Patents

Literature

71results about How to "Reduce gas leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

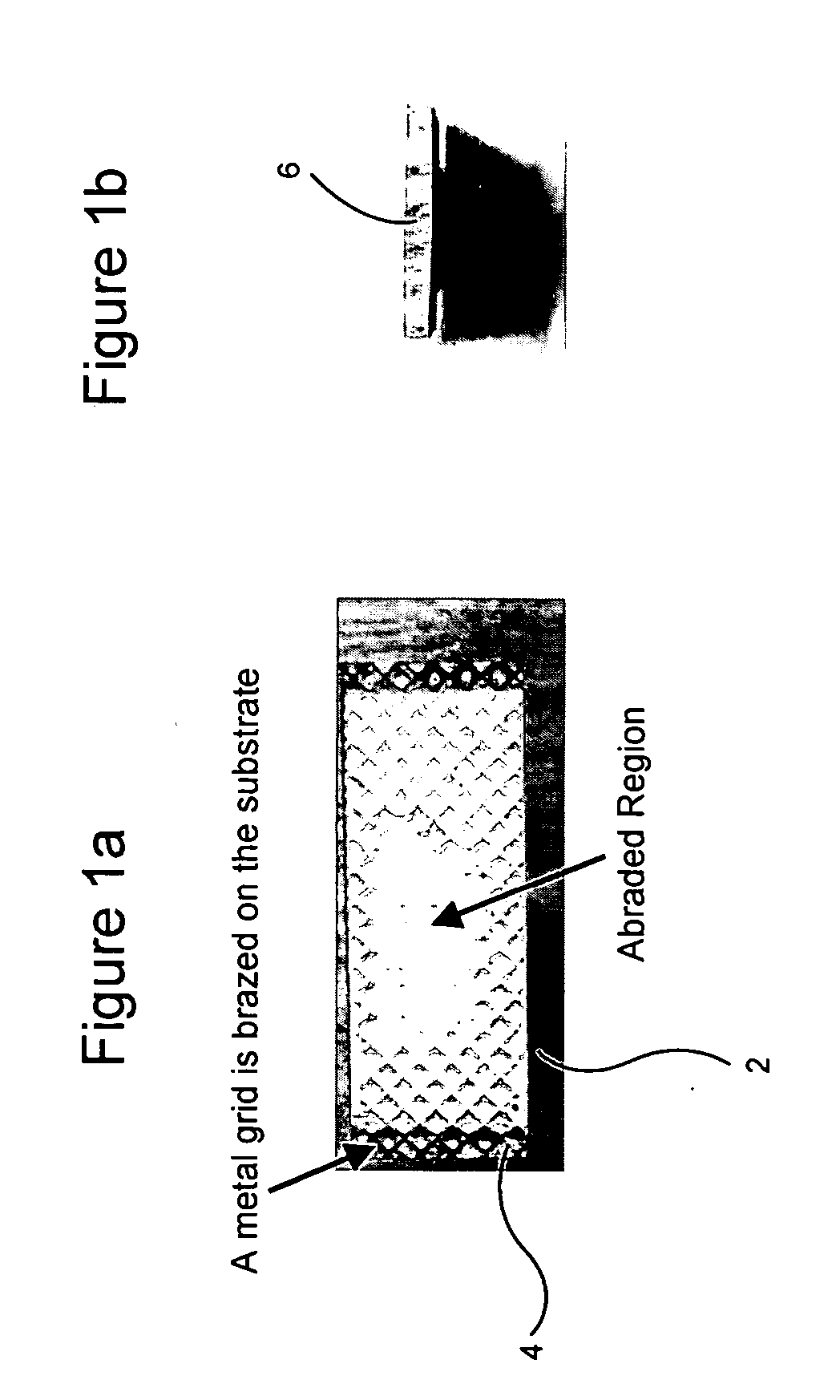

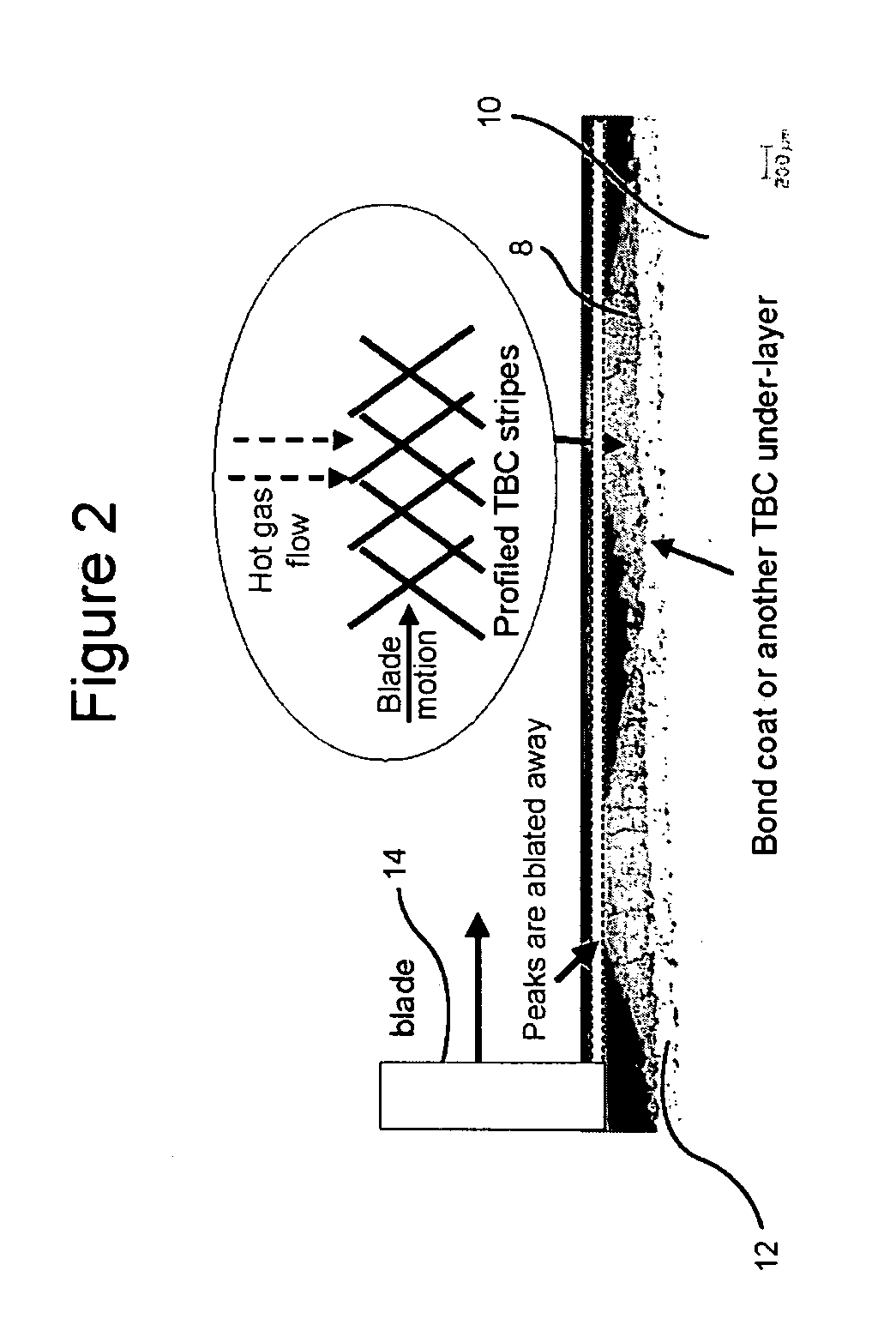

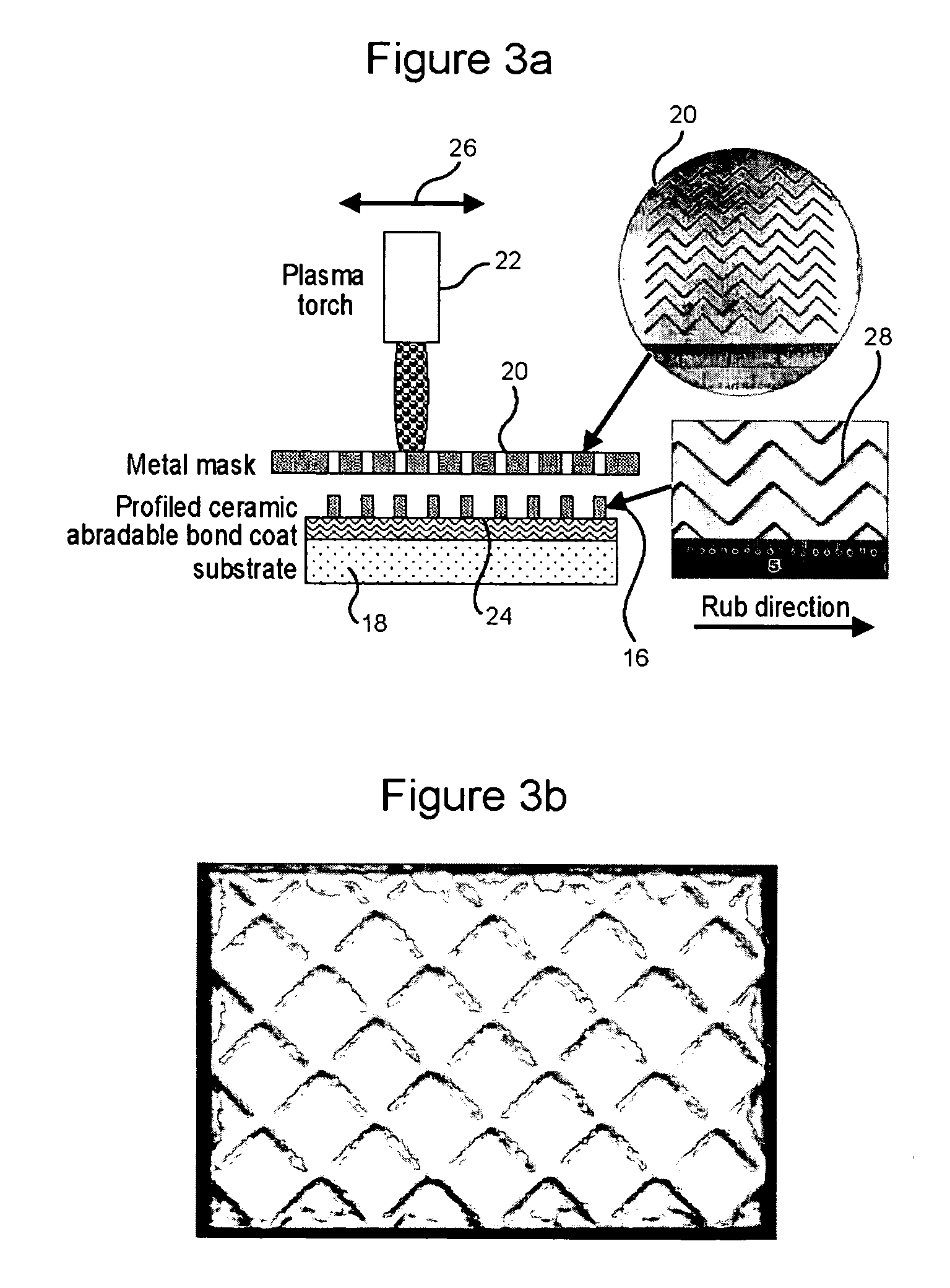

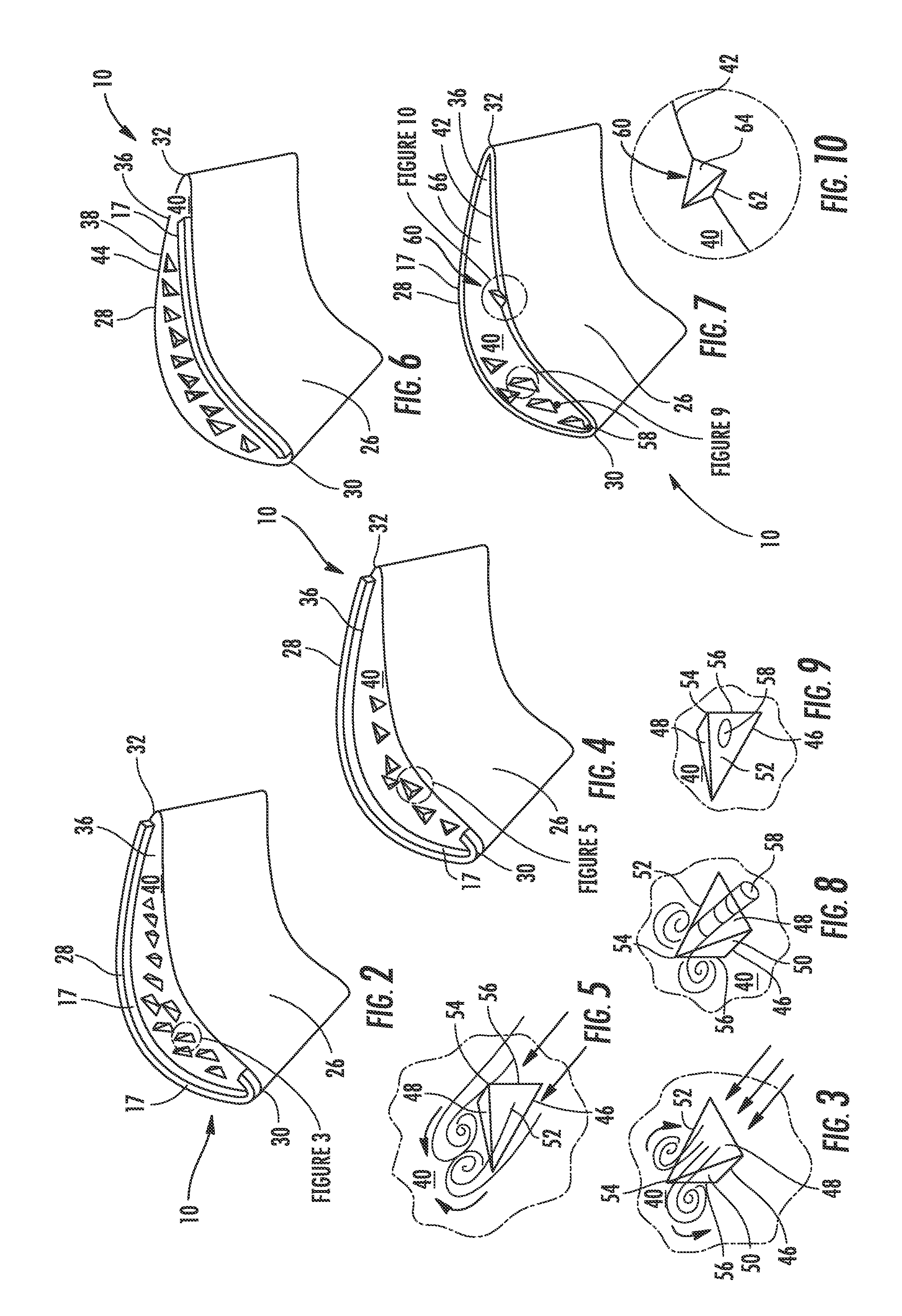

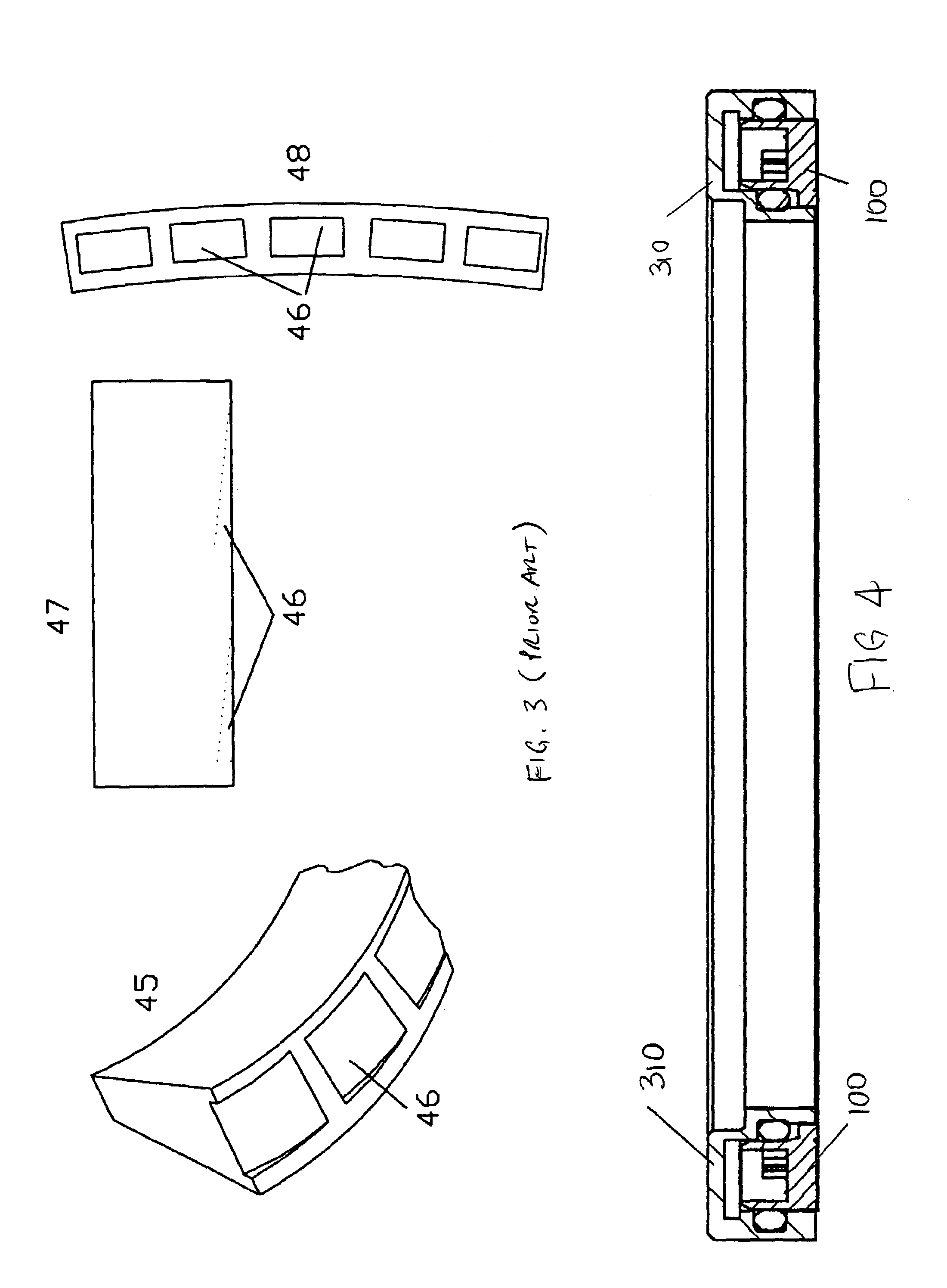

7FAstage 1 abradable coatings and method for making same

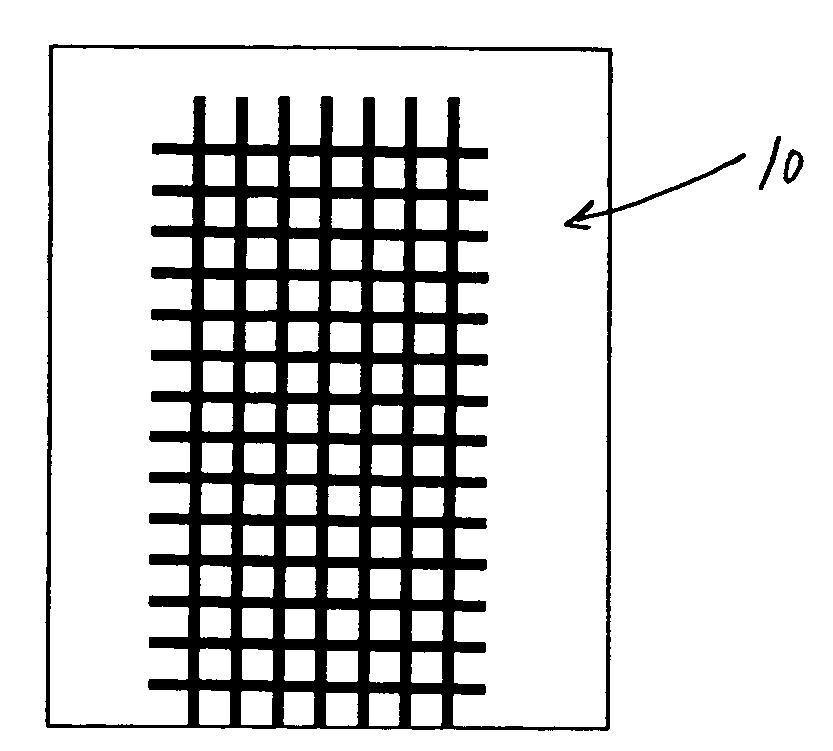

InactiveUS20050003172A1Minimal wearReduce gas leakageMolten spray coatingEngine manufactureLeading edgeGrid pattern

A method of applying a profiled abradable coating onto a substrate in which an abradable ceramic coating composition is applied to a metal substrate using one or more coating application techniques to produce a defined ceramic pattern without requiring a separate web or grid to be brazed onto the substrate. The invention is particularly designed to withstand the higher operating temperatures encountered with the stage 1 section of 7FA+e gas turbines to allow for increased coating life without significant deterioration in structural or functional integrity. Typically, the grid pattern coating begins approximately 0.431″ after the leading edge of the shroud, and ends approximately 1.60″ before the trailing edge of the shroud. In the case of diamond-shaped patterns, the grid pattern will be about 0.28″ long and 0.28″ wide, with an overall thickness of about 0.46.″ The coatings thus provide the required levels of abradability and leakage performance and may be applied as a chevron or diamond pattern with the shape oriented such that the diagonals run perpendicular and parallel to the sides of the shroud.

Owner:GENERAL ELECTRIC CO

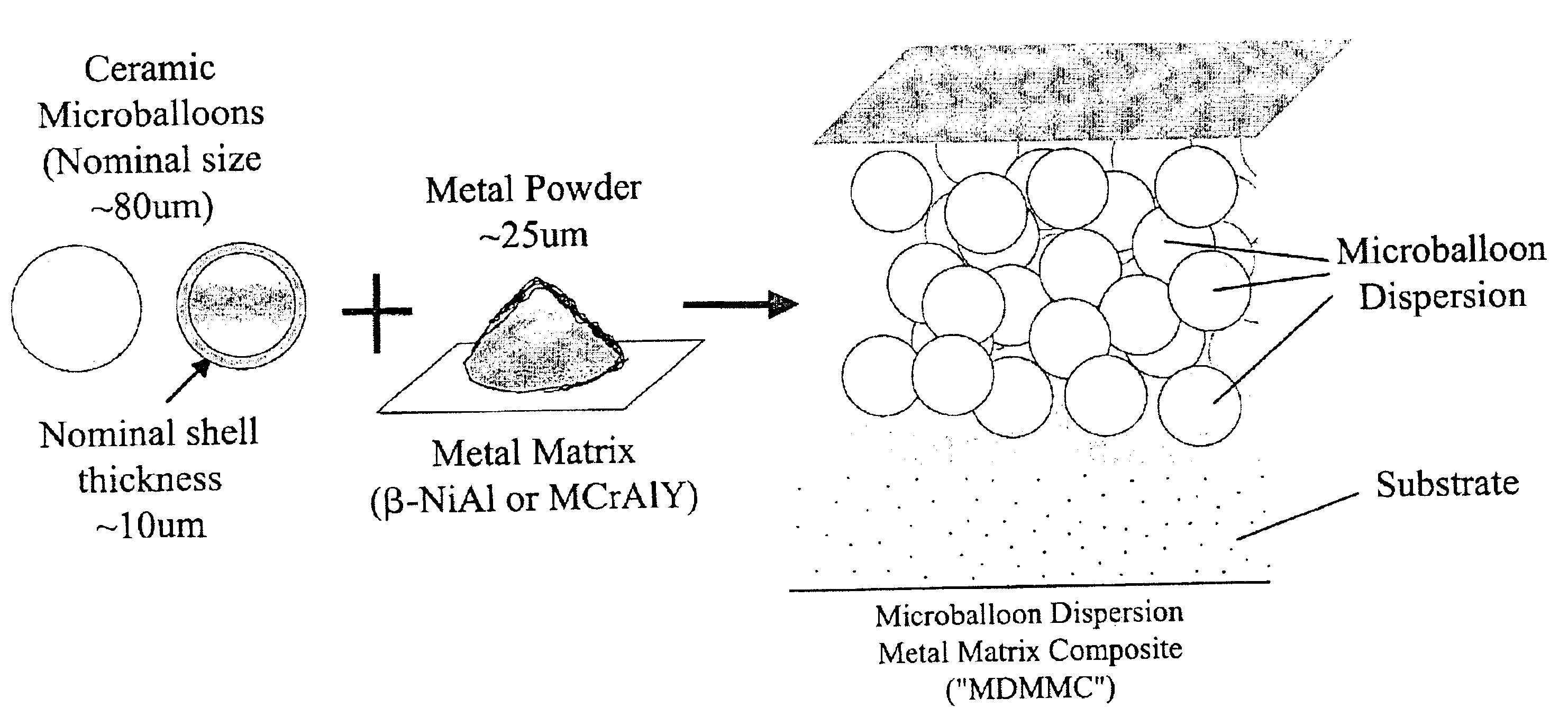

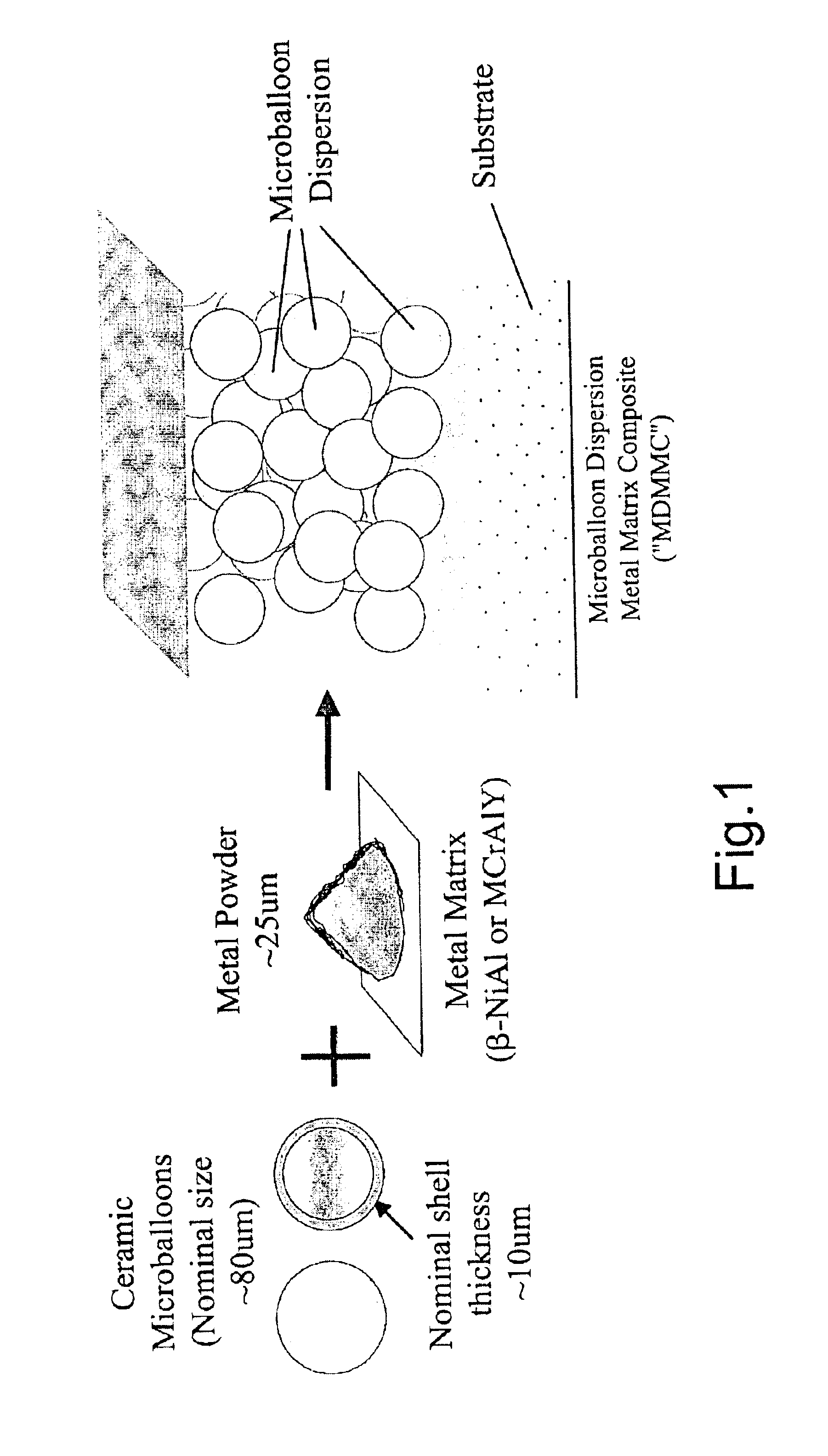

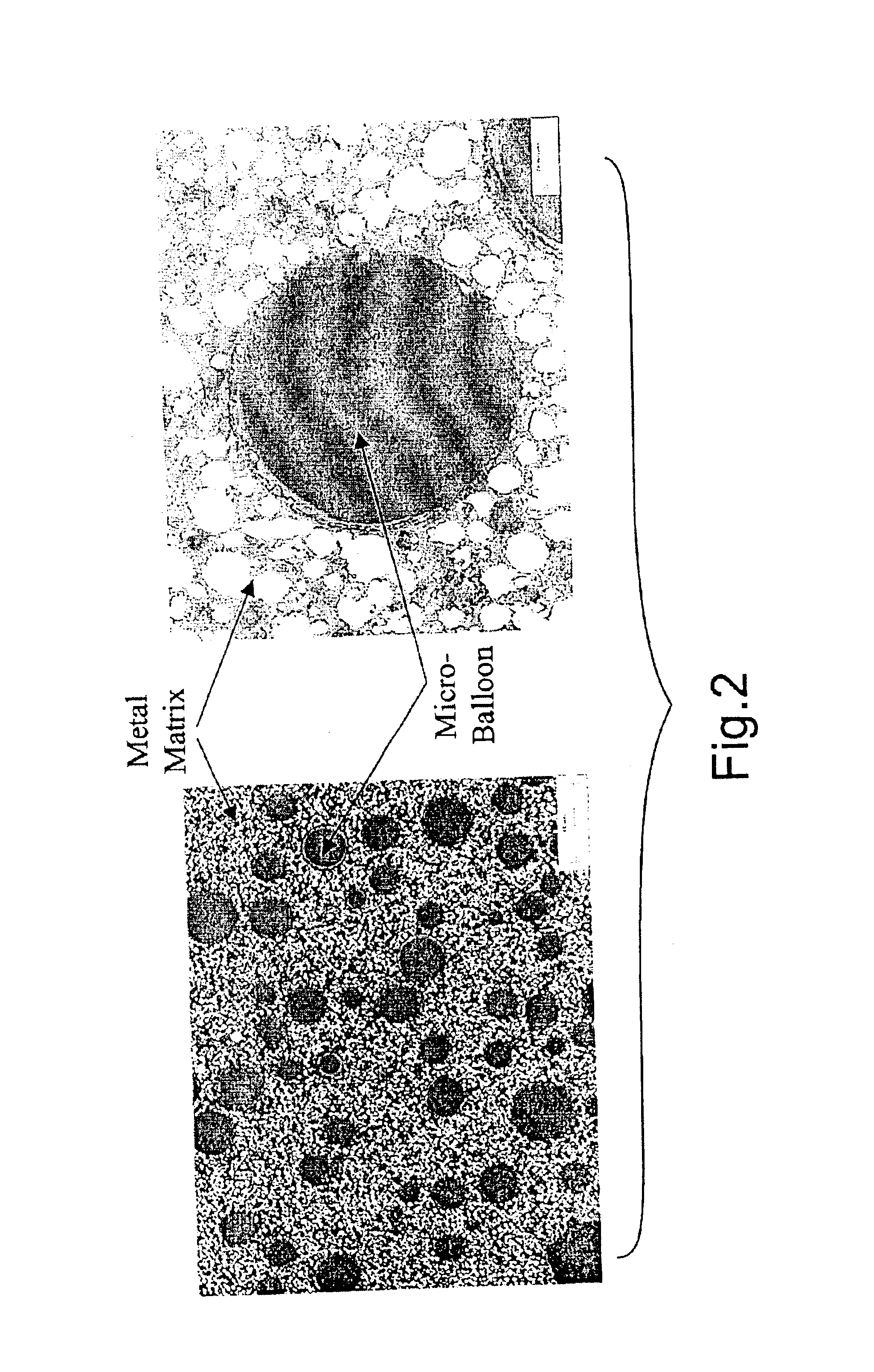

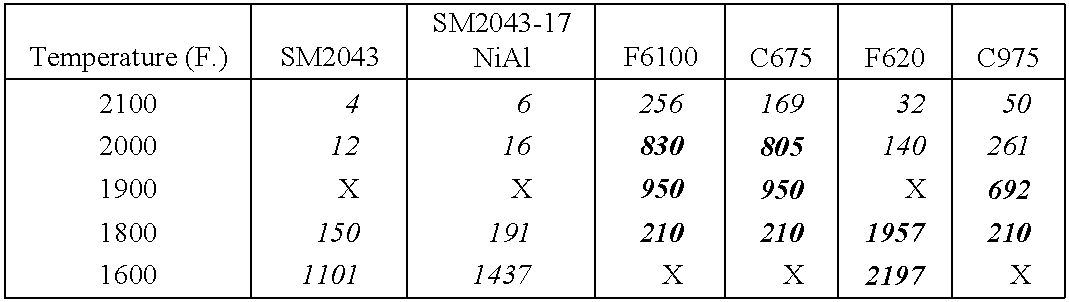

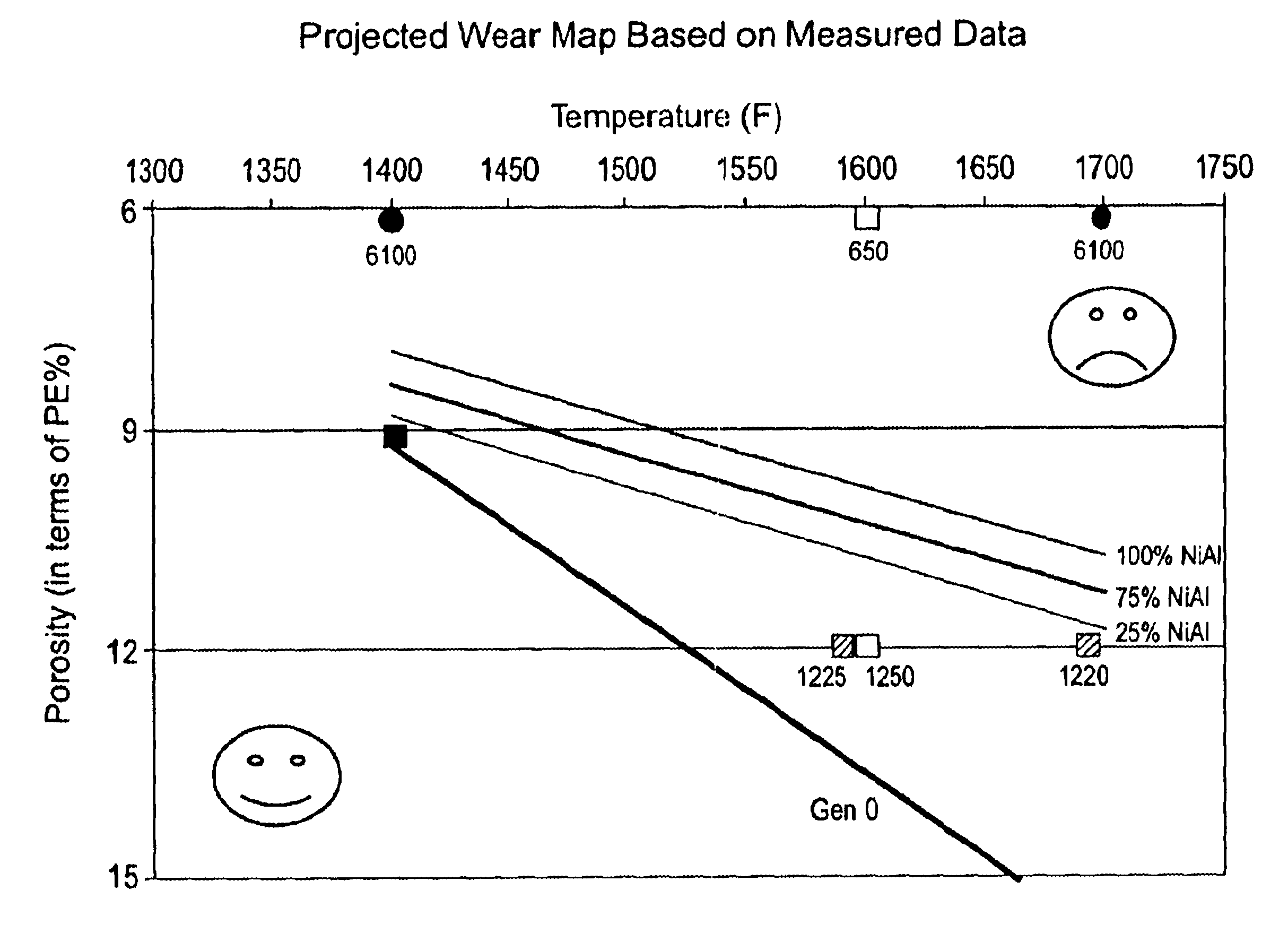

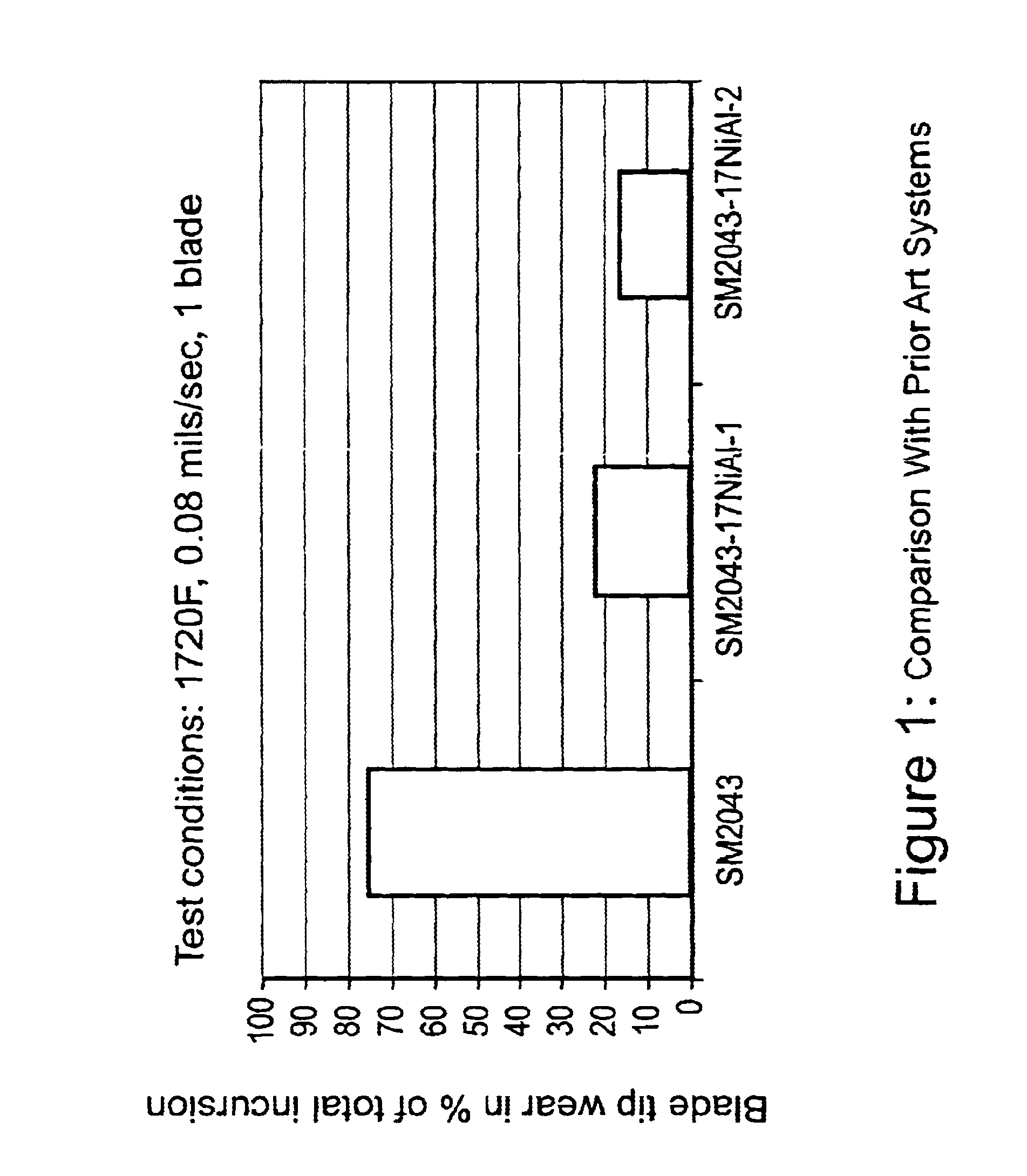

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

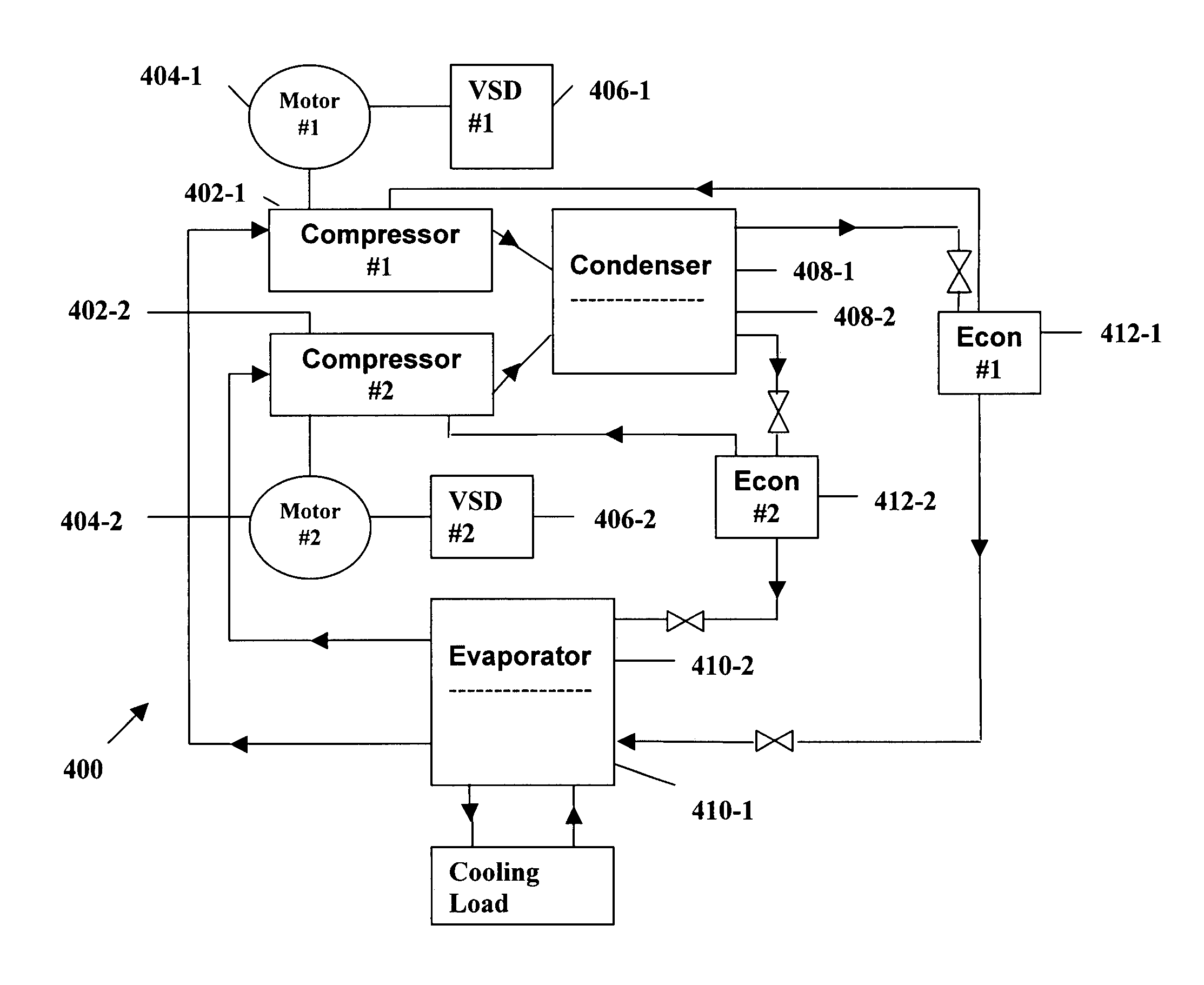

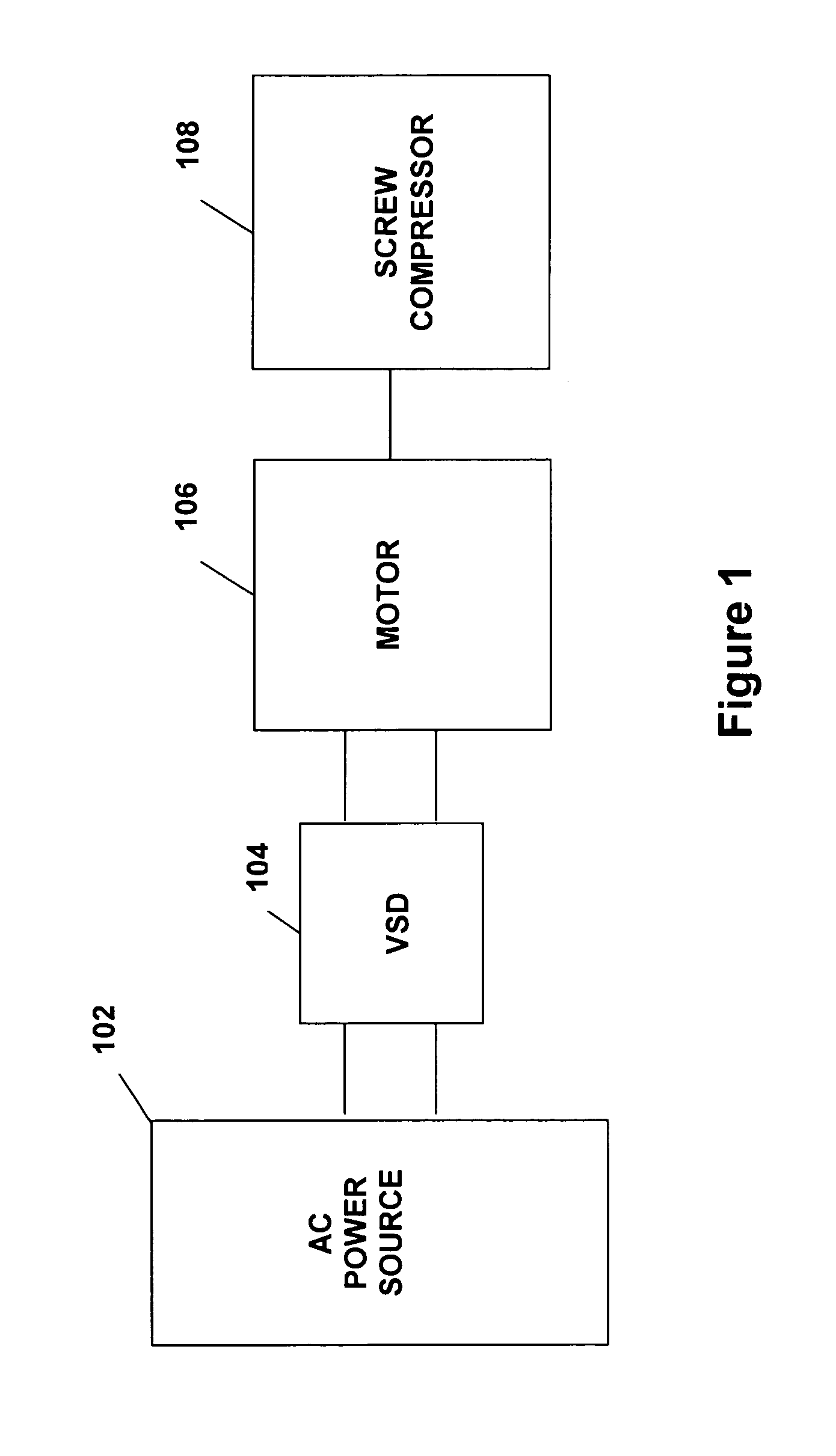

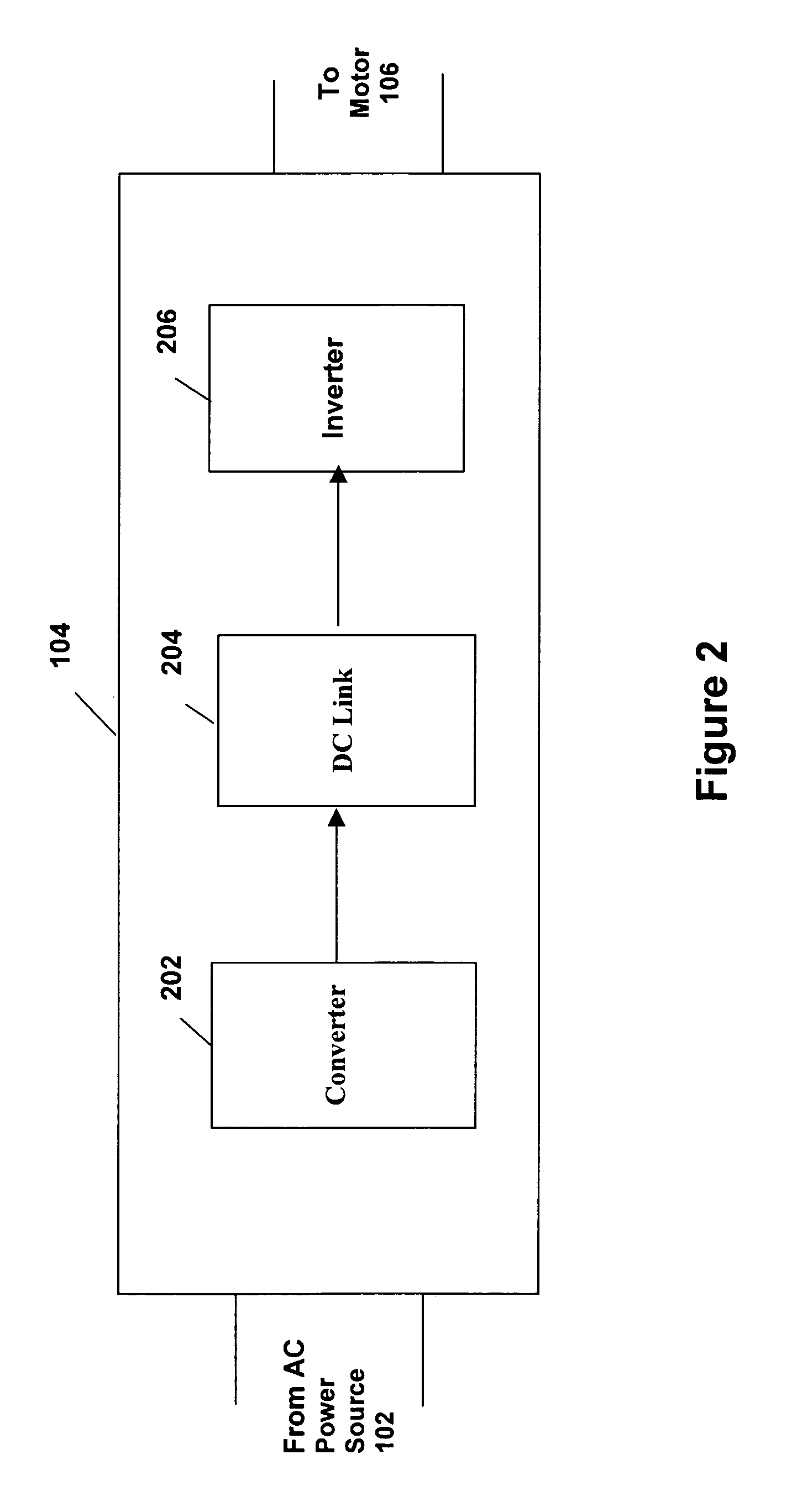

System and method for variable speed operation of a screw compressor

ActiveUS7096681B2Guaranteed uptimeIncrease rotor speedAC motor controlRotary piston pumpsInduction motorEngineering

A system and method are provided for variable speed operation of a screw compressor to obtain increased capacity and efficiency. The screw compressor is connected to an induction motor driven by a variable speed drive, wherein the screw compressor has a variable output capacity that is dependent on the output speed of the motor. To obtain increased capacity and efficiency, the screw compressor is operated at a speed greater than the screw compressor's rated speed and does not include a slide valve. The maximum operating speed of the screw compressor, which speed is greater than the rated speed, is related to the maximum operating speed of the motor when operated at a voltage and frequency provided by the variable speed drive that is greater than the motor's rated voltage and frequency in a constant flux or constant volts / Hz mode.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

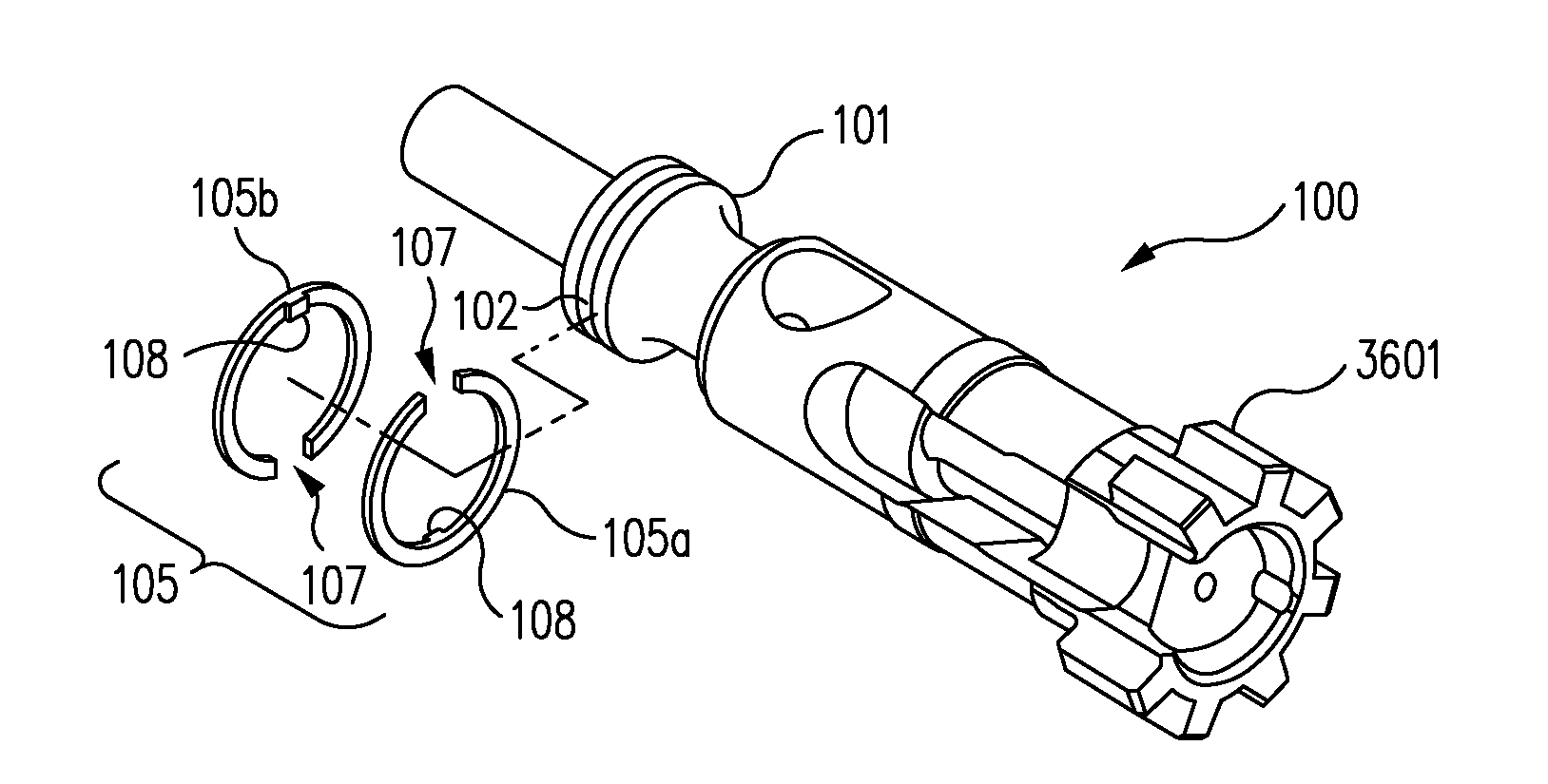

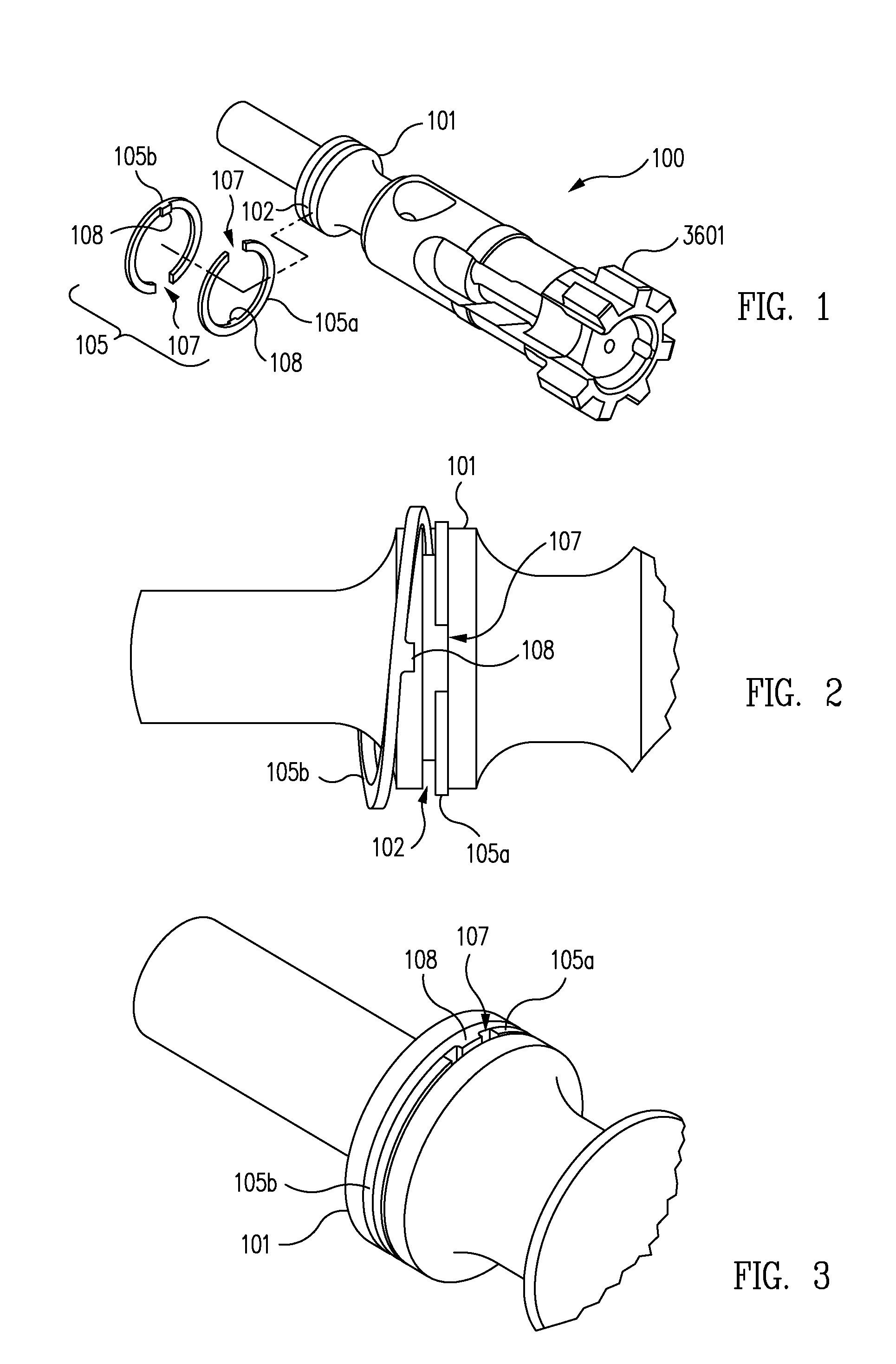

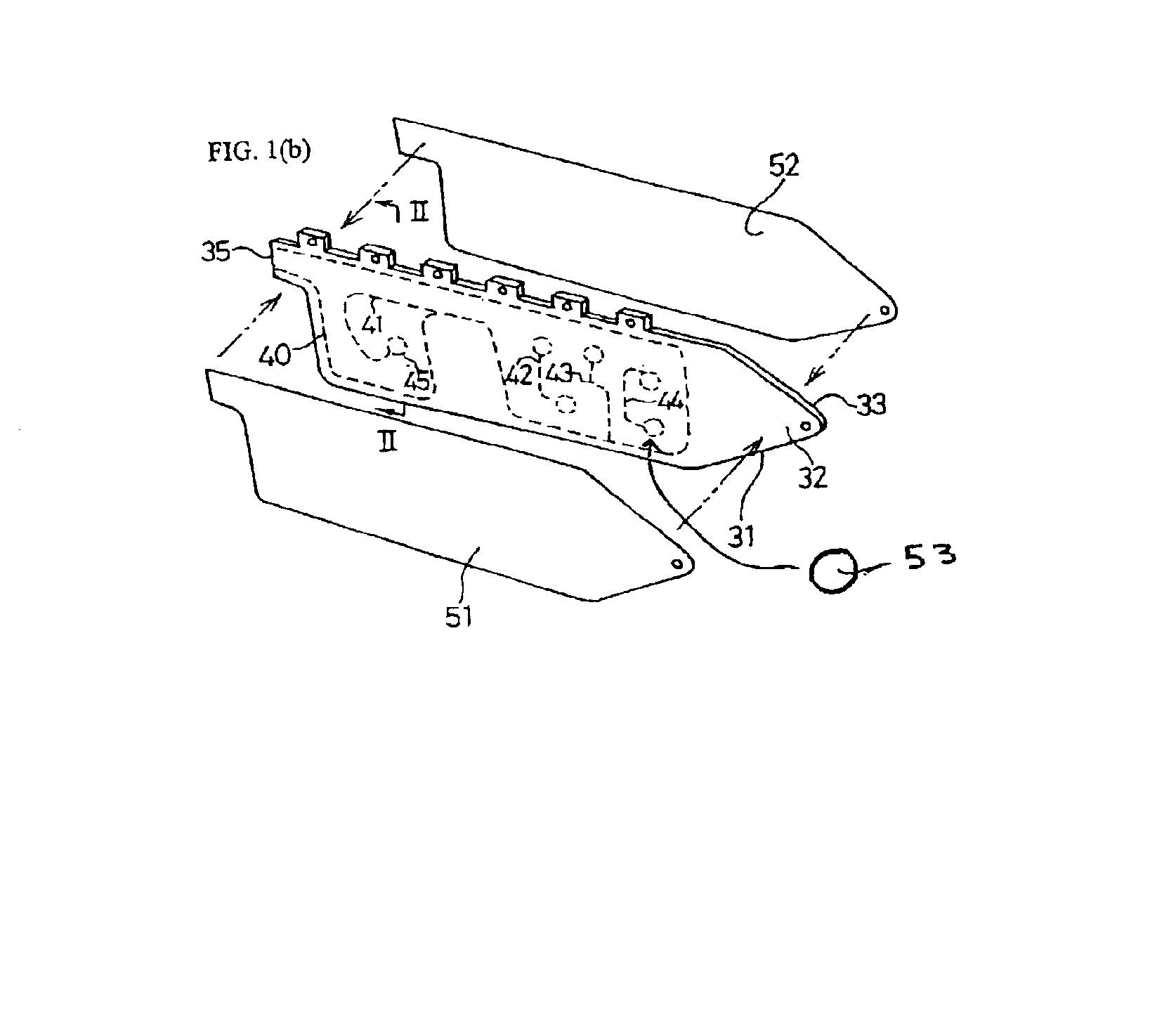

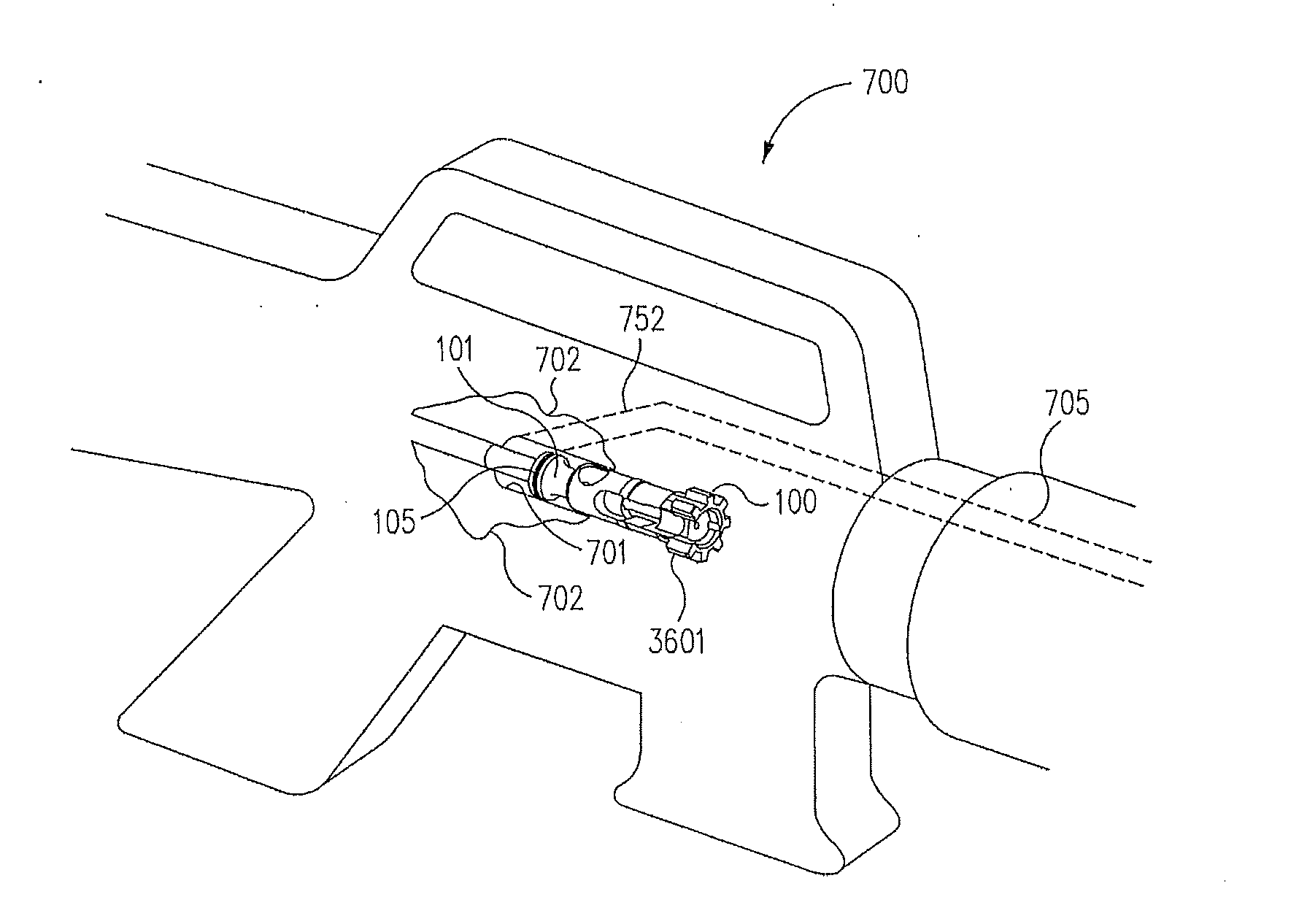

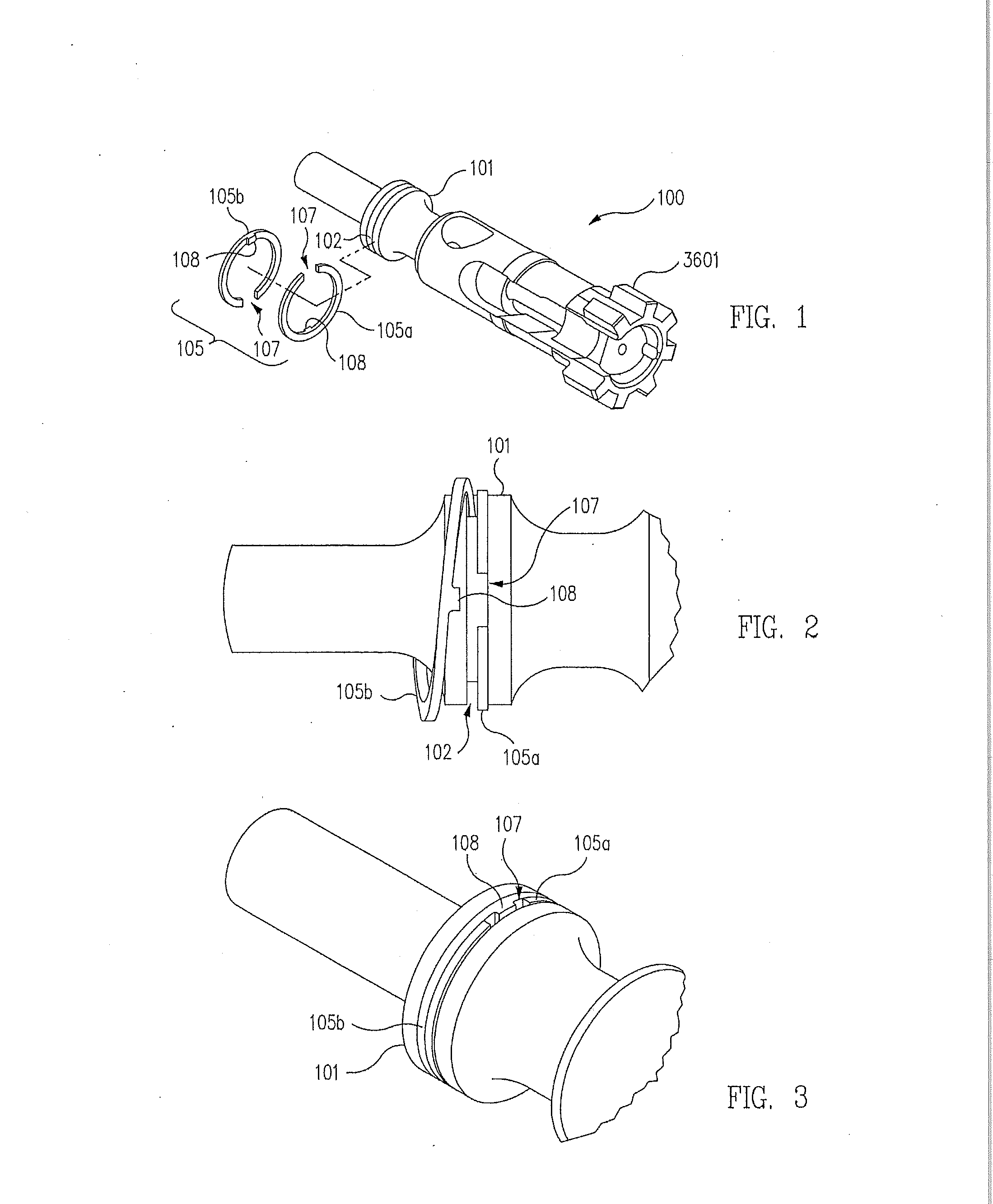

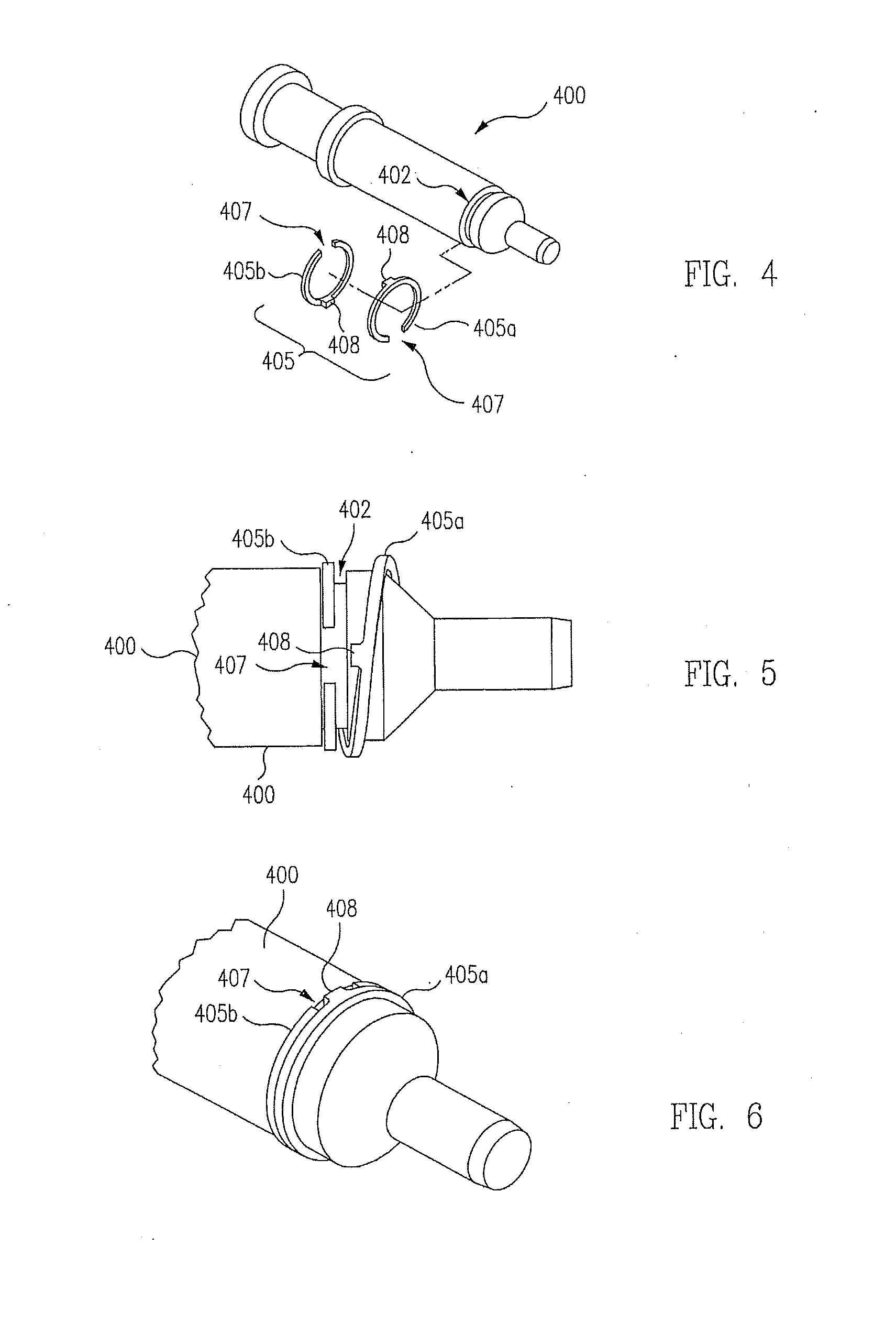

Firearm

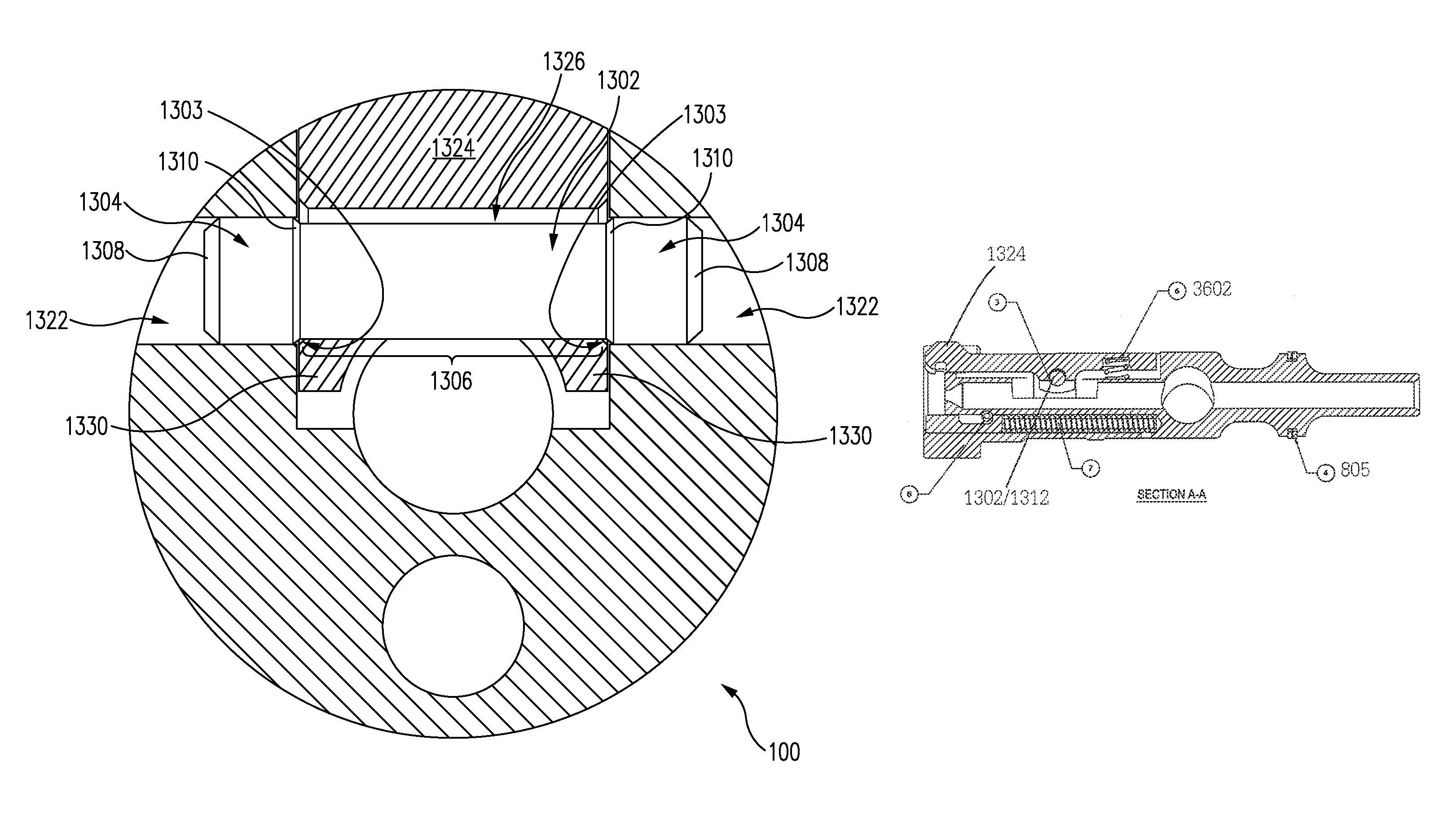

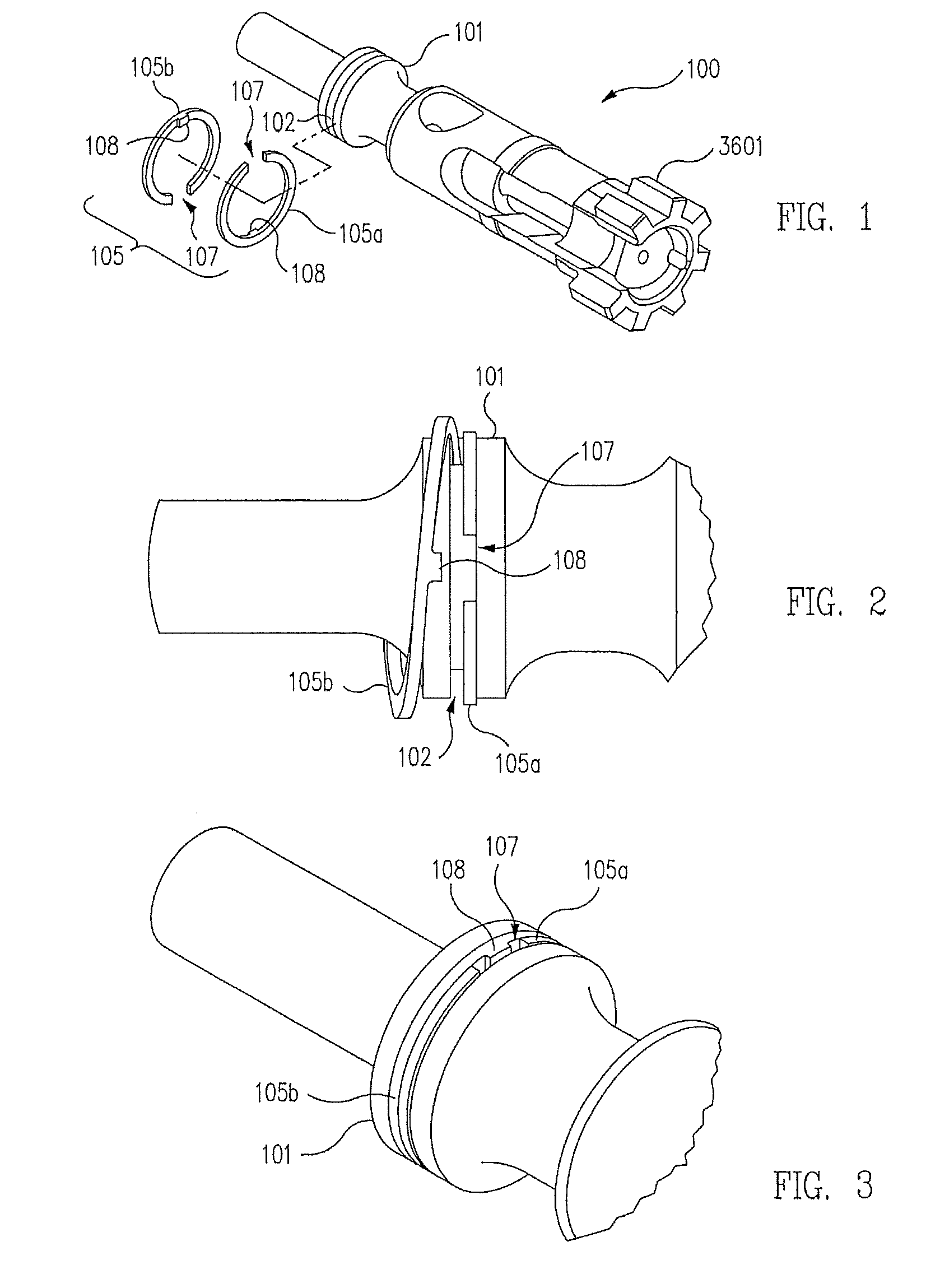

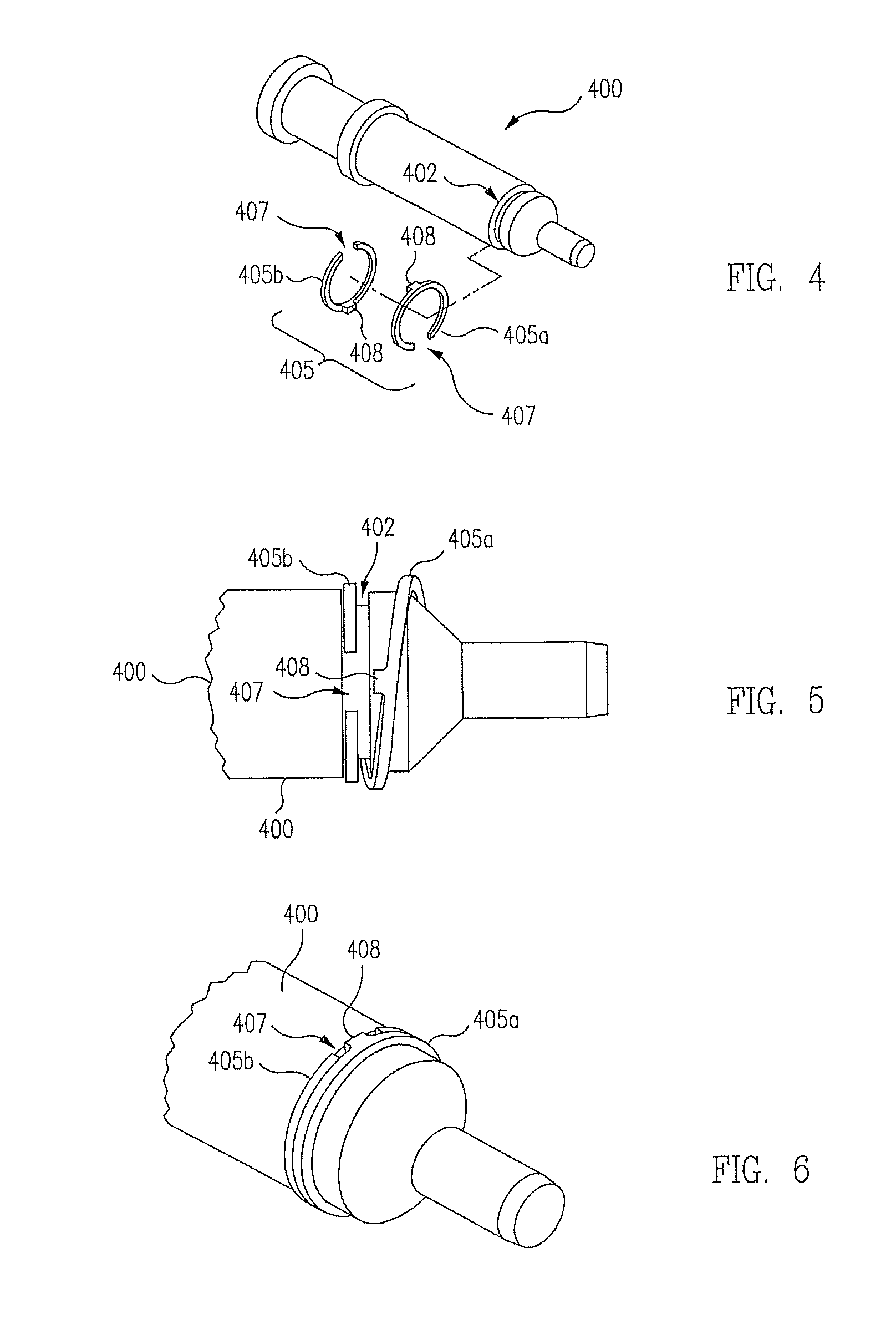

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is at least approximately 1.3 times that of a standard M16 / M4. A piston can be formed on the bolt and can have a plurality of rings that are configured to cooperate with the piston to mitigate gas leakage past the piston. Each of the rings can have a key formed thereon and a gap formed therein such that the gap of one ring is configured to receive at least a portion of the key of another ring. The bolt carrier can have a double cut cam.

Owner:ARMWEST

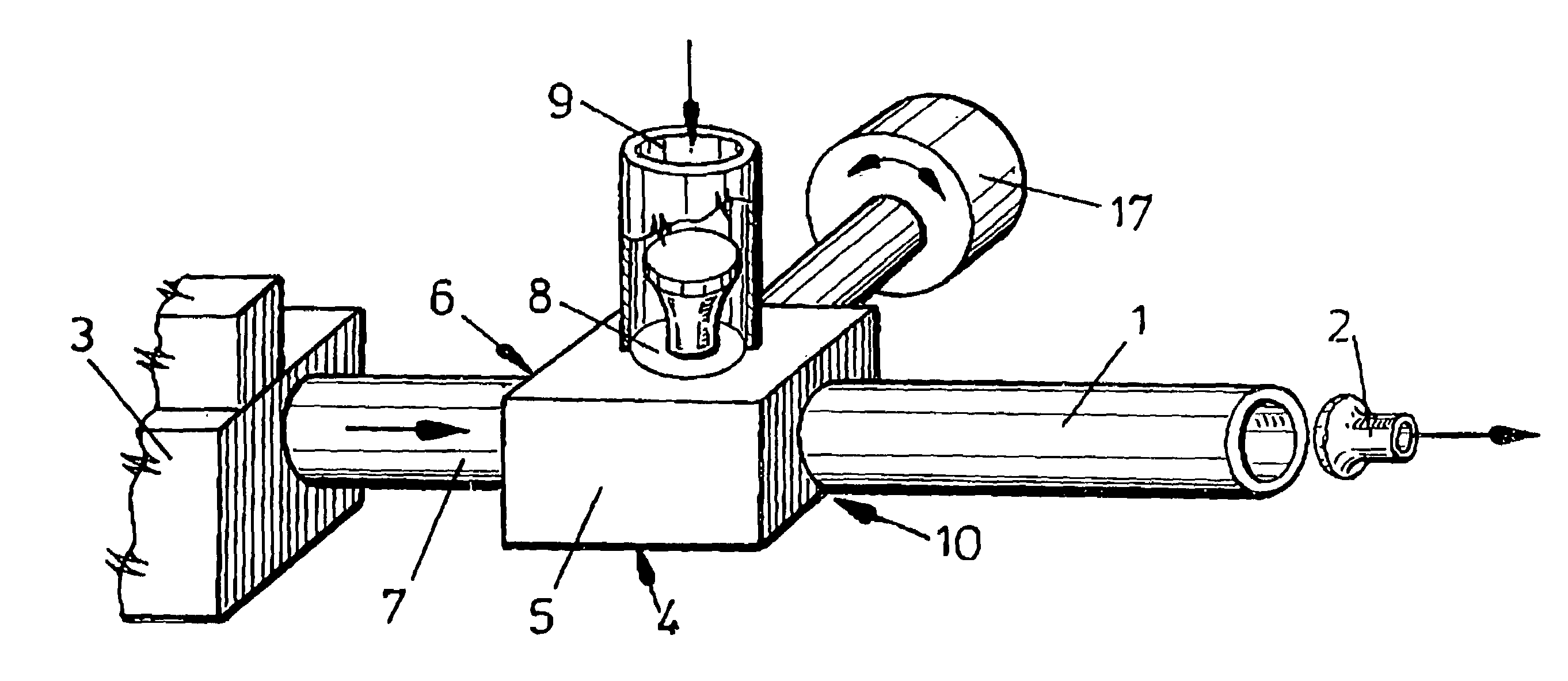

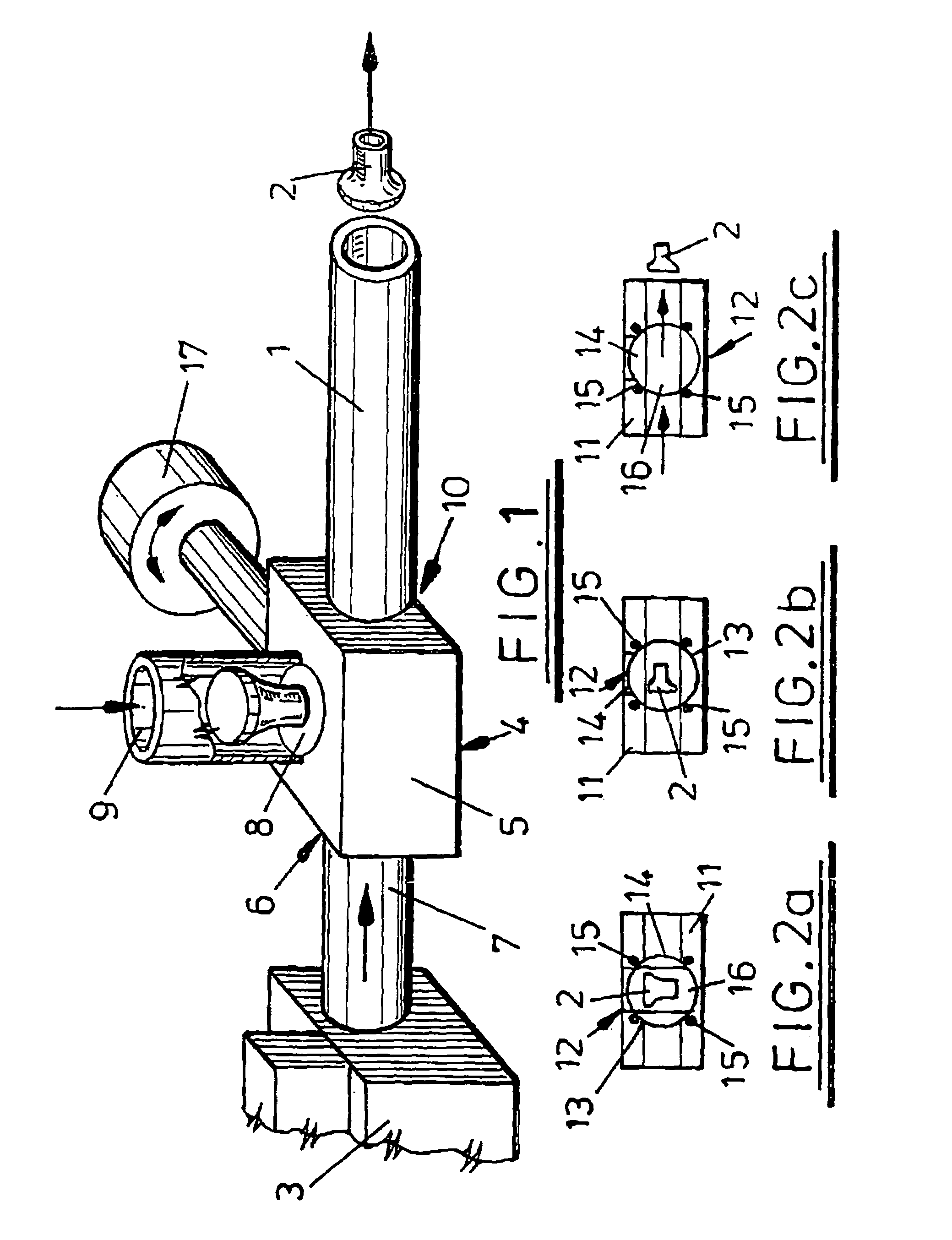

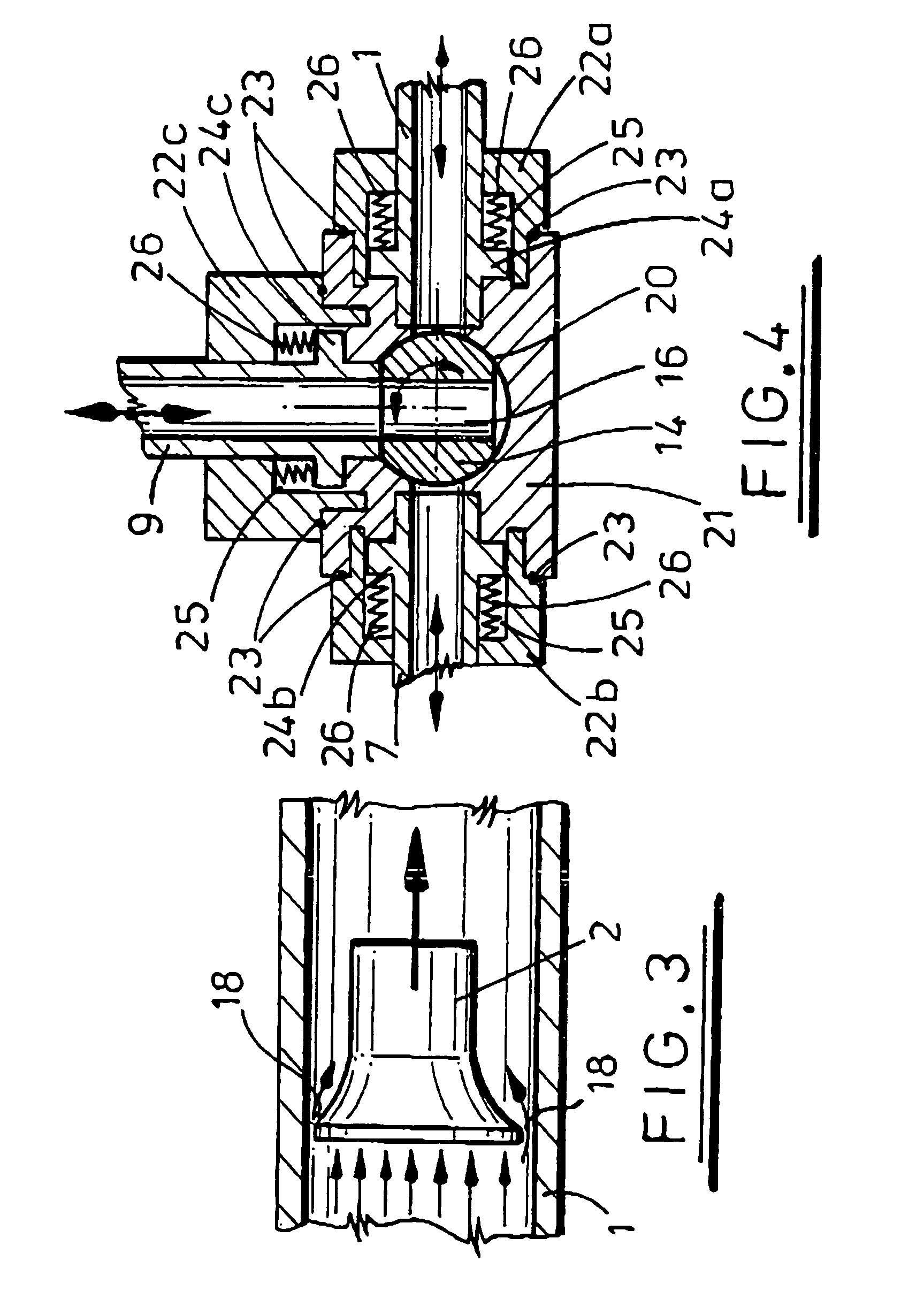

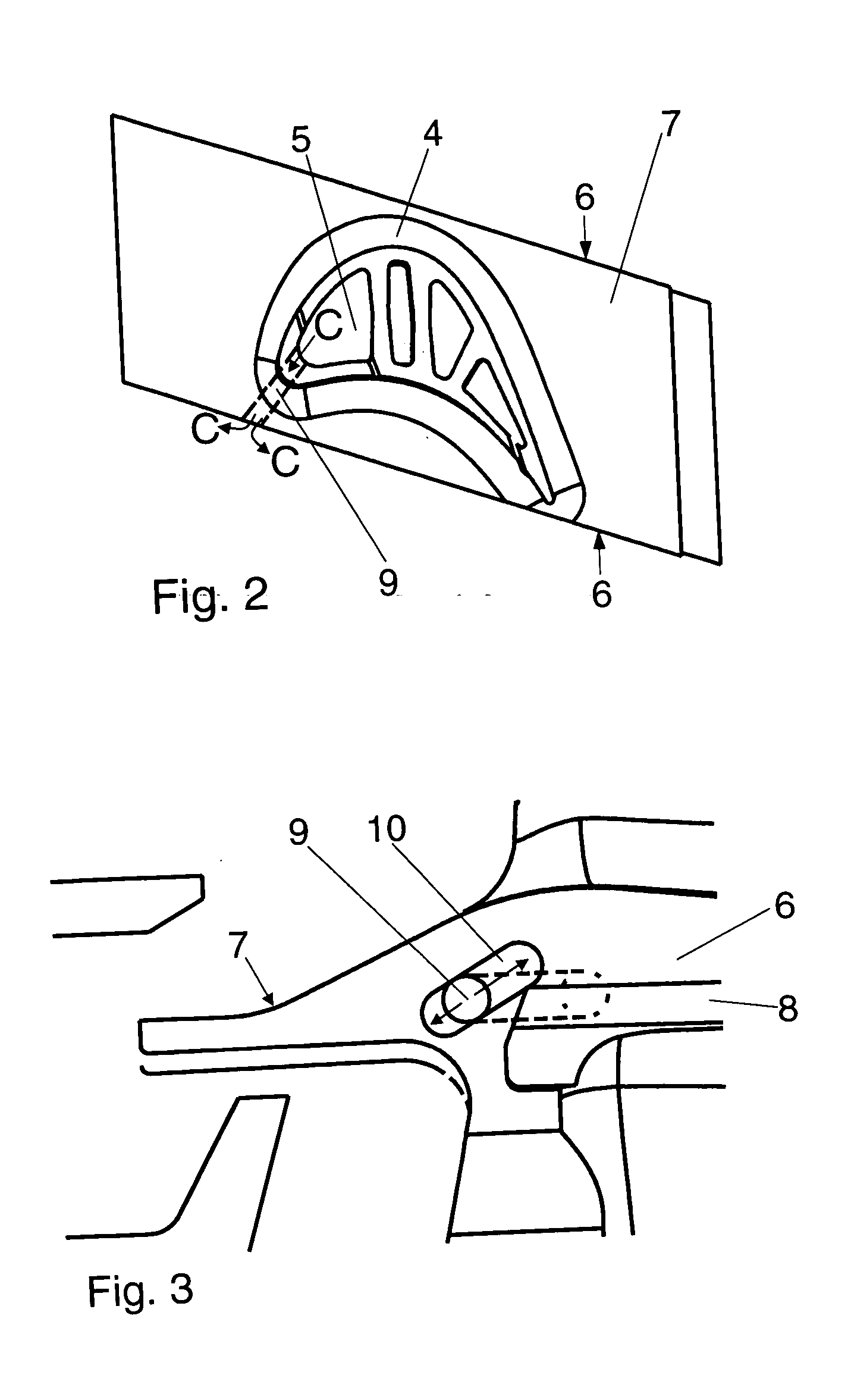

Fastener delivery apparatus

InactiveUS6951298B1Reduce frictionReduce the power requiredStapling toolsMetal working apparatusEngineeringRivet

A fastener delivery tube (1) is connected between a supply of fasteners, such as rivets (2), and the nose of a fastener setting machine. The delivery tube (1) is connected to an outlet tube (7) of a source of compressed air (3), the outlet tube (7) having an internal bore substantially equal in size to the internal bore of the delivery tube (1). The supply of fasteners is connected to the delivery tube via a feeder tube (9) and transfer gate (4). The transfer gate (4) is sealed so as to prevent leakage of air from the delivery tube (1). The arrangement reduces turbulence in the delivery tube (1) ensures that friction between the fastener (2) and the tube (1) is reduced and permits compressed air to be supplied at significantly lower pressure than has heretofore been possible.

Owner:ATLAS COPCO IAS UK LIMITED +1

High temperature abradable coating for turbine shrouds without bucket tipping

InactiveUS6660405B2Reduce gas leakageImprove turbine efficiencyLiquid surface applicatorsMolten spray coatingPolyesterPorous coating

An abradable coating composition for use on shrouds in gas turbine engines (or other hot gas path metal components exposed to high temperatures) containing an initial porous coating phase created by adding a "fugitive polymer" (such as polyester or polyimide) to the base metal alloy, together with a brittle intermetallic phase such as .beta.-NiAl that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability of the coating at elevated temperatures, and to improve the oxidation resistance of the coating at elevated temperatures. Coatings having about 12 wt % polyester has been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides the best performance for turbine shrouds exposed to gas temperatures between 1380.degree. F. and 1850.degree. F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment.

Owner:GENERAL ELECTRIC CO

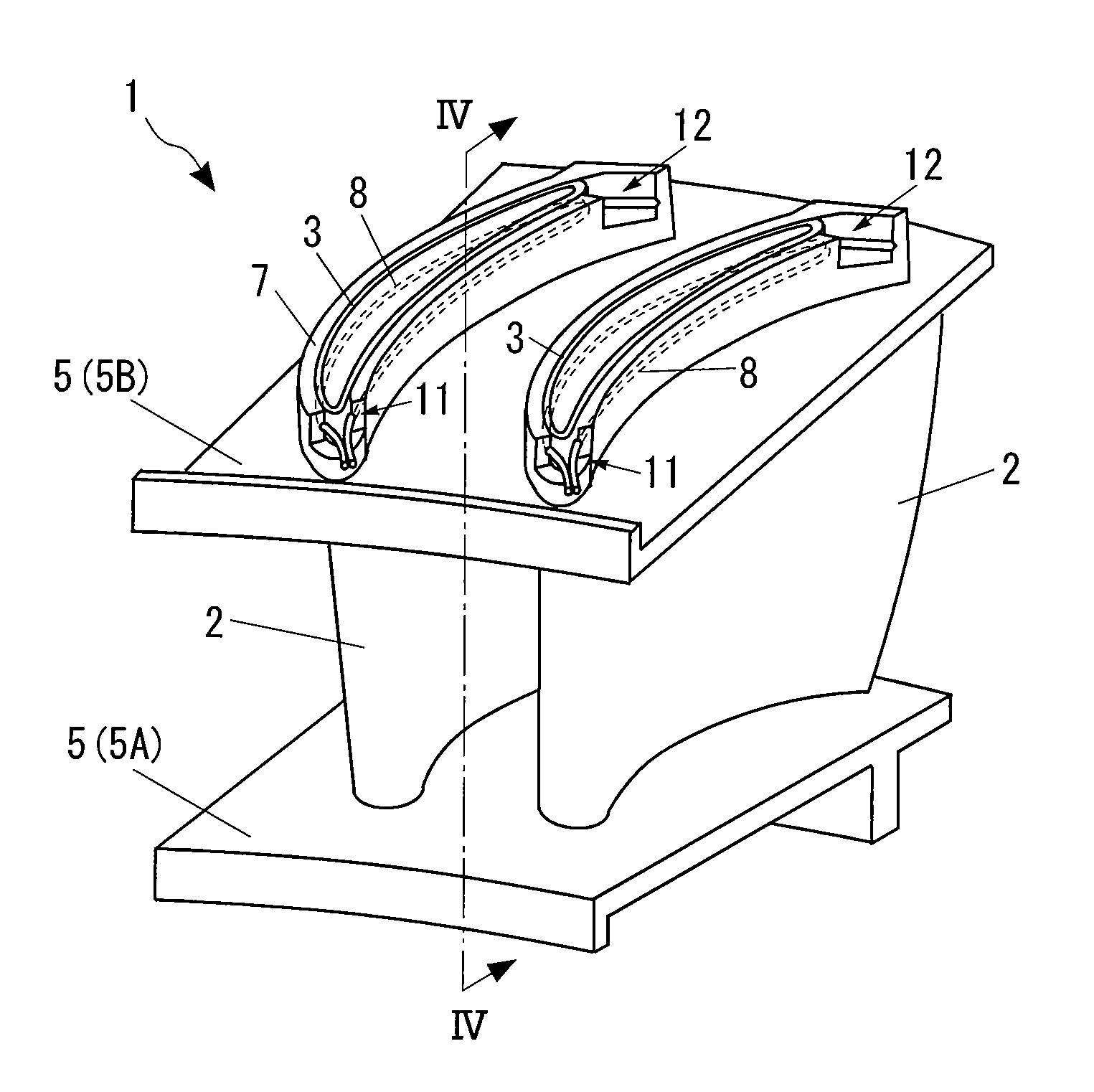

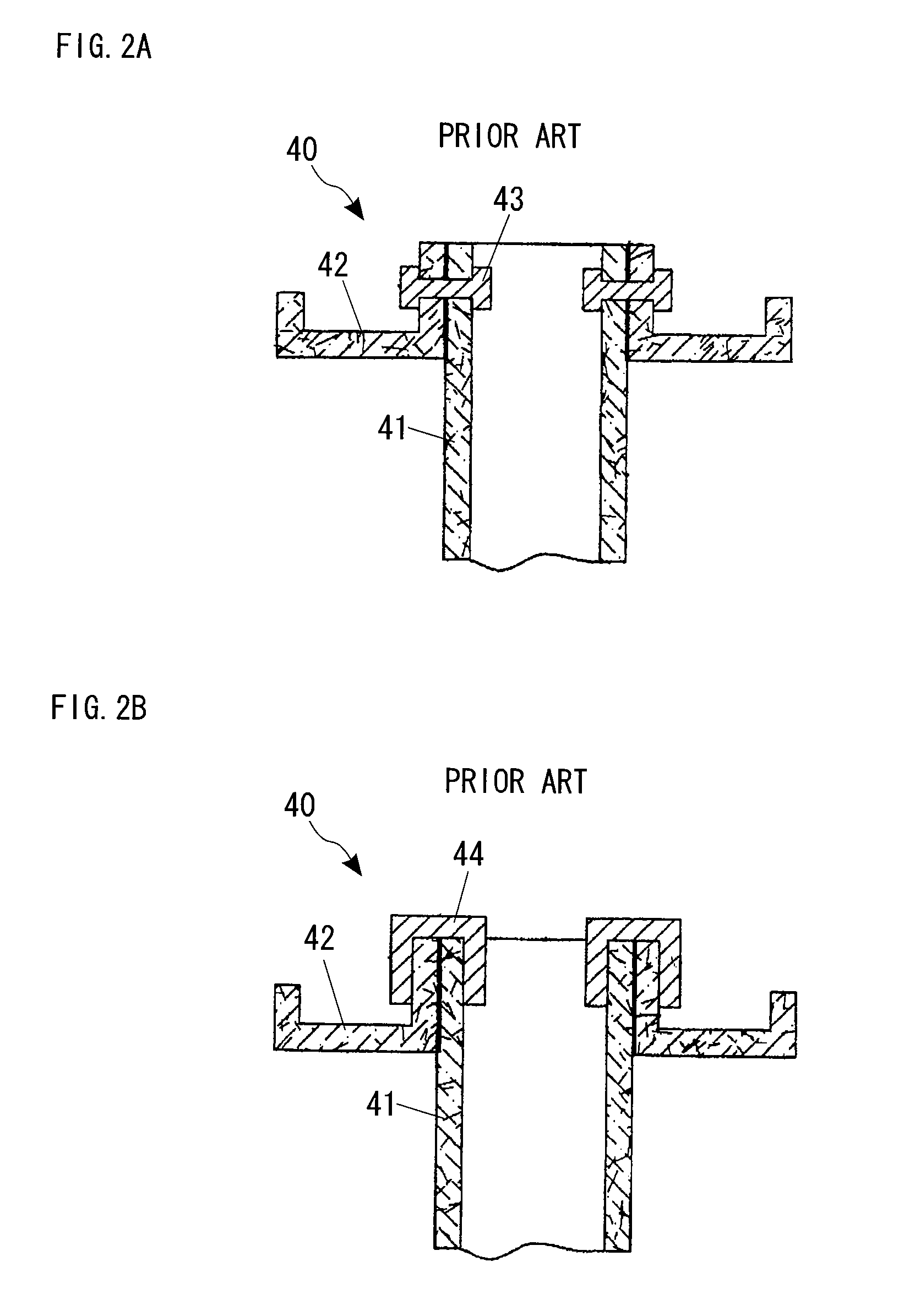

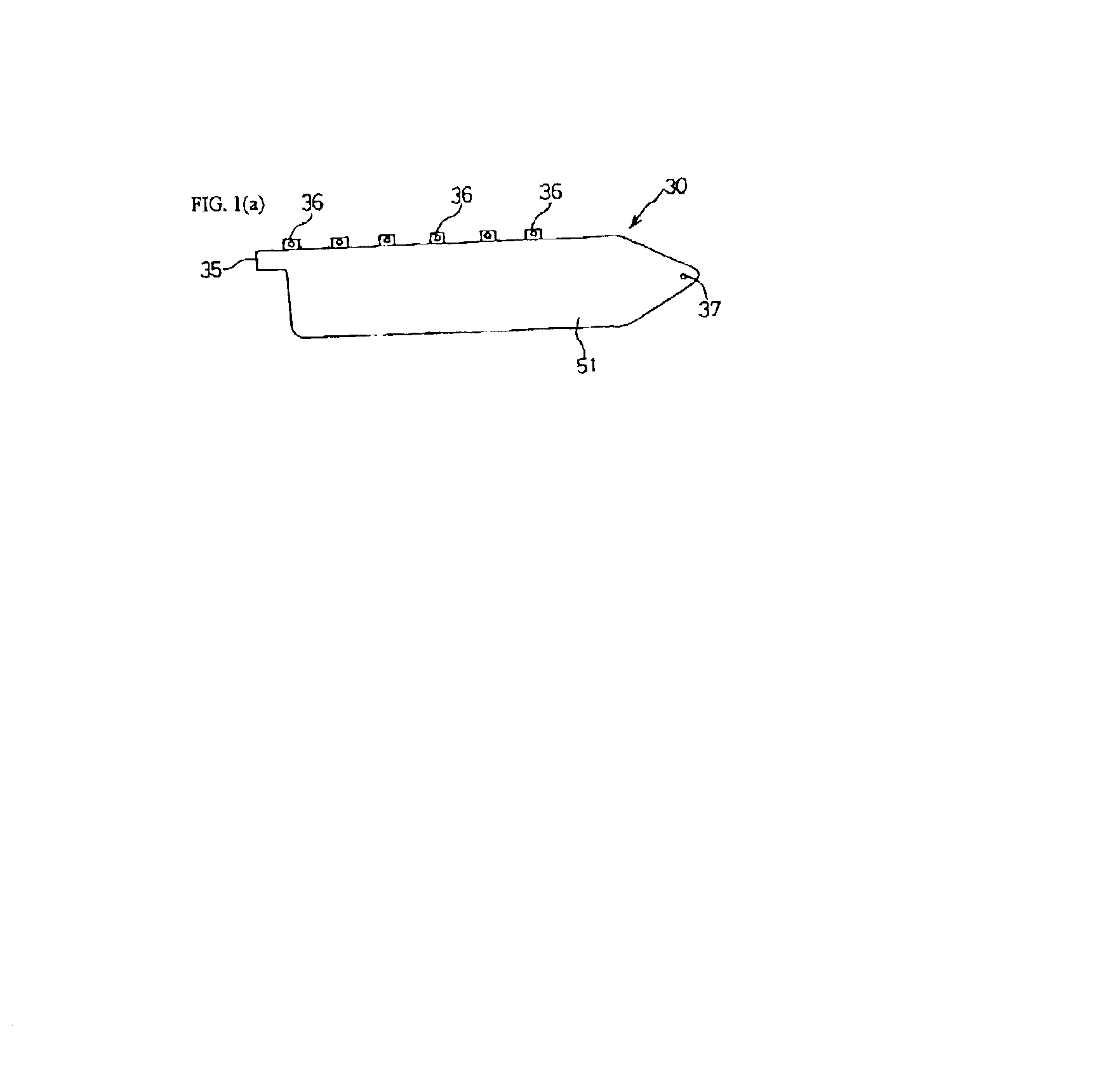

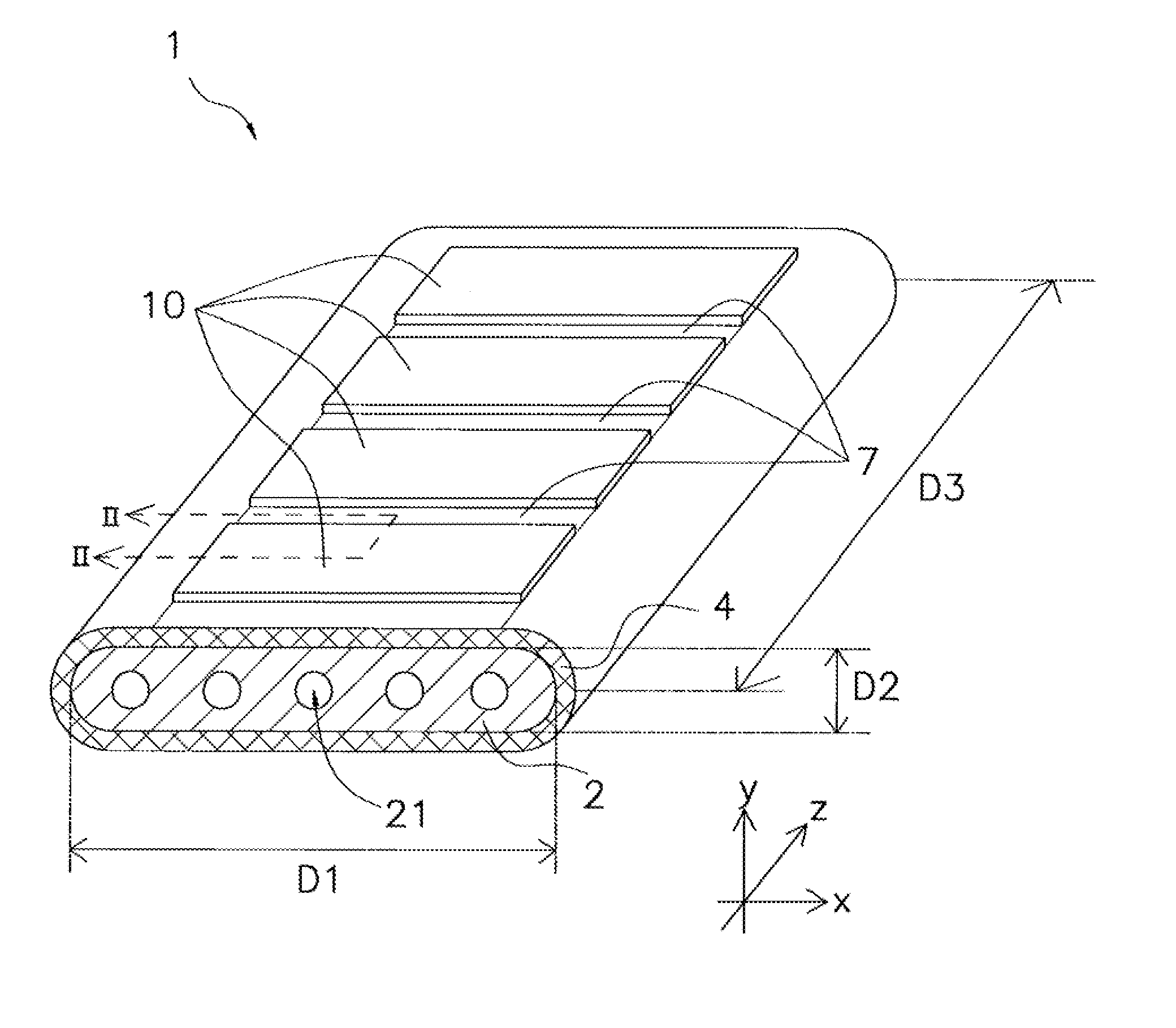

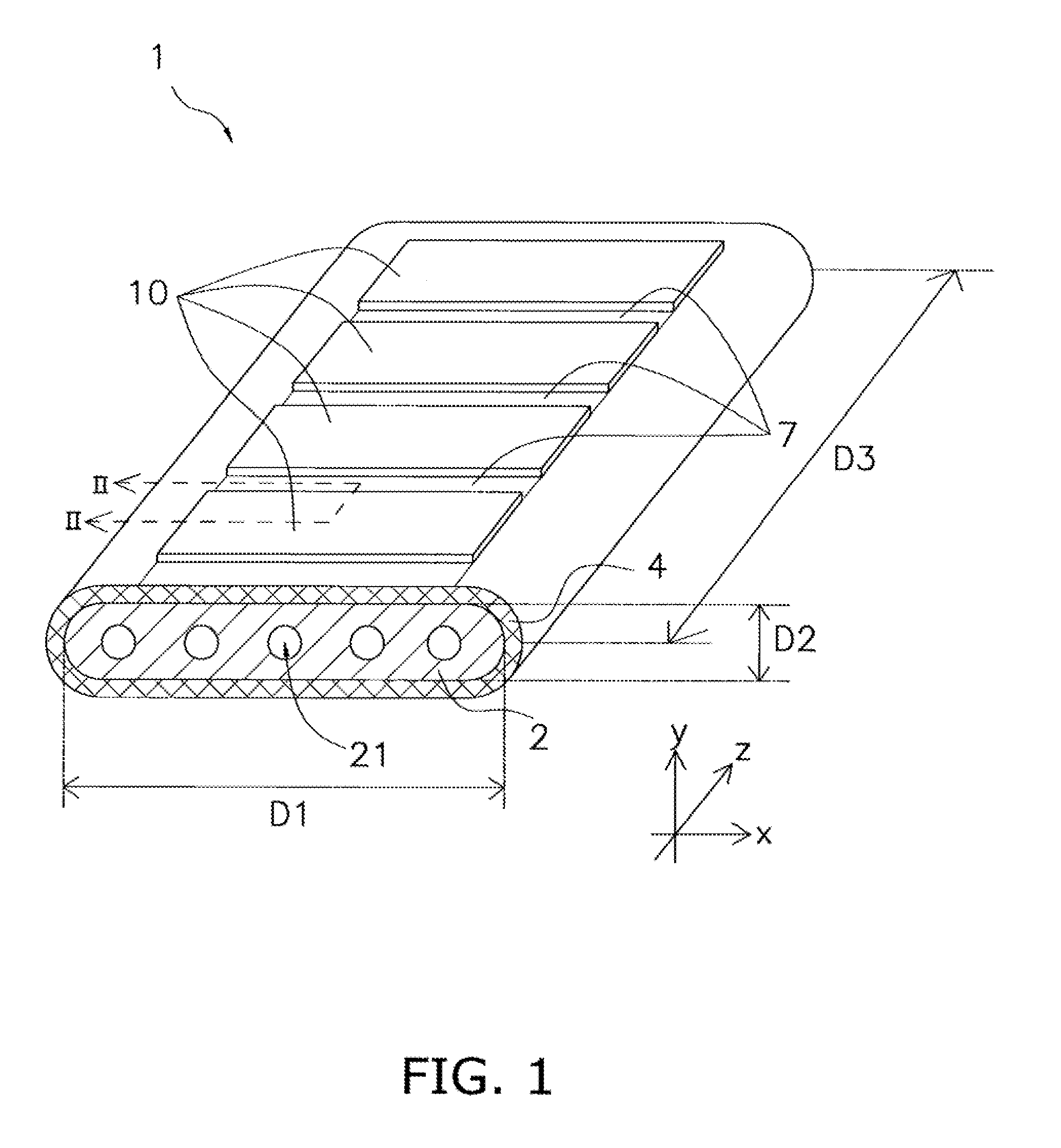

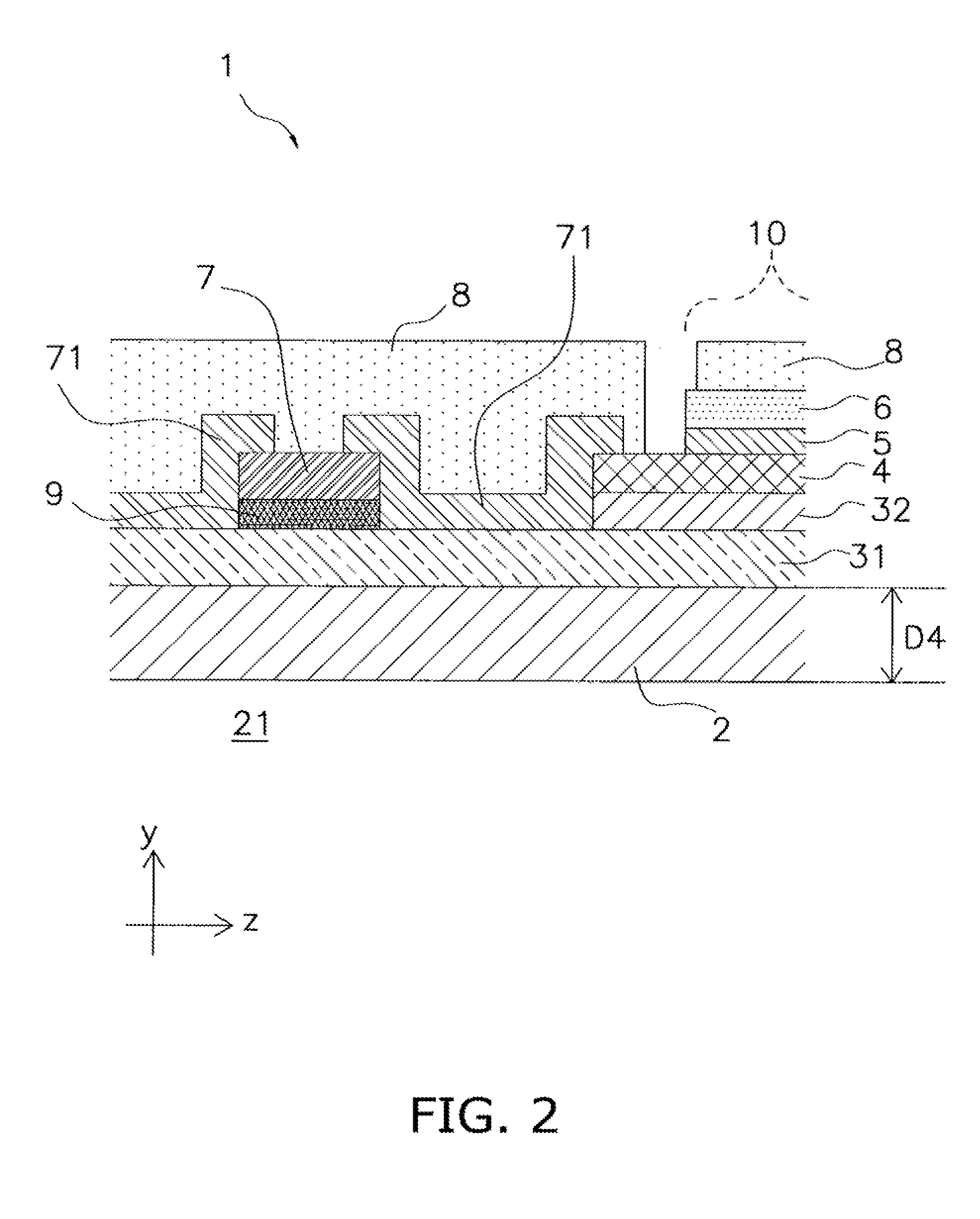

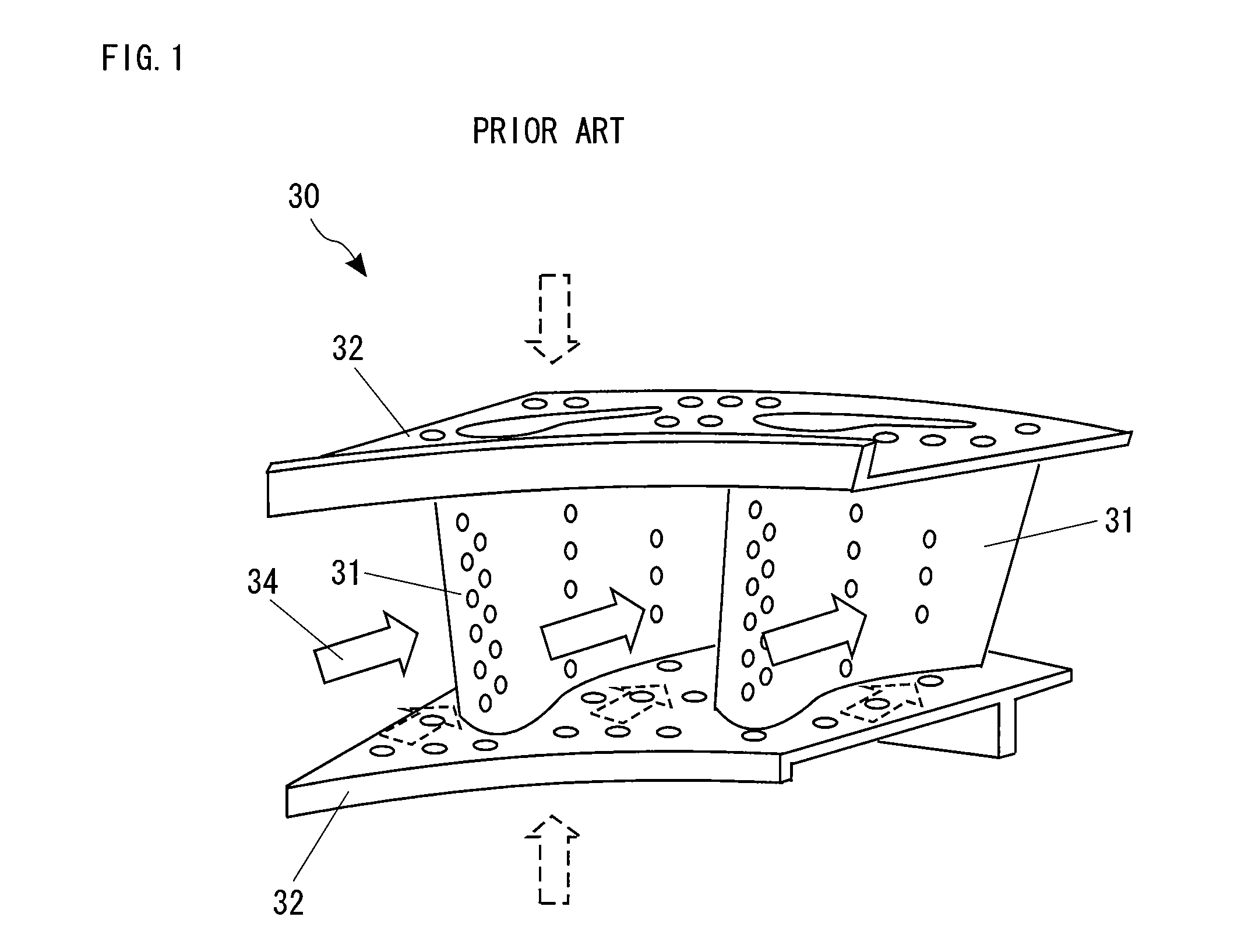

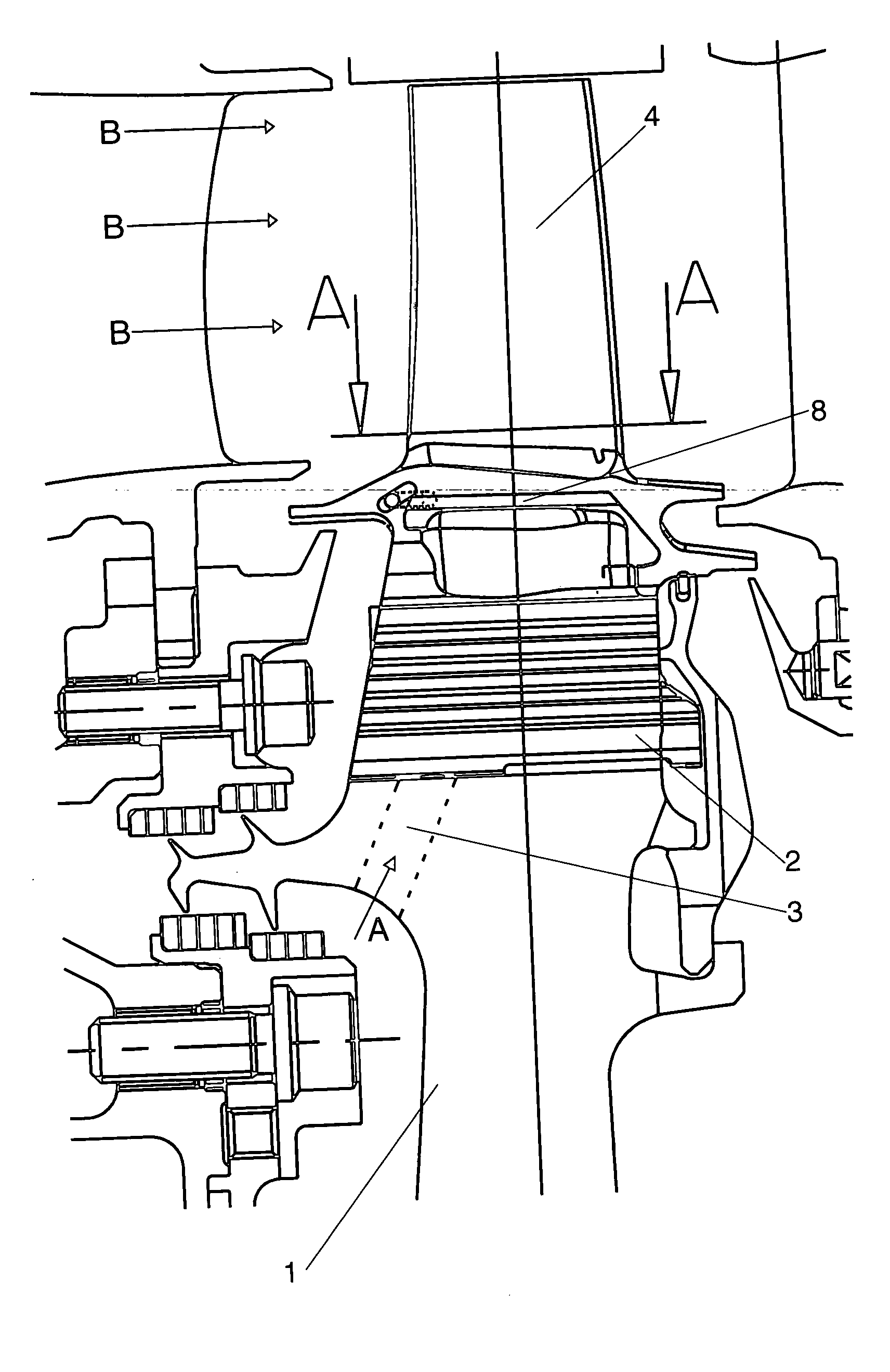

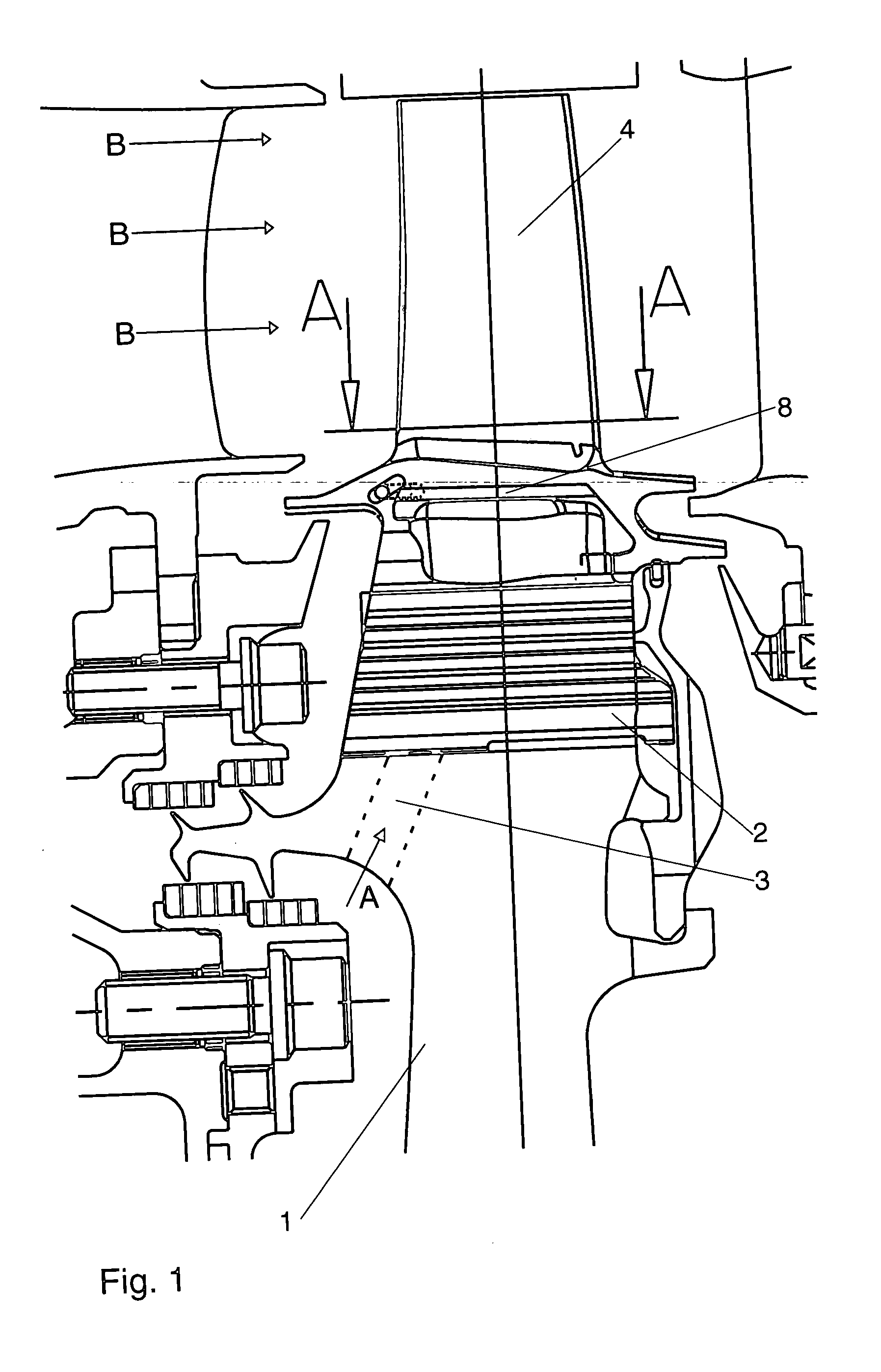

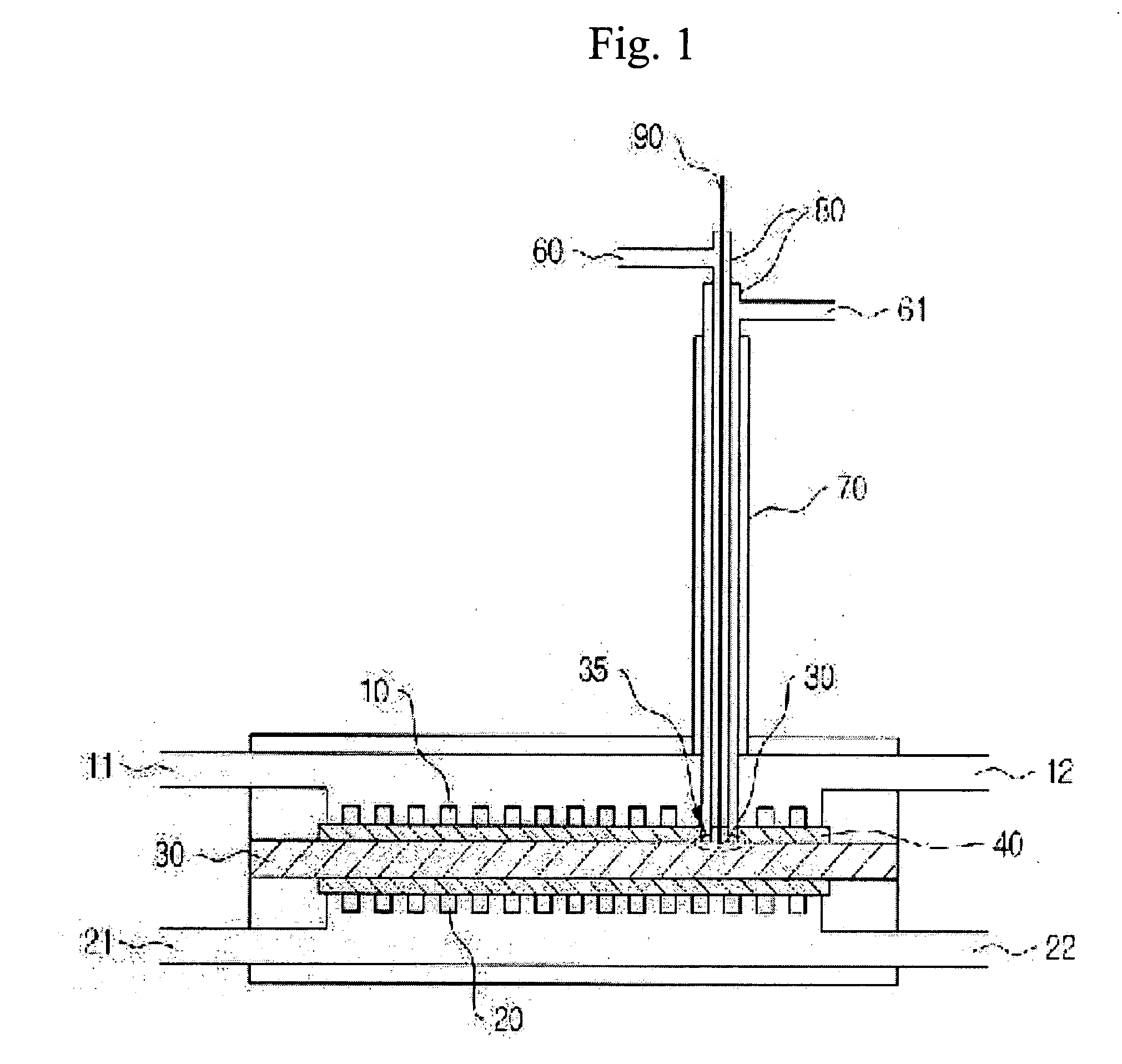

CMC turbine stator blade

ActiveUS8926262B2Reduce stress concentrationReduce gas leakagePropellersReaction enginesMetallic materialsEngineering

A CMC turbine stator blade 1 includes a blade 2 of a ceramic matrix composite material formed or a metallic material, and a band 5 formed of a ceramic matrix composite material and supporting the blade 2. The blade 2 includes a first fitting portion 3 to which the band 5 is fitted outside. The band 5 includes a second fitting portion 7 to which the first fitting portion 3 is fitted inside. A flexible wire 8 is disposed between the fitting portions 3, 7 to fix the blade 2 and the band 5. A first groove 3a in the outer peripheral surface of the first fitting portion 3 extends in the front-to-rear direction of the blade 2. A second groove 7a in the inner peripheral surface of the second fitting portion 7a extends along the first groove 3a. The wire 8 is disposed between the grooves 3a,7a.

Owner:IHI CORP

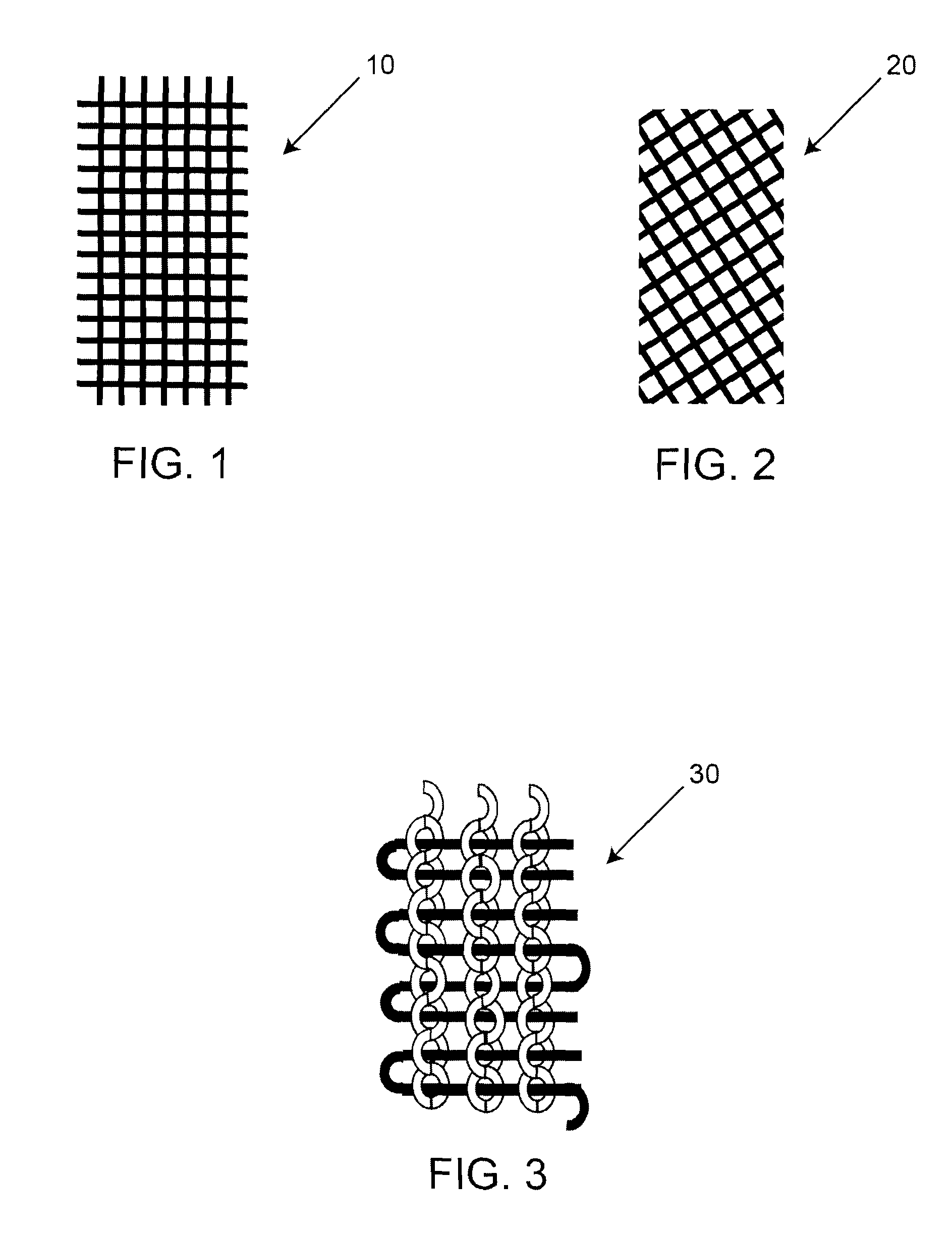

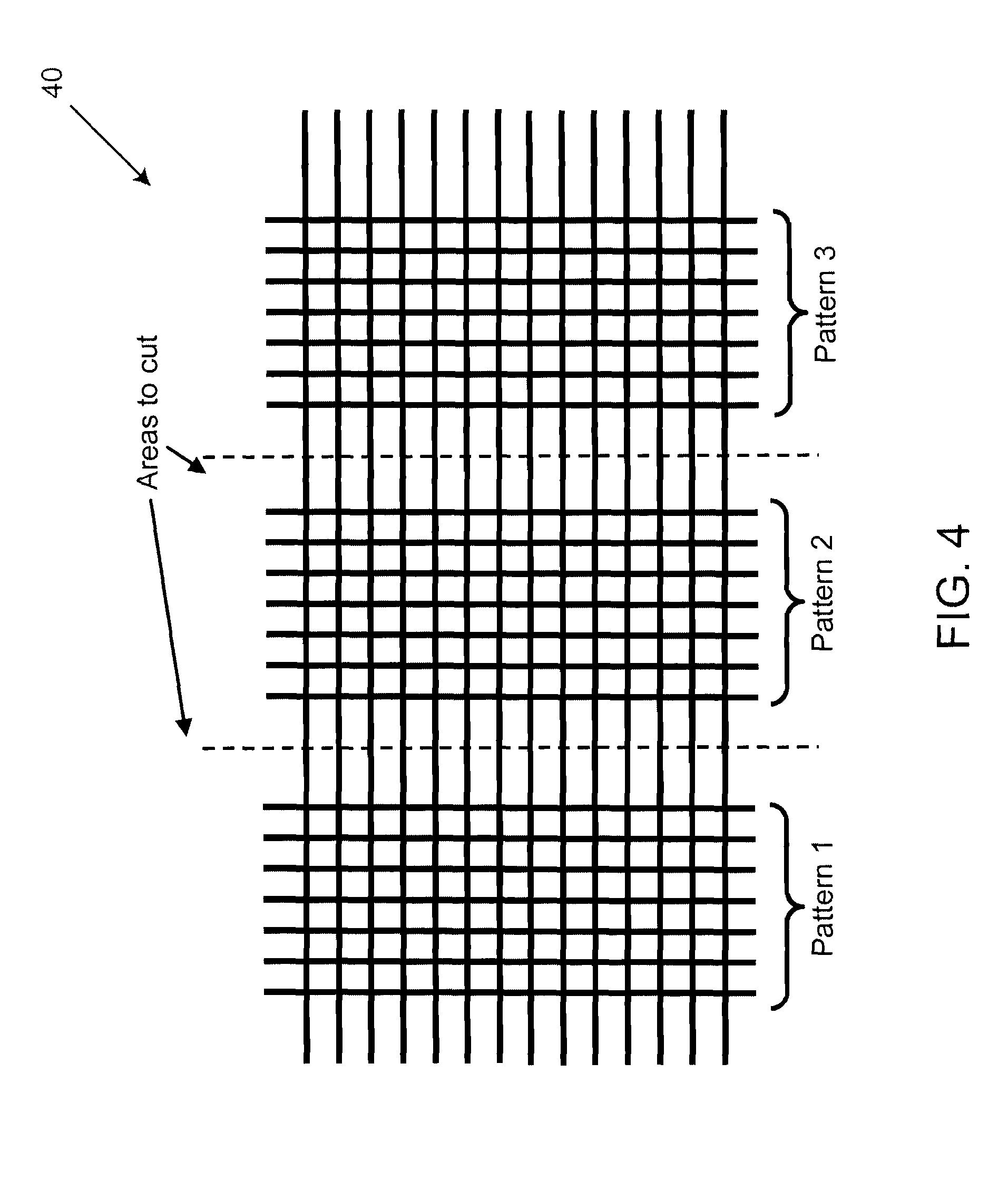

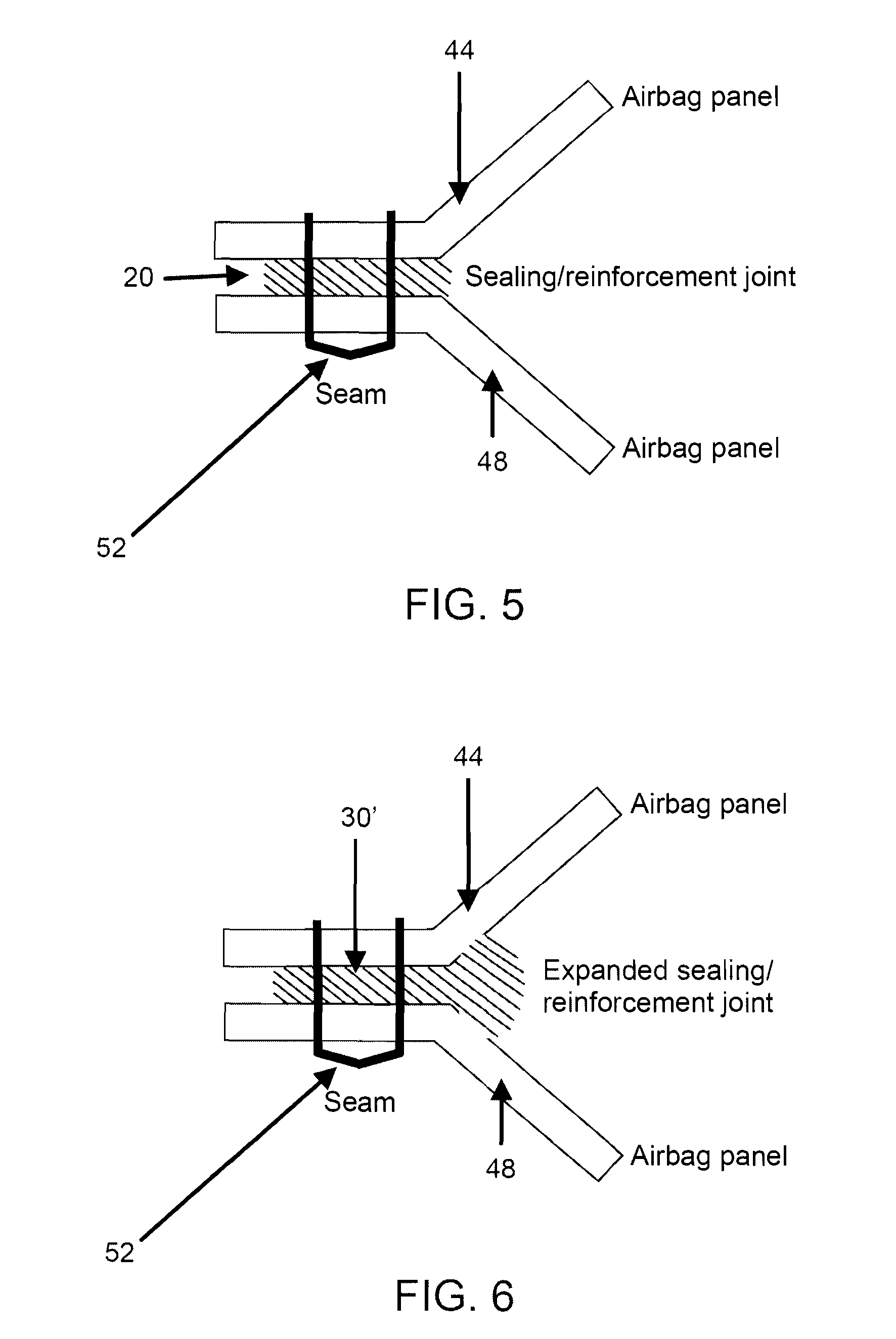

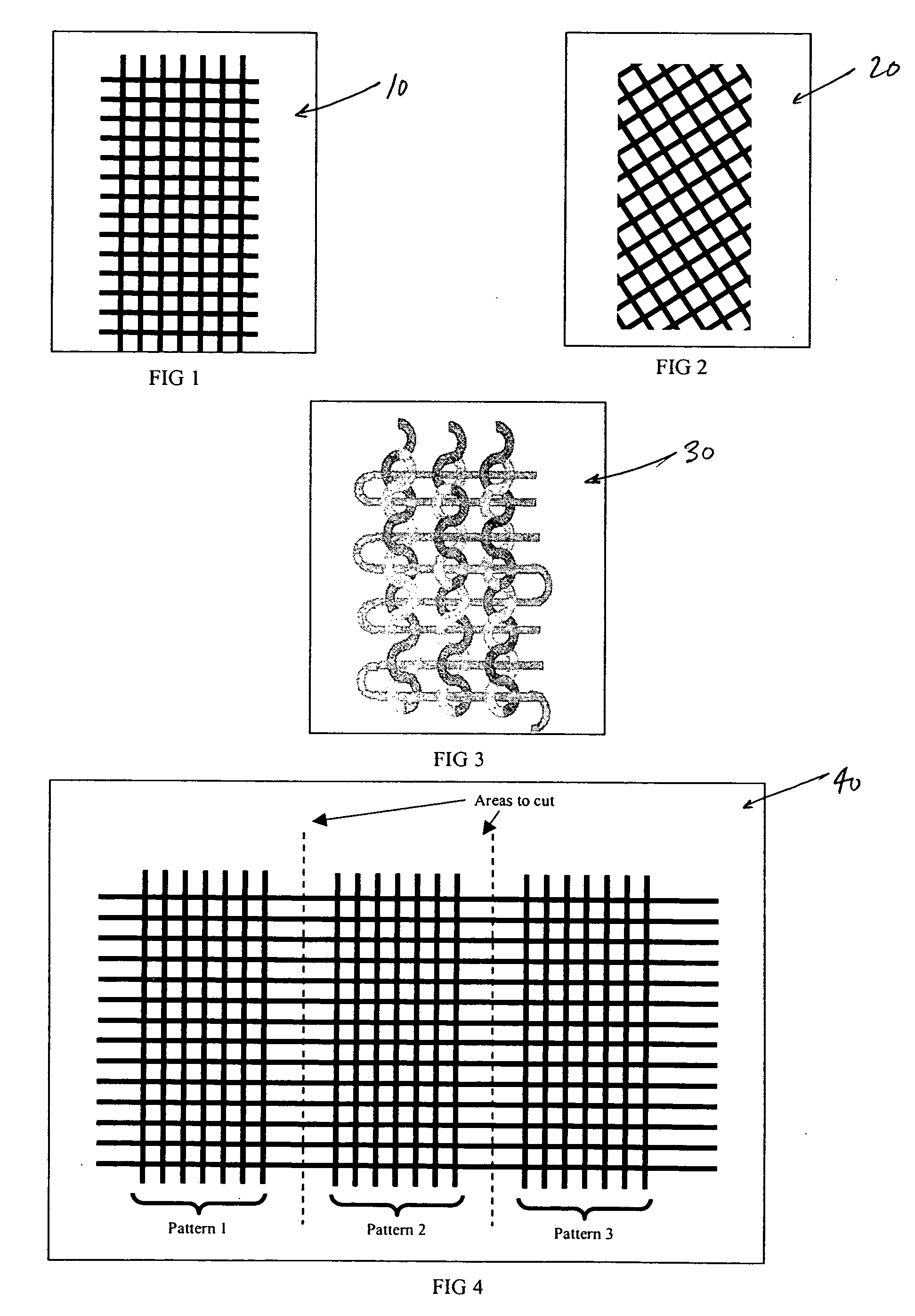

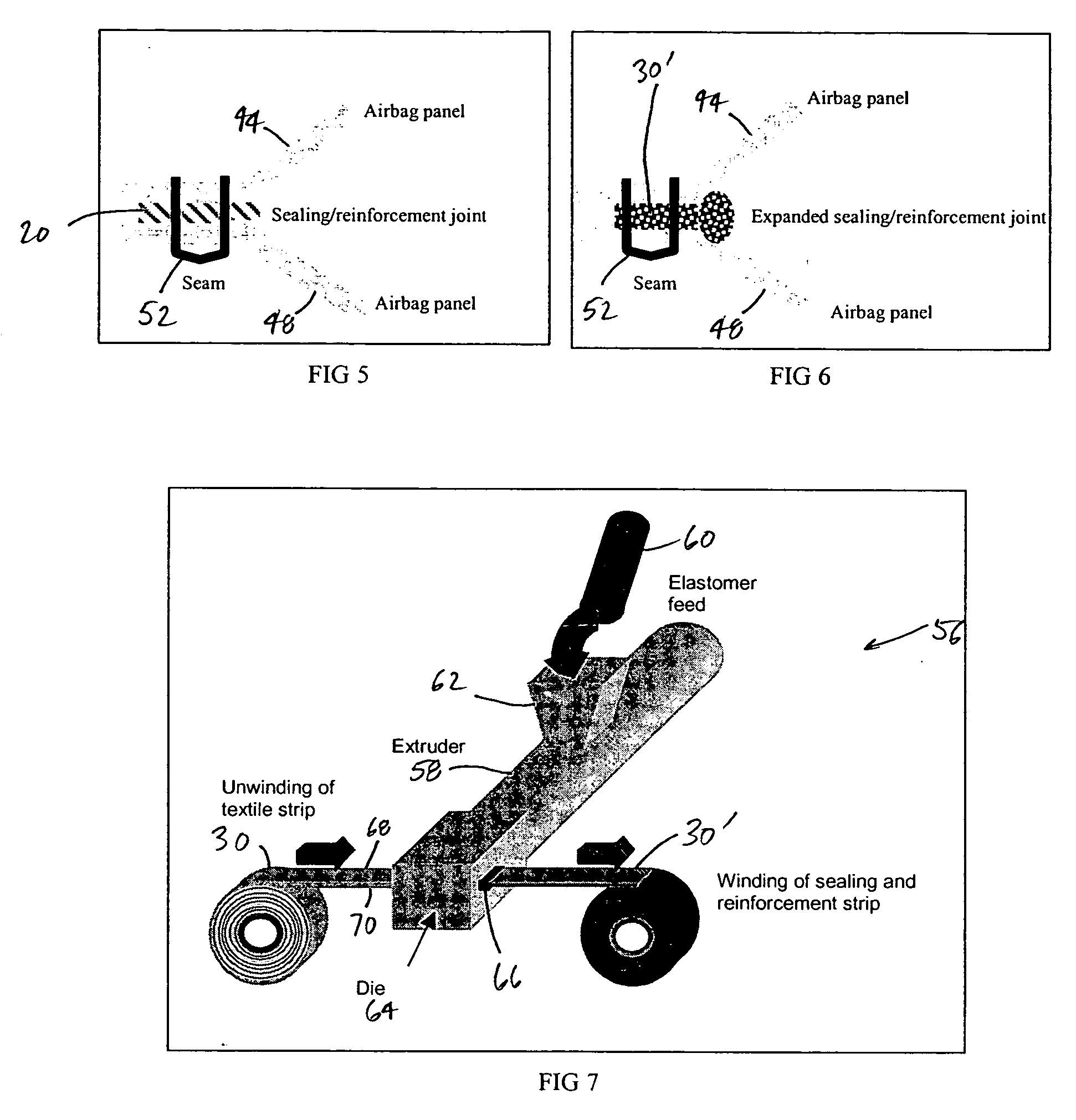

Sealing and reinforcing strips principally for airbag assembly joints

InactiveUS7681917B2Reduce gas leakageLayered productsPedestrian/occupant safety arrangementMechanical engineering

Owner:ZODIAC AUTOMOTIVE US

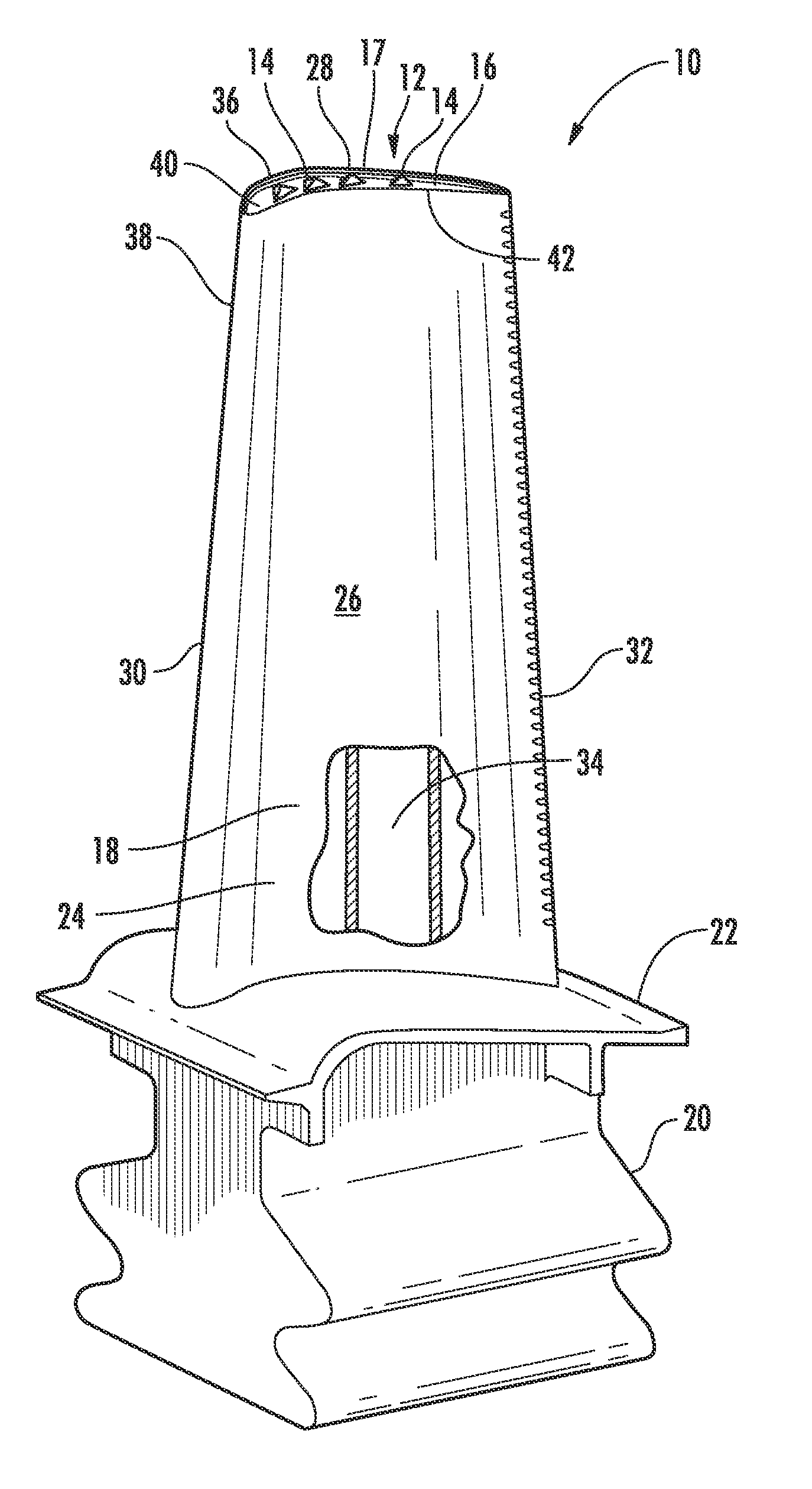

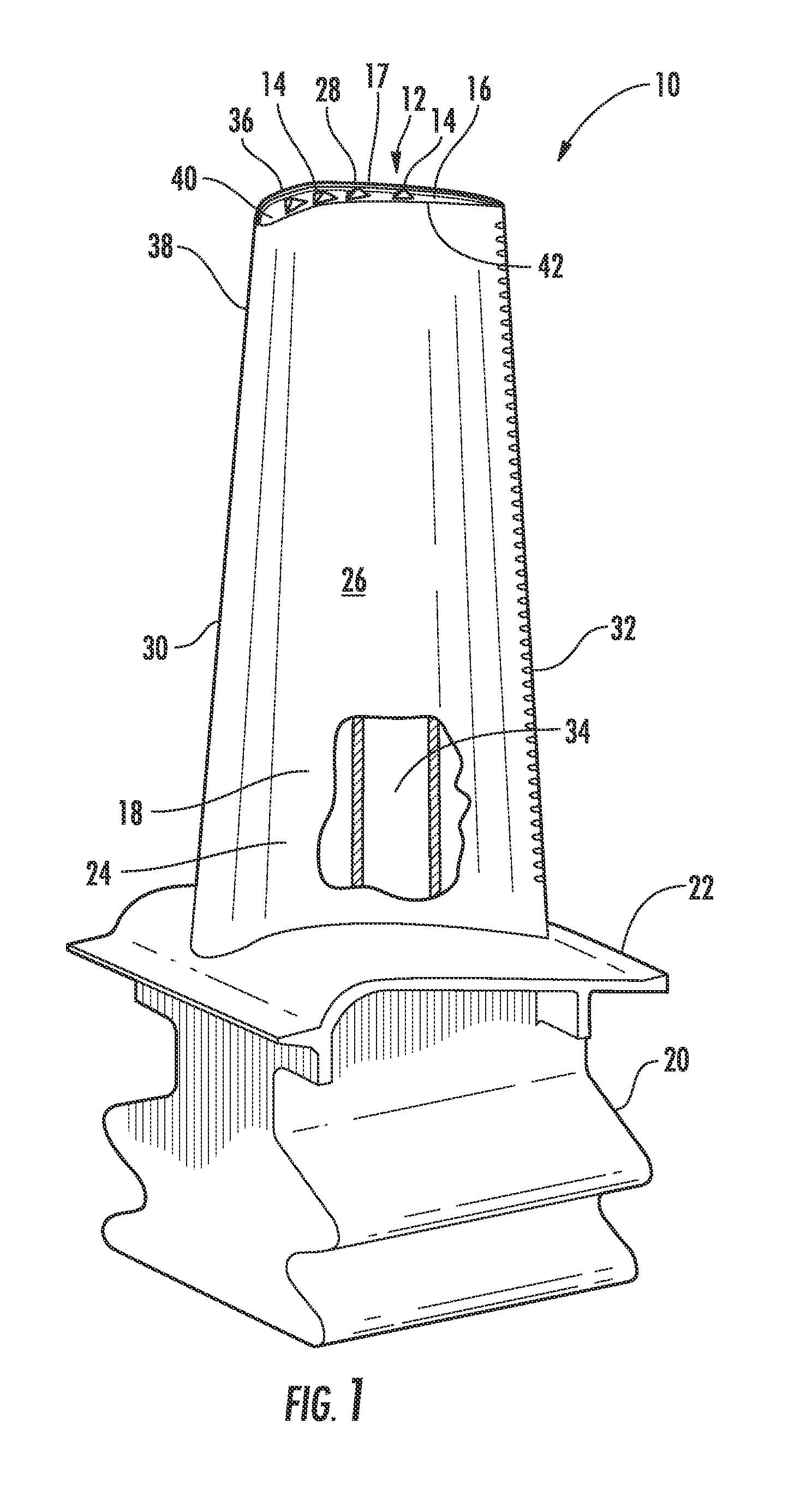

Turbine blade tip with vortex generators

A turbine blade for a turbine engine having a tip with one or more vortex generators for reducing tip leakage during operation of the turbine engine. The vortex generators may extend radially outward from the radially outer surface of the tip wall. The vortex generator may be positioned between a rib extending radially outward from the radially outer surface of the tip wall and an intersection between the outer surface of the tip wall and an outer surface on the pressure side. The vortex generators may include a base and three sides forming a triangular point with a first side having a larger surface are than second and third sides. One or more film cooling holes may be formed in the tip wall to provide cooling air to the tip. In one embodiment, film cooling holes may be positioned in one or more vortex generators.

Owner:SIEMENS ENERGY INC

Firearm

Owner:ARMWEST

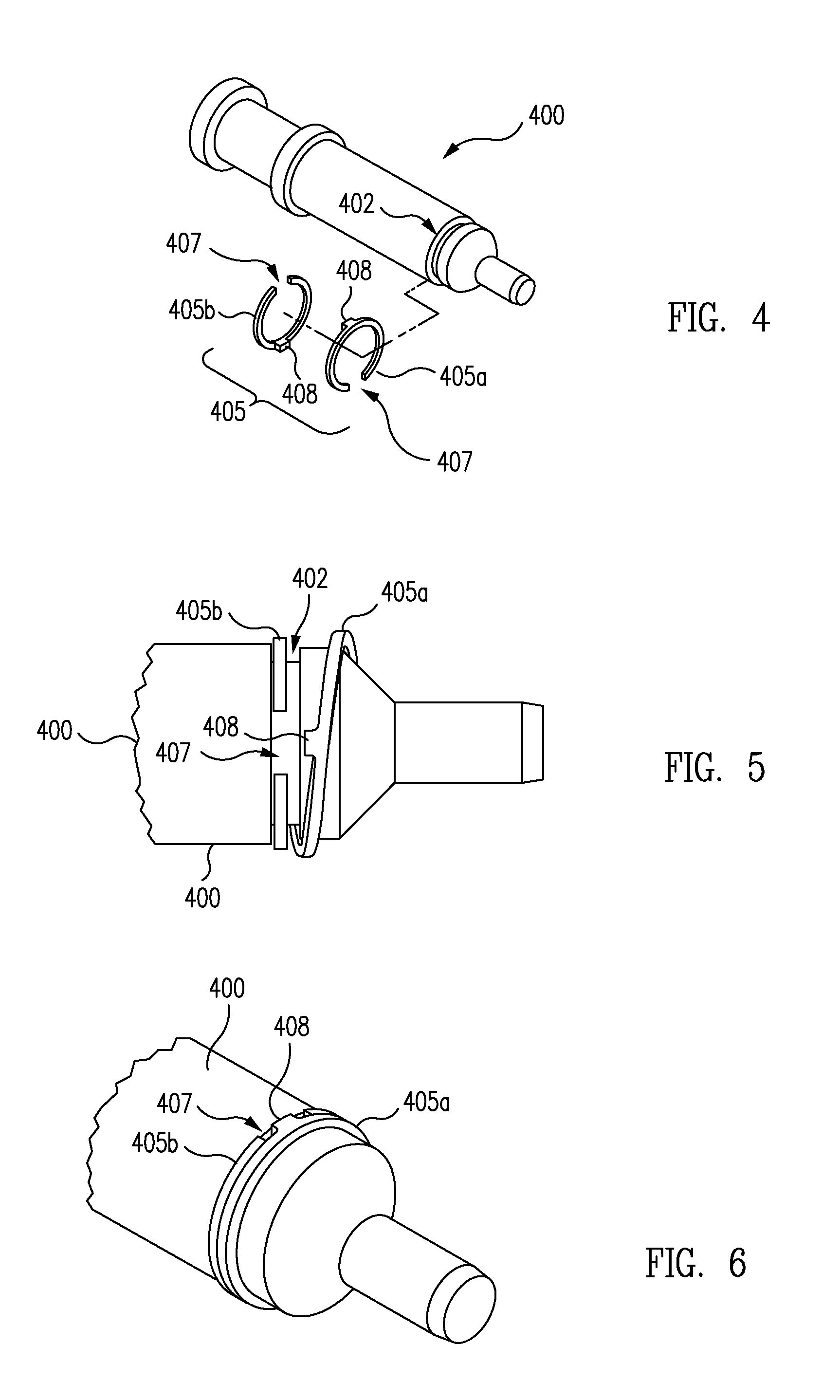

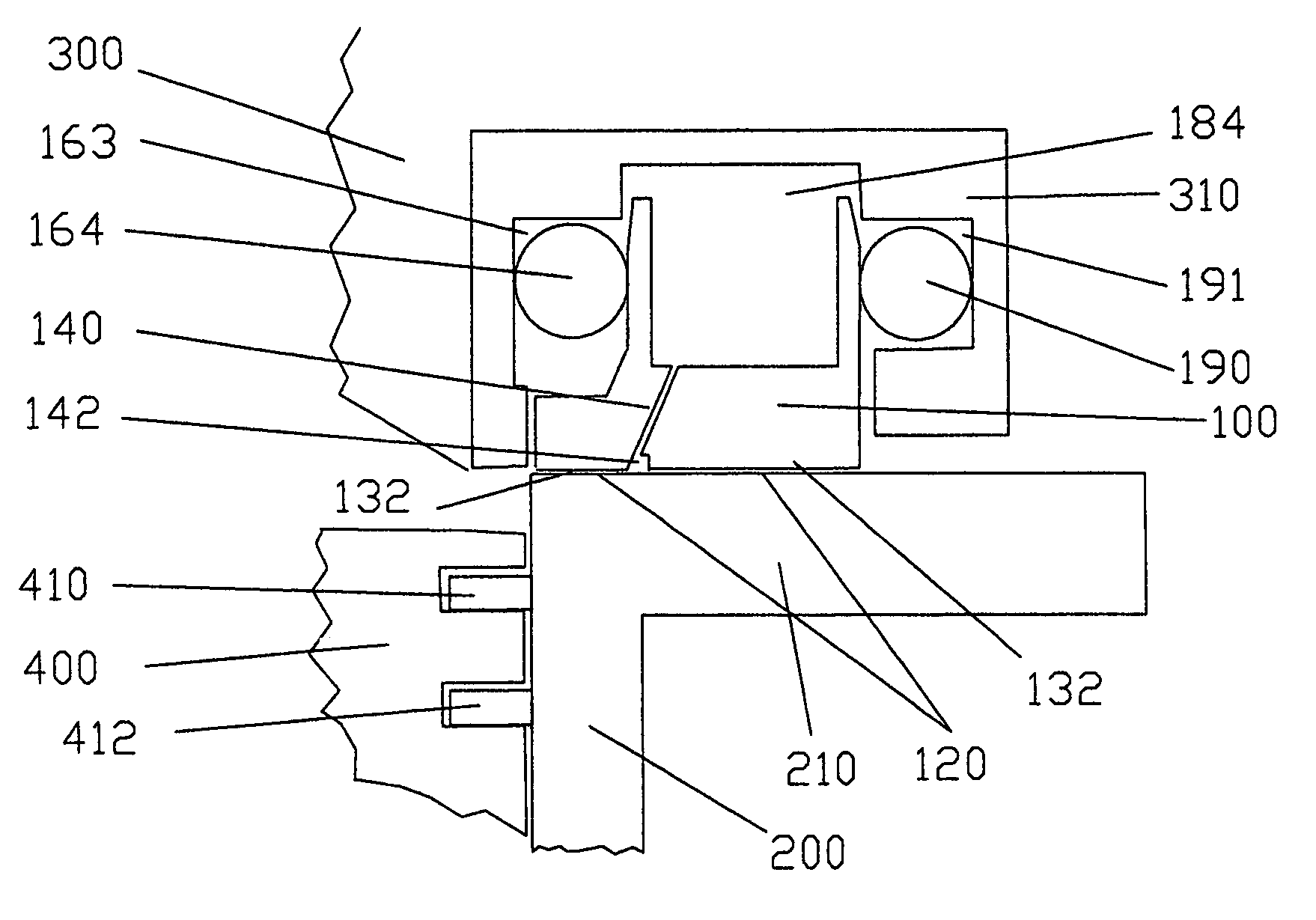

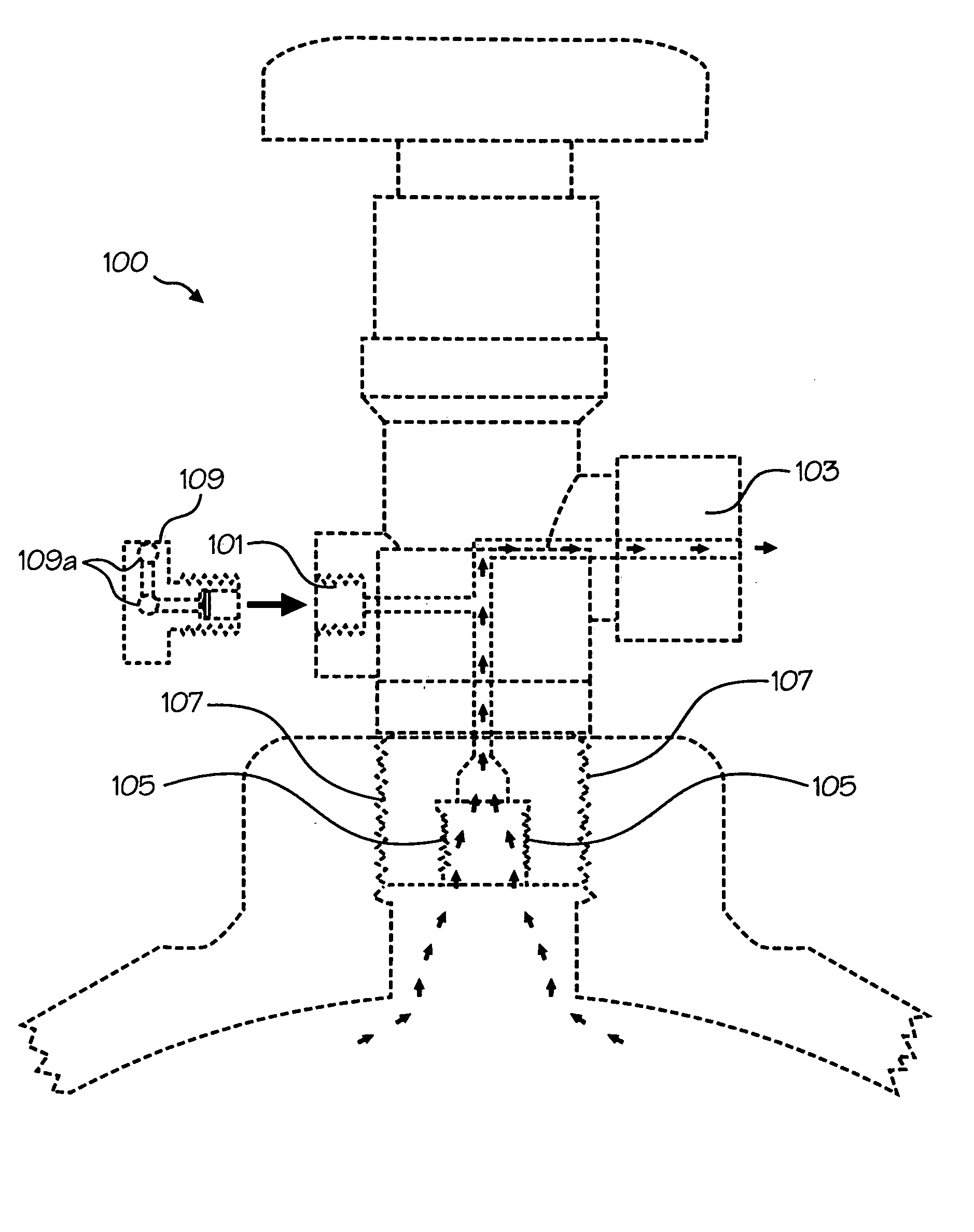

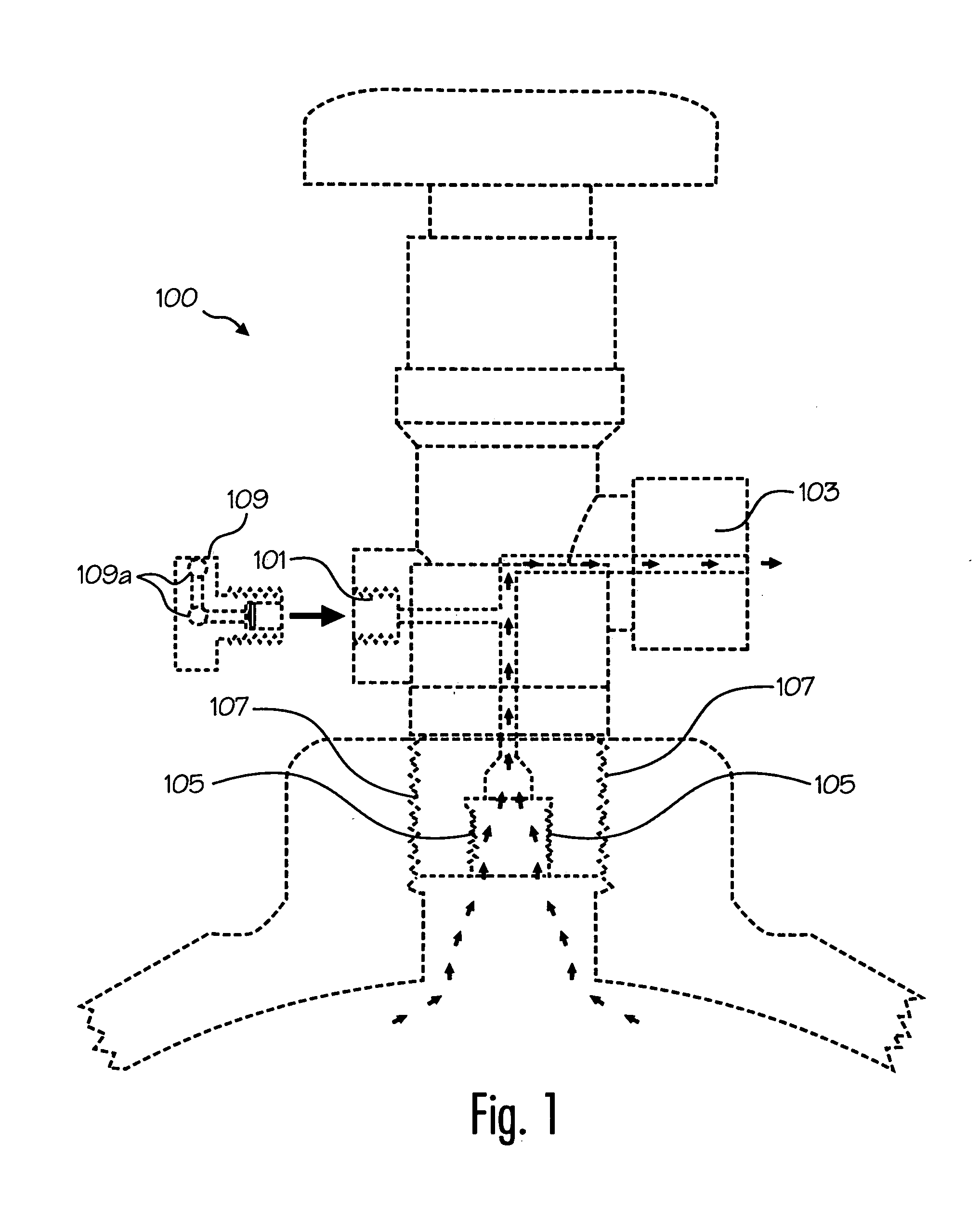

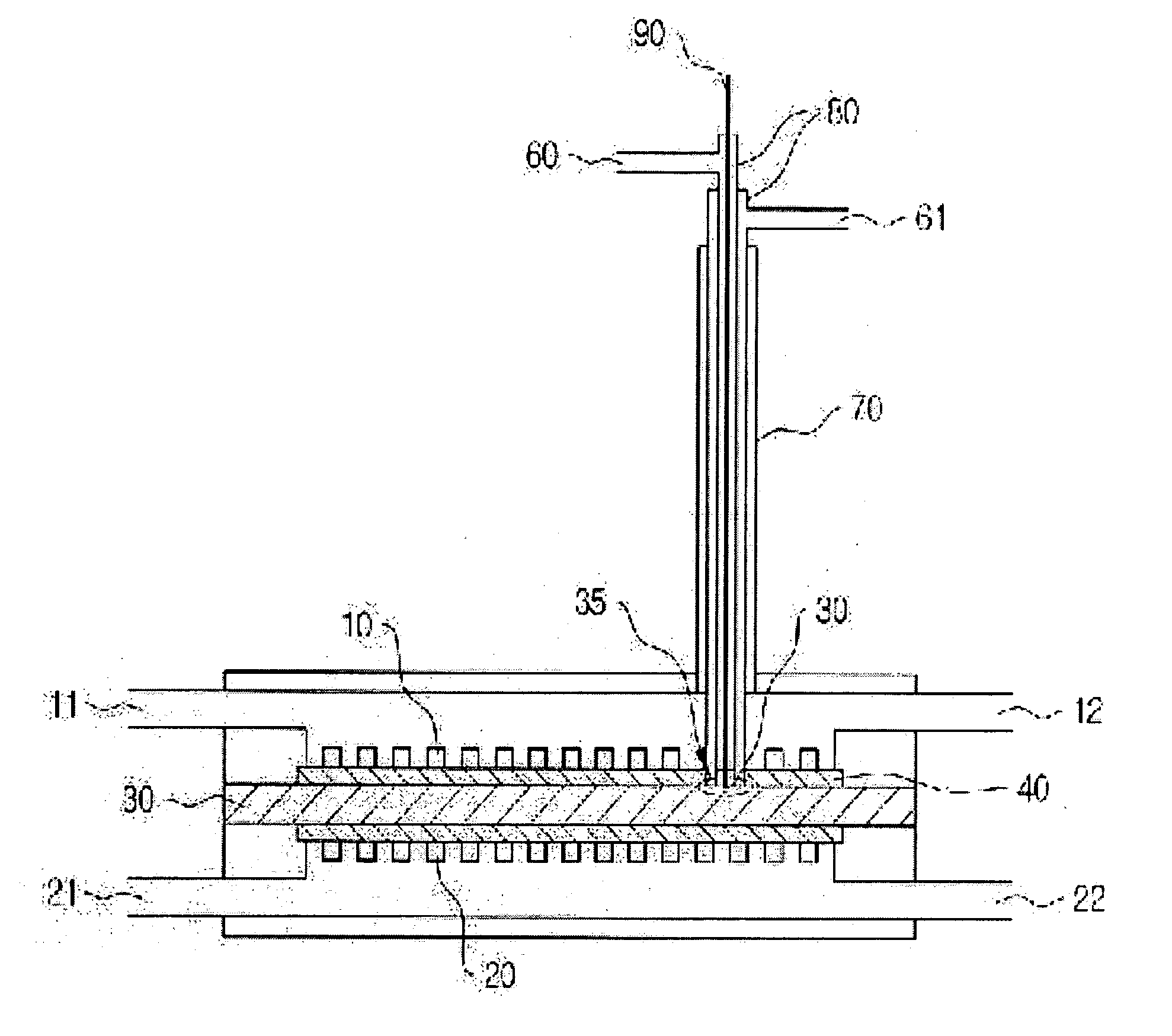

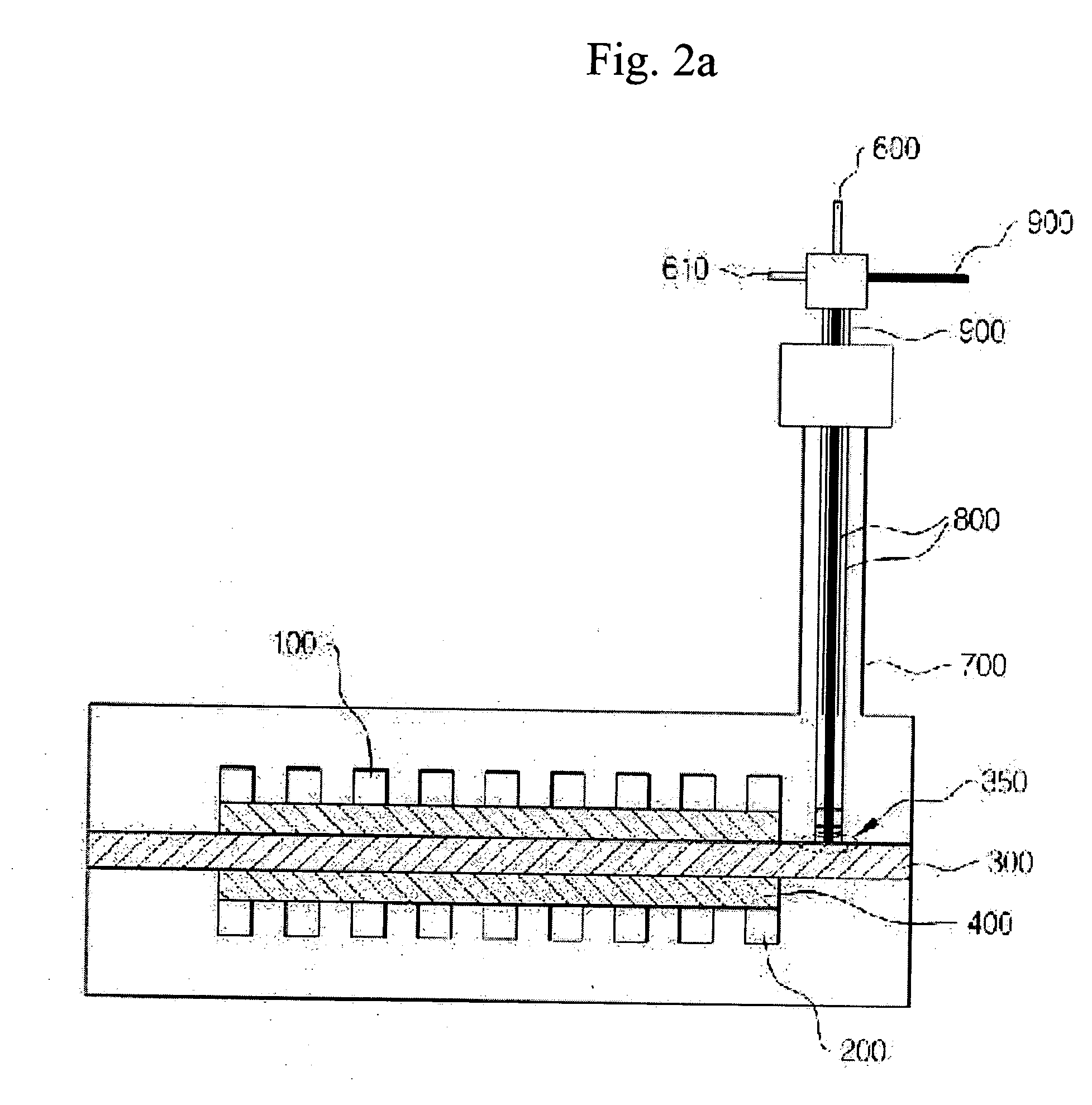

Apparatus and method for rotating sleeve engine hydrodynamic seal

ActiveUS7004119B2Add partsMinimize and prevent expansionEngine sealsLubrication of auxillariesCombustionCylinder head

A hydrodynamic face seal 100 for sealing between the cylinder head 300 and rotating sleeve 200 of a rotating liner engine. The face of the face seal provides a sealing zone 130 for maintaining a lubricant layer of about 2 micrometers between the face seal and the sleeve; and a loading zone 132. The loading zone includes hydrodynamic lift features such as inclined pads 150 or recessed step pads 152. Oil is supplied to annular oil supply passage 142 between the sealing zone and the loading zone, and flows from the annular oil supply passage to radial passages 144 located between the step pads. A spring pre-load is provided to the seal. An outer secondary seal 190 is provided to contain the lubricant. One or more inner secondary seals is provided to contain lubricant and combustion gases. Spiral oil pumping grooves may be provided.

Owner:DARDALIS DIMITRIOS

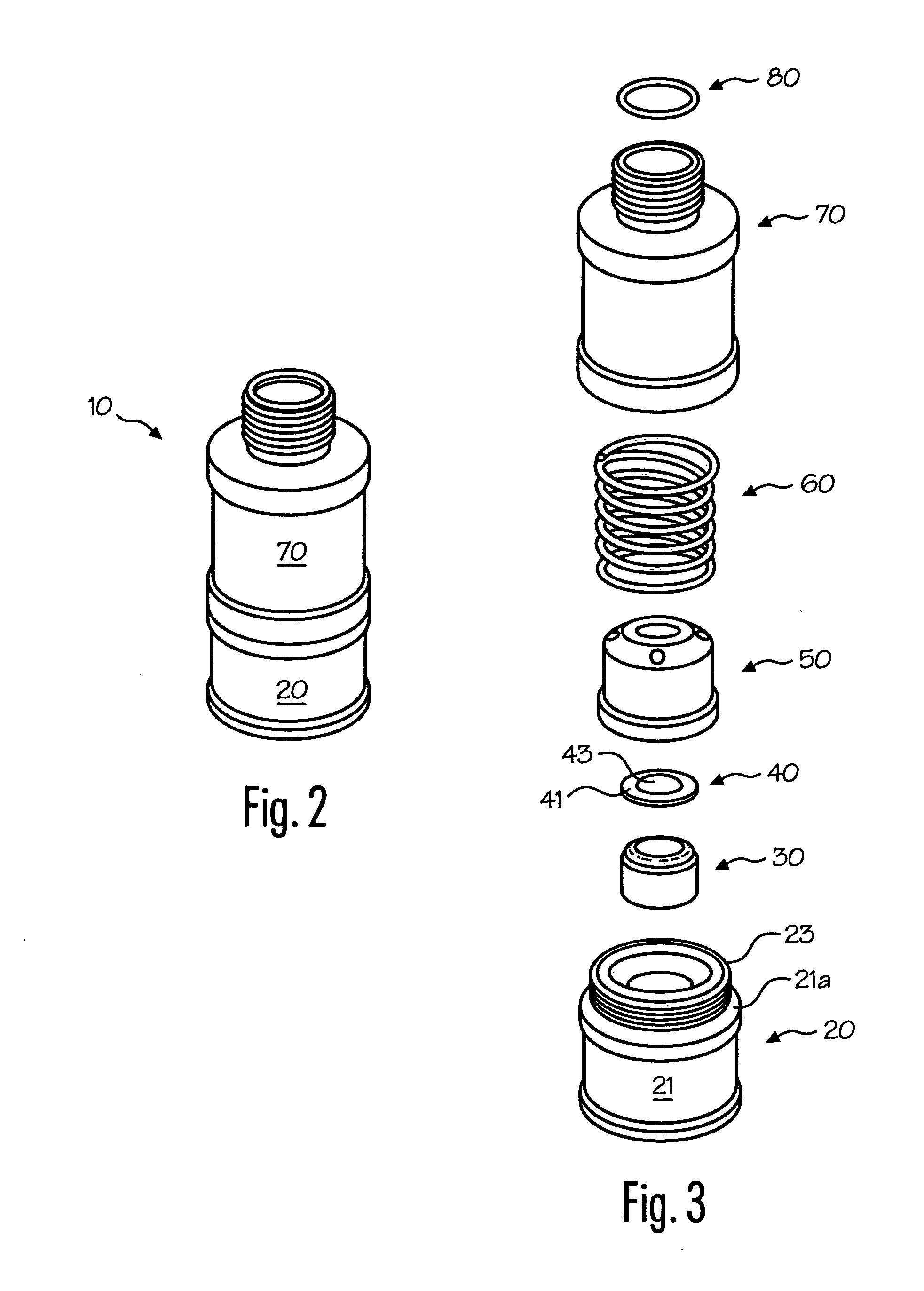

High pressure safety valve, system and method

InactiveUS20080289700A1Reduce gas leakageVessel mounting detailsOperating means/releasing devices for valvesGas cylinderProduct gas

The present invention comprises, in one embodiment, a compression safety valve apparatus adapted to engagingly connect to an existing gas cylinder valve. In one embodiment, the present invention comprises a housing base having a first bore, a rupture disc holding means having a second bore, at least one rupture disk, a piston having at least a third bore, a spring, and an outer housing cylinder having a forth bore, the first bore, the second bore and the third bore all being in gas flow communication with the compressed content of the tank. In operation, for example, during an over-pressurization event occurs, the extreme force of the escaping gas places a force on the bottom surface of the present invention's rupture disc assembly, so that the piston's beveled surface substantially mechanically engages the outer housing's upper ceiling. This mechanical engagement allows gas to continue to escape from the tank through one or more bleeder bores and a gap.

Owner:MASINGALE LEVI D

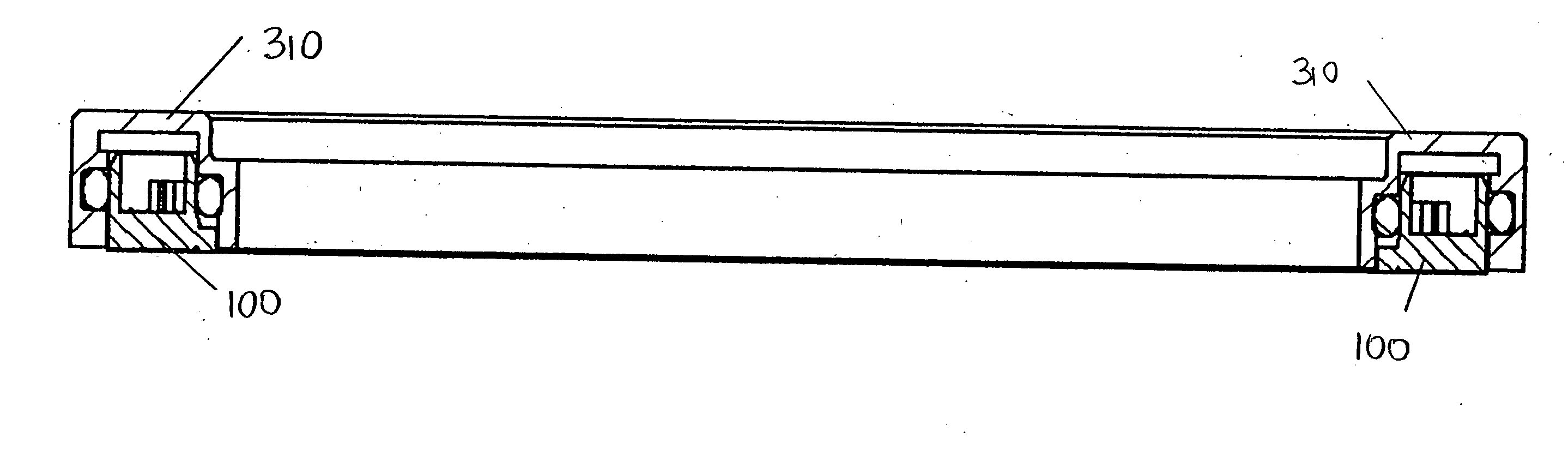

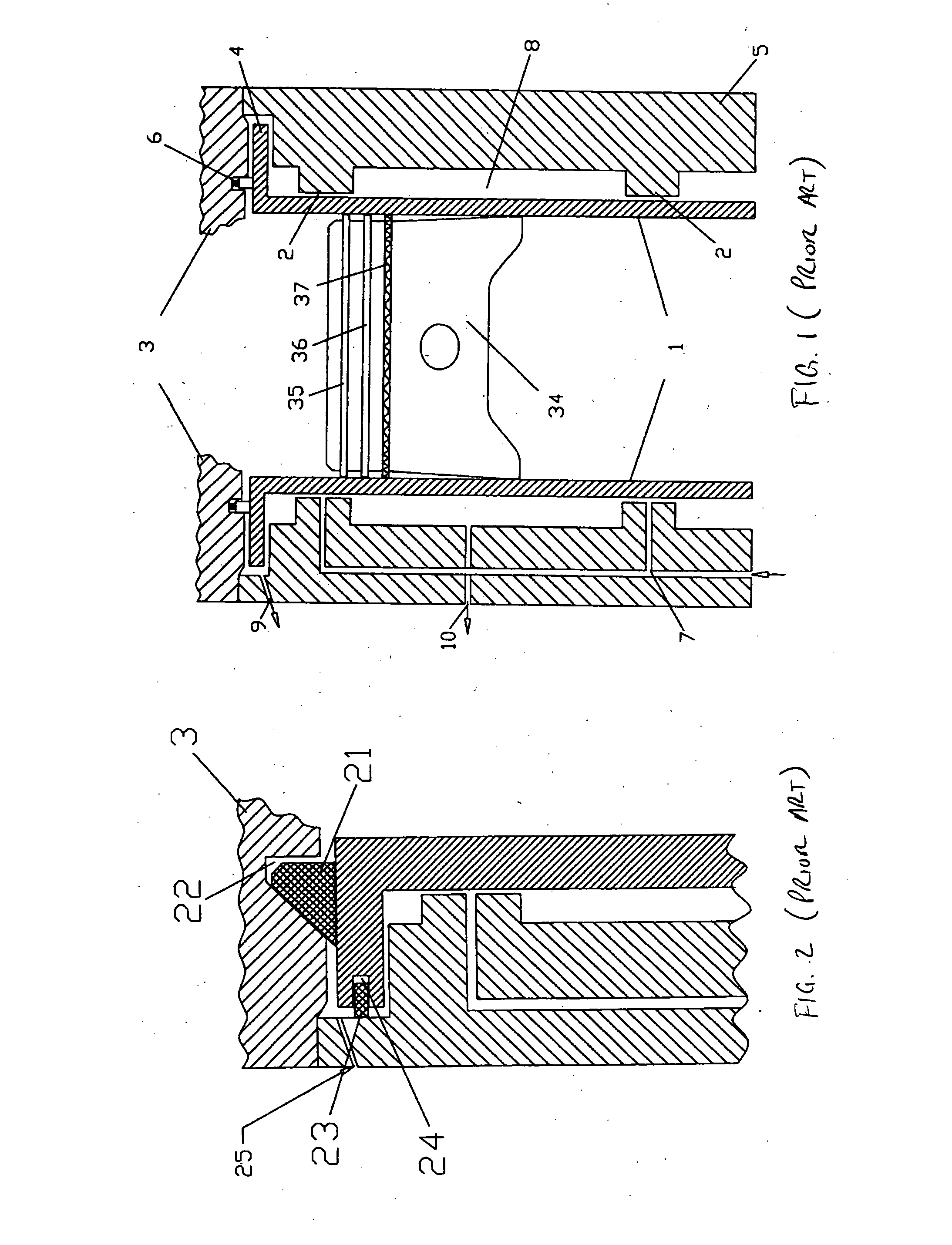

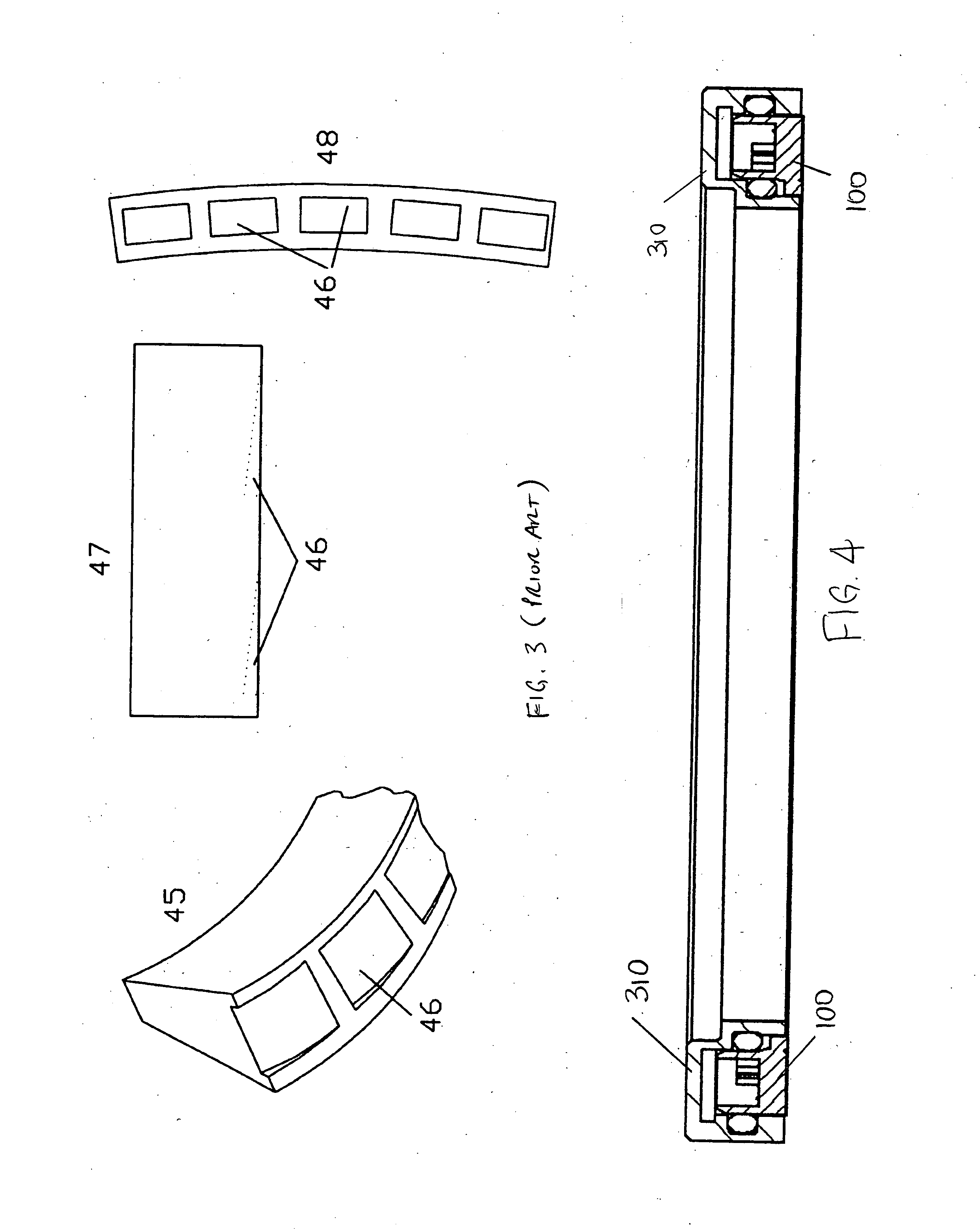

Apparatus and method for rotating sleeve engine hydrodynamic seal

ActiveUS20040256809A1Add partsPreventing and minimizing sleeve expansionEngine sealsLubrication of auxillariesCombustionCylinder head

A hydrodynamic face seal 100 for sealing between the cylinder head 300 and rotating sleeve 200 of a rotating liner engine. The face of the face seal provides a sealing zone 130 for maintaining a lubricant layer of about 2 micrometers between the face seal and the sleeve; and a loading zone 132. The loading zone includes hydrodynamic lift features such as inclined pads 150 or recessed step pads 152. Oil is supplied to annular oil supply passage 142 between the sealing zone and the loading zone, and flows from the annular oil supply passage to radial passages 144 located between the step pads. A spring pre-load is provided to the seal. An outer secondary seal 190 is provided to contain the lubricant. One or more inner secondary seals is provided to contain lubricant and combustion gases. Spiral oil pumping grooves may be provided.

Owner:DARDALIS DIMITRIOS

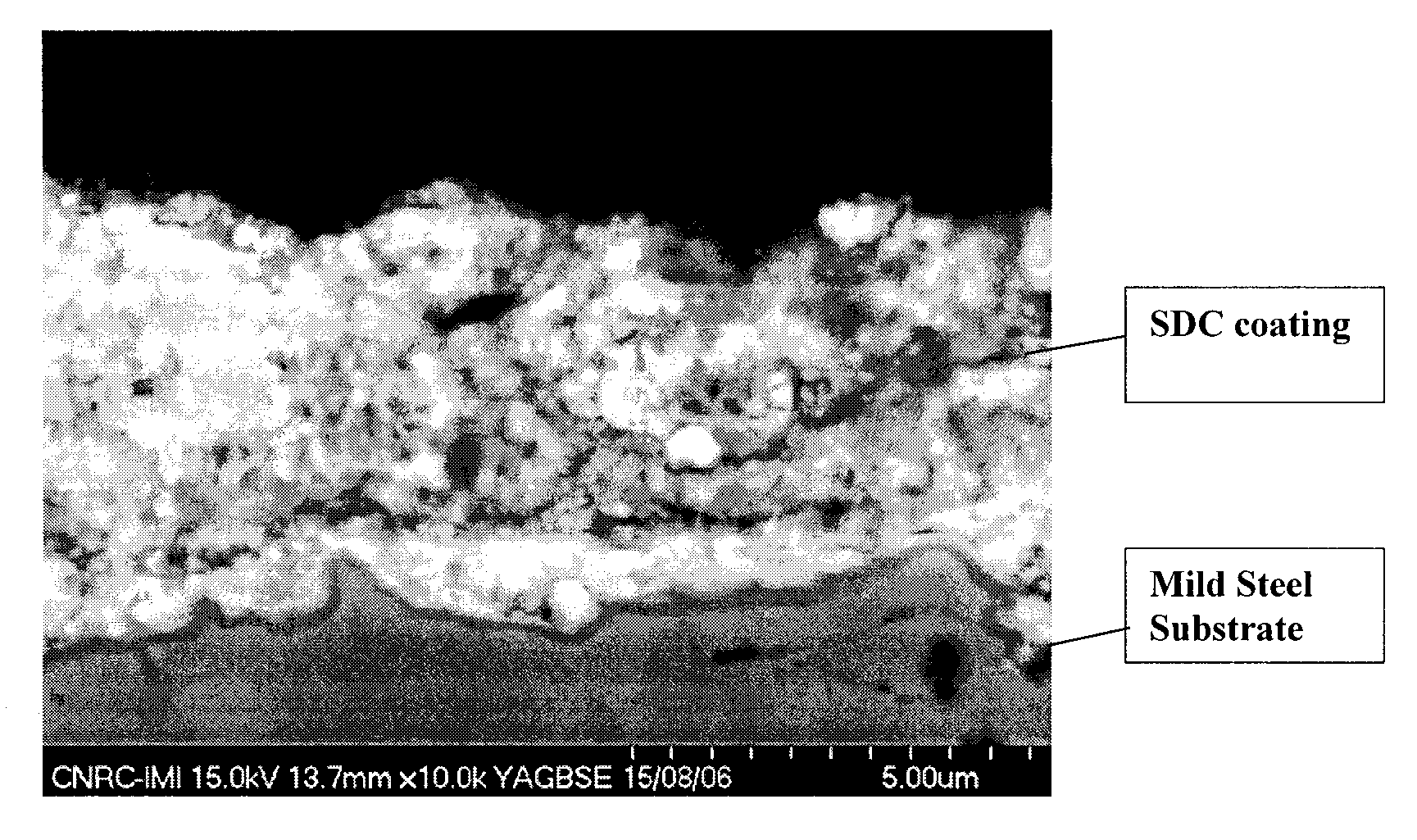

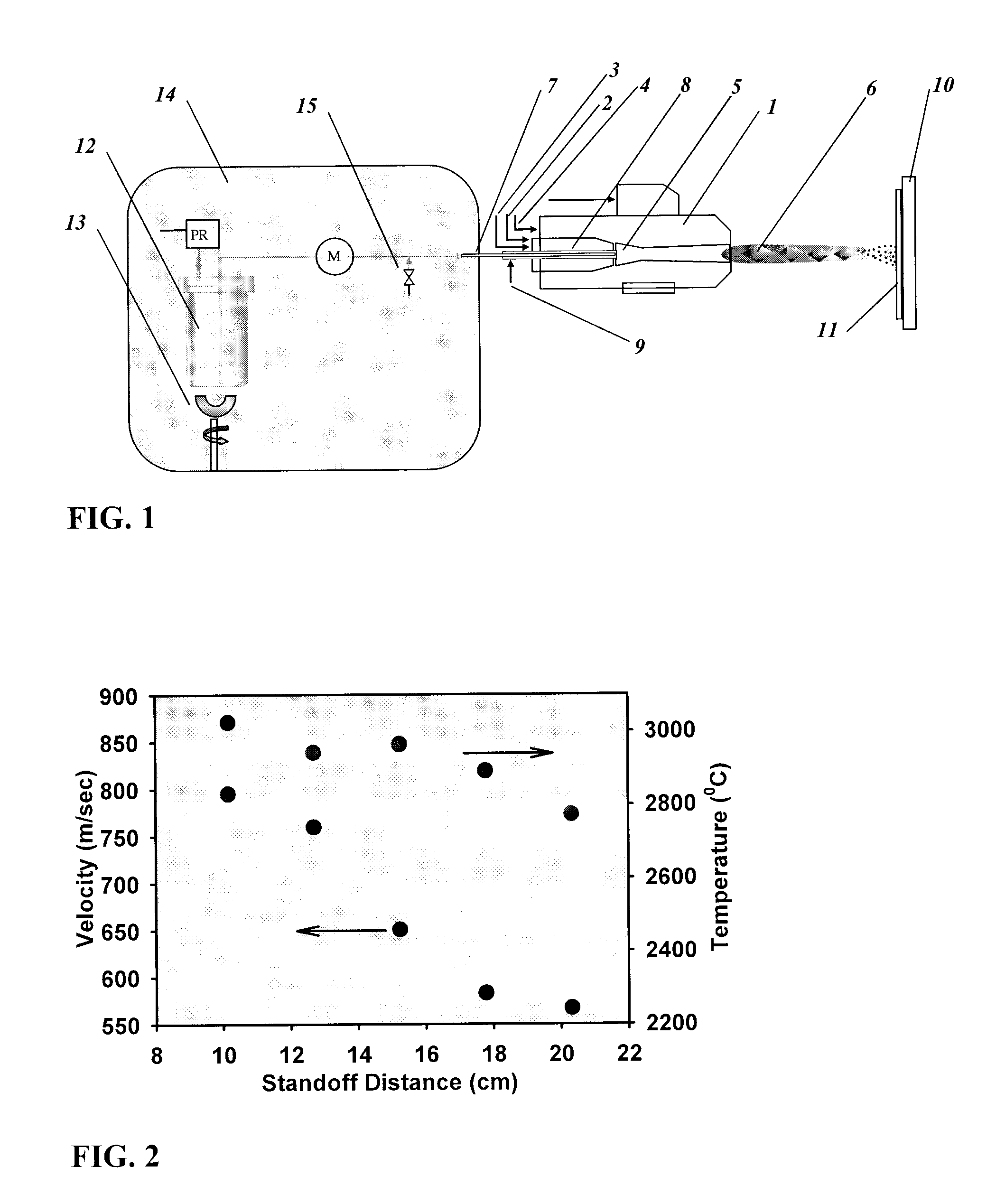

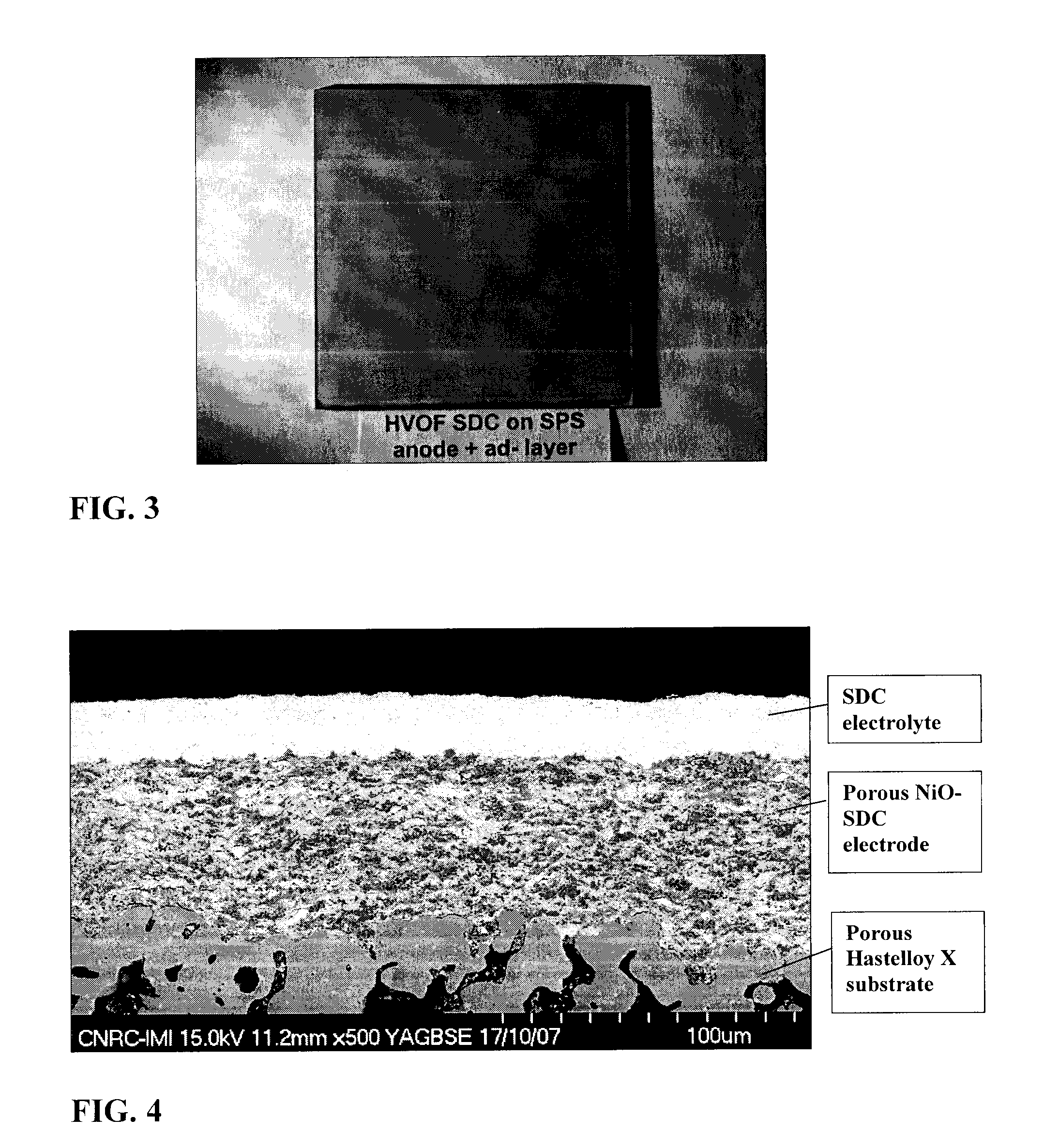

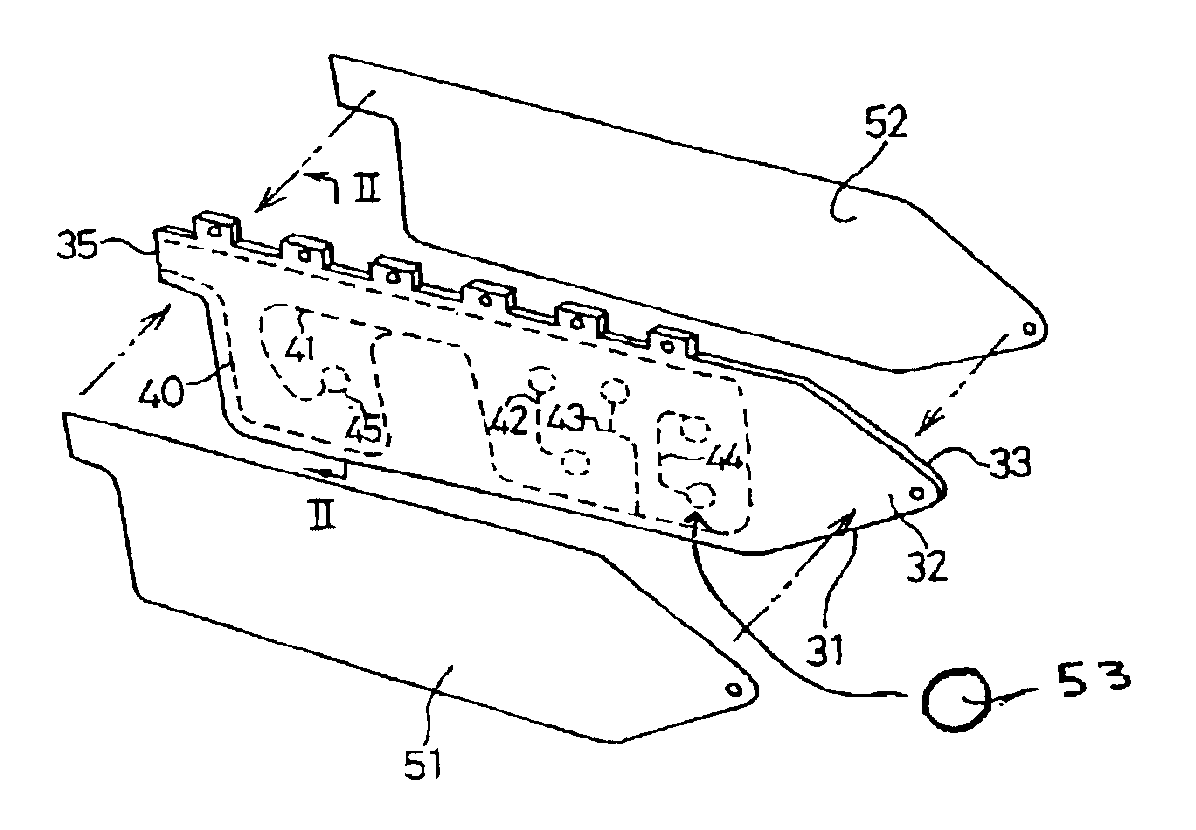

Process of Making Ceria-Based Electrolyte Coating

InactiveUS20110003084A1Reduce gas leakageMolten spray coatingFinal product manufactureThermal sprayingMaterials science

It has been surprisingly found that injecting ceria-based particles (mean size less than 200 nm) suspended in a combustible organic solvent into a plume having a maximum temperature between about 2,600° C. and 4,000° C. to impart a mean temperature to the particles from about 2,600° C. to about 3,800° C., and to accelerate the particles to a mean velocity between about 600 to 1000 m / s, produces a thin, uniform, dense, crack-free, nanocrystalline ceria-based coating, which may be applied on porous cermet or metal substrate, for example. The physical environment of a high-velocity oxy-fuel (HVOF) thermal spraying gun suitably ably deployed using standard fuels produces these conditions. The method of the present invention is particularly useful for the cost-effective fabrication of ceria-containing electrolytes for solid oxide fuel cells (SOFCs).

Owner:NAT RES COUNCIL OF CANADA

Cushion for protection of a vehicle occupant's head

InactiveUS6877768B2Minimal gas leakageImprove pressure resistancePedestrian/occupant safety arrangementYarnInternal pressure

A cushion for protecting a vehicle occupant's head. The cushion inflates and deploys smoothly and is configured so that gas leakage out of the cushion is reduced in order to maintain the inner pressure high for an extended period of time. The cushion includes a protective cushion element and outer shell fabrics superposed on both outer surfaces of the protective cushion element. The cushion element includes a cabin-side base fabric and a window-side base fabric that are sewn together by sewing yarns after bonded to each other by adhesive. The outer shell fabrics are bonded to the protective cushion element by adhesive. The adhesive is applied to the outer surfaces of the protective cushion element the joint wherein the base fabrics are sewn together.

Owner:TAKATA CORPORATION

Solid oxide fuel cell

InactiveUS20120107716A1Reduce gas leakageGas leak can be reduceedFuel cells groupingFuel cell shape/formFuel cellsInterconnector

A solid oxide fuel cell includes two or more power generating elements each having a cathode, an anode, and an electrolyte layer placed between the cathode and the anode; an interconnector electrically connecting the power generating elements and containing a chromite-based material; and a sealing portion provided between the electrolyte layer and the interconnector and not containing either Ni or ZrO2.

Owner:NGK INSULATORS LTD

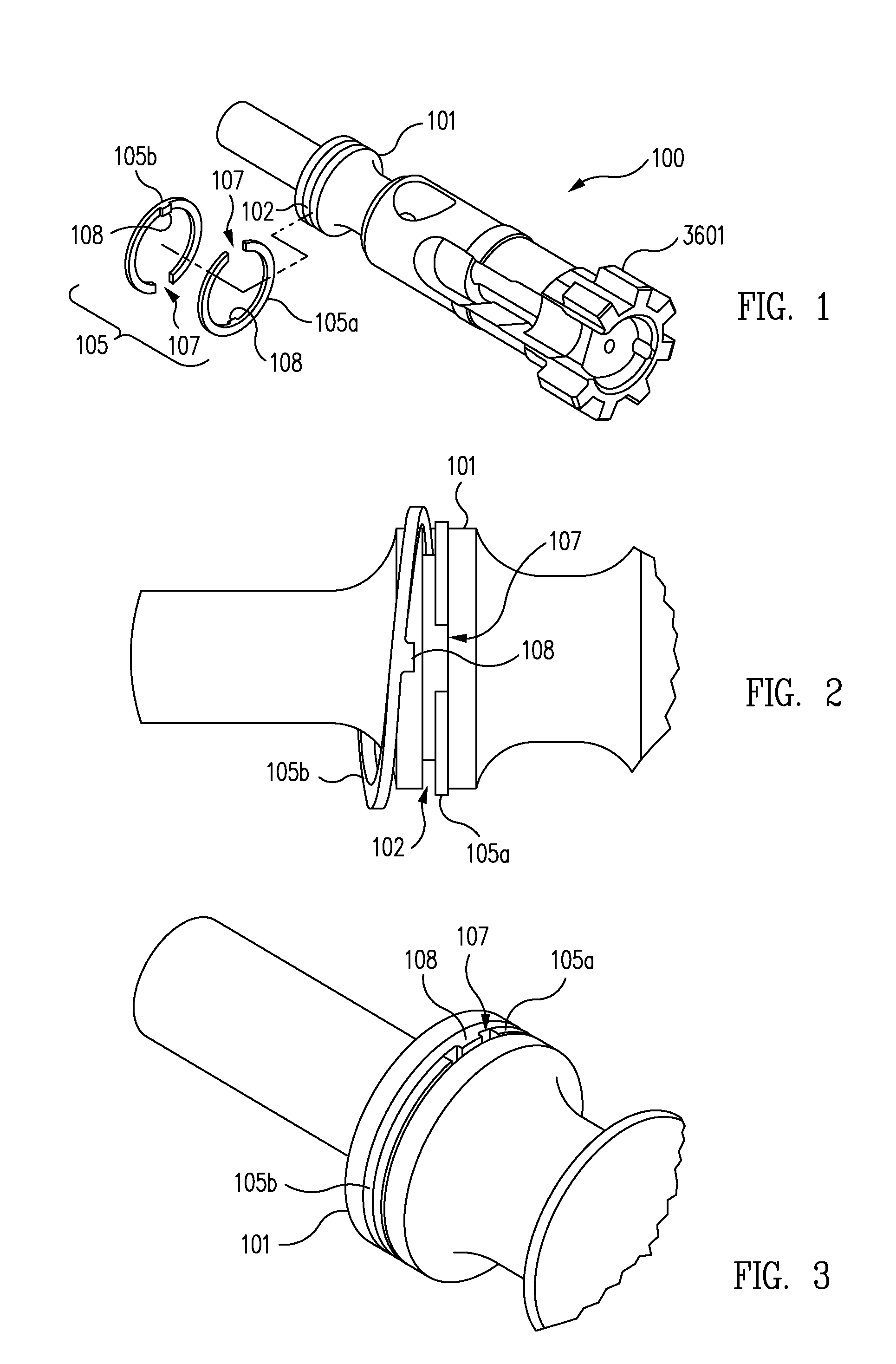

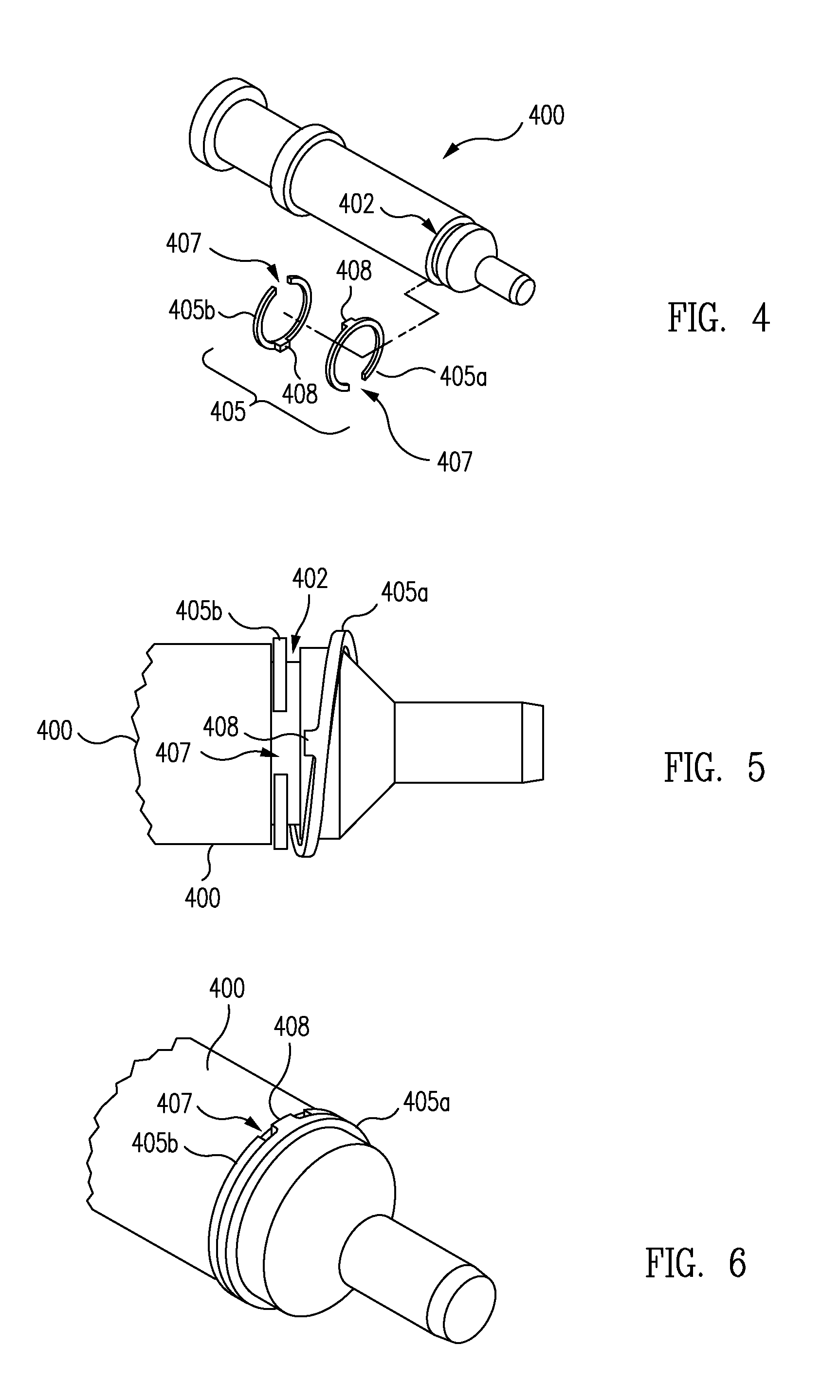

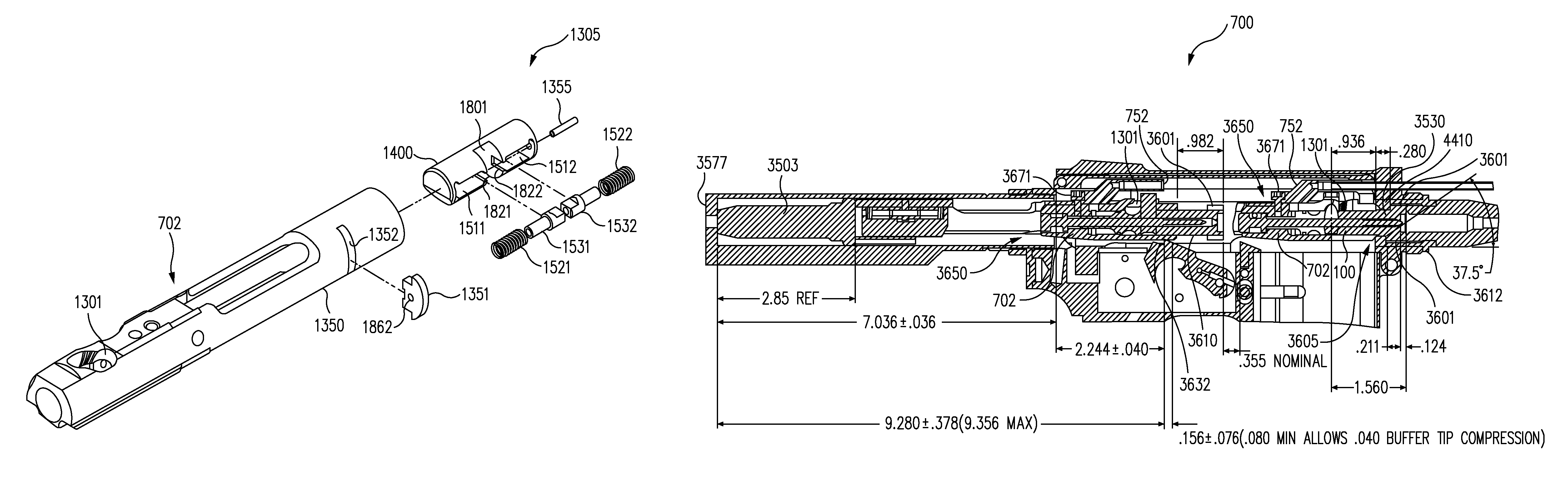

Firearm systems and methods

ActiveUS9488423B2Improve reliabilityFacilitate strokePiston ringsCartridge extractorsMatched pairCam

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is larger than that of a standard M16 / M4. A bolt carrier can have a bolt that has a double cut cam having an unlocking cam surface that has sufficient dwell increase to delay a start of unlocking when the bolt carrier is used in an M4 carbine. A stepped extractor pin may be provided that prevents disengagement of the extractor pin. A tube can be configured to provide gas from a barrel of the firearm to the piston via the carrier key. The tube can have a heat radiator formed from triangular shaped threads on at least a portion of the tube. A piston on the bolt can have a plurality of rings including pairs of mating rings that are formed and maintained as a matched pair.

Owner:ARMWEST

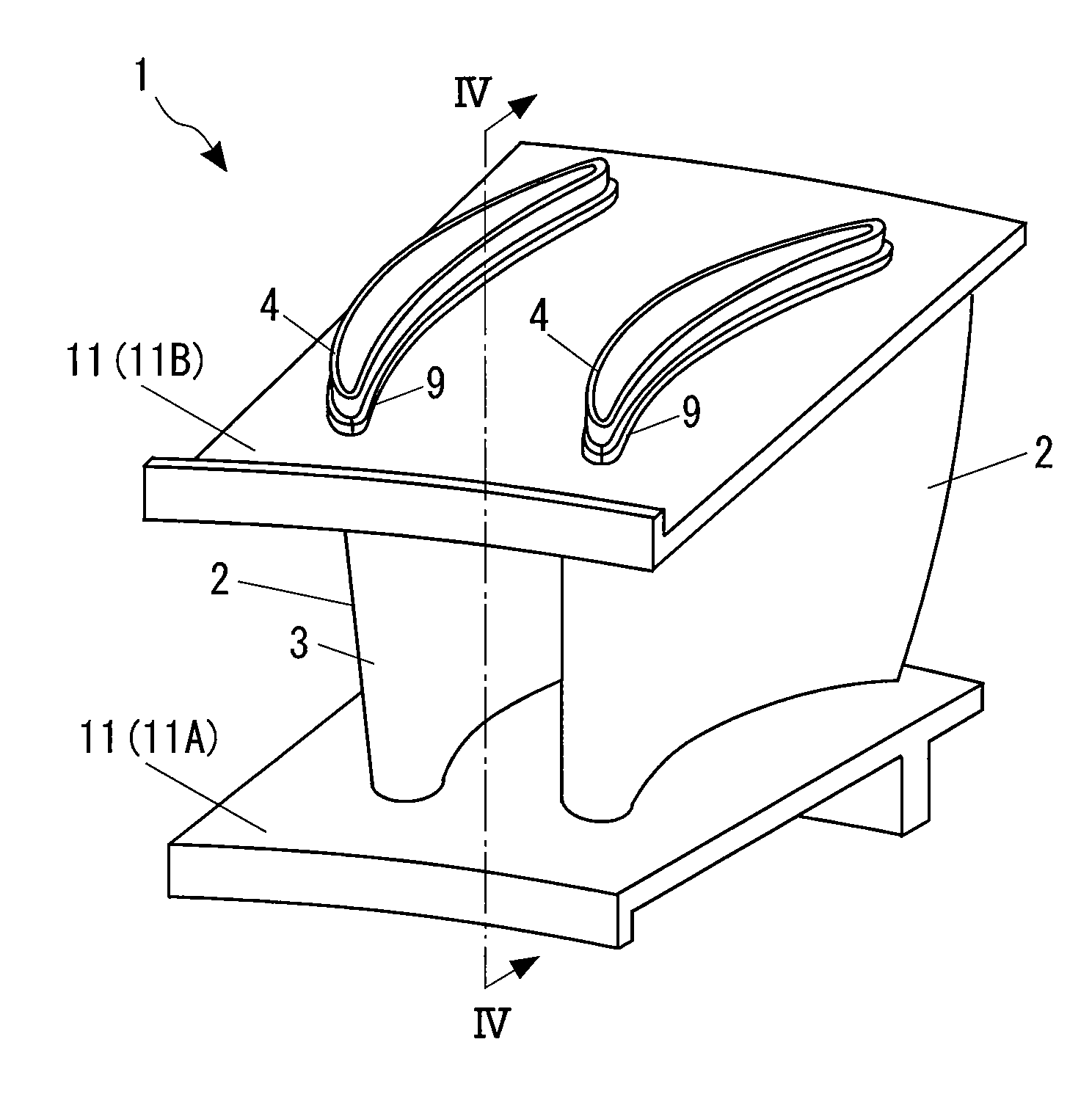

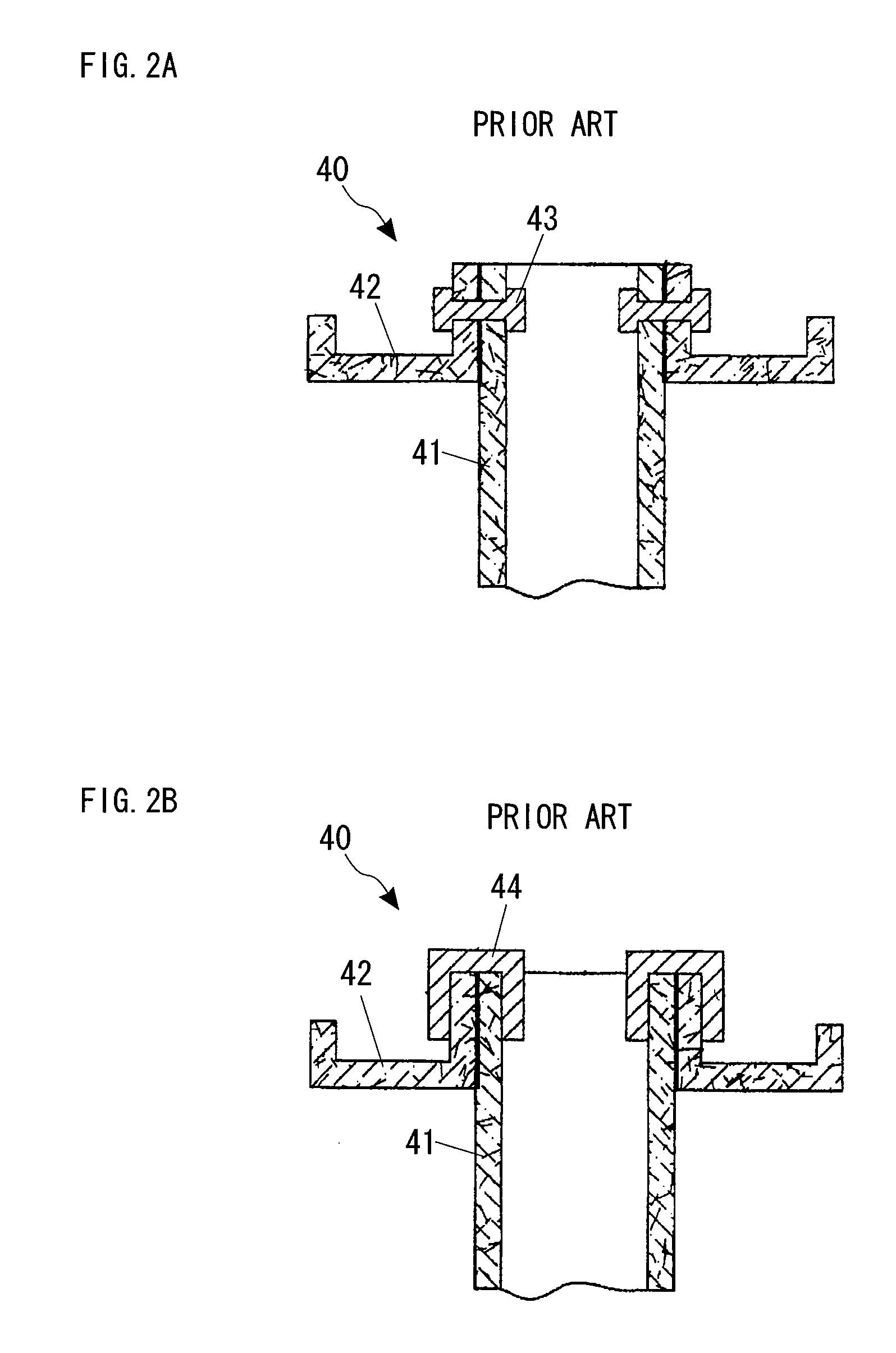

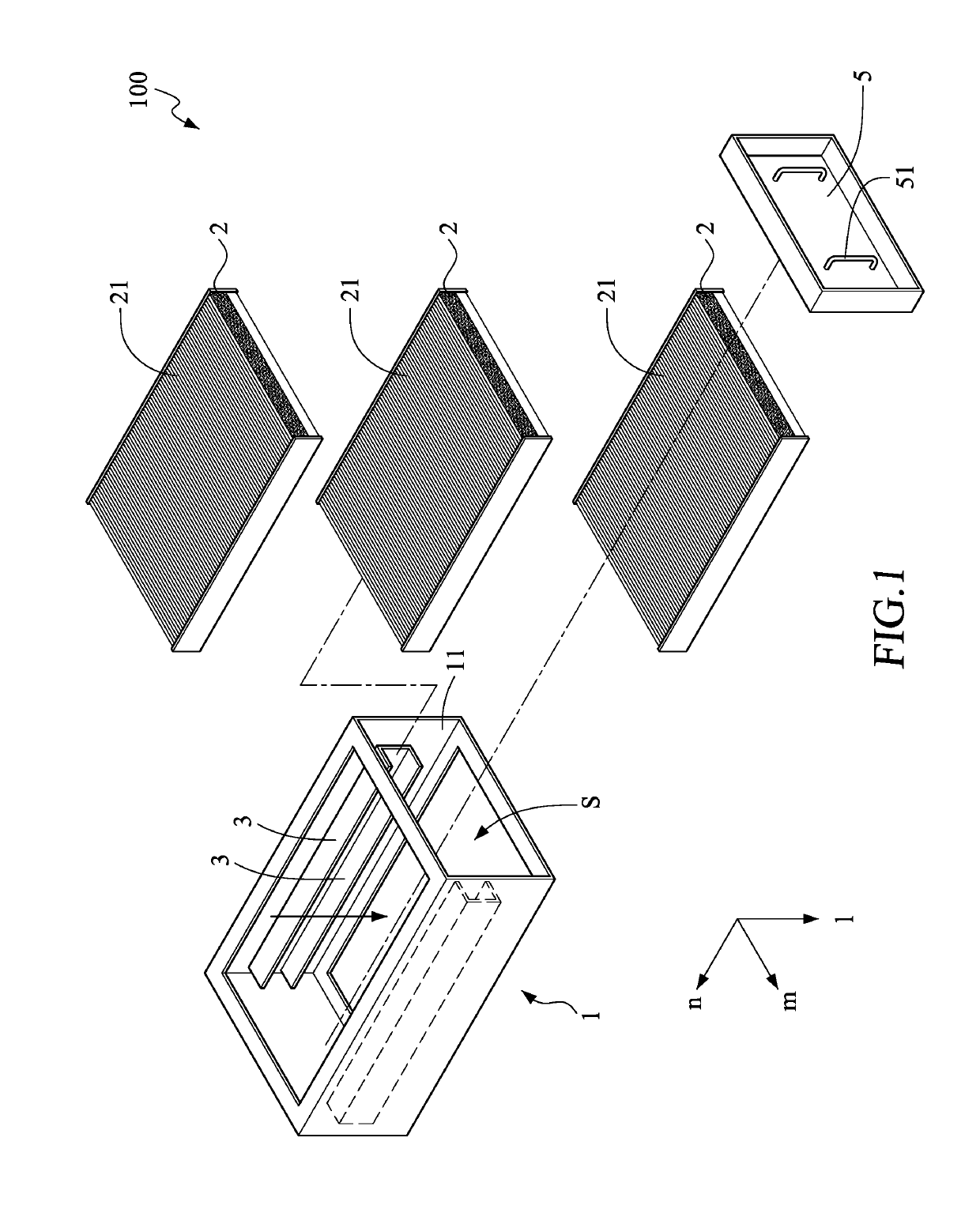

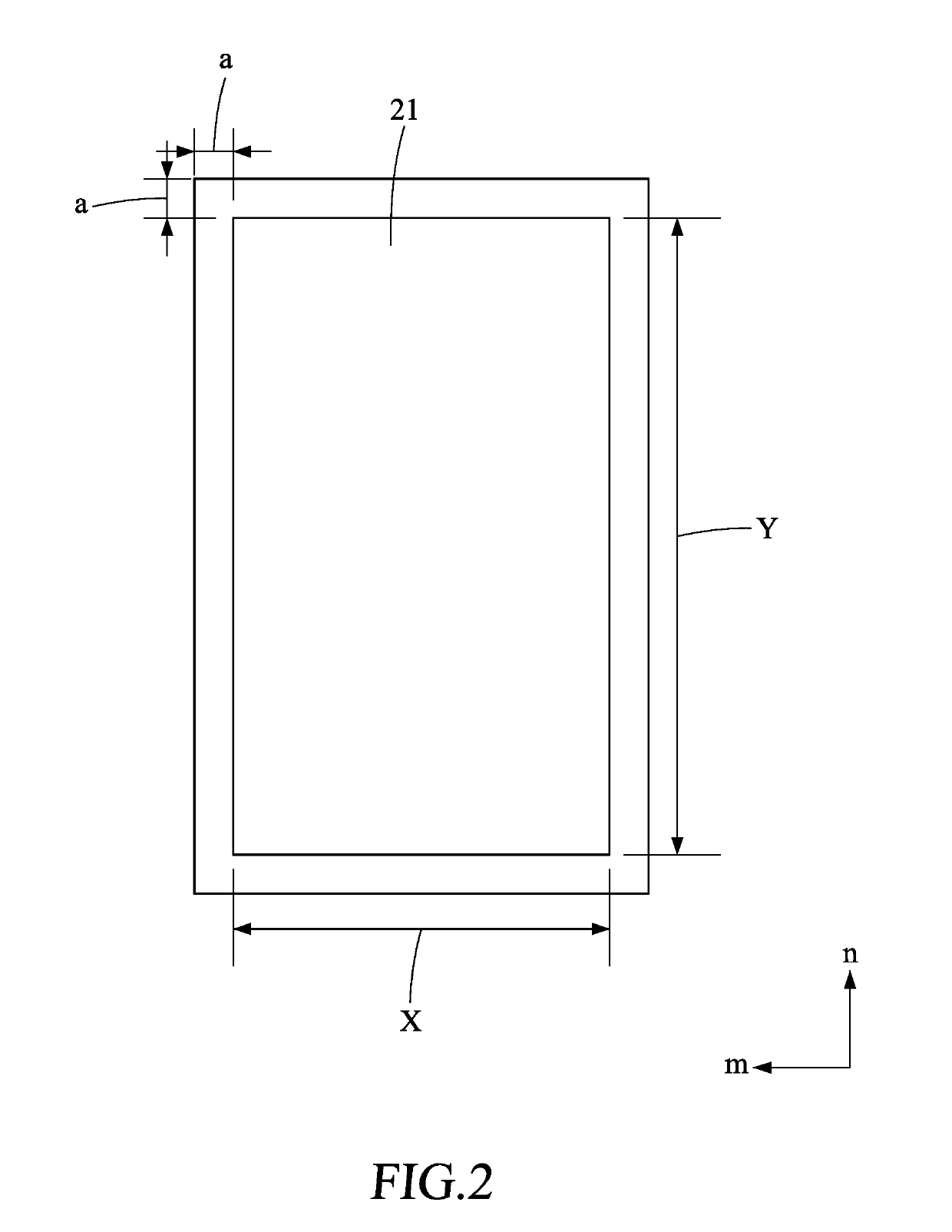

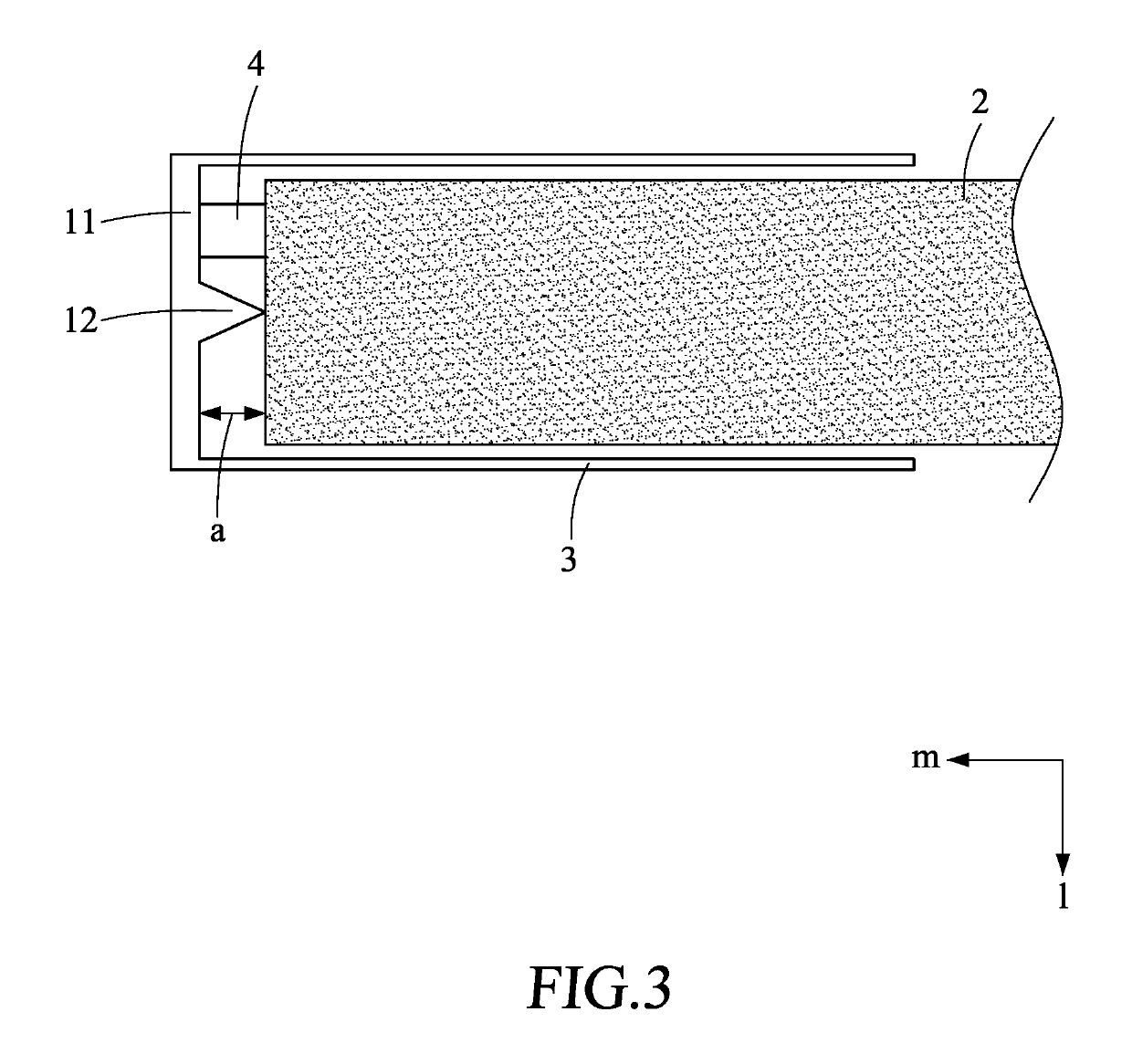

CMC turbine stator blade

ActiveUS8956112B2Reduce stress concentrationReduce gas leakagePropellersRotary propellersMetallic materialsEngineering

A CMC turbine stator blade 1 includes a blade 2 which is formed of a ceramic matrix composite material, and a band 11 which is formed of a ceramic matrix composite material or a metallic material and supports the blade 2. The blade 2 includes a first fitting portion 5 to which the band 11 is fitted at the outside thereof. The band 11 includes a second fitting portion 12 to which the first fitting portion 5 is fitted at the inside thereof. The CMC turbine stator blade 1 includes fixing means 6 which sandwiches the second fitting portion 12 from both sides in the height direction of the blade so that the blade 1 and the band 11 are fixed.

Owner:IHI CORP

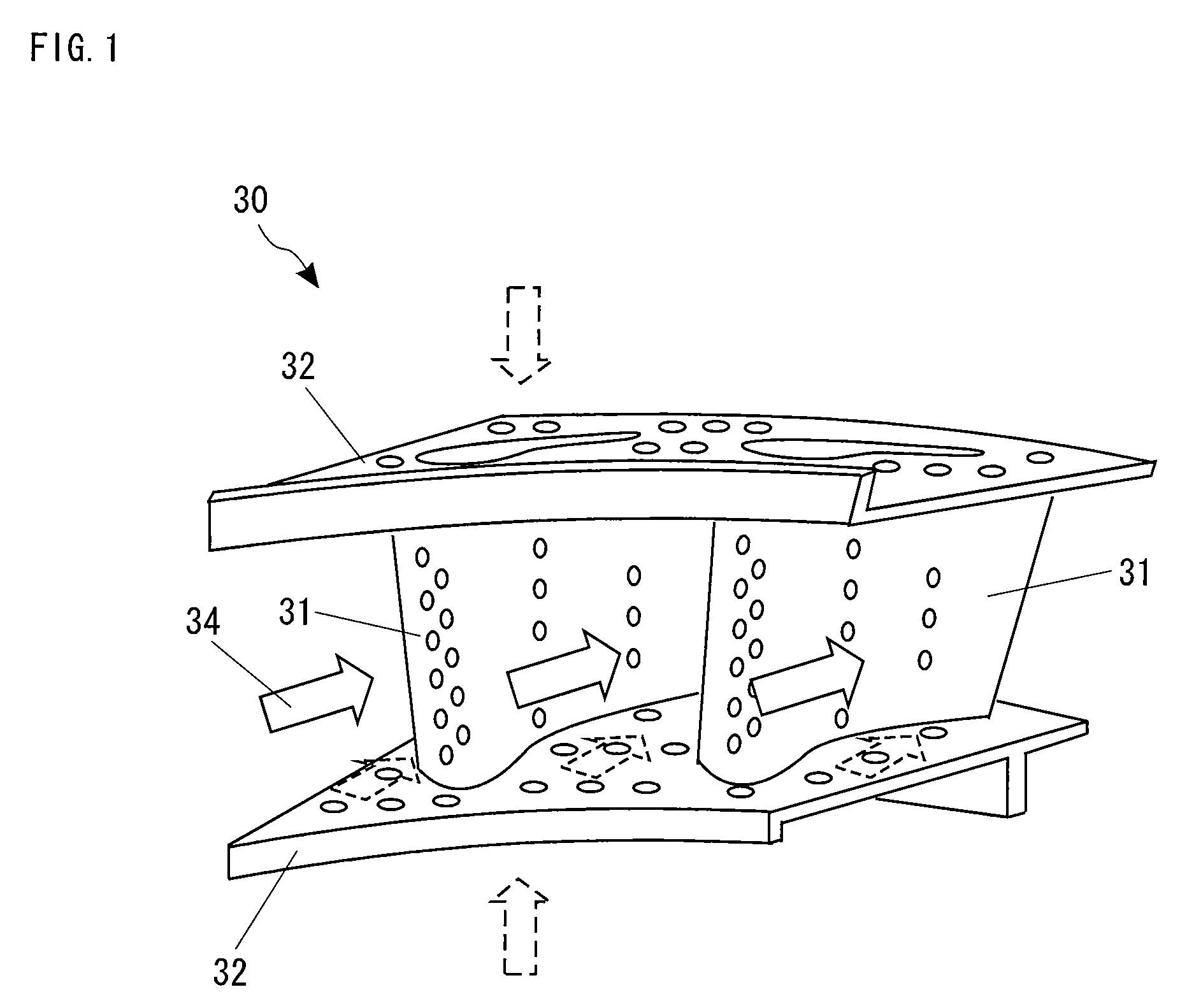

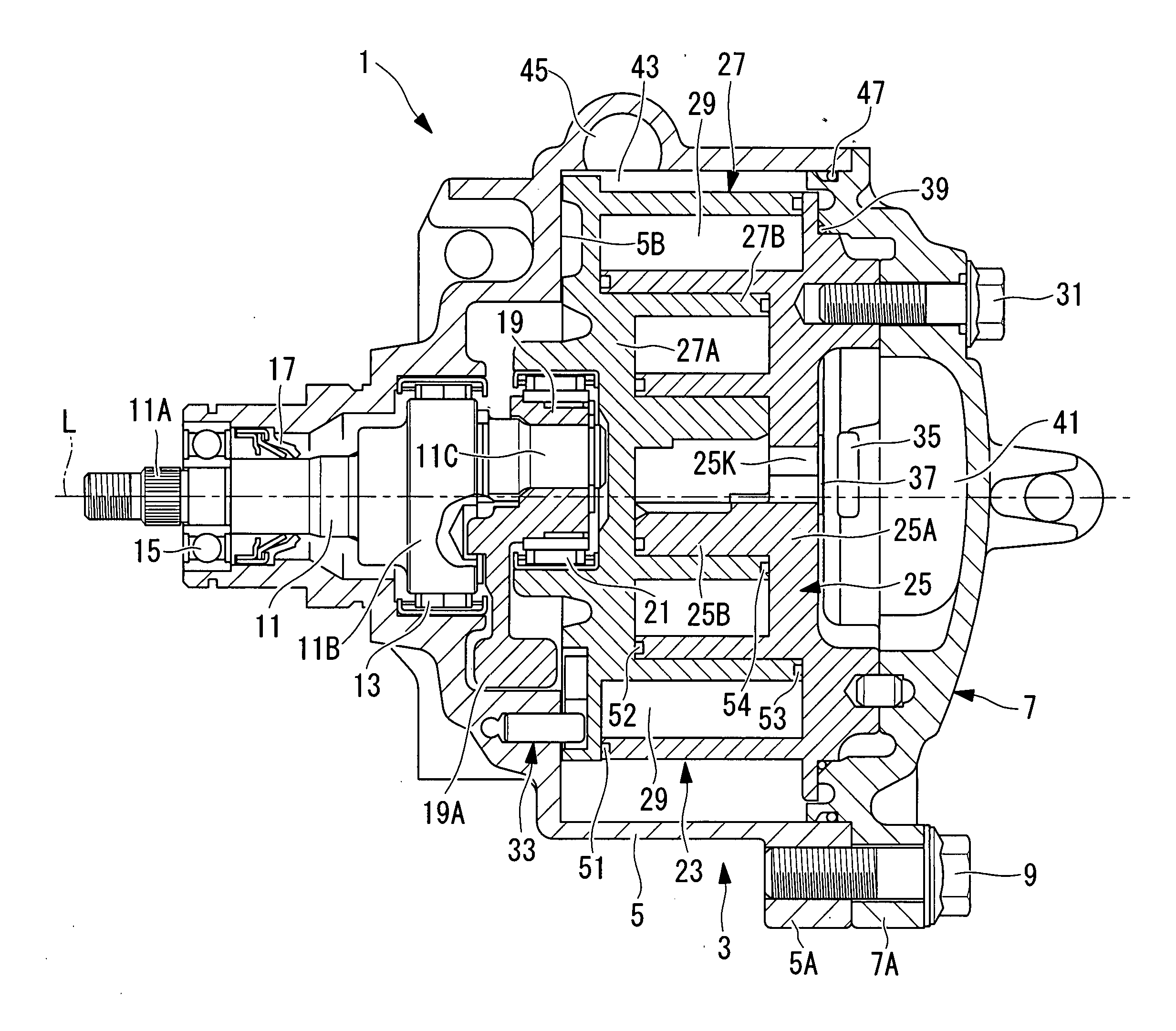

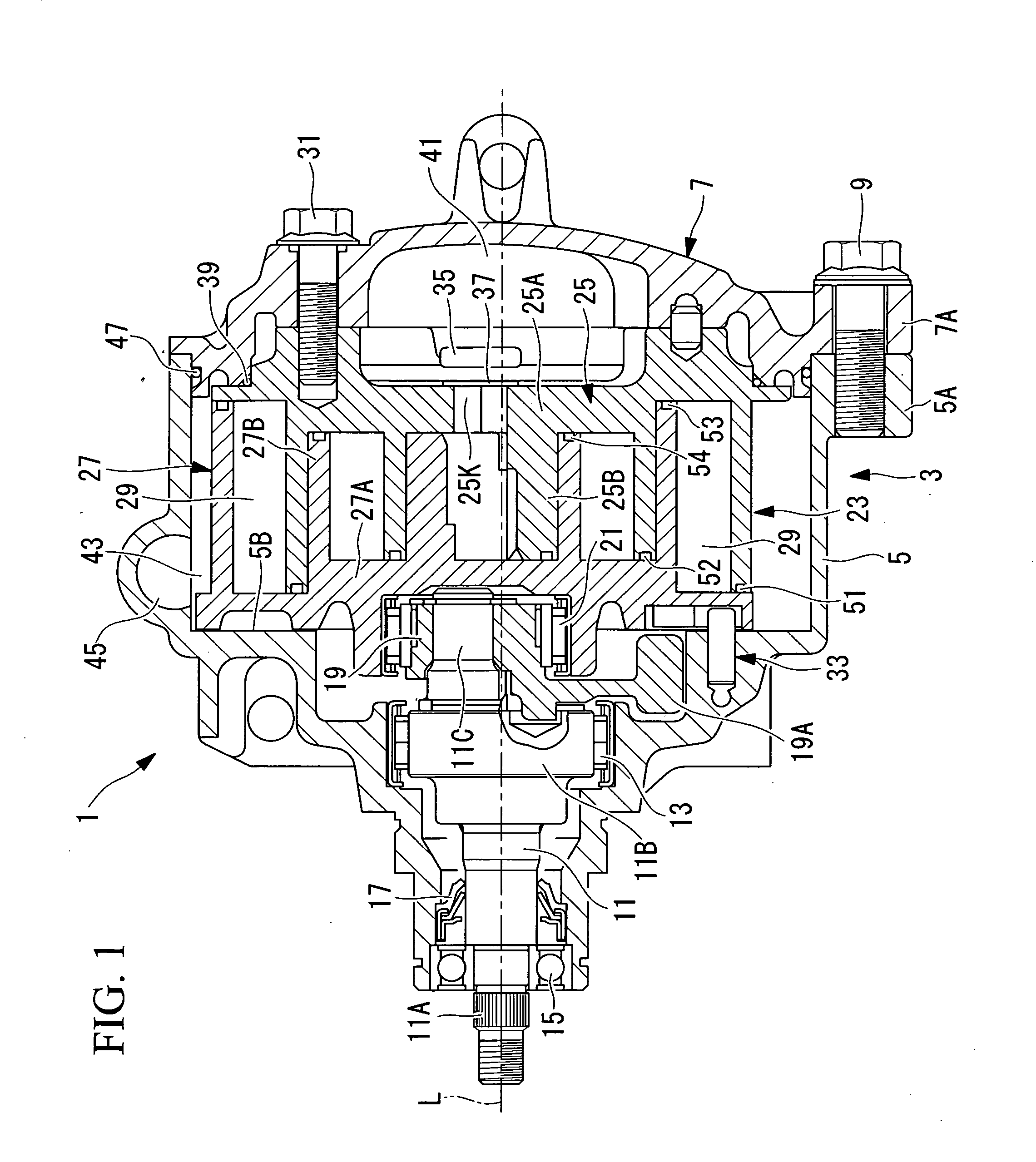

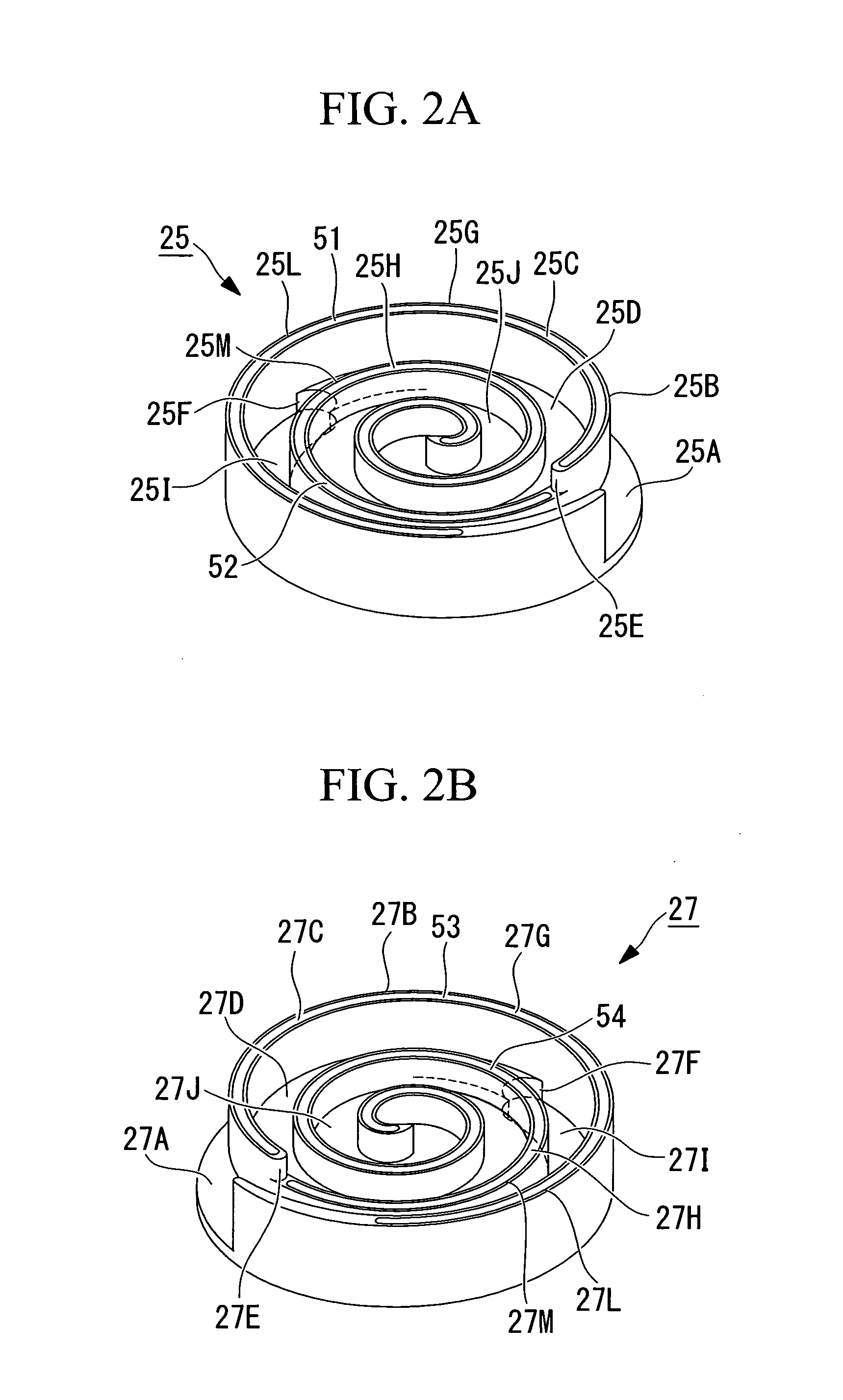

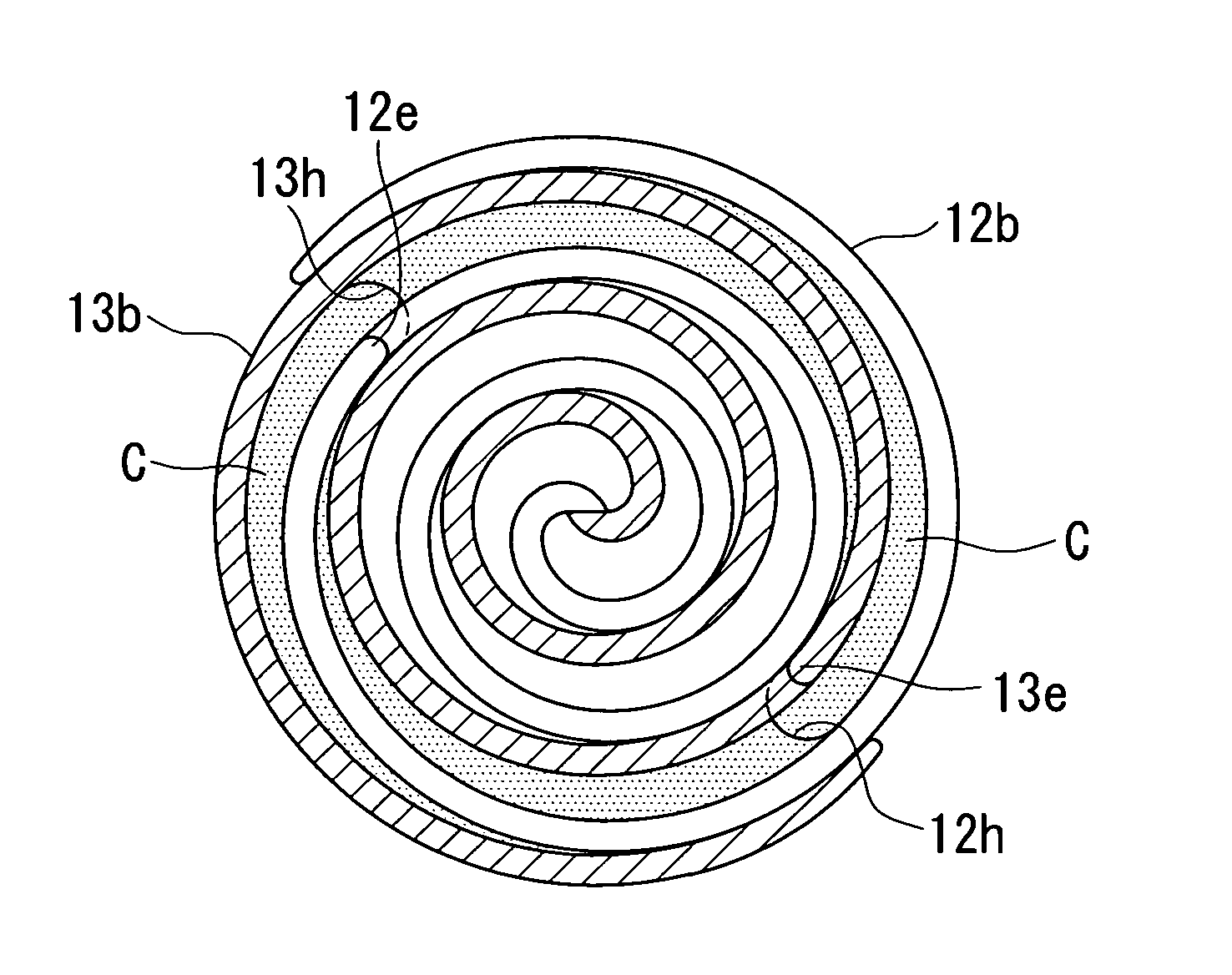

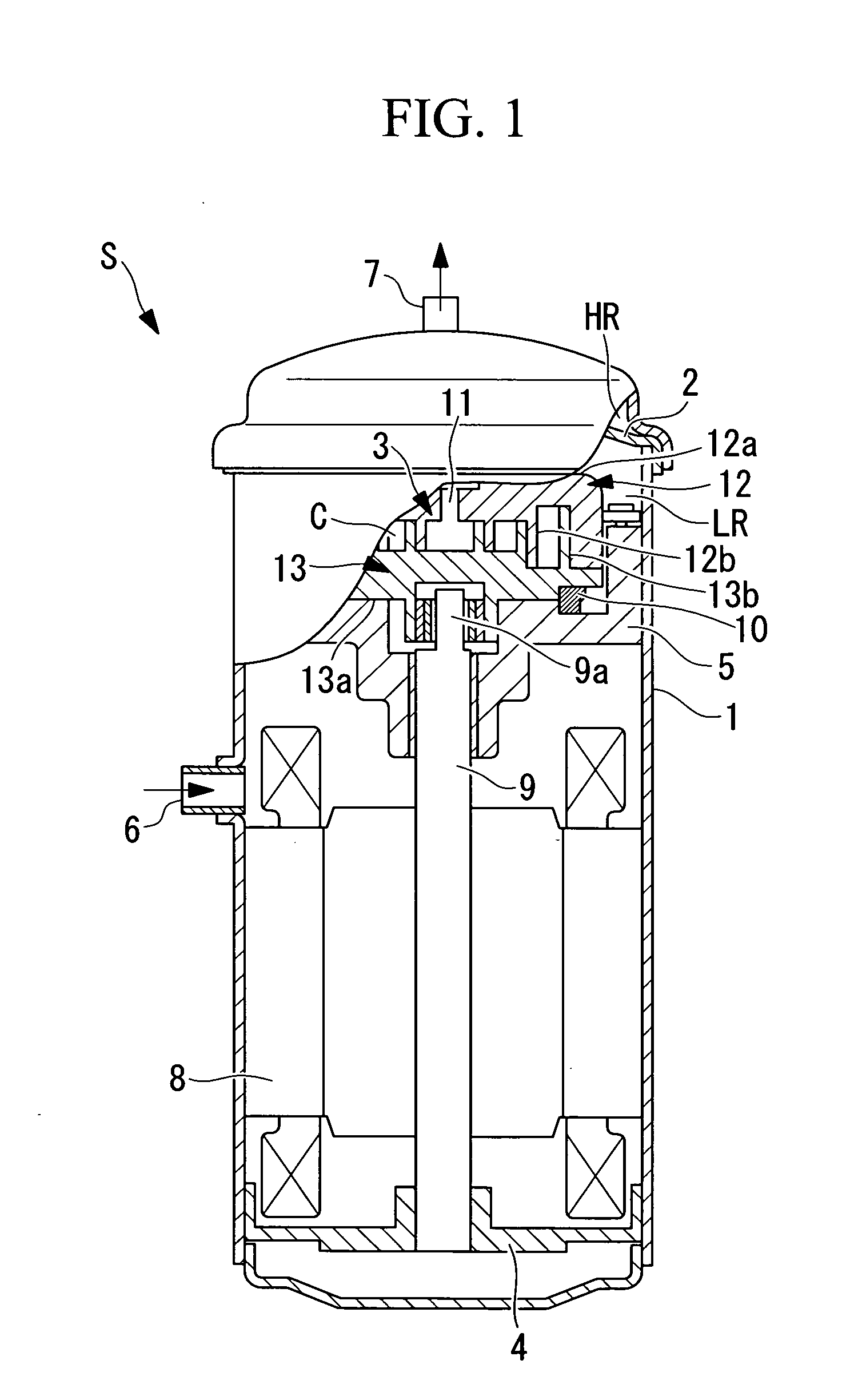

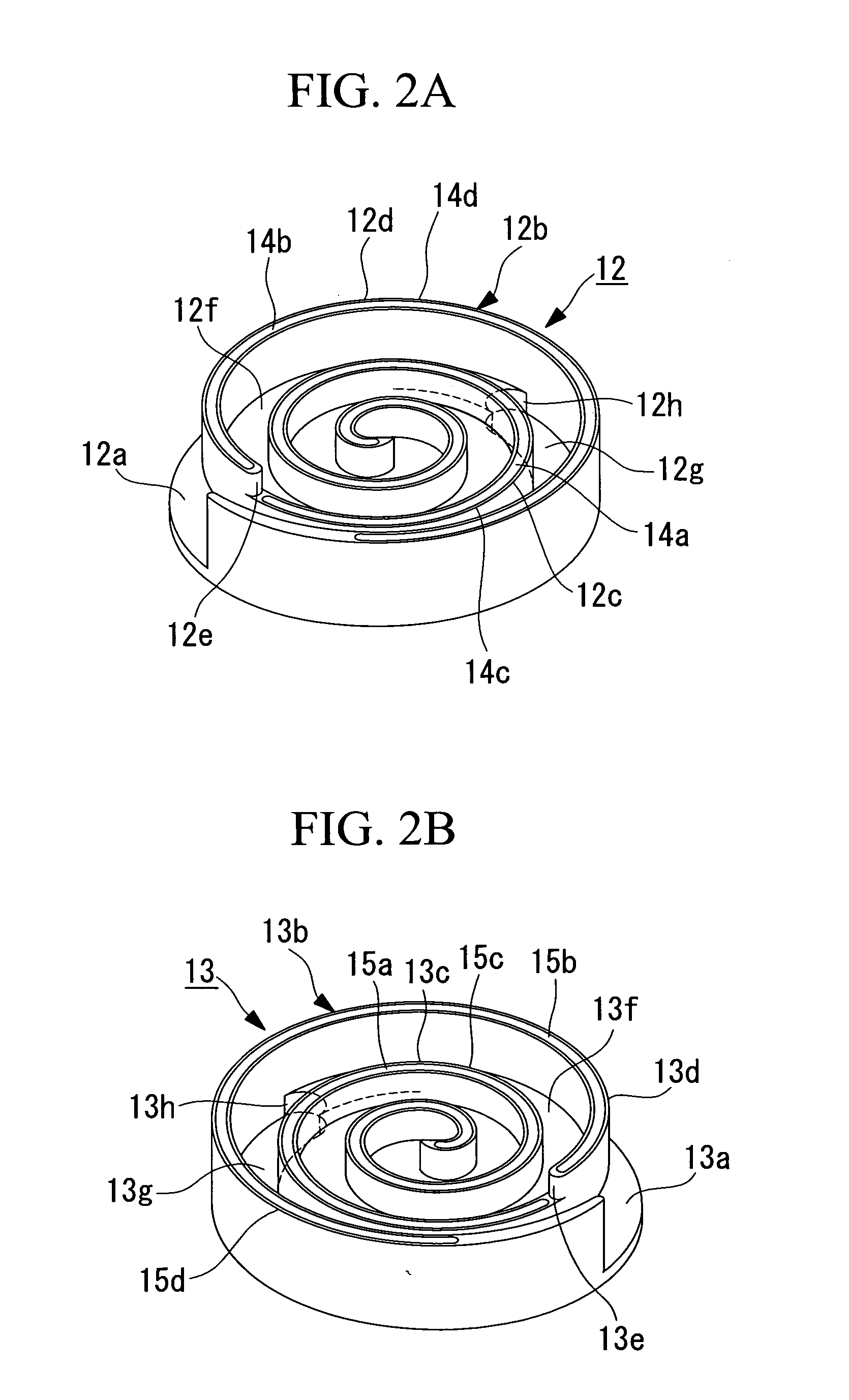

Scroll Compressor

ActiveUS20100172780A1Performance deteriorationPrevent performance variationEngine of arcuate-engagement typeOscillating piston enginesEngineeringHelix

An object of the present invention is to provide a scroll compressor capable of three-dimensional compression, which can prevent performance deterioration and performance variation due to gas leakage occurring on an outer peripheral side of a step portion of a spiral wrap and can achieve performance stabilization and performance improvement. In a scroll compressor configured to be capable of three-dimensional compression in a circumferential direction and a height direction of spiral wraps, in which top surfaces and bottom surfaces of spiral wraps (25B and 27B) are provided with step portions (25E and 27E) and the wrap height on the outer peripheral side of the step portion is made higher than the wrap height on the inner peripheral side, back-pressure introducing portions (55 and 57) where gaps between the back surfaces at step-portion ends of tip seals and groove bottom surfaces of tip seal grooves are made larger than a gap at the other portion are formed between the step-portion ends of tip seals (51 and 53) provided on top surfaces (25G and 27G) on the outer peripheral side of the spiral wraps and tip seal grooves (25L and 27L) to which the tip seals are fitted.

Owner:MITSUBISHI HEAVY IND LTD

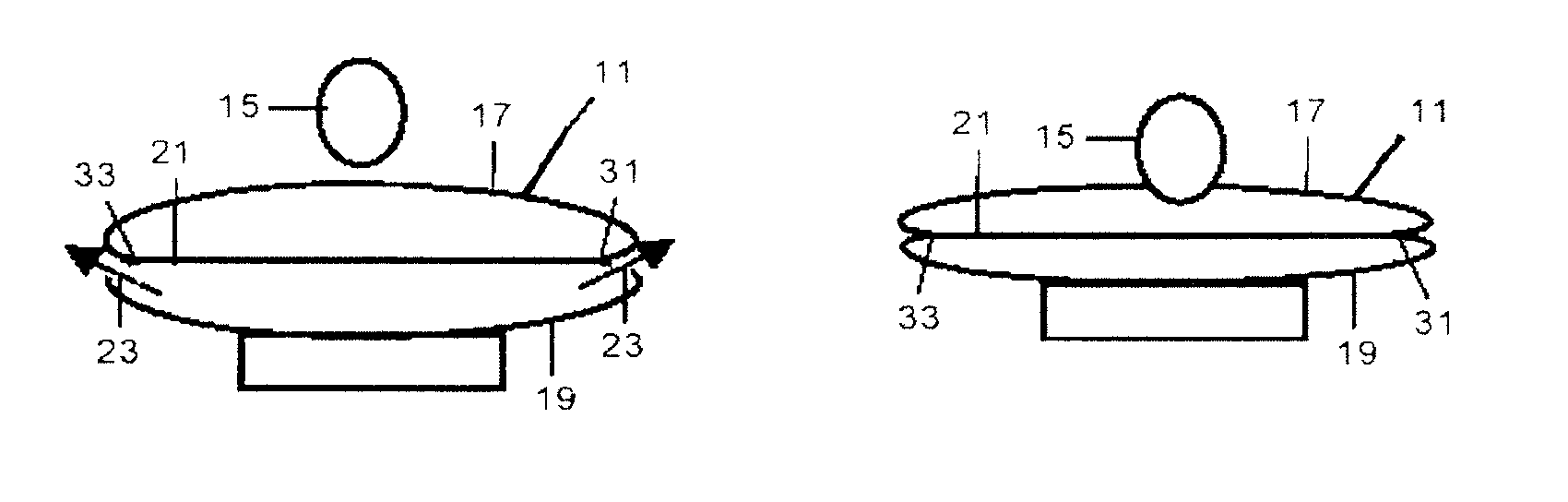

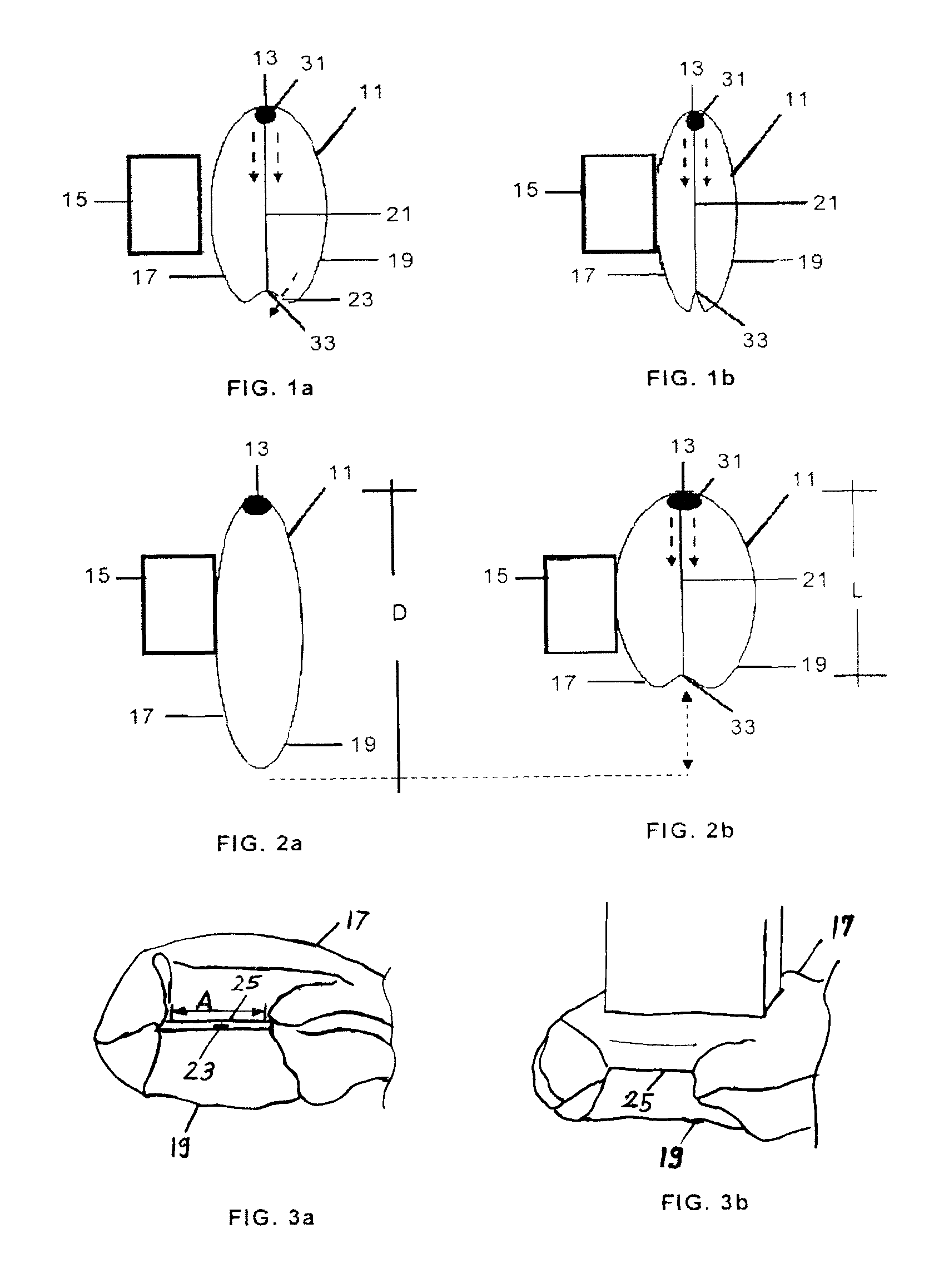

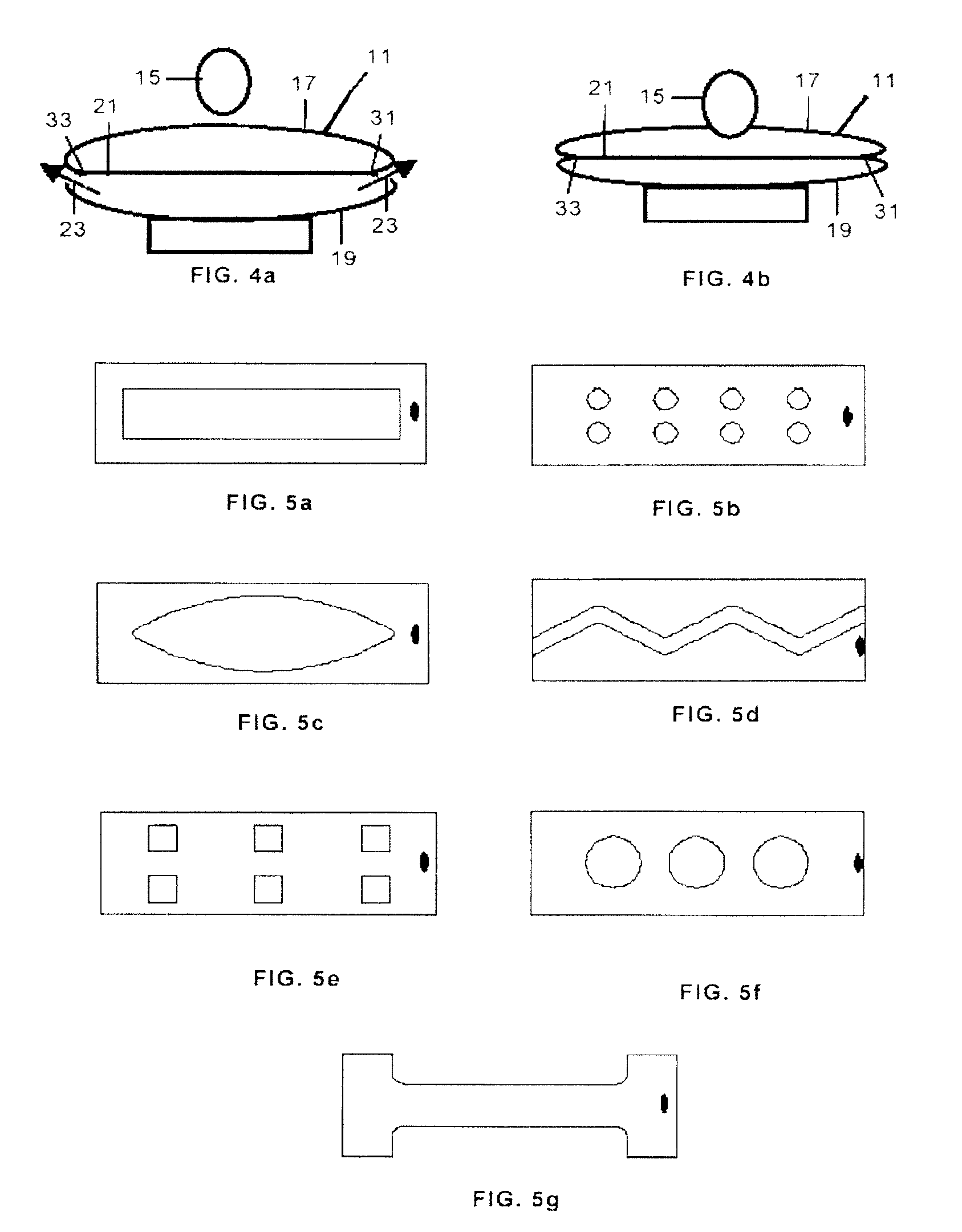

Adaptive airbag with a tension retension band that shapes bag areas into a V

ActiveUS7828326B2Reduce gas leakageImprove performancePedestrian/occupant safety arrangementEngineeringMaximum pressure

Airbag module for protecting an occupant of car with a bag (11) that includes a main front panel (17) and main rear panel (19) connected by its ends and a retention band (21) connected to the panels in two opposite ends (31, 33), capable of withstanding maximum pressure during the unfolding of the bag (11) without breaking or disconnecting from said panels, and whose length L is less than the maximum distance D that would exist between said opposite areas (31, 33) during the unfolding of the bag should said retention band (21) not exist; the bag has a ventilation orifice (23) around one of the union areas (31, 33) that can be covered by the main front and rear panels (17, 19) when the bag (11) contacts the occupant (15).

Owner:DALPHI METAL ESPANA

Scroll compressor

ActiveUS20100092318A1Improve compression efficiencyReduce gas leakageRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringThermal expansion

Intended is to provide a scroll compressor capable of performing three-dimensional compressions, which can optimize a tip clearance in operation while considering a thermal expansion and a pressure deformation and which can reduce a compression leakage to improve a compression efficiency thereby to realize a high performance. The leading end faces (13c and 13d) and the bottom face of a spiral wrap (13b) have a step portion (13e), and the wrap height on the outer circumference side of the spiral wrap (13b) is made larger than that on the inner circumference side wrap height, so that the scroll compressor can perform three-dimensional compressions capable of compressing in the circumferential direction of the spiral wrap (13b) and in the wrap height direction. The spiral wrap (13b) on the inner circumference side with respect to the step portion (13e) is stepwise or continuously made gradually lower toward the center side of the spiral wrap (13b), and the tip clearance (Δi) of the spiral wrap on the inner circumference side with respect to the step portion (13) is made gradually larger toward the center side of the spiral wrap (13b).

Owner:MITSUBISHI HEAVY IND LTD

Sealing and reinforcing strips principally for airbag assembly joints

InactiveUS20060292949A1Reduce gas leakagePedestrian/occupant safety arrangementWoven fabricsAirbag deploymentEngineering

Owner:ZODIAC AUTOMOTIVE US

Gas turbine rotor

InactiveUS20060024166A1Improve sealingWell-controlled mannerPropellersRotary propellersGas turbinesTurbine rotor

On a gas turbine rotor with internally cooled airfoils (4) of the turbine rotor blades and a mechanical sealing and damping element arranged between opposite side faces (6) of adjacent blade platforms (7), the gap is additionally aerodynamically sealed against the hot gas flow, by cooling air supplied from a cavity (5) of the airfoils via a cooling duct (9) into the gap between the side faces (6).

Owner:ROLLS ROYCE DEUT LTD & CO KG

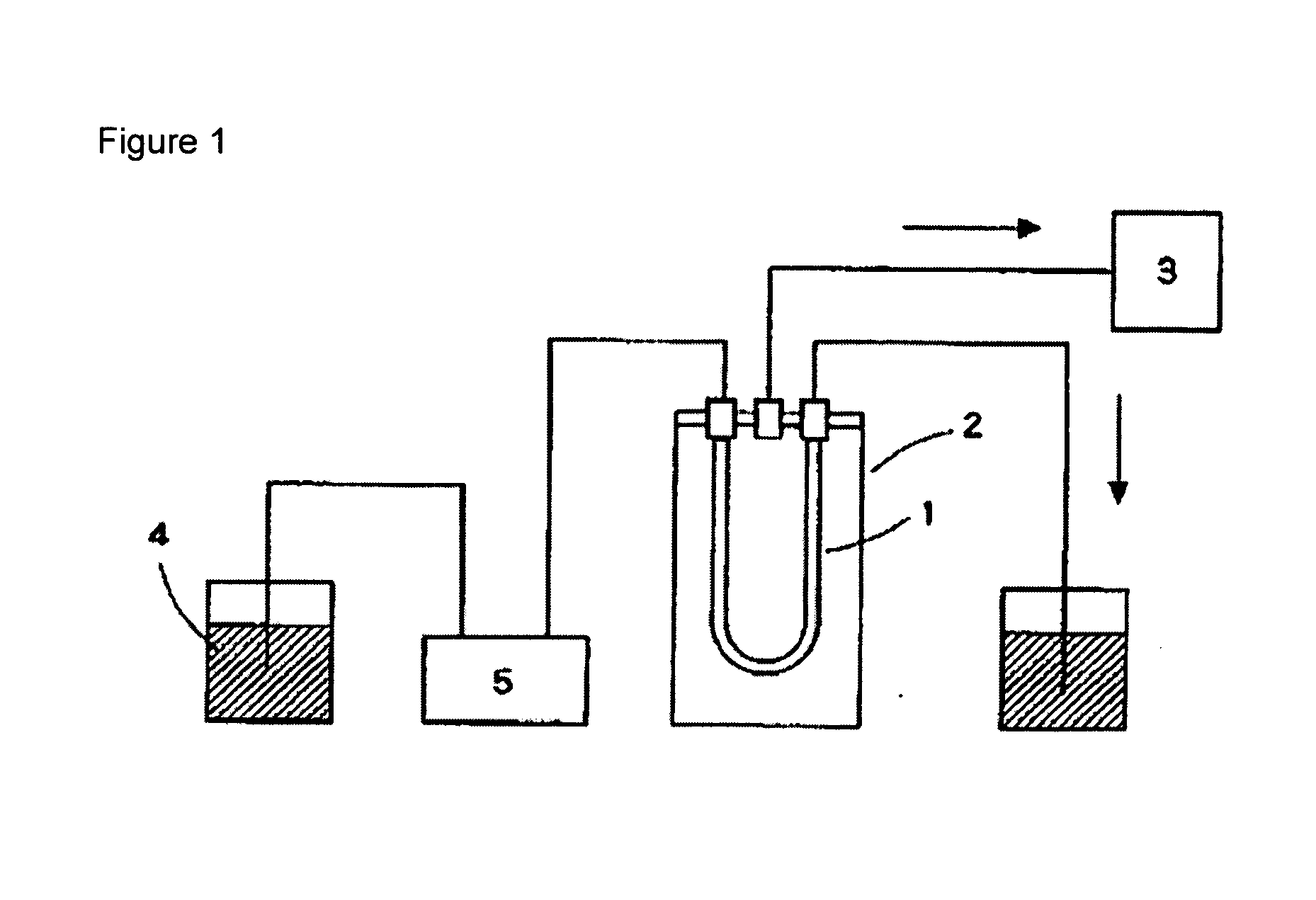

Three electrodes system cell for evaluation of performance of molten carbonate fuel cell

InactiveUS20060049045A1Avoid crackingReduce gas leakageFuel cell auxillariesActive material electrodesFuel cellsMolten carbonate fuel cell

Disclosed is a three electrodes system cell for evaluation of performance of a molten carbonate fuel cell. A lower part of the reference electrode is fixed to a wet seal part of the single cell without penetrating a current collector plate and an electrode of the single cell. Preferably, the reference electrode comprises cured matrix slurry and powders of electrolyte stacked on the matrix slurry in the lower part thereof. Preferably, a diameter of an electrolyte-interchanging hole formed in a bottom of the lower part of the reference electrode is 1ψ. Preferably, an outer diameter of an alumina tube in the reference electrode is 6ψ. According to a three electrodes system cell for evaluation of performance of a molten carbonate fuel cell of the invention, it is possible to separately evaluate the performance of each electrode which cannot be evaluated by the prior method of evaluating the performance of the single cell. Particularly, contrary to the prior art, it is possible to prevent a crack of the matrix due to a physical shock and a heat shock resulting from the outflow and inflow of the supply gas, to reduce the gas leakage resulting from a decrease of adhesive strength between the matrix and the alumina tube and a heat shock due to the gas leakage, to improve the problem of electrolyte depletion and to reduce the physical defects resulting from a size of the reference electrode. Accordingly, it is possible to clearly measure the variation of the performance of each electrode while reducing the physical errors to the highest degree, to provide an exact criterion regarding the factor influencing on the variation of performance of the single cell when evaluating the performance of the single cell having 100 cm2 of large area, and to directly evaluate the performance of the molten carbonate fuel cell.

Owner:KOREA INST OF SCI & TECH

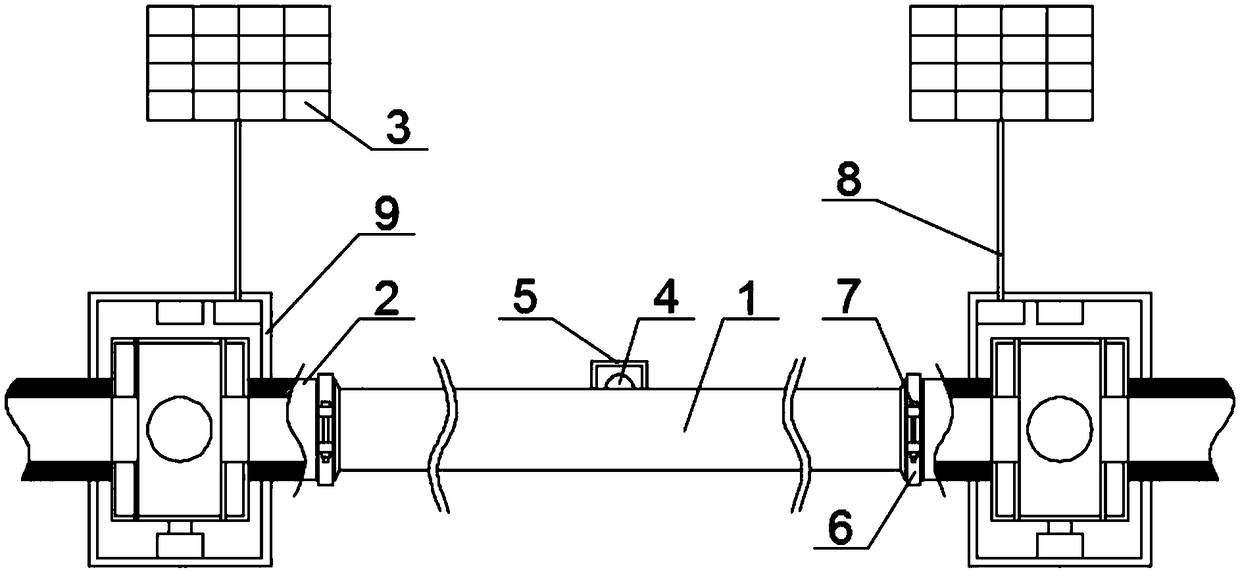

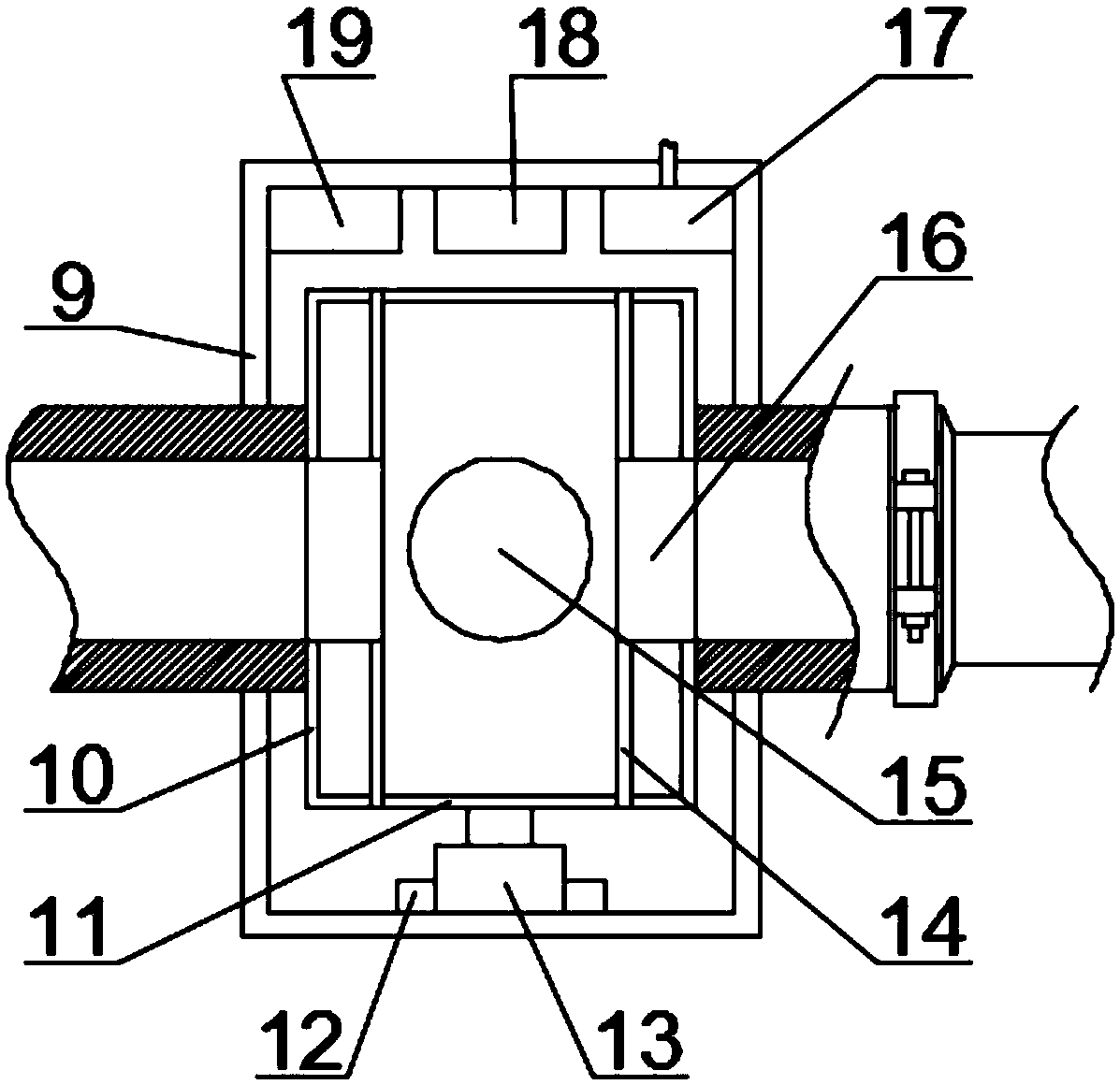

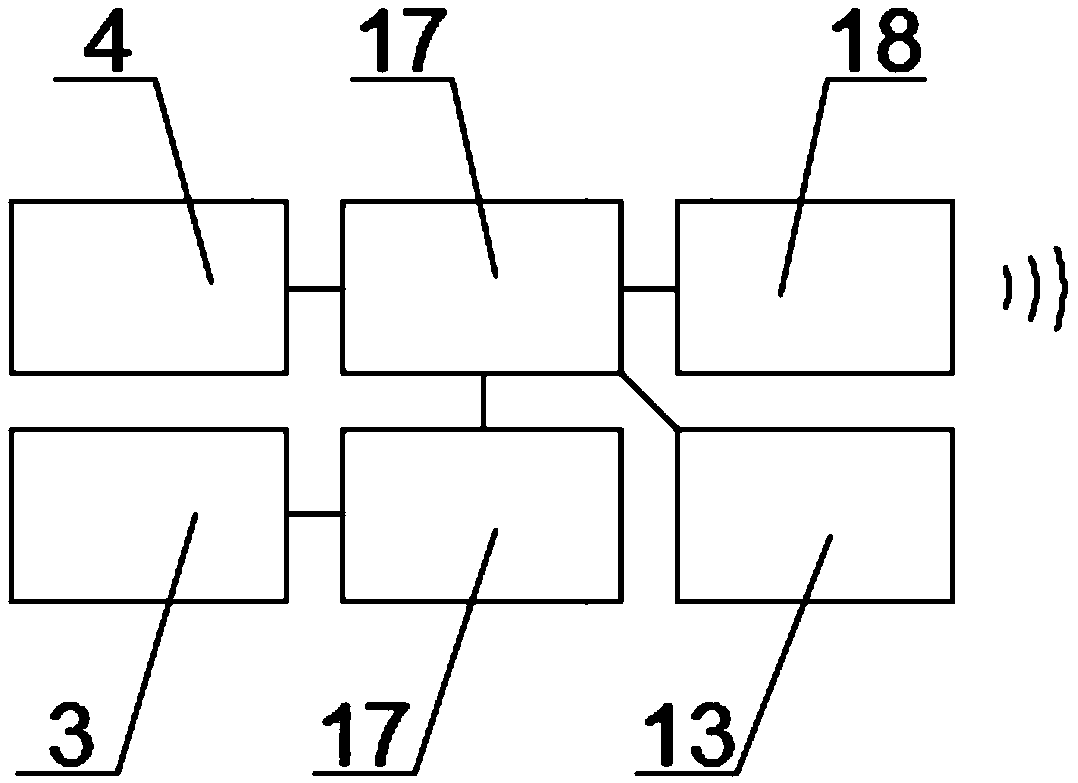

Anti-leakage gas pipeline

InactiveCN108980474AImprove toughnessCorrosion resistantCorrosion preventionPipeline systemsMoisture resistanceGlobal Positioning System

The invention relates to an anti-leakage gas pipeline, and belongs to the technical field of pipelines. The anti-leakage gas pipeline comprises a pipeline body, a bushing and a gas concentration sensor are mounted on the pipeline body, the bushing is provided with an inner shell and an outer shell, a motor is arranged in a fixed seat, the inner shell is provided with a sleeve, a first through hole, a sealing pad and a second through hole, the outer shell is provided with a motor, a storage battery, a controller and a wireless communication device, and the storage battery is electrically connected with a solar panel through a lead. The pipeline body has good toughness, corrosion resistance, oxidation resistance, moisture resistance, compression resistance and vibration reduction performance, gas does not easily leak, the solar panel supplies power for other components, leakage places are conveniently and timely monitored and accurately positioned by the gas concentration sensor with a GPS (global positioning system), rush repair is facilitated, the controller isolates gas in the bushing by the motor when leakage happens, and gas leakage is decreased.

Owner:郑州拓华仪器有限公司

Firearm Systems and Methods

ActiveUS20170045317A1Improve reliabilityFacilitate strokePiston ringsBreech mechanismsMatched pairEngineering

A firearm can have a bolt having a plurality of locking lugs that are configured to have a shear area that is larger than that of a standard M16 / M4. A bolt carrier can have a bolt that has a double cut cam having an unlocking cam surface that has sufficient dwell increase to delay a start of unlocking when the bolt carrier is used in an M4 carbine. A stepped extractor pin may be provided that prevents disengagement of the extractor pin. A tube can be configured to provide gas from a barrel of the firearm to the piston via the carrier key. The tube can have a heat radiator formed from triangular shaped threads on at least a portion of the tube. A piston on the bolt and can have a plurality of rings including pairs of mating rings that are formed and maintained as a matched pair.

Owner:ARMWEST

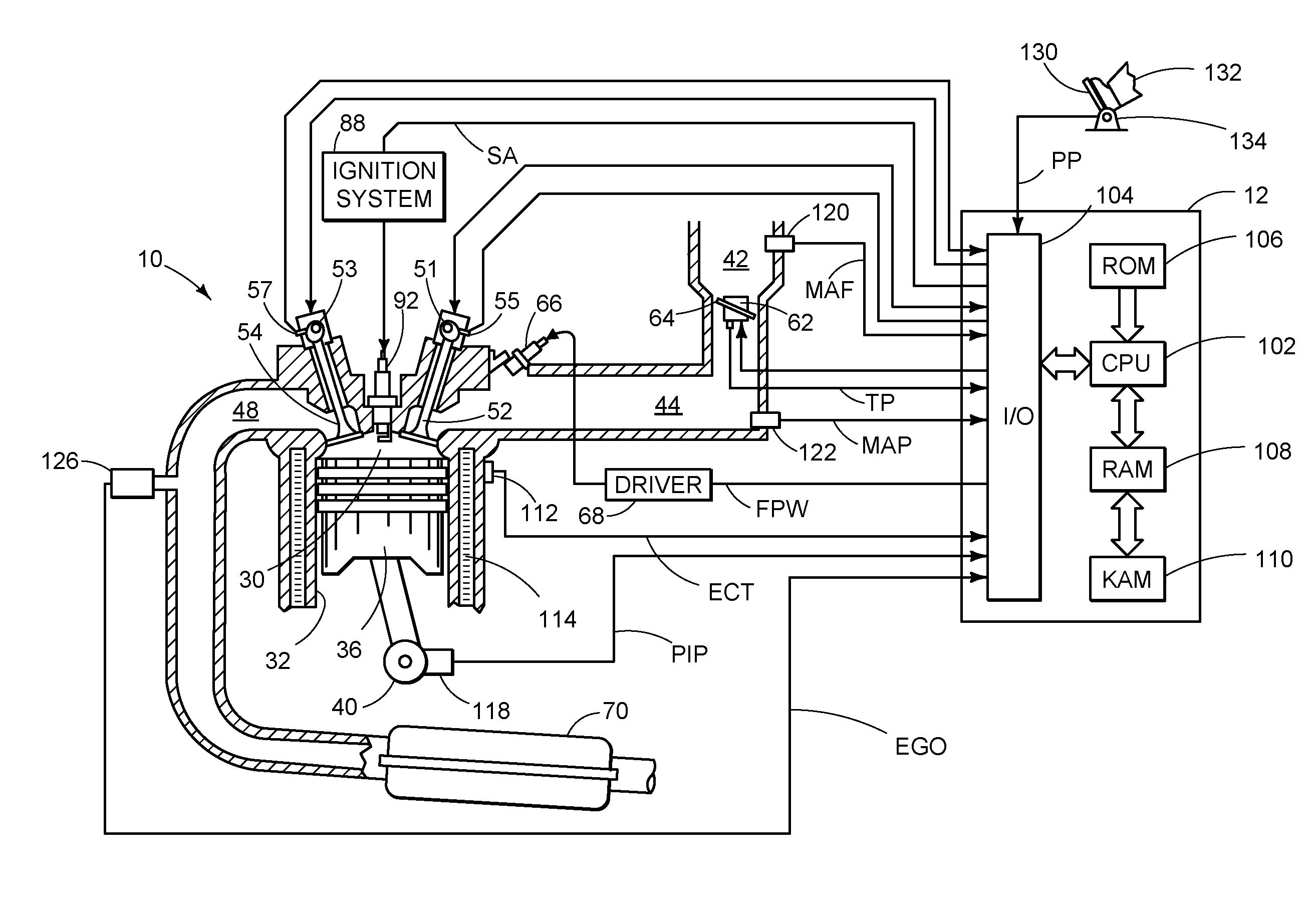

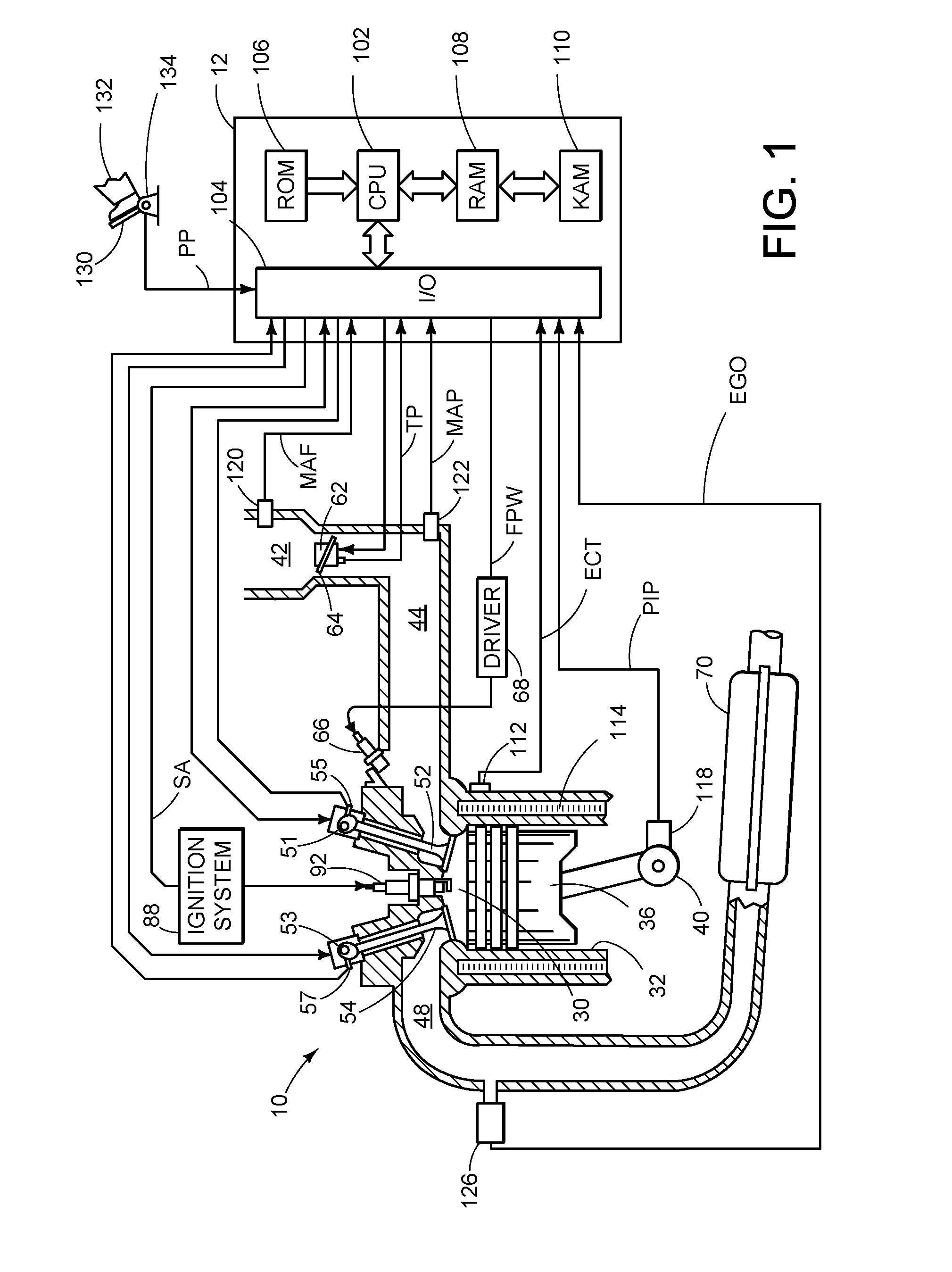

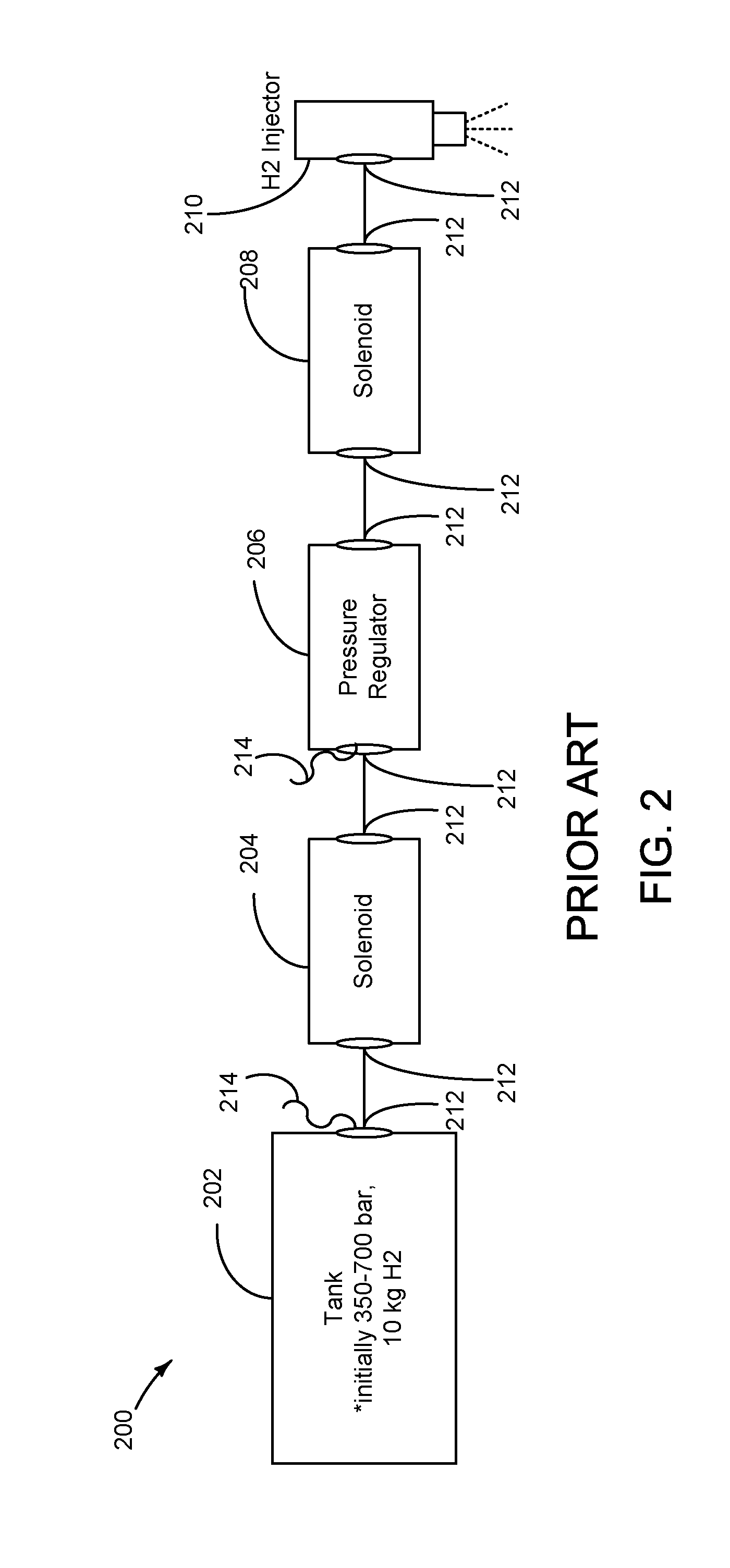

Integrated Gaseous Fuel Delivery System

InactiveUS20080135005A1Reduce and limit fuel leakageIncrease costElectrical controlInternal combustion piston enginesProduct gasProcess engineering

An integrated gaseous fuel delivery system is provided. The system includes a storage tank to hold a gaseous fuel and a pressure regulation system disposed interior the storage tank and configured to regulate a pressure of gaseous fuel delivered from the storage tank.

Owner:FORD GLOBAL TECH LLC

Glue-free airtight filtering equipment

ActiveUS20190160408A1Reduce replacement costsReduce gas leakageDispersed particle filtrationTransportation and packagingFilter elementWaste management

Disclosed is glue-free airtight filtering equipment comprising a filter housing, a plurality of filter elements and a plurality of receiving supporting elements, each filter element having a filtering surface, the plurality of filter elements being detachably disposed in the filtering space in a manner that the filtering surface is parallel to the upper surface and the bottom surface of the filter housing, and the plurality of receiving supporting elements allocating on an inner wall of the filter housing and being spaced apart from each other with a designated distance so as to correspondingly receive and support the plurality of filter elements, wherein a gap is provided between the filter element and the inner wall of the filter housing, and the filtering surface of the filter element and the maximum value of the gap satisfy a relational expression.

Owner:GREENFILTEC PTE LTD

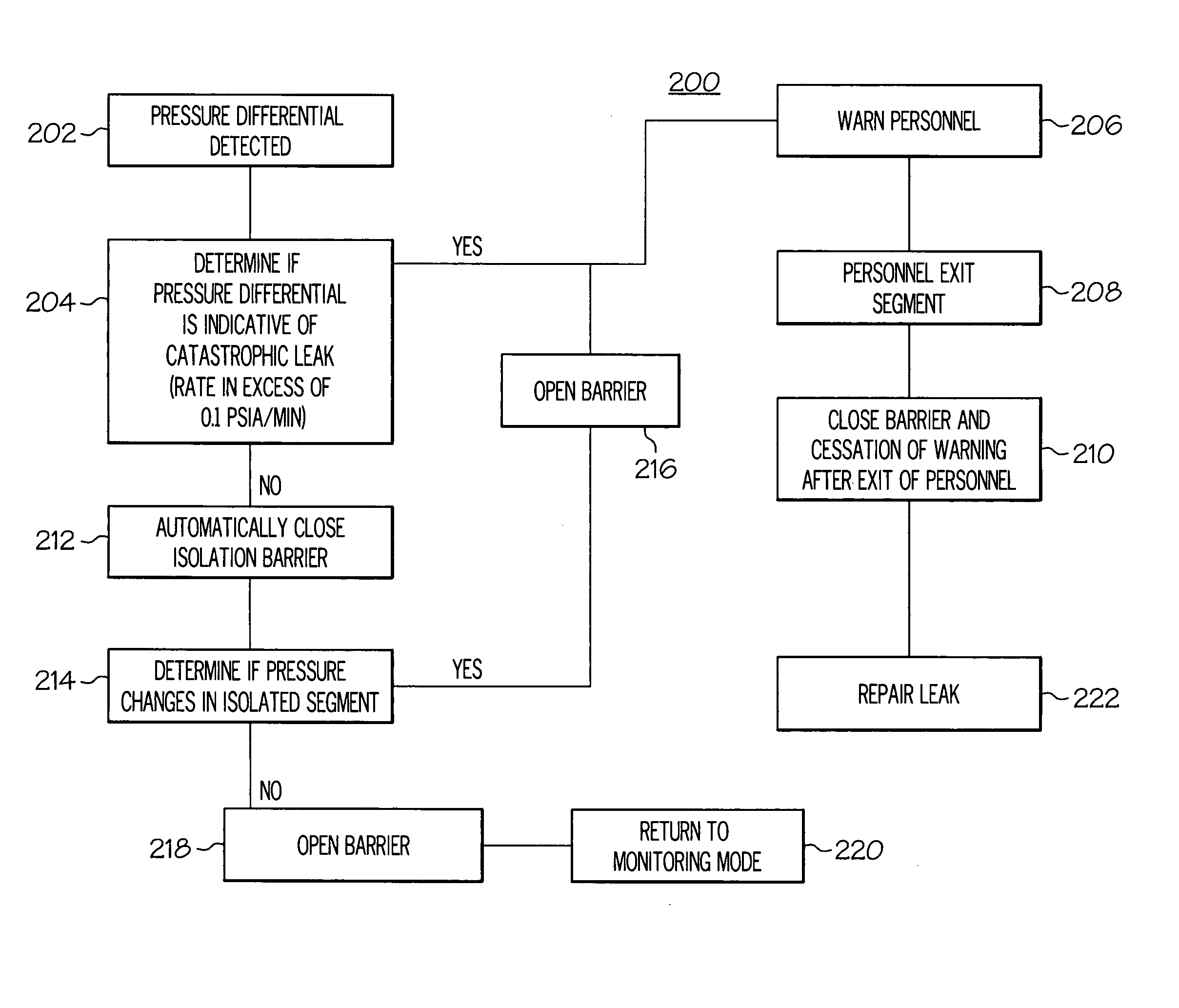

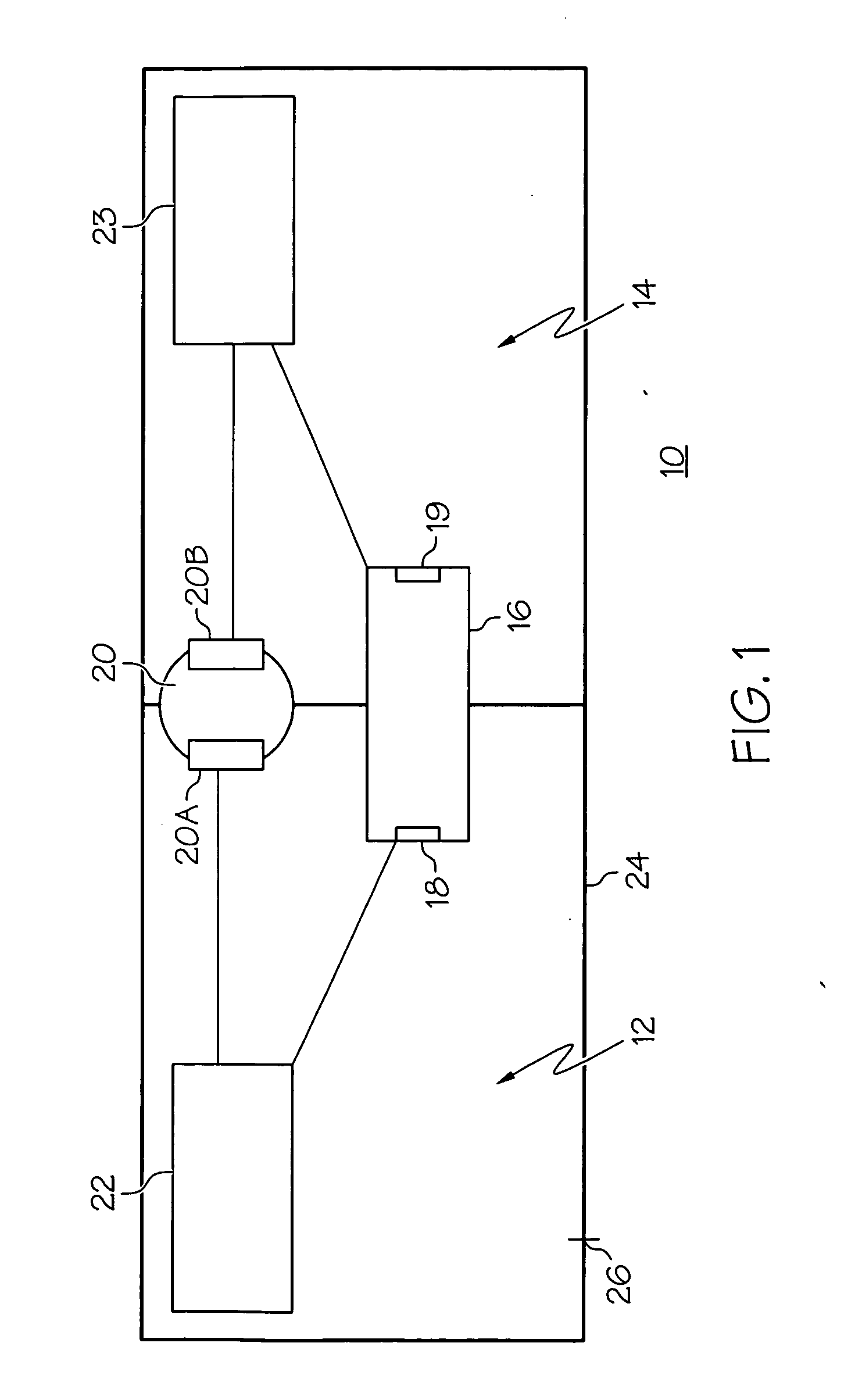

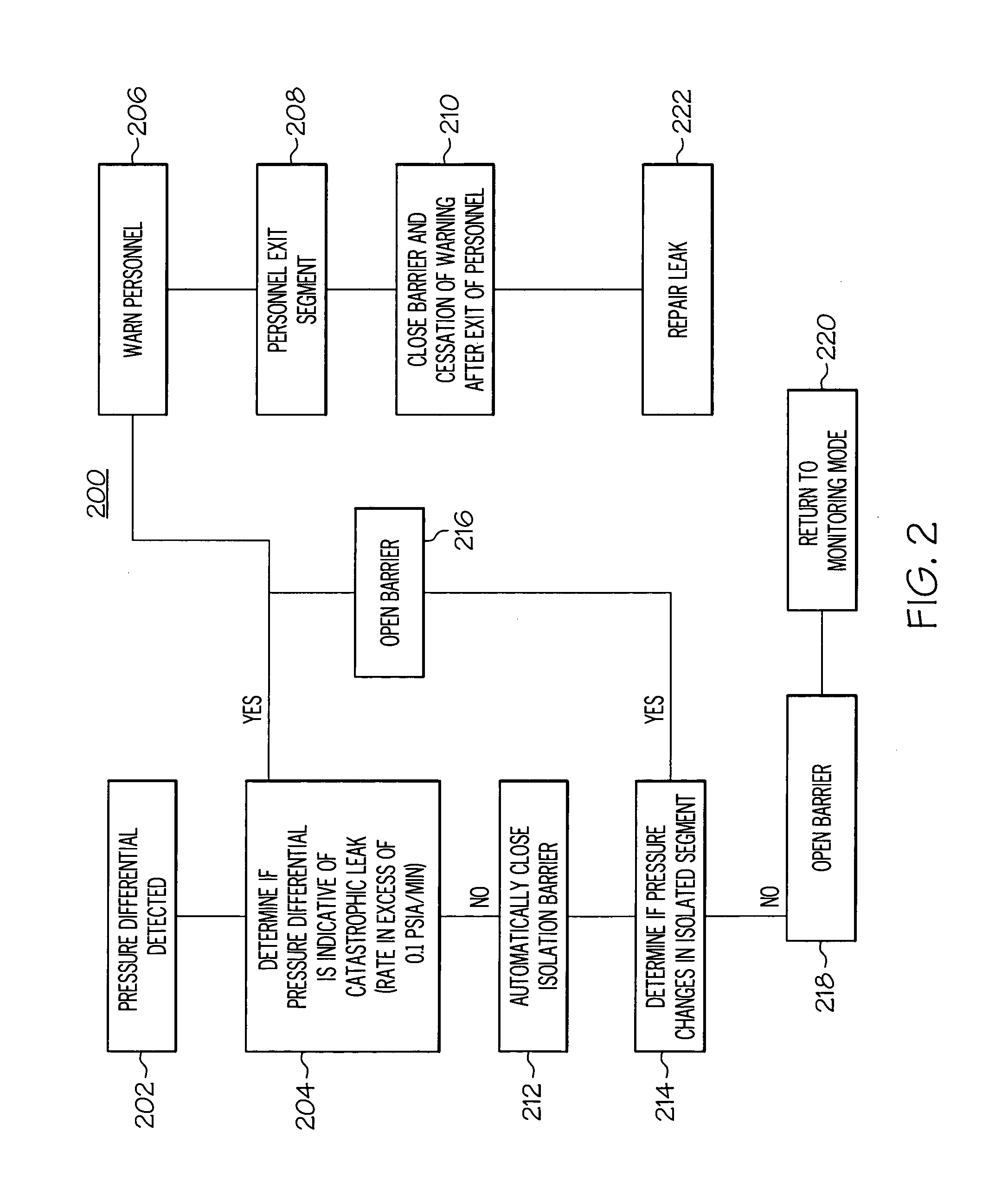

Leak detection and isolation for segmented inflatable structures

InactiveUS20070056638A1Mitigating atmospheric gas leakageReduce gas leakageCheck valvesEqualizing valvesDifferential pressureTransducer

Space vehicles such as space stations are often constructed as segmented inflatable structures which are susceptible to being punctured by small meteoric materials, resulting in small insidious leaks which are difficult to locate and repair. A method and apparatus are described in which a differential pressure transducer is positioned between segments of the space vehicle. Atmospheric gas pressure of all segments is continuously monitored. Analysis is performed on any pressure differentials which are determined to exist between adjacent segments. Detection of small leaks initiates an automatic isolation of the leaking segment. Detection of catastrophic leaks initiates an emergency evacuation of personnel from the affected segment.

Owner:HONEYWELL INT INC

Tubular member made of fluororesin

InactiveUS20050048240A1Reduce condensationReduce gas leakageLayered productsBottlesShell moldingBiomedical engineering

The invention relates to a fluororesin tube. More specifically, the invention provides a fluororesin tubular member that has low gas permeability. The fluororesin tubular member of the present invention uses a fluororesin as a starting material and is stretched in the axial direction and heat set once molding has been performed. Gas permeability may accordingly be reduced as compared to tubular bodies obtained merely by means of the molding of a fluororesin; therefore, if the tubular member is used as a material for chemical supply lines or other pipework that requires a fluororesin tube, it is possible to prevent gas from leaking and condensation from forming on the piping surface.

Owner:JUNKOSHA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com