New method for forming manual well wall in oil and gas well by water-absorbing resin

A water-absorbing resin, artificial well wall technology, applied in wellbore/well components, chemical instruments and methods, earth-moving drilling, etc., can solve the problems of high risk of snubbing operation, foam pollution, high cost, and achieve leakage loss The effect of circulation and safe operation, strong leakage prevention and high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

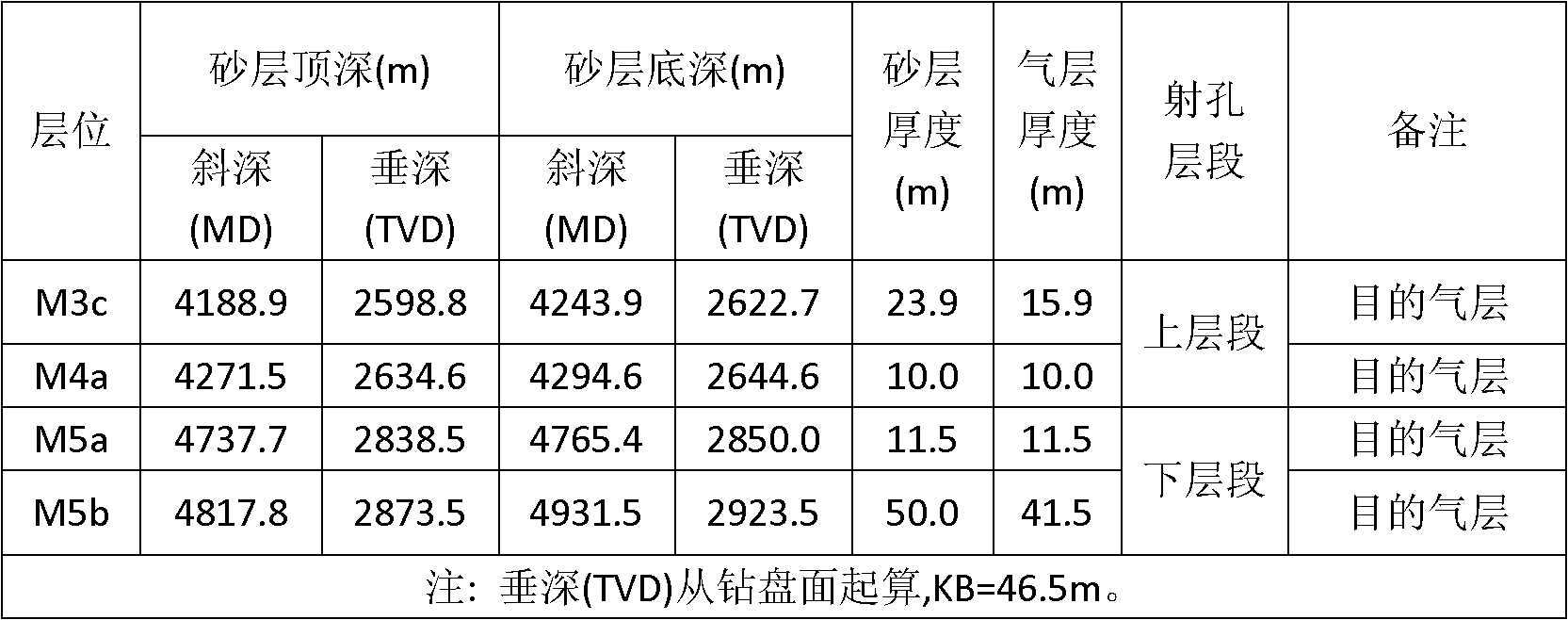

[0058] Example 1: Completion and re-completion of well X7 in an offshore gas field

[0059] The basic geological data are as follows:

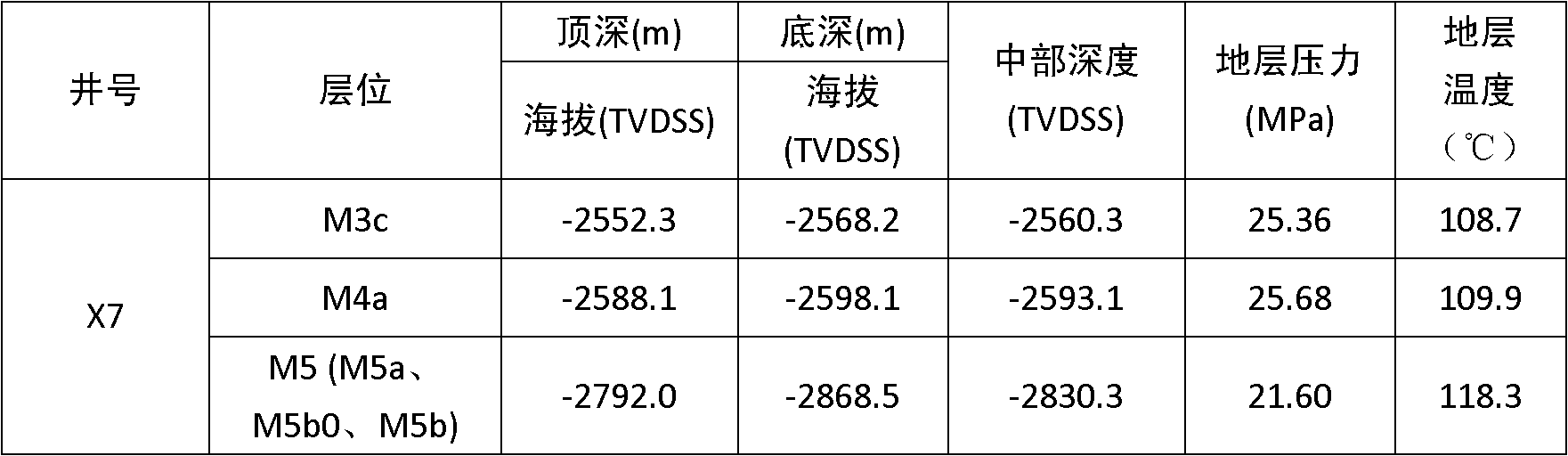

[0060] (1) Formation pressure data

[0061] The M group gas reservoir in this gas field is a normal pressure system with a pressure coefficient of 1.03. The predicted M3c and M4a gas layers encountered are 25.37 and 25.68 MPa respectively. The drilled M5a and M5b are gas reservoirs that have been produced. The original formation pressure of the gas reservoir is 28.53MPa. Drilling to M5 in mid-April 2008, it is predicted that the formation pressure will drop to around 21.6MPa, and the formation pressure coefficient will be about 0.77. When drilling into this gas layer, there will be problems of leakage.

[0062] (2) Gas reservoir temperature

[0063] The geothermal gradient of the gas layer is 0.0356°C / m, and the temperature of the reservoir section is predicted to be around 120°C. The temperature and pressure prediction data of the gas lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com