Method for improving pore structure of kaolin microsphere in-situ crystallization product

A kaolin microsphere, in-situ crystallization technology, applied in chemical instruments and methods, chemical/physical processes, molecular sieve catalysts, etc. The proportion of medium and large holes and the effect of obvious hole reaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

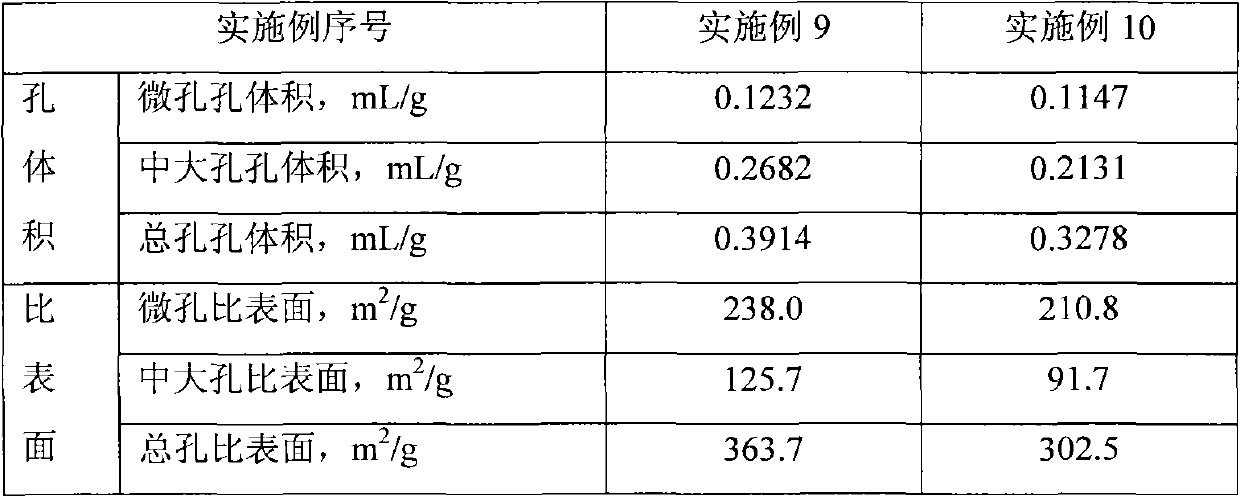

Examples

Embodiment 1

[0015] 2000g of kaolin (naphthyl), 4% of sodium silicate, 3% of polyvinylpyrrolidone, and deionized water are added to prepare a mixed slurry with a kaolin solid content of 46%, spray-dried to obtain 1625g of kaolin with a particle size of 20-110 μm Spray microspheres AS1.

Embodiment 2

[0017] 2000g kaolin (calcium base), 9% sodium pyrophosphate, 6% polyvinylpyrrolidone, and deionized water are added to prepare a mixed slurry with a kaolin solid content of 32%, spray-dried to obtain 1730g of kaolin with a particle size of 20-110 μm Spray microspheres AS2.

Embodiment 3

[0019] 2000g of kaolin (calcium base), 6% of sodium silicate, 8% of polyvinyl alcohol, and deionized water were added to prepare a mixed slurry with a kaolin solid content of 40%, spray-dried to obtain 1582g of kaolin spray with a particle size of 20-110 μm Microsphere AS3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com