Supported hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, supported technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven deposition of active components, affecting catalyst activity, etc., to avoid metal utilization The efficiency is not high, the order is improved, and the effect of hydrogenation activity is exerted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

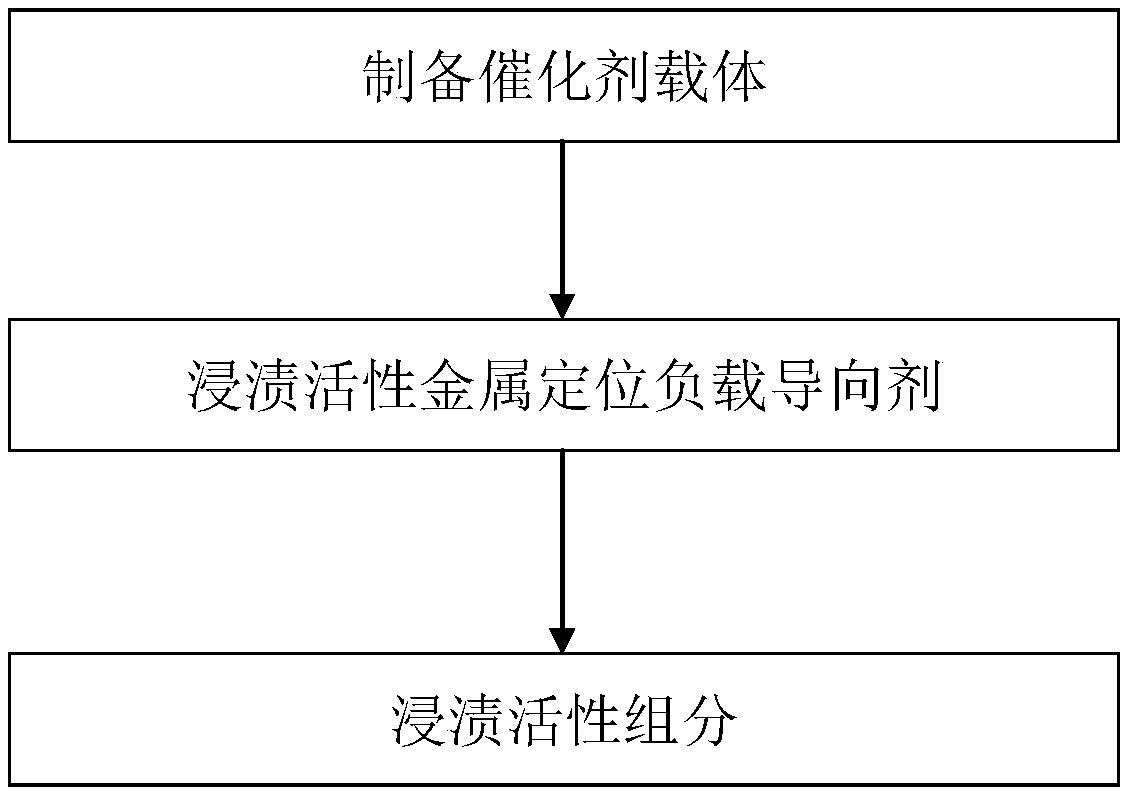

[0035] The invention discloses a preparation method of a supported hydrogenation catalyst, which preparation method comprises the following steps (such as figure 1 ):

[0036] Step 1, preparation of γ-Al 2 o 3 carrier;

[0037] Step 2, the γ-Al 2 o 3 The carrier is impregnated with the solution of the active metal positioning and loading directing agent, and dried; and

[0038] Step 3, the γ-Al obtained in step 2 2 o 3 The carrier is impregnated with an impregnation solution containing active components, and dried and calcined to obtain a supported hydrogenation catalyst;

[0039] Wherein, the active metal positioning load-directing agent is one or more of the group consisting of sodium ethylenediamine tetramethylene phosphate, tetrabutylammonium fluoride and tartaric acid.

[0040]Among them, the present invention is useful for the preparation of γ-Al 2 o 3 The specific method of the carrier is not particularly limited, the preparation of γ-Al known in the art 2 o ...

Embodiment 1

[0050] (1) γ-Al 2 o 3 Preparation of vector

[0051] Weigh 1000g of pseudoboehmite powder, 30g of Tianqing powder, 30g of citric acid, and 700ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry at 110°C for 10h, and roast at 650°C in an air atmosphere After treatment, γ-Al was obtained 2 o 3 carrier.

[0052] (2) Impregnated active metal positioning load-directing agent

[0053] Adopt the method of unsaturated spray impregnation, weigh the γ-Al prepared by 500g step (1) 2 o 3 Carrier, measure 135g of the prepared active metal positioning load-directing agent solution and spray immerse. The mass ratios of three solutes in the solution are: the mass ratio of sodium ethylenediaminetetramethylene phosphate is 65.4%, tetrabutylammonium fluoride The mass proportion of tartaric acid is 15.0%, and the mass proportion of tartaric acid is 19.6%. The mass concentration of the solution of the active metal positioning load-directing agent is 4.7%. It...

Embodiment 2

[0057] (1) γ-Al 2 o 3 Preparation of vector

[0058] Weigh 1000g of pseudoboehmite powder, 30g of Tianqing powder, 30g of citric acid, and 700ml of 3-5% dilute nitric acid, mix them evenly, extrude them with an extruder, dry at 110°C for 10h, and roast at 650°C in an air atmosphere After treatment, γ-Al was obtained 2 o 3 carrier.

[0059] (2) Impregnated active metal positioning load-directing agent

[0060] Adopt the method of unsaturated spray impregnation, weigh the γ-Al prepared by 500g step (1) 2 o 3 Carrier, measure 132g of the prepared active metal positioning load-directing agent solution and spray immerse. The mass ratios of three solutes in the solution are: the mass ratio of sodium ethylenediamine tetramethylene phosphate is 56.4%, tetrabutylammonium fluoride The mass proportion of tartaric acid is 27.3%, and the mass proportion of tartaric acid is 16.3%. The mass concentration of the solution of the active metal positioning load-directing agent is 3.0%. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com