Patents

Literature

112results about How to "Recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

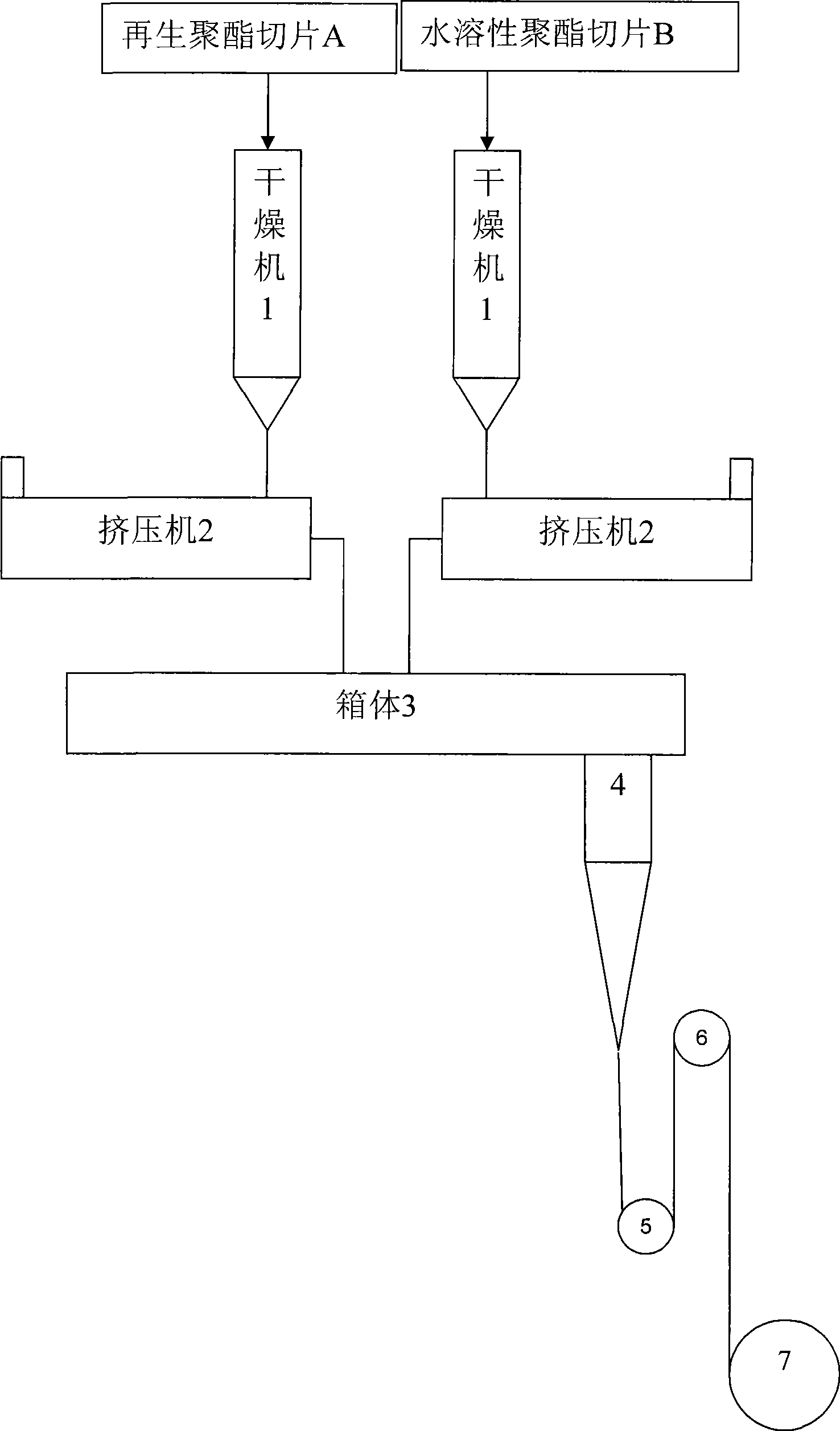

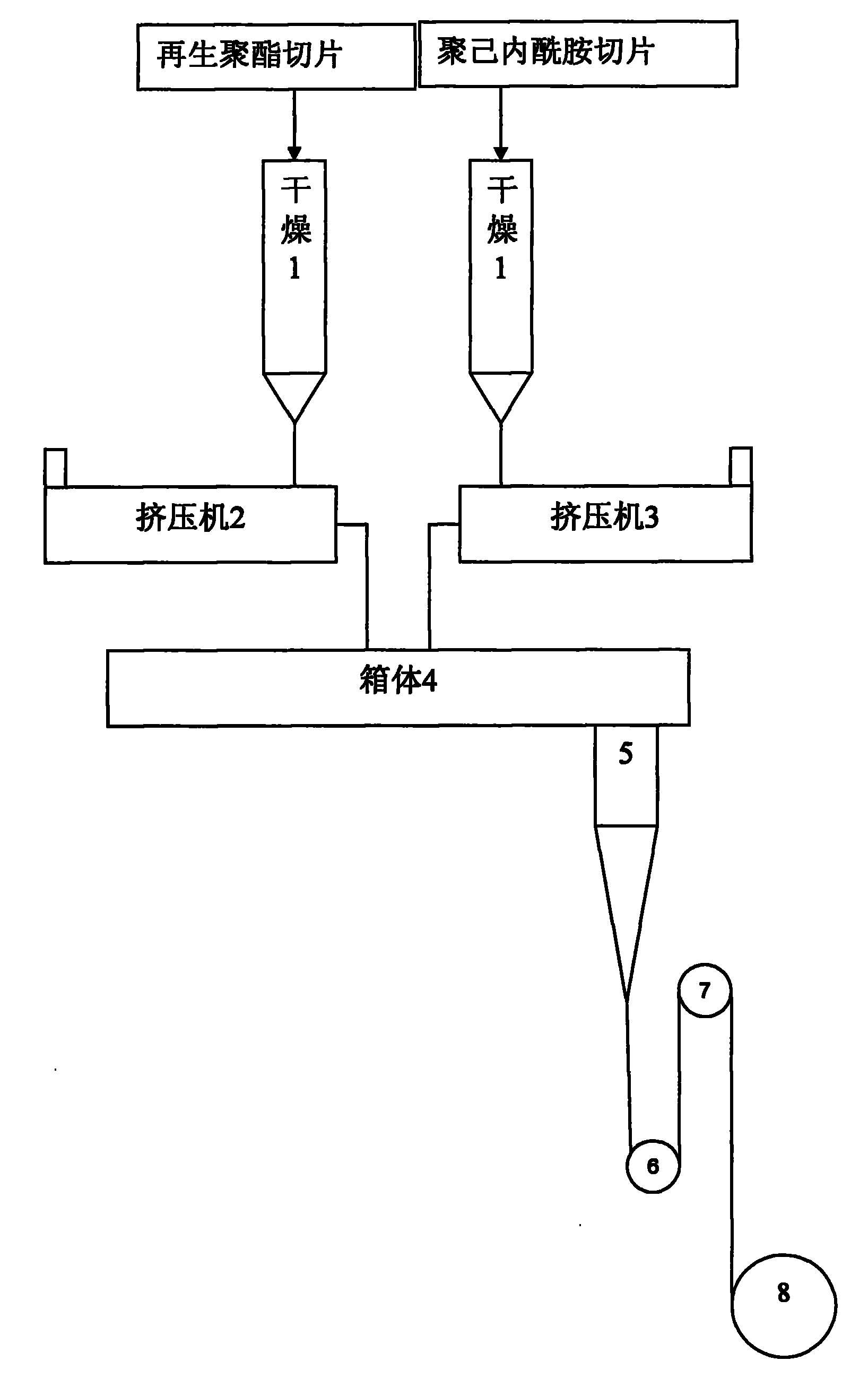

Superfine fibre material and producing method thereof

InactiveCN101429689ARaw materials are cheapSmall fiber finenessFilament forming substance formingSpinning head liquid feederPolyesterMicrofiber

The invention discloses a method for producing regenerated polyester ultrafine fiber based on bicomponent fiber production equipment. The method comprises the following steps: a regenerated polyester slice and a water soluble polyester slice are used as raw materials; after the two raw materials are subjected to crystallizing and drying, extruding and fusing respectively, the two raw materials are fed to a composite spinning manifold, are extruded through an insulated spinning metering pump with accurate measurement, and are distributed to each composite spinning component; the two components are compounded to be shaped according to shapes set by a spinneret component, are extruded to be shaped through side ram cooling and oiled by a nozzle tip, and are wound by a winding head to form a regenerated polyester ultrafine POY spinning cake; and then the spinning cake is processed to obtain an applicable ultrafine fiber through subsequent texturing. After the method is adopted, through adjusting the processing technology, the regenerated polyester raw material can be applied to high grade fiber so as to improve effective application of resource, and save cost. The method has double significances of economy and environmental protection.

Owner:无锡海丝路纺织新材料有限公司

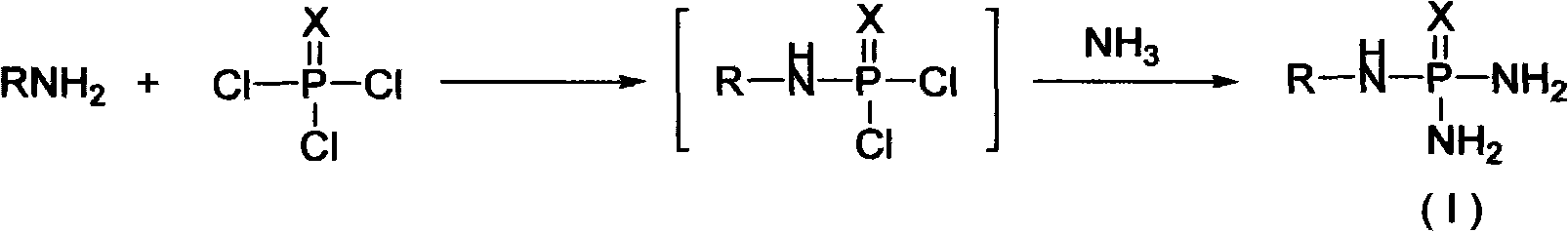

Method for producing N-alkyl substituted phosphoric triamide

InactiveCN101337976AReduce energy consumptionEasy to operateGroup 5/15 element organic compoundsOrganic phosphatic fertilisersOrganic solventDesiccant

The invention provides a method for producing N-alkyl substitution phosphoryl triamide, which comprises the following steps: phosphorus chloride liquid is mixed with at least one organic solvent for precooling, then alkylamine solution is added drop by drop, and the reaction temperature ranging from 10 to 12 DEG C is kept; refluxing through heating is performed after adding drop by drop until the reaction is completed; after the reaction feed solution is washed and an organic layer is dried through dryer, ammonia gas is pumped in the next reaction; the pumping speed of ammonia gas is controlled, and the temperature of a reaction system is kept within 10 to 30 DEG C until the reaction is completed; generated solid in the reaction system is separated; the obtained organic layer is distilled to remove most solvent after being washed and separated; residue is a crude product that is N-alkyl substitution phosphoryl triamide containing a formula (1), and the crude product is recrystallized so as to obtain a fine product, the purity quotient of which is more than 98 percent. Compared with other prior arts, the method has the characteristics that the reaction condition is mild, the technology is simple, the cost is low, the purity quotient of the product is high, etc., and the method is particularly suitable for industrialized production.

Owner:张九治

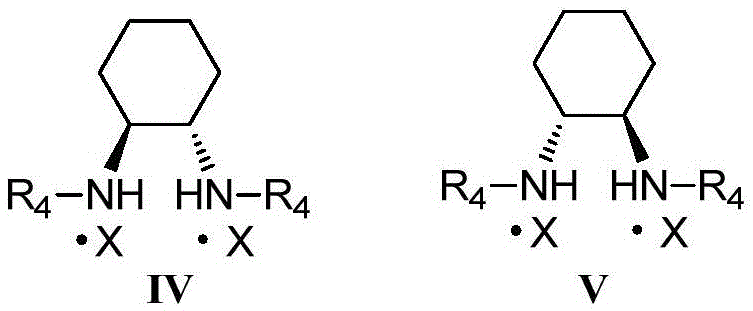

Method for preparing optically active carbonyl compound

ActiveCN105541579AEasy to separate and purifyMild reaction conditionsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenDihydropyridine

The invention discloses a method for preparing an optically active carbonyl compound, which comprises the following step: under catalysis of a chiral amine salt and a transition metal catalyst, carrying out asymmetric catalytic hydrogenation reaction on alpha, beta-unsaturated aldehyde or alpha, beta-unsaturated ketone compound by taking hydrogen gas and a catalysis amount of dihydropyridine compound as a hydrogen source, so as to obtain the optically active carbonyl compound. The method has mild reaction conditions and simple operation, and the use amount of the dihydropyridine compound is the catalysis amount, so that a target product is easily separated and purified from a reaction system; and at the same time, the metal catalyst can be recycled, thereby meeting the economy requirement.

Owner:ZHEJIANG NHU CO LTD +2

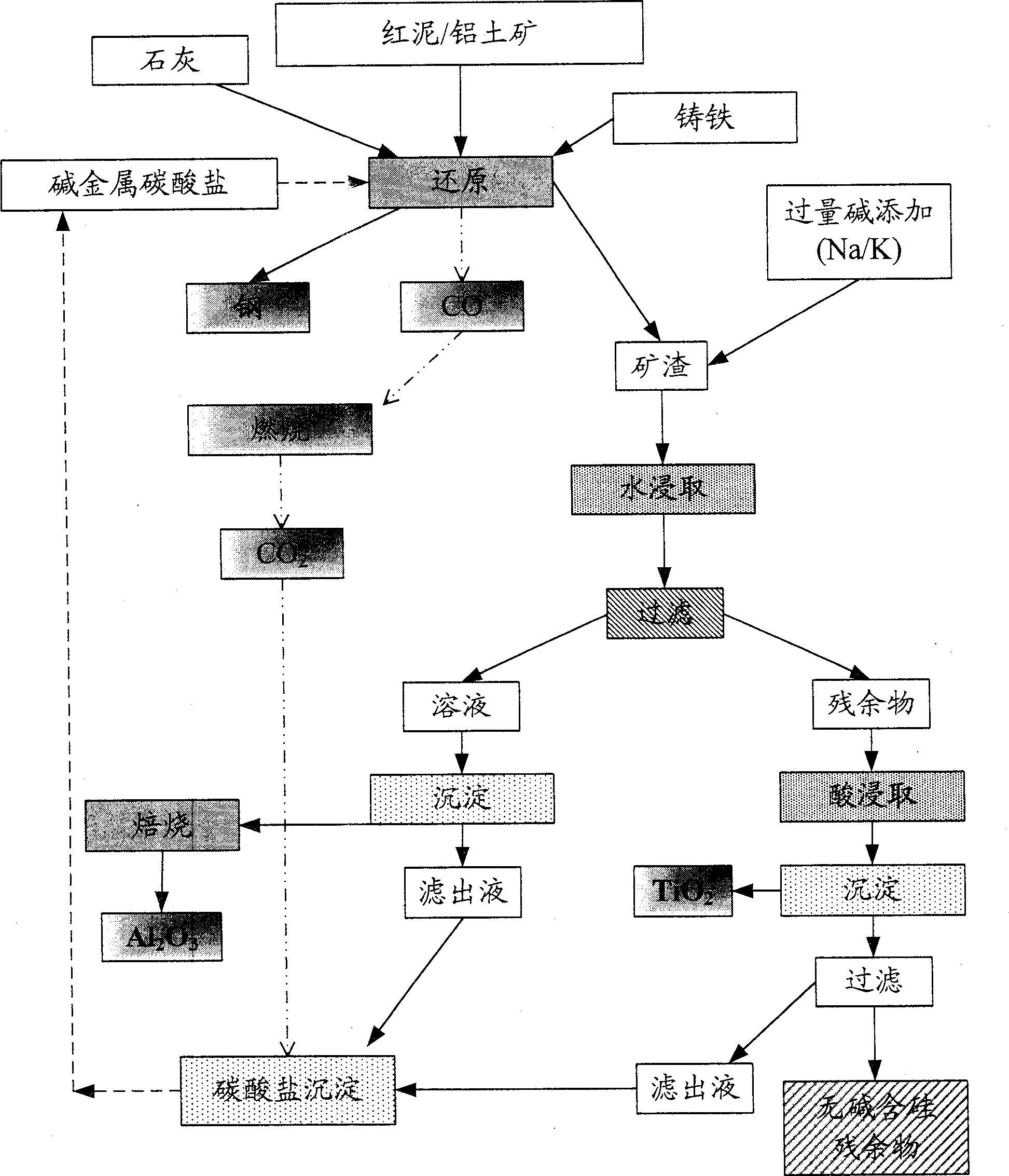

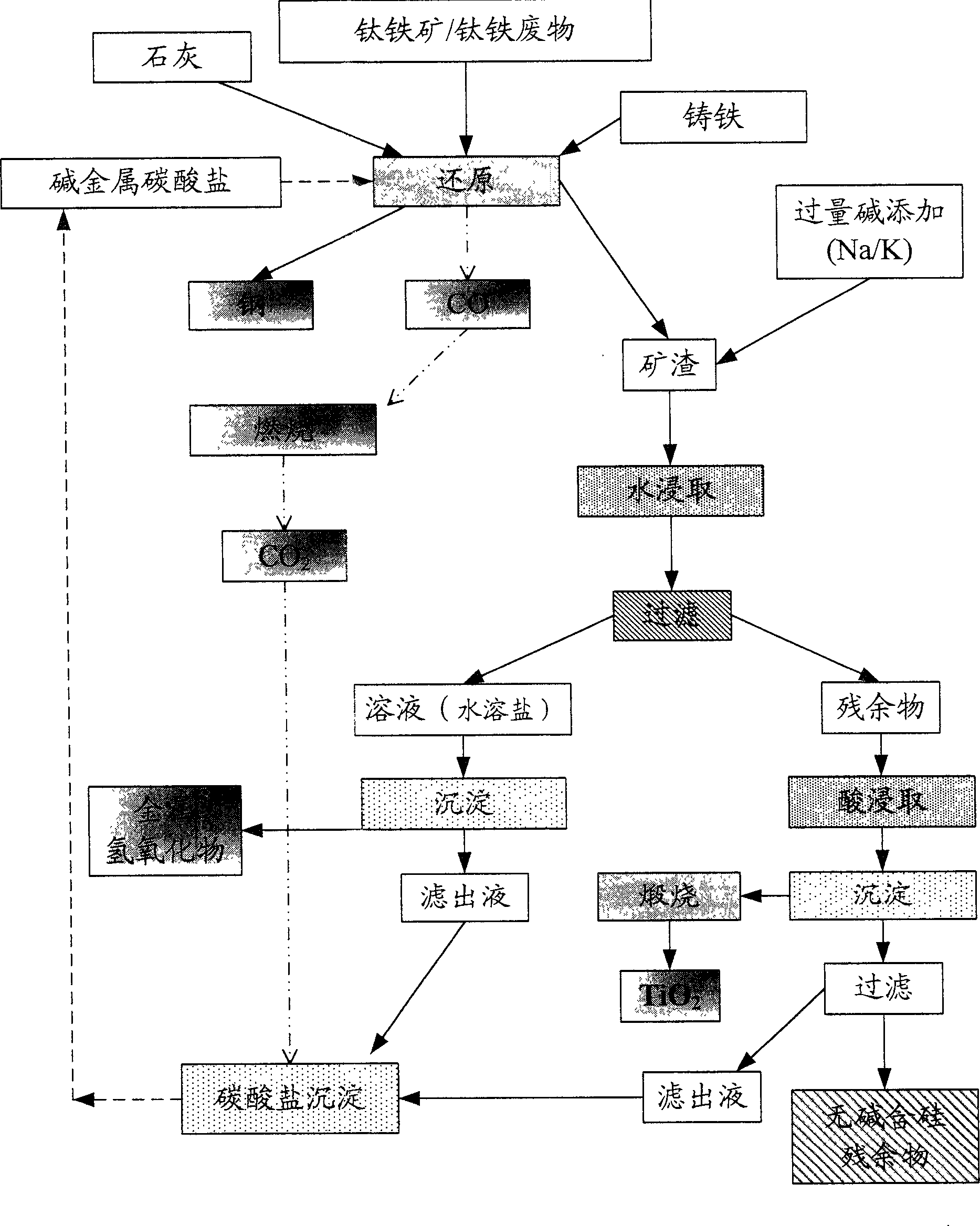

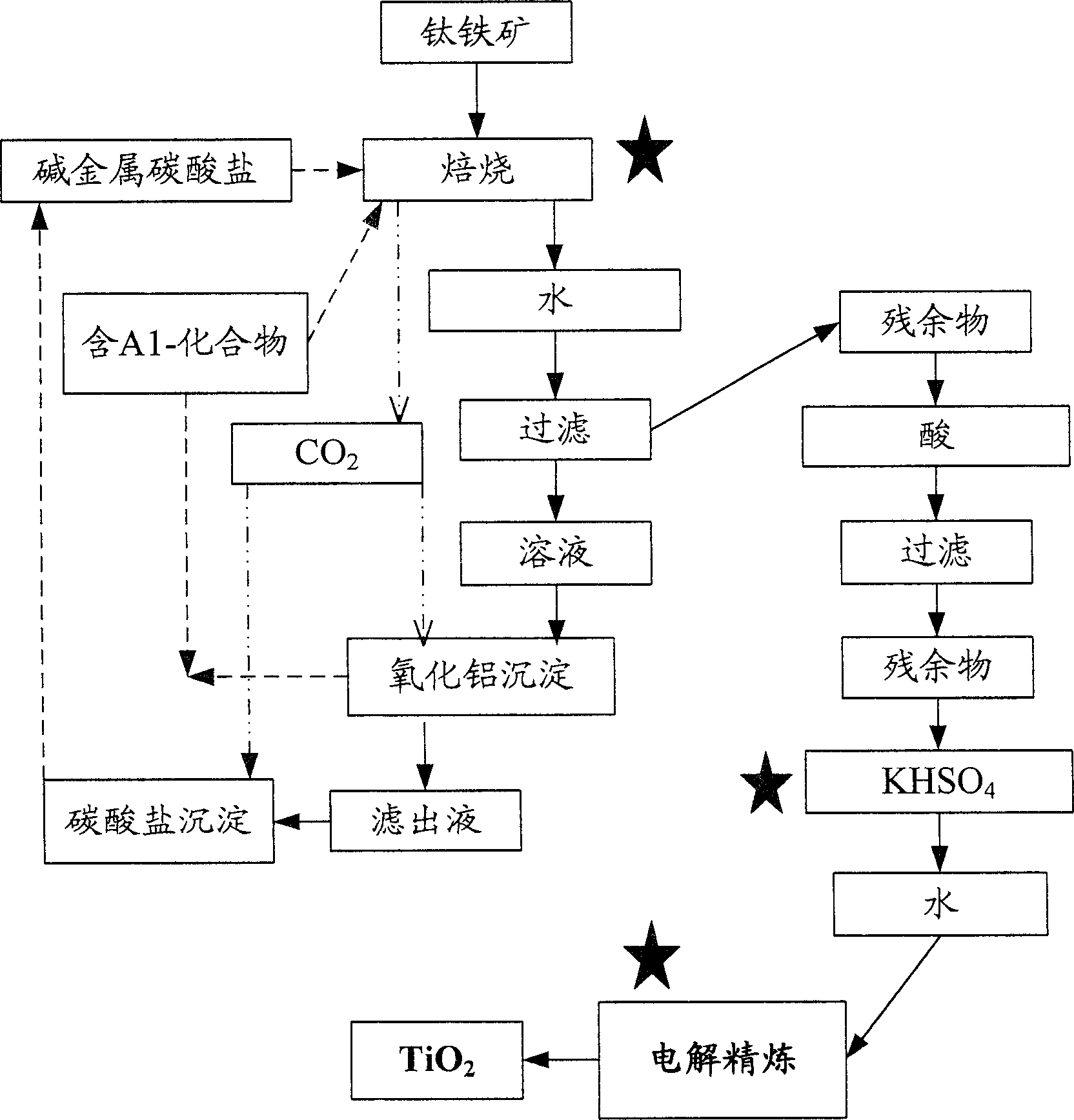

Extraction process for reactive metal oxides

ActiveCN1805903AReduce the impactEmission reductionAluminium oxide preparationFerric oxidesSlagCast iron

The present invention relates to a zero-waste process for extraction of alumina from different types of bauxite ores and red mud residues and of titanium dioxide from ilmenite. Iron oxide is first reduced to metallic iron above the melting point of C-saturated cast iron alloy which yields a high-C iron alloy and an Al and Ti metal oxide rich slag which is then treated with alkali carbonate to form alkali aluminates and titanates. The alkali aluminates are separated by water leaching from which the hydroxide of alumina is precipitated by bubbling C02. The residue from water leaching is treated with sulphuric acid and Ti02 is precipitated via a hydrolysis route. The process recovers most of the metal values and generates only small quantities of silicious residues at pH 4-5 which can be used for soil conditioning. The present also relates to a method for selective separation of Ti02-rich oxides from titaniferrous ore / residue materials via oxidative roasting in the presence of alkali carbonate or carbonates followed by aqueous leaching of the roasted material and selective precipitation of Ti02 under controlled condition below pH=4.

Owner:UNIV OF LEEDS

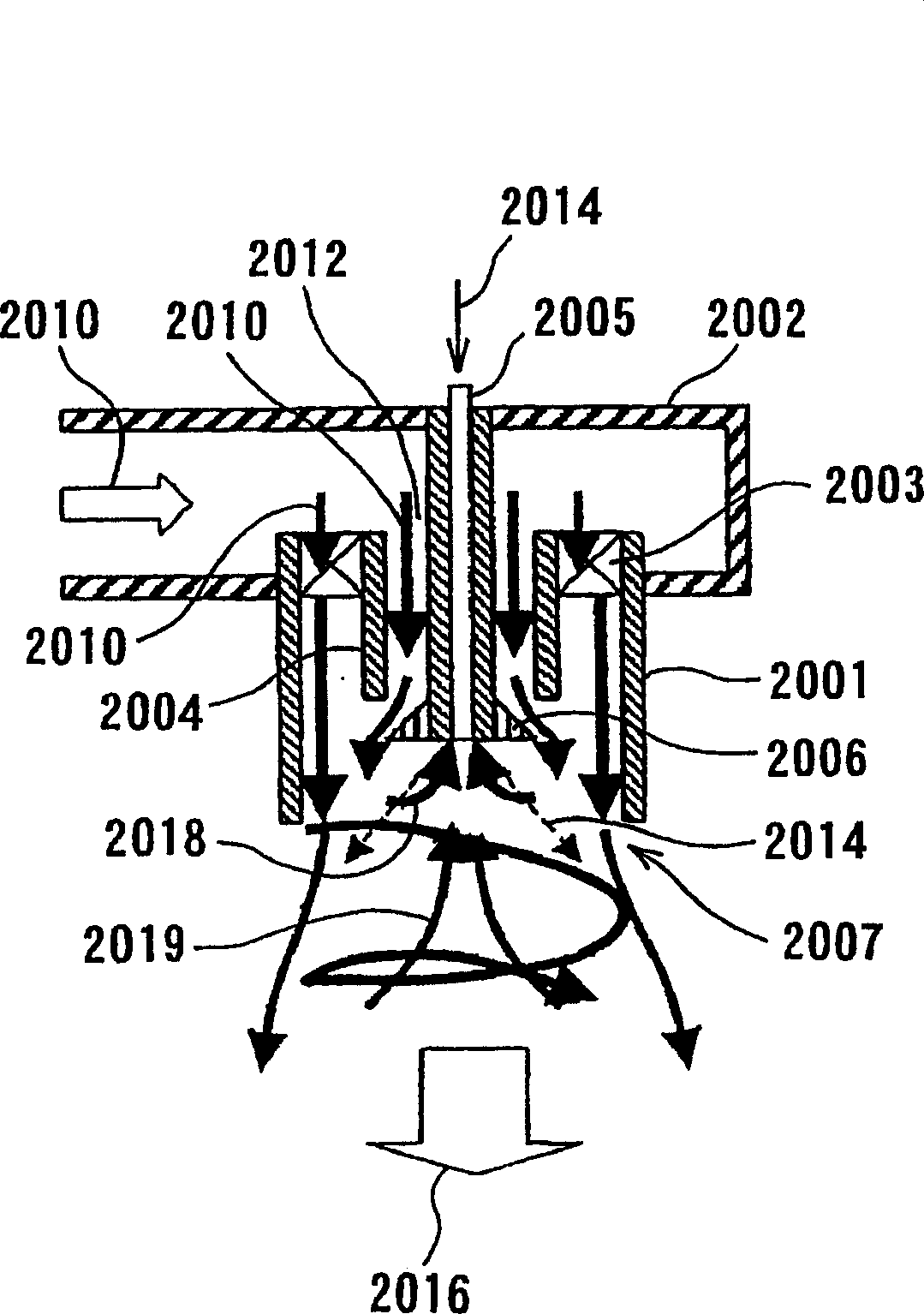

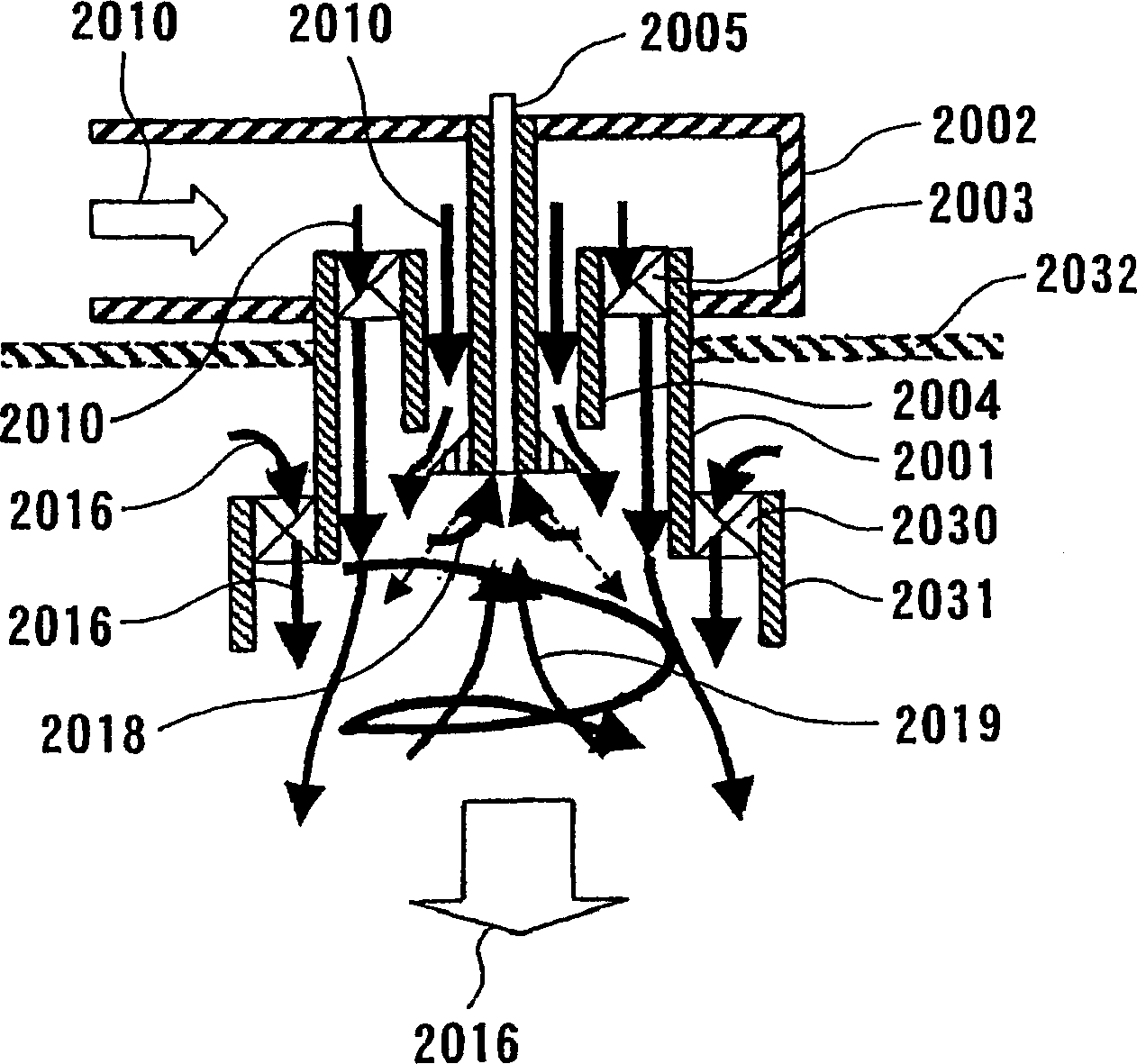

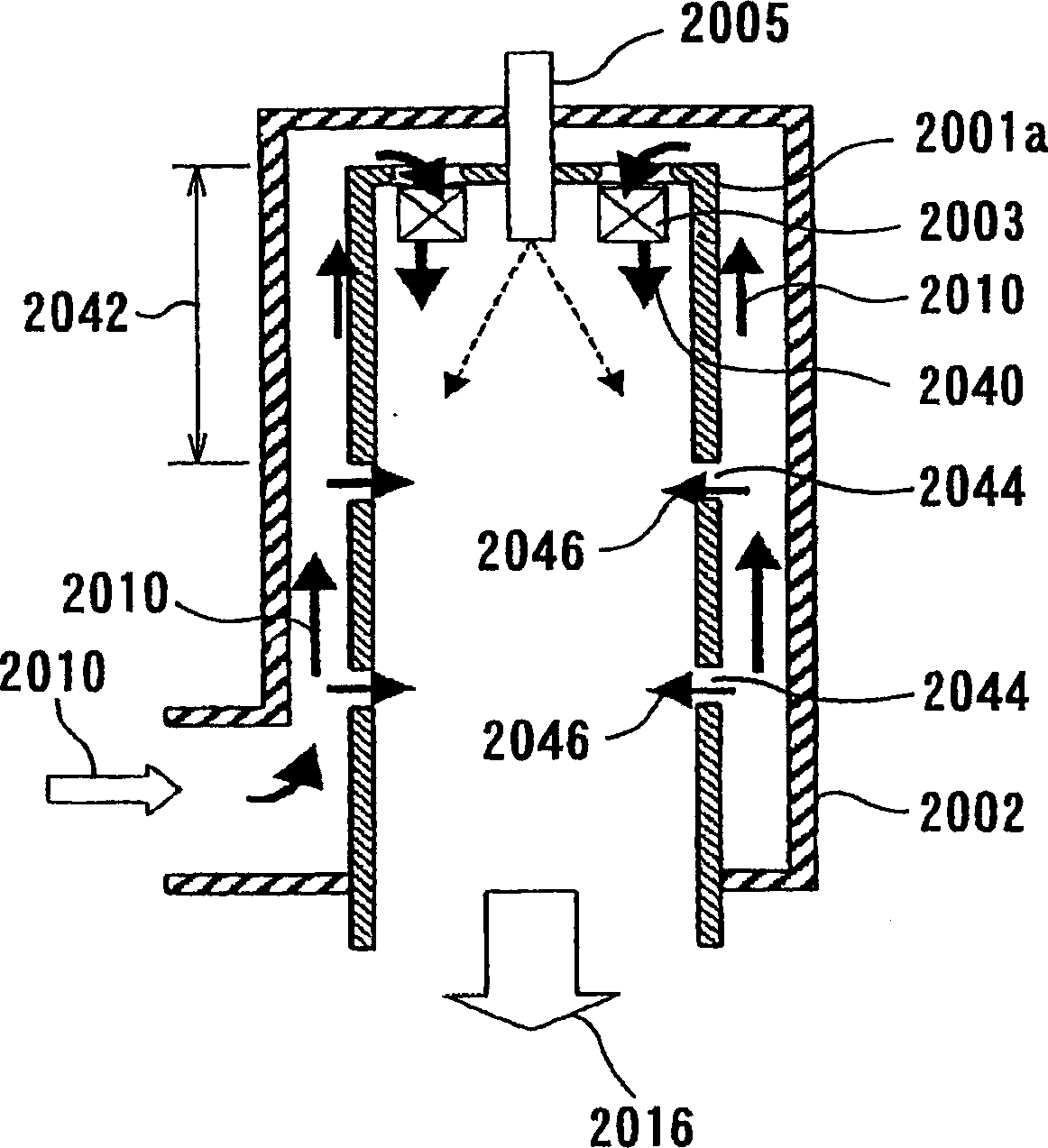

Combustion apparatus and combustion method

InactiveCN1918431AActive recyclingImprove stabilityContinuous combustion chamberAir/fuel supply for combustionCombustion chamberEngineering

Owner:EBARA CORP

Coal ash lightweight board

InactiveCN101186470AImprove toughnessImprove mechanical propertiesSolid waste managementCeramicwarePulverized fuel ashCoal

The invention discloses a light-quality partition of pulverized fuel ash. The raw materials of the light-quality partition comprise pulverized fuel ash, cement, perlite, polypropylene fiber, water reducing agent, acrylic emulsion, foaming agent and water, and each component of the raw materials is calculated in ratio by weight: 40-60 portions of the pulverized fuel ash, 15-25 portions of the cement, 5-10 portions of the perlite, 0.1-0.5 portions of the polypropylene fiber, 0.5-1.0 portions of the water reducing agent, 1.0-5.0 portions of the acrylic emulsion, 0.1-0.5 portions of the foaming agent and 20-30 portions of the water. The invention takes the pulverized fuel ash as the main raw material; besides, various components are added into the pulverized fuel ash so as to be mixed organically. The invention not only conforms to the energy saving, waste utilizing, environmental protection policy advocated by the State, but also improves the intensity and toughness of the plates and leads the plates to be uneasy to be broken.

Owner:SHANDONG HONGTAI CONSTR GROUP

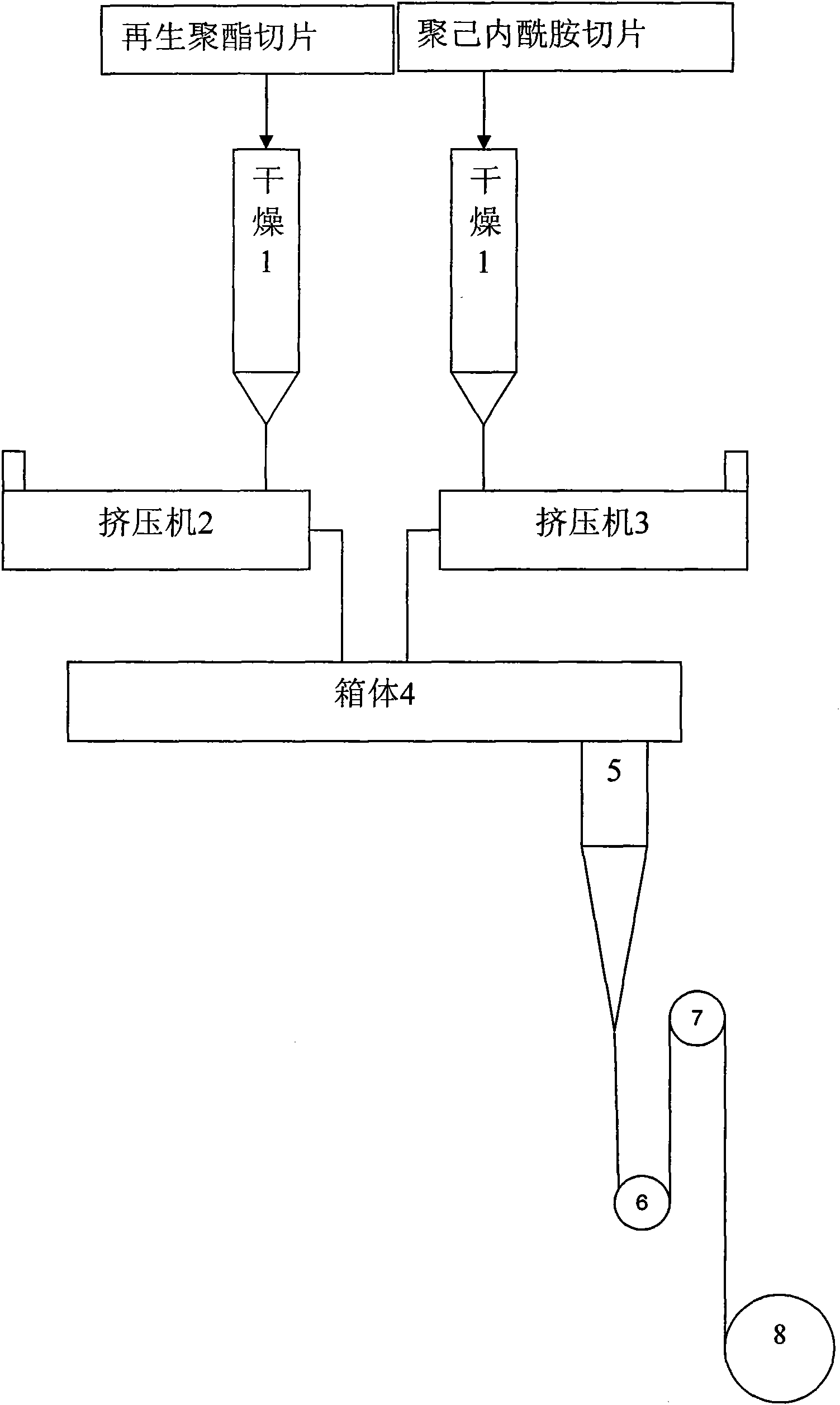

Ultrafine fiber based on recycled polyester and production method thereof

InactiveCN101787581ALow priceSmall finenessConjugated synthetic polymer artificial filamentsMonocomponent polyesters artificial filamentPolyesterMaterials science

The invention discloses a production method of recycled polyester ultrafine fiber based on bi-component fiber production equipment. The method comprises the following steps: taking recycled polyester chips and polycaprolactam chips as raw materials, conveying the two raw materials to a composite spinning box body after respectively crystallizing drying and extrusion melting; extruding by an insulating spinning measuring pump with accurate measurement; distributing the materials to each composite spinning assembly; compounding and forming the two components according to a shape set by a spinning assembly; extruding and cooling by side air blowing for forming; oiling by a nozzle tip; coiling into a recycled polyester ultrafine POY spinning cake by a coiling head; and then carrying out subsequent texturing processing to obtain applicable ultrafine fibers. After the method is adopted, by adjusting the processing technique, the recycled polyester raw materials are applied to high grade fibers, thereby improving effective application of resources, saving cost and having double significances of economy and environmental protection.

Owner:无锡海丝路纺织新材料有限公司

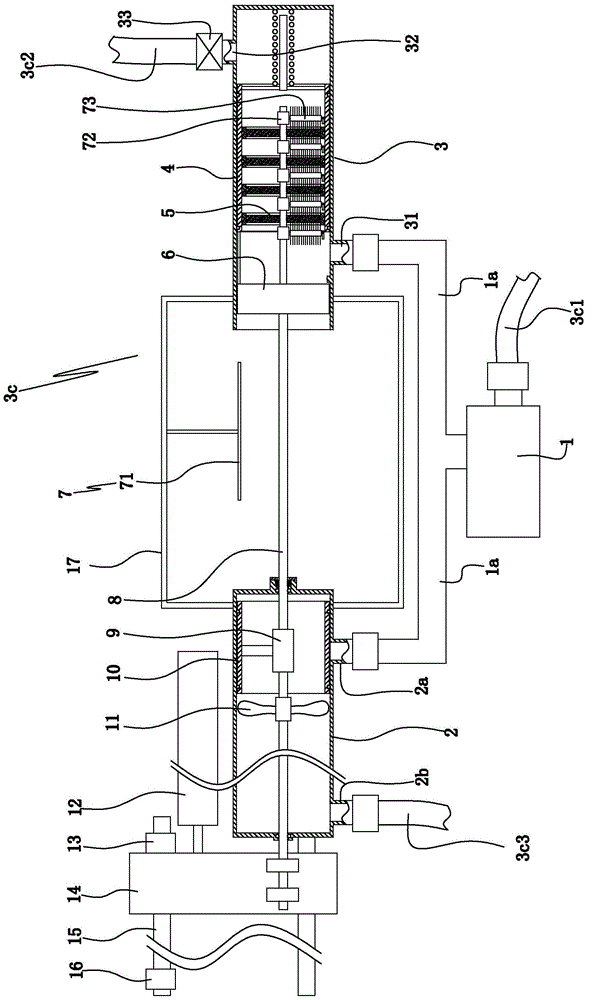

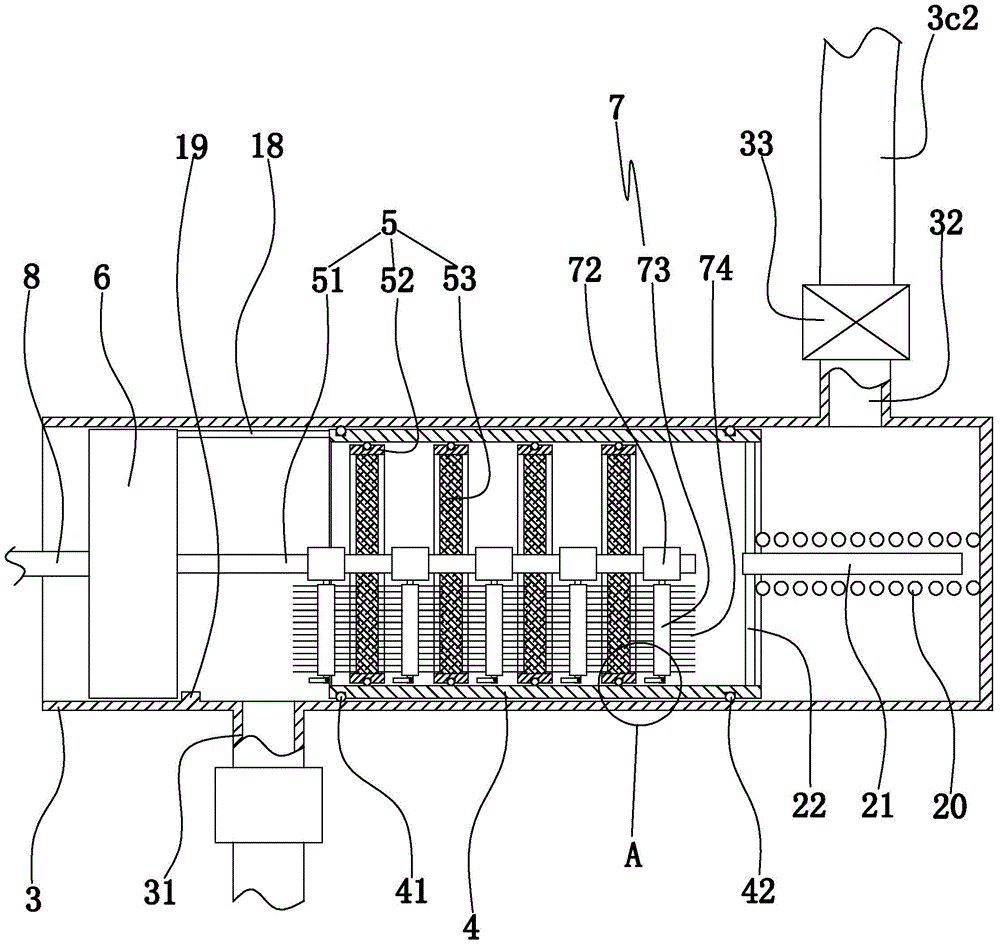

Mechanical and plant purification system for artificial culturing tail water

ActiveCN105084644AEasy to operateImprove equipment utilizationMultistage water/sewage treatmentAlgaeEngineering

The invention discloses a mechanical and plant purification system for artificial culturing tail water, and aims to provide the artificial culturing tail water mechanical and plant purification system capable of recycling aquaculture waste water. The system comprises a precipitation tank, an aeration tank, mechanical filter equipment, algae purification tank and an ozone disinfection tank, wherein the precipitation tank is communicated with the aeration tank; the mechanical filter equipment comprises a water pumping pipe, a water pump and a first draining pipe; one end of the water pumping pipeline is connected with the aeration tank, and the other end of the water pumping pipeline is connected with the water inlet of the water pump; the water inlet port of the first draining pipe is communicated with the water outlet of the water pump, and the water outlet port of the first draining pipe is connected with the algae purification tank; and the algae purification tank is communicated with the ozone disinfection tank.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

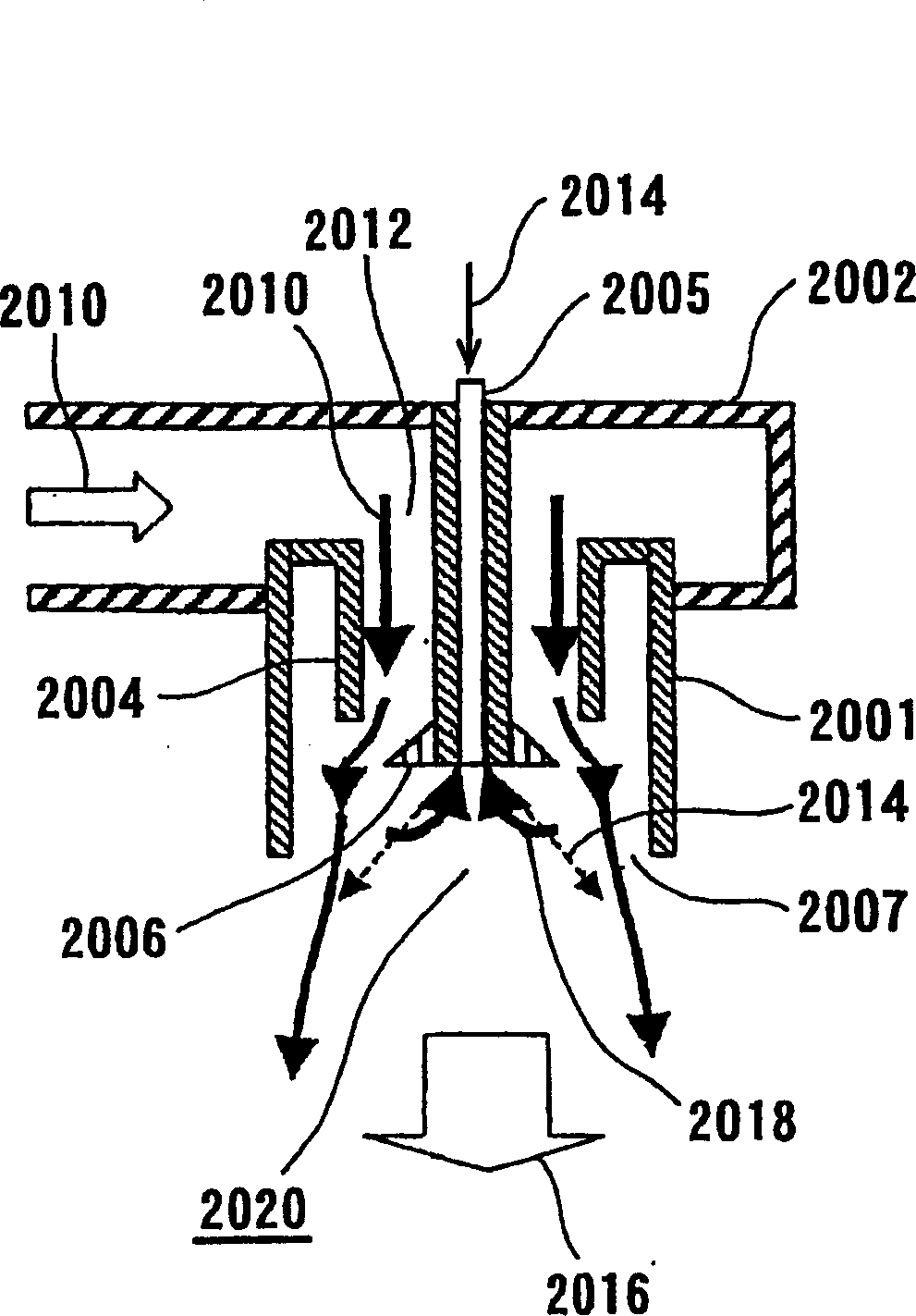

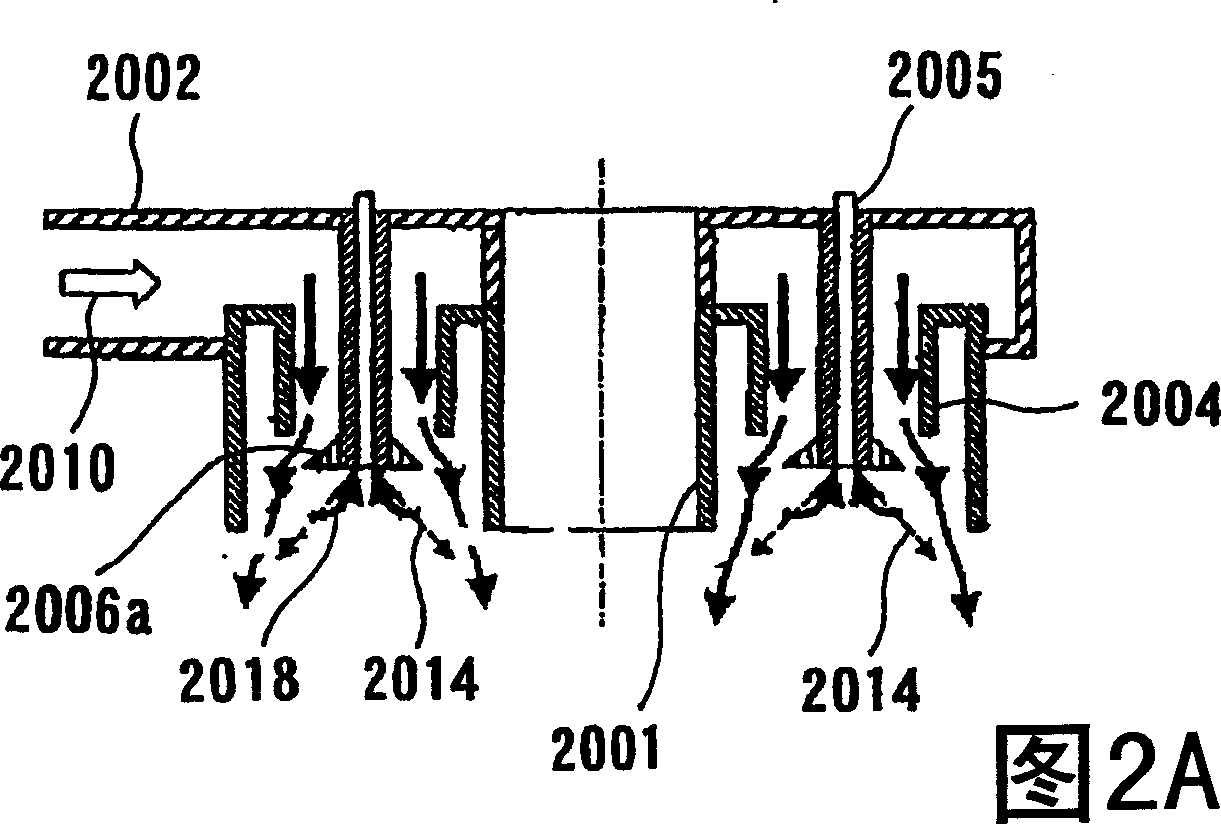

Combustion device

InactiveCN1918432AAchieve flowIncreased durabilityContinuous combustion chamberGaseous fuel burnerCombustionEngineering

A combustion apparatus capable of producing the recirculation of combustion gas by positively controlling the recirculation by a simple structure. The combustion apparatus comprises an annular container (12) having an inner tube part (15) forming an inner peripheral side face, an outer tube part (13) forming an outer peripheral side face, an open end part (26), and a closed end part (10). An air flow (28) having a speed component in the direction of a center axis (J) starting at the open end part (26) toward the closed end part (10) and a speed component in the circumferential direction of the annular container (12) is formed in the apparatus. A fuel (23) is jetted to have a speed composition in the direction of the center axis (J) starting at the closed end part (10) toward the open end part (26) and a speed component in the radial outer direction.

Owner:EBARA CORP

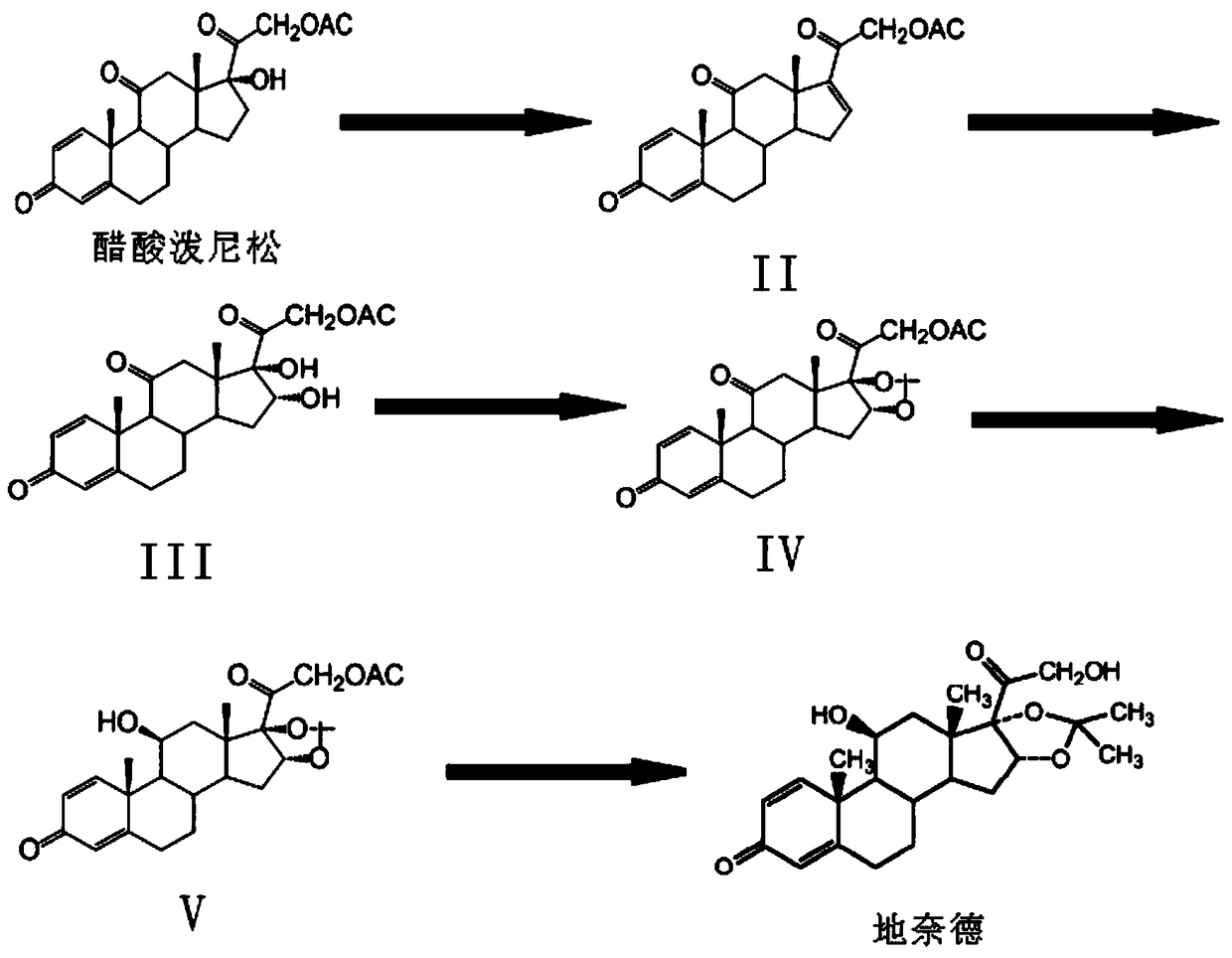

A kind of synthetic method of desonide

The invention discloses a synthetic method of desonide. The synthetic method is characterized by carrying out elimination reaction on prednisone acetate by using sulfur dioxide in the presence of a first catalyst and an inert gas, then carrying out oxidation reaction on a product after elimination by using an oxidant in the presence of a second catalyst, then carrying out condensation treatment on a product after oxidation by using acetone in the presence of a third catalyst, carrying out selective reduction on a product after condensation in the presence of a fourth catalyst and finally carrying out hydrolysis reaction on a product after reduction in the presence of a fifth catalyst, thus preparing desonide. The synthetic method has the beneficial effects that desonide can be obtained by using prednisone acetate as the raw material and carrying out elimination, oxidation, condensation, reduction and hydrolysis; all the solvents in the synthetic process are recycled and reused, heavy metals do not participate in reaction in the reaction process, the technical process is mild and the energy consumption is low, so that the synthetic method is environment-friendly and clean.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD

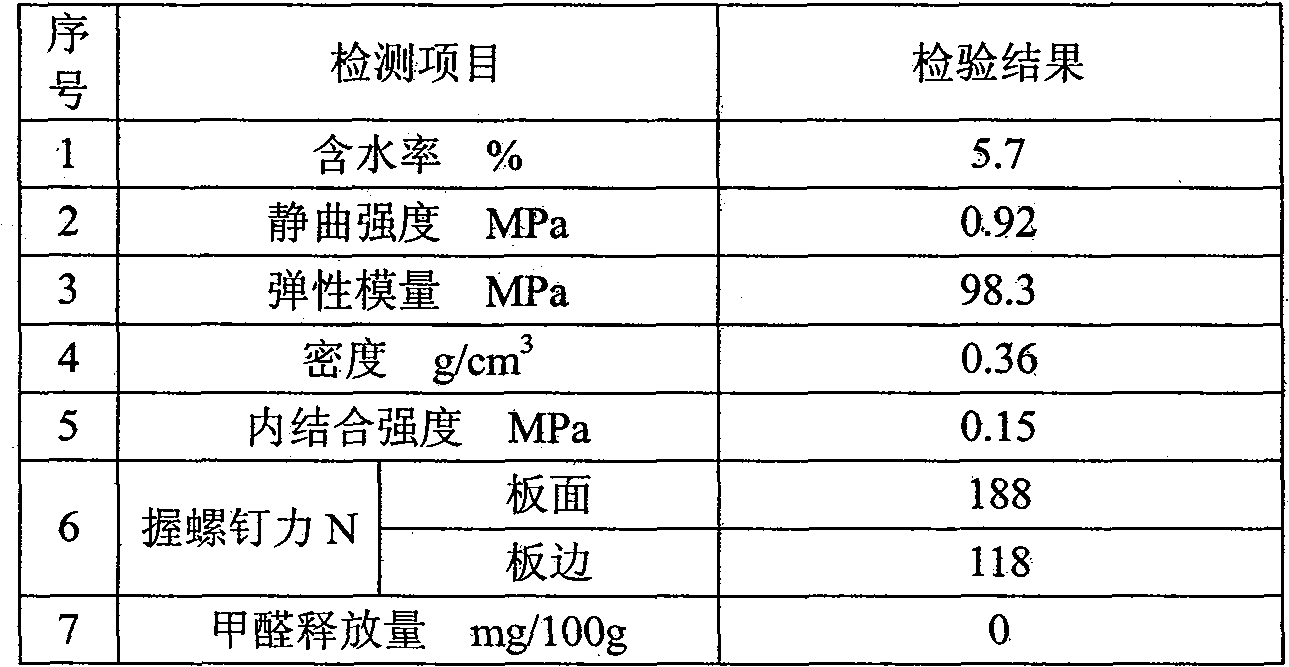

Method for preparing sheets from potatoes or potato residues and discarded vegetable fibers

InactiveCN101967289AUniform materialSmooth materialWood working apparatusDomestic articlesVegetable fibersMaterials science

The invention discloses a method for preparing sheets from potatoes or potato residues and discarded vegetable fibers. The method comprises the following steps of mixing cooked potatoes or potato residues and discarded vegetable fiber powder uniformly, putting the mixture into a die, and forming, polishing, demoulding and drying to obtain sheets. The sheets of the invention have the characteristics of light weight, no toxicity, low cost, simple preparation process, and recycle waste, and contribute to environmental protection, and can be widely applied in fields of decoration, packaging and the like.

Owner:INNER MONGOLIA UNIVERSITY

Preparation method of 1,1,2,3-tetrachloropropene

InactiveCN110511112ARecyclingLow costPreparation by hydrogen halide split-offOrganic-compounds/hydrides/coordination-complexes catalystsGas phaseCarbon tetrachloride

The invention discloses a preparation method of 1,1,2,3-tetrachloropropene, and the method comprises the following steps: (1) preparing a neodymium-containing synergist for later use; (2) preparing acarbon tetrachloride mixed solution for later use; (3) continuously introducing the carbon tetrachloride mixed solution and ethylene into a second reactor for reaction to obtain a reaction product; (4) separating the reaction product to obtain a first stream and a second stream, and separating the second stream to obtain a third stream and a fourth stream; (5) rectifying the first stream and the third stream to obtain 1,1,1,3-tetrachloropropane and recovered carbon tetrachloride; (6) cracking the 1,1,1,3-tetrachloropropane, condensing and separating tail gas to obtain a cracking product; (7) performing gas phase chlorination on the cracking product, and condensing and separating tail gas to obtain a gas phase chlorination product; (8) cracking the gas phase chlorination product, collectingthe reaction product, condensing and separating tail gas to obtain the1,1,2,3-tetrachloropropene product. The preparation method has the advantages of simple process, high efficiency, low cost and environmental friendliness.

Owner:JUHUA GROUP TECH CENT

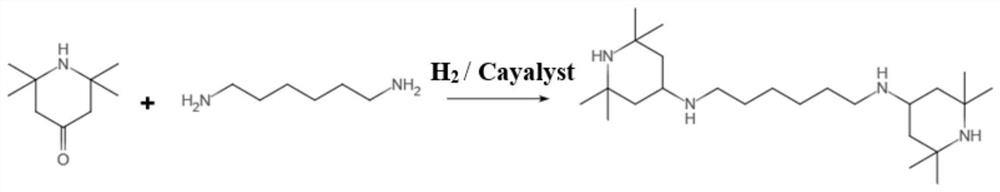

Synthesis process of hexamethylenediamine piperidine

InactiveCN111825602AReduce generationImprove responseOrganic chemistryChemical recyclingPtru catalystHexamethylenediamine

The invention relates to a synthesis process of hexamethylenediamine piperidine. The process comprises the steps of: carrying out heating dehydration reaction on 2, 2, 6, 6-tetramethyl-4-piperidone and 1, 6-hexamethylenediamine in a negative pressure environment until no water is removed from the system, and adding a water removing agent to separate the residual water from the liquid system so asto obtain an intermediate Schiff base; introducing hydrogen into the obtained Schiff base in the presence of a catalyst for hydrogenation reaction to obtain hydrogenation liquid; and filtering out thecatalyst from the hydrogenation liquid, rectifying the filtrate, and carrying out crystallization-desolvation to obtain the hexamethylenediamine piperidine finished product. According to the method,a small amount of residual water is removed by using the water removal agent, so that the Schiff base is prevented from being decomposed in the presence of trace water, the purity of the Schiff base is improved, the yield of hexamethylenediamine piperidine is increased, and few solid wastes are generated; according to the method, negative pressure reaction and crystallization treatment are innovatively adopted, so that the quality of hexamethylenediamine piperidine is high, the solvent can be continuously recycled and reused, and no organic waste liquid is generated.

Owner:江苏富比亚化学品有限公司

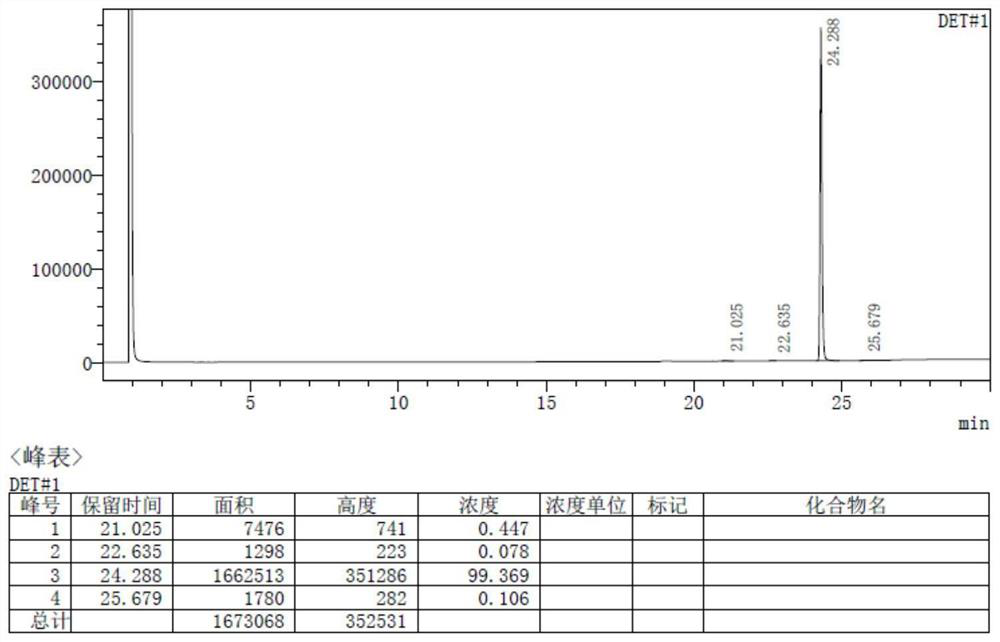

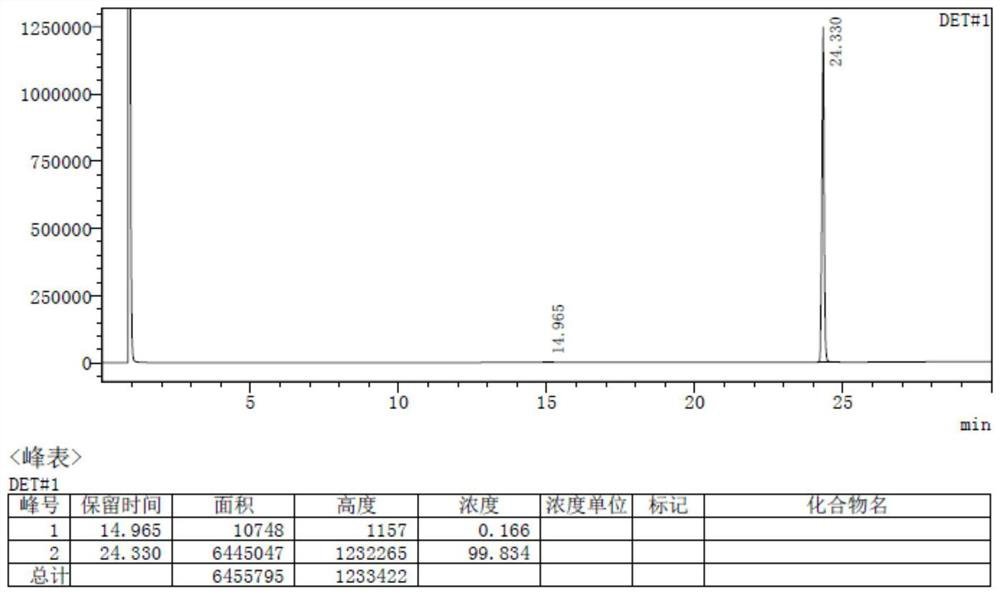

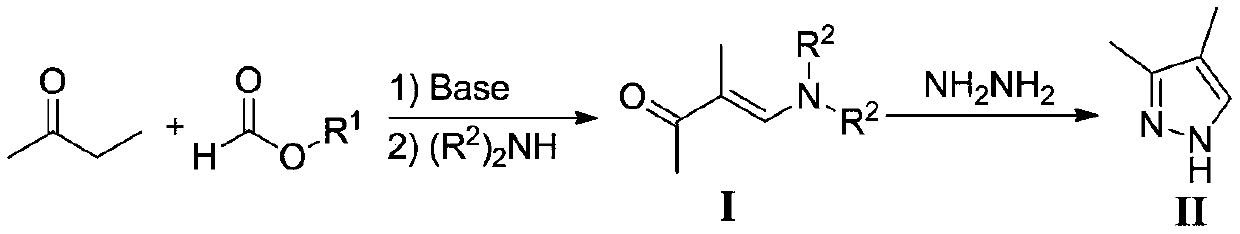

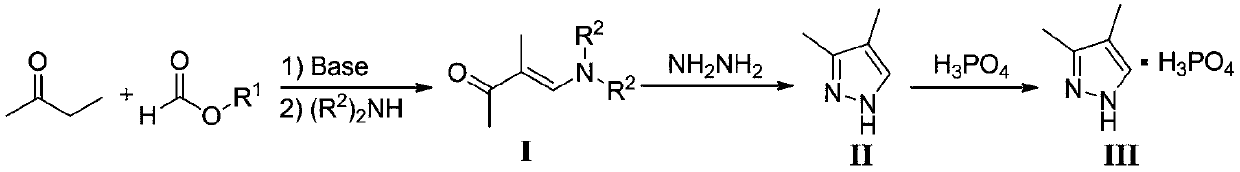

Preparation method of 3,4-dimethylpyrazole and preparation method of 3,4-dimethylpyrazole phosphate

PendingCN110218188ARecyclingRaw materials are cheap and easy to getOrganic chemistryPhosphatePhosphoric acid

The invention discloses a preparation method of 3,4-dimethylpyrazole and a preparation method of 3,4-dimethylpyrazole phosphate. The methods comprise the following steps: performing condensation by using 2-butanone and formate as raw materials, performing aminolysis, performing cyclization to prepare the 3,4-dimethylpyrazole; and performing a salt forming reaction on the 3,4-dimethylpyrazole and phosphoric acid to obtain the 3,4-dimethylpyrazole phosphate. The preparation method of the 3,4-dimethylpyrazole and the preparation method of the 3,4-dimethylpyrazole phosphate provided by the invention have the significant advantages that the raw materials are cheap and easy to obtain, the operation is simple and convenient, the yield is high, the product quality is high, the solvent can be recovered and reused, and the methods are suitable for industrial production.

Owner:武威金仓生物科技有限公司

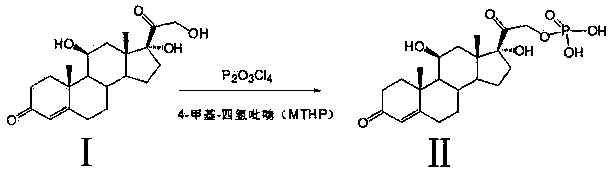

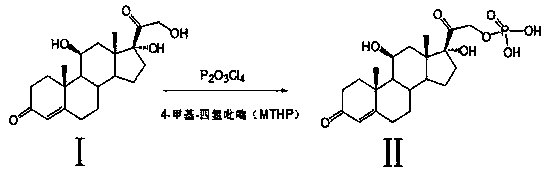

Preparation method of prednisolone sodium phosphate intermediate

The invention discloses a preparation method of a prednisolone sodium phosphate intermediate. The prednisolone sodium phosphate intermediate is prednisolone phosphate as shown in a formula II, prednisolone is used as a raw material and reacts with diphosphoryl chloride, and reaction steps include: A adding a compound I into an organic solvent MTHP under nitrogen protection, stirring and dissolvingthe compound I, slowing dropping the diphosphoryl chloride at the temperature ranging from -50 DEG C to -60 DEG C and performing heat reaction; B adding purified water after reaction to terminate reaction and performing standing layering for 2-4 hours; C adding an organic phase into the purified water, performing extraction twice, adding activated carbon into the organic phase and performing heatinsulation discoloration at the heat insulation temperature of 30-50 DEG C for 1-2 hours; D performing filtration, vacuum concentration, cooling, discharging and vacuum drying to obtain a compound II. The preparation method is economical and environmentally friendly.

Owner:HENAN LIHUA PHARMA

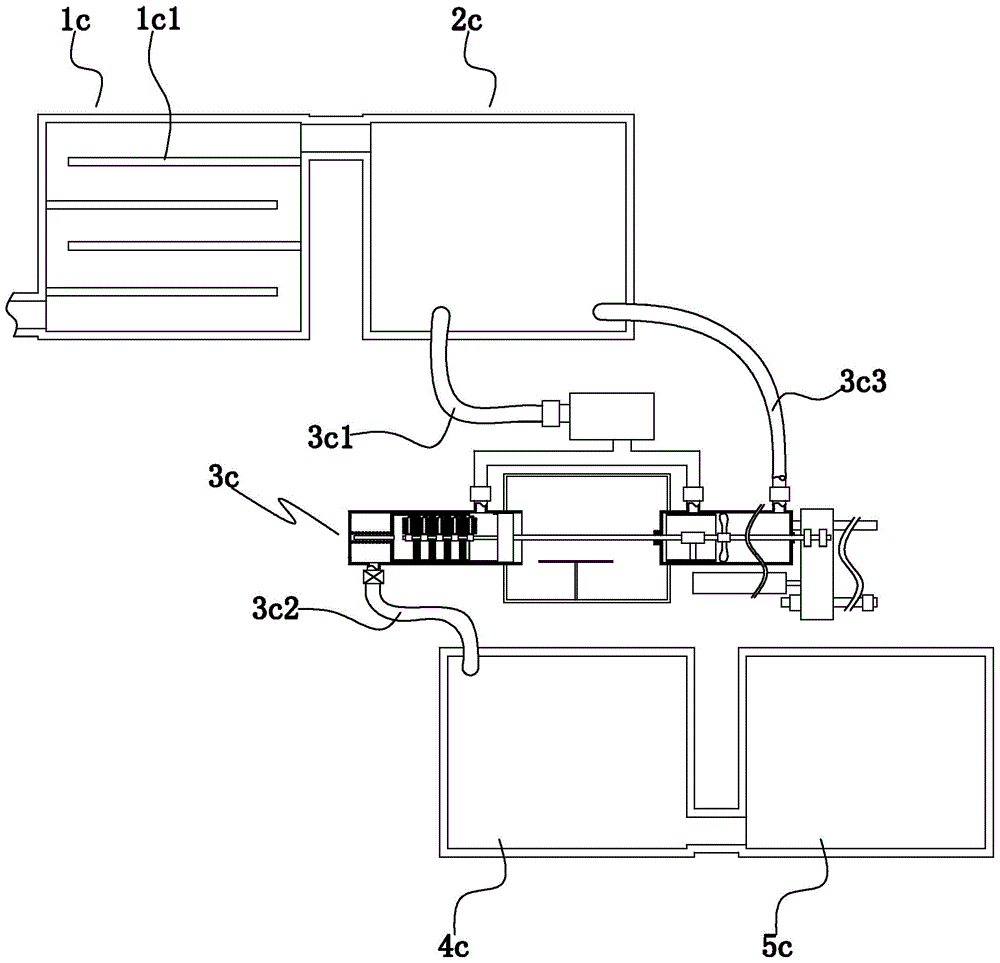

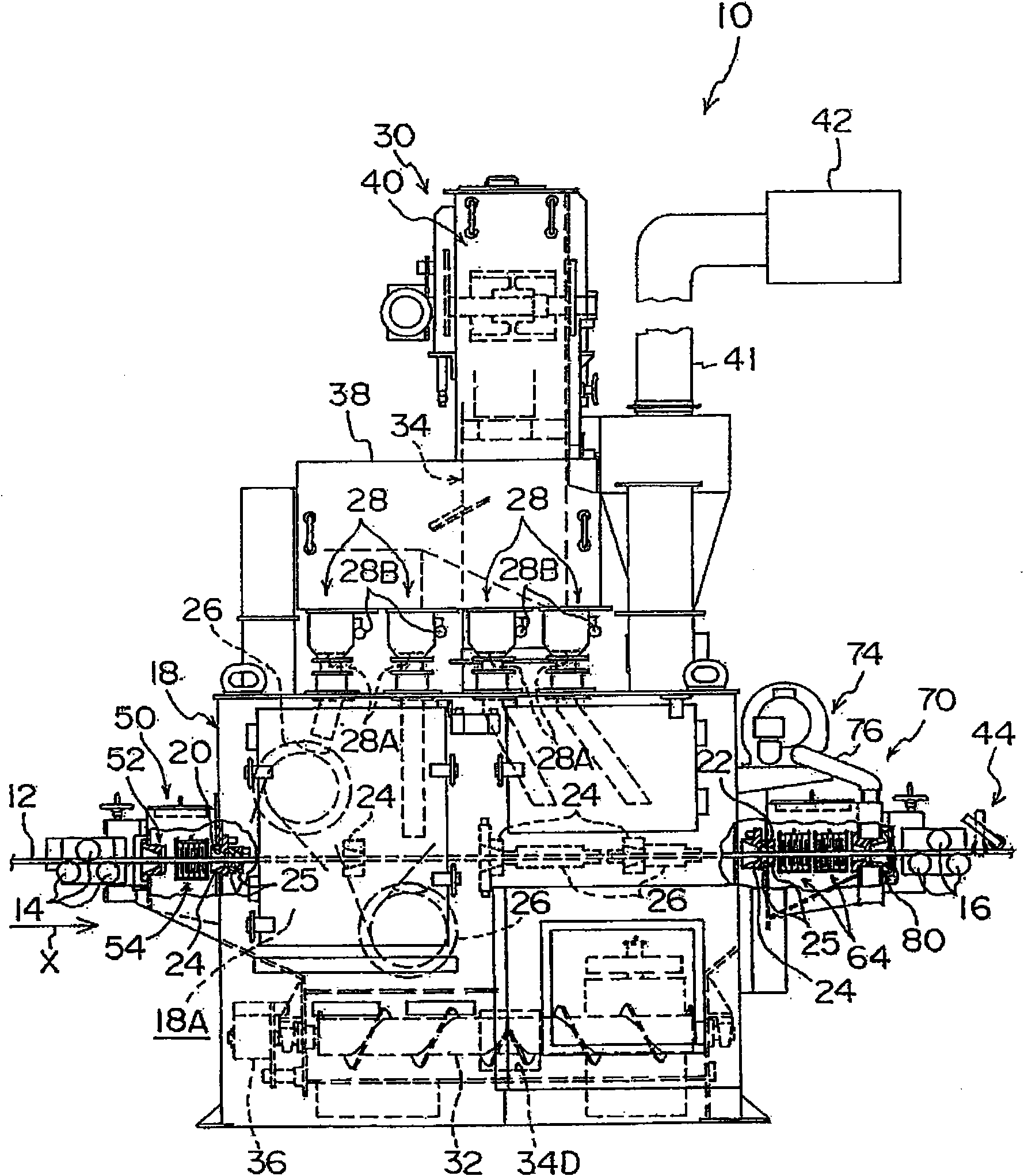

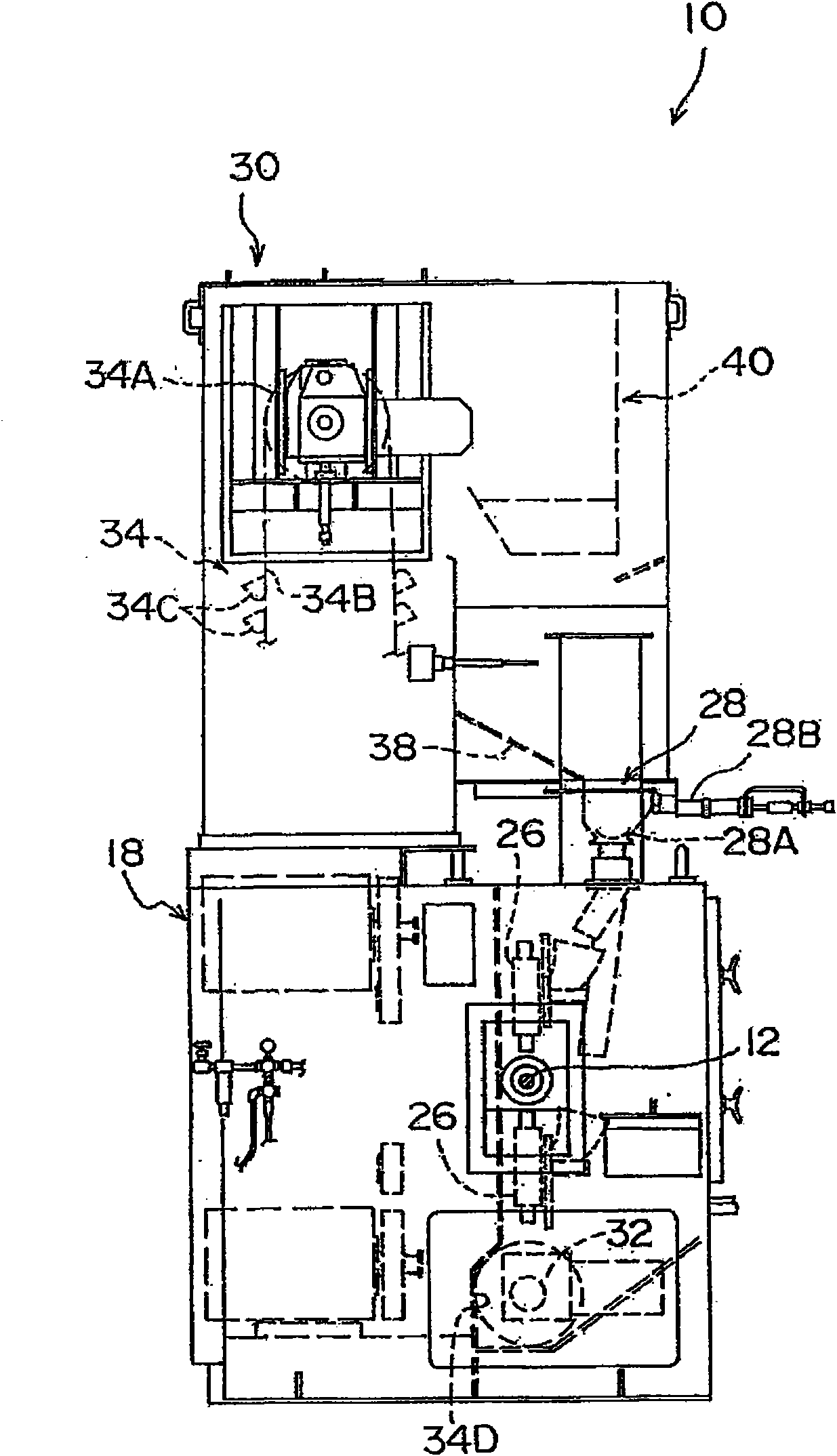

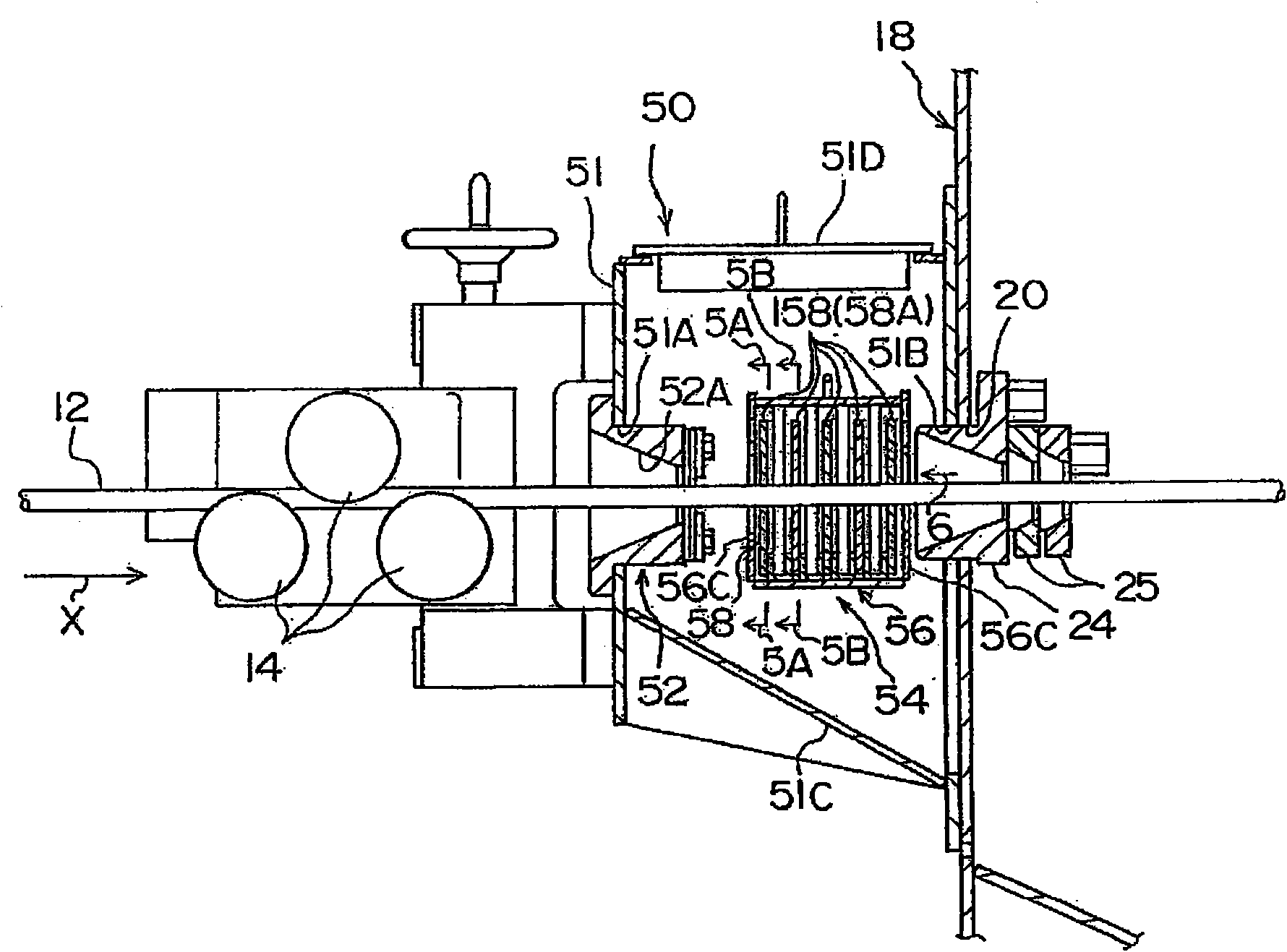

Surface treatment device

ActiveCN102371544APrevent or contain leakage within the devicePrevent or suppress projectilesAbrasive feedersAbrasive machine appurtenancesSurface finishingAirflow

In order to obtain a surface treatment device capable of preventing or suppressing the leakage of a projection material and the like from within the device, a first seal part (54) is disposed on the carry-in port (20) side of a cabinet (18), and a second seal part (64) is disposed on the carry-out port (22) side of the cabinet (18). A blowoff port (72) of an air current production unit (70) is disposed downstream from the second seal part (64) in a wire rod transfer direction, and the air current production unit (70) produces an air current directed toward the inside of the cabinet (18). Consequently, even if a projection material and the like remain on a wire rod (12), the projection material and the like are returned to the inside of the cabinet (18) by the air current.

Owner:SINTOKOGIO LTD

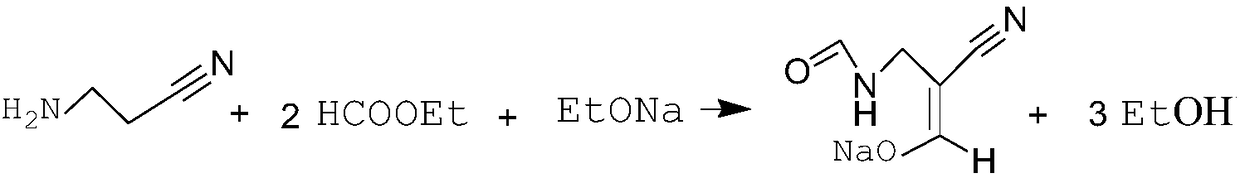

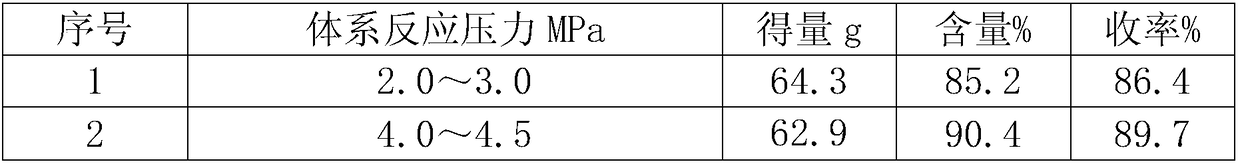

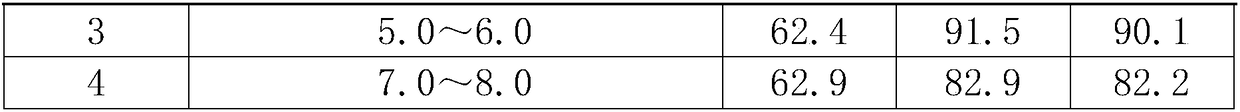

Preparation method of alpha-formyl-beta-formamido-propionitrile alkali metal salt

ActiveCN108484439AHigh yieldLess impuritiesCarboxylic acid nitrile preparationOrganic compound preparationChemical synthesisFormylation reaction

The invention belongs to a preparation method of alpha-formyl-beta-formamido-propionitrile alkali metal salt in the field of chemical synthesis. The preparation method comprises the following steps: (1) adding formic ester into a container, and slowly adding solid alkali metal C1-4 alkyl alcoholate to form a first mixture at a certain temperature, (2) controlling a temperature of the first mixture, dropwise adding beta-aminopropionitrile into the first mixture to form a second mixture, and (3) moving the second mixture into an autoclave, allowing beta-aminopropionitrile and formic ester to generate a formylation reaction to form alpha-formyl-beta-formamido-propionitrile alkali metal salt liquid, and performing filtration to form the alpha-formyl-beta-formamido-propionitrile alkali metal salt. The method is high in yield, low in cost, simple to operate and suitable for industrial massive production, and the produced alpha-formyl-beta-formamido-propionitrile alkali metal salt is high inyield and low in impurity content.

Owner:NORTHEAST PHARMA GRP

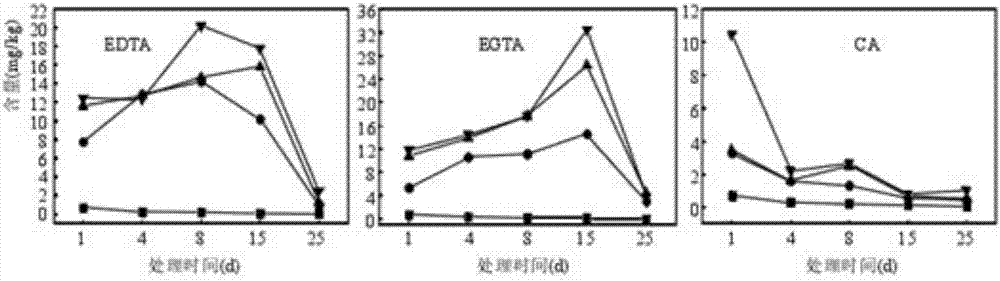

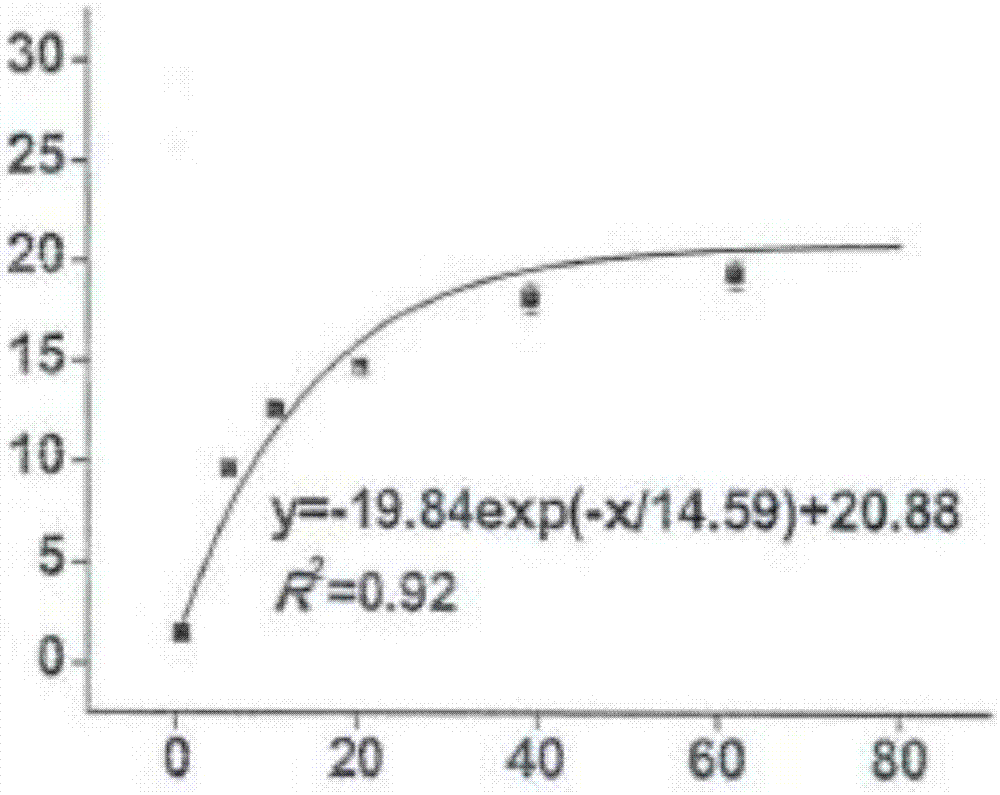

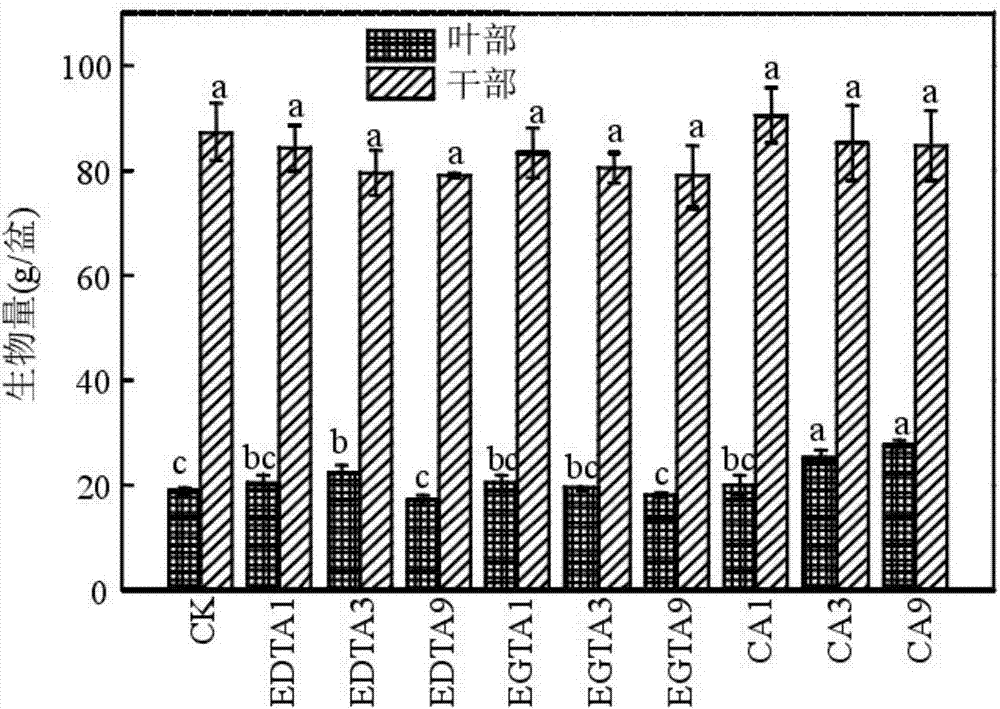

Method for treating heavy metal contaminated soil by using plants and chelating agents

InactiveCN106925604AChange the form of existenceImprove bioavailabilityContaminated soil reclamationNitraria sibiricaPlant cultivation

The invention discloses a method for treating heavy metal contaminated soil by using plants and chelating agents. The method comprises the steps of planting the plants having enrichment capacity for heavy metals in the heavy metal contaminated soil with heavy metal contamination type Zn, Pb, Cd and Cu, and putting the chelating agents in the heavy metal contaminated soil. The plants which have enrichment capacity for the heavy metals comprise aspens, peganum harmala or nitraria sibirica palls. The aspens are populus alba var.pyramidalis bunge. The chelating agents are EDTA, EGTA or CA (citric acid). By adopting the method, plant cultivation and soil recycling industry development is pushed, reutilization of nonrenewable resources is benefited, economy, zoology and environmental protection regeneration treatment is carried on the areas after being contaminated by the heavy metals, and whole ecological balance is facilitated.

Owner:HUIZHOU DONGJIANG LANDSCAPE ENG

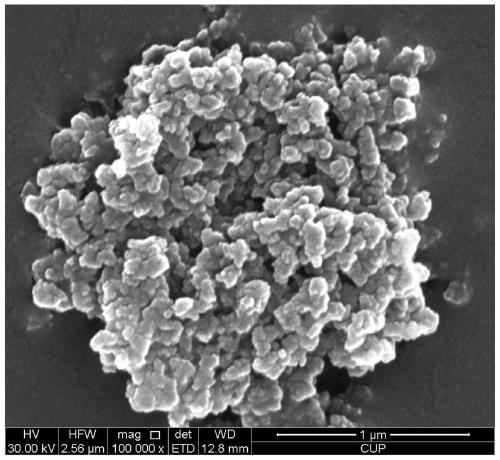

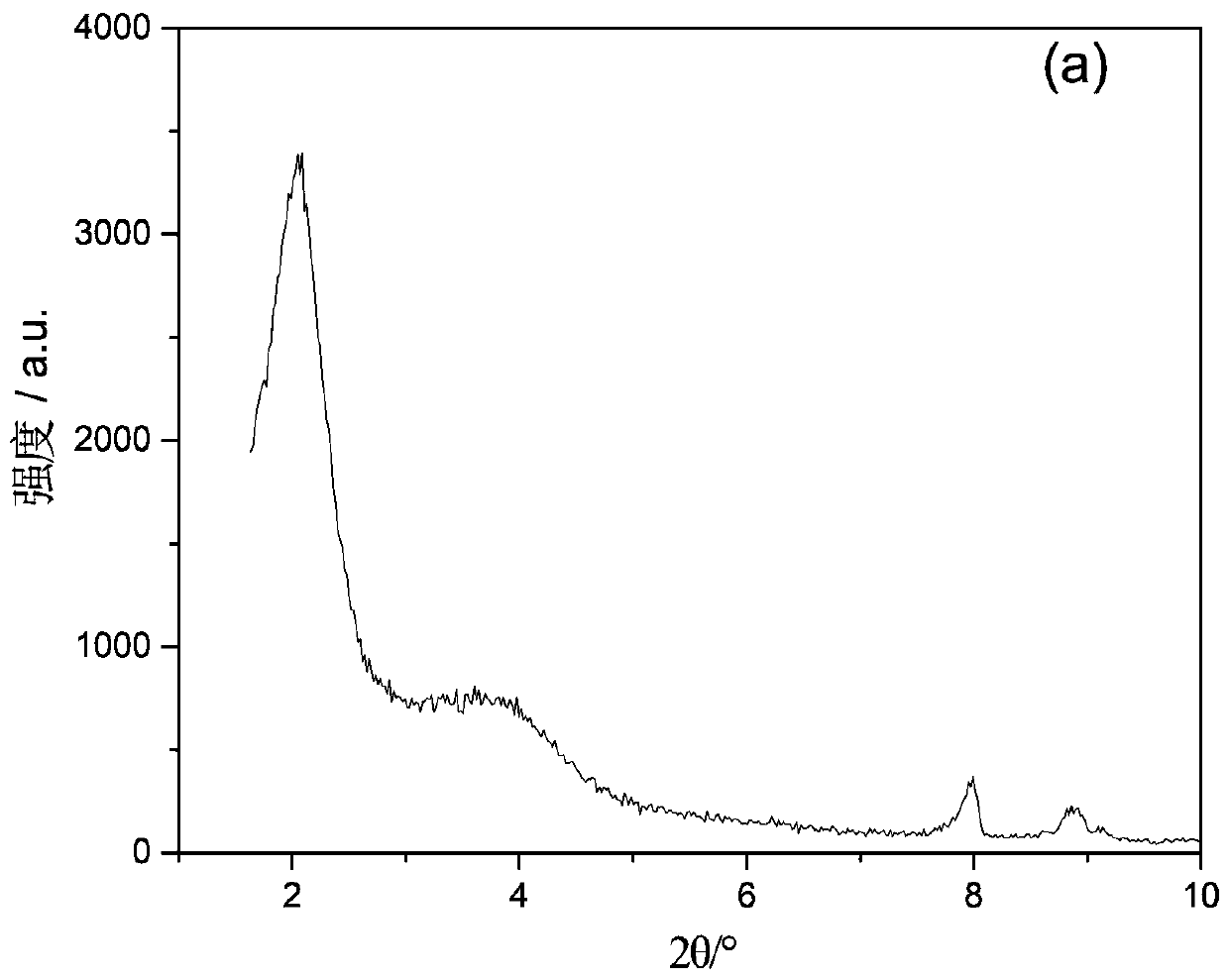

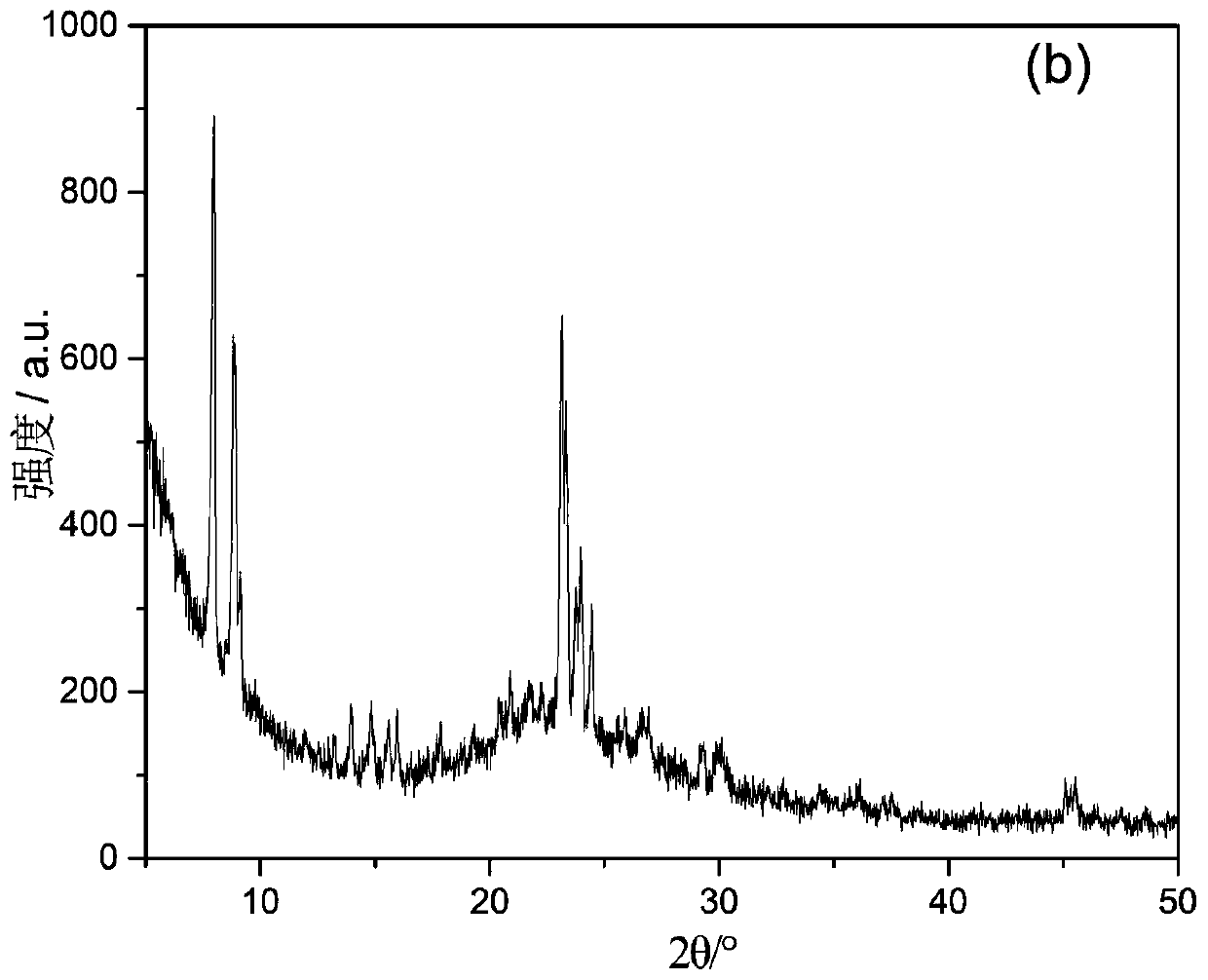

Composite molecular sieve, desulfurization adsorbent and preparation method and application thereof

ActiveCN111420632AImprove removal efficiencyUnblockOther chemical processesFaujasite aluminosilicate zeoliteMolecular sieveSorbent

The invention provides a composite molecular sieve, a desulfurization adsorbent as well as a preparation method and application thereof. The preparation method of the composite molecular sieve comprises the following steps: adding a template agent for preparing a mesoporous molecular sieve into an alkaline solution, and stirring to obtain a clear solution; adding a metal zinc in-situ modified silicon-aluminum molecular sieve into the clear solution, and stirring to obtain a turbid liquid; adding a silicon source into the turbid liquid for stirring reaction, and filtering, drying and roasting after reaction to obtain the composite molecular sieve. The desulfurization adsorbent is prepared from the following raw materials in parts by weight: 30-70 parts of a composite molecular sieve, 1-10 parts of an IA group and / or IIA group metal oxygen-containing compound precursor and 30-60 parts of a binder. The desulfurization adsorbent disclosed by the invention is high in adsorption capacity, good in selectivity, high in desulfurization precision, capable of being recycled and long in service life; and C5 oil desulfurized by the desulfurization adsorbent can be directly used as a raw material for high-value utilization.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Waste water treatment method for paraquat synthesized through ammonia cyanidation process

InactiveCN105884105AReduce contentIncrease concentrationWater contaminantsTreatment involving filtrationParaquatEnvironmental engineering

The invention discloses a waste water treatment method for paraquat synthesized through an ammonia cyanidation process. The method comprises the steps of steam stripping, chlorine oxidizing, decoloring and filtering and concentrating crystallization. In the specific process, firstly, collected waste water is subjected to steam stripping, chlorine is introduced, cyanogens ions in the paraquat waste water are damaged, meanwhile, reduced chloridions and ammonium group ions in the paraquat waste water are combined to generate ammonium chloride, then a screen mesh is used for filtering for decoloring, then the waste water is concentrated through double effect evaporation, ammonium chloride in the waste water is recycled, the remaining waste water is directly incinerated in an incinerator or used for a next batch of waste water to be evaporated till the concentration of cyanogens in ammonium chloride obtained after the current batch of waste water is cooled and crystallized is larger than 100 ppm or the content of sodions is larger than 1% (w / v), and the current batch of filtrate is incinerated. According to the method, resource utilization of the waste water is achieved, pollutants in the waste water are reduced, pollution to the environment is reduced, and meanwhile the treatment cost of the paraquat waste water is greatly reduced.

Owner:NANJING REDSUN BIOCHEM CO LTD

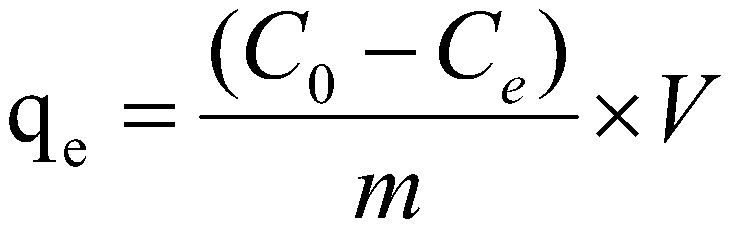

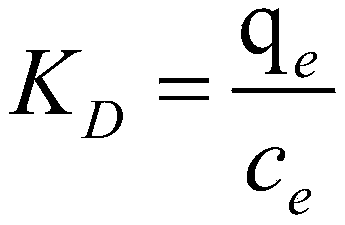

Chitosan-based lead ion imprinted adsorbent and preparation method thereof

InactiveCN111450805AImprove stabilityHigh mechanical strengthOther chemical processesWater contaminantsPhysical chemistryMolecular adsorption

The invention belongs to the field of functional polymer adsorption materials and specifically relates to a chitosan-based lead ion imprinted adsorbent and a preparation method thereof. The preparation method comprises the following steps: dissolving CS and EDTA-2Na in diluted hydrochloric acid to prepare a mixed solution; adjusting the pH value of the solution to 5.5, adding EDC-HCl under an icebath condition for a reaction to obtain EDTA-CS gel, soaking and adsorbing the gel in a Pb<2+> solution, adding glutaraldehyde for cross-linking, then washing off Pb<2+> in the gel with an eluent, washing the gel with deionized water until the gel is neutral, and drying and crushing the gel to obtain the adsorbent. The adsorbent prepared by the method has good adsorbability and selectivity to Pb<2+>, can be recycled, uses harmless raw materials, and is simple in preparation process, friendly to environment and applicable to treatment of lead ion-containing wastewater.

Owner:FUZHOU UNIV

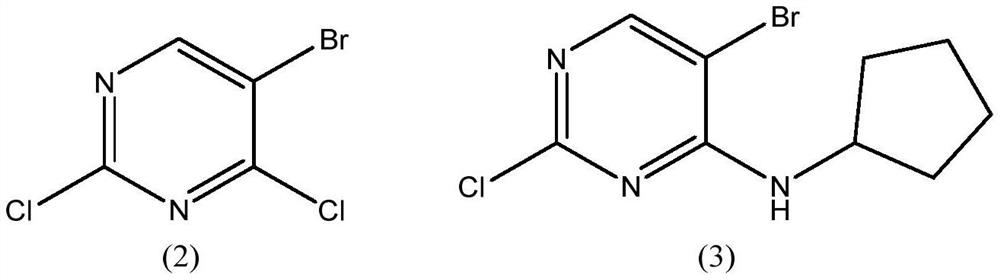

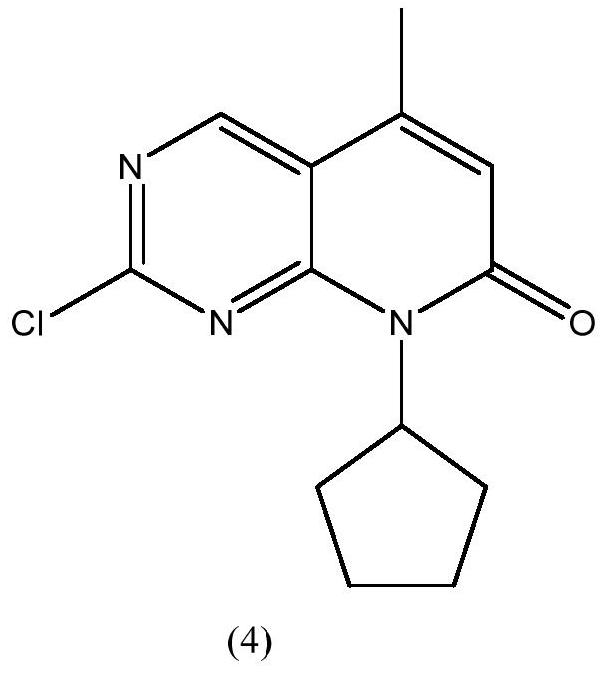

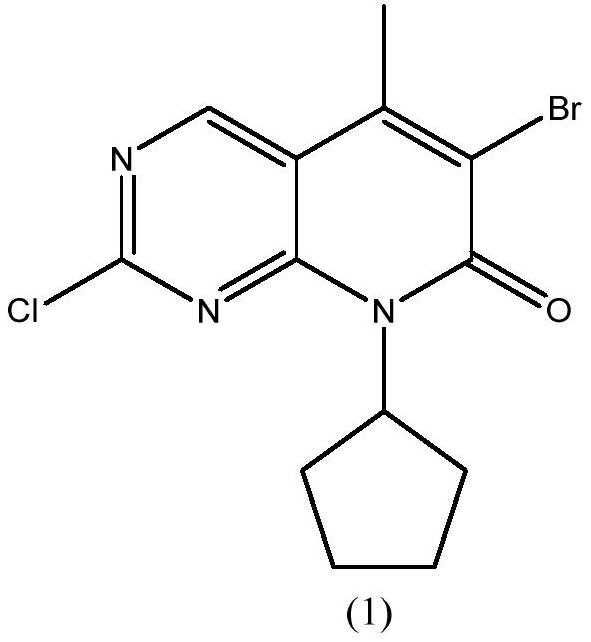

Preparation method of palbociclib intermediate

ActiveCN112898299AMild reaction conditionsSimple post-processingOrganic chemistryAcetic anhydrideKetone

The invention discloses a preparation method of a palbociclib intermediate. The method comprises the following steps: preparing 5-bromine-2-chloro-N-cyclopentylamine pyrimidine-4 amine from 5-bromine-2,4-dichloropyrimidine and cyclopentylamine by taking solvents such as dichloromethane and water as solvents and taking inorganic base as an acid-binding agent; with DIEA as an acid-binding agent, DMF as a solvent and TBAB as a phase transfer catalyst, in the presence of water, catalyzing with a trace amount of palladium, and carrying out normal hexane reflux dehydration; further subjecting the acetic anhydride to dehydration cyclization, such that 2-chloro-8-cyclopentyl-5-methylpyridino[2,3-D]pyrimidine-7-(8H)-ketone is obtained; and reacting the obtained compound with NBS (N-bromosuccinimide) in acetonitrile to obtain the 6-bromo-2-chloro-8-cyclopentyl-5-methylpyridino[2, 3-D]pyrimidine-7(8H)-ketone. The method is mild in reaction, simple and convenient to operate, recyclable in solvent, less in environmental pollution, high in yield, low in cost, high in product quality and suitable for industrial production.

Owner:SHANDONG BOYUAN PHARM CO LTD

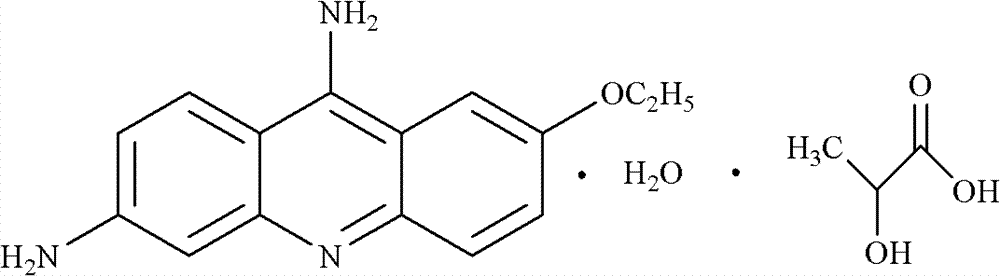

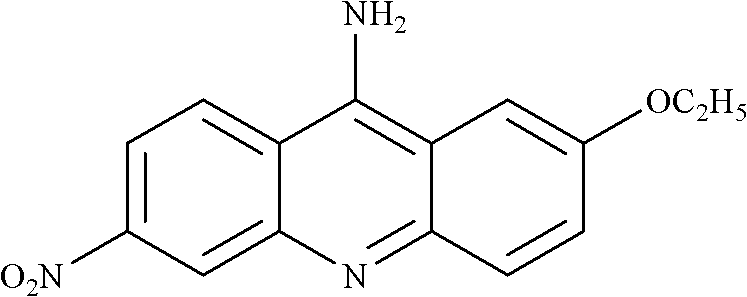

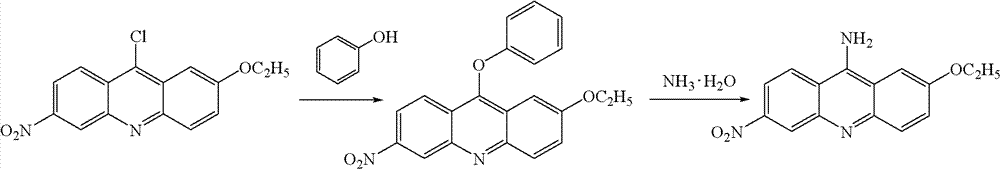

Preparation method of ethacridine lactate intermediate

InactiveCN102786471AAvoid environmental pollutionReduce raw material cost inputOrganic chemistrySolventAcridine

The invention relates to a preparation method of an ethacridine lactate intermediate. The preparation method comprises the following steps that phosphorus oxychloride and 2-p-ethoxyphenylamino-4-nitrobenzoic acid are mixed according to a mole ratio of 2: 1; the mixture undergoes a reaction at a temperature of 70 to 120 DEG C for 0.5 to 2 hours; reaction products are cooled to a room temperature and are directly added with a polar aprotic solvent and a multi-fatty alcohol catalyst; the mixture is added with a nitrogen source at a low temperature of -10 to 20 DEG C; and the mixture with the nitrogen source is heated to a temperature of 80 to 180 DEG C and undergoes a reaction for 1 to 6 hours to produce 2-ethoxy-6-nitro-9-aminoacridine. The preparation method can be operated simply, is safe, realizes recovery and recycle of a reaction waste liquid thereby avoiding environmental pollution, reduces a raw material cost and improves a reaction yield.

Owner:BEIJING UNIV OF CHEM TECH +1

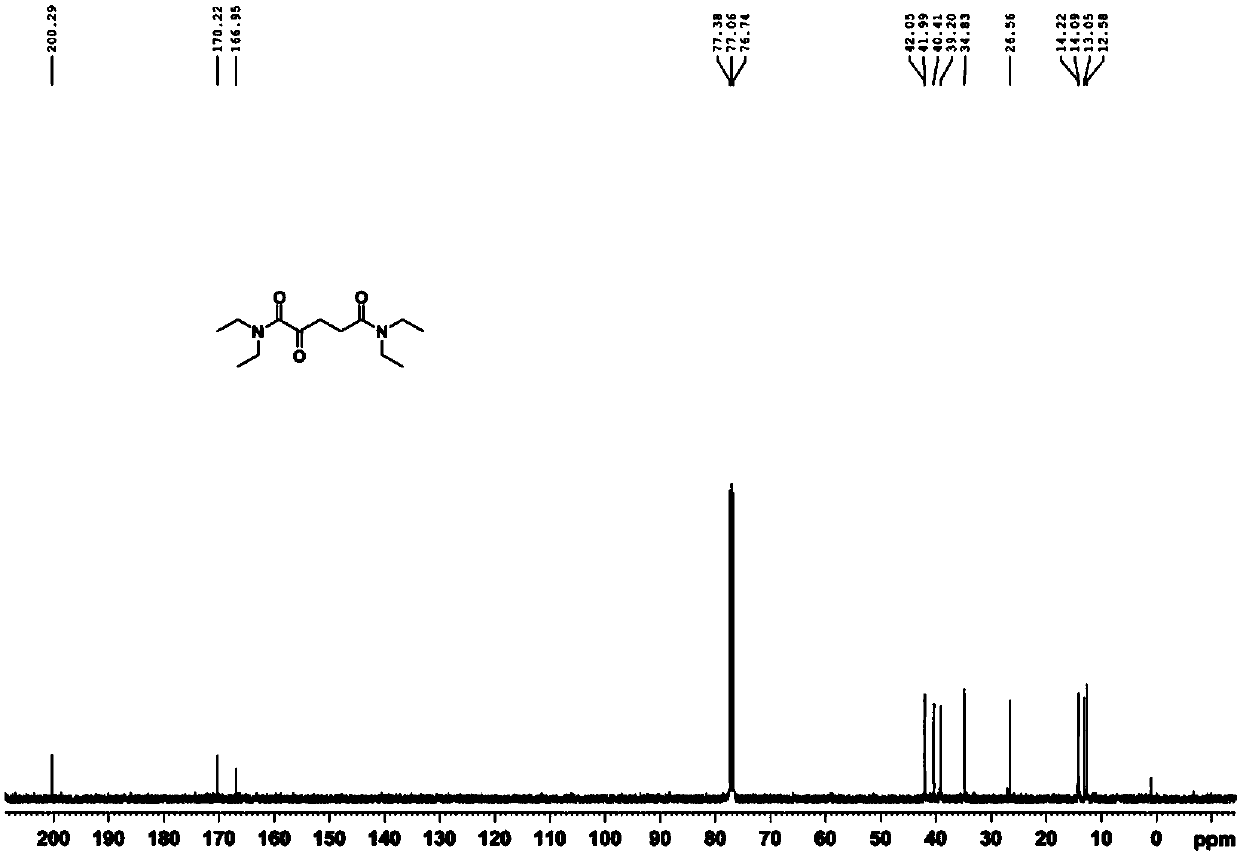

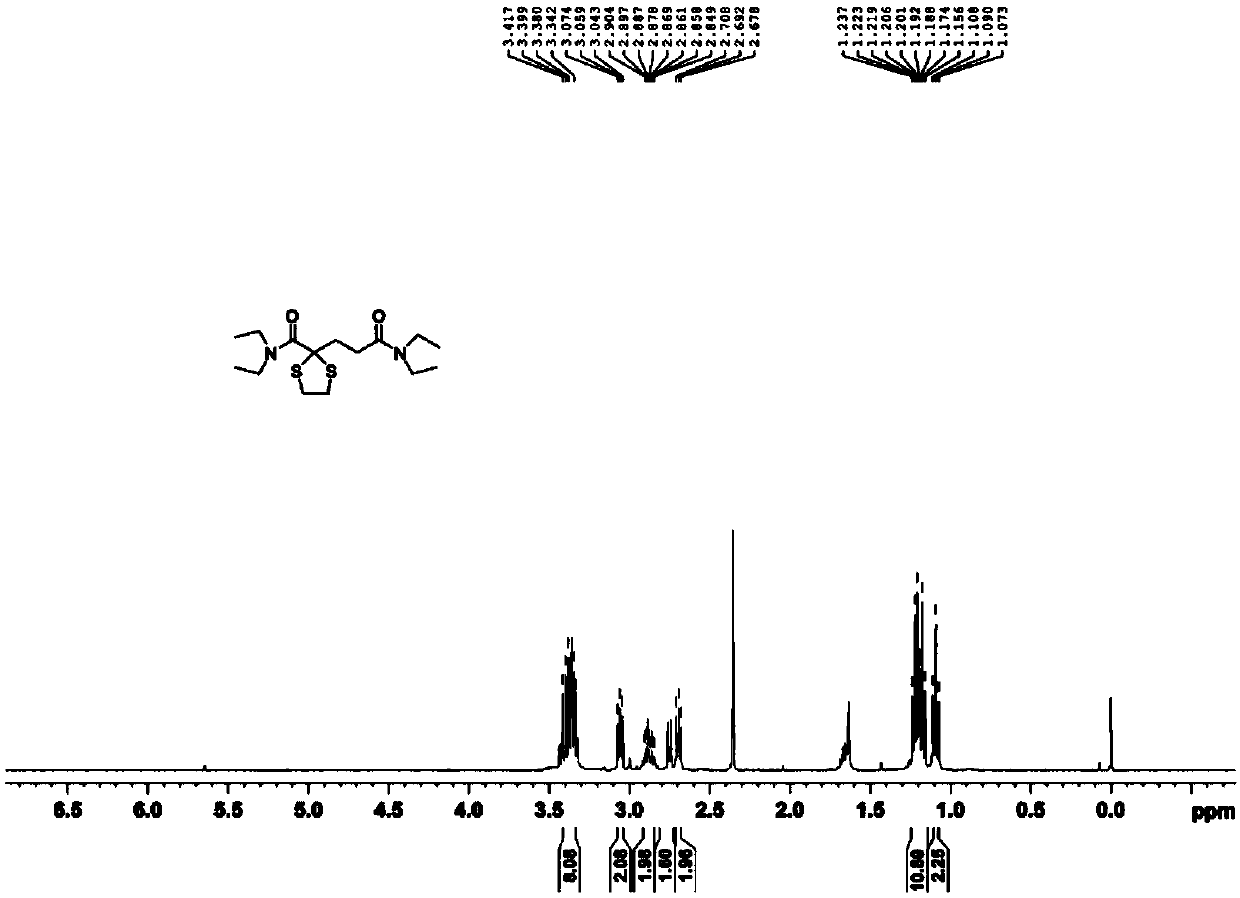

Method for synthesizing glutaric acid from alpha-ketoglutaric acid

ActiveCN108047032AWide variety of sourcesReduce manufacturing costOrganic compound preparationCarboxylic acid amides preparationGlutaric acidKetone

The invention relates to a method for synthesizing glutaric acid from alpha-ketoglutaric acid. Specifically, under the mild condition, protected ketone thioacetal is subjected to catalytic hydrogenation reduction with raney nickel, recycling and reusing of reactants, solvent and a catalyst are achieved in a carbonyl reduction part in the most critical step, and the method for preparing the largely-demanded glutaric acid with the simple four-step method is developed. According to the method, the glutaric acid with the high yield is synthesized with the method for the first time, the yields of all steps are 92%, 78.6%, 90% and 85% in sequence, and the total yield is 55.32%; the method has broad prospects in synthetic application of compound library establishment.

Owner:TIANJIN UNIV OF SCI & TECH

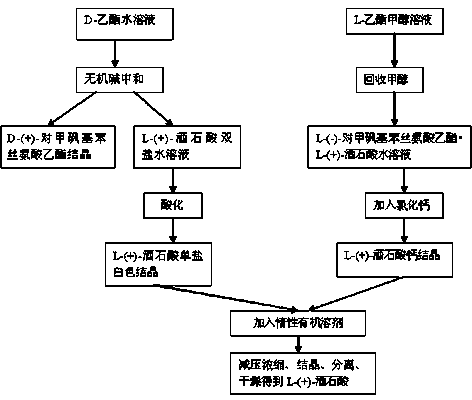

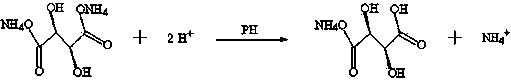

Method for recycling and reusing L-(+)-tartaric acid in production of D-p-methyl sulfone phenyl ethyl serinate

ActiveCN104355990AMild reaction conditionsEasy to controlPreparation from carboxylic acid saltsOrganic compound preparationCalcium tartrateChiral resolution

The invention discloses a method for recycling and reusing L-(+)-tartaric acid in production of D-p-methyl sulfone phenyl ethyl serinate. The method comprises the following steps: (1), a L-(+)-calcium tartrate dihydrate crystal is recovered from L-ethyl ester mother liquor; (2), an L-(+)-tartaric acid double brine solution is recovered from D-p-methyl sulfone phenyl ethyl serinate mother liquor; (3), L-(+)-tartaric acid double hydrochlorination is performed; (4), L-(+)-tartaric acid is recovered through L-(+)-tartaric acid single hydrochlorination; and (5), processes of vacuum concentration, crystallization, separation, drying and the like are performed. An insert organic solvent is used for replacing a conventional water phase method to recover L-(+)-tartaric acid, the possibility of side reaction is avoided, the purity and specific rotation of a product can both reach the raw material quality standard, and L-(+)-tartaric acid can be directly and circularly applied to chiral resolution of D-p-methyl sulfone phenyl ethyl serinate. Different recovery processing technologies are adopted for different mother liquor of two components in the production process of D-p-methyl sulfone phenyl ethyl serinate, the product quality is improved remarkably, the whole recovery condition is mild, and the operation is simpler and easy to control.

Owner:兰州鑫隆泰生物科技有限公司

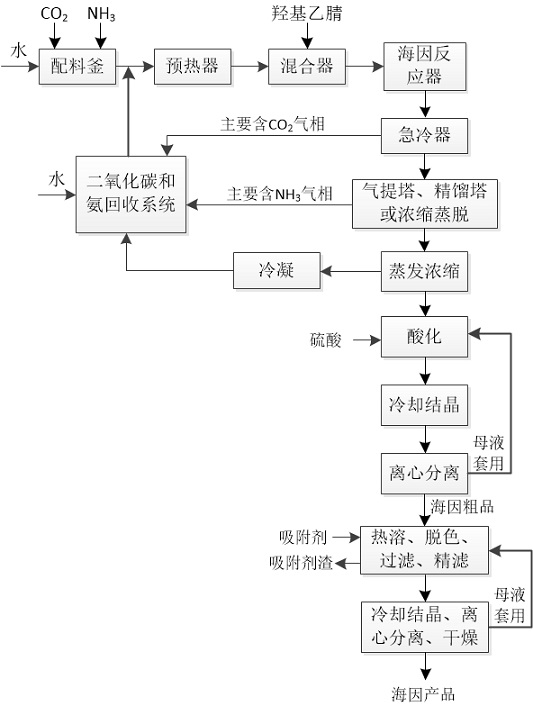

Clean production process for continuously synthesizing hydantoin

A clean production process for continuously synthesizing hydantoin comprises the following steps: preheating a carbon dioxide ammonia water solution prepared from an ammonia source, a carbon source and water, mixing with hydroxyacetonitrile, continuously synthesizing, carrying out reduced pressure flash evaporation, carrying out gas stripping, concentrating, acidifying, crystallizing, separating to obtain a crude hydantoin product, and refining to obtain the high-purity hydantoin product. A carbon dioxide and ammonia recovery system sequentially absorbs the gas phase separated by gas strippingand reduced pressure flash evaporation to obtain a carbon dioxide ammonia water solution, and the carbon dioxide ammonia water solution returns to a reaction system. By increasing the amount of carbon dioxide in the ratio, side reactions generating iminodiacetonitrile, nitrilotriacetonitrile and glycine are restrained, and the hydantoin yield is increased; and through timely release of each gas phase in the system and reasonable arrangement of a recovery sequence, the difficulty of recycling carbon dioxide and ammonia in the system is reduced, the loss of carbon dioxide and ammonia is reduced, zero discharge of wastewater and waste liquid can be realized, and the method is an environment-friendly and clean hydantoin production process method.

Owner:龙智

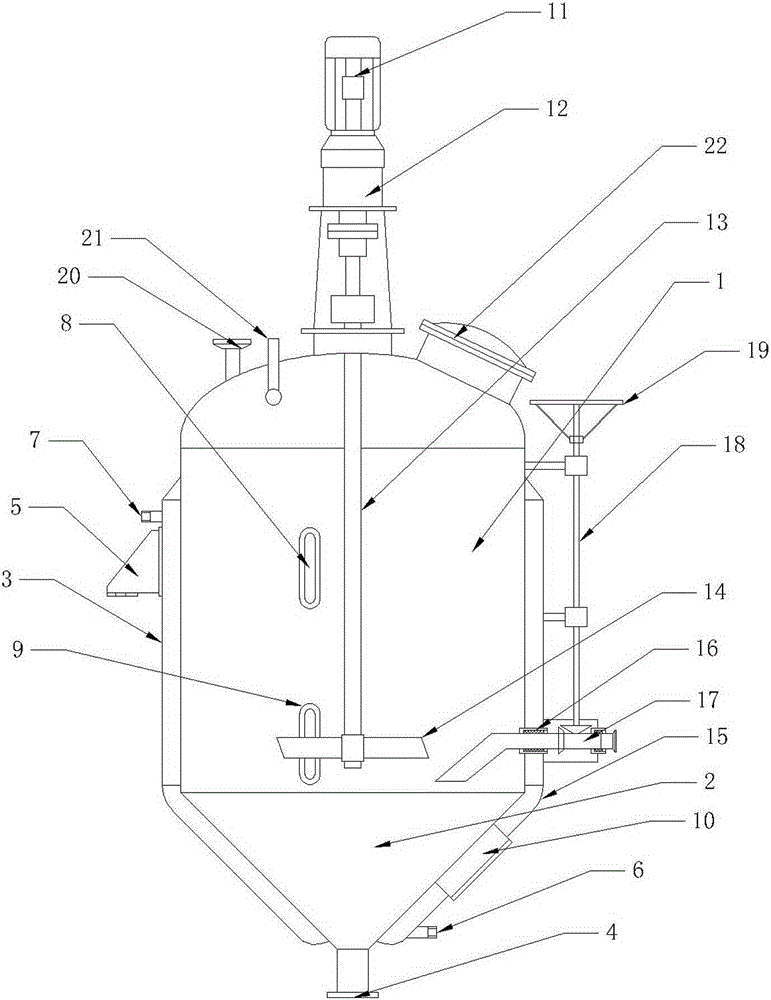

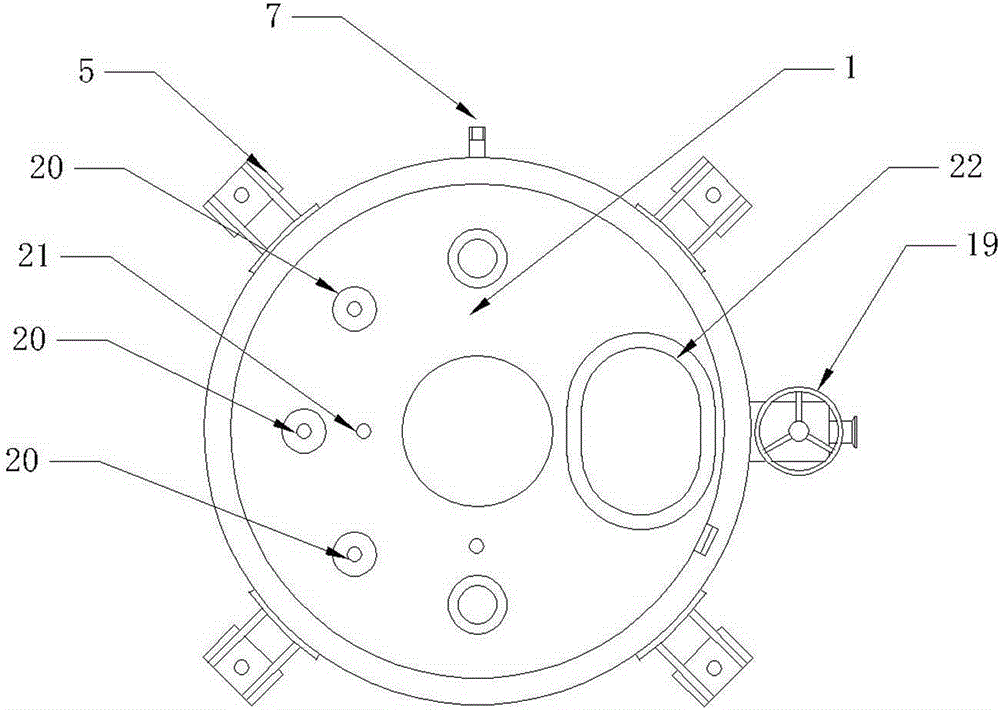

Alcohol precipitation tank

InactiveCN106474781AImprove cooling effectRecyclingSedimentation settling tanksWater dischargeAlcohol

The invention relates to an alcohol precipitation tank, which comprises a cylinder body and a cone body, wherein the cylinder body and the cone body are connected in a sealed manner to form an alcohol precipitation space, the cylinder body and the cone body are fixed through a jacket, the lower portion of the cone body is provided with a residue discharging connection pipe, the cylinder body is fixed through a bracket fixed on the cylinder body, a stirring device is arranged in the cylinder body, the cylinder body and the cone body are provided with an observation device for observing the condition of the alcohol precipitation space, the cylinder body and the cone body are provided with a cooling water pipe, the cooling water inlet of the cooling water pipe is arranged on the lower portion of the cone body, the cooling water discharging port of the cooling water pipe is arranged on the upper portion of the cylinder body, the cooling water pipe is spirally wound in the cone body and the cylinder body, and the water inlet and the water discharging port of the cooling water pipe are connected to a cooling water circulation system. The alcohol precipitation tank of the present invention can utilize heat during the use and further has the advantage of water resource saving.

Owner:衡阳春天医药化工设备有限公司

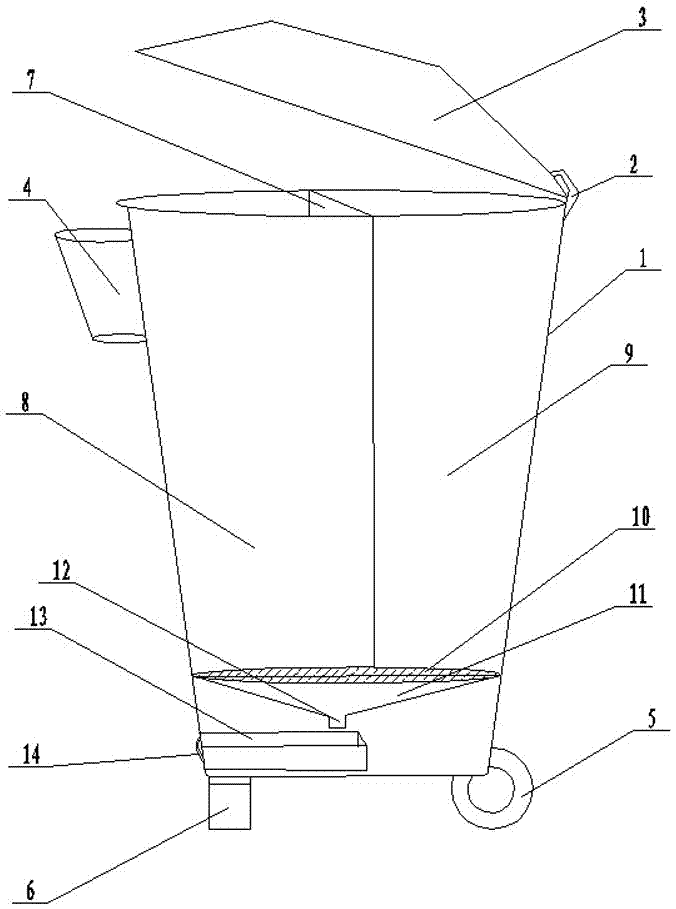

Multifunctional rubbish bin

InactiveCN107539677AReduce the degree of rancidityRecycling clearRefuse receptaclesEngineeringWater reservoir

The invention discloses a multifunctional trash can with good recycling effect, which comprises: a barrel body, a barrel cover is arranged on one side of the upper end of the barrel body through hinge rotation, and a battery is arranged on the other side of the upper end of the barrel body The recovery box is provided with rollers on one side of the lower end of the barrel, and supporting feet are arranged on the other side of the lower end of the barrel, and a recyclable garbage box and an unrecyclable garbage box are arranged in the barrel through a vertical partition. To recycle the garbage box, a filter screen is arranged in the barrel at the lower end of the vertical partition, and a conical funnel is connected in the barrel at the lower end of the filter screen, and a water hole is arranged on the conical funnel A water storage drawer is slidably arranged in the barrel at the lower end of the water hole, and a handle is arranged on the water storage drawer.

Owner:沈嘉冰

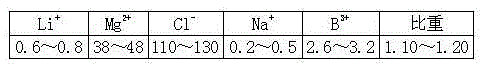

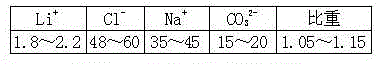

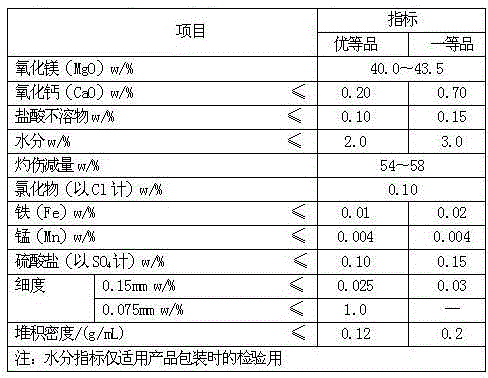

A method of recovering and utilizing salt lake lithium extraction mother liquor and producing a by-product basic magnesium carbonate

ActiveCN104030322AReal recyclingRecyclingMagnesium carbonatesLithium carbonates/bicarbonatesHydration reactionLithium carbonate

The invention provides a method of recovering and utilizing salt lake lithium extraction mother liquor and producing a by-product basic magnesium carbonate. The method includes: mixing first lithium carbonate mother liquor and second lithium carbonate mother liquor according to a certain ratio, reacting, filtering, washing, and drying to obtain industrial basic magnesium carbonate hydrate; and removing carbonate ion residue in the mother liquor after reaction with industrial hydrochloric acid having a concentration of 31%, mixing the mother liquor after the carbonate ion removal with brine that is a raw material for producing lithium carbonate according to a ratio, and performing natural crystallization and sodium precipitation for 10-20 days. After the natural crystallization and sodium precipitation, the content of Li+ is 5-6 g / L and the content of Na+ is smaller than 2.5 g / L, thus reaching requirements for using in workshops. By the manner, the lithium carbonate lithium extraction mother liquor is prepared into the raw material brine for production of the lithium carbonate. The method is simple in process and low in cost, and effectively increases the comprehensive utilization rate of the lithium resource.

Owner:QINGHAI LITHIUM IND

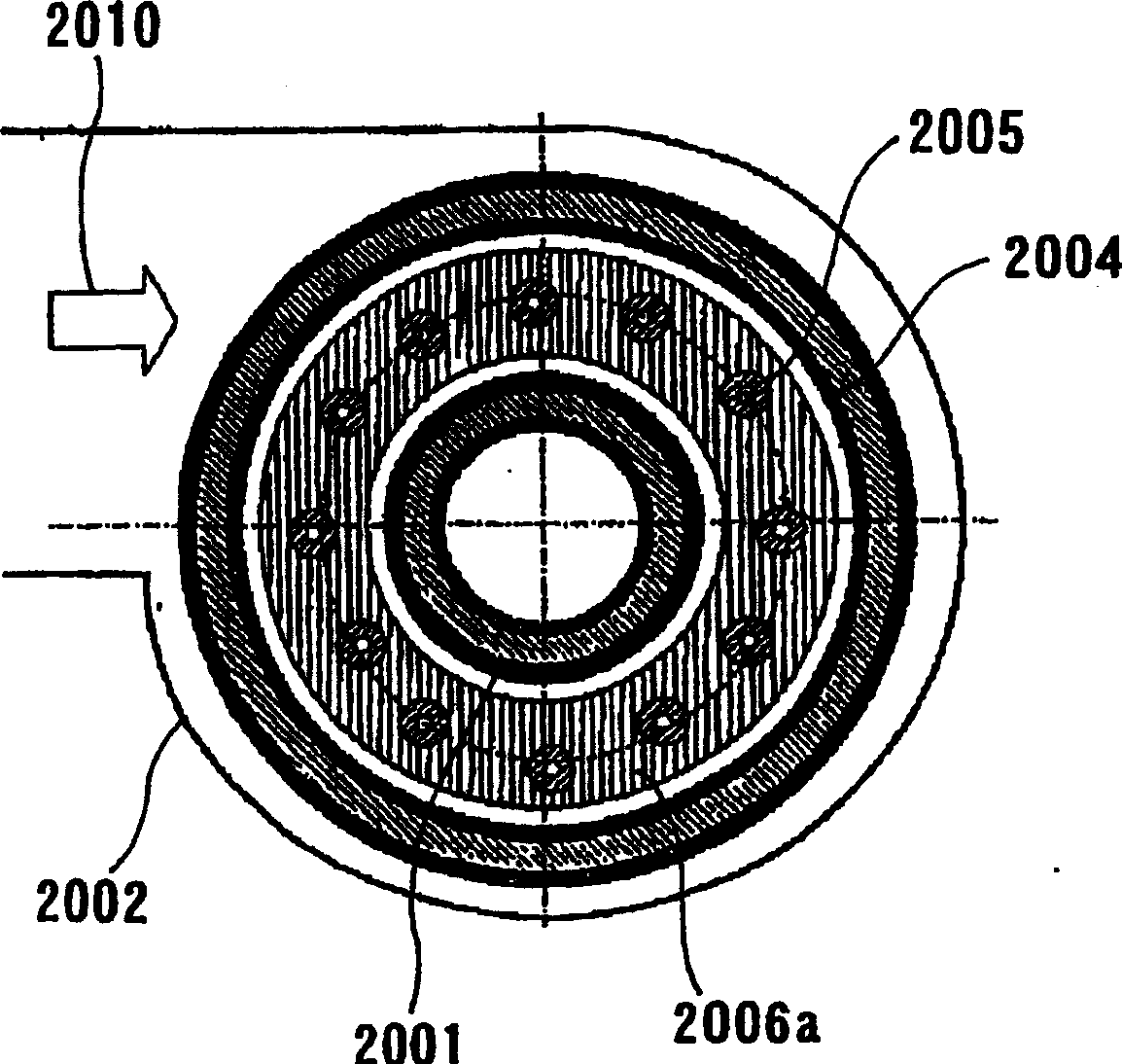

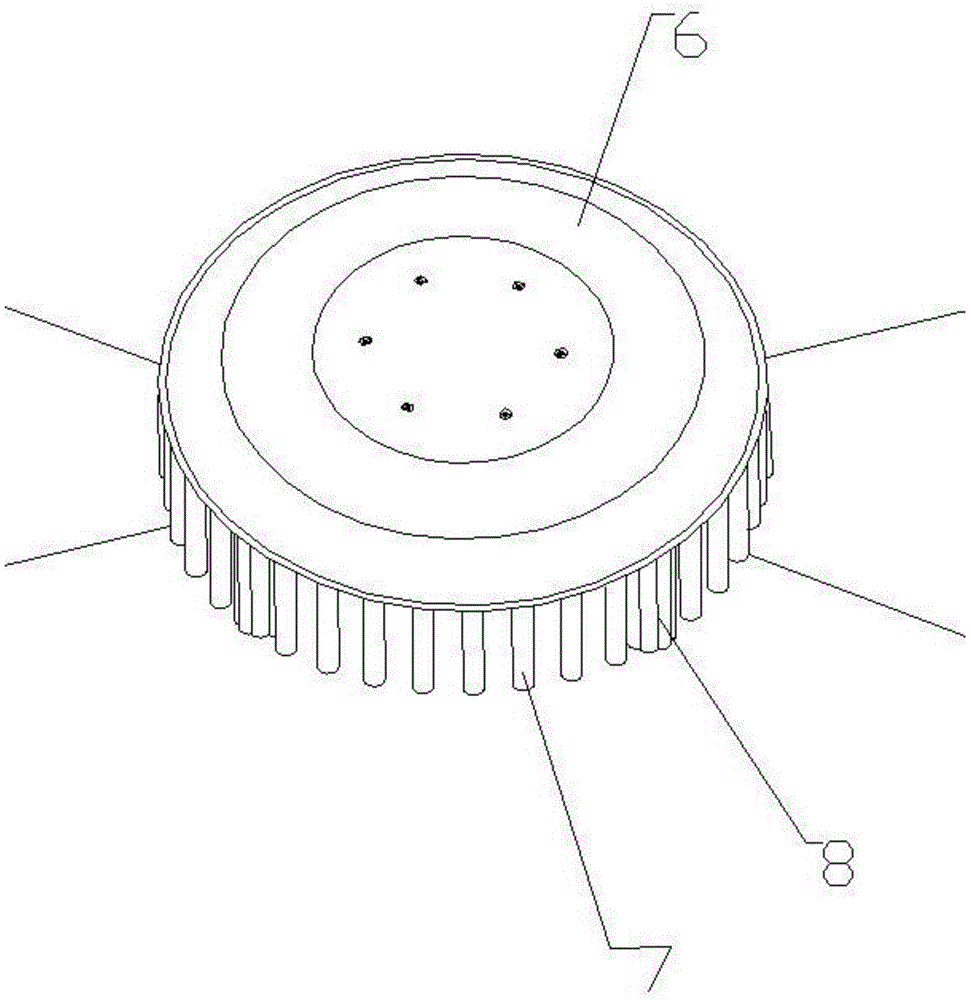

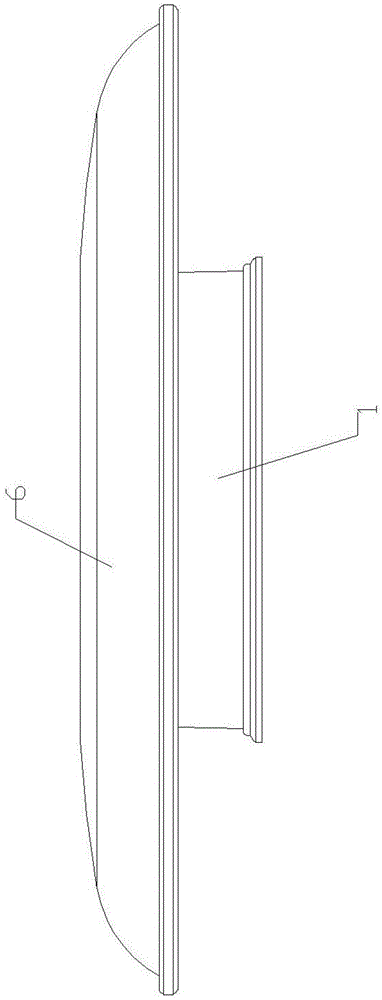

Fabric shade unfolding assisting mechanism for full-automatic automobile shade

ActiveCN104149588AAvoid residueAvoid accumulationRemovable external protective coveringsEngineeringPinion

The invention discloses a fabric shade unfolding assisting mechanism of a full-automatic automobile shade. The fabric shade unfolding assisting mechanism of the full-automatic automobile shade comprises an inner gear ring (2), multiple pinions (4) meshed with the inner gear ring (2), an outer gear ring (5) meshed with all the pinions (4), a top cover (6) movably combined with the outer gear ring (5) in a sleeved mode, and a plurality of brush strips (7) which are arranged on the edge of the top cover (6) in the circumferential direction and are used for smoothening the fabric shade so as to enable the fabric shade to be unfolded or folded smoothly, wherein a first one-way rotating structure is arranged on the outer gear ring (5) and the top cover (6), the outer gear ring (5) drives the top cover (6) to rotate in one direction through the one-way rotating structure when the fabric shade is unfolded, a second one-way rotating structure is arranged on the inner gear ring (2) and the top cover (6), the inner gear ring (2) drives the top cover (6) to rotate in one direction through the second one-way rotating structure when the fabric shade is folded, and the outer gear ring (5) and the inner gear ring (2) drive the top cover (6) to rotate in the same direction. The fabric shade unfolding assisting mechanism of the full-automatic automobile shade can assist in smooth unfolding and folding of the fabric shade, and impurities on the fabric shade can be removed when the fabric shade is folded.

Owner:胡建明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com