Patents

Literature

205results about How to "Safe and efficient production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane reinforcing and filling materials for coal mine

The invention relates to a polyurethane reinforcing and filling materials for coal mines. A component A is a polymethylene polyphenyl isocyanate, a component B is obtained via the follow steps: mixing and stirring the following ingredients: 33 to 70 wt% of polyether polyol, 0 to 40 wt% of polyester polyol, 0.1 to 1.5 wt% of composite catalyst, 6 to 30 wt% of composite flame retardant, 0 to 15 wt%of foaming agent, 0.5 to 2.5 wt% of stabilizer, 0.5 to 10 wt% of foam stabilizing agent, 0.1 to 5 wt% of antistatic agent , 5 to 25 wt% of plasticizer at 30 DEG C to 50 DEG C for 0.5 to 2 hrs; and when in use, the component A and the component B are together pressed into a coal (rock) layer according to the mass ratio of 1 to 2 : 1, penetrate into tiny cracks and expand, meanwhile react and generate CO2 gas and further expand, thereby effectively reinforcing and sealing processing areas. The compressive strength of polyurethane reinforcing and filling materials for coal mines is more than 55 MPa, the bond strength is more than or equal to 4 MPa, the foaming factor is less than or equal to two times. The invention can meet the need of coal mine safe production, and can be used for hydropower, construction, mining, transportation and other industries.

Owner:SHANXI ZHAOXIN BIO TECH

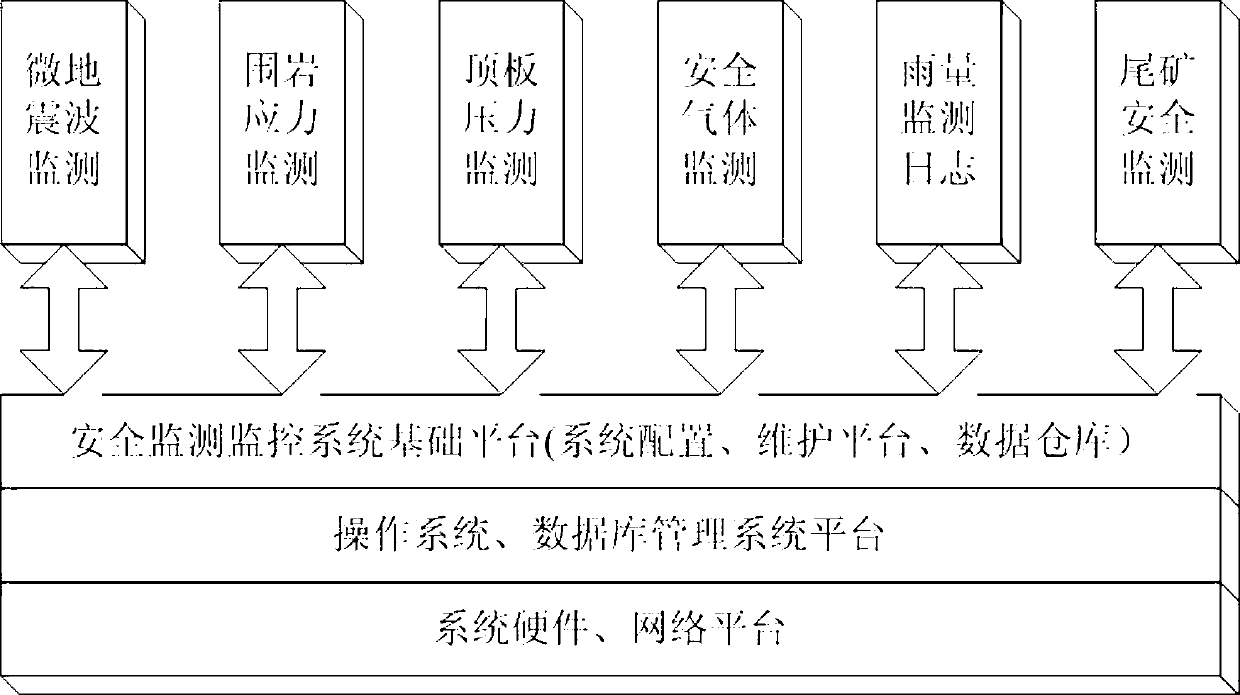

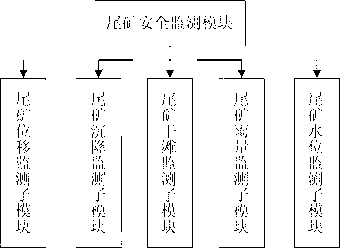

Digital mine safety monitoring and inspecting system

InactiveCN102999873AReduce outputSafe and efficient productionData processing applicationsInformation processingRelational system

The invention provides a digital mine safety monitoring and inspecting system which sequentially comprises four layers, namely a system hardware and network platform, an operation system and database management system platform, a safety monitoring and inspecting system base platform and a safety monitoring and inspecting system software platform, wherein in the four layers, the lower layer provides service for the upper layer and provides interactive connectors. The digital mine safety monitoring and inspecting system is integrally constructed on the hardware platform and network platform, and interaction between the digital mine safety monitoring and inspecting system and a bottom layer hardware facility and a monitoring and inspecting system is achieved through an operation system and a database management system, the interactive information is processed and stored in the safety monitoring and inspecting system base platform in distributing mode, and the safety monitoring and inspecting system software platform at the highest layer achieves scanning and processing on the interactive information through different functional subsystems and issues control information to the operation system and database management system platform through the safety monitoring and inspecting system base platform. The digital mine safety monitoring and inspecting system has the advantages of being capable of achieving safety monitoring, safety alarm and safety control on mines.

Owner:SHANDONG GOLD GROUP

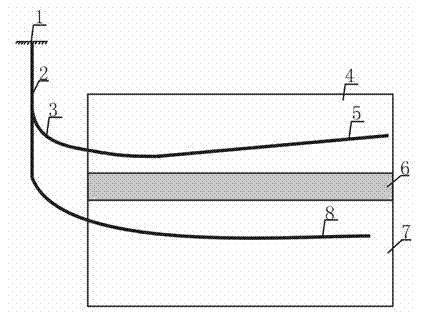

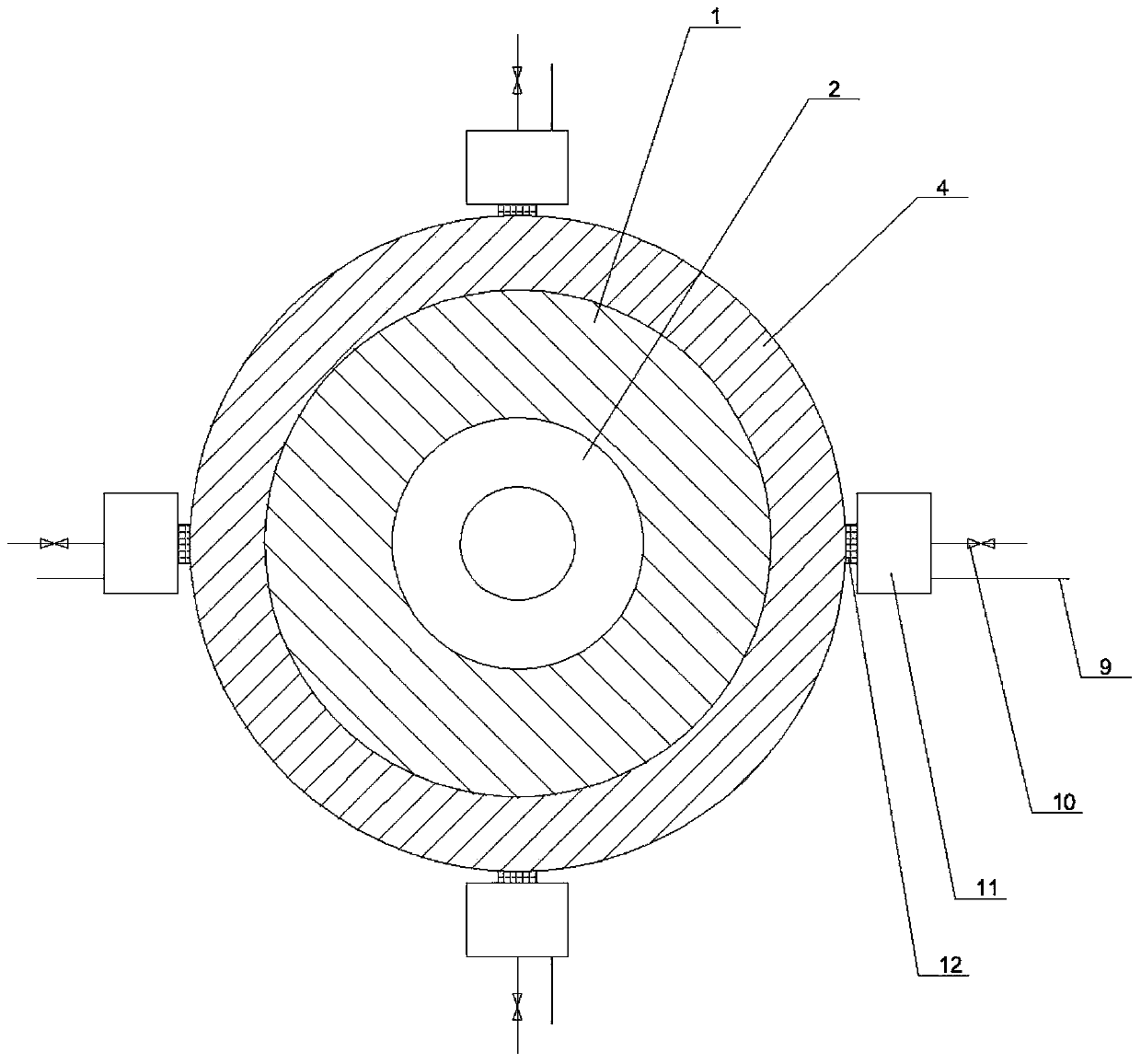

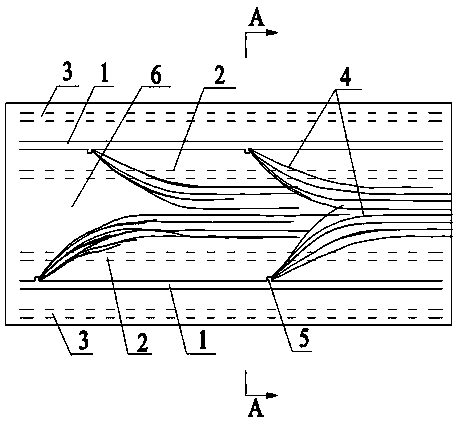

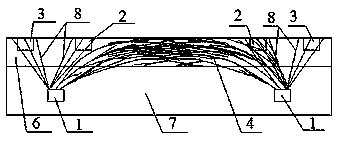

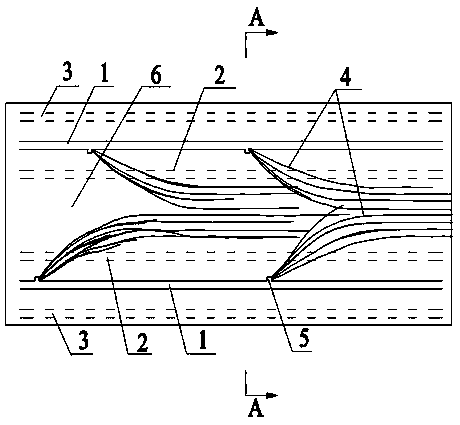

Permeability improvement technology for coal bed gas reservoir cap by using three-dimensional fracture network modification

InactiveCN102392677AImprove permeabilityIncrease contact areaFluid removalGas removalMining engineeringHorizontal wells

The invention relates to a permeability improvement technology for a coal bed gas reservoir cap by using three-dimensional fracture network modification. The technology is as follows: building a bedding horizontal well from ground to top and bottom plates of the coal bed of an area not mined; building bedding, three-dimensional cross-type or multi-branch long boreholes on the top and bottom plates of the coal bed of the area not mined through perforation and segmented fracturing or existing sinking and driving engineering, and then carrying out hydraulic fracturing; modifying the coal bed gas reservoir cap into a crisscross fracture network system to form a modified volume; building various types of drainage boreholes in the modified volume; and carrying out negative pressure extraction together with a fractured well, so that coal bed gas can be continuously desorbed and dispersed and then extracted out in large scale through the modified volume. According to the invention, the crisscross fracture network system is formed in the coal bed gas reservoir cap, so that the coal bed gas can be continuously desorbed and dispersed at negative pressure and then extracted out in large scale through the modified volume, thus the content of coal bed gas in the modified bed can be quickly reduced to be below the safety standard in the outburst prevention formulation, and safe and high-efficiency production of mines can be realized on the basis of forming scale coal bed gas development.

Owner:HENAN COAL CHEM IND GROUP INST

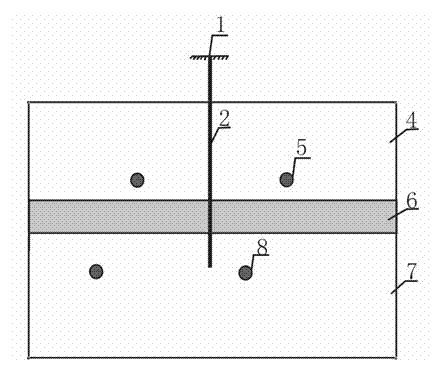

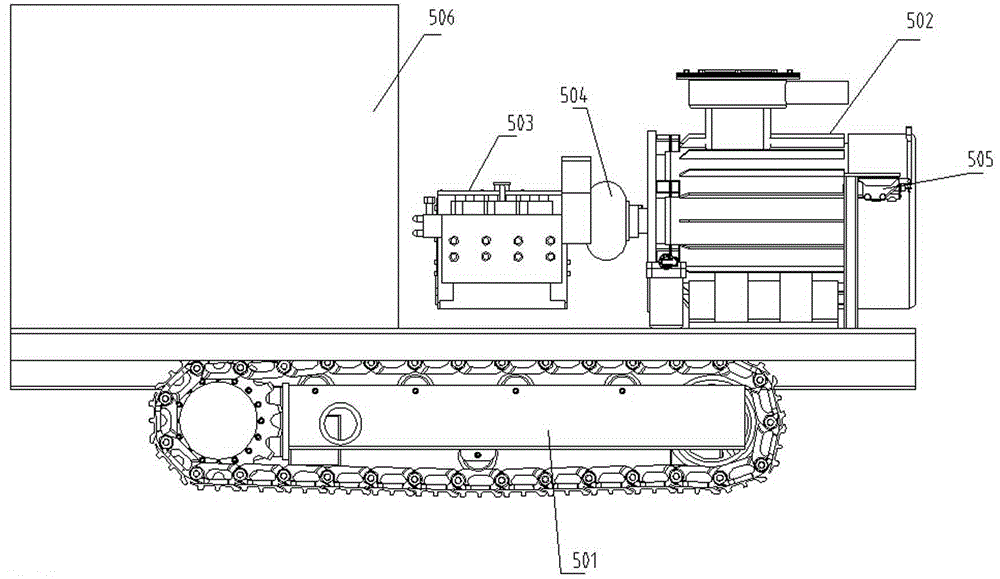

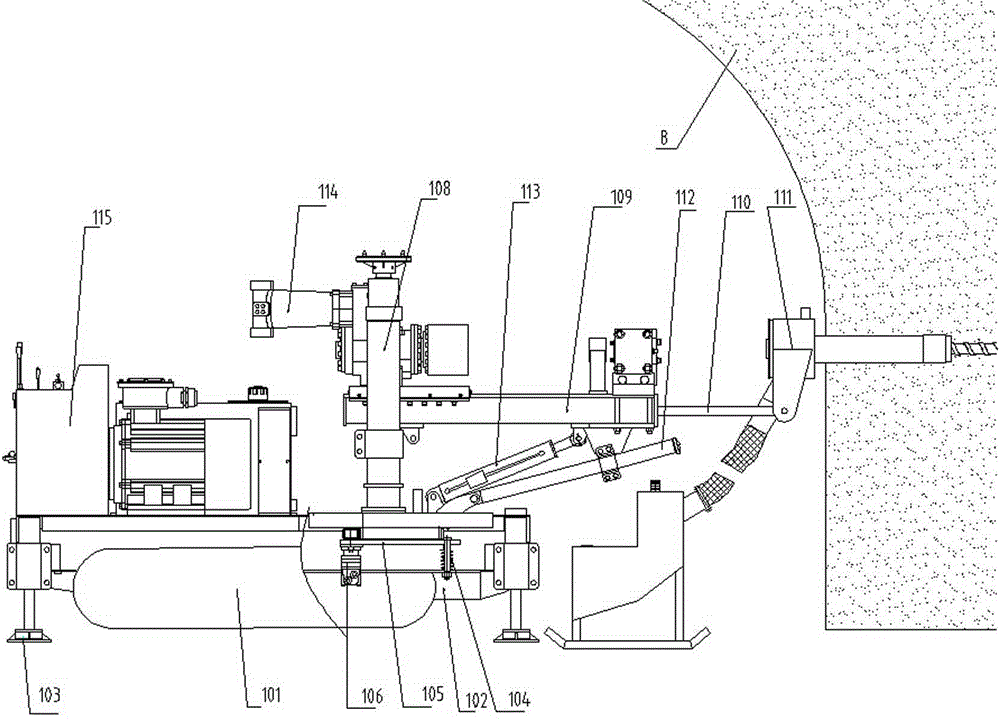

Coal mine downhole crawler type drilling and punching integrated equipment

ActiveCN104895484ASafe and efficient productionImprove extraction efficiencyConstructionsBorehole drivesPunchingDual purpose

Coal mine downhole crawler type drilling and punching integrated equipment comprises a crawler type hydraulic drilling machine, a high-pressure-resistant sealing drill stem, a drilling and punching dual-purpose drill bit, a high-pressure rotation connector and a high-pressure water pump station, wherein the body of the high-pressure-resistant sealing drill stem penetrates and is fixed in the power head inner hole of the crawler type hydraulic drilling machine, a power head provides rotation speed and torque to the body of the high-pressure-resistant sealing drill stem, one end of the high-pressure-resistant sealing drill stem is connected with the high-pressure water pump station through the high-pressure rotation connector, the high-pressure water pump station provides high-pressure water needed by punching, the other end of the high-pressure-resistant sealing drill stem is connected with the drilling and punching dual-purpose drill bit, and hydraulic operations can be performed after drilling without replacing the drill bit. The coal mine downhole crawler type drilling and punching integrated equipment has the advantages that streamlined operations of coal mine downhole gas pressure relief, drilling and punching can be completed by the equipment, safe and efficient production of outburst mines is guaranteed, coal seam coal and gas outburst danger is eliminated, a regional pre-drainage gas drilling construction period is shortened, coal seam drilling and punching and gas extraction efficiency are increased, and gas disaster prevention and control cost is reduced.

Owner:HENAN TIEFULAI EQUIP MFG CO LTD +1

Coal bed gas drainage effective radius measuring method

InactiveCN101824982AImprove accuracyIncrease the pumping rateSurveyGas removalEffective radiusProtection layer

The invention provides a coal bed gas drainage effective radius measuring method, relating to designing of spacing of wells for coal bed gas drainage and adapting to occasions of water power slit drainage, intensive hole stripping drainage, hydrofracturing drainage, hydraulic holing drainage, and coal bed gas drainage with enhanced drainage of protection layer mining. According to the correspondence of coal bed gas pressure and gas content, the effective radius of the coal bed gas drainage is determined by utilizing the gas pressure change conditions so as to direct the implementation of the effective radius determination of the coal bed gas drainage. An observing hole is constructed on a design point as required, then is sealed and is provided with a pressure gage; When the pressure is stable, a drainage hole is constructed and networked for drainage, the pressure changing condition of gas at the observing hole is observed and well recorded so as to obtain the effective radius of the coal bed gas drainage corresponding to the specific drainage time, thus laying a foundation for designing a drainage scheme and achieving the purpose of safe and efficient production.

Owner:CHINA UNIV OF MINING & TECH

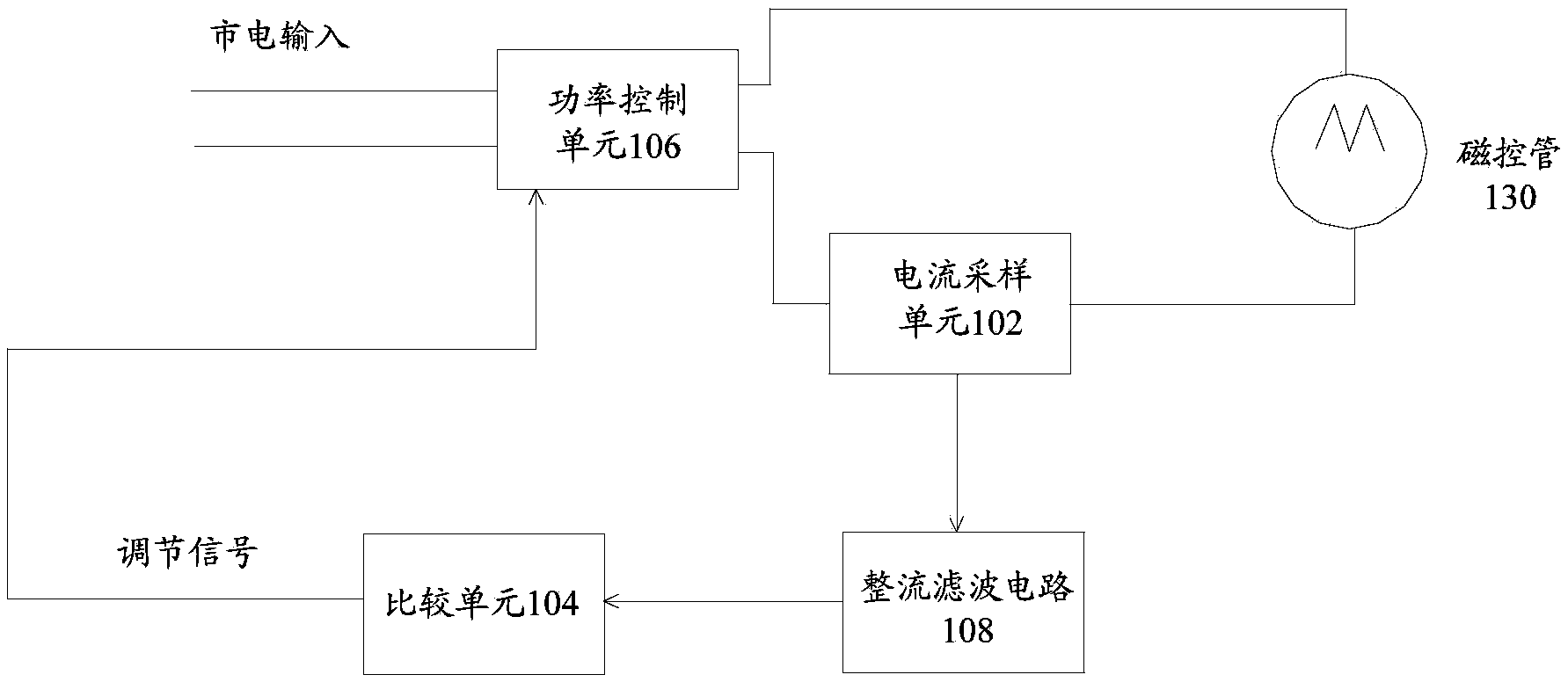

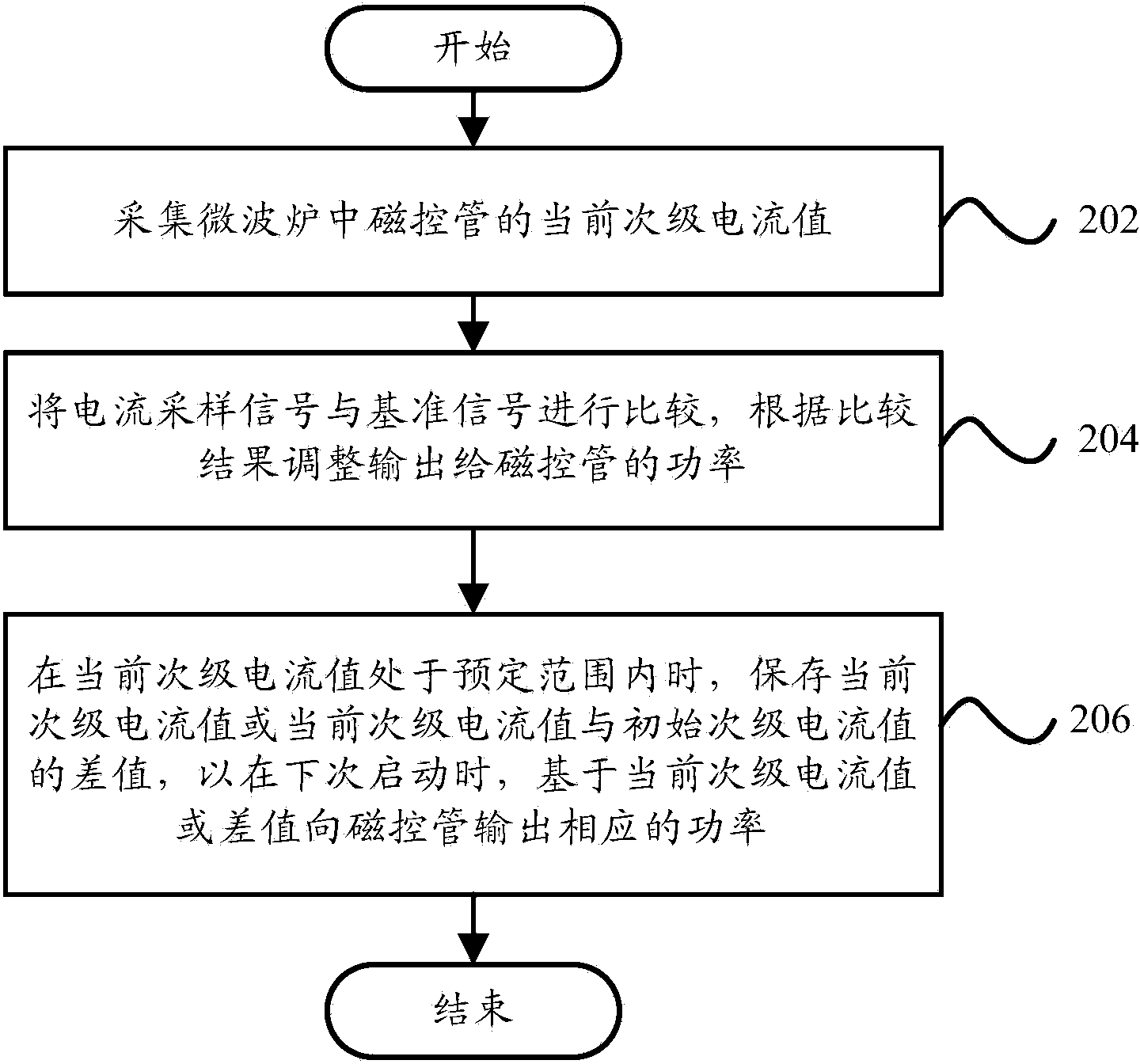

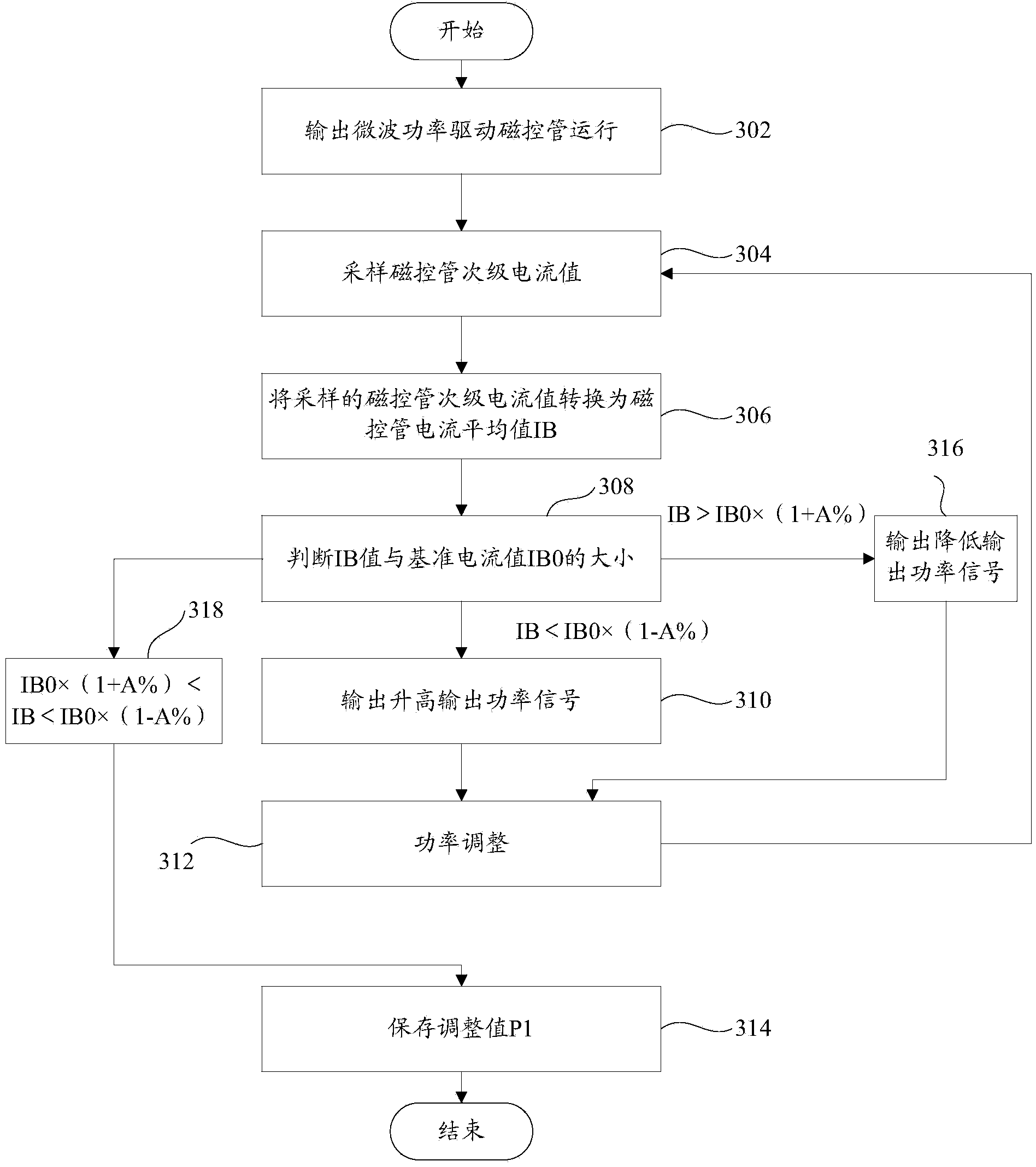

Power regulating circuit, microwave oven and power regulating method

ActiveCN103906285AIncrease productivityLow costDomestic stoves or rangesLighting and heating apparatusPower flowMicrowave oven

The invention provides a power regulating circuit, a microwave oven and a power regulating method. The power regulating circuit comprises a current sampling unit, a comparing unit and a power control unit. The current sampling unit is used for collecting current secondary current values of a magnetron in the microwave oven. The comparing unit is used for receiving current sampling signals from the current sampling unit, comparing the current sampling signals with a reference signal, outputting regulating signals to the power control unit according to comparison results, and storing current secondary current values or the difference values of the current secondary current values and an initial secondary current value when the current secondary current values are within a preset range, so that the power control unit can output power to the magnetron based on the current secondary current values or the difference values in the next-time starting process. The power control unit is used for regulating the power output to the magnetron according to the regulating signals of the comparing unit. Through the technical scheme, the power output to the magnetron can be regulated automatically to obtain proper power values, and the output power of microwave ovens leaving a factory is made to be maintained the same basically.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

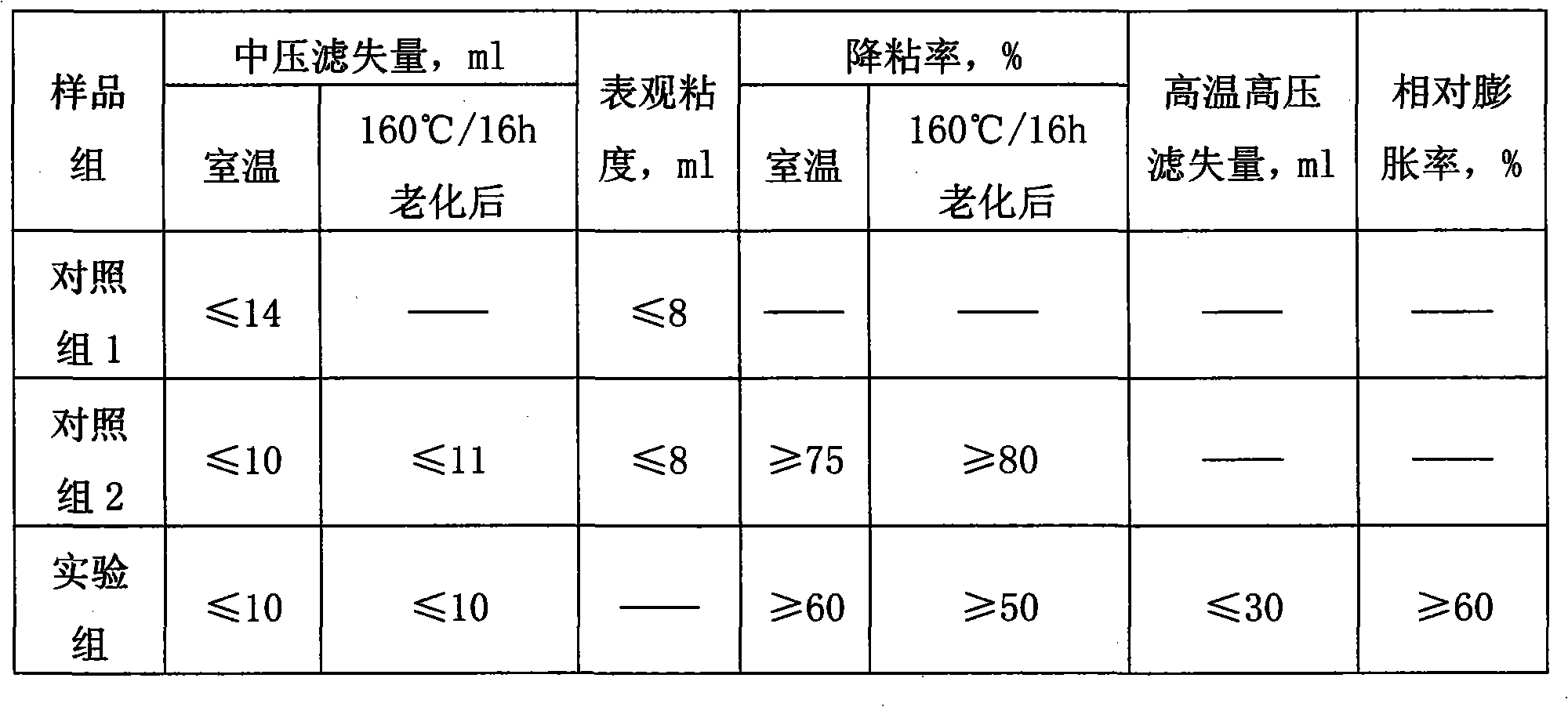

Anti-sloughing diluted filtration reducing agent for drilling fluid and preparation method thereof

ActiveCN101560378AReduce manufacturing costGood viscosity reduction effectDrilling compositionFiltrationPotassium hydroxide

The invention relates to an anti-sloughing diluted filtration reducing agent for drilling fluid and a preparation method thereof. The filtration reducing agent is prepared from the following raw materials by weight portion: 80 to 120 portions of substance containing humic acid, 30 to 80 portions of sodium metabisulfite, 300 to 500 portions of water, 10 to 30 portions of ammonium hydrolyzed polyacrylonitrile, 2 to 15 portions of cross linking agent, 30 to 50 portions of potassium hydroxide, 5 to 20 portions of complexing agent, 1 to 10 portions of urea and 10 to 20 portions of organic silicone resin. The preparation method comprises the following steps: weighting the water, the potassium hydroxide, lignite or peat or weathered coal and the sodium metabisulfite by weight portion, adding the materials into a stirred autoclave, sealing the stirred autoclave, raising the temperature, performing reaction and reducing the temperature; adding the ammonium hydrolyzed polyacrylonitrile, the cross linking agent, the complexing agent, the urea and the organic silicone resin by weight portion into the stirred autoclave after the temperature reduction, sealing the stirred autoclave, raising the temperature and stirring for reaction; and discharging, and performing spray drying on a product to obtain a finished product. The anti-sloughing diluted filtration reducing agent has good comprehensive performance, can prevent slough of mineshafts and reduce the filtration loss and viscosity of slurry, and is easy to realize safe production.

Owner:石家庄华莱鼎盛科技有限公司

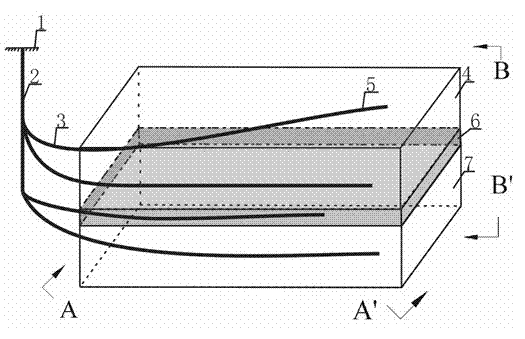

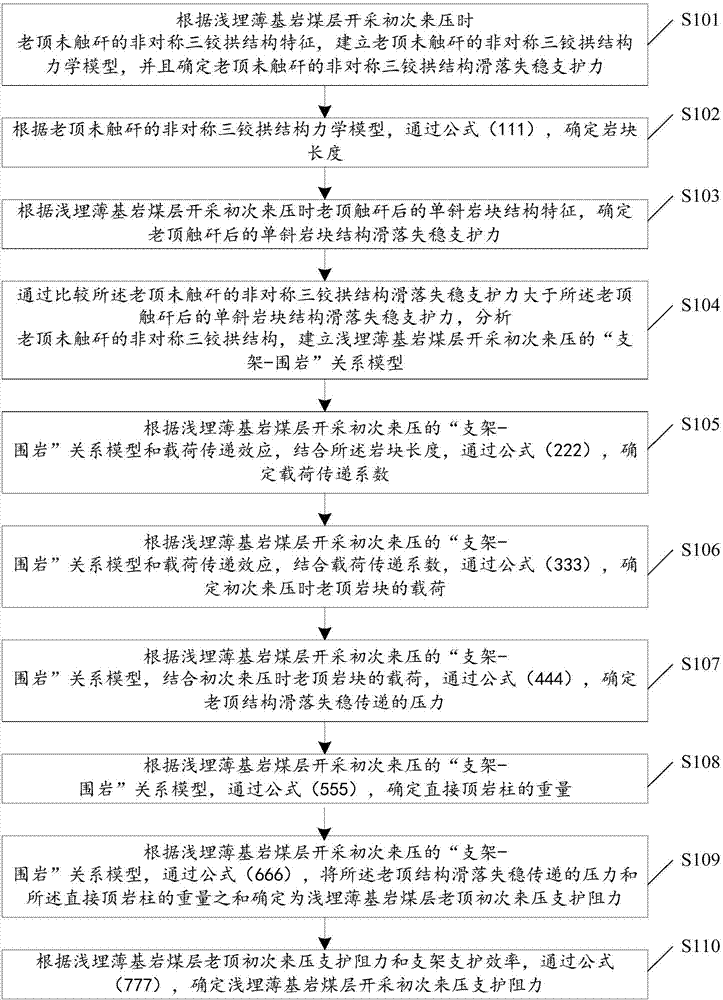

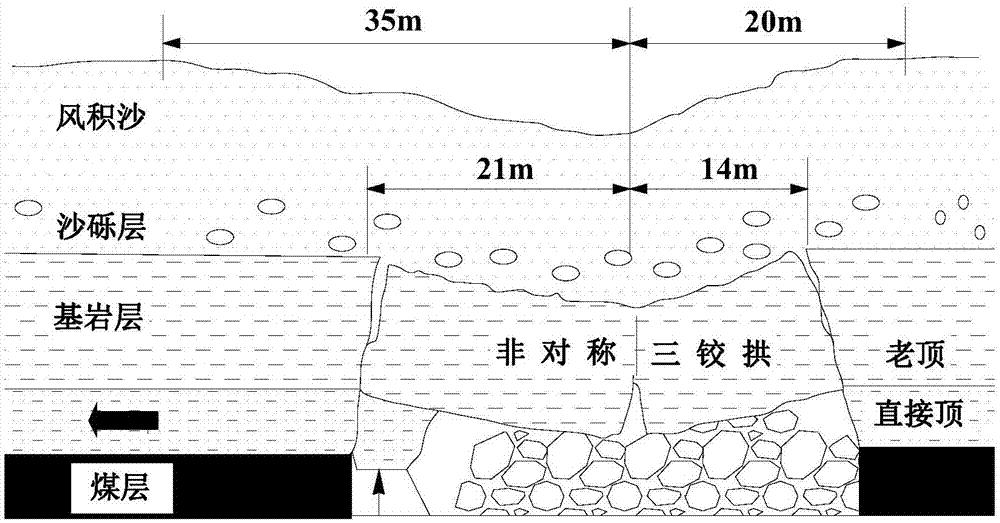

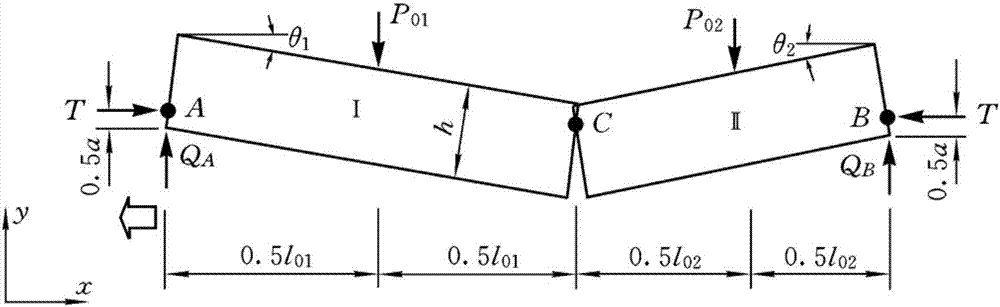

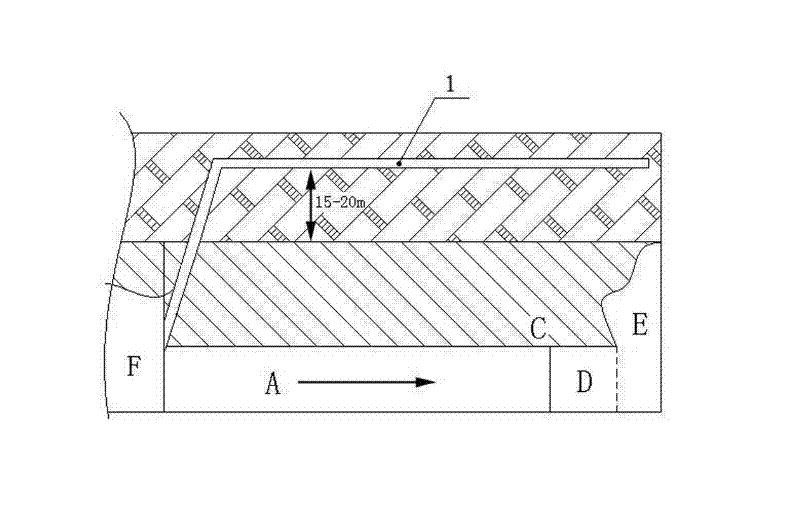

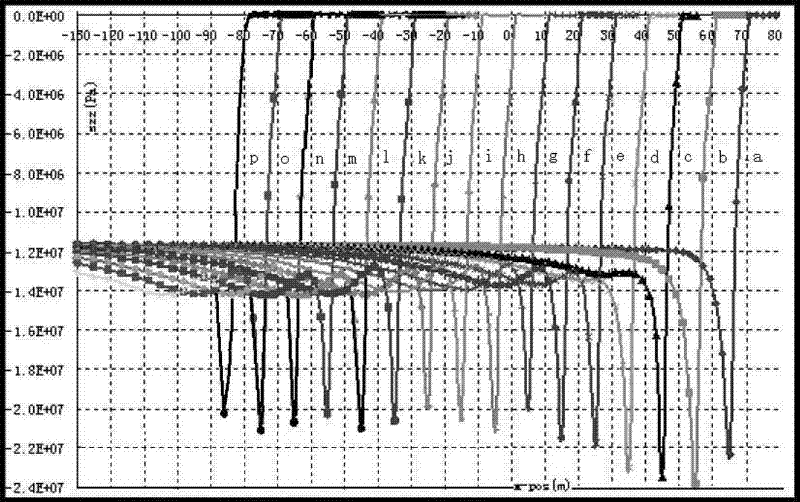

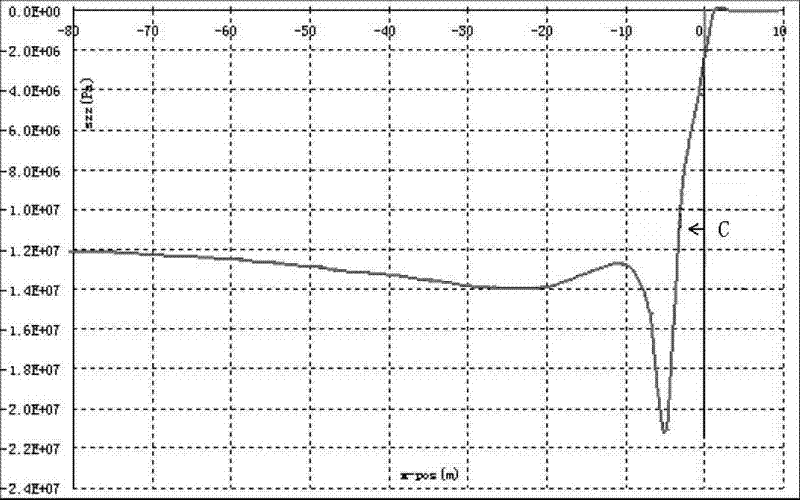

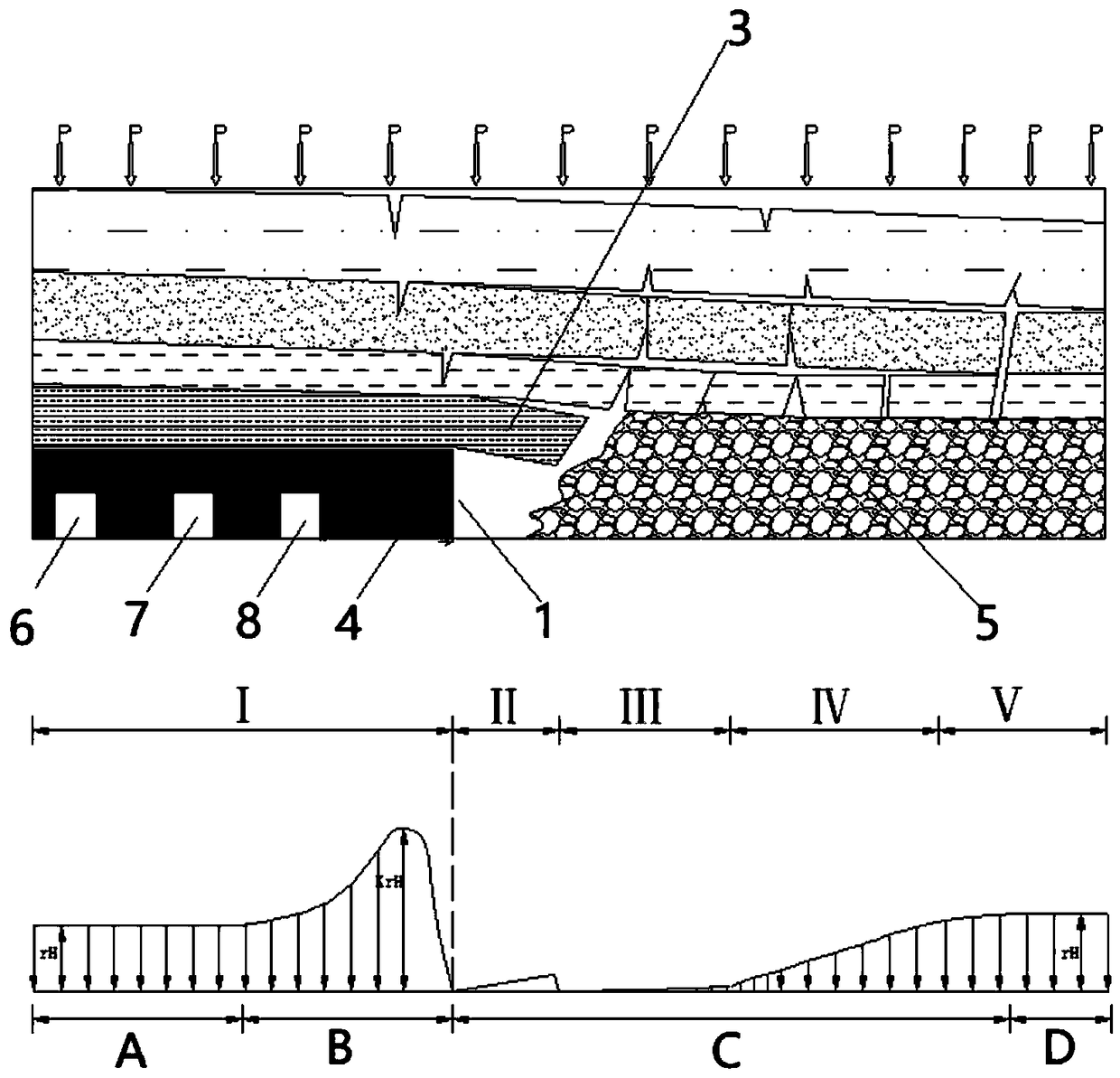

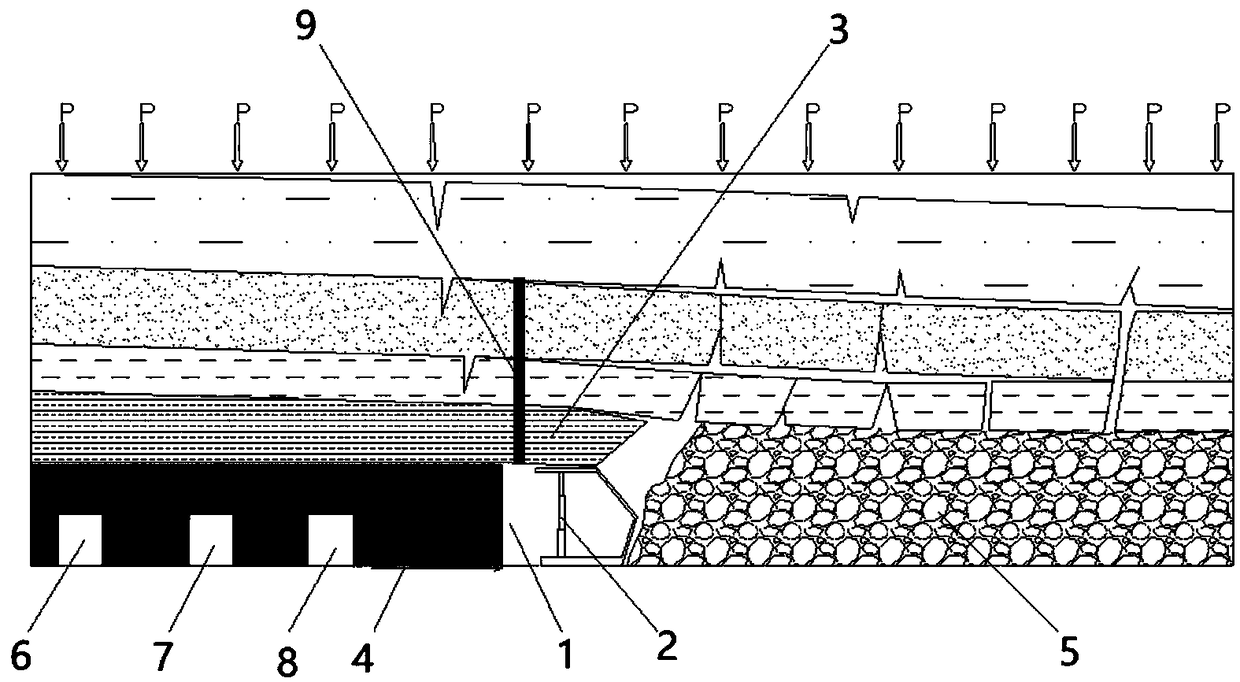

Method for determining first weighting supporting resistance of shallow thin bedrock coal seam mining

ActiveCN107391859ARealize the load transfer phenomenonPoint out the load transfer phenomenonGeometric CADDesign optimisation/simulationNon symmetricRelational model

The invention discloses a method for determining the first weighting supporting resistance of shallow thin bedrock coal seam mining, and relates to the technical field of coal seam mining. The method comprises the steps that the sliding instability supporting force of a non-symmetric three-hinged arch structure with an upper roof not picked and the length of a rock are determined; the sliding instability supporting force of a monocline rock structure is determined after the upper roof is picked; the non-symmetric three-hinged arch structure with the upper roof not picked is analyzed, and a first weighting support-surrounding rock relation model of shallow thin bedrock coal seam mining is established; a load transfer coefficient is determined; the load of the rock on the upper roof during first weighting is determined; the pressure transferred through sliding instability of the upper roof structure is determined; the weight of an immediate roof rock column is determined, and the first weighting supporting resistance of shallow thin bedrock coal seam upper roof is determined. According to the method, a top plate structure for first weighting of a shallow thin bedrock coal seam is fully considered, a mechanical model is established for resolving, the reasonable supporting resistance of a support in the first weighting period is obtained, and the method has important theoretical significance and practical value in achieving safe and efficient production of a mine.

Owner:XIAN UNIV OF SCI & TECH

Foamable phenolic resin strengthening and filling material for coal mine

ActiveCN102558763AAdjustable curing speedCured body with high strengthUnderground chambersTunnel liningOrganic acidUrea

The invention relates to a foamable phenolic resin strengthening and filling material for coal mine. In the foamable phenolic resin strengthening and filling material for coal mines, a component A is one of inorganic acid and organic acid or a mixture of inorganic acid and organic acid; and a component B is prepared by mixing 90 to 100 weight parts of urea modified phenolic resin with solid content of 65 to 90 weight percent, 6 to 10 weight parts of composite fire retardant, 0 to 15 weight parts of foaming agent, 1 to 5 weight parts of stabilizing agent, 1 to 15 weight parts of cosolvent, 2 to 16 weight parts of antistatic agent and 10 to 30 weight parts of plasticizer, stirring at the temperature of between 30 and 50 DEG C and reacting for 0.5 to 2 hours. When the foamable phenolic resin strengthening and filling material is used, the component A and the component B are mixed and injected into a coal (rock) layer according to the weight ratio of (1-2) : 1 and permeated into small cracks to expand and generate curing reaction for strengthening and sealing the region. According to the foamable phenolic resin strengthening and filling material for coal mines, the compressive strength is more than 40 MPa; the bonding strength is more than or equal to 3.0 MPa; and the foaming coefficient is less than or equal to two times. The foamable phenolic resin strengthening and filling material for coal mines can meet the requirement of coal mine on safety production and can be applied to the industries such as hydroelectric powder, buildings, mining, traffic and the like.

Owner:SHANXI ZHAOXIN BIO TECH

Comprehensive and integrative gas drainage method

The invention discloses a comprehensive and integrative gas drainage method which can be used for solving the problems that gas drainage is difficult to realize due to soft coal beds and low air permeability of the existing mines and the drainage effect of the current single gas drainage technology is unsatisfied. The method disclosed by the invention comprises the following steps: (1) high-position fracture borehole drainage of the top plate of a coal bed; (2) heterotropic high-position borehole drainage of a return airway; and (3) upper corner pipe-laying drainage of a gob. According to the invention, the stress field and fracture field caused by mining and a gas migration rule are fully utilized, so that drilled holes are high in drainage efficiency and flexible in arrangement, a drainage system is simple, the gas concentration at a drainage outlet can be up to 15-24%, and the gas drainage efficiency can reach 55-67.3%. The method disclosed by the invention is a new technology and method in fully mechanized caving face gas control methods, can be used for reducing the occurrence of excessive gas accidents and reducing the losses of life and property, has very important and far-reaching significance and is strongly worthy to be popularized and applied.

Owner:DATONG COAL MINE GRP

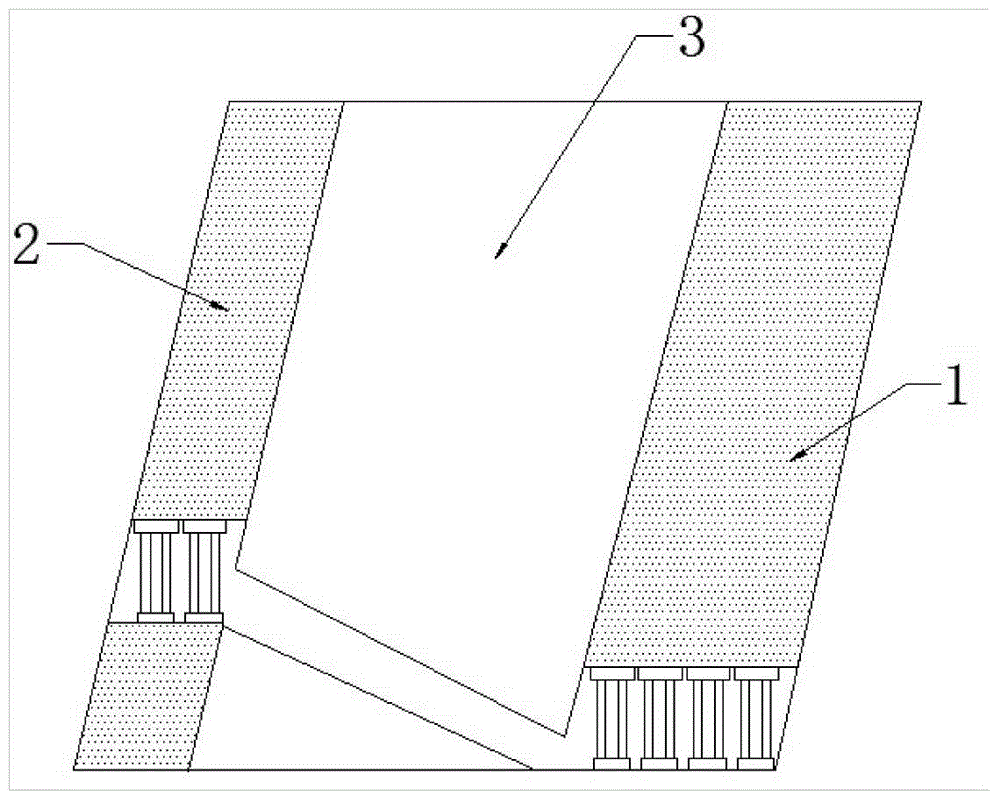

High-dipping extremely-close-distance coal seam top coal caving mining method

InactiveCN104088643AHigh-yield and efficient miningLarge inclinationUnderground miningSurface miningTelecommunicationsCoal

The invention provides a high-dipping extremely-close-distance coal seam top coal caving mining method. According to the method, a transportation gateway is constructed along one side of a coal layer bottom plate and an air returning gateway is constructed on the other coal layer; the elevation of a bottom plate of the air returning gateway is 4-4.5m higher than that of a bottom plate of the transportation gateway; rectangular roadways are constructed between the two gateways at an interval of 10m and are used as connection roadways; hydraulic brackets are distributed on two coal layers along the thickness directions of the coal layers; each circulating unit advance of a worktable bracket is the same as the distance of the connection roadways; in a top coal caving process, top coal discharged by the coal layers of the transportation gateway and manually-mined falling coal in a manner of manually shoveling coal and filling into a scraper plate conveyor to be transported out; the top coal discharged by the coal layers of the air returning gateway is filled into enamel chutes of the connection roadways in a manner of manually shoveling the coal to flow into a bracket tail beam of the coal layers of the transportation gateway, and is put into the scraper plate conveyor to be transported out by manually shoveling the coal. The high-dipping extremely-close-distance coal seam top coal caving mining method has the advantages of being simple in arrangement of a working surface, strong in adaptability, good in ventilation, relatively good in safety degree, large in supporting space and high in production efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

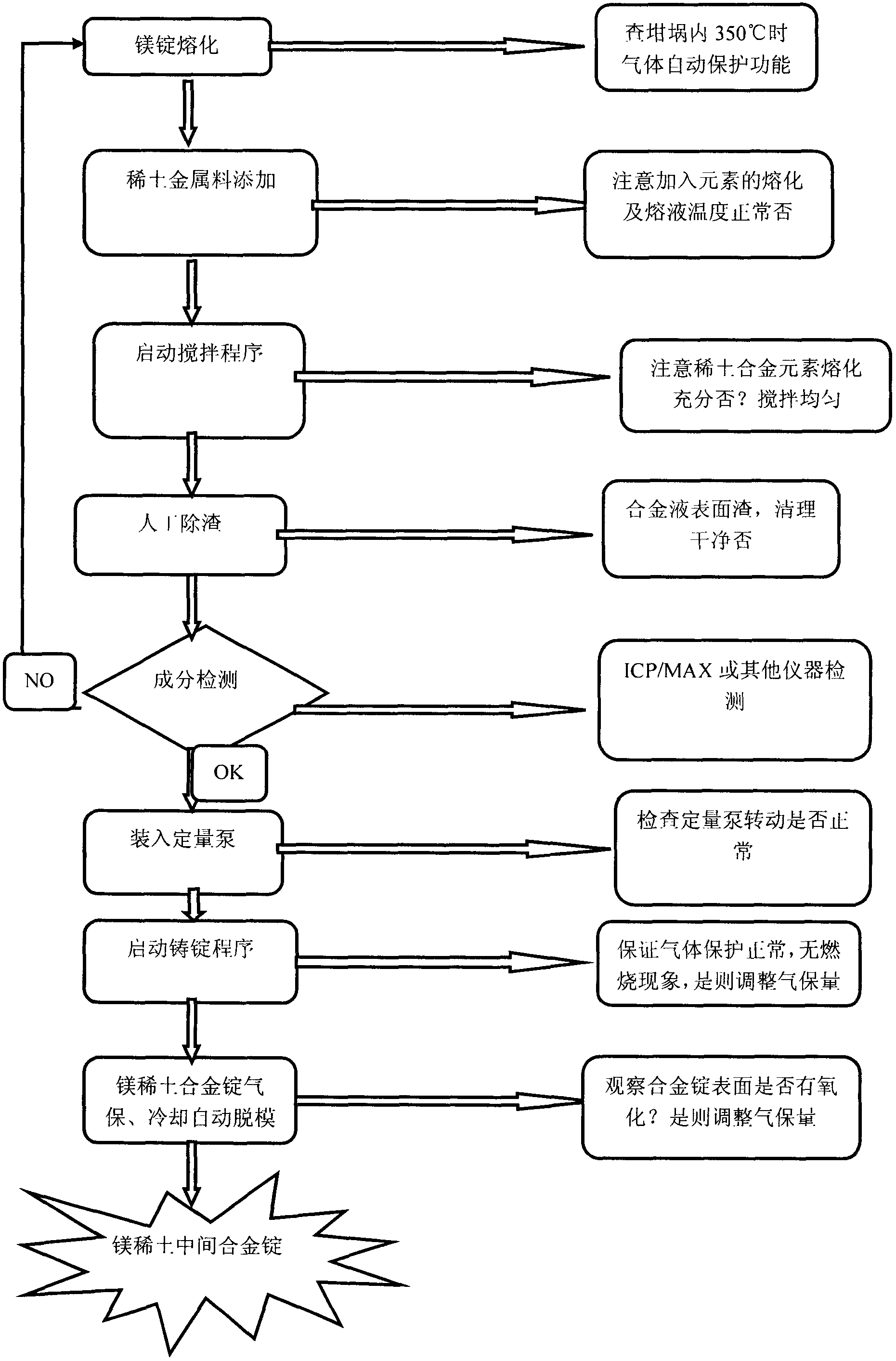

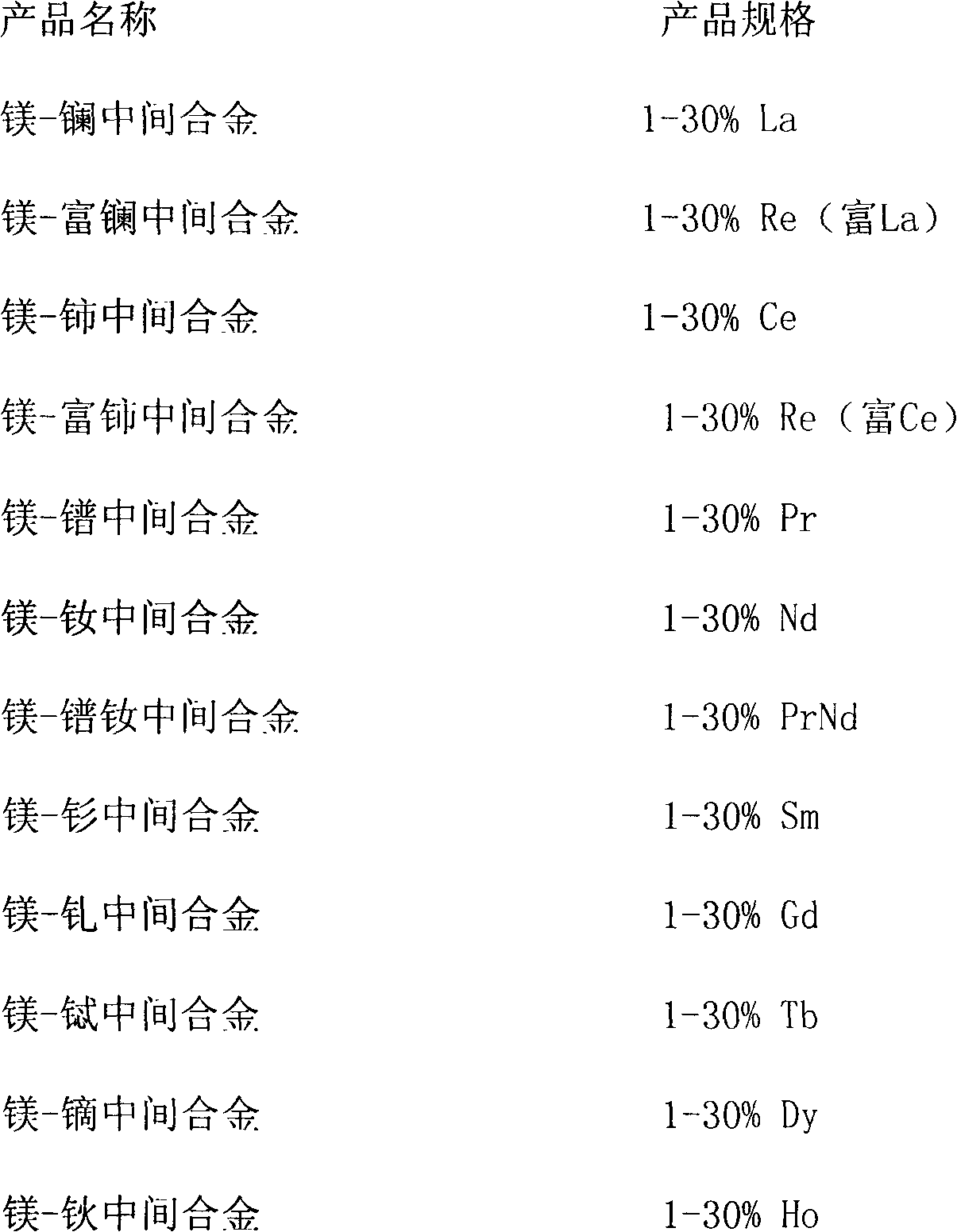

Method for continuously and automatically producing magnesium-rare earth intermediate alloys

ActiveCN103540777ASafe and efficient productionNo pollution in the processMolten metal pouring equipmentsRare earthNickel free

The invention discloses a method of continuously and automatically producing 16 magnesium-rare earth intermediate alloys such as a magnesium-neodymium intermediate alloy. The method comprises the following steps: after melting a magnesium ingot raw material by a finery, adding a rare earth metal material, manually deslagging, and automatically stirring and homogenizing by a system, and sampling and testing alloy components which are qualified; then pouring an alloy liquid to an ingot case of a pig moulding machine through a metering pump to form a continuous and automatic ingot casting; and cooling the alloy liquid to form standard magnesium-rare earth intermediate alloys. The key point of the invention is as follows: the method is applicable to continuous and automatic ingot casting production of 16 magnesium-rare earth intermediate alloys such as the magnesium-neodymium intermediate alloy, so that the labor intensity of production is reduced, and the production safety is greatly improved in anhydrous environment production. The produced product is consistent and high in yield. According to a crucible manufactured by a nickel-free high temperature alloy steel plate, carbon content is not introduced in the production process, the production efficiency is high, and the method is applicable to continuous production on a large scale, free from environmental pollution. Waste residues can be recycled, thereby truly realizing safe and efficient production of the magnesium-rare earth intermediate alloys on a large scale.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

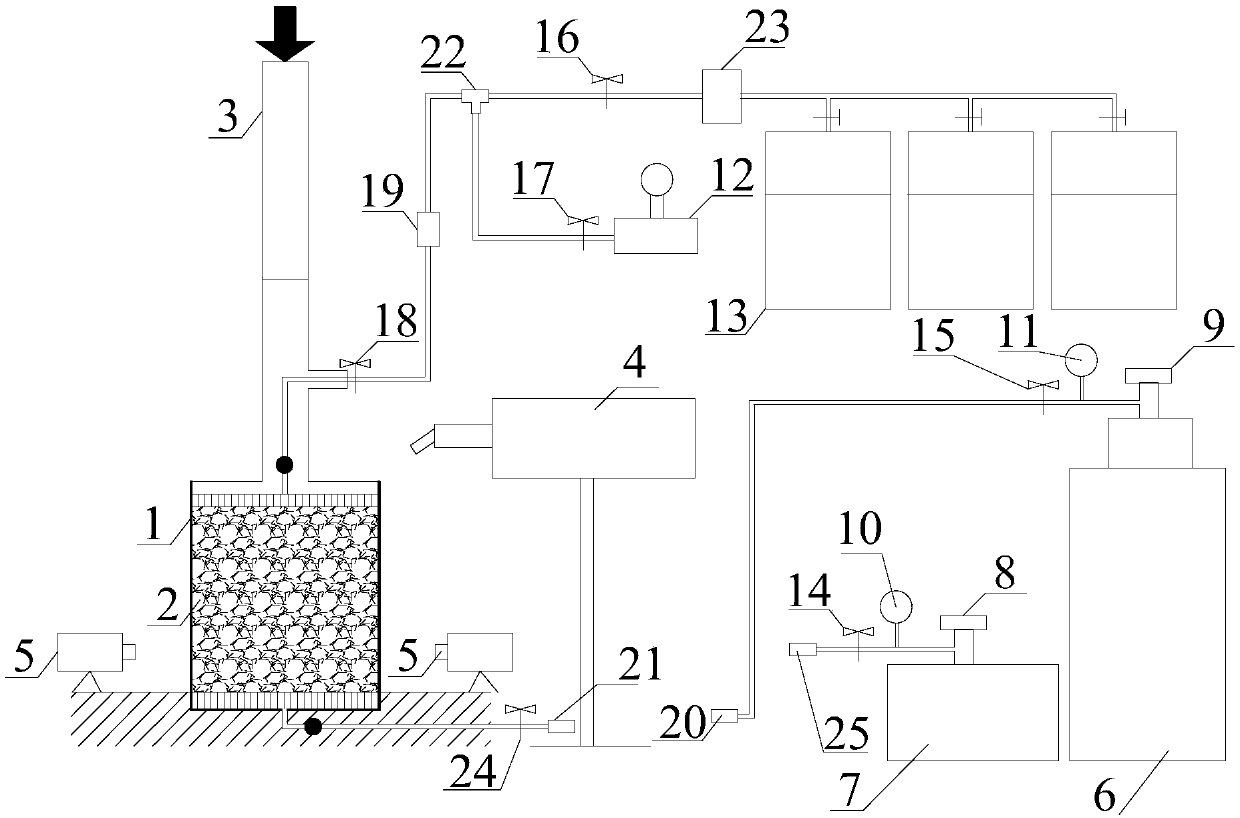

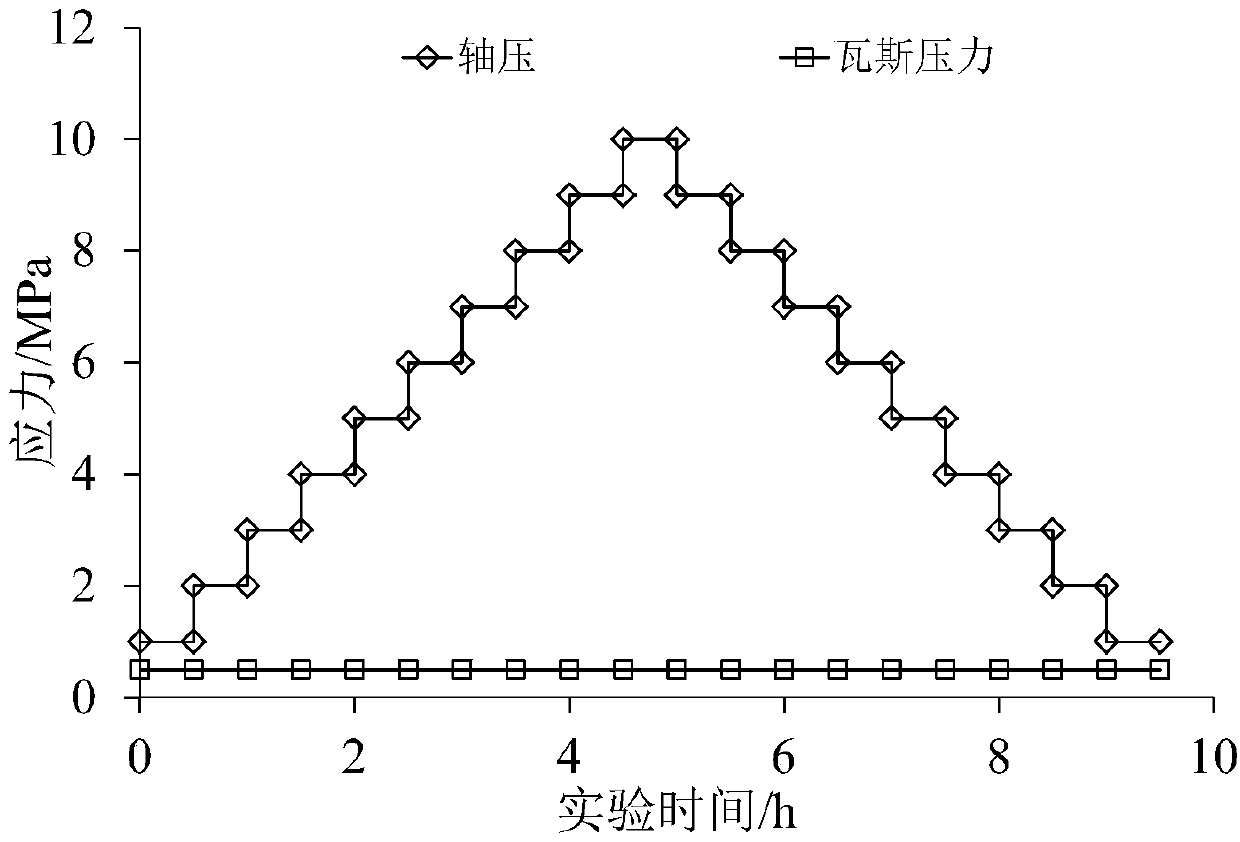

Visual servo-loading seepage test method for cracked coal and rock sample

ActiveCN109655392ASafe and efficient productionSafe and Efficient MeasurementMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesComputed tomographyStress path

The invention discloses a visual servo-loading seepage test method for a cracked coal and rock sample, aims to test pore structure change and seepage evolution characteristics of the cracked coal androckmass compaction process in a coal mining goaf and can construct the pore structure of the cracked coal and rockmass. The test method is characterized in that 1), according to an experimental design scheme, the crushed coal and rock sample with suitable particle sizes is selected and placed in a visual transparent kettle; (2), the compaction stress of a collapse zone in the goaf is measured, and a laboratory loading and unloading stress path of the cracked coal and rock sample is designed; (3), according to the designed loading and unloading stress path, the cracked coal and rock sample isloaded; (4), in the stress loading process, the gas or liquid permeability test is performed by an automatic gas-liquid seepage system when the specified stress is increased each time; and (5), in theloading process, CT scanning is performed when the compaction stress reaches the specified stress. The test method is advantaged in that the pore structure change and the seepage evolution characteristics of the cracked coal and rockmass compaction process in the goaf are obtained.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

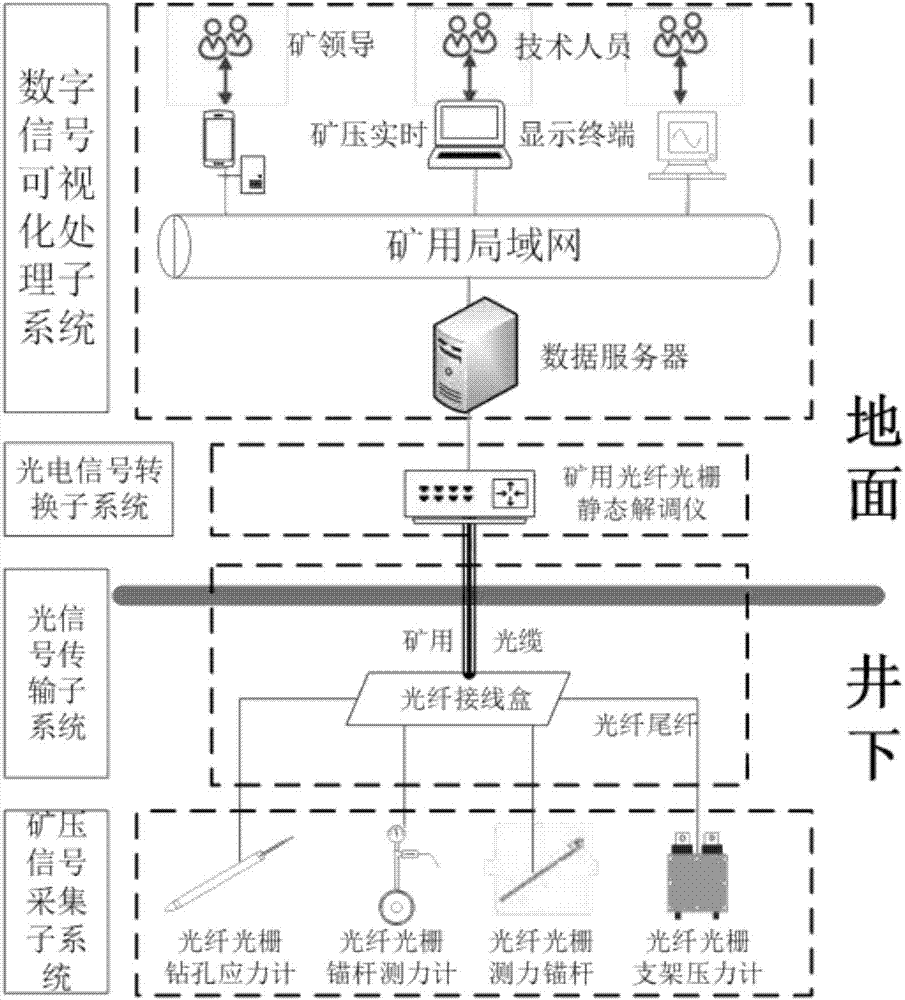

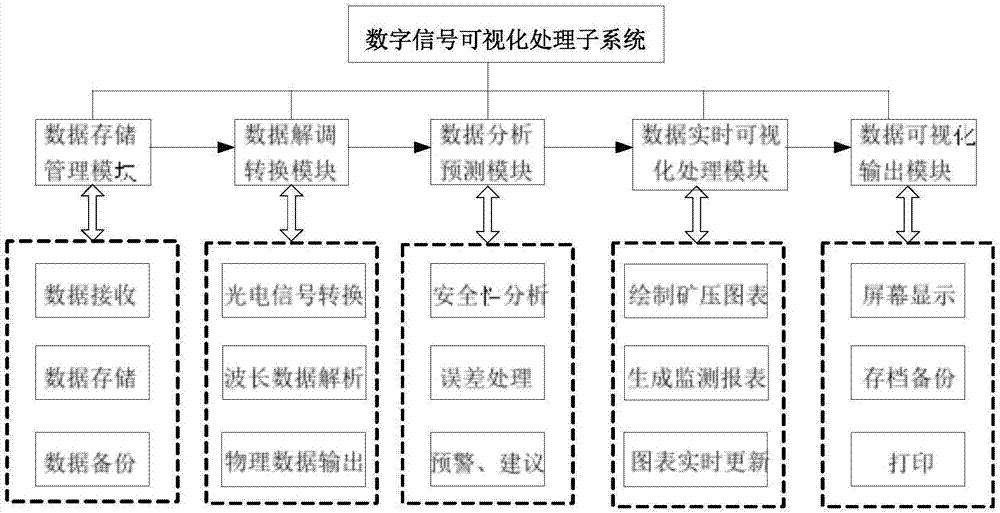

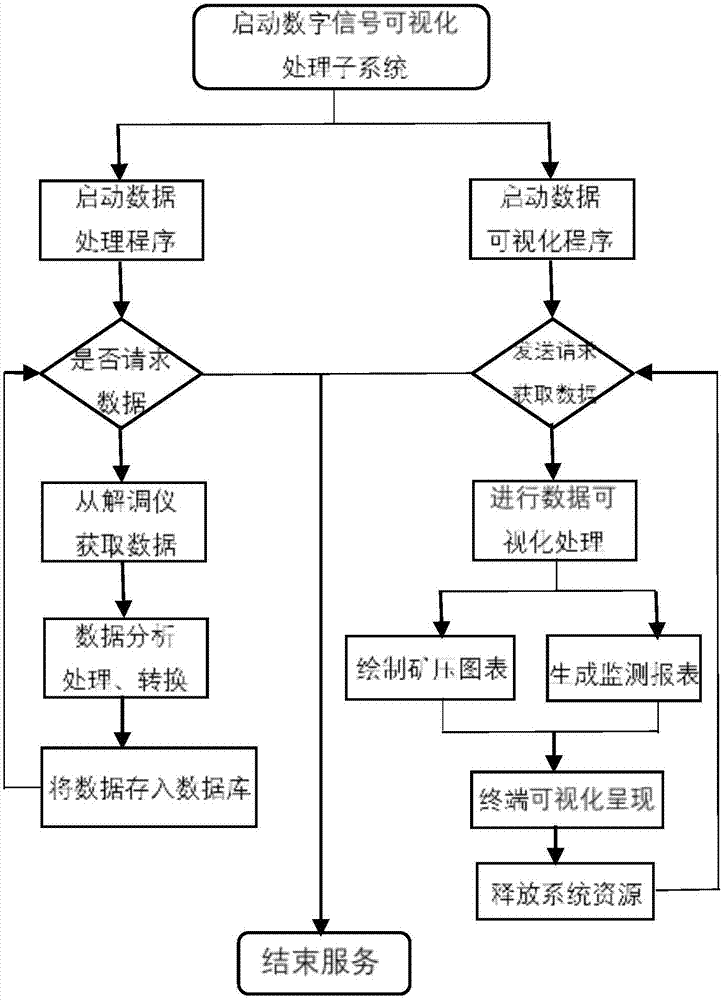

Mine pressure signal real-time visual demodulation system and demodulation method based on optical fiber sensing

InactiveCN107246886AStrong expandabilityImprove anti-interference abilityConverting sensor output opticallyCoalDigital signal

The present invention relates to a mine pressure signal real-time visual demodulation system and demodulation method based on optical fiber sensing. The demodulation system is mainly formed by a mine pressure signal acquisition subsystem, an optical signal transmission subsystem, a photoelectric signal conversion subsystem and a digital signal visual processing subsystem. A mine pressure signal is collected through arranging an optical fiber sensor in a coal mine, the mine pressure signal is transmitted to an optical fiber grating demodulator for a mine in the form of optical waves and is demodulated into wavelength data, the digital signal visual processing subsystem demodulates the wavelength data into a mine pressure physical quantity and automatically outputs a visual mine pressure chart and a mine pressure monitoring report. The system and the method have the advantages that the demodulation system is comprehensive and diversified, the development performance is high; the system equipment is essentially safe and is especially suitable for a complex underground environment; the demodulation algorithm is professional, and the mine pressure demodulation is more accurate; a demodulation result is clear and visual, and the degree of visualization is high; the system response is timely and effective, the underground mine pressure can be displayed in real time, and the safe and efficient production of a coal mine is ensured.

Owner:CHINA UNIV OF MINING & TECH

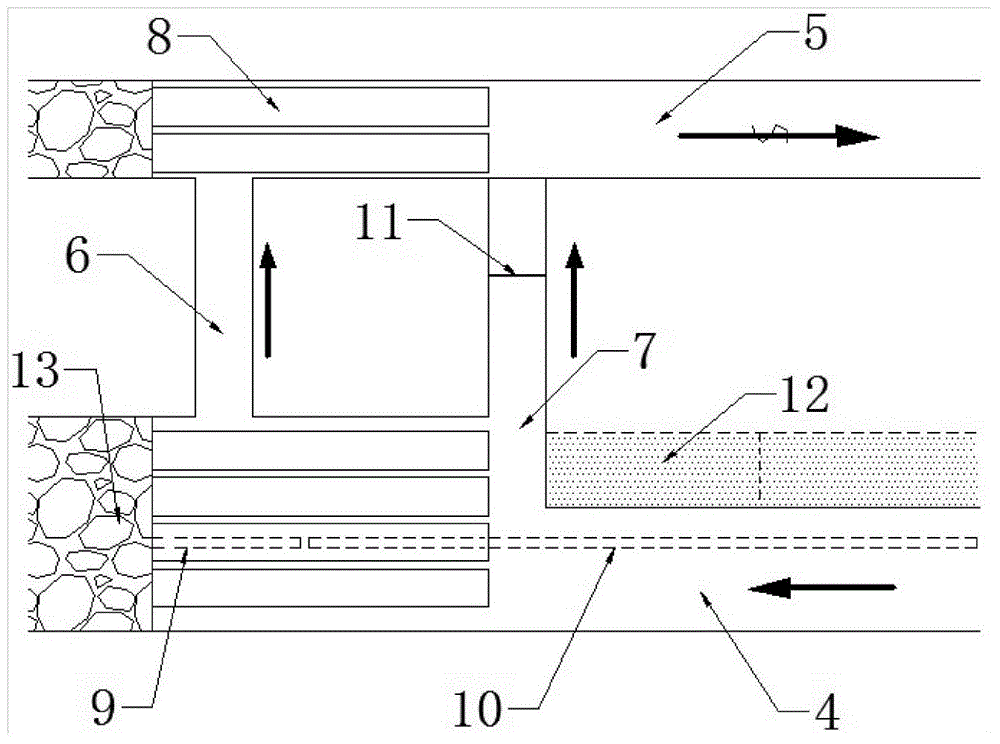

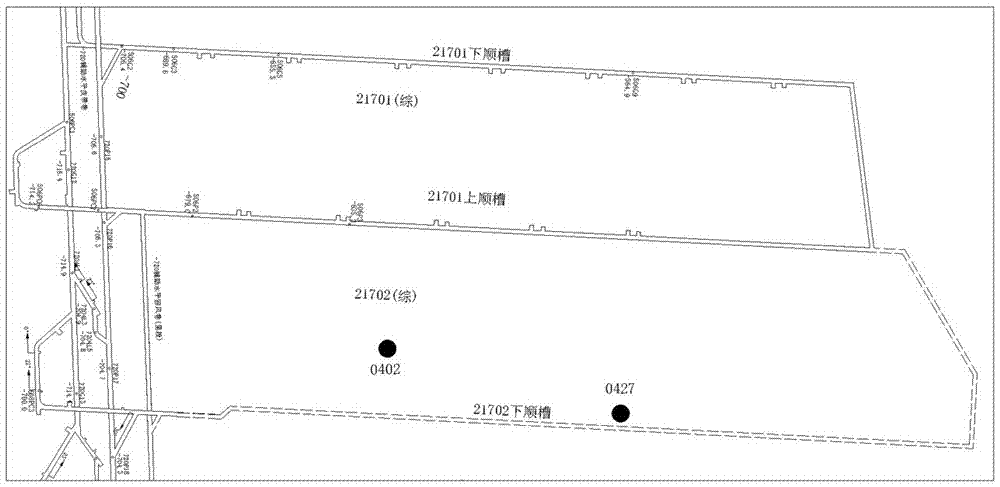

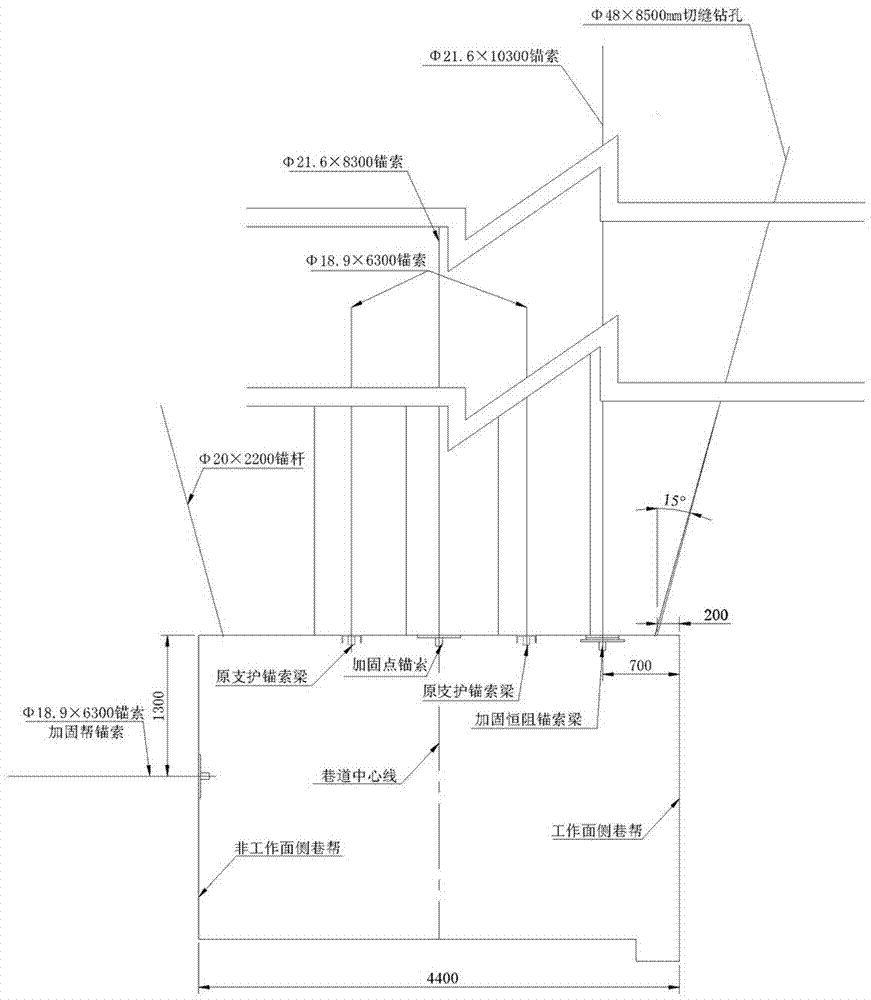

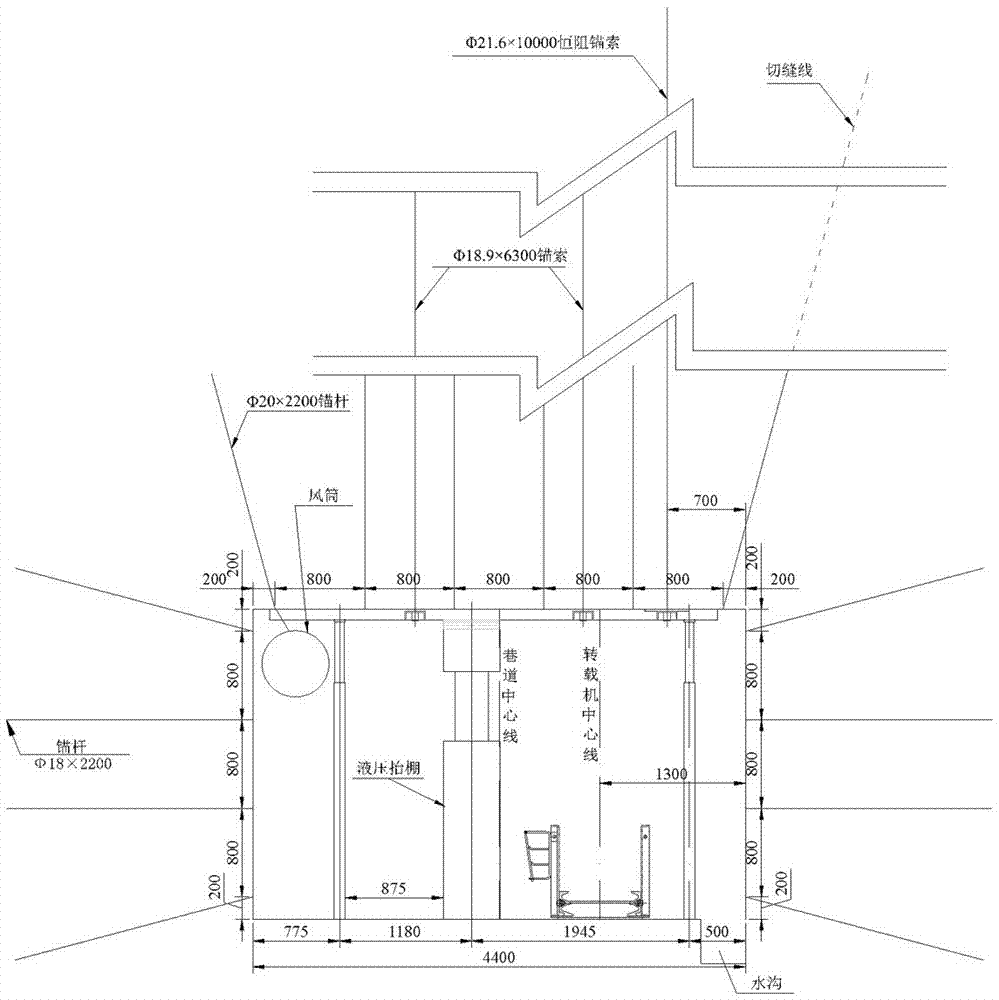

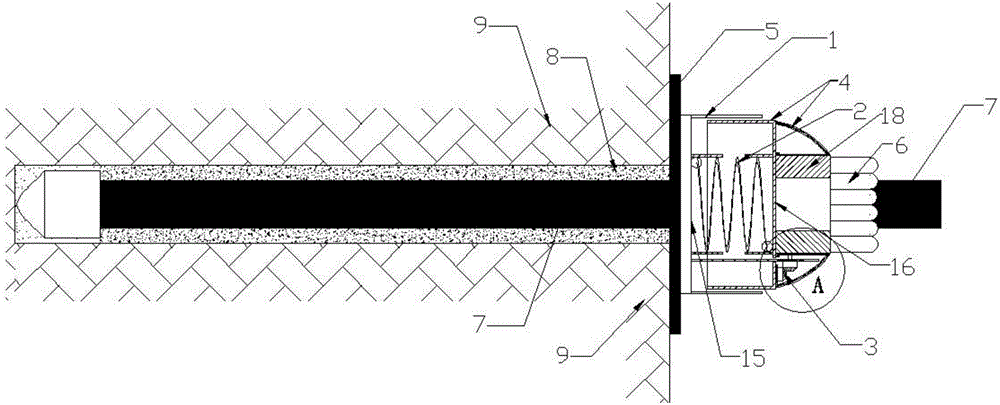

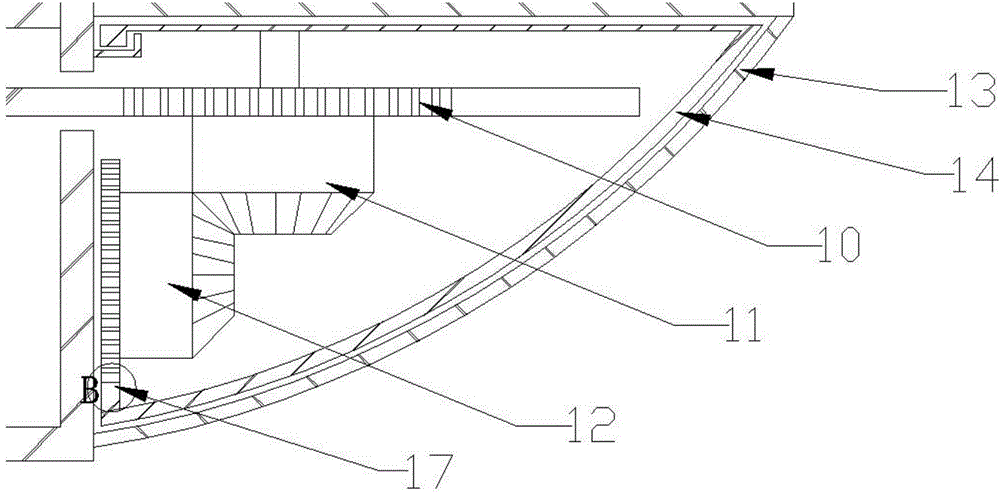

Gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method

ActiveCN107191208AImprove resource recoveryHigh recovery rateMine roof supportsMine roof capsResource recoveryStructural engineering

The invention relates to a gob-side-entry-retaining supporting method, in particular to a gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method. The method comprises the steps that a row of point-anchor rope reinforced roadway top plates are arranged in a roadway in the tunneling period, a row of point-anchor rope reinforced roadway ribs are arranged in the side roadway rib of the non-working surface, and a row of constant-resistance anchor rope beam reinforced roadway top plates are arranged on the position a certain distance away from the side roadway rib of the working surface; and according to the data changing situation of the mine pressure in a retained roadway in the period of backstopping of the working surface and the showing situation of the roadway mine pressure, an entry-in supporting area in the retained roadway is divided into an advance supporting area, a lagging supporting area, a roadway-forming to-be-stable area and a roadway-forming stable area. According to the gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method, through the successful practice of cross heading under the 21702 working surface, an excessive coal safety pillar with the width of 5 m is recycled compared with tunneling of an original gob-side entry driving, the coal resource recovery rate is improved, a solid foundation is laid for popularization of the gob-side entry retaining technology in other mining-area working surfaces of the whole mine, and a brand-new thinking is provided for the excavation-replacement layout of the whole mine.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

Sealwort planting method

InactiveCN107409736APromote growth and developmentIncrease planting areaCalcareous fertilisersSuperphosphatesPest controlInsect pest

A sealwort planting method sequentially comprises the following steps of sealwort rapid propagation and efficient sealwort cultivation. Sealwort rapid propagation can be sealwort rhizoma in-vitro rapid propagation and can also be sealwort seed rapid propagation. Efficient sealwort cultivation includes the substeps of land selection and soil preparation, planting, field management, disease and insect pest prevention, harvesting, processing and the like. The sealwort planting area can be enlarged, and the sealwort planting benefits are improved.

Owner:衡阳市九龙生态农业有限公司

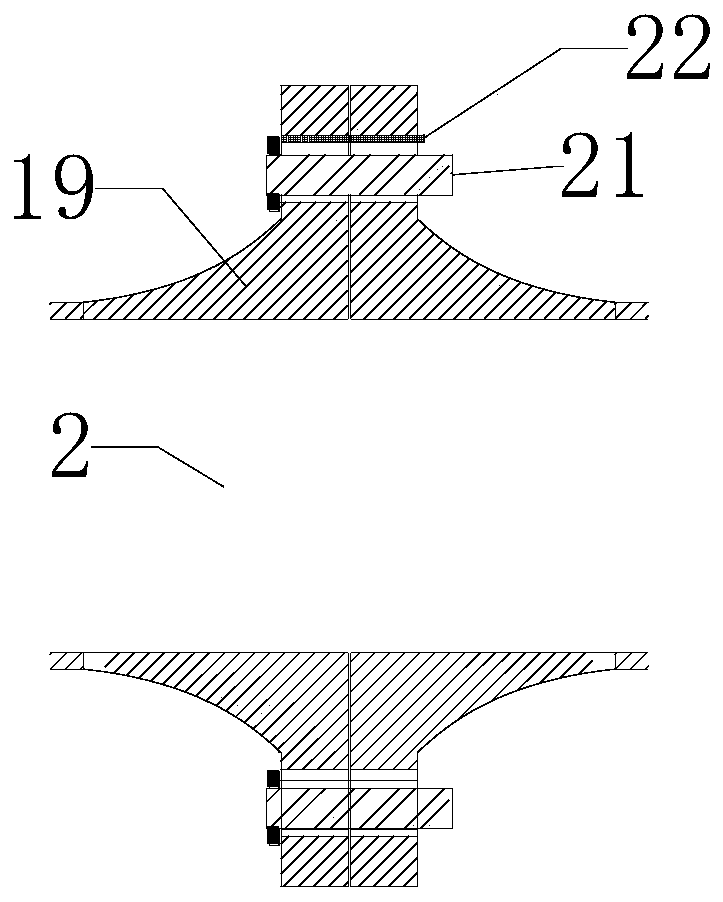

Anchoring force pre-warning device for anchor rod

InactiveCN104568274AImprove integrityImprove the support effectApparatus for force/torque/work measurementGear driveEngineering

The invention discloses an anchoring force pre-warning device for an anchor rod. The anchoring force pre-warning device for the anchor rod comprises an outer shell, a high-strength central spring, a rack, a side reflective band and a rotary wide angle reflective band, gears, an outer piece spherical shell, an inner piece spherical shell, an upper base, a lower base and a hollow core cylinder. The central spring is welded to central circular grooves of the upper base and the lower base. The anchoring force pre-warning device has the functions that when anchoring force of the anchor rod is lowered, the central spring is relaxed, so that the rack drives the vertical gear to rotate, the vertical gear drives the horizontal gear to rotate, the horizontal gear drives the inner piece spherical shell to rotate, the inner piece spherical shell rotates relative to the outer piece spherical shell, the reflective band on the outer surface of the inner piece spherical shell hidden inside the outer piece spherical shell is exposed, and an anchor rod with insufficient anchoring force is distinguished by lighting the reflective light band through lamplight. Therefore, the pre-warning device for nondestructively detecting the anchoring force is simple in structure and easy to operate.

Owner:ANHUI UNIV OF SCI & TECH

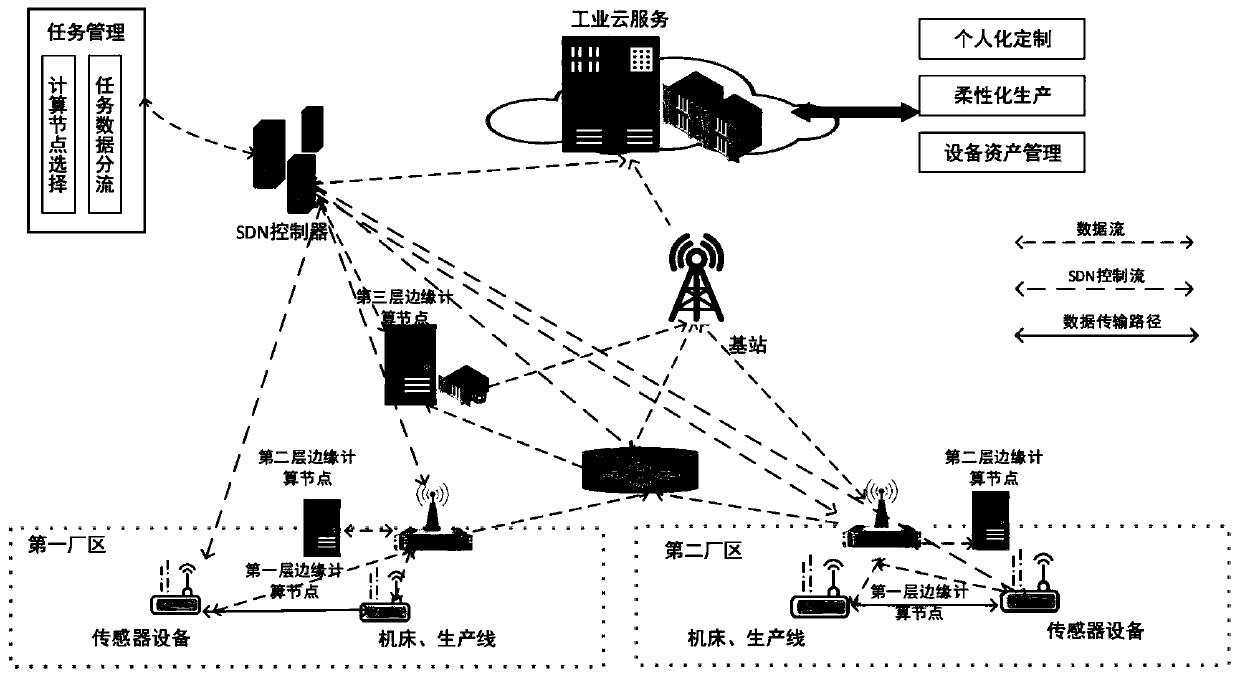

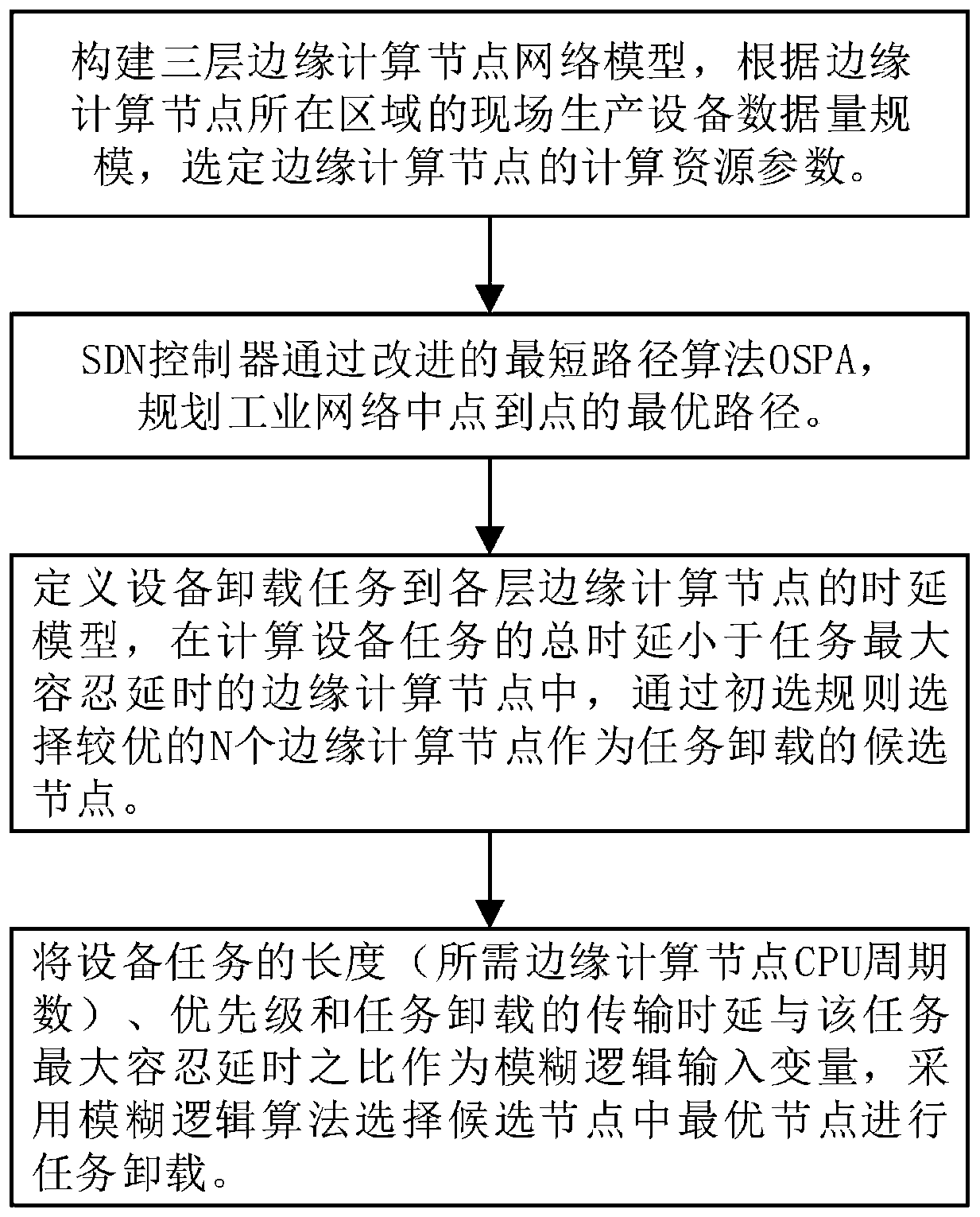

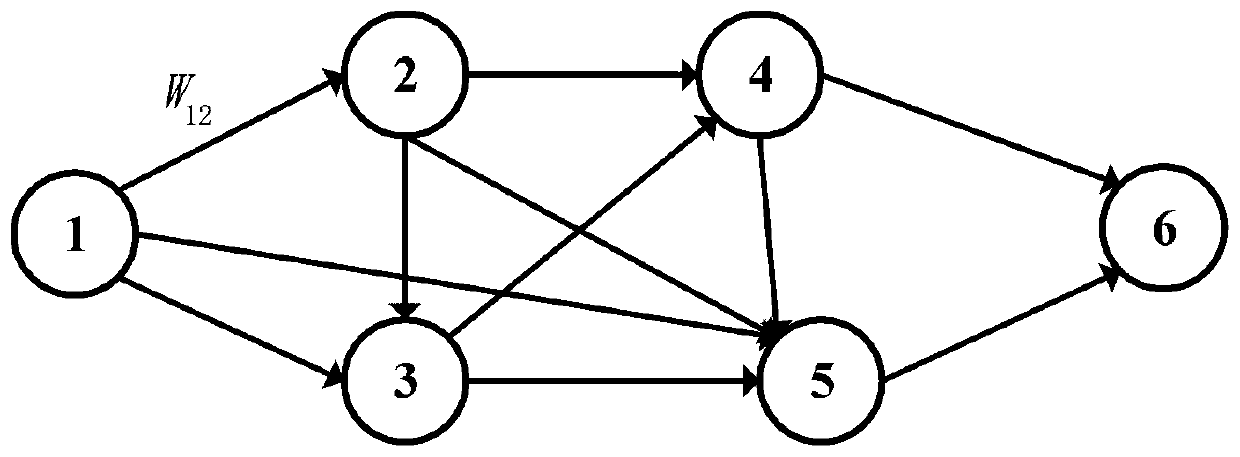

Edge computing task unloading method for industrial internet of things

ActiveCN110933157AAvoid congestionProduction economyNetwork traffic/resource managementData switching networksPathPingIndustrial Internet

The invention relates to an edge computing task unloading method for the industrial internet of things. The method comprises the following steps: constructing a three-layer edge computing node networkmodel; planning a point-to-point optimal path in the network through an SDN (Software Defined Network) controller; defining a time delay model from an equipment unloading task to each layer of edge computing nodes, and selecting N better edge computing nodes as candidate nodes for task unloading through a primary selection rule in the edge computing nodes of which the total time delay of the computing equipment task is less than the maximum tolerable time delay of the task; and taking the length and priority of the equipment task and the ratio of the transmission delay of task unloading to the maximum tolerable delay of the task as fuzzy logic input variables, and selecting an optimal node in the candidate nodes by adopting a fuzzy logic algorithm to unload the task. By means of the taskunloading method, the difference requirements of the equipment for data real-time performance and computing resources are guaranteed, and the transmission and processing time of equipment tasks is shortened.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Roof cutting pressure relief protective method for exploitation stop face of fully mechanized working face

ActiveCN109209495AProtect security and stabilityResolve and eliminate stress effectsMining devicesProps/chocksMachining systemHigh stress

The invention relates to a roof cutting pressure relief protective method for an exploitation stop face of a fully mechanized working face, and belongs to the technical field of surrounding rock stability protection for a permanent tunnel by the fully mechanized working face. In the protection method, the exploitation stop face of the fully mechanized working face is preset between a coal mining tunnel area and a goaf, an overlying stratum layer over the exploitation stop face is cut vertically upwardly before that a three-machine system is evacuated from the exploitation stop face to obtain aroof cutting surface, the overlying stratum layer over the exploitation stop face is disconnected from the overlying stratum layer over the coal mining tunnel area by the roof cutting surface, so that when the three-machine system is used for support, stress connection between the overlying stratum layers over the exploitation stop face and the coal mining tunnel area is cut off rapidly. Influence of high stress of the overlying stratum layer over the exploitation stop face on stress of the overlying stratum layer over the coal mining tunnel area is eliminated effectively, a dynamic pressuresource acted on the tunnel is eliminated fundamentally, a large tunnel or a concentrated tunnel of the goaf is avoided from high concentrated stress, and the permanent tunnel is kept safe and stable for long time.

Owner:TIANDI SCI & TECH CO LTD +1

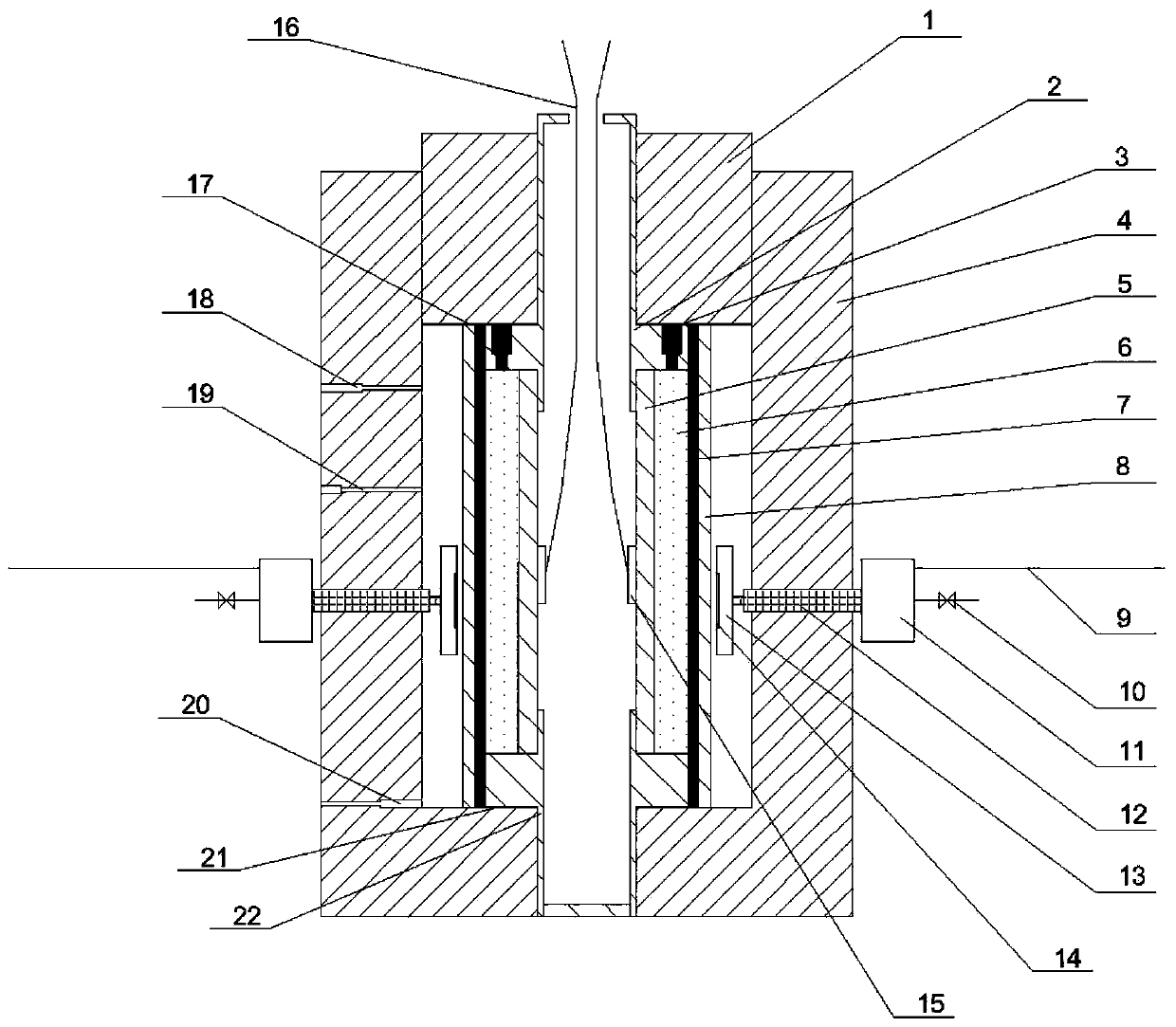

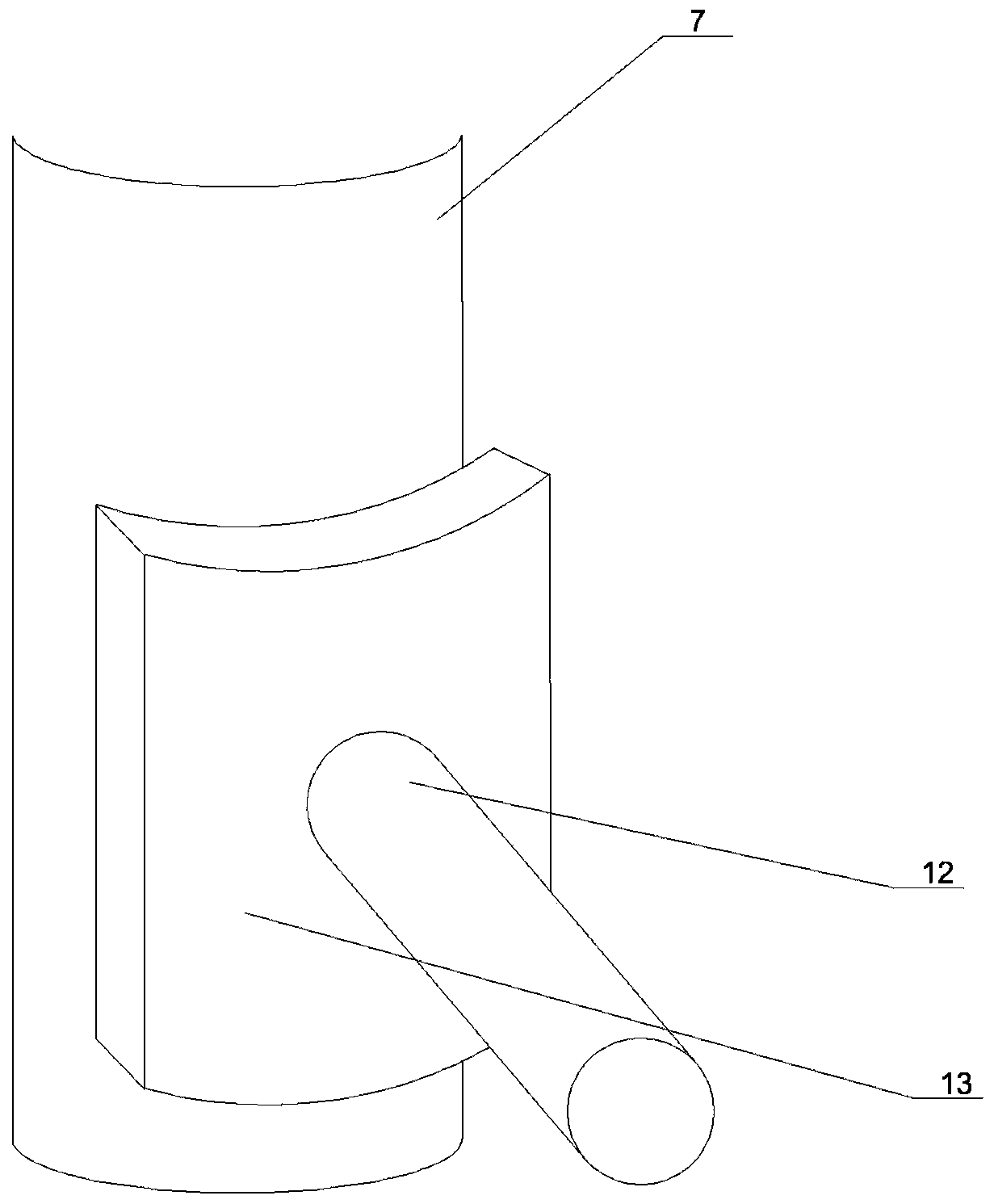

Experimental device for hydraulically simulating non-uniform confining pressure of casing pipe and using method

PendingCN111044382APrevent damage from instabilityPrevent casing damage from instabilityMachine part testingMaterial strength using tensile/compressive forcesExperimental DevicesStrain gauge

The invention provides an experimental device for hydraulically simulating non-uniform confining pressure of a casing pipe and a using method. The experimental device comprises a kettle body assembly,an experimental assembly, a pressurizing assembly and a data acquisition assembly, wherein the kettle body assembly comprises a kettle body and a kettle cover; the casing pipe in the experiment assembly is arranged in the kettle body, the casing pipe, a casing pipe upper cover, a casing pipe lower cover and a rubber cylinder form a sealed interlayer for curing cement, the outer layer of the rubber cylinder is wrapped with a double-semicircle cylinder sleeve, and the cement is injected into the sealed interlayer by means of a cement injection port of the casing pipe upper cover to be cured into a cement sheath; on the side surface of the kettle body, the pressurizing assembly composed of a pneumatic hydraulic pump, a hydraulic push rod and a mechanical pushing hand applies non-uniform confining pressure to the casing pipe in a direction perpendicular to the axial direction of the casing pipe, so as to simulate non-uniform load under the stratum condition; and the obtained experimentaldata are collected by means of strain gauges in the data acquisition assembly on inner side of the casing pipe and strain patches on the surface of the mechanical pushing hand and are transmitted to acomputer in real time by means of data lines, the experimental result is visual and precise, and the compression condition of the casing pipe under the real stratum condition can be effectively simulated.

Owner:SOUTHWEST PETROLEUM UNIV

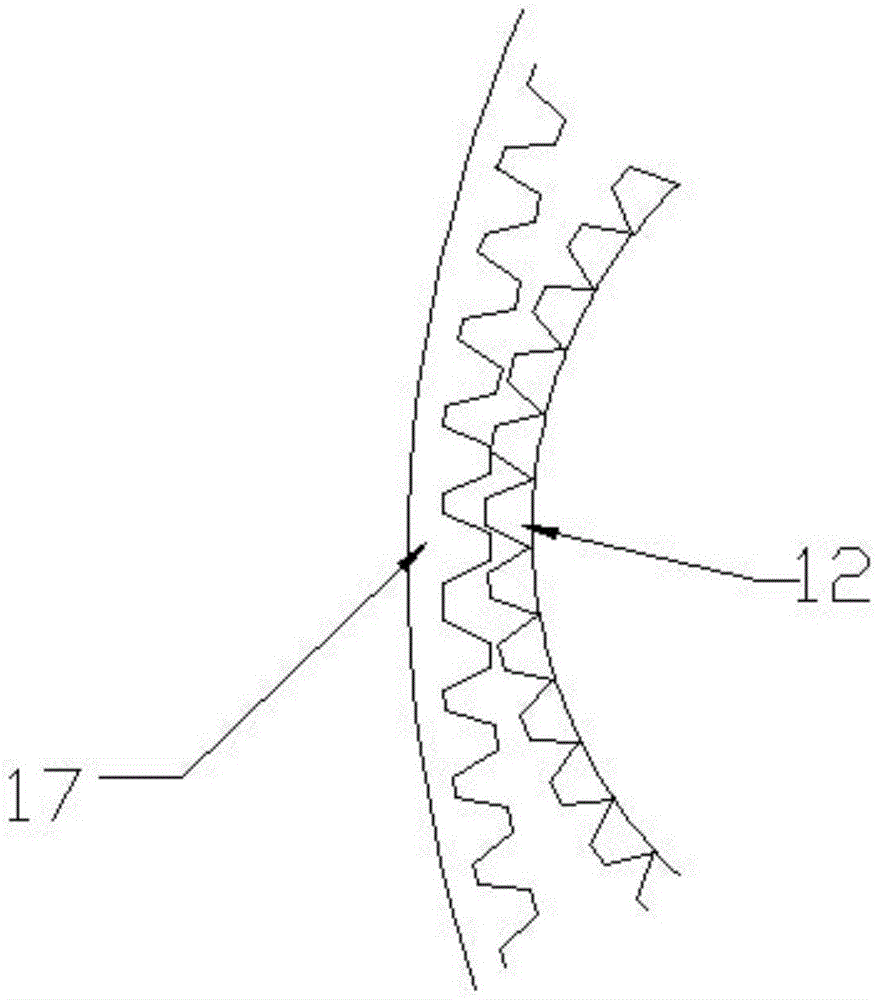

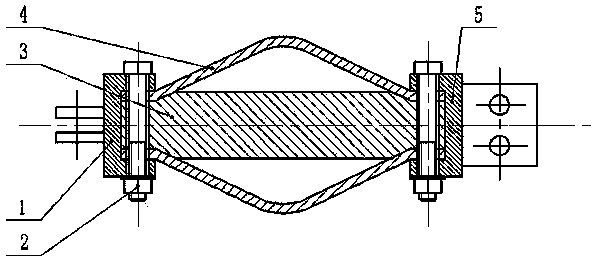

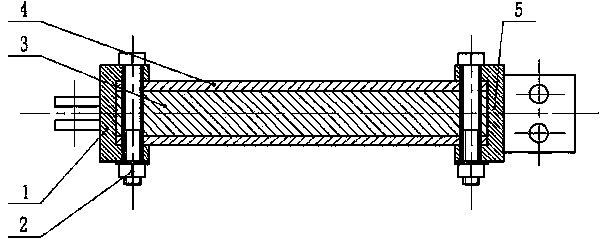

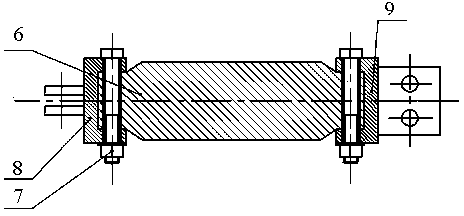

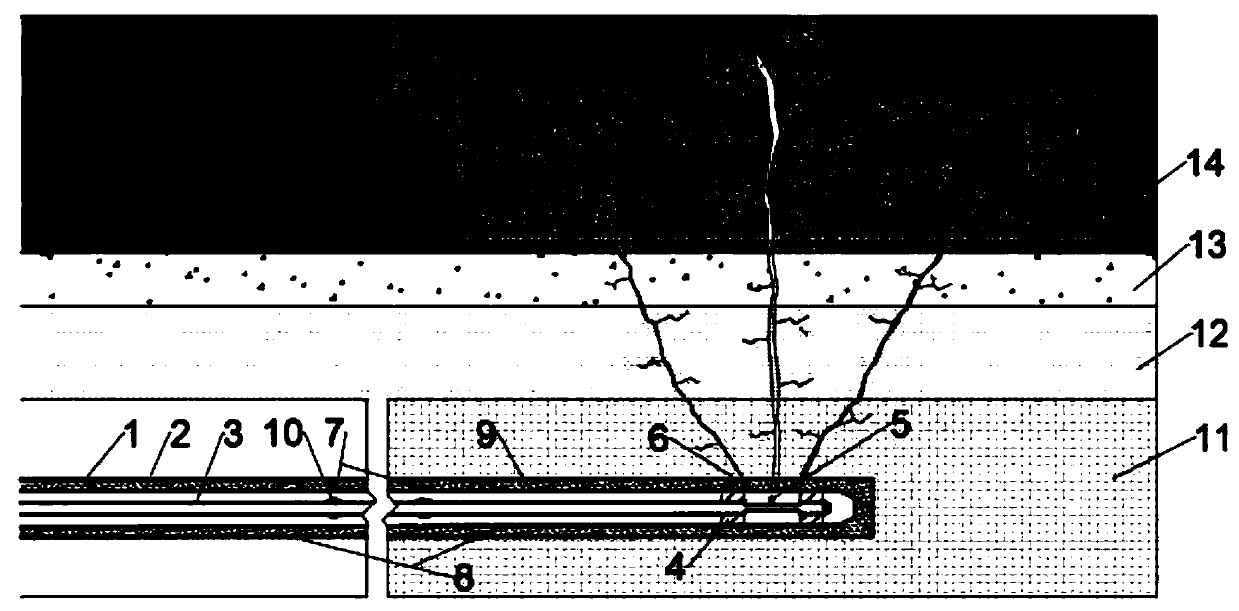

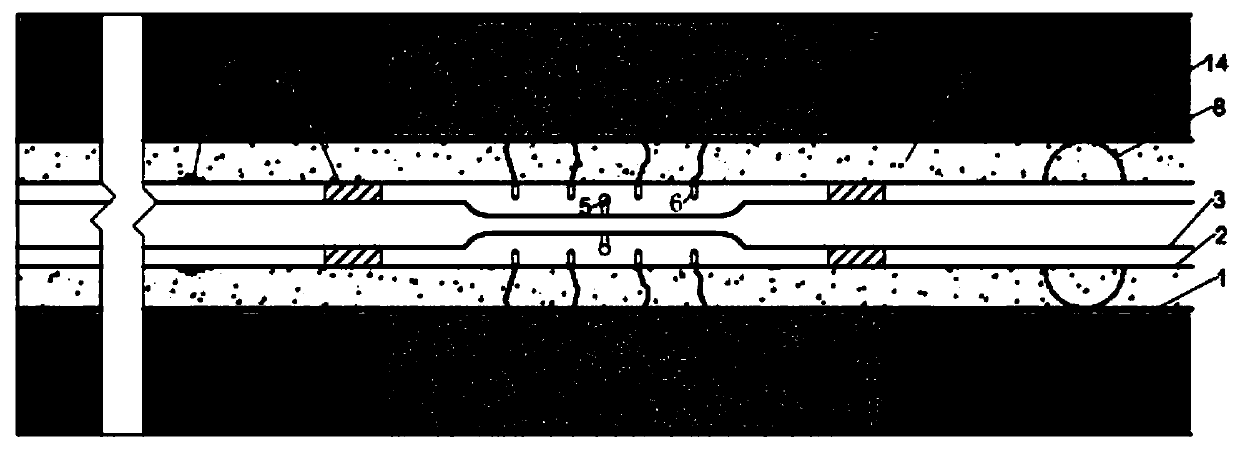

Directional fracturing device and method for underground drilling

ActiveCN110344805AAvoid mindless fracturingImprove fracturing precisionFluid removalGas removalEngineeringFracture control

The invention discloses a directional fracturing device and method for underground drilling. The device comprises a plurality of sections of casing pipes and fracturing pipes which are connected end to end, wherein the casing pipes are provided with directional fracturing control devices, and each directional fracturing control device comprises a screw hole with an adjustable angle and a one-way destructive conical screw matched with the screw hole; and the casing pipes are connected through stroke-controllable threaded connection assemblies or flange connection assemblies, and alignment scribed lines corresponding to the positions of the directional fracturing control devices in the circumferential direction are arranged on the casing pipes, so that the alignment scribed lines and the directional fracturing devices are always aligned. The method is mainly characterized in that after a hole is drilled in a roadway, the casing pipes are sent into the drilled hole, and the annular spacebetween the casing pipes and the drilled hole is sealed by grouting; and fracturing pipes provided with front packers and rear packers are sent into the casing pipes, and after entering the casing pipes from the fracturing pipes, the pressurized fluid flushes the casing pipes to fracture the coal rock mass when the pressure reaches the maximum bearing pressure of the directional fracturing controldevices. According to the directional fracturing device and method for underground drilling, provided by the invention, the fracturing direction is controllable, and various directional expansion forms can be realized.

Owner:CHINA UNIV OF MINING & TECH

Method for replacing middle bottom-extraction rock roadway with bottom-extraction rock roadway kilometer directional long borehole

InactiveCN109915197AExtended extraction timeConvenient drainage and slag dischargeDirectional drillingGas removalGeomorphologyDrill site

The invention relates to a method for replacing a middle bottom-extraction rock roadway with a bottom-extraction rock roadway kilometer directional long borehole. According to the method, a construction mode for commonly constructing a gate road bottom-extraction rock roadway in a high-gas outburst mine to protect stope face gate road roadway excavation is utilized, a coal body in front of a common crossing hole pre-extraction roadway is constructed on the gate road bottom-extraction rock roadway, before the stope face gate road roadway and a standby stope face gate road roadway are constructed, advanced construction is carried out on the gate road bottom-extraction rock roadway, a drill site is constructed in the gate road bottom-extraction rock roadway, a crossing kilometer directional long borehole is constructed in the drill site, and advanced extraction is carried out on gas of a working face of an upper working seam. The method has the beneficial effects that the mining economiccost and the time cost of the working face are saved, the outburst risk and the gas emission quantity during the mining period of the working face are fundamentally eliminated, and the safe and efficient production of a mine is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

Method for pumping coal bed gas from long-distance pressure-relieved coal bed

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Vacuum freeze-drying method for chitin fiber or chitosan fiber

ActiveCN105020989ASimple processThe process is simple and easy to controlDrying solid materials without heatTime rangeFiber

The invention discloses a vacuum freeze-drying method for chitin fiber or chitosan fiber. The vacuum freeze-drying method includes the pre-freezing step and the freeze-drying step; in the pre-freezing step, the freezing temperature is lower than or equal to -20 DEG C, the freezing time is larger than or equal to 1 h, and moisture contained in the chitin fiber or the chitosan fiber is all condensed into the solid state; and in the freeze-drying step, freeze-drying is conducted in a vacuum freeze-drying machine, the cold trap temperature ranges from -85 DEG C to -50 DEG C, the vacuum degree ranges from 1 pa to 70 pa, the freeze-drying time ranges from 2 h to 8 h, and the chitin fiber or the chitosan fiber is obtained when the moisture content of the chitin fiber or the chitosan fiber ranges from 0 to 14.82%. Compared with the prior art, the vacuum freeze-drying method has the technical characteristics and the beneficial effects that the process is simple and is easy to control, the production process is safe, efficient, good in quality, stable and reliable, and the processing cost is low; and the production process is green and environment-friendly.

Owner:QINGDAO UNIV

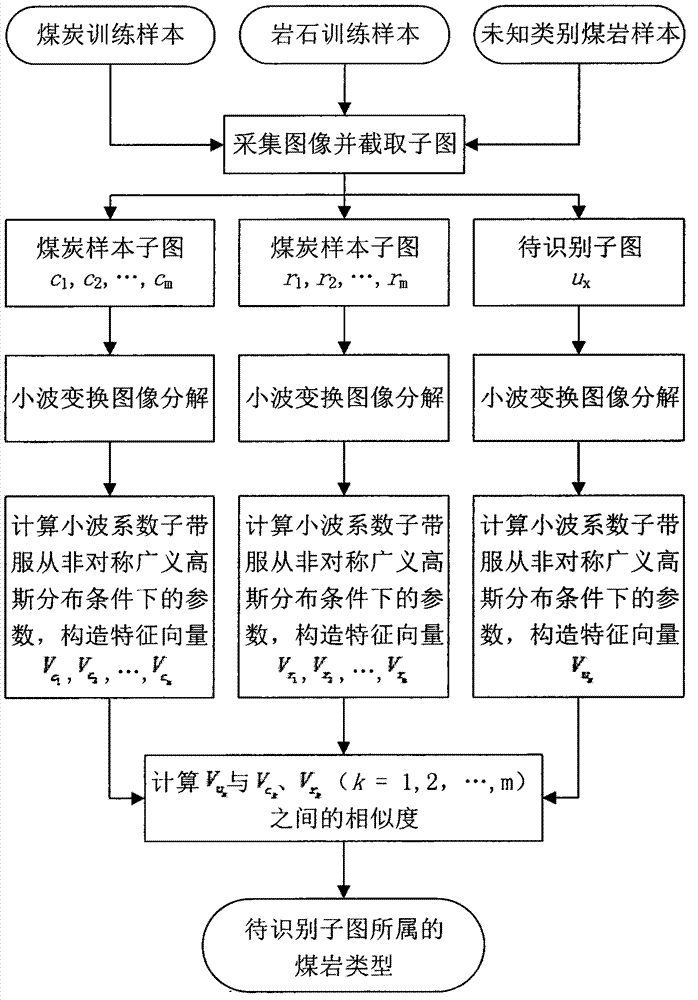

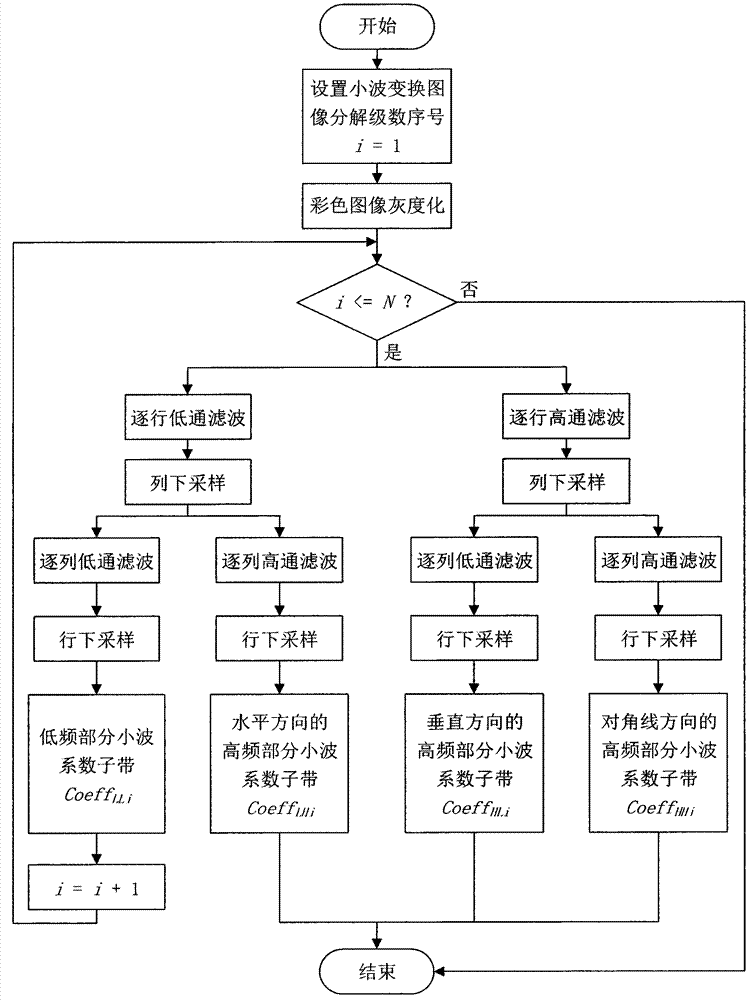

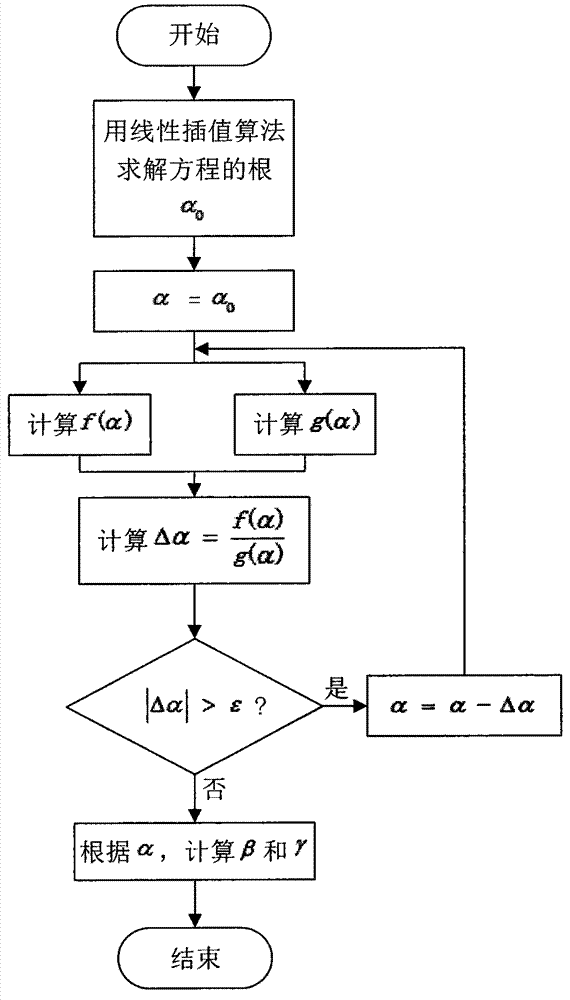

Coal and rock classification method based on wavelet domain asymmetric generalized Gaussian model

ActiveCN104732239ASafe and efficient productionImprove recognition rateCharacter and pattern recognitionNon symmetricDecomposition

The invention discloses a coal and rock classification method based on a wavelet domain asymmetric generalized Gaussian model. The method comprises the steps of obtaining m known coal sample images and m known rock sample images which are of the same size and do not contain backgrounds in the sample training stage, conducting wavelet transform image decomposition on each image, calculating parameters of each wavelet coefficient sub-band meeting the asymmetric generalized Gaussian distribution condition of each image, and using all the parameters of each image for constructing a training sample characteristic column vector; in the coal and rock recognition stage, collecting and obtaining unknown type coal and rock images ux which are of the same size of the training sample image and do not contain the background, conducting wavelet transform image decomposition on the ux, calculating parameters of each wavelet coefficient sub-band meeting the asymmetric generalized Gaussian distribution condition of the ux to form a characteristic column vector Vux, and judging the type of coal and rock of the ux by comparing the similarities between the Vux and the training sample characteristic column vector. The coal and rock classification method is good in reliability and high in classification accuracy, and software and hardware are convenient to maintain.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

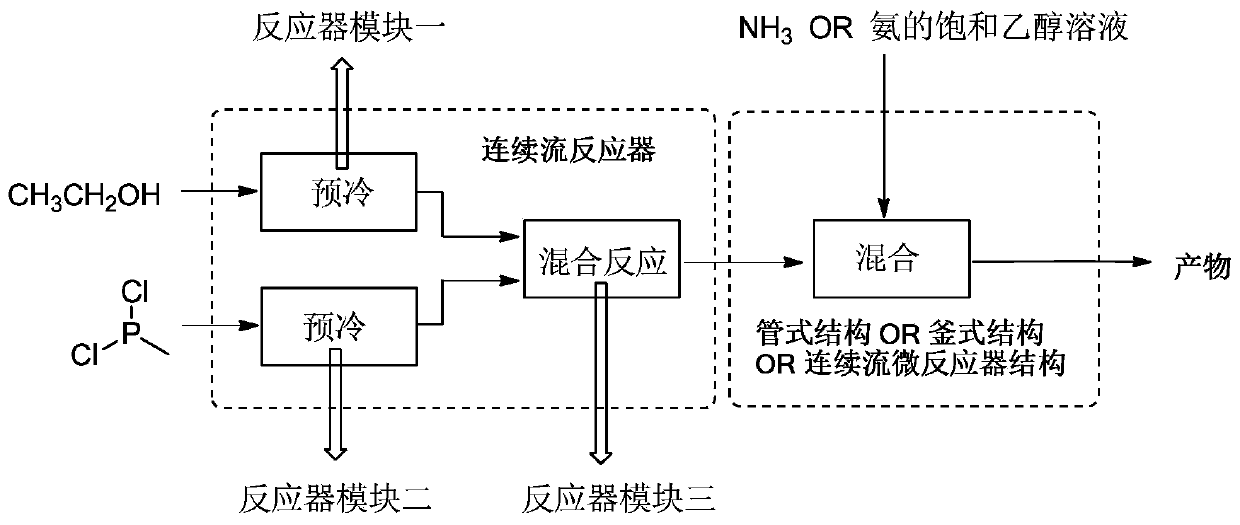

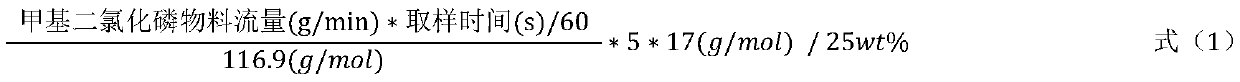

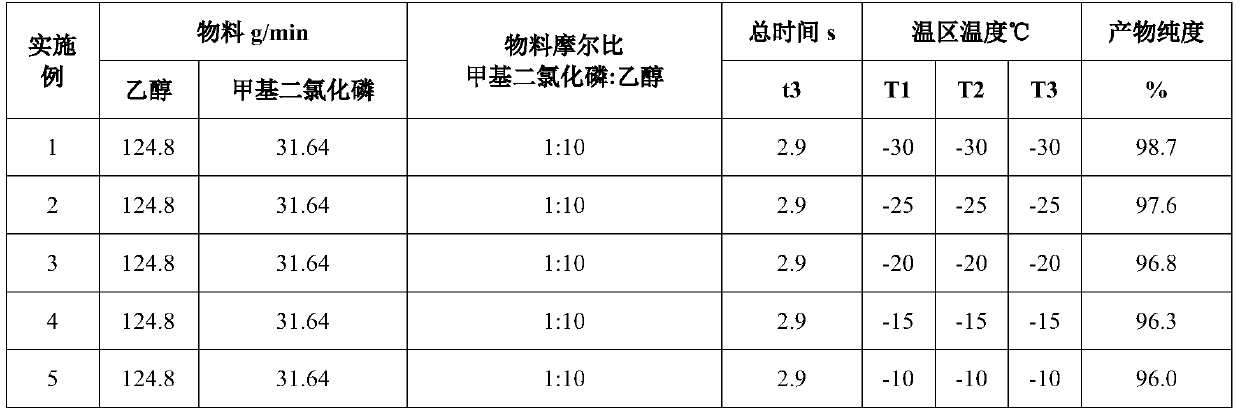

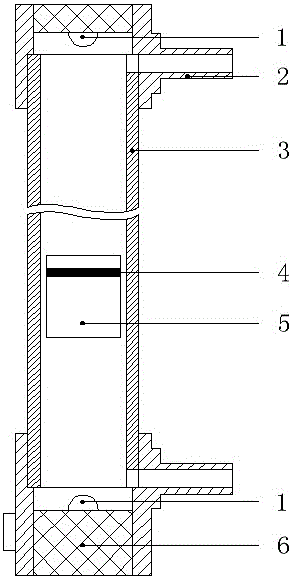

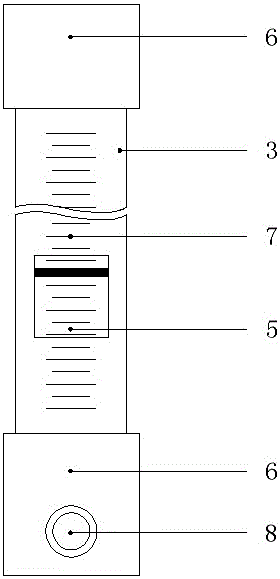

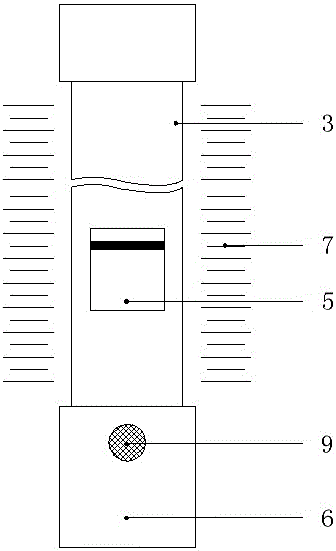

Continuous flow preparation method of diethyl methyl phosphite

PendingCN111004280ASmall liquid holding capacitySafe and efficient productionGroup 5/15 element organic compoundsChemical/physical/physico-chemical microreactorsDiethyl phosphateCombinatorial chemistry

The invention discloses a continuous flow preparation method of diethyl methyl phosphite, which comprises the following steps: continuously adding ethanol and methyl phosphorus dichloride into a feedport of a continuous flow reactor, and continuously obtaining diethyl methyl phosphite at a discharge port of the continuous flow reactor. The method has the advantages of small liquid holdup, safe and efficient production process, solving of the problems of long reaction time and low efficiency in kettle type reaction, high product yield and purity, and simple and efficient process operation.

Owner:LIER CHEM CO LTD +1

Manufacturing control agent and its usage in preparing tea with selenium enriched

InactiveCN1430897ASafe and efficient productionImprove stress resistanceBiocideAnimal repellantsBudCell budding

Owner:NANJING AGRICULTURAL UNIVERSITY

Luminous liquid level meter

InactiveCN105203186AClear liquid level indicationSafe and efficient productionLevel indicators by floatsElectricityEngineering

The invention discloses a luminous liquid level meter for indicating a liquid level position in a liquid storage container, which solves the problem that liquid level is not easy for clear observation at night and in places with relatively dark light at relatively low cost. According to the technical scheme adopted by the invention, a light source and an electrical box are arranged at the end of a liquid level indicating tube which is made from a transparent material and vertically installed on the outer wall of the liquid storage container, a liquid level buoy with a reflective mark is placed in the tube, and scale marks are arranged on the tube wall or positions close to the left side and the right side of a tube body. In case of need, the electrical light source is started to form a bright light area inside and surrounding the liquid level indicating tube to facilitate observation; and the reflective liquid level mark on the liquid level buoy reflects light rays and then clearly indicates the current liquid level, and can indicate the current liquid volume in the liquid storage container by matching with the scale marks.

Owner:杨瑾婷 +1

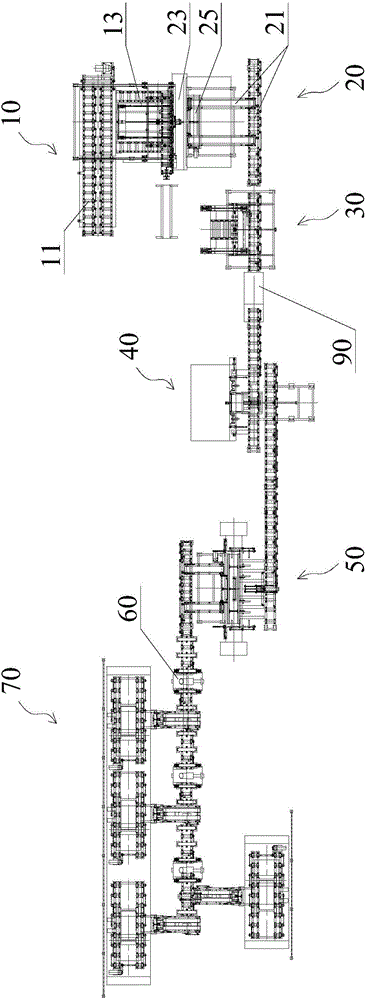

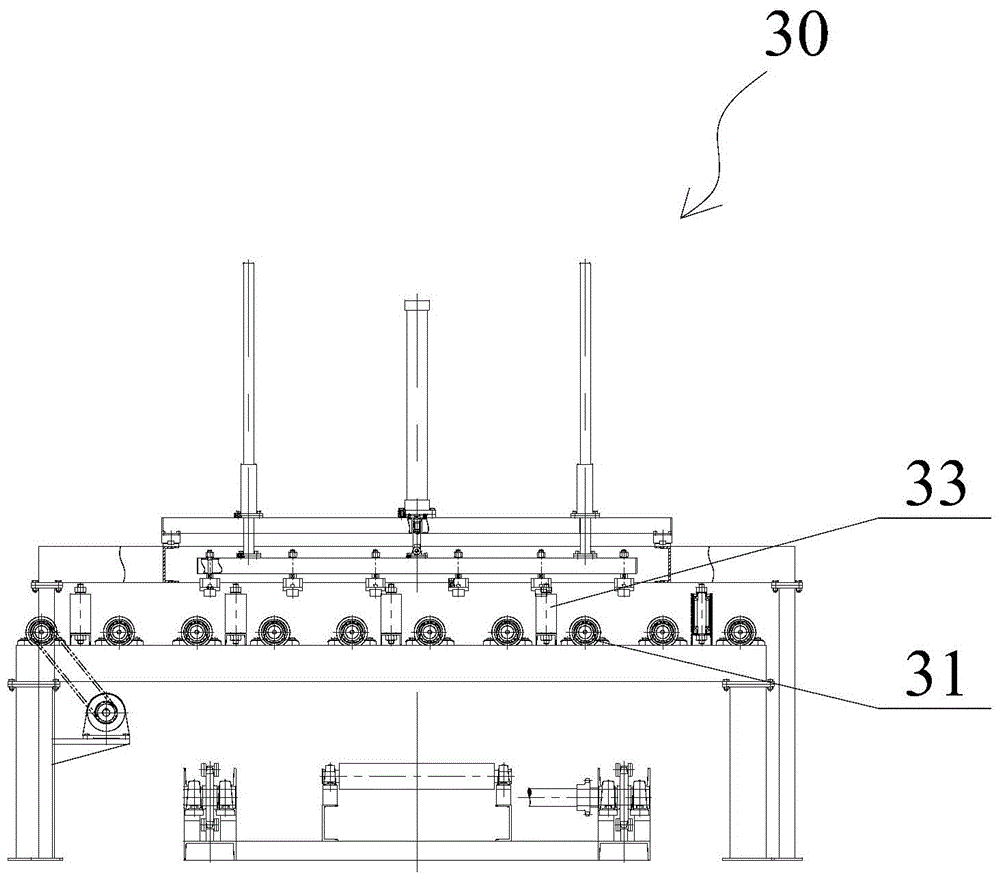

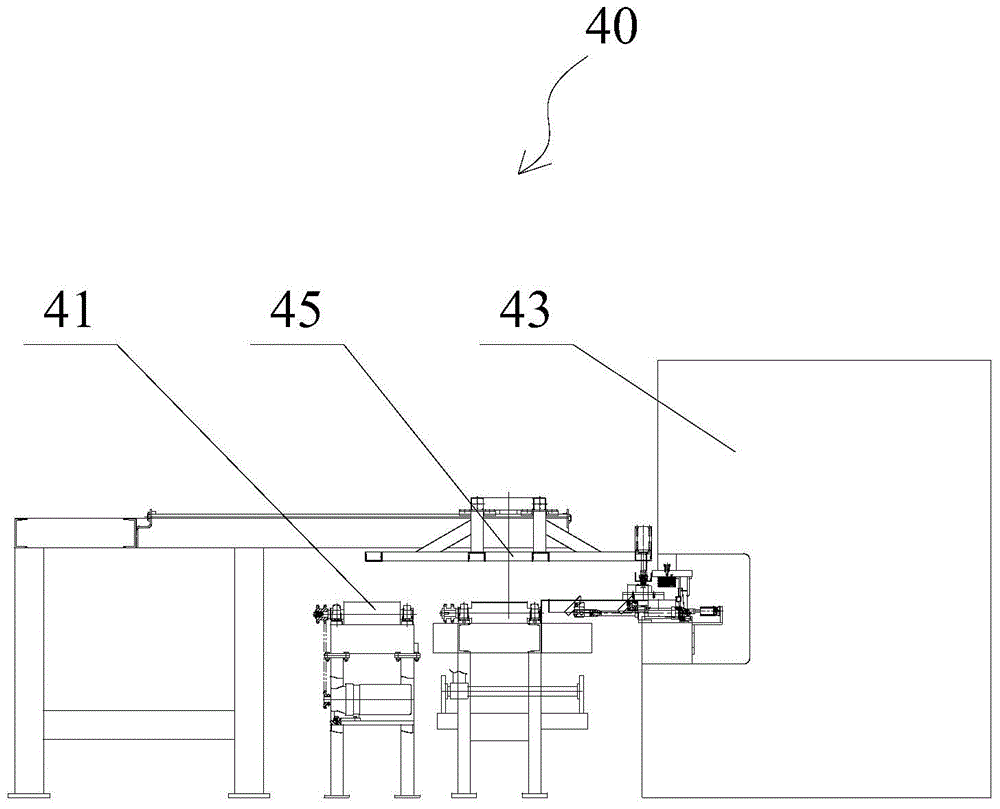

Container short bottom beam stamping production line

InactiveCN104801976ASafe and efficient productionLow costOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses a container short bottom beam stamping production line. The container short bottom beam stamping production line comprises a feeding device, a gap stamping device, a molding device and at least one thrusting device. Plate raw materials are automatically conveyed to the corresponding downstream device after the operation of every device is achieved so as to enable the plate raw materials to be machined into a short bottom beam finally. According to the container short bottom beam stamping production line, the different machining devices are connected in series, the plate raw materials are automatically transferred between the different machining devices through a transfer mechanism and do not need to be transferred from one machining device to another machining device through a lifting device any more, the lifting device is omitted, and accordingly the cost of the integral stamping production line is reduced and meanwhile the safe and efficient production on the short bottom beam is ensured.

Owner:CIMC CONTAINERS HLDG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com