Ohm contact of gallium nitride base device and preparation method thereof

A gallium nitride-based, ohmic contact technology, applied in the direction of semiconductor devices, laser components, lasers, etc., can solve the problem that metal interdiffusion cannot be completely blocked, achieve good surface morphology, improve comprehensive performance, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] Taking AlGaN / GaN HFET devices as an example, the specific technical solutions are as follows:

[0031] (1) Ohmic metal structure layout of photolithographic devices;

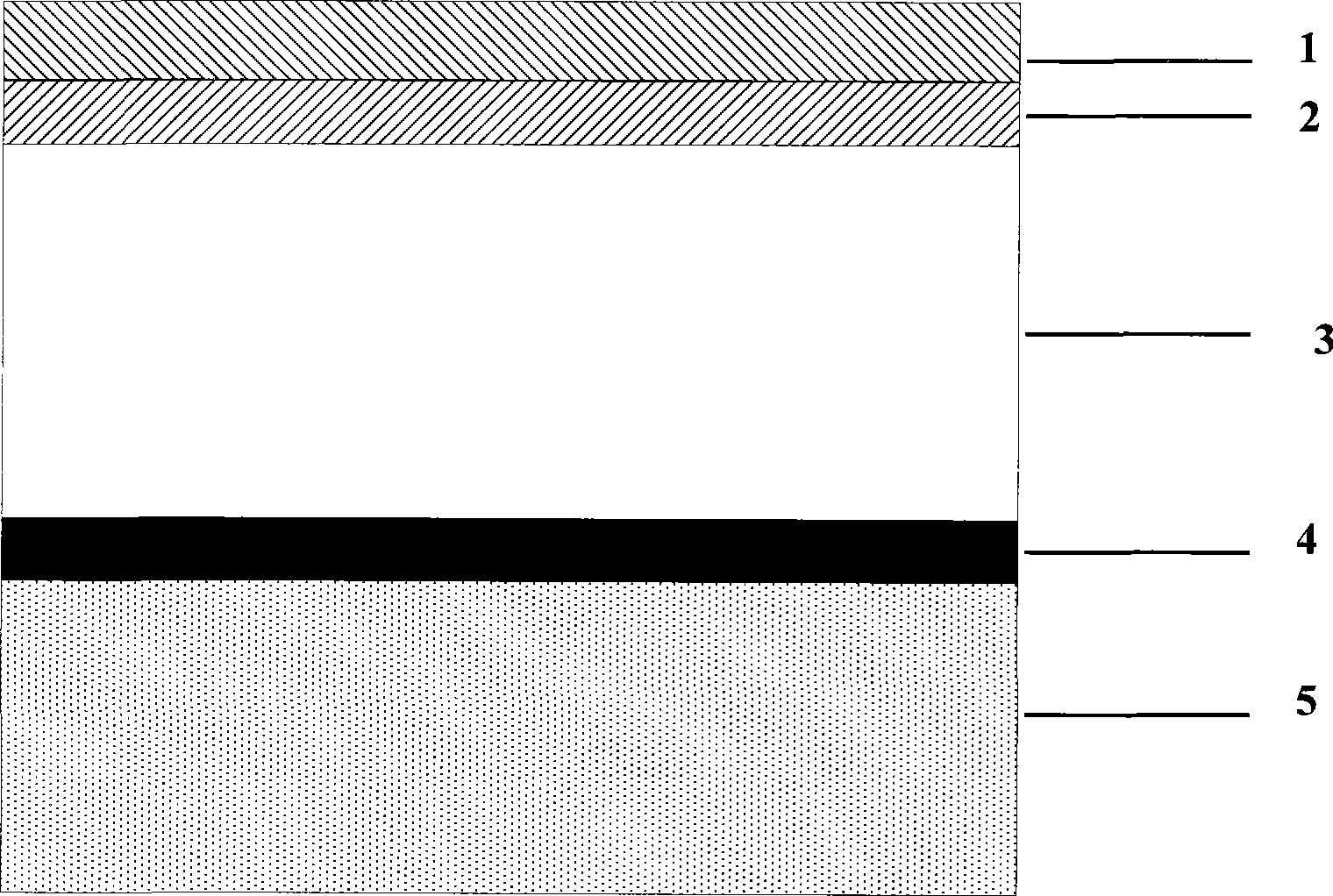

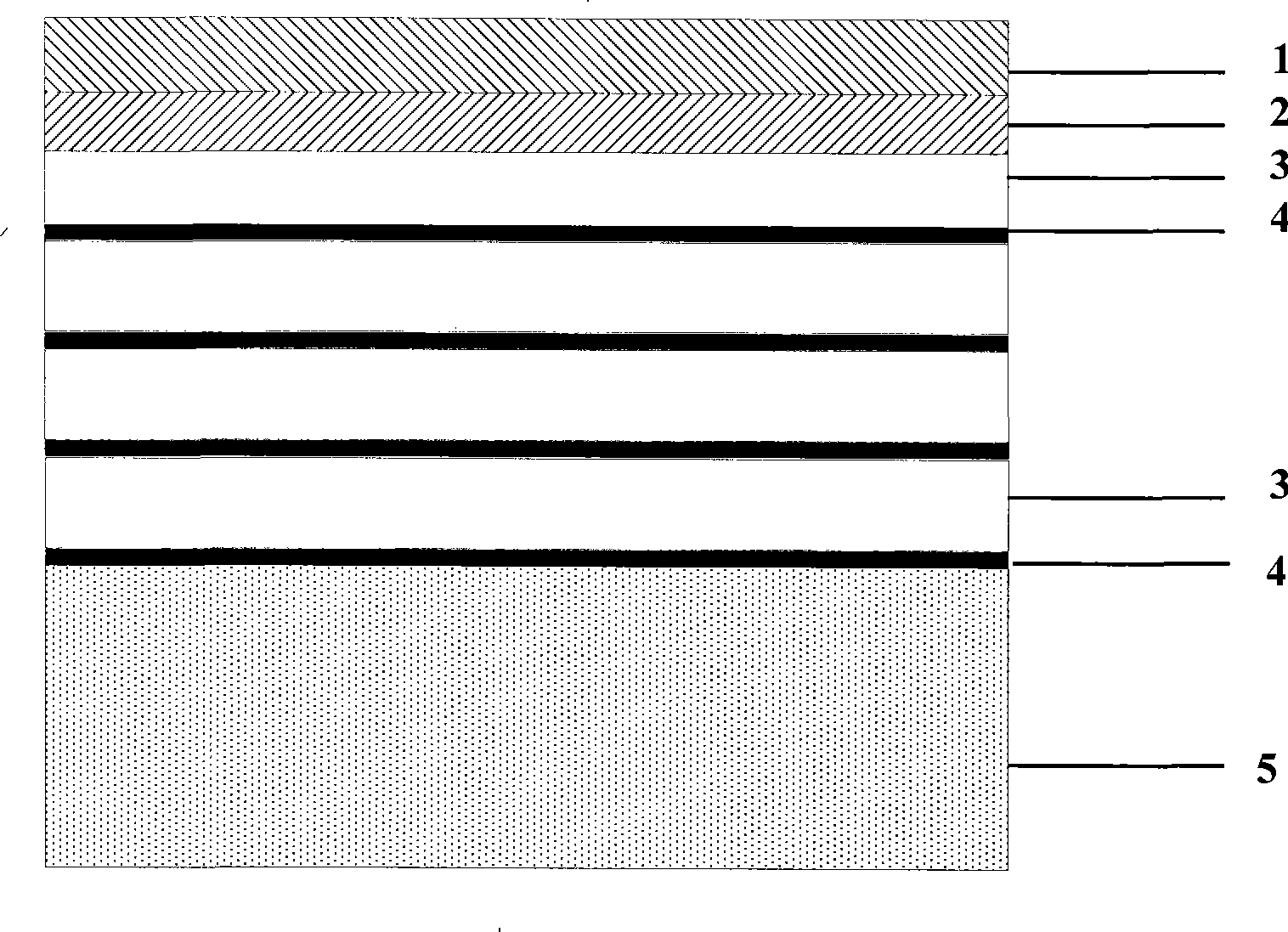

[0032] (2) Deposition of the metal layer structure, using magnetron sputtering to deposit Ti 5nm, Al 30nm, Ti 5nm, Al 30nm, Ti 5nm, Al 30nm, Ti 5nm, Al 30nm, Ni 50nm, Au 200nm.

[0033] (3) Peeling off: Ultrasonic the device sample on which the metal has been deposited in acetone to form an ohmic pattern.

[0034] (4) Rapid thermal annealing: Clean the device sample and put it into the rapid annealing furnace. Two annealing schemes are adopted: the temperature range of the first annealing is 800-900°C, and the time is 30S; the temperature range of the second annealing is 400~600℃, the time is 120S.

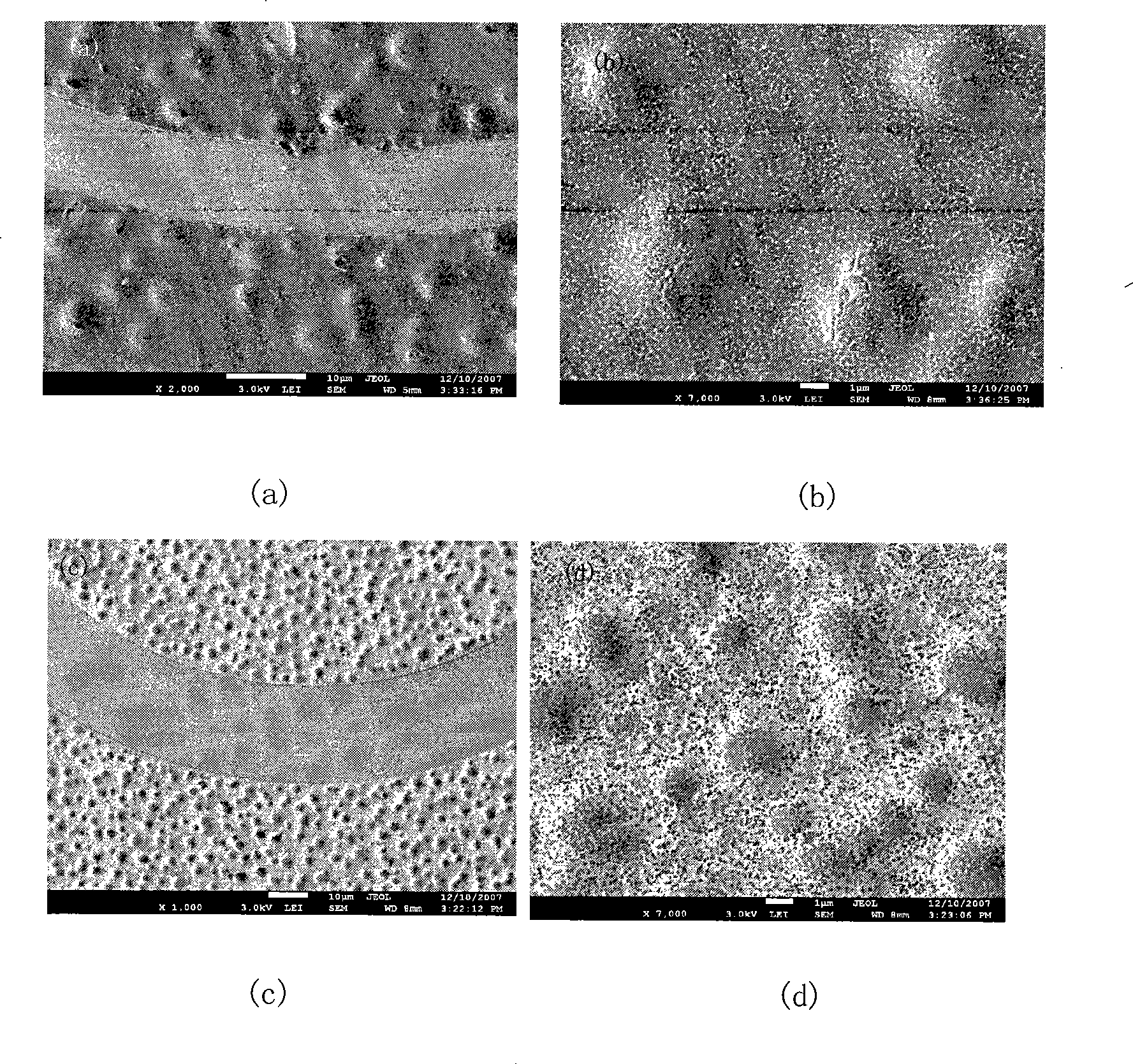

[0035] The resistivity comparison between the ohmic contact of this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com