Synthesizing method of nano-grade lithium ion battery composite positive electrode material LiMnPO4/C

A composite positive electrode material and lithium-ion battery technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of inability to ensure the tight packaging of conductive carbon, reduce the material volume energy density, material processing and coating performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

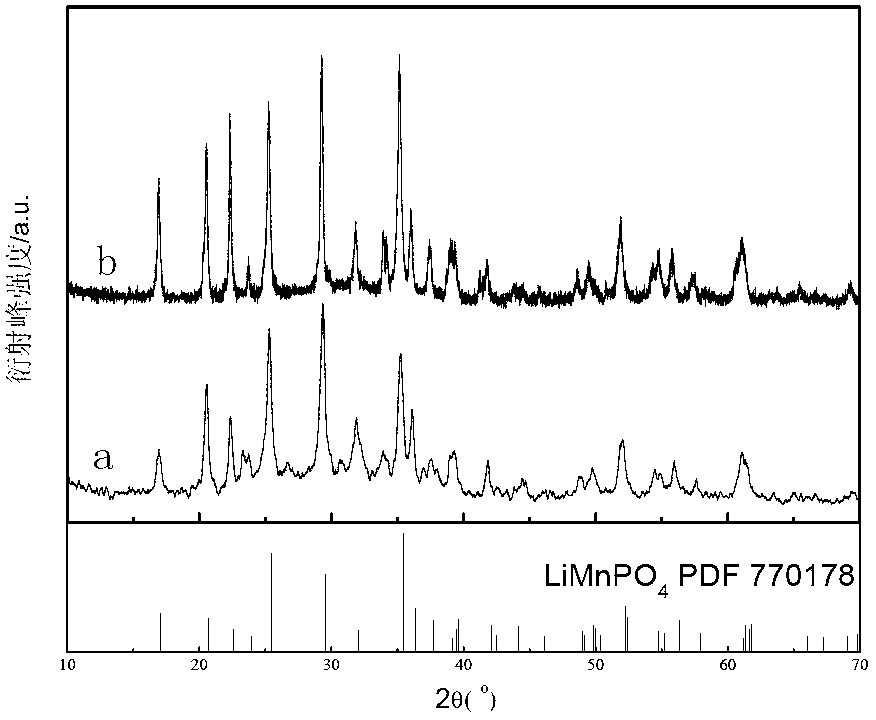

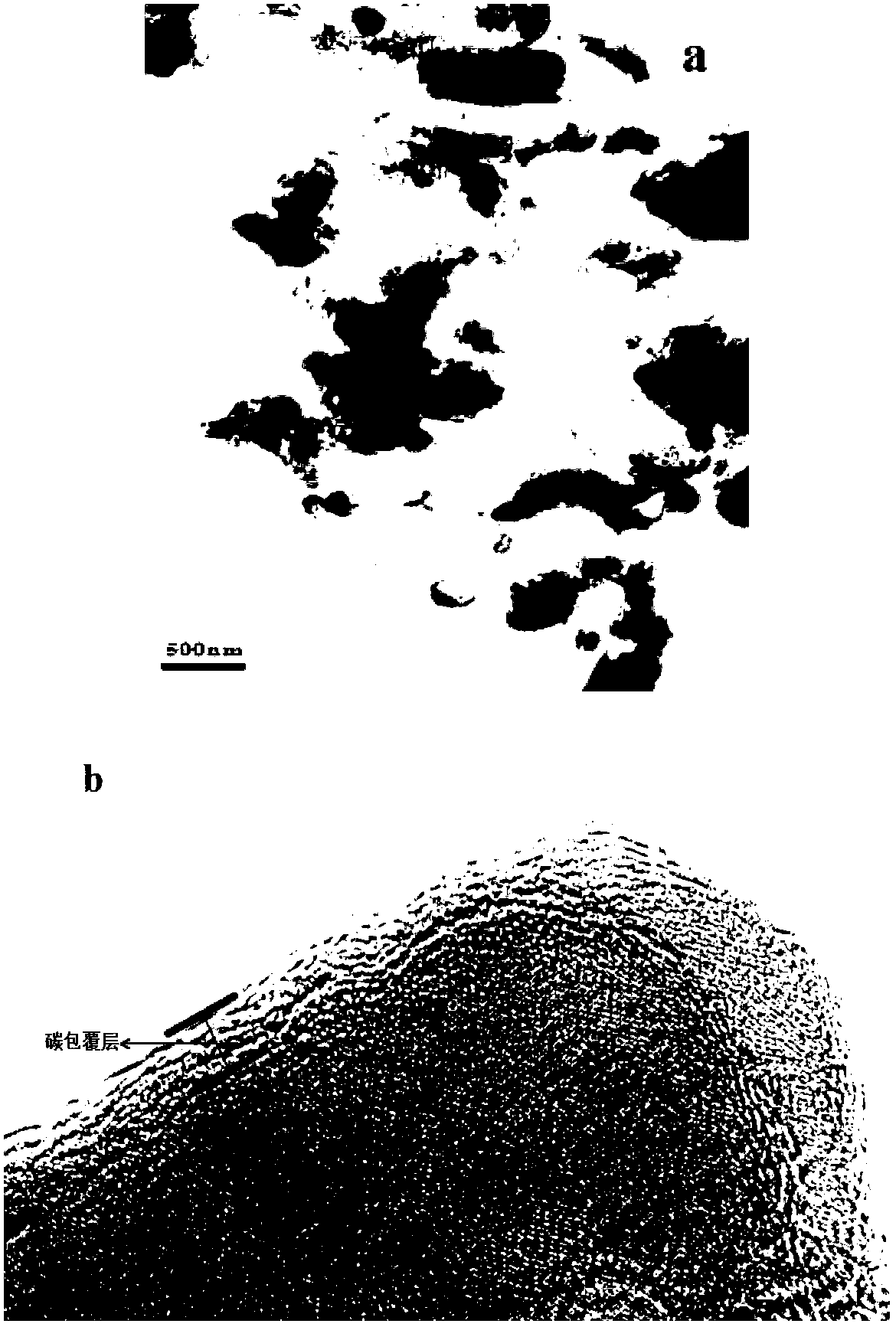

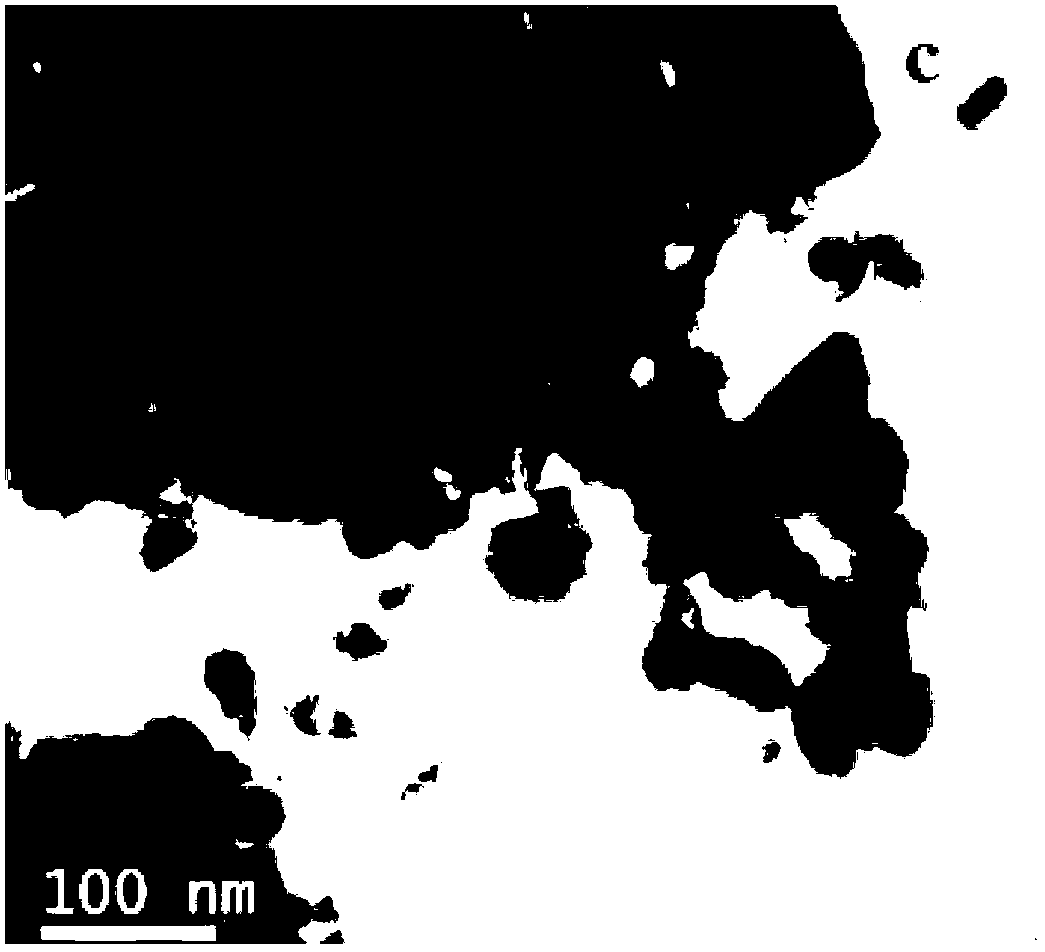

[0030] Lithium dihydrogen phosphate and manganese powder were weighed according to a molar ratio of 1:1, and 50 wt% glucose was added to the mixed material, dispersed in deionized water-triethylene glycol medium, and subjected to high-energy ball milling for 4 hours to obtain a precursor slurry. Transfer the slurry into a round-bottomed flask with a reflux device, and add an appropriate amount of triethylene glycol as a dispersant and reflux medium. After ultrasonic treatment for 30 min, the reaction was strengthened for 4 h at a stirring speed of 300 r / min in a boiling state. Gained product obtained gray product through high-speed centrifugation after alcohol washing 3 times (XRD sees embodiment figure 1 a). Then the gray product was placed in an atmosphere furnace, calcined at 600 °C for 9 h under the protection of argon and cooled to room temperature to obtain nano-sized LiMnPO 4 / C composite cathode material (TEM sees embodiment figure 2 a and b), XRD detection of the ...

Embodiment 2

[0032] Lithium carbonate, manganese phosphate (MnPO 4 ·H 2 O) Weigh it according to the molar ratio of 0.5:1, add 20wt% sucrose of the mixed material, disperse in the deionized water-tetraethylene glycol medium, and undergo high-energy ball milling for 5 hours to obtain the precursor slurry. Transfer the slurry into a round-bottomed flask with a reflux device, and add an appropriate amount of tetraethylene glycol as a dispersant and reflux medium. After ultrasonic treatment for 20min, the reaction was strengthened for 8h at the stirring speed of 400r / min in the boiling state. The obtained product was washed with alcohol for 3 times, and then separated by high-speed centrifugation to obtain a gray product. Then the gray product was placed in an atmosphere furnace, calcined at 700 °C for 2 h under the protection of argon and cooled to room temperature to obtain nano-sized LiMnPO 4 / C composite cathode material. Detect 3.5wt% carbon in the composite positive electrode materia...

Embodiment 3

[0034] Lithium dihydrogen phosphate and manganese monoxide were weighed according to a molar ratio of 1:1, and 30 wt% citric acid was added to the mixed material, dispersed in an anhydrous ethanol-glycerol medium, and subjected to high-energy ball milling for 6 hours to obtain a precursor slurry . Transfer the slurry into a round-bottomed flask with a reflux device, and add an appropriate amount of glycerol as a dispersant and reflux medium. After ultrasonic treatment for 40 min, the reaction was strengthened for 6 h at a stirring speed of 450 r / min in a boiling state. The obtained product was washed with alcohol for 3 times, and then separated by high-speed centrifugation to obtain a gray product. Then the gray product was placed in an atmosphere furnace, calcined at 500 °C for 10 h under the protection of argon and cooled to room temperature to obtain nano-sized LiMnPO 4 / C composite positive electrode material, XRD detects that this material has a single olivine structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com