyst, and doxofylline is synthesized, wherein the mole ratio of theophylline, 2-chloromethyl-1,3-dioxolane and the alkali is 1:1-2:1-3, the phase transfer catalyst accounts for 3%-5% of the molar weight of theophylline, and the phase transfer catalyst is selected from one or moreof tetrabutylammonium chloride, tetrabutylammonium bromide and tetrabutylammonium fluoride. The provided new synthetic method of doxofylline is short in reaction time and only needs 3-6 h, is low inreaction temperature which is lower by 20-30 DG C than that of the conventional method, is high in yield which is 10% or higher than that of the conventional method, and is beneficial to industrial production of the drug.

Owner:HUBEI HUNTIDE BIOTECH

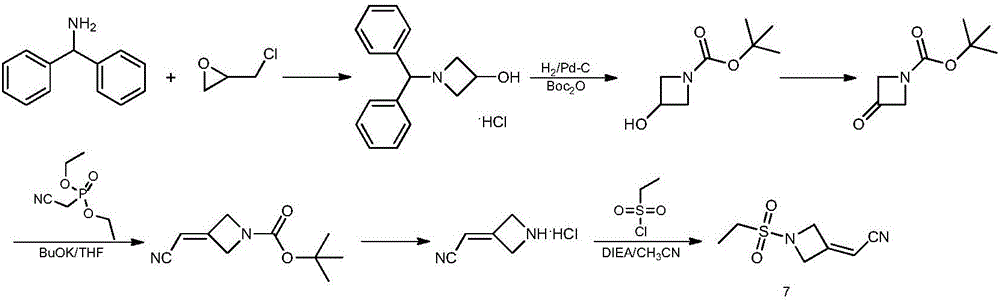

Method for synthesizing tert-butyl 6-oxo-8-oxa-2, 5-diazaspiro[3.5]nonane-2-carboxylate

InactiveCN109503624AReasonable reaction process designMethod route shortOrganic chemistryNonaneSolvent

The invention relates to a method for synthesizing tert-butyl 6-oxo-8-oxa-2, 5-diazaspiro[3.5]nonane-2-carboxylate, and mainly solves a technical problem of absence of a method suitable for industrialsynthesis at present. The method provided by the invention comprises the following three steps: step one, firstly enabling a compound 1, paraformaldehyde and tetrabutylammonium fluoride added into asolvent N, N-dimethylformamide to be in reaction to obtain a compound 2; step two, enabling the compound 2, ethyl bromoacetate and cesium carbonate to be in reaction in acetone to obtain a compound 3;and step three, enabling the compound 3 and iron and ammonium chloride to be in reaction in ethanol and water to obtain a final compound 4, wherein a reaction formula is as shown in the Specification.

Owner:SHANGHAI SYNTHEALL PHARM CO LTD

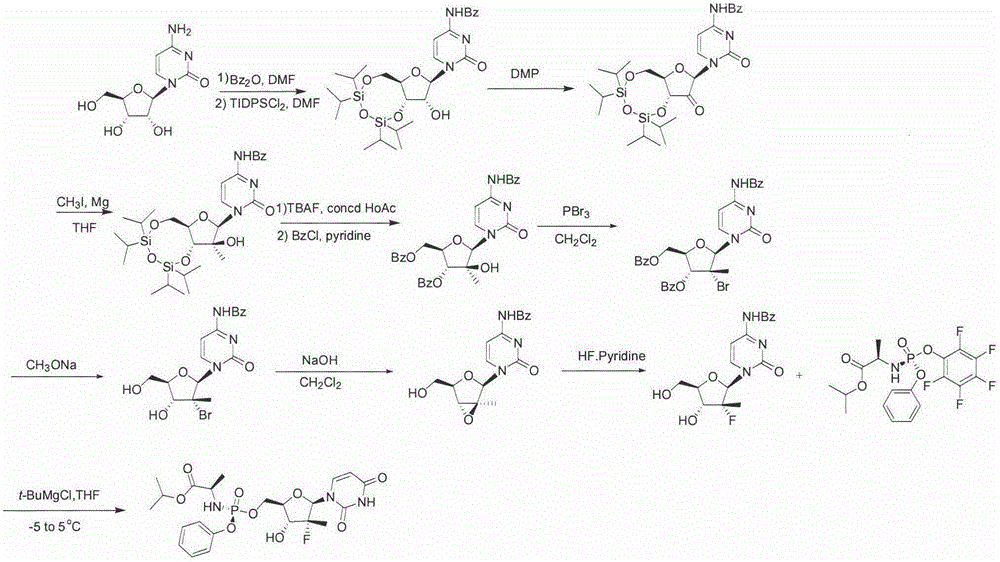

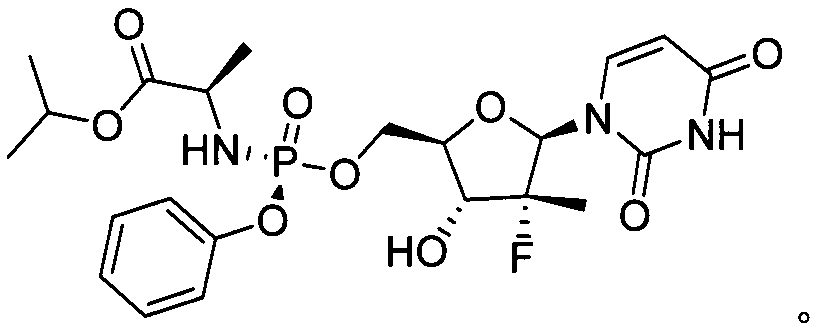

High-yield synthesis method of sofosbuvir and sofosbuvir prepared with method

ActiveCN105646626AOvercome the conditionsOvercome by-productsSugar derivativesSugar derivatives preparationSodium methoxidePhosphorus tribromide

The invention relates to a high-yield synthesis method of sofosbuvir and sofosbuvir prepared with the method. The method comprises steps as follows: (a) cytidine and benzoic anhydride are dissolved in a first organic solvent for a reaction; TIDPSCl2 is added for a reaction; (b) a product and dimethyl phthalate are dissolved in a second organic solvent for a reaction; (c) a Grignard reagent is dissolved in tetrahydrofuran, and the temperature is reduced to subzero 35 DEG C to subzero 20 DEG C; tetrahydrofuran containing a third product is dropwise added and has a reaction, and a fourth product is obtained through purification; (d) the fourth product is dissolved in acetic acid containing tetrabutylammonium fluoride and has a reaction, and a sixth product is obtained through purification; (e) the sixth product is dissolved in the second solvent, phosphorus tribromide is added and has a reaction, and a seventh product is obtained through purification; (f) the seventh product is dissolved in methanol containing sodium methoxide and has a reaction, and an eighth product is obtained through purification. Accordingly, the reaction steps are reduced, the cost is greatly reduced, and the yield of the product is increased.

Owner:GUIZHOU INST OF TECH +1

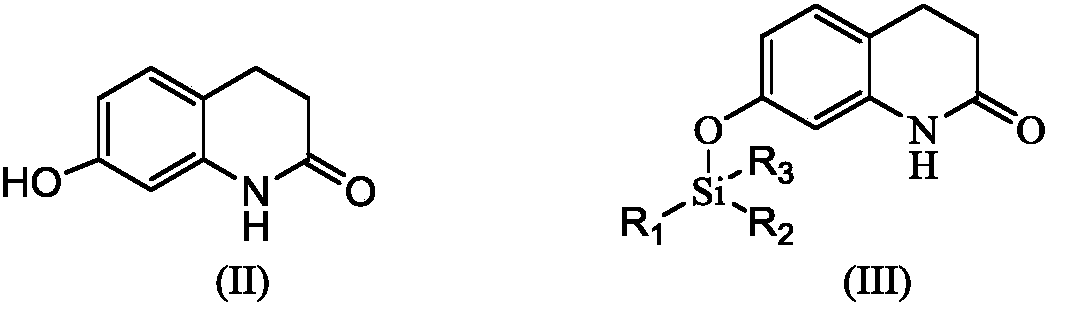

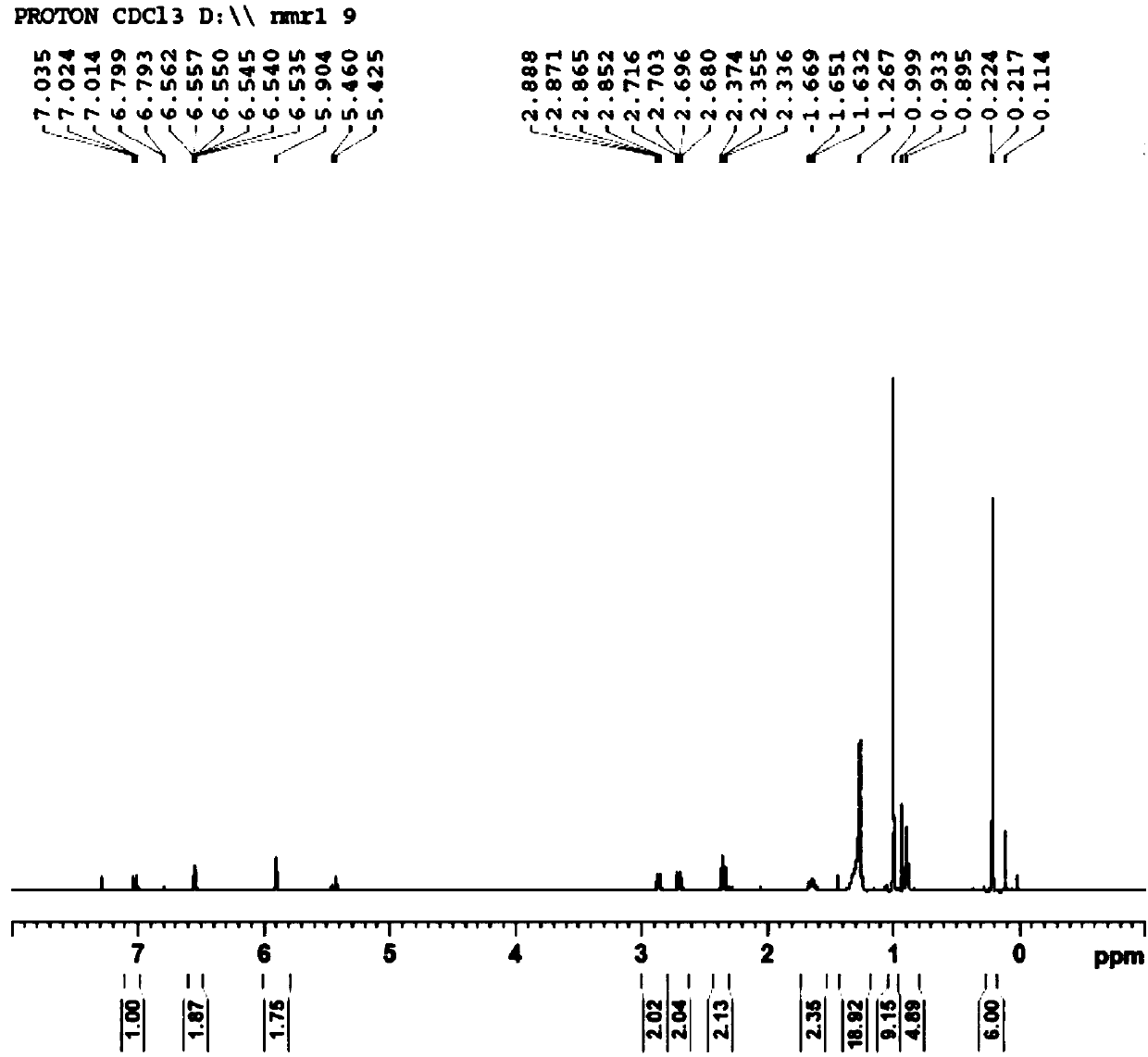

Preparation method of aripiprazole lauroxil

The invention provides a preparation method of aripiprazole lauroxil. The method comprises steps as follows: S1, a compound (II) and halogenated silane react in amide solvents in the presence of an acid-binding agent, and a compound (III) is obtained, wherein R1, R2 and R3 are alkyls; S2, in alcohol solvents, the compound (III) and paraformaldehyde react in the presence of the acid-binding agent,a treated intermediate product reacts with n-dodecanoyl chloride in a furan or amide solvent in the presence of the acid-binding agent, and a compound (IV) is produced; S3, the compound (IV) is subjected to silyl ether removal in a furfural solvent by use of tetrabutylammonium fluoride, and a compound (V) is obtained; S4, the compound (V), 1-bromo-4-chlorobutane and 1-(2,3-dichlorophenyl) piperazine react in a mixed solvent of one or more of an acetone solvent, an amide solvent and a nitrile solvent in the presence of the acid-binding agent and sodium iodide, and aripiprazole lauroxil is prepared. The method adopts a simple process, can notably increase the yield and the purity of products, can be reproducible and facilitates industrial production.

Owner:苏州华健瑞达医药技术有限公司

Preparation method of low-odor plastic master-batches

InactiveCN107325455ASolve the technical problem of excessive odorImprove uniformityPolymer scienceAntioxidant

The invention discloses a preparation method of low-odor plastic master-batches. The operation method comprises the following steps that firstly, after tetrabutylammonium fluoride, 3-((2-aminoethyl)amino) propanesulfonic acid, anisyl alcohol and cinnamic acid benzyl ester are mixed, stirring is continuously conducted for 120-150 min at the rotate speed of 500 r / min, and then a plastic deodorant is prepared; secondly, after polyvinyl chloride resin, Peru smelling glue, talcum powder, a coupling agent, an antioxidant and the plastic deodorant are mixed evenly at high speed, the mixture is extruded and granulated by using a plastic extruder, and the low-odor plastic master-batches are prepared. According to the preparation method of the low-odor plastic master-batches, the operation is simple, the cost is low, the prepared PVC plastic master-batches almost have no pungent odor, and the technical problem that in the prior art, a PVC material is excessively strong in odor is solved.

Owner:阜南县鲲鹏塑业科技有限公司

Preparation method of heat-resistant PVC (polyvinyl chloride) pipe

InactiveCN107805357AGood mechanical propertiesStable heat resistancePolyvinyl chlorideMechanical property

The invention discloses a preparation method of a heat-resistant PVC (polyvinyl chloride) pipe. The preparation method includes the operation steps: (1) mixing PVC resin and tetrabutylammonium fluoride, heating mixture to reach the temperature of 68-72 DEG C, uniformly mixing and stirring the mixture after completely melting of the tetrabutylammonium fluoride, and cooling the mixture to reach indoor temperature to prepare modified PVC resin; (2) mixing, stirring and heating polybenzimidazole fibers, polytetrafluoroethylene resin and acetaldehyde ammonia trimers, adding aluminum borate and zirconium oxide when the temperature reaches 80 DEG C, continuing to keep temperature and mix mixture for 15-20 minutes, and cooling the mixture to reach the indoor temperature to prepare heat-resistant agents; (3) adding the modified PVC resin, calcium-zinc stabilizers, the heat-resistant agents and calcium carbonate into a extruding machine, and performing extrusion molding, cooling and sizing to obtain the heat-resistant PVC pipe. The preparation method is stable in production process, continuous mass production can be achieved, the prepared PVC pipe is excellent in mechanical property and particularly has excellent heat resistance, and the quality of the PVC pipe is greatly improved.

Owner:安徽金昊天塑胶科技发展有限公司

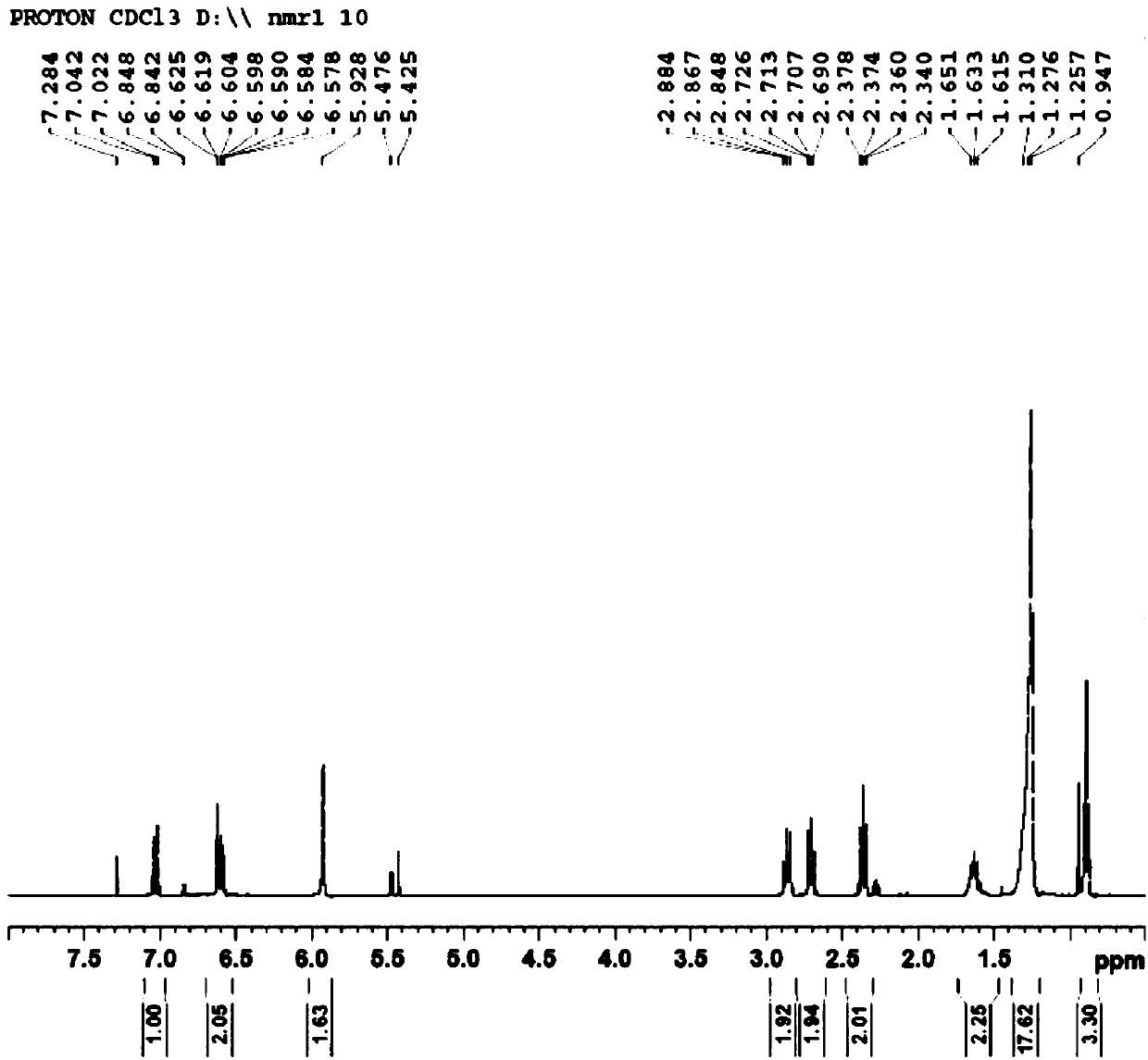

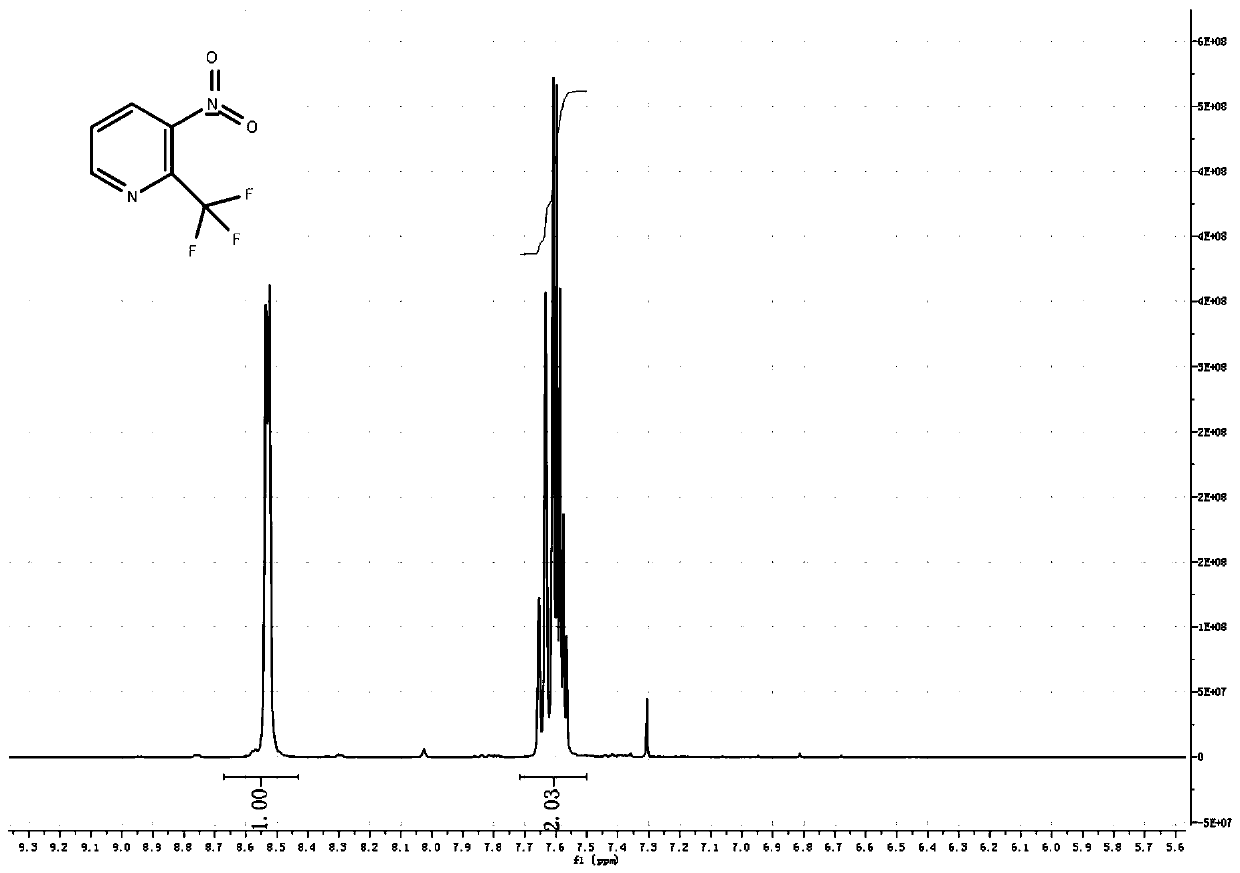

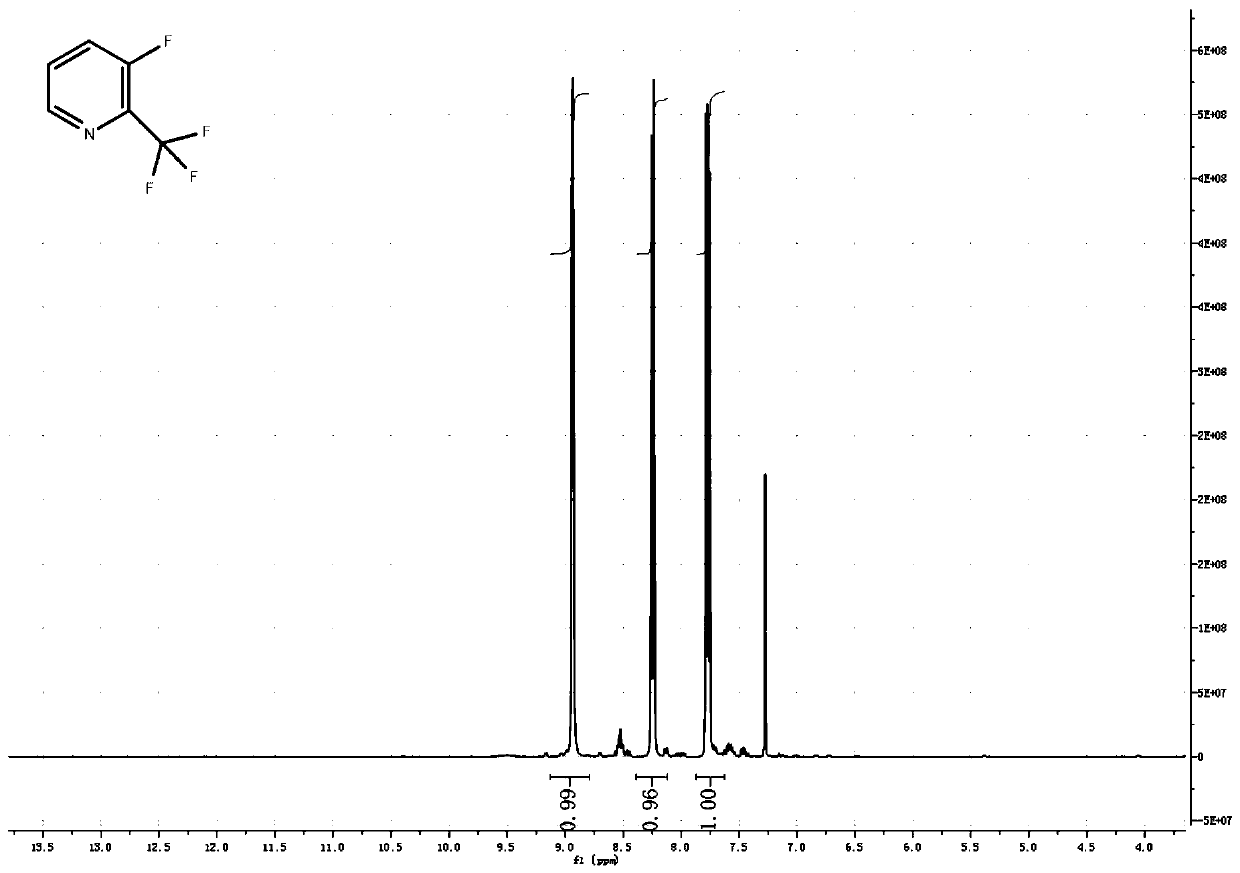

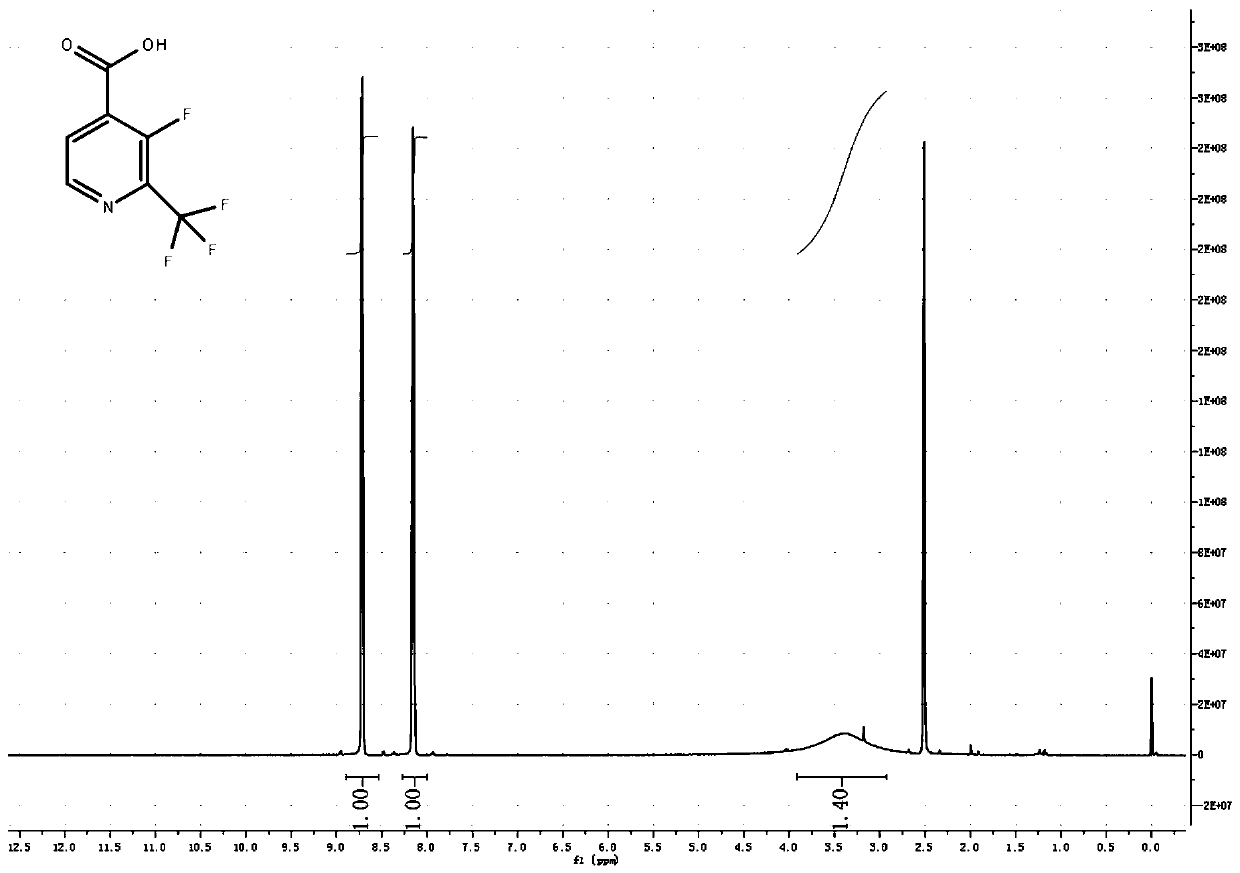

Synthesis method of 3-fluoro-2-trifluoromethyl isonicotinic acid

The invention discloses a synthesis method of a fluorine-containing heterocyclic compound medical intermediate. The method comprises the following steps: (1) taking 2-chloro-3-nitropyridine as a raw material to carry out reacting with trifluoromethyltrimethylsilane in dimethyl formamide (DMF) under catalysis of cuprous iodide and 1,10-phenanthroline to obtain 2-trifluoromethyl-3-nitropyridine; (2)carrying out a reflux reaction on the obtained 2-trifluoromethyl-3-nitropyridine in tetrabutylammonium fluoride by using acetonitrile, dimethyl sulfoxide (DMSO) or DMF as a solvent to obtain 2-trifluoromethyl-3-fluoropyridine; and (3) removing hydrogen from the obtained 2-trifluoromethyl-3-fluoropyridine under action of a lithium reagent, and introducing dry carbon dioxide gas to obtain the 3-fluoro-2-trifluoromethyl isonicotinic acid. The method has the advantages of high product yield, high operability, environmental friendliness, high safety factor and the like.

Owner:ANQING BOMAN BIOTECHNOLOGY CO LTD

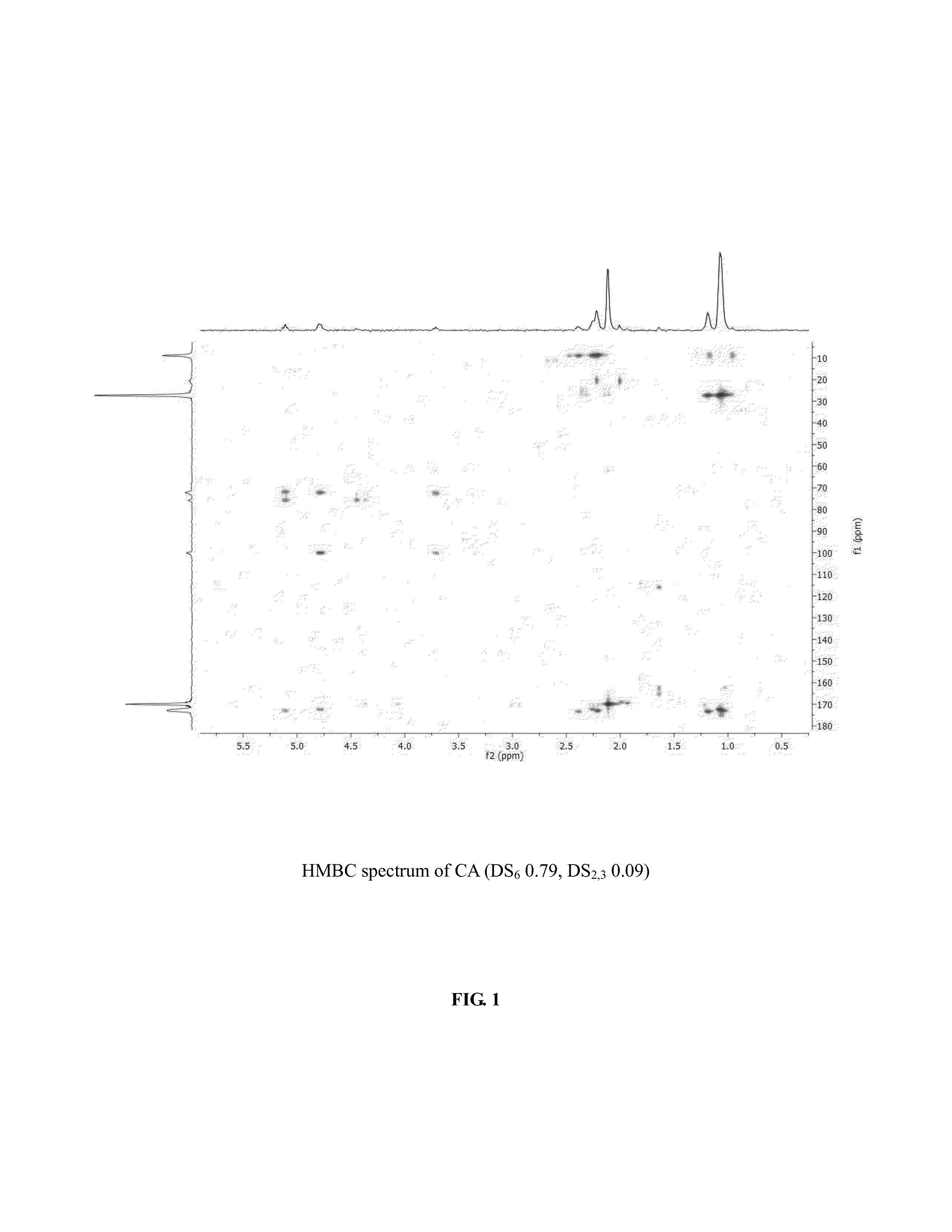

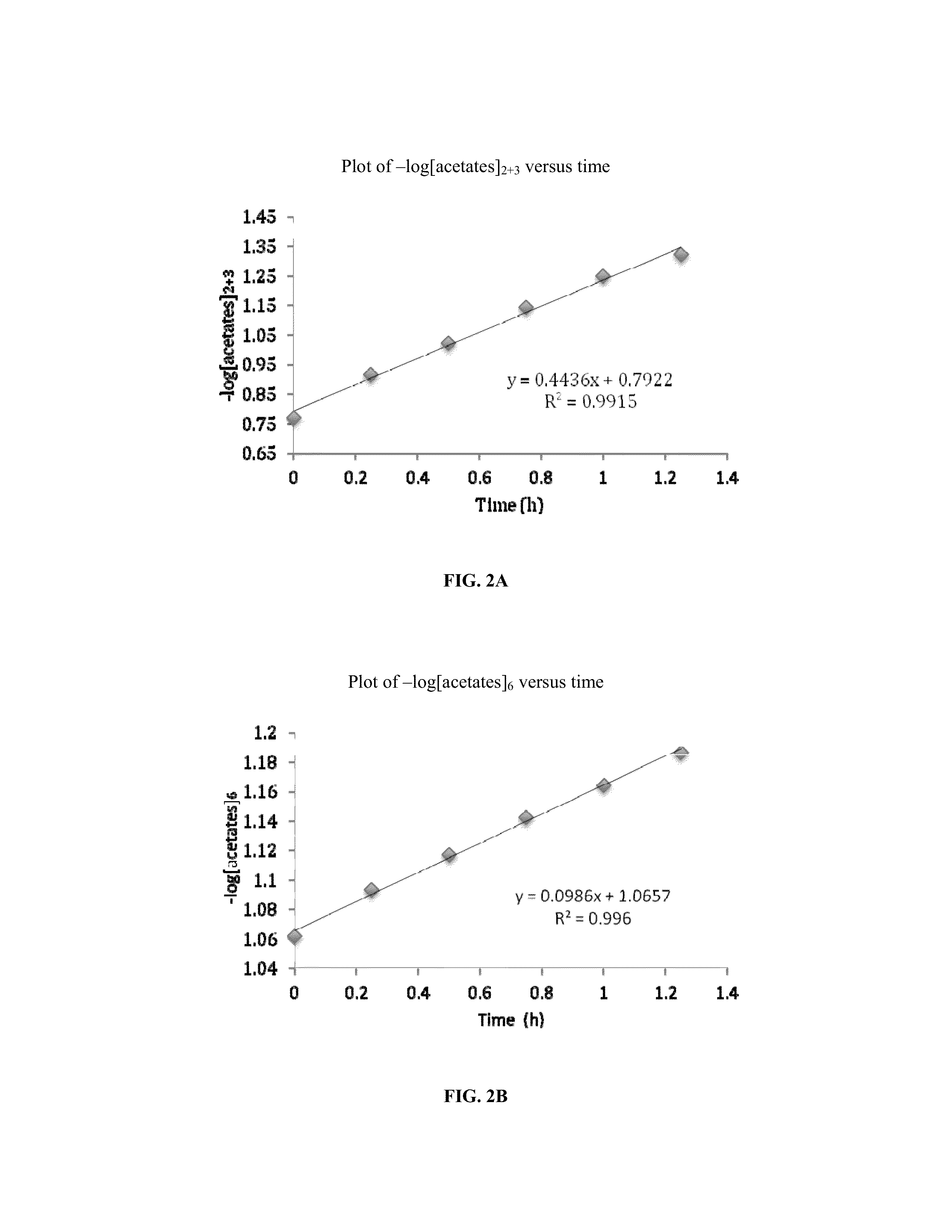

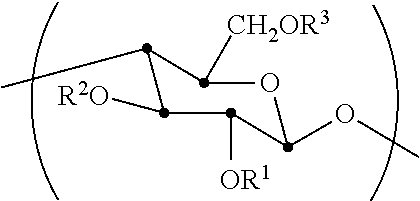

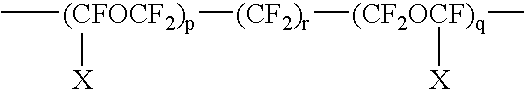

Regioselectively substituted cellulose esters and efficient methods of preparing them

Embodiments of the invention provide regioselectively substituted carbohydrate and polysaccharide derivatives, such as cellulose esters, and methods for preparing them. Particular methods of the invention include deacylation of esters using tetrabutylammonium fluoride to obtain selective substitution at desired hydroxyl position(s) of the ester. Preferred is deacylation of an ester, which shows selectivity for removal of acyl groups from the ester of the secondary alcohols at C-2 and C-3, and which affords cellulose-6-O-esters with high regioselectivity by a simple one-step process employing no protective groups. Inventive regioselectively substituted cellulose esters can be prepared by such methods to obtain esters with the following anhydroglucose repeating units:wherein R1, R2, and R3 are each independently chosen from a hydrogen atom, and, whether substituted or unsubstituted, branched or unbranched, an alkanoyl group, an aroyl group, and a heteroaroyl group. In embodiments, the alkanoyl, aroyl and heteroaroyl groups can comprise from 1-20 carbon atoms.

Owner:VIRGINIA TECH INTPROP INC

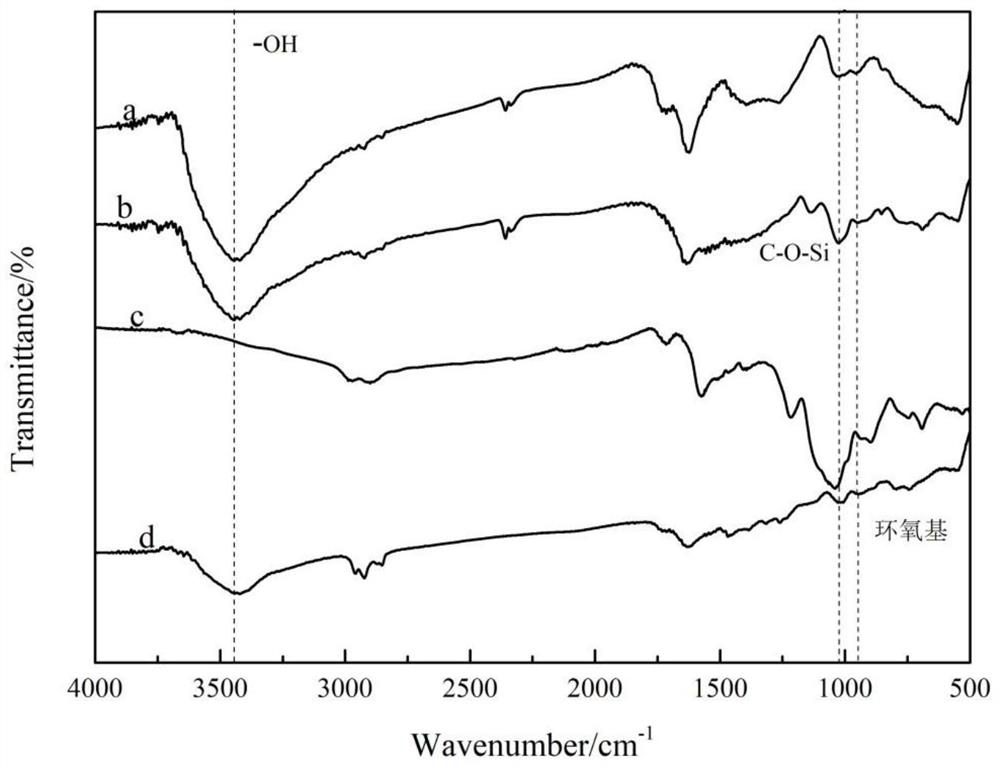

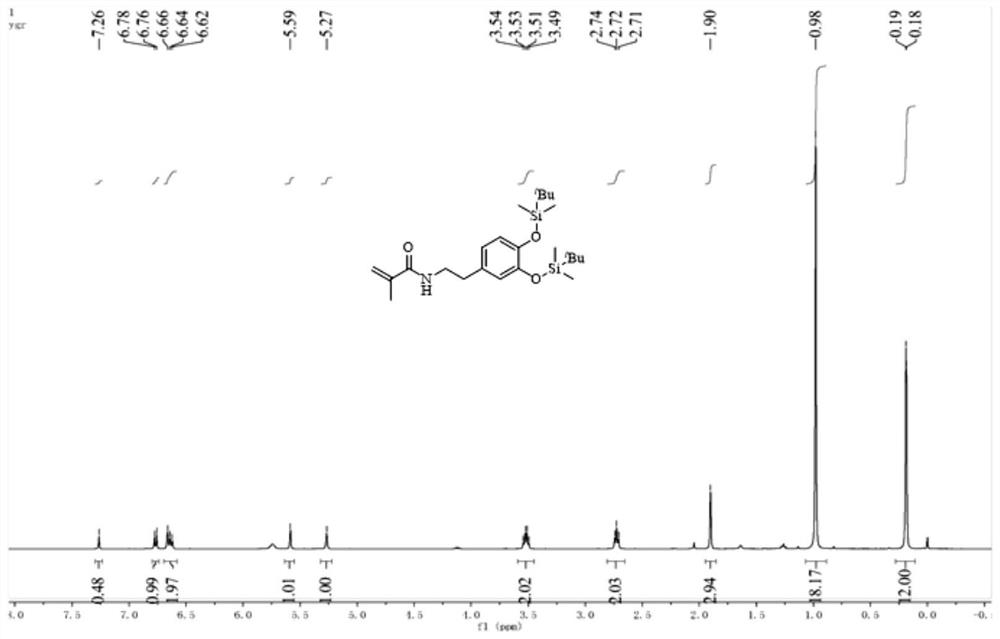

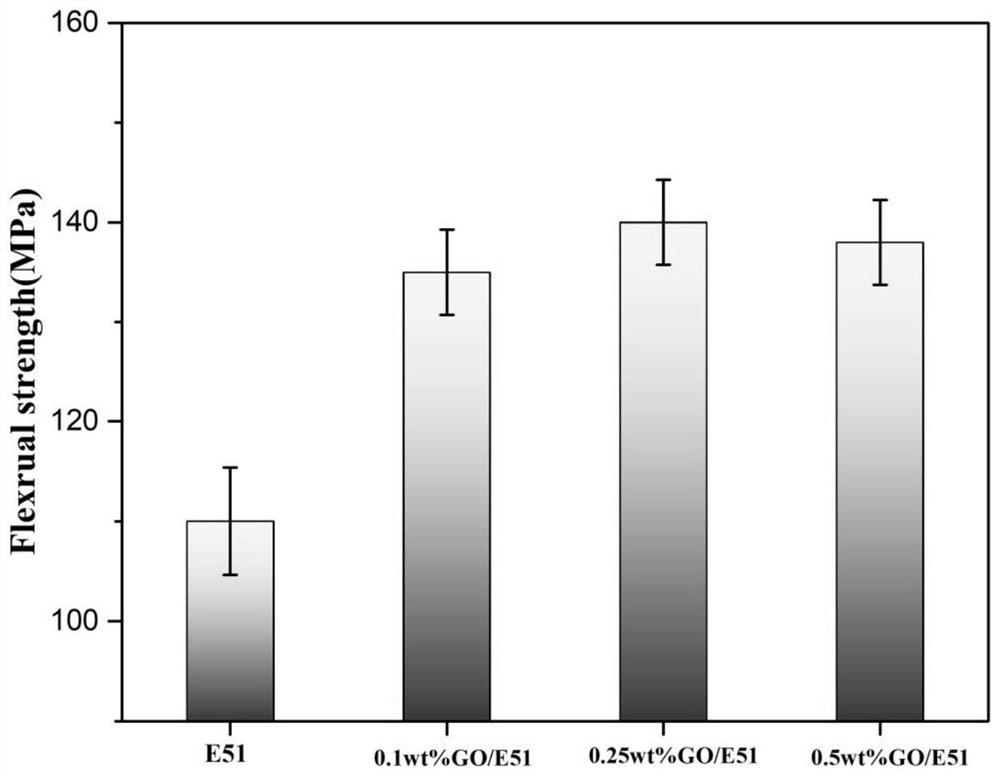

Preparation method of modified graphene oxide and method for preparing epoxy resin composite material by using modified graphene oxide

The invention relates to the field of composite materials, and in particular, relates to a preparation method of modified graphene oxide and a method for preparing an epoxy resin composite material by applying the modified graphene oxide. The preparation method of the modified graphene oxide comprises the following steps: 1, preparing aminated graphene oxide; 2, further preparing bromine-terminated graphene oxide; 3, preparing a monomer containing a catechol group; 4, preparing an intermediate product from the bromine-terminated graphene oxide and a monomer containing a catechol group; and 5, reacting the intermediate product with tetrabutylammonium fluoride to obtain the modified graphene oxide containing the catechol group. The preparation method of the epoxy resin composite material comprises the following steps: adding the modified graphene oxide into the epoxy resin, uniformly stirring and mixing, performing ultrasonic dispersion, adding the curing agent, uniformly stirring and mixing, performing vacuum drying, removing bubbles, and pouring into a mold for curing and molding. According to the modified graphene oxide prepared by the method provided by the invention, the compatibility with an epoxy resin matrix can be improved by low-dosage addition, and the mechanical property of an epoxy nano composite material can also be improved.

Owner:CHANGCHUN UNIV OF TECH

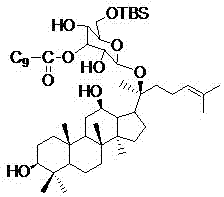

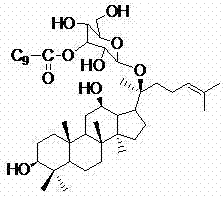

Synthesis method for increasing ginsenoside M1 and decanoylchloride monoesterification selectivity

The present invention provides a synthesis method for increasing ginsenoside M1 and decanoylchloride monoesterification selectivity. According to the synthesis method, the hydroxyl at the site 6 of the ginsenoside M1 glycoside group is protected by using tert-butyldimethylsilyl chloride through an etherification manner, the obtained material and equivalent decanoylchloride are subjected to a monoesterification reaction in an ice water bath under nitrogen protection by adopting dichloromethane as a solvent and adopting triethylamine as an acid binding agent under a DMAP (4-dimethylaminopyridine) catalysis condition, and finally tetrabutylammonium fluoride is adopted to remove the silicon-protected group to obtain the product of the monoesterification reaction of the tert-butyldimethyl siloxane of the ginsenoside M1 and the decanoylchloride.

Owner:大连杰信生物科技有限公司

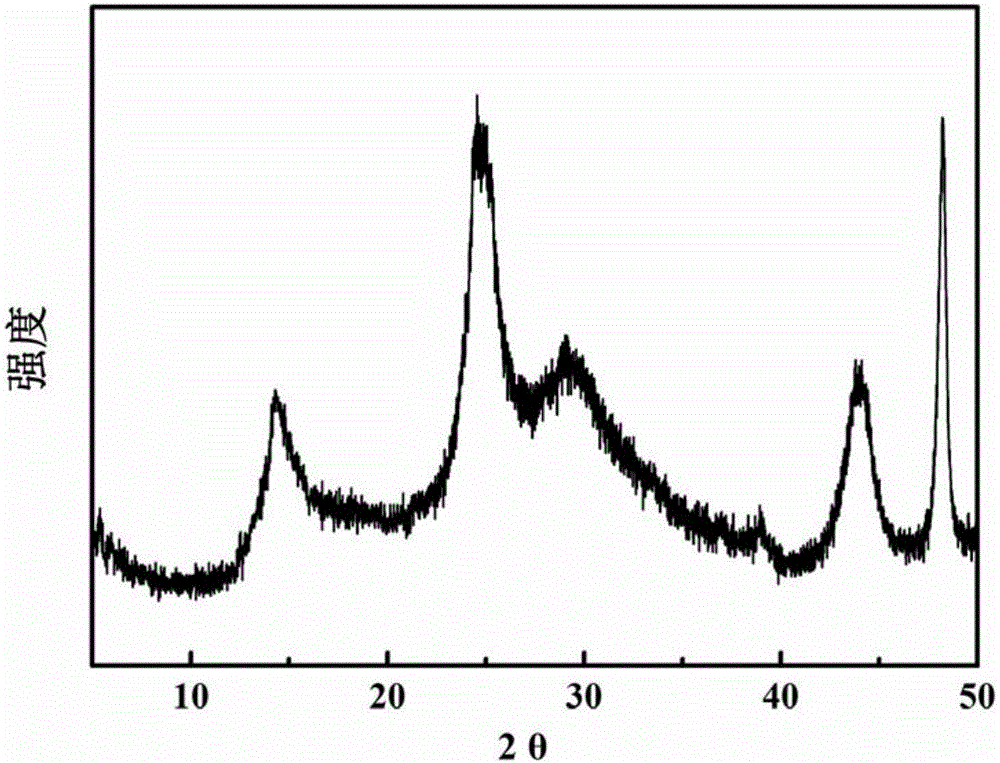

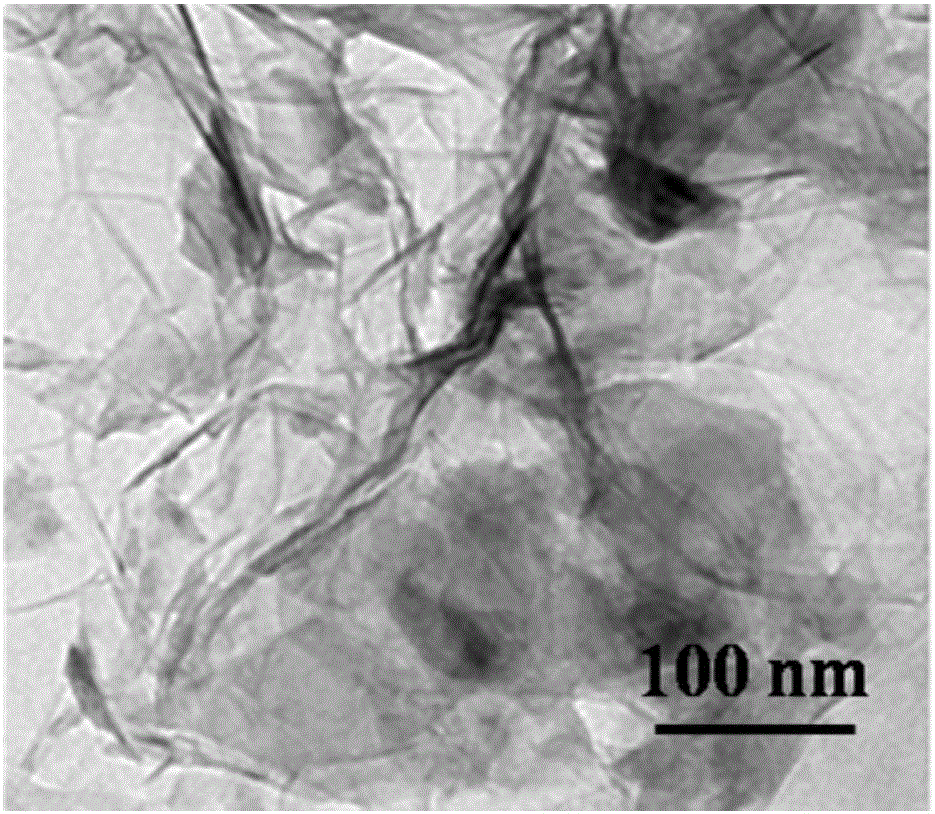

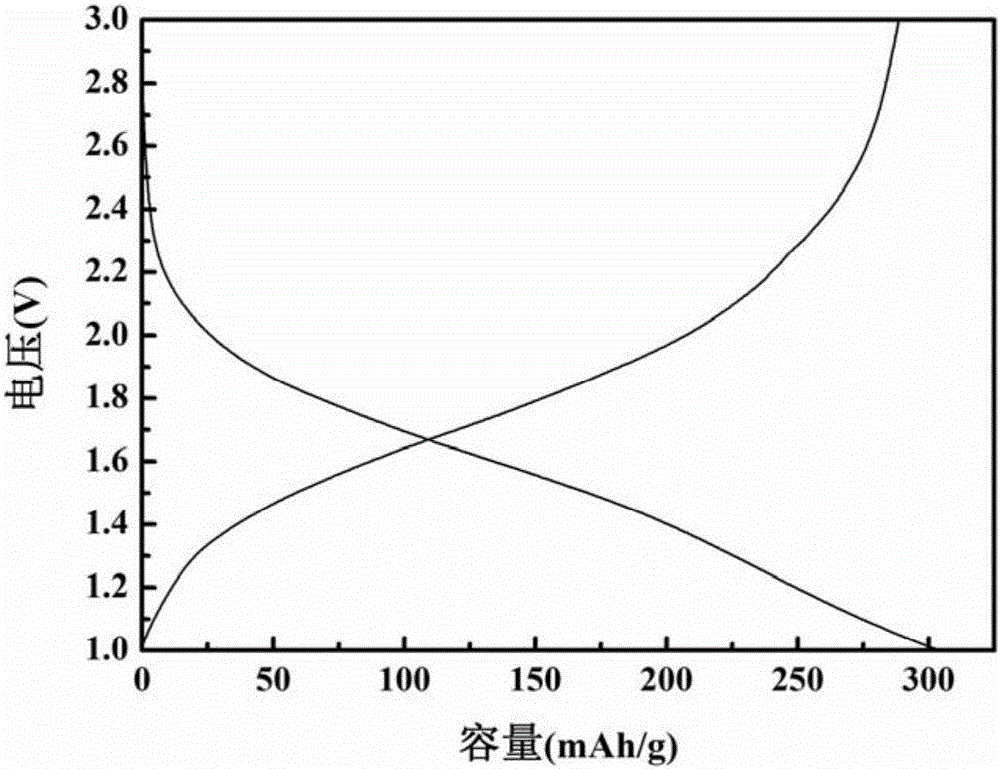

Inlaid polyaniline/H2Ti12O25 nanosheet composite material and preparation method thereof

ActiveCN106058194AHigh specific capacityExcellent rate performanceCell electrodesSecondary cellsAir atmospherePolyol

The invention discloses an inlaid polyaniline / H2Ti12O25 nanosheet composite material and a preparation method thereof. The preparation method comprises the following steps: under assistance of polyol, carrying out reflux reaction on a titanium source and an alkaline solution to obtain a Na2Ti6O13 nanosheet precursor; (2) washing the Na2Ti6O13 nanosheet precursor with acidic materials for a plurality of times to obtain H2Ti6O13 nanosheets; (3) carrying out heat treatment on the H2Ti6O13 nanosheets in an air atmosphere to obtain H2Ti12O25 nanosheets; (4)dispersing the H2Ti12O25 nanosheets in a tetrabutylammonium fluoride solution, and carrying out ultrasonic treatment for 6 hours at normal temperature to form suspension; (5) respectively dissolving a certain amount of aniline monomers and ammonium persulfate in 1M hydrochloric acid, then adding the mixture in the suspension obtained from the step (4), and reacting in ice-water bath to obtain the inlaid polyaniline / H2Ti12O25 nanosheet composite material. According to the structure, polyaniline is inlaid among layers of the H2Ti12O25 nanosheets to form the composite structure with the inlaid structure, wherein H2Ti12O25 has a nanosheet-shaped structure. The preparation method is simple and high in applicability, and the product is high in specific capacity, good in rate capability, long in cycle life and good in safety.

Owner:TIANJIN B&M SCI & TECH

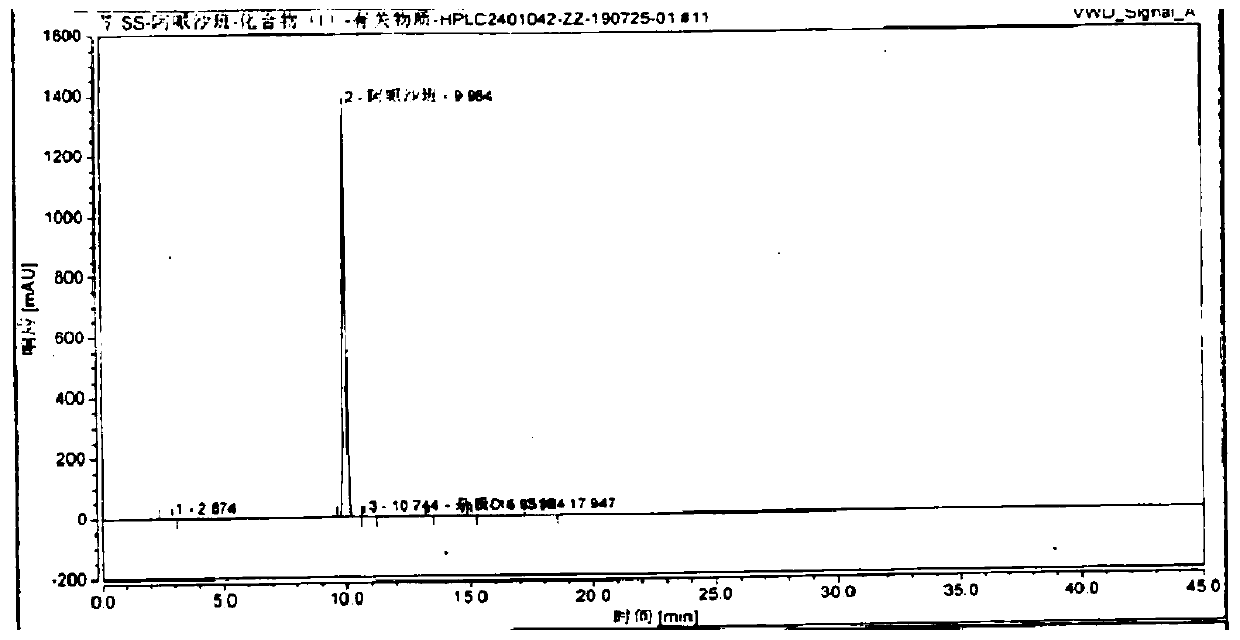

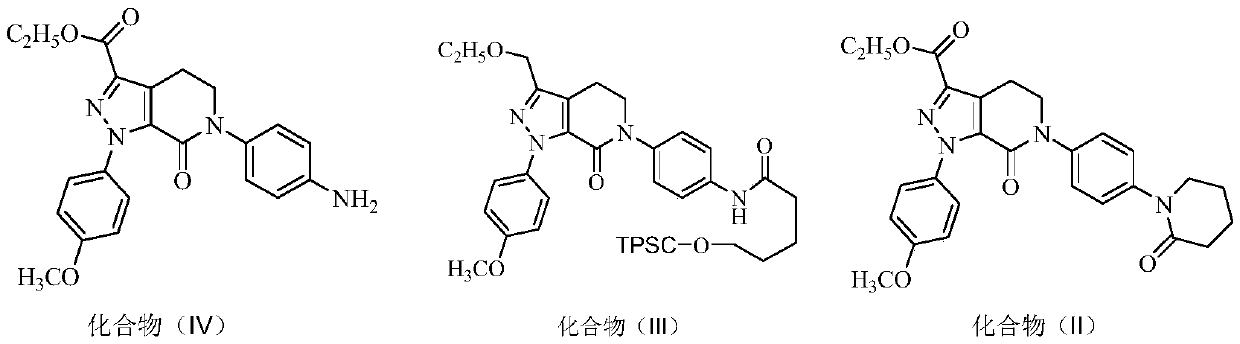

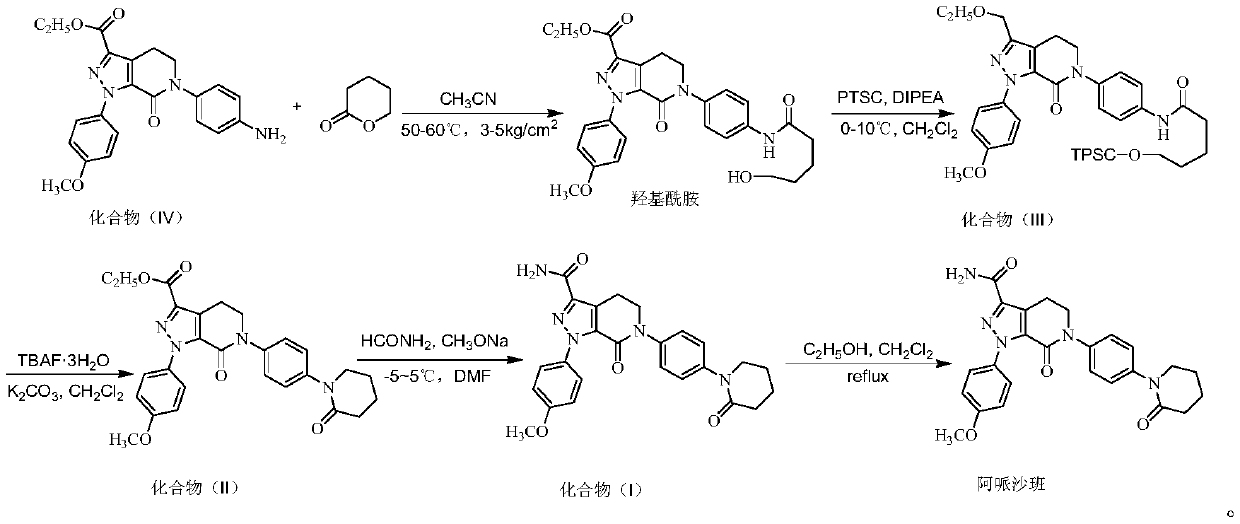

Preparation process of high-purity apixaban

The invention discloses a preparation process of apixaban. The method comprises the following steps of: performing amidation on an initial raw material compound (IV) and delta-valerolactone under pressure; performing a one-pot reaction on the obtained hydroxyl amide and p-toluenesulfonyl chloride (PTSC)to obtain a compound (III); carrying out a reaction with tetrabutylammonium fluoride trihydrateto obtain a cyclization product compound (II); preparing a compound (I) from 2,4-dichlorobenzaldehyde and formamide under the action of sodium methoxide and a molecular sieve; refining the crude product by adopting an optimized ethanol / dichloromethane mixed solvent, so that impurity A is removed well; by means of the method, the apixaban product with high yield and high purity is prepared, whereinthe purity of the apixaban product is not lower than 99.5%, the impurity A does not exceed 0.05%, and any single impurity does not exceed 0.1%.

Owner:JIANGXI GUOYAO PHARMA LLC

High-strength fishing net

InactiveCN107201029ASmall finenessLittle flexibilityConjugated synthetic polymer artificial filamentsArtifical filament manufactureCouplingNylon 6

The invention discloses a high-strength fishing net. The high-strength fishing net is prepared from the following components in parts by weight: 60-75 parts of nylon 6 chips, 30-40 parts of polypropylene chips, 5-7 parts of tetrabutylammonium fluoride, 1-3 parts of zinc undecylenate, 6-9 parts of nano-zinc oxide, 2-4 parts of 4-hydroxyl-PMT, 11-16 parts of hollow glass beads and 6-9 parts of an aluminate coupling agent. The high-strength fishing net is low in fishing twine fineness, high in strength, light in weight, good in flexibility, convenient to unfold and collect and greatly improved in quality.

Owner:巢湖市强力渔业有限责任公司

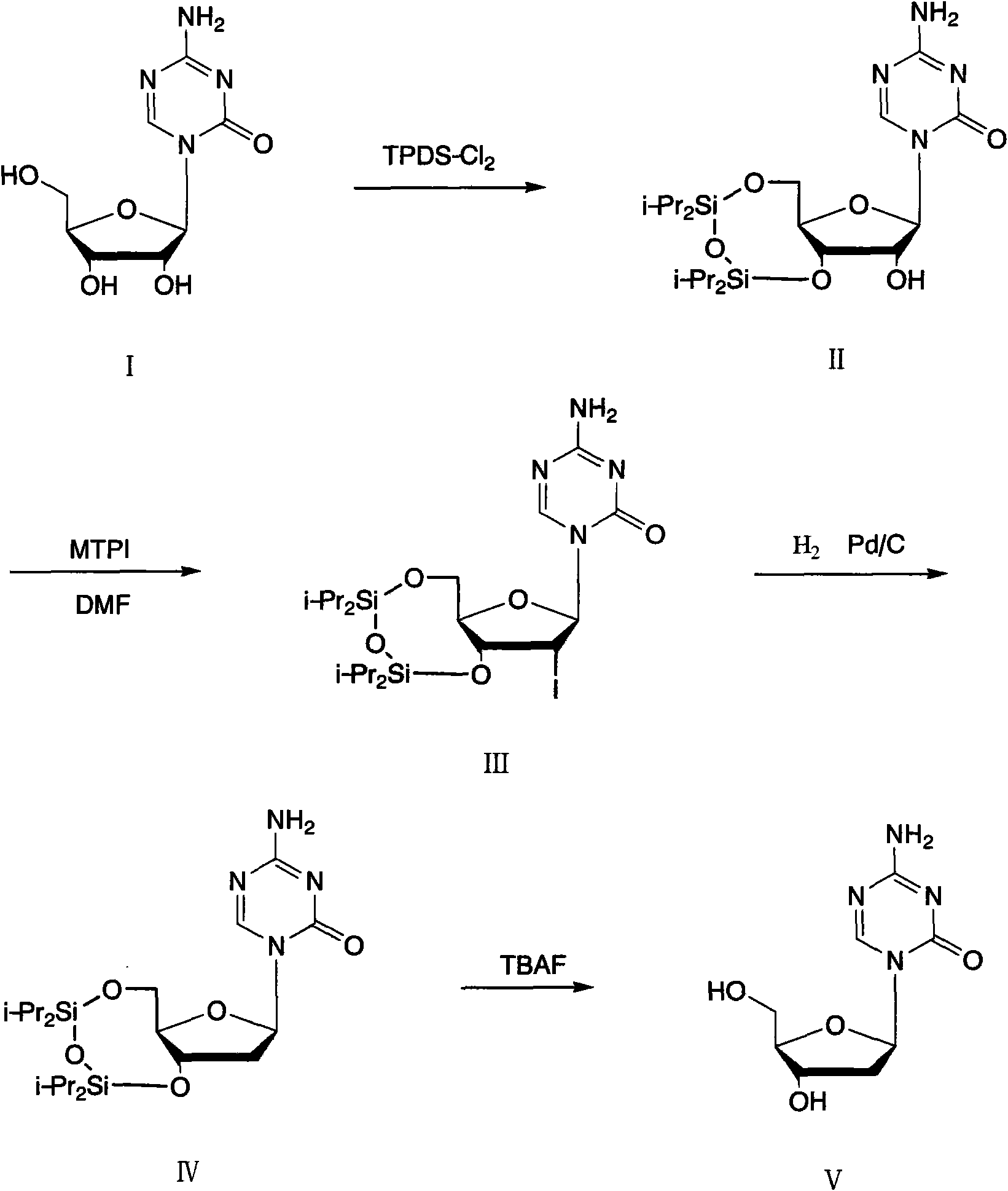

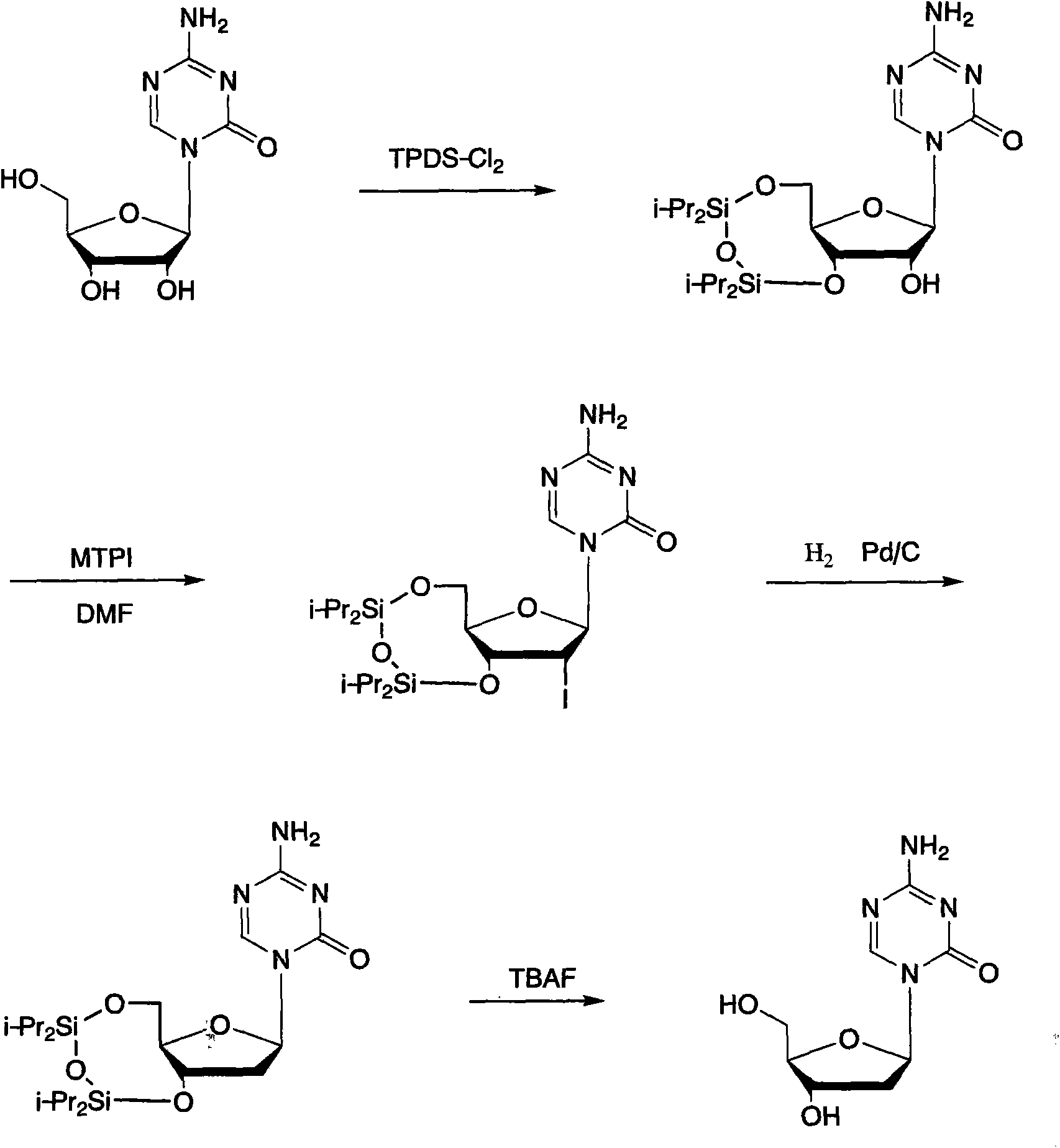

Method for preparing decitabine

ActiveCN102485737AReduce usageEasy to operateSugar derivativesSugar derivatives preparationDisiloxaneSilane compounds

The invention provides a method for preparing decitabine, which takes azacitidine as a raw material, the method comprises the following steps: reacting with 1,3-dichloro-1,1,3,3,-tetraisopropyldisiloxane (TPDS-C12) by taking pyridine as a solvent to prepare silane compounds, then reacting with methyl triphenoxyl phosphonium iodide (MTPI) to obtain 2-iodine substituent, reducing by introducing H2 under Pd / C catalysis to obtain the deoxidant, reacting with tetrabutylammonium fluoride (TBAF) and carrying out deprotection to obtain the decitabine. The product purity can reach 99%, the overall yield is 62%, the technology operation is simple and easy for large scale production realization.

Owner:苏州科耐尔医药科技有限公司

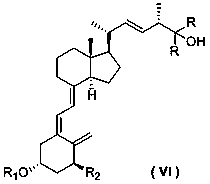

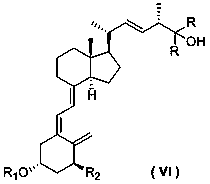

Production method of labelled vitamin D2 internal standard compound

InactiveCN110272367AGroup 4/14 element organic compoundsIsotope introduction to acyclic/carbocyclic compoundsPhosphonium saltVitamina D2

The invention relates to a production method of a labelled vitamin D2 internal standard compound. The production method of the labelled vitamin D2 internal standard compound comprises the following steps of firstly, subjecting a gamma-amide phosphonium salt compound as shown in a formula (IV) in the specification and an aldehyde as shown in a formula (III) in the specification to a reaction at -40 DEG to 0 DEG C to obtain an intermediate as shown in a formula (V) in the specification; then adding a Boc anhydride and a catalyst, carrying out a reaction, and then adding an isotope labelled methyl Grignard reagent dropwise to obtain an intermediate as shown in a formula (VI) in the specification; and then adding tetrabutylammonium fluoride, and carrying out a reaction to obtain a finished product, namely, the labelled vitamin D2 internal standard compound. The production method of the labelled vitamin D2 internal standard compound has the advantage that the produced labelled vitamin D2 internal standard compound can be used for 25-hydroxyvitamin D2, 1,25-dihydroxyvitamin D2 and tandem mass spectrometry for detecting the content of VD in human serum by means of the 25-hydroxyvitamin D2 and the 1,25-dihydroxyvitamin D2.

Owner:无锡贝塔医药科技有限公司

Method used for preparing tetrabutylammonium fluoride trihydrate

ActiveCN104803858AShort stepsEasy to operateOrganic compound preparationAmino compound preparationHydrofluoric acidOrganic solvent

The invention relates to a method used for preparing tetrabutylammonium fluoride trihydrate. According to the method, a tetrabutylammonium salt and potassium fluoride are dissolved in water; low temperature crystallization is carried out; pumping filtration is carried out so as to obtain tetrabutylammonium fluoride clathrate hydrate; and tetrabutylammonium fluoride trihydrate is obtained via vacuum drying. Reaction conditions of the method are mild; reaction processes are carried out in water; no organic solvent is used; the method is green and friendly to the environment; tetrabutylammonium fluoride trihydrate is obtained via crystallization separation of the tetrabutylammonium fluoride clathrate hydrate; steps are short; operation is simple and convenient; hydrofluoric acid is not used; no ion exchange column is used; no special requirement on equipment is proposed; cost is low; yield is high; and the method is suitable for industrialized production.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

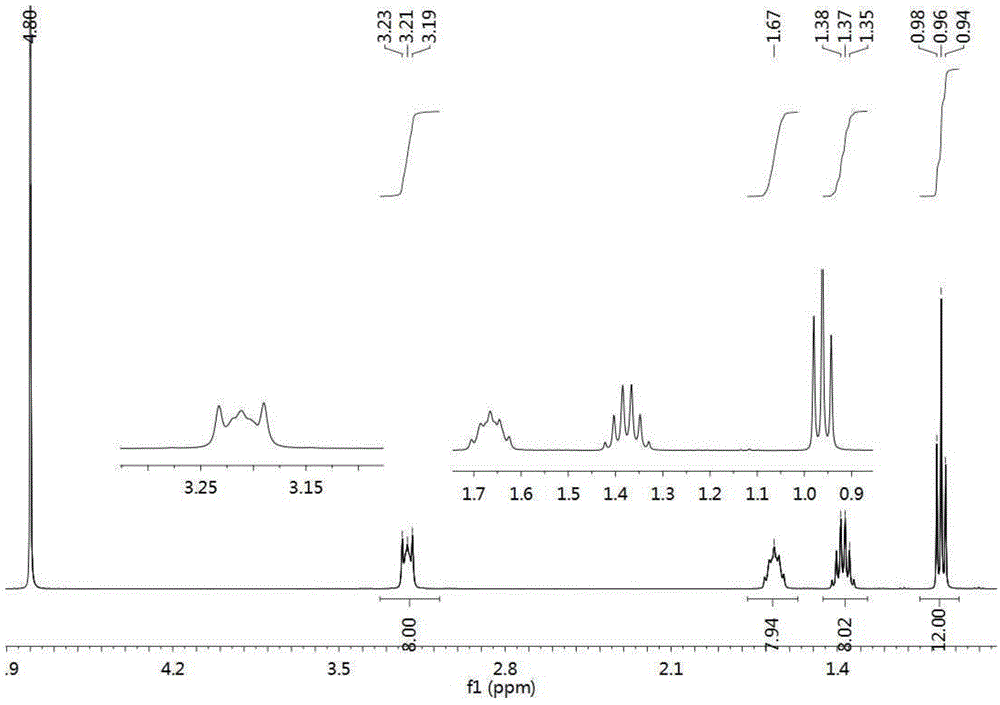

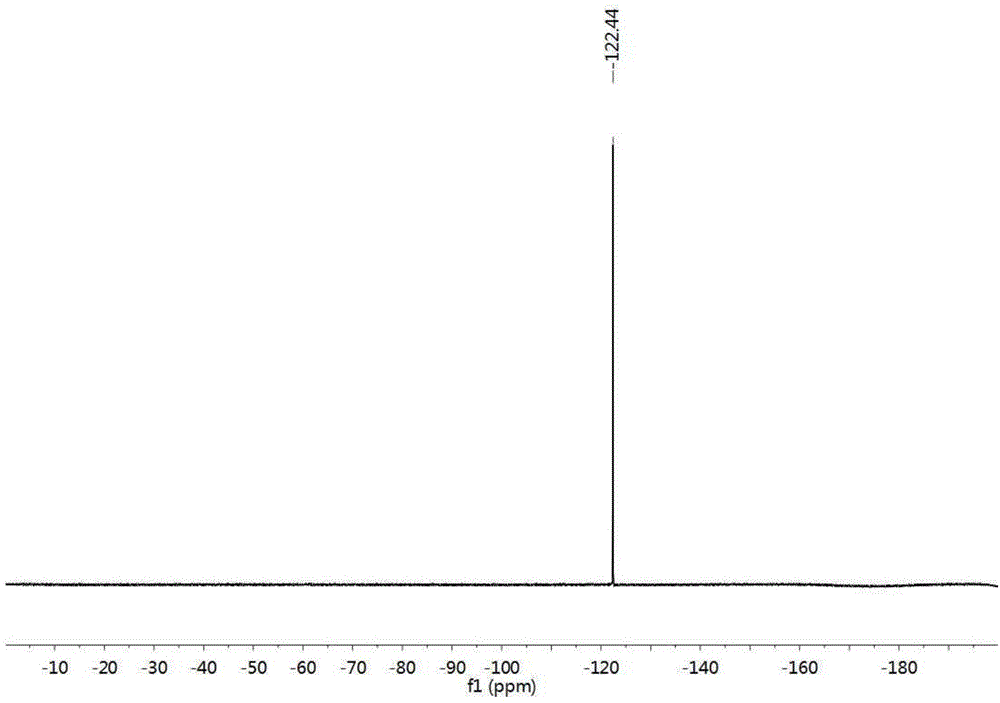

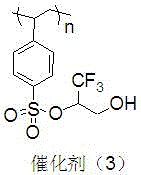

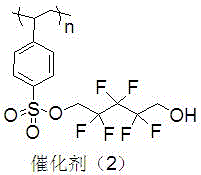

Immobilized fluorine-containing alcohol, method for preparing same and application of immobilized fluorine-containing alcohol

InactiveCN105665016ANovel structureEasy to manufactureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkSulfonyl chloride

The invention discloses an immobilized fluorine-containing alcohol catalyst (shown as a formula I), a method for preparing the immobilized fluorine-containing alcohol catalyst and application thereof.An A in the formula I is independently selected from C2-C8 saturated multi-fluorine or total-fluorine carbon chains and C2-C8 unsaturated multi-fluorine or total-fluorine carbon chains.The method for preparing the immobilized fluorine-containing alcohol catalyst shown as the formula I includes steps of a, carrying out reaction on styrene-divinylbenzene cross-linked resin and sulfonyl chloride to obtain immobilized sulfonyl chloride (shown as a formula II); b, carrying out reaction on the immobilized sulfonyl chloride (shown as the formula II) and trimethyl silica fluorine-containing alcohol (shown as a formula III) to obtain sulfonate (shown as a formula IV) with immobilized trimethyl silica fluorine-containing alcohol; c, carrying out desilylation on the sulfonate (shown as the formula IV) with the immobilized trimethyl silica fluorine-containing alcohol under the effect of tetrabutylammonium fluoride to obtain the immobilized fluorine-containing alcohol catalyst (shown as the formula I).The immobilized fluorine-containing alcohol catalyst, the method and the application have the advantages that the immobilized fluorine-containing alcohol catalyst is easy to prepare and can be recycled; the immobilized fluorine-containing alcohol catalyst can be applied to Baeyer-Villiger oxidation reaction, and products are high in yield.

Owner:SHIJIAZHUANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing tert-butyl 6-oxo-8-oxa-2, 5-diazaspiro[3.5]nonane-2-carboxylate Method for synthesizing tert-butyl 6-oxo-8-oxa-2, 5-diazaspiro[3.5]nonane-2-carboxylate](https://images-eureka.patsnap.com/patent_img/c0d300b0-9773-430c-84c7-853737052f0a/DEST_PATH_IMAGE001.png)

![Method for synthesizing tert-butyl 6-oxo-8-oxa-2, 5-diazaspiro[3.5]nonane-2-carboxylate Method for synthesizing tert-butyl 6-oxo-8-oxa-2, 5-diazaspiro[3.5]nonane-2-carboxylate](https://images-eureka.patsnap.com/patent_img/c0d300b0-9773-430c-84c7-853737052f0a/DEST_PATH_IMAGE003.png)