Filtering material for purifying volatile organic compounds and preparation method thereof

A technology of volatile organic compounds and filter materials, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of maintaining the stable structure of the honeycomb body, shedding molecular sieves, hindering gas adsorption, etc., to reduce the desorption time and The effect of heat energy consumption, faster heating and cooling rate, and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

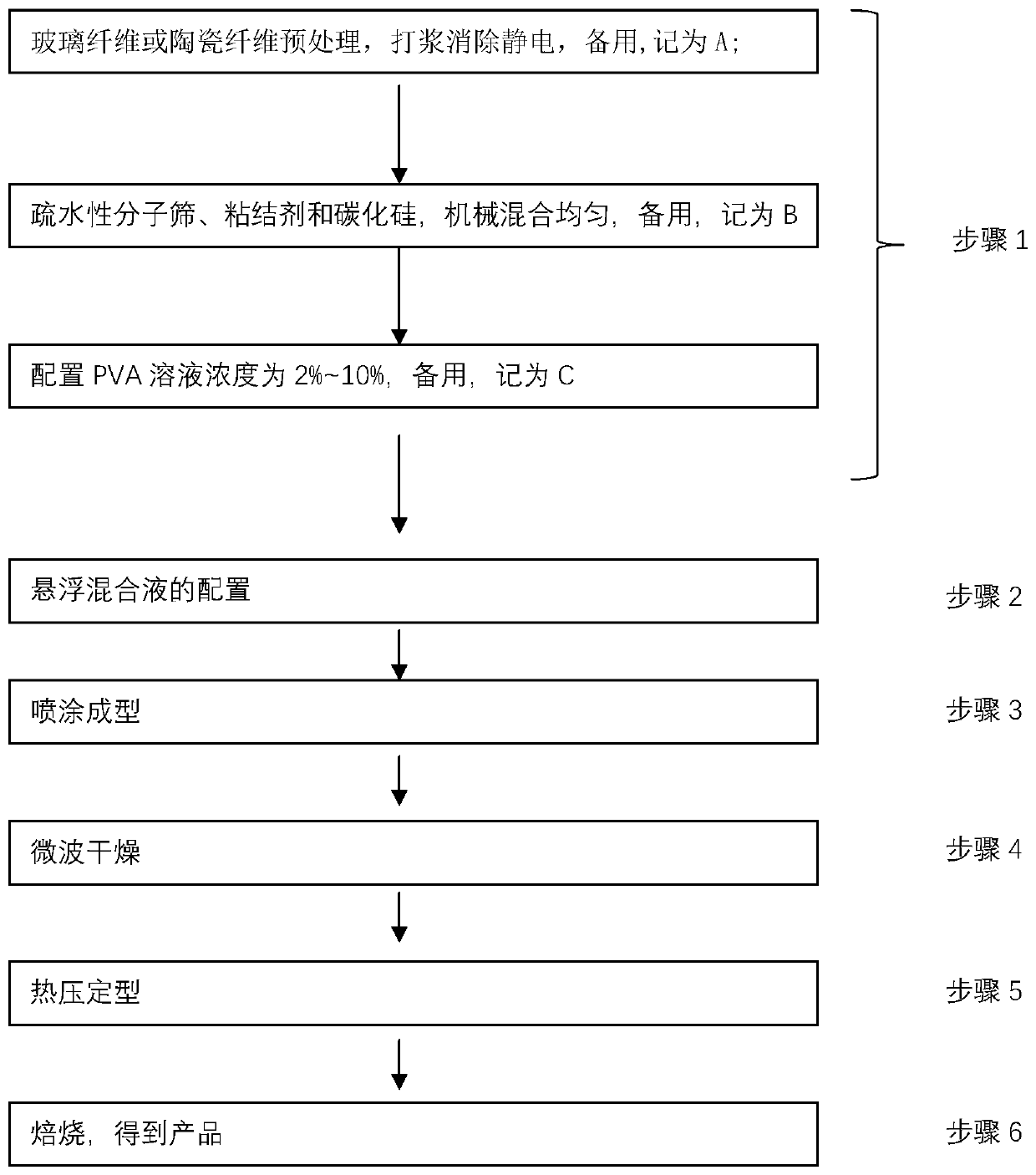

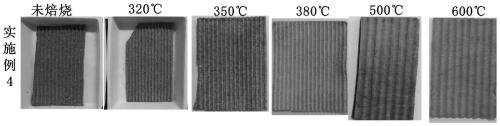

[0068] The present embodiment provides a kind of filter material, by the following method (flow chart sees figure 1 ) to obtain:

[0069] Step 1: Raw material pretreatment. According to the number of parts by mass, weigh 5 parts of glass fiber with a diameter of 0.02 mm and a length of 5 mm, add it into a container containing 100 parts of deionized water, add 3 parts of antistatic agent dropwise, and transfer it to beating after 20 minutes of mechanical stirring machine, carry out slight beating; after filtering with 200-mesh sieve, wash with deionized water for 5 times, then dry, set aside, record as A. According to the mass parts ratio of 5:2:1, weigh the hydrophobic molecular sieve, binder and silicon carbide respectively, mechanically mix them uniformly, set aside, record as B, wherein the inorganic binder and organic binder in the binder The ratio of parts by mass is 5: 1; according to the parts by mass, the PVA solution concentration is 2%, and it is reserved as C;

...

Embodiment 2

[0077] The present embodiment provides a filter material, which is prepared by the following method:

[0078] Step 1: Raw material pretreatment. According to the number of parts by mass, weigh 1 part of ceramic fiber with a diameter of 0.1 mm and a length of 0.1 mm, add it into a container containing 100 parts of deionized water, add 3 parts of antistatic agent dropwise, and transfer it to In the beater, carry out light beating; After filtering with 200 mesh sieve, wash with deionized water for 5 times and then dry, set aside, record as A. According to the mass parts ratio of 5:2:1, weigh the hydrophobic molecular sieve, binder and silicon carbide respectively, mechanically mix them evenly, set aside, record as B, wherein the inorganic binder and organic binder in the binder The ratio of parts by mass is 5: 1; according to the parts by mass, the PVA solution concentration is 2%, and it is reserved as C;

[0079] Step 2: Configuration of suspension mixture. According to the ...

Embodiment 3

[0083]The present embodiment provides a filter material, which is prepared by the following method:

[0084] Step 1: Raw material pretreatment. According to the number of parts by mass, take 5 parts of ceramic fibers with a diameter of 0.05 mm and a length of 0.5 mm, add them into a container containing 100 parts of deionized water, add 10 parts of antistatic agent dropwise, and transfer to In the beater, carry out light beating; After filtering with 200 mesh sieve, wash with deionized water for 5 times and then dry, set aside, record as A. According to the mass parts ratio of 7:3:2, weigh the hydrophobic molecular sieve, binder and silicon carbide respectively, mechanically mix them evenly, set aside, record as B, wherein the inorganic binder and organic binder in the binder The ratio of parts by mass is 5:5; according to the parts by mass, the PVA solution concentration is 10%, and it is reserved as C;

[0085] Step 2: Configuration of suspension mixture. According to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com