Patents

Literature

62results about How to "Facilitate synthesis reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing selenide or sulfide semiconductor film material of copper-indium-gallium

InactiveCN1547239AEliminate condensationAvoid deformationFinal product manufactureVacuum evaporation coatingWater bathsIndium

The invention refers to a manufacturing method for selenide or sulfide of copper, indium or gallium. In the manufacturing process of copper, indium or gallium selenide and / or sulphur optical absorbing layer film, uses vacuum magnetism control splattering, heating and evaporating method or chemical water bath electrodeposition method to deposit a metal preprocessed layer with chemical formula proportion of Cu, In, Ga on the natrium calcium glass Mo substrate, then carries on optical selenide or / and sulfide reaction in the thermal process vacuum room, the character lies in: the battery base board deposited with the preprocessed layer are heated upon the two surfaces, the back surface of the base board is heated with contacting heat reservoir, the surface coated with metal preprocessed layer is heated with light irradiation, when the temperature rises to the 400-560oC evenly and quickly, carries on the cooperative heating with contacting heat reservoir and light irradiation to the selenium source or the sulphur source, makes the metal preprocessed layer converted into the compound semiconductor photoelectric film material.

Owner:NANKAI UNIV

Method for synthesizing doping lithium manganic acid

InactiveCN101152963ALow priceFair priceCell electrodesManganates/permanganatesElectrolysisPhysical chemistry

The present invention provides a synthesizing method of doping lithium manganese oxide, which is essentially used for lithium ion battery anode active material. A doping material is mixed into Li2CO3 and electrolysis MnO 2 material. The doping material comprises any two of Al, Co, Cr, Fe, Y trivalent cations and any one of F, Cl, I anions. The raw material is mechanically mixed, high-speed milled and sieved to prepare a mixture. The mixture is roasted according to a set program in a rotary resistance furnace. After cooling, the mixture is milled and sieved again to prepare the product. The method is simple in reaction process, low in cost and even in mixture, which effectively improves the electrochemical property and recycling property of material and causes no pollution to the environment.

Owner:JIANGSU SHUANGDENG GROUP

Thioamide analog compound synthesis method

The invention discloses a synthesis of an addition reaction which uses accelerant to catalyze alkali and hydrogen sulfide in order to synthesize relevant thioamide compounds by high yield. The concrete things are thioacetamide, propanethioamide, thioisonicotinamide, thiobenzamide, 2-cyanothioacetamide, 4-chlorphenylthioacetamide, 4-methylthiobenzamide. The process of this invention is: dissolving nitrile in a suitable organic solvent, adding alkali solution and phase transfer catalyst, mixing adequately to homogeneous phase, then importing hydrogen sulfide until the reaction end and getting thioamide.

Owner:朱凯琴

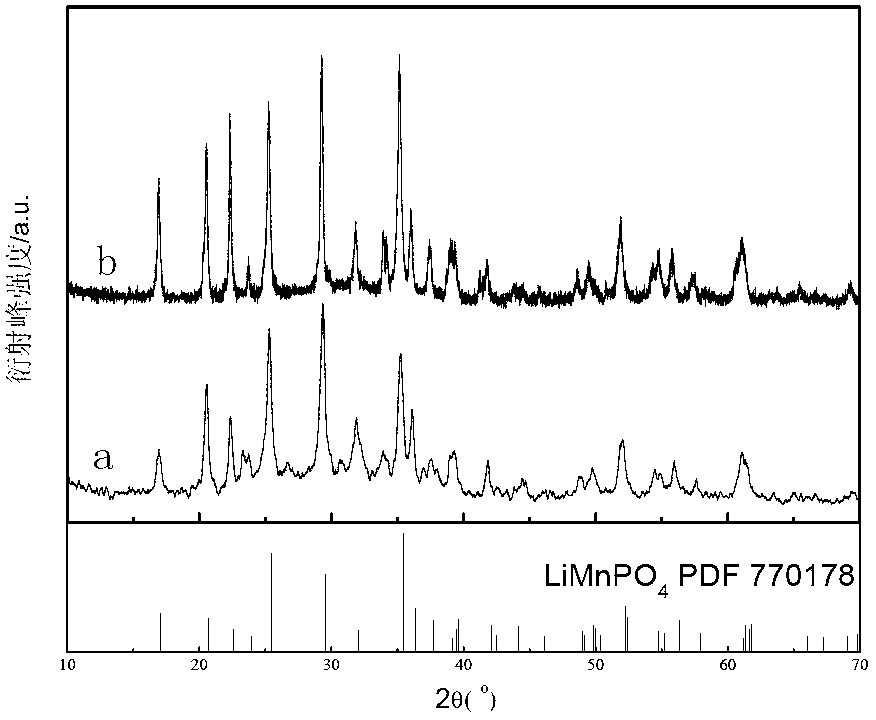

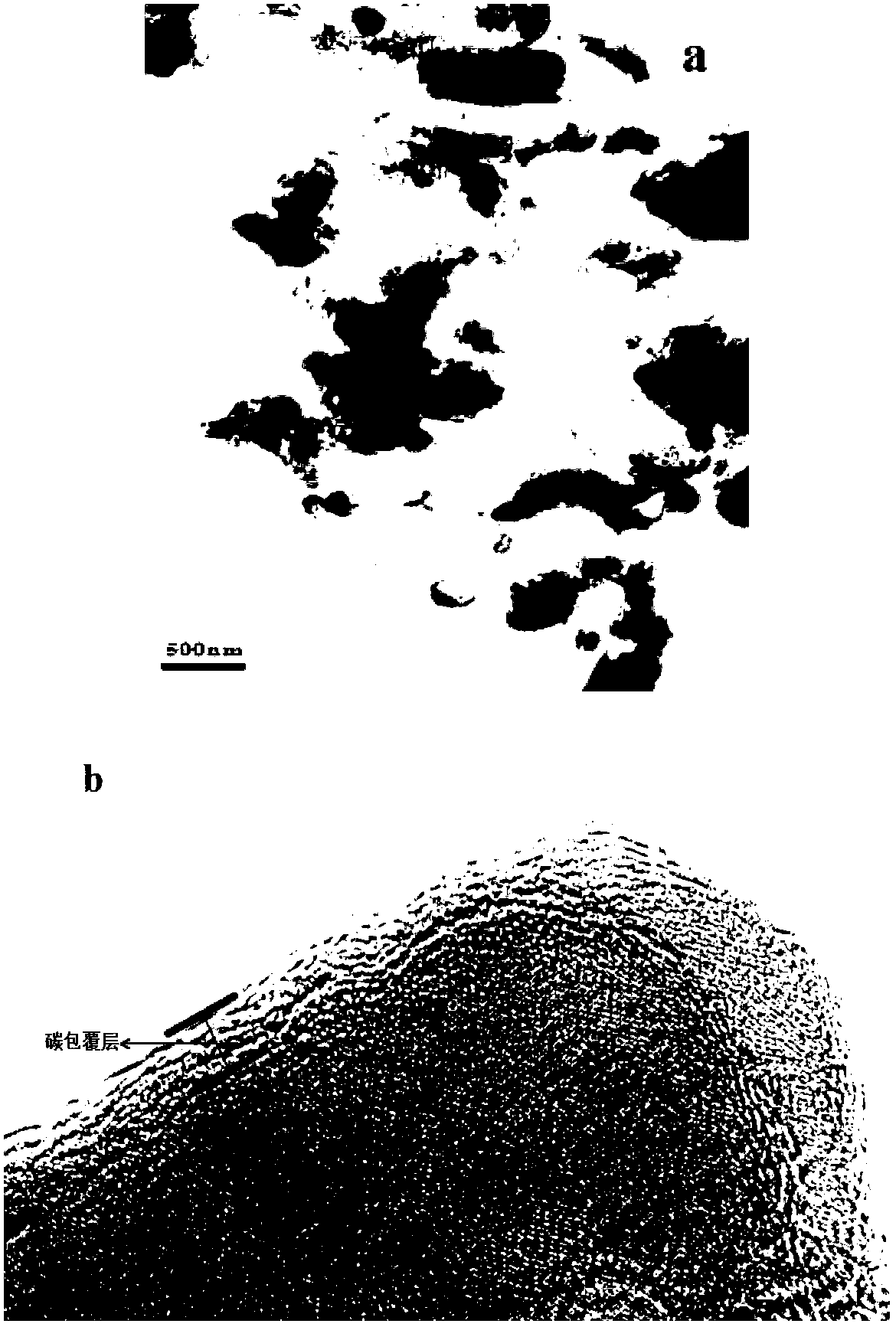

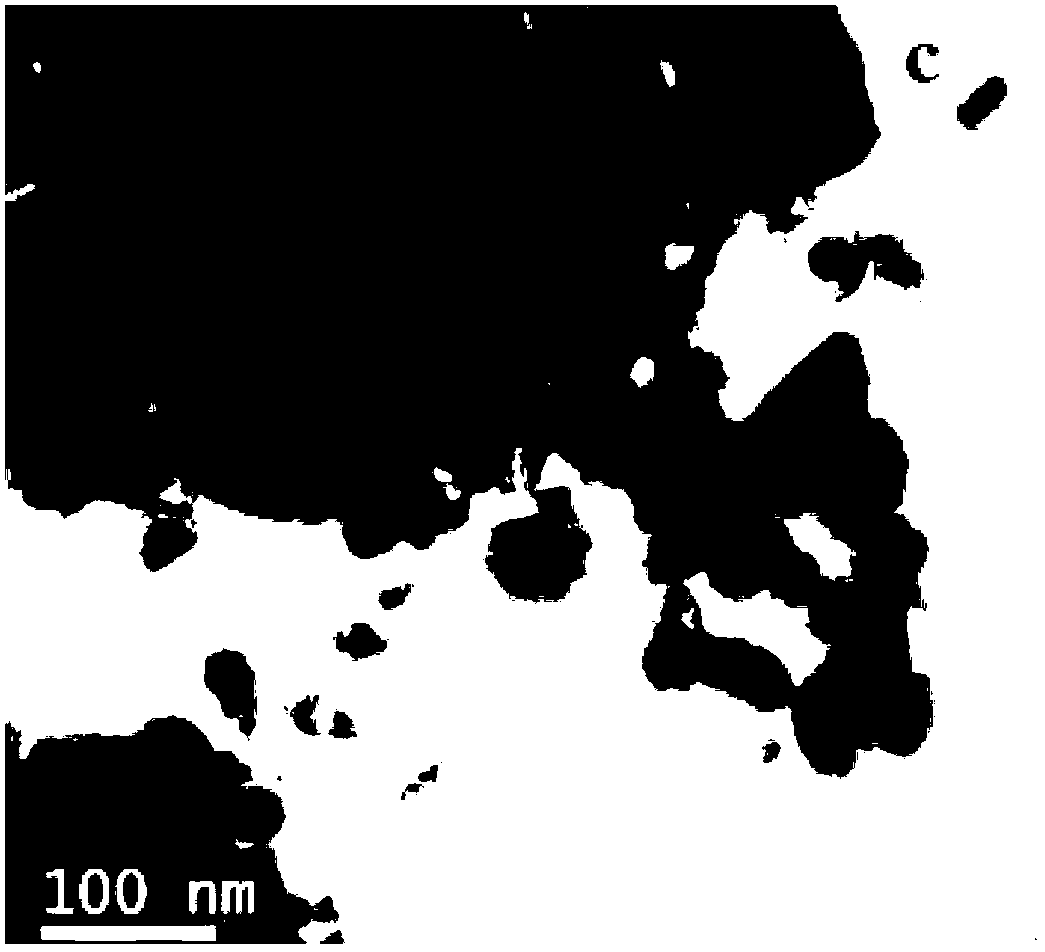

Synthesizing method of nano-grade lithium ion battery composite positive electrode material LiMnPO4/C

InactiveCN102931400AIncrease contact interfacePromote interdiffusionCell electrodesCarbon layerHigh energy

The invention relates to a synthesizing method of a nano-grade lithium ion battery composite positive electrode material LiMnPO4 / C. According to the invention, a lithium source, a phosphorous source, a manganese source and an organic carbon source are well mixed in a solvent medium; the mixture is processed for 2-7h in a high-energy ball mill, and a uniformly dispersed precursor slurry is obtained with the activation effect of mechanical forces; the precursor slurry is subjected to ultrasonic dispersion in a high-boiling-point polyol solvent, and is subjected to a reflux reaction; an obtained product is filtered and washed; and the product is subjected to a heat treatment for 1-10h under inert atmosphere protection and under a temperature of 600-800 DEG C, such that the nano-grade lithium manganese phosphate / carbon (LiMnPO4 / C) positive electrode material is obtained. According to the material provided by the invention, primary particles are well distributed nano-particles, and a conductive carbon layer is formed in-situ on the surfaces of the LiMnPO4 / C particles. The method provided by the invention is simple and highly efficient. With the method, no pollutant such as ammonia gas or wastewater is produced during the entire process. Therefore, a development requirement of green chemistry is satisfied.

Owner:CENT SOUTH UNIV

Preparation method for solid thermosetting phenolic resin

InactiveCN102286135AFacilitate synthesis reactionThe synthesis reaction is controllableAldehyde/ketone condensation polymer adhesivesCoatingsAdhesiveSolvent

The invention discloses a preparation technology of solid thermosetting phenolic resin with high molecular weight. The thermosetting phenolic resin with stable and reliable quality can be prepared in an ethanol solvent by using a sequential acid and alkali process, gel can be formed in 1 minute by thermally treating the thermosetting phenolic resin at the temperature of between 150 and 180 DEG C,and the thermosetting phenolic resin is totally cured in 30 minutes. The preparation method is environment-friendly, simple, convenient and reliable; and the solid thermosetting phenolic resin has broad application prospect in adhesive, coating and composite matrix.

Owner:BEIHANG UNIV

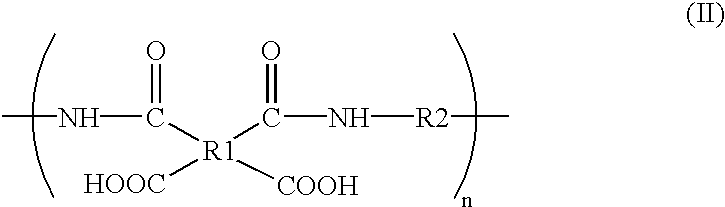

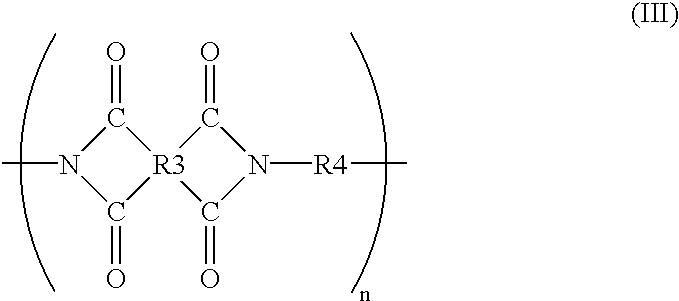

Liquid crystal aligning film

InactiveUS6562420B2Facilitate synthesis reactionEasy to synthesizeLiquid crystal compositionsSynthetic resin layered productsPolymer scienceOligomer

Owner:IND TECH RES INST

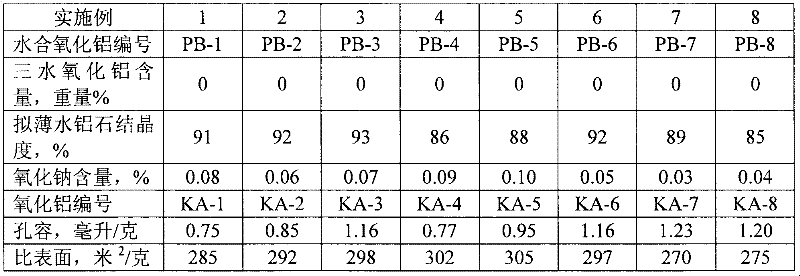

Preparation method of pseudo-boehmite

ActiveCN102442689AFacilitate synthesis reactionEasy to operateAluminium oxides/hydroxidesReaction temperatureDawsonite

The invention provides a preparation method of pseudo-boehmite. The preparation method, which comprises a gel formation reaction which is carried out on a sodium aluminate solution and an acidic gas, is characterized in that: the acidic gas is a mixed gas containing CO2 and at least one gas with the pressure of less than 6.38kPa; the gel formation reaction temperature is 10-100DEG C; and the amount of the acidic gas and the ratio of CO2 to the gas with the pressure of less than 6.38kPa in the acidic gas make the pH value of the gel formation reaction be 3-7. Compared with the prior art, the method provided by the invention, which ensures that contents of gibbsite and dawsonite in the obtained pseudo-boehmite are zero or very small, allows the synthetic reaction of pseudo-boehmite to be convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

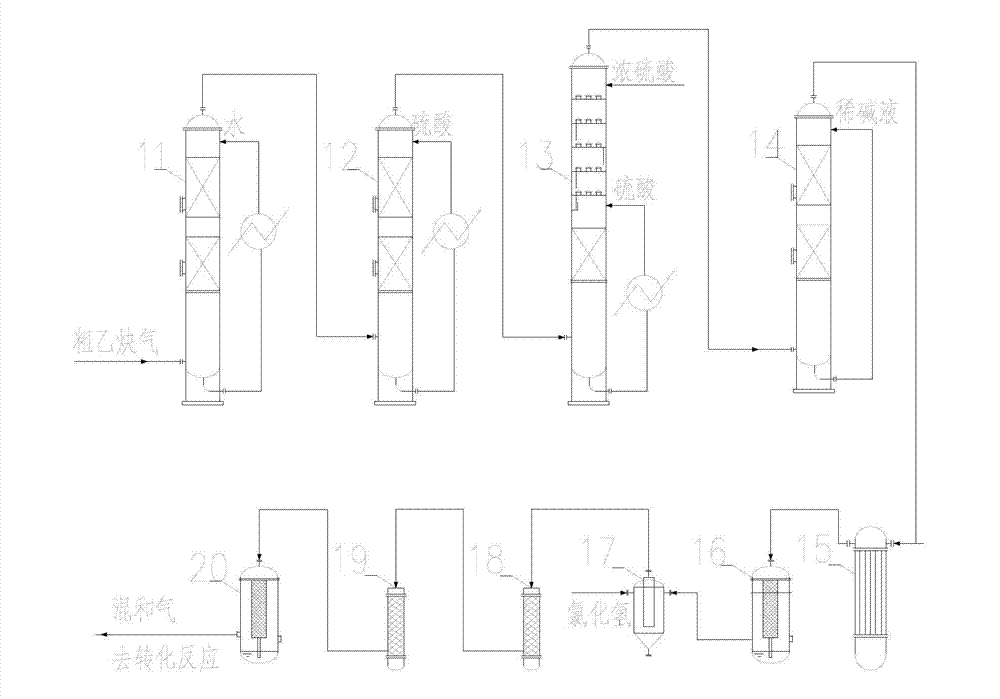

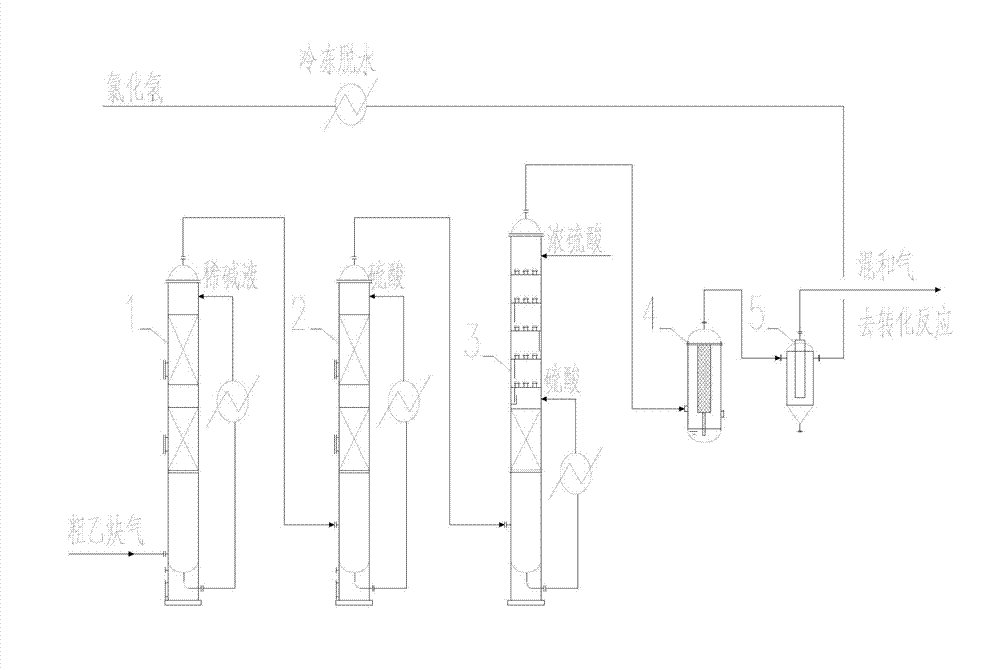

Technique for purifying acetylene gas with sulfuric acid and application thereof

ActiveCN102826952AReduce consumptionLess investmentPreparation by halogen halide additionAbsorption purification/separationCooling towerFreeze-drying

The invention relates to a technique for purifying acetylene gas with sulfuric acid and application thereof. An alkali cleaning cooling tower and a sulfuric acid purification tower are connected sequentially; the alkali cleaning cooling tower is moved before the sulfuric acid purification tower; and the sulfuric acid purification tower is formed by connecting two towers in series, wherein the primary tower is a packing tower, and the secondary tower is a packing / bubbling hood combined tower. The technique for purifying acetylene gas with sulfuric acid is suitable for technical processes for purifying and drying acetylene, and especially synthesis techniques of vinyl chloride. In the acetylene gas purification process, the acetylene gas is dried, and the drying effect is better than that of mixed freeze drying, thereby reducing the occurrence of side reaction and being beneficial to the proceeding of the synthetic reaction; and meanwhile, the invention can reduce the equipment investment and the consumption of freezing water or freezing salt water, thereby lowering the operating cost.

Owner:CHINA TIANCHEN ENG +1

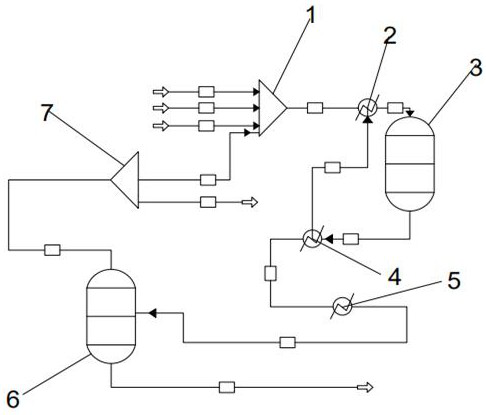

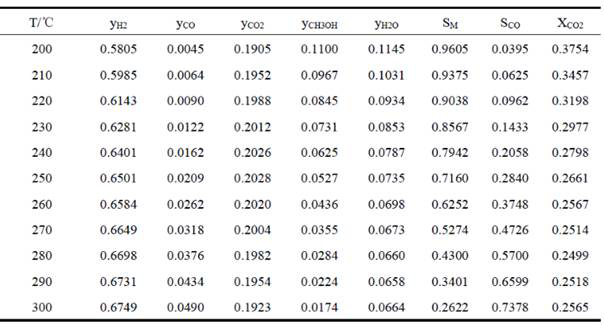

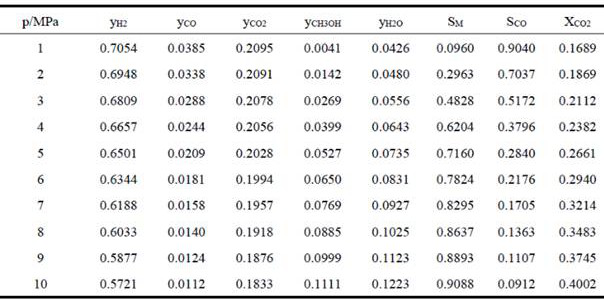

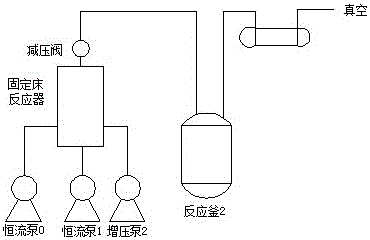

Device and process for synthesizing methanol based on hydrogenation of carbon dioxide

PendingCN112194566ALow input costReduce processing costsOrganic compound preparationHydroxy compound separation/purificationMethanol waterPtru catalyst

The invention discloses a device and process for synthesizing methanol based on hydrogenation of carbon dioxide. The device comprises a mixer, a reactor, a cooler, a flash tank and a tail gas diverging device, wherein the reactor is filled with a catalyst; gas raw materials including CO2 and H2 are introduced into the mixer; an outlet of the mixer is connected with an inlet of the reactor througha pipeline; an outlet of the reactor is connected with the flash tank through the cooler and a pipeline; aquatic methanol products are discharged from a liquid outlet in the bottom of the flash tank,and a gas outlet in the top of the flash tank is connected with an inlet of the tail gas diverging device through a pipeline; and an outlet of the tail gas diverging device is divided into two paths,one path is discharged to a tail gas treatment system, and the other path is connected with an inlet of the mixer through a pipeline, so a part of tail gas is separated out and enters a next cycle ascycle gas. According to the process, the effective utilization rate of CO2 can be greatly increased, and tail gas emission is reduced; and compared with other similar device processes, raw material input cost and tail gas treatment cost are saved, and high economic benefits are achieved.

Owner:ZHEJIANG UNIV OF TECH

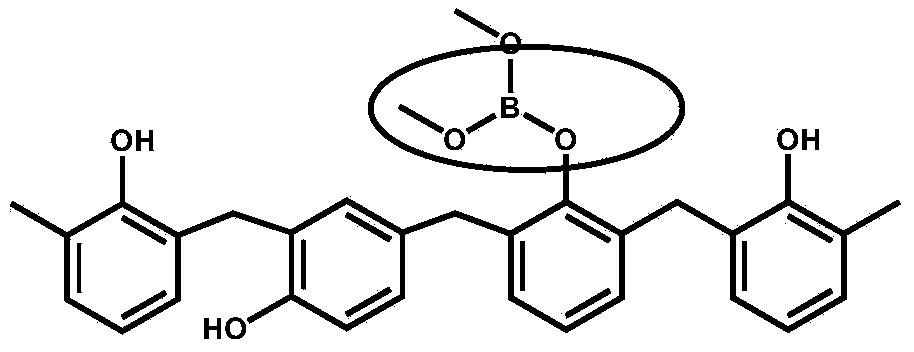

Technique for synthesizing boron-containing thermoplastic phenol formaldehyde resin by solvothermal process

The invention relates to a technique for synthesizing a boron-containing thermoplastic phenol formaldehyde resin by a solvothermal process, which comprises the following steps: adding a thermoplastic phenol formaldehyde resin, a boron-containing compound, oxalic acid and a solvent into a solvothermal reaction kettle, sealing, heating to 120-160 DEG C, keeping the temperature for 0.5-6 hours, cooling to room temperature, and removing the solvent contained in the product, thereby obtaining the boron-containing thermoplastic phenol formaldehyde resin, wherein the boron-containing compound uses an aromatic ring structure as the parent nucleus and hydroxymethyl and boron-containing structure as the substituent group of the aromatic ring structure, and the solvent is water or an alcohol solvent or a mixture of an alcohol solvent and water in a mass ratio of 1:(0.05-0.7). The method has the advantages of high raw material conversion rate and simple technical process; and the obtained product has the advantages of uniform molecular weight distribution and favorable heat resistance. Since the conversion rate of various raw materials is higher, the residual micromolecules do not need to be removed by water washing, thereby effectively reducing the sewage discharge.

Owner:XI AN JIAOTONG UNIV +1

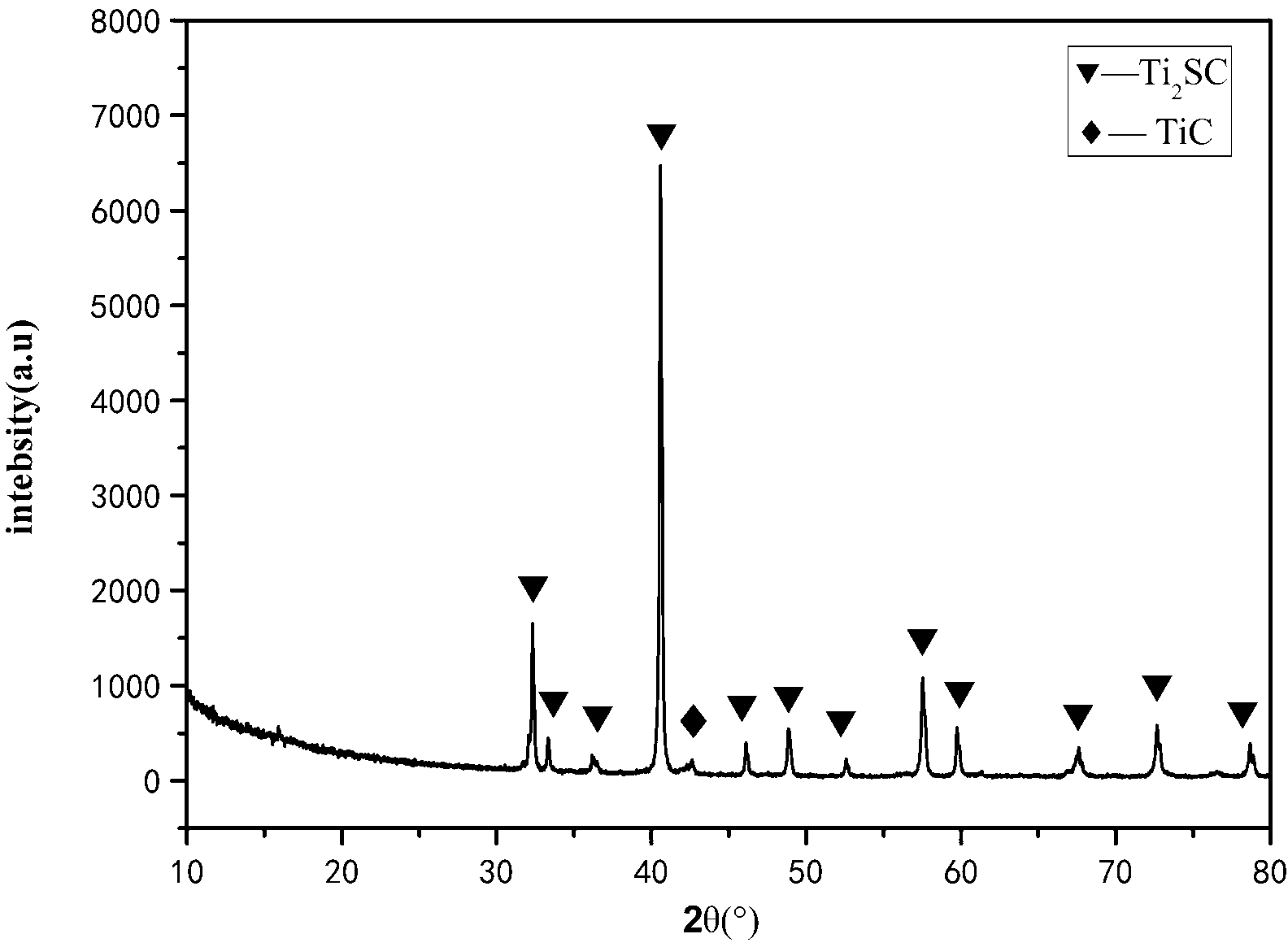

Preparation method of ternary layered carbide Ti2SC (titanium sulfur carbide) material

InactiveCN103253667ALower eutectic pointSynthesis temperature is lowOxy/sulfo carbidesAl powderCarbide

The invention relates to a preparation method of a ternary layered carbide Ti2SC (titanium sulfur carbide) material. Al (aluminum) is used as an assistant, and a high-temperature high-pressure synthesis method is used for preparing a compact Ti2SC material. Raw materials include Ti (titanium) powder, S (sulfur) powder, C (carbon) powder and Al powder, and the mol ratio of the four raw materials is as follows: Ti: S: C: Al=2: (1-1.4): 1: (0.1-0.2). The Ti2SC block material synthesized by the method is compact in structure, and the content of Ti2SC is more than 80 percent by weight; Al is used as the assistant, so that the melting point can be lowered; and by adopting the high-temperature high-pressure sintering method, the volatilization of the S powder can be maximally inhibited, and the Ti2SC material can be rapidly sintered and synthesized.

Owner:WUHAN UNIV OF TECH

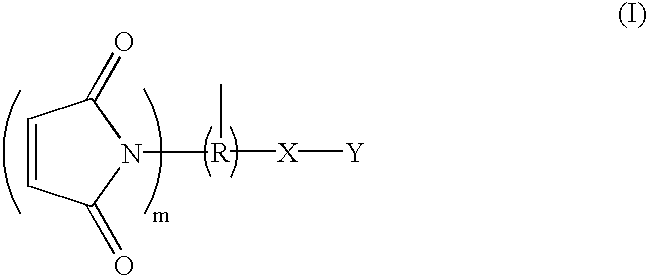

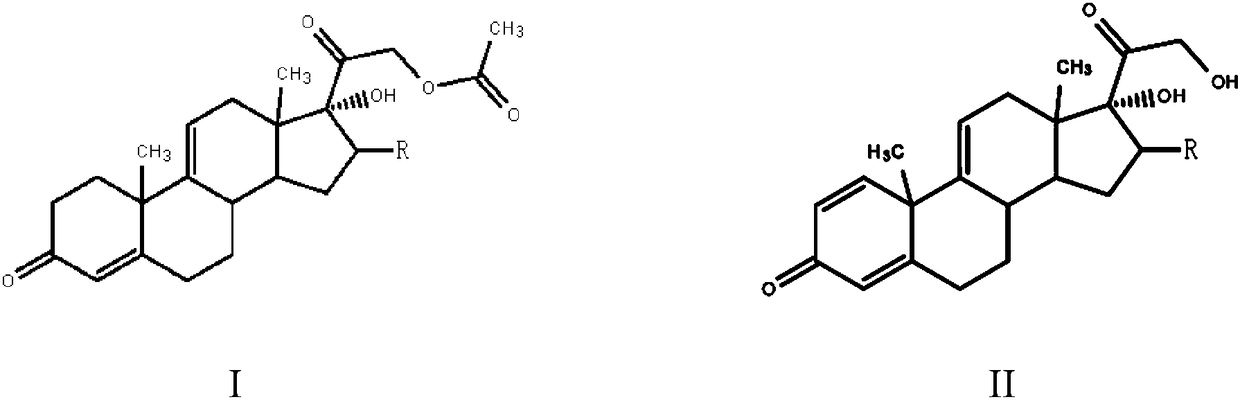

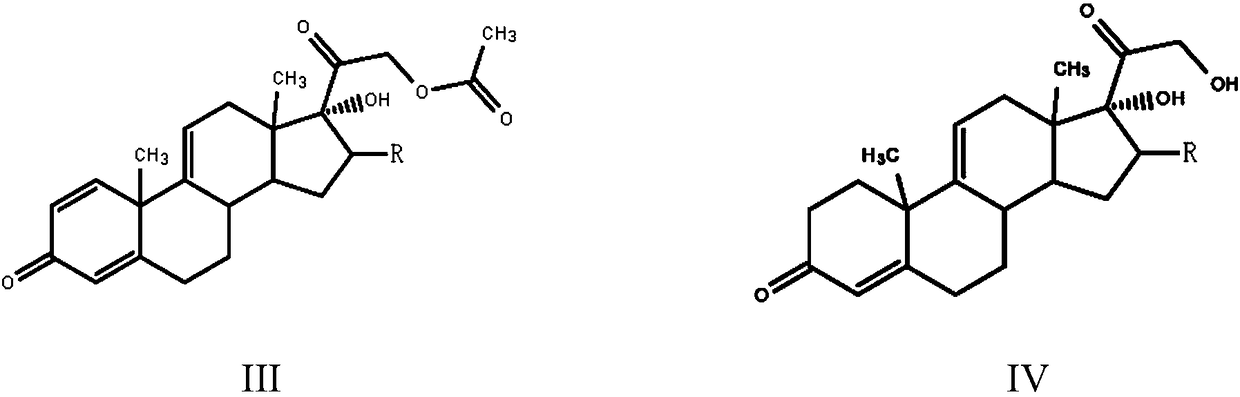

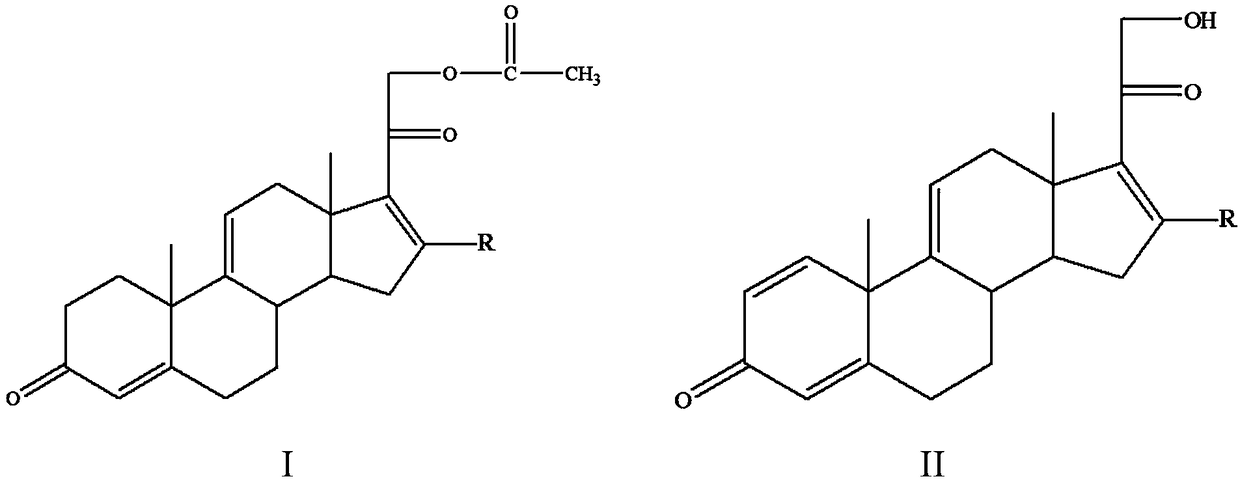

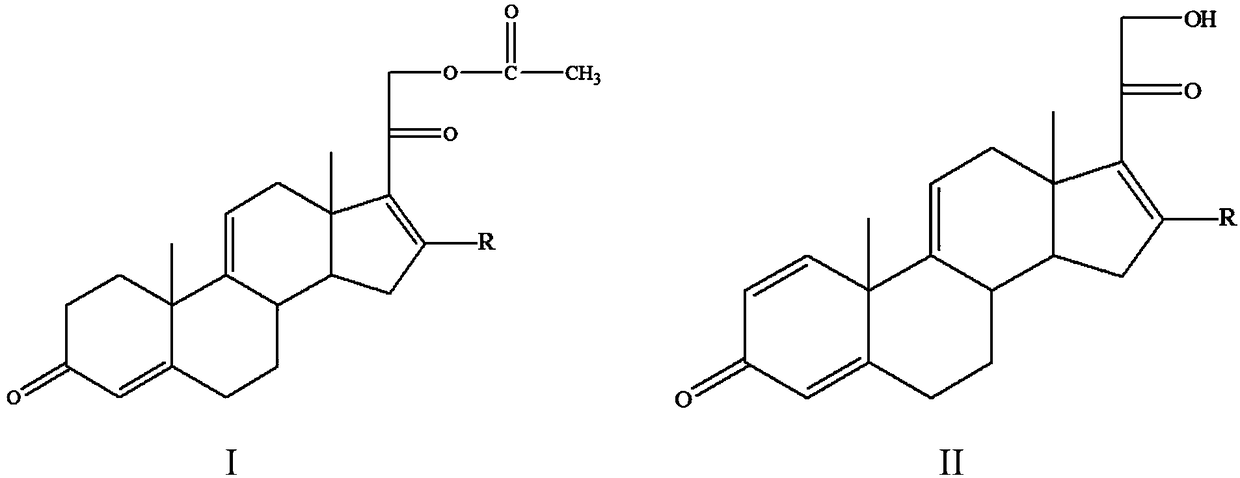

Method for preparing steroidal drug intermediate

ActiveCN108559766AIncrease productivityReduce manufacturing costMicroorganism based processesSteroidsDrug biotransformationSteroid drugs

The invention relates to a method for preparing a steroidal drug intermediate. The method comprises the steps that microbial conversion is conducted on a first compound with Nocardioides simplex to obtain the steroid drug intermediate, the first compound is shown as a formula I, the steroidal drug intermediate is as shown in a formula II, and in the formula I and the formula II, R is H, a halogenatom, an alkyl group, an alkoxy group, a hydroxyl group or a phenyl group. The method selects 4, 9 (11)-pregnant-17-hydroxy group-3,20 dioxin-21-acetate as a substrate, uses only the Nocardioides simplex for biotransformation, dehydrogenation at position 1,2 and hydrolysis of acetate at position 21 are simultaneously conducted on the substrate, 1,4,9 (11)-pregnene-17,21-diol-3,20-dione is obtained, products formed through transformation are mainly the 1,4,9(11)-pregnene-17,21-diol-3,20-dione, the proportion of by-products is low, the purified products are white or off-white crystals, relativesubstrate weight yield is 75%-85%, a target product yield is high, after a HPLC analysis, the purity is >=99%, and external standard content is 98%.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

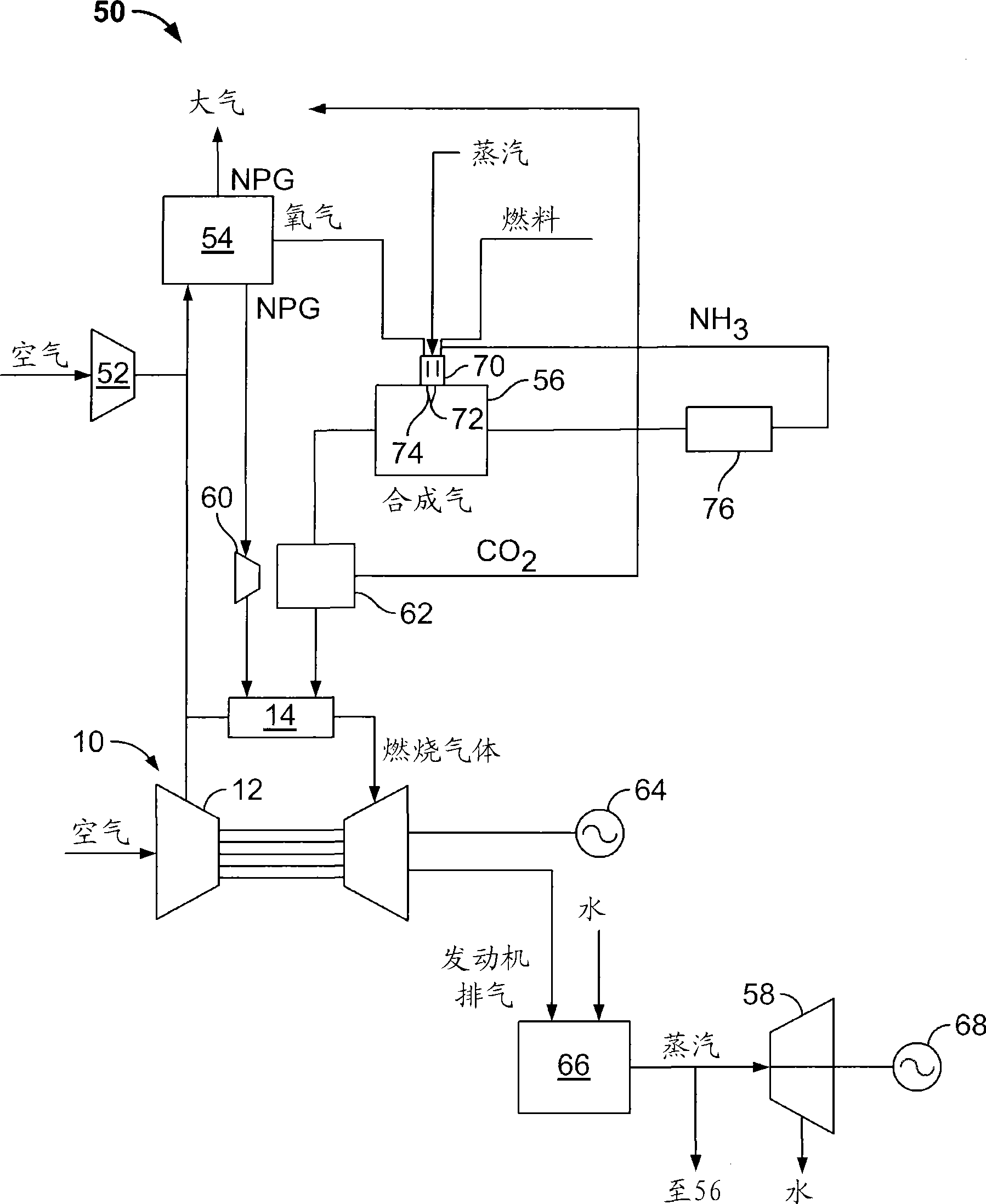

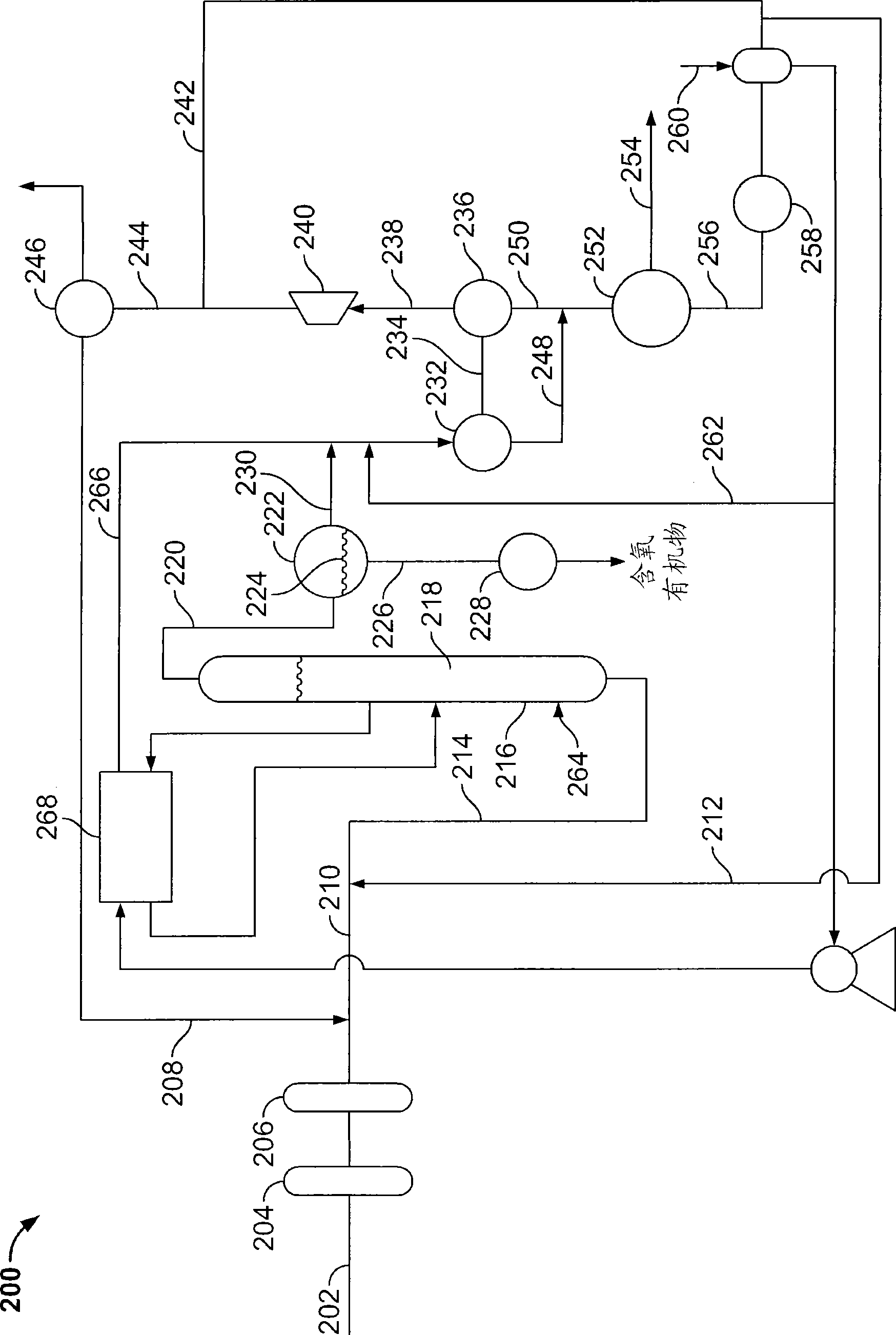

Methods and systems for fischer tropsch reactor low product variation

InactiveCN101544527AFacilitate synthesis reactionHydrocarbon from carbon oxidesCombustible gas catalytic treatmentSyngasProcess engineering

Owner:GENERAL ELECTRIC CO

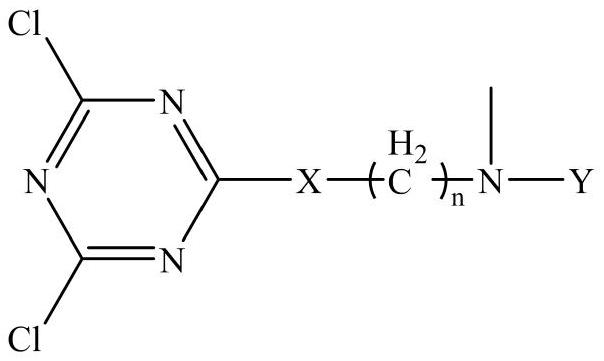

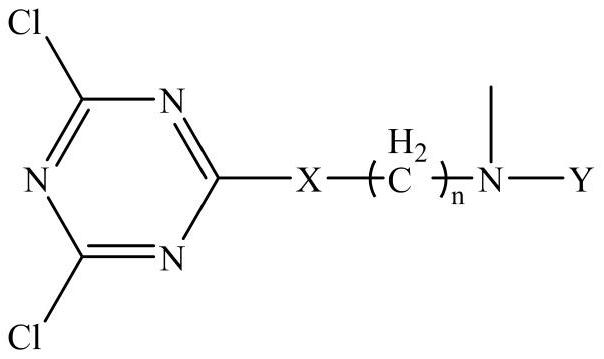

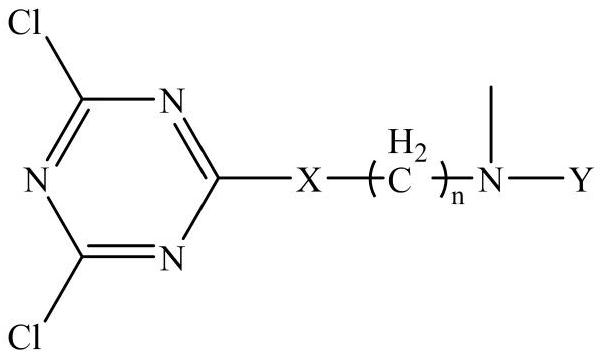

Cationic cyanuric chloride derivative tanning agent and preparation method thereof

InactiveCN112778226AImprovement of cationic propertiesPromote absorptionOrganic chemistryTanning treatmentFiberWhite powder

The invention relates to the technical field of tanning, and discloses a cationic cyanuric chloride derivative tanning agent and a preparation method thereof. The preparation method comprises the following steps of stirring and uniformly mixing 9.22-36.88 parts by mass of cyanuric chloride, 21.35-100.31 parts by mass of solvent and 7.12-33.44 parts by mass of deionized water under the ice-water bath condition to obtain a mixture A, dropwise adding 2.98-20.44 parts of tertiary ammonia compounds into the mixture A, and maintaining the temperature at 0-5 DEG C to obtain a mixed system, adjusting the pH value of the mixed system by using an acid-binding agent solution until the pH value is stabilized at 6.0-7.0, and reacting for 4-6 hours to obtain a mixture B, and filtering the mixture B to obtain a filter cake, washing the filter cake, carrying out vacuum drying under a vacuum condition for 4-6 hours to obtain a solid C, and grinding and crushing the solid C to obtain the white powdery cationic cyanuric chloride derivative tanning agent. In use, the characteristic that the cationic property of tanning leather fibers of a conventional chrome-free tanning agent is weakened can be improved, and meanwhile, the absorption and combination of crust leather on anion dyeing and finishing materials in the later dyeing and fat liquoring section can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

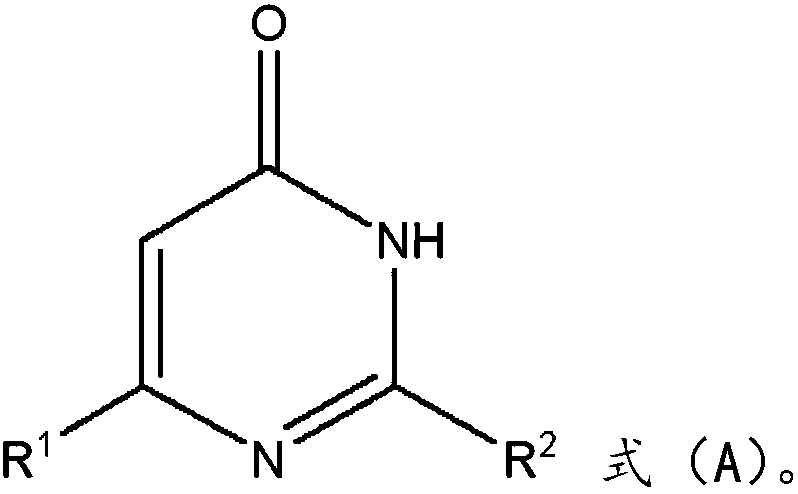

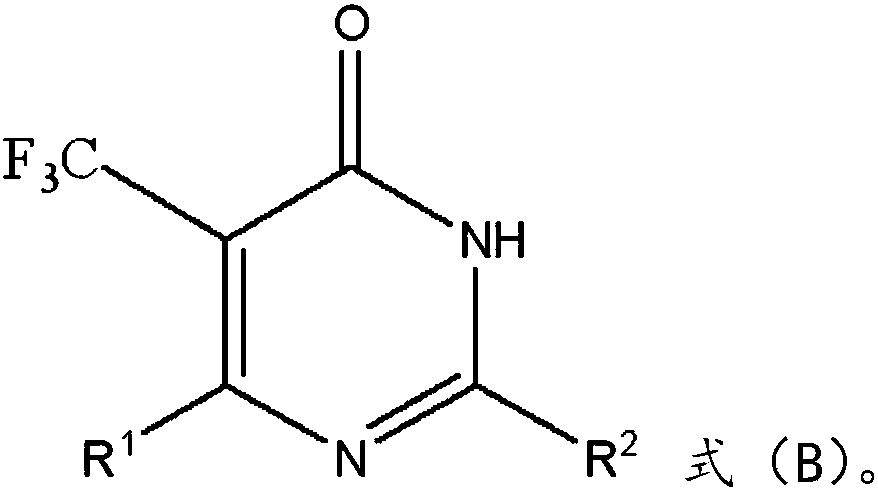

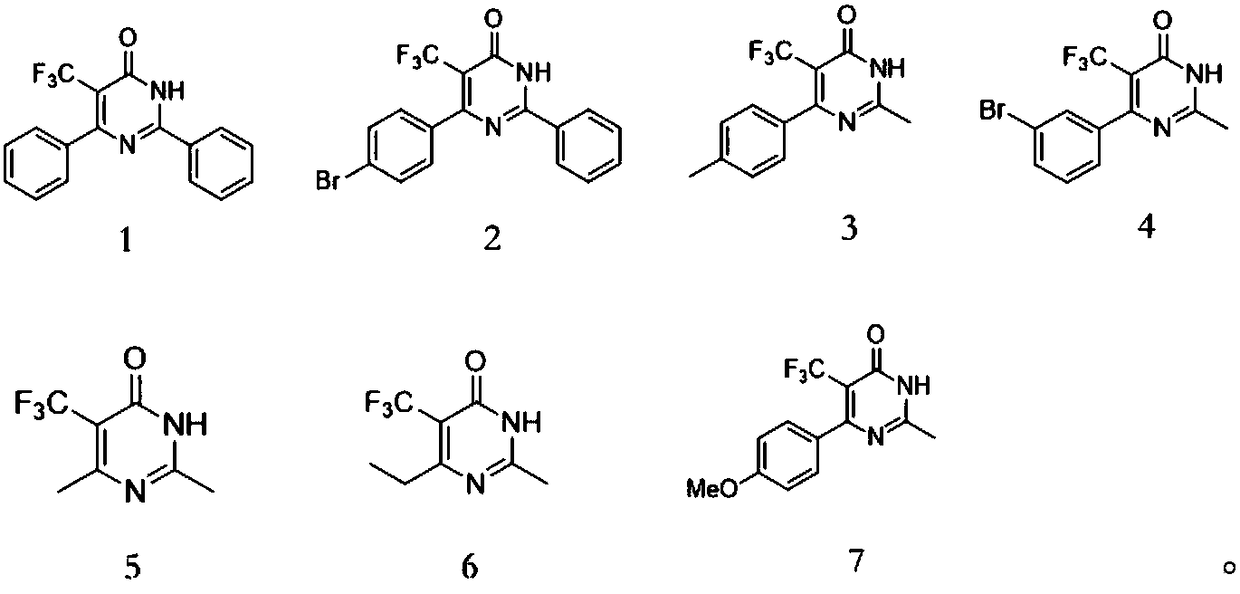

Method for synthesizing fluorine-containing pyrimidinone compound

InactiveCN108218793AFacilitate synthesis reactionSimple reaction systemOrganic chemistryChromatographic separationOrganic solvent

The invention provides a method for synthesizing a fluorine-containing pyrimidinone compound, and belongs to the field of organic synthesis. The method does not use a metal reagent and an organic solvent, is environmentally friendly, and is suitable for industrial production. The method comprises the following steps: separately adding the pyrimidinone compound and sodium trifluoromethylsulfinate into a reaction flask for reacting under the action of tert-butyl peroxybenzoate (TBPB) and water at temperature of 25 DEG C to 80 DEG C for 2 to 4 hours; and after completion of the reaction, performing column chromatography to obtain the fluorine-containing pyrimidinone compound. The method can be applied to the synthesis of a trifluoroalkyl-substituted pyrimidinone compound.

Owner:QINGDAO AGRI UNIV

Protein-based surfactant for carrying out cleaning care on skin and hairs and preparation method thereof

ActiveCN108143641AFacilitate synthesis reactionRealize industrial productionCosmetic preparationsConnective tissue peptidesChemistryNative protein

The invention discloses a protein-based surfactant for carrying out cleaning care on skin and hairs and a preparation method thereof. The preparation method comprises the following steps: (1) pretreating a natural protein raw material; (2) adding alkaline protease and catalase into the pretreated natural protein raw material, and carrying out enzymolysis and enzyme deactivation, thus obtaining anenzyme deactivation protein hydrolysate; (3) purifying and refining the enzyme deactivation protein hydrolysate, removing moisture, and drying, thus obtaining collagen; (4) carrying out amidation reaction on the collagen and diethanolamine by taking a microreactor as a reaction device, and generating collagen polypeptide amide; carrying out esterification reaction on the collagen polypeptide amideand lauric acid, thus preparing the protein-based surfactant. According to the protein-based surfactant and the preparation method, disclosed by the invention, the functional protein-based surfactantwhich is suitable for cleaning the skin and the hairs and for other special demands can be produced by using natural protein which can be easily abandoned or lowly utilized as a raw material, so thatthe utilization efficiency of a natural protein resource is increased.

Owner:东营市庄溶生物科技有限公司

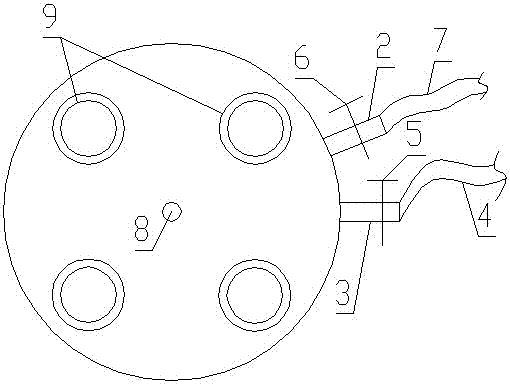

Multi-channel solid-phase polypeptide synthesis method

ActiveCN106892959AHigh synthesis efficiencyImprove efficiencySequential/parallel process reactionsPeptide preparation methodsSynthesis methodsCoupling

The invention discloses a multi-channel solid-phase polypeptide synthesis method. The multi-channel solid-phase polypeptide synthesis method comprises the following steps: 1, connecting; 2, charging resin respectively; 3, swelling the resin; 4, performing a deprotection reaction; 5, washing the resin; 6, detecting whether the deprotection reaction is completed or not; 7, performing a coupling reaction; and 8, detecting whether the coupling reaction is completed or not. During using, polypeptide synthesis tubes are grouped according to coupling solutions needed in a next reaction step, and the polypeptide synthesis tubes needing the same coupling solutions are grouped into the same group, so that a basis is provided for achieving a batch reaction; the invention further designs a technical scheme in which a plurality of polypeptide synthesis tubes correspond to the same reaction cylinder. Compared with the conventional synthesis device and the conventional synthesis method, the multi-channel solid-phase polypeptide synthesis method has the significant advantage of high efficiency, so that the efficiency of seeking for a polypeptide substance with the best effect is improved.

Owner:HENAN INST OF ENG

Preparation method of nano antimony thioantimonate

InactiveCN108163890AImprove leaching rateIncrease profitMaterial nanotechnologyAdditivesSulfurPotassium sodium tartrate

The invention discloses a preparation method of nano antimony thioantimonate, wherein the preparation method comprises the steps: adding a sodium thioantimonate solution into a complex solution of trivalent antimony, dispersing with ultrasonic waves, controlling the temperature of the reaction system at 20-35 DEG C, adjusting the pH value of the reaction system to 6.3-7.8 with hydrochloric acid, after completion of addition of the sodium thioantimonate solution, continuing to disperse for 10-15 min by ultrasonic waves, filtering to take a filter residue, washing the filter residue with a potassium sodium tartrate solution and purified water, and grinding for 3-5 h by a ball mill, and thus obtaining the product. The content of sulfur in antimony thioantimonate obtained by the preparation method provided by the invention is low, the product is stable and pure, the yield is high, the properties are good, the particles are in nanoscale, and the nano antimony thioantimonate has the advantages of good compatibility with lubricating grease, good extreme pressure wear resistance and good lubrication performance; as an additive, the nano antimony thioantimonate has various properties far beyond the requirements of the national standards on extreme pressure lubricating grease, can be industrially produced and has a good application prospect.

Owner:广西生富锑业科技股份有限公司

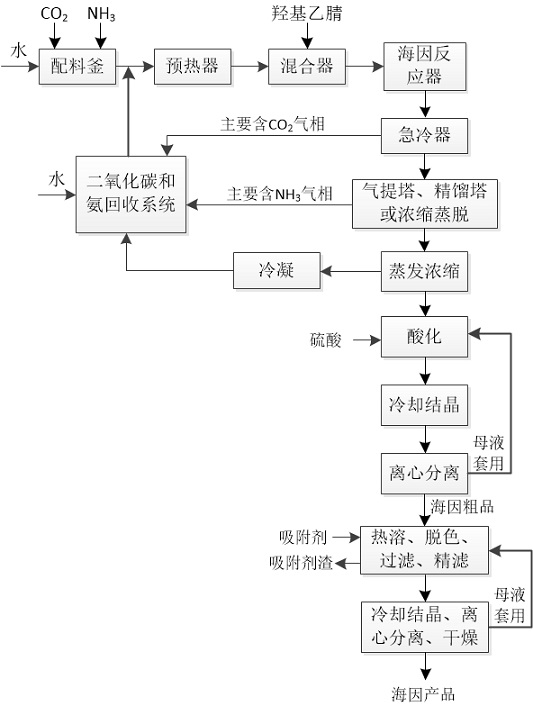

Clean production process for continuously synthesizing hydantoin

A clean production process for continuously synthesizing hydantoin comprises the following steps: preheating a carbon dioxide ammonia water solution prepared from an ammonia source, a carbon source and water, mixing with hydroxyacetonitrile, continuously synthesizing, carrying out reduced pressure flash evaporation, carrying out gas stripping, concentrating, acidifying, crystallizing, separating to obtain a crude hydantoin product, and refining to obtain the high-purity hydantoin product. A carbon dioxide and ammonia recovery system sequentially absorbs the gas phase separated by gas strippingand reduced pressure flash evaporation to obtain a carbon dioxide ammonia water solution, and the carbon dioxide ammonia water solution returns to a reaction system. By increasing the amount of carbon dioxide in the ratio, side reactions generating iminodiacetonitrile, nitrilotriacetonitrile and glycine are restrained, and the hydantoin yield is increased; and through timely release of each gas phase in the system and reasonable arrangement of a recovery sequence, the difficulty of recycling carbon dioxide and ammonia in the system is reduced, the loss of carbon dioxide and ammonia is reduced, zero discharge of wastewater and waste liquid can be realized, and the method is an environment-friendly and clean hydantoin production process method.

Owner:龙智

Preparation process of geopolymer light foaming material

InactiveCN113493319AIncreased durabilityImproves carbonation resistanceCement productionCeramic materials productionFoaming agentAlkali metal oxide

The invention relates to the technical field of comprehensive utilization of coal gangue, in particular to a preparation process of a geopolymer light foaming material, which comprises the following steps: S1, adding 0.3-0.5% of triethanolamine into coal gangue subjected to heat treatment, and grinding to obtain coal gangue powder; s2, preparing foaming foam: mixing the coal gangue powder, a foaming agent, an auxiliary agent, alkali metal oxide, alkali metal silicate and water according to a ratio of 100: (0.6-8): (2-12): (6-18): (25-60); ands3, allowing the prepared foaming material in S2 to be subjected to foaming forming to obtain the geopolymer light foaming material. The geopolymer light foaming material has excellent mechanical performance, acid and alkali resistance, fire resistance, high temperature resistance and the like, and the formed material is excellent in durability, carbonization resistance and the like; and in the material forming process, the method is fast in forming, green, environment-friendly, energy-saving and efficient in the production and preparation process, the carbon emission of the building material production end can be greatly reduced, and the social overall carbon neutralization target can be achieved as soon as possible.

Owner:北京荣露材料科技有限公司

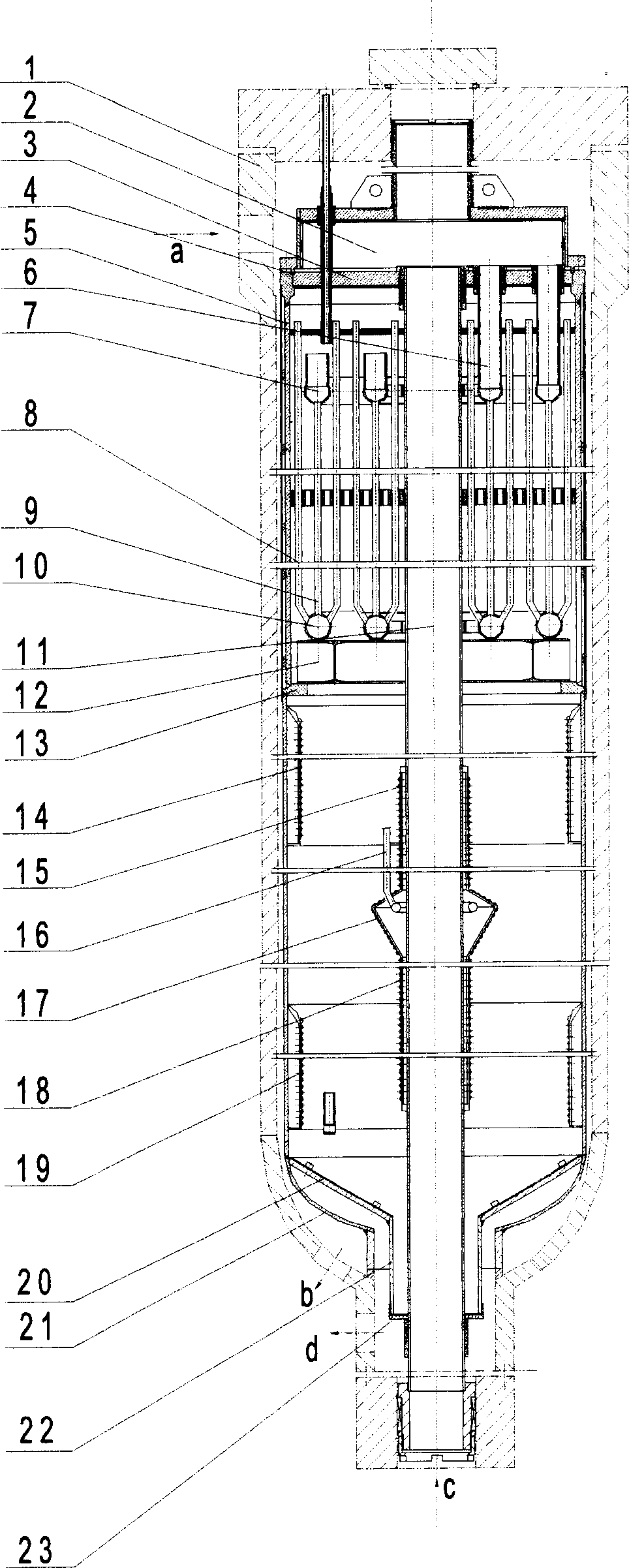

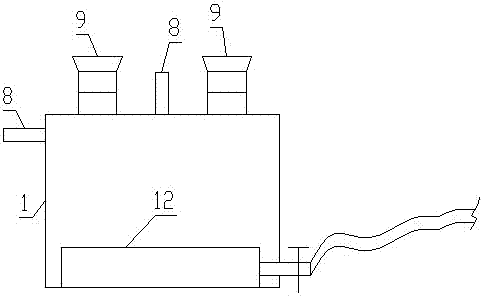

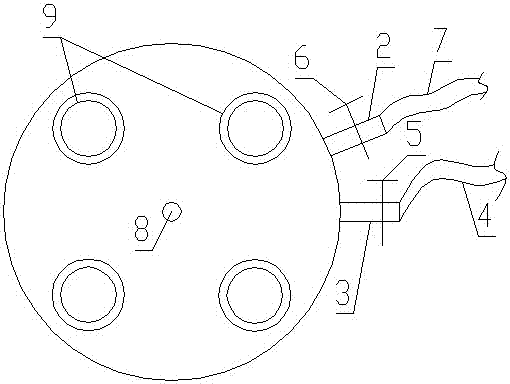

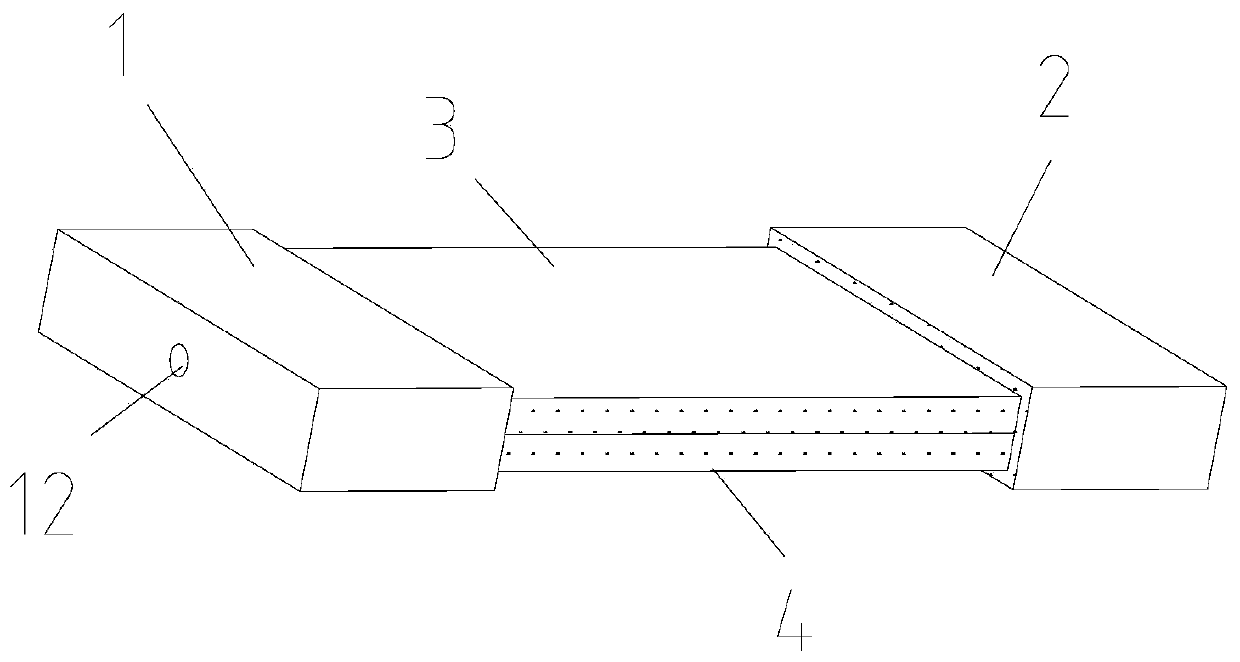

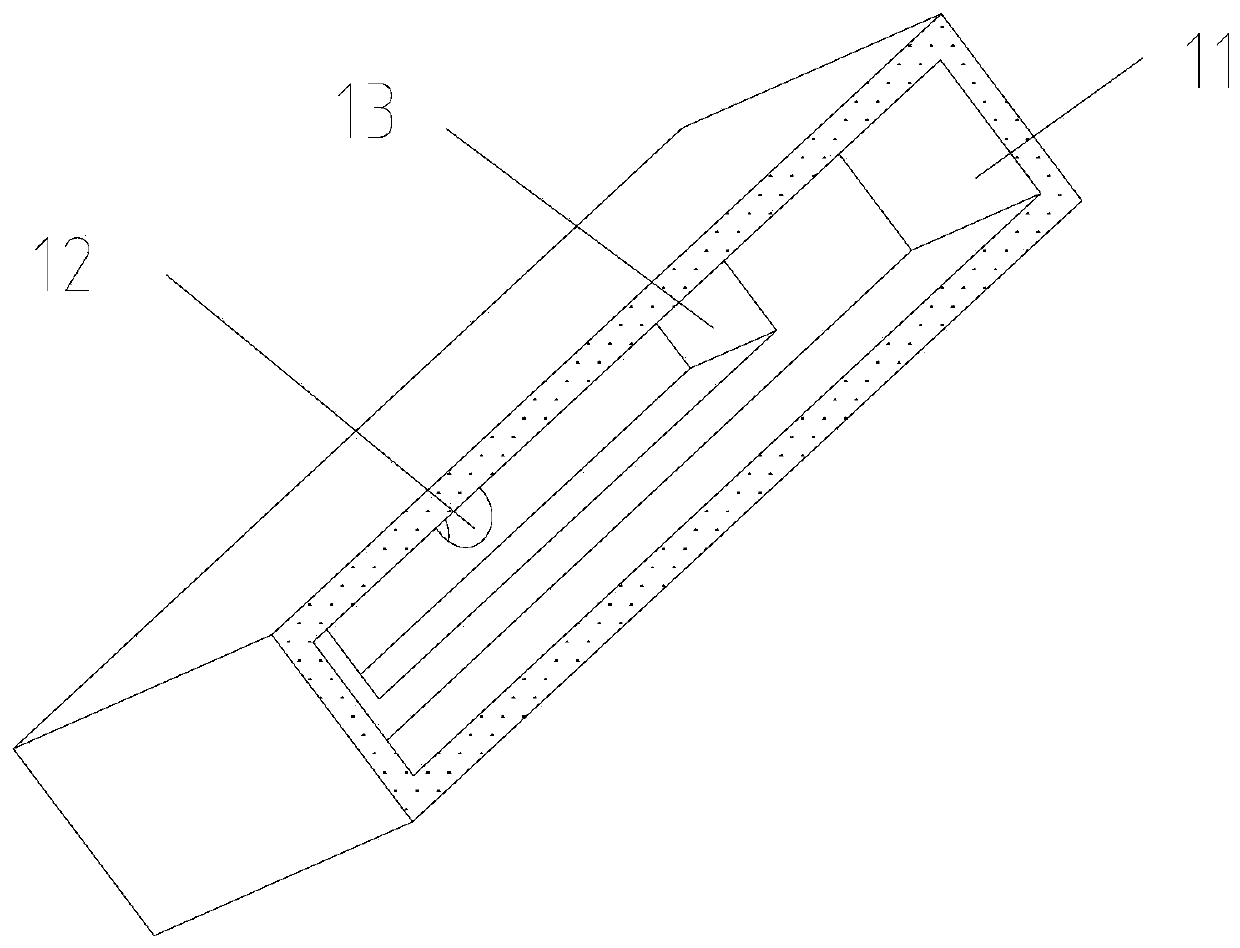

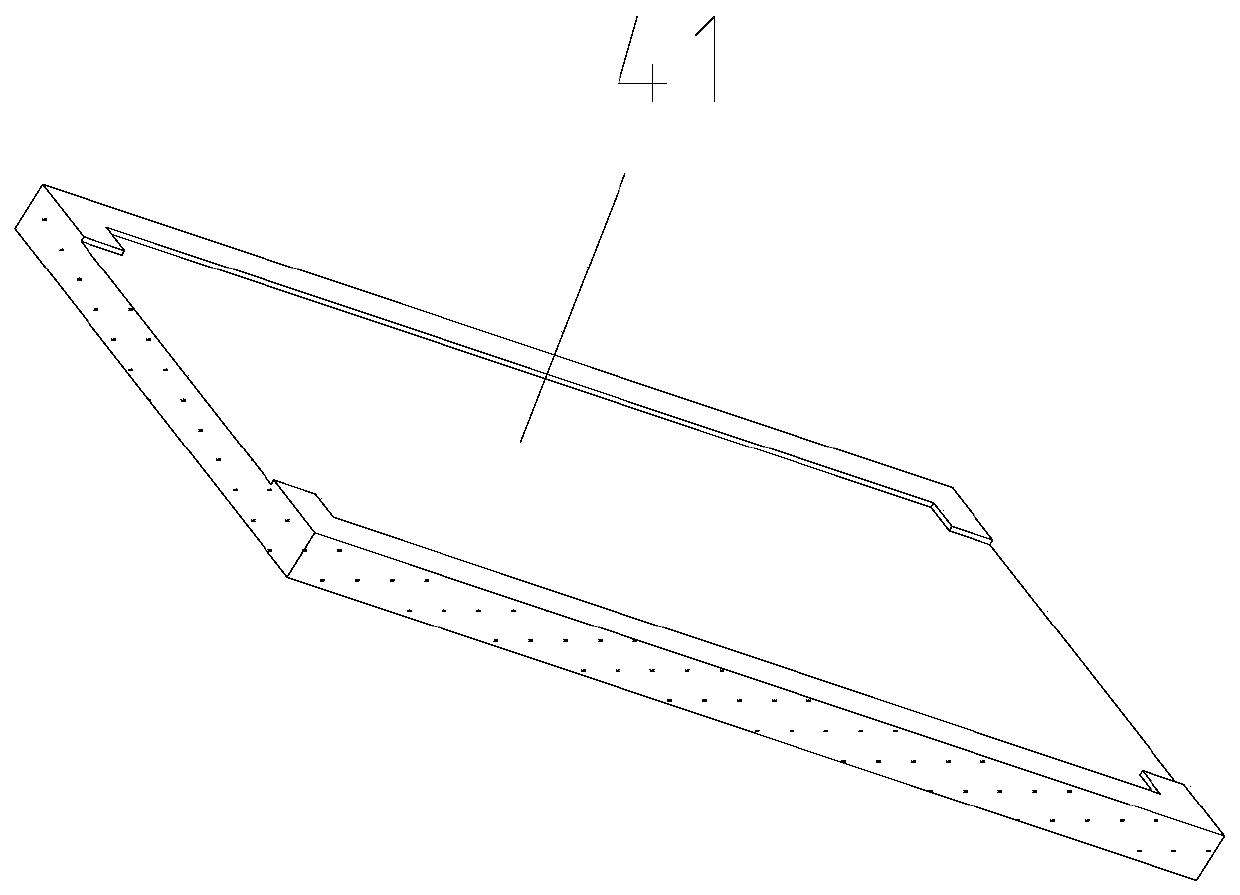

Front-placed type axial-radial synthesis tower

InactiveCN1876223AReduce resistanceIncrease production capacityChemical/physical processesEngineeringTower

The related front axis-radial converter comprises an outside drum and an inside drum, wherein the inside drum comprises: a collection box, a cover plate, a pad, an body, a cold-tube liner, a central tube, a #-shaped frame, a support ring, a radial outside drum I / II, a radial inside drum I / II, a quench tube, a distributor, a taper figure pattern board, a low head-seal bearing, a catalyst-out tube, and a bulkhead. This invention has ideal temperature distribution, large production capacity, and applies conveniently.

Owner:ZHEJIANG UNIV OF TECH

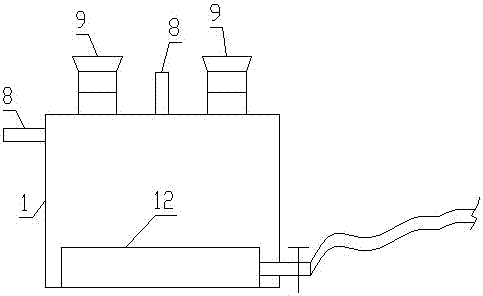

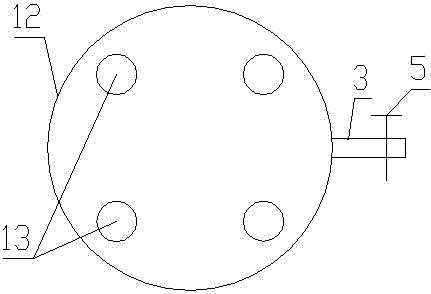

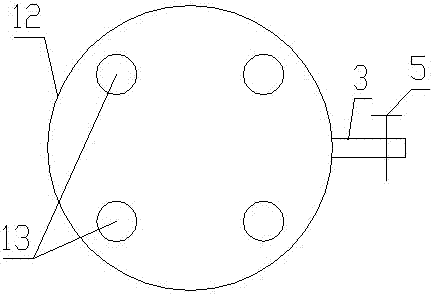

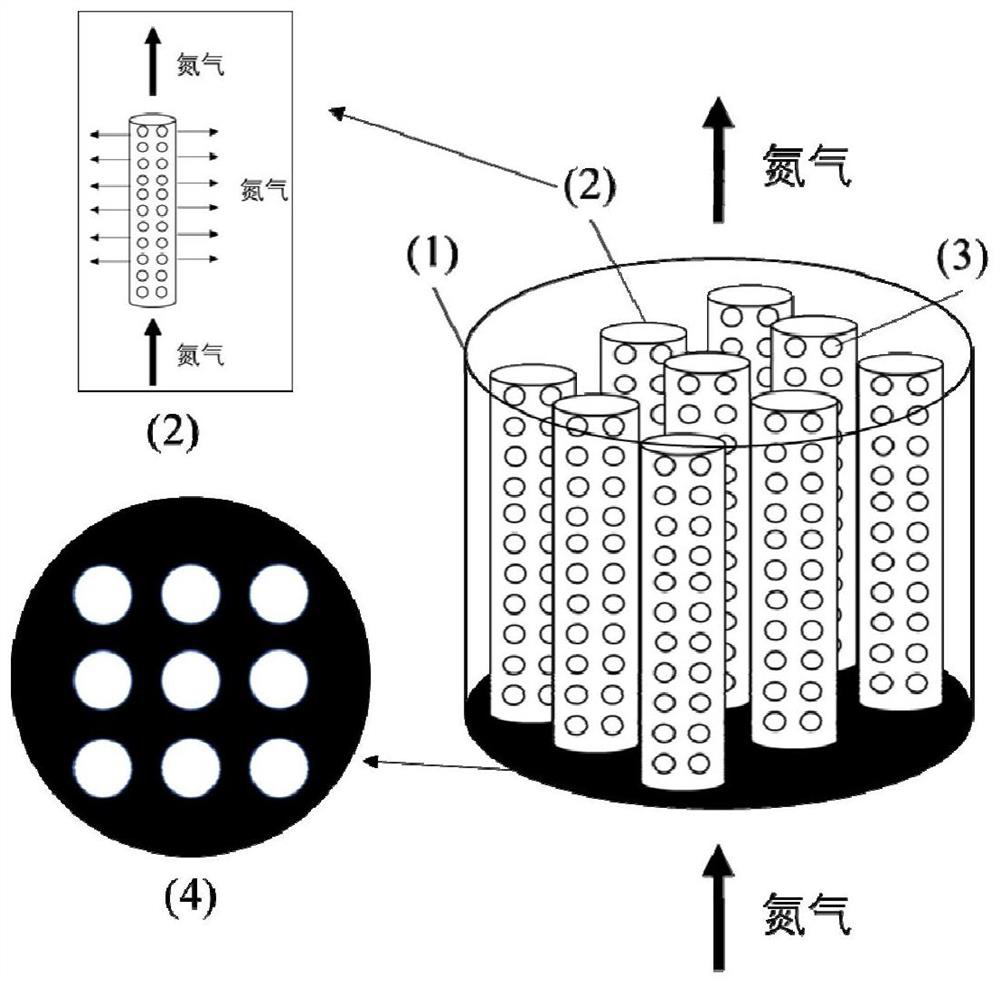

Multi-channel polypeptide solid-phase synthesis device

PendingCN107056879AFacilitate synthesis reactionHigh synthesis efficiencyPeptide preparation methodsEngineeringNitrogen gas

The invention discloses a multi-channel polypeptide solid-phase synthesis device which comprises a reaction cylinder, wherein a suction filtration connecting pipe and a nitrogen connecting pipe are connected to the bottom of the reaction cylinder, the nitrogen connecting pipe is connected to a nitrogen hose, a nitrogen valve is arranged on the nitrogen connecting pipe, and a suction filtration valve is arranged on the suction filtration connecting pipe; the suction filtration connecting pipe is connected to a vacuumizing hose; a gas in-out pipe is arranged at the top of the reaction cylinder, a plurality of connecting ground openings are connected to the top surface of the reaction cylinder, a polypeptide synthesis pipe is inserted into each of the connecting ground openings, and the bottom end of the polypeptide synthesis pipe is inserted into the lower portion of the reaction cylinder and is provided with a sand core filter element; and a frosted connecting portion is arranged in the middle of the polypeptide synthesis pipe. By inserting different polypeptide synthesis pipes into the same reaction cylinder at the same time for batch reactions, compared with the prior art, the polypeptide solid phase synthesis efficiency is greatly increased, the corresponding research time is shortened, and various derived peptides can be quickly synthesized.

Owner:HENAN INST OF ENG

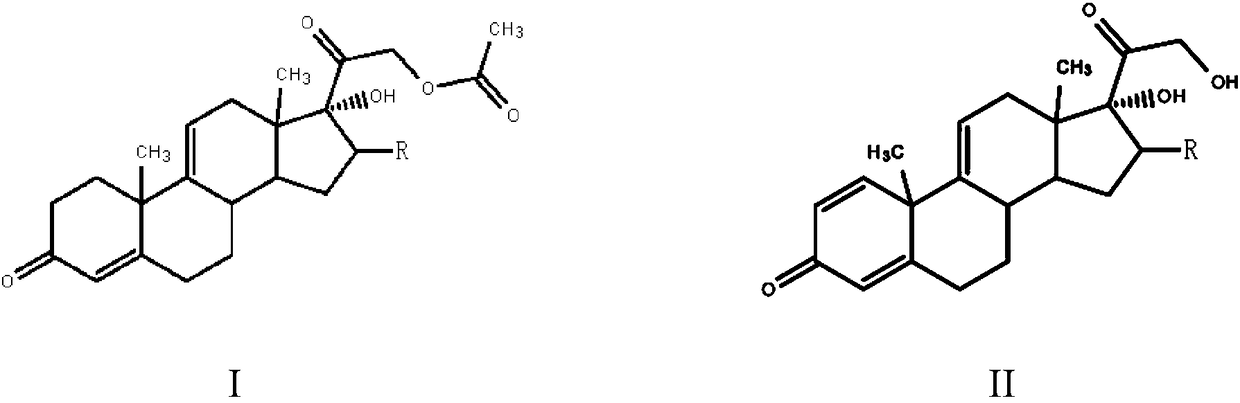

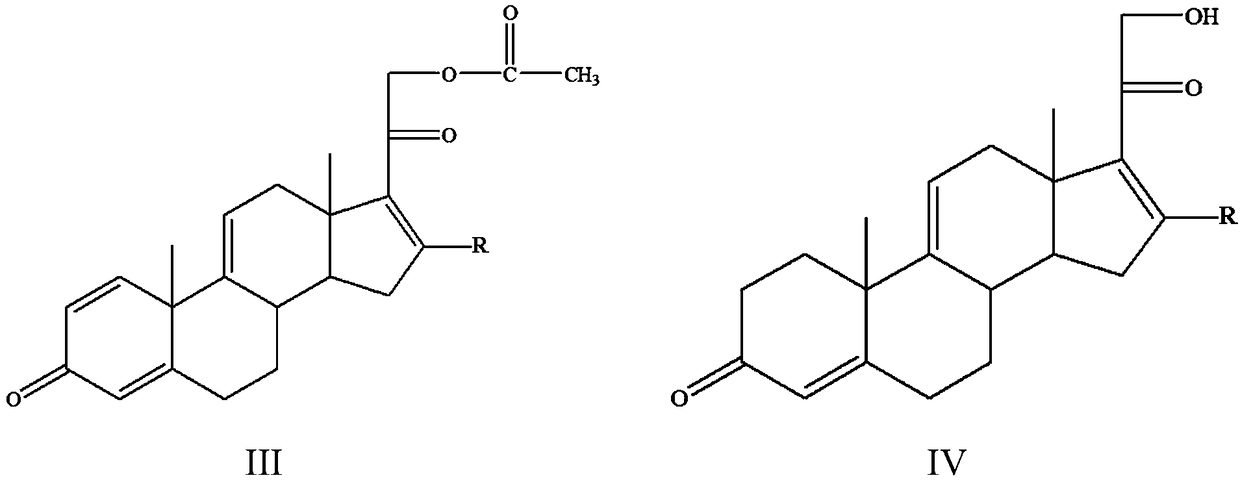

Preparation method of tetraene intermediates

ActiveCN108165602AReduce the ratioHigh yieldMicroorganism based processesFermentationMicrobial transformationDehydrogenation

The invention relates to a preparation method of tetraene intermediates. According to the preparation method, a first compound is converted by Nocardioides simplex to obtain tetraene intermediates; wherein the first compound is represented by a formula I, tetraene intermediates are represented by a formula II, and R in the formula I and the formula II represents H, a halogen atom, an alkyl group,an alkoxyl group, a hydroxyl group, or a phenyl group. According to the preparation method, the first compound is taken as the substrate, only Nocardioides simplex is used to carry out biological conversion; the substrate is subjected to 1,2-dehydrogenation and 21-acetate hydrolysis at the same time; most of the conversion products is target products, the byproduct ratio is low; after purification, the product is white or white-like crystals; relative to the weight of the substrate, the yield is 80-90%; the target product yield is high; through HPLC analysis, the purify of the product is not less than 95%; and the total content of target products and secondary products is not less than 99%.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

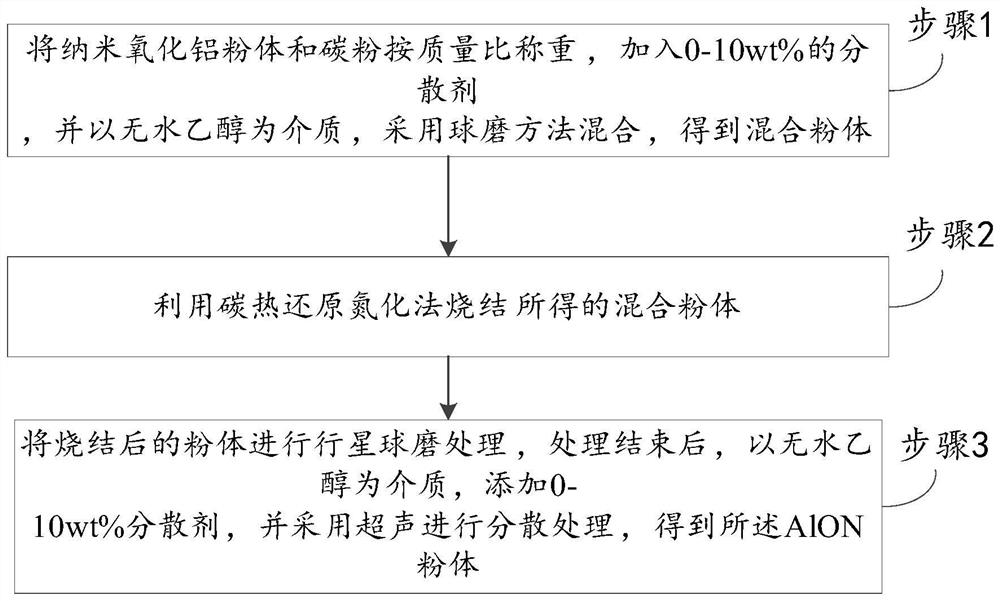

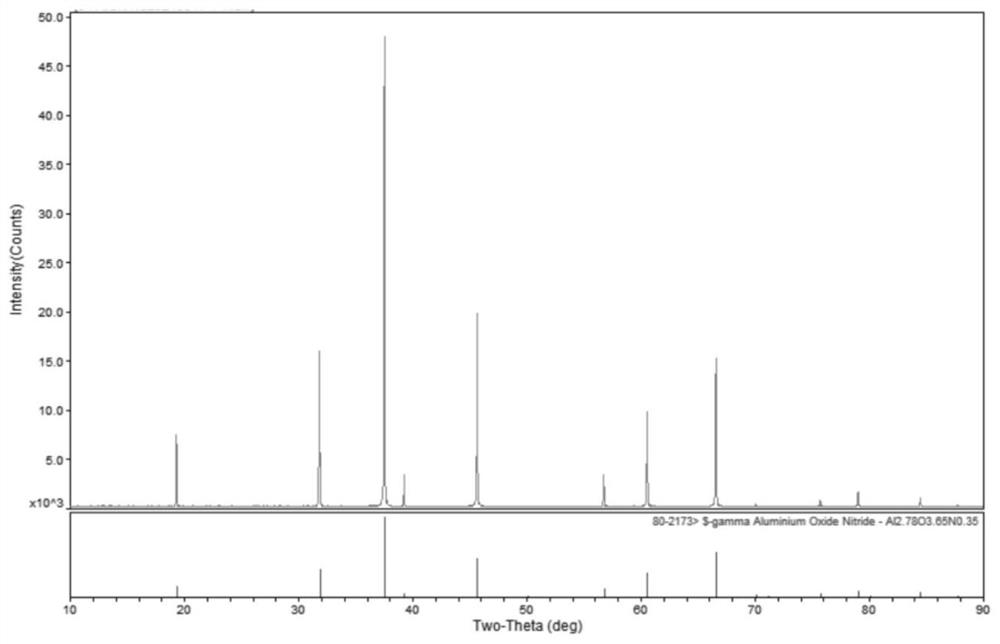

Preparation method of AlON powder, AlON powder and application of AlON powder

The invention provides a preparation method of AlON powder, the AlON powder and application of the AlON powder, and the method comprises the following steps: weighing nano aluminum oxide powder and carbon powder according to a mass ratio, adding 0-10wt% of a dispersant, and mixing by taking absolute ethyl alcohol as a medium and adopting a ball milling method to obtain mixed powder; sintering the mixed powder by using a carbon thermal reduction nitridation method; carrying out planetary ball milling treatment on the sintered powder, adding 0-10wt% of a dispersing agent by taking absolute ethyl alcohol as a medium after the treatment is finished, and carrying out dispersion treatment by adopting ultrasonic waves, so as to obtain the AlON powder, the dispersing agent is added step by step, the overall dispersing performance of the powder is improved, the AlON powder with high dispersity, high phase purity, small particle size and high sintering activity is prepared, the AlON powder is applied to preparation of the AlON transparent ceramic, and the AlON transparent ceramic with good performance can be obtained.

Owner:有研资源环境技术研究院(北京)有限公司 +1

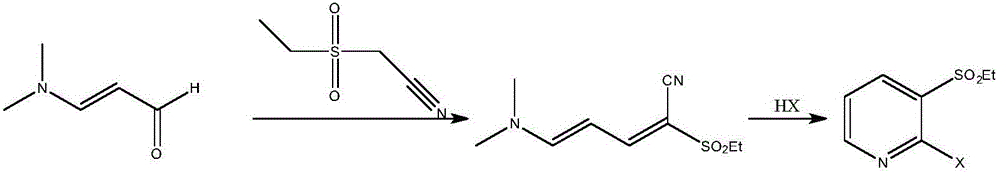

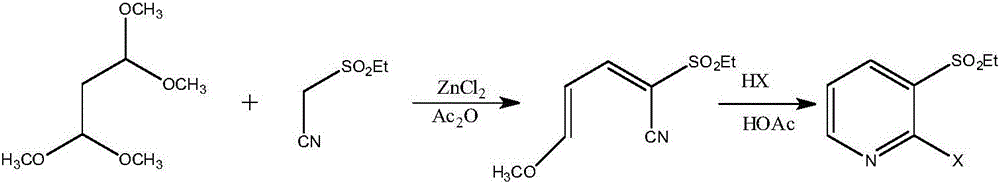

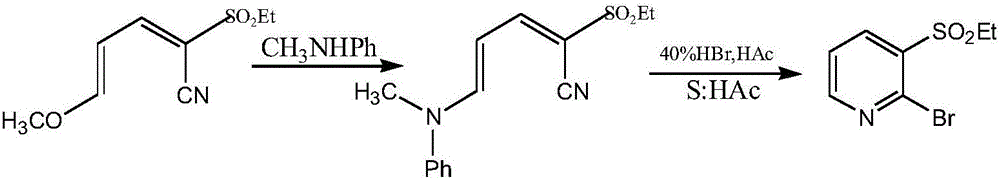

Method for synthesizing 2-hylogen-3-alkyl substituted sulfonyl pyridine and midbody thereof in ultrasonic method

InactiveCN106748988AFacilitate synthesis reactionImprove protectionOrganic chemistryOrganic compound preparationOrganic synthesisOrganic layer

The invention discloses a method for synthesizing 2-hylogen-3-alkyl substituted sulfonyl pyridine and midbody thereof in an ultrasonic method. The method comprises the following steps: enabling substituted amino acraldehyde, a catalyst and substituted cyanoethyl sulfone to react under ultrasonic until the complete reaction to prepare a reaction solution of a 2-hylogen-3-alkyl substituted sulfonyl pyridine midbody; adding halogen hydride into the reaction solution at a certain of temperature, facilitating the continuous reaction until the complete reaction, adding an alkaline solution into the reaction solution, adjusting a pH value to 7 to 8, standing, layering into a water layer and an organic layer, extracting the water layer by using an organic solvent, combining the organic layer, refining to obtain the 2-hylogen-3-alkyl substituted sulfonyl pyridine. The 2-hylogen-3-alkyl substituted sulfonyl pyridine is synthesized by adopting the ultrasonic method, so that the organic synthetic reaction can be effectively facilitated, the reaction speed is increased, the reaction yield is increased, and the environmental protection is facilitated; and the reaction time is short, the operation is simple, the reaction can be completed generally in two hours, the product yield is high, the quality is good, and the yield can reach 90 percent or more which is higher than the yield of the traditional solvent-method heating refluxing method.

Owner:SHANDONG NORMAL UNIV

Method for producing high-quality epoxy compound

ActiveCN106397370ALess side effectsHigh product contentOrganic chemistryChemical recyclingEpoxyFiltration

The invention provides a method for producing a high-quality epoxy compound. The method comprises the following steps: carrying out a ring opening reaction on hydrogen sulfide and chloropropylene oxide in a fixed bed reaction device in the presence of a catalyst solid alkali, and carrying out oxidation and a ring closing reaction to produce the high-quality epoxy compound. The fixed bed reaction device adopted in the invention improves the product purity to 98%, reduces the content of impurities, controls the content of monothio impurities to be 1% or less, and improves the refractive index of the product. The chroma of the product is reduced to 10-20. The method has the advantages of mild reaction conditions, easiness in filtration and recovery of the solid alkali catalyst, realization of repeated use of the catalyst after being activated, continuous production of the reaction device, and facilitation of industrial production application.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

Method for preparing selenide or sulfide semiconductor film material of copper-indium-gallium

InactiveCN1257560CEliminate condensationAvoid deformationFinal product manufactureVacuum evaporation coatingWater bathsIndium

The invention refers to a manufacturing method for selenide or sulfide of copper, indium or gallium. In the manufacturing process of copper, indium or gallium selenide and / or sulphur optical absorbing layer film, uses vacuum magnetism control splattering, heating and evaporating method or chemical water bath electrodeposition method to deposit a metal preprocessed layer with chemical formula proportion of Cu, In, Ga on the natrium calcium glass Mo substrate, then carries on optical selenide or / and sulfide reaction in the thermal process vacuum room, the character lies in: the battery base board deposited with the preprocessed layer are heated upon the two surfaces, the back surface of the base board is heated with contacting heat reservoir, the surface coated with metal preprocessed layer is heated with light irradiation, when the temperature rises to the 400-560oC evenly and quickly, carries on the cooperative heating with contacting heat reservoir and light irradiation to the selenium source or the sulphur source, makes the metal preprocessed layer converted into the compound semiconductor photoelectric film material.

Owner:NANKAI UNIV

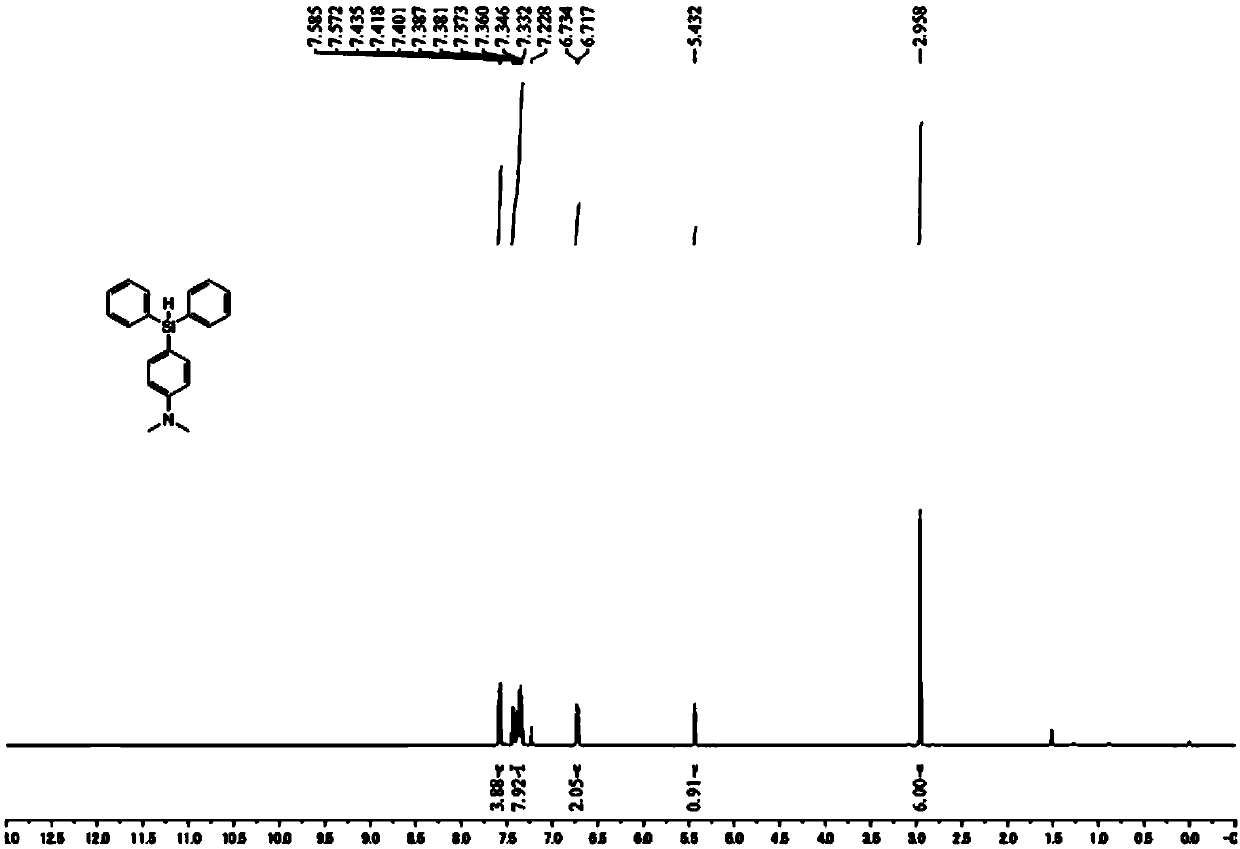

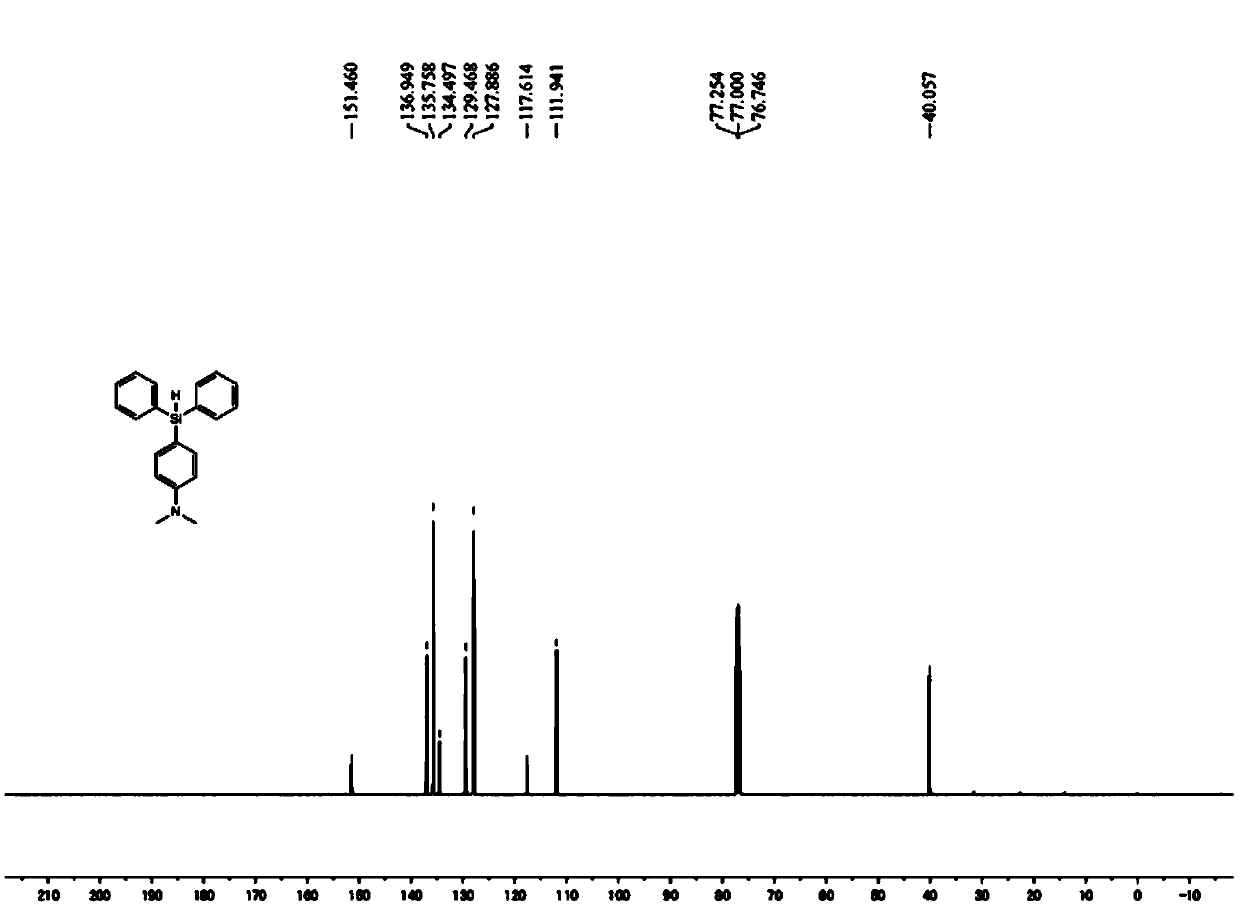

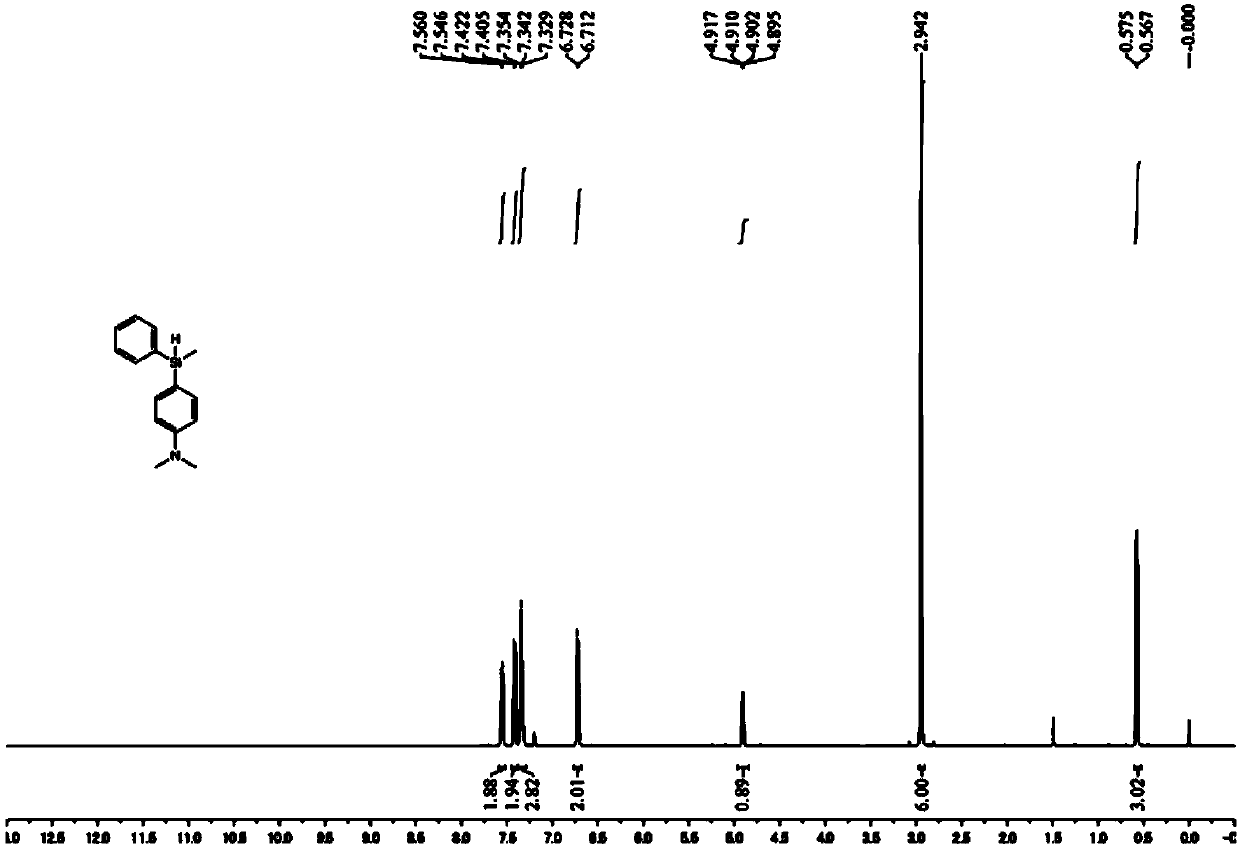

Catalyst for silylation of aromatic amines

ActiveCN109529930ASimple post-processingAbundant sources of raw materialsSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsToxicityAfter treatment

The invention discloses application of Al(C6F5)3 as a catalyst for silylation of aromatic amines, thus providing a novel reaction catalyst for synthesizing silylated aromatic amines. The aluminum element is abundant and the price is low so that the Al(C6F5)3 as a catalyst can effectively reduce the synthesis cost of the silylated aromatic amines. In addition, the aluminum element is low in toxicity so that a synthetic process is more environmentally friendly, the synthesized silylated aromatic amines are suitable for application in the fields of optoelectronics and medicine, and product performance and safety are improved. The Al(C6F5)3 has high catalytic activity, and the yield of the prepared silylated aromatic amine is high. In addition, a hydrogen acceptor is not needed when the Al(C6F5)3 is adopted as the catalyst, and the silylation reaction occurs only at the para-position C-H bond of the aromatic amine, thus simplifying after-treatment and making reaction selectivity high.

Owner:NANJING XIAOZHUANG UNIV

A protein-based surfactant for cleaning and nursing skin and hair and preparation method thereof

ActiveCN108143641BFacilitate synthesis reactionRealize industrial productionCosmetic preparationsConnective tissue peptidesActive agentEngineering

Owner:东营市庄溶生物科技有限公司

A discharge module based on surface catalytic thin film to enhance ozone synthesis

InactiveCN109179337BFacilitate dissociationHigh synthesis efficiencyOzone preparationThermodynamicsMetallic electrode

Owner:DALIAN MARITIME UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com