Patents

Literature

141 results about "Matched pair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Matched Pairs Design. A matched pairs design is a special case of a randomized block design. It can be used when the experiment has only two treatment conditions; and subjects can be grouped into pairs, based on some blocking variable.

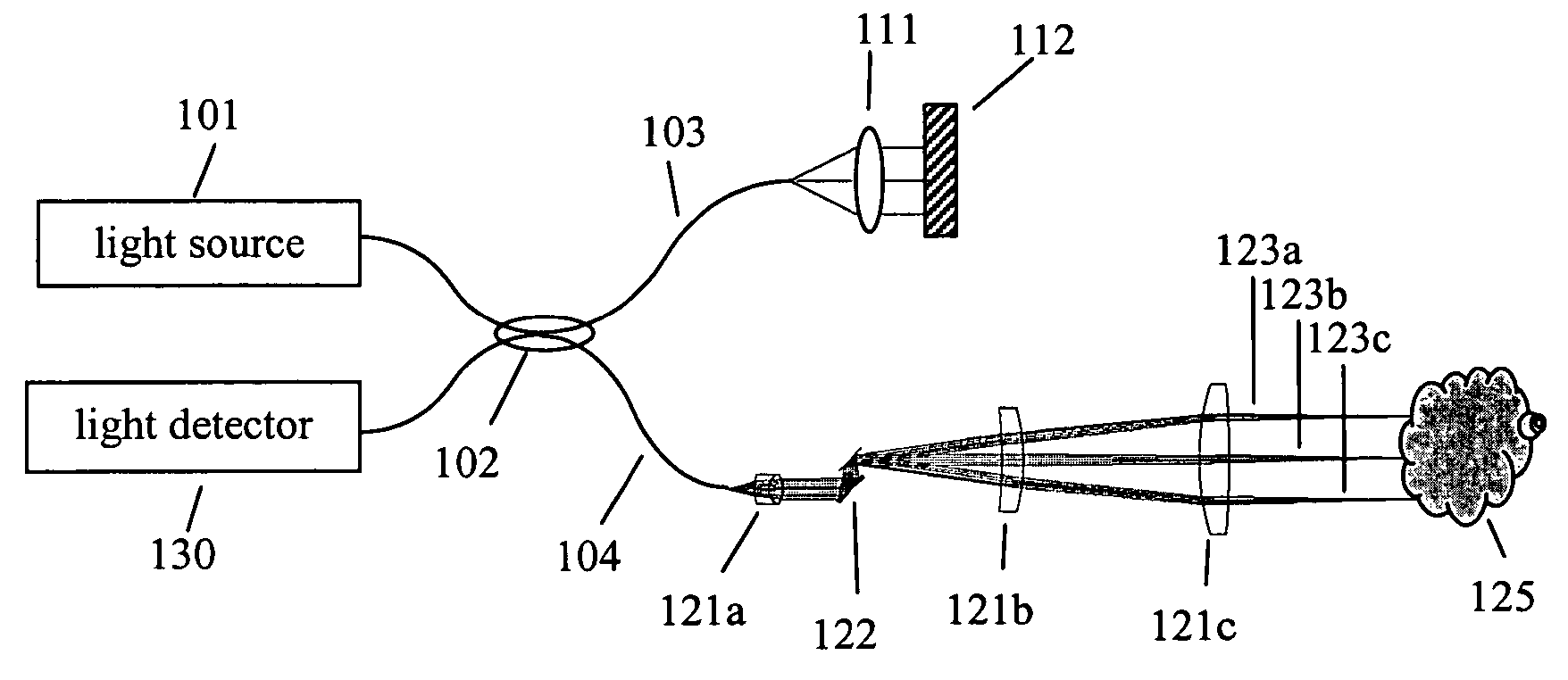

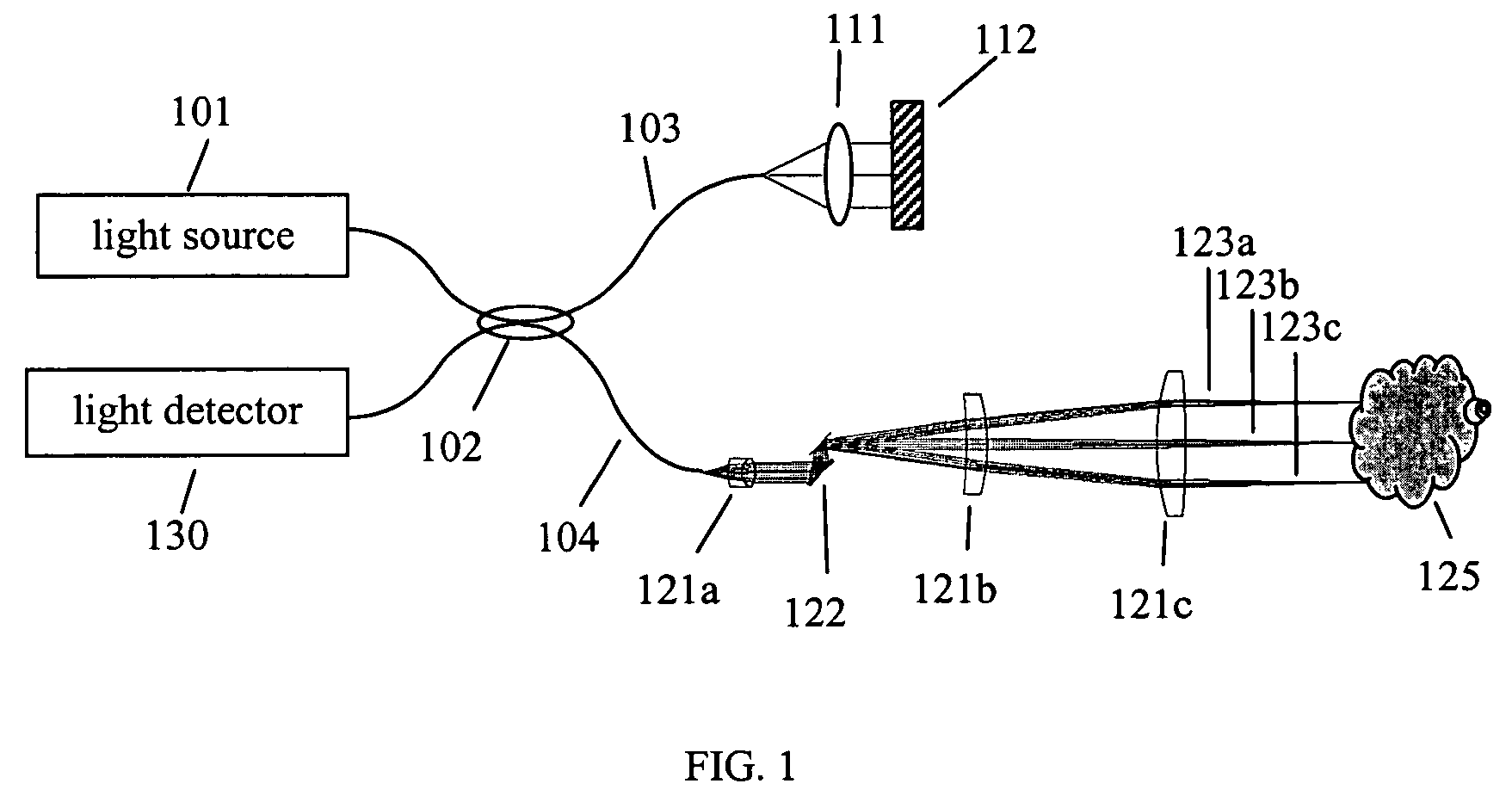

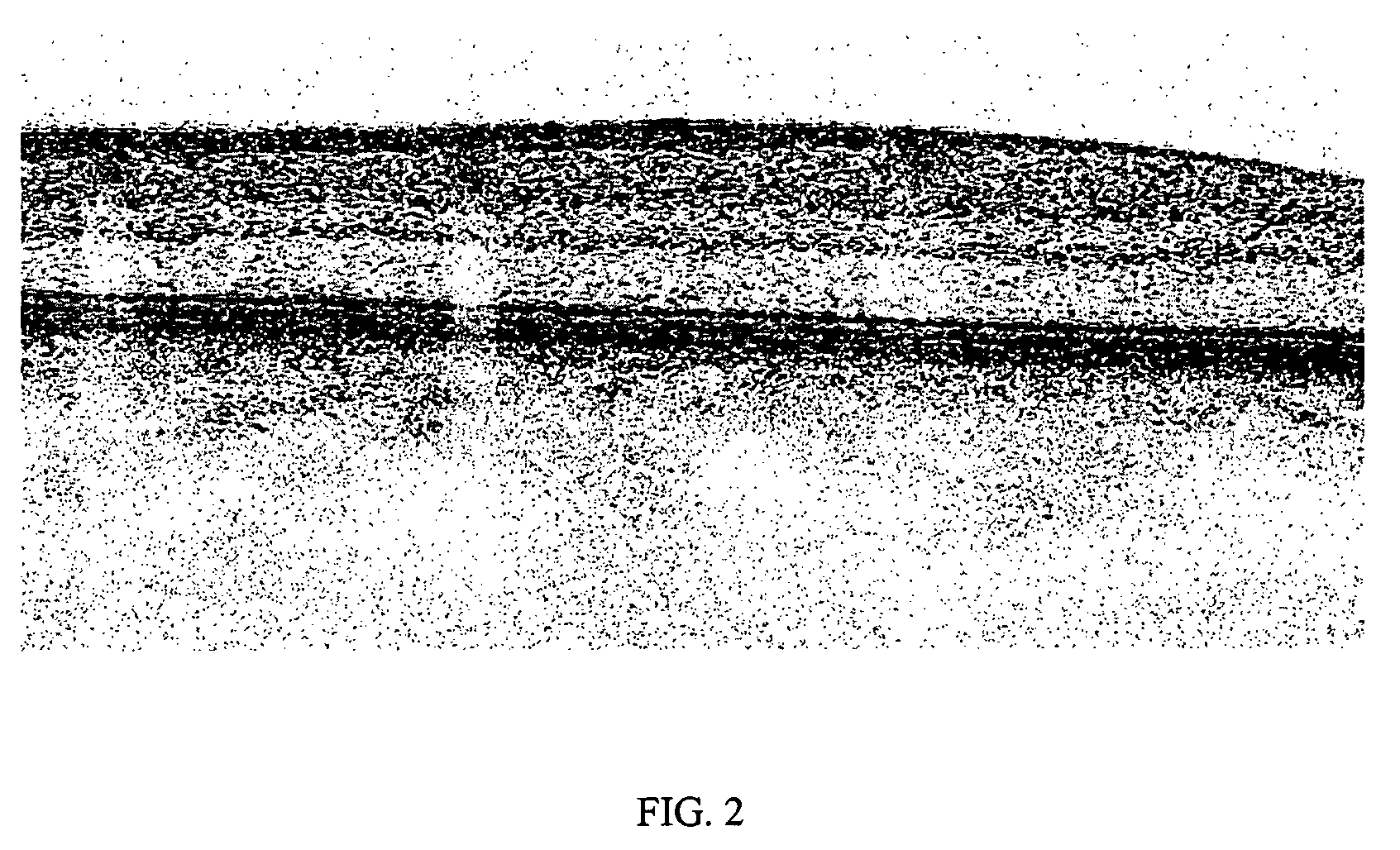

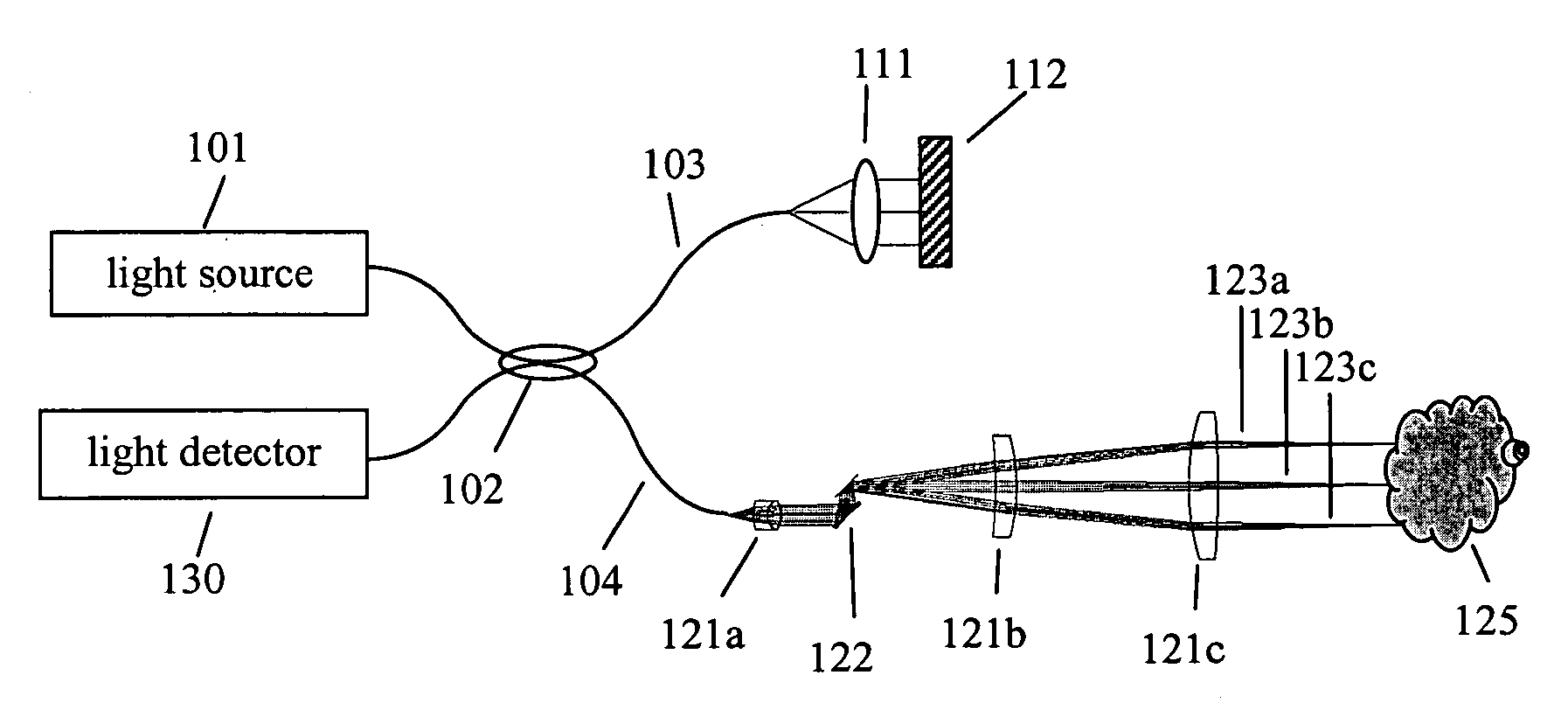

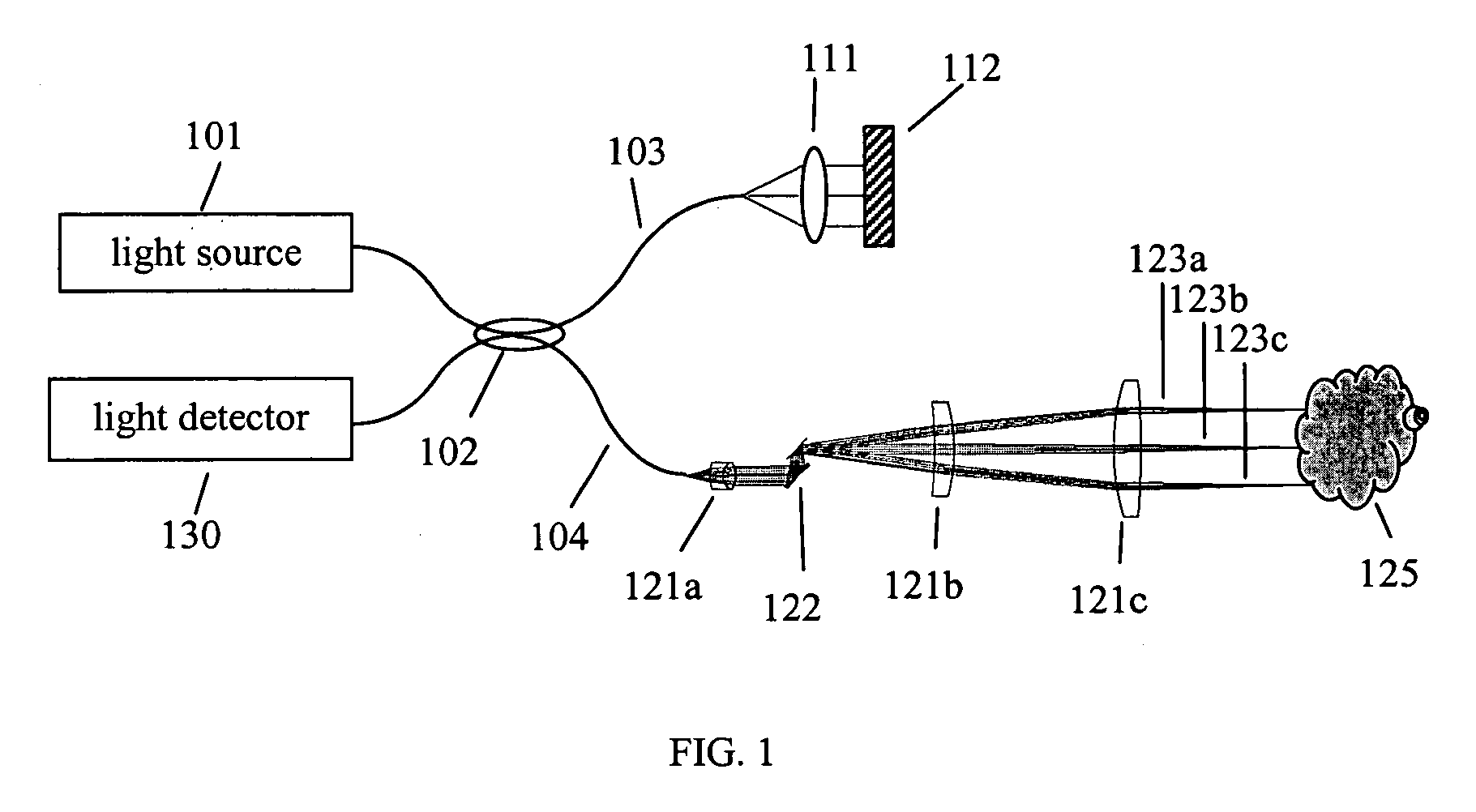

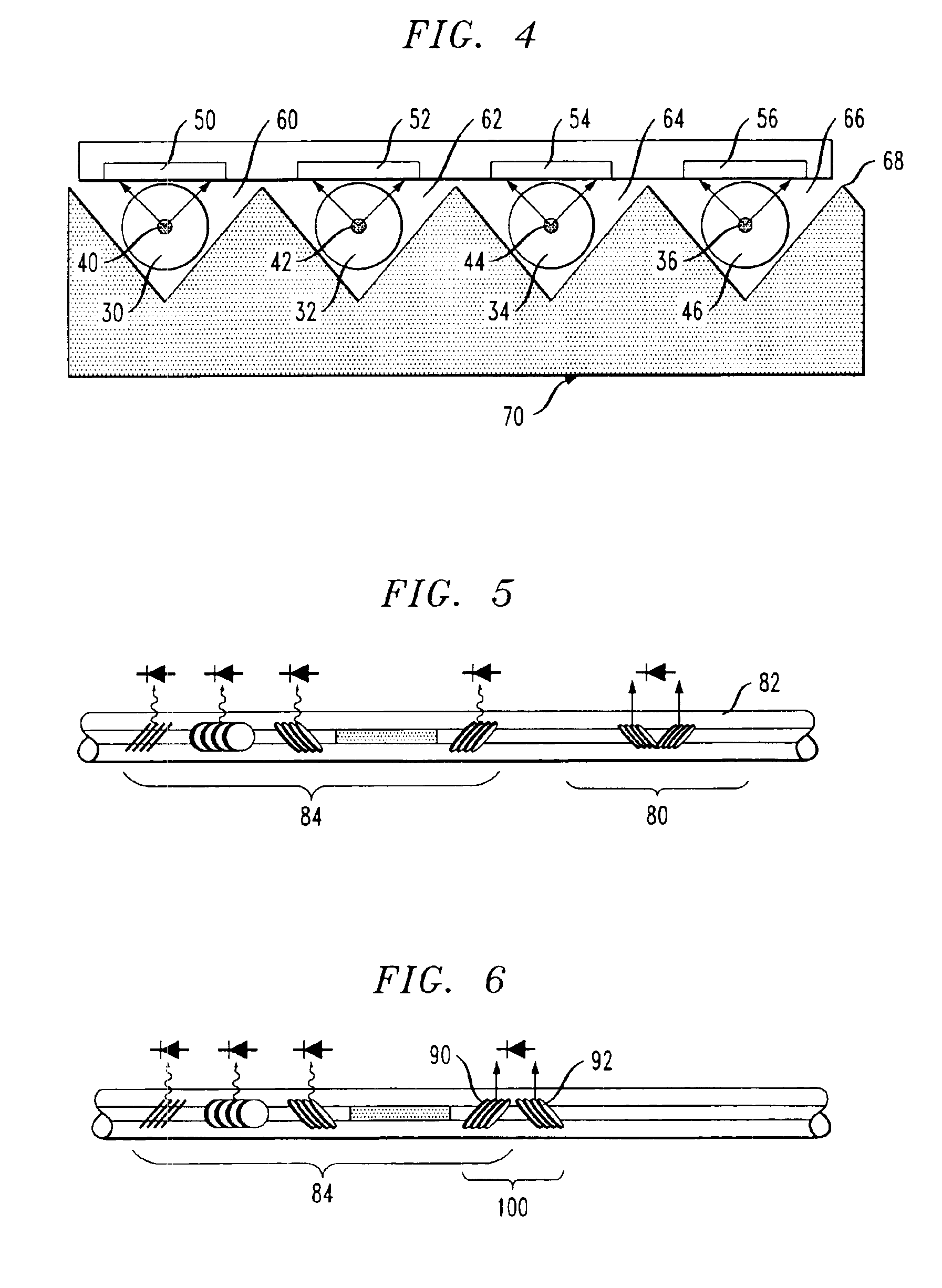

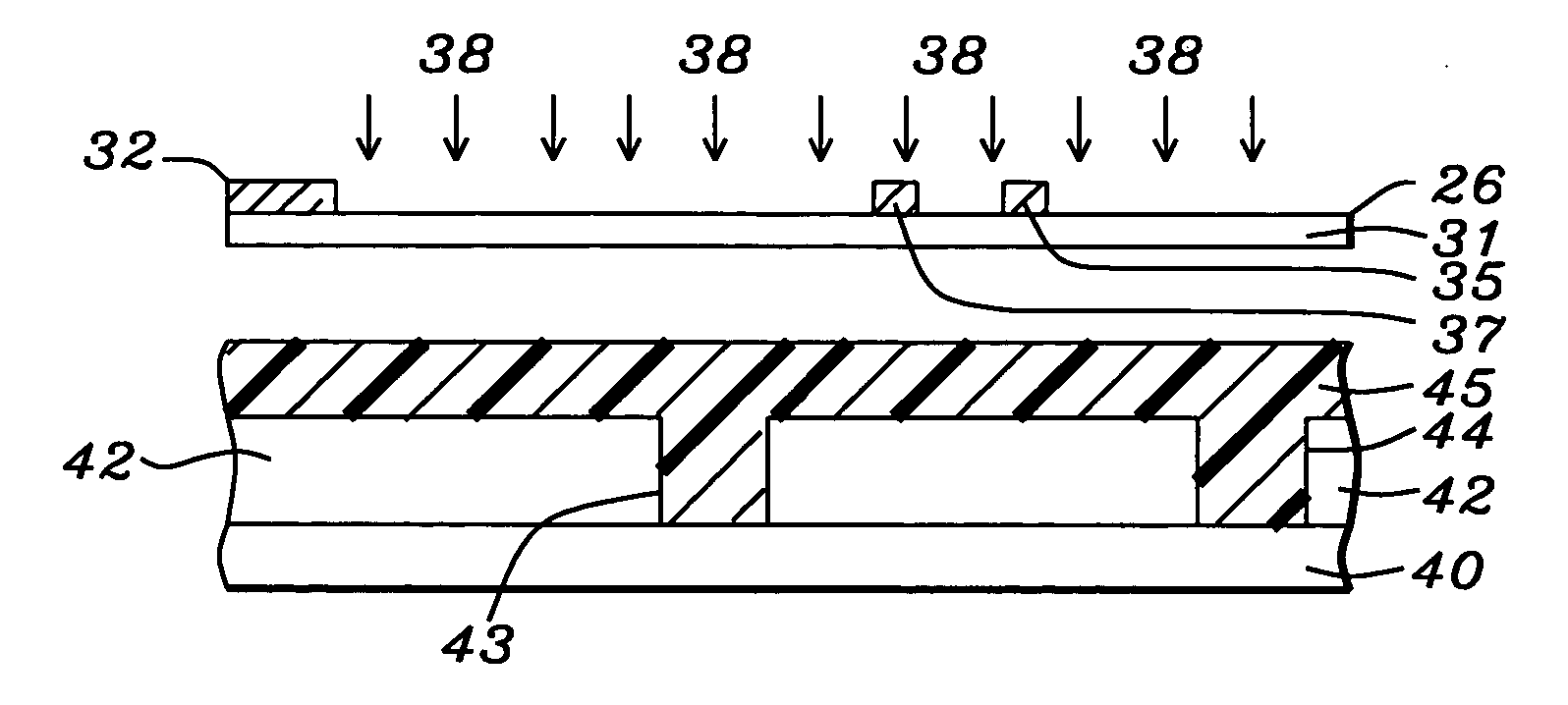

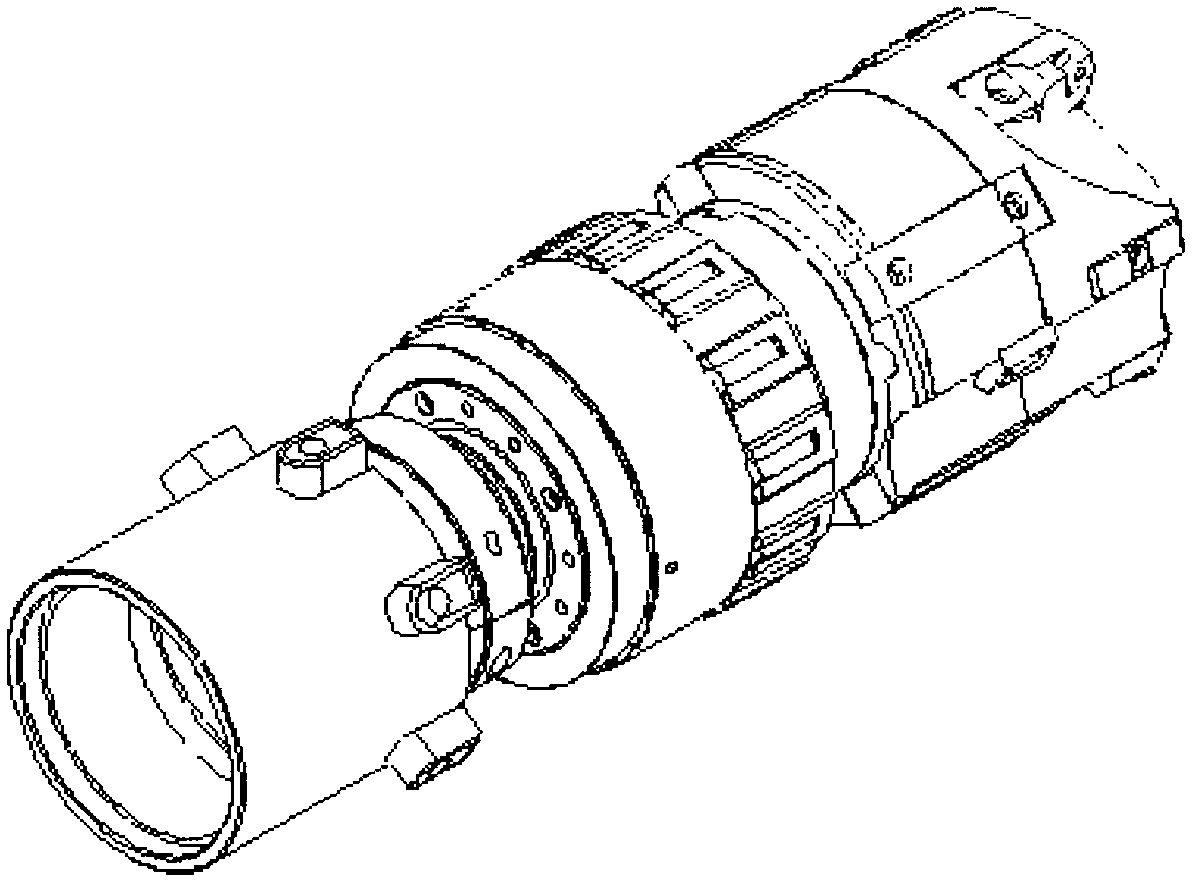

Method of motion correction in optical coherence tomography imaging

An image data set acquired by an optical coherence tomography (OCT) system is corrected for effects due to motion of the sample. A first set of A-scans is acquired within a time short enough to avoid any significant motion of the sample. A second more extensive set of A-scans is acquired over an overlapping region on the sample. Significant sample motion may occur during acquisition of the second set. A-scans from the first set are matched with A-scans from the second set, based on similarity between the longitudinal optical scattering profiles they contain. Such matched pairs of A-scans are likely to correspond to the same region in the sample. Comparison of the OCT scanner coordinates that produced each A-scan in a matching pair, in conjunction with any shift in the longitudinal scattering profiles between the pair of A-scans, reveals the displacement of the sample between acquisition of the first and second A-scans in the pair. Estimates of the sample displacement are used to correct the transverse and longitudinal coordinates of the A-scans in the second set, to form a motion-corrected OCT data set.

Owner:CARL ZEISS MEDITEC INC

Method of motion correction in optical coherence tomography imaging

An image data set acquired by an optical coherence tomography (OCT) system is corrected for effects due to motion of the sample. A first set of A-scans is acquired within a time short enough to avoid any significant motion of the sample. A second more extensive set of A-scans is acquired over an overlapping region on the sample. Significant sample motion may occur during acquisition of the second set. A-scans from the first set are matched with A-scans from the second set, based on similarity between the longitudinal optical scattering profiles they contain. Such matched pairs of A-scans are likely to correspond to the same region in the sample. Comparison of the OCT scanner coordinates that produced each A-scan in a matching pair, in conjunction with any shift in the longitudinal scattering profiles between the pair of A-scans, reveals the displacement of the sample between acquisition of the first and second A-scans in the pair. Estimates of the sample displacement are used to correct the transverse and longitudinal coordinates of the A-scans in the second set, to form a motion-corrected OCT data set.

Owner:CARL ZEISS MEDITEC INC

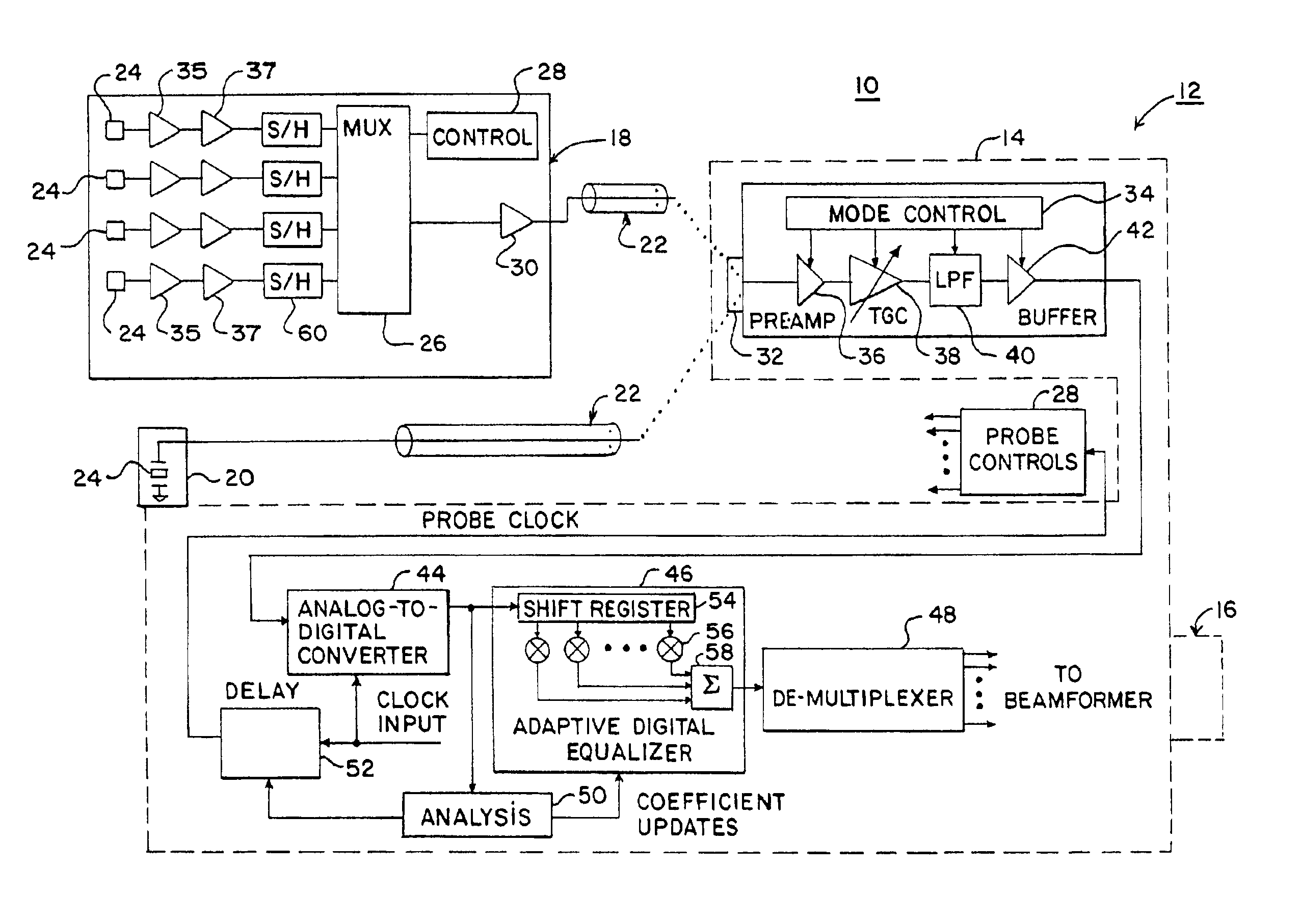

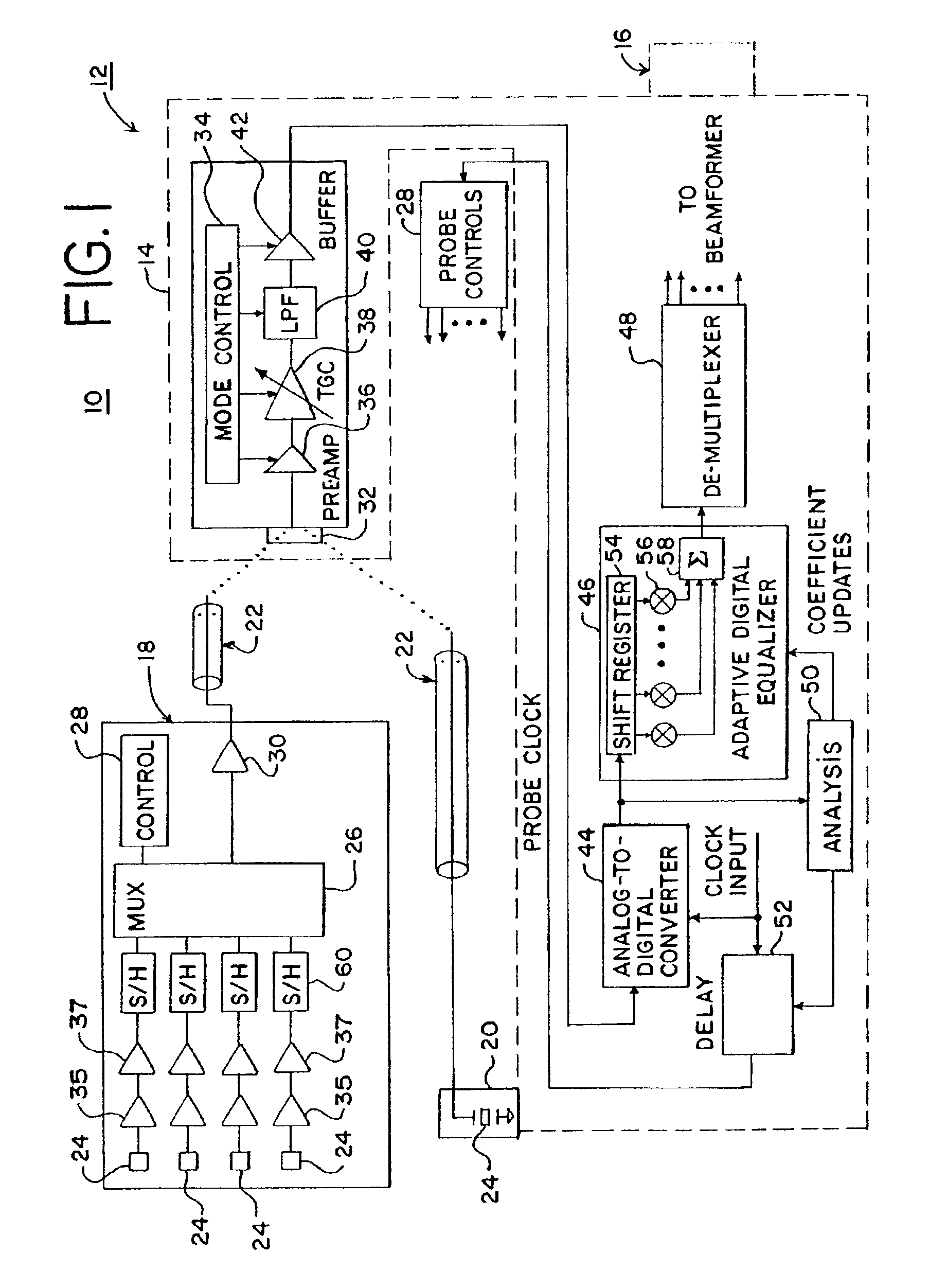

Ultrasound transmit pulser with receive interconnection and method of use

InactiveUS6891311B2Piezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationPhase differenceEngineering

A transmit pulser includes an H-bridge of four transistors. First and second transistors of the H-bridge connect with a first electrode of a transducer element, and third and fourth transistors of the H-bridge connect with a second electrode of the transducer element. A differential receive amplifier connects with the first and third transistors. First and second diode clamps connect with the first and third transistors, respectively, and the inputs to the differential receive amplifier. The second and fourth transistors connect to a same power or voltage source, imposing a same voltage in either a forward or a reverse direction. By using matched transistor pairs (e.g. first and third matched pair and second and fourth matched pair), symmetrical transmit waveforms are generated. Symmetrical transmit waveforms allow for using phase inversion or phase differences between transmit waveforms for imaging, such as for harmonic imaging of tissue. The spectral content of symmetrical waveforms is narrower or includes less harmonic information.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

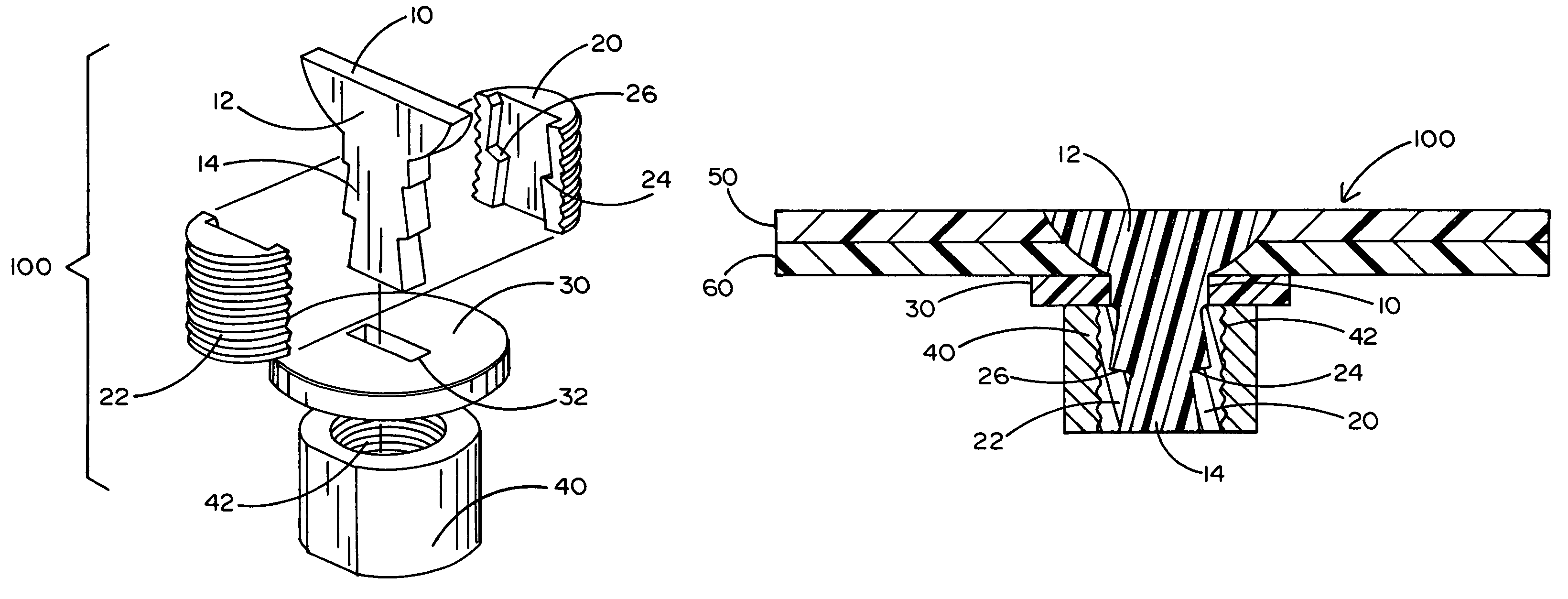

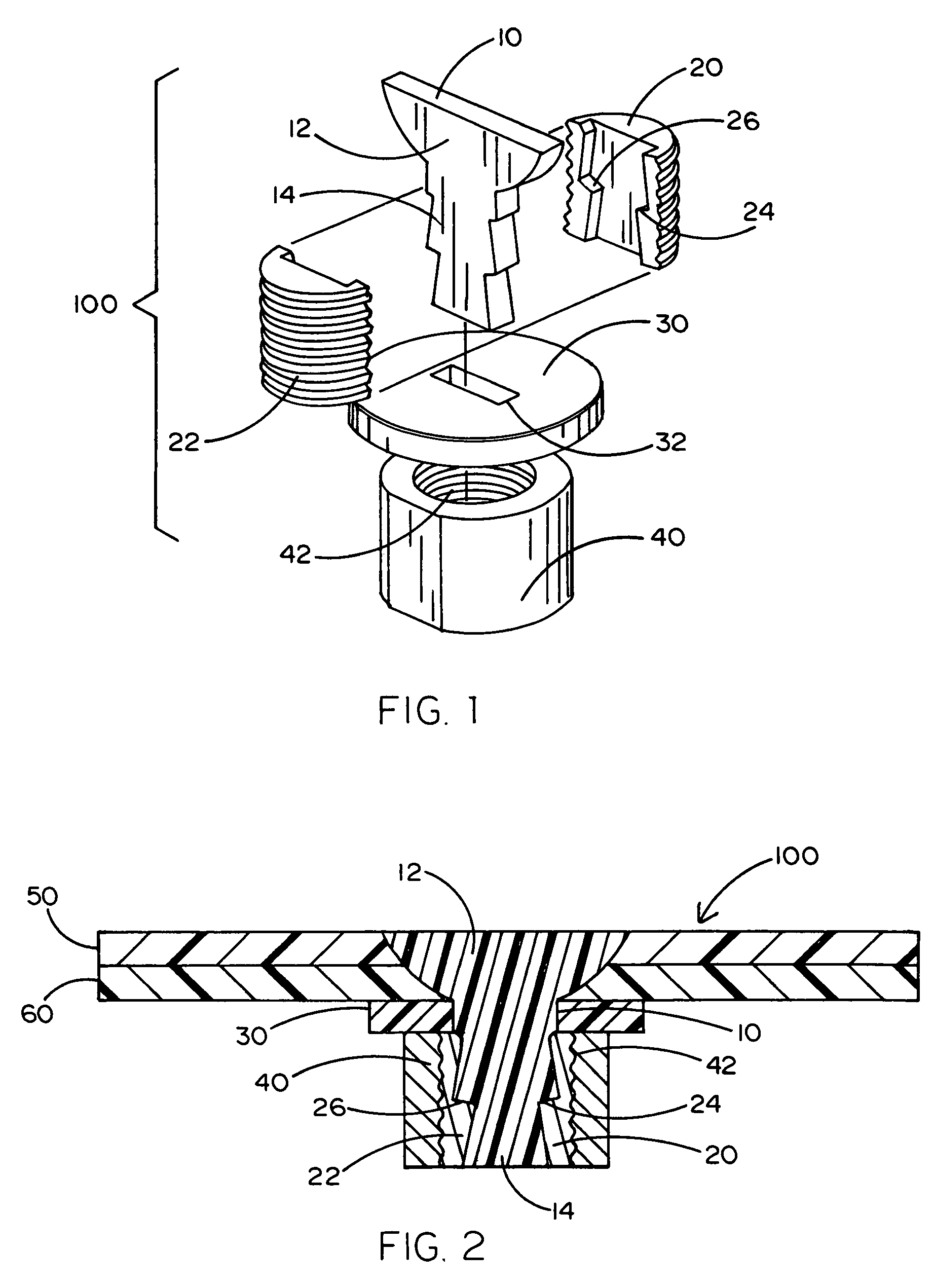

Mechanical fastener system for high-temperature structural assemblies

ActiveUS7988395B2Prevent removalAvoid separationNutsKey type connectionsMatched pairCeramic composite

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

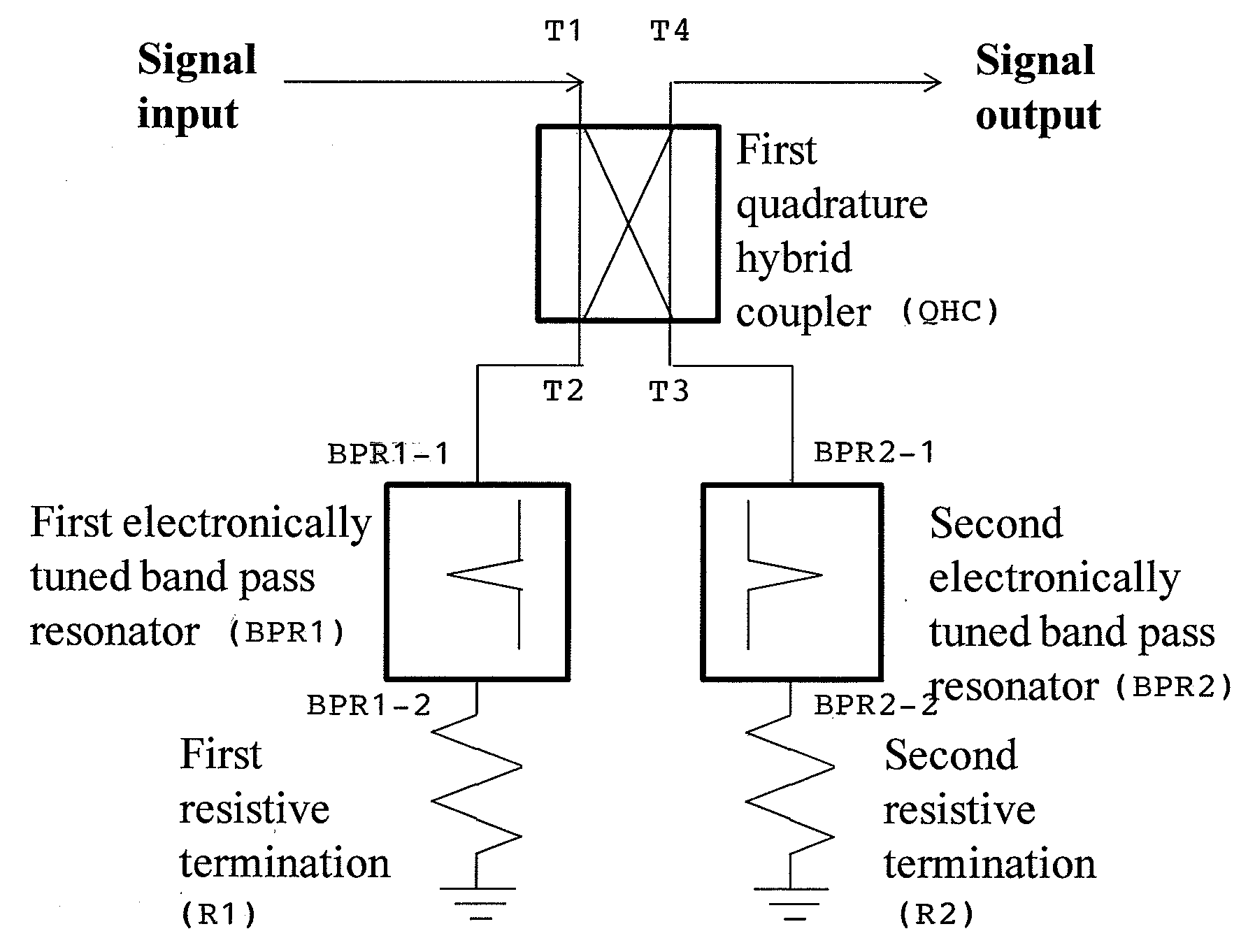

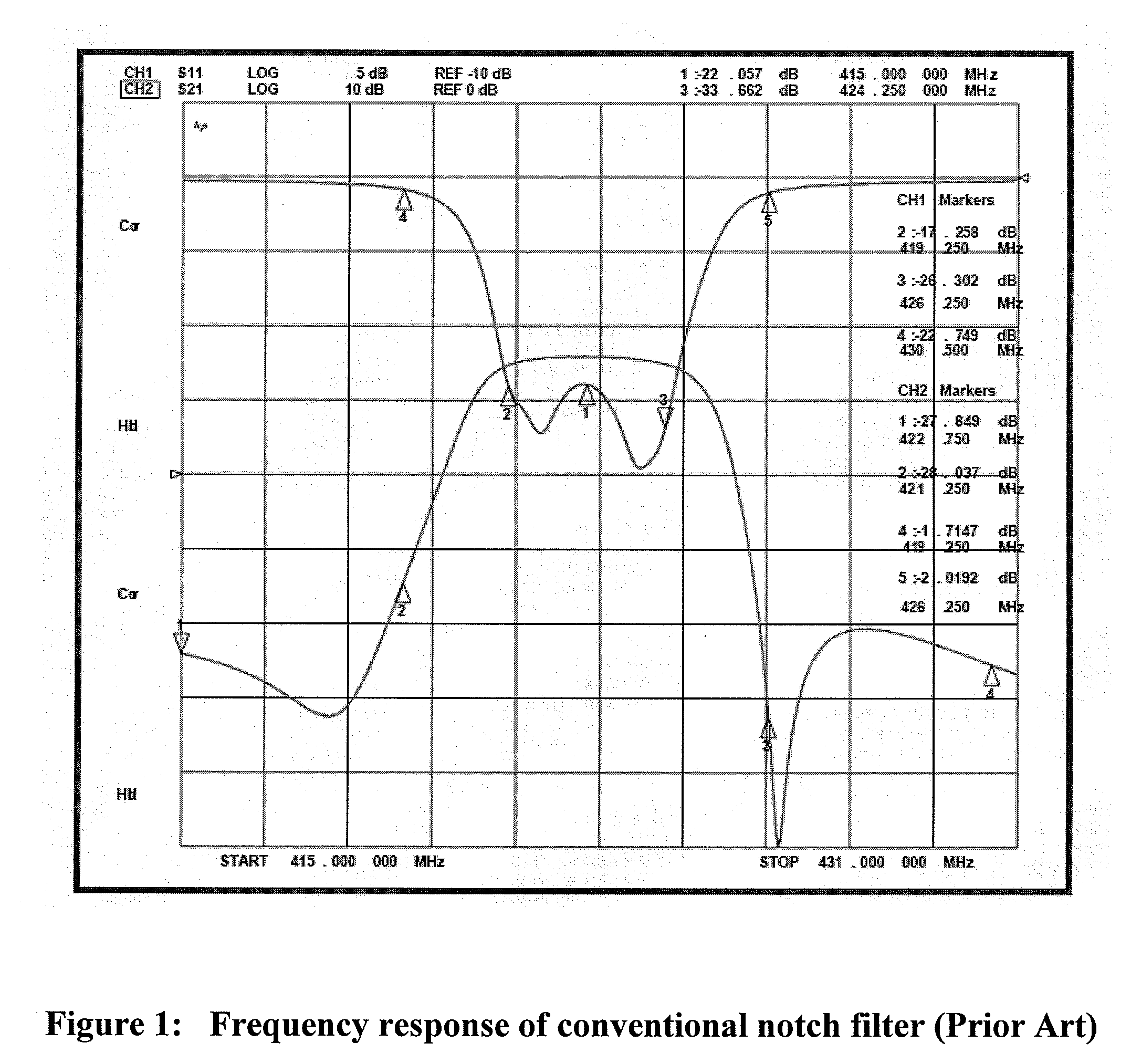

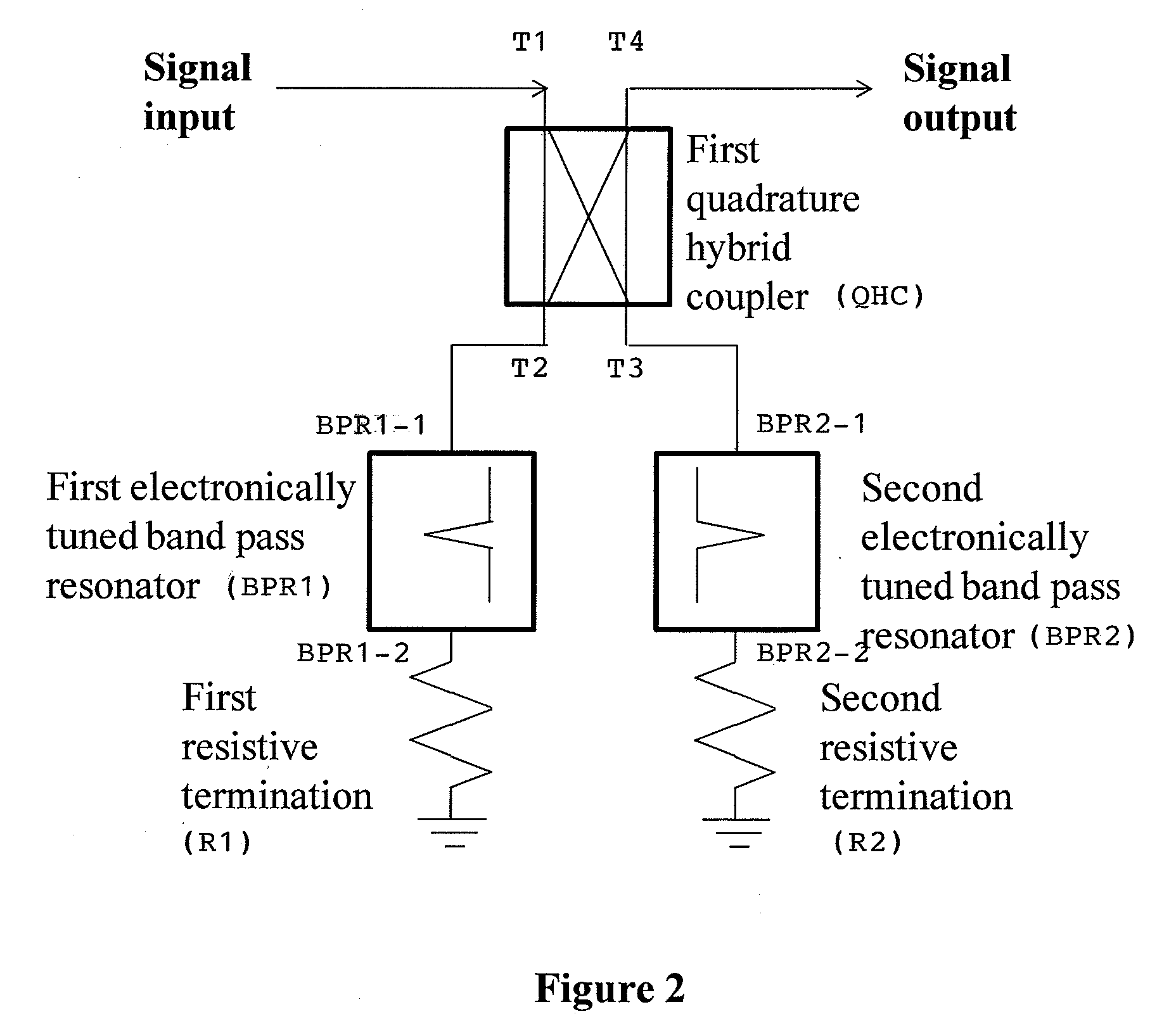

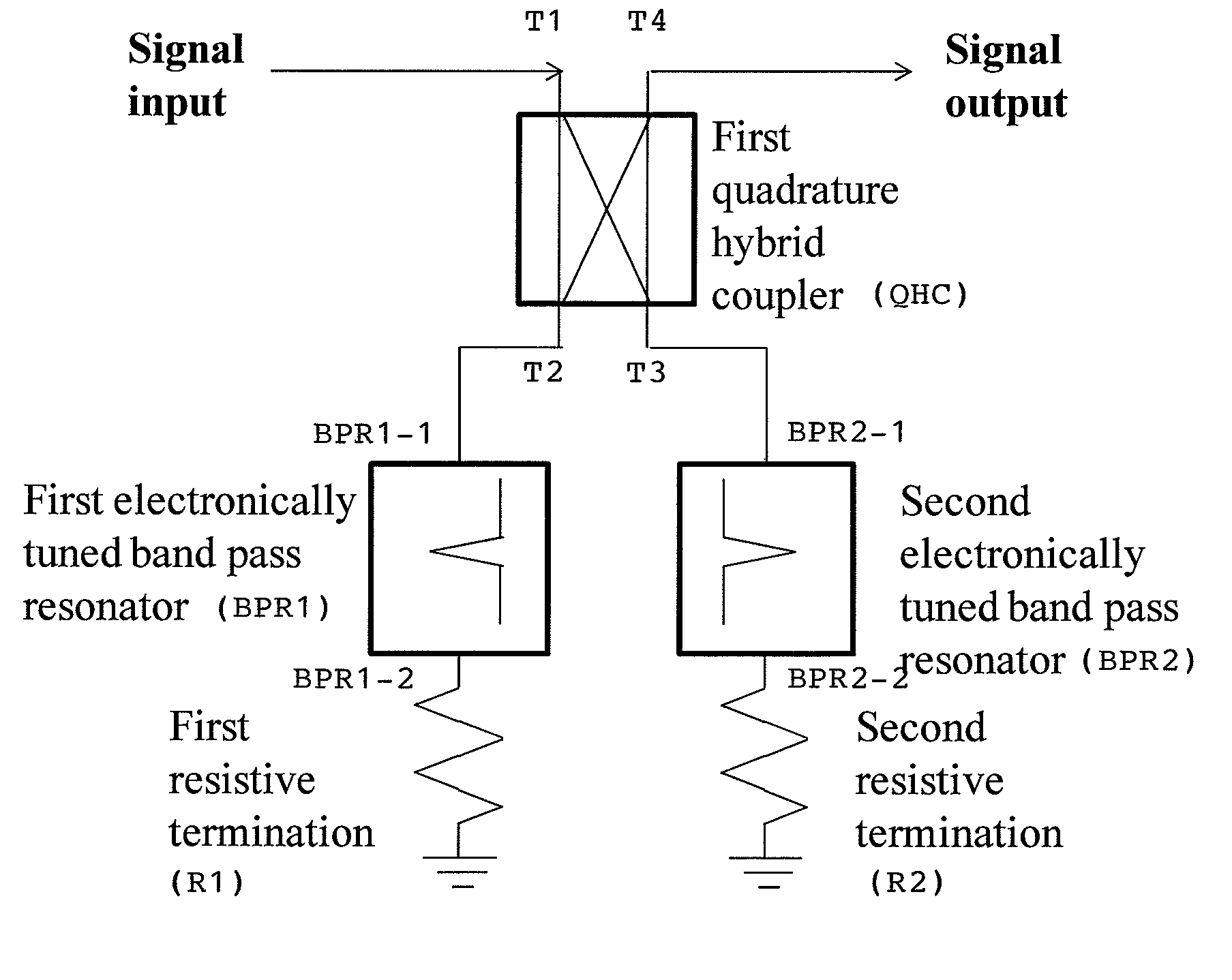

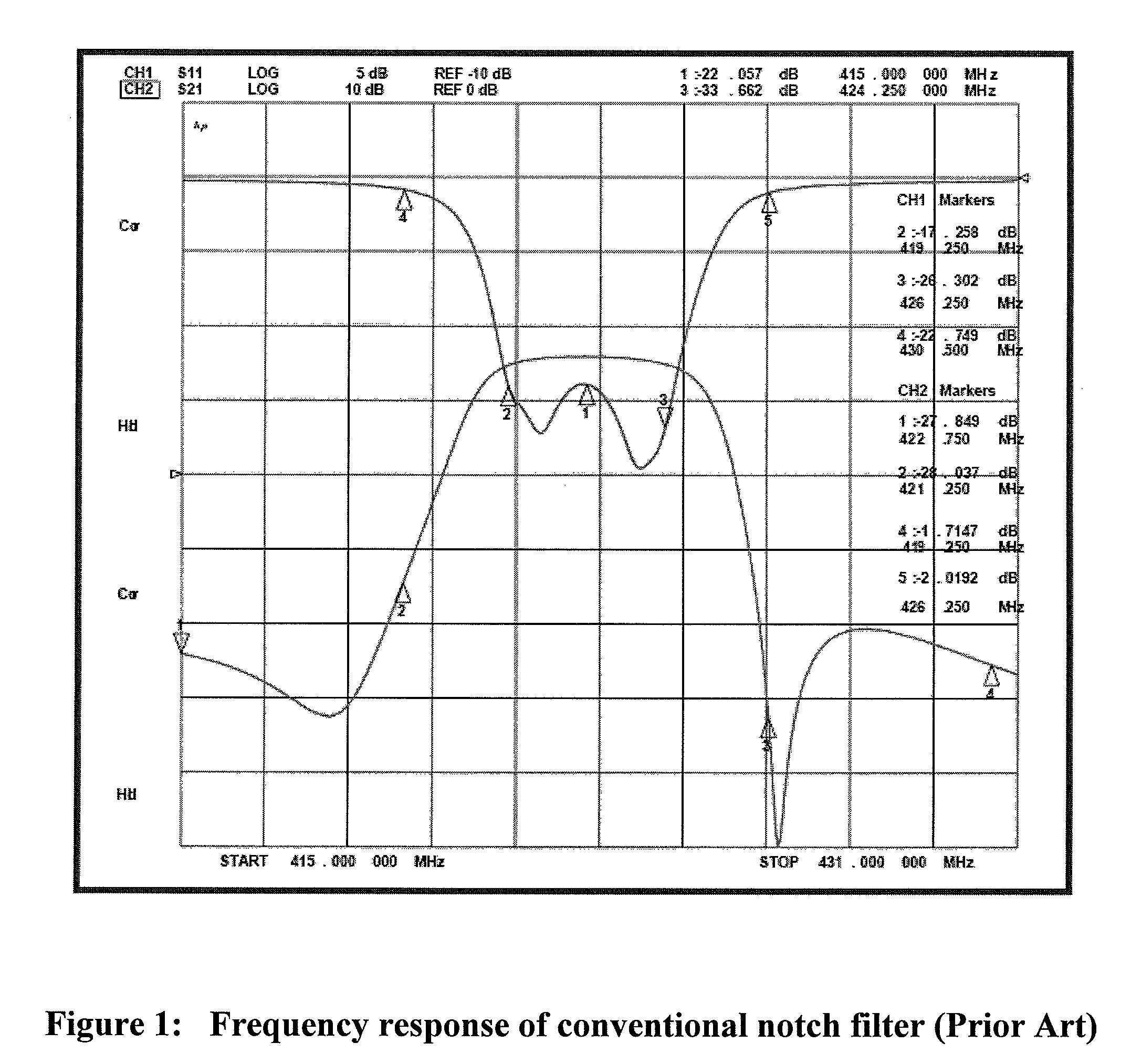

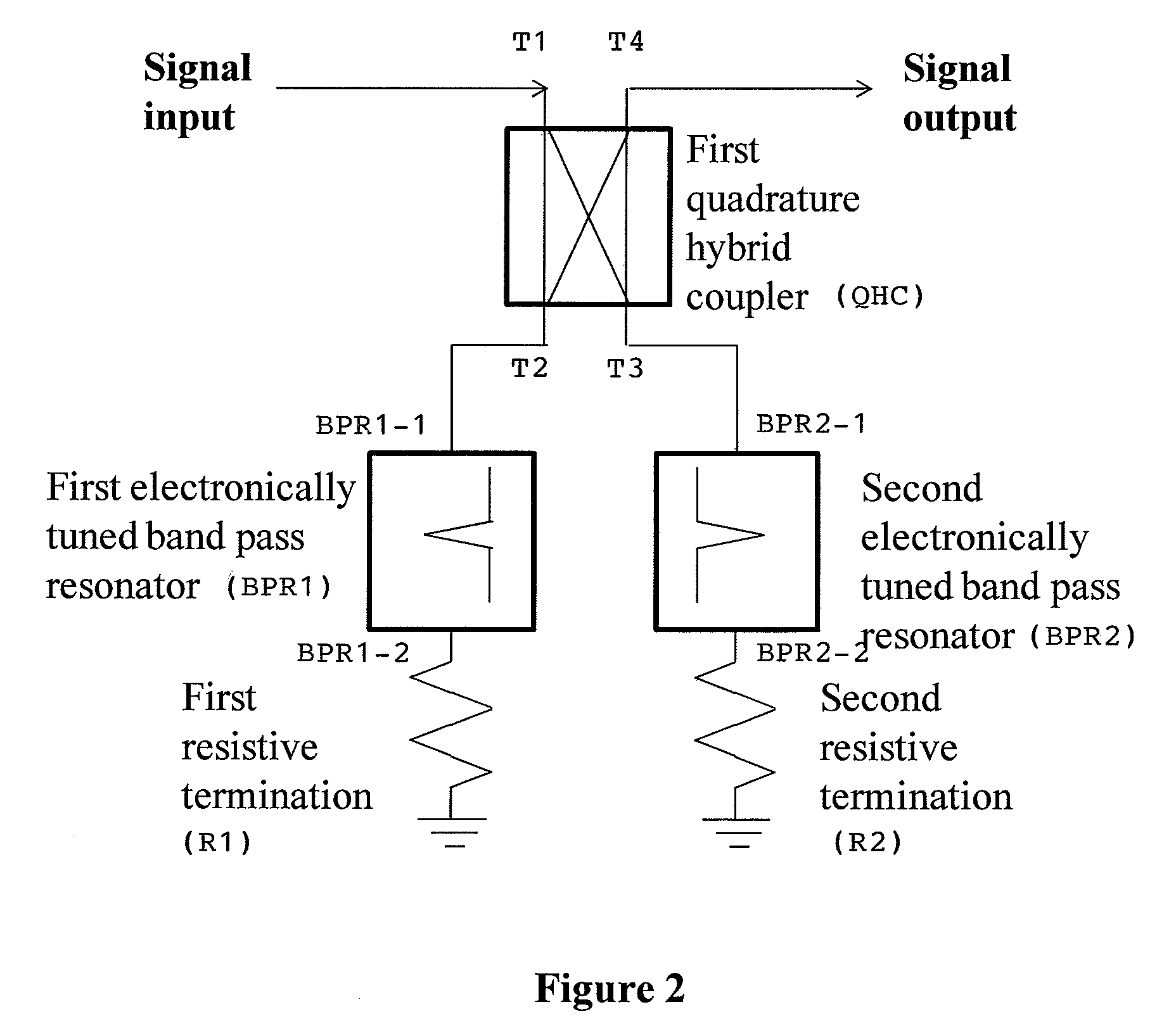

Electronically tunable, absorptive, low-loss notch filter

InactiveUS20090289744A1Little and no lossImproved power handlingMultiple-port networksTunable filtersWireless routerMatched pair

An electronically tuned, absorptive, low-loss notch filter with high RF power handling capability is obtained using a four-port quadrature hybrid coupler connected to a matched pair of band pass resonator devices and resistive terminations. The notch filter design uses series-only tuning elements for the band pass resonator devices to raise the RF power handling of the band pass resonators far above conventional techniques while also being tunable at high speeds. The notch filter architecture and method can be used for interference cancellation in a wide range of wireless technologies, such as cellular phone, wireless routers, hand-held radios, satellite communications, and any other environments where there are a number of wireless technologies in close signal proximity.

Owner:TERASYS TECH

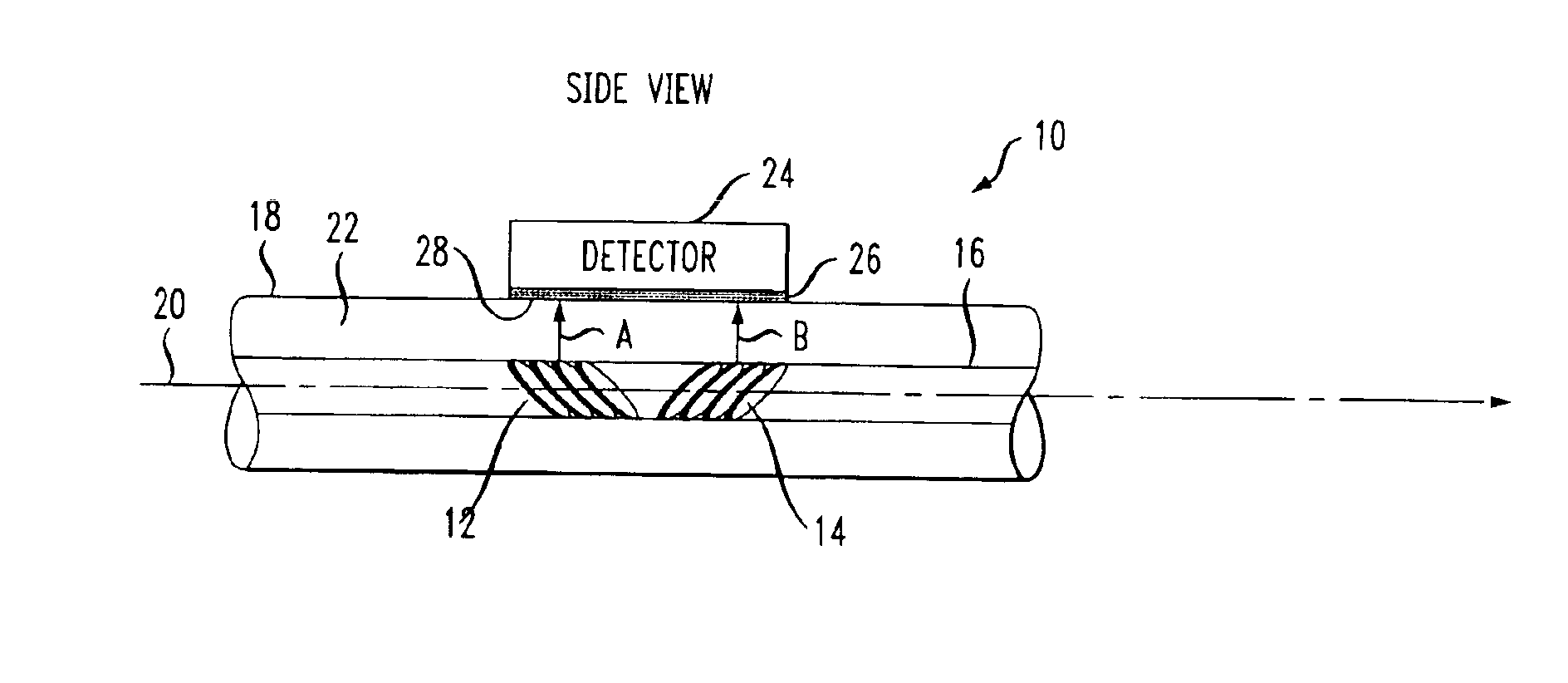

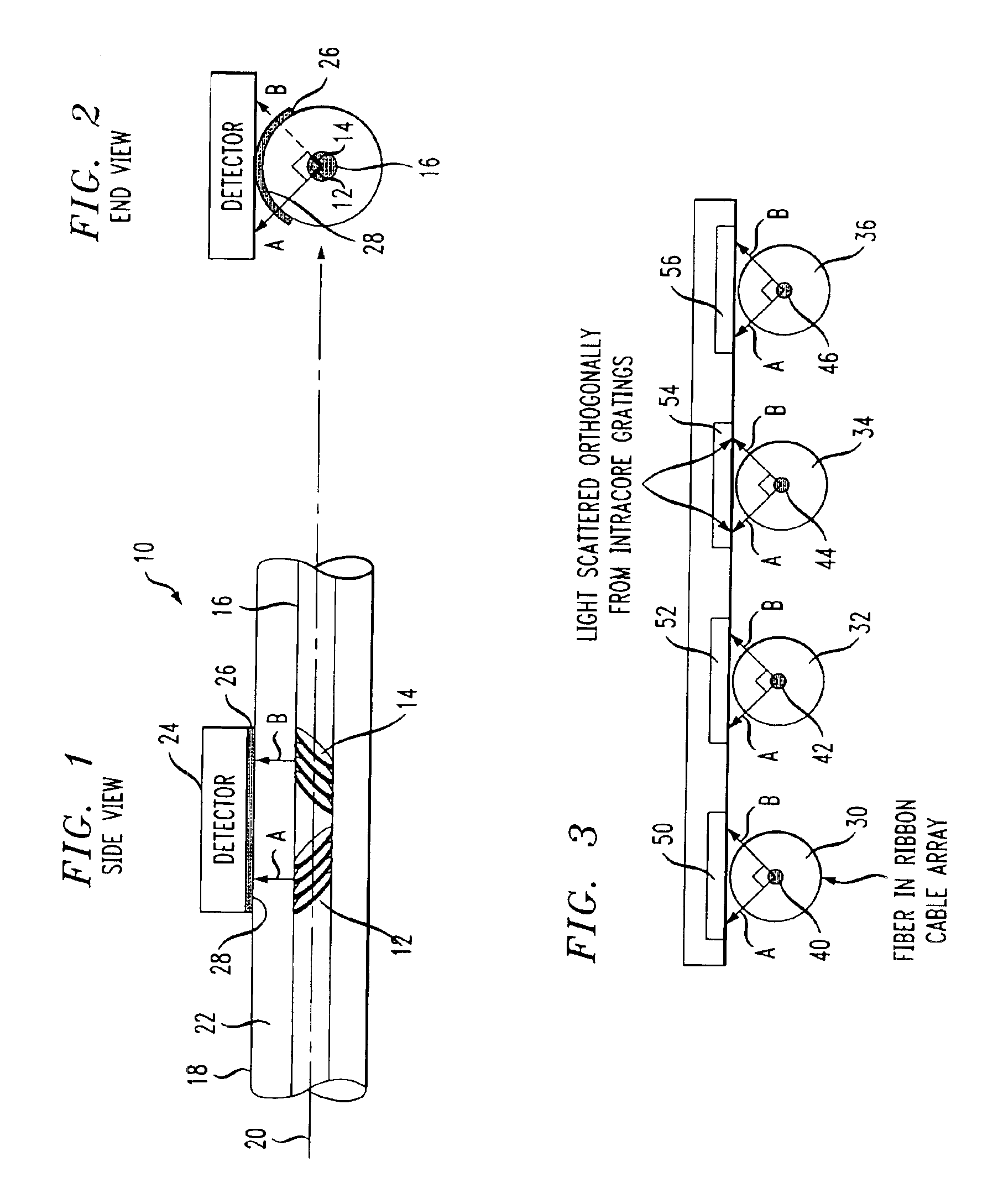

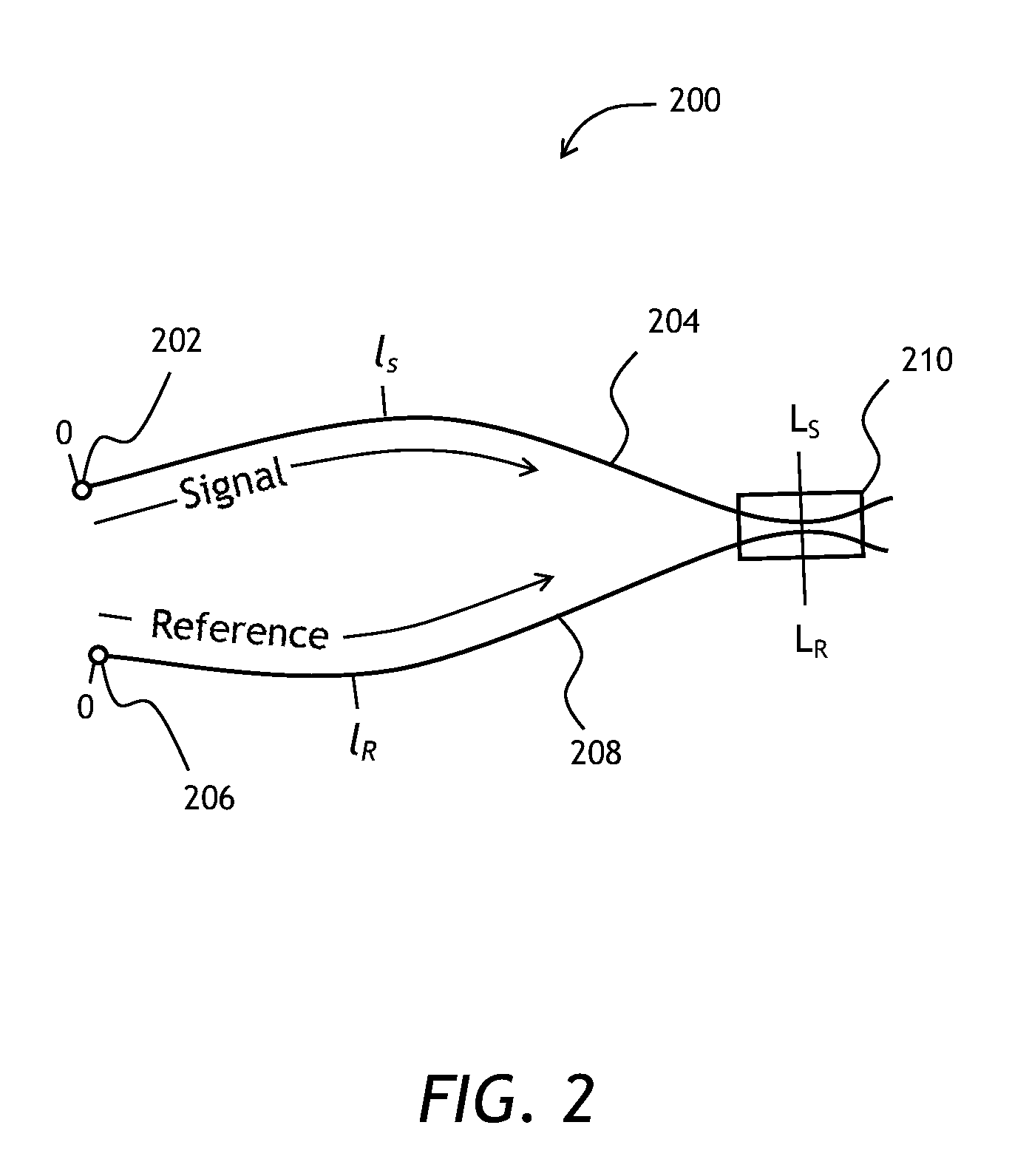

Optical taps formed using fiber gratings

A matched pair of tilted gratings may be formed in a section of optical fiber (or waveguide) and used as a “tap” to measure the power of an optical signal passing through the fiber. By using a pair of highly-tilted gratings (e.g., tilted at an angle of 45° with respect to the optical axis) and orienting the gratings to be orthogonal with respect to one another (i.e., azimuthal orthogonality around the fiber axis), a pair of orthogonally polarized beams will be out-coupled from the propagating signal. Since the pair of beams are orthogonal, their sum can be made insensitive to variations in polarization of the optical signal propagating along the fiber.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

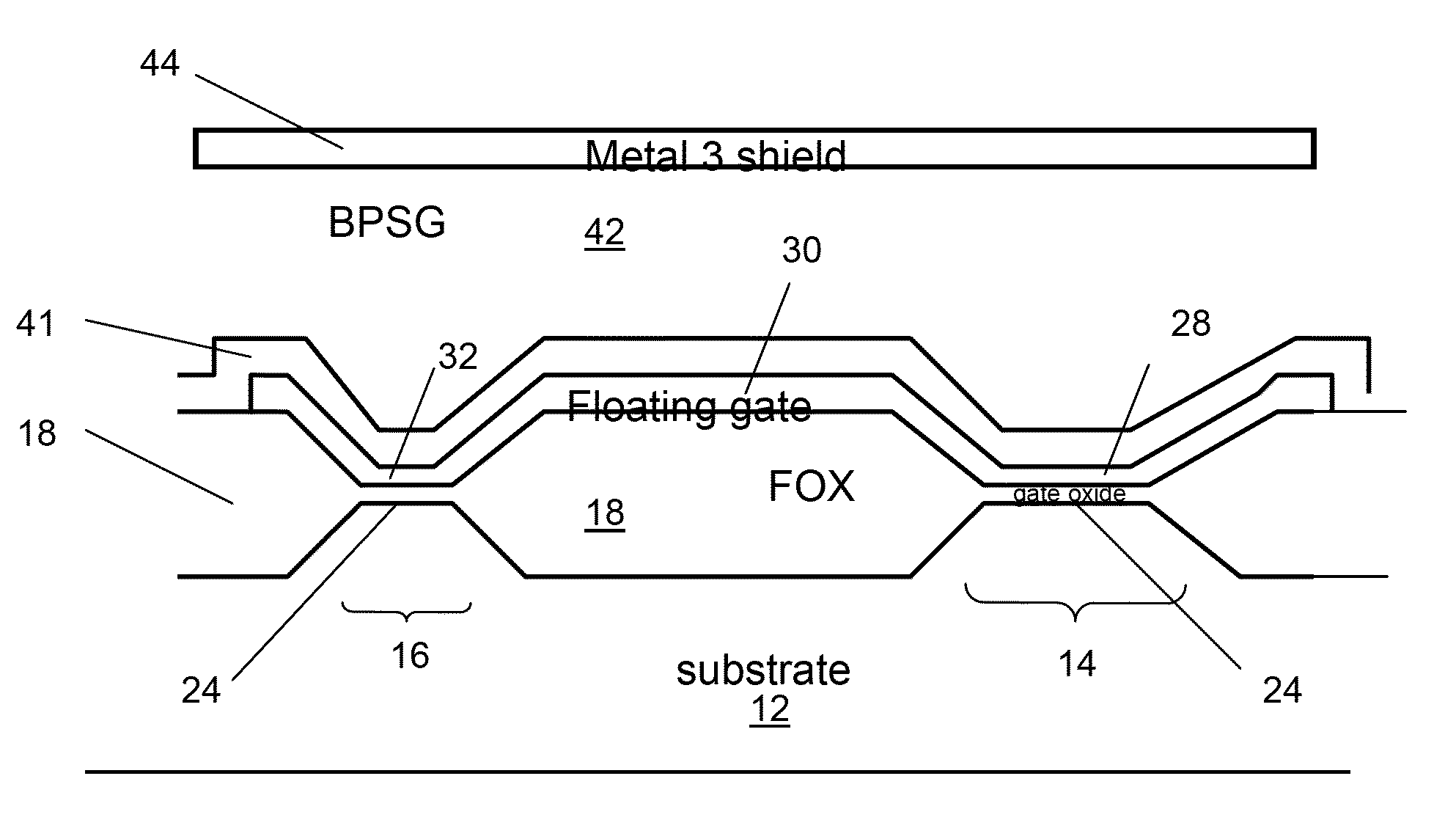

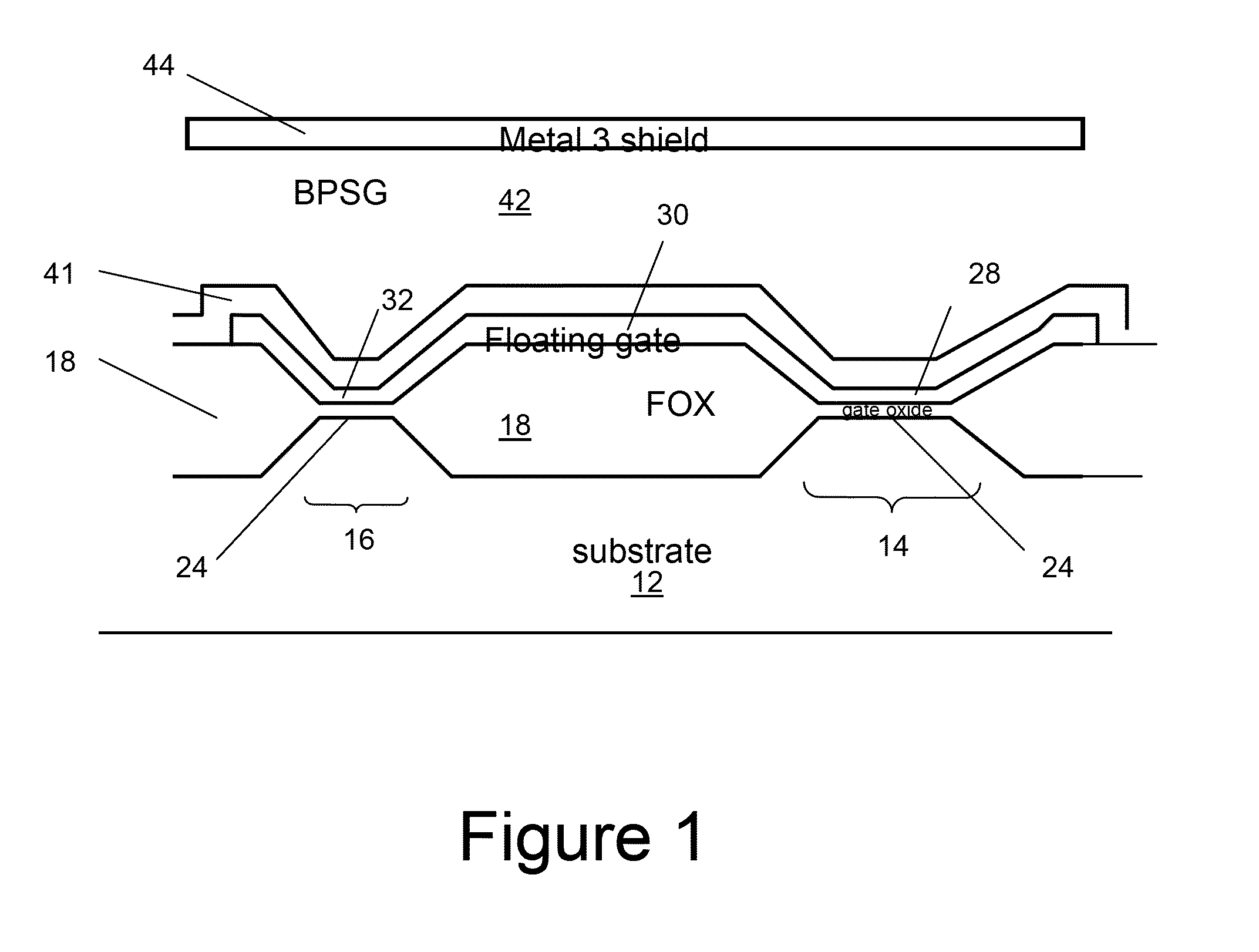

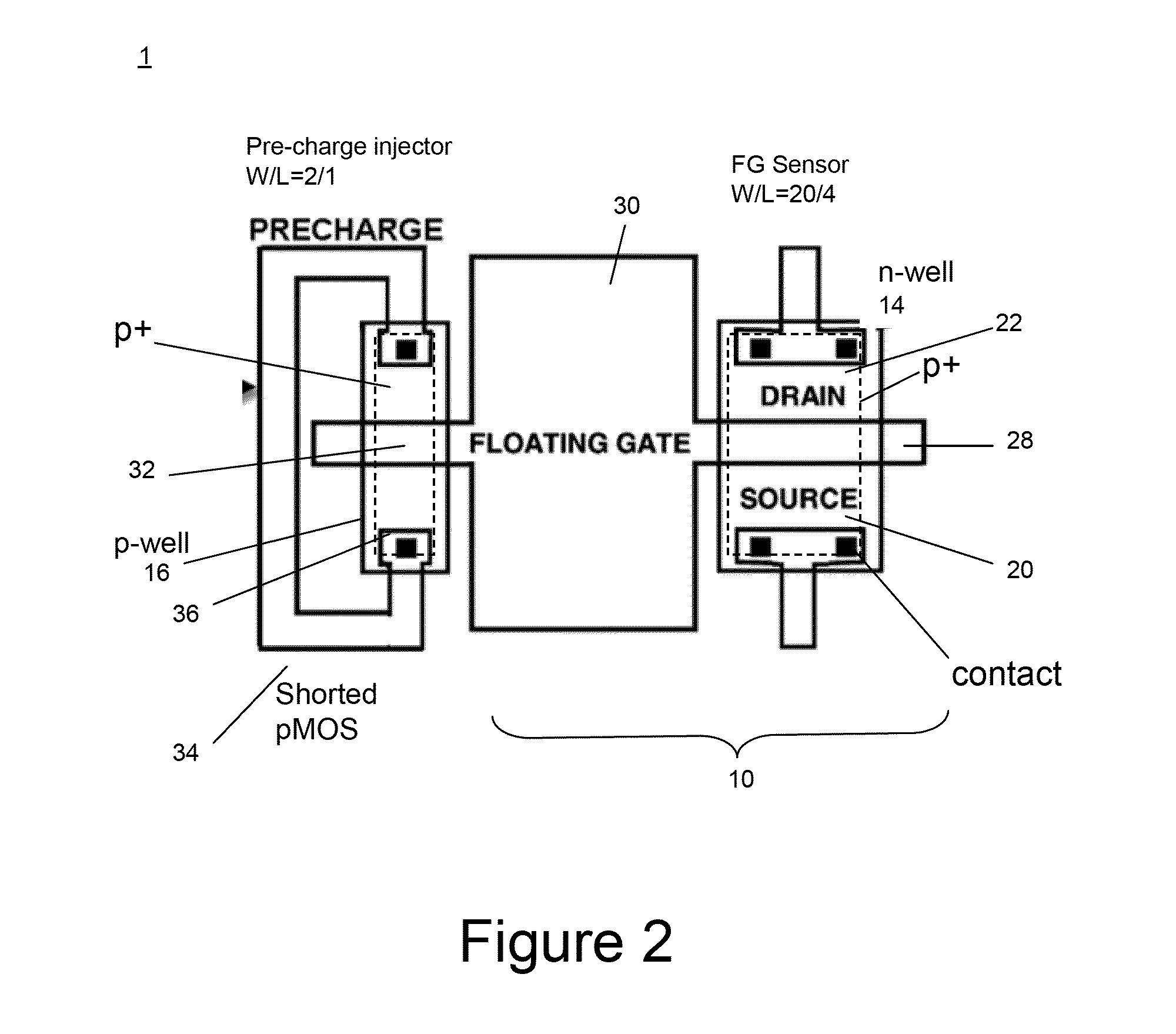

Miniaturized, low power fgmosfet radiation sensor and wireless dosimeter system

ActiveUS20100096556A1Reduce capacitanceHigh sensitivityDosimetersSolid-state devicesCapacitanceMOSFET

A miniaturized floating gate (FG) MOSFET radiation sensor system is disclosed, The sensor preferably comprises a matched pair of sensor and reference FGMOSFETs wherein the sensor FGMOSFET has a larger area floating gate with an extension over a field oxide layer, for accumulation of charge and increased sensitivity. Elimination of a conventional control gate and injector gate reduces capacitance, and increases sensitivity, and allows for fabrication using standard low cost CMOS technology. A sensor system may be provided with integrated signal processing electronics, for monitoring a change in differential channel current ID, indicative of radiation dose, and an integrated negative bias generator for automatic pre-charging from a low voltage power source. Optionally, the system may be coupled to a wireless transmitter. A compact wireless sensor System on Package solution is presented, suitable for dosimetry for radiotherapy or other biomedical applications.

Owner:KING ABDULLAH UNIV OF SCI & TECH

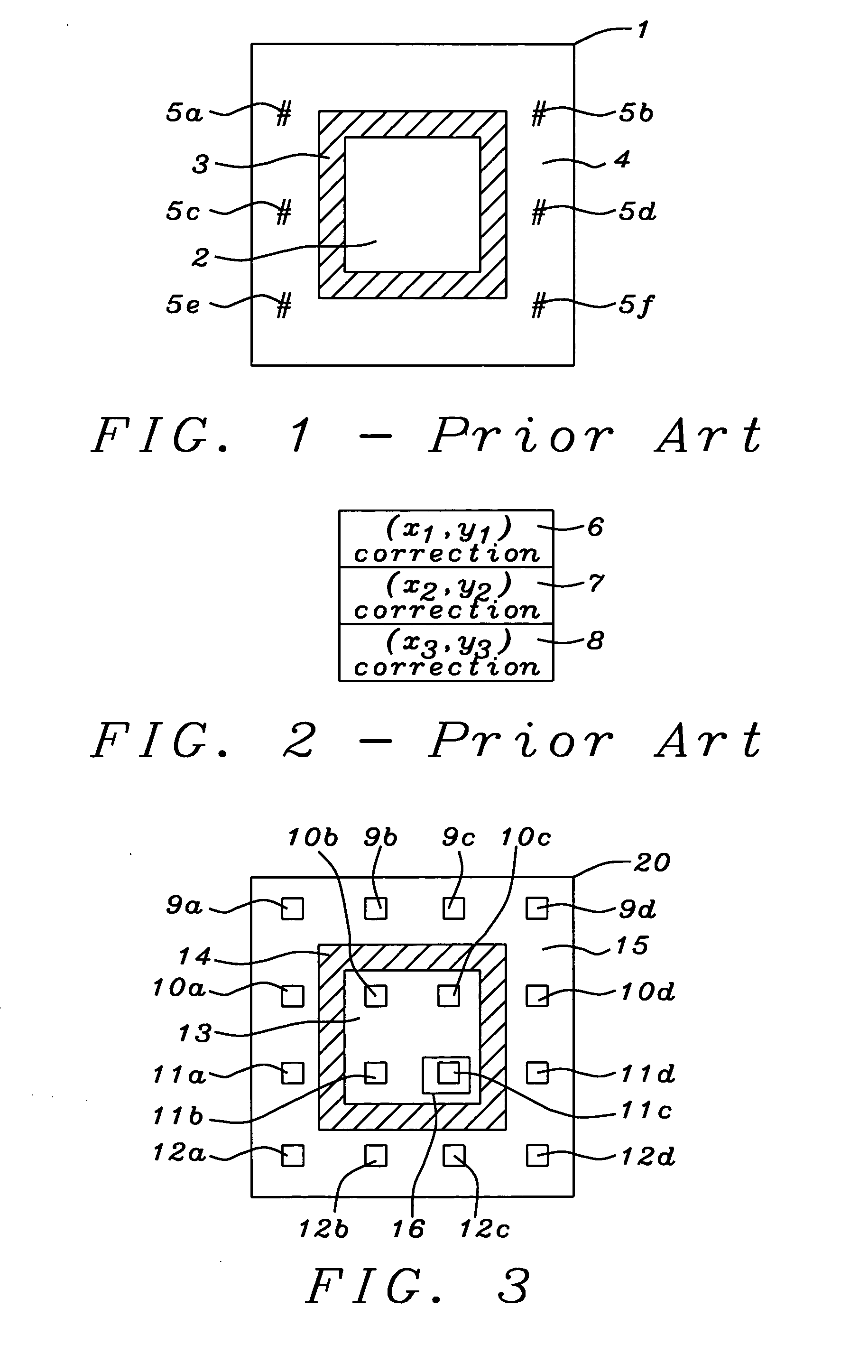

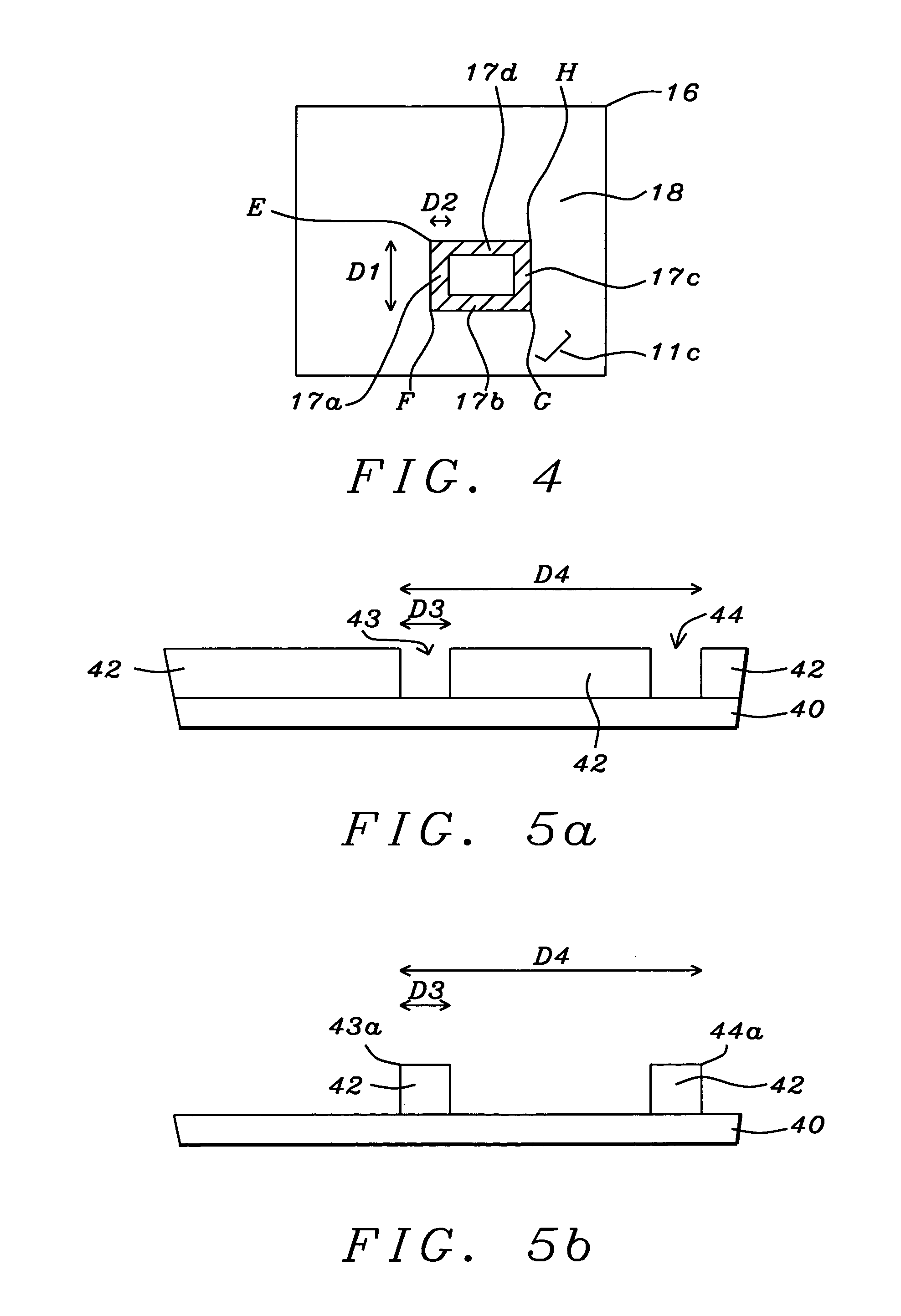

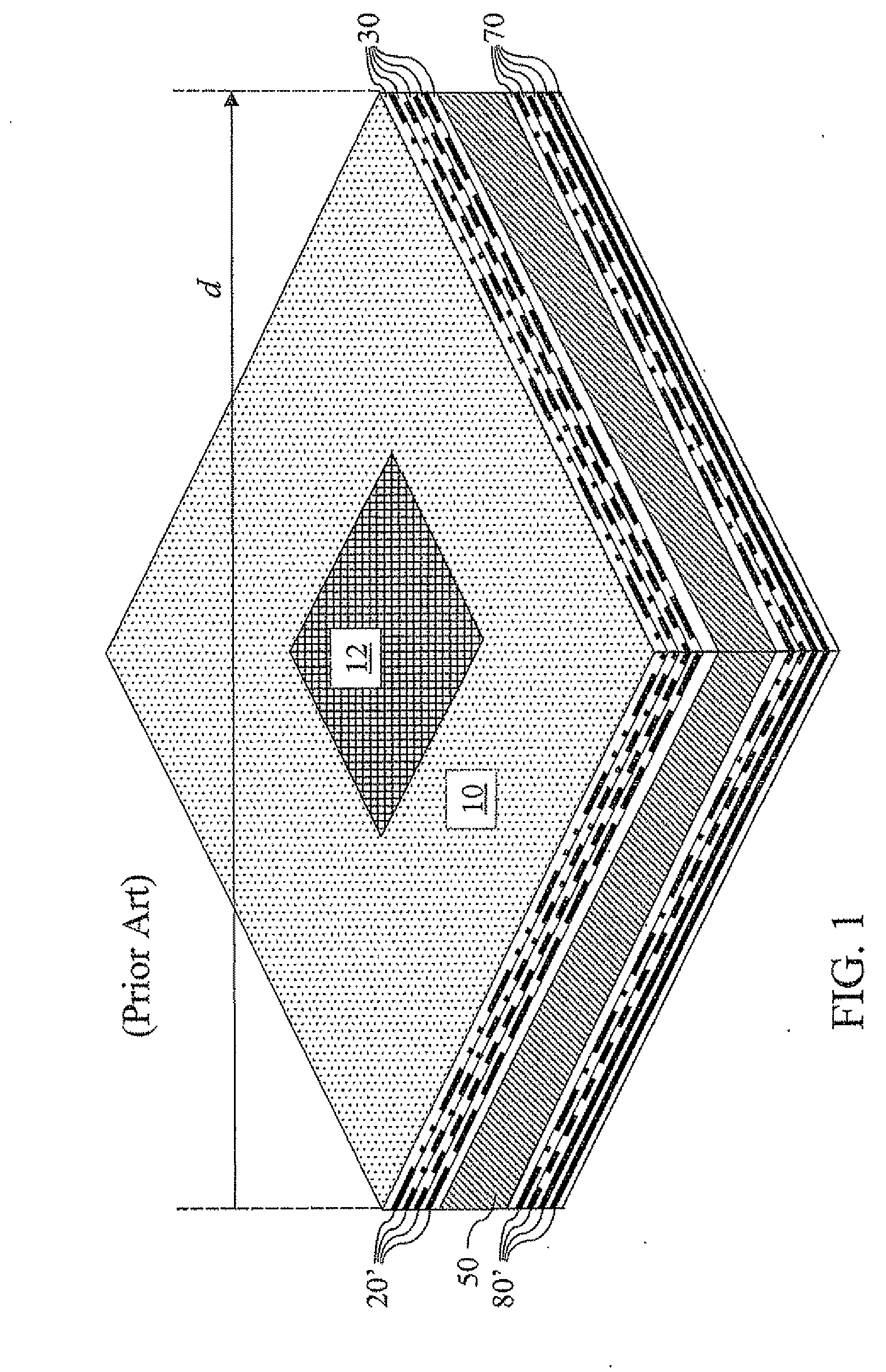

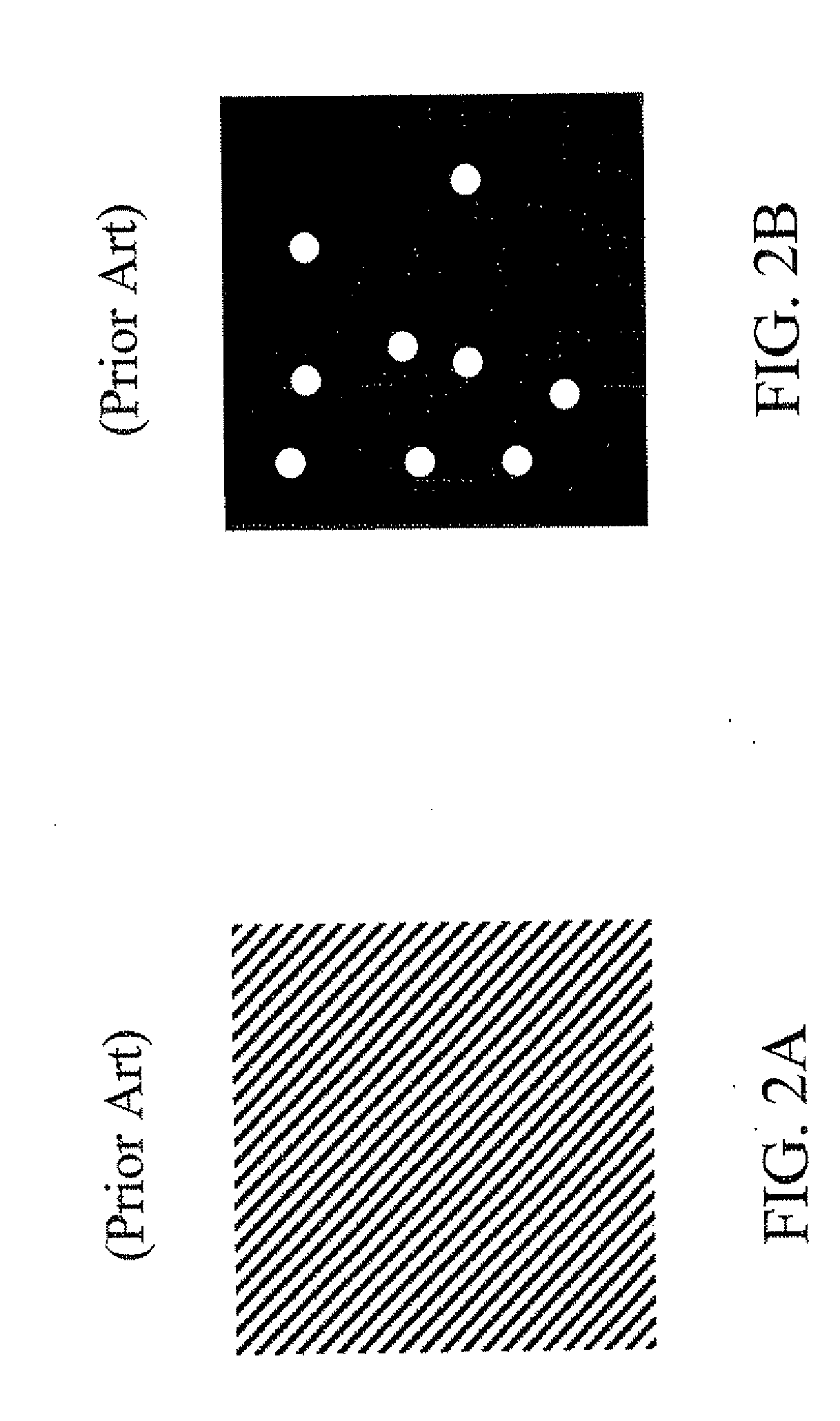

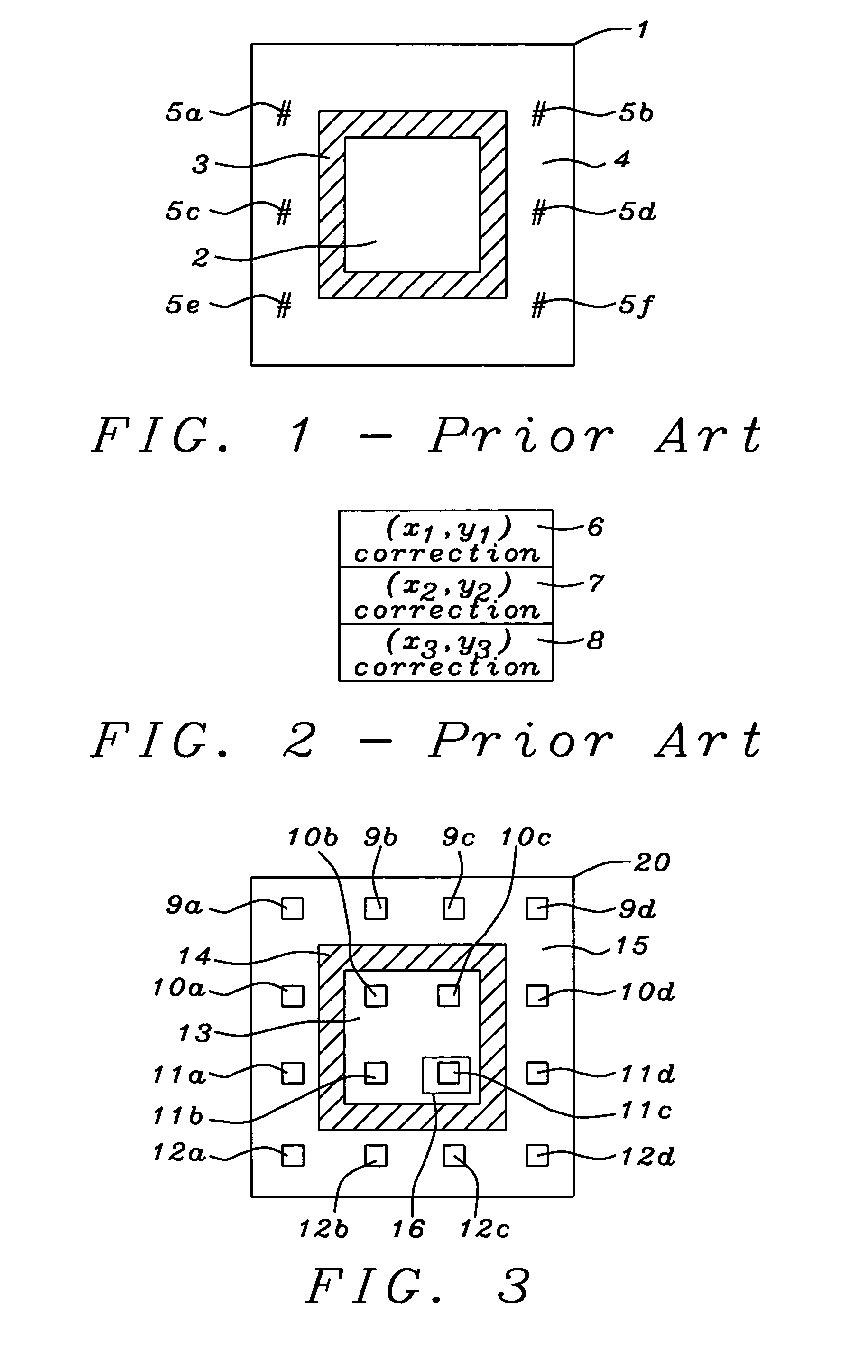

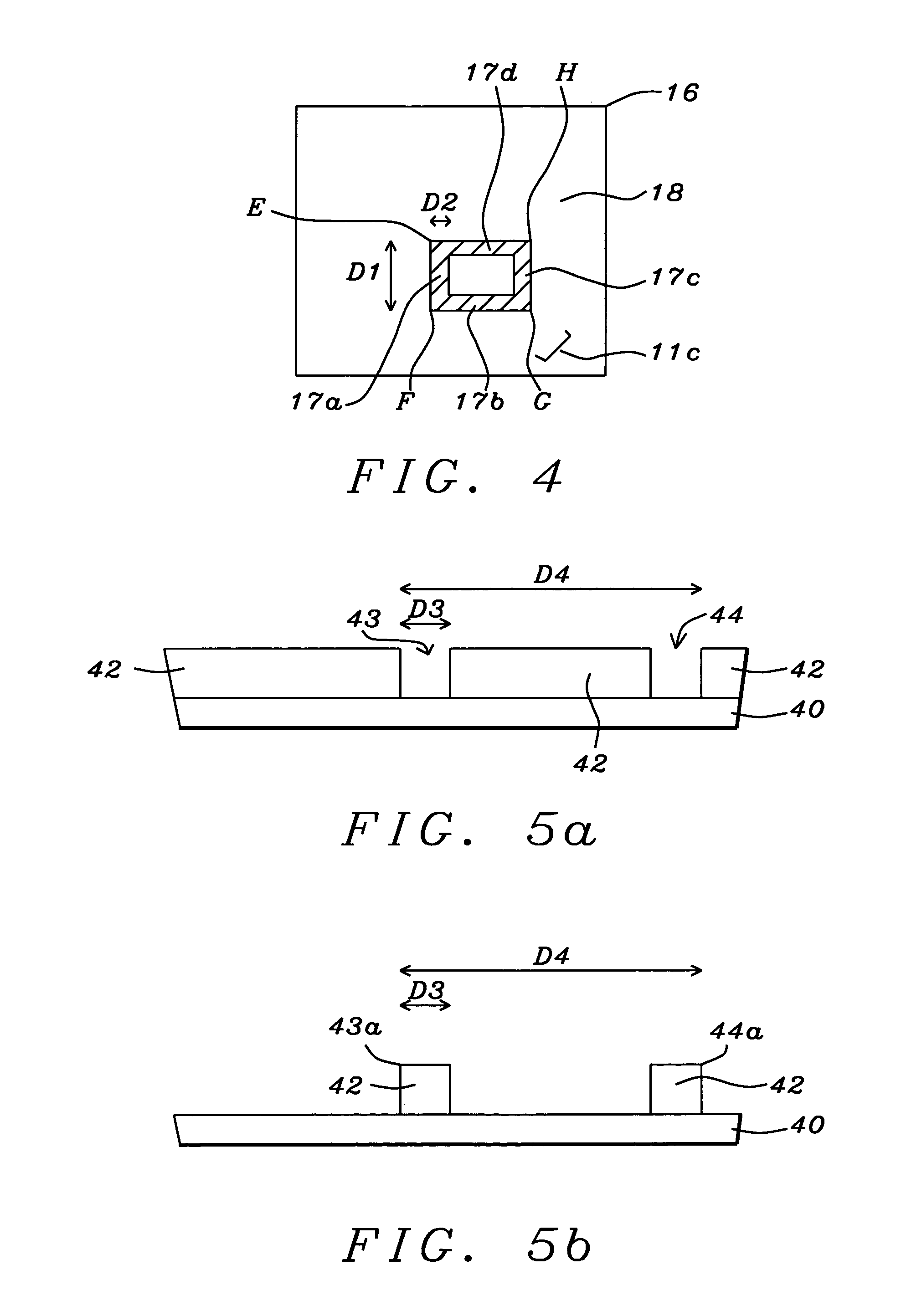

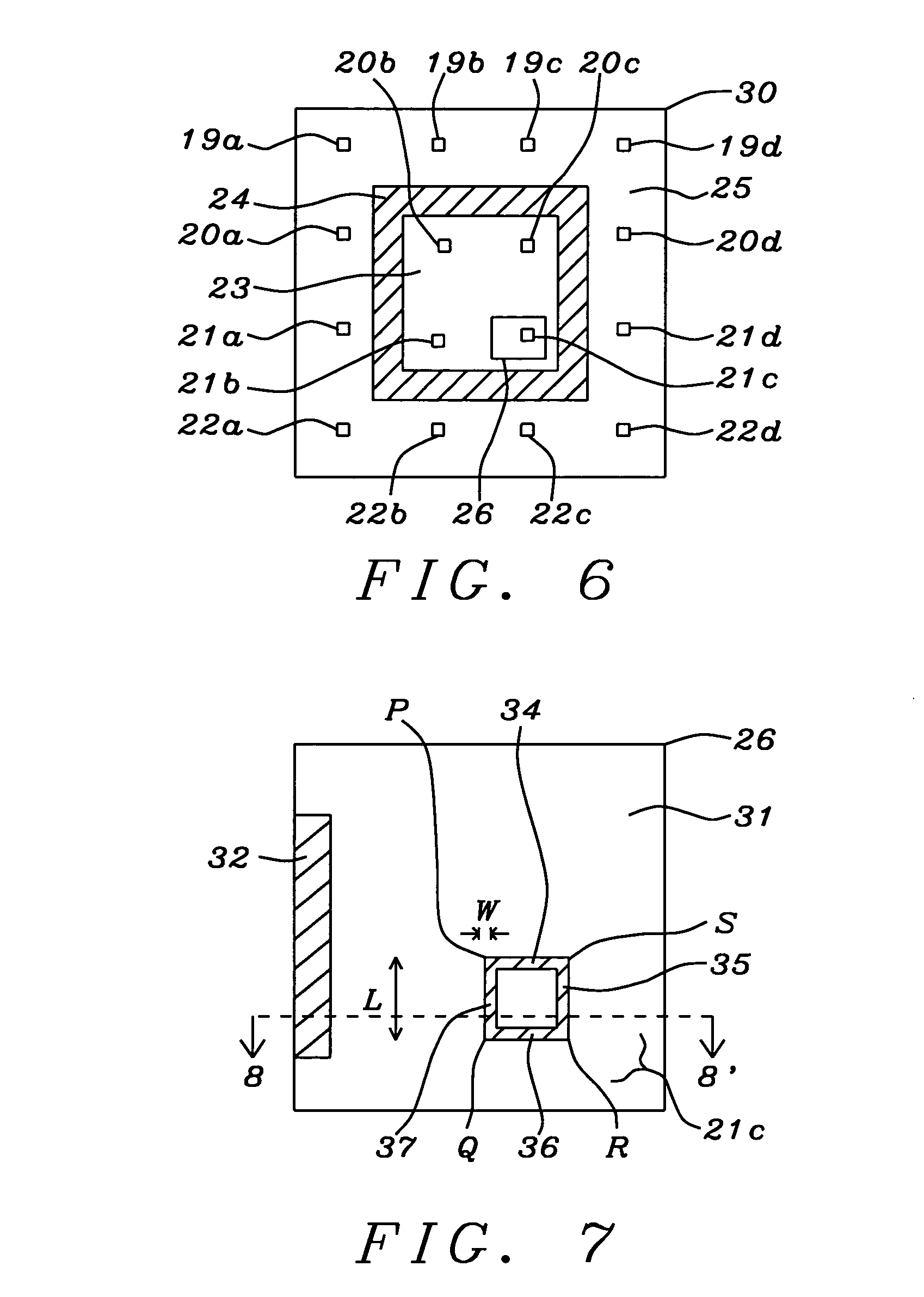

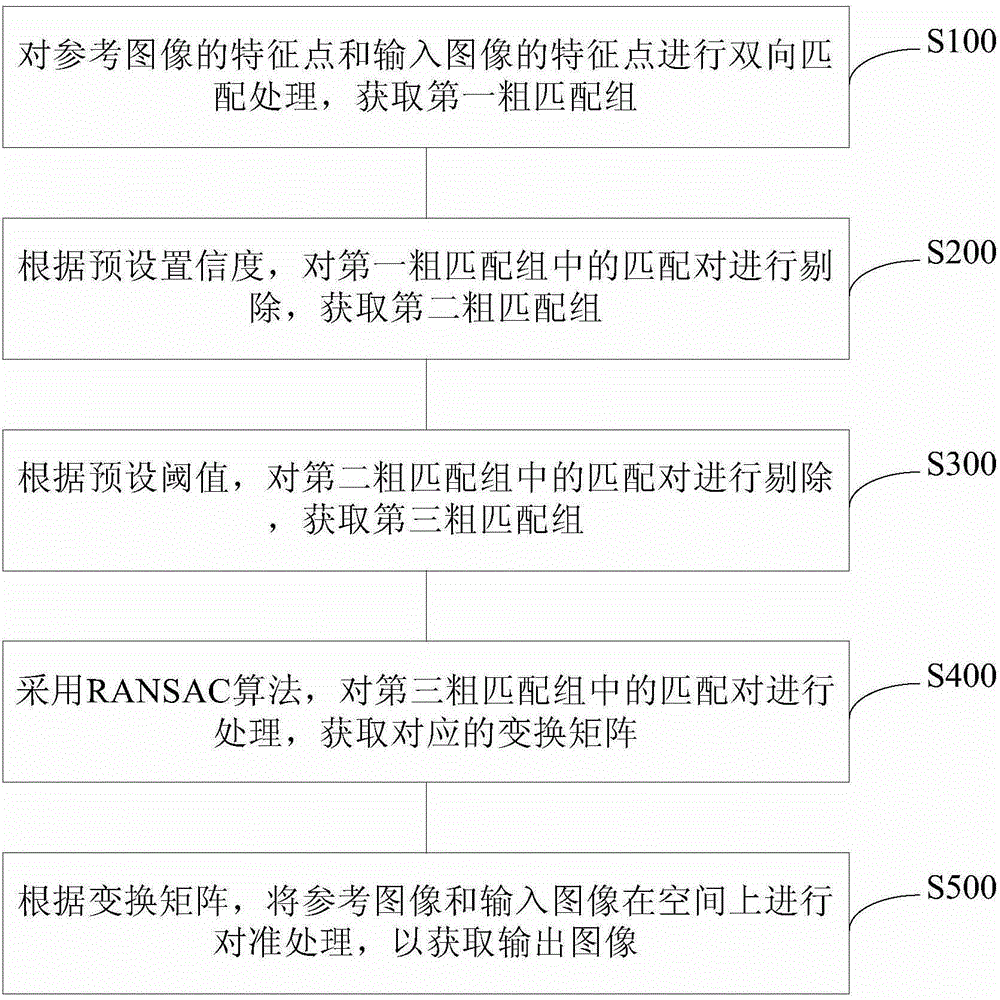

Method of the adjustable matching map system in lithography

InactiveUS20050118514A1Improve accuracyReduce layeringSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusCorrection algorithmMetrology

A method is provided for improving layer to layer overlay of a second layer pattern on a first layer pattern formed in a substrate. A plurality of first reference marks is placed inside a pattern area on a first layer mask which is used to form the first layer pattern. A plurality of second reference marks is placed on a second layer mask which is used to form the second layer pattern and in which one second reference mark is matched with a first reference mark having the same (x,y) coordinates. Reference mark placement in the resulting first and second layer patterns is determined by metrology to determine an x-deviation and a y-deviation for each matched pair of reference marks. A correction algorithm is then used to calculate adjustments in exposure tool settings for improved overlay of the second layer pattern on the first layer pattern in subsequent exposures.

Owner:TAIWAN SEMICON MFG CO LTD

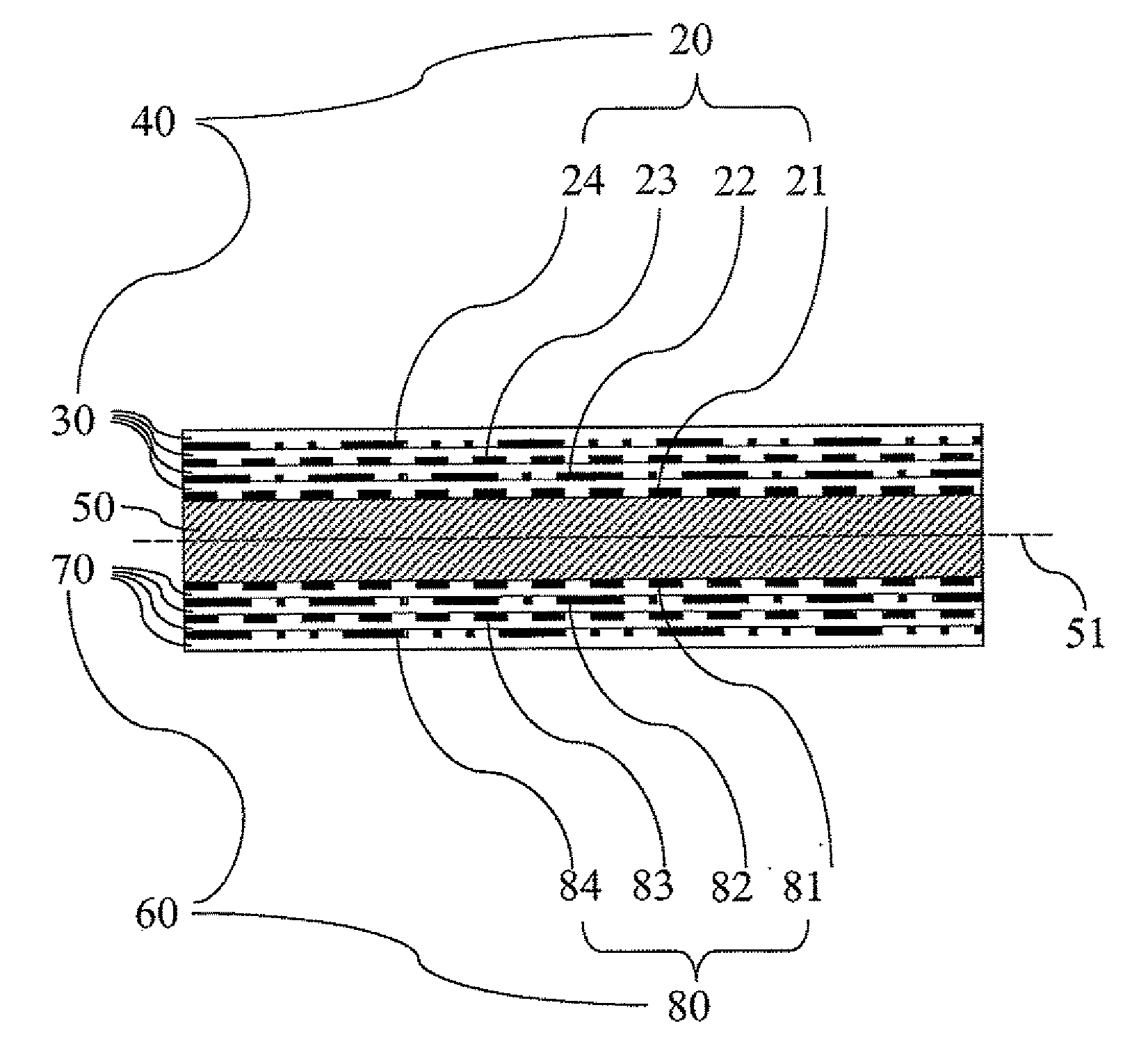

Packaging substrate having pattern-matched metal layers

InactiveUS20090114429A1Maximum flexibilitySemiconductor/solid-state device detailsPrinted circuit aspectsElectricityMetal interconnect

A pattern matched pair of a front metal interconnect layer and a back metal interconnect layer having matched thermal expansion coefficients are provided for a reduced warp packaging substrate. Metal interconnect layers containing a high density of wiring and complex patterns are first developed so that interconnect structures for signal transmission are optimized for electrical performance. Metal interconnect layers containing a low density wiring and relatively simple patterns are then modified to match the pattern of a mirror image metal interconnect layer located on the opposite side of the core and the same number of metal interconnect layer away from the core. During this pattern-matching process, the contiguity of electrical connection in the metal layers with a low density wiring may become disrupted. The disruption is healed by an additional design step in which the contiguity of the electrical connection in the low density is reestablished.

Owner:GLOBALFOUNDRIES INC

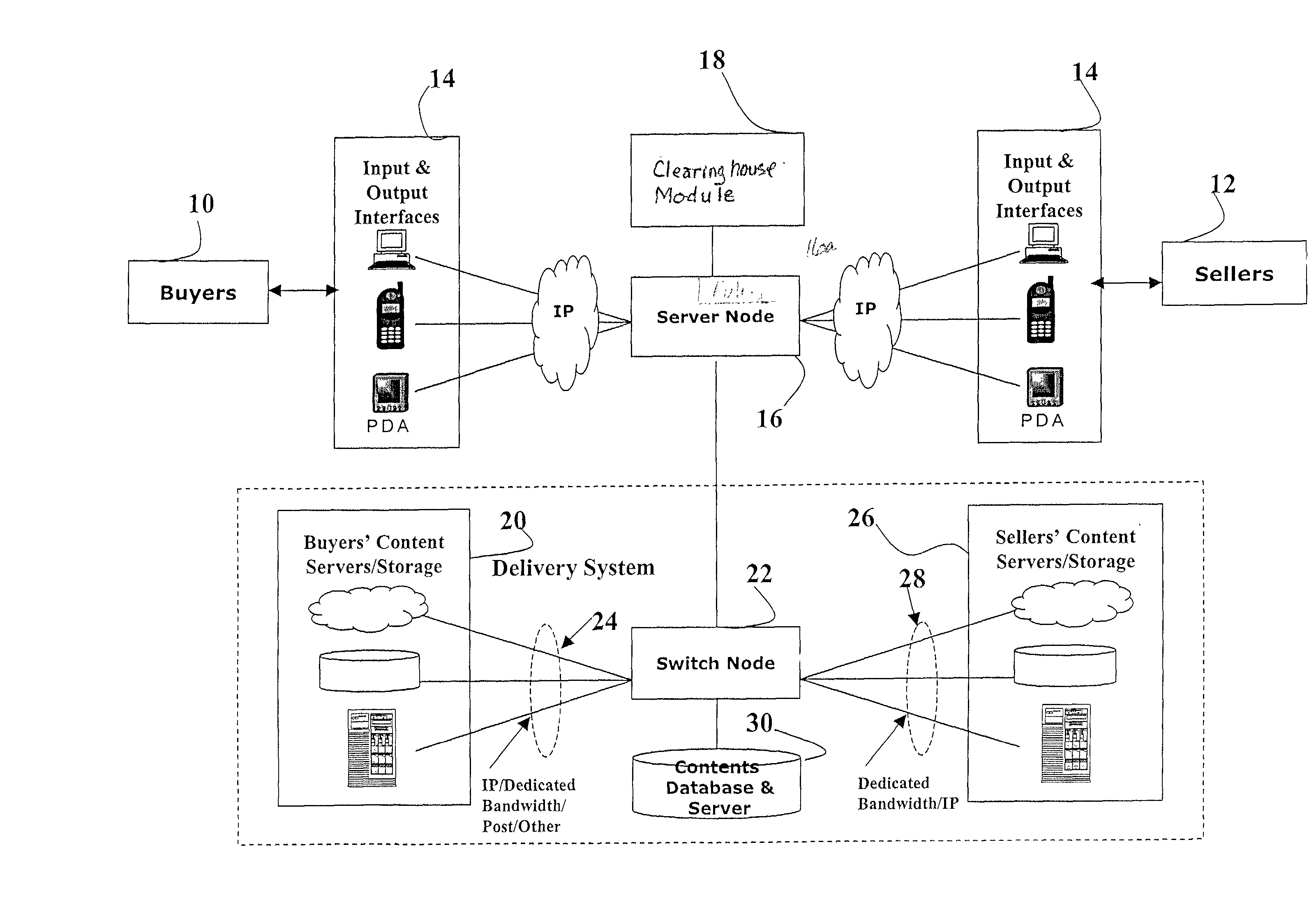

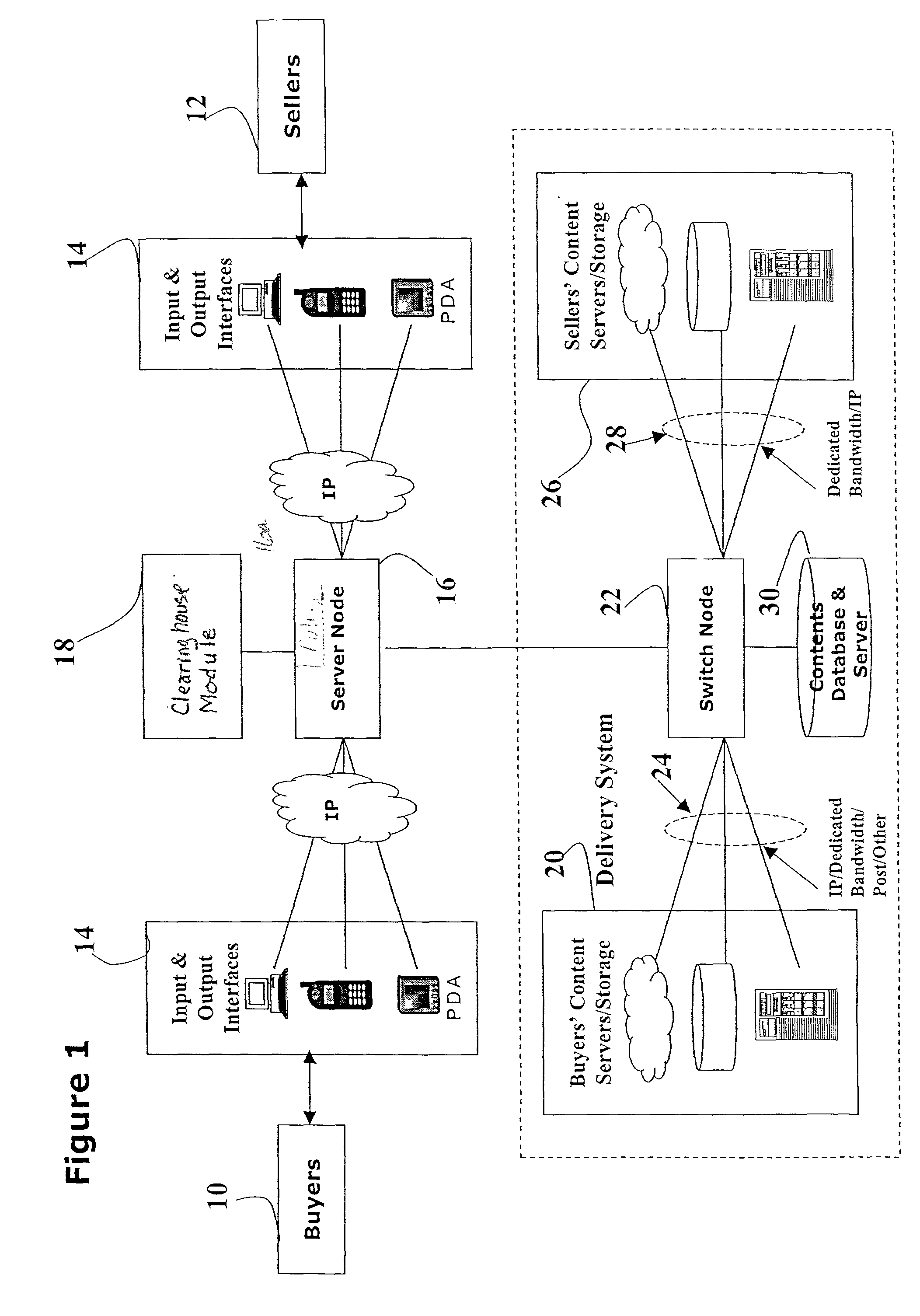

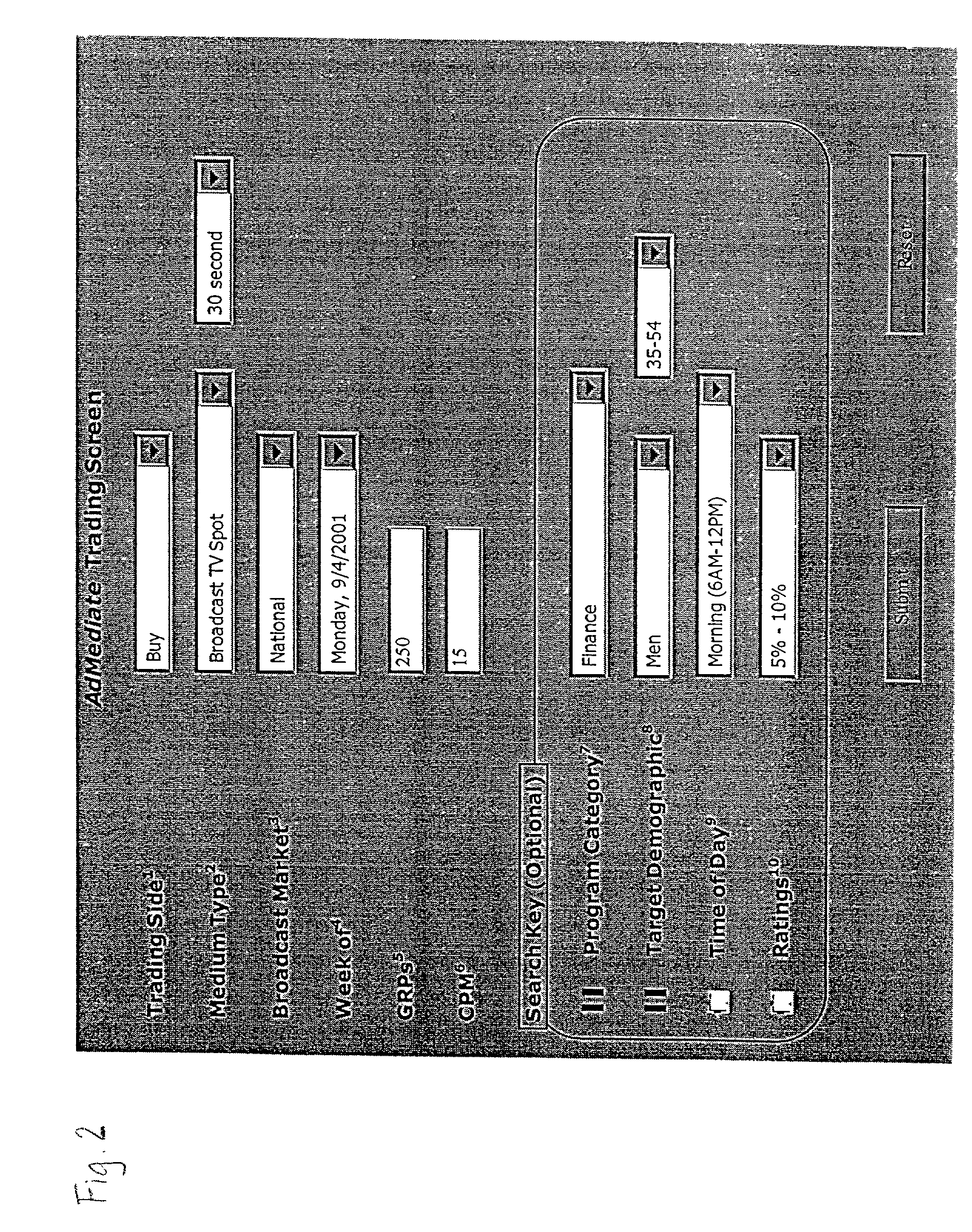

Method and system for facilitating trading of media space

A system for trading media space includes a server node which receives requests for media space from buyers and offers of media space from sellers. The server node includes a set of rules for matching one of the requests and one of the offers to form a matched request and offer pair. A delivery system is connected to said server node for facilitating delivery of media content between the buyer and seller of the matched pair.

Owner:MEDIA TRADING SOLUTIONS LLC

Electronically tunable, absorptive, low-loss notch filter

InactiveUS8013690B2Fast tuningHigh levelMultiple-port networksCoupling devicesWireless routerHybrid coupler

Owner:TERASYS TECH

Automatic two-camera calibration method and system

ActiveCN104537659AGuaranteed accuracySimplify the calibration processImage enhancementImage analysisMatched pairCalibration result

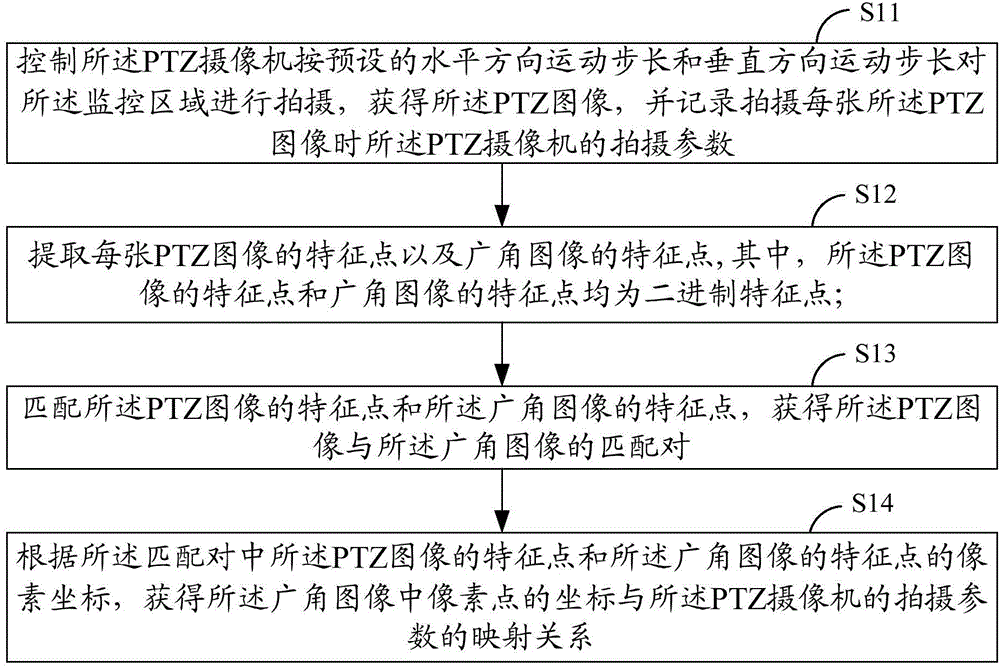

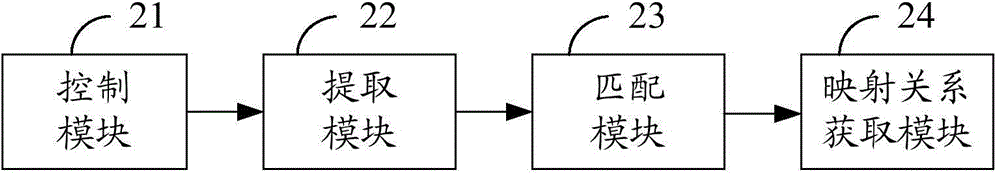

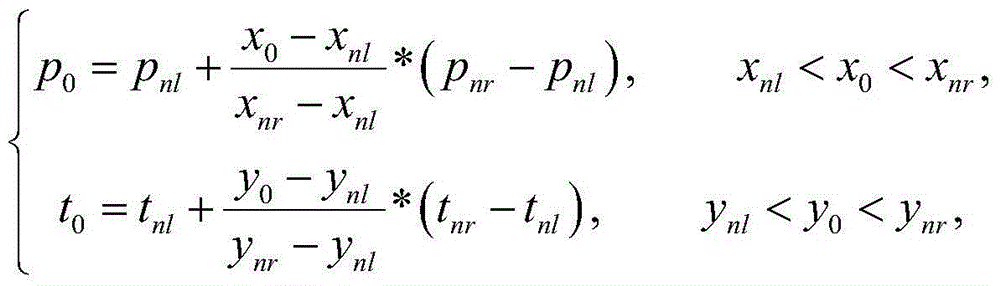

The invention provides an automatic two-camera calibration method and system. The method comprises the steps of controlling PTZ cameras for shooting a monitored region according to the preset movement step length in the horizontal direction and the movement step length in the perpendicular direction to obtain PTZ images, and recording shooting parameters needed when each PTZ image is shot, wherein the overlapping region of the previous and later PTZ images shot by the PTZ cameras is larger than the preset overlapping range, and the shooting parameters of the PTZ cameras include the current shooting multiples of the PTZ cameras, movement values of the PTZ cameras in the horizontal direction and movement values of the PTZ cameras in the perpendicular direction; extracting feature points of each PTZ image and feature points of a wide-angle image; matching the feature points of each PTZ image with the feature points of the wide-angle image to obtain a matched pair of each PTZ image and the wide-angle image; according to pixel coordinates of the feature points of the PTZ images and the wide-angle image in the matched pairs, obtaining a mapping relation between the coordinates of the pixel points in the wide-angle image and the shooting parameters of the PTZ cameras. According to the automatic two-camera calibration method and system, the calibration process is simple, and the calibration result is high in accuracy.

Owner:JINPENG ELECTRONICS INFORMATION MACHINE

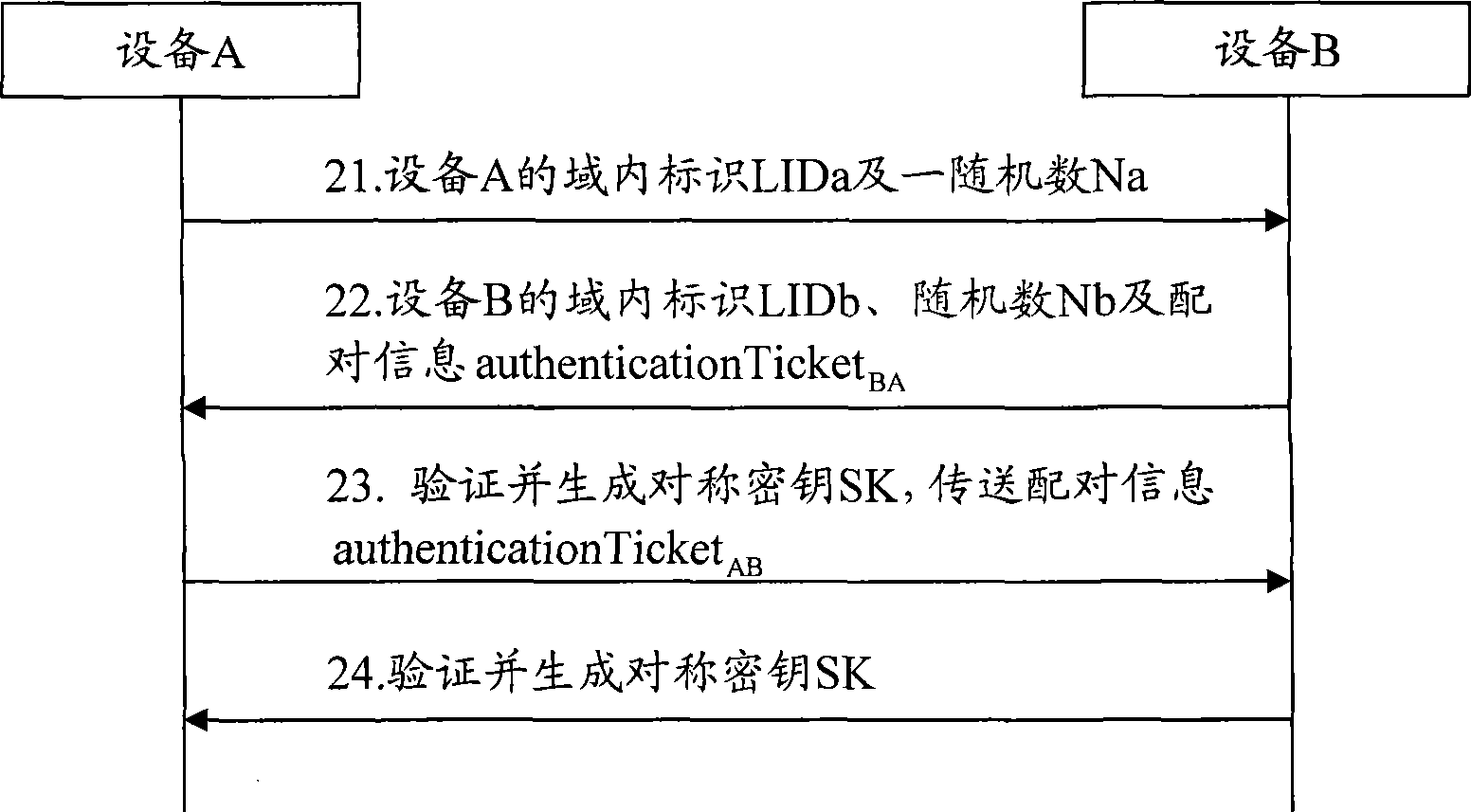

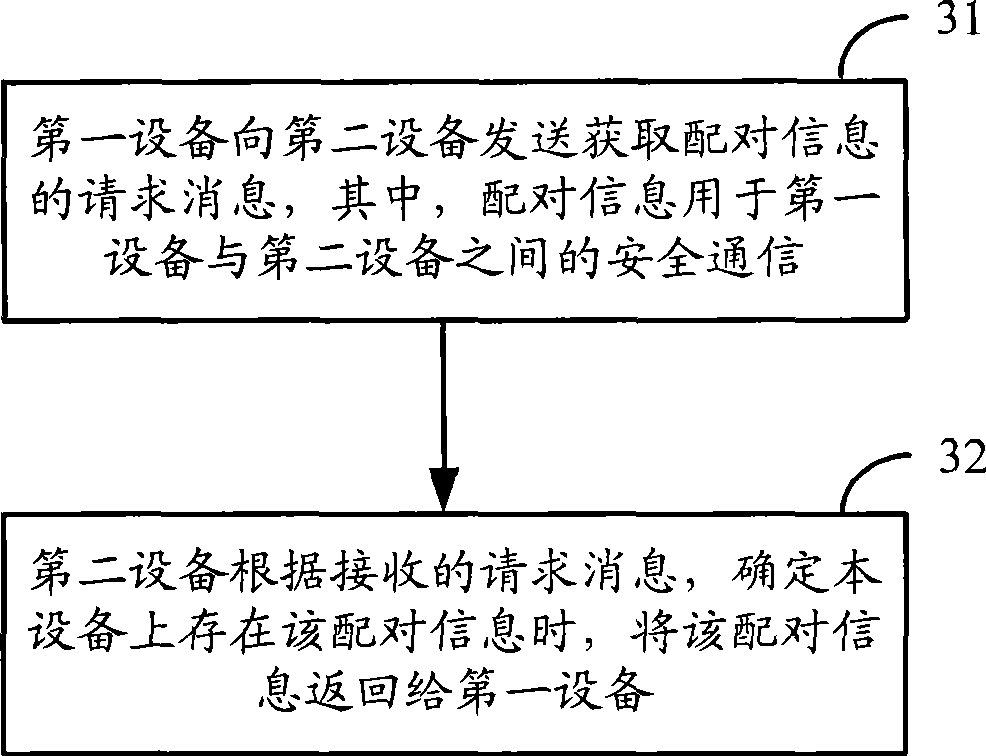

Method, device and system for sharing matched pair information between equipments

InactiveCN101399825AEnsure safetyEnsure controllabilityProgram/content distribution protectionSecuring communicationSecure communicationMatched pair

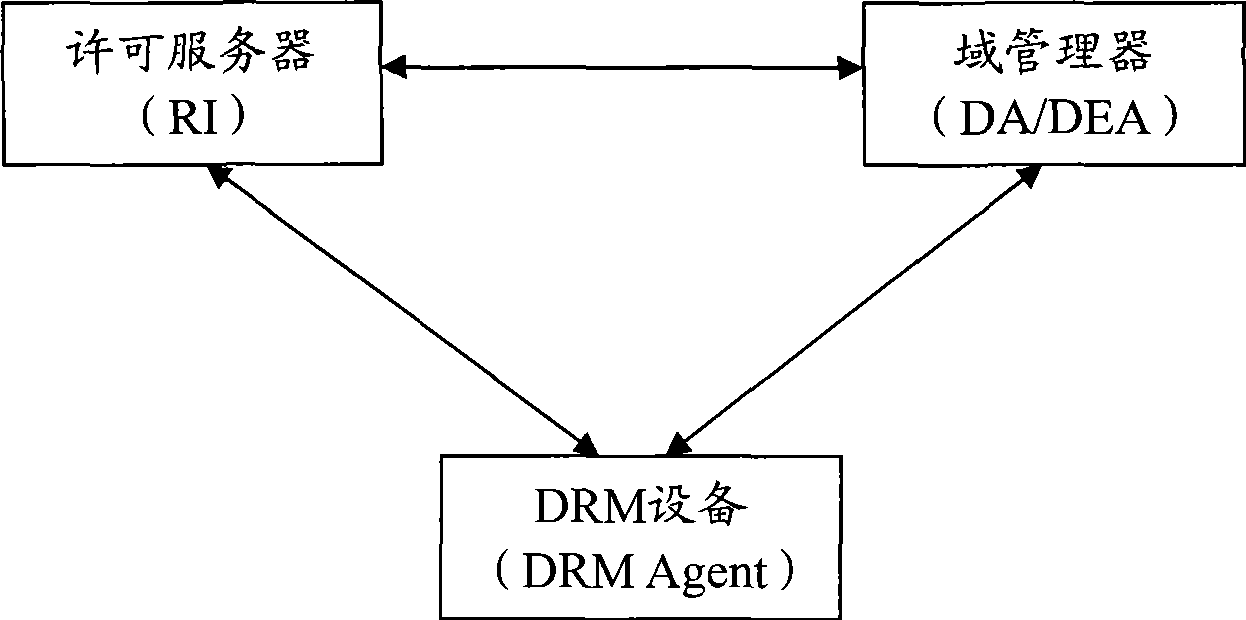

The invention discloses a method for sharing paired information between two devices. The method comprises that a first device sends out a request message for obtaining the pairing information to a second device, and the pairing information is used for secure communication between the first device and the second device; the second device returns the pairing information to the first device when determining that the pairing information exists on the device according to the request message. The invention also discloses a communication device and a communication system. By adopting the invention, the identical pairing information can be utilized between the two devices to carry out the secure communication, thereby the processing flow is simplified, and device resources are saved.

Owner:HUAWEI TECH CO LTD

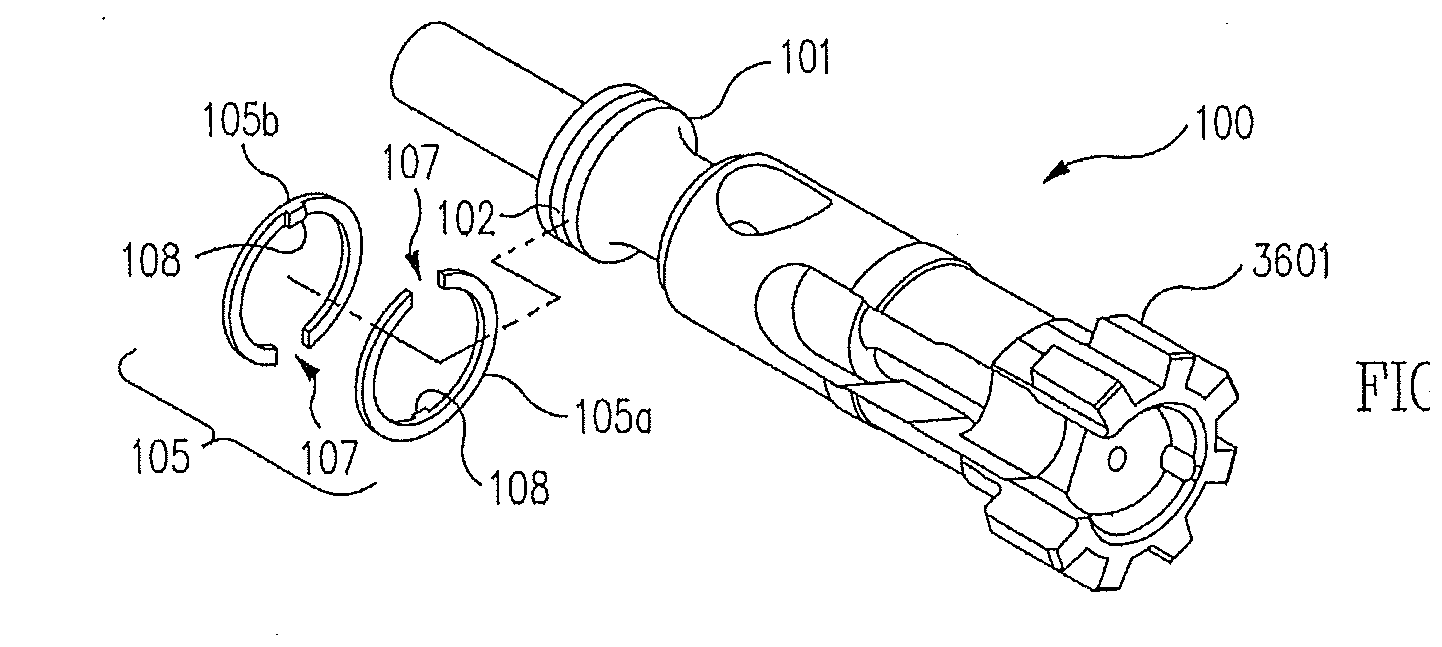

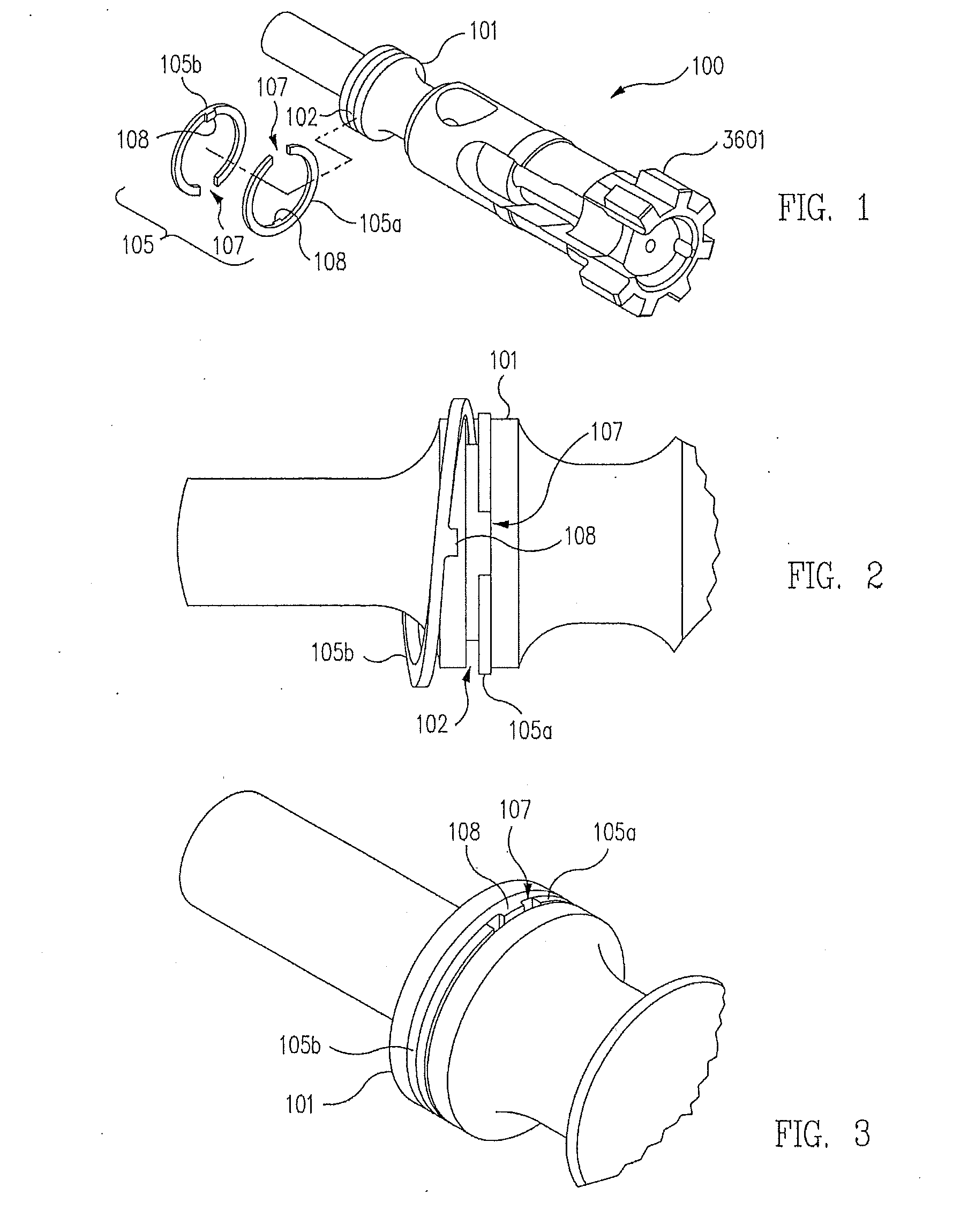

Firearm systems and methods

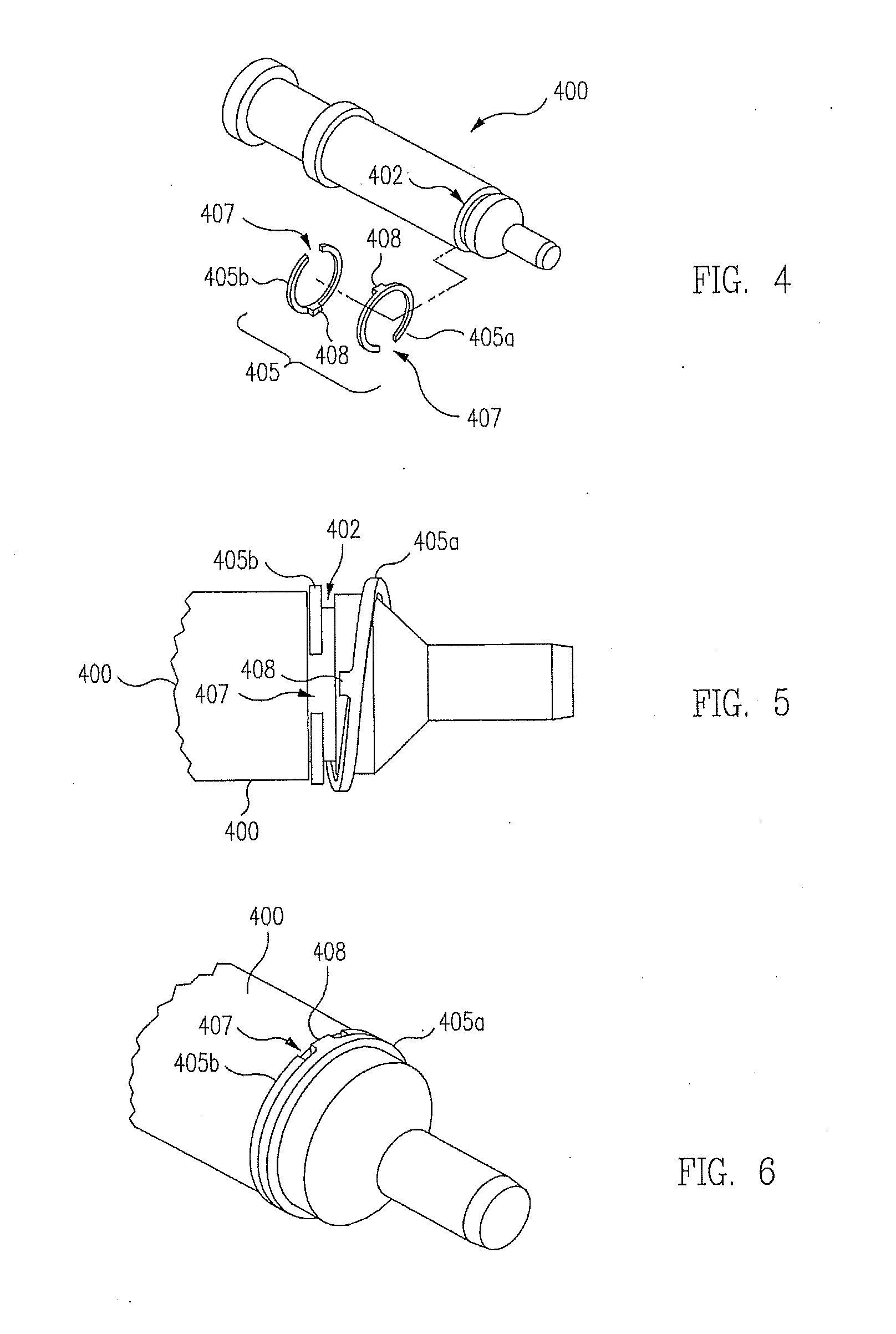

ActiveUS20160047612A1Improve reliabilityReduce gas leakagePiston ringsCartridge extractorsMatched pairEngineering

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is larger than that of a standard M16 / M4. A bolt carrier can have a bolt that has a double cut cam having an unlocking cam surface that has sufficient dwell increase to delay a start of unlocking when the bolt carrier is used in an M4 carbine. A stepped extractor pin may be provided that prevents disengagement of the extractor pin. A tube can be configured to provide gas from a barrel of the firearm to the piston via the carrier key. The tube can have a heat radiator formed from triangular shaped threads on at least a portion of the tube. A piston on the bolt and can have a plurality of rings including pairs of mating rings that are formed and maintained as a matched pair.

Owner:ARMWEST

Matched pair of protective baseball batting gloves for right handed and left handed batters to protect the side of the hand and the wrist facing a pitcher with protective shock absorbing members on the exterior of the glove

InactiveUS8132269B1Improve absorbing performanceImprove impact performanceGlovesRacket sportsMatched pairProtection sex

A novel protective batting glove which is used specifically for protecting the most vulnerable parts of a batter's hands and wrists when the batter is standing at home plate and is gripping the end of a baseball bat and awaiting the arrival of a baseball which is thrown by the pitcher. The invention comprises a unique protective system of a design of a matched pair of batting gloves with one matched pair designed for a right handed batter and one matched pair designed for a left handed batter. For each matched pair of batting gloves, impact and shock absorbing material is incorporated onto selected portions of the exterior of the glove where the grip on the bat causes the hand to be most exposed to a pitch thrown at the batter. Alternatively, the glove has a cuff with an affixed interior impact and shock absorbing material to provide double protection for the ulna bone of an arm.

Owner:XPROTEX SPORT GROUP WORLDWIDE

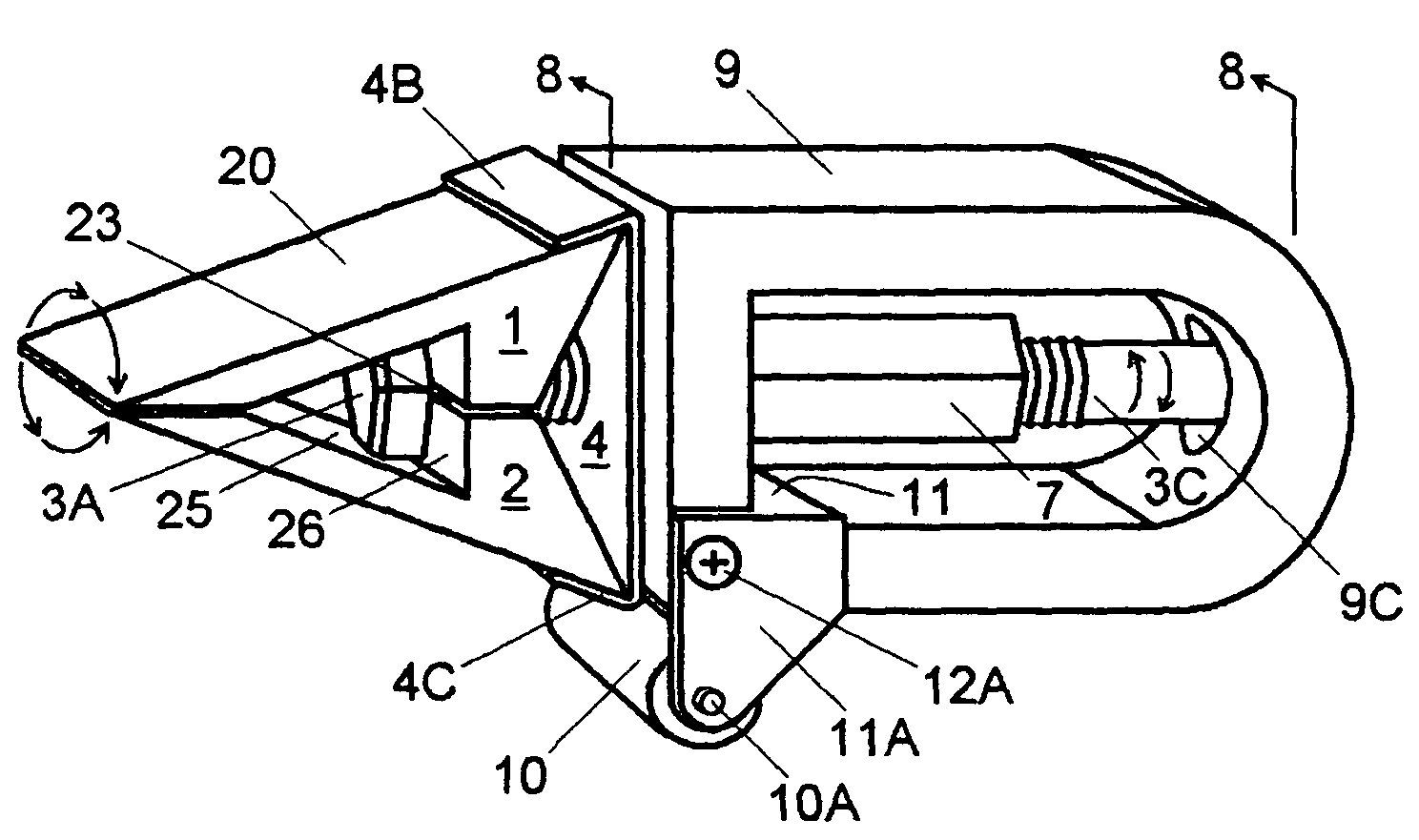

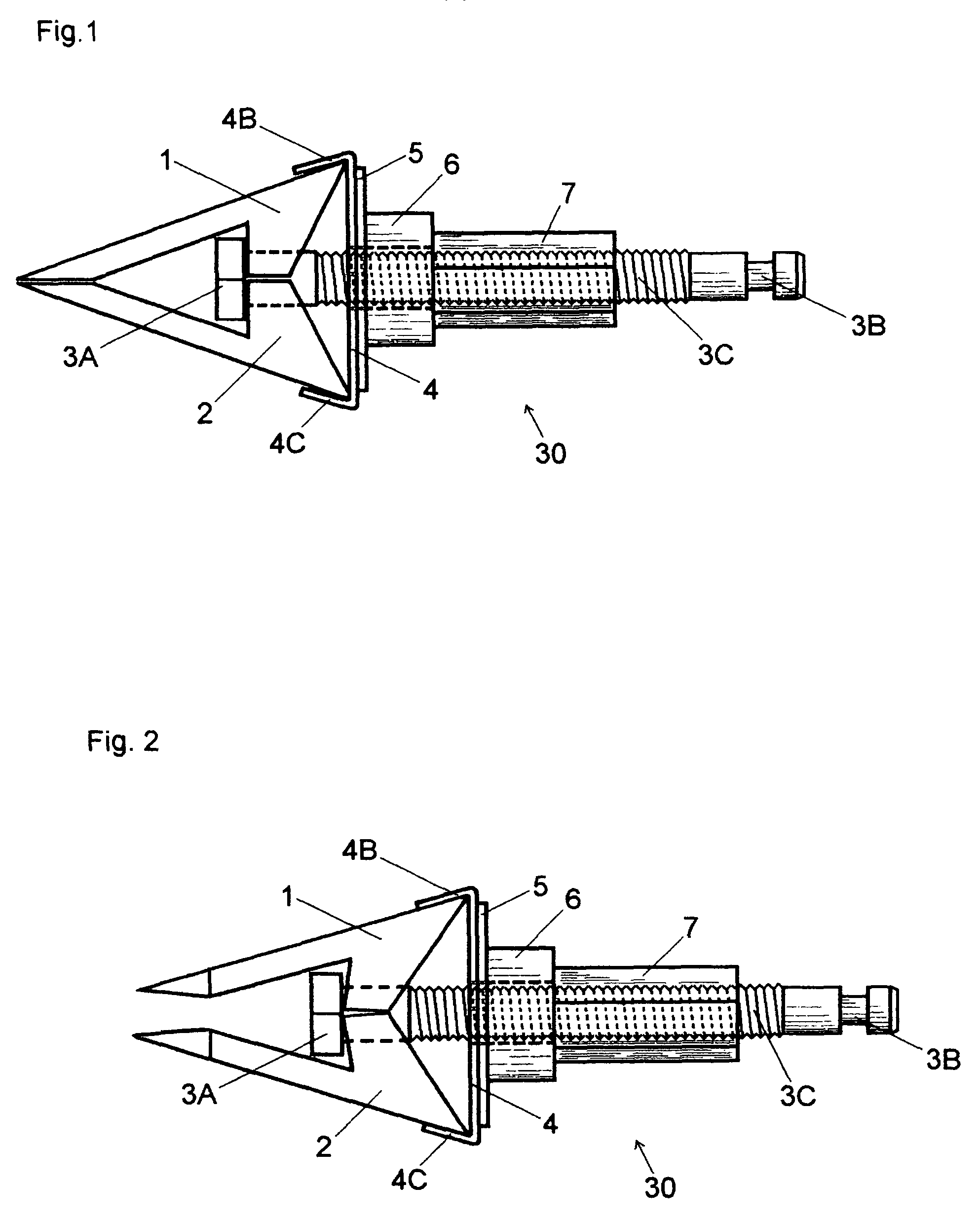

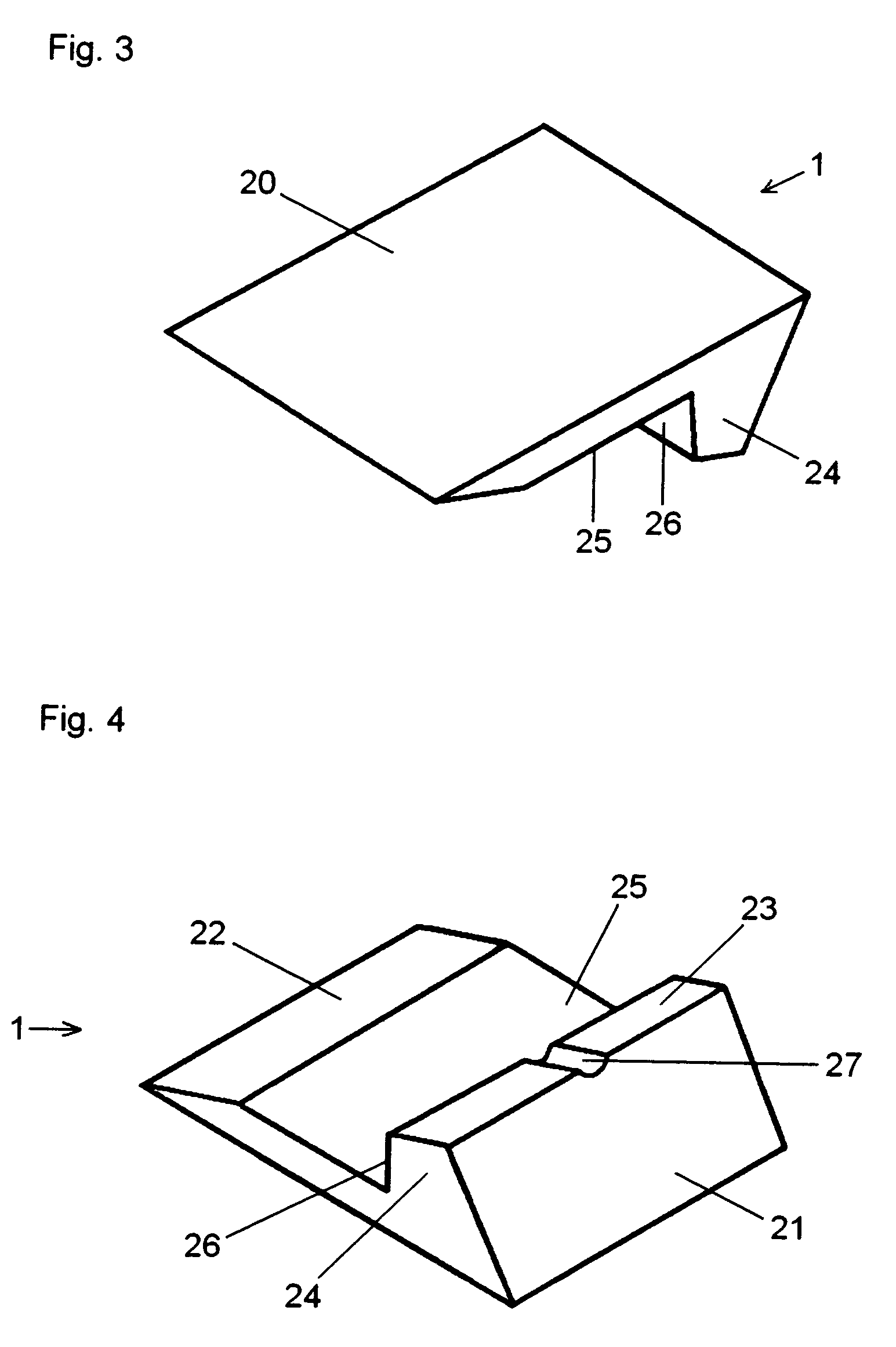

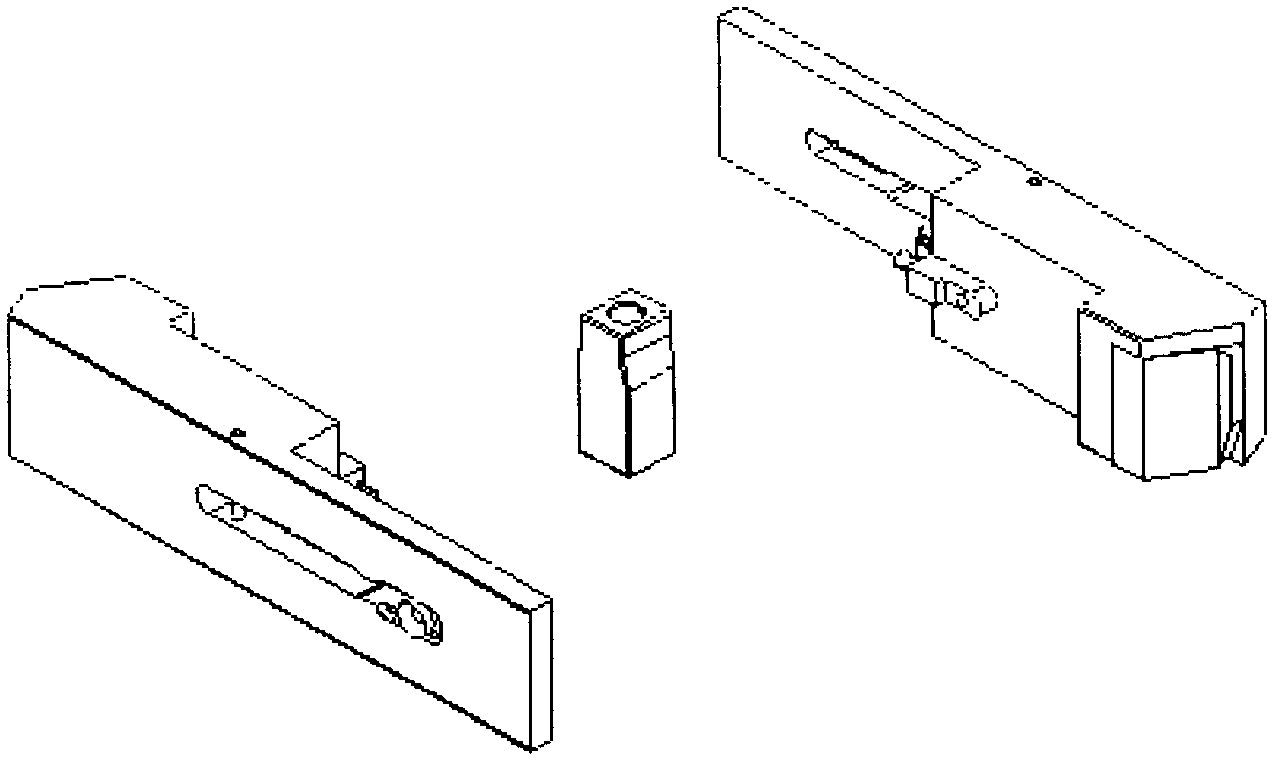

Self-aligning blade angle guide

InactiveUS7052385B1Minimal effortOpportunity for errorCutting toolsOther manufacturing equipments/toolsFree rotationMatched pair

A device for use in the manual sharpening of arrow broadheads, razor blades and the like includes a unique symmetrical clamp and axle assembly having interchangeable, matched pairs of special purpose jaw members for gripping blades of differing configurations. When coupled to the frame, the clamp and axle assembly is freely rotatable, and this free rotation automatically aligns the length of the edge of the blade with the surface of a whetstone. Additionally these rotational and self-aligning capability enable the user to service both sides of the blade's edge with a single blade clamping operation, by manually rotating the clamp 180 degrees between passes along the surface of the whetstone.

Owner:SWARTZ RONALD

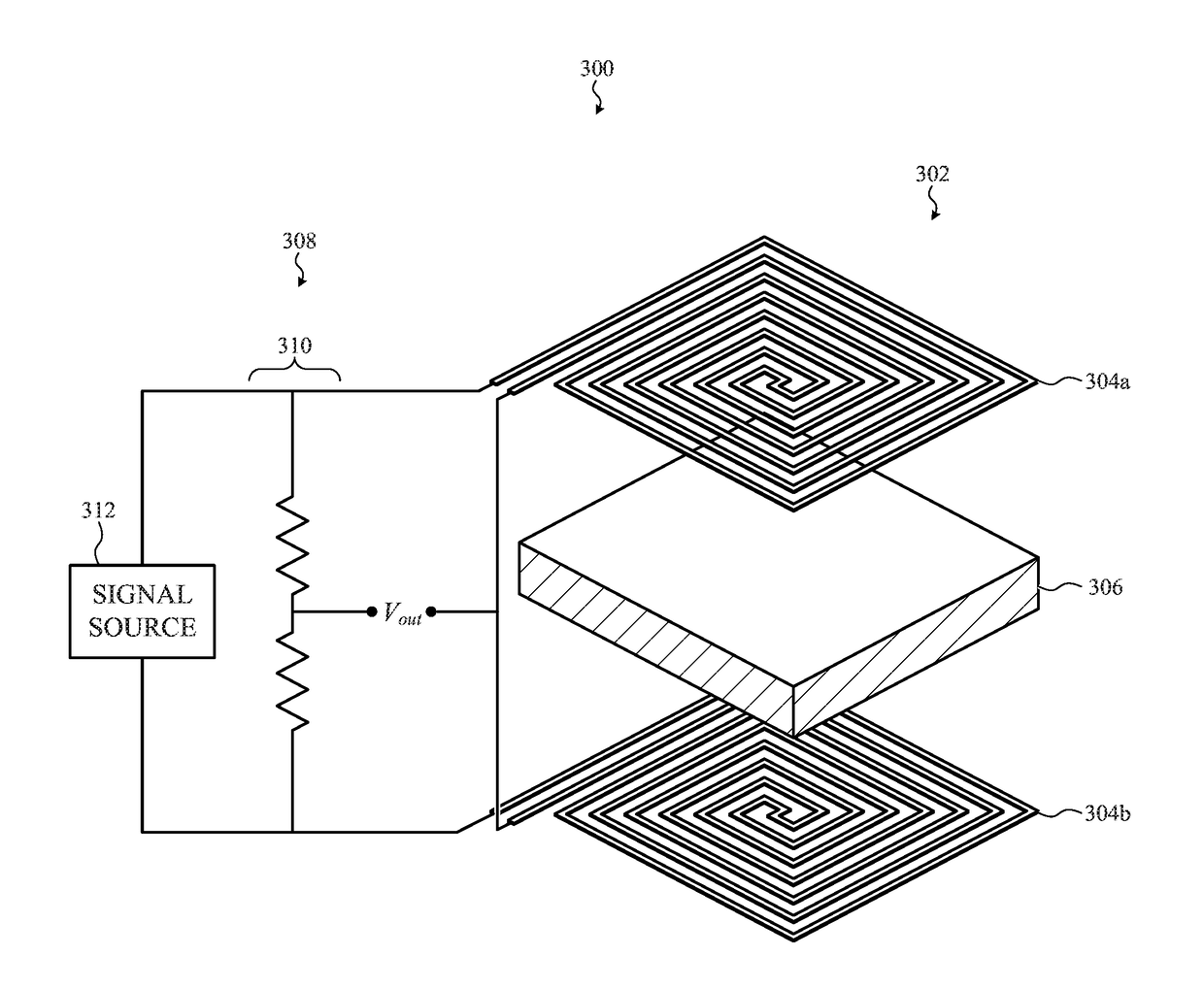

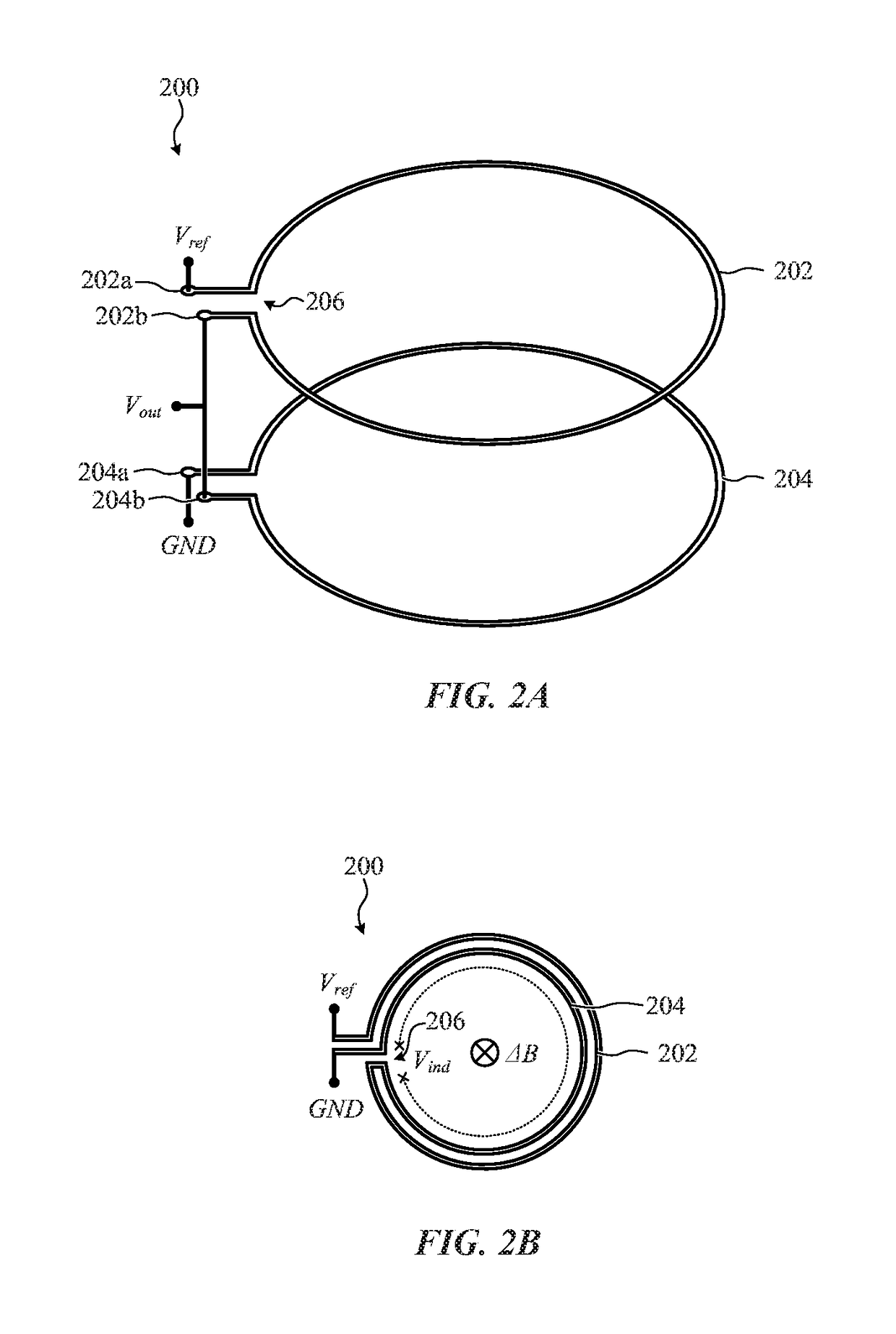

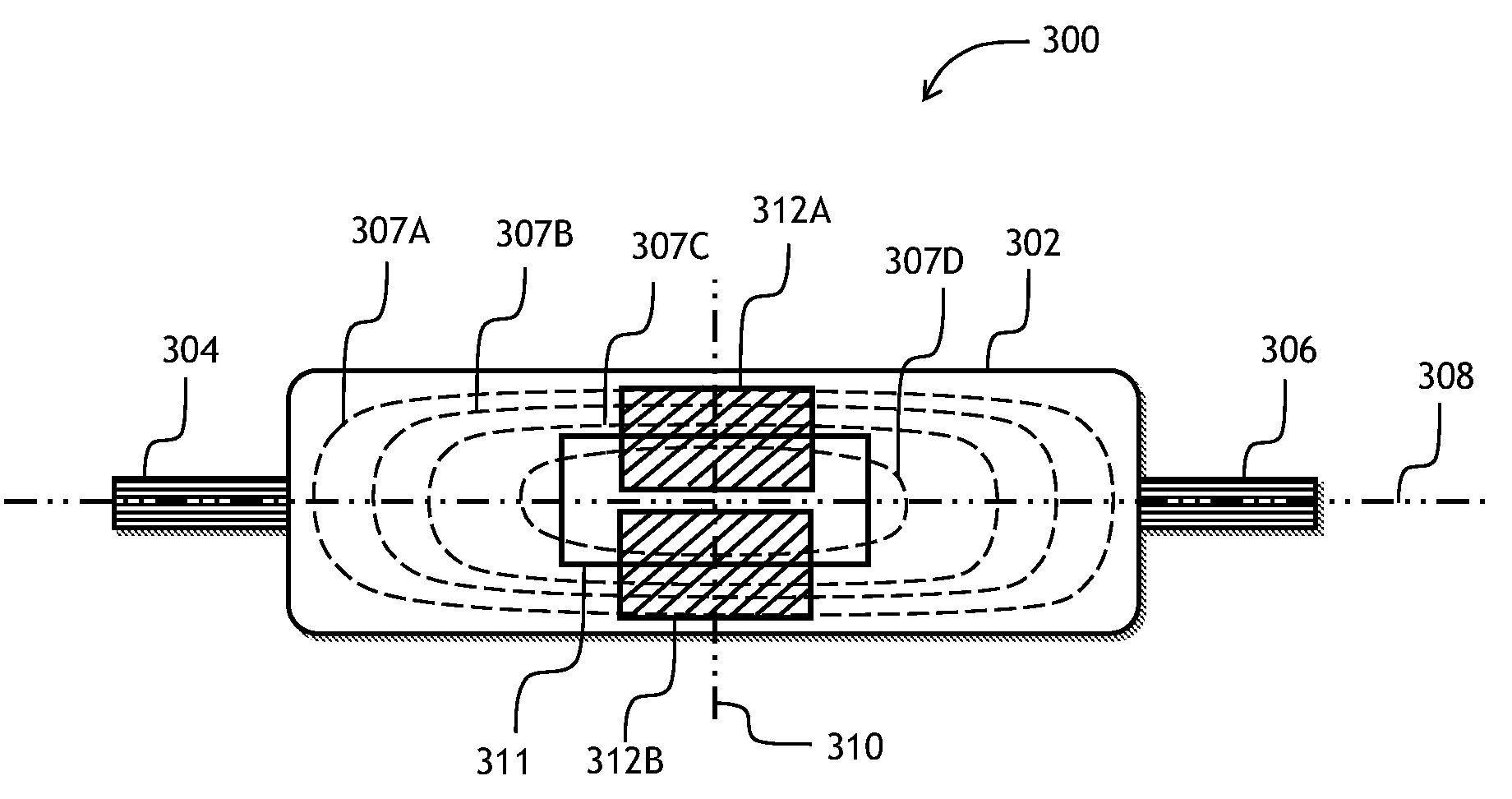

Magnetic Interference Avoidance in Resistive Sensors

ActiveUS20170261387A1Force measurementElectrical/magnetic solid deformation measurementResistive sensorsPower flow

A strain-responsive sensor incorporating a strain-sensitive element is disclosed. The strain-sensitive element includes a matched-pair of resistive structures disposed on opposite sides of a substrate. One resistive structure of the matched pair is coupled to a crossover, either a physical crossover or a soft crossover, such that current within the resistive structures of the matched pair flows in the same direction.

Owner:APPLE INC

Multi-parameter shaft analyzer (MPSA)

Methods and apparatus are provided for measuring multiple operating parameters of a rotating shaft with a sensor. One embodiment of the apparatus comprises a sensor in close proximity to a matched pair of thumbnail depressions on the surface of a rotating shaft body. The thumbnail depressions enable the sensor to detect axial displacement and rotational speed of the shaft in addition to detecting radial displacement of the shaft body. Signal processing circuitry analyzes the sensor output data and computes separate values for the axial displacement, speed and radial displacement parameters. Additional filtering and signal processing techniques can be used to ascertain peak axial displacement, to reduce noise, and to compute other parameters, such as acceleration and power spectral density.

Owner:THE BOEING CO

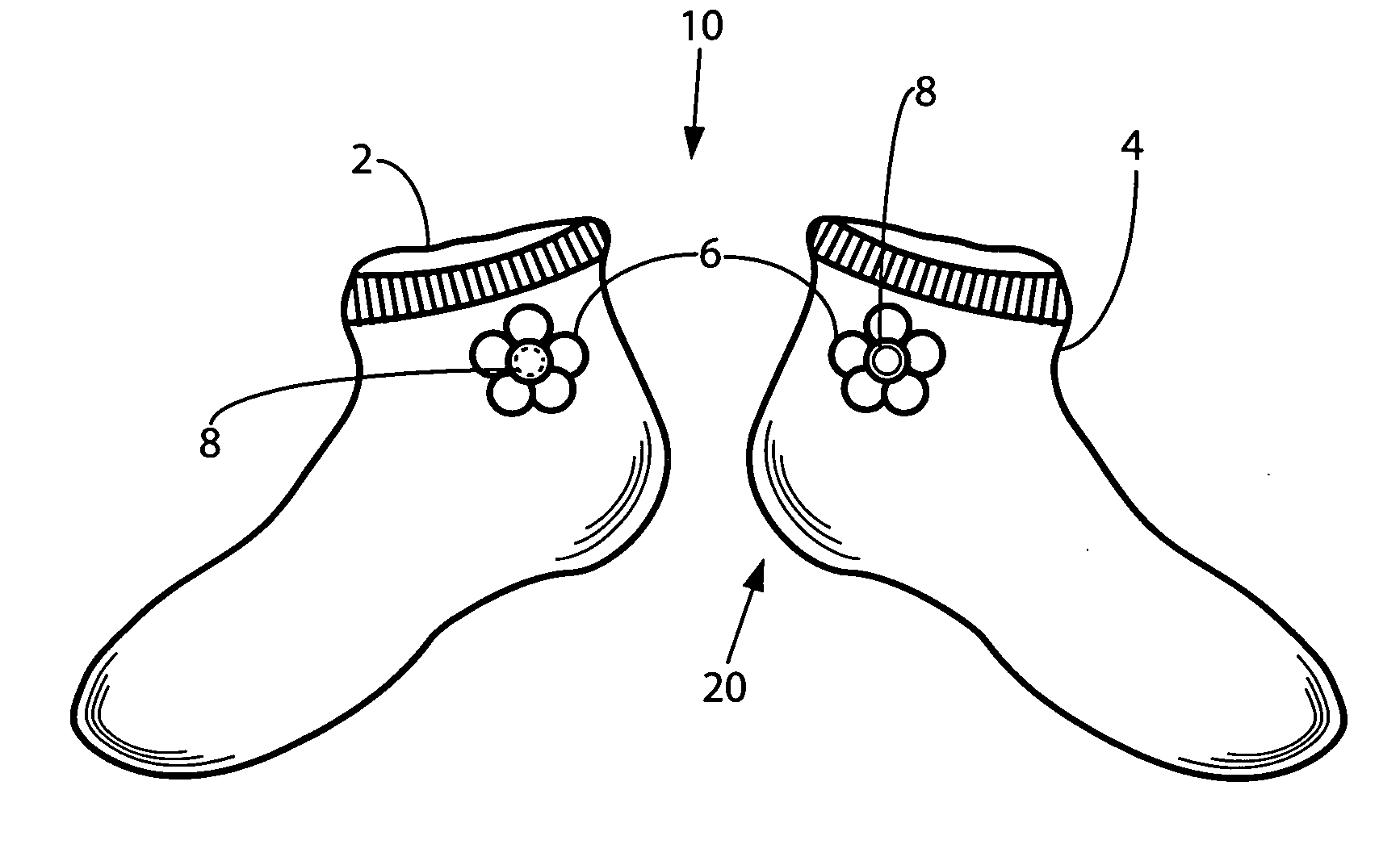

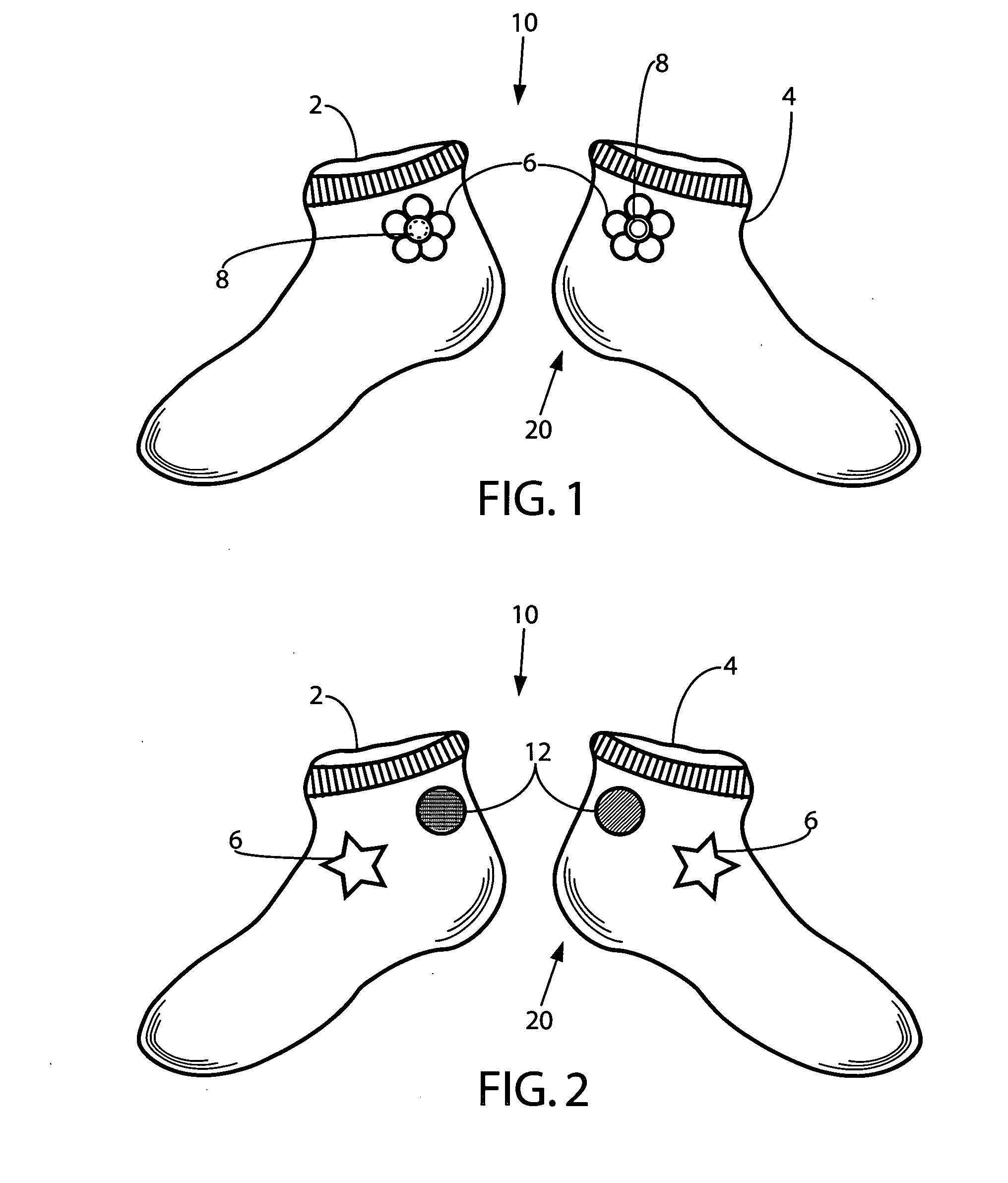

Lock socks

An apparatus for keeping a matched pair of socks together through all of the laundry steps and subsequent sorting for placing clothes back in drawers. Such apparatus comprises a first sock of a pair of socks, such first sock having one of a male and a female pre-selected fastening device disposed on an upper portion thereof. A second sock member of such pair of socks, such second sock member having an opposite one of a male and female pre-selected fastening device disposed on an upper portion of such second sock member. An embroidered design is disposed one of around and closely adjacent such fastening device on each of such pair of socks.

Owner:ALLEN SUSAN

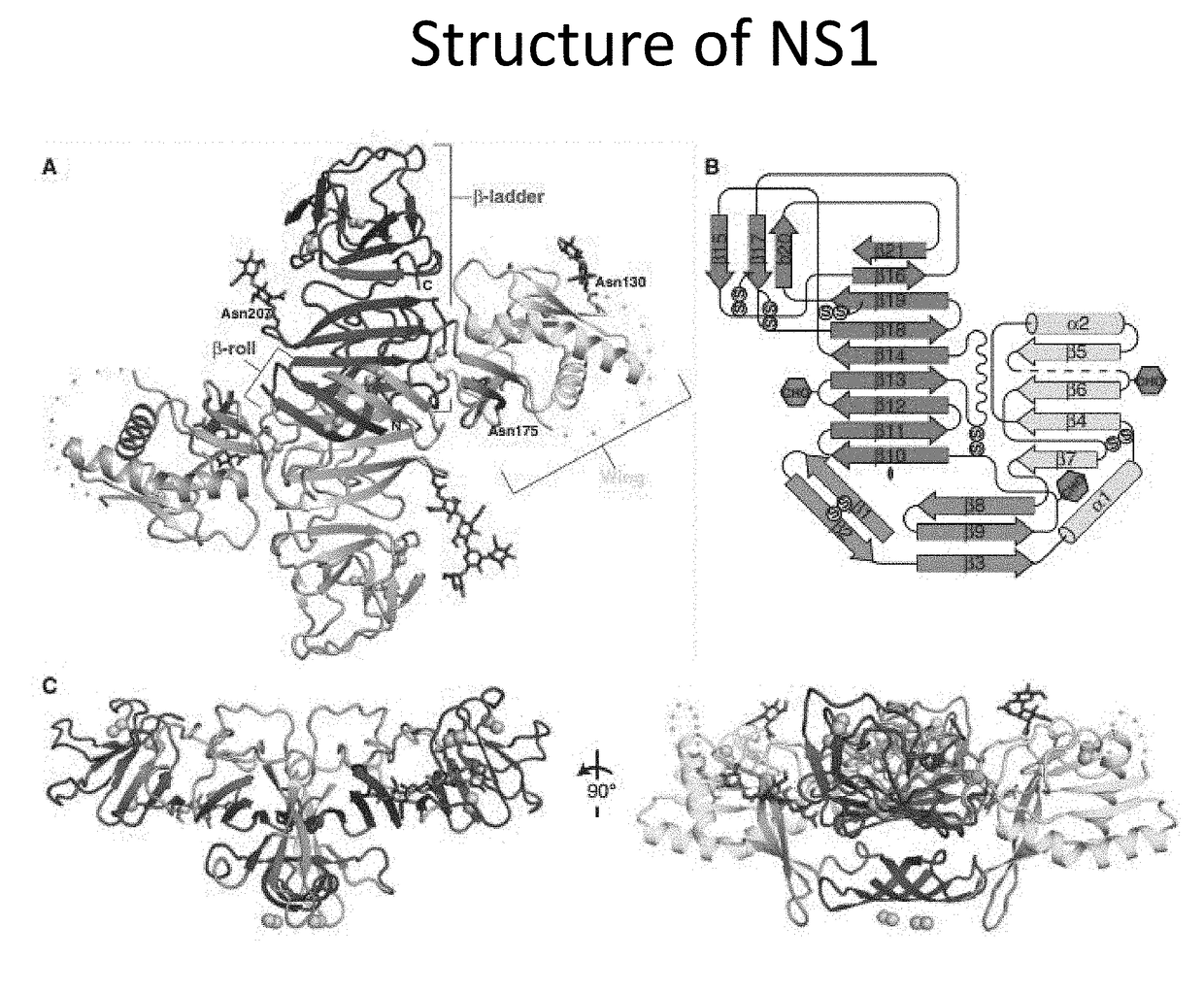

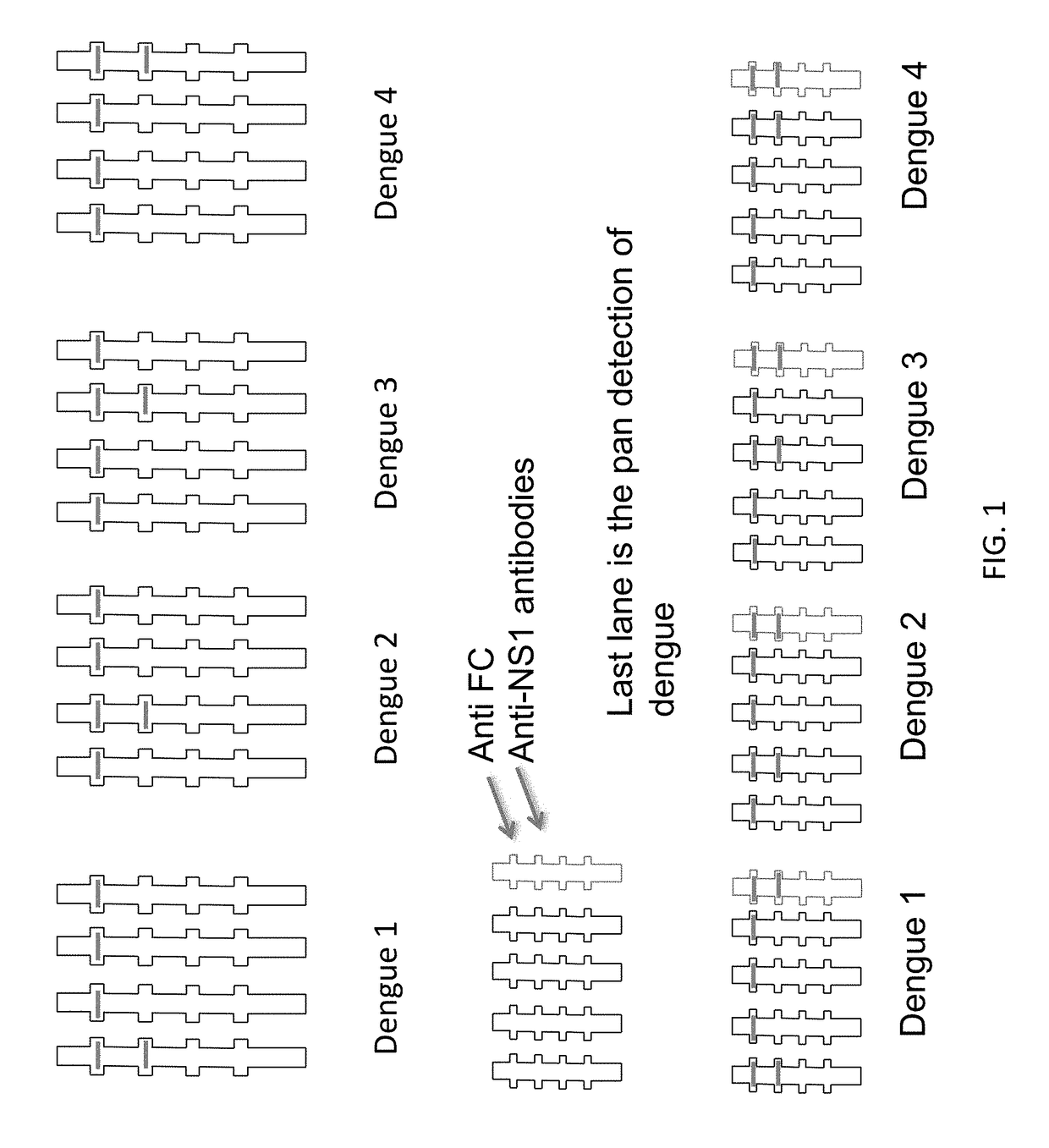

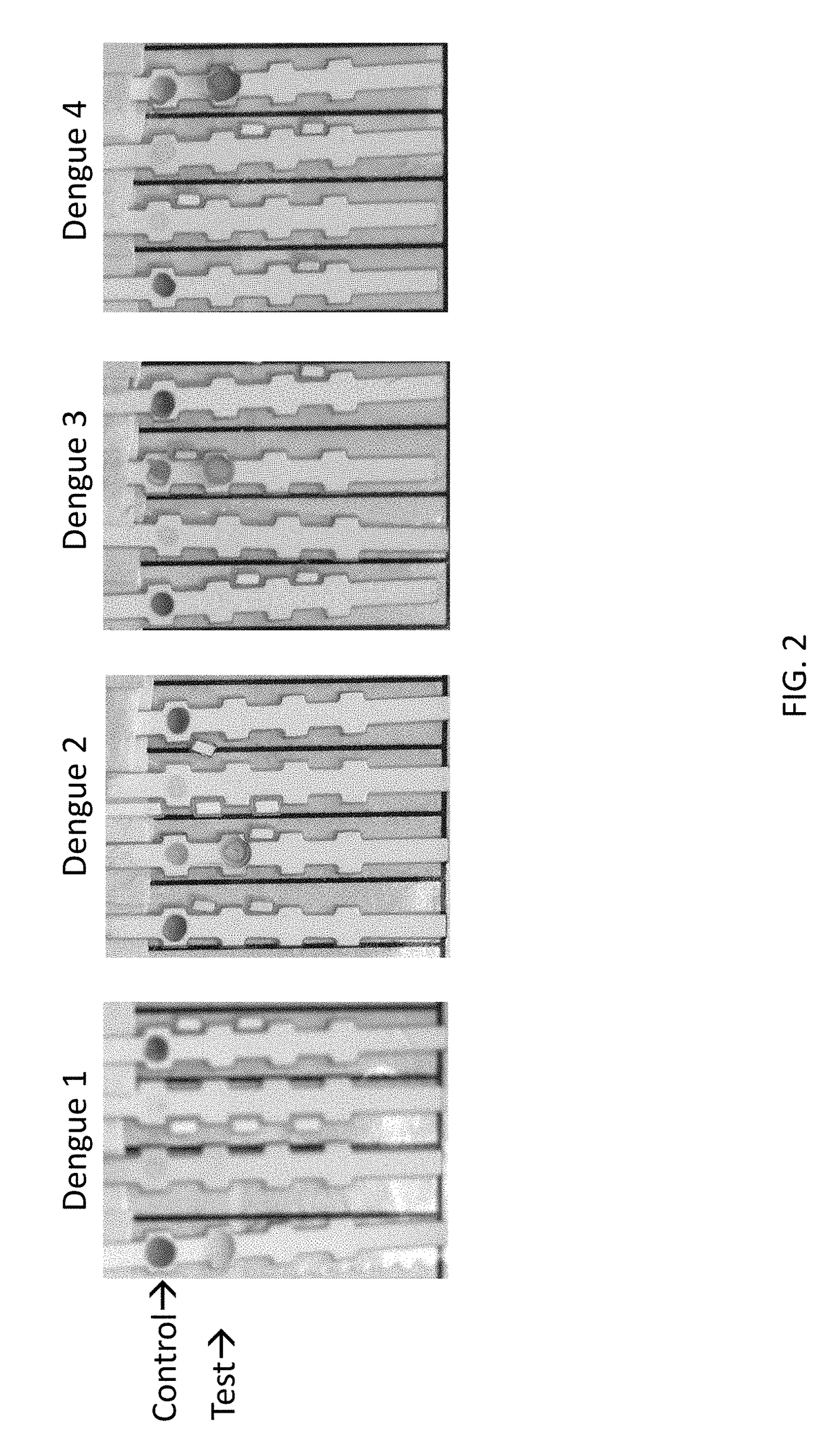

Anti-Dengue Virus NS1 Protein Monoclonal Antibodies

ActiveUS20170233460A1Improve developmentUseful in therapyImmunoglobulins against virusesAntibody ingredientsProtein.monoclonalSpecific detection

The present invention provides matched antibody pairs for the specific detection of one or more of the four dengue virus serotypes in a biological sample that may contain one or more of such dengue virus serotypes. Each matched antibody pair is capable of detecting not more than one serotype of dengue virus NS1 protein that may be present in the sample and will not cross react with other serotypes that may be present in the sample. Multiple matched pairs may be used to detect one or more dengue virus serotypes that may be present in a sample. Such matched pair antibodies, facilitate the development of confirmatory in vitro diagnostic tests such as sandwich immunoassays, that detect and distinguish the presence of one or more dengue virus serotypes in a biological sample, preferably a sample derived from human subject. The invention also provides kits comprising the matched antibody pairs of the invention and methods for using the kits for immunoassays for the specific detection of one or more serotypes of dengue virus in a patient population. The present invention also provides monoclonal antibodies specific for the NS1 protein of dengue virus and therapeutic compositions and methods for treating dengue virus infection.

Owner:THE FOOD & DRUG ADMINISTATION +1

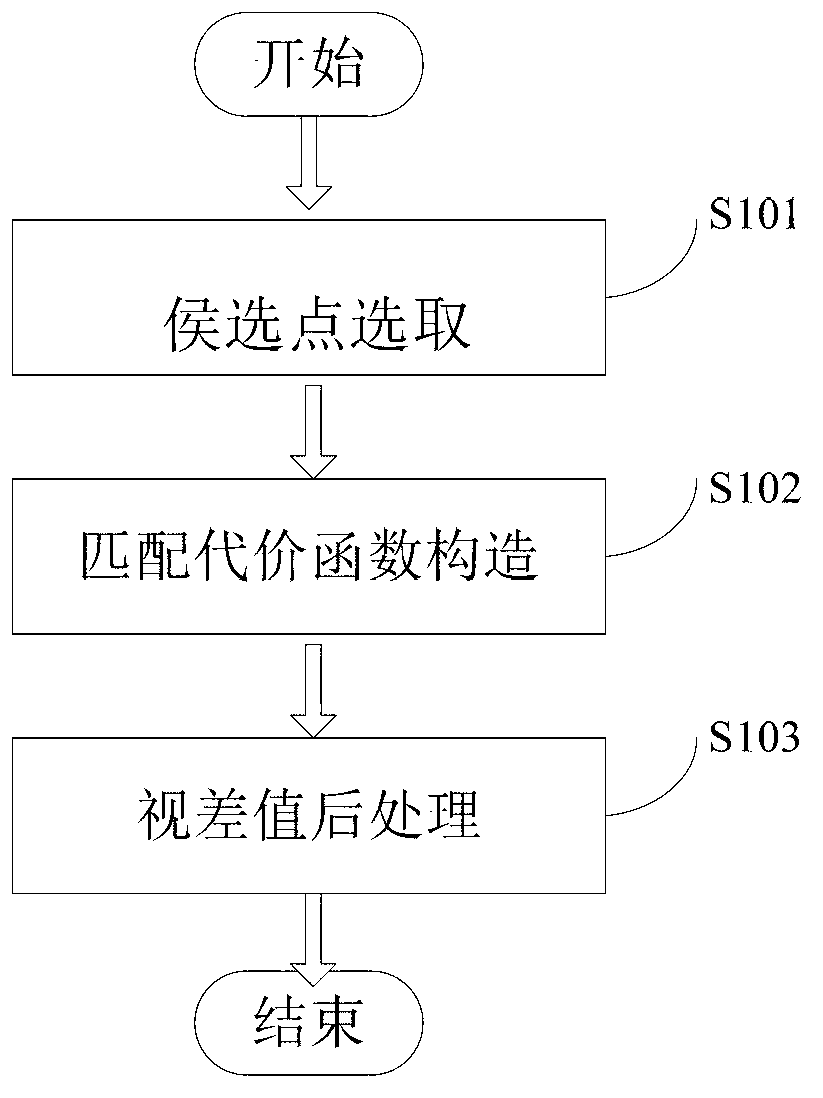

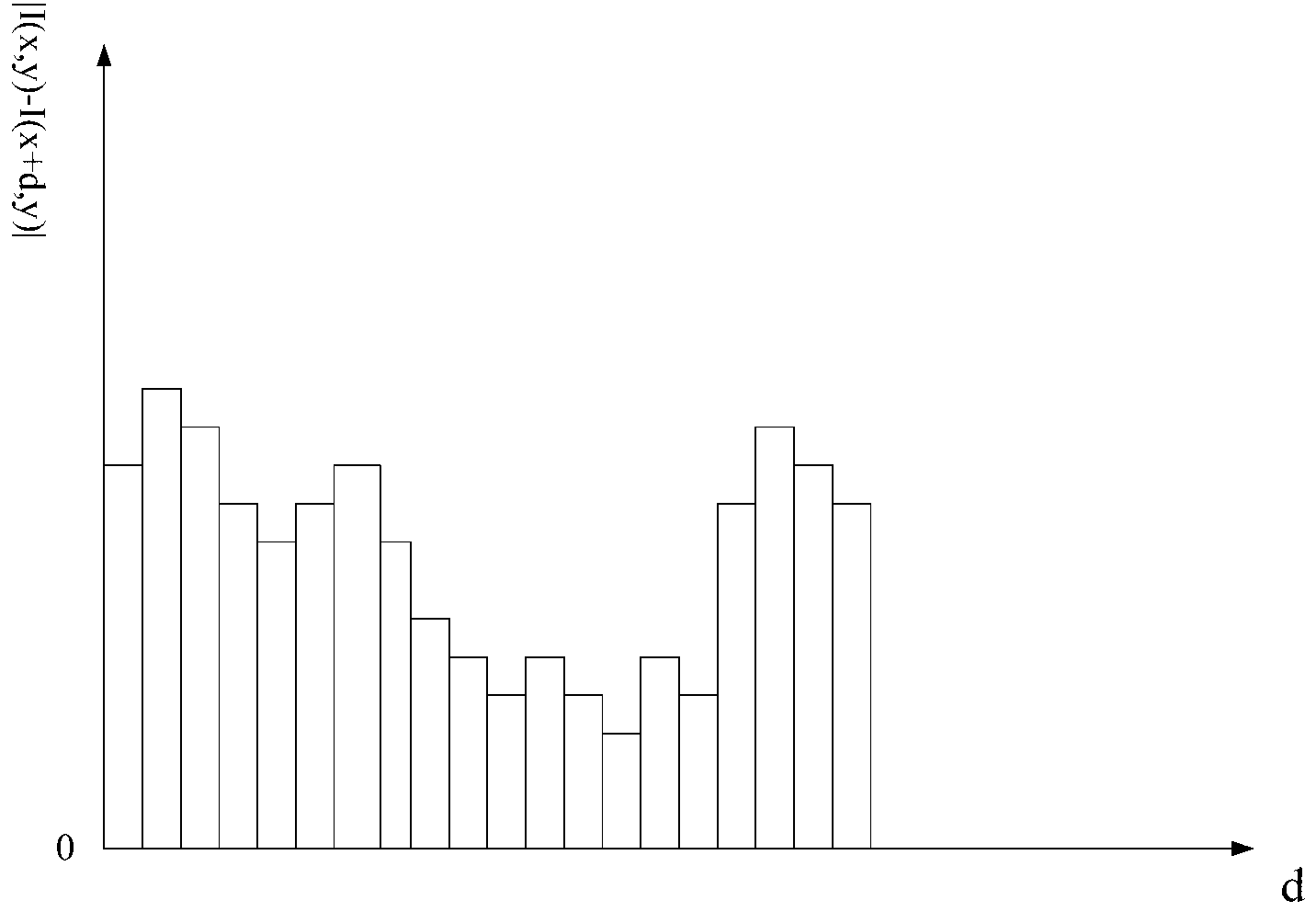

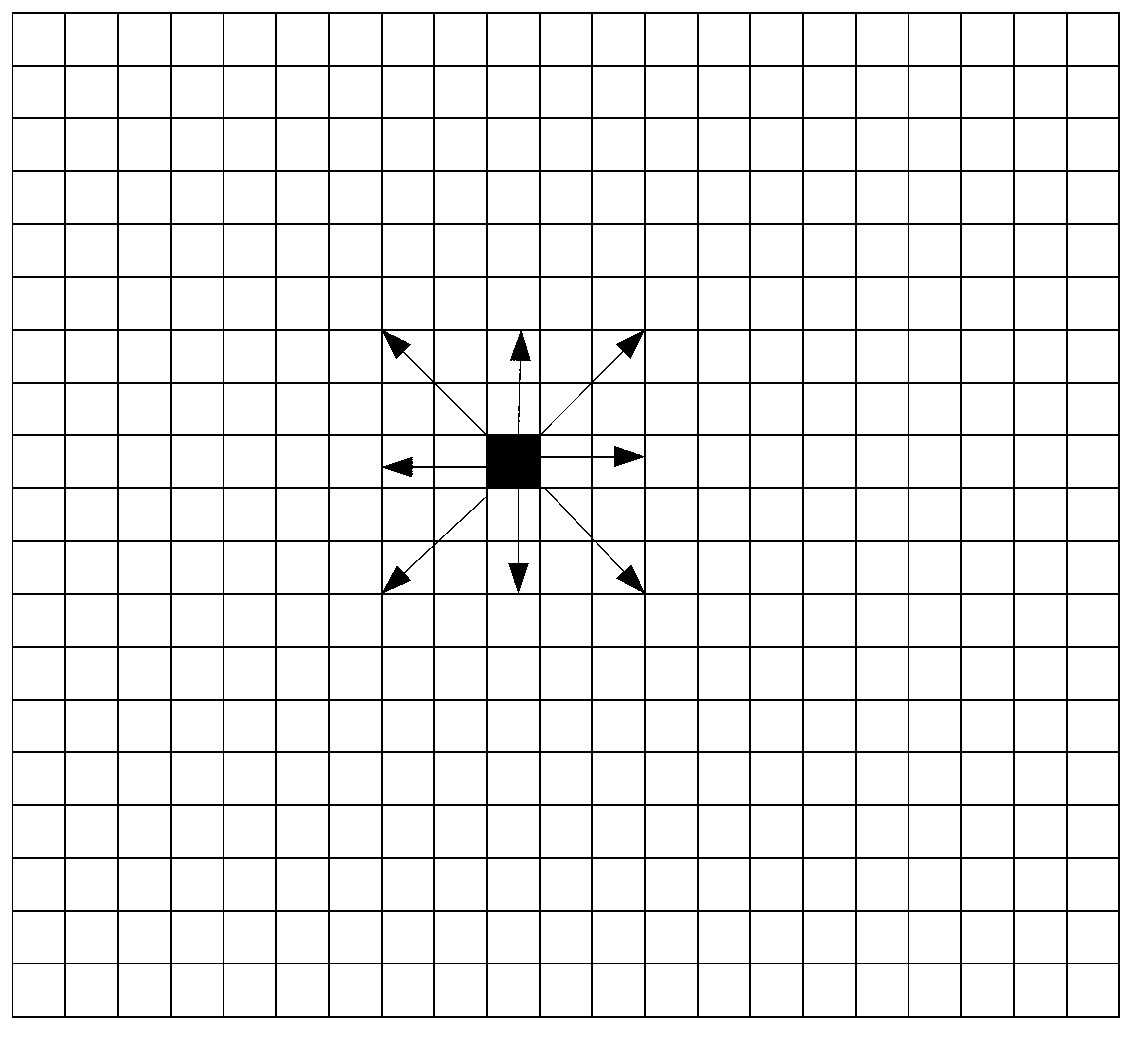

Rapid stereo matching method and disparity map obtaining method both aiming at high-definition image pair

ActiveCN103310421ANarrow searchReduce the amount of calculationImage enhancementImage analysisParallaxMatched pair

The invention relates to a stereo matching method aiming at the high-definition image pair and a high-precision disparity map obtaining method based on the method. Aiming at high-definition left and right eye images, a rapid stereo matching method and a disparity map obtaining method both aiming at a high-definition image pair are provided. Due to the estimation of the scope of the optical parallax, the search scope of the matched counter points is reduced greatly, and calculation redundancy and calculation amount in the method are reduced; as a reasonable matched cost function is constructed, a correct matched pair is selected, and post-treatment for the disparity map is finally carried out by aiming at the candidate matched point pairs, improvement for a plurality of common problems in the disparity map can be carried out, and a smooth and precise disparity map can be obtained.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

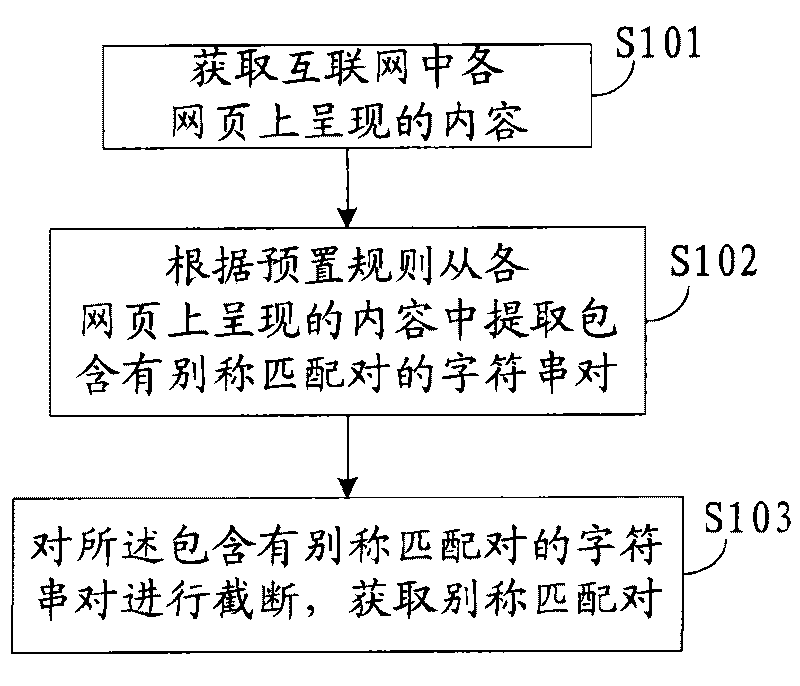

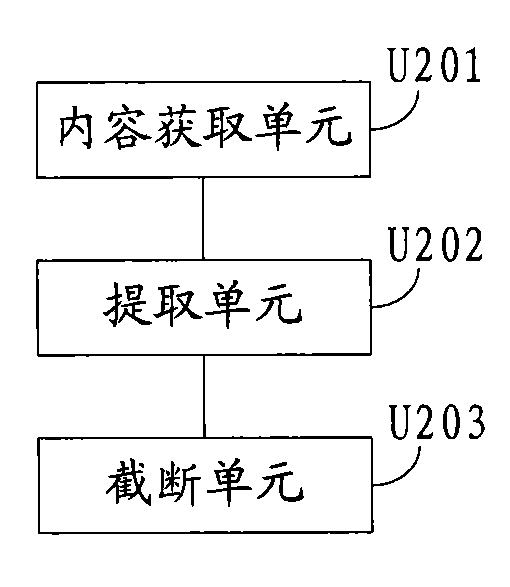

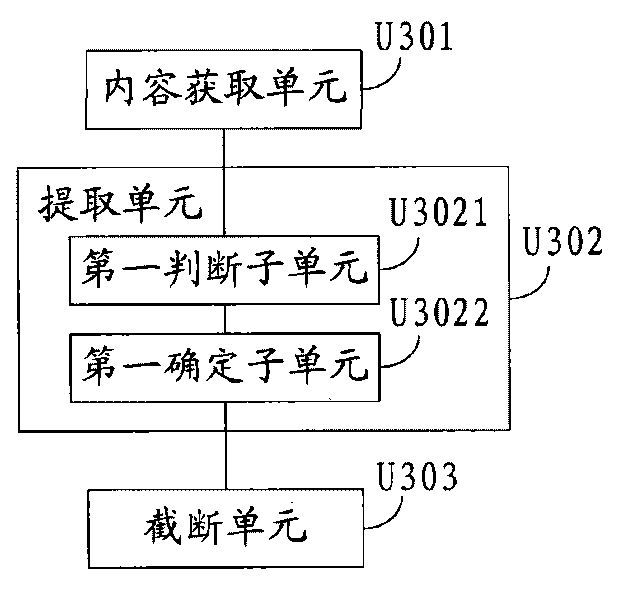

Method and device for acquiring alternative name matched pair

ActiveCN101727464AIncrease profitImprove experienceSpecial data processing applicationsMatched pairThe Internet

The invention discloses a method for acquiring an alternative name matched pair, comprising the following steps: acquiring contents presenting on each webpage in an internet; extracting a character string pair containing alternative name matched pair in the contents presenting on each webpage according to preset rules; truncating the character string pair containing the alternative name matched pair to acquire the alternative name matched pair. The invention also discloses a device for acquiring the alternative name matched pair. The invention can more and more roundly distinguish possibly emerging alternative name matched pairs, further effectively utilizes the distinguished alternative name matched pairs to improve the experience of users and the utilization rate of data.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

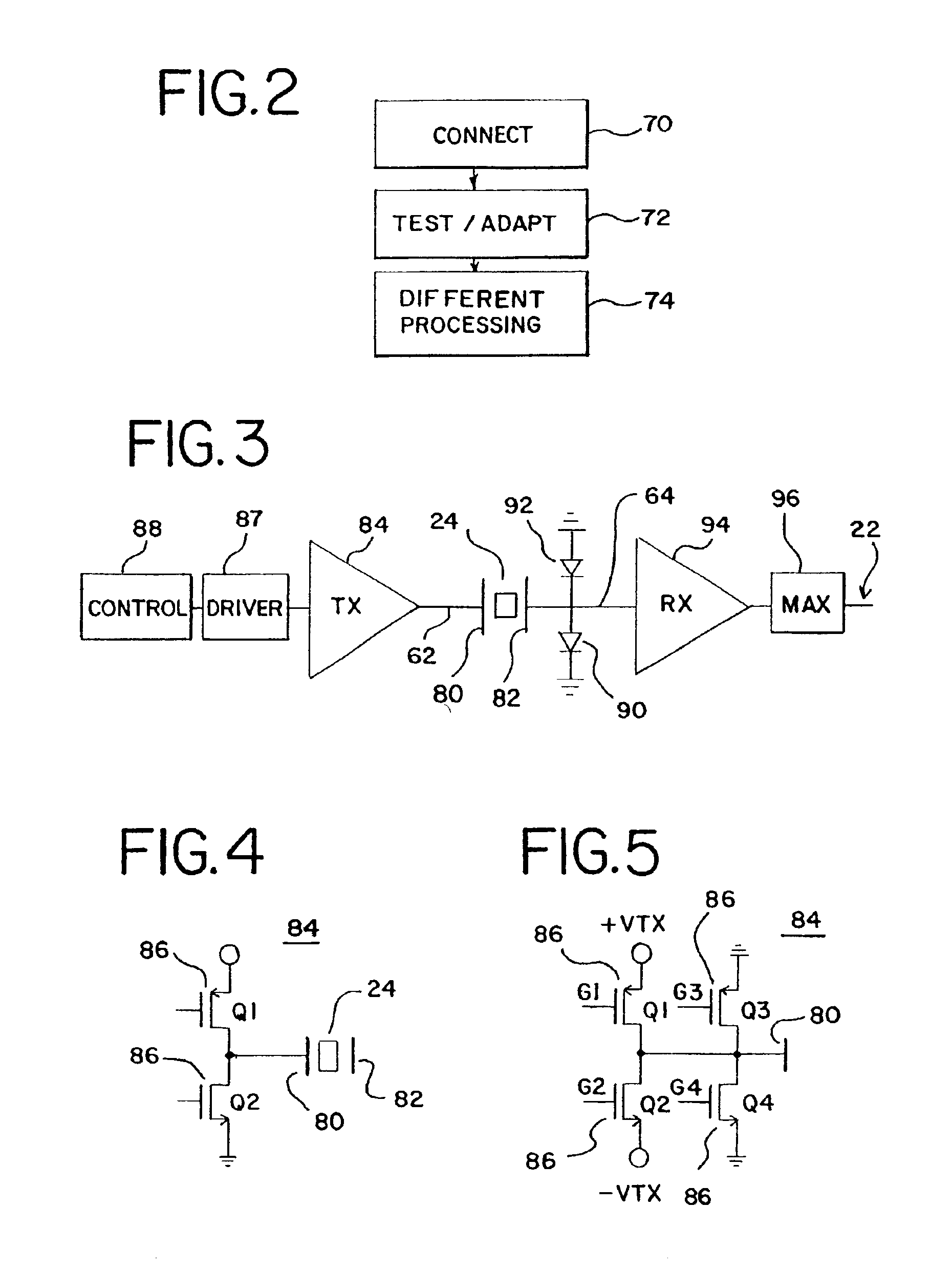

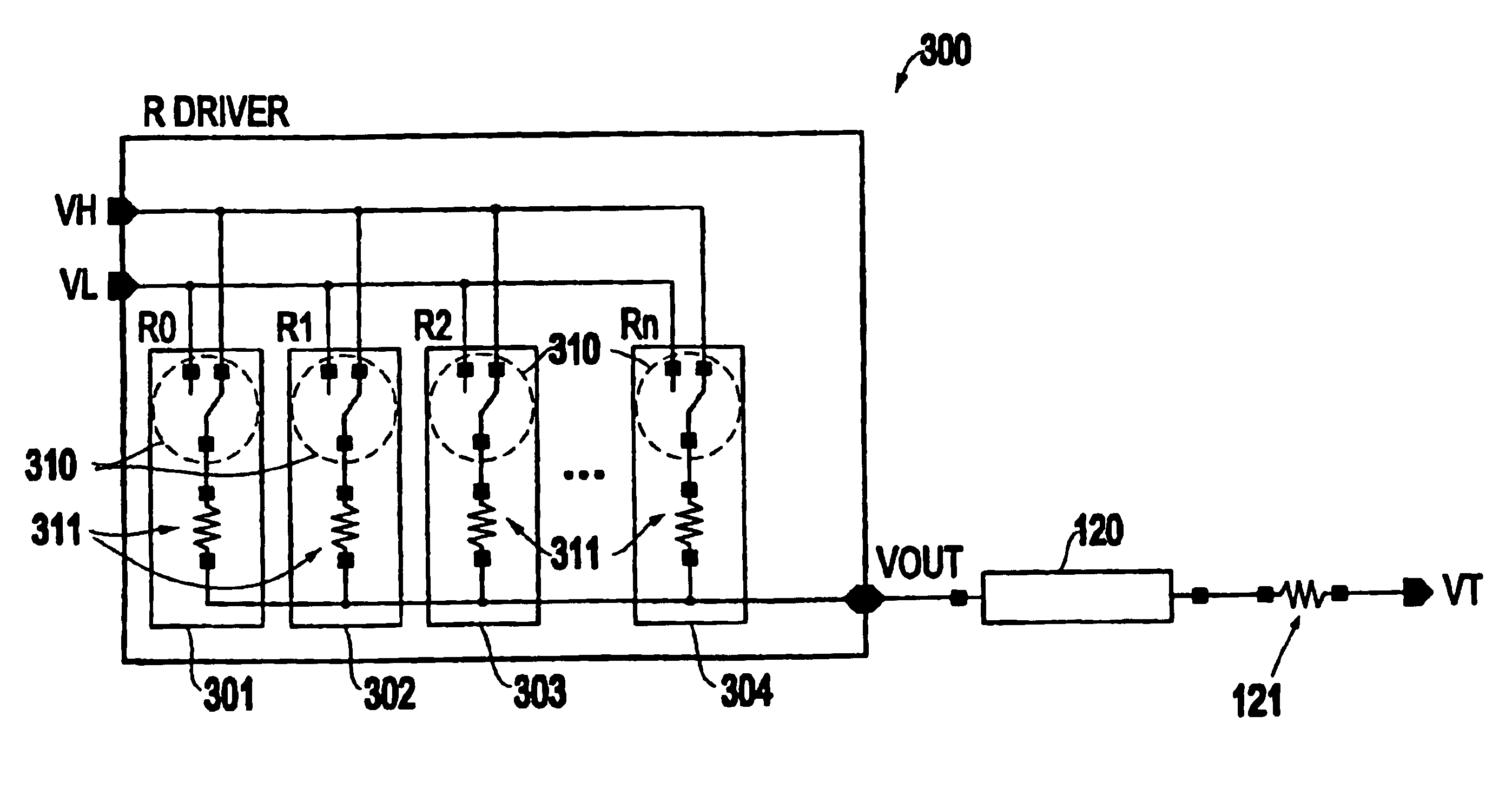

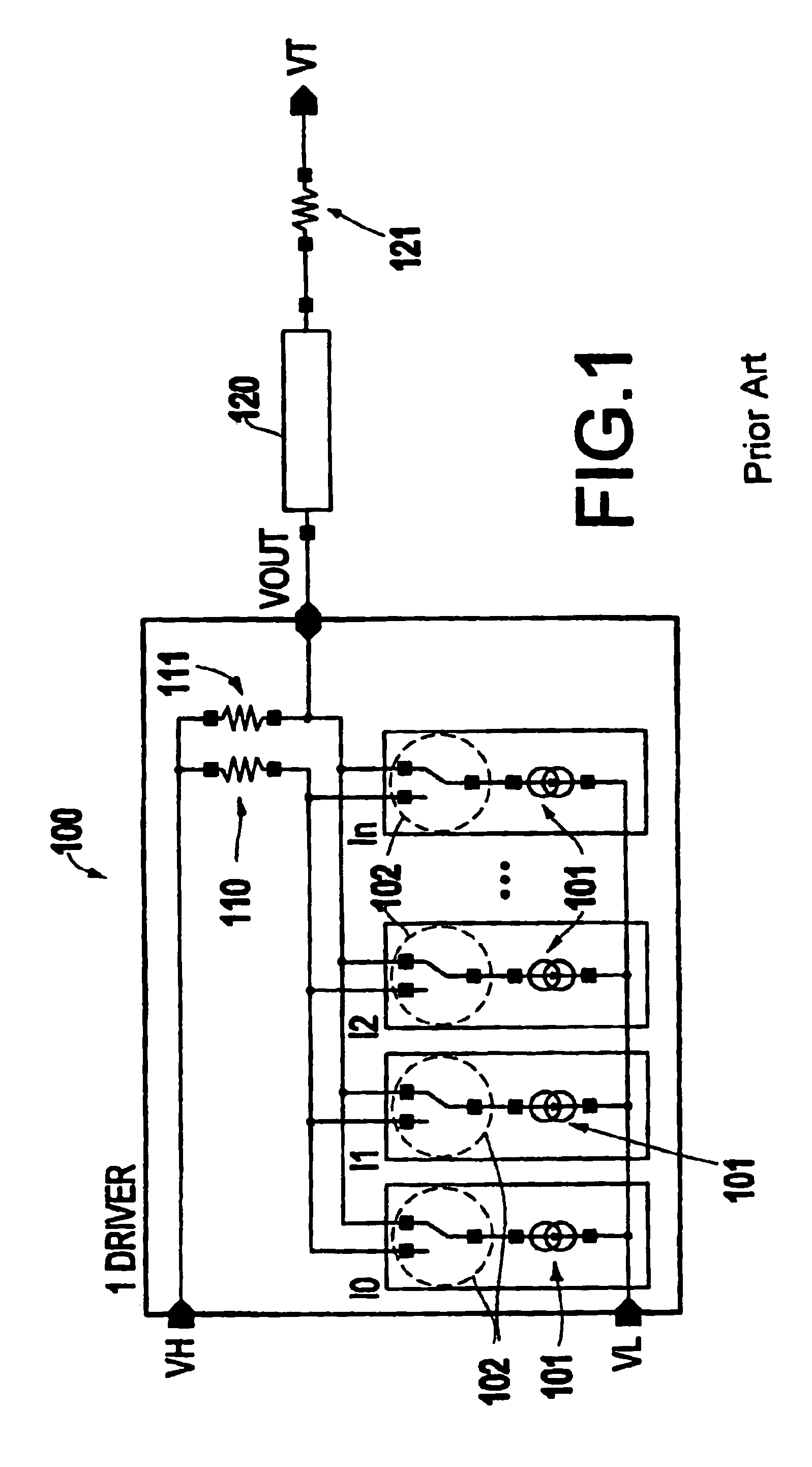

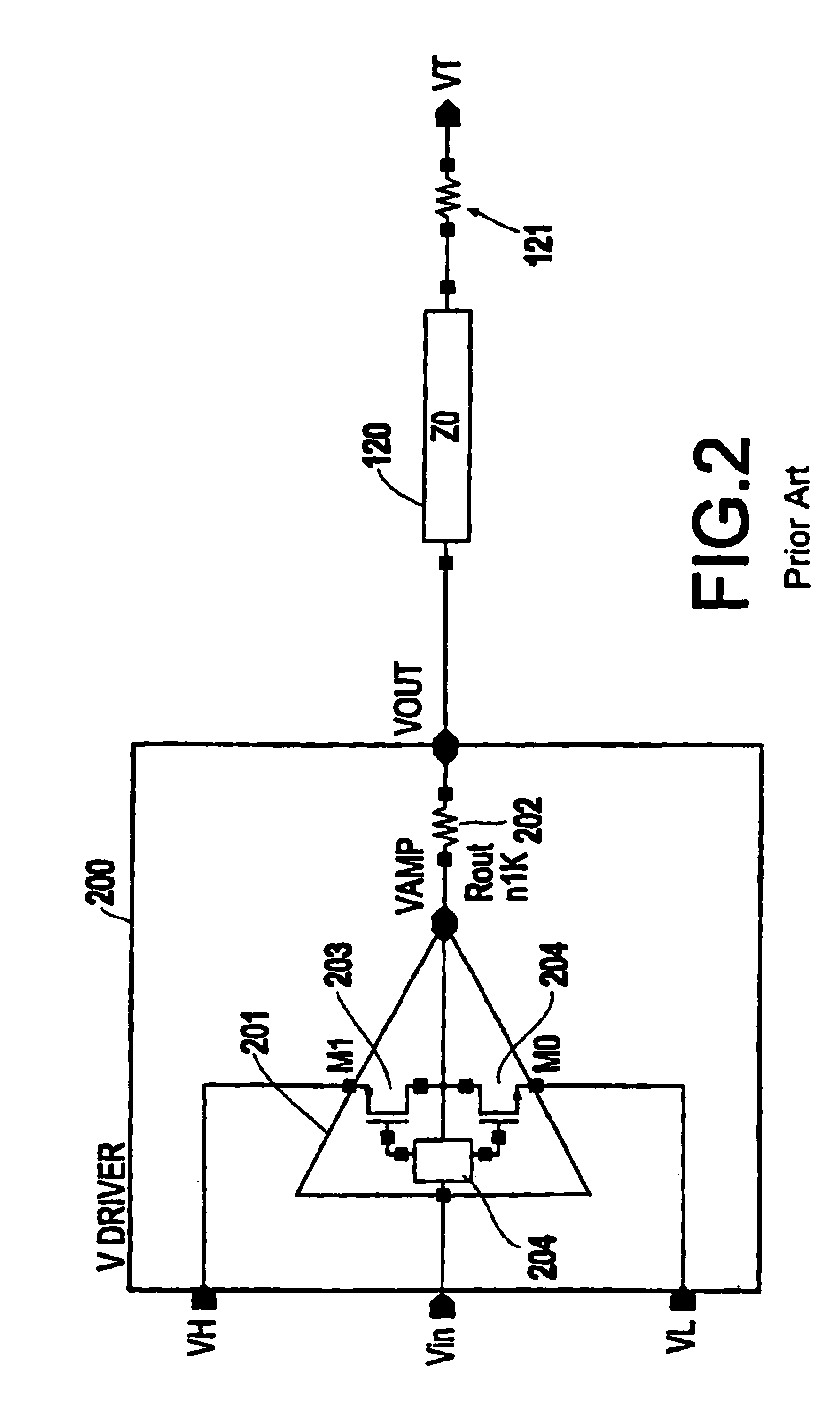

Terminating resistor driver for high speed data communication

InactiveUS6930506B2Input/output impedence modificationReliability increasing modificationsDriver circuitMatched pair

A method and structure for a driver circuit having a plurality of parallel resistors, where a total impedance of all the resistors equals an impedance of an associated transmission line and a switch adapted to combine the resistors to control an output level of the driver. The driver circuit's switch selectively connects the resistors to either a voltage high signal or a voltage low signal. The first set of the switches connect a voltage high signal to a first resistor of the resistors and a second set of switches connect a voltage low signal to a second resistor of the resistors. The switch has a matched pair of opposite type transistors. The driver circuit has balancing resistors connected to the switch, the balancing resistors are sized to balance the resistance within the driver circuit. The resistors are the balancing resistors and the drivers are connected to the switches.

Owner:MARVELL ASIA PTE LTD

Automatically expanding and shrinking scraping-rolling combined deep hole cutter

ActiveCN102152118AImprove static stiffnessImprove dynamic stiffnessOther manufacturing equipments/toolsBoring headsMatched pairEngineering

The invention discloses an automatically expanding and shrinking scraping-rolling combined deep hole cutter. A scraping part of the cutter comprises at least one pair of scrapers, a top block, and a reset device; the top block is positioned in the centre of a thick boring head body and is provided with a taper structure, and a corresponding conical surface is jacked by an endocentric end of the scraper; and the reset device is arranged between each matched pair of scrapers for resetting the scrapers; and a rolling part of the cutter comprises a rolling path and a keeper. The combined boring head also comprises a manipulating device which comprises a first driving part and a second driving part, wherein the first driving part drives the keeper to move axially along a spindle, and the second driving part penetrates a centre hole and acts on the top block in order to drive the top block to move axially along the spindle. The cutter disclosed by the invention is compact in structure, high in processing precision, convenient to use, and can expand and shrink automatically.

Owner:德州普利森机床有限公司

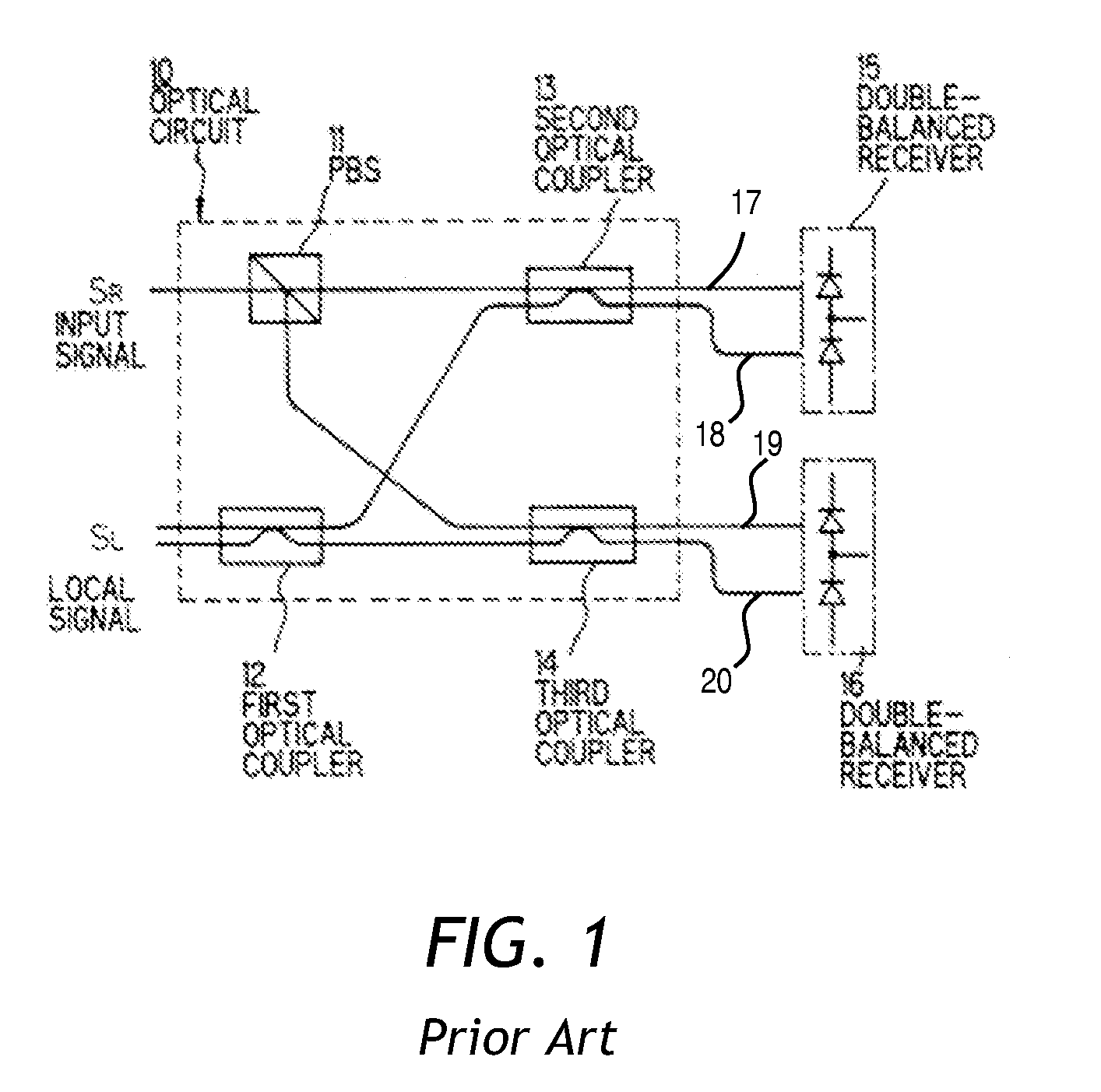

Coherent optical mixer and a method of coherent detection of light

A coherent planar lightwave circuit (PLC) optical mixer chip is described comprising a matched pair of symmetrical four-coupler interferometers for in-phase and in-quadrature detection of two polarization components of light using a polarization diversity arrangement. The waveguide structure of the chip is symmetrical about two orthogonal central axes of the chip, whereby the effect of temperature gradients on the mixer is reduced. A light traveling from an input to an output of any of the two interferometers is cross-coupled by one of the two couplers it passes through, and is bar-coupled by the other of the two couplers, so as to compensate for polarization, wavelength, and manufacturing process dependence of bar-coupling with that of cross-coupling.

Owner:LUMENTUM OPERATIONS LLC

Method for synthesizing liquid rubber-epoxy resin polymer

Using the fluid rubber of acrylonitrile-polybutadiene end-capped with hydroxy and the multi-isocyanate to react and then the prepolmer of acrylonitrile fluid rubber end-capped with isocyanate was obtained; using the fluid rubber of polybutadiene end-capped with hydroxy and the multi-isocyanate to react and then the prepolymer of polybutadiene fluid rubber end-capped with isocyanate was obtained. According to the ratio of 10-40 / 90-60, the above two prepolymers were mixed, and then the mixed prepolymer was obtained. The optimum multi-isocyanate are TDL and MDI. The fluid bisphenol epoxy resin with the style A and the flexible epoxy resin were matched pair again according the ratio of 80-50 / 20-50. The built-epoxy resin then obtained. followed by the reaction between the isocyanate in the mixed prepolymer and the hydroxyl in the built-epoxy resin, so as to lead the fluid rubber in the built-epoxy resin by the form of chemical bonding. Finally, the polymer of fluid rubber- epoxy resin was obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method of the adjustable matching map system in lithography

InactiveUS7160654B2Improve accuracyReduce layeringSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusCorrection algorithmMatched pair

A method is provided for improving layer to layer overlay of a second layer pattern on a first layer pattern formed in a substrate. A plurality of first reference marks is placed inside a pattern area on a first layer mask which is used to form the first layer pattern. A plurality of second reference marks is placed on a second layer mask which is used to form the second layer pattern and in which one second reference mark is matched with a first reference mark having the same (x,y) coordinates. Reference mark placement in the resulting first and second layer patterns is determined by metrology to determine an x-deviation and a y-deviation for each matched pair of reference marks. A correction algorithm is then used to calculate adjustments in exposure tool settings for improved overlay of the second layer pattern on the first layer pattern in subsequent exposures.

Owner:TAIWAN SEMICON MFG CO LTD

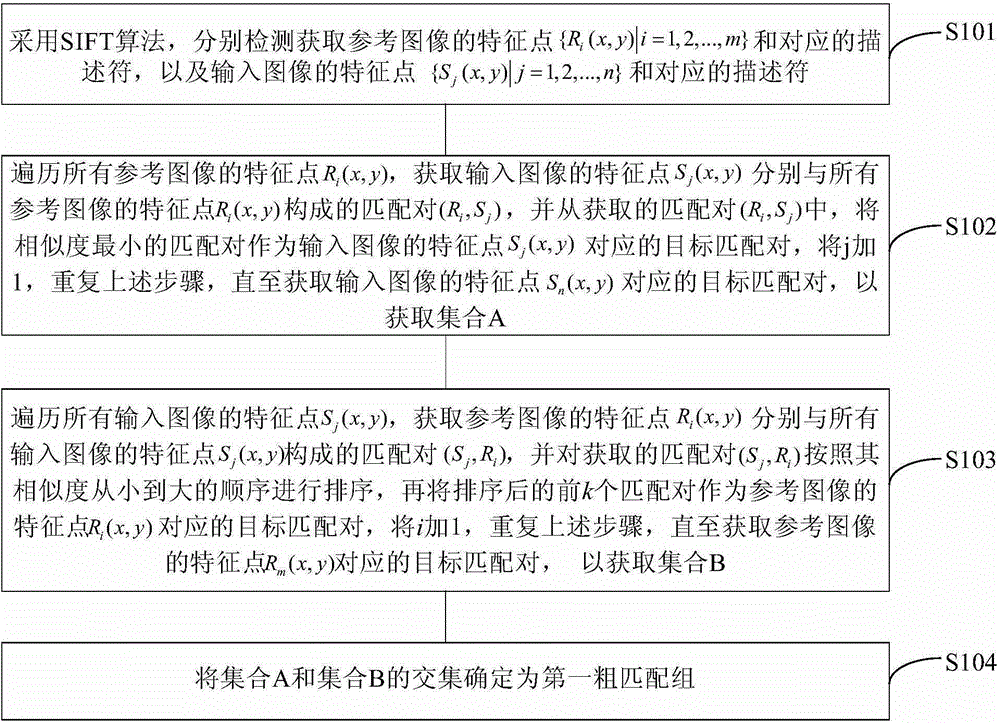

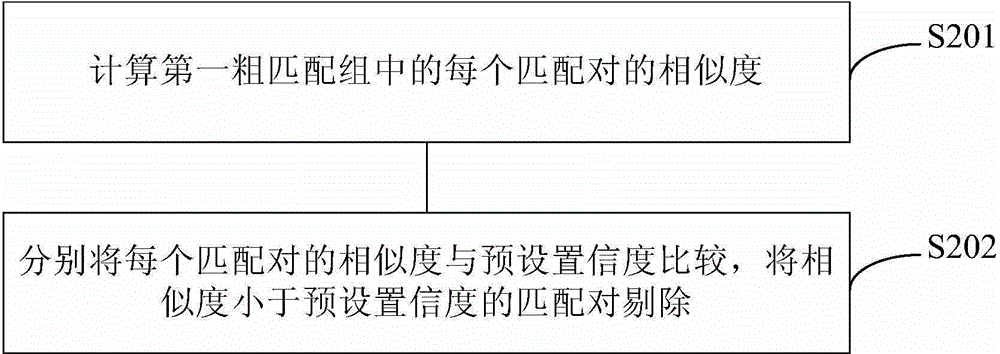

Image registration method and image registration device based on cascade structure

ActiveCN104978742AGuaranteed resolutionGuaranteed clarityImage enhancementImage analysisPattern recognitionMatched pair

The invention provides an image registration method and an image registration device based on a cascade structure. The method comprises the steps: carrying out bilateral matching processing on a characteristic point of a reference image and that of an input image to obtain a first coarse matching group; eliminating matched pairs in the first coarse matching group according to a predetermined confidence coefficient to obtain a second coarse matching group, wherein the similarity of the matched pairs eliminated from the first coarse matching group is lower than the predetermined confidence coefficient; eliminating the matched pairs in the second coarse matching group according to a predetermined threshold value to obtain a third coarse matching group, wherein the gray distance or the space distance between any two matched pairs in the matched pairs eliminated from the second coarse matching group is greater than the predetermined threshold value; processing the matched pairs in the third coarse matching group by adopting an RANSAC (RANdom SAmple Consensus) algorithm; and aligning the reference image with the input image spatially according to a transformational matrix so as to obtain an output image.

Owner:BEIJING UNIV OF POSTS & TELECOMM

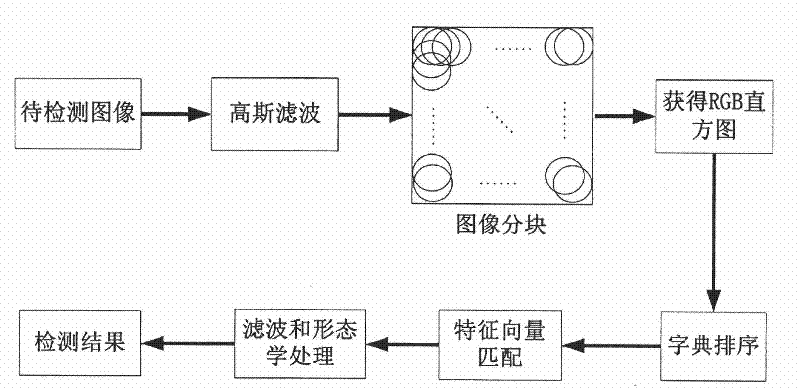

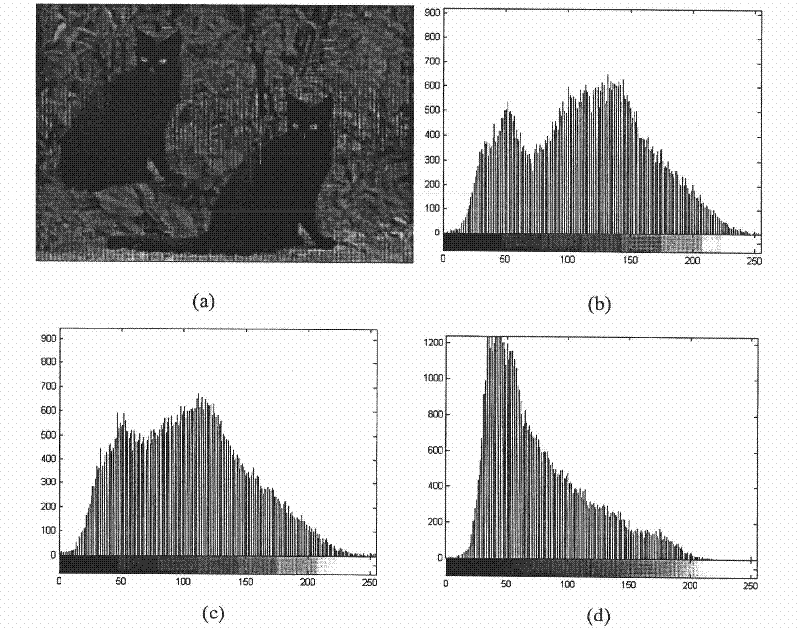

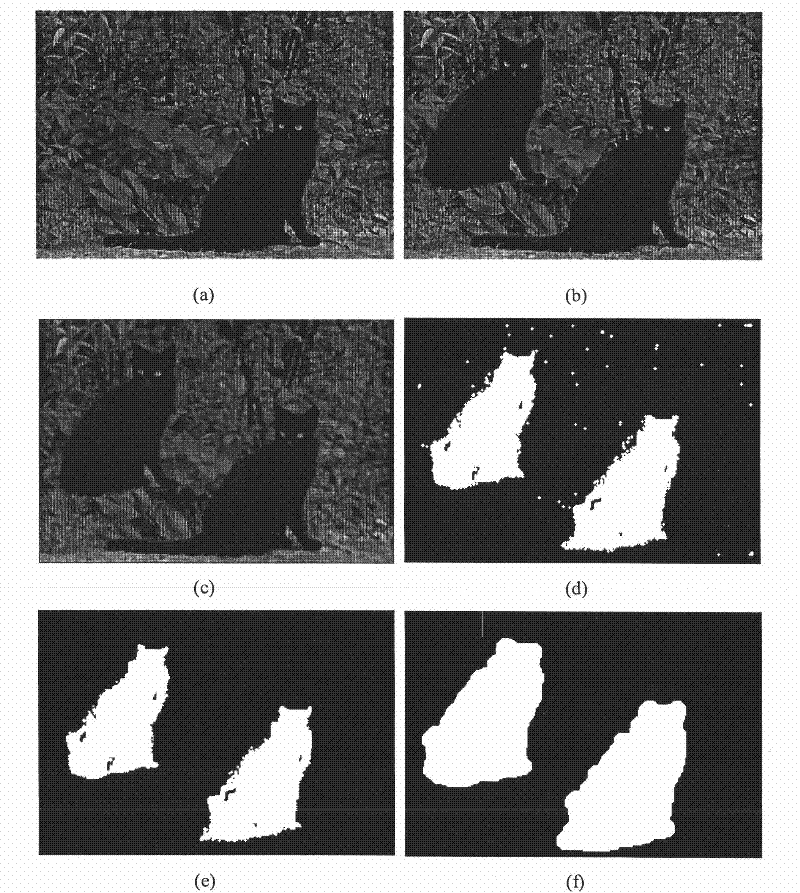

Method for detecting region duplication and forgery of color image

InactiveCN102693522ASimple calculationImprove computing efficiencyImage analysisImage data processing detailsFeature vectorColor image

The invention discloses a method for detecting region duplication and forgery of a color image, comprising first removing noises in a color image to be detected; dividing the color image subjected to noise processing into blocks with pixels in only one row or one column being different between two adjacent image blocks; quantizing pixels of the three channels of red, green, and blue for each image block, dividing each channel into M segments according to gray scales, calculating the number of pixels in each segment and taking the number as a feature value of the corresponding image block, combining all the obtained feature values of the three channels and taking the combined value as a feature vector D of the image block; a similarity matching between one image block and the other image blocks by using feature vectors of each image block to acquire a correctly matched pair of image blocks; and building a binary image which is of the same size as the detected image with gray scale of each pixel point being zero, labeling the position of the obtained correctly matched pair of image blocks into the binary image, and detecting region duplication and forgery of the color image in the obtained binary image which is generated by detecting results.

Owner:CHINA UNIV OF MINING & TECH

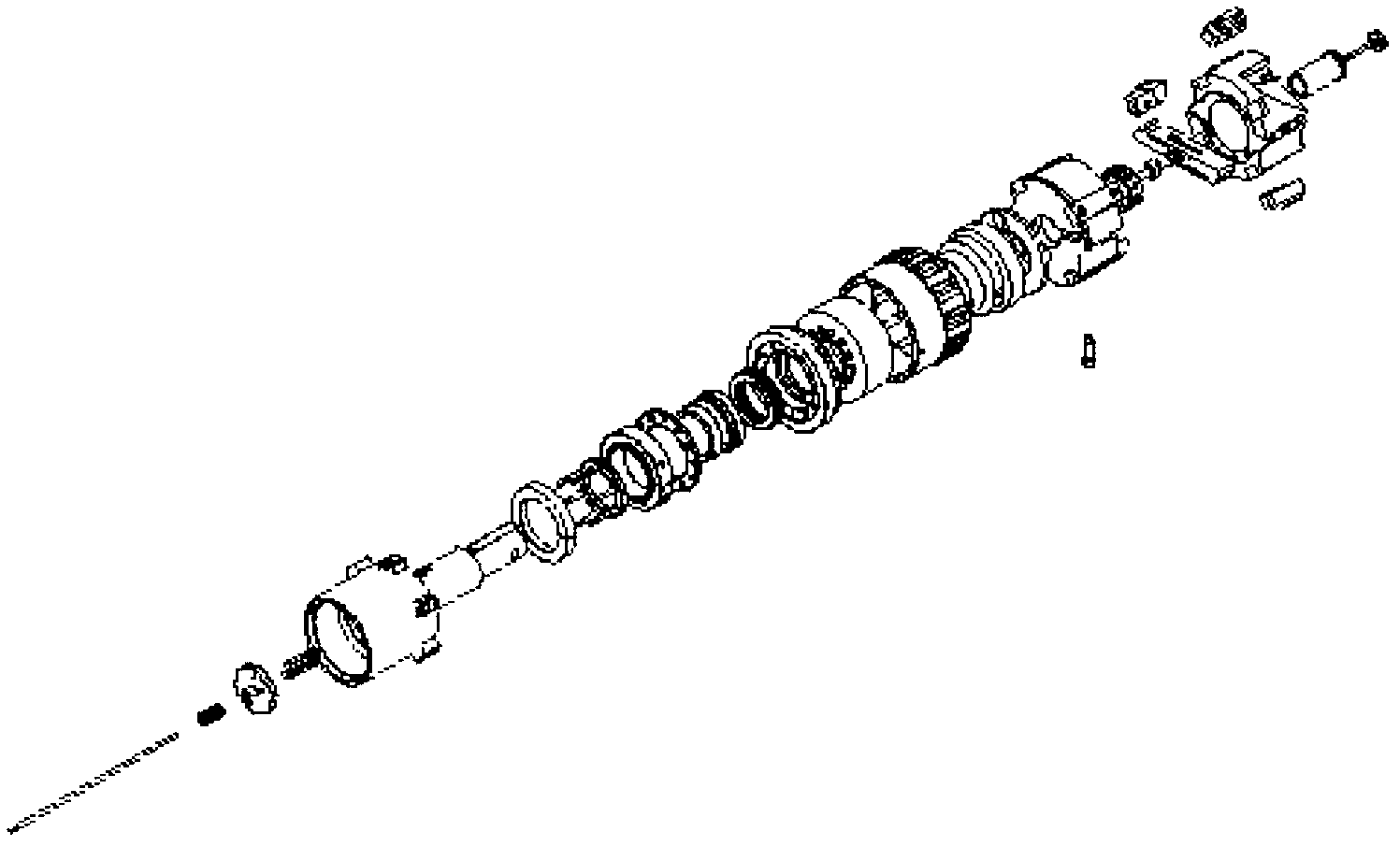

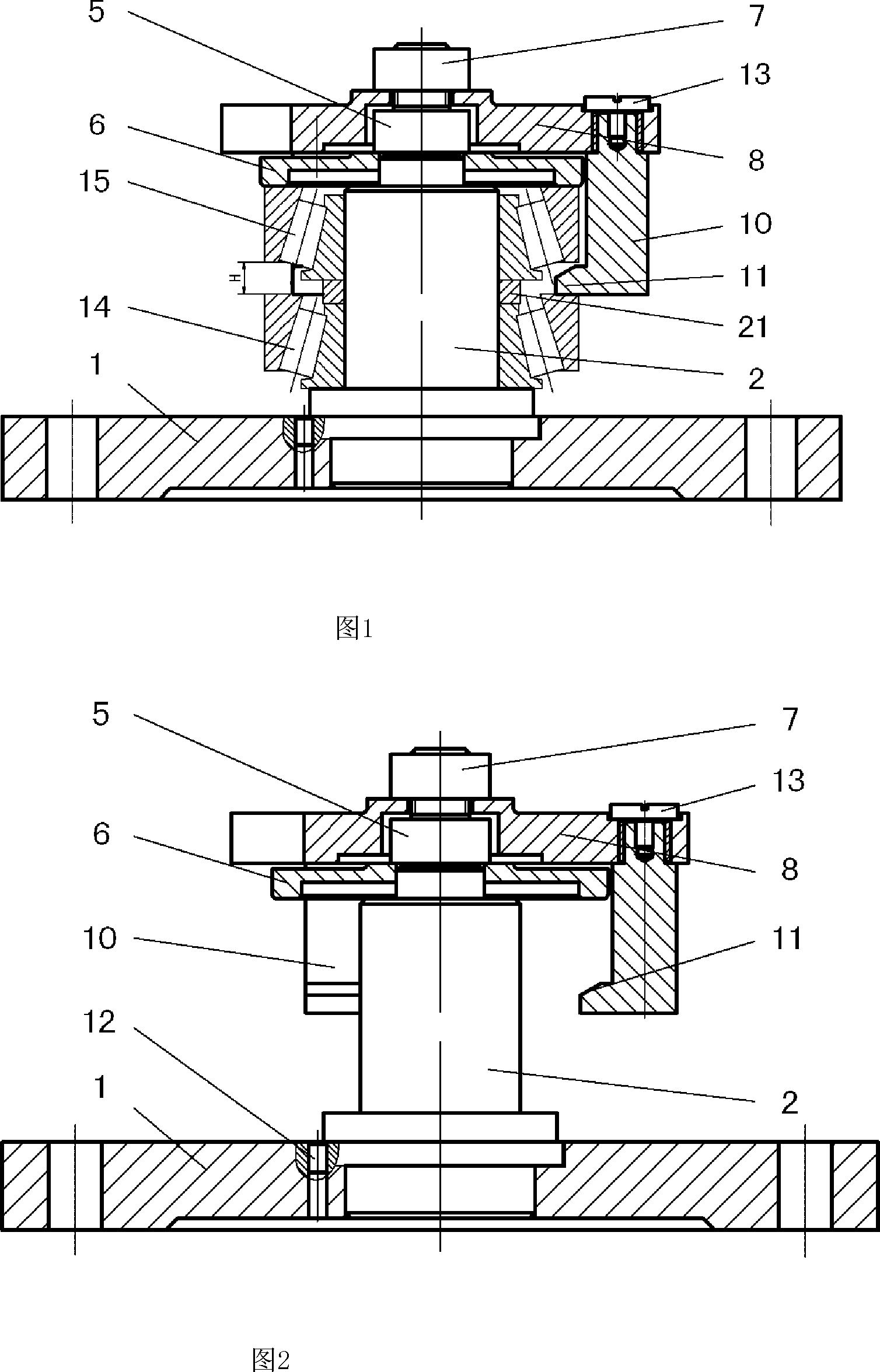

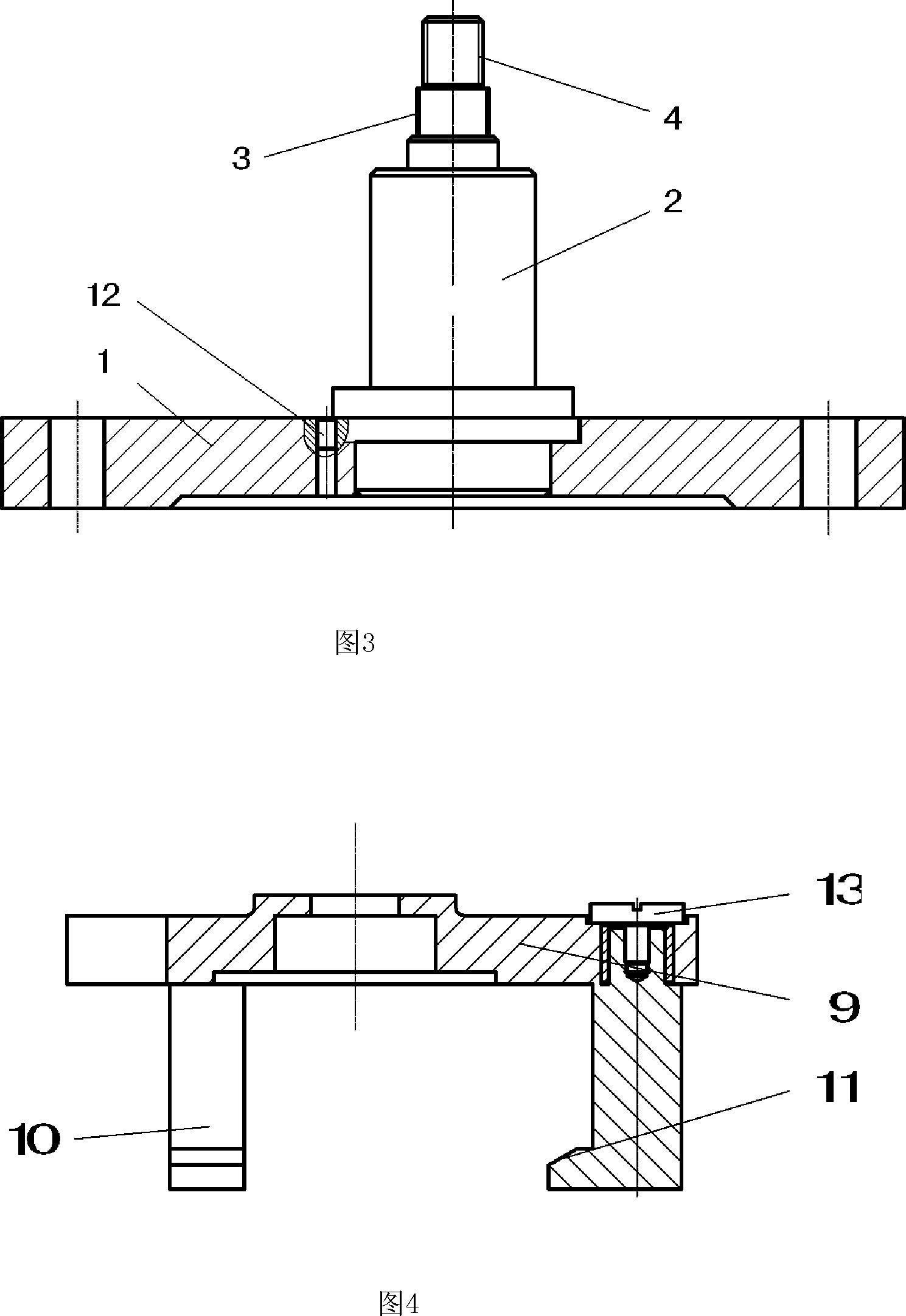

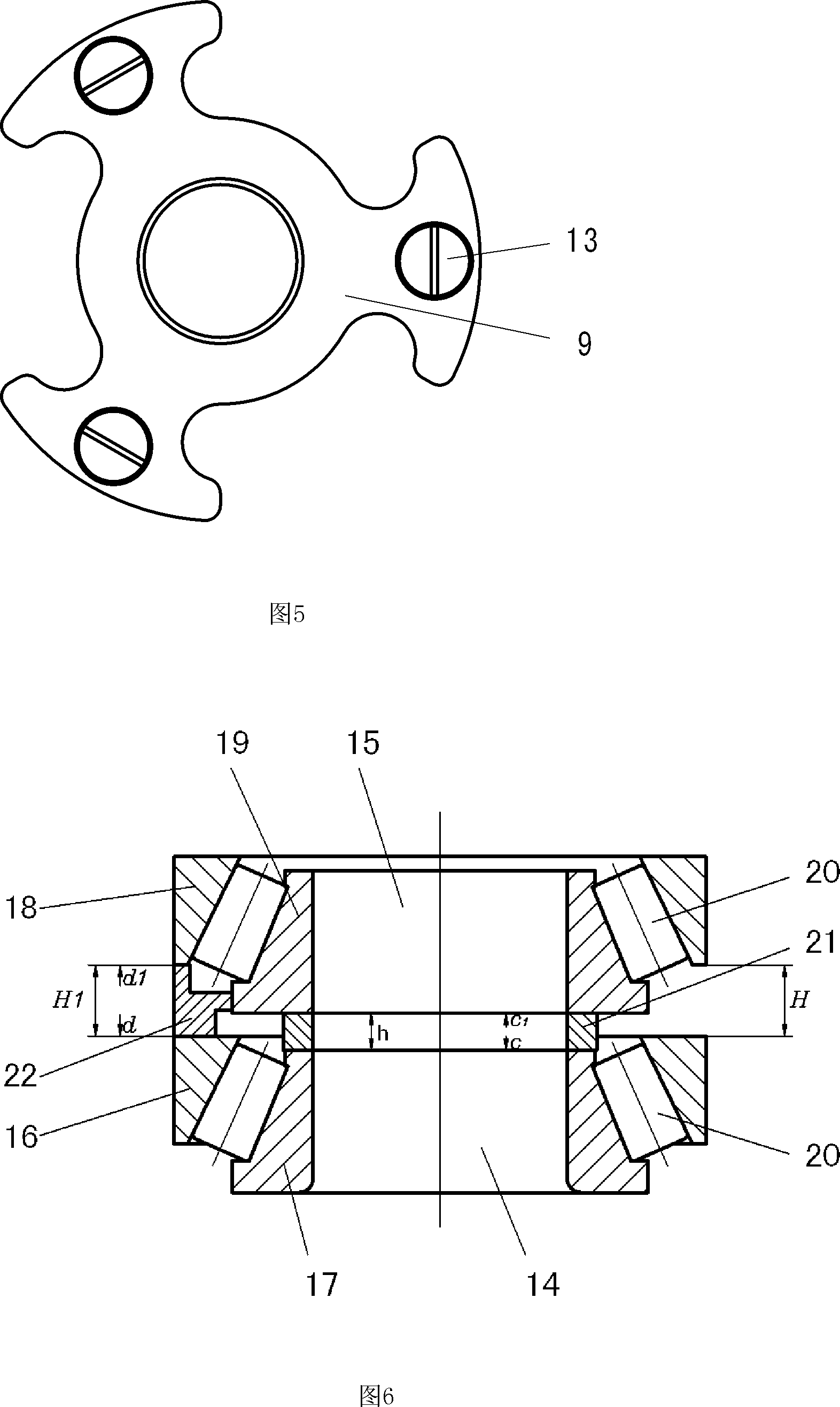

Method for measuring single row conical bearing connection in series matched pair inter space

ActiveCN101113940AHigh measurement accuracySimple and fast operationMachine bearings testingMechanical clearance measurementsMatched pairHeight difference

The invention discloses a mating clearance measuring method and device for single-row conical bearings in series. The method comprises the processes: first, a bearing A, an inner spacer, a bearing B and a platen are sequentially sleeved on a mandrel of a base; a nut A is sleeved on a thread A of the mandrel, a housing washer of the bearing B is rotated while the nut A is tightened, causing the platen to press the housing washer of the bearing B tightly; a support arm-panel part is arranged on the mandrel, causing a pawl of the support arm-panel part to press on a housing washer of the bearing A; a nut B is sleeved on the thread B of the mandrel, the housing washer of the bearing A is rotated while the nub B is tightened, causing the pawl of the support arm-panel to press tightly on the housing washer of the bearing A; then the distance between the two adjacent end faces and the heights of the housing washers of the two bearings are measured respectively and the distance between the two adjacent end faces of and the height difference between the two housing washers are calculated, thus, the mating clearance of the single-row conical bearing in series is obtained. The measuring method is characterized by high measuring accuracy, easy operation, etc. and can improve the measuring efficiency.

Owner:AVIC LIYUAN HYDRAULIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com