Patents

Literature

34results about How to "High molecular sieve content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

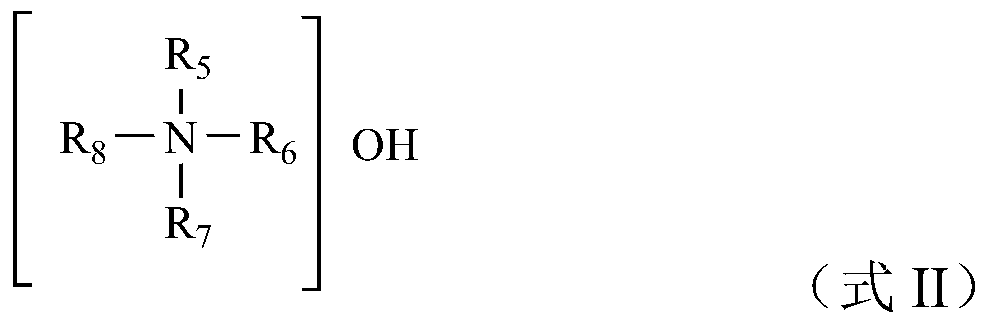

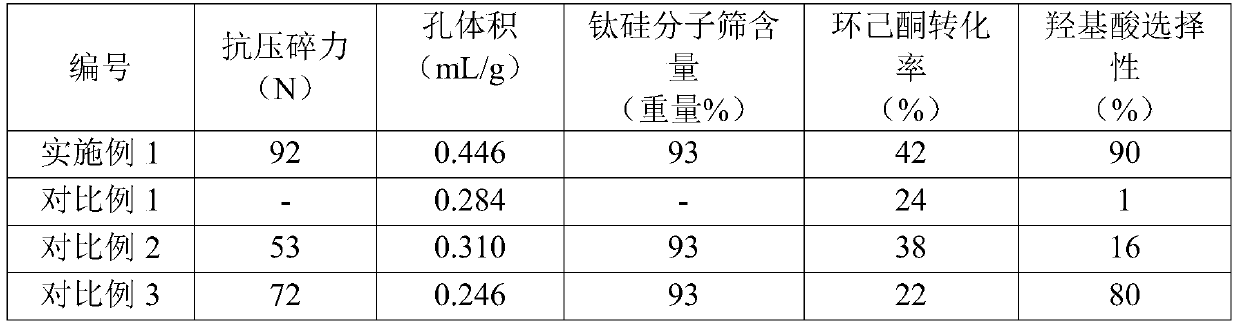

Titanium-silicon molecular sieve molding, molding catalyst, applications of molding catalyst, and cyclohexanone oxidation method

ActiveCN106964400AEfficient use ofOvercoming complexityMolecular sieve catalystsOrganic compound preparationCyclohexanoneSlurry

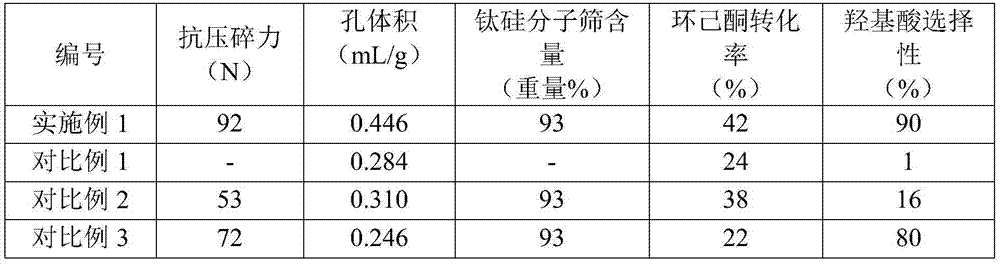

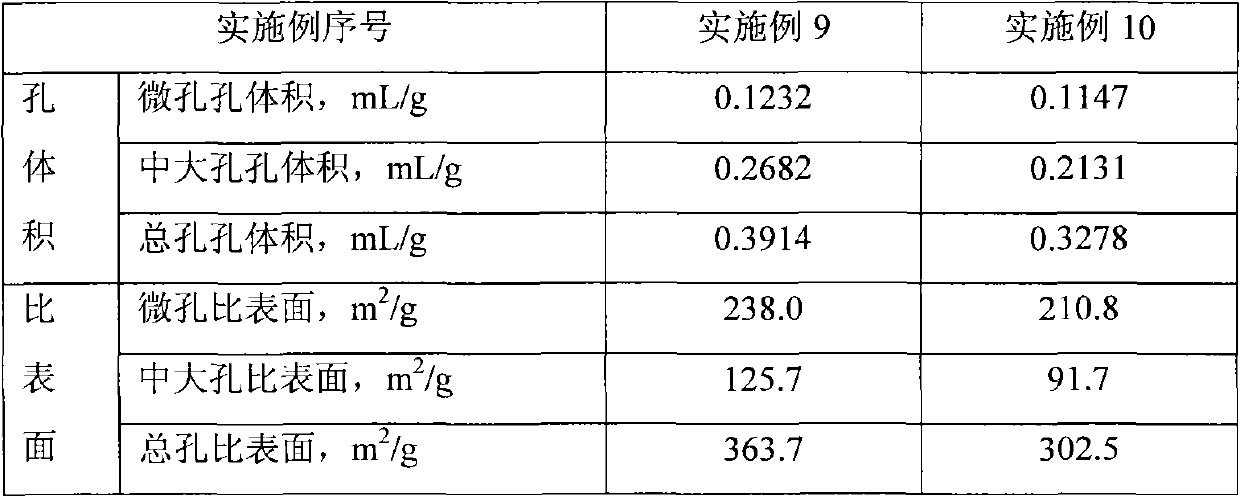

The present invention relates to the field of catalyst molding, and particularly provides a titanium-silicon molecular sieve molding method, which comprises: mixing a titanium-silicon molecular sieve and a water-containing mixture, carrying out hydrothermal treatment under a sealed condition, molding the slurry obtained from the hydrothermal treatment to obtain a molding body, and calcining the molding body, wherein the water-containing mixture contains a silicon element, a titanium element and a nitrogen element, and is at least partially derived from the crystallization mother liquor of the titanium silicon molecular sieve. The present invention provides a molding catalyst prepared according to the preparation method, and applications thereof. The invention further provides a cyclohexanone oxidation method. According to the present invention, with the titanium-silicon molecular sieve molding method, the industrial waste liquid is effectively utilized, and the problems of complex process, corrosion on equipment, harmful emission and the like of the traditional process are overcome; and the molding catalyst has characteristics of high titanium-silicon molecular sieve content, high pore volume, high crushing resistance, and high selectivity to the target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

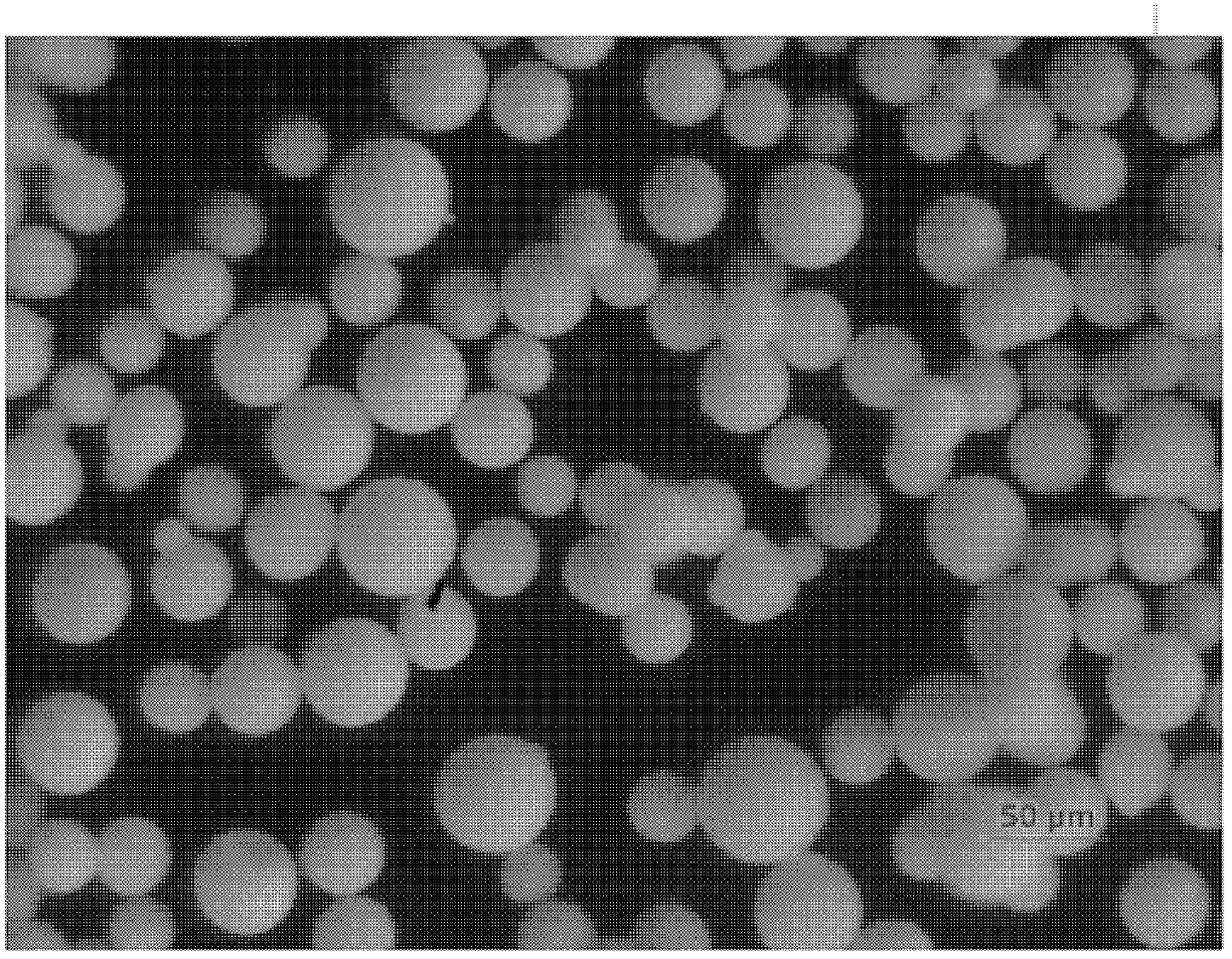

Method for improving pore structure of kaolin microsphere in-situ crystallization product

ActiveCN102019196AHigh molecular weightRegular structureMolecular sieve catalystsCatalyst activation/preparationPolyvinyl alcoholMicrosphere

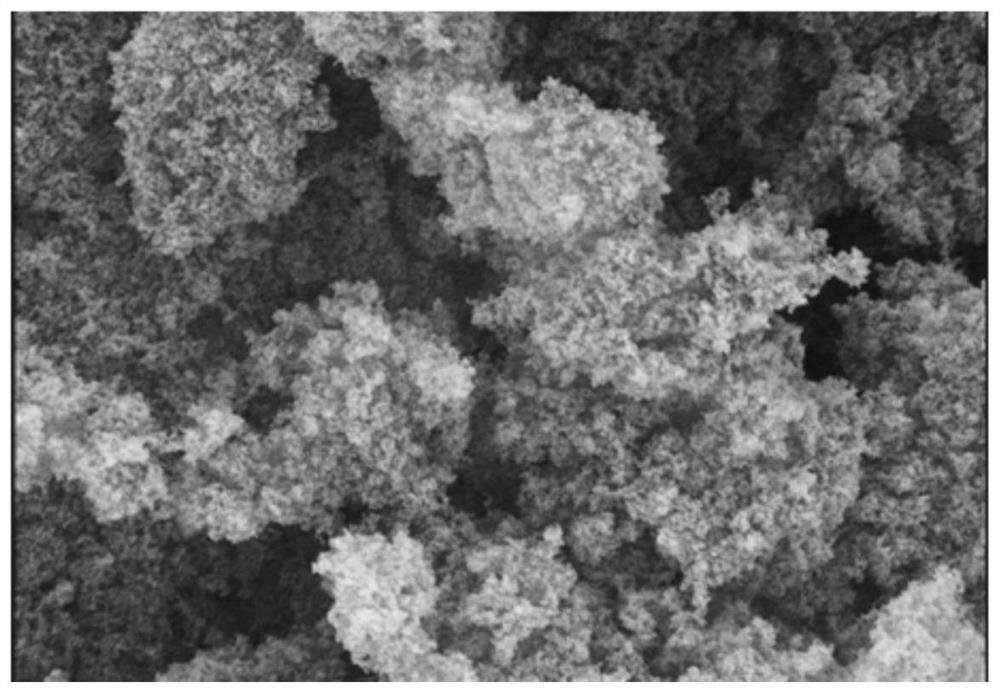

The invention relates to a method for improving the pore structure of a kaolin microsphere in-situ crystallization product. The method comprises the following steps of: preparing kaolin spray microspheres with the particle sizes of between 20 and 110 mu m by using mixed kaolin grout by spray drying, wherein the mixed grout comprises kaolin, deionized water, a dispersant and an organic pore cannelforming template agent; the dispersant is sodium silicate or sodium pyrophosphate; and the organic pore cannel forming template agent is polyvinyl pyrrolidone or polyvinyl alcohol; baking the spray microspheres at the temperature of between 900 and 1,100 DEG C for 1 to 3 hours so as to obtain kaolin baked microspheres; mixing the kaolin baked microspheres with the mullite content of between 2 and12 percent, sodium silicate, a directing agent, solution of sodium hydroxide and deionized water; crystalizing the mixture at the temperature of between 90 and 95 DEG C for 16 to 36 hours; and filtering and drying so as to obtain a crystallization product which has a medium / large-pore structure and comprises a NaY molecular sieve. The crystallization product has a well-developed large-pore structure and the abrasion index of not more than 1.5 percent and comprises 20 to 50 percent of NaY molecular sieve.

Owner:PETROCHINA CO LTD +1

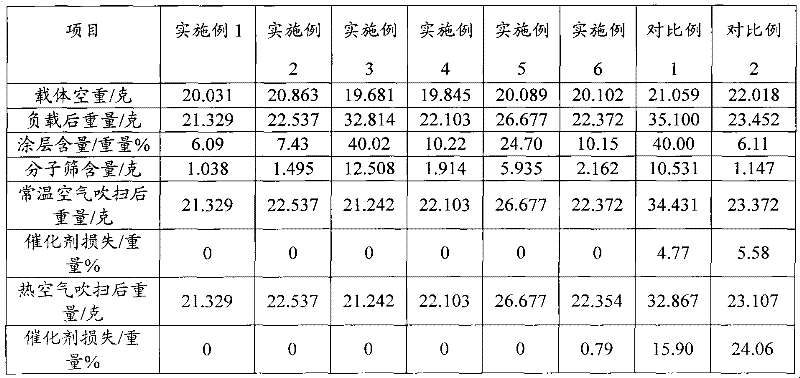

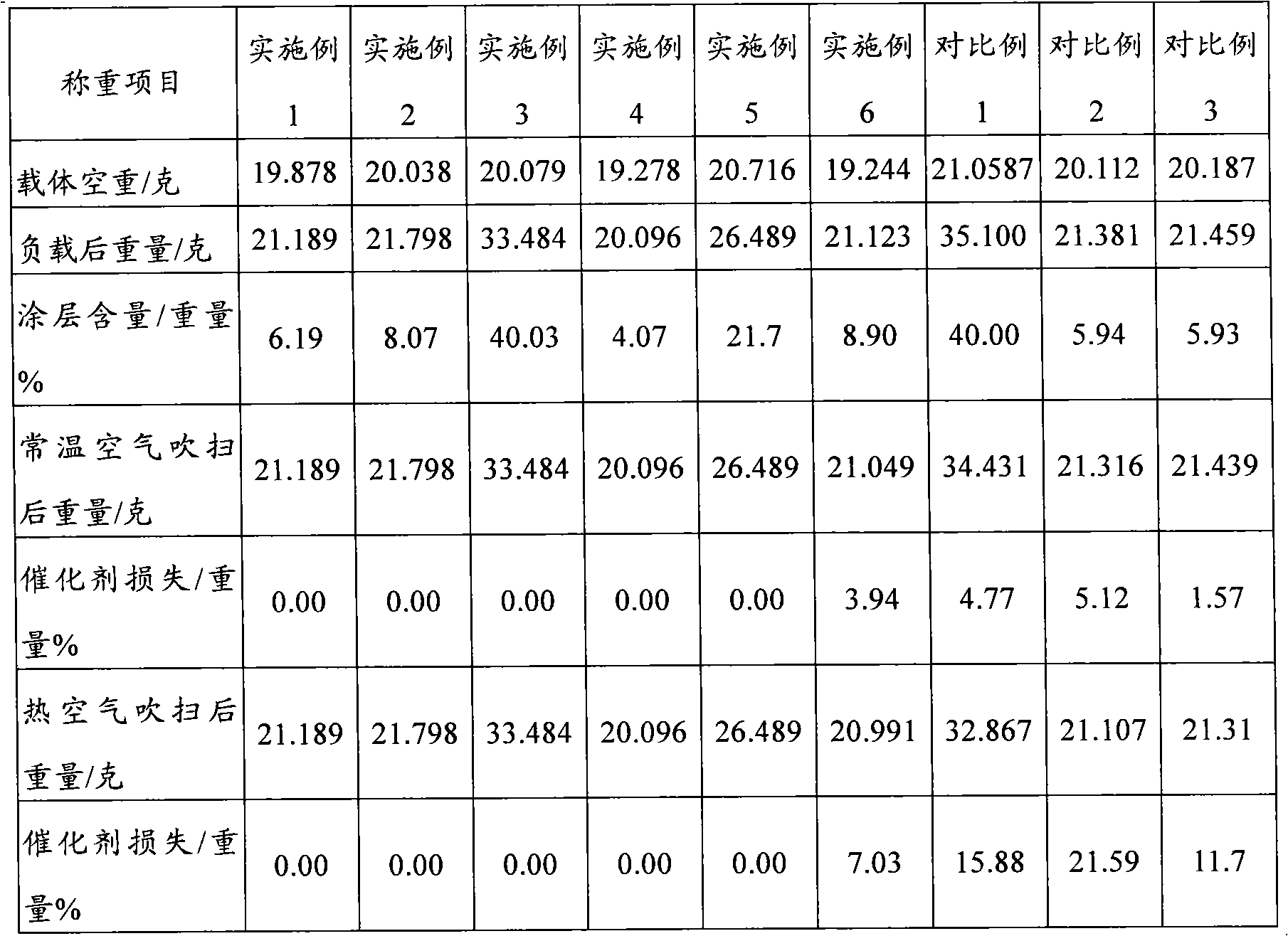

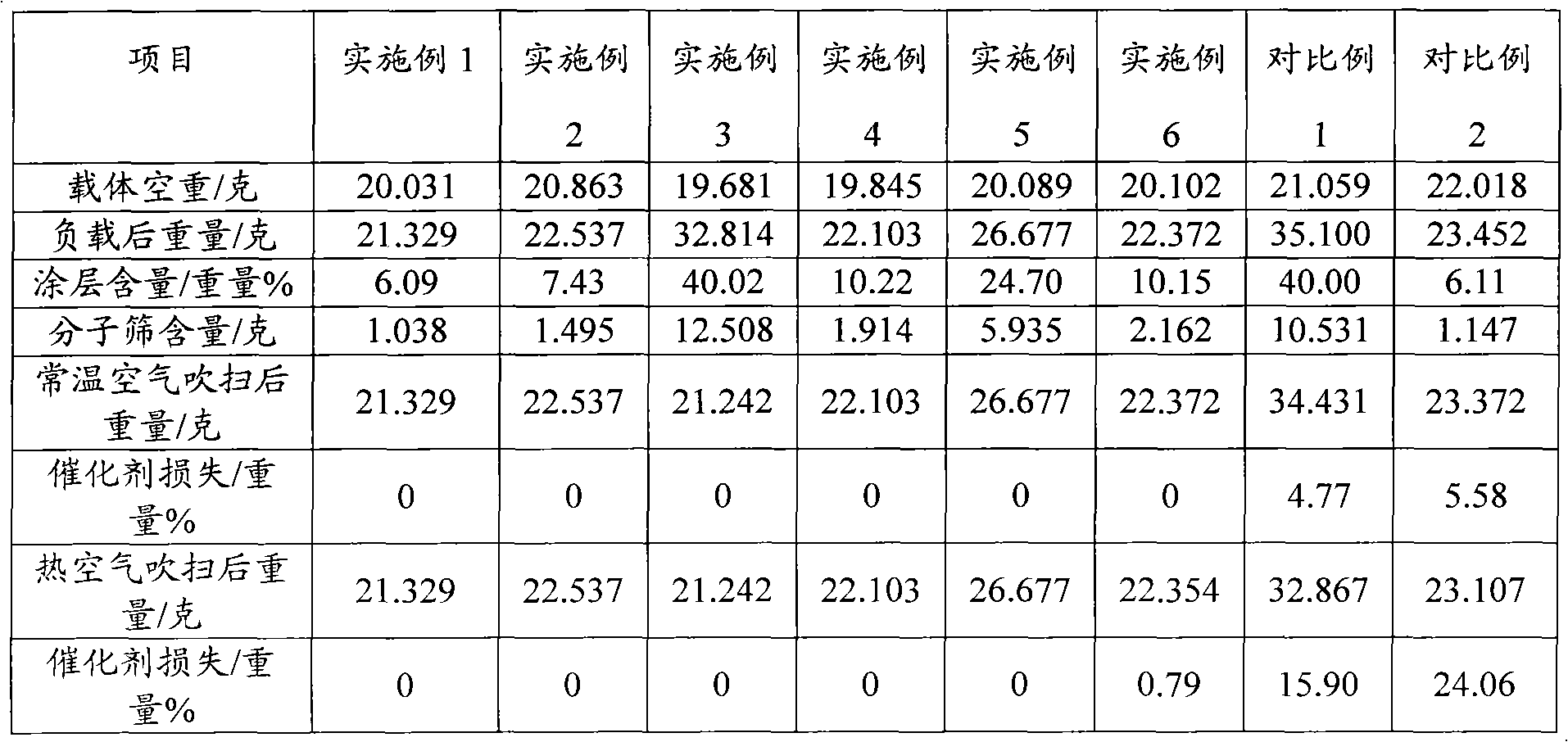

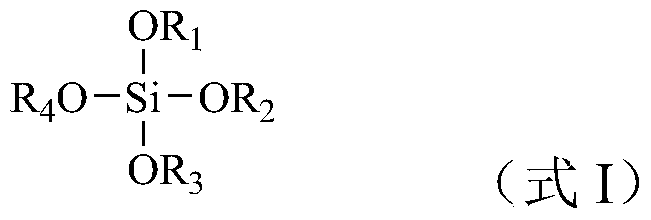

Preparation method for honeycomb supported catalyst containing coating of molecular sieve composition

The invention provides a preparation method for a honeycomb supported catalyst containing a coating of a molecular sieve composition. The method comprises the step of coating a honeycomb support with coating slurry, wherein, the coating slurry comprises a molecular sieve, phosphorus and aluminum components, a dispersant and water, on the basis of the weight of the coating slurry, the content of the molecular sieve in the slurry is 3 to 60 wt %, the weight ratio of the phosphorus and aluminum components to the molecular sieve is 0.1-30:100, the weight ratio of the dispersant to the molecular sieve is 0-20:100, the weight of the phosphorus and aluminum components is counted on the basis of total weight of P2O5 and Al2O3, the weight of the molecular sieve is counted in terms of a dry basis, the dispersant is one compound or more compounds containing polyhydroxy groups, polyoxyethylene groups or polycarboxylic groups, the particle diameter of the phosphorus and aluminum components is lessthan 100 nm, and the particle diameter d90 of the molecular sieve is 1 to 10 mu m. The honeycomb supported catalyst containing the molecular sieve composition in the invention has a firm coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

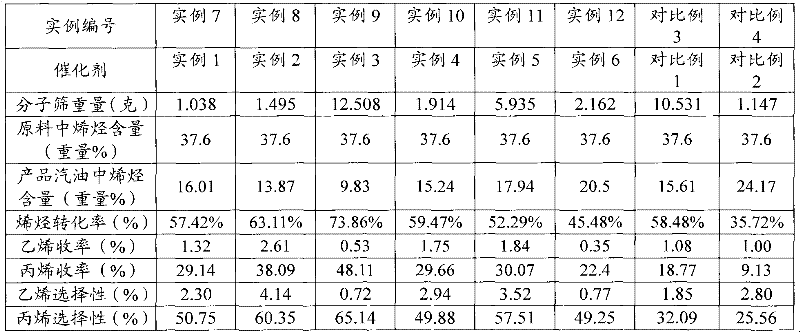

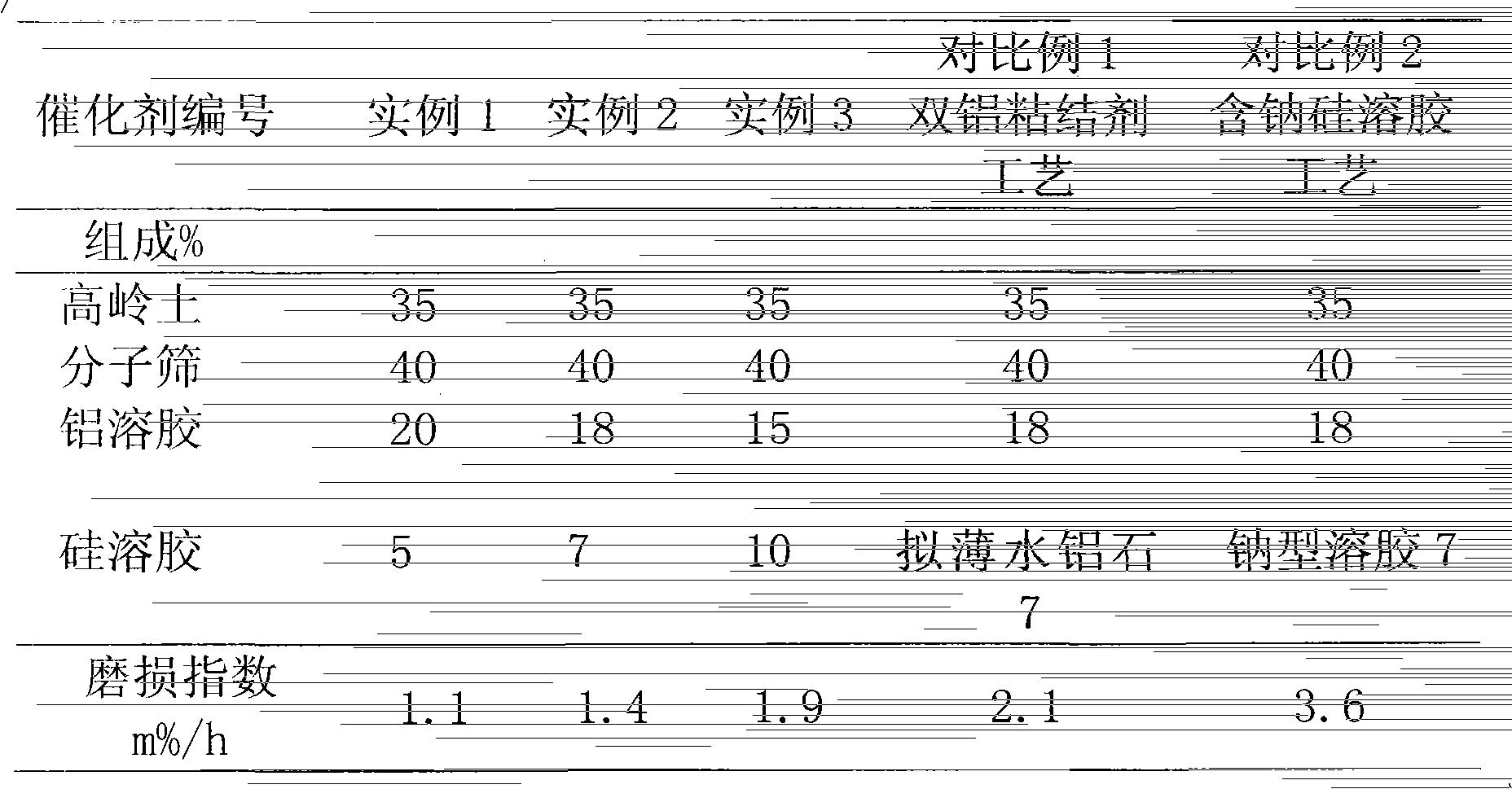

FCC (Fluid Cracking Catalyst) catalyst containing silicon binder and preparation method thereof

InactiveCN103447070AHigh molecular sieve contentModulation responsivenessCatalytic crackingMolecular sieve catalystsBoehmiteChemistry

The invention provides a preparation method of an FCC (Fluid Cracking Catalyst) catalyst containing a silicon binder. The method comprises the following steps: mixing and pulping clay, molecular sieve slurry, pseudo-boehmite, hydroxyl aluminum chloride (alumina sol) and a silica sol binder to prepare catalyst slurry; then, spraying and drying the catalyst slurry; then, washing and drying the catalyst slurry to obtain a catalyst product. The method is characterized in that three binders pseudo-boehmite, alumina sol and silica sol serve as a compound binder, and the use level of silica sol can be regulated in a larger amplitude, thereby, providing an effectively method for preparing an alumino silica gel FCC catalyst. The catalyst prepared by the method provided by the invention has the characteristics of good strength, strong heavy oil cracking capacity, high light liquid yield and the like.

Owner:湖北赛因斯科技开发有限公司

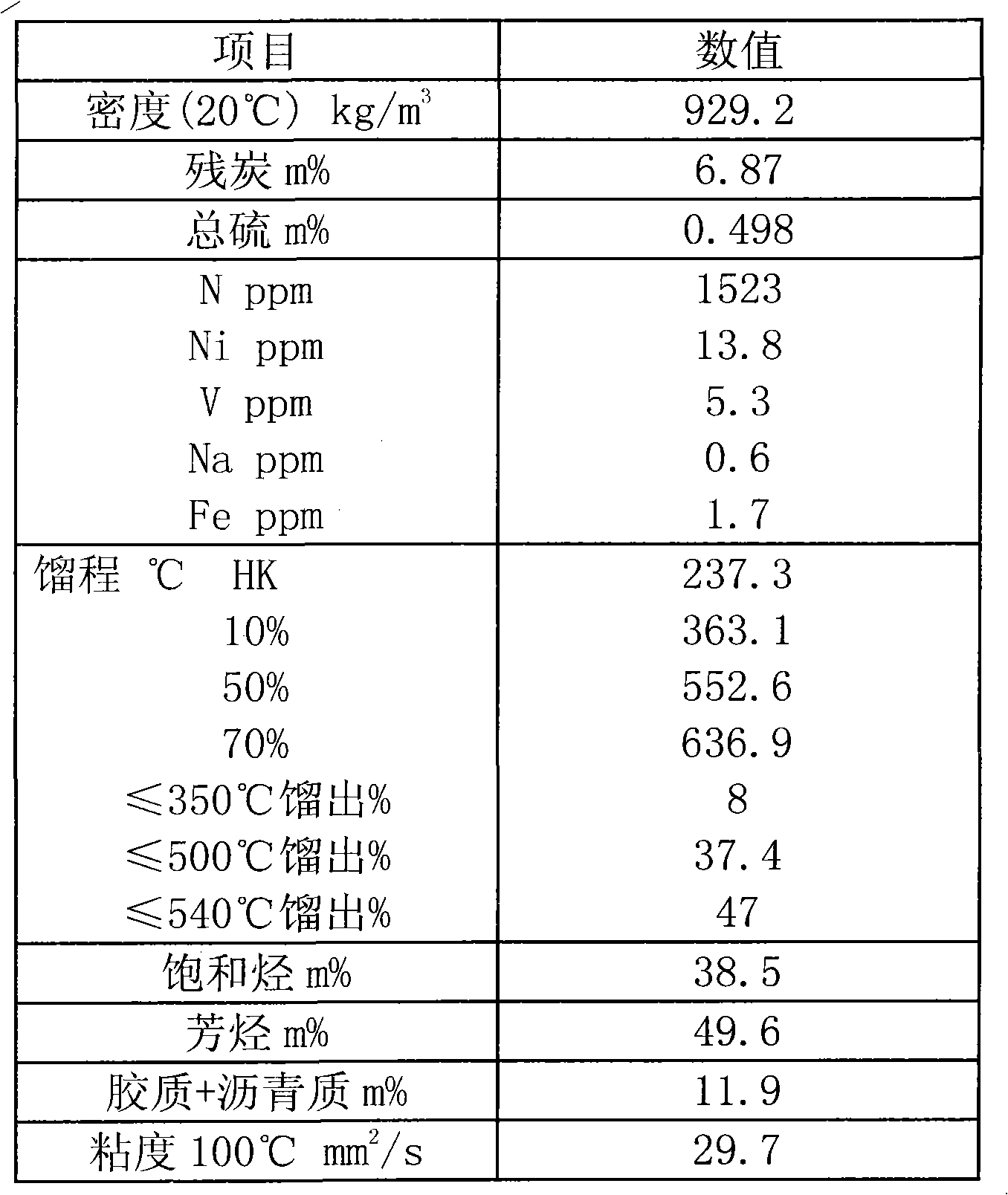

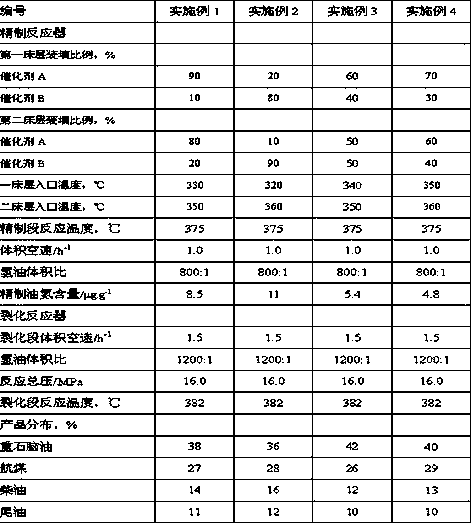

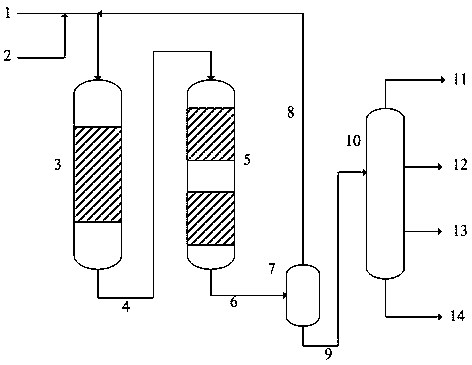

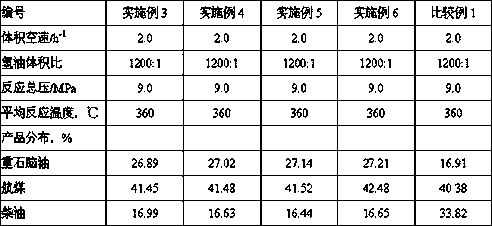

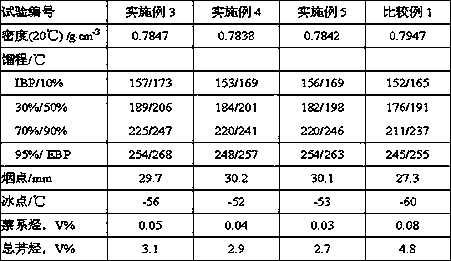

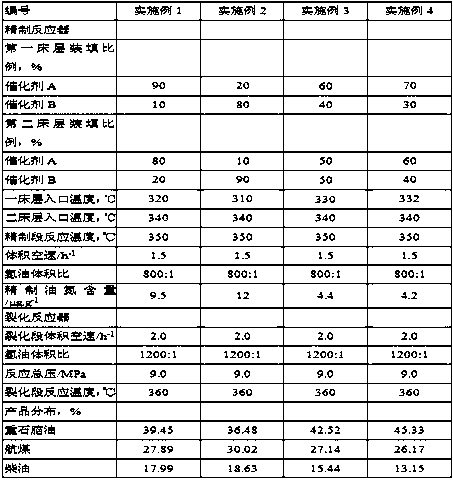

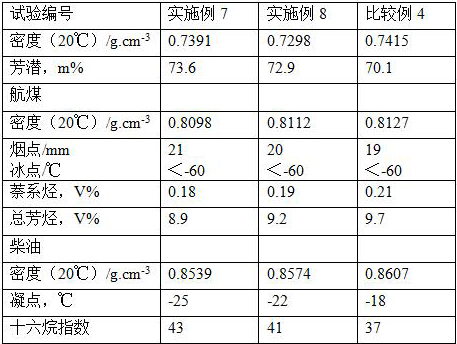

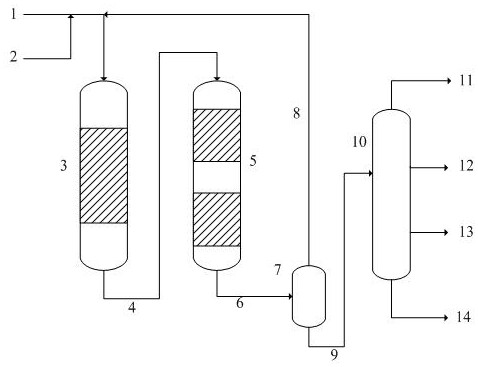

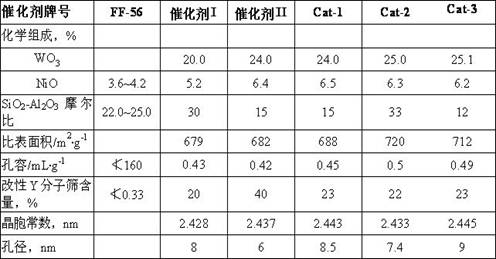

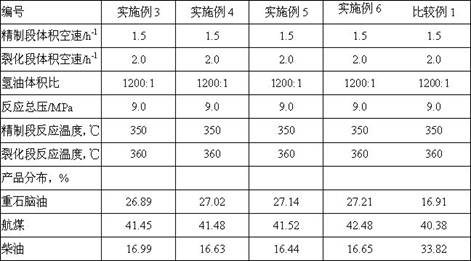

Wax oil hydrocracking method

ActiveCN110938466AExtended stayHigh molecular sieve contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sieveProcess engineering

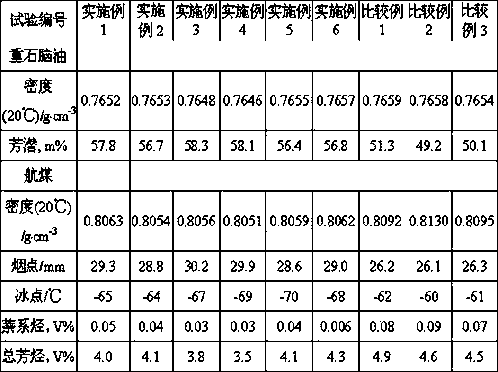

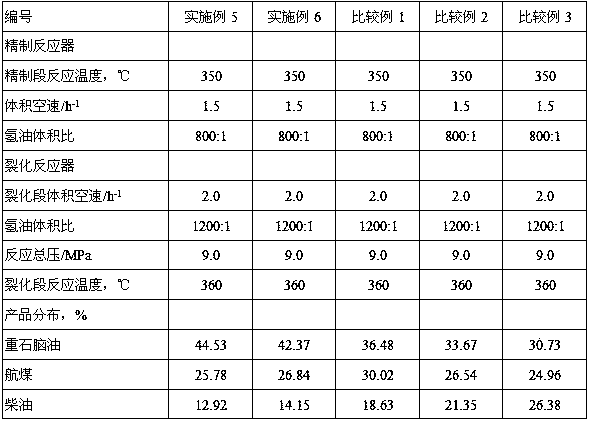

The invention discloses a wax oil hydrocracking method, which comprises the following steps that (1) a wax oil raw material and hydrogen enters a hydrofining reactor in a mixed manner and are subjected to desulfurization, denitrification and aromatic hydrocarbon saturation reaction; (2) the effluent obtained in the step (1) enters a hydrocracking reactor, wherein the hydrocracking reactor comprises first to nth catalyst bed layers in a material direction, n is greater than or equal to 3, preferably 3 or 4, the first to (n-1)th catalyst bed layers are filled with a hydrocracking catalyst containing a modified Y molecular sieve, and the nth catalyst bed layer is filled with a hydroisomerization catalyst containing beta and / or ZSM-series molecular sieves and other molecular sieves with high isomerization performance; and (3) the effluent of the hydrocracking reactor is subjected to gas-liquid separation and liquid-phase fractionation to obtain naphtha, aviation kerosene, diesel oil and tail oil. According to the method, by using wax oil as a raw material, the yield of heavy naphtha with high aromatic potential is increased and the quality of aviation kerosene and diesel oil products is improved by setting a reasonable catalyst grading mode and modulating the catalyst composition and the structure in grading bed layers.

Owner:CHINA PETROLEUM & CHEM CORP +1

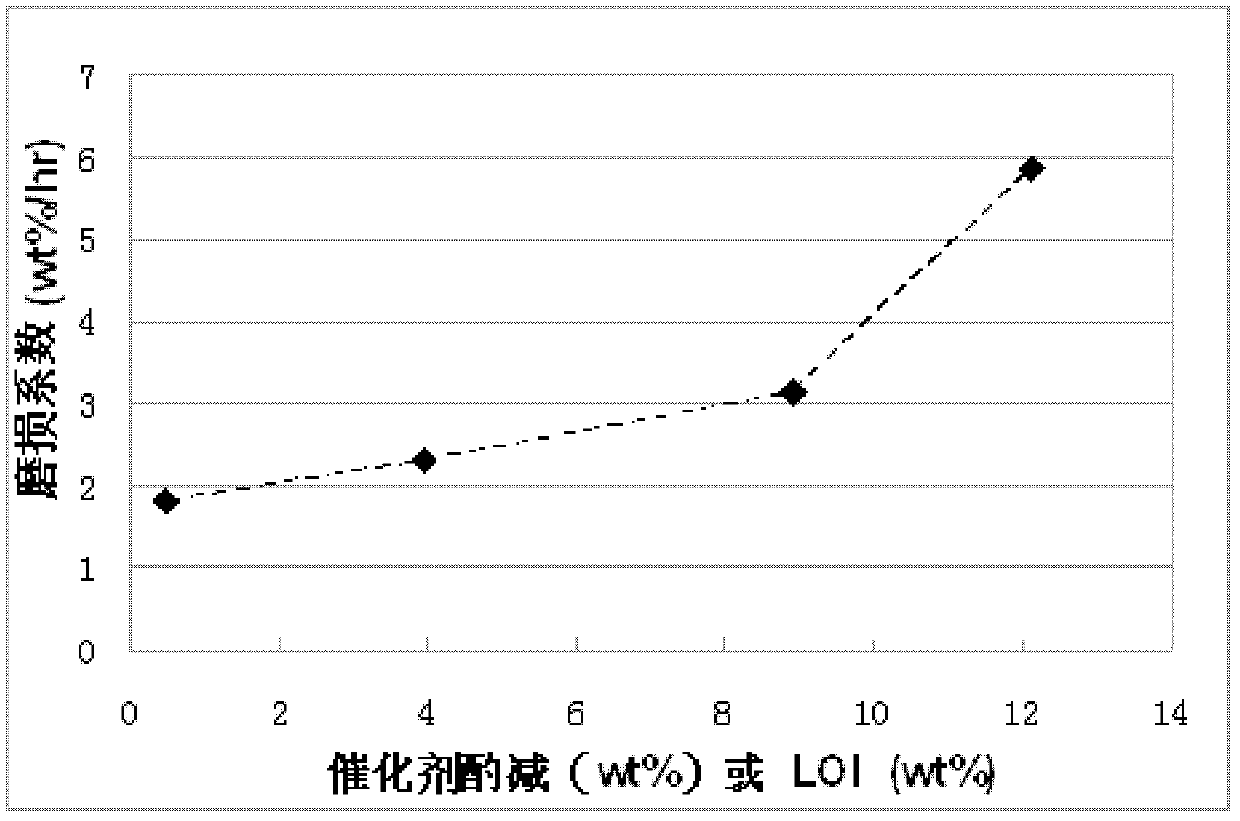

Preparing method of wearing-resistant catalyst

InactiveCN102631945AReduce LOI (discretionary) valueReduce wear rateCatalytic crackingMolecular sieve catalystsMolecular sieveWear resistant

Owner:常云峰 +1

Method for preparing low-carbon olefin through methanol dehydration

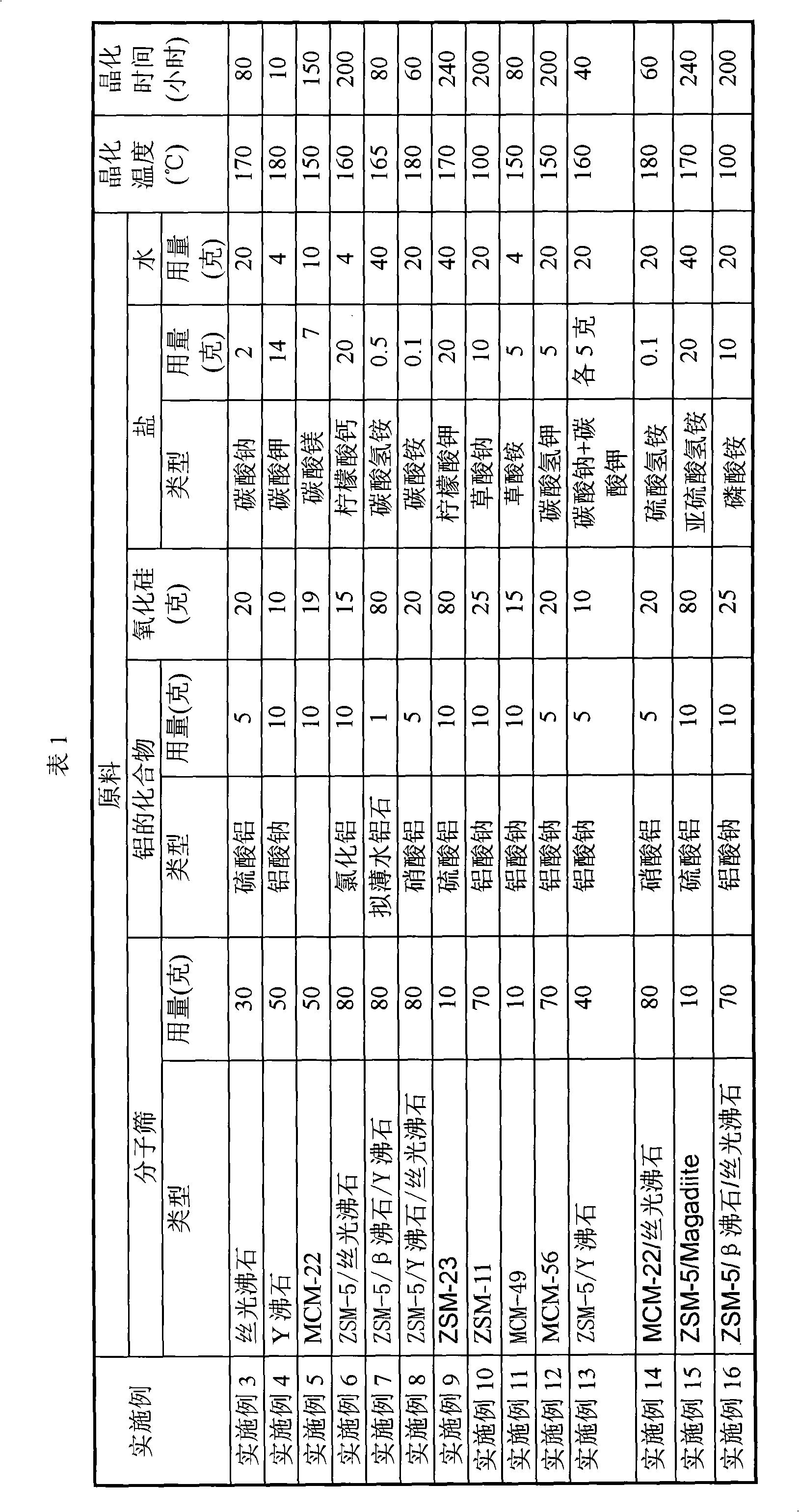

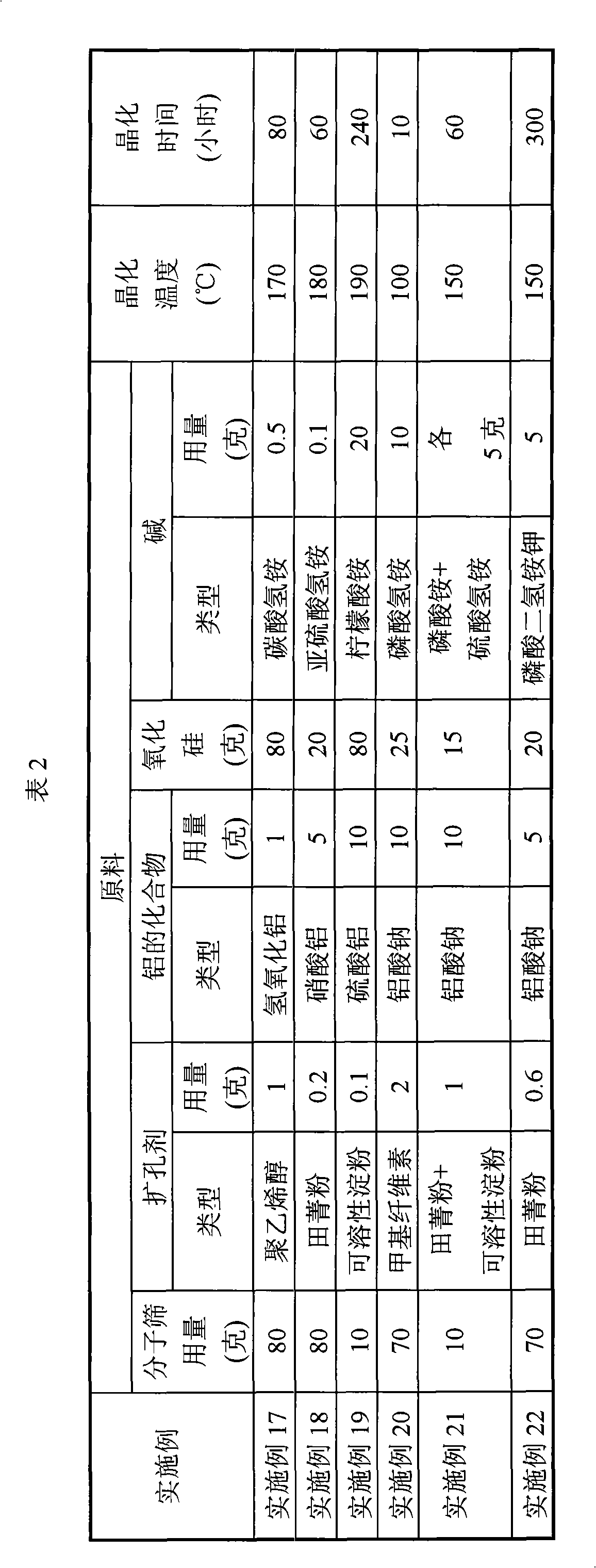

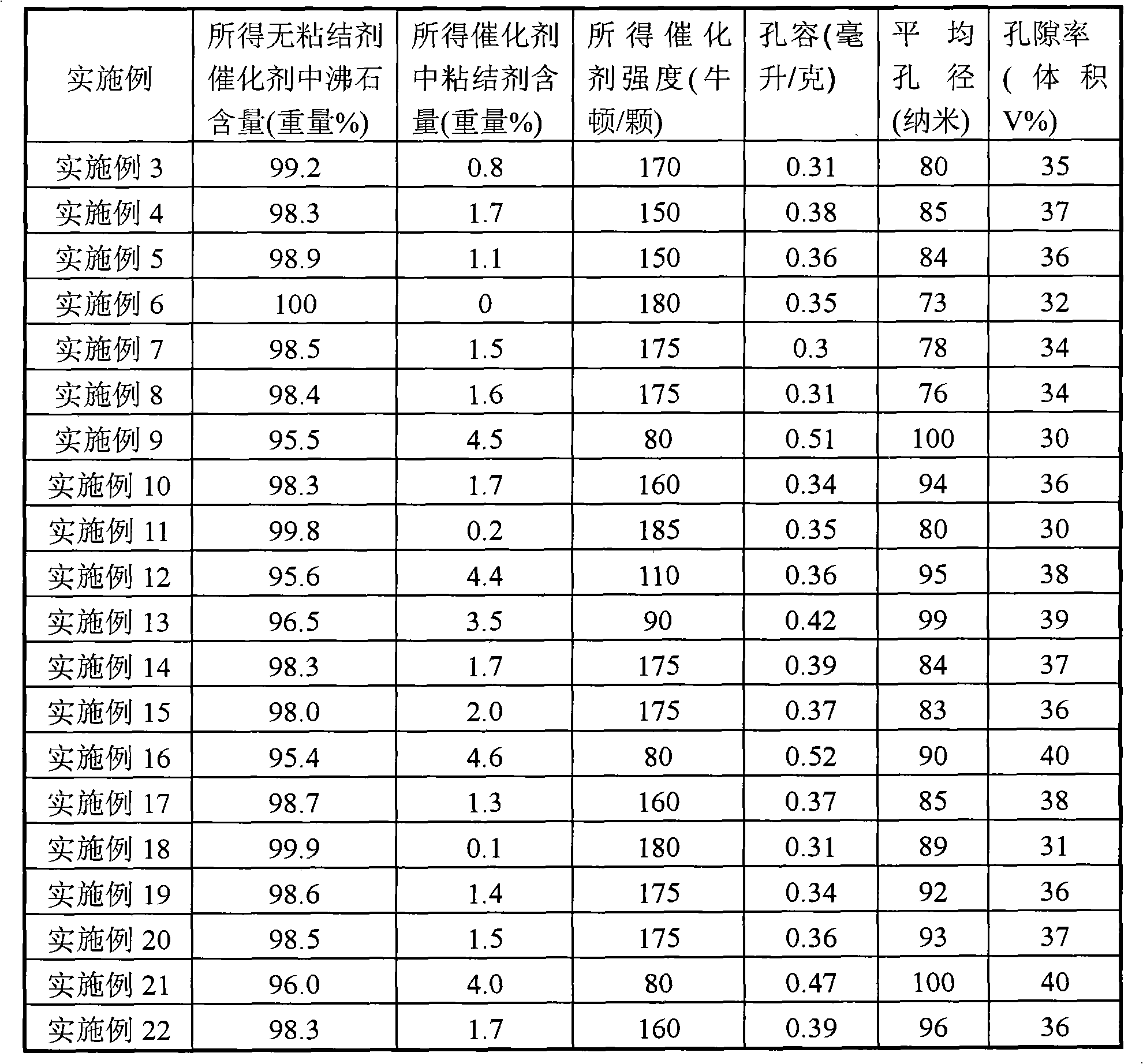

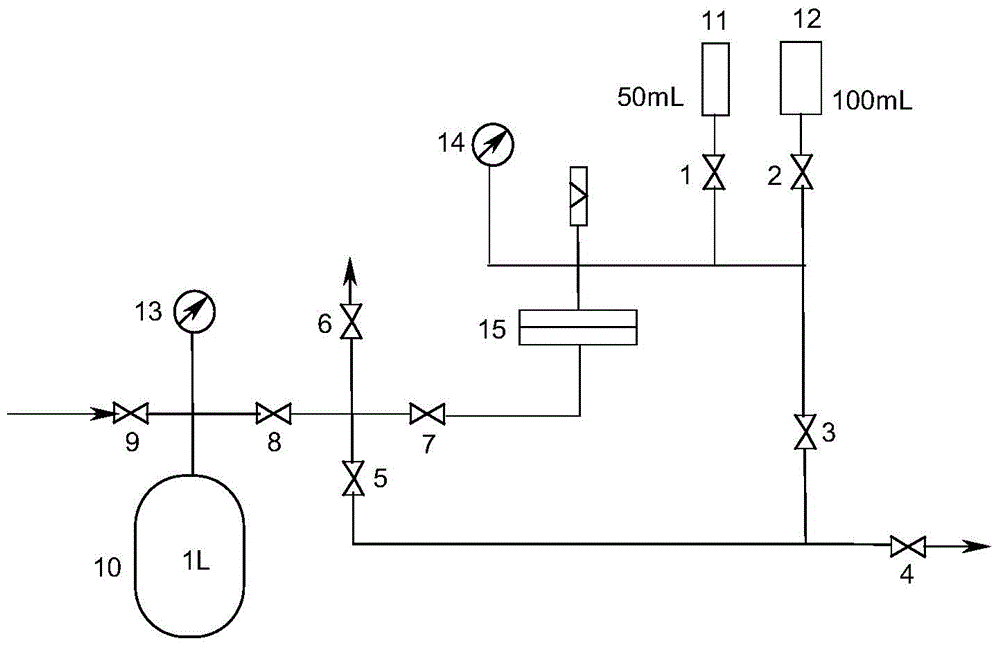

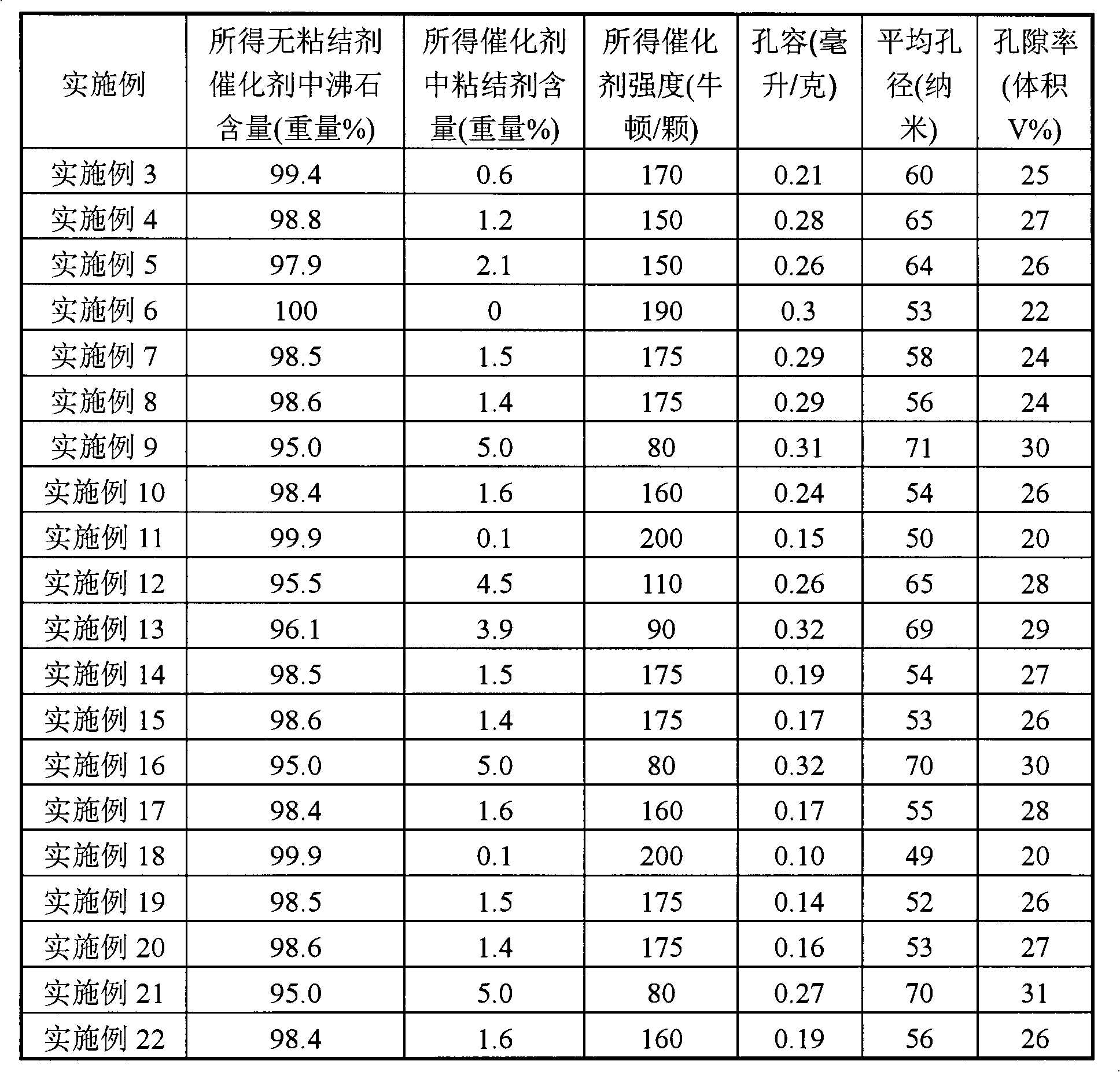

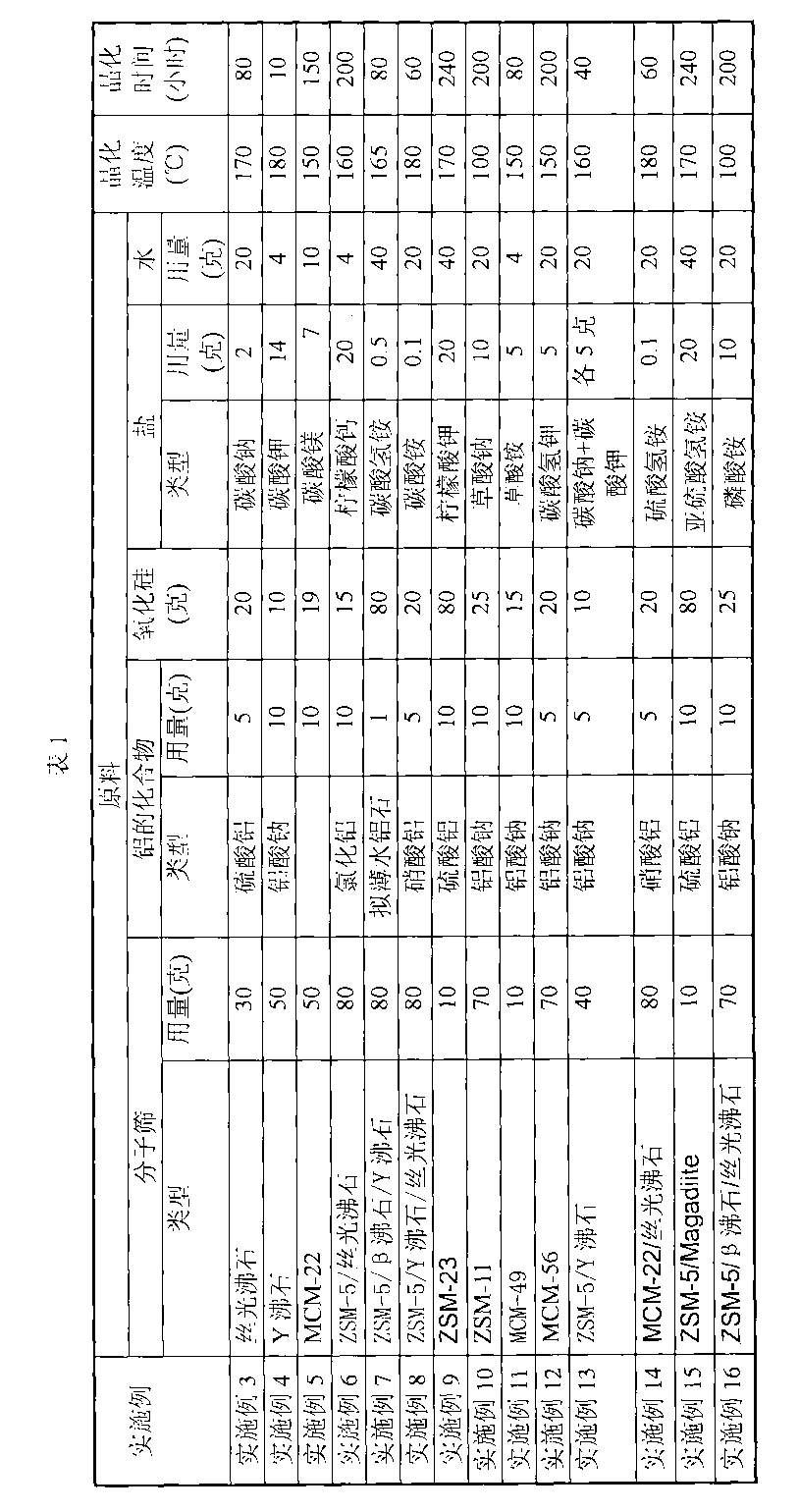

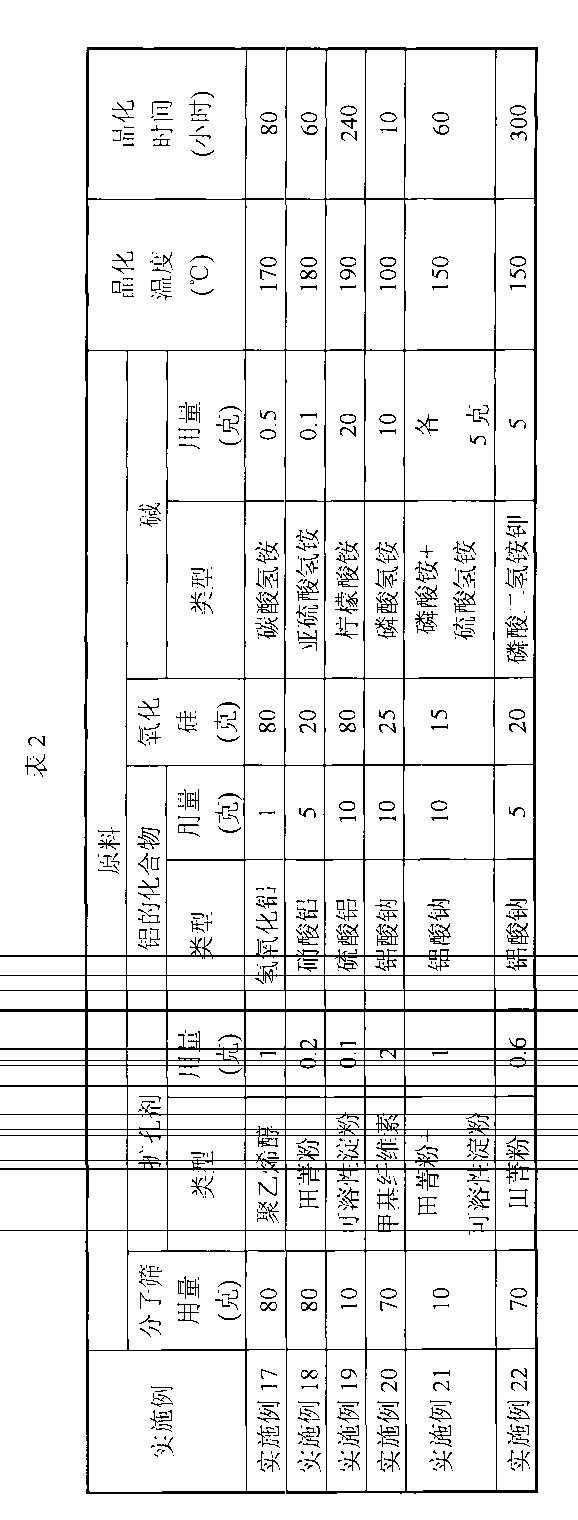

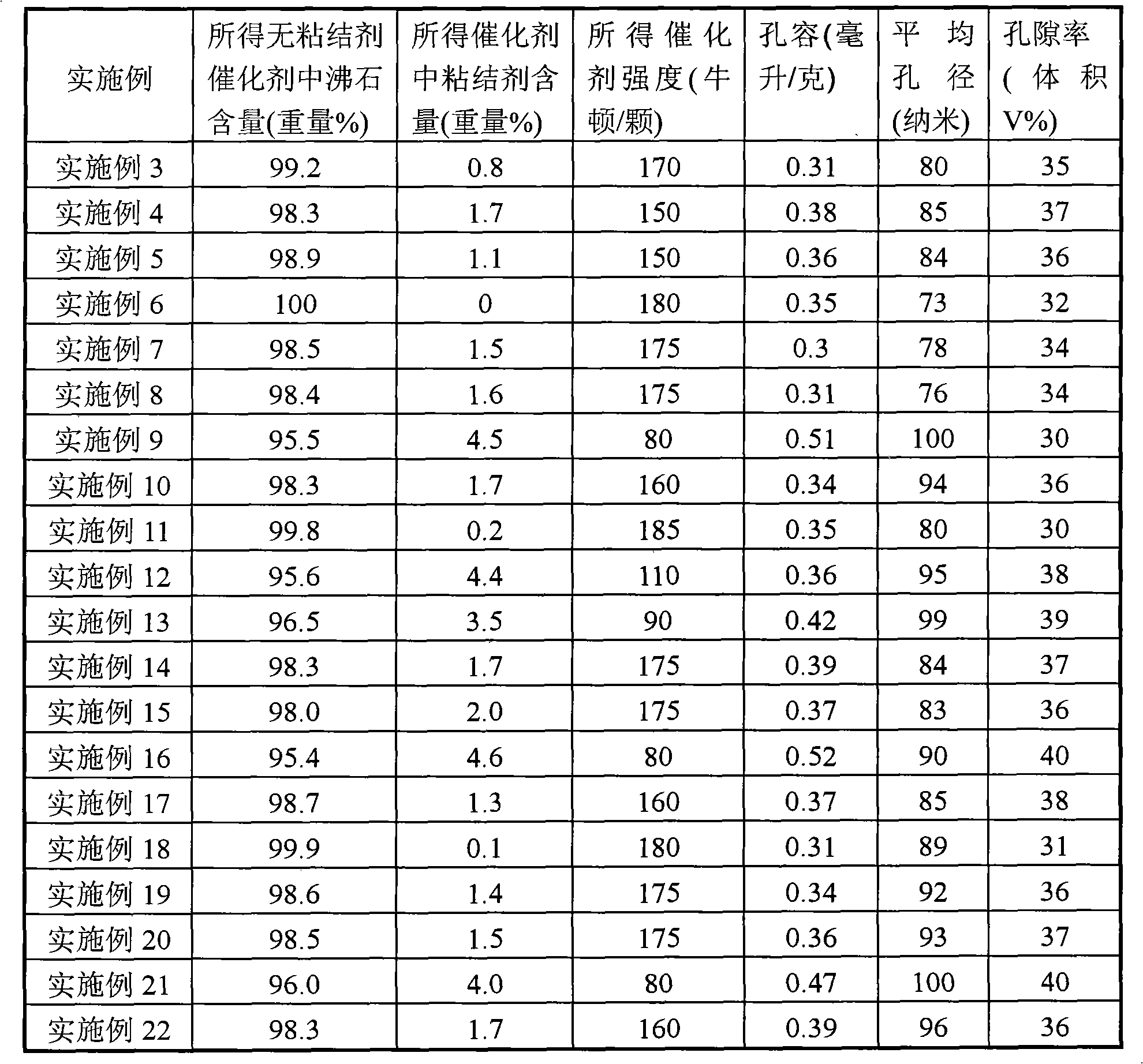

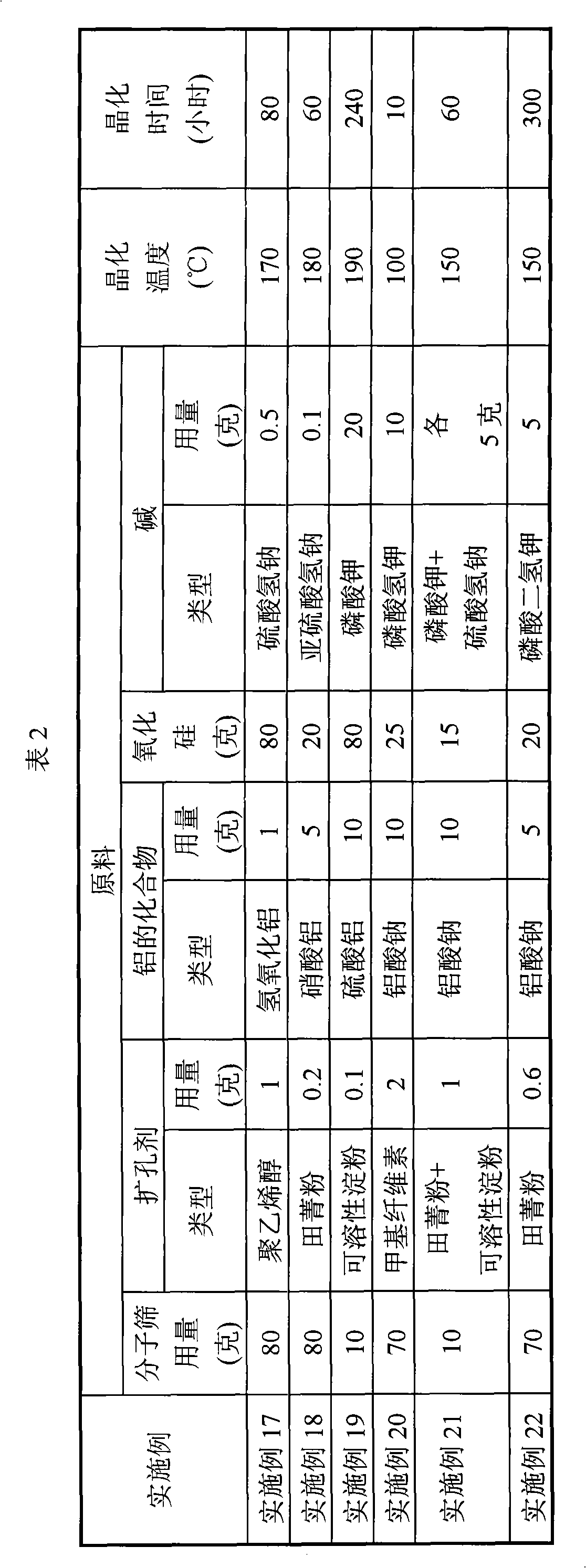

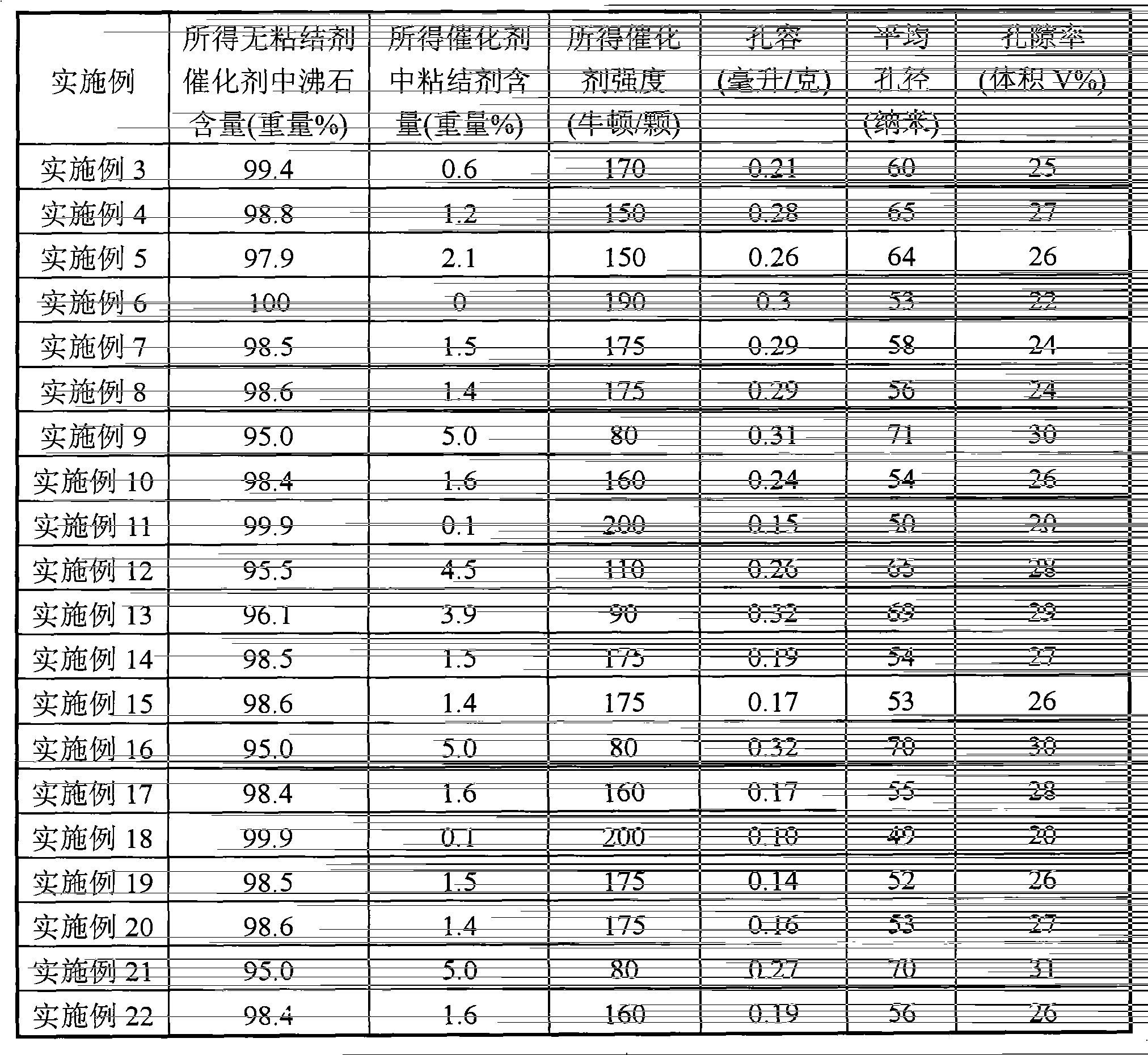

ActiveCN102372548AHigh strengthLarge hole volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCatalytic pyrolysis

The invention relates to a method for preparing low-carbon olefin through methanol dehydration, and mainly solves the problems that the activity of a catalyst and the yield of the low-carbon olefin are low in the conventional technology for preparing the low-carbon olefin through catalytic pyrolysis. In the invention, methanol which is taken as a raw material is contacted with an adhesive-free molecular sieve catalyst through a catalyst bed to generate the low-carbon olefin under the conditions that the reaction temperature is 400 to 600 DEG C, the gauge pressure of the reaction is 0.001 to 0.5MPa, the weight space velocity of the reaction is 0.1 to 4h<-1> and the weight ratio of water to methanol is (0.1-3):1, wherein the pore volume, the average aperture and porosity of the adhesive-free molecular sieve catalyst are tested by mercury porosimetry, the pore volume is 0.31 to 0.5ml / g, the average aperture is 71 to 100nm, and the porosity is 31 to 40 percent. Through the technical scheme, the problems are better solved. The method can be used for the industrial production of the low-carbon olefin through methanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

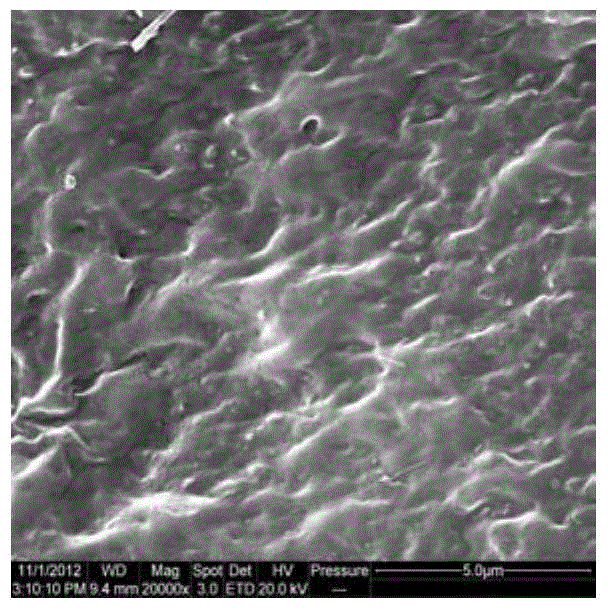

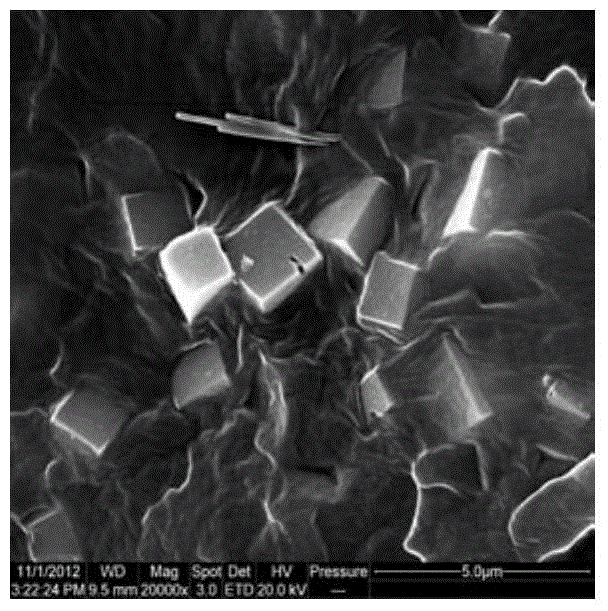

Preparation method and application of mixed matrix membrane with thermoplastic elastomer as matrix

ActiveCN104689730AIncrease the permeability coefficientAvoid influenceSemi-permeable membranesDispersed particle separationMolecular sieveThermoplastic elastomer

The invention relates to a preparation method and application of a mixed matrix membrane with a thermoplastic elastomer as the matrix. An unconventional solvent (acid) is employed to prepare a casting solution, and casting is carried out to prepare the mixed matrix membrane. When the molecular sieve content reaches certain degree, a layered structure similar to a composite membrane is formed, under the circumstance of substantial increase of the permeation flux, the selectivity remains unchanged, and the compromise relationship between traditional permeability / selectivity can be overcome. The method has a simple process and is convenient, and the obtained membrane can be used for gas separation, especially CO2 / light gas (N2, CH4, H2, O2) separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

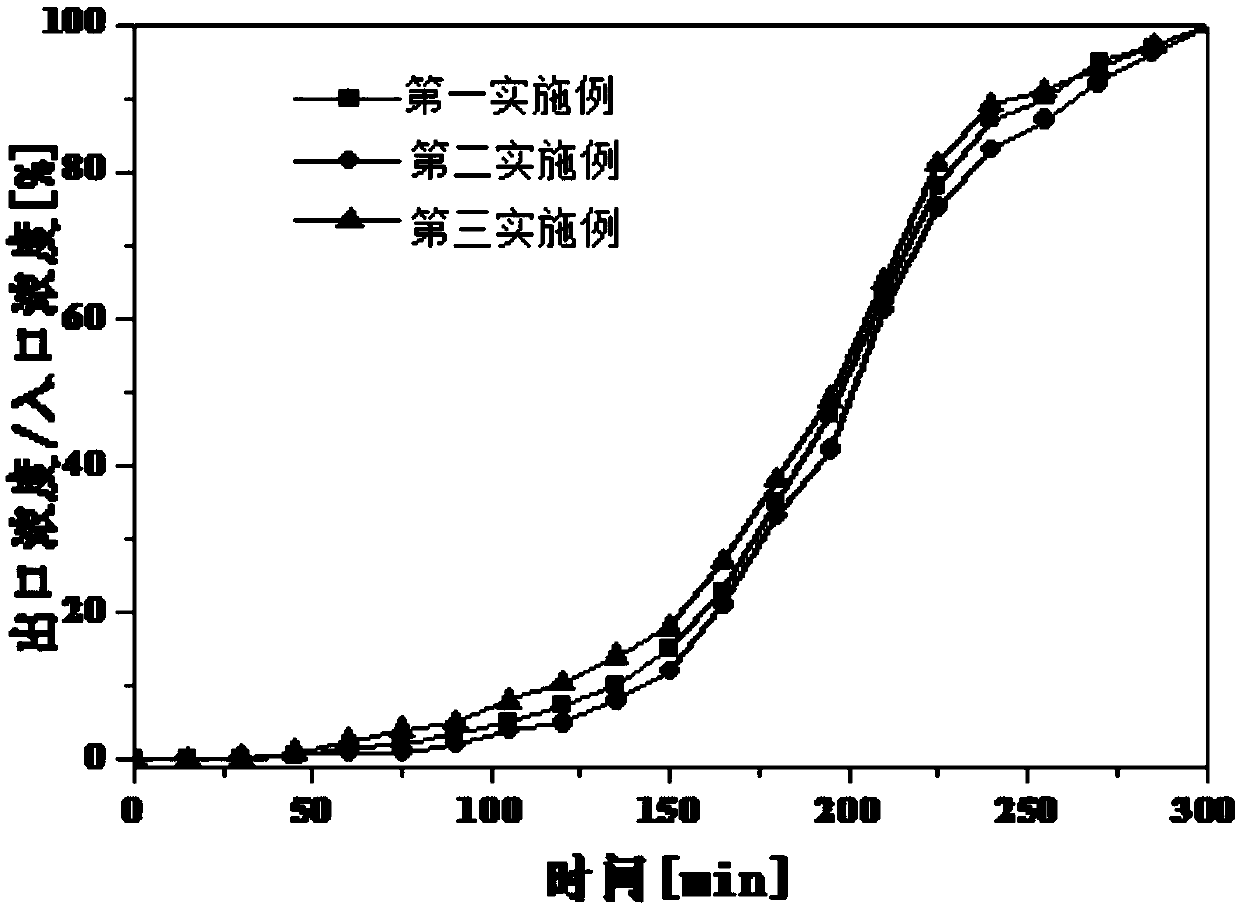

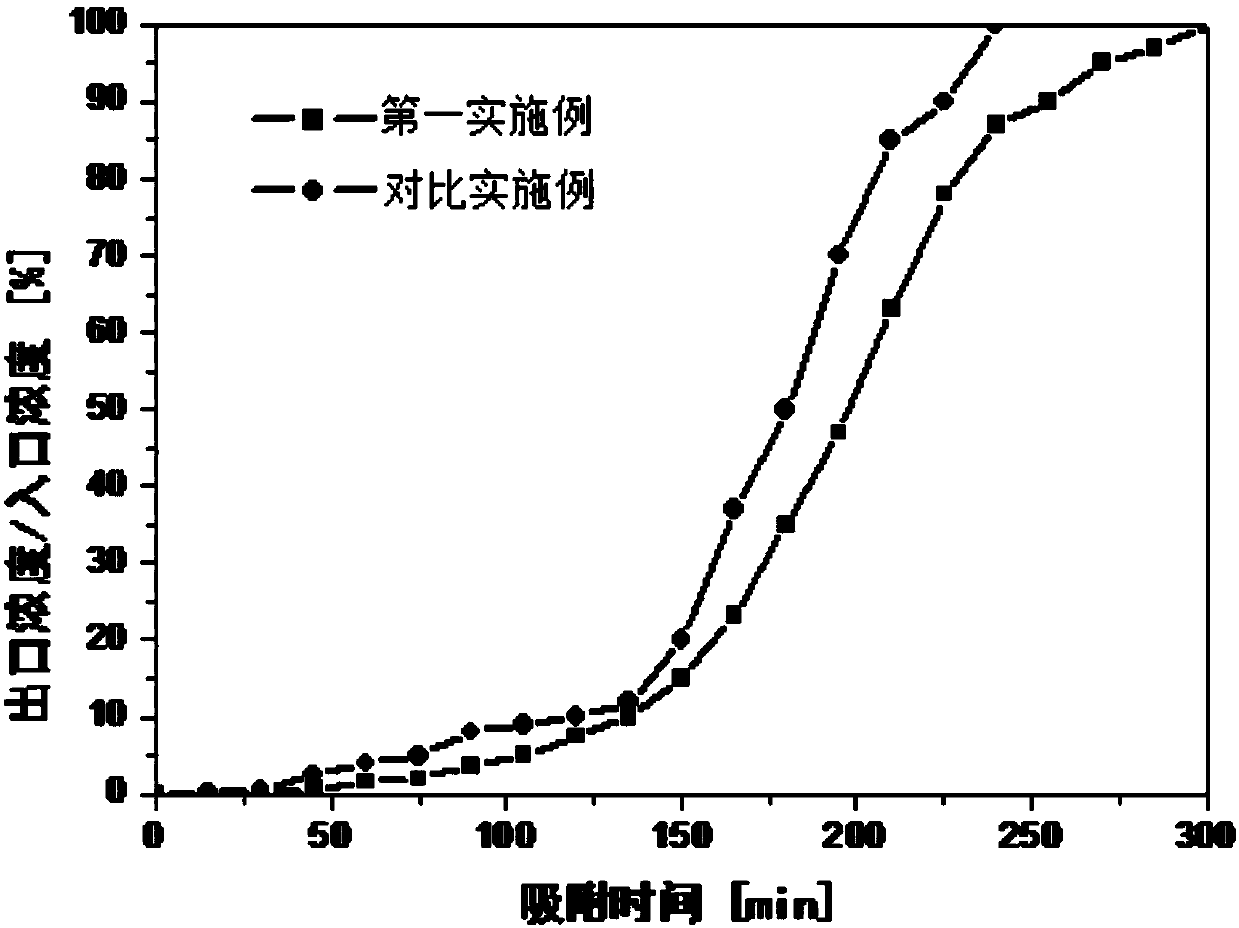

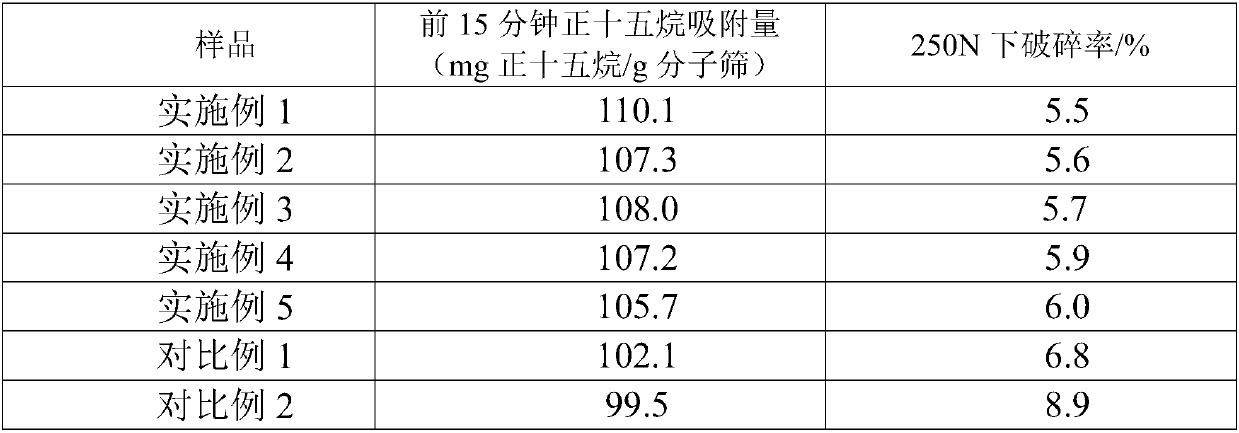

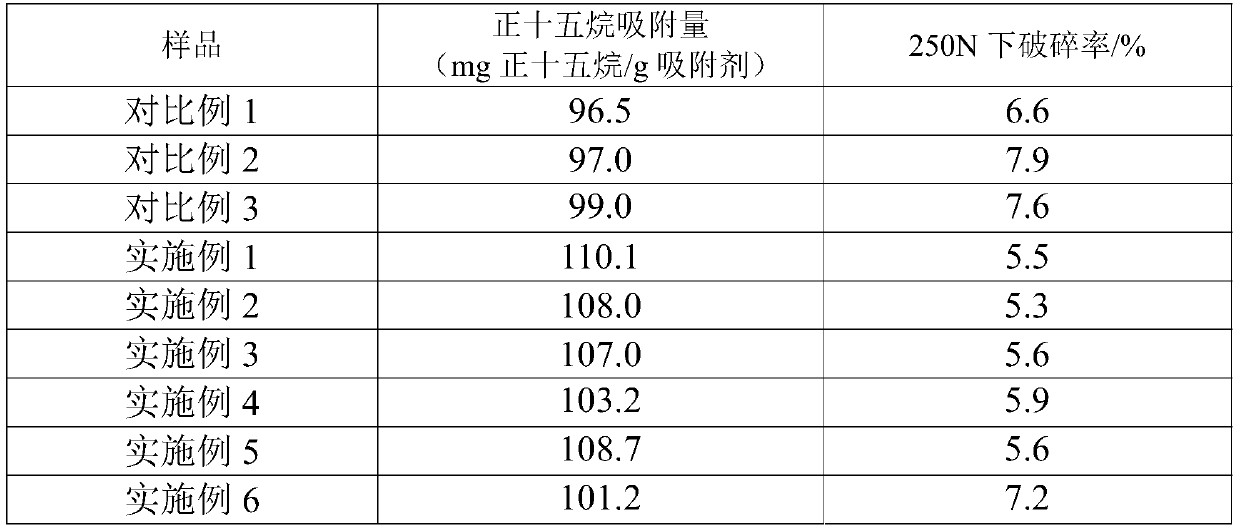

5A molecular sieve adsorbent, and preparation method and application thereof

ActiveCN107961759AHigh content of 5A molecular sieveLarge adsorption capacityOther chemical processesHydrocarbon oils refiningCrystal transformationMolecular sieve

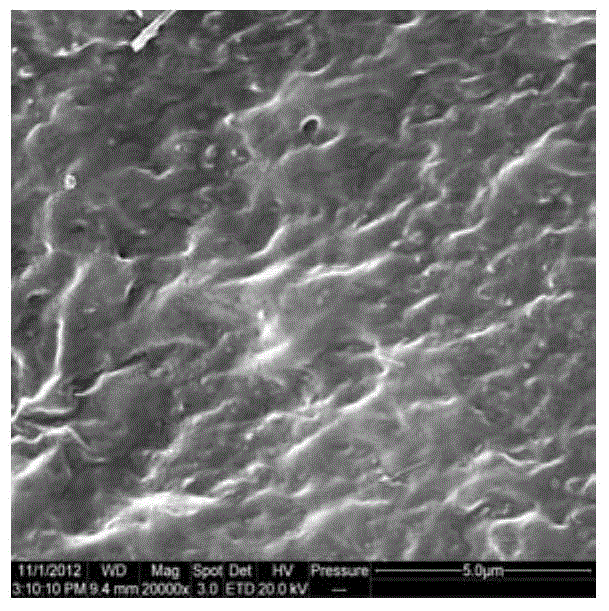

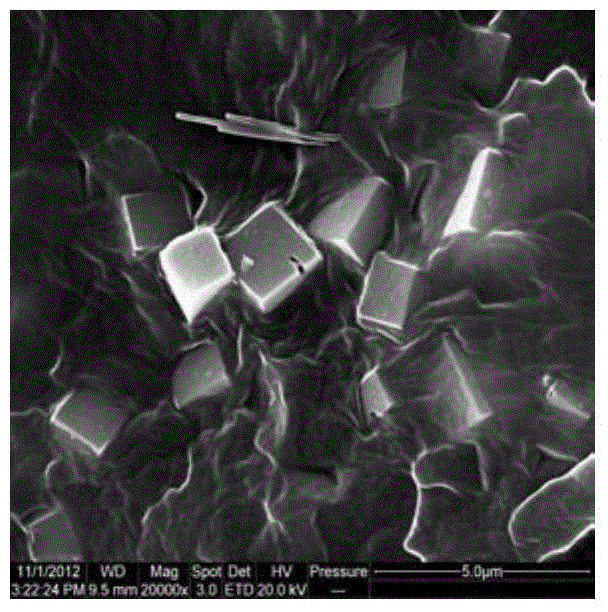

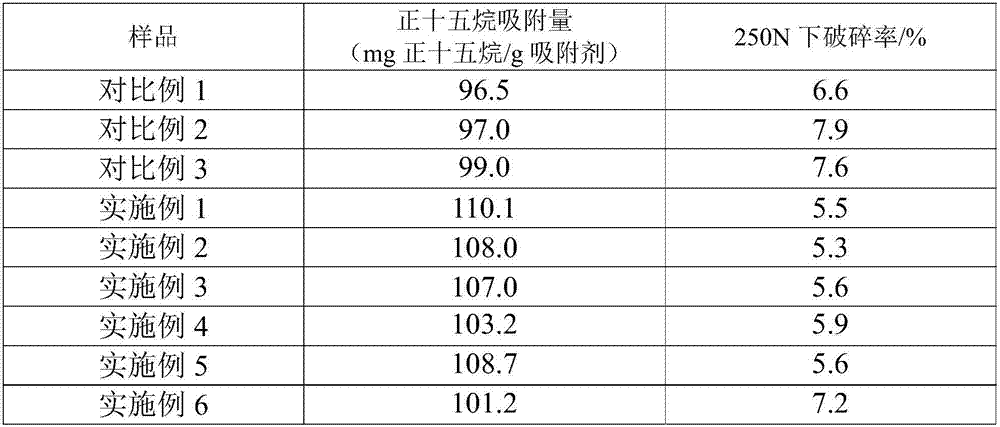

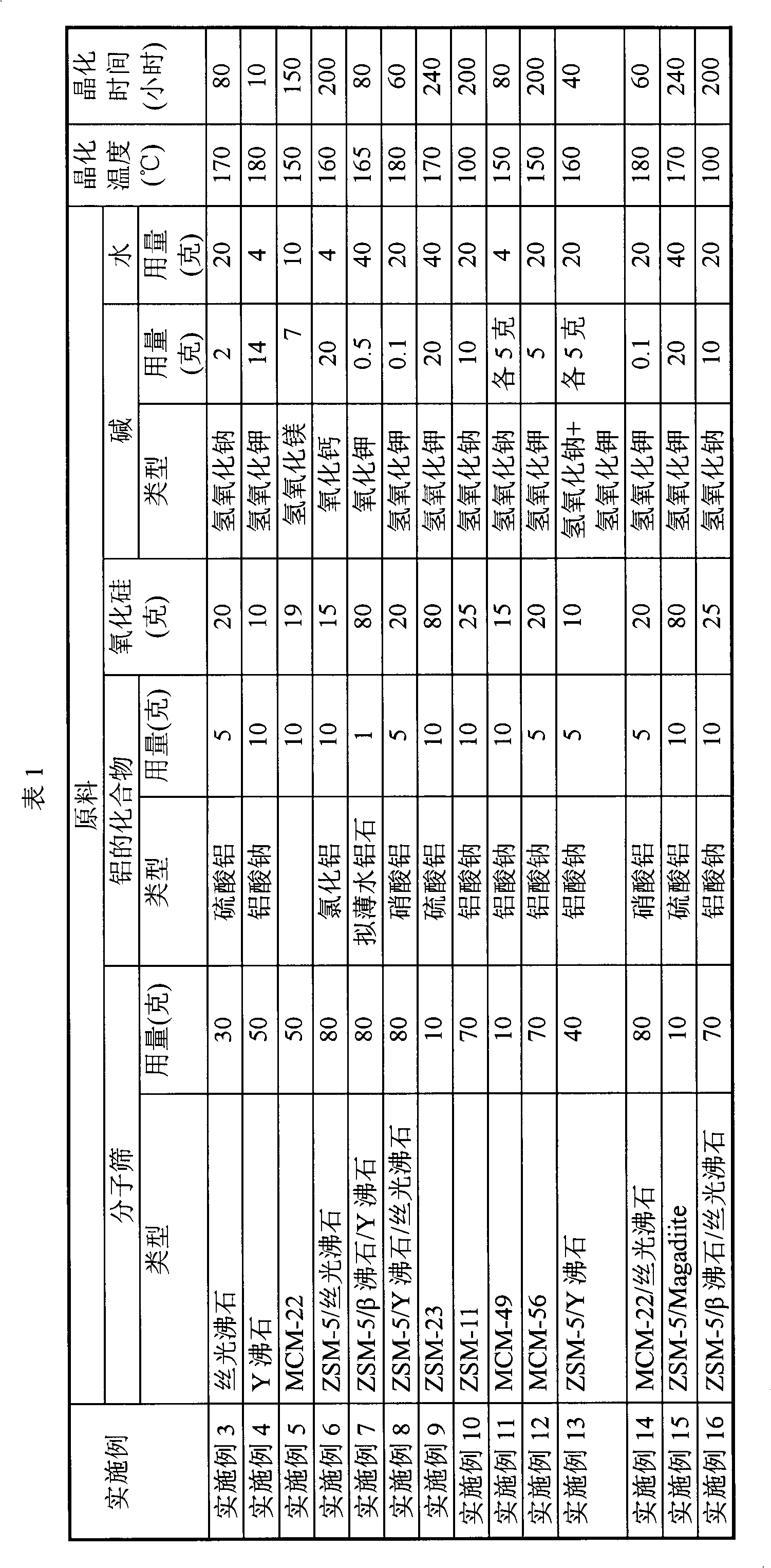

The invention relates to the field of adsorbents, and concretely provides a 5A molecular sieve adsorbent, and a preparation method and an application thereof. The method comprises the following steps:(1) carrying out rolling molding on a powder containing 4A molecular sieve and a binder source to obtain pellets, and drying and calcining the pellets to obtain matrix pellets; (2) pre-wetting the matrix pellets, and carrying out crystal transformation to basically convert the binder in the matrix pellets into 4A molecular sieve in order to obtain 4A molecular sieve pellets; and (3), washing the4A molecular sieve pellets with water, carrying out calcium exchange to obtain 5A molecular sieve pellets, washing the 5A molecular sieve pellets with water, drying the washed 5A molecular sieve pellets, and calcining the dried 5A molecular sieve pellets, wherein the pre-wetting process comprises a stage (1), a stage (2) and a stage (3), and the ambient humidity in the stage (1) and the ambient humidity in the stage (3) are higher than the ambient humidity in the stage (2). The 5A molecular sieve adsorbent has the advantages of high 5A molecular sieve content, large n-pentadecane adsorbing capacity, high adsorbing efficiency and good strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

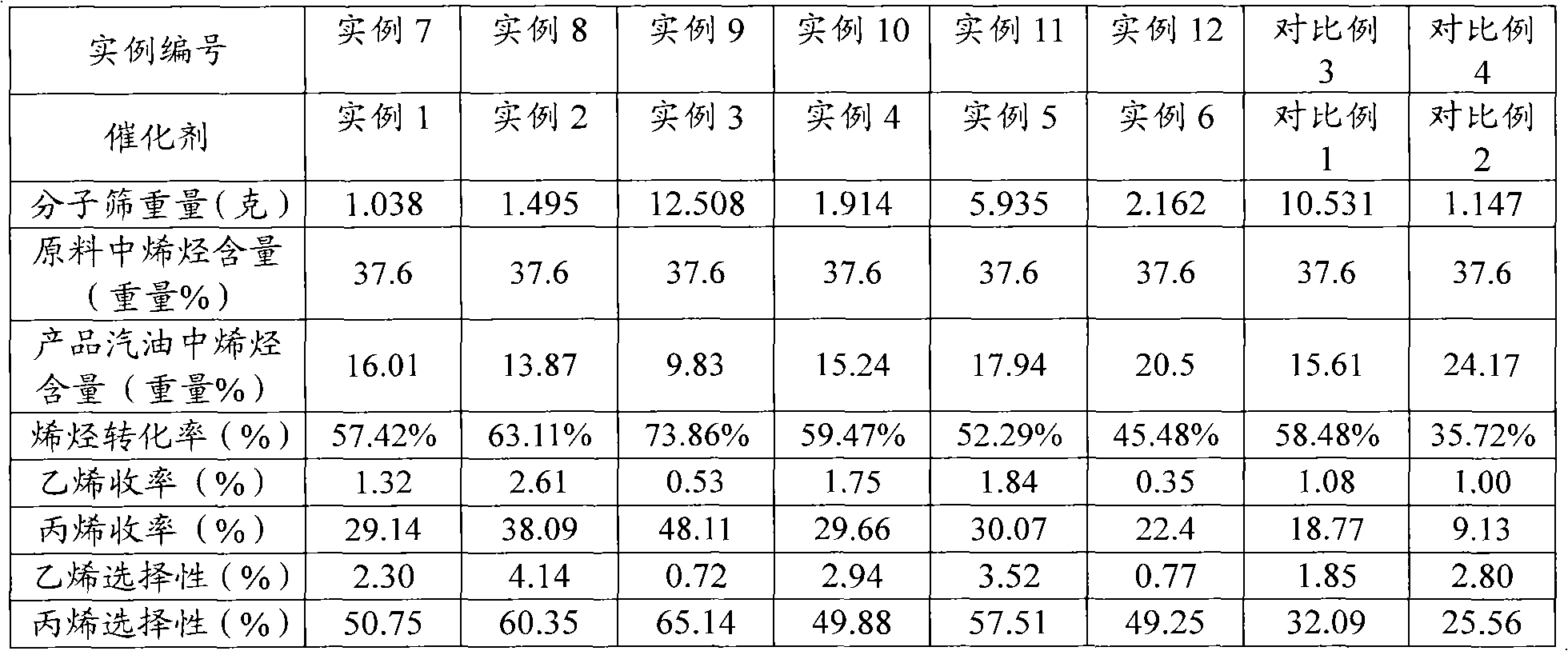

Method for preparing olefins by catalytic cracking of light oil

ActiveCN102372554AHigh strengthTightly boundMolecular sieve catalystsBulk chemical productionMolecular sievePorosity

The invention relates to a method for preparing olefins by catalytic cracking of light oil, mainly solving the problems of low catalyst activity and low yield of low-carbon olefins in the process of preparing low-carbon olefins by catalytic cracking in the prior art. The method is characterized in that: a binderless molecular sieve are used as a catalyst, light oil containing C4-C10 hydrocarbon is used as a raw material, the raw material is contacted with the catalyst through a catalyst bed to generate low-carbon olefins under the condistions of a reaction temperature of 550-750 DEG C, a reaction gauge pressure of 0.001-0.5 MPa, a reaction weight hourly space velocity of 0.1-4 h<-1>, and a weight ratio of water to light oil of 0.1-3:1, wherein, the binderless molecular sieve catalyst has a pore volume of 0.1-0.3 ml / g, an average aperture of 50-70 nm, a porosity of 20-30 %, and a binder content of 0-5 %; after forming and sintering, the strength of the catalyst is 60-200 N. The invention can be applied in the industrial production of preparing olefins by catalytic cracking of light oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Concentrated rotating wheel adsorbing material and preparation method thereof

ActiveCN109589912ASmall particle sizeLarge specific surface areaGas treatmentOther chemical processesAlcoholDesorption

The invention belongs to the technical field of adsorbing materials, and particularly relates to a concentrated rotating wheel adsorbing material and a preparation method of the adsorbing material. The adsorbing material comprises a base material, a high-silicon type zeolite molecular sieve ZSM-5, an inorganic binding agent, fumed silica, an activated aluminum oxide precursor, a dispersing agent,alcohol ether, a lubricating agent, oil, an organic binding agent, alcohol and / or cellulose and pure water. The concentrated rotating wheel adsorbing material has the beneficial effects that the adsorbing material prepared from the raw materials by adopting the technology has the advantages of high molecular sieve content, high strength, high specific surface area, high adsorption and desorption ratio, low specific heat capacity, low wind resistance and the like, and solves the problems that a traditional molecular sieve adsorbing material is low in adsorption efficiency, low in strength, poorin thermal stability, short in usage period and the like.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

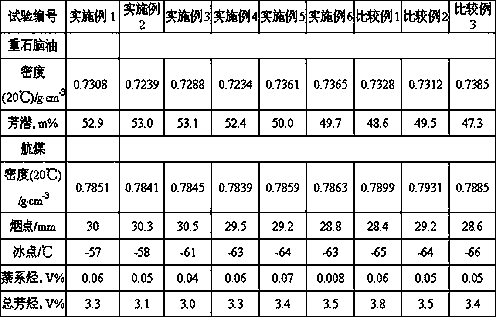

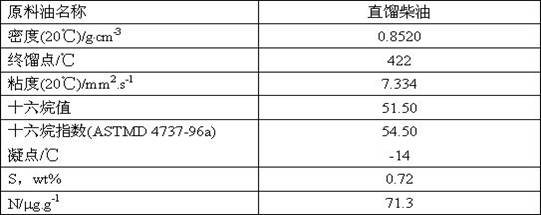

Hydrocracking method

ActiveCN109423336AQuality improvementSmall average pore sizeTreatment with hydrotreatment processesHydrocarbon oils treatment productsChemistryMolecular sieve

The invention discloses a hydrocracking method, which comprises the following steps: (1) a diesel oil feedstock is mixed with hydrogen gas and then enters a hydrorefining reactor to carry out desulfurization, denitrification and aromatic saturation reaction; (2) the effluent from step (1) enters a hydrocracking reactor, wherein the hydrocracking reactor comprises at least two catalyst beds, wherein the molecular sieve content of the hydrocracking catalyst containing the modified Y molecular sieve in each catalyst bed increases progressively along the flow direction, and the average pore diameter of the catalyst decreases progressively; (3) the effluent of the hydrocracking reactor is separated into a gas phase and a liquid phase, the gas phase is recycled, the liquid phase enters a fractionation tower, and the fractionating products are obtained and comprise naphtha, aviation fuel, diesel oil and tail oil. The method takes diesel oil as a feedstock and increases the production of high-aromatic latent heavy naphtha through reasonable combination of different functional hydrocracking catalysts, thereby improving the quality of aviation fuel and diesel oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Glass fiber framework molecular sieve paper with porous structure and preparation method of paper

InactiveCN109647328ASimple manufacturing methodEasy to operateGas treatmentOther chemical processesGlass fiberMolecular sieve

The invention discloses glass fiber framework molecular sieve paper with a porous structure. The paper is prepared from, by mass, 70-80% of molecular sieves, 5-15% of glass fibers and 5-15% of silicondioxide. The invention also discloses a preparation method of the glass fiber framework molecular sieve paper with the porous structure. In the prepared glass fiber framework molecular sieve paper with the porous structured, the content of the molecular sieves reaches 75% or above, the content of adsorption materials is high, and the adsorption capacity in unit volume is large. The porous structure in the paper can obviously increase the specific surface area of the glass fiber framework molecular sieve paper, increase the contact area between the paper and organic waste gas and the adsorption capacity, prolong the service life, reduce the pressure drop loss and adapt to different temperature and humidity environments.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

5A molecular sieve adsorbent as well as preparation method and application thereof

ActiveCN109772261AHigh molecular sieve contentHigh strengthOther chemical processesPetroleum wax refiningMolecular sieveN-pentadecane

The invention relates to the field of molecular sieve adsorbents and specifically discloses a 5A molecular sieve adsorbent as well as a preparation method and application thereof. According to the 5Aadsorbent disclosed by the invention, the content of 5A molecular sieves in the adsorbent is 92 weight % or more according to the dry weight of the adsorbent; the breakage rate of the adsorbent under250 N is 6.9% or less; furthermore, the n-pentadecane adsorption quantity of the adsorbent is 103 mg / g or more. The 5A molecular sieve adsorbent disclosed by the invention has the advantages of high molecular sieve content, good strength, and large adsorption quantity and is especially suitable for adsorbing n-pentadecane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation and application of coating slurry for cellular carrier catalyst

ActiveCN102451731BNot easy to fall offImprove conversion rateCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a method for preparing a coating slurry for a cellular carrier catalyst, which comprises the following steps: mixing a molecular sieve and water, and grinding to obtain a slurry with the molecular sieve particle diameter d90 of 1-10 microns; mixing the slurry and an Si-Al component with the particle diameter of less than 100nm in the presence or absence of a dispersant; based on the weight of the coating slurry, allowing the content of the molecular sieve in the coating slurry to be 3 to 60% by weight, allowing the weight ratio of a matrix component to the molecular sieve to be 0.1-30:100, and allowing the weight ratio of the dispersant to the molecular sieve to be 0-20:100; and the dispersant being selected from one or more of compounds with molecules containing polyhydroxyl, polyoxyethylene poly vinyl or polycarboxylic acid. The cellular carrier catalyst prepared by the coating slurry containing the molecular sieve composition prepared by the method providedby the invention has the advantages of firmer coating, gasoline conversion, strong ability of olefin conversion and high propylene yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of aluminum-free MFI structure spherical molecular sieve catalyst

The invention relates to a preparation method of an aluminum-free MFI structure spherical molecular sieve catalyst. The method includes the steps of: molding an aluminum-free MFI structure molecular sieve, then contacting the molded molecular sieve with an alkaline buffer solution of a nitrogen-containing compound. Specifically, the molding process of the aluminum-free MFI structure molecular sieve consists of: under the rotating operation conditions of a turntable molding machine, (1) placing a molecular sieve raw material of 200-500 meshes in the turnable molding machine to undergo mixing contact with water and / or a binder, thus obtaining spherical particles with a diameter of 0.1-1mm; (2) then adding a molecular sieve raw material of 100-1000 meshes and the binder to obtain a spherical catalyst with a diameter of 1.5-2.5mm; and (3) drying and roasting the spherical catalyst. The spherical molecular sieve catalyst prepared by the method has a high molecular sieve content, crushing strength of 1.5-5.0kg / particle, and can satisfy the technological requirements of fixed-bed and moving-bed reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-carbon olefin through methanol dehydration

ActiveCN102372548BHigh strengthLarge hole volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCatalytic pyrolysis

Owner:CHINA PETROLEUM & CHEM CORP +1

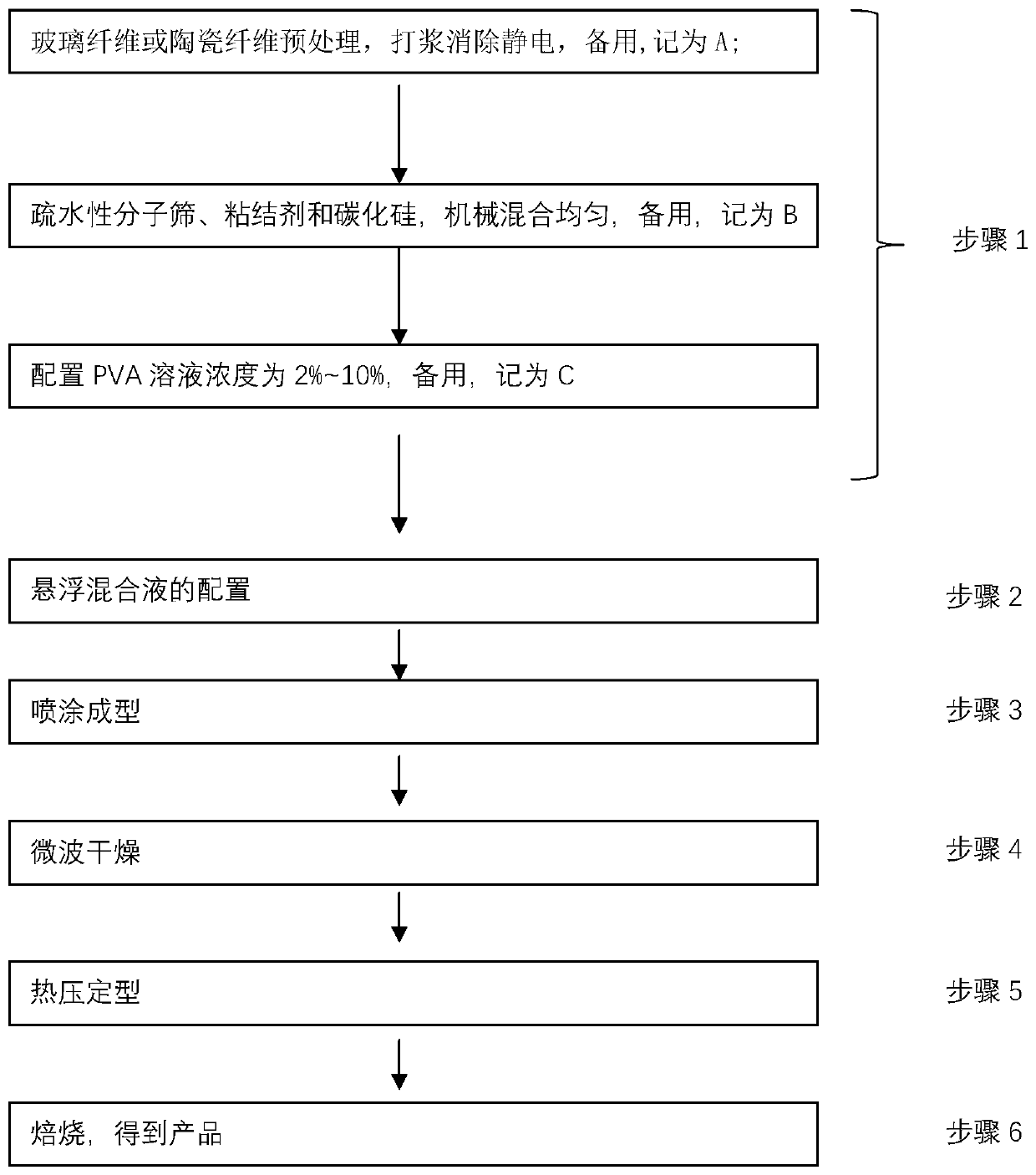

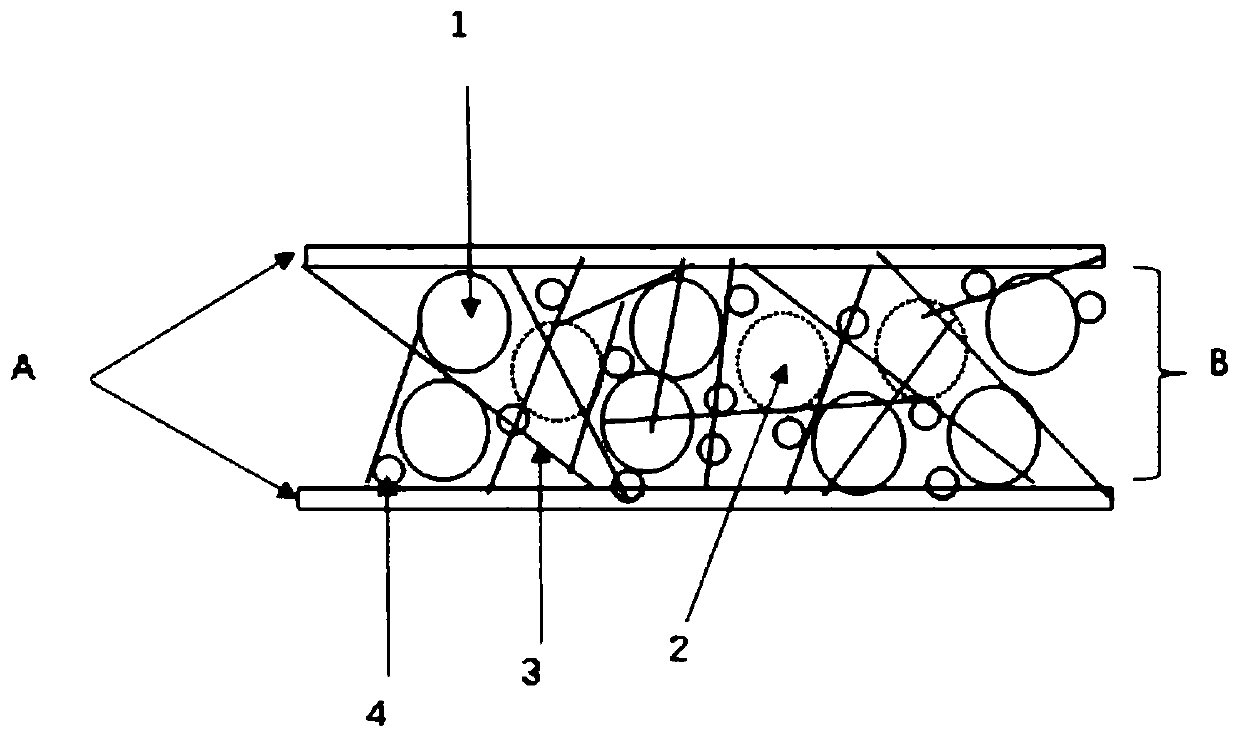

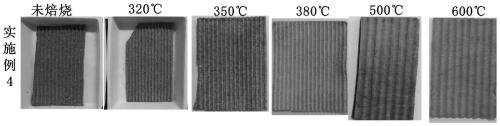

Filtering material for purifying volatile organic compounds and preparation method thereof

ActiveCN111545164AWide temperature rangeHigh molecular sieve contentGas treatmentOther chemical processesMolecular sieveGlass fiber

The invention belongs to the field of environmental protection, and particularly relates to a filtering material for purifying volatile organic compounds and a preparation method thereof. The filtering material comprises a filling layer and high-temperature-resistant fabric layers arranged on the two sides of the filling layer, wherein the filling layer comprises a three-dimensional porous fiber net and micron particles distributed in pores of the fiber net; the fiber net is made of glass fibers and / or ceramic fibers; the materials of the micron particles comprise a hydrophobic molecular sieve, an inorganic binder and silicon carbide in a weight ratio of (5-7): (1.5-2): (1-2); the weight ratio of the fiber net to the micron particles is (5-10): (70-80). The filtering material disclosed bythe invention has the characteristics of high temperature resistance, high molecular sieve content, light weight and the like, is similar to paper in shape, belongs to a flexible material and is convenient to process into various shapes. And meanwhile, the structure is stable, the service life is long, and application in actual production is facilitated.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

Hydrocracking method

ActiveCN110938468ASmall average pore sizeExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a hydrocracking method, which comprises the following steps: (1) mixing a diesel oil raw material and hydrogen, feeding the mixture into a hydrofining reactor, and carrying outa desulfurization, denitrification and aromatic hydrocarbon saturation reaction; and (2) feeding the effluent obtained in the step (1) into a hydrocracking reactor, wherein the hydrocracking reactorcomprises first to nth catalyst bed layers in a material direction, n is greater than or equal to 3, preferably n is 3 or 4, the first to (n-1)th catalyst bed layers are filled with a hydrocracking catalyst containing a modified Y molecular sieve, and the nth catalyst bed layer is filled with a hydroisomerization catalyst containing a beta or ZSM molecular sieve and other molecular sieves with strong isomerization performance. According to the method, diesel oil is used as a raw material, and through reasonable combination of hydrocracking catalysts with different functions, the yield of heavynaphtha with high aromatic potential is increased, and the low-temperature fluidity of aviation kerosene and diesel oil products is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

ActiveCN110938468BSmall average pore sizeExtended stayTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sieveNaphtha

The invention discloses a hydrocracking method, which includes the following contents: (1) Diesel feedstock is mixed with hydrogen and first enters a hydrorefining reactor for desulfurization, denitrogenation and aromatics saturation reaction; (2) Step (1) effluent enters Hydrocracking reactor, along the material direction, the hydrocracking reactor includes the 1st to nth catalyst beds, wherein n≥3, preferably n is 3 or 4, wherein, the 1st to n-1th catalyst beds are filled A hydrocracking catalyst containing a modified Y molecular sieve; the nth catalyst bed is filled with a hydroisomerization catalyst containing molecular sieves such as β or ZSM with strong isomerization performance. The method uses diesel oil as a raw material, increases the production of heavy naphtha with high aromatic potential, and improves the low-temperature fluidity of jet fuel and diesel products through a reasonable combination of hydrocracking catalysts with different functions.

Owner:CHINA PETROLEUM & CHEM CORP +1

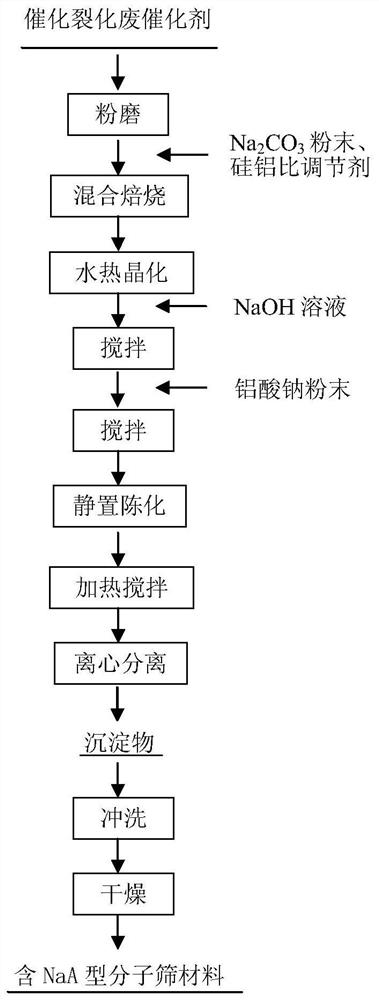

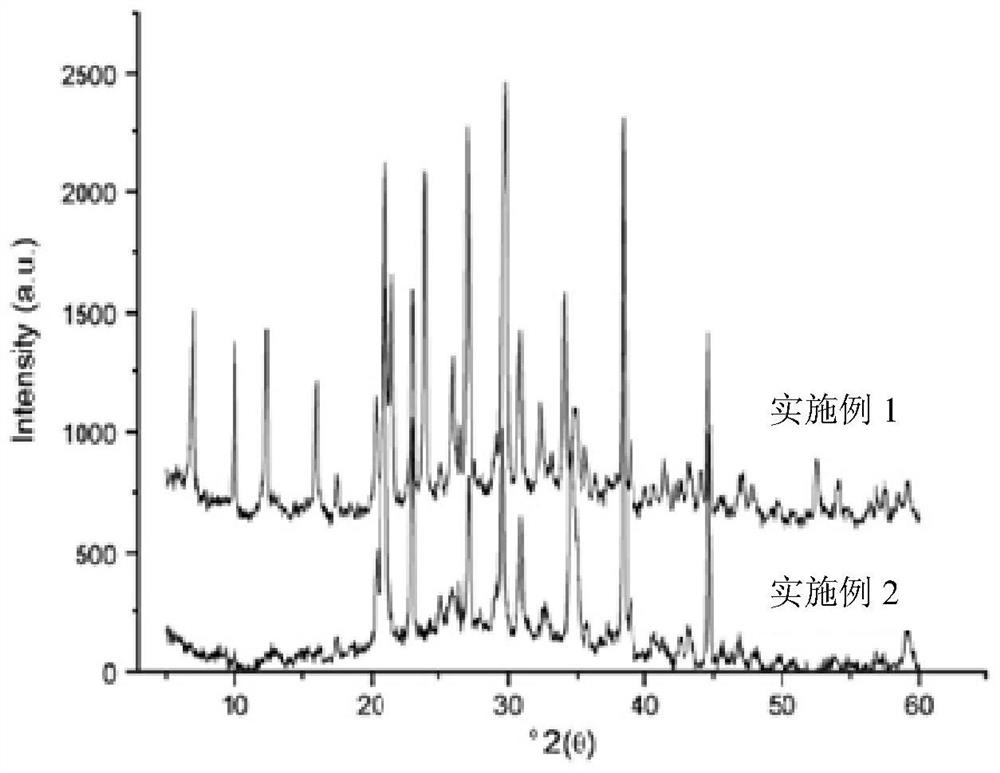

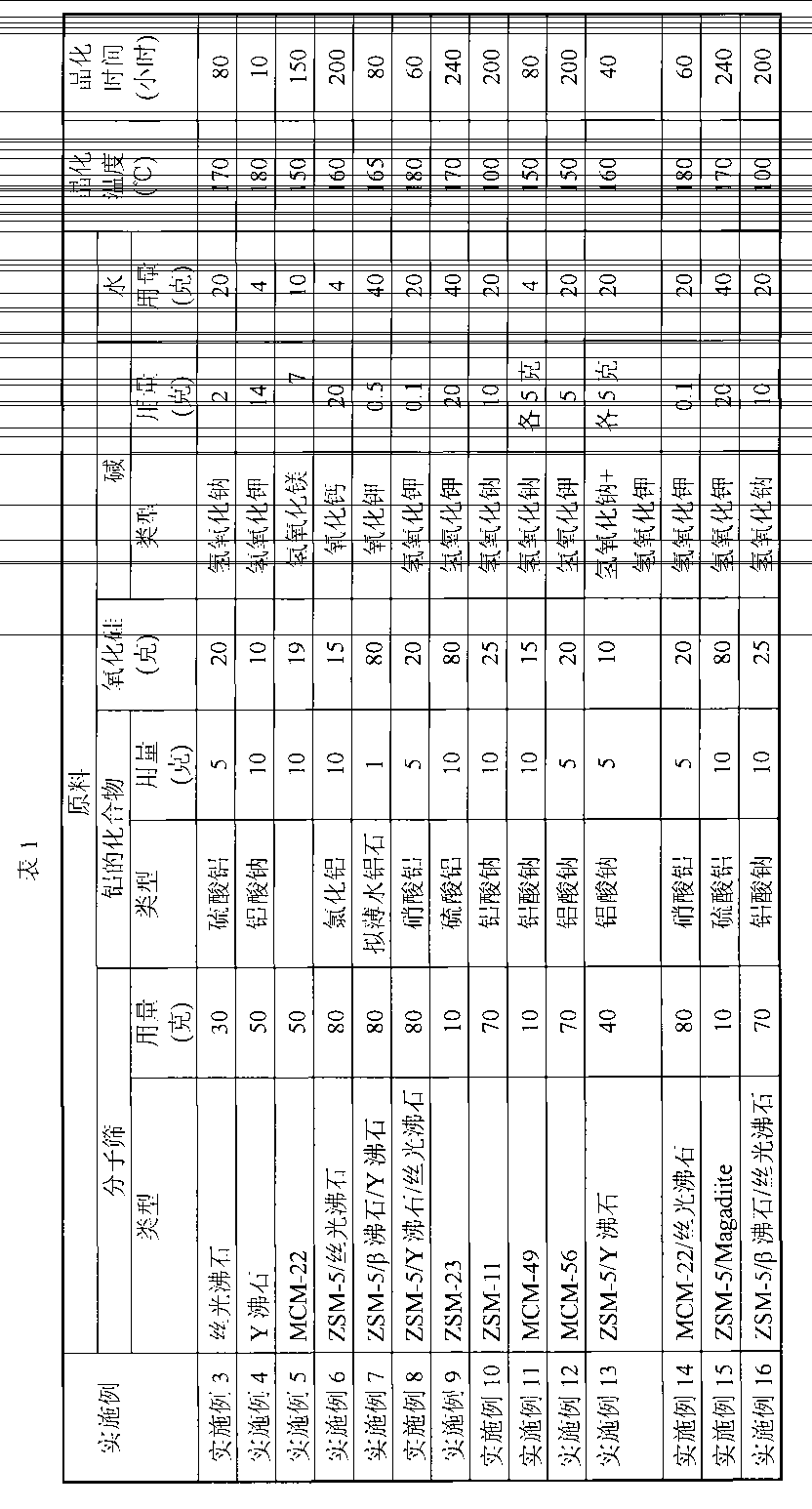

A method for synthesizing naa type molecular sieve material from catalytic cracking waste catalyst

ActiveCN109305688BSimple compositionRelaxed reaction conditionsAluminosilicate zeolite type-AMolecular sievePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing light olefin by dehydrating oxygen compound

ActiveCN102372547BHigh strengthLarge hole volumeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPorosityCatalytic pyrolysis

The invention relates to a method for preparing light olefin by dehydrating oxygen compound, mainly solving the problems that activity of a catalyst is low and yield of the light olefin is low in the traditional technology for preparing the light olefin through catalytic pyrolysis. In the invention, a method for preparing the light olefin by dehydrating the oxygen compound is adopted, a binder-free molecular sieve is taken as a catalyst, methanol or dimethyl ether is taken as raw material, the raw material is contacted with the catalyst by virtue of a catalyst bed and reaction is carried out to generate the light olefin under the conditions that reaction temperature is 400-600 DEG C, reaction gauge pressure is 0.001-0.5MPa, reaction weight airspeed is 0.1-4 / hour and weight ratio of water to methanol is (0.1-3): 1, wherein pore volume of the binder-free molecular sieve catalyst is 0.1-0.3ml / g, average pore size is 50-70nm, porosity factor is 20-30%, and content of the binder is 0-5%; and strength of the catalyst after moulding and sintering is 60-200N. By adopting the technical scheme, the problems are solved, and the method provided by the invention can be applied to industrial production of the light olefin prepared by dehydrating the oxygen compound.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of concentrated runner adsorption material and its preparation method

ActiveCN109589912BHigh molecular sieve contentHigh strengthGas treatmentOther chemical processesCelluloseSilicon dioxide

The invention belongs to the technical field of adsorption materials, and in particular relates to a concentrated runner adsorption material, and also relates to a preparation method of the above-mentioned adsorption material. The adsorption material includes: base material: high silica zeolite molecular sieve ZSM‑5; inorganic binder: fumed silica and activated alumina precursor; dispersant: alcohol ether, lubricant: oil; organic binder : Alcohol and / or cellulose; Purified water. The beneficial effect of the present invention is that the adsorption material obtained by using the raw material and process of the present invention has the advantages of high molecular sieve content, high strength, high specific surface area, high adsorption-desorption ratio, low specific heat capacity, low wind resistance, etc., which solves the problem of traditional molecular sieve Adsorbent materials have problems such as low adsorption efficiency, low strength, poor thermal stability, and short service life.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

A kind of preparation method and application of thermoplastic elastomer as matrix mixed matrix film

ActiveCN104689730BHigh molecular sieve contentEasy to separateSemi-permeable membranesDispersed particle separationMolecular sieveThermoplastic elastomer

A preparation method and application of a mixed matrix membrane with a thermoplastic elastomer as a matrix. An unconventional solvent (acid) is used to configure a casting liquid, and the mixed matrix membrane is prepared by casting. When the molecular sieve content reaches a certain level, a layered structure similar to a composite membrane is formed, and the selectivity remains unchanged when the permeation flux is greatly increased, overcoming the traditional compromise relationship between permeability / selectivity . The process of the method is simple and convenient, and the obtained membrane can be used for gas separation, especially CO2 / light gas (N2, CH4, H2, O2) separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method for honeycomb supported catalyst containing coating of molecular sieve composition

The invention provides a preparation method for a honeycomb supported catalyst containing a coating of a molecular sieve composition. The method comprises the step of coating a honeycomb support with coating slurry, wherein, the coating slurry comprises a molecular sieve, phosphorus and aluminum components, a dispersant and water, on the basis of the weight of the coating slurry, the content of the molecular sieve in the slurry is 3 to 60 wt %, the weight ratio of the phosphorus and aluminum components to the molecular sieve is 0.1-30:100, the weight ratio of the dispersant to the molecular sieve is 0-20:100, the weight of the phosphorus and aluminum components is counted on the basis of total weight of P2O5 and Al2O3, the weight of the molecular sieve is counted in terms of a dry basis, the dispersant is one compound or more compounds containing polyhydroxy groups, polyoxyethylene groups or polycarboxylic groups, the particle diameter of the phosphorus and aluminum components is less than 100 nm, and the particle diameter d90 of the molecular sieve is 1 to 10 mu m. The honeycomb supported catalyst containing the molecular sieve composition in the invention has a firm coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of 5a molecular sieve adsorbent and its preparation method and application

ActiveCN107961759BHigh molecular sieve contentHigh strengthOther chemical processesHydrocarbon oils refiningMolecular sieveAmbient humidity

The invention relates to the field of adsorbents, and concretely provides a 5A molecular sieve adsorbent, and a preparation method and an application thereof. The method comprises the following steps:(1) carrying out rolling molding on a powder containing 4A molecular sieve and a binder source to obtain pellets, and drying and calcining the pellets to obtain matrix pellets; (2) pre-wetting the matrix pellets, and carrying out crystal transformation to basically convert the binder in the matrix pellets into 4A molecular sieve in order to obtain 4A molecular sieve pellets; and (3), washing the4A molecular sieve pellets with water, carrying out calcium exchange to obtain 5A molecular sieve pellets, washing the 5A molecular sieve pellets with water, drying the washed 5A molecular sieve pellets, and calcining the dried 5A molecular sieve pellets, wherein the pre-wetting process comprises a stage (1), a stage (2) and a stage (3), and the ambient humidity in the stage (1) and the ambient humidity in the stage (3) are higher than the ambient humidity in the stage (2). The 5A molecular sieve adsorbent has the advantages of high 5A molecular sieve content, large n-pentadecane adsorbing capacity, high adsorbing efficiency and good strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Forming method and forming catalyst of titanium silicon molecular sieve and its application and method for oxidation of cyclohexanone

ActiveCN106964400BEfficient use ofHigh molecular sieve contentMolecular sieve catalystsOrganic compound preparationMolecular sieveCyclohexanone

The invention relates to the field of catalyst molding, and specifically provides a molding method of titanium-silicon molecular sieve. The method includes: mixing the titanium-silicon molecular sieve with a water-containing mixture, then performing hydrothermal treatment under closed conditions, and molding the slurry obtained by the hydrothermal treatment to obtain a molded shape. and calcining the shaped body, wherein the aqueous mixture contains silicon element, titanium element and nitrogen element, and the aqueous mixture is at least partly derived from the crystallization mother liquor of titanium silicon molecular sieve. The invention provides shaped catalysts prepared according to the method of the invention and their applications. The invention provides a method for oxidation of cyclohexanone. The titanium-silicon molecular sieve forming method provided by the present invention effectively utilizes industrial waste liquid and overcomes the problems of complex traditional production processes, equipment corrosion, and harmful emissions. The shaped catalyst of the present invention has high content of titanium silicon molecular sieve, high pore volume and crushing resistance, and high selectivity for target products.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of aluminum-free MFI structure spherical molecular sieve catalyst

ActiveCN103908975BHigh molecular sieve contentMolecular sieve catalystsMolecular sieveMolding machine

The invention relates to a preparation method of an aluminum-free MFI structure spherical molecular sieve catalyst. The method includes the steps of: molding an aluminum-free MFI structure molecular sieve, then contacting the molded molecular sieve with an alkaline buffer solution of a nitrogen-containing compound. Specifically, the molding process of the aluminum-free MFI structure molecular sieve consists of: under the rotating operation conditions of a turntable molding machine, (1) placing a molecular sieve raw material of 200-500 meshes in the turnable molding machine to undergo mixing contact with water and / or a binder, thus obtaining spherical particles with a diameter of 0.1-1mm; (2) then adding a molecular sieve raw material of 100-1000 meshes and the binder to obtain a spherical catalyst with a diameter of 1.5-2.5mm; and (3) drying and roasting the spherical catalyst. The spherical molecular sieve catalyst prepared by the method has a high molecular sieve content, crushing strength of 1.5-5.0kg / particle, and can satisfy the technological requirements of fixed-bed and moving-bed reactors.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking method

ActiveCN109423336BQuality improvementSmall average pore sizeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

5a molecular sieve adsorbent and its preparation method and application

ActiveCN109772261BHigh molecular sieve contentHigh strengthOther chemical processesPetroleum wax refiningMolecular sieveN-pentadecane

The invention relates to the field of molecular sieve adsorbents, and specifically discloses a 5A molecular sieve adsorbent and its preparation method and application. The 5A molecular sieve adsorbent of the present invention, based on the dry weight of the adsorbent, has a content of 5A molecular sieve in the adsorbent. 92% by weight or more, the crushing rate of the adsorbent at 250N is below 6.9%, and the n-pentadecane adsorption capacity of the adsorbent is above 103 mg / g. The 5A molecular sieve adsorbent provided by the invention has high molecular sieve content, good strength and large adsorption capacity, and is especially suitable for the adsorption of n-pentadecane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com