Anti-sloughing diluted filtration reducing agent for drilling fluid and preparation method thereof

A technology for reducing fluid loss and drilling fluid, which is applied in the field of oil drilling aids and fluid loss reducing agents for drilling fluids. , the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

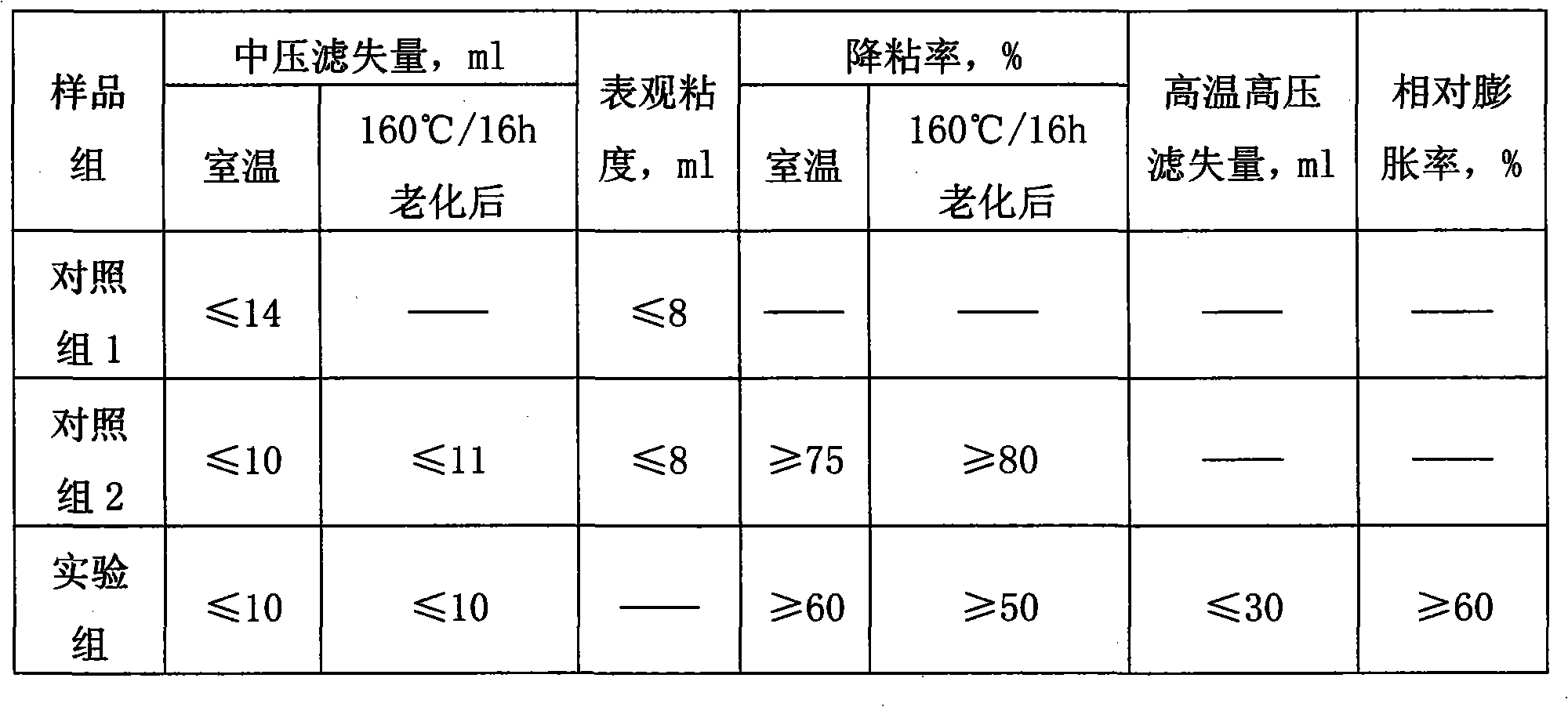

Examples

Embodiment 1

[0051] Embodiment 1: The fluid loss control agent of the present invention is made from the raw materials of following weight ratio:

[0052] Lignite (or peat or weathered coal, that is, substances containing humic acid) 120 kg, sodium metabisulfite 30 kg, water 500 kg, hydrolyzed polyacrylonitrile ammonium salt 20 kg, cross-linking agent (formaldehyde) 5 kg, potassium hydroxide 30 kg kg, 5 kg of complexing agent (ferric chloride), 2 kg of urea, and 20 kg of silicone resin.

[0053] The preparation method of anti-slump dilution fluid loss reducer for drilling fluid, it (sequentially) comprises the following steps: (1), water, potassium hydroxide, lignite (or peat or weathered coal), sodium pyrosulfite are added and stirred according to the above weight In the reaction kettle, seal it, heat up to 160°C, react for 2 hours, and cool down to below 60°C (such as 55°C). This step improves the temperature resistance and viscosity-reducing function of the product by extracting humic a...

Embodiment 2

[0054] Embodiment 2: the fluid loss control agent of the present invention is made from the raw material of following weight ratio: weathered coal (or peat or lignite, namely the material containing humic acid) 110 kilograms (or 80 kilograms or 100 kilograms ), sodium metabisulfite 35 kg (or 55 kg or 80 kg), water 400 kg (or 300 kg or 450 kg), hydrolyzed polyacrylonitrile ammonium salt 20 kg (or 10 kg or 30 kg), crosslinking agent (formaldehyde) 5 kg (or 2 kg or 15 kg), 40 kg of potassium hydroxide (or 30 kg or 50 kg), 8 kg of complexing agent (ferric chloride) (or 5 kg or 20 kg), 5 kg of urea (or 1 kg or 10 kg), silicone resin 15 kg (or 10 kg or 20 kg).

[0055] The preparation method of the anti-slump dilution fluid loss reducer for drilling fluid comprises the following steps: (1), water, potassium hydroxide, lignite (or peat or weathered coal), and sodium pyrosulfite are added to the stirred reaction kettle according to the above weight medium, sealed, heated to 150°C (or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com