Repairing method for damaged casing pipe of oil-water well

A repair method and oil-water well technology, which is applied in earthwork drilling, wellbore/well components, cleaning tools, etc., and can solve the problems of oil-water well scrapping, difficult repair, casing cracking and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

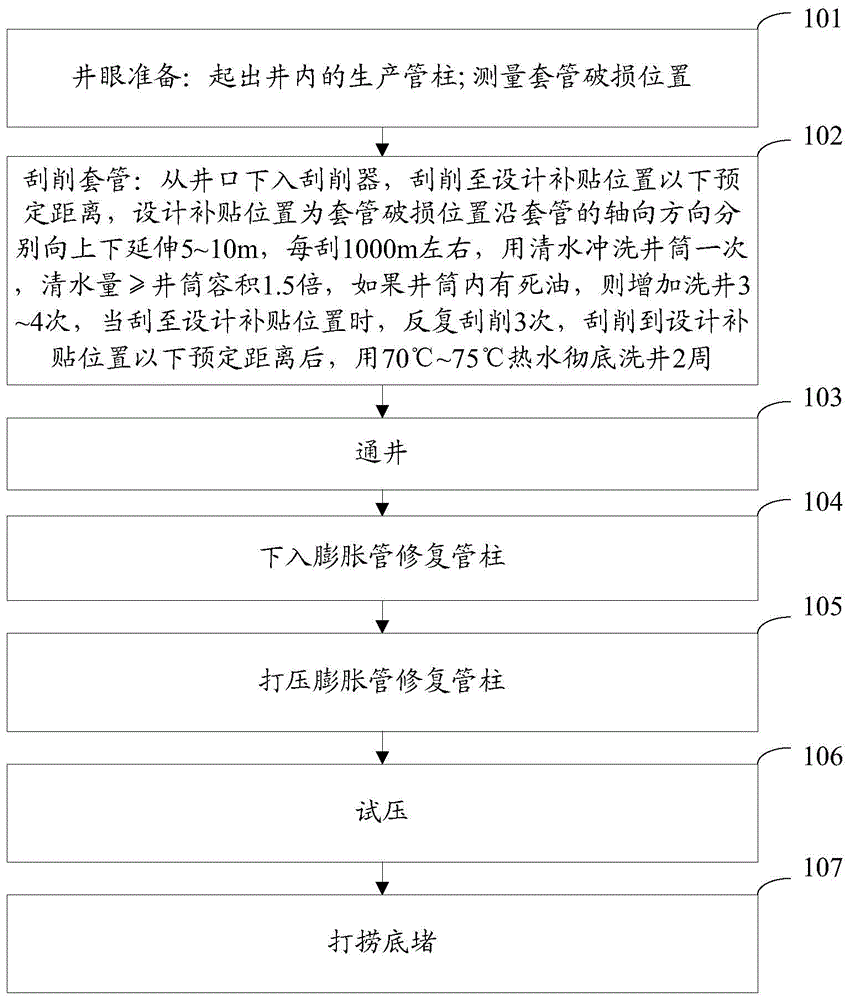

[0093] The embodiment of the present invention provides a method for repairing damaged casings of oil and water wells, which is suitable for repairing casings with a damaged length exceeding 20m. See figure 1 , the repair method for oil and water well casing damage includes:

[0094] Step 101: Wellbore preparation: pulling out the production string in the well; measuring the casing damage position.

[0095] Step 102: Scraping the casing: Run the scraper from the wellhead to scrape to a predetermined distance below the design subsidy position. The design subsidy position is the casing damage position extending 5-10m up and down along the axial direction of the casing, and each scraping is about 1000m , flush the wellbore once with clean water, the amount of clean water ≥ 1.5 times the volume of the wellbore, if there is dead oil in the wellbore, then increase the well flushing 3 to 4 times, when scraping to the design subsidy position, repeat the scraping 3 times, and scrape to...

Embodiment 2

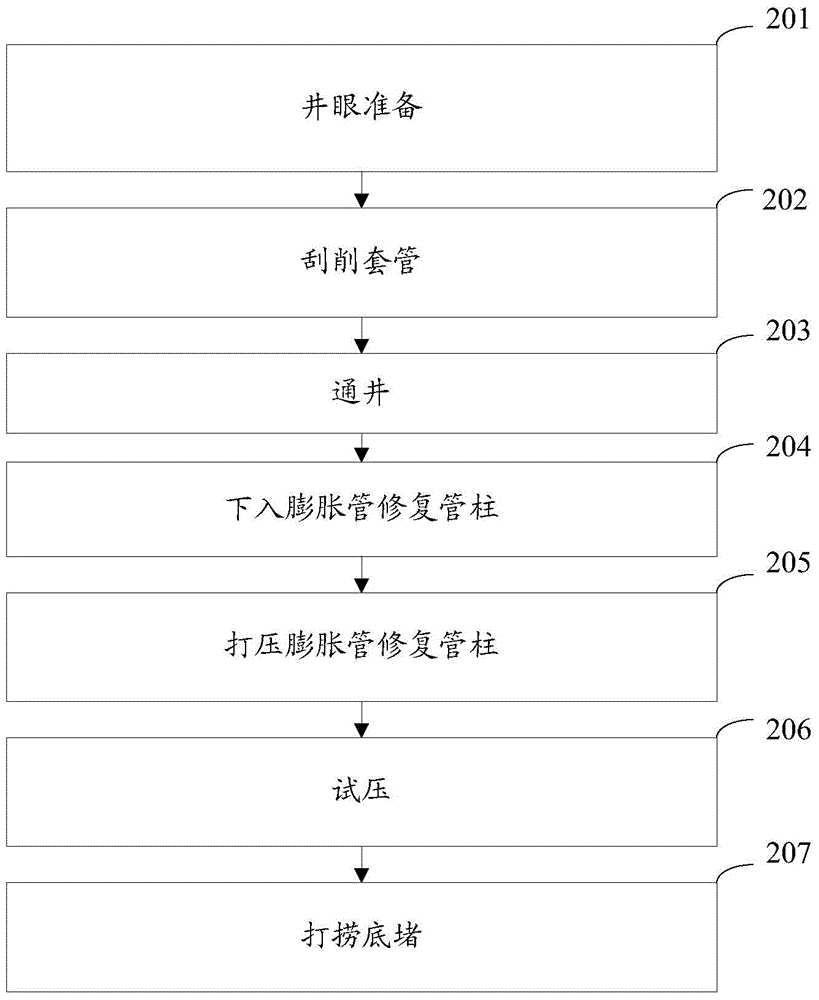

[0113] The embodiment of the present invention provides a method for repairing damaged casings of oil and water wells, which is suitable for repairing casings with a damaged length exceeding 20m. See figure 2 , the method includes:

[0114] Step 201: Borehole preparation.

[0115] Specifically, it may include: measuring the damaged position of the casing;

[0116] Among them, measuring the damaged position of the casing may include:

[0117] According to the geological data, the running depth, wall thickness and deformation section of oil and water well casings are checked and corrected in detail;

[0118] Use instruments and tools to accurately measure the location of casing damage;

[0119] Pull out all the pipe strings and tools in the well, accurately measure the length of the pipe string entering the well on the ground, and accurately measure the location of the casing damage.

[0120] When implemented, the instruments and tools may be turbine flow meters. On the on...

Embodiment 3

[0163] The embodiment of the present invention provides a method for repairing casing damage in oil and water wells. In this embodiment, well H16 Ping 3 is taken as an example for illustration. The H16 Ping 3 casing damage section is 1780m-1850m, a total of 70m. The method includes:

[0164] 1. Wellbore preparation

[0165] A. According to the geological data, check and correct the running depth, wall thickness and deformation section of the oil and water well casing in detail;

[0166] B. Use instruments and tools to accurately measure the location of casing damage;

[0167] C. Pull out all the pipe strings and tools in the oil and water well, open the channel, repair the deformed section, and restore the diameter of the casing;

[0168] D. Accurately measure the length of the pipe string on the ground, and accurately measure the damaged position of the casing.

[0169] 2. Scraping casing

[0170] Lower the spring-type scraper from the wellhead of the oil-water well, scrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com