Low-density high-strength leak-resistant slurry method for sealing leakage producing formation

A leak-proof, high-strength technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of large reduction in compressive strength of cement stone, limited application range, difficult performance adjustment, etc., to improve mechanical properties, Large social benefits, the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment:

[0029] The low-density, high-strength anti-leakage cement slurry method used to seal the lost production layer, according to the principle of particle gradation, mixes cement, micro-silicon, floating beads, fluid loss reducer, expansion agent, drag reducer and water in a certain proportion.

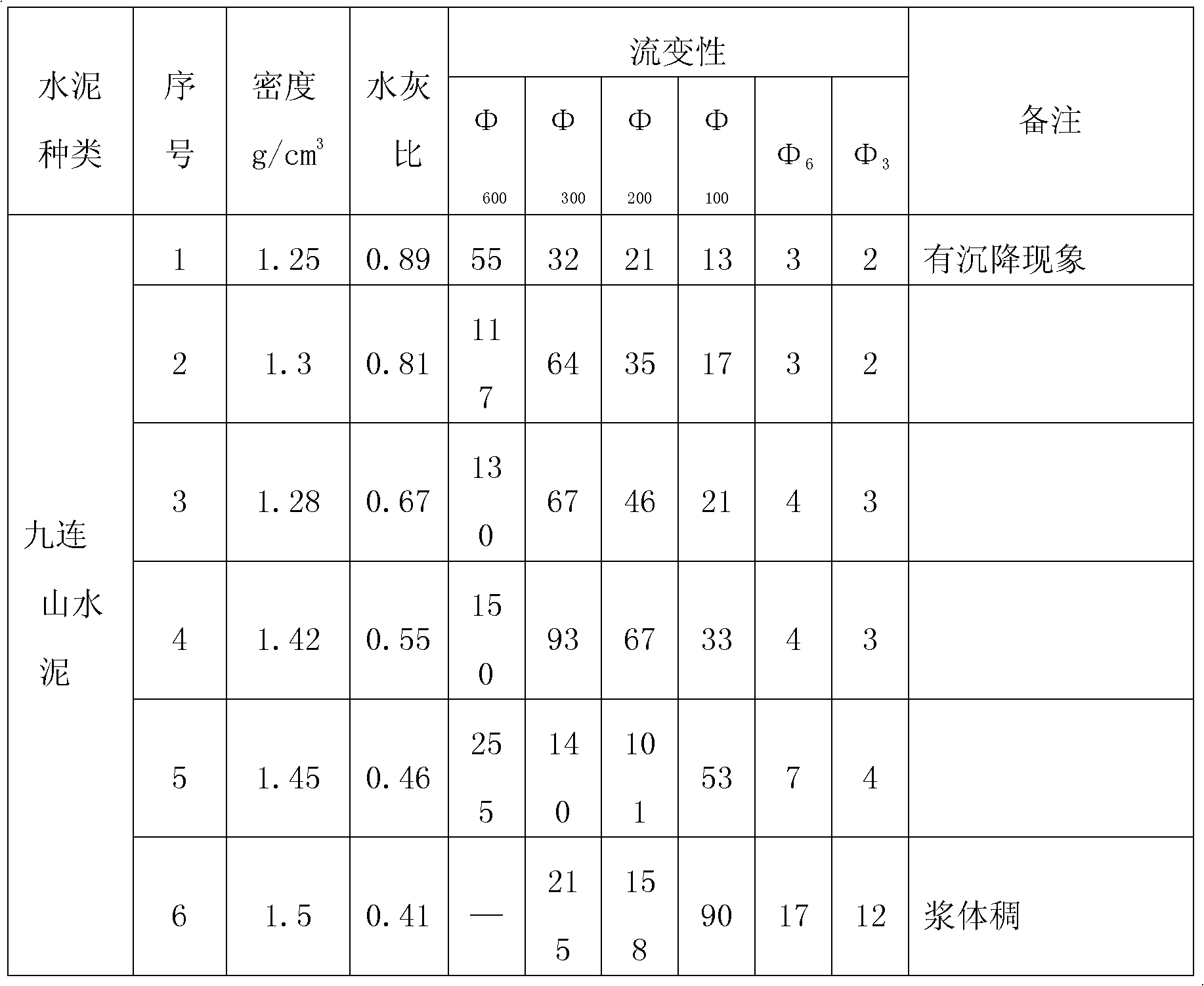

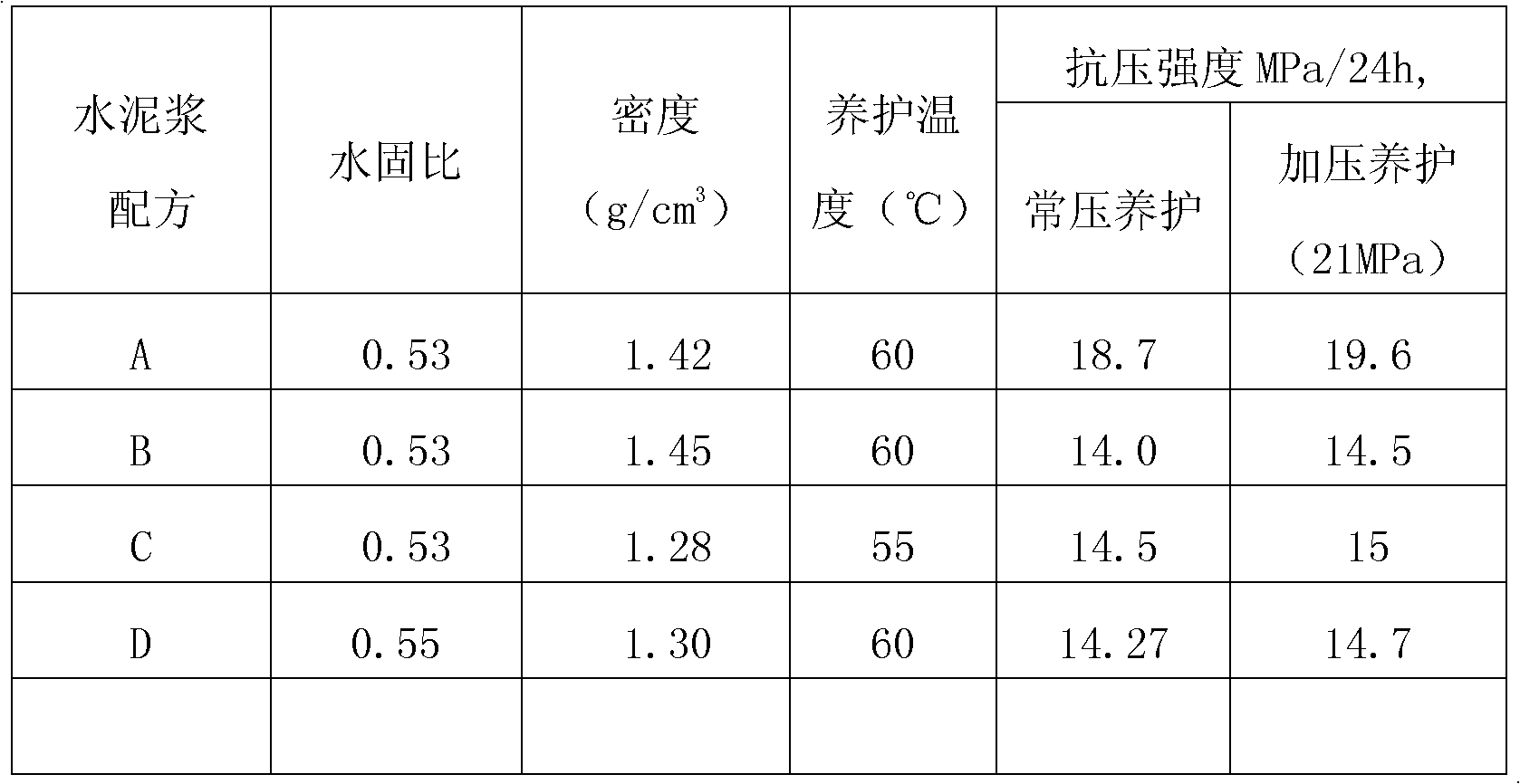

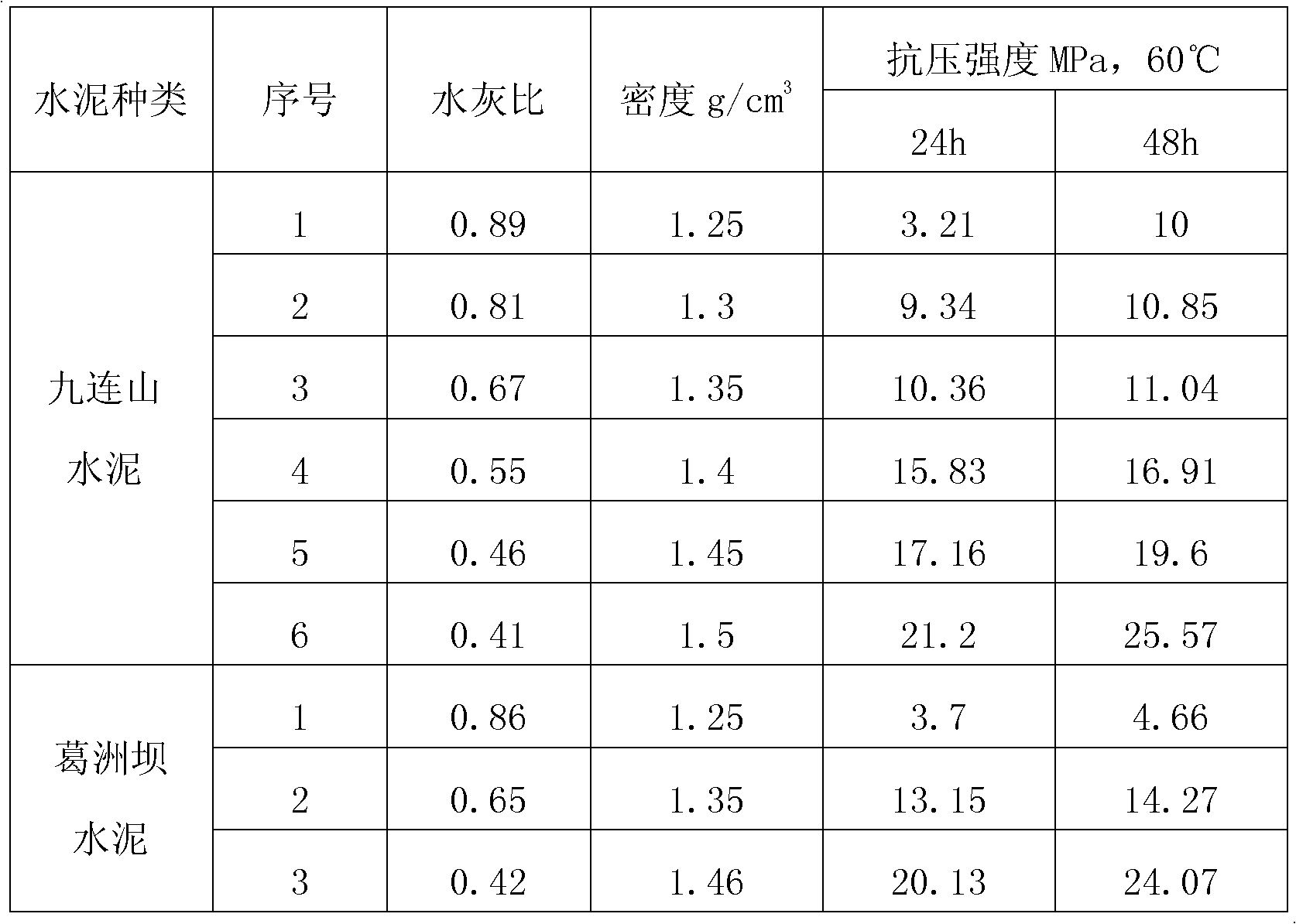

[0030] Table 1 shows the thickening time performance data table of low-density high-strength anti-leakage cement. From the data of the following examples, it can be seen that the determined cement slurry formula has good compatibility with changes in the cement production area and the amount of lightening agent. The thickening time of the cement slurry is more than 110 minutes, which can meet the requirements of the performance parameters of the cementing site construction.

[0031] Table 1

[0032]

formula

water solid ratio

temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com