Patents

Literature

108 results about "Chemical content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass spectrometer method and apparatus for analyzing a sample in a solution

InactiveUS7247495B2Fast and reliable identificationHigh sensitivityComponent separationSamples introduction/extractionSpray nozzleMass analyzer

The invention provides a mass spectrometric method for analyzing a sample in a solution, including the steps of directing a flow of a solution containing sample compounds to be analyzed towards a supersonic nozzle having an input end and an output end; vaporizing the solution and sample prior to its expansion from the output end of said supersonic nozzle; allowing expansion of the vaporized sample and solution from said supersonic nozzle into a vacuum system, forming a supersonic molecular beam with vibrationally cold sample molecules; ionizing the vaporized sample compounds with electrons while contained as vibrationally cold molecules in said supersonic molecular beam; mass analyzing the ions formed from said sample compounds; detecting said ions formed from said sample compounds after mass analysis, and processing the data obtained from the resulting mass spectral information, for identifying and / or quantifying the chemical content of said sample. The invention also provides apparatus for analyzing a sample in a solution.

Owner:AMIRAV AVIV

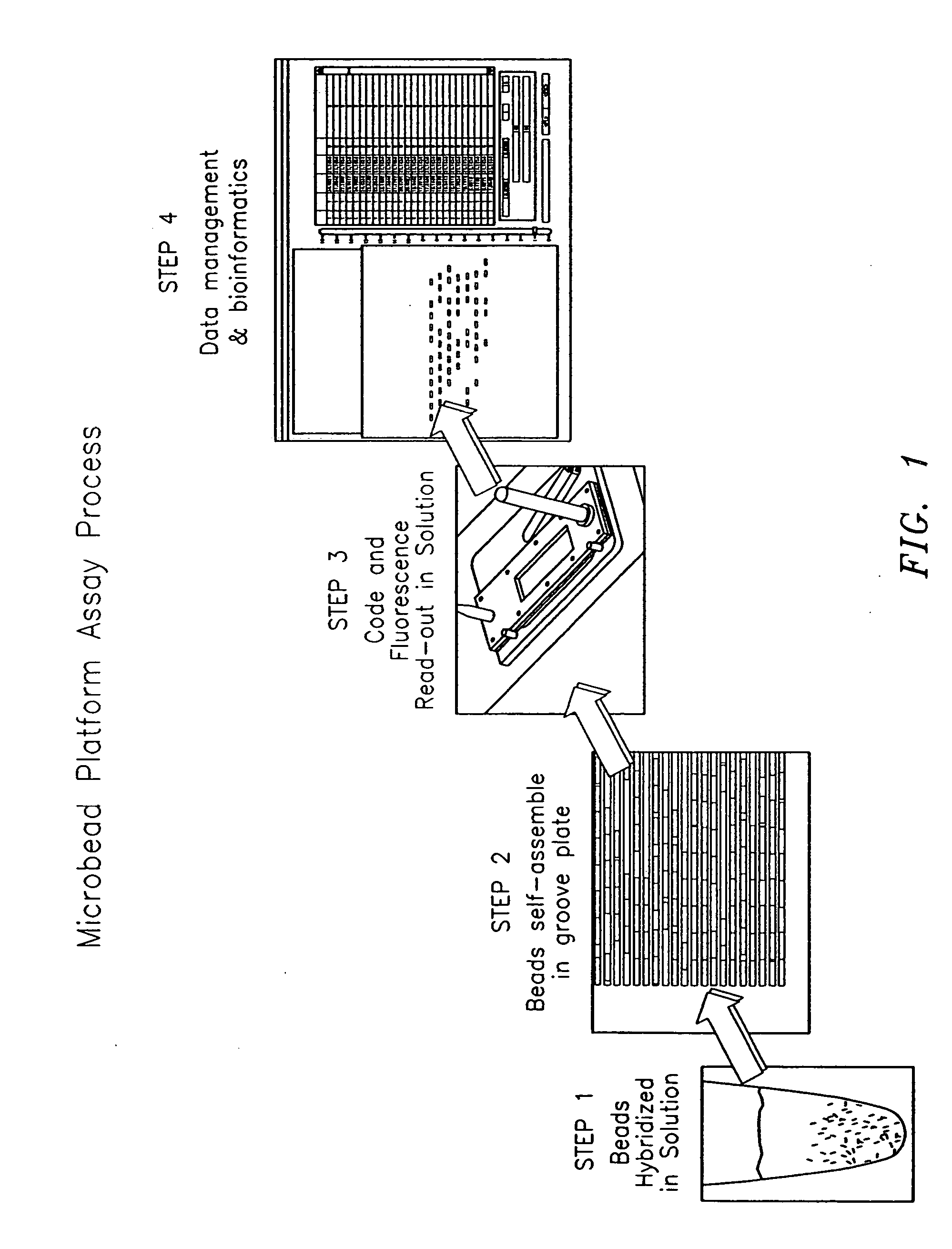

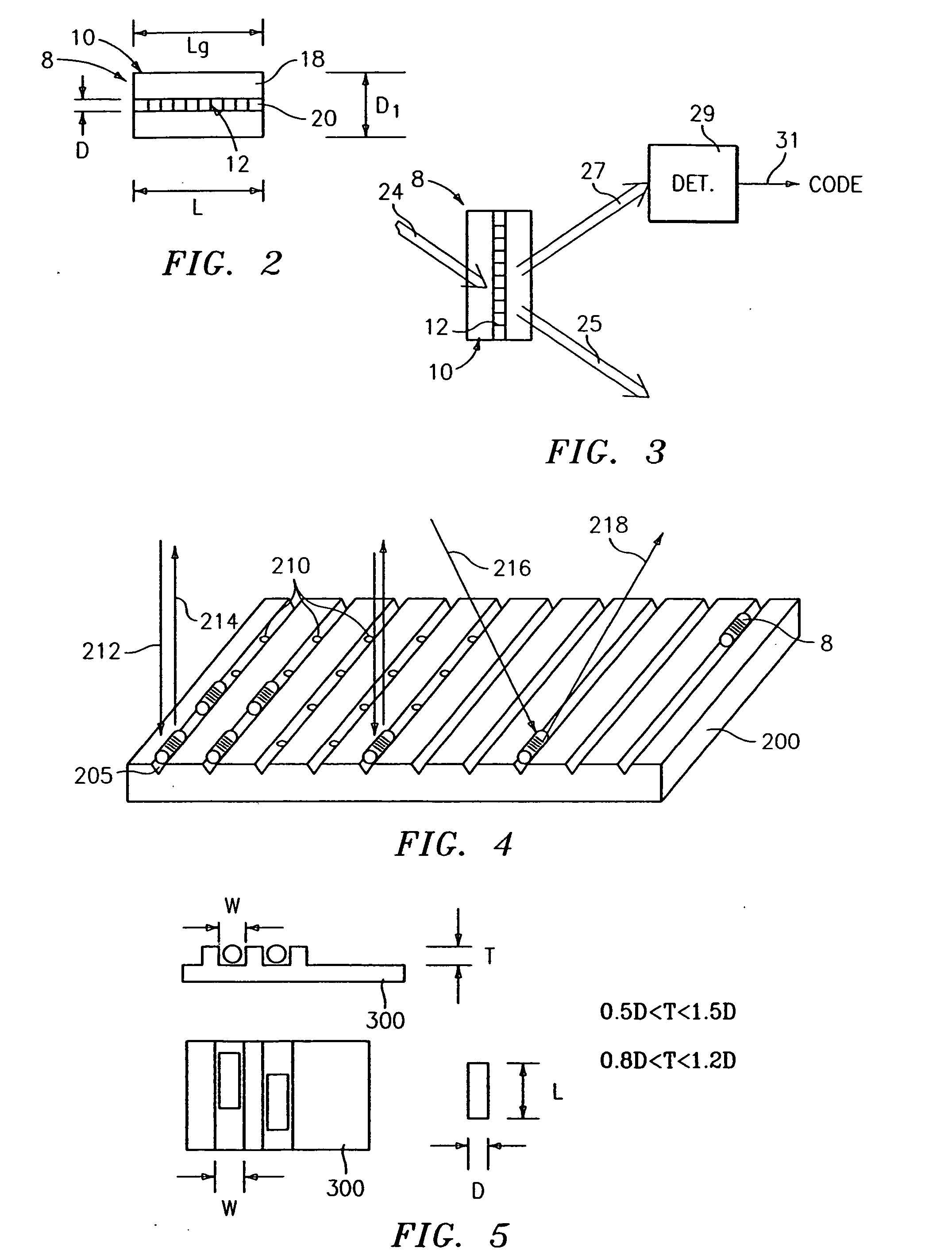

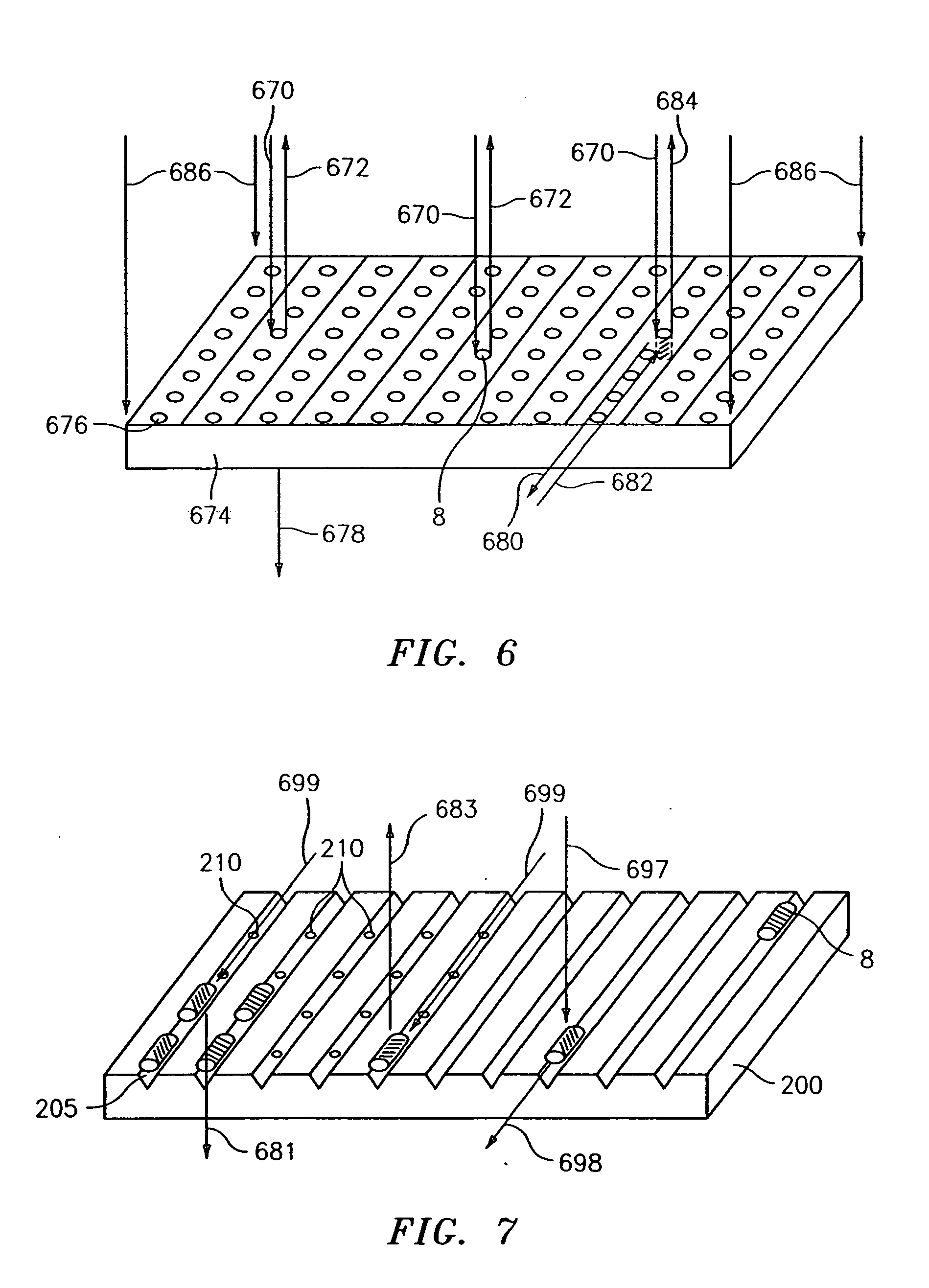

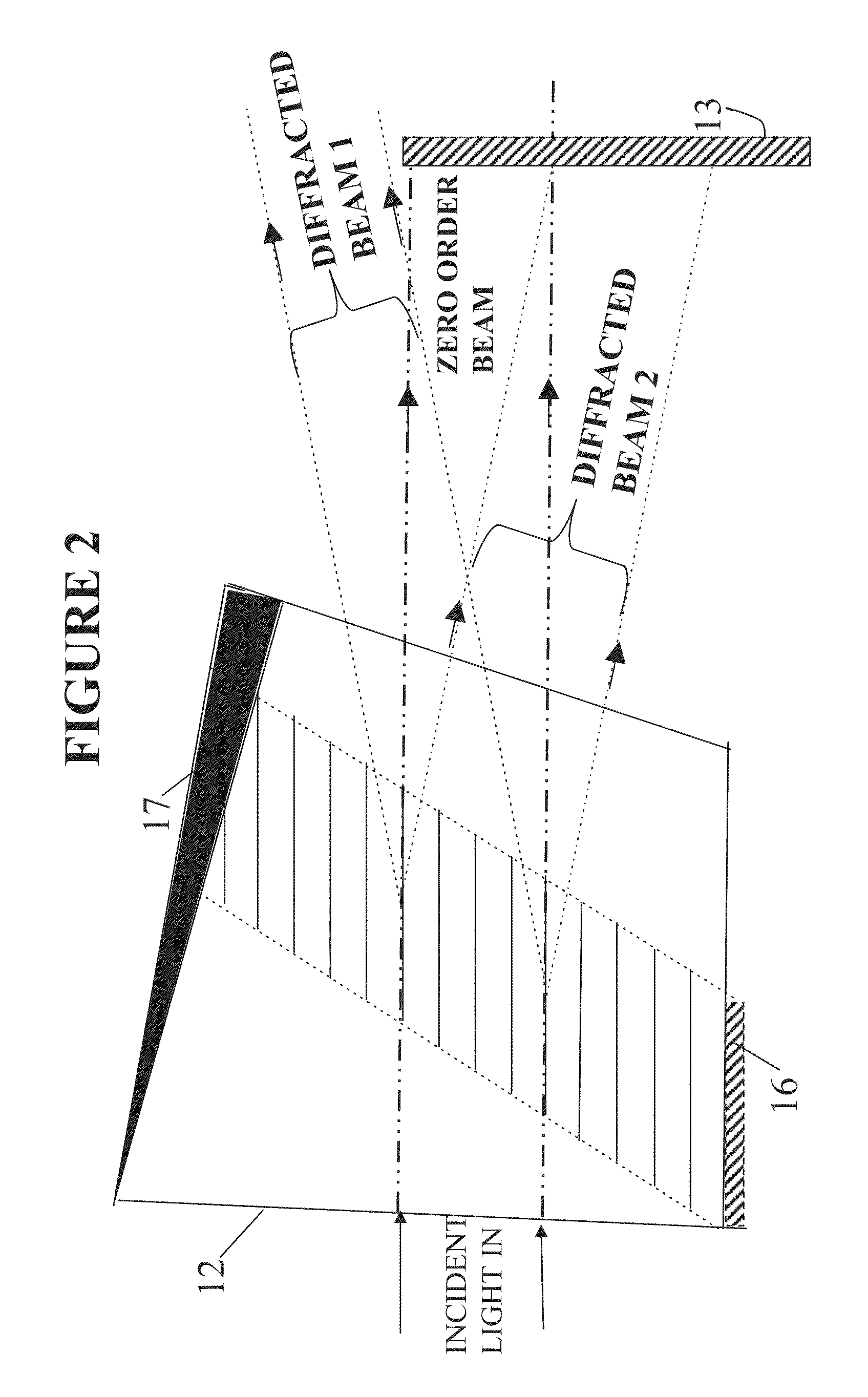

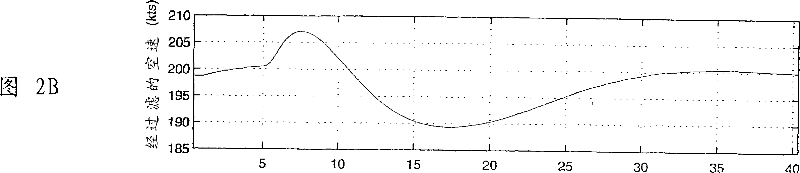

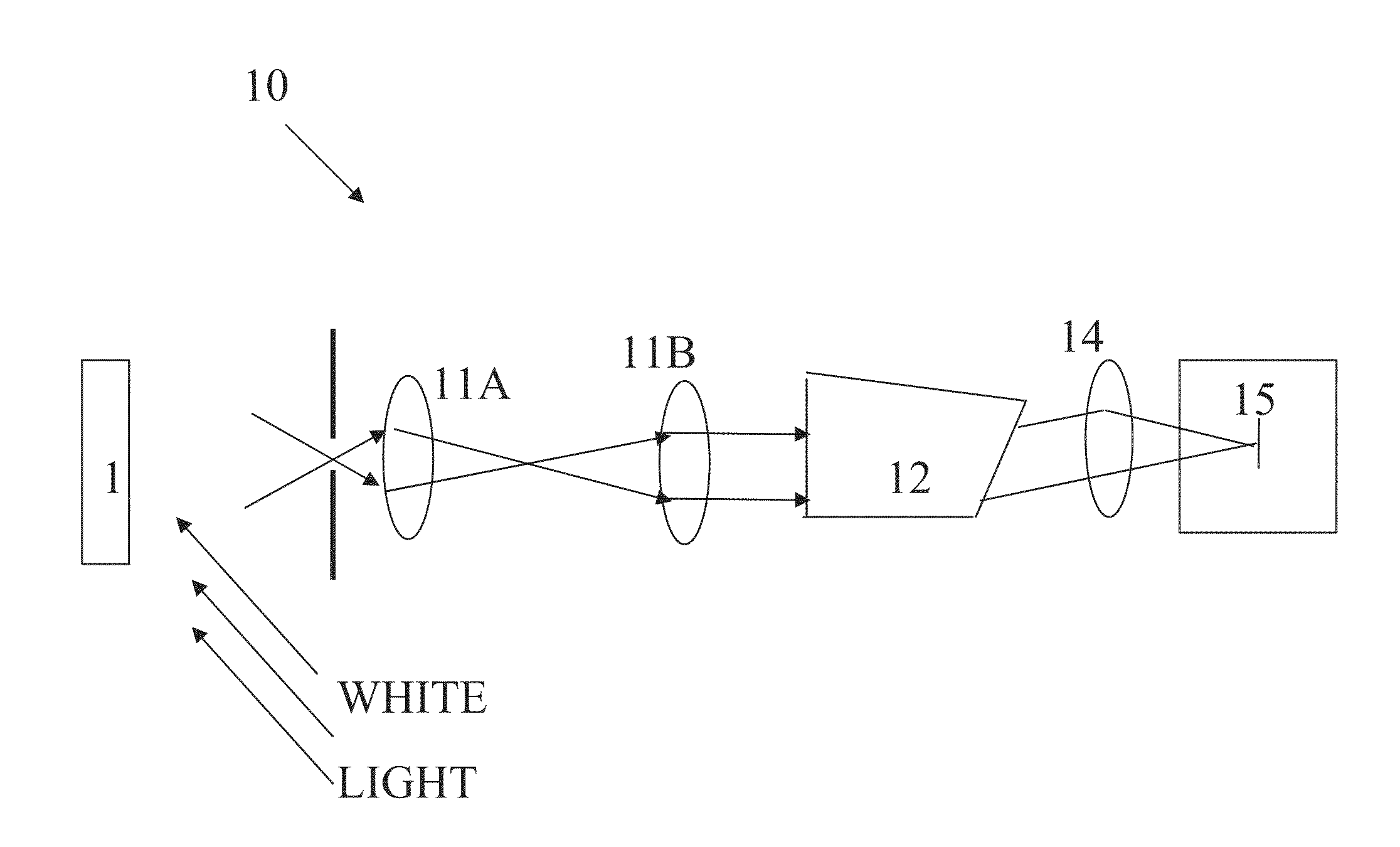

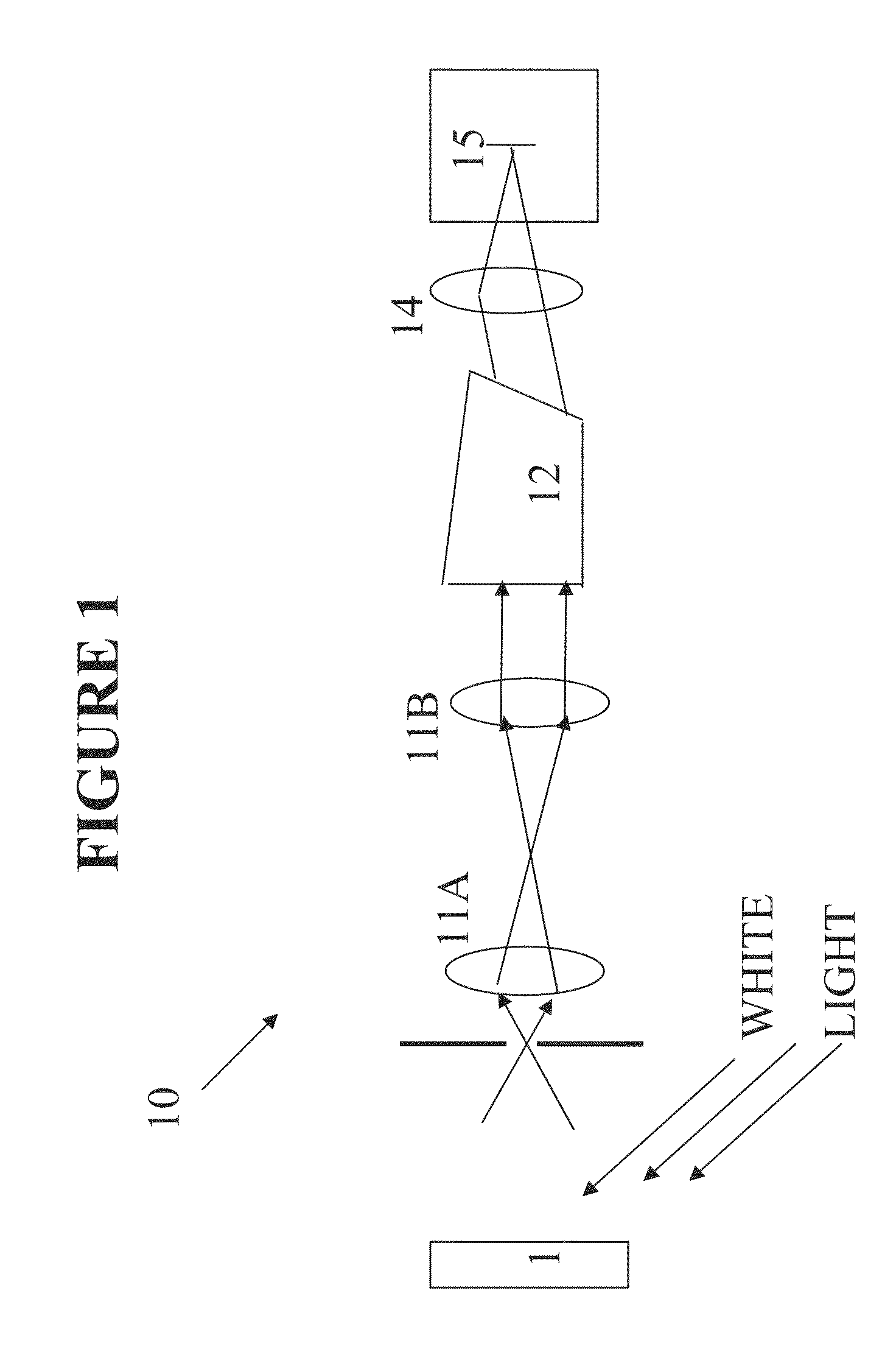

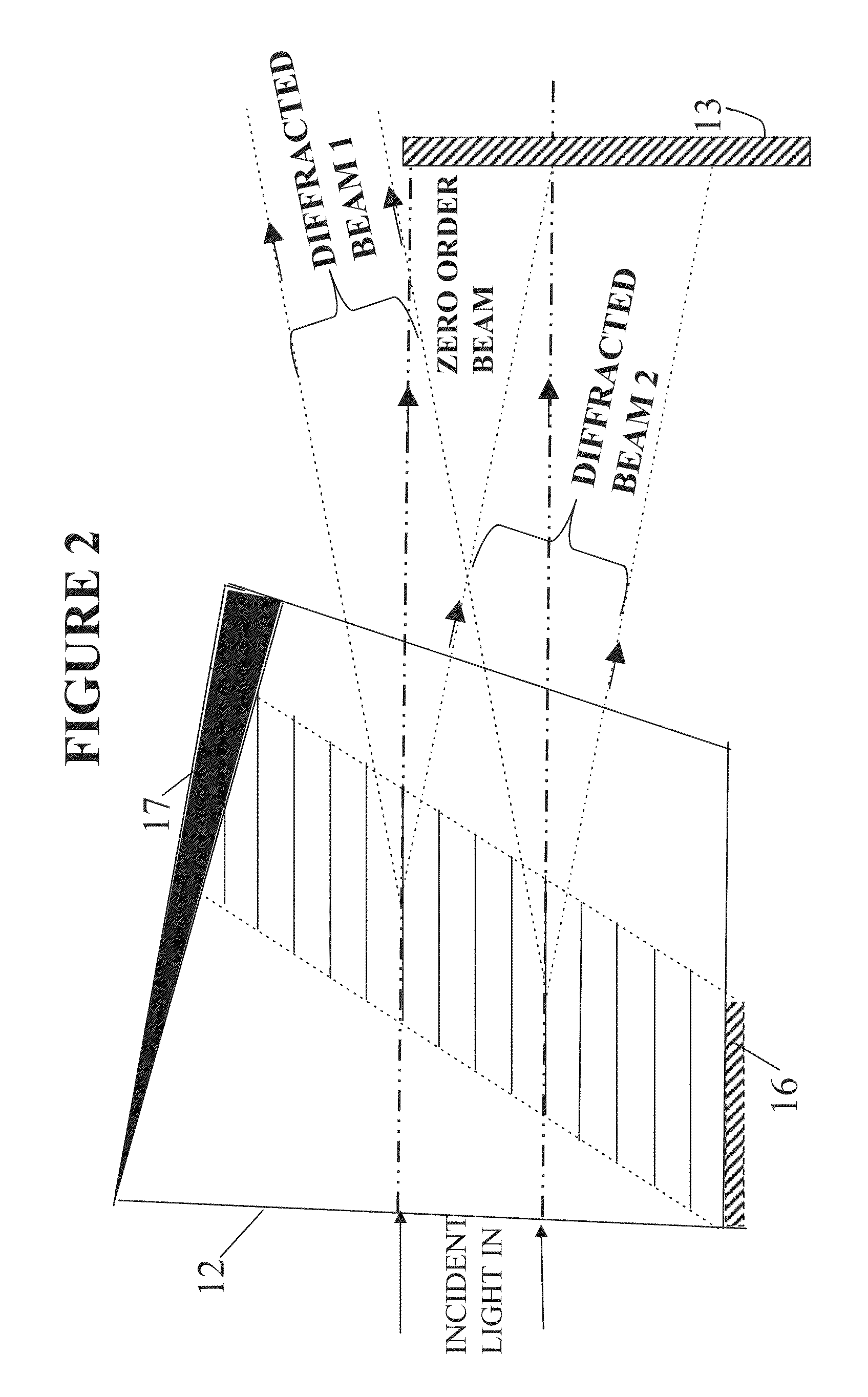

Multi-well plate with alignment grooves for encoded microparticles

InactiveUS20060160208A1Fast readoutQuick alignmentBioreactor/fermenter combinationsBiological substance pretreatmentsRotational axisFluorescence

A method and apparatus are provided for aligning optical elements or microbeads, wherein each microbead has an elongated body with a code embedded therein along a longitudinal axis thereof to be read by a code reading device. The microbeads are aligned with a positioning device so the longitudinal axis of the microbeads is positioned in a fixed orientation relative to the code reading device. The microbeads are typically cylindrically shaped glass beads between 25 and 250 microns (μm) in diameter and between 100 and 500 μm long, and have a holographic code embedded in the central region of the bead, which is used to identify it from the rest of the beads in a batch of beads with many different chemical probes. A cross reference is used to determine which probe is attached to which bead, thus allowing the researcher to correlate the chemical content on each bead with the measured fluorescence signal. Because the code consists of a diffraction grating typically disposed along an axis, there is a particular alignment required between the incident readout laser beam and the readout detector in two of the three rotational axes. The third axis, rotation about the center axis of the cylinder, is azimuthally symmetric and therefore does not require alignment.

Owner:ILLUMINA INC

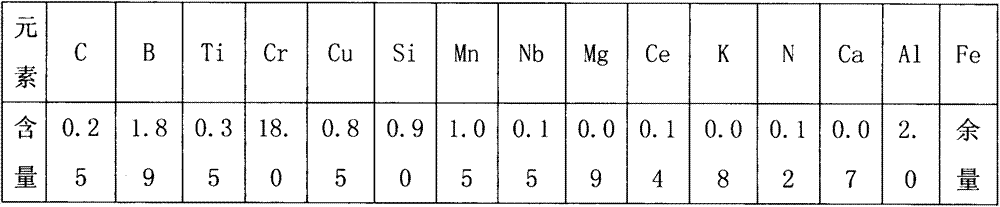

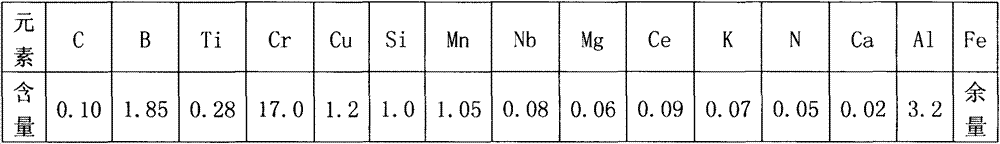

High-boron high-chromium low-carbon high-temperature-resistant wear-resisting alloy steel and manufacturing method thereof

InactiveCN103498107AReduce manufacturing costHigh heat and cold fatigue resistanceProcess efficiency improvementSilicon alloyCerium

The invention provides high-boron high-chromium low-carbon high-temperature-resistant wear-resisting alloy steel and manufacturing method thereof. The chemical content of the alloy steel includes, by weight, 0.10%-0.5% of C, 3%-26% of Cr, 0.5%-4% of W, 0.5%-1.2% of Si, 0.5%-1.5% of Mn, 0.7%-3.5% of B, 0.3%-2.6% of Cu, 1.5%-2.4% of Al, 0.8%-1.6% of Ti, 0.02%-0.15% of Ca, 0.03-0.25% of Ce, 0.02%-0.18% of N, 0.05%-0.3% of Nb, 0.12%-0.25% of Mg, 0.04%-0.13% of K, 0.05%-0.12% of Ca, 0.06%-0.15% of Ba, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. After steel scrap and ferrochromium are melted in an electric furnace, a copper plate, silicon iron and ferromanganese are added to the electric furnace, after content is qualified through pre-furnace adjustment, the temperature of a melt rises to 1560-1620 DEG C, calcium-silicon alloy and deoxidation aluminum are added, ferrotitanium, ferroboron and metal aluminum are sequentially added and poured out of the furnace after being melted, granular rare earth magnesium alloy with a diameter of less than 12mm and a composite inoculant composed of metal cerium, Si3N4, VN, Nb and K are placed at the bottom of a steel ladle after being roasted, metaphoric inoculation processing is carried out on smelt liquid steel in a in-ladle pouring mode, the liquid steel pouring temperature ranges from 1400 DEG C to 1450 DEG C, and a casting piece undergoes air cooling for 2-4 hours at the temperature of 920-1150 DEG C.

Owner:江苏盛伟模具材料有限公司

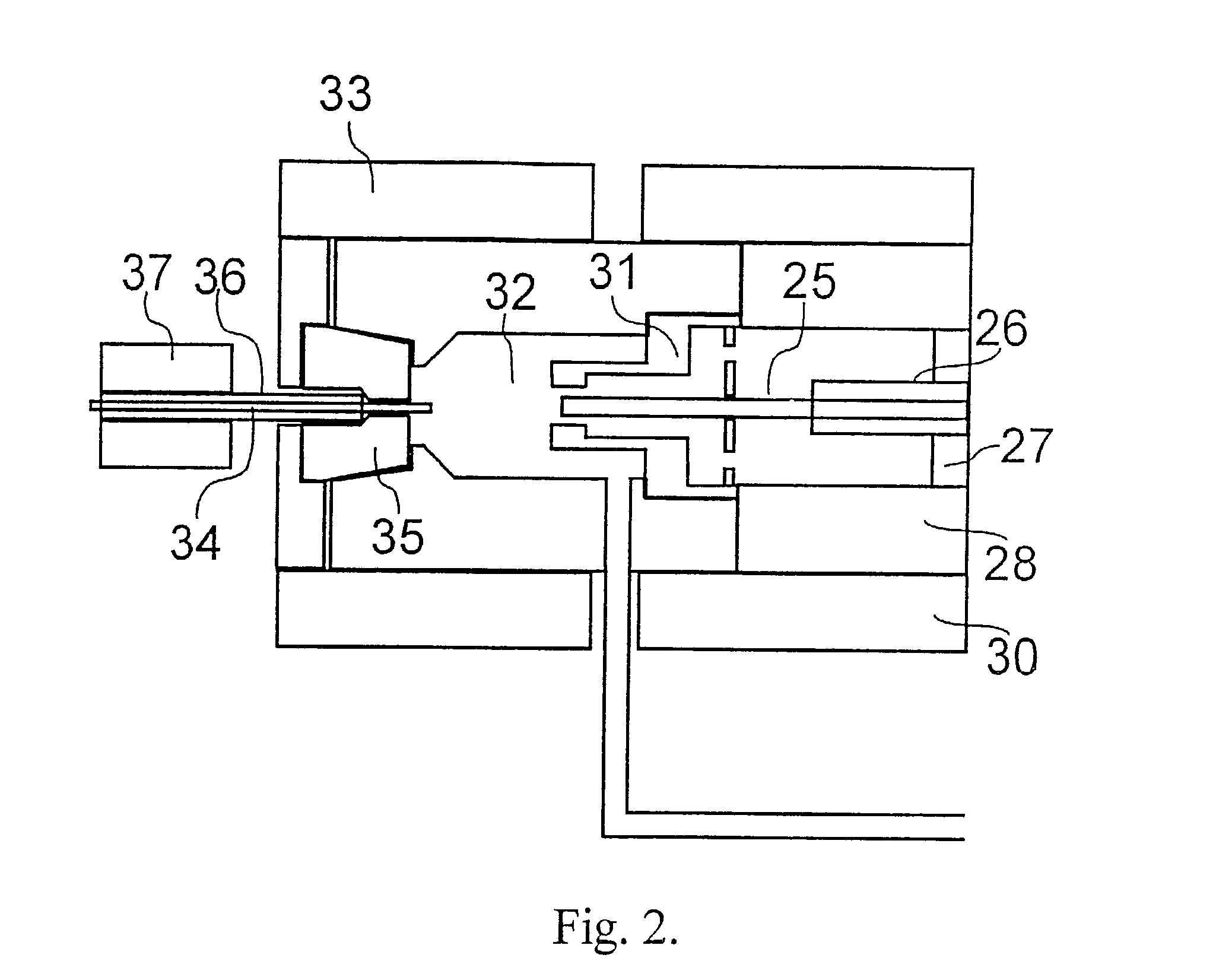

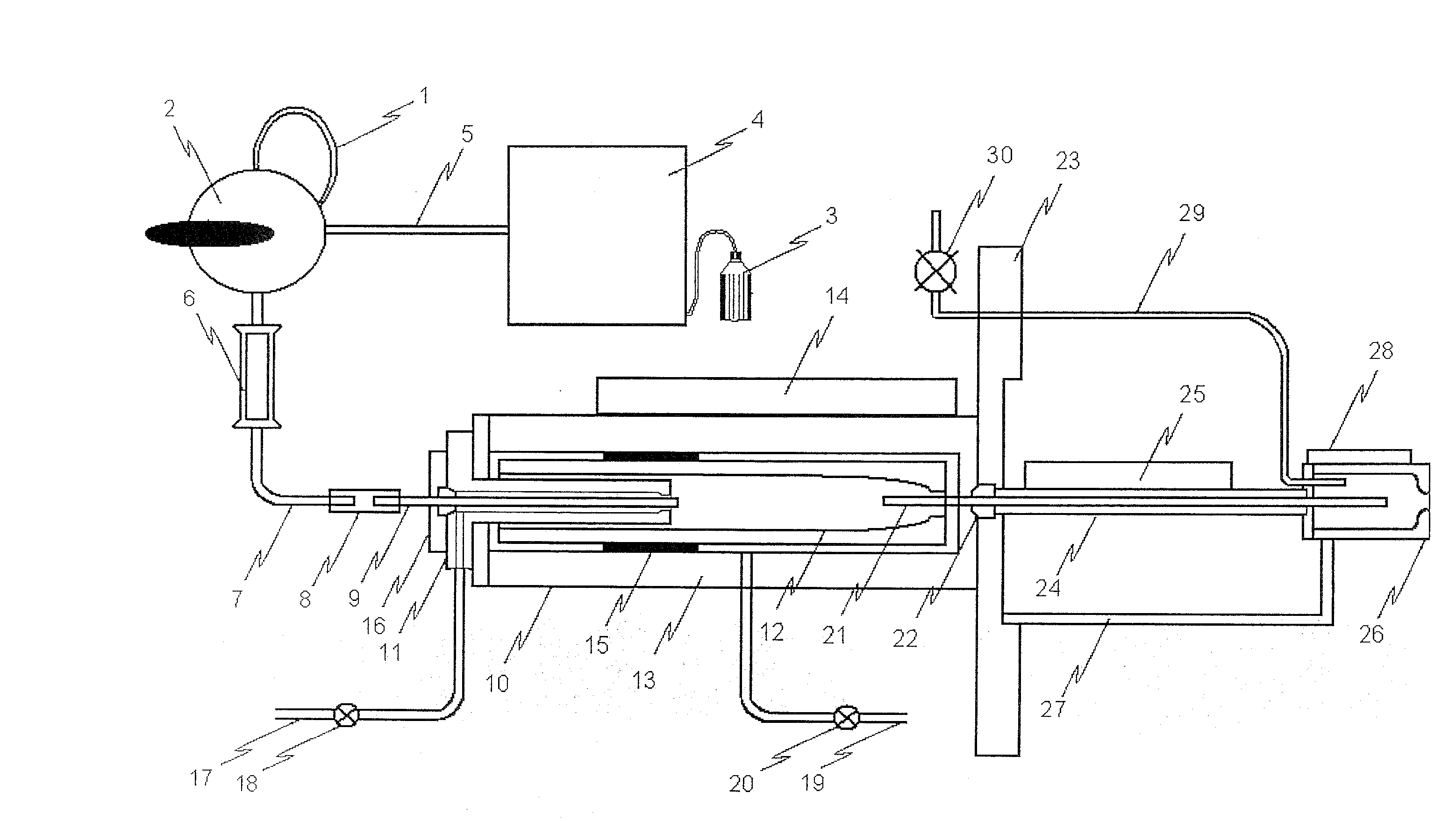

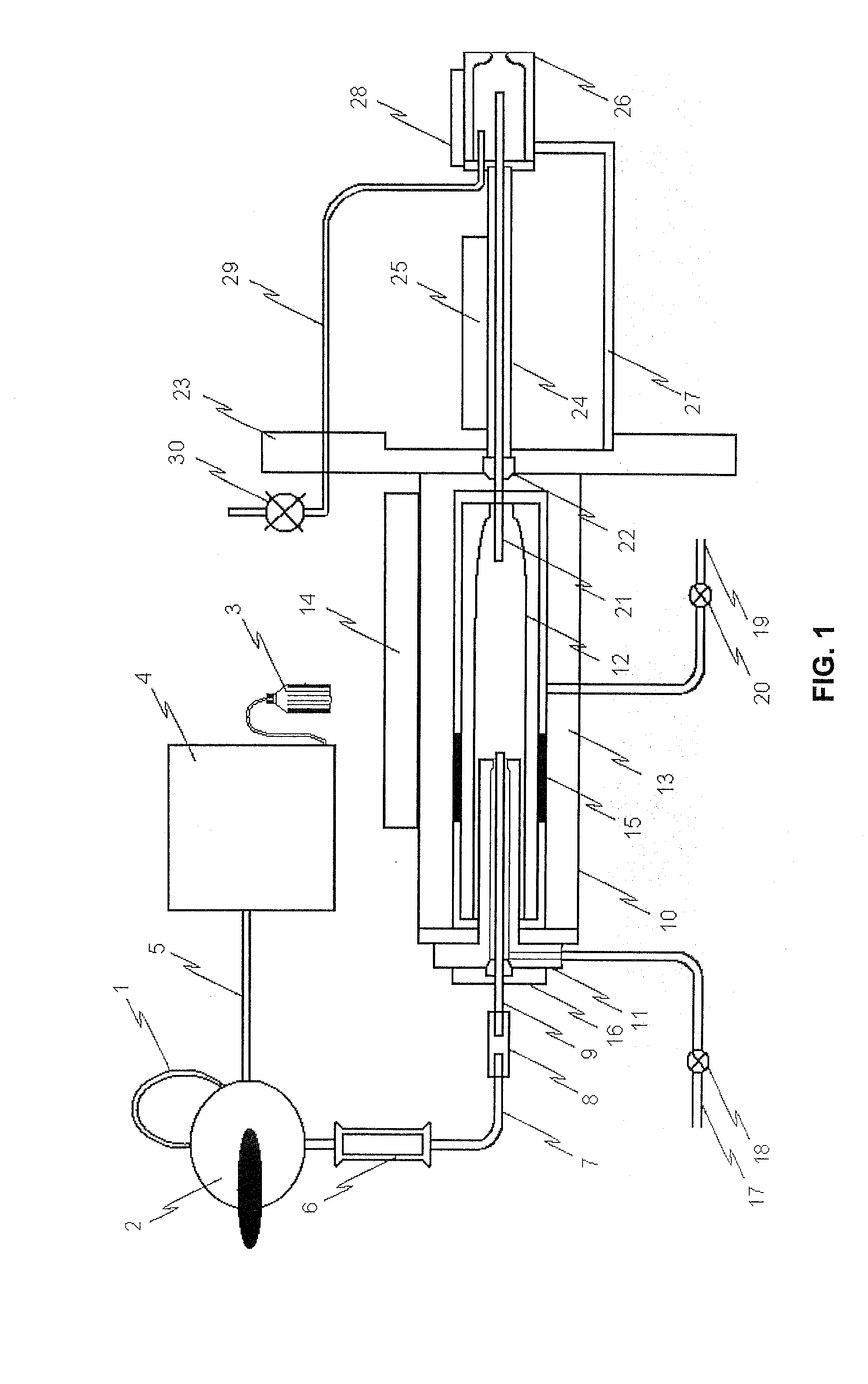

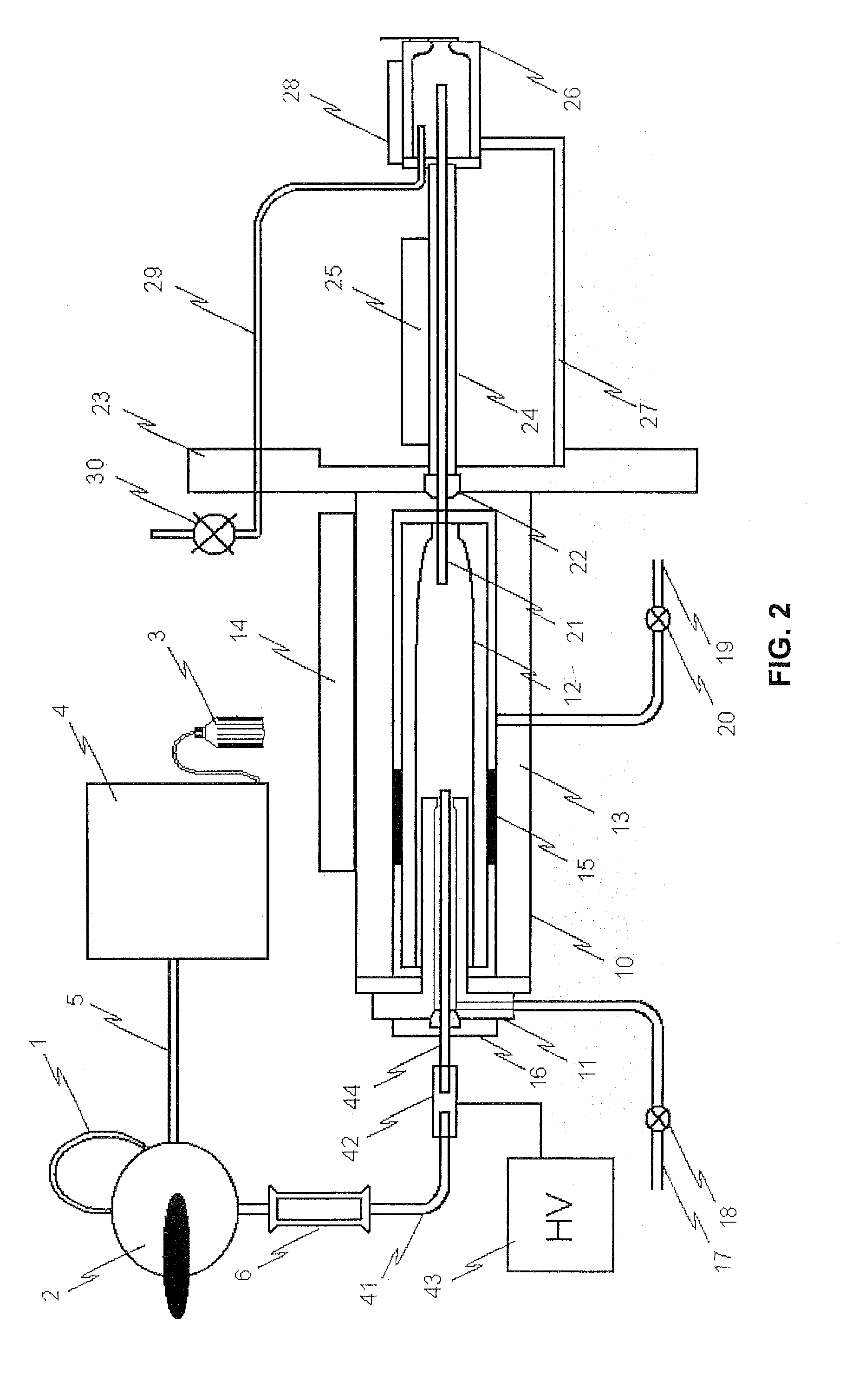

Capillary separated vaporization chamber and nozzle device and method

There is provided a capillary separated vaporization chamber and nozzle method and device for improved electron ionization liquid chromatography mass spectrometry of samples in a supersonic molecular beam. The device includes a vaporization chamber located upstream of a supersonic nozzle; a capillary separating the vaporization chamber and the supersonic nozzle, means for spray formation from sample in a flowing liquid; a vacuum system into which the supersonic nozzle induces supersonic expansion of the vaporized sample compounds and solvent vapor, for forming a supersonic molecular beam with vibrationally cold sample molecules and vaporized solvent; flythrough electron ionization ion source; mass analyzer; an ion detector and means for data processing of the resulting mass spectral information, for identifying and / or quantifying the chemical content of the sample.

Owner:AMIRAV AVIV

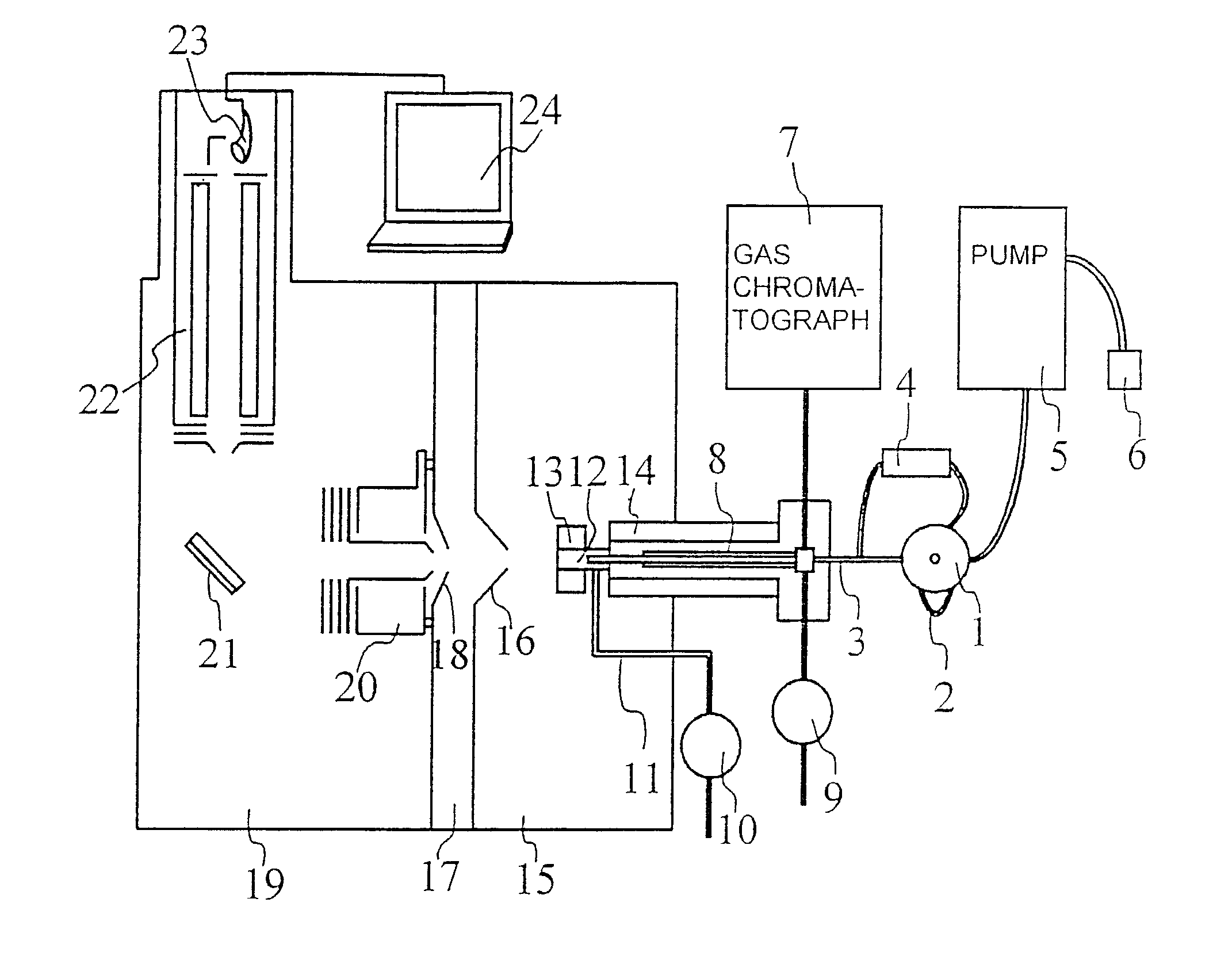

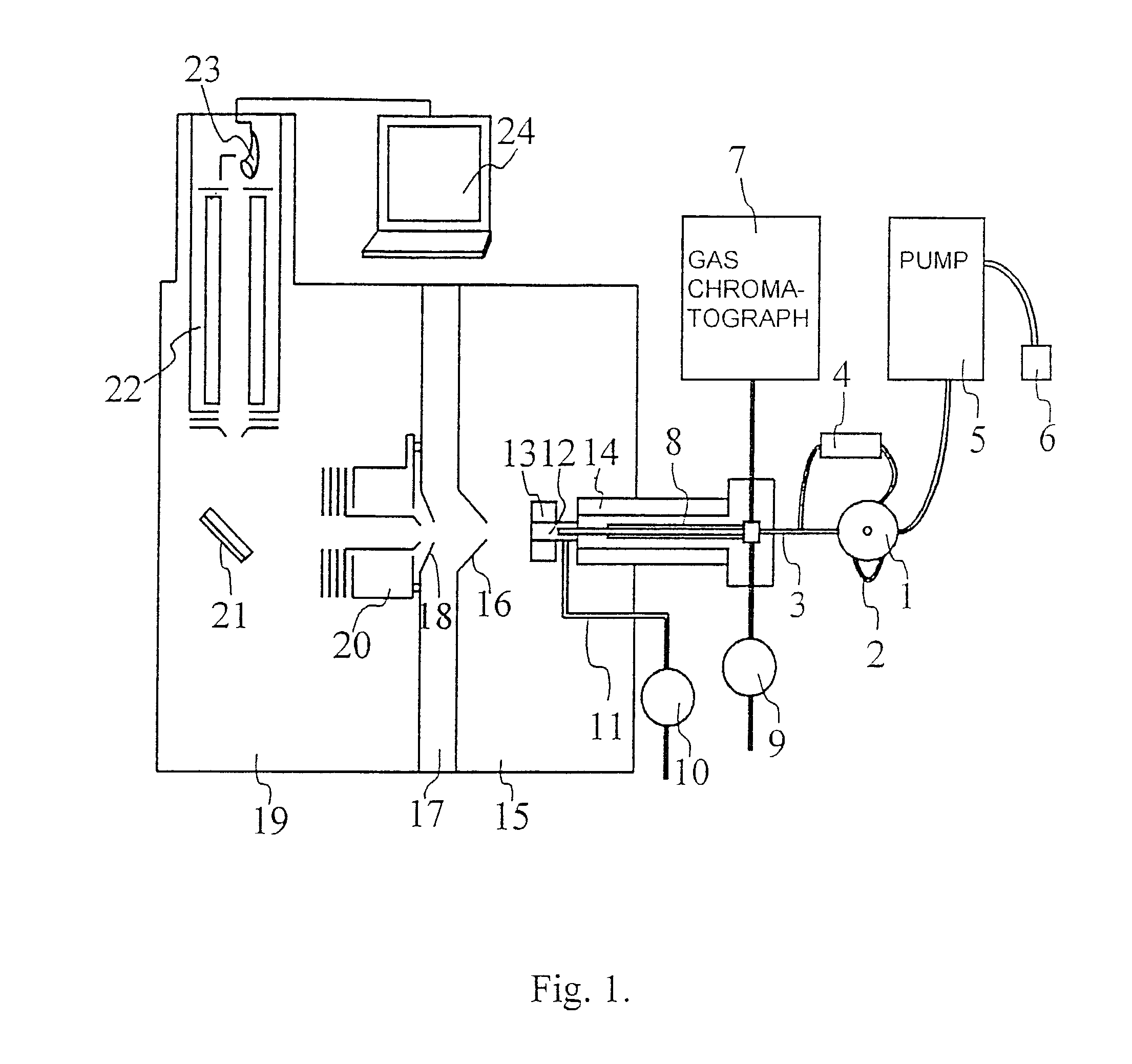

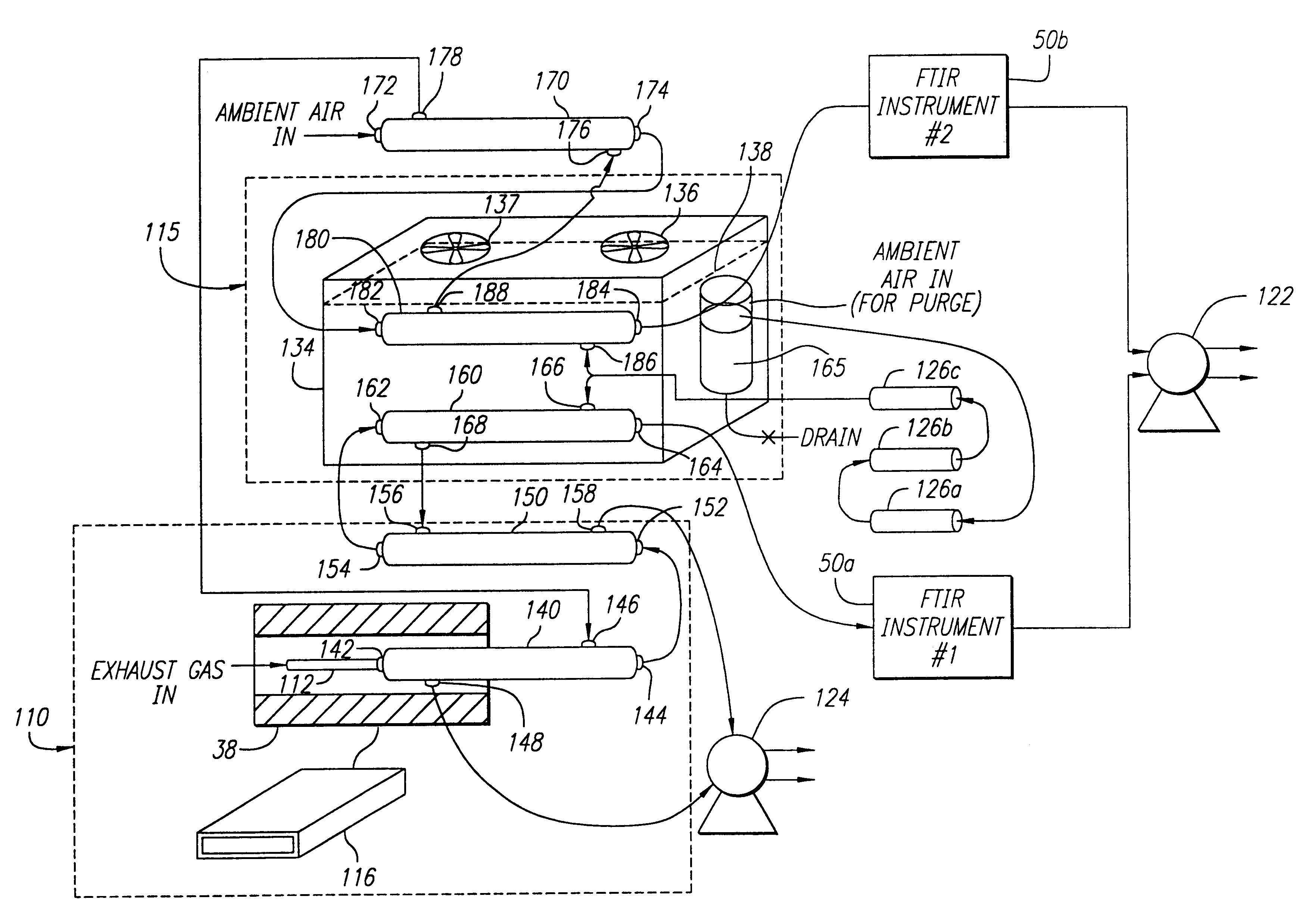

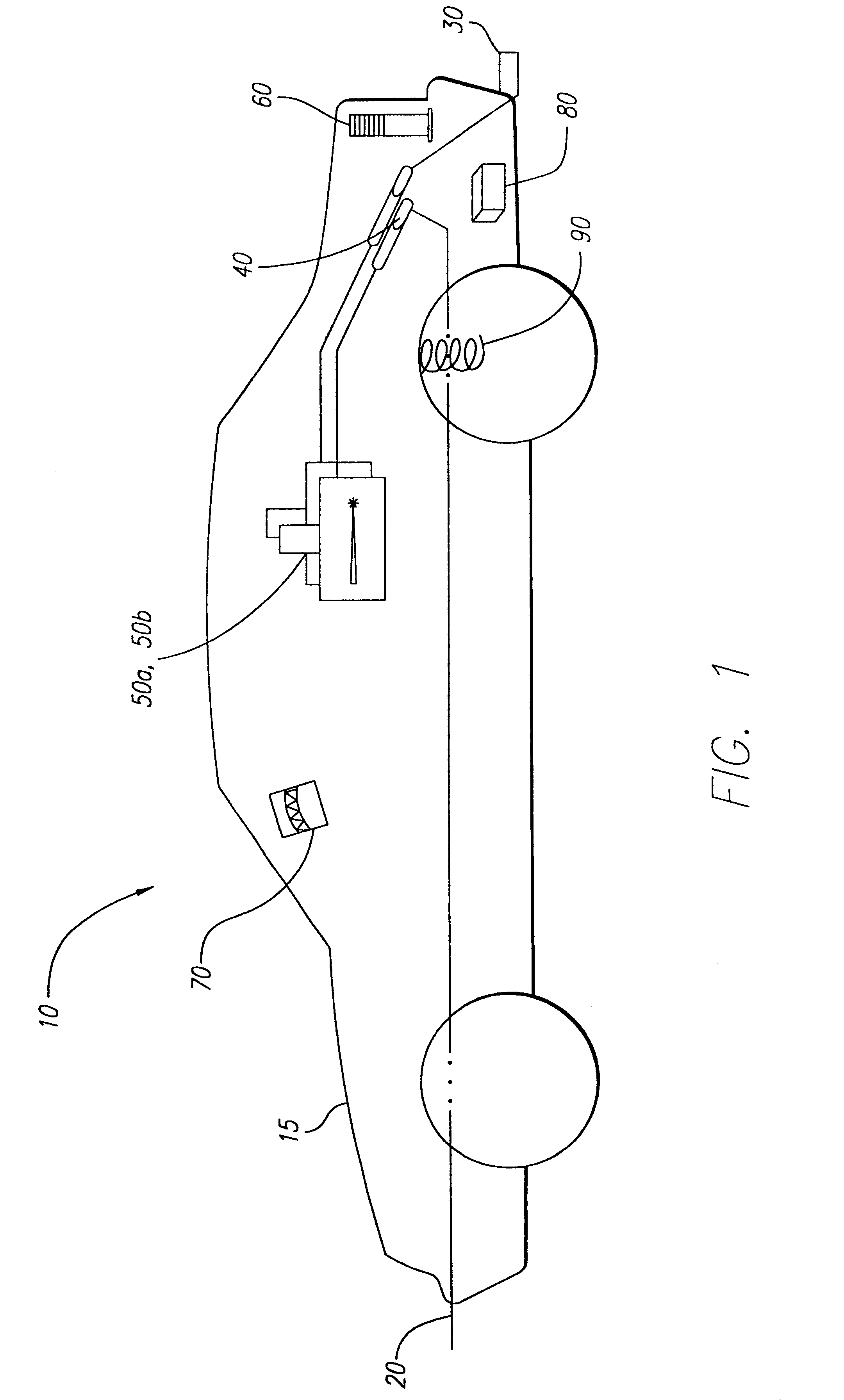

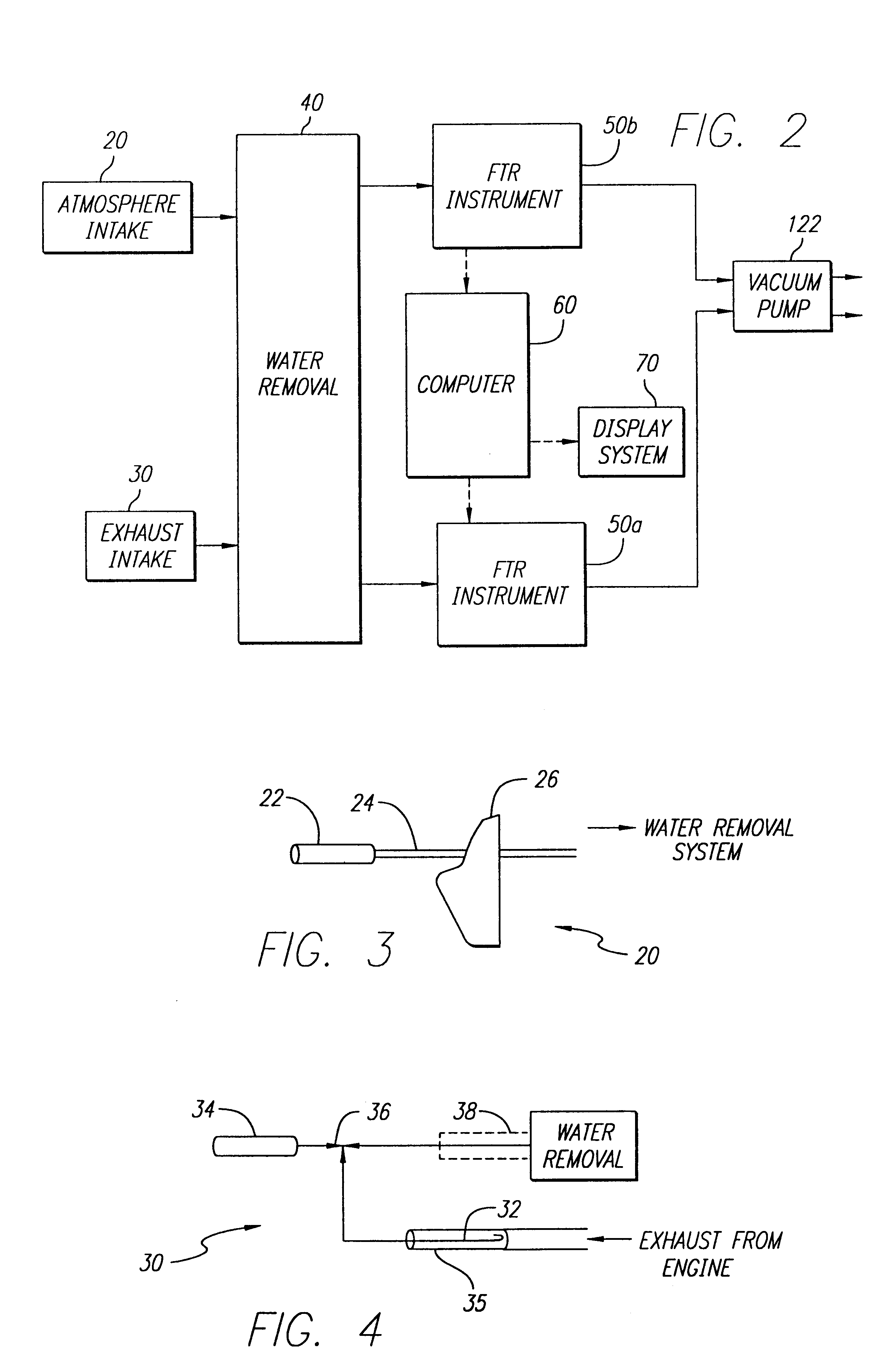

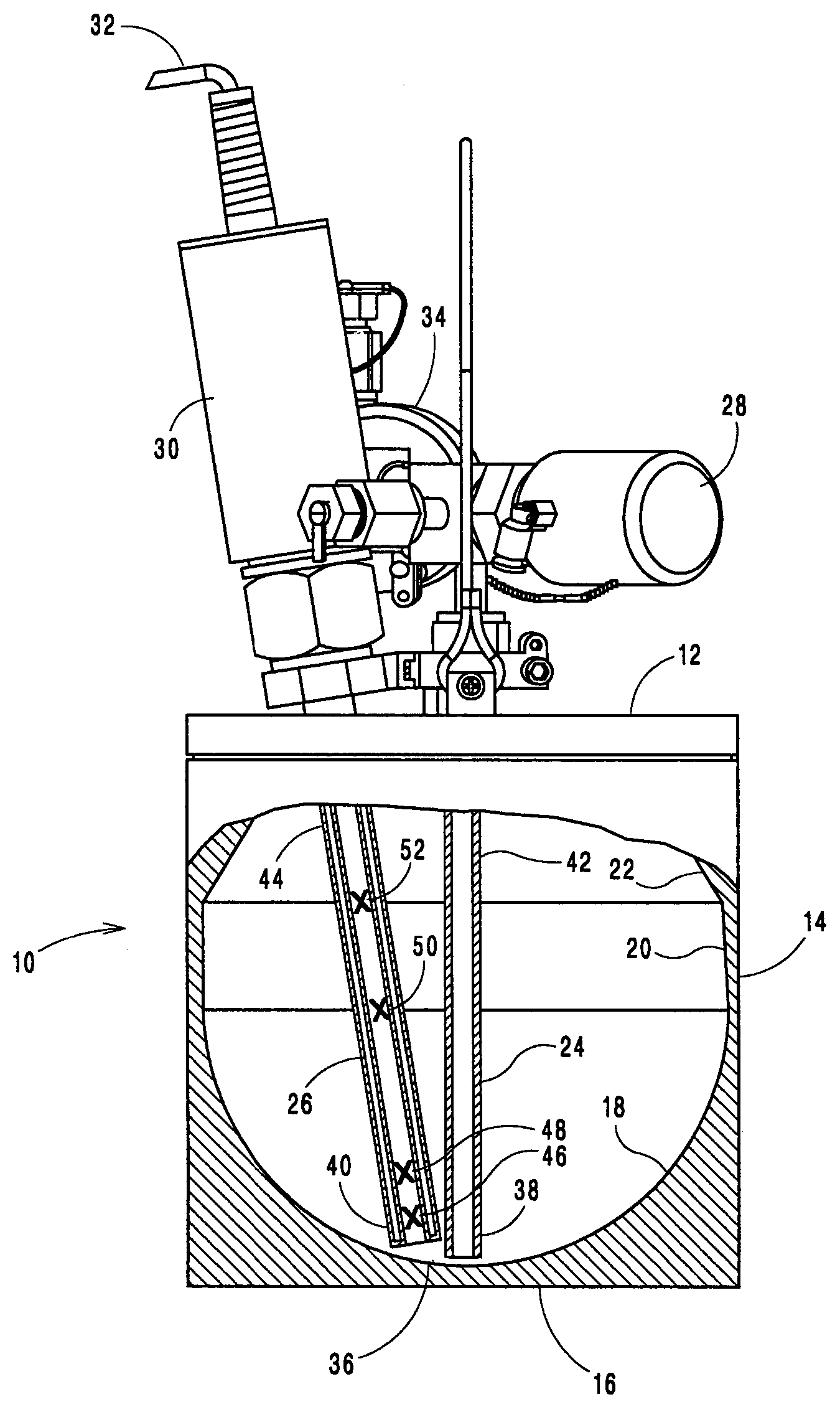

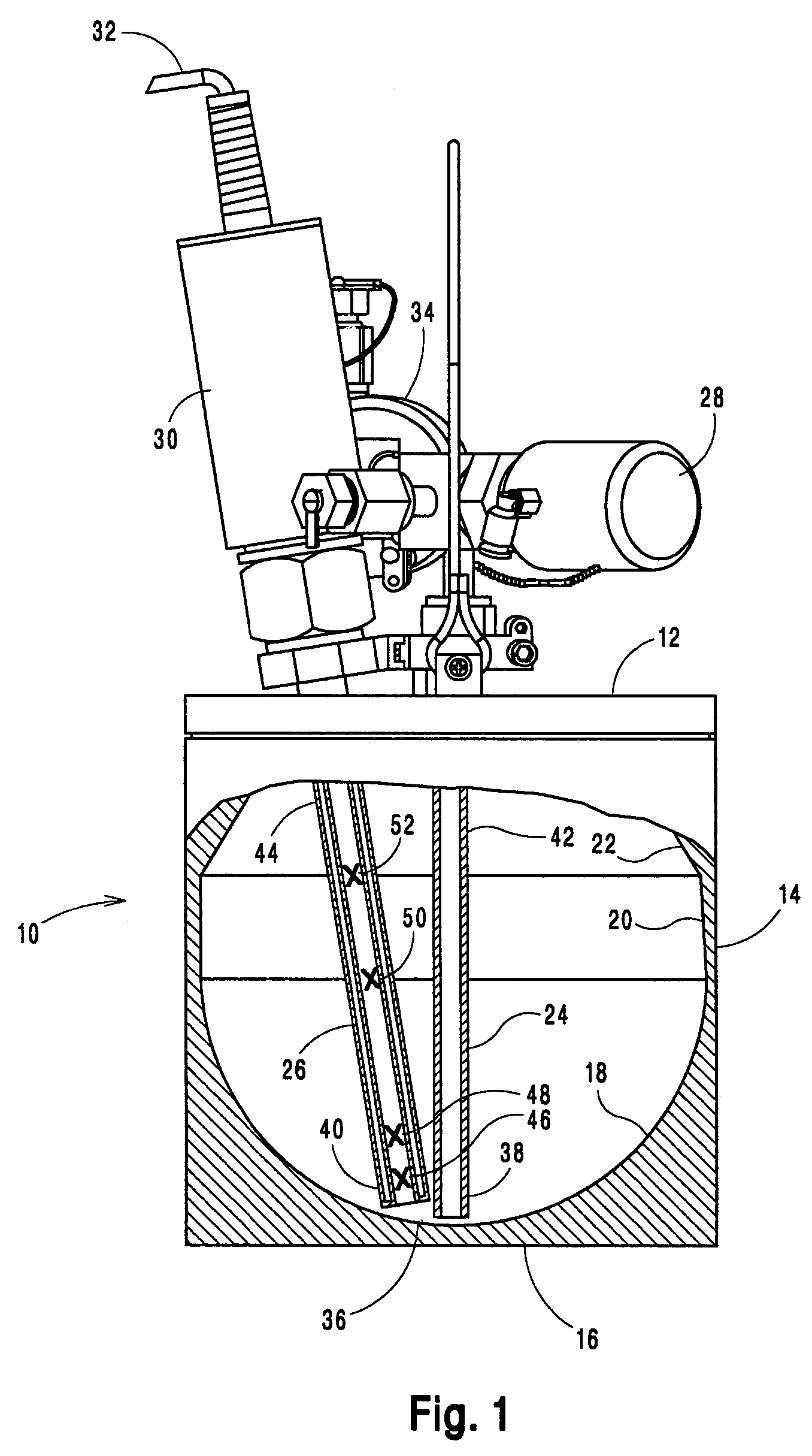

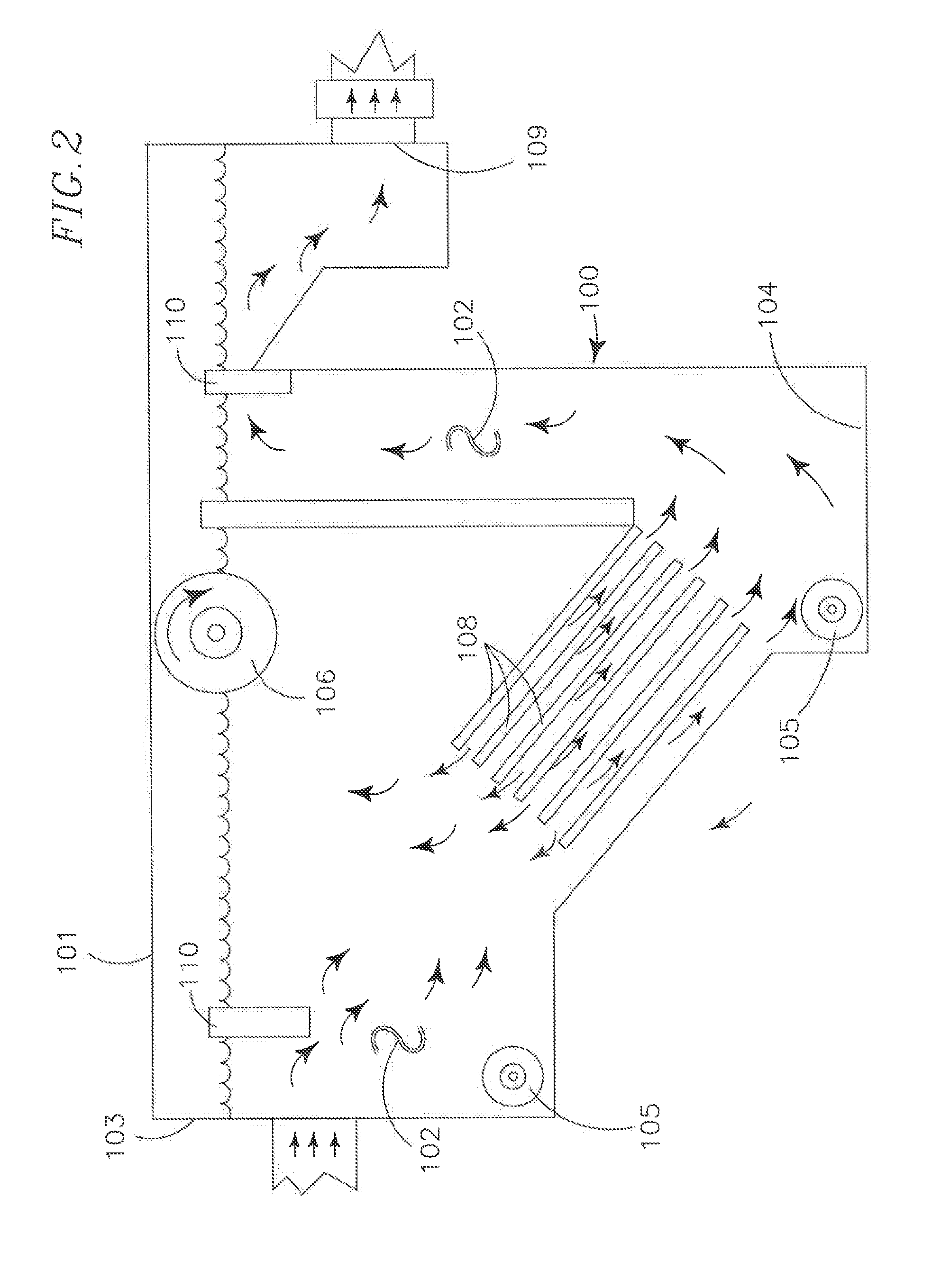

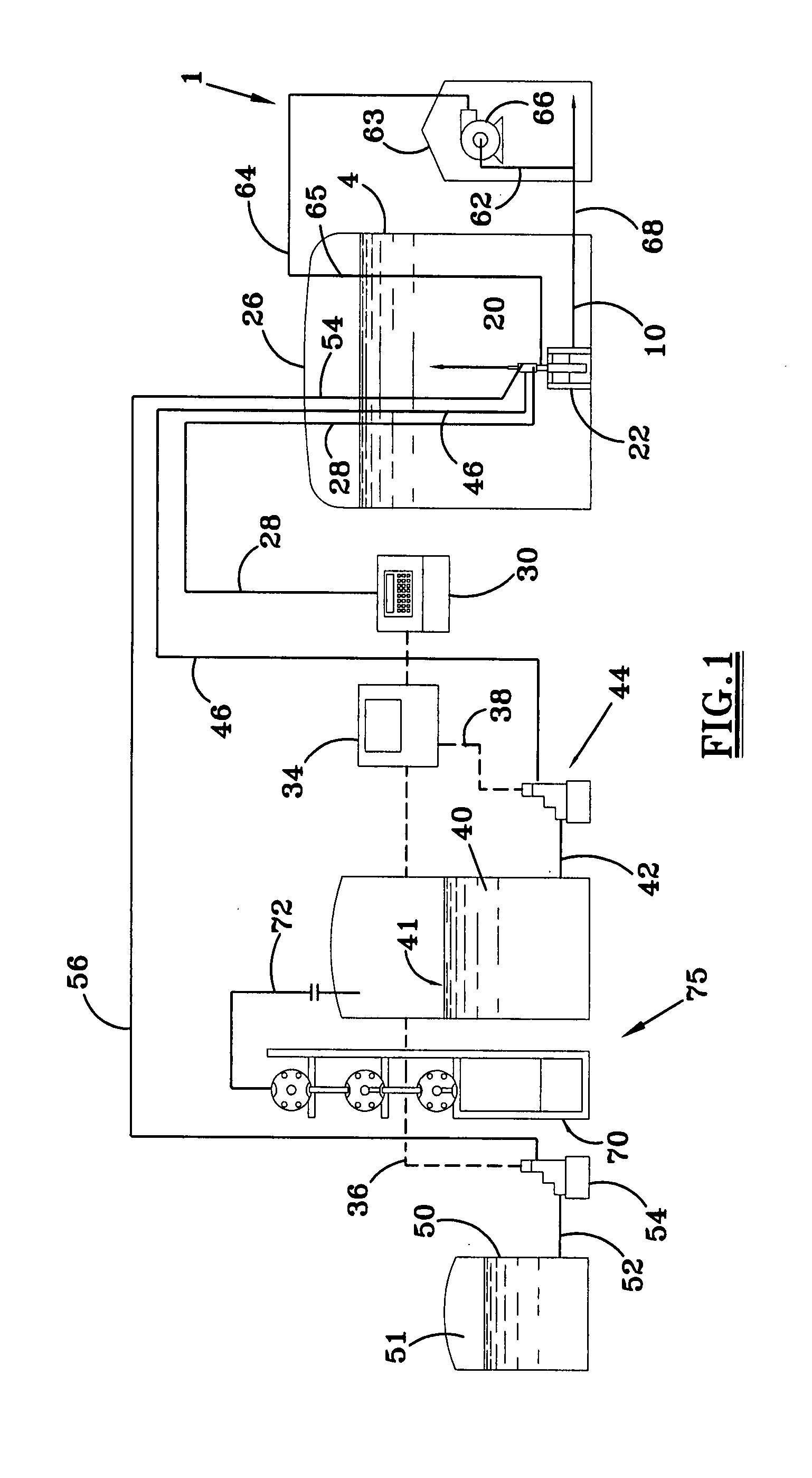

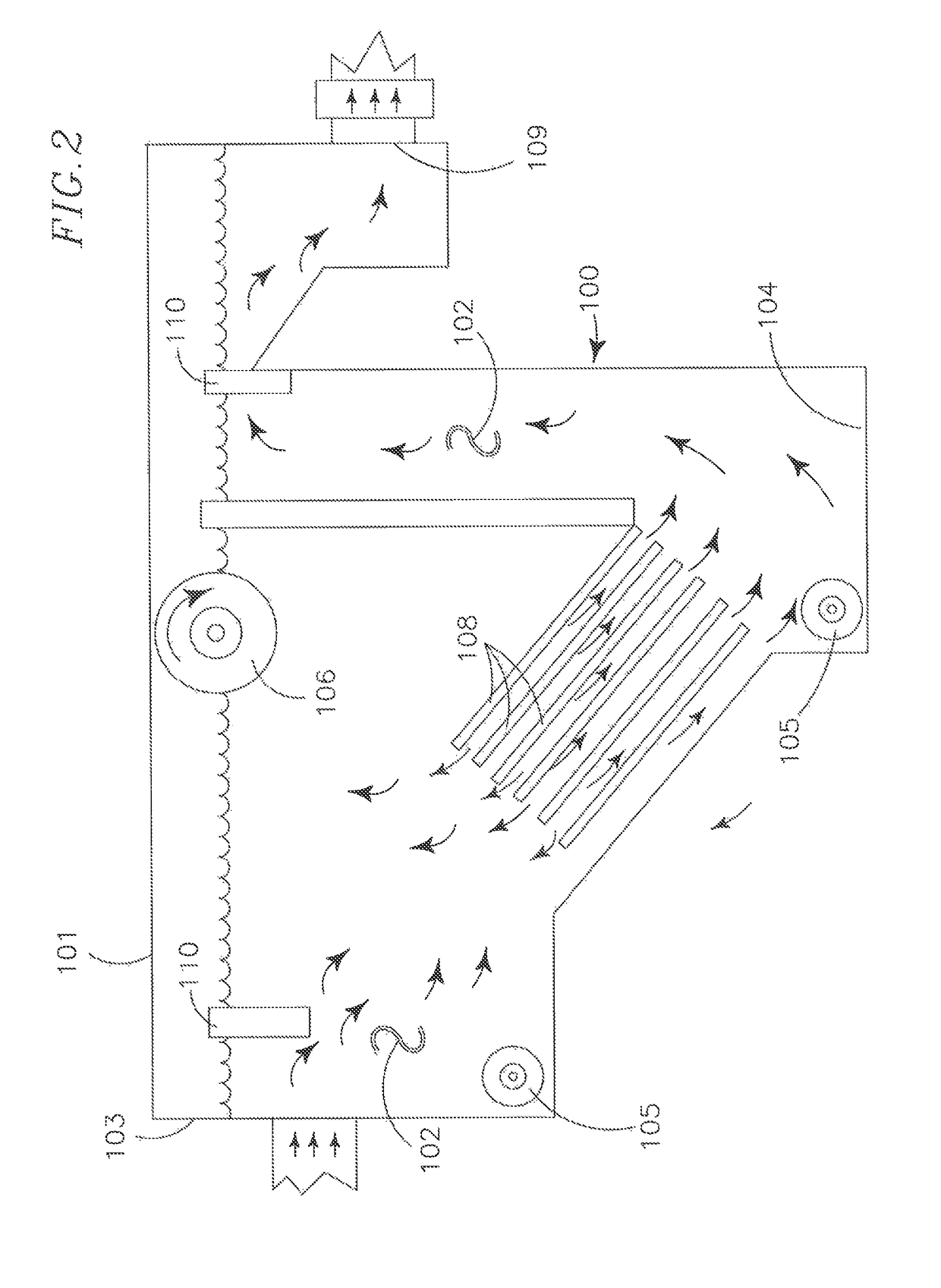

System for vehicle emission sampling and measurement

InactiveUS6516656B1Improve drying efficiencyImprove efficiencyInternal-combustion engine testingChemical compositionEngineering

An improved emission sampling and measurement system is provided for continuously sampling and analyzing the chemical content of a vehicle emissions and the ambient air for data evaluation and comparison. The emission sampling and measurement system comprises a vehicle having an emissions source, devices for intaking vehicle emissions and ambient air, and analysis devices for determining the chemical content of the emissions and ambient air. The gas streams may be dried in a series of selectively permeable drying tubes prior to measurement in the analysis devices, in order to effectuate a more precise sample of the constituent elements of the gases. Following analysis, the data collected is processed, stored, and compared, and the results displayed on a screen in the vehicle driver's compartment in a real-time manner. In this fashion, real-time comparative data analysis is presented in a format not presently available.

Owner:HONDA MOTOR CO LTD

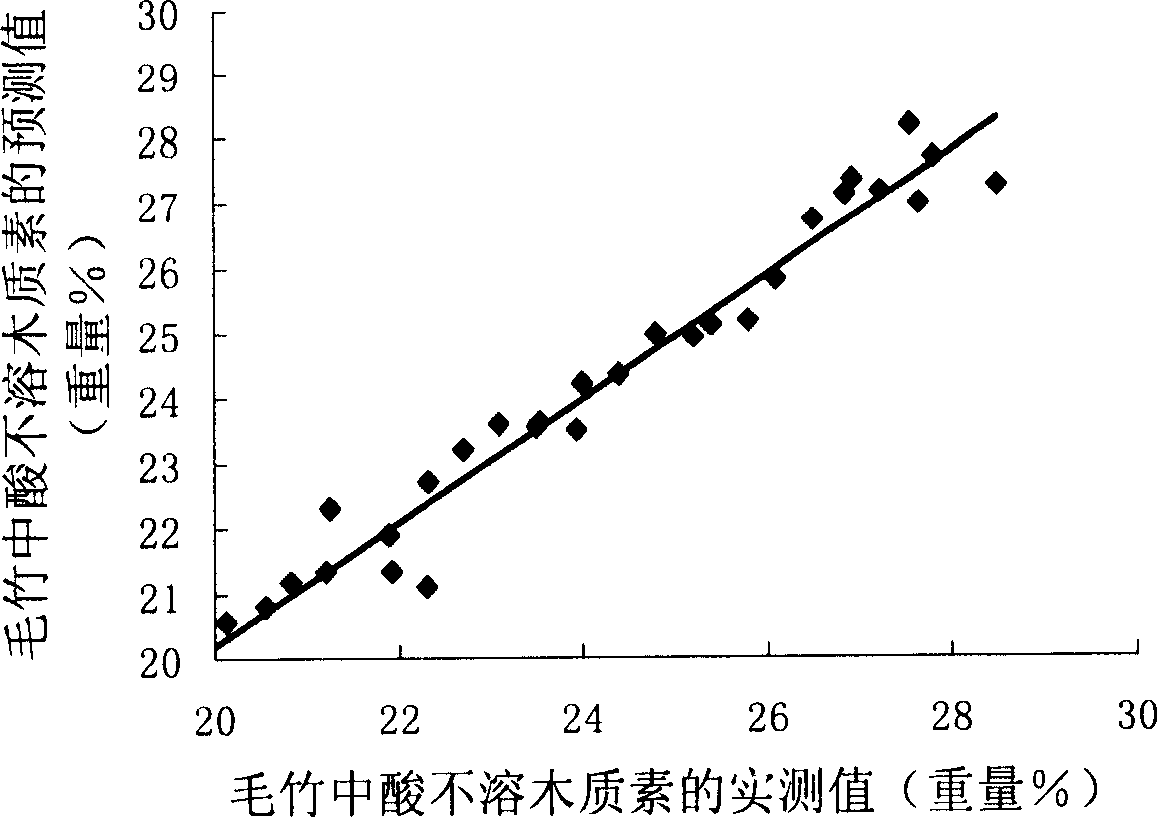

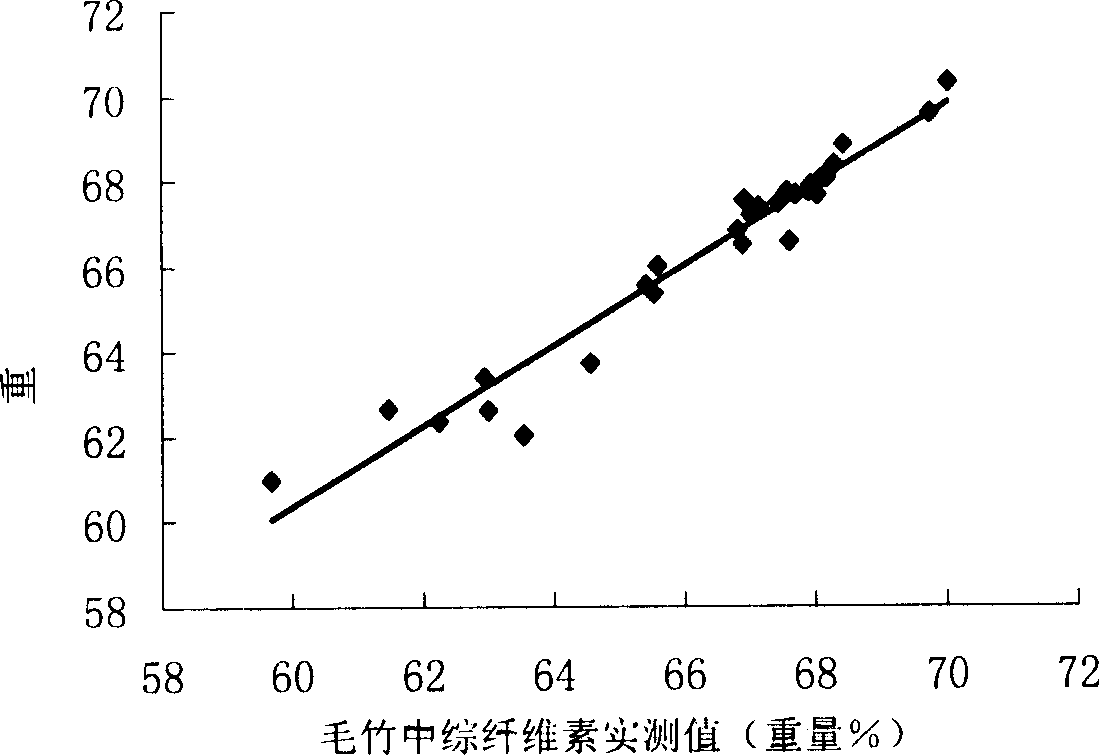

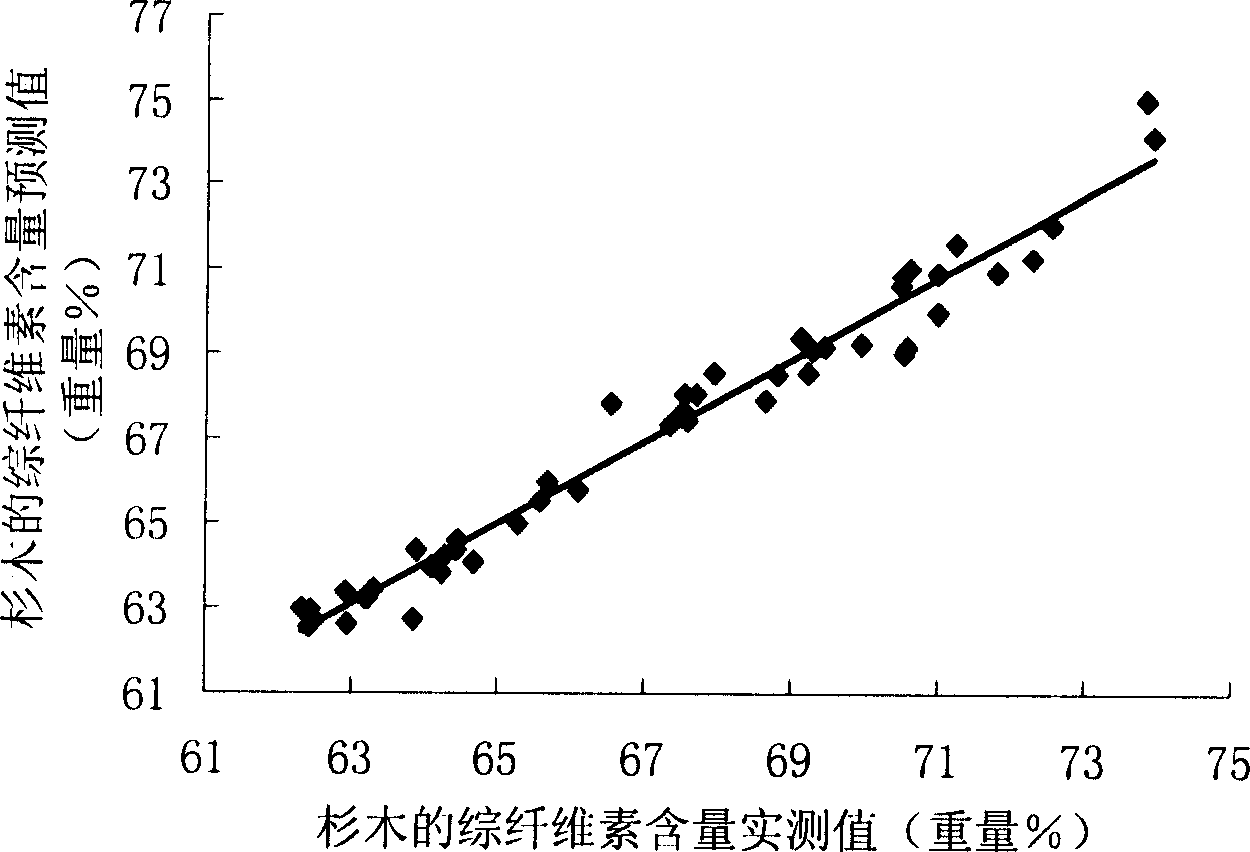

Establishment of chemical composition content model in plant fiber material and content determining method

InactiveCN1888860AReduce the amount of field collectionImprove accuracyScattering properties measurementsColor/spectral properties measurementsFiberChemical composition

A former foundation method of chemistry component content to plant fibrin material gathers close infrared spectroscopic to plant fibrin material sample and sets up quantitative analysis former according the chemistry component content to the plant fibrin material sample based on the close infrared spectroscopic by adopting chemistry metrology method. A part of the said plant fibrin material sample is at least mixed plant fibrin material sample. The said mixed plant fibrin material sample is at least one of the mixtures of plant fibrin material sample with known chemistry component content. According the former establishing method

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Noninvasive detection of elements and/or chemicals in biological matter

InactiveUS20100185067A1Lower Level RequirementsEffectively canceling out the spectral response of the light source and the imagerRadiation pyrometrySpectrum investigationSpectral responseReference image

A method of detecting oxygen and / or chemical content in a subject, comprising generating at least one spectral image of the subject; generating at least one spectral image of a reference object; comparing spectrum from the subject image to the reference image to thereby reveal the relative oxygen content of the subject. A system for determining the level of oxygenation of the blood of a subject body part comprising: a hyperspectral image generator for generating a plurality of spectral images; an image capture device for capturing the spectral images; a processor for generating hyperspectral image cubes such that the spectrum of the body part is extracted and normalized using the spectrum from the reference object to cancel out the spectral response of the light source and the imager; said processor comparing spectral from a subject image to reference images to thereby reveal the relative oxygen content of the subject.

Owner:ARMY US SEC THE THE

Washing-free continuous dyeing method of terylene fabric with disperse dyes

The invention relates to a washing-free continuous dyeing method for polyester fabrics with disperse dyes. The invention mixes disperse dyes, surfactants and water and grinds them uniformly to obtain disperse dye slurry; then dilutes with water, and adds emulsified paste and Thickening agent to obtain liquid disperse dyes; add water to obtain disperse dye dyeing baths, padding polyester fabrics for dyeing, then drying, and then baking to fix the color, and finally drop the cloth to cool, and the dyeing is completed. The dyeing process of the invention is simple, the chemicals used are ecological and environment-friendly, the production efficiency is high, no dyeing waste water is discharged, energy is saved, and the invention has important practical significance for energy saving and emission reduction. The dye uptake rate of the dyed product obtained by the present invention is higher than 95%, the chemical content on the fabric is not more than 3%, the dyed fabric does not need to be washed, and the dry and wet rubbing fastness and staining fastness can reach 4-5 grades. The color fastness to fading is grade 5, meeting the quality requirements for textile dyeing.

Owner:DONGHUA UNIV

High purity chemical container with diptube and level sensor terminating in lowest most point of concave floor

ActiveUS7124913B2High purityLow costLiquid fillingLiquid flow controllersChemical compositionLevel sensor

A transportable container for high purity, high cost, liquid chemicals capable of maximizing dispensing of the liquid chemical content of the container at deviations from an upright position, comprising; a top wall, a side wall and a bottom wall, the bottom wall having an internal surface contacting liquid chemical with a concave upward contour having a lowest most point axially central to the container, an inlet, an outlet comprising a diptube through which the liquid chemical can be dispensed from said container with an outlet end adjacent the top surface and an inlet terminal end adjacent the lowest most point, a level sensor assembly having an output end adjacent the top surface and a terminal end adjacent the lowest most point; the diptube and the level sensor assembly being more proximate to one another at their terminal ends than their ends adjacent the top surface.

Owner:VERSUM MATERIALS US LLC

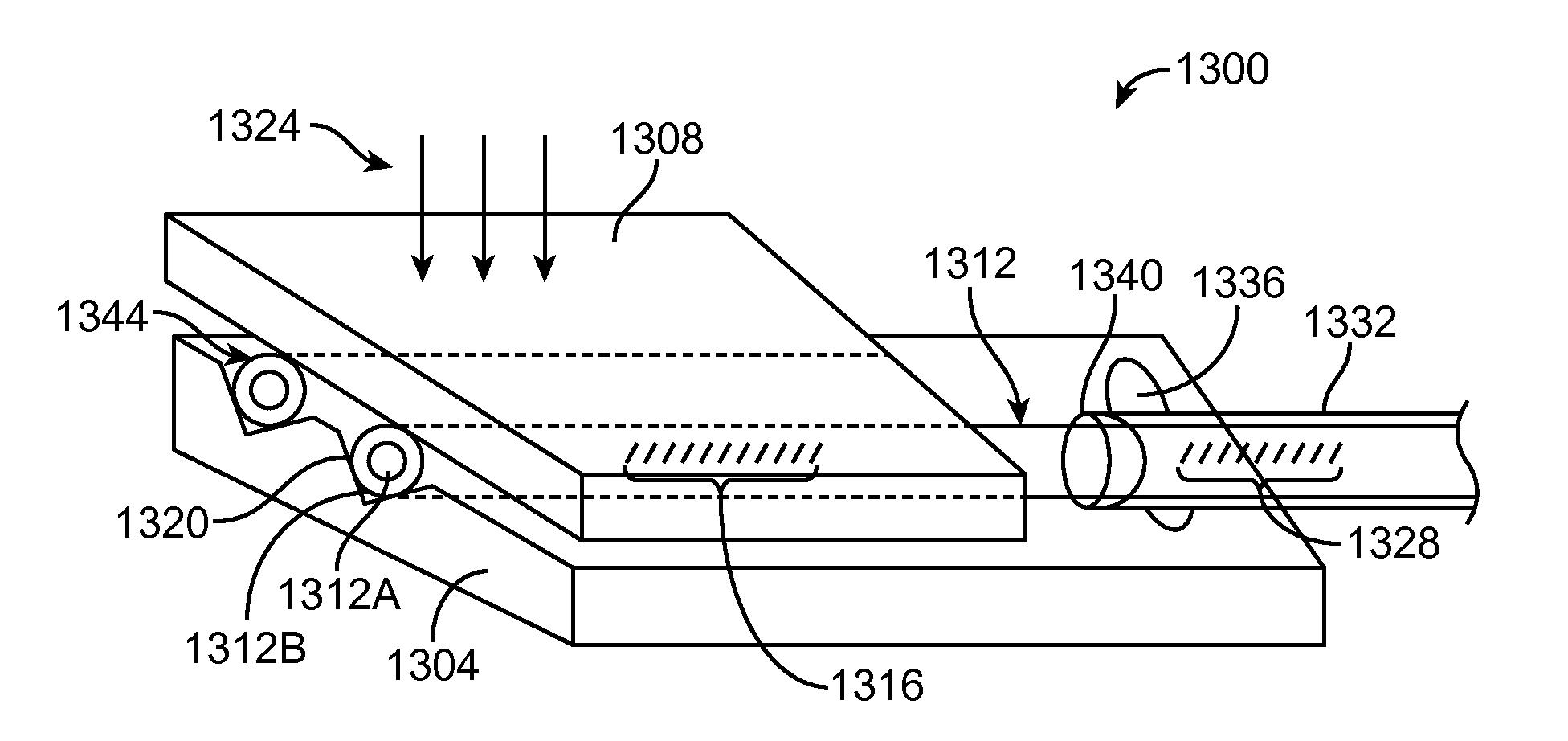

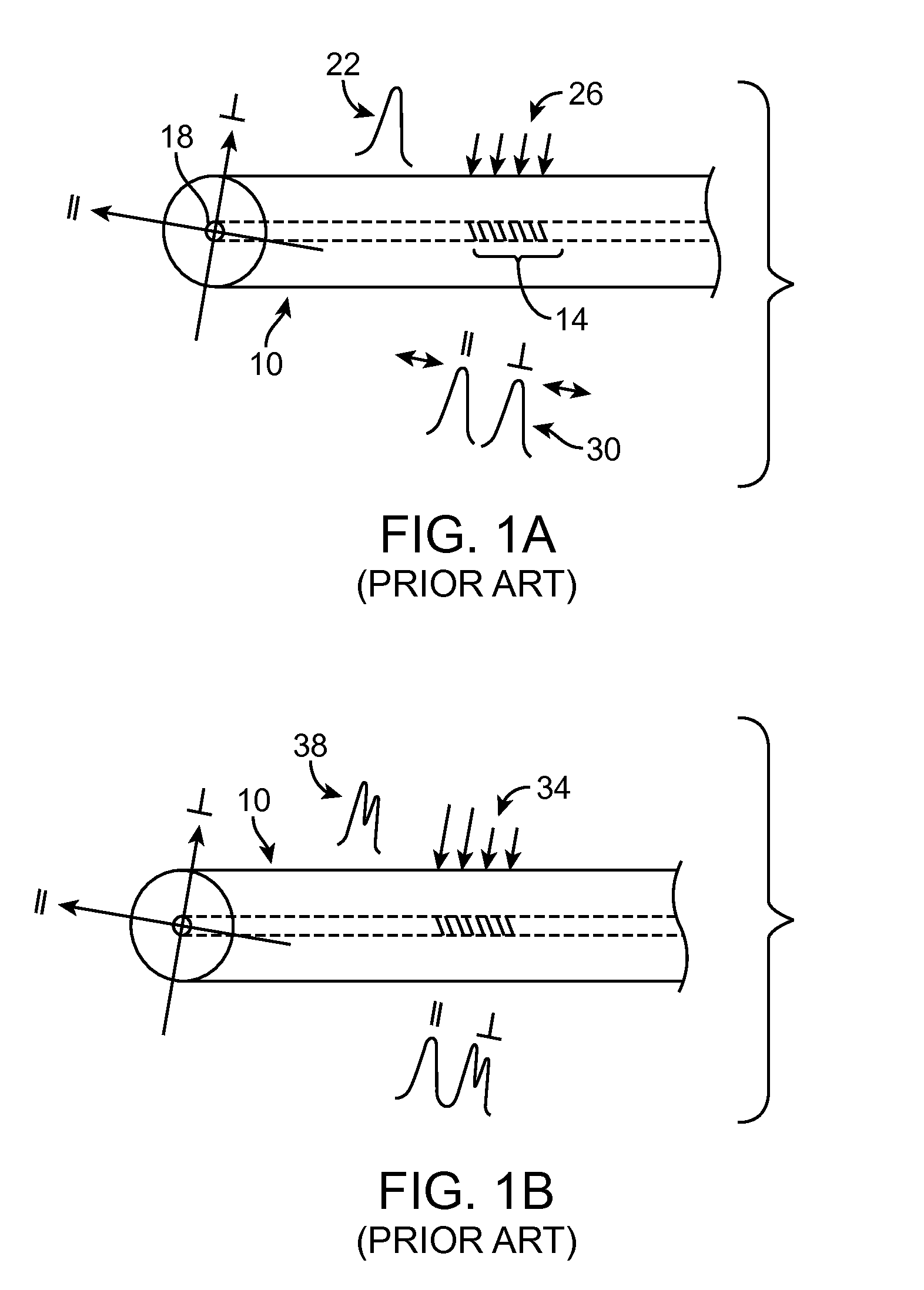

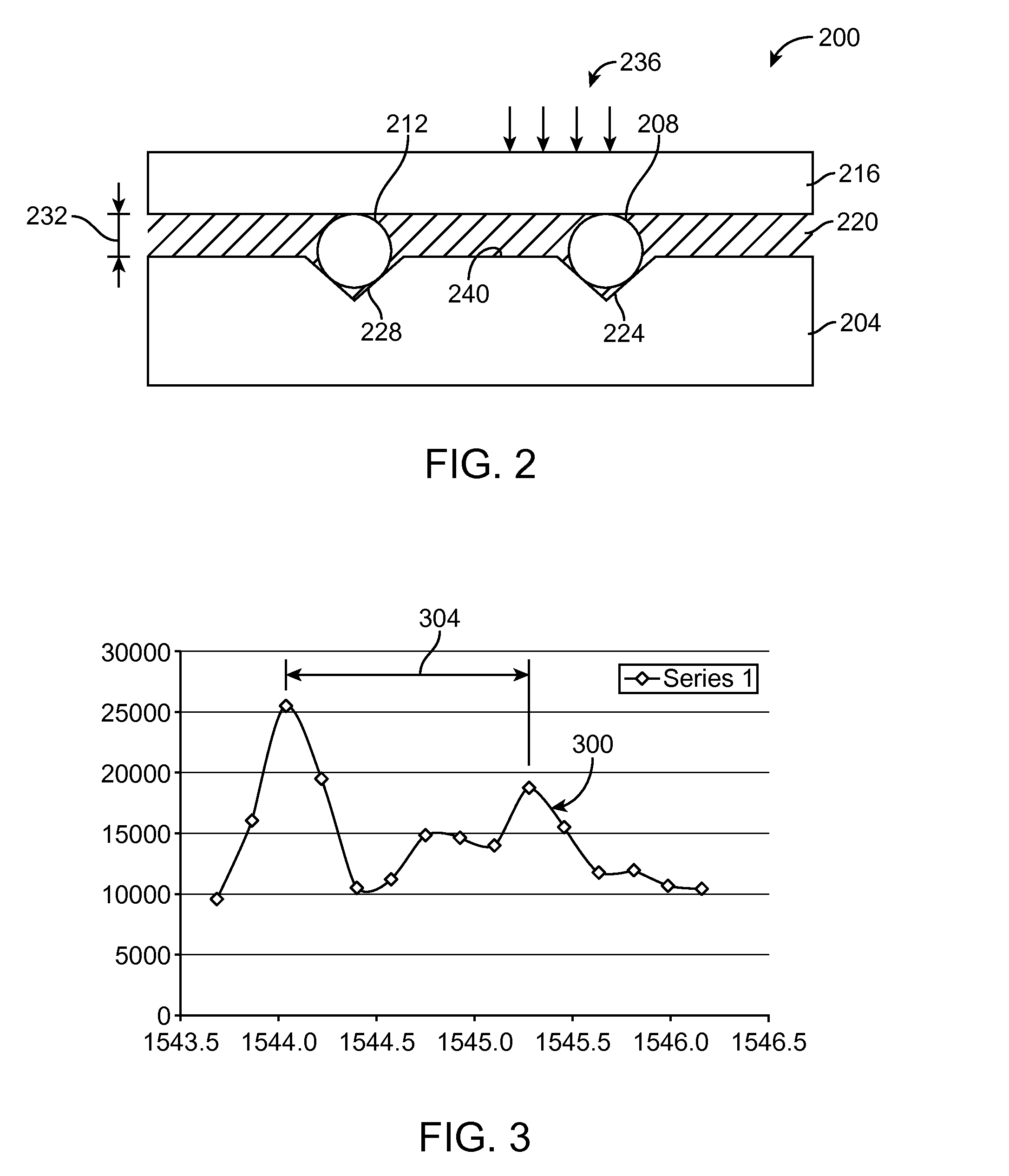

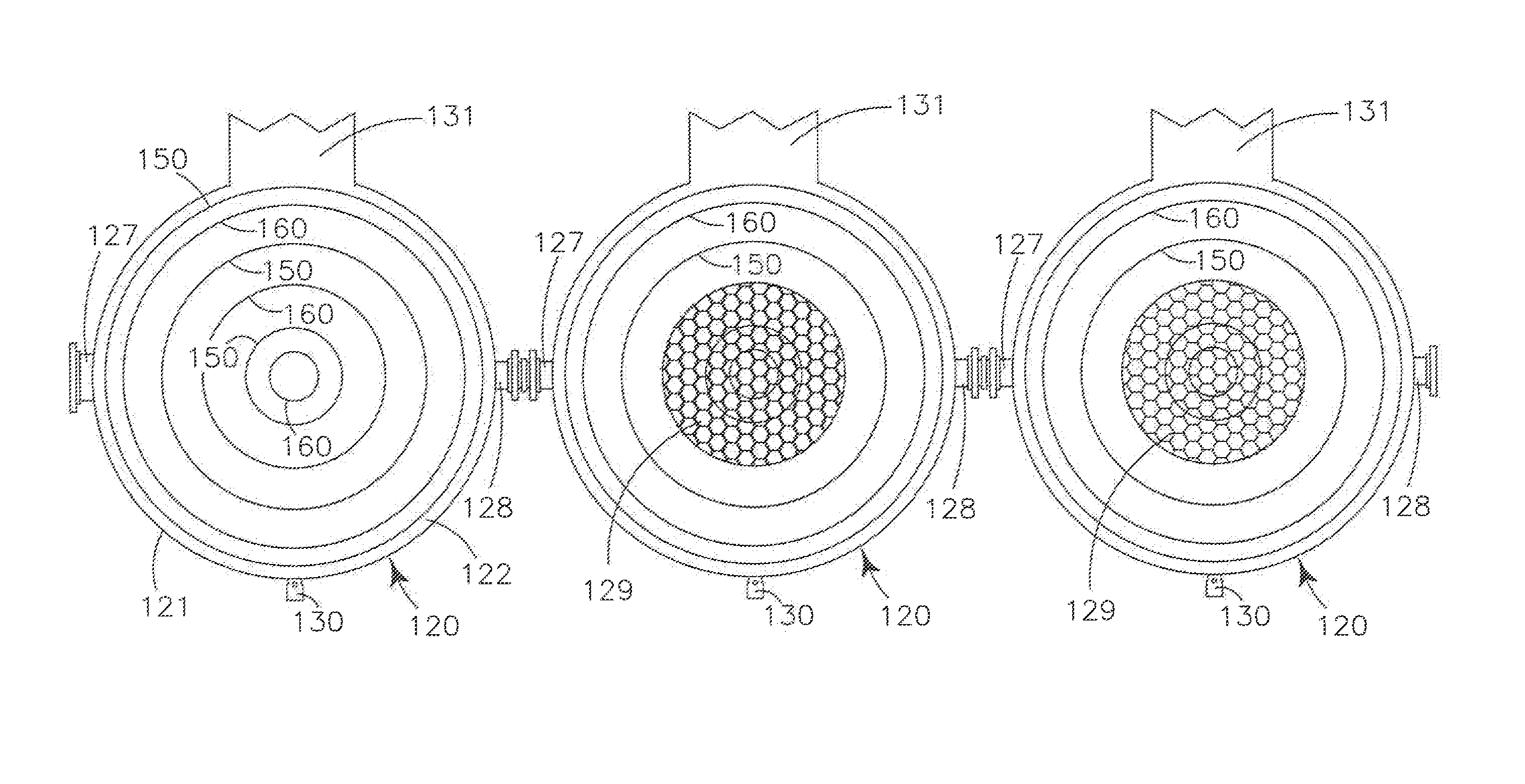

Fiber-Grating Sensors Having Longitudinal-Strain-Inducing Jackets and Sensor Systems and Structures Including Such Sensors

InactiveUS20140321799A1Increased tensile strainIncreases magnitudeForce measurement by measuring optical property variationConverting sensor outputFiberGrating

A sensor comprising an optical fiber that includes a Bragg grating and a longitudinal-strain-inducing (LSI) jacket for inducing longitudinal strain into the optical fiber as a function of a transverse load, i.e., pressure or force. As the LSI jacket induces strain into the optical fiber, the fiber grating deforms, thereby changing the character of light reflected from the grating. The changes in character of the reflected light can be measured using suitable optical instrumentation. Additional physical characteristics that can be measured / sensed using an LSI-jacket-based sensor include moisture content / presence, chemical content / presence, and temperature. A transverse-load-sensing sensor can include transverse-load-applying structures that compress the LSI jacket under transverse load, causing the jacket to controllably elongate and thereby induce longitudinal strain into the optical fiber. Chemical and moisture LSI jackets can comprise materials that swell in the presence of the chemical or moisture.

Owner:WICOR HOLDING

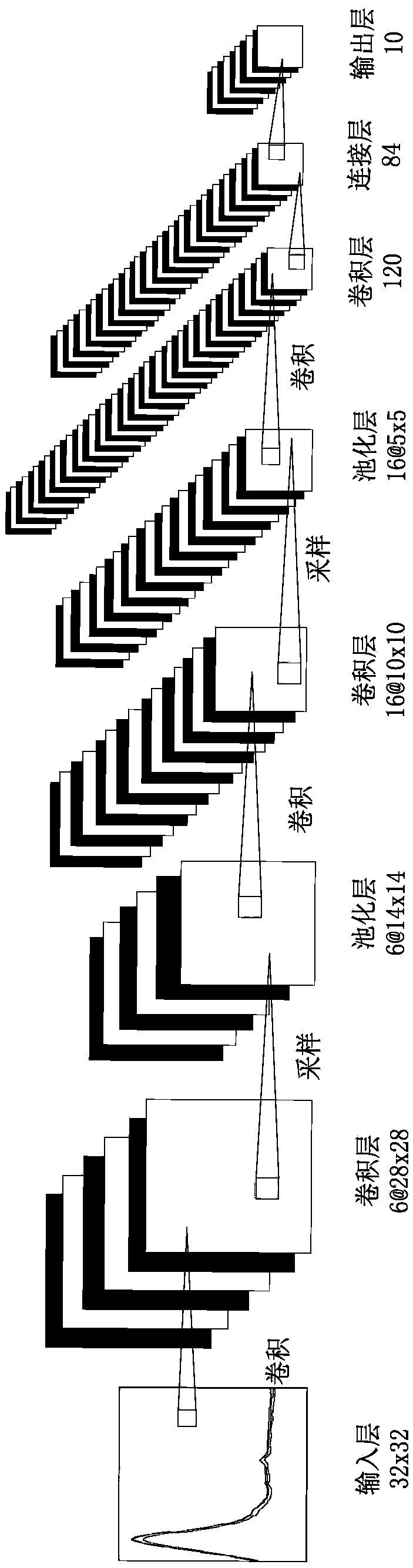

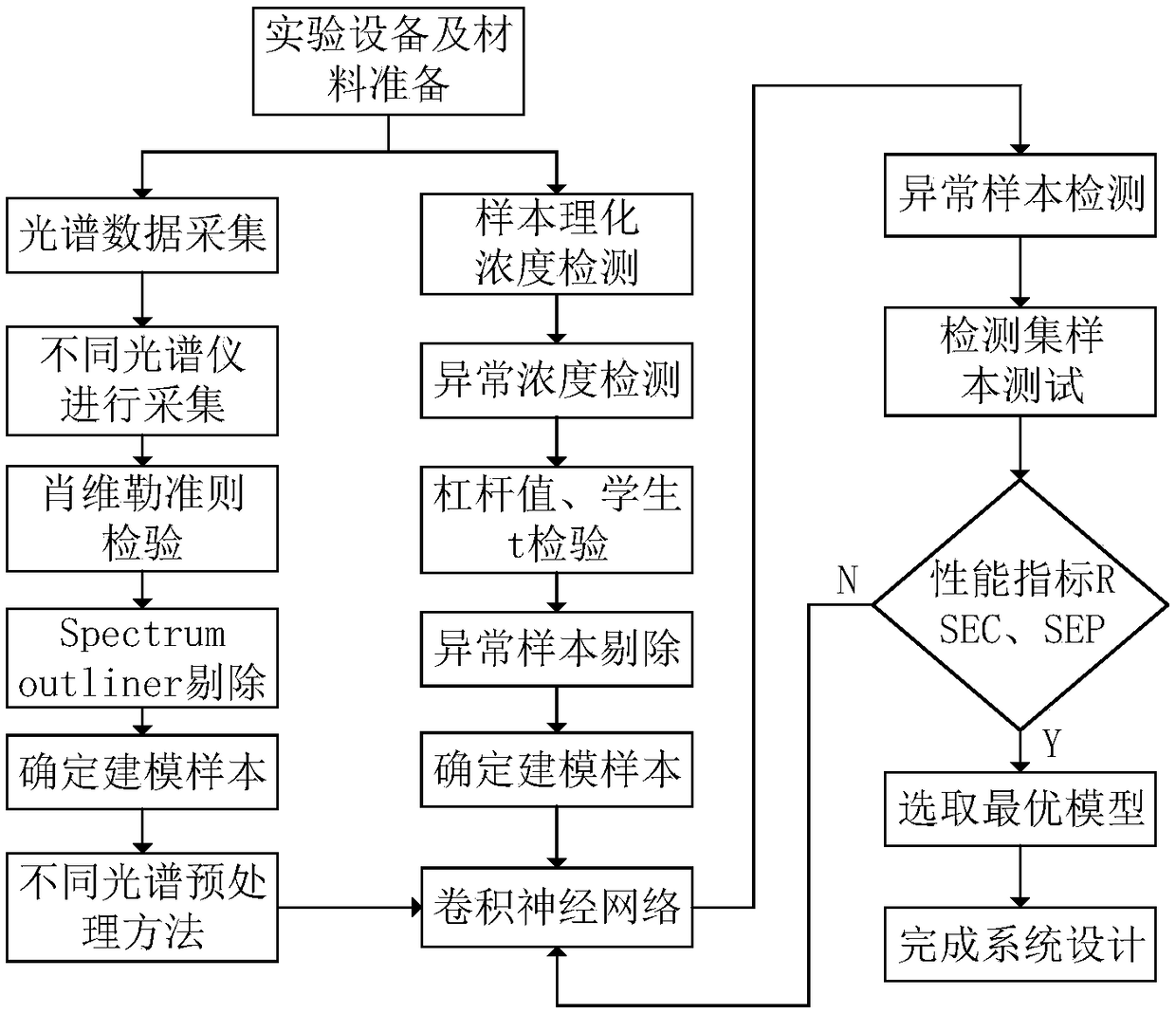

Tricholoma matsutake fast nondestructive testing system and method based on convolutional neural network

ActiveCN108875913ASmall amount of calculationGuaranteed accuracyMaterial analysis by optical meansNeural architecturesTricholoma matsutakeData acquisition

The invention discloses a tricholoma matsutake fast nondestructive testing system and method based on a convolutional neural network. The system comprises a deep learning convolutional neural networkmodel, a control end and a consumer terminal; the deep learning convolutional neural network model comprises sample collection, data acquisition, and deep learning convolutional neural network modeling and optimization; in the sample collection, a sample set is established by finishing sample screening of a detection object, and the sample set is divided into a training set, a verification set anda test set; the data acquisition comprises sample chemical content measurement and spectral data acquisition; in the deep learning convolutional neural network modeling and optimization, preprocessedspectral data and corresponding chemical content are modeled through the deep learning convolutional neural network model and pooling processing; a detection result of the tricholoma matsutake by thedeep learning convolutional neural network model is stored in the control end; and the consumer terminal can obtain detection data of the tricholoma matsutake by accessing the control end. Accordingto the tricholoma matsutake fast nondestructive testing system and method, the detection cost can be effectively reduced, and the market supervision of the supervision department can be facilitated.

Owner:JIANGSU UNIV

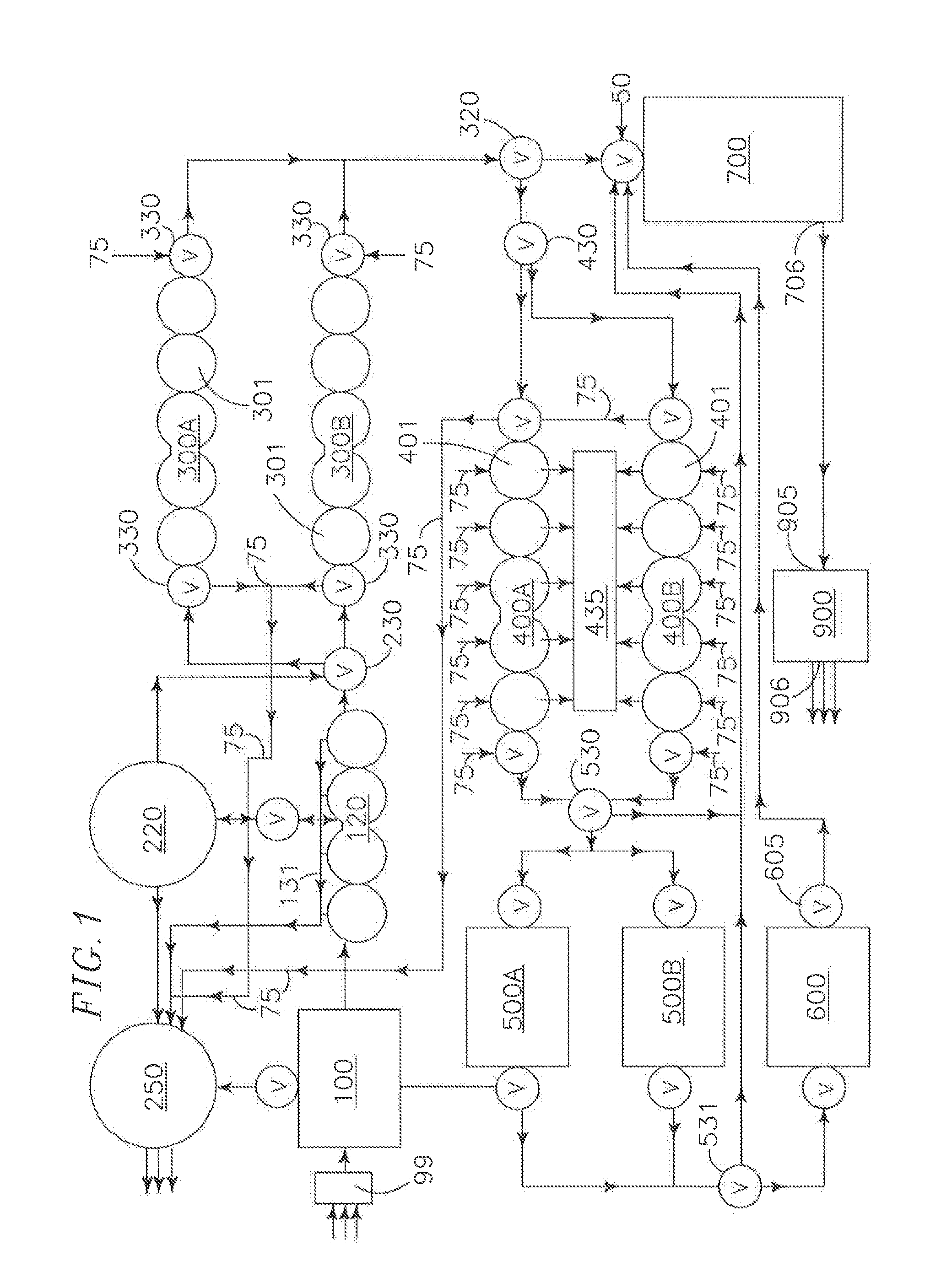

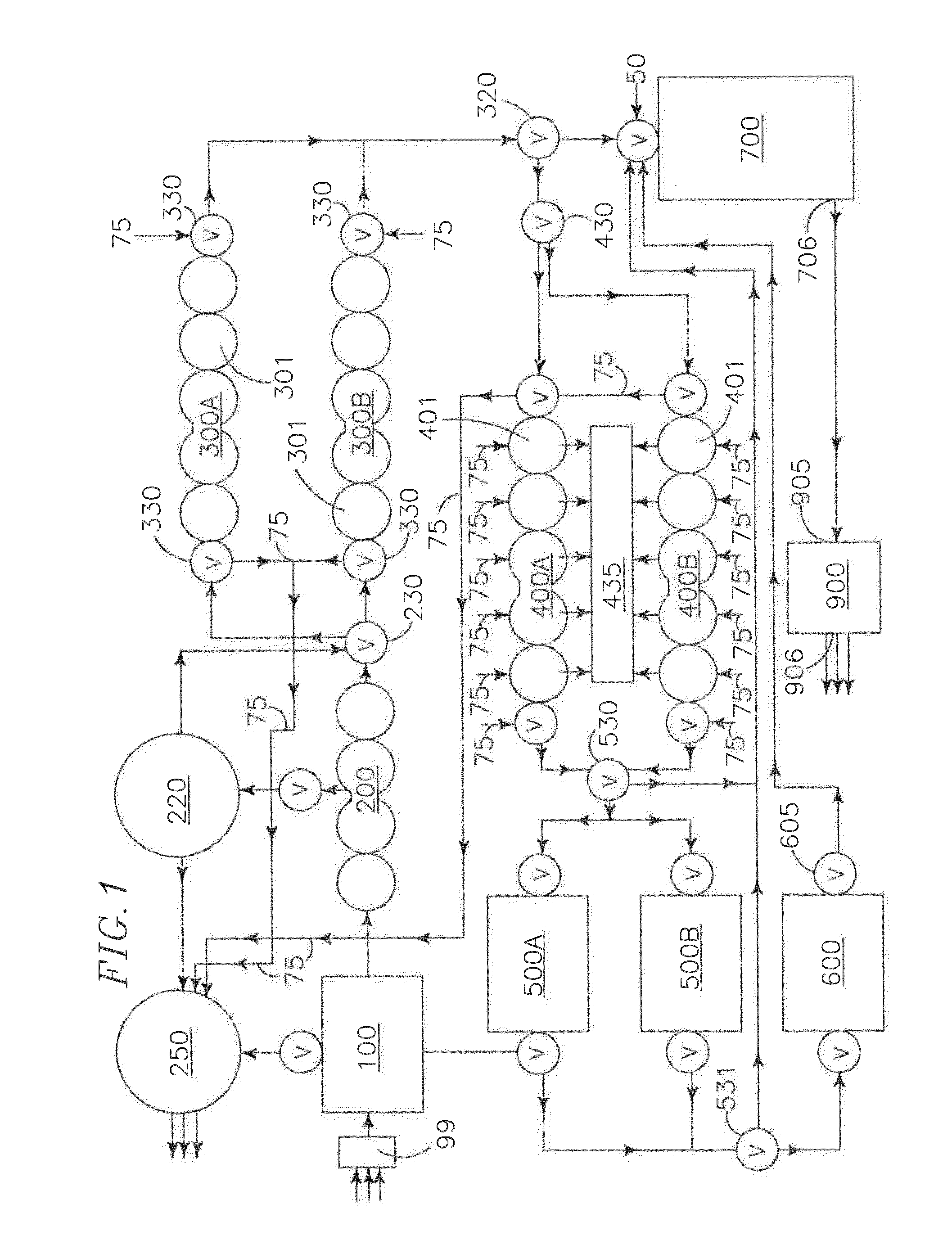

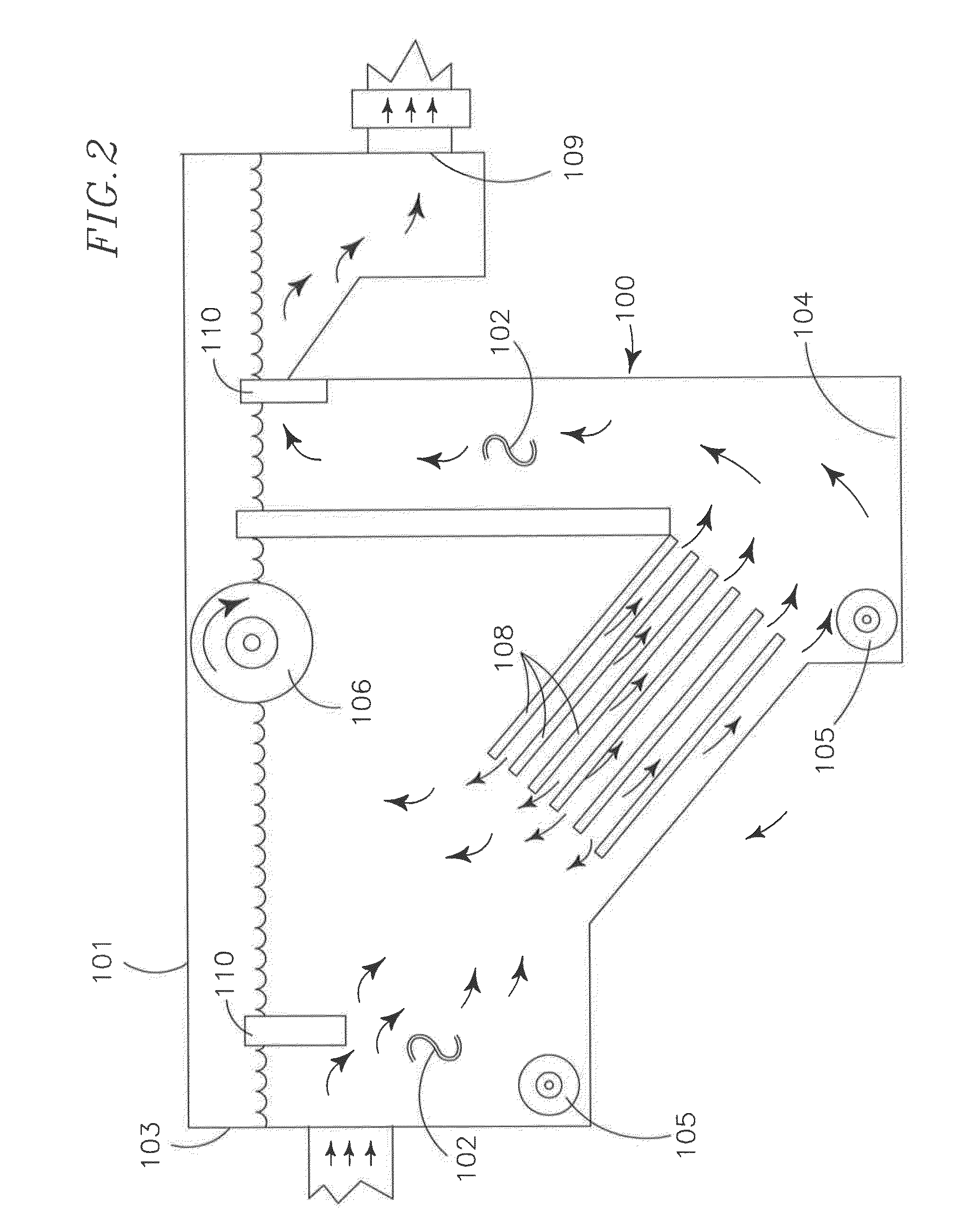

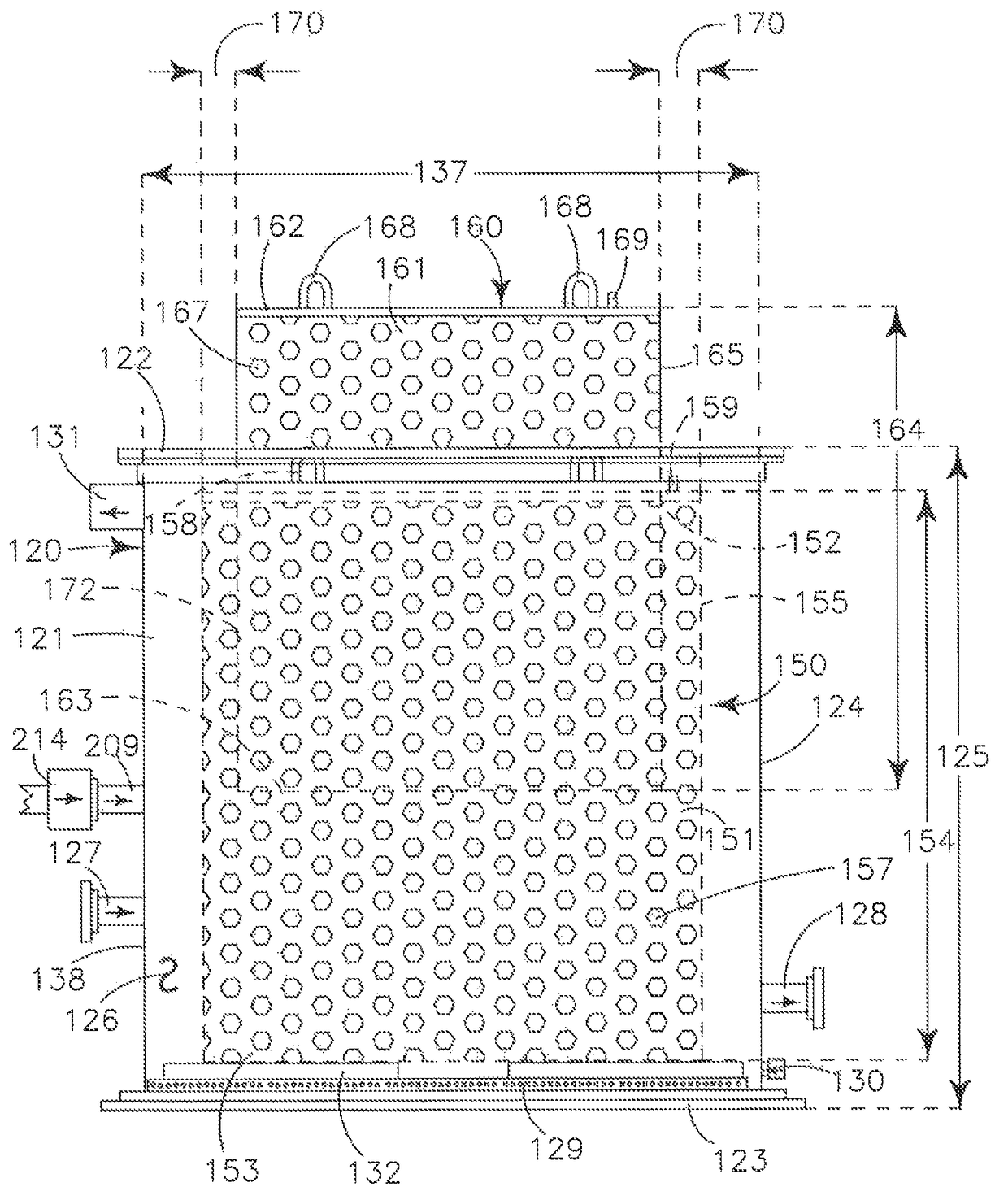

System for separating contaminents from fluids

ActiveUS20160280566A1Easy to separateEfficient precipitationWater treatment parameter controlSpecific water treatment objectivesParticulatesSensor array

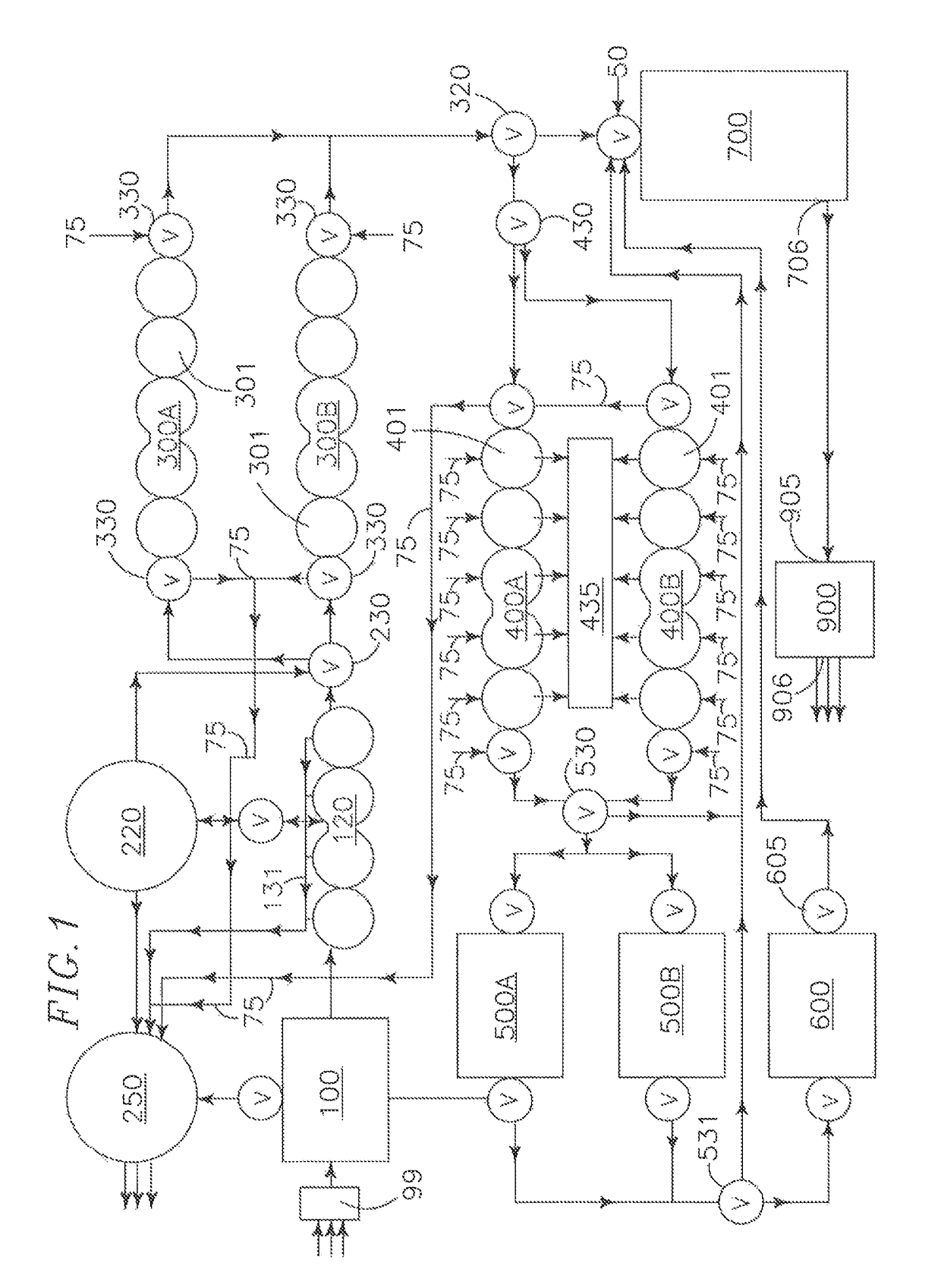

A system for separating contaminants from fluids provides a modular mobile continuously operable site configurable multi-phase filtering system having an oil water separator 100, a dwell tank 220, a waste tank 250, an electrocoagulator 120 having plural concentrically aligned perforated tubular sacrificial electrodes, a first and a parallel second particulate filter 300A, 300B, a first and parallel second step-down membrane filter 400A, 400B, an optional ultra filtration filter 500, an optional reverse osmosis filter 600, a mixing station 700 and a totalizer and sensor array 900 to analyze, filter and treat fluids by separating contaminants and particulates and adjusting chemical content to meet specifications desired which will allow the use and re-use of the filtered fluid and the separated contaminants.

Owner:ECO SQUARED SOLUTIONS

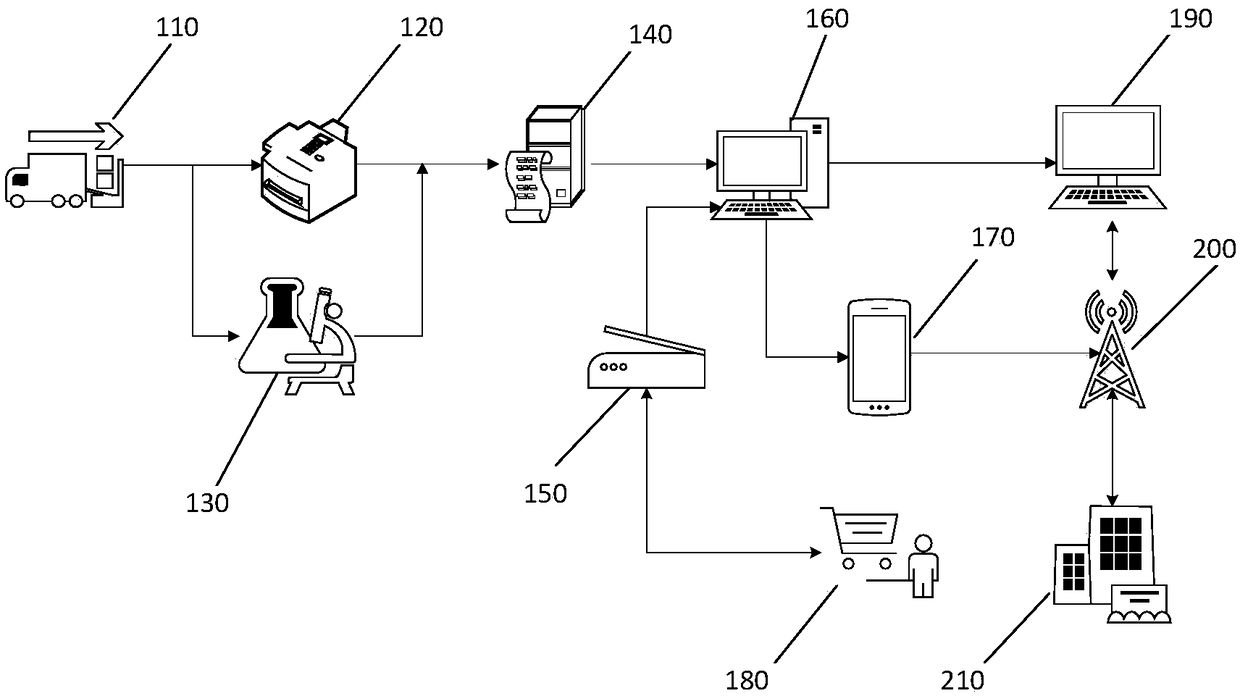

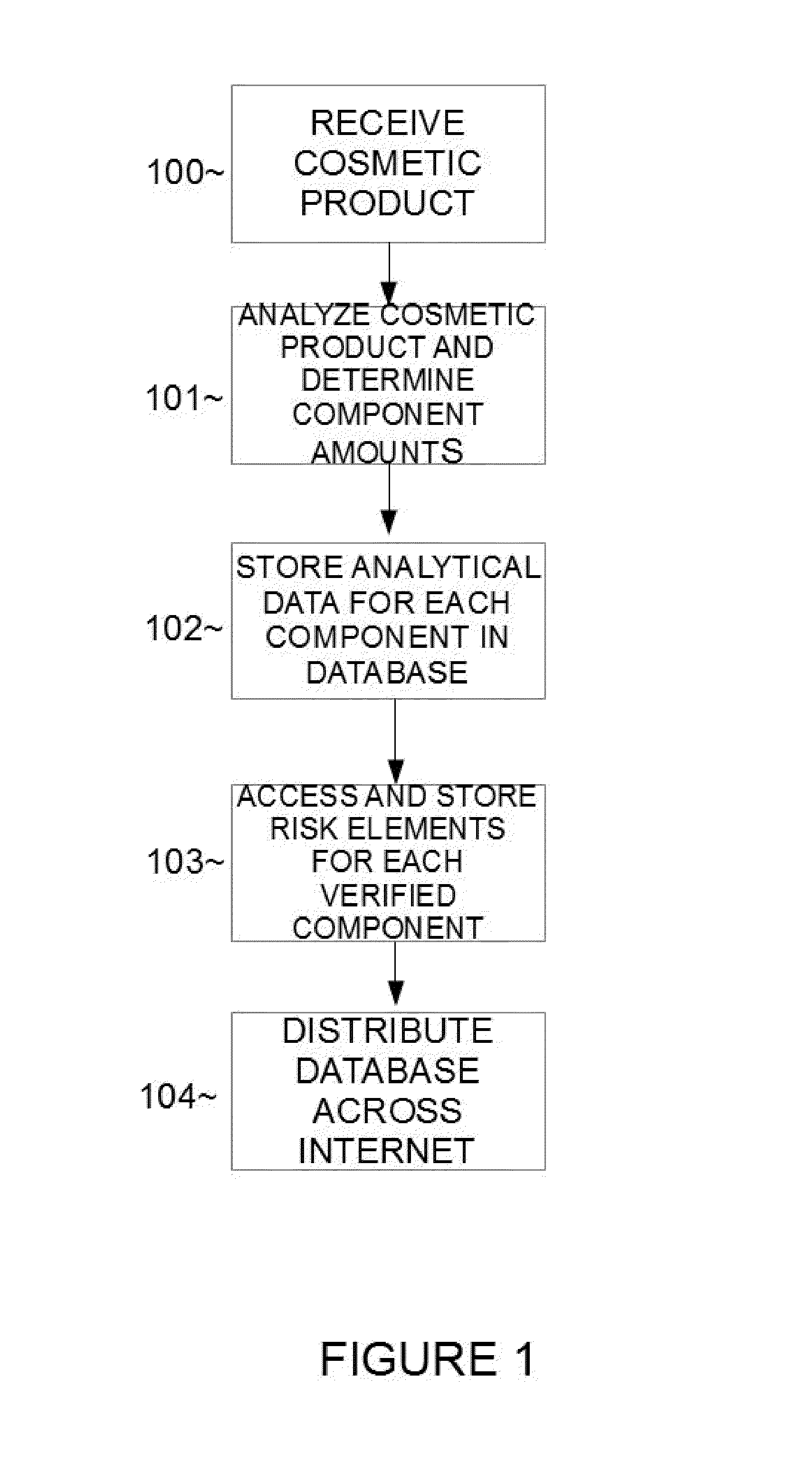

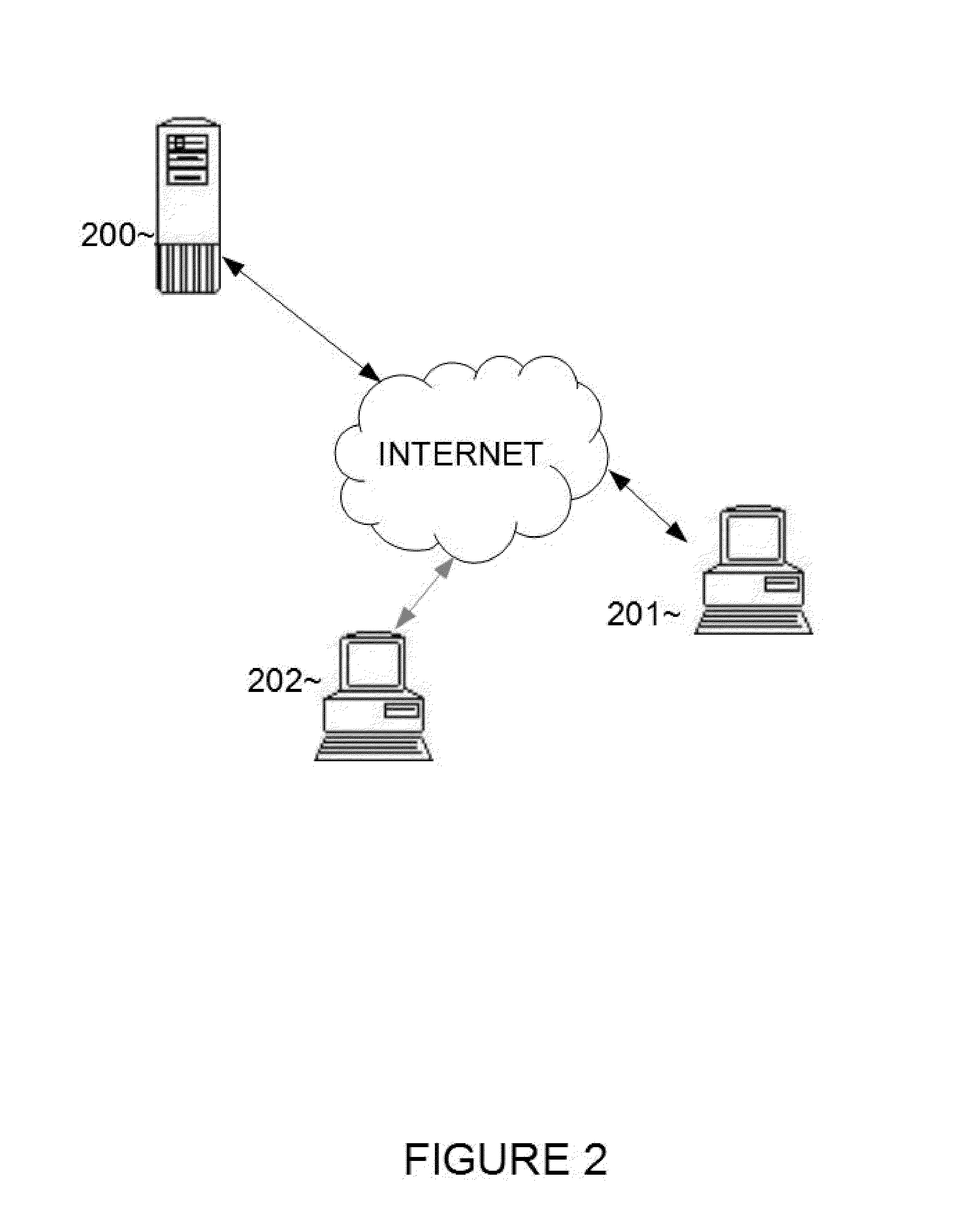

Method of analyzing and scoring cosmetic products

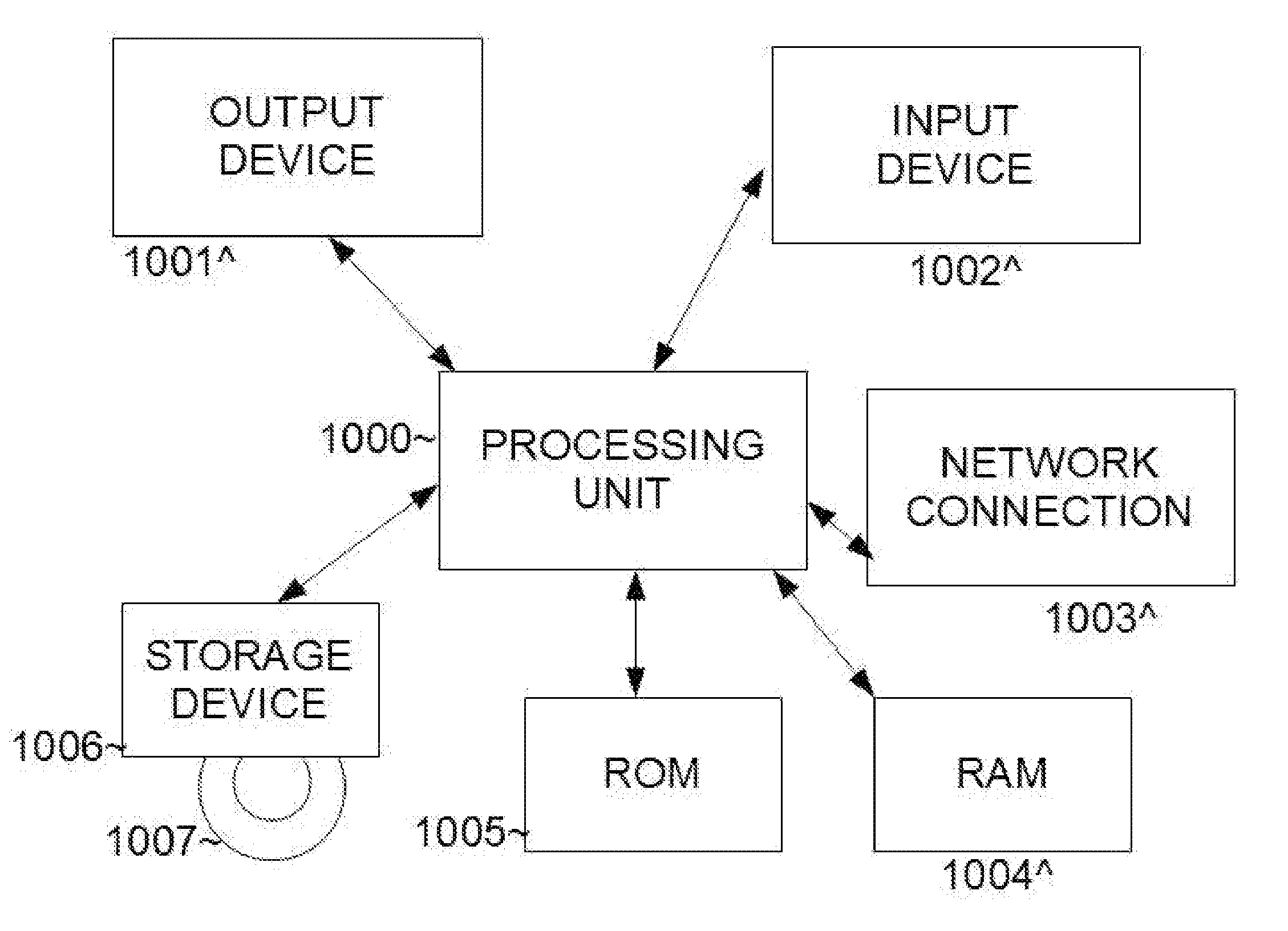

A method, apparatus, and computer readable storage medium to implement a cosmetic product data warehouse and rating system. Cosmetic products can be analyzed by a laboratory for their chemical contents and such data can be stored on a secure computer database. A certification authority can retrieve the contents and perform computations on them to determine a numerical score indicating a desirability of the cosmetic product in view of a particular condition. The scores can then be distributed publicly by placing them on labels on bottles of cosmetic products and / or distributed to shoppers on an electronic database.

Owner:HICKS KEVIN +1

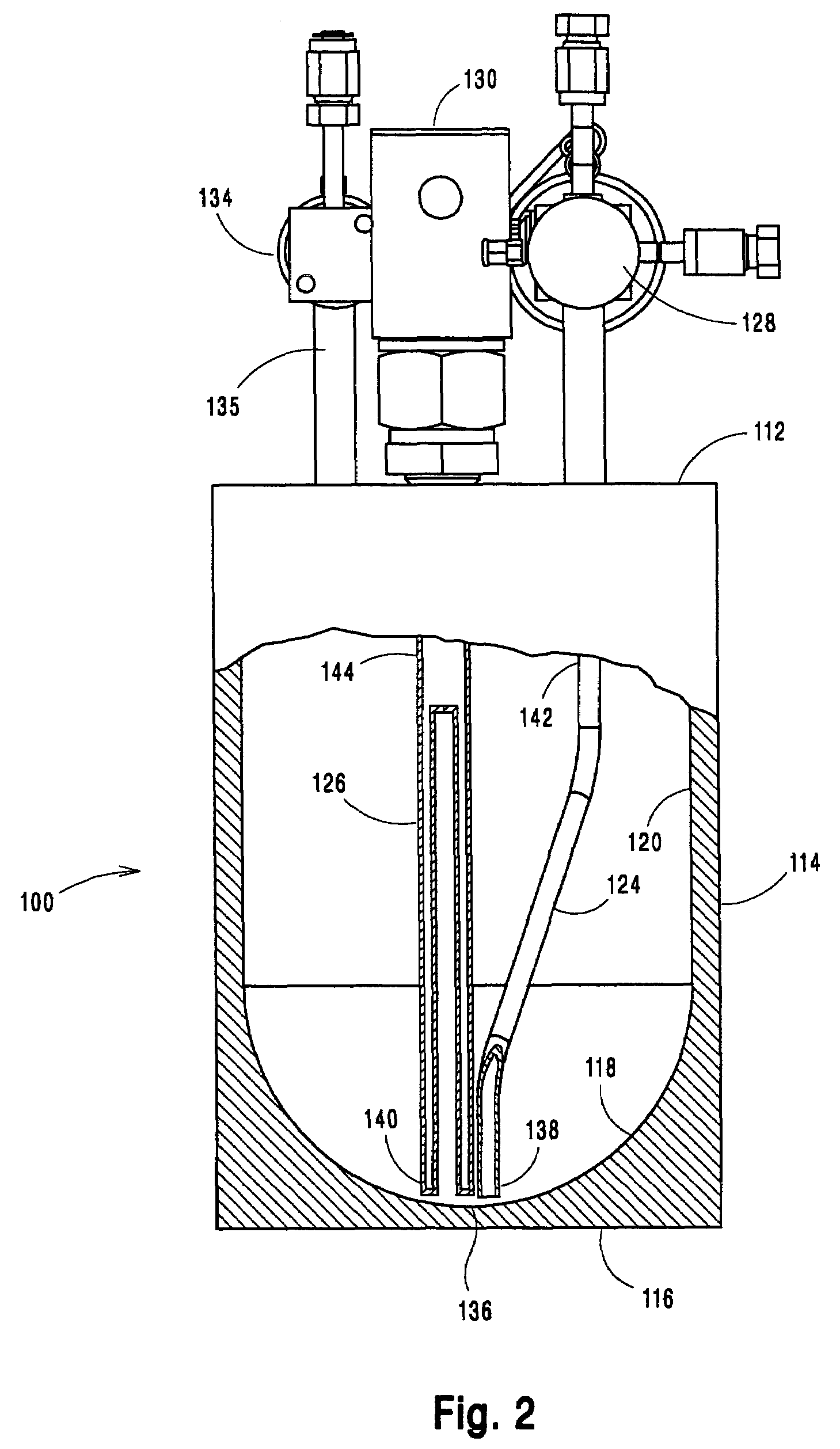

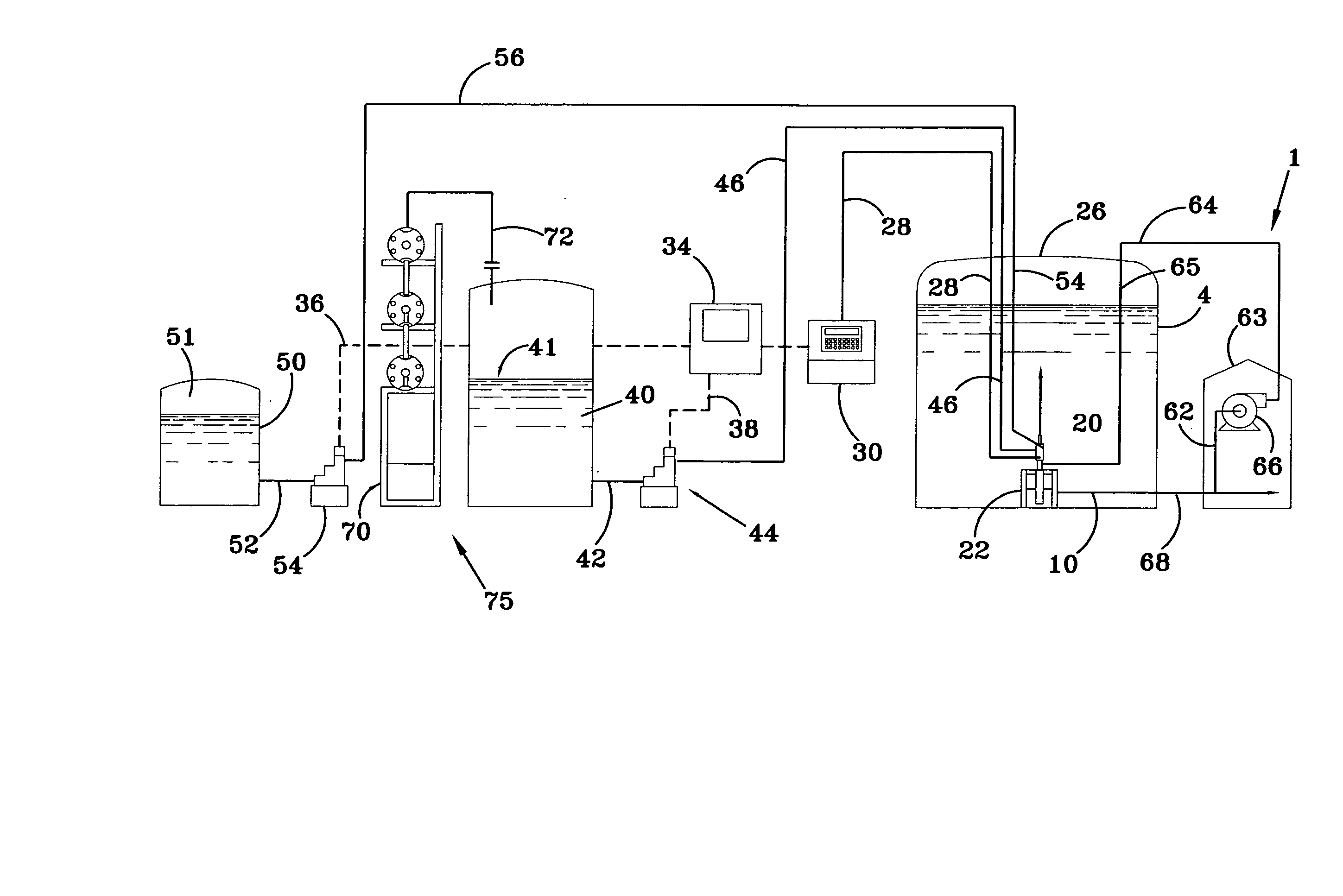

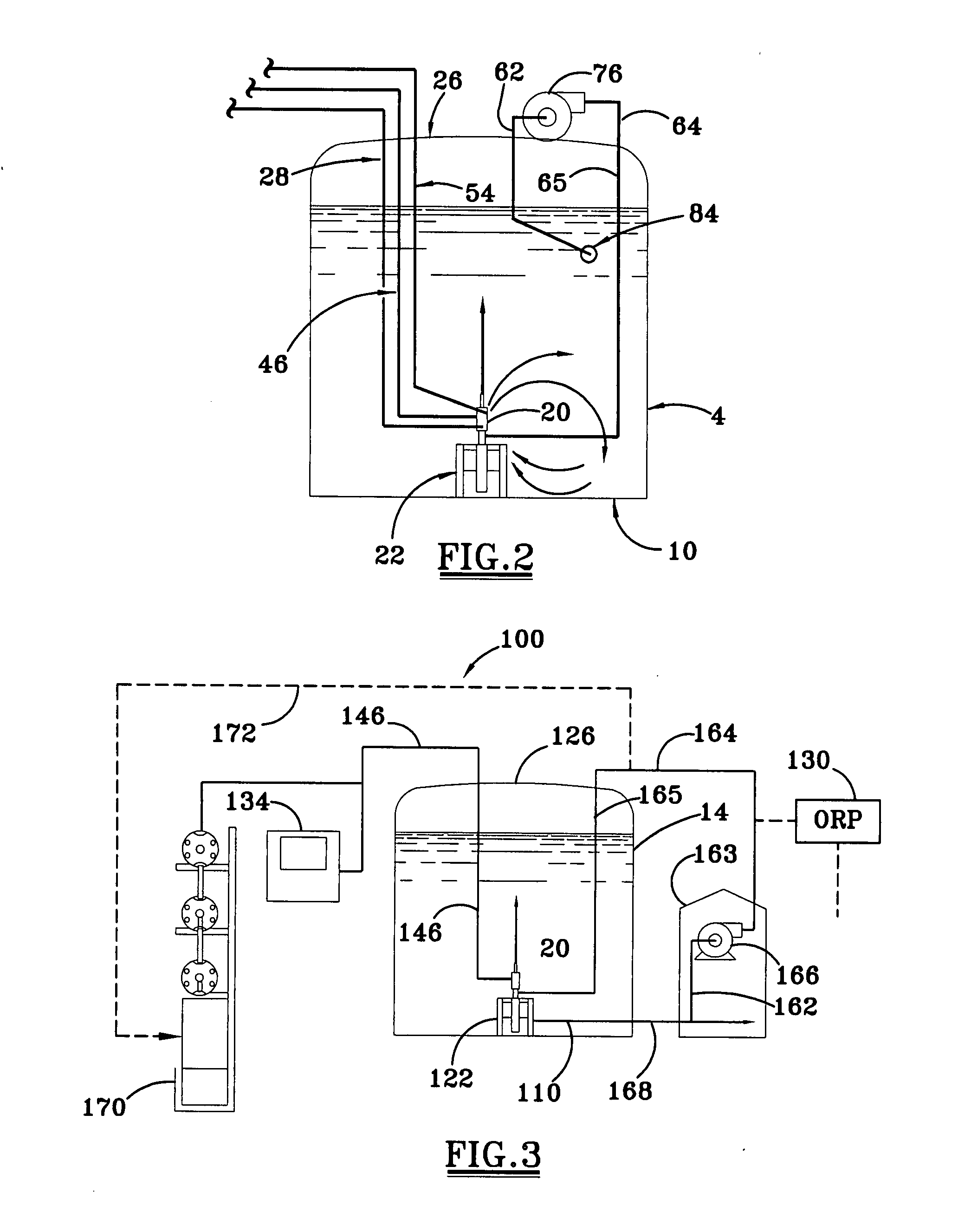

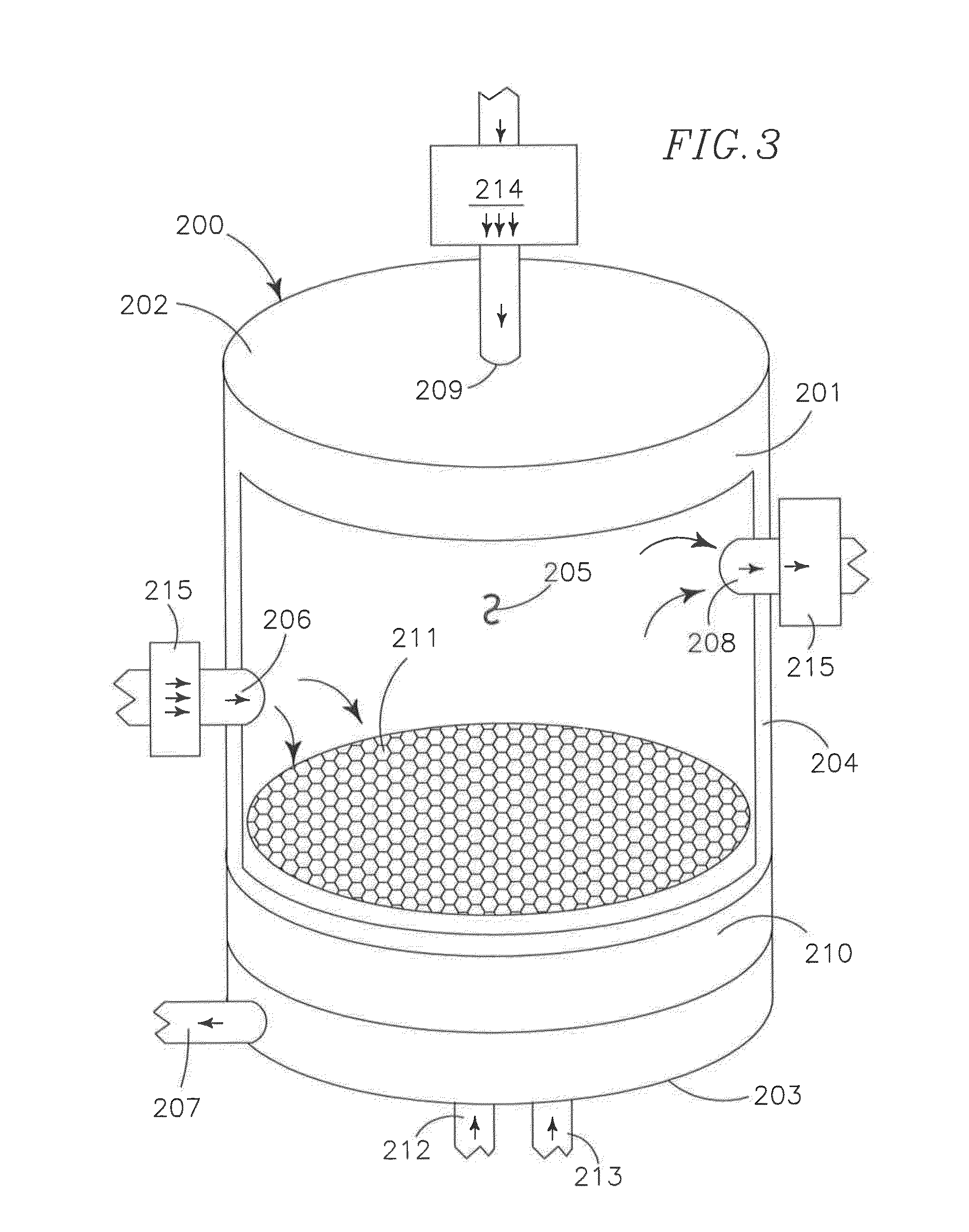

Ballast tank circulation management system

InactiveUS20080017586A1Maximize disinfectionEasy maintenanceAuxillariesIon-exchanger regenerationChemical compositionWater flow

A ballast tank circulation system having inlet and outlet piping and means for adding one or more halogens in controlled amounts to the water within the ballast tank. One or more eductors are positioned within the ballast tank to mix and circulate water within the ballast tank. A recirculating pump is located externally to the ballast tank to ingest water from the ballast tank and discharge a stream of pressurized water. The recirculating pump receives water from the ballast tank through an inlet line that taps into the outlet piping from the ballast tank. An outlet line transport the pressurized water to the ballast tank. The eductor draws in the pressurized water entering the ballast tank and emits a high pressure jet of water that circulates within the ballast tank thereby circulating the chemical content of the ballast water. Test streams of water from the ballast tank can be analyzed to determine the level of at least one of halogens in the test stream to provide a halogen content signal. A controller receives the signal and compares the signal to a set point indicative of the level of halogen desired within the ballast tank to maintain, increase, or decrease the amount of chemical added to the water within the ballast tank in controlled amounts.

Owner:SEVEN TRENT WATER PURIFICATION INC

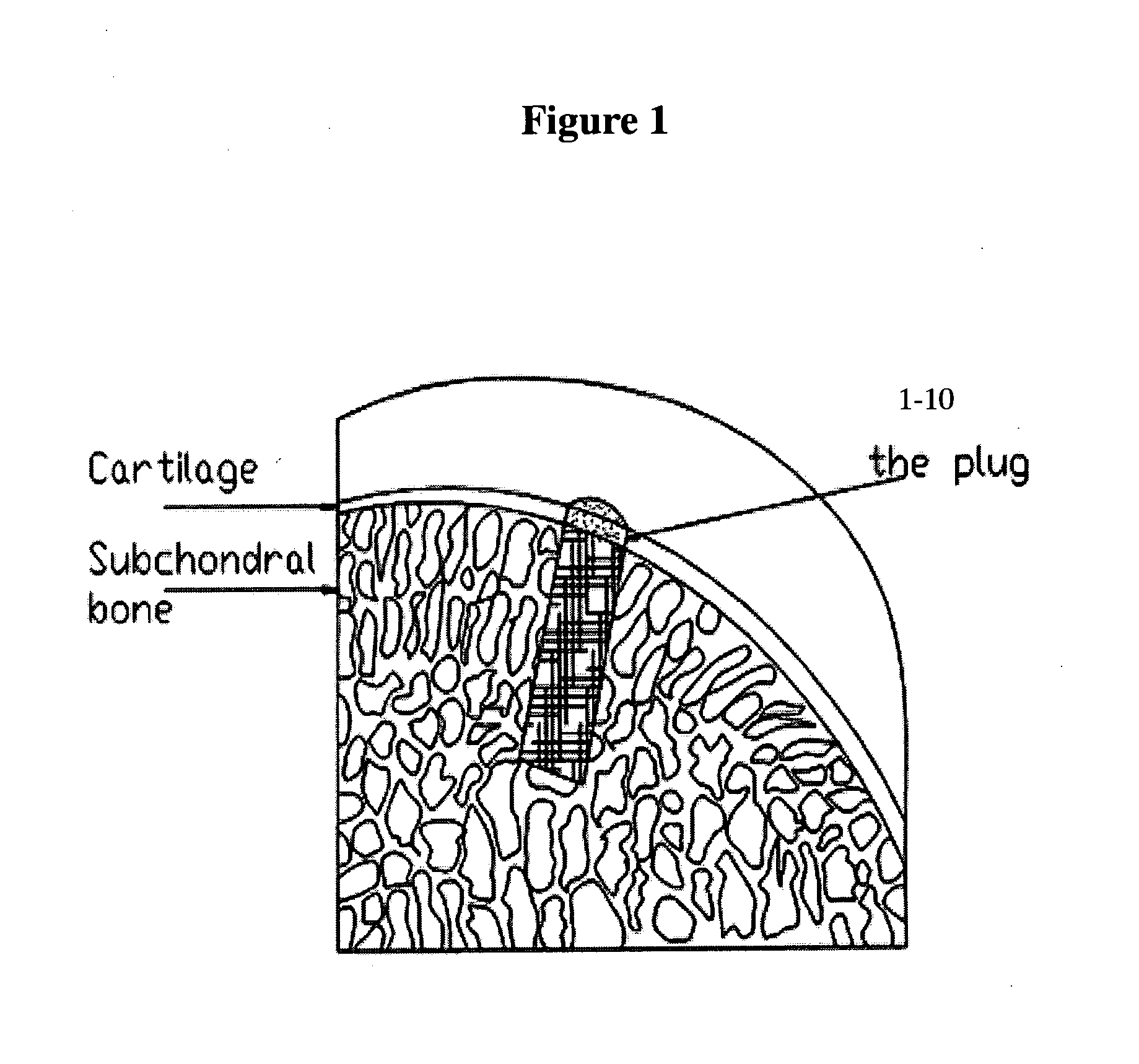

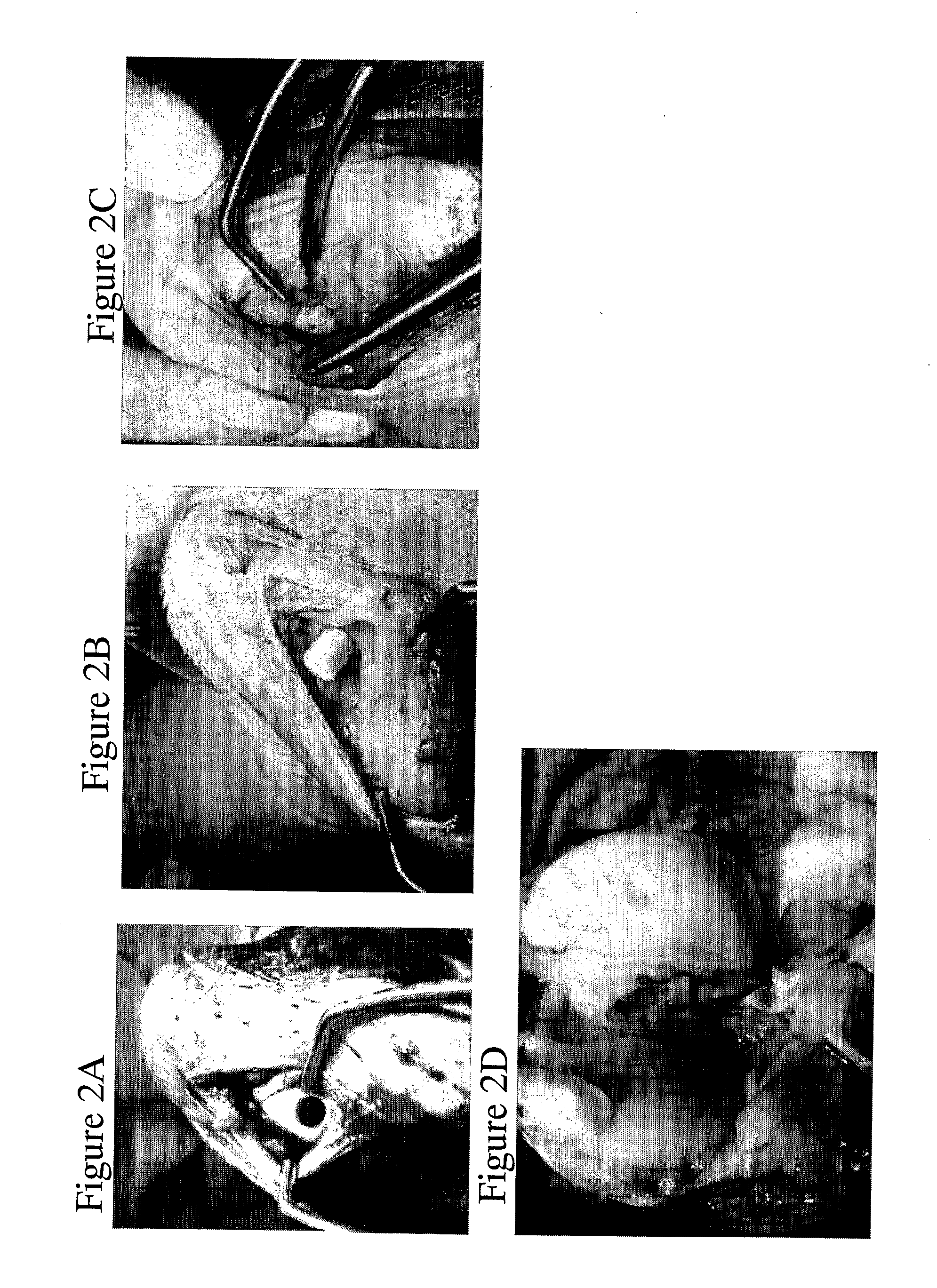

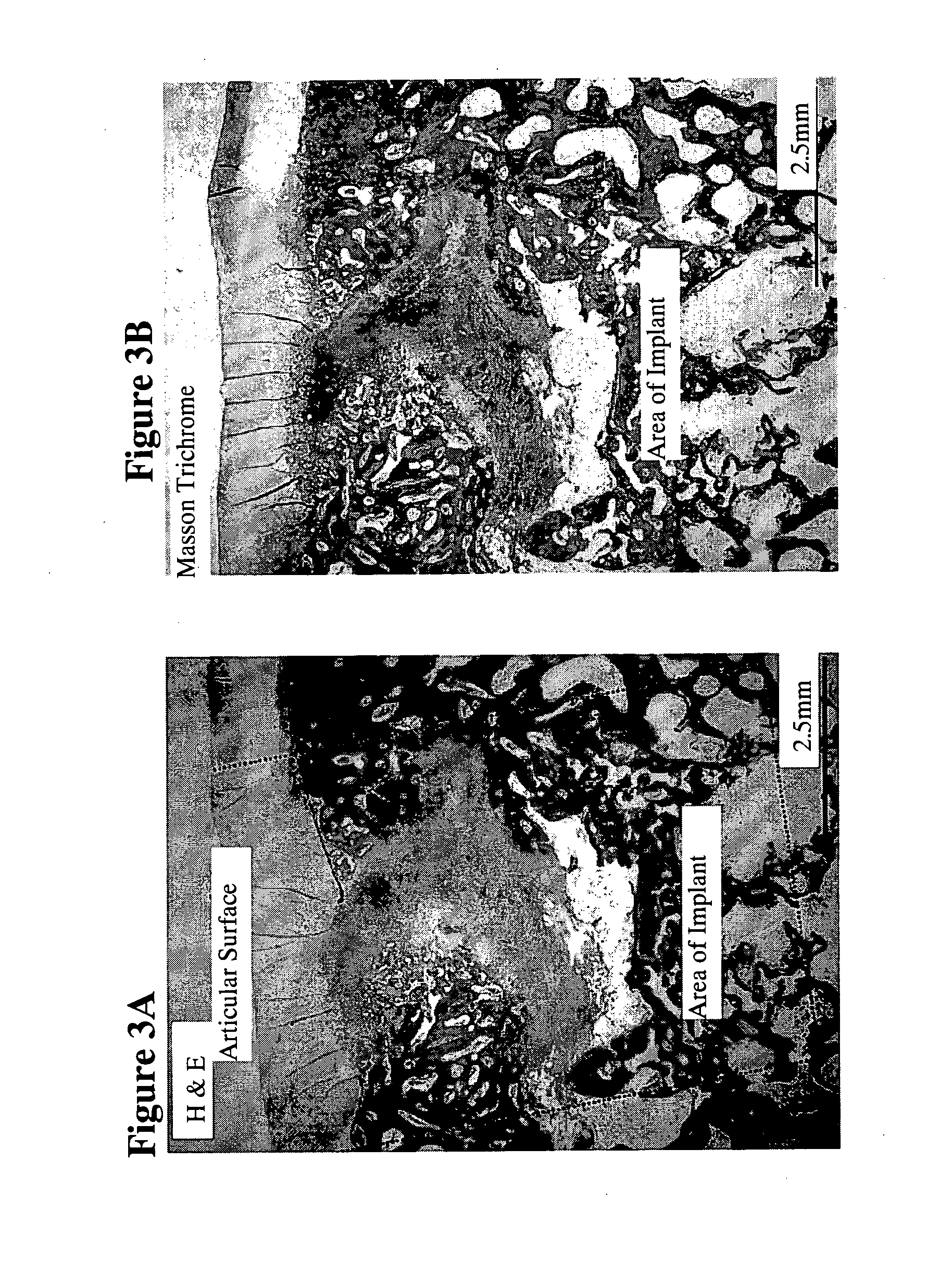

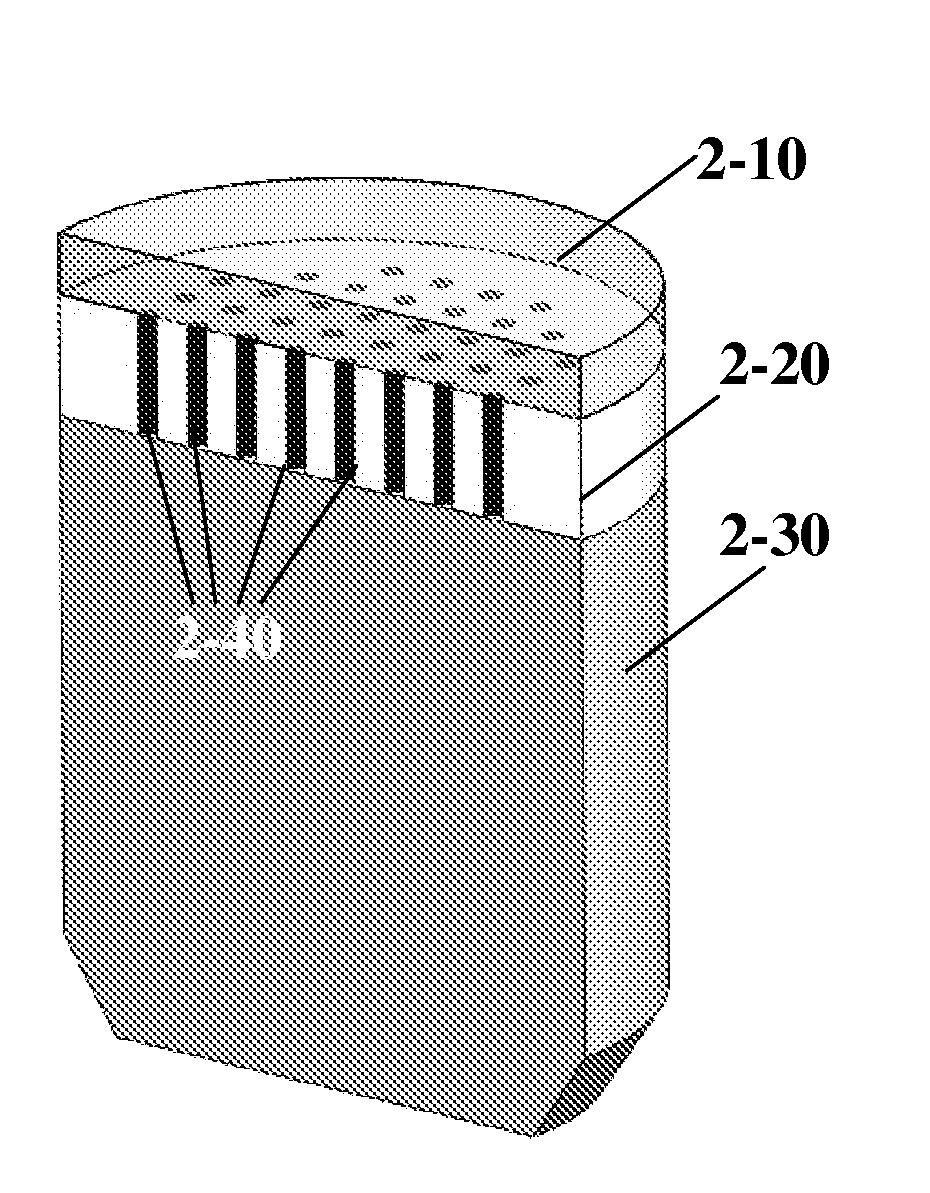

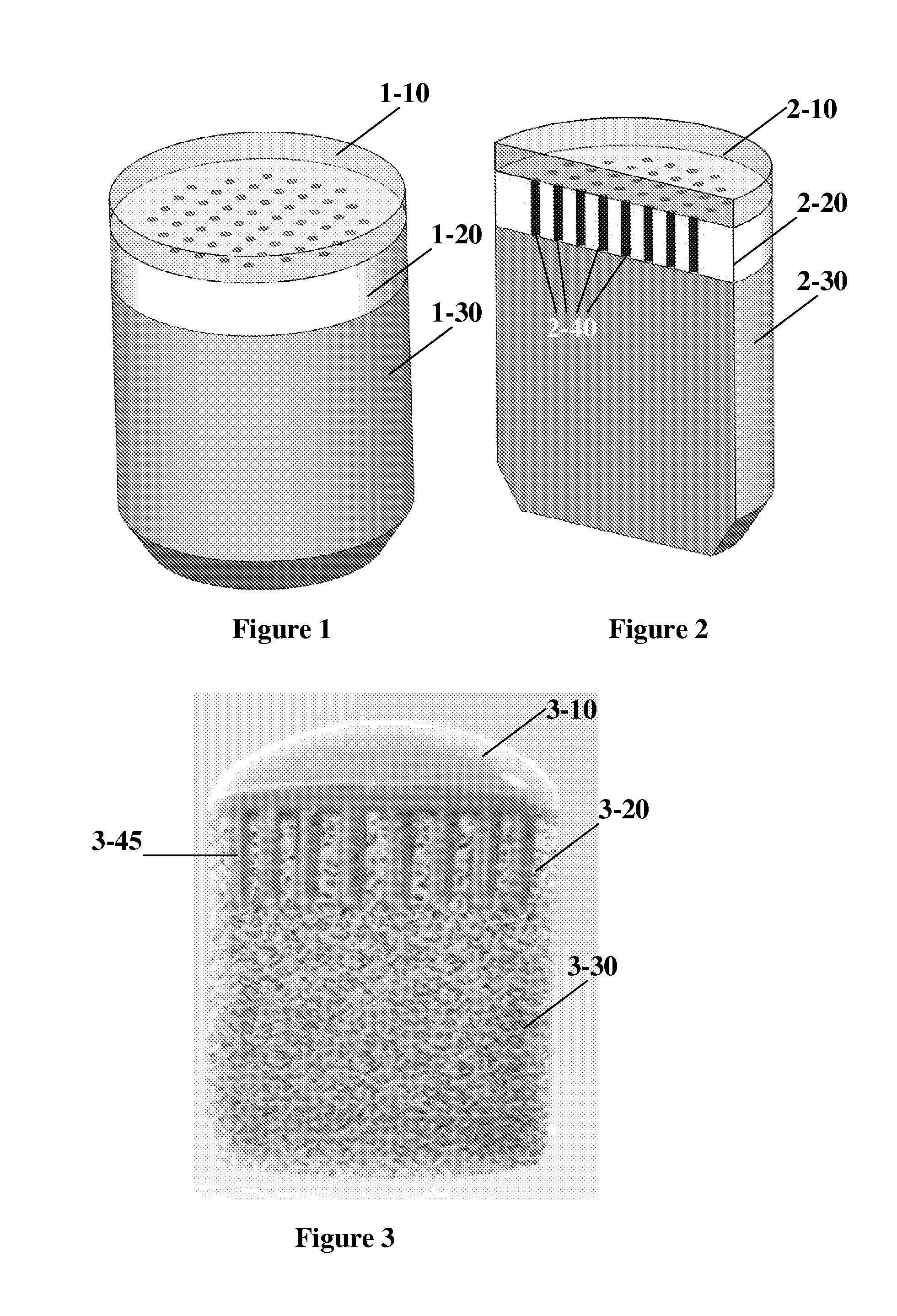

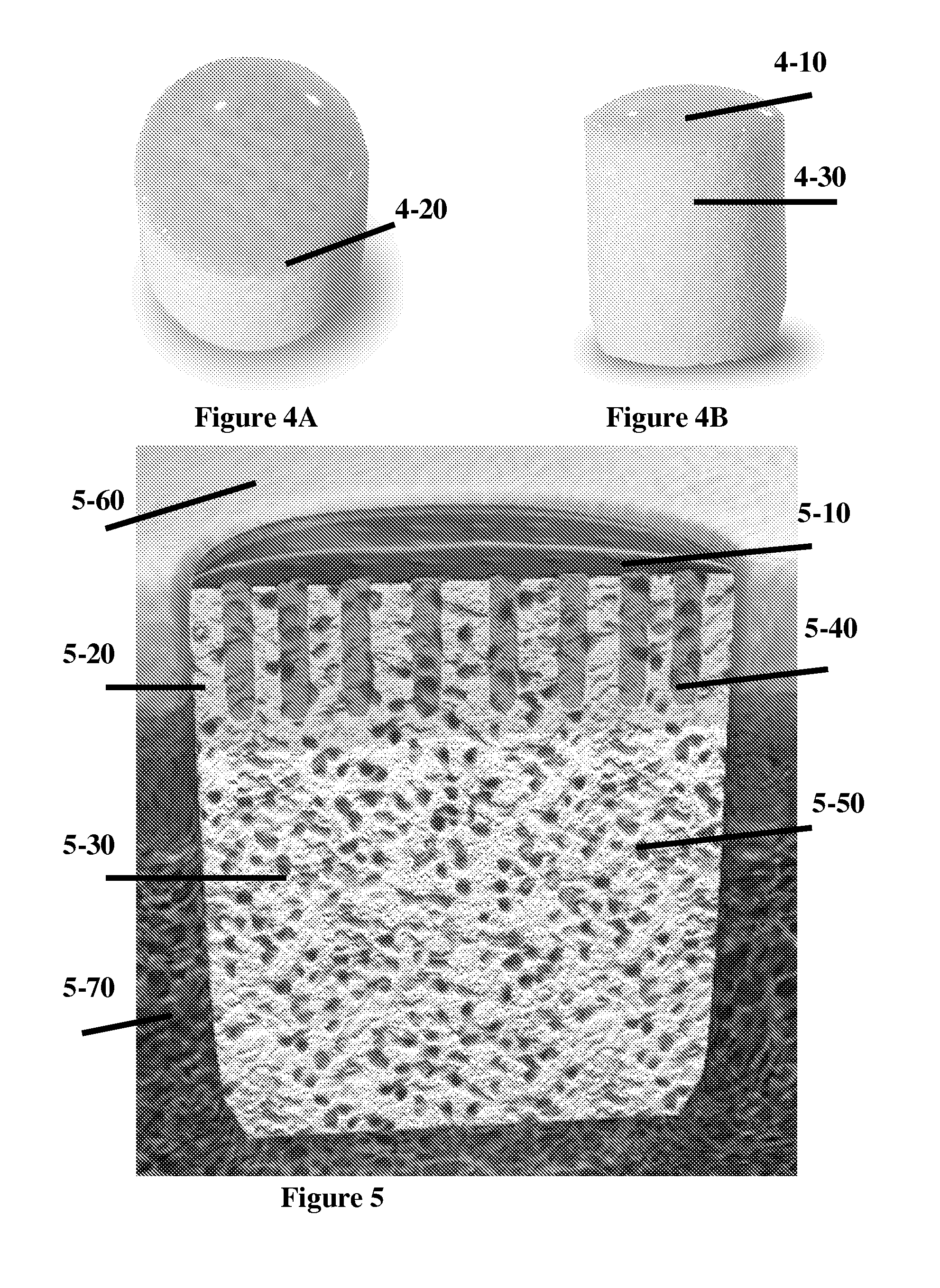

Solid Forms for Tissue Repair

ActiveUS20120189669A1Easy adhesionPromote blood vessel formationPeptide/protein ingredientsAntipyreticTissue repairAragonite

This invention provides aragonite- and calcite-based scaffolds for the repair, regeneration, enhancement of formation or a combination thereof of cartilage and / or bone, which scaffolds comprise at least two phases, wherein each phase differs in terms of its chemical content, or structure, kits comprising the same, processes for producing solid aragonite or calcite scaffolds and methods of use thereof.

Owner:CARTIHEAL 2009

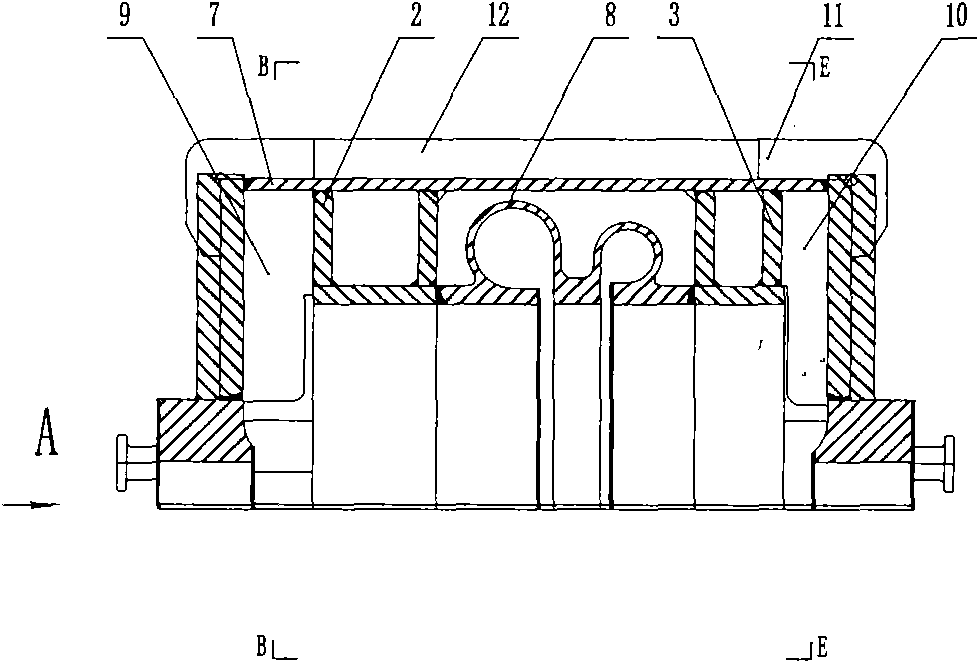

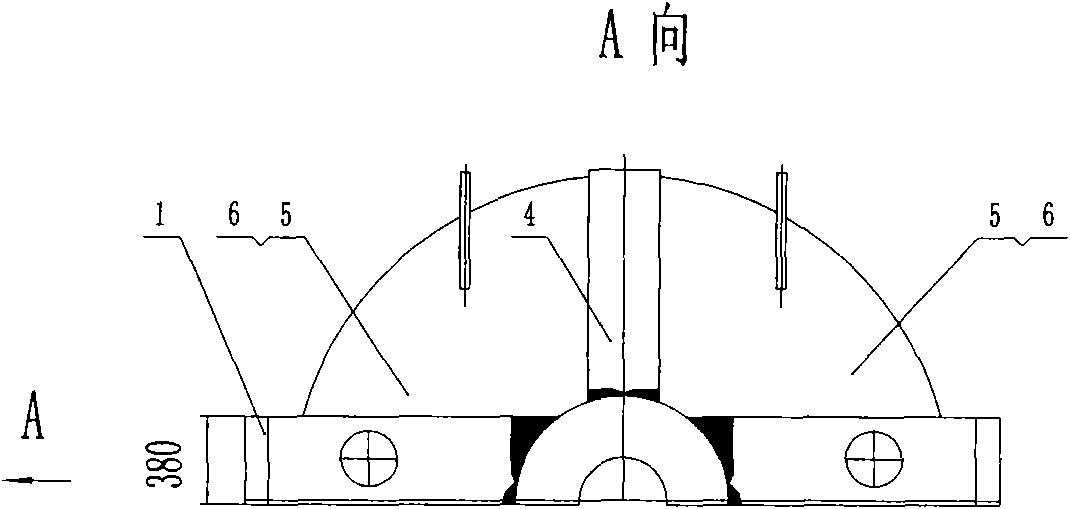

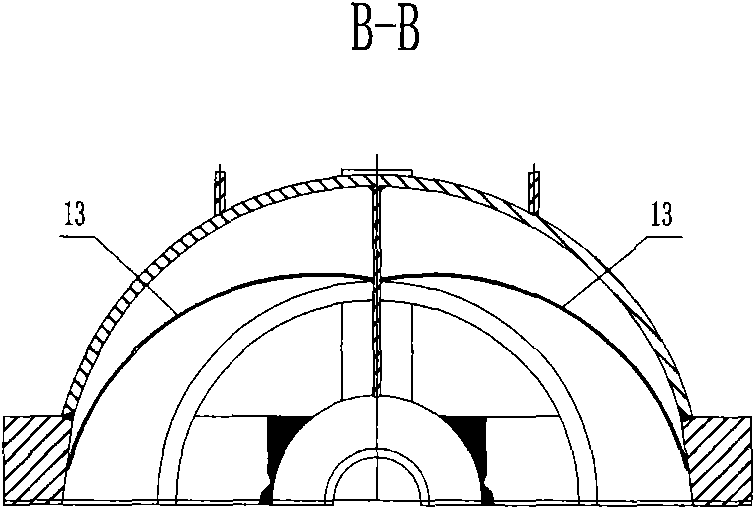

Welding process of megaton ethane compressor casing

ActiveCN101890557AShorten welding cycleQuality assuranceWelding/cutting media/materialsSoldering mediaShielding gasWeld seam

The invention relates to a welding technology in the equipment manufacture industry and relates a special welding technology of an MCL (Mean Control Limit) type horizontally-split centrifugal compressor welder casing, in particular to a welding technology of a megaton ethane centrifugal compressor welder casing with forgeable pieces of 16 Mn and Q345R and ZQ230-450 materials. Gas shielded welding is adopted to weld the welder casing with the forgeable pieces of 16 and the Q345R low alloyed steel, and an electrode in a brand of H08Mn2SiS with a diameter shown in the specification, power supply polarity of DCRP (Direct Current Reverse Polarity) is adopted and comprises fore-welding treatment, welding process and post-welding treatment, wherein the welding process comprises the following process parameters: a welding current is 250-280 A, a welding voltage is 28-32 V, a protective mixed gas comprises 80 percent by volume of Ar and 20 percent by volume of CO2, a welding speed is 280-320 mm / min, the dry extension is 20-25 mm, and the gas flow is 15-20 L / min. The invention can solve the problems of welding deformation, layered tearing, low welding efficiency, and the like and ensure the welding seam strength by selecting an MAG (Metal Active Gas) shielded welding material with similar chemical contents and matched strength with a welder casing material.

Owner:SHENYANG BLOWER WORKS GROUP CORP

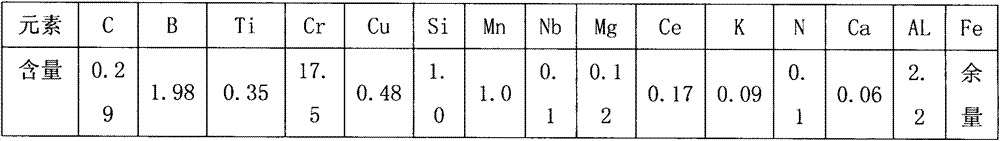

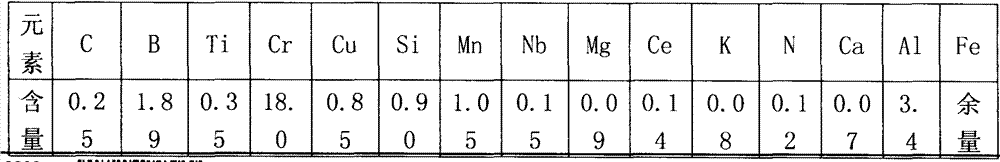

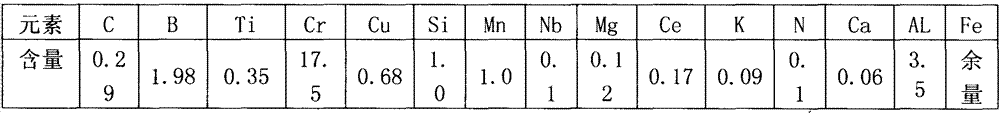

High-boron high-chromium low-carbon wear-resisting alloy steel with good red hardness and manufacturing method thereof

InactiveCN103498108AImprove red hardnessReduce manufacturing costProcess efficiency improvementSilicon alloyRare earth

The invention provides high-boron high-chromium low-carbon wear-resisting alloy steel with good red hardness and a manufacturing method thereof. The chemical content of the high-boron high-chromium low-carbon wear-resisting alloy steel includes, by weight, 0.10%-0.5% of C, 12%-26% of Cr, 0.5%-1.2% of Si, 0.5%-1.5% of Mn, 2.5%-3.6% of B, 0.7%-2.4% of Cu, 3.2%-3.9% of Al, 0.8%-1.6% of Ti, 0.02%-0.15% of Ca, 0.03-0.25% of Ce, 0.02%-0.18% of N, 0.05%-0.3% of Nb, 0.12%-0.25% of Mg, 0.04%-0.13% of K, 0.05%-0.12% of Ca, 0.06%-0.15% of Ba, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. After steel scrap and ferrochromium are melted in an electric furnace, a copper plate, silicon iron and ferromanganese are added to the electric furnace, after content is qualified through pre-furnace adjustment, the temperature of a melt rises to 1560-1620 DEG C, calcium-silicon alloy and deoxidation aluminum are added, ferrotitanium, ferroboron and metal aluminum are sequentially added and poured out of the furnace after being melted, granular rare earth magnesium alloy with the diameter of less than 12mm and a composite inoculant composed of metal cerium, Si3N4, VN, Nb and K are placed at the bottom of a steel ladle after being roasted, metaphoric inoculation processing is carried out on smelt liquid steel in a in-ladle pouring mode, the liquid steel pouring temperature ranges from 1400 DEG C to 1450 DEG C, and a casting piece undergoes air cooling for 2-4 hours at the temperature of 920-1150 DEG C.

Owner:江苏盛伟模具材料有限公司

Solid Forms for Tissue Repair

ActiveUS20120177702A1Promote regenerationPromote repairCalcium/strontium/barium carbonatesPeptide/protein ingredientsTissue repairAragonite

This invention provides aragonite- and calcite-based scaffolds for the repair, regeneration, enhancement of formation or a combination thereof of cartilage and / or bone, which scaffolds comprise at least two phases, wherein each phase differs in terms of its chemical content, or structure, kits comprising the same, processes for producing solid aragonite or calcite scaffolds and methods of use thereof.

Owner:CARTIHEAL 2009

System for separating contaminants from fluids

InactiveUS20160221842A1Efficient precipitationEnhance and facilitate separationWaste water treatment from quariesWater treatment parameter controlSensor arrayParticulates

A system for separating contaminants from fluids provides a modular mobile continuously operable site configurable multi-phase filtering system having an oil water separator, a dwell tank, a waste tank, an optimizer, a first and a parallel second particulate filter, a first and parallel second step-down membrane filter, and optional ultra filtration filter, an optional reverse osmosis filter, a mixing station and a totalizer and sensor array to analyze, filter and treat fluids by separating contaminants and particulates and adjusting chemical content to meet specifications desired which will allow the use and re-use of the filtered fluid and the separated contaminants.

Owner:ECO SQUARED SOLUTIONS

Amination process for preparing butralin as chemical herbicide

InactiveCN101066928ACODcr amount decreasedReduce processing loadOrganic compound preparationAmino compound preparationChemical industryChlorobenzene

The present invention relates to amination process for preparing butralin as chemical herbicide, and belongs to the field of chemical industry technology. The present invention includes a process of treating 2, 6-dinitro-p-tert-butyl chlorobenzene through heating in water at 85-100 deg.c, washing in boiling water, neutralizing with 30 % concentration NaOH solution to pH 7-8, cooling and other steps; and an amination process with NaHCO3 as buffering agent. The present invention can reach chemical content of 89-91 % and nitrated amine yield of 79-82 %, higher than available technology, and has less waste water treating load.

Owner:易文中

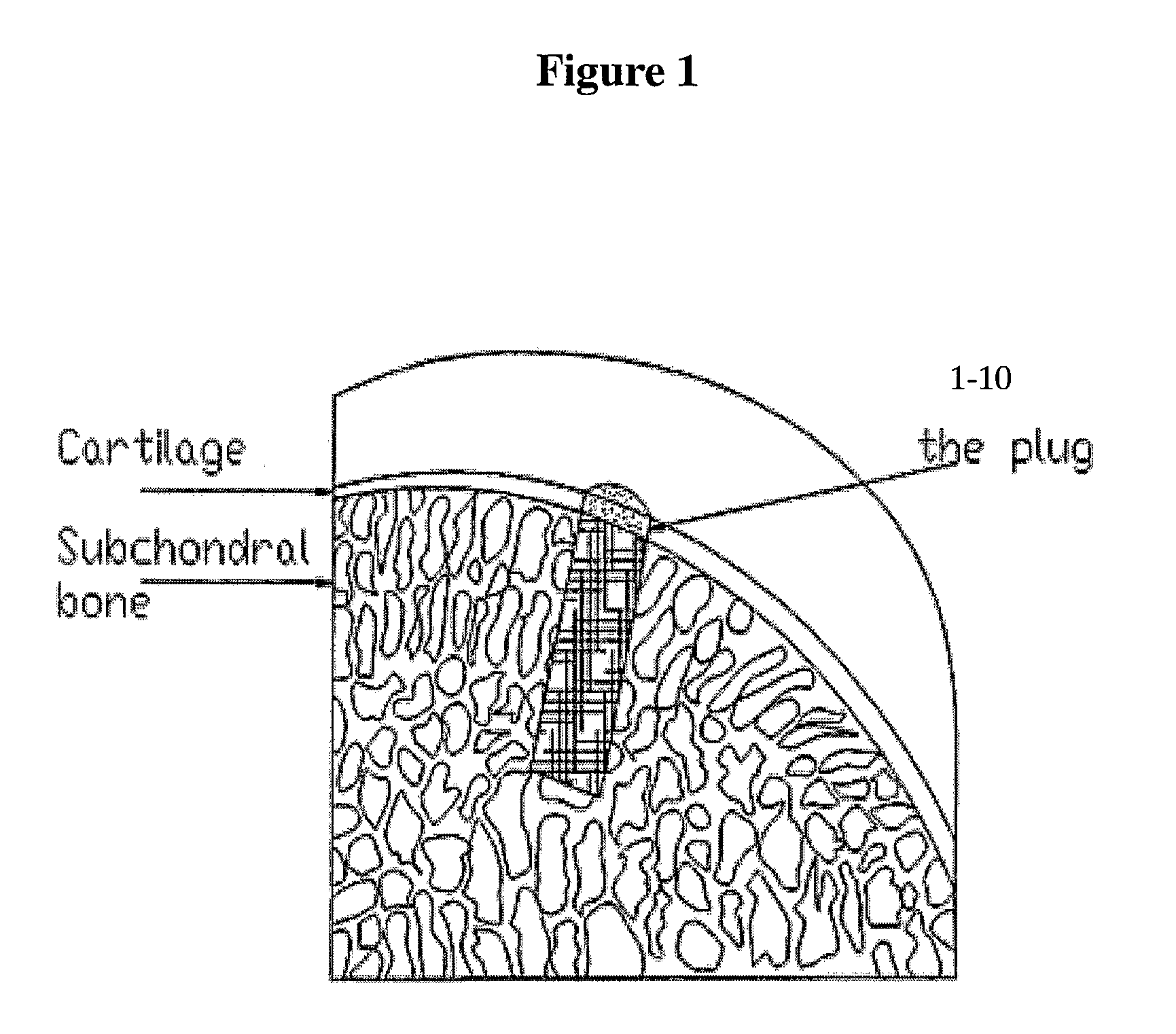

Mulit-Phasic Solid Implants for Tissue Repair

This invention provides aragonite- and calcite-based solid substrates for the repair, regeneration, enhancement of formation or a combination thereof of cartilage and / or bone, which solid substrates comprise or are made to ultimately comprise three phases, wherein each phase differs in terms of its chemical content, or structure, kits comprising the same, and methods of use thereof.

Owner:CARTIHEAL 2009

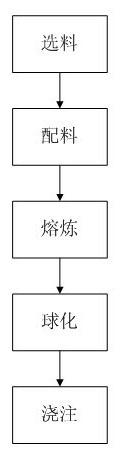

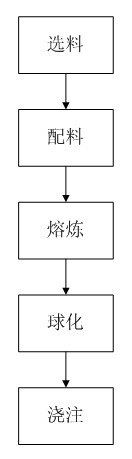

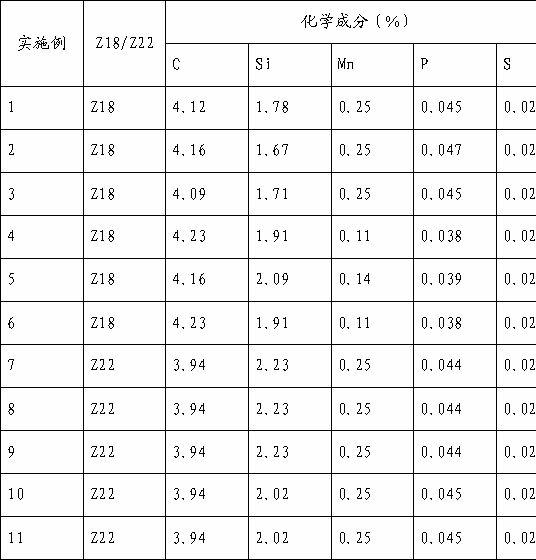

Production process of high-elongation nodular cast iron being as cast condition

The invention discloses a production process of high-elongation nodular cast iron being as cast condition. The production process comprises the following steps: sorting; burdening: taking materials by weight percentage as follows: 35-45% of cast iron Z18 or Z22, less than 35% of foundry returns and 30-55% of steel scraps; melting: putting burdened materials into a furnace for melting, melting the materials into molten iron, rising the temperature of the molten iron to be 1600-1650 DEG C, carburetting and complementing silicon; then conducting desulfuration process; complementing oxygen and reducing manganese and conducting dephosphorization process; finally carrying out on-the-spot chemical contents analysis, adjusting the chemical contents, conducting the next operation after the chemical contents are qualified; balling by utilizing pour-over method; and breeding instantly by adopting an inoculant when in casting so as to obtain the high-elongation nodular cast iron being as cast condition. According to the high-elongation nodular cast iron being as cast condition provided by the invention, the cost is lowered, the production period of a cast is shortened; the sorting range of the raw materials of the nodular cast iron is enlarged; the cast can not shrink easily; and the cost is saved, silicon iron alloy does not need to be added or is little added after the casting treatment.

Owner:CHAGNSHU QIANJINDING CASTING

Production method of low-cost and high-elongation nodular cast iron being as cast condition

The invention discloses a production method of low-cost and high-elongation nodular cast iron being as cast condition. The production method comprises the following steps: sorting; burdening: taking materials by weight percentage as follows: 35-45% of cast iron Z18 or Z22, less than 35% of foundry returns and 30-55% of steel scraps; melting: putting burdened materials into a furnace for melting, melting the materials into molten iron, rising the temperature of the molten iron to be 1600-1650 DEG C, carburetting and complementing silicon; then conducting desulfuration process; complementing oxygen and reducing manganese and conducting dephosphorization process; finally carrying out on-the-spot chemical contents analysis, adjusting the chemical contents, conducting the next operation after the chemical contents are qualified; balling by utilizing pour-over method; and breeding instantly by adopting an inoculant when in casting so as to obtain the high-elongation nodular cast iron being as cast condition. According to the low-cost and high-elongation nodular cast iron being as cast condition provided by the invention, the cost is lowered, the production period of a cast is shortened; the sorting range of the raw materials of the nodular cast iron is enlarged; the cast can not shrink easily; and the cost is saved, silicon iron alloy does not need to be added or is little added in the content after the casting treatment.

Owner:CHAGNSHU QIANJINDING CASTING

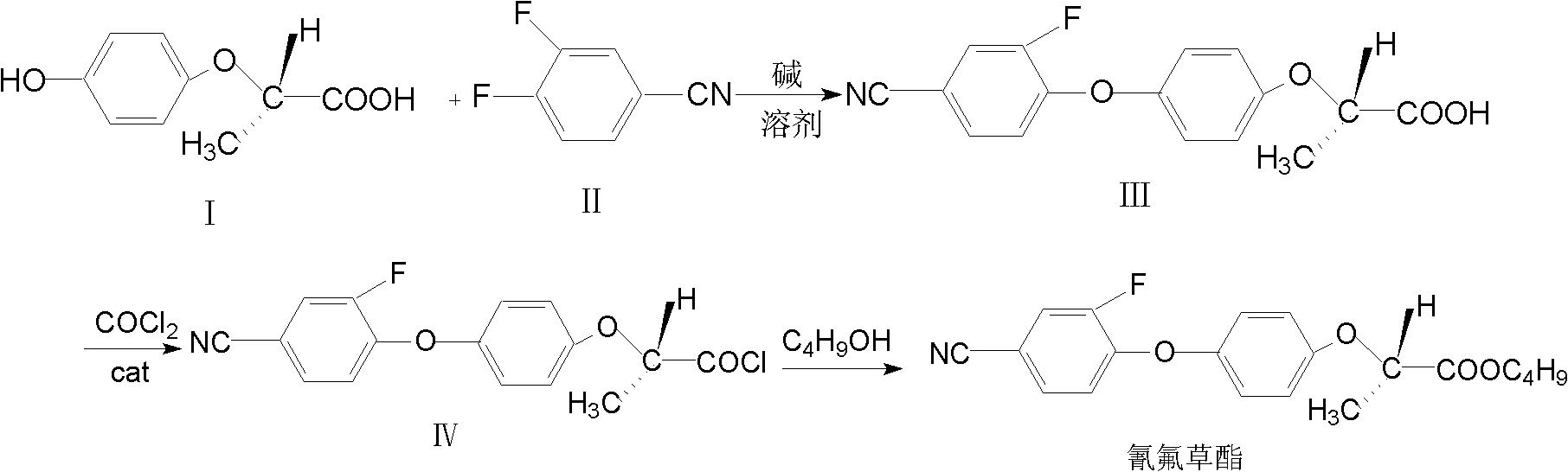

Synthetic method of cyhalofop-butyl active compound

ActiveCN102584627AAvoid it happening againHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationPropanoic acidN-Butyl Alcohol

The invention discloses a synthetic method of a cyhalofop-butyl active compound. The method comprises the following steps of: undergoing a condensation reaction on (R)-4-hydroxyphenoxypropanoic acid and 3,4-difluorobenzonilyile serving as raw materials in an organic solvent under an alkaline catalysis condition to generate an intermediate, i.e., (R)-2-[4-(2-fluoro-4-nitrile)-phenoxyl]-propanoic acid; undergoing a photochemical reaction on the intermediate, i.e., (R)-2-[4-(2-fluoro-4-nitrile)-phenoxyl]-propanoic acid to generate an intermediate, i.e., (R)-2-[4-(2-fluoro-4-nitrile)-propionyl chloride; and undergoing a third step esterification reaction on the intermediate, i.e., (R)-2-[4-(2-fluoro-4-nitrile)-propionyl chloride and n-butyl alcohol to generate the cyhalofop-butyl active compound. The method has the advantages of simple process, low production cost, high chemical content, high optical purity and the like.

Owner:JIANGSU KUAIDA AGROCHEM

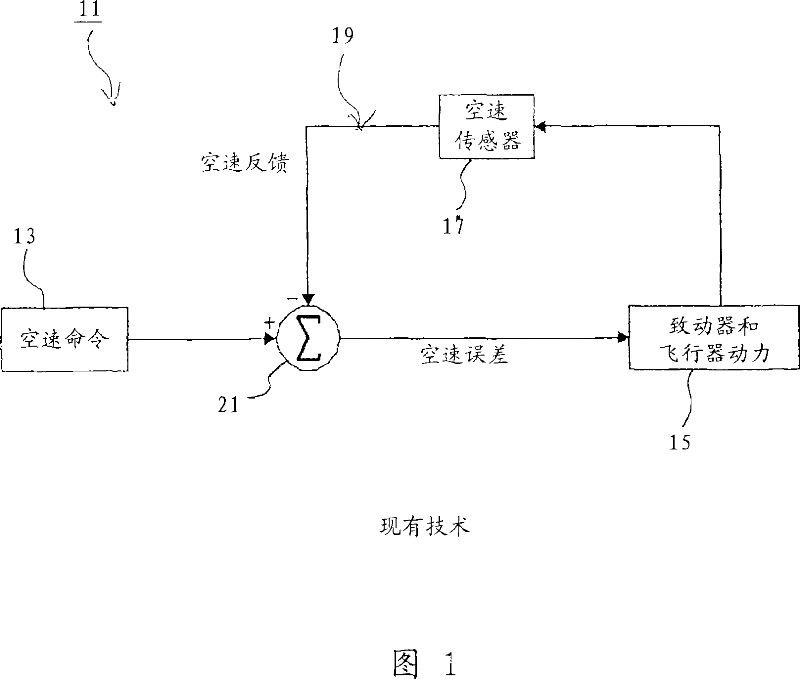

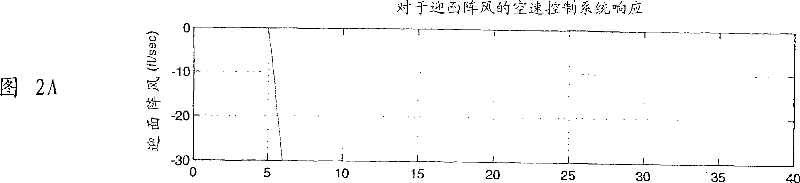

Automatic velocity control system for aircraft

ActiveCN101044055AReduced Power VariationsLittle changeAircraft power plantsAircraft controlGlass furnaceSpeed control system

The invention relates to a molten and cast refractory AZS-type product whose chemical content consists of 15.5 to 22 % by weight ZrO2,10.5 to 15 % by weight SiO2, 1.0 to 2.5 % by weight Na2O+K2O+Li2O and <1 % by weight impurities. Said invention is used for glass furnaces, in particular for the superstructures and roofs thereof.

Owner:BELL HELICOPTER TEXTRON INC

Method for removing defect of casting surface with spherical sand by sandblasting

ActiveCN101985552ATight textureHigh bulk densityOther chemical processesAbrasive blastingFluorescence

The invention discloses a method for removing defect of casting surface with spherical sand by sandblasting. Sandblasting is performed by using emergy as an abrasive in a conventional sandblasting method. Two abrasives used in the conventional method are easy to pulverize, so the production efficiency is low. The method of the invention comprises: a first step: selecting the spherical sand, wherein the particles of the spherical sand are required to be hard and round, chemical contents meet the sandblasting requirement, the sand aggregate has the advisable particle size of 16-30 meshes; and 5-15% by weight of irregular shaped sand aggregate is added to the spherical sand and used as a cutting abrasive; a second step: drying the spherical sand to less than 2% of water content; a third step: removing soil and other impurities in the spherical sand; a fourth step: selecting a sandblasting pressure according to the casting size and thickness, controlling the pressure at 0.55-0.6 MPa, packing the spherical sand into a sandblasting bucket, sucking the sand into a sandblasting pipe by compressed air generated by an air compressor, sandblasting the surface through a secondary inlet type gun head, then subjecting the casting to fluorescence detection after sandblasting. The method is used for sandblasting.

Owner:HARBIN XINRUN IND

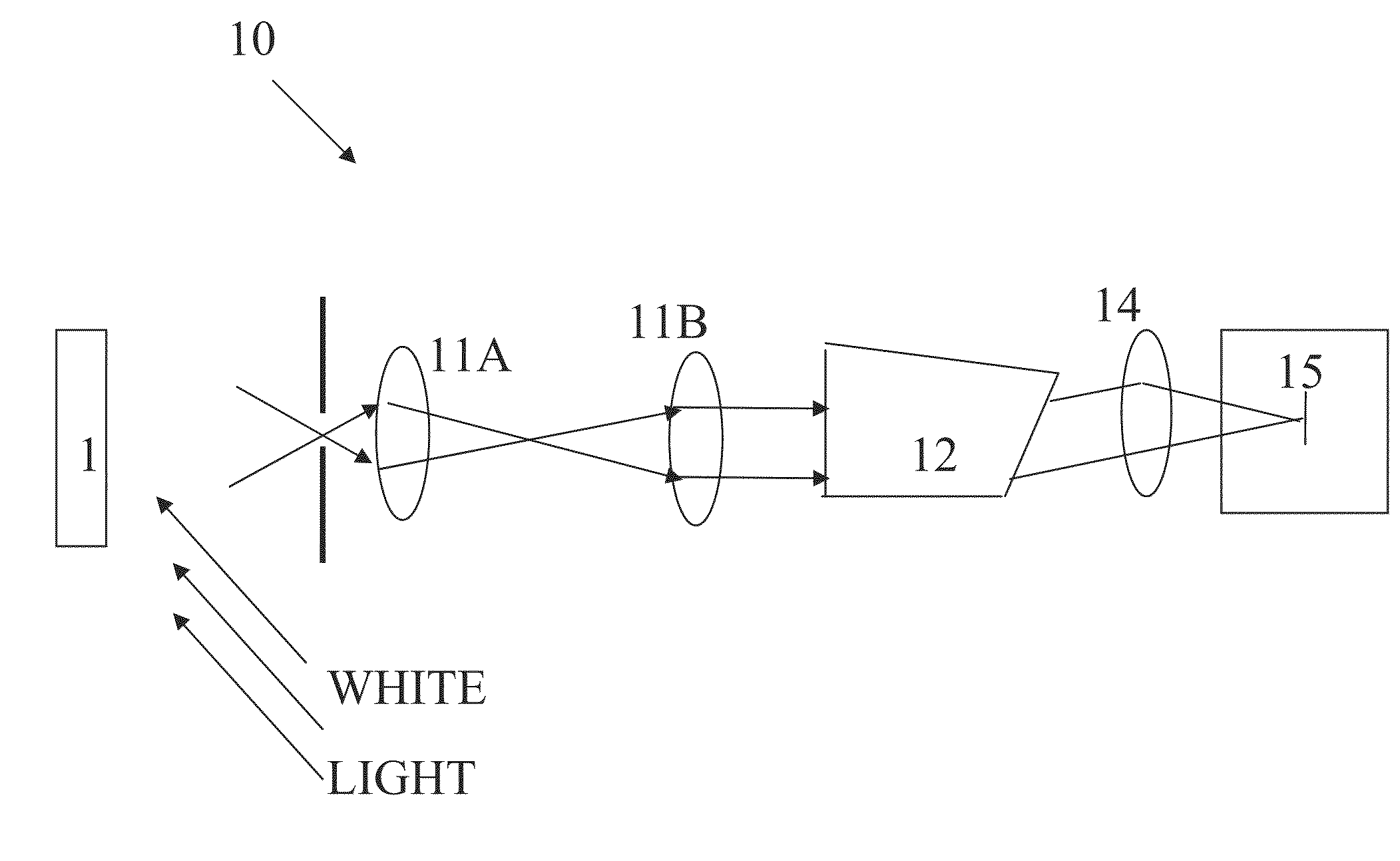

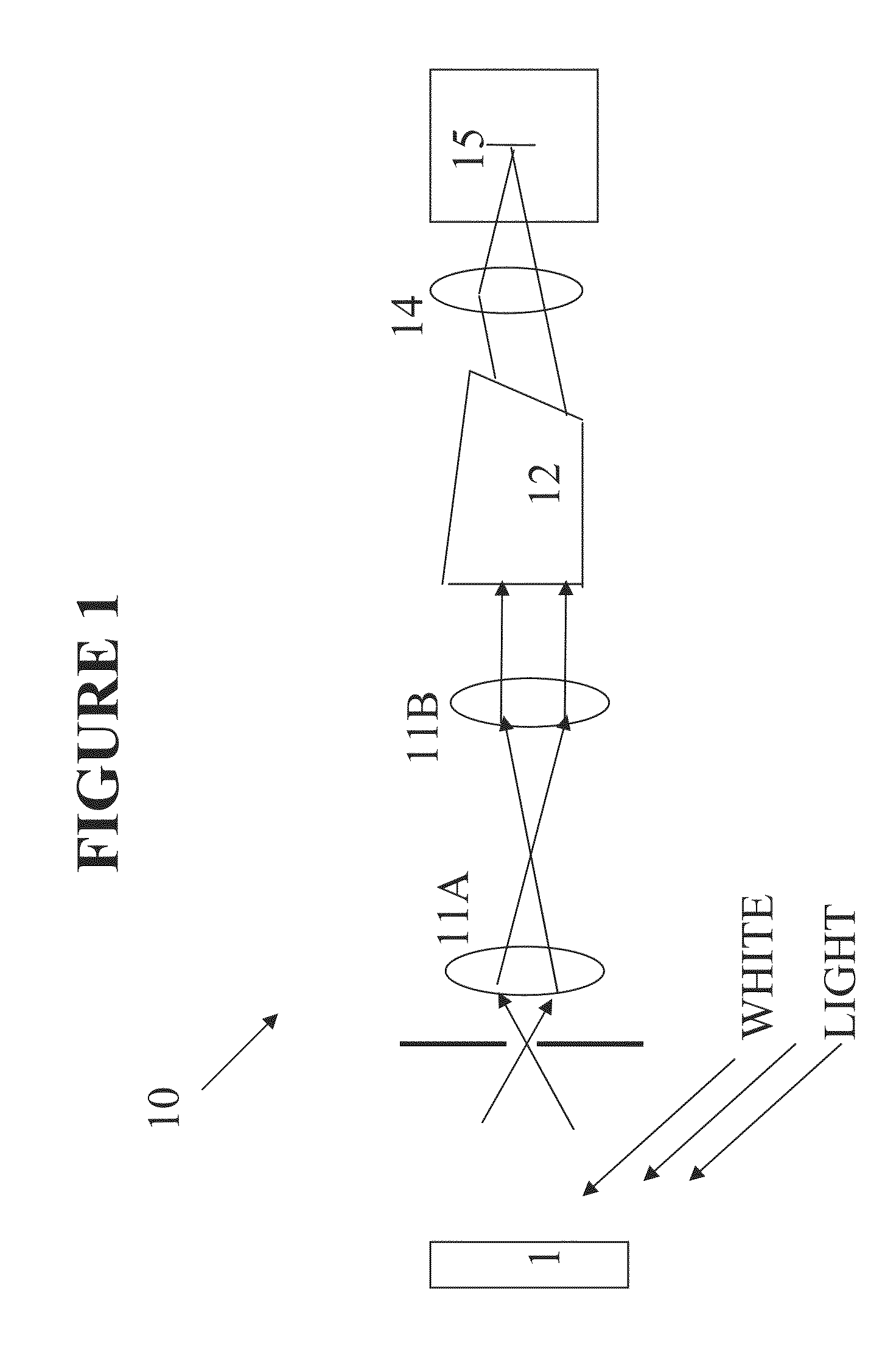

Noninvasive detection of elements and/or chemicals in biological matter

InactiveUS8218143B2Lower Level RequirementsEffectively canceling out the spectral response of the light source and the imagerRadiation pyrometrySpectrum investigationSpectral responseReference image

A method of detecting oxygen and / or chemical content in a subject, comprising generating at least one spectral image of the subject; generating at least one spectral image of a reference object; comparing spectrum from the subject image to the reference image to thereby reveal the relative oxygen content of the subject. A system for determining the level of oxygenation of the blood of a subject body part comprising: a hyperspectral image generator for generating a plurality of spectral images; an image capture device for capturing the spectral images; a processor for generating hyperspectral image cubes such that the spectrum of the body part is extracted and normalized using the spectrum from the reference object to cancel out the spectral response of the light source and the imager; said processor comparing spectral from a subject image to reference images to thereby reveal the relative oxygen content of the subject.

Owner:ARMY US SEC THE THE

System for separating contaminants from fluids

ActiveUS9758389B2Efficient precipitationEnhance and facilitate separationWater treatment parameter controlSpecific water treatment objectivesSensor arrayParticulates

A system for separating contaminants from fluids provides a modular mobile continuously operable site configurable multi-phase filtering system having an oil water separator 100, a dwell tank 220, a waste tank 250, an electrocoagulator 120 having plural concentrically aligned perforated tubular sacrificial electrodes, a first and a parallel second particulate filter 300A, 300B, a first and parallel second step-down membrane filter 400A, 400B, an optional ultra filtration filter 500, an optional reverse osmosis filter 600, a mixing station 700 and a totalizer and sensor array 900 to analyze, filter and treat fluids by separating contaminants and particulates and adjusting chemical content to meet specifications desired which will allow the use and re-use of the filtered fluid and the separated contaminants.

Owner:ECO SQUARED SOLUTIONS

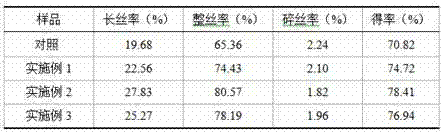

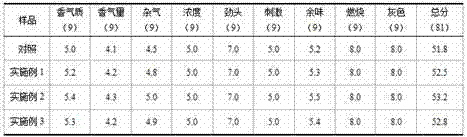

Method for improving expansion effect of microwave expansion tobacco stems

ActiveCN104489894AGood expansion performanceLess severeTobacco treatmentMicrowaveChemical composition

The invention relates to a method for improving the expansion effect of microwave expansion tobacco stems, and belongs to the technical field of tobacco stem processing. The process method includes the steps of tobacco stem screening, stem soaking, stem storing, air drying and microwave expansion. In the tobacco stem pre-processing process, ammonium carbonate or ammonium bicarbonate is added; the ammonium carbonate or the ammonium bicarbonate is soaked into cores of the tobacco stems by controlling the stem storing condition; at the lower power, the tobacco stems are expanded by 3-5 times; in this way, the acute degree of changes of chemical contents and aroma components of the tobacco stems is reduced; losses of natural tobacco incense of tobaccos are reduced; carbonization and fire striking are avoided; the quality of microwave expansion stem strips is improved; and meanwhile energy resources are saved.

Owner:CHINA TOBACCO YUNNAN IND

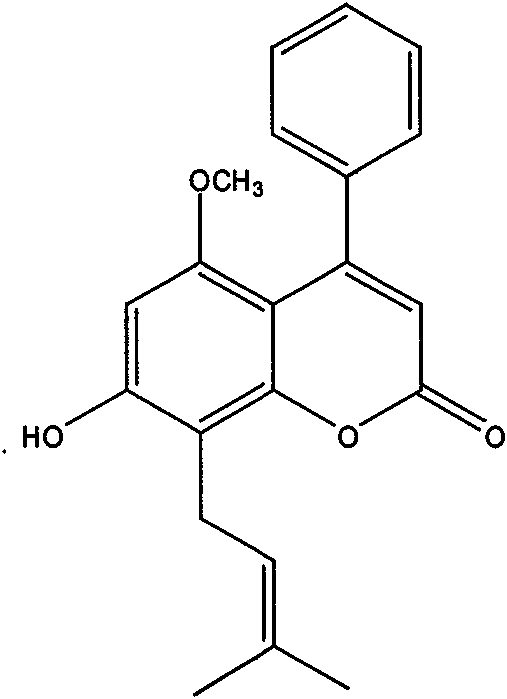

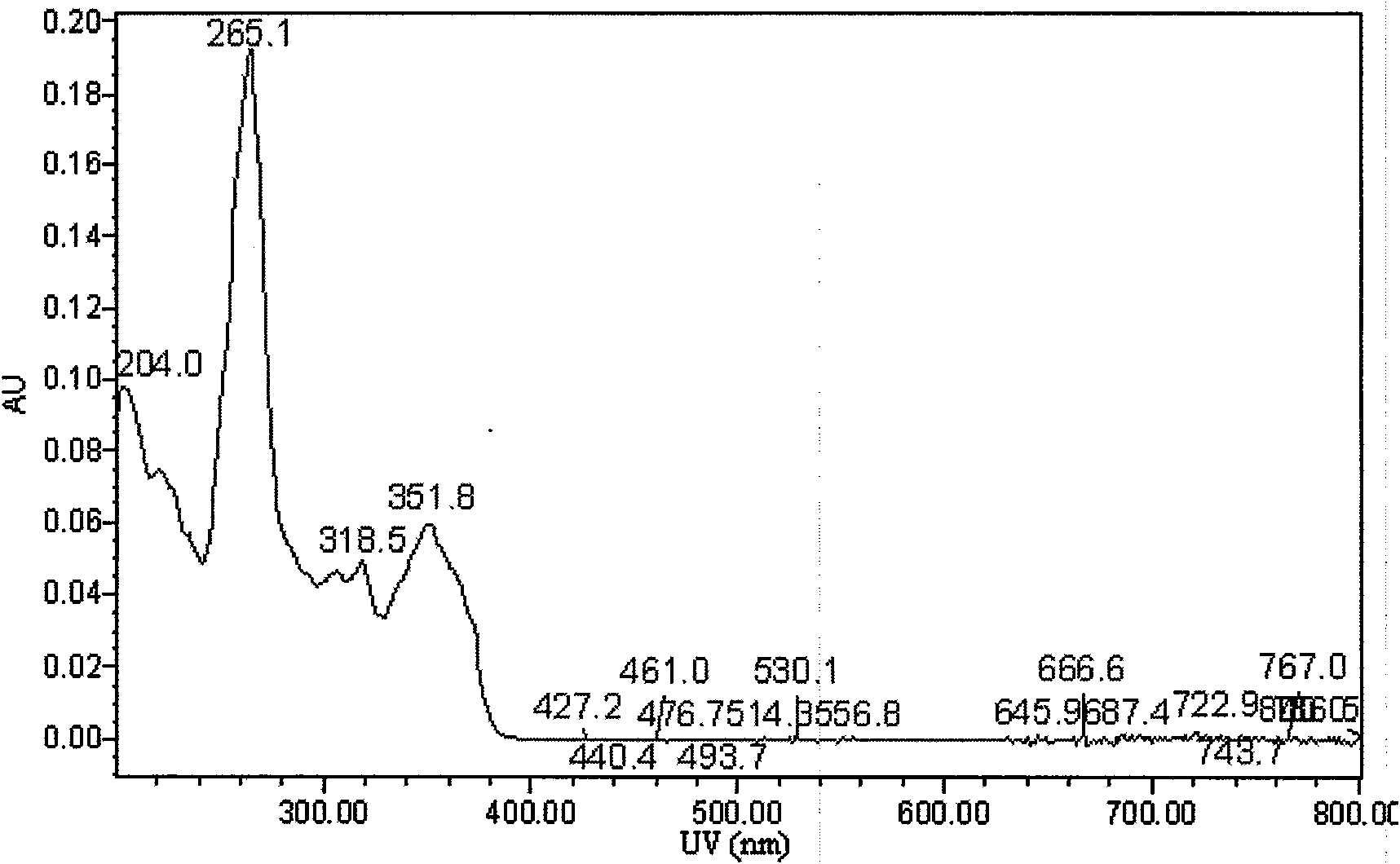

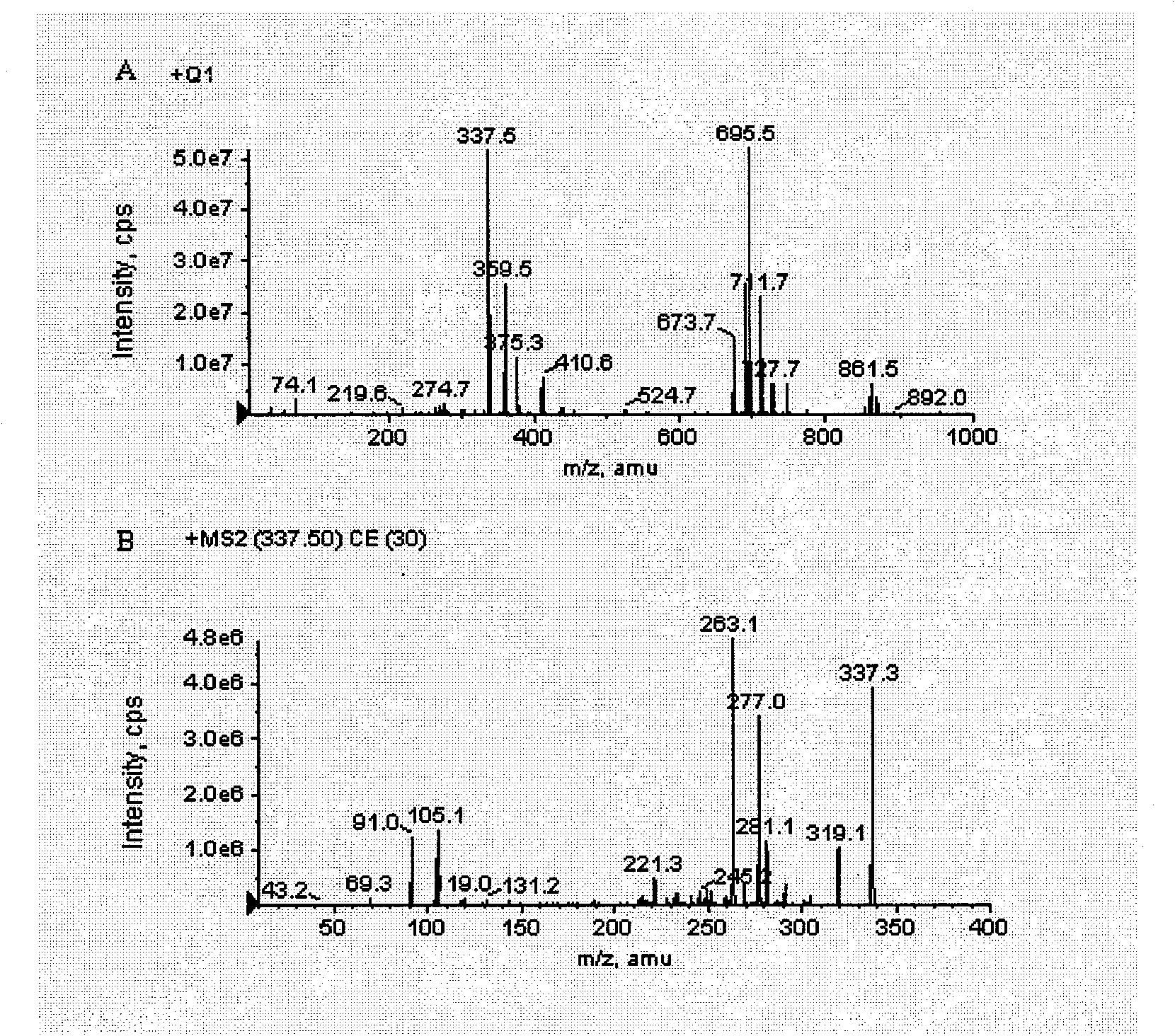

New coumarin active content, preparation method and application thereof

ActiveCN101619054AStrong free radical scavenging activityHigh activityNervous disorderOrganic chemistrySolventPlatelet inhibition

The invention relates to a new coumarin active content, i.e. pigeon pea lactone extracted and separated from cajan leaves, an extraction and separation method and an application thereof. The structure of the compound is shown as a figure 1. The invention adopts the technical scheme that agricultural waste of cajan leaves is used as raw material which is extracted by a solvent; the extracting solution is concentrated and dispersed in water; an ultrasonic oscillation flocculation technology, a bubble column extraction technology and a column chromatography separation technology in positive-phase silica gel are adopted and combined with a low-temperature crystallization and recrystallization technology to obtain the content with the purity higher than 95 percent; and the anti-oxidation activity and the action of the chemical content on cardiovascular diseases are detected by a DPPH model, a beta-renieratene-linoleic acid model, an in-texture SOD enzyme model, a platelet aggregation model induced by ADP in corpora and an aorta systole model induced by phenylephrine. Results show that the active content has favorable free radical scavenging activity, anti-oxidation activity in corpora and in vitro, platelet aggregation restraining action in corpora and a certain hemangiectasis action. Meanwhile, the preparation method of the pigeon pea lactone in the invention is easy and practical and can obtain a product with high purity high yield and high added value in a short period which is suitable for industrialized production and application, can be further developed and researched into a new antioxidant as an additive for medicines, foods and cosmetics.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com