Anti-leakage gas pipeline

A gas pipeline and anti-leakage technology, applied in the field of pipelines, can solve problems such as heavy workload, hidden safety hazards, inconvenient monitoring, etc., and achieve the effects of not easy gas leakage, moisture resistance, compression resistance and shock absorption, and reducing gas leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

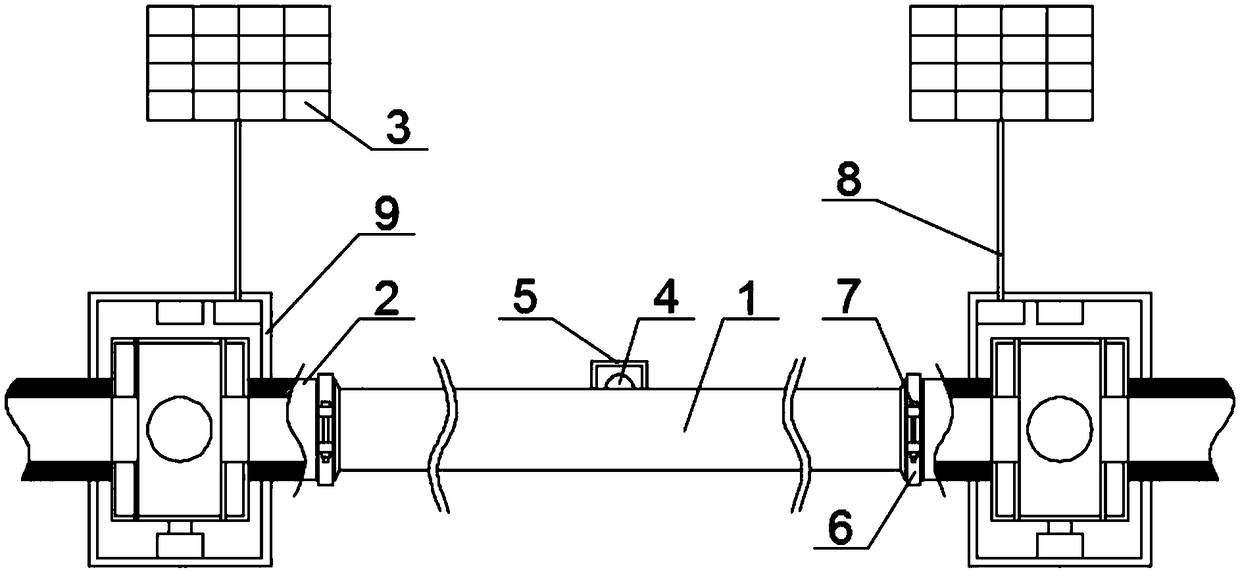

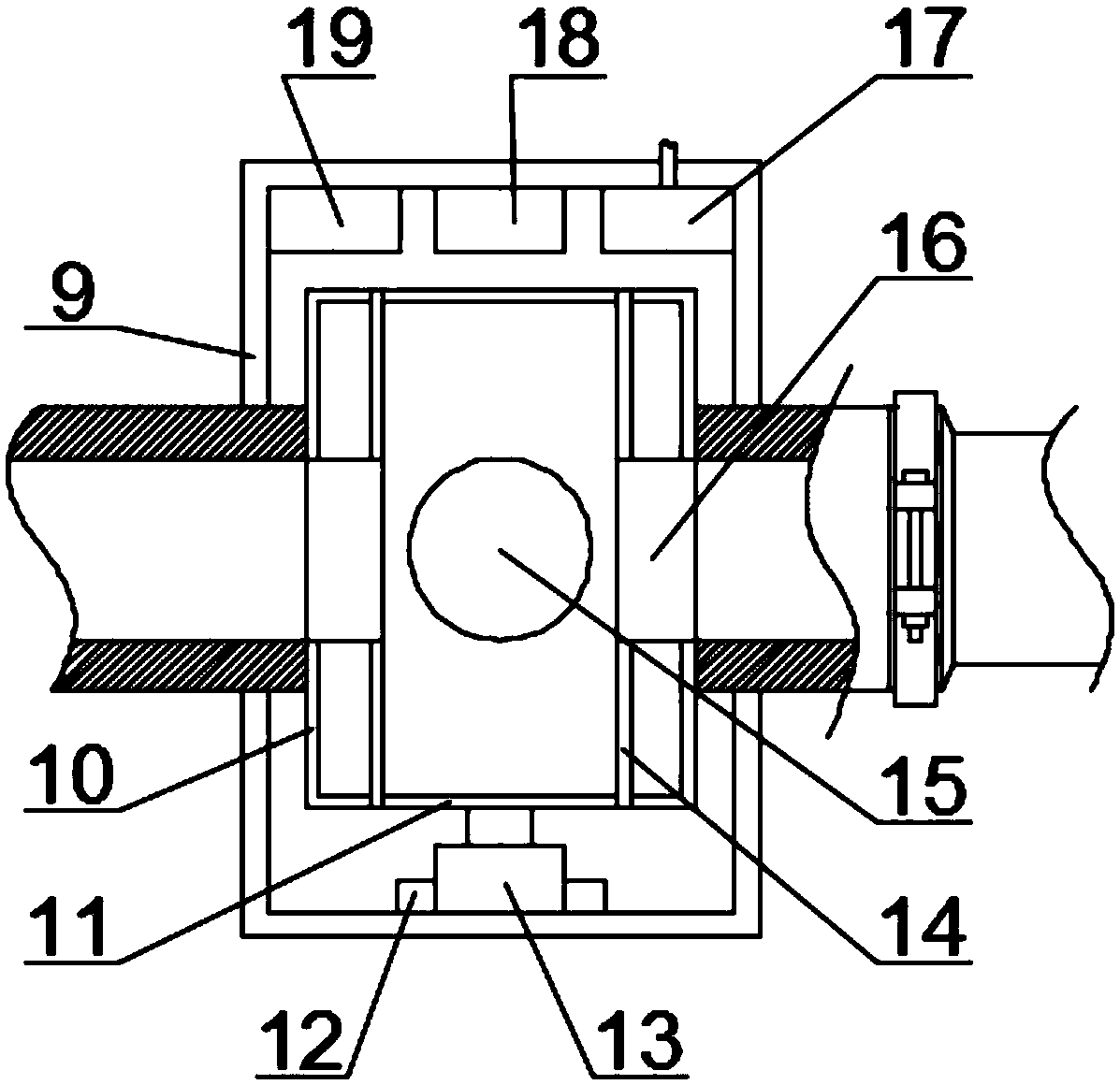

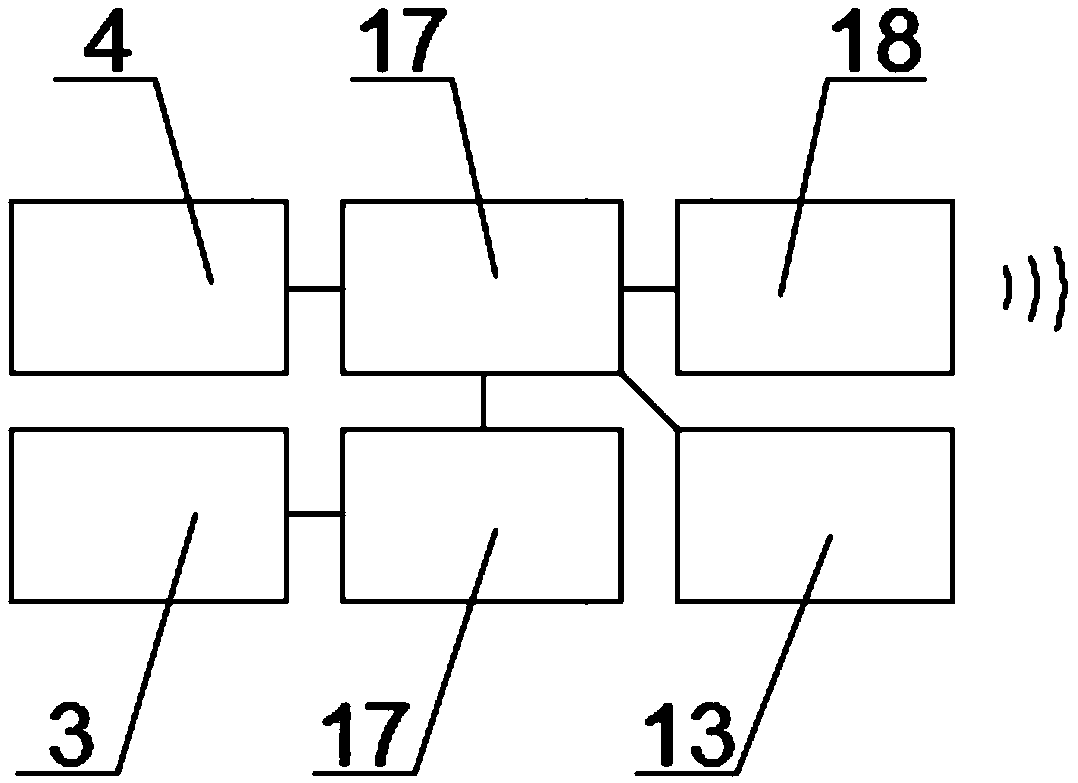

[0024] Such as figure 1 , 2 The anti-leakage gas pipeline shown in . An inner shell 10 is arranged inside, and an outer shell 9 is arranged on the outside of the inner shell 10, and the outer shell 9 is installed on the casing 2, and a fixing seat 12 is installed on the bottom of the outer shell 9, and a motor 13 is arranged inside the fixing seat 12 , the inside of the inner shell 10 is provided with a sleeve 11, the bottom of the sleeve 11 is fixedly connected with the output end of the motor 13, the inside of the sleeve 11 is provided with a first through hole 15, and the outside of the sleeve 11 is provided with a fixed connected gasket 14, the inner shell is also provided with a second through hole 16, and the top of the outer shell 9 is provided with a storage battery pack 17, a controller 18 and a wireless communication device 19, and the storage battery pack 17 communicates with the solar cell through a wire 8 The panels 3 are electrically connected, the solar panel ...

Embodiment 2

[0030] As shown in the figure, the difference between this embodiment and Embodiment 1 is that the number of gas concentration sensors 4 is set to two, and the two gas concentration sensors 4 are installed on the top and bottom of the pipeline body 1 respectively. The soil is covered, and the gas leaking from the bottom may not be detected at the bottom. By setting the gas concentration sensor 4 at the bottom, it is convenient to monitor whether there is gas leakage at the bottom of the pipeline body 1, so that the monitoring is more accurate.

[0031] The working principle is as follows: the converted energy is stored in the underground battery pack 17 through the wire 8 through the solar panel 3 on the ground surface, and is controlled by the controller 18 to provide electric energy for the gas concentration sensor 4, the motor 13 and the wireless communication device 19. The gas concentration sensor 4 checks whether the gas is leaking. When the gas concentration exceeds the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com