Clean production process for continuously synthesizing hydantoin

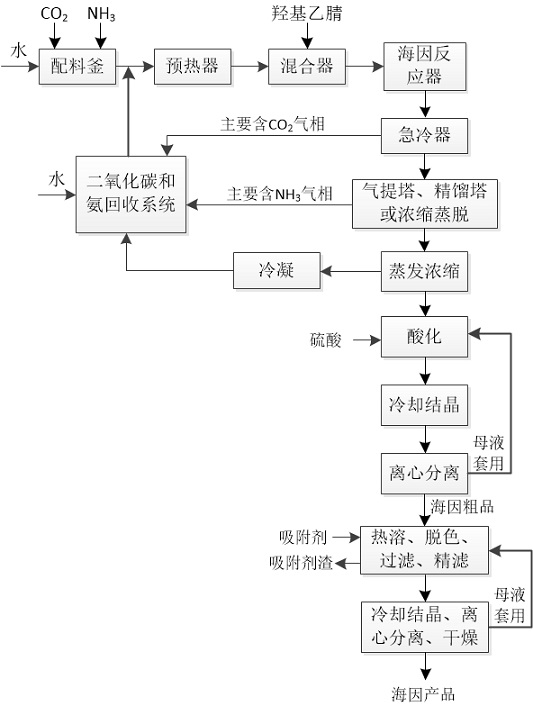

A clean production and chemical synthesis technology, applied in organic chemistry and other directions, can solve the problems of difficult to suppress side reactions, difficult to recover and apply ammonia and carbon dioxide, and achieve increased intermolecular contact opportunities, high yield and high purity, and low solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Ammonia, carbon dioxide and water are prepared in a molar ratio of 1:1:12 to prepare an aqueous solution of carbon dioxide and ammonia. The feed flow rate is 390kg / h, which is preheated to 80°C by a preheater, and 44wt% of the feed flow rate is 63.5kg / h The concentrated hydroxyacetonitrile solution is quickly mixed in a static mixer, enters three column reactors in series from the bottom, reacts at a pressure of 4.5MPa and a temperature of 70-100°C for 2.5h to obtain hydantoin synthetic liquid, and then flows out from the top of the reactor Enter the quencher; the operating pressure of the quencher is 0.8MPa, the gas phase separated by flash evaporation is removed from the carbon dioxide and ammonia recovery system, the liquid phase enters the stripping tower, and the carbon dioxide and ammonia remaining in the liquid phase are extracted under negative pressure and ≤100°C into the gas phase Removal of carbon dioxide and ammonia recovery system; the liquid phas...

Embodiment 2

[0046] Example 2: Ammonia, carbon dioxide and water are prepared in a molar ratio of 1:1.15:15 to prepare an aqueous solution of carbon dioxide and ammonia. The feed flow rate is 4200kg / h, which is preheated to 90°C by a preheater, and the feed flow rate is 590kg / h with a concentration of 40wt%. The hydroxyacetonitrile solution was quickly mixed in a static mixer, and entered into 5 tube-bundle reactors connected in series from the bottom, reacted at a pressure of 4.0 MPa and a temperature of 80-105°C for 3.5 hours to obtain hydantoin synthetic liquid, and then flowed out from the top of the reactor into Quench cooler; the operating pressure of the quencher is 1.3MPa, the gas phase of the flash separation is removed from the carbon dioxide and ammonia recovery system, the liquid phase enters the stripping tower, and the residual carbon dioxide and ammonia in the liquid phase are extracted under the conditions of negative pressure and ≤100°C into the gas phase to remove Carbon d...

Embodiment 3

[0049] Example 3: Ammonia, carbon dioxide and water are prepared in a molar ratio of 1:1.2:15 to prepare an aqueous solution of carbon dioxide and ammonia. The feed flow rate is 4250kg / h, preheated to 90°C by a preheater, and the feed flow rate is 670kg / h with a concentration of 38wt%. The hydroxyacetonitrile solution was quickly mixed in a static mixer, and entered from the bottom into a composite reactor consisting of five series-connected column reactors and tube bundle reactors, and reacted at a pressure of 5.5 MPa and a temperature of 80-105°C for 4 hours to obtain hydantoin The synthetic liquid then flows out from the top of the reactor into the quencher; the operating pressure of the quencher is 1.5MPa, the gas phase of the flash separation is removed from the carbon dioxide and ammonia recovery system, the liquid phase enters the stripping tower, and the liquid is extracted under negative pressure and ≤100°C The carbon dioxide and ammonia remaining in the phase enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com