Patents

Literature

339results about How to "Reduce heat absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

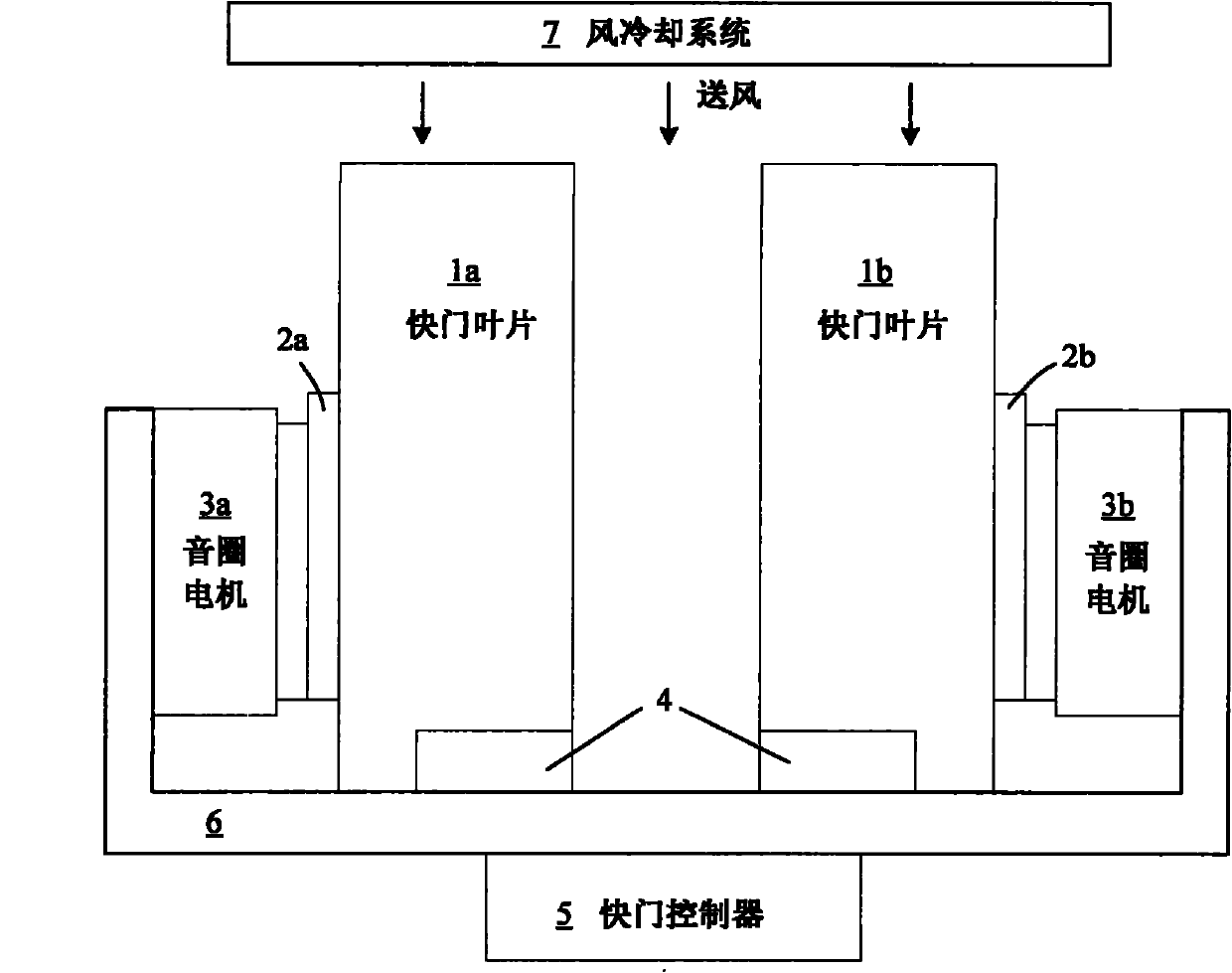

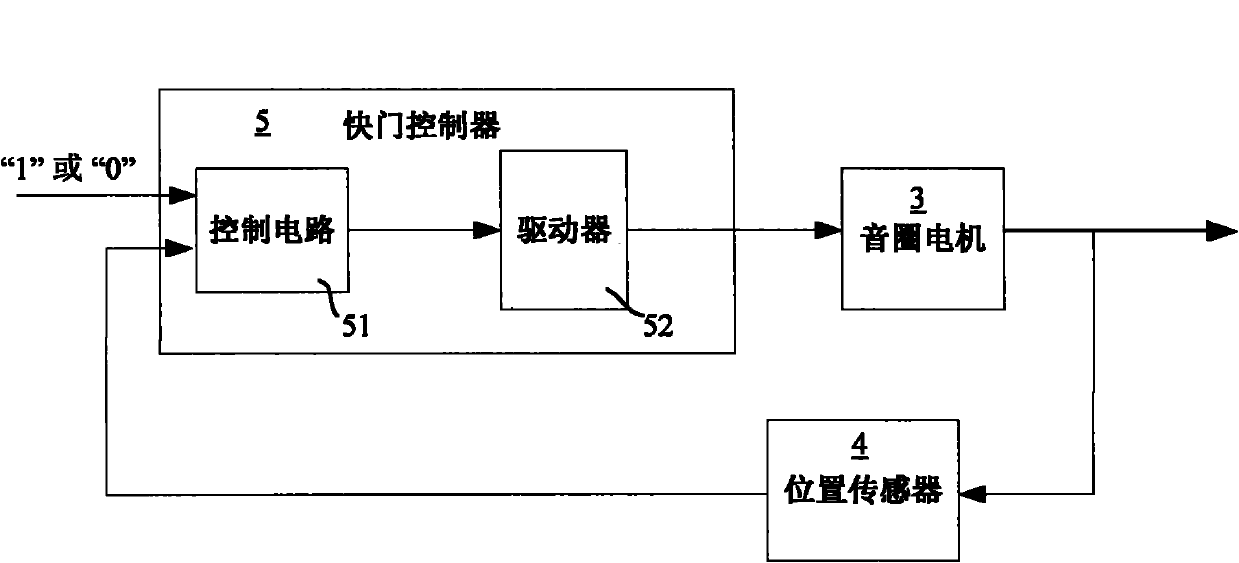

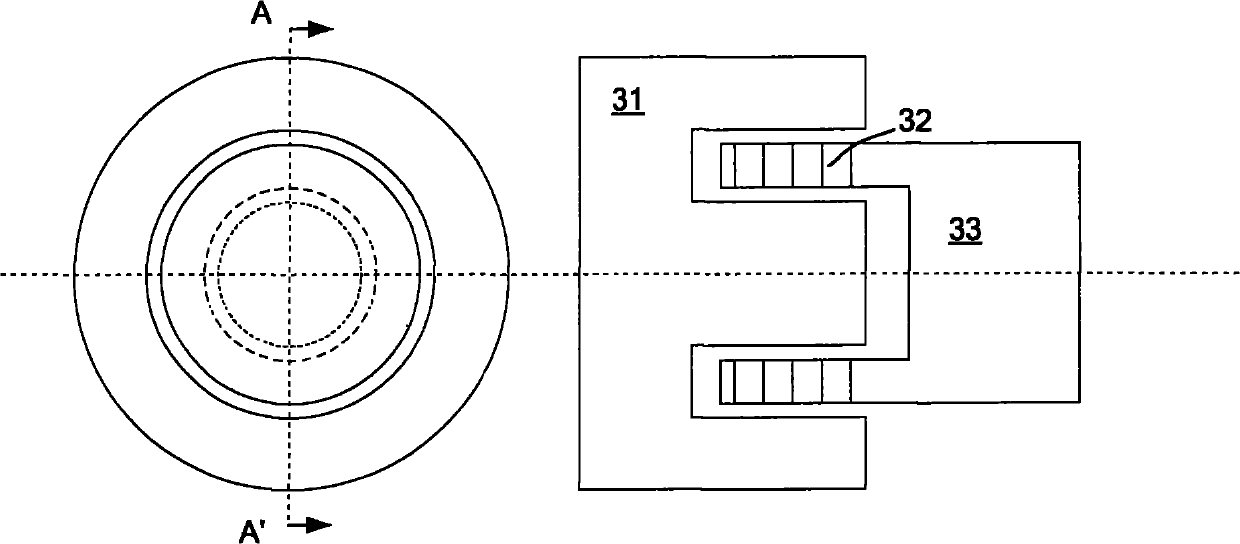

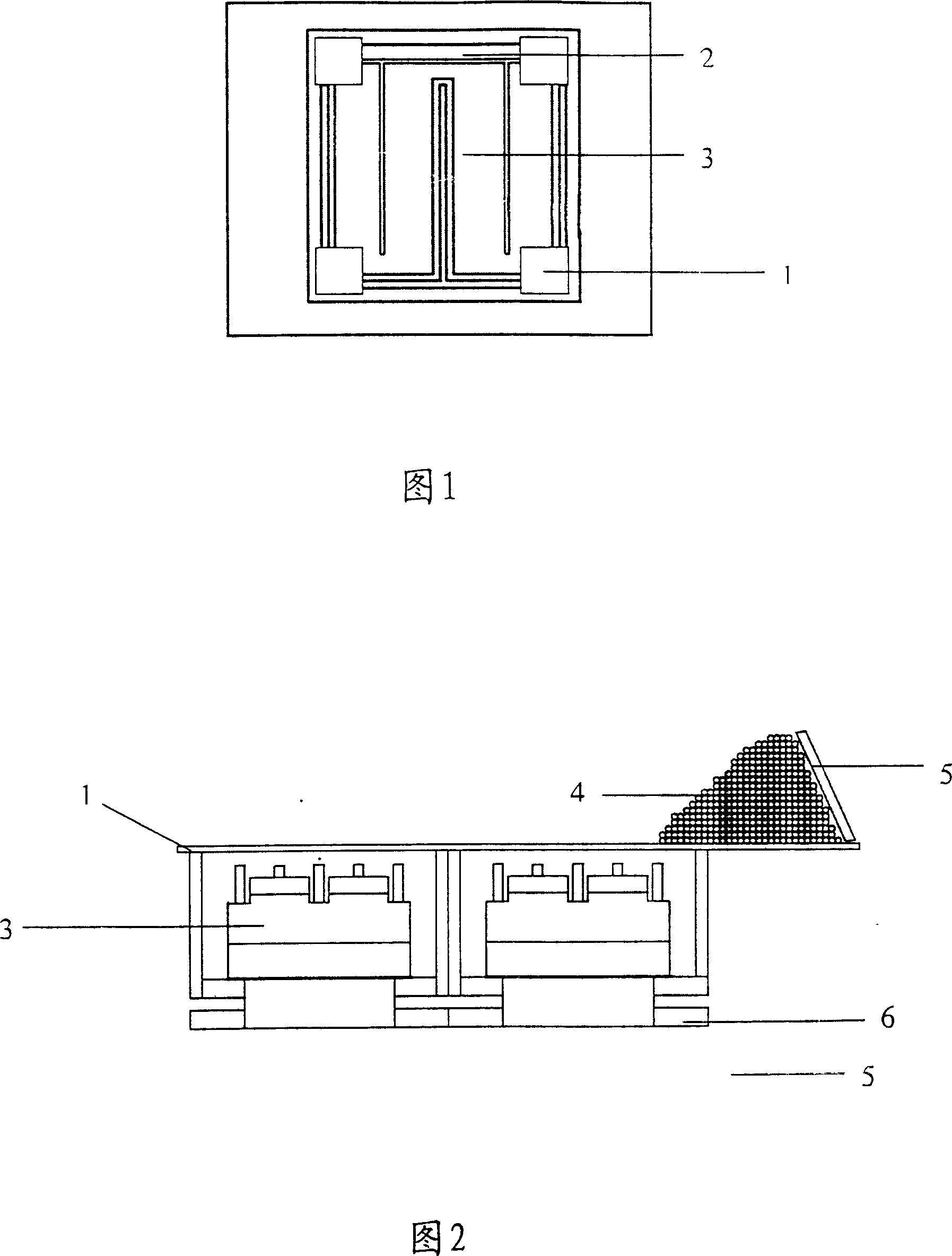

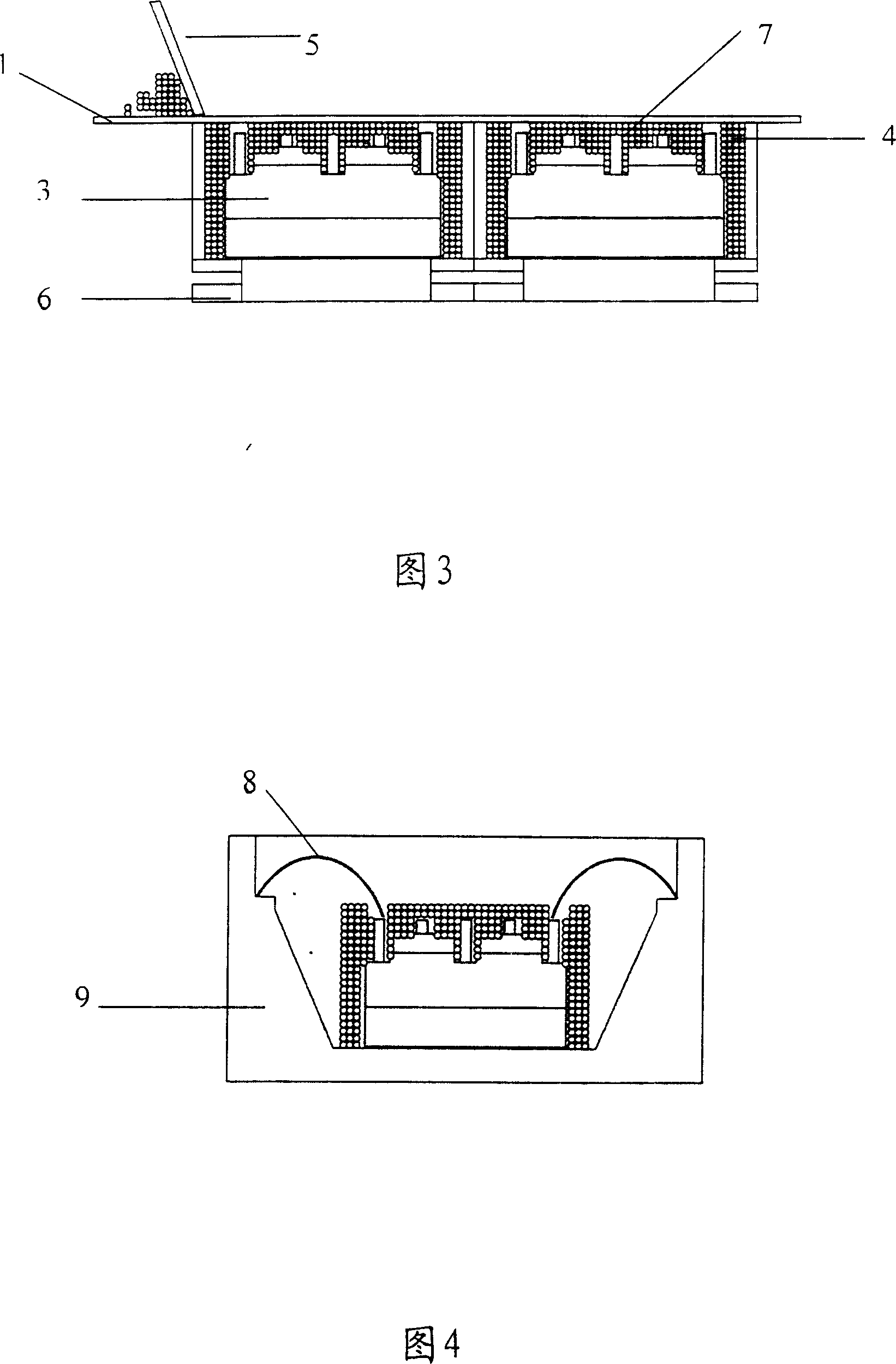

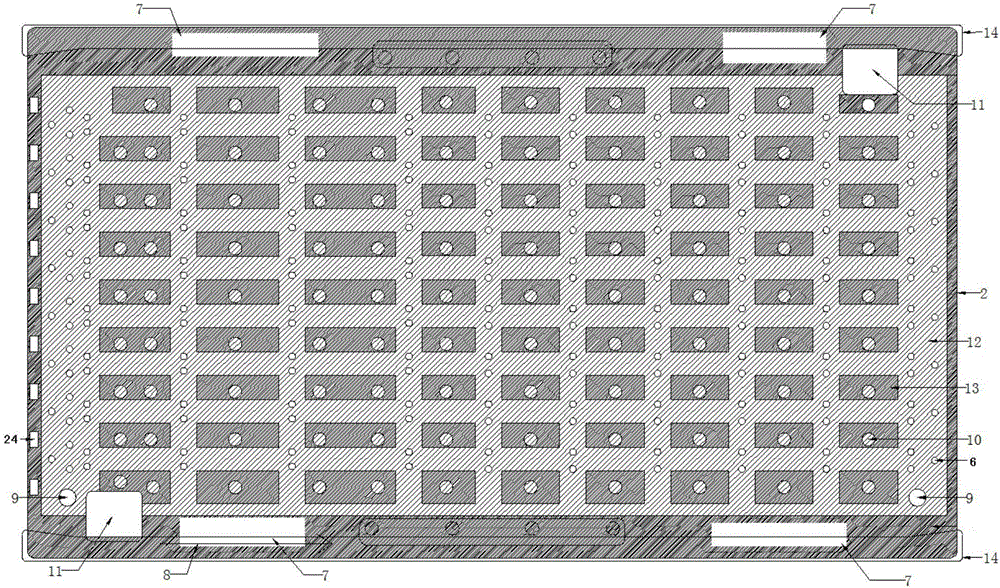

Shutter device for exposure subsystem of photoetching machine

InactiveCN102087476ARealize the photolithography processFast shutter speedPhotomechanical exposure apparatusMicrolithography exposure apparatusMotor driveControl theory

The technical problem to be solved by the invention is to provide a shutter device for an exposure subsystem of a photoetching machine. The shutter device comprises at least one shutter blade, a shutter controller, a position sensor, a bracket and a voice coil motor, wherein the shutter controller is used for controlling opening and closing of the shutter blade; the positioning sensor is coupled with the shutter controller and the shutter blade and provides movement position information of the shutter blade for the shutter controller; the bracket is positioned below the shutter controller and the position sensor and is used for supporting the voice coil motor and the position sensor; the voice coil motor is controlled by the shutter controller to move; the voice coil motor is positioned on the bracket, is coupled with the shutter controller and is controlled by the shutter controller to move; the voice coil motor drives the shutter blade to move so as to form the operation of opening and closing the shutter blade; and the thickness of the shutter blade is 0.5 to 2mm. The shutter device is suitable for a large-dose exposure device. Due to the adoption of the shutter device, a thin photoresist process and a thick photoresist process can be realized simultaneously and on the premise of guaranteeing the speed of a shutter, the service life of the shutter in the high temperature environment is prolonged.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

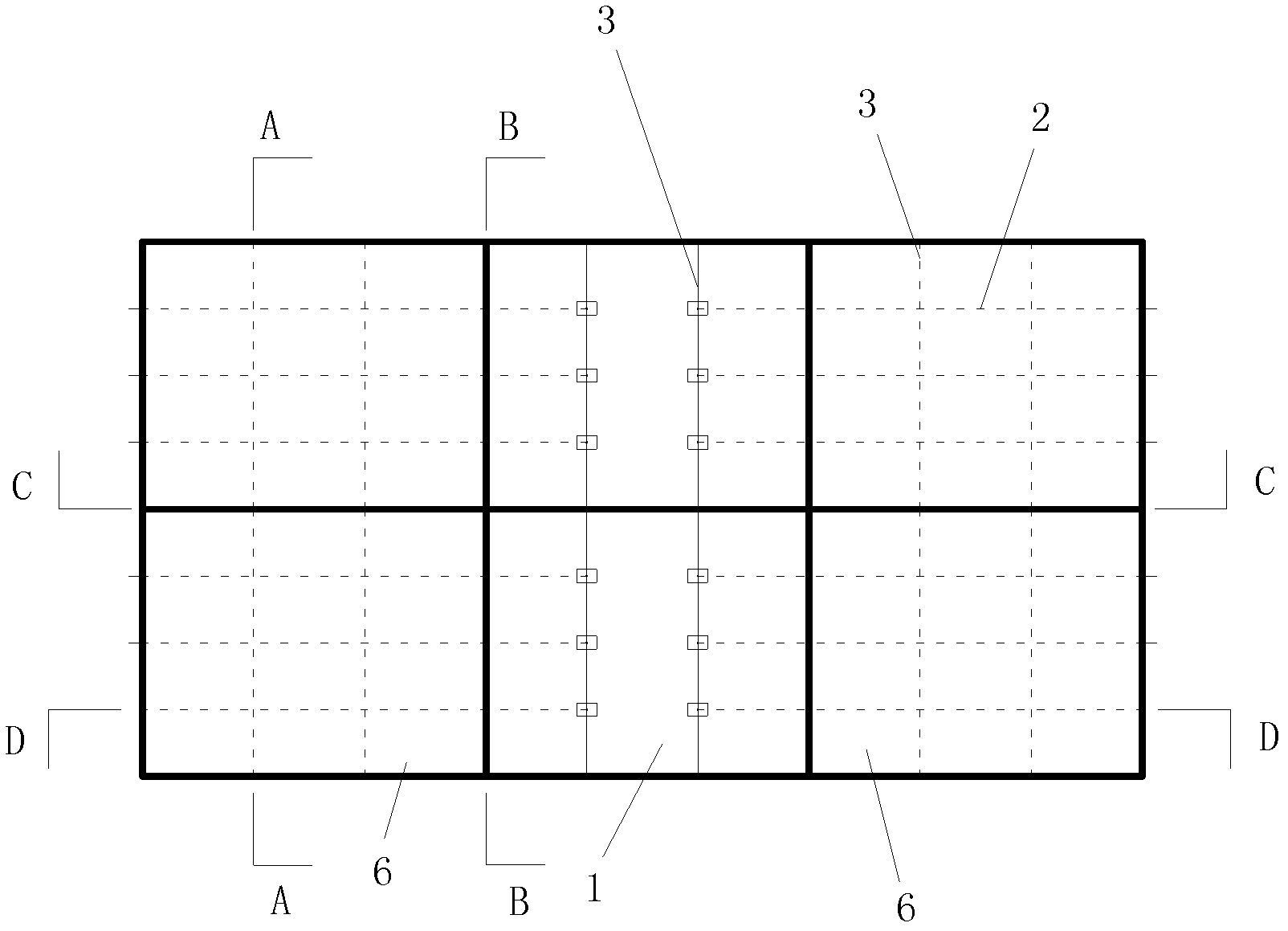

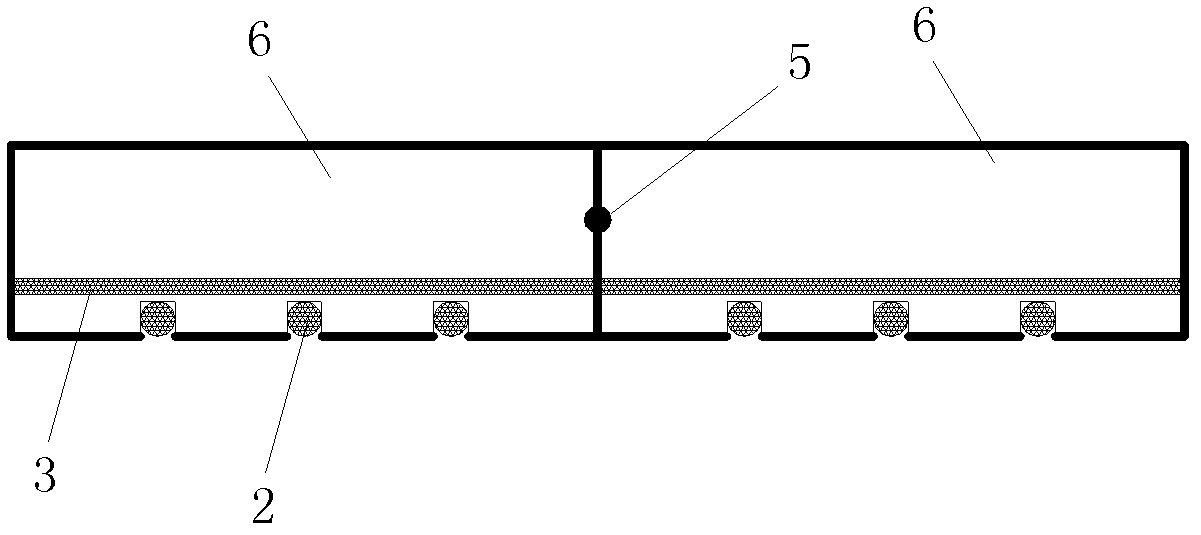

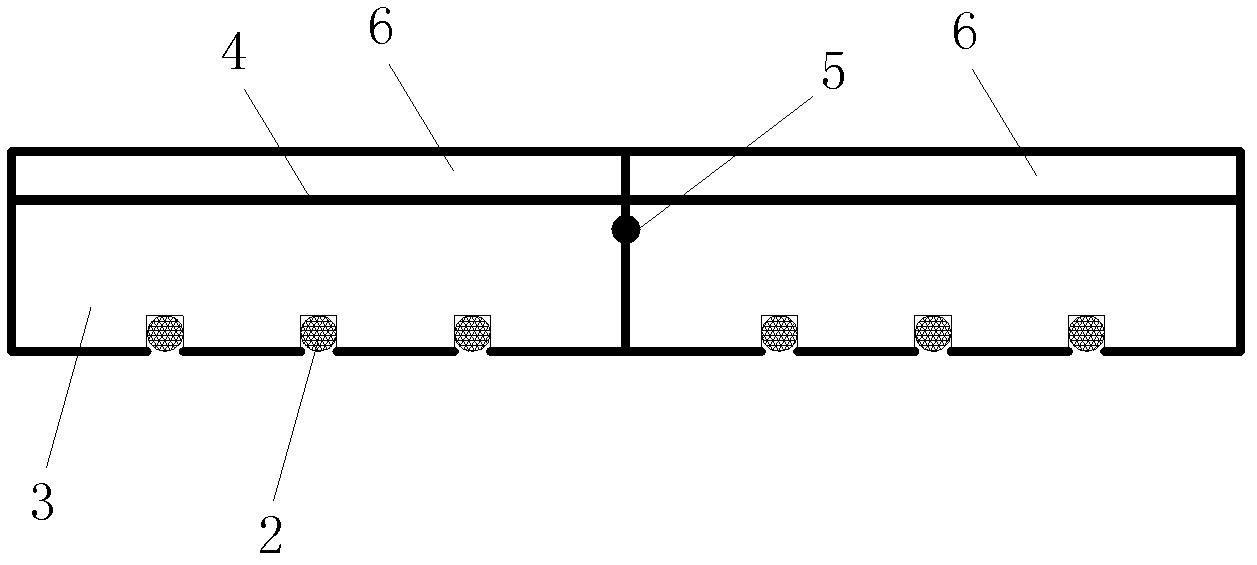

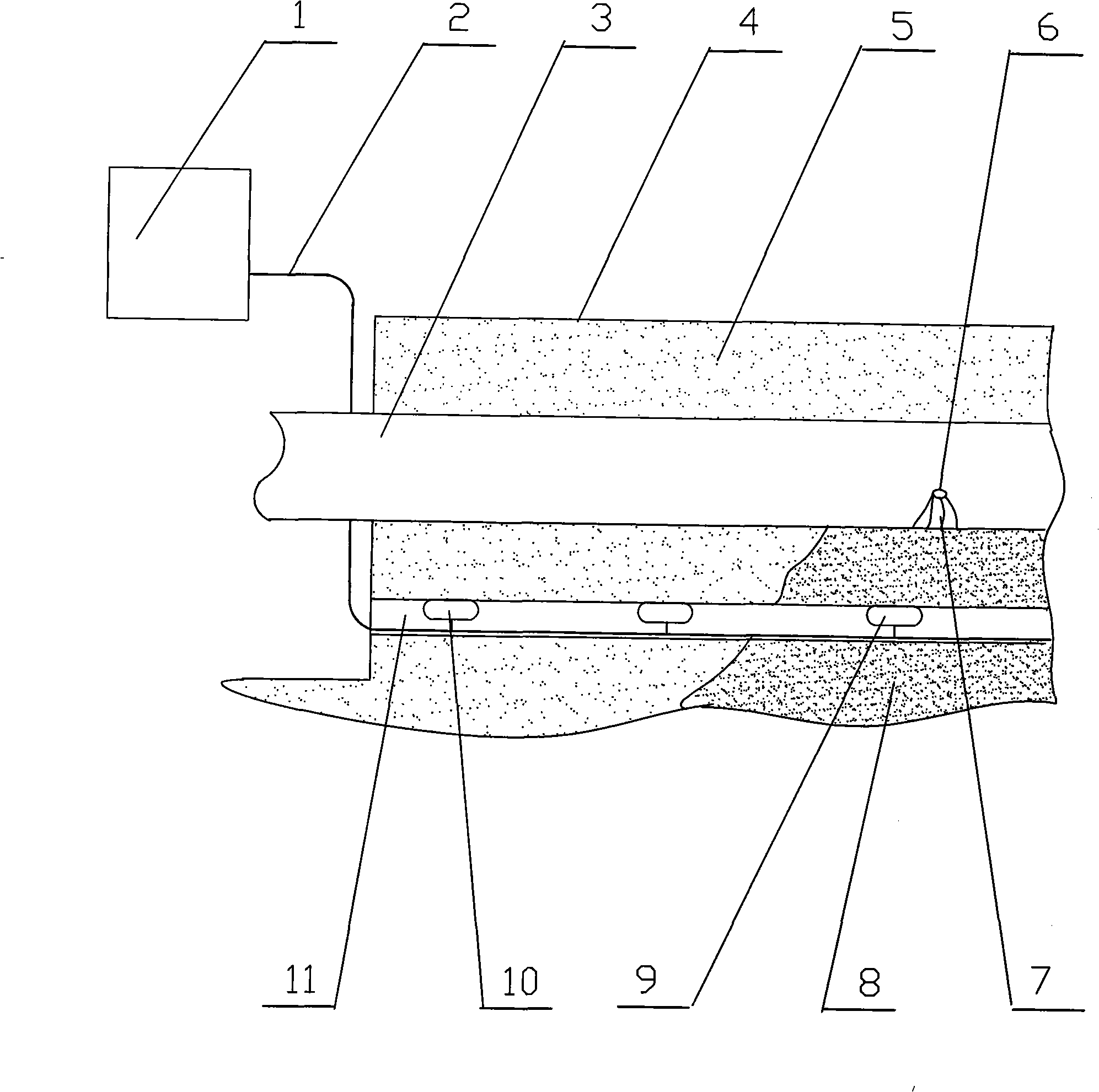

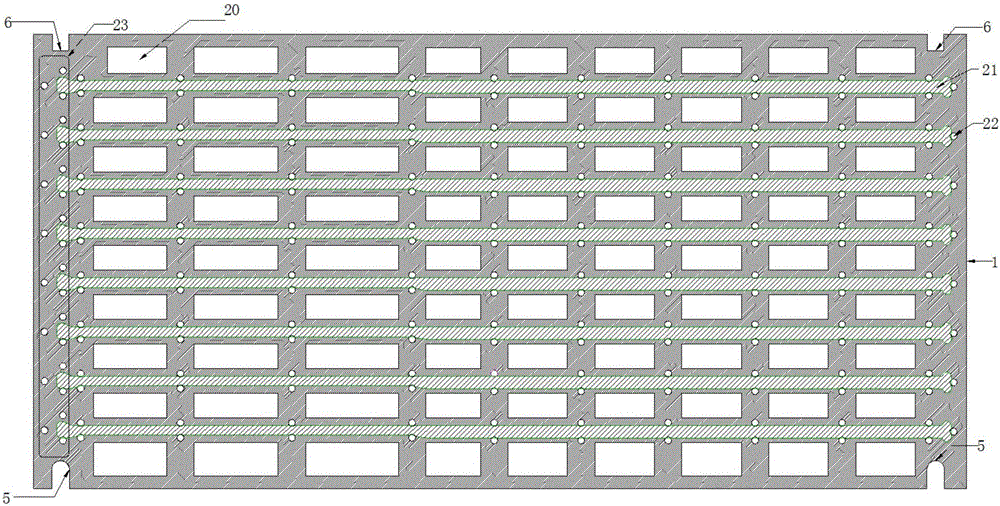

Fabricated prestressed heat-resistant cement concrete pavement and construction process thereof

ActiveCN102535295AReasonable structural designEasy to laySingle unit pavingsPaving detailsHeat resistancePre stress

The invention discloses a fabricated prestressed heat-resistant cement concrete pavement and a construction process thereof. The pavement is formed by splicing a plurality of fabricated prestressed heat-resistant pavement plates which are parallelly paved and connected into a whole through transverse prestressed steel stranded wires, wherein each fabricated prestressed heat-resistant pavement plate comprises a fabricated prestressed pavement plate which consists of a plurality of pavement plate blocks connected through connecting plates, and a vermiculite concrete heat-resistant paving layer which is paved on the fabricated prestressed pavement plate; each pavement plate block comprises a plurality of common plates which are connected into a whole through longitudinal prestressed steel stranded wires; and the connecting plates and the common plates are cement concrete prefabricated plate blocks. The construction process comprises the following steps of: 1, prefabricating the cement concrete prefabricated plate blocks; 2, transporting the cement concrete prefabricated plate blocks; and 3, paving the pavement. The pavement is reasonable in structural design, convenient to construct, low in input cost and short in construction period, and has heat resistance, construction quality is easy to ensure, and various practical problems of the traditional fabricated cement concrete pavement can be solved.

Owner:CHANGAN UNIV

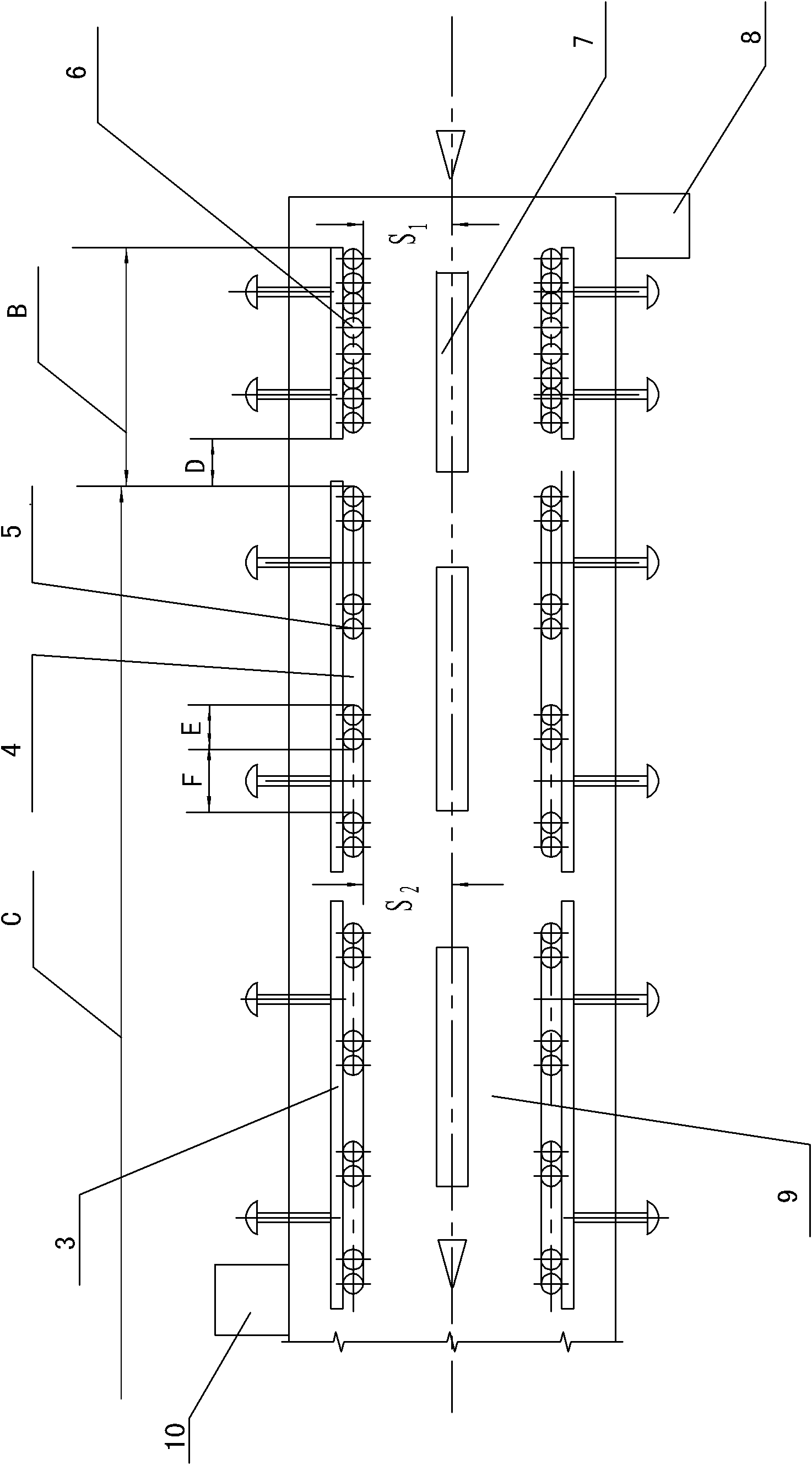

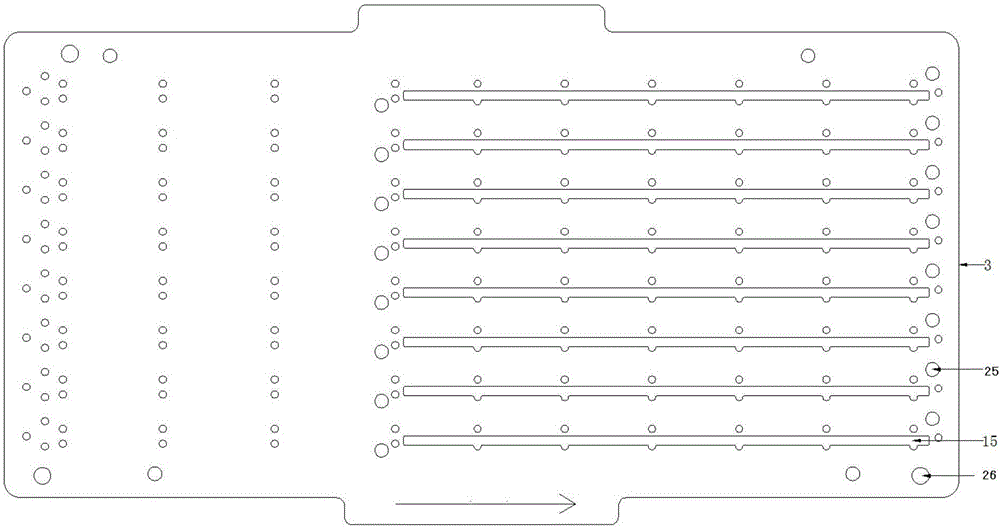

LED chip surface fluorescent powder layer coating method

InactiveCN101099964AImprove uniformityImprove unevennessLiquid surface applicatorsCoatingsScreen printingFluorescence

The present invention is process of painting fluorescent powder layer to the surface of LED chip. The fluorescent powder is first mixture with glue to form homogeneous fluorescent glue, and the fluorescent glue is then painted to the front side and lateral sides of the LED chip homogeneously by means of simple screen printing process. Painting fluorescent powder layer to the surface of LED chip can convert the fluorescent emitting wavelength of the LED and makes it possible to produce LED devices of different colors.

Owner:INTEX OPTOELECTRONICS XIAMEN CO LTD

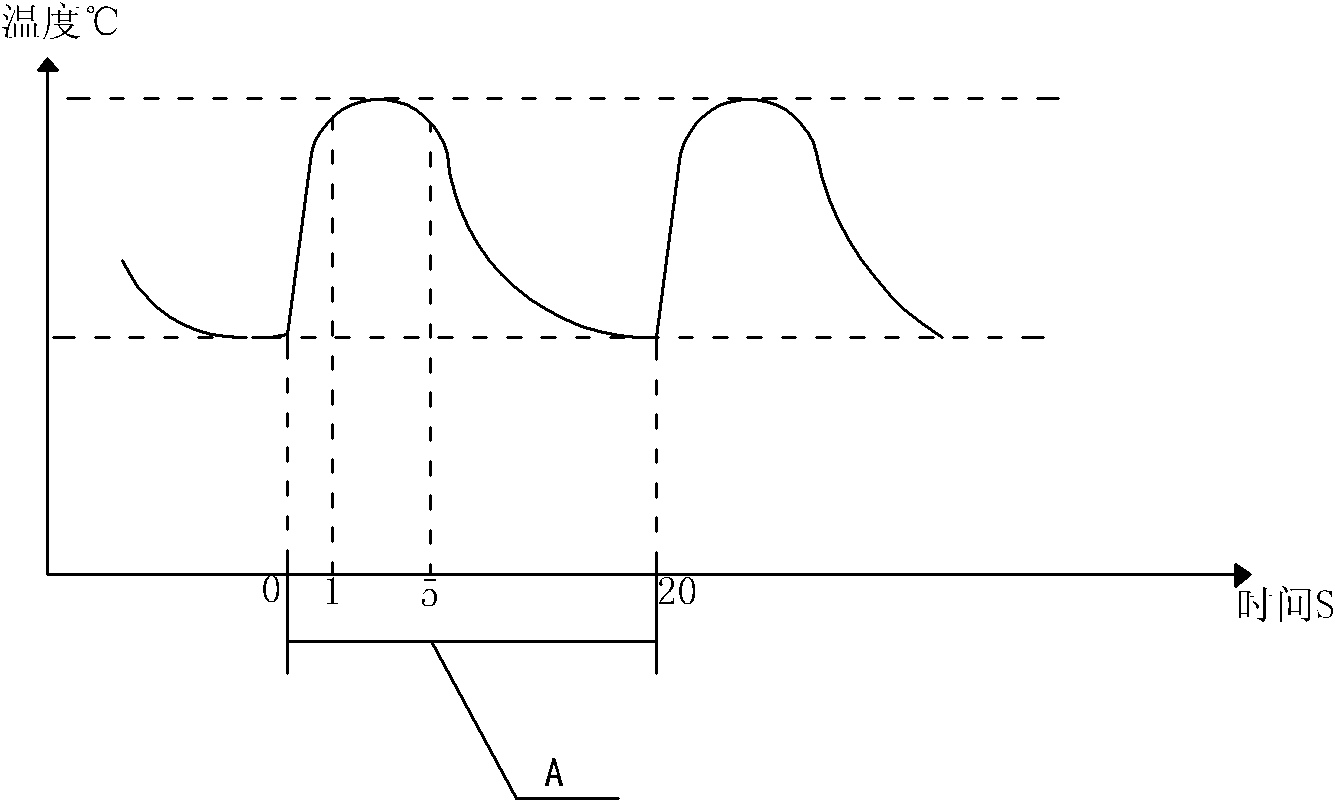

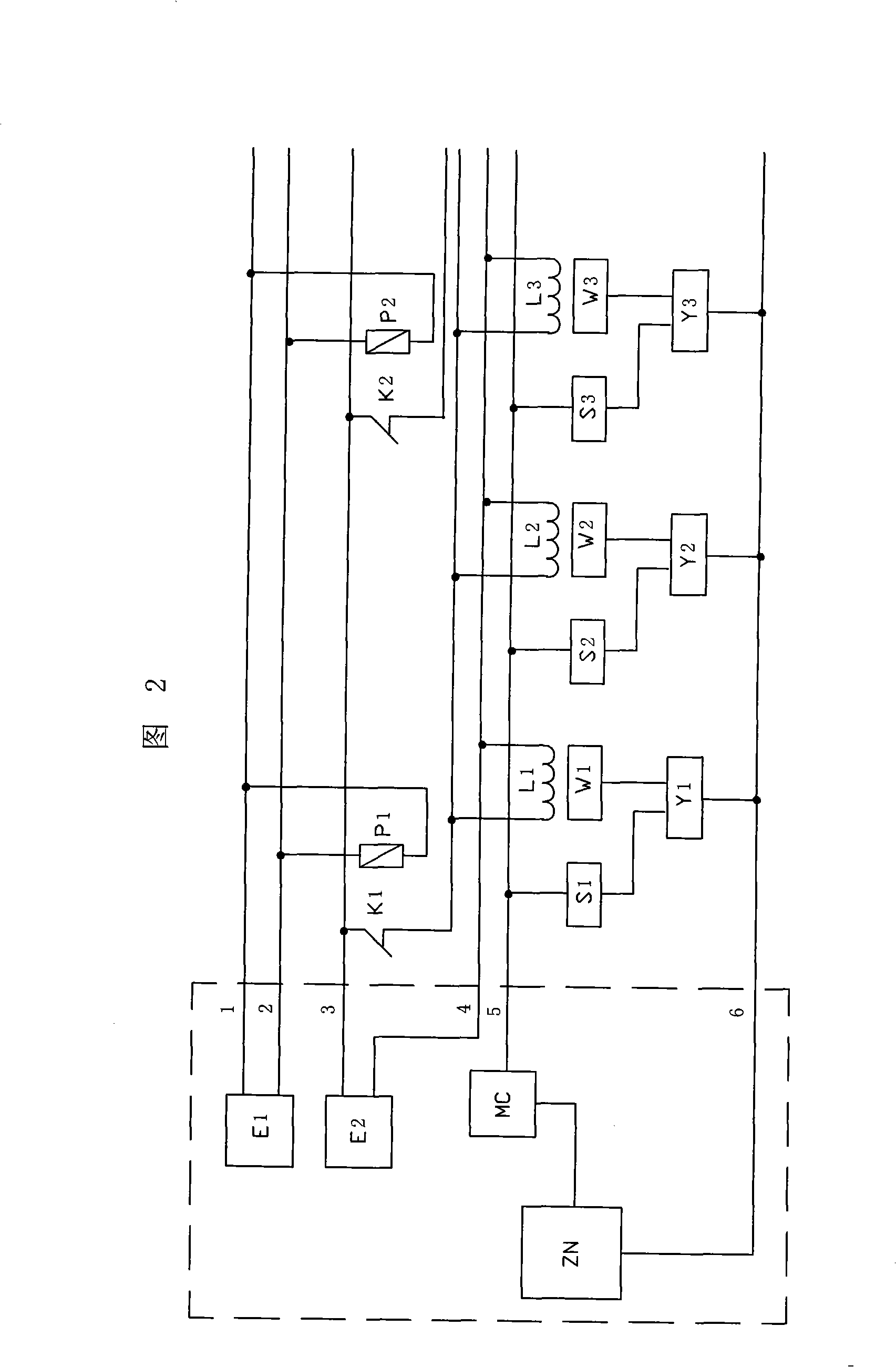

Infrared pulse radiation heating method for curing board surface powder and equipment for implementing method

InactiveCN102580902AAvoid heat damageShort curing timeDrying solid materials with heatPretreated surfacesPhysical chemistryMedium density fiberboard

The invention relates to an infrared pulse radiation heating method for curing board surface powder and equipment for implementing the method, which belong to the field of infrared technology application. The heating method uses the new concept of a medium-wave infrared pulse radiation heating unit, and pulsed high-temperature curing is performed for artificial MDF (medium density fiberboard) surface powder coatings by the aid of short-time pulsed high temperature, so that heat damage of a board surface is avoided. By the aid of a pulsed high-temperature curing accumulation effect, coated film curing time is greatly shortened, the heat absorption capacity of a board matrix is greatly decreased, and an MDF is ensured to be at the temperature lower than 100 DEG C during discharge. By the aid of the equipment for implementing the method, effective heating space and the length of a drying tunnel can be reduced, MDF surfaces in an automatic coating production line are ensured to be in the same heated state, coated films are uniformly cured, and an energy-saving effect is extremely remarkable.

Owner:SHANDONG LANGFARBE POWDER COATING TECH

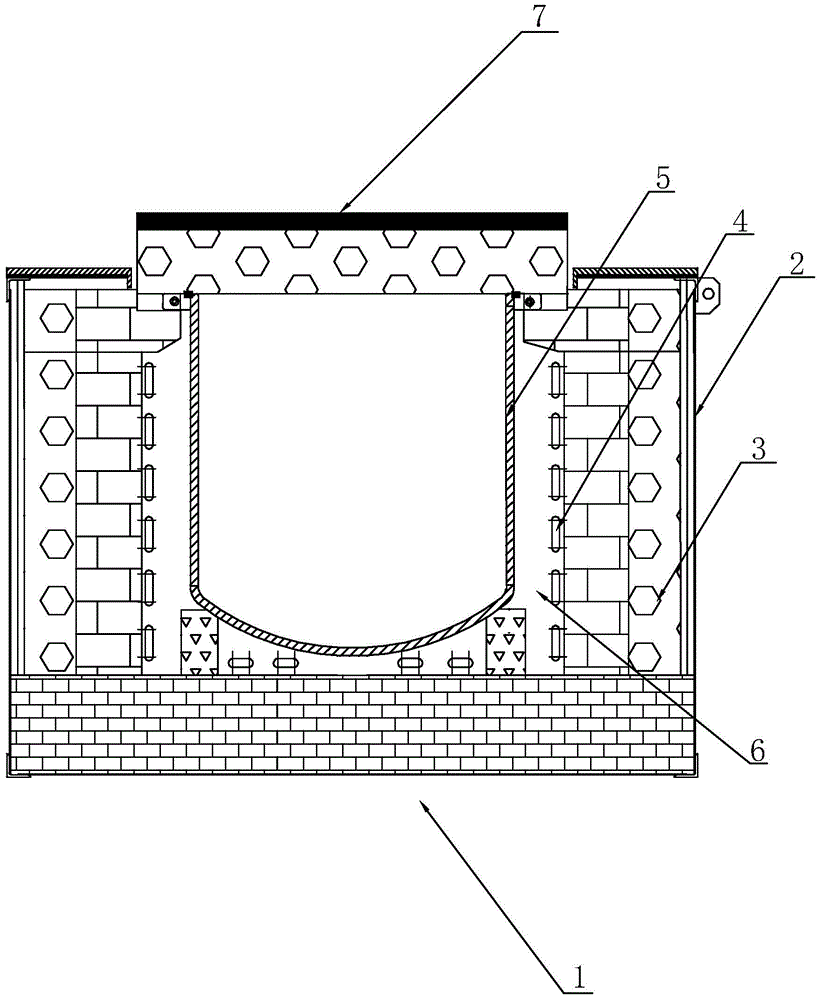

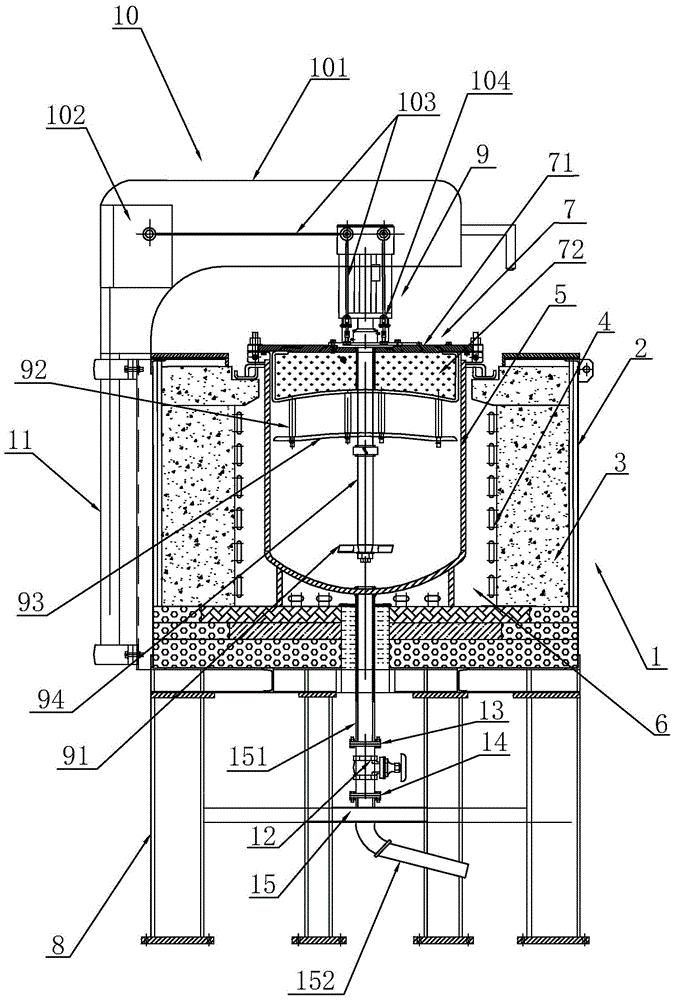

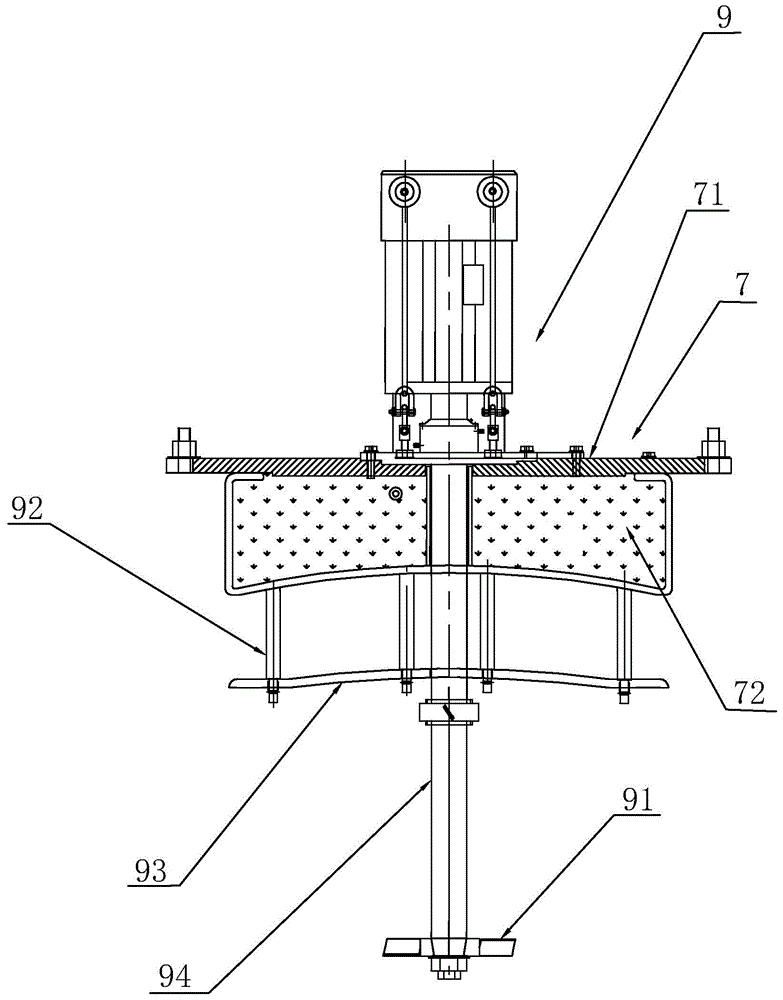

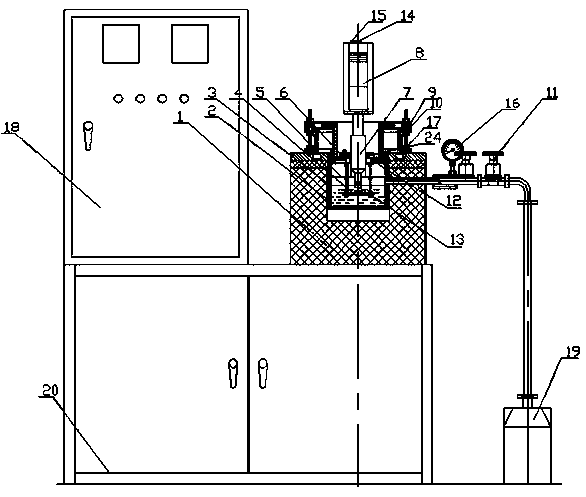

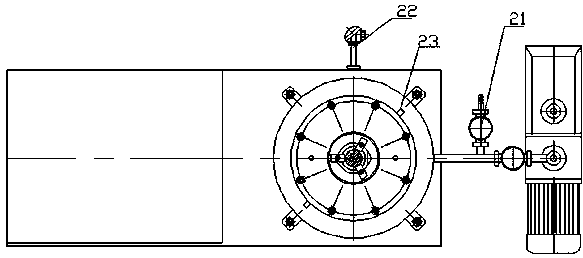

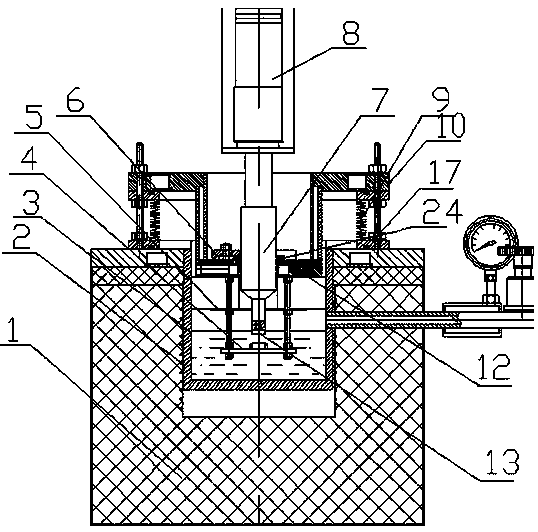

Metal homogenizing melting furnace

InactiveCN104390457AWith lossOxidation resistantStirring devicesCrucible furnacesCrucibleMolten metal

The invention relates to a metal homogenizing melting furnace. The metal homogenizing melting furnace comprises a furnace body and a support used to fix the furnace body, wherein the furnace body comprises a furnace shell, a furnace lining, a heating element and a crucible, which are sequentially arranged from outside to inside, the heating element is arranged around the outer surface of the crucible, the crucible is provided with a furnace cover, a stirrer is arranged on the furnace cover, and a stirring shaft of the stirrer is stretched into the crucible, and stirs molten liquid in the crucible through stirring impellers arranged at the bottom of the stirring shaft. The metal homogenizing melting furnace stirs molten metal through the stirrer, uniforms constituents of the molten metal obtained after melting metal, and greatly improves product quality.

Owner:贵州鑫凯达金属电源有限责任公司

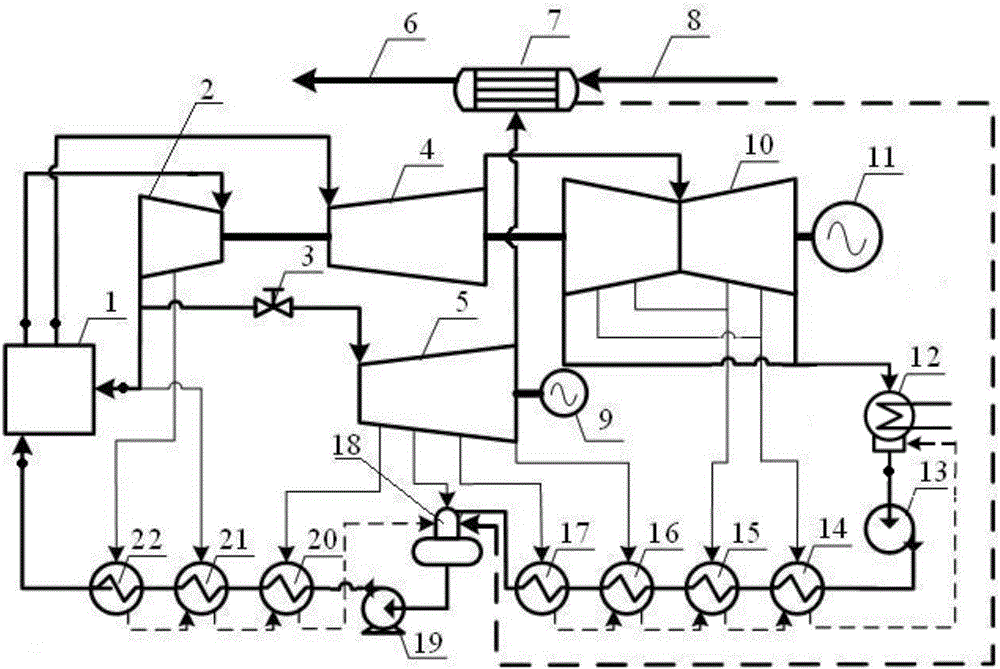

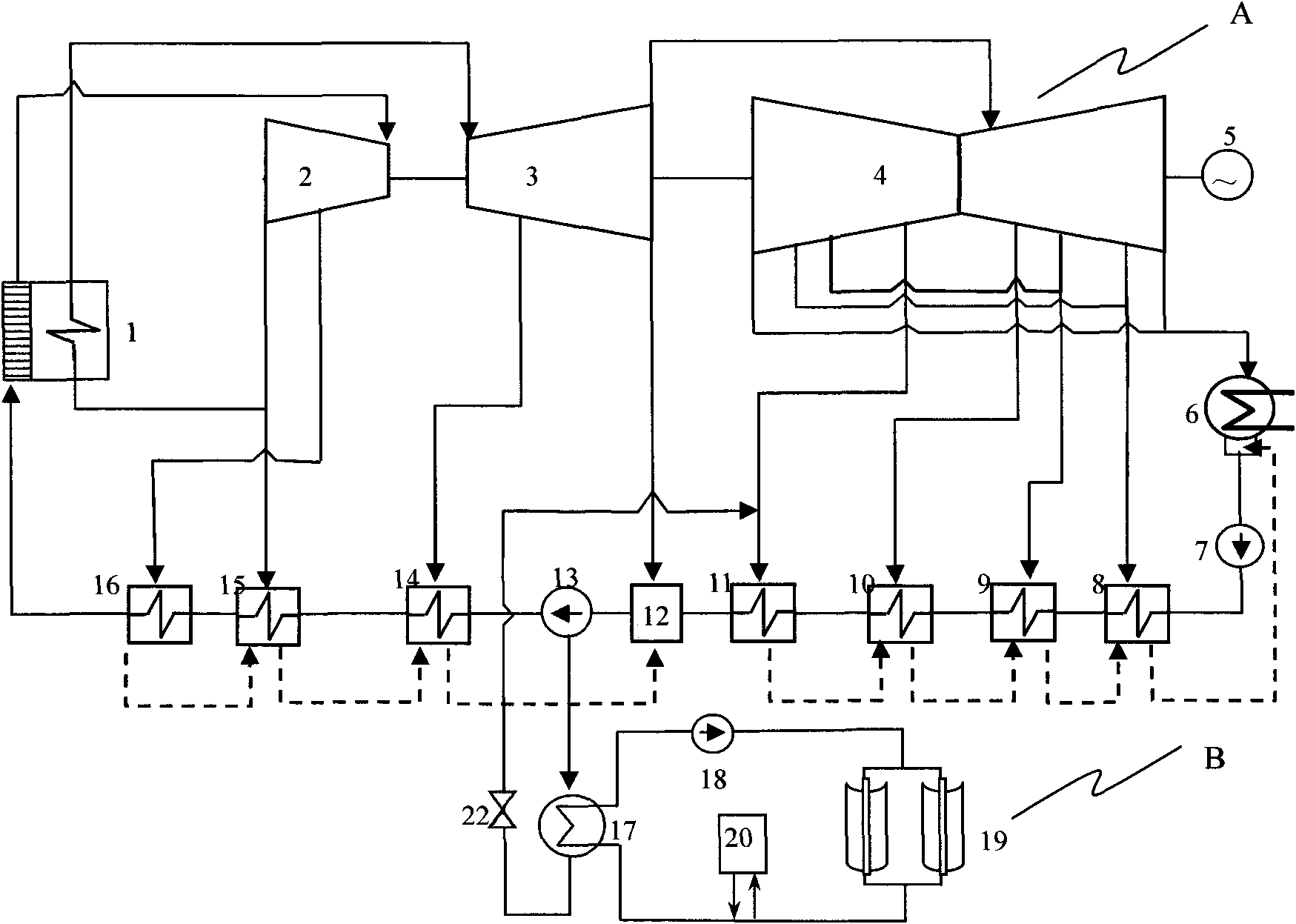

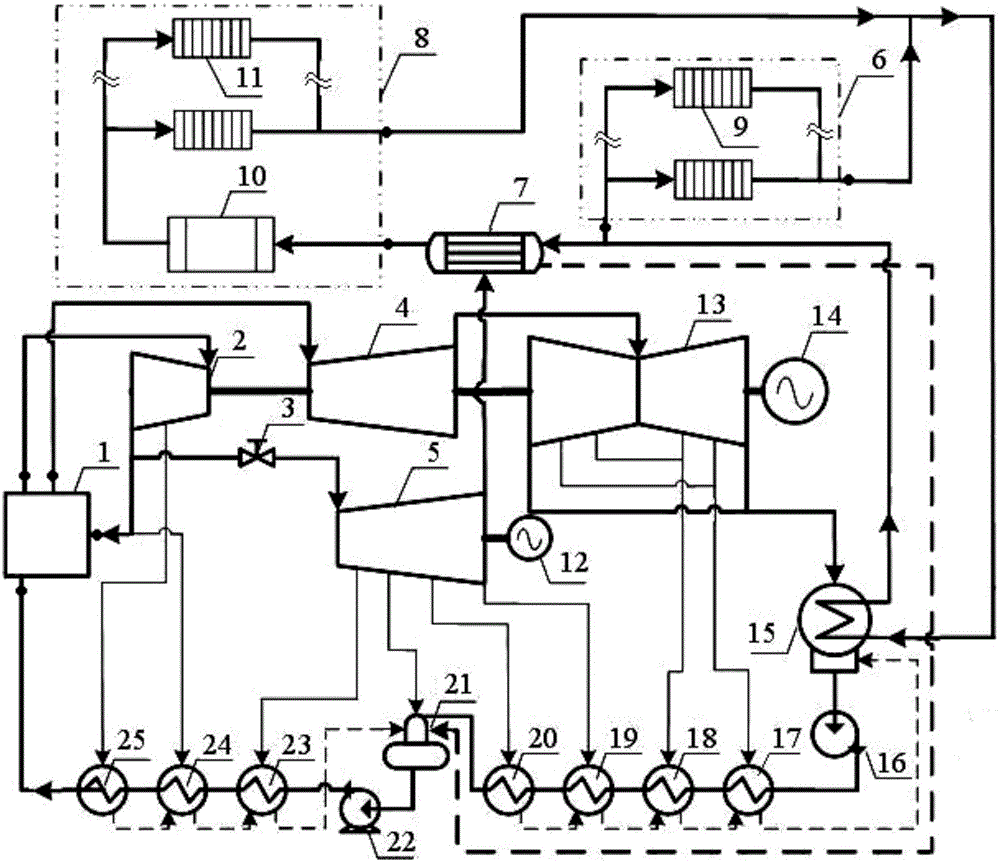

Extraction condensing heat supply system additionally provided with non-reheat medium-pressure steam turbine

InactiveCN105697075AReduce superheatImprove the flow structureLiquid degasificationSteam useEngineeringHeat losses

The invention belongs to the technical field of thermoelectricity, and relates to an extraction condensing heat supply system additionally provided with a non-reheat medium-pressure steam turbine. A part of steam is separated from a steam exhaust port of a high-pressure cylinder of a main steam turbine to enter the added non-reheat medium-pressure steam turbine, and the rest of steam enters a reheater of a boiler and a No.II high-pressure heater; the steam entering the medium-pressure steam turbine does not need to be reheated, an independent generator II is driven, four-stage extraction steam of the medium-pressure steam turbine serves as a heat source for a No.III high-pressure heater, a No.V low-pressure heater, a No.VI low-pressure heater and a deaerator to replace a part of regenerative extraction steam of the main steam turbine, and the extraction steam of the medium-pressure steam turbine is discharged into a heater for heating network to heat heating network water. An effect of additionally installing the medium-pressure steam turbine in the extraction condensing heat supply system disclosed by the invention is to reduce heat exchange exergy loss by reducing heat exchange temperature difference of a part of regenerative heaters and the deaerator; work capability of heat supply steam flow is increased, and therefore heat loss of a high-capacity heat supply unit is caused by a high extraction steam parameter is reduced; and the extraction condensing heat supply system disclosed by the invention is suitable for heat supply and energy conservation transformation on 300 MW (megawatt), 600 MW and above steam turbine units.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Physical and thermal protective coating

InactiveUS20050019552A1Reduce temperatureReduce heat absorptionBox making operationsPretreated surfacesCorrosion resistantMechanical force

The invention provides a strong, corrosion resistant protective coating comprising a homogeneous mixture of polyurea and microscopic granules capable of imparting the property of diffuse reflectivity and emissivity and its method of use as a means for reduction of thermal and radiant energy transmission and absorption as well as damage due to water, corrosion or mechanical forces when applied to the outer surface of an object or container.

Owner:WIERSMA JACK +1

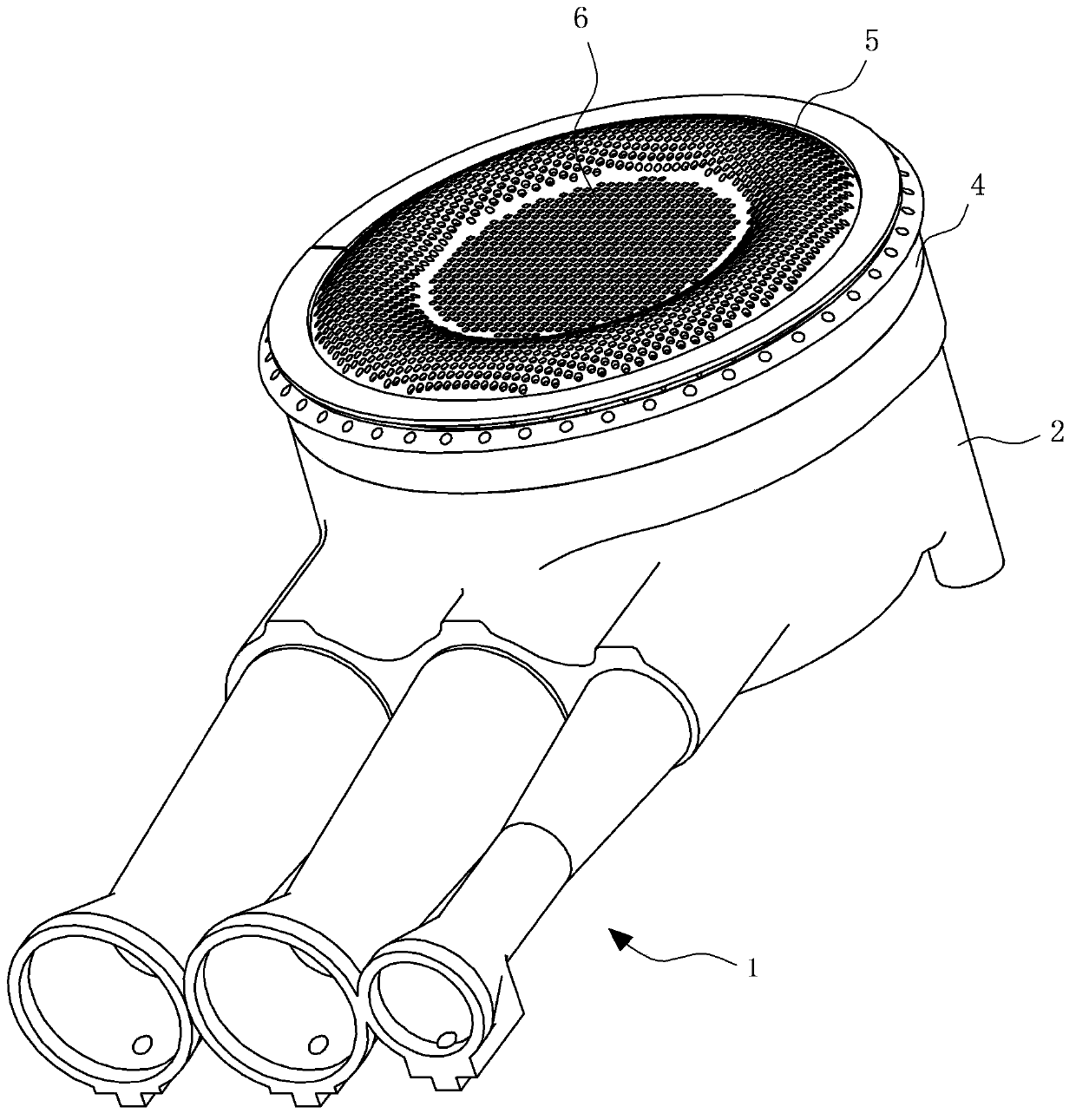

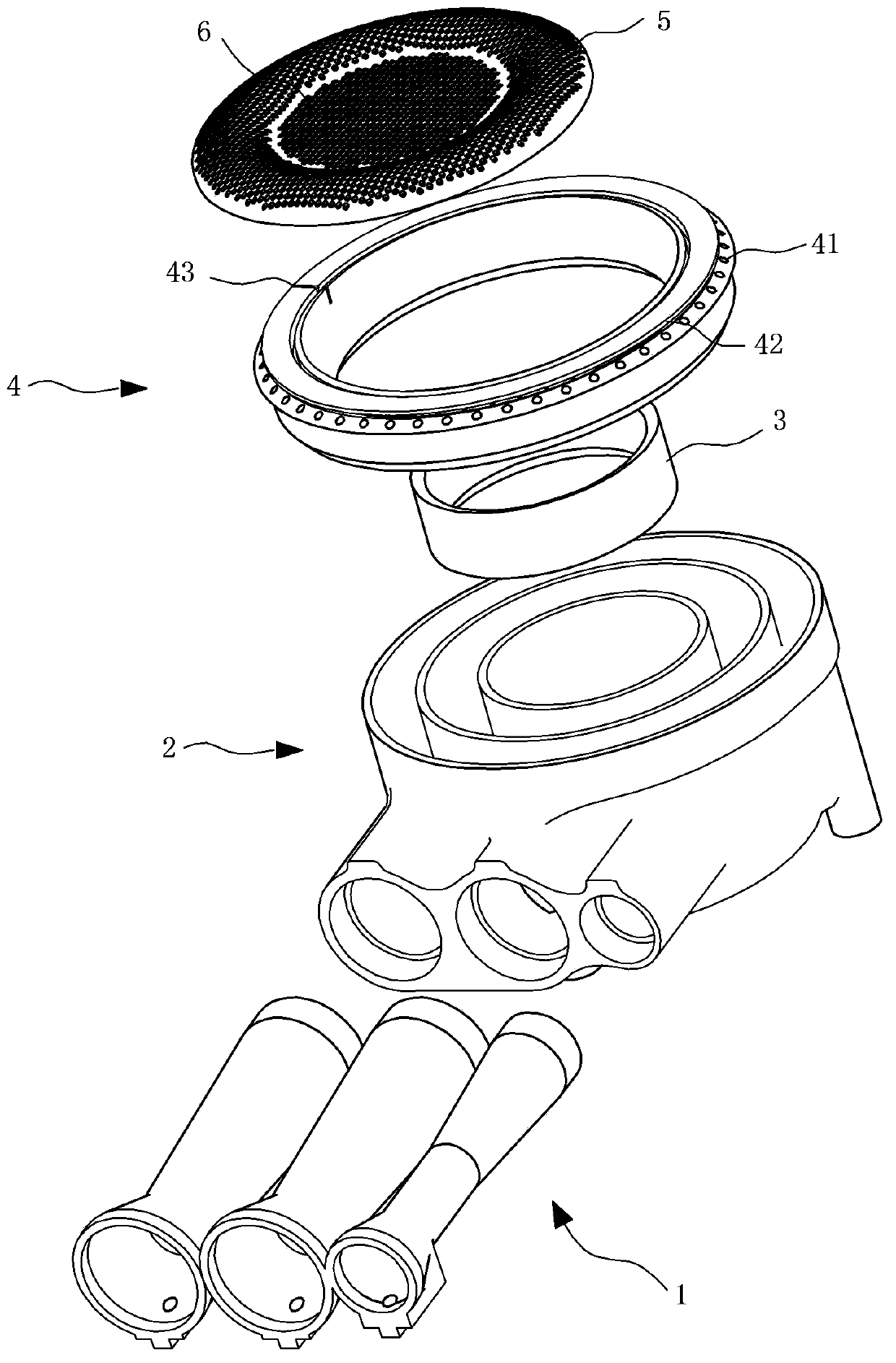

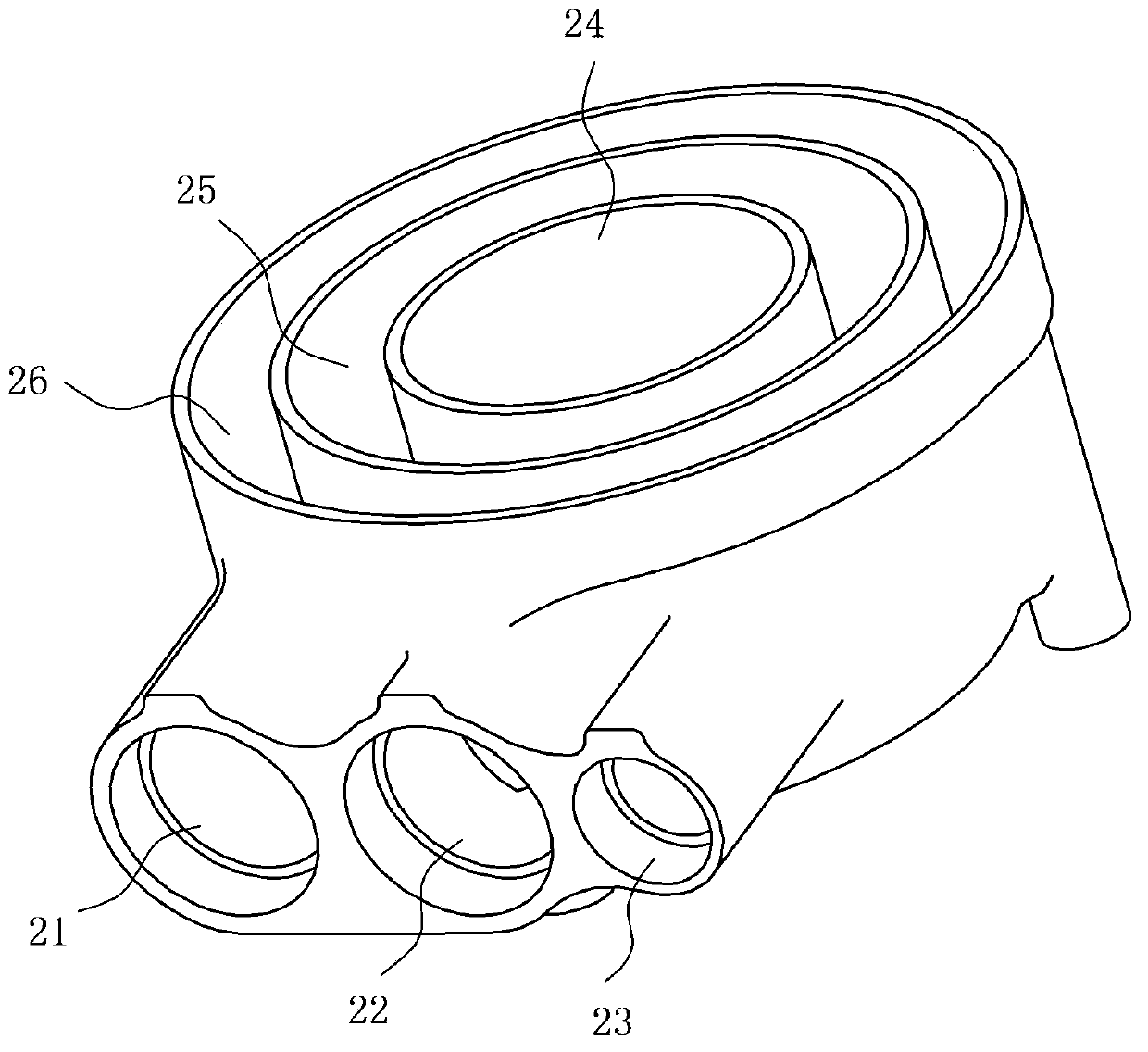

Novel high-efficiency energy-saving environmentally-friendly combustor

ActiveCN103388843AReduce heat absorptionImprove efficiencyDomestic stoves or rangesLighting and heating apparatusEnvironmentally friendlyEngineering

The invention belongs to the technical field of combustors and relates to a novel high-efficiency energy-saving environmentally-friendly combustor. The novel high-efficiency energy-saving environmentally-friendly combustor comprises a main body. The main body comprises an outer ring flame generator with an outer ring mixing chamber. An outer ring combustor cover is arranged above the outer ring mixing chamber. The outer ring combustor cover is provided with an outer ring fire hole. The outer ring mixing chamber is connected to an outer ring injection tube. The novel high-efficiency energy-saving environmentally-friendly combustor is characterized in that an infrared combustor is arranged in the main body; the infrared combustor comprises an inner mixing chamber connected to an inner injection tube and a combustor plate arranged above the inner mixing chamber; the combustor plate is arranged above the main body formed from the outer ring combustor cover; and the combustor plate is provided with a fire hole. The novel high-efficiency energy-saving environmentally-friendly combustor realizes combination of an atmospheric combustor adopting an open fire combustion technology and an infrared combustor adopting an infrared low fire combustion technology and improves combustor combustion efficiency and exchange efficiency.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

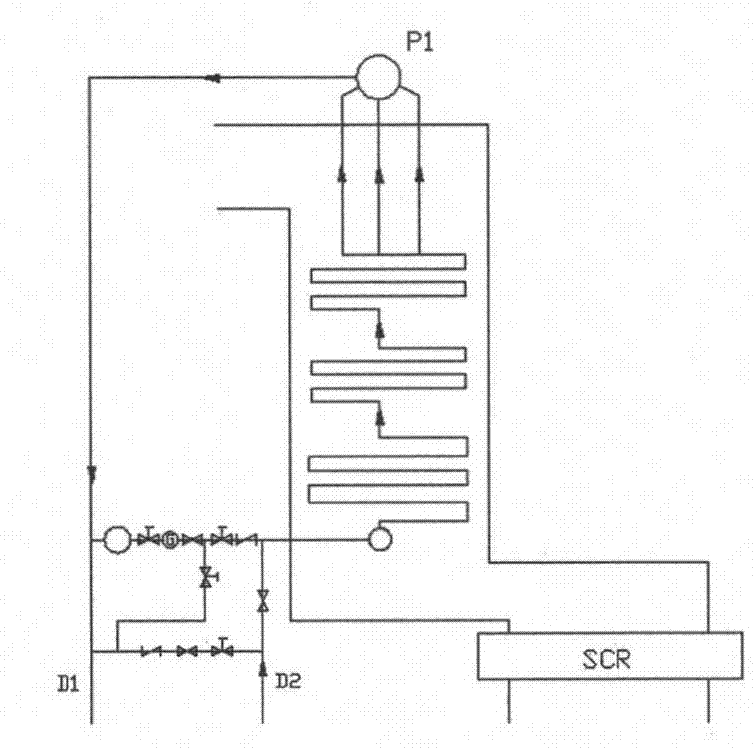

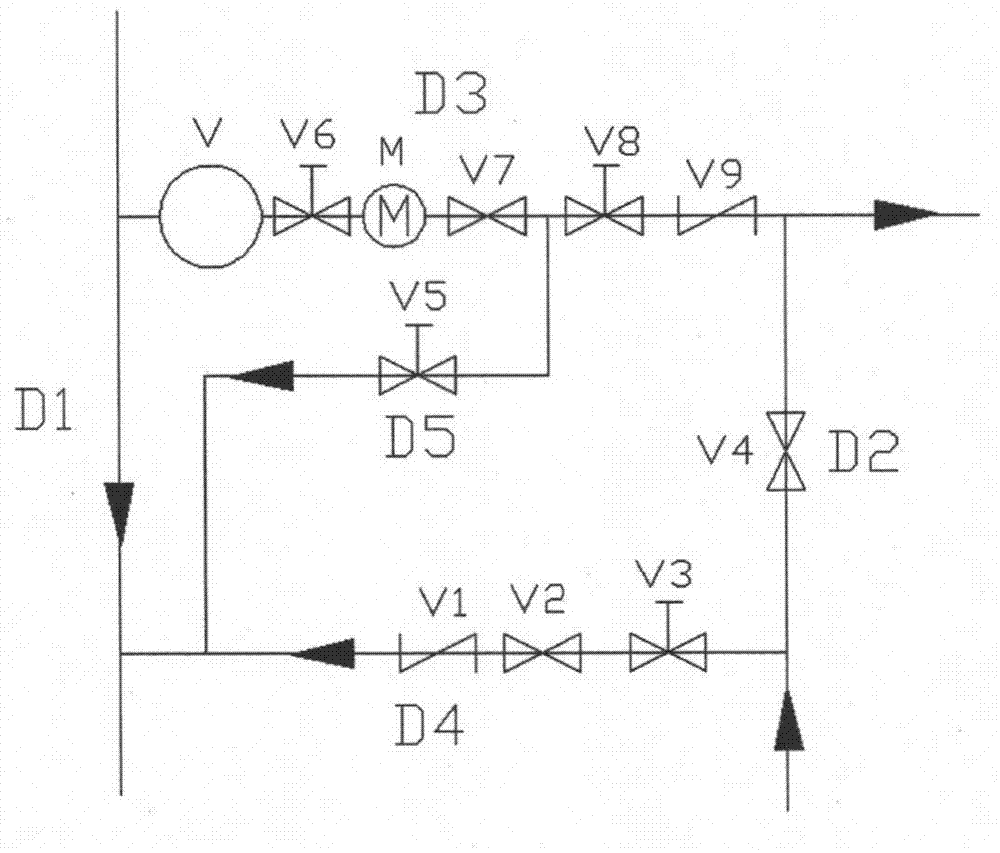

Feedwater replacement type economizer system for whole commissioning of denitration device

The invention provides a feedwater replacement type economizer system for whole commissioning of a denitration device. The feedwater replacement type economizer system is characterized in that the feedwater replacement type economizer system comprises a first bypass, a second bypass and a third bypass, the first bypass and the second bypass are arranged between a downcomer and a feedwater pipeline, the first bypass is provided with a vessel pot, a stop valve, a circulating pump, a flow control valve, a stop valve and a check valve in sequence from the downcomer to the feedwater pipeline, the second bypass is provided with a stop valve, a flow control valve and a check valve in sequence from the feedwater pipeline to the downcomer, one end of the third bypass is in the position between the flow control valve and the stop valve of the first bypass, the other end of the third bypass is connected with the downcomer, the third bypass is provided with a stop valve, and a flow control valve is arranged between the first bypass and the second bypass in the feedwater pipeline. By means of the feedwater replacement type economizer system, economy of a boiler is not sacrificed under heavy load, the smoke temperature of an inlet of the denitration device can be increased under low load, and the feedwater replacement type economizer system is suitable for boilers with the smoke temperature of the denitration device inlet under low load reaching 40 DEG C.

Owner:SHANGHAI POWER EQUIP RES INST +1

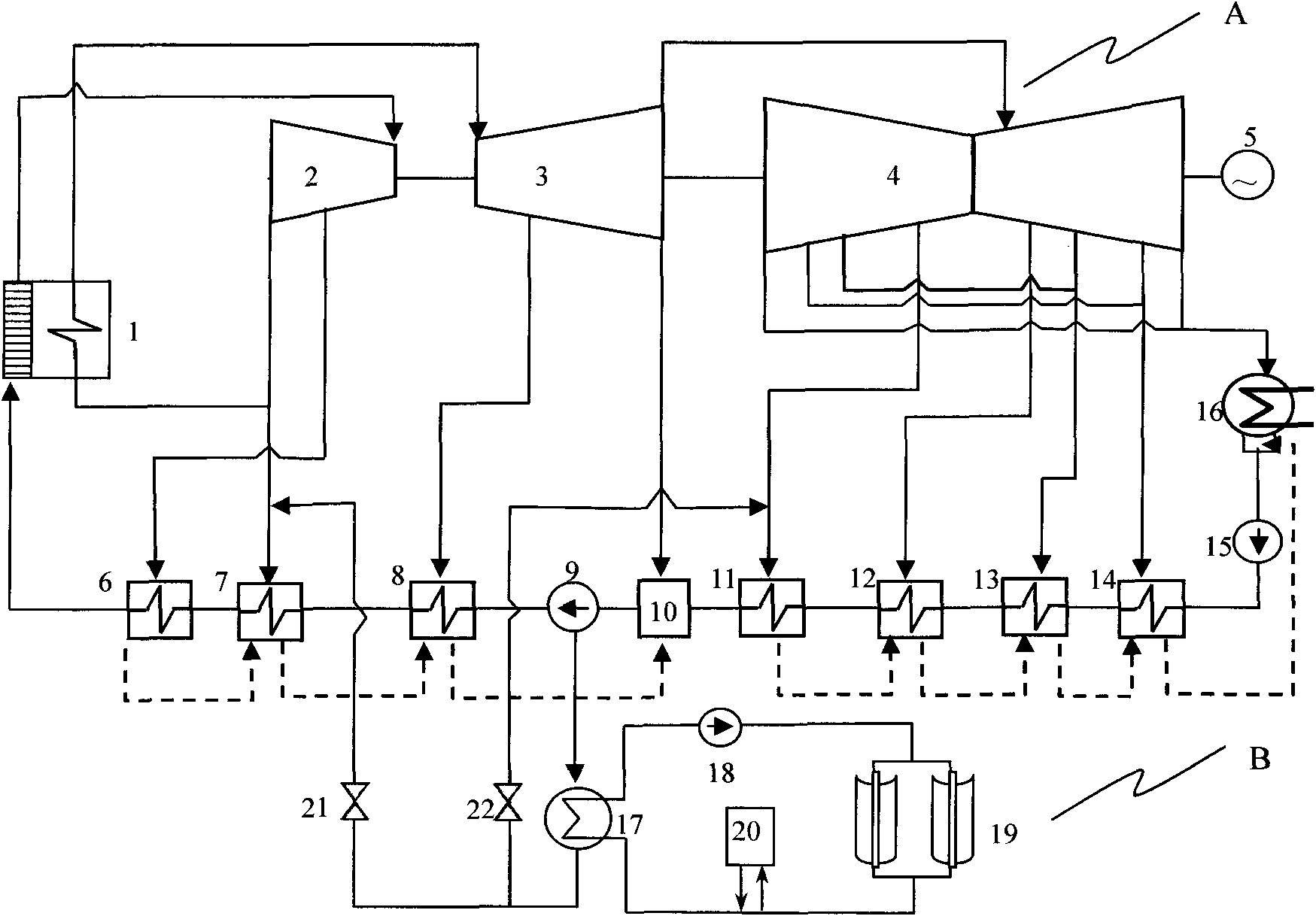

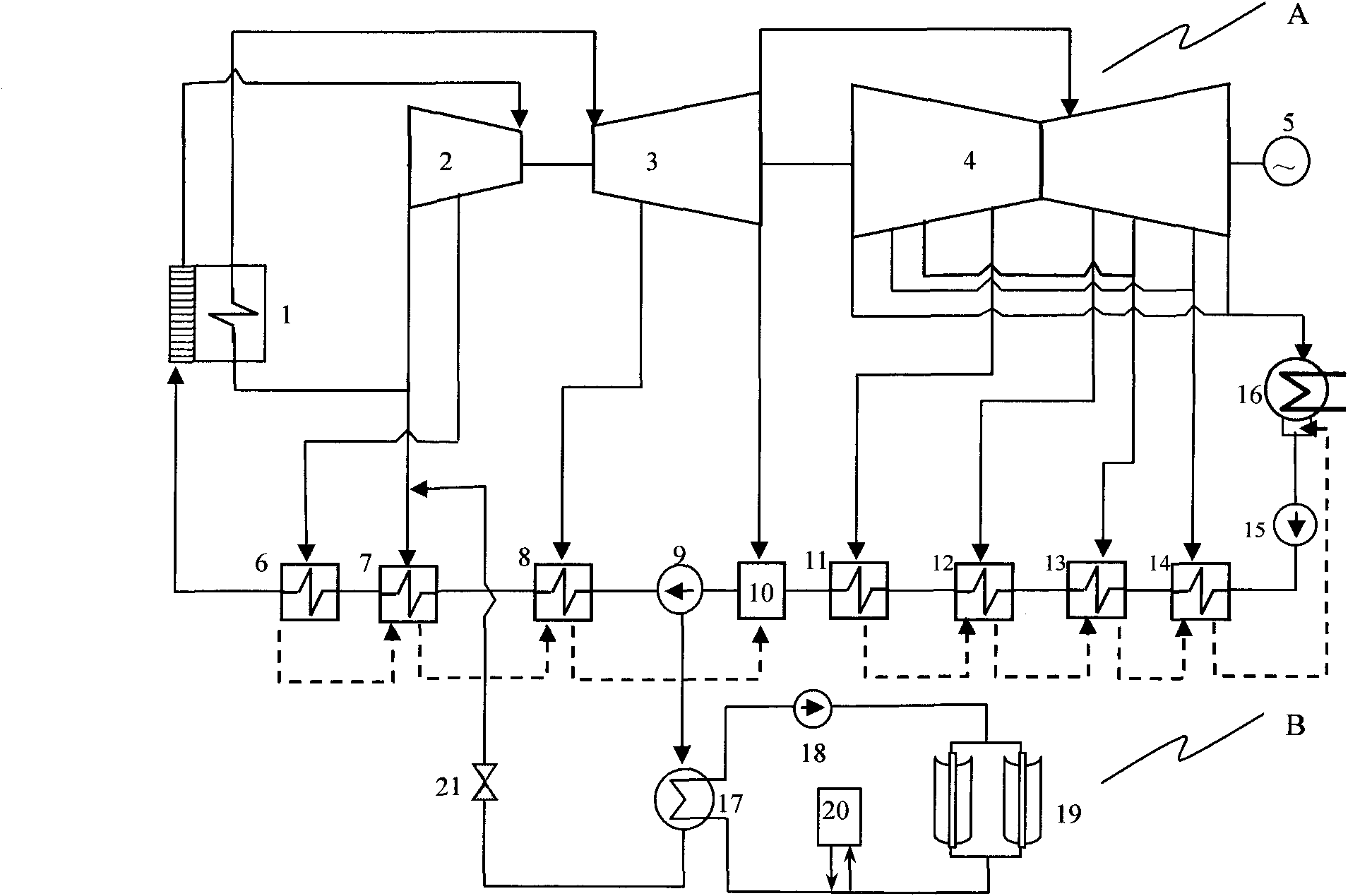

Solar heat collection, energy storage and back heating system applied to thermal generator set

InactiveCN101846044ARealize the goal of energy saving and emission reductionReduce regenerative steam extractionSteam generation heating methodsFrom solar energyClosed loopEngineering

The invention discloses a solar heat collection, energy storage and back heating system applied to a thermal generator set, and belongs to the field of energy conservation and emission reduction of the thermal generator set. The solar heat collection, energy storage and back heating system provided by the invention is connected with the conventional thermal generator set through a pipeline and a valve. The solar heat collection, energy storage and back heating system consists of a heat exchanger, an oil pump, a solar heat collection field, a heat accumulator and a heat exchanger which are connected in turn in a closed-loop mode; a heating working medium input end of the heat exchanger is connected with a center tap of a water supply pump of the thermal generator set; and a heating working medium input end of the heat exchanger is connected with a certain back heating steam extraction pipeline of the thermal generator set. The system can provide qualified heating steam for a certain back-heat heater through proper valve switching operation without changing a thermodynamic system structure of the conventional thermal generator set to stop using back heating extracted steam of a primary steam turbine so that the generating coal consumption of the thermal generator set is reduced and the purposes of energy conservation and emission reduction of the thermal generator set are fulfilled.

Owner:HUAZHONG UNIV OF SCI & TECH

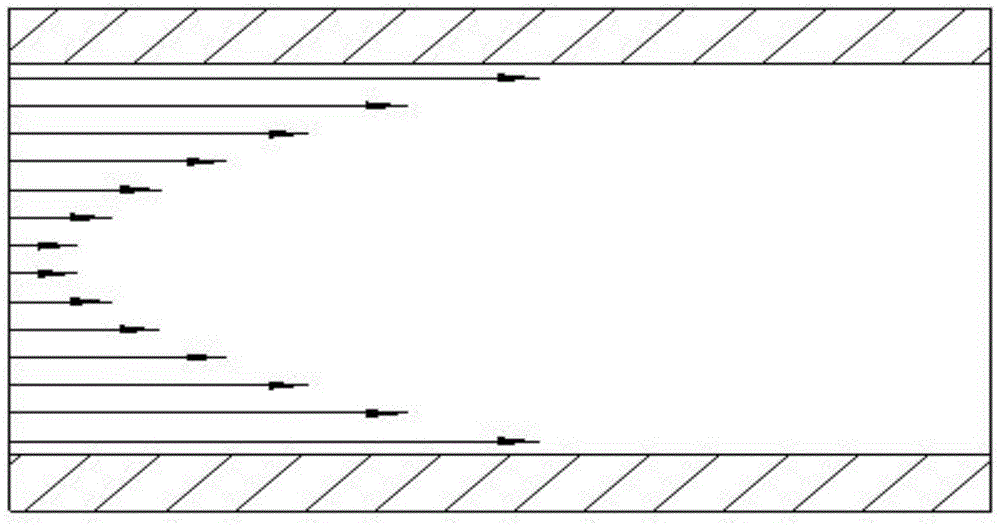

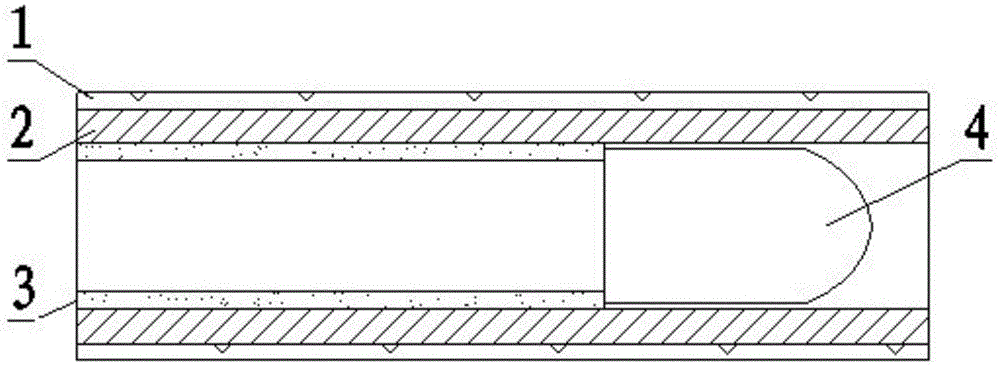

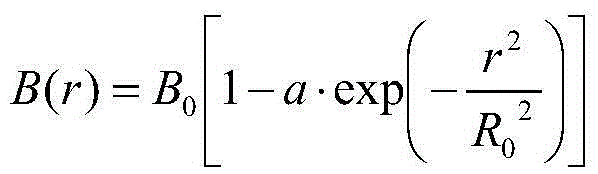

Magnetized plasma artillery

InactiveCN104697397AReduce heat absorptionReduce radial forceBarrelsThermal insulationHeat resistance

The invention discloses magnetized plasma artillery. A magnetic field is arranged in an artillery body pipe, the direction of the magnetic field points to an artillery port along the direction of an axis of the artillery body pipe, the magnetic field strength is gradually reduced from an inner wall of the artillery body pipe to the axis of the artillery body pipe, and the gas in the artillery body pipe can be ionized into the plasma for forming a plasma sheath layer on the inner wall of the artillery body pipe under the action of the magnetic field while the artillery is launched. The magnetized plasma sheath layer formed on the inner wall of the artillery body pipe of the magnetized plasma artillery has stress anisotropic characteristic and has thermal insulation function, and then, the radial force for the artillery body pipe is greatly reduced, the driving force for the bullet is greatly improved, the heat resistance of the artillery body pipe is greatly improved and the service life is prolonged.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

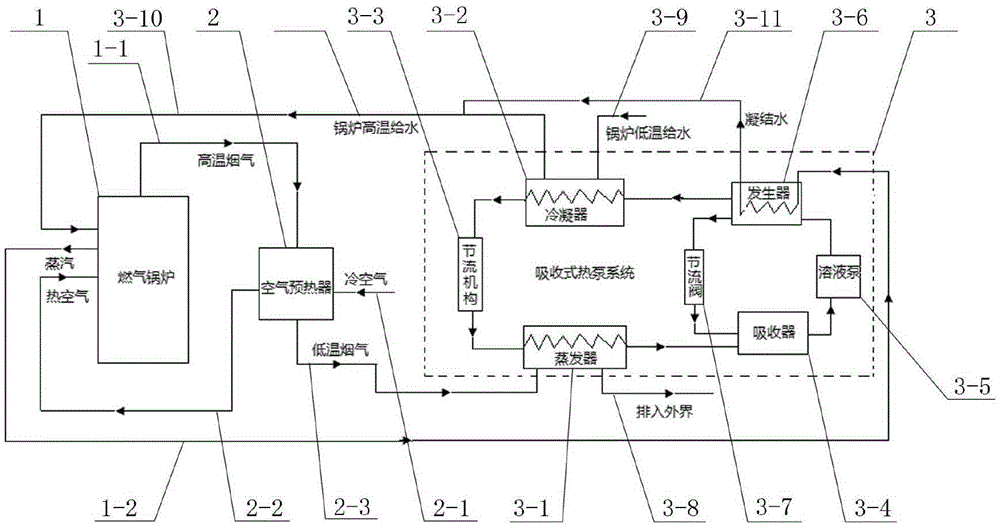

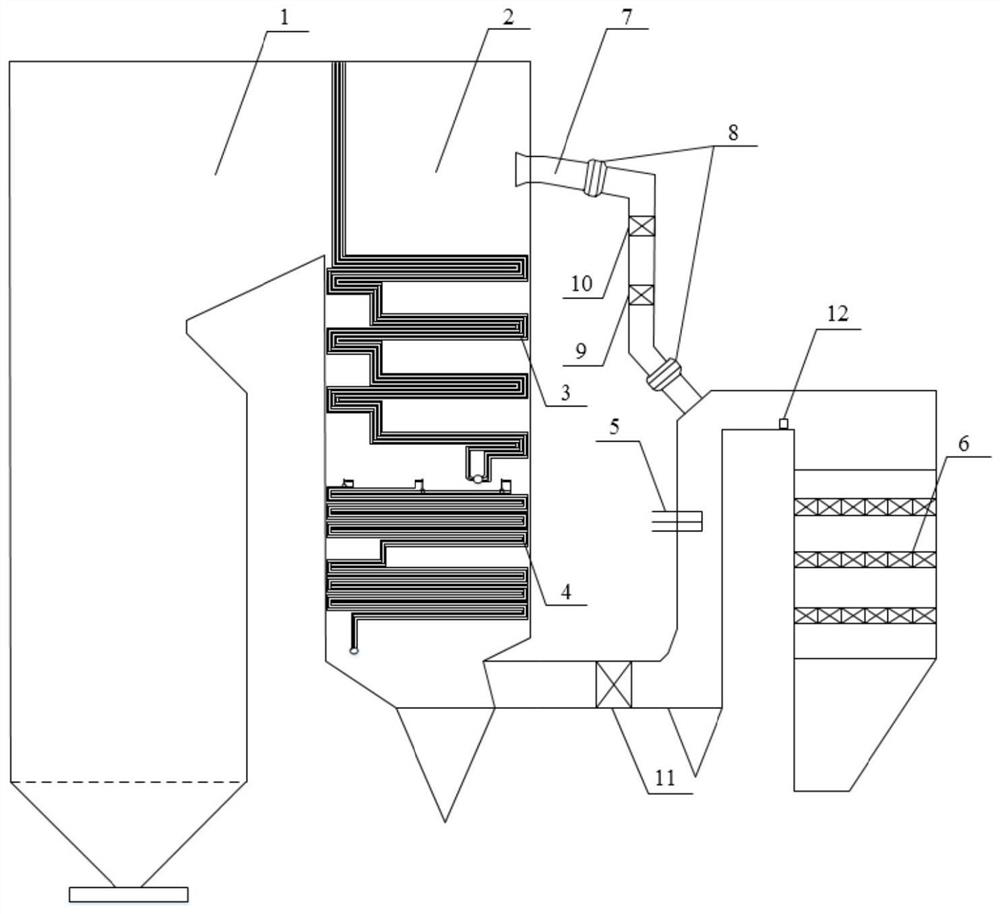

Flue gas residual heat recovery system with absorption type heat pump circulation

InactiveCN104359103AReduce the amount of gasIncrease temperatureHeat recovery systemsFeed-water heatersProcess engineeringEvaporator

The invention discloses a flue gas residual heat recovery system with absorption type heat pump circulation. The system comprises a gas boiler, an air preheater and an absorption type heat pump device, wherein the absorption type heat pump device comprises an evaporator, a condenser, a throttle mechanism, an absorber, a solution pump, a generator and a throttle valve, the absorber, the solution pump, the generator and the throttle valve are connected sequentially, so as to form a loop, and the generator is sequentially connected with the condenser, the throttle mechanism and the evaporator and is finally connected to the absorber; the evaporator is provided with discharging pipes which are used for discharging flue gas and condensation water, the condenser is provided with a boiler low-temperature water supplying passage and a boiler high-temperature water supplying passage, and the boiler high-temperature water supplying passage is connected to the gas boiler; the gas boiler is provided with a high-temperature flue gas passage and a steam branch passage. Compared with the prior art, the system has the advantages that the temperature of supplied water is increased by 5-8 DEG C, and the heat absorption capacity of the supplied water in the boiler is lowered, so that the volume of combusted gas is reduced, and the aims of energy saving and emission reduction are achieved.

Owner:XINJIANG INST OF ENG

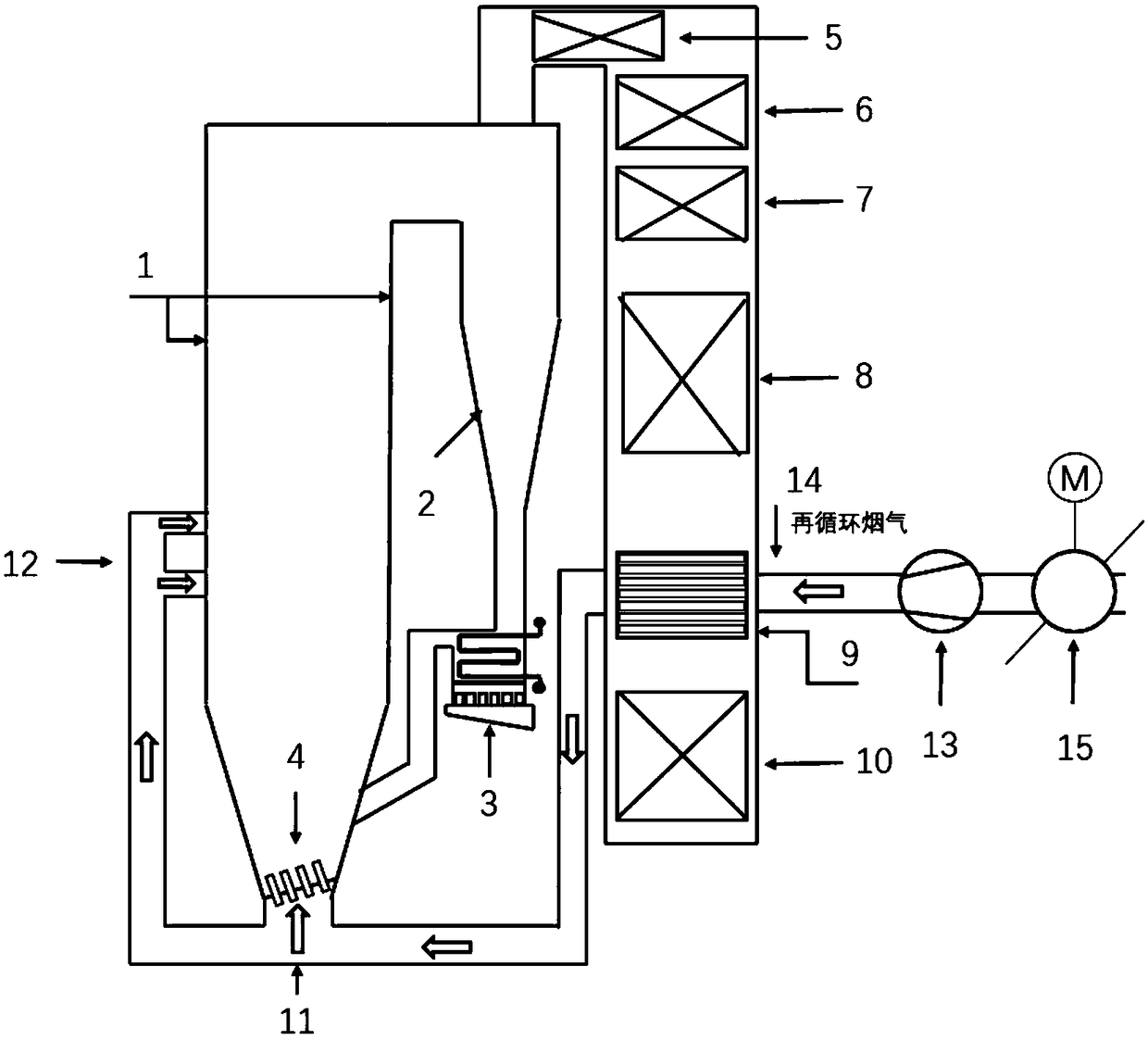

Circulating fluidized bed boiler applicable to garbage incineration

InactiveCN108758651AOvercoming the problem of insufficient combustion temperatureReduce heat absorptionFluidized bed combustionIncinerator apparatusAir volumeEvaporation

The invention discloses a circulating fluidized bed boiler applicable to garbage incineration. The circulating fluidized bed boiler applicable to garbage incineration comprises a hearth, an air distribution device, a separator, a material return valve, an external bed heat exchanger, a tail flue, a water-cooling pipe bundle, an evaporation pipe bundle, a low-temperature superheater, a coal economizer, a recirculating smoke heat exchanger, an air pre-heater and the like. According to the circulating fluidized bed boiler applicable to garbage incineration, an in-boiler water-cooling wall is completely poured-covered with a refractory material, so that a high combustion temperature of the circulating fluidized bed boiler is ensured. Meanwhile, recirculating smoke is heated by virtue of hot smoke in the tail flue, so that charge heat is increased, and the combustion stability of garbage incineration in the circulating fluidized bed boiler is further improved. The heated recirculating smokeis mixed with primary air and secondary air, so that a primary air amount used for fluidization is reduced while an air temperature is increased, the effect of enhanced graded combustion is further achieved, and the original generation of NOx is reduced. The problem of insufficient heating surface in the heat-insulation hearth is solved through arranging a high-temperature superheater in an external bed; and meanwhile, the problems of high-temperature corrosion of smoke, and coking in a biomass and garbage incineration process, are greatly solved.

Owner:HUANENG CLEAN ENERGY RES INST

High-back pressure combined heat and power generation system coupled with exhaust steam and supply heat of non-reheat steam turbine

InactiveCN105736068AReduce superheatImprove the flow structureCombination enginesSteam useProcess engineeringDynamo

The invention belongs to the technical field of thermoelectricity, and relates to a high back pressure heat and power cogeneration system coupled with exhaust steam heat supply of a non-reheat steam turbine. A non-reheat medium-pressure steam turbine and generator II are added to the power generation system, and the heating system mainly includes a high backpressure heating condenser, a non-reheat medium-pressure steam turbine, a heat network heater, a remote heat network and a short-range heat network. The exhaust steam from the low-pressure cylinder of the main steam turbine enters the heating condenser to condense and release heat. The circulating water in the condenser absorbs heat and enters the short-distance heating network or heating network heater. The exhaust steam from the steam turbine is further heated and enters the remote heating network, and the return water from the remote and short-range heating networks is mixed and then enters the condenser. The invention utilizes the waste heat of the exhaust steam of the steam turbine to reduce the loss of the cooling source; the return water of the short-range and remote heating network is mixed, so that the temperature of the return water of the heating network entering the condenser is reduced, and the utilization efficiency of waste heat is improved. The invention is suitable for the heat supply transformation of 300MW and above large-capacity units with short-range low-temperature heat demand.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

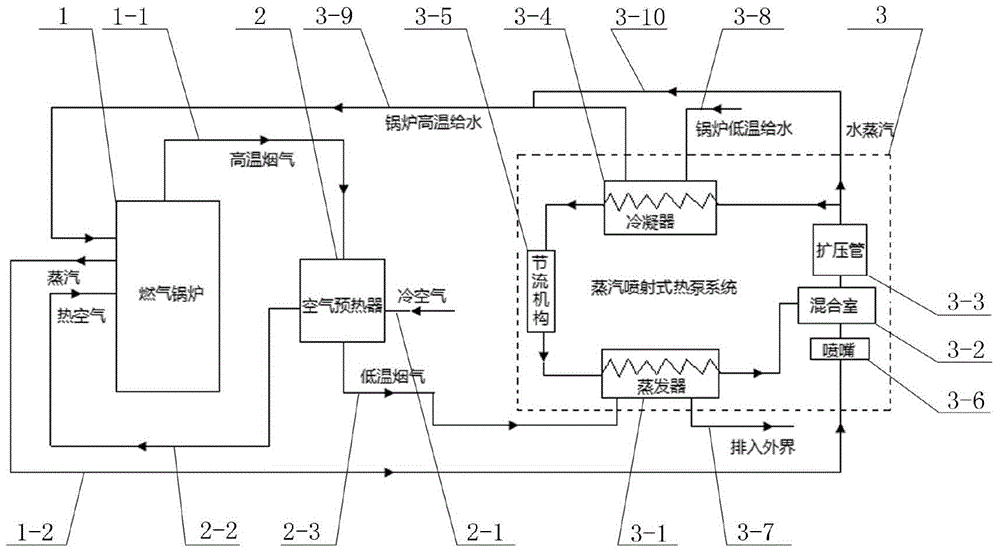

Steam jet type heat pump circulating flue gas waste heat recovery system

InactiveCN104456610AIncrease temperatureReduce heat absorptionFluid heatersHeat pumpsEvaporatorFlue gas

Owner:XINJIANG INST OF ENG

Iron ore tunnel kiln magnetizing roasting layering material distributing reduction method

The invention discloses an iron ore tunnel kiln magnetizing roasting layering material distributing reduction method. Iron ore is divided into different granularity degrees according to the granularity range; the reduction coal is flatly laid in the bottom of a tunnel kiln car according to the proportion that the reduction coal accounts for 4-6% of the total weight of iron ore; the iron ore of various granularity degrees is laid at the upper portion of the reduction coal of the tunnel kiln car, and the granularity range of each layer of iron ore is gradually increased from the bottom layer to the top layer in a layer-by-layer manner; facing materials are flatly laid at the upper portion of iron ore of various granularity degrees of the tunnel kiln car; the tunnel kiln car loaded with materials is pushed into a tunnel kiln for magnetizing roasting; and after magnetizing roasting is finished, the tunnel kiln car loaded with the materials is pushed out of the tunnel kiln. According to the method, over reduction of iron ore can be effectively prevented, the control means of iron ore magnetizing roasting is improved, and the surplus carbon recycling and utilizing cost is low. In addition, the mixing technology of iron ore and a reducing agent before magnetizing roasting of the iron ore tunnel kiln is reduced or eliminated, and the production cost of the roasted ore is reduced.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Method and device for preparing H2 and separating CO2 based on calcium-based sorbent

InactiveCN103060003AReduce energy lossReduce heat absorptionCarbon compoundsHydrogen separation using solid contactSorbentWater vapor

The invention discloses a method and a device for preparing H2 and separating CO2 based on a calcium-based sorbent. The method comprises that a calcium-based sorbent and pulverized coal are fed into a gasification reactor by a screw charging machine; the pulverized coal is gasified by steam to produce water gas; CH4 in the water gas is reformed into CO and H2 and CO undergoes conversion reactions to produce CO2 and H2; CO2 is absorbed by the calcium-based sorbent; H2 and residual CO2 enter into an absorption reactor; unreacted coke and CaCO3 enter into a calcination reactor; pure oxygen is fed into the calcination reactor; the coke and the pure oxygen burn and produce CO2; CaCO3 is decomposed into CaO and CO2; after separation adopting a separator, CO2 enters into a preheater and gives out heat; CaO is separated into two parts by a returning valve and one of the two parts enters into the gasification reactor and the other one of the two parts enters into the absorption reactor; CaO in the absorption reactor absorbs residual CO2 and produces CaCO3; after separation adopting a separator and condensation, clean H2 is obtained; and the separated CaCO3 enters into the calcination reactor so that sorbent recycle is realized.

Owner:SOUTHEAST UNIV

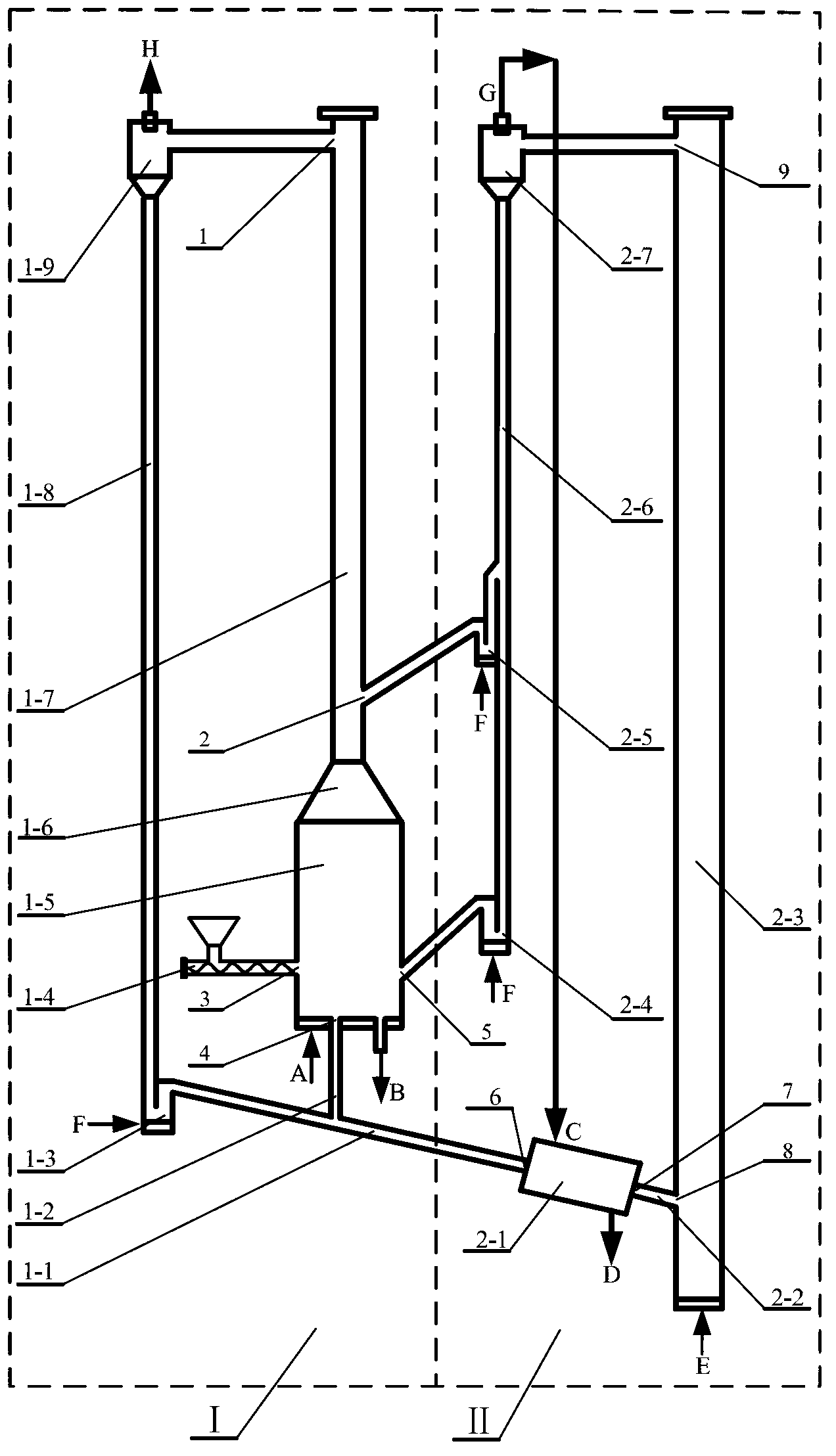

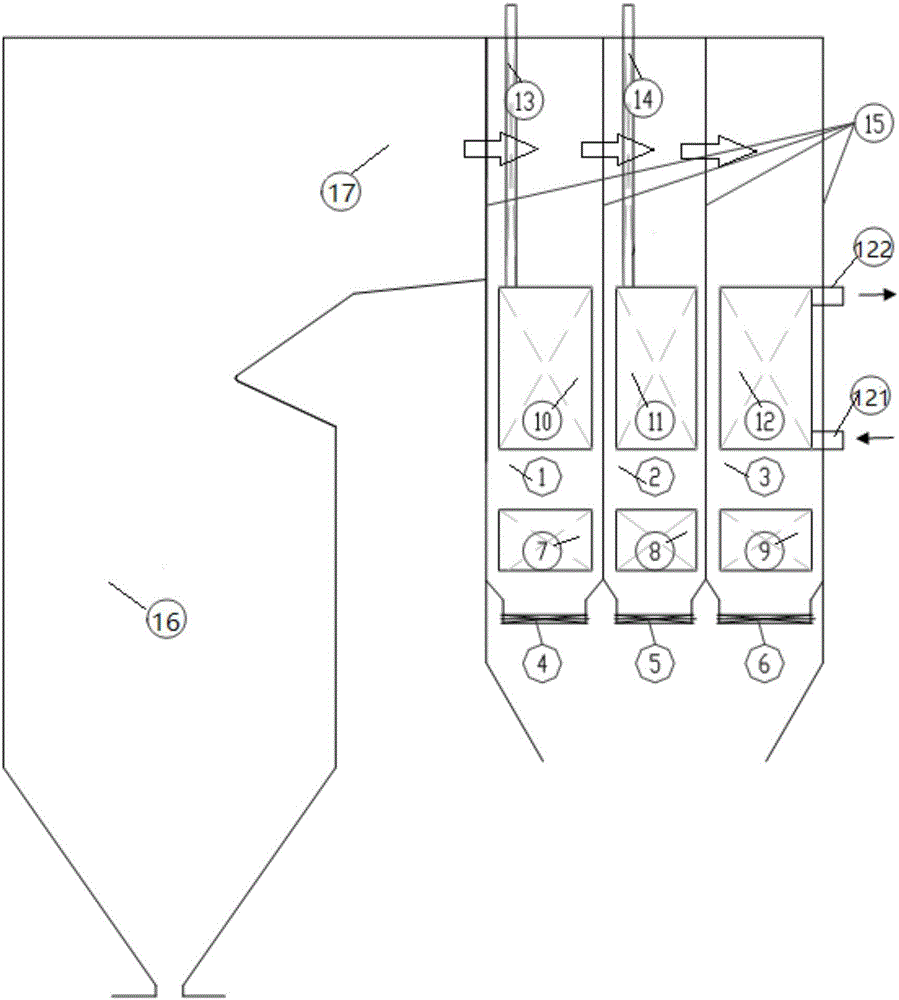

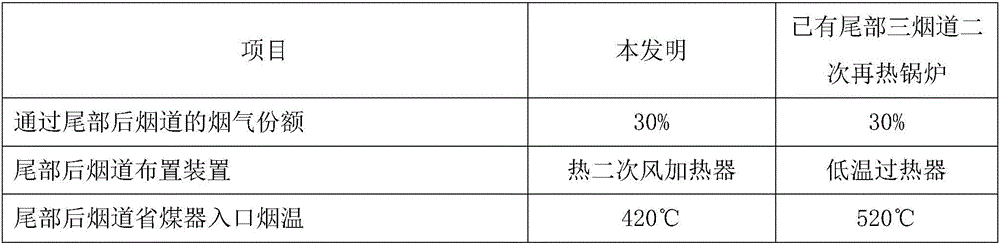

Secondary reheating boiler type with three gas flues arranged at tail part

ActiveCN106247304AImprove efficiencyDecrease in steam temperatureSteam superheatersSteam boilersAir preheaterPower station

The invention discloses a secondary reheating boiler type with three gas flues arranged at a tail part, and belongs to the field of power station boilers. The secondary reheating boiler type with the three gas flues arranged at the tail part comprises a tail part gas flue; the tail part gas flue is divided into a front gas flue, a middle gas flue and a rear gas flue; each of the front gas flue and the middle gas flue is provided with a low-temperature re-heater vertical section, a low-temperature re-heater horizontal section, an economizer and a flue gas adjusting baffle in sequence in a flue gas direction; the rear gas flue is provided with a hot secondary air heater, an economizer and a flue gas adjusting baffle in sequence in the flue gas direction; a hot secondary air outlet of an air pre-heater is communicated with a hot secondary air inlet of the hot secondary air heater; the hot secondary air outlet of the hot secondary air heater is communicated with a hearth. According to the secondary reheating boiler type with the three gas flues arranged at the tail part, the requirements on balancing primary and secondary low resorbent heat, regulating a reheating steam temperature and matching the resistance of the flue gas among the three gas flues are met; the absorbed heat of the economizers is reduced to prevent the economizers from vaporizing; the temperature of exhaust gas is decreased; the boiler efficiency is improved; the coal consumption of a machine set is reduced.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Water leakage heat absorption type pipeline leak detecting method

InactiveCN101281077AReduce heat absorptionShort heating timeFluid-tightness measurement using fluid/vacuumWater leakageEngineering

The invention relates to a leakage detection method for leakage water endothermic type pipelines, comprising power lines arranged in the direction of pipelines, controlled heat source lines, pulse lines and back transmission buses for signals. A heat source body is parallelly arranged on a controlled heat source line at an interval of distance with each heat source body is closely attached to a temperature transmitter and a encoding detection device. leakage water makes the temperature of the vicinity land drop, simultaneously taking away part heat of the heating heat source body, as a result, the time for the temperature transmitter in the section reaching the temperature threshold is longer than that under conditions without water leakage, the water leaking section can be identified by a smart identification recorder through identifying the two different heating-up times mentioned above.

Owner:陈宜中

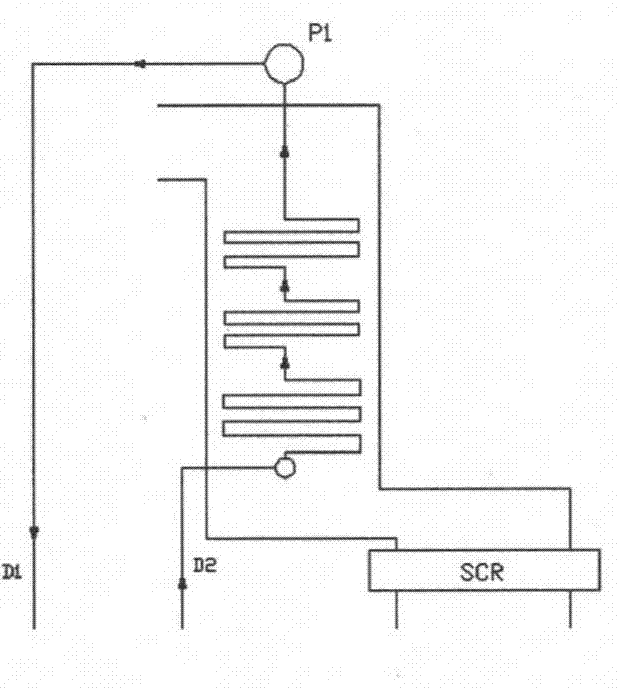

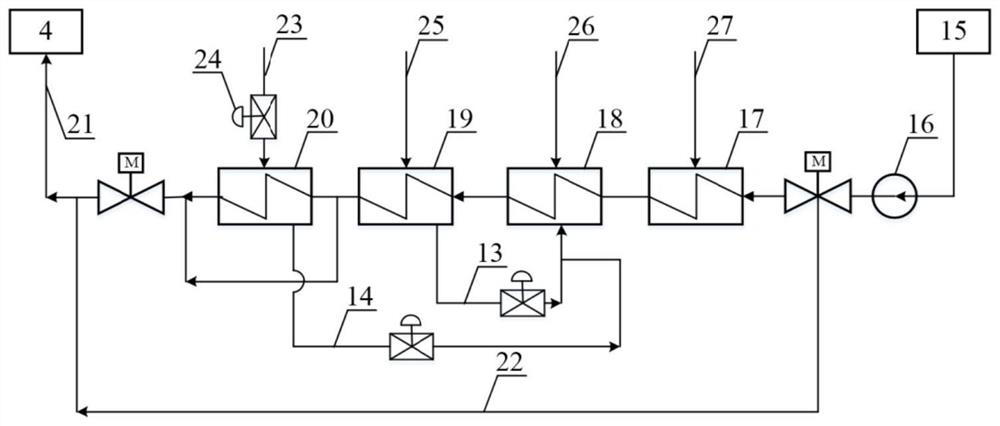

Full-load denitrification system for boiler deep peak load regulation and operation method thereof

PendingCN111649349AIncrease smoke temperatureReduce heat absorptionGas treatmentEmission preventionThermodynamicsFlue gas

The invention discloses a full-load denitrification system for boiler deep peak load regulation and an operation method thereof. The system has a structure that a main flue is sequentially provided with a tail flue shaft steering chamber, a heater and an economizer along the flow direction of flue gas; the inlet of a bypass flue is communicated with the tail flue shaft steering chamber, and the outlet of the bypass flue is set on the flue at the entrance of an SCR reactor; the economizer is connected with a water supply pipe; a No.0 high pressure heater, a No.1 high pressure heater, a No.2 high pressure heater, a No.3 high pressure heater, a water supply pump and a deaerator are provided in sequence on the water supply pipe along the opposite direction of water supply; the No.0 high pressure heater is connected with a No.0 high pressure pump-out pipe, and the No.0 high pressure pump-out pipe is provided with a No.0 high pressure pump-out pipe regulating valve. The system provided by the invention can realize the full-load denitrification of a unit and the regulation of the operating flue gas temperature by controlling the flue gas flow rate of the flue gas bypass and coupling and putting the No.0 high pressure heater into operation.

Owner:STATE GRID SHAANXI ELECTRIC POWER RES INST +2

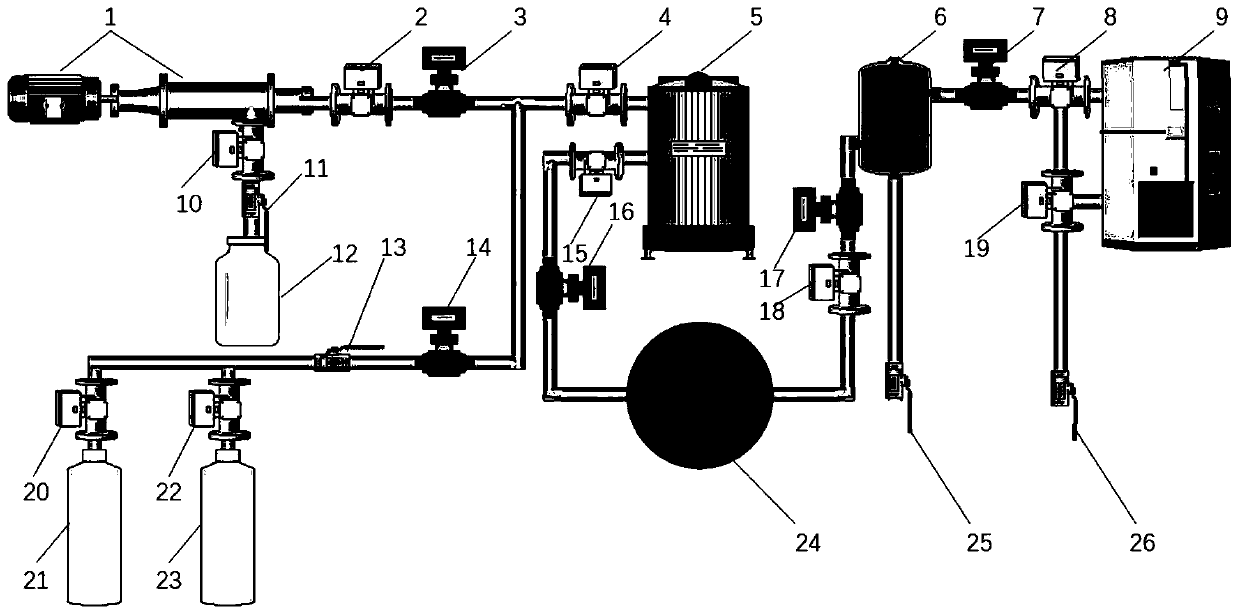

Experiment-type metallic solution cavitation corrosion apparatus

InactiveCN105510210AReduce heat absorptionSimplify the tedious processWeather/light/corrosion resistancePulverizerTransformer

The invention relates to the field of nuclear industry, and especially relates to an experiment-type metallic solution cavitation corrosion apparatus. The experiment-type metallic solution cavitation corrosion apparatus is mainly formed by an ultrasonic cell pulverizer and a vacuum resistance furnace. The ultrasonic cell pulverizer is mainly formed by an ultrasonic amplitude transformer, an energy transducer, a control box and a compression refrigerating machine, ultrasonic power is 3000W, cavitation can be generated in a metallic solution, ultrasonic frequency is 20KHz, amplitude is 50+ / -5% [mu]m, the highest work temperature is 550 DEG C, and operation of the ultrasonic cell pulverizer can be continuously carried out at the temperature of 550 DEG C for 10-15 hours. The vacuum resistance furnace is mainly formed by a control cabinet, a furnace system, a vacuum system and a water cooling system, operation temperature is 400-600 DEG C, a crucible is made of a 304 stainless steel alloy, and a material of the vacuum resistance furnace employs common carbon steel. The apparatus can simulate the condition that cavitation corrosion of nuclear reaction equipment is generated by liquid metal with high speed flow in the field of the nuclear industry, and difficulty of research and experiment in the field of the nuclear industry can be solved, and the apparatus provides powerful guarantee for scientific research.

Owner:JIANGSU UNIV

Thermochemical hydrogen production reaction performance evaluation system and thermochemical hydrogen production reaction performance evaluation method based on solar light-concentrating simulator

ActiveCN110407171AApplicable temperature rangeReduce heat absorptionHydrogenComponent separationEvaporatorXenon lamp

The invention relates to a thermochemical hydrogen production reaction performance evaluation system and a thermochemical hydrogen production reaction performance evaluation method based on a solar light-concentrating simulator. The system comprises a raw material input part, an evaporator / pre-heater, a micro multi-channel reactor, a condenser, a chromatograph, a flow pipeline system and a solar light-concentrating simulator, wherein the raw material input part comprises a liquid input part and a gas input part, the liquid input part and the gas input part are converged before the evaporator / pre-heater, the evaporator / pre-heater is a large chamber tank performing heating through electricity or solar energy, and is provided with a spraying device inside, the pre-heater simultaneously performs primary heating on a gas, the micro multi-channel reactor is connected to the evaporator / pre-heater and the condenser through pipelines, the chromatograph is used for detecting the components of the generated mixed gas, and the solar light-concentrating simulator comprises a high-power xenon lamp light source and an elliptical high-reflectivity reflection cover.

Owner:恒基能脉新能源科技有限公司

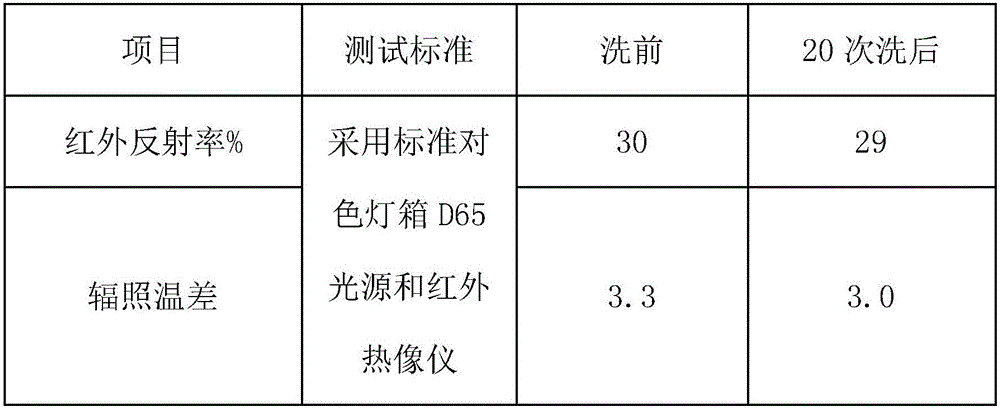

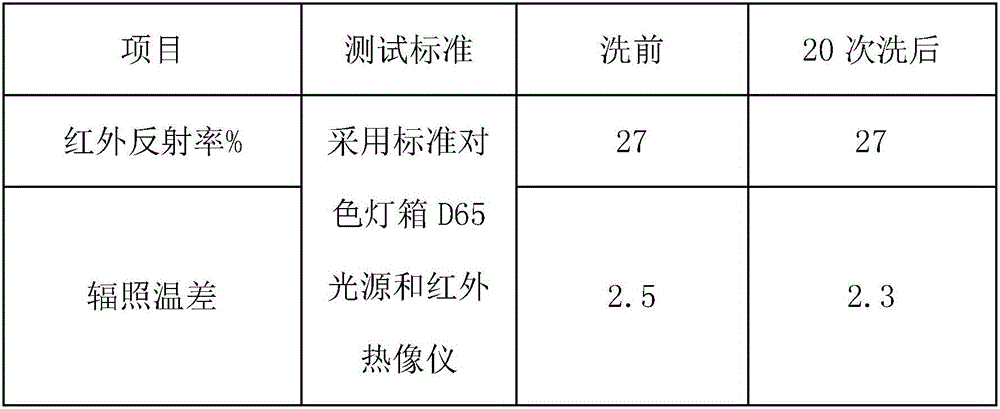

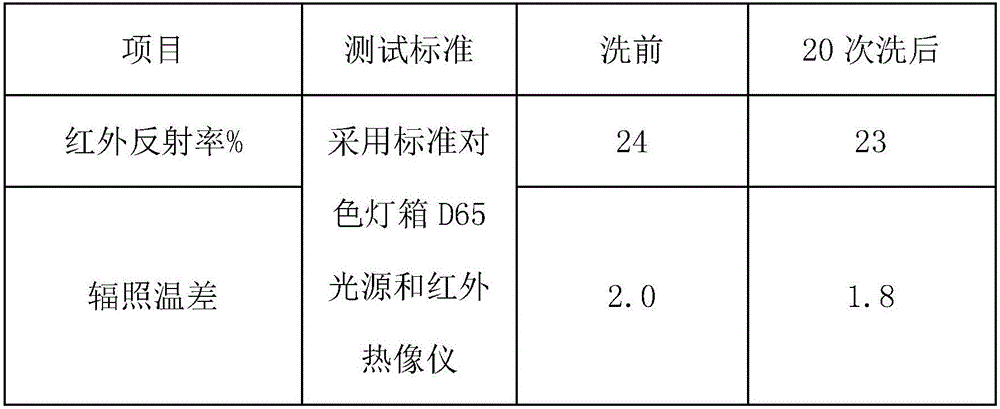

Heat-reflection fabric and application thereof to clothes

InactiveCN106637454AReduce heat absorptionWith heat reflection functionMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentYarnPolymer science

The invention discloses a heat-reflection fabric which is formed by adopting and weaving yarn with a heat-reflection function. The yarn is prepared by adding 300 PPM-1000PPM heat-reflection particles during spinning; the heat-reflection particles are the mixture of nanoscale titanium dioxide, aluminum oxide, zinc oxide and indium tin oxide, wherein the content of the nanoscale titanium dioxide is 40%-80%, the content of the aluminum oxide is 0%-30%, the content of the zinc oxide is 0%-30% and the content of the indium tin oxide is 0%-30%. Y-type, V-type or W-type terylene-based, nylon-based or polypropylene-based yarn with the branch angle larger than 85 degrees is adopted and woven to form a knitted fabric or a woven fabric. When the fabric is used for summer clothes, the yarn used on an outer layer of the fabric can reflect sunlight, reduce heat absorbed by the fabric, and play a role of reflecting a cool feeling; when the fabric is used for winter clothes, the yarn used on an inner layer of the fabric or used as a lining material can reflect far infrared rays emitted by a human body, and play a role of keeping warm.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

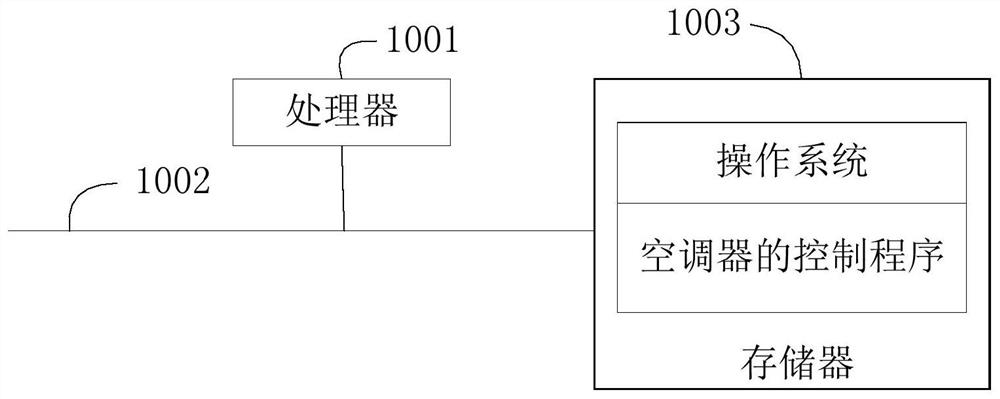

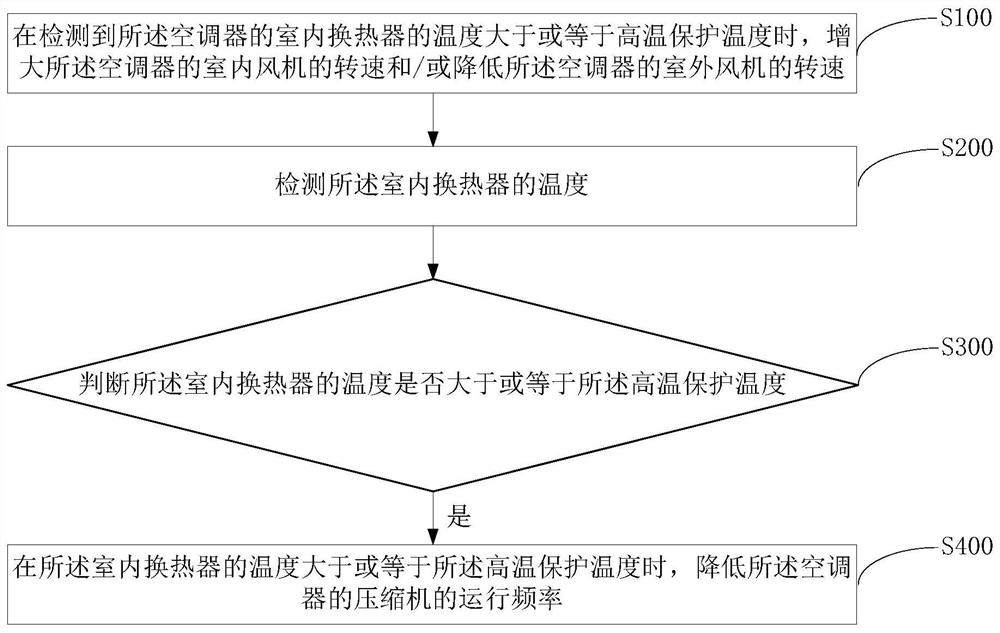

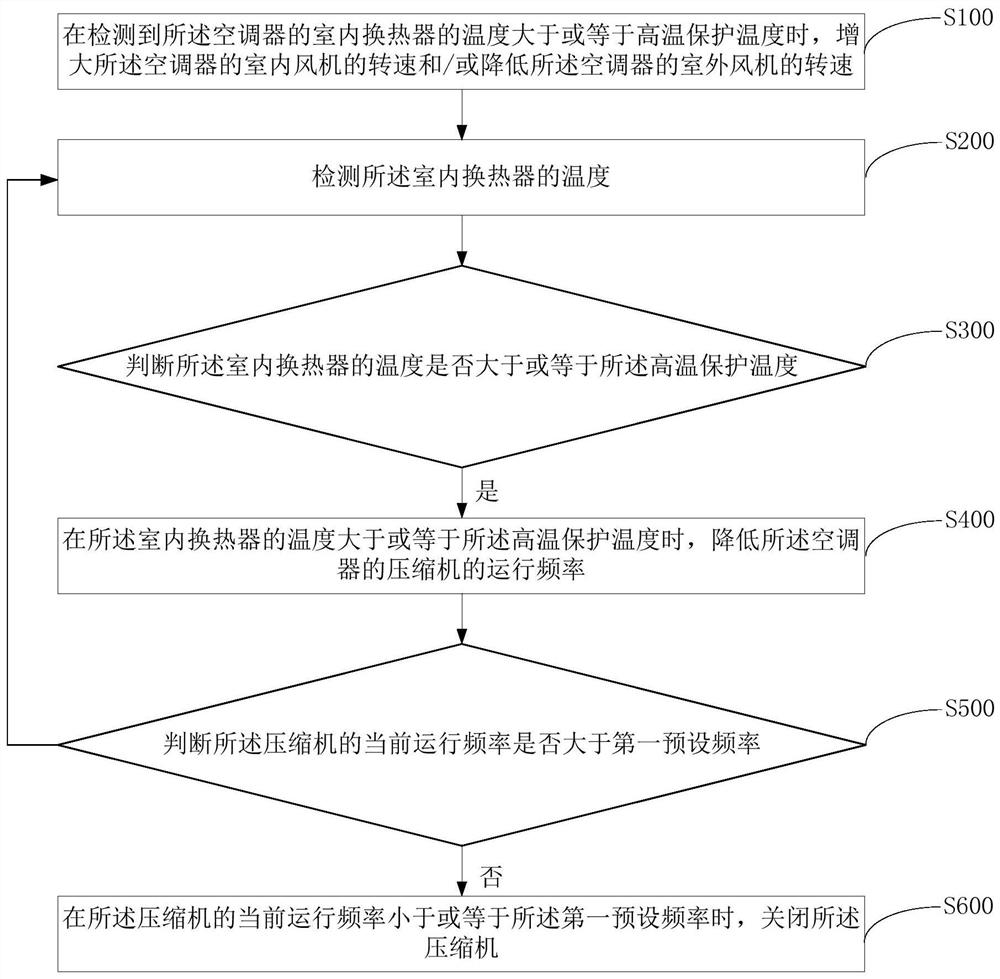

Control method of air conditioner, air conditioner and storage medium

ActiveCN111706974AReduce operating frequencyIncrease speedMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention discloses a control method of an air conditioner. The control method comprises the following steps that when it is detected that the temperature of an indoor heat exchanger of the air conditioner is greater than or equal to a high-temperature protection temperature, the rotating speed of an indoor fan of the air conditioner is increased and / or the rotating speed of an outdoor fan ofthe air conditioner is decreased; the temperature of the indoor heat exchanger is detected; whether the temperature of the indoor heat exchanger is greater than or equal to the high-temperature protection temperature or not is judged; and when the temperature of the indoor heat exchanger is larger than or equal to the high-temperature protection temperature, the operation frequency of a compressorof the air conditioner is reduced. The invention further discloses the air conditioner and a storage medium. Heat dissipation of the indoor heat exchanger is increased, and heat absorption of the outdoor heat exchanger and / or heating of the compressor are / is reduced, so that the temperature of a refrigerant is gradually reduced, the restarting frequency of the compressor is reduced, and meanwhilethe beneficial effect of well maintaining the stability of the indoor environment temperature can be well achieved.

Owner:MIDEA GRP WUHAN HEATING & VENTILATING EQUIP CO LTD +1

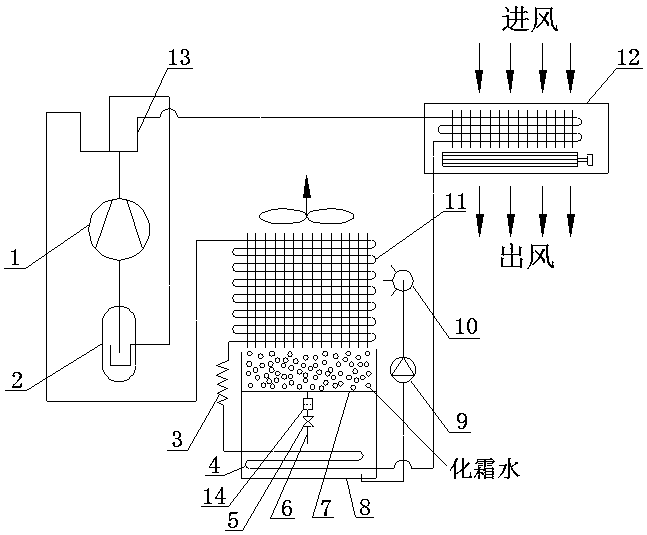

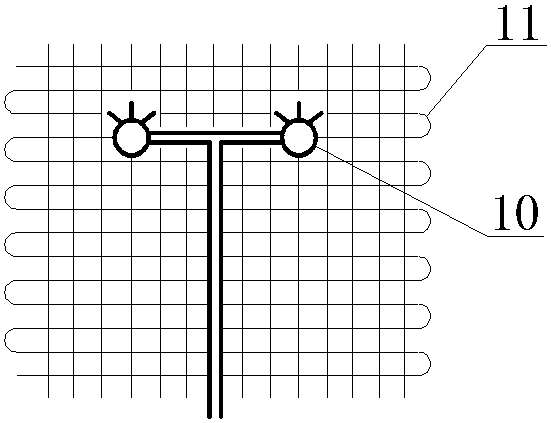

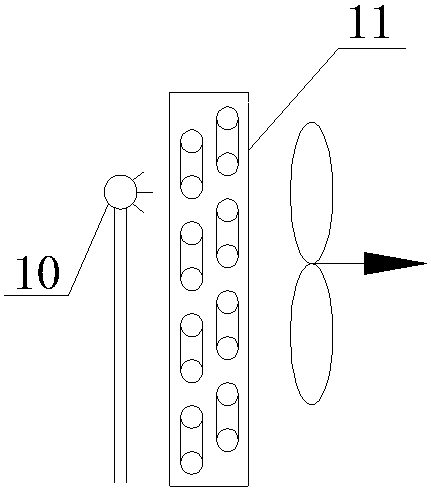

Heat pump air conditioner provided with thermal storage defrosting humidification device based on existing defrosting water

InactiveCN108361883AImprove cooling efficiencyLower condensation temperatureCondensate preventionLighting and heating apparatusFrostThermal energy storage

The invention provides a heat pump air conditioner provided with a thermal storage defrosting humidification device based on existing defrosting water. The air conditioner comprises an air conditioning device and is characterized in that the air conditioner further comprises the thermal storage defrosting humidification device, the thermal storage defrosting humidification device is arranged belowan outdoor heat exchanger of the air conditioning device, a water collecting port of the thermal storage defrosting humidification device is located below the outdoor heat exchanger, a water outlet of the thermal storage defrosting humidification device is located on the side surface of the outdoor heat exchanger, one end of the thermal storage defrosting humidification device communicates with acapillary tube of the air conditioning device, and the other end of the thermal storage defrosting humidification device communicates with an indoor heat exchanger of the air conditioning device. According to the heat pump air conditioner, defrosting water is utilized for storing excessive heat of a unit during heat supply in winter, during defrosting, the high-temperature defrosting water is sprayed to a frost layer for defrosting firstly and then used as the low-temperature heat source of the unit so as to evaporate retained defrosting water to dryness or to perform deicing, and meanwhile,excessive defrosting water can also be used for indoor humidification; and during refrigerating in summer, generated condensate water is used for indoor humidification or used as part of the cold source. According to the heat pump air conditioner, the defrosting time is short, no indoor heat is sucked away, a humidification function is also achieved, and wasting caused by discharging of the largeamount of defrosting water and condensate water is avoided.

Owner:NORTHEAST DIANLI UNIVERSITY

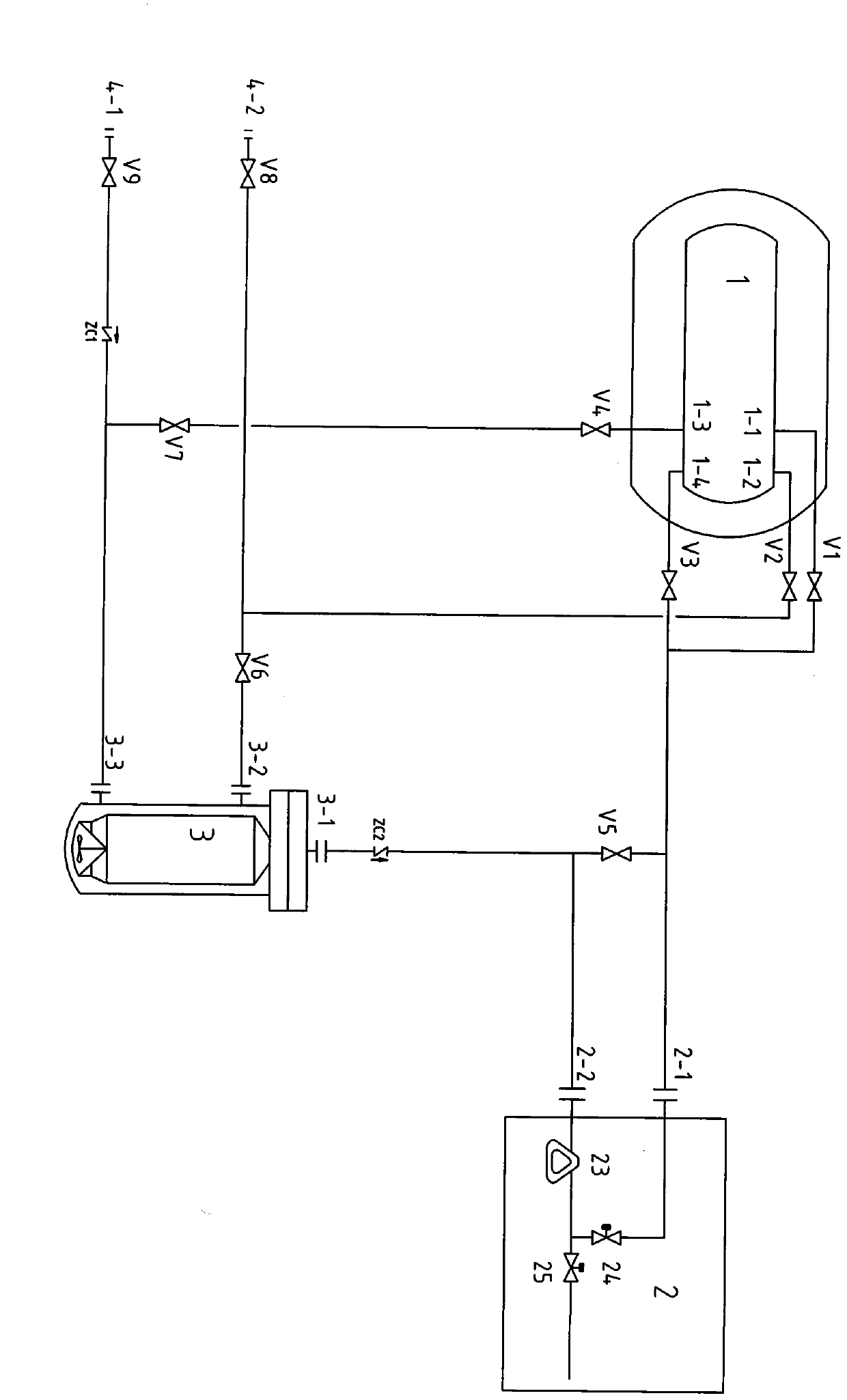

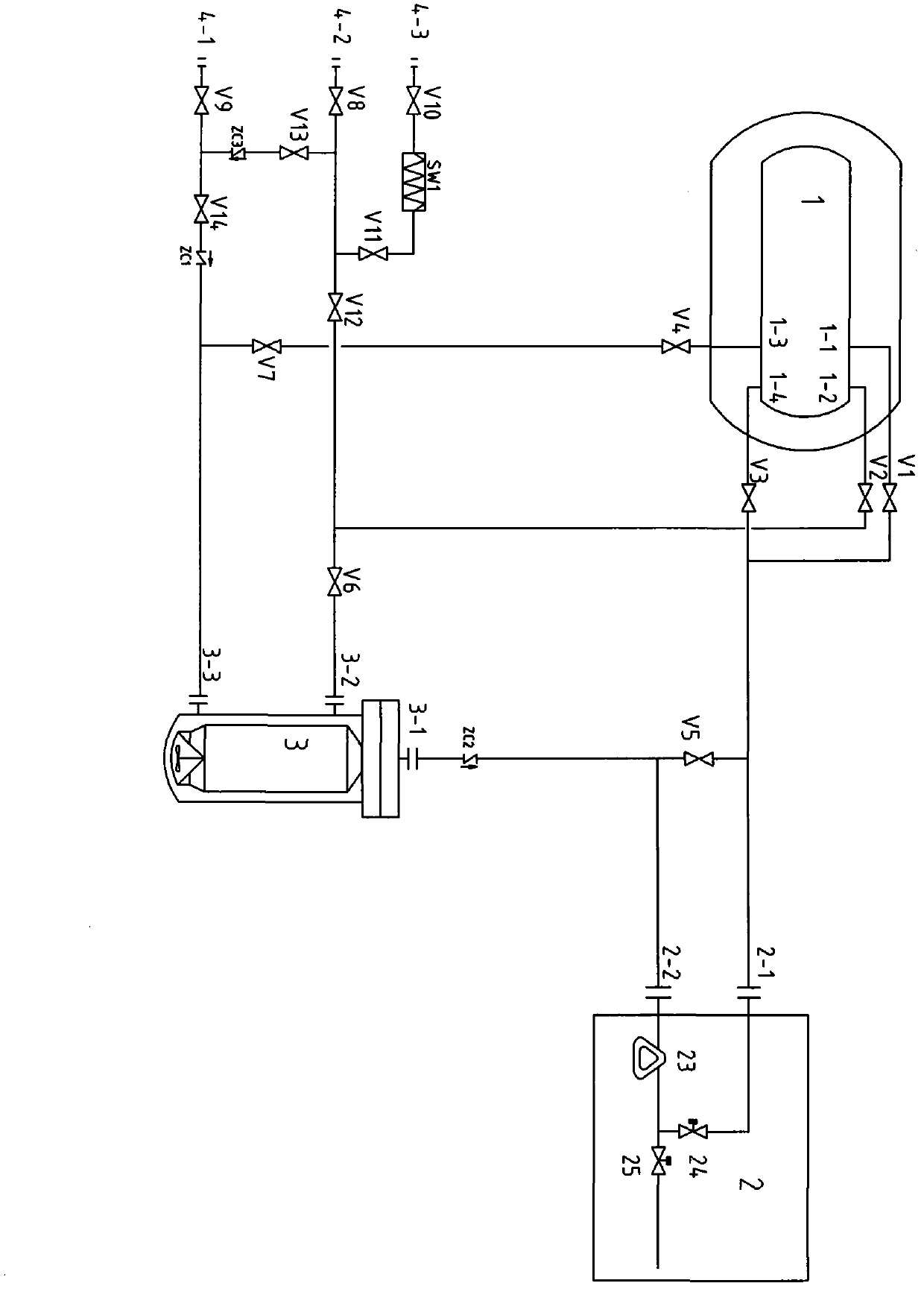

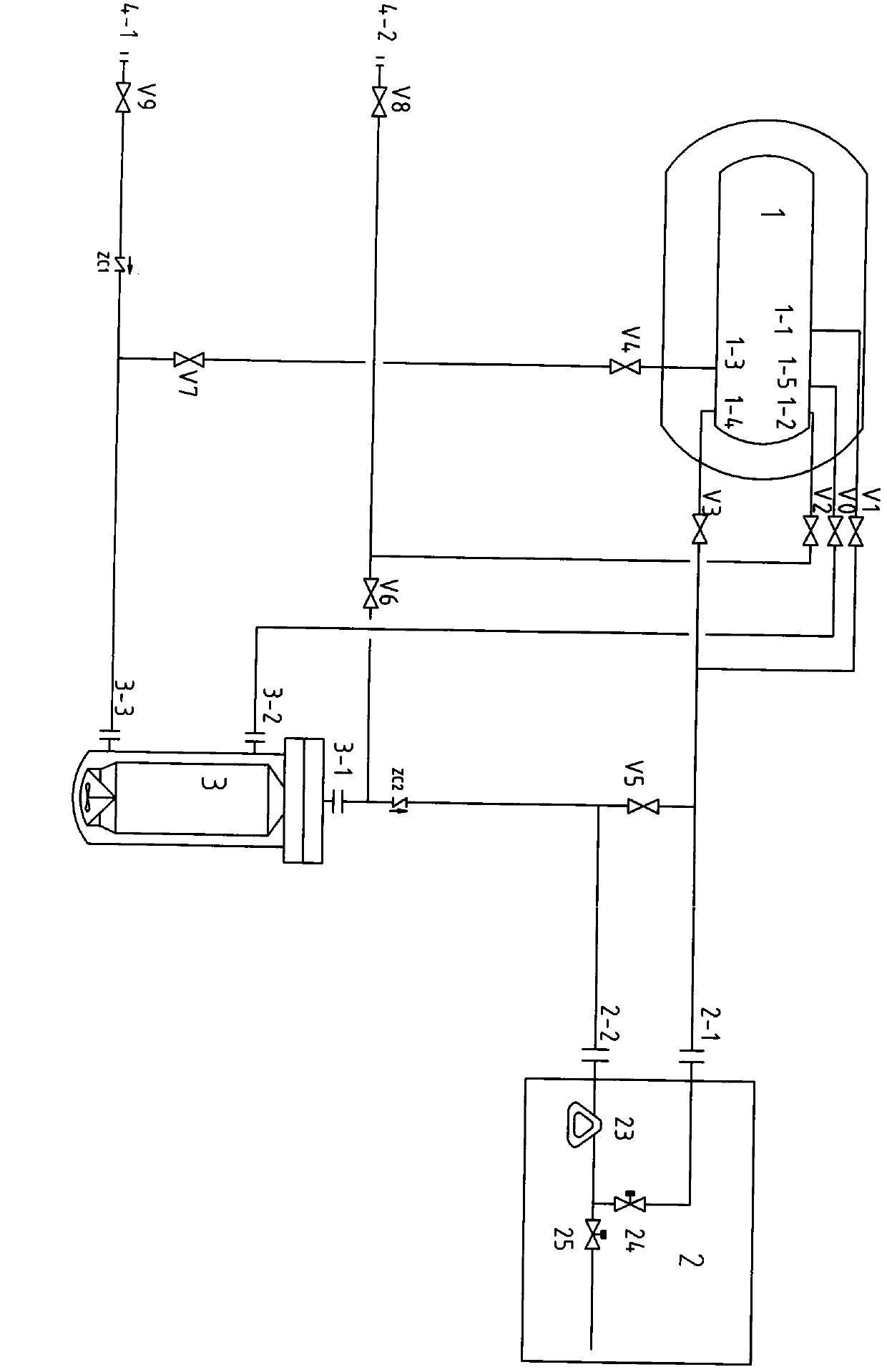

Liquefied natural gas station

ActiveCN102606883AReduce emissions and wasteSimple processPipeline systemsContainer filling under pressureGas phaseEngineering

A liquefied natural gas station comprises a storage tank, a pump, a gas dispenser, an electric control system, valves and pipelines, and is characterized in that an unloading liquid-phase opening, a liquid inlet of the pump and a liquid outlet at the bottom of the storage tank are connected by the valves and the pipelines, an unloading gas-phase opening, a gas return opening of the pump and a gas-phase opening on the upper portion of the storage tank are connected by the valves and the pipelines, after a liquid inlet and a liquid return opening of the gas dispenser are connected in parallel by a pipeline and a valve to form a parallel connection circuit, one end of the parallel connection circuit is connected with an upper liquid inlet and a lower liquid inlet of the storage tank in parallel by pipelines, and the other end of the parallel connection circuit is connected with a liquid outlet of the pump by a valve and a pipeline. Alternatively, the unloading liquid-phase opening, the liquid inlet of the pump and the liquid outlet at the bottom of the storage tank are connected by the valves and the pipelines, the unloading gas-phase opening, a liquid outlet of the pump and the gas-phase opening of the upper portion of the storage tank are connected by the valves and the pipelines, the gas-phase opening of the storage tank is directly connected with the gas return opening by a valve and a pipeline, after the liquid inlet and the liquid return opening of the gas dispenser are connected in parallel by pipelines and a valve to form a parallel connection circuit, one end of the parallel connection circuit is connected with the upper liquid inlet and the lower liquid inlet of the storage tank in parallel by pipelines, and the other end of the parallel connection circuit is connected with the liquid outlet of the pump by a valve and a pipeline.

Owner:沈军

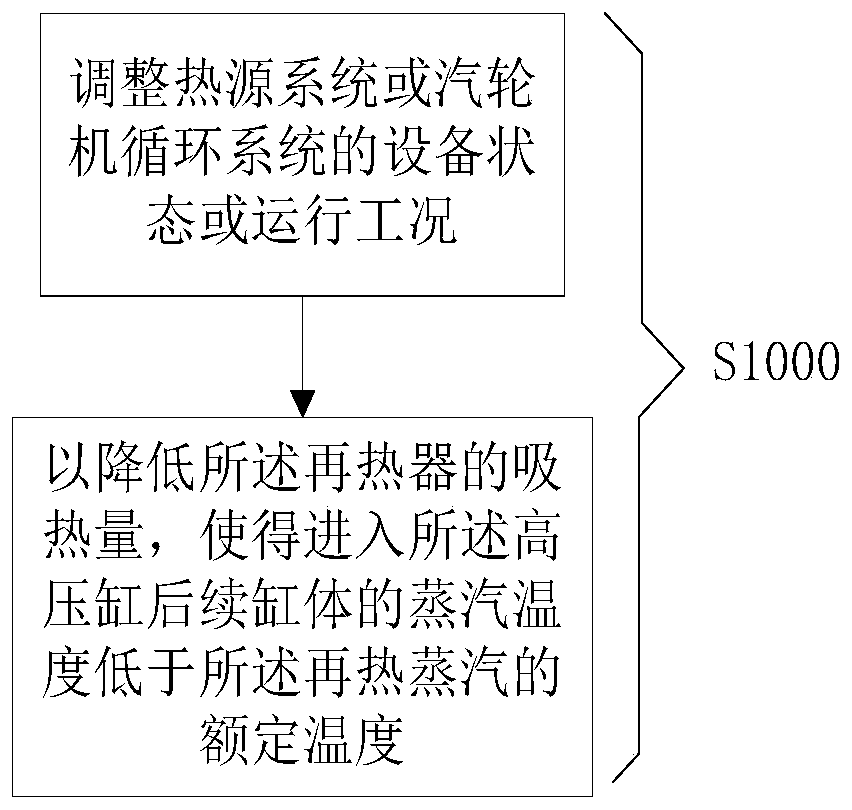

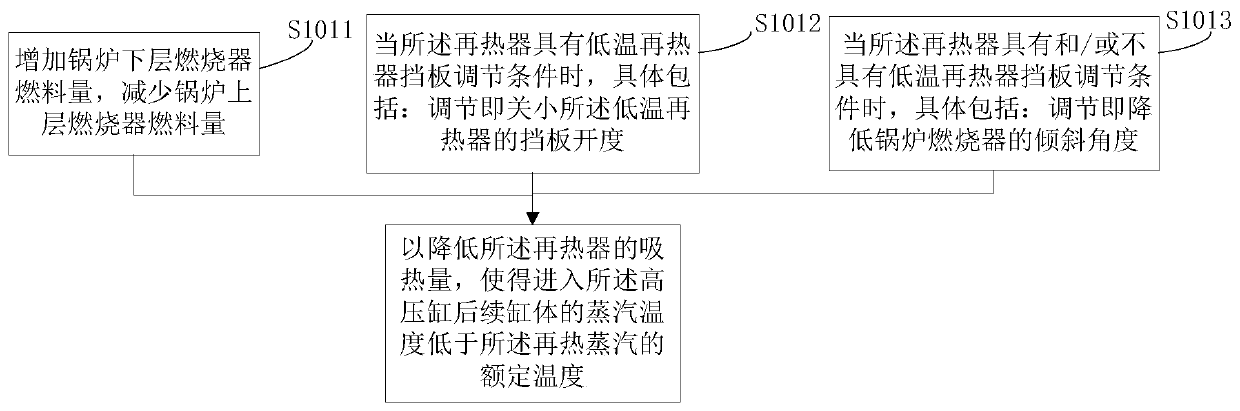

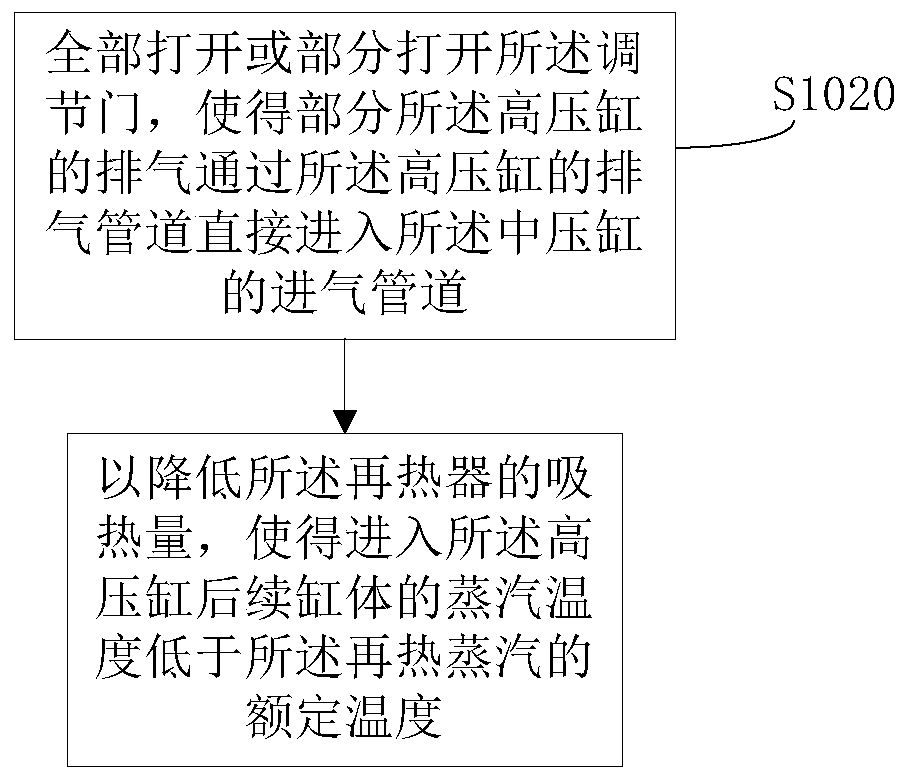

Method for improving efficiency of large-scale steam turbine power generation system

ActiveCN110284932AReduce heat absorptionLower steam temperatureSteam engine plantsNuclear powerEconomizer

The invention relates to a method for improving the efficiency of a large-scale steam turbine power generation system. The method comprises the steps of reducing or canceling a reheating steam system, and a canceled reheater is replaced with a new coal economizer, so that the efficiency of a steam turbine is improved. According to the method, the coal-fired power generation efficiency is improved, and the operation state of a denitration system is improved. For a system with steam extraction regeneration, the efficiency of the generator set can be further improved by reducing the temperature of the main steam and increasing the humidity of the main steam. According to the method, the efficiency of a fossil fuel generating set can be increased by 5%-20%, and the emission level of the greenhouse gas can be reduced. The method is also suitable for a nuclear power unit, a combined cycle unit and a solar photo-thermal unit, and has important significance in improving the power generation efficiency of the steam turbine and reducing the emission of greenhouse gas.

Owner:北京互嘉联盟科技中心(有限合伙)

Preparation method of microenvironment conditioned paper of museum

InactiveCN101624801AFast phase transition temperatureFast heat absorptionSpecial paperPaper/cardboardPolyethylene glycolPollution

The invention relates to a preparation method of microenvironment conditioned paper of a museum, which is characterized by comprising the following steps: (A) adding sepiolite, decalso, isinglass and urea into deionized water, stirring and reacting for 4-6h at 50-60 DEG C; (B) adding cyclic acid, polyethylene glycol, ammonium persulfate and the deionized water into reactant of the (A), stirring and reacting for 3-5h at 50-60 DEG C; (C) cooling mixture obtained by the (B) to be room temperature, drying to obtain temperature and humidity adjustment material; (D) adding the temperature and humidity adjustment material and magnesium sulfate into paper pulp for manufacturing paper to prepare the microenvironment conditioned paper of the museum. Compared with the conditioned paper, the invention has rapid humidity adjustment response, low material phase-transition temperature, high humidity content, rapid heat absorption, good balance of humidity maintenance, simple and convenient manufacture, low cost, good effect, no toxicity, harm or pollution to the environment, and the like, and accords with the trend of the environment protection development.

Owner:ZHEJIANG SCI-TECH UNIV +1

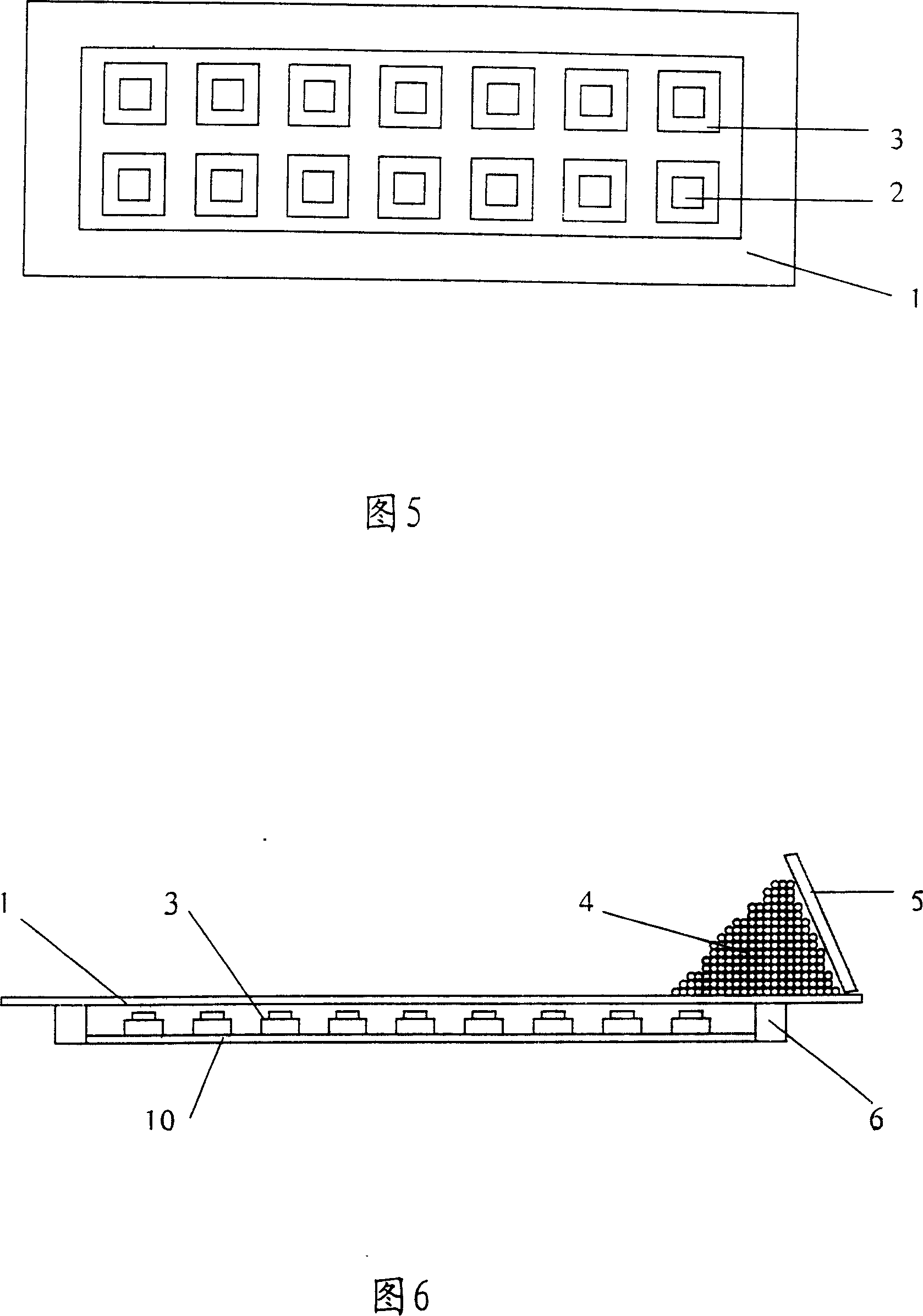

Multifunctional reflow jig for FPC lamp bar

ActiveCN106180956ANo soldering requiredEasy to usePrinted circuit assemblingWelding/cutting auxillary devicesReusabilityDie casting

The invention discloses a multifunctional reflow jig for an FPC lamp bar, and solves the technical problems that the influence of an existing jig for an FPC lamp bar on the temperature of a reflow welding furnace is excessive, and a steel cover piece and a magnetic structure of the jig both need welding, and have poor reusability. The following technical scheme is adopted: the multifunctional reflow jig for the FPC lamp bar comprises a carrying disc formed from a synthetic stone material in a die-casting manner, a location base matched and clamped with the carrying disc to form one piece and formed from an aluminium alloy material in a die-casting manner, a magnet embedded on the location base, and a steel cover piece closely attracted through the magnet, used for sealing the carrying disc on the location base and formed from a steel material in a die-casting manner. The multifunctional reflow jig has the following advantages: heat absorption influence is reduced through using the carrying disc formed from the synthetic stone material and a reflow fixing fixture, clip connection is used in the structure for many times, and a lighting fixture is designed, thus an assembly process is greatly simplified, and the production efficiency is increased.

Owner:NANJING CHINA ELECTRONICS PANDA LIGHTING

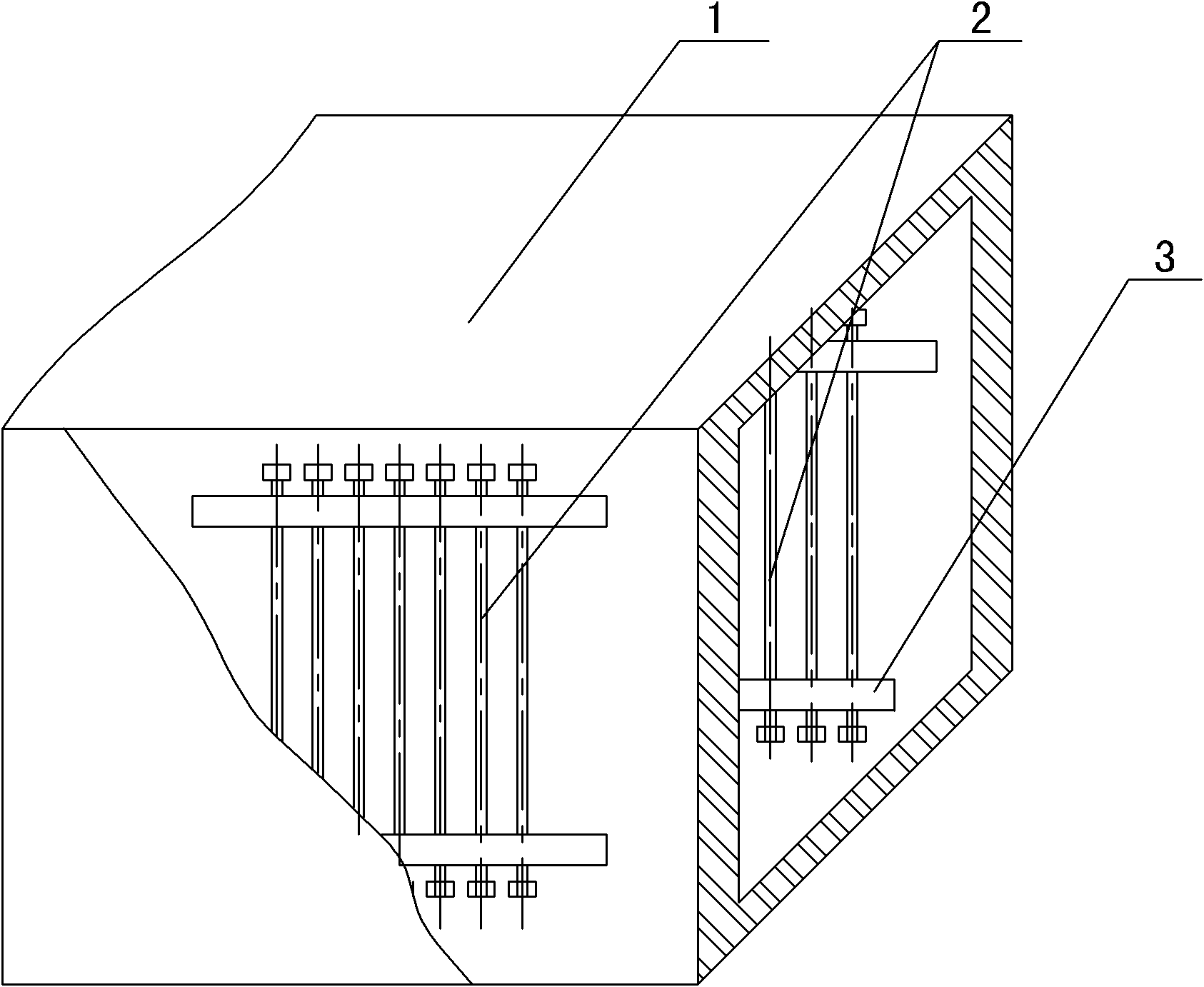

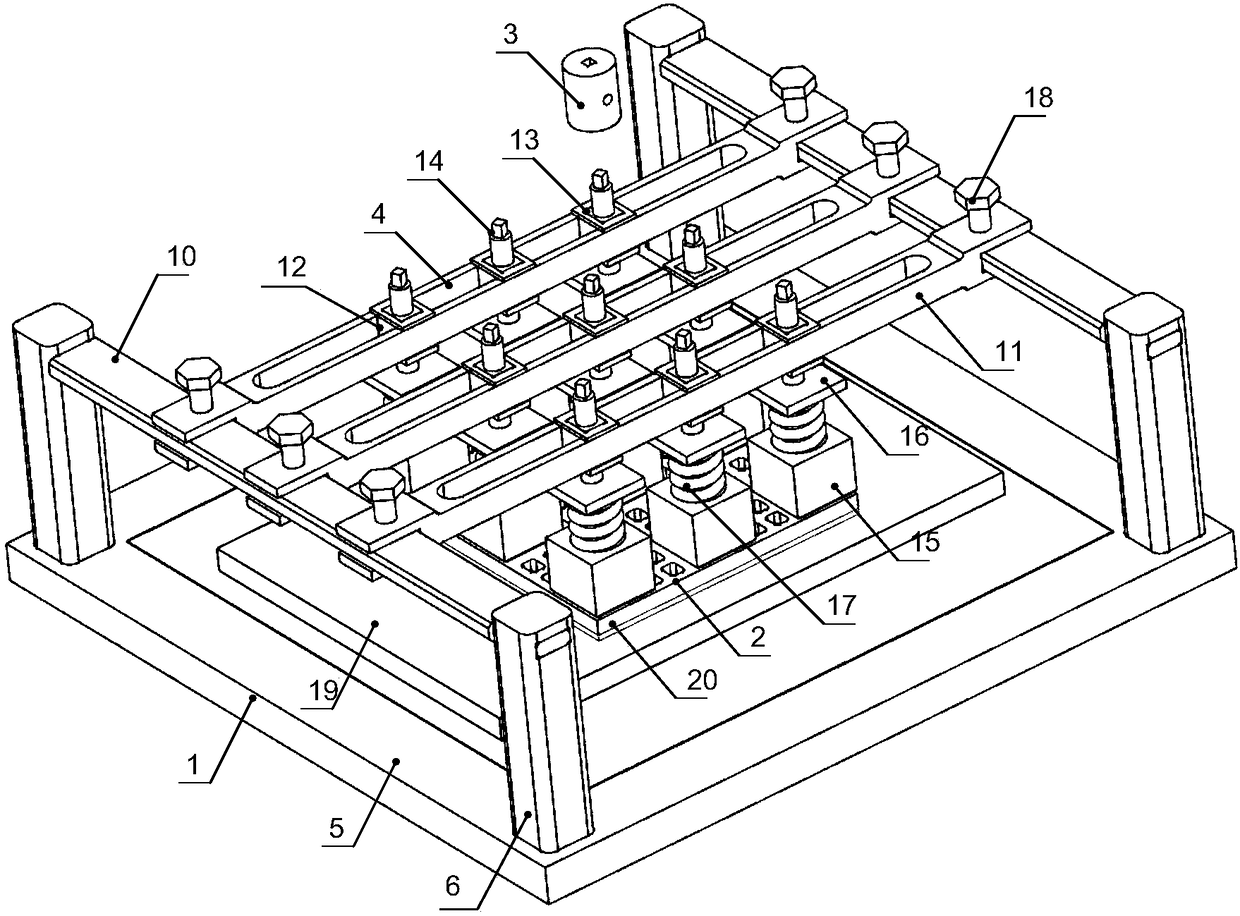

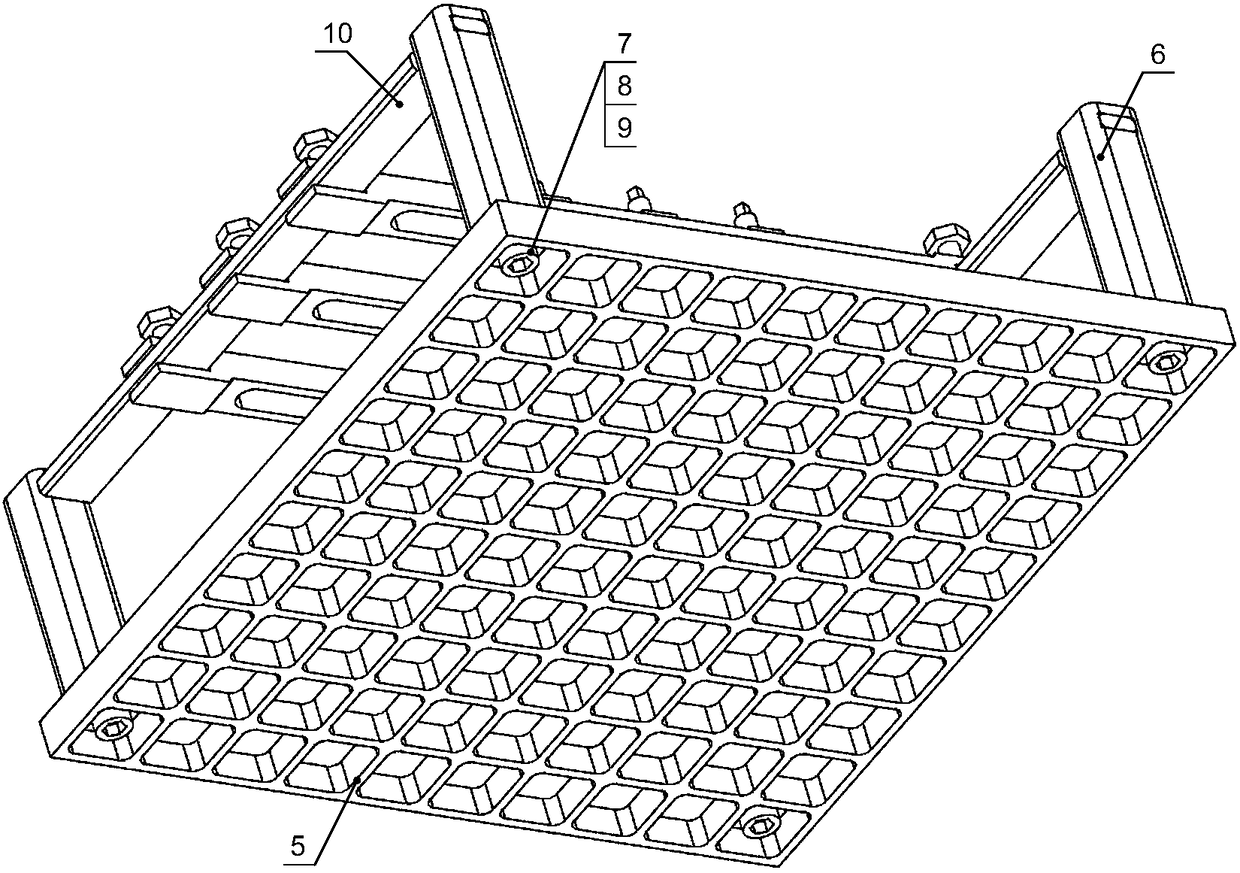

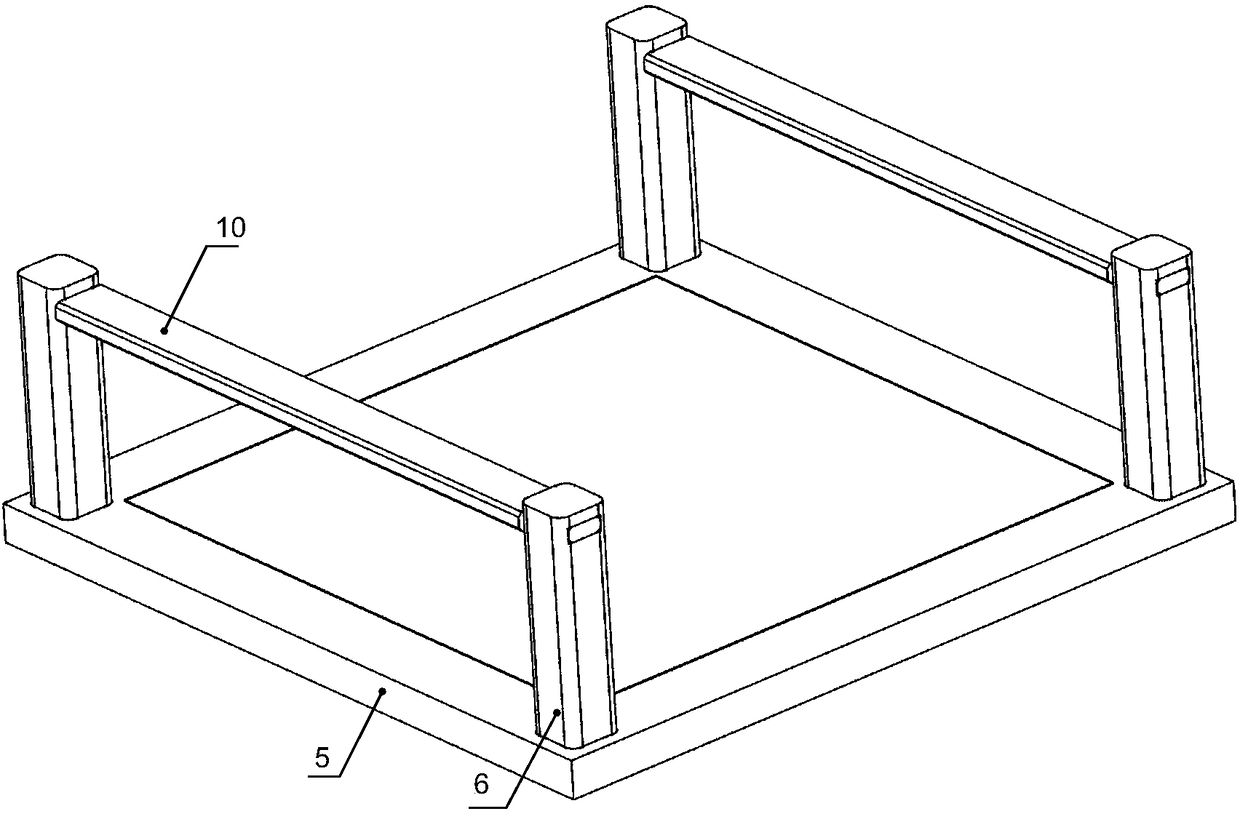

Pressure resisting airtight cold plate vacuum brazing universal tool

ActiveCN108067701AEnough pressureEnsure pressurization failure phenomenonWelding/cutting auxillary devicesAuxillary welding devicesCold plateWelding deformation

The invention relates to a pressure resisting airtight cold plate vacuum brazing universal tool. The universal tool comprises a mother-son plate and a base plate with the back face provided with square grooves, wherein the mother-son plate is provided with square grooves arranged in a matrix manner. A cold plate is placed on the front face of the base plate, the mother-son plate is located on theother face of the cold plate, and the universal tool is used for pressing the cold plate by pressing the mother-son plate. The device can provide enough pressure in the pressure resisting airtight cold plate welding process, effective pressurizing is achieved, component deformation is corrected, and the welding gap and welding deformation of the cold plate are controlled; the welding quality, an inner runner and boundary dimension precision of the cold plate are guaranteed; and the base plate, the mother-son plate and the other components are provided with square groove structures, radiation heat absorbing and heat releasing of products in a vacuum braking furnace are facilitated, and the brazing efficiency is improved.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com