Patents

Literature

3600 results about "Turbine rotor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

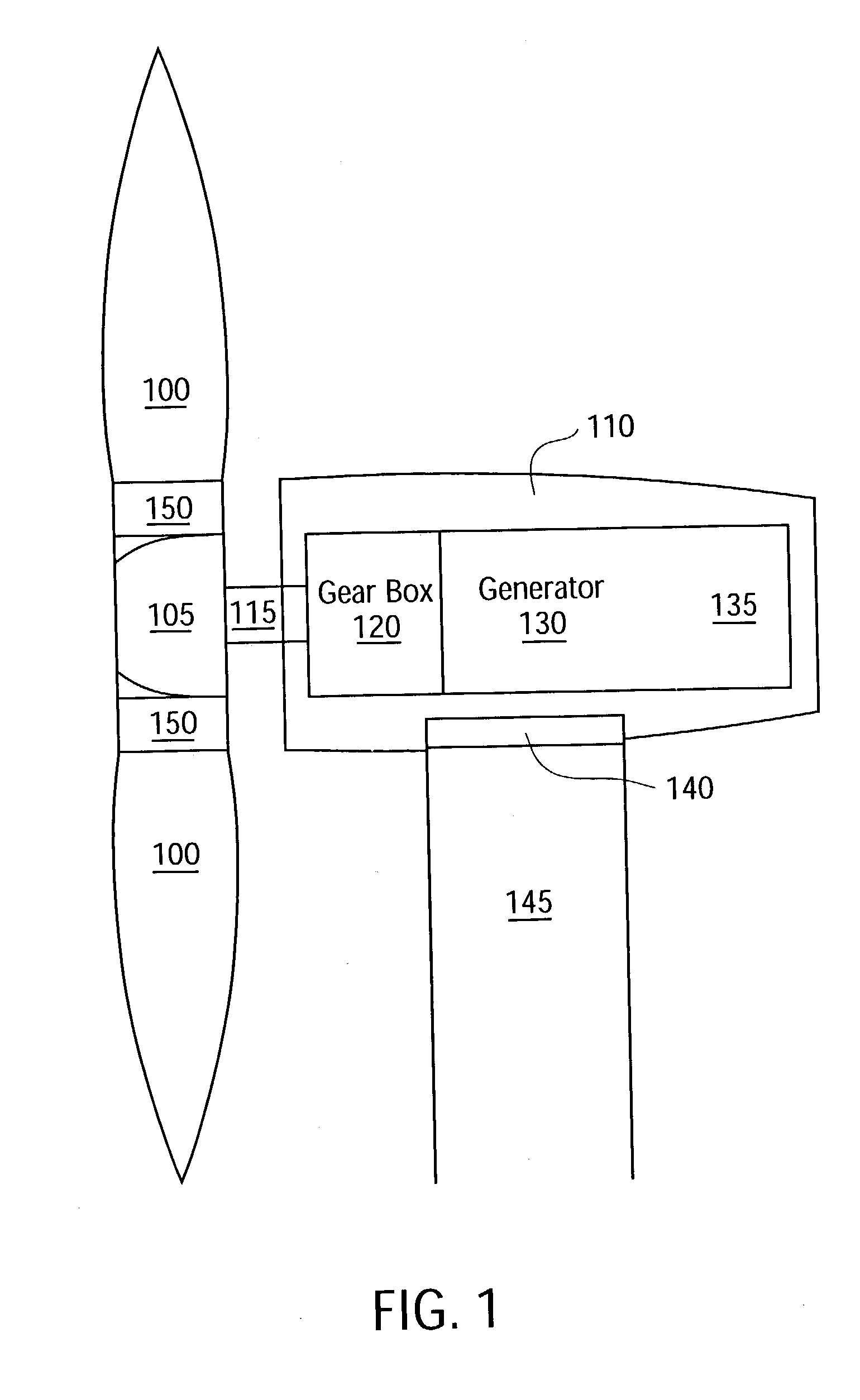

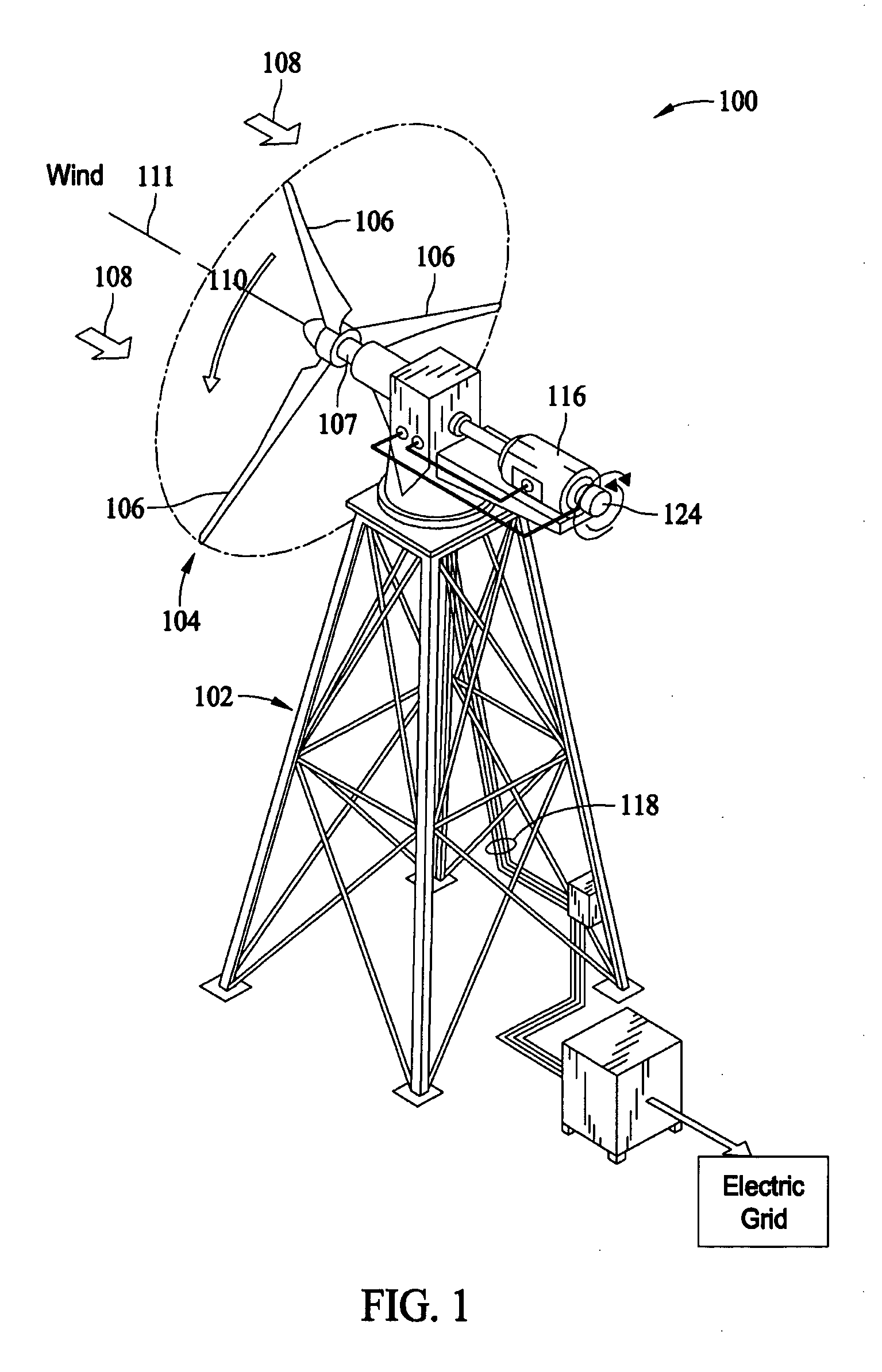

A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor.

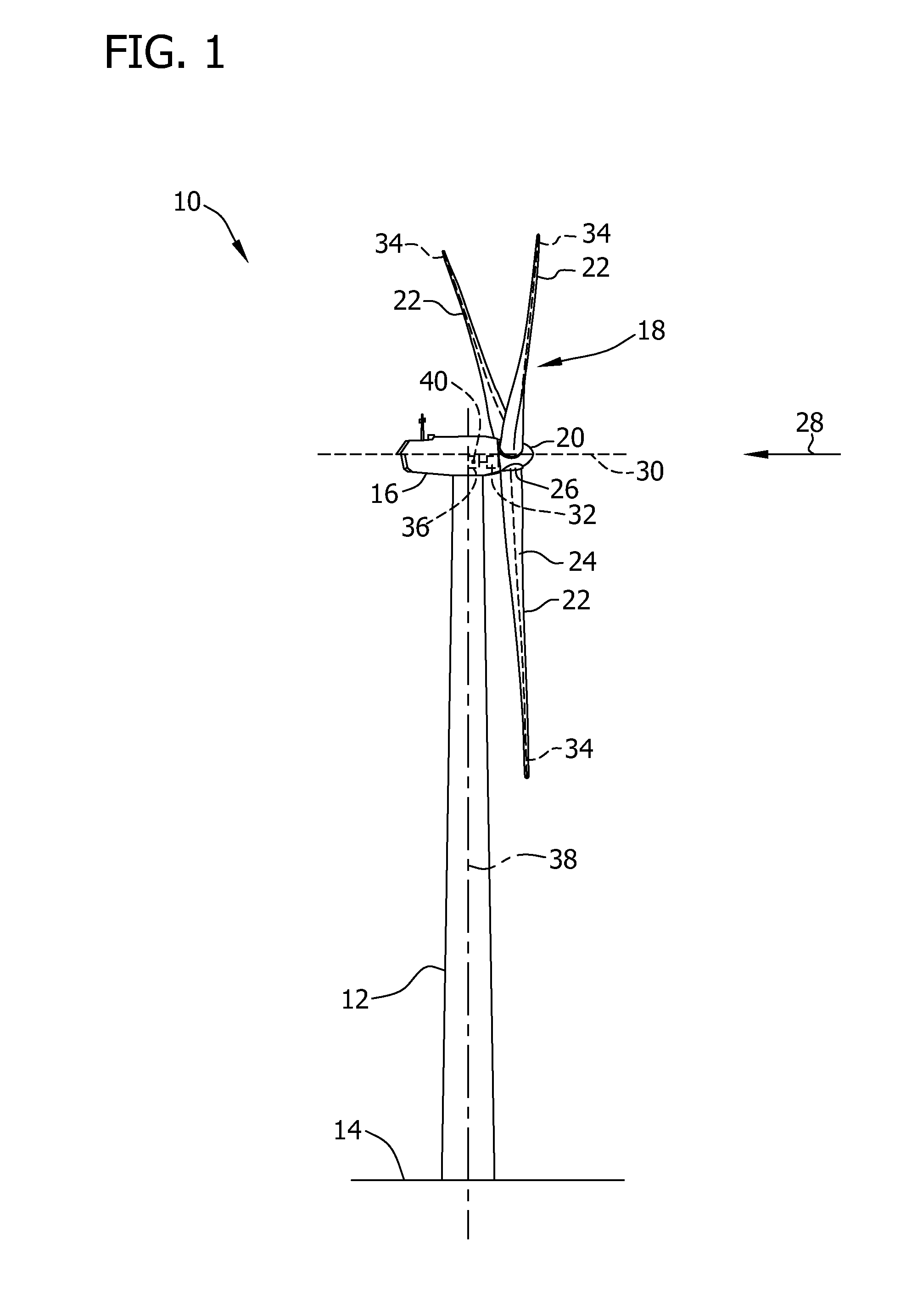

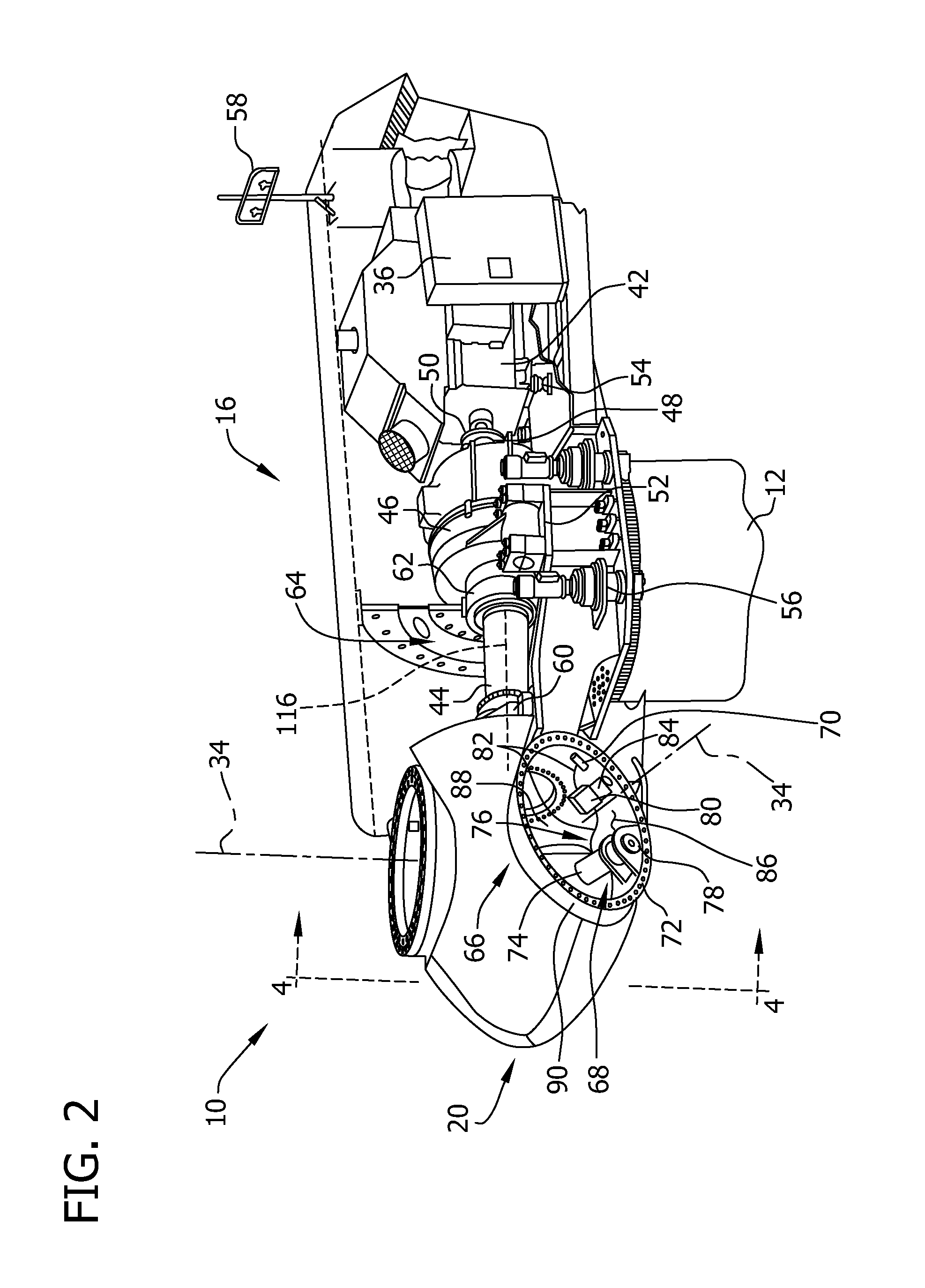

Wind turbine

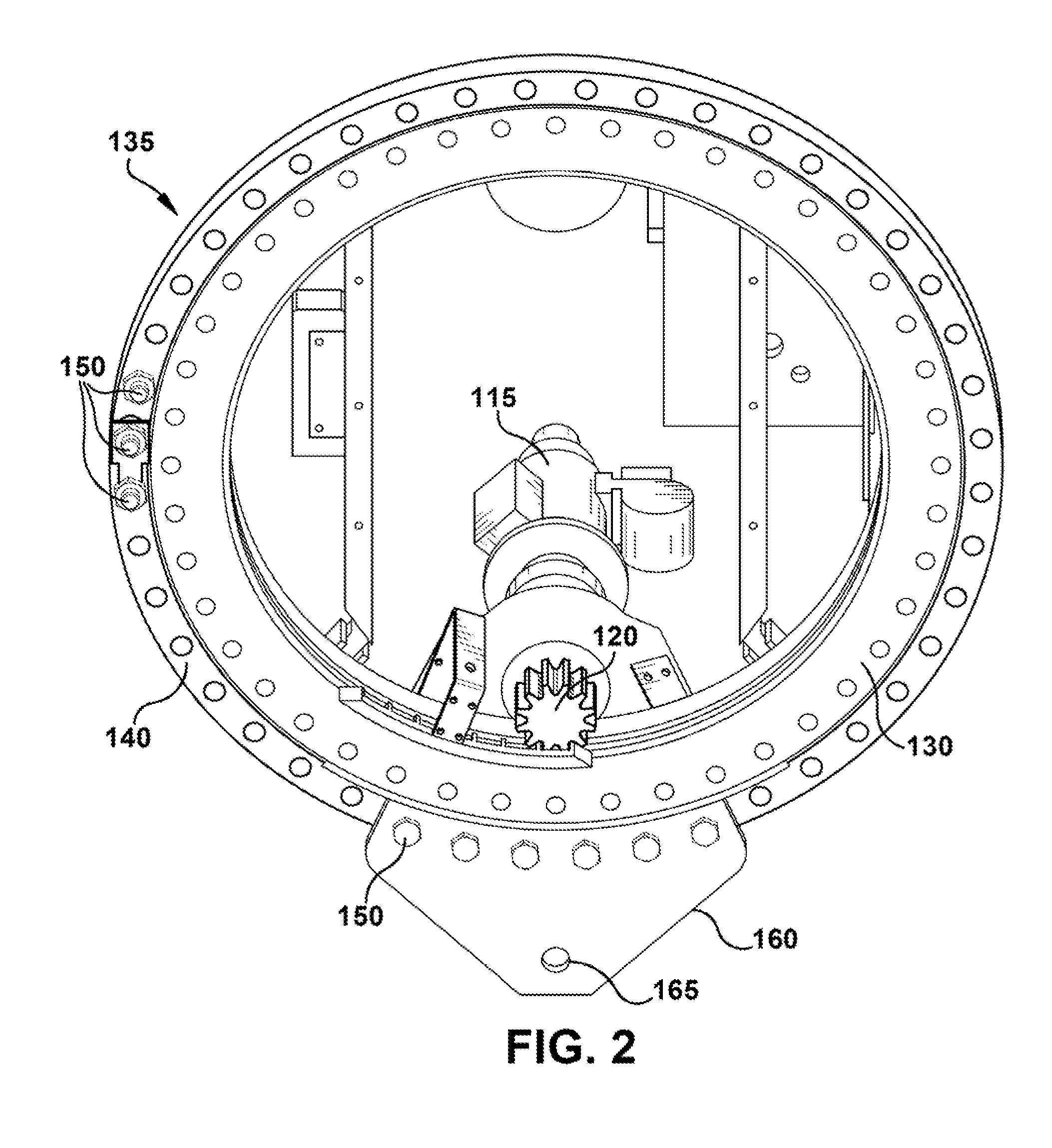

InactiveUS7042109B2Improve efficiencyCost per unit power generationWindingsWind motor controlRotational energyAir core

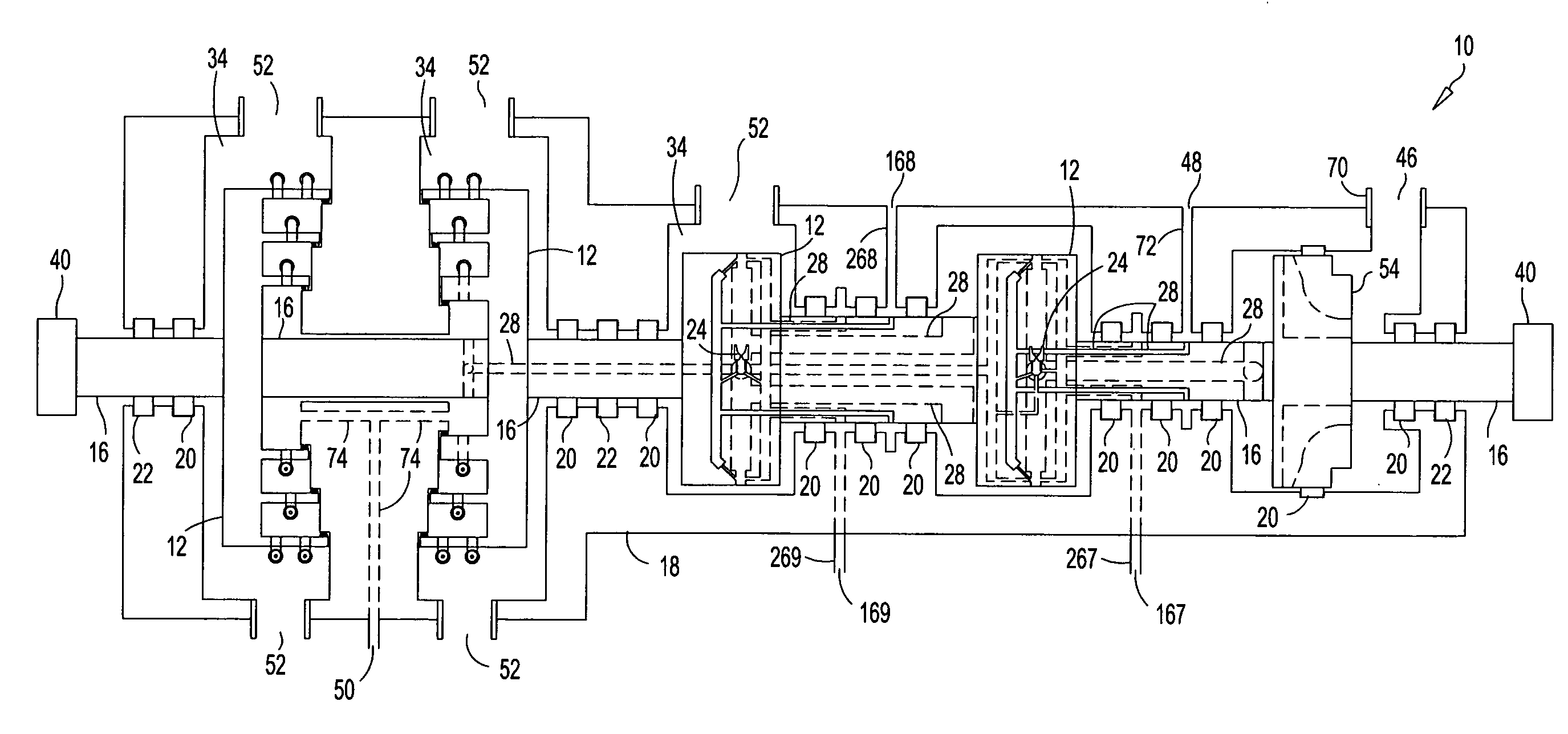

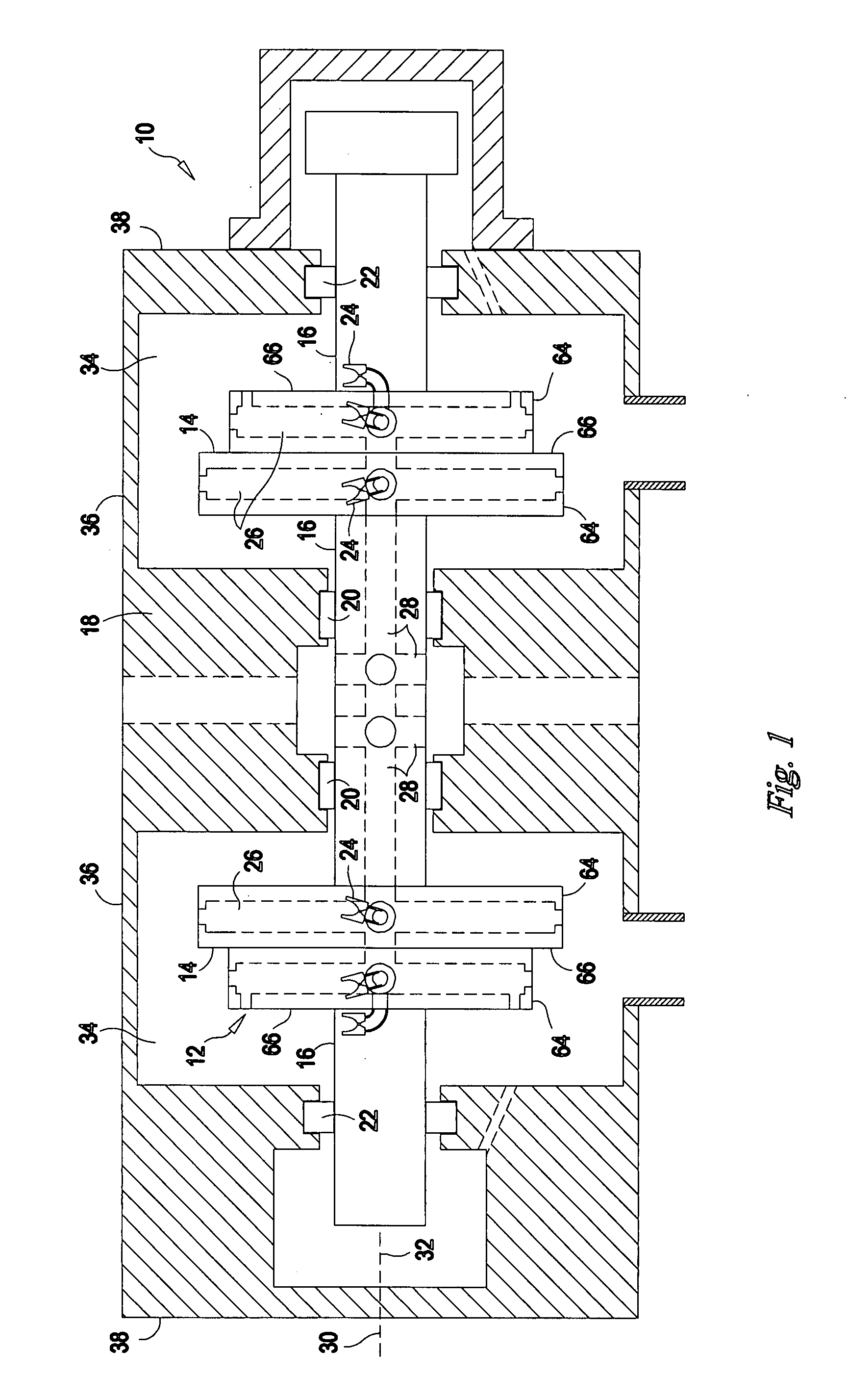

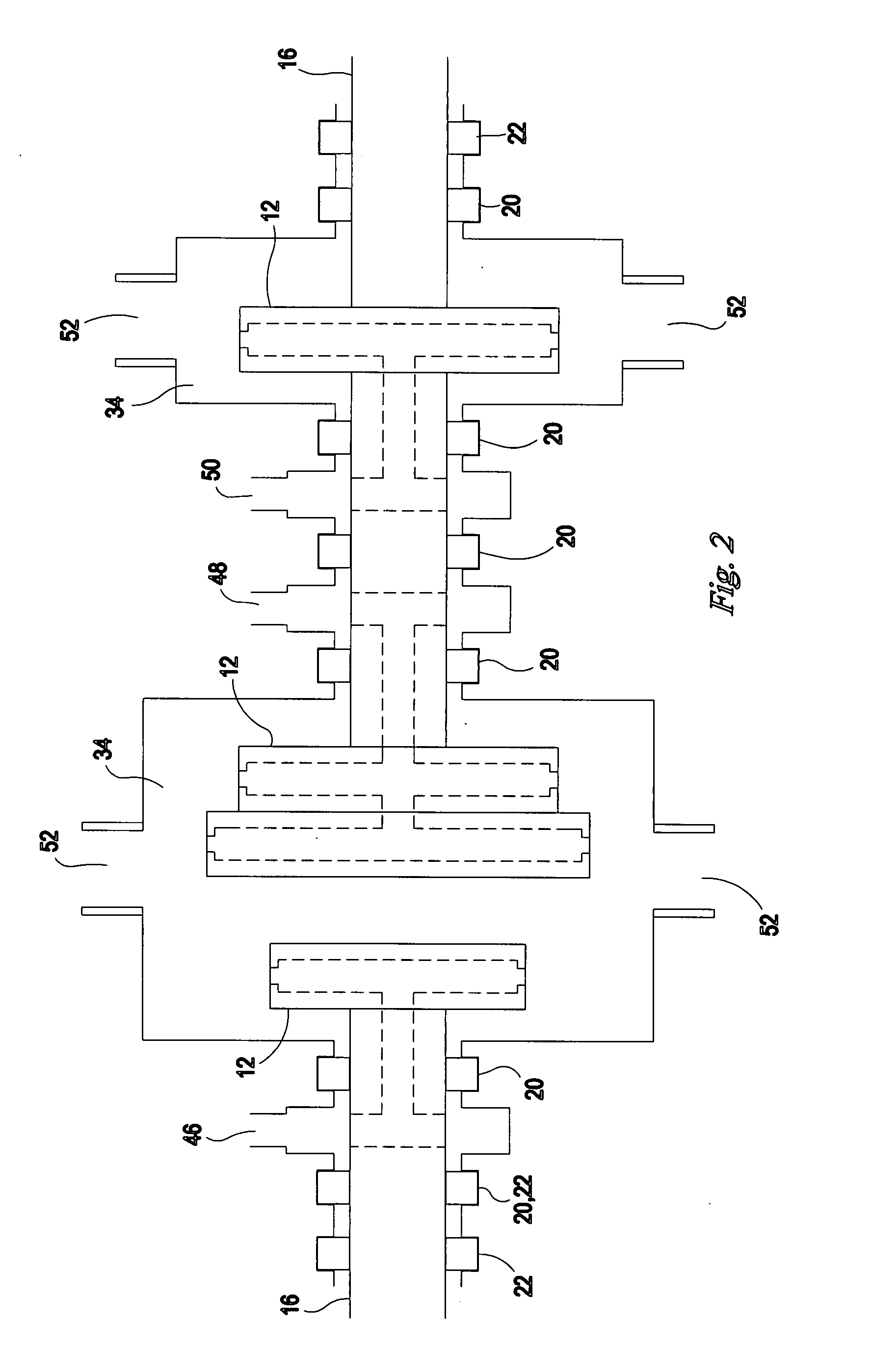

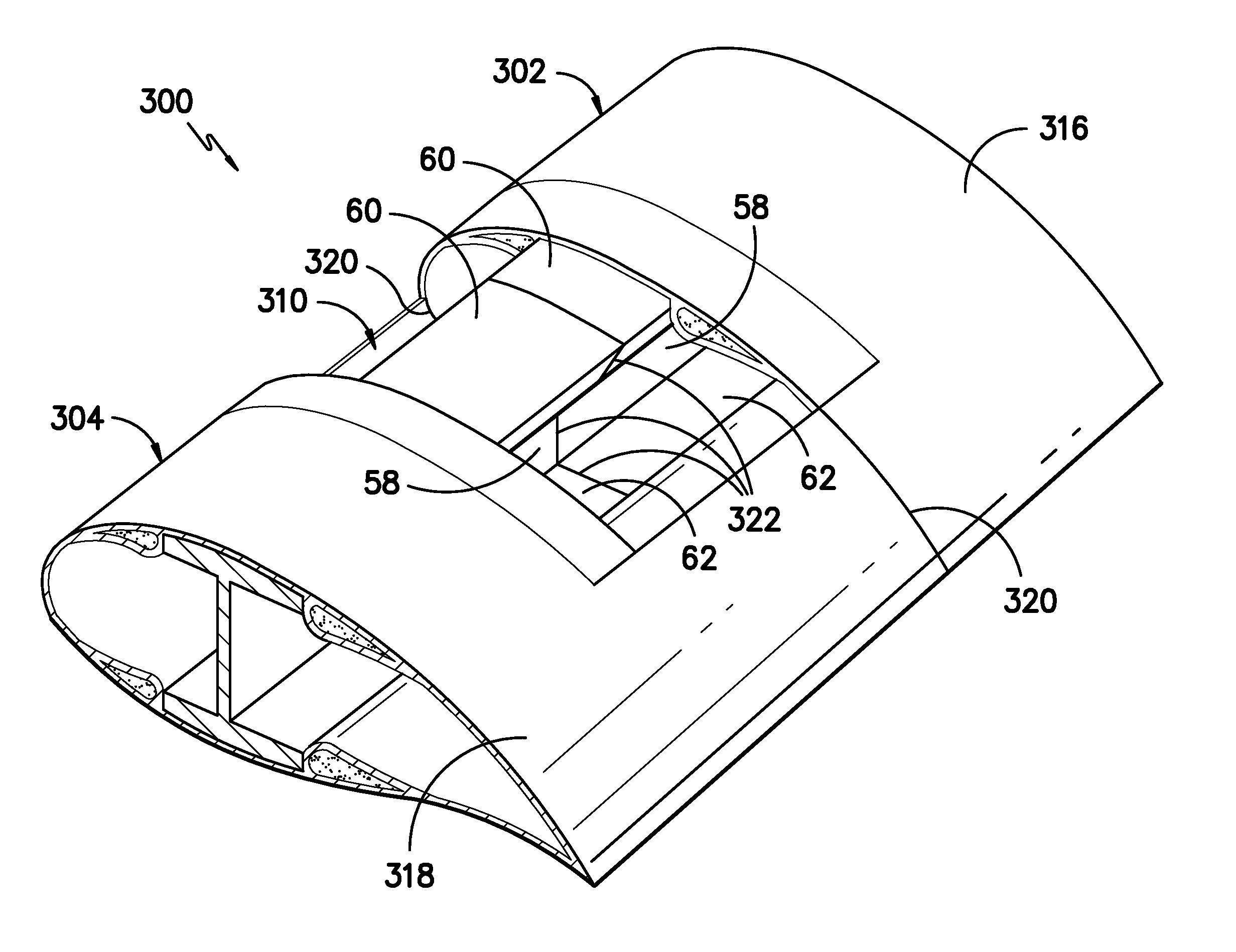

A wind turbine for generating electrical power from wind energy includes a turbine rotor mounted for rotation in wind, and having multiple blades for converting energy in the wind into rotational energy. A generator is coupled with said turbine rotor such that said turbine rotor drives said generator. The generator has a stationary air core armature that is located in a magnetic airgap between two generator rotor portions. The generator rotor portions have circumferential arrays of multiple alternating polarity permanent magnets attached to ferromagnetic back irons such that the permanent magnets drive magnetic flux back and forth between each rotor portion and through the stationary air core armature. The stationary air core armature has multiple phase windings of multiple individually insulated strand conductor wire that is wound with two separate portions including an active length portion and an end turn portion. The end turn portion is located outside the magnetic airgap and traverses predominately circumferentially, and the active length portion is located in the magnetic airgap and traverses predominately non-circumferentially and perpendicular to the direction of the magnetic airgap. The end turn portion has a thickness that is greater than the thickness of said active length portion in the direction of said magnetic airgap. AC voltage is induced in the multiple phase windings as the turbine rotor rotates.

Owner:MARIAH POWER

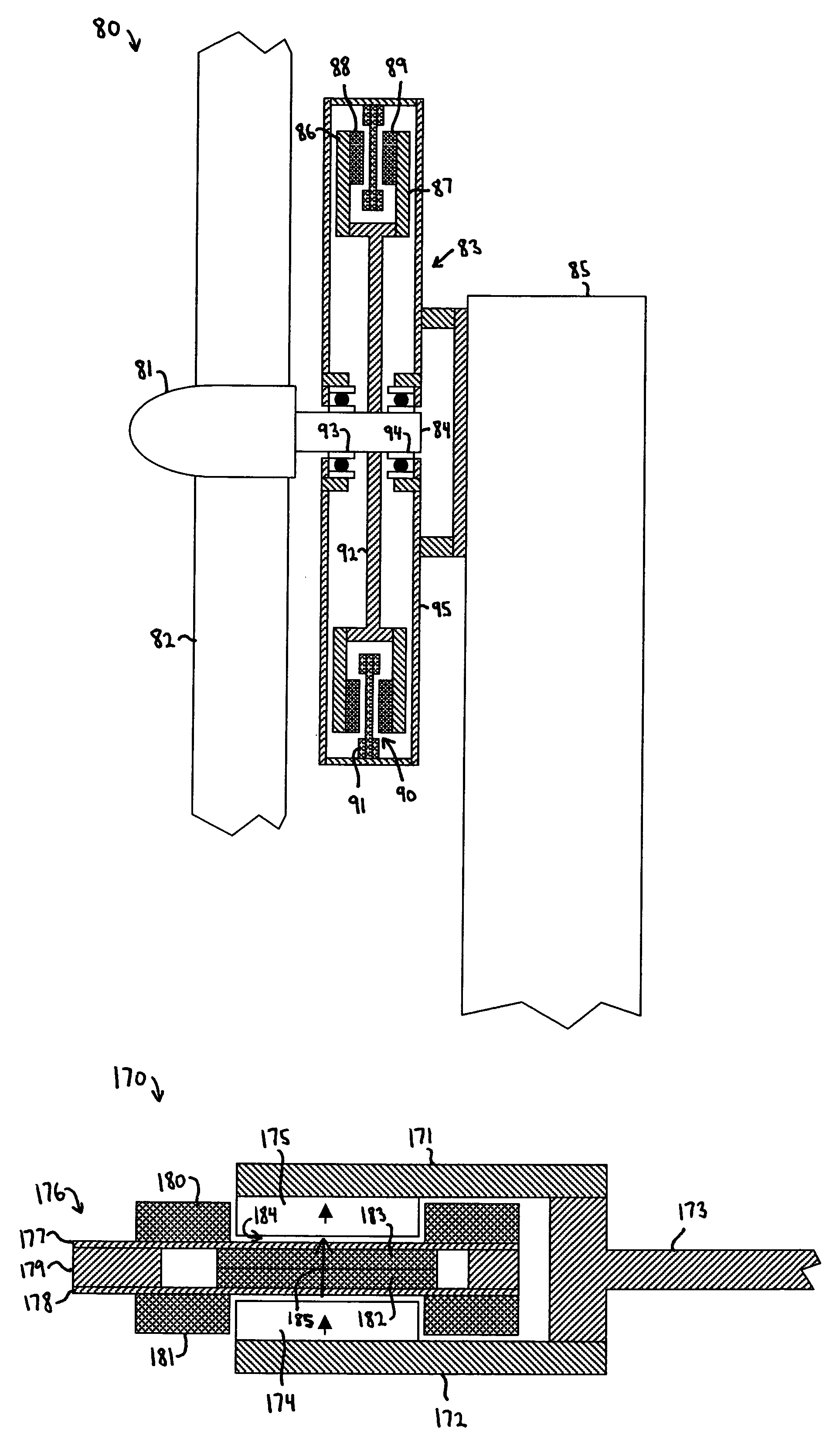

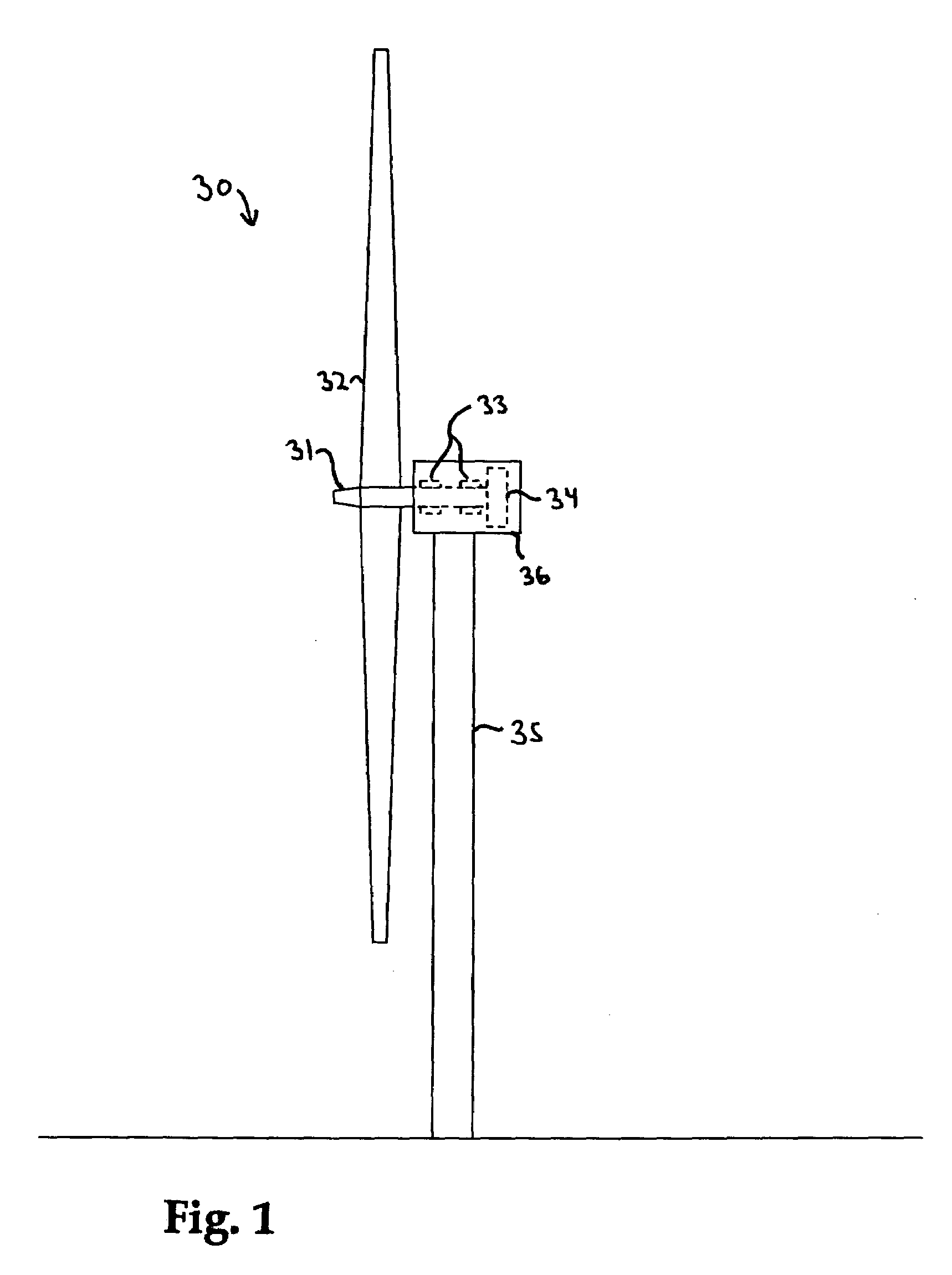

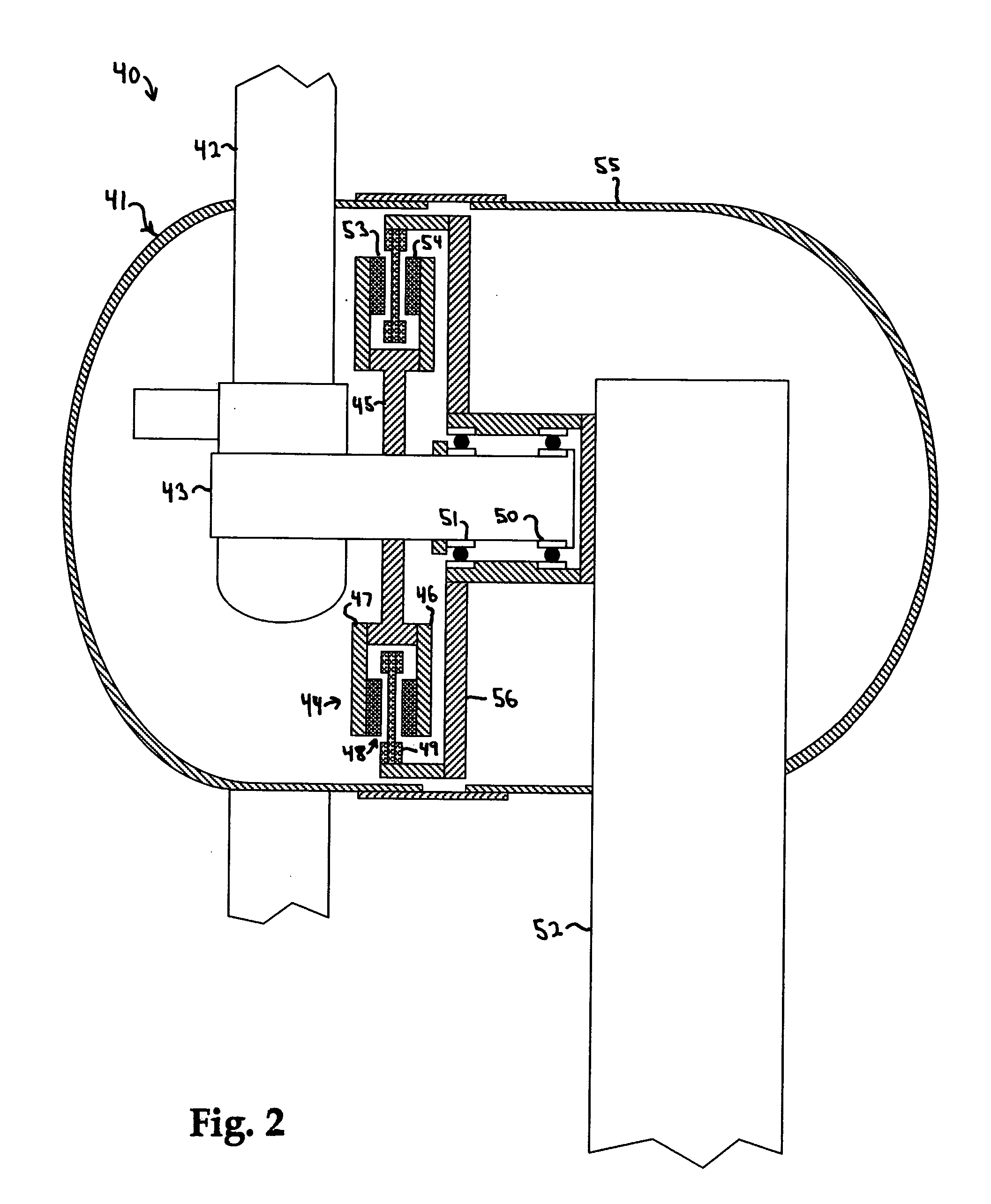

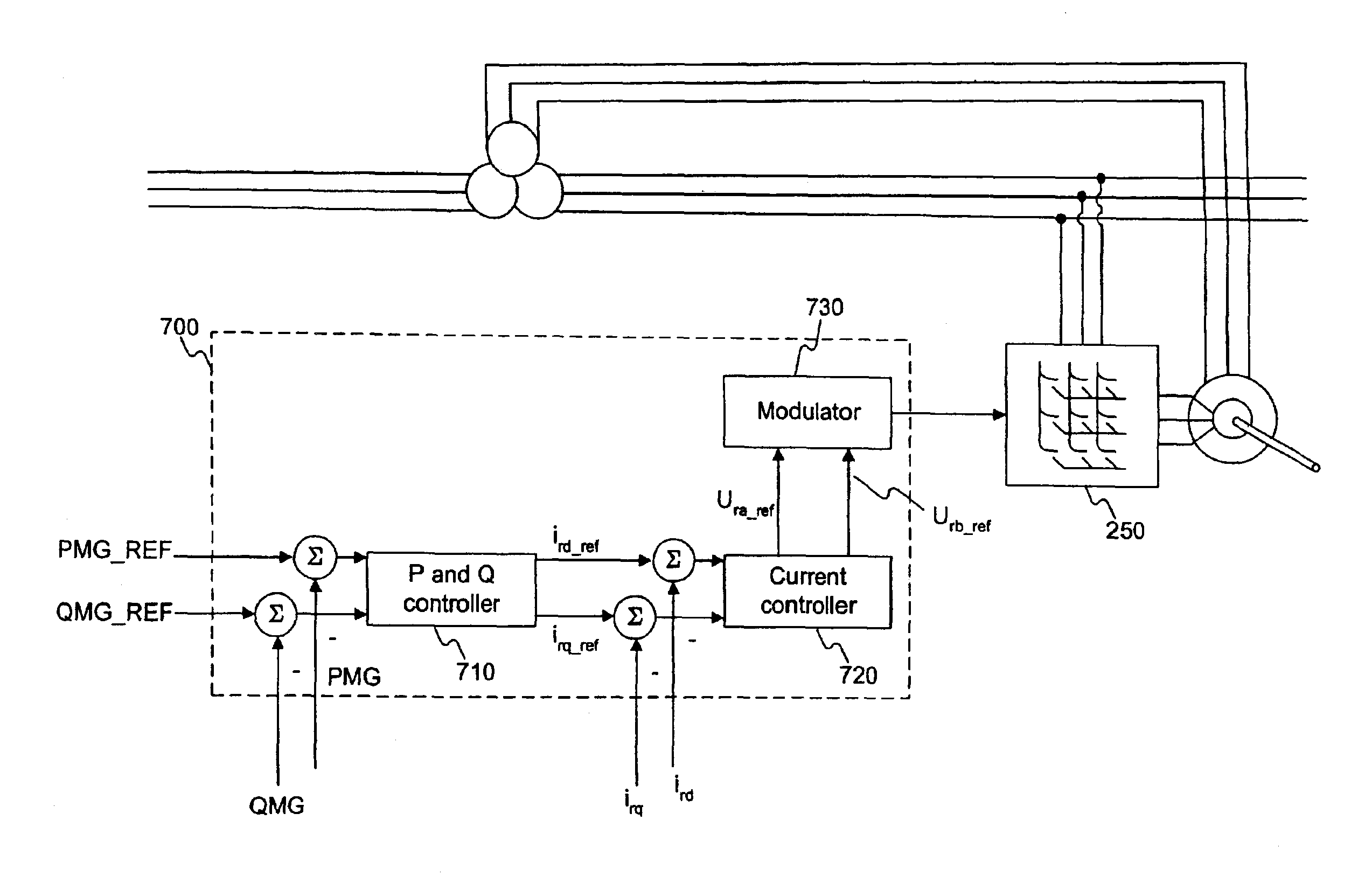

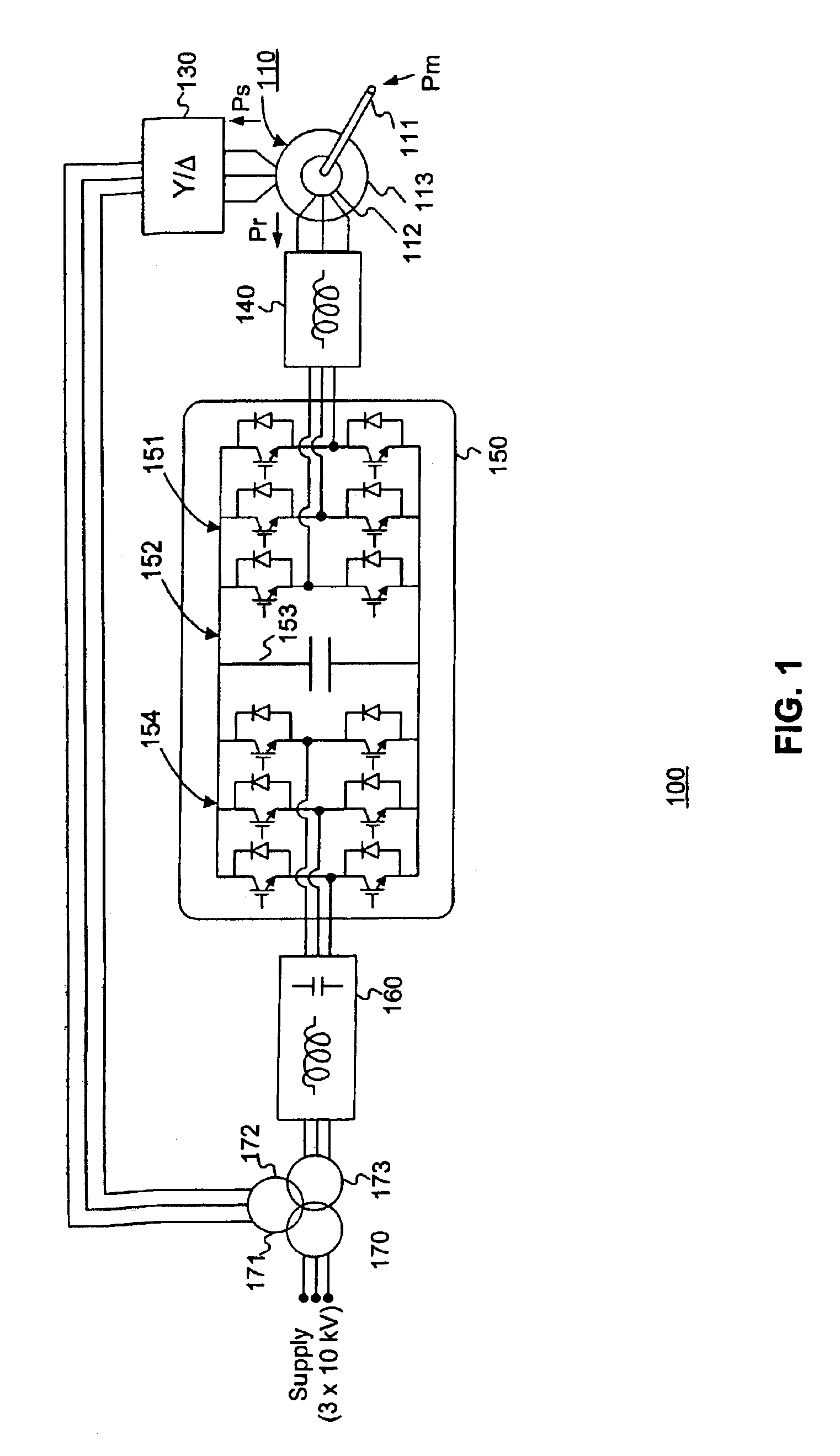

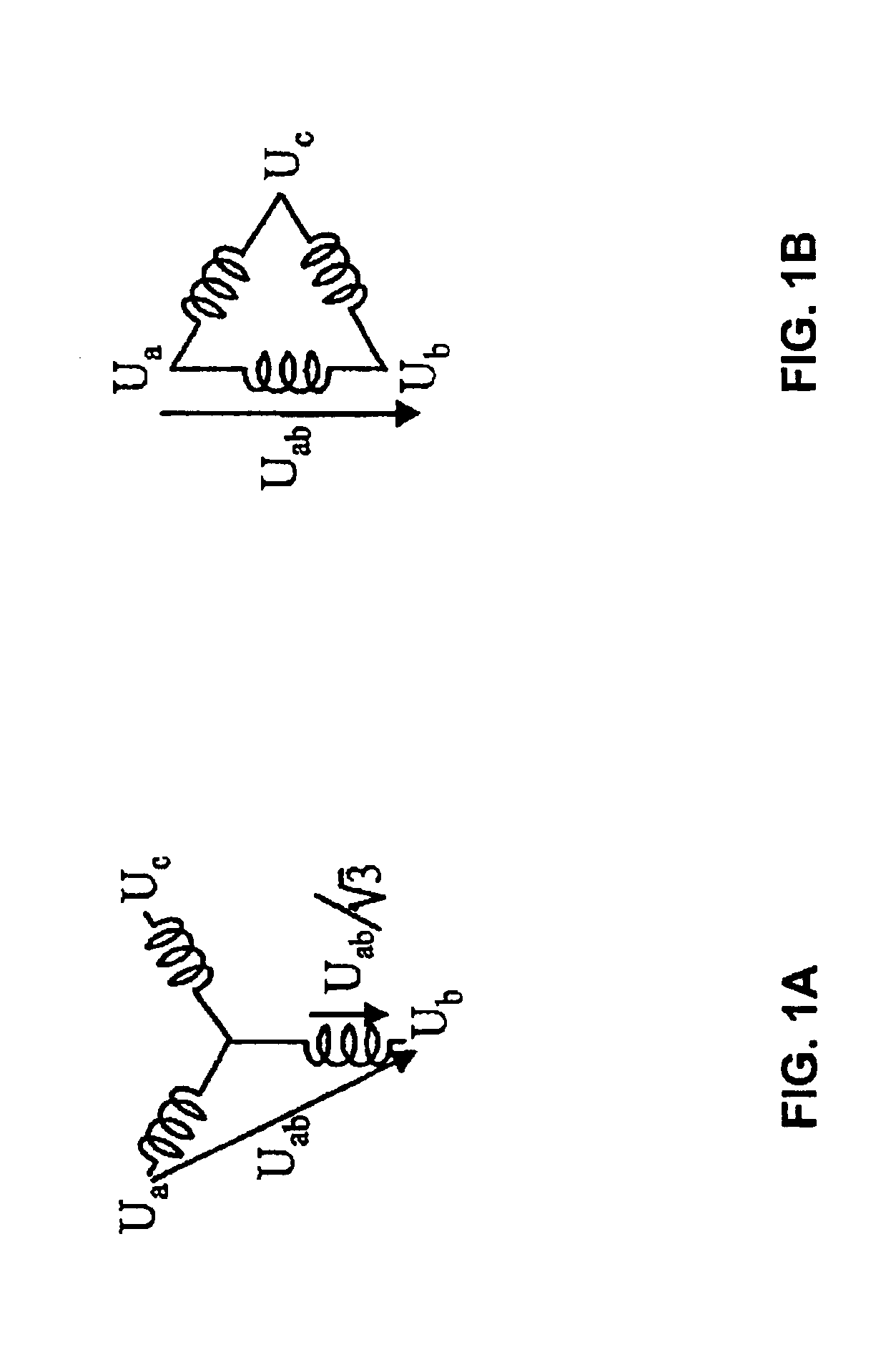

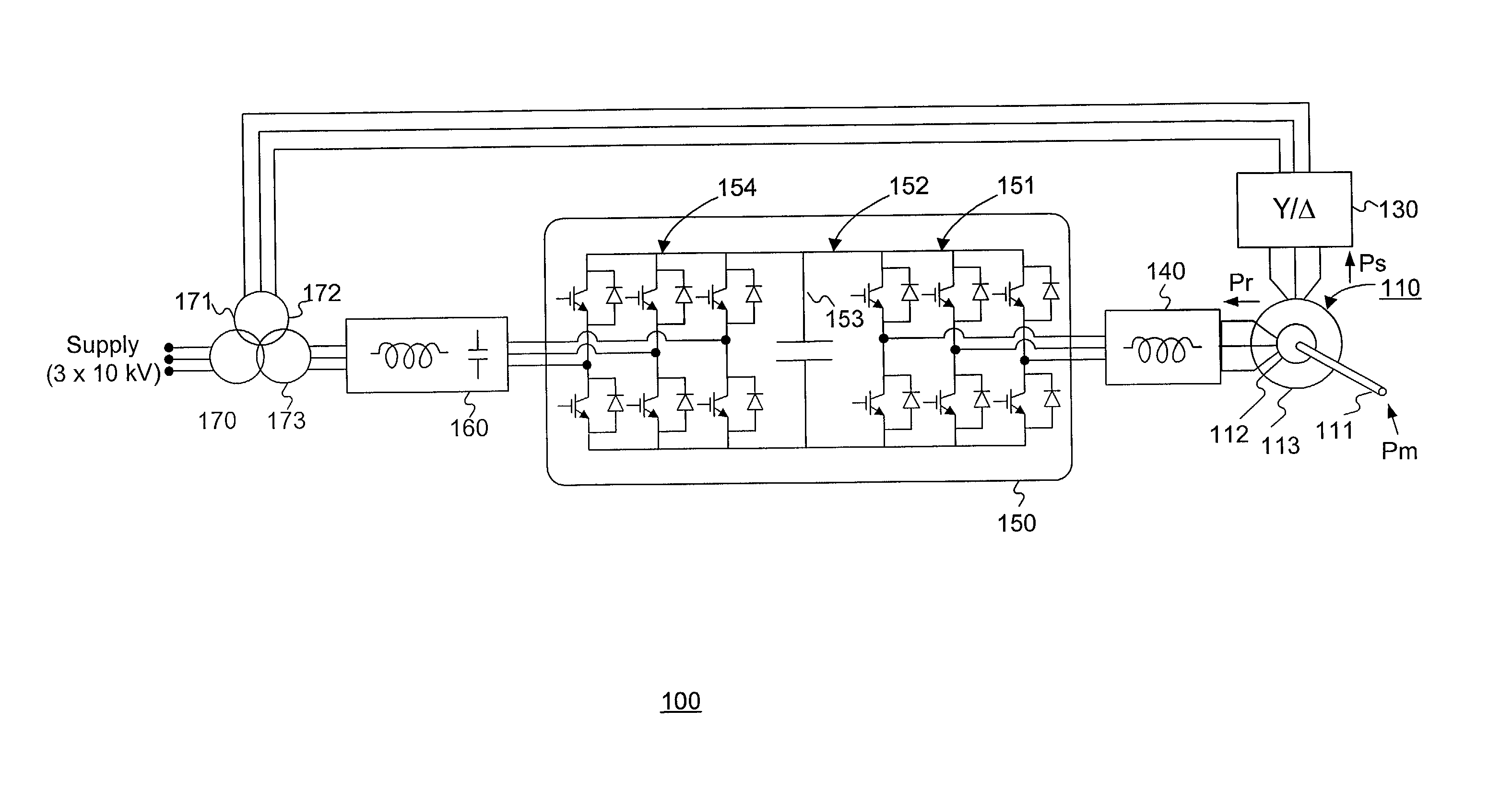

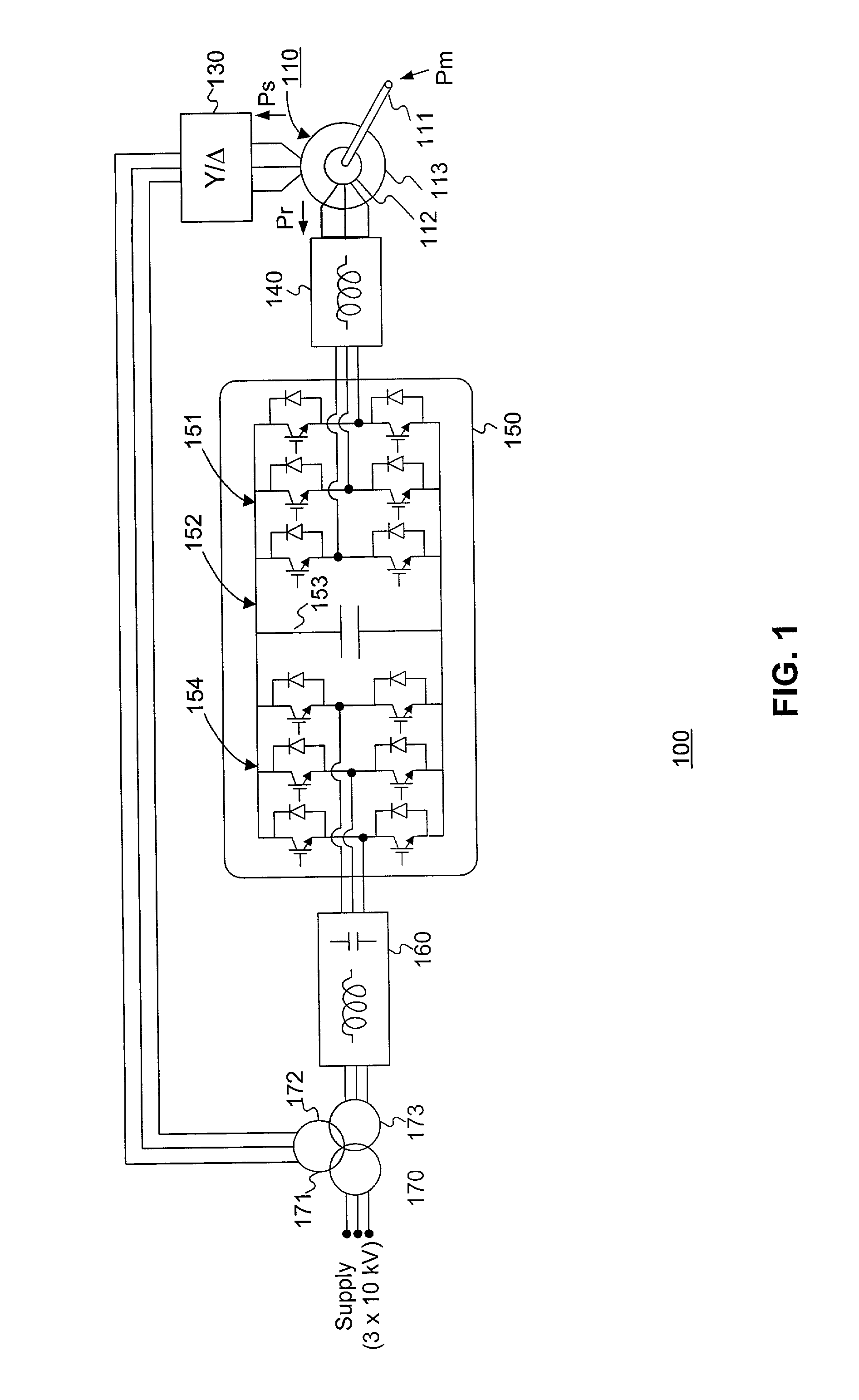

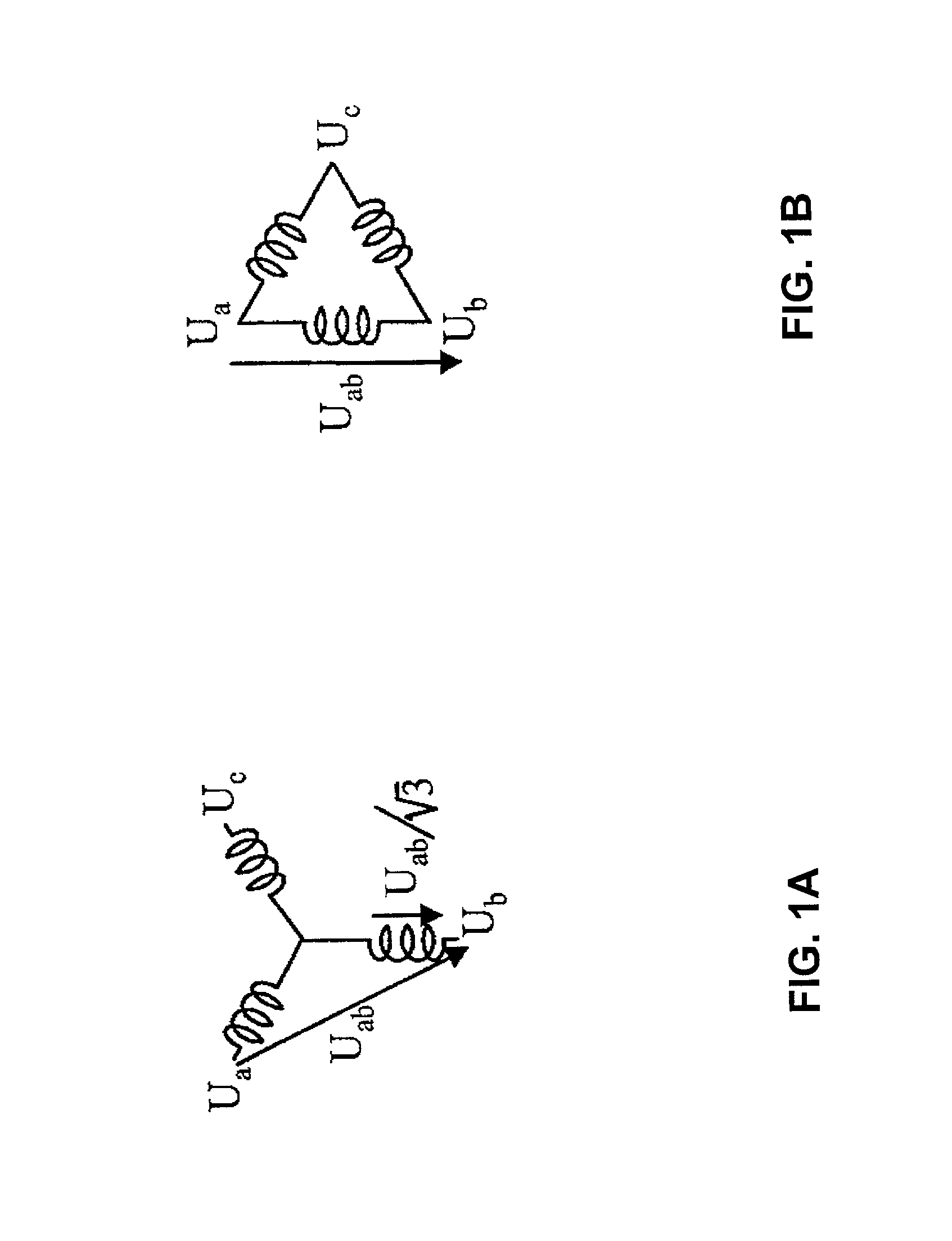

Variable speed wind turbine having a matrix converter

InactiveUS6856038B2Generator control circuitsEfficient power electronics conversionMatrix convertersConstant frequency

A variable speed wind turbine is disclosed comprising a turbine rotor that drives a doubly-fed induction generator, a matrix converter which converts variable frequency output into constant frequency output, and a control unit and a protection circuit for the matrix converter. Power is circulated in the system allowing for sensorless detection of rotor position and better output ratios of power from the system.

Owner:VESTAS WIND SYST AS

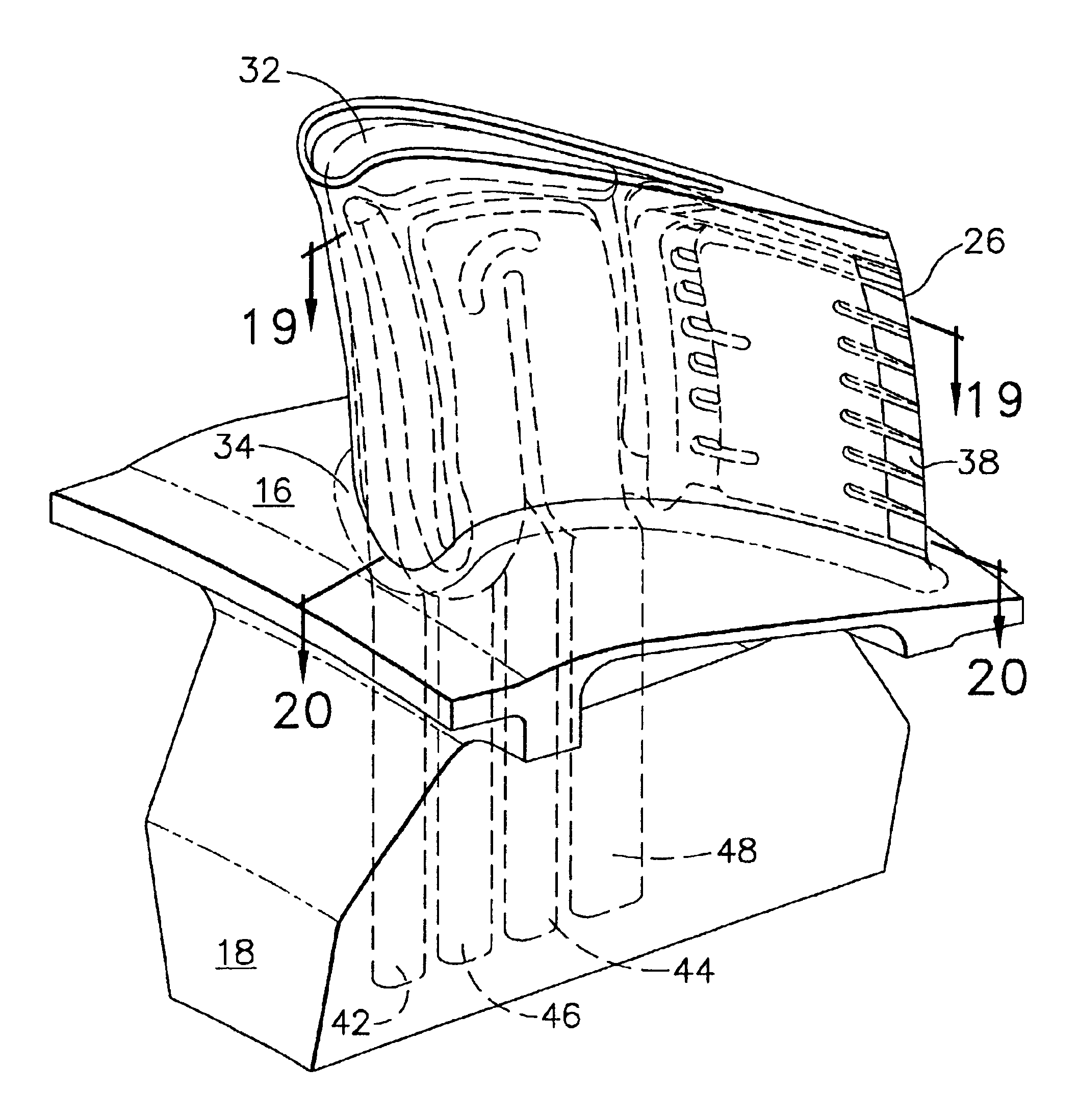

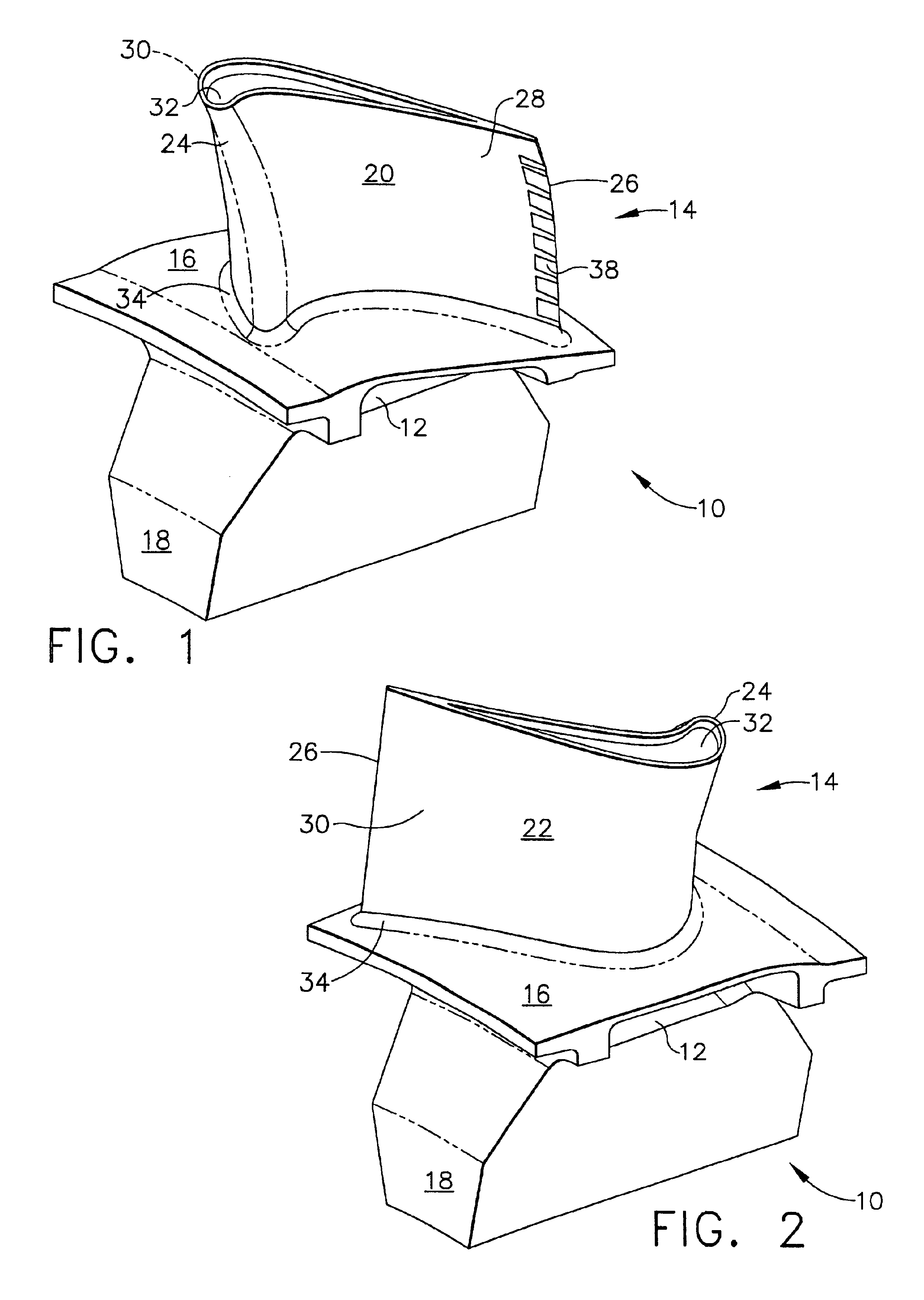

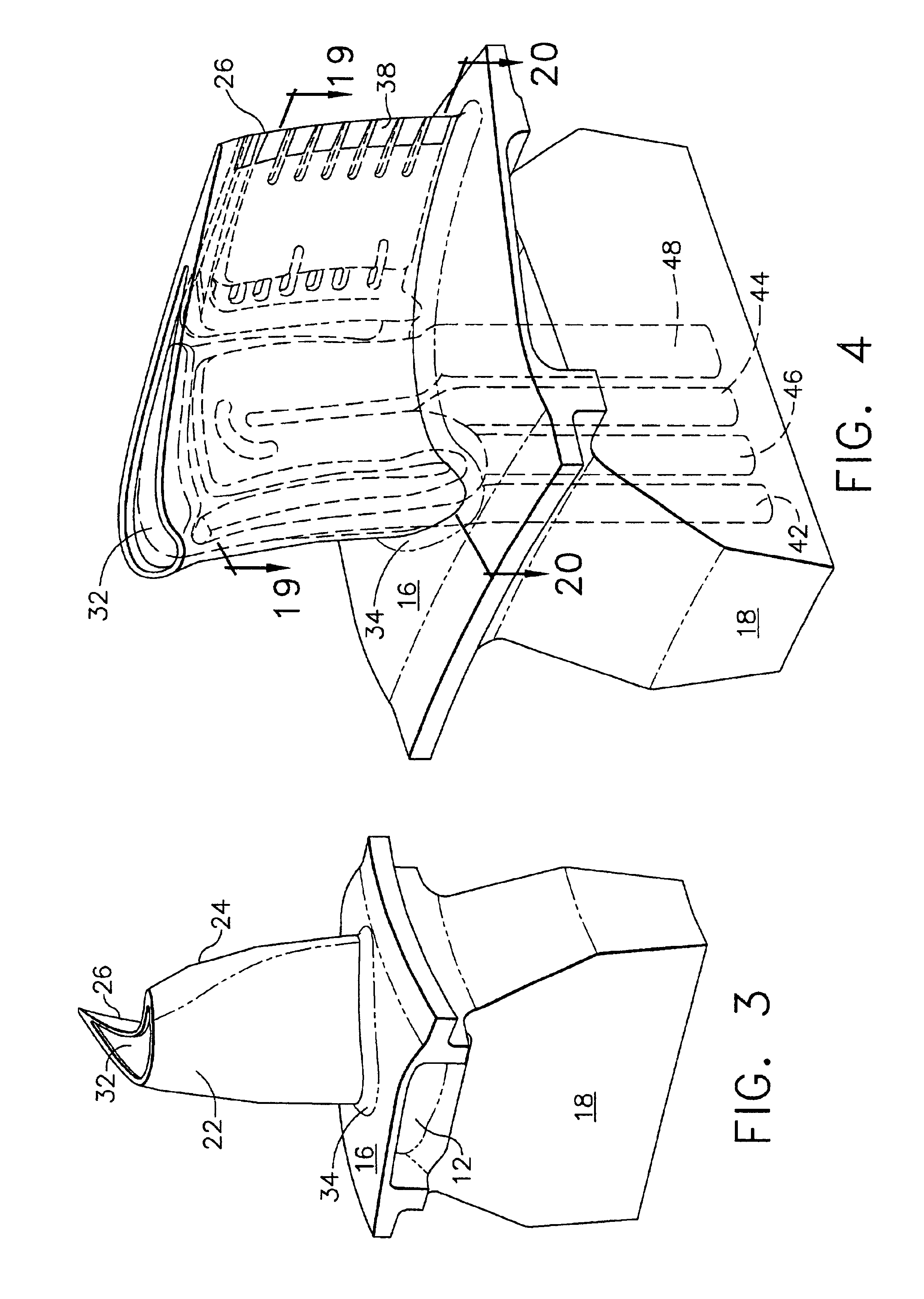

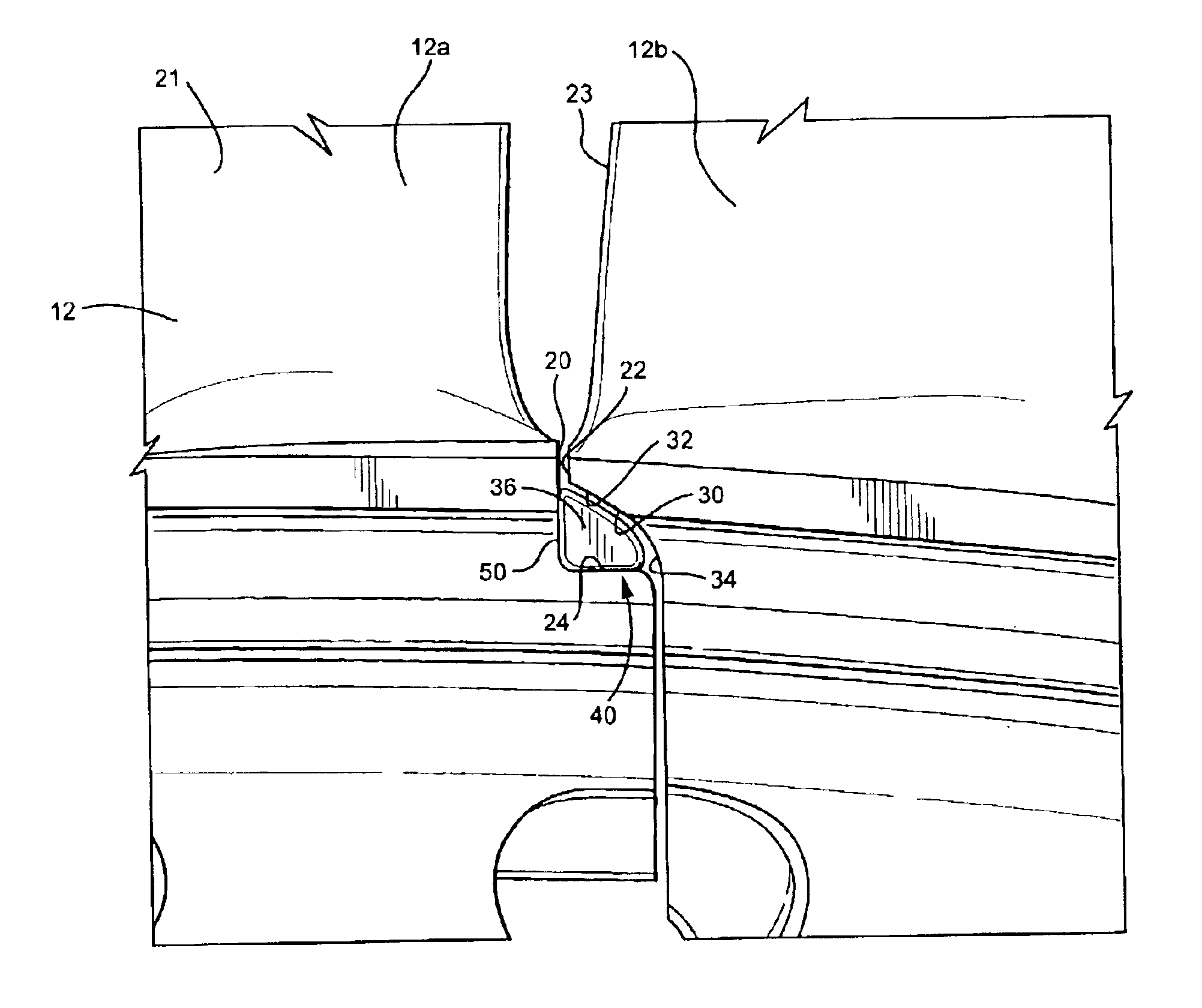

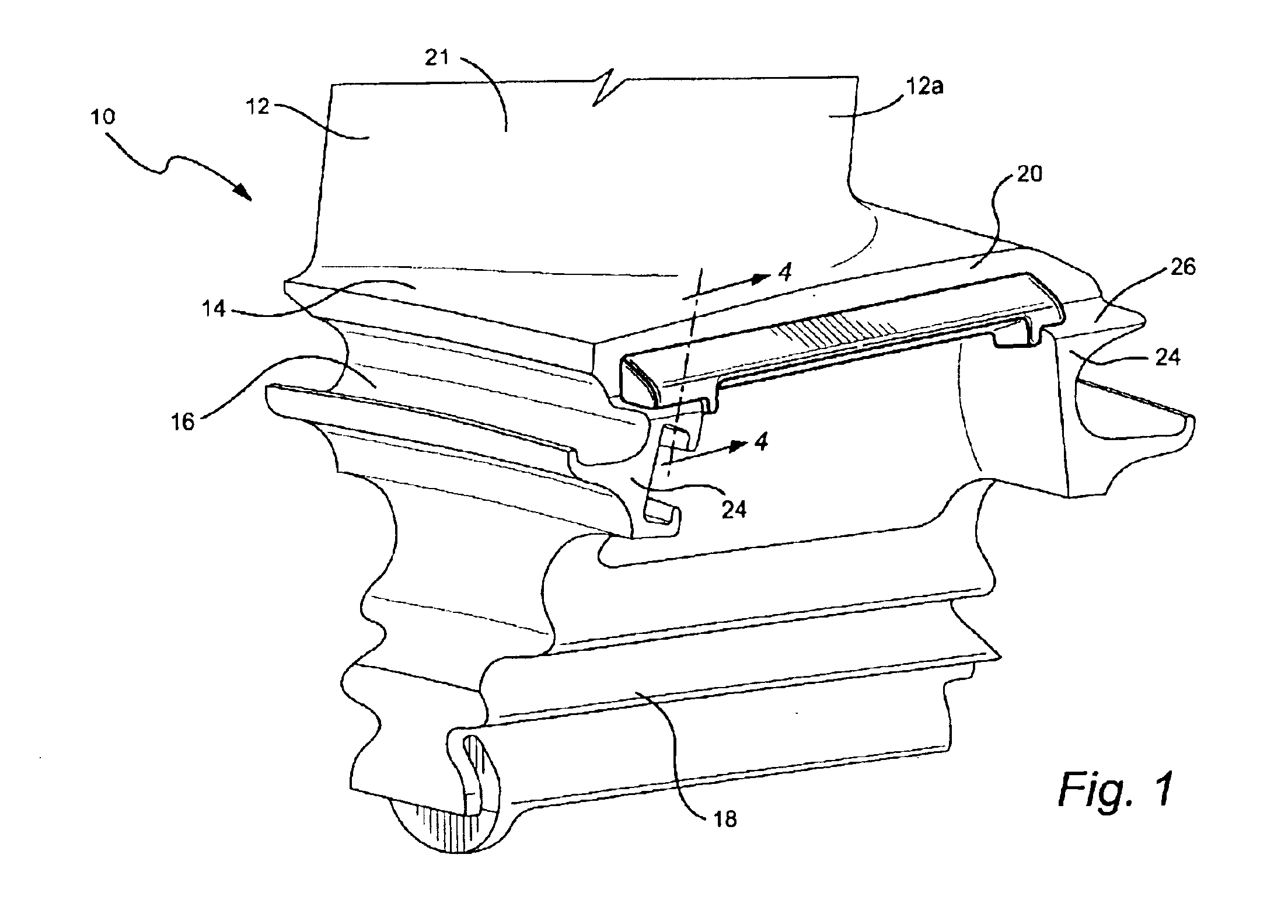

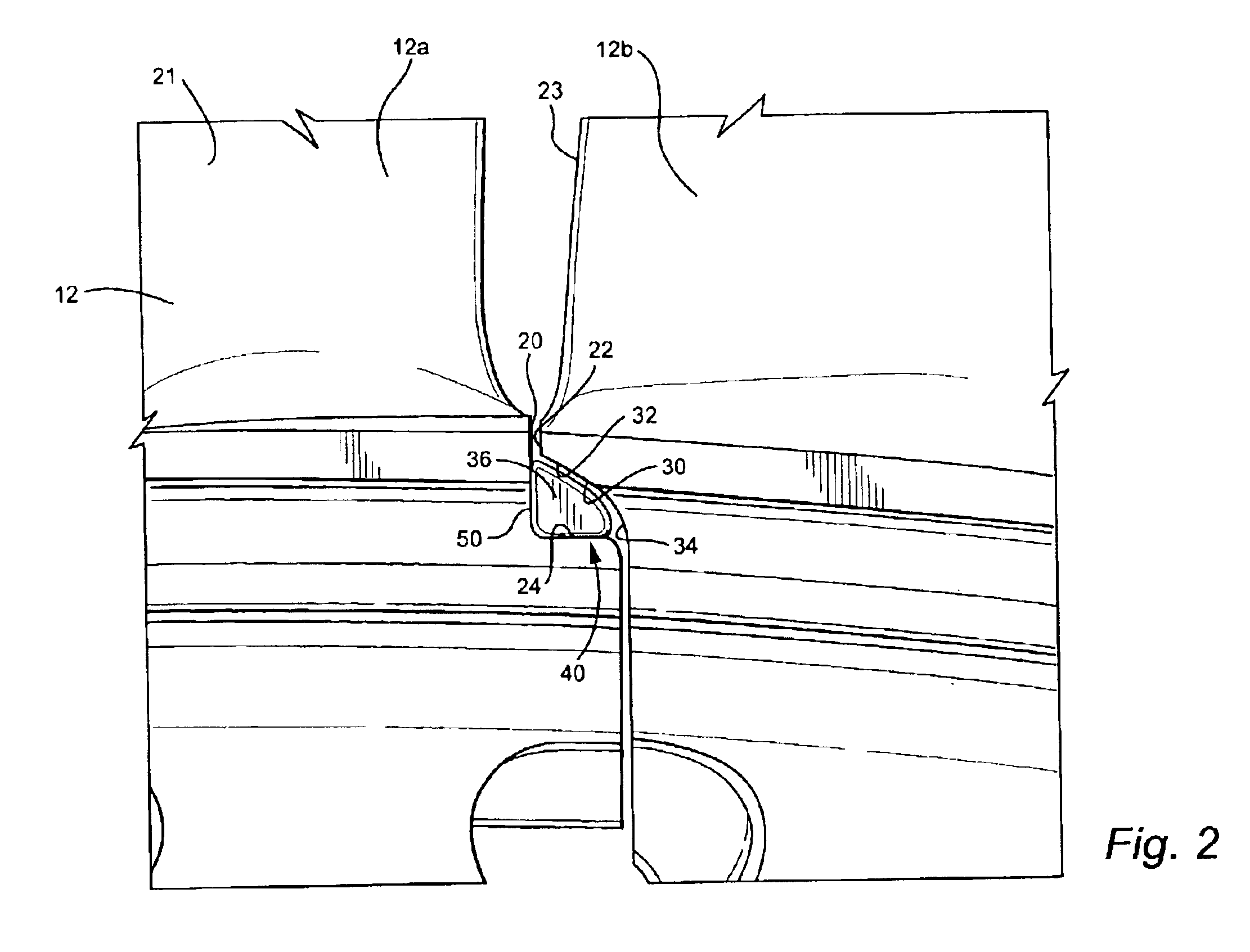

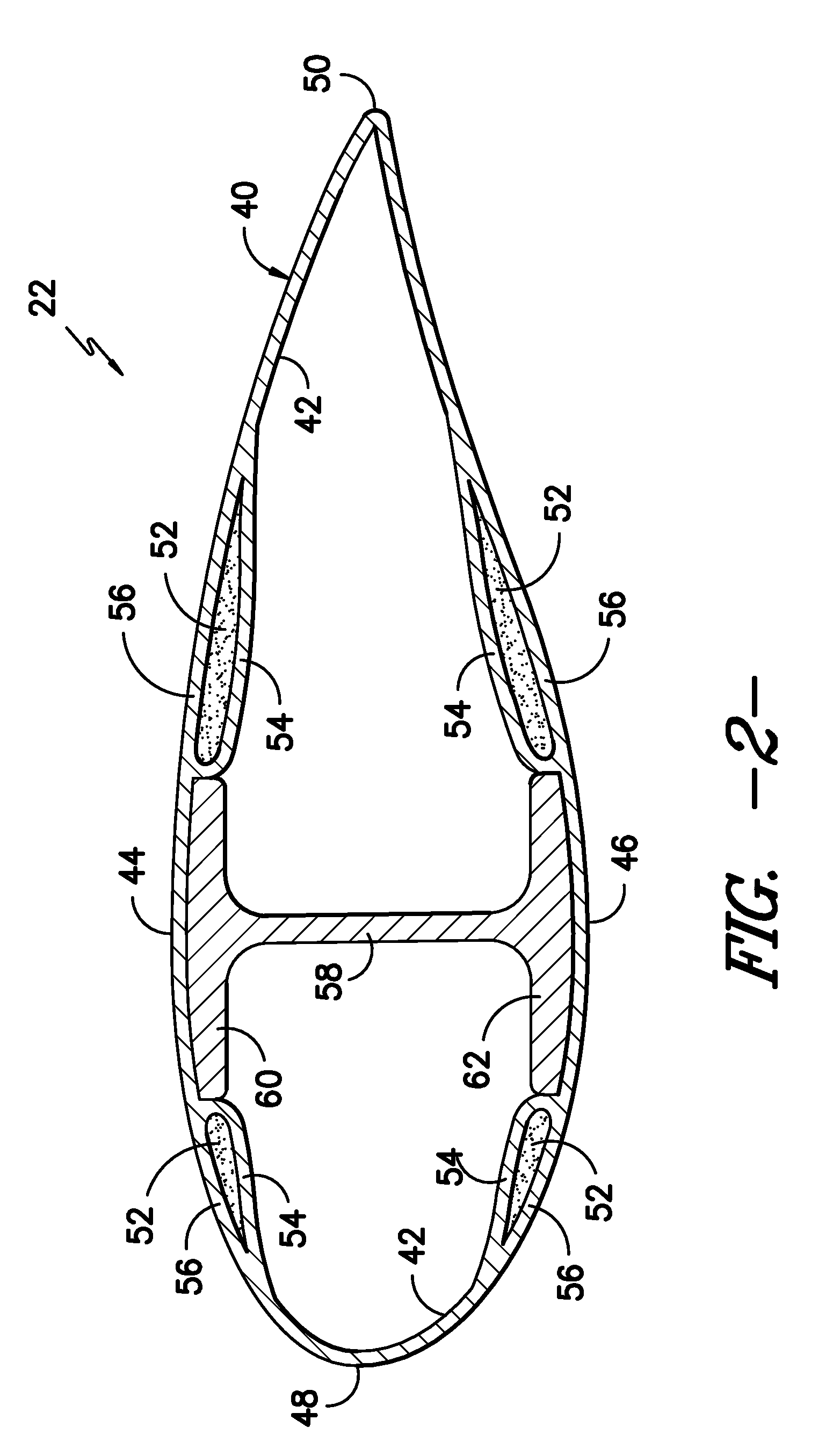

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

Variable speed wind turbine having a matrix converter

InactiveUS20020079706A1Generator control circuitsWind motor controlMatrix convertersConstant frequency

A variable speed wind turbine is disclosed comprising a turbine rotor that drives a doubly-fed induction generator, a matrix converter which converts variable frequency output into constant frequency output, and a control unit and a protection circuit for the matrix converter. Power is circulated in the system allowing for sensorless detection of rotor position and better output ratios of power from the system.

Owner:VESTAS WIND SYST AS

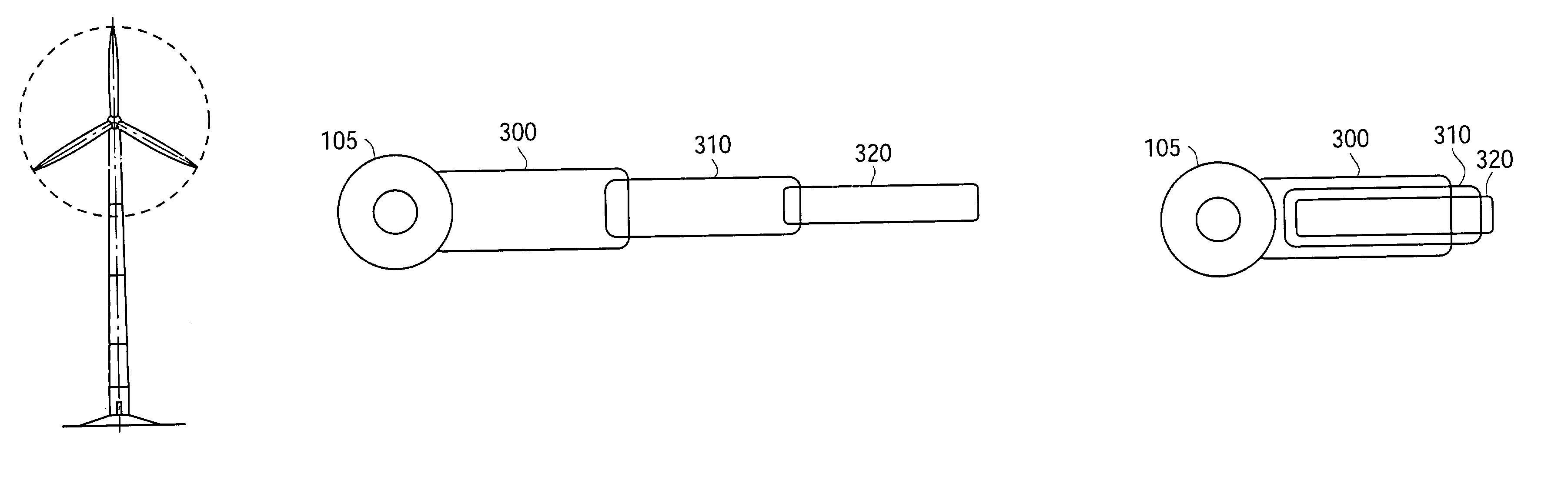

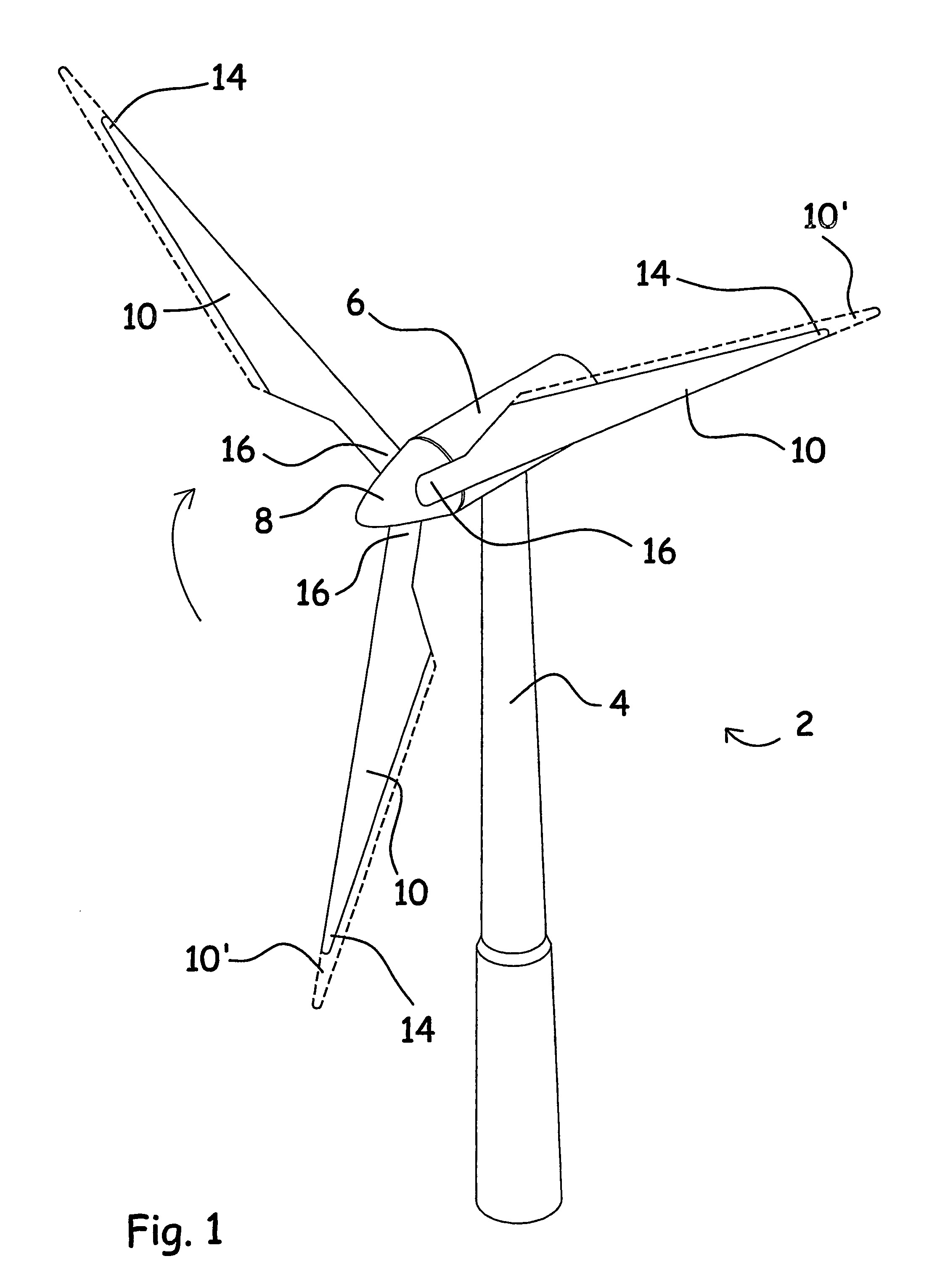

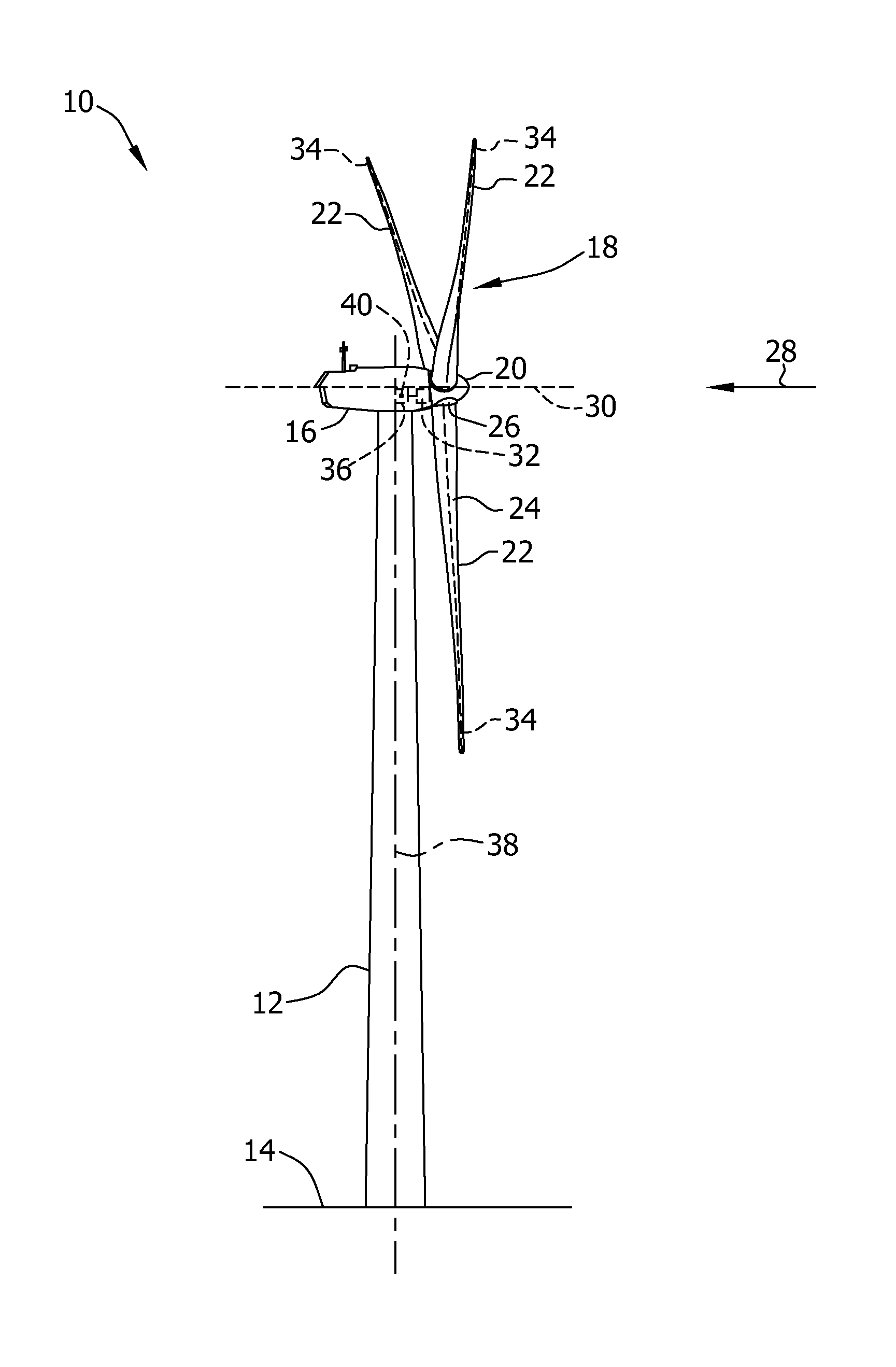

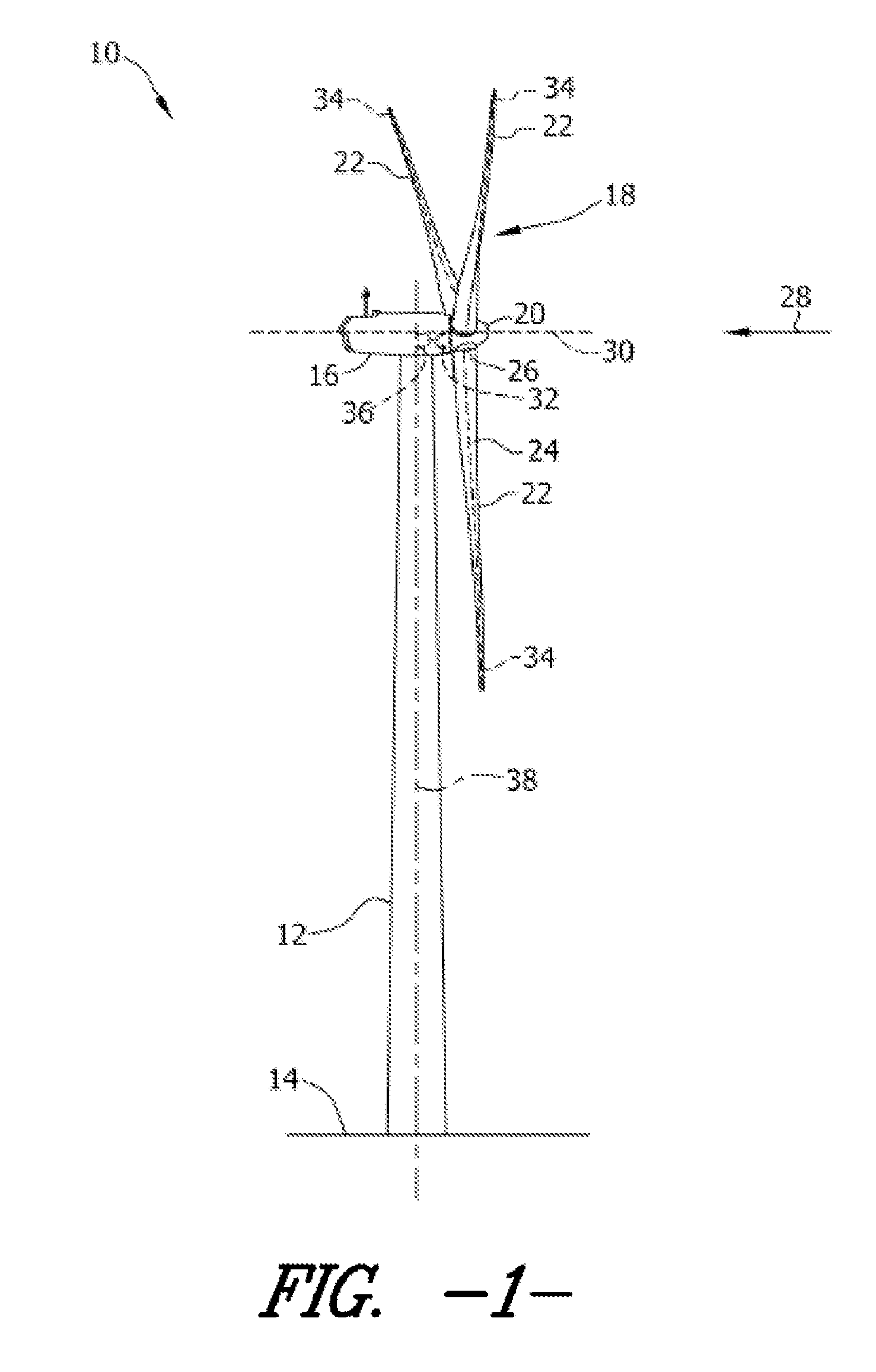

Variable diameter wind turbine rotor blades

A system and method for changing wind turbine rotor diameters to meet changing wind speeds and control system loads is disclosed. The rotor blades on the wind turbine are able to adjust length by extensions nested within or containing the base blade. The blades can have more than one extension in a variety of configurations. A cable winching system, a hydraulic system, a pneumatic system, inflatable or elastic extensions, and a spring-loaded jack knife deployment are some of the methods of adjustment. The extension is also protected from lightning by a grounding system.

Owner:GENERAL ELECTRIC CO

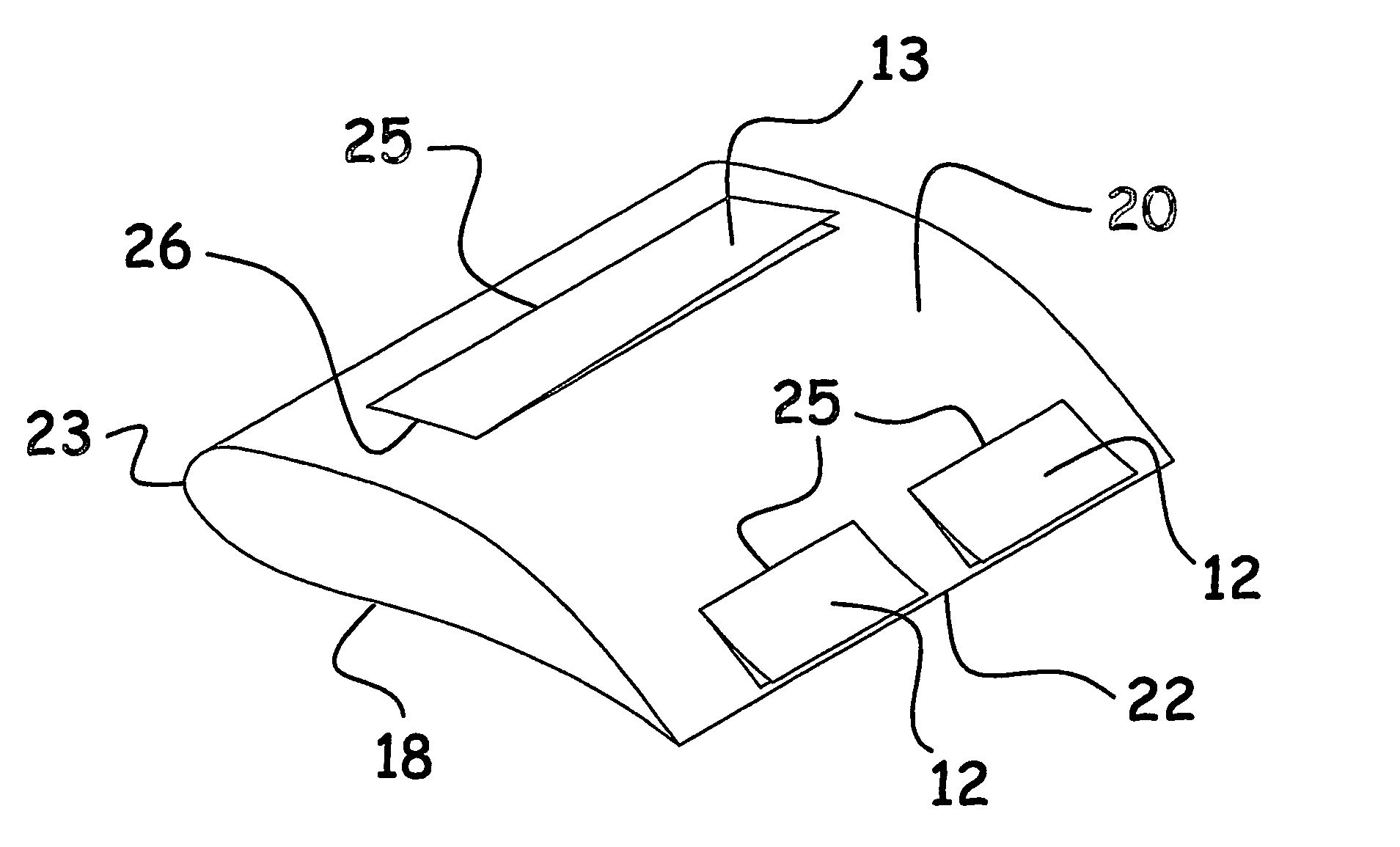

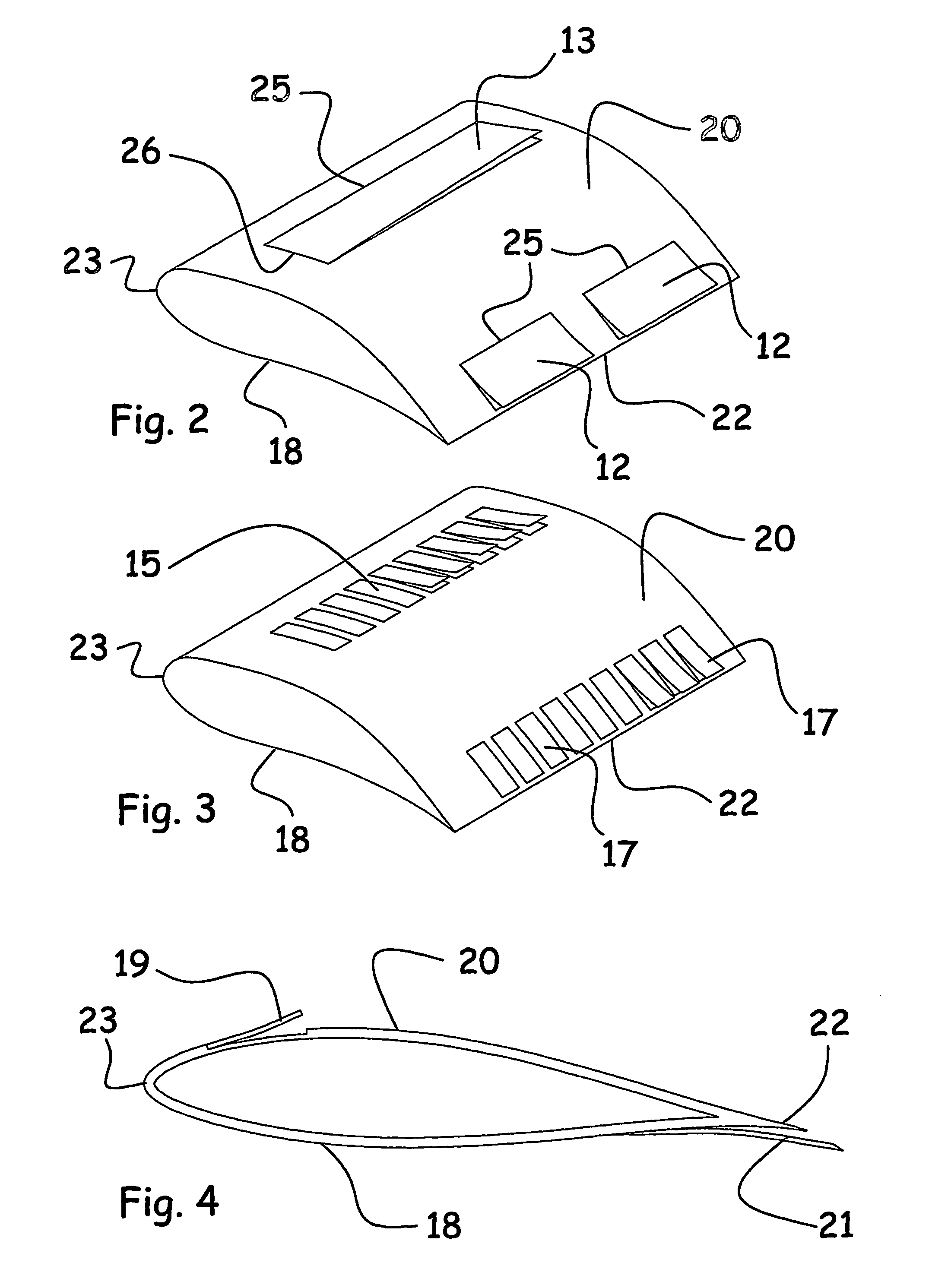

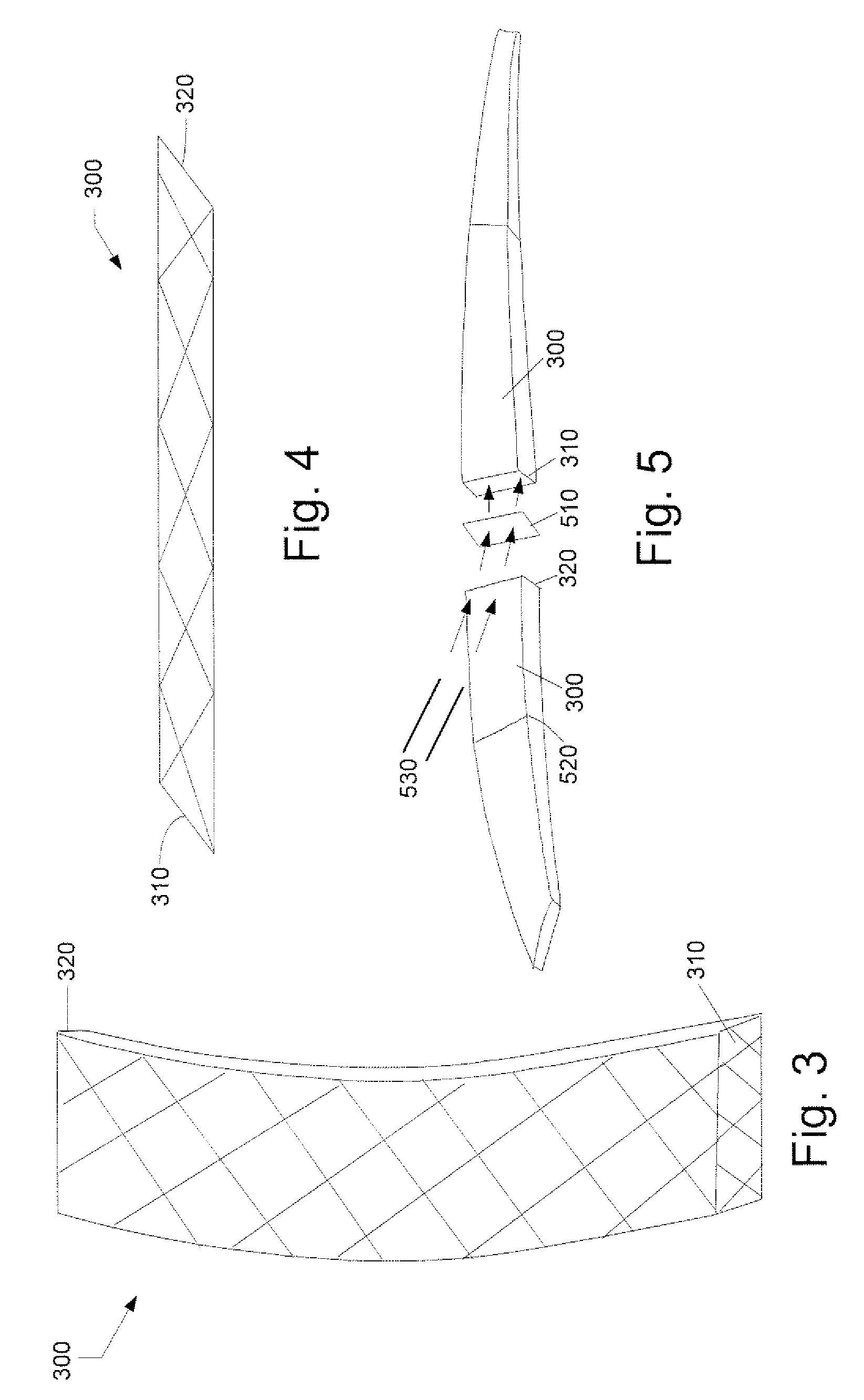

Method for improvement of the efficiency of a wind turbine rotor

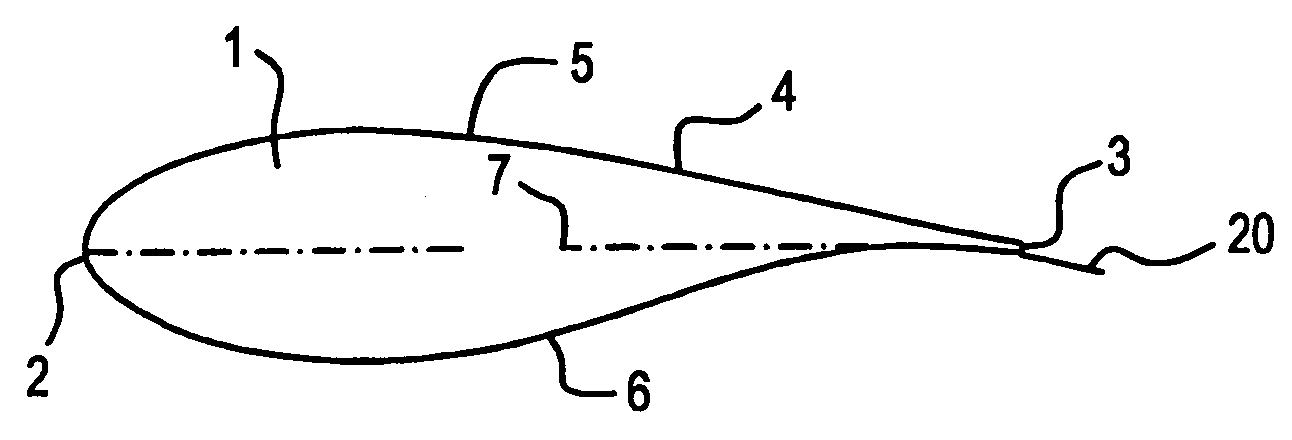

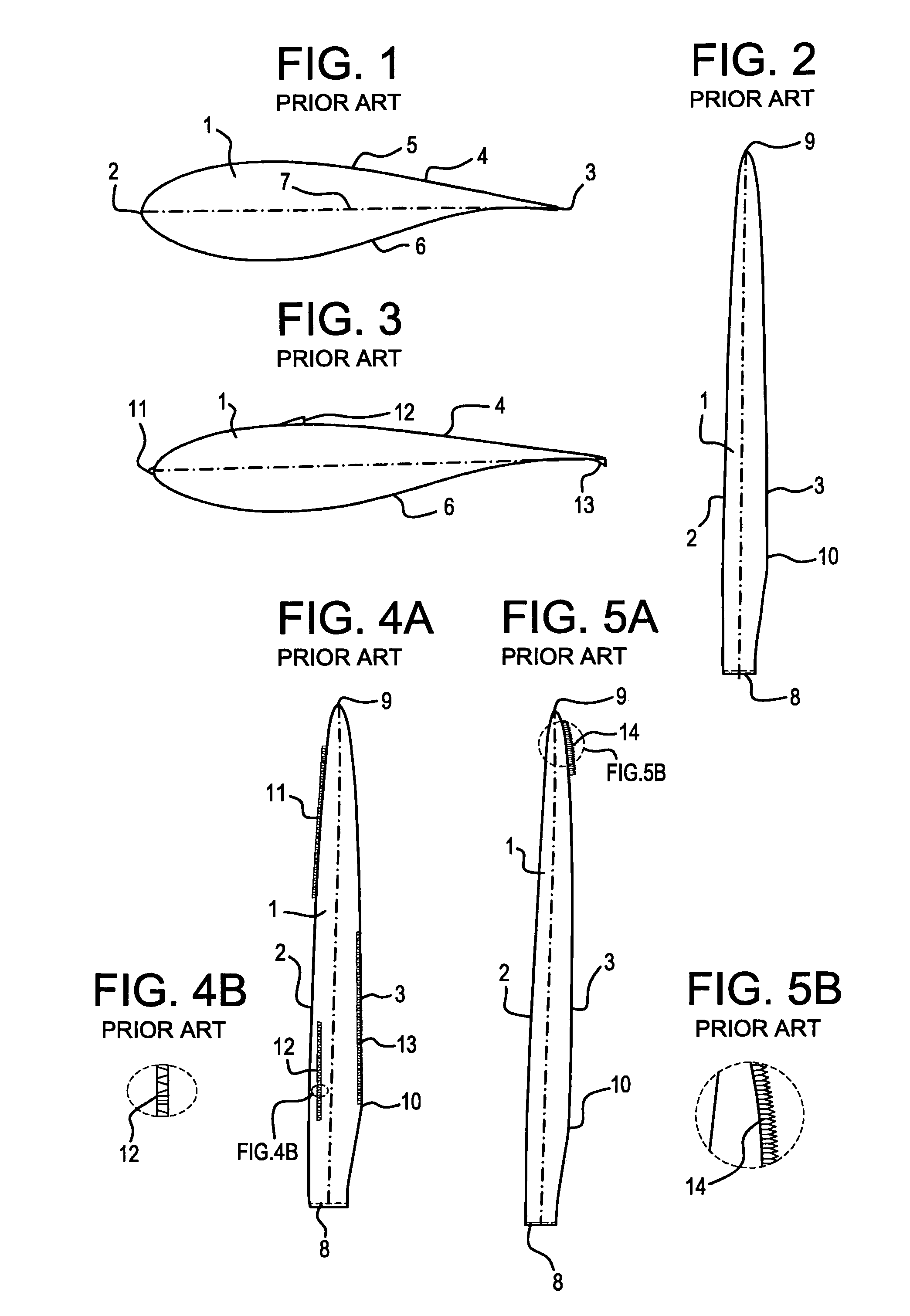

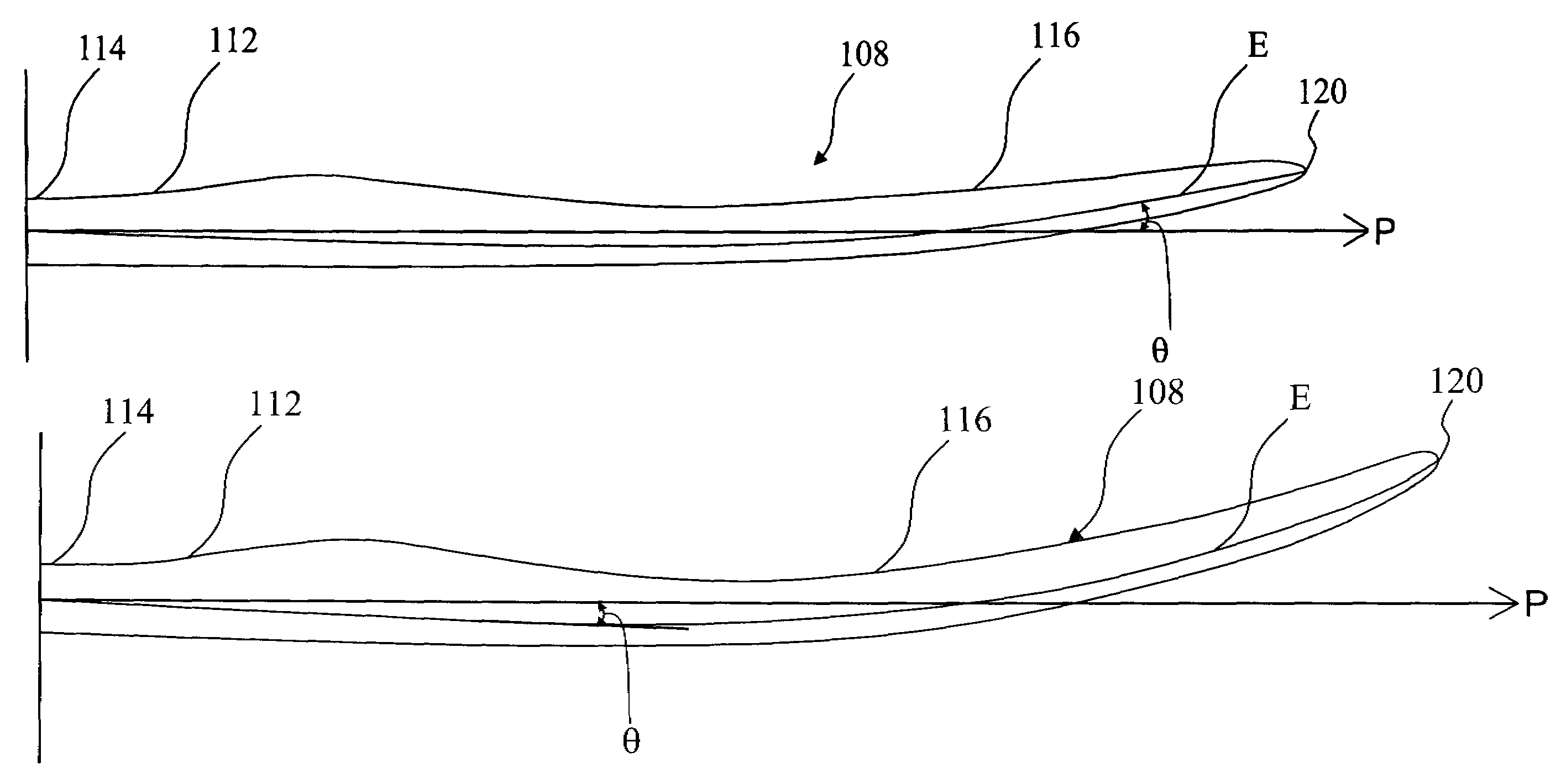

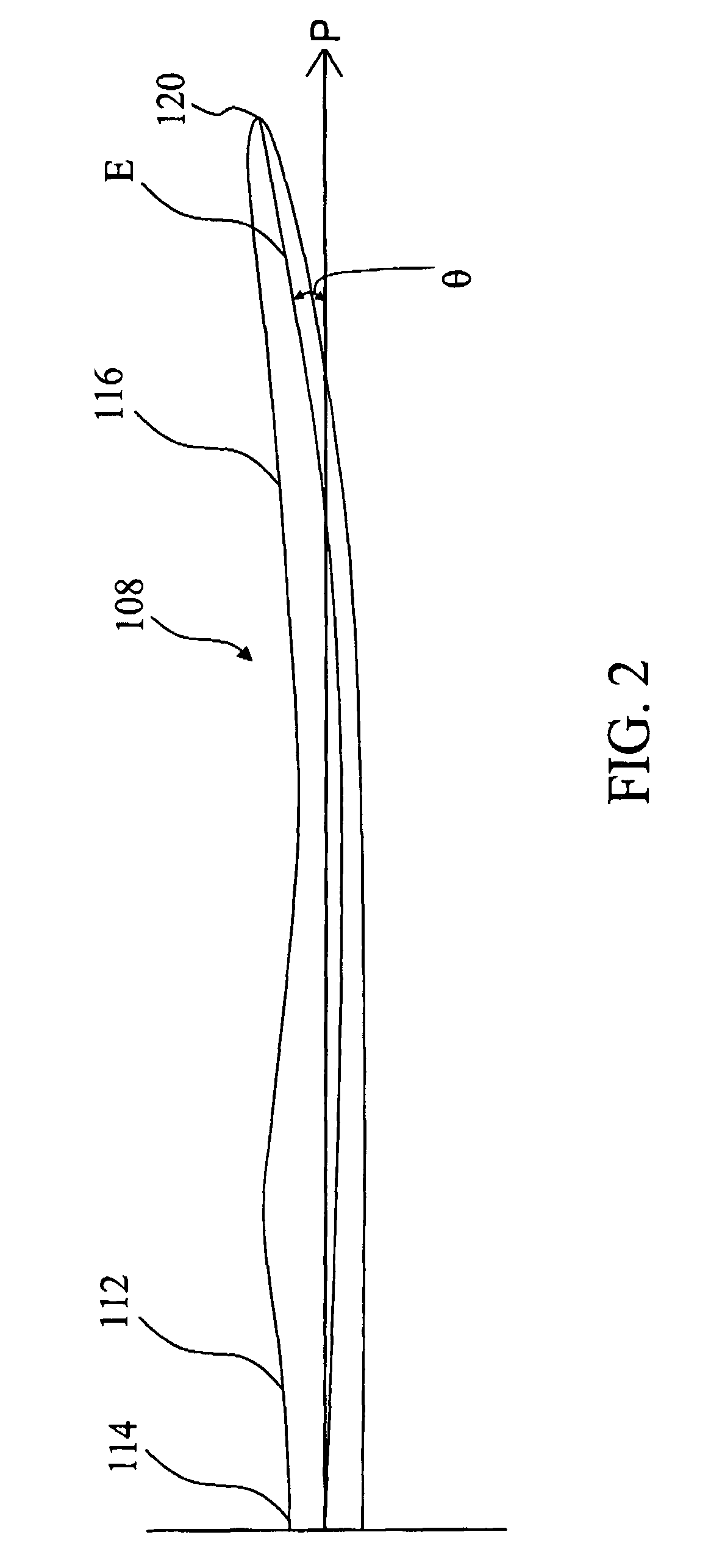

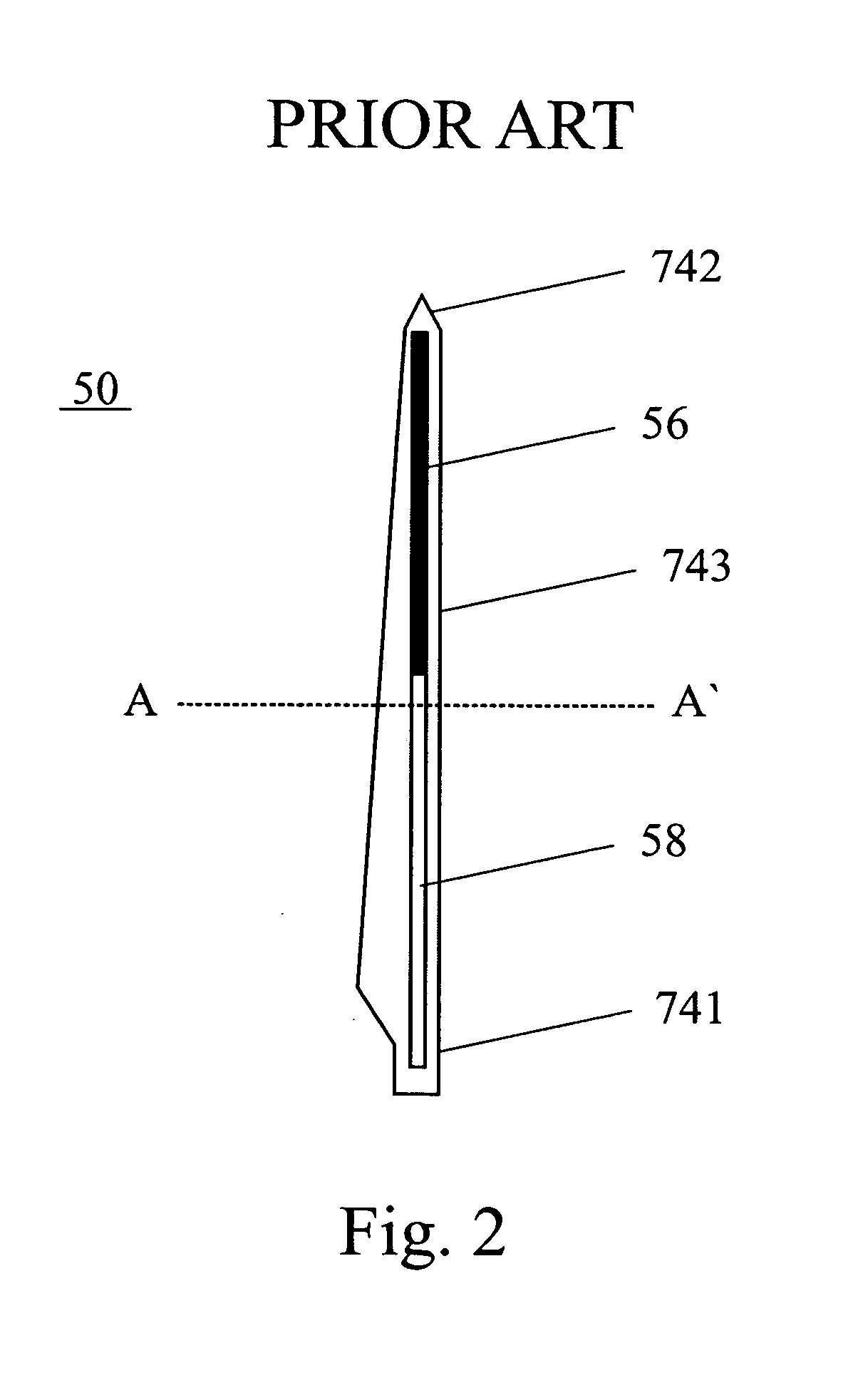

InactiveUS7059833B2Improvement of wind turbine rotor efficiencyImprove efficiencyPropellersWind motor controlTurbine bladeTrailing edge

A method for the improvement of wind turbine rotor efficiency blades of a wind turbine rotor with serrated trailing edges each having a plurality of span-wise, periodic indentations, in the form of saw teeth having approximately 60 degrees included angles between adjacent vertices. The efficiency of an existing wind turbine rotor is improved by the attachment of an apparatus to at least part of the trailing edge of the wind turbine blades, the apparatus being in the form of a serrated panel that is fixed to the surface of the blade and has the serrations extending into the airflow behind the trailing edge of the existing blade. The efficiency of a new wind turbine blade is improved by manufacturing the blade with serrations of at least part of the trailing edge of the wind turbine blade.

Owner:BONUS ENERGY +1

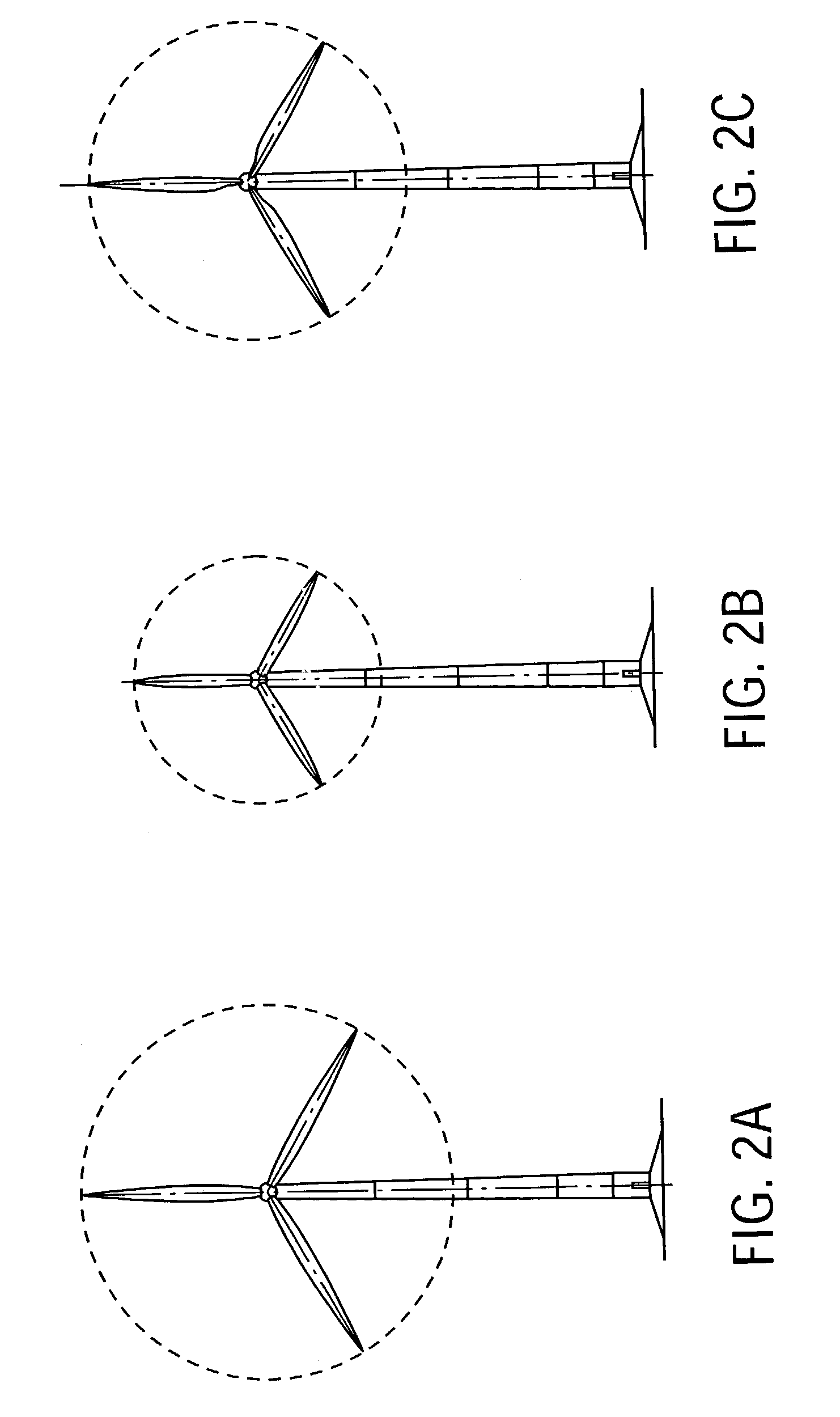

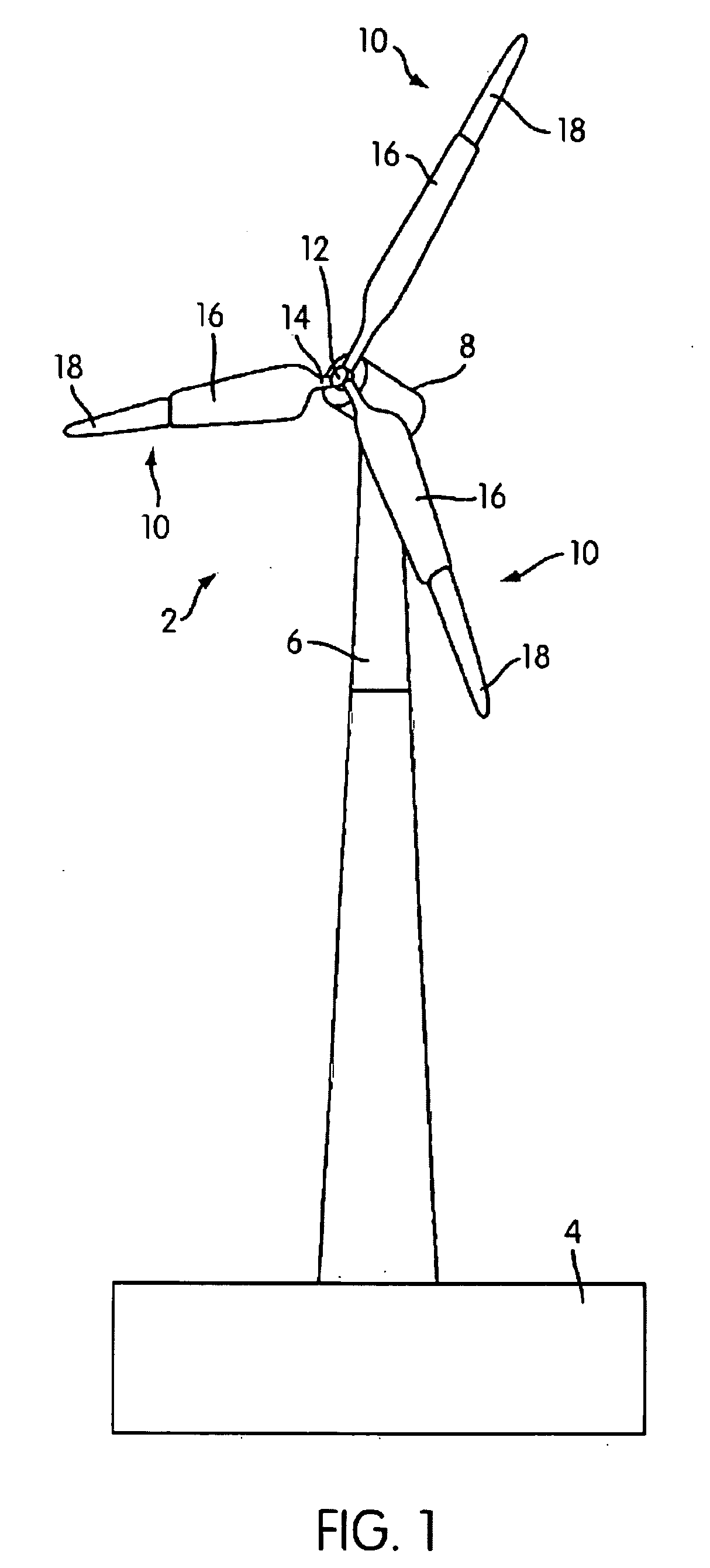

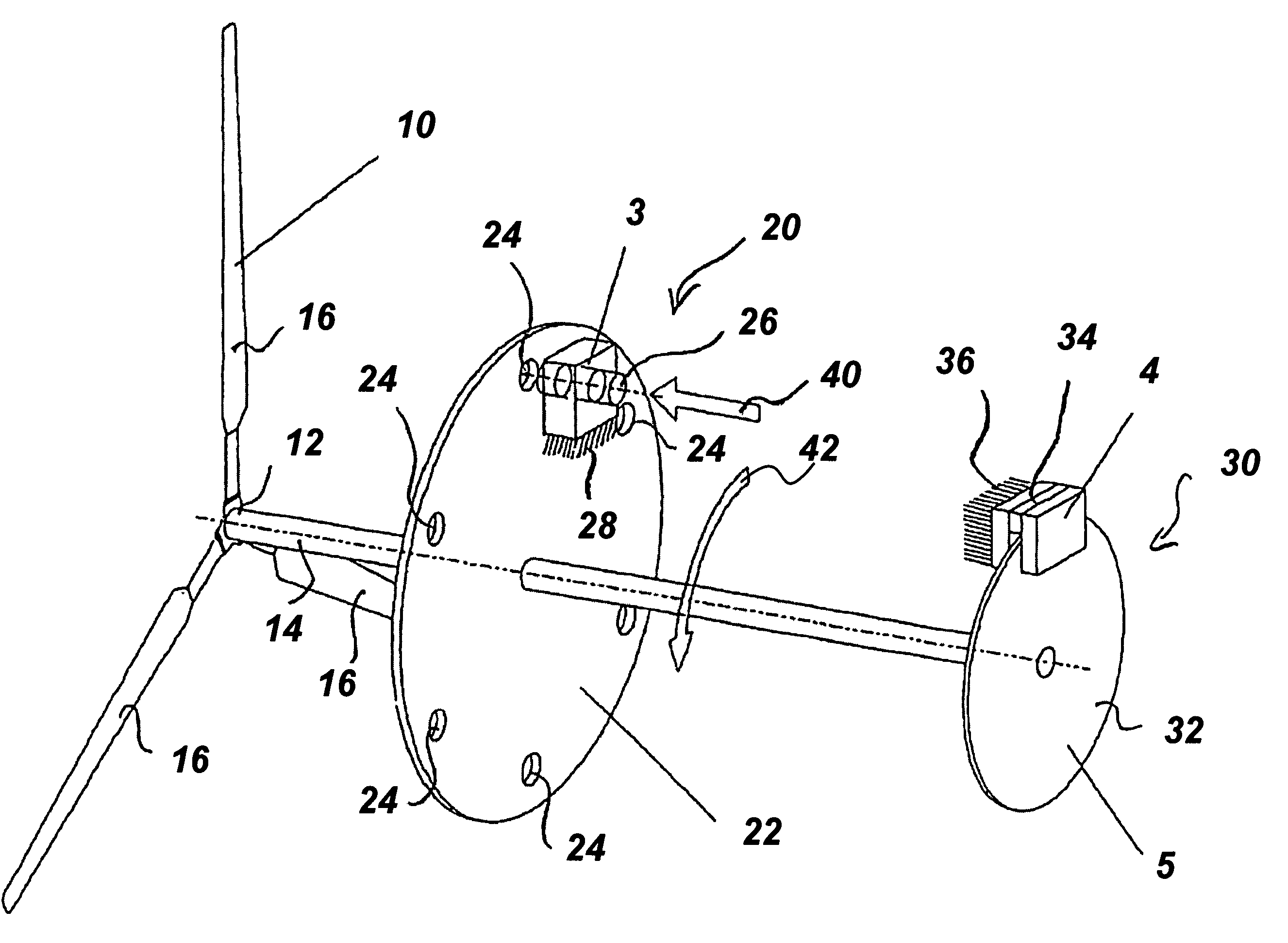

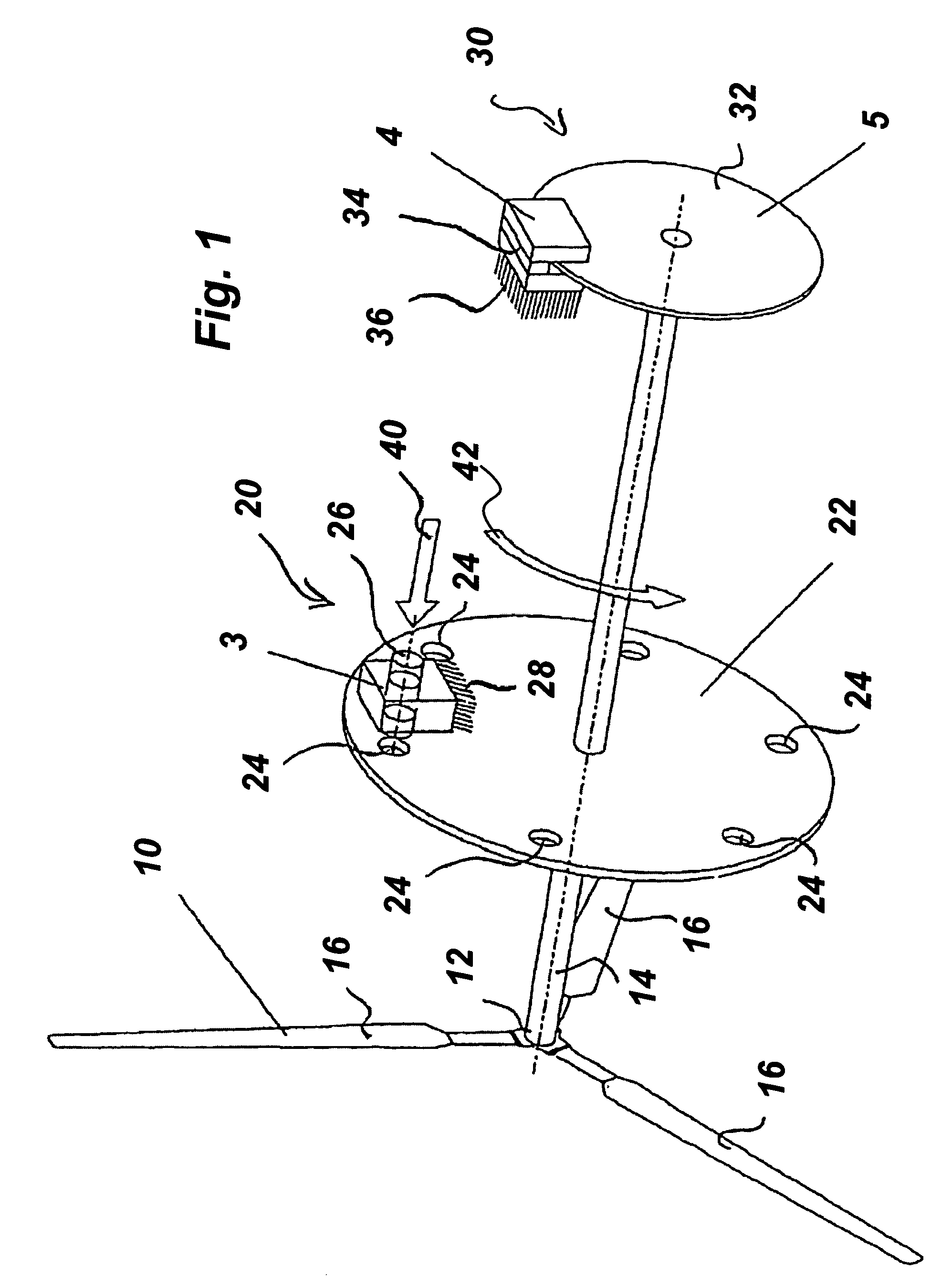

Lowering and raising a single wind turbine rotor blade from six-o'clock position

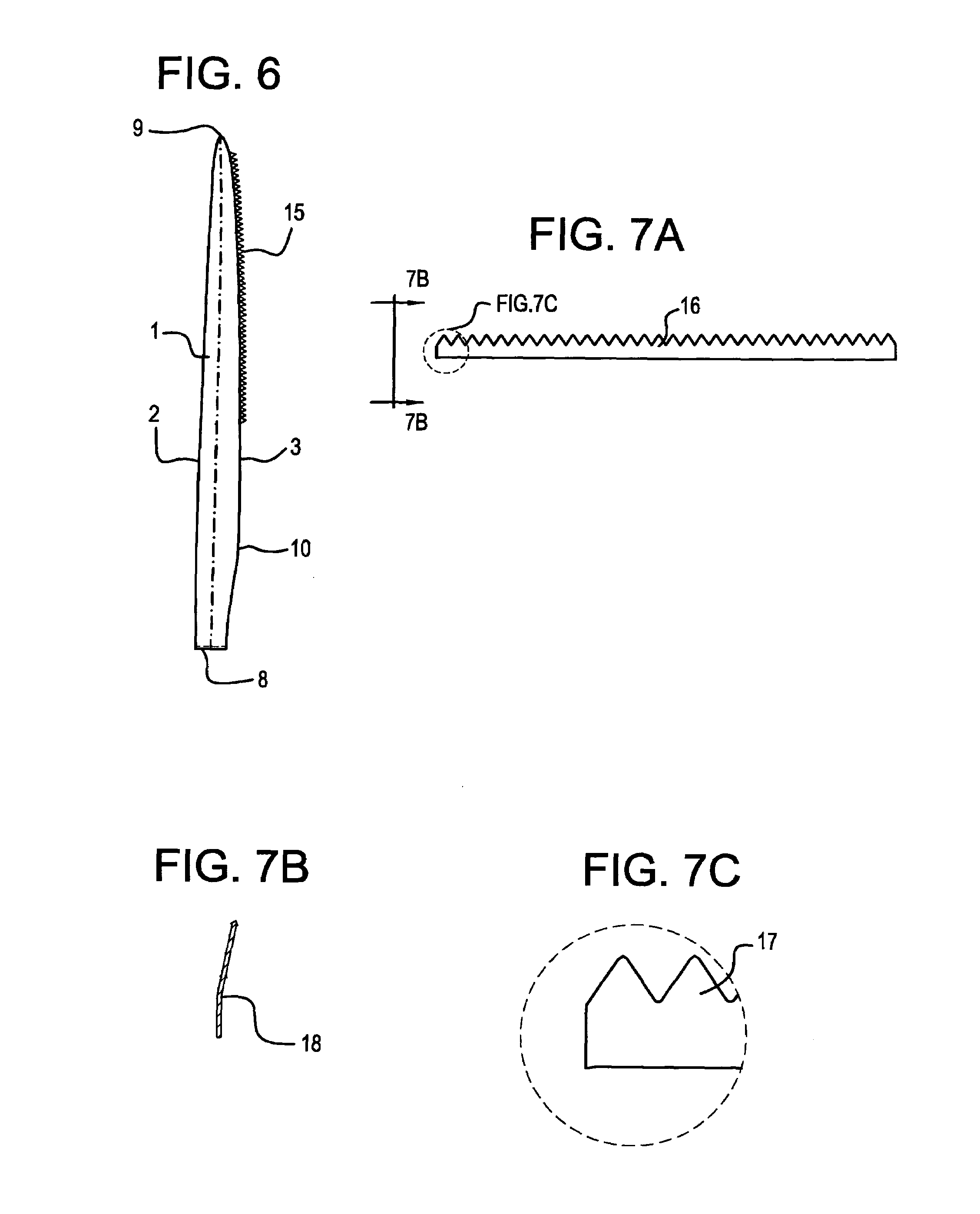

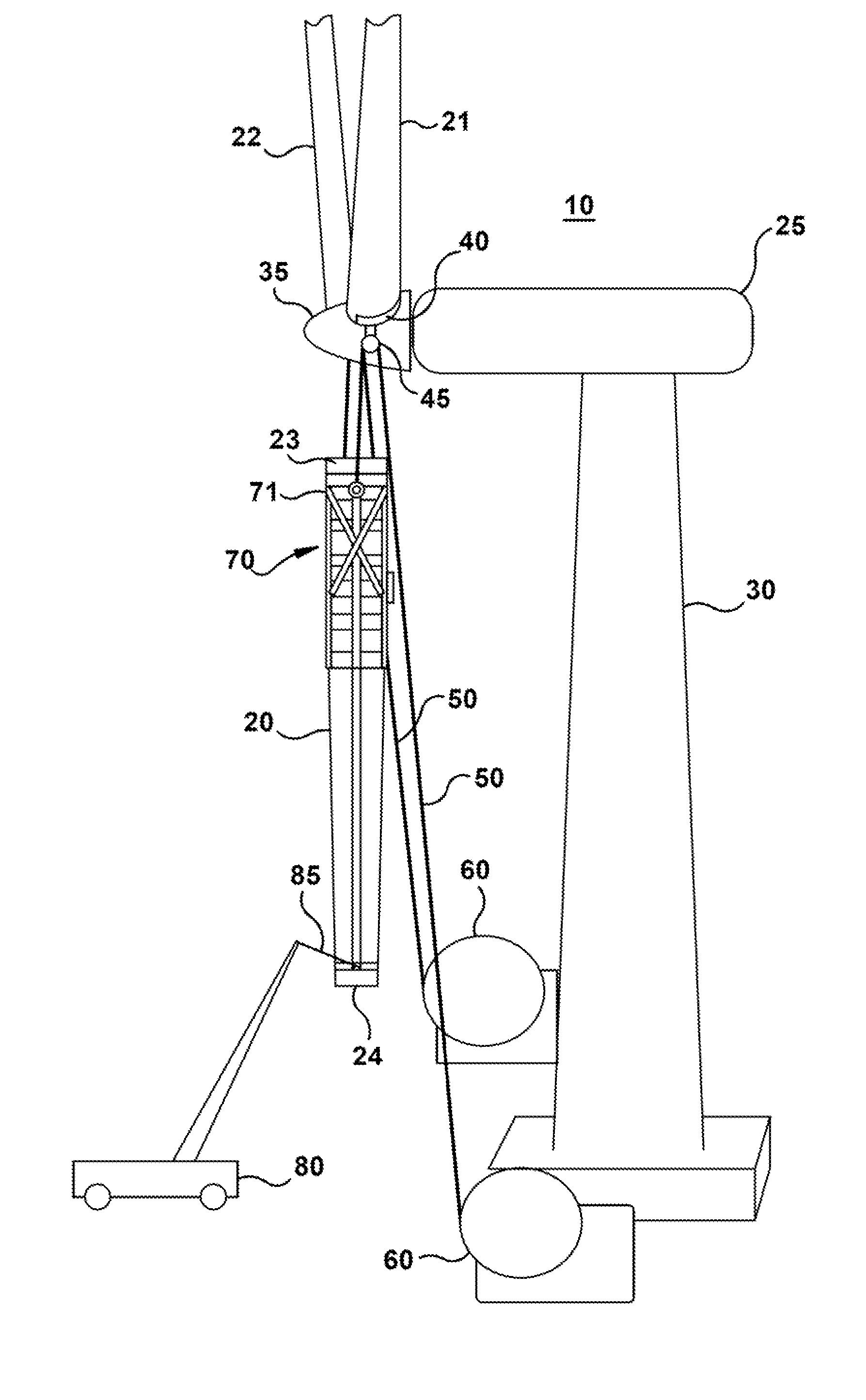

InactiveUS20100139062A1Prevent insufficient load capacityMetal-working apparatusWind motor assemblyLift lineWinch

A method and lifting arrangement for lowering and raising a single rotor blade of a wind turbine from a six-o'clock position is provided. Lifting fixtures are symmetrically installed on a hub surface about the rotor blade being replaced. Lifting lines from coordinated ground winches pass over the lifting fixtures to support the blade and attach to a blade harness. The blade harness attaches over a substantial length of the rotor blade, distributing the blade weight broadly. A tail pick crane facilitates transfer of the rotor blade between a vertical and a horizontal position stored position.

Owner:GENERAL ELECTRIC CO

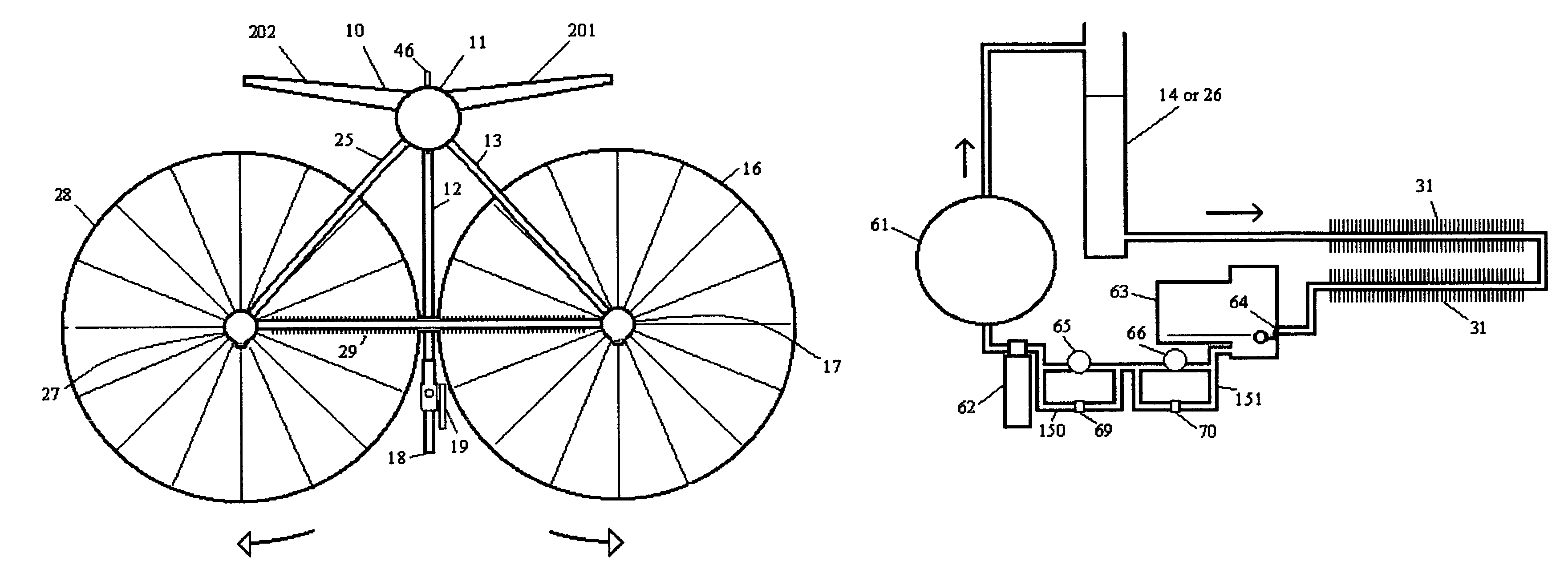

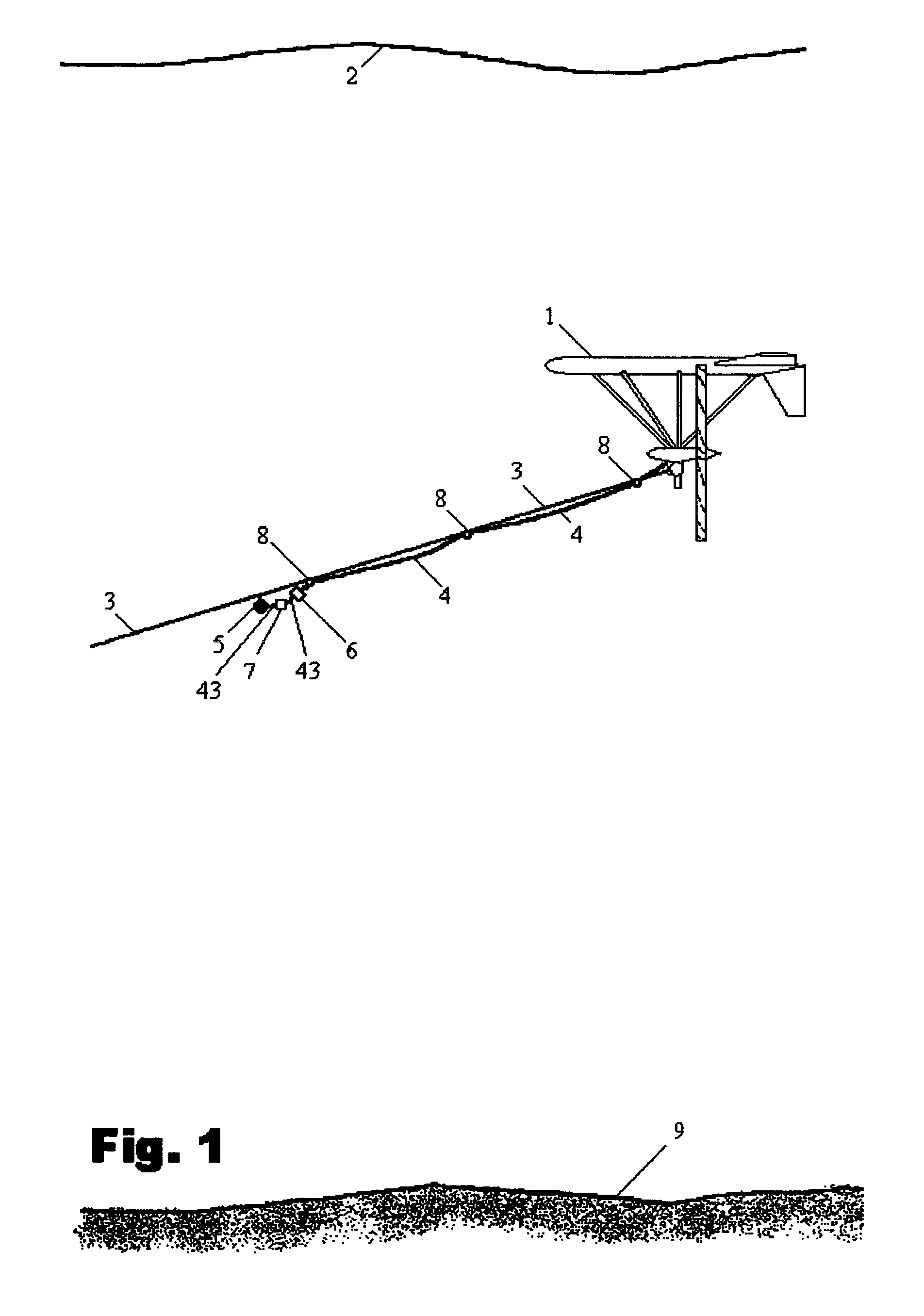

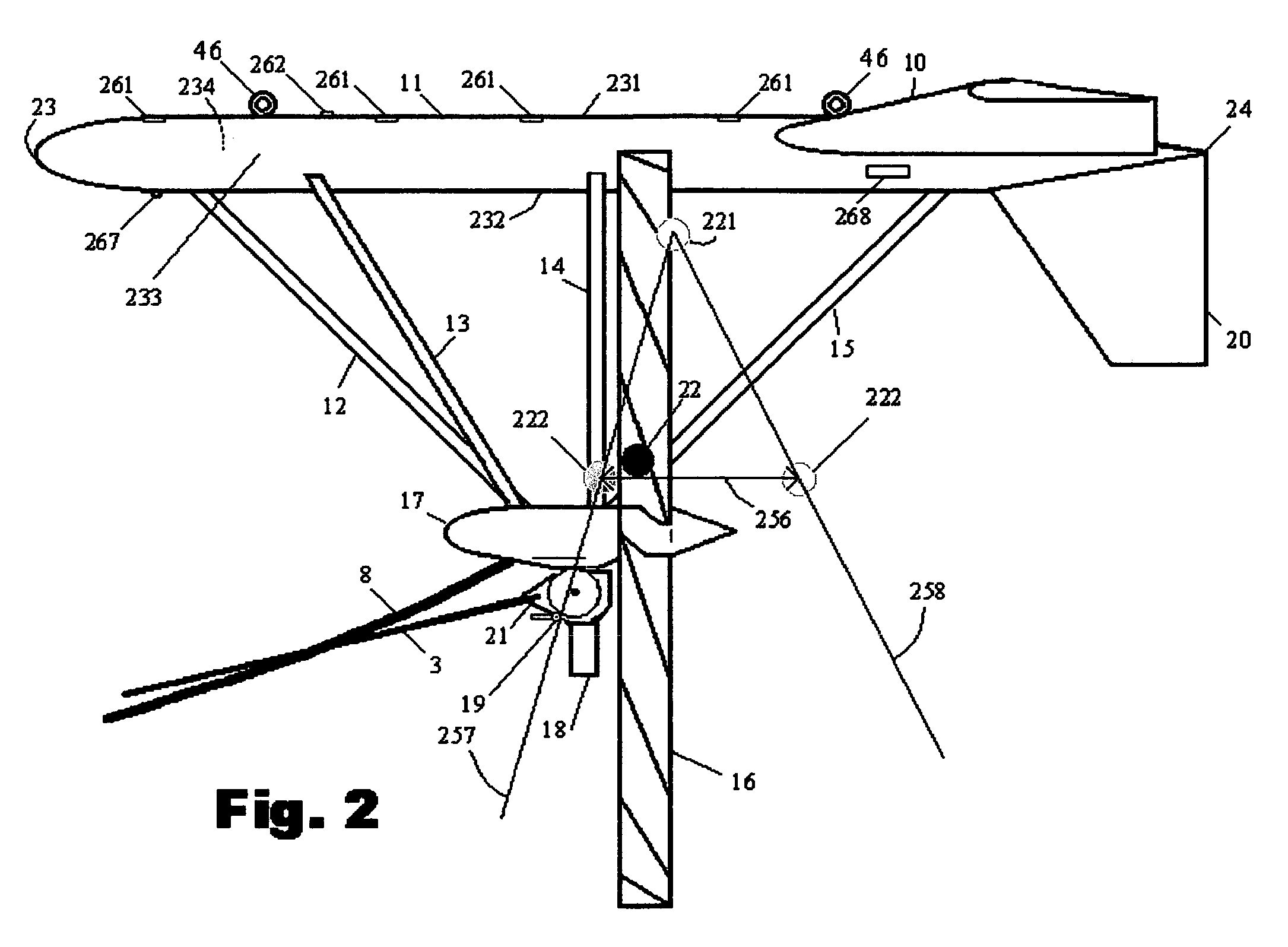

Submersible electrical power generating plant

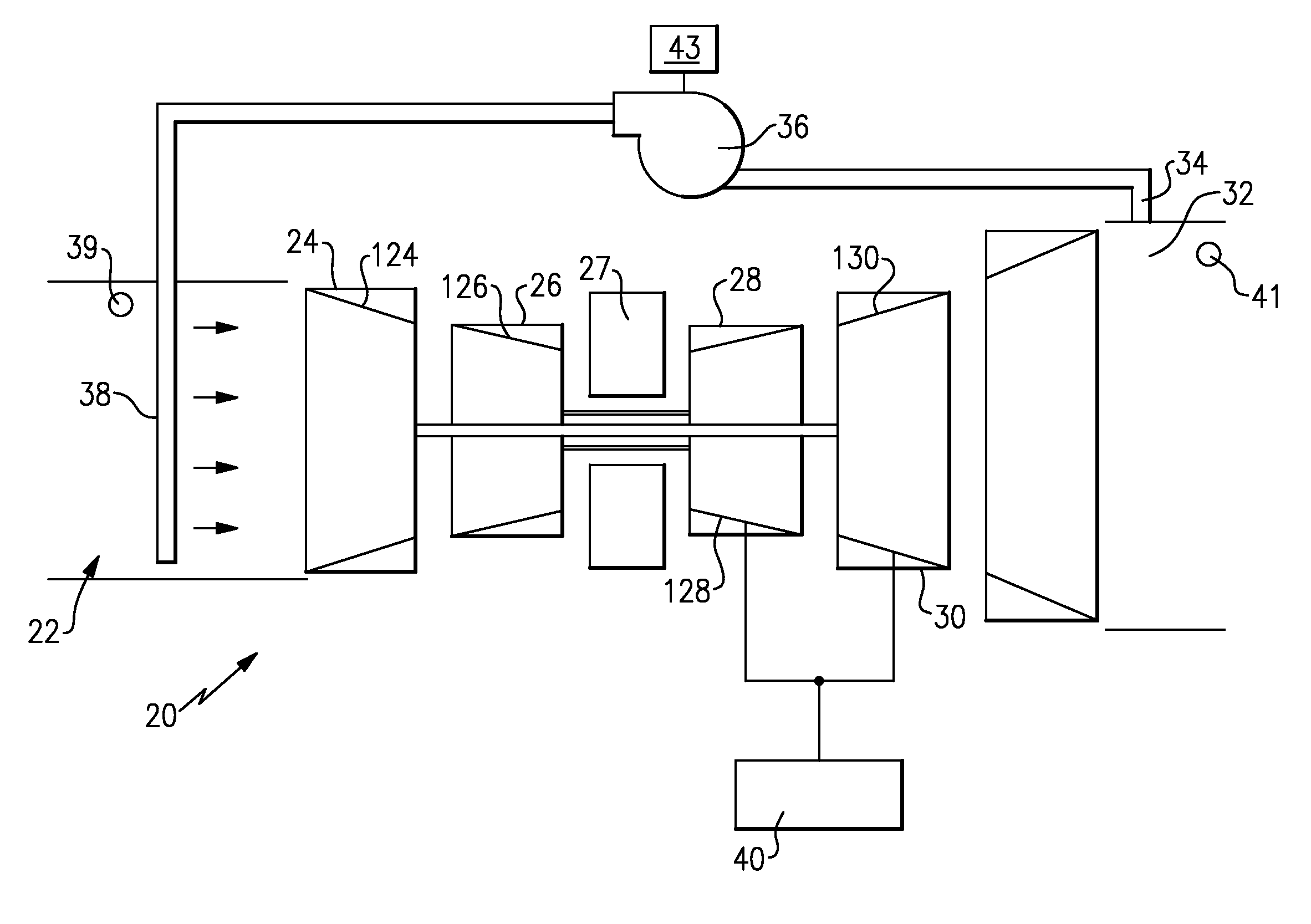

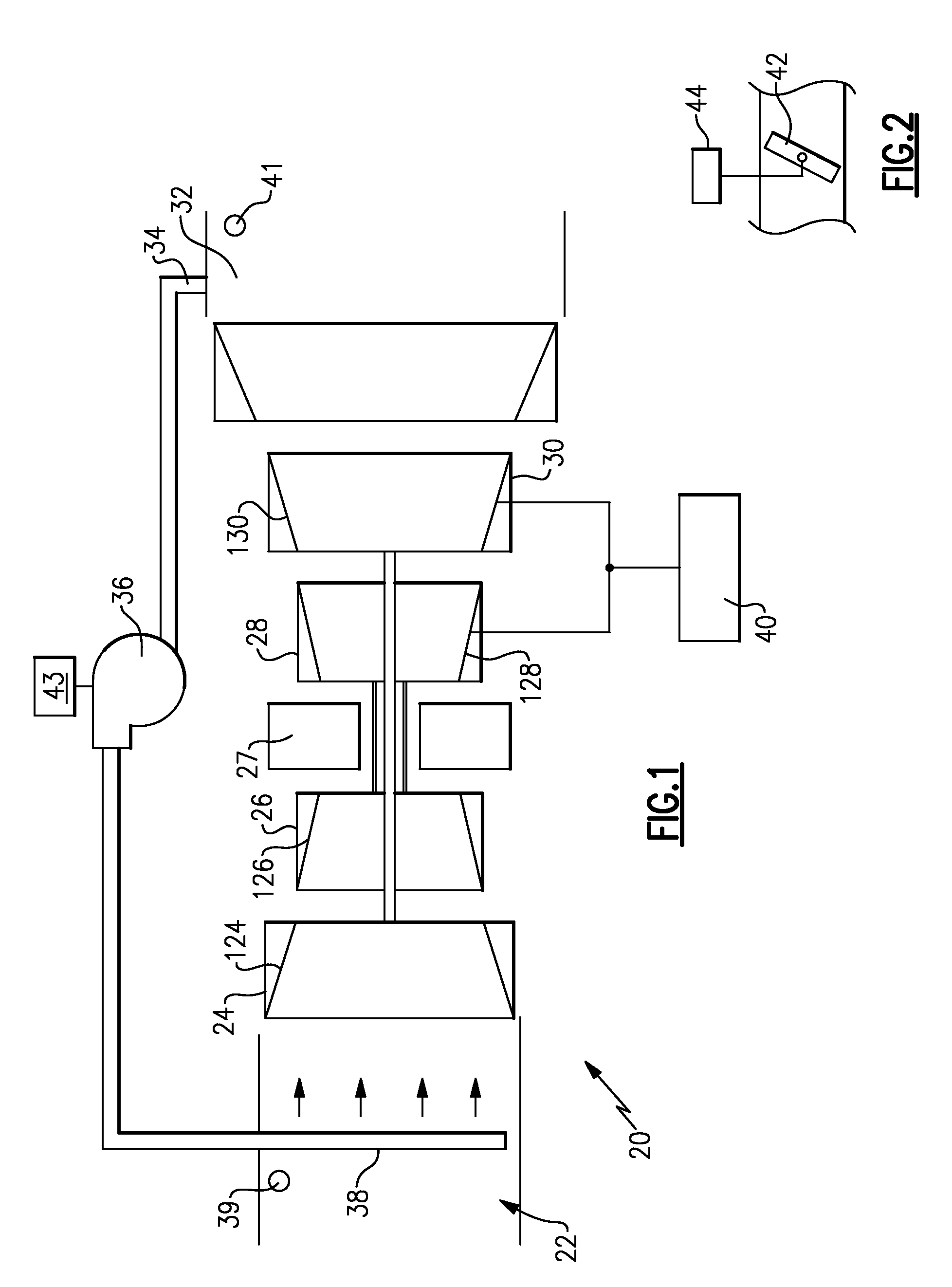

InactiveUS7291936B1Prevent siphonImproved directional stabilityEnergy industryWind motor combinationsNacelleHorizontal axis

A self-supporting, submersible generating plant for producing electricity from ocean currents, consisting of two counter-rotating, rear-facing turbines with a plurality of rotor blades extending radially outward from two separate horizontal axis that convey the kinetic energy from the two side-by-side, counter-rotating turbine rotors through separate gearboxes to separate generators that are housed in two watertight nacelles that are located sufficiently far apart to provide clearance for the turbine rotors. The two generators and their gearboxes serve as ballast and are located far below a streamlined buoyancy tank that extends fore and aft above and between them. A combination of a leverage system and a pressure-controlled system adjusts the hydrodynamic lifting forces to maintain constant depths. There are systems to purge the ballast water to facilitate the recovery of both individual submersible power plants and a group of many submersible power plants.

Owner:ROBSON JOHN H

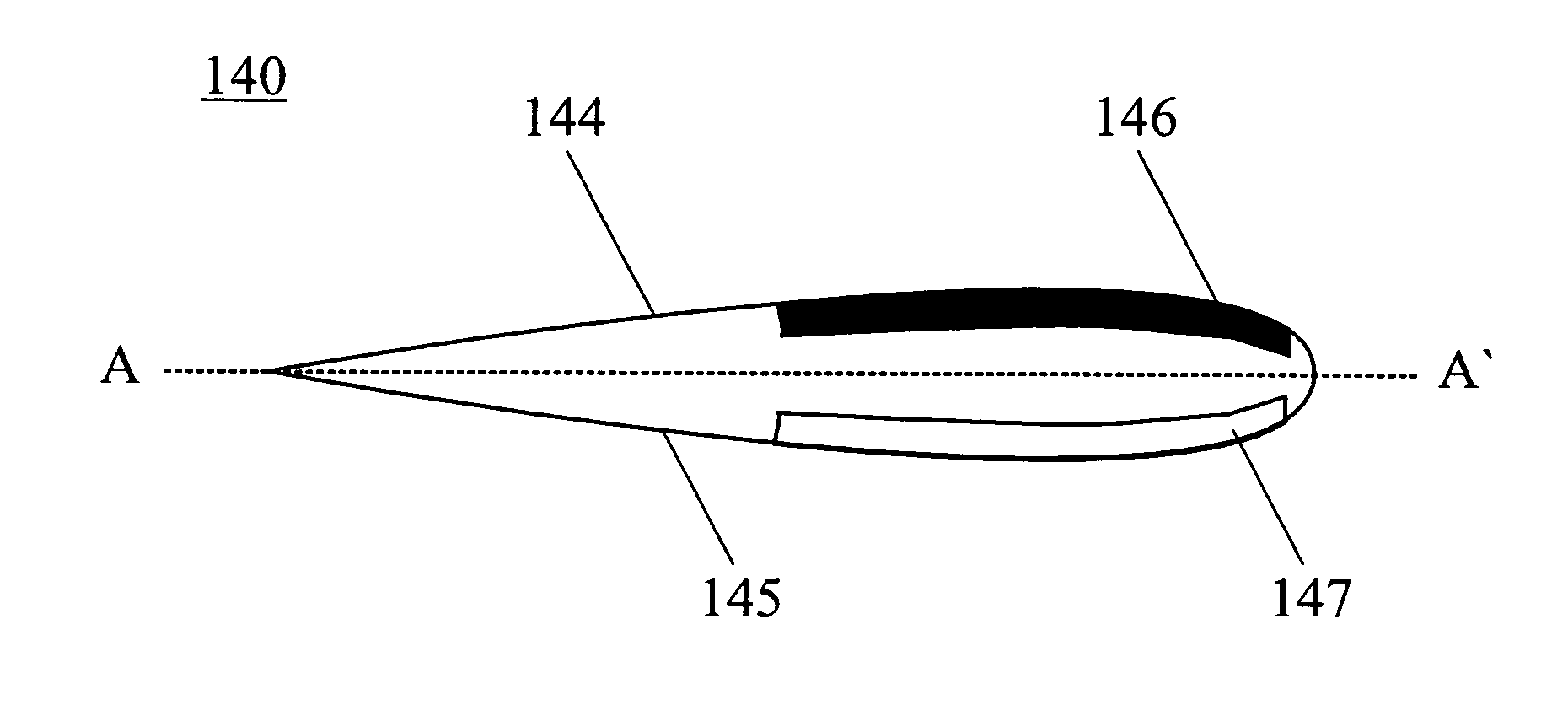

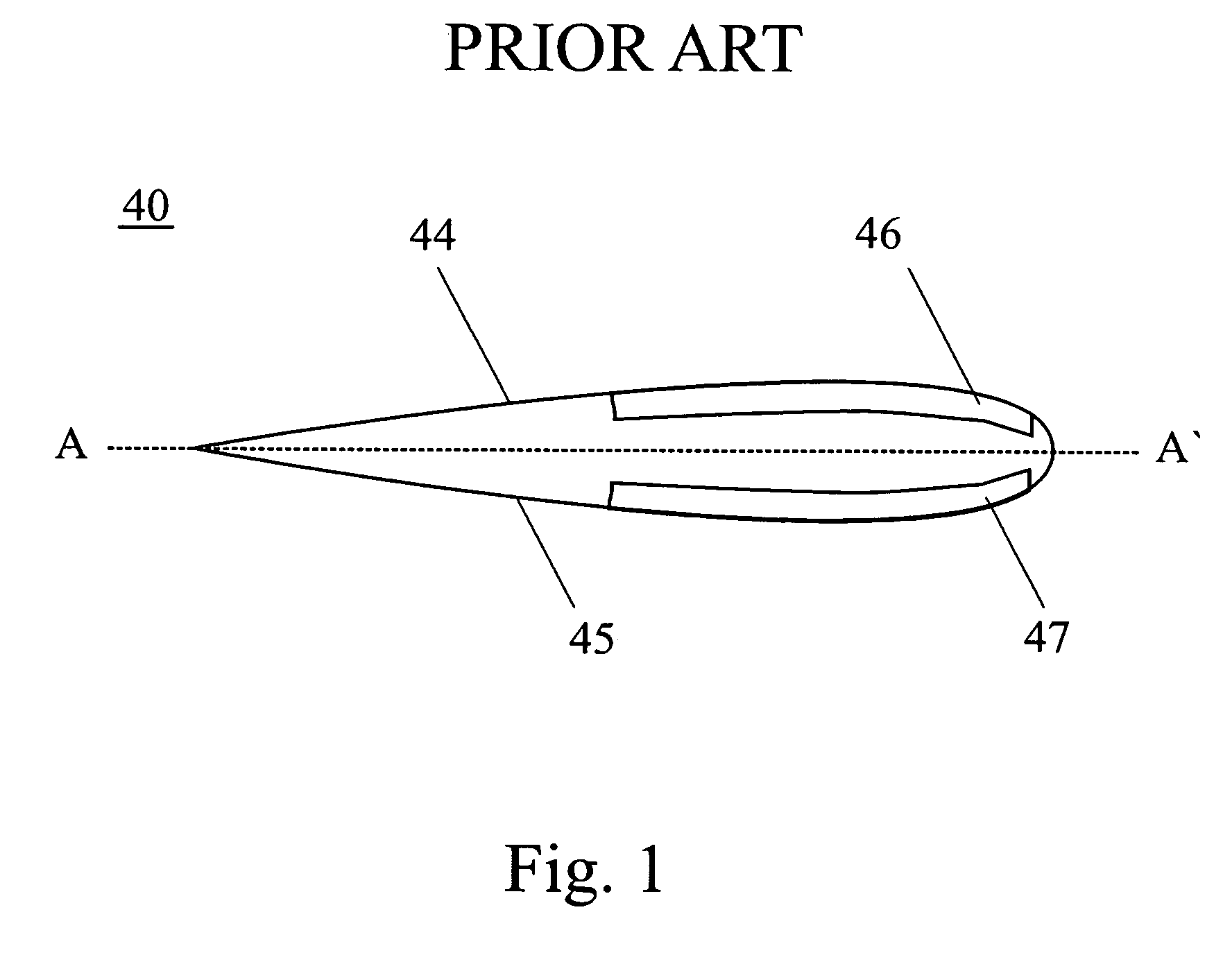

Wind turbine blade with lift-regulating means

ActiveUS7293959B2Smooth and gradual change in liftSimple wayPropellersPump componentsTurbine bladeBiological activation

Owner:LM GLASSFIBER

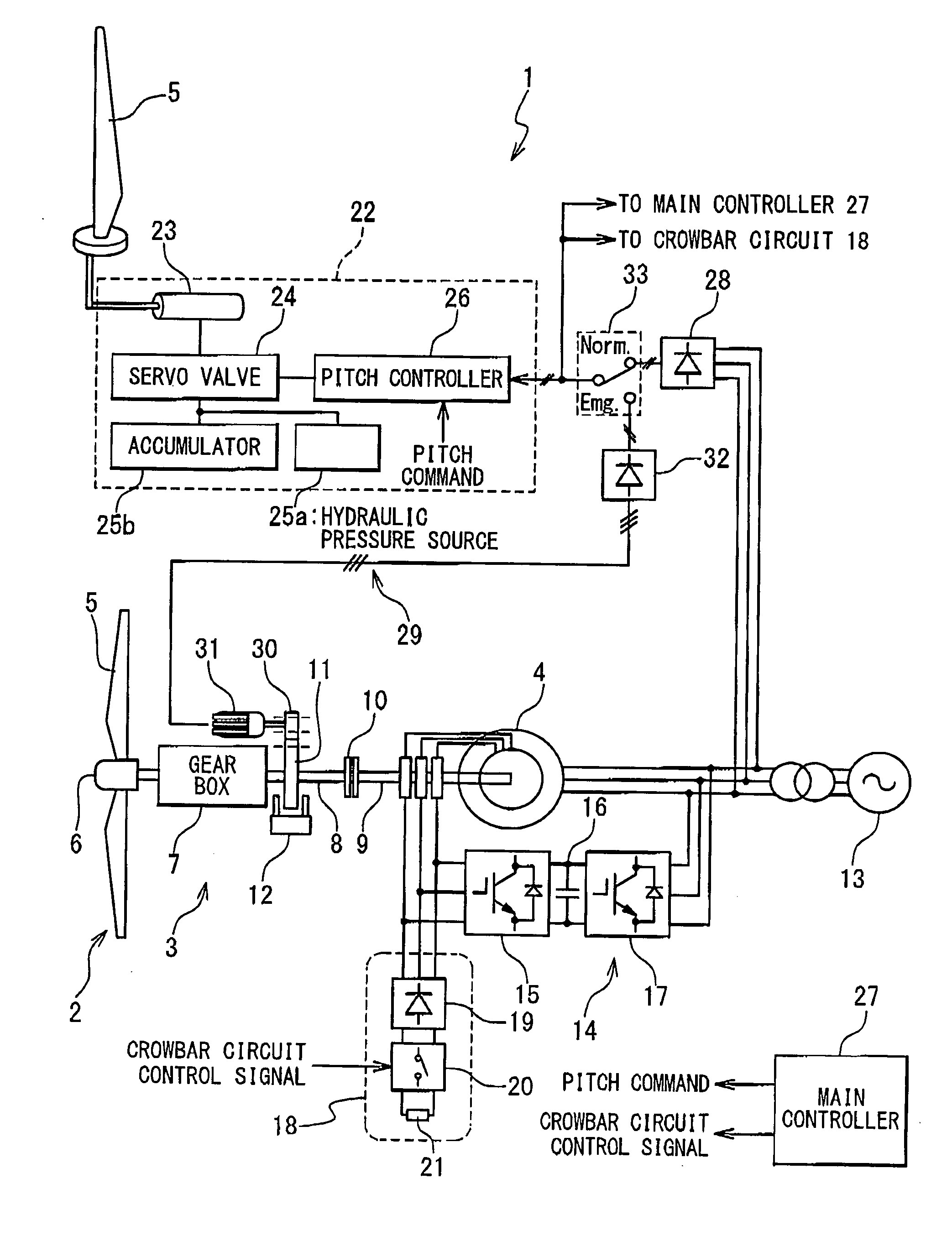

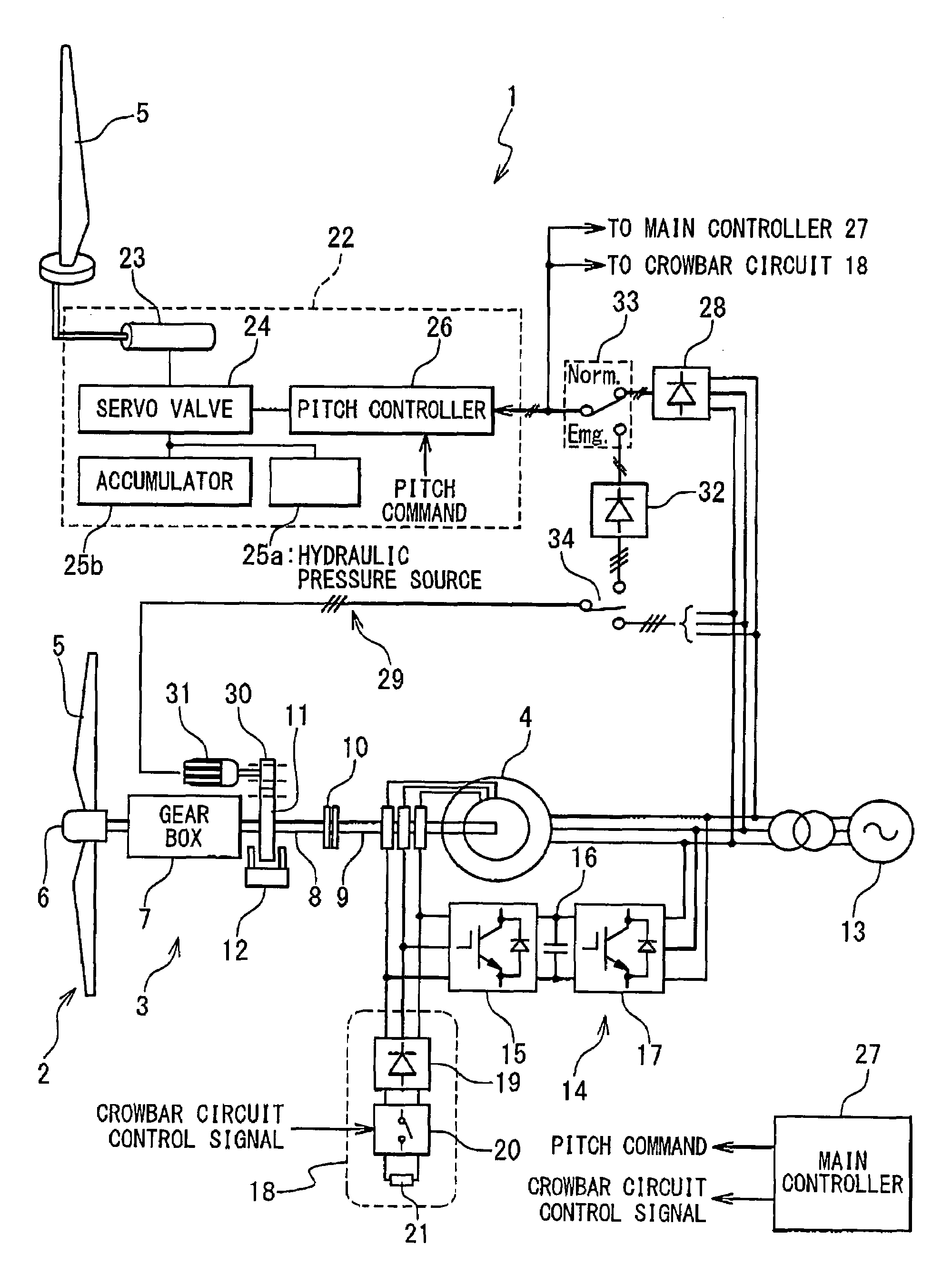

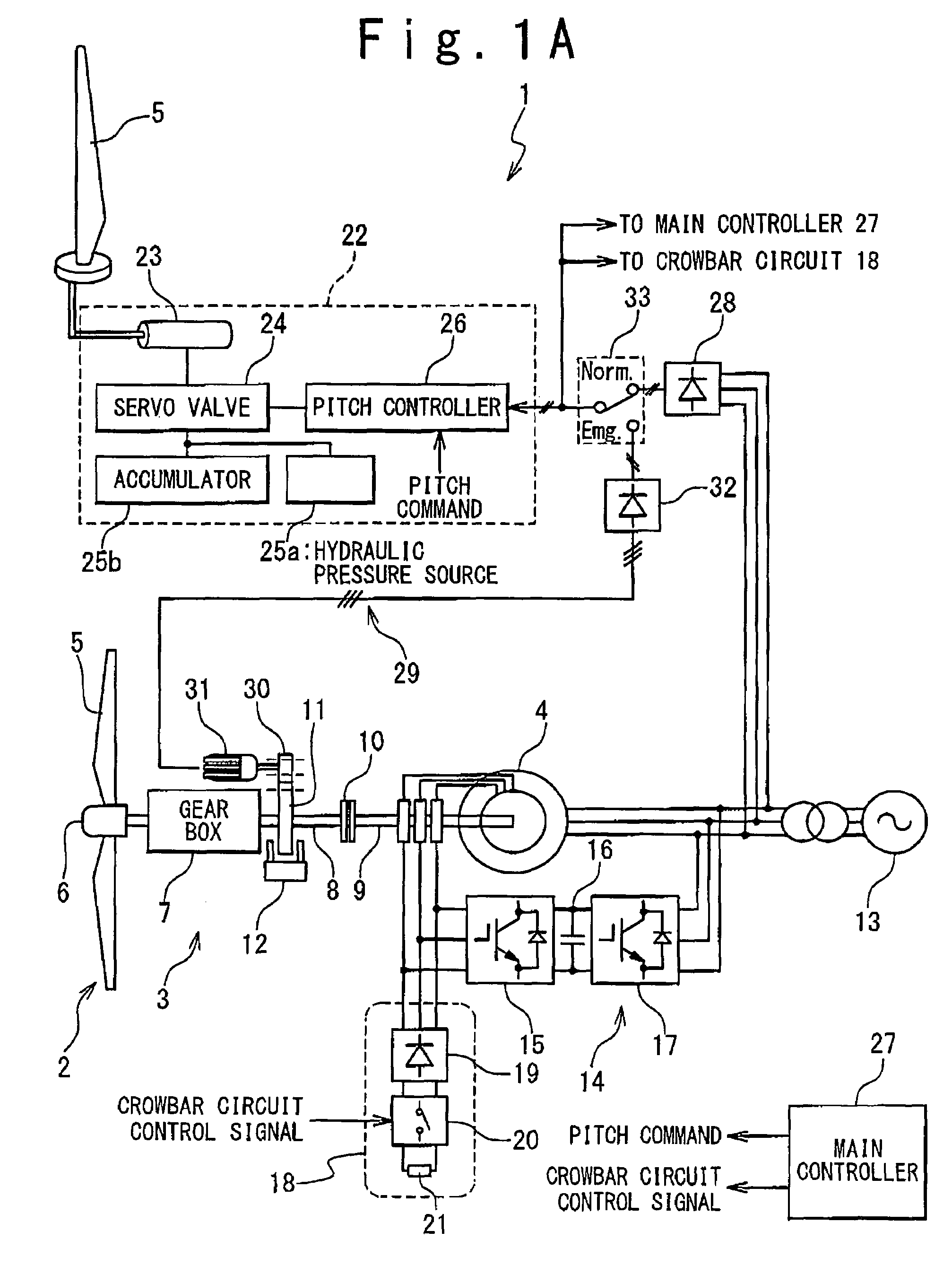

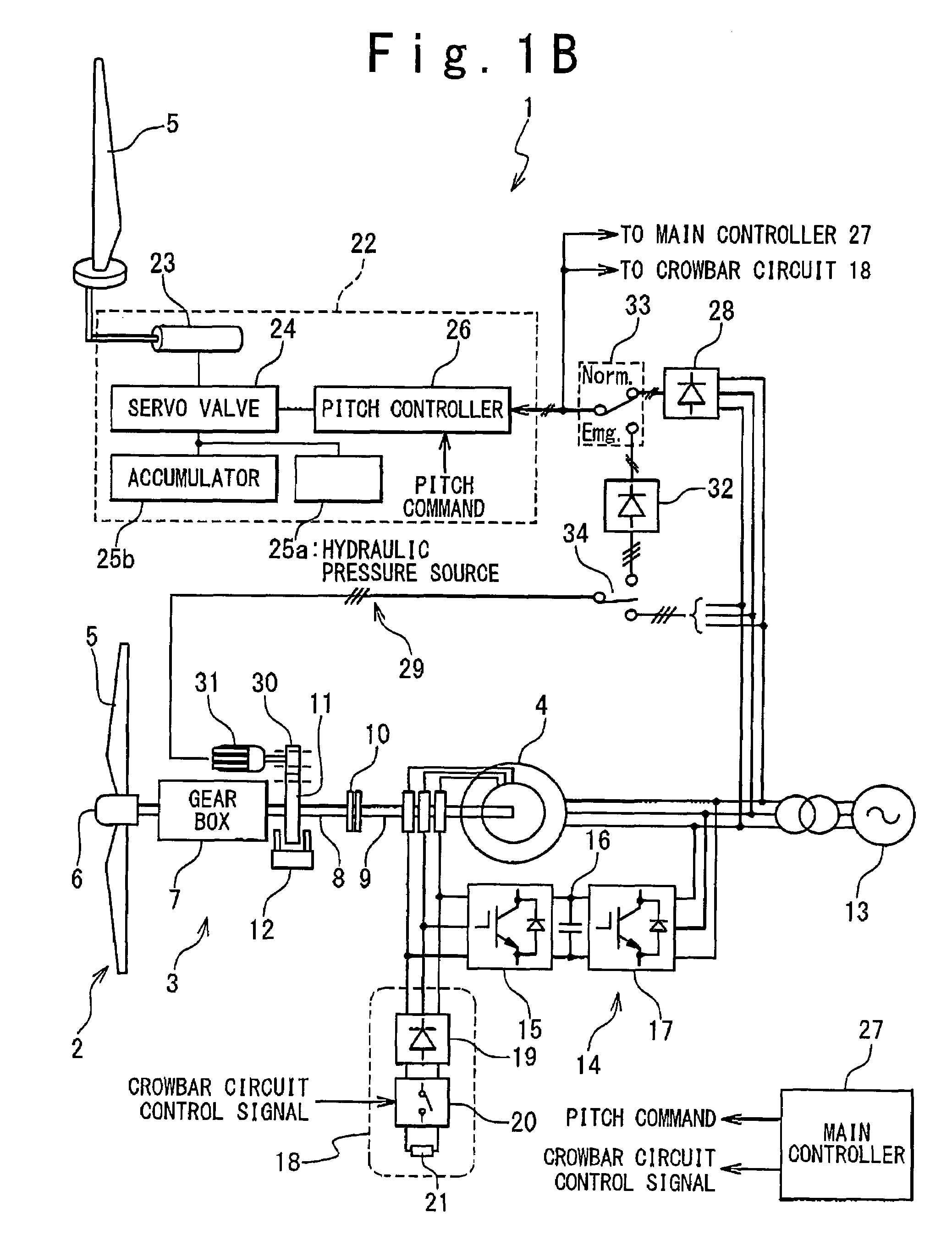

Wind turbine system for satisfying low-voltage ride through requirement

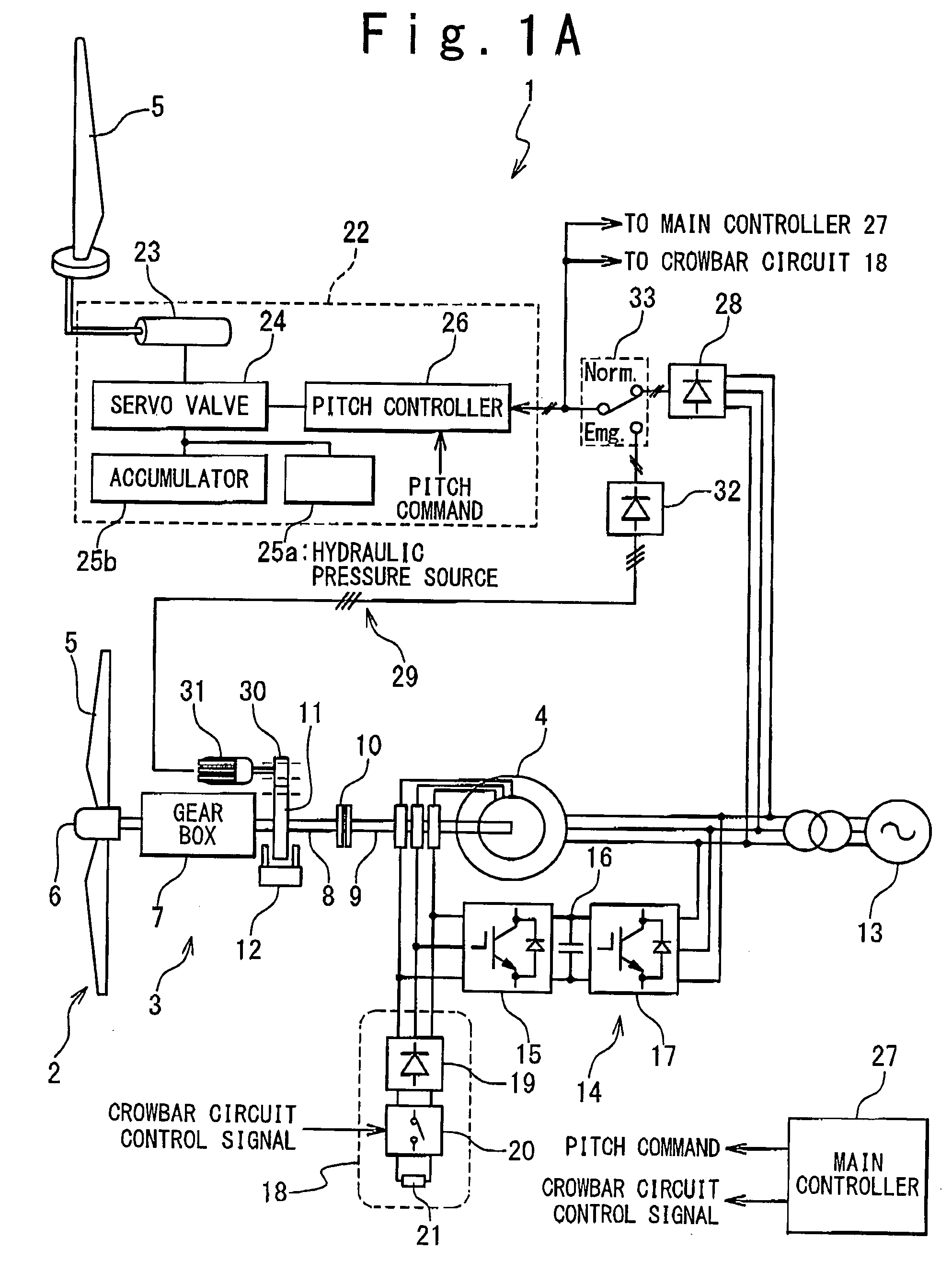

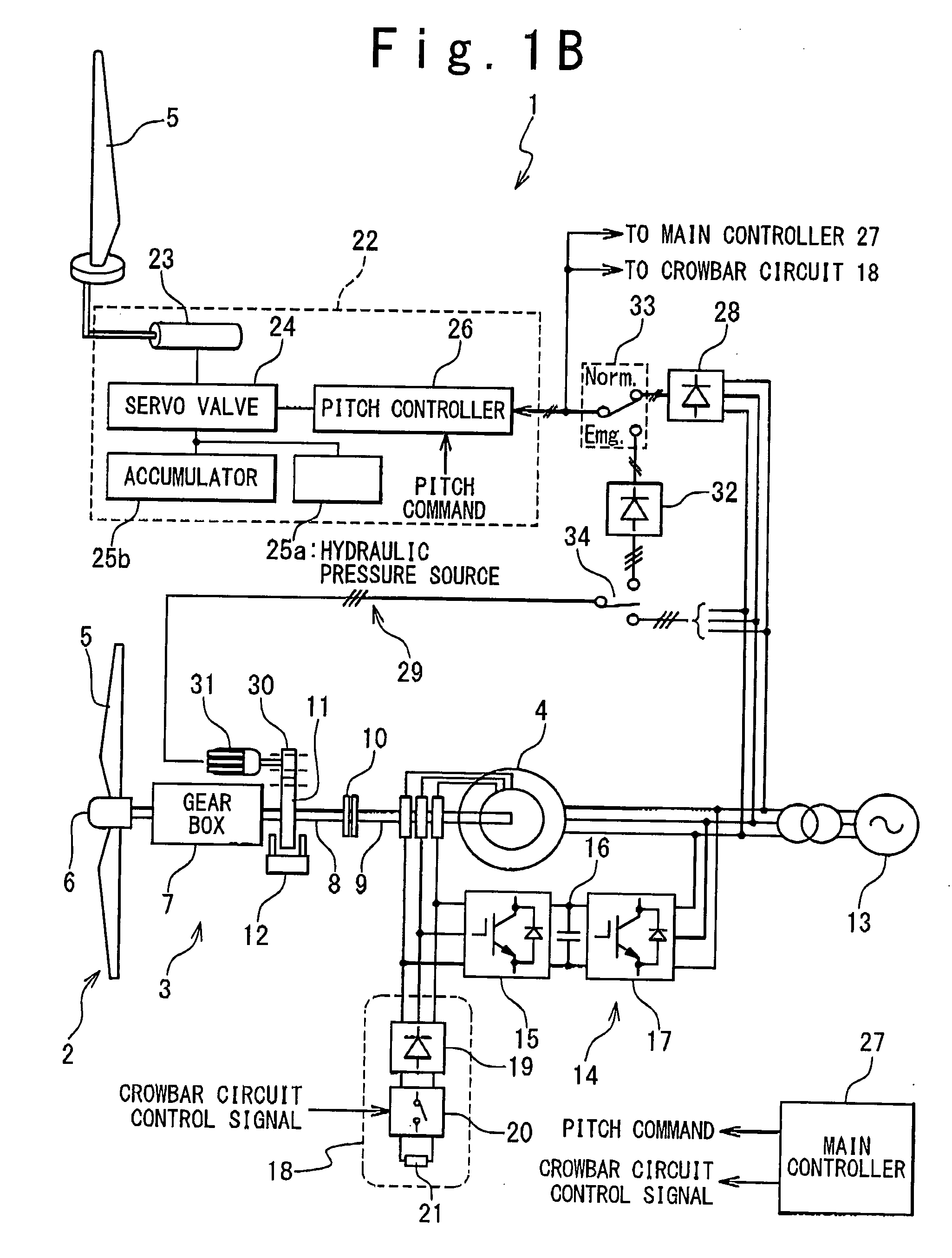

ActiveUS20090058086A1Reduce maintenanceReduce necessityPropellersWind motor controlPower gridBlade pitch

A wind turbine system is provided with a wind turbine rotor, a pitch control mechanism, and an emergency power supply mechanism. The wind turbine rotor includes a blade having a variable pitch angle. The pitch control mechanism drives the blade to control the pitch angle. The emergency power supply mechanism generates electric power from rotation of the wind turbine rotor and feeds the electric power to the pitch control mechanism, in response to occurrence of an accidental drop of a system voltage of a power grid.

Owner:MITSUBISHI HEAVY IND LTD

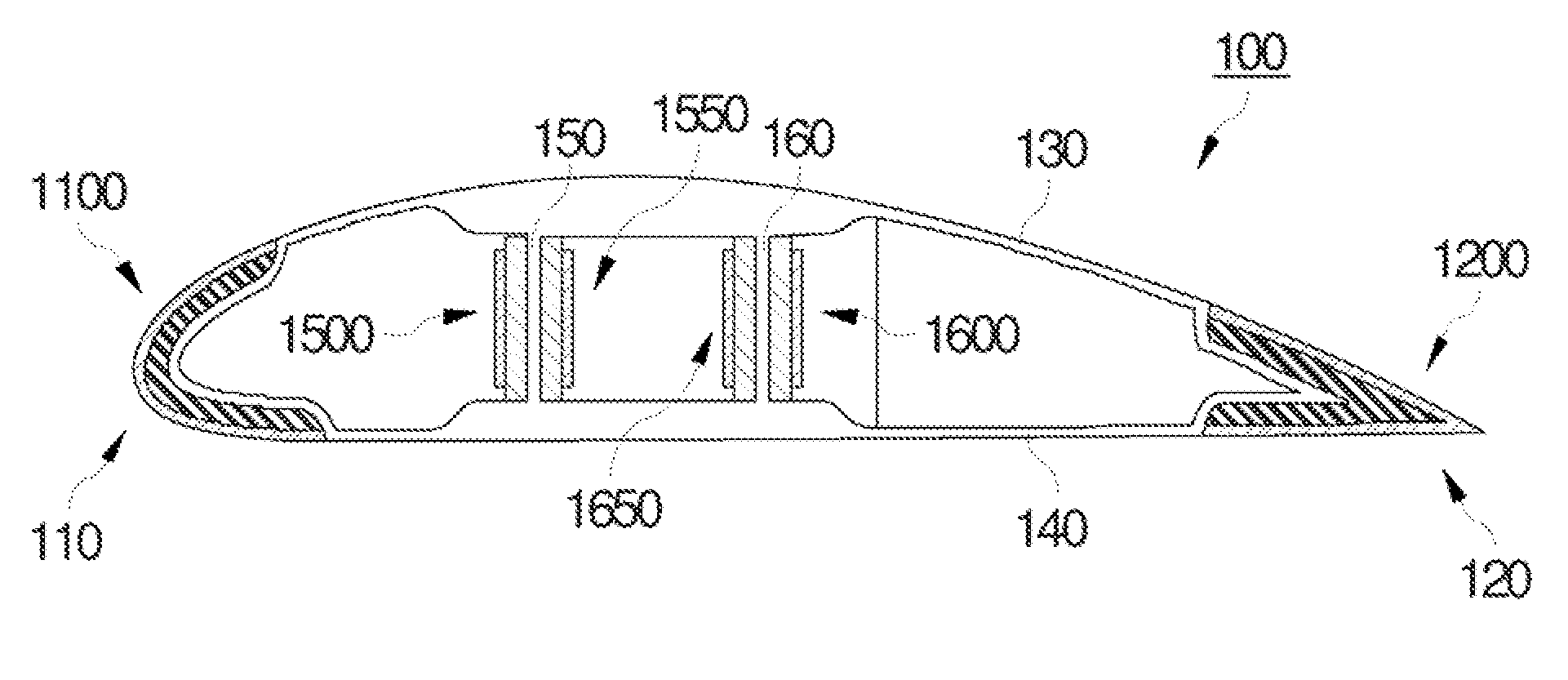

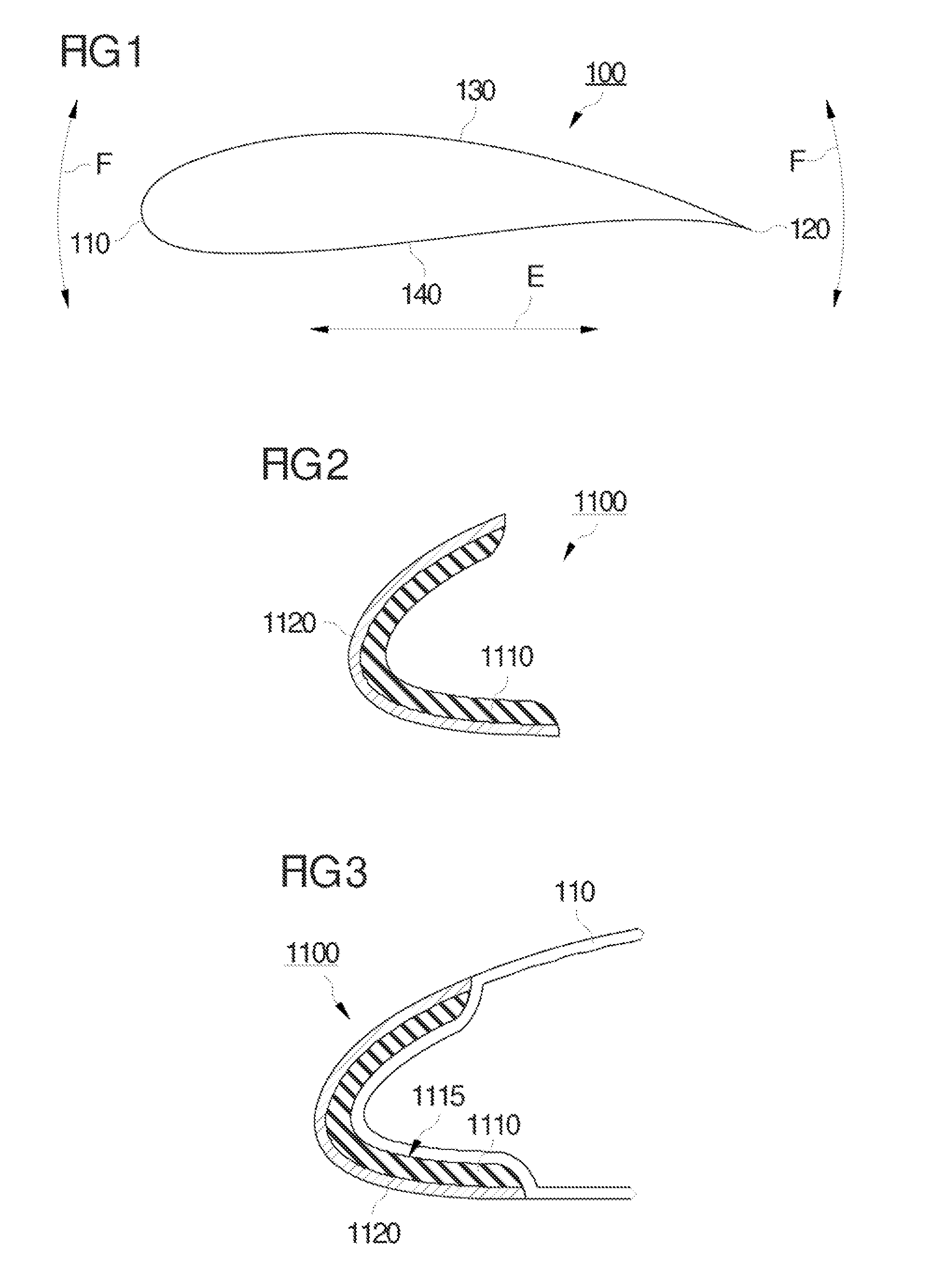

Damping element for a wind turbine rotor blade

InactiveUS20080107540A1Reduce maintenanceDynamic fatigue is reducedPropellersRotary propellersEngineeringTurbine rotor

A damping element for a wind turbine rotor blade is provided, the damping element comprising a laminate material made of at least one viscoelastic layer and at least one stiff layer adhered to said viscoelastic layer, wherein the damping element is adapted to be attached to a body of the rotor blade so that the at least one viscoelastic layer is in contact with the body of the rotor blade.

Owner:GENERAL ELECTRIC CO

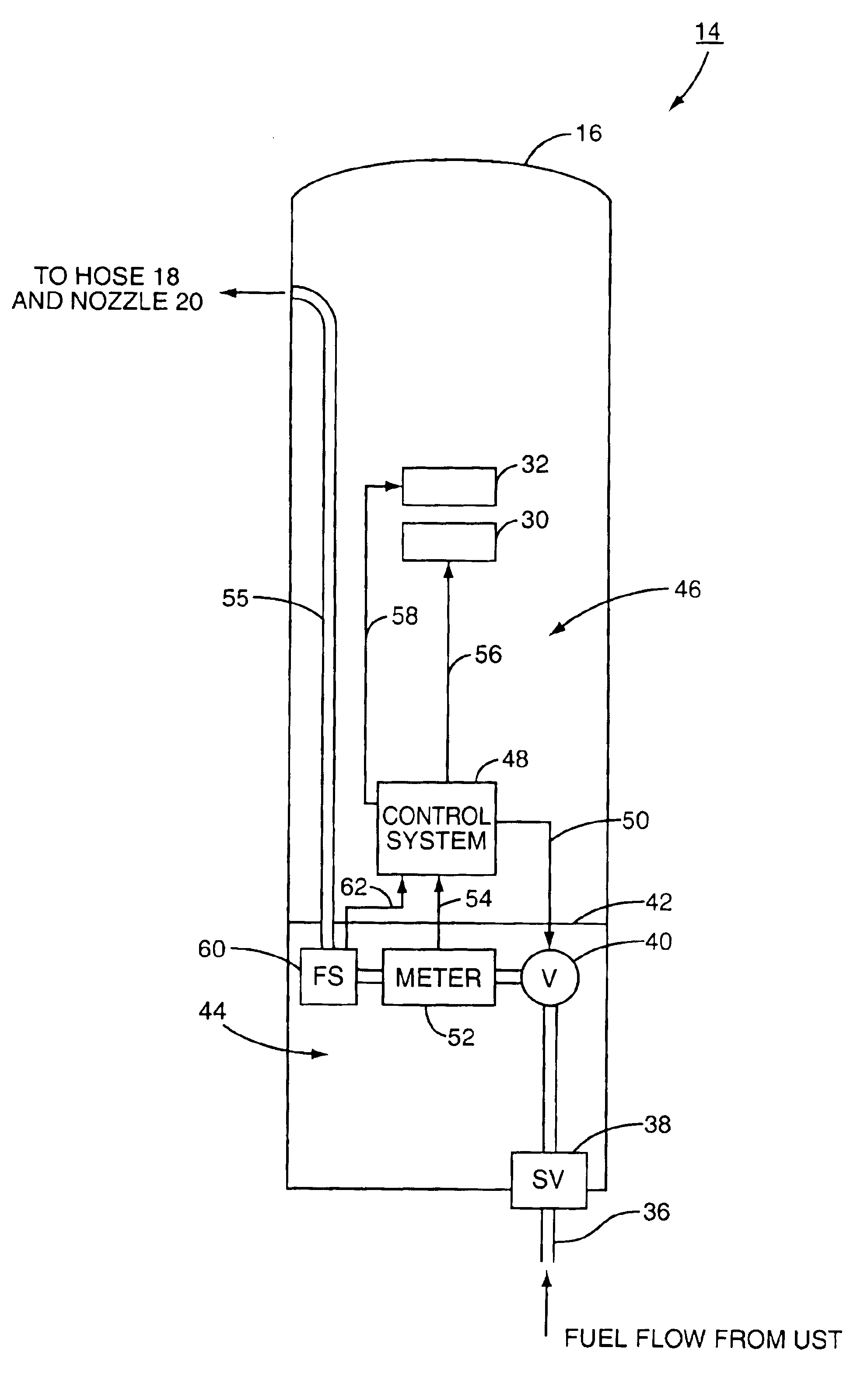

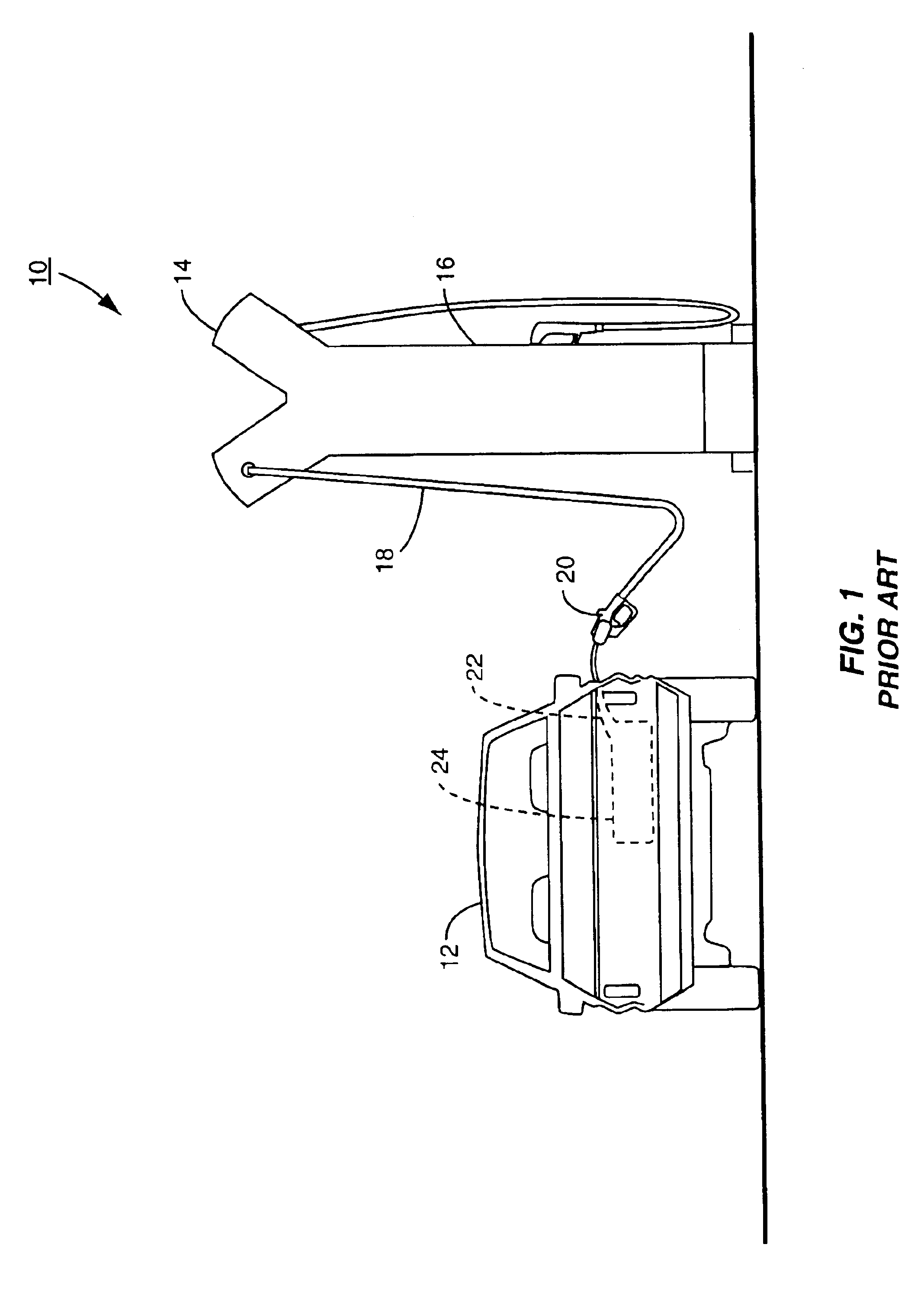

Fuel dispenser fuel flow meter device, system and method

ActiveUS6935191B2Accurate measurementImproper chargingValve arrangementsLiquid transferring devicesCombined useEngineering

A flow switch used on conjunction with a fuel flow meter in a fuel dispenser to determine when fuel flow rate signals form a fuel flow meter should be ignored in the calculation of flow rate and / or volume of fuel dispensed. An inferential fuel flow meter may be used as the fuel flow meter. The inferential fuel flow meter may be a turbine flow meter that comprises one or more turbine rotors that rotate in response to fuel flow flowing through the turbine flow meter. The turbine rotors may continue to generate pulses even when fuel is no longer flowing. A flow switch determines when fuel is actually flowing and fuel is not actually flowing. The flow switch is described as either a single poppet or dual poppet flow switch in examples described herein.

Owner:GILBARCO +1

Inlet air heating system for a gas turbine engine

InactiveUS20100003123A1Without loss in engine efficiencyReduce the required powerGas turbine plantsEngine controlOperant conditioningHeating system

A gas turbine engine has an inlet for delivering air into a compressor section. The compressor section is connected to feed air into a combustion section, wherein the air mixes with fuel and combusts. The combustion section is connected to turbine rotors such that products of combustion can pass over the turbine rotors to drive the turbine rotors. An exhaust communicates with the turbine sections to receive the products of combustion. A bleed tap communicates the exhaust to the inlet. A control controls the amount of exhaust gasses tapped into the inlet to achieve desired operating conditions.

Owner:PW POWER SYST LLC

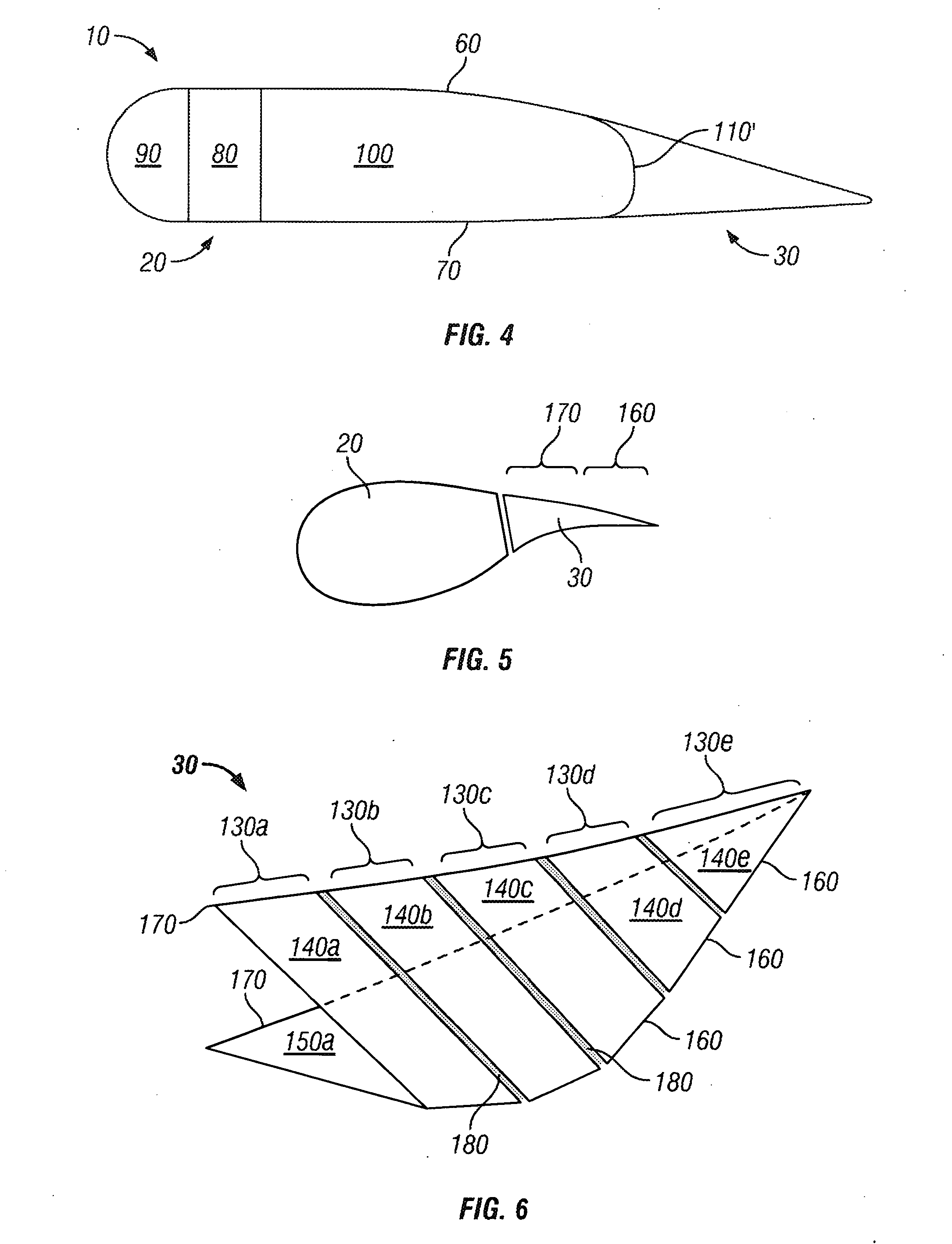

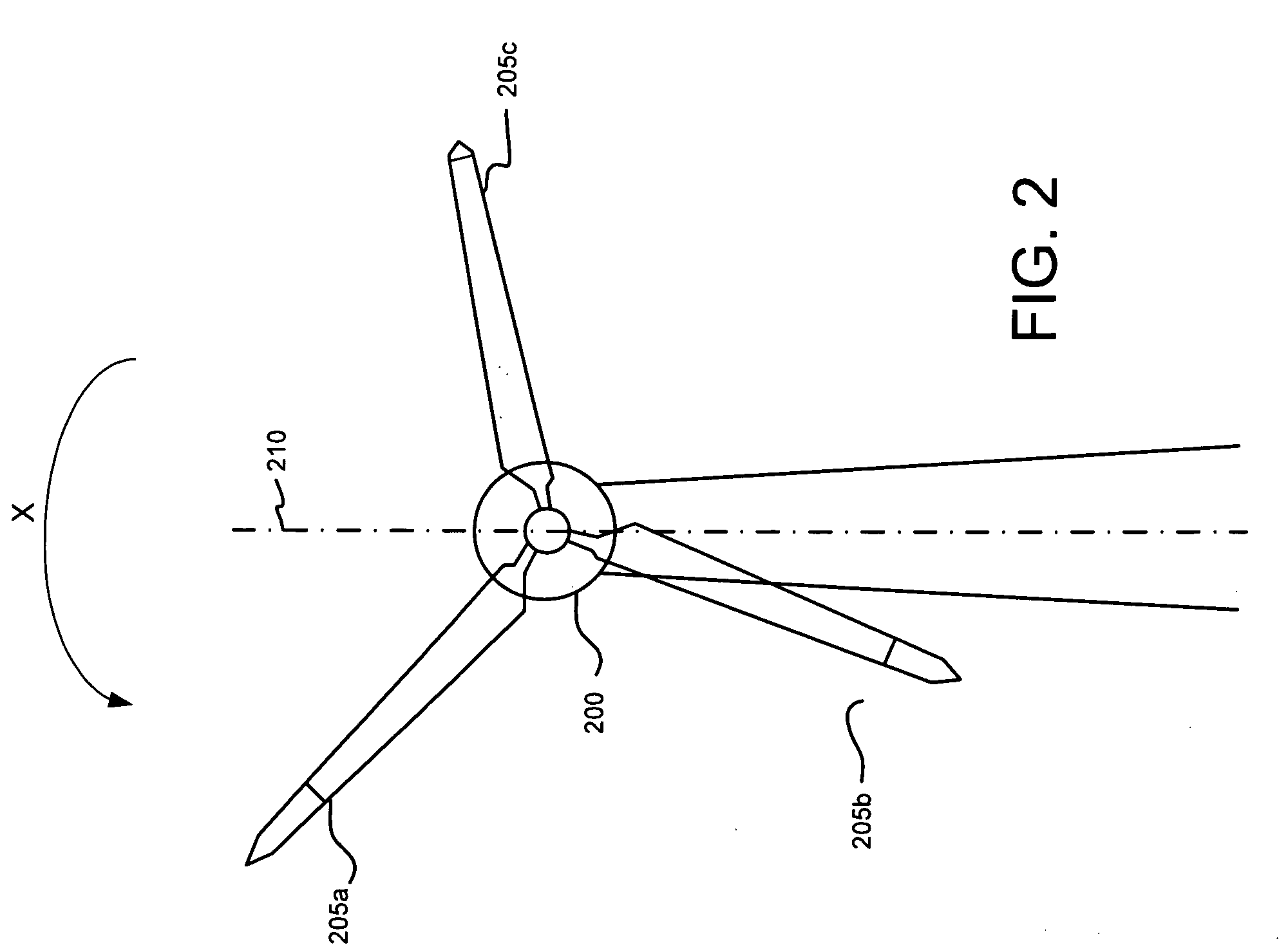

Wind turbine rotor blade with in-plane sweep and devices using same, and methods for making same

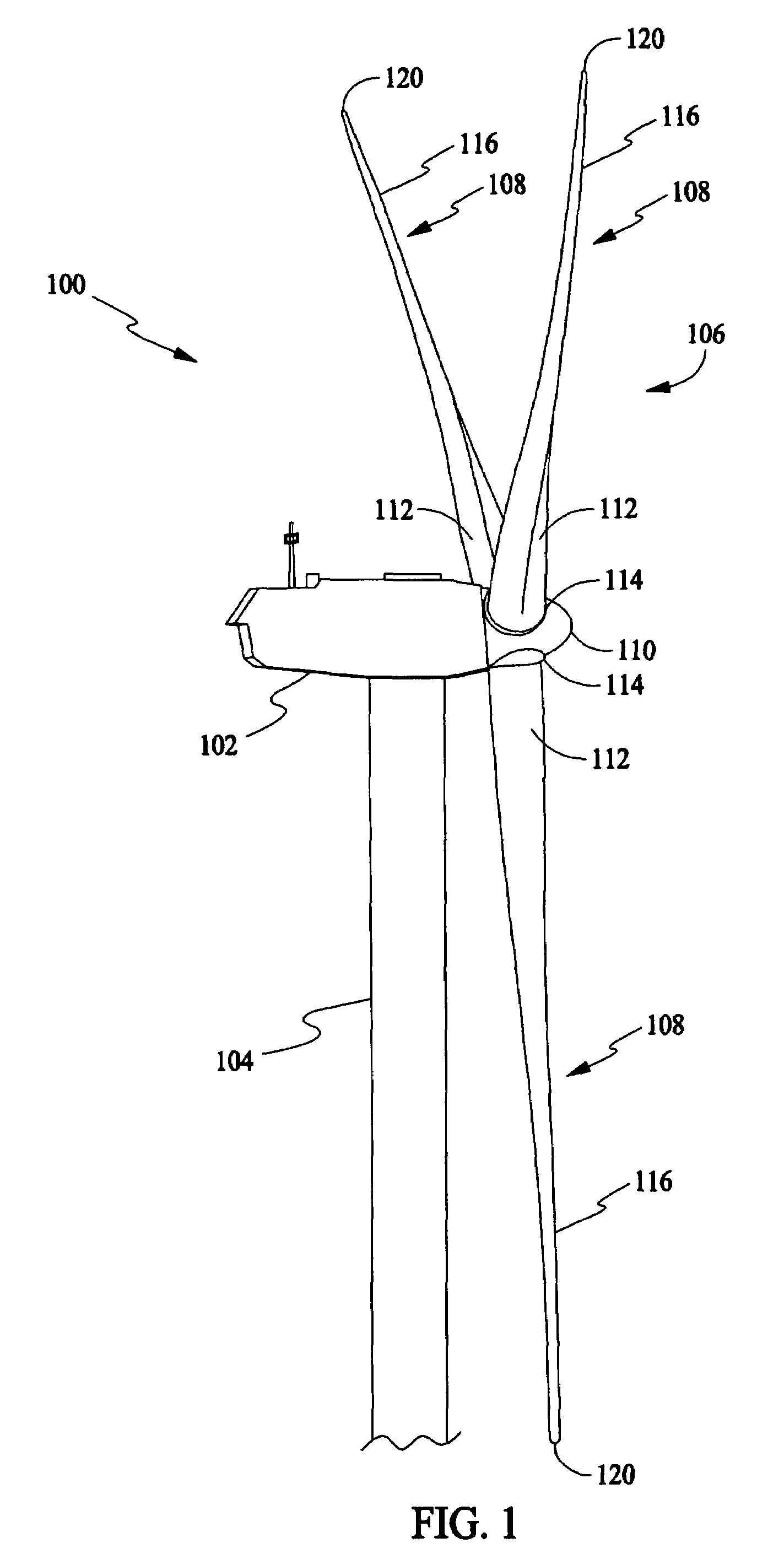

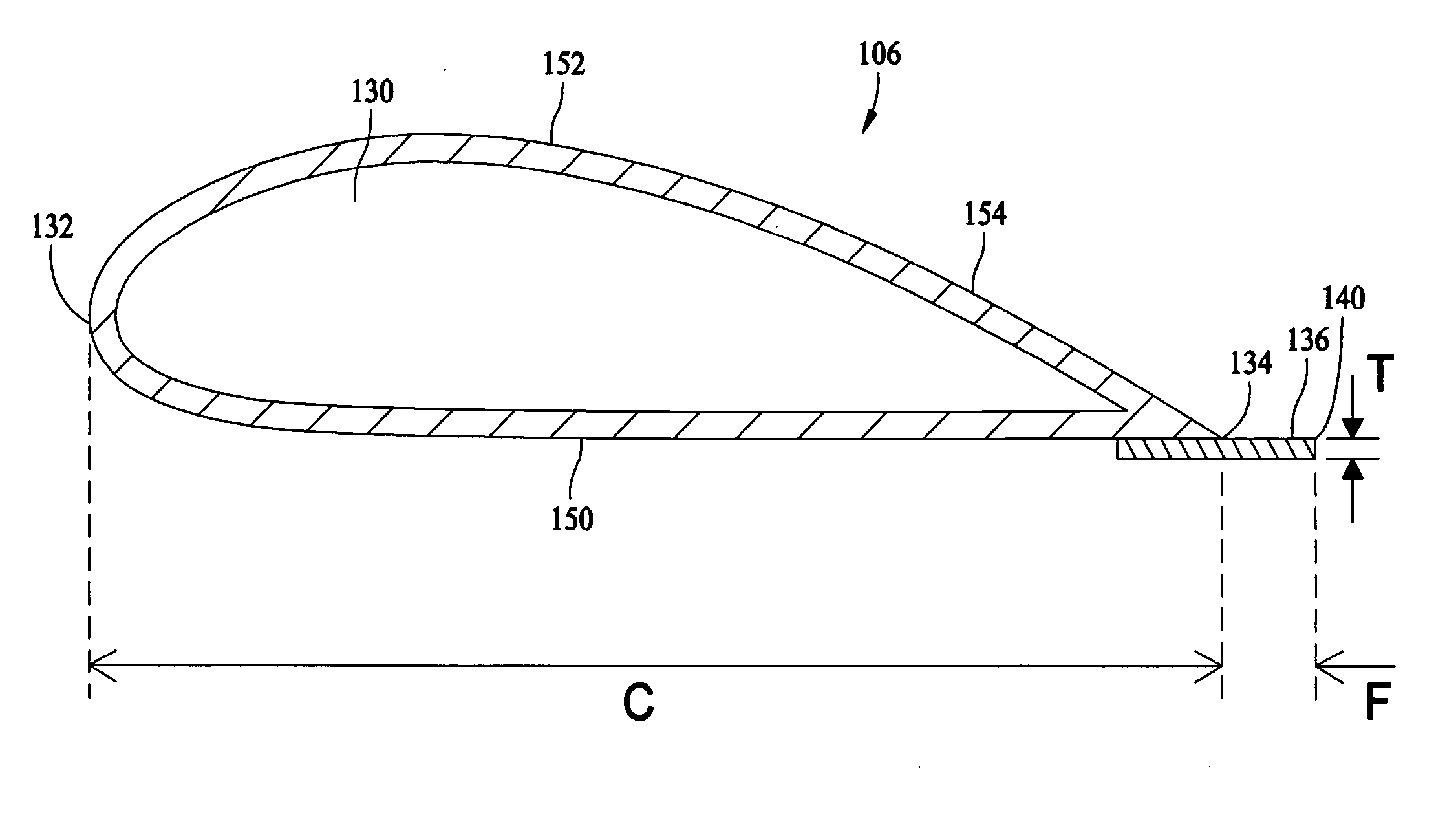

ActiveUS7344360B2Quantity maximizationReduce loadPropellersPump componentsClassical mechanicsEngineering

A wind turbine includes a rotor having a hub and at least one blade having a torsionally rigid root, an inboard section, and an outboard section. The inboard section has a forward sweep relative to an elastic axis of the blade and the outboard section has an aft sweep.

Owner:GENERAL ELECTRIC CO

Wind turbine system

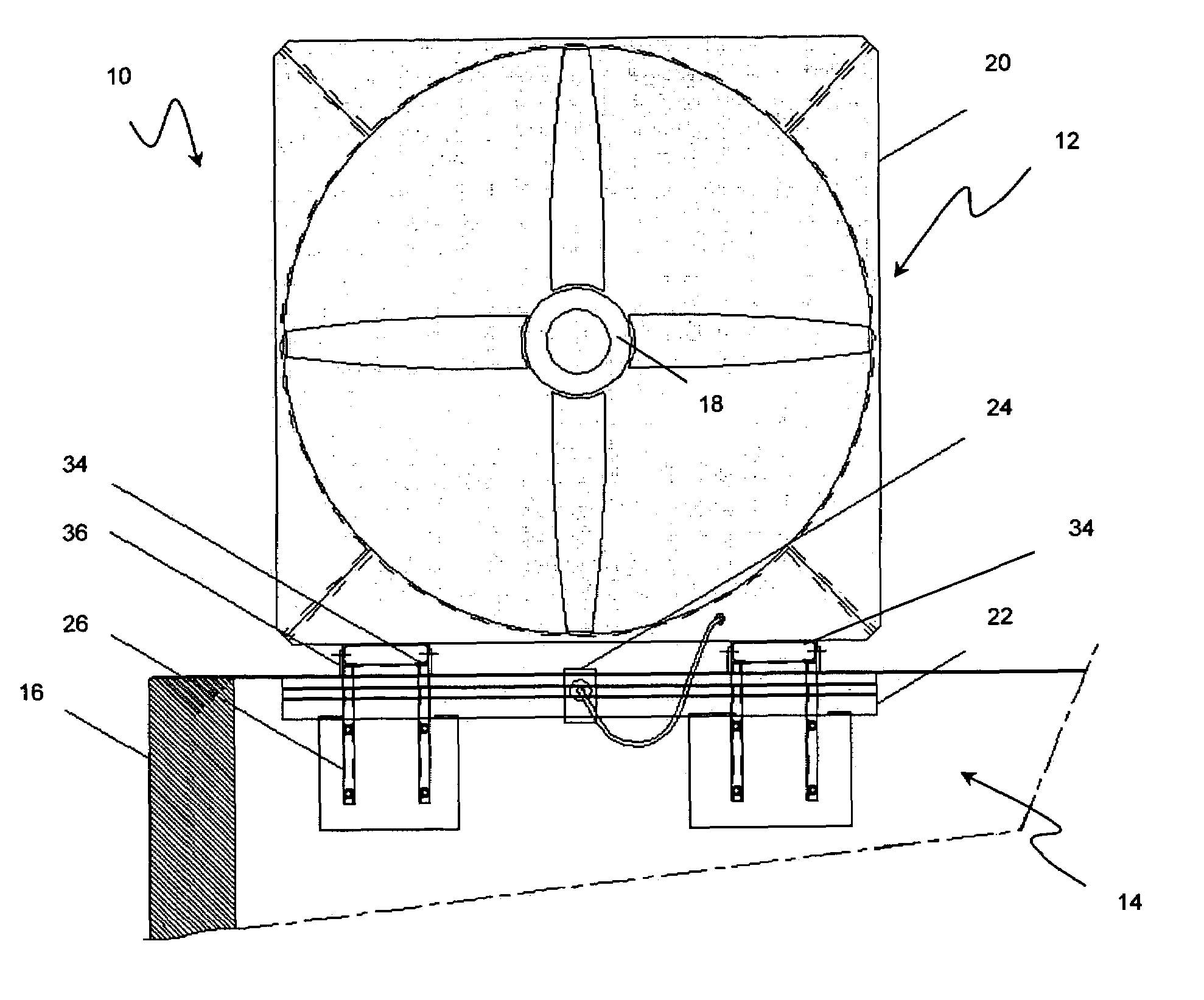

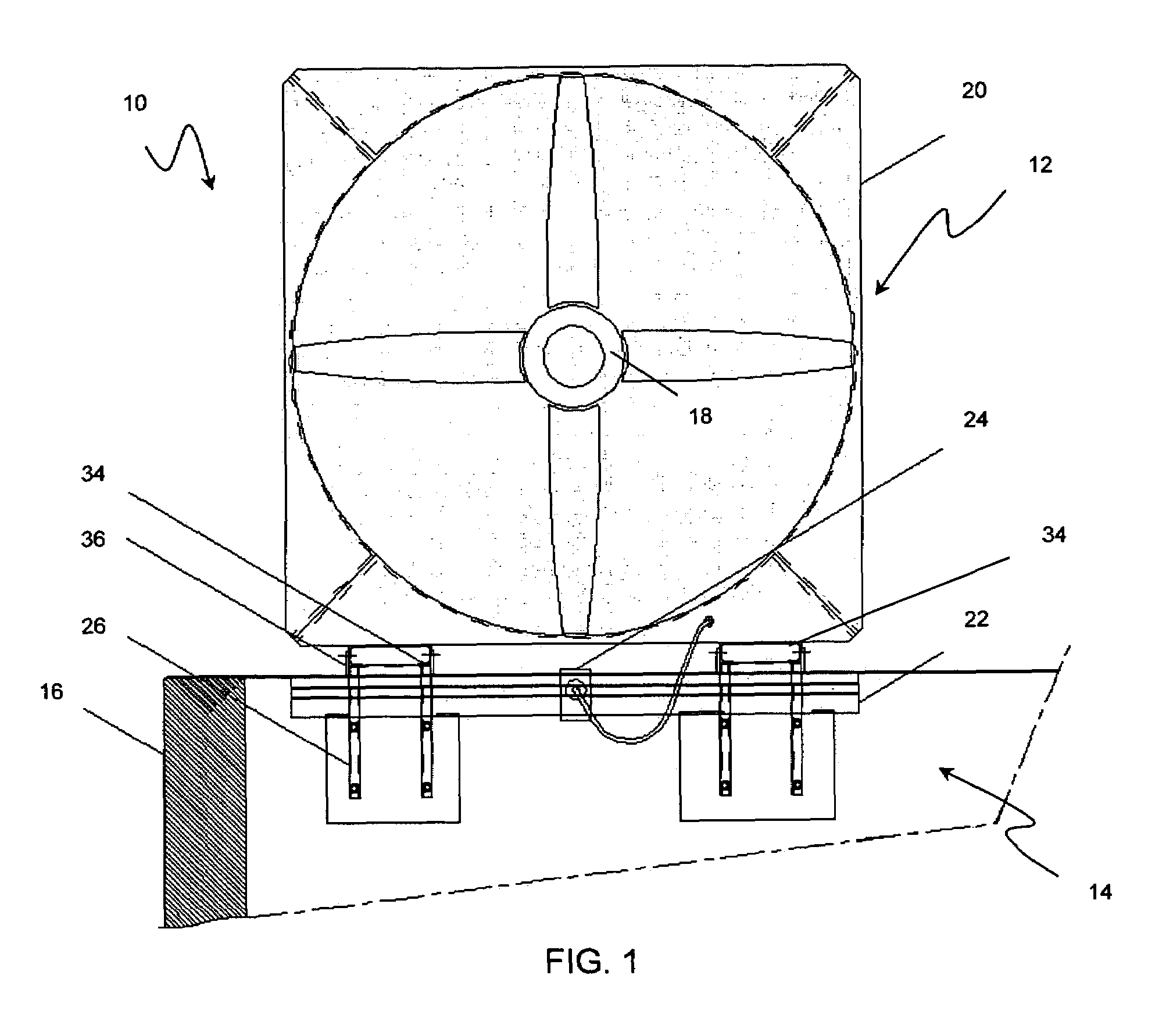

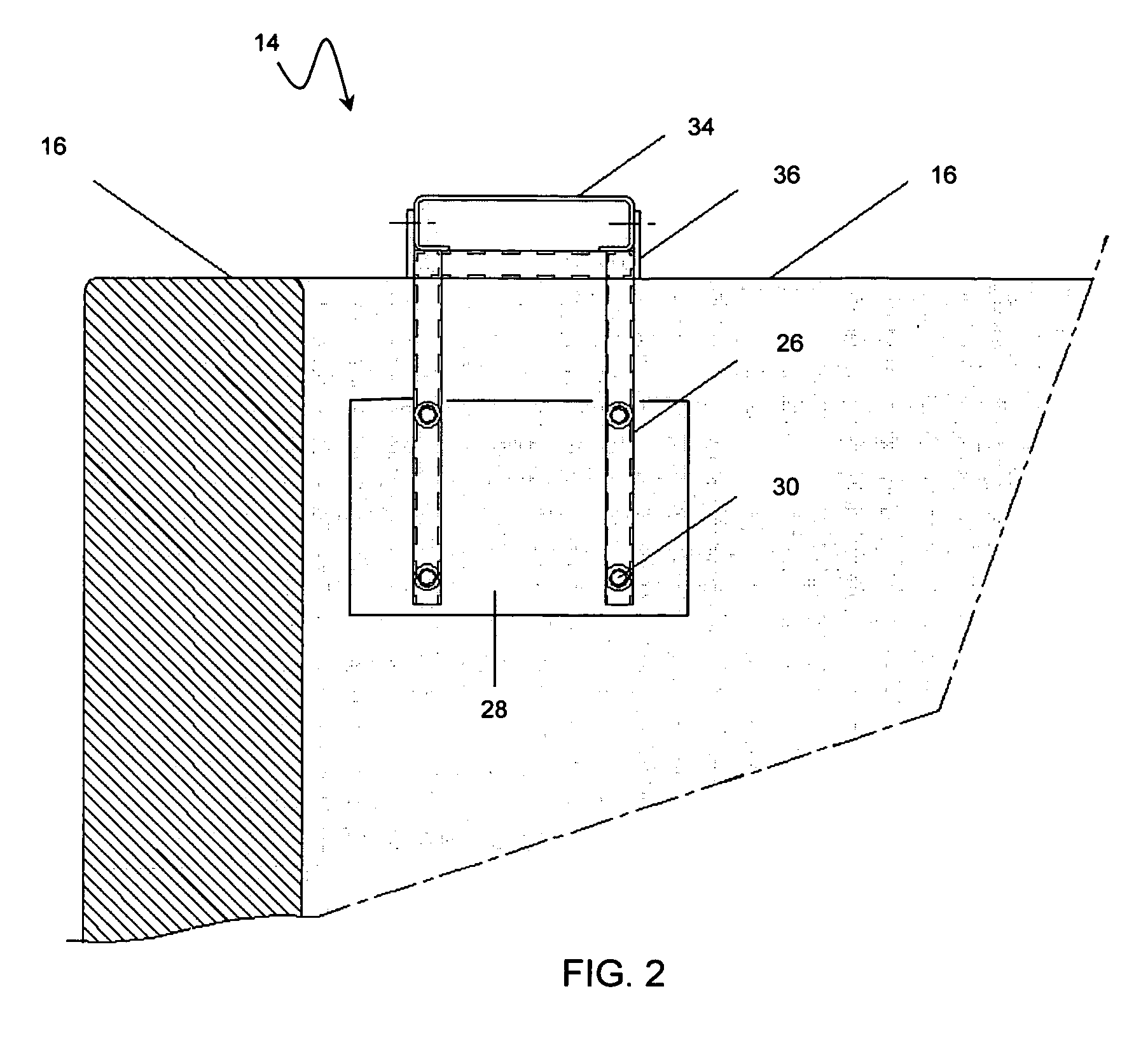

InactiveUS7084520B2Easy retrofit attachmentEngine fuctionsWind motor supports/mountsHorizontal orientationWind force

Wind turbine system, and related method, is provided that exploits an aerodynamically enhanced wind zone of a structure by aligning a wind turbine generator, and preferably a plurality thereof, along a wall thereof. Each generator includes a structural support, a wind turbine rotor and a generator set. The system includes a mounting assembly that attaches the generators to the upper edge of a wall of the building and that allows for easy retrofit attachment to existing structures. The system includes a busway extending along the mounting assembly and configured to provide electrical contact between the generator assembly and the electrical infrastructure of the building. Preferably, the generator assembly is mounted such that the rotor's axis of rotation is in a generally horizontal orientation. The system may further include a fairing attached to the mounting assembly and configured to extend outward from a front side of the wall. The fairing can be provided with a downwardly curved planar shape to facilitate airflow towards the rotors.

Owner:AEROVIRONMENT INC

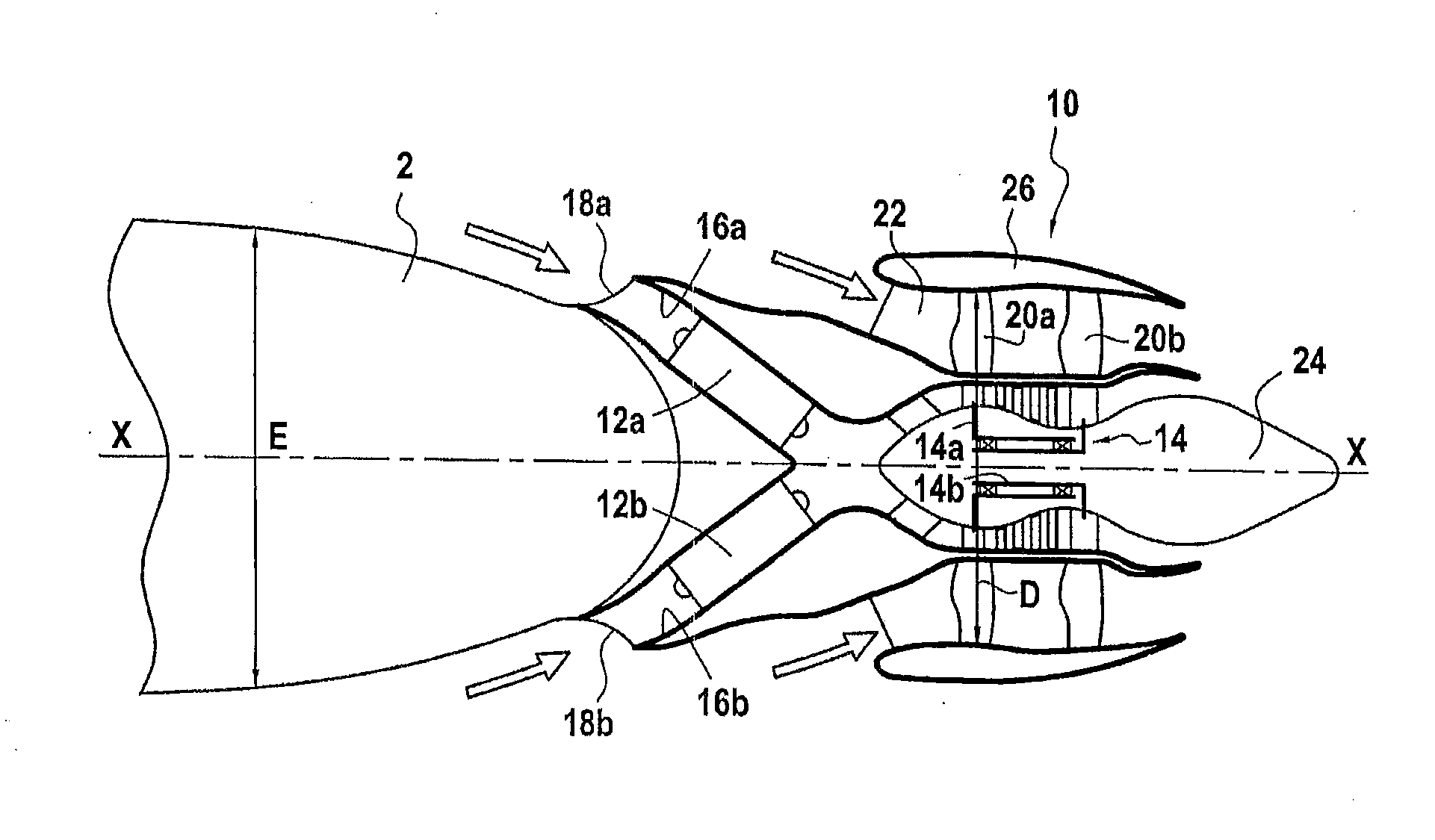

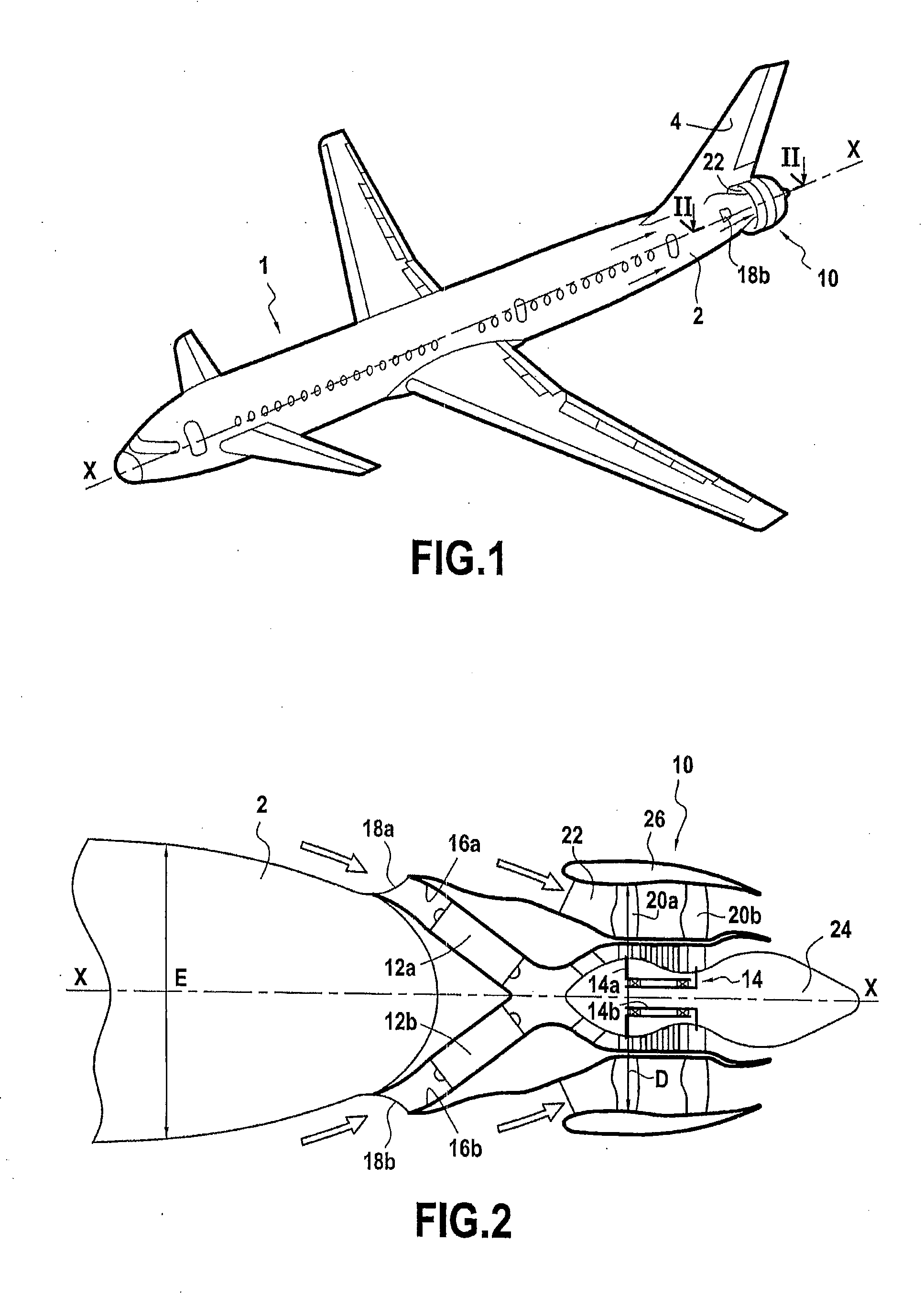

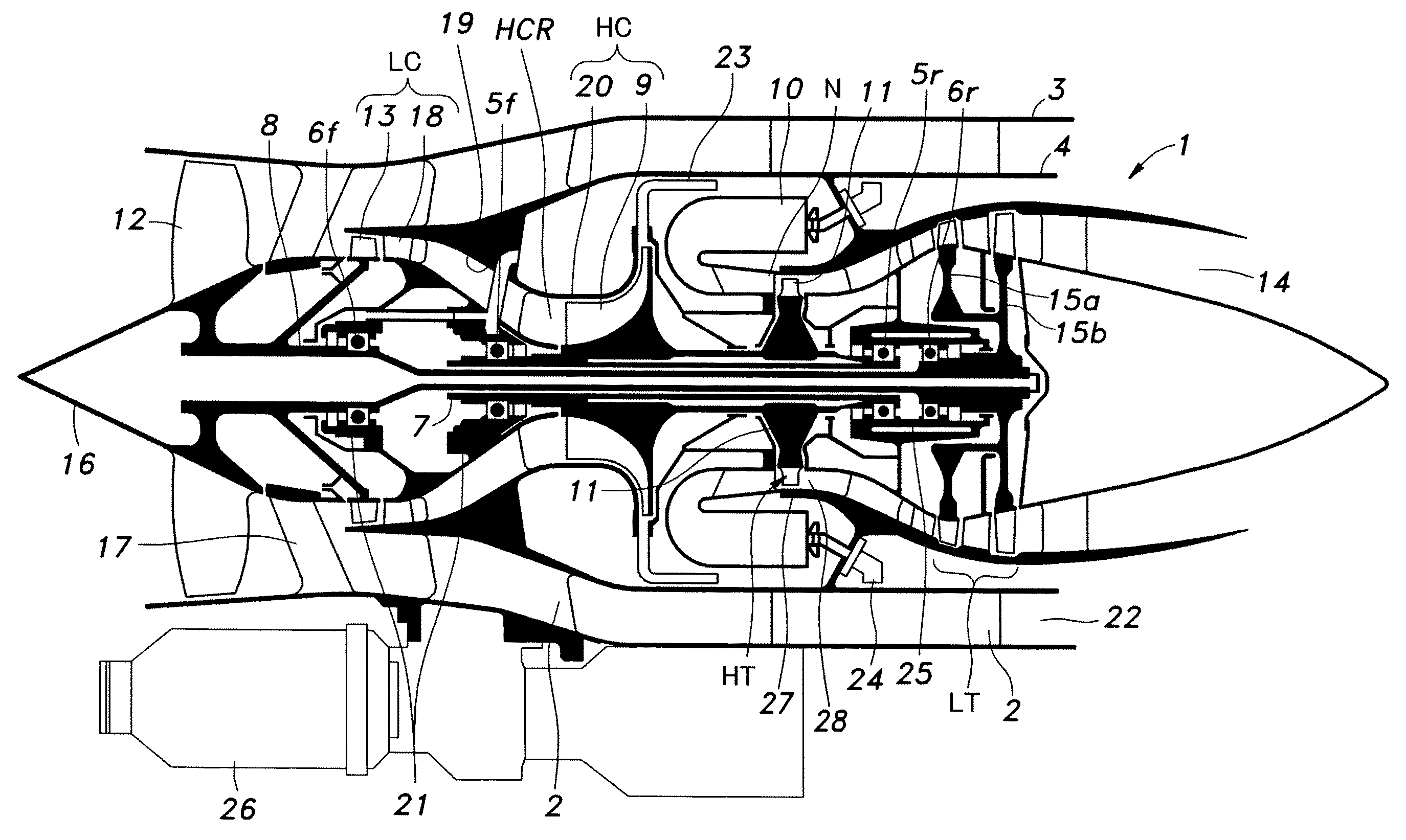

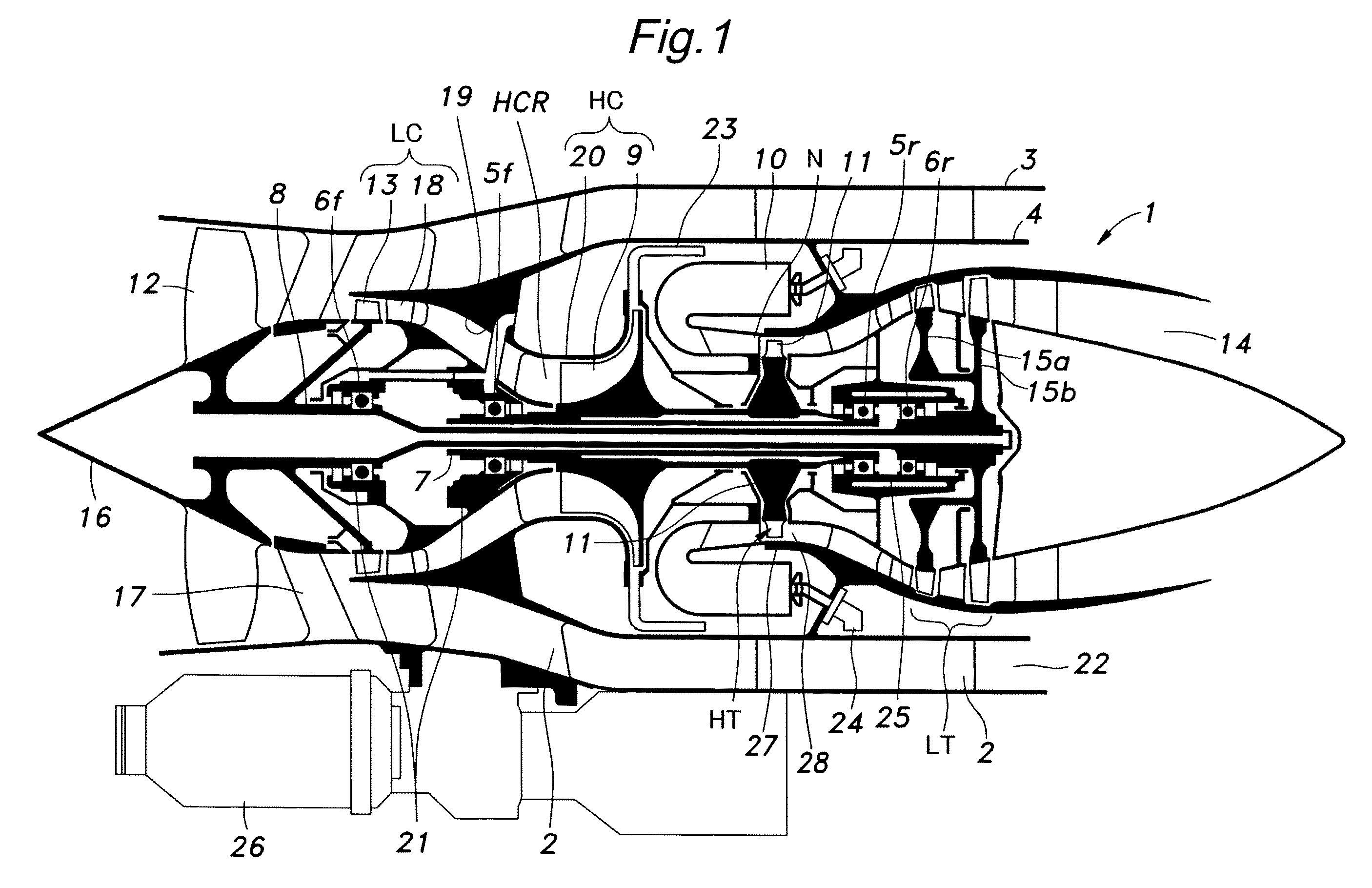

Aircraft propelled by a turbojet engine with contrarotating fans

ActiveUS20150291285A1Reduce fuel consumptionLimiting aerodynamic dragGas turbine type power plantsCombination enginesJet aeroplaneFuselage

An aircraft propelled by a turbojet having contrarotating fans, the turbojet being incorporated at the rear of a fuselage of the aircraft and in line therewith and including two gas generators that feed a working turbine having two contrarotating turbine rotors for driving two fans arranged downstream from the gas generators, and distinct air intakes for feeding each gas generator, the air intakes being connected to the fuselage of the aircraft so as to take in at least a portion of the boundary layer formed around the fuselage of the aircraft.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

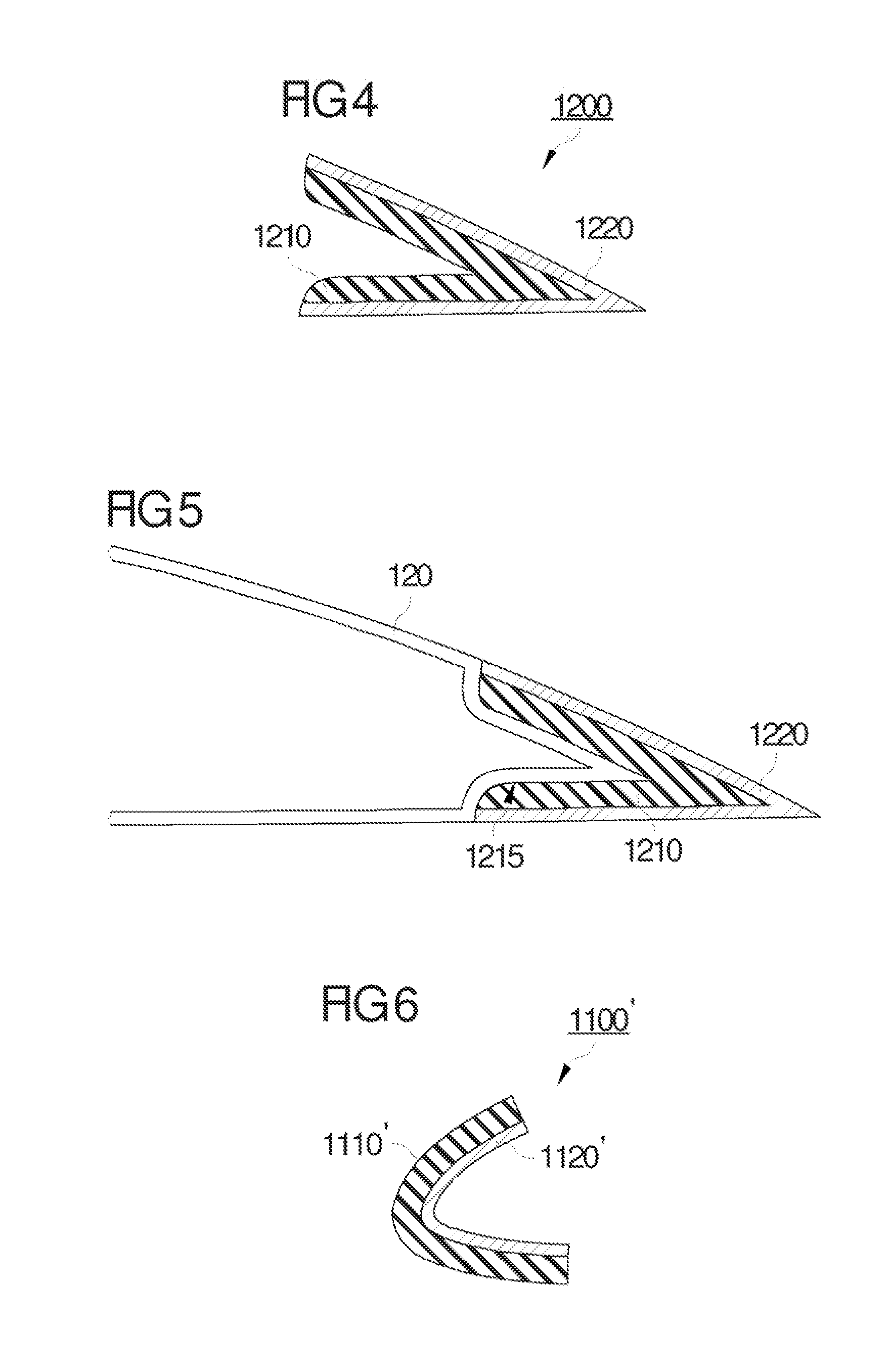

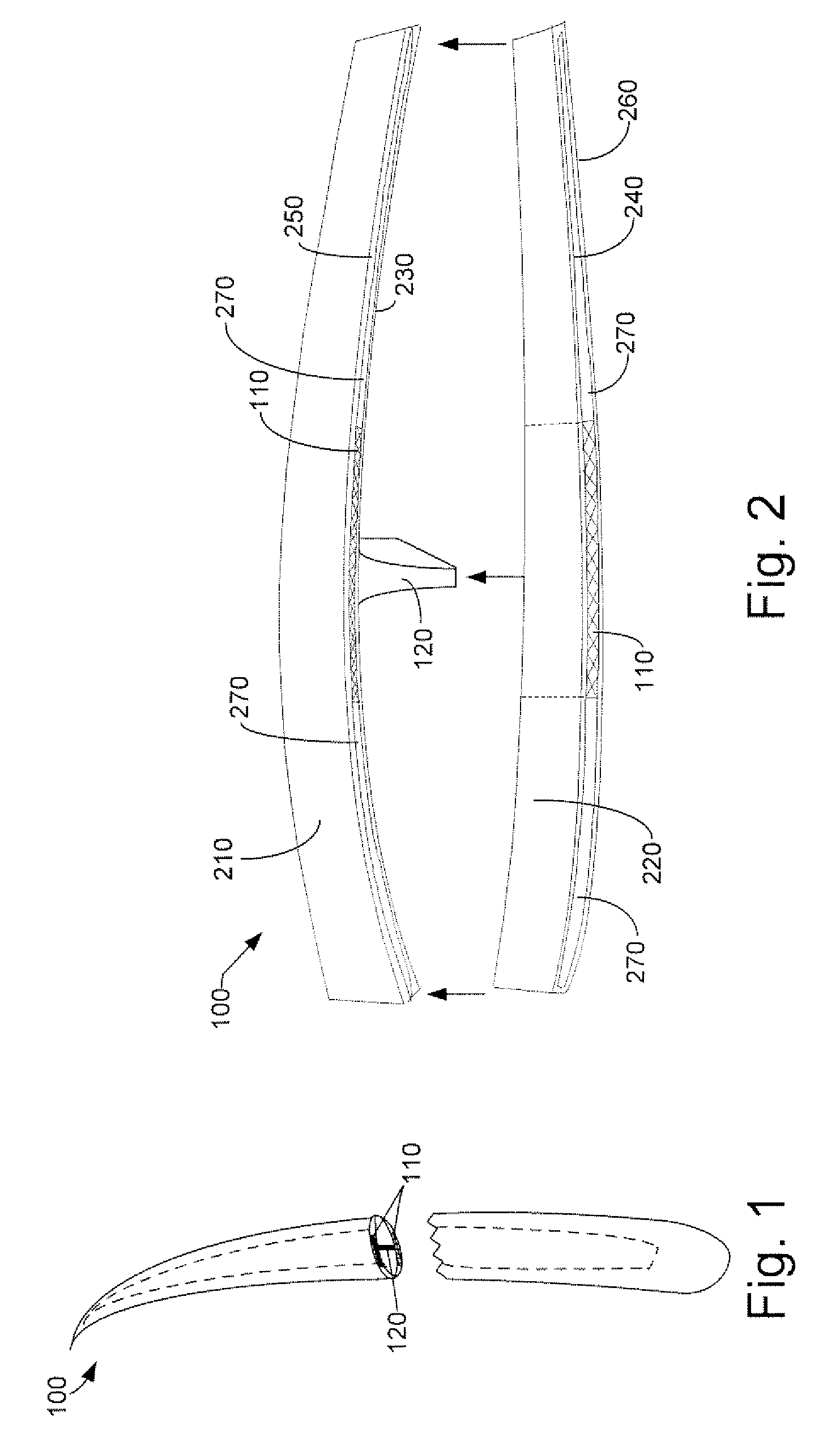

Segmented Rotor Blade Extension Portion

ActiveUS20100028161A1Optimize structural configurationEasy to dismantlePropellersEngine manufactureEngineeringMechanical engineering

A wind turbine rotor blade extension portion having a plurality of segments, located adjacent one another in a span-wise sense. An interface between adjacent segments is configured to minimise disruption to fluid passing thereover and to inhibit transmission of longitudinal loads between segments. Each segment has a first surface and a second surface. The first surface is spaced from the second surface at a proximal region of the extension portion and the first surface is connected to the second surface at a distal region of the extension portion to thereby generate a fair surface for a rotor blade to which the extension portion is connected, in use.

Owner:VESTAS WIND SYST AS

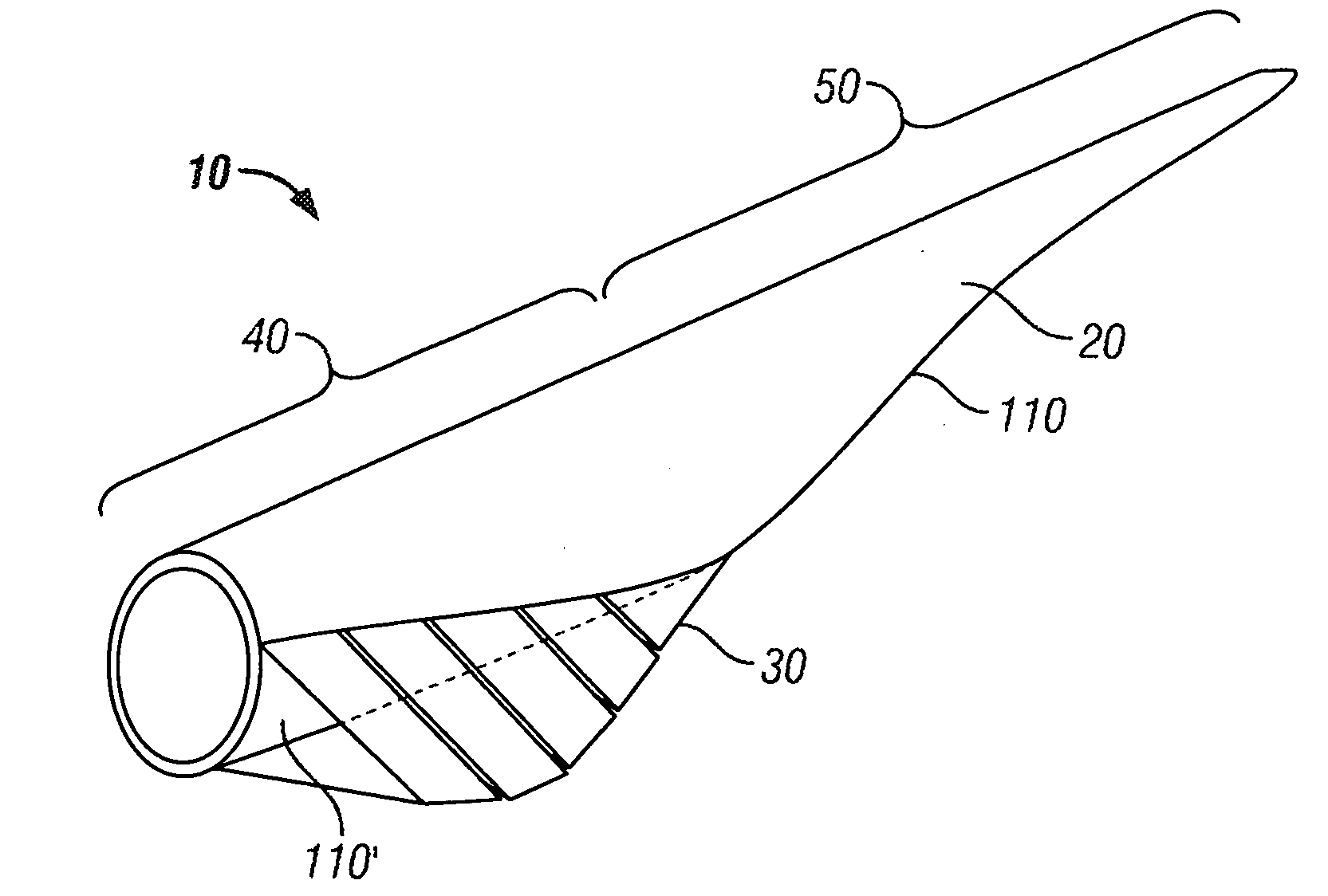

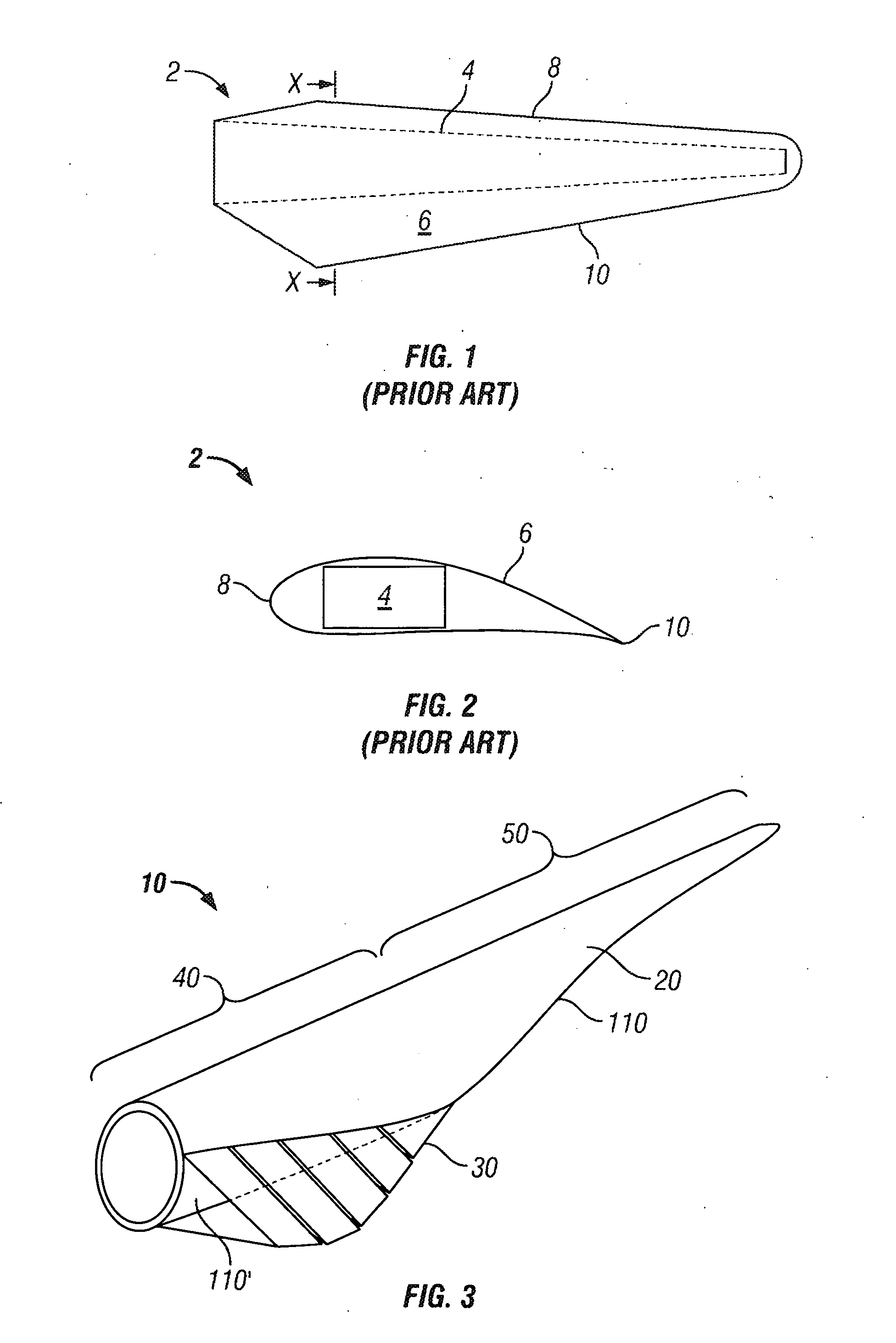

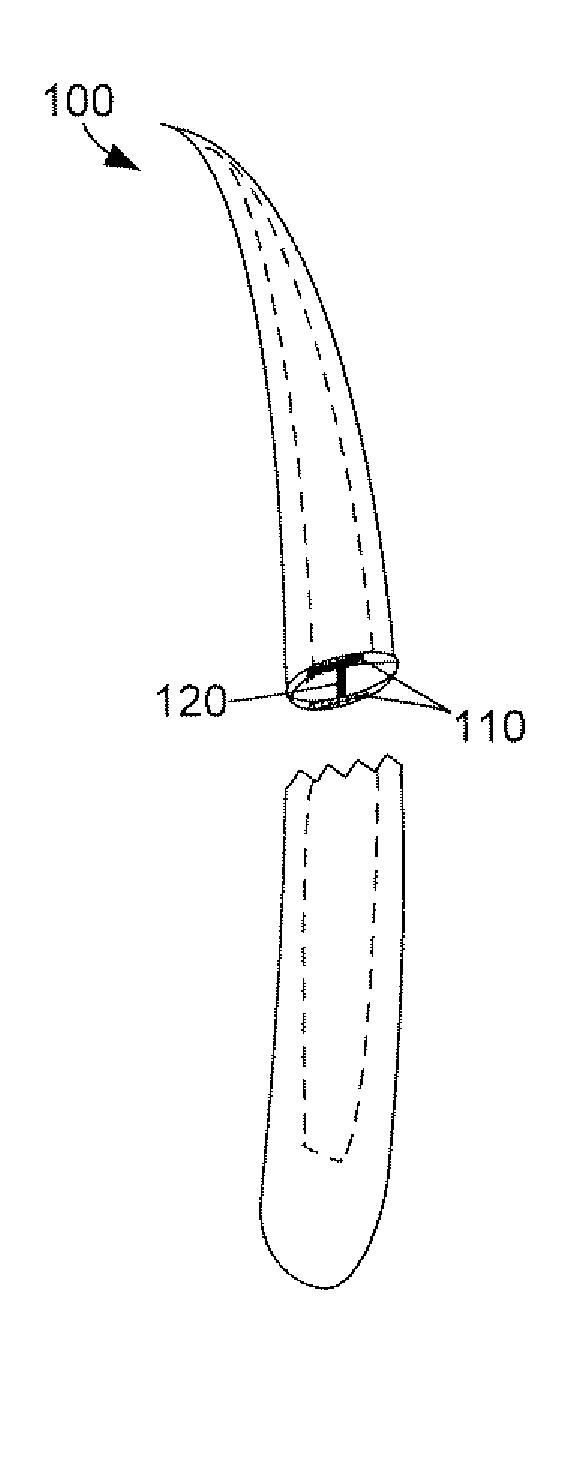

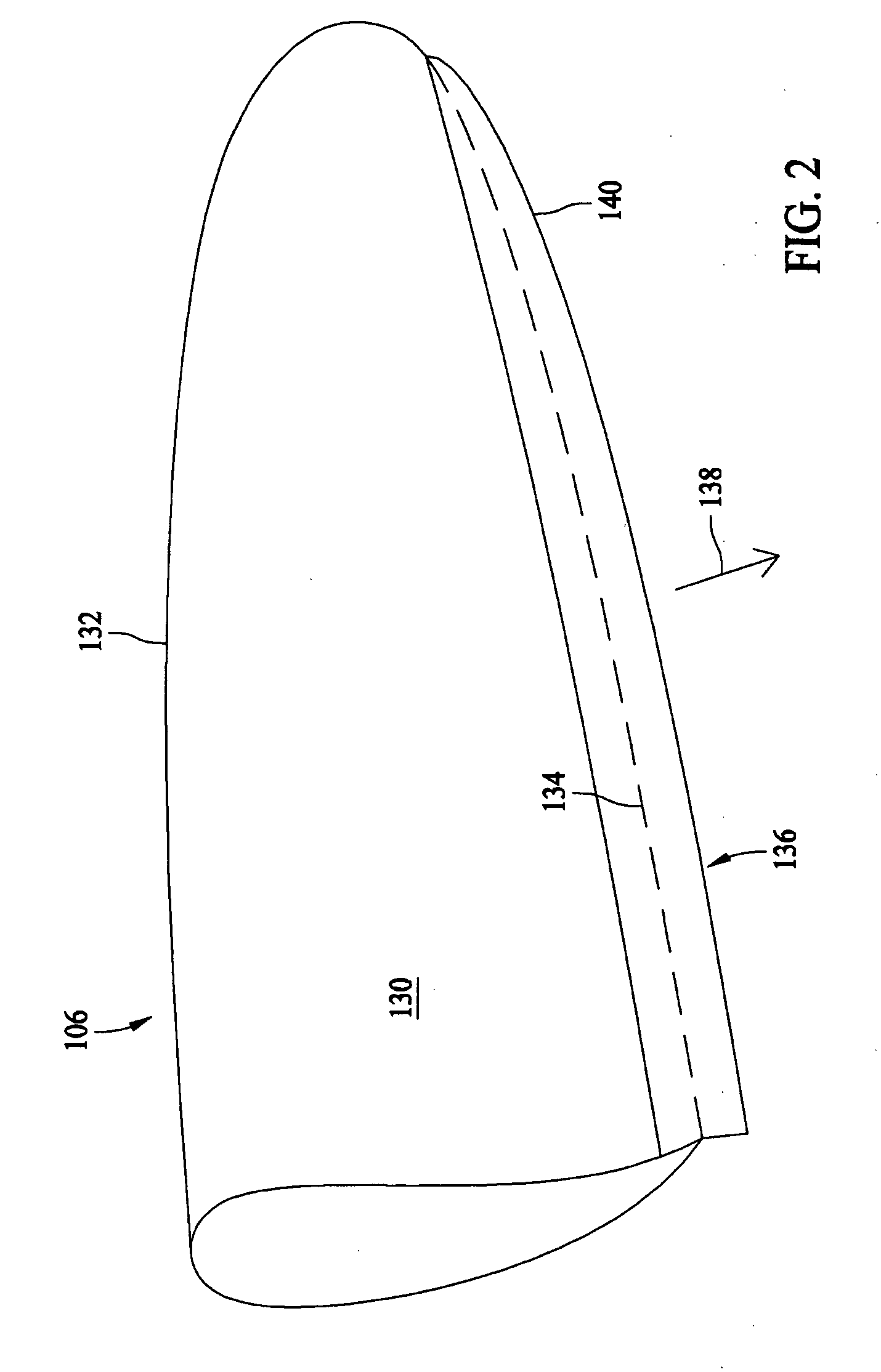

Preform Spar Cap for a Wind Turbine Rotor Blade

A spar cap for a wind turbine rotor blade. The spar cap may include multiple preform components. The multiple preform components may be planar sheets having a swept shape with a first end and a second end. The multiple preform components may be joined by mating the first end of a first preform component to the second end of a next preform component, forming the spar cap.

Owner:GENERAL ELECTRIC CO

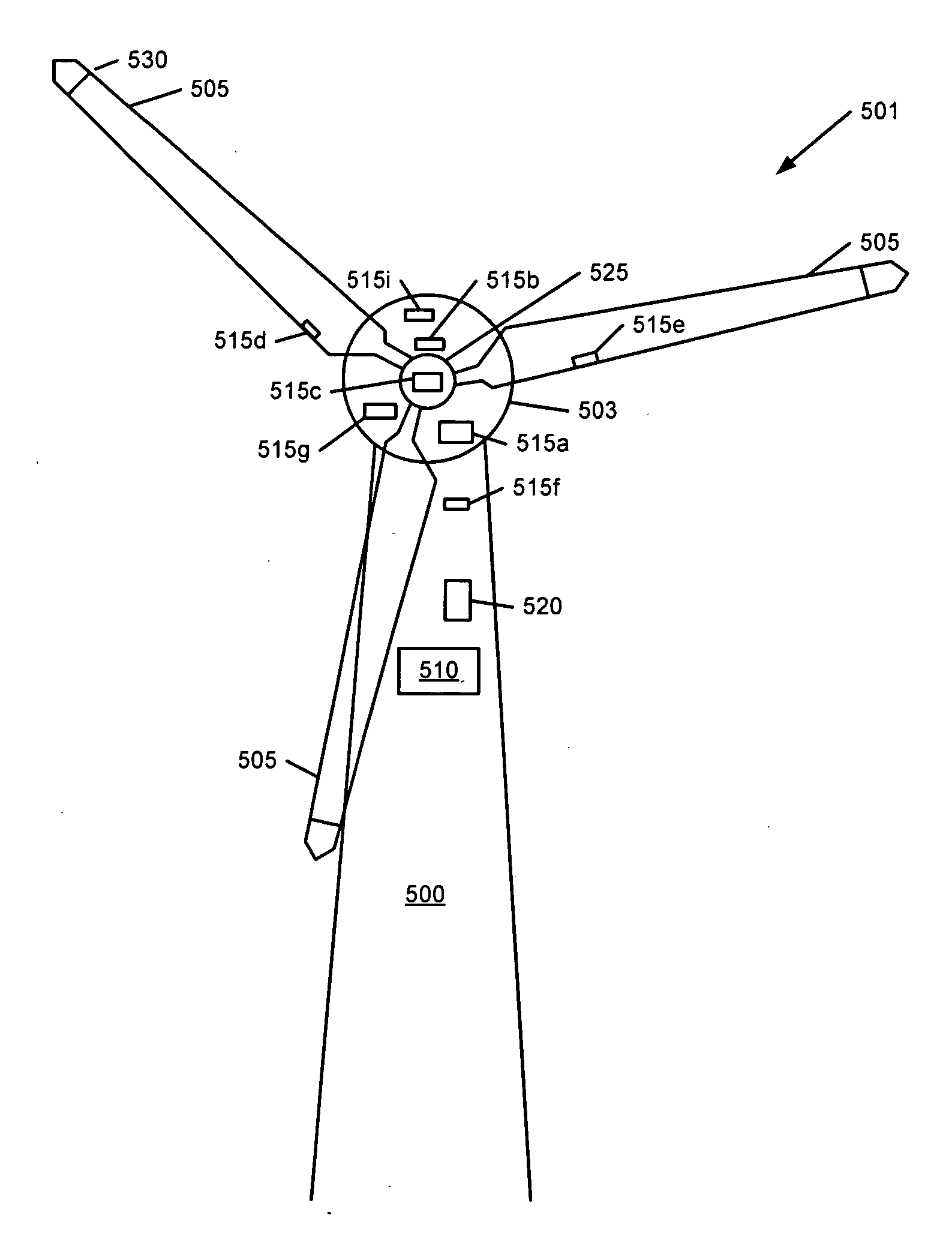

Control Modes for Extendable Rotor Blades

InactiveUS20100158687A1Maximize incomeReduce paymentPropellersRotary propellersAccelerometerEngineering

A wind turbine may be controlled in a variety of manners to optimize operating parameters. In one arrangement, for example, the length or the pitch of a wind turbine rotor blade may be adjusted to avoid harmonic resonance frequencies. In another example, the length of a rotor blade may be modified to reduce noise or to optimize profits or both. The controls may be based on data from various types of sensors including accelerometers, sound meters, strain gauges and the like. Actuation of extendable rotor blades can rotate wind turbine rotors without wind or generator pulsing affording multiple advantages. A battery test control may also be used to determine the operational readiness of a battery useful for a variety of purposes in a turbine.

Owner:FRONTIER WIND LLC

Wind turbine rotor blade with precured fiber rods and method for producing the same

A wind turbine rotor blade comprises a rotor blade body, including a root portion, a leading edge, a trailing edge, and at least one spar cap; a plurality of parallel, elongated elements of a pre-cured composite material, which comprise fibers and a resin, and a resin connecting the plurality of elements. Further, a method for producing a rotor blade is provided.

Owner:GENERAL ELECTRIC CO

Wind turbine rotor blade

A wind turbine rotor blade includes a pressure side sparcap having a carbon fiber reinforced section extending substantially a full longitudinal length of the pressure side sparcap and a suction side sparcap having a glass fiber reinforced section extending substantially a full longitudinal length of the suction side sparcap.

Owner:GENERAL ELECTRIC CO

Wind turbine rotor assembly and blade having acoustic flap

A wind turbine includes a rotor assembly having at least one blade with a blade body defining a leading edge and a trailing edge and adapted for movement in response to a wind flow over the body to produce electricity. A rigid acoustic flap extends outward from the trailing edge, and a distal end of the acoustic flap is substantially smooth and continuous. The flap reduces acoustic noise generated by the blade in use.

Owner:GENERAL ELECTRIC CO

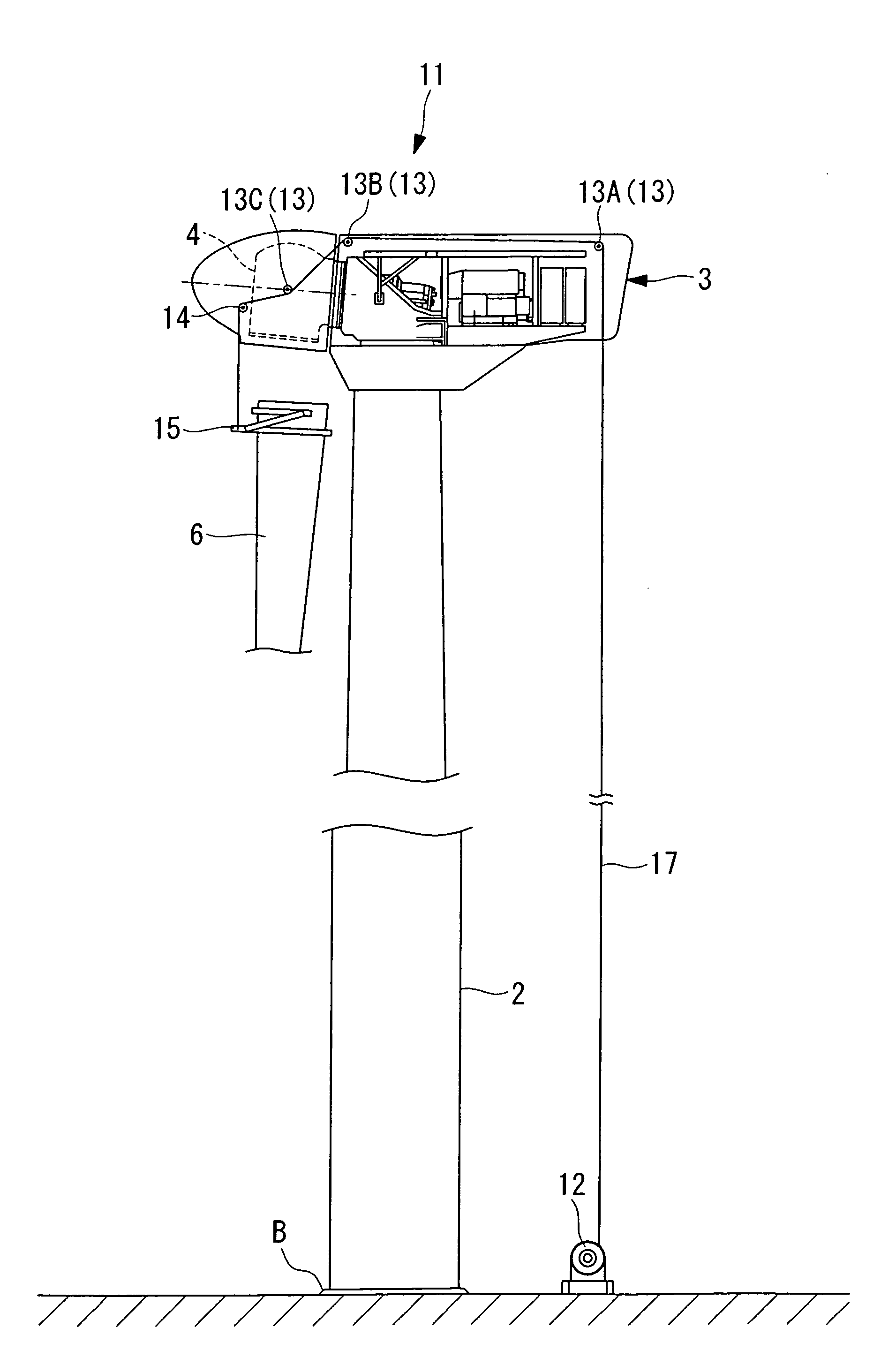

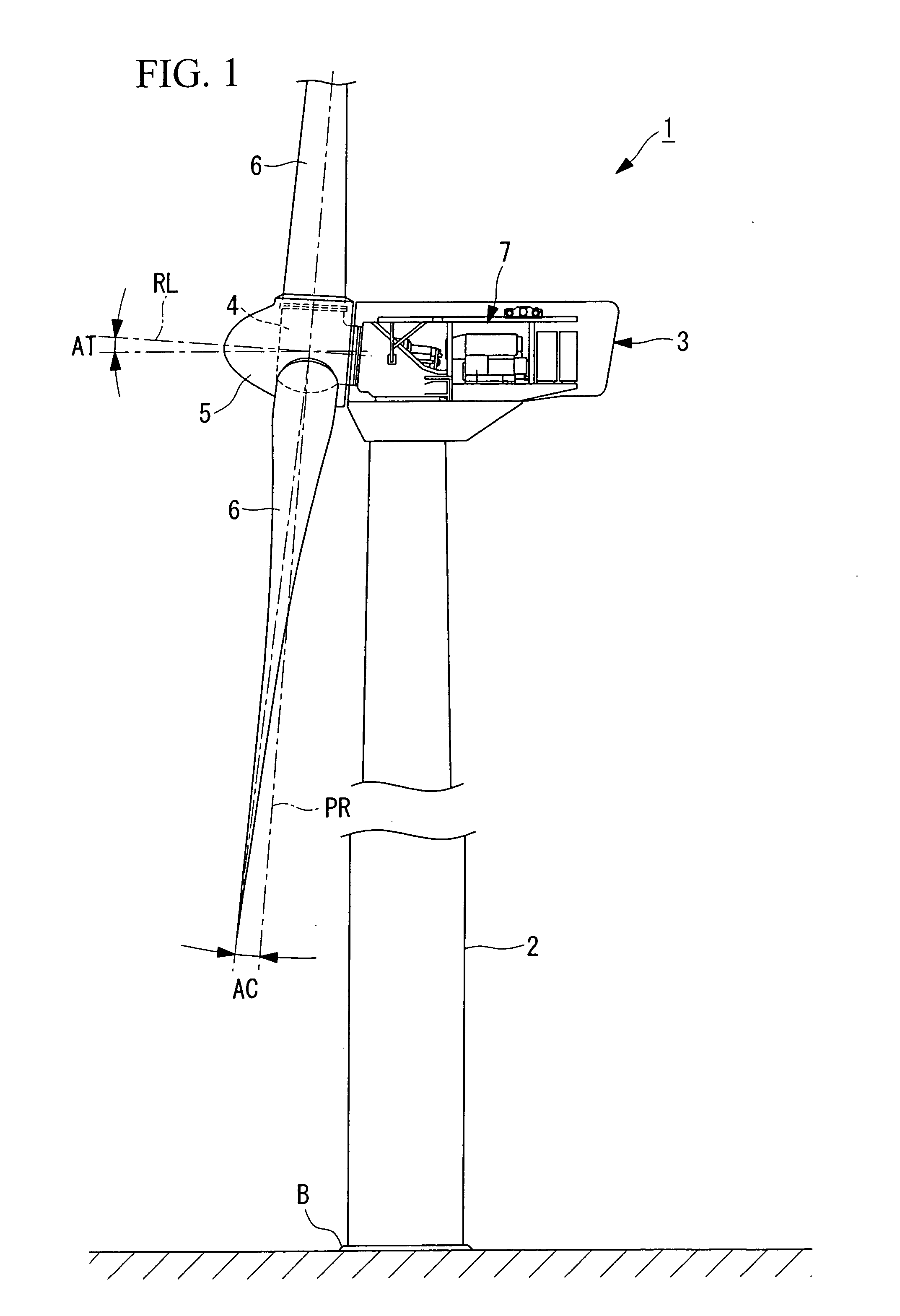

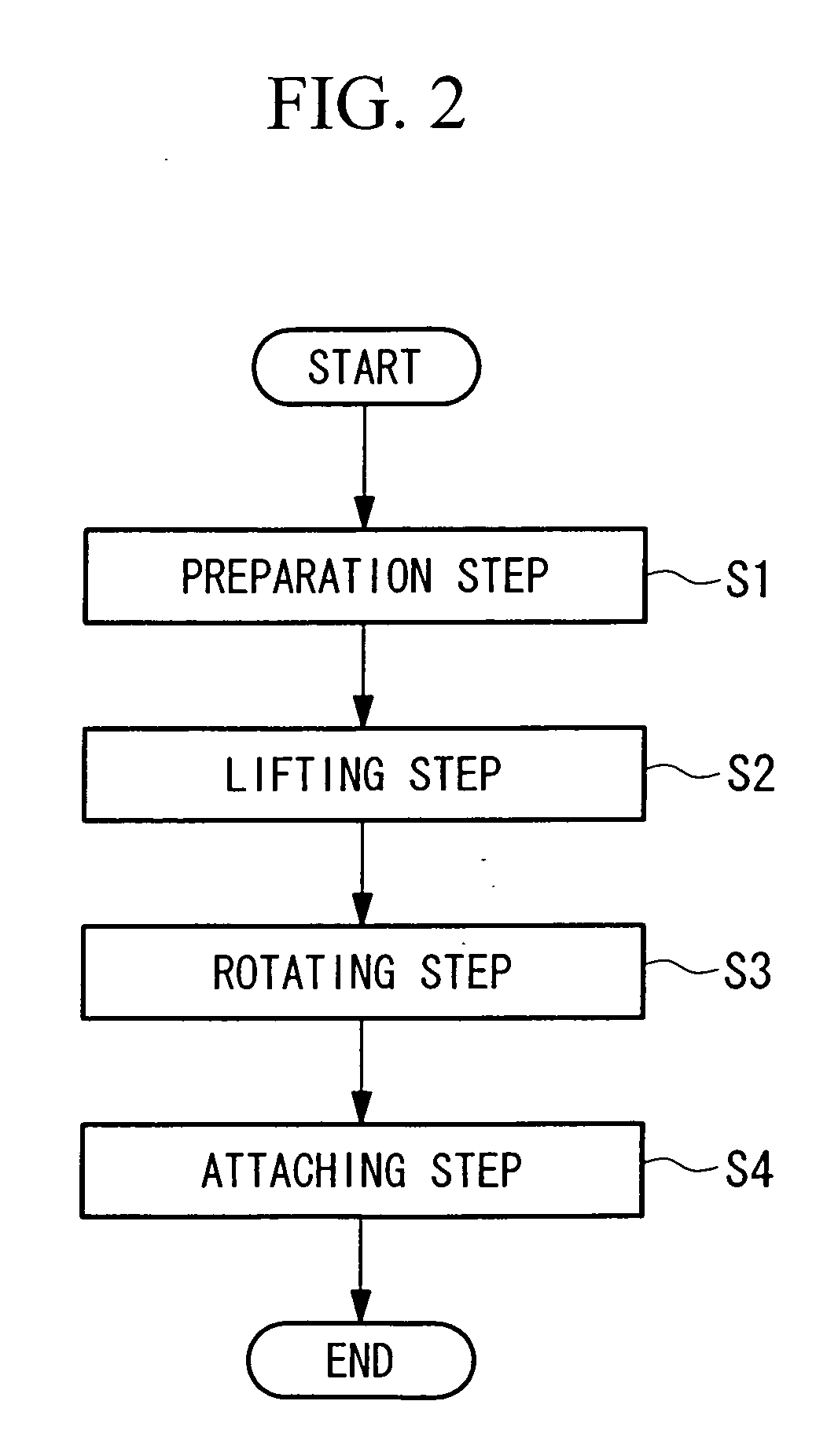

Wind-turbine rotor-blade hoisting apparatus, method for attaching wind-turbine rotor blade, and method for constructing wind power generator

The present invention provides a wind-turbine rotor-blade hoisting apparatus that enables attachment and removal of wind-turbine rotor blades without using a plurality of heavy machines and that enables attachment and removal of wind-turbine rotor blades on a site having a complex land shape with little flat land, a method for attaching a wind-turbine rotor blade, and a method for constructing a wind power generator. The present invention is characterized in that it includes a sheave (14) that guides a hoisting wire (17) from a rotor head (4), to which a wind-turbine rotor blade (6) is to be attached, toward the wind-turbine rotor blade (6) and that is arranged so as to be movable in a direction along the rotation axis of the rotor head (4); a retaining portion (15) that retains an attaching end of the wind-turbine rotor blade (6) such that a line connecting the center of gravity of the wind-turbine rotor blade (6) and a connecting portion, to which the hoisting wire (17) is connected, crosses the longitudinal axis of the wind-turbine rotor blade (6); and a winch (12) that is disposed on the ground and that draws the hoisting wire (17) to wind up or let out the retaining portion (15).

Owner:MITSUBISHI HEAVY IND LTD

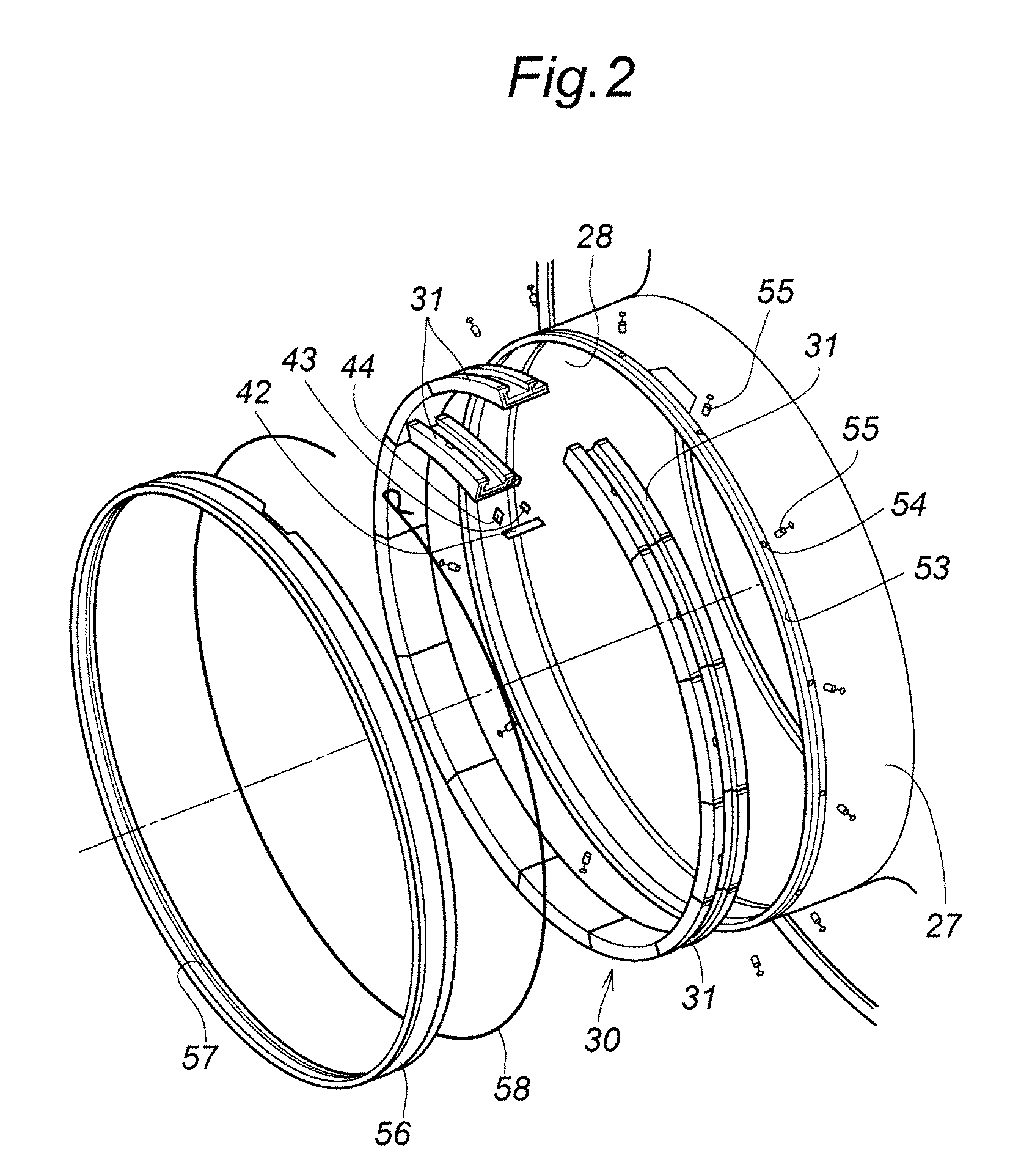

Turbine shroud

ActiveUS20100247298A1Minimize thermal stressReduce leakagePump componentsBlade accessoriesTurbine bladeThermal expansion

A turbine shroud (30) of a gas turbine engine comprises a plurality of arcuate shroud segments (31) combined into an annular configuration, each shroud segment including a main body (32) defining an inner circumferential surface opposing the tips of the turbine rotor blades (11a) at a small clearance and an engagement feature including an axial wall (33a, 34a) having a prescribed circumferential length and a prescribed axial length, the turbine casing including an axial slot (51, 52) extending coaxially around the center line of the engine and configured to receive the axially extending wall of each shroud segment. A clearance defined between each circumferential end part (E) of the axial wall and an opposing inner circumferential surface of the turbine casing is greater than that defined between a circumferentially middle part (M) of the axial wall and an opposing inner circumferential surface of the turbine casing under a cool condition of the engine. A radial temperature gradient that develops in each shroud segment when the engine is warmed causes a deformation of the shroud segment such that the clearance can be made substantially uniform over the entire circumference of the shroud segment and the cooling air leakage can be minimized while minimizing thermal stress that may be caused by the thermal expansion of the shroud segment.

Owner:HONDA MOTOR CO LTD

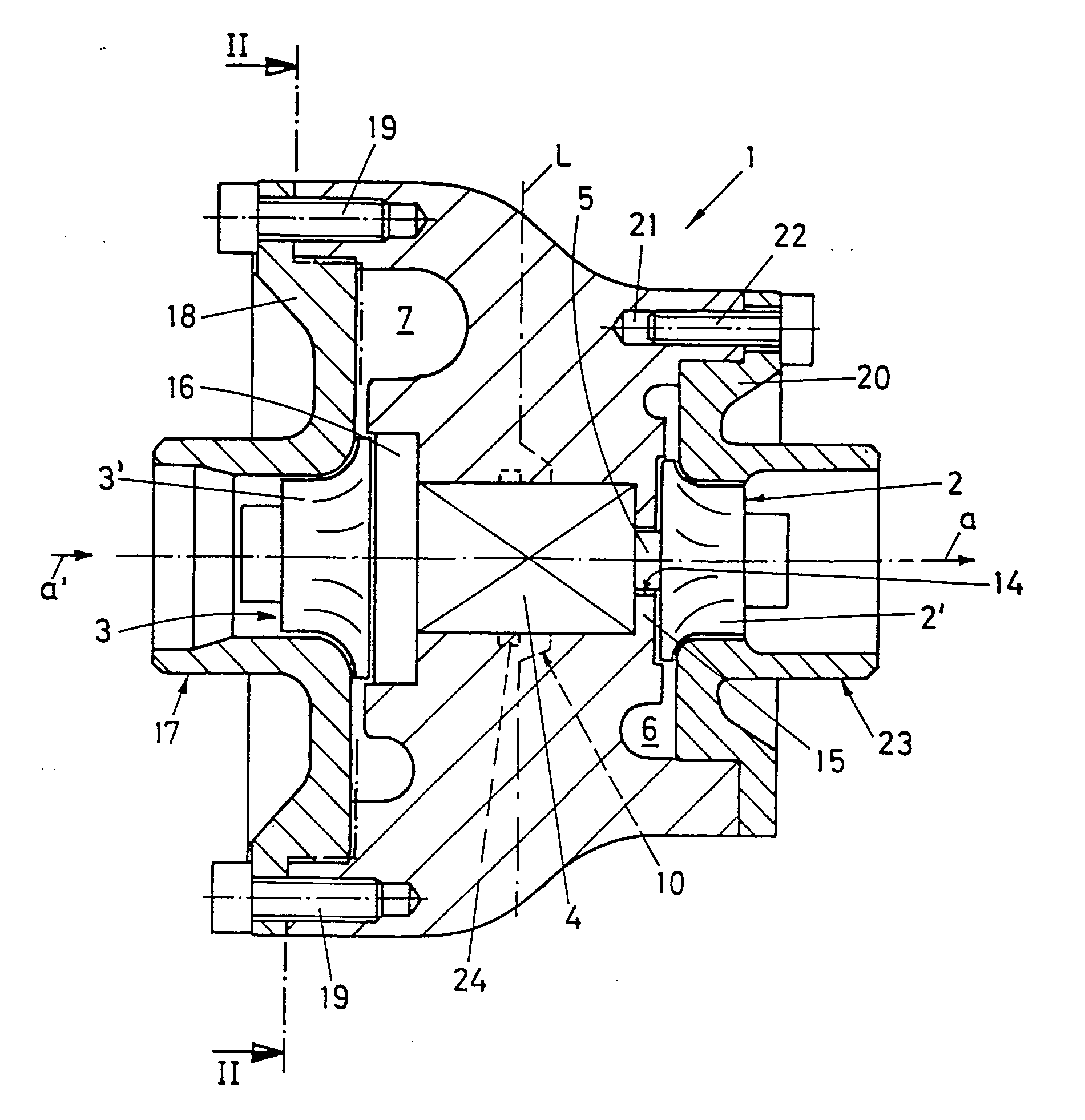

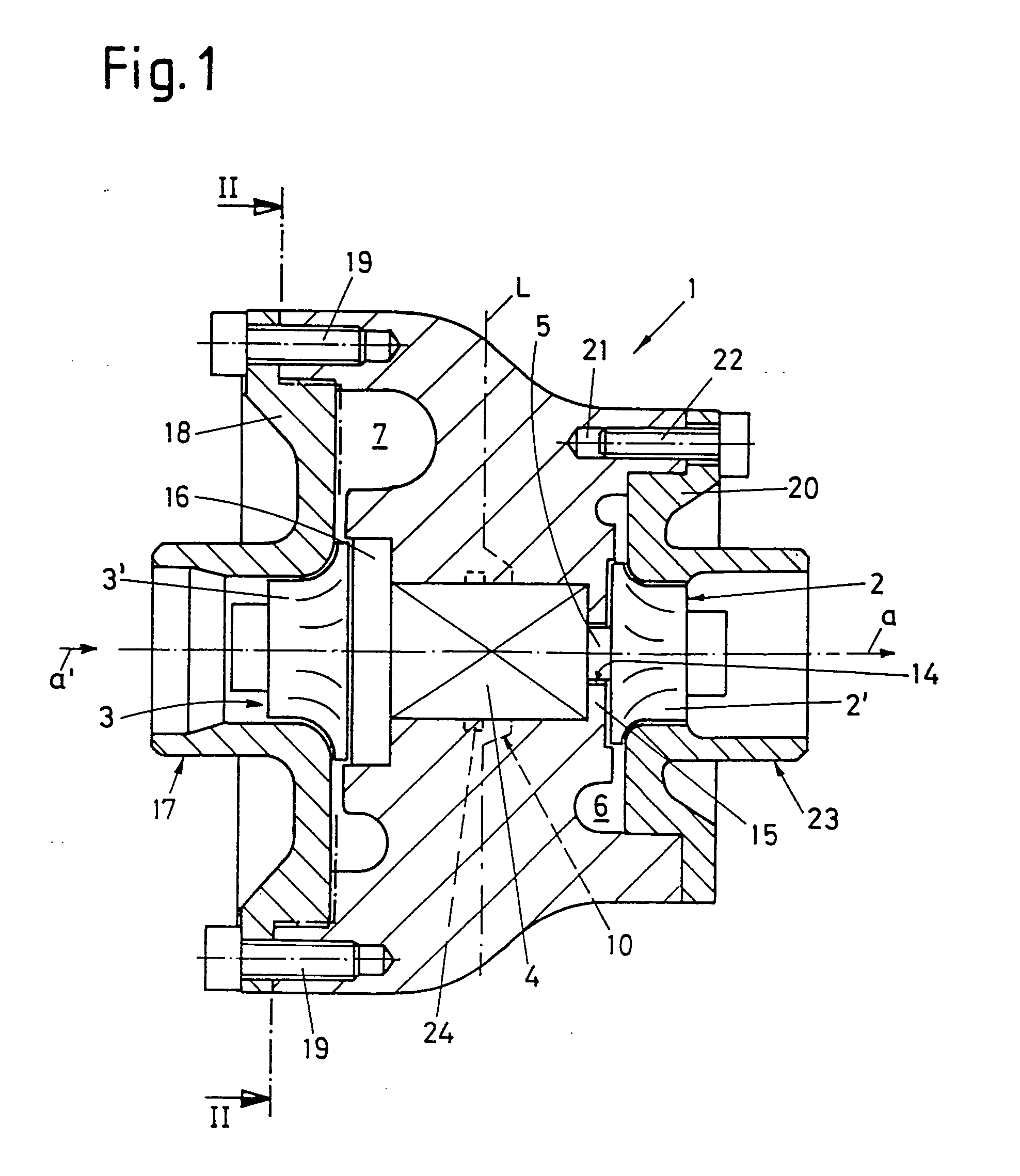

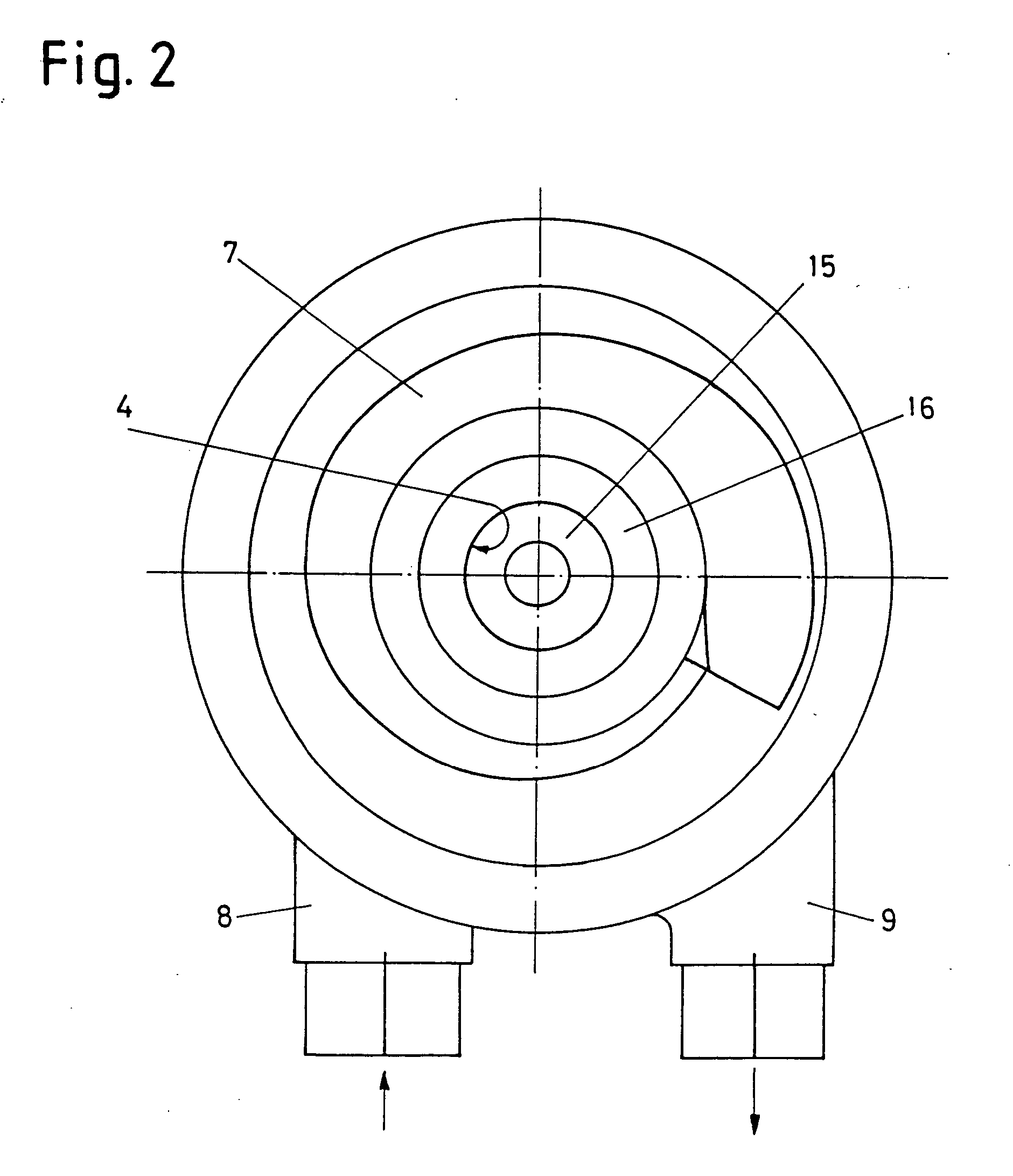

Housing for a fluid flow engine

InactiveUS20050069427A1Large spacingLess cumbersomePump componentsStatorsEngineeringMechanical engineering

A housing (1) for a fluid flow engine comprises a first rotor space (2) for receiving and housing a turbine rotor, a bearing space (4) to house a shaft (5) of said turbine rotor, and a second rotor space (3) for receiving and housing a compressor rotor. The housing portions, which surround the bearing space (4), are integrally formed at least in part with those portions that surround at least one of the rotor spaces (2,3).

Owner:BORGWARNER INC

Vibration damper assembly for the buckets of a turbine

InactiveUS6851932B2Increase dampingRisk minimizationPropellersPump componentsEngineeringControl theory

A damper pin is disposed between adjacent buckets of a turbine rotor. A first bucket has circumferentially extending supports defining a pair of axially spaced surfaces on which a damper pin rests in a cold condition of the turbine. The adjacent bucket is undercut adjacent its platform to provide an angled surface overlying a generally correspondingly angled surface of the damper pin. The damper pin fits slightly loose within the recess and, upon turbine rotation at speed, the angled surfaces of the damper pin and recess cooperate to bias the damper pin against the first bucket whereby the damper pin engages both buckets and dissipates vibratory action.

Owner:GENERAL ELECTRIC CO

Turbine Engine

ActiveUS20110173991A1Easy dischargeLow costBlade accessoriesGas turbine plantsRadial surfaceMultiple stages

A multiple-fluid, multiple-substance, multiple-phase, multiple-pressure, multiple-temperature, multiple-stage turbine engine. In preferred embodiments, one or more fluids are supplied by passageways in the turbine shaft or supplied by non-shaft passageways, or both, through rotor passageways to multiple-phase, multiple-fluid, multiple-substance nozzles affixed to one or more perimeters, radial surfaces, axial surfaces, and / or curved or slanted surfaces of the turbine rotor assemblies. The multiple perimeters, radial surfaces, axial surfaces, and / or curved or slanted surfaces of the turbine rotor assemblies are preferably configured and located for multiple inlet and exit velocities of the nozzles, multiple inlet and exit pressures of the nozzles, or combinations thereof. The one or more fluids entering the turbine may each be a substance of single phase, or a substance of multiple phases, or a mix of the single-phase and / or multiple-phase conditions for two or more entrance fluids.

Owner:RECOGEN

Wind turbine rotor blade assembly having an access window and related methods

A rotor blade assembly having an access window and methods for assembling a rotor blade are disclosed. The rotor blade assembly may generally include a first shell component and a second shell component. The first shell component may be secured to the second shell component. Additionally, an access region may be defined in the first shell component and / or the second shell component. The access region may generally be configured such that an access window is defined in the rotor blade assembly. The access window may be configured to provide access to the interior of a portion of the rotor blade assembly.

Owner:GENERAL ELECTRIC CO

Wind turbine system for satisfying low-voltage ride through requirement

A wind turbine system is provided with a wind turbine rotor, a pitch control mechanism, and an emergency power supply mechanism. The wind turbine rotor includes a blade having a variable pitch angle. The pitch control mechanism drives the blade to control the pitch angle. The emergency power supply mechanism generates electric power from rotation of the wind turbine rotor and feeds the electric power to the pitch control mechanism, in response to occurrence of an accidental drop of a system voltage of a power grid.

Owner:MITSUBISHI HEAVY IND LTD

Automatic braking and locking of a wind turbine

InactiveUS7397145B2Reduce riskImprove work safetyWind motor controlEngine fuctionsRotational axisAutomatic braking

A wind turbine rotor is decelerated and locked in a target rotational position in relation to rotation of the rotor about the rotor axis. The rotational position of the rotor in relation to the rotational axis is detected relative to at least one target rotational position. Once the rotor reaches one of the target rotational positions, the rotor is halted and automatically locked in the target rotational position.

Owner:S B PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com