Patents

Literature

919results about "Preparation from carboxylic acid salts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

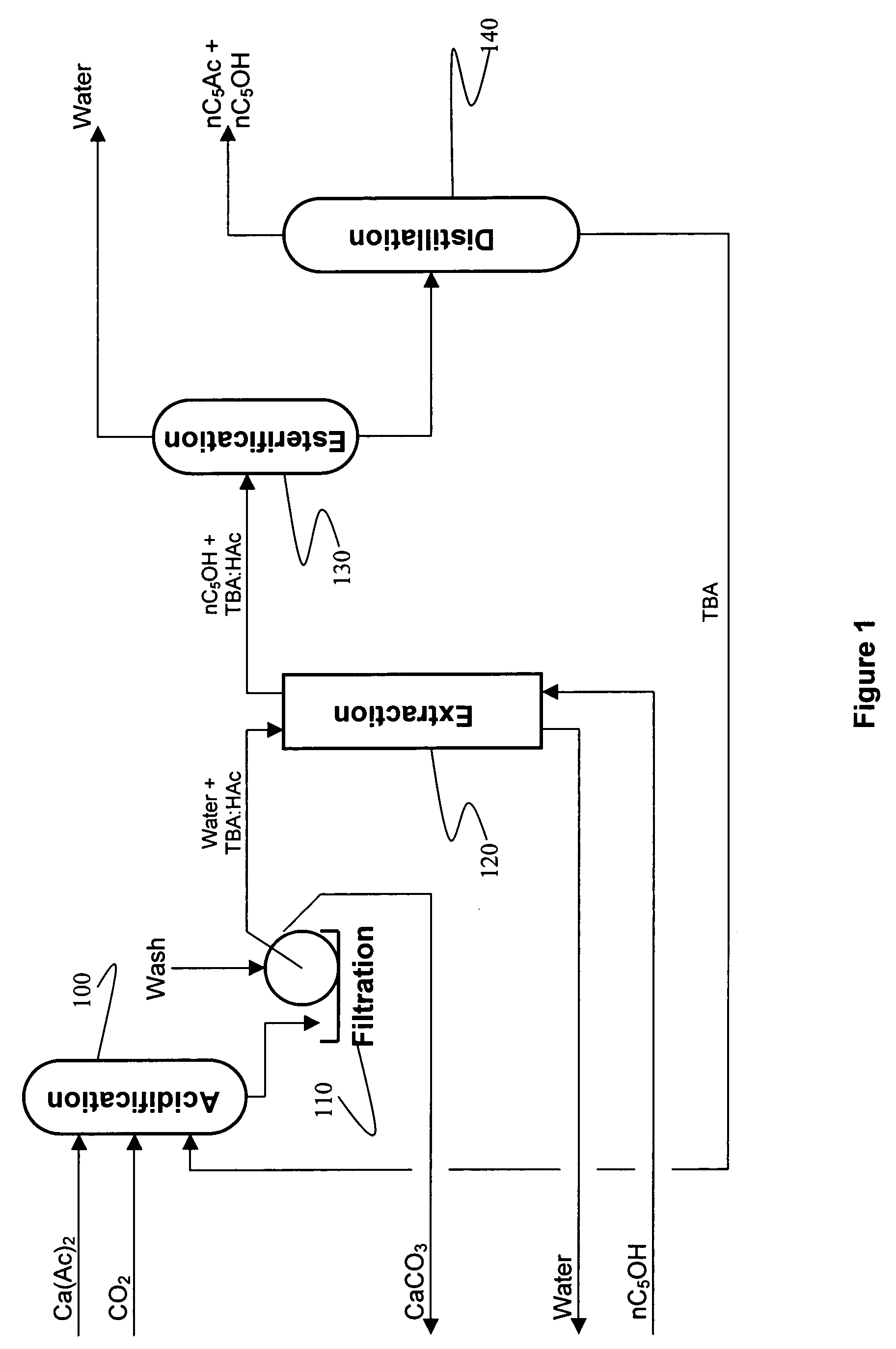

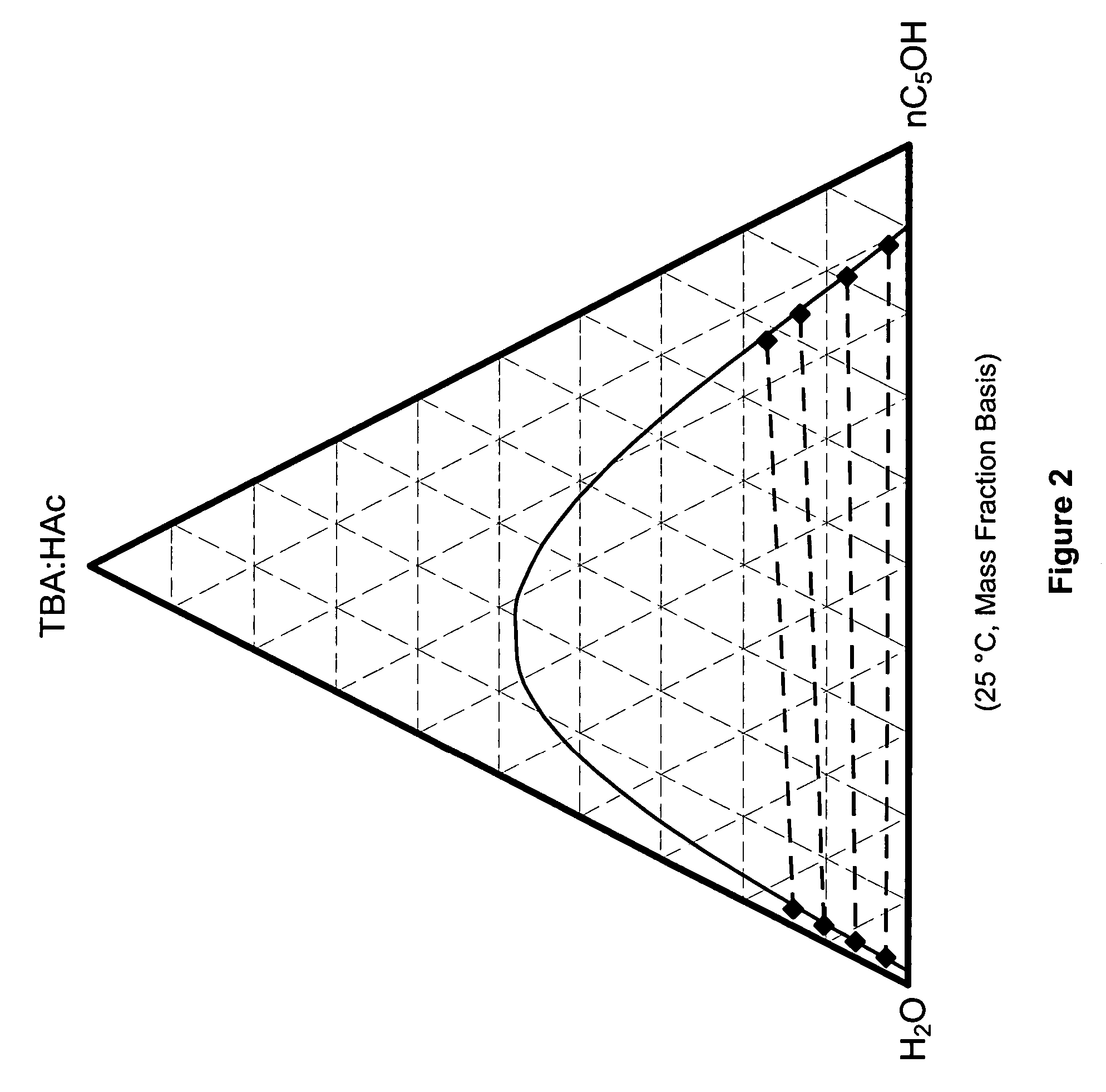

Recovery of organic acids

InactiveUS20090281354A1Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidReactive distillation

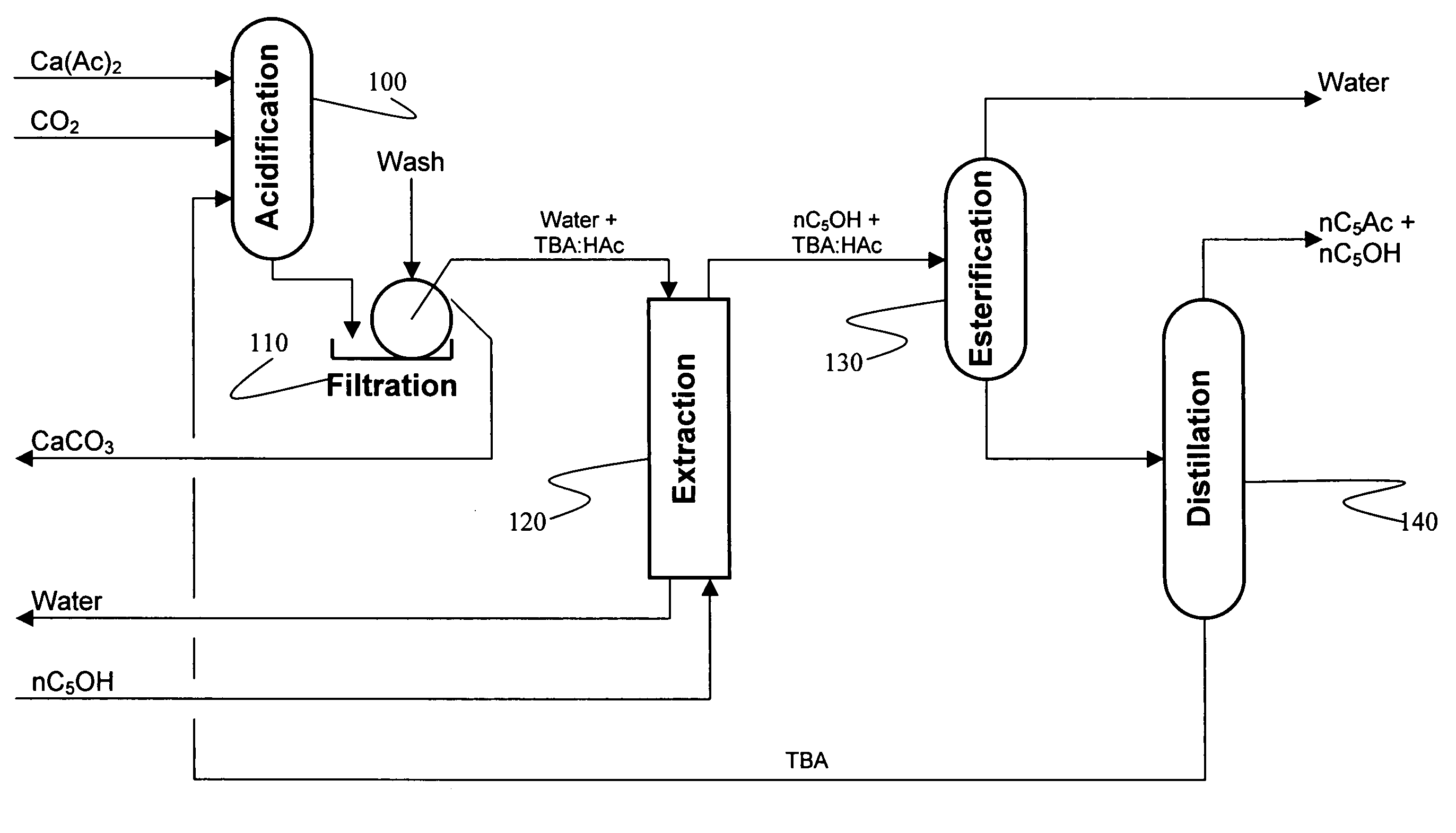

A method is disclosed for the recovery of an organic acid from a dilute salt solution in which the cation of the salt forms an insoluble carbonate salt. An amine and CO2 are introduced to the solution to form the insoluble carbonate salt and a complex between the acid and the amine. The acid / amine complex is thermally dissociated, or “cracked”, in the presence of a water immiscible solvent in which the amine is selectively soluble and in which the acid is not appreciably soluble. The organic acid may then be recovered from the water by any suitable means such as distillation, reactive distillation, extraction, or reactive extraction.

Owner:ZEACHEM

Recovery of organic acids

InactiveUS7601865B2Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidAlcohol

Owner:ZEACHEM

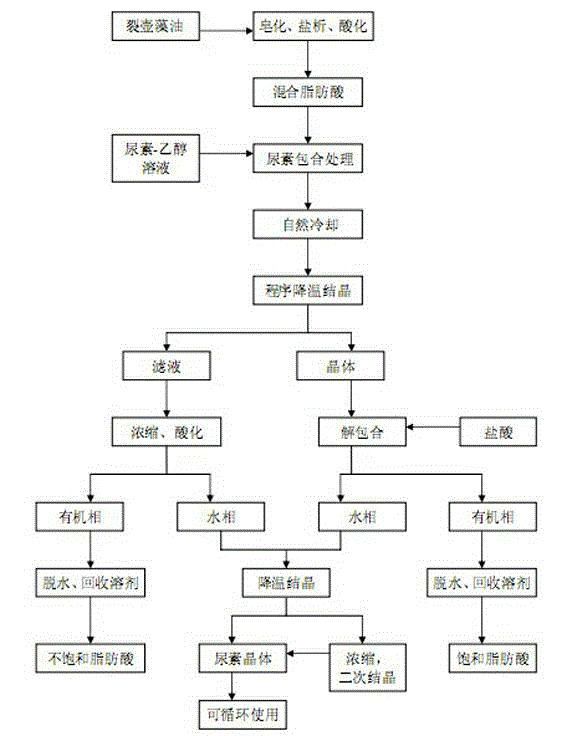

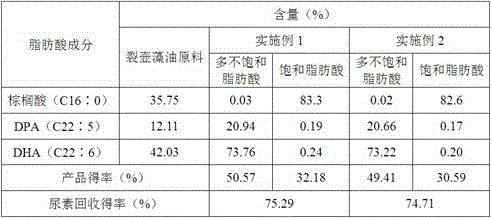

Method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil

ActiveCN102746947AIncrease contentPrevent oxidationPreparation from carboxylic acid saltsFatty acids production/refiningMixed fatty acidSalting out

The invention discloses a method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil. The method includes: firstly, saponifying, salting out and acidizing the schizochytrium limacinum oil under protection of nitrogen so as to obtain free mixed fatty acid, and separating the fatty acid different in degree of saturation by urea adduction fractionation so as to obtain filtrate and solids after filtration; concentrating and extracting the filtrate so as to obtain polyunsaturated fatty acid rich in DHA and DPA (docosapentenoic acid); and allowing the solids to leach by means of acidolysis, extracting the saturated fatty acid (mainly comprising palmic acid) and recovering urea, wherein the urea is recyclable. The method is performedat a low temperature, oxidization of the unsaturated fatty acid is avoided, biological activity and nutrition of the unsaturated fatty acid are kept intact, and the problem of residual solvent is avoided. Products are high in purity, and the obtained polyunsaturated fatty acid mainly comprises the DHA and the DPA and hardly comprises EPA (eicosapentaenoic acid), the content of the DHA and the DPAis higher than 93%, and the content of the palmic acid of the saturated fatty acid is higher than 82%.

Owner:福建华尔康生物科技有限公司

Process for converting a hydroxycarboxylic acid, or salts thereof, to an unsaturated carboxylic acid and/or its esters

ActiveUS20090076297A1Preparation from carboxylic acid saltsOrganic compound preparationAmmonium CationIon-exchange resin

A process for converting a salt of a hydroxycarboxylic acid to an unsaturated carboxylic acid, or esters thereof. The process involves converting an ammonium salt of a hydroxycarboxylic acid in aqueous solution to a corresponding hydroxycarboxylic acid and ammonium cation in aqueous solution; and separating the ammonium cation from the aqueous solution, leaving the hydroxycarboxylic acid in aqueous solution. The converting and separating steps may be accomplished by employing a hydrophobic acid or an acid ion exchange resin, each of which must have an acid dissociation constant, i.e., pKa, at least 0.5 less that that of the salt of the hydroxycarboxylic acid. Where a hydrophobic acid is used, it must be immiscible in water, and its salt must also be immiscible in water, and the resulting multi-phase solution comprises an aqueous phase comprising the corresponding hydroxycarboxylic acid, as well as a non-aqueous phase comprising a neutralized acid. Alternatively, where the ion exchange resin is used, the aqueous solution of the ammonium salt of a hydroxycarboxylic acid is contacted with the resin, thereby converting the salt to a hydroxycarboxylic acid and capturing the ammonium cations on the resin. In either case, the aqueous solution is treated, such as by heating, to separate and recover the hydroxycarboxylic acid. The non-aqueous phase or resin is treated to separate and recover ammonia useful for preparing additional ammonium salt of a hydroxycarboxylic acid.

Owner:ROHM & HAAS CO

Process for producing acetic acid

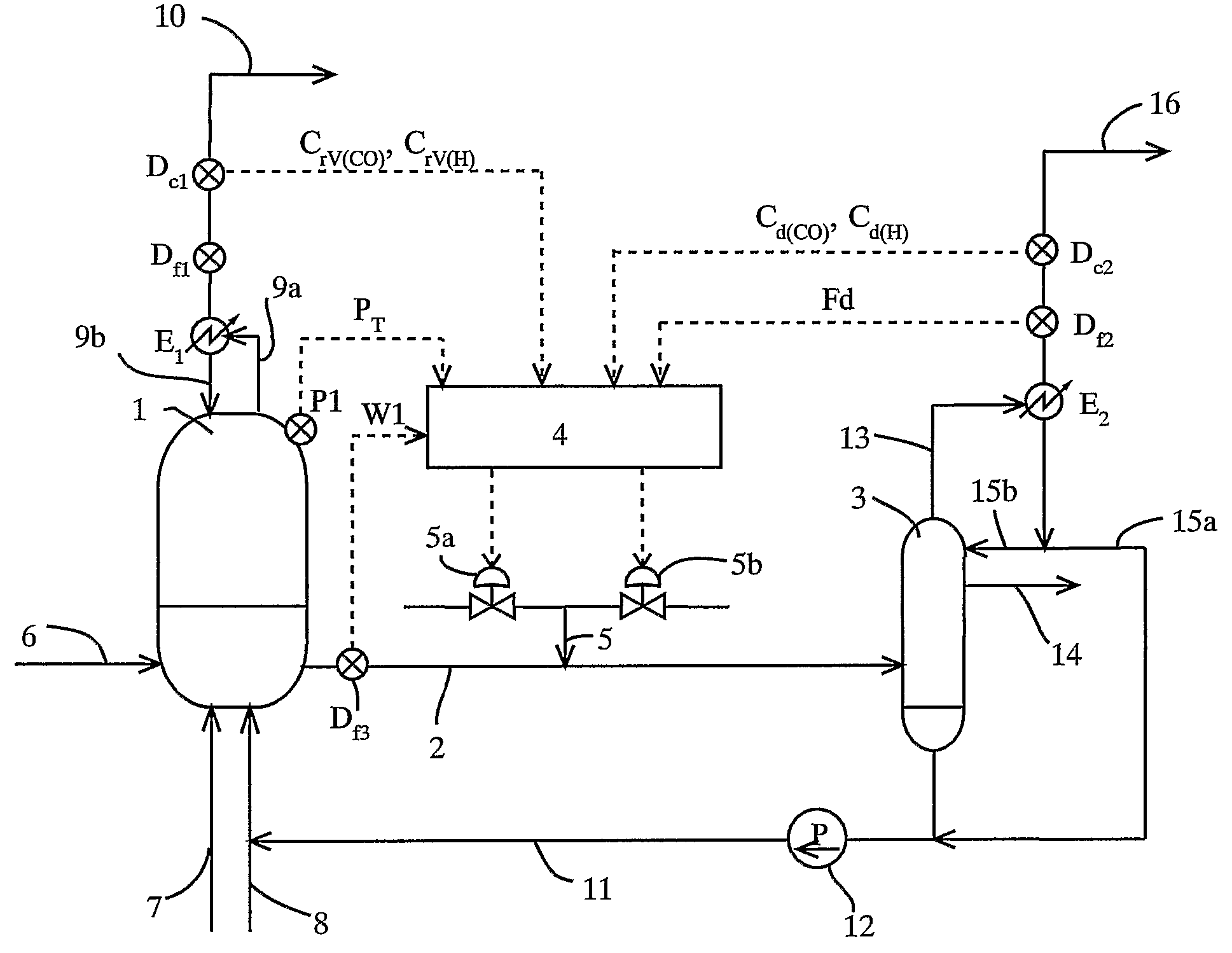

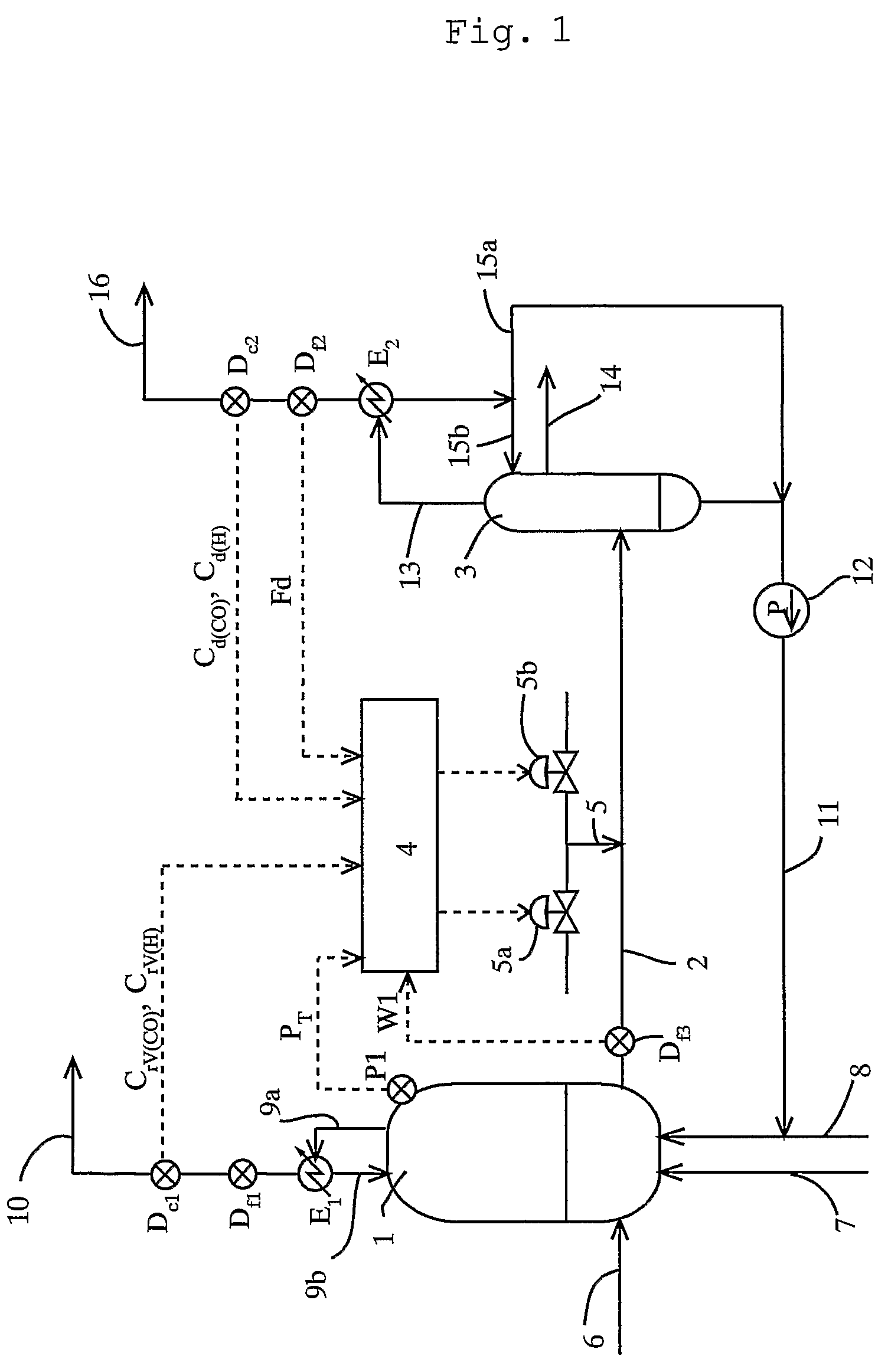

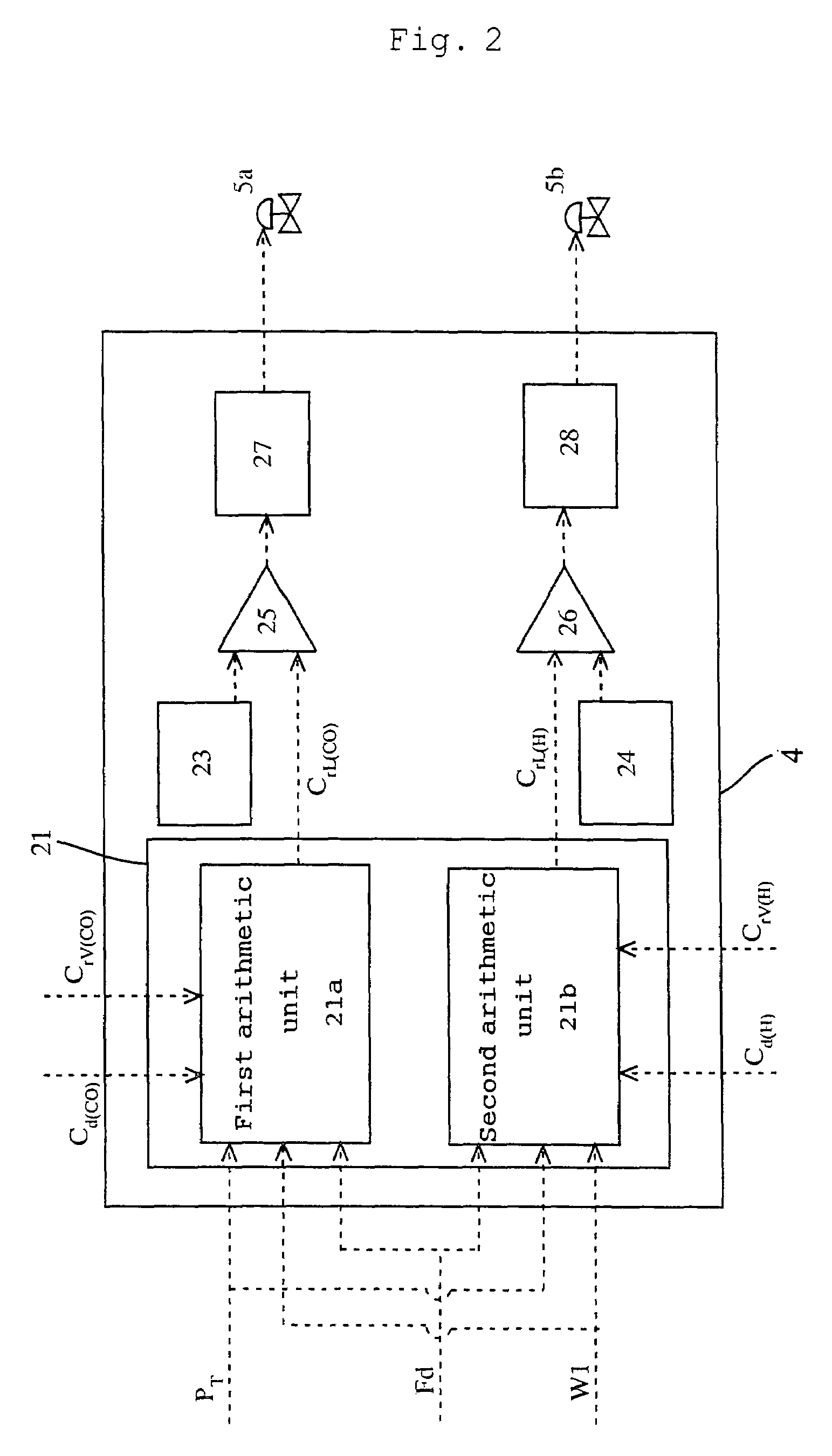

ActiveUS7476761B2Decrease in reaction rate can be inhibitedIncrease hydrogen partial pressurePreparation from carboxylic acid saltsOrganic compound preparationCarbon numberReaction rate

A process for producing a carboxylic acid comprises allowing an alcohol having a carbon number of “n” to continuously react with carbon monoxide in the presence of a carbonylation catalyst system, and a limited amount of water, continuously withdrawing the reaction mixture from the reaction system 1, introducing the withdrawn reaction mixture into a distillation step (distillation columns 3a and 3b), and separating a higher-boiling component and a lower-boiling component containing a carboxylic acid having a carbon number of “n+1”, respectively. In the process, the amount of carbon monoxide and / or hydrogen contained in a liquid phase of the reaction system is adjusted to at least one of the following conditions (i) and (ii): (i) the amount of carbon monoxide relative to 1 kilogram of the liquid phase by weight is at least 2 mmol per 1 MPa of carbon monoxide partial pressure of the reaction system, and (ii) the amount of hydrogen relative to 1 kilogram of the liquid phase by weight is at least 50 mmol per 1 MPa of hydrogen partial pressure of the reaction system. Such a process inhibits deactivation of a metal catalyst and deterioration in a reaction rate, and decreases formation of by-products in producing a carboxylic acid under a low water content.

Owner:DAICEL CHEM IND LTD

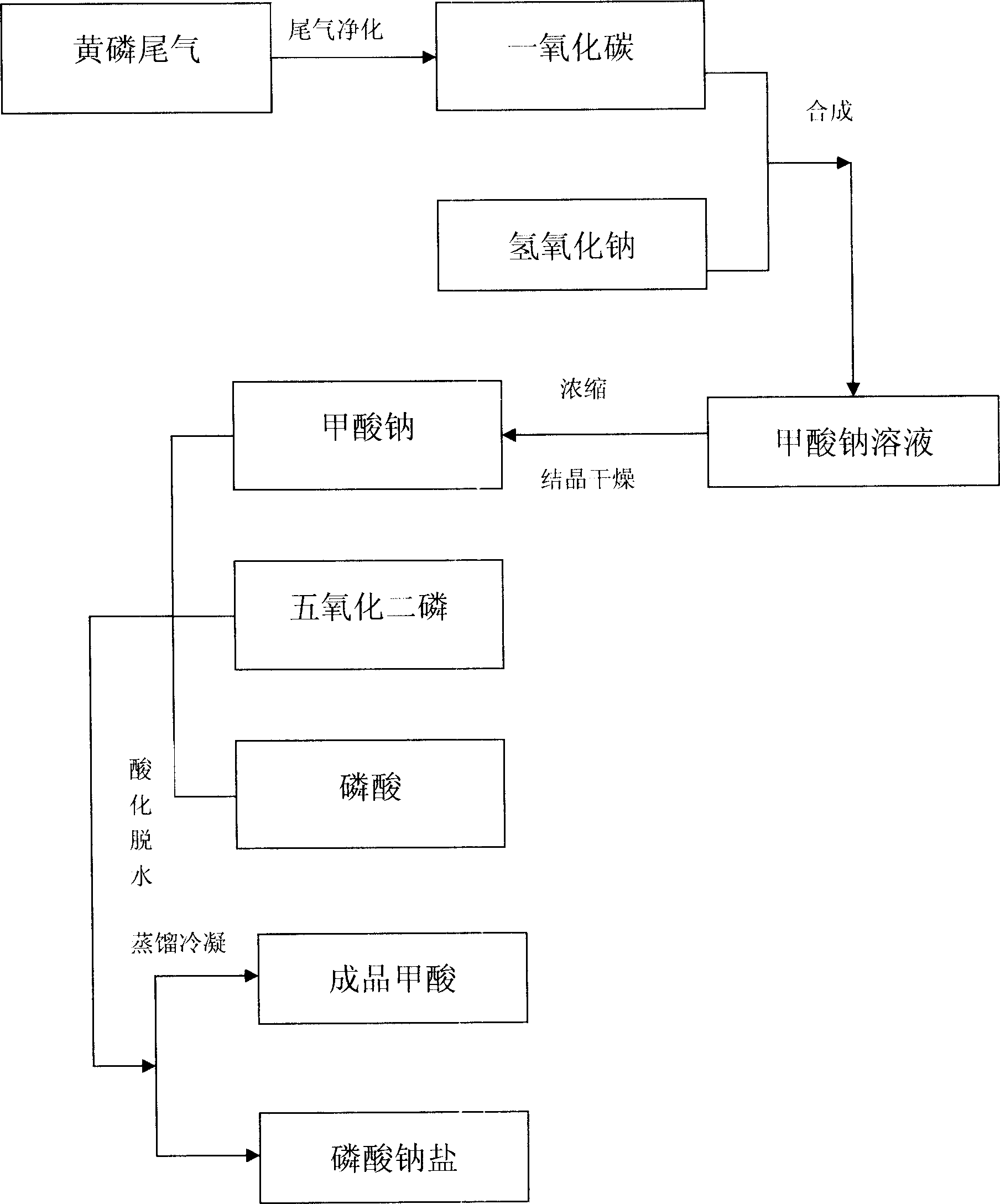

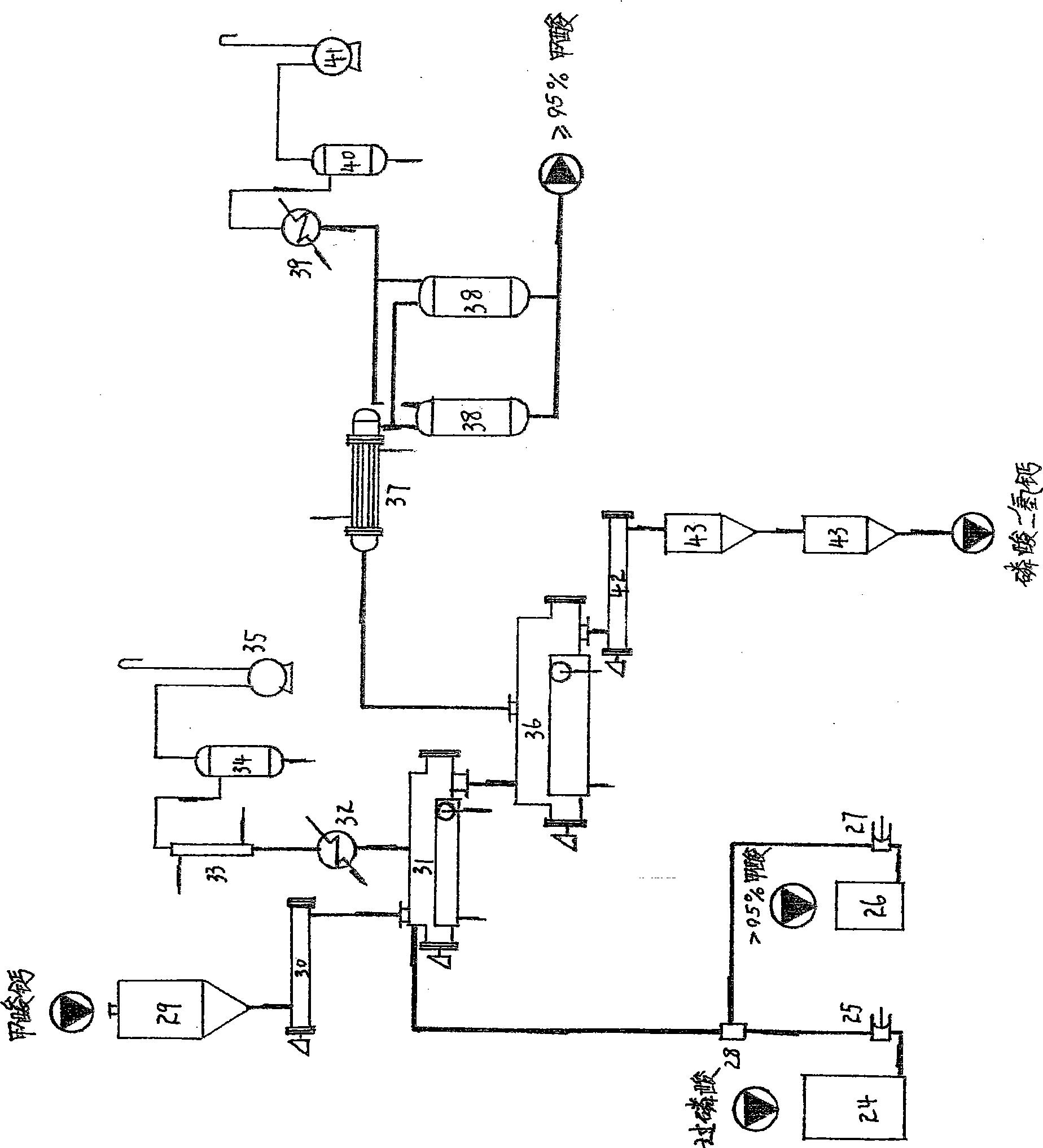

Method for producing formic acid through phosphoric acid and sodium formate

InactiveCN1915954AImprove utilizationEmission reductionPreparation from carboxylic acid saltsPhosphoric acidFormic acid

This invention discloses a method for preparing formic acid from phosphoric acid and sodium formate. The method comprises: reacting CO produced from yellow phosphorus manufacture with caustic soda to obtain sodium formate, then reacting with phosphoric acid, dehydrating with P2O5, and distilling to obtain formic acid. The method can reduce CO2 emission, thus is environmentally friendly. Besides, the method can lower the cost of yellow phosphorus and formic acid manufacture.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Method for the production of free carboxylic acids

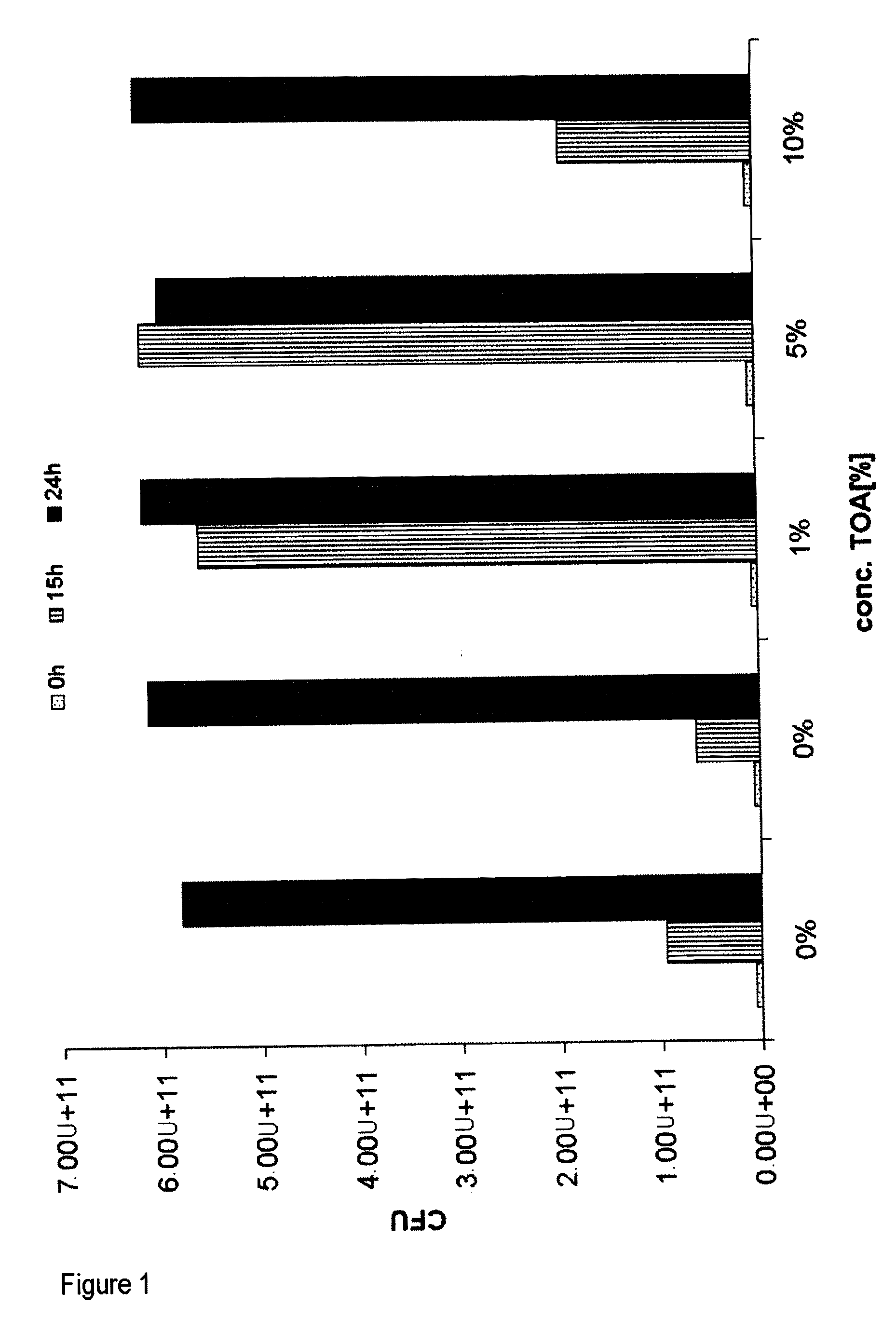

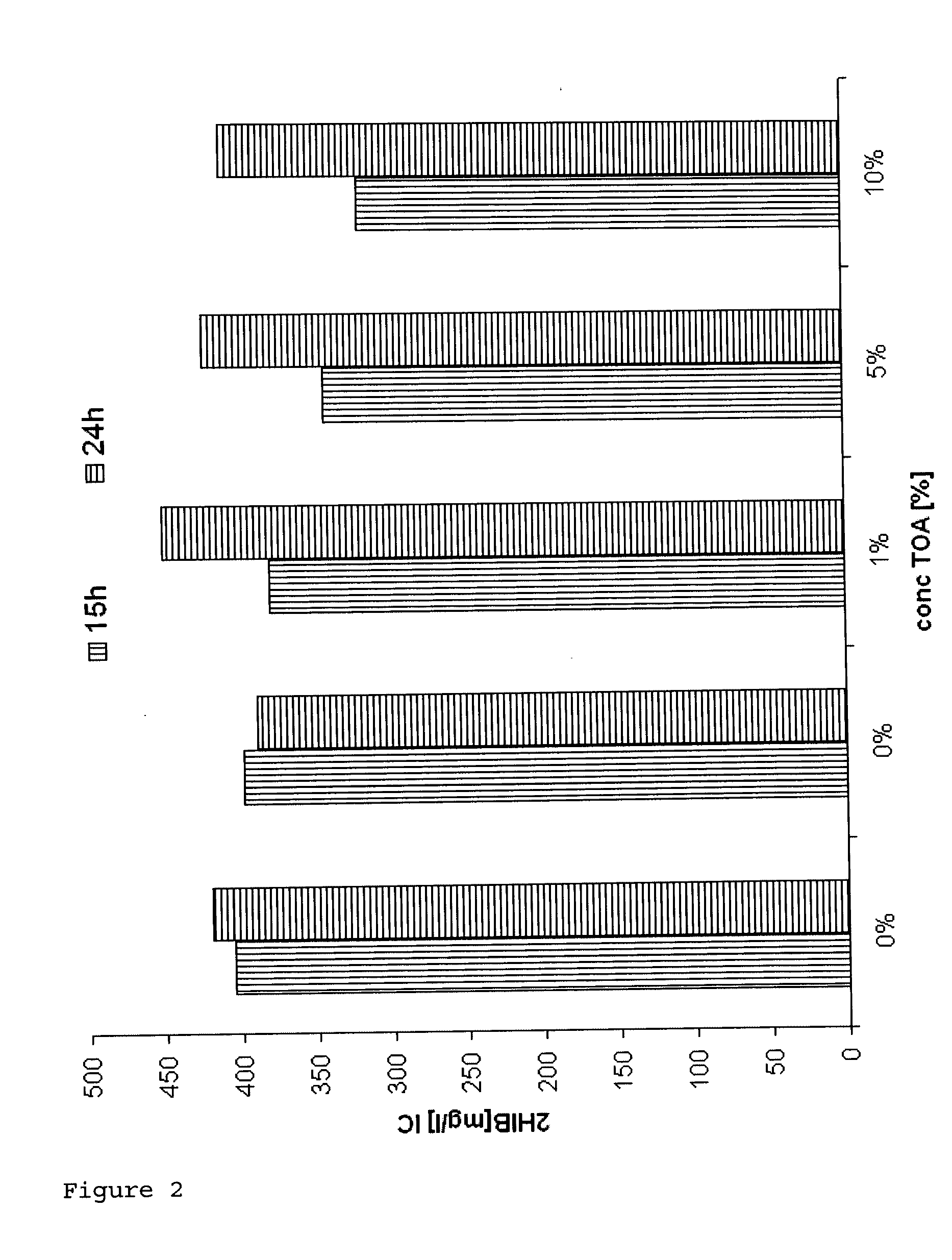

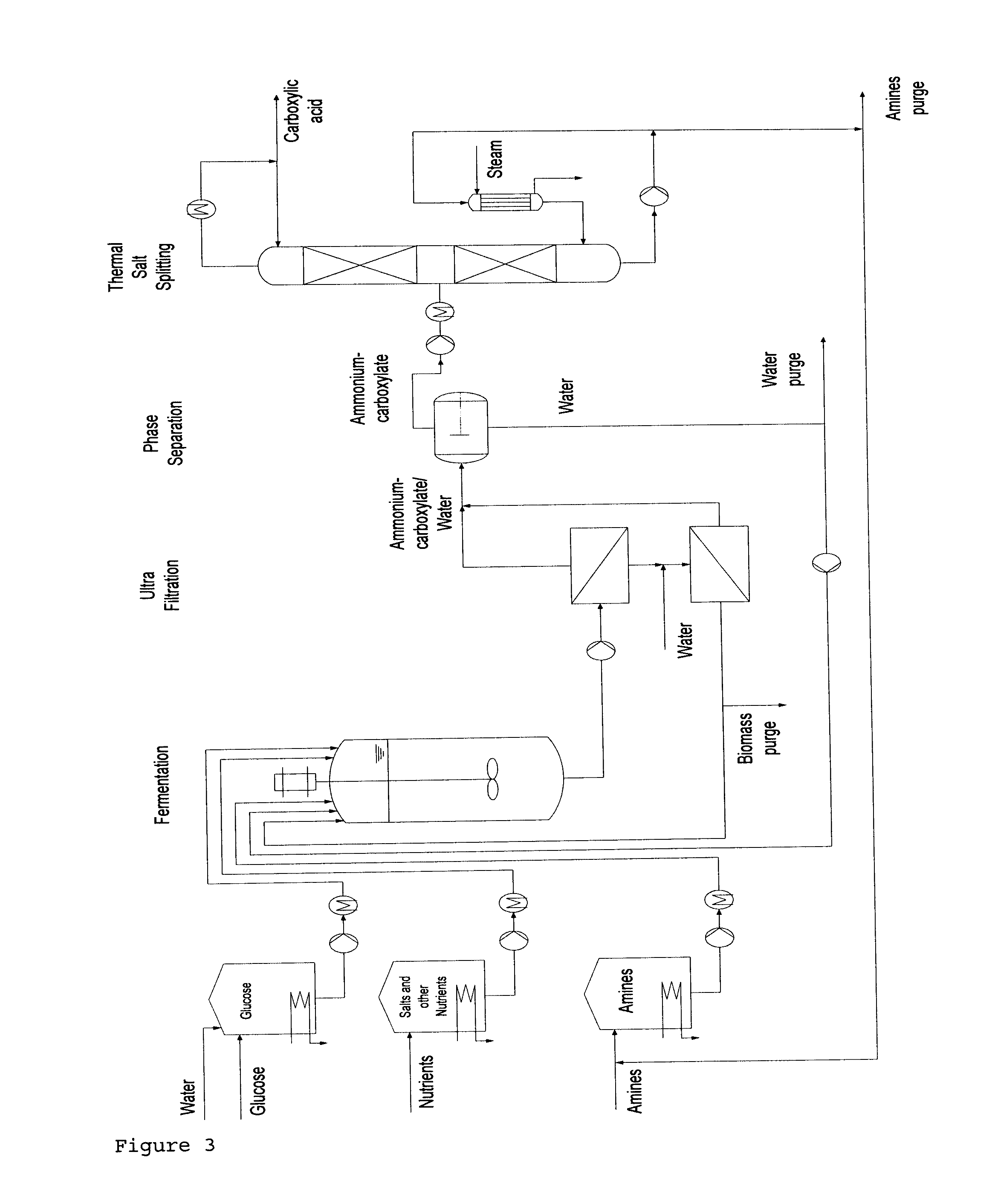

InactiveUS8703451B2Substance reductionLow viscosityPreparation from carboxylic acid saltsOrganic compound preparationBiological cellWater insoluble

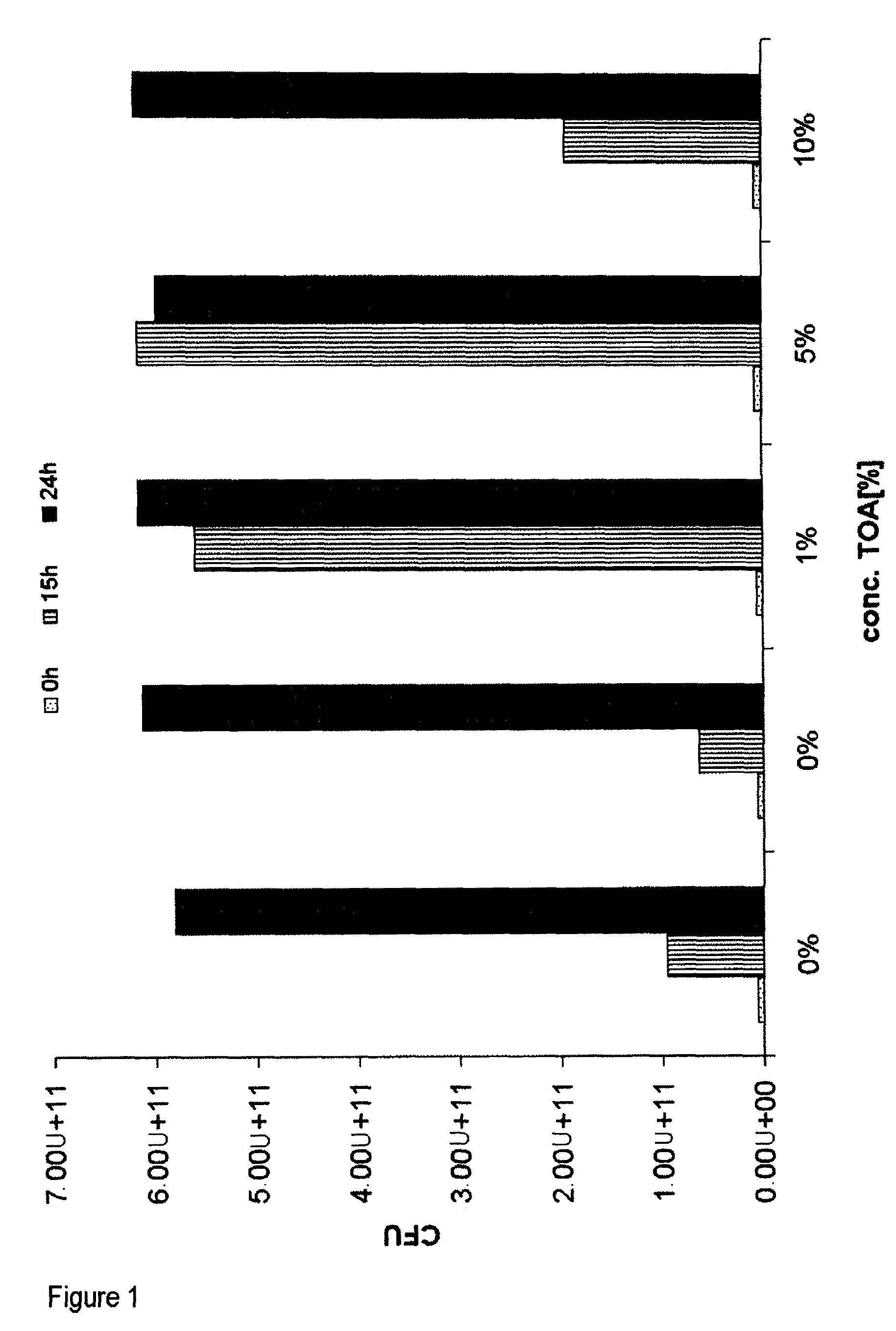

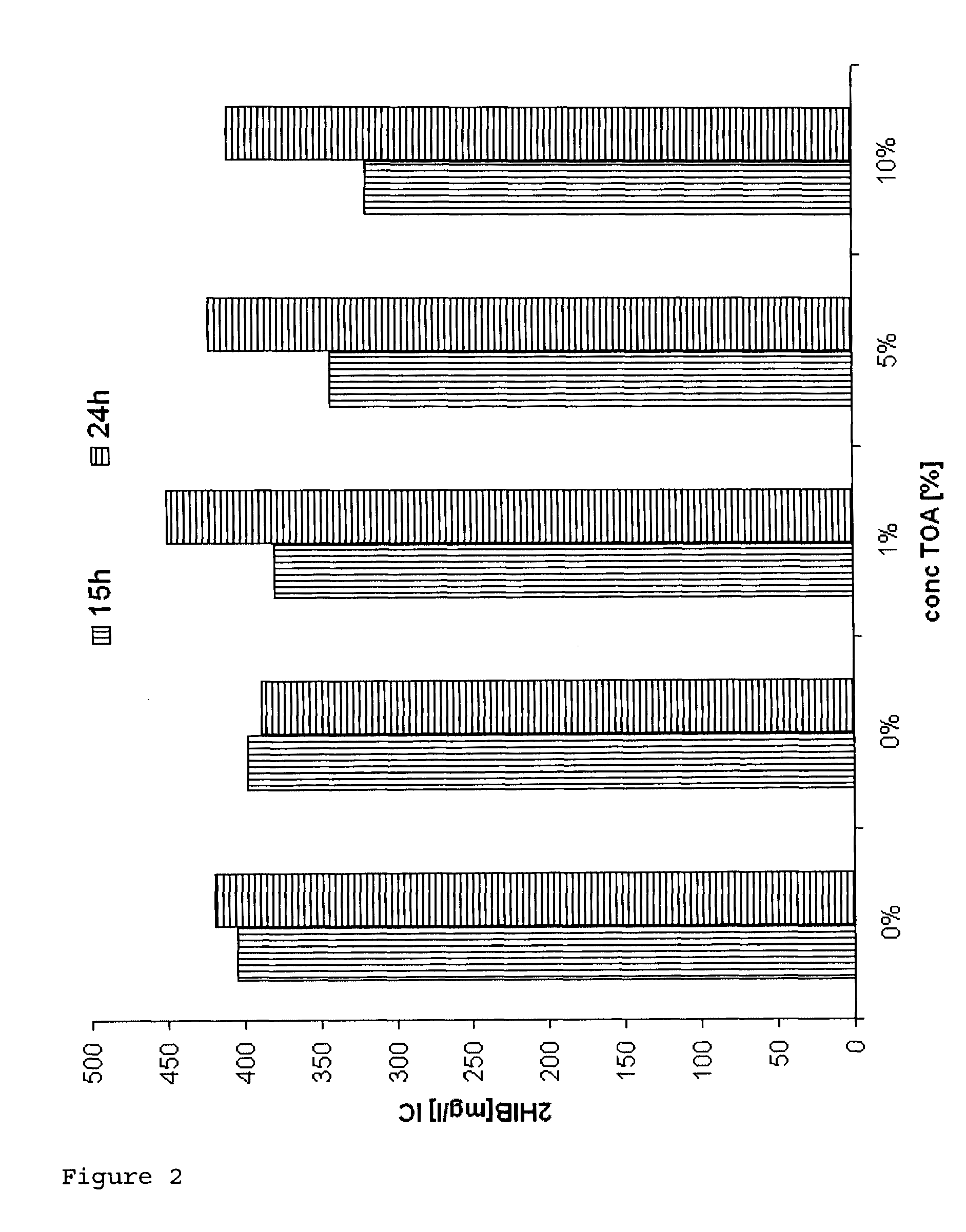

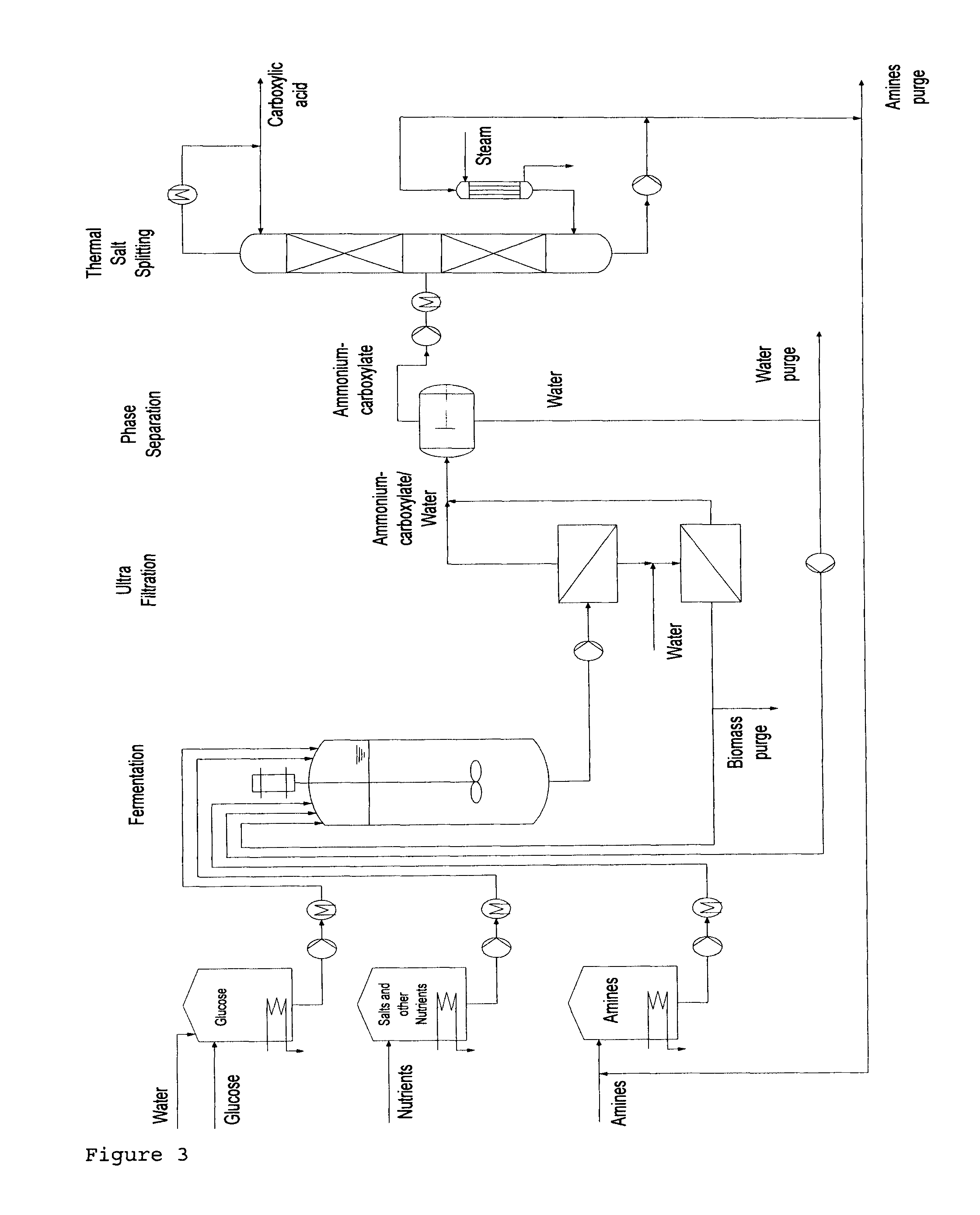

A process for the preparation of free carboxylic acids including: A) preparation of carboxylic acid by a biological cell located in an aqueous medium with addition of an amine of formula (I)where R1, R2 and R3, independently of one another, are identical or different, branched or unbranched, optionally substituted hydrocarbon radicals or H; B) for cases where the added amine A) is water-soluble, addition of a water-insoluble amine of formula (I), where, in A) or B), a multiphase system is obtained and the corresponding ammonium carboxylate is formed from the water-insoluble amine and the carboxylic acid; C) removal of the water-insoluble phase; and D) heating of the water-insoluble phase with release of free carboxylic acid.

Owner:EVONIK ROEHM GMBH

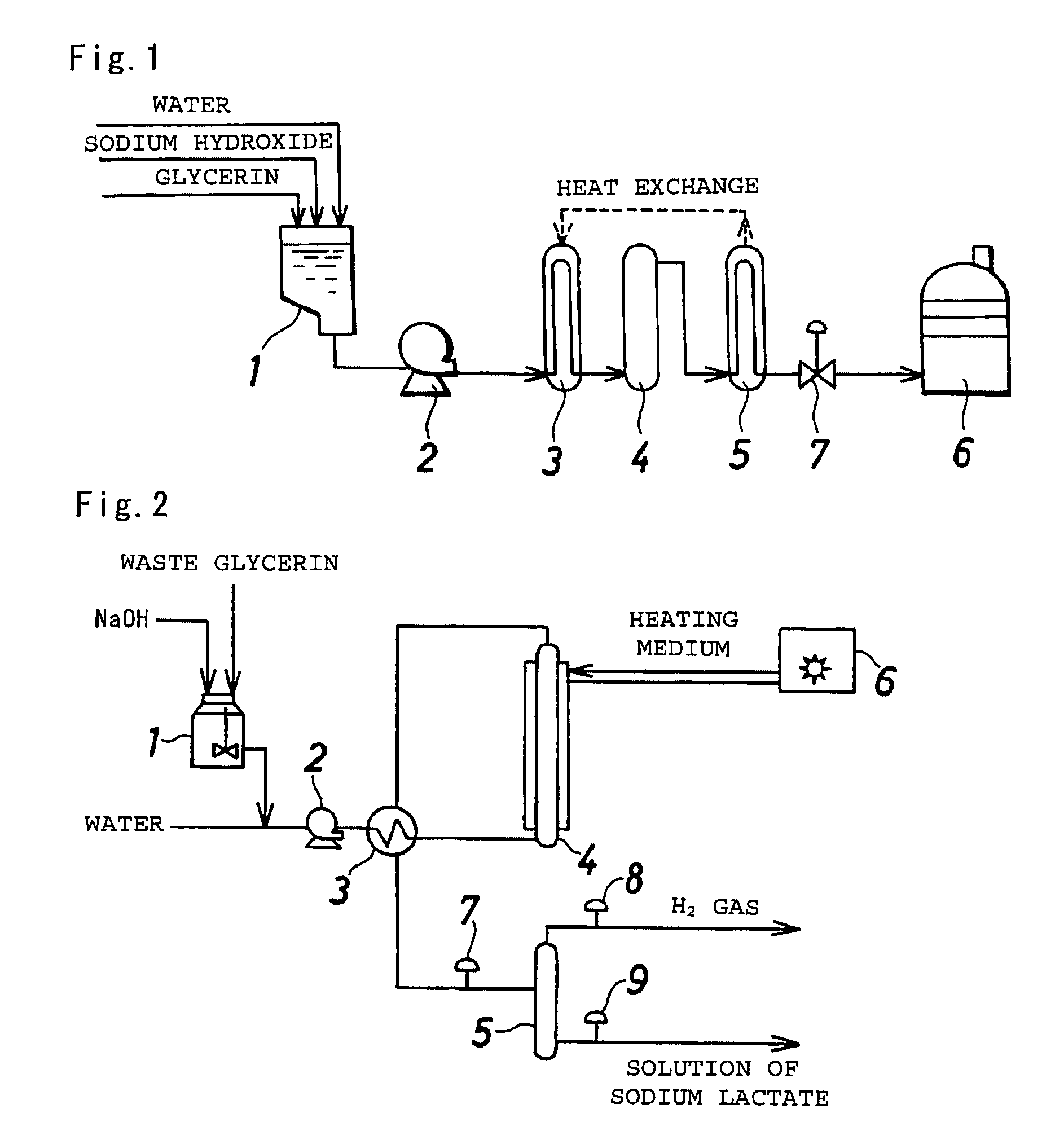

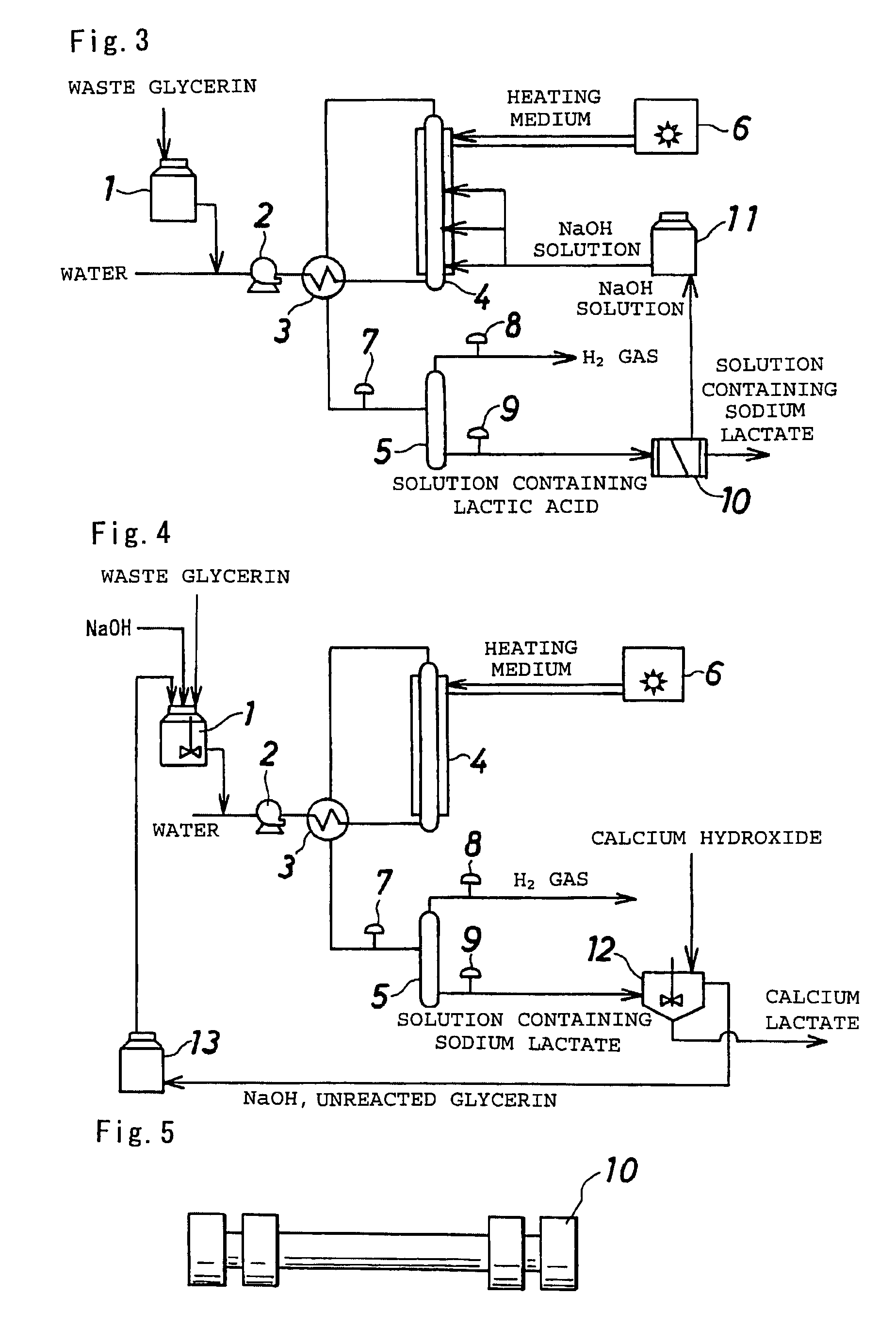

Process for production of lactic acid and equipment for the production

InactiveUS7829740B2Easy to useIncrease conversion ratePreparation from carboxylic acid saltsFatty acid esterificationChemical synthesisAlcohol

A process for producing lactic acid according to the invention is characterized in that glycerin is subjected to a hydrothermal reaction under an alkaline condition at a temperature in the range of 150 to 400° C. and under pressure equal to or more than the saturated vapor pressure at the temperature. The glycerin produced from plant fats, animal fats or the like or pure product synthesized chemically or a discharge containing glycerin generated at the production of diesel fuel oil from fats, in which the fats are subjected to a transesterification with alcohol in the presence of an alkali catalyst in order to obtain fatty acid ester is preferably used as a starting material.

Owner:ENOMOTO HEIJI +2

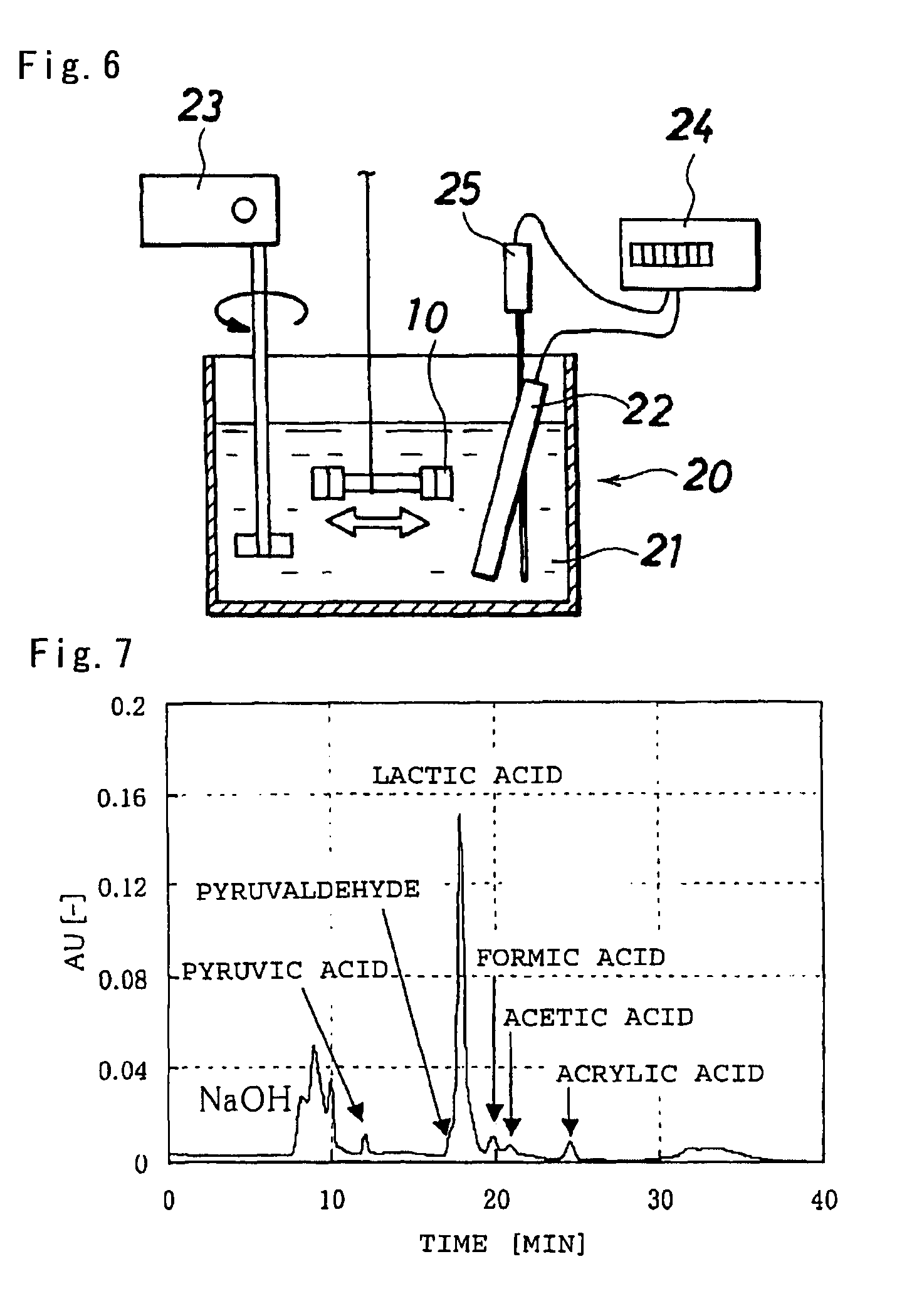

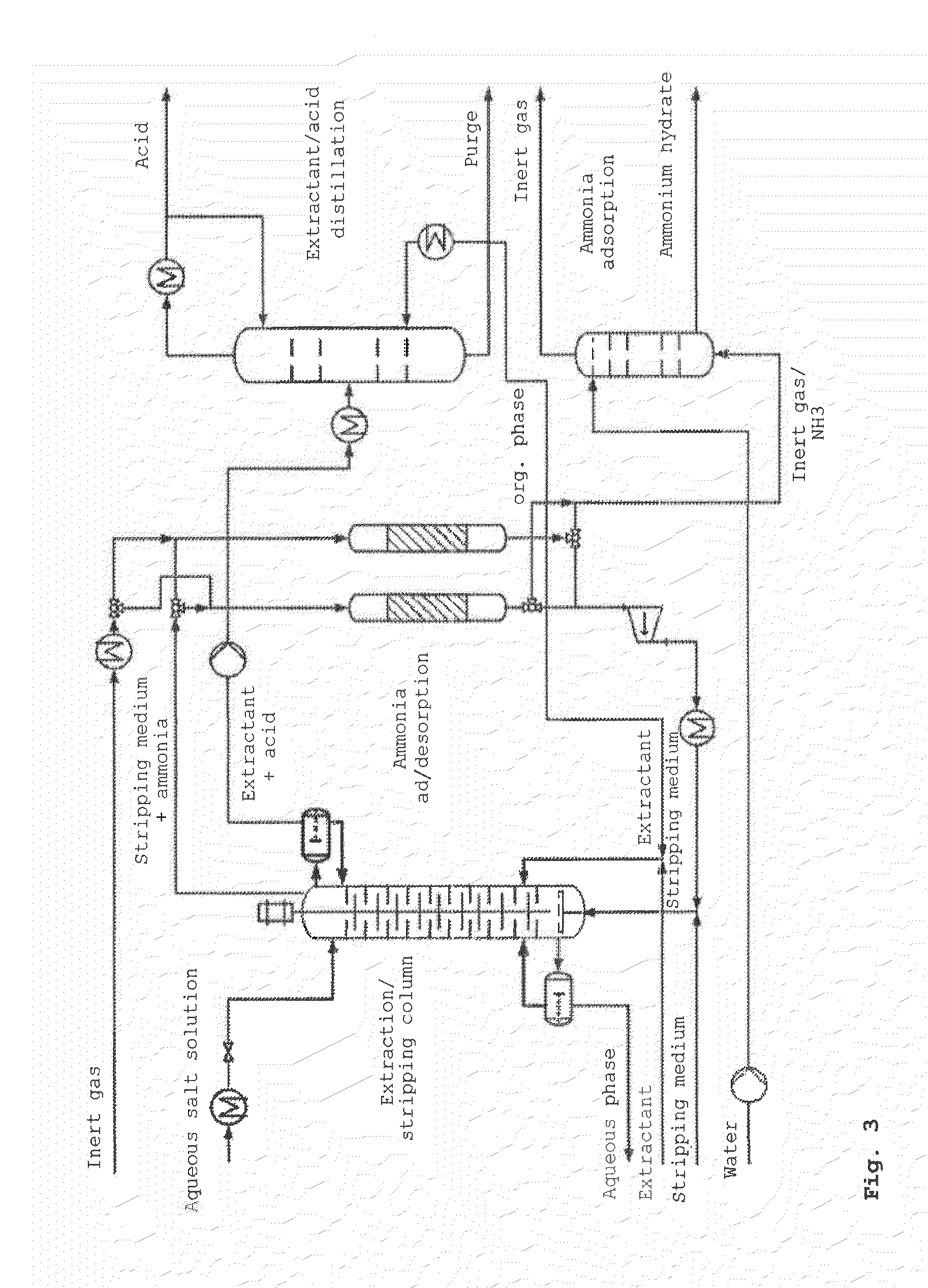

Method for producing a free acid from the salt thereof

InactiveUS8809576B2Less expensiveLow costPreparation from carboxylic acid saltsGroup 5/15 element organic compoundsWater vaporDistillation

The invention relates to an improved method for releasing an organic acid, preferably a carbon, sulfone or phosphone acid, particularly an alpha or beta hydroxycarbon acid, from the ammonia salt thereof by releasing and removing ammoniac and simultaneous extraction of the released acid, having an amine as a suitable extraction means from the aqueous phase. This method corresponds to a reactive extraction. The reactive extraction of an organic acid from the aqueous ammonia salt solution thereof can be significantly improved by the use of a strip medium or carrier gas, such as nitrogen, air, water vapor or inert gases such as argon. The released ammoniac is removed from the aqueous solution by the continuous gas flow and can be resupplied into a production process. The free acid can be obtained by a method such as distillation, rectification, crystallization, reextraction, chromatography, adsorption or by a membrane method from the extraction means.

Owner:EVONIK DEGUSSA GMBH

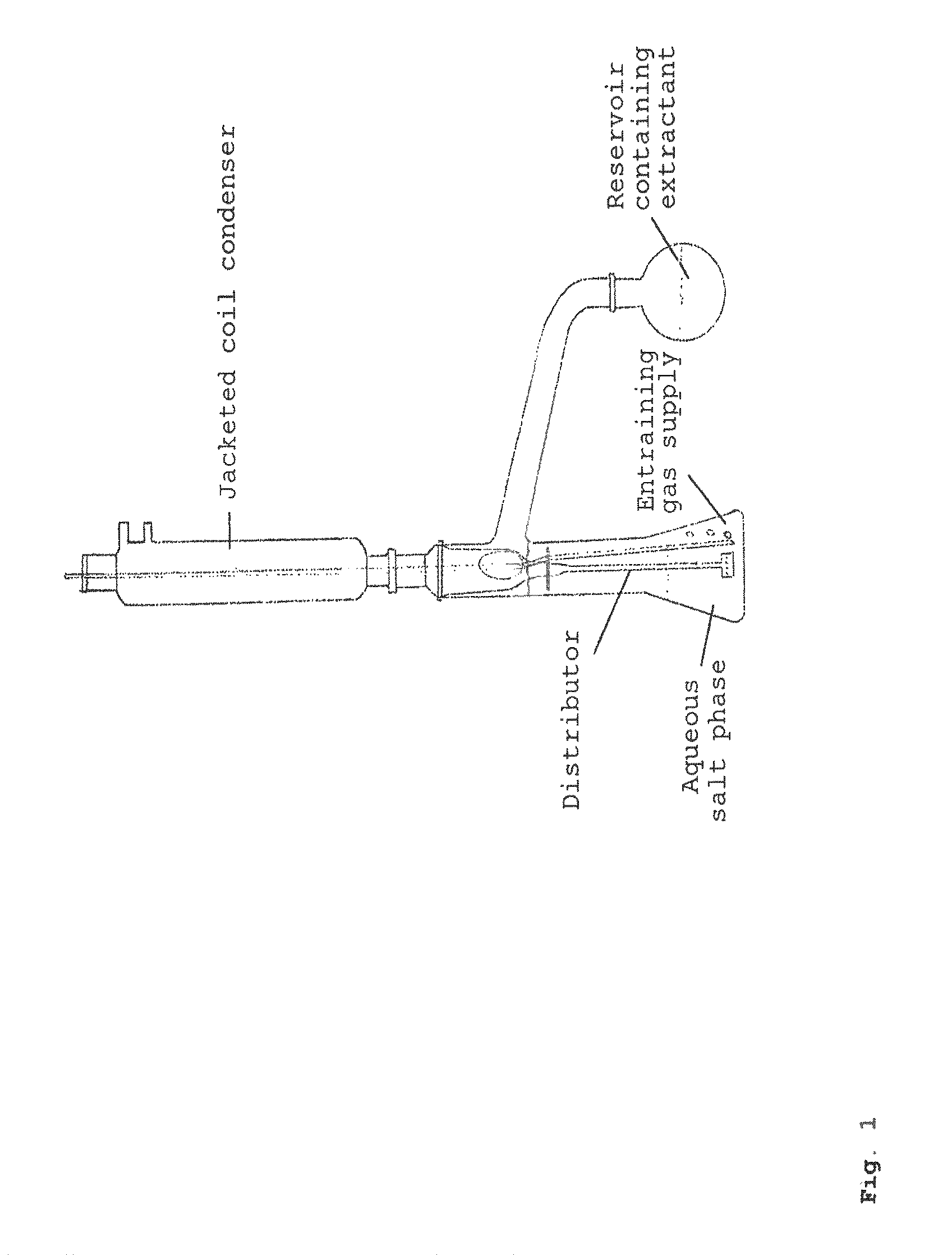

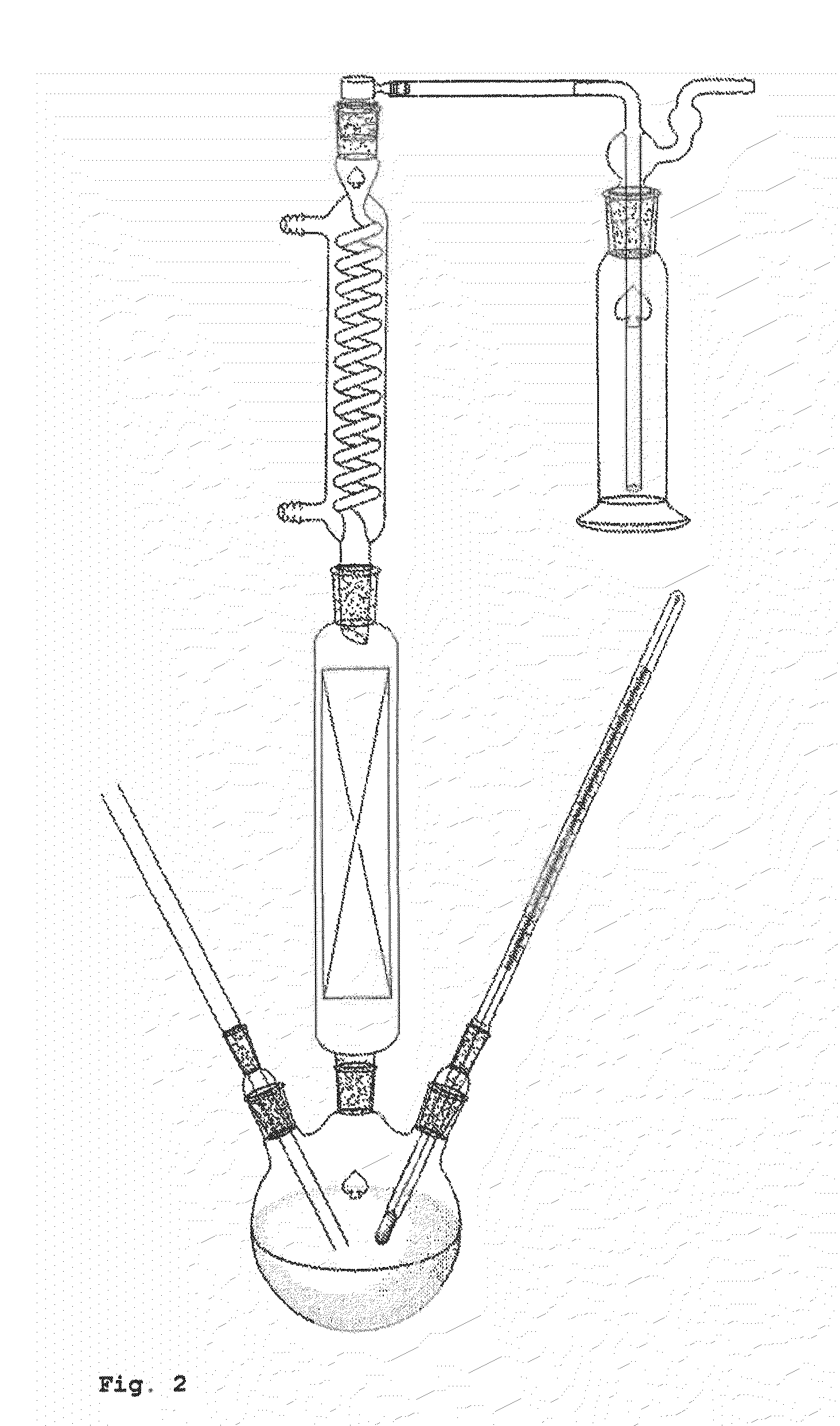

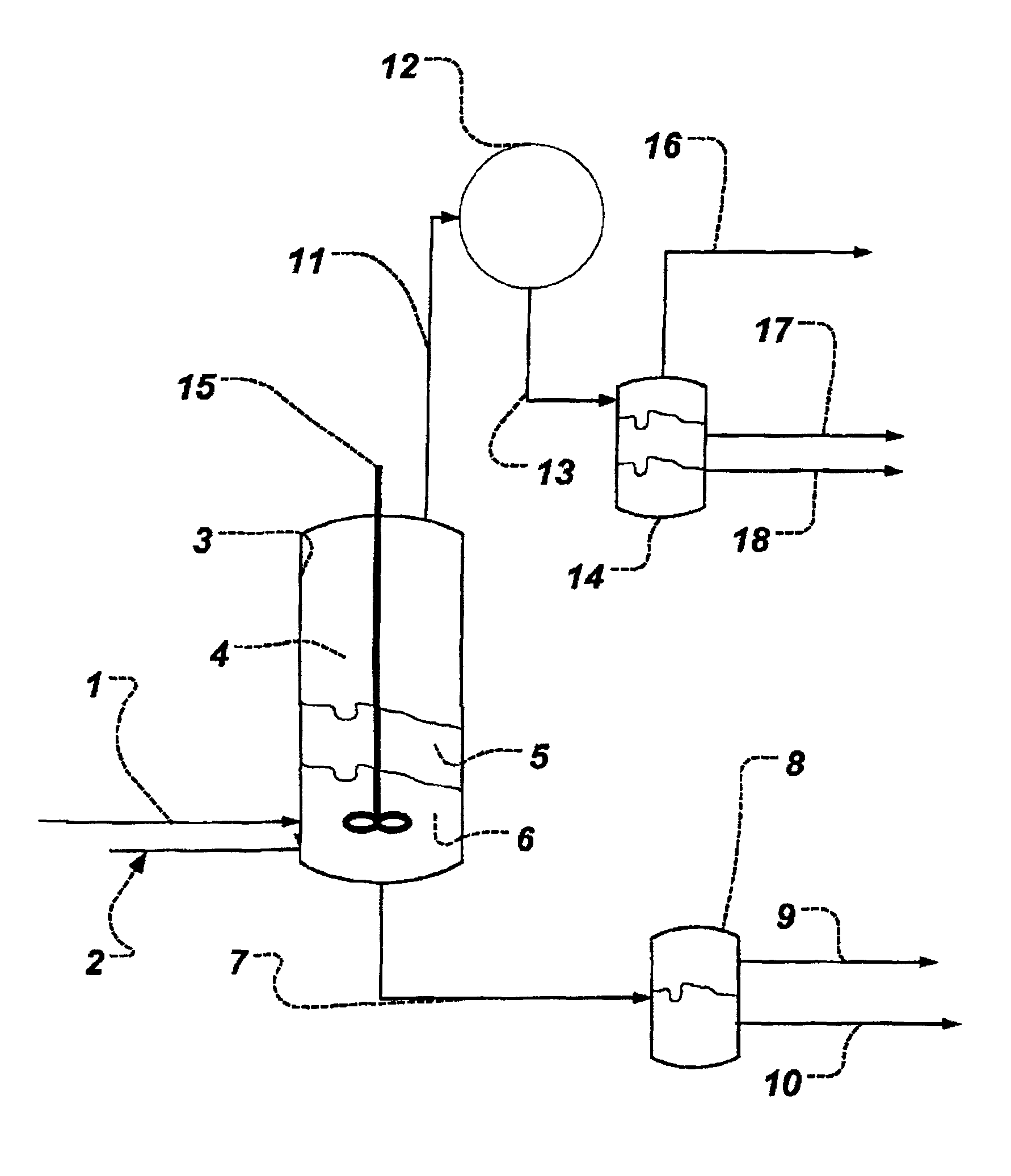

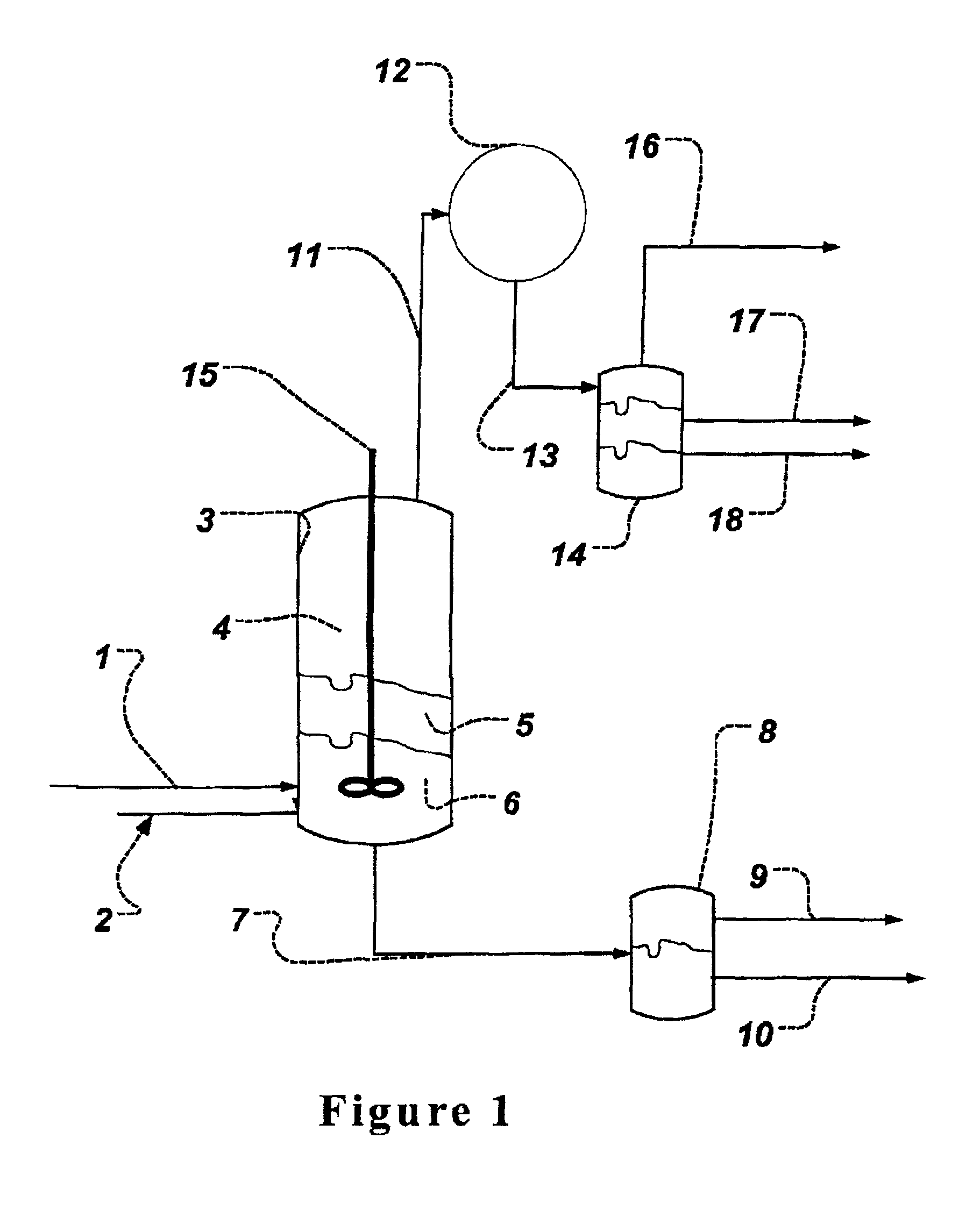

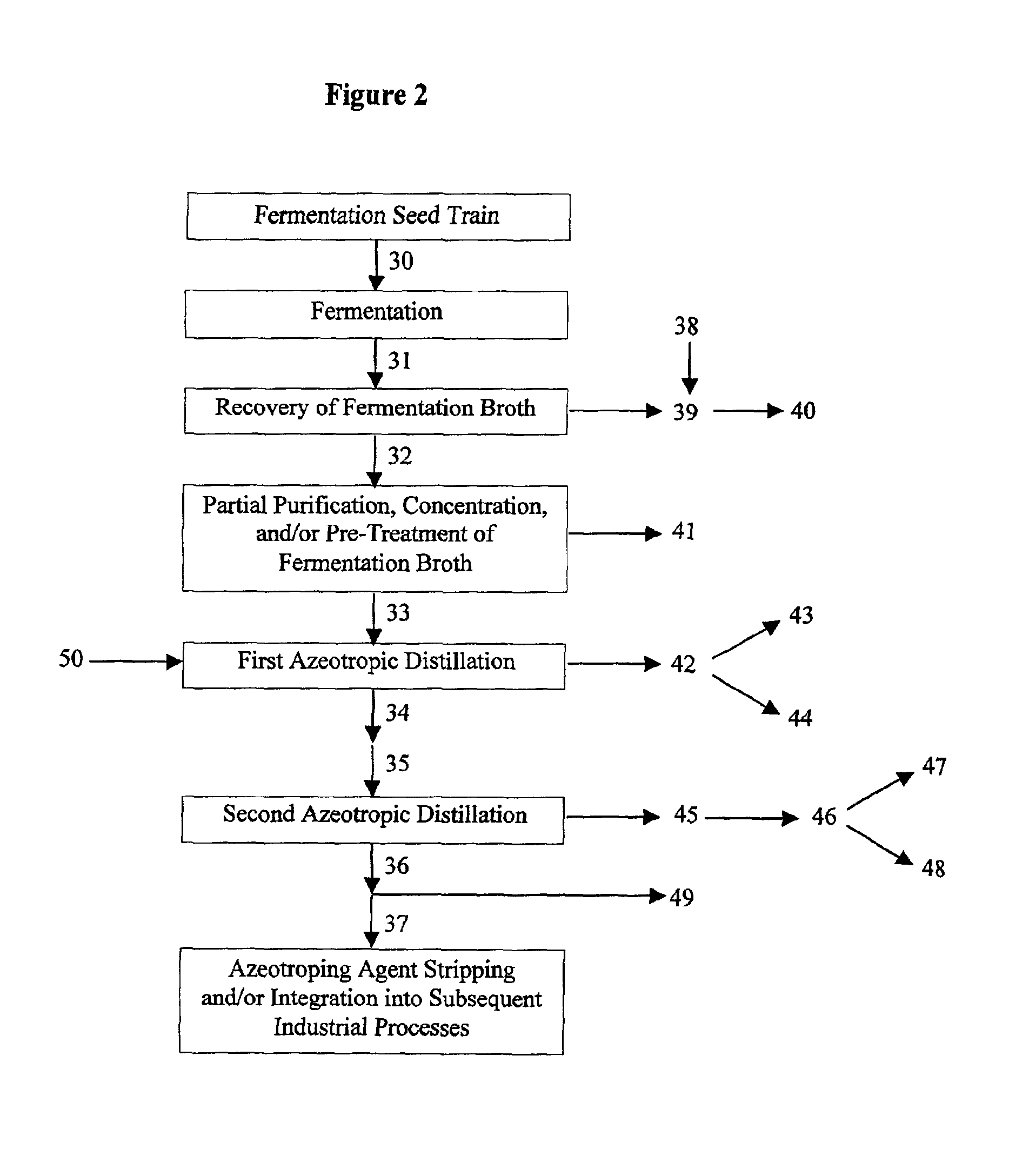

Process for obtaining an organic acid from an organic acid ammonium salt, an organic acid amide, or an alkylamine organic acid complex

InactiveUS6926810B2Simple and cost-effective recoveryPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidHeteroazeotrope

Disclosed herein are methods for the recovery of an organic acid, such as a heat stable lactic acid, from a feed stream which contains at least one of an organic acid amide, an organic acid ammonium salt, or an alkylamine-organic acid complex. The feed stream is mixed with at least one azeotroping agent. The azeotroping agent is a hydrocarbon capable of forming at least one azeotrope with the organic acid that is produced by the thermal decomposition of the amide, ammonium salt, or complex in the feed stream. Preferably the azeotrope is a heteroazeotrope. The mixture of the feed stream and the azeotroping agent is heated to produce a vapor stream. The azeotrope is a component of the vapor stream. The vapor stream can be condensed to a liquid stream, and the organic acid is recovered in the liquid stream that is produced. When the azeotrope is a heteroazeotrope, the vapor stream can be condensed into a liquid stream, which can be separated into a first phase and a second phase. The first phase contains the highest concentration of organic acid and the second phase contains azeotroping agent. The organic acid can be further purified and / or concentrated from the separated first phase or from the liquid stream.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

Method for the production of free carboxylic acids

InactiveUS20110189742A1Substance reductionLow viscosityPreparation from carboxylic acid saltsSolvent extractionWater solubleAmmonium

A process for the preparation of free carboxylic acids including: A) preparation of carboxylic acid by a biological cell located in an aqueous medium with addition of an amine of formula (I)where R1, R2 and R3, independently of one another, are identical or different, branched or unbranched, optionally substituted hydrocarbon radicals or H; B) for cases where the added amine A) is water-soluble, addition of a water-insoluble amine of formula (I), where, in A) or B), a multiphase system is obtained and the corresponding ammonium carboxylate is formed from the water-insoluble amine and the carboxylic acid; C) removal of the water-insoluble phase; and D) heating of the water-insoluble phase with release of free carboxylic acid.

Owner:EVONIK ROEHM GMBH

Chemical Process For Recycling Polyethylene Terephtalate (Pet) Waste

InactiveUS20070219339A1Improve efficiencyPreparation from carboxylic acid saltsPlastic recyclingPolyethylene terephtalateCompanion animal

The present invention relates to a process for chemical recycling of PET waste that comprises, among other stages, a saponification reaction stage, wherein PET waste particles are reacted with stoichiometric or excessive amounts of a strong base metal in an alcoholic reaction media, the reaction being brought to the boiling temperature of the alcoholic reaction media, preferably at atmospheric pressure, thereby obtaining as reaction products a salt of terephthalic acid with the base metal and ethylene glycol, the latter being incorporated to the alcoholic reaction media. From this reaction it is possible to afford ethylene glycol, terephthalic acid and salts thereof, which are products with a high commercial value.

Owner:UNIV IBEROAMERICANA A C

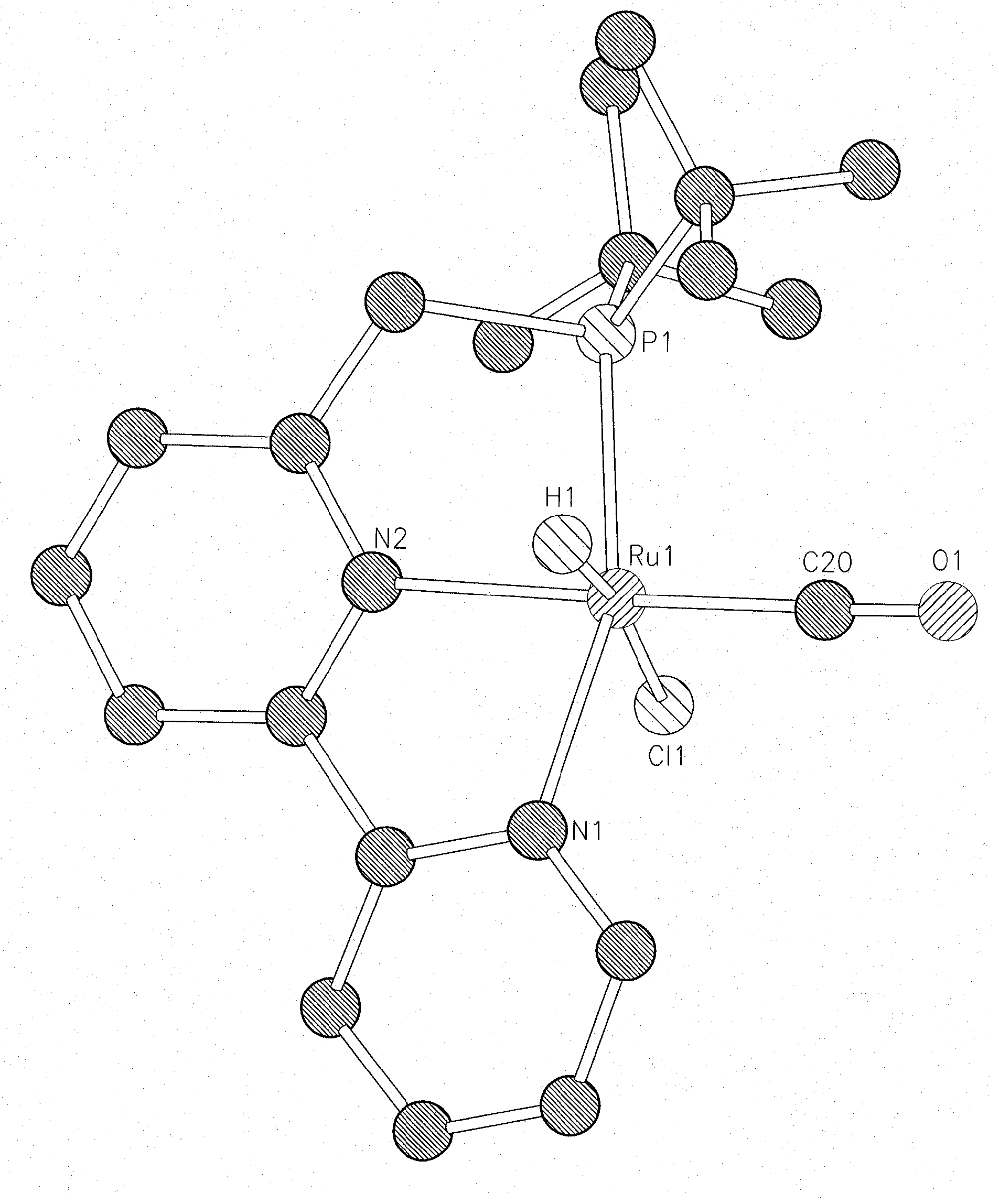

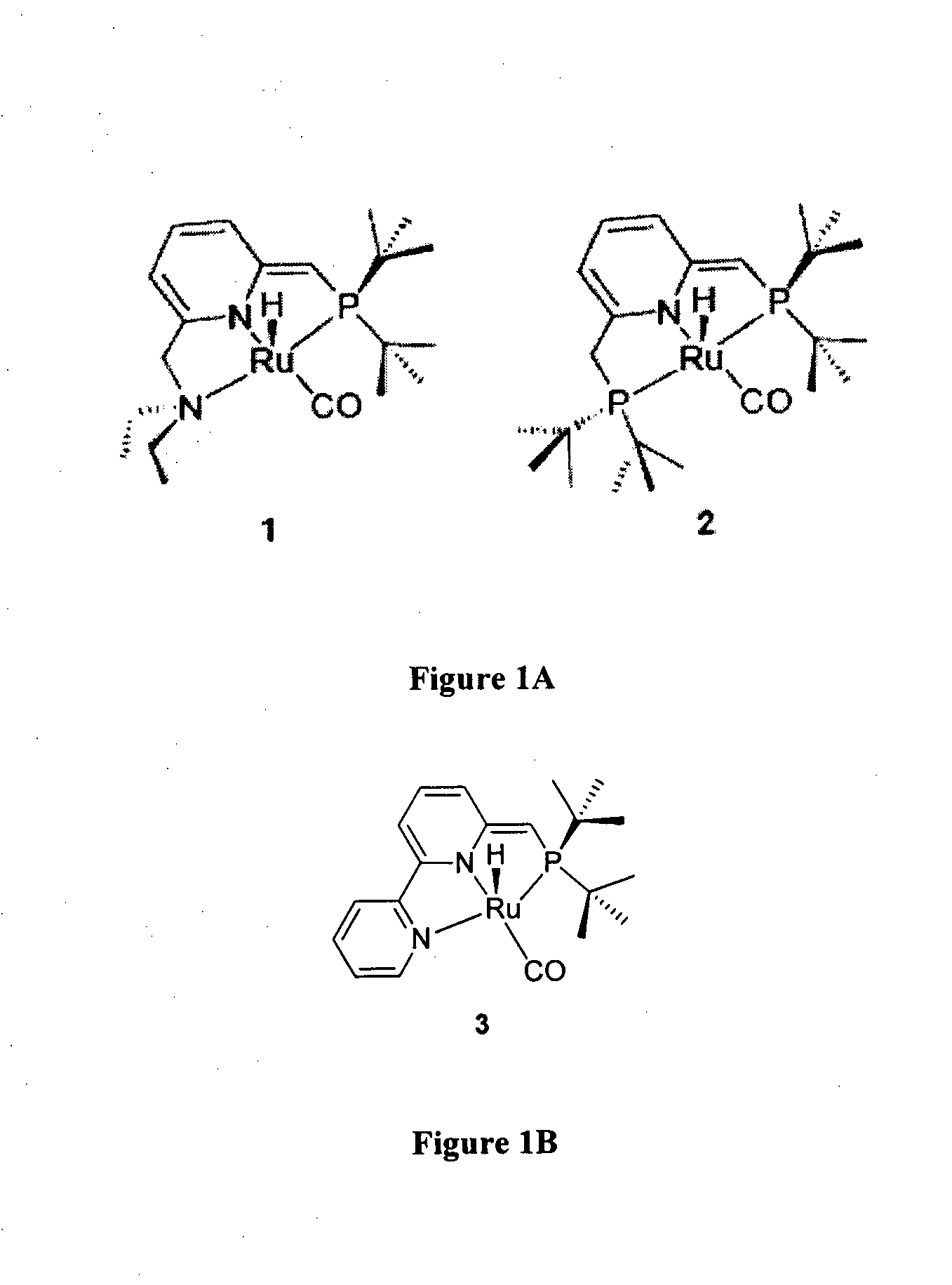

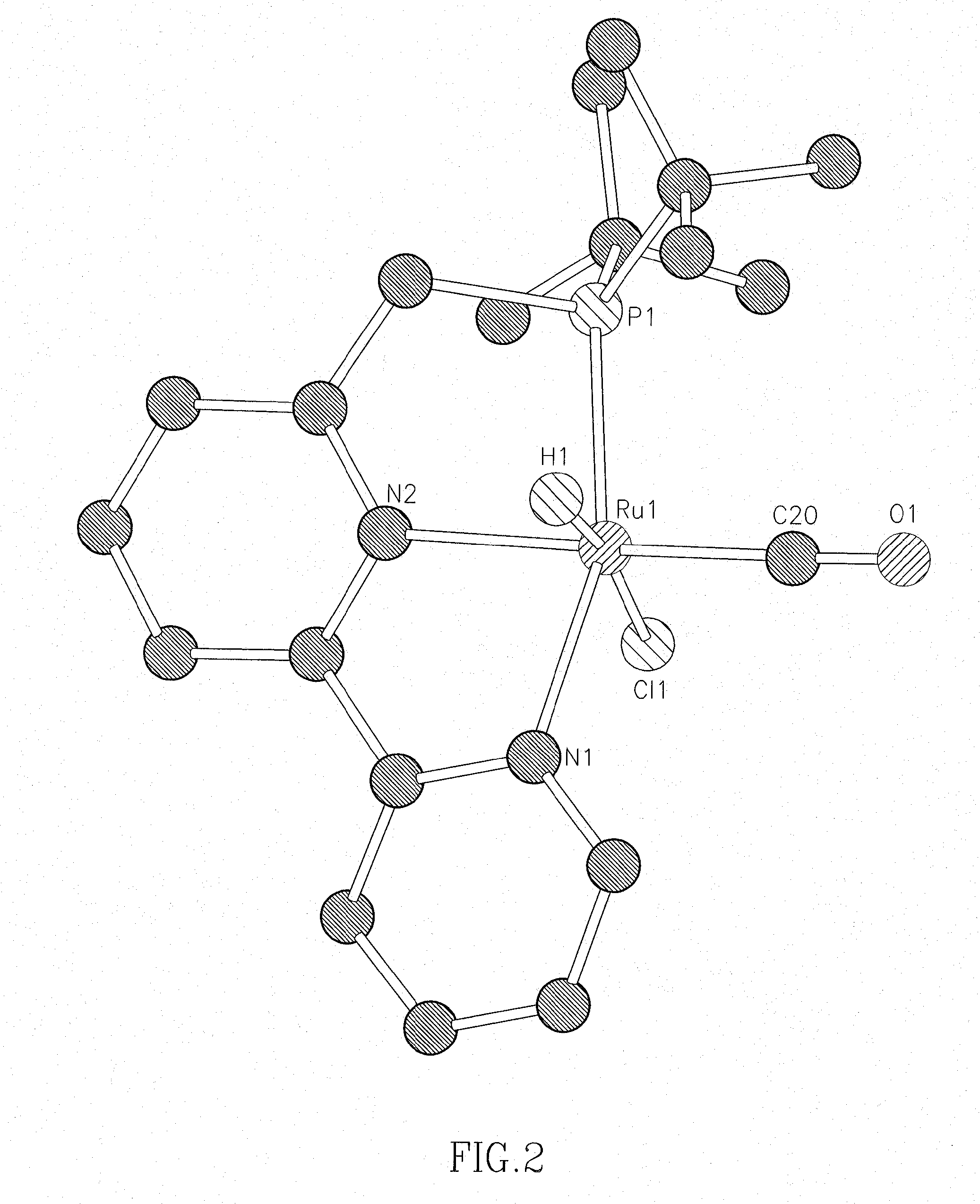

Novel ruthenium complexes and their uses in processes for formation and/or hydrogenation of esters, amides and derivatives thereof

ActiveUS20130281664A1High yieldImprove turnover ratePreparation from carboxylic acid saltsPlatinum group organic compoundsUrea derivativesPolyester

The present invention relates to novel Ruthenium catalysts and related borohydride complexes, and the use of such catalysts, inter alia, for (1) hydrogenation of amides (including polyamides) to alcohols and amines; (2) preparing amides from alcohols with amines (including the preparation of polyamides (e.g., polypeptides) by reacting dialcohols and diamines and / or by polymerization of amino alcohols); (3) hydrogenation of esters to alcohols (including hydrogenation of cyclic esters (lactones) or cyclic di-esters (di-lactones) or polyesters); (4) hydrogenation of organic carbonates (including polycarbonates) to alcohols and hydrogenation of carbamates (including polycarbamates) or urea derivatives to alcohols and amines; (5) dehydrogenative coupling of alcohols to esters; (6) hydrogenation of secondary alcohols to ketones; (7) amidation of esters (i.e., synthesis of amides from esters and amines); (8) acylation of alcohols using esters; (9) coupling of alcohols with water to form carboxylic acids; and (10) dehydrogenation of beta-amino alcohols to form pyrazines. The present invention further relates to the novel uses of certain pyridine Ruthenium catalysts.

Owner:YEDA RES & DEV CO LTD

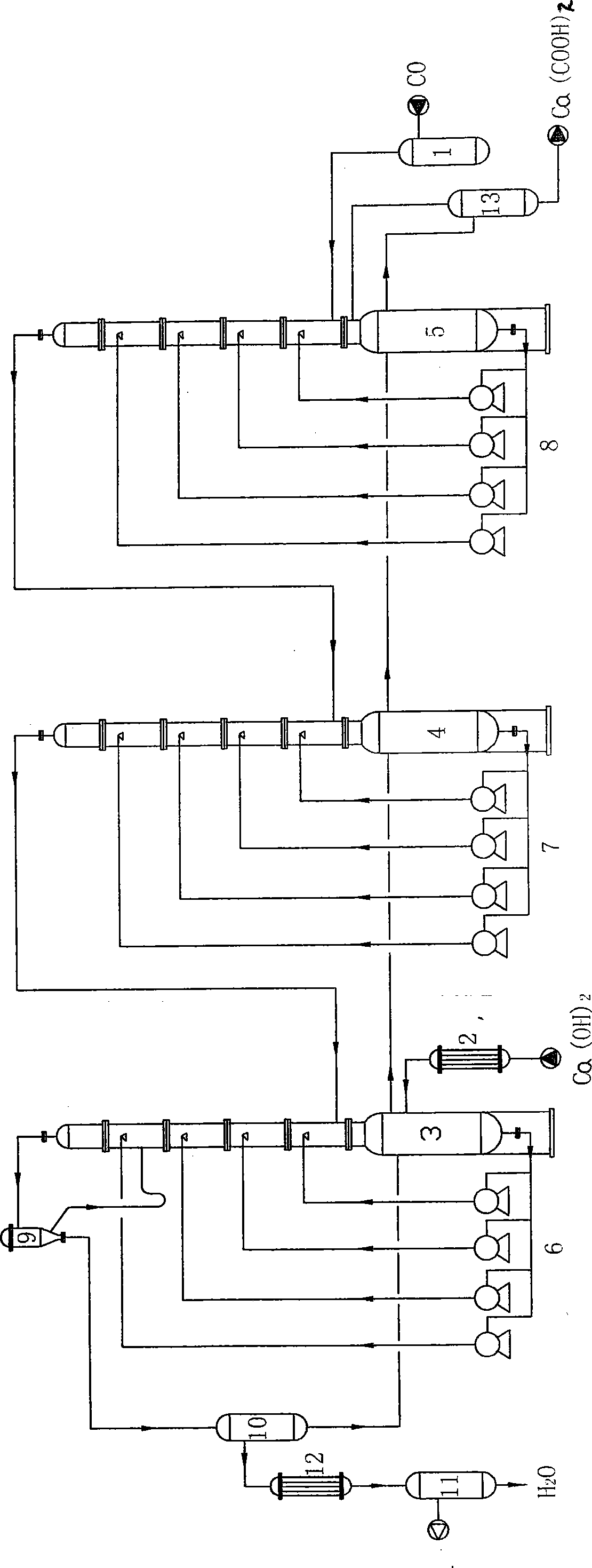

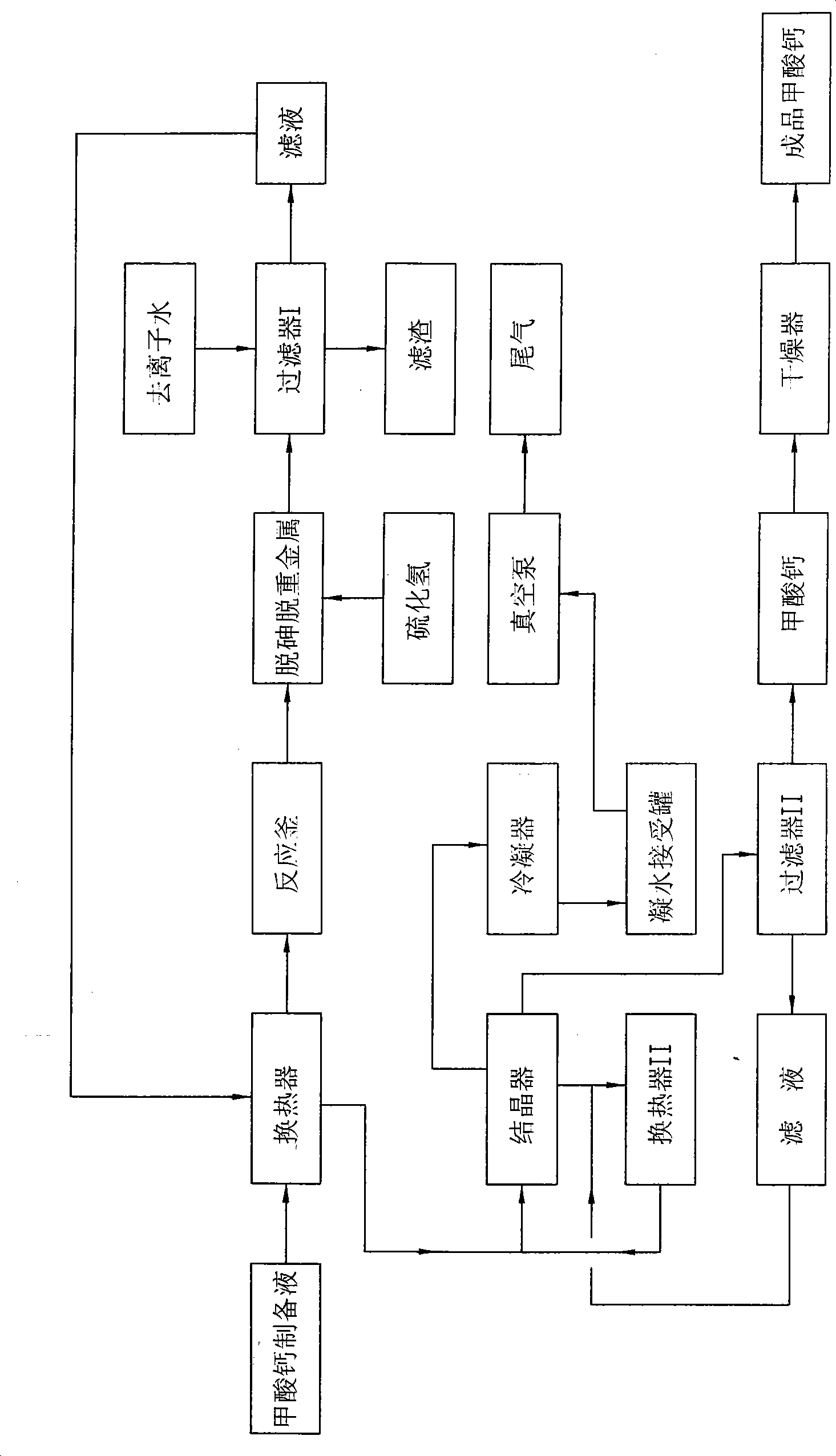

Method for coproduction of high purity aminic acid and acid sodium phosphate by reaction of calcium formate and peroxyphosphoric acid

InactiveCN101475463ASimple production processReduce manufacturing costPreparation from carboxylic acid saltsPhosphorus compoundsCalcium hydroxideHydrogen

The invention relates to a method for coproducing high-purity methanoic acid and monobasic sodium phosphate by reaction of calcium formate and ultraphosphate. The method comprises the following steps that: carbon monoxide enters a reaction tower III; calcium hydroxide enters a reaction tower I to perform a counterflow reaction with carbon monoxide from a reaction tower II, a reaction solution overflows to the reaction tower II to perform the counterflow reaction with the carbon monoxide from the reaction tower III, the reaction solution enters the reaction tower III to perform the couterflow reaction with the carbon monoxide, the reaction solution overflows into a discharge tank from the reaction tower III to prepare a calcium formate preparation solution; the calcium formate preparation solution enters a reaction kettle, methanoic acid is dripped into the reaction kettle, sulfureted hydrogen is introduced into the reaction kettle, the mixture is separated and filtered through a filter I, a filtrate enters a continuous crystallizer, a crystalline liquid enters a filter II, and the filtered calcium formate is prepared into a finished product calcium formate through a drier; ultraphosphate, the methanoic acid and the calcium formate are conveyed into a horizontal double screw reactor to generate the methanoic acid and monobasic calcium phosphate; the methanoic acid and the monobasic calcium phosphate enter a methanoic acid distilling still for reduced pressure distillation; and the monobasic calcium phosphate is delivered to a monobasic calcium phosphate measurement receiving tank, while the monobasic acid enters a methanoic acid receiving tank. The method has high yield of the methanoic acid and low manufacturing cost.

Owner:曹勇

Method for treating metronidazole waste water

ActiveCN102344220AAvoid pollutionAchieve recyclingPreparation from carboxylic acid saltsOrganic compound preparationNitroimidazoleSODIUM SULFATE ANHYDROUS

The invention relates to a method for treating metronidazole waste water, which comprises the following steps of: concentrating the metronidazole waste water into 1 / 3-1 / 5 of total amount, and crystallizing and filtering the concentrated metronidazole waste water at 45-100 DEG C to obtain anhydrous sodium sulfate and sodium formate; adjusting the PH to 3-6 by using sulfuric acid or formic acid, and precipitating 2-methy-5-nitro imidazole; concentrating the filter liquid to anhydrous sticky state, dissolving organic matter by using methanol or ethanol, and filtering the solution to obtain anhydrous sodium sulfate and sodium formate; merging the sodium formate and the anhydrous sodium sulfate obtained in two times, successively adding formic acid and sulfuric acid, and recovering the formic acid to obtain anhydrous sodium sulfate; and rectifying and separating the organic mixture extract of methanol or ethanol to obtain methanol or ethanol and glycol. The method for treating metronidazole waste water provided by the invention is simple and convenient to operate, the content of polluting organic matter and inorganic slats in the metronidazole waste water can be obviously reduced, environmental pollution can be preveneted, various kinds of useful organic matter and inorganic matter can be recovered, raw materials are saved, and the production cost is lowered.

Owner:HUBEI HONGYUAN PHARMA

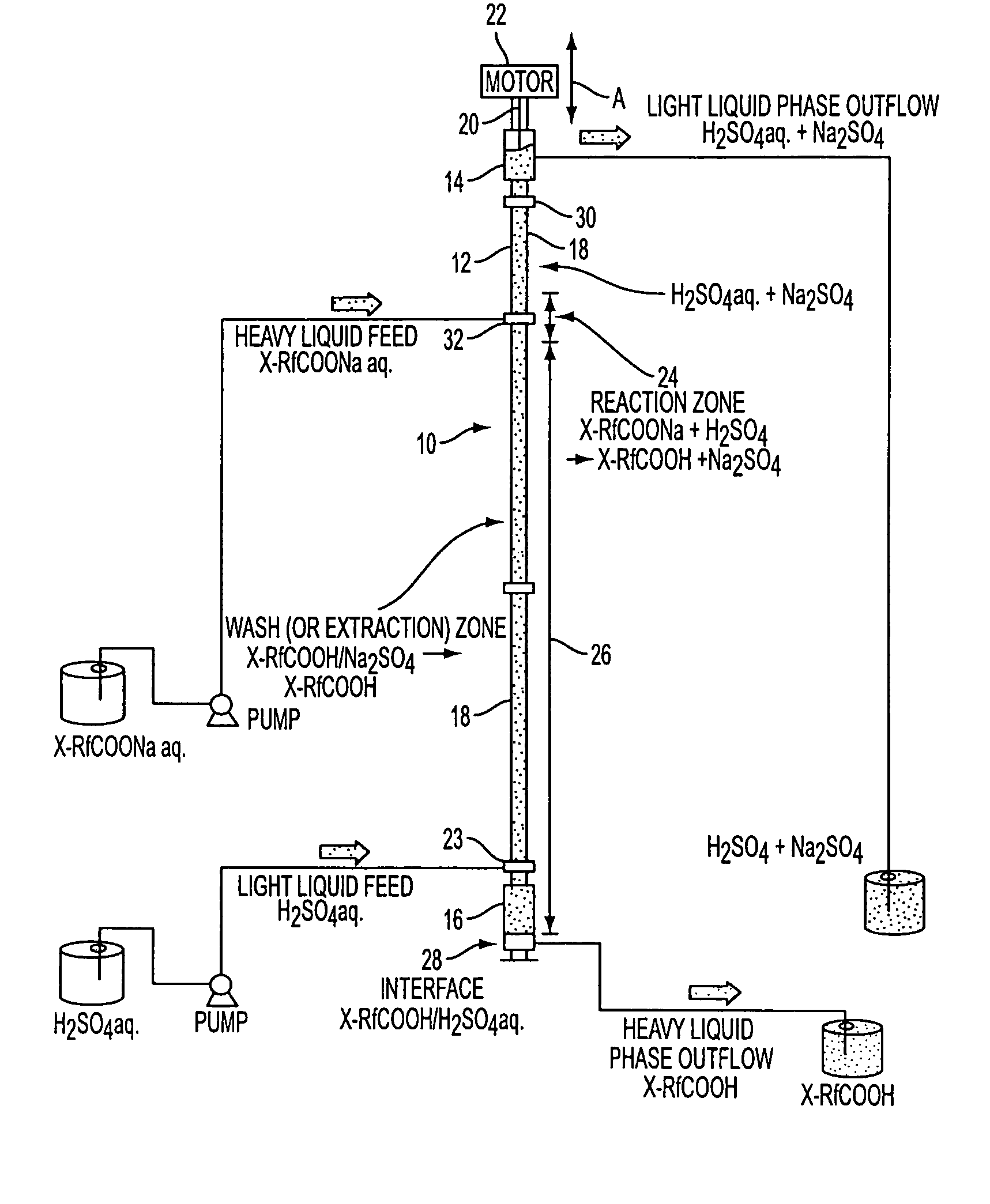

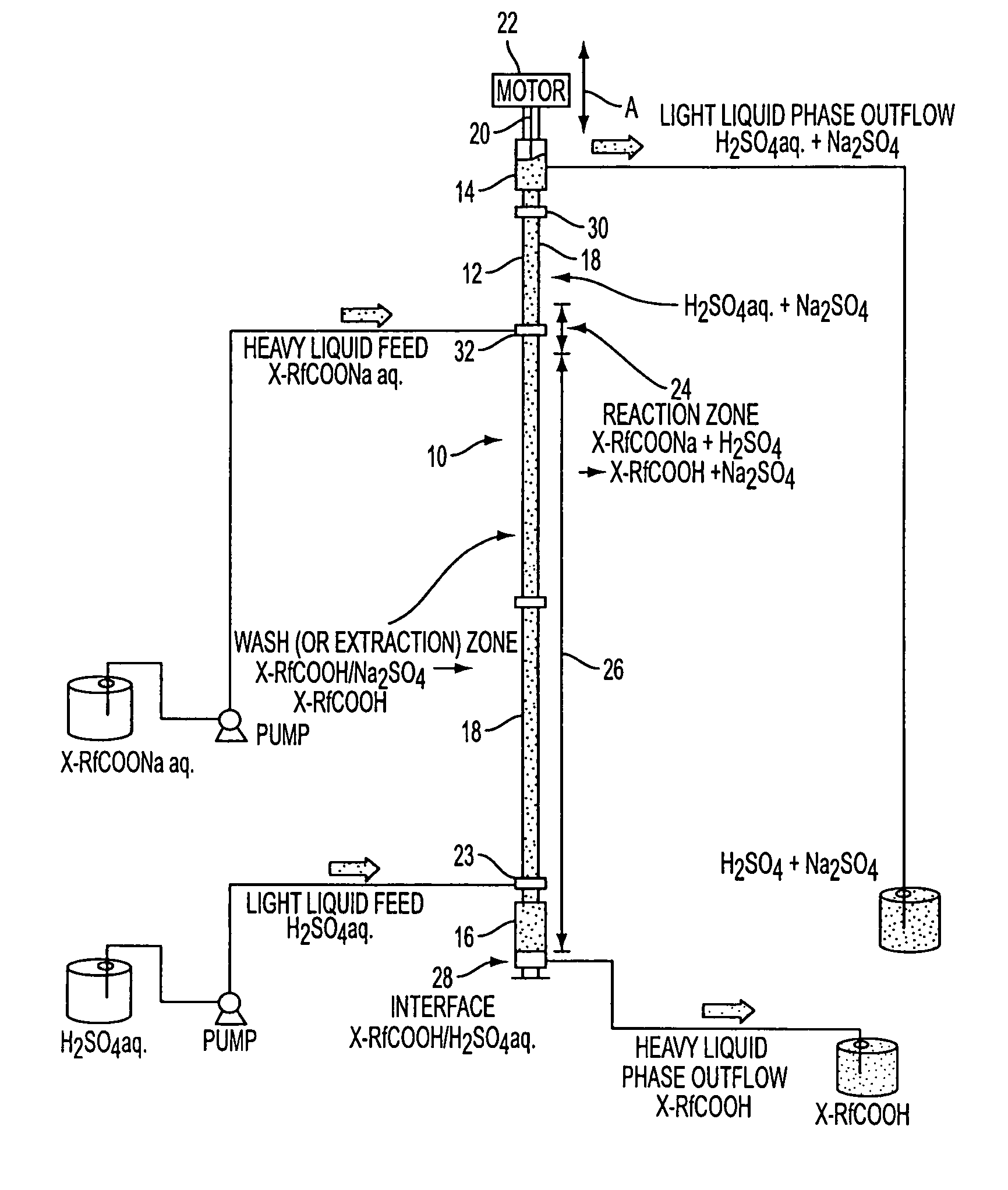

Process for preparing fluorocarboxylic acids

InactiveUS7126016B2Minimize releaseReduce lossesPreparation from carboxylic acid saltsOrganic compound preparationSulfateCarboxylic acid

A fluorocarboxylic acid preparation process continuously carries out acidification reaction treatment and washing treatment, and includes subjecting a fluorocarboxylate-containing aqueous solution to acidification reaction treatment in the presence of sulfuric acid so as to form a sulfate-containing fluorocarboxylic acid phase; and subjecting the fluorocarboxylic acid phase to washing treatment using an aqueous sulfuric acid solution.

Owner:DAIKIN IND LTD +1

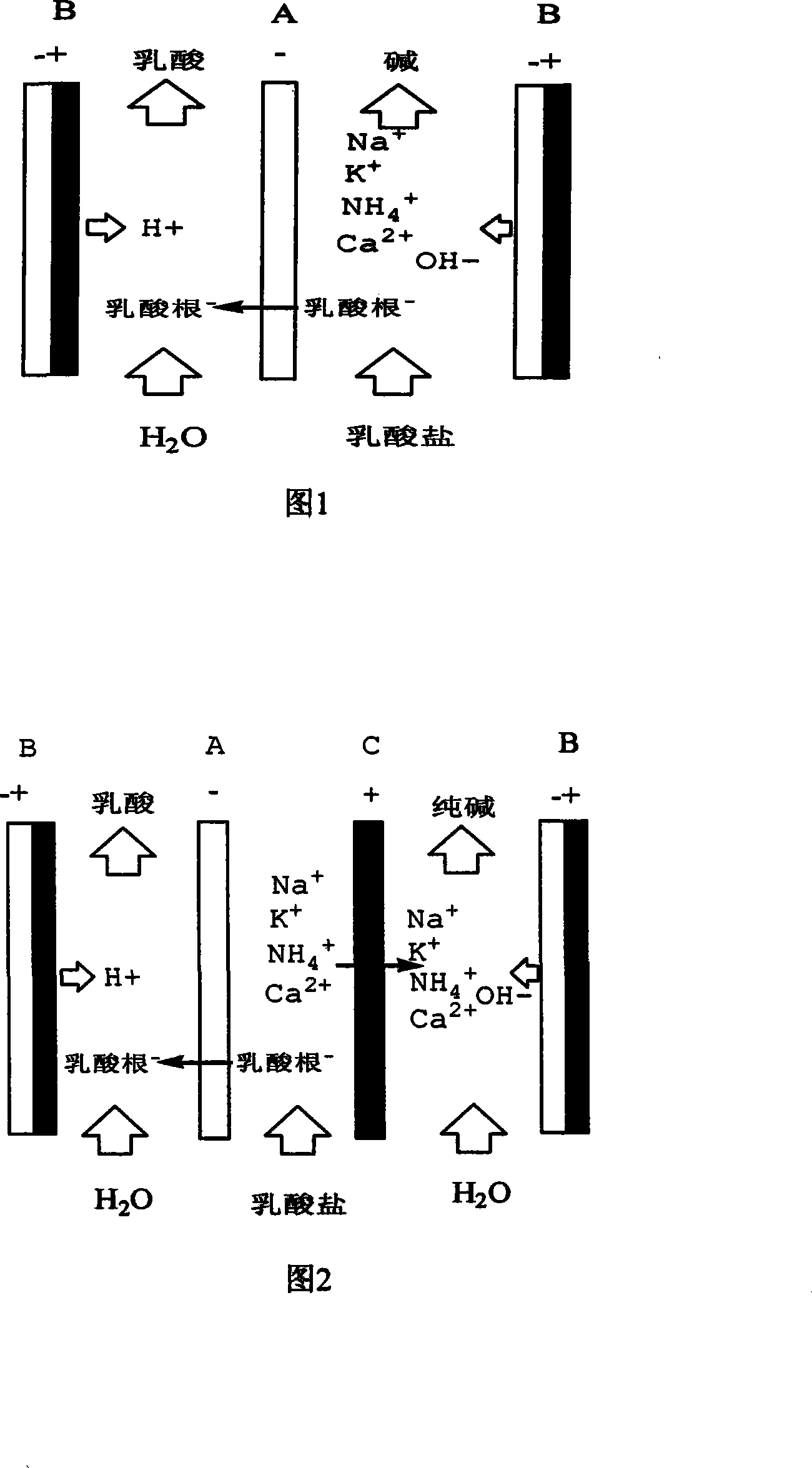

Method for preparing lactic acid by applying double pole film electrodialysis technique

InactiveCN101234961ASignificant industrial application valueSignificant environmental benefitsPreparation from carboxylic acid saltsElectrodialysisTransformation efficiencyPollution

The invention discloses a method for preparing lactic acid with bipolar membrane electrodialysis technology. Lactic acid fermentation liquid passes through an electrodialyzer, which transforms contained lactates into lactic acid. The membrane tank configuration of the adopted electrodialyzer can be of two-cell type including an acid cell and a salt cell divided by an anion membrane or of three-chamber type including an acid cell, a salt cell and a base cell divided by a cation membrane and an anion membrane. For preparation, lactic acid fermentation liquid is transmitted into the salt cell and water is transmitted into the acid cell or the base cell. Under the effect of a circulating pump, the materials flow circularly with a current density of 80-160mA / cm2 at an operation temperature of 25-60 DEG C. The invention can completely supersede the prior calcium lactate acidifying technology without addition of acids for H+ supply and without production of waste acid, salt or base liquid. The transformation efficiency of lactic acid is higher than 98 percent, the recovery of lactic acid is higher than 90 percent and the current efficiency is higher than 70 percent, so the method can reduce environment pollution and lower consumption of chemical raw materials and energy and has remarkable industrial application value and environmental benefit.

Owner:江苏道森生物化学有限公司

Production of organic acid and ammonium nitrate

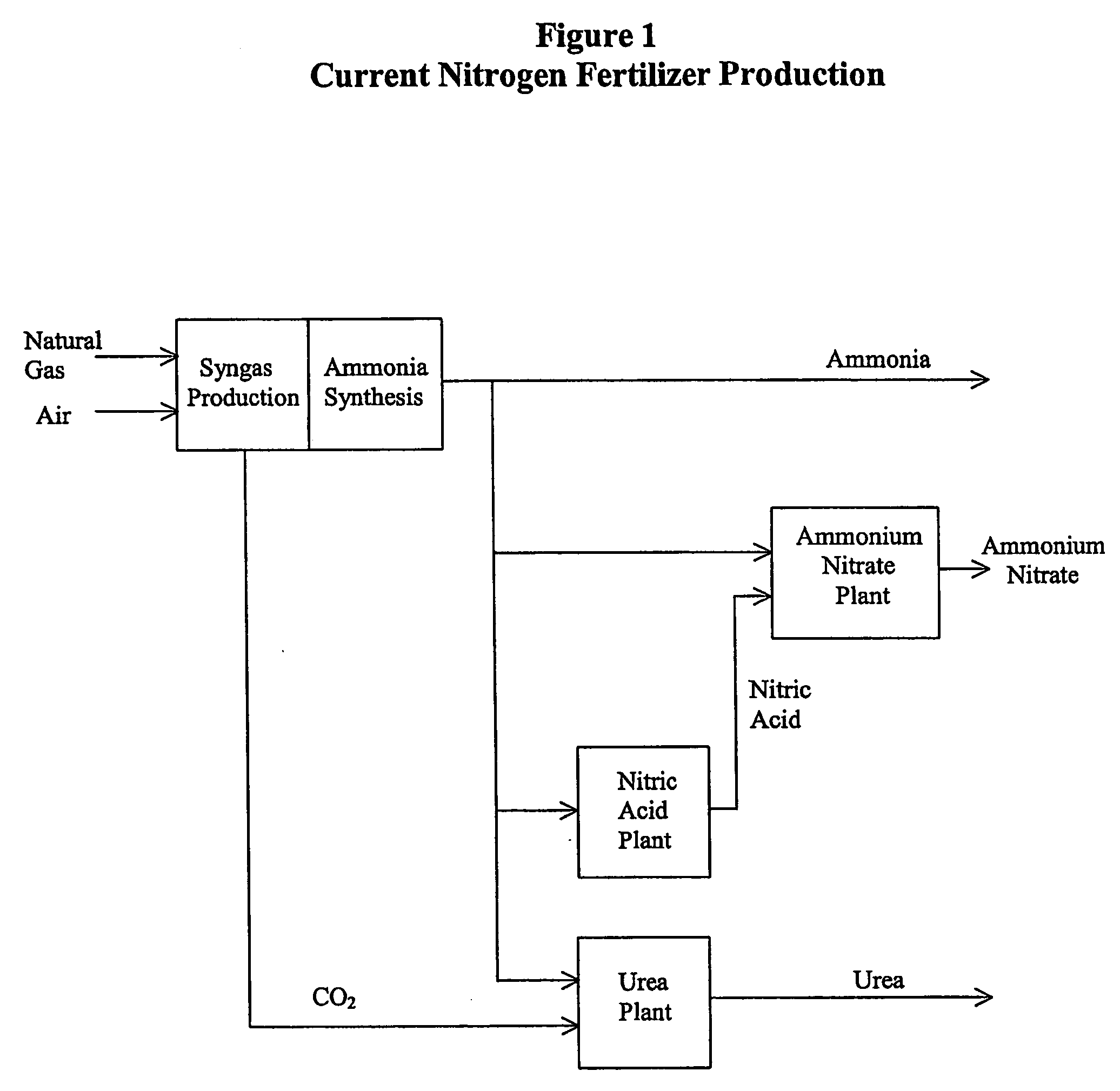

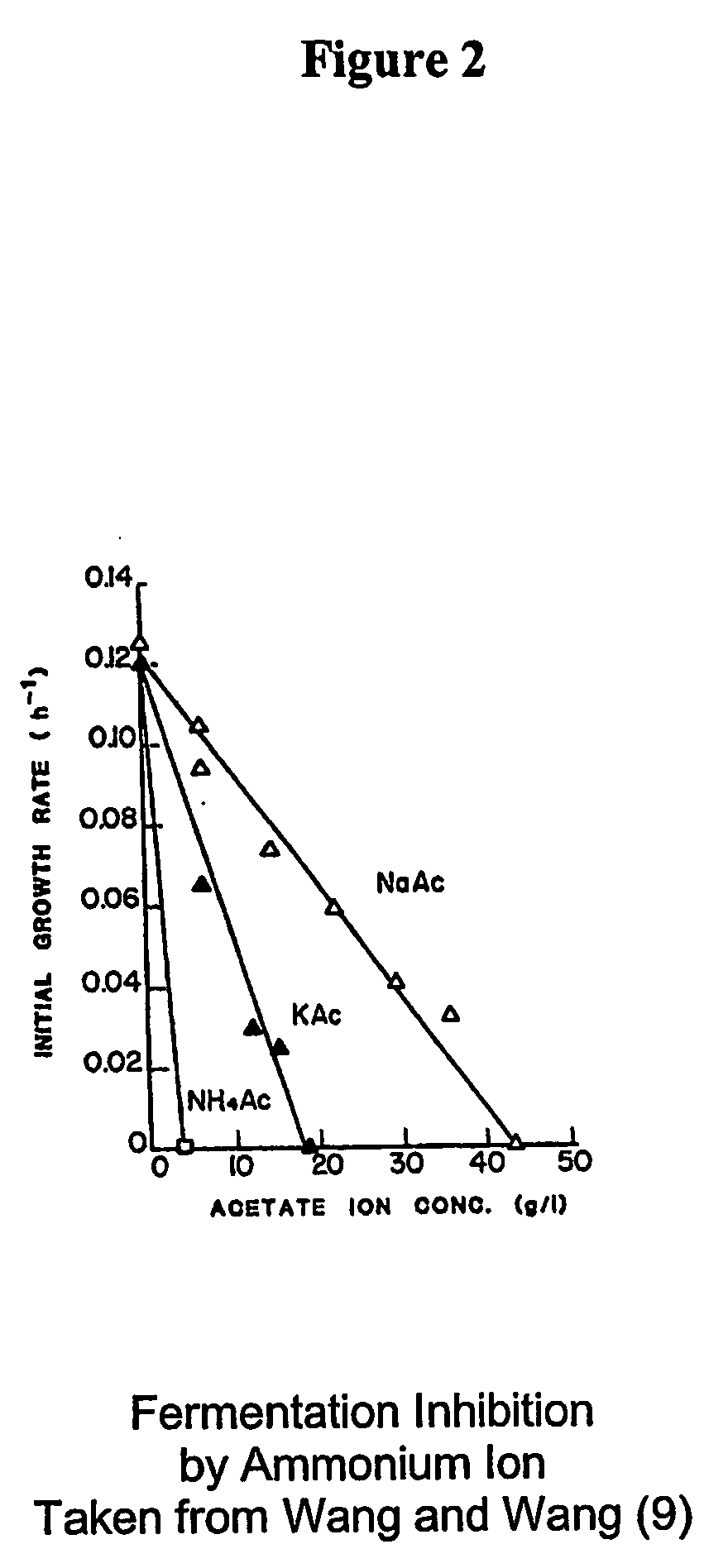

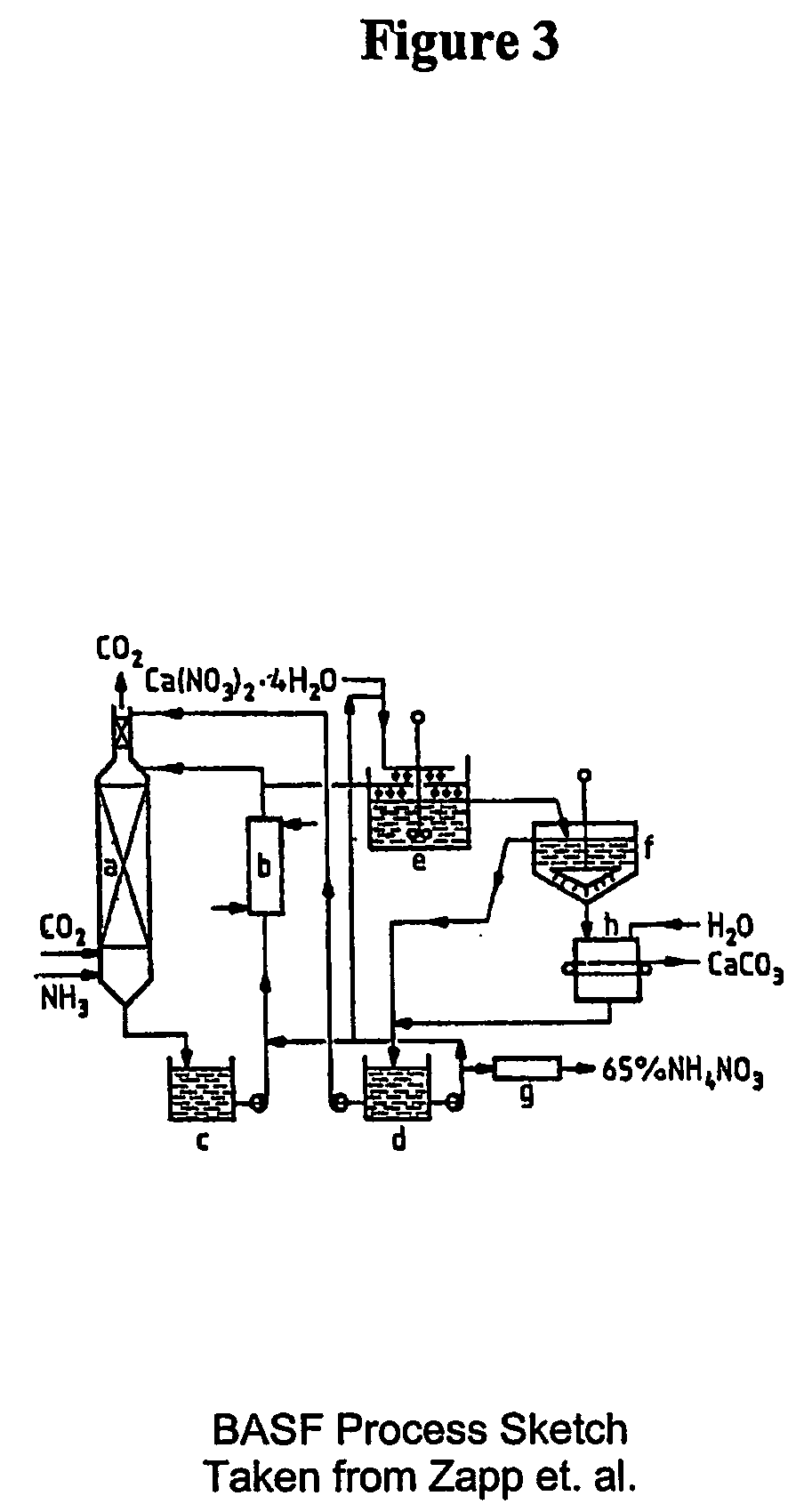

InactiveUS20060222585A1Preparation from carboxylic acid saltsCalcium/strontium/barium carbonatesOrganic acidAmmonium nitrate

A process for the recovery of organic acids from dilute solutions such as those produced by fermentation, when the organic acids are present as dilute salt solutions, is provided. The organic acid production process is integrated with a nitrogen fertilizer production process by utilizing wasted chemical energy from the fertilizer process for acidification of the organic acid solution.

Owner:ZEACHEM

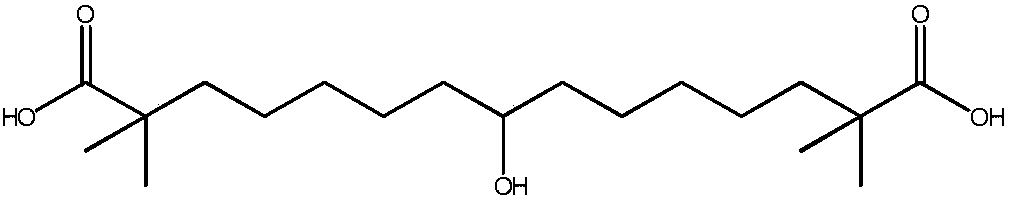

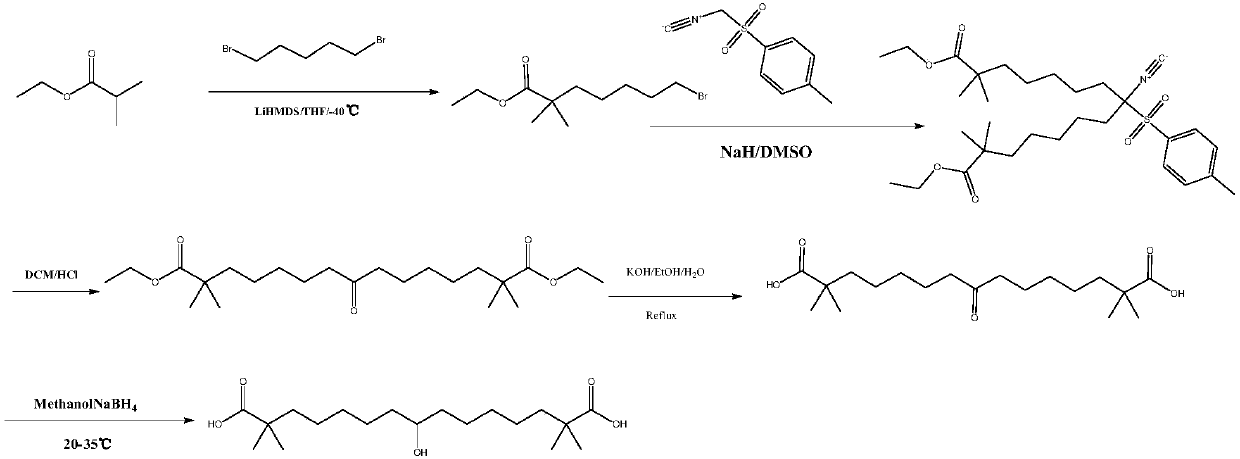

Synthetic method for 8-hydroxyl-2,2,14,14-tetramethyl-pentadecanedioic acid

PendingCN109721486AReduce cost inputReduce dosagePreparation from carboxylic acid saltsOrganic compound preparationSolventMethyl group

The invention belongs to the technical field of medicines, and specifically provides a synthetic method for 8-hydroxyl-2,2,14,14-tetramethyl-pentadecanedioic acid. The synthetic method comprises the following steps: (1) pouring 8-keto-2,2,14,14-tetramethyl-pentadecanedioic acid into purified water, and adding a proper amount of alkali until the 8-keto-2,2,14,14-tetramethyl-pentadecanedioic acid iscompletely dissolved so as to obtain 8-keto-2,2,14,14-tetramethyl-pentadecanediate; (2) adding sodium borohydride into an above-mentioned reaction solution, and carrying out a carbonyl reduction reaction under the condition of 20 to 25 DEG C so as to obtain 8-hydroxyl-2,2,14,14-tetramethyl-pentadecanediate; and (3) adding concentrated hydrochloric acid into an above-mentioned reaction solution until the pH value of the reaction solution is adjusted to 1 to 3 so as to generate the 8-hydroxyl-2,2,14,14-tetramethyl-pentadecanedioic acid. The synthetic method provided by the invention reduces theusage amount of the sodium borohydride, decreases the dangerousness of a reaction, simplifies operation, reduces the cost input amounts of a solvent and raw materials, and is applicable to industrialproduction.

Owner:LUNAN PHARMA GROUP CORPORATION

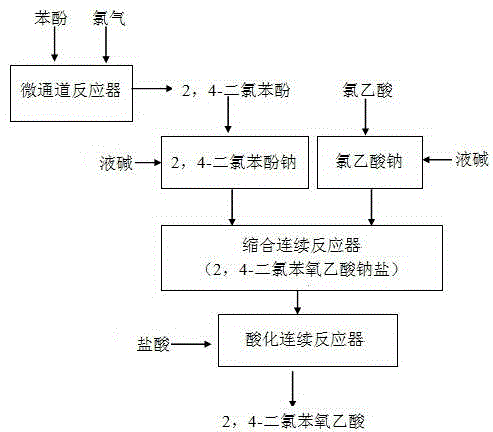

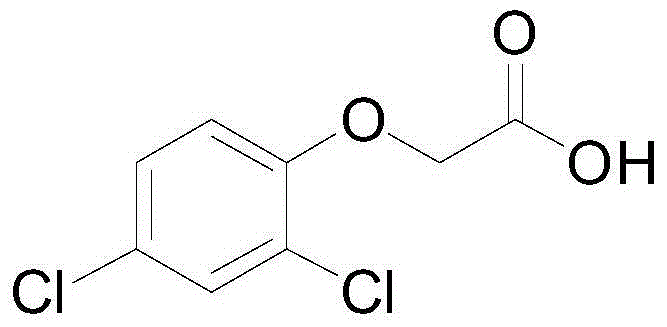

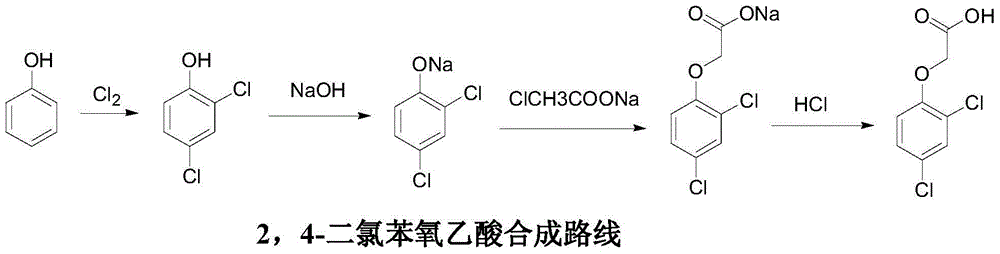

Method for continuously producing herbicide 2,4-dichlorophenoxyacetic acid

ActiveCN104529757AEmission reductionSafe and efficient productionPreparation from carboxylic acid saltsOrganic compound preparationPhenol2,4-Dichlorophenol

The invention discloses a method for continuously producing herbicide 2,4-dichlorophenoxyacetic acid. According to the method, phenol and chlorine gas are used as raw materials; a continuous chlorination reaction is conducted through a micro-channel reactor to prepare 2,4-dichlorophenol, a condensation reaction is conducted through a tandem condensation reaction kettle to prepare 2,4-dichlorphenoxyacetic acid sodium salt, and then a continuous acidification reaction is conducted through a tandem acidification reaction kettle to prepare the 2,4-dichlorphenoxyacetic acid. Since continuous operation is realized in all the three reactions, the technological process is efficient, environmentally friendly, sustainable and suitable for industrial production; the method has the advantages that energy is saved, consumption is lowered, and emission of pollutants is reduced, and therefore safe and continuous industrial production is achieved.

Owner:台州煜农生物科技有限公司

Processs for production and purification of fermentation derived organic acids

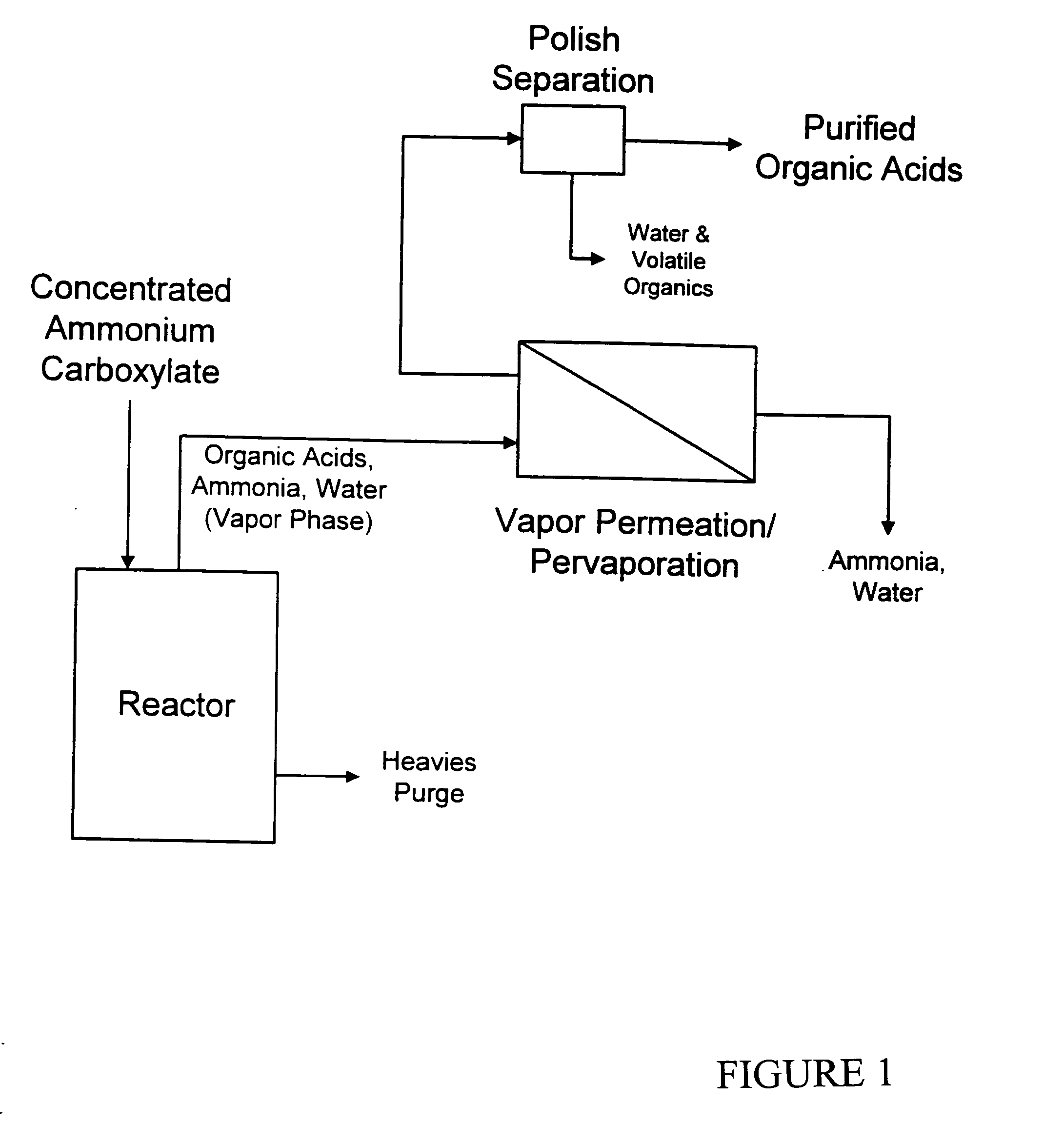

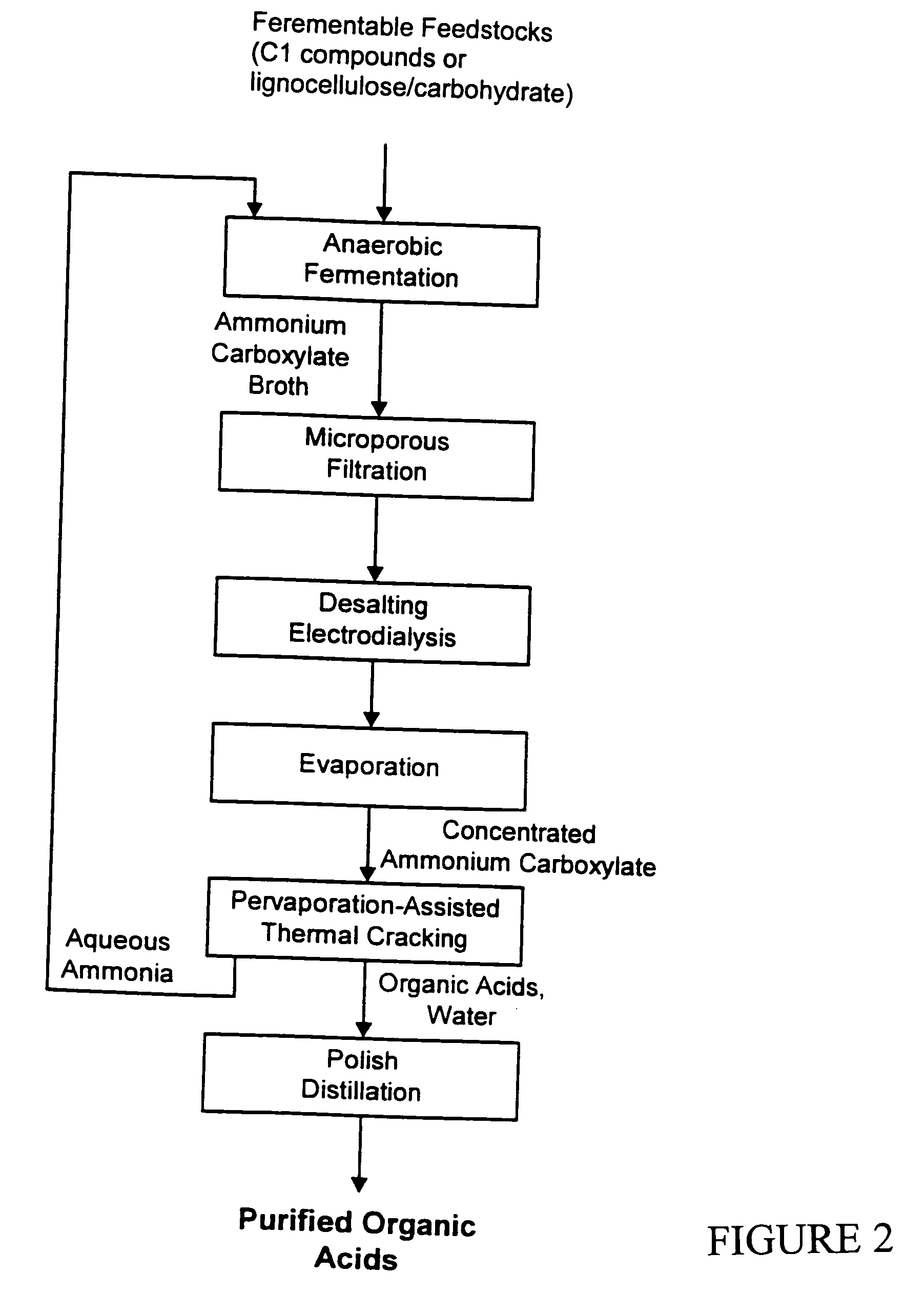

InactiveUS20050272135A1Easy to handlePreparation from carboxylic acid saltsOrganic compound preparationOrganic acidGas phase

A method of producing and purifying an organic acid by producing an aqueous solution of the ammonium salt of the organic acid through fermentation and / or bioconversion and neutralization. The solution is heated to thermally crack the ammonium salt of the organic acid producing a vapor phase of ammonia and water and organic acid which is thereafter passed in contact with a membrane permeable to water and ammonia and substantially impermeable to the organic acid vapor to concentrate the aqueous solution of organic acid, and remove the ammonia and excess water.

Owner:UCHICAGO ARGONNE LLC

Method for extracting succinic acid from fermentation liquor

ActiveCN101643400AOptimize process flowHigh extraction yieldPreparation from carboxylic acid saltsButanedioic acidMaterial consumption

The invention relates to a method for extracting succinic acid from fermentation liquor, comprising the following steps: 1) degerming and decontaminating succinic acid fermentation liquor to obtain succinate solution; 2) allowing the succinate solution to react with calcium chloride to generate calcium succinate precipitate; 3) carrying out solid-liquid separation on reaction liquid to obtain a calcium succinate solid; 4) allowing the calcium succinate solid to react with hydrochloric acid, and separating out a succinic acid solid at a reduced temperature; and 5) carrying out solid-liquid separation on the reaction liquid to obtain the succinic acid. The method has high yield, good product quality, small original auxiliary material consumption, low energy consumption and applicability to large-scale production.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

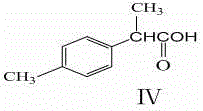

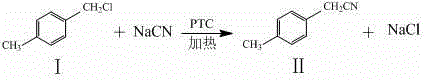

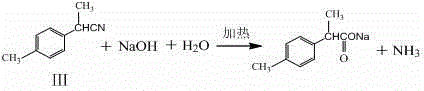

2-(4-methylphenyl)propionic acid syntehsis method

ActiveCN104402698AShort process routeReduce the discharge of three wastesPreparation from carboxylic acid saltsOrganic compound preparationPropanoic acidPropionitrile

The invention relates to a synthesis method of a fine chemical product 2-(4-methylphenyl)propionic acid. According to the method, para-xylene is adopted as a raw material, and a chlorination reaction is carried out, such that a compound I which is p-methylbenzyl chloride is obtained; p-methylbenzyl chloride is subjected to a nitrilation reaction, such that a compound II which is p-methylbenzyl cyanide is adopted; p-methylbenzyl cyanide is subjected to methylation, such that a compound III which is 2-(4-methylphenyl)propionitrile is obtained; and 2-(4-methylphenyl)propionitrile is subjected to hydrolysis acidification, such that a compound IV which is 2-(4-methylphenyl)propionic acid is obtained. The method provided by the invention has the advantages of short process route, low three-waste discharge, low environment pollution, no solid waste production during reaction processes, relatively low production cost, less chemical substances used during reaction processes, less raw material types, easy-to-obtain raw materials, simple operation, high yield, relatively mild process conditions, and the like.

Owner:柳州丰康泰科技有限公司 +2

Production method of mixed binary acid with long carbon chain

ActiveCN102795984AReduce pollutionImprove efficiencyPreparation from carboxylic acid saltsHydroxy compound separation/purificationCarbon chainTower

The invention belongs to the technical field of solid waste recovery and regeneration, and in particular relates to a production method of mixed binary acid with a long carbon chain. The method comprises the following steps of: with heavy constituents remained after ethanol obtained in the dodecanedioic acid refining process is recovered as raw materials, enabling the heavy constituents to react with and a superfluous alkali solution at the temperature of 95-100 DEG C to generate sodium binary acid with a long carbon chain and ethanol; recovering the ethanol in the reaction process by using an alcohol fog recovery tower; and after the reaction is ended, carrying out aftertreatment on the obtained sodium salt to obtain the mixed binary acid with the long carbon chain. According to the invention, the heavy constituents remained after the ethanol obtained in the dodecanedioic acid refining process is recovered as raw materials and reacts with the superfluous alkali solution to generate the binary acid with the long carbon chain, and thus not only are wastes utilized, but also the environment pollution is reduced, and the benefit is increased.

Owner:山东广通新材料有限公司

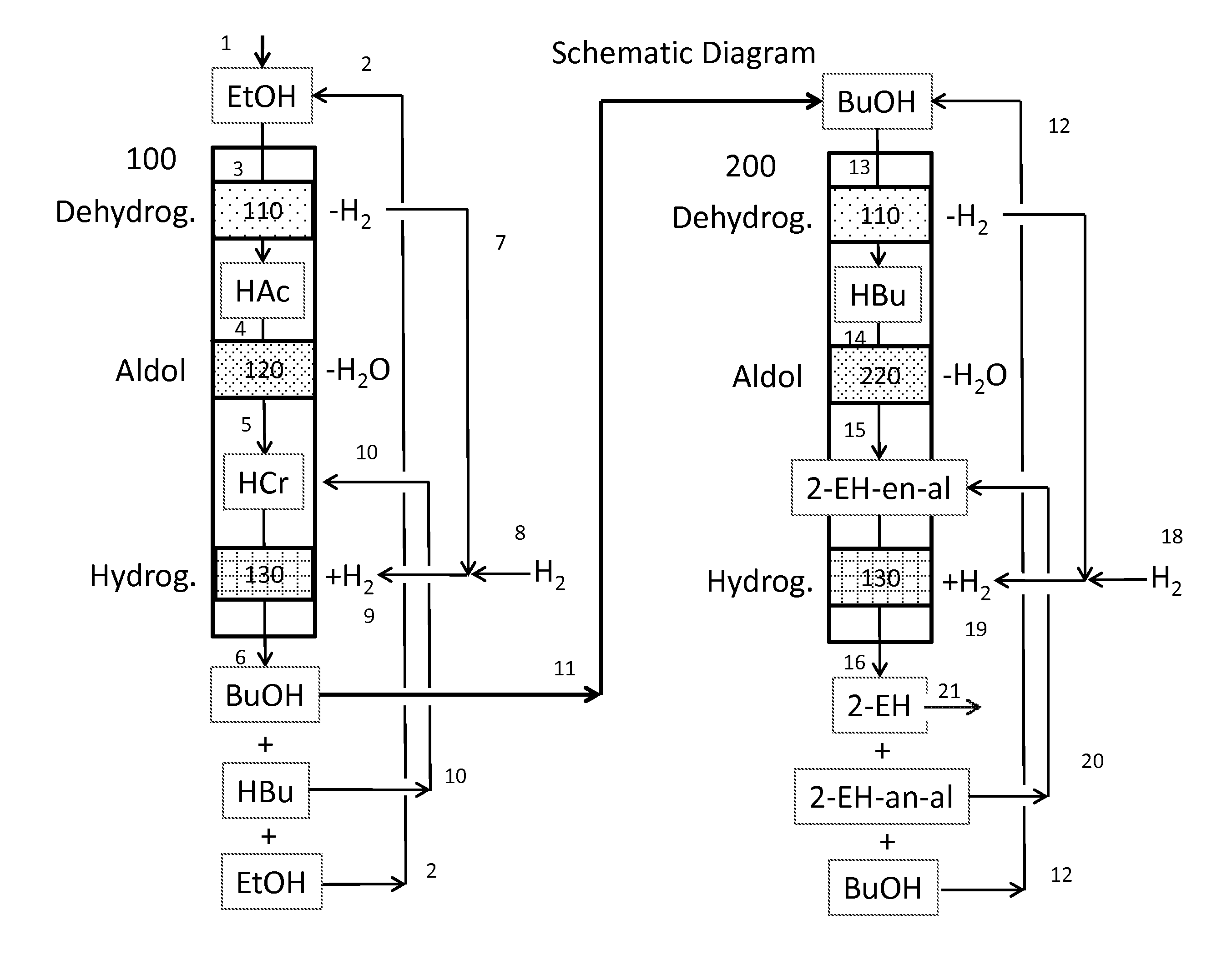

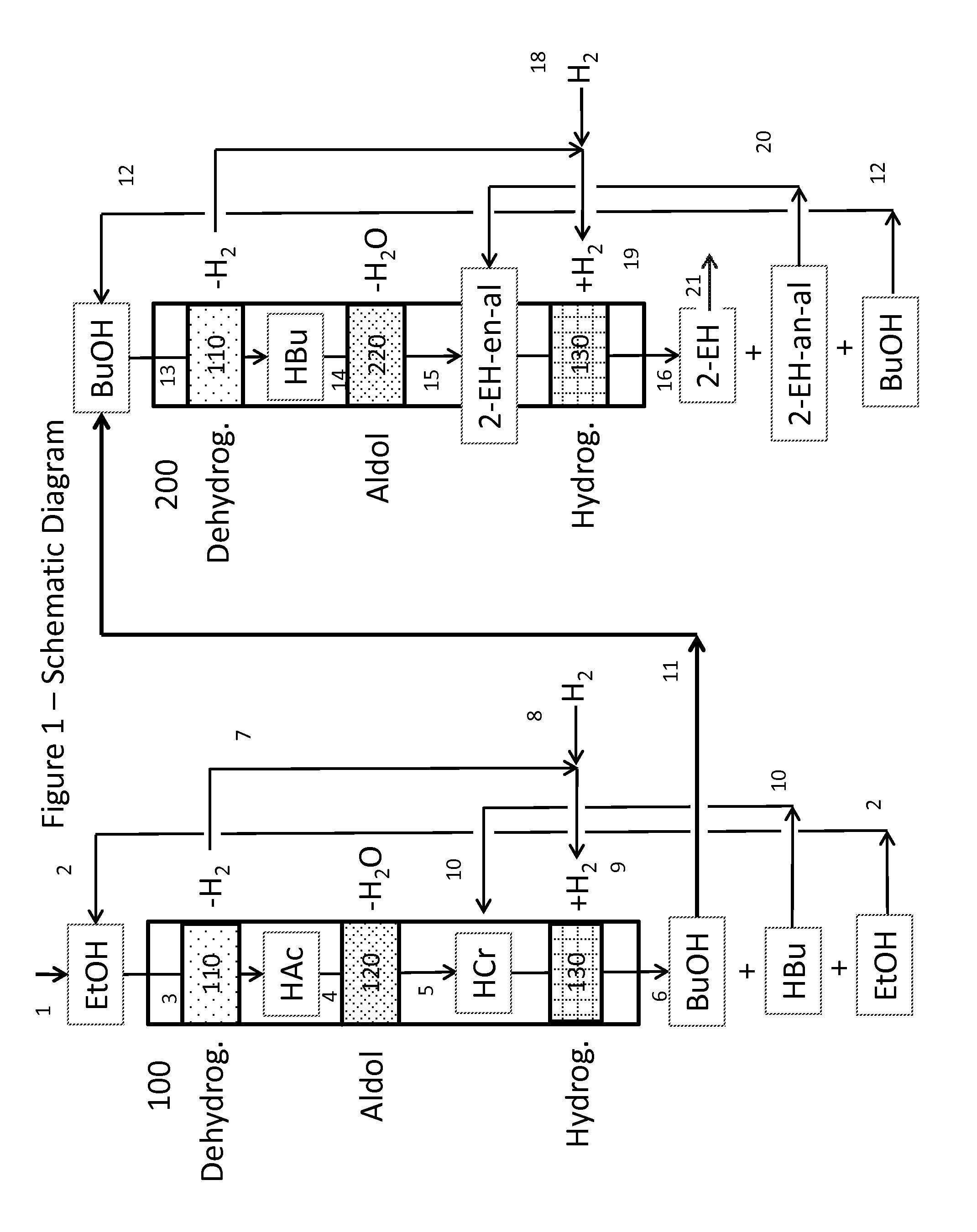

Dual catalyst system for the self-condensation of alcohols

ActiveUS20140088326A1Preparation from carboxylic acid saltsOrganic compound preparationCrotonaldehydeAlcohol

Disclosed is a process for the production of higher aldehydes from lower alcohols using a two-stage vapor phase heterogeneous catalyst system. Ethanol feeds afford aldehydes such as butyraldehyde and crotonaldehyde while butanol feeds yield 2-ethylhexanal and 2-ethylhexenal. Higher product selectivities are obtained when the alcohol is first dehydrogenated in the upper catalyst stage followed by aldol condensation of the resulting lower aldehyde to a higher aldehyde.

Owner:EASTMAN CHEM CO

Process of recycling terephthalic acid to produce DOTP (dioctyl terephthalate) by using polyester alkaline to reduce wastewater

InactiveCN104230714AExcellent ester contentSolve the problem that the color is difficult to meet the downstream use standardPreparation from carboxylic acid saltsOrganic compound preparationBenzeneActivated carbon

The invention discloses a process of recycling terephthalic acid to produce DOTP (dioctyl terephthalate) by using polyester alkaline to reduce wastewater. The process comprises the following process steps: adding terephthalic acid reclaimed materials and isooctyl alcohol into a reaction kettle in a certain proportion, stirring and heating, adding a catalyst and activated carbon when water yield is obviously reduced, continuously stirring and heating the mixture, controlling the temperature of the mixture to 190-230 DEG C, carrying out dealcoholization in vacuum after reaction is ended, heating to 265-285 DEG C and distilling under reduced pressure under -0.09MPa to -0.1MPa to obtain raw ester, adding H2O2 in a certain proportion to discolor; and finally, absorbing impurities by use of activated carbon and kaolin and carrying out filter-pressing to obtain a nearly colorless DOTP finished product. According to the process, the raw materials can adopt untreated alkaline which is low in purity and chromaticity to reduce wastewater to recycle the terephthalic acid, so that a complex pretreatment process is avoided, the terephthalic acid reclaimed materials are utilized to the greatest extent, and the high ester content and the low colour and luster of the DOTP product are guaranteed while the efficiency is high and the energy consumption is low.

Owner:上海蓓奕化工有限公司 +1

Treatment and resource-utilizing technology of tert-butyl peroxy benzoate production wastewater

InactiveCN102092906AHigh purityQuality improvementPreparation from carboxylic acid saltsSulfur-trioxide/sulfuric-acidBenzoic acidHigh concentration

The invention discloses a treatment and resource-utilizing technology of the production wastewater of tert-butyl peroxy benzoate (initiator is C). The technology is as follows: high concentration production wastewater is collected from the sewage outlet of a production device to perform stabilization treatment, and after the risk that the organic peroxide in wastewater is violently decomposed when heated is basically eliminated, the mixture of tertiary butanol and tert-butyl peroxide, sulfuric acid, benzoic acid and sodium chloride are recycled from wastewater. the mixture of tertiary butanol and tert-butyl peroxide, benzoic acid and sulfuric acid can be used repeatedly in production and sodium chloride is a by-product. After most of tertiary butanol and tert-butyl peroxide are removed and benzoic acid, sulfuric acid and sodium chloride are recycled, the wastewater performs hydrolysis-contact oxidation and C-Fe micro-electrolysis decoloring treatment and the main indexes of discharged water meet the requirements of the discharge standard of water pollutants for pharmaceutical industry chemical synthesis products category (GB21904-2008) on the water pollutants emission limits of new business.

Owner:NORTHWEST NORMAL UNIVERSITY

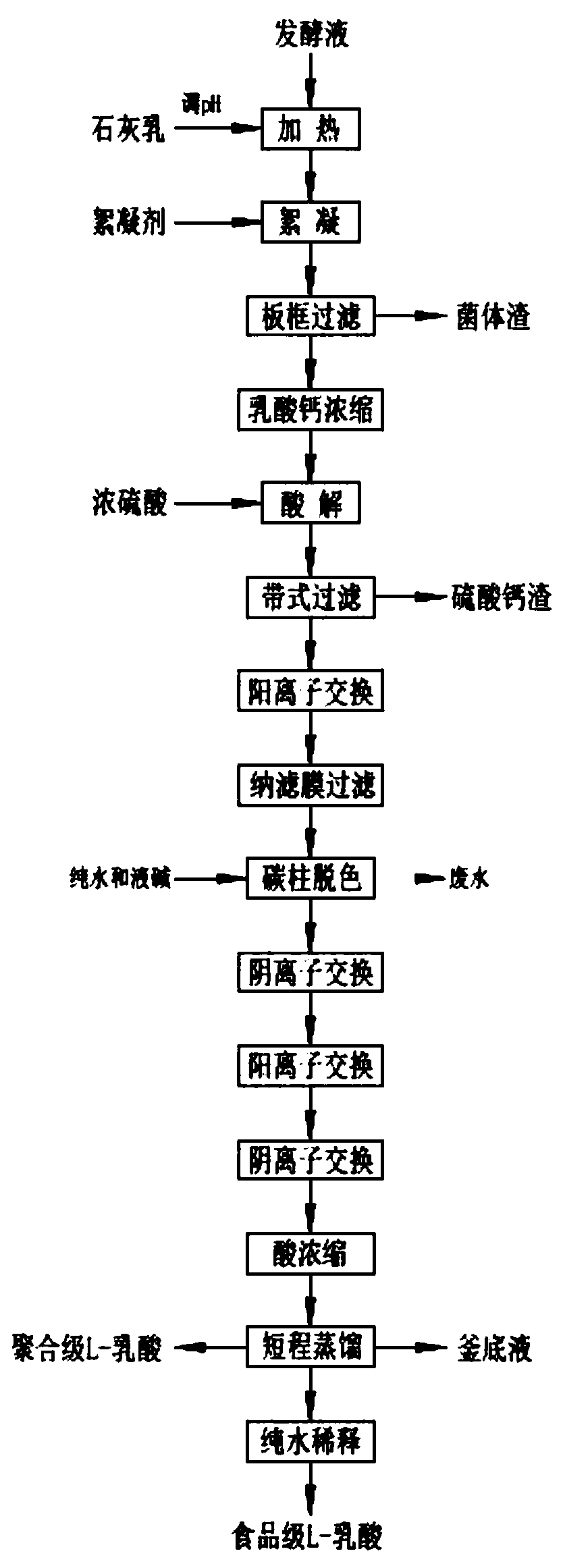

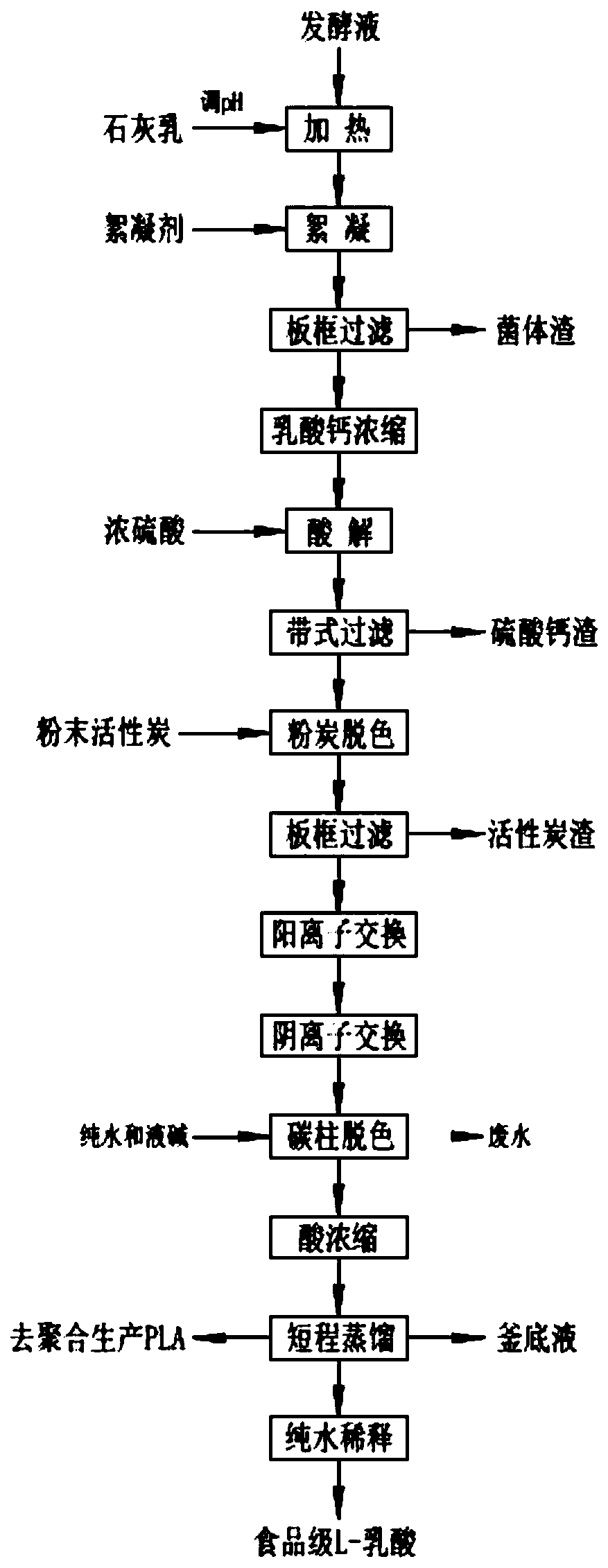

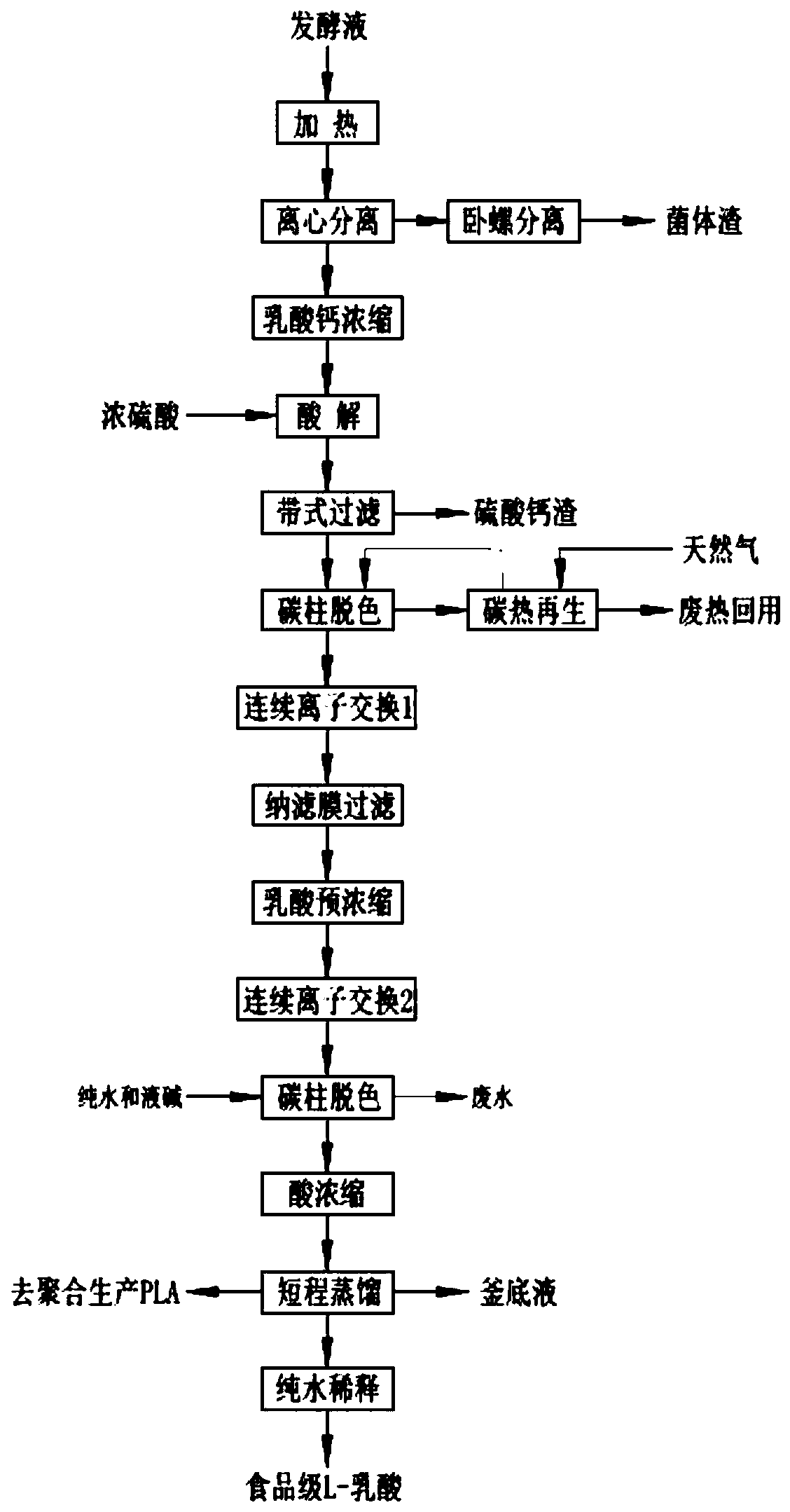

Method for purifying and refining L-lactic acid

ActiveCN111269107AOffset production costsReduce consumptionPreparation from carboxylic acid saltsCalcium/strontium/barium sulfatesBiotechnologyActivated carbon

The invention belongs to the technical field of L-lactic acid production, and particularly discloses a method for purifying and refining L-lactic acid. The method for purifying and refining L-lactic acid comprises the following steps: removing thalli in a fermentation liquor through separation to obtain thallus residues which can be used as a feed raw material; decolorizing an acidolysis filteredclear liquid by using activated carbon, feeding the decolorized acidolysis filtered clear liquid into a first ion exchange column, carrying out cation and anion exchange to obtain a primary ion exchange liquid, filtering the primary ion exchange liquid by using a nanofiltration membrane, carrying out pre-concentration, and sequentially carrying out cation and anion exchange to obtain a secondary ion exchange liquid; decolorizing the secondary ion exchange solution by adopting an activated carbon decolorizing column, and then concentrating to obtain a lactic acid concentrate with the L-lactic acid content of 80-90%; and carrying out short-path distillation and purification on the lactic acid concentrate to obtain high-purity food-grade lactic acid or produce polylactic acid. According to the L-lactic acid purification and refining method provided by the invention, the finished product quality of the L-lactic acid is improved, and the finally obtained L-lactic acid is good in quality andhigh in yield and particularly meets the quality requirement of the L-lactic acid serving as a PLA raw material.

Owner:安徽固德生物工程有限公司

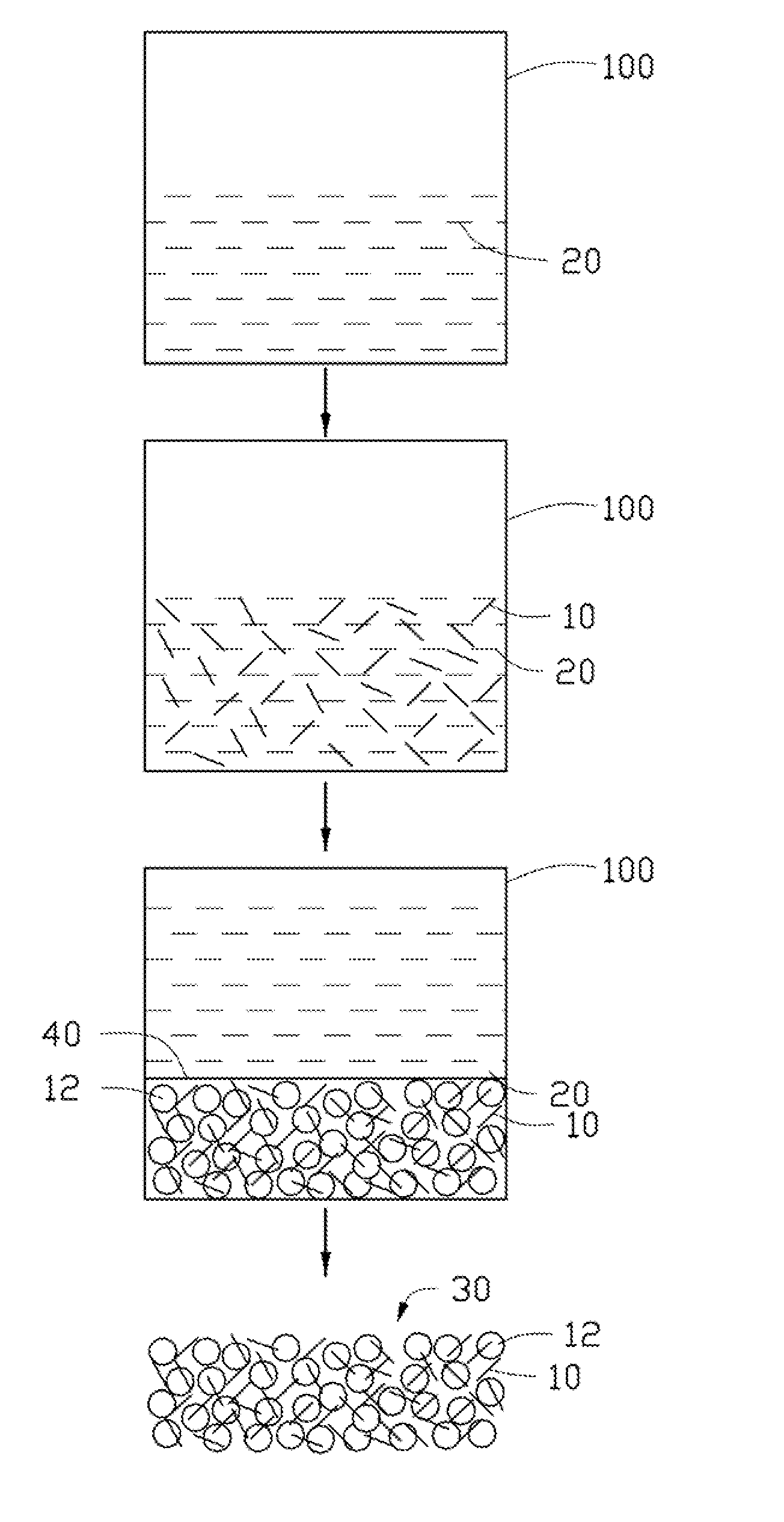

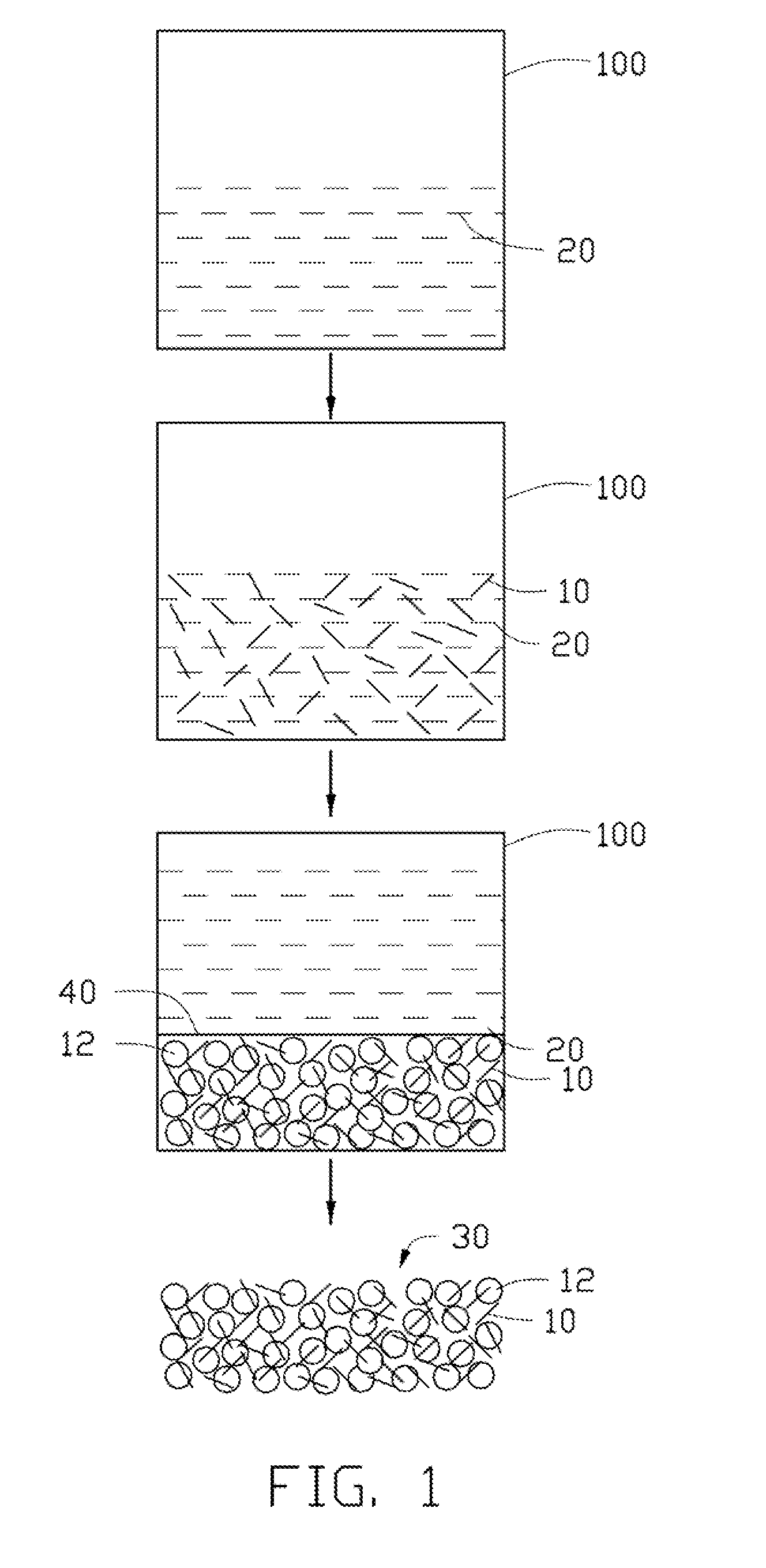

Method for making carbon nanotube metal composite

ActiveUS20110180968A1Preparation from carboxylic acid saltsOrganic compound preparationCarbon nanotubeSolvent

A method for making a carbon nanotube metal composite includes the following steps. A number of carbon nanotubes is dispersed in a solvent to obtain a suspension. Metal powder is added into the suspension, and then the suspension agitated. The suspension containing the metal powder is allowed to stand for a while. The solvent is reduced to obtain a mixture of the number of carbon nanotubes and the metal powder.

Owner:TSINGHUA UNIV +1

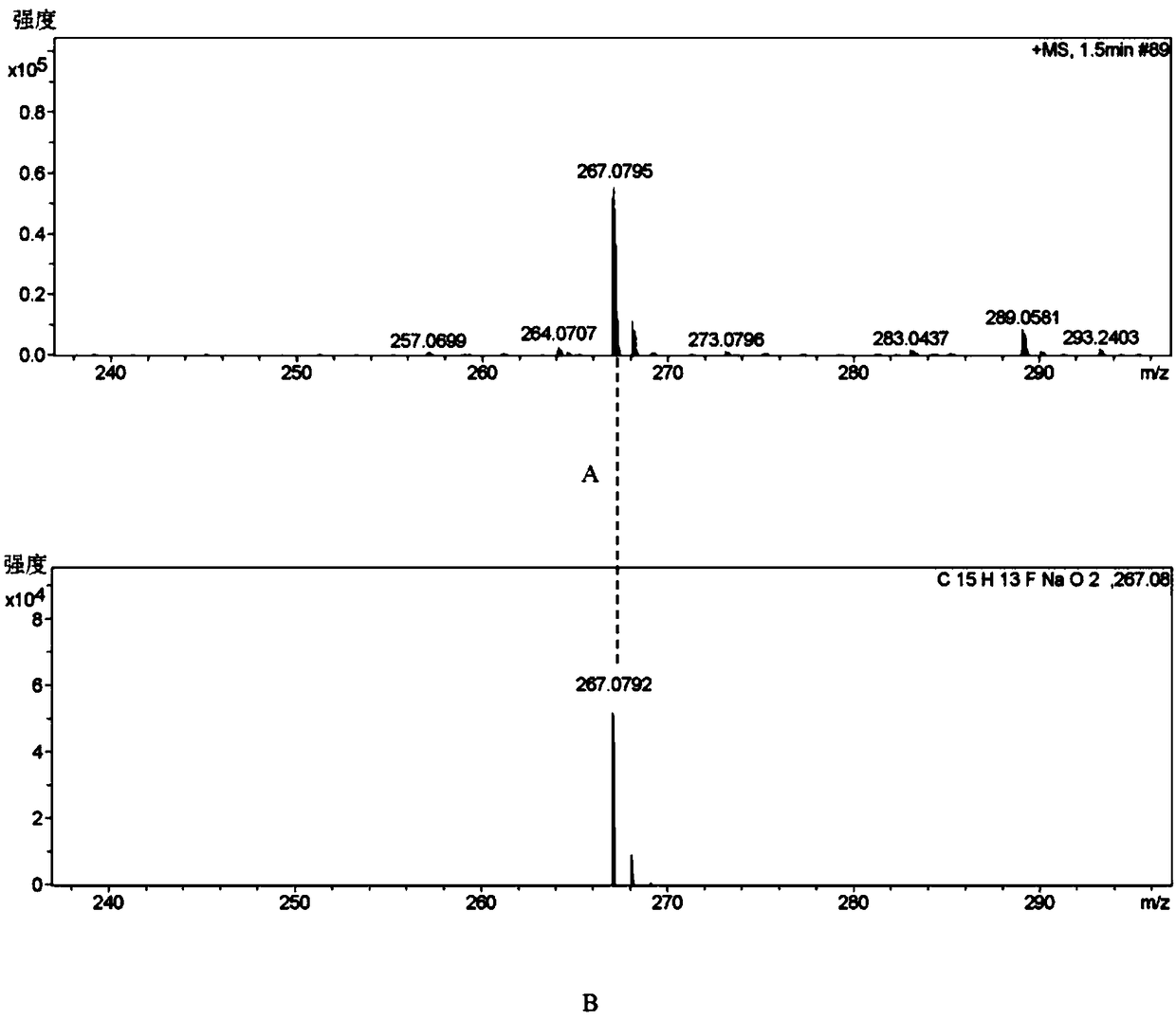

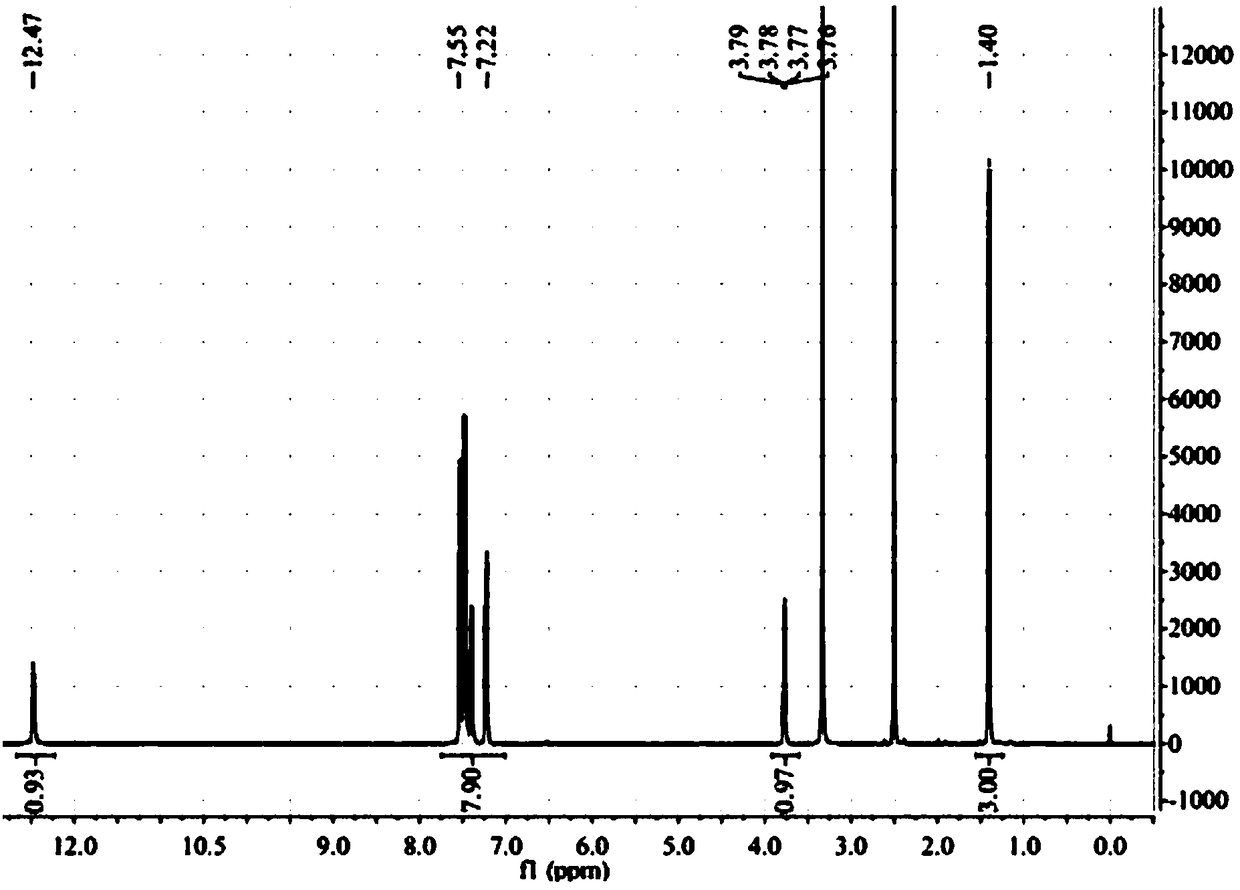

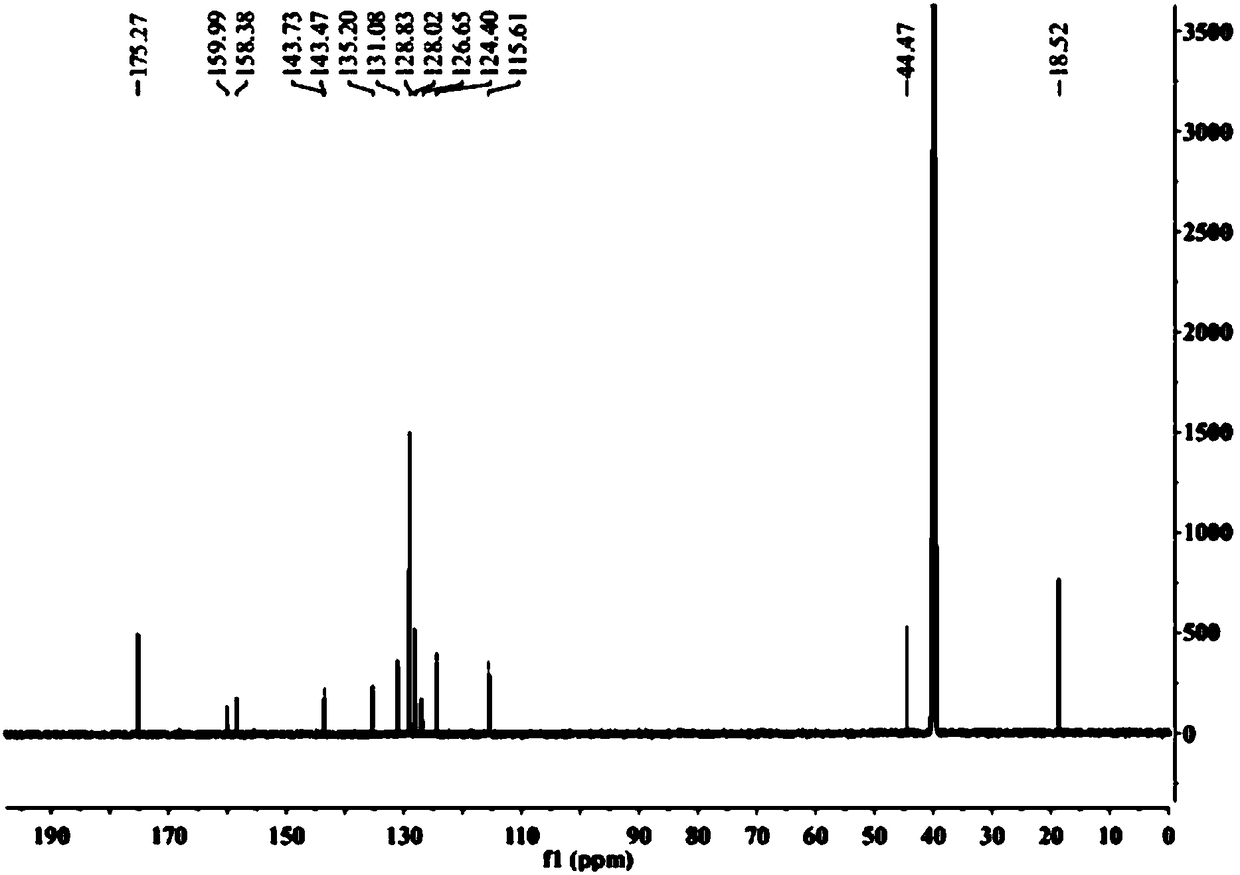

Preparation method of flurbiprofen and preparation method of flurbiprofen axetil

InactiveCN108558651ALow costHigh purityPreparation from carboxylic acid saltsOxygen-containing compound preparationChemical synthesisBromine

The invention relates to the field of pharmaceutical chemical synthesis, in particular to a preparation method of flurbiprofen and a preparation method of flurbiprofen axetil. The preparation method of the flurbiprofen comprises the steps of carrying out a Grignard reaction by using 4-bromine-2-fluorine biphenyl as a raw material, carrying out a coupling reaction, and acidizing to obtain the flurbiprofen; the yield is 90%, and the purity is 99.5%; then, the flurbiprofen axetil is prepared by using the flurbiprofen, obtained by the method, as a raw material, the yield reaches up to 90%, and thepurity reaches up to 99.5%. The preparation methods are high in quality controllability and industrial reproducibility.

Owner:上海峰林生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com