Housing for a fluid flow engine

a fluid flow and engine technology, applied in the direction of liquid fuel engines, positive displacement liquid engines, piston pumps, etc., can solve the problems of small tolerances and high cost, and achieve the effect of less cumbersom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

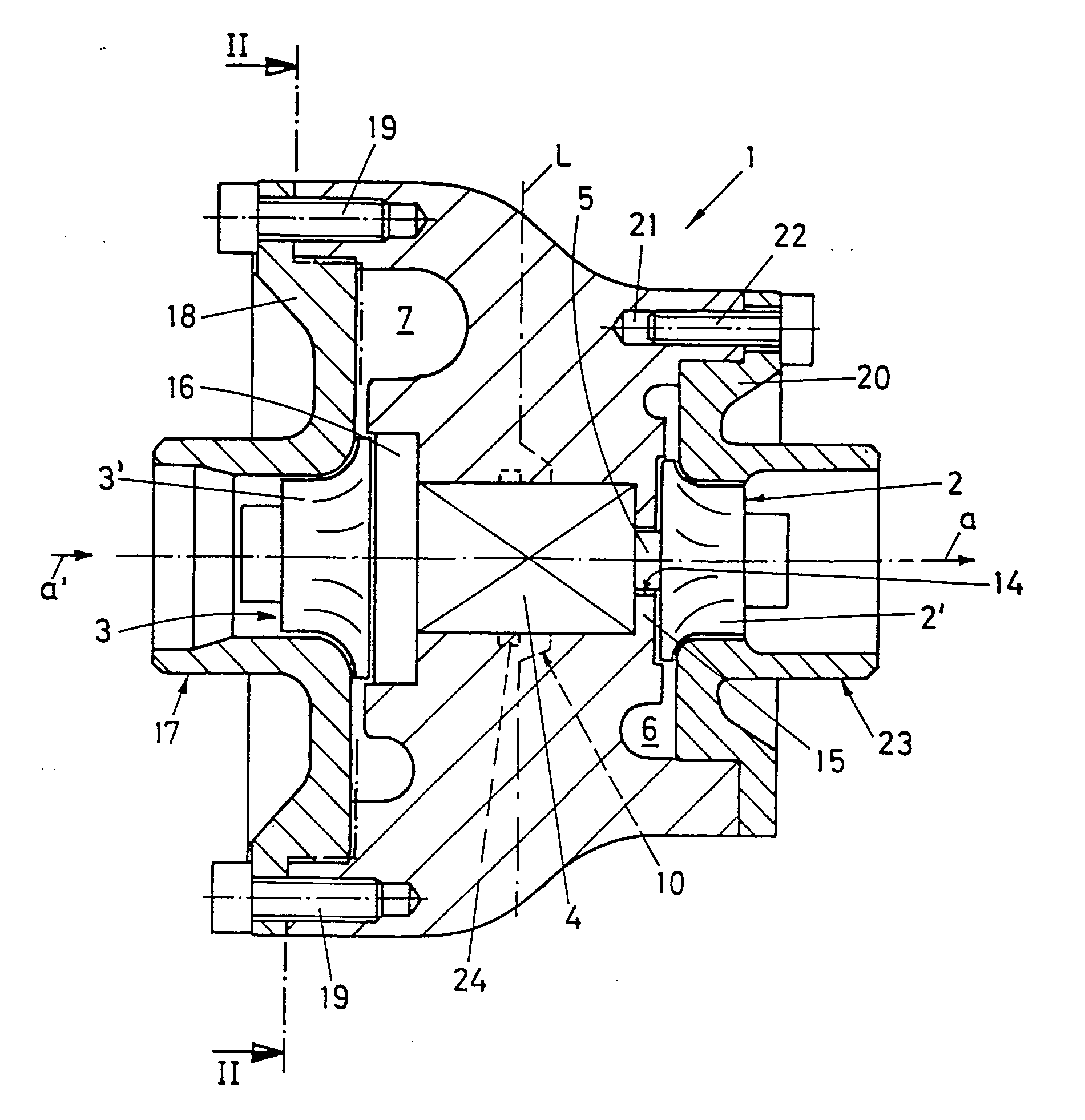

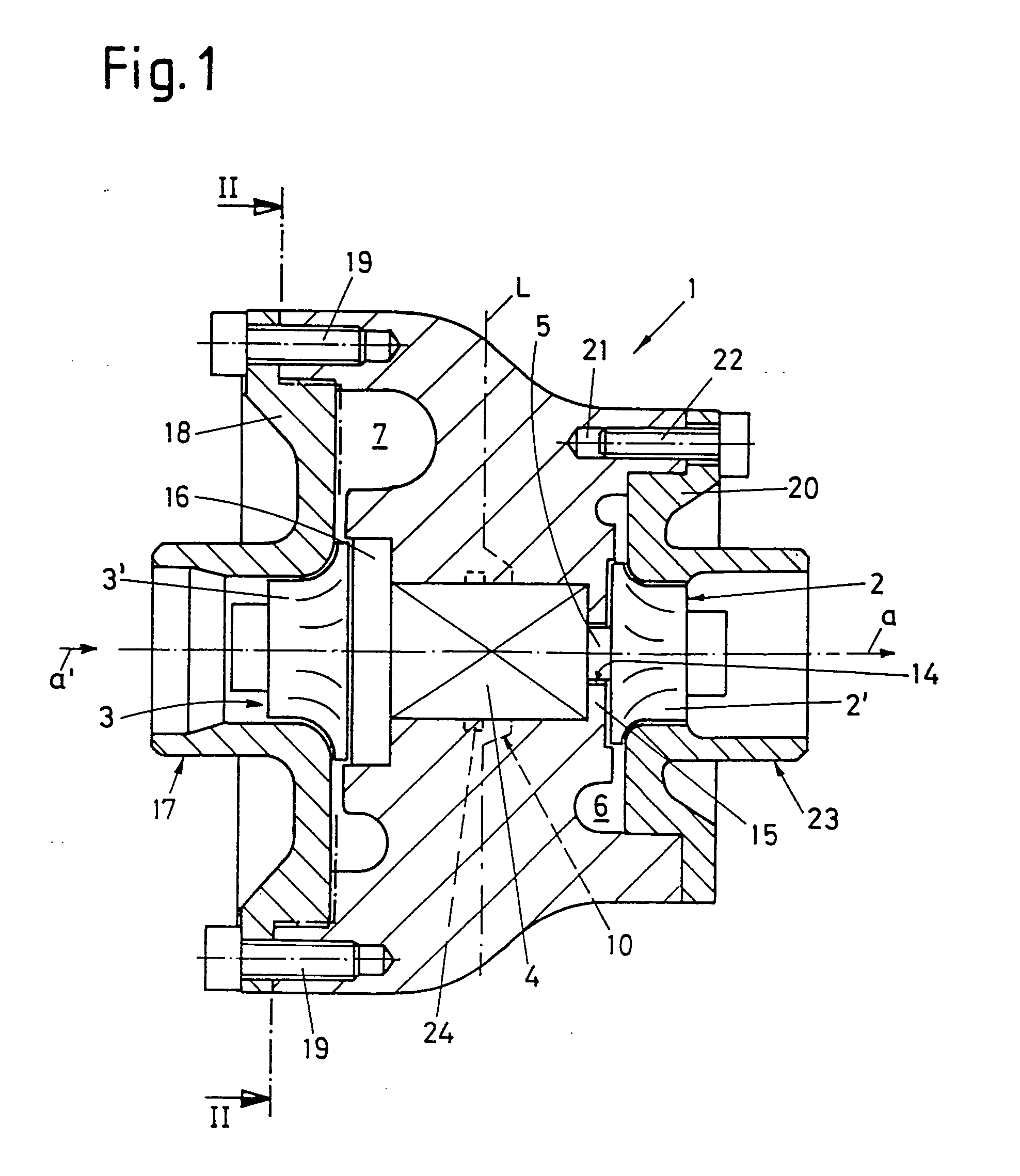

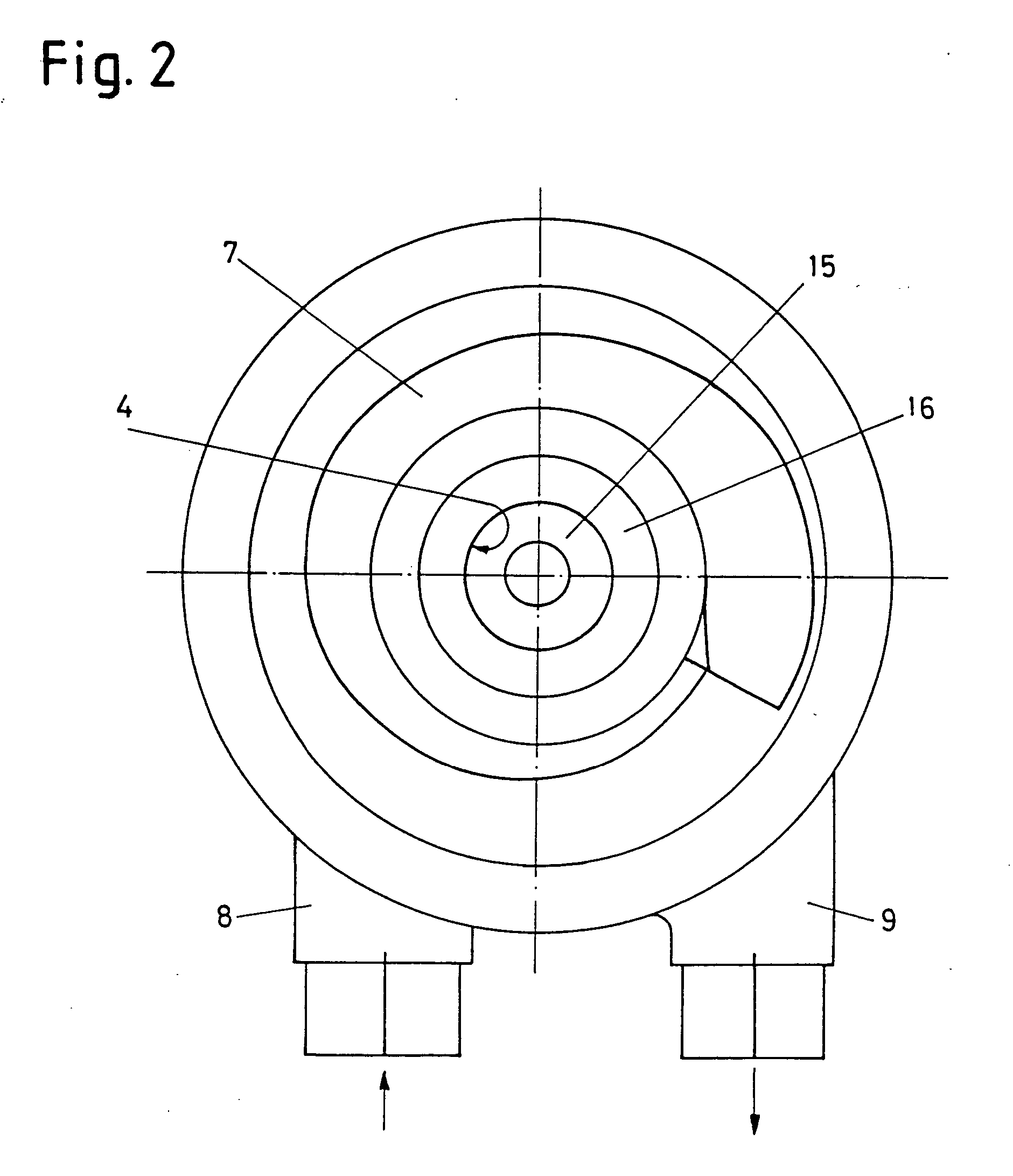

[0012] A single piece housing 1 which is, for example, produced from cast material, such as gray cast iron or a light metal casting, surrounds and defines with its inner walls a turbine rotor space 2 for a turbine rotor 2′, shown in FIG. 1, at one of its axial ends, a compressor rotor space 3 for a compressor rotor 3′ to be accommodated therein at the opposite axial end of the housing, and in-between a bearing space 4 for a shaft 5 which, as known to one of ordinary skill in the art, supports each of the two rotors 2′ and 3′ on one of its ends. To each of the rotor spaces 2, 3 a channel is assigned which, ordinarily, surrounds the rotor space in an approximately annular or spiral form, i.e. a supply channel 6 and a discharge channel 7.

[0013] A gaseous medium, i.e. in the case of a turbocharger an exhaust gas of a combustion motor, in the case of a secondary air charger it is air, or any other fluid, such as a liquid, is supplied to the supply channel 6 from a connection piece 8 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com