Patents

Literature

470results about "Barrels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

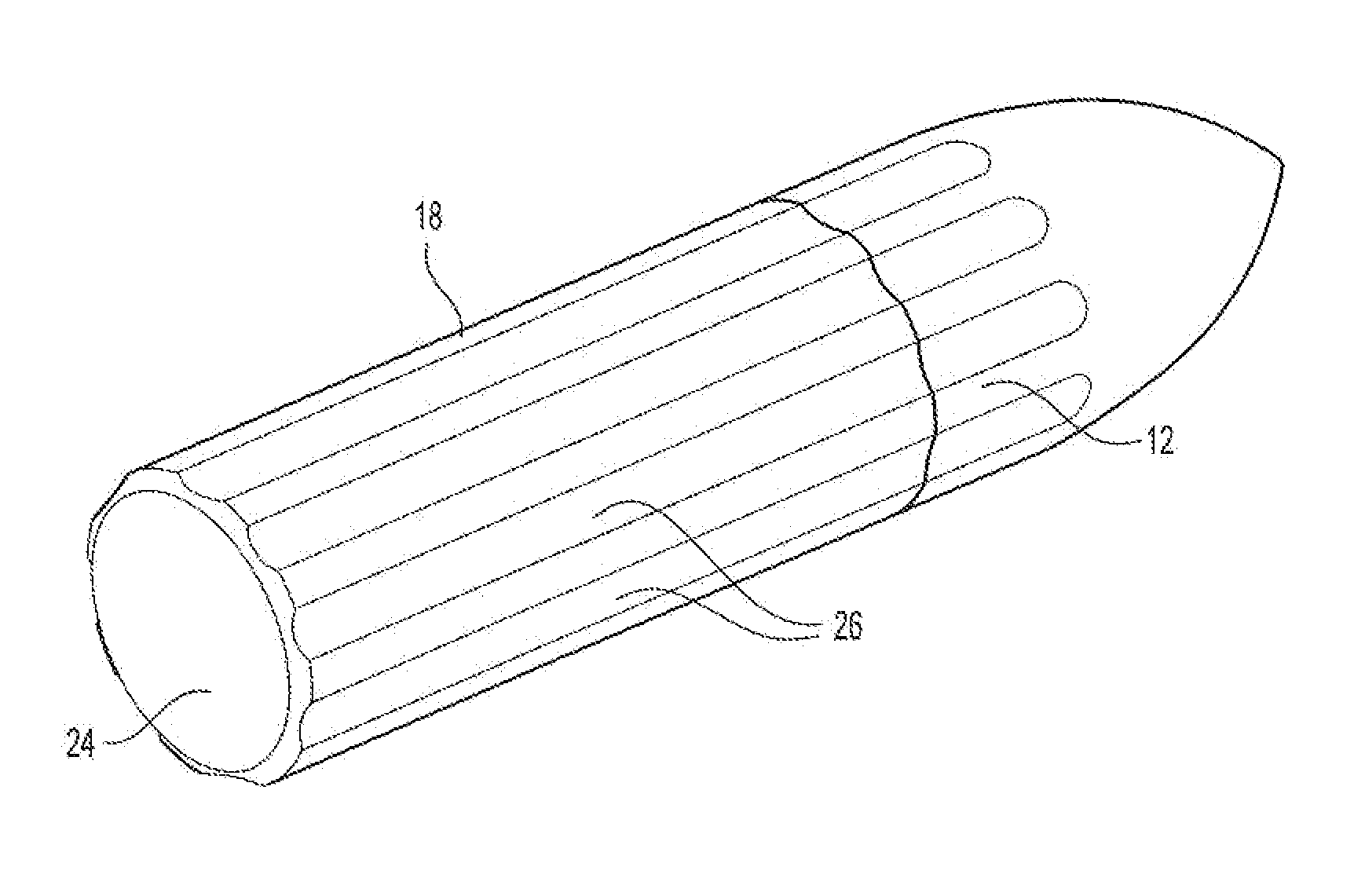

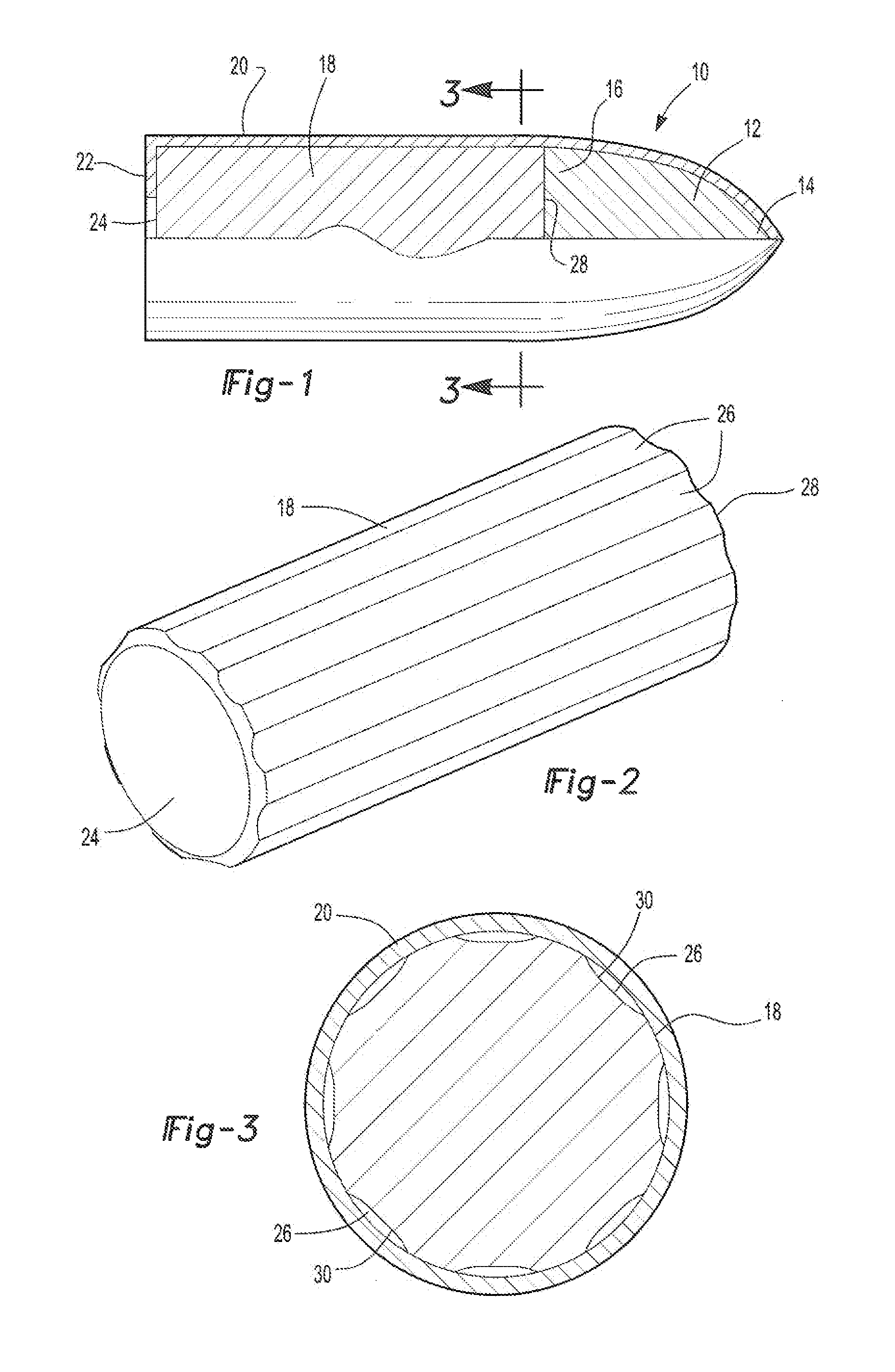

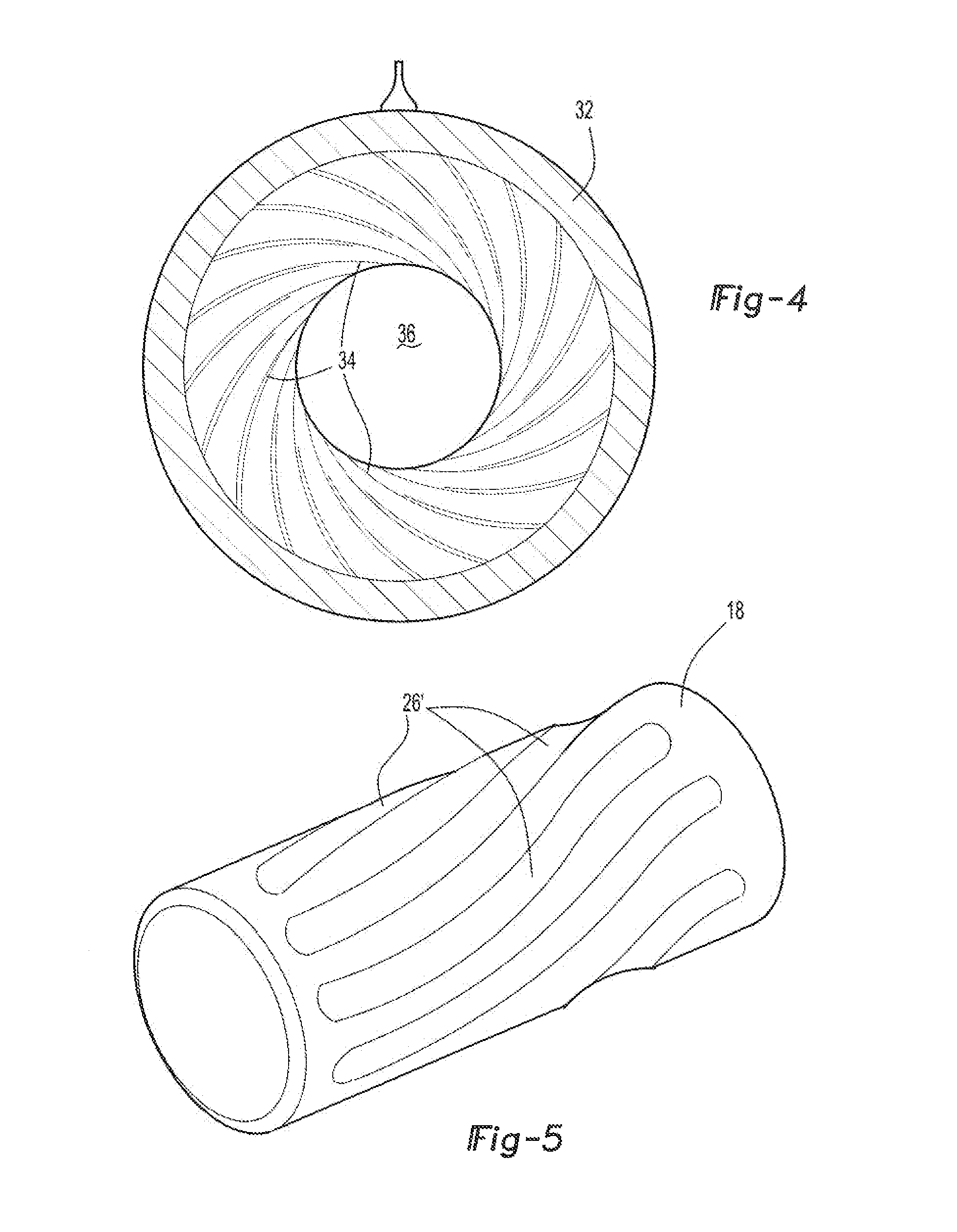

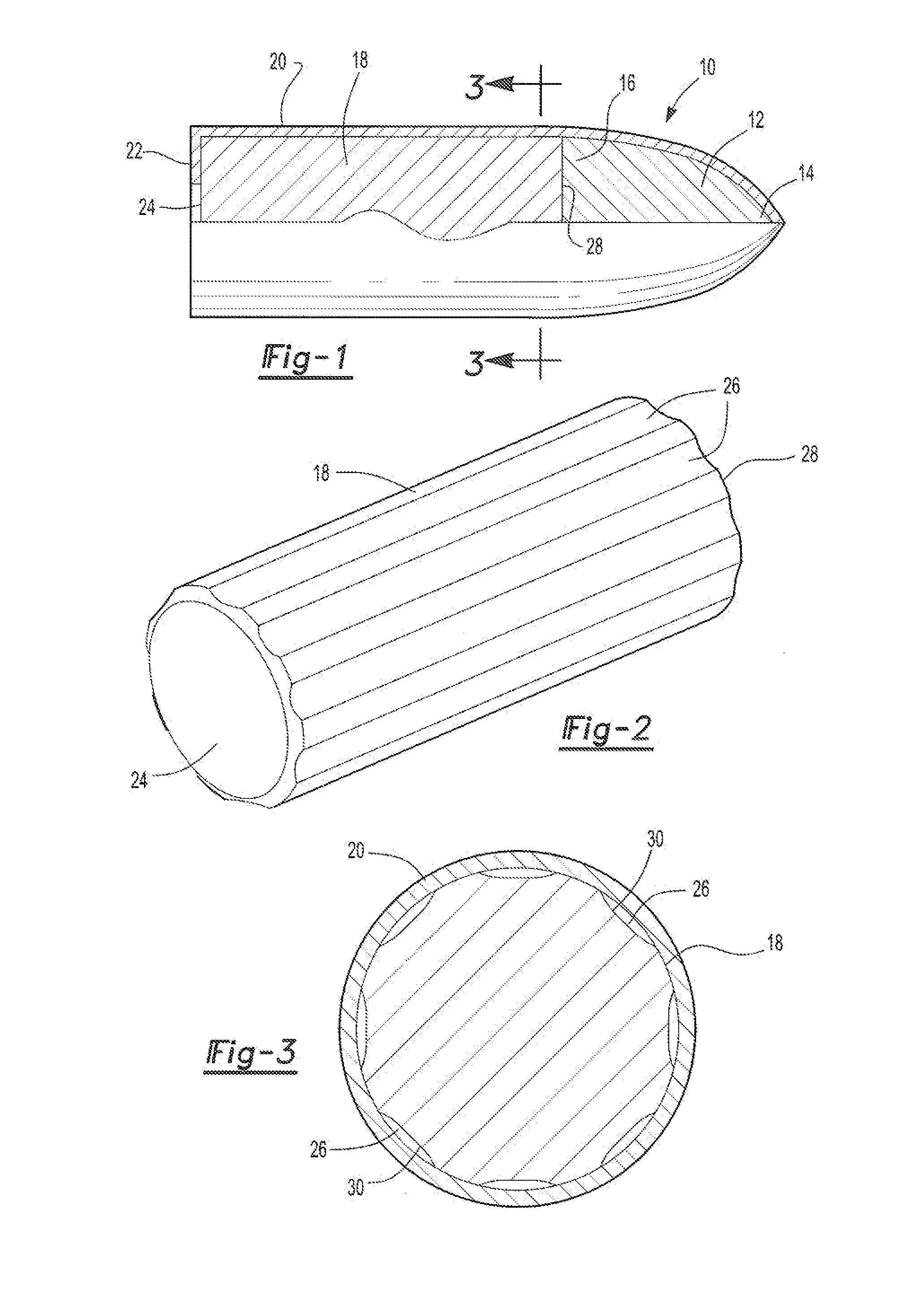

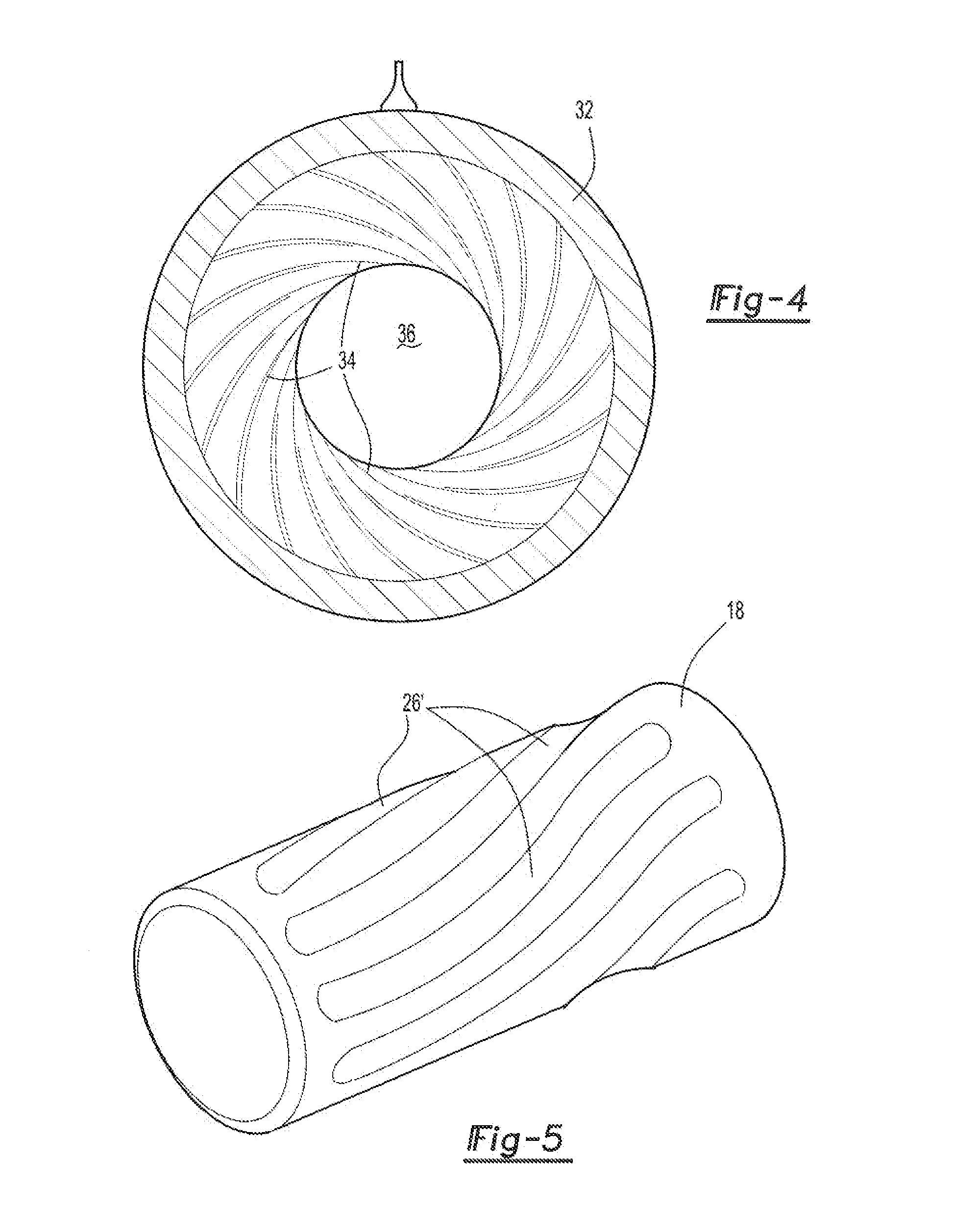

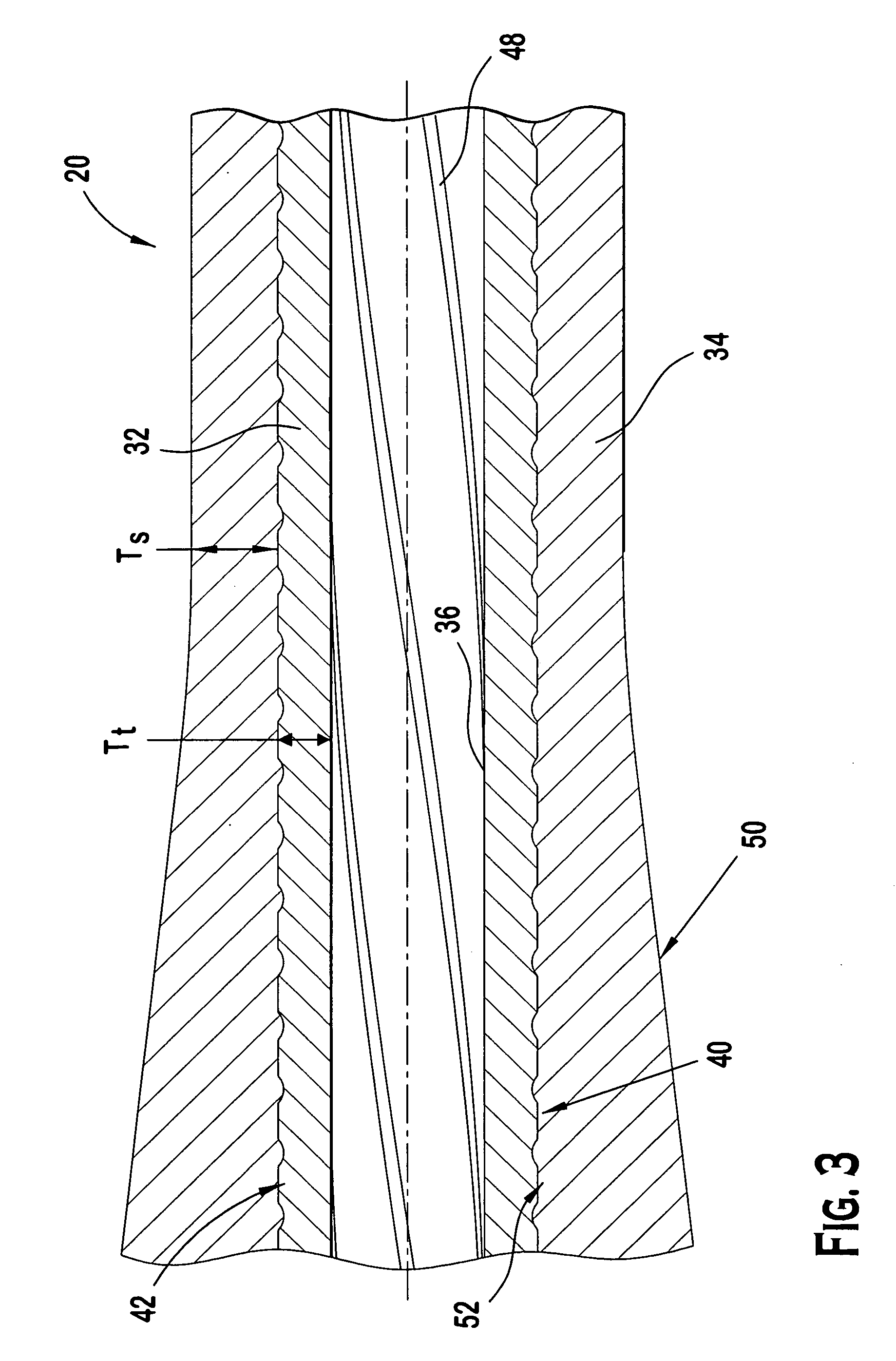

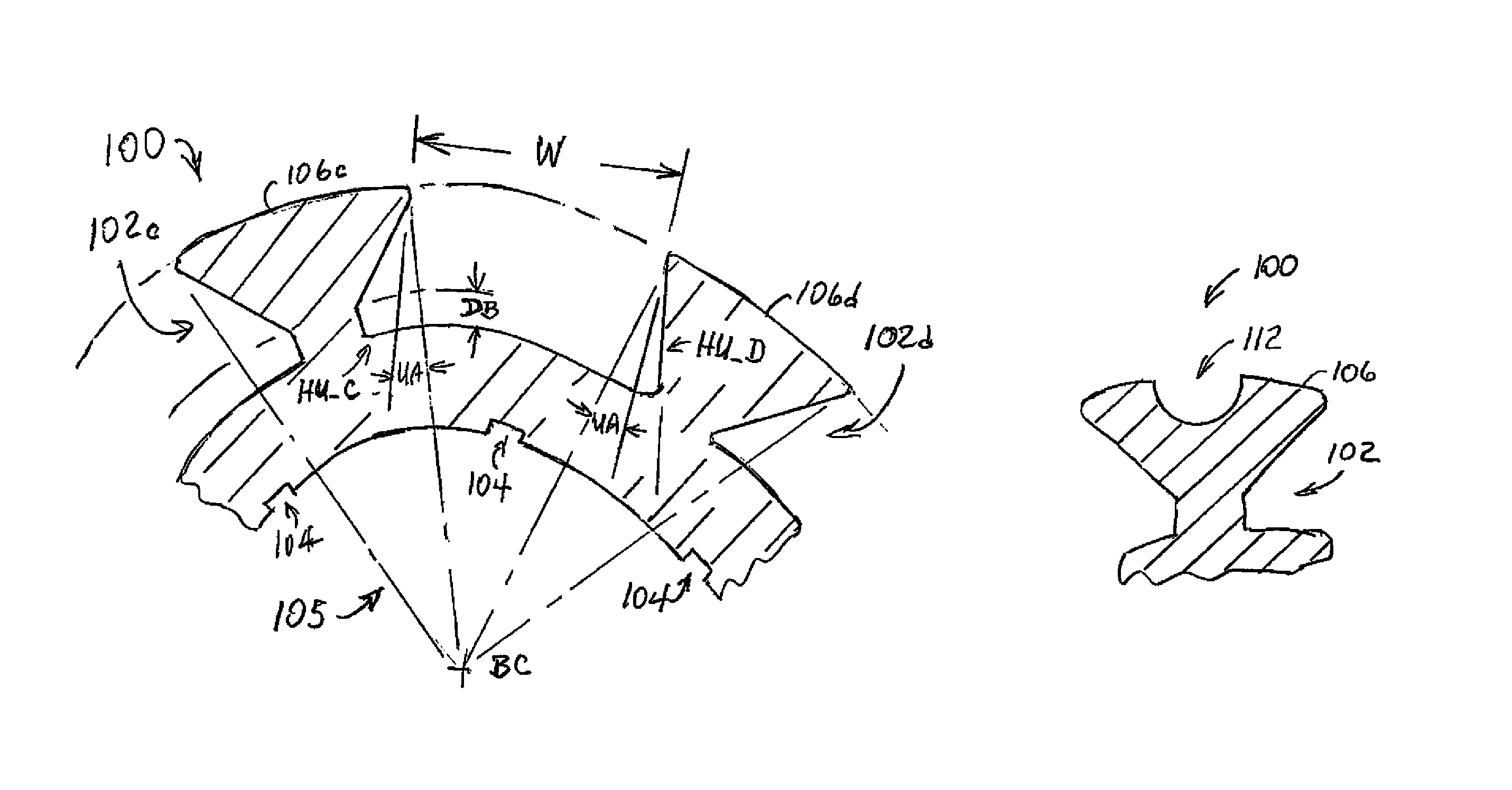

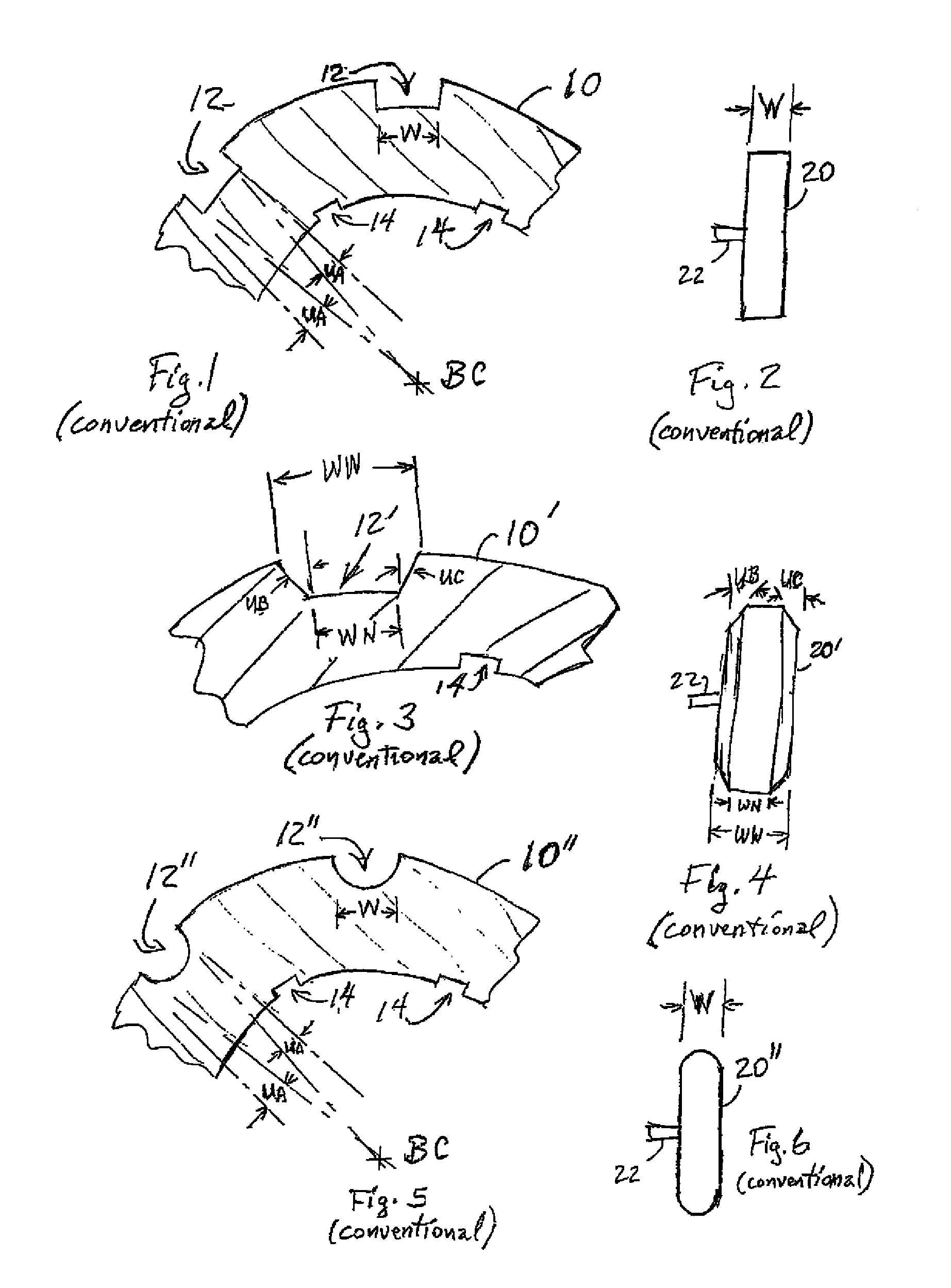

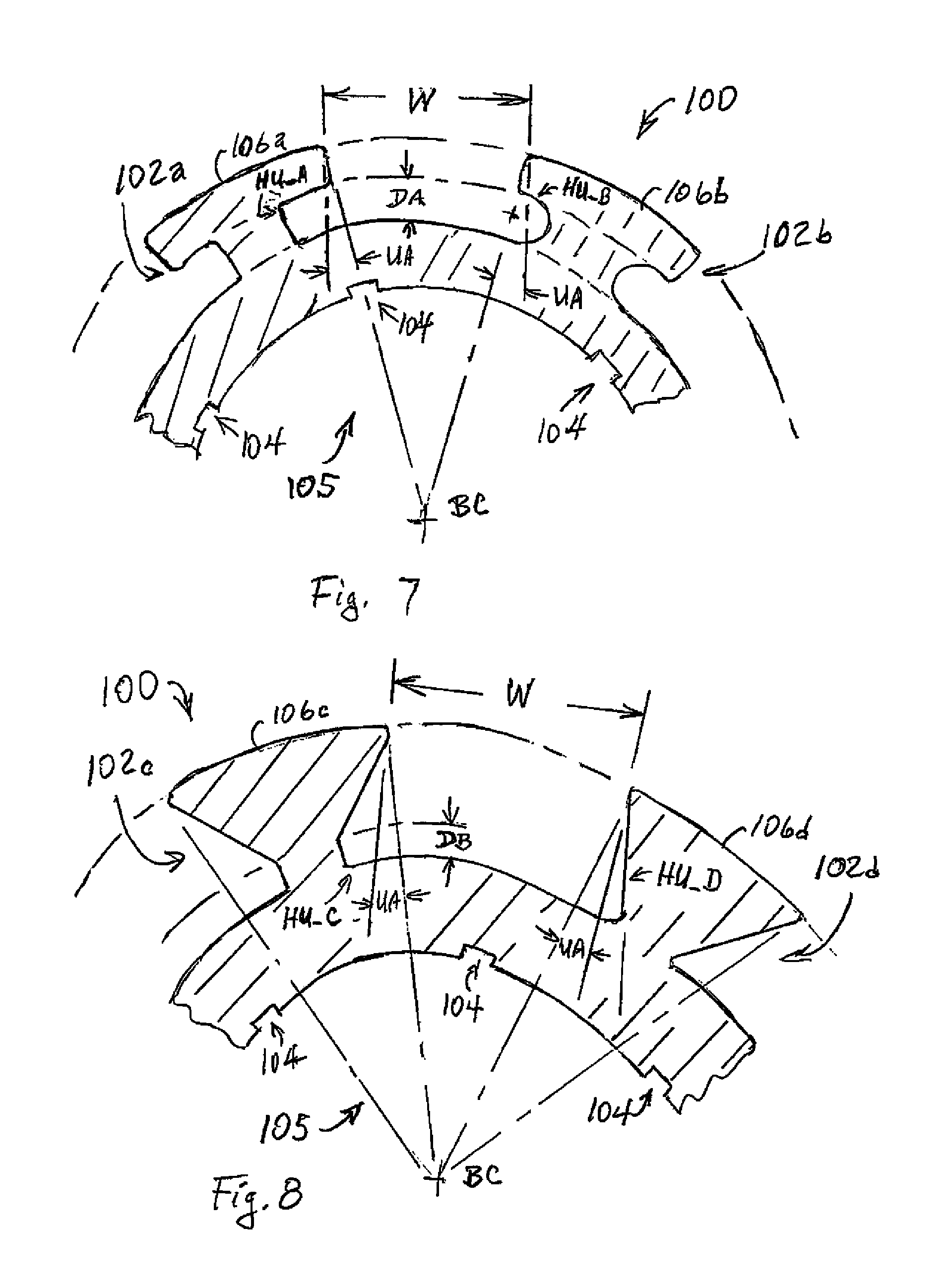

Jacketed bullet

ActiveUS9389052B2Reduced energy storageVelocity increasesAmmunition projectilesBarrelsEngineeringMechanical engineering

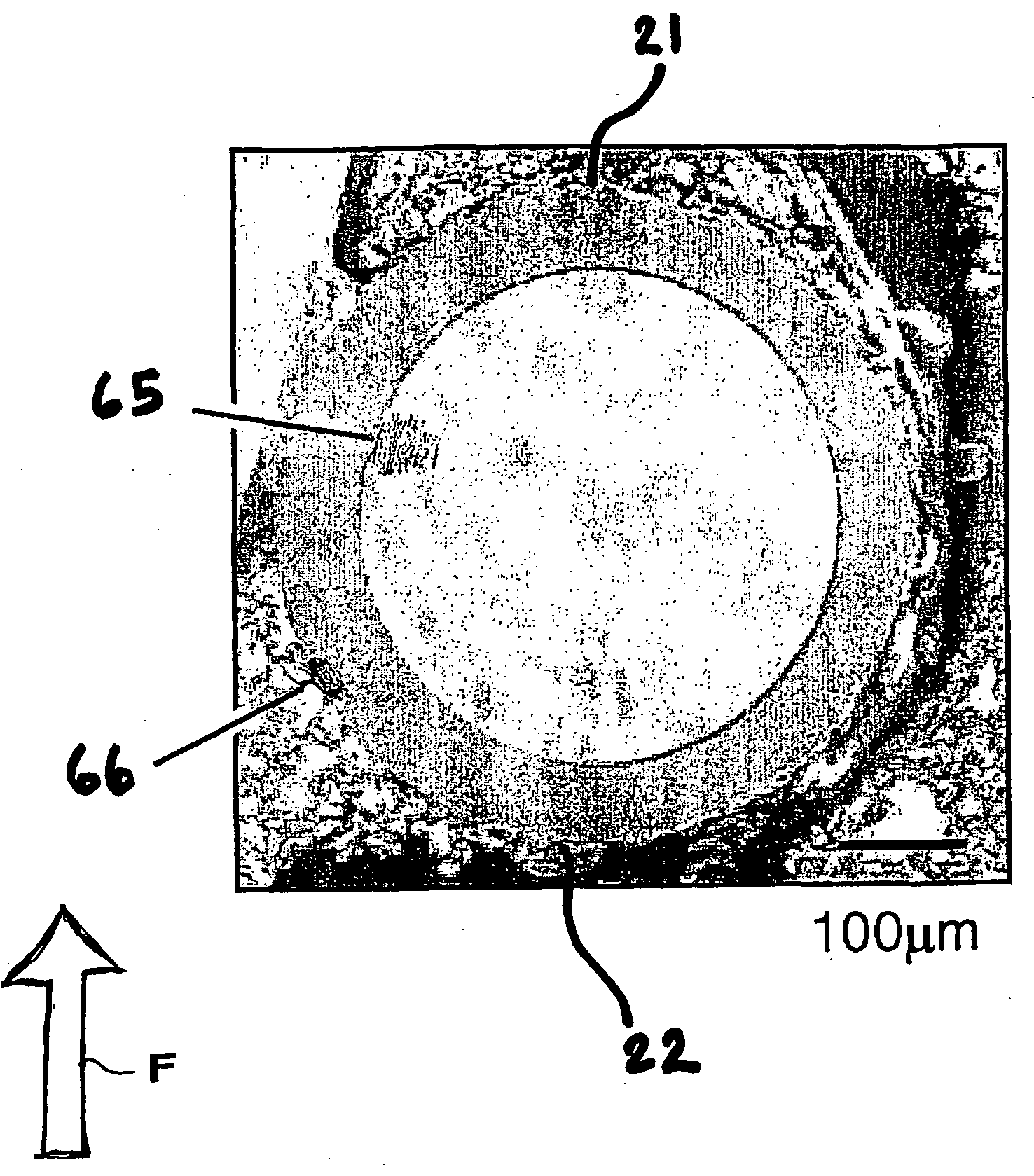

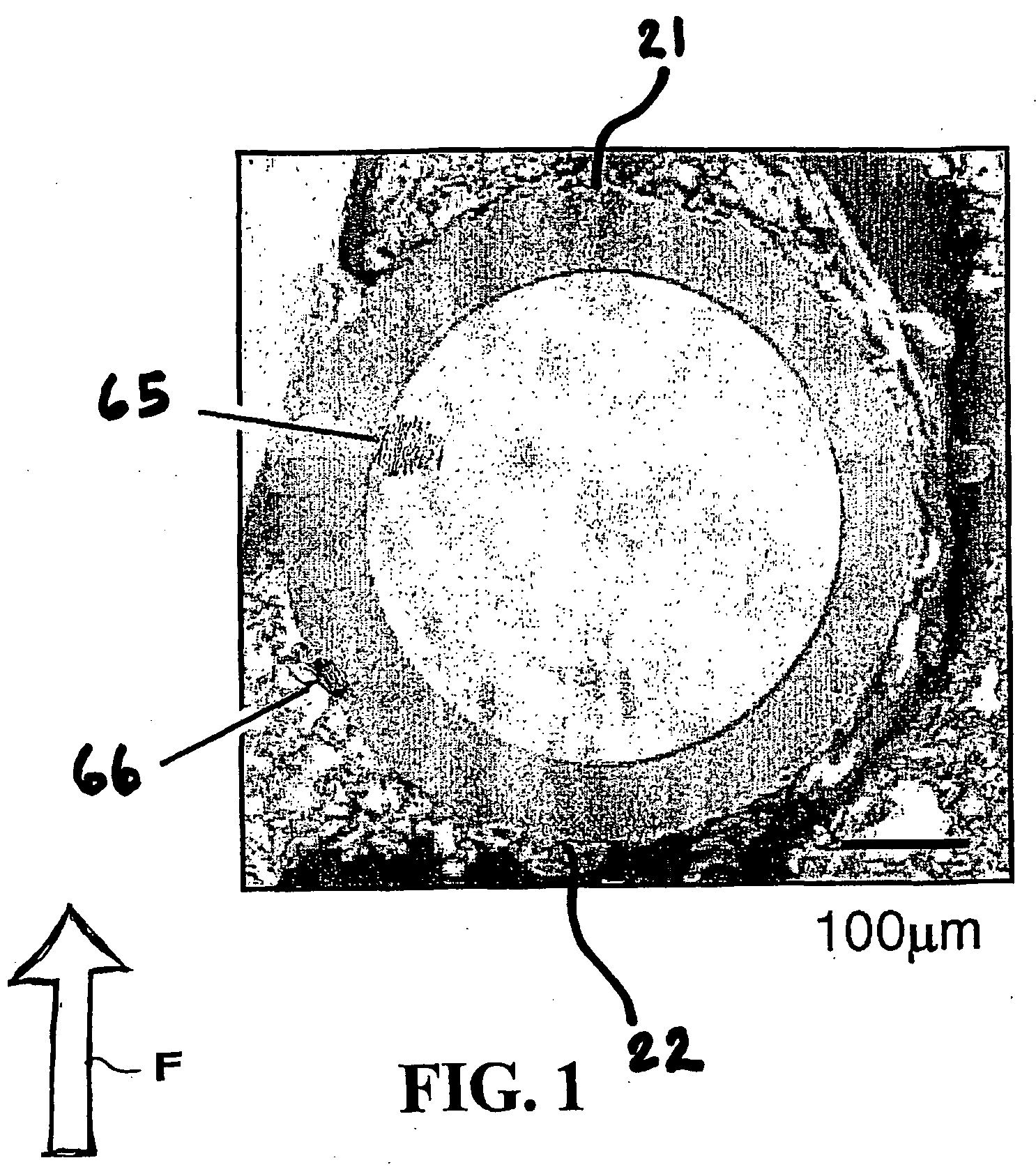

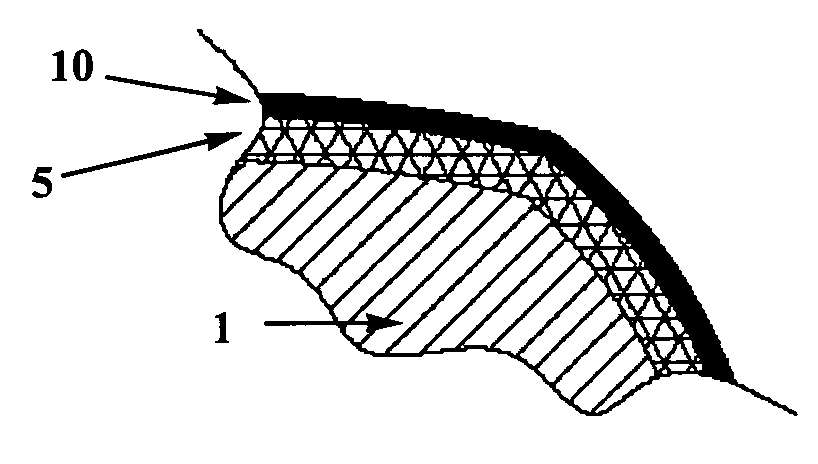

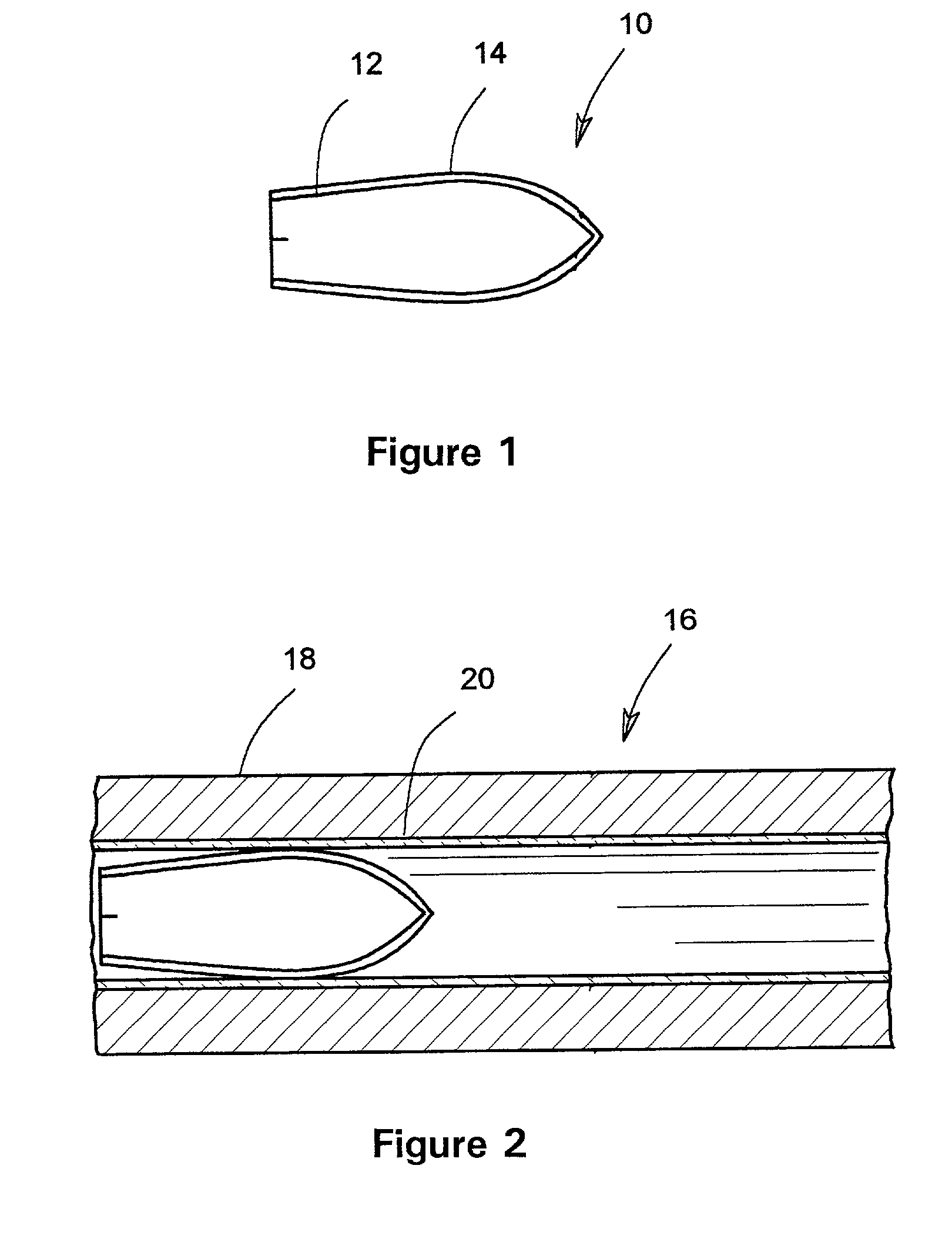

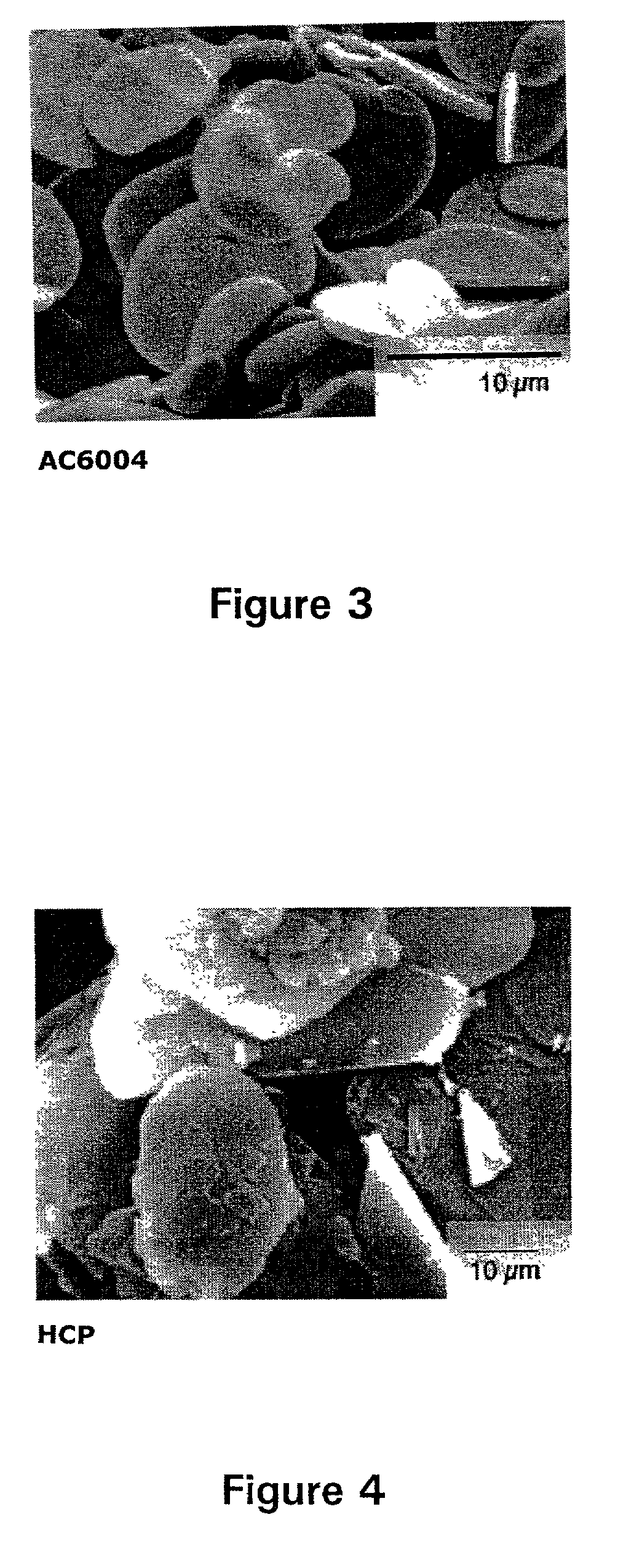

A jacketed bullet having a penetrator constructed of a hard material in line with a slug having a lower modulus. At least a portion of both the slug and the penetrator are then encased by a metal jacket. A plurality of circumferentially spaced and axially extending flutes are formed along the slug and possibly the penetrator. These flutes receive deformation of the jacket upon firing of the bullet into a rifled gun bore to thereby reduce friction between the bullet and the gun bore during operation.

Owner:ARMY US SEC THE

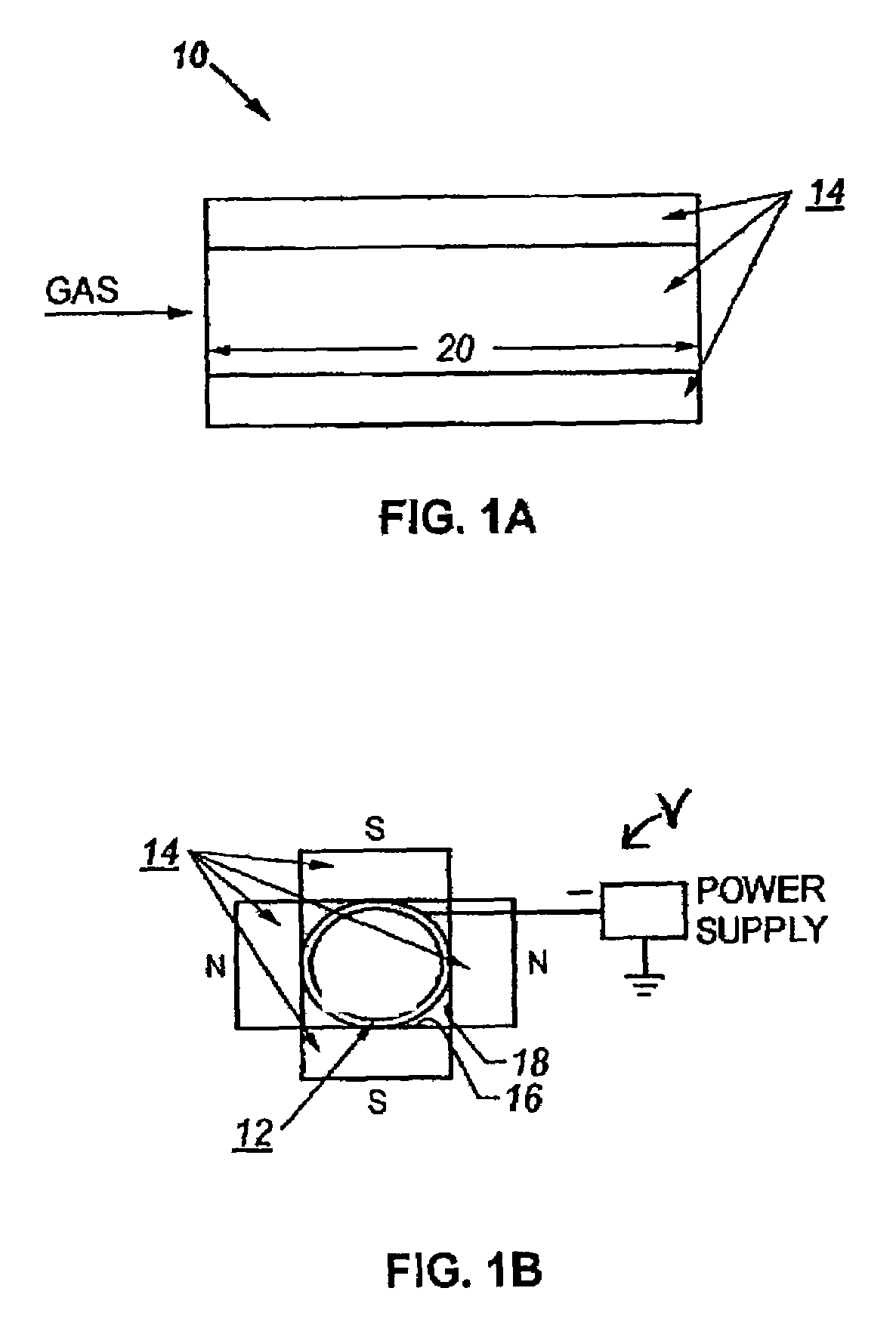

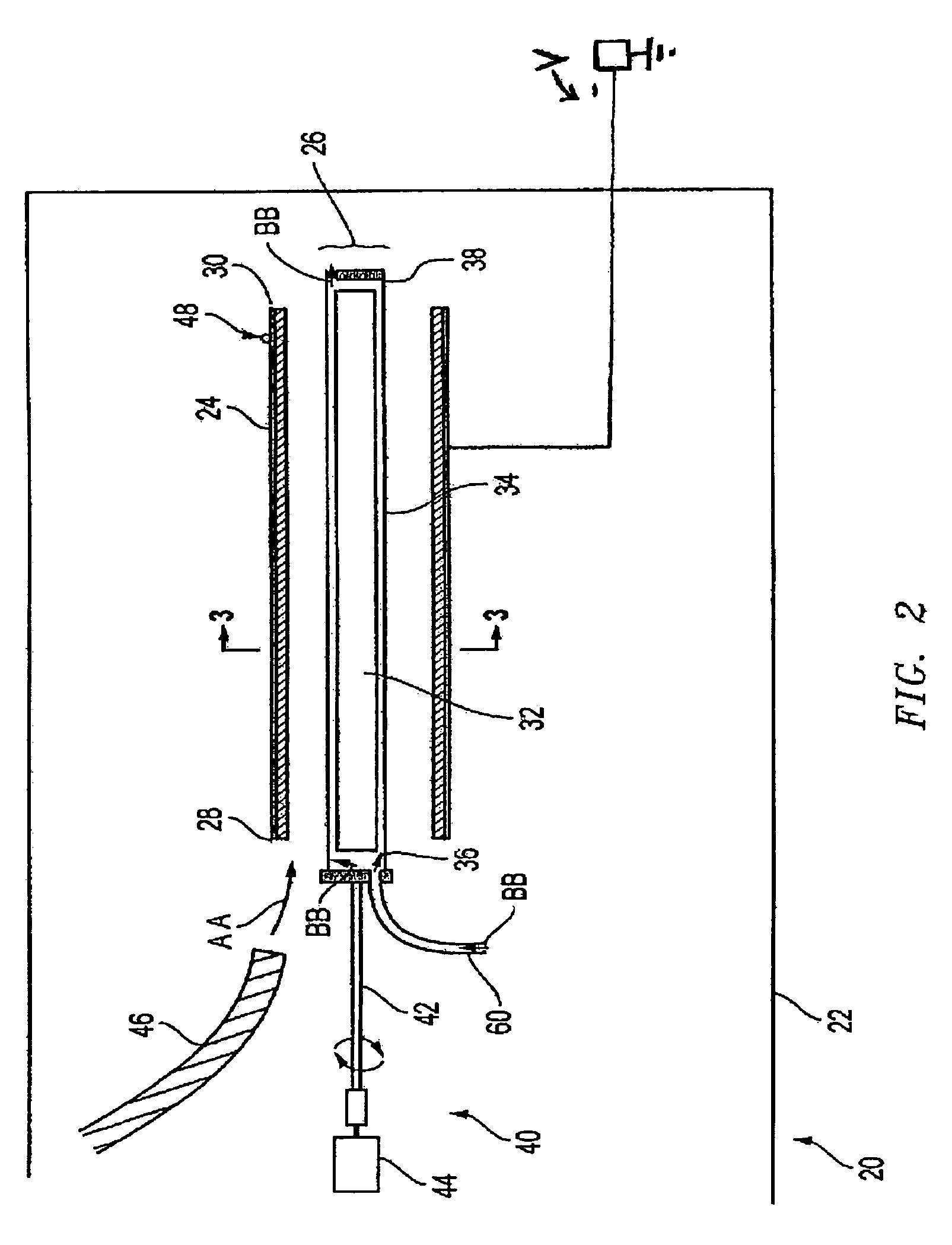

Method for depositing coatings on the interior surfaces of tubular structures

A method is disclosed for substantially uniformly coating an interior surface of a ferromagnetic tubular structure such as a ferromagnetic tube having a high aspect ratio. The method entails inducing a magnetic field of a given magnitude within the tubular structure. Further, a bias is applied at a given voltage to the tubular structure. Then, the interior surface of the tubular structure is exposed to a gaseous precursor material under conditions effective to convert a quantity of the gaseous precursor material to ionize gaseous precursor material. The given magnitude and voltage is such that it is effective to deposit the ionized the gaseous precursor material onto the interior surface and converts the ionized gaseous precursor material to a substantially uniform protective coating in the interior surface.

Owner:SOUTHWEST RES INST

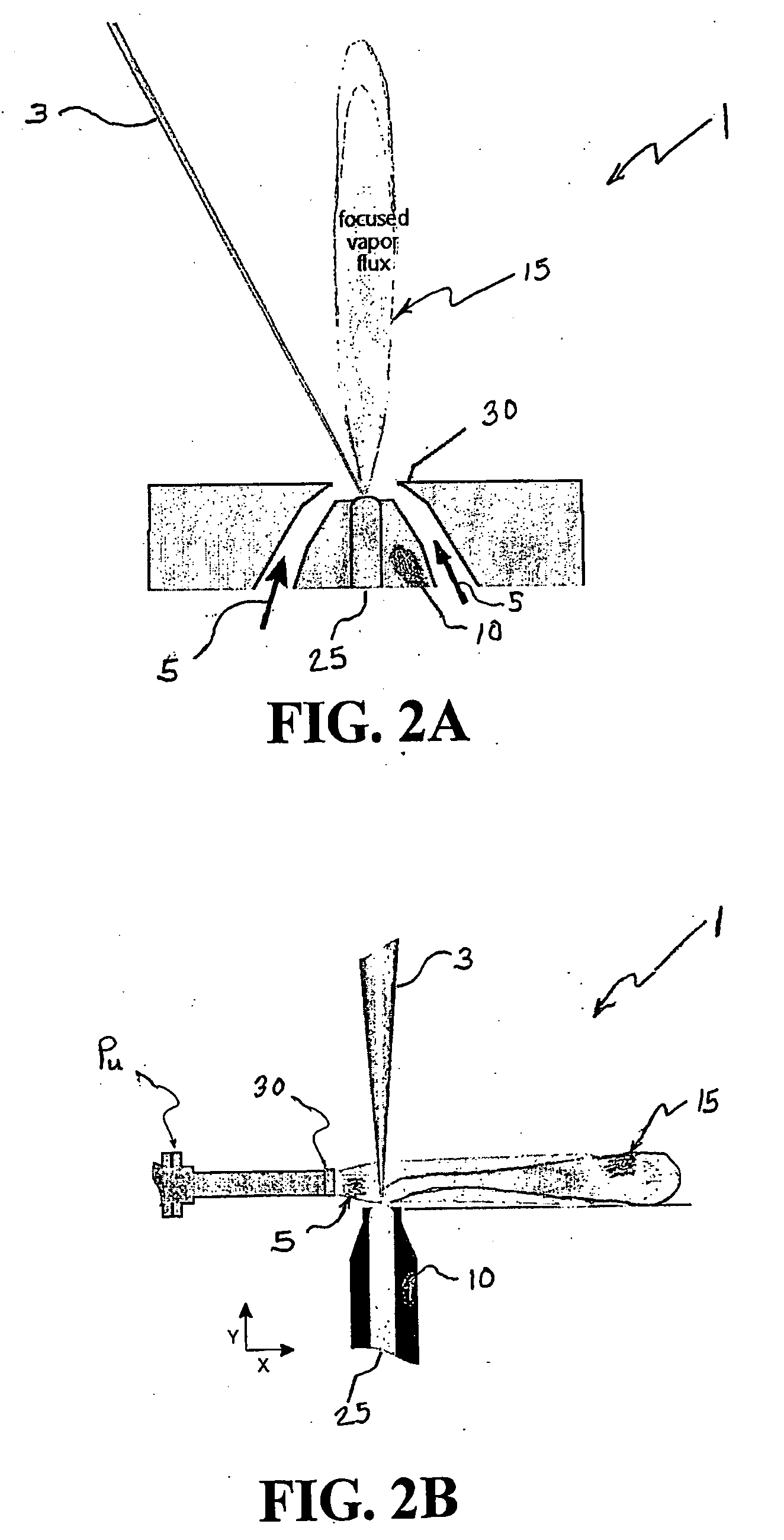

Apparatus and method for applying coatings onto the interior surfaces of components and related structures produced therefrom

ActiveUS20090017217A1Limited effectivenessWide rangeMolten spray coatingElectric discharge heatingEngineeringVacuum chamber

Provided is a methodology and system for applying coatings onto the interior surfaces of components. The approach comprises a vapor creation device (for example an electron beam or laser that evaporates a single or multiplicity of solid or liquid sources), a vacuum chamber having a moderate gas pressure (between about 10−4 to about 103 Torr) and a inert gas jet having controlled velocity and flow fields of gas jet. The gas jet is created by a rarefied, inert gas supersonic expansion through a nozzle. By controlling the carrier gas flow into a region upstream of the nozzle an upstream pressure is achieved (i.e. the gas pressure prior to its entrance into the processing chamber through the nozzle). The carrier gas flow and chamber pumping rate control the downstream (or chamber) pressure (i.e., downstream of the nozzle). The ratio of the upstream to downstream pressure along with the size and shape of the nozzle opening controls the speed of the gas entering the chamber. The carrier gas molecular weight (compared to that of the vapor) and the carrier gas speed controls its effectiveness in redirecting the vapor atoms via binary collisions towards the substrate. The speed and flux of the atoms entering the chamber, the nozzle parameters, and the operating chamber pressure can all vary leading to a wide range of accessible processing conditions. Vapor created from a source is transported into the interior regions of a component using binary collisions between the vapor and gas jet atoms. Under certain process conditions these collisions enable the vapor atoms to scatter onto the interior surfaces of the component and deposit.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

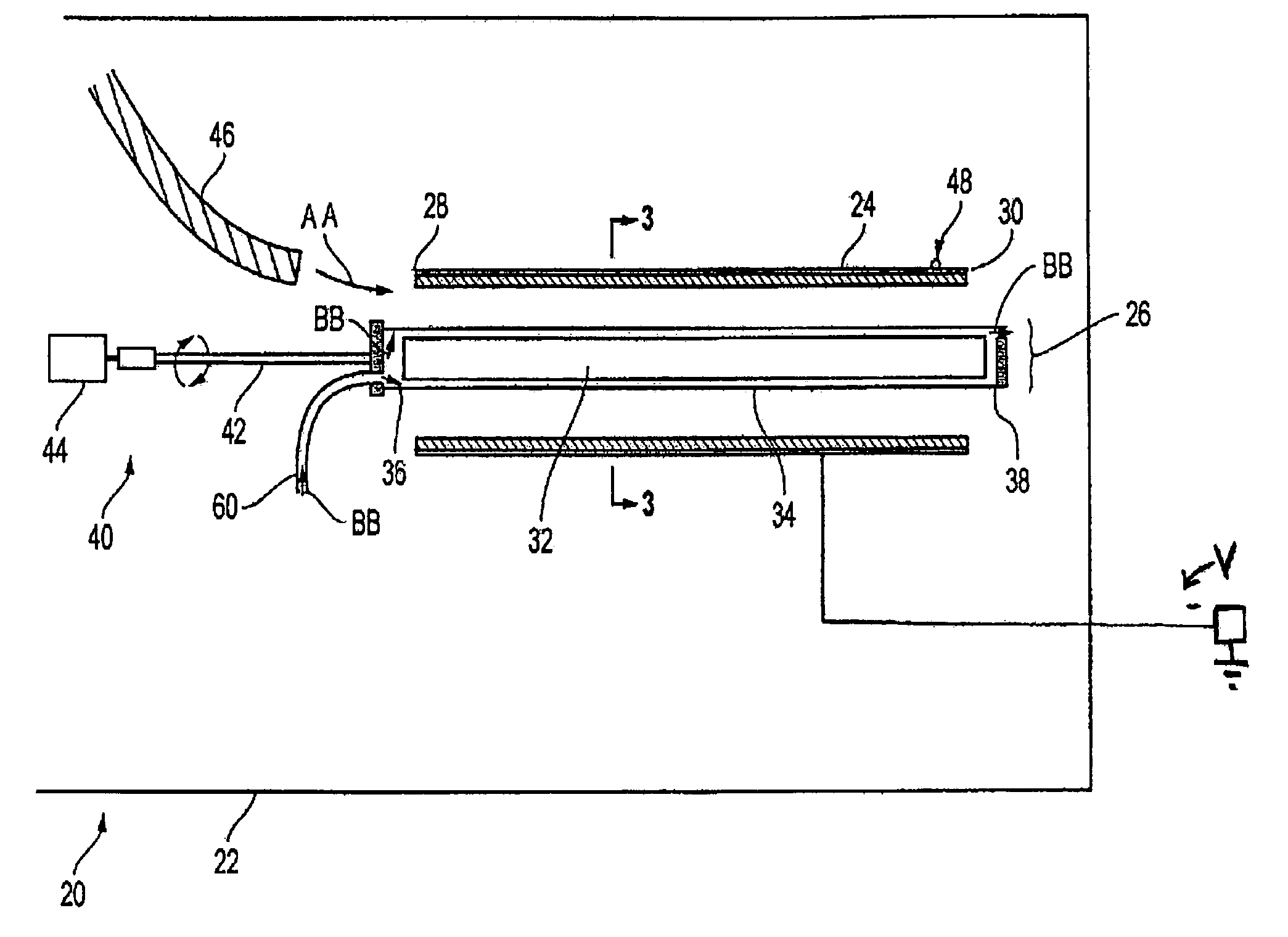

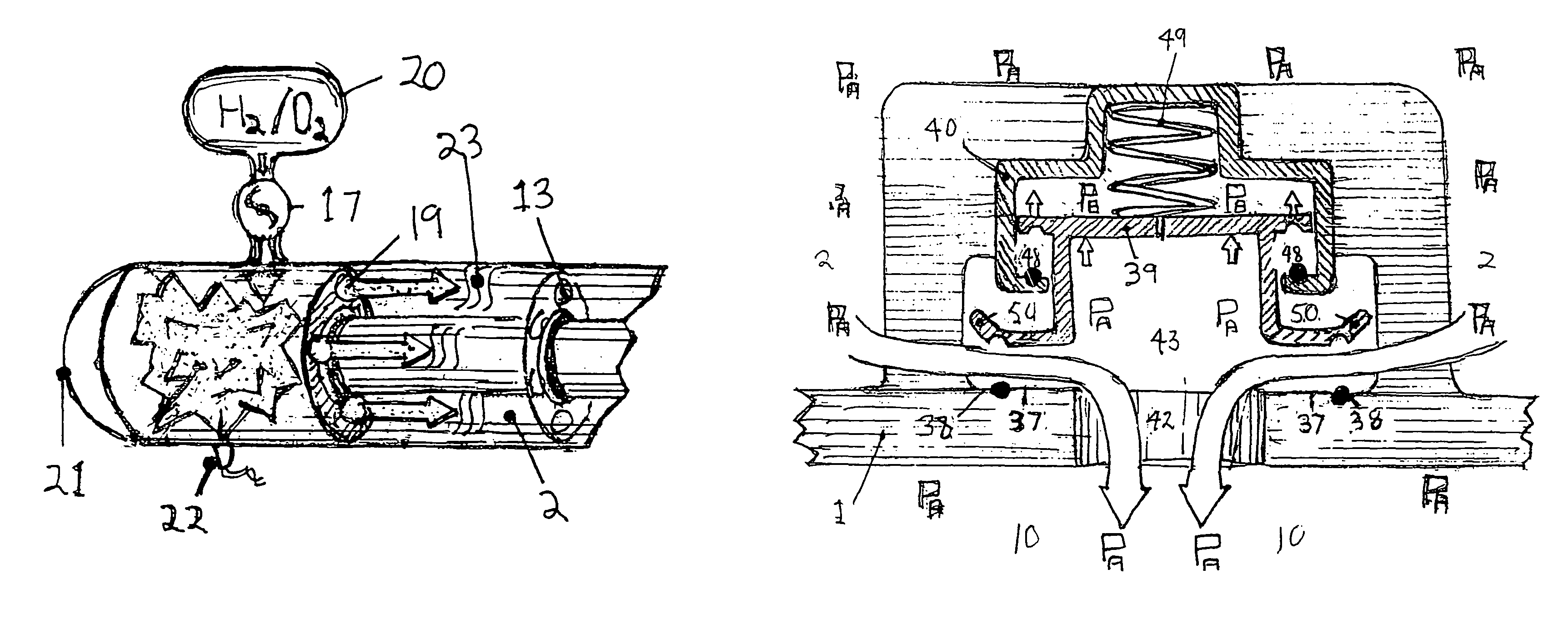

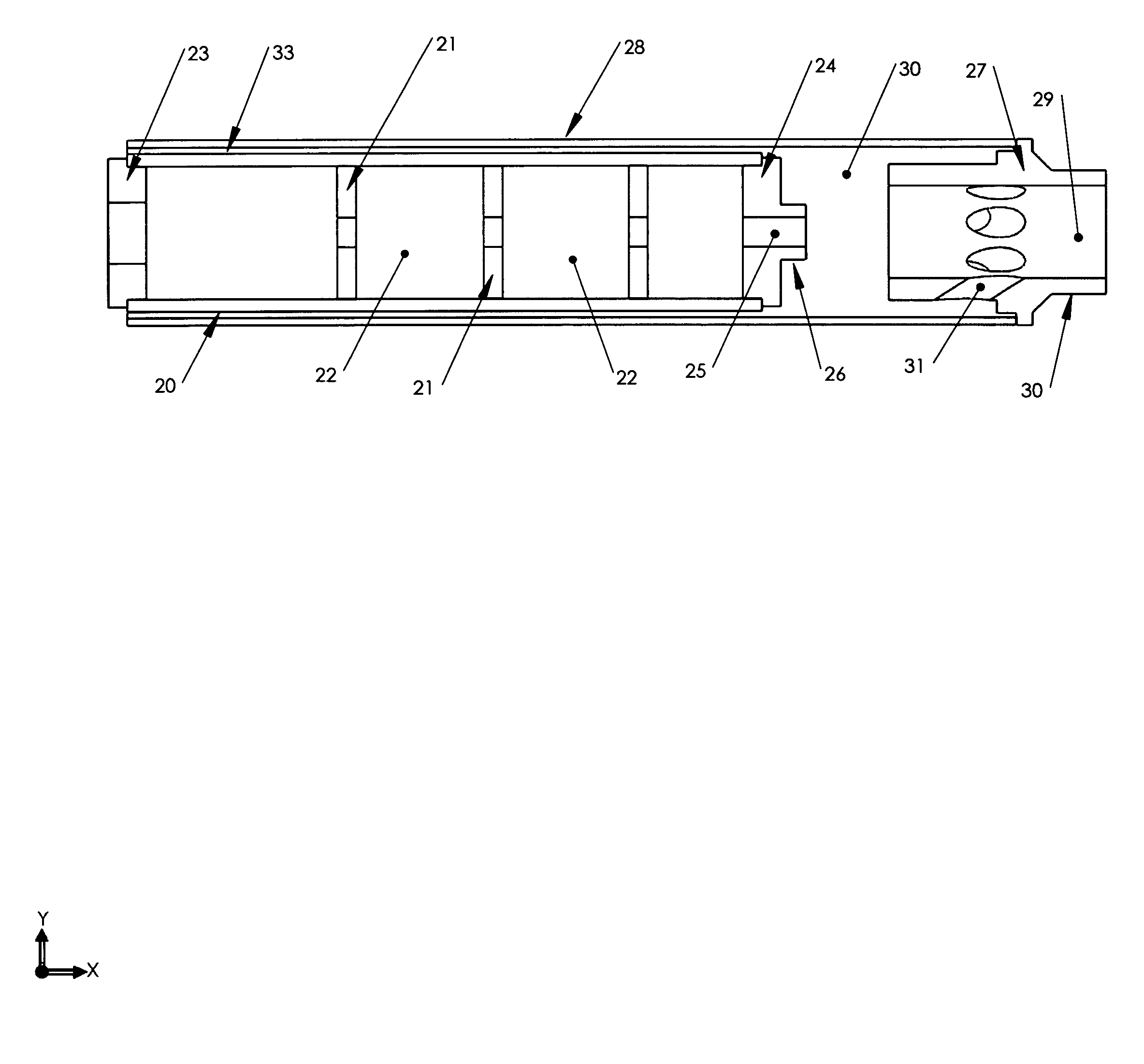

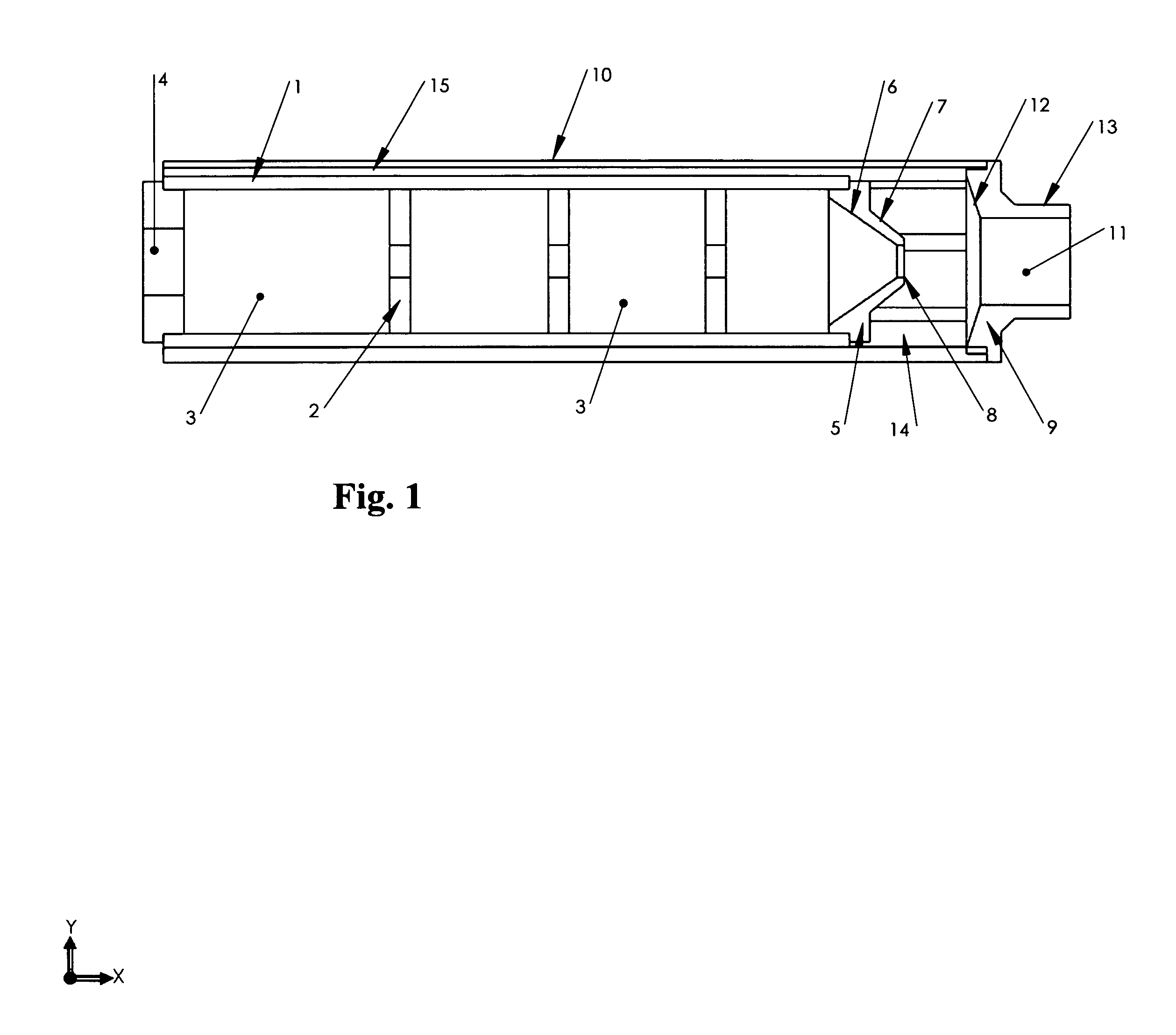

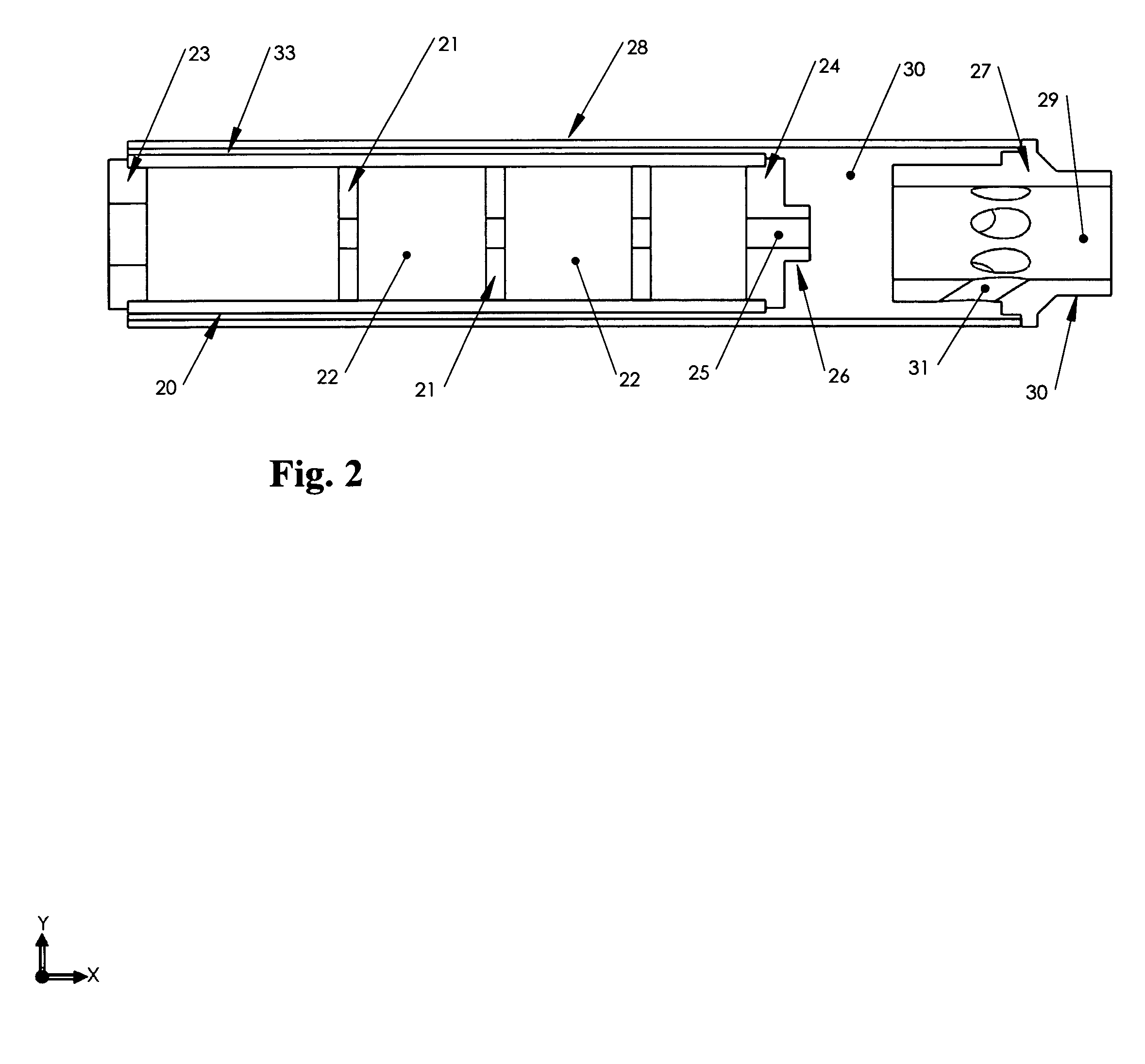

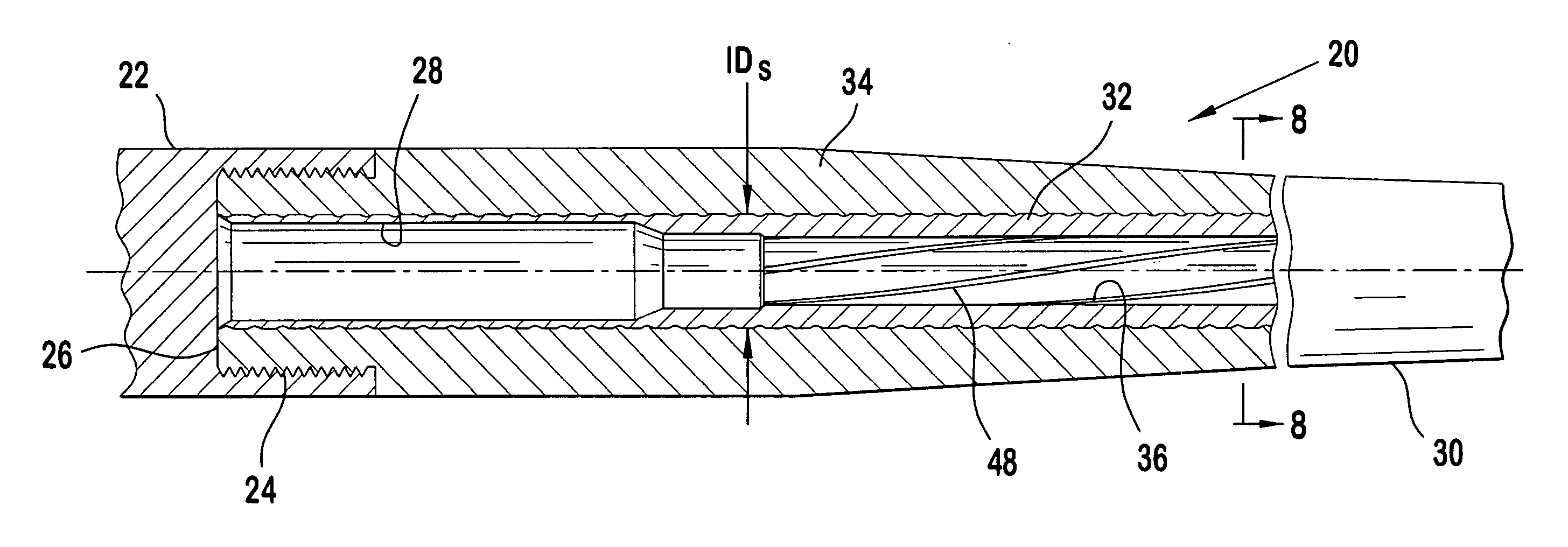

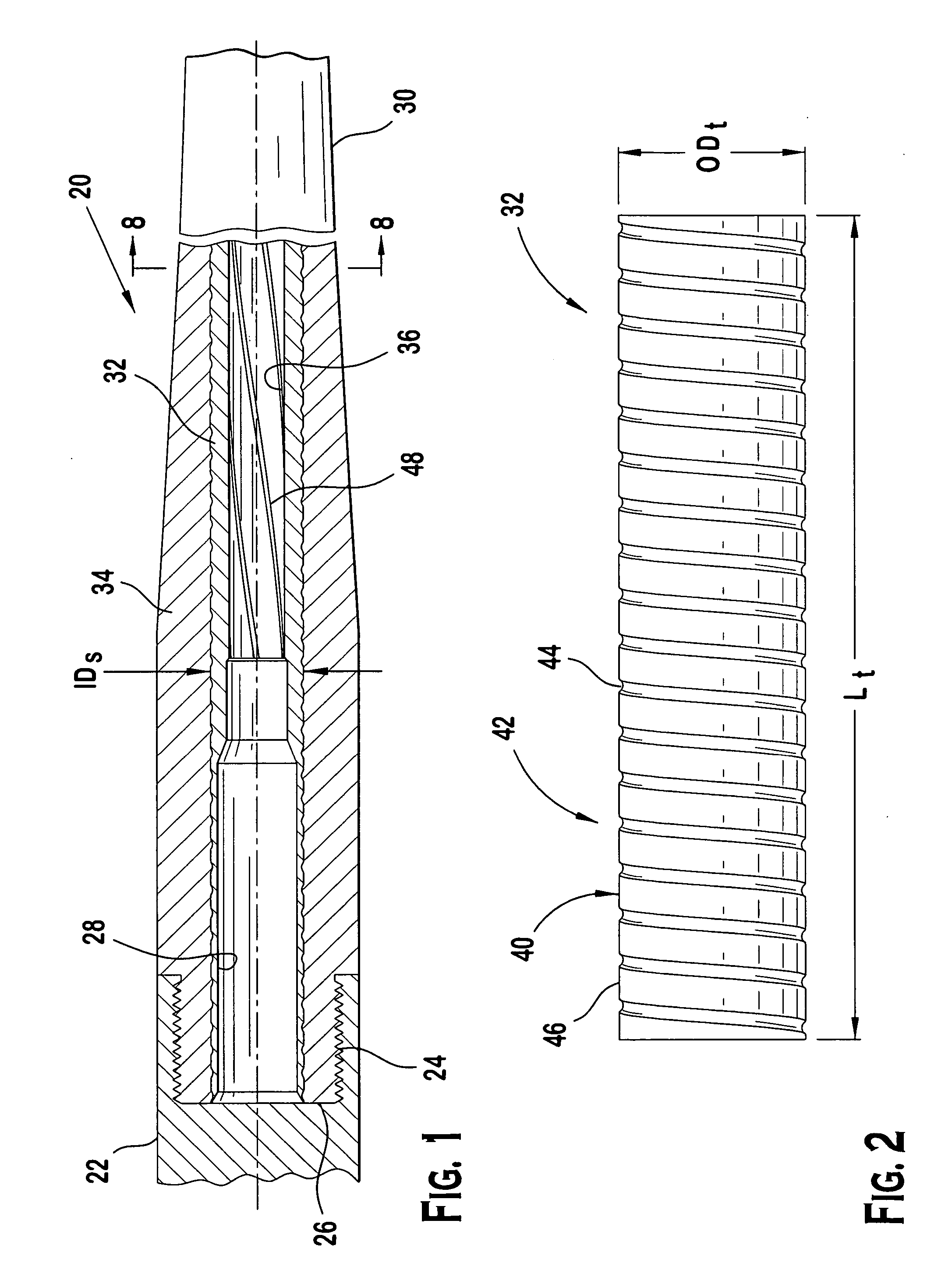

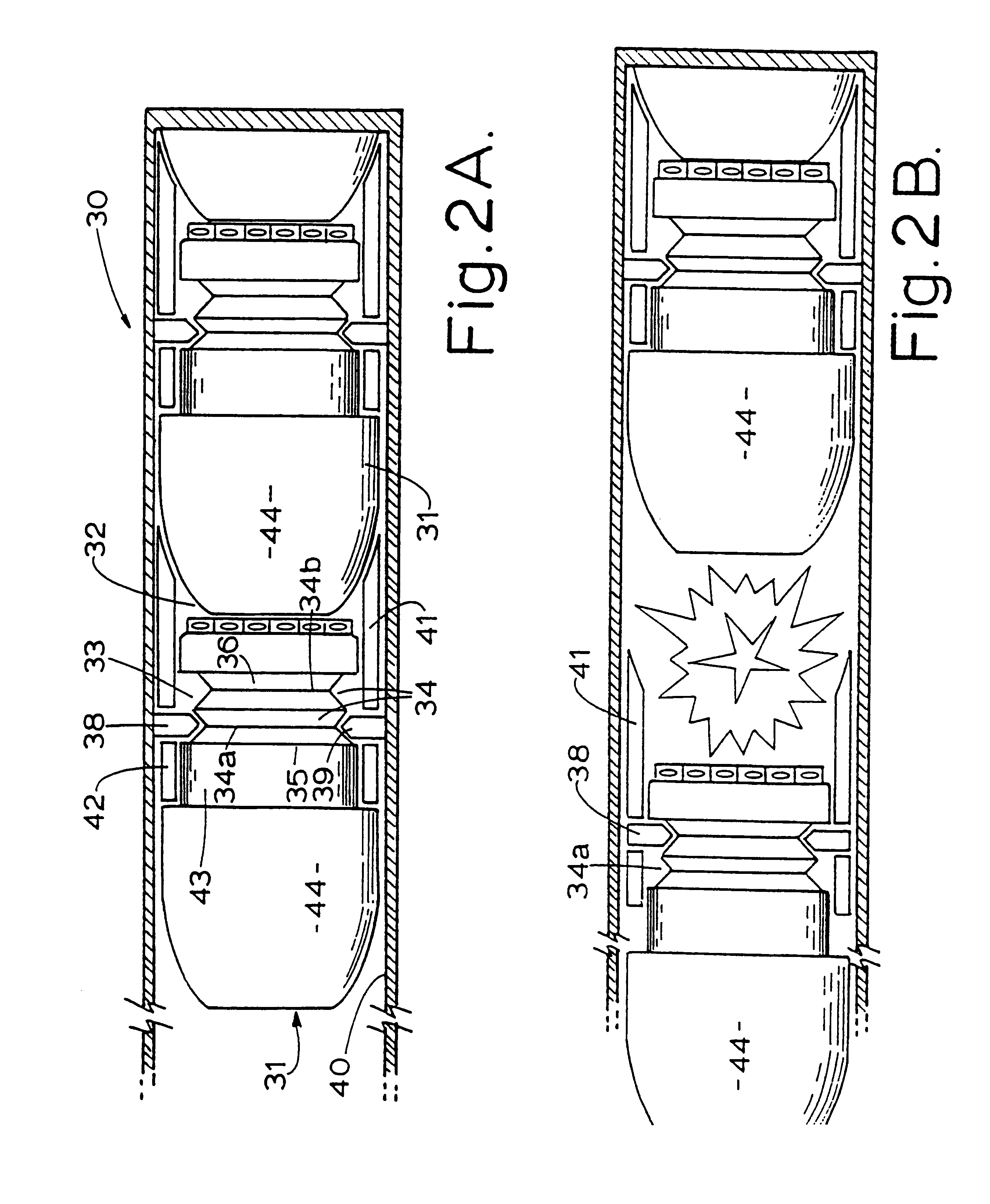

Multivalve hypervelocity launcher (MHL)

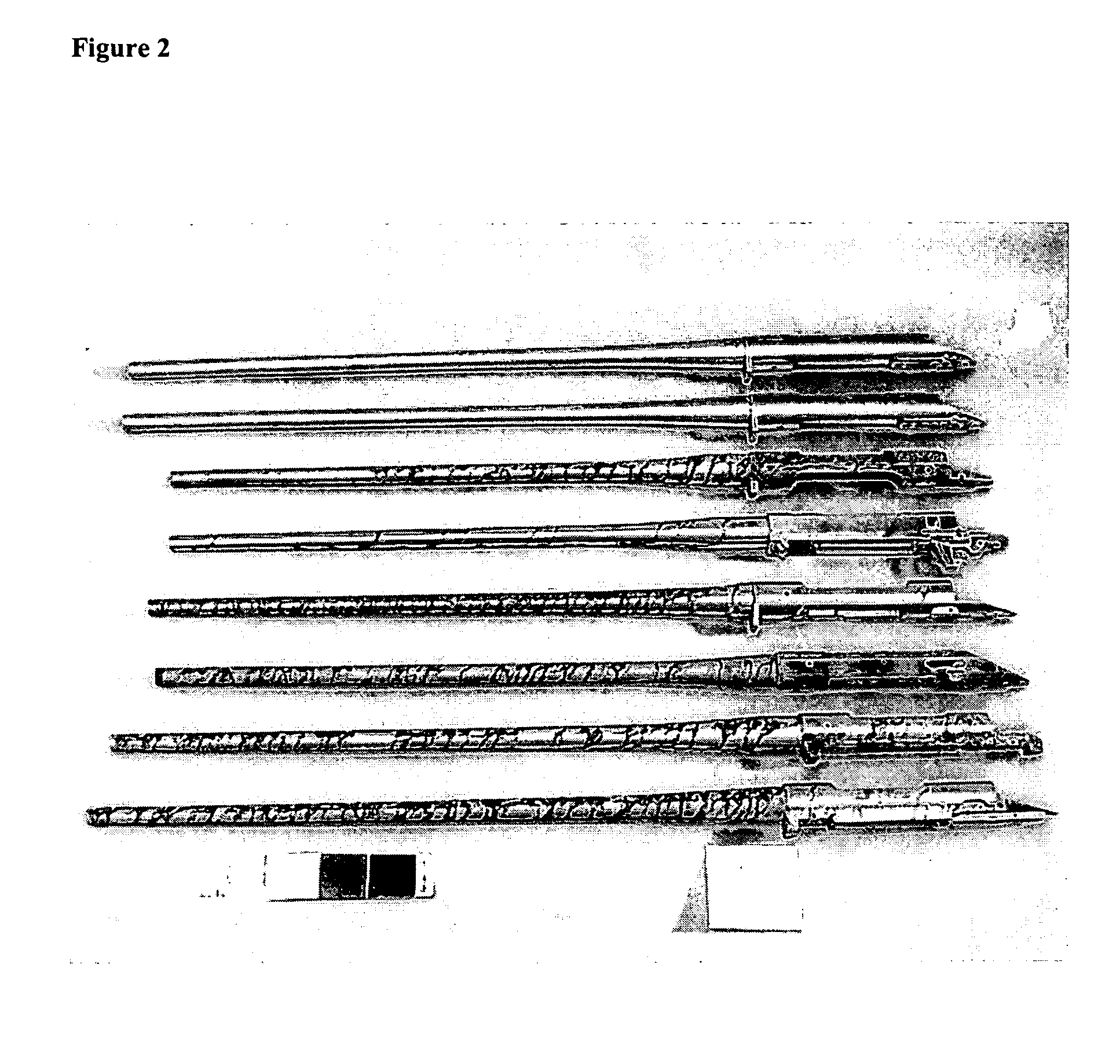

InactiveUS7775148B1Low costOvercome limitationsRocket launchersMissile propulsionHypervelocityHigh energy

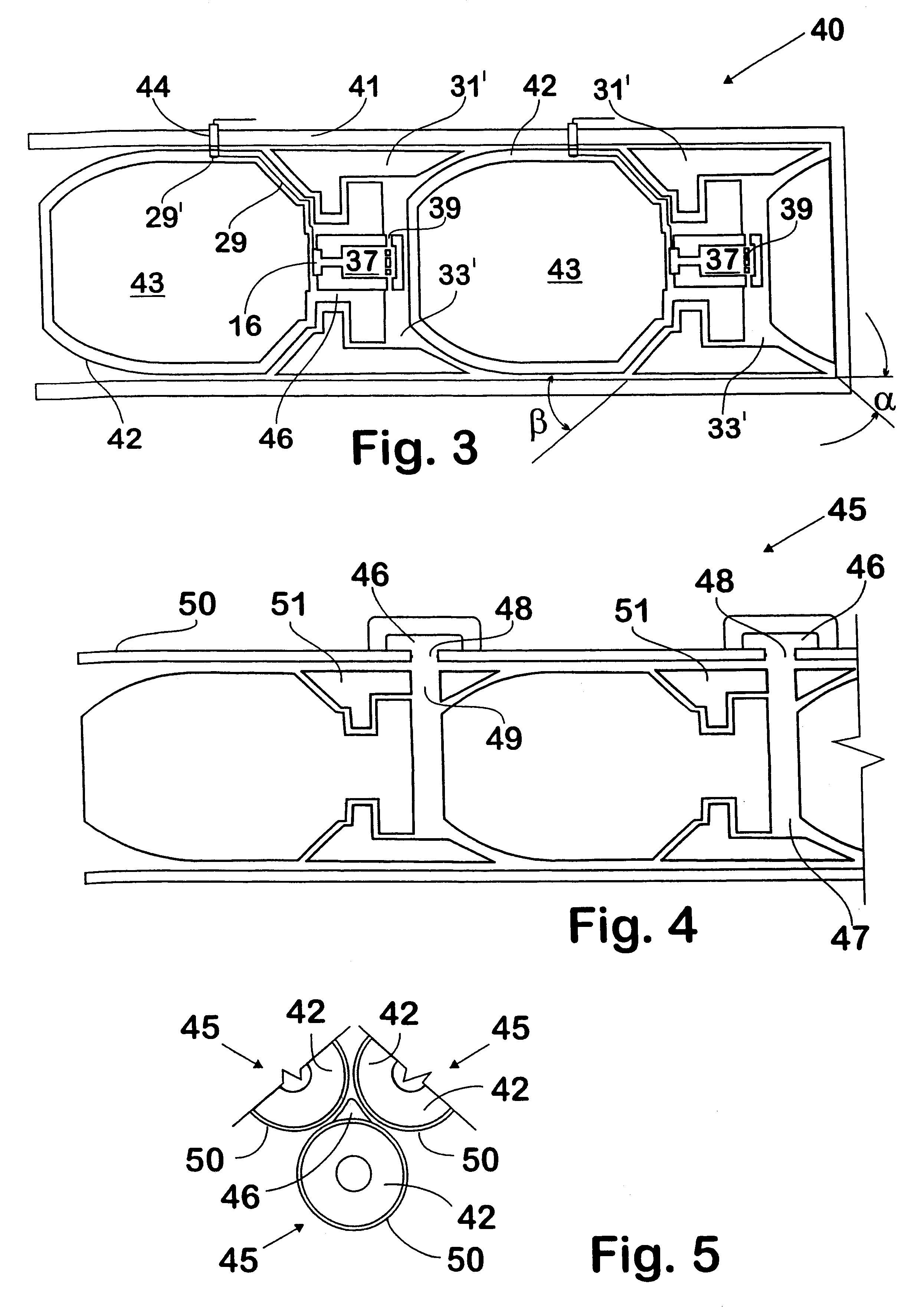

Launching payloads at high velocity uses high-pressure gas or combustion products for propulsion, with injection of high pressure gas at intervals along the path behind the payload projectile as it accelerates along the barrel of the launcher. An inner barrel has an interior diameter equal to the projectile diameter or sabot containing the projectile. An outer casing surrounds the inner barrel. Structures at intervals attach the outer casing and the inner barrel. An axial gas containment chamber (AGC) stores high pressure gas between the inner barrel wall, the outer casing wall, and enclosure bulkheads. Pressure-activated valves along the barrel sequentially release the high pressure gas contained in the AGC in to the barrel to create a continuously refreshed high energy pressure heads behind the projectile as it moves down the barrel. A frangible cover at the exit end of the barrel allows the barrel to be evacuated prior to launch. The launcher is rapidly recyclable. The valves close automatically after the projectile has exited the barrel, allowing a new projectile to be introduced into the breech and the AGC to be recharged with high-pressure gas.

Owner:MCDERMOTT PATRICK P

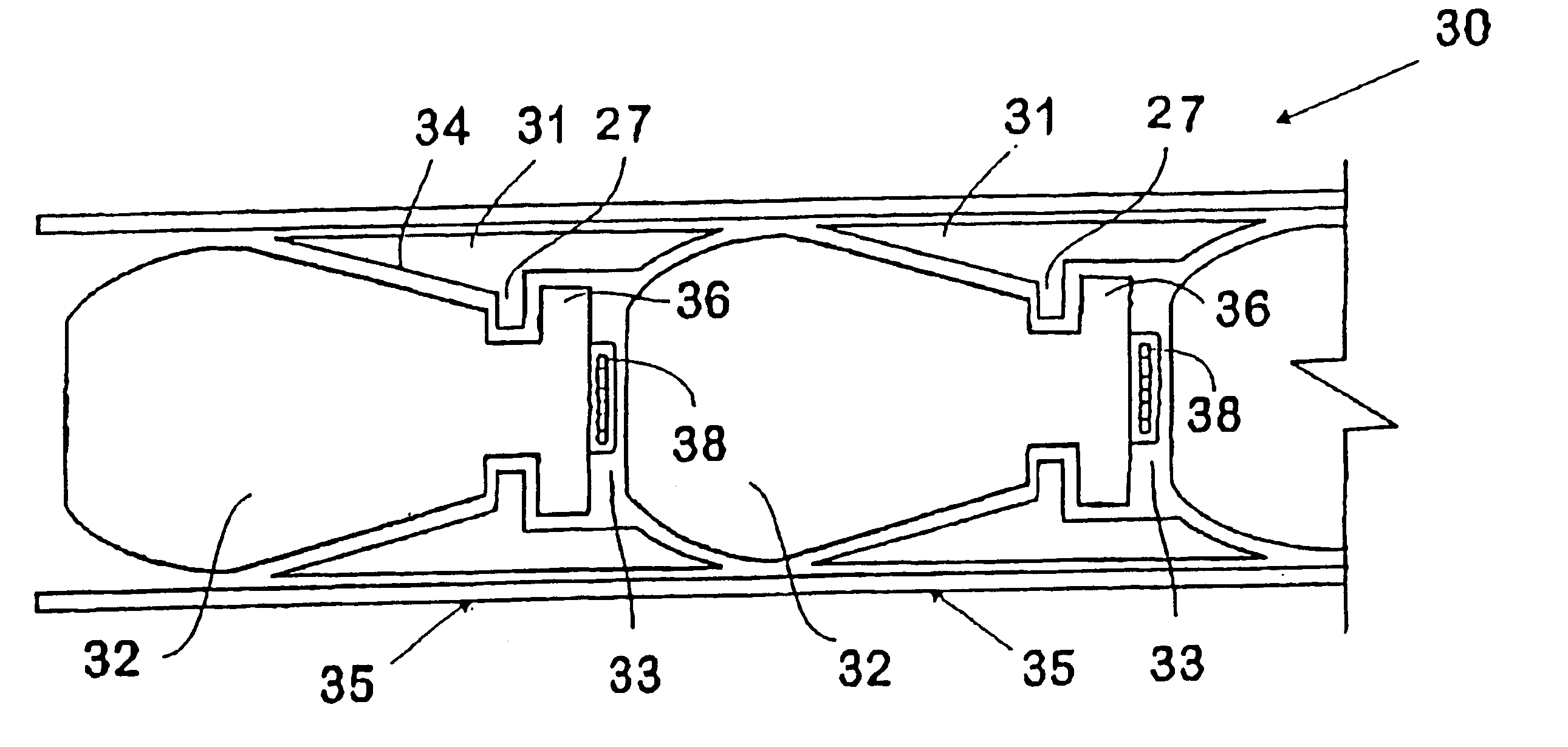

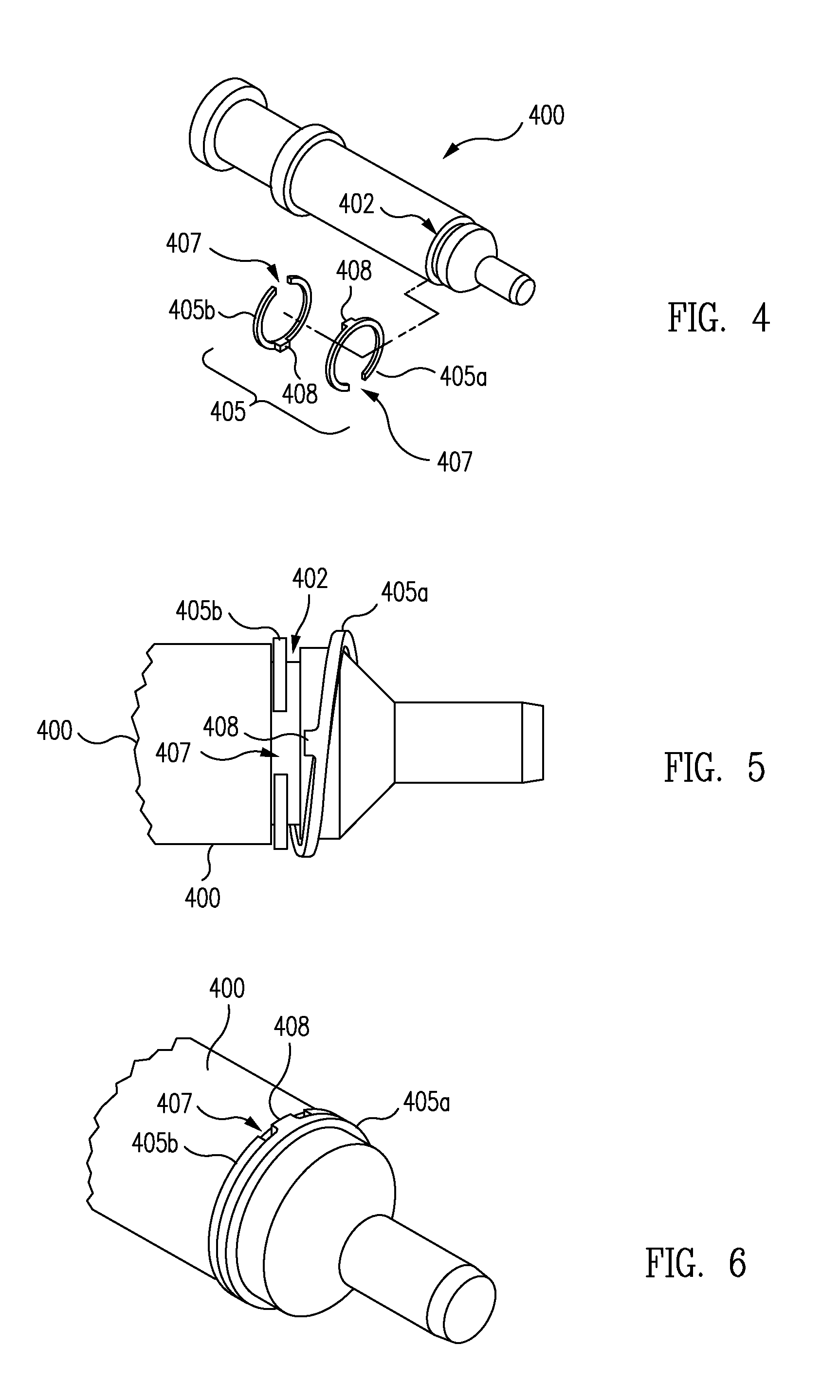

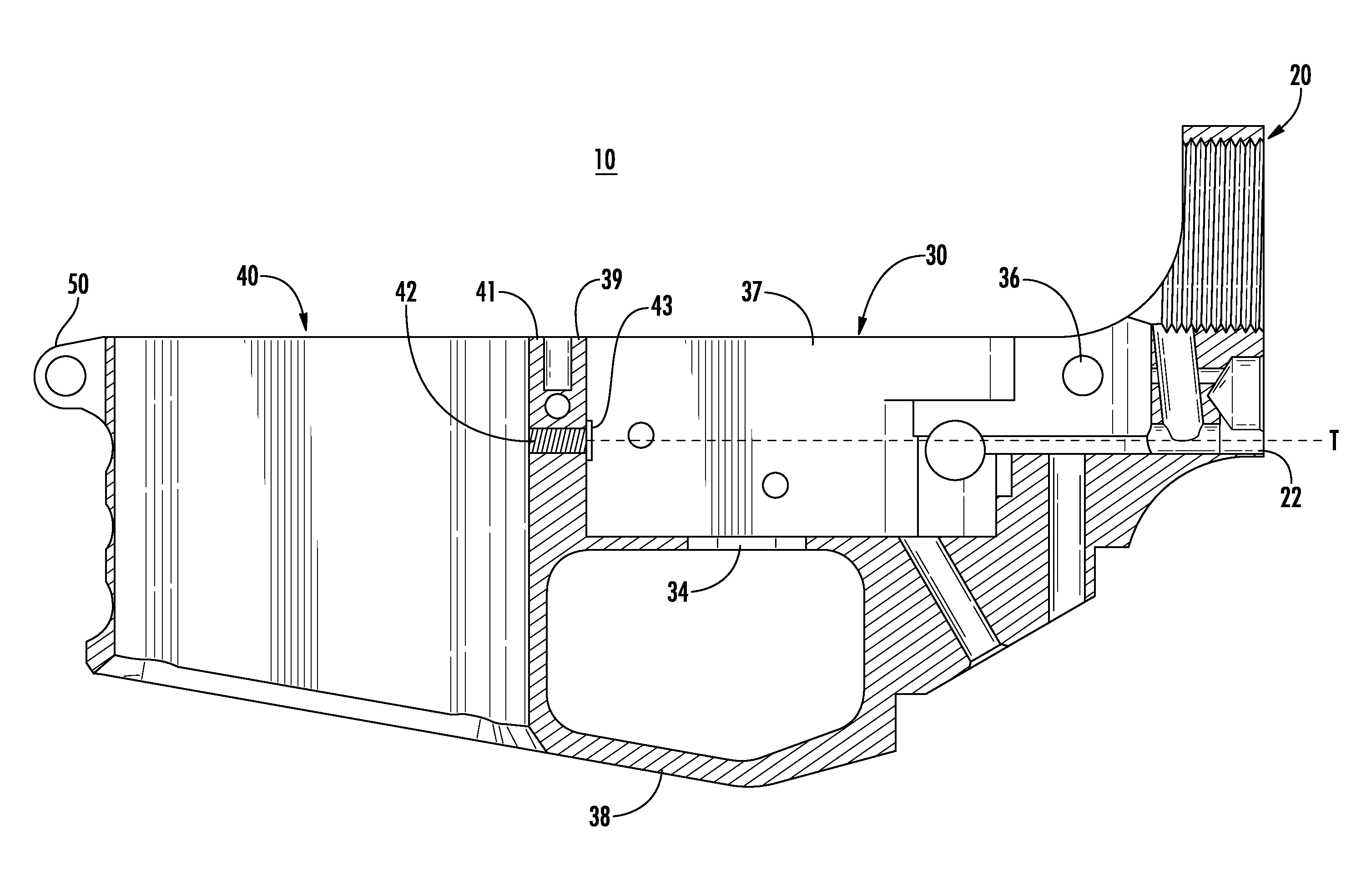

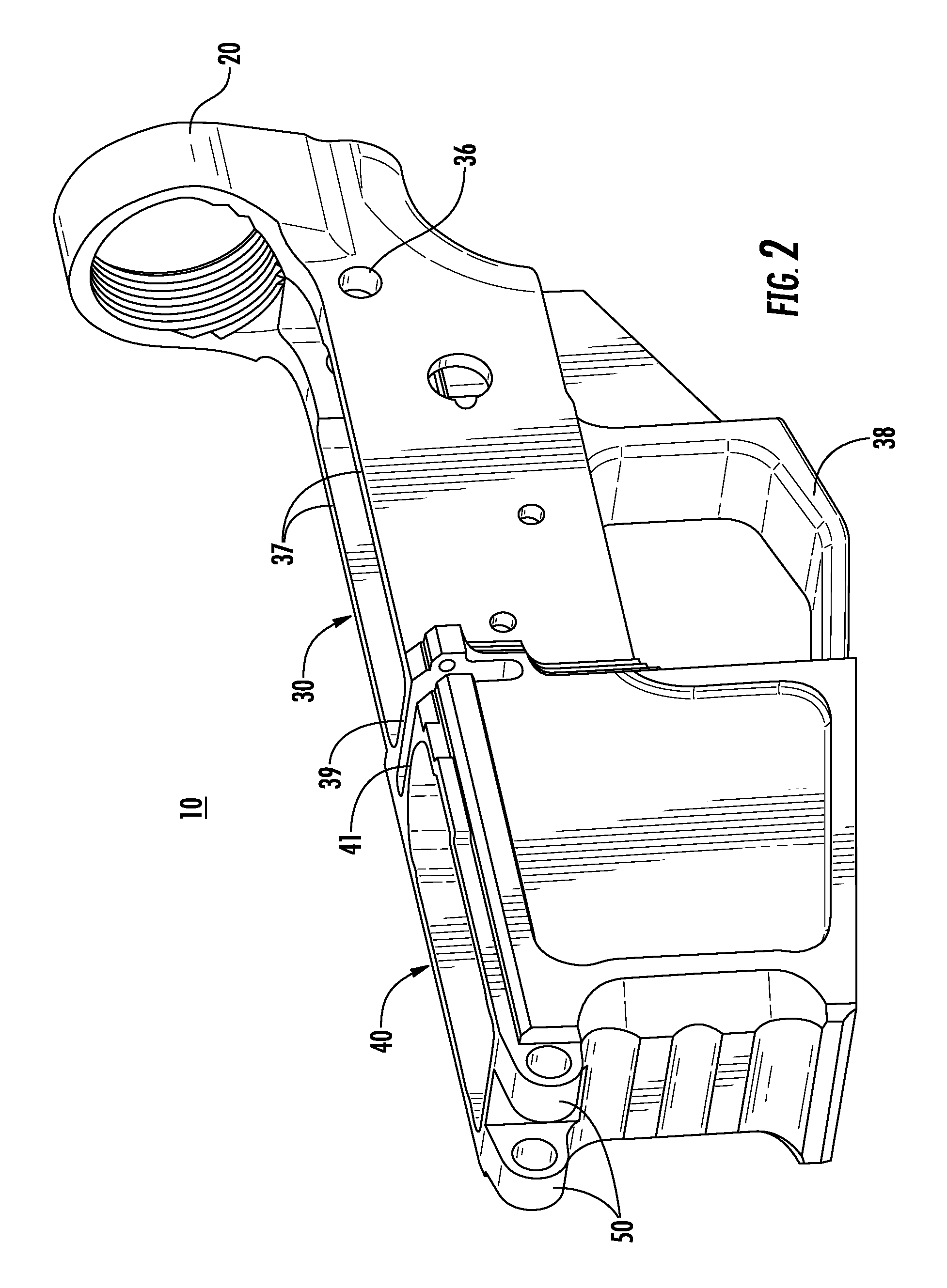

Heat exchanger barrel nut

A barrel nut for coupling a barrel of a firearm to a receiver includes a body having a first end, an opposing second end, and an outer surface. A bore extends centrally through the body from the first end to the second end. A plurality of heat conducting fins extends radially outwardly from the outer surface of the body. A fastening element fastens the breach end of the barrel nut to the receiver.

Owner:PATRIOT ORDNANCE FACTORY INC

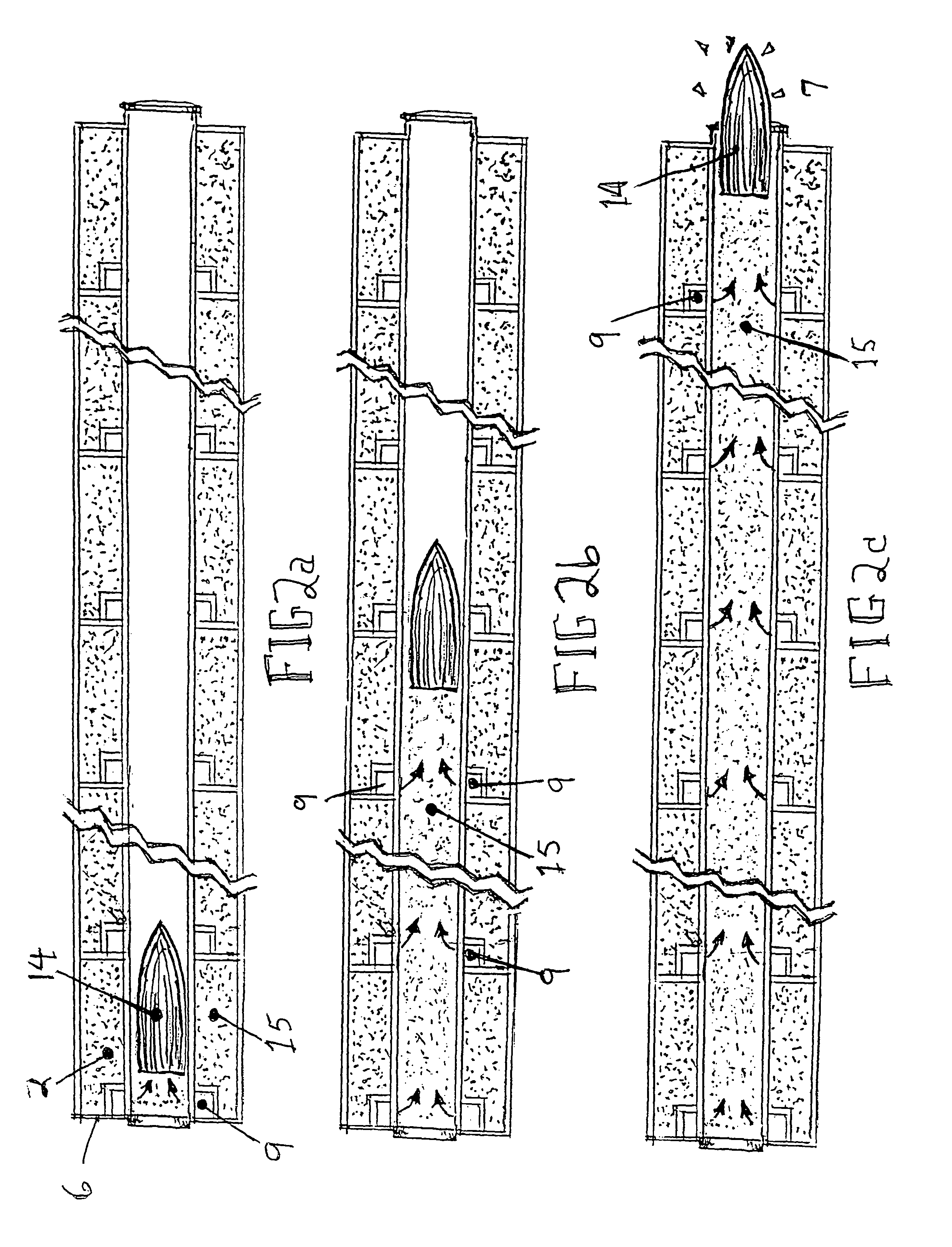

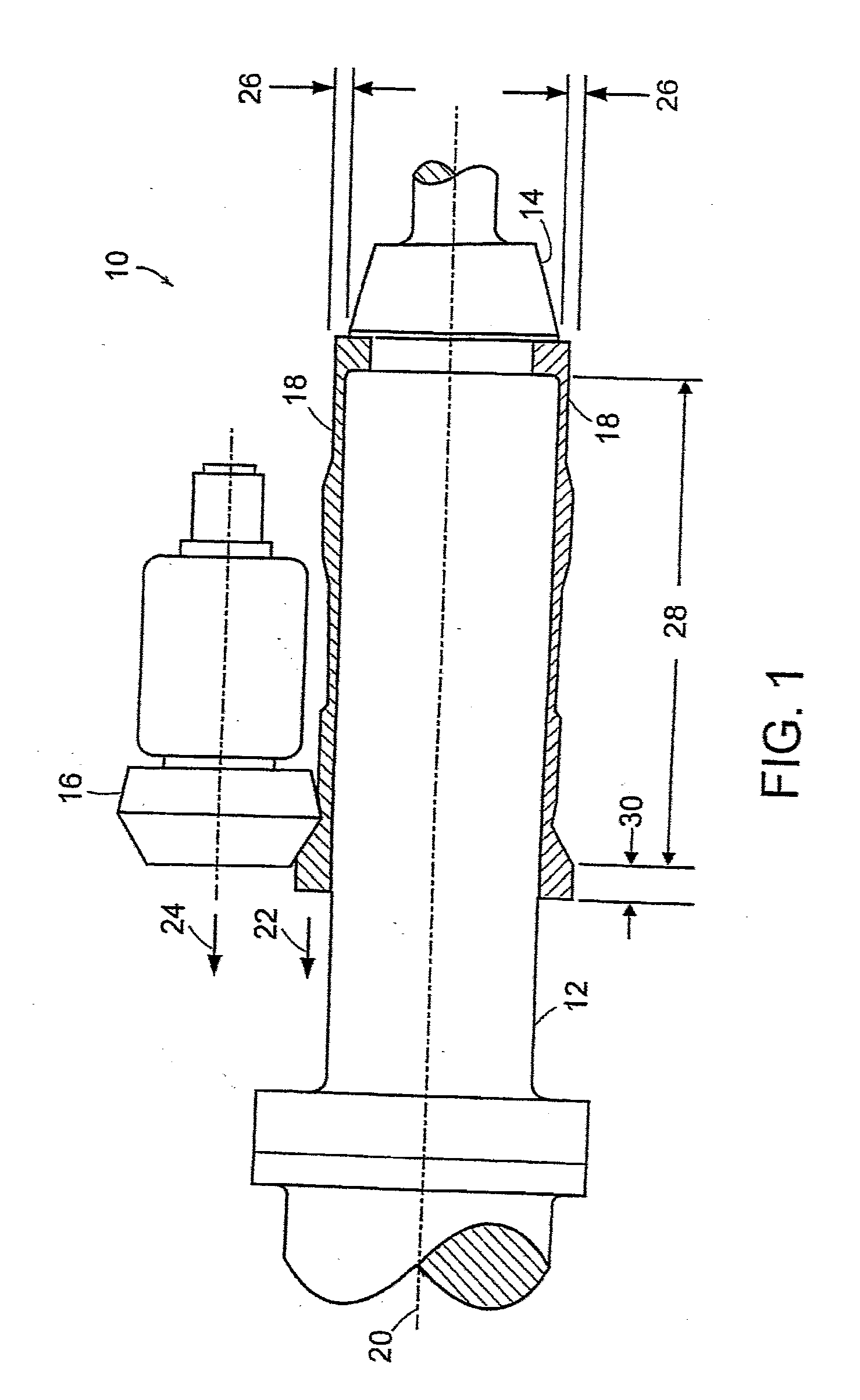

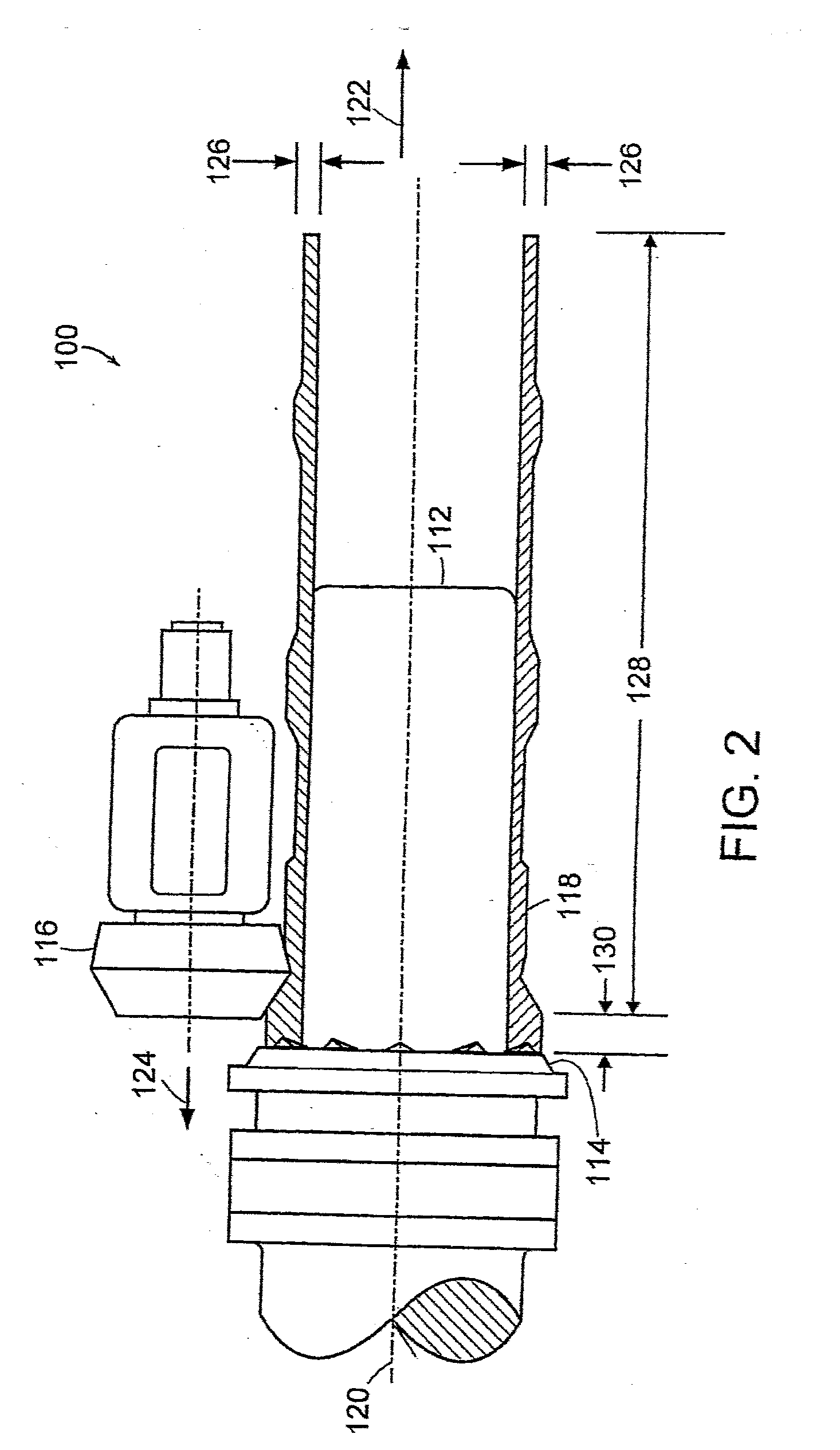

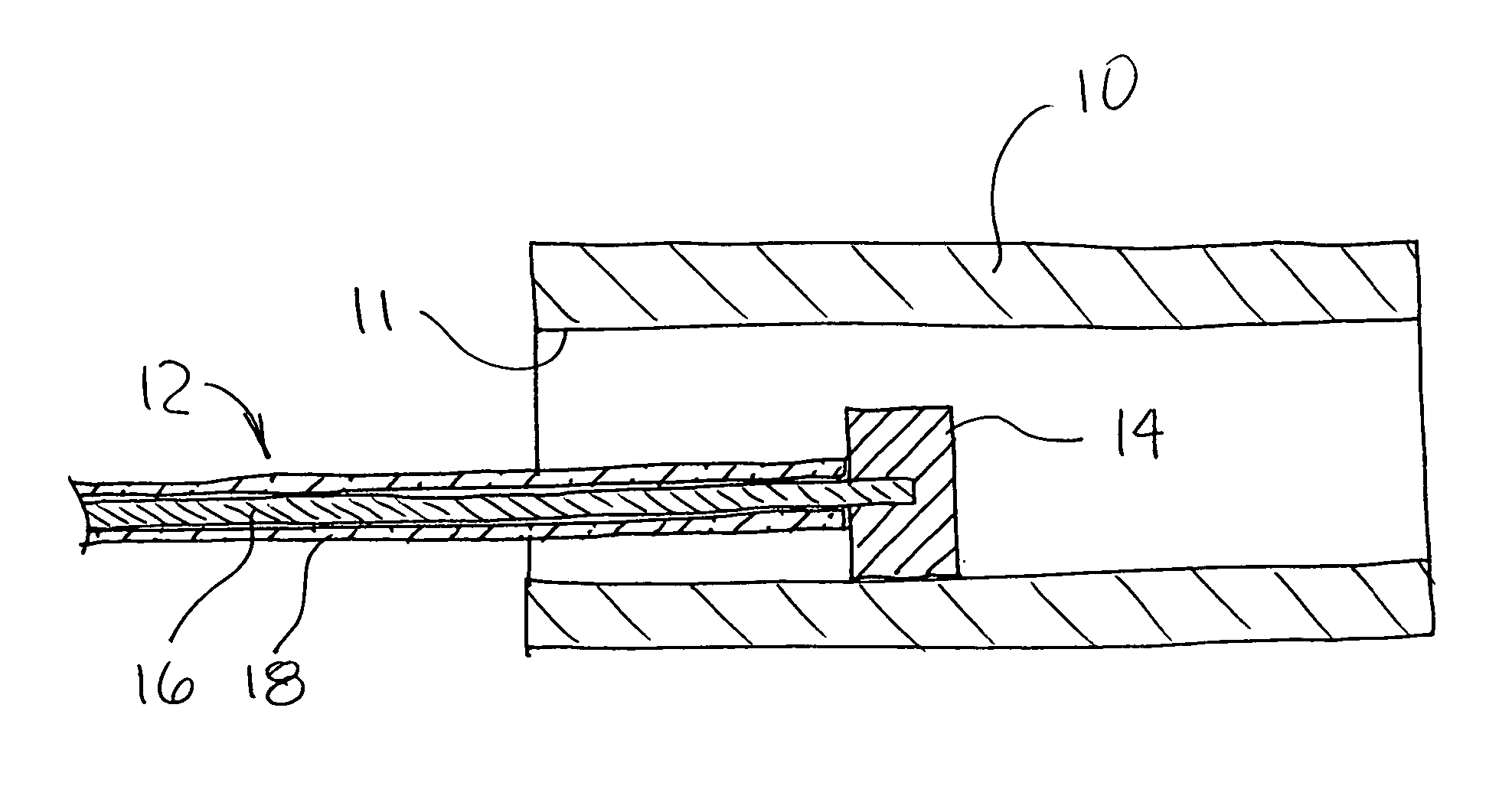

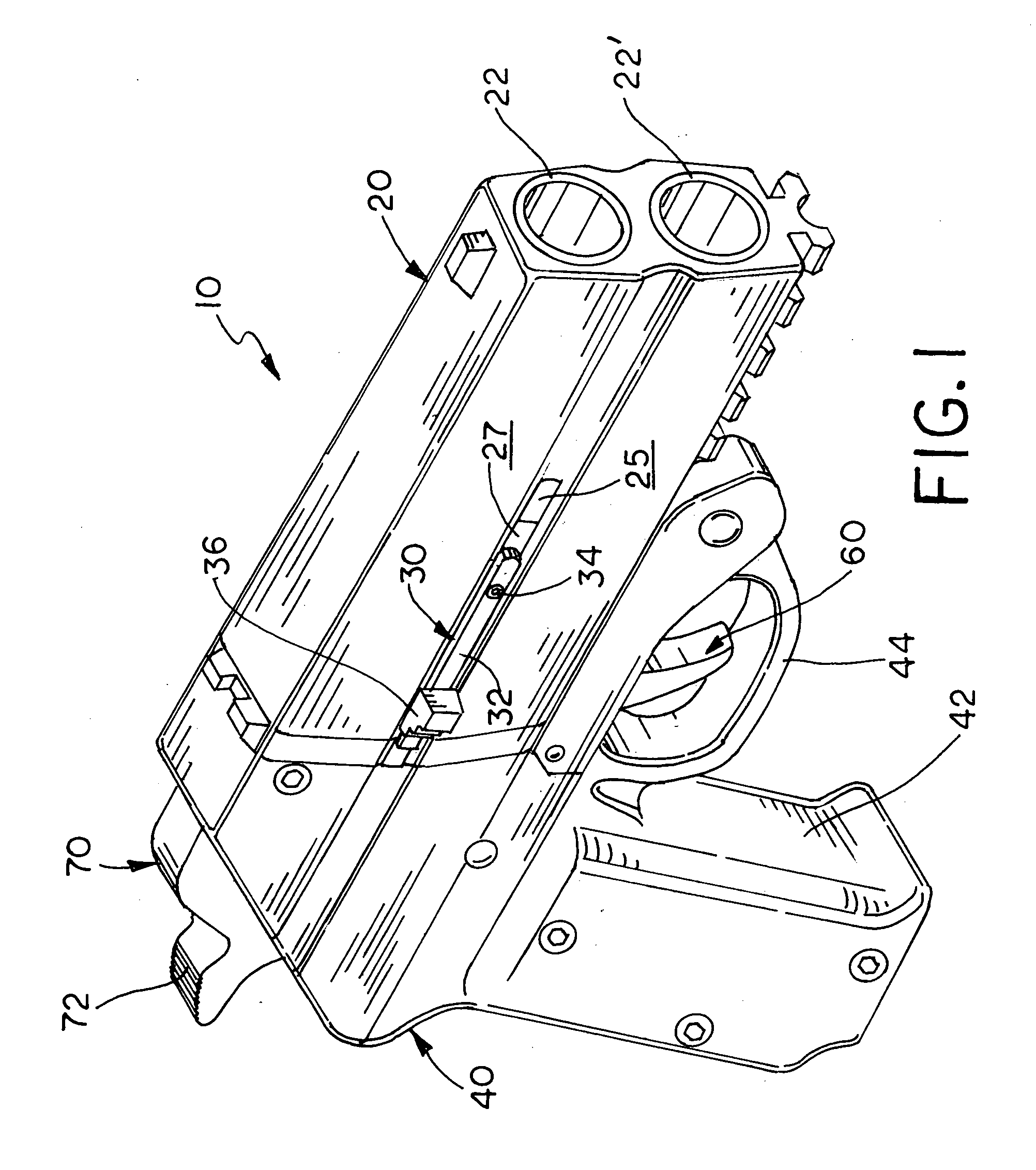

Projectile firing apparatus

InactiveUS6722252B1Minimal set-up timeFiring/trigger mechanismsAmmunition storageProjectileAerospace engineering

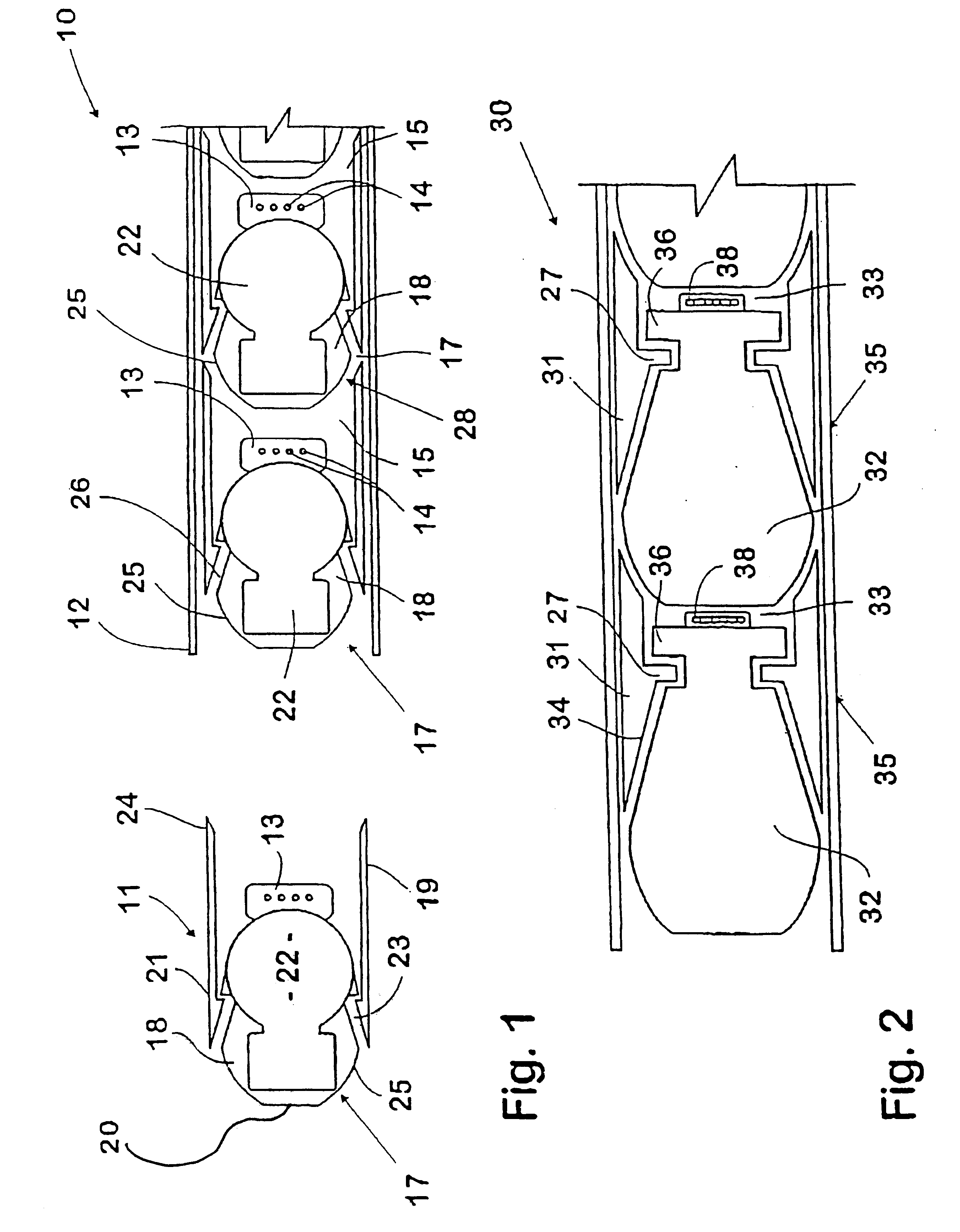

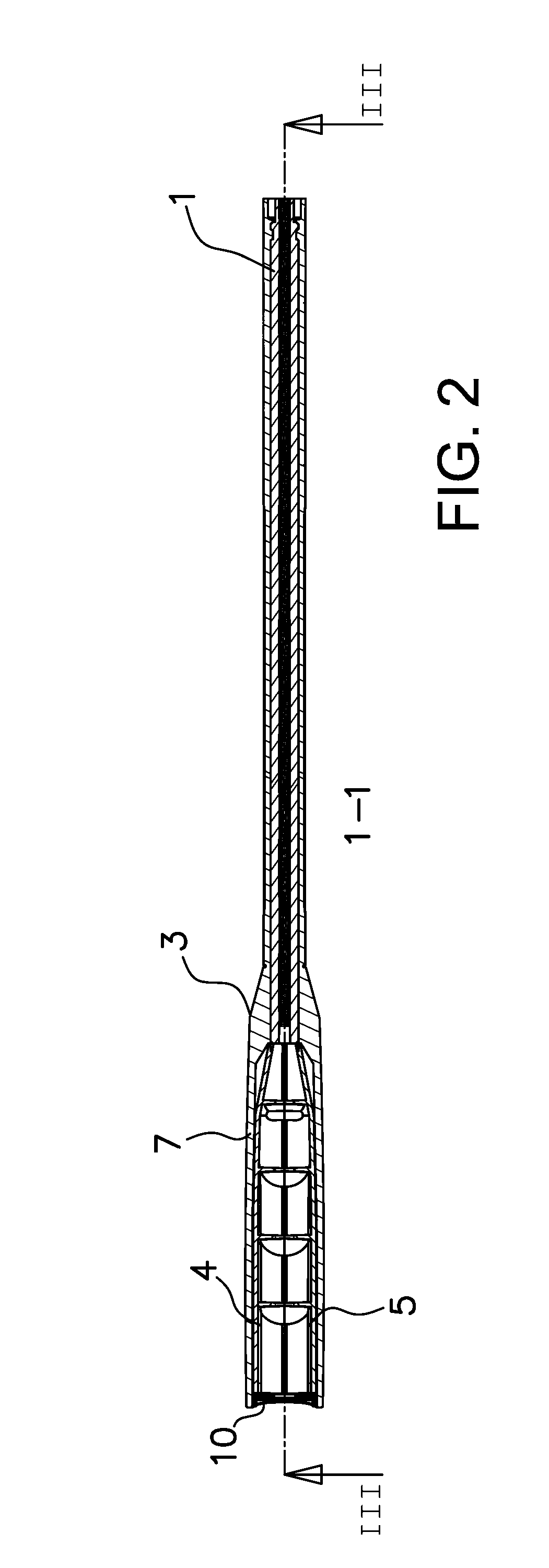

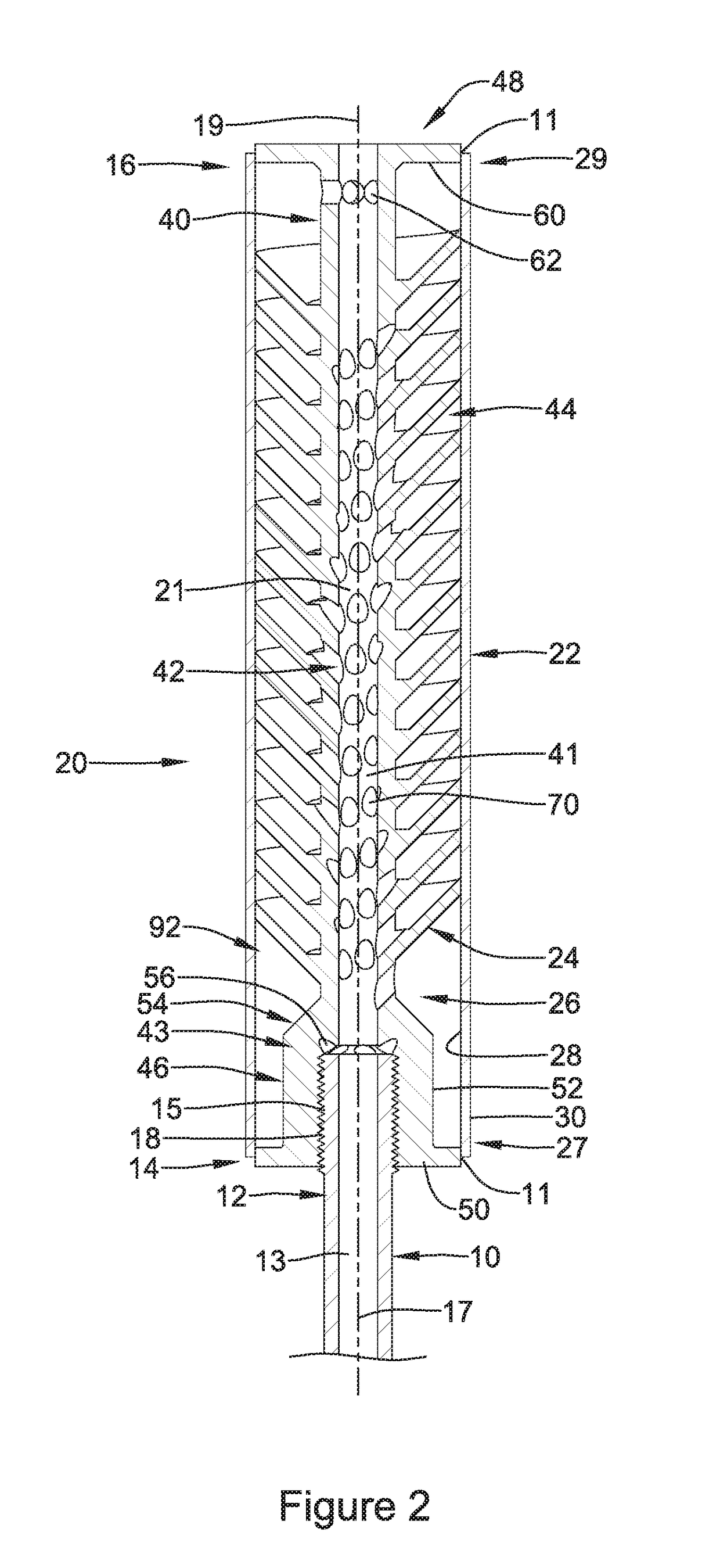

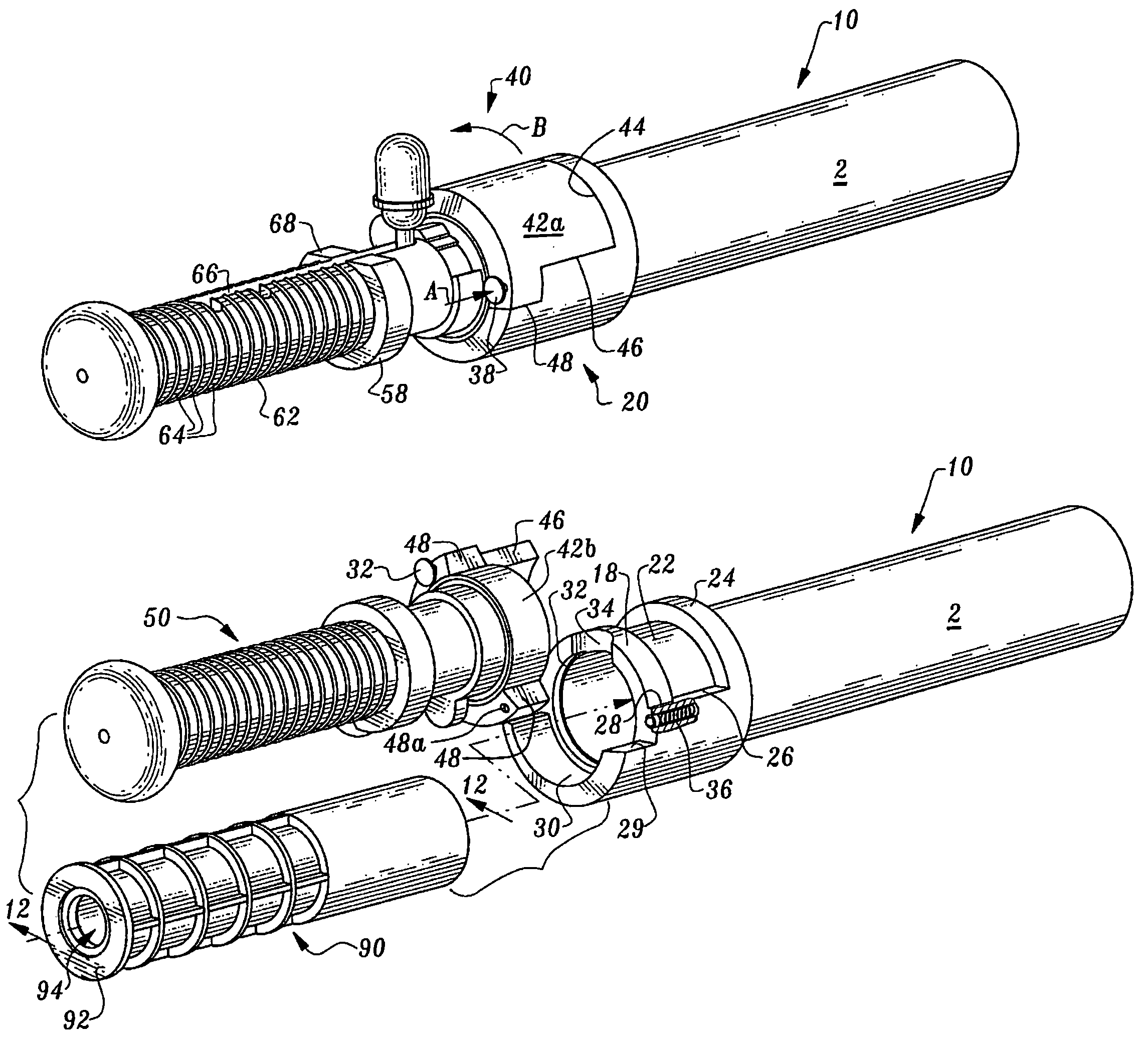

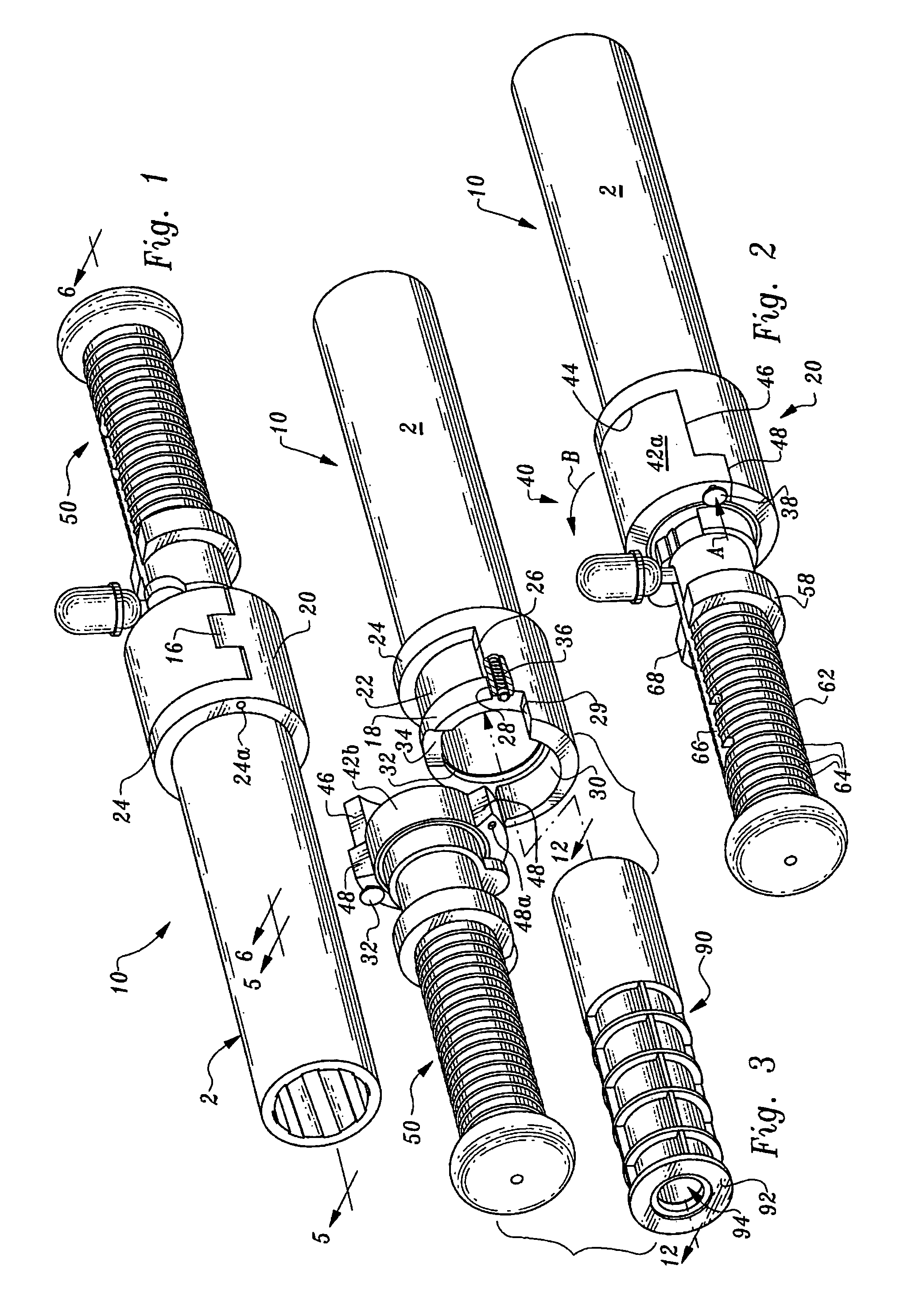

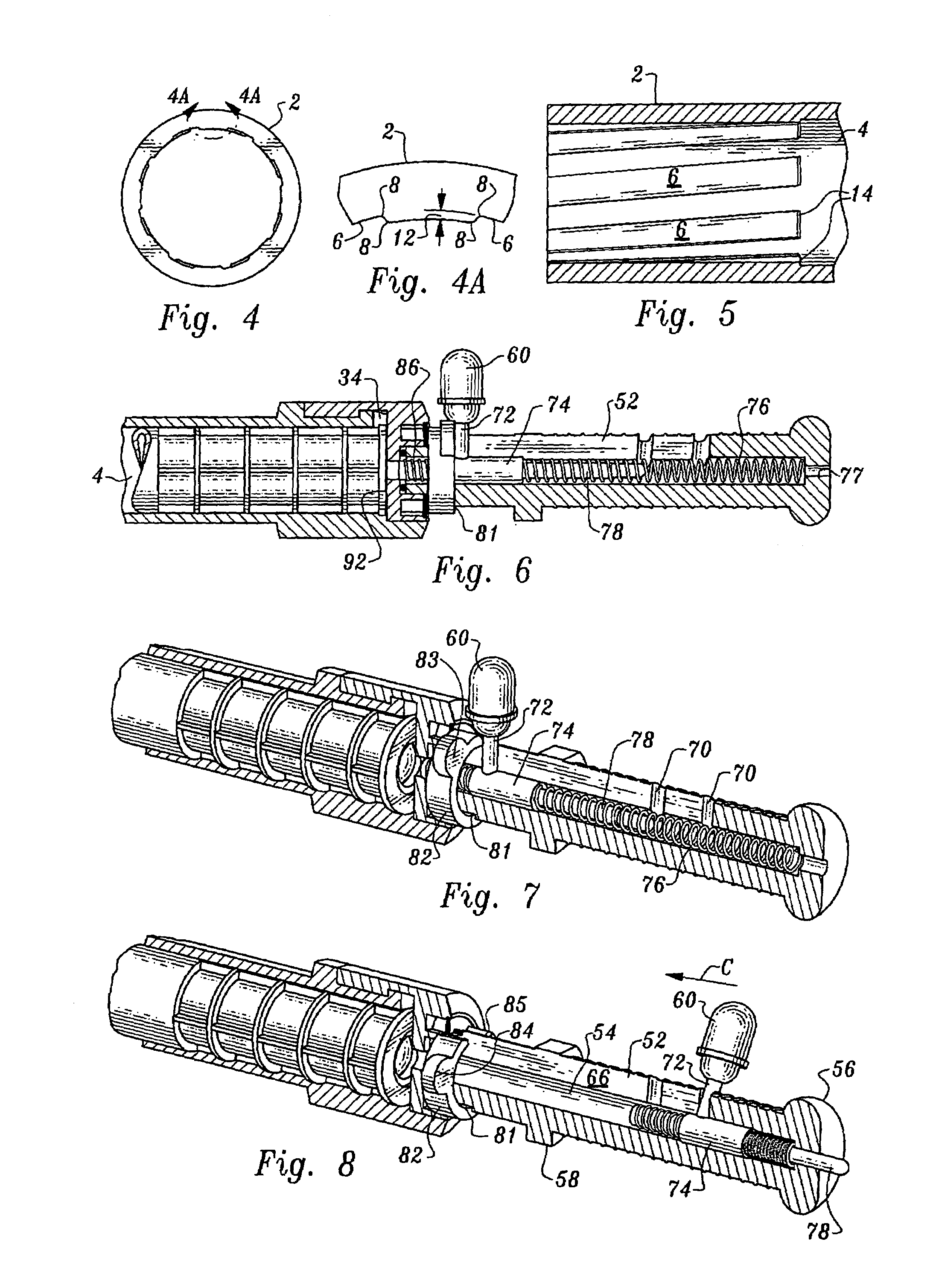

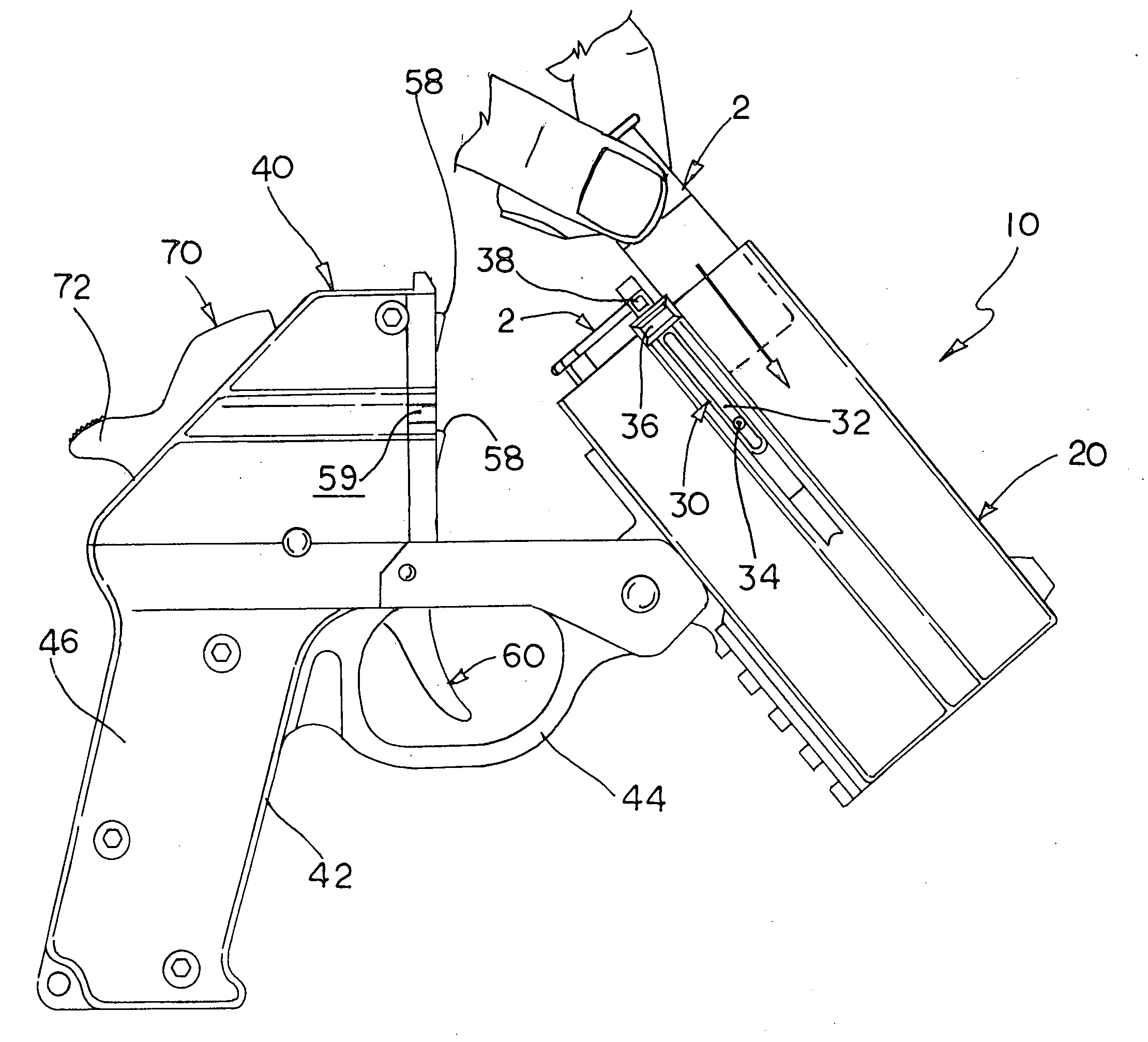

A weapon comprising a transportable pod having a plurality of barrel assemblies (10) of the type including a plurality of projectiles (11) arranged in-line within barrel (12). Each projectile (11) is associated with a discrete, selectively ignitable propellant charge (13) for propelling each projectile (11) sequentially through the muzzle of the barrel (12). Each projectile (11) includes projectile body (22) which matter or objects may be transported. Projectiles (11) are arranged with one another and barrel (12) so as to prevent rearward travel of an ignited propellant charge to the trailing propellant charge. The pod can include a direction control means for selectively varying the relative alignment between barrel assembles (10) so as to selectively vary the relative delivered position of projectile (11) fired from different barrels (12). The weapon may be used for military or civilian applications.

Owner:METAL STORM LIMITED ACN 064 370 006

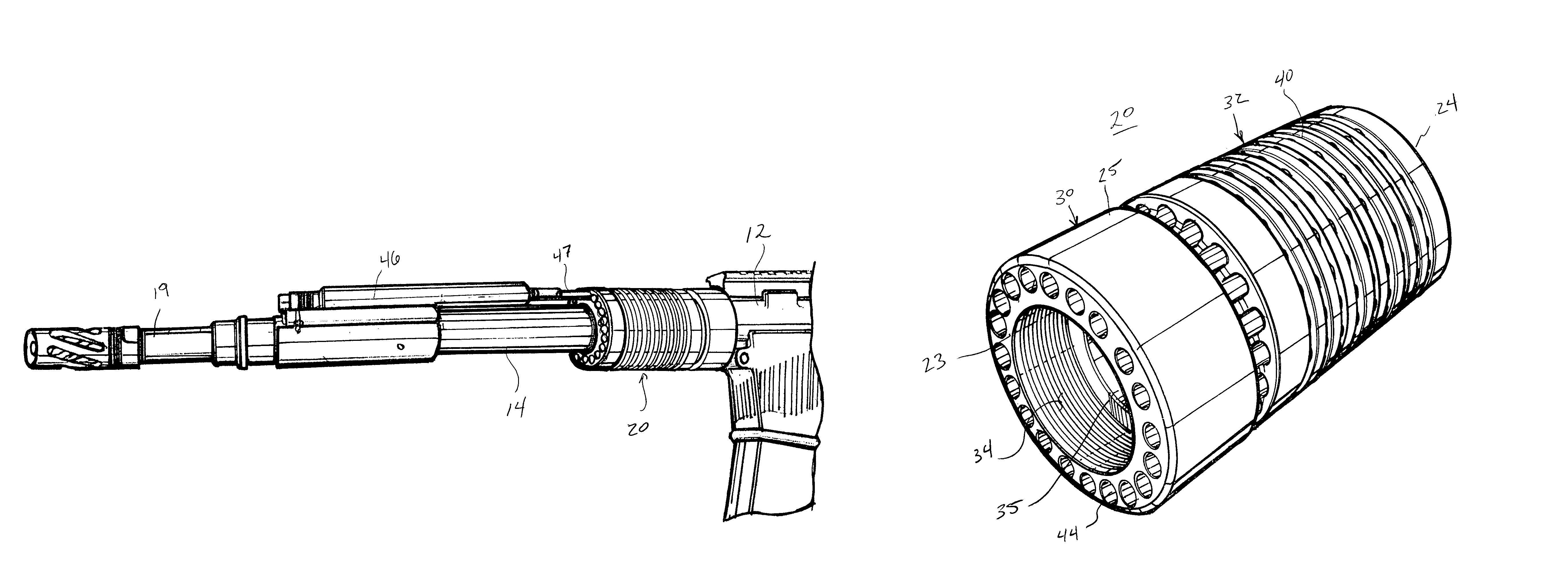

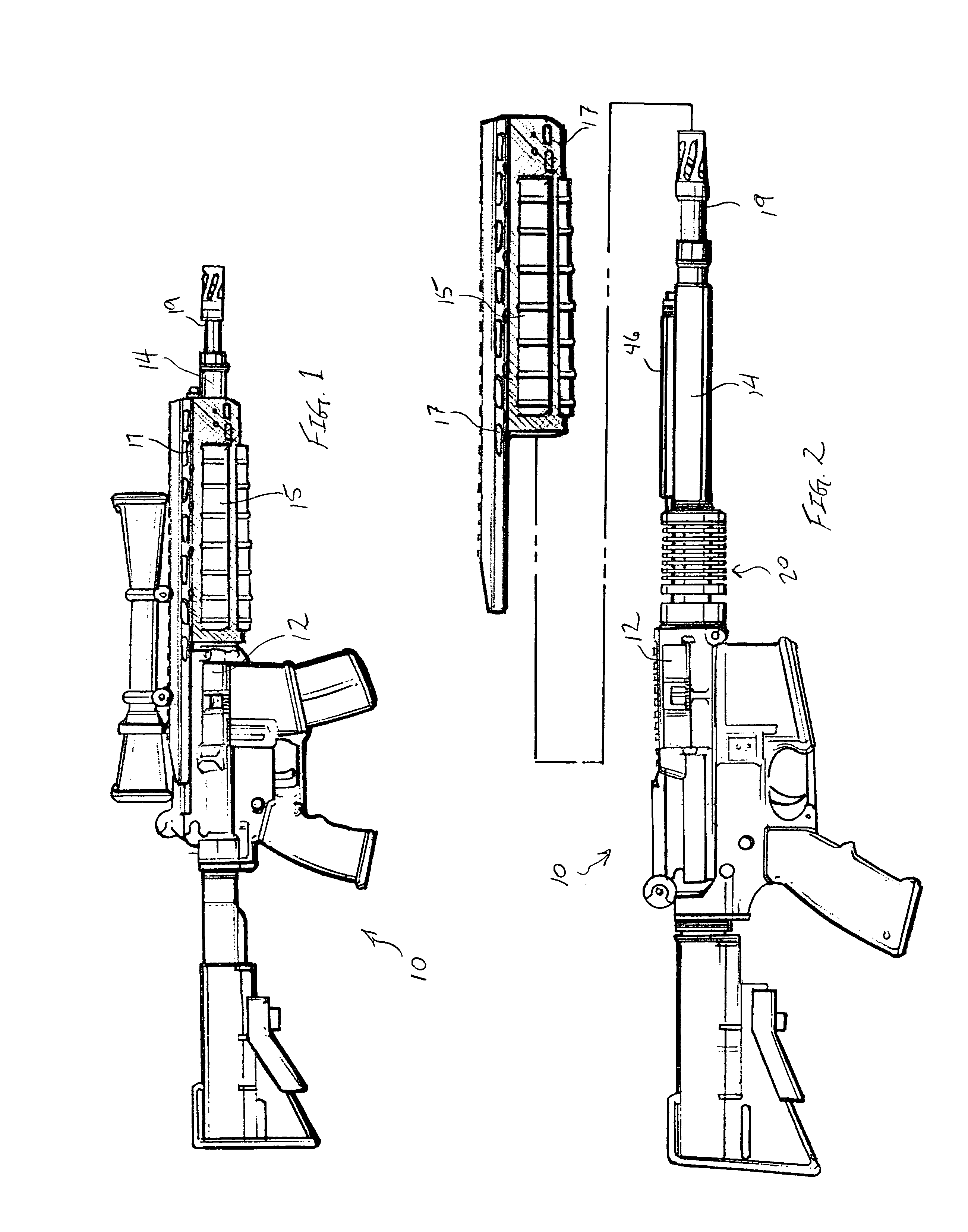

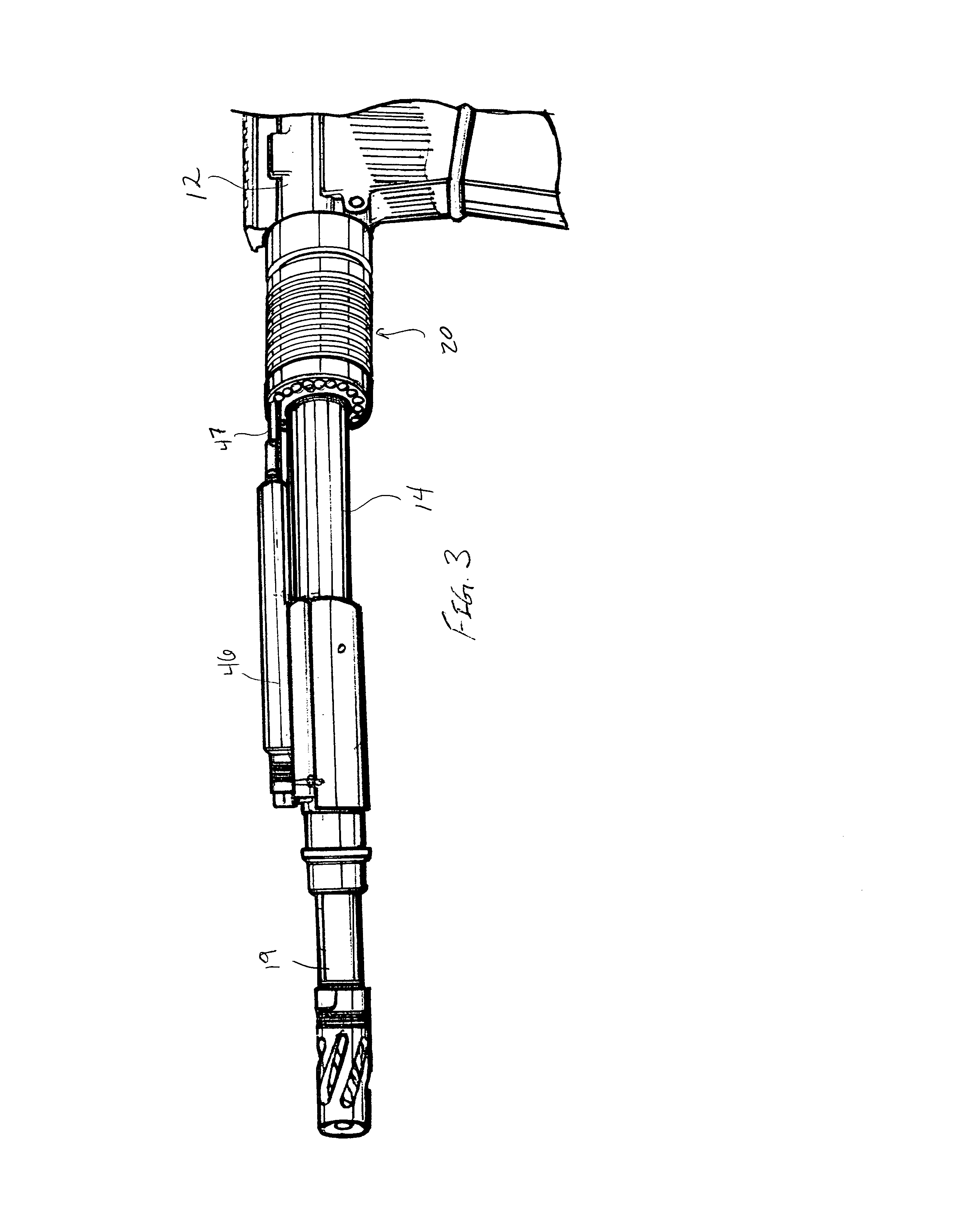

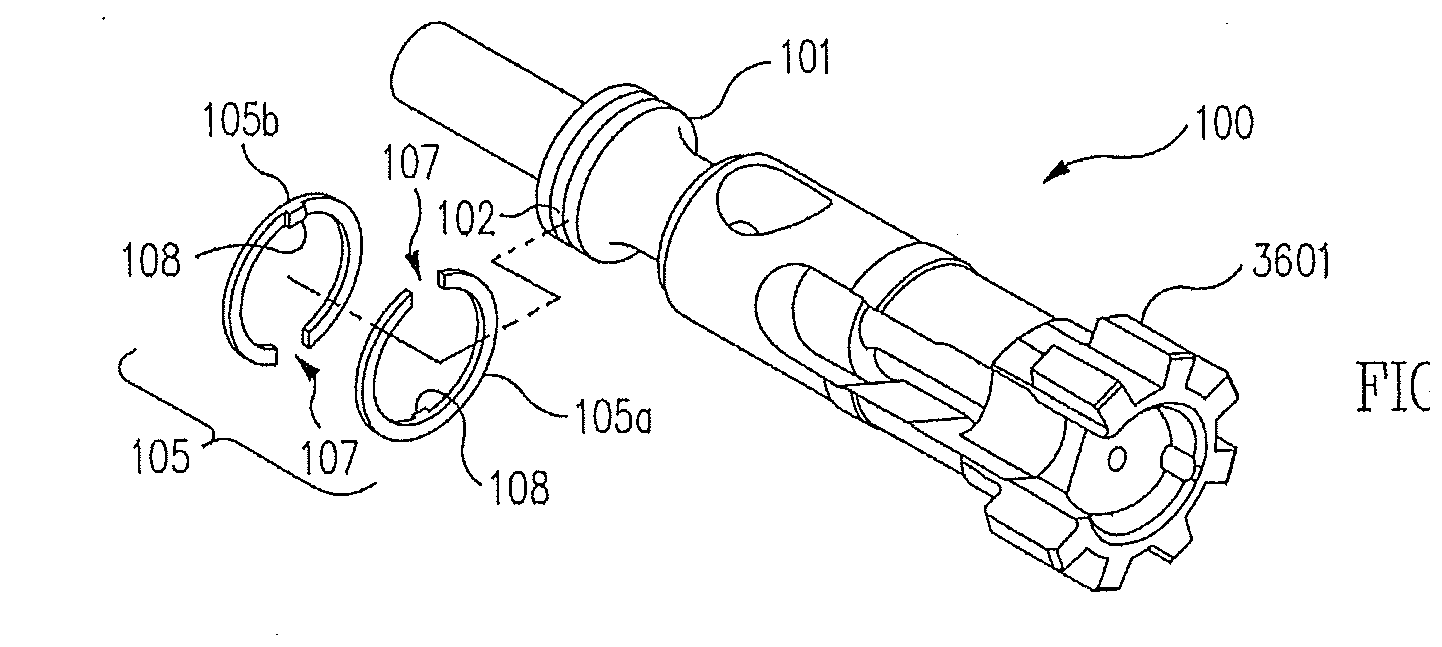

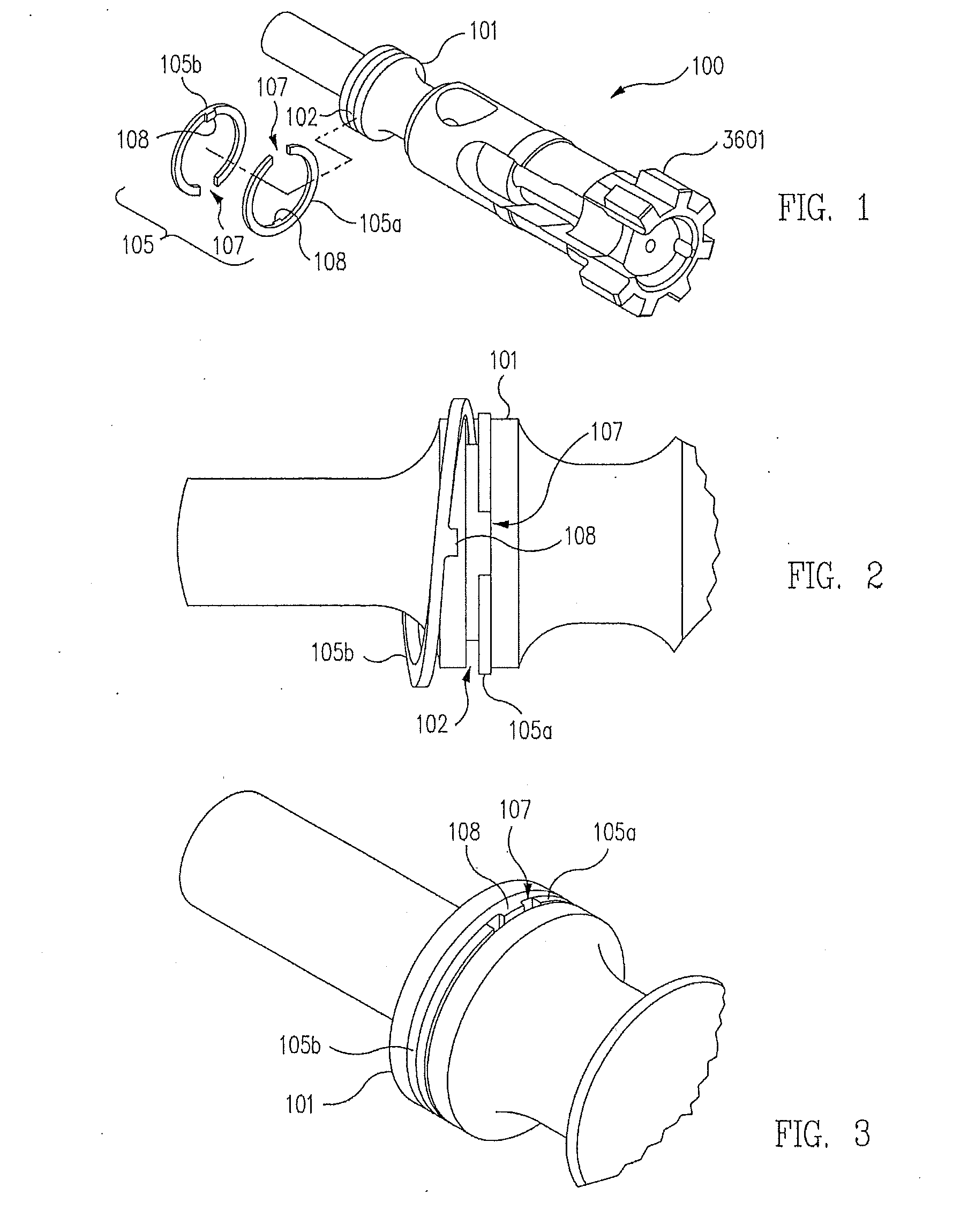

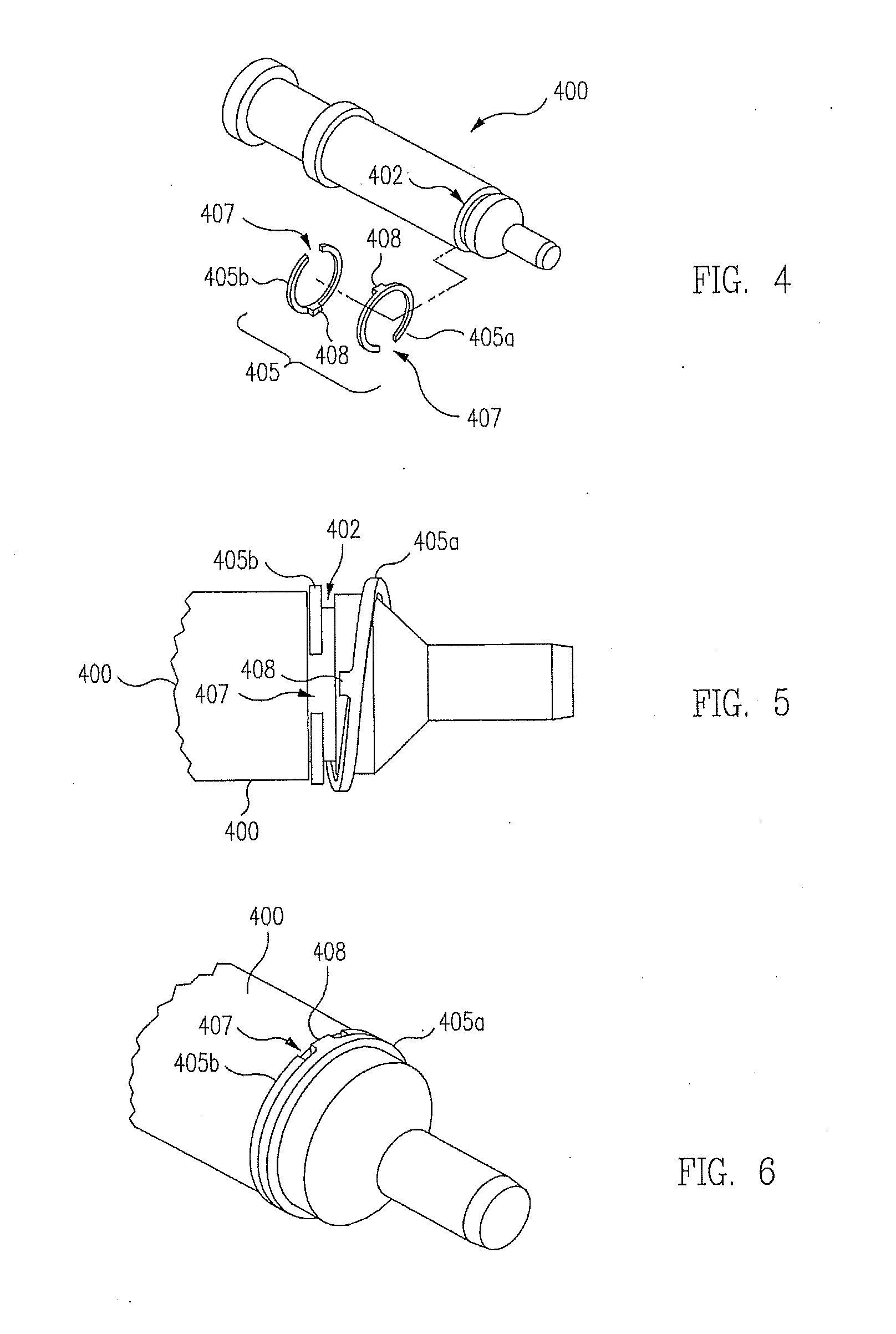

Firearm

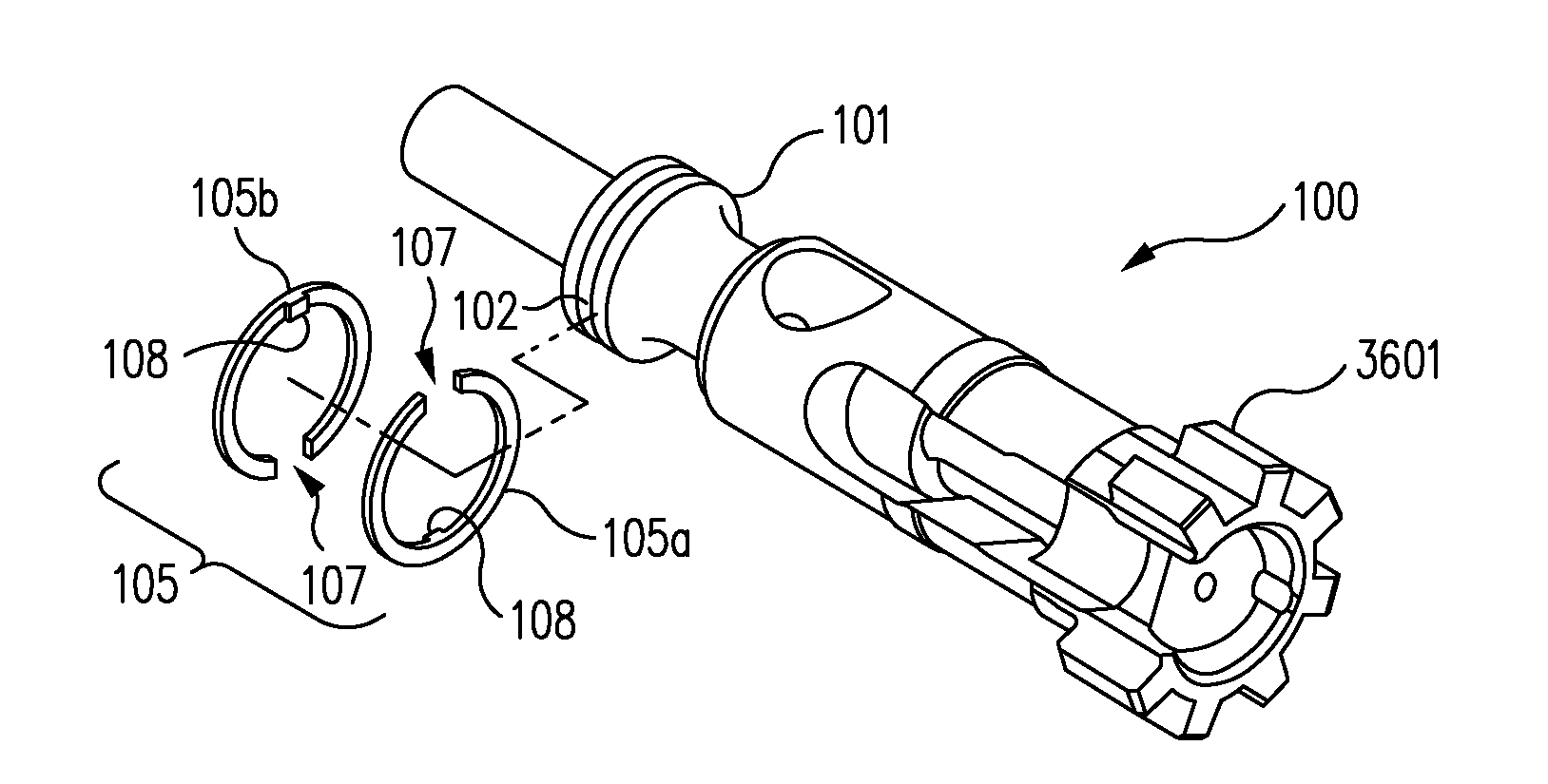

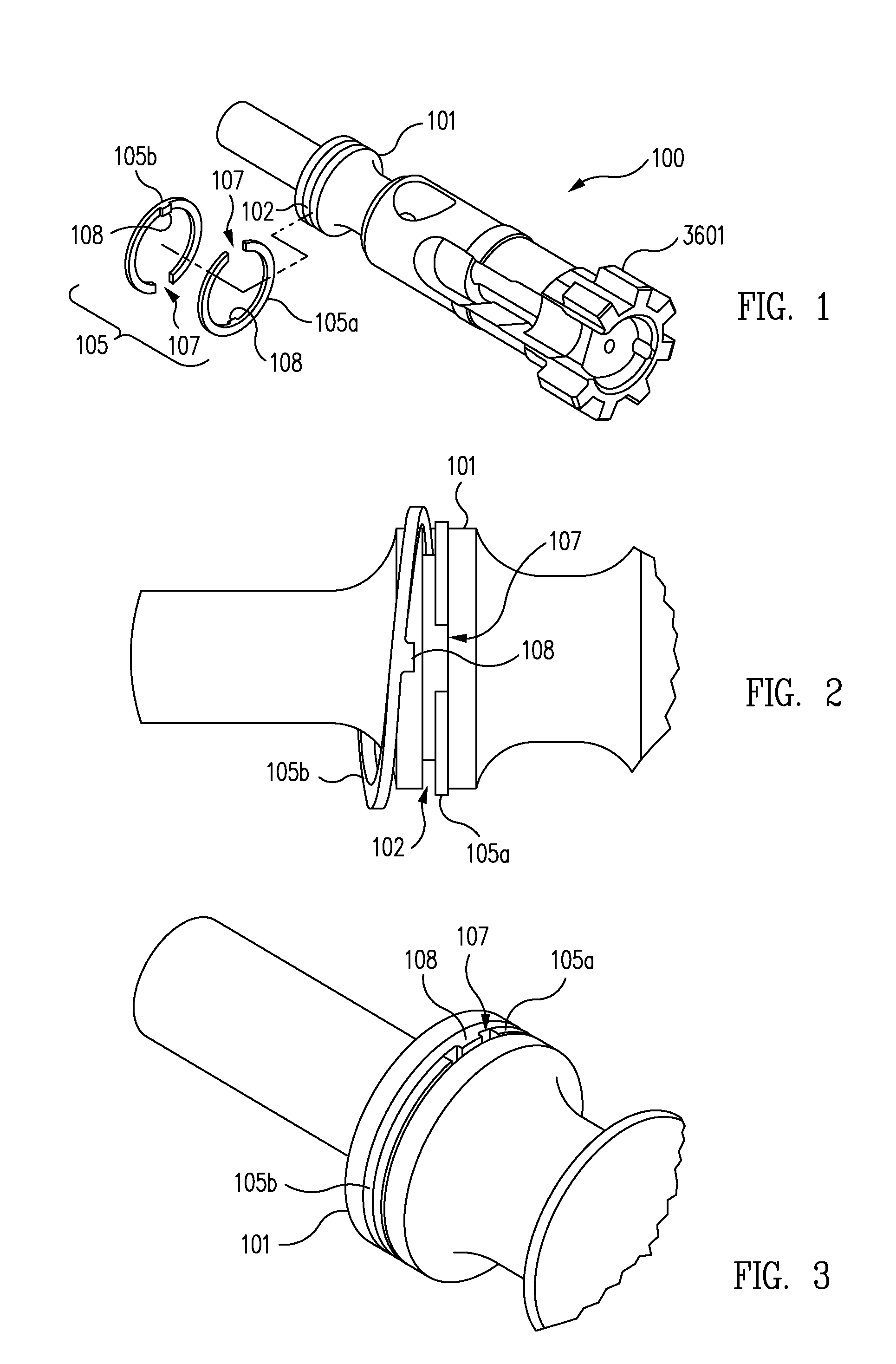

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is at least approximately 1.3 times that of a standard M16 / M4. A piston can be formed on the bolt and can have a plurality of rings that are configured to cooperate with the piston to mitigate gas leakage past the piston. Each of the rings can have a key formed thereon and a gap formed therein such that the gap of one ring is configured to receive at least a portion of the key of another ring. The bolt carrier can have a double cut cam.

Owner:ARMWEST

Sound suppressor cooling system

InactiveUS8967325B1Speed up the flowImprove cooling effectVentillation systemsBarrelsSuppressorSpray nozzle

A firearm sound suppressor cooling system comprising a sound suppressor housing with means for reducing the pressure of gases exiting from a discharged firearm with a shroud that is attached to the exterior of the sound suppressor housing, an annular chamber formed between the sound suppressor housing and the shroud, and a nozzle positioned at the distal end of the sound suppressor and the shroud. The nozzle produces a suction effect upon discharge of the firearm and due to the suction effect, ambient air is aspirated through the annular chamber, and cools the firearm sound suppressor.

Owner:CRONHELM PETER WILLIAM

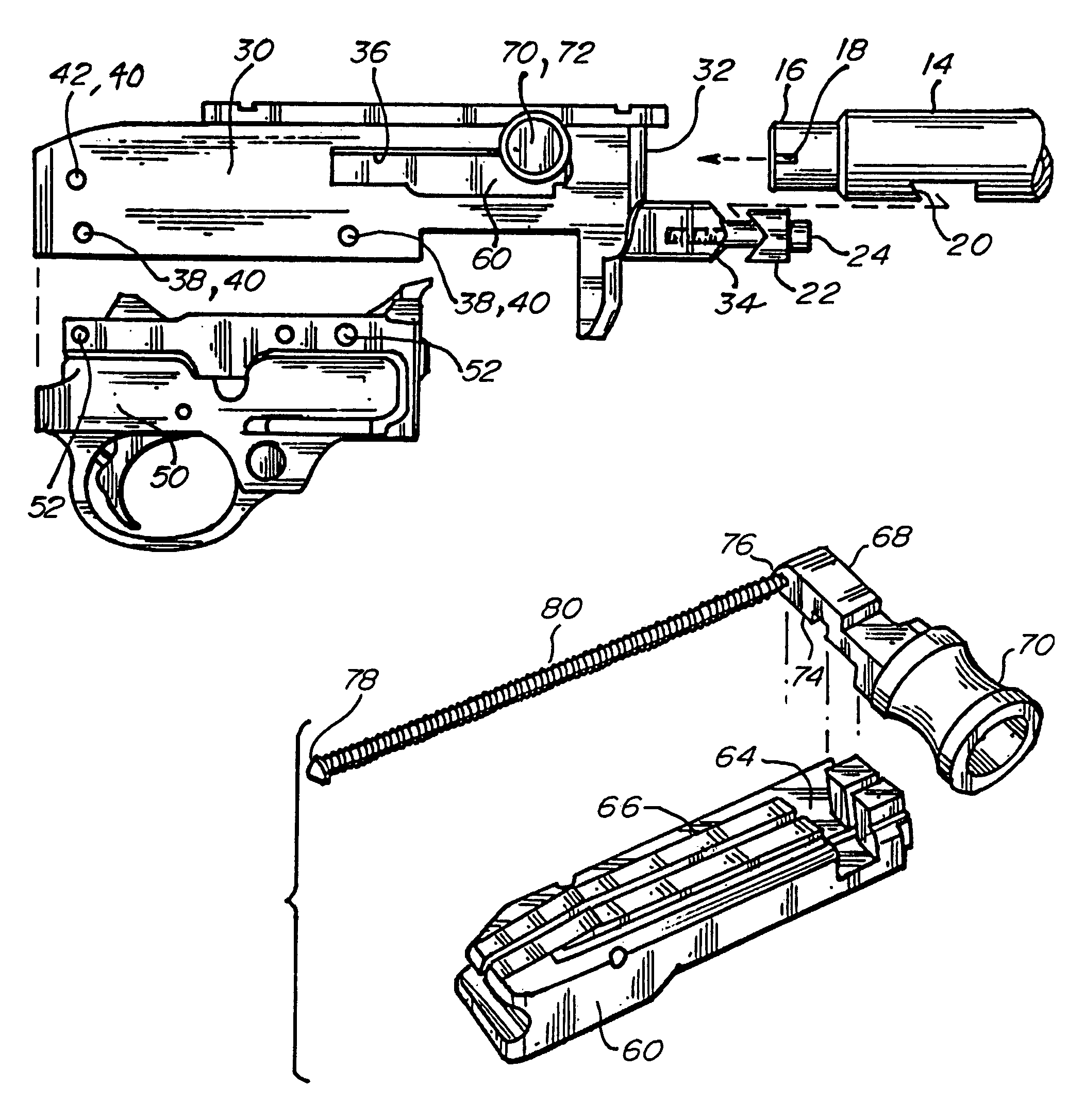

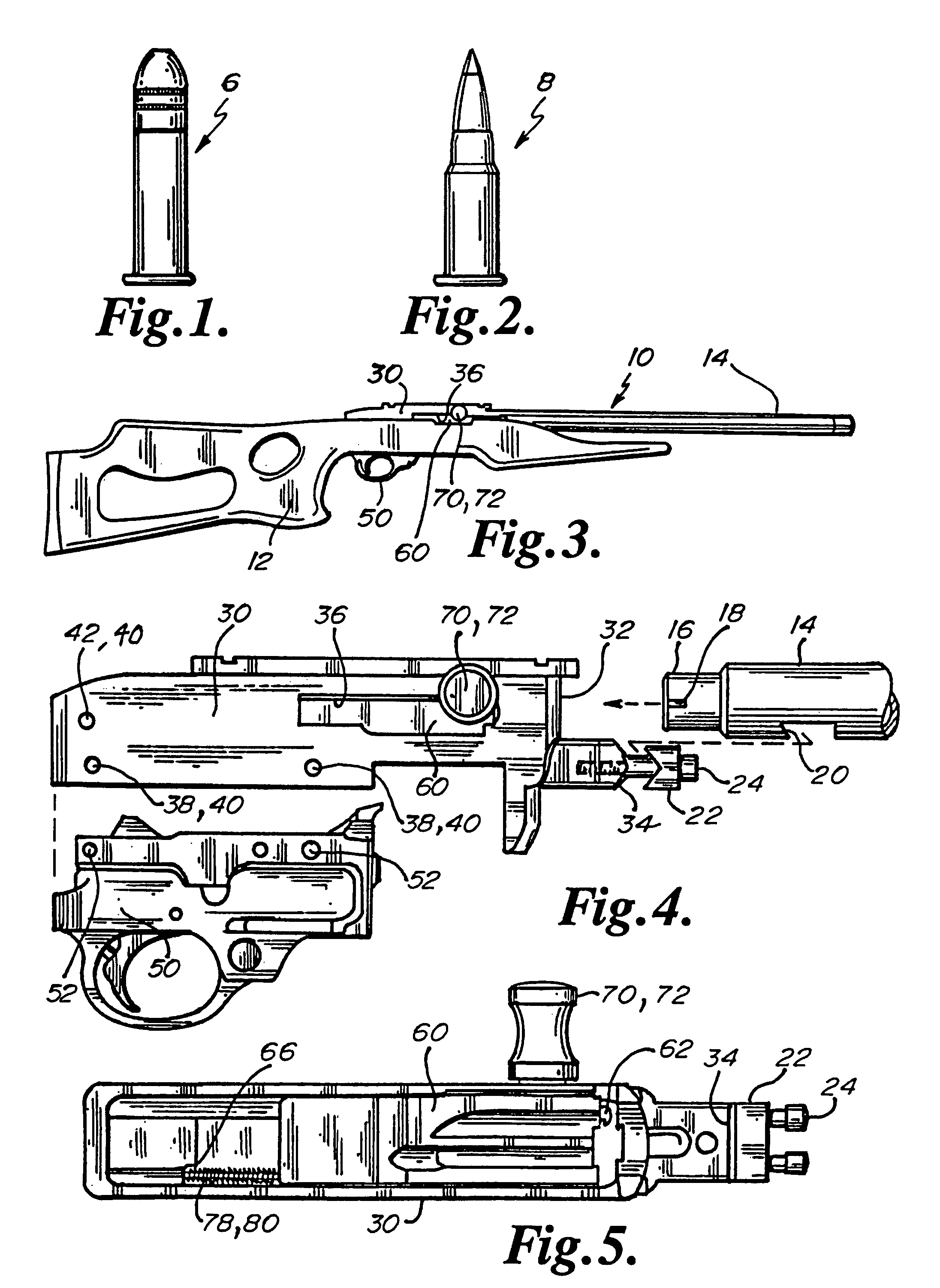

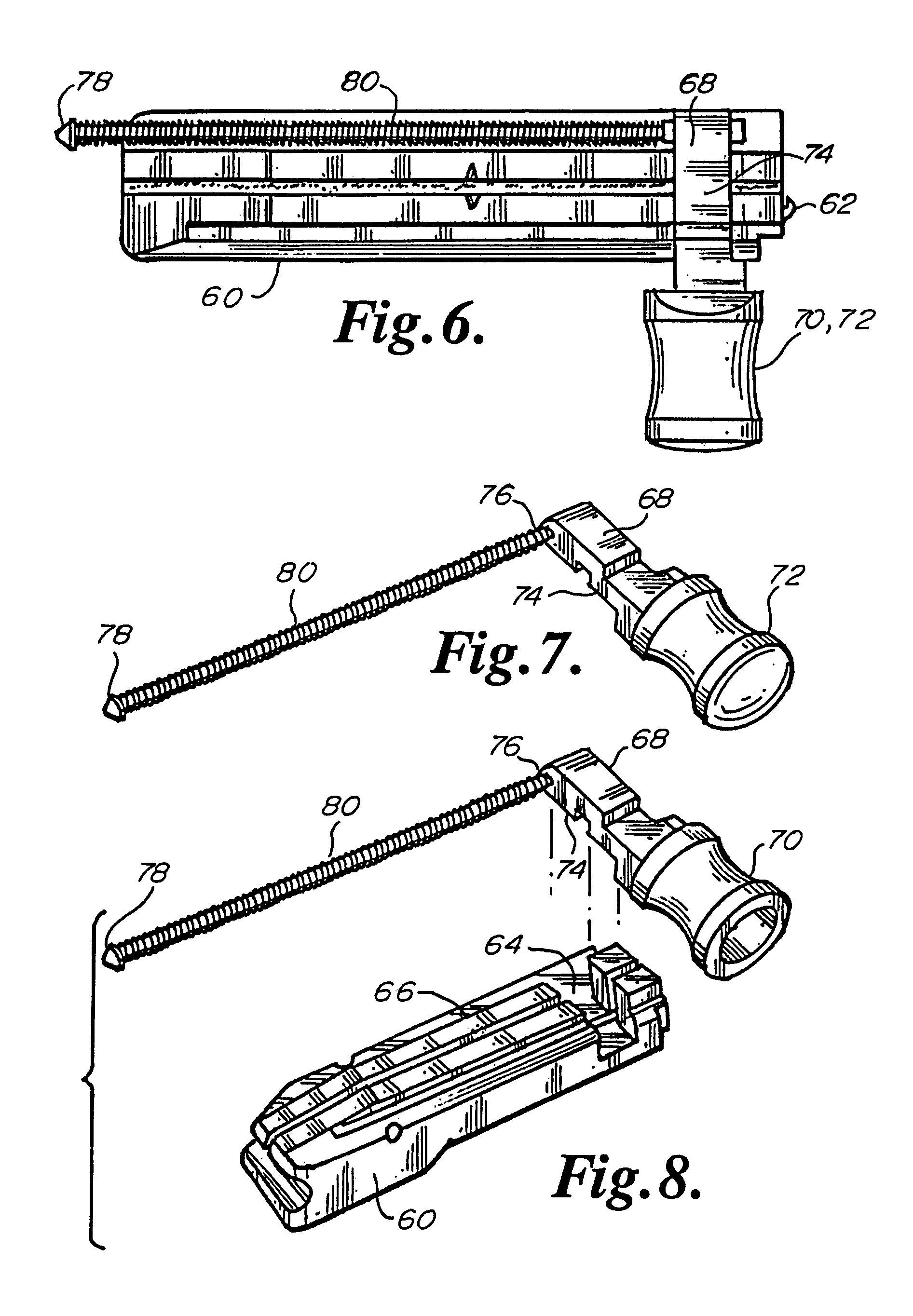

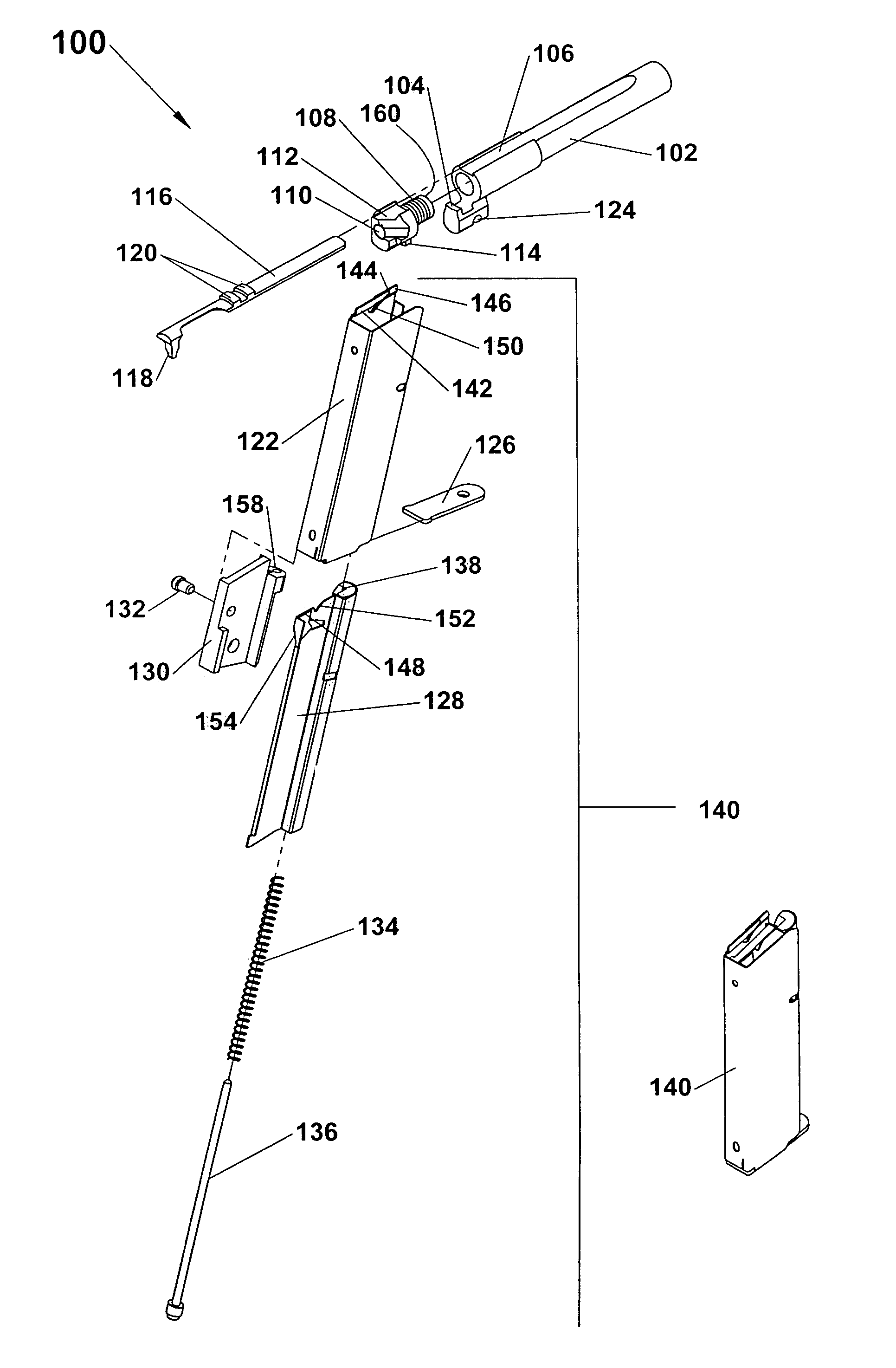

Conversion kit and method for a ruger 10/22 semi-automatic .22 caliber rim fire rifle to shoot .17 mach 2 cartridges

InactiveUS7302881B1Low costEasy to operateWeapon assembly/disassemblyBreech mechanismsSemi automaticEngineering

A conversion kit and method for converting the RUGER® 10 / 22® semi-automatic .22 caliber rim fire rifle to shoot .17 HM 2 cartridges utilizes the original bolt in the receiver and replaces the bolt operating handle with increased weight to replace the original bolt handle along with a .17 caliber barrel to permit the modified rifle to safely fire, eject and reload the .17 caliber cartridges.

Owner:SAEILO ENTERPRISES

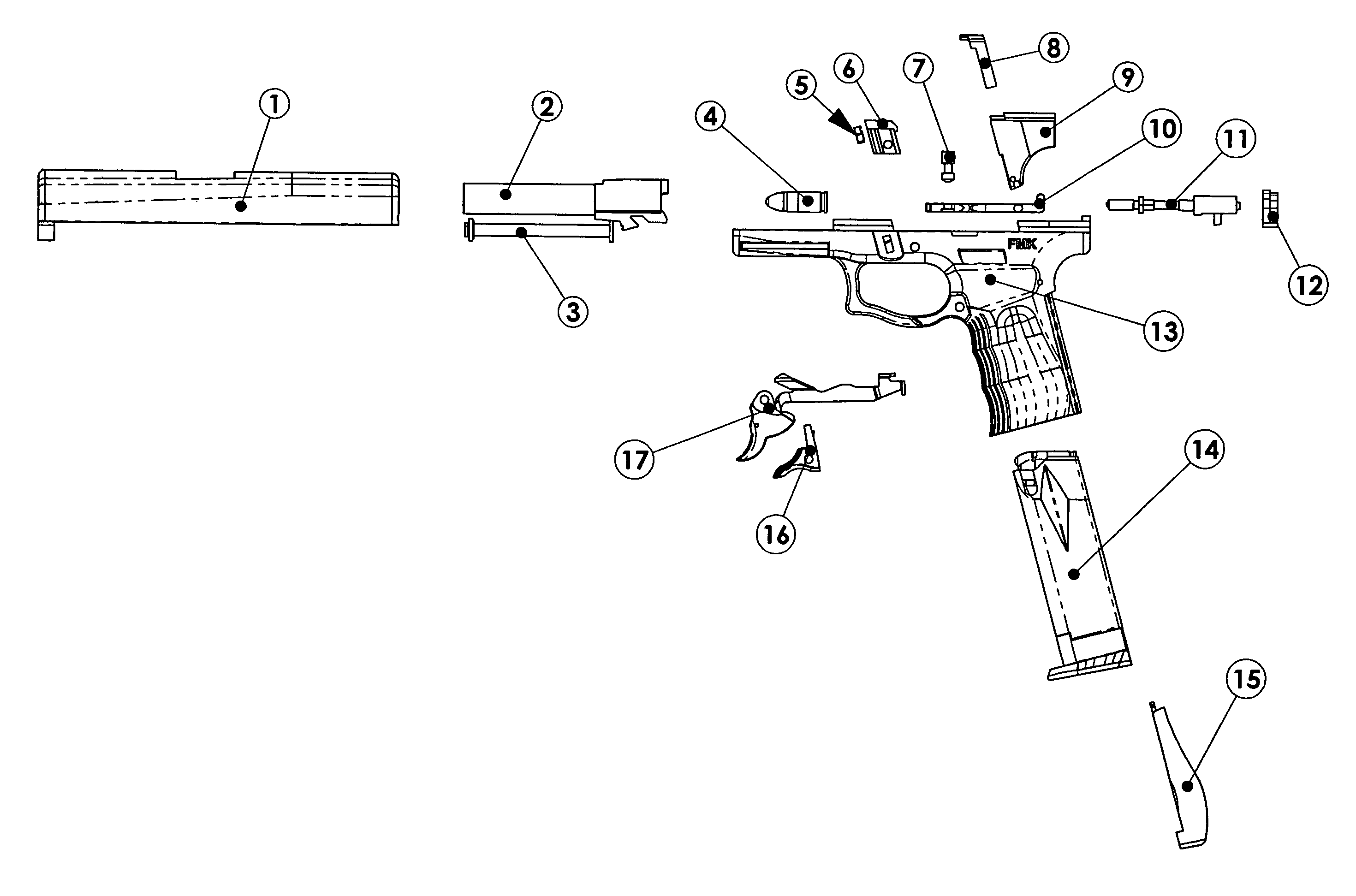

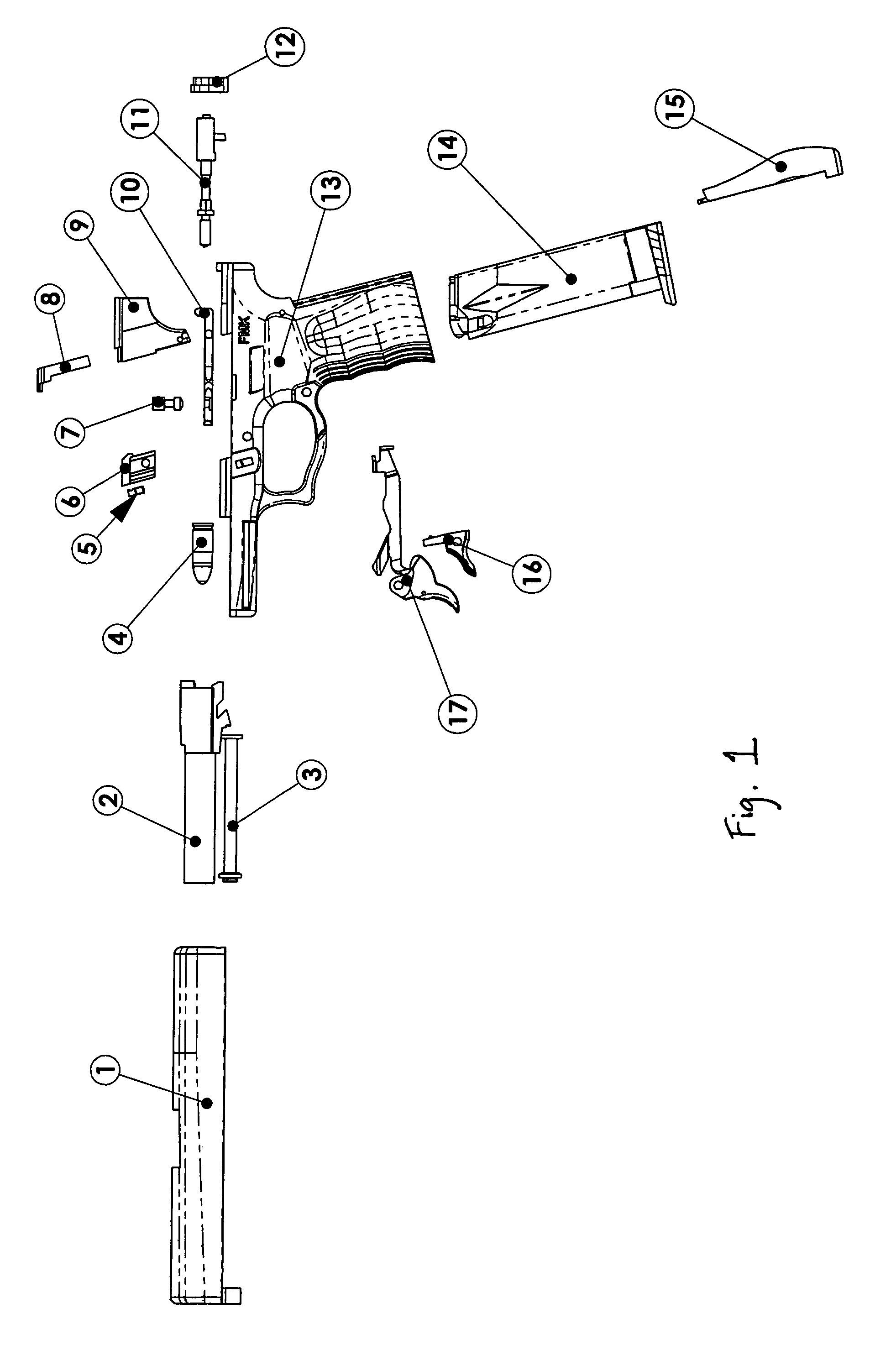

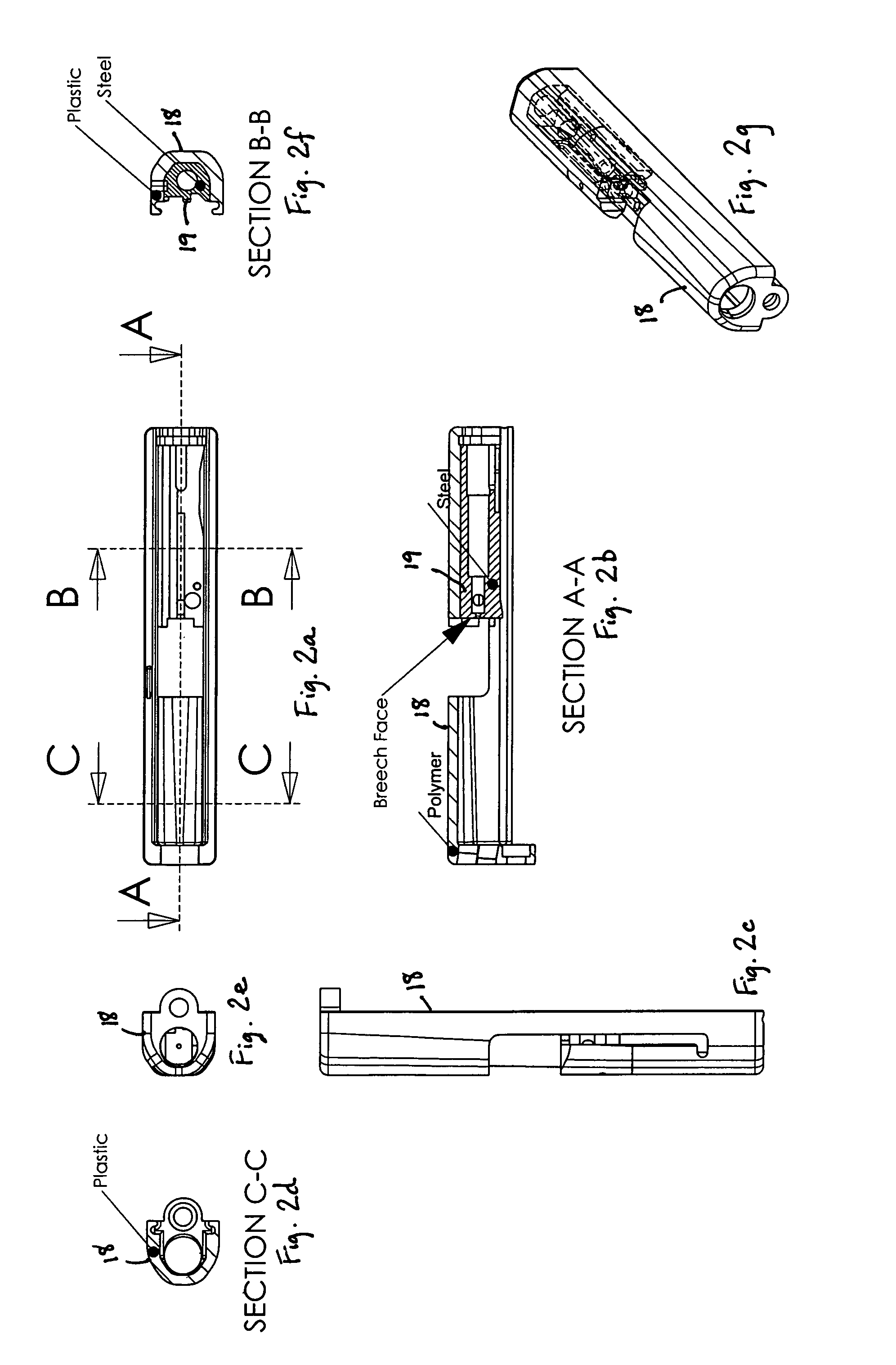

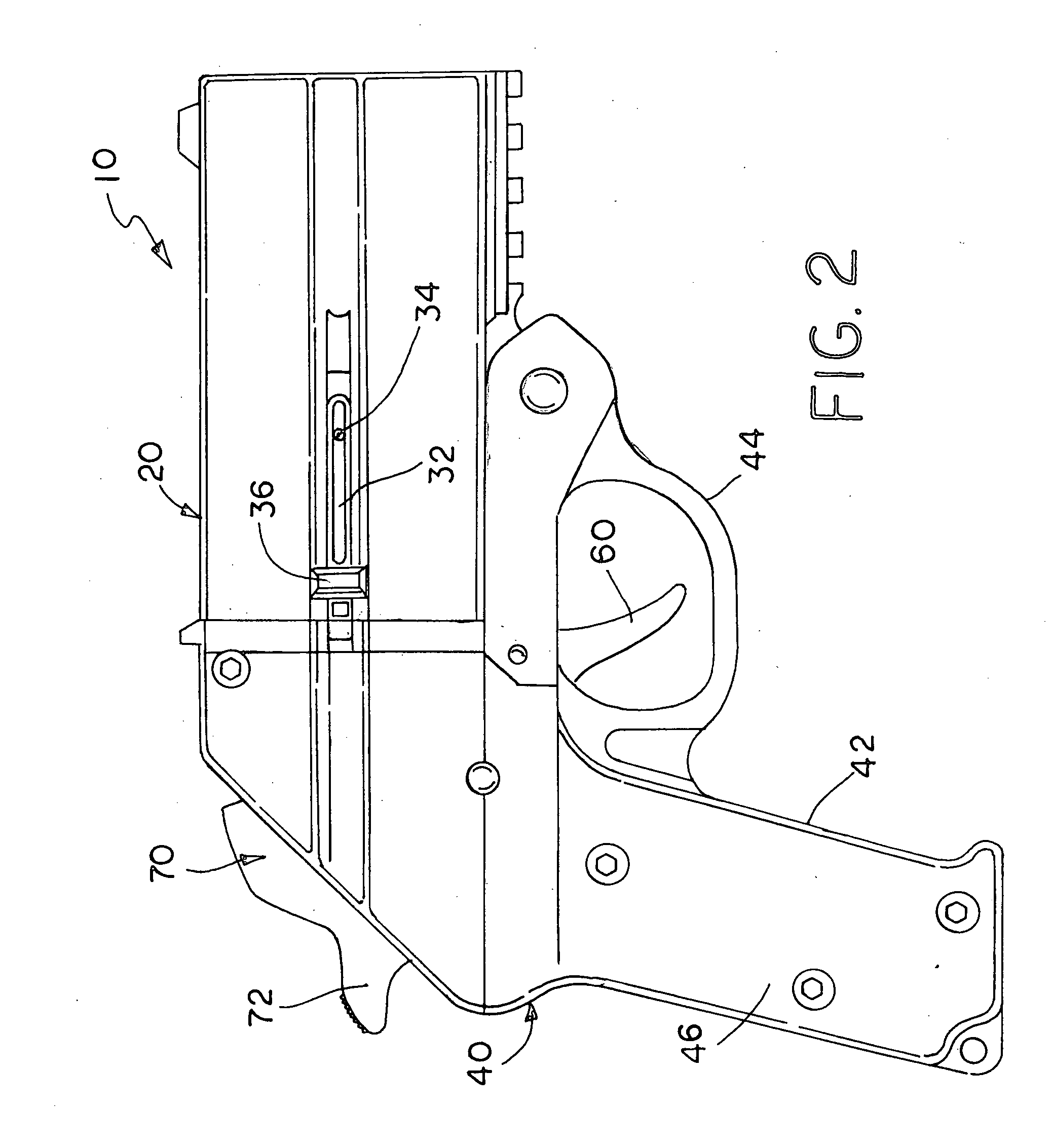

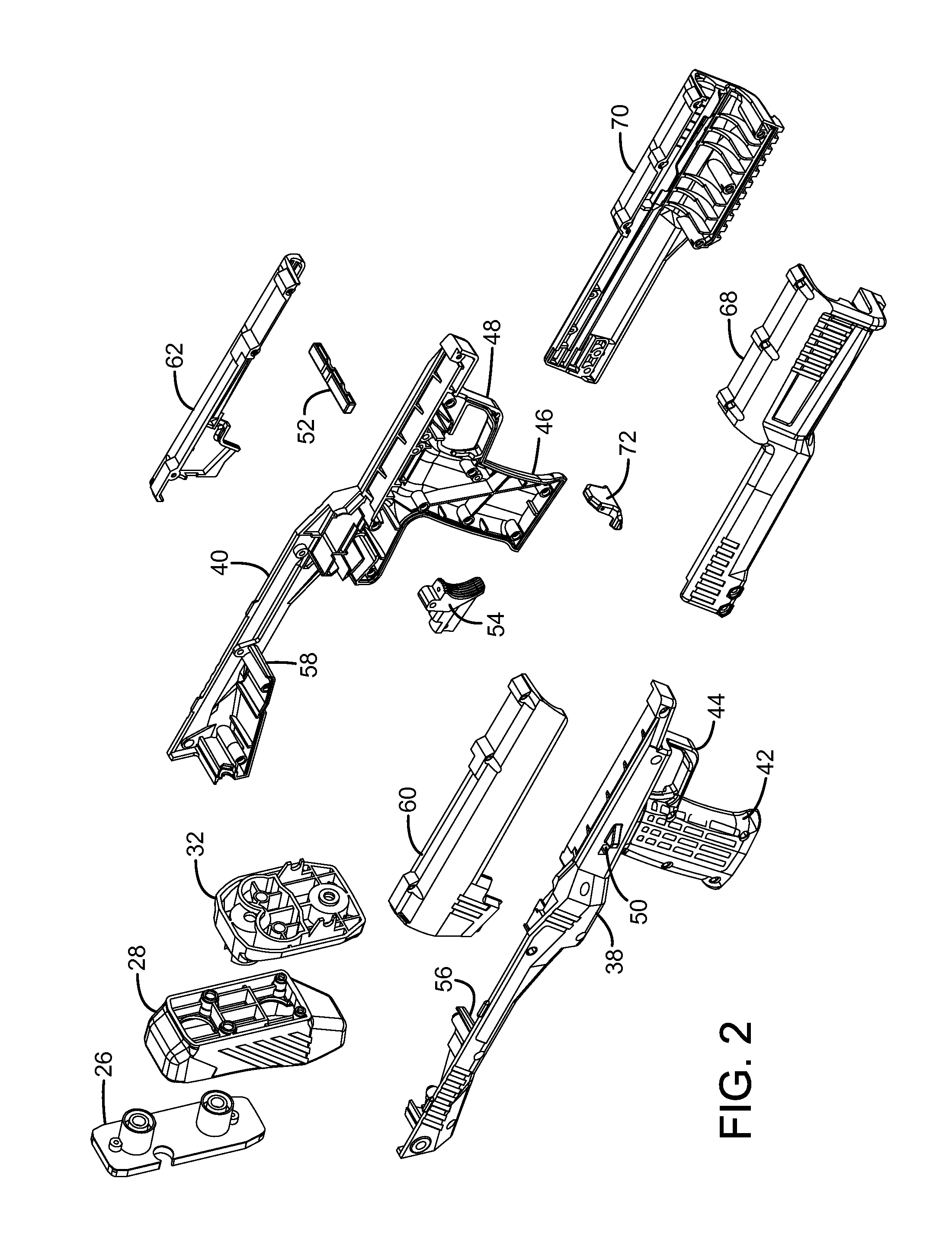

Plastic pistols

The present invention comprises plastic pistols and individual parts therefore having an increased use of plastic in comparison to prior art plastic pistols, reducing the number and simplifying the design of the metal parts to reduce the cost of the pistols while still maintaining gun quality. One aspect of the invention is the use of plastic in certain critical areas, simplifying the configuration of the metal inserts used. In many cases, this can eliminate expensive machining of metal parts in favor of parts injection molded to finished dimensions. In that regard, legal requirements can still be met with respect to metal content, yet that metal content may be simplified in configuration for ease of manufacture. Certain preferred embodiments of the invention are illustrated.

Owner:PONTILLO II JAMES V

Air or fire rifle with noise dampener

A rifle has a barrel defining a bore therein. A noise damper is provided adjacent a distal end of the barrel and defines a distal extension of the bore of the barrel. The noise damper includes a housing that is over-molded or over-injected on the barrel, such that the barrel, the noise damper and its housing define an integral assembly.

Owner:GAMO OUTDOOR SL

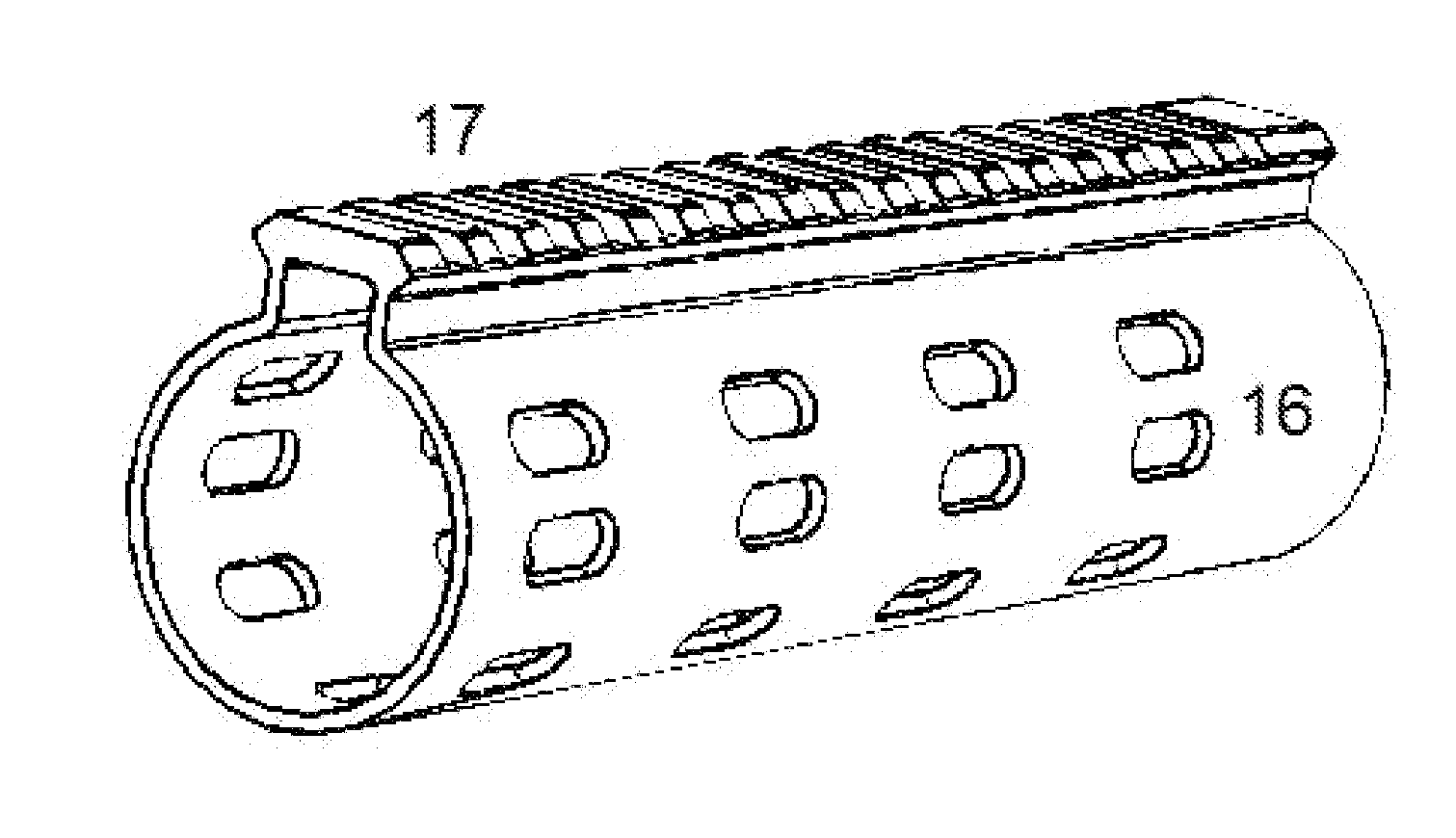

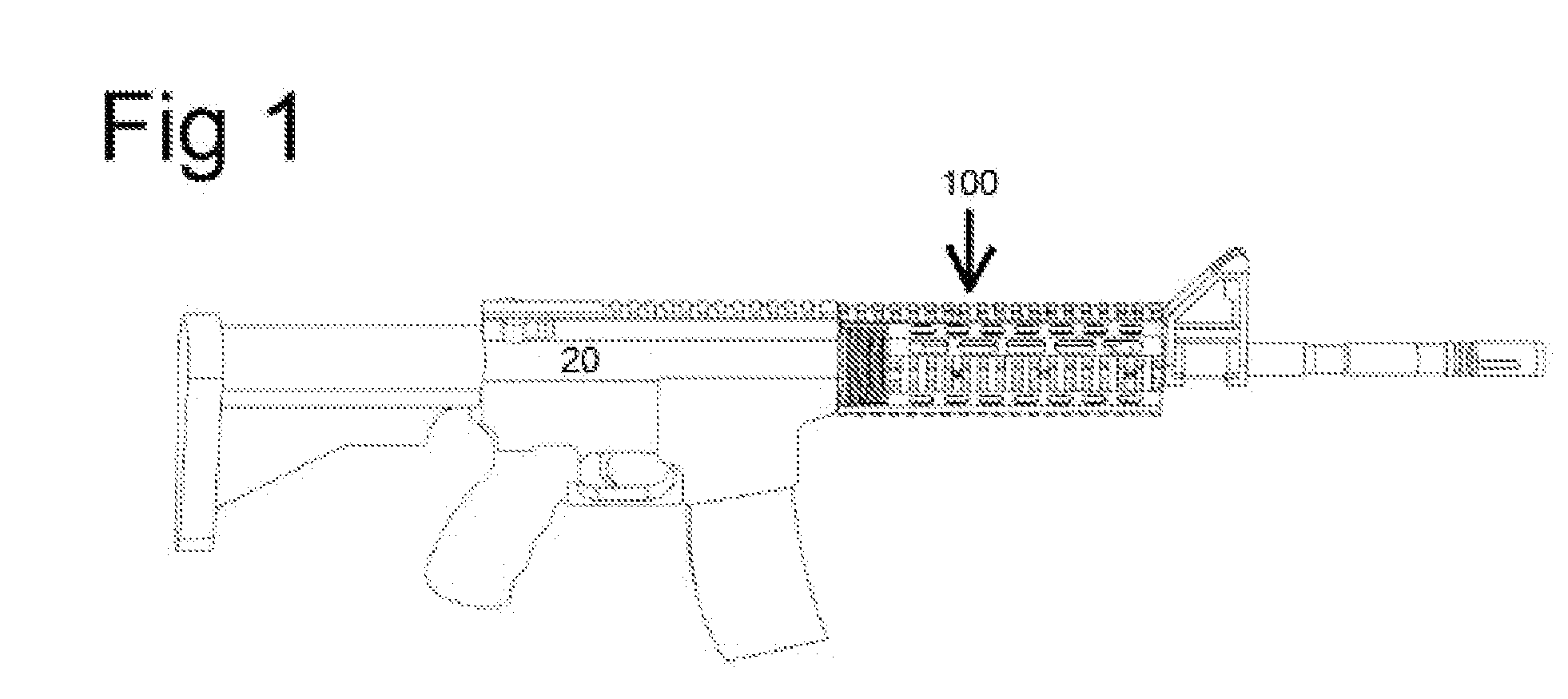

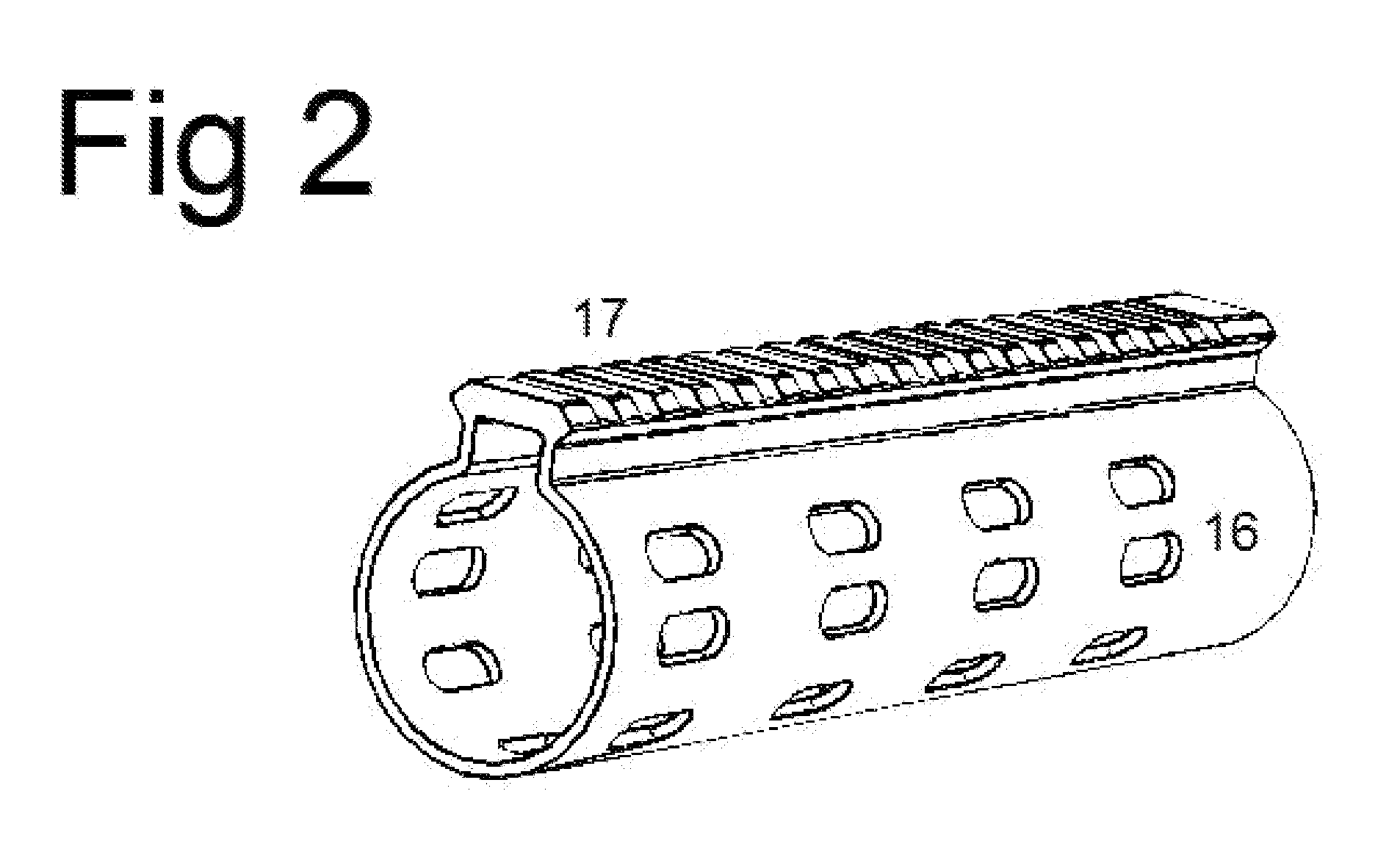

Heat Sink Rail System

A method and apparatus providing for a rail system which further acts to cool a firearm. Wherein said cooling process acts by the passage of air through fins of the apparatus. Whereby said method and apparatus provides for a cooling mechanism which does not inhibit the firearm from attaching accessories.

Owner:LEE SHANYAO

Firearm with enhanced corrosion and wear resistance properties

ActiveUS20060265926A1Accelerated corrosionEnhanced wear propertyEfficient propulsion technologiesSuperimposed coating processDiamond-like carbonWear resistance

This invention encompasses articles, compositions, and methods that provide enhanced corrosion resistance and wear resistance to firearms, firearm components, and firearm accessories. In one aspect, for example, a substrate comprising a firearm component is coated with a first layer of a corrosion-resistant material such as a first metal, followed by a second thin film layer of an abrasion-resistant material such as a second metal, a ceramic material such as a metal nitride, diamond-like carbon material, or other materials.

Owner:REM TML HLDG LLC

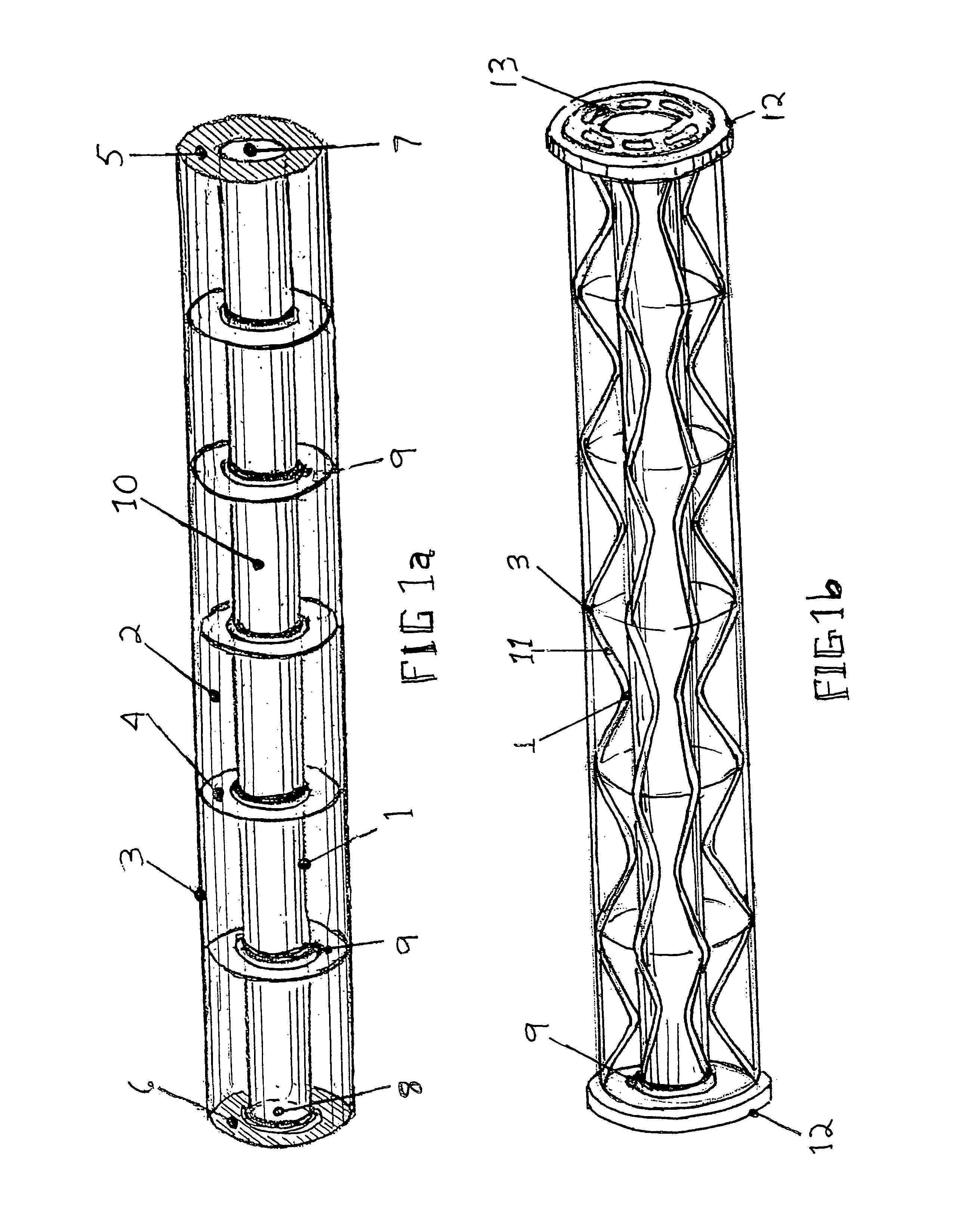

Flowforming Gun Barrels and Similar Tubular Devices

InactiveUS20100236122A1Efficient manufacturingStrong and light weightBarrelsHollow articlesTitanium metalTitanium

Gun barrels and similar tubular devices for repeatedly guiding fired projectiles are fabricated from superalloys, titanium metals, tantalum metals, and similar metal materials by a flowforming process. Combinations of these metals are also flowformed to produce gun barrels and projectile-guiding tubes. In addition, inner liners for such barrels and tubes are made with these metals and flowforming processes. These barrels and tubular devices can withstand high temperatures and corrosive environments. The flowforming process is efficient and produces strong, yet thin and / or light weight, gun barrels and similar tubular devices.

Owner:ATI PROPERTIES LLC

Firearm suppressor

Disclosed herein are suppressors for use with firearms or the like, and methods of making and using such firearm suppressors. Some aspects relate to a firearm suppressor including a helical portion extending helically around a cylindrical body portion, at least a section of the helical portion being canted such that it extends radially outward from the cylindrical body portion at an oblique angle relative to a plane normal to the central longitudinal axis. In some cases, the helical portion is canted distally.In another respect, a firearm suppressor including a helical portion extending radially outward from and helically around a cylindrical body portion having a bore to define a crest and a root, and at least one channel extends from an inner opening along the bore to an outer opening along the root of the helical portion.In yet another respect, a firearm suppressor including a cylindrical wall defining a central bore extending about a longitudinal axis, and one or more cooling bores spaced from the central bore, the cooling bores extending into the wall offset from the central longitudinal axis.

Owner:STEALTH PROJECT LLC

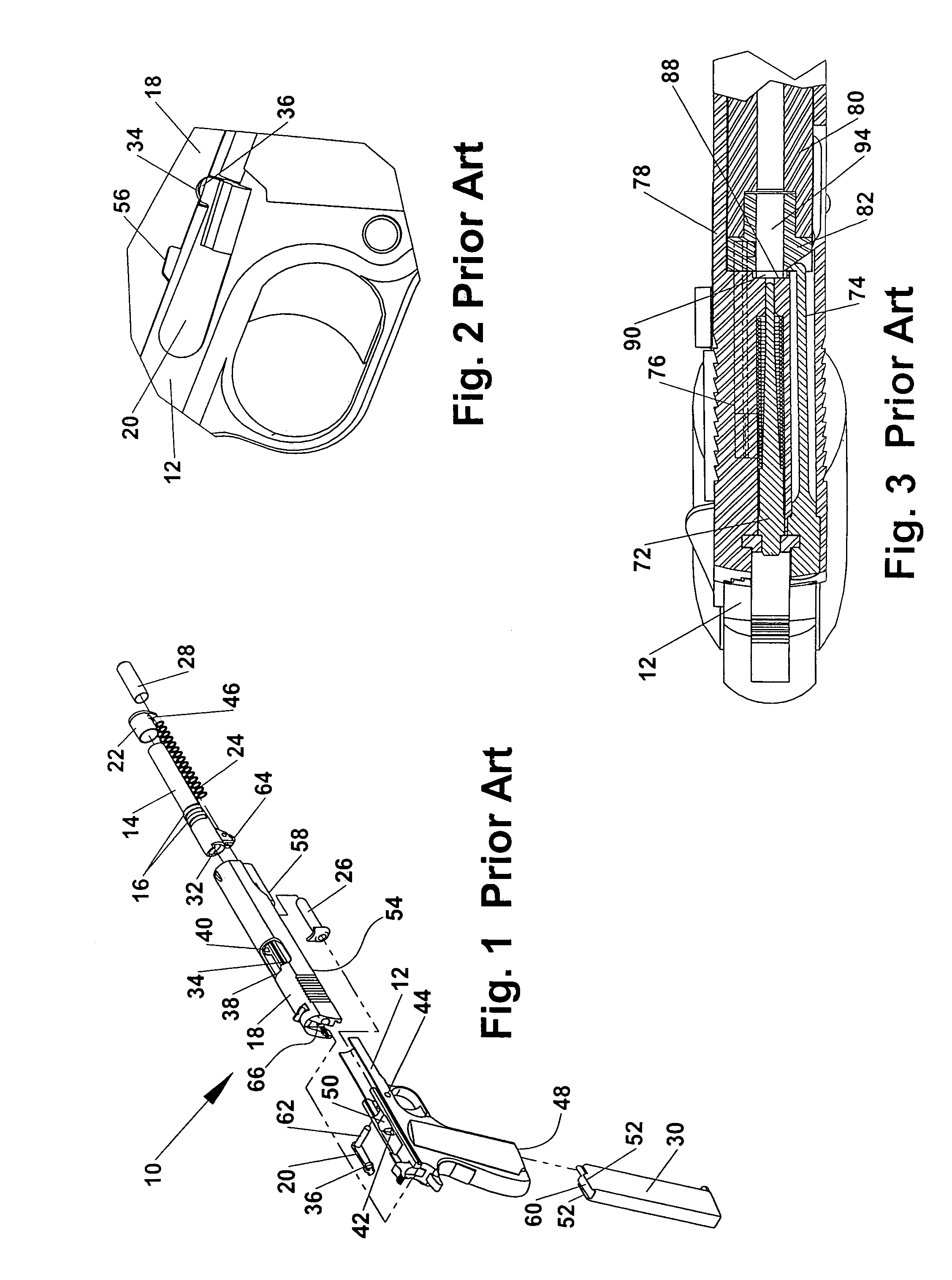

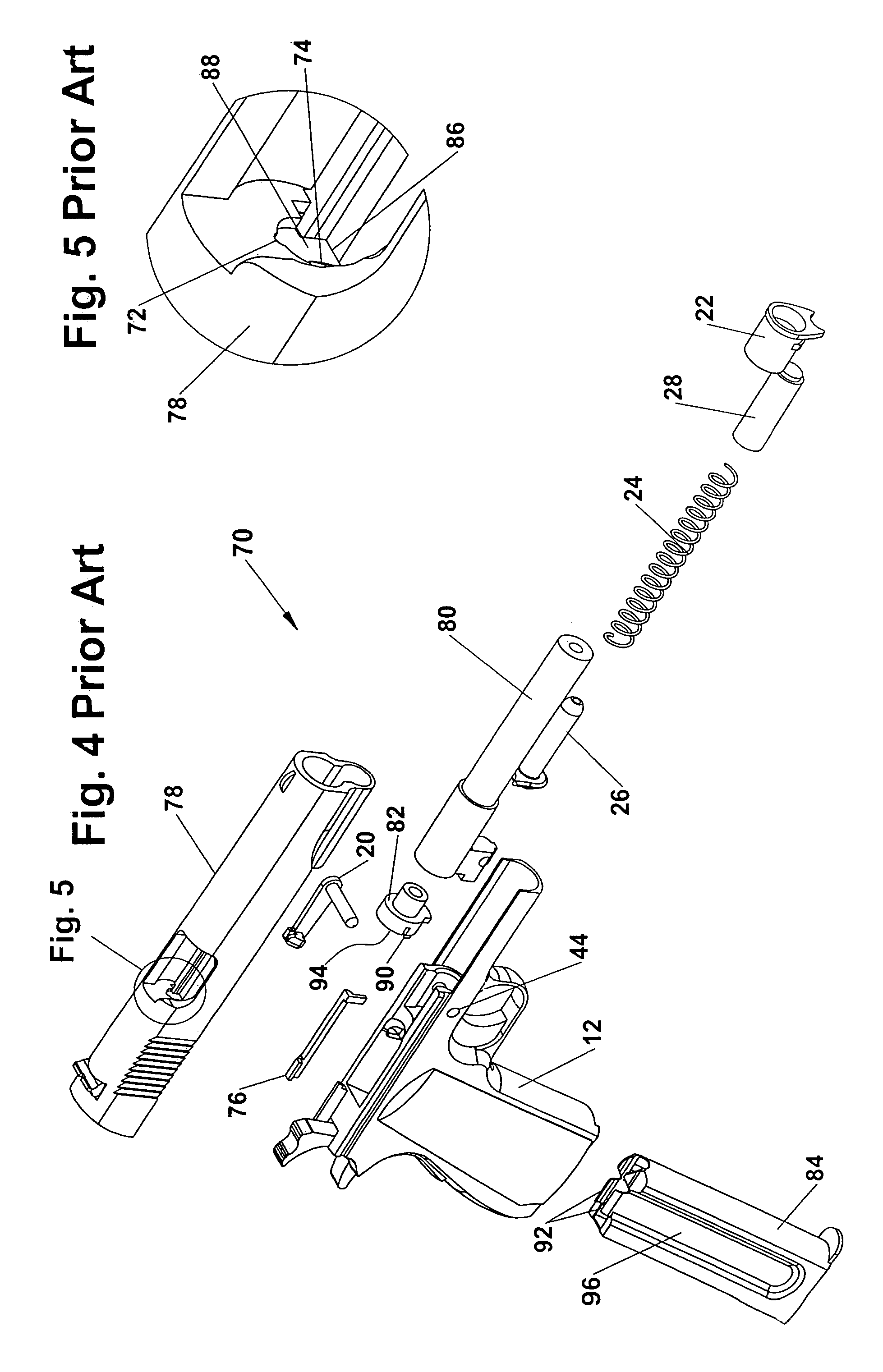

Sight-preserving, partially self-cleaning, divergent-axis caliber conversion in handguns

InactiveUS7121035B2Less-expensive to useImprove effectivenessWeapon assembly/disassemblyBarrelsSemi automaticEngineering

Owner:GREER DWIGHT

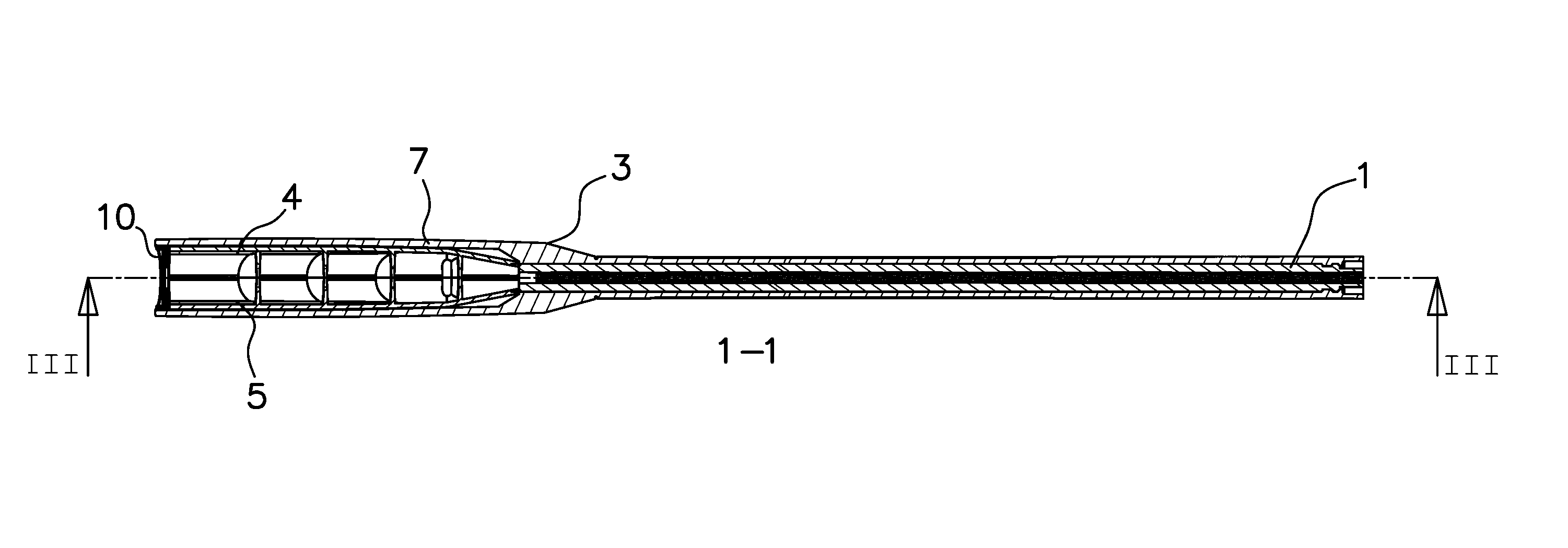

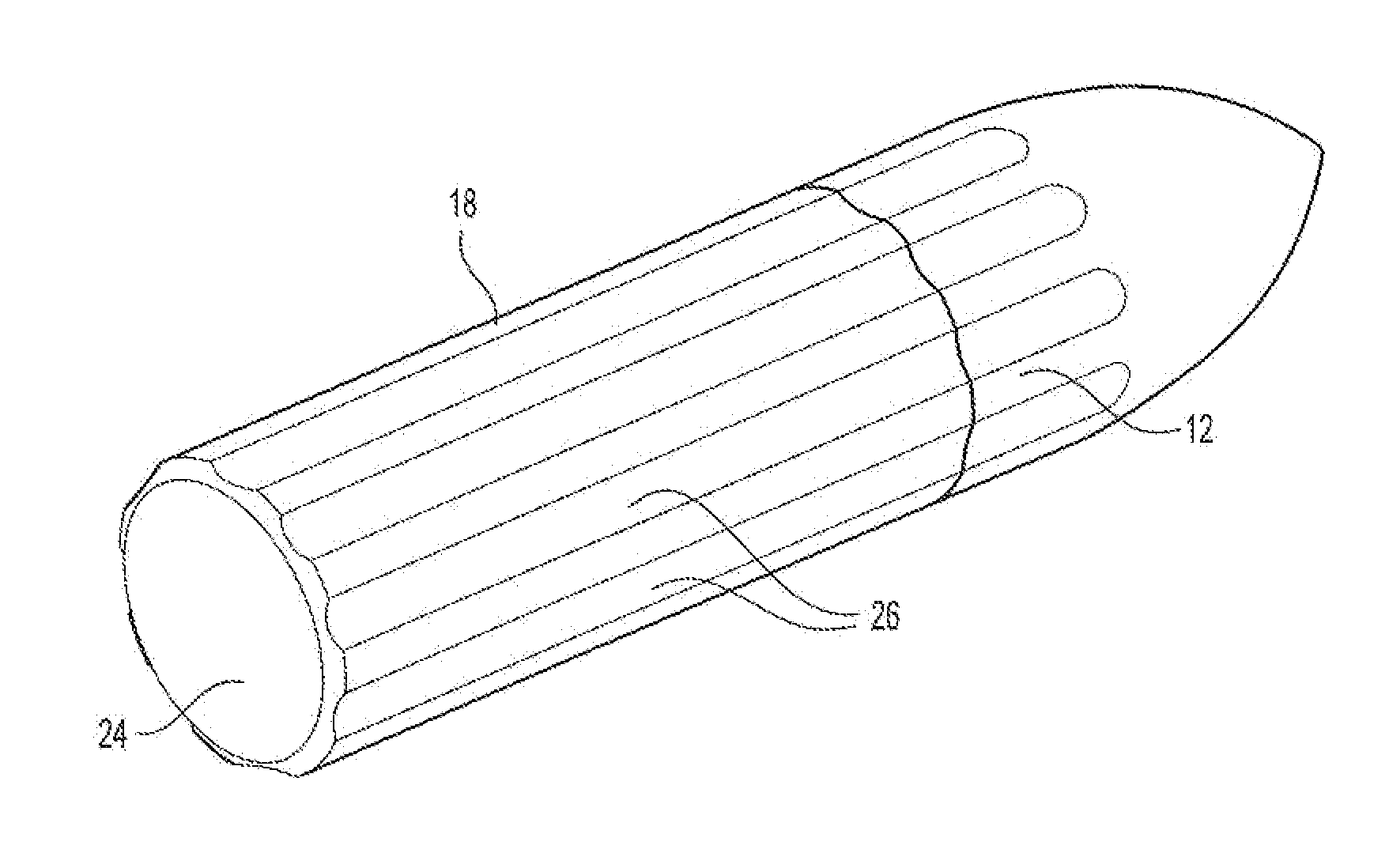

Jacketed bullet

ActiveUS20140326157A1Reduced energy storageIncrease in muzzle velocityAmmunition projectilesBarrelsEngineeringMechanical engineering

A jacketed bullet having a penetrator constructed of a hard material in line with a slug having a lower modulus. At least a portion of both the slug and the penetrator are then encased by a metal jacket. A plurality of circumferentially spaced and axially extending flutes are formed along the slug and possibly the penetrator. These flutes receive deformation of the jacket upon firing of the bullet into a rifled gun bore to thereby reduce friction between the bullet and the gun bore during operation.

Owner:ARMY US SEC THE

Composite firearm barrel

InactiveUS20070193102A1Superior and strong bondEfficient and economical manufactureFiring/trigger mechanismsMetal working apparatusAlloyTitanium

A composite barrel for a firearm and method for forming by forging. The barrel includes at least two materials joined together by forging. In a preferred embodiment, at least one material is preferably lighter in weight than the other material. The barrel may include an inner tube and an outer sleeve. The inner tube defines a bore that provides a bullet path and in one embodiment may be made of steel or alloys thereof. The outer sleeve surrounds the inner tube and in some embodiments may be made of aluminum, titanium, or alloys of either thereof. The tube preferably includes an exterior surface containing recessed areas therein for receiving material displaced from the outer sleeve by the forging process. The preferred barrel forming method generally may include inserting the tube into the sleeve, striking an outer surface of the sleeve, and deforming the sleeve to force material to flow into the recessed exterior surface of the tube to bond the tube and sleeve together. The method of forming may be used to produce long and short barrels for rifles and handguns respectively, and more broadly to produce other composite components unrelated to firearms.

Owner:STURM RUGER & CO INC

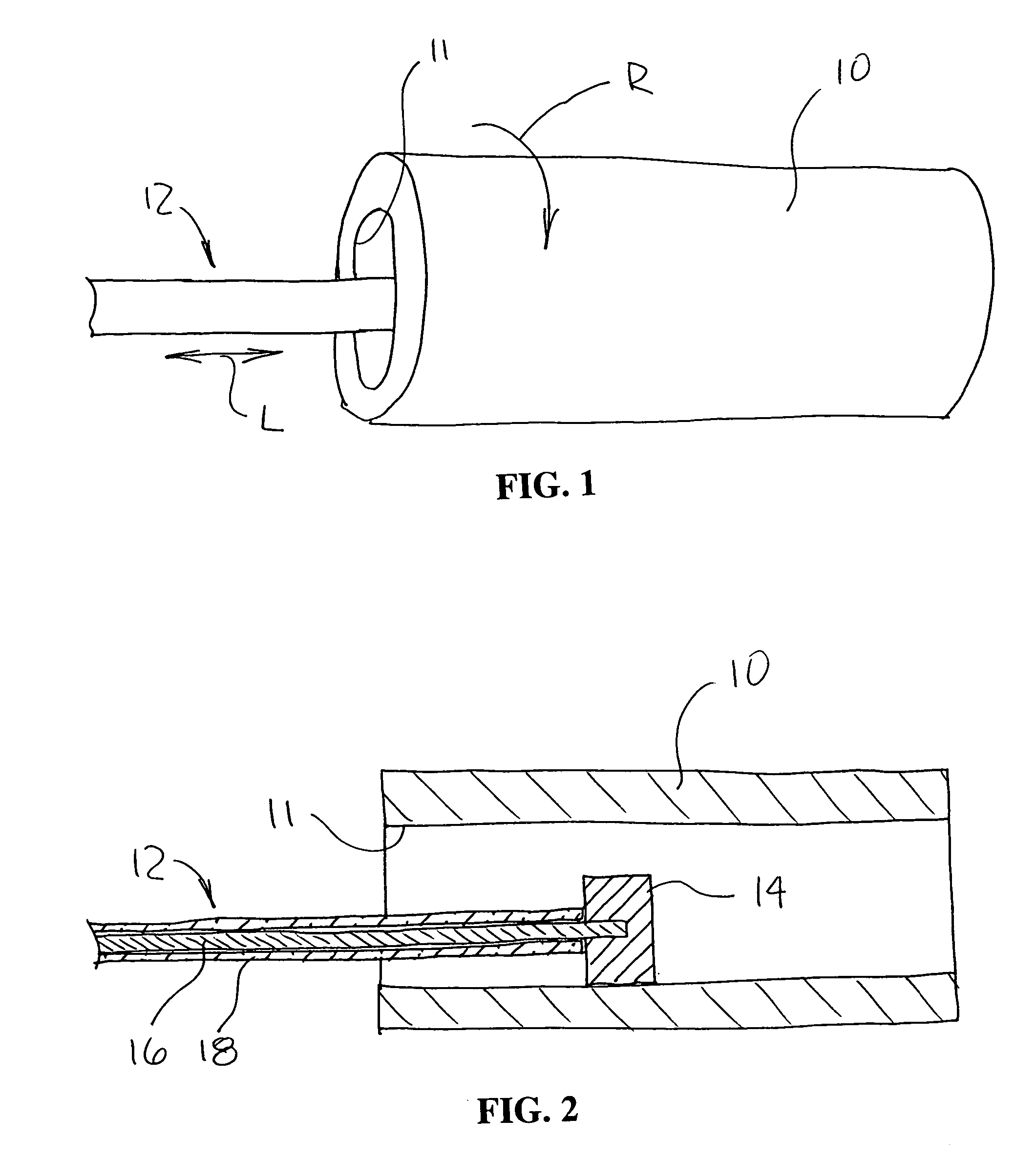

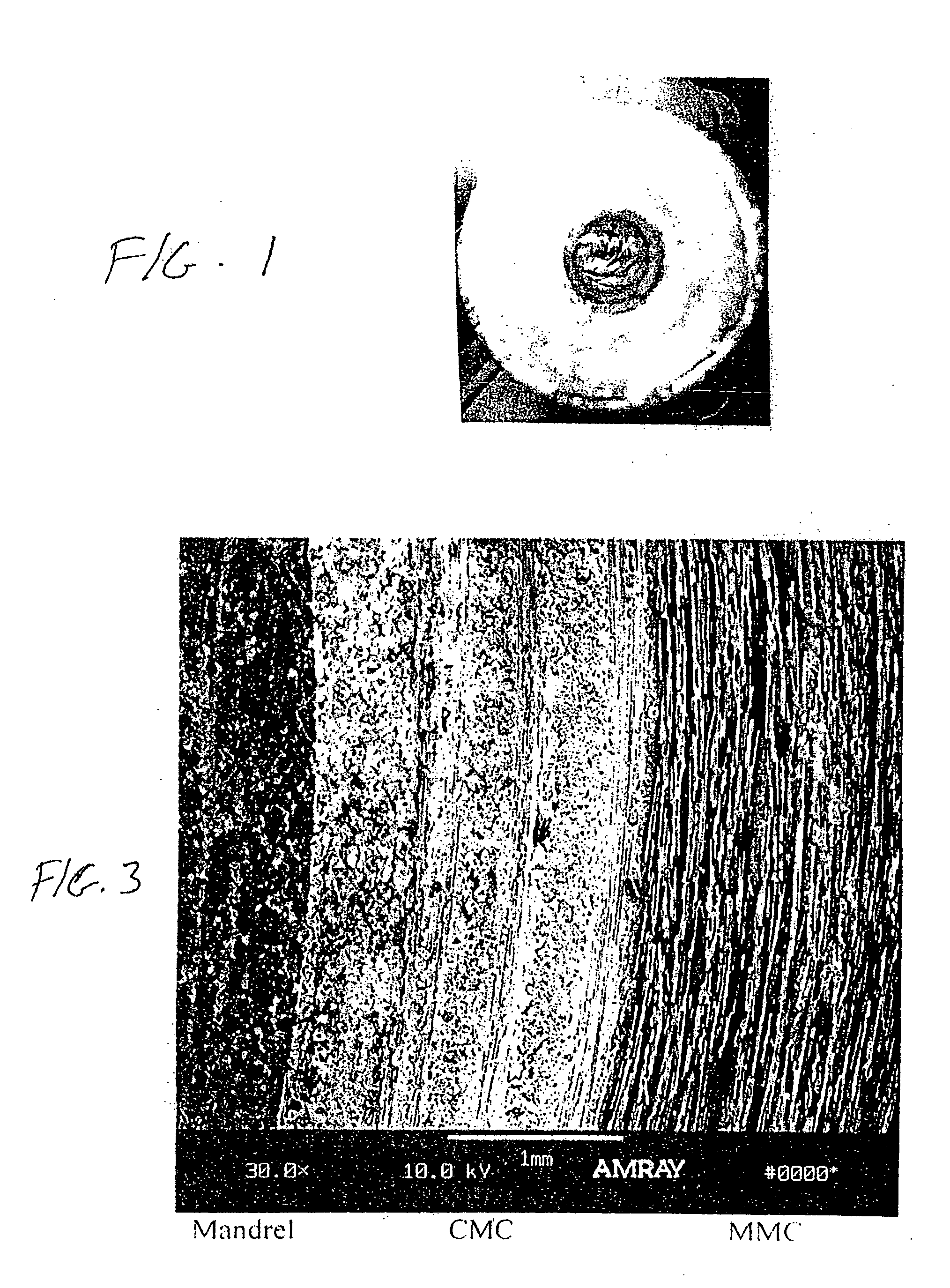

Micro-welded gun barrel coatings

InactiveUS20040140292A1High strengthImproved wear/erosion resistance and thermal managementArc welding apparatusPlasma welding apparatusWear resistantRifling

A micro-welding process is used to apply erosion and wear resistant coatings to the internal diameter of gun barrels. The applied coatings are then treated by methods such as honing and / or rotary forging. The protective micro-welded coatings may comprise ceramic, cermet and / or refractory metal materials, and may be used with rifled or smooth gun barrels of various sizes.

Owner:KELLEY JOHN E +2

Ballistics conditioning

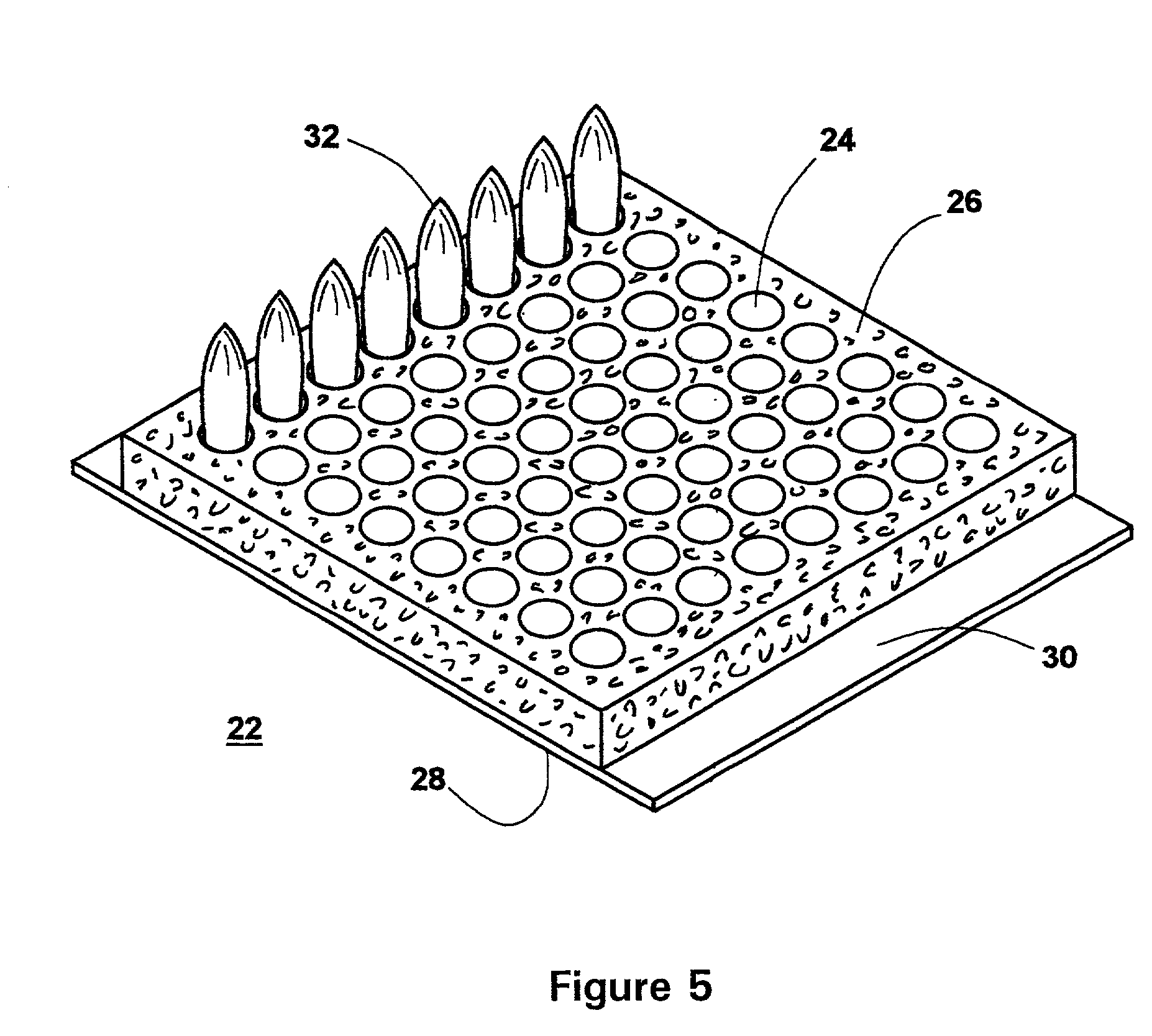

InactiveUS20030078170A1Quick and easy spray-coatingHigh hardnessAmmunition projectilesMoulding toolsHexagonal boron nitrideAcrylic resin

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

Less-lethal ballistic projectile launcher

ActiveUS20110072704A1Conveniently carriedConveniently holsteredSafety arrangementCartridge extractorsFire controlEngineering

The light-weight handheld less-lethal ballistic projectile launcher is configured as an “over / under” double barrel handheld device with a “break open” loading action. The launcher includes a barrel section pivotally connected to receiver section. The barrel section pivots between an open load / unload position and a closed firing position. The barrel section includes two metal barrel sleeves that are press fit into axial bores formed in the body of the barrel section. The barrel section also includes an ejector, which locks the barrel section in the closed firing position and partially expels spent rounds from the barrel sleeves when the barrel section is opened. The receiver section houses the launcher's fire control mechanism. The fire control mechanism uses a traditional single action operation and ensures that rounds are alternatively discharged from each barrel and prevents rounds from both barrels from being discharged simultaneously.

Owner:NAMACLE LLC

Gun barrel and method of forming

A fabrication technique is described for producing lighter weight and improved wear and erosion resistant gun barrels. The barrels are produced in an unconventional manner from the inside bore to the outside diameter of the barrel and combine a refractory metal, metal alloy, or ceramic composite inner liner with a metal matrix composite (MMC) or titanium or other suitable high strength, lightweight metal or metal alloy outer shell. A unique aspect of the invention is that there is a compositional gradation from the liner at the inside bore to the overwrap which extends to the outside diameter of the barrel. A process is also described to produce barrels with a refractory metal liner with improved wear and erosion resistance by depositing the refractory metal on the ID of a pre-fabricated barrel.

Owner:ATS MER LLC

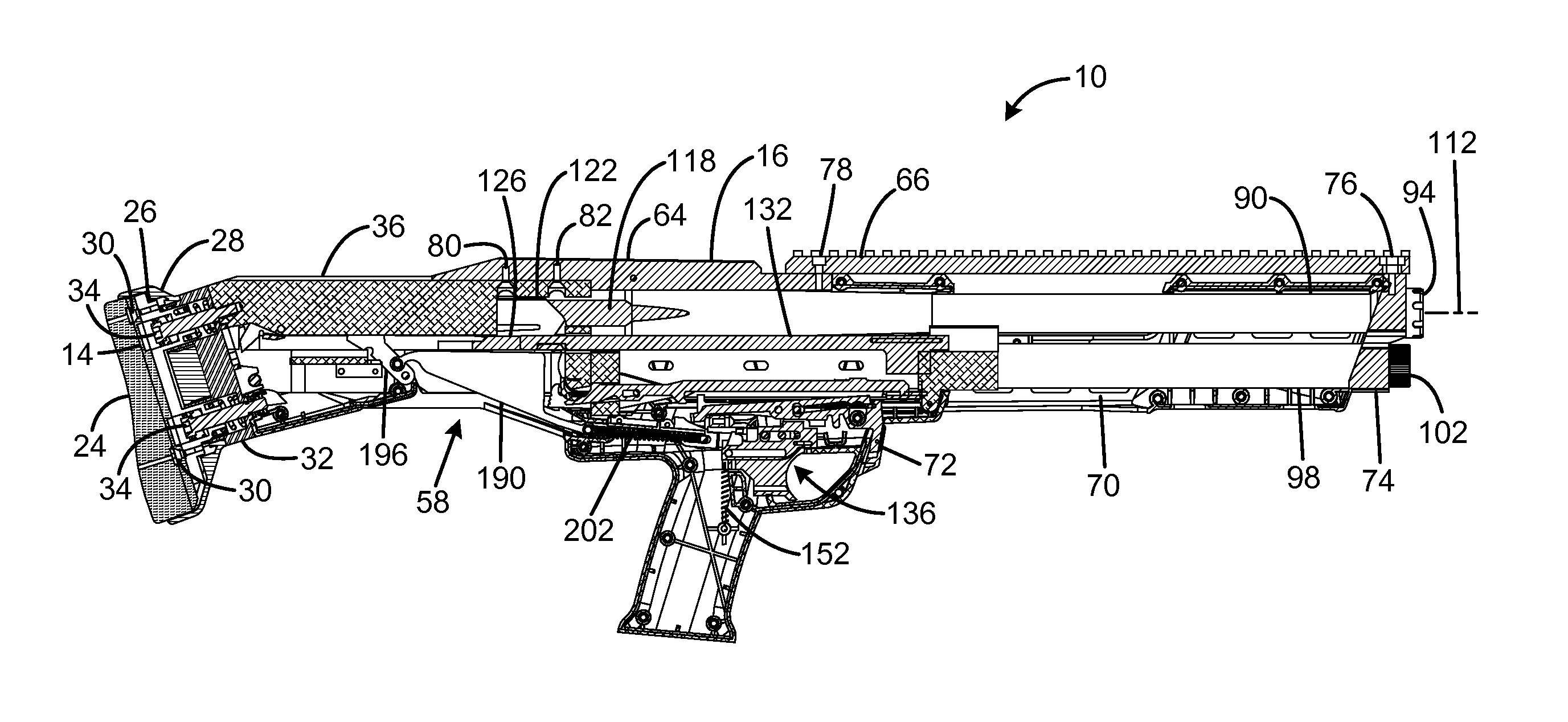

Double-barreled bullpup pump-action shotgun

ActiveUS9115954B1Great contributionFiring/trigger mechanismsMissile propulsionEngineeringShotgun pellet

A double-barreled bullpup pump-action shotgun has a frame with two forward-extending barrels arranged side-by-side, a pair of tube magazines, each positioned beneath a respective barrel, an action attached to the frame and operable to load ammunition from the tube magazines to the barrels, and a trigger assembly attached to the frame, the action being located at least in part behind the trigger assembly, and the trigger assembly including a trigger linkage to connect the trigger assembly to the action and to operate the hammers behind the bolts. The action may be a pump action. The trigger assembly may include a plurality of hammer trips, each having a sloped forward surface. The trigger assembly may include a plurality of sears having tails, and the sloped surfaces of the hammer trips may lift the tails of the sears during a portion of a complete cycle of the action.

Owner:CONNECTICUT SHOTGUN MFG

Fluted firearm barrel

InactiveUS8025003B1Enhanced barrel coolingMaintaining barrel stiffnessVentillation systemsWeapon cleaningFluteEngineering

A firearm barrel having barrel flutes on the outer surface of the barrel where the barrel flutes are undercut relative to an outward radial vector from the center of the barrel at an arcuate radial distance that exceeds the arcuate radial distance of an undercut produced by a straight walled flute cutter such that the barrel flutes are hyper-undercut.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

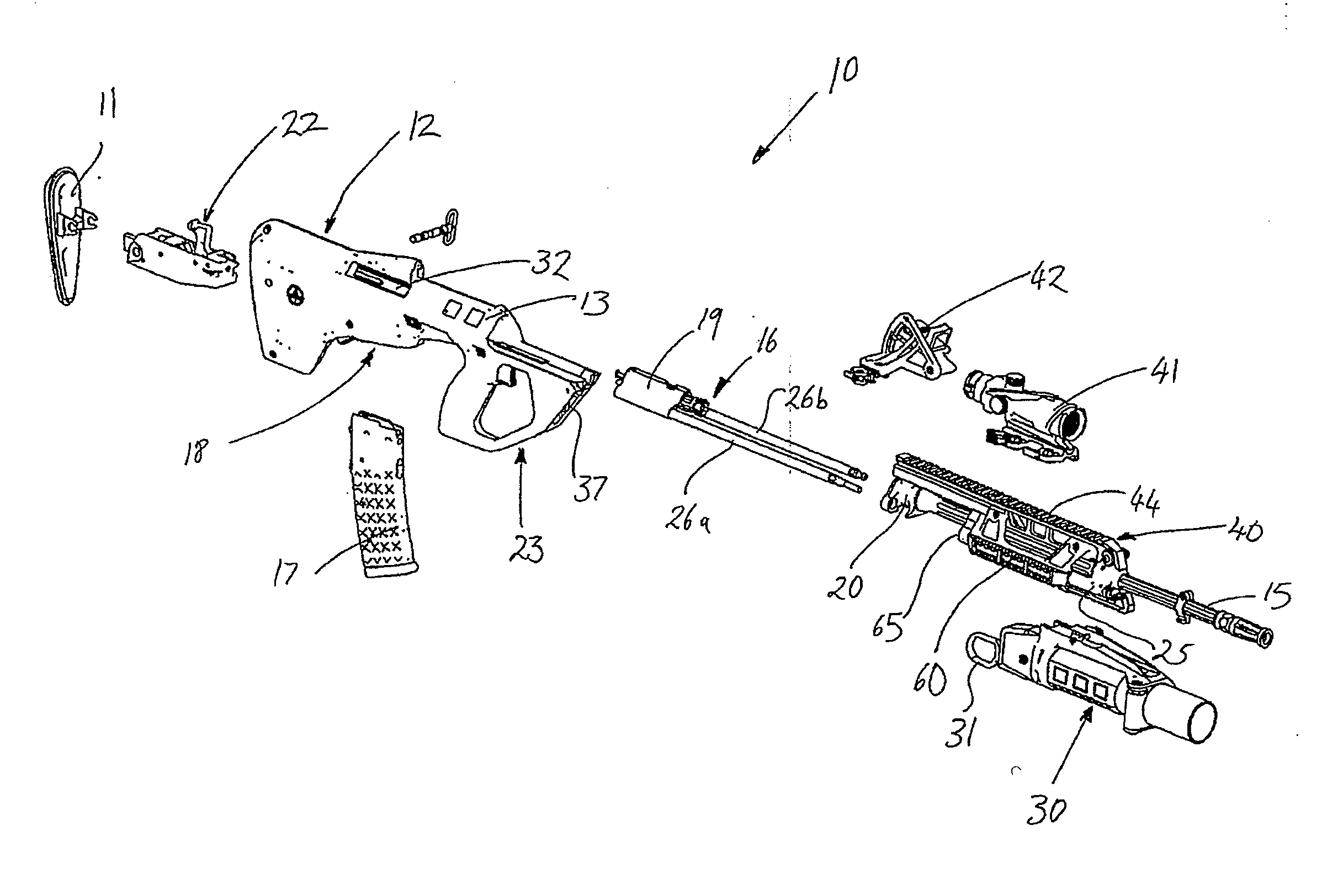

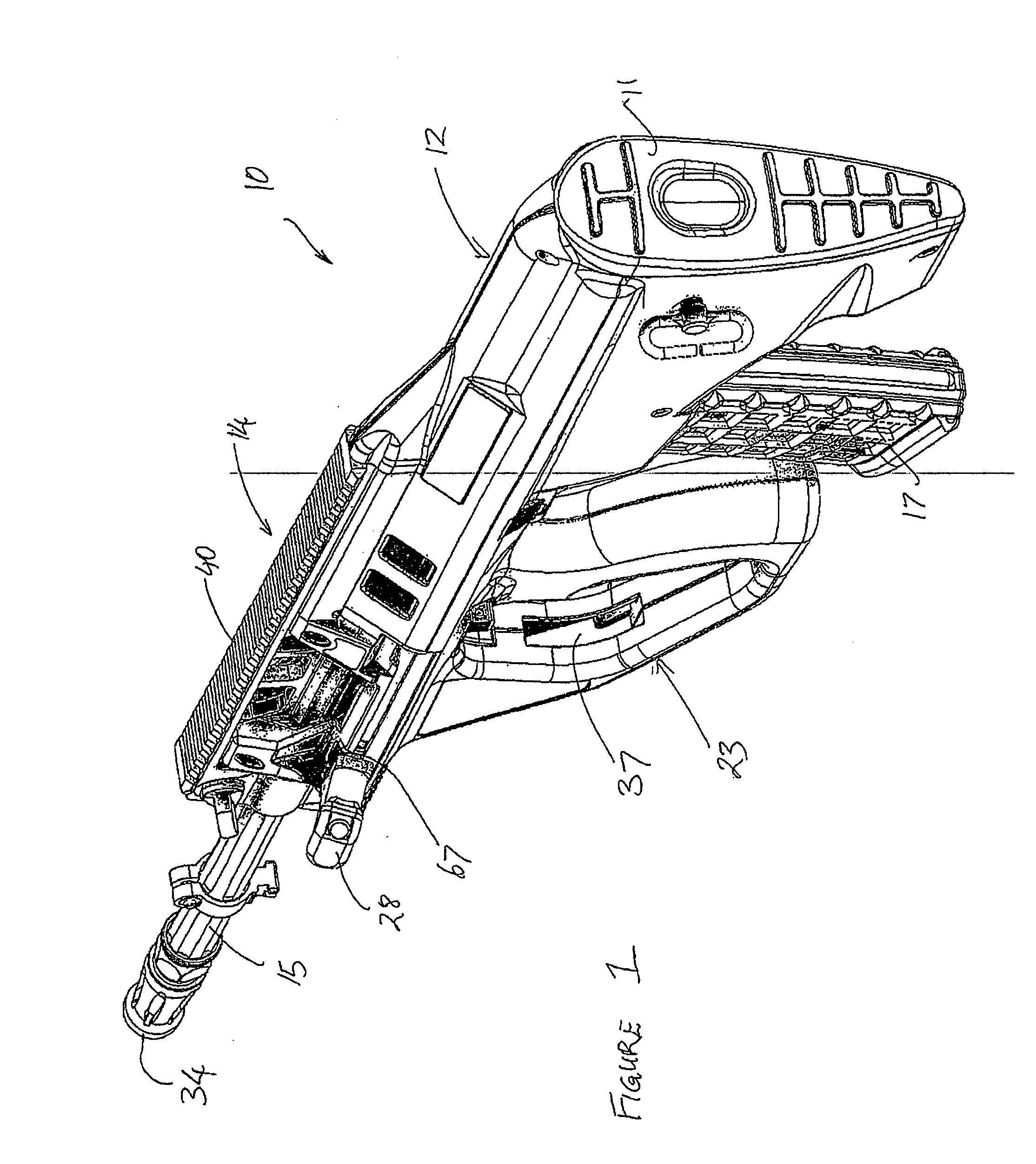

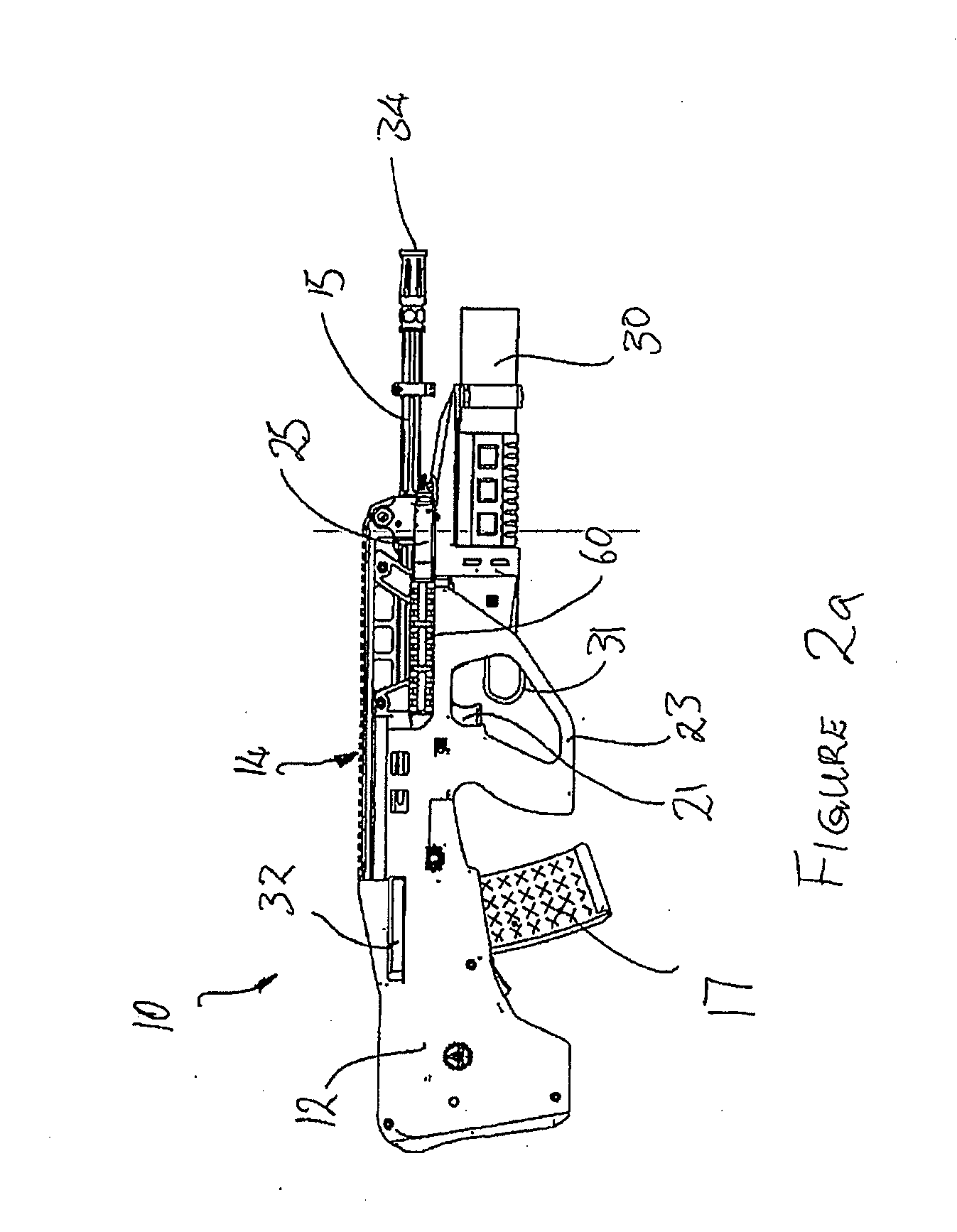

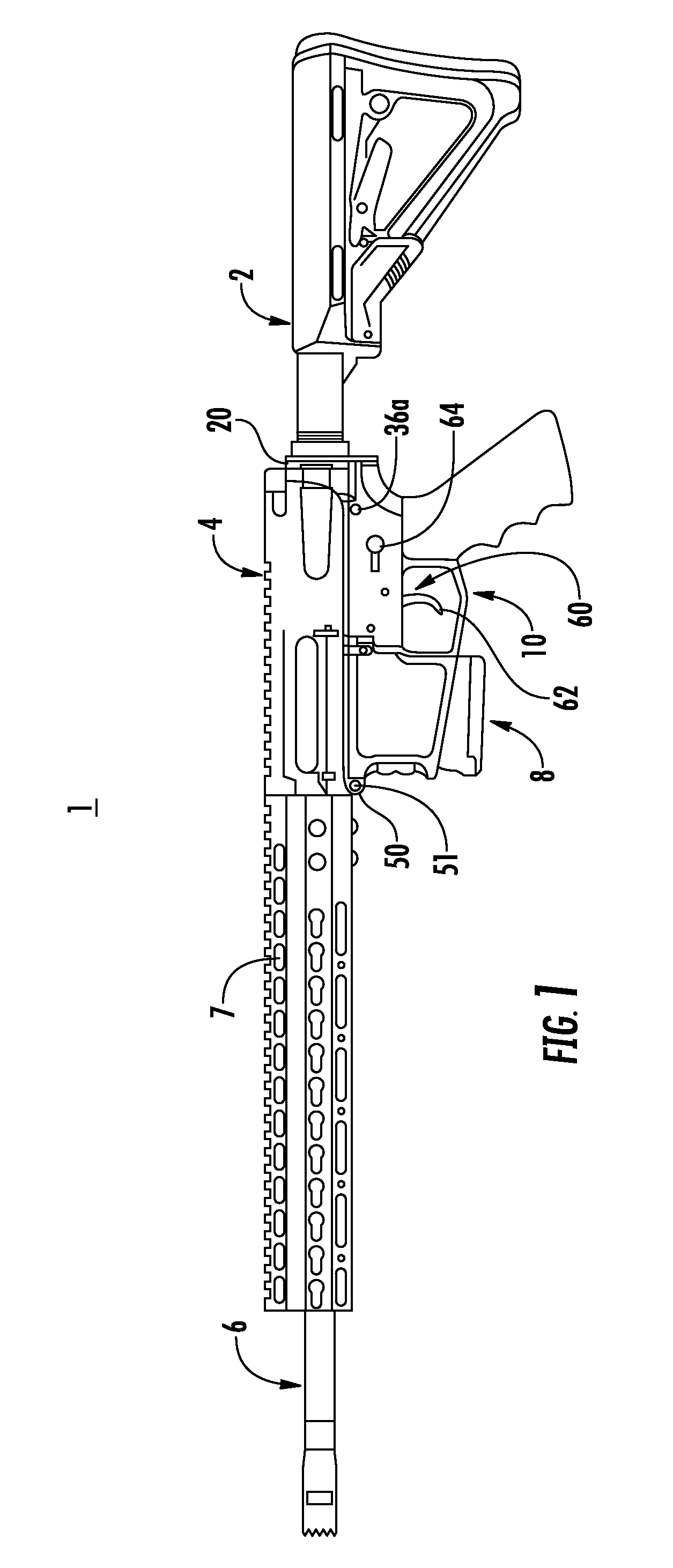

Firearm systems and methods

ActiveUS20160047612A1Improve reliabilityReduce gas leakagePiston ringsCartridge extractorsMatched pairEngineering

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is larger than that of a standard M16 / M4. A bolt carrier can have a bolt that has a double cut cam having an unlocking cam surface that has sufficient dwell increase to delay a start of unlocking when the bolt carrier is used in an M4 carbine. A stepped extractor pin may be provided that prevents disengagement of the extractor pin. A tube can be configured to provide gas from a barrel of the firearm to the piston via the carrier key. The tube can have a heat radiator formed from triangular shaped threads on at least a portion of the tube. A piston on the bolt and can have a plurality of rings including pairs of mating rings that are formed and maintained as a matched pair.

Owner:ARMWEST

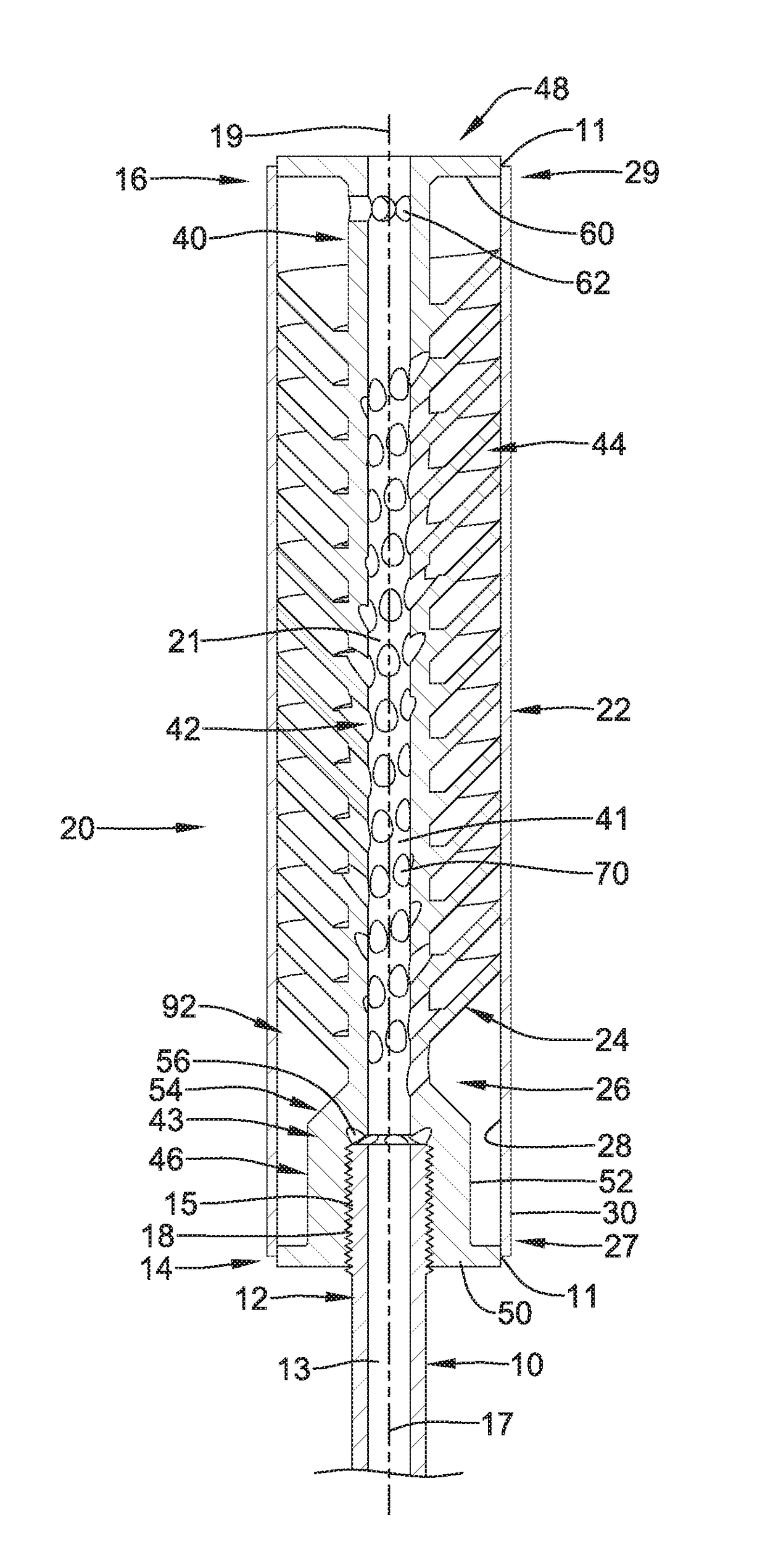

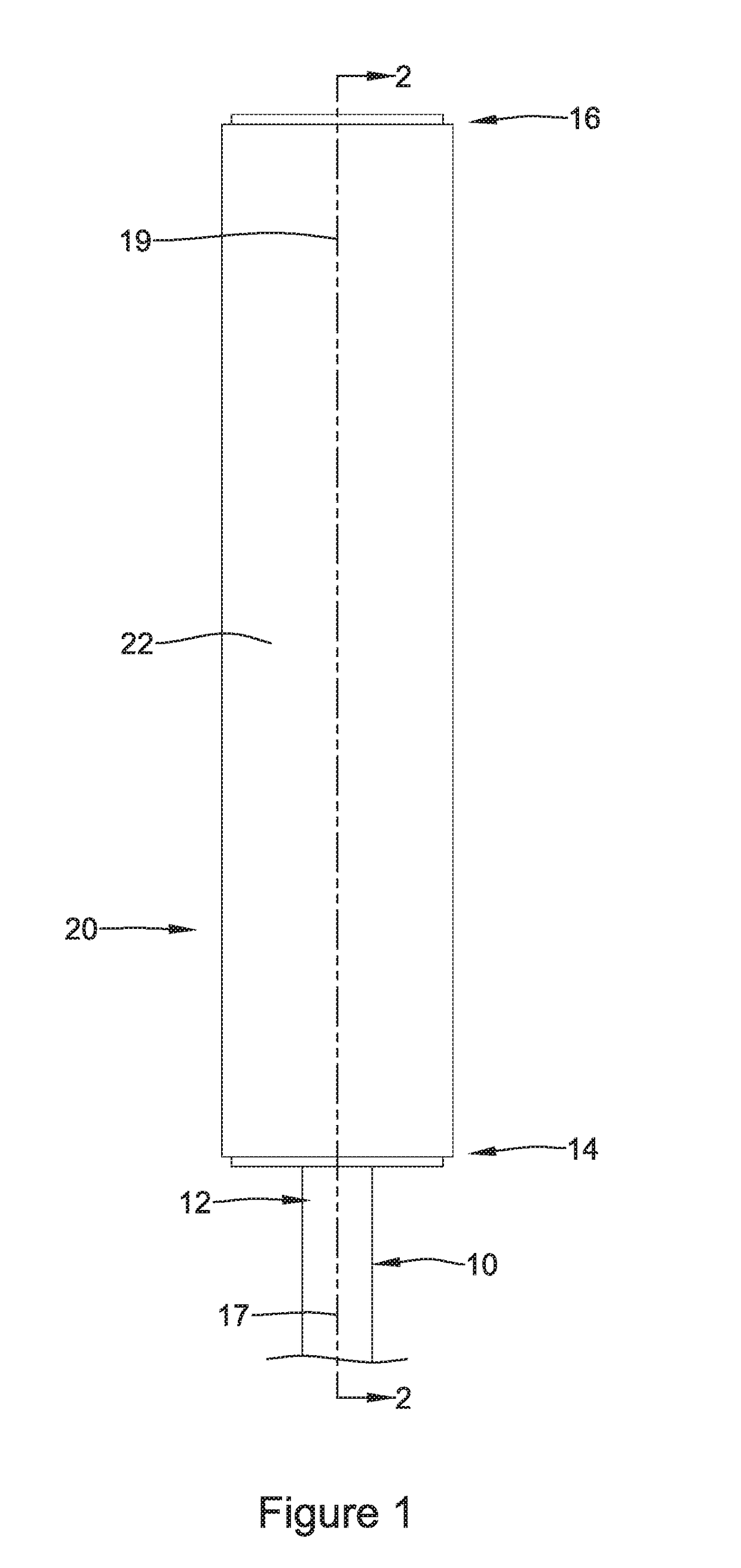

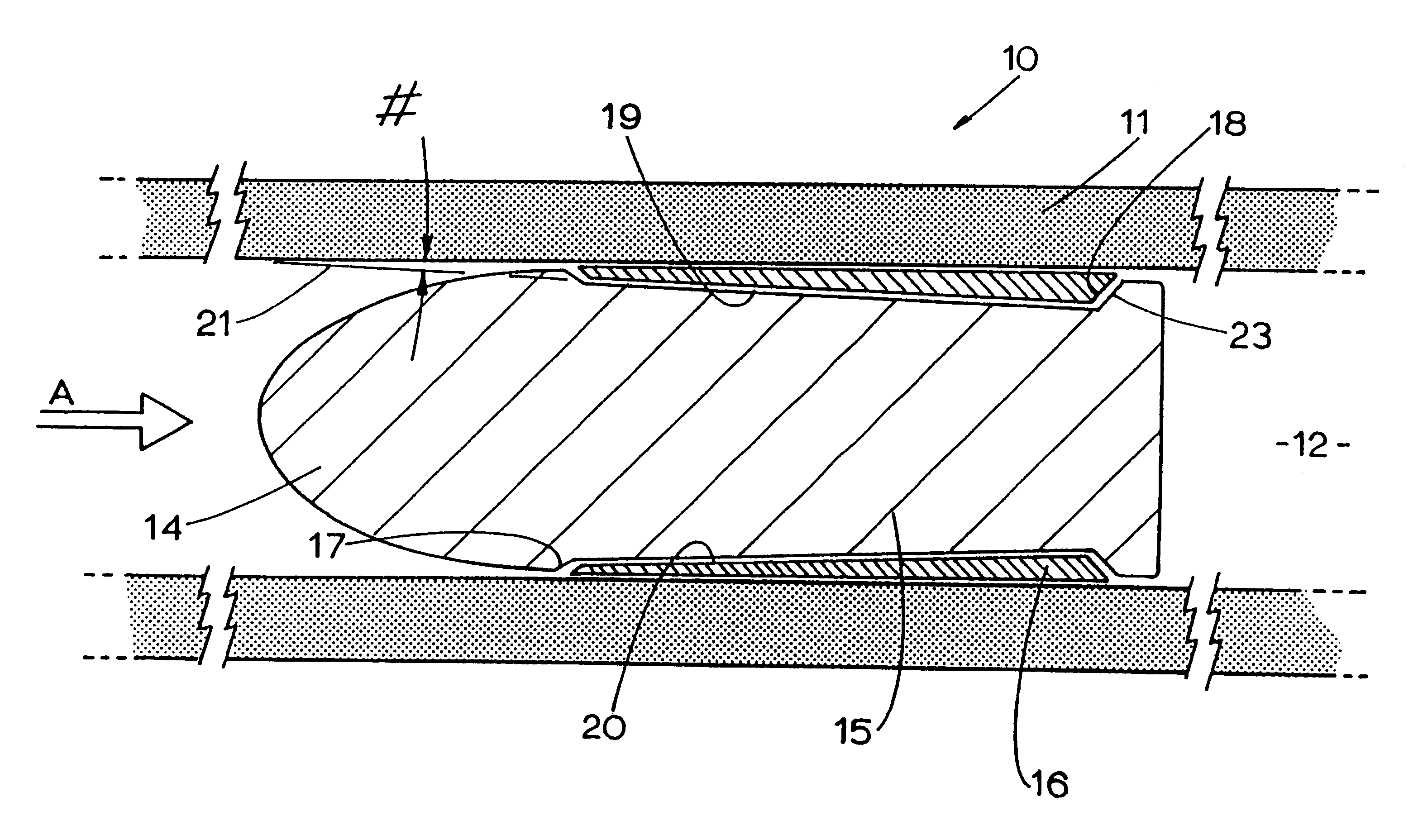

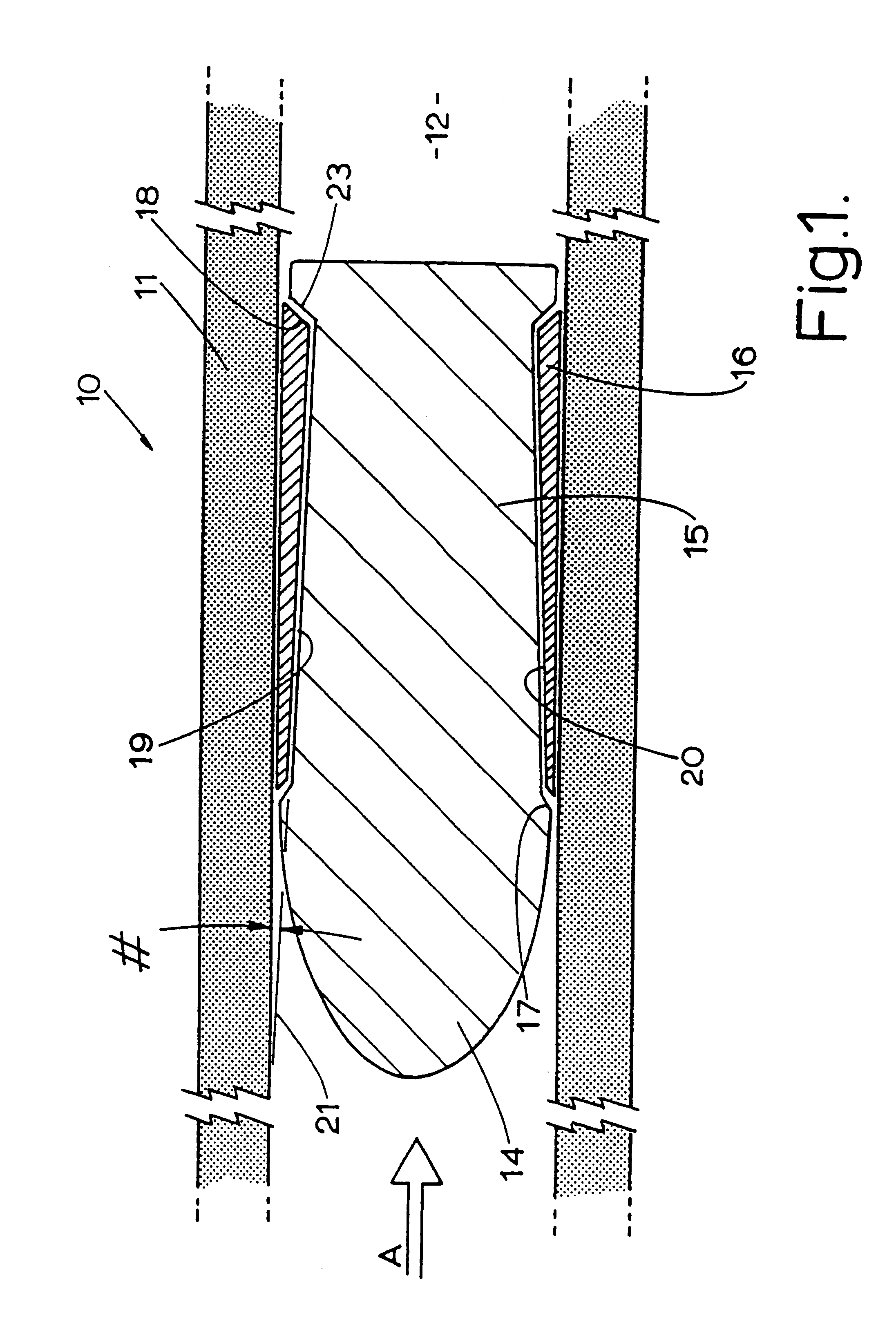

Firearms

This invention provides a projectile assembly (10) having a body part (14) including a trailing portion (19) which reduces in diameter rearwardly and supports a sealing band (16) having a substantially cylindrical outer face for engagement with the bore (21) of the barrel (11). The body part (14) may move rearwardly through the sealing band (16) to expand it outwardly into sealing engagement with the bore (21). Upon firing the body part (14) moves forwardly relative to the sealing band (16) to free it from the bore (21).

Owner:DEFENDTEX

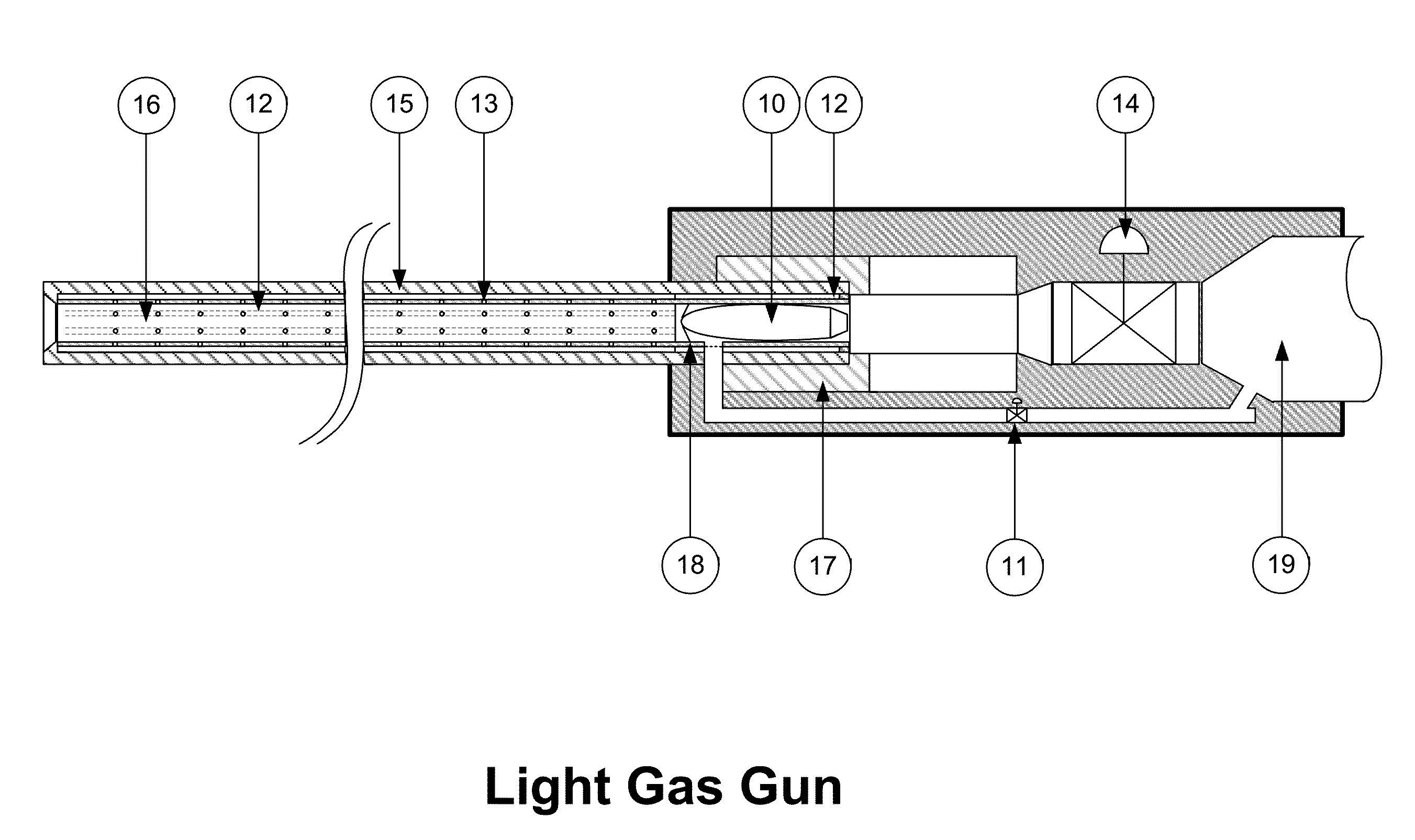

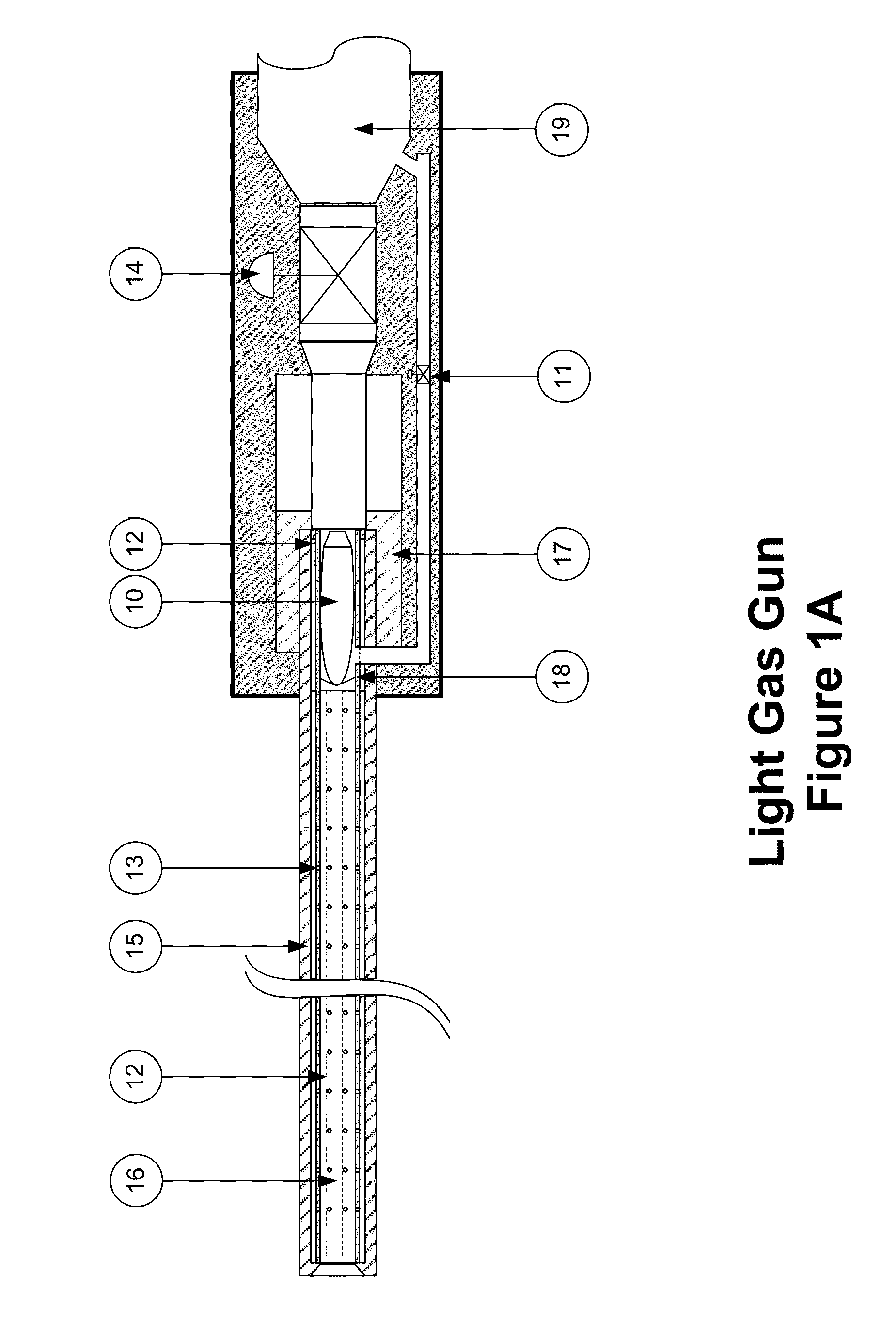

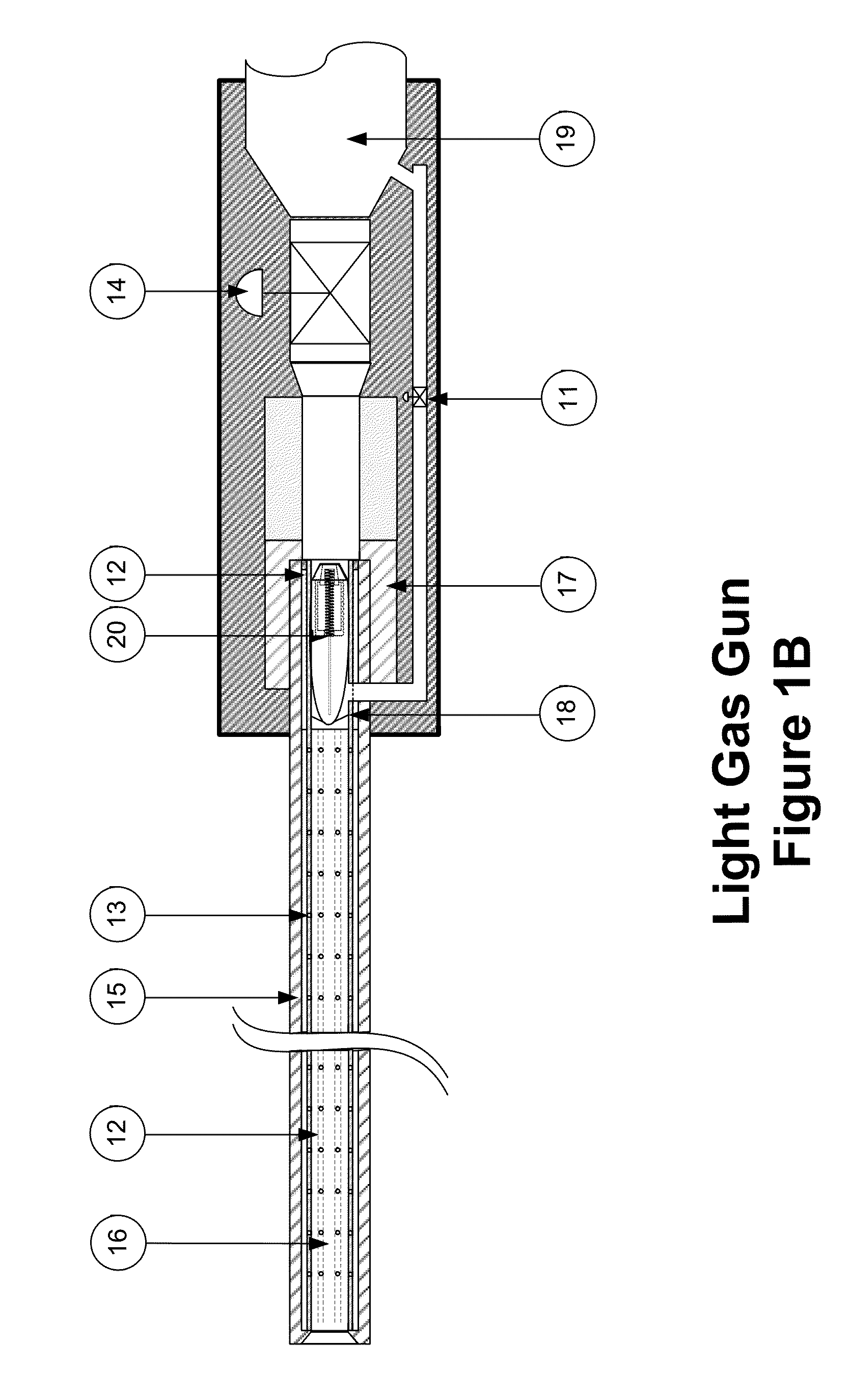

Light Gas Gun

ActiveUS20160161212A1Optimization rangeIncrease lethalityAmmunition projectilesMissile propulsionEngineeringAcoustic signature

An improved light gas gun launches a projectile in a light gas atmosphere as it travels through a frictionless barrel to achieve high muzzle velocities, decreased acoustic signatures, and increased ranges. The light gas atmosphere is introduced by a purge valve prior to firing or by a muzzle valve that holds a positive light gas pressure on the barrel and breech. The muzzle valve also routes the majority of propellant gases through a suppression canister, reducing the light gas gun's acoustic signature. The frictionless barrel uses light gas propellant routed through gas bearings to keep the projectile centered in the barrel and preclude the projectile from contacting the barrel walls, eliminating barrel wear. The system includes a projectile assembly that stores light gas from the firing and injects it into the boundary layer, reducing drag, increasing range and lethality, and decreasing acoustic signature of the projectile down range.

Owner:BERGERON DAVID WAYNE

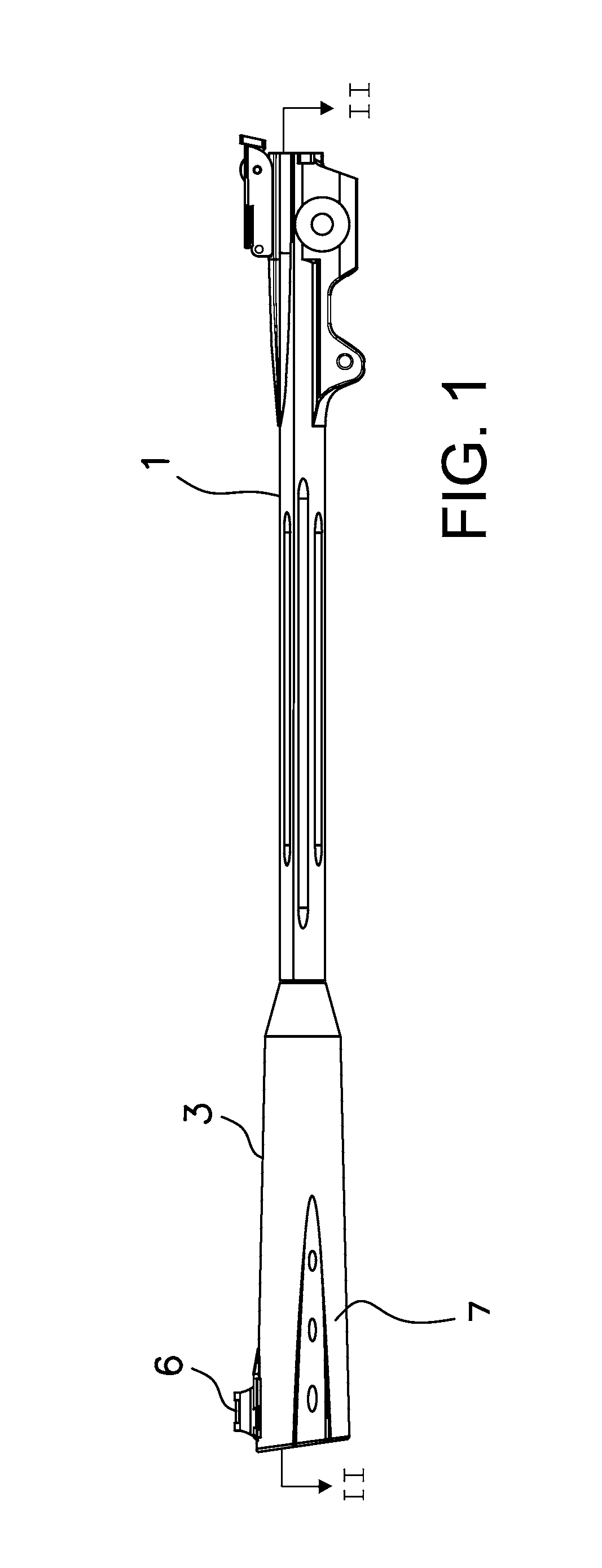

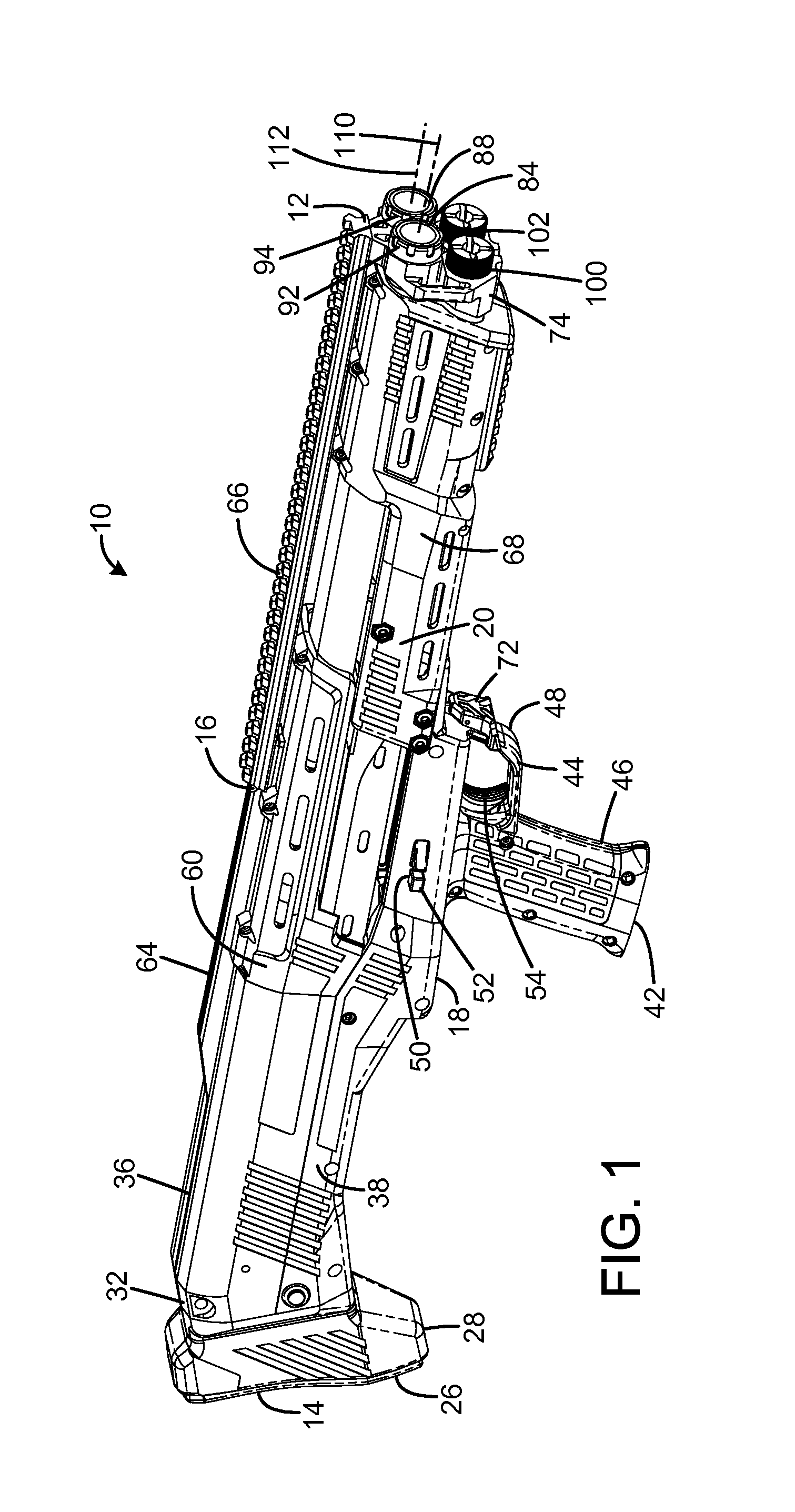

Firearm

InactiveUS20150107143A1Improve cooling effectReduces material usedFiring/trigger mechanismsBreech mechanismsEngineeringGun barrel

A firearm comprising a barrel assembly mounted at one end to a butt group, the butt group including a firing mechanism and an ammunition entry point; a gun lock group slidably mounted between the barrel assembly and butt group that slides to load ammunition from the ammunition entry port into a barrel of the barrel assembly upon cocking of the firearm; and a rail for accessory attachment that is mounted on the barrel and in direct contact with a portion of the barrel. The second invention relates to a hammer pack in the butt group that automatically resets the firing mechanism upon recoiling of the gun lock group during firing, wherein the hammer pack includes a hammer biased to pivot under the force of a hammer spring, and an autofire lever biased through an autofire lever spring to engage the hammer.

Owner:THALES AUSTRALIA

Non-detachable magazine lower receiver

A non-detachable magazine lower receiver for a firearm includes a stock mount, a trigger well extending from the stock mount, and a magazine well. The trigger well is configured to receive a firing mechanism. The magazine well is configured to receive a magazine. A proximal wall of the magazine defines a retention opening that passes through a distal wall of the trigger well. The retention opening is configured to receive a magazine retention member for fixing a magazine recovered in the magazine well to the lower receiver.

Owner:DARK STORM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com