Patents

Literature

145results about How to "Less severe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

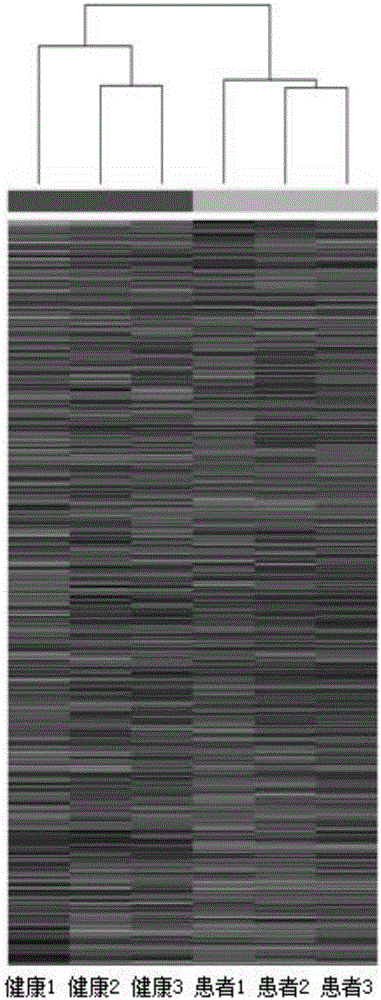

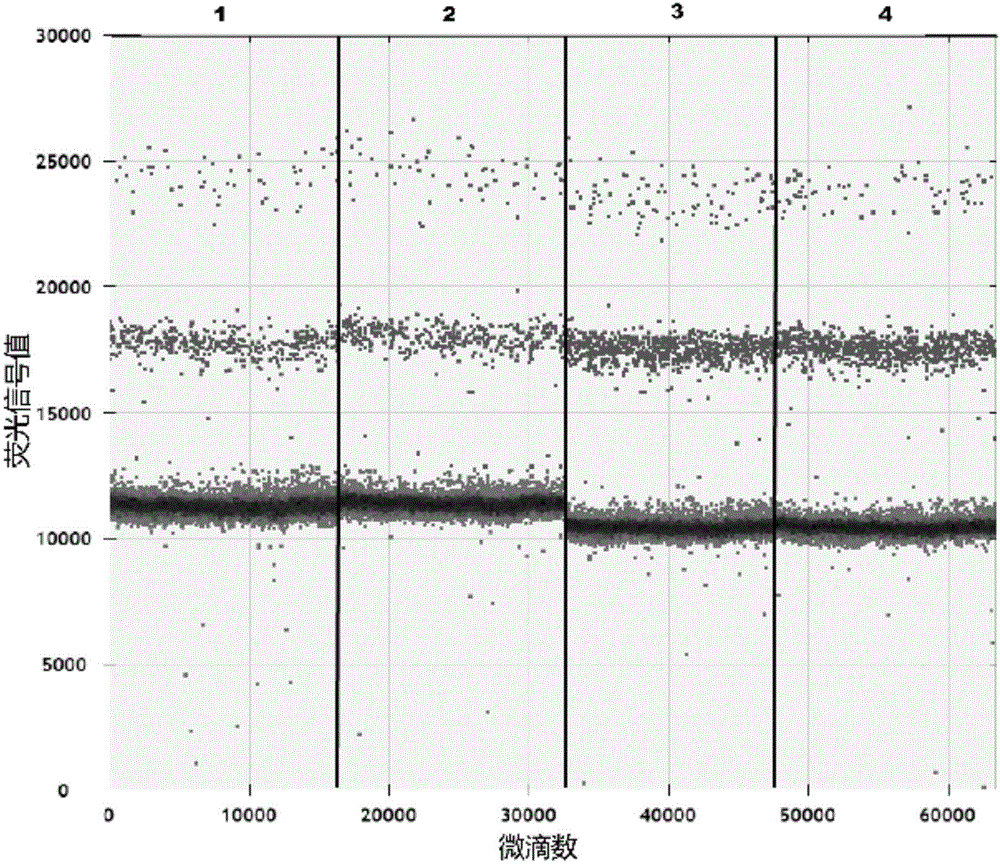

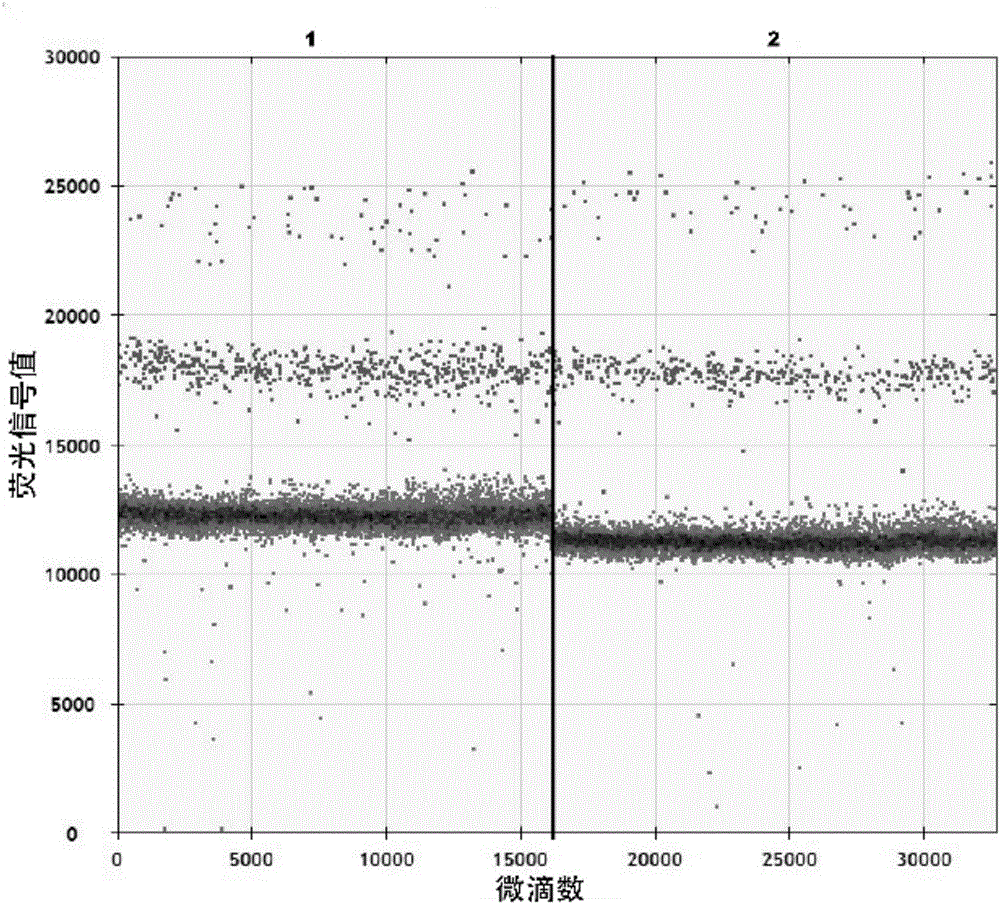

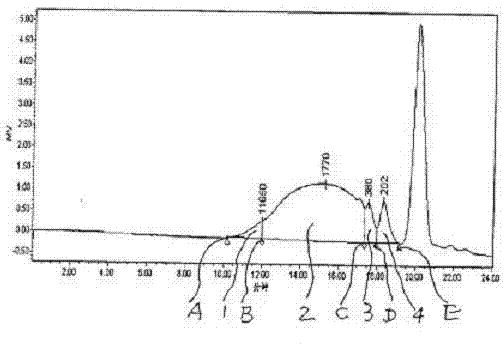

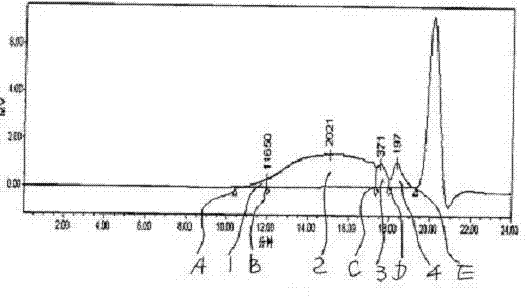

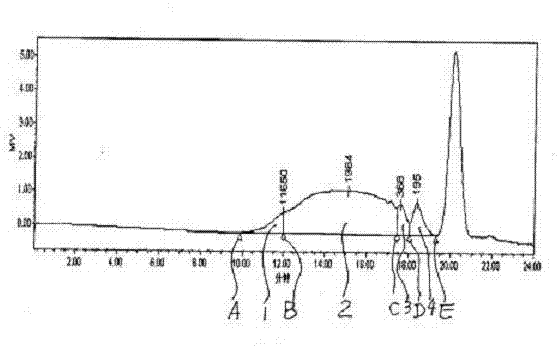

Detection and application of new molecular marker hsa-circ-0001017 of gastric cancer

ActiveCN106591428AReduce yieldHigh yieldMicrobiological testing/measurementDNA/RNA fragmentationHousekeeping geneFluorescence

The invention relates to a cyclic RNA molecular marker for diagnosis of gastric cancer, the cyclic RNA molecular marker is characterized in that the cyclic RNA is hsa-circ-0001017, the invention also provides a method for detection of the cyclic RNA molecular marker in plasma, and the method comprises the following steps: (1) collecting blood, and extracting total RNA in the plasma; (2) performing reverse transcription of the total RNA into cDNA; (3) performing droplet digital PCR detection of a cDNA solution of the step (2) by use of specific amplification back-to-back primers and amplification upstream and downstream primers of housekeeping gene GAPDH, after the completion of the reaction, detecting fluorescence signal values of all droplets, setting a threshold, and determining whether the droplets include the cyclic RNA or the housekeeping gene GAPDH, wherein the droplets higher than the threshold are positive droplets, and the droplets below the threshold are negative droplets; and (4) counting the number of the positive droplets, and calculating the copy number of the hsa-circ-0001017 and the housekeeping gene GAPDH in the plasma for quantitative detection of the hsa-circ-0001017 and the housekeeping gene GAPDH in the plasma. Compared with the prior art, the advantages are that the hsa-circ-0001017 can be specifically expressed in plasma in patients with gastric cancer, and can be used as a new molecular marker for diagnosis of the gastric cancer.

Owner:NINGBO UNIV

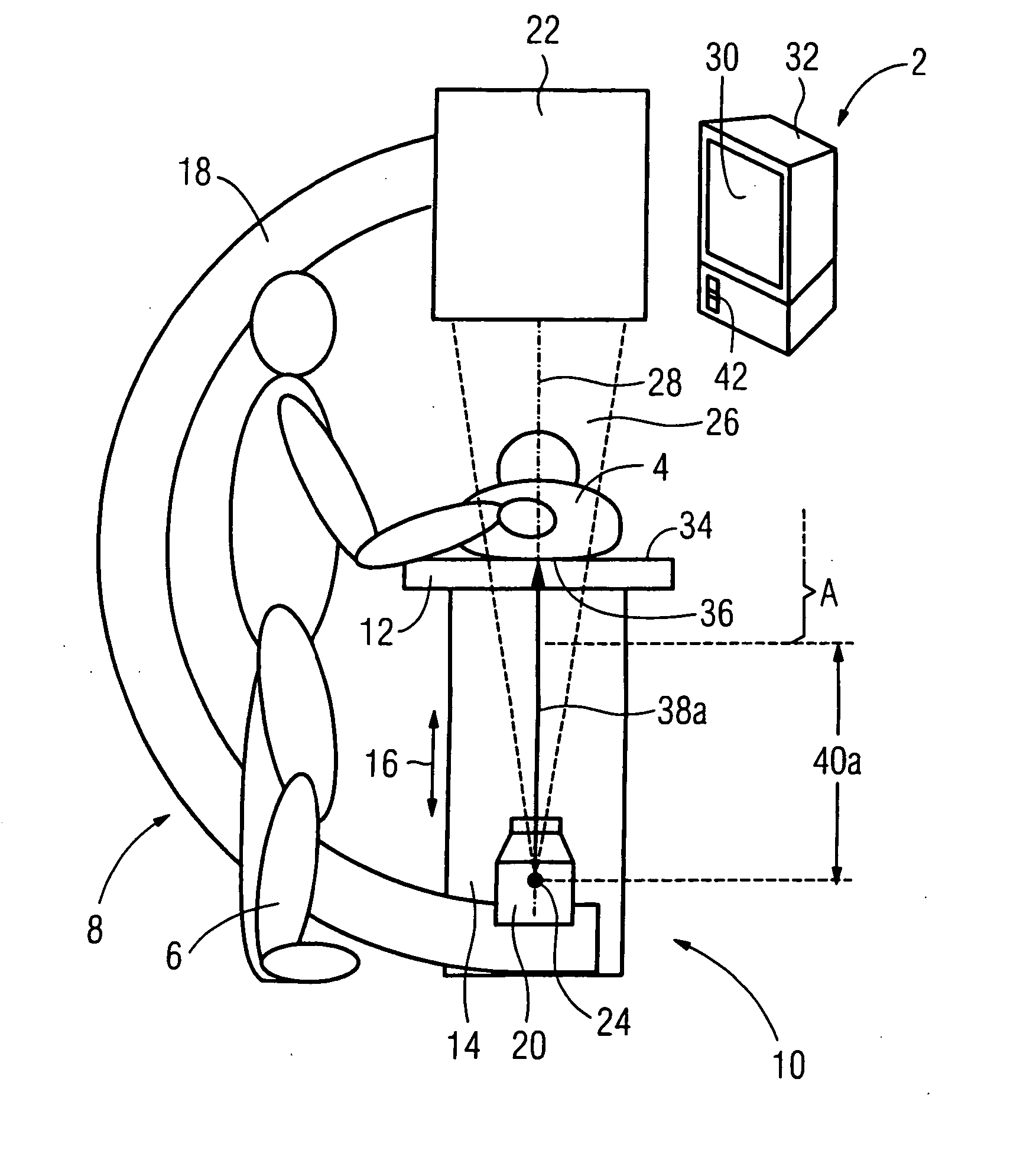

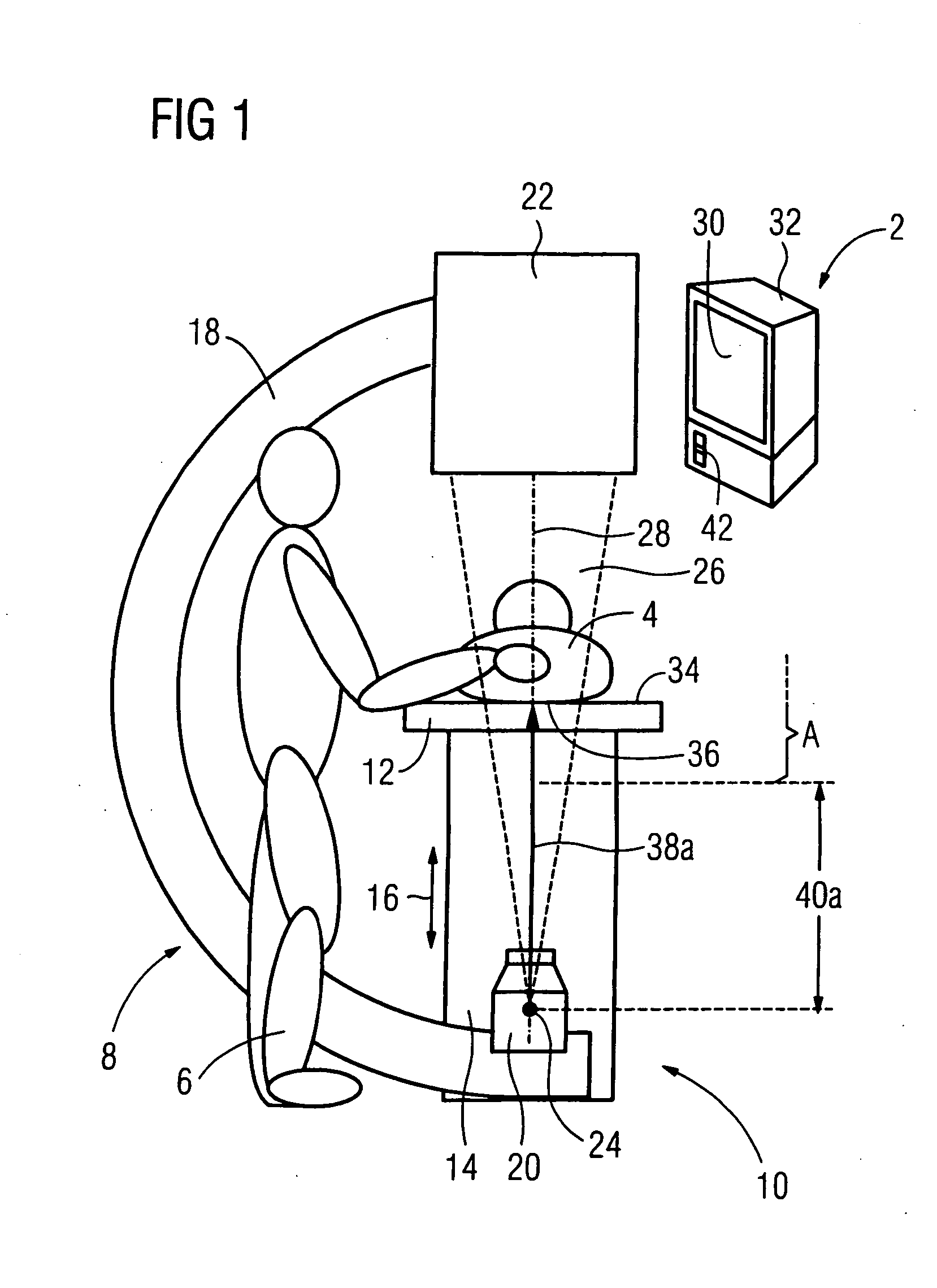

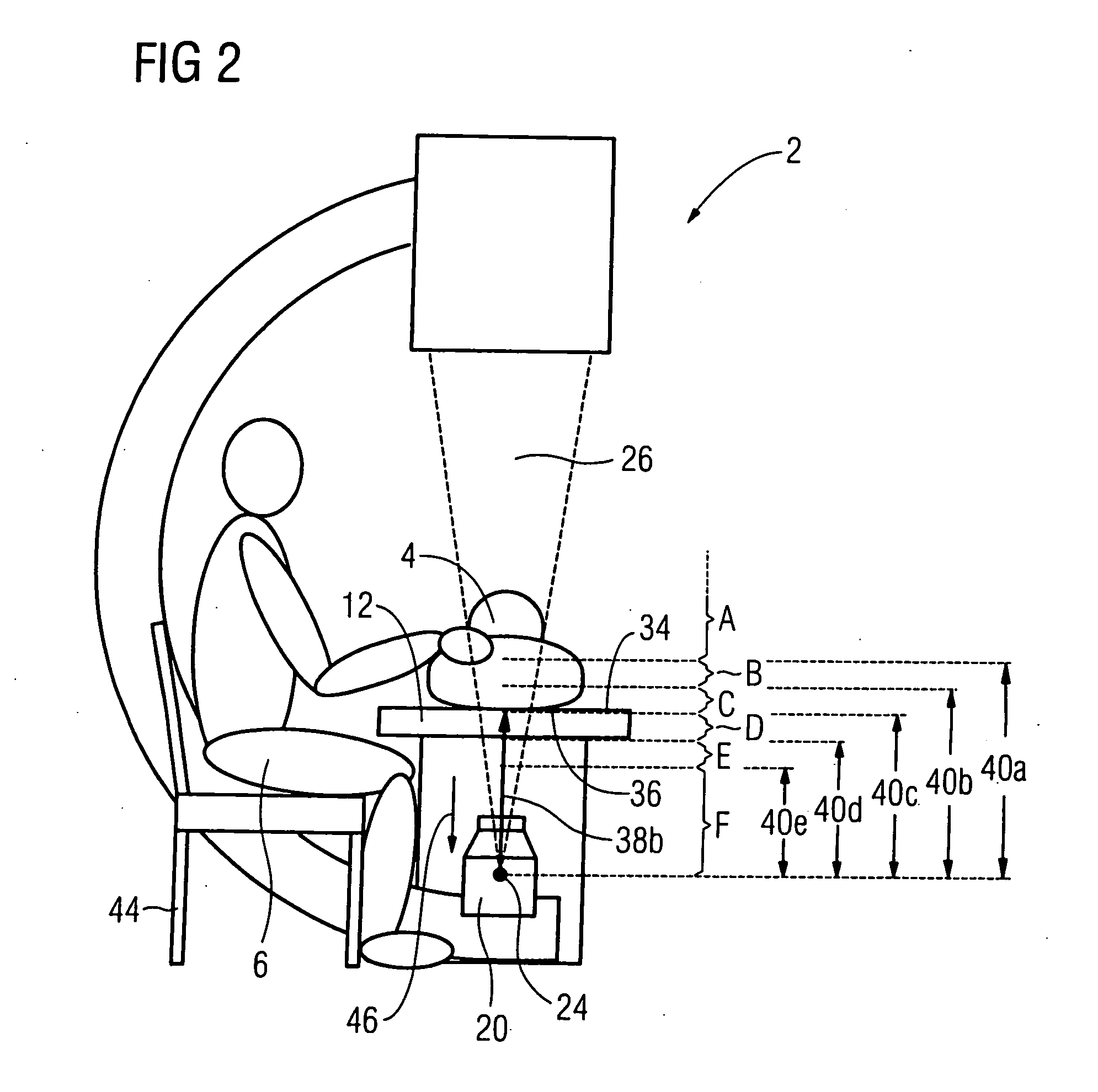

Method and x-ray apparatus for exposure of a patient who can be placed at a variable distance relative to an x-ray source

InactiveUS20060269044A1Less severeQuality improvementTomographyDiaphragms for radiation diagnosticsDose rateX-ray

Owner:SIEMENS HEALTHCARE GMBH

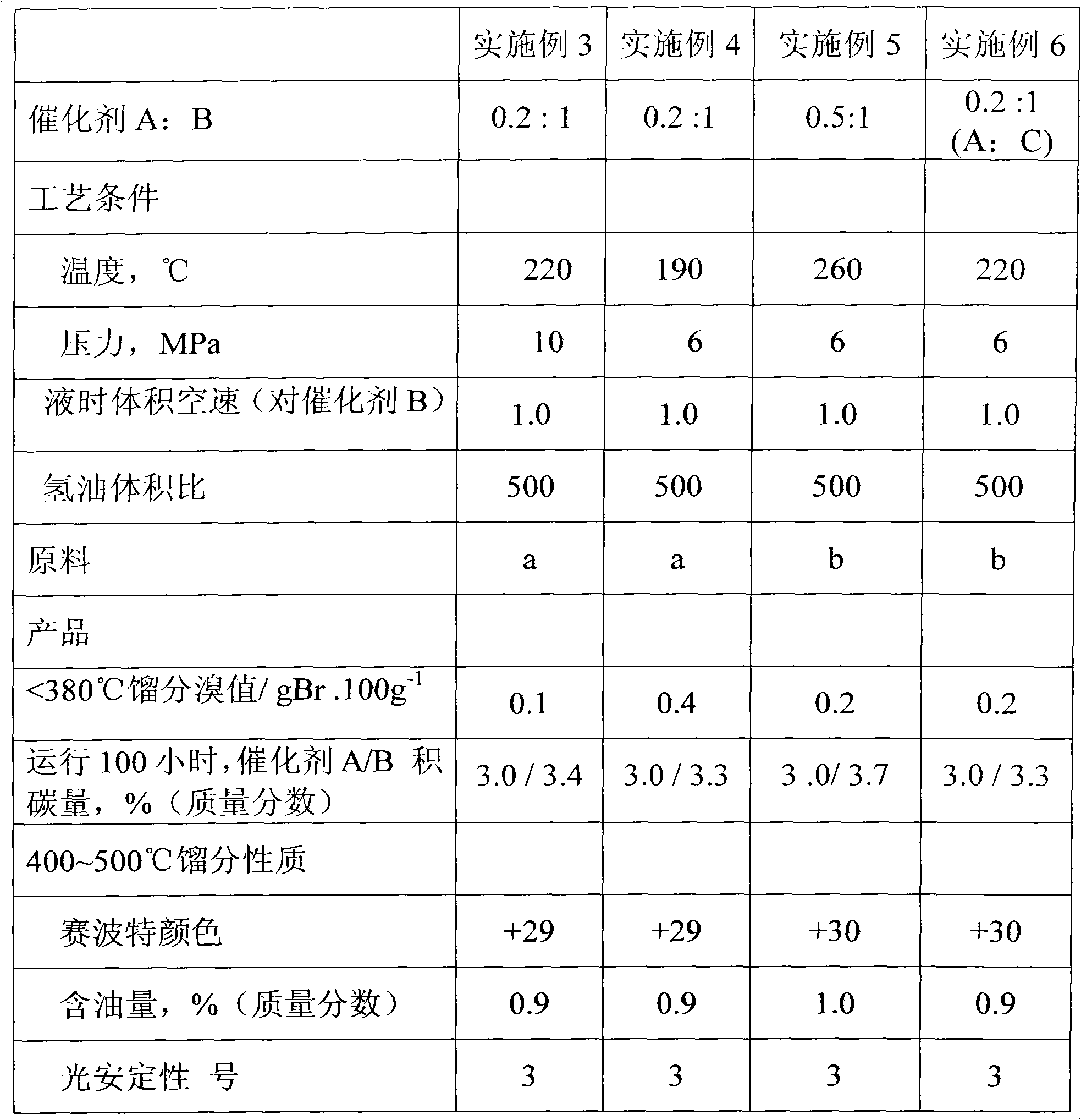

Hydrofining method for Fischer-Tropsch oil

ActiveCN102041067AReduce carbon depositionLess severePetroleum wax refiningTreatment with hydrotreatment processesHydrodeoxygenationFixed bed

The invention discloses a hydrofining method for Fischer-Tropsch oil. In the method, a fixed bed reactor is used, and the Fischer-Tropsch oil is contacted with the diolefins hydrogenation saturation catalyst so as to hydrogenate and saturate diolefins and then is contacted with the hydrogenated deoxidized catalyst in order to carry out olefin saturation and hydrodeoxygenation reactions, so as to obtain the hydrofined products. Compared with the method using a single catalyst, the method disclosed by the invention can reduce the coke and deposited carbon formed by polymerizing dienes. Compared with the method using a double reactor, the method disclosed by the invention simplifies the process flow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing phenolic resins by using paraformaldehyde

ActiveCN103087280AReduce generationImprove performanceAldehyde/ketone condensation polymer adhesivesOXALIC ACID DIHYDRATEParaformaldehyde

The invention belongs to the technical field of phenolic resin synthesis, and discloses a method for synthesizing phenolic resins by using paraformaldehyde. The method comprises the following steps: opening a reaction kettle stirring mechanism, pumping preheated phenol into a reaction kettle in a reduced pressure state, then pumping recycled phenol containing wastewater into the reaction kettle and carrying out vacuum removal on the reaction kettle, and putting paraformaldehyde into the reaction kettle to uniformly heat at normal pressure so as to heat the obtained mixture to be boiled; after the boiling reaction is completed, cooling the obtained mixture, and adding an oxalic acid solution into the reaction kettle; after the obtained mixture is heated to be boiled and the pressure-reduced dehydration temperature rises to 150 DEG C, carrying out slow vacuum enrichment and then emptying on the obtained product so as to obtain phenolic resins, wherein the proportion of macromolecular weights of the phenolic resins is less than 6%, and the proportion of middle molecular weights of the phenolic resins is more than 80%. The phenolic resins prepared by using the method disclosed by the invention have high fluidity, and have a higher bonding strength when being taken as a binder under the condition that the resin adding amount is less.

Owner:河北泽田化工有限公司

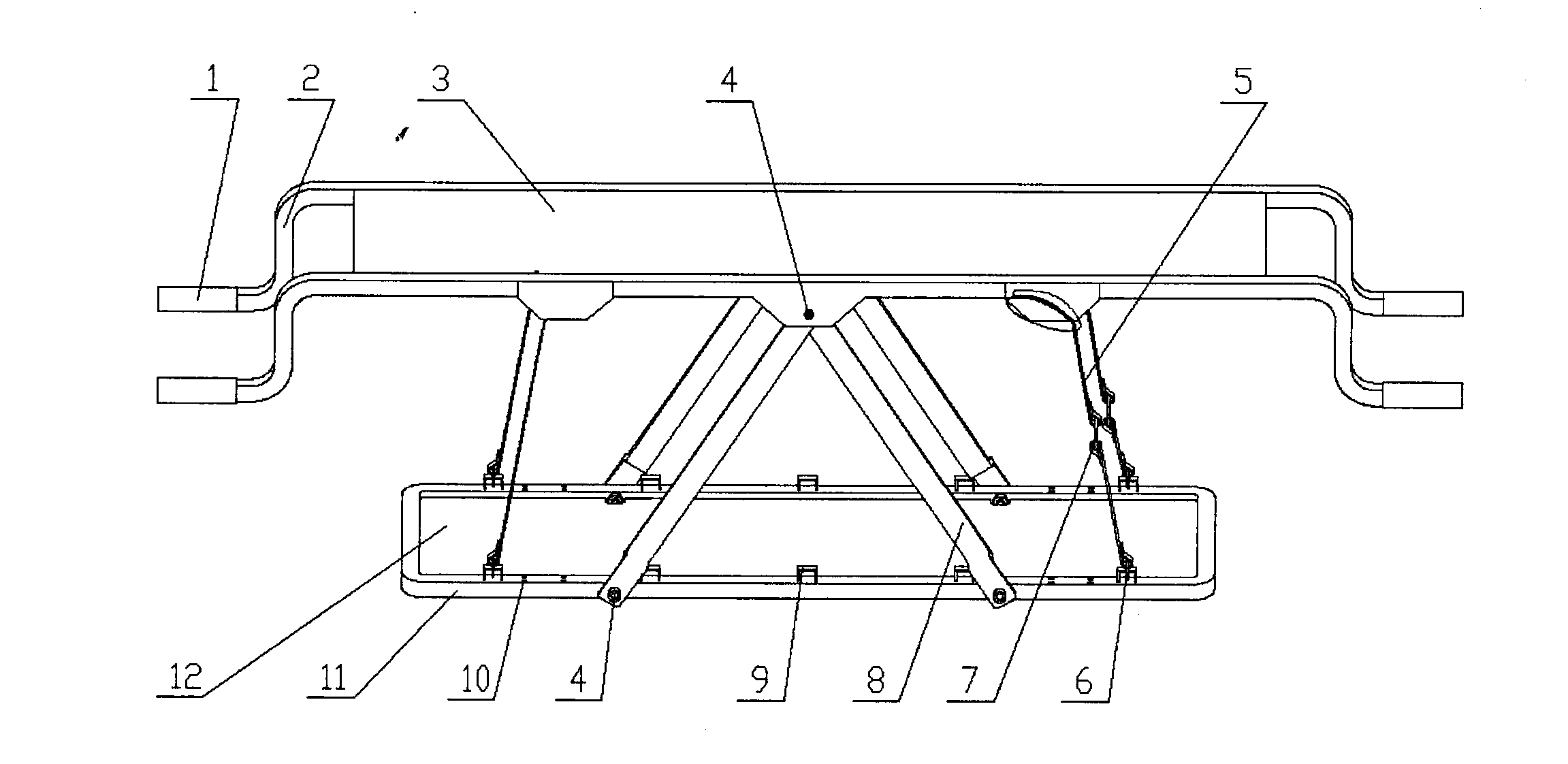

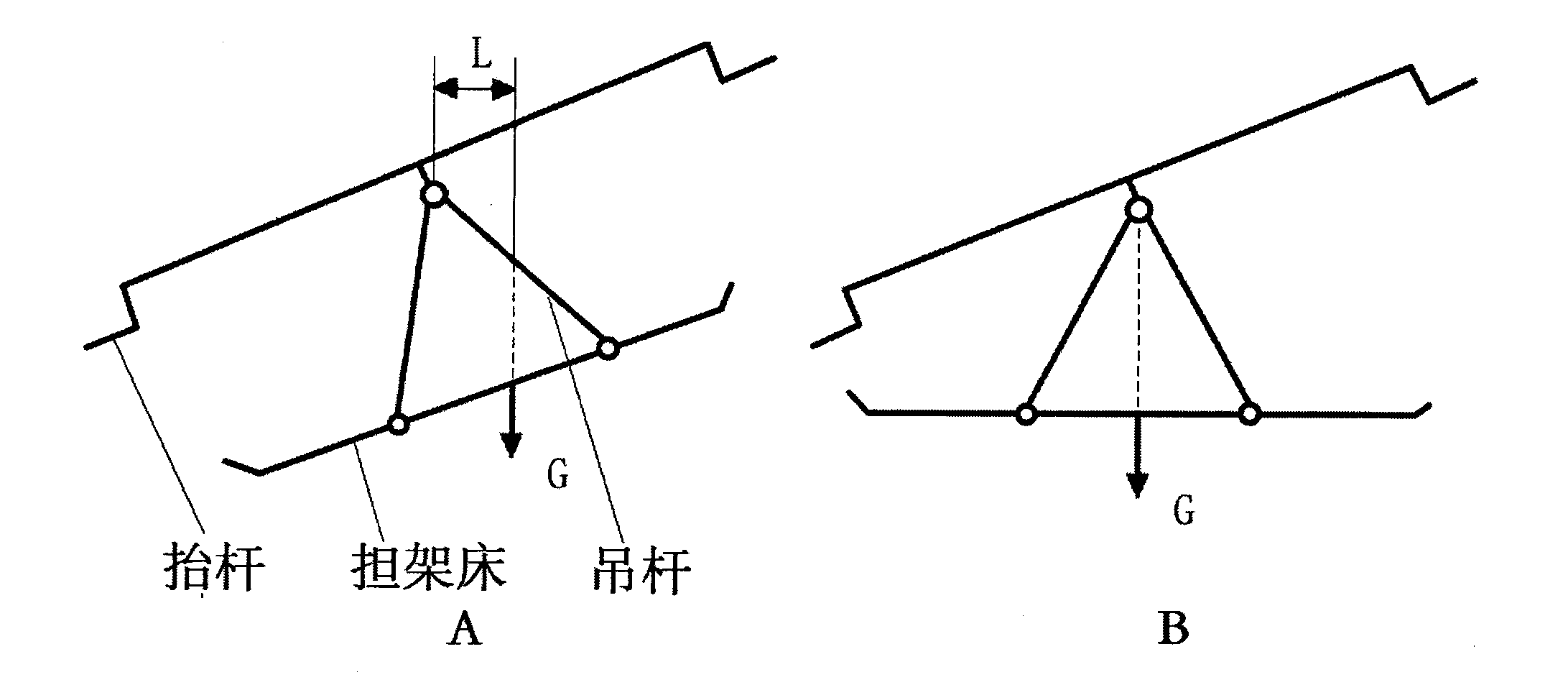

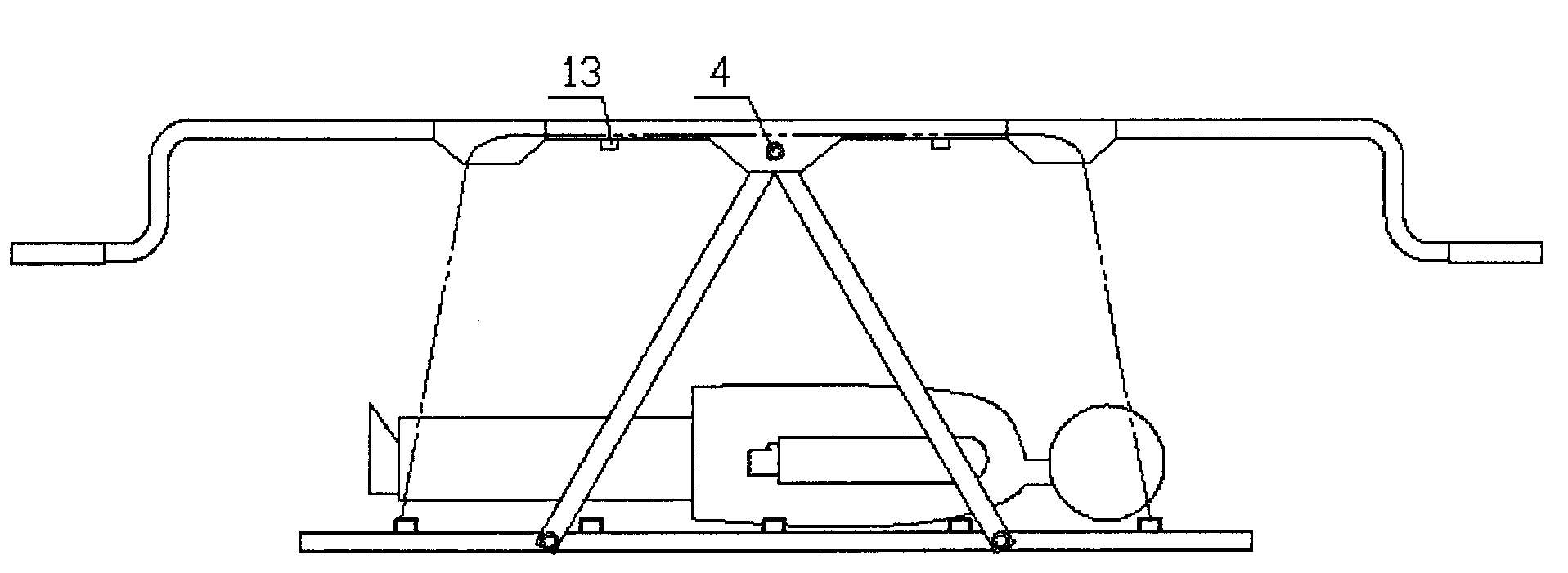

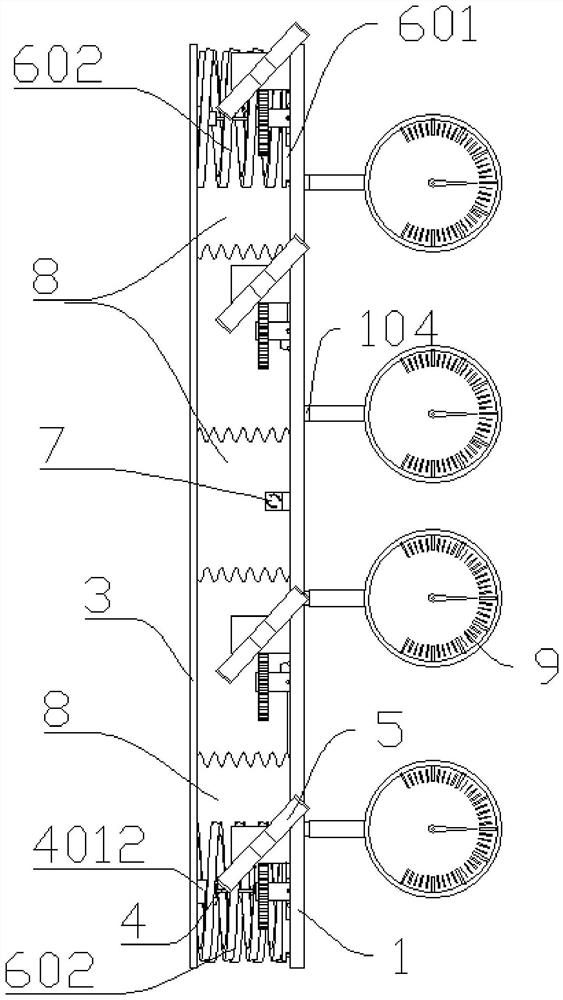

Automatically leveled type multifunctional rescue stretcher

InactiveCN103230318AEasy to disassembleAutomatic level realizationStretcherEngineeringMultiple function

The invention belongs to the field of medical conveying appliances, and particularly relates to an automatically leveled type multifunctional rescue stretcher. In order to cope with the characteristics of complex locality and various disastrous conditions during the field rescue, the automatically leveled type multifunctional rescue stretcher which mainly comprises a left lifting rod, a right lifting rod both located at the top part, four suspension rods and a stretcher bed located at the bottom is provided. Four rotation pairs composed of the lifting rods, the suspension rods and the stretcher bed encircle to form two isosceles triangle hanger frames; the stretcher bed is automatically leveled when persons climb slope or get down slope by utilizing moment of force generated by the gravities of the ill and wounded persons and the stretcher bed; and the damping stabilization function of the stretcher bed is realized by utilizing a friction force between stabilizing belts and the lifting rods. The lifting rods, the stabilizing belts, the suspension rods and the stretcher bed are connected by pins; and a rescuer can detach the stretcher into two simple stretchers based on the practical need so as to be used for conveying a common ill and wounded person and an ill and wounded person with fracture respectively. As the relatively angles of the stretcher bed and the lifting rods can be locked, the automatically leveled type multifunctional rescue stretcher after being locked can serve as a simple tent, a simple operating table and a double-layer stretcher.

Owner:王文鹏

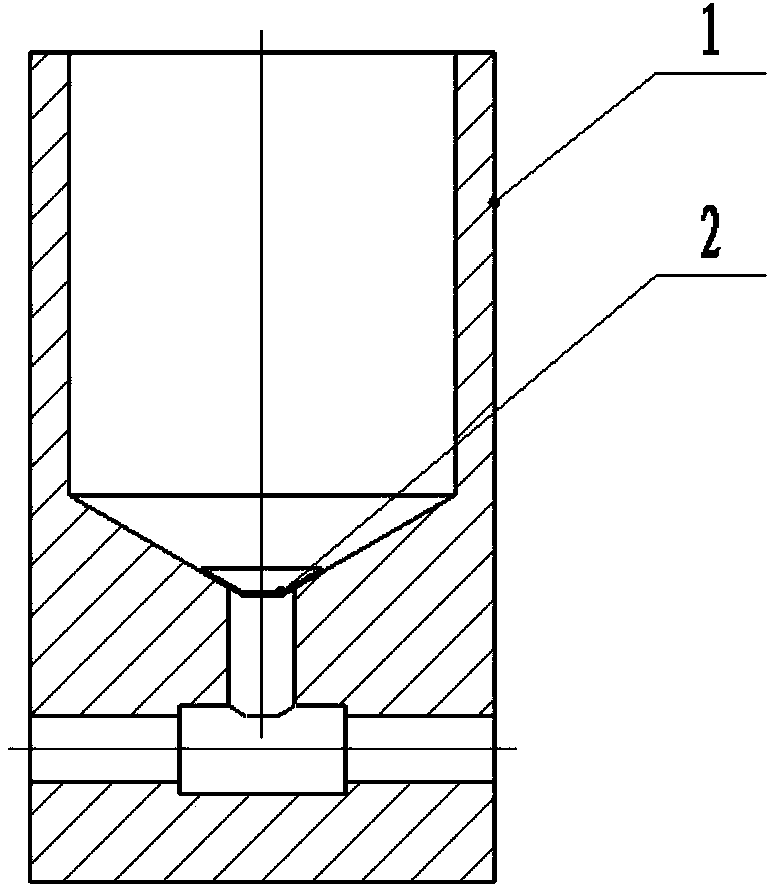

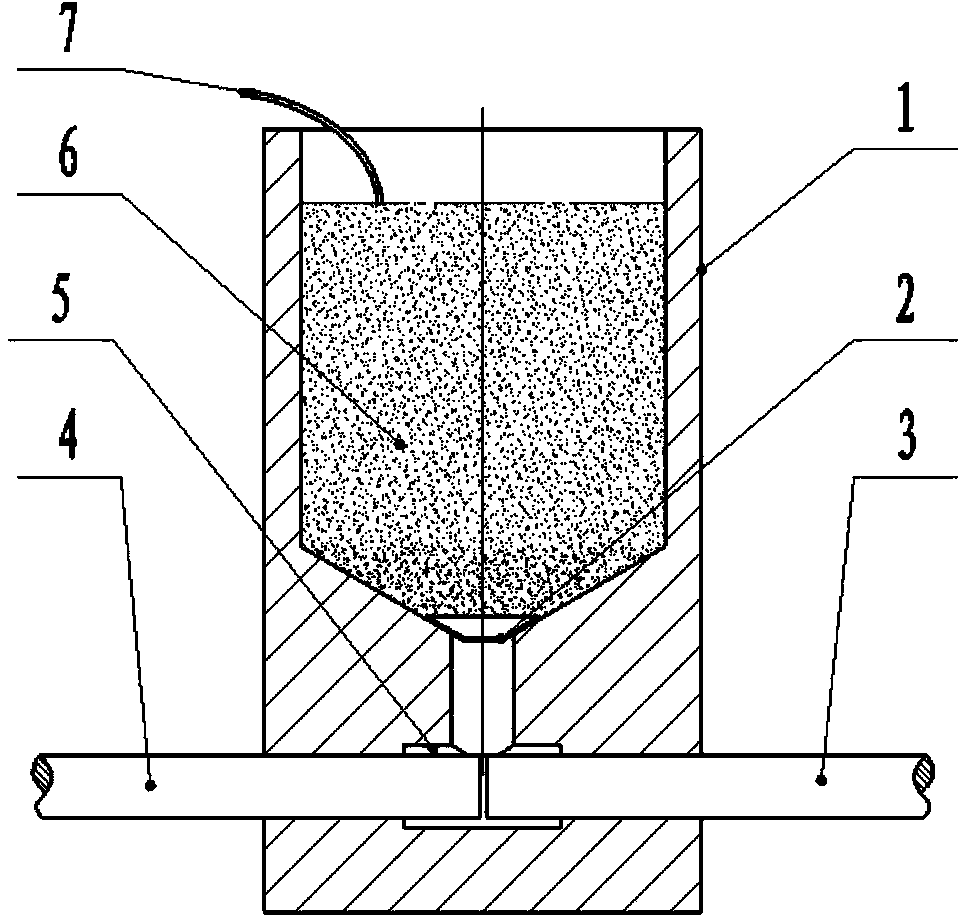

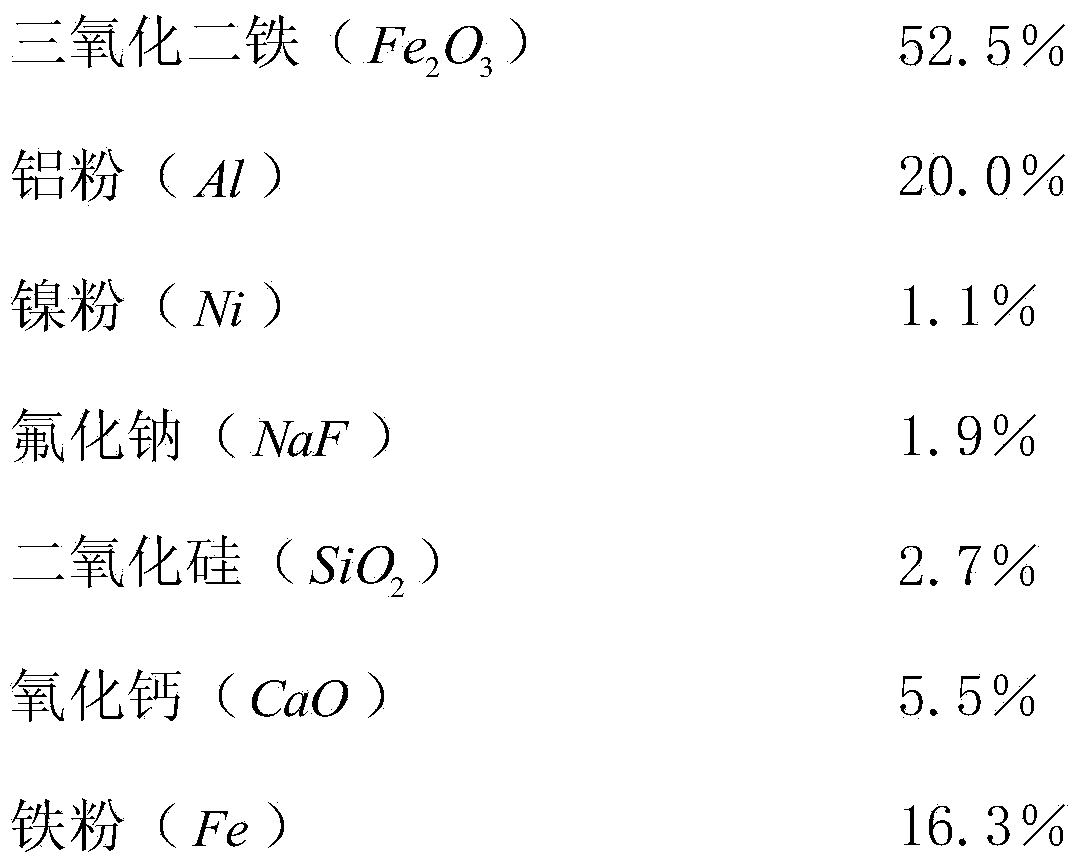

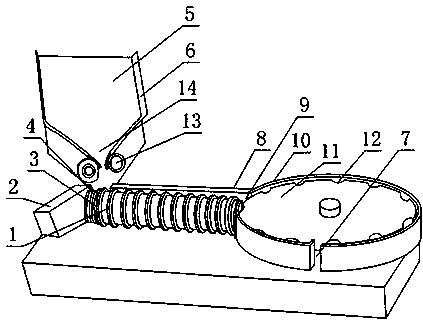

Iron-based nonelectric welding device

ActiveCN103506755ARealize the purpose of weldingReduce the extent of galvanic corrosionWelding/cutting media/materialsSoldering mediaElectrode potentialMetallic aluminum

Provided is an iron-based nonelectric welding device. The body of the iron-based nonelectric welding device is a disposable die filled with iron-based soldering flux, wherein the iron-based soldering flux contains 48%-57% of ferric oxide powder, 15%-25% of metallic aluminum powder, 0.2%-2.8% of metallic nickel powder, 0.5%-4% of fluorite powder, 1%-6% of silicon dioxide powder, 3.1%-8.2% of calcium oxide powder and 12%-21% of metallic iron powder. The disposable die is formed through single-pressing and stoving after rick fat oil is mixed with standard sand. The soldering flux mainly comprises ferric oxide, ferrous powder and a little of nickel powder, and iron-nickel alloy is produced on soldering points through self-propagating reaction after ignition; the iron-nickel alloy is approximately equal to parent metal steel of a grounding device in electrode potential, and galvanic corrosion of parent metal cannot caused. The die is good in thermal insulation effect and low in price, links of cleaning, die sinking, die filling and the like are reduced through one-time use, time is saved, and scalding risks of staff are reduced. The reaction speed of soldering flux ranges from 45 seconds to 60 seconds and longer than common self-propagation by 20 seconds, the possibility of splashing of reaction products is reduced, evacuation is facilitated, and safety is good.

Owner:武汉长威电气有限责任公司

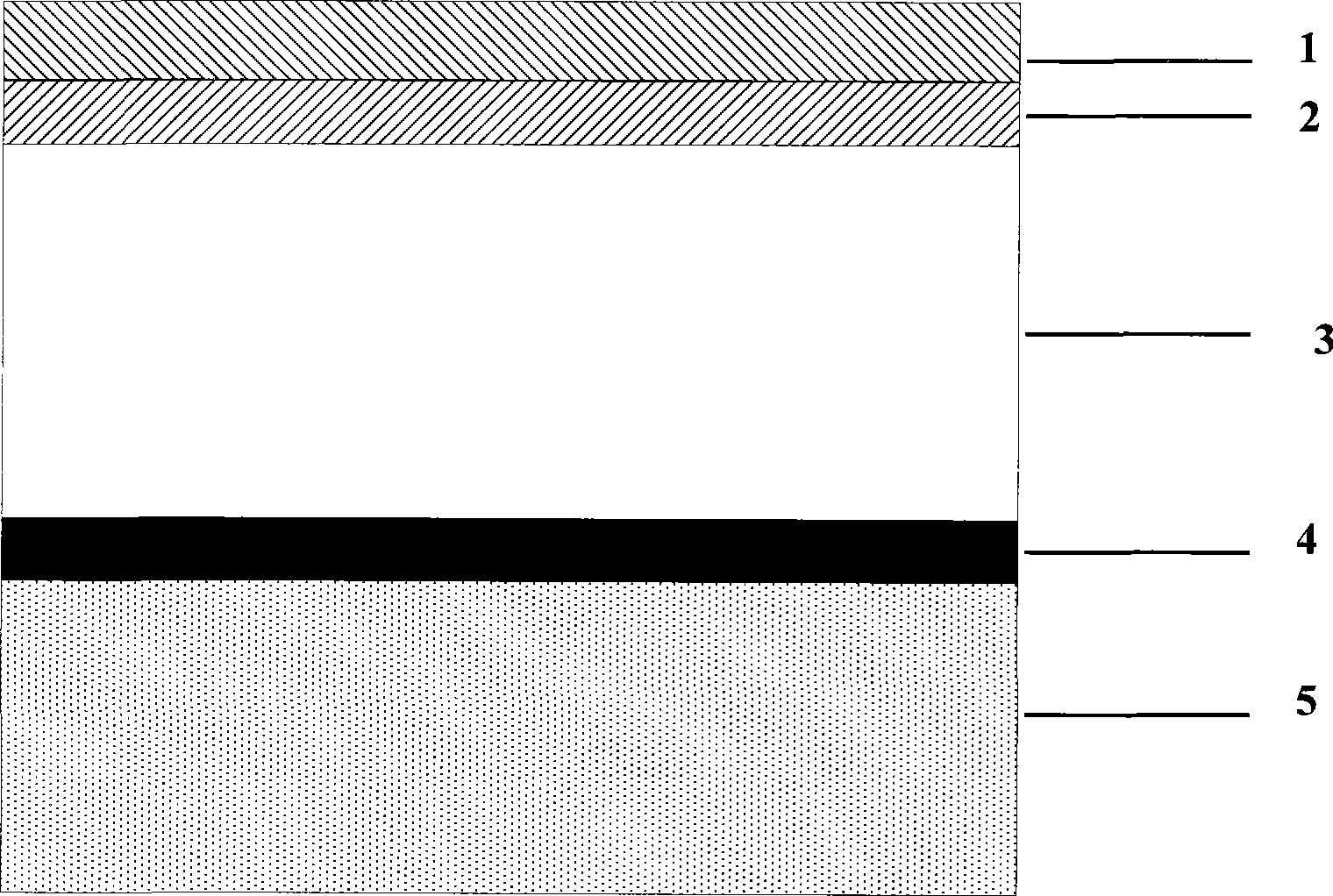

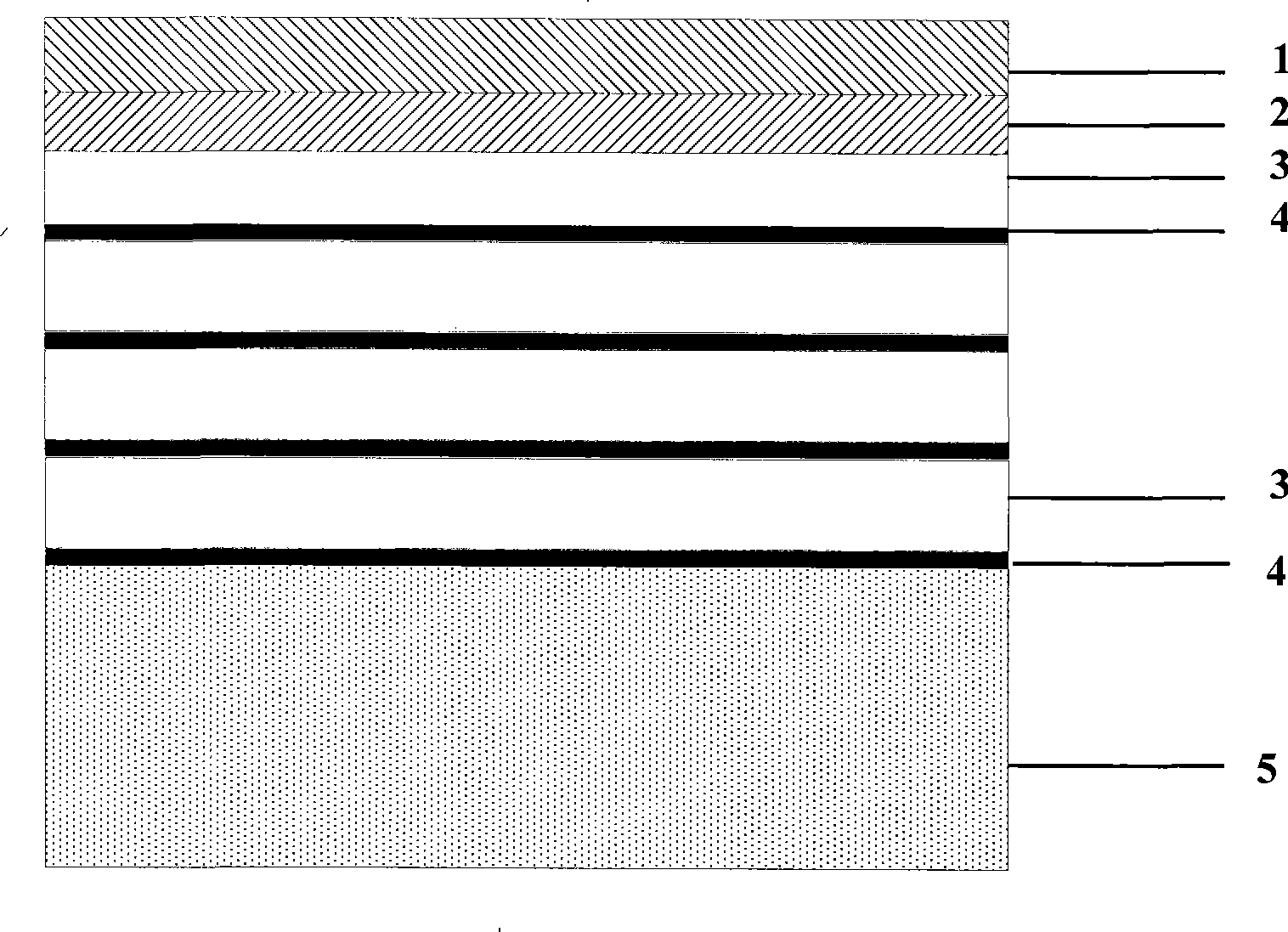

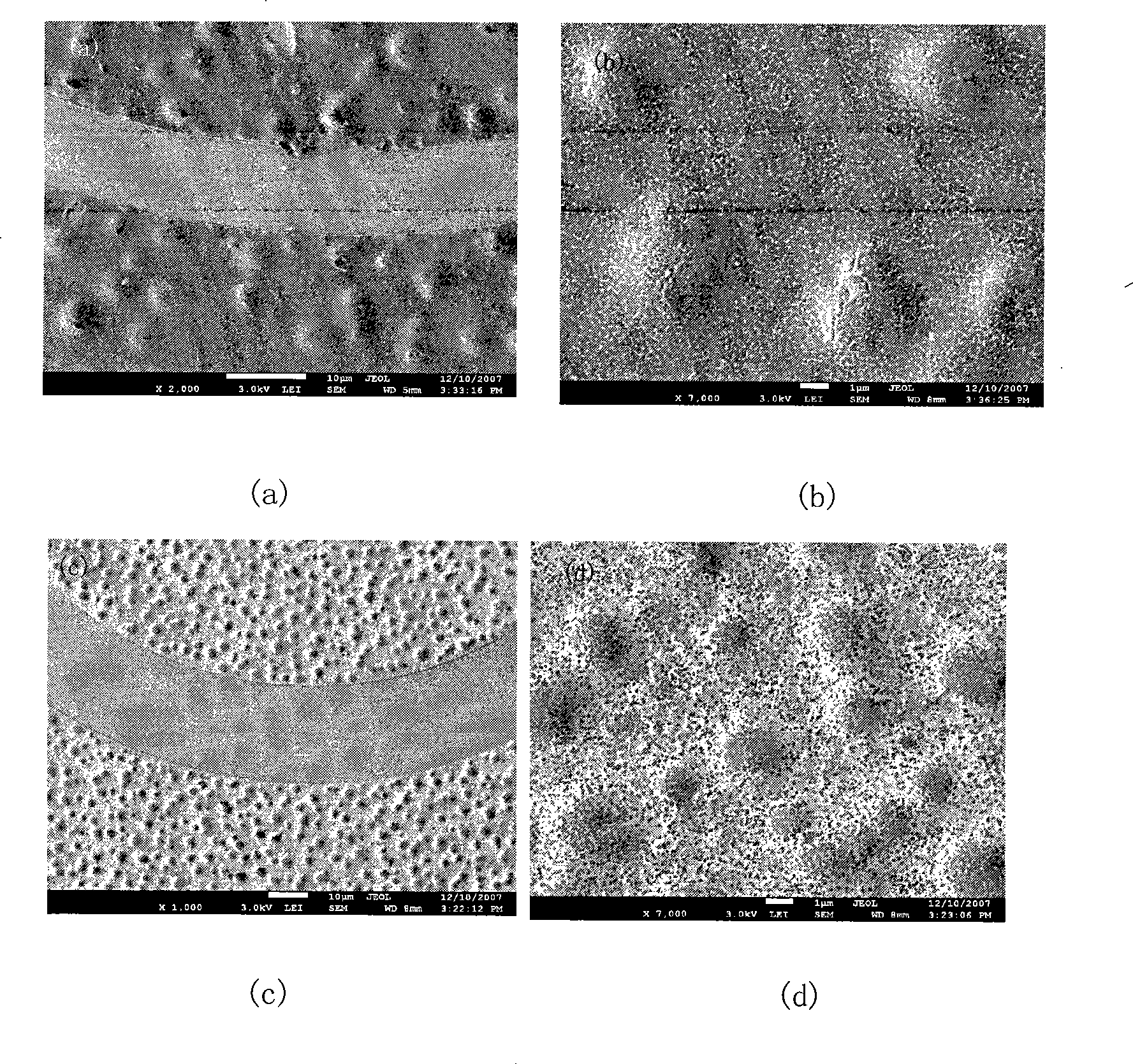

Ohm contact of gallium nitride base device and preparation method thereof

InactiveCN101369599AIncrease contact interfaceFully fixed lateral flowLaser detailsFinal product manufactureTitanium metalOhmic contact

The invention discloses an ohmic contact of a GaN-based apparatus and a manufacturing method thereof, belonging to the technical field of semiconductors. The ohmic contact of the GaN-based apparatus is composed of a titanium metal layer, an aluminum metal layer, a barrier metal layer and a gold metal layer; the titanium metal layer is contacted with the ohmic contact of the GaN-based apparatus, the aluminum metal layer is covered on the titanium metal layer, the barrier metal layer and the gold metal layer are covered on the titanium metal layer and the aluminum metal layer in sequence, wherein, the titanium metal layer and the aluminum metal layer are overlapped in two to ten periods. Compared with the prior ohmic contact structure, the invention balances low ohmic contact ratio based on the ohmic contact of a multilayer Ti / Al structure, has good surface appearance and high reliability, can improve the combination property of the ohmic contact, and has an important meaning for realizing the GaN-based apparatus with high performance and high reliability.

Owner:PEKING UNIV

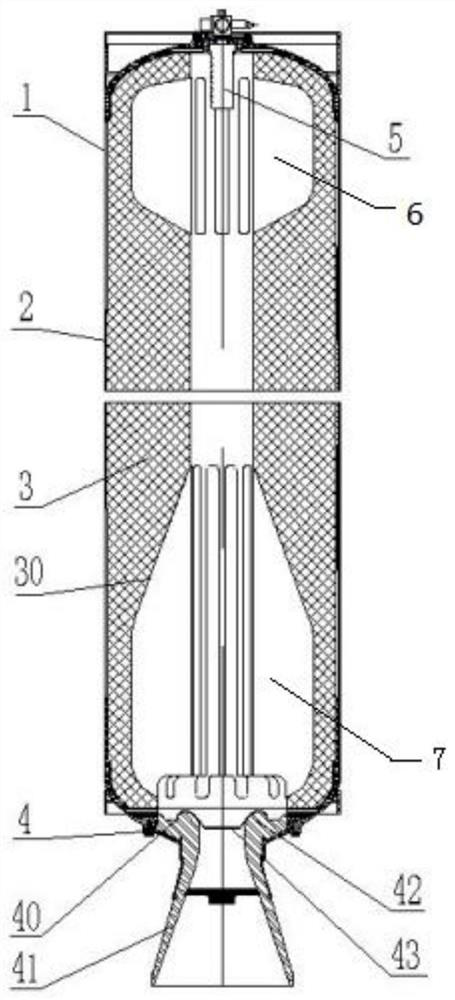

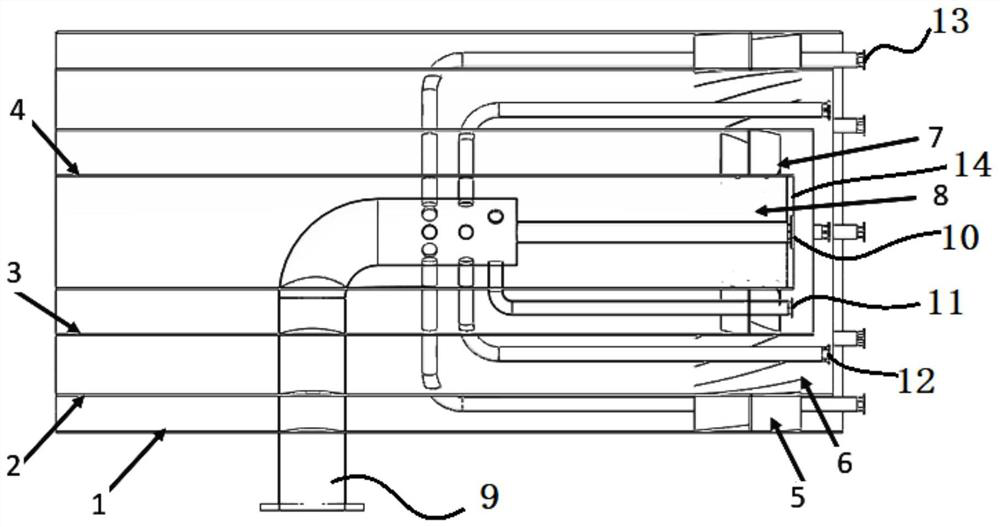

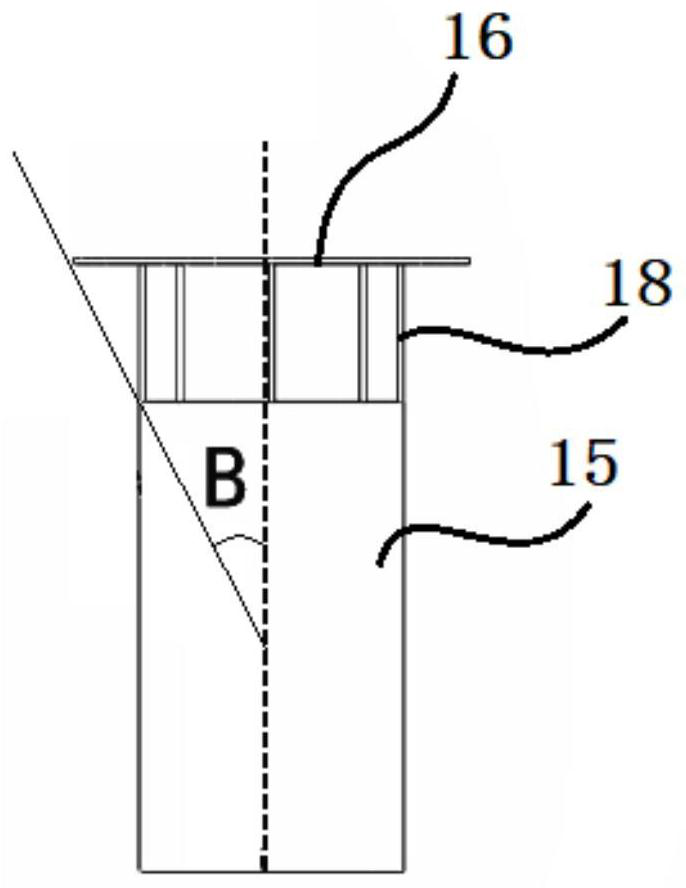

Single-compartment dual-thrust solid rocket engine and rocket

ActiveCN111810318AIncreased thrust rangeLess severeRocket engine plantsCombustion chamberClassical mechanics

The invention provides a single-compartment dual-thrust solid rocket engine and a rocket. The engine comprises a combustion chamber housing, a heat insulating layer attached to the inner surface of the combustion chamber housing, a propellant grain positioned in the combustion chamber housing, an igniter arranged at one end of the combustion chamber housing and a spray tube assembly arranged at the other end of the combustion chamber housing, wherein the propellant grain is provided with an inner hole which penetrates through the two ends of the propellant grain; the position, at one end closeto the igniter, of the inner hole, of the propellant grain is uniformly provided with a front wing slot which extends in a radial direction, and the position, at one end close to the spray tube assembly, of the inner hole, of the propellant grain is provided with a tail wing slot which extends in the radial direction; a ratio of wing slot depth of the front wing slot and the tail wing slot to thebiggest thickness of the propellant grain is greater than or equal to 0.81; and the slope range of the rear wing axial slope of the grain ranges from 160 degrees to 170 degrees. The single-compartment dual-thrust solid rocket engine is great in thrust change range, is stable in grain structure, is small in grain combustion surface change speed while an engine thrust mode is converted, can effectively reduce pressure intensity change speed of the combustion chamber, and enables thrust change speed to be gentle.

Owner:北京凌空天行科技有限责任公司

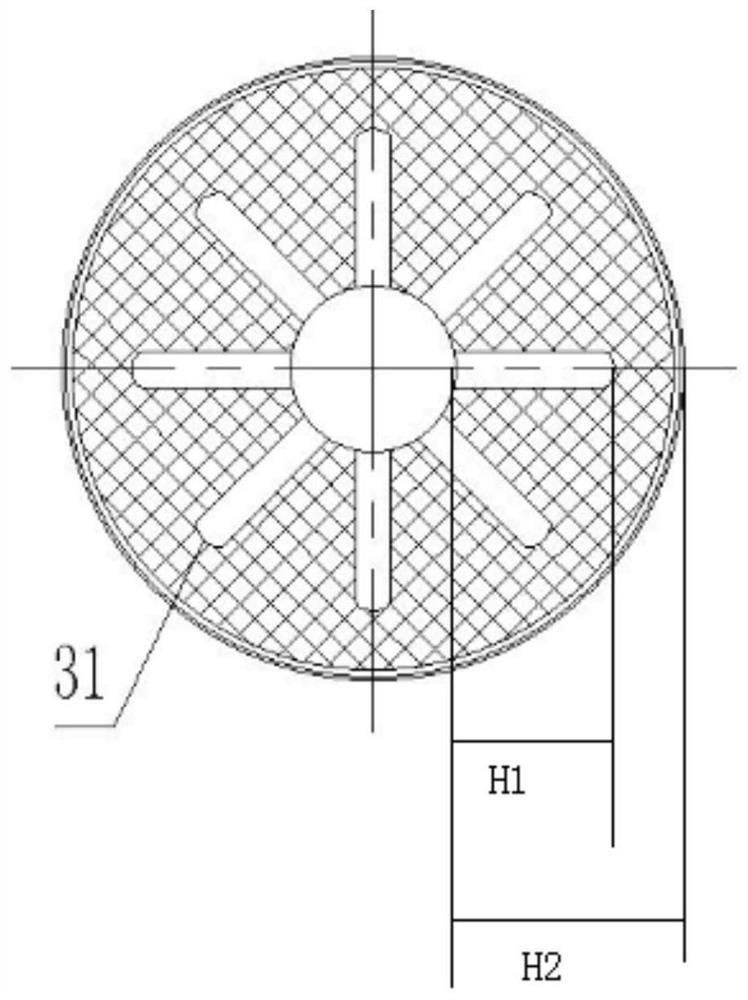

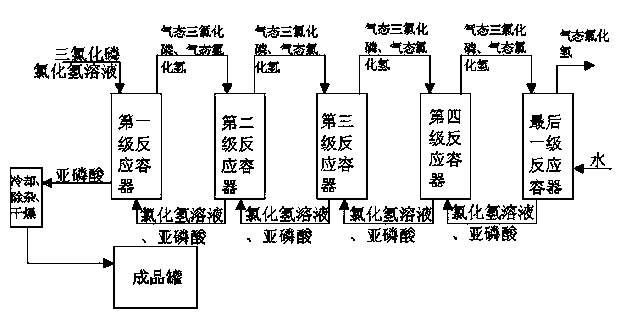

Process for preparing phosphorous acid by hydrolyzing phosphorus trichloride

The invention relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride, and in particular relates to a process for preparing phosphorous acid by hydrolyzing phosphorus trichloride under a mild reaction condition. According to the process, phosphorus trichloride and a hydrogen chloride solution are subjected to hydrolysis reaction in sequence in at least four stages of cascade reaction vessels under the condition that the temperature is 65-85 DEG C and the pressure is not more than 0.1Mpa to generate a phosphorous acid solution and gaseous hydrogen chloride. In the process, the phosphorus trichloride reacts with the water in a hydrochloric acid solution, the phosphorus trichloride is subjected to an exothermic reaction, the temperature of the process can reduce the hydrolysis rate to ensure that the reaction is performed mildly, and at least four stages of cascade bubbling reactions are adopted by the process, so that the utilization ratio of raw materials is improved, the phosphorus trichloride in the reaction vessel of the previous stage can enter the reaction vessel of the next stage, the content of the phosphorus trichloride in the reaction vessel of the previous stage is reduced in other ways, the intensity of the reaction is reduced again, the production safety is improved, and the service life of equipment is prolonged.

Owner:HENAN QINGSHUIYUAN TECH

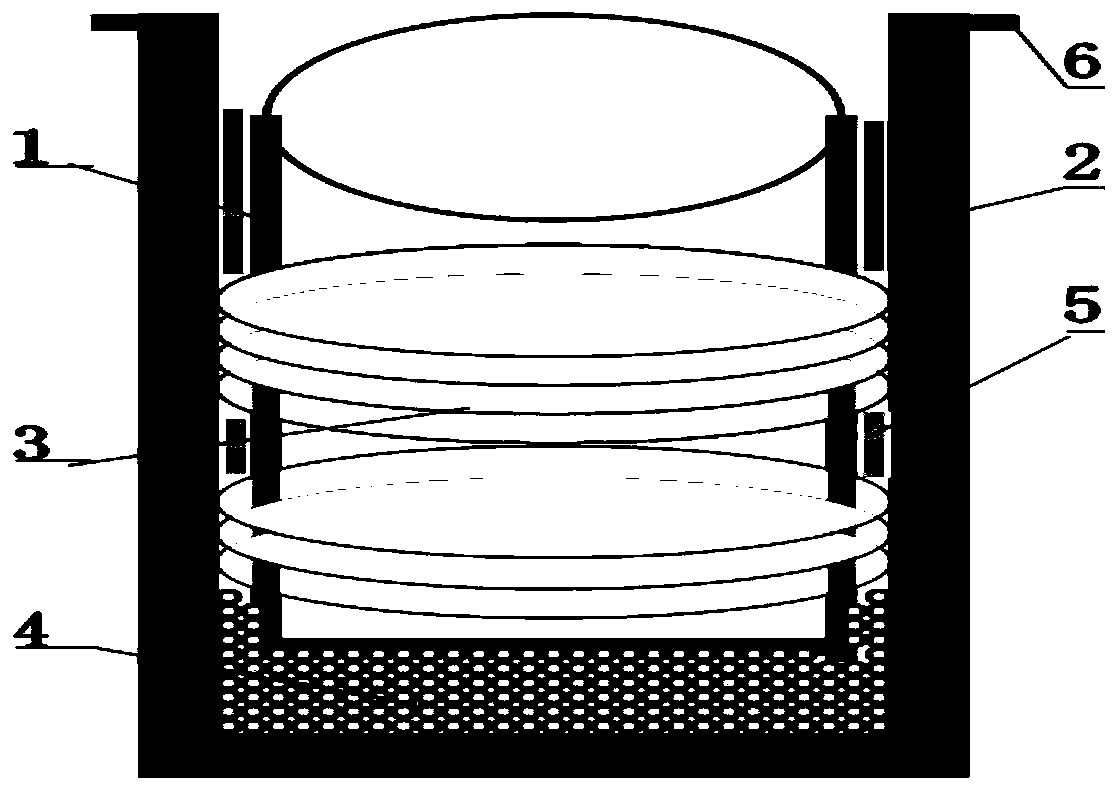

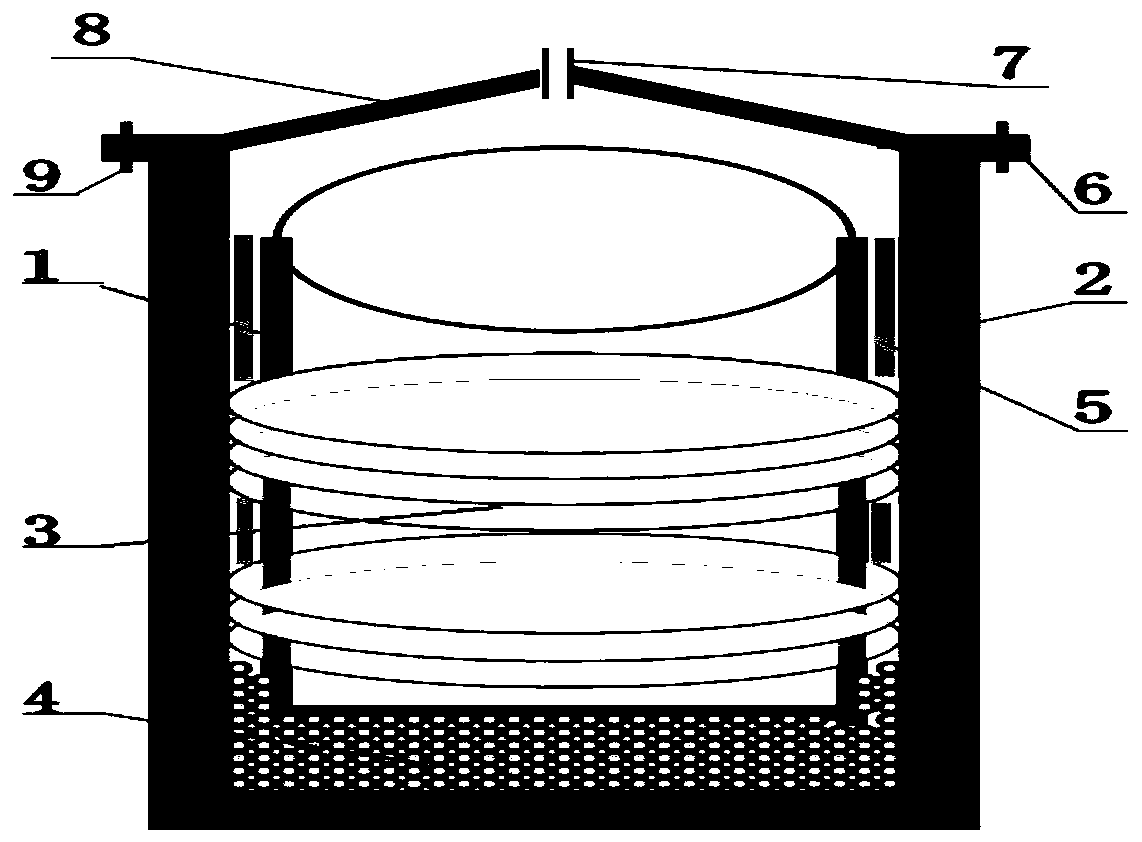

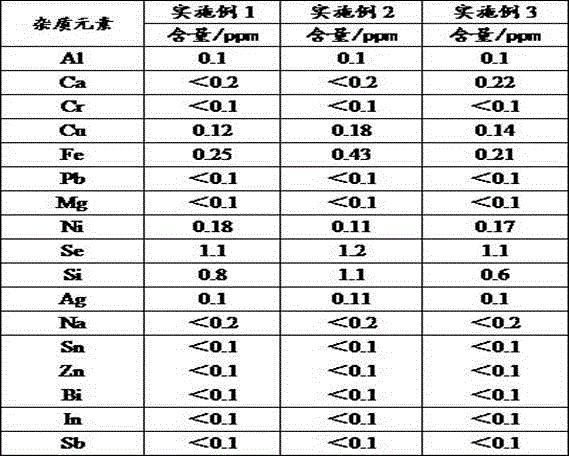

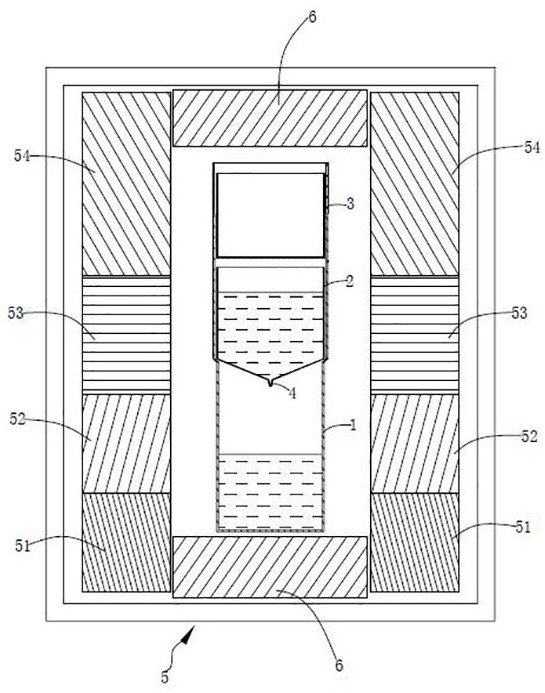

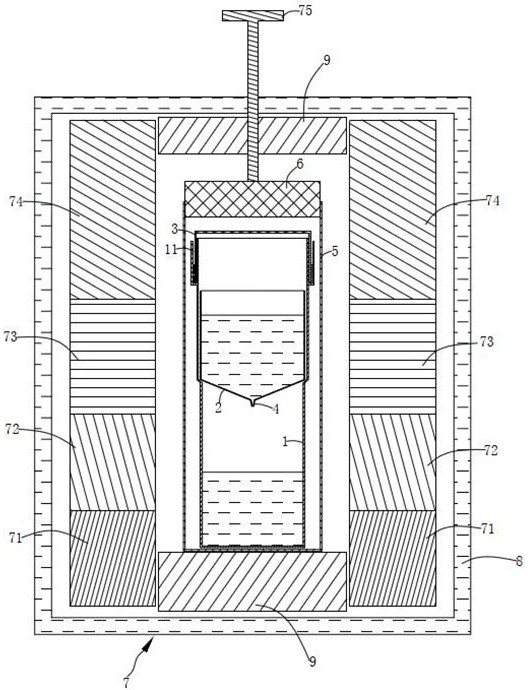

Preparation method for vanadium-aluminum alloy and reactor

The invention provides a preparation method for a vanadium-aluminum alloy and a reactor. The preparation method provided by the invention comprises the following steps: 1) mixing a vanadium source, analuminum source and a slag former to obtain a material mixture; 2) heating the material mixture to obtain a reaction product; and 3) under a vacuum-pumping condition or protective gas introducing condition, cooling the reaction product to obtain the vanadium-aluminum alloy. The reactor comprises a U-shaped container, a reaction container arranged in the U-shaped container, a heating device positioned on the outer wall of the reaction container, and a filler arranged between the U-shaped container and the reaction container. The preparation method provided by the invention solves the problemsthat a vanadium yield is low, the alloy separating effect is poor and an oxidization film appears in the prior art, overcomes splash due to fierce reaction, volatilization, due to a high temperature,of vanadium pentoxide, poor alloy separating effect, and vanadium loss due to the fact that the vanadium-aluminum alloy enters a slag phase.

Owner:HEBEI IRON AND STEEL

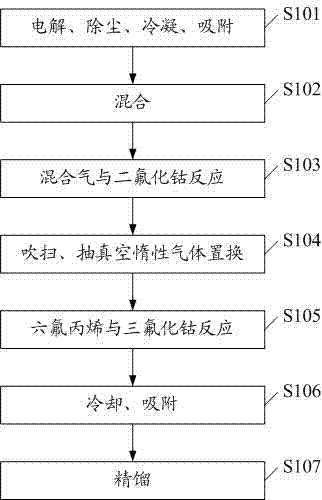

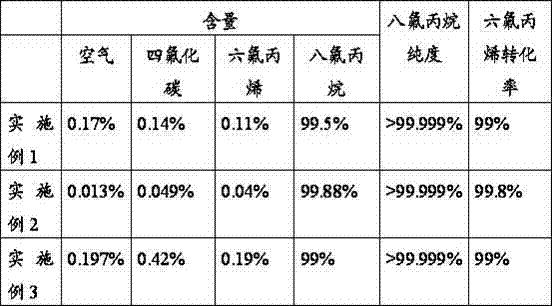

Preparation method of perfluoropropane

InactiveCN103497086AReduce corrosionExtend your lifePreparation by halogen additionElectrolysisHexafluoropropylene

The invention discloses a preparation method of perfluoropropane. The preparation method sequentially comprises the following steps: (1) electrolyzing potassium bifluoride to obtain a mixed fluorine gas, and sequentially carrying out dust extraction, condensation and adsorption treatments on the mixed fluorine gas to purify the mixed fluorine gas to raw material fluoride; (2) pressurizing the raw material fluoride and uniformly mixing the raw material fluoride with an inert gas to obtain a mixed gas; (3) introducing the mixed gas into a reactor filled with cobaltous fluoride to react to obtain cobaltic oxide; (4) carrying out purging and vacuumizing replacement treatments on the reactor and related pipelines and pipe fittings after the reaction; (5) introducing hexafluoropropylene into the reactor to react with the cobaltic oxide to obtain perfluoropropane containing impurities; (6) cooling and adsorbing the perfluoropropane; and (7) introducing the perfluoropropane into a rectifying column through a compressor to be rectified. By adopting the preparation method disclosed by the invention, the corrosion of impurities on the reactor can be reduced, such unfavorable side reactions as hexafluoropropylene pyrolysis, self polymerization, addition, and the like, are inhibited, and perfluoropropane with high purity is prepared.

Owner:FOSHAN HUATE GASES +1

Method of preparing fluorine-containing olefin

InactiveCN103922890AReduce the impactLow flash pointPreparation by dehalogenationAlkaneOrganofluorine chemistry

The invention relates to a method of preparing fluorine-containing olefin, and belongs to the technical field of organofluorine chemistry. The method comprises the following steps: firstly adding non-alcohol organic solvents, water and a metal dechlorinating agent with grain size of 40-150 microns into a container for stirring and mixing, and then rising the container temperature to 45 DEG C-65 DEG C; then, adding the chlorine-fluorine alkane material and keeping the temperature at 50 DEG C-80 DEG C; finally, rectifying to obtain the fluorine-containing olefin product. The method disclosed by the invention ensures that the dechloridation reaction can be kept at a certain reaction speed from beginning to end, has the advantages of being safer and more efficient, and is suitable for industrial production.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Ampoule fixed-distance conveying device

ActiveCN104029991ASimple structureSmall footprintConveyor partsRotary conveyorsEngineeringControllability

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

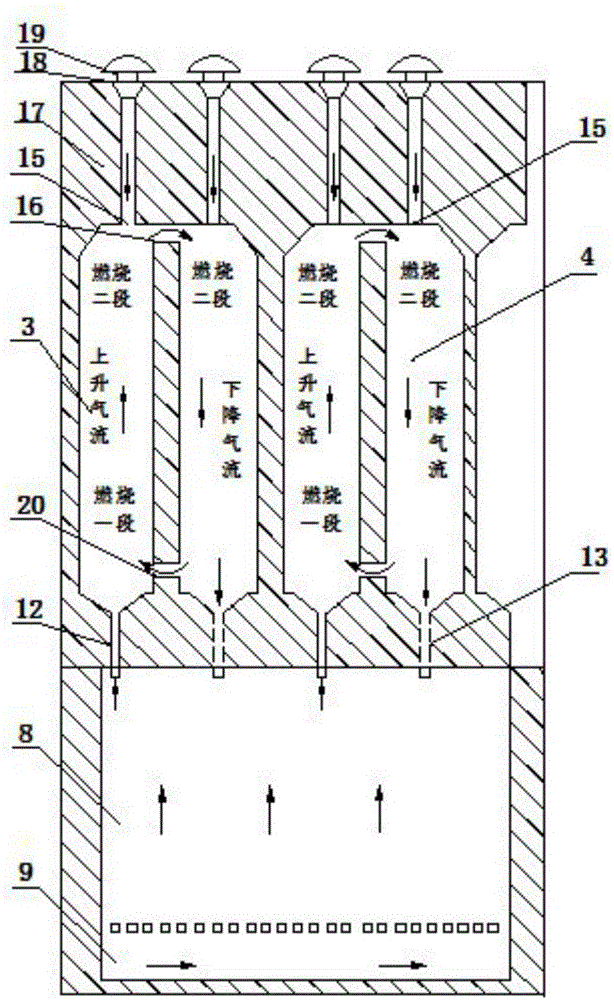

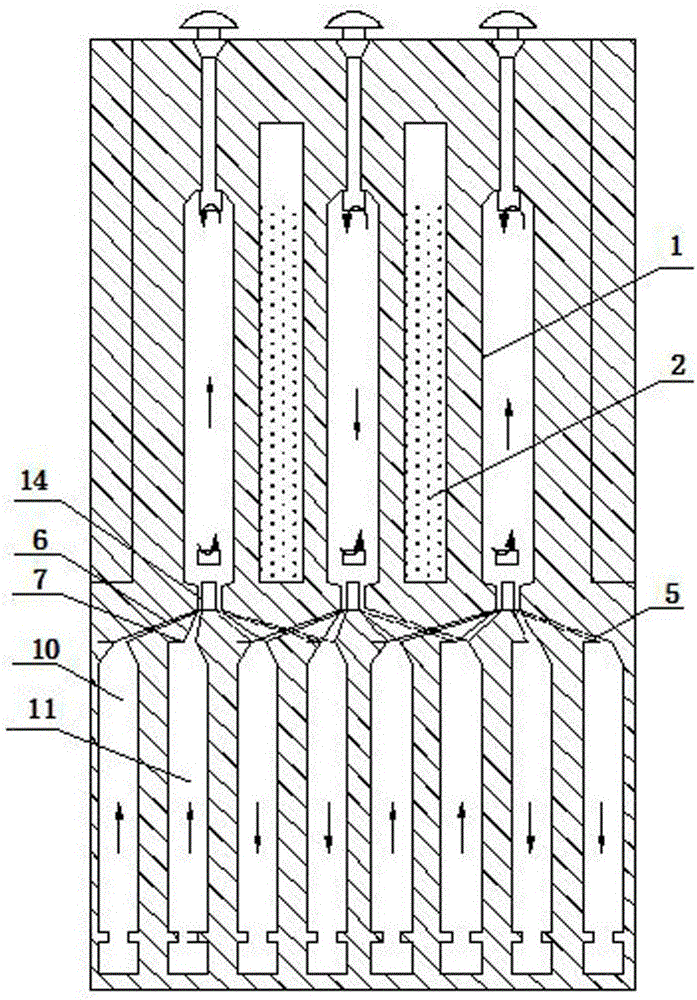

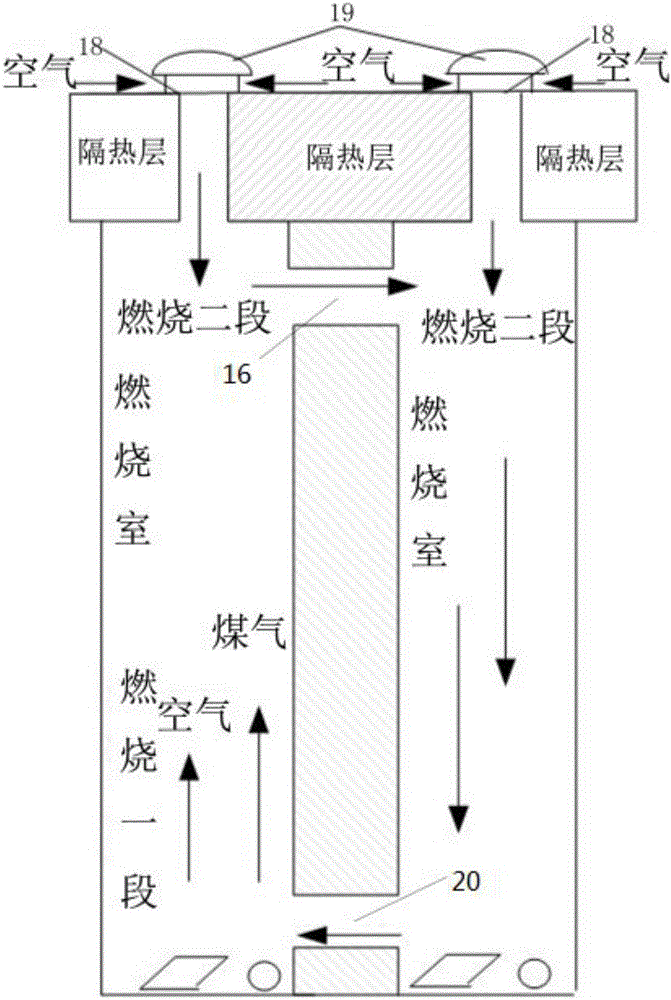

Coking furnace heating method and device capable of reducing generation of NOx

InactiveCN106190184ARealize staged combustionLow retrofit costCombustible gas coke oven heatingEnergy inputBrickCarbonization

The invention provides a coking furnace heating method and device capable of reducing generation of NOx. Vertical flues are double connected, coal for coking is put in a carbonization chamber and refined to be coke, coking furnace gas is downwards injected, air is supplied to the vertical flues in a segmented manner and mixed with the coking furnace gas for combustion, waste gas after segmented combustion enters each downdraft vertical flue after being turned through a crossing hole, and complete combustion is performed at the top of the downdraft vertical flue; after complete combustion, the waste gas enters an adjacent heat storage chamber through inclined channels of the downdraft vertical flues and exchanges heat with lattice bricks, the cooled waste gas enters a small flue through adjustable grate holes, and finally, the waste gas is discharged through a branch flue, a main flue and a chimney. Segmented combustion of coking furnace gas can be realized, adjustment is performed according to the combustion condition, the coke quality is improved, heat loss is reduced, the heat efficiency is improved, high temperature points in the vertical flues are reduced, generation of NOx is reduced, and environmental protection is realized.

Owner:HUNAN QIANMENG INTELLIGENT INFORMATION TECHCO LTD

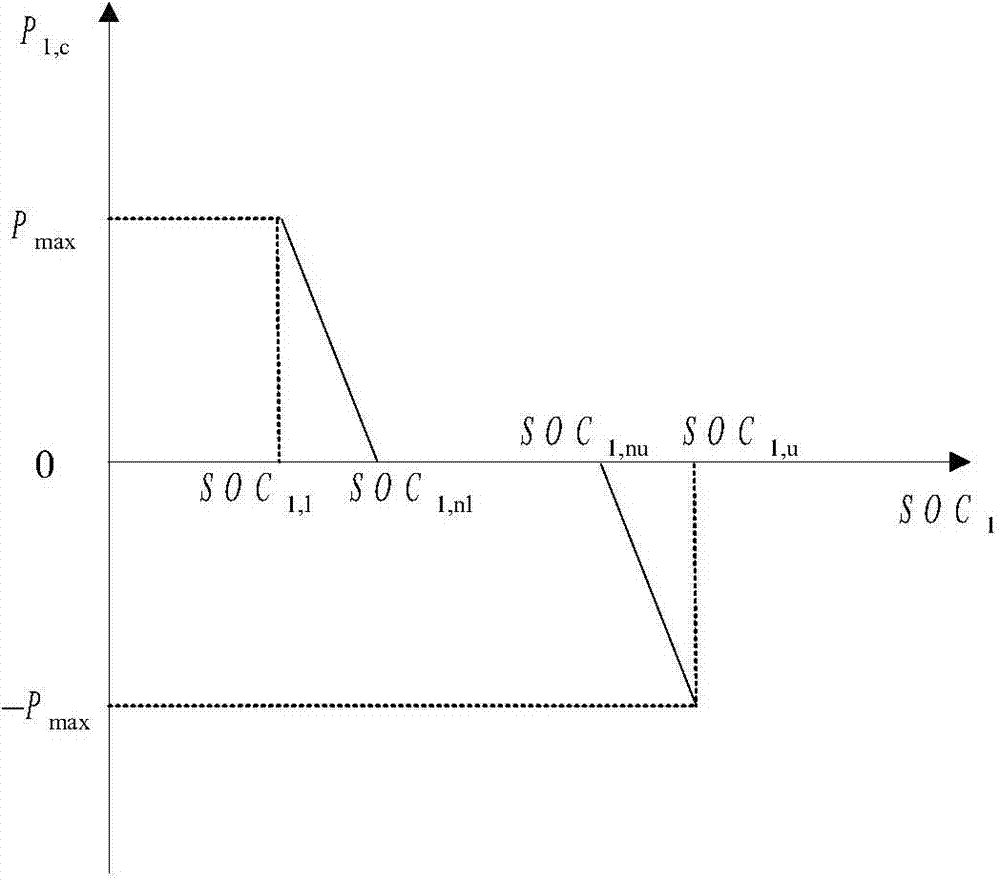

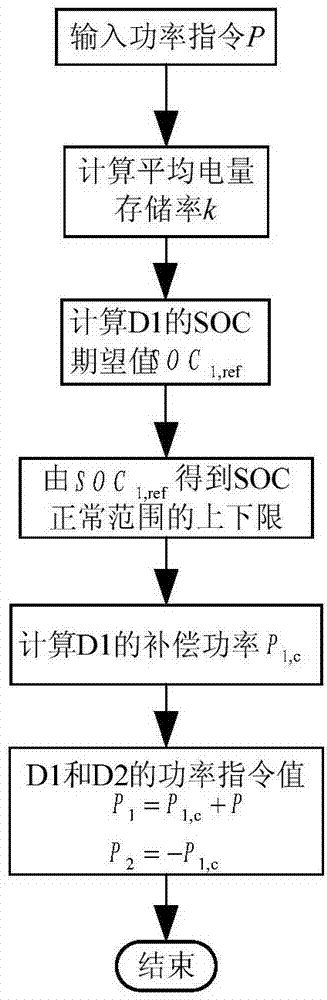

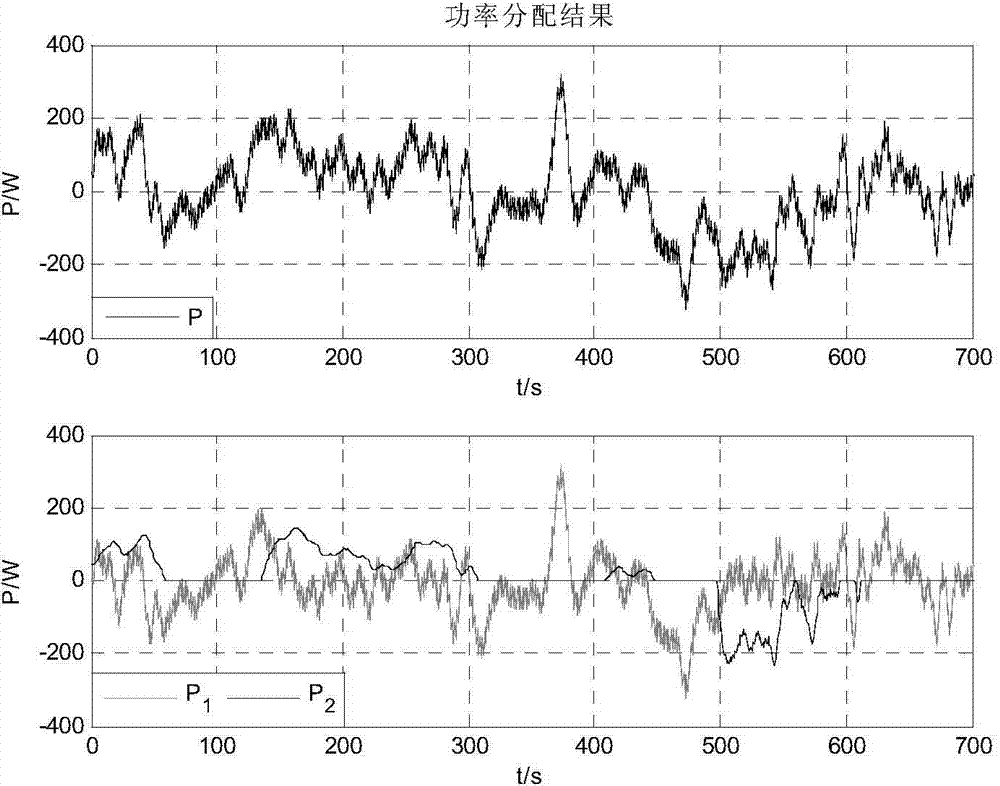

Hybrid energy storage system power distribution method based on states of charge

ActiveCN103501022ALess severeExtend your lifeSingle network parallel feeding arrangementsPower oscillations reduction/preventionState of chargeCharge and discharge

A hybrid energy storage system power distribution method based on states of charge includes the following steps that an energy storing device which is long in cycle life and capable of achieving large-current deep charge and discharge is set to be a first energy storing device D1, an energy storing device which is short in cycle life and the cycle life of the energy storing device is affected by large-current deep charge and discharge is set to be a second energy storing device D2, the second energy storing device D2 provides compensation power for the first energy storing device D1 according to the states of charge of the first energy storing device D1 to enable the states of charge to be in a reasonable level. According to the hybrid energy storage system power distribution method, capacity of the first energy storing device D1 is utilized to convert seriously-changing power fluctuation into stably-changing fluctuation of the states of charge, therefore, the intensity of power instruction fluctuation of the second energy storing device D2 can be reduced, and the service life of the second energy storing device D2 can be prolonged.

Owner:GUANGXI POWER GRID CORP +1

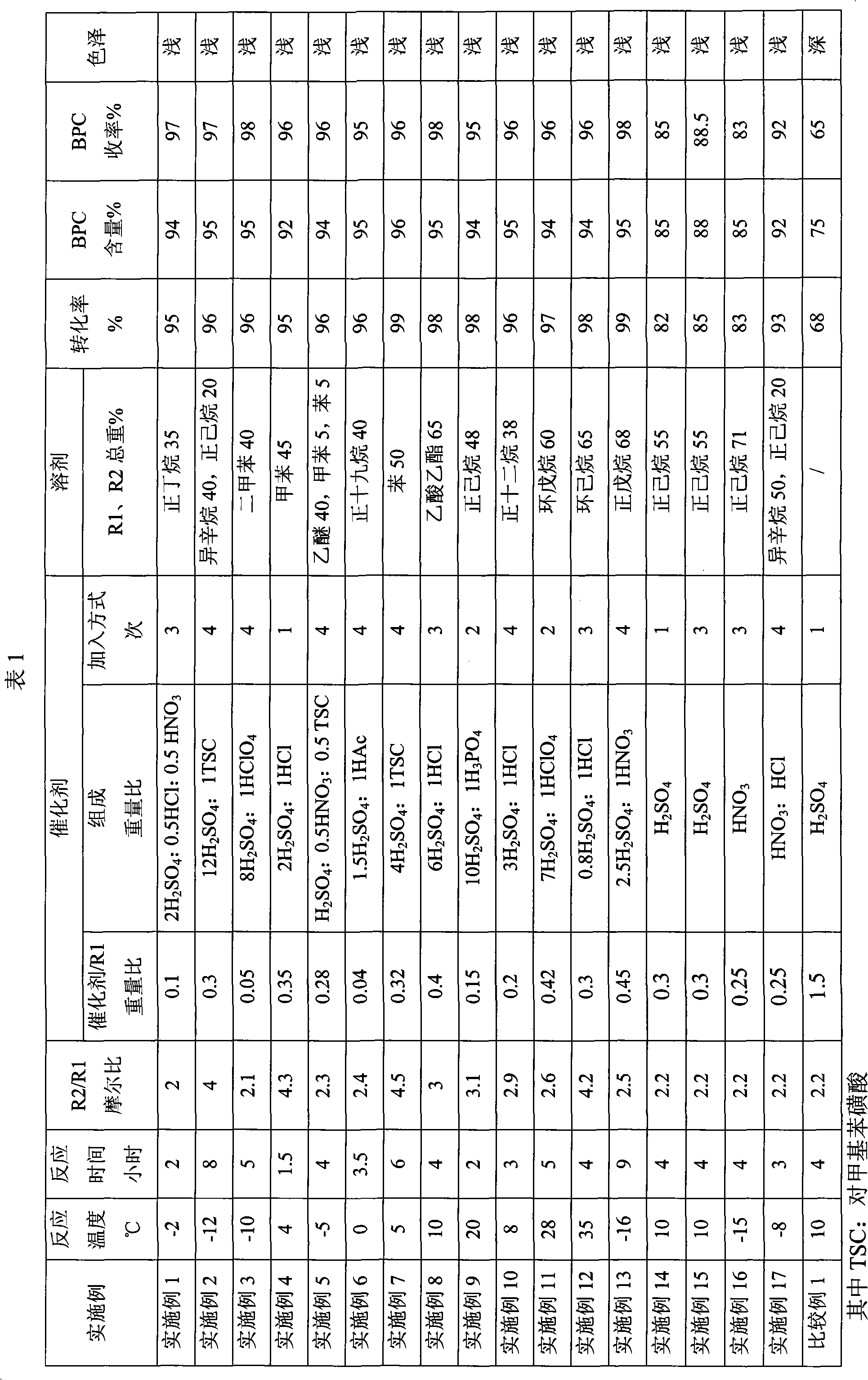

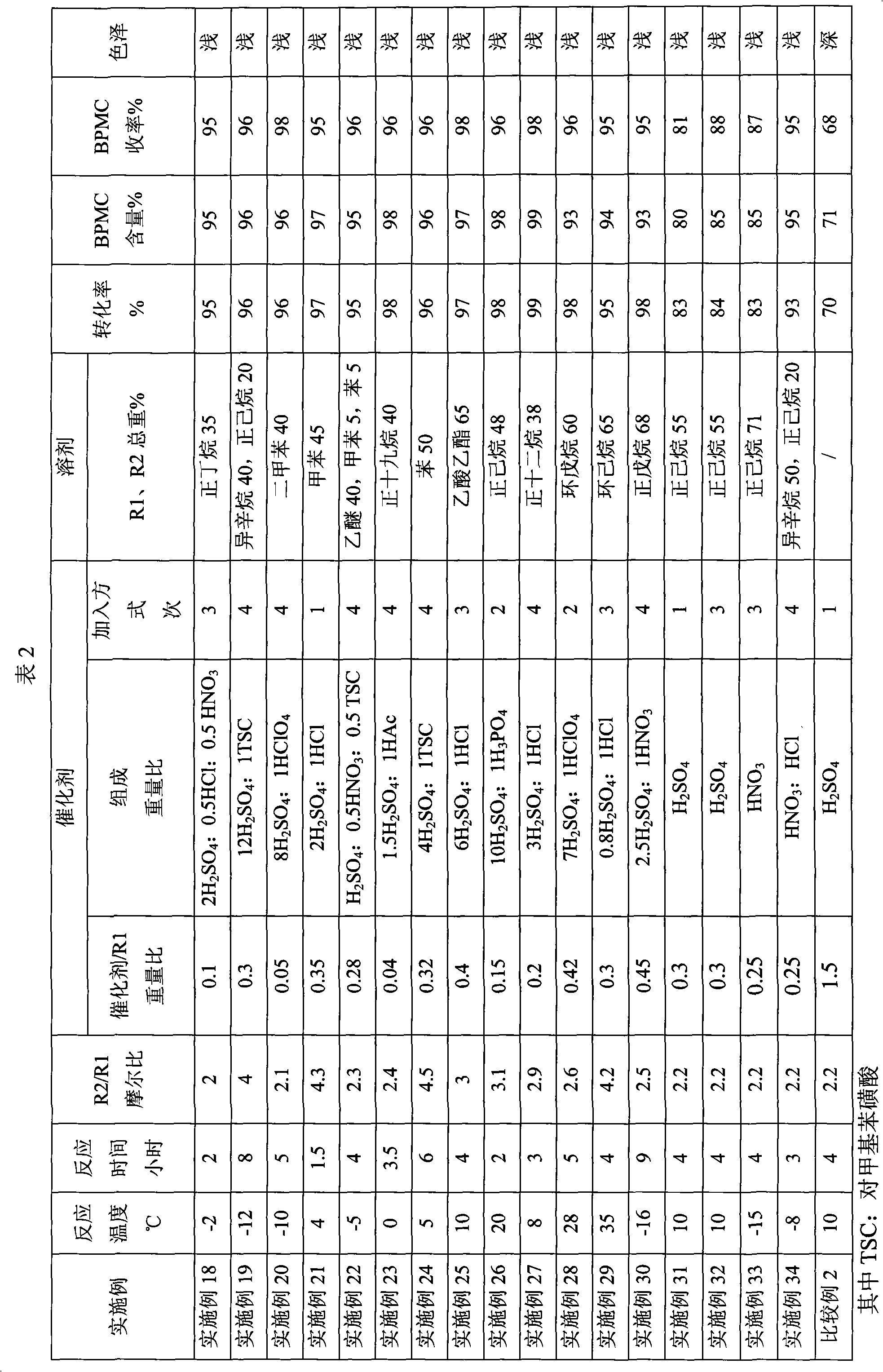

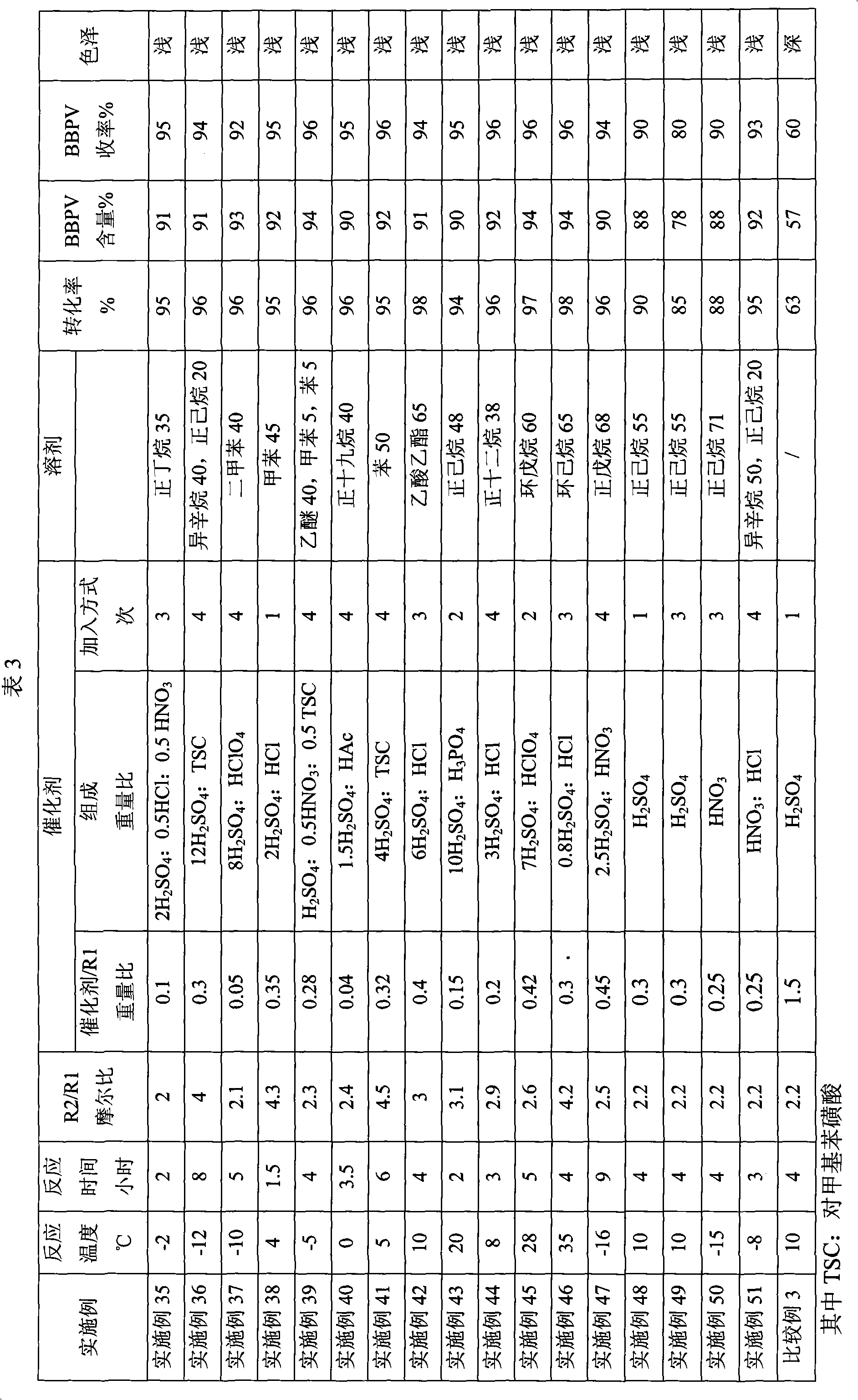

Production method of di(tert-butylperoxy)ketal

ActiveCN102336695AReduce dosageSmooth responseOrganic compound preparationPeroxy compound preparationCyclohexanoneReaction temperature

The invention relates to a production method of di(tert-butylperoxy)ketal, and mainly solves the problems of low product content, low yield, deep color and low production safety caused by violent side reaction in the previous technique. In the invention, R1 selected from cyclohexanone, 3,3,5-trimethylcyclohexanone or butyl levulinate and R2 tert-butyl hydroperoxide, which are used as raw materials, react in the presence of solvent at -20-40 DEG C under normal pressure for 0.5-10 hours to obtain the corresponding product 1,1-di(tert-butylperoxy)cyclohexane, 1,1-di(tert-butylperoxy)-3,3,5-trimethylcyclohexanone or 4,4,-di(tert-butylperoxy)-n-butyl valerate, wherein the mol ratio of R2 to R1 is (2-10):1, the weight ratio of solvent to R1 is (0.01-0.50):1, and the amount of the solvent accounts for 20-80% of the total weight of the reactants R1 and R2; and the catalyst is selected from at least one of sulfuric acid, phosphoric acid, hydrochloric acid, perchloric acid, p-methylbenzenesulfonic acid, nitric acid or acetic acid. The technical scheme provided by the invention solves the problems in the previous technique, and can be used for industrial production of di(tert-butylperoxy)ketal.

Owner:CHINA PETROCHEMICAL CORP

Cadmium telluride preparation method

ActiveCN106495108AEasy to peelLess severeMetal selenides/telluridesBinary selenium/tellurium compoundsTe elementCadmium zinc telluride

The invention provides a cadmium telluride preparation method. Cadmium telluride powder is added into tellurium powder and cadmium powder, and the powder is homogeneously mixed and heated to synthesize cadmium telluride. Severity of cadmium telluride synthesis reaction is relieved, waste caused by attaching of materials to the inner wall of a reaction vessel and a quartz tube is avoided, reaction is sufficient, product yield is improved, and cadmium telluride products are easily stripped from the reaction vessel. Both the reaction vessel and the quartz tube can be recycled, high temperature and high pressure are omitted in reaction, requirements for equipment are low, the technical process is short, the product yield is high, output is high, and batch production can be realized.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Method for preparing cadmium telluride or cadmium zinc telluride polycrystal material

ActiveCN111809242AReduce the amount of instantaneous responseLess severePolycrystalline material growthSingle crystal growth detailsCarbon filmPhysical chemistry

The invention relates to a preparation method of a cadmium telluride or cadmium zinc telluride polycrystal material. The preparation method is characterized by comprising the following preparation process flows of: 1) cleaning and drying a large quartz crucible, a small crucible capable of being loaded into the large quartz crucible and a quartz plug; wherein a hole is formed in the bottom of thesmall crucible; 2) putting the large quartz crucible into a carbon plating furnace, and plating a layer of carbon film on the inner surface of the large quartz crucible; and 3) weighing elemental tellurium and elemental cadmium according to the ratio of cadmium telluride to be synthesized, or weighing elemental tellurium, elemental cadmium and elemental zinc according to the ratio of cadmium zinctelluride to be synthesized. By the preparation method, tellurium and cadmium can slowly react, the instantaneous reaction amount is reduced, and the risk of leakage caused by quartz tube cracking isreduced.

Owner:中科宏芯(常州)传感科技有限公司

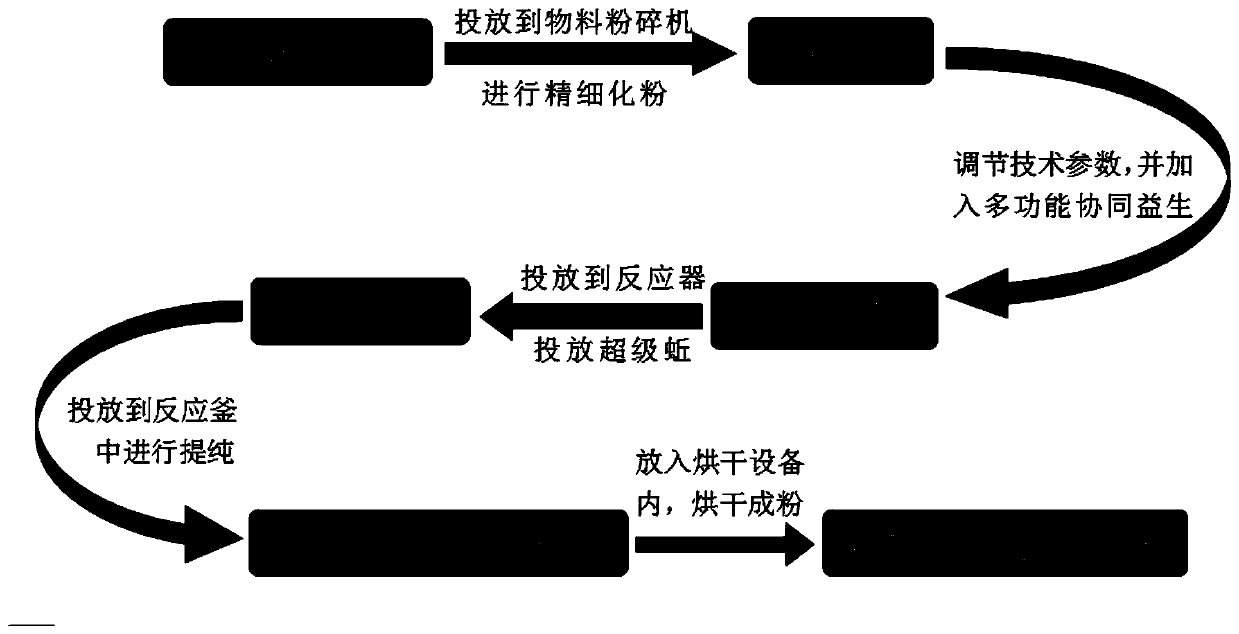

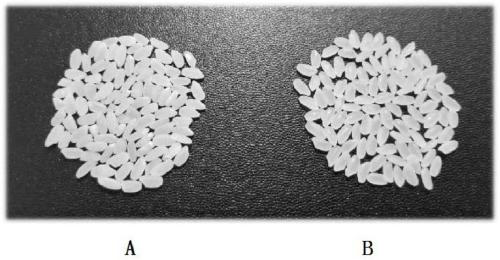

Preparation method of earthworm bioactive fulvic acid

ActiveCN110205354AImprove qualityPlay a decisive roleOrganic chemistryMicroorganismsMicroorganismLivestock manure

The invention discloses a preparation method of earthworm bioactive fulvic acid, and relates to a preparation method of fulvic acid. The invention aims to solve the problems in the process of converting livestock manure and crop straws into fulvic acid through a biochemical method and extracting the fulvic acid. The existing biochemical treatment needs to meet the temperature conditions, and the obtained fulvic acid has low purity, poor stability and short shelf life. According to the method, a mixture of livestock manure and straw is processed by 5 earthworm species in cooperation with microbial biological fermentation to produce an earthworm bait, and the earthworm bait is fed with high-efficiency earthworm varieties bred through independent hybridization to obtain earthworm manure withspecific components, and then the earthworm manure is extracted to finally obtain the earthworm bioactive fulvic acid. The method is applied to the field of preparation of fulvic acid.

Owner:黑龙江奥创生物科技发展有限公司

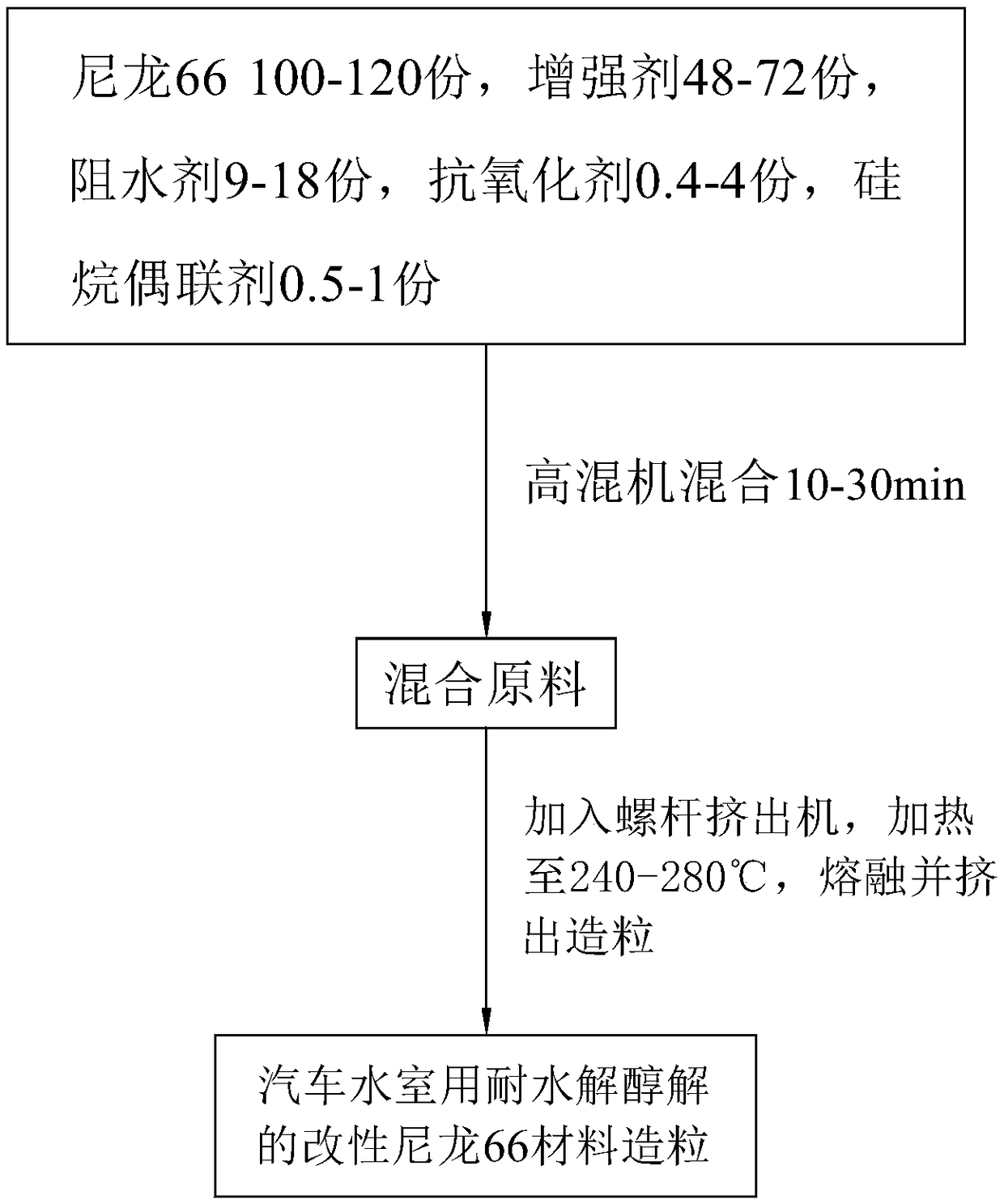

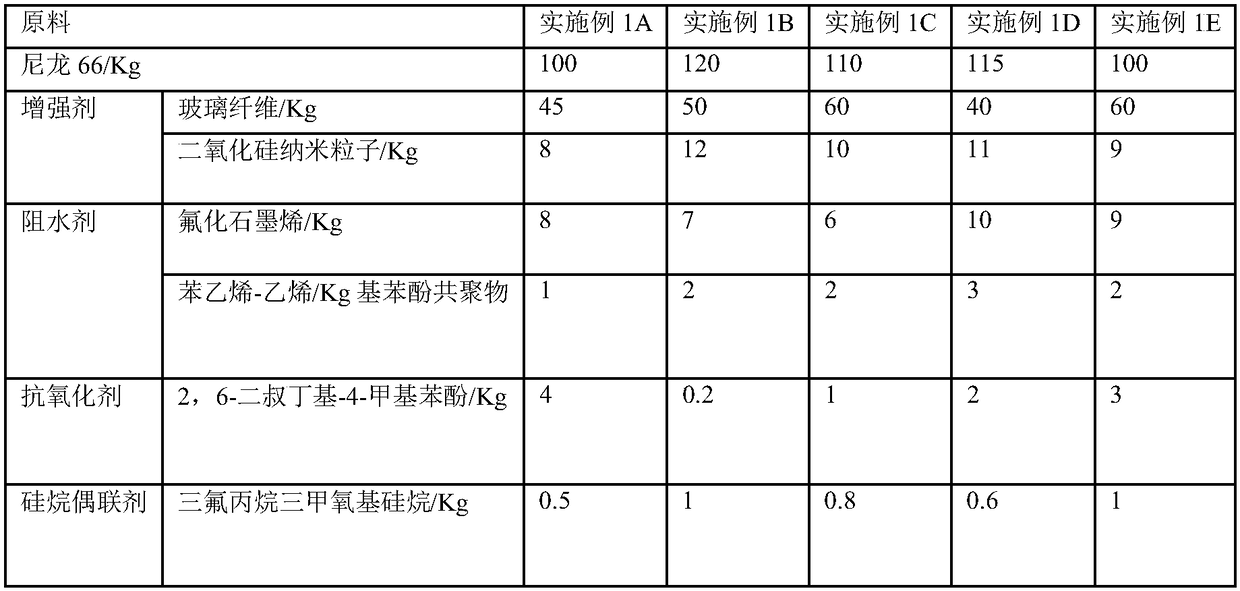

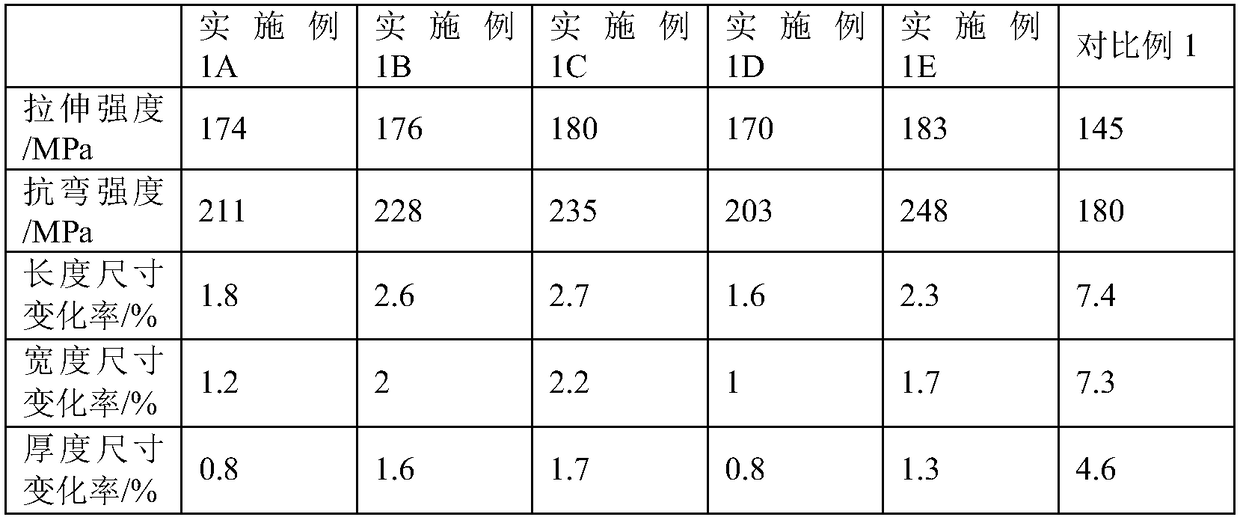

Hydrolysis and alcoholysis resistant modified nylon 66 material for automotive water chamber and preparation method of modified nylon 66 material

The invention relates to modified nylon materials and discloses a hydrolysis and alcoholysis resistant modified nylon 66 material for an automotive water chamber and a preparation method of the modified nylon 66 material. The modified nylon 66 material comprises the following raw materials: 100-120 parts of nylon 66, 48-72 parts of an enhancer, 9-18 parts of a water resistance agent, 0.4-4 parts of an antioxidant and 0.5-1 part of a silane coupling agent, wherein the enhancer comprises 40-60 parts of glass fibers; and the water resistance agent comprises 6-10 parts of fluorinated graphene and3-8 parts of a styrene-vinyl phenol copolymer. The preparation method comprises the following steps: weighing the raw materials in parts by mass, mixing after drying, adding the mixture into a screw extruder, heating and melting, and performing extrusion pelletizing, thereby obtaining the modified nylon 66 material. The tensile property and bending performance of the modified nylon 66 material areimproved, and the nylon material has hydrolysis and alcoholysis resistance and excellent dimensional stability, difficultly causes size distortion at a high temperature and meets the service conditions and environment of the automotive water chamber.

Owner:NINGBO EAGLE NEW MATERIAL

Industrialization method for improving purity of lycopene oil resin

ActiveCN102924967AHigh purityReduce packageNatural dyesChemical modification purification/separationLong chain fatty acidAlcohol

The invention discloses an industrialization method for improving purity of lycopene oil resin. The method comprises process steps of (1) adding an alcohol solvent in the lycopene oil resin for evenly stirring to obtain mixed liquor; (2) adding an alkaline aqueous solution in the mixed liquor to stir, and neutralizing a fatty acid compound in the oil resin to obtain neutralization liquor; (3) adding an alkaline aqueous solution in the neutralization liquor to stir, and saponifying an oil compound in the neutralization liquor to obtain saponification liquor; and (4) adding an alcohol-water solution in the saponification liquor to stir, then adding 6# solvent naphtha, stewing and laying after evenly stirring, collecting a 6# solvent layer, concentrating and obtaining the lycopene oil resin with improved purity. The method firstly neutralizes long-chain fatty acid in the lycopene oil resin, then saponifies the oil, can effectively reduce intensity of saponification, reduces packing of produced saponin on lycopene and obviously improves yiels. The method is simple in process and strong in maneuverability, the yield of the lycopene is higher than 90%, and obtained products are stable in state.

Owner:CHENGUANG BIOTECH GRP CO LTD

Air fuel multi-layer three-dimensional grading low-nitrogen gas burner

ActiveCN112984507AReduce aggregationLess severeIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsCombustor

The invention discloses an air fuel multi-layer three-dimensional grading low-nitrogen gas burner. Four-stage combustion-supporting gas can be formed through a central air cylinder, an annular cavity between the central air cylinder and an inner rotational flow air cylinder, an annular cavity between the inner rotational flow air cylinder and an outer direct flow air outer cylinder, and an annular cavity between the outer direct flow air outer cylinder and an outer secondary air outer cylinder; gas fuel sprayed by the center fuel gun, an inner primary fuel gun, an outer primary fuel gun and a secondary fuel gun can be mixed with the four-stage combustion-supporting gas, on one hand, the mode that the whole burner is in an oxygen-deficient and outer-ring oxygen-enriched combustion mode in the center area of the combustion end can be achieved, and the gathering degree of fuel in the center area and the intense degree of combustion in the initial stage are reduced, so that the combustion temperature is reduced, and generation of thermal NOx is inhibited; and on the other hand, direct-flow air and rotational-flow air are arranged in the center while the fuel is diffused to the outer ring as much as possible for combustion, so that the flame mixing stability in the center area is guaranteed, the combustion efficiency is improved, and emission of nitric oxide is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

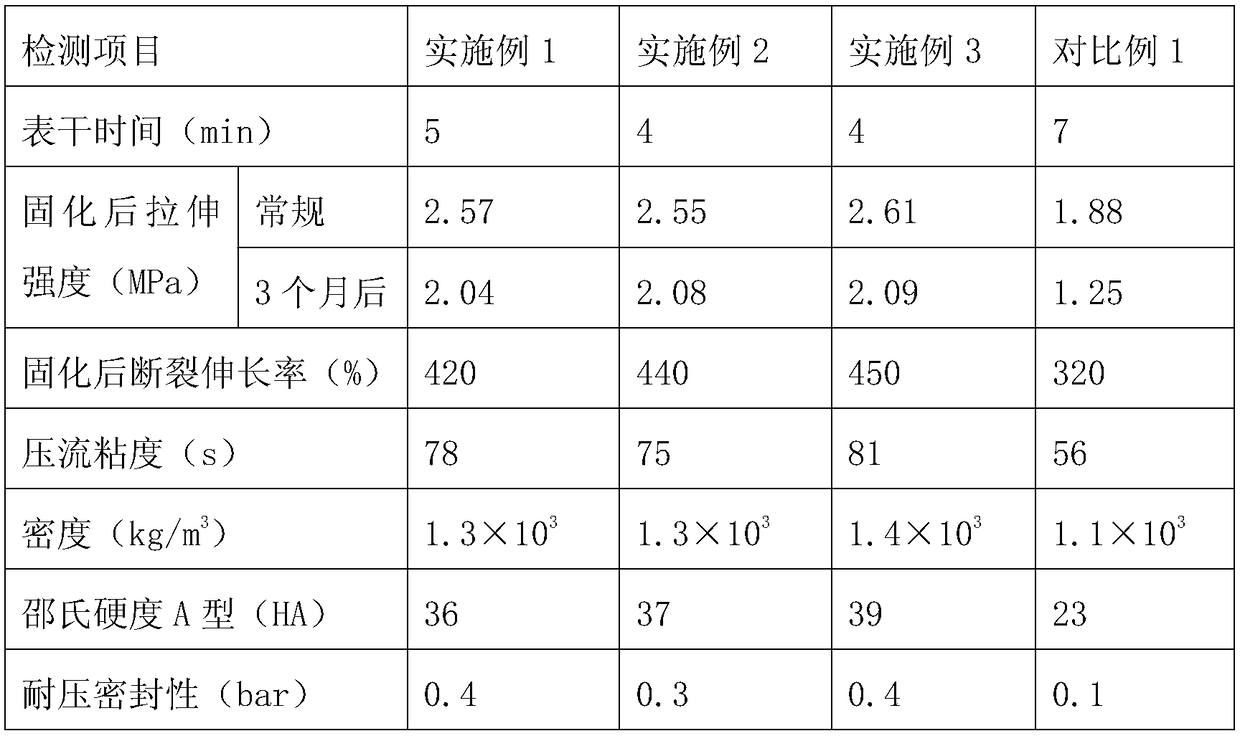

High-strength sealant for electronic product and preparation method of high-strength sealant

InactiveCN109337589AGood flow viscosityGood Shore hardnessNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyPhosphate

The invention provides a high-strength sealant for an electronic product and a preparation method of the high-strength sealant. The high-strength sealant is prepared from the following components: waste rubber, epoxy resin, acrylic acids, monolauryl phosphate, dioctyl phthalate, polyether polyol, nano calcium carbonate, titanium dioxide, epoxidized soybean oil, modified lignin, isocyanate, a silane coupling agent, an amine catalyst and an antioxidant. The sealant prepared according to the preparation method provided by the invention has good pressure flow viscosity, Shore hardness, elongationat break and tensile strength, is high in pressure tightness, firm in adhesion, long in service life, excellent in performance and wide in application range; the preparation method is simple, and theraw material cost is relatively low; therefore, the high-strength sealant is suitable for industrial large-scale production.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Medium and low temperature energetic heat source for cigarette and preparation method thereof

InactiveCN107149167ARate-limited releaseStable physical propertiesTobacco devicesCombustionHot Temperature

The invention discloses a medium and low temperature energetic heat source for heating a cigarette and a preparation method of the medium and low temperature energetic heat source. The heat source comprises the components of 17%-32% of phenolic resin, 60%-63% of strontium nitrate and 5%-23% of assistant by weight in the formula, and the particle size is 0.1 mm to 0.2 mm. The heat source is ignited without external oxygen supply, the produced medium and low temperature is used for pyrolysis of a tobacco shred, and the contents of toxic and hazardous gases produced in the high temperature combustion of the tobacco shred are effectively reduced. The heat source, when applied to heating the tobacco, effectively inhibits the release of toxic and hazardous gases produced from certain ingredients in the tobacco in the high temperature combustion without affecting the smoking taste as much as possible, and is of popularization significance for reducing the harm of smoking.

Owner:NANJING UNIV OF SCI & TECH

Wing type splitting energy absorption anchor rod and structure for preventing rockburst and large deformation

ActiveCN107725088AStable resistanceEnhanced interactionAnchoring boltsEnergy absorptionLarge deformation

The invention belongs to the technical field of anchor rods, and discloses a wing type splitting energy absorption anchor rod for preventing rockburst and large deformation. The anchor rod comprises an anchor rod body, a tray, a nut and an anchoring wing, the tray and the nut are arranged at the tail part of the anchor rod body, and the anchoring wing is radially arranged on the outer wall of theanchor rod body. The invention provides the wing type splitting energy absorption anchor rod and the wing type splitting energy absorption structure for preventing rockburst and large deformation, andthe energy absorption anchor rod effectively improves the energy absorption yield and the effect on controlling the disasters of deep underground works like rockburst or large deformation.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

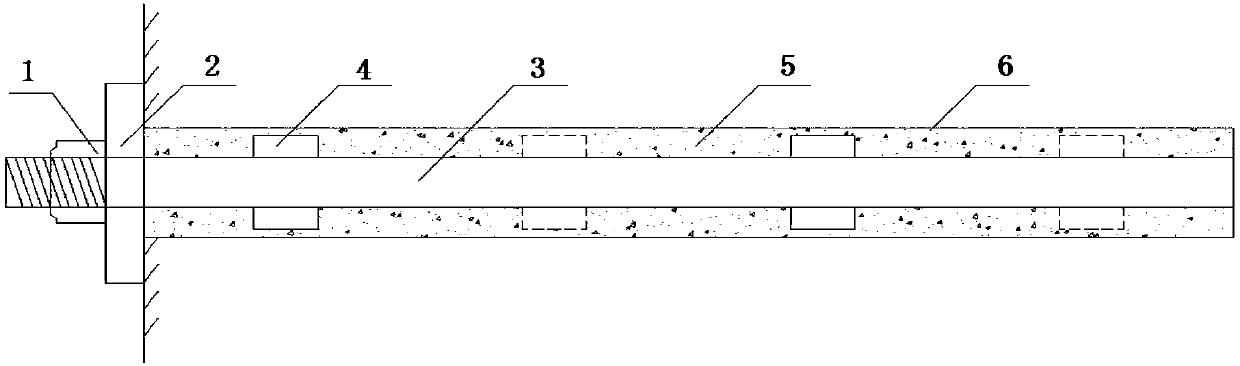

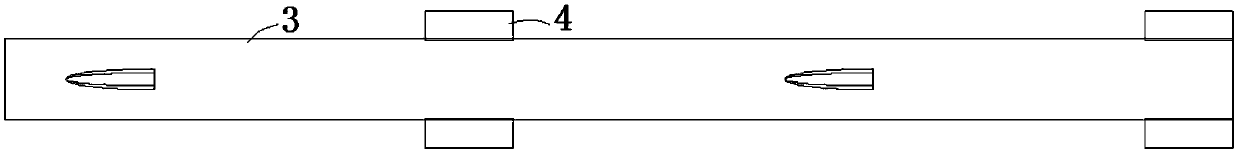

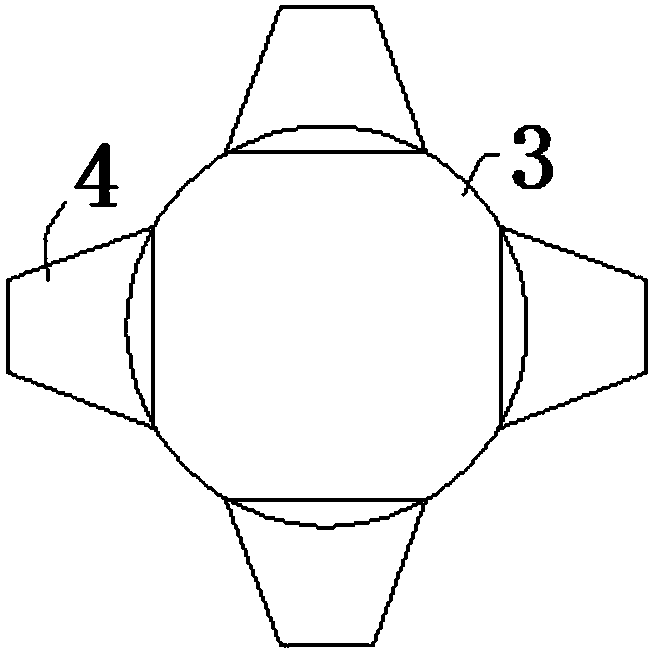

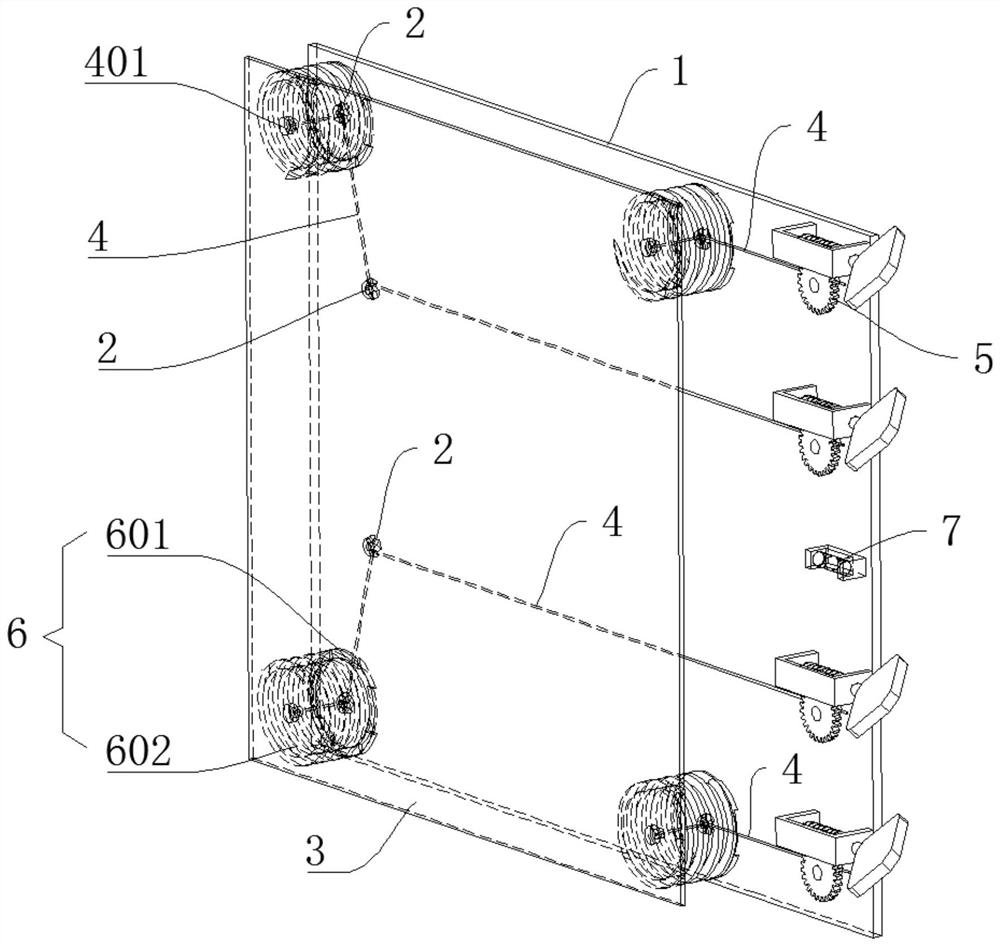

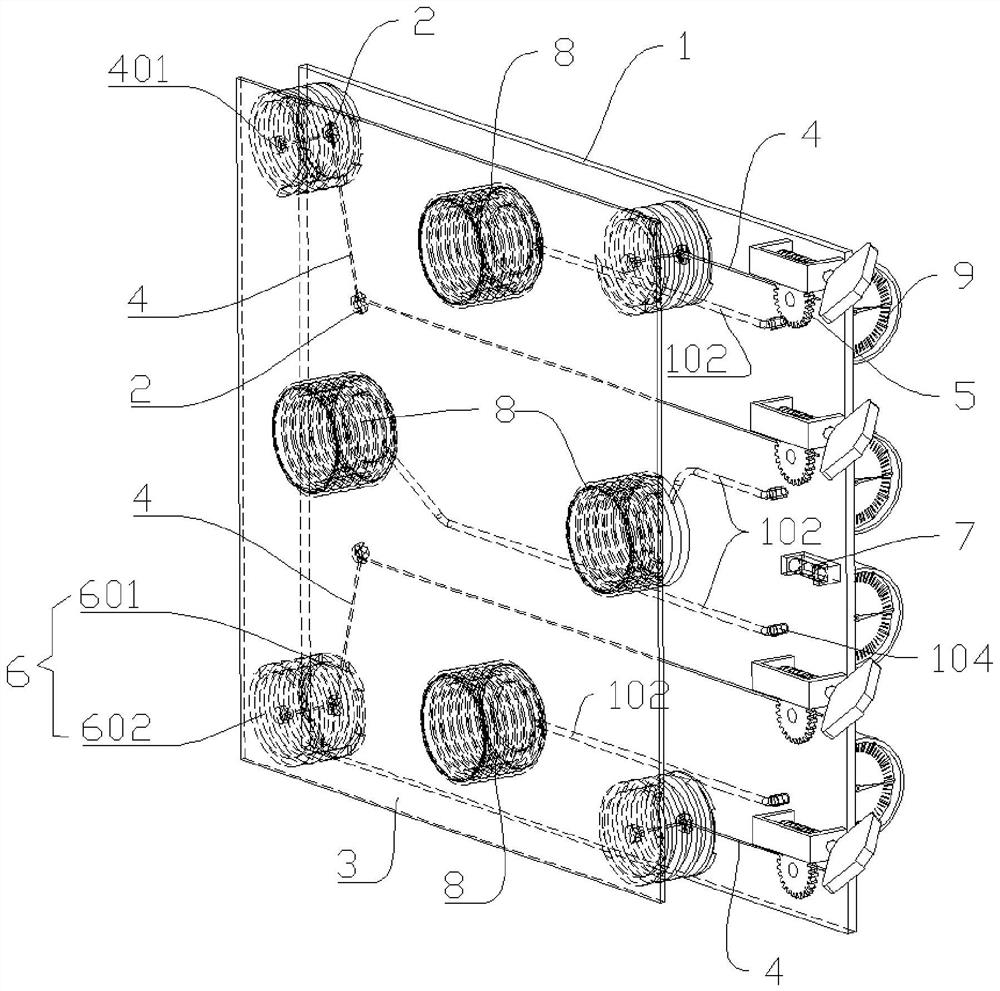

Longitudinal seam impaction device and longitudinal seam impaction resetting method

PendingCN114482602AVersatileMeet earthquake resistance requirementsBuilding repairsProtective buildings/sheltersPhysicsEngineering

The invention relates to the technical field of building structure engineering, in particular to a longitudinal joint impaction device and a longitudinal joint impaction resetting method.The longitudinal joint impaction device comprises a first impaction plate, a second impaction plate and a third impaction plate, the second impaction plate is arranged opposite to the first impaction plate; the stranded wire is wound on a stranded wire connecting seat, the first end of the stranded wire is connected with a stranded wire end seat, the stranded wire end seat is fixedly connected with the second impaction plate, and the second end of the stranded wire extends out of the space between the second impaction plate and the first impaction plate and is connected with a stranded wire take-up and pay-off device; the stranded wire take-up and pay-off device can tighten and release the stranded wire; the elastic structures are arranged between the first impaction plate and the second impaction plate, the first ends of the elastic structures are fixedly connected with the first impaction plate, and the second ends of the elastic structures are fixedly connected with the second impaction plate.

Owner:CHINA THREE GORGES CORPORATION

Method for preparing cadmium telluride or cadmium zinc telluride polycrystal material

ActiveCN111809235AReduce pressure requirementsReduce the amount of instantaneous responsePolycrystalline material growthSingle crystal growth detailsCrucibleCadmium zinc telluride

The invention relates to a preparation method of a cadmium telluride or cadmium zinc telluride polycrystal material. The preparation method is characterized by comprising the following preparation process flows of: (1) cleaning and drying a first crucible, a second crucible capable of being put into the first crucible and a first cover covering the first crucible; wherein the first crucible is provided with an annular groove along the peripheral wall; the top of the first cover is closed, the bottom is open, and the side wall can be inserted into the annular groove; and a hole is formed in thebottom of the second crucible; 2) weighing elemental tellurium and elemental cadmium according to the proportion of cadmium telluride to be synthesized; or weighing elemental tellurium, elemental cadmium and elemental zinc according to the ratio of cadmium zinc telluride to be synthesized. According to the preparation method, a liquid sealing technology is adopted to prevent volatilization loss of cadmium vapor, and the first crucible can be repeatedly used, so that the cost is reduced; by reducing the instantaneous reaction amount of tellurium and cadmium, the severe degree of the telluriumand cadmium combination reaction is reduced, the pressure resistance requirement on synthesis equipment is reduced, and the equipment cost is reduced.

Owner:中科宏芯(常州)传感科技有限公司

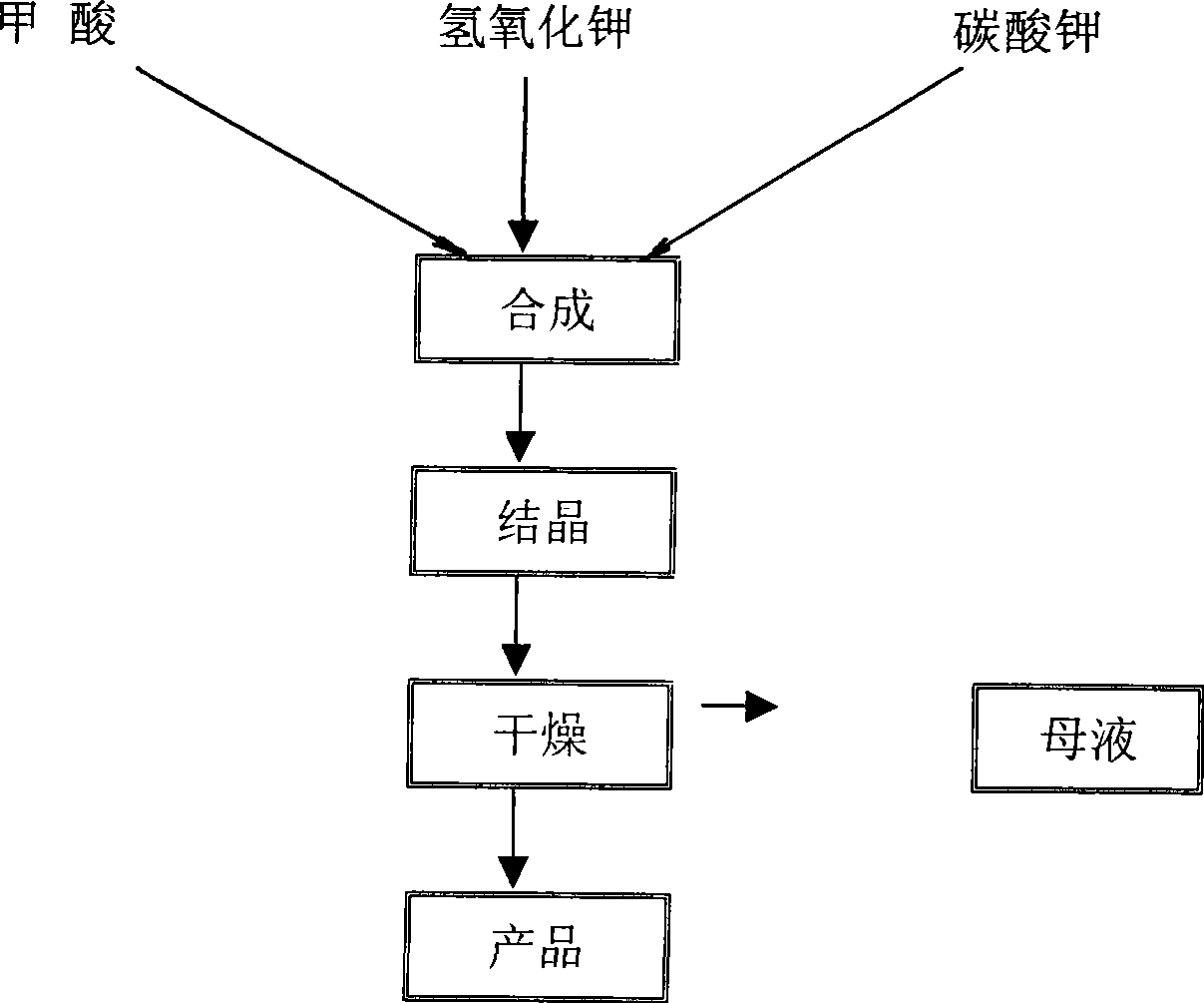

Method for producing potassium diformate by reaction of aminic acid and mixed base

InactiveCN101434531AReduce generationNo emissionsCarboxylic acid salt preparationPotassiumPotassium hydroxide

The invention provides a production method of potassium diformate by the use of methanoic acid and a mixed base, which adopts the methanoic acid and a mixture of potassium carbonate and potassium hydroxide as raw materials. The reaction between the methanoic acid and the mixed base is that a methanoic acid solution with mass percentage concentration of 50 percent to 98 percent reacts with the mixture of solid or liquid potassium carbonate and potassium hydroxide with matching valent weight at 20 DEG C to 95 DEG C for 1 hour to 20 hours. And then the reaction solution obtained is cooled to obtain crystal. After centrifugalization and crystal drying, a product is obtained and a crystal mother liquid is recovered. The method has the advantages of mild reaction conditions, easy-control process, low requirements on equipment, indiscriminately recyclable mother liquid after centrifugalization, and no emission problems of acid, base and other pollutants. The product of potassium diformate, produced by the method, has product yield of over 94 percent and purity of more than 98 percent. The product yield is improved and costs are reduced. The product can be used as a non-antibiotic growth promoting agent to be directly added into pannage.

Owner:BEIJING SUNPU BIOCHEM TECH

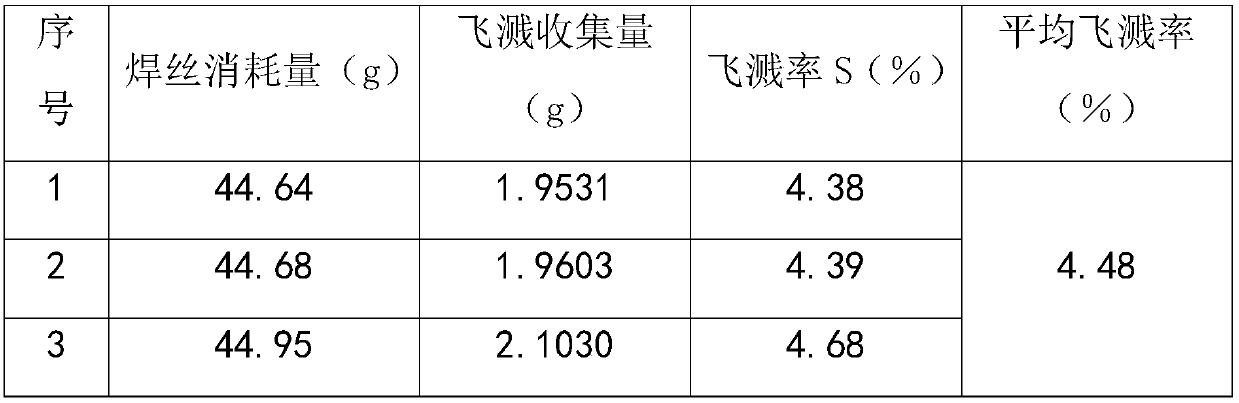

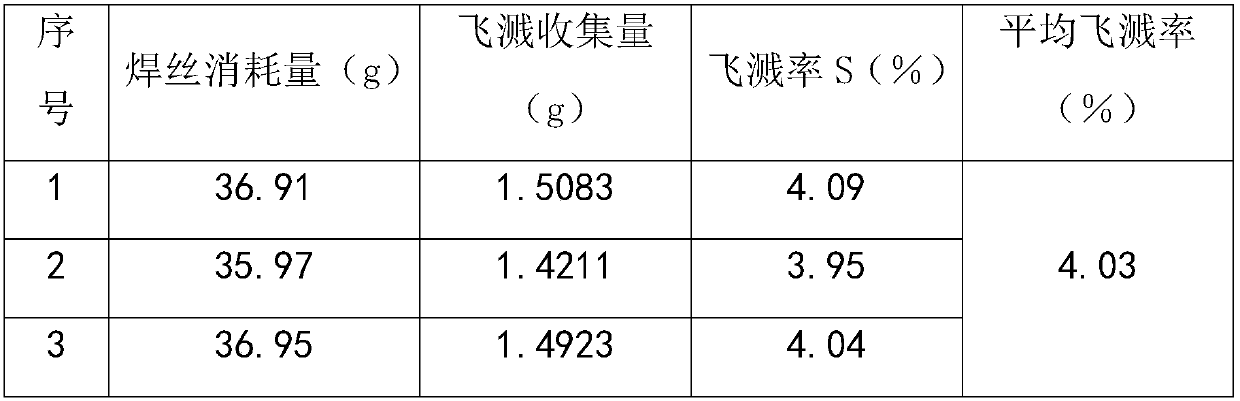

Low-spatter-rate ER50-6 gas-protection solid welding wire

InactiveCN109514127AGuaranteed stabilityReduce welding spatter rateArc welding apparatusWelding/cutting media/materialsCopperGas protection

The invention provides a low-spatter-rate ER50-6 gas-protection solid welding wire. The low-spatter-rate ER50-6 gas-protection solid welding wire comprises a steel wire base body and a copper platinglayer which is coated on the surface of the steel wire base body. The steel wire base body comprises the following components of, by weight percentage, 0.06%-0.10% of C, 0.80%-1.00% of Si, 1.40%-1.60%of Mn, 0.010%-0.015% of S, less than or equal to 0.015% of P, less than or equal to 0.015% of Mo, less than or equal to 0.015% of Ni, less than or equal to 0.30% of Cu, less than or equal to 0.015% of Cr, less than or equal to 0.03% of V, 0.02-0.08% of Al, less than or equal to 0.008% of O, less than or equal to 0.007% of N and less than or equal to 0.0012% of Ca, the balance being Fe. The low-spatter-rate ER50-6 gas-protection solid welding wire adopts the method of chemical component control to control the transition form of dissolved drops and ensure the stability of transition of the dissolved drops, so that the effect of reducing the welding spattering rate is realized.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

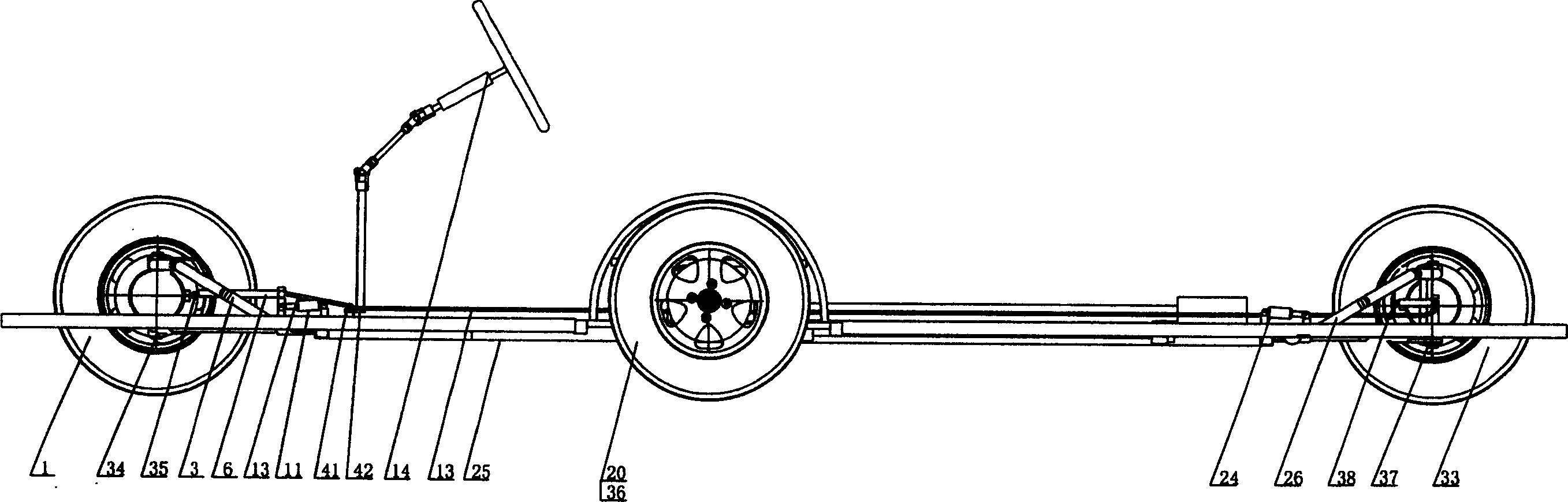

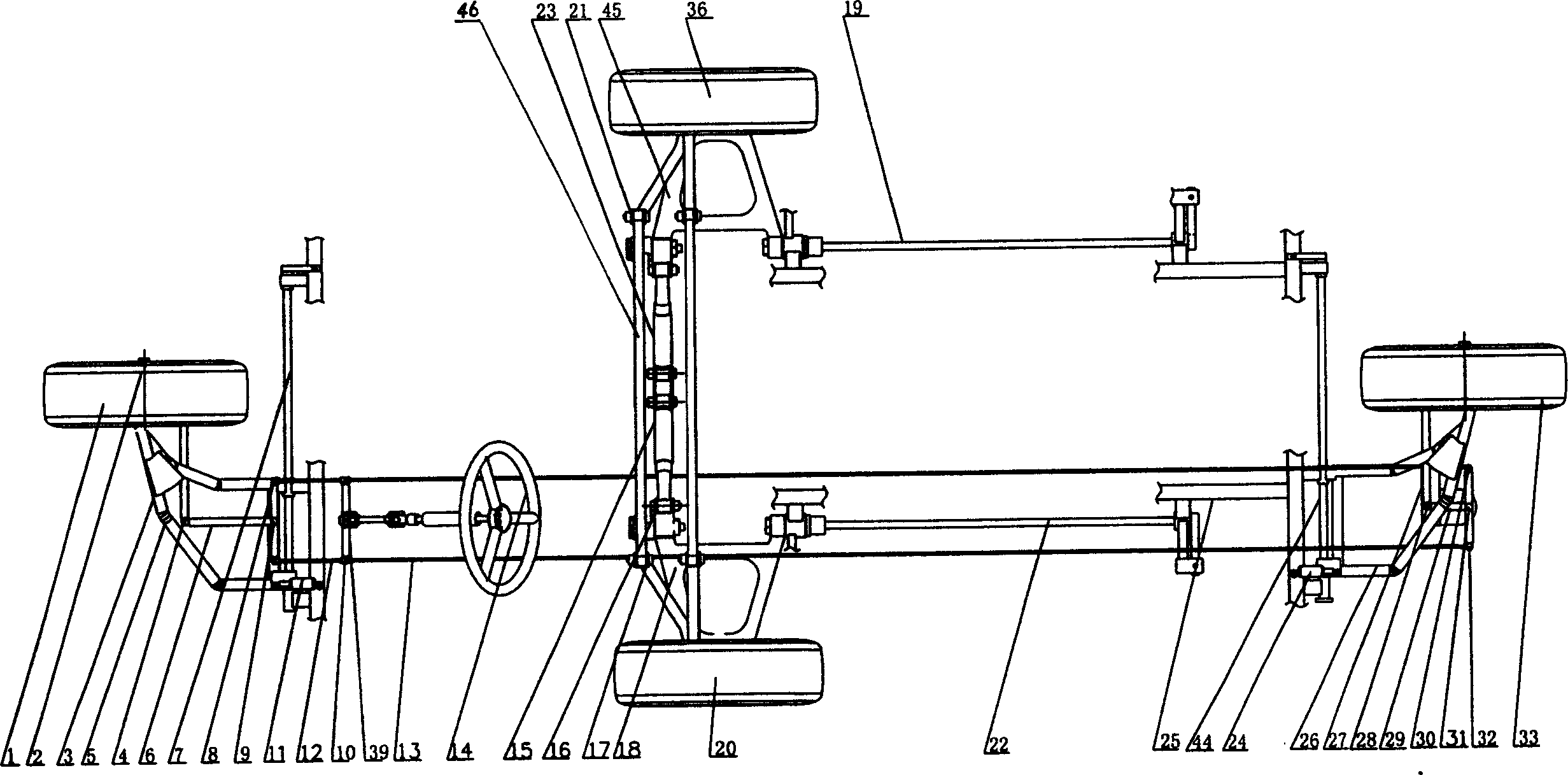

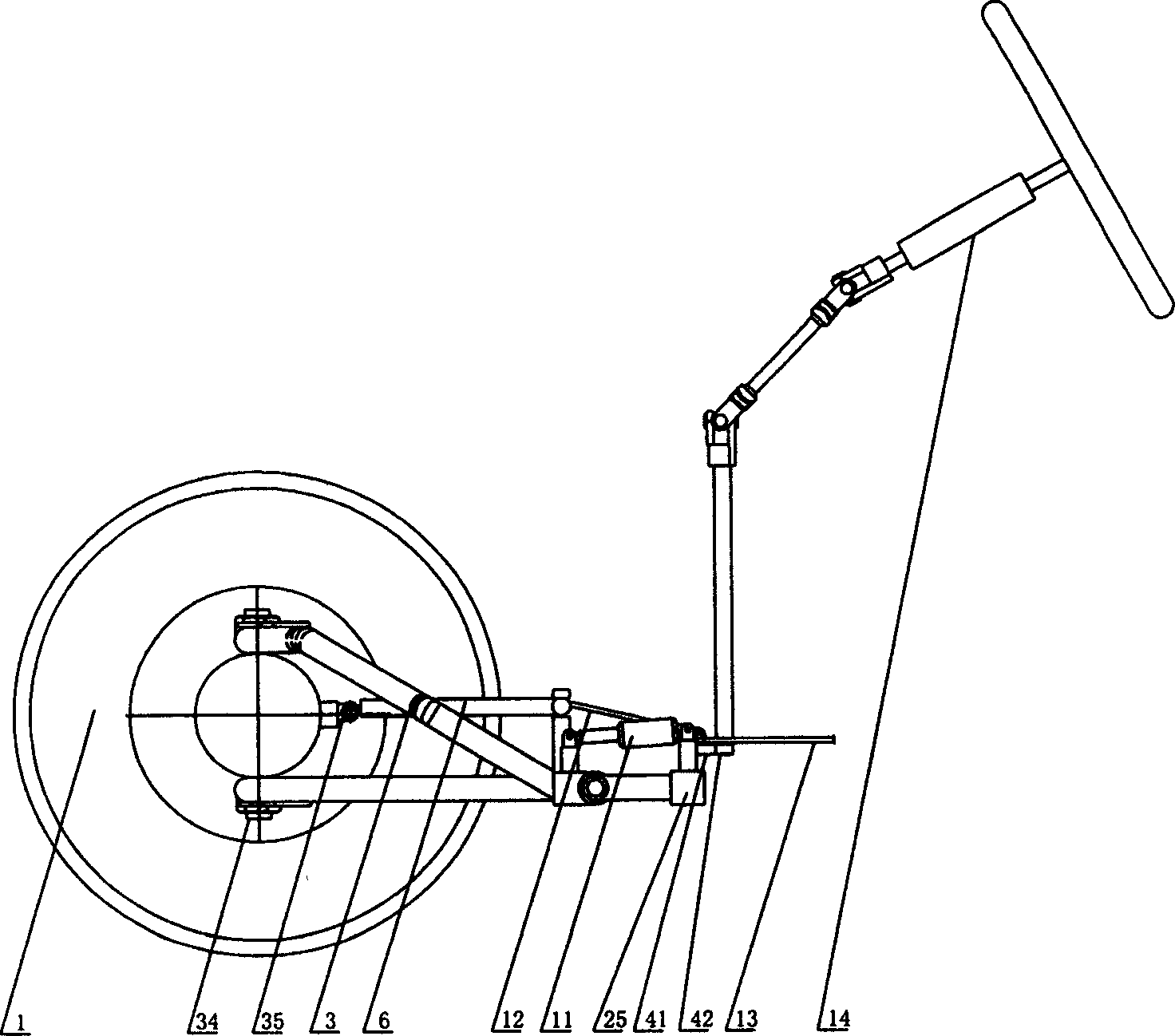

Rhombic carriage supporting steering mechanism

This invention relates to a rhombic suspending and steering mechanism. Its suspending part consists of a front-rear suspending and a middle-suspending unit. The front-rear suspending unit consists of two longitudinal swing arms and torsion springs. The both longitudinal swing arms are respectively connected with front and rear wheel at their both ends, and connected with chassis via a torsion spring. The middle suspending unit consists of two lateral swing arms and torsion springs. The both lateral swing arms are respectively connected with one of side wheels at one of their ends, and connected with the chassis via a torsion spring. The steering part consists of a steering frame and a swing lever. The steering frame is connected with the front and rear wheels, and the swing lever, of which front portion is equipped with a large gear wheel engaged with a small gear wheel that is connected with the steering wheel. The front wheel and rear wheel are located on a lnogitudinal line. The suspending mechanism occupies space less and can turn in a short radius. It has a bumping effect due to its front suspending unit when a collision occurs.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com