Magnetized plasma artillery

A technology of plasma and artillery, applied in barrels and other directions, can solve the problems of complex manufacturing process of composite material barrels, difficult promotion and use, long production cycle, etc., and achieve the effects of increasing thrust, prolonging life, and reducing thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

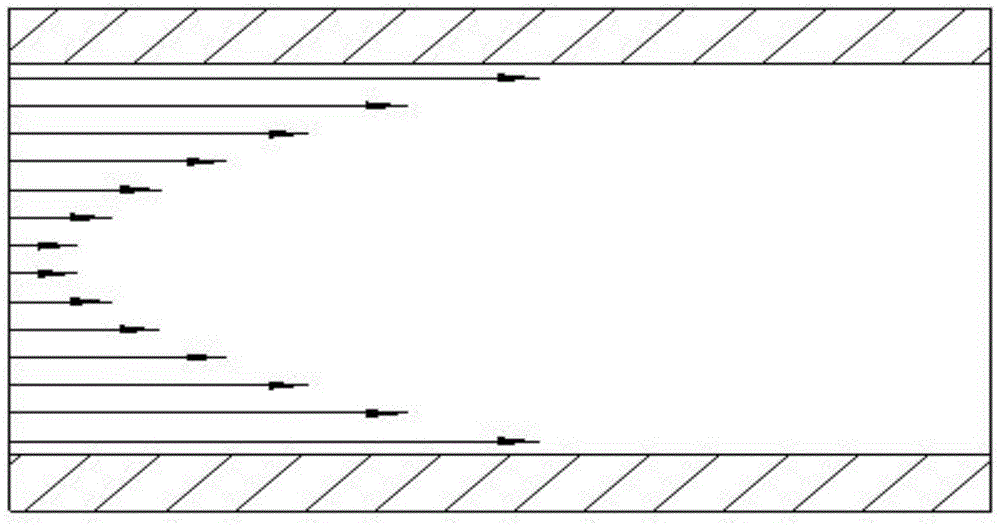

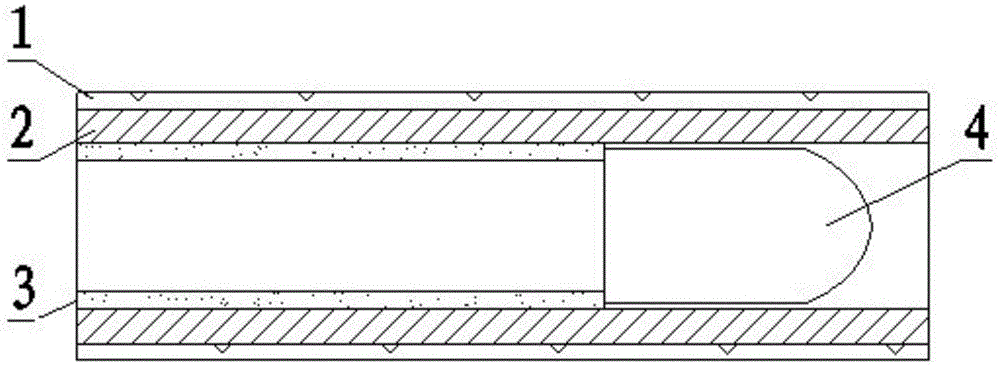

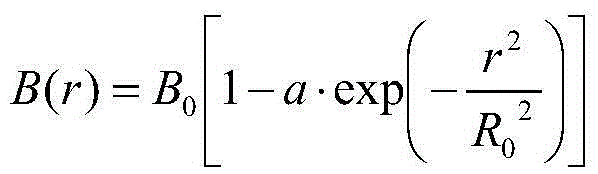

[0022] Such as figure 1 , figure 2 As shown, the present invention provides a magnetized plasma cannon, a magnetic field is provided inside the barrel. The direction of the magnetic field is along the axis of the barrel, pointing to the muzzle, and the magnetic field strength is attenuated from the inner wall of the barrel to the axis of the barrel. When the magnetized plasma cannon of the present invention is launched, the gas in the barrel can be ionized into plasma under the action of the magnetic field, and a magnetized plasma sheath is formed on the inner wall of the barrel.

[0023] Since the magnetized plasma sheath exhibits pressure anisotropy and has a heat insulation effect, the radial force on the gun barrel can be greatly reduced, and the driving force of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com