Method for improving expansion effect of microwave expansion tobacco stems

A technology of microwave expansion and tobacco stems, which is applied in tobacco, tobacco processing, application, etc., can solve the problems of low yield of cut stems, poor expansion effect of tobacco stems, and poor quality, so as to enrich the aroma of cigarettes, improve the expansion effect, reduce the The effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

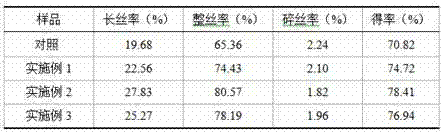

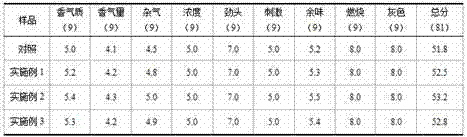

Examples

Embodiment 1

[0024] A method for improving the expansion effect of microwave-expanded tobacco stems is as follows:

[0025] (1) Screening of tobacco stems: 300 kg of upper stems of Honghe K326 are screened through a vibrating screen (the aperture of the screen is 5 mm×25 mm, and the mesh is a waist-shaped hole), and 212 kg of tobacco stems are screened.

[0026] (2) Stem soaking: put the tobacco stems screened in step (1) into water added with ammonium carbonate or ammonium bicarbonate and soak for 1 min, wherein the water temperature is 20°C, and the concentration of ammonium carbonate or ammonium bicarbonate aqueous solution is 1wt.%.

[0027] (3) Stem storage: store the tobacco stem impregnated in step (2) at 20°C for 1 hour, the penetration rate of the tobacco stem is 98.4%, and the moisture content of the tobacco stem is 22.4%;

[0028] (4) Air-drying: the tobacco stems stored in step (3) were air-dried at 30°C for 4 hours, and the moisture content of the tobacco stems was 11.2%.

[...

Embodiment 2

[0031] A method for improving the expansion effect of microwave-expanded tobacco stems is as follows:

[0032] (1) Screening of tobacco stems: 300 kg of upper stems of Honghe K326 are screened through a vibrating screen (the aperture of the screen is 5 mm×25 mm, and the mesh is a waist-shaped hole), and 212 kg of tobacco stems are screened.

[0033] (2) Stem soaking: put the tobacco stems screened in step (1) into water added with ammonium carbonate or ammonium bicarbonate and soak for 3 minutes, wherein the water temperature is 30°C, and the concentration of ammonium carbonate or ammonium bicarbonate aqueous solution is 5wt.%.

[0034] (3) Stem storage: store the tobacco stem impregnated in step (2) at 30°C for 3 hours, the penetration rate of the tobacco stem is 100%, and the moisture content of the tobacco stem is 24.8%;

[0035] (4) Air-drying: the tobacco stems stored in step (3) were air-dried at 20°C for 4 hours, and the moisture content of the tobacco stems was 12.8%. ...

Embodiment 3

[0038] A method for improving the expansion effect of microwave-expanded tobacco stems is as follows:

[0039] (1) Screening of tobacco stems: 300 kg of upper stems of Honghe K326 are screened through a vibrating screen (the aperture of the screen is 5 mm×25 mm, and the mesh is a waist-shaped hole), and 212 kg of tobacco stems are screened.

[0040] (2) Stem soaking: put the tobacco stems screened in step (1) into water added with ammonium carbonate or ammonium bicarbonate and soak for 2 minutes, wherein the water temperature is 25°C, and the concentration of ammonium carbonate or ammonium bicarbonate aqueous solution is 3wt.%.

[0041] (3) Stem storage: the tobacco stems impregnated in step (2) were stored at 25°C for 2 hours, the penetration rate of the tobacco stems was 99.1%, and the moisture content of the tobacco stems was 23.1%.

[0042] (4) Air-drying: the tobacco stems stored in step (3) were air-dried at 25°C for 6 hours, and the moisture content of the tobacco stems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com