Patents

Literature

637 results about "Apparent viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparent viscosity (sometimes denoted η) is the shear stress applied to a fluid divided by the shear rate (η=τ/γ). For a Newtonian fluid, the apparent viscosity is constant, and equal to the Newtonian viscosity of the fluid, but for non-Newtonian fluids, the apparent viscosity depends on the shear rate. Apparent viscosity has the SI derived unit Pa·s (Pascal-second, but the centipoise is frequently used in practice: (1 mPa·s = 1 cP).

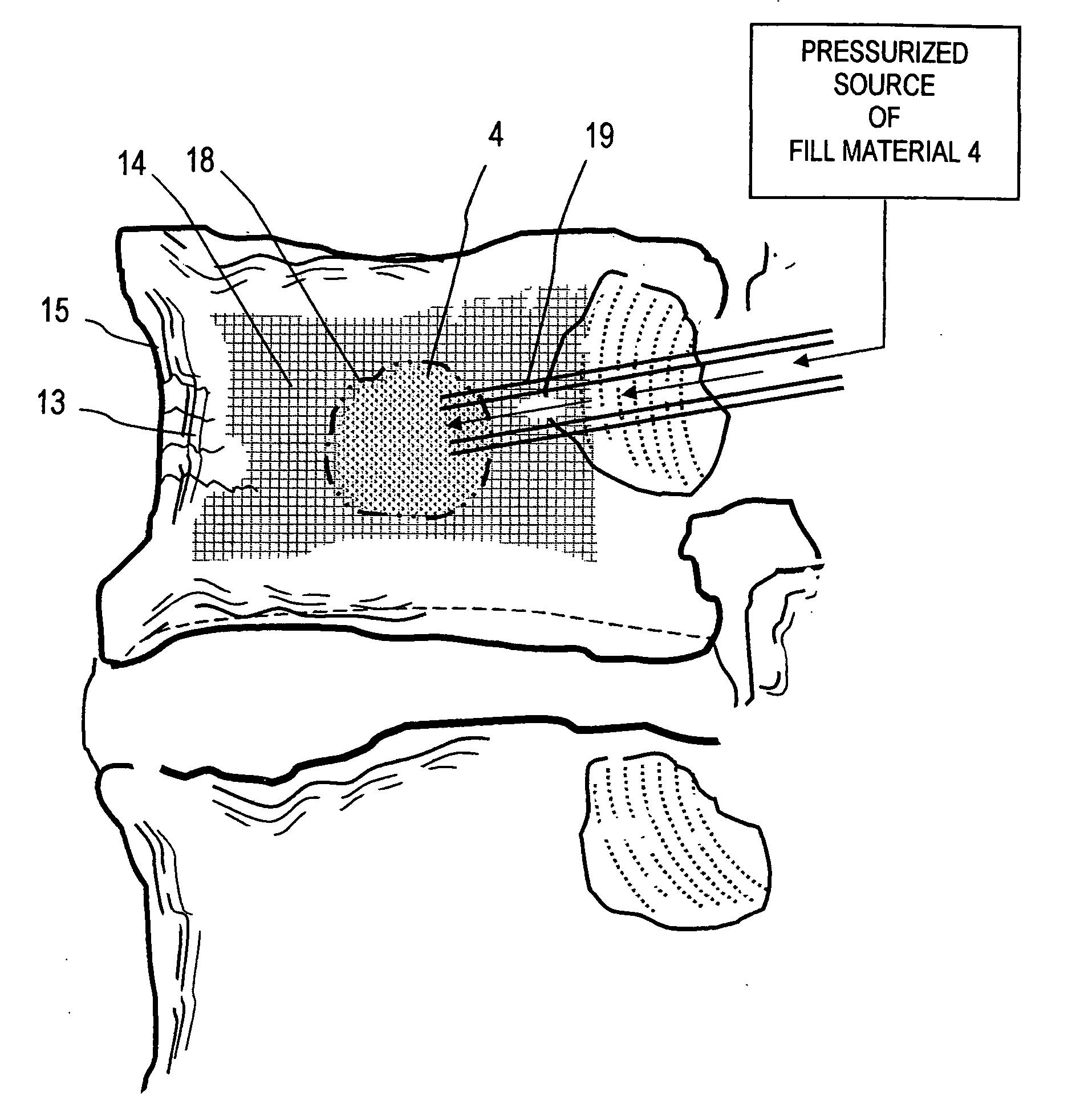

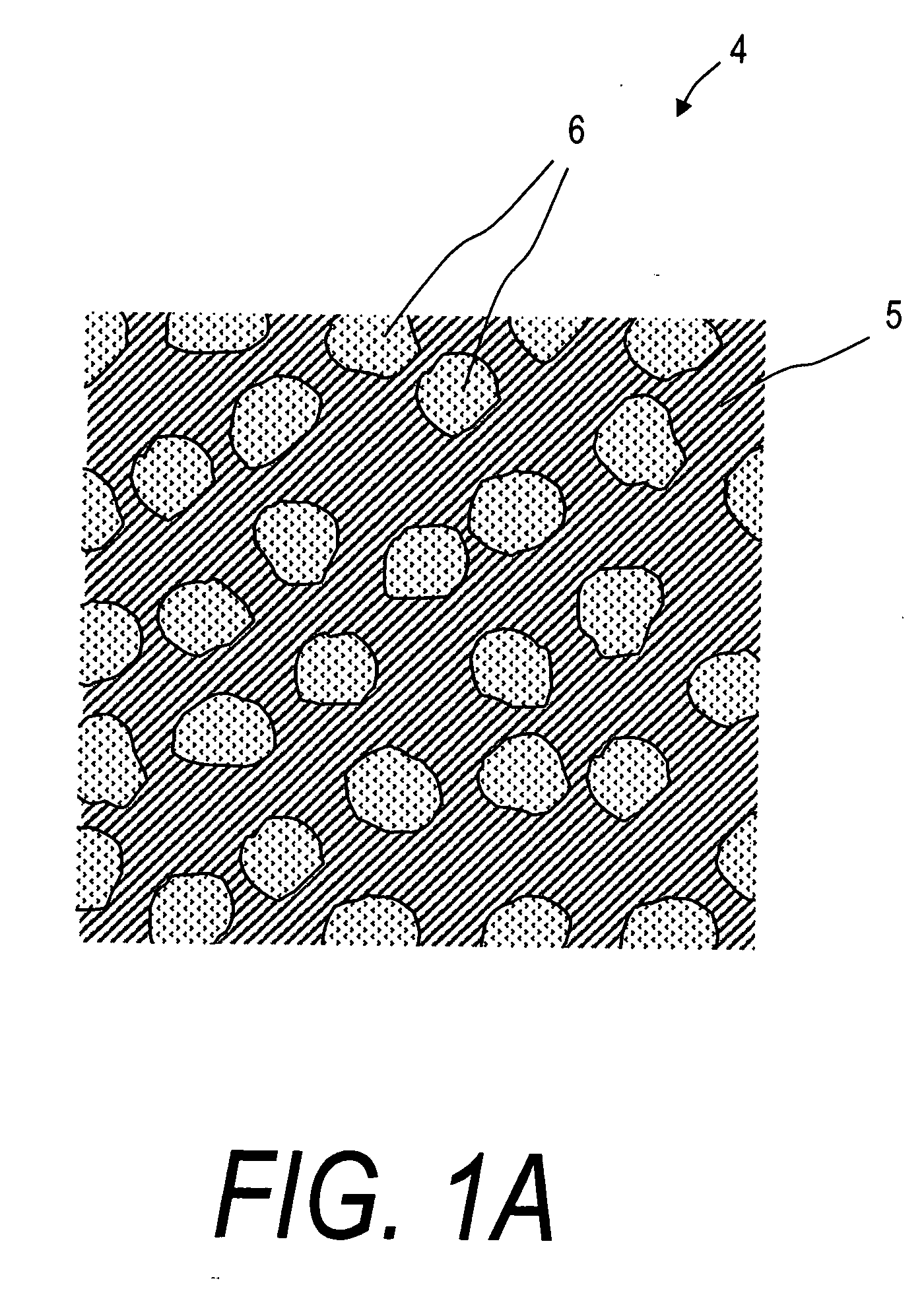

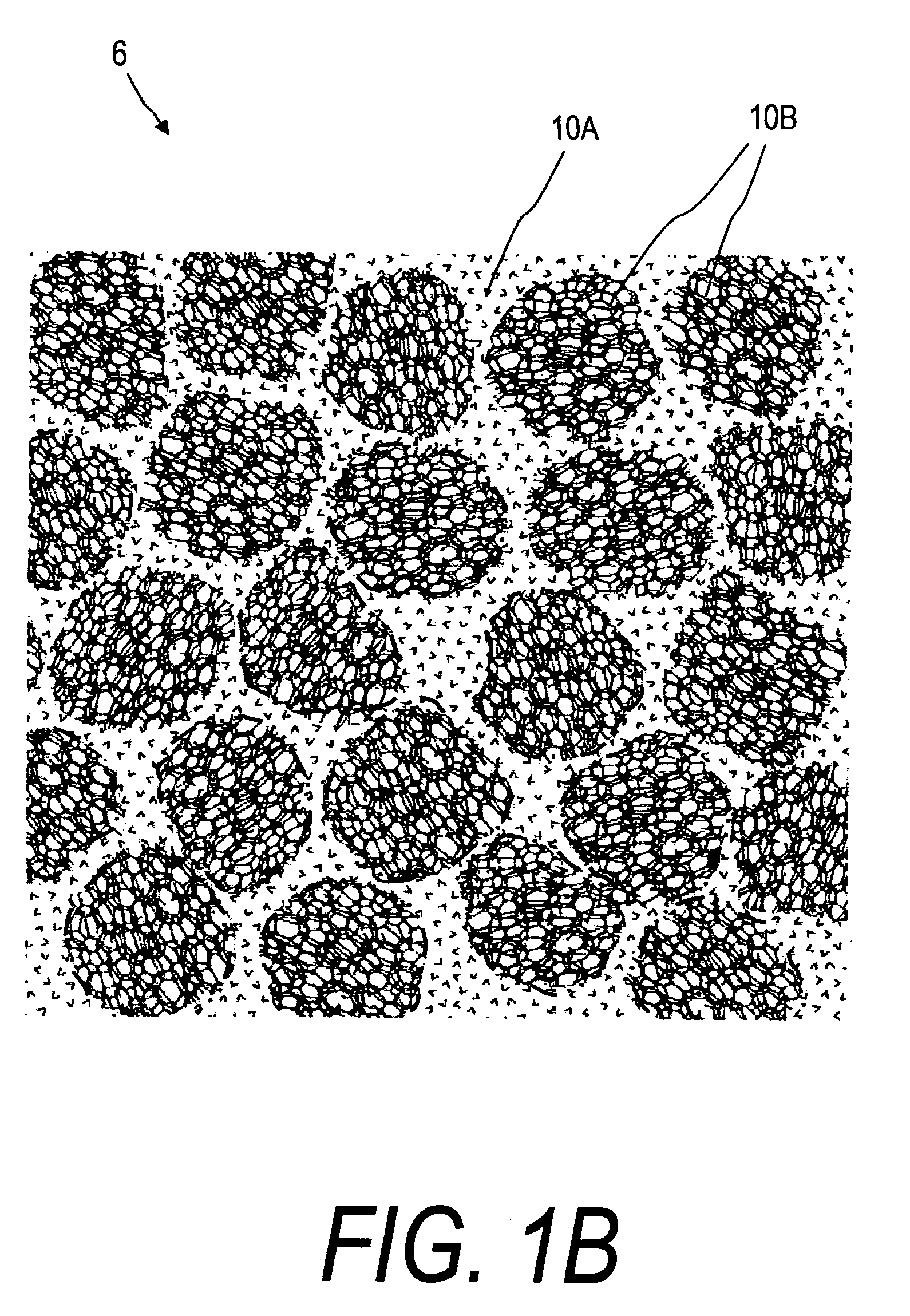

Composites and methods for treating bone

A system and method for treating bone abnormalities including vertebral compression fractures and the like. In one vertebroplasty method, a fill material is injected under high pressures into cancellous bone wherein the fill material includes a flowable bone cement component and an elastomeric polymer component that is carried therein. The elastomer component can further carry microscale or mesoscale reticulated elements. Under suitable injection pressures, the elastomeric component ultimately migrates within the flowable material to alter the apparent viscosity across the plume of fill material to accomplish multiple functions. For example, the differential in apparent viscosity across the fill material creates a broad load-distributing layer within cancellous bone for applying retraction forces to cortical bone endplates. The differential in apparent viscosity also transitions into a flow impermeable layer at the interface of cancellous bone and the flowable material to prevent extravasion of the flowable bone cement component.

Owner:DFINE INC

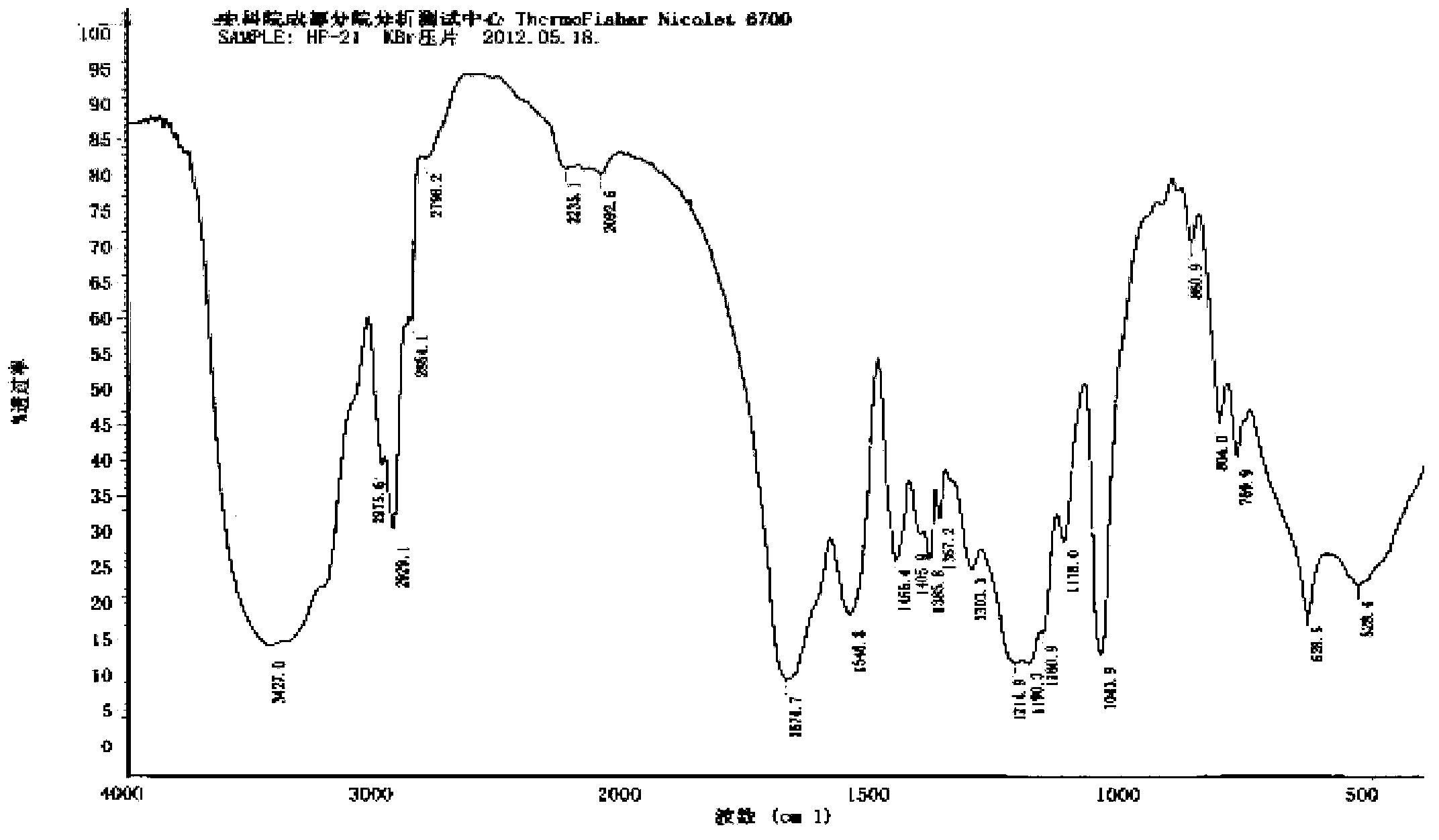

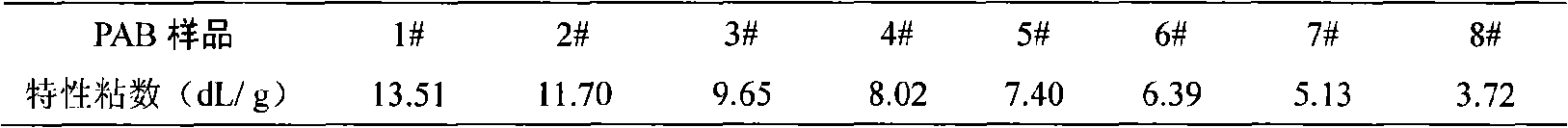

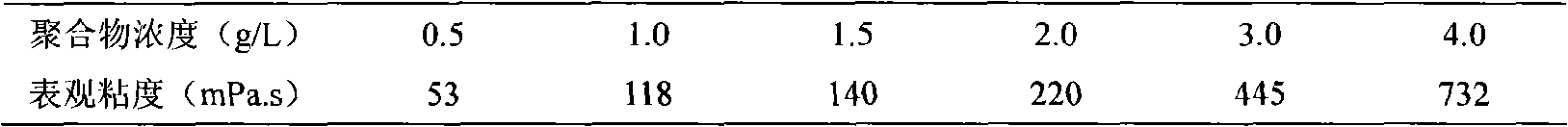

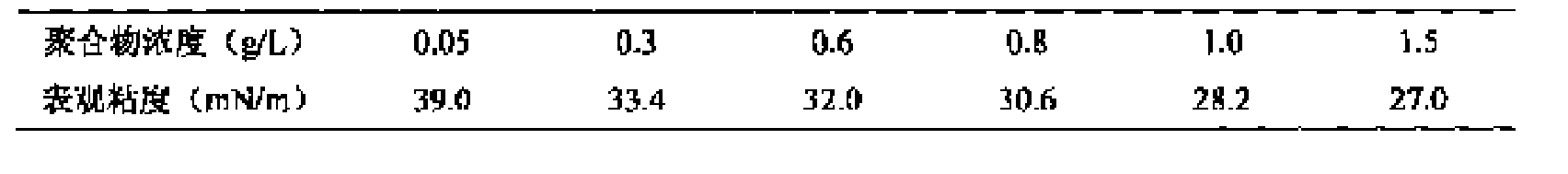

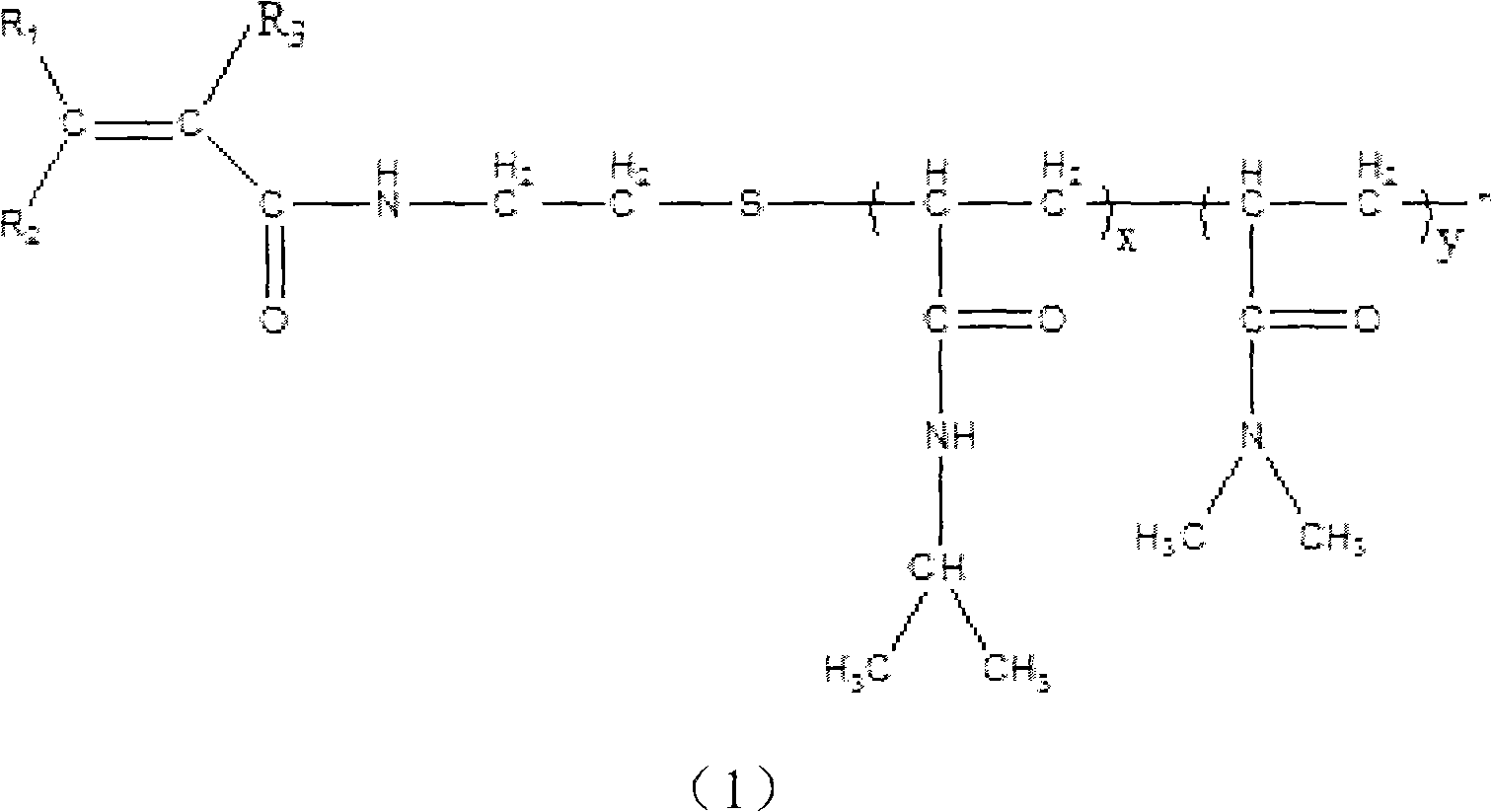

Acrylic amide modified graft copolymer, preparation method and application thereof

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Resin composition and jig for use in transportation

InactiveUS6344513B1Excellent static charge dissipating performanceLittle changeSemiconductor/solid-state device manufacturingSpecial tyresFiberCarbon fibers

Owner:TEIJIN LTD

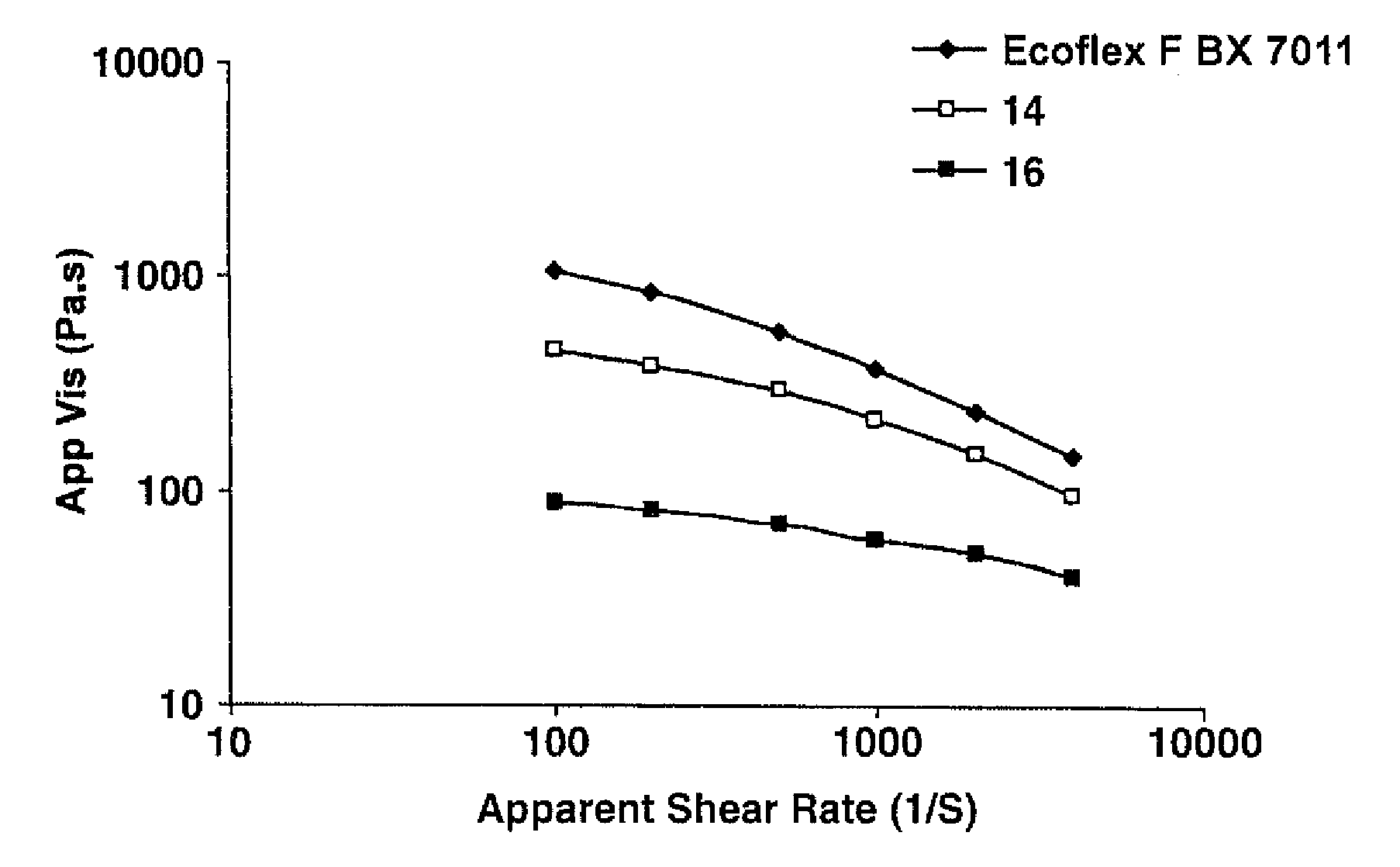

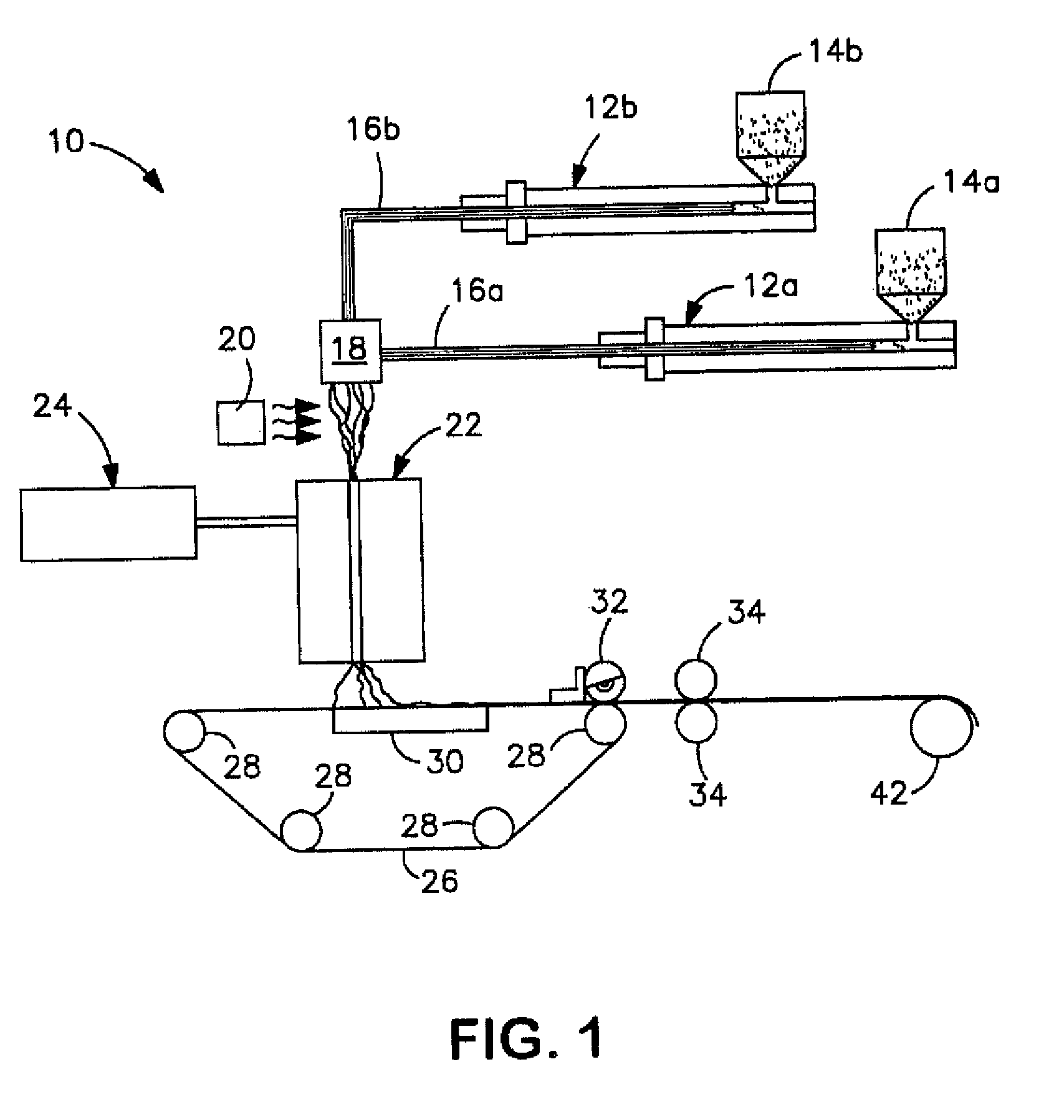

Multicomponent biodegradable filaments and nonwoven webs formed therefrom

A biodegradable, substantially continuous filament is provided. The filament contains a first component formed from at least one high melting polyester and a second component formed from at least one low melting polyester. The low melting point polyester is an aliphatic-aromatic copolyester formed by melt blending a polymer and an alcohol to initiate an alcoholysis reaction that results in a copolyester having one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the alcoholysis conditions (e.g., alcohol and copolymer concentrations, catalysts, temperature, etc.), a modified aliphatic-aromatic copolyester may be achieved that has a molecular weight lower than the starting aliphatic-aromatic polymer. Such lower molecular weight polymers also have the combination of a higher melt flow index and lower apparent viscosity, which is useful in the formation of substantially continuous filaments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

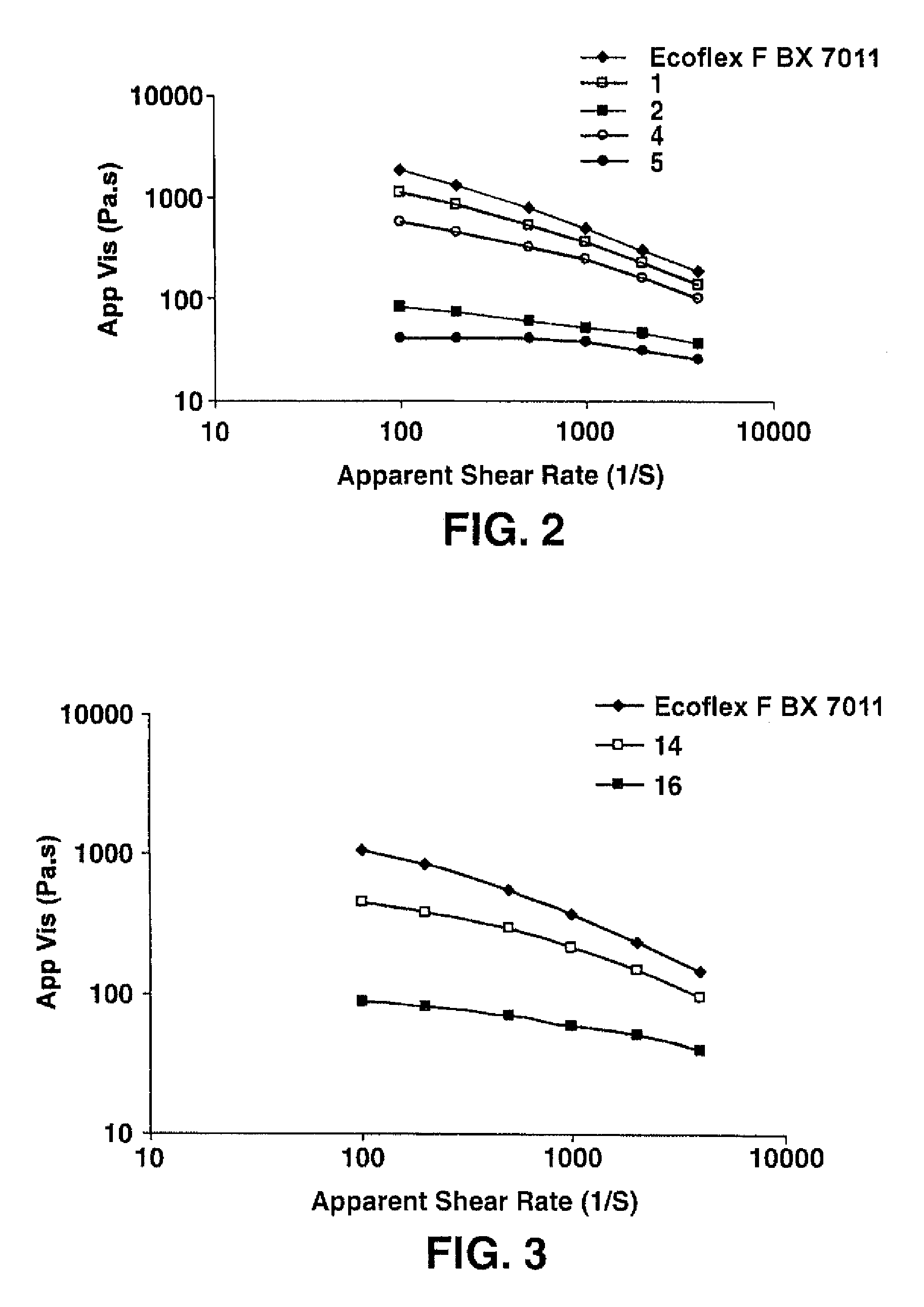

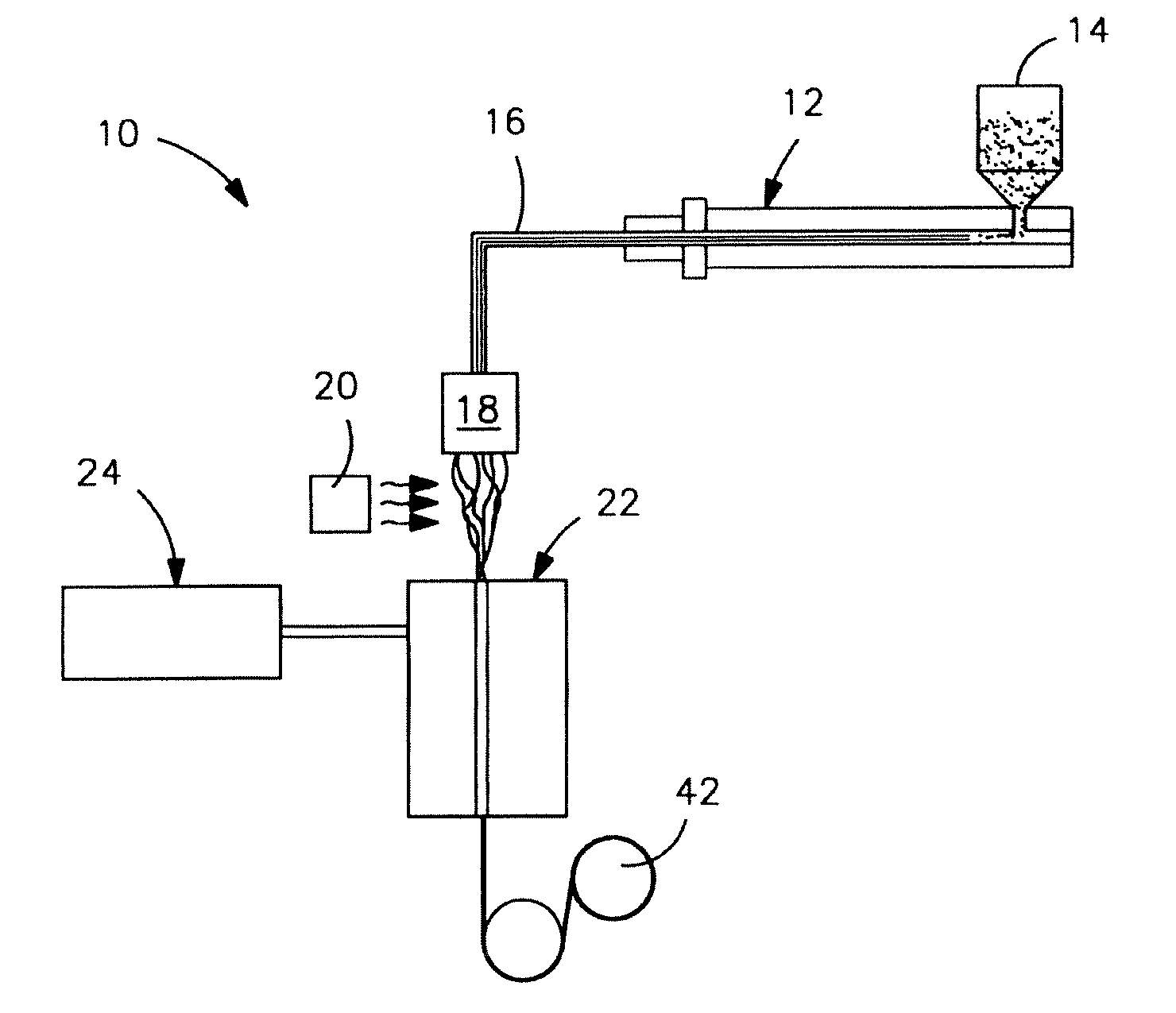

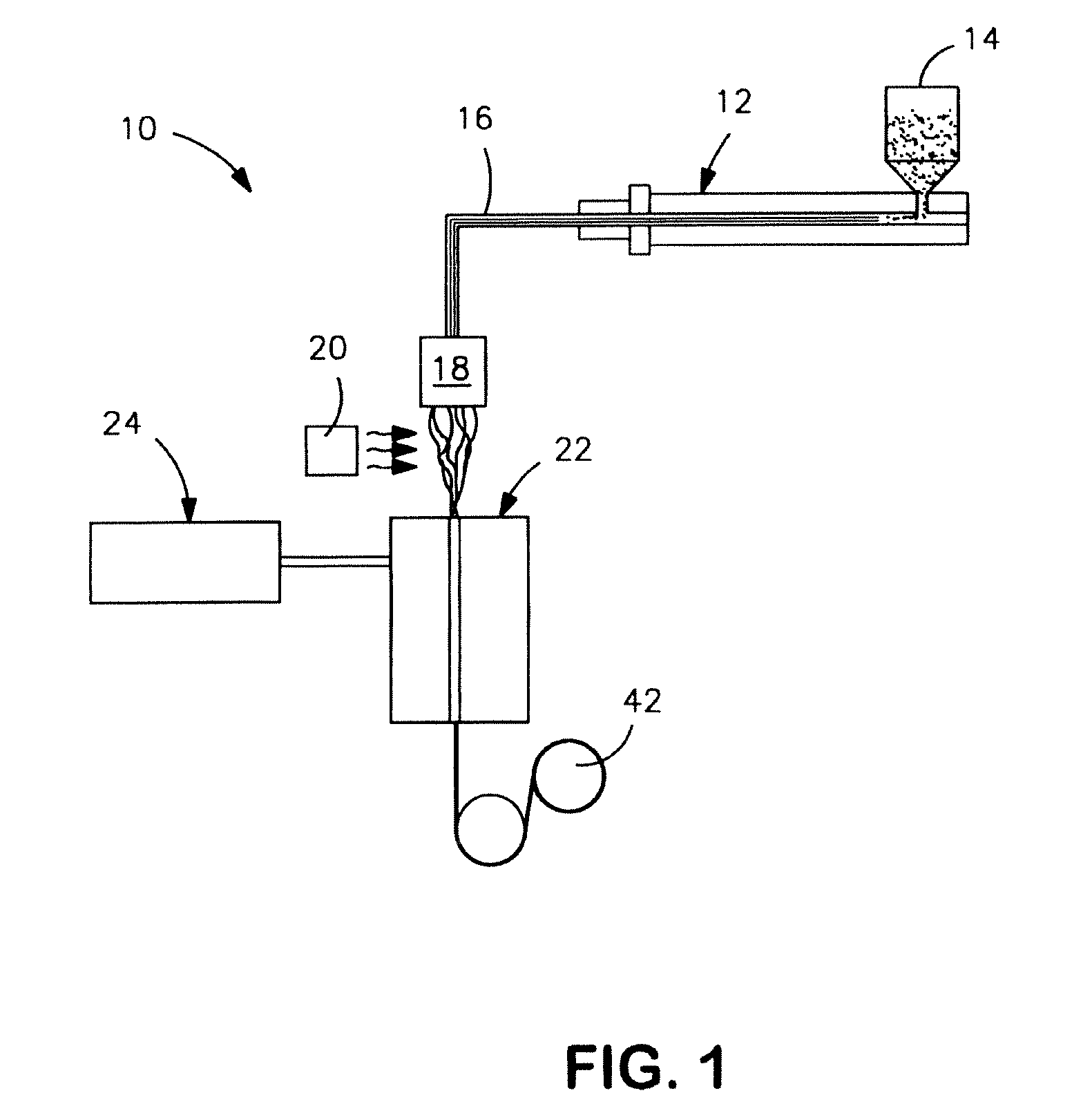

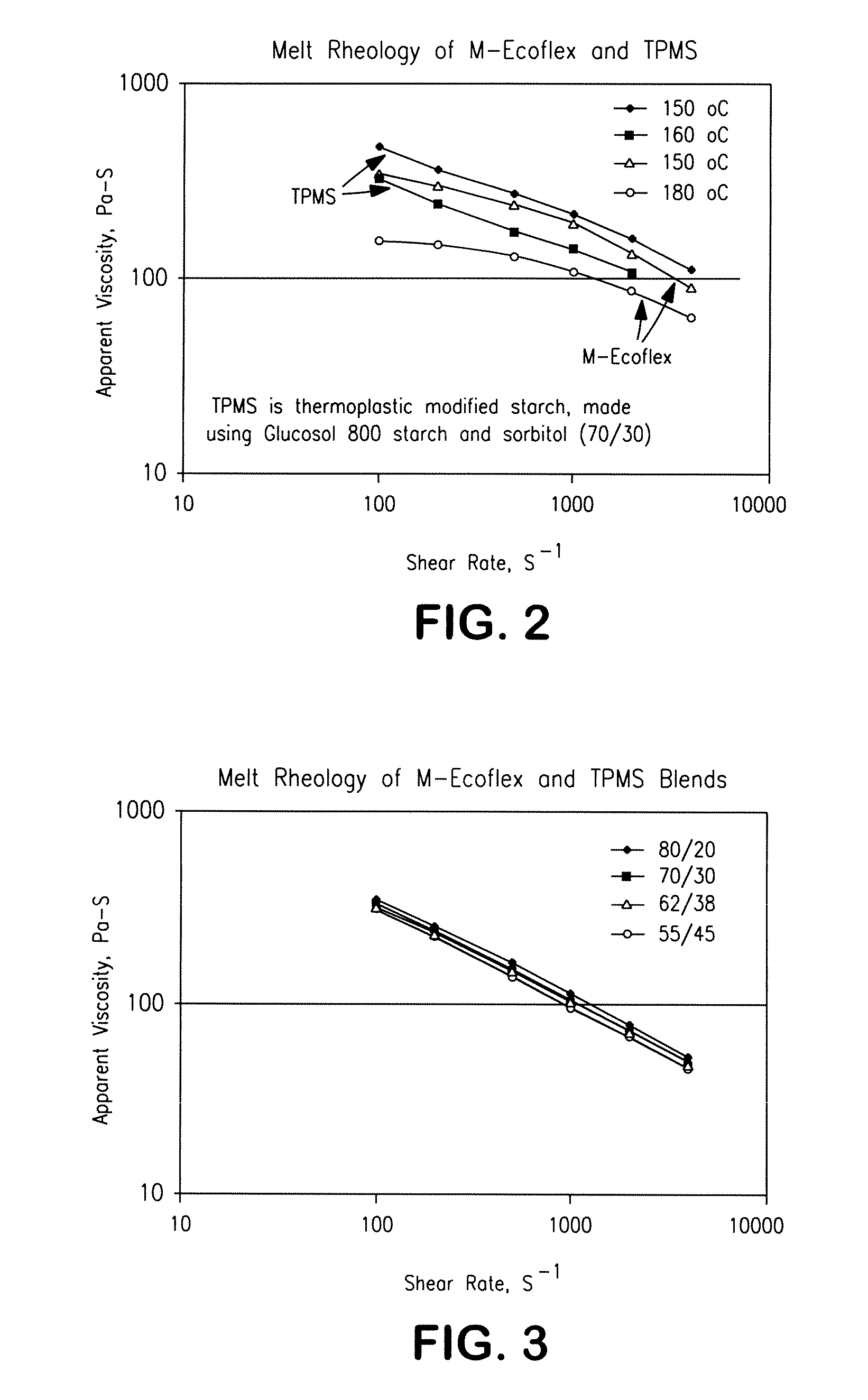

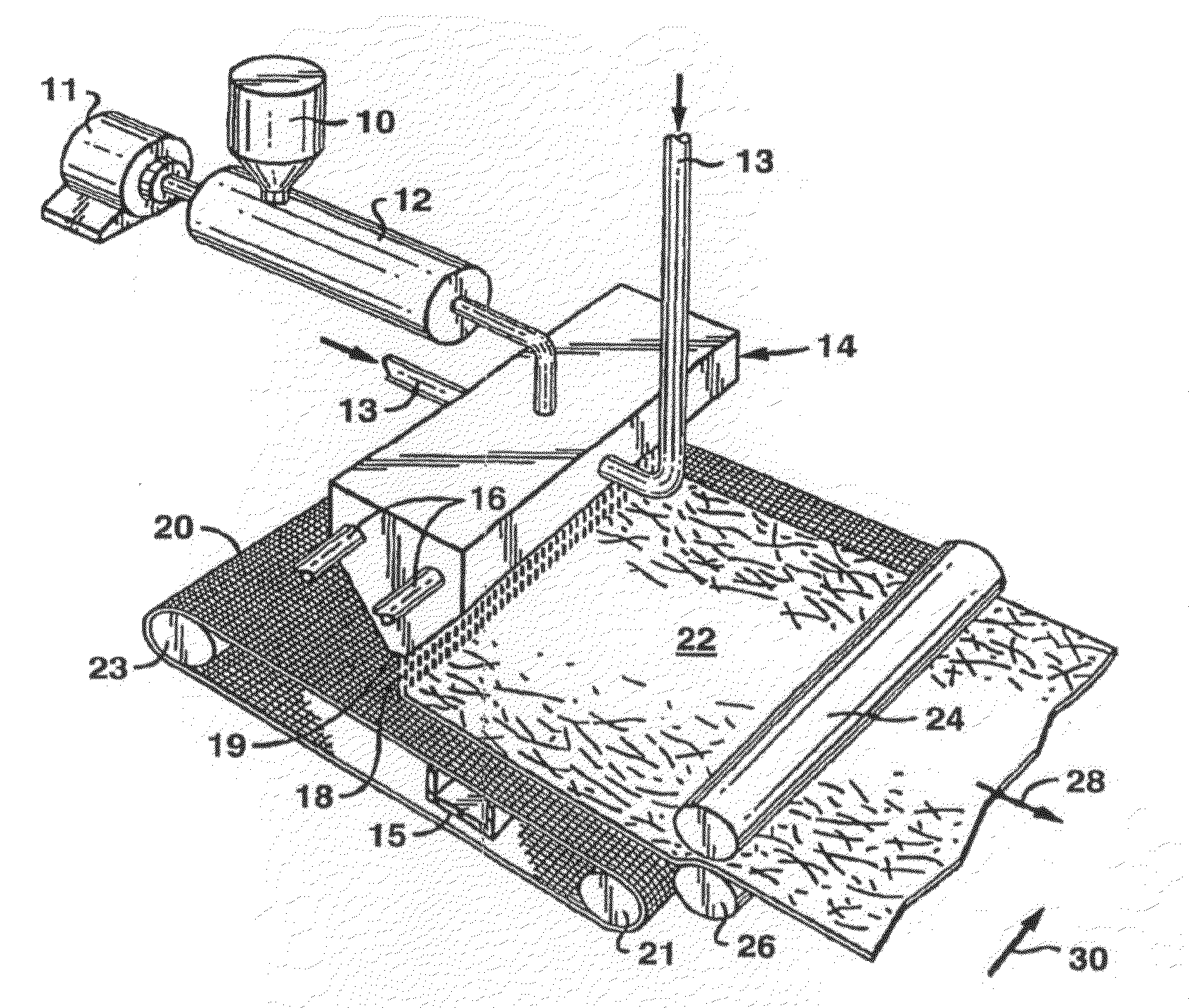

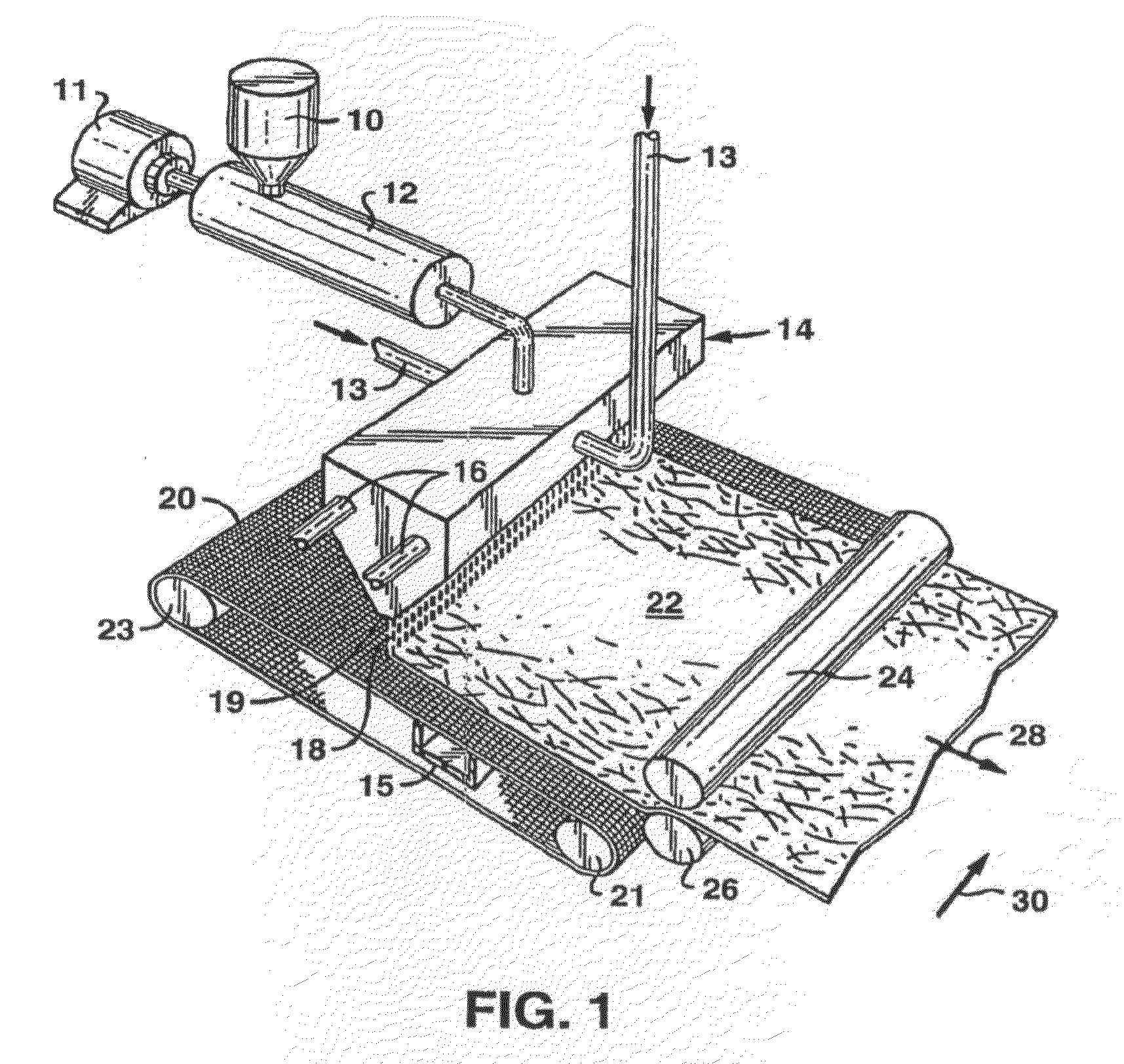

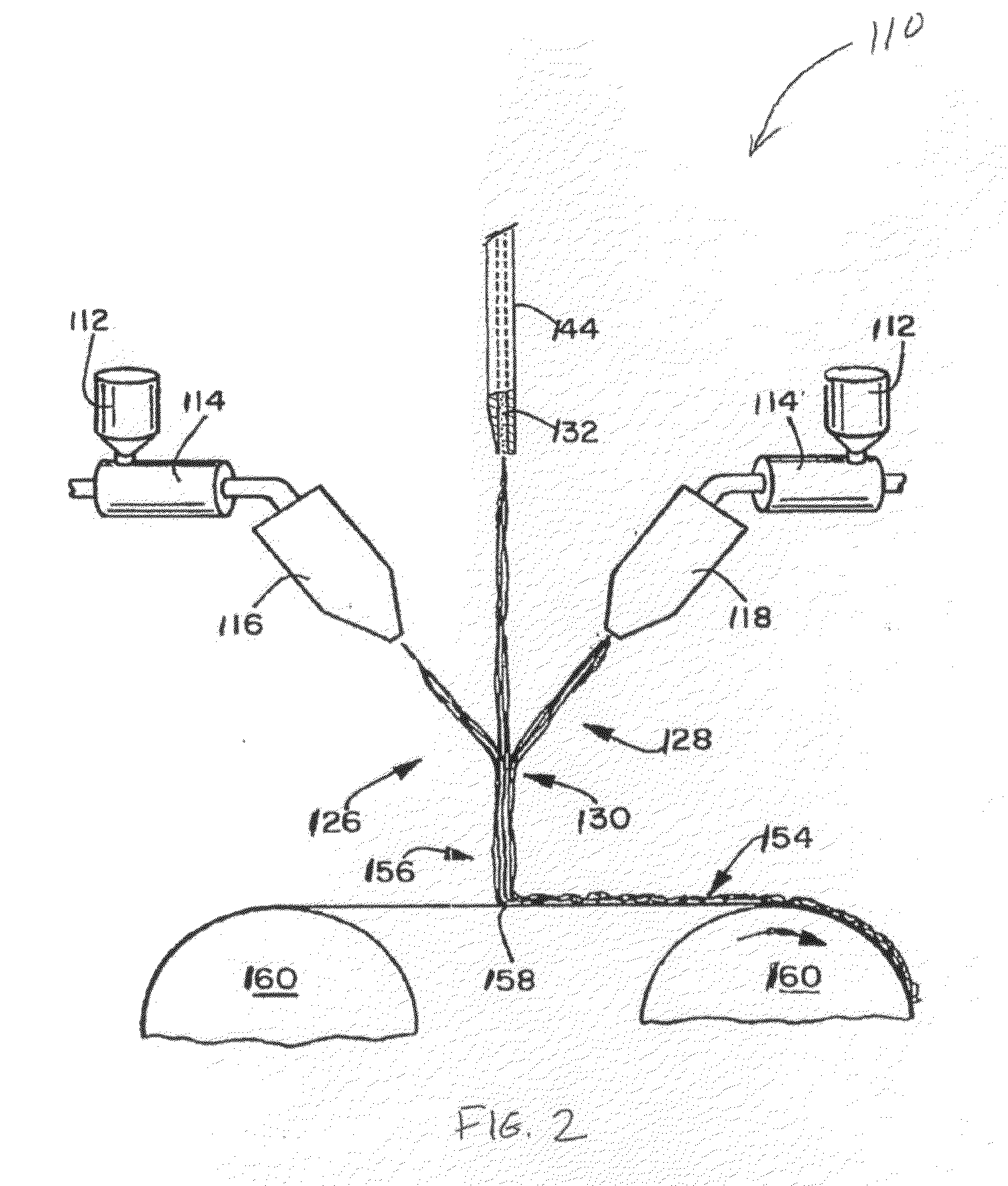

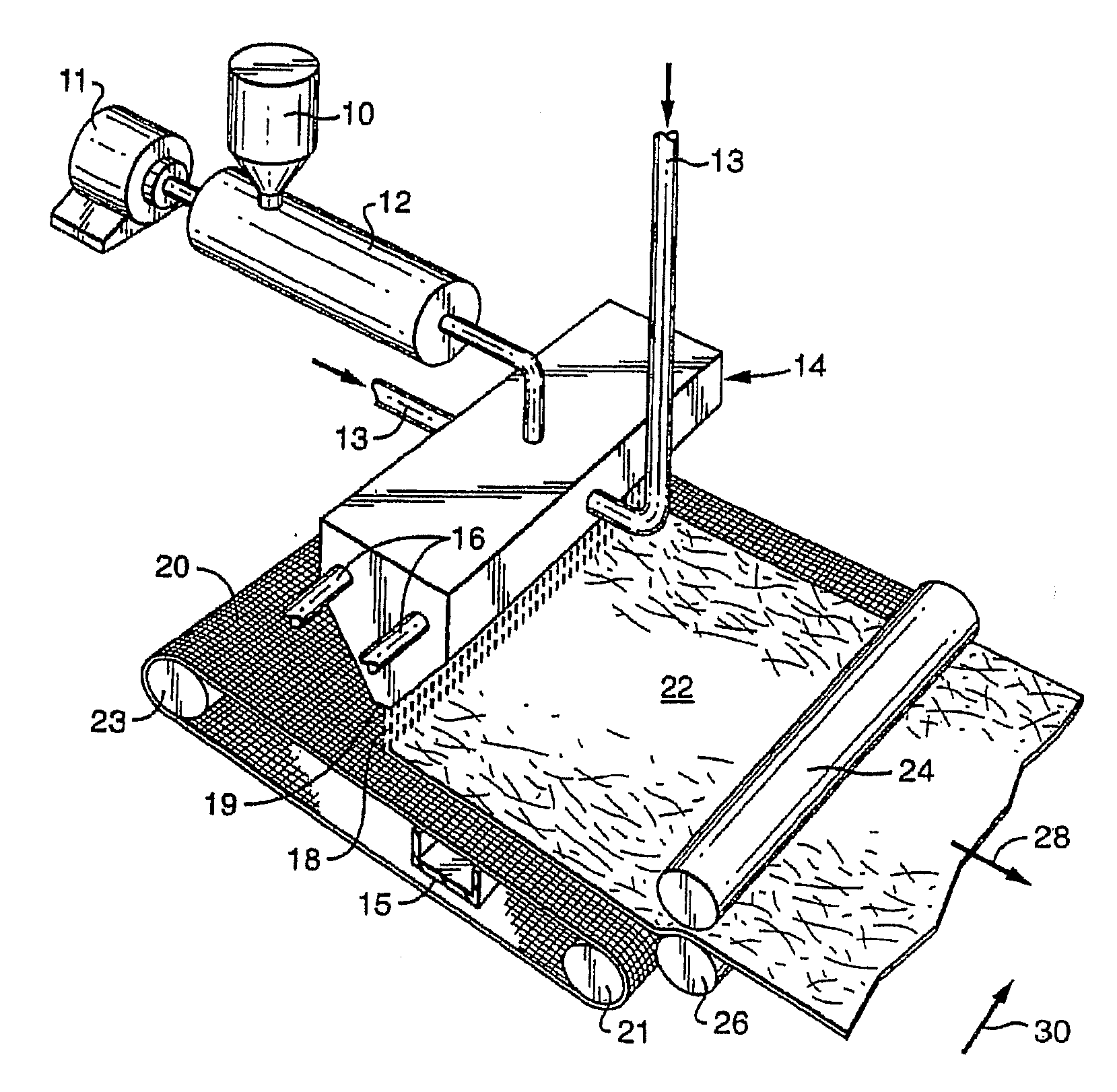

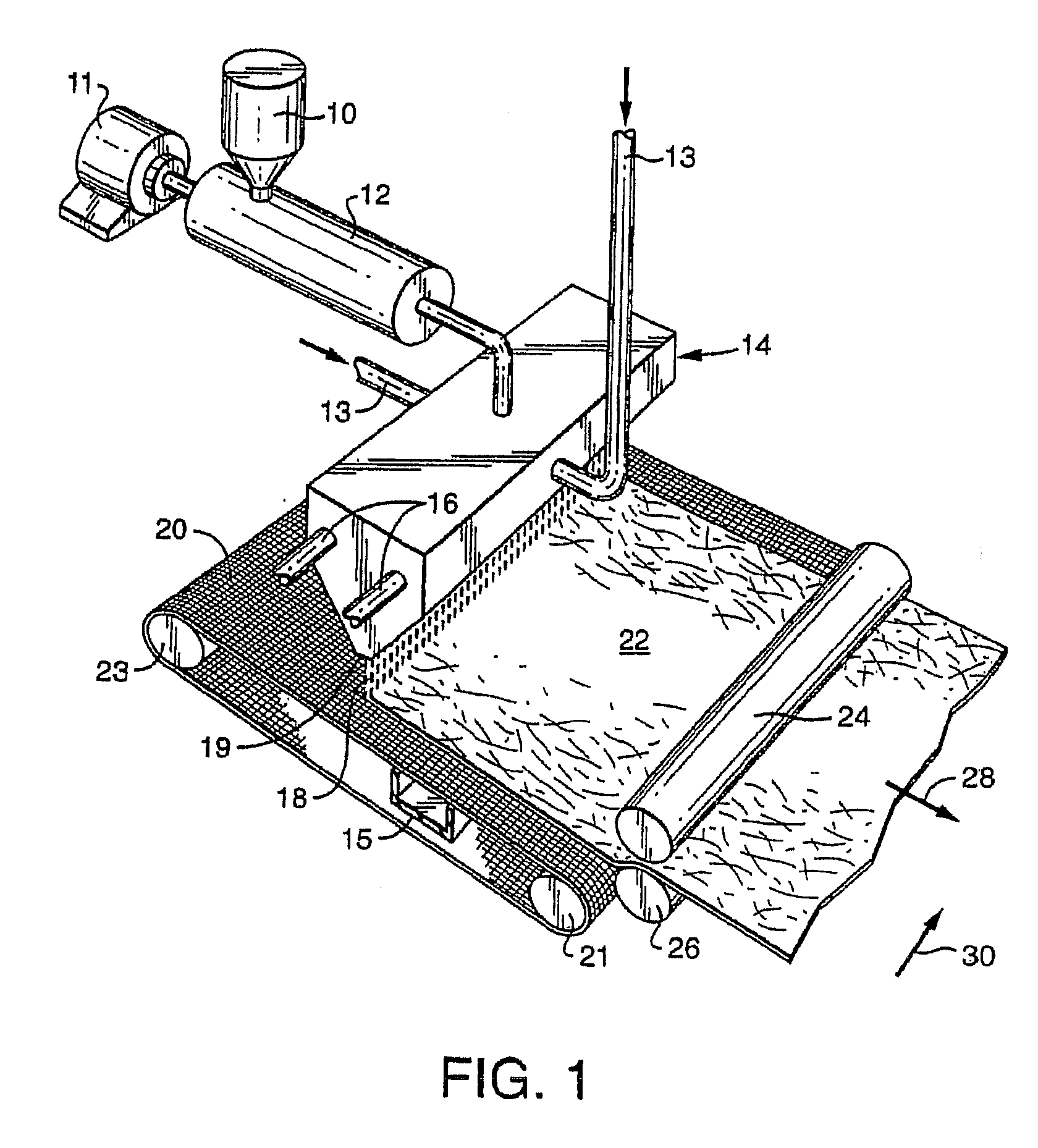

Fibers Formed from a Blend of a Modified Aliphatic-Aromatic Copolyester and Thermoplastic Starch

ActiveUS20090305592A1Ceramic shaping apparatusMonocomponent copolyesters artificial filamentFiberAlcohol

A fiber formed from a thermoplastic composition that contains a thermoplastic starch and an aliphatic-aromatic copolyester is provided. The copolyester enhances the strength of the starch-containing fibers and also facilitates the ability of the starch to be melt processed. Due to its relatively low melting point, the aliphatic-aromatic copolyester may also be extruded with the thermoplastic starch at a temperature that is low enough to avoid substantial removal of the moisture found in the starch. Furthermore, the aliphatic-aromatic copolyester is also modified with an alcohol so that it contains one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the conditions of the alcoholysis reaction (e.g., alcohol and copolymer concentrations, temperature, etc.), the resulting modified aliphatic-aromatic copolyester may have a molecular weight that is relatively low. Such low molecular weight polymers have the combination of a higher melt flow index and lower apparent viscosity, which is useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

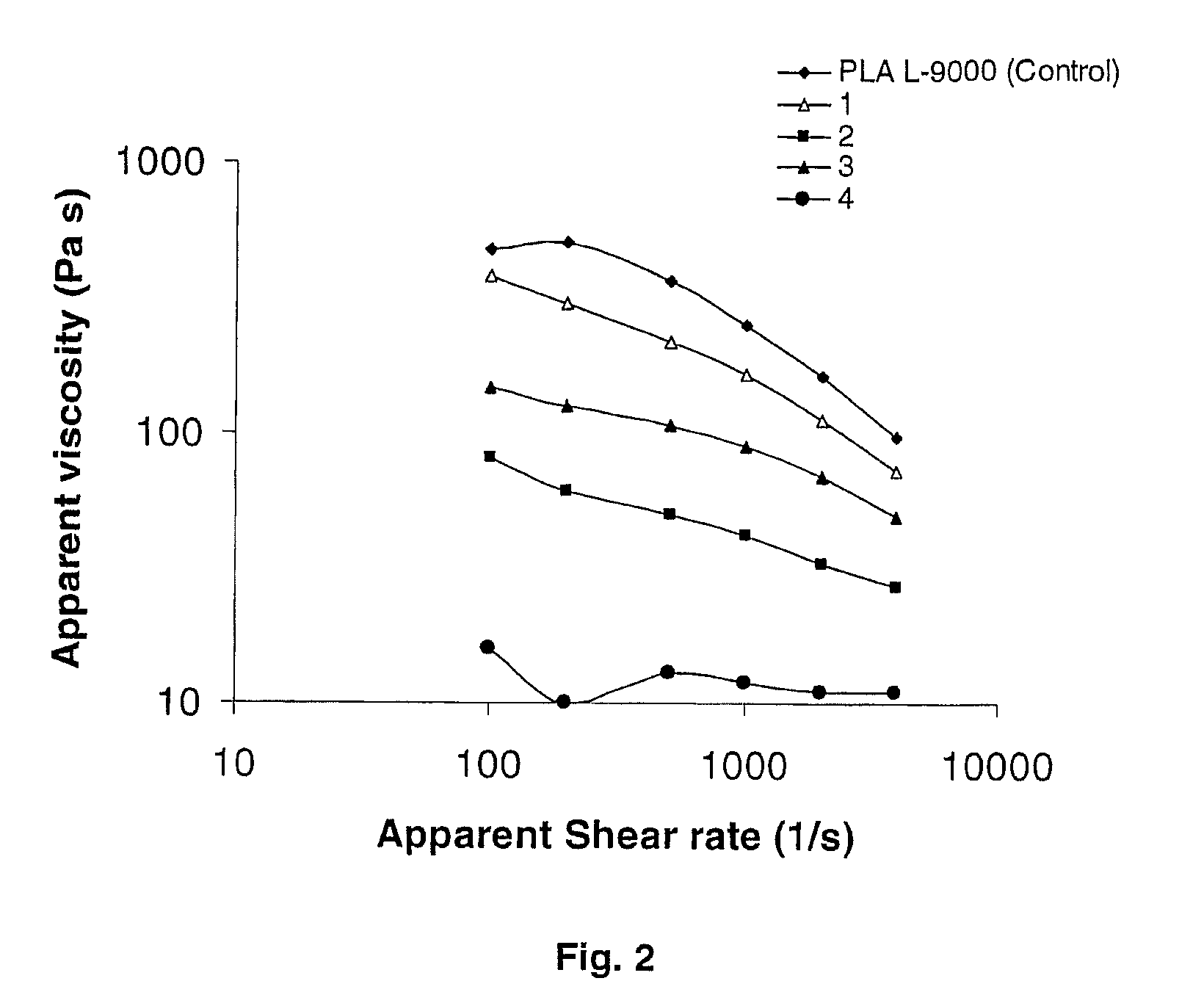

Biodegradable polylactic acids for use in forming fibers

A method for forming a biodegradable polylactic acid suitable for use in fibers is provided. Specifically, a polylactic acid is melt processed at a controlled water content to initiate a hydrolysis reaction. Without intending to be limited by theory, it is believed that the hydroxyl groups present in water are capable of attacking the ester linkage of polylactic acids, thereby leading to chain scission or “depolymerization” of the polylactic acid molecule into one or more shorter ester chains. The shorter chains may include polylactic acids, as well as minor portions of lactic acid monomers or oligomers, and combinations of any of the foregoing. By selectively controlling the hydrolysis conditions (e.g., moisture and polymer concentrations, temperature, shear rate, etc.), a hydrolytically degraded polylactic acid may be achieved that has a molecular weight lower than the starting polymer. Such lower molecular weight polymers have a higher melt flow rate and lower apparent viscosity, which are useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

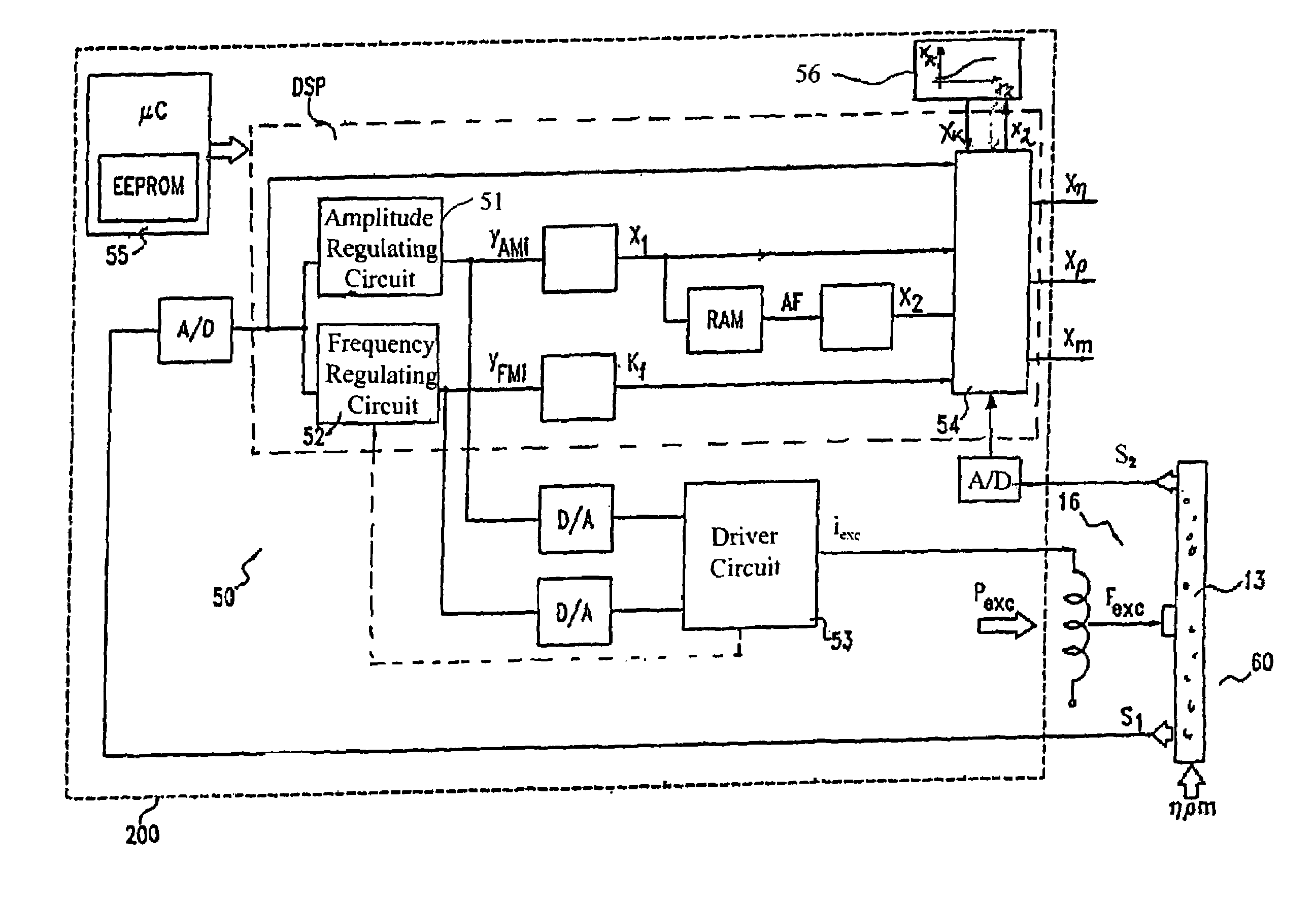

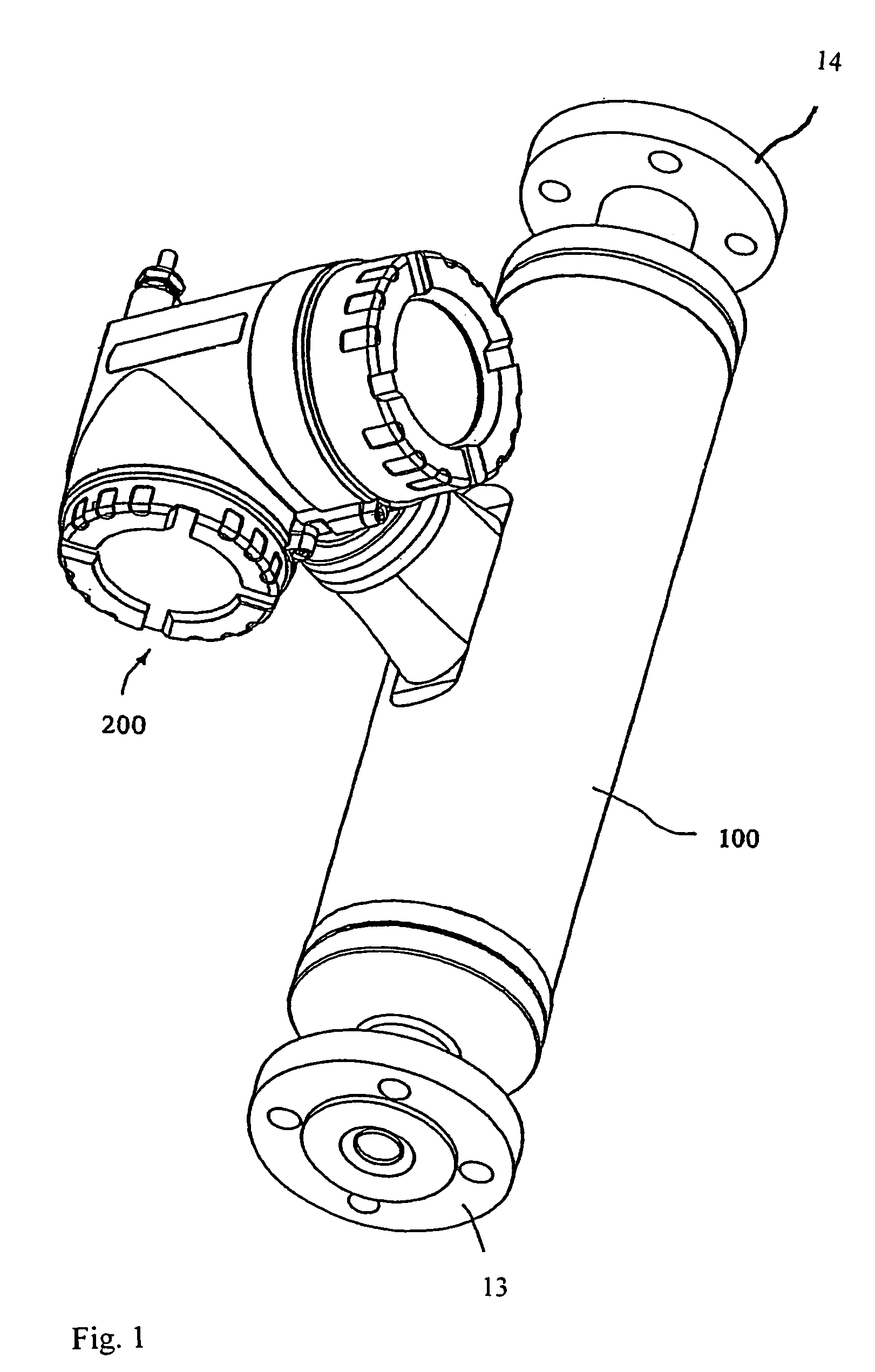

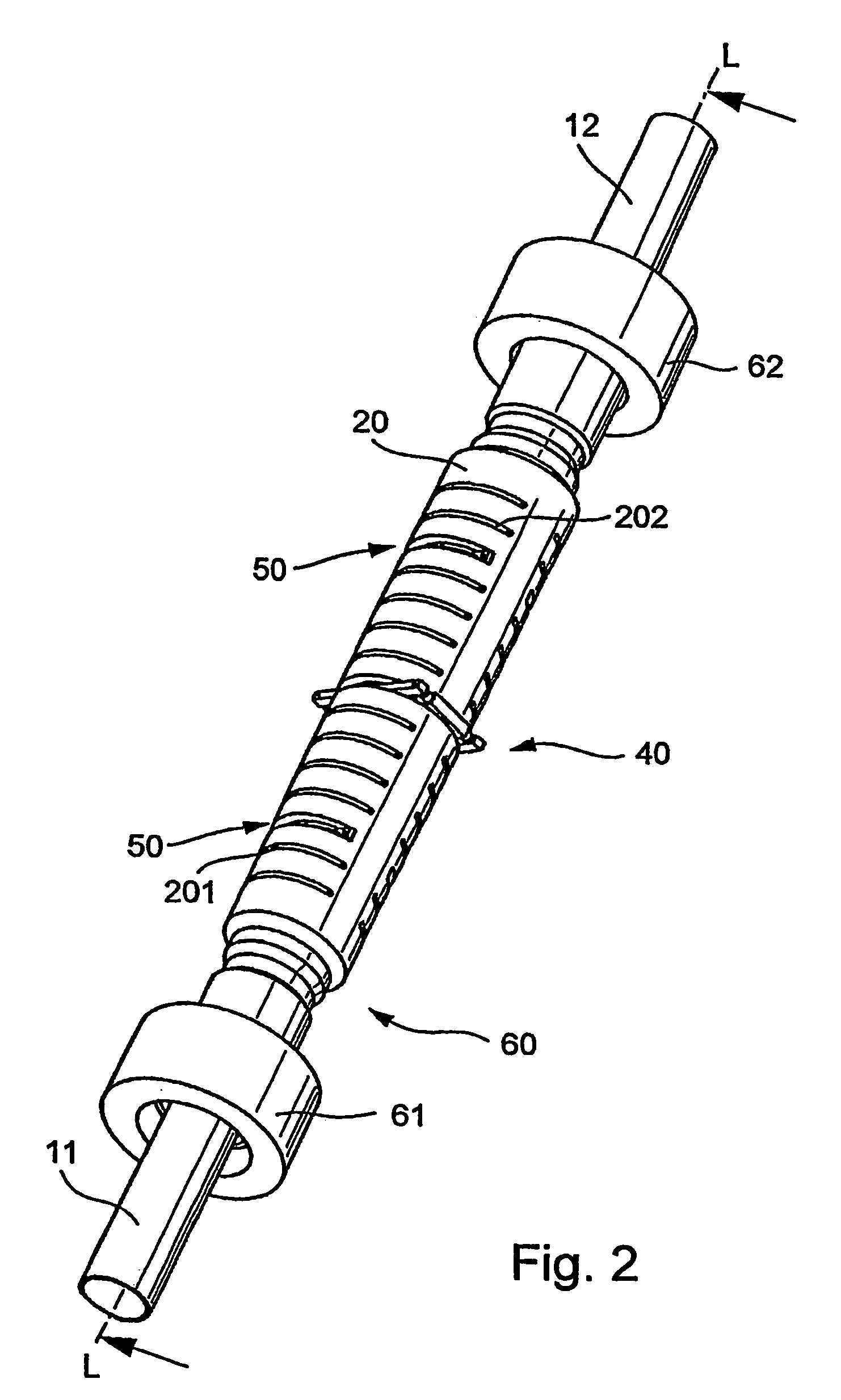

Coriolis mass measuring device

ActiveUS7040181B2Accurate measurementImprove accuracyFlow propertiesVolume meteringMeasurement deviceApparent viscosity

A Coriolis mass flow measuring device includes a vibratory measuring transducer having at least one measuring tube, which has medium flowing through it during operation. In operation, the measuring tube is caused by an exciter arrangement to undergo mechanical oscillations, especially bending oscillations. Additionally, the Coriolis mass flow measuring device includes a sensor arrangement for producing oscillation measurement signals (s1, S2) representing the inlet-end and outlet-end oscillations of the measuring tube. Measuring device electronics controlling the exciter arrangement produces an exciter current (iexc) and an intermediate value (X′m) derived from the oscillation measurement signals (s1, s2). This intermediate value represents an uncorrected mass flow. Derived from the exciter current and / or from a component of the exciter current (iexc), an intermediate value (X2) is produced, which corresponds to a damping of the oscillations of the measuring tube. This damping is especially a function of an apparent viscosity, and / or a viscosity-density product, of the medium guided in the measuring tube. Furthermore, a correction value (XK) is produced for the intermediate value (X′m) utilizing the intermediate value (X2) and a viscosity measurement value (Xη) determined initially or during operation. The viscosity measurement value (Xη) corresponds to a viscosity of the medium guided in the measuring tube and / or to a predetermined reference viscosity. On the basis of the intermediate value (X′m) and the correction value (XK), the measuring device electronics then produces an exact mass flow rate measurement value (Xm).

Owner:ENDRESS HAUSER FLOWTEC AG

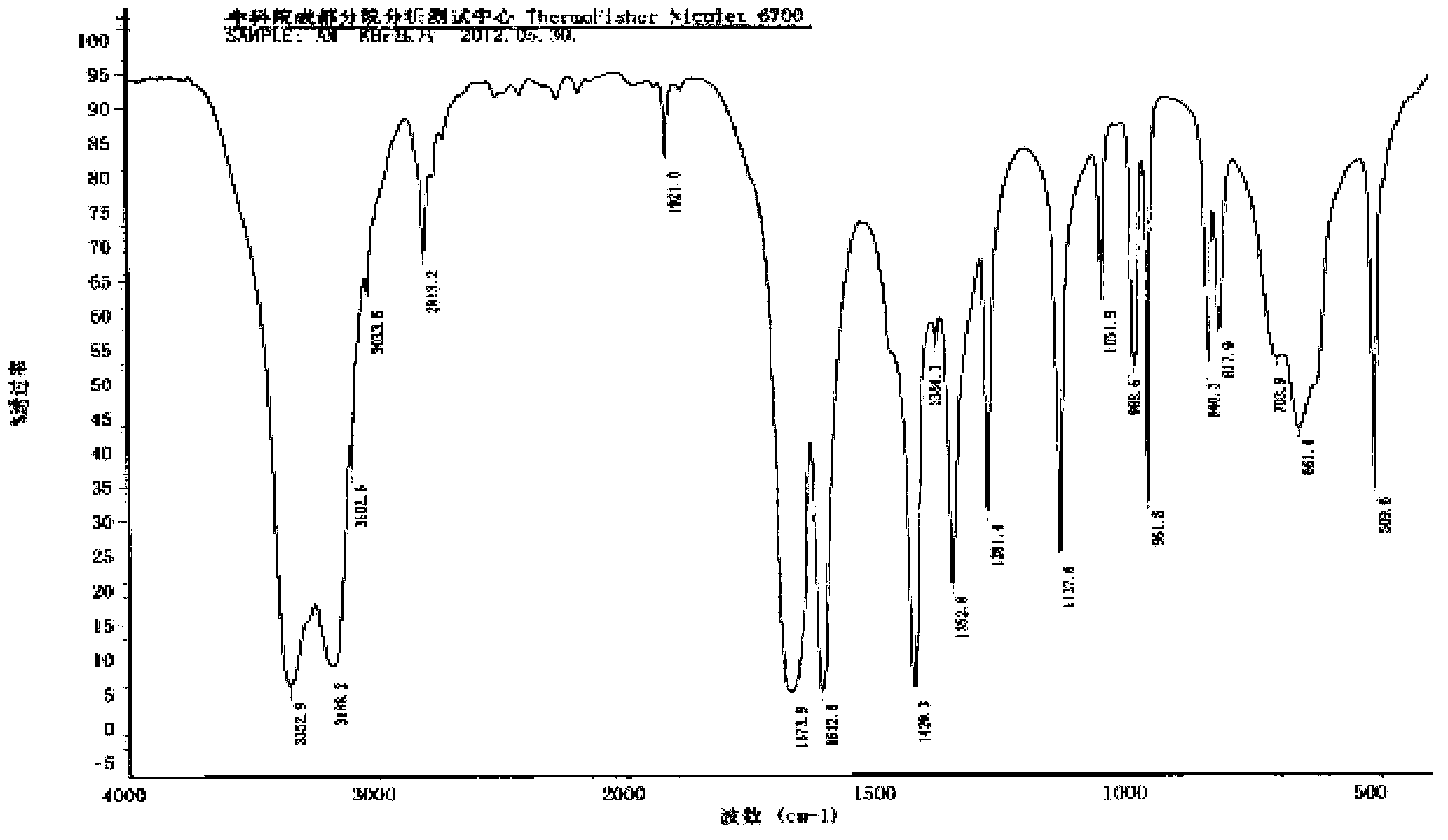

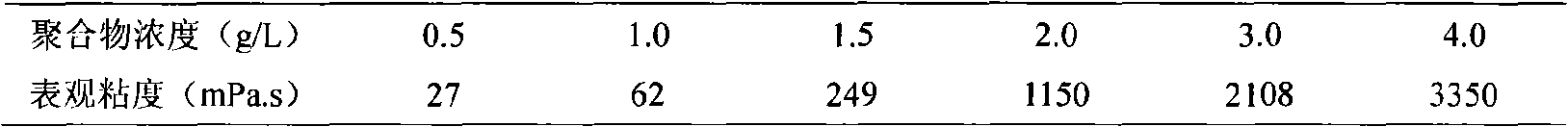

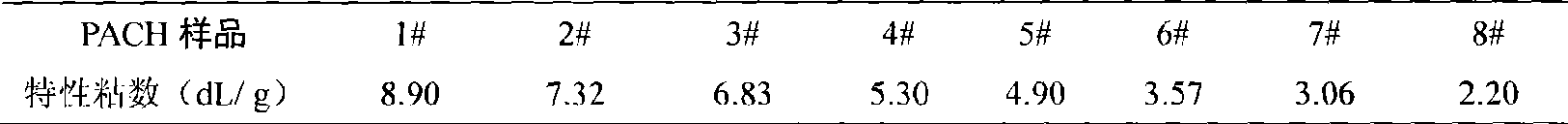

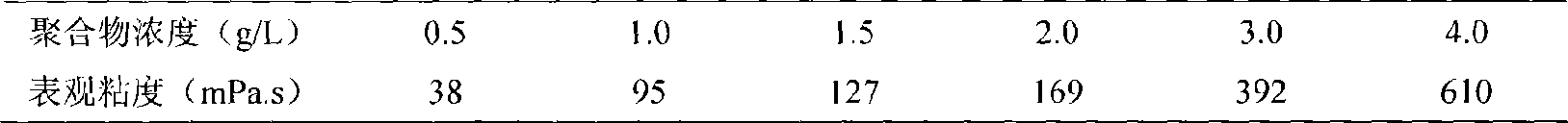

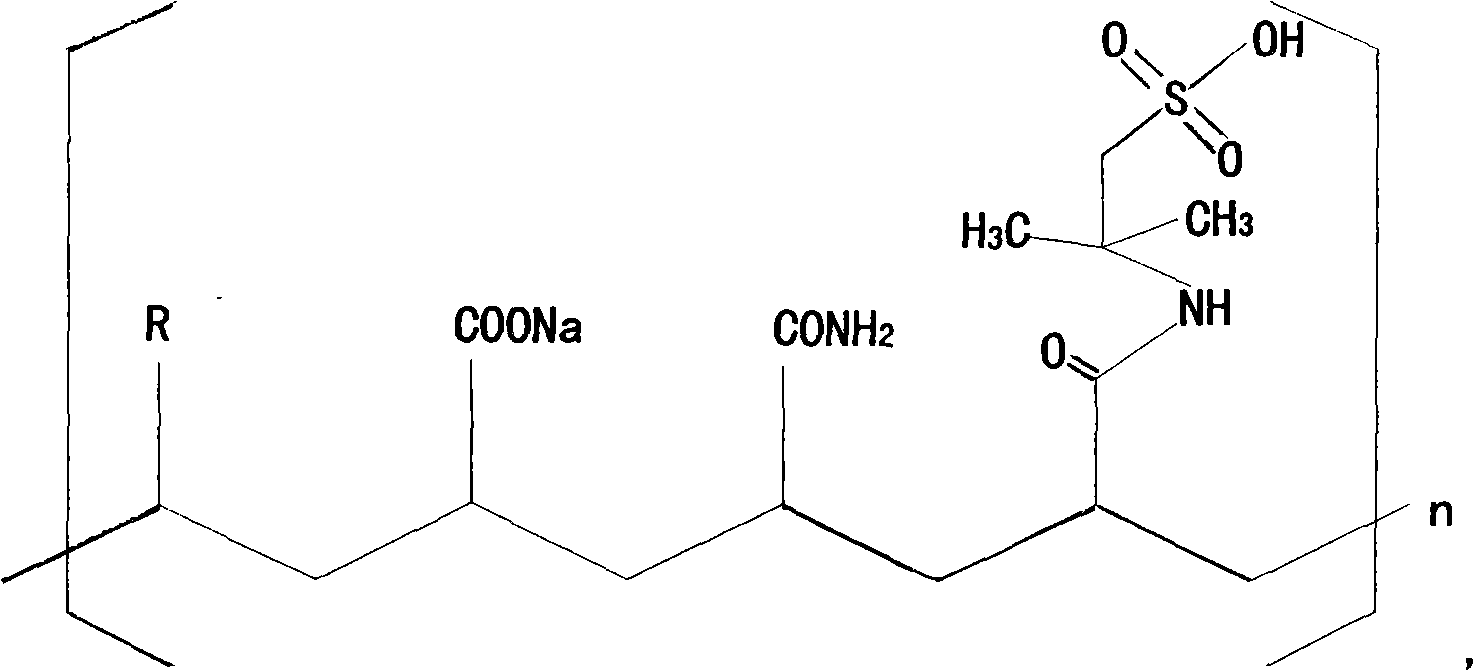

Non-linear associating water-soluble quadripolymer, and preparation and use thereof

InactiveCN101463116AImprove rigidityHigh temperature resistanceTransportation and packagingMixingIonChemistry

The invention discloses a non-linear associated water soluble quadripolymer as well as a preparation method and use thereof, comprising: adding 20 parts of acrylamide, 1-20 parts of nionic monomer or / and cationic monomer, 0.1-15 parts of macromonomer, 0.05-10 parts of hydrophobic monomer, 0.1-50 parts of surfactant and 60-1000 parts of deionized water to a three-necked reaction flask, adjusting the pH to be 3-9, adding 0.002-1 part of initiator (persulphate) at 30-75 DEG C after introducing N2 for 30min, reacting for 8-36h to obtain the quadripolymer PACH, diluting with water, and obtaining concentrated PACH solution. The macromonomer with a long chain and the hydrophobic monomer with a molecular association function are simultaneously introduced in a copolymer PACH, which can obtain the best synergistic viscosifying between rigid conformation of a molecular chain and molecular association and salt resistance. The non-linear associated water soluble quadripolymer is obtained. The copolymer is prepared into aqueous solution with the mass concentration of 0.2-3g / l and the surfactant concentration of 0.01-2mmol / l, added to a mixing vessel with a stirring device and evenly stirred at the room temperature to obtain a viscosified, salt-resistant and shear-resistant polymer oil displacement agent. The PACH has dual functions of a viscosifier and a high molecular surfactant; minute amount of a low molecular surfactant is added to the PACH solution, thus improving the apparent viscosity of the solution, reducing the surface tension of solution and the water-oil interfacial tension, and being beneficial to improving the crude oil recovery ratio. A copolymer PABE is prepared into the aqueous solution with the mass concentration of 0.05-7% to obtain high molecular surfactant with excellent surface activity, and the high molecular surfactant is used as an emulsifier, a demulsifier, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

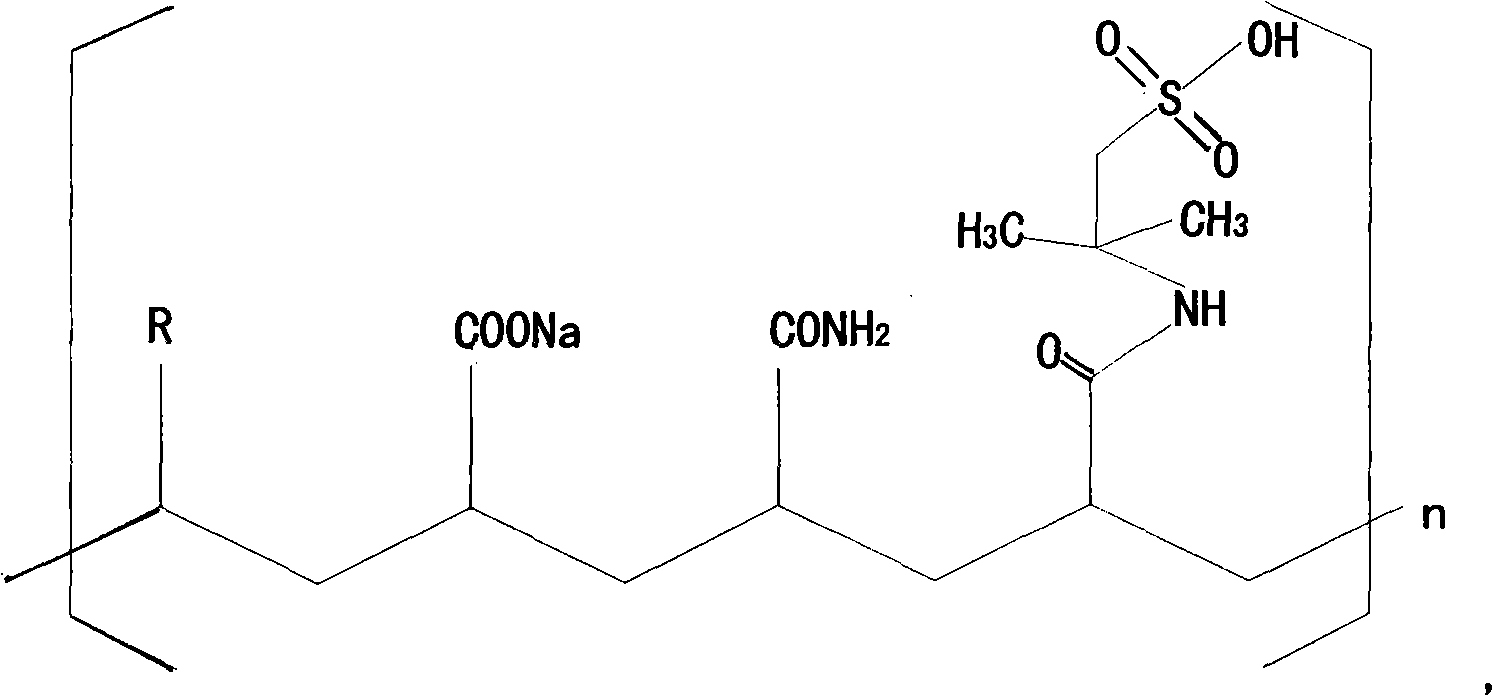

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

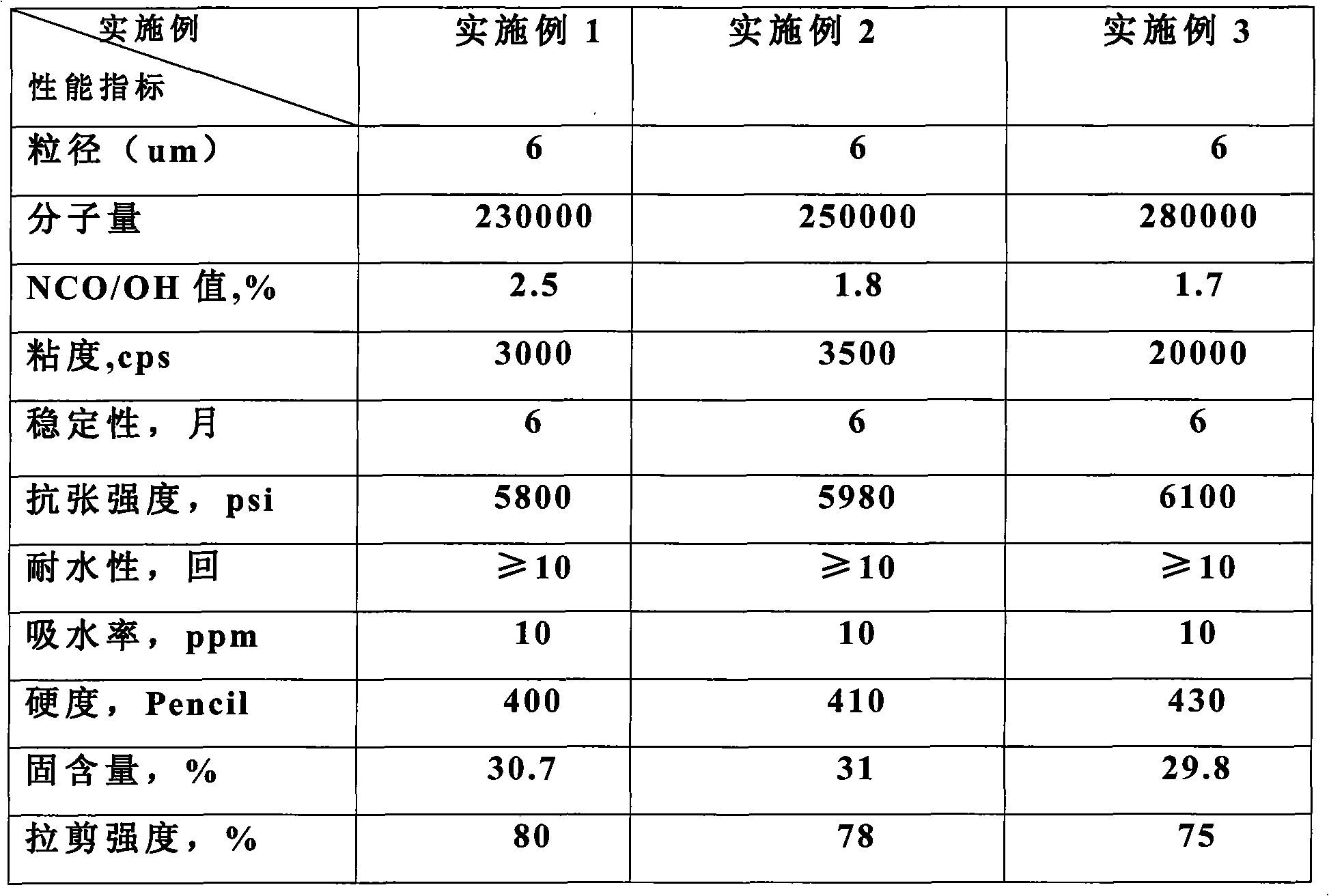

Two-package curing type polyurethane paint and preparation thereof

InactiveCN101565590ALow viscosityImprove the level ofFibre treatmentPolyurea/polyurethane coatingsApparent viscosityPolyol

The invention relates to a two-package curing type polyurethane paint and preparation thereof. The raw material system of the paint comprises a polyether polyol, a isocyanate, a small molecular chain expander and a solvent, wherein polydihydrofuran ether glycol with molecular weight between 700 to 1500 is used as the plyether polyol; methyl diphenylene diisocyanate is used as the isocyanate, 1,4-butanediol is used as the small molecular chain expander, dimethylformamide is used as the solvent. Weight proportion between the plyether polyol, the small molecular chain expander and the solvent is 1:0.7 - 0.85:8 - 15. Colloidal viscosity of the polyether polyol at 25 DEG C. is between 3000 and 2000cps. The paint is obtained by primarily charging DMF as the solvent, the polyether polyol and the chain expander into the reaction container simultaneously at one time, and then gradually charging the isocyanate for the reaction. By using MDI to substitute TDI for preparation of the polyurethane paint preparation, the invention is low in viscosity, great in levelability, easy for hardness adjustment, low in cost, safe and environment friendly in use.

Owner:顾建荣

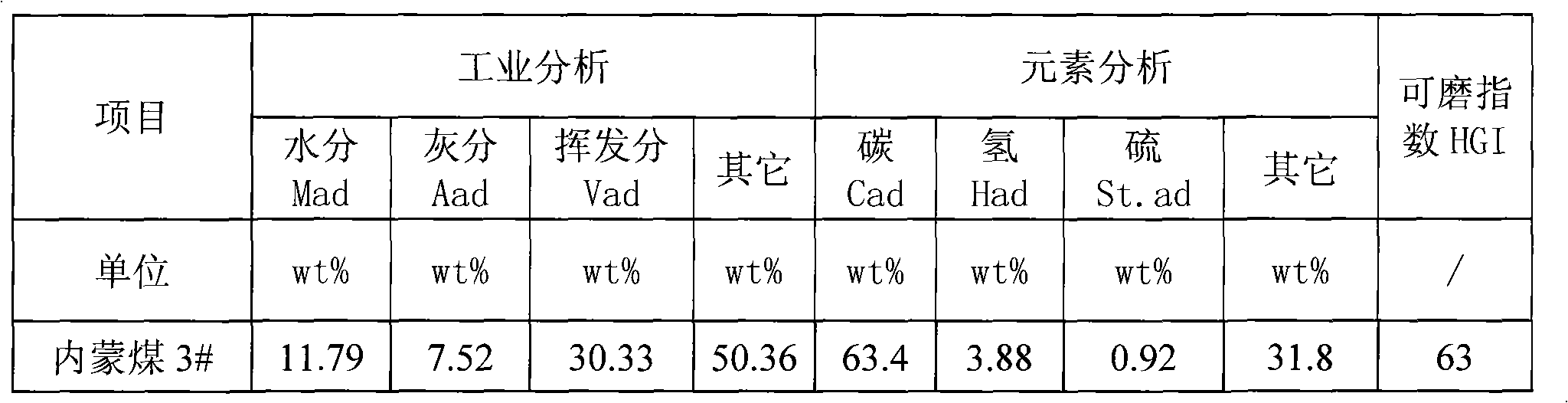

High concentration sludge coal slurry and method for preparing the same

InactiveCN1908134AImprove pulpingEasy to operateLiquid carbonaceous fuelsHigh concentrationHigh density

Owner:EAST CHINA UNIV OF SCI & TECH

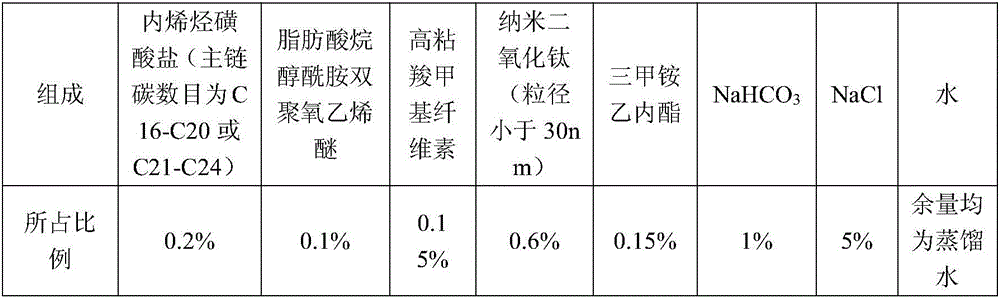

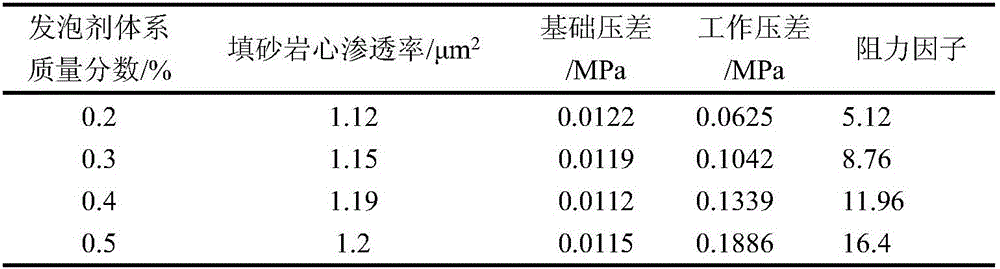

Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

InactiveCN106753307AImprove solubilityImprove performanceDrilling compositionInorganic saltsSolubility

The invention relates to the technical field of heavy oil recovery, in particular to a foam agent system used for switching water drive into steam drive of a heavy oil reservoir or steam huff and puff to improve the oil recovery efficiency. According to the technical scheme, the temperature-resistant and salt-tolerant foaming agent system for thermal recovery of the heavy oil reservoir is characterized by comprising a foaming agent base, a foam stabilizer, a foam fixing agent, a foam promoter, an alkali substance, inorganic salt and a solvent. The foaming agent system can resist the temperature of 350 DEG C and has good thermal stability and better foamability; the foaming agent base in the system is lower than the critical micelle concentration and can produce more foam, the apparent viscosity is substantially increased, and the cost is saved; the foaming agent system has better solubility, causes little damage to formation and is environment-friendly.

Owner:NORTHEAST GASOLINEEUM UNIV

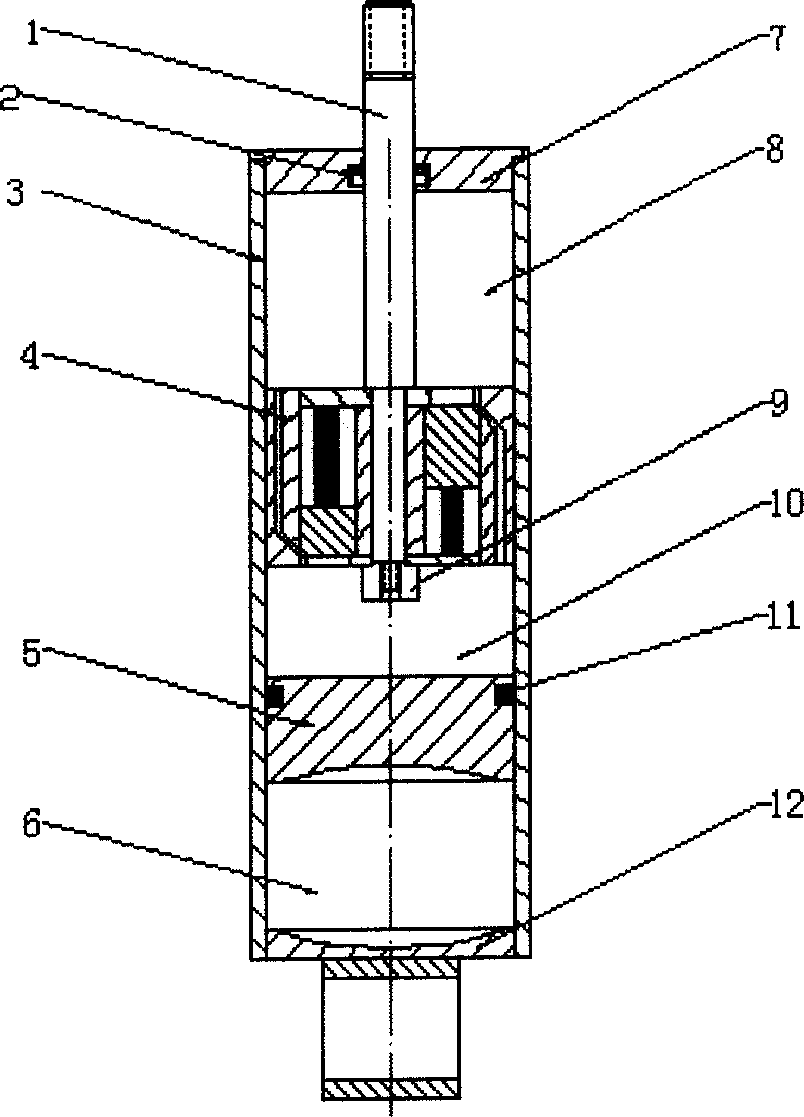

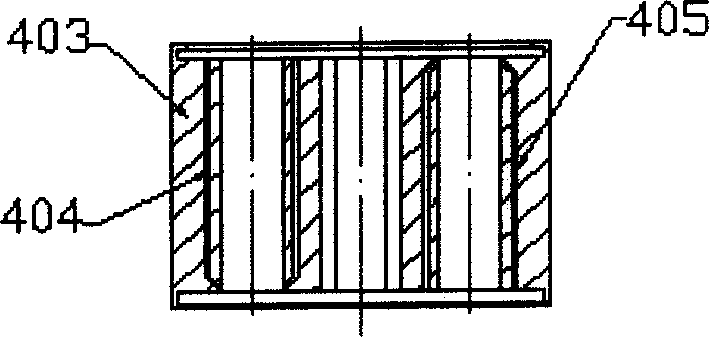

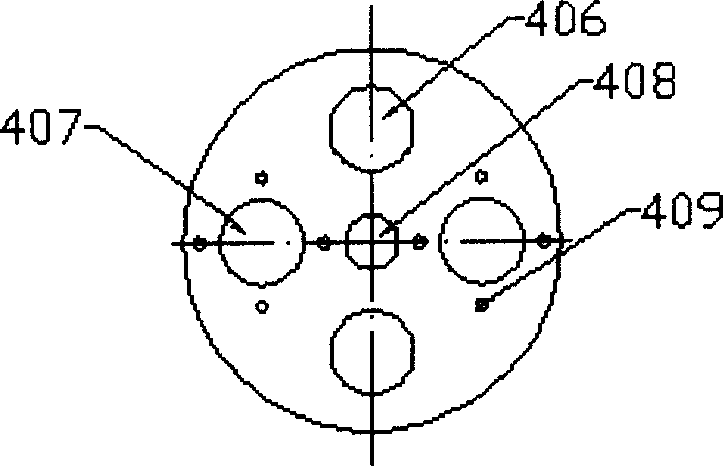

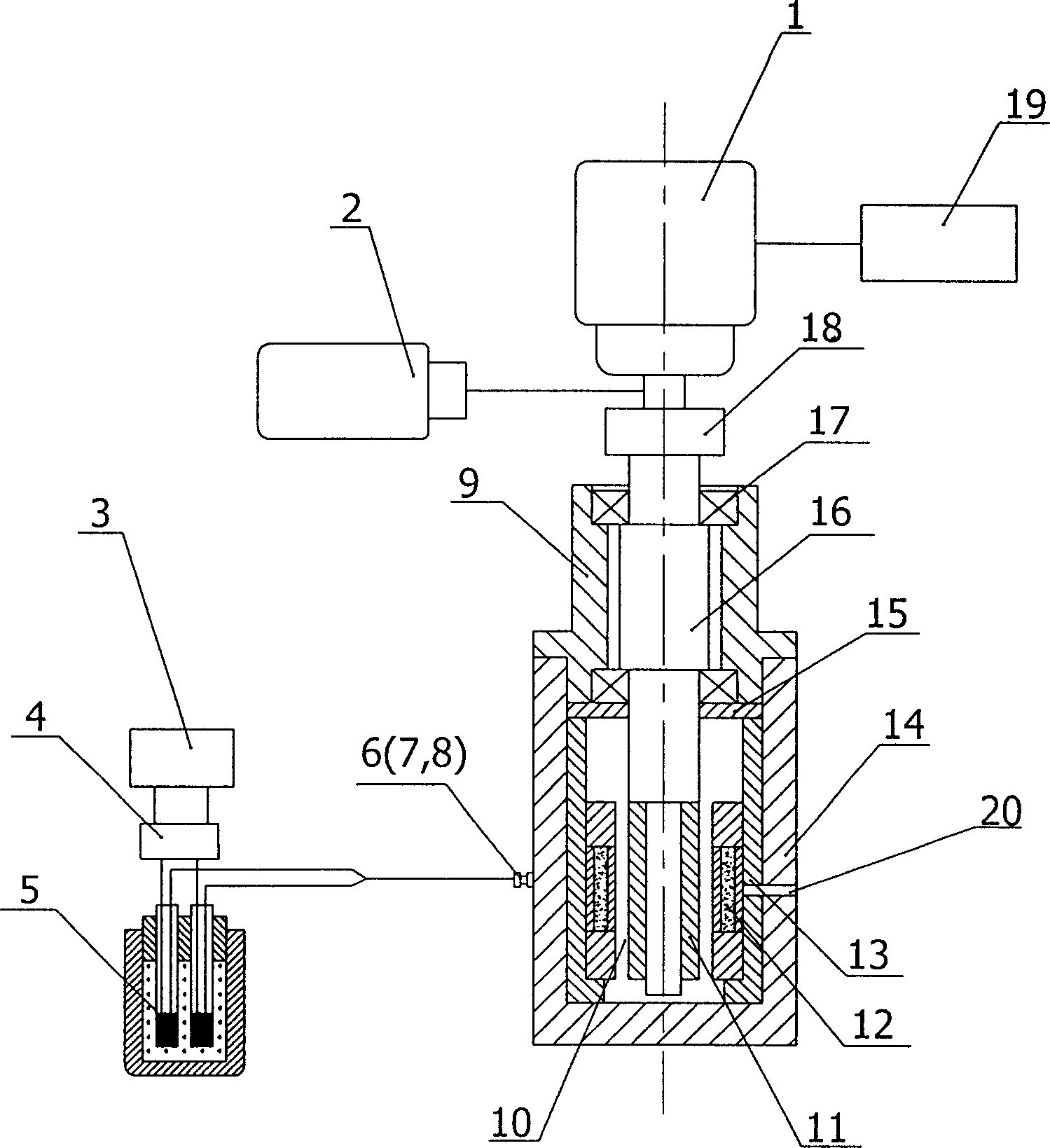

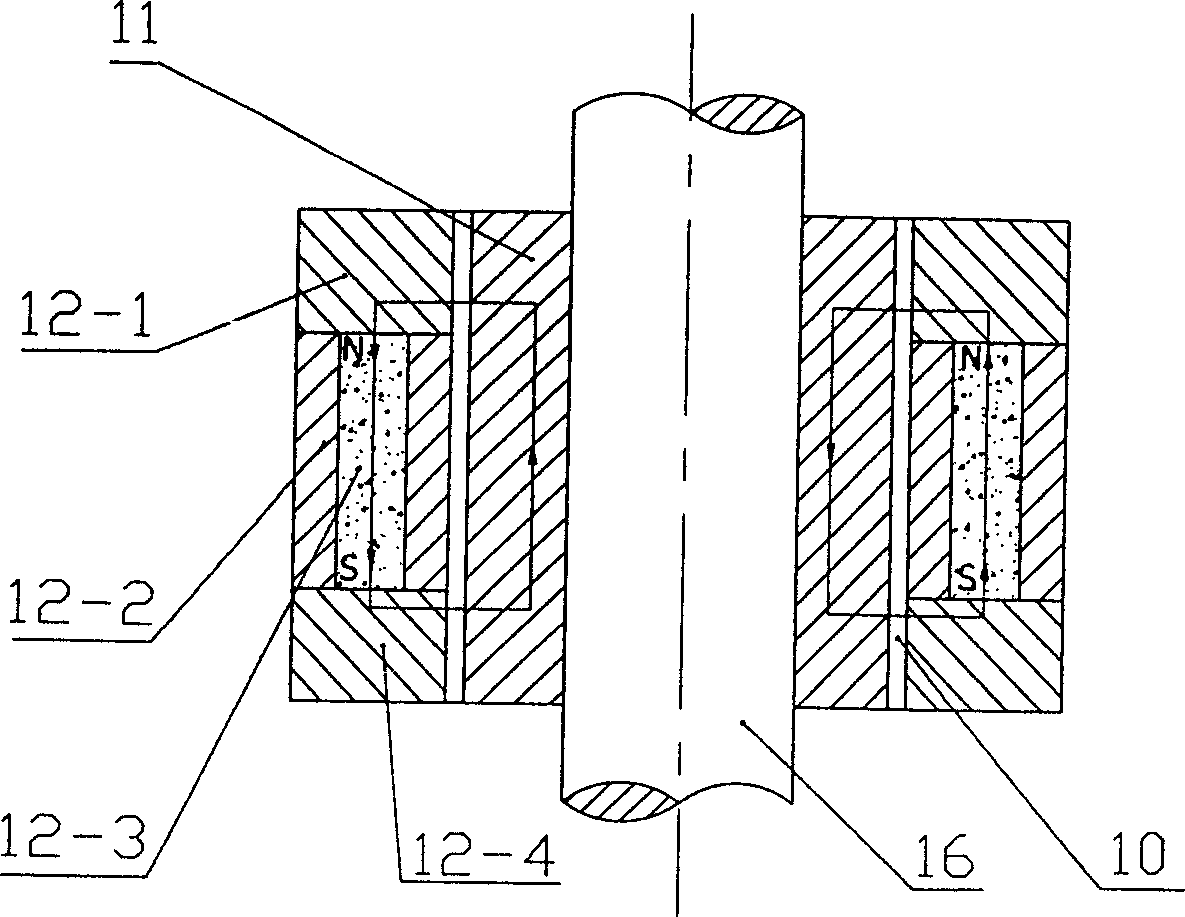

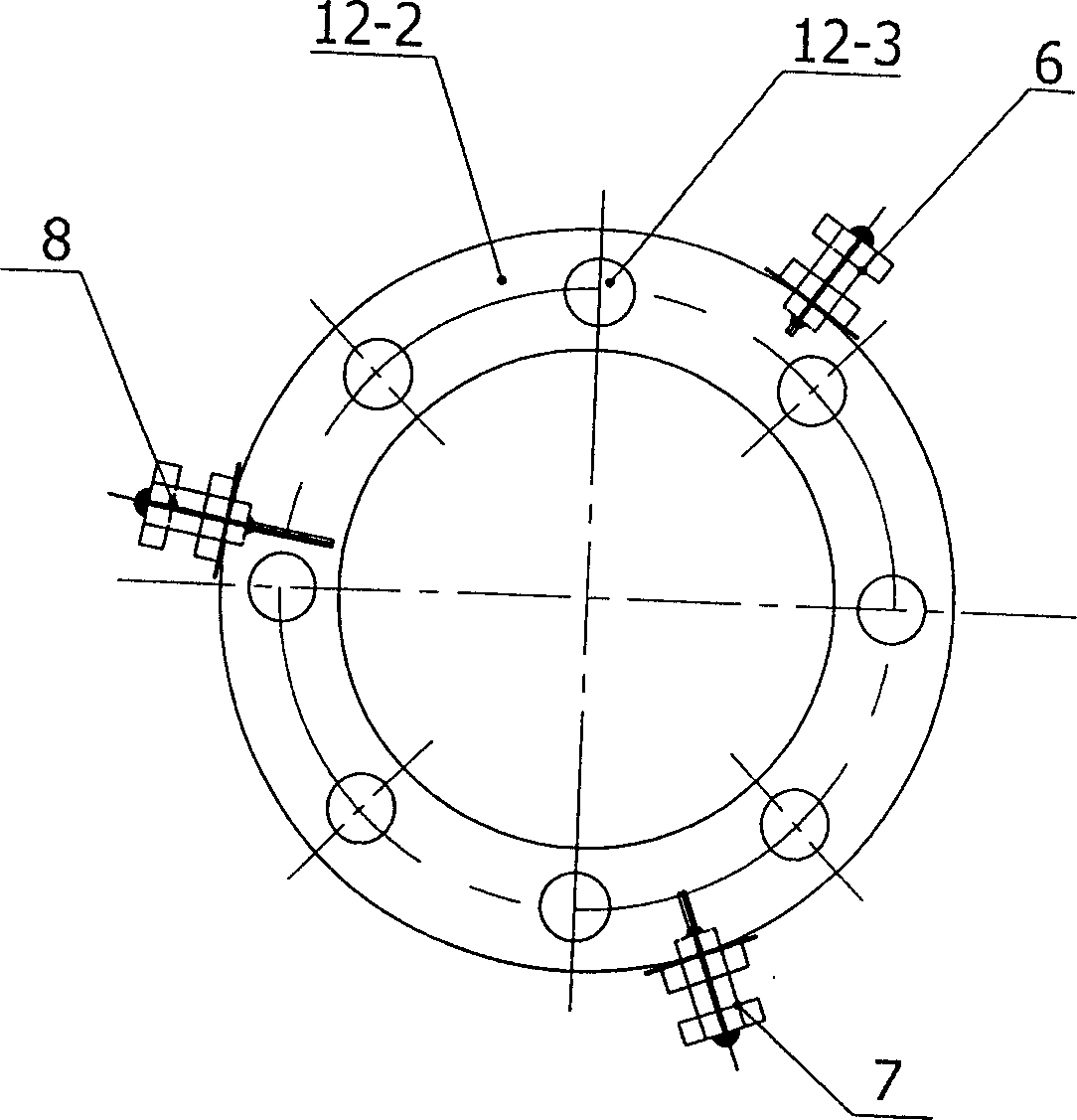

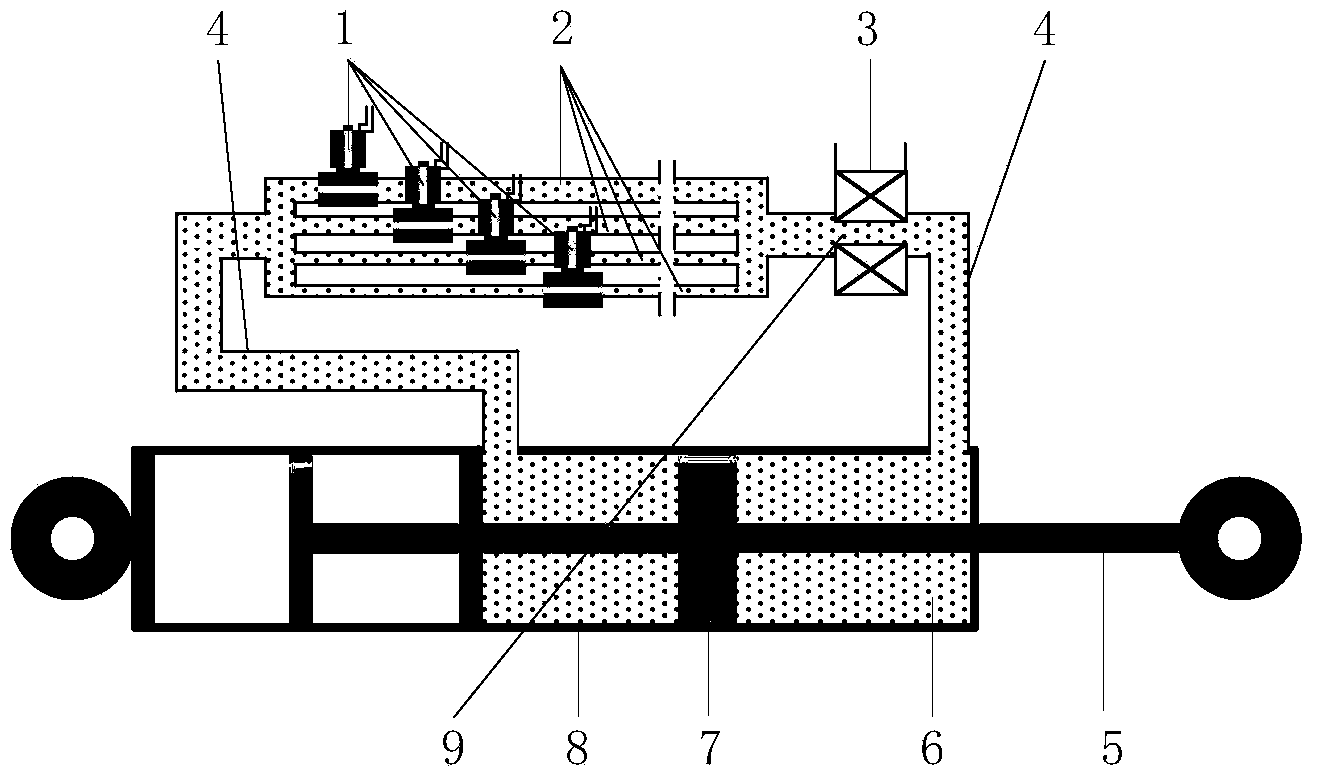

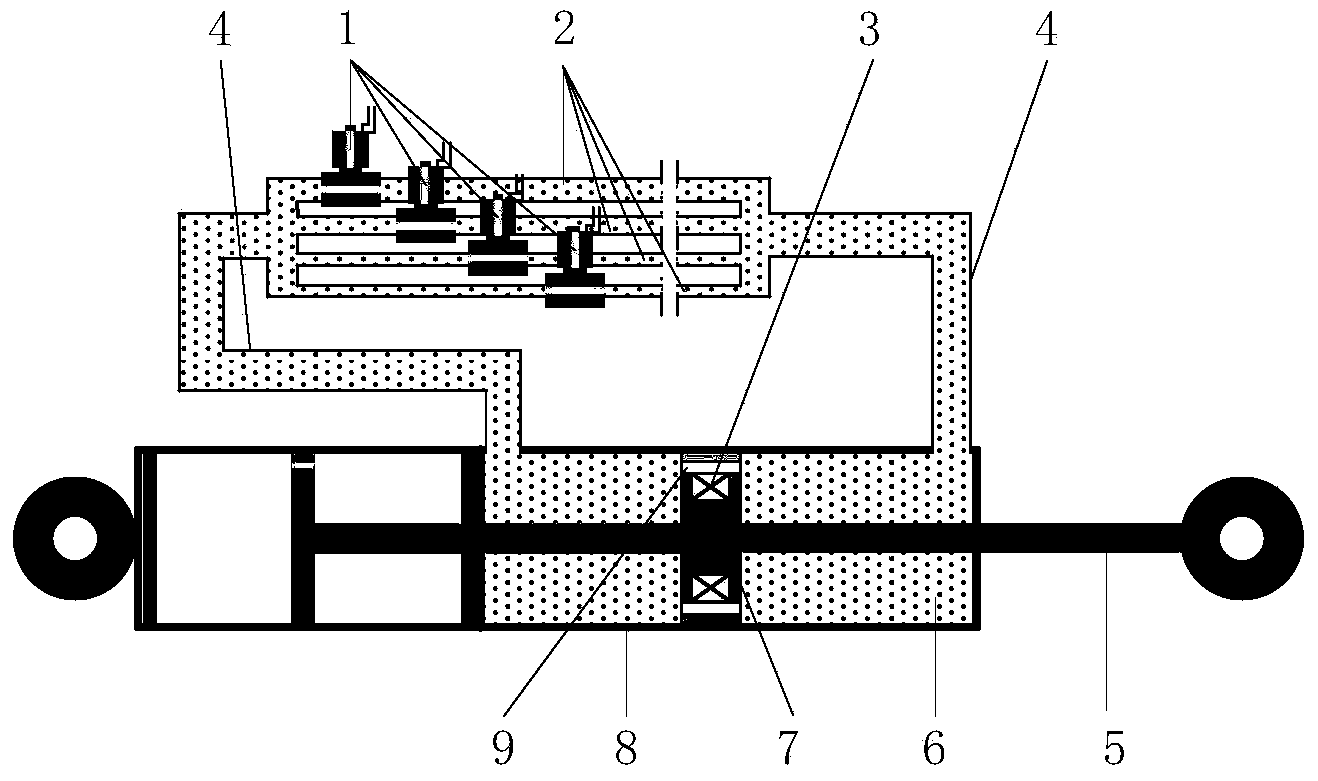

Inerter and damping controllable magneto-rheological inerter device and control method thereof

ActiveCN103644248ASolve the problem that dynamic adjustment of inertia cannot be realizedTo overcome the shortcomings of only dynamically adjusting the dampingNon-rotating vibration suppressionSemi activeInertial effect

The invention relates to an inerter and damping controllable magneto-rheological inerter device and a control method thereof. The device comprises a cylinder, a piston, a piston rod, long and thin pipes, a thick pipe, a magneto-rheological fluid, switch valves, MR (magnetic resonance) conductors and a damping hole. According to the inerter and damping controllable magneto-rheological inerter device and the control method thereof, an apparent viscosity changing process of the magneto-rheological fluid is a continuous, stepless and reversible magneto-rheological effect under the action of an applied magnetic field, simultaneously, the low viscosity of the magneto-rheological fluid without the applied magnetic field and an inertial effect of the magneto-rheological fluid flowing in the long and thin pipes are utilized, the two effects are integrated in one device, further, the switch valves are adopted to control switching on and off of the long and thin pipes which have different pipe diameters and are filled with the magneto-rheological fluid, then the inerter is adjusted in a stepping manner,; and damping is adjusted steplessly by changing the magneto-rheological viscosity through the applied magnetic field simultaneously According to the invention, requirements for semi-active control when dynamical combination adjustment of inerter and damping is applied to a vibration isolation device for engineering are met, so that mounting and using are facilitated, the cost is reduced, and the production efficiency is improved.

Owner:JIANGSU UNIV

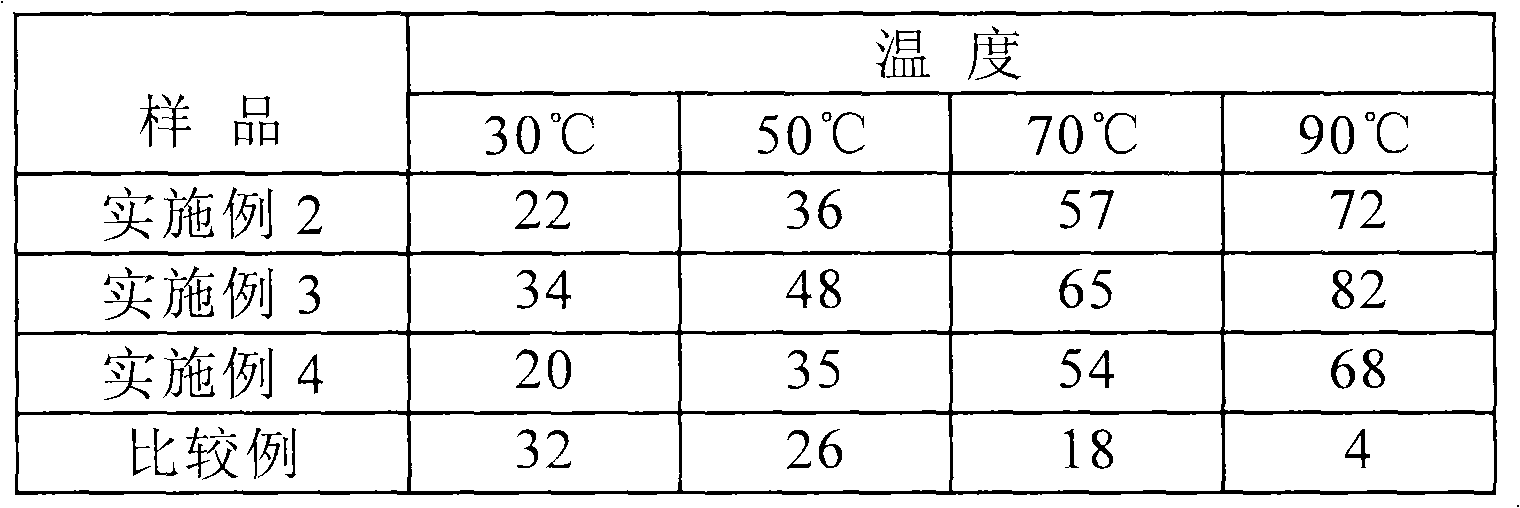

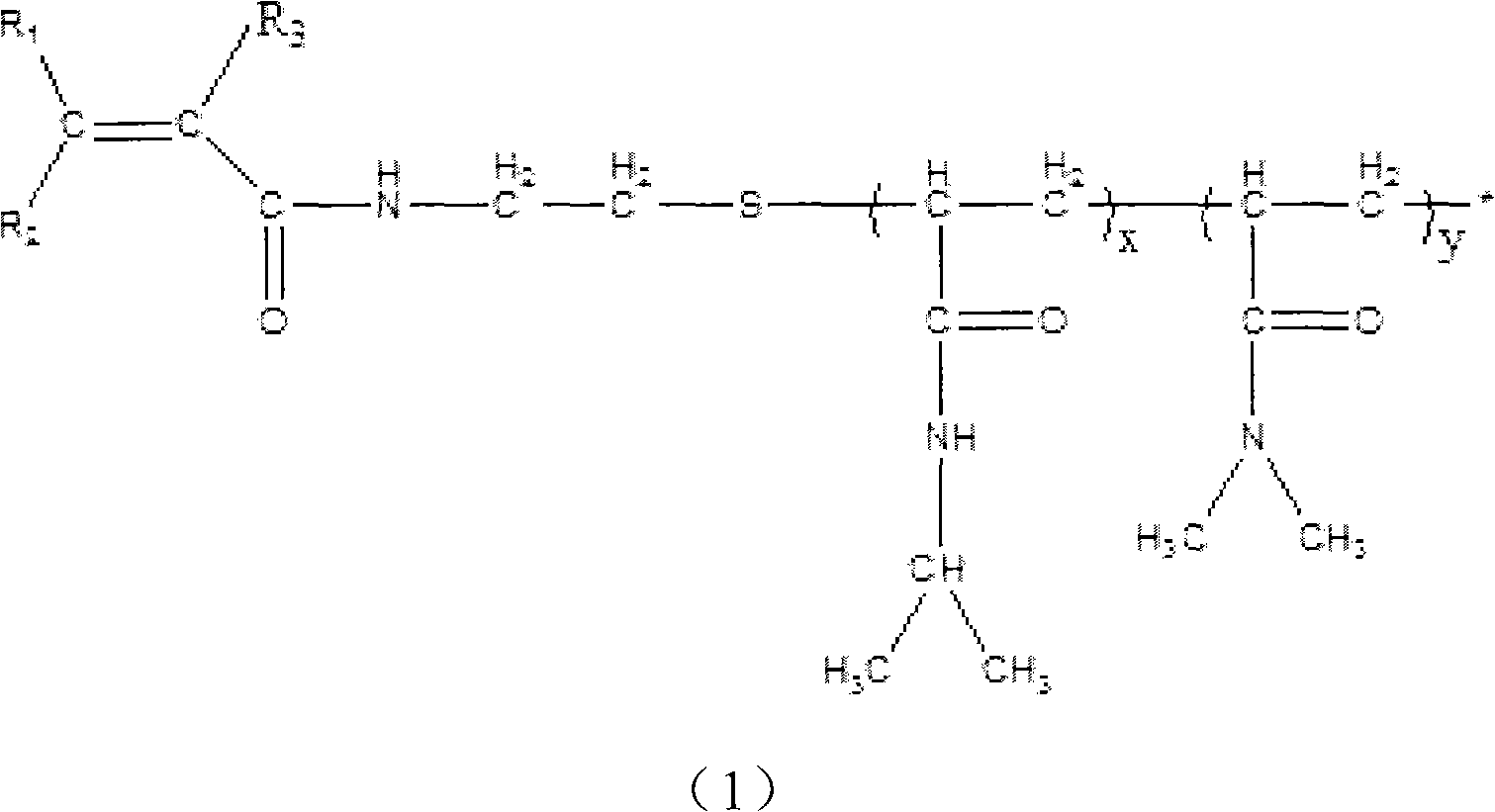

Thermothickening terpolymer, its preparation method and application

ActiveCN102464781AHas thermal thickening propertiesGood water solubilityDrilling compositionApparent viscositySalinity

The invention provides a thermothickening terpolymer and its preparation method. The water solution viscosity of the copolymer provided in the invention increases with the rise of temperature within a certain temperature range. The water solution of the copolymer has a thermothickening property, and has high apparent viscosity under high temperature and high salinity conditions. Thus, the terpolymer of the invention boasts good application prospects in tertiary oil recovery of high temperature and high salinity oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

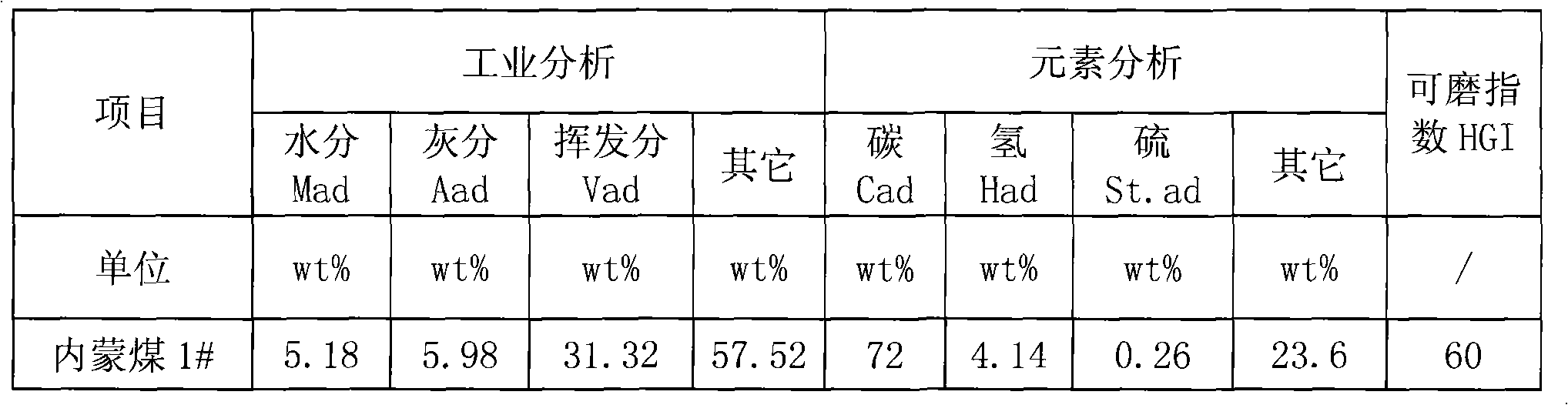

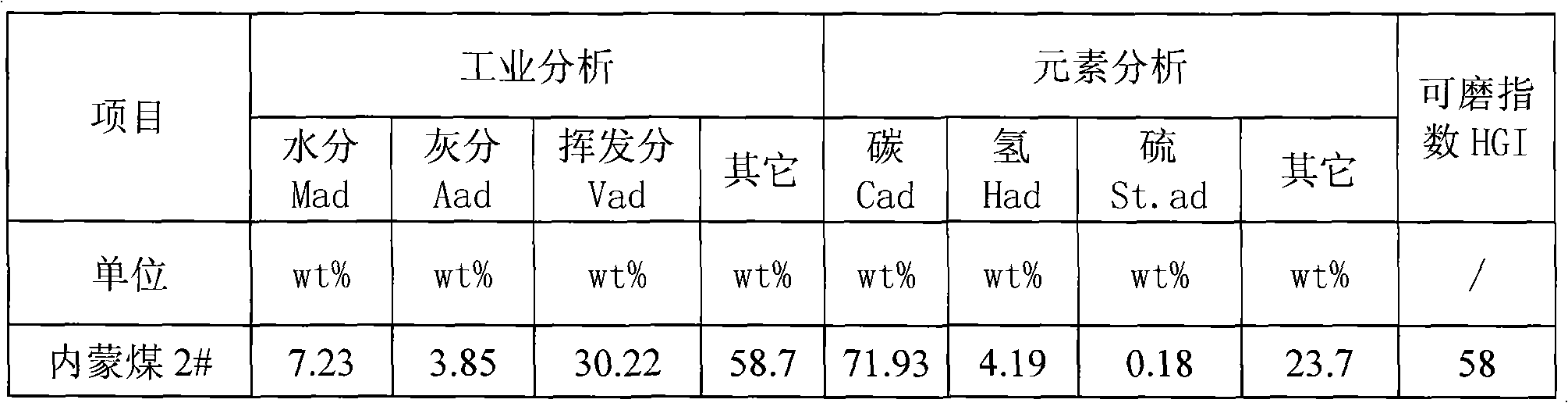

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

Improved preparation of cellulose spinning solution with ion liquid as solvent

InactiveCN101476166AImprove solubilityReduced gel particle contentArtificial filaments from cellulose solutionsSpinning solutions preparationApparent viscosityDistillation

The invention provides a method for preparing an improved fibrino spinning original solution that ion liquid is used as solvent, which includes: two phases of swelling and dissolution, namely, placing dried fibrino dissolving pulp and 1-butyl-3-methyl imidazole villaumite with 1%-20% water ratio into a dissolution device for uniform mixing, firstly, leaving and swelling in 70-100 DEG. C, then stronger stirring for swelling to plasm shape without dissolution; secondly, raising temperature to 80-125 DEG. C slowly in stirring state, stirring and reducing pressure distillation for removing water component, fibrino can be dissolved completely after 2-8h; finally, reducing stirring speed, and reducing temperature of plasm to 90-100 DEG. C and keeping 30-60 min for obtaining straw yellow spinning original solution. The method provided by the invention has advantages that the spinning original solution is more uniform, dissolution is more fully, gelatin particle in the spinning original solution is reduced, the spinning original solution quality is increased; apparent viscosity of the spinning original solution is reduced, accordingly, solid content in the spinning original solution is increased further.

Owner:DONGHUA UNIV

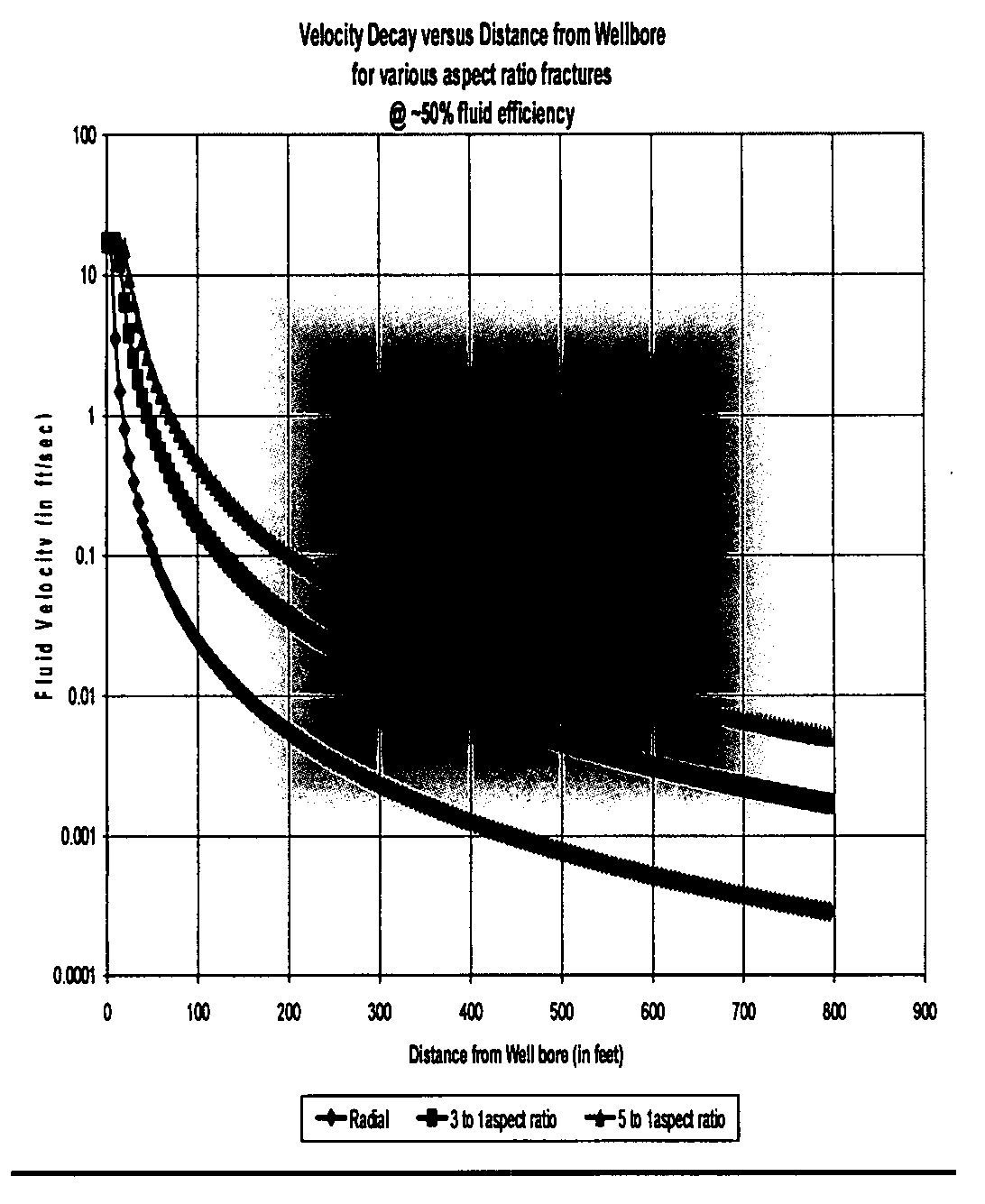

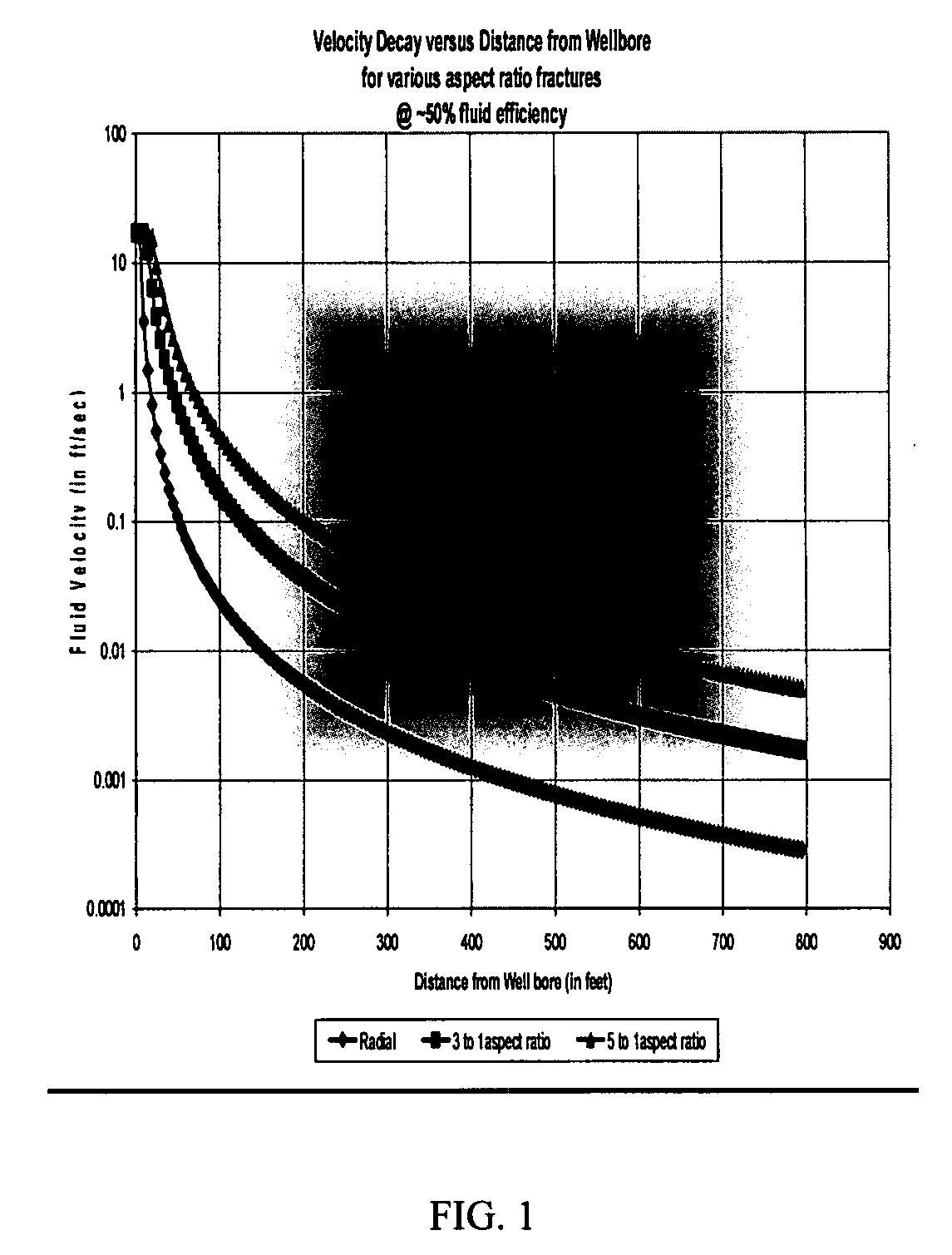

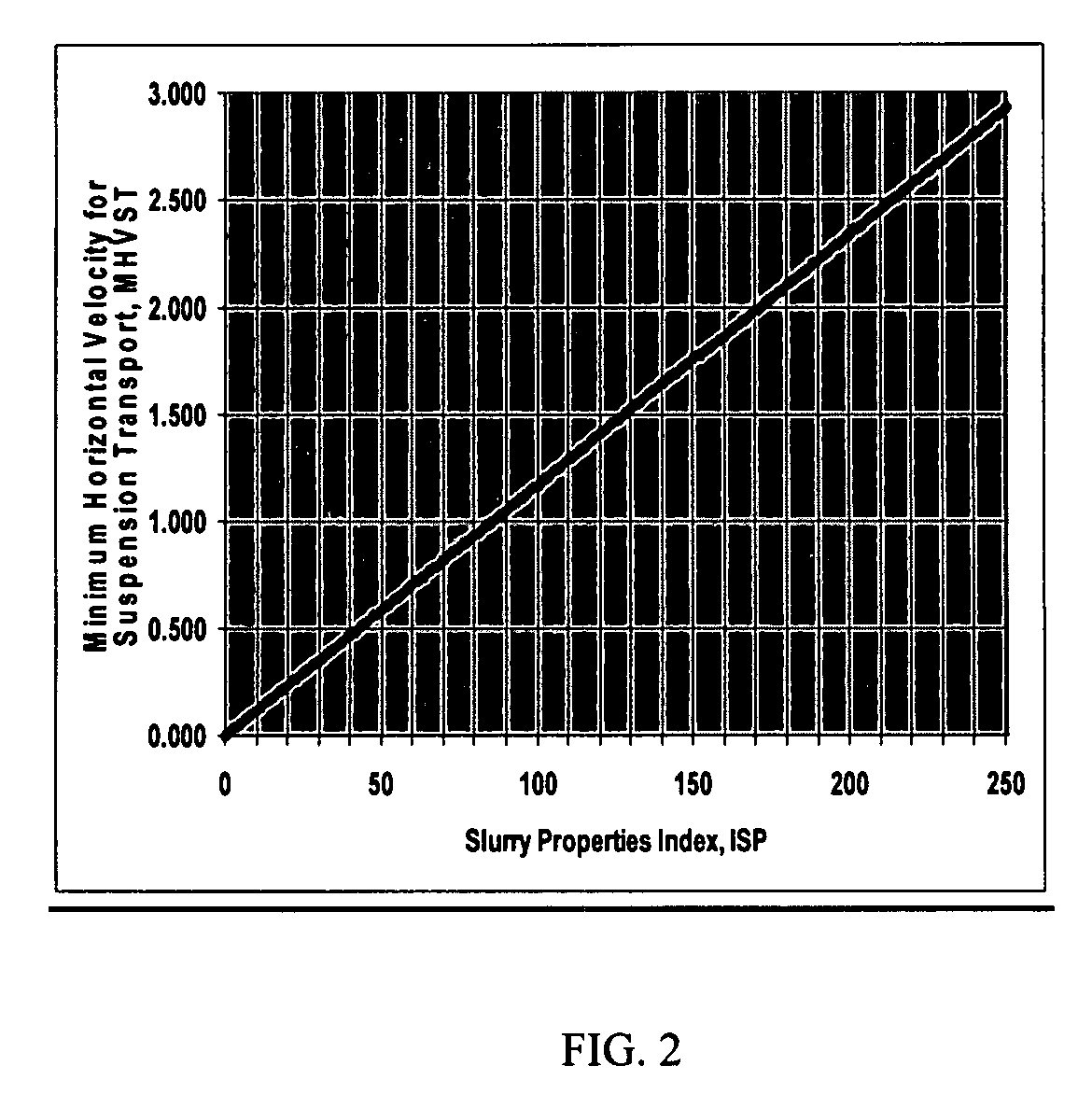

Method of fracturing a subterranean formation at optimized and pre-determined conditions

Prior to a hydraulic fracturing treatment, the estimated fracture length may be estimated with knowledge of certain physical properties of the proppant and transport fluid such as fluid viscosity, proppant size and specific gravity of the transport slurry as well as fracture geometry and the treatment injection rate. The estimated fracture length may be determined by the equation:(DPST)B=qi×(1 / A)×CTRANS×(d2prop)×(1 / μfluid)×(ΔSGPS) (I)wherein:DPST is thus the estimated propped fracture length;B is the exponent from the Power Law equation describing the transport slurry velocity vs. distance for the fracture geometry;qi is the injection rate per foot of injection height, bpm / ft.; andA is the multiplier from the Power Law equation describing the transport slurry velocity vs. distance for the fracture geometry;CTRANS, the transport coefficient, is the slope of the linear regression of the ISP vs. MHVST.dprop is the median proppant diameter, in mm.;μfluid is the apparent viscosity of the transport fluid, in cP; andΔ SGPS is SGprop−SGfluid, SGprop being the specific gravity of the proppant andSGfluid being the specific gravity of the transport fluid.The minimum horizontal flow velocity, MHVST, for transport of the transport slurry based upon the terminal settling velocity of the proppant, Vt, may be determined in accordance with Equation (II):MHVST, =Vt×10 (II)Via rearrangements of the same derived equations, a model for optimizing the transport fluid, proppant, and / or treating parameters necessary to achieve a desired propped fracture length may further be determined.

Owner:BAKER HUGHES INC

Biodegradable polylactic acid for use in nonwoven webs

A method for forming a biodegradable polylactic acid suitable for use in fibers is provided. In one embodiment, for example, a polylactic acid is melt blended with an alcohol to initiate an alcoholysis reaction that results in a polylactic acid having one or more hydroxyalkyl or alkyl terminal groups. By selectively controlling the alcoholysis conditions (e.g., alcohol and polymer concentrations, catalysts, temperature, etc.), a modified polylactic acid may be achieved that has a molecular weight lower than the starting polylactic acid. Such lower molecular weight polymers also have the combination of a higher melt flow index and lower apparent viscosity, which is useful in a wide variety of fiber forming applications, such as in the meltblowing of nonwoven webs.

Owner:KIMBERLY-CLARK WORLDWIDE INC

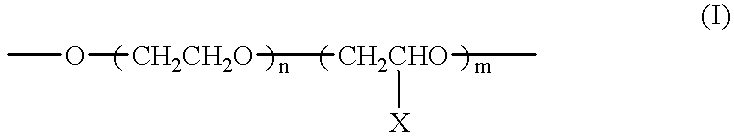

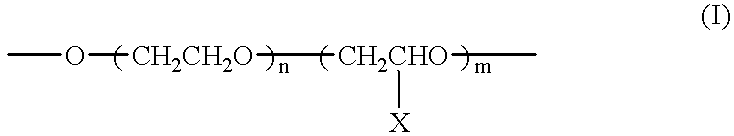

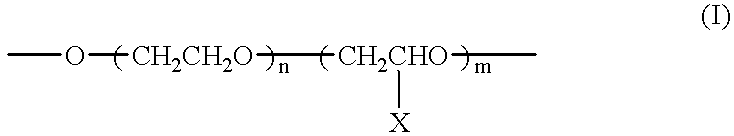

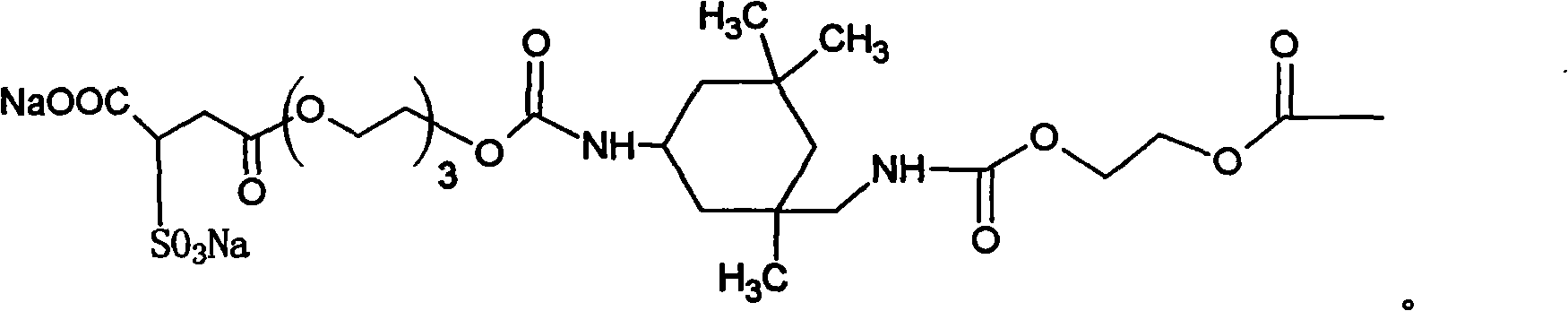

Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation

The subject invention provides a pharmaceutical tablet formulation comprising per unit dosage form e.g. per tablet the following ingredients:(a) a compound as an active ingredient, wherein the compound has a formula:wherein R is substituted adamantyl and n is an integer from 0 to 3 or a pharmaceutically acceptable salt thereof;(b) a hydroxypropyl methylcellulose with an apparent viscosity of 80,000 cP to 120,000 cP (nominal value 100,000 cP) when present in a 1% solution;(c) a microcrystalline cellulose; and(d) a magnesium stearate

Owner:KOWALSKI JAMES +3

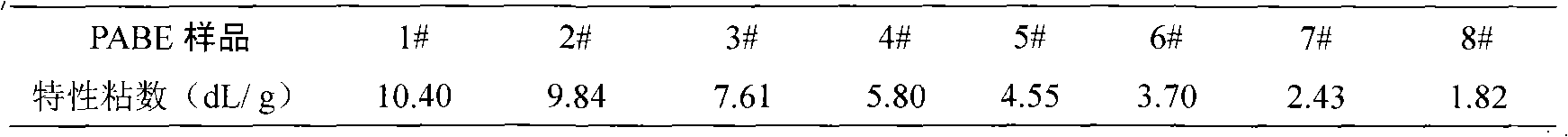

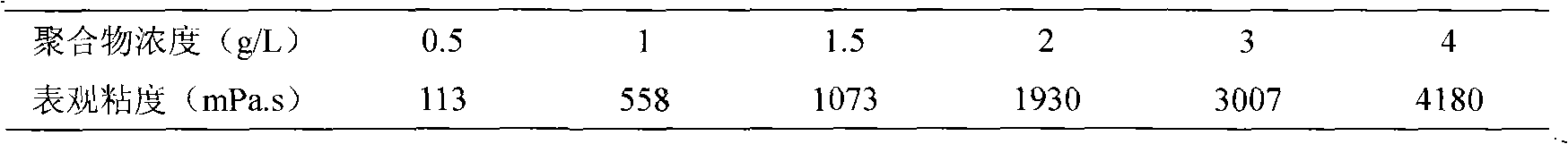

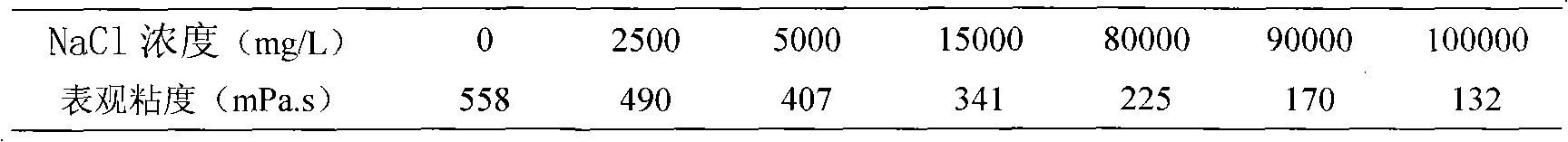

Comb-typed amphiphilic water-soluble co-polymer, method for preparing same and use

The invention discloses a comb-type amphipathicity water-solubility multipolymer and a method for making the same as well as an application. The method is characterized in that: 20 portions of acrylamide, 0.1 to 10 portions of negative ion monomer, 0.5 to 15 portions of at least one of the surface activity macromolecular monomer 4-vinyl benzyl alkylphenol polyoxyethylene ether or / and allyl alkylphenol polyoxyethylene ether and 30 to 600 portions of deionized water are added into a three-necked reaction bulb, the pH value of the solution is adjusted to between 4 and 9, N2 is introduced into the solution for 30 minutes, 0.002 to 0.3 portion of evocating agent sulphate is added at the temperature of between 30 and 70 DEG C to react 12 to 36 hours in order to prepare PABE which is diluted by water to obtain the PABE strong solution; the comb-type amphipathicity water-solubility multipolymer which can viscosify, has salt resistance and the low surface tension as well as the molecular association ability and can be used for the fuel scavenge. The multipolymer is prepared into a water solution with a mass concentration between 0.3 and 3g / L and a surface active agent concentration between 0.01 and 2mmol / L, the water solution is added into a blending container with a stirring device and is stirred evenly at room temperature so that the polymer oil-displacing agent which can viscosify and shear-resistant and has excellent anti-aging performance in a hyperhaline state and at the temperature of 70 DEG C. The PABE has the double function of a tackifier and a macromolecule surfactant. Infinitesimal low molecular surface active reagent is added into the PABE solution, thereby evidently increasing the apparent viscosity of the solution, reducing the surface tension and the oil-water boundary tension of the solution and contributing to improving the recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

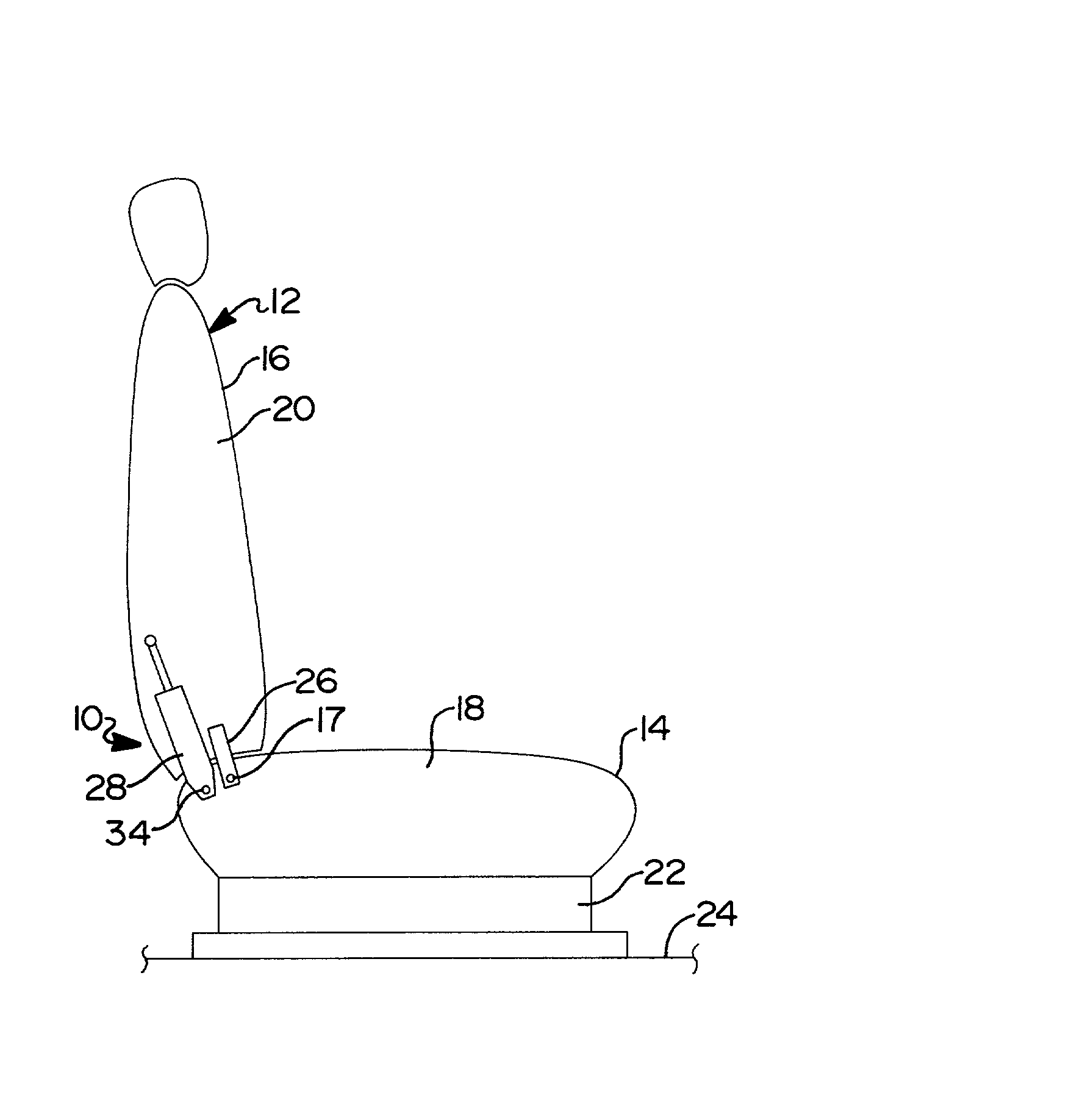

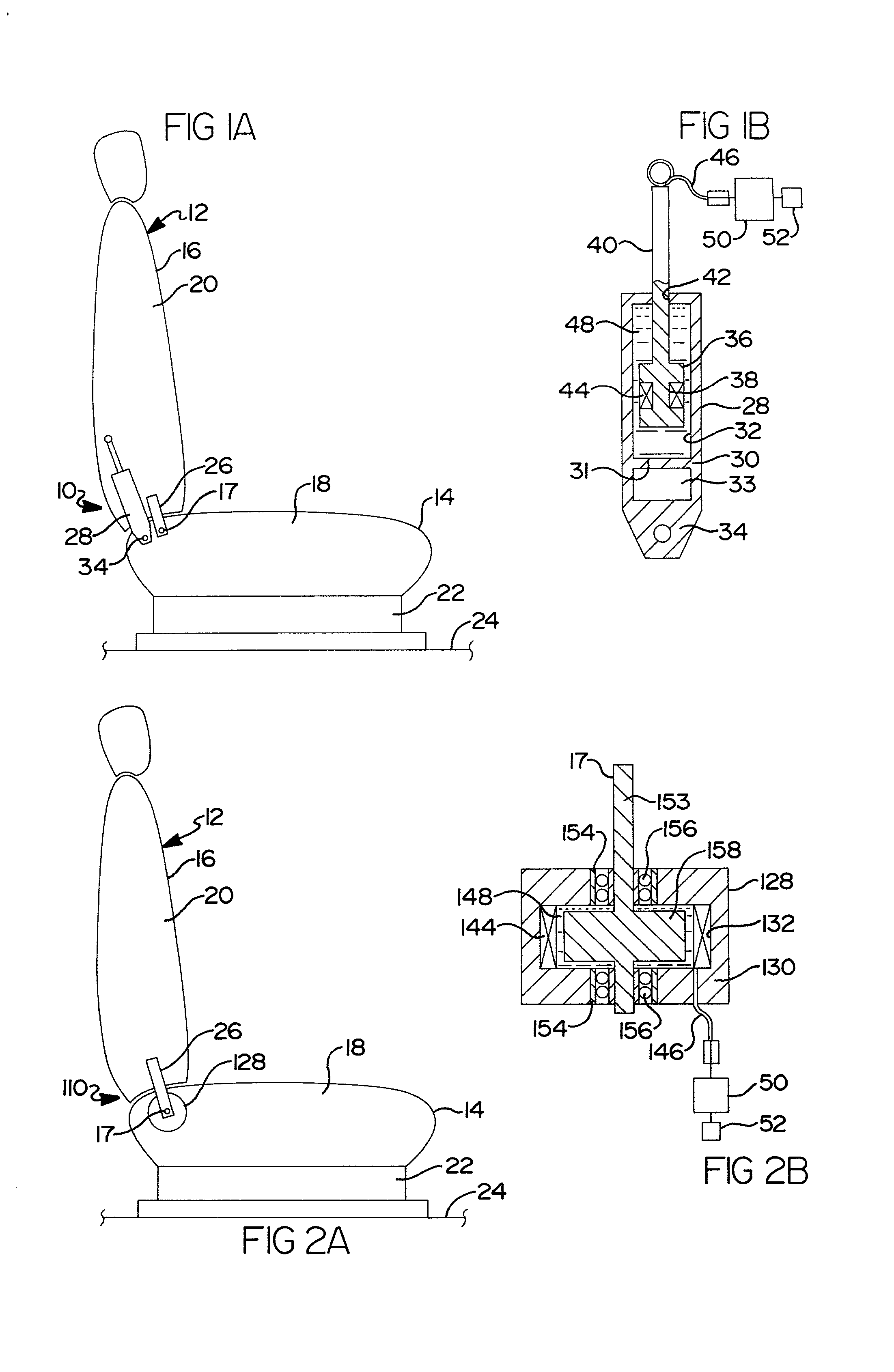

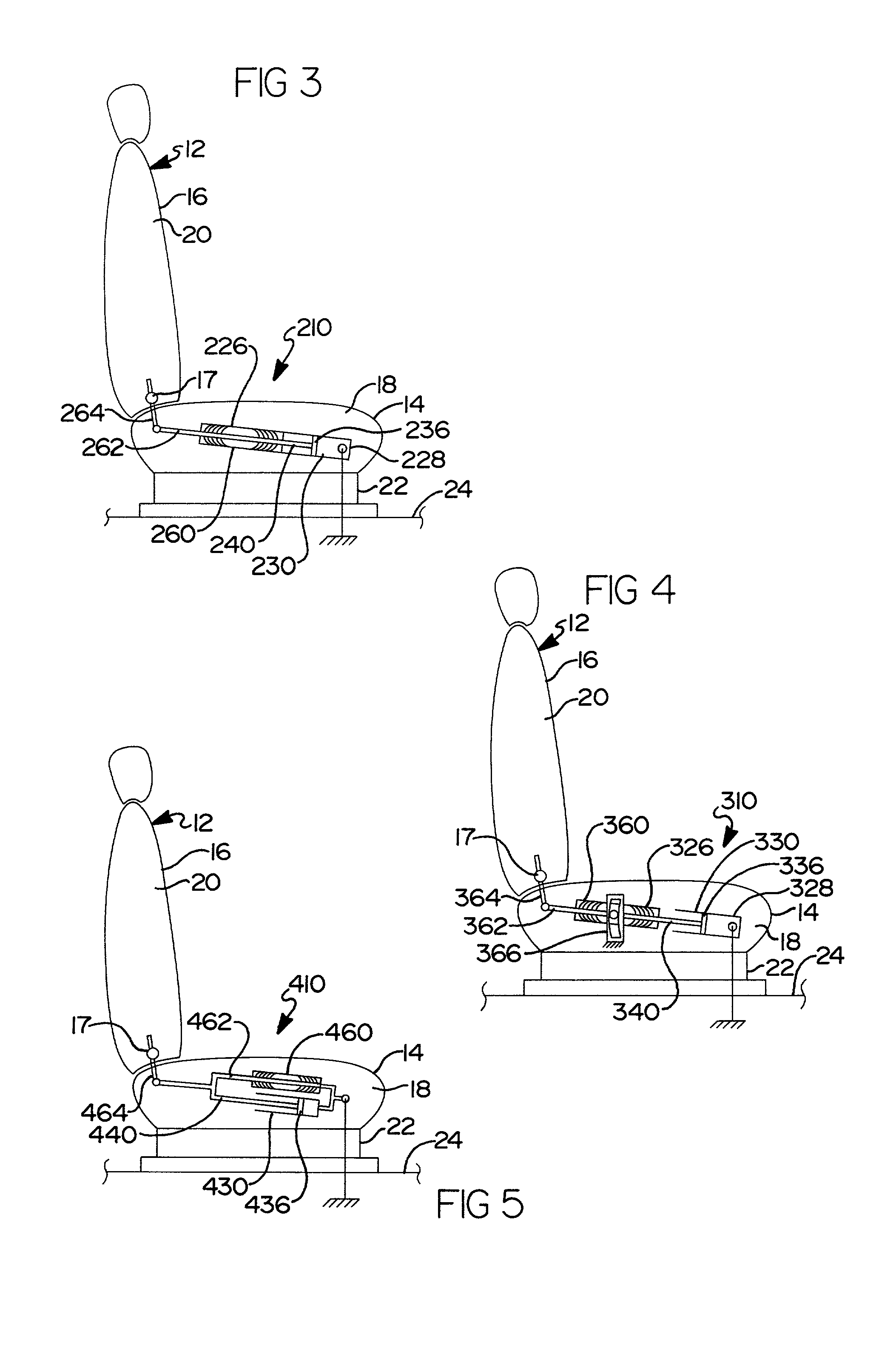

Programmable seat back damper assembly for seats

InactiveUS20020047295A1Pedestrian/occupant safety arrangementMovable seatsMobile vehicleApparent viscosity

A programmable seat back damper assembly for a motor vehicle includes a generally horizontal seat cushion portion and a generally upright back portion operatively connected to the seat cushion portion. The programmable seat back damper assembly includes a recliner for operative connection to the seat back portion and the seat cushion portion. The programmable seat back damper assembly also includes a damper for operative connection to the seat back portion and the seat cushion portion and having a magneto-rheological (MR) fluid therein. The programmable seat back damper assembly further includes a controller electrically connected to the damper to control an apparent viscosity of the MR fluid to increase and decrease damping of the damper for adjusting an angle of the seat back portion relative to the seat cushion portion.

Owner:FORD GLOBAL TECH LLC

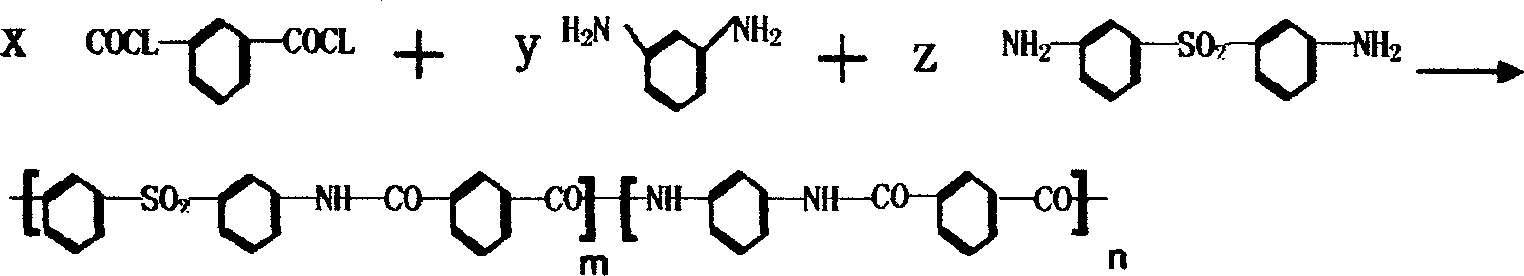

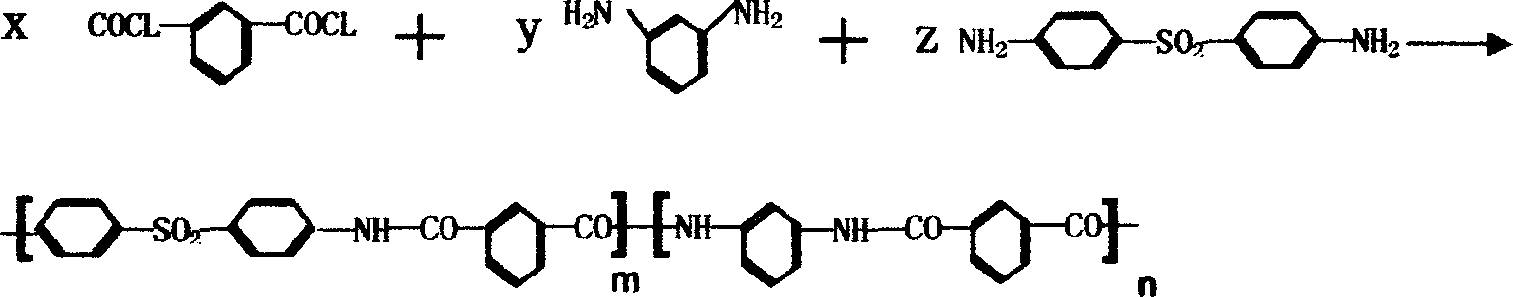

Method for increasing fire resistance of meta-aromatic polyamide polymer

InactiveCN1683431AImprove solubilityRaise the glass transition temperatureVitrificationApparent viscosity

The preparation process of aromatic mata-polyamide with raised fire resistance includes mixing m-phenylene-diamine and R, R'-dismino diphenylsulfone and dissolveing in solvent to compound solution in certain concentration, cooling to -10 deg.c to 0 deg.c, adding m-phenyldimethyl acyl chloride to produce condensation while controlling the reaction temperature in 0-40 deg.c until the solution reaches the target apparent viscosity to obtain aromatic mata-polyamide with raised fire resistance. The present invention has raised production efficiency, lowered production cost, raised vitrification point and raised strength and module of subsequent product.

Owner:邢哲

New method for forming manual well wall in oil and gas well by water-absorbing resin

InactiveCN102134979APrevent leakageEasy to transformDrilling compositionSealing/packingFresh water organismVolumetric Mass Density

The invention relates to a new method for forming manual well walls in an oil and gas wells by water-absorbing resin. In the method, the water-absorbing resin is mixed with freshwater or saline to form a well completion fluid or a workover fluid; the water-absorbing resin is starch-type water-absorbing resin or cellulose-type water-absorbing resin or synthetic water-absorbing resin and comprises the following components by weight percentage: 1 to 2% of water-absorbing resin, 0.2 to 0.5% of water-absorbing initiator, 0.2 to 0.5% of colloid protective agent, and the remaining quantity of water or monovalent saline. The density of the water-absorbing resin well-completion fluid or the workover fluid can be adjusted by adding monovalent salt NaCl or KCl; the solution apparent viscosity can be controlled by adjusting the concentration of the water-absorbing resin; and the dosage of the well completion fluid or the workover fluid can be designed according to the volume of a shaft. In the method, the physical and the chemical changes can occur under the high temperature to form a manual well wall, namely a gelatine temporary plugging layer; therefore, the bearing capability of the high-and low-pressure stratum can be effectively improved; the leakage of the well completion fluid or the workover fluid can be prevented at the producing layer, the operation safety and the capacity of the oil and gas well can be ensured, the construction technology is simple, and the cost is relatively low.

Owner:CHINA NAT OFFSHORE OIL CORP +3

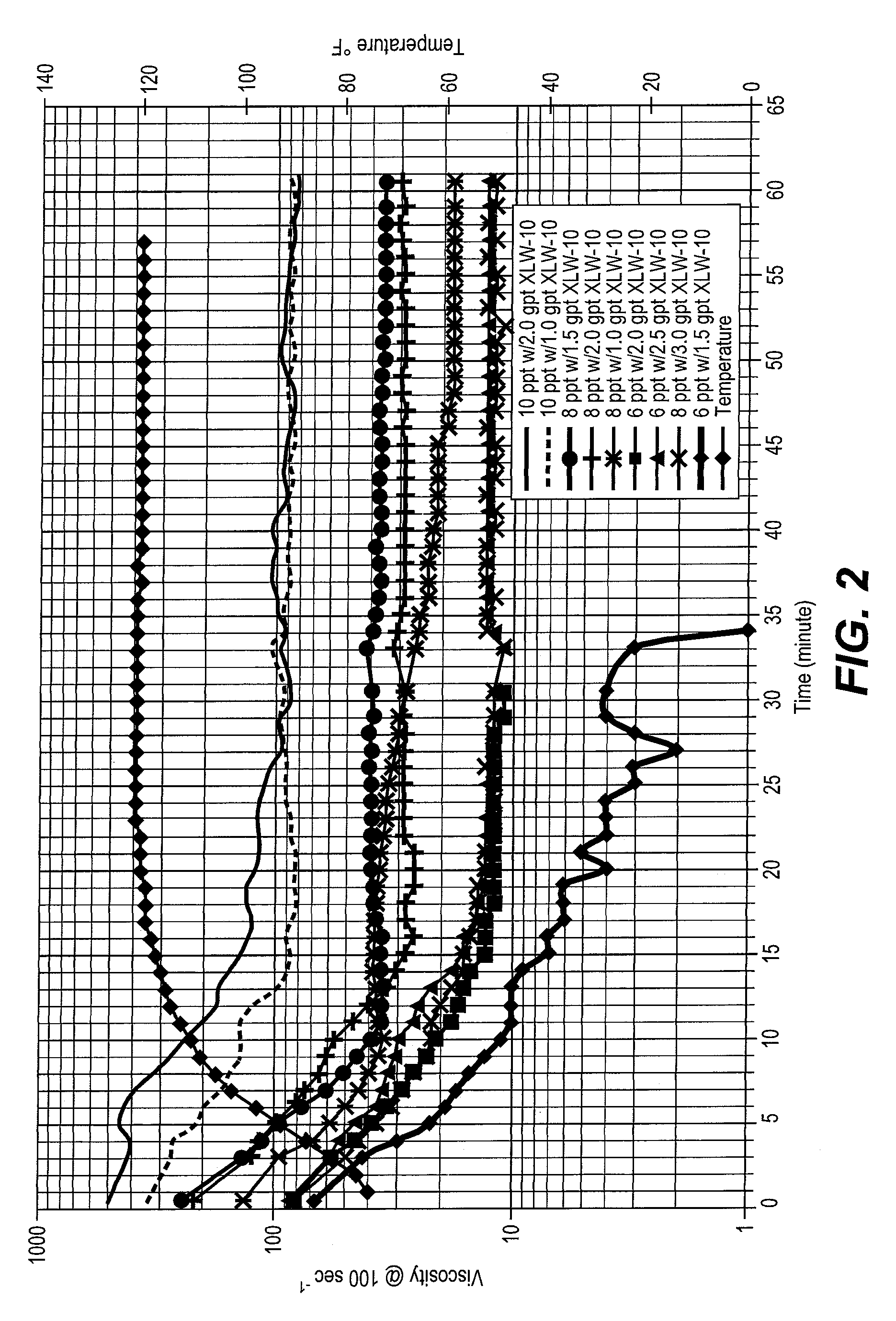

Method of fracturing subterranean formations with crosslinked fluid

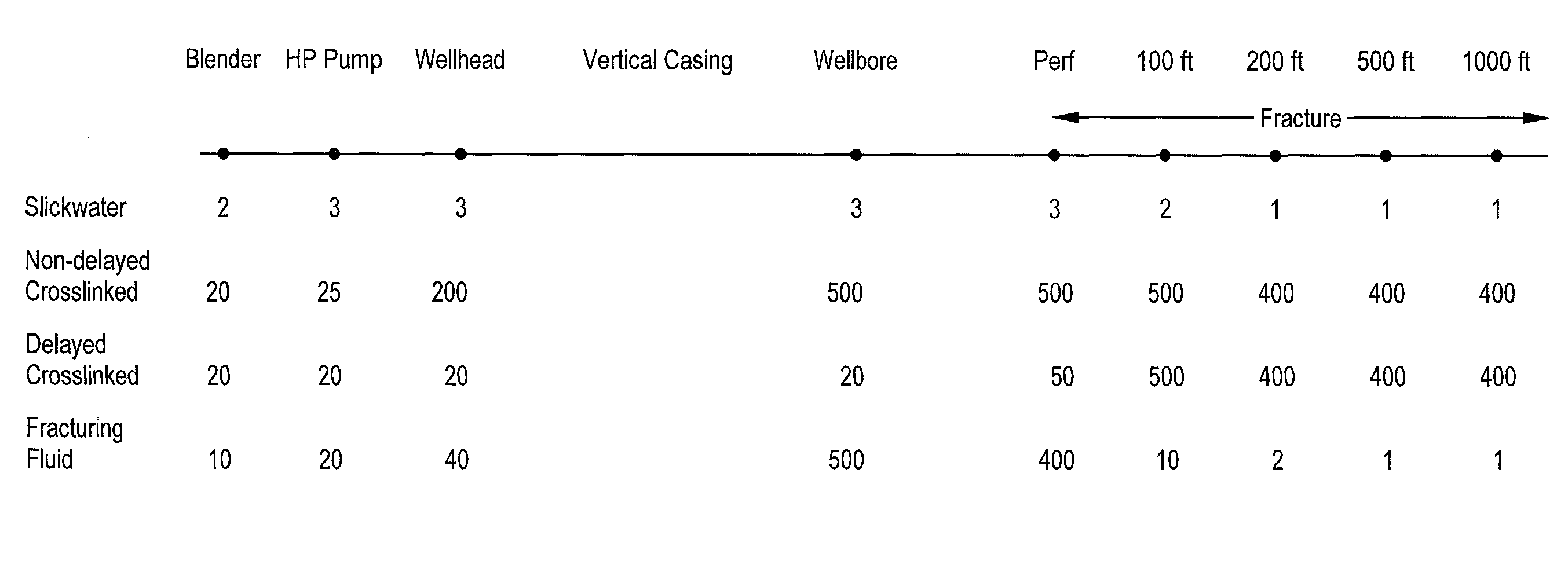

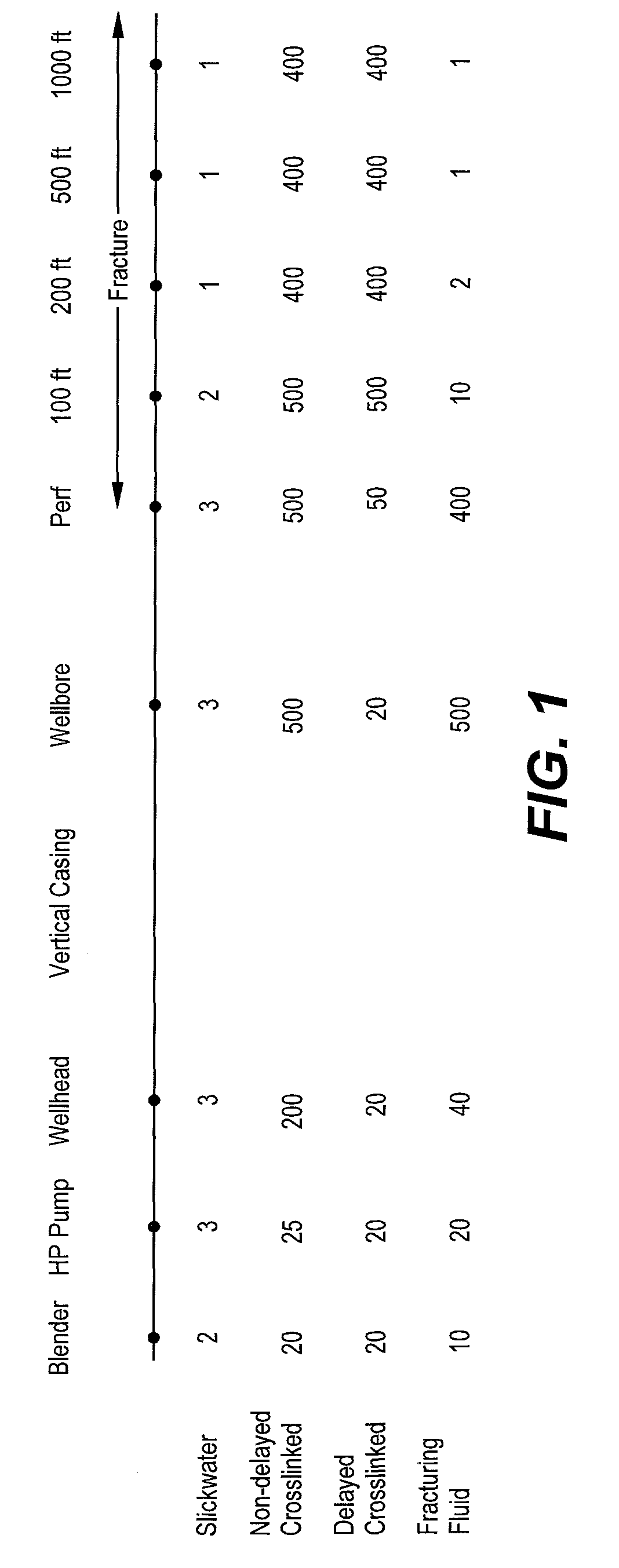

ActiveUS8371383B2Particular applicabilityHigh viscosityFluid removalDrilling compositionApparent viscosityFracturing fluid

Subterranean formations, such as tight gas formations, may be subjected to hydraulic fracturing by introducing into the formation a fracturing fluid of an aqueous fluid, a hydratable polymer, a crosslinking agent and proppant. The fracturing fluid is prepared in a blender and then pumped from the blender into the wellbore which penetrates the formation. The fluid enters the reservoir through an entrance site. The apparent viscosity of the fluid decreases distally from the entrance site such that at least one of the following conditions prevails at in situ conditions:(a) the apparent viscosity of the fracturing fluid 100 feet from the entrance site is less than 10 percent of the apparent viscosity of the fracturing fluid at the entrance site;(b) the apparent viscosity of the fracturing fluid 15 minutes after introduction into the entrance site is less than 15% of the apparent viscosity of the fracturing fluid at the entrance site; or(c) the apparent viscosity of the fracturing fluid is less than 10 cP within 15 minutes after being introduced through the entrance site.

Owner:BAKER HUGHES INC

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980AIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inflation damping continuous adjusting current transformation vibration damper

InactiveCN1912419AContinuous adjustment of damping forceGuaranteed damping effectNon-rotating vibration suppressionGas and liquid based dampersApparent viscosityEngineering

An electro-rheologic vibration absorber with damping continuously adjustable function in air charging type is prepared as embedding columnar electro-rheologic spring and compressing valve as well as drawing valve in piston of said absorber, setting oil channel on piston to let hydraulic oil flow in reciprocation way, using float piston to divide cylinder to be two parts of up oil chamber and down air chamber, setting piston rod to be hollow structure being used to pass wire to be connected with electro-rheologic spring and charging electro-rheologic fluid with apparent viscosity being controlled by externally exerted magnetic field in said spring.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Magnetic liquid apparent viscosity tester and testing method thereof

This invention relates to magnetic liquid surface viscosity test meter and its method, which adopts adjustable magnetic stator and rotor axis with high conductive magnetic cover matched with temperature measurement device and non-contact speed meter. The device is located with high conductive magnetic cover and adjustable permanent magnetic iron stator with liquid gap and the temperature measurement device and the stators are located with multiple heat couple through rotation axis moving in the stators and adopt direct current constant torque motor speed changes to test torque and adopts imbedded magnetic to control added magnetic field with the magnetic field direction vertical to the shearing surface to realize the magnetic flow viscosity testing.

Owner:CHINA UNIV OF MINING & TECH

Coal water slurry addition agent, preparation method thereof and coal water slurry based on same

InactiveCN101812338AGood dispersionImprove stabilityLiquid carbonaceous fuelsPotassium hydroxideSodium hydroxide

The invention discloses a coal water slurry addition agent, a preparation method thereof and coal water slurry based on the same. The addition agent comprises the following components in percentage by weight: 55-90% of dispersant, 5-44% of stabilizer and 0.1-5% of PH regulator; the dispersant is one or mixture of several of polystyrene sulfonate and polyacrylate; the stabilizer is Arabic gum; and the PH regulator is sulfuric acid, nitric acid, sodium hydroxide or potassium hydroxide. The coal water slurry adopting the addition agent is the coal powder water slurry with the concentration of 68 percent which is prepared by enabling the weight of the addition agent to be 0.5-1.2% of the weight of dry-base coal powder, adding water and stirring well. The coal water slurry addition agent has good dispersibility and stability, the raw materials for preparing the addition agent has wide source and low cost, the preparation method is simple and easy to realize, and the addition agent has wide application range for coal types, low cost, low concentration and good stability. The coal water slurry which is prepared by adopting the addition agent has the apparent viscosity of 760mPa.s and can be stably stored for more than 30 days at 25DEG C and at the shear rate of 100S-1.

Owner:SHAANXI UNIV OF SCI & TECH

Starch-based aqueous macromolecule-isocyanate wood adhesive and preparation method thereof

InactiveCN101157833AImprove stabilityImprove the defects of dehydration and drynessGraft polymer adhesivesWater basedAdhesive cement

A wood adhesive made from isocyanate which is starch base water based polymer is made into main agent consisting of 40 portions to 65 portions of composite modified corn starch emulsion, 8 portions to15 portions of dibasic acid esterifying agent, and 10 portions to 30 portions of polyvinyl alcohol; polymerization isocyanate that is not closed is used for curing agent. The type I and II nonformadehyde with different compression-shear strength are adhesive. The type I repeatedly boiling, type II impregnation in hot water and type II normal state, etc., can be made when being used. The adhesive can be widely applied to wood or bamboo adhesive products such as multi-layer plywood, three-layer wood or bamboo parquet floor, a multi-layer wood parquet floor, a block board, bending wood furniture, a particle board and so on, characterized by inimitable design, low making cost, a long activity period, low apparent viscosity, an easily available equipment, good prepressing performance, easy operation, and no environment pollution. Ecological environmental benefits social and economic benefits come into being after the application and popularization of the product.

Owner:BEIHUA UNIV

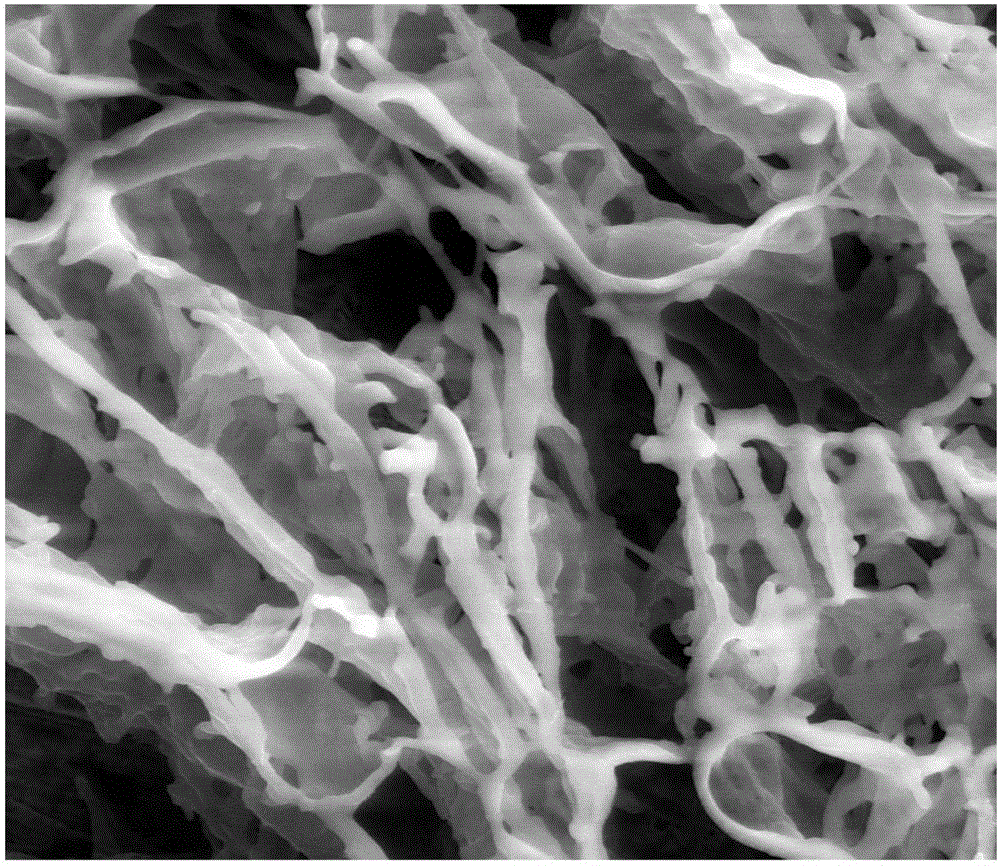

Method for preparing high-stability heat-resistance and salt-tolerance air foam oil displacing agent

InactiveCN104059625AReduce formulation costsEasy to useDrilling compositionFoaming agentApparent viscosity

The invention discloses a method for preparing a high-stability heat-resistance and salt-tolerance air foam oil displacing agent. According to the method, a nanometer and nanometer modification technology is adopted, and nanometer hectorite is used as a foam stabilizer and a high-temperature stabilizer to prepare the high-stability heat-resistance and salt-tolerance air foam oil displacing agent. The technology includes the following steps that the hectorite is added into deionized water at the temperature of 50-90 DEG C, stirred and dispersed evenly, cooled to the room temperature and stewed and aged for a period of time to obtain hectorite aqueous dispersion, quantitative cationic surface active agents are added, evenly stirred, stewed and aged, finally, foaming agents are added, high-speed stirring is conducted on a high-speed emulsification machine, and the high-stability heat-resistance and salt-tolerance air foam oil displacing agent is obtained. The foam half-life period reaches up to 768 hours, the high foam stability is achieved, the foam half-life period reaches up to 70 hours under the condition that the degree of mineralization is 30000 mg / L, the good salt tolerance is achieved, the apparent viscosity reaches up to 2000 mPa.s, the heat resistance performance reaches 90 DEG C, the high foam strength and the heat resistance are achieved, the shearing rate is 170 per second, the foam apparent viscosity reaches 800 mPa.s after shearing is conducted for 60 minutes, the good shearing performance is achieved, and the method is suitable for exploration and development of conventional and unconventional oil fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation](https://images-eureka.patsnap.com/patent_img/a0afd315-9f4c-4f27-b3eb-5346c6a36a85/US20100021539A1-20100128-D00000.png)

![Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation](https://images-eureka.patsnap.com/patent_img/a0afd315-9f4c-4f27-b3eb-5346c6a36a85/US20100021539A1-20100128-D00001.png)

![Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation Modified Release 1-[(3-Hydroxy-Adamant-1-Ylamino)-Acetyl]-Pyrrolidine-2(S)-Carbonitrile Formulation](https://images-eureka.patsnap.com/patent_img/a0afd315-9f4c-4f27-b3eb-5346c6a36a85/US20100021539A1-20100128-D00002.png)