Patents

Literature

1912results about How to "Improve pressure bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temporary leakage-stopping agent for well drilling shielding and its application

The temporary leakage-stopping agent is developed for stopping leakage in well drilling and reducing damage to oil reservoir. It consists of swelling material, bridging material, stuffing material and inhibitor material. The swelling material is nanmu rood powder, contton boll and other water swelling material of grain size below 838 micron and capable of forming fibrous gel; the bridging material is flaky mica of grain size 97-381 micron; the stuffing material may be common or light calcium carbonate of grain size below 117 micron; and the inhibitor material may be polyacrylonitrile sodium salt, polyacrylonitrile potassium salt, polyacrylonitrile ammonium salt, potassium humate or their mixture.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-efficiency plugging oil-base drilling fluid and preparation method thereof

ActiveCN103045210AEffective blockingPrevent penetrationDrilling compositionAlkalinityDifferential pressure

The invention discloses a high-efficiency plugging oil-base drilling fluid and a preparation method thereof. The drilling fluid is prepared from the following raw materials in parts by mass: 70-80 parts of slurrying oil, 20-30 parts of slurrying water, 2.5-3.0 parts of main emulsifier, 1.5-2.0 parts of auxiliary emulsifier, 2.0-2.5 parts of wetting agent, 2.0-2.5 parts of flow pattern regulator, 2.5-3.0 parts of fluid loss agent, 1.5-2.0 parts of alkalinity regulator, 0.5-0.8 part of extracting agent and 7-9 parts of plugging material. A weighting material is added so that the density of the drilling fluid reaches 1.45-1.56 g / cm<3>. By utilizing the well-drilling positive differential pressure, the high-efficiency plugging oil-base drilling fluid quickly implements bridging, filling and filming to plug the formation fractures on the well wall surface and near the well wall, effectively prevents the drilling fluid and filtrate thereof from permeating into microfractures, enhances the bearing capacity of the formation, has favorable plugging effect, and is beneficial to the stability of the well wall.

Owner:CHINA PETROLEUM & CHEM CORP +1

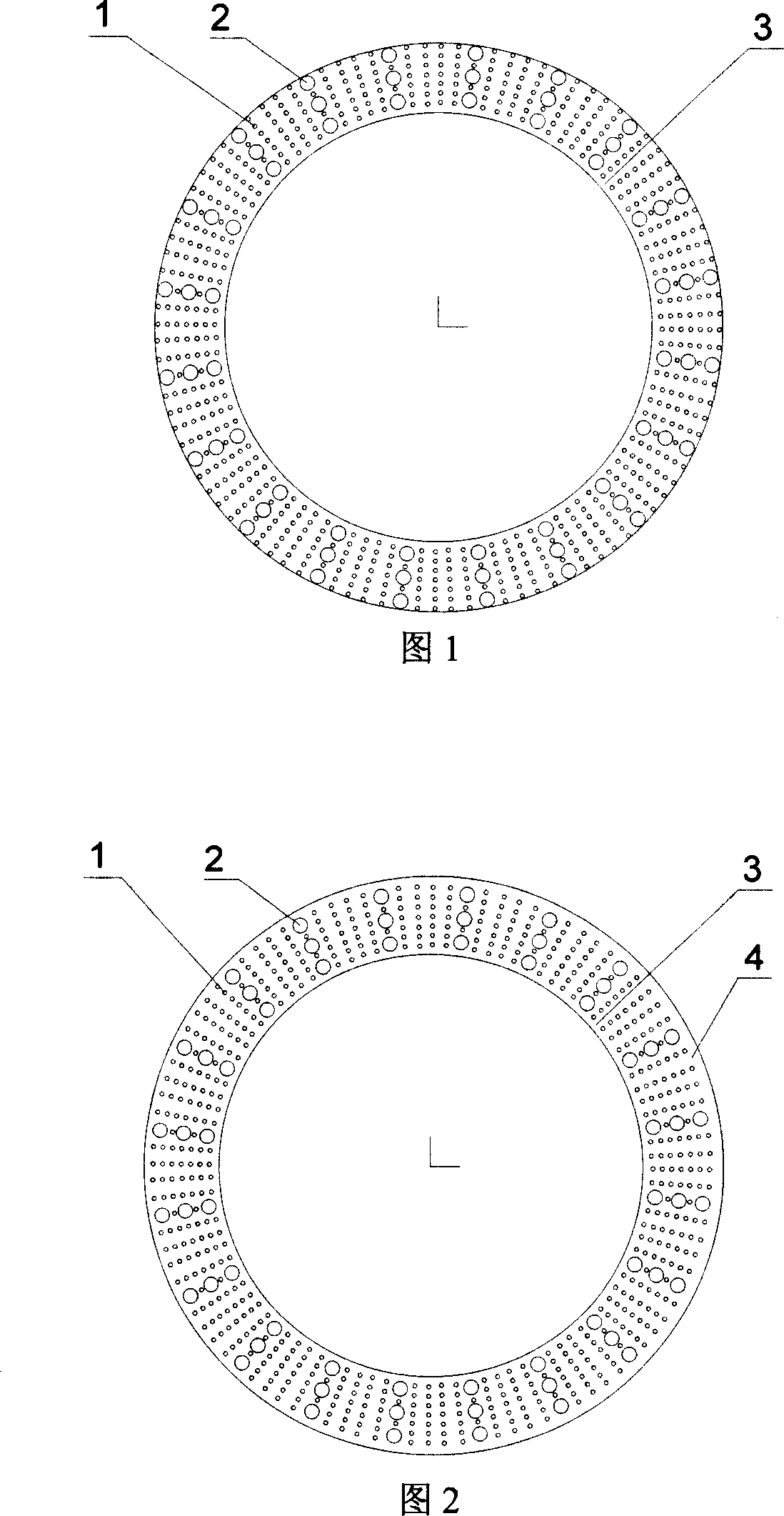

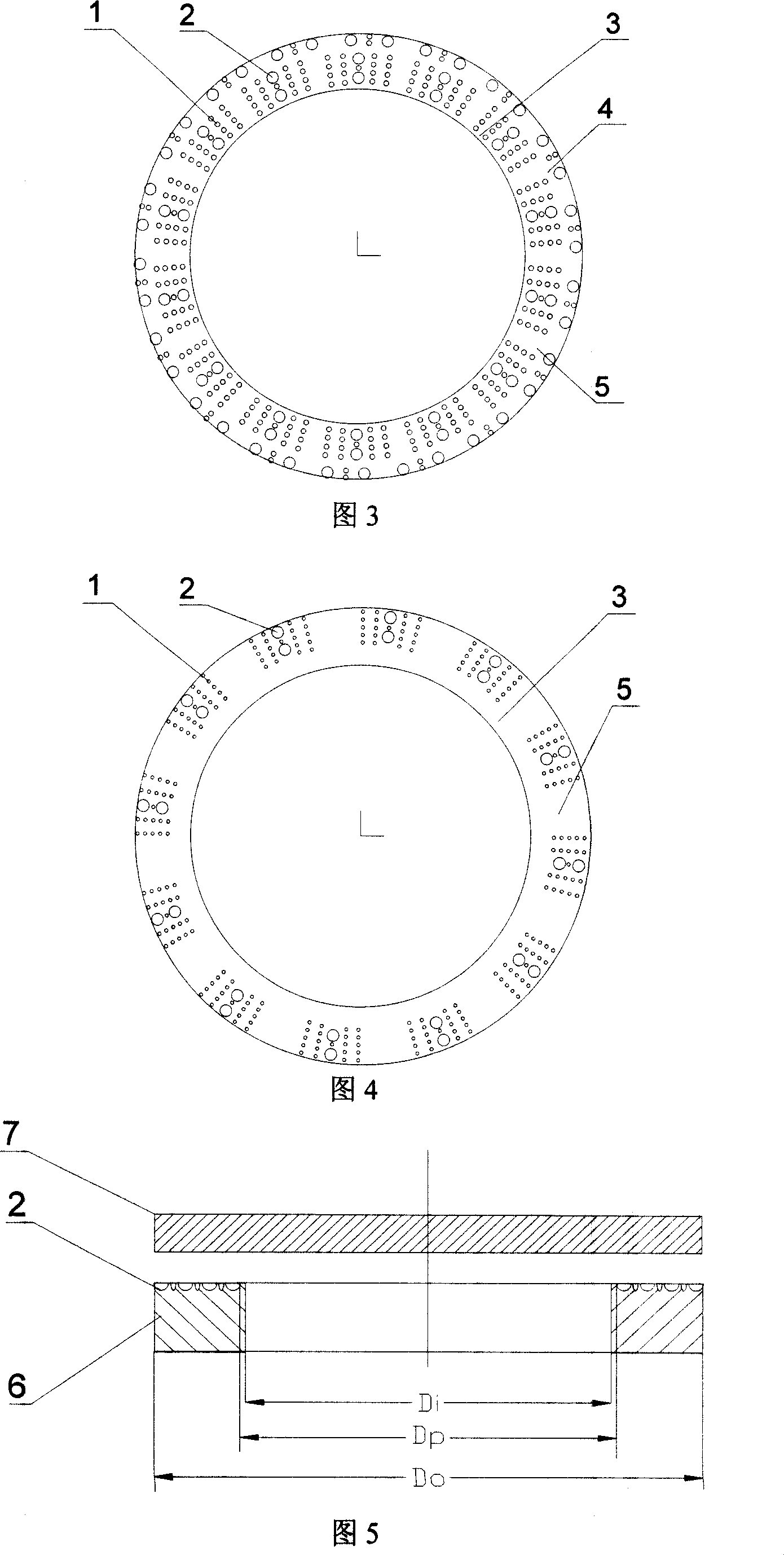

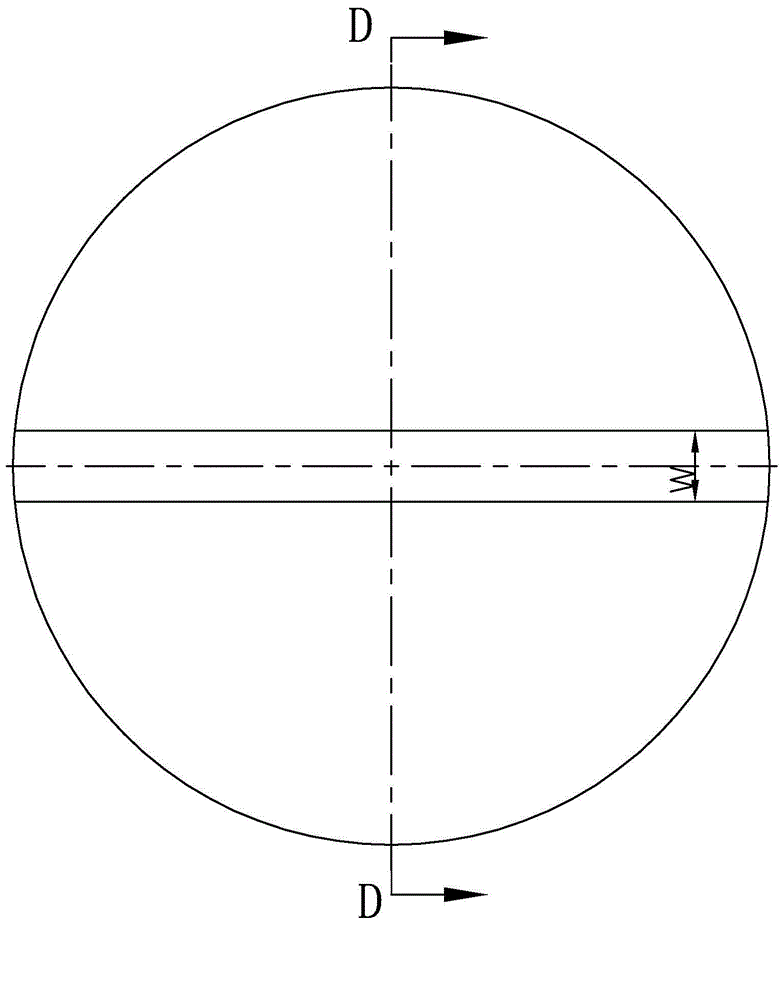

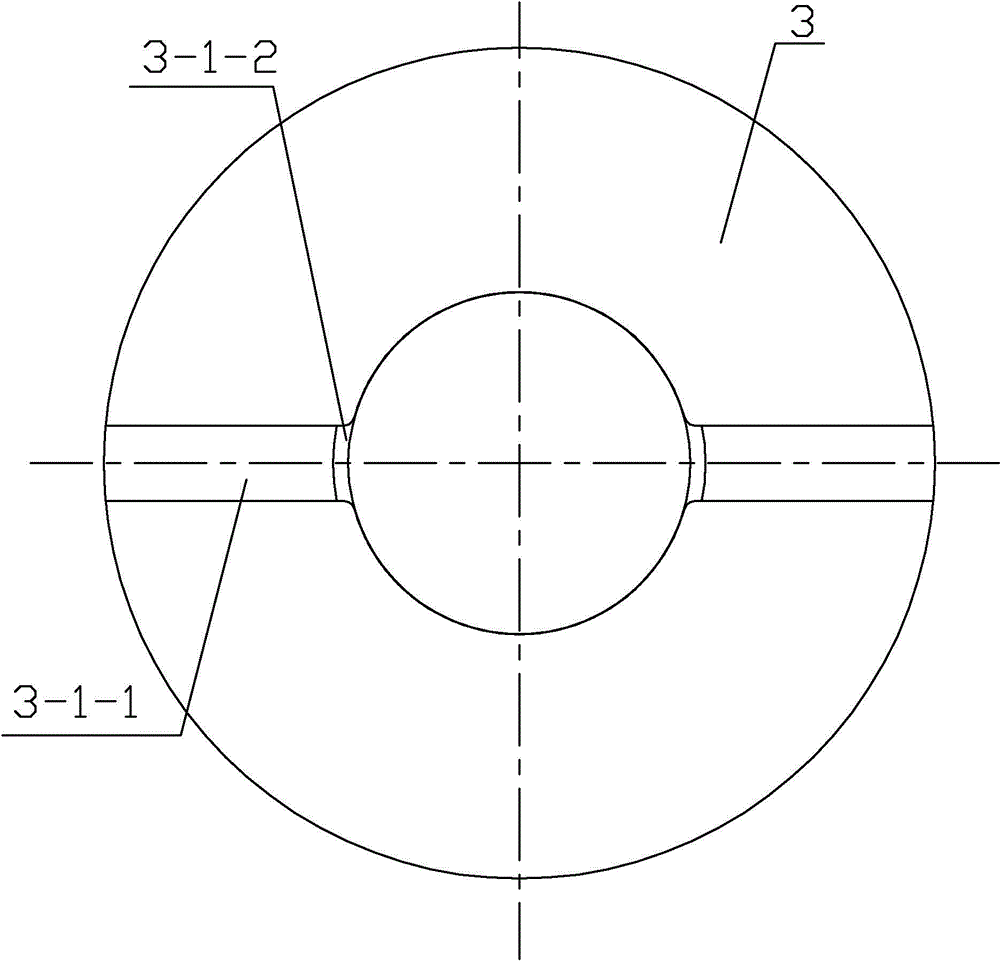

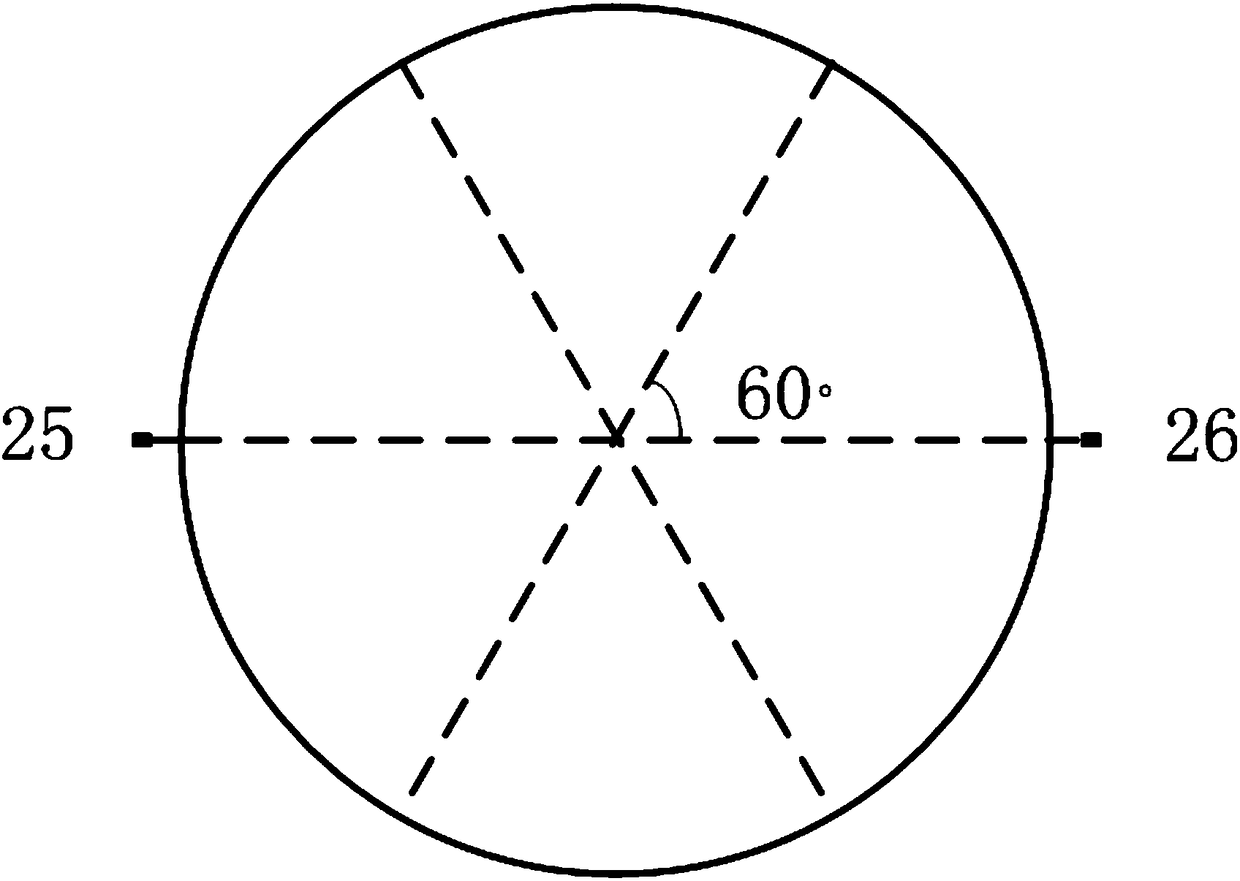

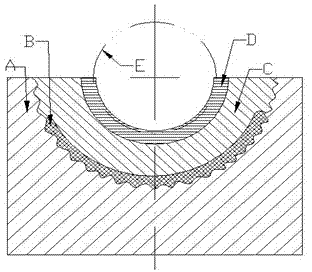

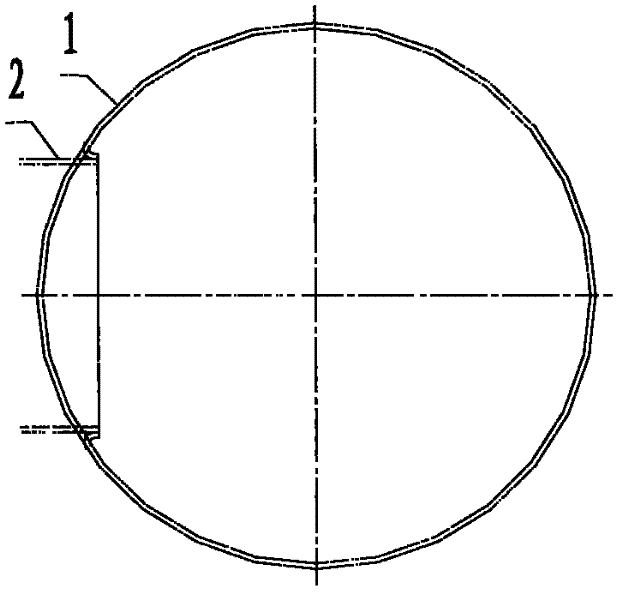

Variable distribution porous end face mechanical sealing structure

ActiveCN101016949AImprove wear resistanceImproved opening/stopping performanceEngine sealsHigh pressureWear resistance

The invention relates ton a variable-distribution porous end mechanical sealing structure, comprising a movable ring and a stable ring which are mechanically sealed, to form an annular sealing end. One side of the sealing end is high pressure side as ascending, while another end is low pressure side as descending, at least one sealing end is disposed with porous structure in different sizes symmetry distributed on the sealed end. Compared with present screw or groove mechanical sealing structure, the invention has better pressure resistance, abrasion resistance and better dynamic pressure effect on fluid membrane, to improve the carrier ability of fluid membrane.

Owner:ZHEJIANG UNIV OF TECH

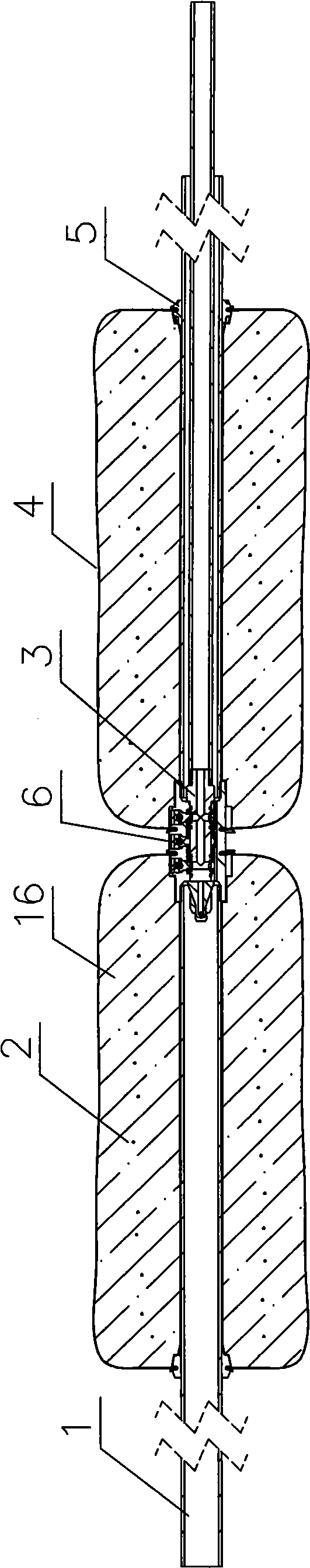

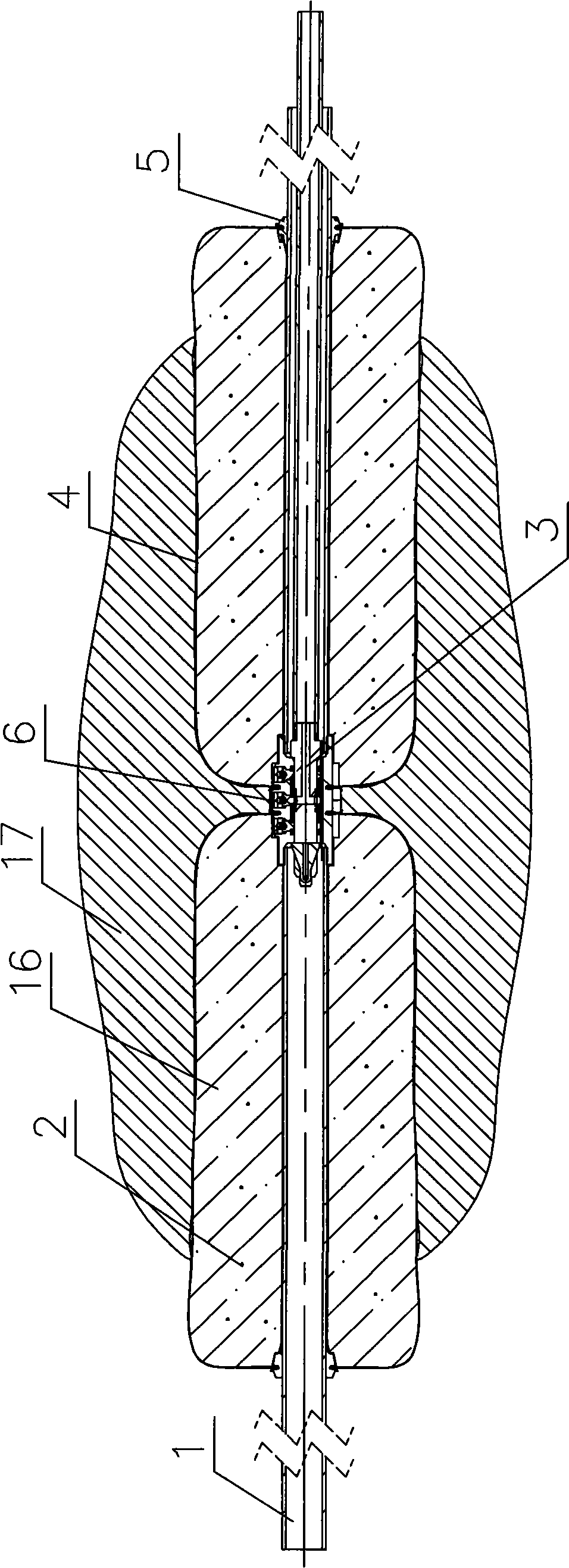

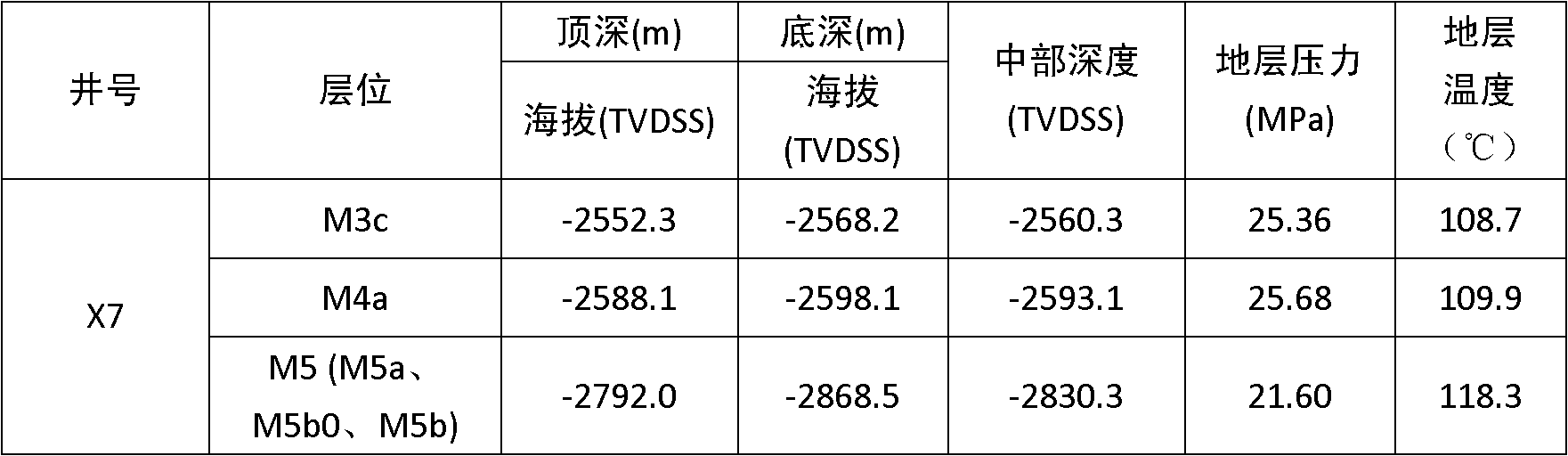

Gas extraction secondary high-pressure slip-casting hole-sealing apparatus and its hole-sealing method

InactiveCN101482026AImprove pressure bearing capacityImprove sealingGas removalSealing/packingDrill holeHigh pressure

A secondary high-press pulp injection and hole sealing device for collecting gas comprises collection pipes, bags and a secondary pulp inflow device, wherein collection pipes are connected with two sides of the secondary pulp inflow device; plugs are sleeved on the collection pipes; the bags are located between each plug and the secondary pulp inflow device; three pulp inflow holes having unidirectional valves are arranged on the secondary pulp inflow device; the pulp inflow holes on the two sides communicate with the bags on the same side; and the pulp inflow hole in the middle spatially communicates with the bags. A method of using the device for pulp injection and hole sealing comprises the following steps of: inserting a pulp injection plug in the secondary pulp injection device and performing the low-pressure pulp injection to the pulp inflow holes that communicate with the bags; and after the injected pulp is solidified, performing the high-pressure pulp injection to the pulp inflow hole in the middle of the secondary pulp inflow device by using the pulp injection plug. The invention adopts the pulp injection materials to inject the pulp to the drill hole wall so as to seal the drill hole wall and the peripheral deflated passages thereof, and basically eliminates the drill deflated cracks through the primary low-pressure pulp injection and the secondary high-pressure pulp injection close to the ground stress.

Owner:HENAN POLYTECHNIC UNIV

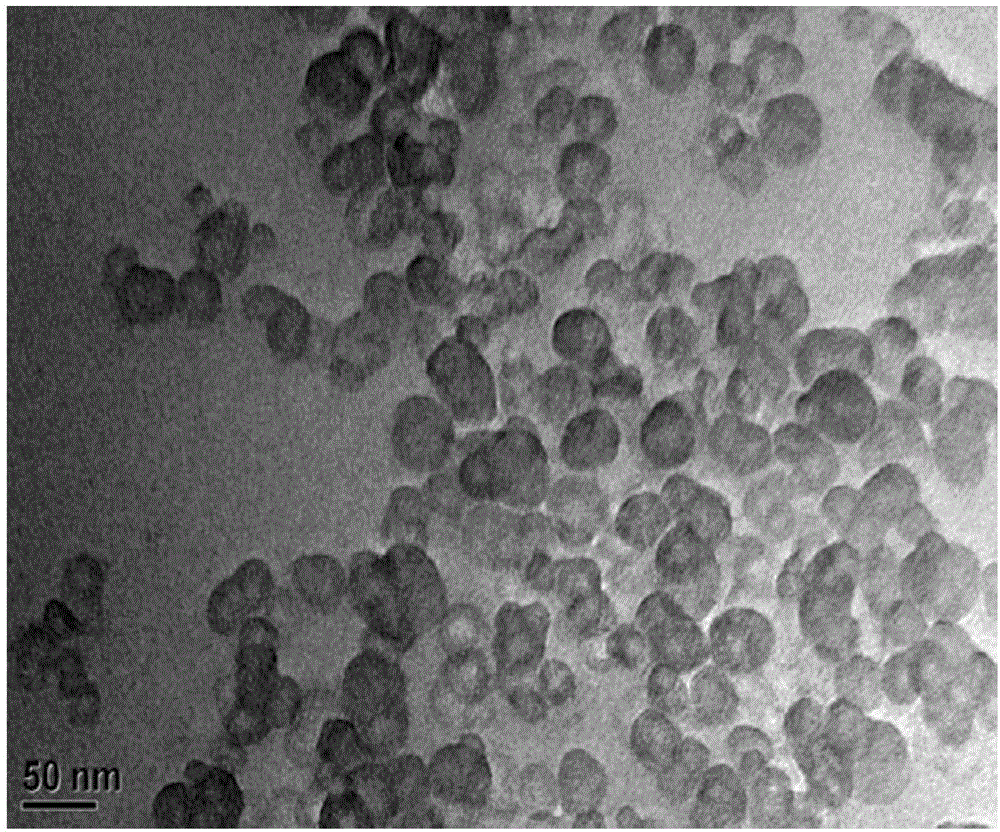

Core-shell polyacrylamide microsphere profile controlling oil displacement agent and preparation method thereof

ActiveCN103739778AEfficient recyclingAchieving a green cycleDrilling compositionMicrosphereMicrometer

The invention discloses a core-shell polyacrylamide microsphere profile controlling oil displacement agent and a preparation method thereof. The method comprises the following steps: fully stirring and dissolving acrylamide, cationic monomer, a crosslinking agent and an initiator to synthetize a core part by adopting a dispersion polymerization method; fractionally adding a mixed solution of the acrylamide, anionic monomer, third monomer, the crosslinking agent and the initiator into a reaction device, controlling reaction conditions to be invariant, and reacting on the surface of the core to generate a shell part, thereby obtaining the core-shell polyacrylamide microsphere profile controlling oil displacement agent taking the cationic polyacrylamide as the core and taking the anionic polyacrylamide polymerized on the surface of the core as the shell, wherein the particle size range of the microsphere profile controlling oil displacement agent is from 1micrometer to100 micrometers. The microsphere profile controlling oil displacement agent has the advantages that the microsphere has an interpenetrating polymer network system and is capable of forming a viscoelastic body after absorbing water and forming a gel body after a certain time, so that the oil displacement agent is long in plugging time and little in leakage and is capable of bearing the pressure of more than 5MPa.

Owner:TIANJIN UNIV

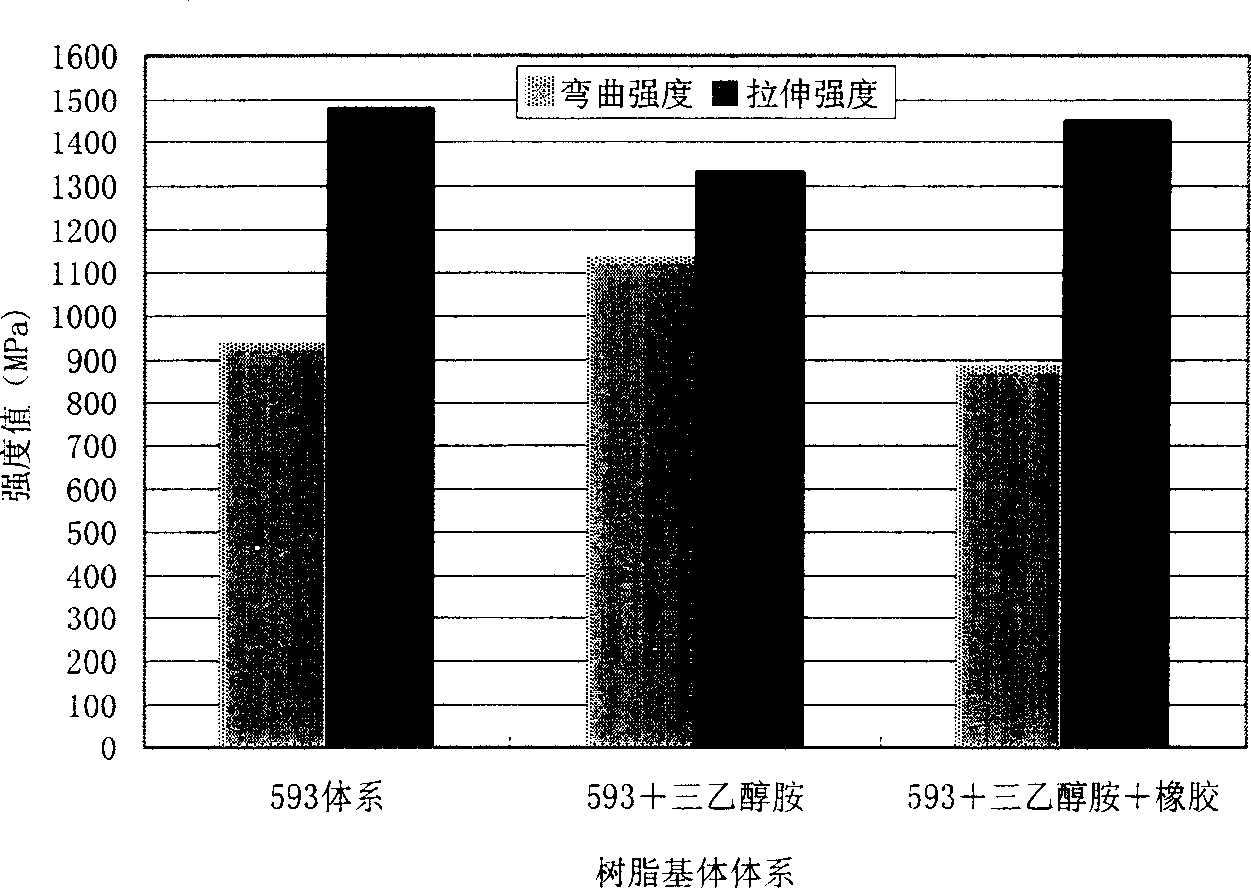

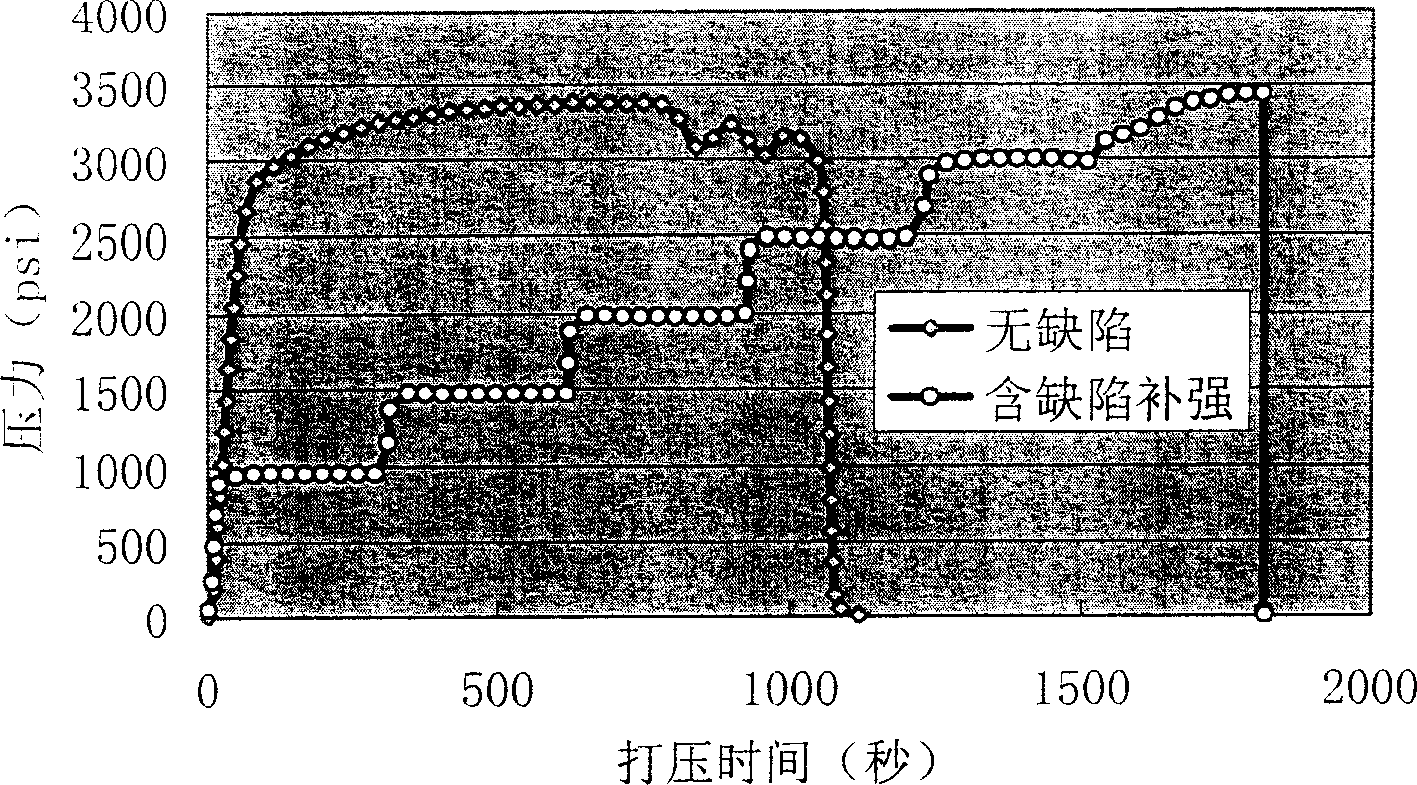

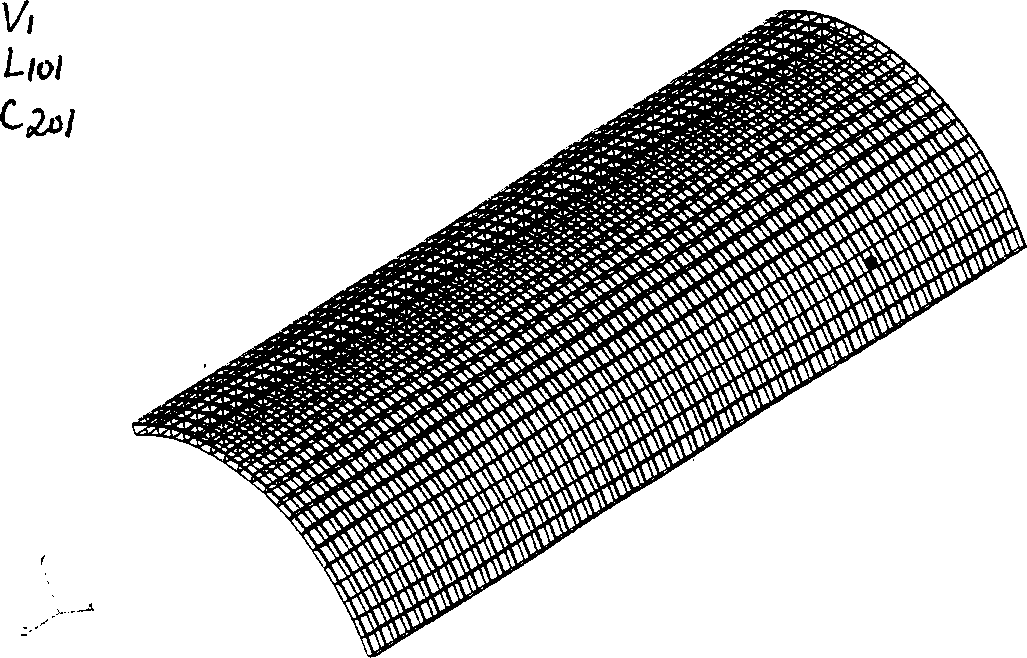

Method for reinforcing defective pipeline and composite material therefor

ActiveCN1766400AImprove pressure bearing capacityBearing capacity up toPipe elementsEpoxy resin adhesivesEpoxyGlass fiber

The invention discloses a defect pipe reinforced method and composite material, which is characterized by the following: adapting reinforced composite material, defect filling material and interlaminar adhesive agent to restore and reinforce the defect position; disposing the defect surface only; filling the defect position with the reinforced filling material; wrapping the reinforced film on the pipe; adapting interlaminar adhesive agent and hardening agent among layers, wherein the reinforced composite material piece is high-strength glass fiber unidirectional cloth or carbon fiber unidirectional cloth, which is composed of 593 hardening agent or triethanolamine hardening agent, epoxide-resin glue of acrylate liquid rubber and interlaminar adhesive agent. The invention can restore the defect pipe of more than half thickness without welding, leakage and cracking, which displays normal pipe after restoring the explosion-hole.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

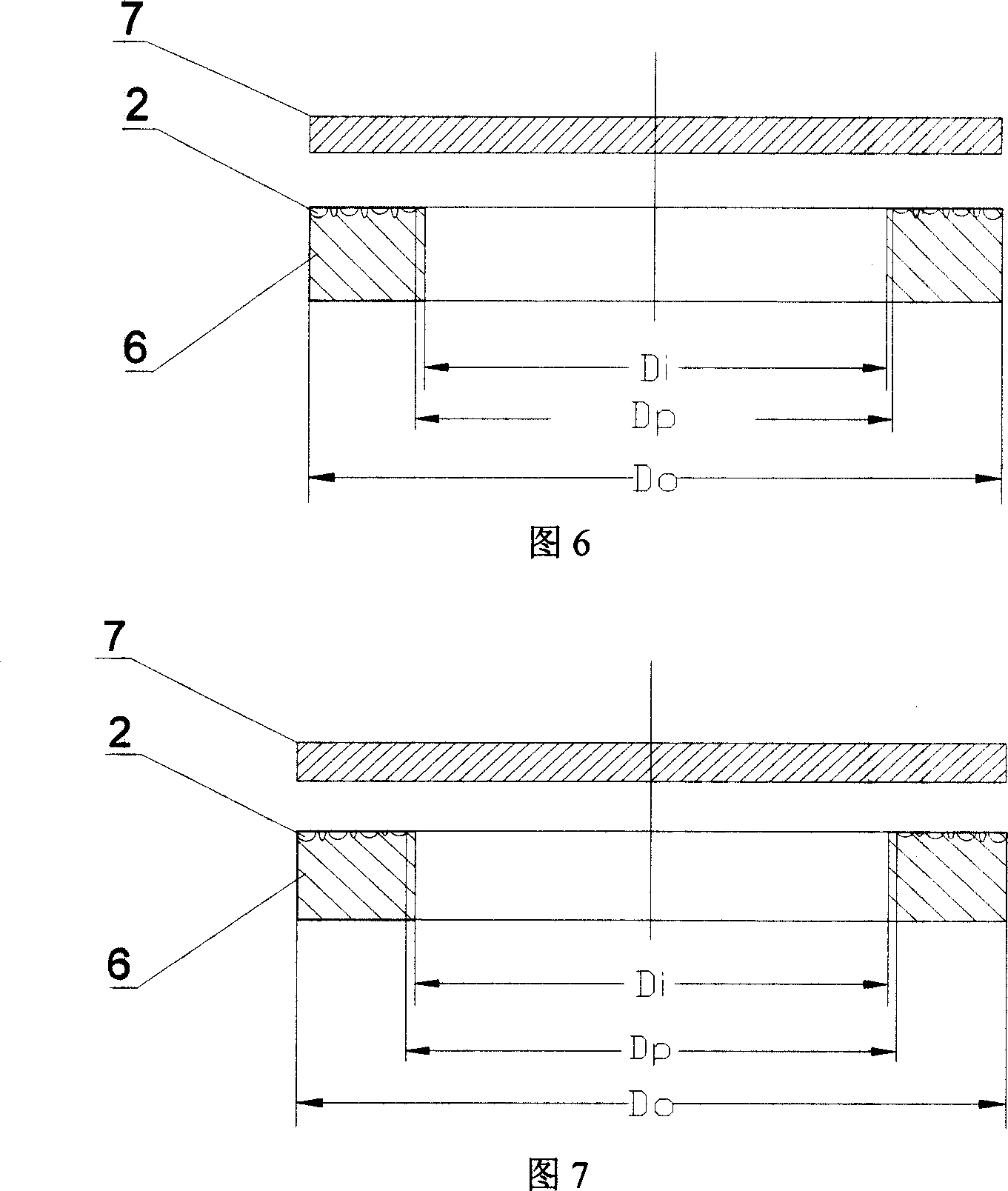

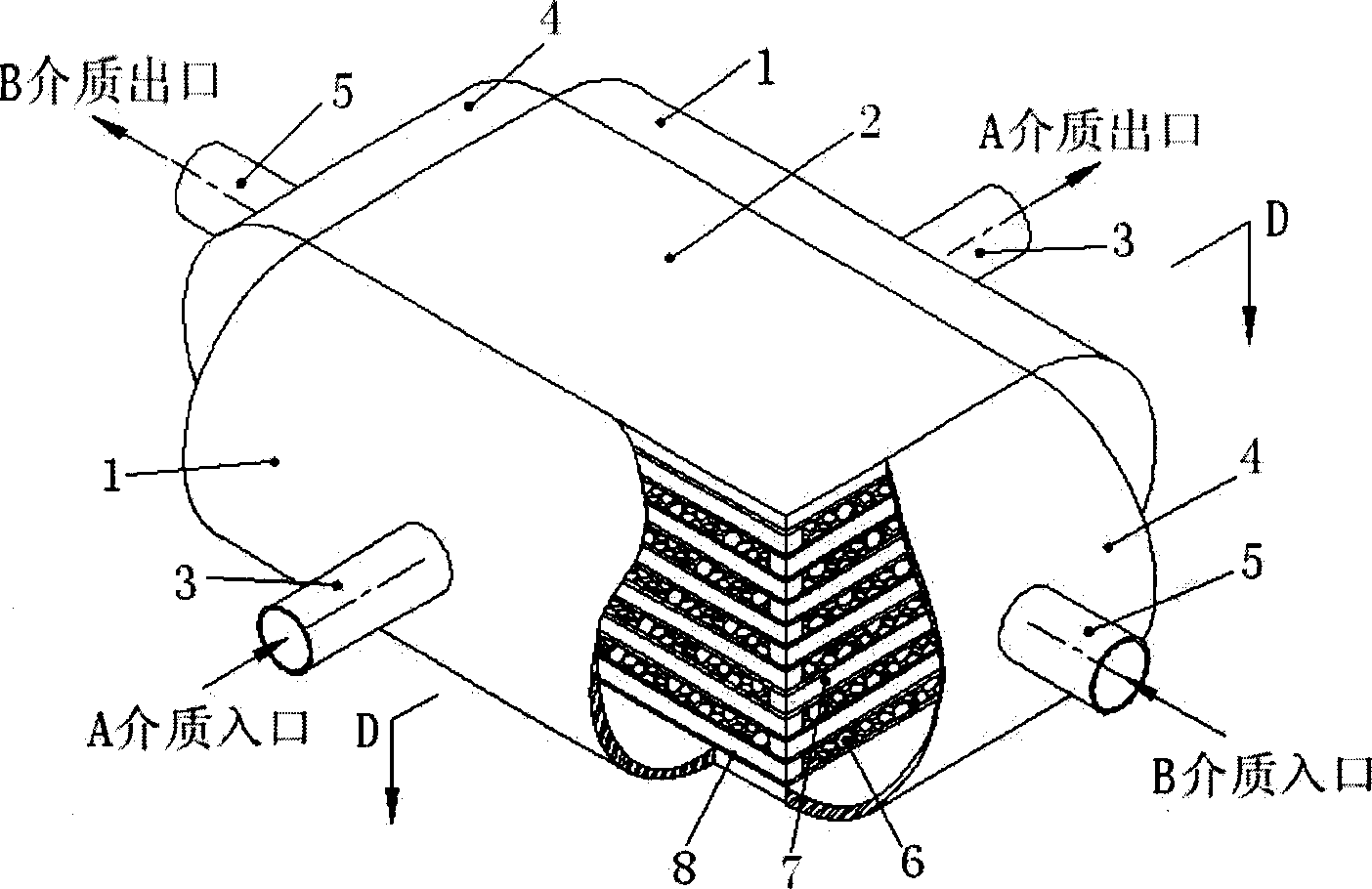

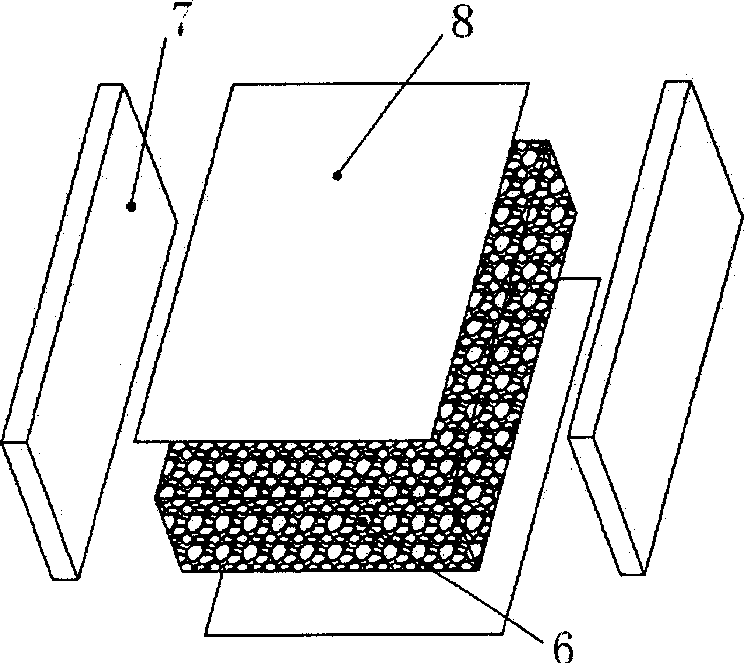

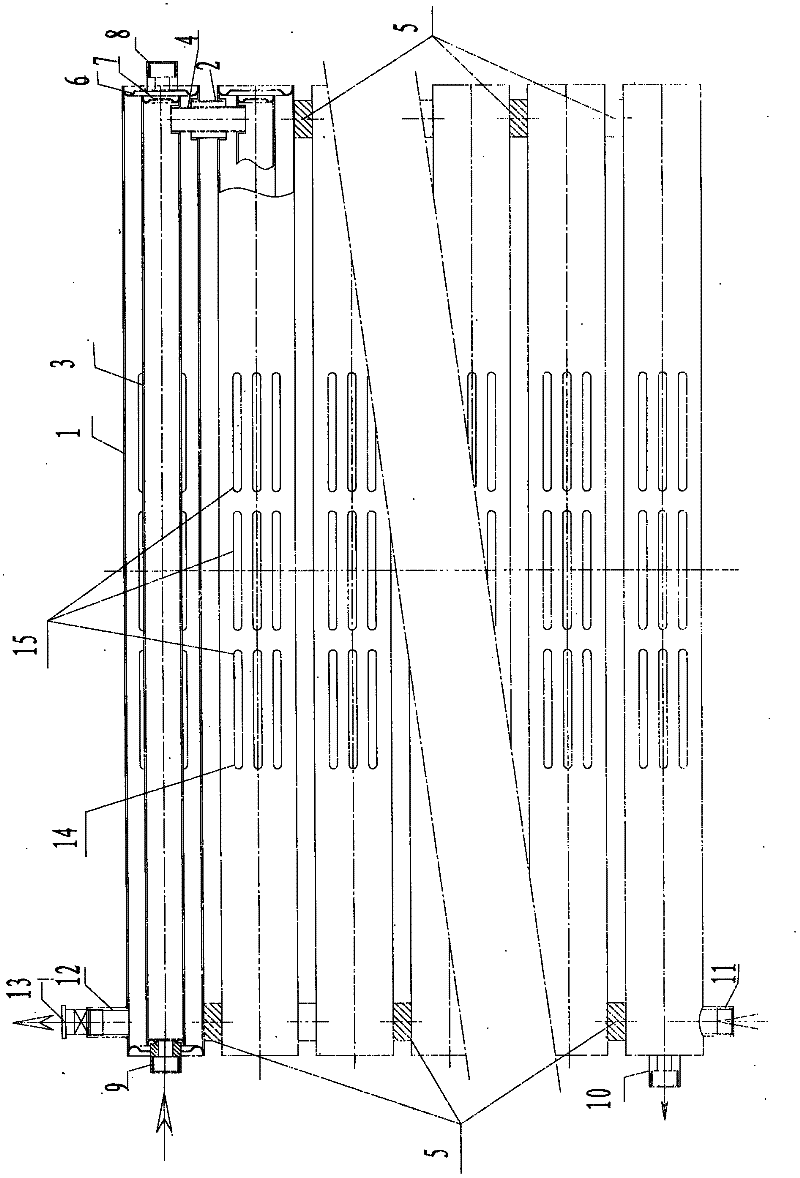

Band-bubble type heat-exchanger

InactiveCN1851377AImprove pressure bearing capacityDoes not create mutual leakage deficiencyLaminated elementsStationary plate conduit assembliesReticular formationEngineering

The invention relates to a heat exchanger with new type structure that has end plate, nipple, and core identity. And the end plate is set at the two sides of liquid channel. The core identity is formed by plural cool liquid channel and hot liquid channel. The liquid channel is formed by porous material of 3D solid reticular formation, and is sealed by guarantee strip. Catalyst coating layer is coated on the surface of the porous material liquid channel inner holes and make the exchanger has high heat efficiency.

Owner:EAST CHINA UNIV OF SCI & TECH

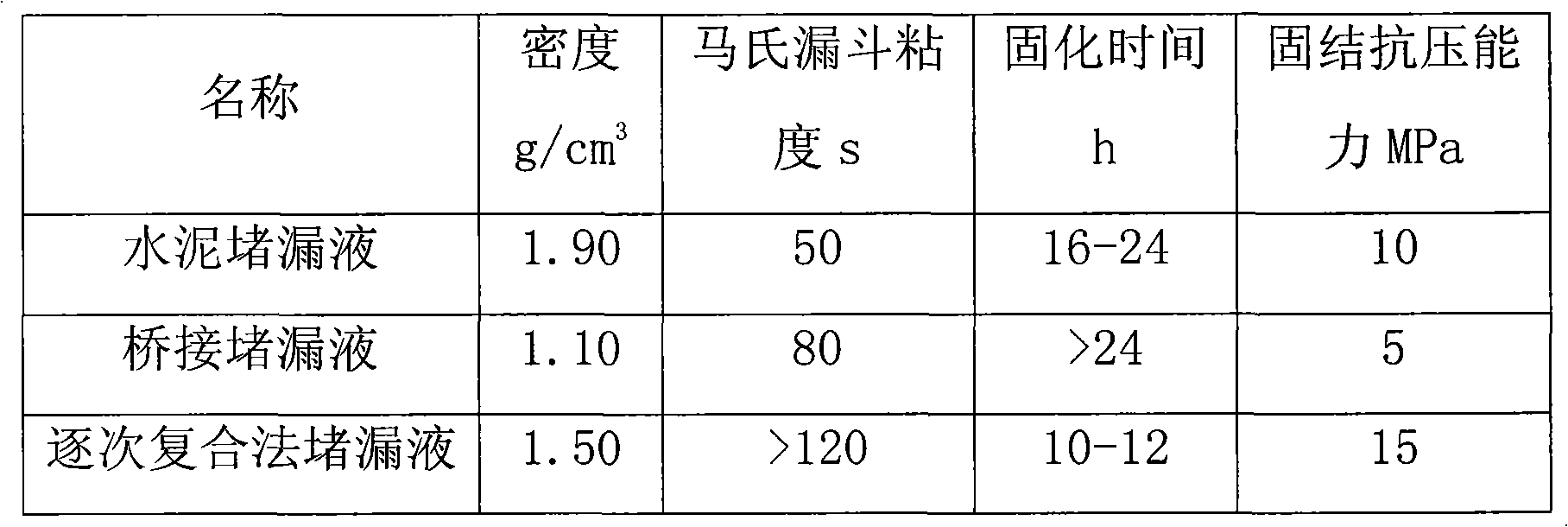

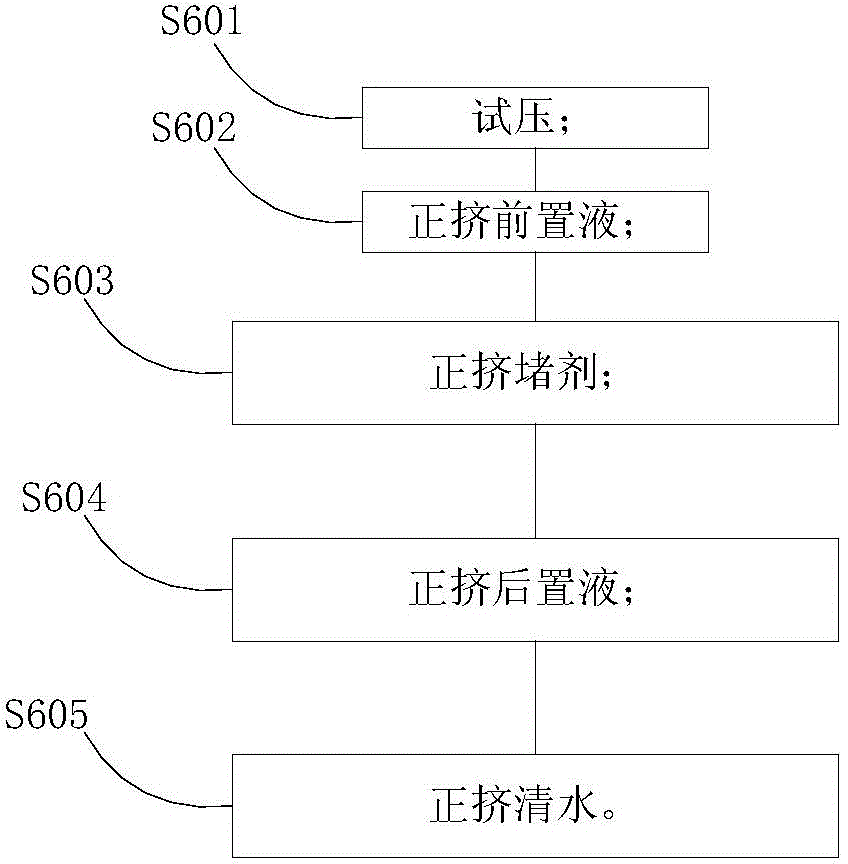

Successive-compounding-process based plugging method for well drilling

InactiveCN102434124AImprove pressure bearing capacitySolve the problem of low plugging success rateDrilling compositionSealing/packingWell drillingPorous medium

The invention discloses a successive-compounding-process based plugging method for well drilling. In the plugging method, a well-cementing cement pump or a mud pump is used for pumping two or more than two kinds of plugging fluids with different components and properties into an underground leakage zone successively in proportion. By means of the plugging method, the applicable range of the plugging fluids can be broadened, the loading capacity of a barefoot interval stratum can also be greatly increased, and the problem of low plugging success rate can be solved. According to the plugging method, a retention layer can be formed in porous media; the purpose of increasing the loading capacity and compressive strength of the stratum can be achieved by compounding the plugging fluids with different components and different properties; in addition, the construction process is simple, the plugging success rate is high, and the well drilling cost is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

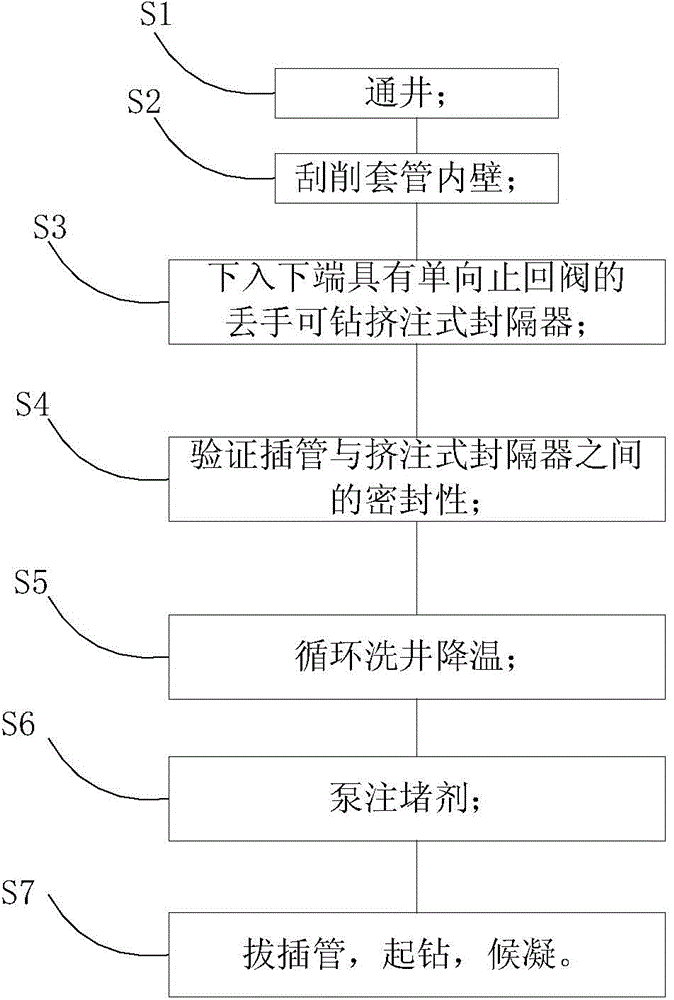

Ultralow-pressure well leakage plugging method

ActiveCN104632123ARealize pluggingImprove pressure bearing capacityDrilling compositionSealing/packingPositive pressureCement slurry

The invention provides an ultralow-pressure well leakage plugging method and belongs to the technical field of oil field well leakage plugging. According to the method, after a certain perforation well section is selected as an inlet of cement slurry, a squeezing packer is arranged in a casing pipe of the upper portion of the perforation well section in a setting mode, and a drillable one-way check valve is arranged under the squeezing packer; a squeezing pipe column is fed, an insertion pipe at the lower end of the squeezing pipe column is inserted into a socket of the packer so that the pipe column and the squeezing packer can be sealed, and the situation that due to the fact that plugging agents return to the portion above the squeezing packer in the plugging construction process, engineering accidents are caused can be prevented; gel spacer fluid is pumped into the squeezing pipe column, then the cement slurry is pumped, finally the gel spacer fluid is pumped, positive pressure squeezing is carried out, and therefore the gel spacer fluid and the cement slurry enter an oil-water layer or a channeling groove part to be sealed through the perforation well section serving as the inlet; pumping is stopped, the insertion pipe is pulled out, the one-way check valve is automatically closed, flow return is stopped, the pipe column is lifted to finish the operation of plugging the oil-water layer, kill fluid is poured, and a well is closed to wait on cement setting. The method has the advantages that site adaptation and leakage plugging strength are high, and leakage of the ultralow-pressure well can be plugged.

Owner:PETROCHINA CO LTD

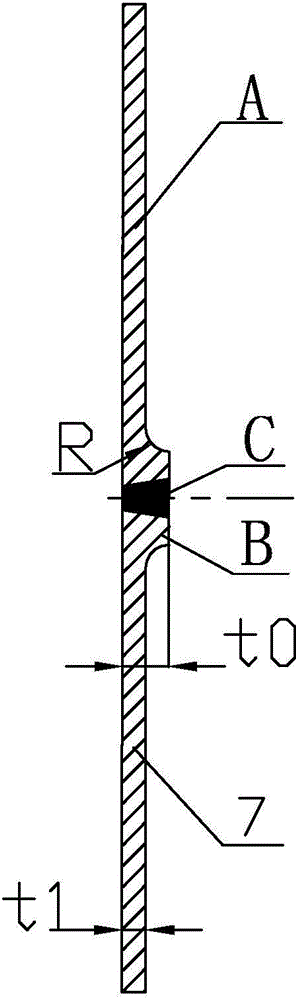

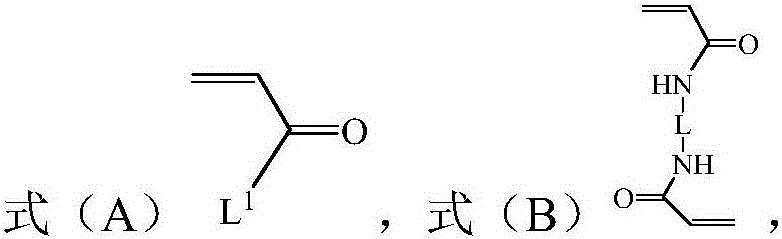

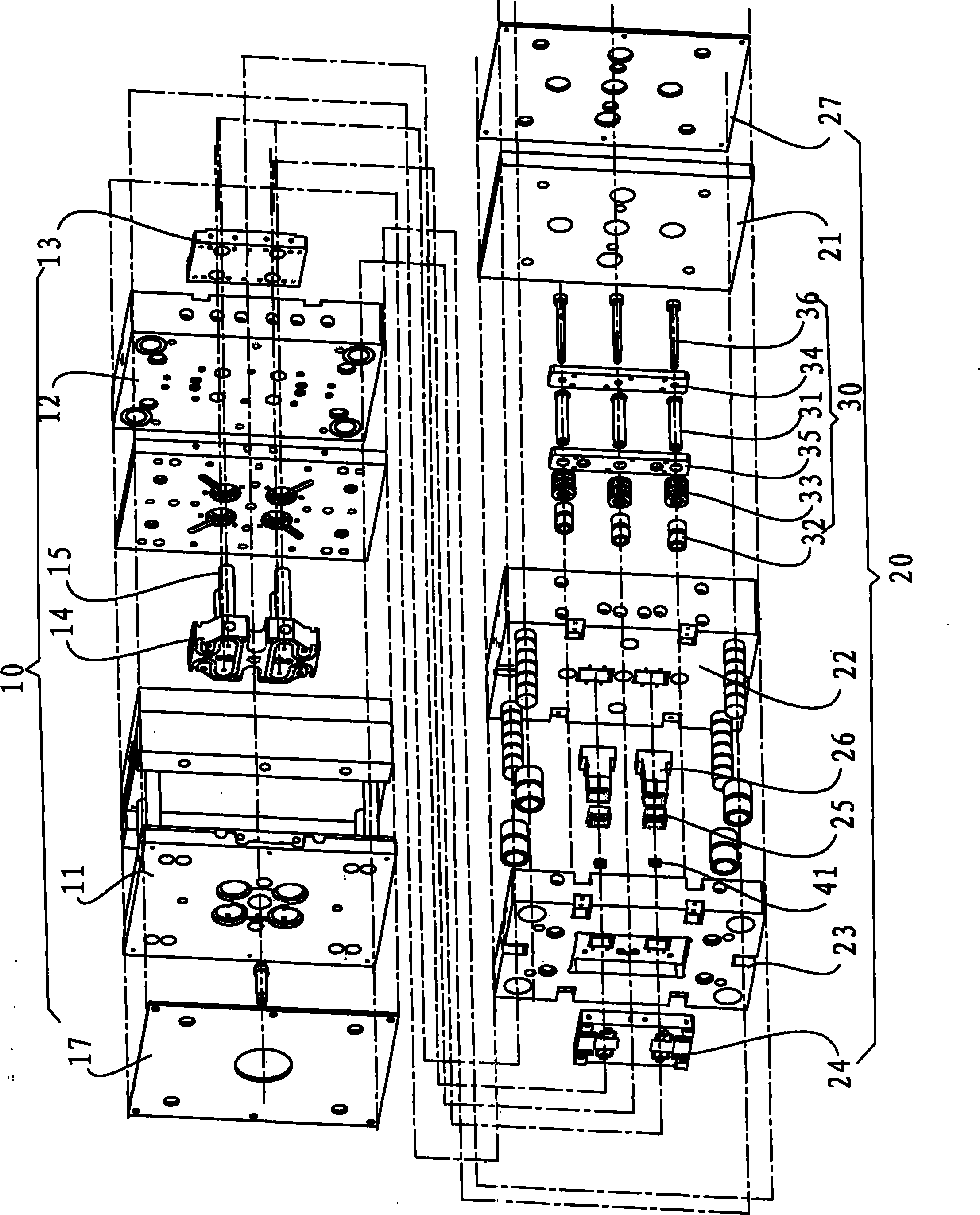

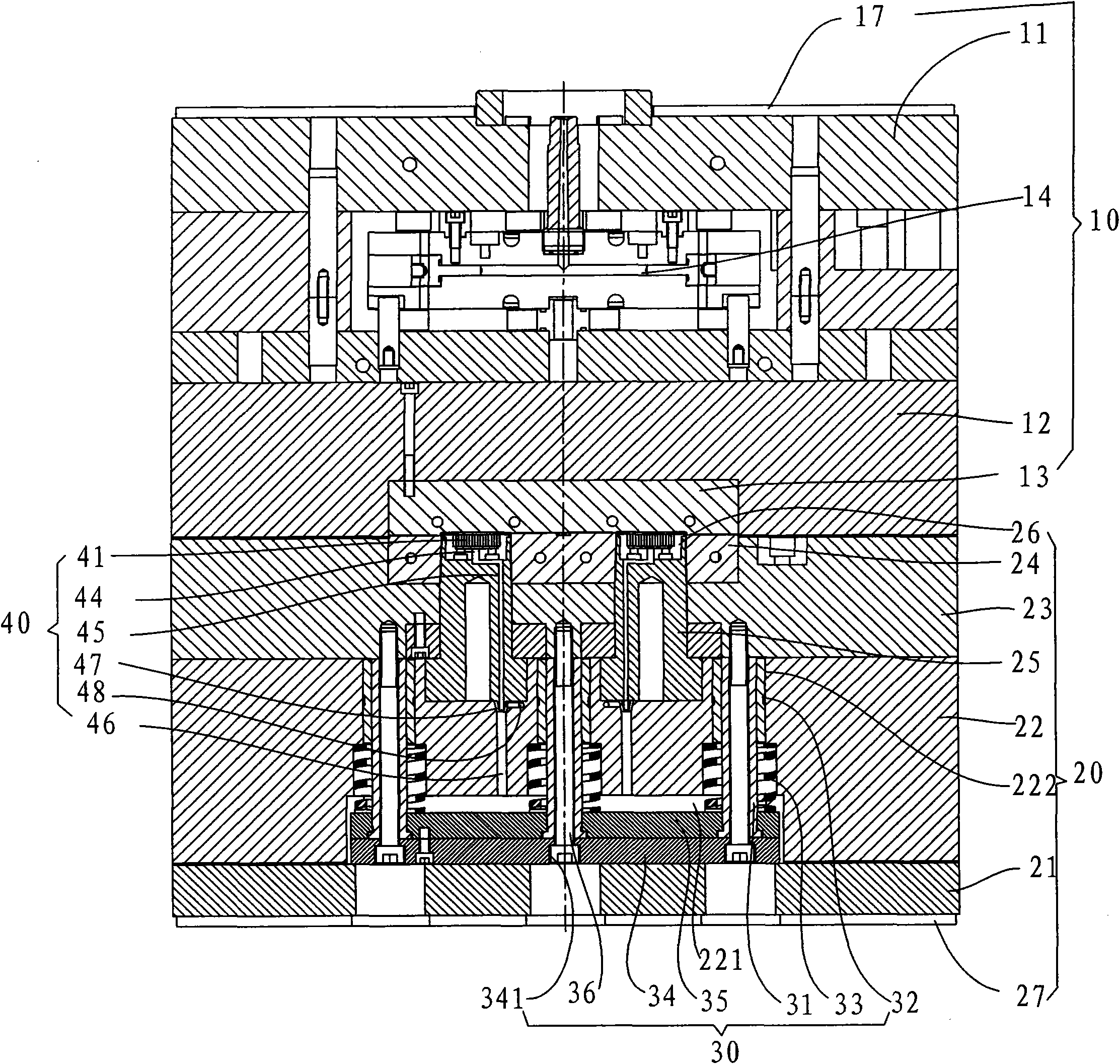

Tailor welded blank integral drawing forming device and method for large-scale curved surface part

The invention discloses a tailor welded blank integral drawing forming device and a method for a large-scale curved surface part, relates to the tailor welded blank integral forming device and method, and the problem that in the prior art, fractures exist in tailor welded blank integral forming is solved. The tailor welded blank integral drawing forming device comprises a male die, a blank holder, a female die and a liquid filling chamber; the portion between the blank holder and the female die is used for containing an unequal thickness tailor welded blank; the profile of the male die is provided with a male die groove which is consistent with the shape of a thick wall area where a sheet metal weld joint is located, blank holder grooves which are consistent with the shape of the thick wall area where the sheet metal weld joint is located are formed in an inner hole of the blank holder and the lower surface of the blank holder simultaneously, and the male die groove and the blank holder grooves are used for preventing the portion, perpendicular to the direction of the weld joint, of the thick wall area from deforming; or female die grooves which are consistent with the shape of the thick wall area where the sheet metal weld joint is located are formed in the upper surface of the female die and an inner hole of the female die and used for preventing the portion, perpendicular to the direction of the weld joint, of the thick wall area from deforming. The invention further provides a tailor welded blank integral drawing forming method of the large-scale curved surface part through using the tailor welded blank integral drawing forming device. The tailor welded blank integral drawing forming device and the method for the large-scale curved surface part are used for filling liquid, drawing and forming for the unequal thickness and symmetrical tailor welded blank through adopting uniform strength bearing design.

Owner:HARBIN INST OF TECH

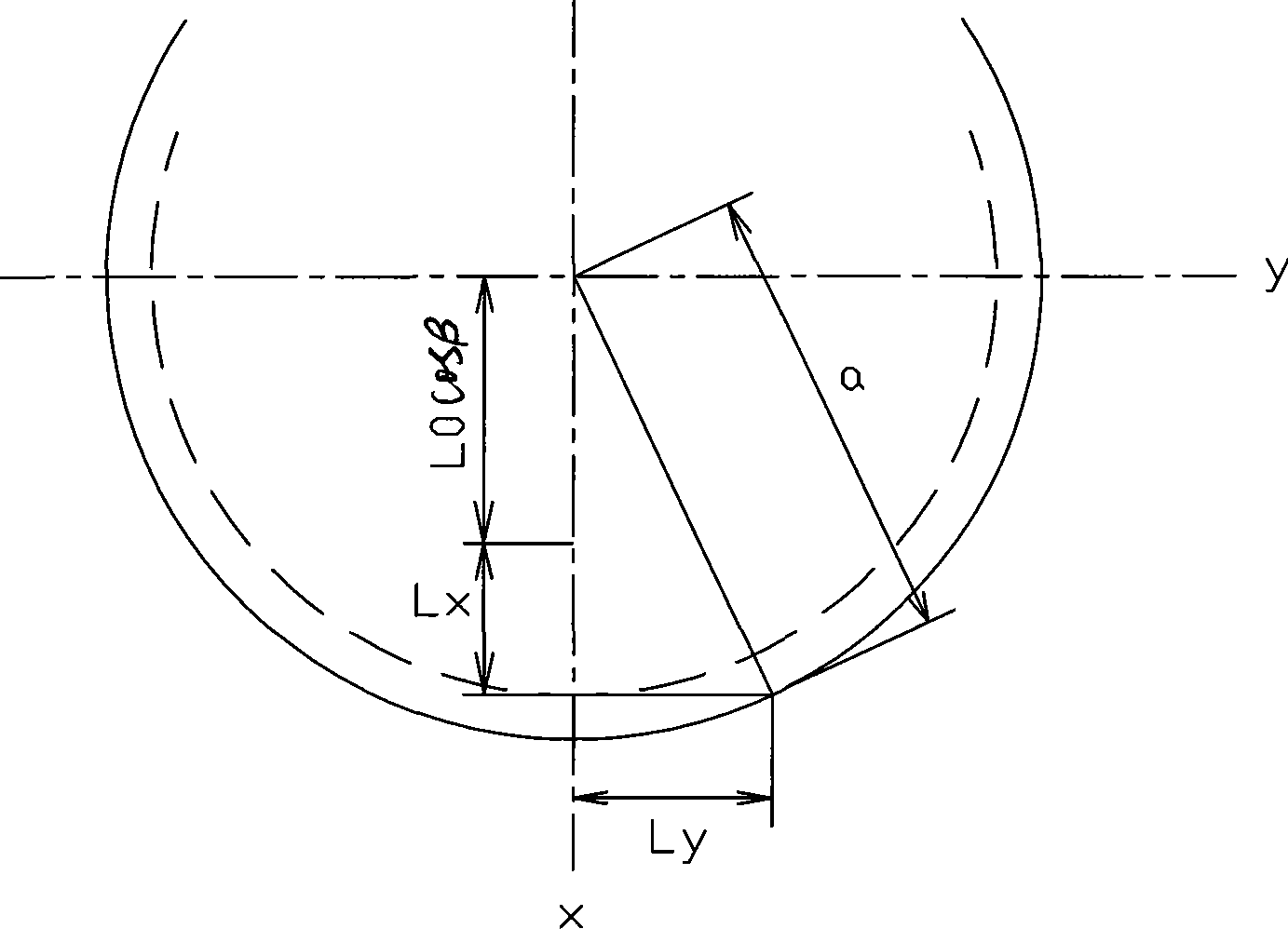

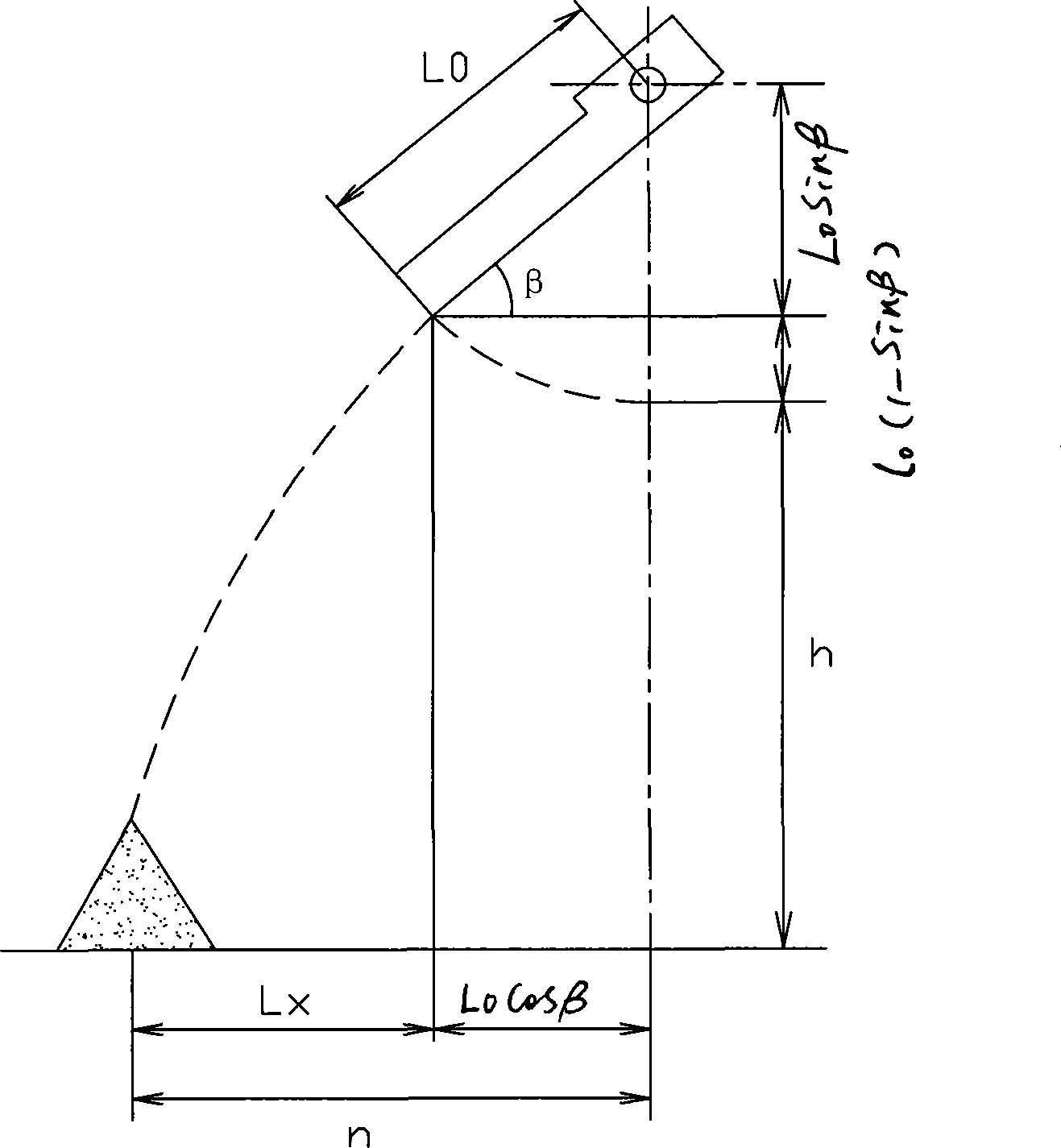

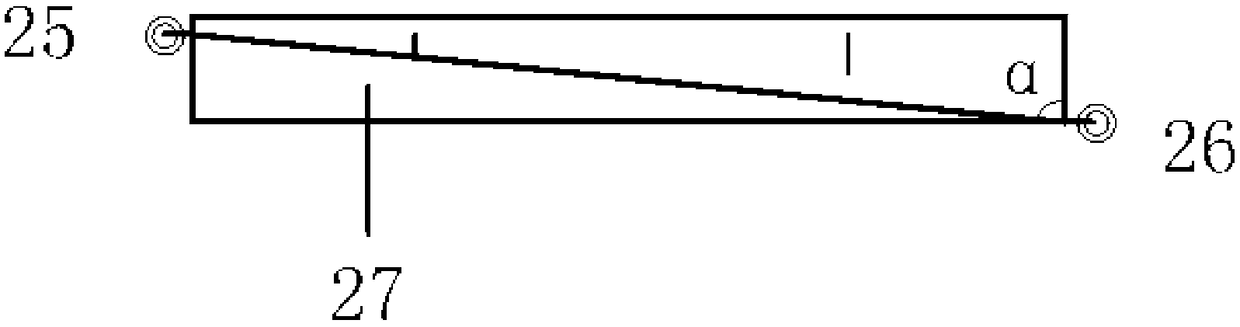

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

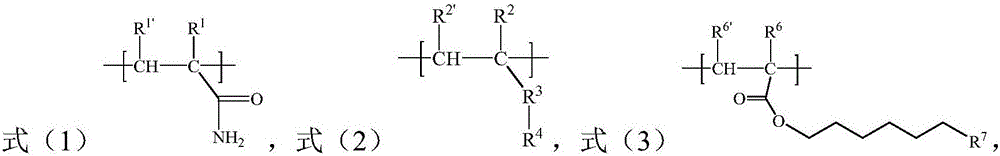

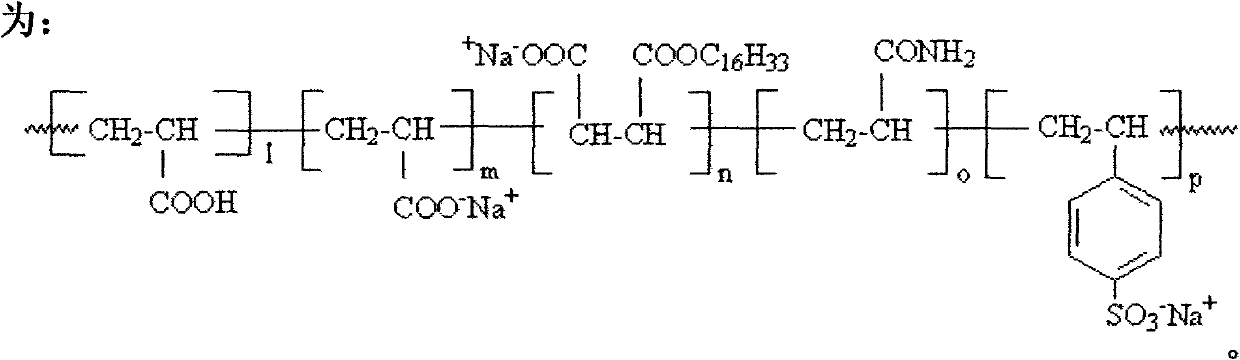

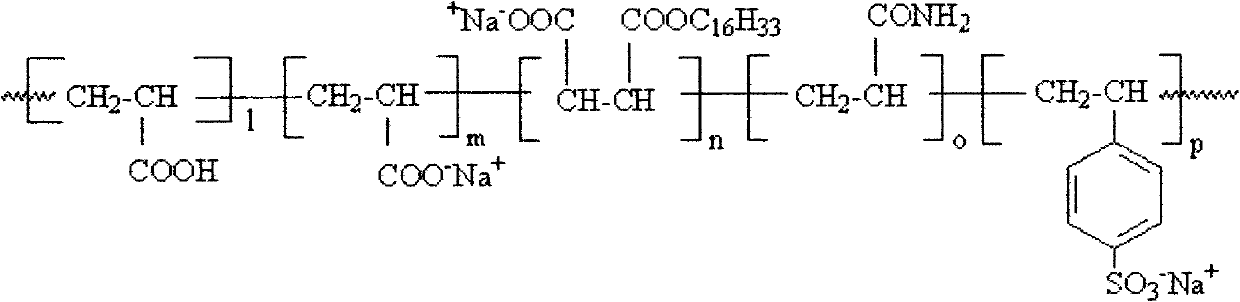

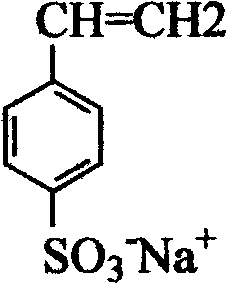

Drilling fluid additive composition application thereof and water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof

ActiveCN106634878AImprove pressure bearing capacityEnhance smoothness and densityDrilling compositionWell drillingDimer acid

The invention relates to the field of well drilling in petroleum industry, in particular to a drilling fluid additive composition application thereof and a water-based drilling fluid suitable for high-bearing-pressure plugging while drilling and application thereof. The composition contains a plugging agent, a nano blocking agent, a shear strength improving agent, a bionic wall fixing agent and a bionic shale inhibitor, wherein the plugging agent is a weak crosslinking copolymer, the content of a crosslinking structure in the weak crosslinking copolymer is 0.1-1% by weight, the nano blocking agent is modified silicon dioxide nano-particles, the shear strength improving agent is a dimer acid-organic amine copolymer, and the bionic wall fixing agent is carboxymethyl chitosan grafted with groups deviated from dopamine on main chains. The composition can make a water-based drilling fluid added with the composition as an additive produce an excellent plugging effect in the process of plugging while drilling through the matching effect of the plugging agent, the nano blocking agent, the shear strength improving agent, the bionic wall fixing agent and the bionic shale inhibitor.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Large-area ultrathin plastic part injection mould

ActiveCN102120357AImprove pressure bearing capacityExtend your lifeAir trappingPlastic injection molding

The invention relates to the field of plastic injection molding moulds, and particularly relates to a large-area ultrathin plastic part injection mould. The mould comprises a static mould and a movable mould, wherein the static mould is composed of a static mould fixing plate, and the static template and a static mould core, a movable mould composed of a movable mould fixing plate, a pad, a movable template and a movable template core; the static template is a thickened static template; the pad is a whole square thick steel block; an ejection device is a push board ejection device; an exhaustsystem comprises a group of exhaust plates at the bottom of a mould cavity, an exhaust groove at the periphery of the mould cavity and an exhaust channel connected with the exhaust plates and the exhaust groove; and a compressed air blow pipe leading the exhaust channel to generate negative pressure is arranged on the exhaust channel. The mould has high strength, the service life is up to 2 million times; the exhaust is smooth, and adverse phenomena, such as insufficient filling, burning, air trapping, heavy fused connecting wire and the like, are prevented, so that the purpose of large area of 1,429mm<2> and ultrathin of 0.18mm molding is achieved; and the extrusion or deformation of a product is effectively avoided by adopting the push board ejection device.

Owner:DONGMING XINGYE SCI TECH CO LTD

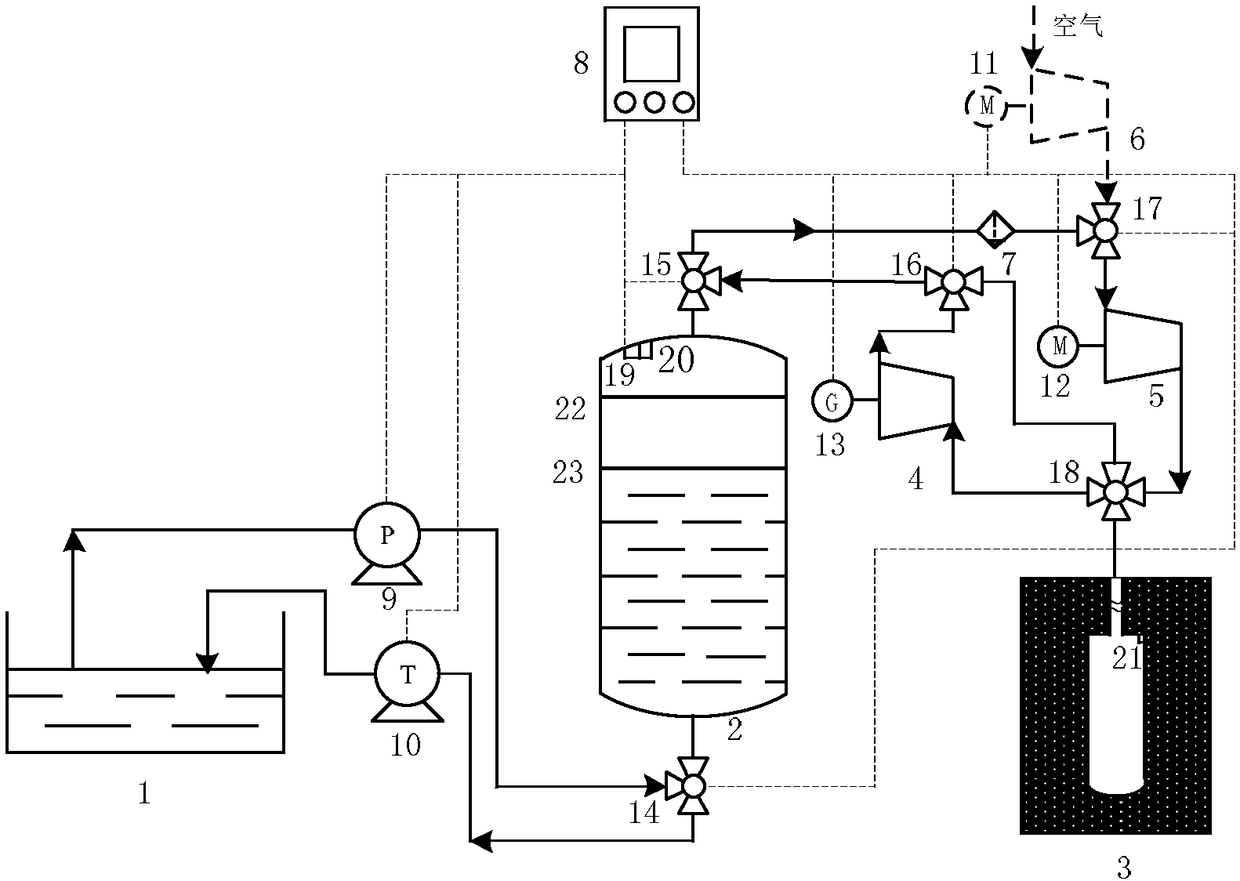

High pressure heat insulation gas storage pumping compressed air energy storage system

ActiveCN108571415AShorten the payback periodConstant flowHydro energy generationEngine componentsThermal energyThermal energy storage

The invention discloses a high pressure heat insulation gas storage pumping compressed air energy storage system. Air in a water-gas common-cabin passes a supercharger and then directly enters a gas storage vertical shaft, and pressure of gas in the water-gas common-cabin passes is kept stable and unchanged. Potential energy and heat of compressed air are stored at the same time because of the thermal storage effect of the gas storage vertical shaft. At the stage of energy releasing, output electric energy of the system comprises the following two parts: for one part, high pressure air with certain temperature in the vertical shaft enters a turbine to do work through expansion; for the other part, water in the water-gas common-cabin pushes the turbine to generate electric energy, and the energy density and operating efficiency of the system are improved. As a heat insulating layer is arranged outside the gas storage vertical shaft, the air is high in temperature and flows through the turbine and is expanded, then the temperature is reduced, the fact that the temperature in the water-gas common-cabin is low is guaranteed, and damage to the turbine caused by temperature rise of wateris avoided. The system stores high pressure air through the gas storage vertical shaft, greatly reduces the investment cost of a high pressure container, shortens the payback time, and improves the operating economy.

Owner:XI AN JIAOTONG UNIV

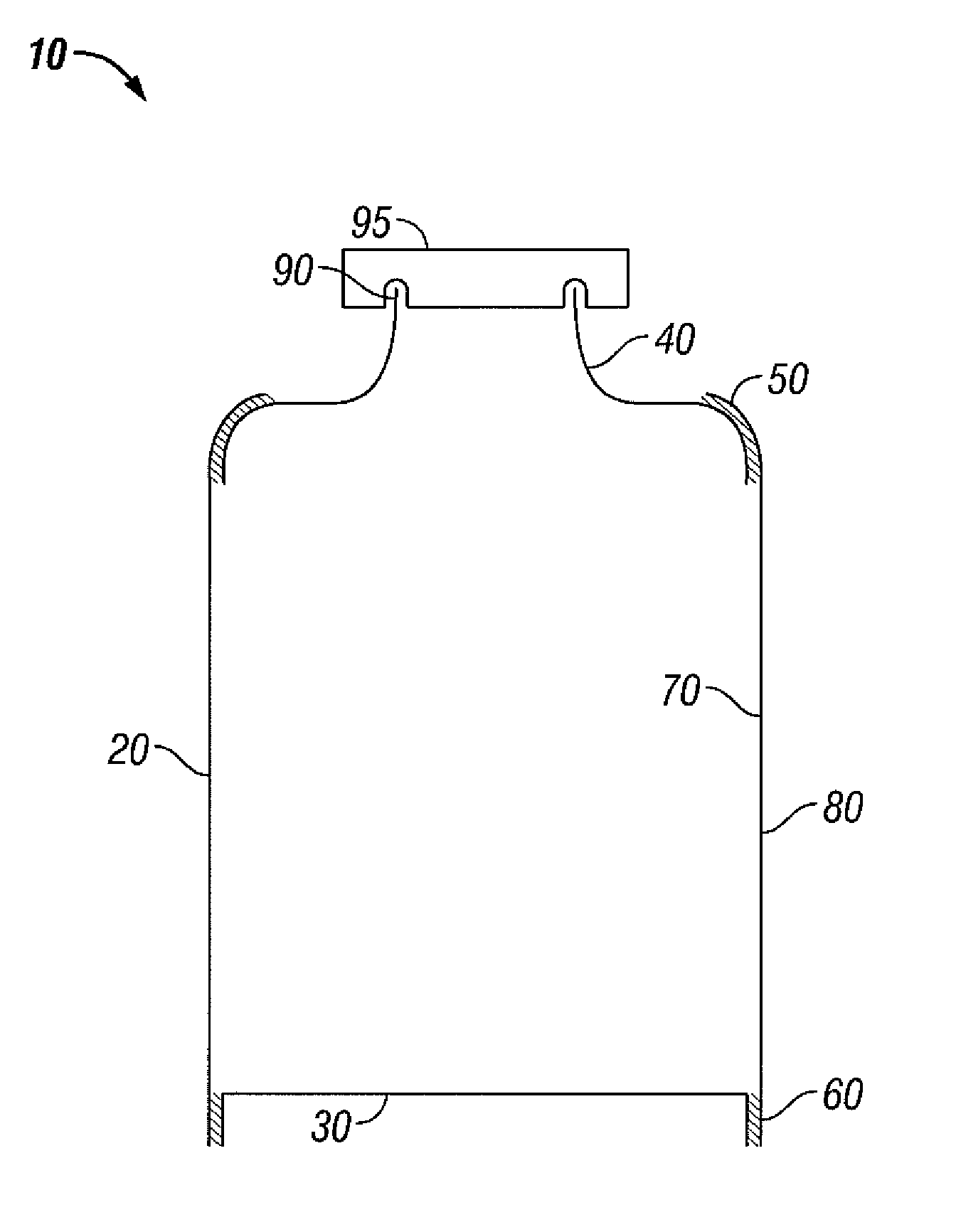

Tubular, especially can-shaped, receptacle for the accommodation of fluids, a method of manufacture, and use

ActiveUS7364047B2Improve pressure bearing capacityImprove stabilityBottlesLarge containersEngineering

Tubular, especially can-shaped, receptacle for the accommodation of fluids, especially drinks, with a tubular body and a base and top section attached to this, wherein the top section is constructed in the shape of a shoulder and is suitable for attaching a closure device, especially a resealable one. The shoulder-shaped top section is at least partially enclosed, especially in the shape of a shoulder, by an upper edge of the tubular body and sealed with this.

Owner:HUHTAMAKI RONSBERG ZWEIGNIEDERLASSUNG DER HUHTAMAKI DEUT

New method for forming manual well wall in oil and gas well by water-absorbing resin

InactiveCN102134979APrevent leakageEasy to transformDrilling compositionSealing/packingFresh water organismVolumetric Mass Density

The invention relates to a new method for forming manual well walls in an oil and gas wells by water-absorbing resin. In the method, the water-absorbing resin is mixed with freshwater or saline to form a well completion fluid or a workover fluid; the water-absorbing resin is starch-type water-absorbing resin or cellulose-type water-absorbing resin or synthetic water-absorbing resin and comprises the following components by weight percentage: 1 to 2% of water-absorbing resin, 0.2 to 0.5% of water-absorbing initiator, 0.2 to 0.5% of colloid protective agent, and the remaining quantity of water or monovalent saline. The density of the water-absorbing resin well-completion fluid or the workover fluid can be adjusted by adding monovalent salt NaCl or KCl; the solution apparent viscosity can be controlled by adjusting the concentration of the water-absorbing resin; and the dosage of the well completion fluid or the workover fluid can be designed according to the volume of a shaft. In the method, the physical and the chemical changes can occur under the high temperature to form a manual well wall, namely a gelatine temporary plugging layer; therefore, the bearing capability of the high-and low-pressure stratum can be effectively improved; the leakage of the well completion fluid or the workover fluid can be prevented at the producing layer, the operation safety and the capacity of the oil and gas well can be ensured, the construction technology is simple, and the cost is relatively low.

Owner:CHINA NAT OFFSHORE OIL CORP +3

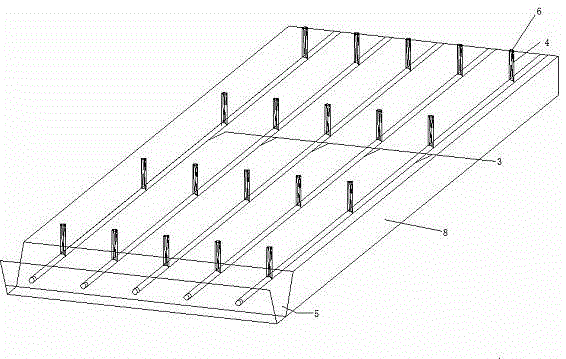

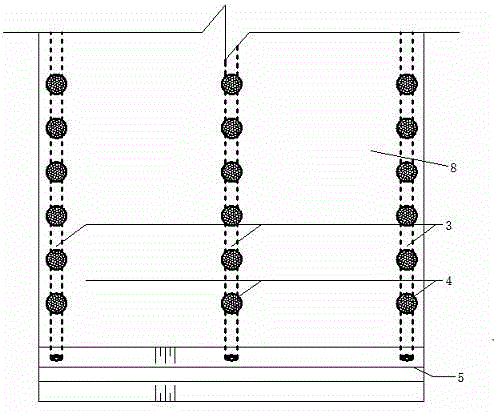

Horizontal and vertical combined underdrainage device for improving interlayer soil of coastal mud flat reclamation area farmland and drainage method thereof

InactiveCN104145552AImprove pressure bearing capacityExtended service lifeConstructionsSoil drainageSubsurface drainageAlkali soil

The invention provides a horizontal and vertical combined underdrainage device for improving interlayer soil of coastal mud flat reclamation area farmland. According to the device, coastal mud flat saline-alkaline land is provided with salt leaching channels, drainage bodies, concealed water flow collection and water suction conduits and open drainage ditches. The concealed water flow collection and water suction conduits are buried under the coastal mud flat saline-alkaline land according to the line spacing of 17-25 meters. The salt leaching channels are respectively provided with a vertical shaft every 4-6 meters in the length direction of the concealed water flow collection and water suction conduits, and the drainage bodies are arranged in the vertical shafts. The water inlet ends of the concealed water flow collection and water suction conduits are higher than the water outlet ends of the concealed water flow collection and water suction conduits, and the water outlet ends are connected with the open drainage ditches. The invention further provides a combined drainage method. According to the method, salt in the soil of the coastal mud flat saline-alkaline land is leached and flows into the vertical shaft type salt leaching channels along with water flow, and the concealed water flow collection and water suction conduits collect the water flow in the salt leaching channels and guide the water flow into the open drainage ditches. The device has the advantages of being reasonable in structure, convenient to construct and install, low in cost, short in improvement period, fast in effect, capable of being widely applied and popularized in the areas with the irrigation and drainage conditions and especially suitable for improving the highly-saline soil of the coastal mud flat reclamation area.

Owner:YANGZHOU UNIV

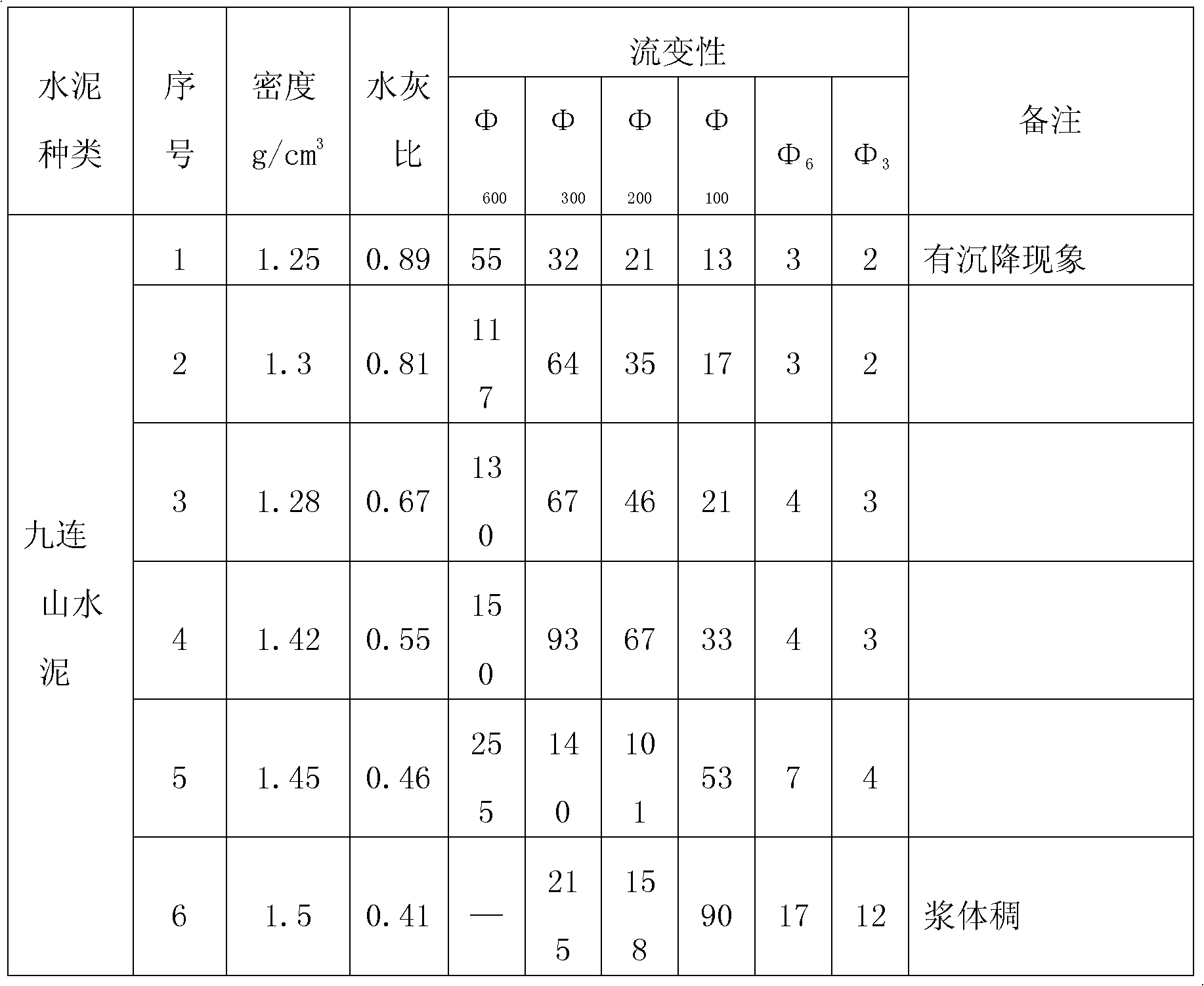

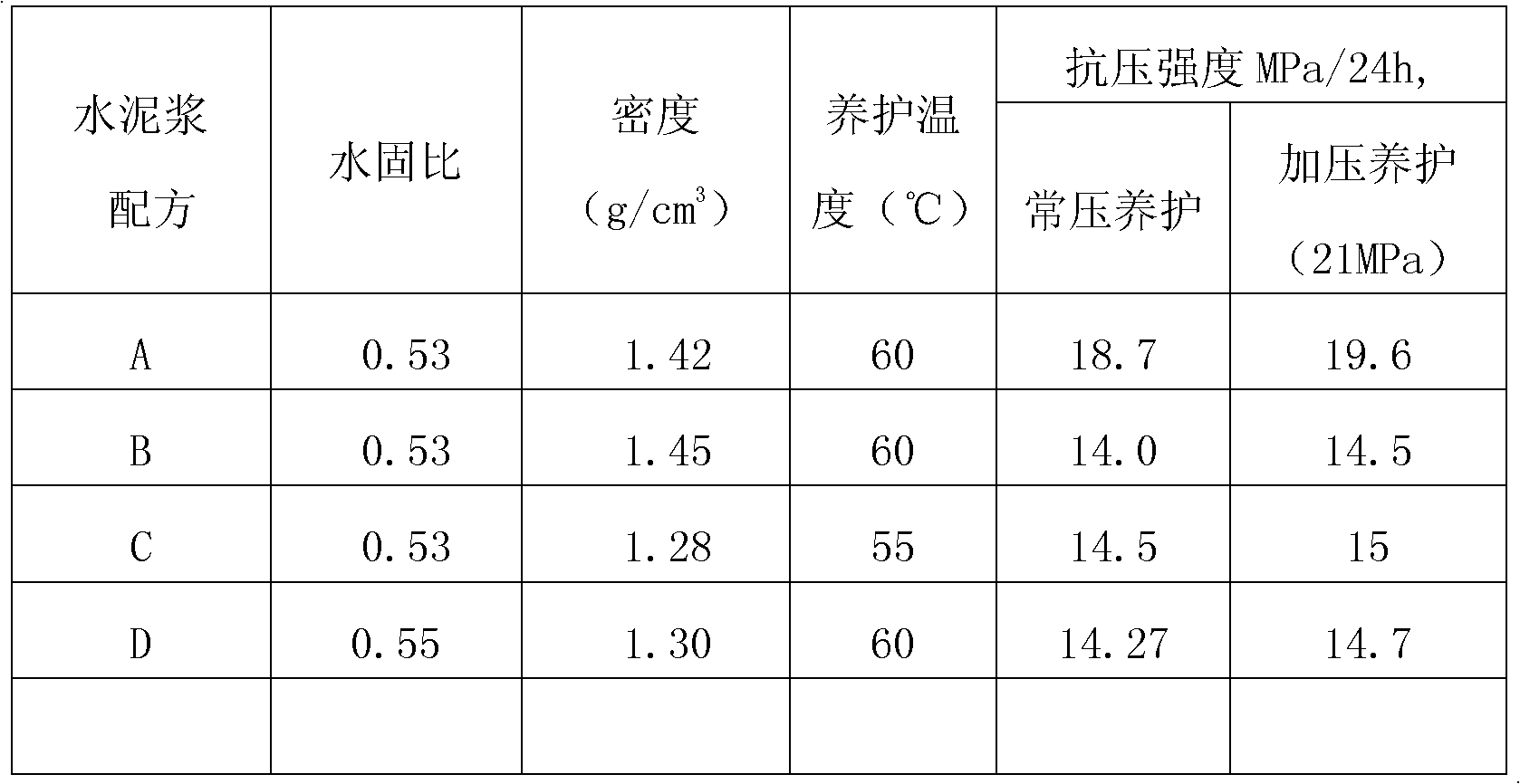

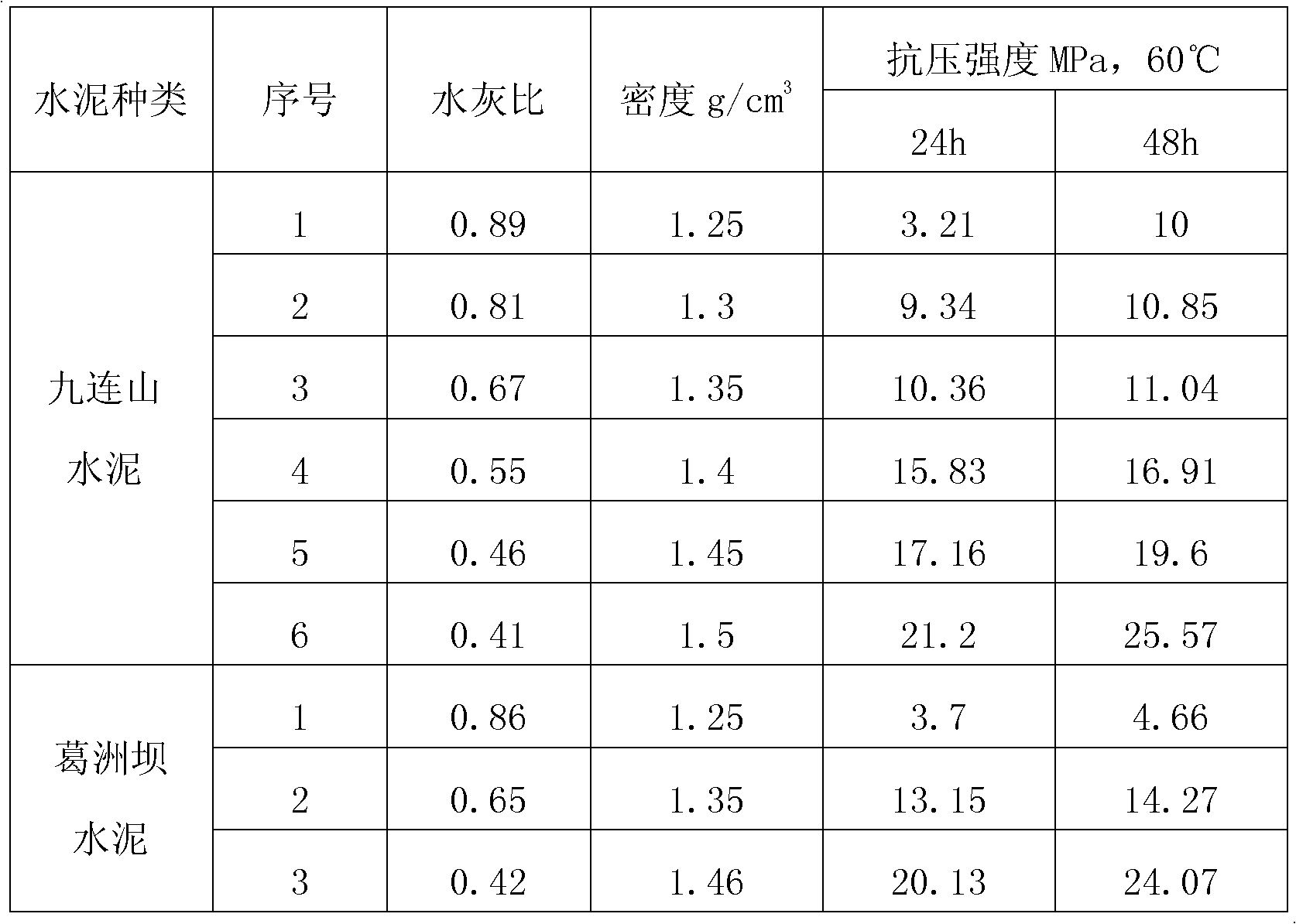

Low-density high-strength leak-resistant slurry method for sealing leakage producing formation

ActiveCN101870862AImprove mechanical propertiesImprove the pressure bearing capacity of the formationDrilling compositionCement slurryVolumetric Mass Density

The invention belongs to the technical field of oilfield cementing, in particular to a low-density high-strength leak-resistant slurry method for sealing leakage producing formation in a well drilling area. The method is characterized in that: cement, micro silicon, hollow micro spheres, a fluid loss agent, an expanding agent, and water are mixed in a certain ratio according to the grain composition principle, and the mixture is mixed with the water in a certain ratio, wherein the ratio of water to solid is 0.67 to 0.46, the cement slurry density is between 1.25 and 1.45g / cm<3>, and the cement slurry thickening time is between 110 and 240 minutes. The invention provides a low-density high-strength leak-resistant slurry method for sealing the leakage producing formation, which realizes balanced pressure well cementation and solves the problems of serious leaker cementing quality and cement top in a bed of interest.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG

Sandwich layer forging die and preparation method of forging die sandwich layer surfacing

ActiveCN104741499AExtended service lifeImprove performanceArc welding apparatusForging/hammering/pressing machinesSoft materialsHigh pressure

The invention discloses a sandwich layer forging die and a preparation method of forging die sandwich layer surfacing. The sandwich layer forging die is used for surfacing a layer of sandwich layer soft welding material which is better in plasticity and lower in yield strength than a cast steel substrate and a double-metal gradient surfacing material between the cast steel substrate and the double-metal gradient surfacing material; the preparation method of the forging die sandwich layer surfacing comprises the following steps of taking cast steel as the cast steel substrate, and welding a sandwich layer soft material on a substrate layer; surfacing a transition layer material on a substrate of a sandwich layer welded, welding and covering all sandwich materials to form a surfacing transition layer; welding a high-temperature wearing layer material; tempering to distress after the completion of the welding, and then mechanically processing to obtain a mould. The sandwich layer forging die provided by the invention is long service life and high in loading capacity of the cast steel substrate. According to the method provided by the invention, the critical bottleneck problems that the forging die is low in life and the die is high in manufacturing cost can be solved thoroughly, the die forging forming of various materials can be supported at high temperature and high pressure, and a brand new manufacturing method can be provided for forging die manufacturing.

Owner:CHONGQING UNIV +2

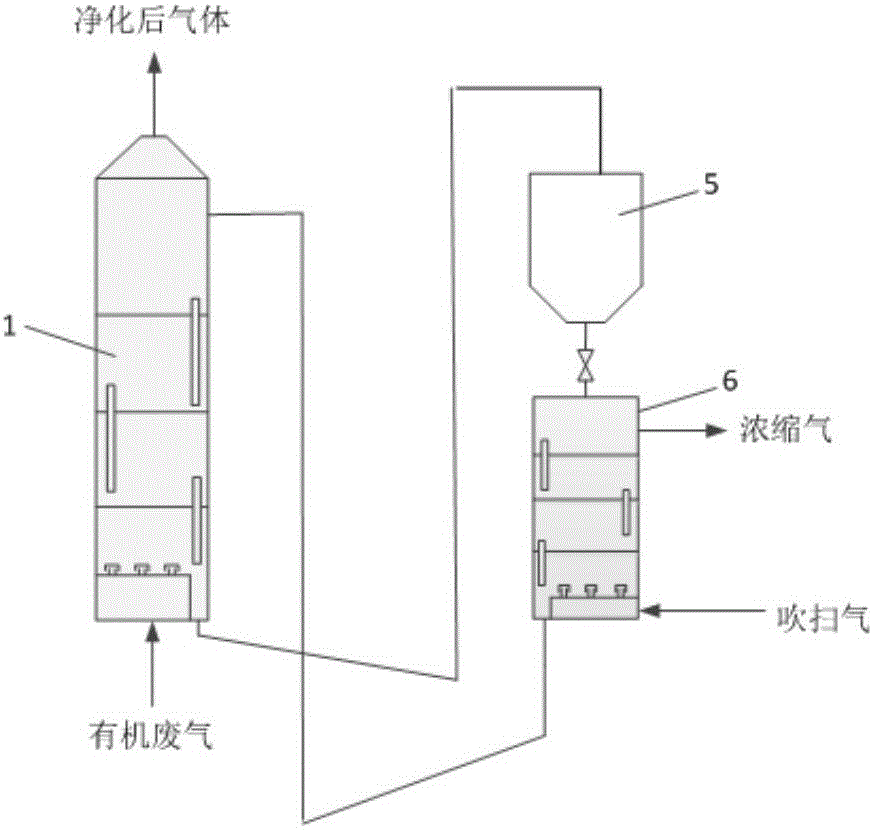

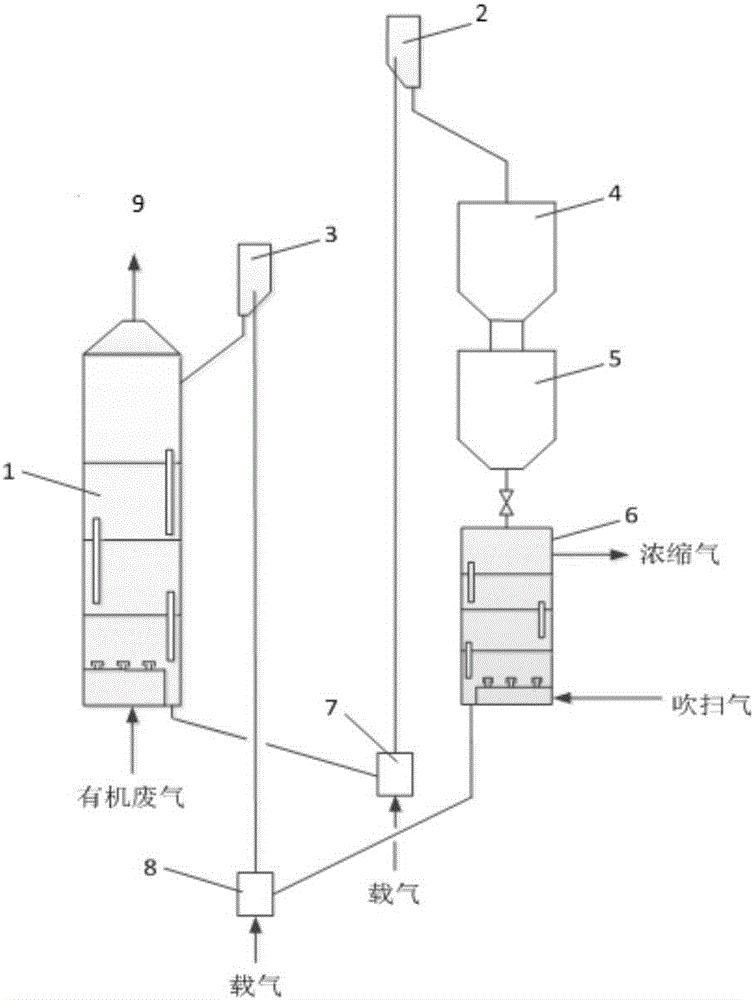

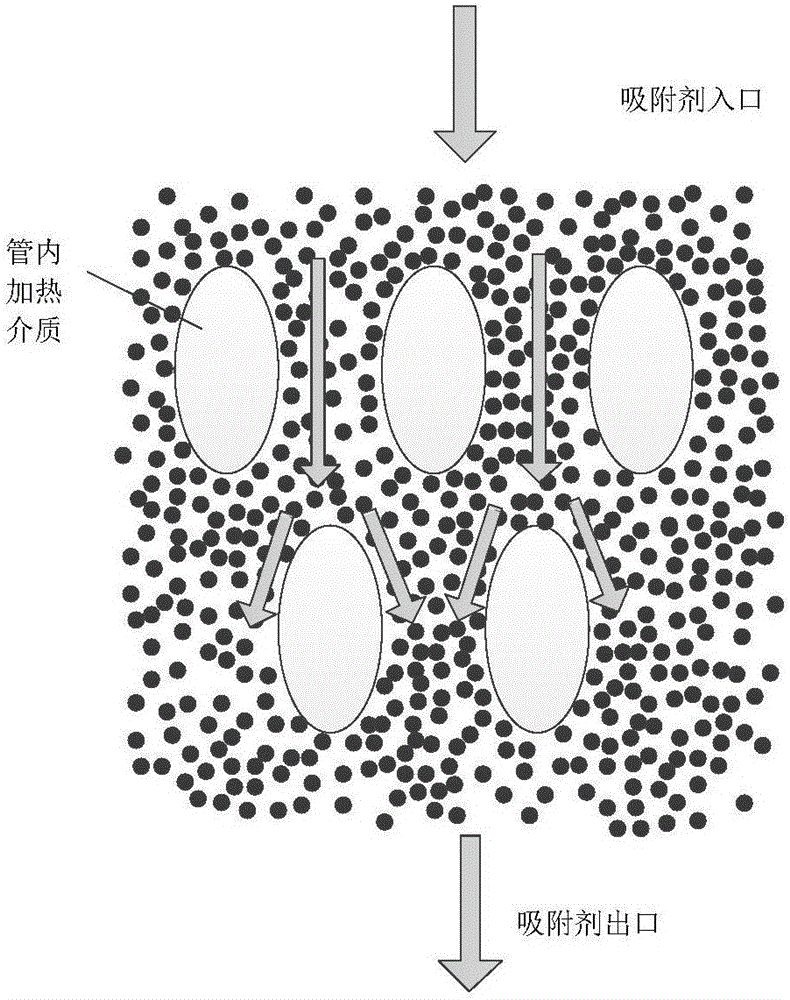

Double-fluidized bed adsorption and desorption device and method for continuous treatment of organic waste gas

InactiveCN106390681AEnhance heat and mass transferAvoid heat buildupGas treatmentDispersed particle separationHigh concentrationDesorption

The invention relates to the field of organic waste gas treatment and resource utilization and particularly relates to a double-fluidized bed adsorption and desorption device and a method for continuous treatment of organic waste gas. The device provided by the invention comprises a fluidized bed adsorption device (1), a preheater (5) and a fluidized bed desorption device (6), wherein an adsorbent outlet at the bottom of the fluidized bed adsorption device (1) is connected with a feed port of the preheater (5); a discharge port of the preheater (5) is connected with a feed port of the fluidized bed desorption device (6); and a solid outlet of the fluidized bed desorption device (6) is connected with a solid inlet of the fluidized bed adsorption device (1). In the invention, continuous treatment of high-concentration organic waste gas can be realized, heat accumulation can be prevented, and the problems such as bed fire and explosion caused by the dissipation failure of the reaction heat due to the excessively high concentration of the high-concentration organic waste gas are avoided; and moreover, the desorption effect of the adsorbent and the exit concentration of concentrated VOC gas are improved, and the catalytic combustion or solvent recycling is facilitated.

Owner:东莞市佳明环保科技有限公司 +1

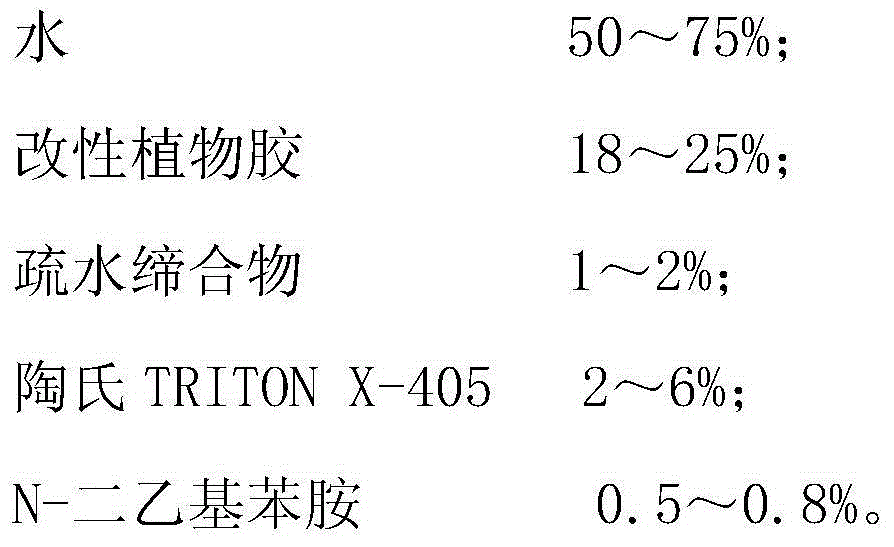

Temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and preparation method thereof

ActiveCN102358771AImprove temperature resistanceMeet construction requirementsDrilling compositionFluid LeakStructure type

The present invention provides a temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and a preparation method thereof. The gel leak-stopping agent of the present invention has the following advantages that: the gel leak-stopping agent has extra-wide temperature adaptability, can adapt to a temperature range of 25-180 DEG C, and can meet requirements of oil field construction; the gel leak-stopping agent has rapid dissolution rate, and forms the structure type gel with good shear thinning behavior after dissolving, wherein the structure type gel is the liquid whichcan be pumped and flow; the gel leak-stopping agent does not require cross-linking; the real fluid leak-stopping is realized; the construction is convenient; the product is completely dissolved in water, no precipitate and flocculent insoluble matter are generated during the whole process, no insoluble matter is generated after the product is degraded, such that the flow back is easy or the flow back is not required, the reservoir is not damaged; the product is safe and environmental protection, and is synthesized by the multi-stage initiation, such that the product conversion rate is high, the stability is good, no toxic damage is generated to the stratum, the production layer can be protected.

Owner:北京爱普聚合科技有限公司

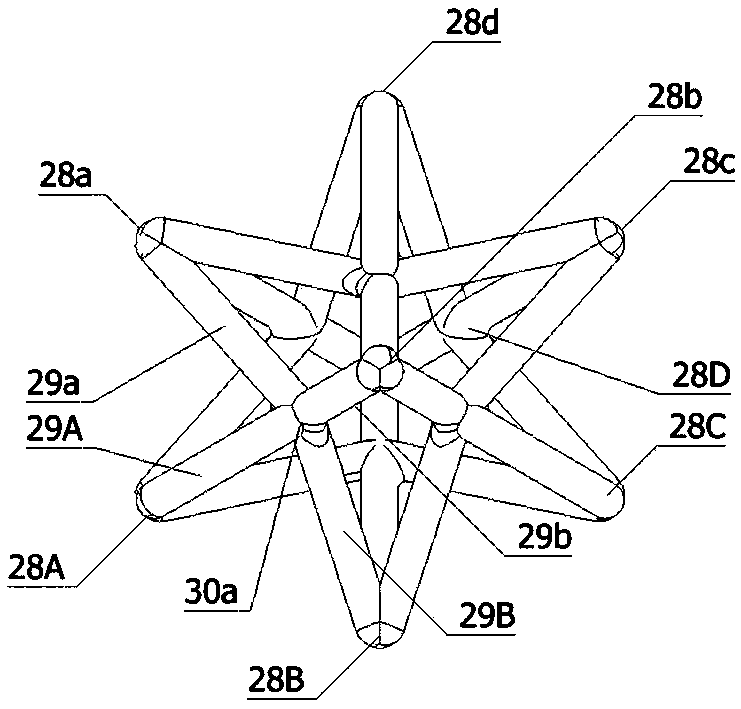

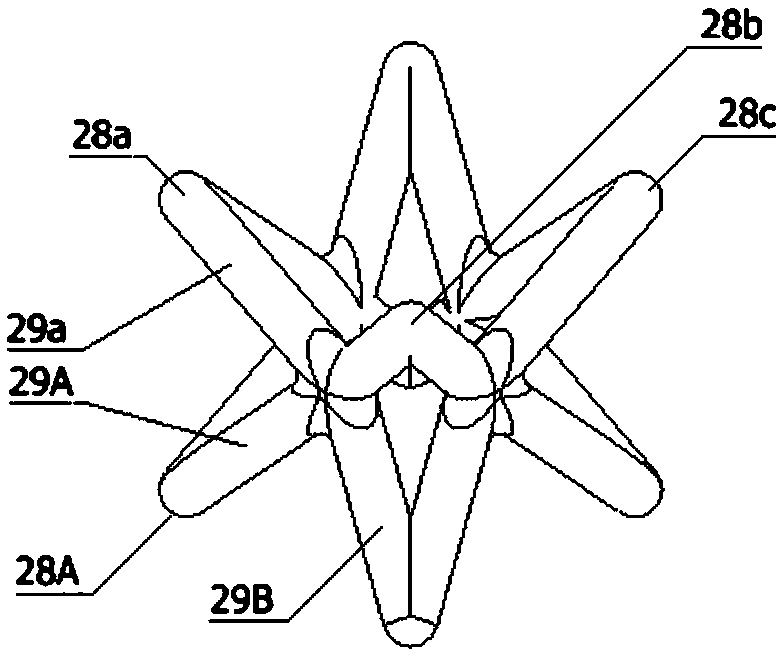

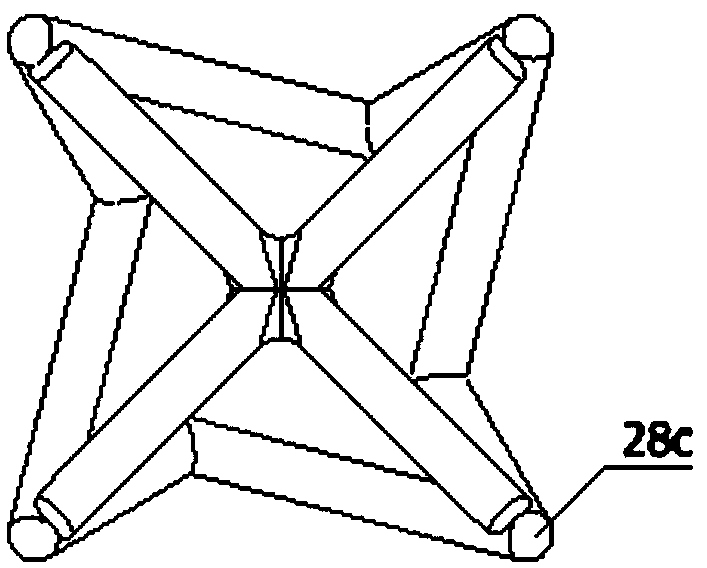

Multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure and pressure bearing plate thereof

PendingCN108386467AImprove ultimate load capacityImprove deformation abilityRubber-like material springsShock absorbersDot matrixPlastic materials

The invention belongs to the field of pressure resistance or pressure bearing or supporting structures and particularly relates to a multi-face inner-sunken pyramid-shaped negative poisson ratio spacedot matrix structure and a pressure bearing plate thereof. Based on the multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure, the pressure-resistant or pressure-bearing structure made of an elastic material and used for supporting can be used, the overall pressure-resistant and pressure-bearing capacity is improved, and the structural damage is avoided; and based on the multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure, the pressure-bearing structure (bridges, flat plates and the like) made of an elastic material or aplastic material and provided with the two ends being constrained can be used, in the middle pressure bearing process, auxiliary supporting lines located on the upper and lower supporting faces can resist thinning of the section of the pressure-bearing structure, breaking of the pressure-bearing structure is prevented, and the pressure-bearing capacity is improved; and based on the multi-face inner-sunken pyramid-shaped negative poisson ratio space dot matrix structure, a protection reinforcing and buffering structure made of a plastic material can be used, the characteristics of small weightand high strength are achieved, and the problems of instantaneous impact damage, reduction of follow-up bearing capacity of a buffering structure and the like are effectively avoided.

Owner:NAVAL UNIV OF ENG PLA

Leak protection plugging agent used during drilling for remarkably enhancing plugging effect

InactiveCN102093853AGood plugging effectHigh blocking rateDrilling compositionCross-linkWell drilling

The invention discloses a leak protection plugging agent used during drilling for remarkably enhancing plugging effect. The plugging agent comprises the following components in percentage by weight: 16.0 to 17.0 percent of 2-methyl-2-acrylamidopropanesulfonic acid, acrylic acid and acrylamide, 80.0 to 82.0 percent of water and the balance of initiator and cross linking agent. The effect of plugging along with drilling and leakage can be achieved, the plugging agent has high plugging rate and high loading capacity, and the plugging effect of well drilling is remarkably enhanced.

Owner:武侯区巅峰机电科技研发中心

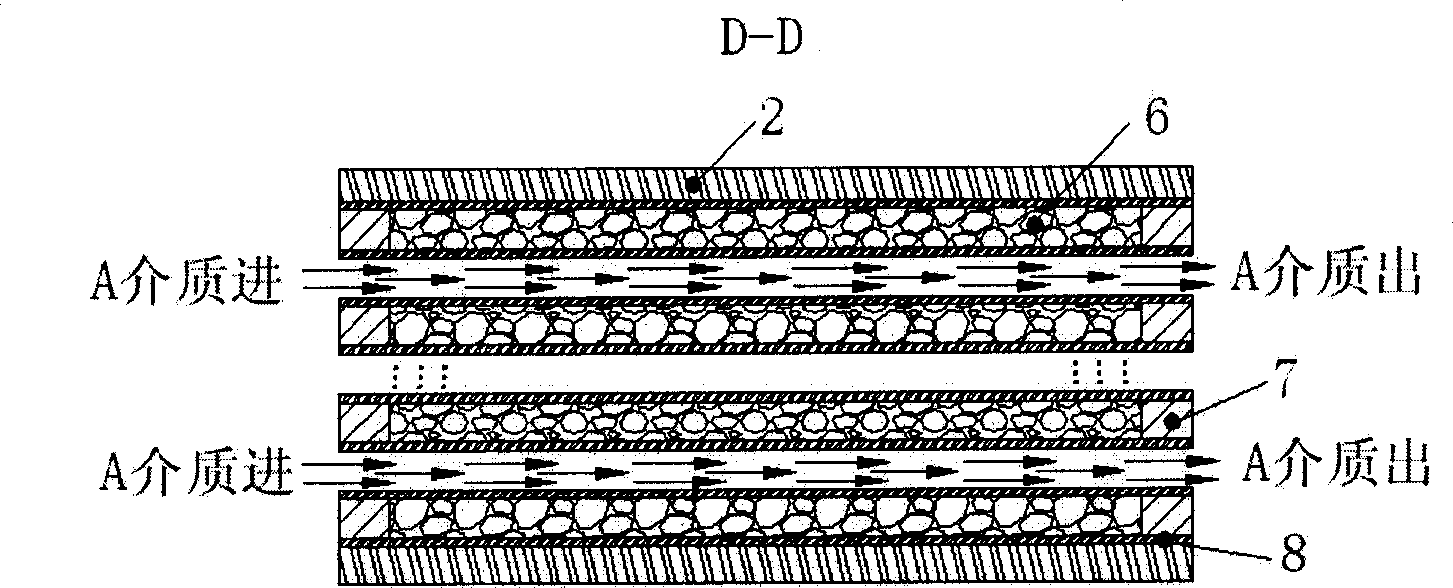

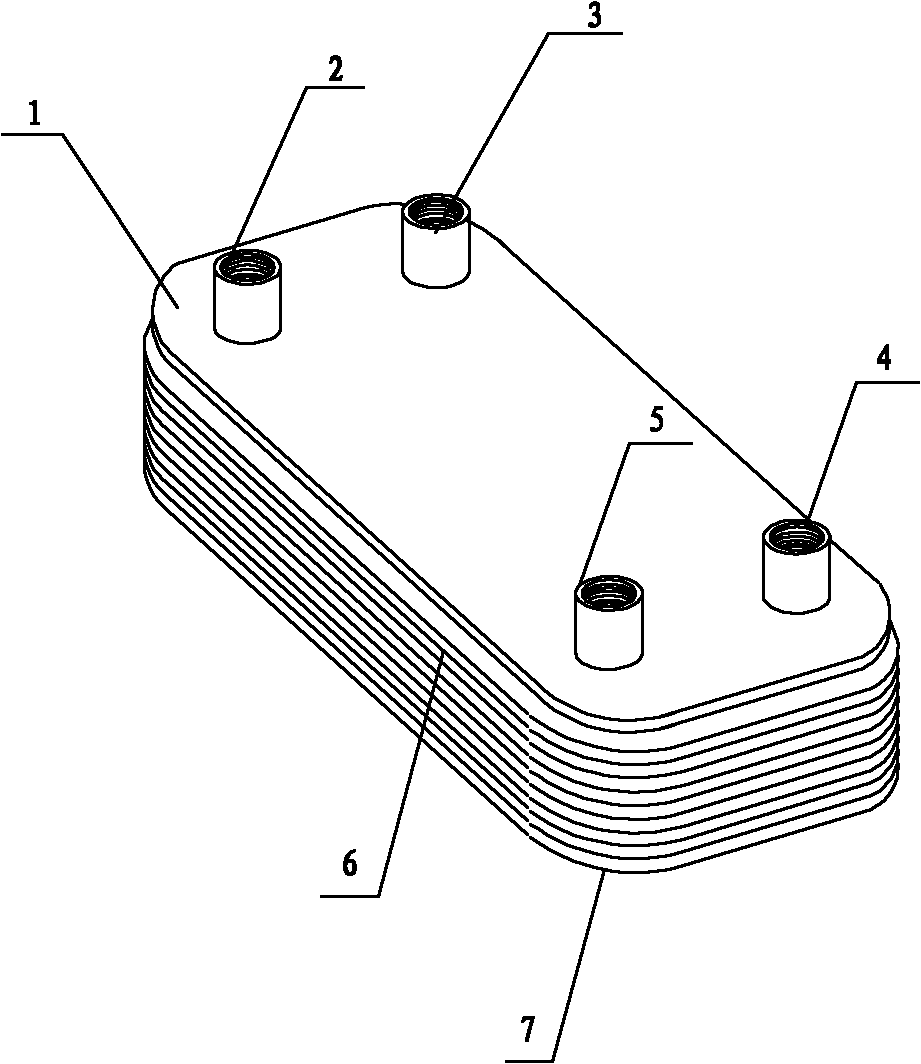

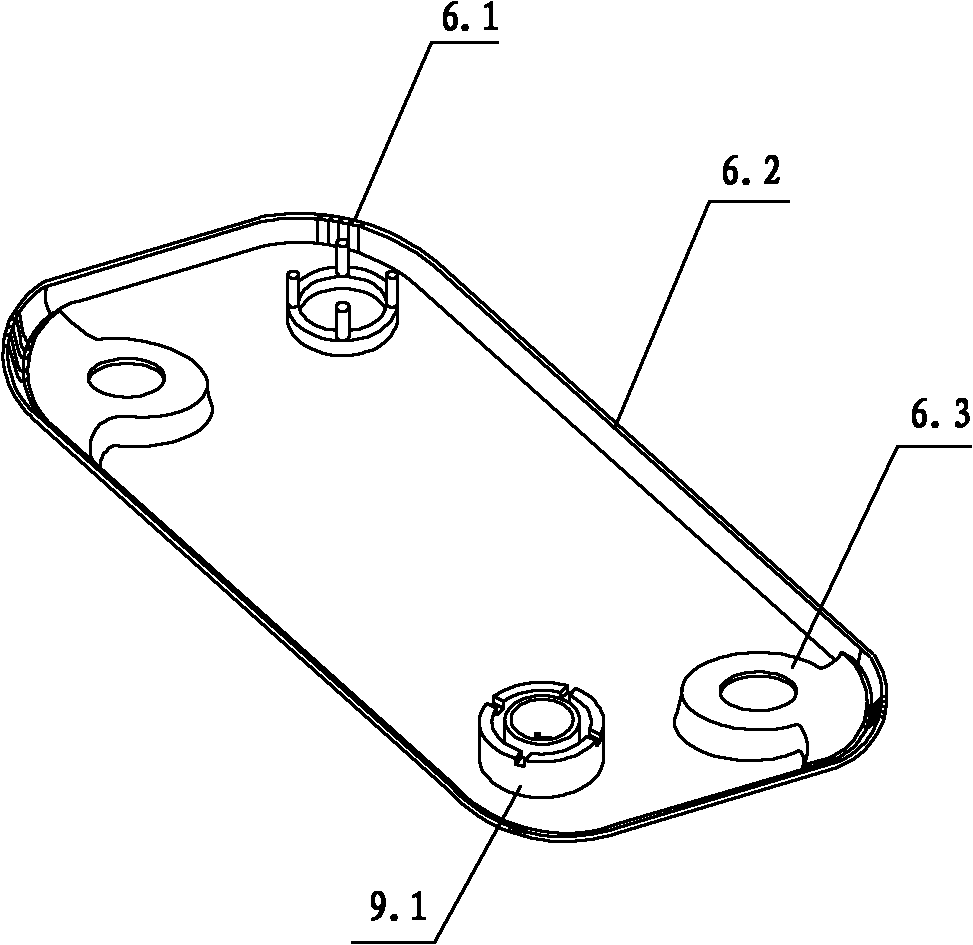

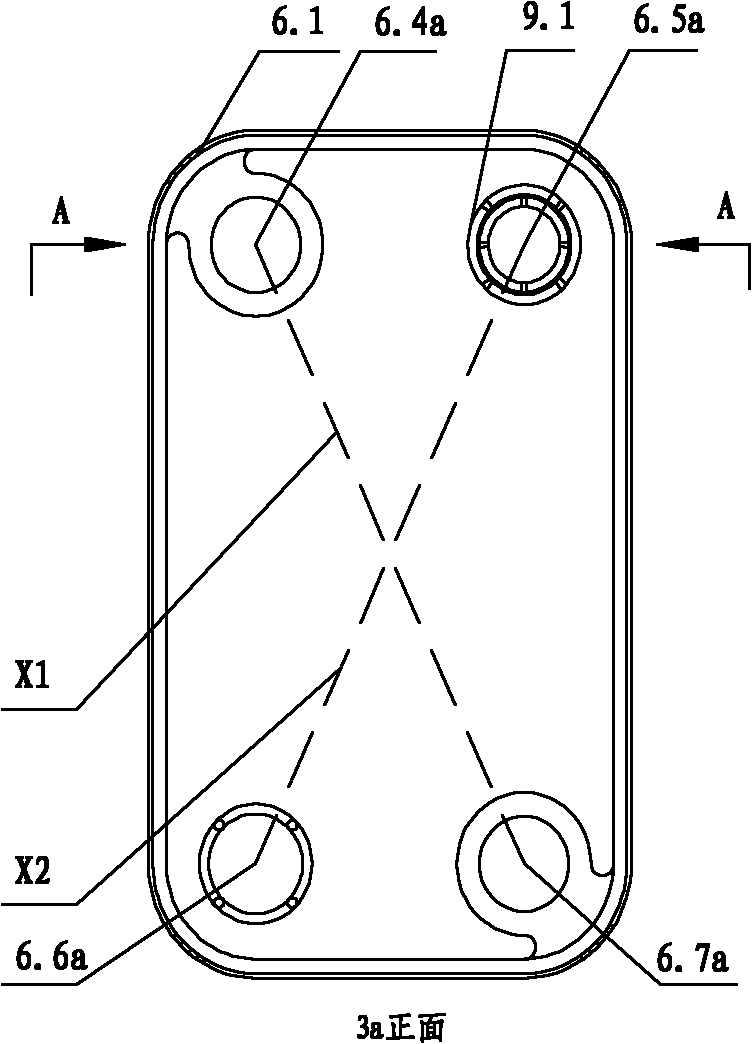

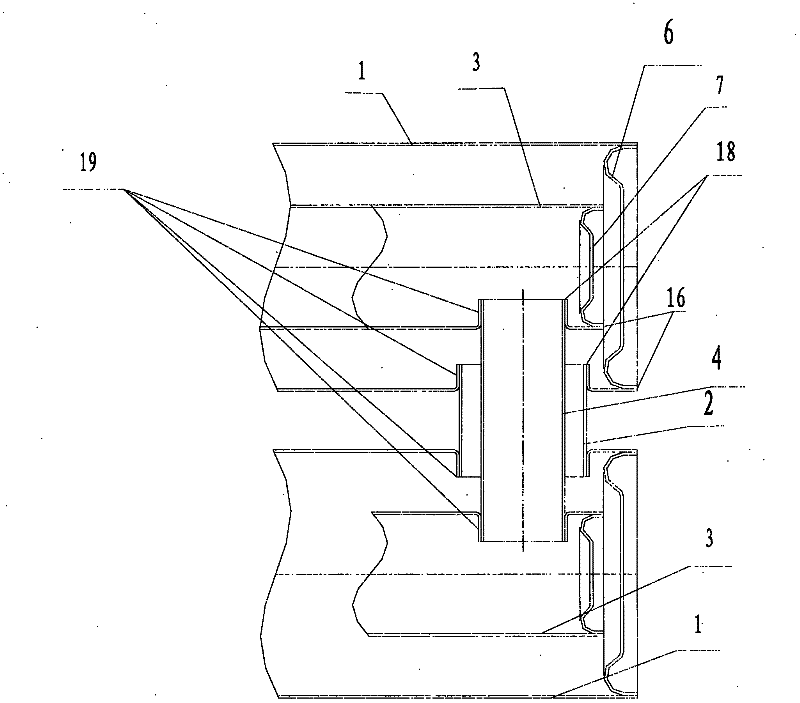

Laminated board fin structured heat exchanger with medium equipartition device

ActiveCN102042772AEvenly distributedImprove sealingEvaporators/condensersHeat exchanger casingsEngineeringMechanical engineering

The invention relates to a laminated board fin structured heat exchanger with a medium equipartition device. An angle hole plane on a first diagonal is arranged on a high plane, an angle hole plane on a second diagonal is arranged on a low plane, and bosses surrounding the first angle hole and the third angle hole are formed at the peripheries of the angle hole planes of a first angle hole and a third angle hole; the angle hole planes of the first angle hole and the third angle hole on the first diagonal on a second baffle are arranged on the low plane; the angle hole planes of a second anglehole and a fourth angle hole on the second diagonal are arranged on the high plane; the bosses surrounding the second angle hole and the fourth angle hole are formed at the peripheries of the angle hole planes of the second angle hole and the third angle hole; the equipartition devices are arranged at the peripheries of the upper surfaces of the second angle hole on the second diagonal of the first baffle and the first angle hole on the first diagonal of the second baffle; ring-shaped jacking columns are arranged at the peripheries of the upper surfaces of the fourth angle hole on the second diagonal of the first baffle and the third angle hole on the first diagonal of the second baffle; and the heights of the equipartition devices and the ring-shaped jacking columns are equal to those ofthe inner sides of the bosses.

Owner:WUXI HONGSHENG HEAT EXCHANGER MANUFACTURING CO LTD

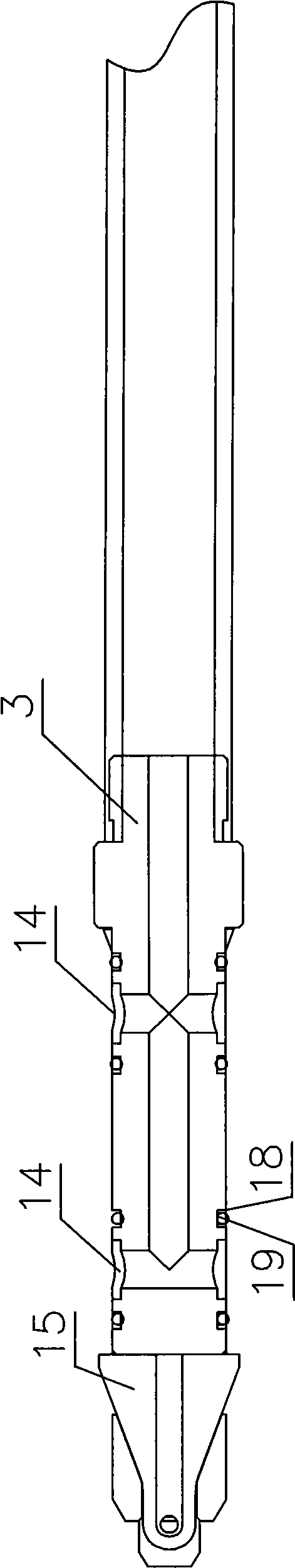

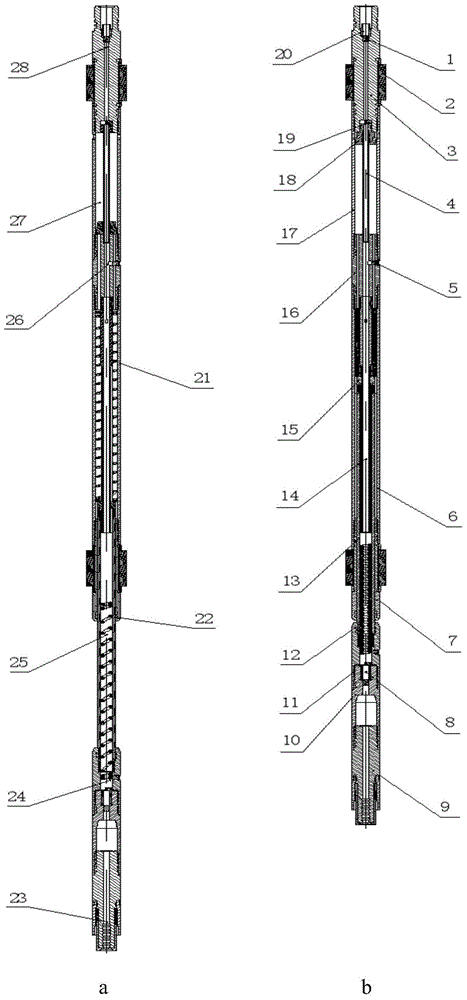

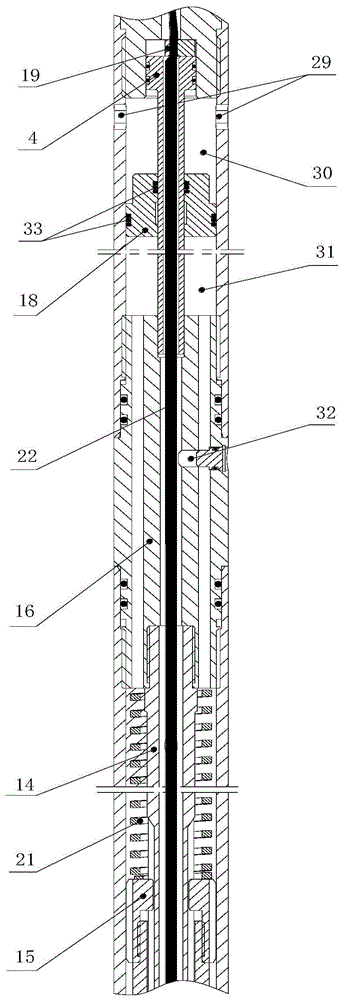

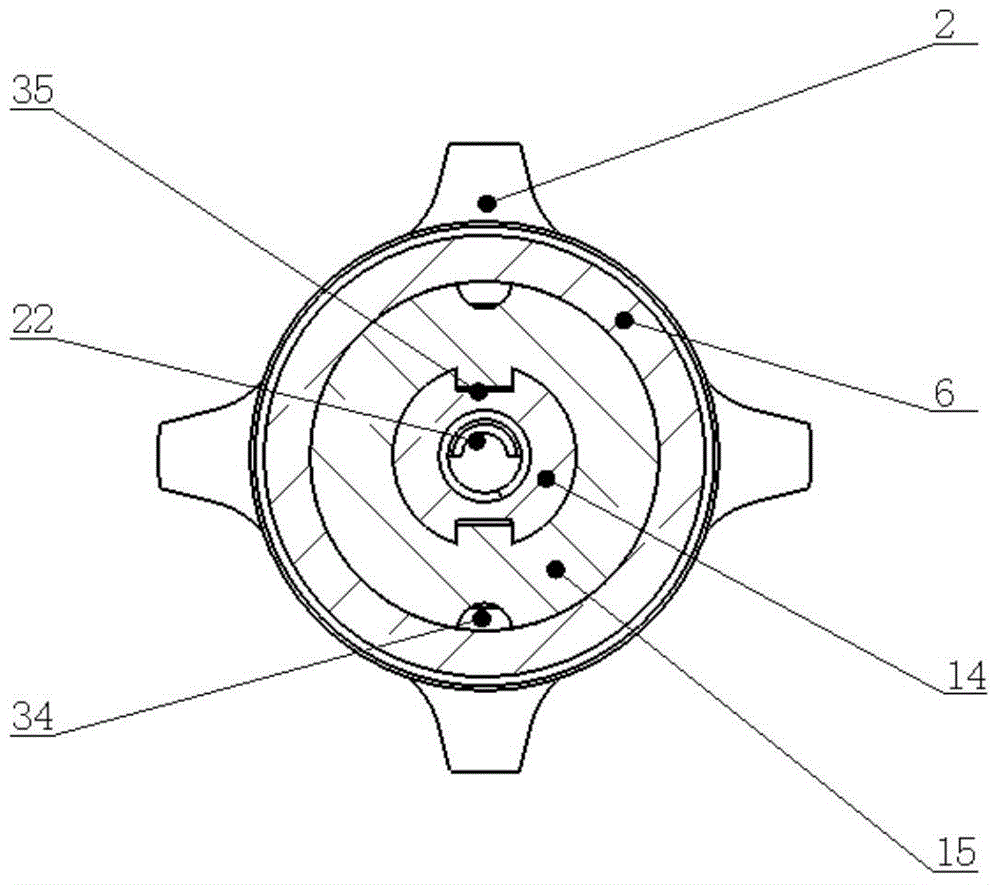

Telescopic connector for logging-while-drilling instrument

ActiveCN105134095ASolve the real problemImprove stabilitySurveyDrilling rodsPressure balanceLogging while drilling

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

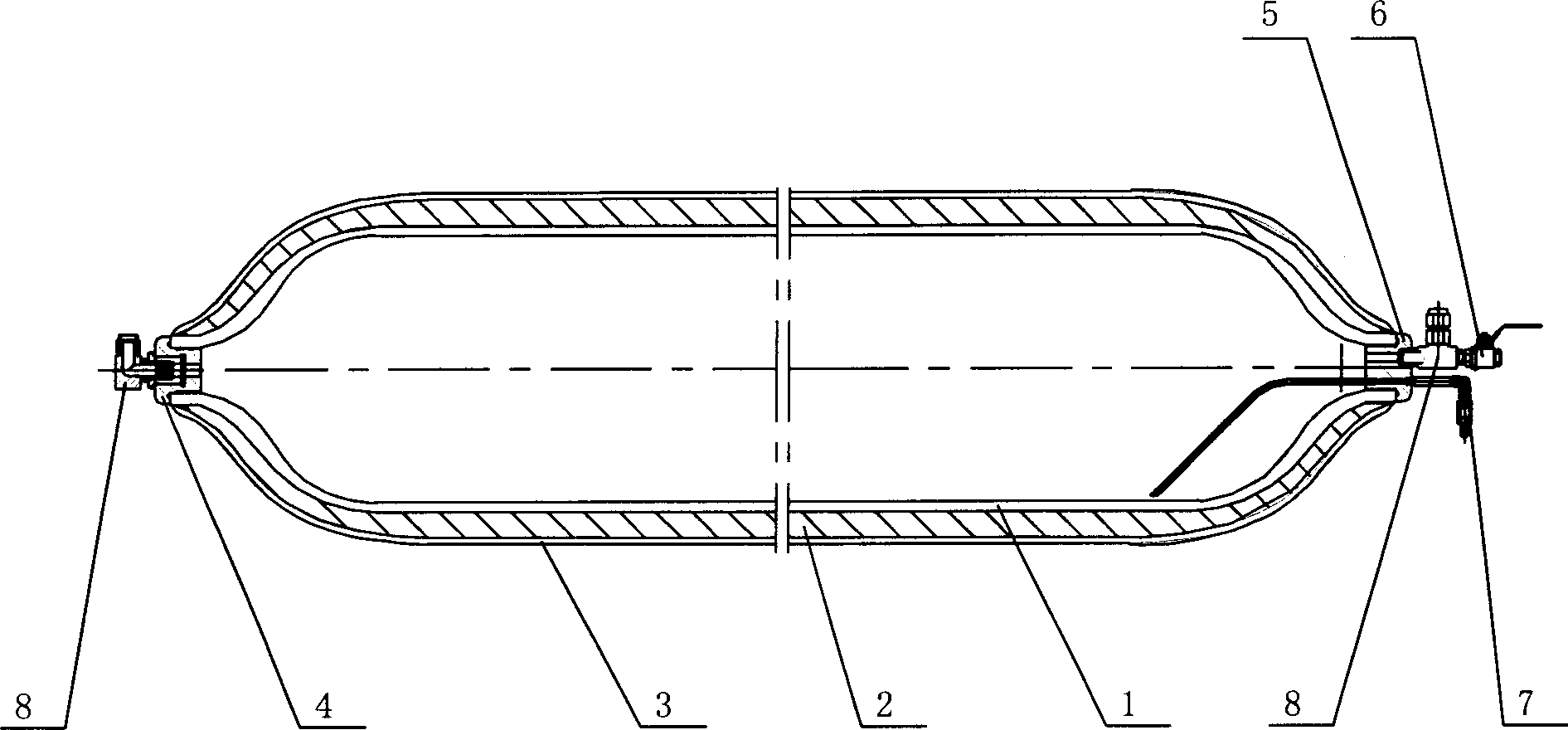

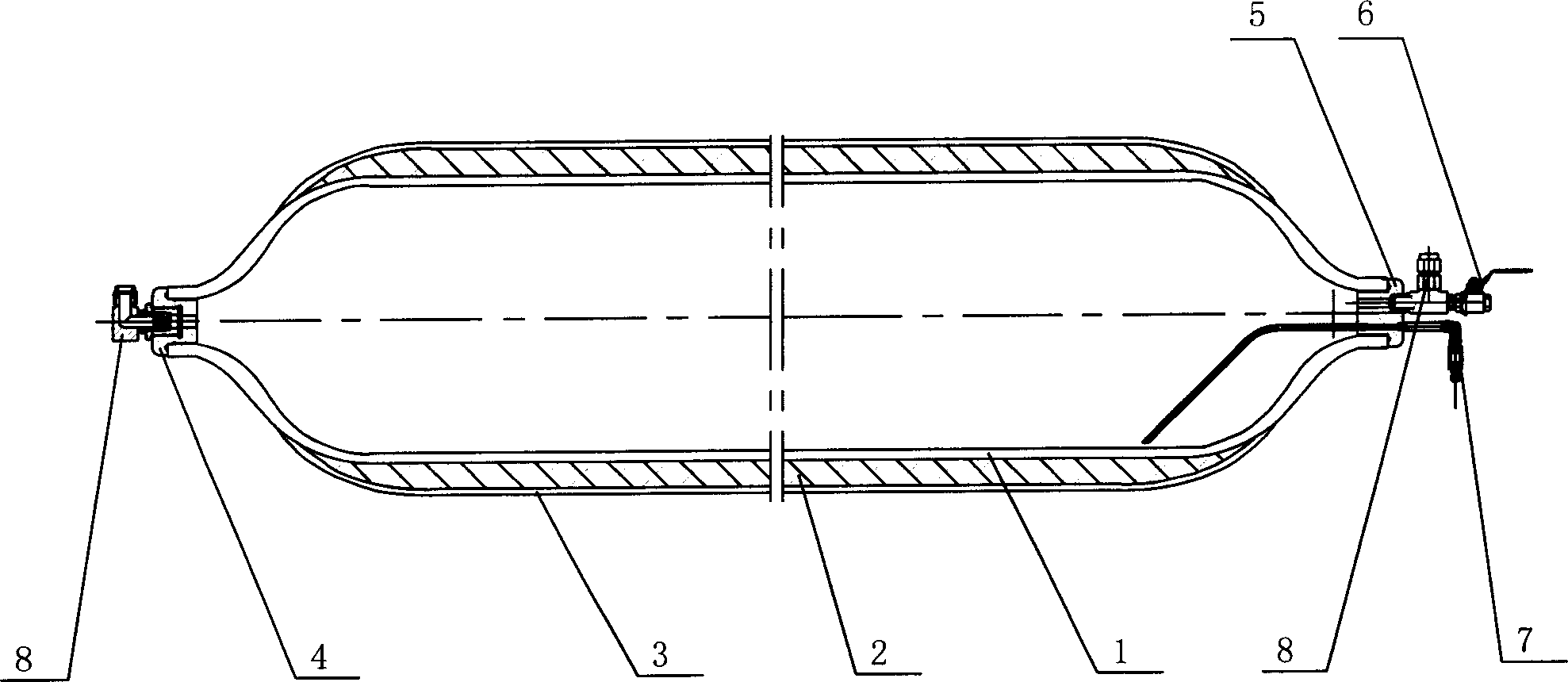

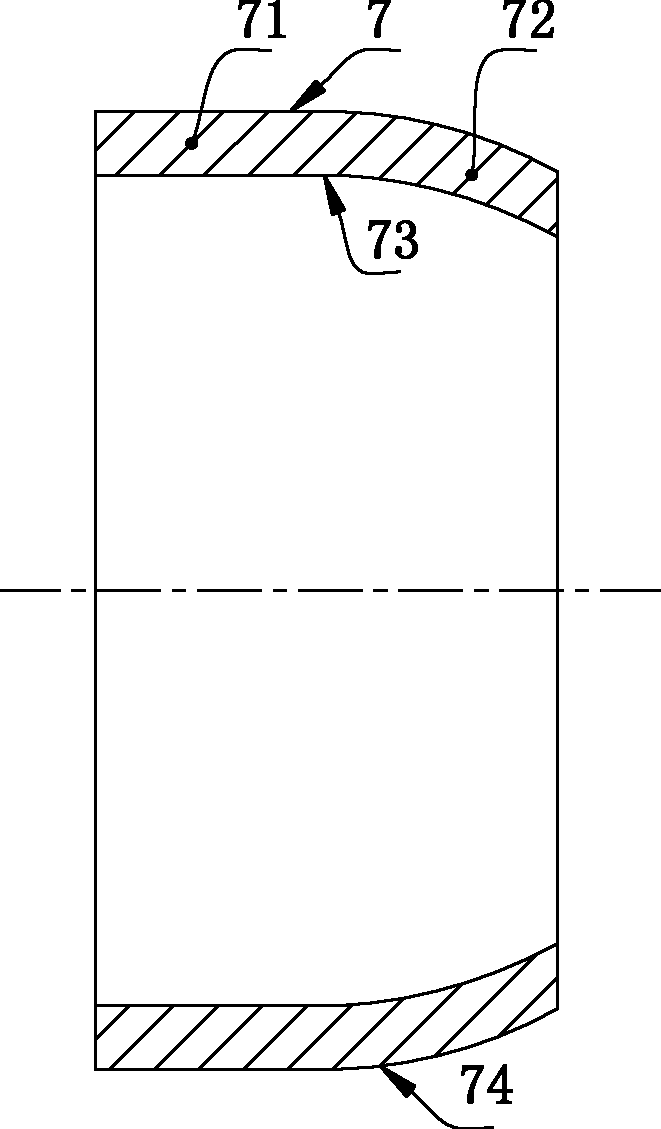

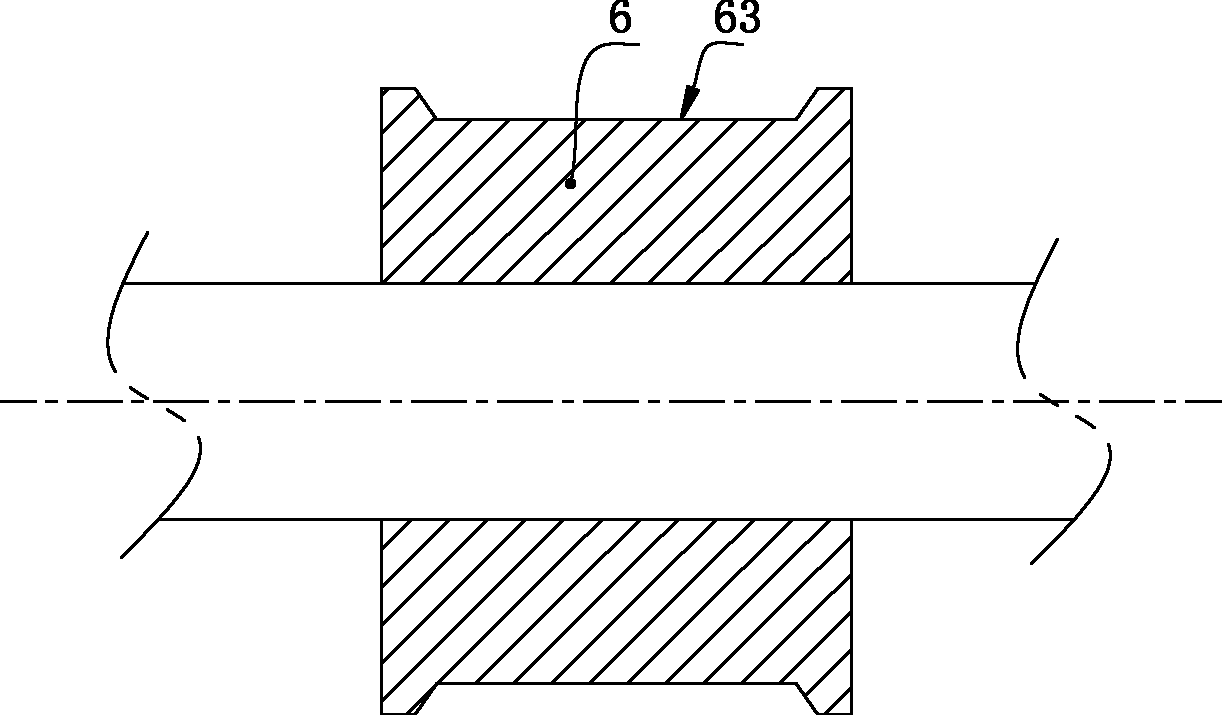

Steel inner container big capacity high pressure tank and its preparation

ActiveCN1908501AImprove pressure bearing capacityLarge water volumePressure vesselsFiber bundleMetallurgy

The present invention relates to a steel inner container big capacity high pressure tank and its preparation, which includes an inner bag made of steel high pressure seamless pipe, an intensive compound shell with the outwall wrap solidified and a protection course. The structure adopts the following steps to process: 1. selecting matching steel high pressure seamless pipe and adopting the spinning beading, heat treatment modulator, trueing machine processing to make the inner bag; 2. rotating the bracket to position the inner bag; 3. setting the high tensile fiber glue roller guide on the inner bag; 4. setting the initial wrap helix angle smaller than 40 degree and the pre-tension 5-15% of the fiber bundle tensile strength; 5. gapless thickly wrapping between the two beadings of the inner bag alternate in the clockwise and counter-clockwise; 6. adding the wrapping angle 0.5-1.5 degree completing the alternation every time; 7.maintaining the design thickness of the intensive compound layer when the wrapping angle increases to the 75-85 degree; 8. being posted into the curing oven for drying, curing, shaping process.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

Forging forming process of heteromorphic transition section of super large pressure vessel

The invention relates to a forging process of super large workpieces and provides a forging forming process of a heteromorphic transition section of a super large pressure vessel. The process comprises the following steps of: 1) punching; 2) drawing out; and 3) reaming with a special lower reaming anvil by adopting free forging, wherein the forming surface of the special lower reaming anvil is raised along the low and middle parts of the two axial ends of a forging stock; aiming at forming of each indexing region of the forging stock, firstly the two axial ends of the indexing region are deformed through forging and pressing and are matched with the middle raise of the special lower reaming anvil to form bidirectional axial limits; and after reaming, the inner circumferential surface of the forging stock comprises an inner concave surface formed through the middle raise of the special lower reaming anvil. The process has the following beneficial effects that: through the final inner concave surface of the inner circumferential surface of the forging stock, the dressing metals are saved, the raw material consumption can be reduced, the machining allowance is reduced, the metal flow lines are prevented from being cut off and the forging block quality is improved; and the process is suitable for manufacturing the heteromorphic transition section forging of the super large pressure vessel.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

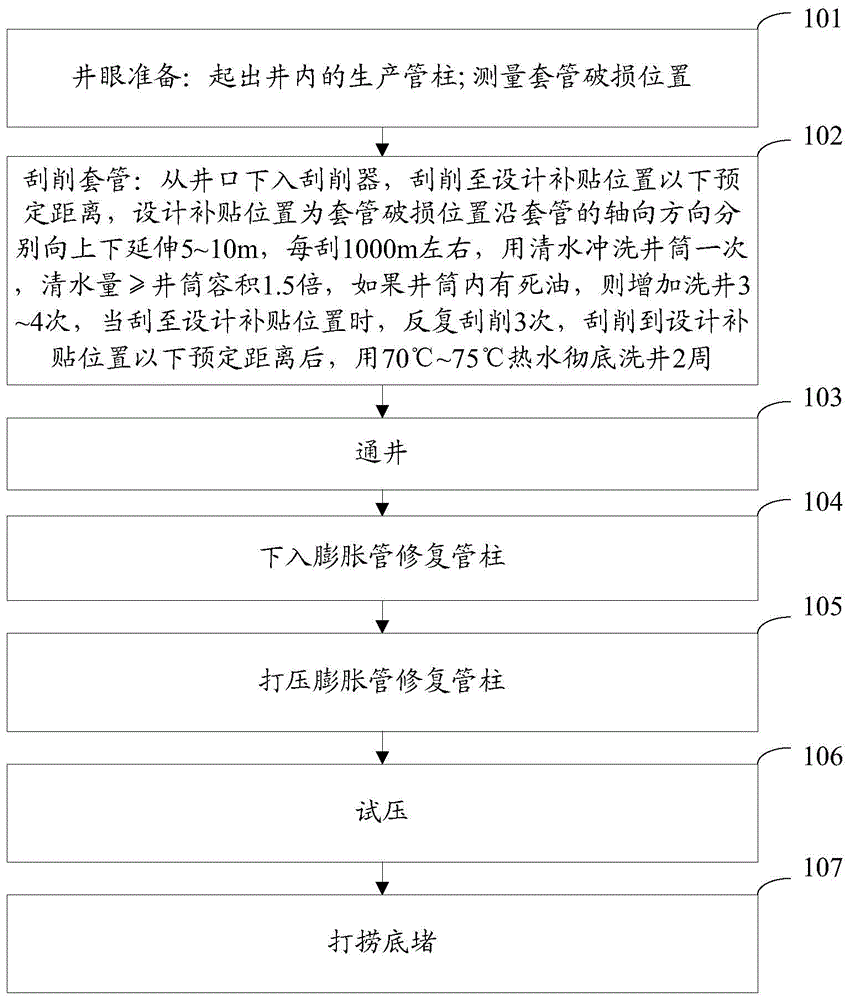

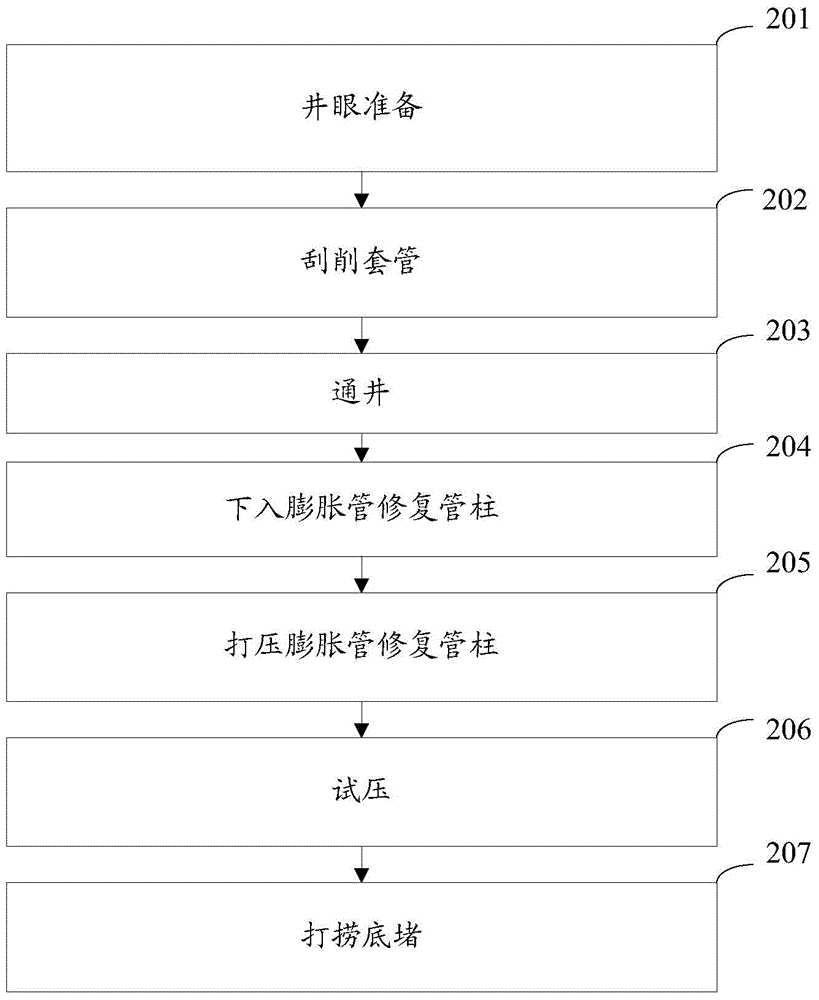

Repairing method for damaged casing pipe of oil-water well

ActiveCN105986776APrecise measurement of damage locationAccurate measurementCleaning apparatusOil waterOil production

The invention discloses a repairing method for a damaged casing pipe of an oil-water well and belongs to the field of oil production engineering of oil industry. The method comprises the following steps: preparing a well: taking a production tubular column out of the well; measuring the damaged position of the casing pipe; scraping the casing pipe: inserting a scraping instrument from the space under the well and scraping for a preset distance under a design repairing position; pigging; inserting into a repairing tubular column of an expansion pipe: connecting the repairing tubular column of the expansion pipe from well, wherein the repairing tubular column of the expansion pipe comprises an expanding repairing tubular column, an expander connecting rod, a dustproof component and a phi 73mm external thickening oil tube tubular column from bottom to top; pressing the repairing tubular column of the expansion pipe; testing pressure; salvaging bottom blockage, thereby realizing the repairing for the casing pipe with damaged length exceeding 20m. When the repairing method provided by the invention is used for repairing the casing pipe of the oil-water well with damaged length exceeding 20m, the success rate reaches 100% in more than 10 times of well applications.

Owner:PETROCHINA CO LTD

Drilling fluid for drilling

ActiveCN101974316AImprove pressure bearing capacityOvercome the disadvantage of difficult density controlDrilling compositionFoaming agentWell drilling

The invention discloses a low temperature microbubble drilling fluid for offshore oil drilling. The drilling fluid comprises water, sodium carbonate, sodium hydroxide, a flow type modifier, a foaming agent and a stabilizing agent in a mass part ratio of 100: (0.1-0.3): (0.1-0.2): (0.3-0.4): (0.2-0.3): (0.1-0.4). A perforation fluid also comprises a collapse prevention inhibitor, a clay stabilizer, a temperature stabilizing agent and a bactericide. The low temperature microbubble drilling fluid for offshore oil drilling provided by the invention is the novel drilling fluid. In performance, thelow temperature microbubble drilling fluid for offshore oil drilling has the novel advantages of leakage controlling and leakage stopping and a characteristic of adjustable density besides the characteristics of the common bubble drilling fluid in the prior art.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Turbulence self-cleaning reduced pressure pipeline exchange water heater

ActiveCN102243029AIncreased Anti-Aging StrengthAvoid erosionHeat exchanger casingsStationary tubular conduit assembliesButt weldingEngineering

The invention relates to a household heating-type exchange water heater utilizing water heating or steam heating as a heat source, and discloses a turbulence self-cleaning reduced pressure pipeline exchange water heater which consists of a plurality of tap-water tensile heat tubes, a heat tube communicating part, heating tubes, an inner tube communicating part, a connecting part, a plurality of inner round arc end socket, a small round arc end socket and a relief valve, wherein the two ends of the plurality of tap-water tensile heat tubes, the heat tube communicating part, the inner tube communicating part and the connecting part are welded, serially connected and communicated into a rectangle, and a plurality of heating tubes placed in the middle are fixedly arranged in the tap-water tensile heat tubes and the plurality of heating tubes and the inner tube connecting part are welded, serially connected and communicated into a rectangle; the plurality of tap-water tensile heat tubes are formed by stretching from the external diameter to the inner diameter of the circumferences of tube bodies to form a plurality of elongated bosses and evenly distributing a plurality of sections on the inner-diameter circumferences of the tube bodies; and the plurality of the inner round arc end sockets and the two ends of each tap-water tensile heat tube are in close fit, are level with one another and are fixedly connected by virtue of welding or are fixedly connected by virtue of butt welding, thus the heat exchange effect of a heat exchange body is effectively increased.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com