Patents

Literature

226 results about "Pigging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

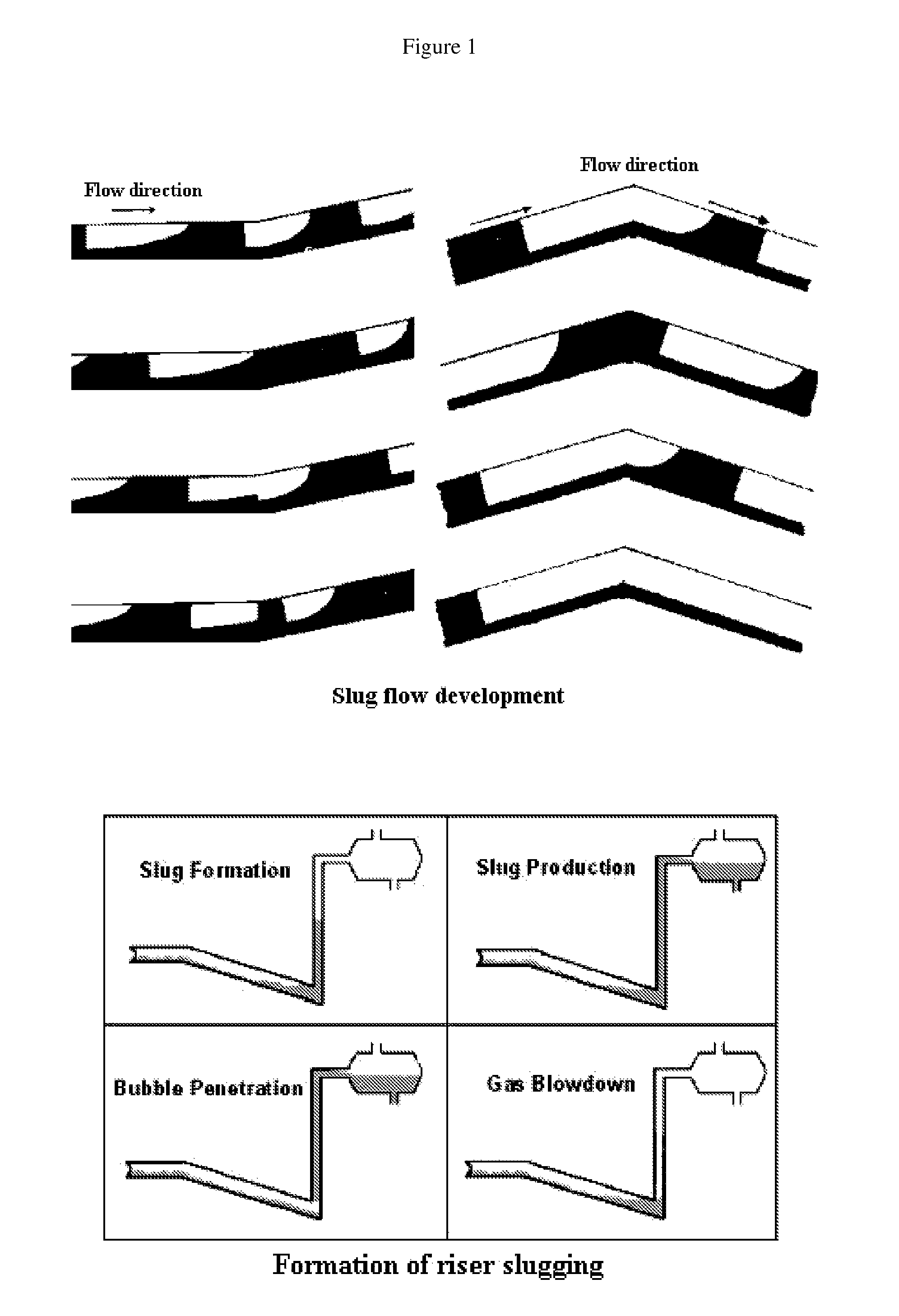

In pipeline transportation, pigging is the practice of using devices known as pigs or scrapers to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline.

Subsea production system

InactiveUS7093661B2Increase supplyEasy to controlCleaning apparatusSettling tanks feed/dischargePetroleum productPigging

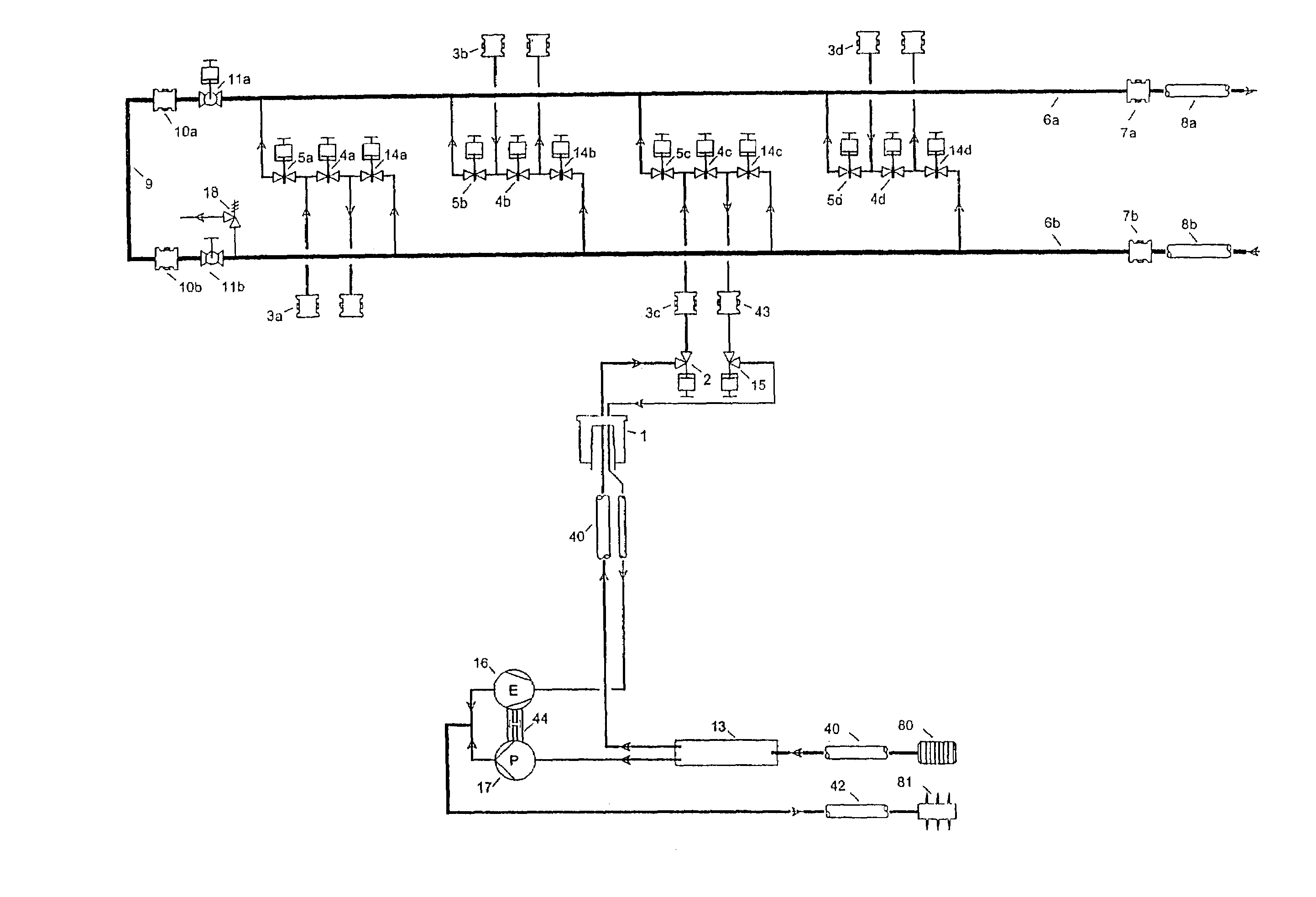

Methods and arrangements for production of petroleum products from a subsea well. The methods comprise control of a downhole separator, supplying power fluid to a downhole turbine / pump hydraulic converter, performing pigging of a subsea manifold, providing gas lift and performing three phase downhole separation. Arrangement for performing the methods are also described.

Owner:AKER SUBSEA LTD

High power laser pipeline tool and methods of use

ActiveUS20120255933A1High energy laserIncrease powerHollow article cleaningArc welding apparatusHigh power lasersPigging

There is provided a high power laser tool system for transmitting and delivering high power laser energy within the interior of pipes, which includes a high power laser-pig and long distance high power optical tether. The high power laser system performs high power laser pigging operations and other operations, such as, cleaning, assembling, maintaining and monitoring of pipelines.

Owner:FORO ENERGY

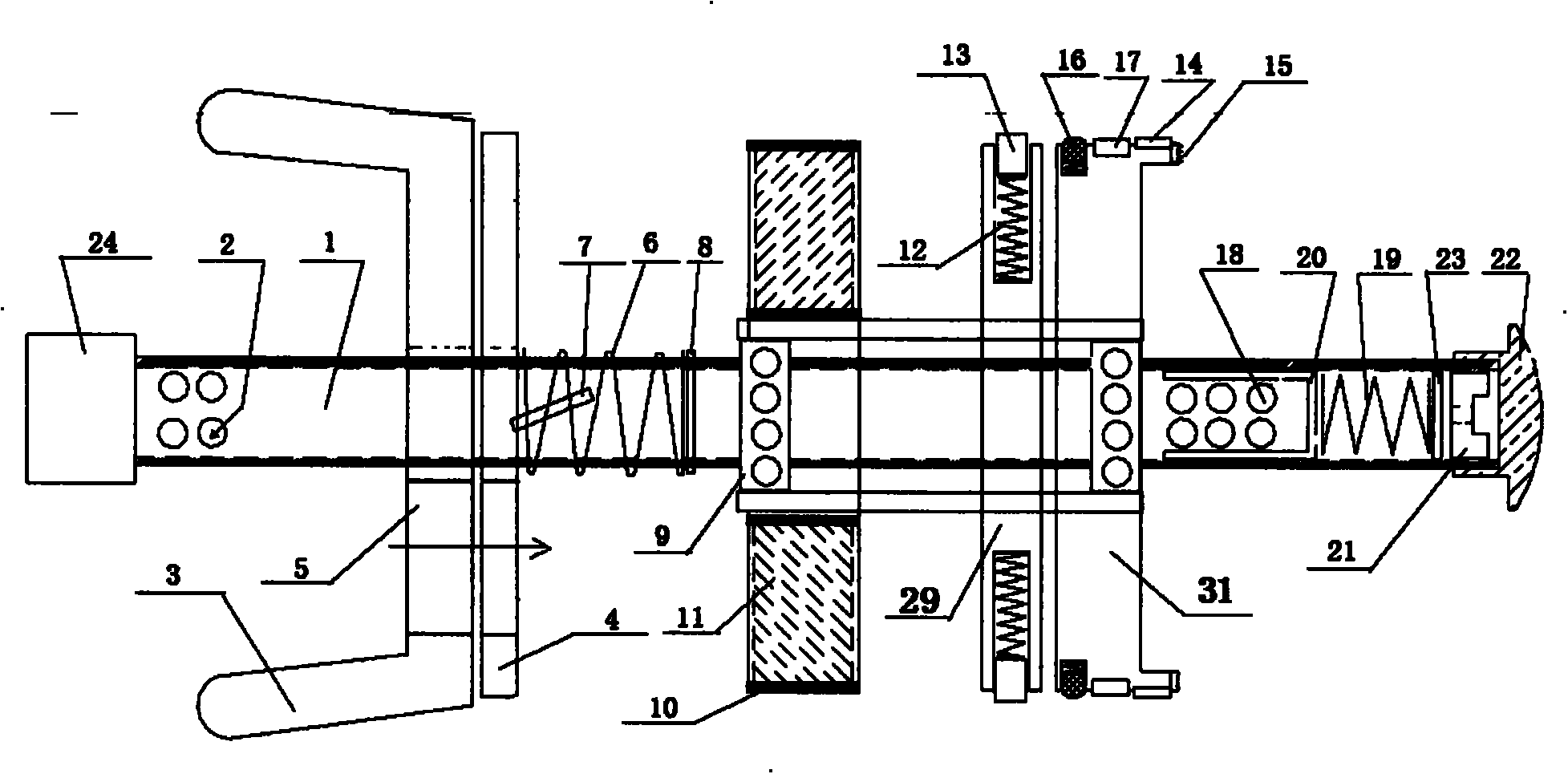

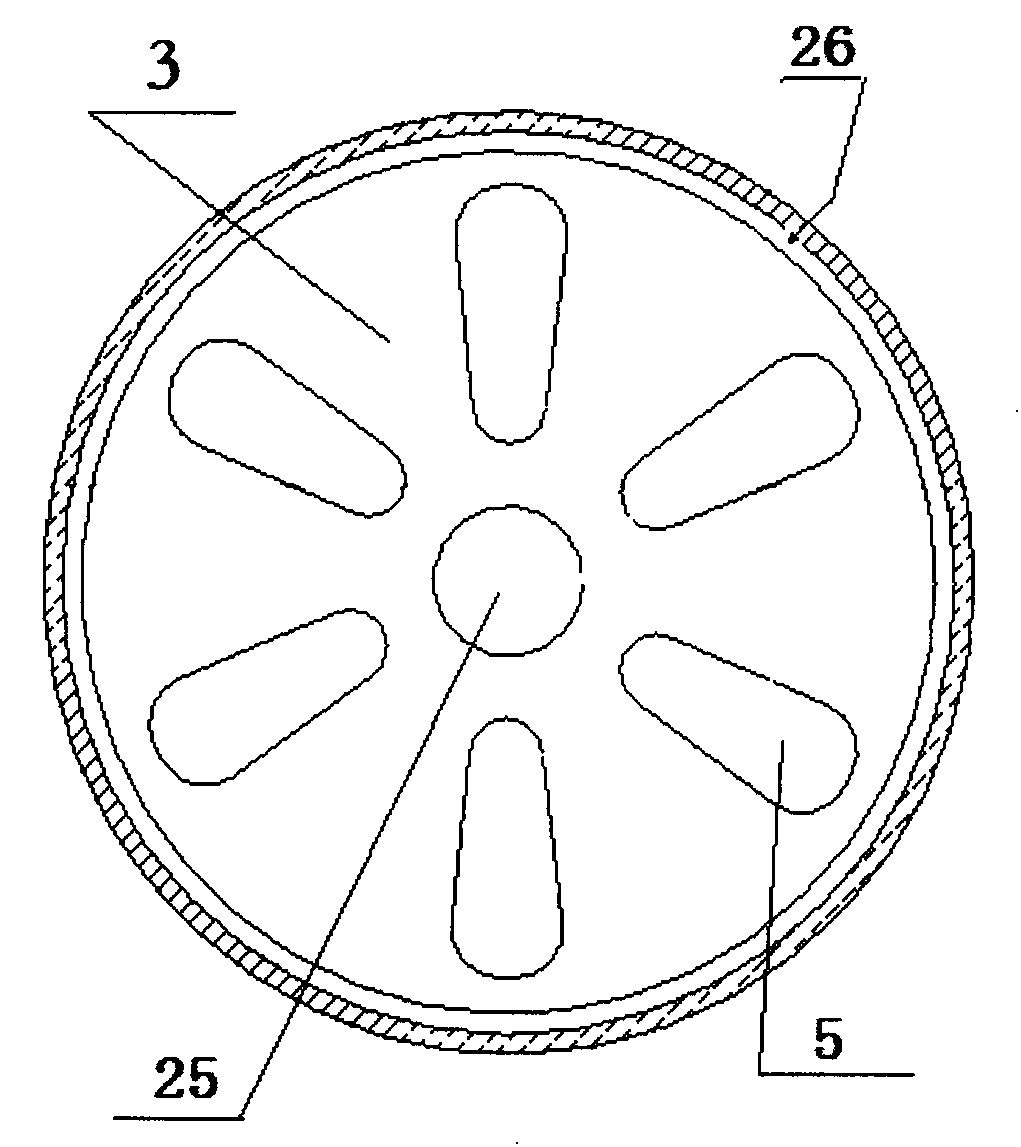

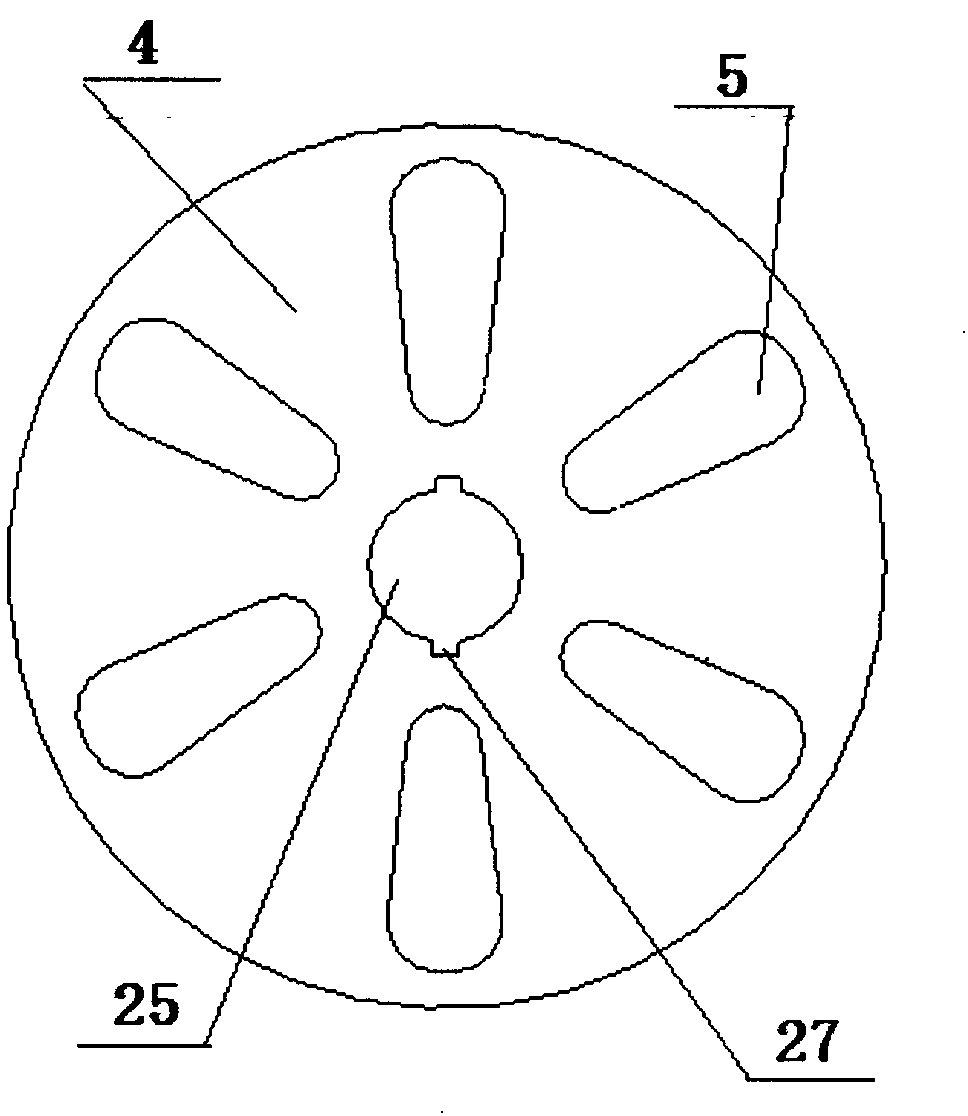

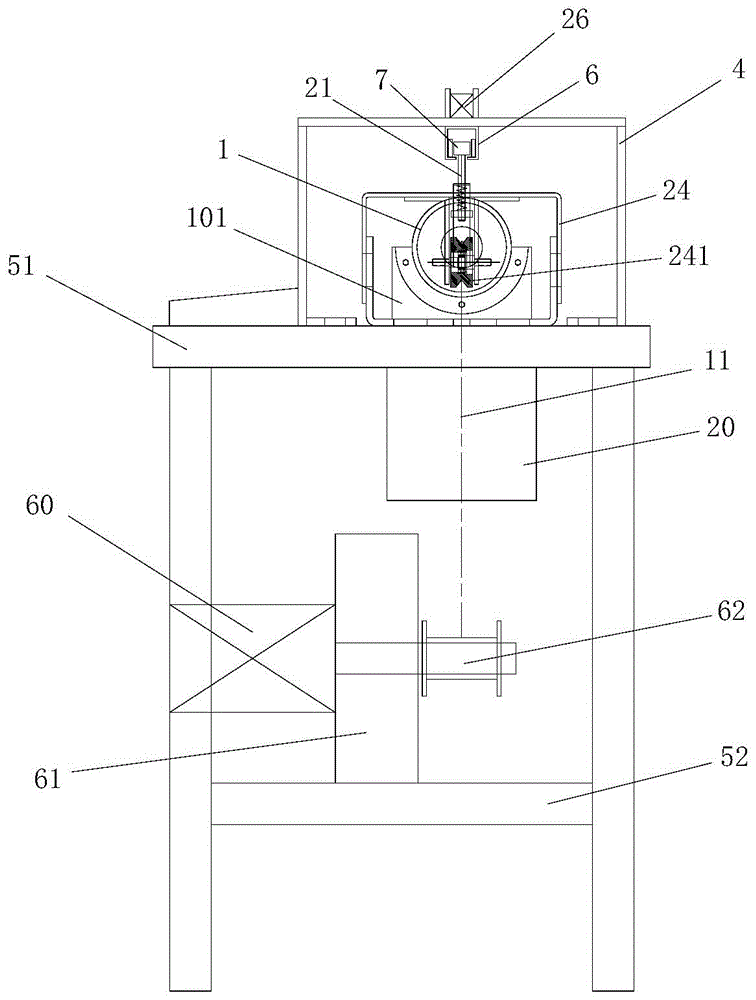

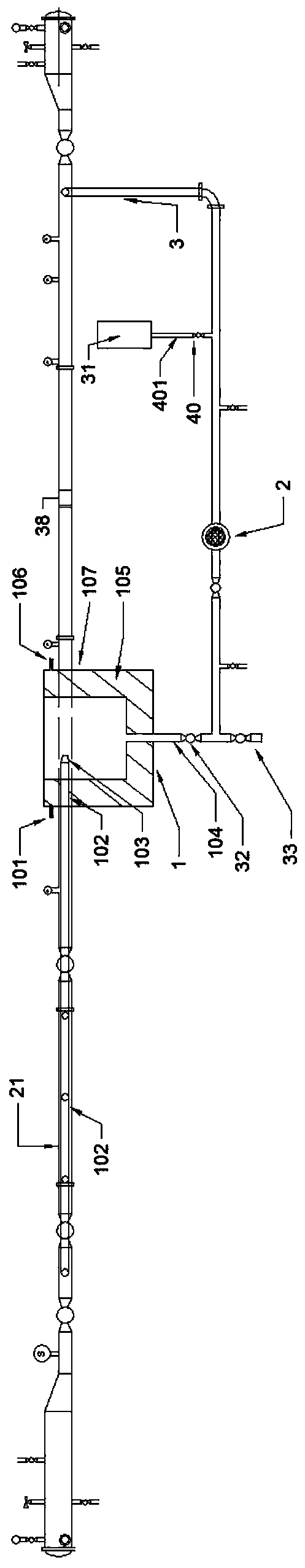

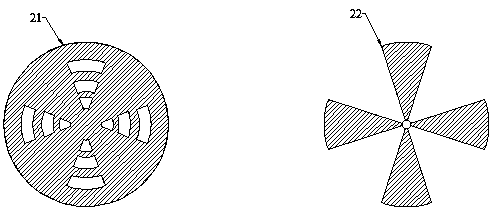

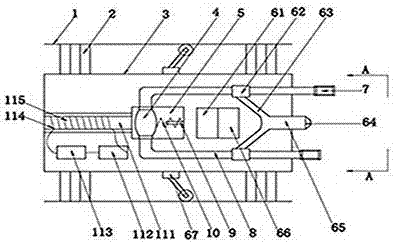

Hydraulic driven built-in rotation scraping type pipeline cleaning device

Disclosed is a hydraulic driven built-in rotation scraping type pipeline cleaning device. A main guide plate and an auxiliary guide plate are adopted to form a one-way pressure relief structure, the operating posture of a spindle on the inner central line of a pipeline is maintained through the guide plates, a sealed impeller and a positioning support frame, fluid kinetic energy is used for driving the impeller to drive a pipeline cleaning cutter to clean the pipeline circumferentially in the pipeline, meanwhile, a rim working portion of the composite pipeline cleaning cutter combining effective functions of various pipeline cleaners is further kept in the maximum and optimal contact with the inner wall of the pipeline, the axial portion adopts an alloy grinding head to remove large-particle dirt and metal scaling bonded on the inner wall of the pipeline, the kinetic energy of fluid is used for driving the pipeline cleaning cutter to work, the pipeline can still be in a normal operation state, cleaned dirt can be carried by the fluid quickly and cannot accumulate, and choking of the pipeline can be avoided. The pipeline cleaning device is compact in structure, convenient and flexible, safe and durable, high in popularity, simple to operate, convenient to implement, energy saving, high in cleaning speed, long in cleaning distance and free of damage to the pipeline wall.

Owner:钟平贵

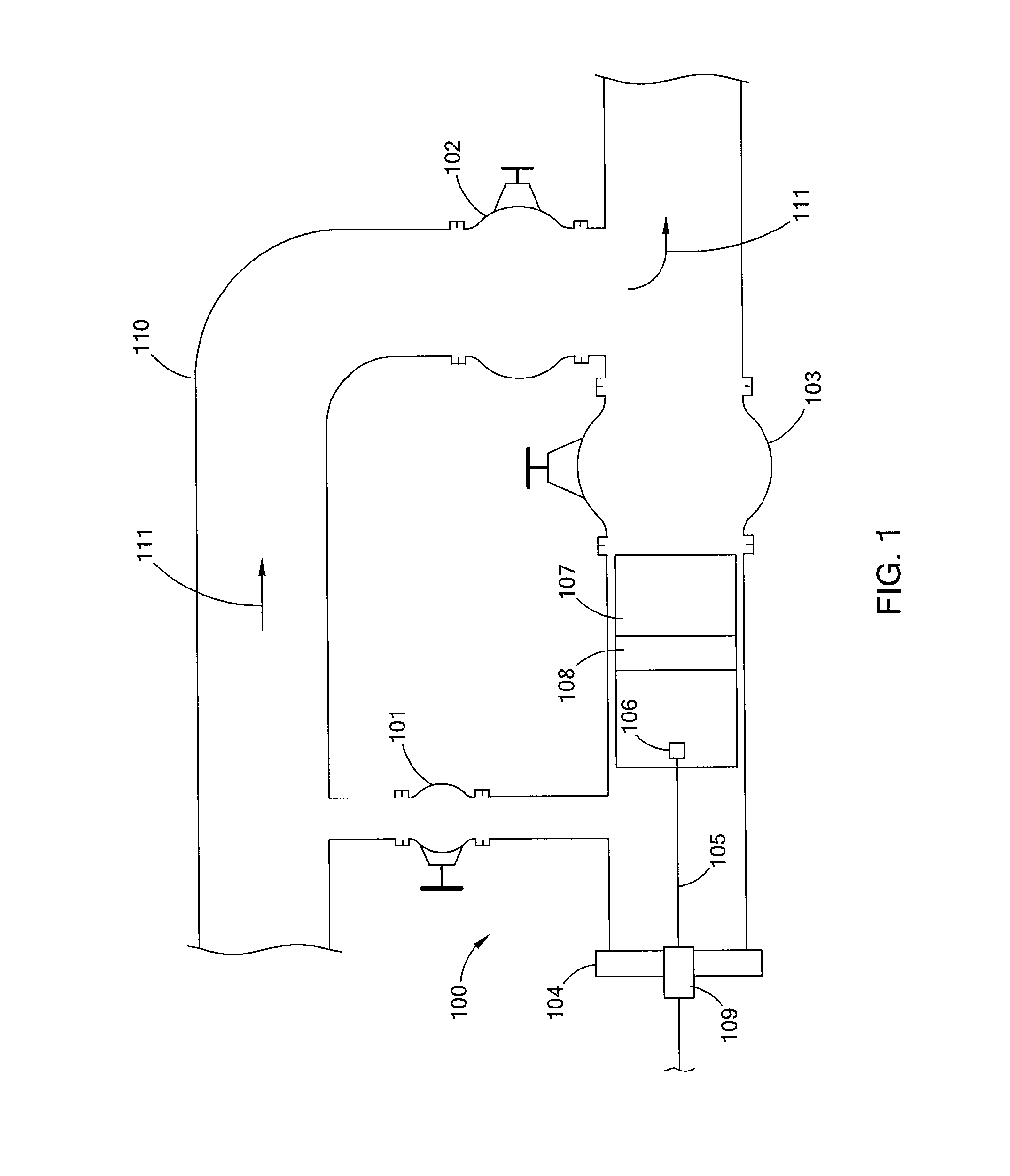

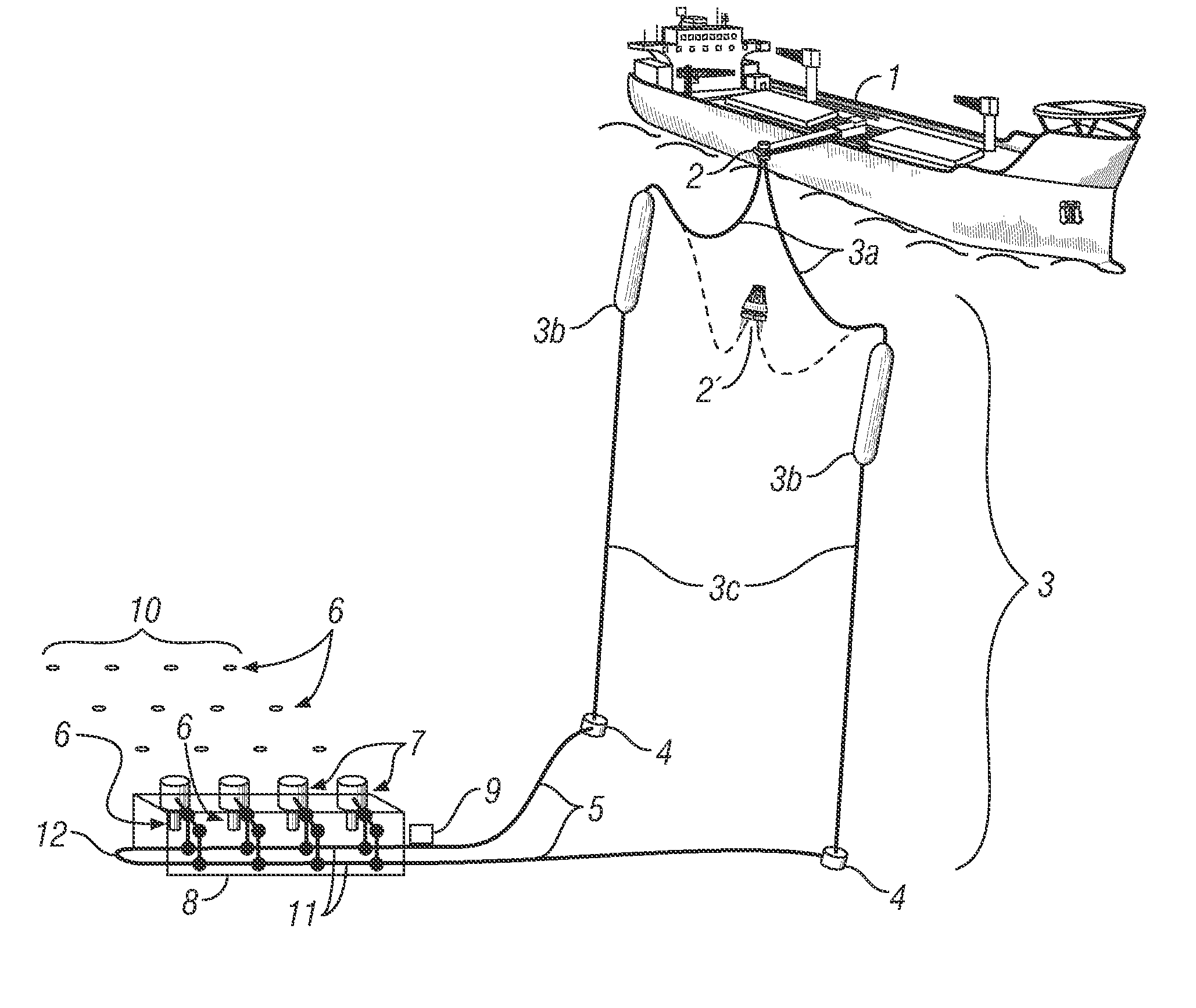

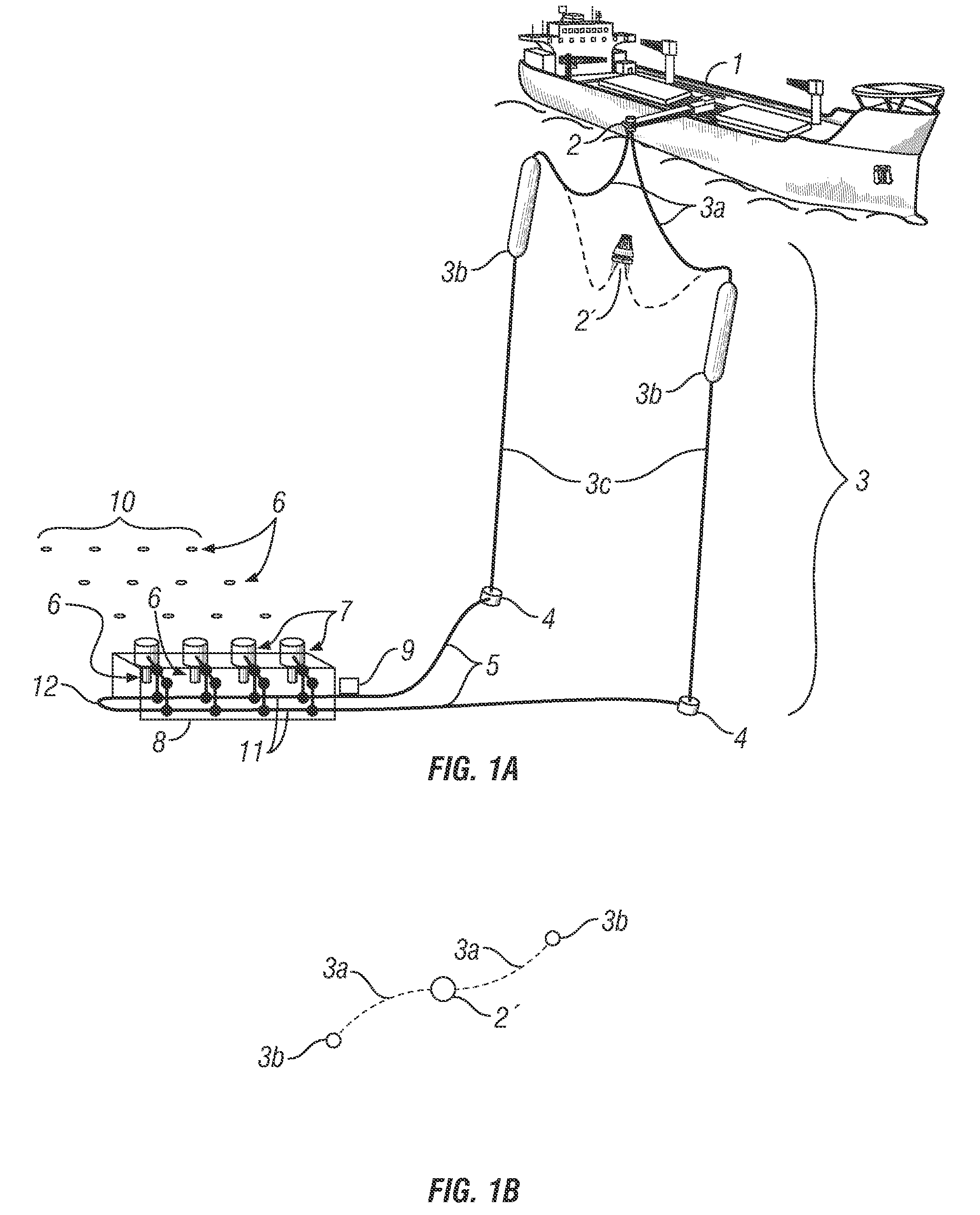

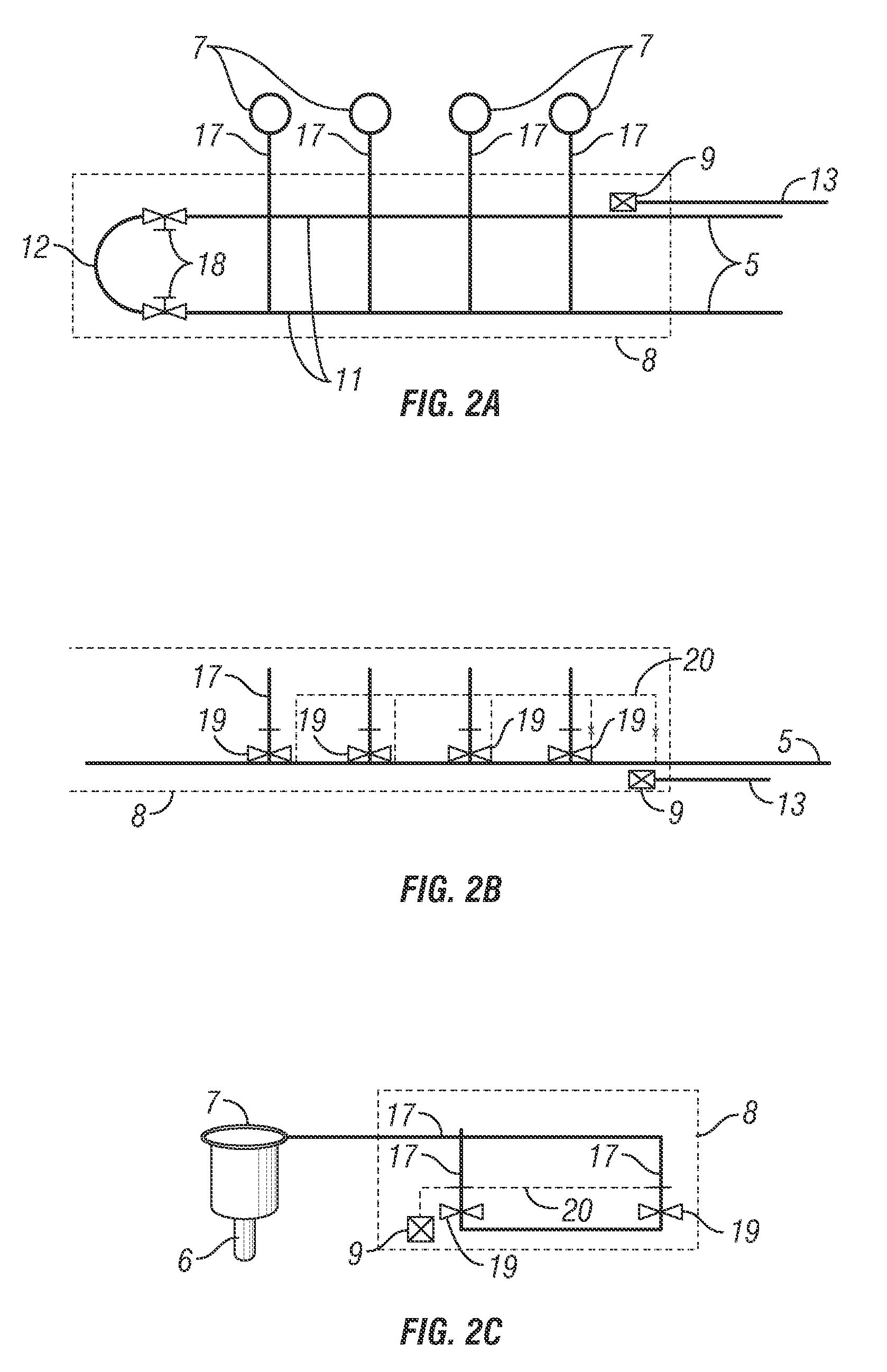

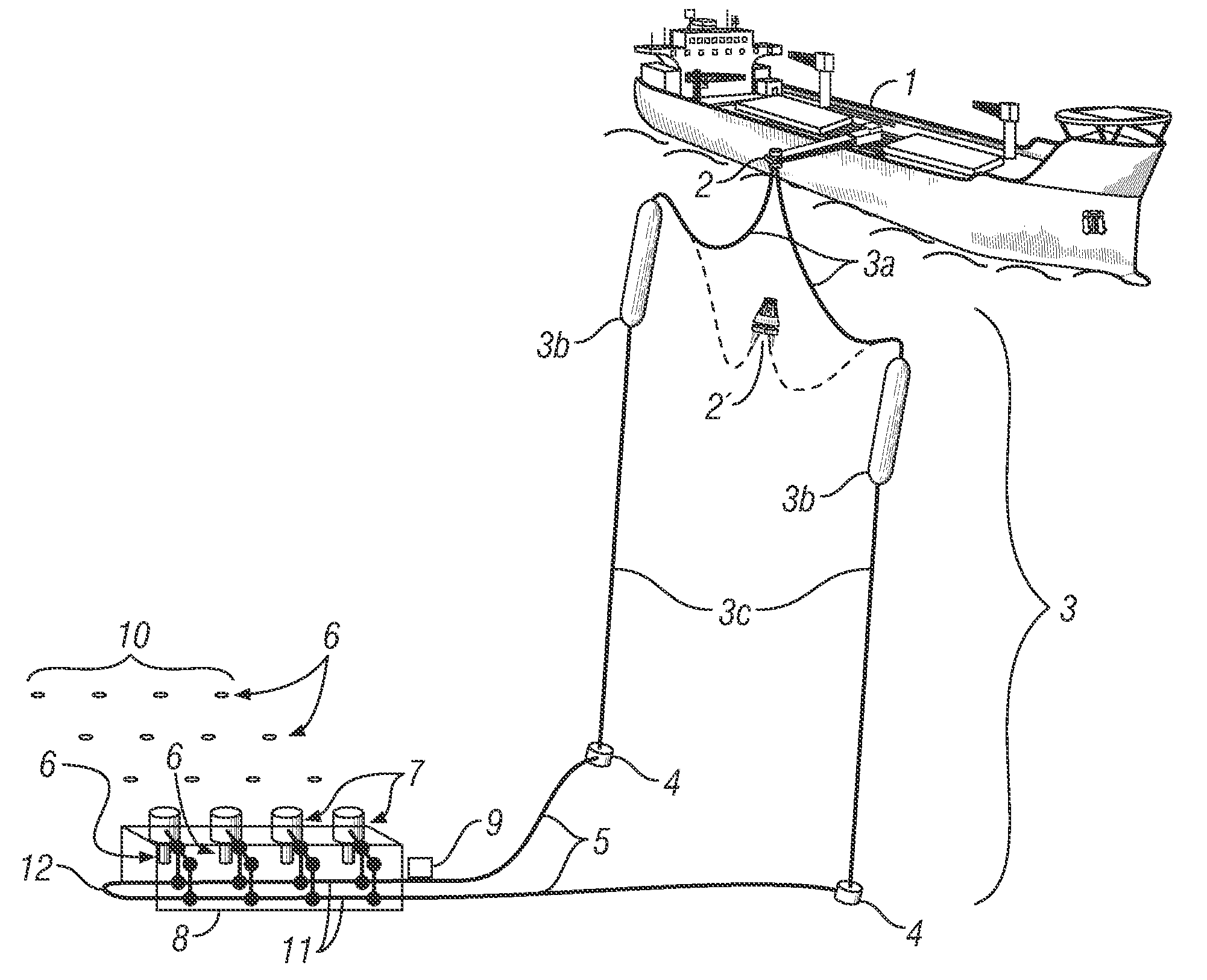

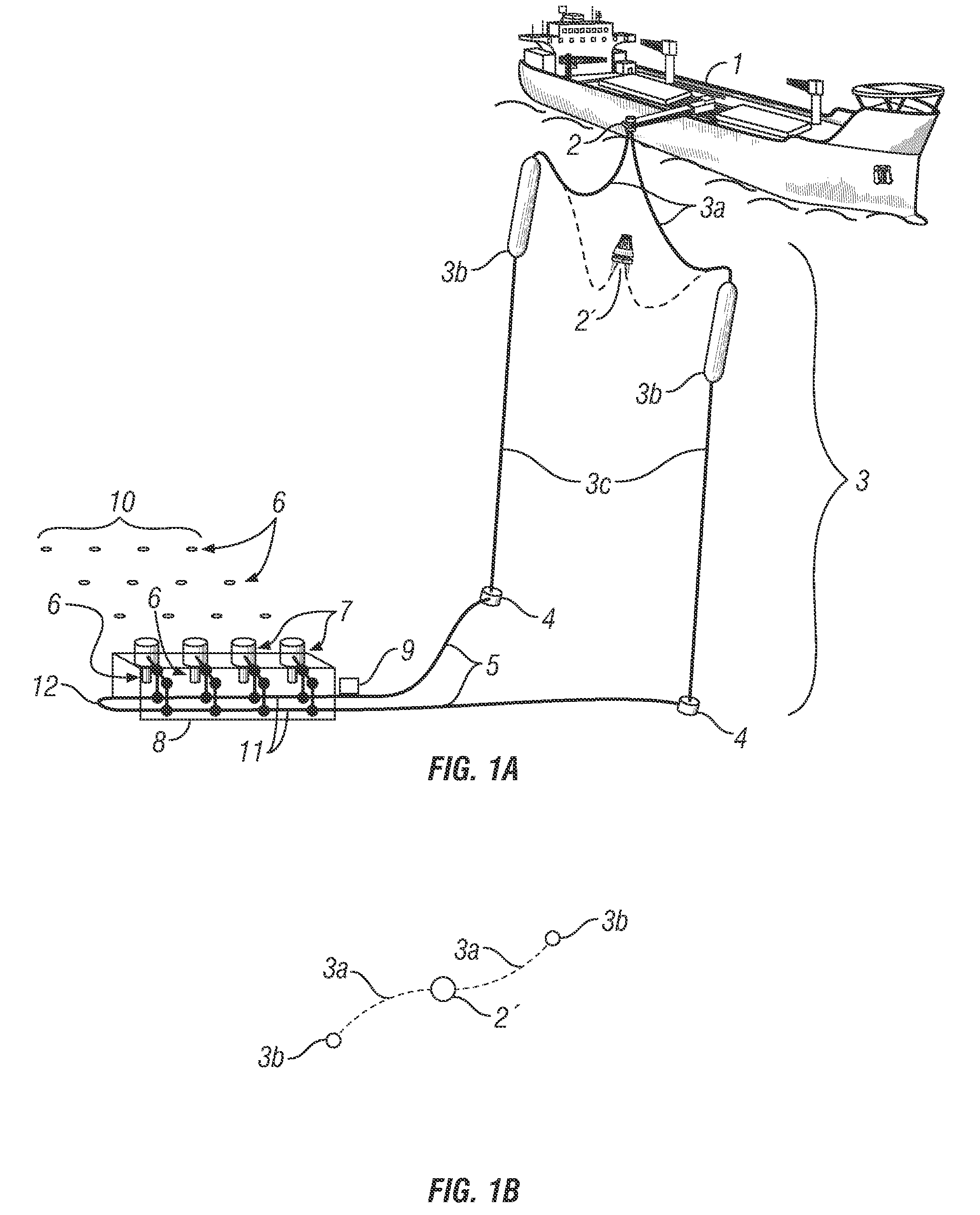

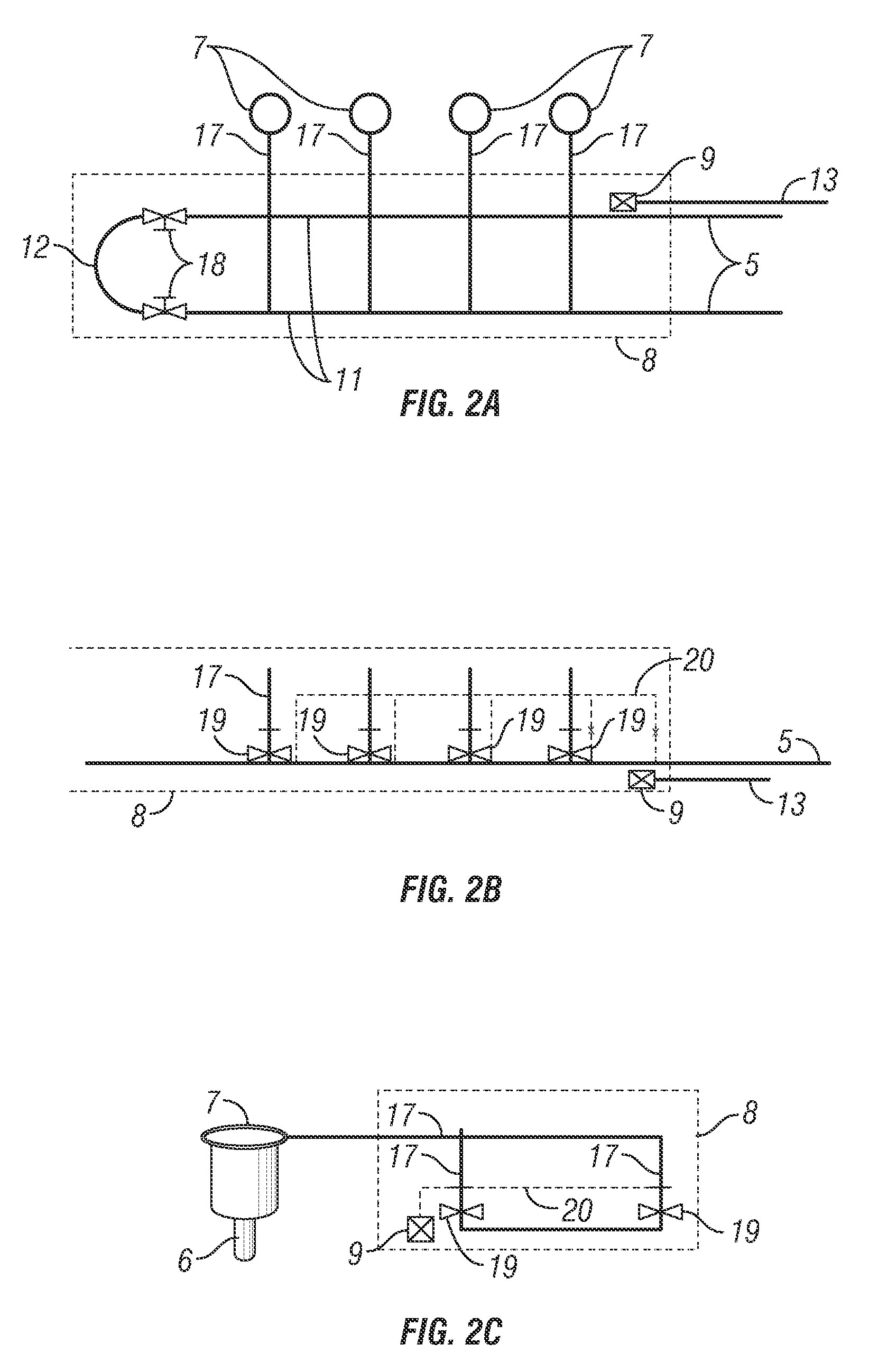

Subsea manifold system

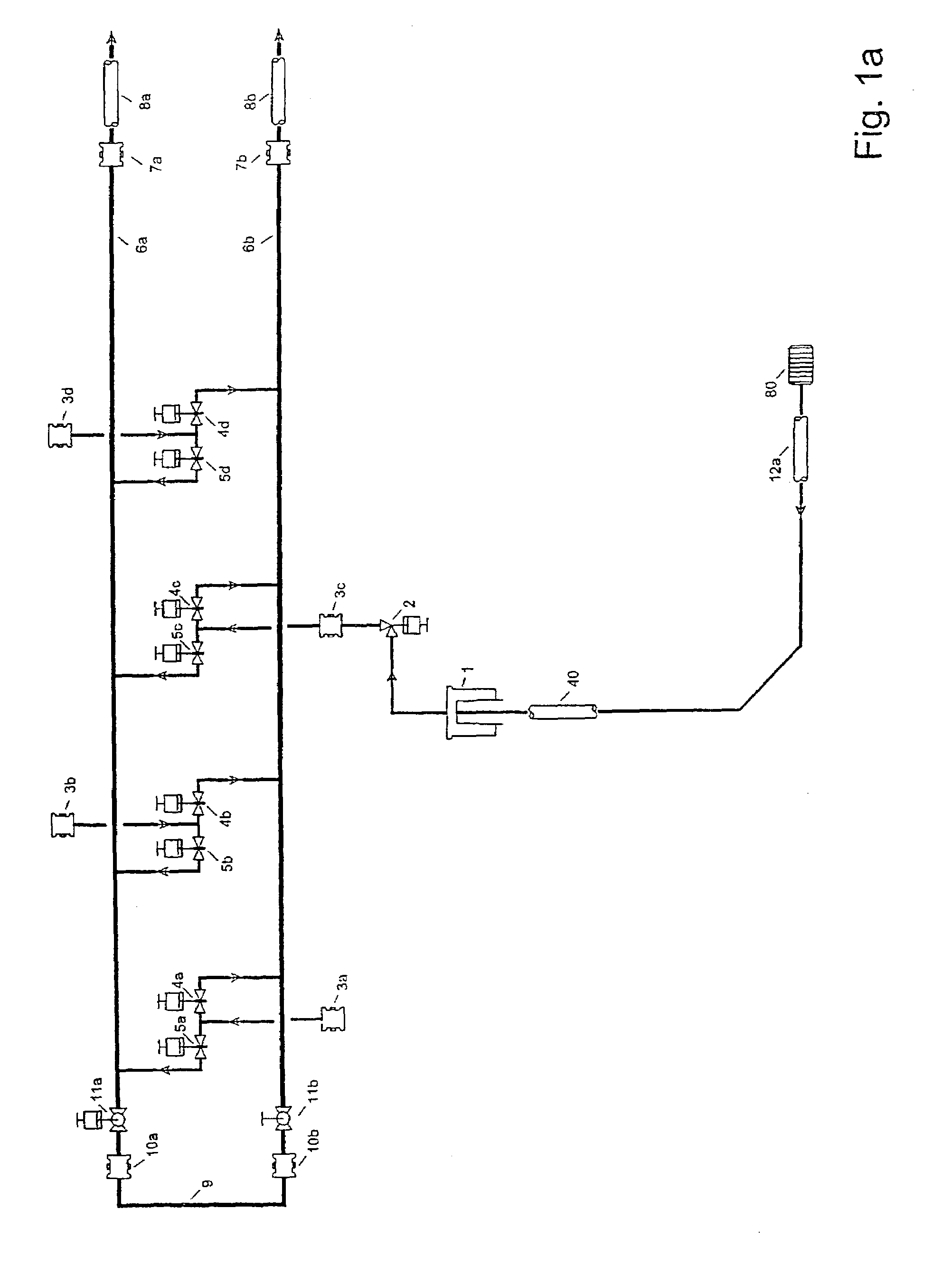

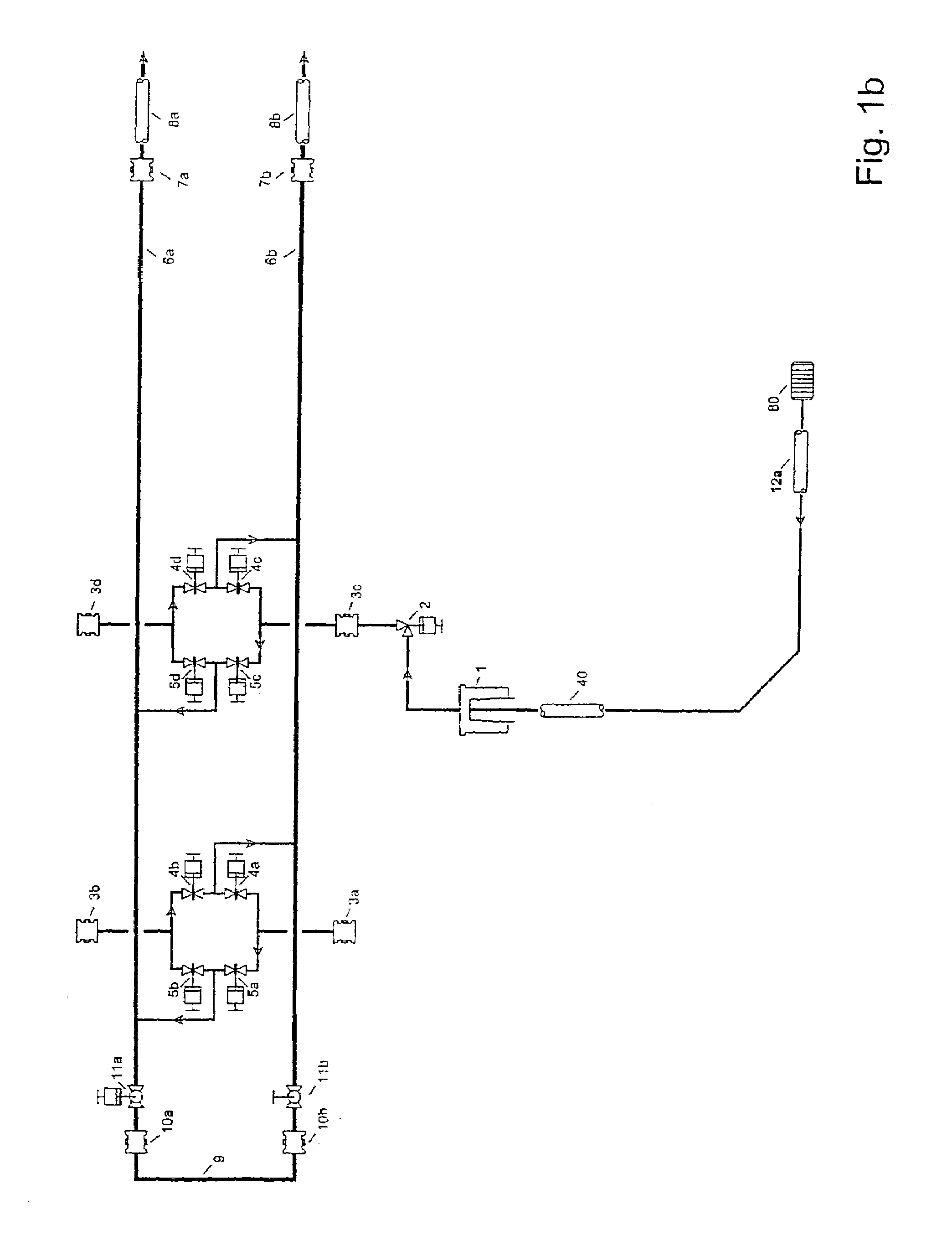

An improved subsea manifold system that is capable of being used in an early production system for producing hydrocarbons from a plurality of wells from a common riser system. The subsea manifold is able to control the fluid from a multiple of subsea wet-tree wells while at the same time giving the operator the option to isolate production from a single subsea well for production evaluation. The subsea manifold also includes a pigging loop which enables efficient pigging of the flowline(s) of the early production system.

Owner:CHEVROU USA INC +1

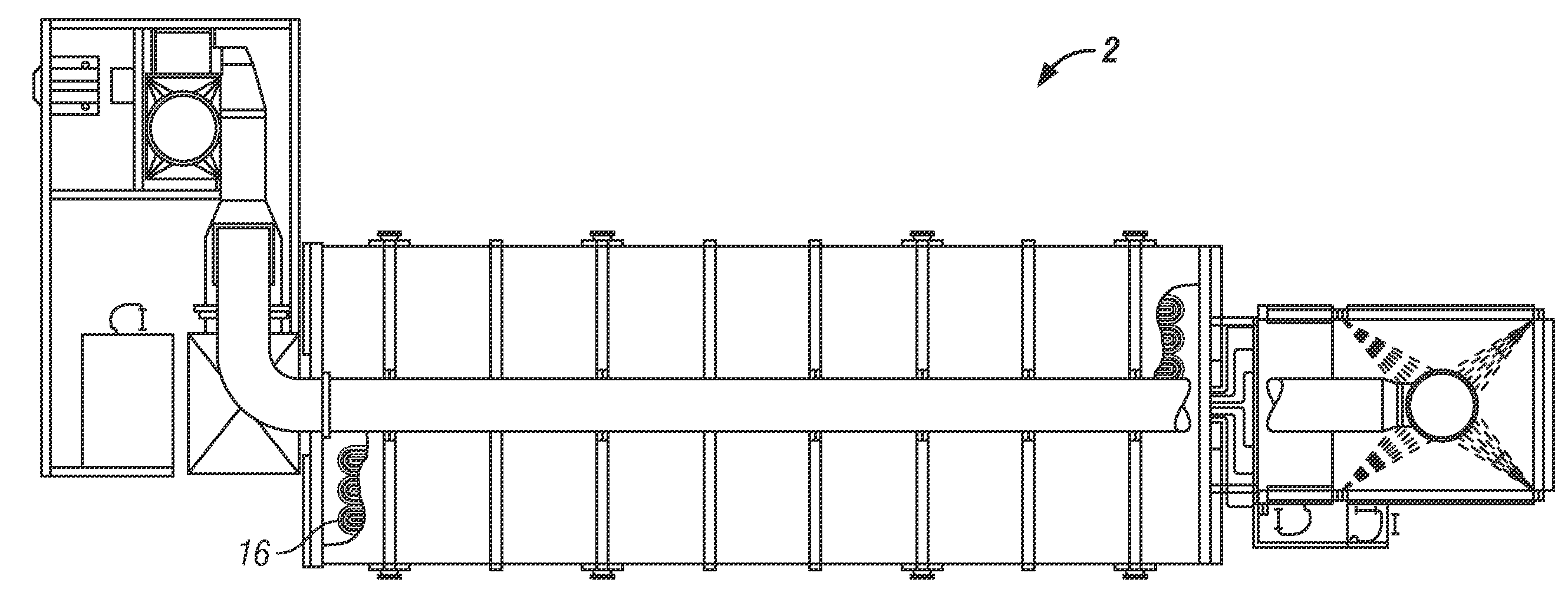

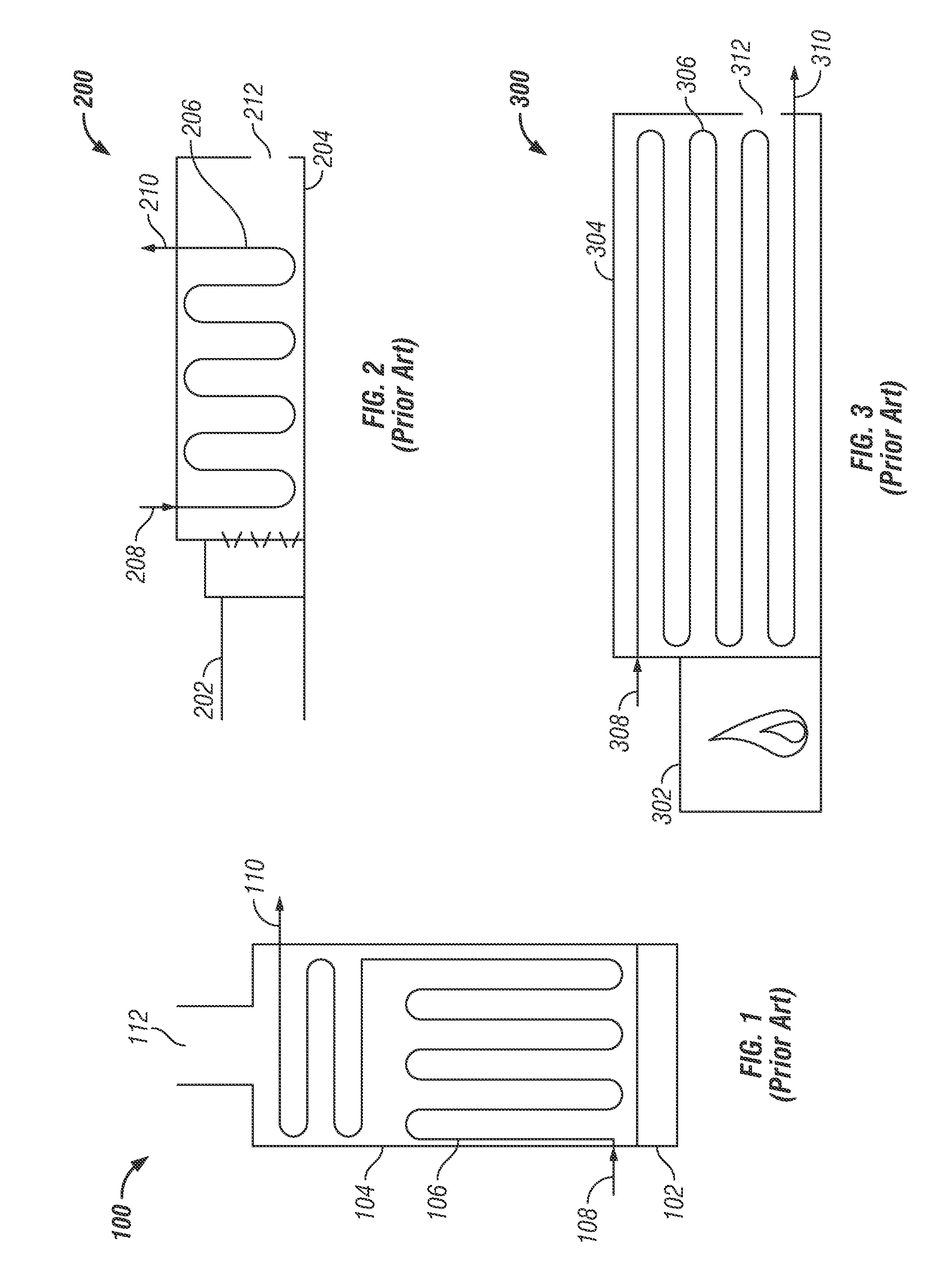

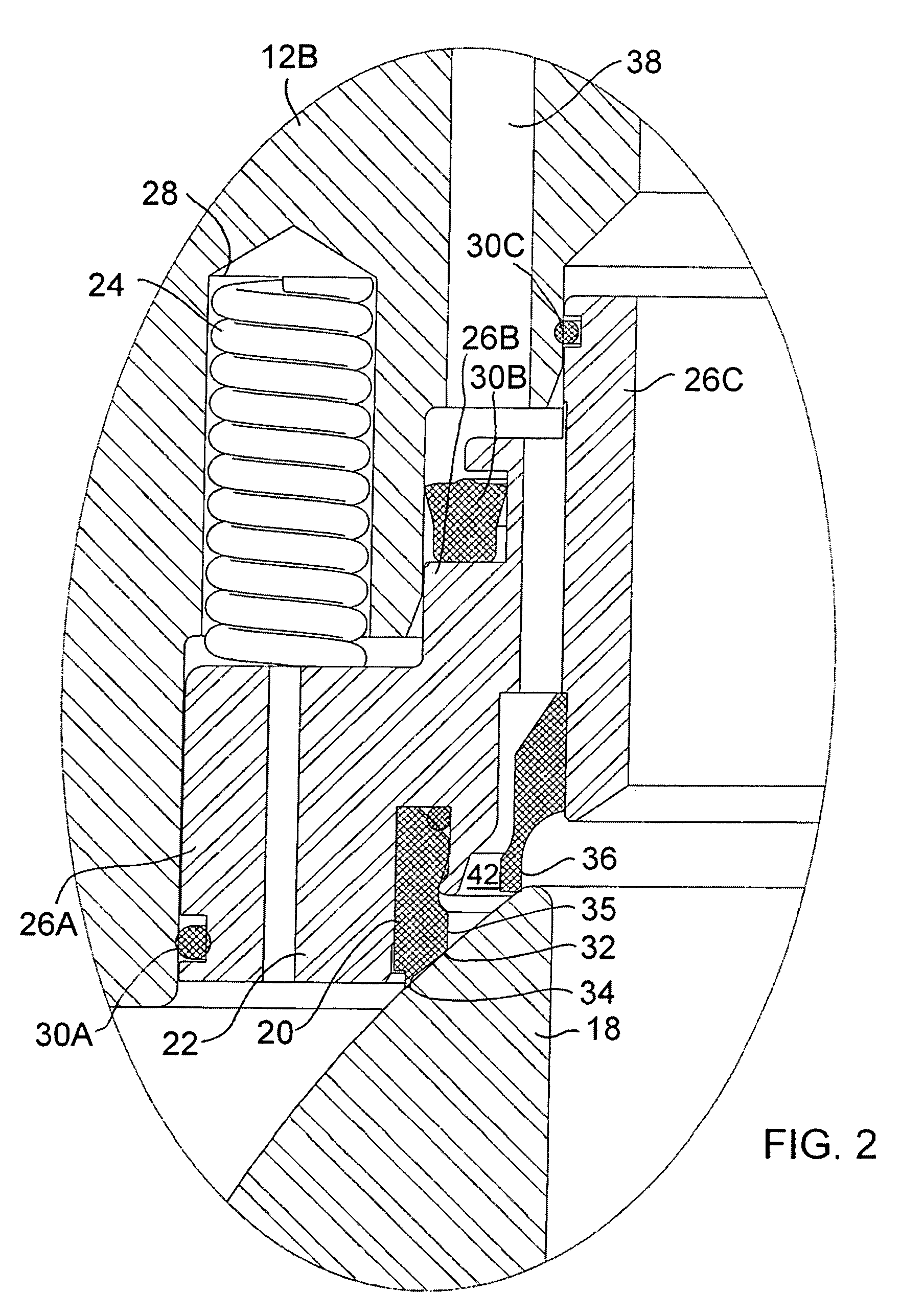

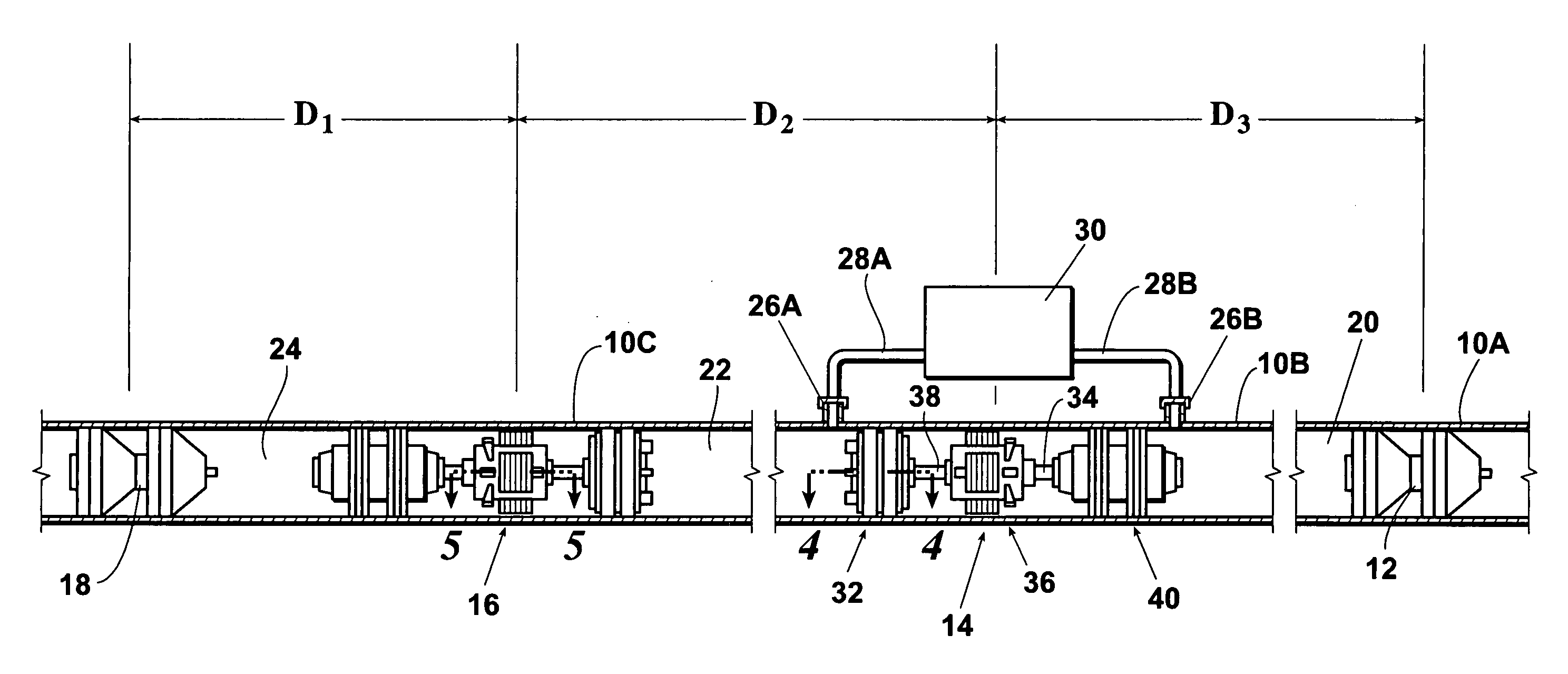

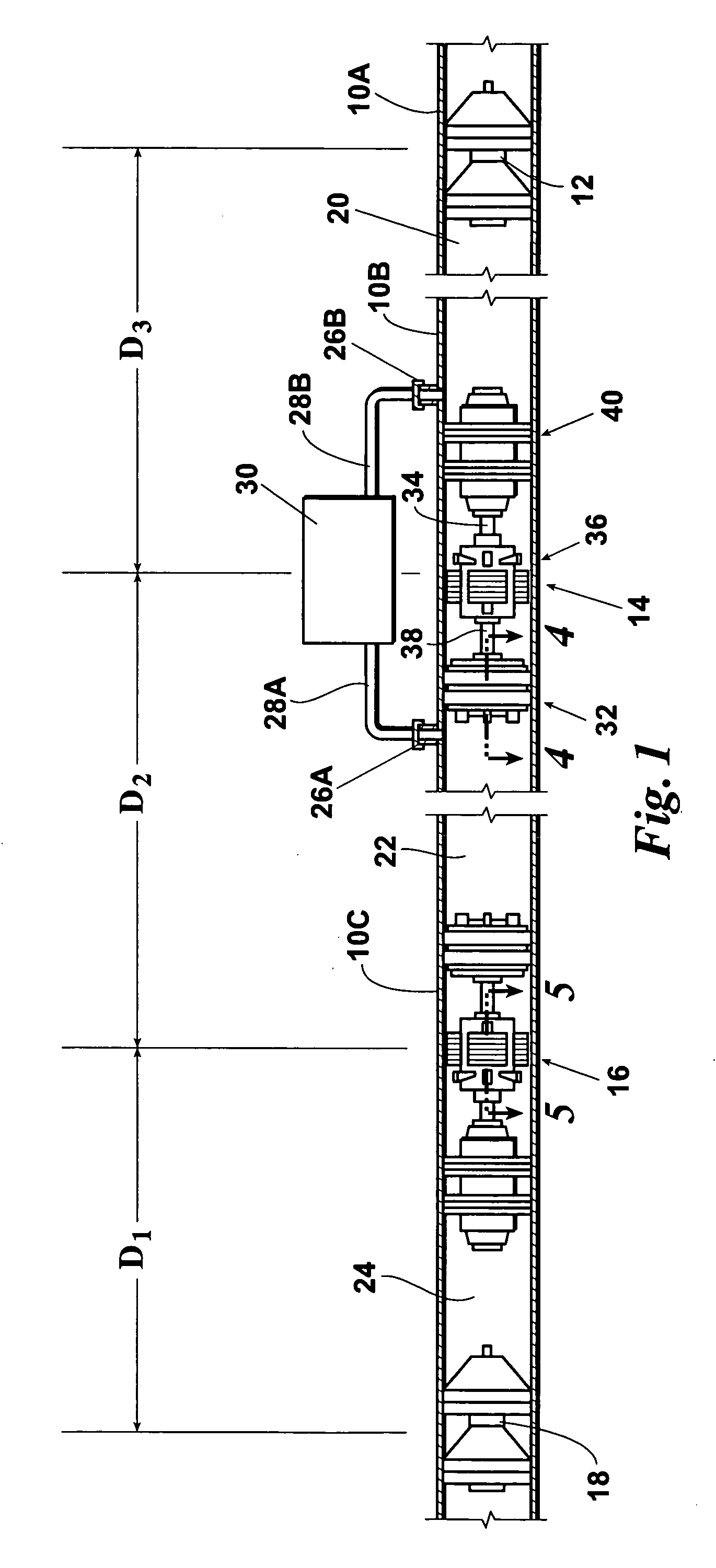

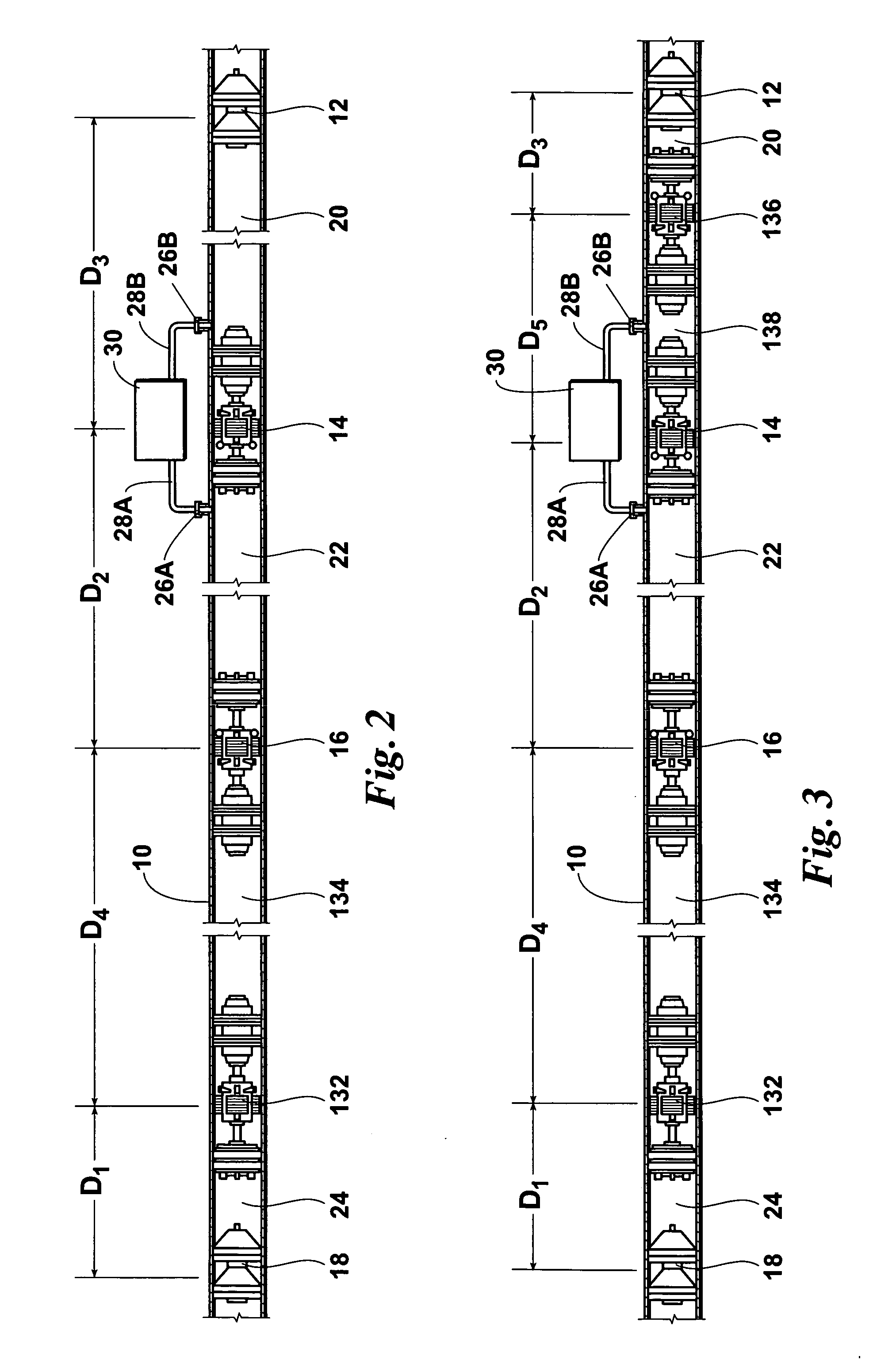

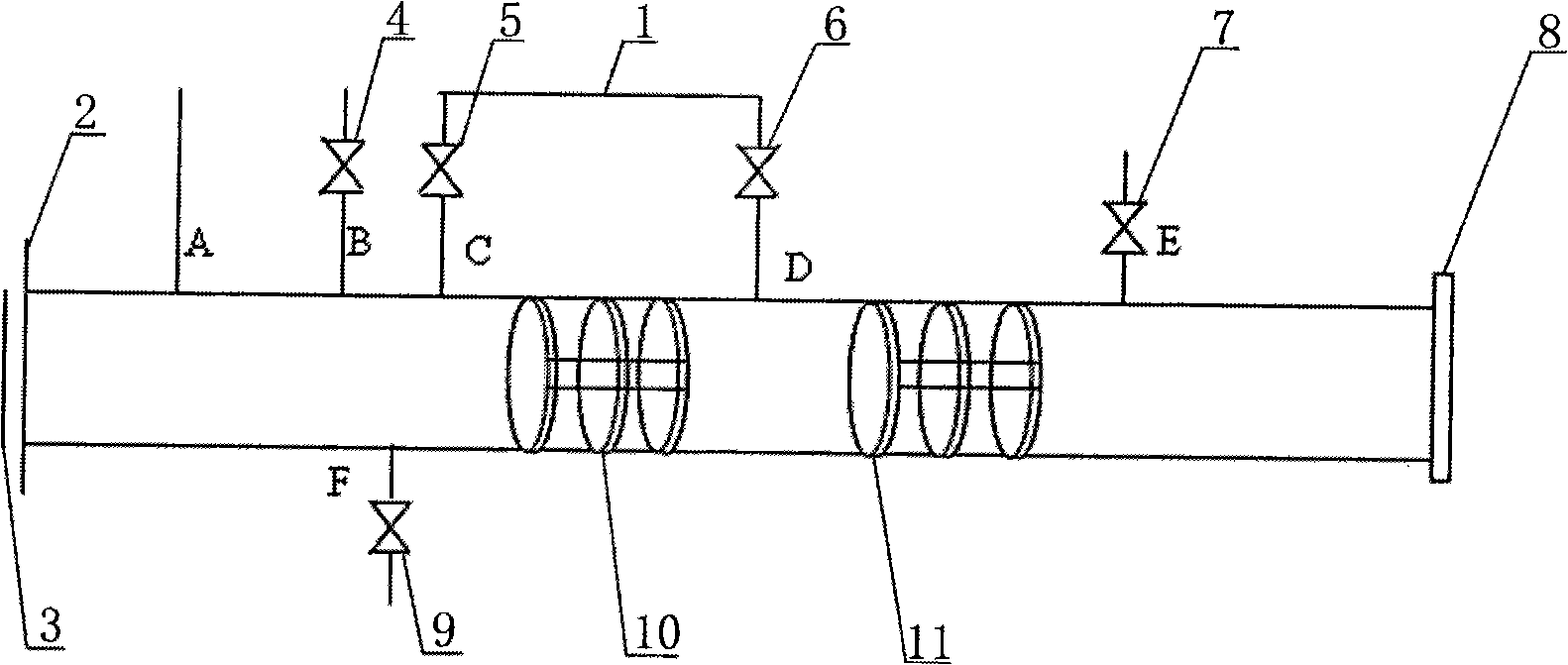

Online pigging system and method

The disclosure provides a heat transfer system having a tubing coil for heating fluid flowing therein, where the tubing coil can be pigged (descaled) while operationally online, instead of offline. The online system uses an assembly of valves and associated equipment to connect to a pig launcher and pig receiver while the system is online. A valve opens and the pig launches into the flow stream under pressure through the valve and travels along the tube with the fluid. The system continues to produce heated fluid with the pig in the flow path. A pig receiver receives the pig after the pigging, and then is isolated from the flow path of the heated fluid by another valve. The pig launcher, pig receiver, and pig are removed, and this process is repeated for any other passes in the tubing coil.

Owner:TECH FRANCE SA

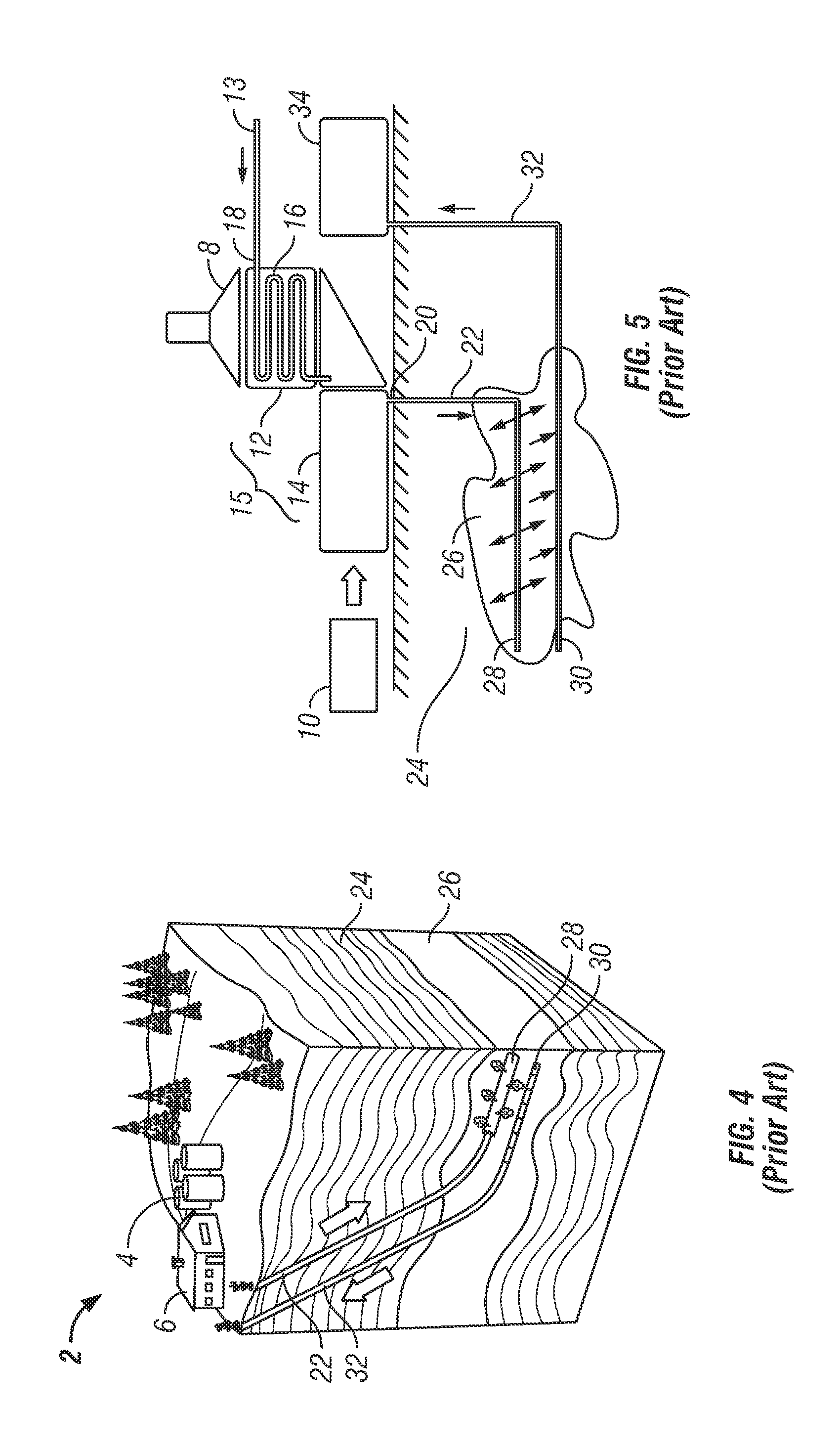

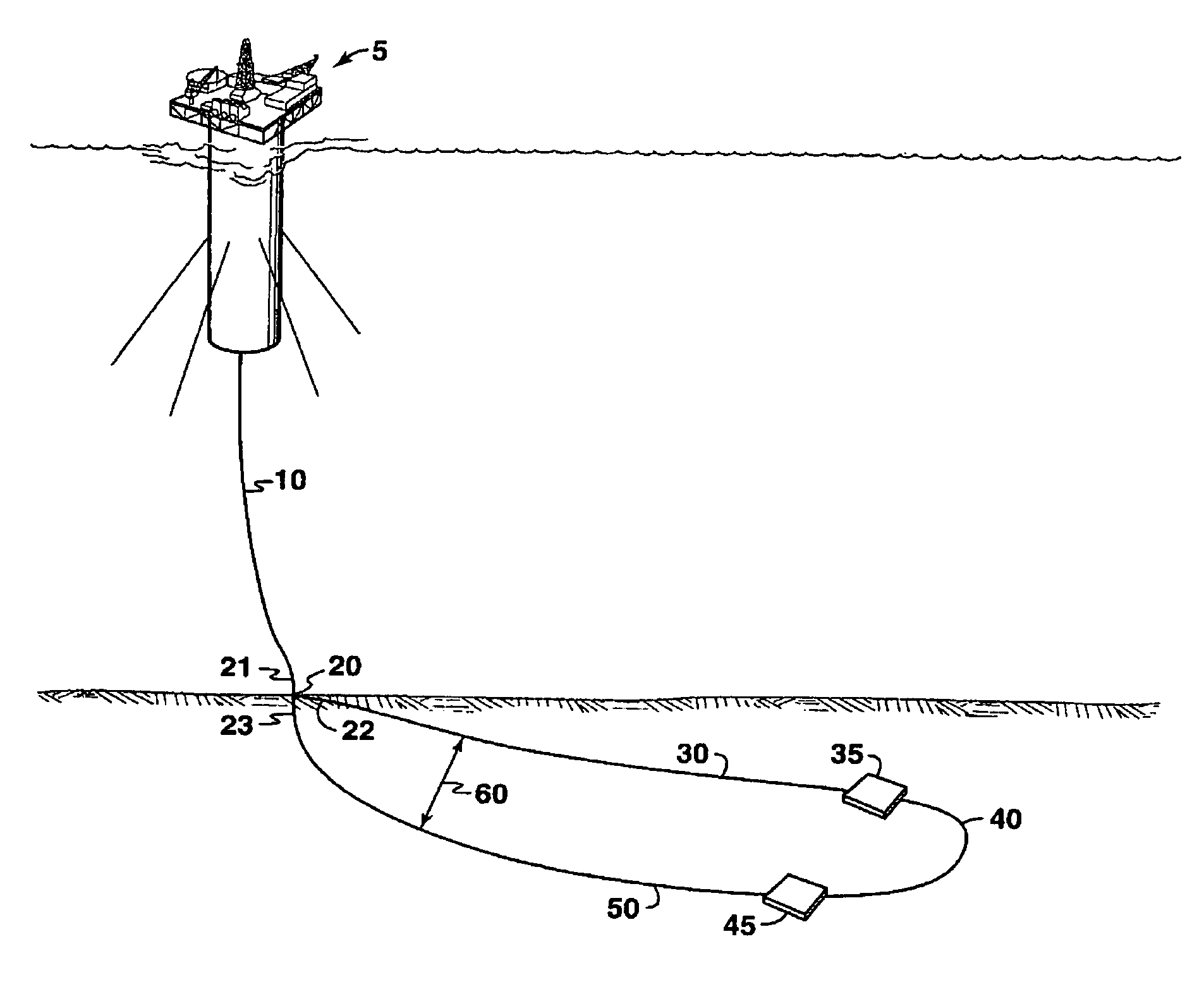

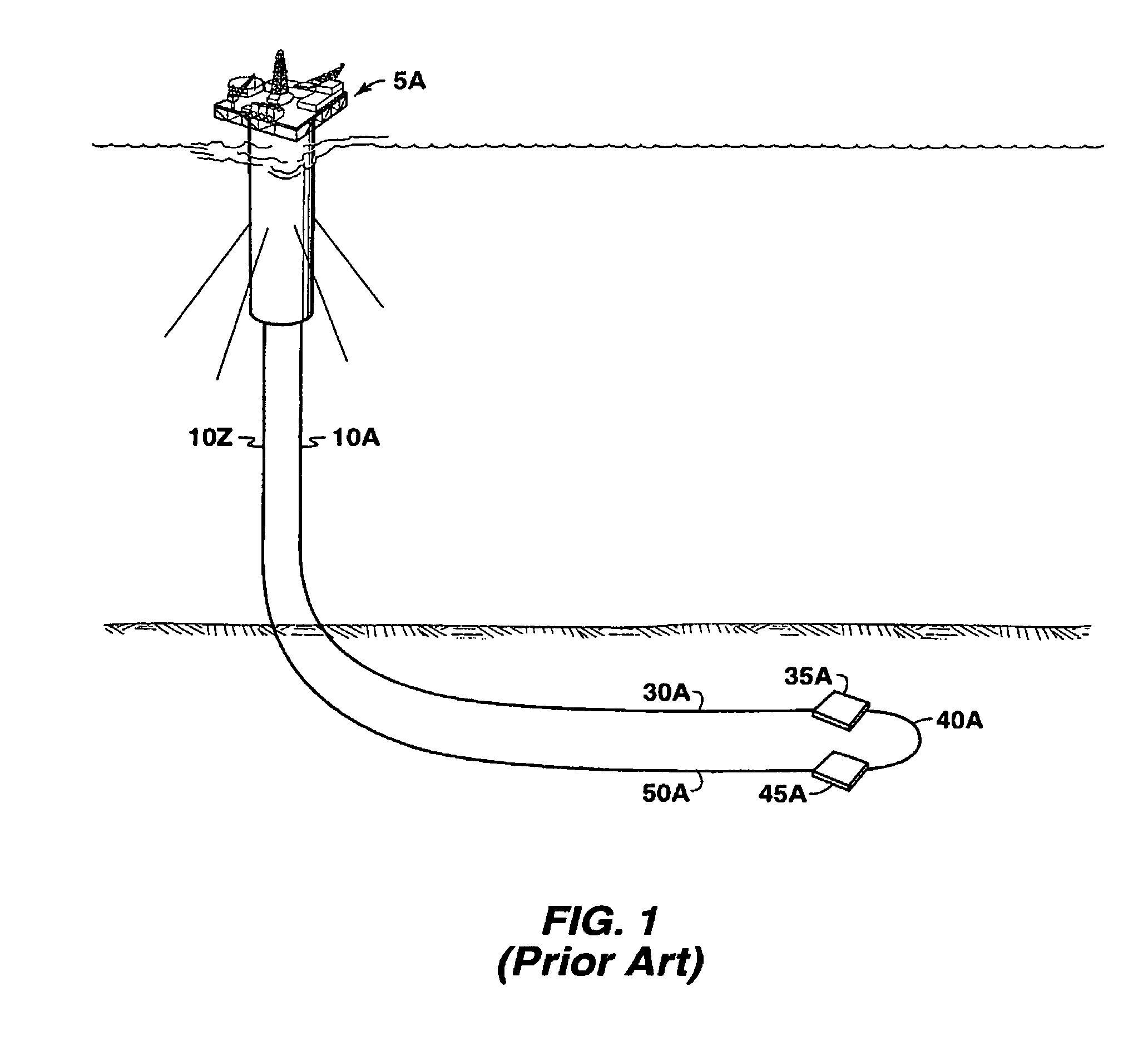

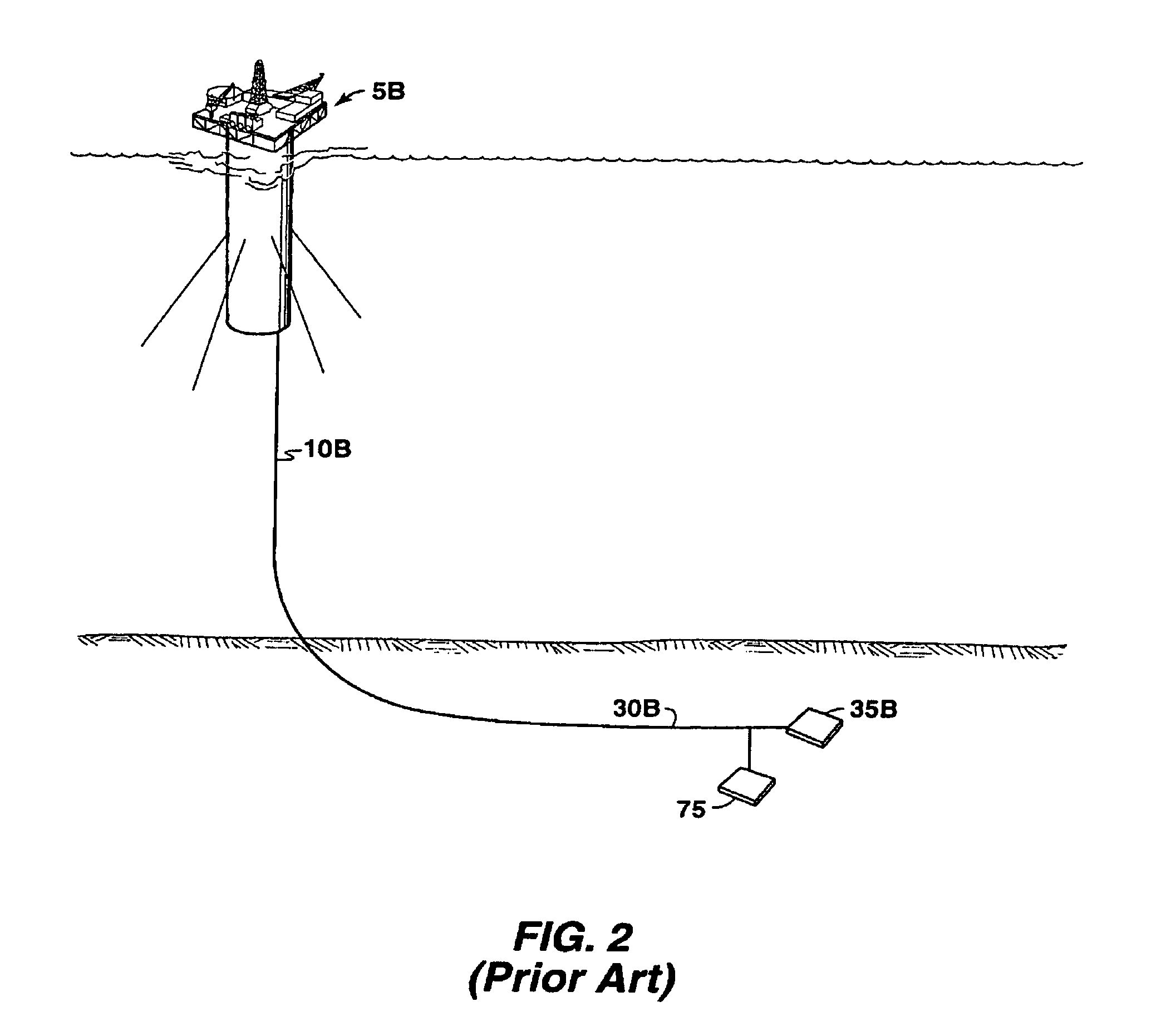

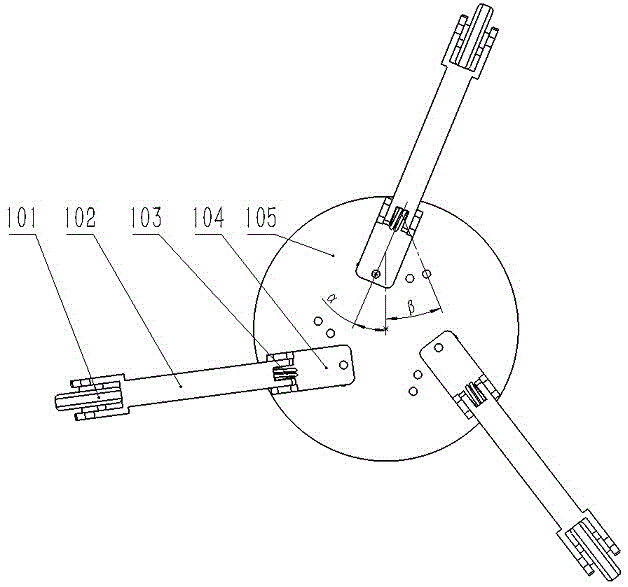

Piggable flowline-riser system

This invention relates to a flowline-riser production system for the recovery of hydrocarbons from offshore wells, and a method for pigging the interior surfaces of the riser and flowlines. More particularly, this invention is a piggable flowline-riser system in which a pig is launched from or near a host production facility, down a riser into a looped flowline and returned up through the same riser. According to one embodiment of the invention, there is a piggable flowline-riser system for producing hydrocarbons comprising a riser, a “Y” joint and a looped flowline, wherein the looped flowline is in fluid communication with at least one subsea well.

Owner:EXXONMOBIL UPSTREAM RES CO

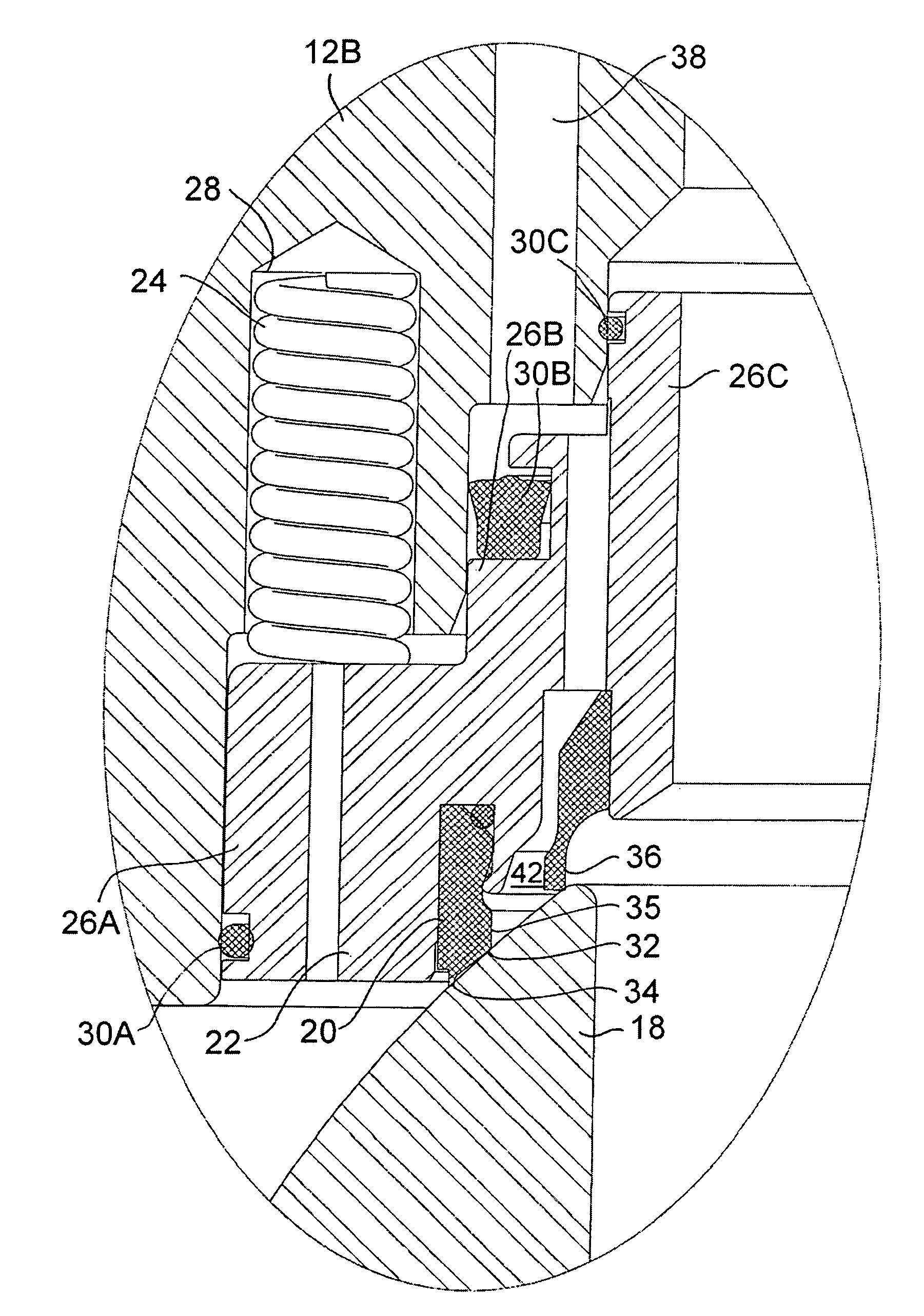

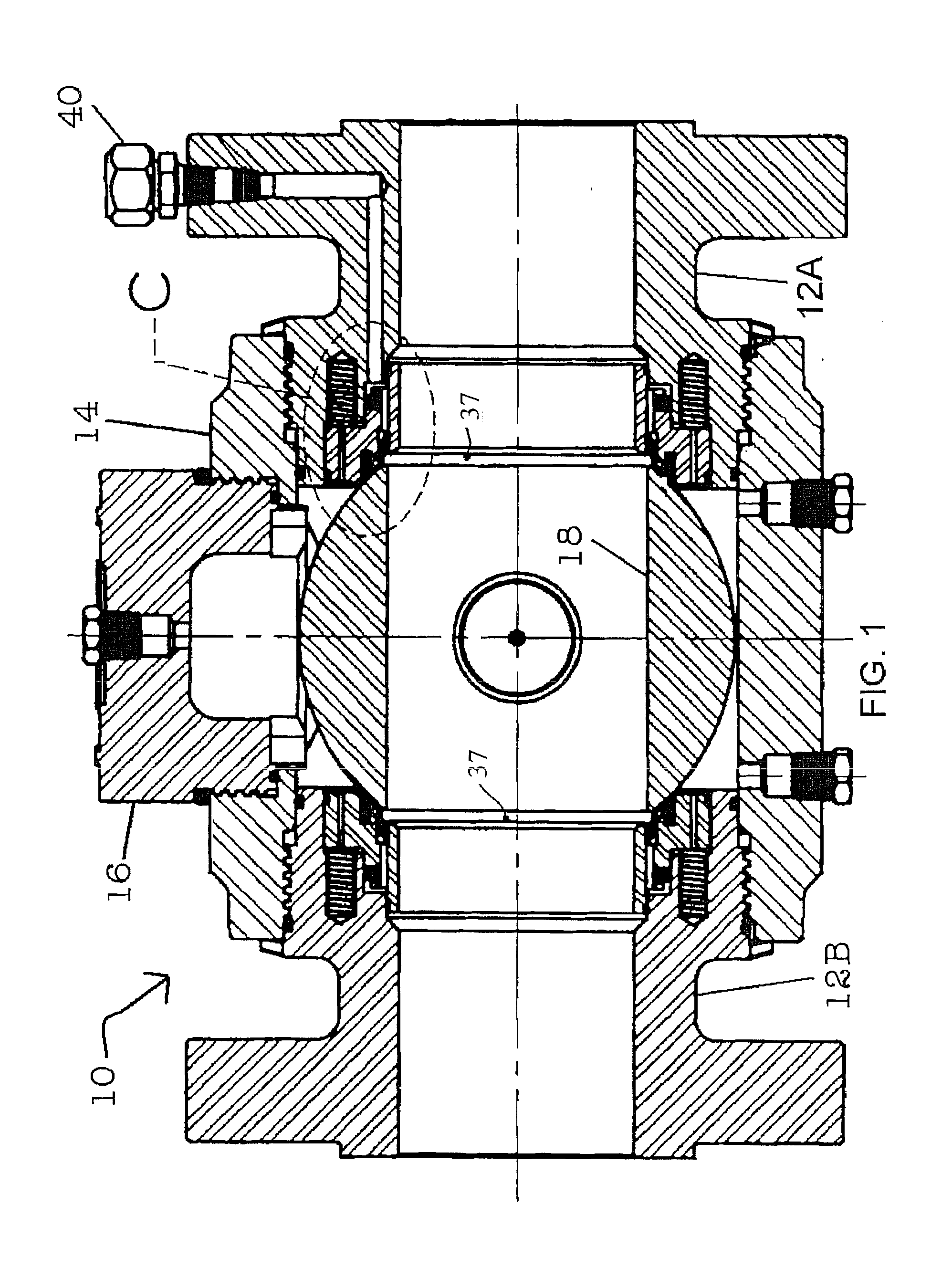

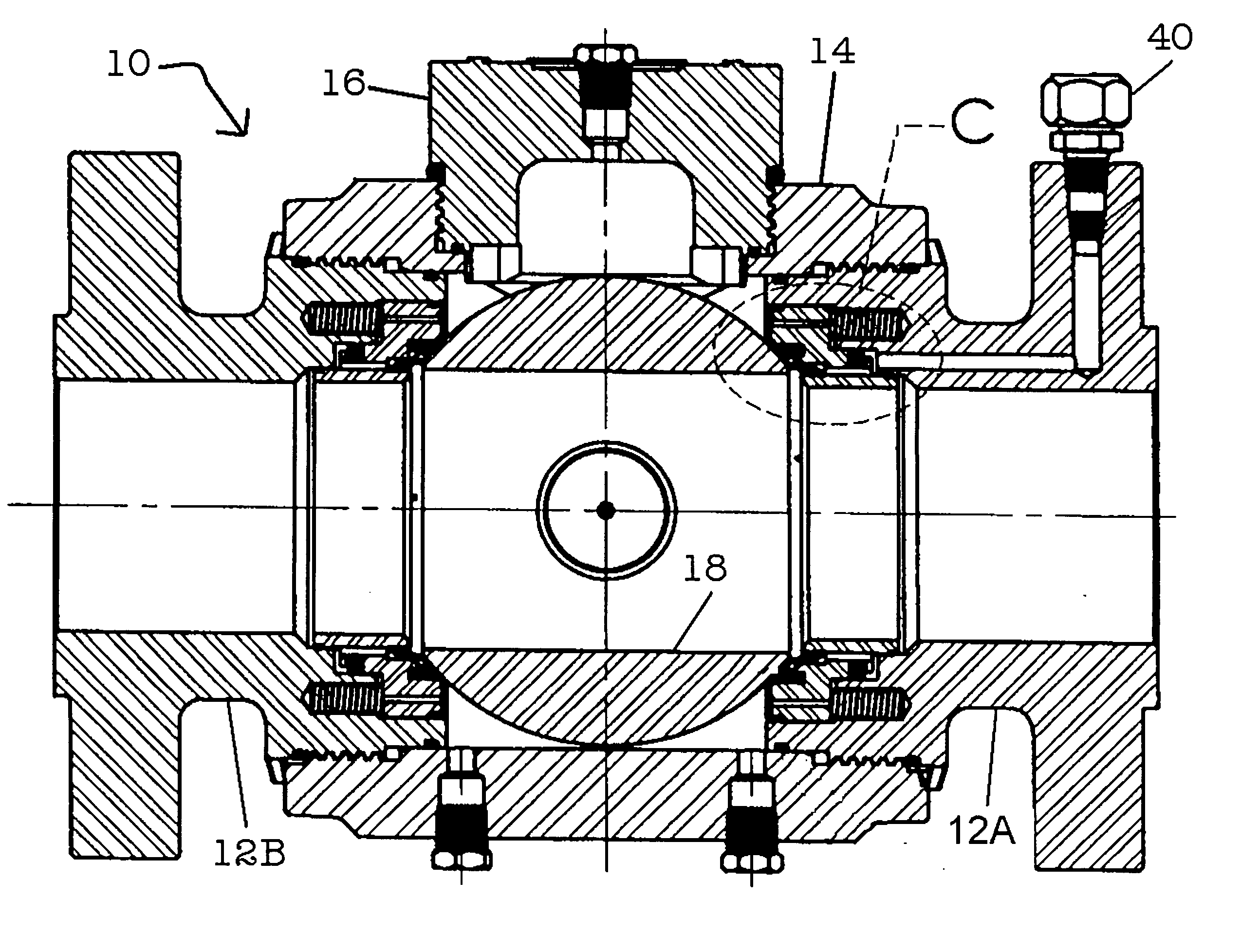

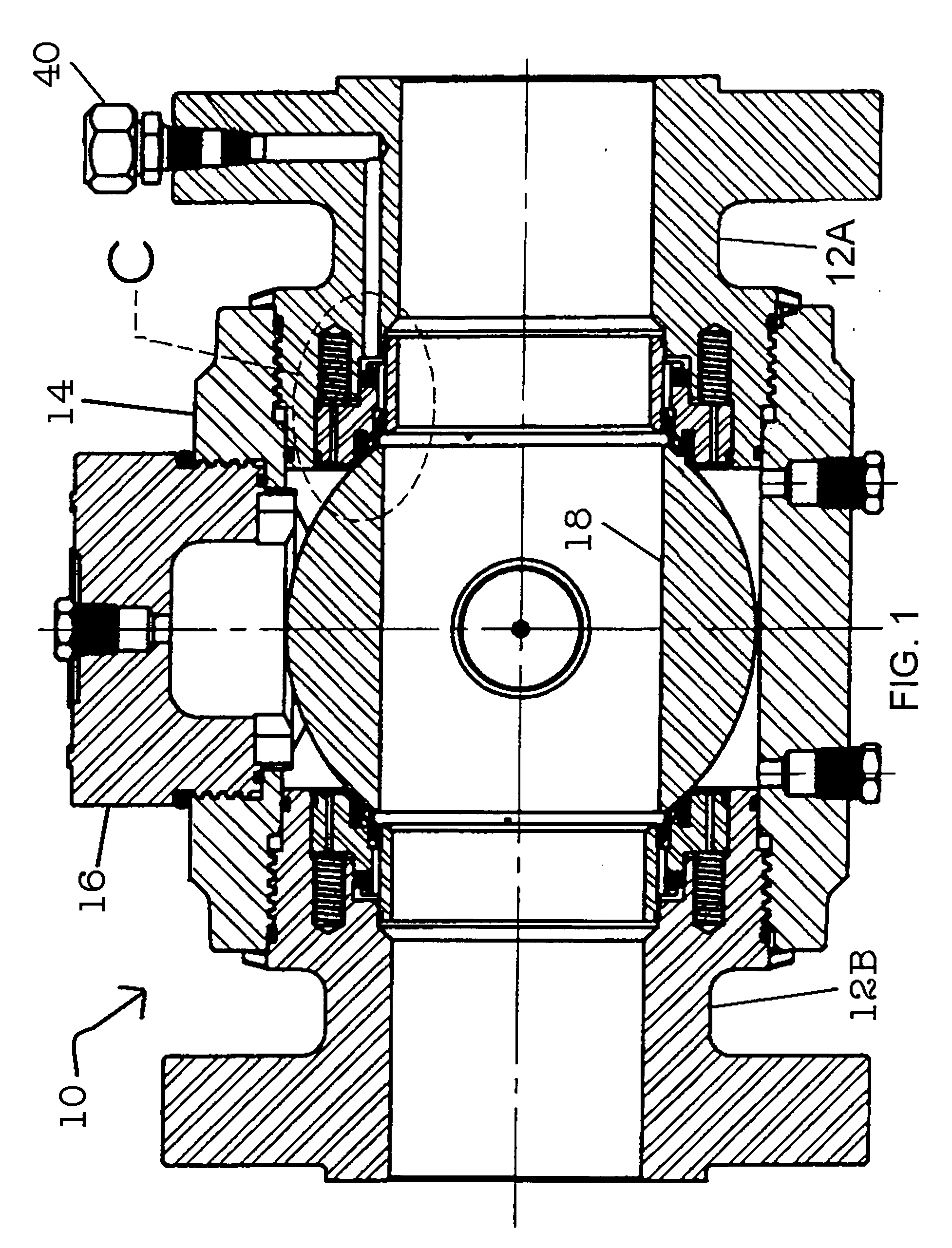

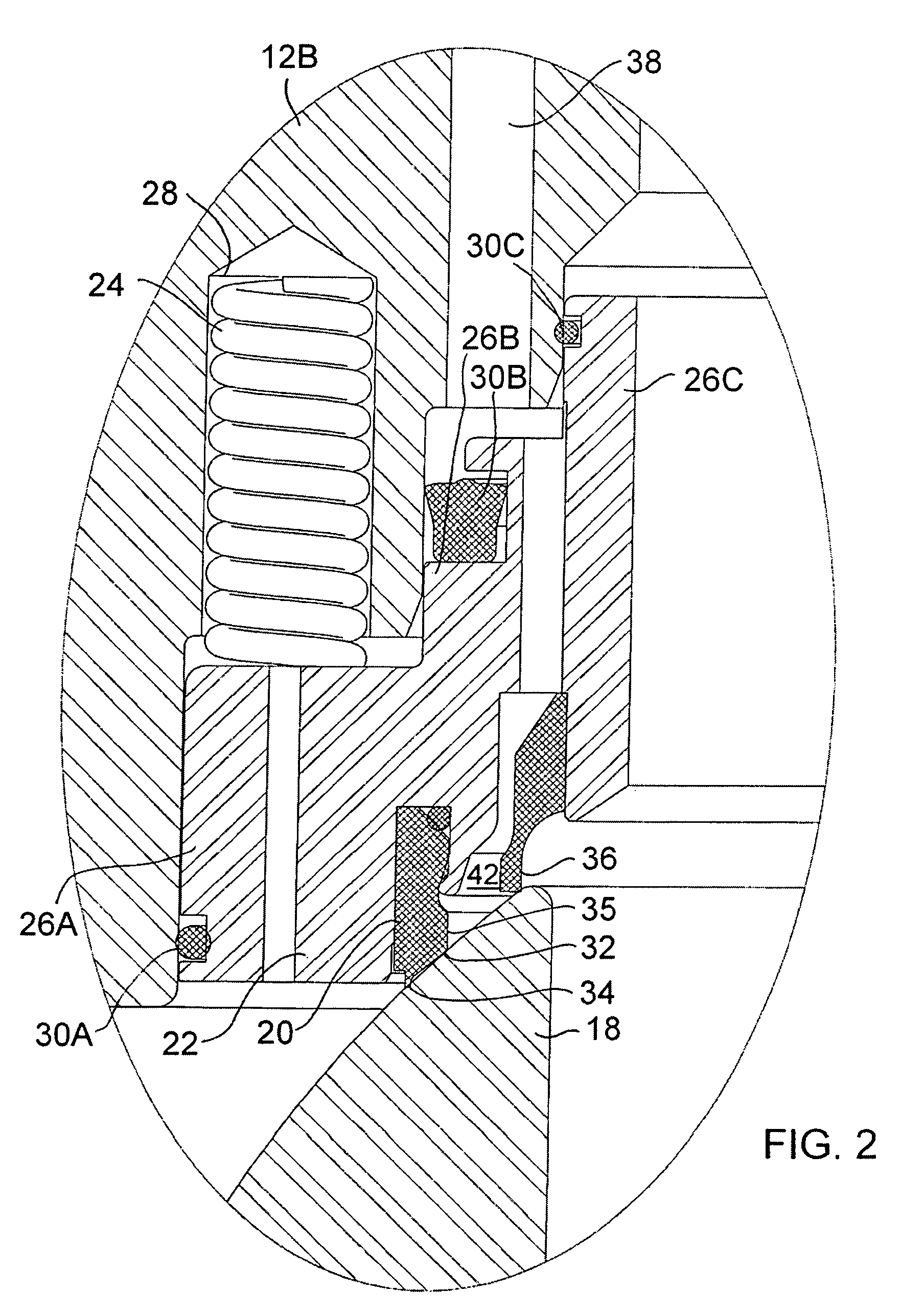

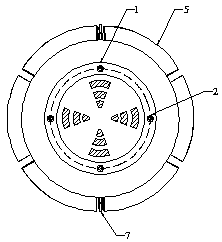

Pigging ball valve

A pigging ball valve with a housing and ball core supported for rotation within the housing. The ball core sits on a valve seat, which is supported by a seat carrier. The valve seat carrier has three distinct diameters that locate the seat in the housing and thus provides an anti-cocking feature. A seat insert has a pressure sealing surface and wiper lip on the outer diameter of the pressure sealing surface. An internal seat deflector ring is provided inside of the pressure sealing surface. The seat carrier is spring loaded.

Owner:ARGUS MACHINE

Methods and systems for hydrostatic testing a pipeline

ActiveUS20070113622A1Increase pressureRelieve stressDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesPiggingEngineering

A method of hydrostatic testing a selected section of a pipeline having fluid flow therethrough, including the steps of introducing into the pipeline a pig train including a leading seal pig, a supply liquid slug, a first isolation tool, a test liquid slug and a second isolation tool; permitting the train to traverse the pipeline interior by the force of fluid flow until the lead isolation tool is forwardly of and the second isolation tool is rearwardly of the selected selection of the pipeline; securing the position of the pig train by applying exteriorly of the pipeline appropriate signals to actuate the isolation tools to each engage and seal the interior of the pipeline trapping the test liquid slug therebetween; and pumping liquid from the supply liquid slugs into the test liquid slug to a hydrostatic testing pressure. In addition to testing, the pipeline can be repaired by moving the pig train into position where a defective area can be isolated by additional isolation tools.

Owner:TDW DELAWARE INC

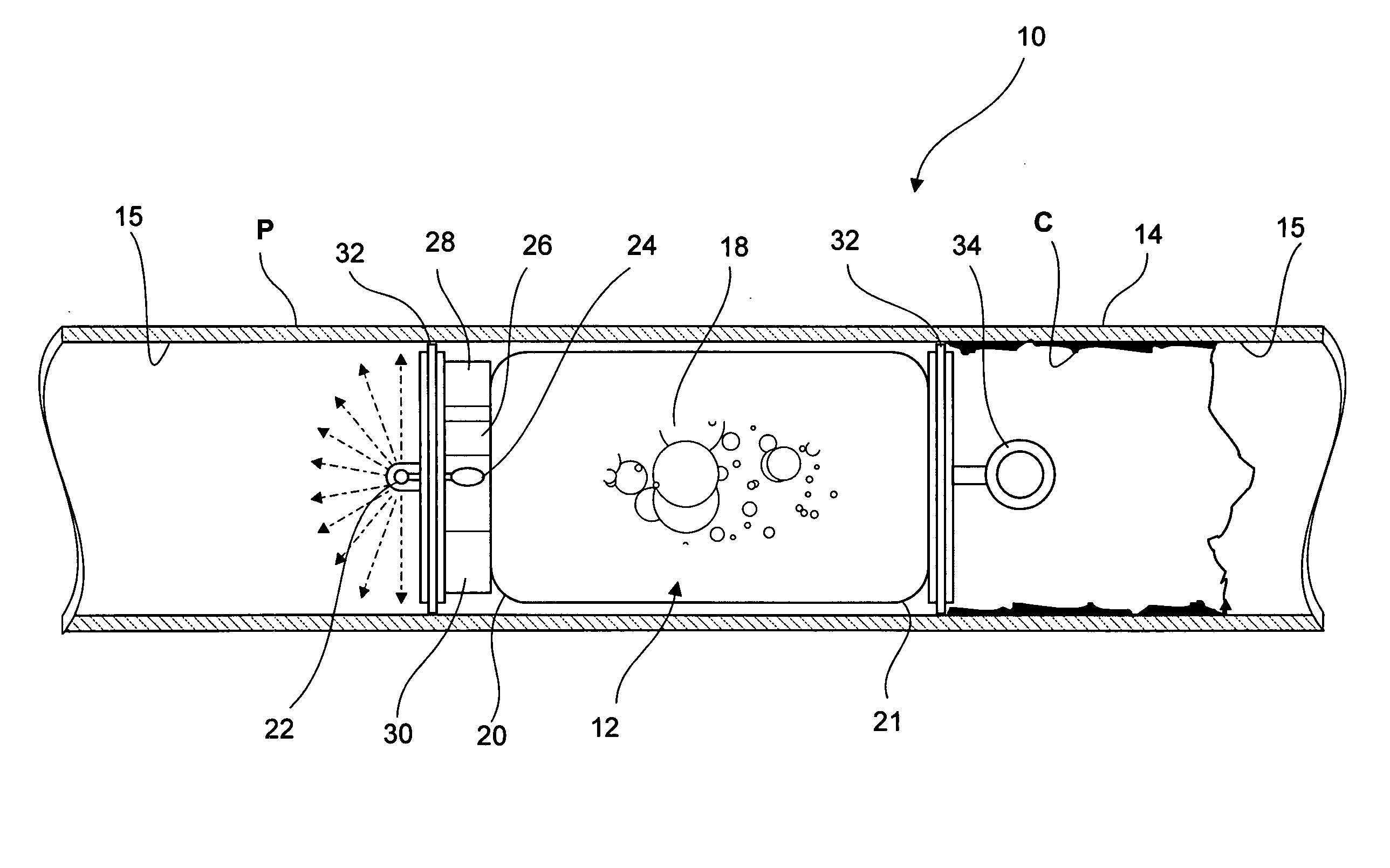

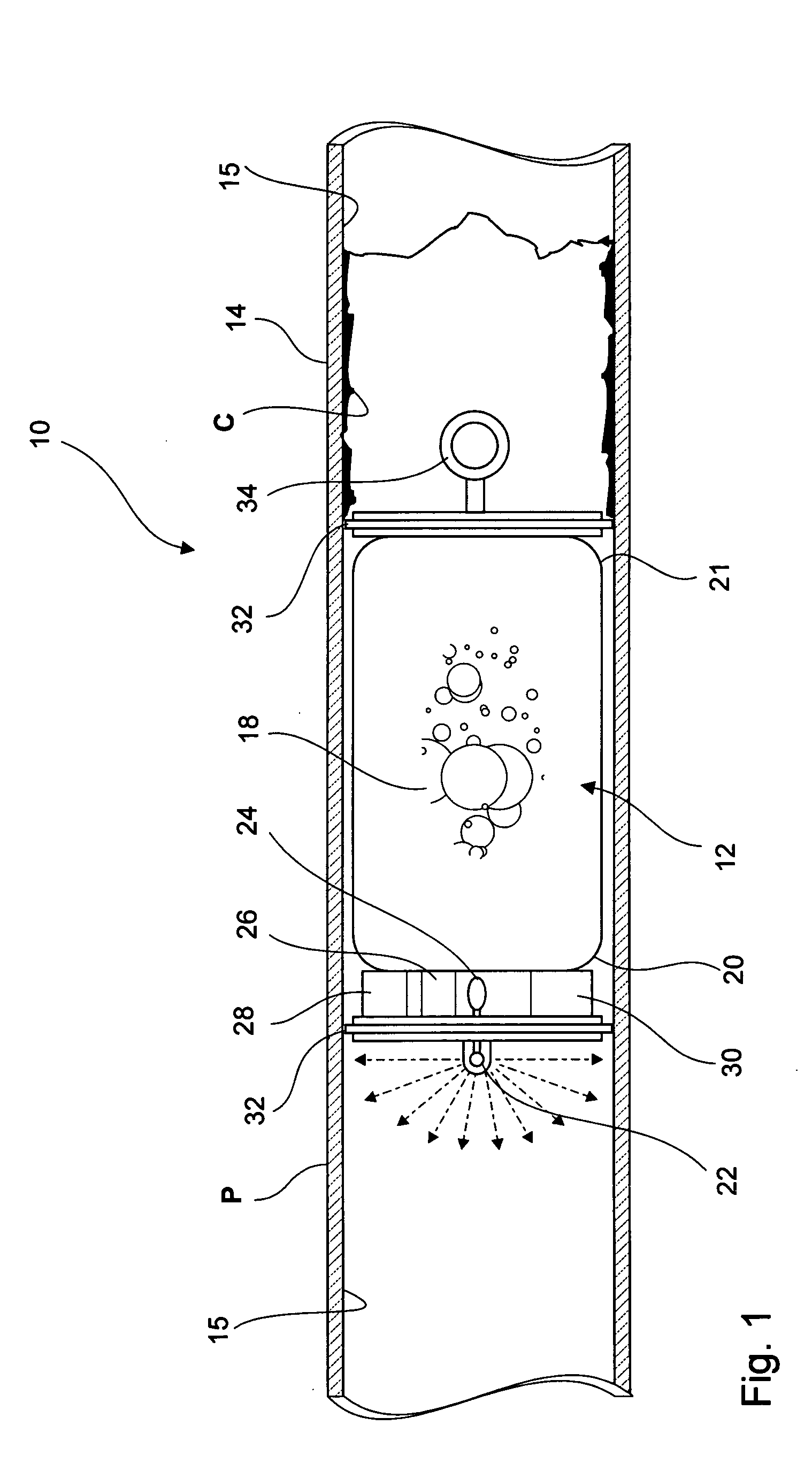

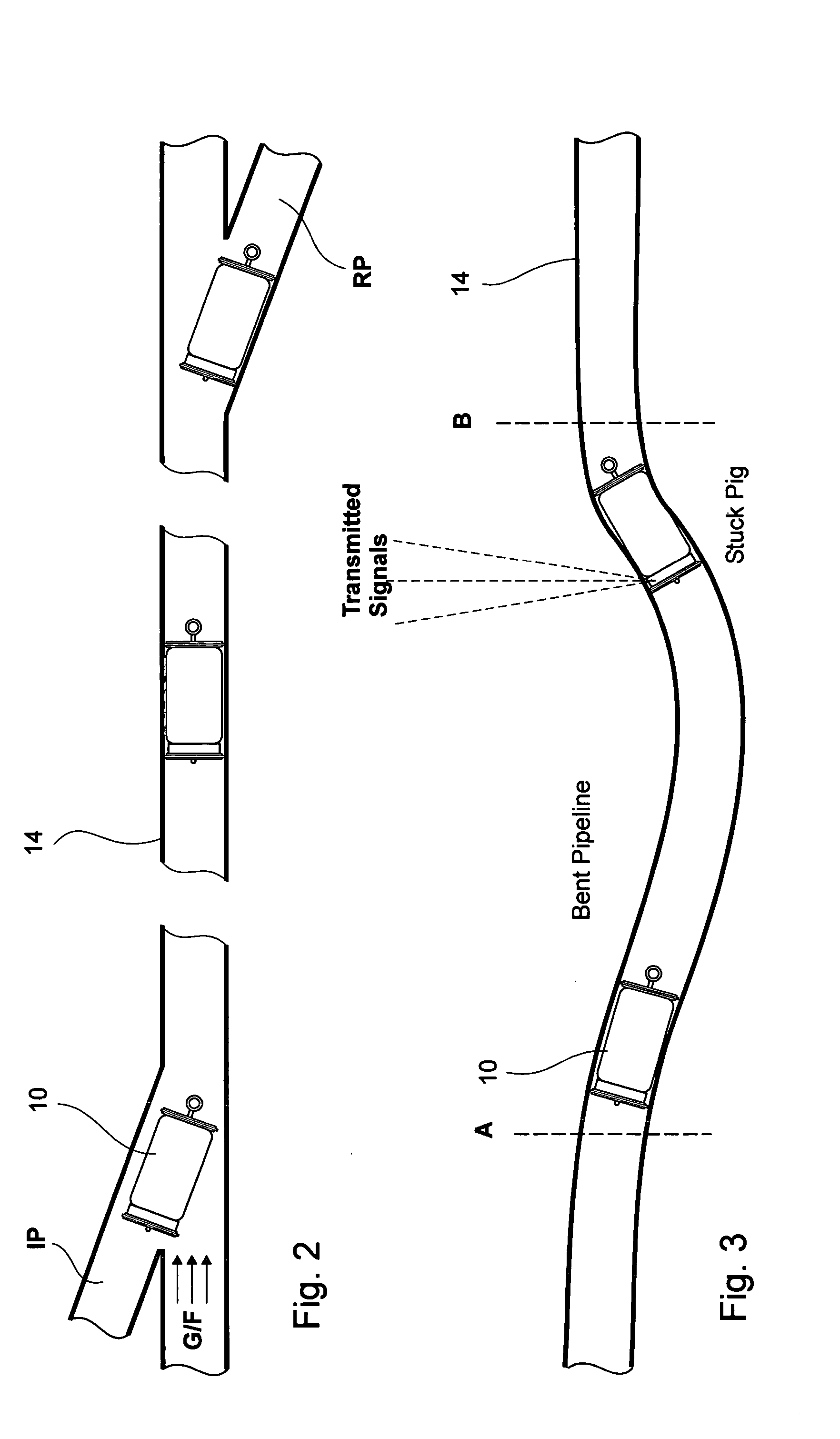

Device and method for transporting and delivering liquid chemical to inside natural gas pipeline

InactiveUS20050115588A1Improve pipeline cleaningEconomical to useHollow article cleaningElectrostatic cleaningCompound (substance)Engineering

A device for transporting and delivering chemical to interior walls of pipelines employs a pig having a tank which contains pressurized chemical therein. Operably connected to the tank is a nozzle which is equipped to deliver the chemical from the tank onto the inner pipeline walls as the pig is transported through the pipeline. The pig is equipped with a device to deliver the chemical at a predetermined point within the pipeline and includes a position tracking device to enable location thereof. A method of cleaning and treating a pipeline is also provided.

Owner:RAMALHO GREG

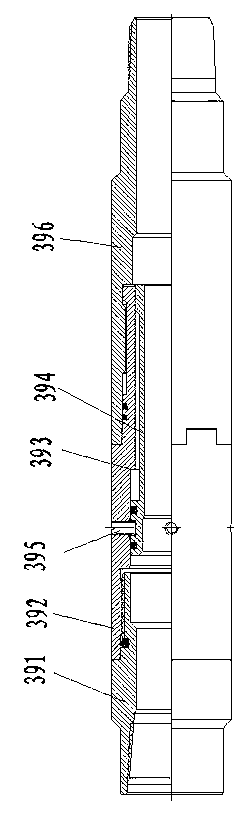

Fracturing operation method of multistage hydraulic jet staged fracturing tubular column

ActiveCN103266875ASimple working method of fracturingFast constructionDrilling rodsFluid removalThermodynamicsLine tubing

The invention discloses a fracturing operation method of a multistage hydraulic jet staged fracturing tubular column. The method comprises the following steps that S1: pigging and well flushing are carried out firstly to the multistage hydraulic jet staged fracturing tubular column before descent; S2: the multistage hydraulic jet staged fracturing tubular column is assembled; S3: a drilling tool is fed and adjusted to a construction position; and S4: wellhead and surface pipelines are arranged, and the pressure is tested. The fracturing operation method is simple, multistage jet packing tools can be connected according to the number of stratums needing acid fracturing, and different stratums are fractured, so that six or more sections of hydraulic jet and fracturing combined construction can be realized currently by one time of drilling in a mode of dragging the tubular column, the tandem connection of the multistage jet packing tools can greatly accelerate the construction speed, and the construction time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

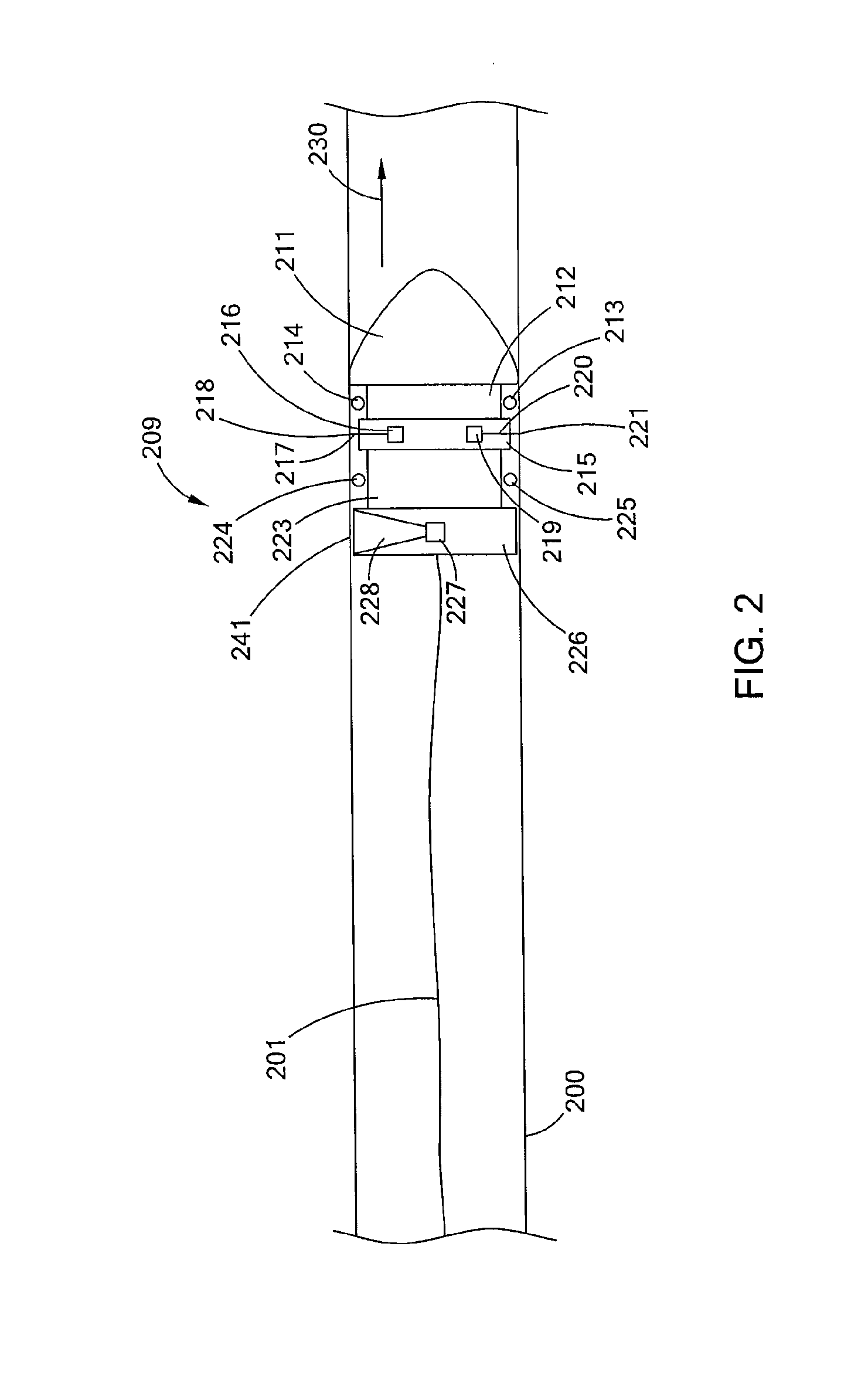

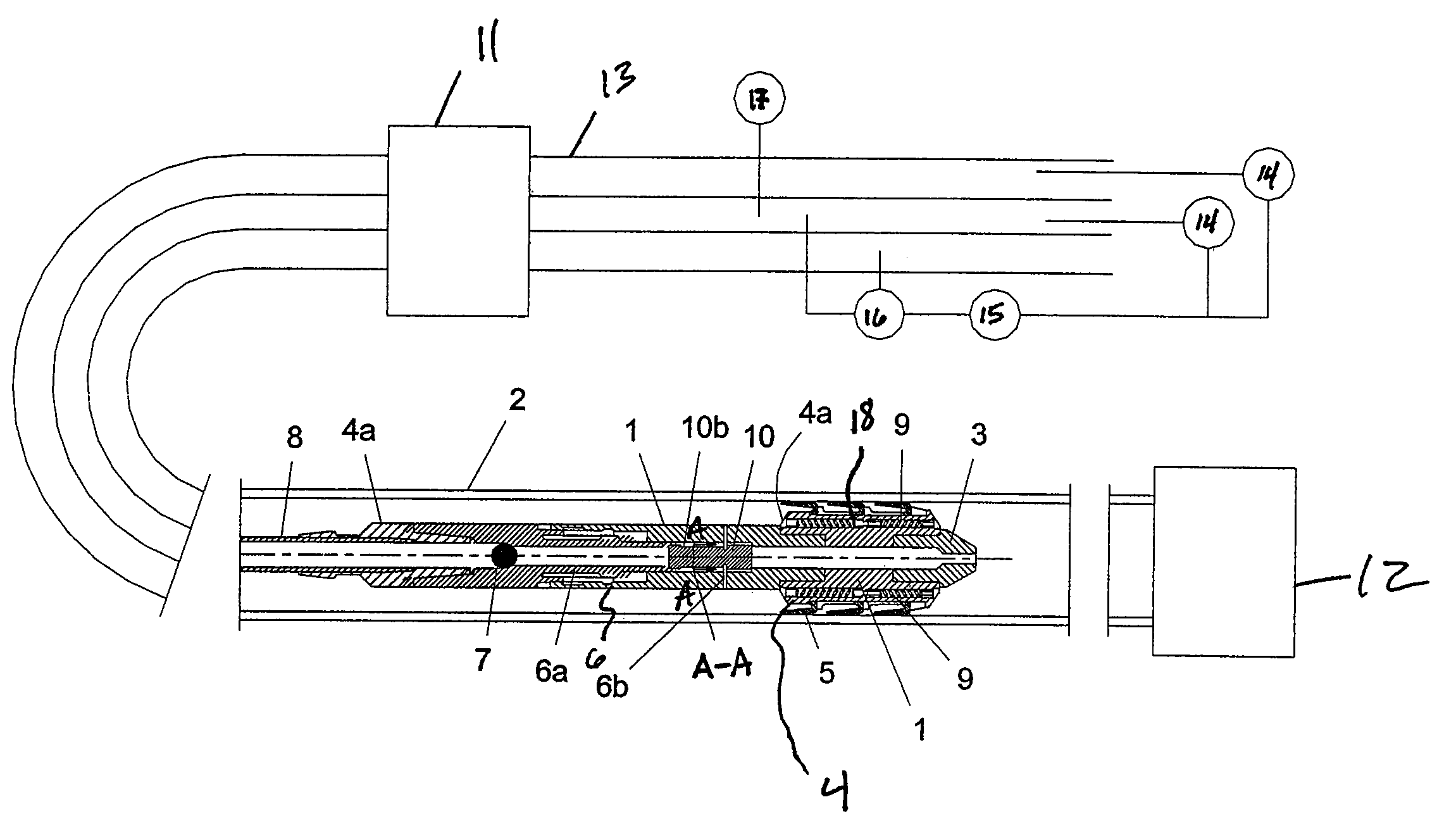

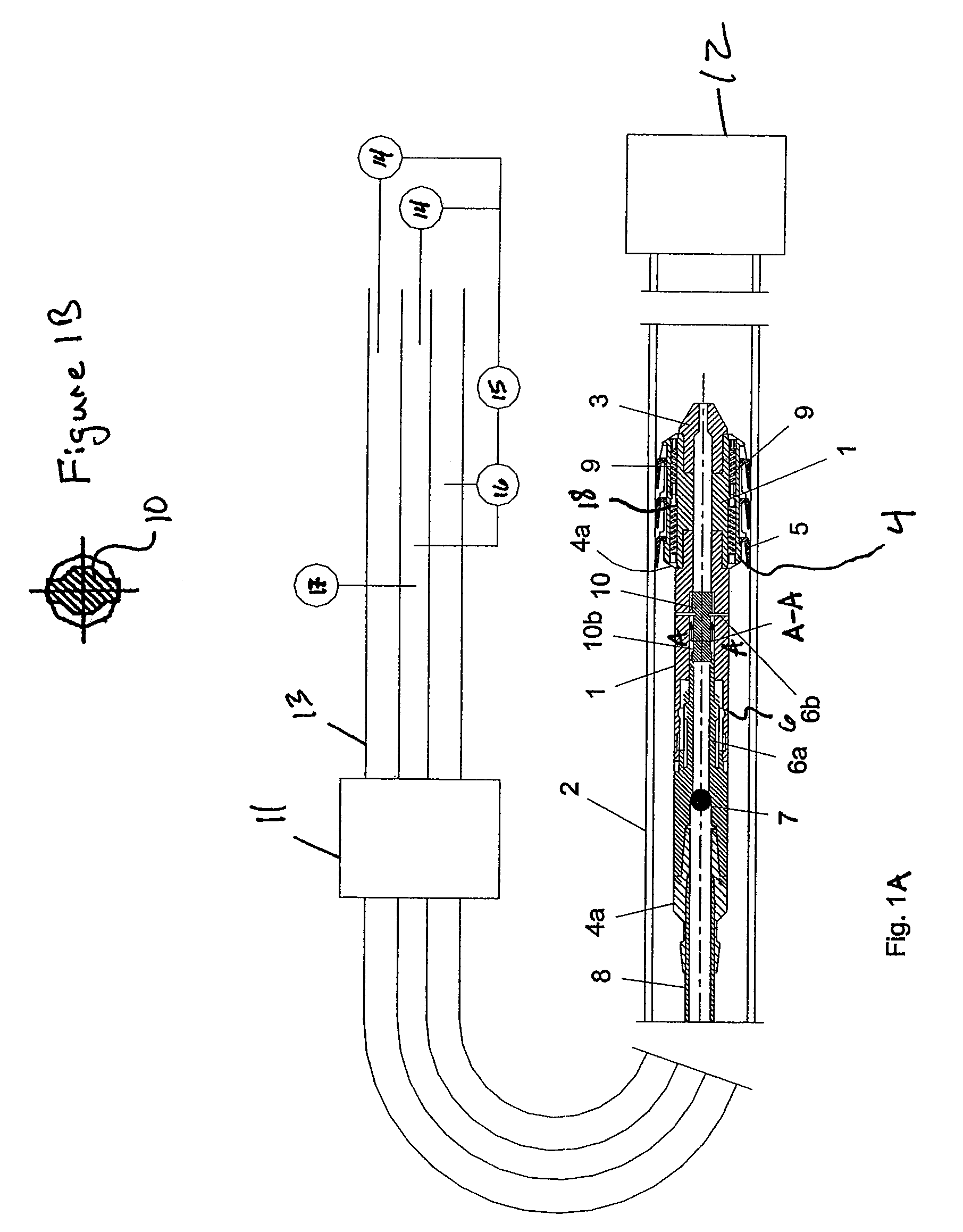

Thruster pig

ActiveUS20050283927A1Uniform sectionCable can be longHollow article cleaningPipe elementsLine tubingDifferential pressure

A thruster pig for sending through a pipe from an entrance facility to a receiving location, for servicing or monitoring, by pumping a thrusting fluid into the pipe to force the pig forward is disclosed. The thruster pig includes a body having a front end and a back end, where the back end includes a reaction surface to which said the thrusting fluid applies a motive force. The body is slightly smaller in diameter than the inner diameter of the pipe. The pig also includes a seal circumferentially arranged on the pig to seal between said body and said pipe. A desired differential pressure is maintained over the pig to urge said pig forward through the pipe by pumping a fluid into the annulus between the pipe and the return flow line while returning fluid through said return flow line utilizing connected servicing or monitoring equipment. A connector releasably connects a return flow line to the pig. The connector includes a shifting mandrel that may be activated to open the connector by a ball pumped through the return flow line, where the ball is retained in the return flow line after releasing the connector. A blanking device is then provided to blank the bore within the pig that is left after the return flow line is disconnected.

Owner:DEN NORSKE STATS OLJESELSKAP AS +1

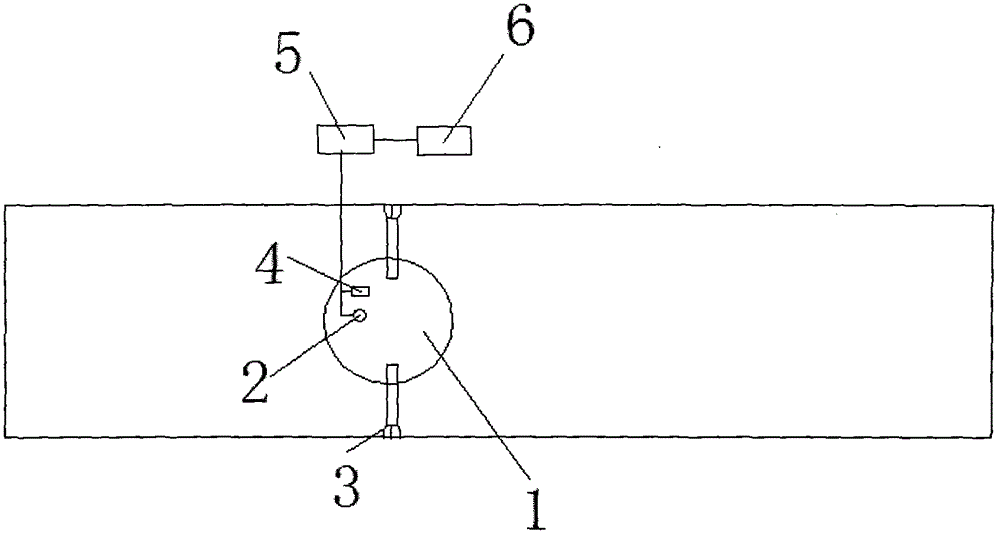

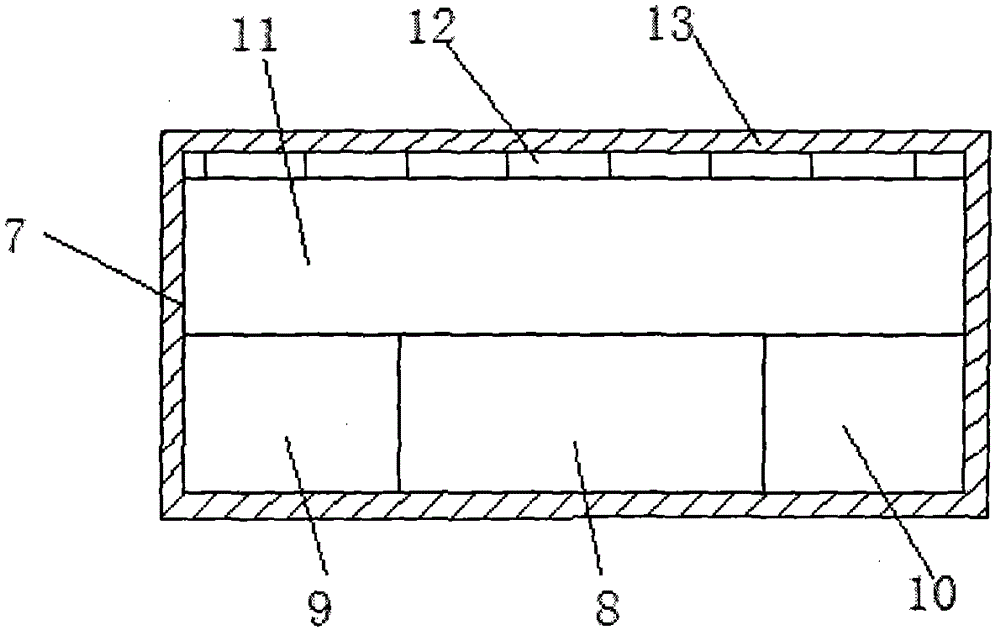

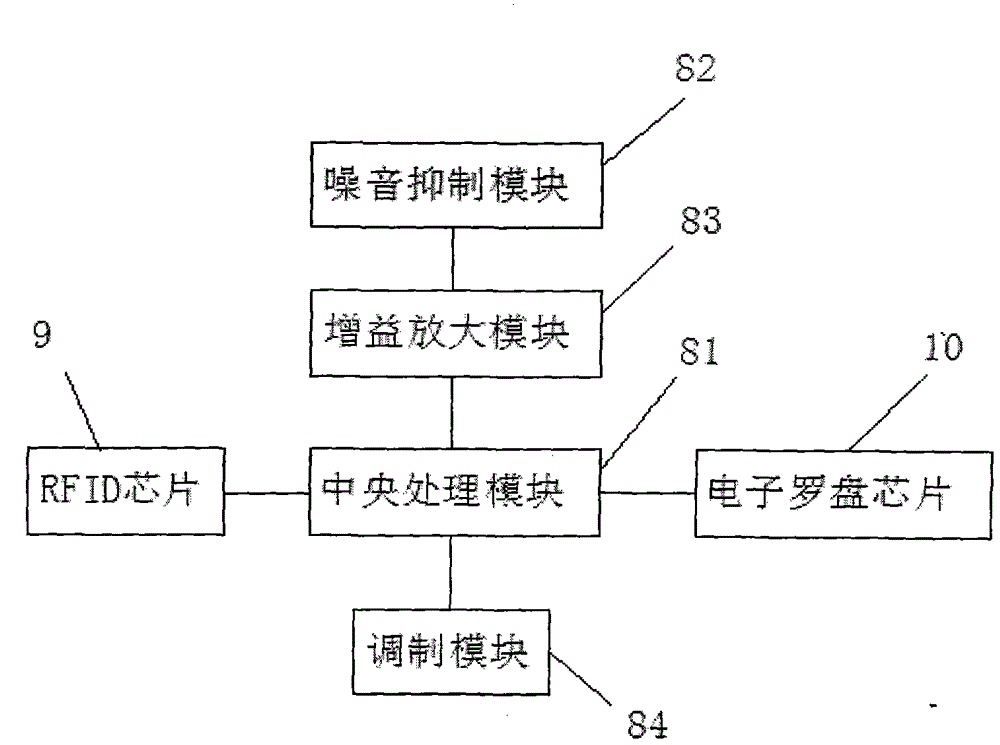

Positioning device for pipeline blockage points

InactiveCN104613320AReduce layoutShock absorberPipeline systemsSatellite radio beaconingDisplay devicePigging

The invention discloses a positioning device for pipeline blockage points. The positioning device for the pipeline blockage points comprises a spherical pig, a GPS positioner, an elastic storage type claw, a fiber optic sensor, a signal collection device and a computer display device. The GPS positioner and the fiber optic sensor are arranged on the spherical pig, the elastic storage type claw is arranged in a hole in the spherical pig, the fiber optic sensor is connected with the computer display device through the signal collection device, the inner end of the elastic storage type claw is connected with the inner wall of the spherical pig through a spring, the outer end of the elastic storage type claw is locked with the outer wall of the spherical pig through a buckle, the GPS positioner comprises a shell, and a GPS chip, a RFID chip, an electronic compass chip, a control circuit board and a lithium battery are arranged in the shell. The positioning device for the pipeline blockage points is simple in structure, convenient to use, reliable in use, accurate in positioning and strong in practicability, and capable of positioning in time and performing breakover.

Owner:XIAN UNIV OF SCI & TECH

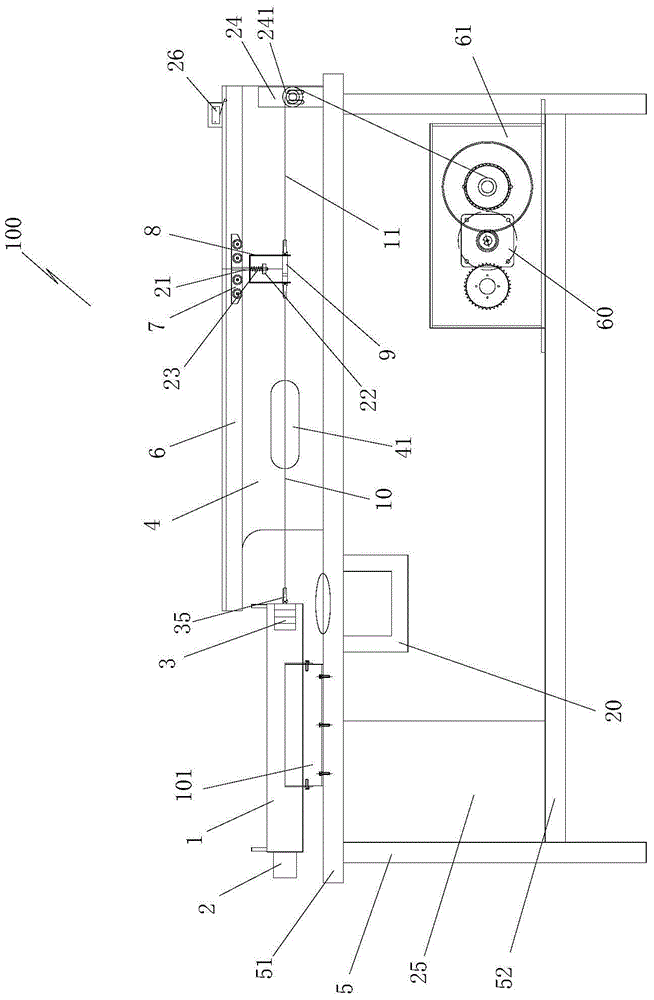

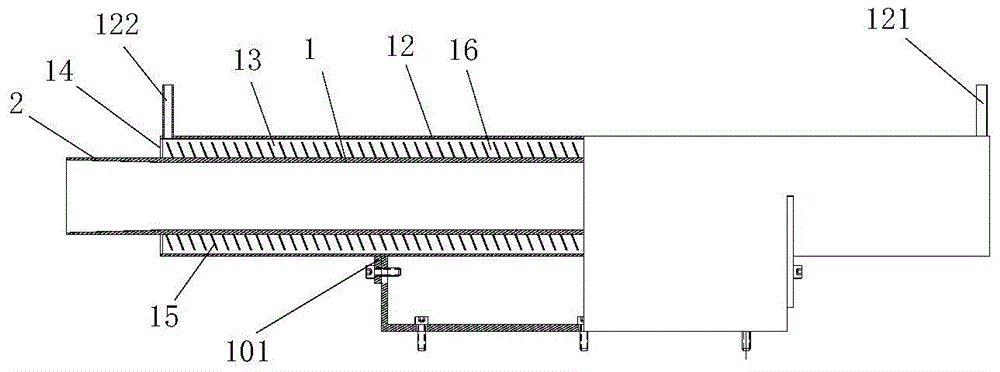

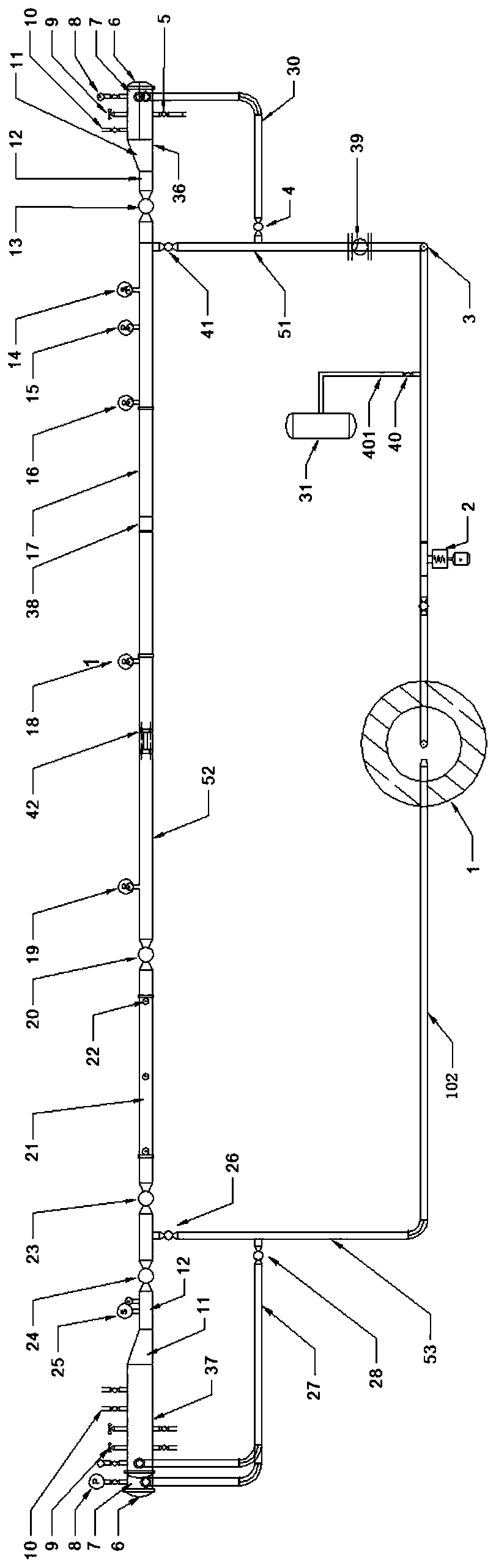

Crude oil pipeline ball passing and wax removal simulation experiment device and experiment method

ActiveCN104568625AMeasuring changes in wax removal resistanceUsing mechanical meansInvestigating material hardnessElectricityData acquisition

The invention relates to a crude oil pipeline ball passing and wax removal simulation experiment device which comprises an operation desk, wherein a test pipeline is fixed on the operation desk; a ball serving barrel is coaxially arranged at the rear end of the test pipeline; a pipeline cleaner is coaxially arranged in the ball serving barrel; an acrylic cover body is arranged on the operation desk; a hanger rail is fixedly arranged on the inner side of the top of the acrylic cover body; a guide pulley block is slidingly arranged on the hanger rail; a sensor hanging bracket capable of adjusting tension is fixedly arranged under the guide pulley block; a tension sensor is horizontally arranged on the sensor hanging bracket; the front end of the pipeline cleaner is connected with the tension sensor via a first hauling rope; the front end of the tension sensor is connected with a hauling driving system via a second hauling rope; the tension sensor is electrically connected with a measurement and data acquisition system; and the hauling driving system is electrically connected with a servo control system. The device can measure the strength of a wax deposit on a wall of a crude oil pipeline and change of wax removal resistance in a pigging process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

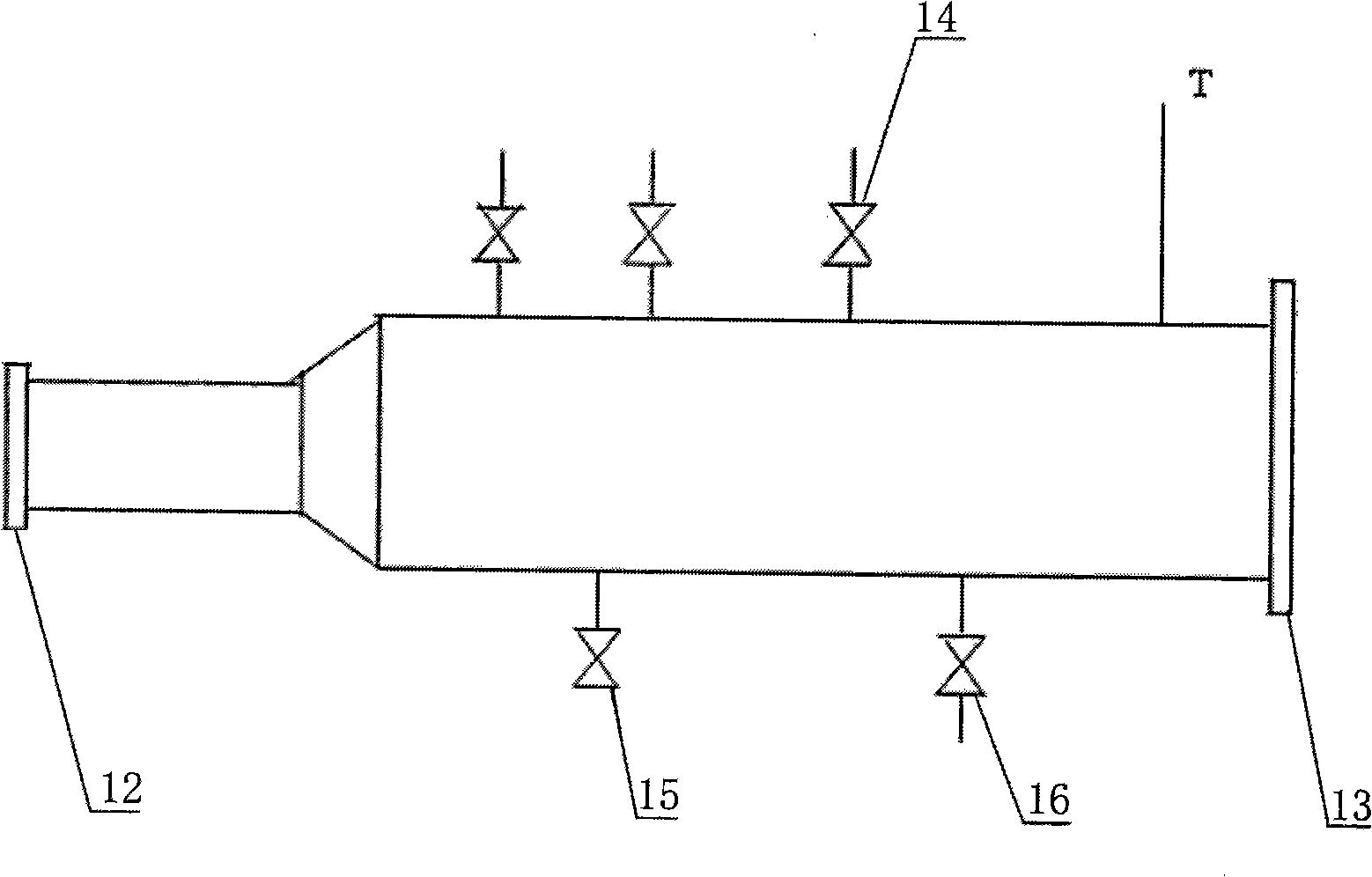

Long conveying pipeline construction method capable of simultaneously clearing pipe and testing pressure

ActiveCN101290075AReduce investmentImprove sciencePipe laying and repairHollow article cleaningPressure risePigging

The invention relates to a long-distance pipeline construction method for carrying out tube clearing and pressure testing procedure at the same time. The invention can combine such two working procedures into one as long-distance pipeline clearing and pressure testing, which simplifies construction procedures, and not only shortens the construction period, reduces construction investment both in manpower and in material resources, but also gains remarkable social effect. The invention comprises the following operation steps that: the lower end of the pipeline acts as a ball-pushing water entry for tube clearing and pressure testing, while the higher end of the pipeline acts as a pipeline ball-pulling end; tube clearing and pressure testing are carried out at the same time, that is, while the water in the tube is fed, a tube cleaner plays a function of ball isolation while feeding water as well as a function of tube cleaner; after the two tube cleaners enter into a ball-pulling device, a thermometer is well installed; water injection pressure of a pressing vehicle at the lower end is controlled so as to slowly inject water into the tube; when the pressure rises to the strength test pressure and after 4 hours of pressure keeping, water is drained and pressure is decompressed to the leaking test pressure through a needle valve at the ball-pulling device, and the pressure is kept for 24 hours; after completion of pressure test, air pressure ball out water drain is carried out by the tube cleaner.

Owner:陕西化建工程有限责任公司

Bypass valve type speed regulating pipe cleaner

The invention relates to a bypass valve type speed regulating pipe cleaner. The defects of an electronic control bypass valve control mode can be overcome. According to the technical scheme of the bypass valve type speed regulating pipe cleaner, a speed acquisition wheel is pressed on the inner wall of a pipe through spring force and hydraulic force and drives a hydraulic pump, the hydraulic pump outputs high-pressure oil, the high-pressure oil flows back to an oil tank through a throttling valve, front end pressure of the throttling valve is introduced into an oil cylinder, the oil cylinder pushes a throttling barrel to slide, and the throttling valve is opened. According to the pipe cleaner, no electrical component exists in a speed controller, safety and reliability are achieved, a storage battery is not needed for energy storage, the pipe cleaner can be used for long-distance pipe cleaning, pipe detection equipment can be carried, and work of pipe detection and pipe cleaning is completed.

Owner:青岛新奥胶城燃气工程有限公司

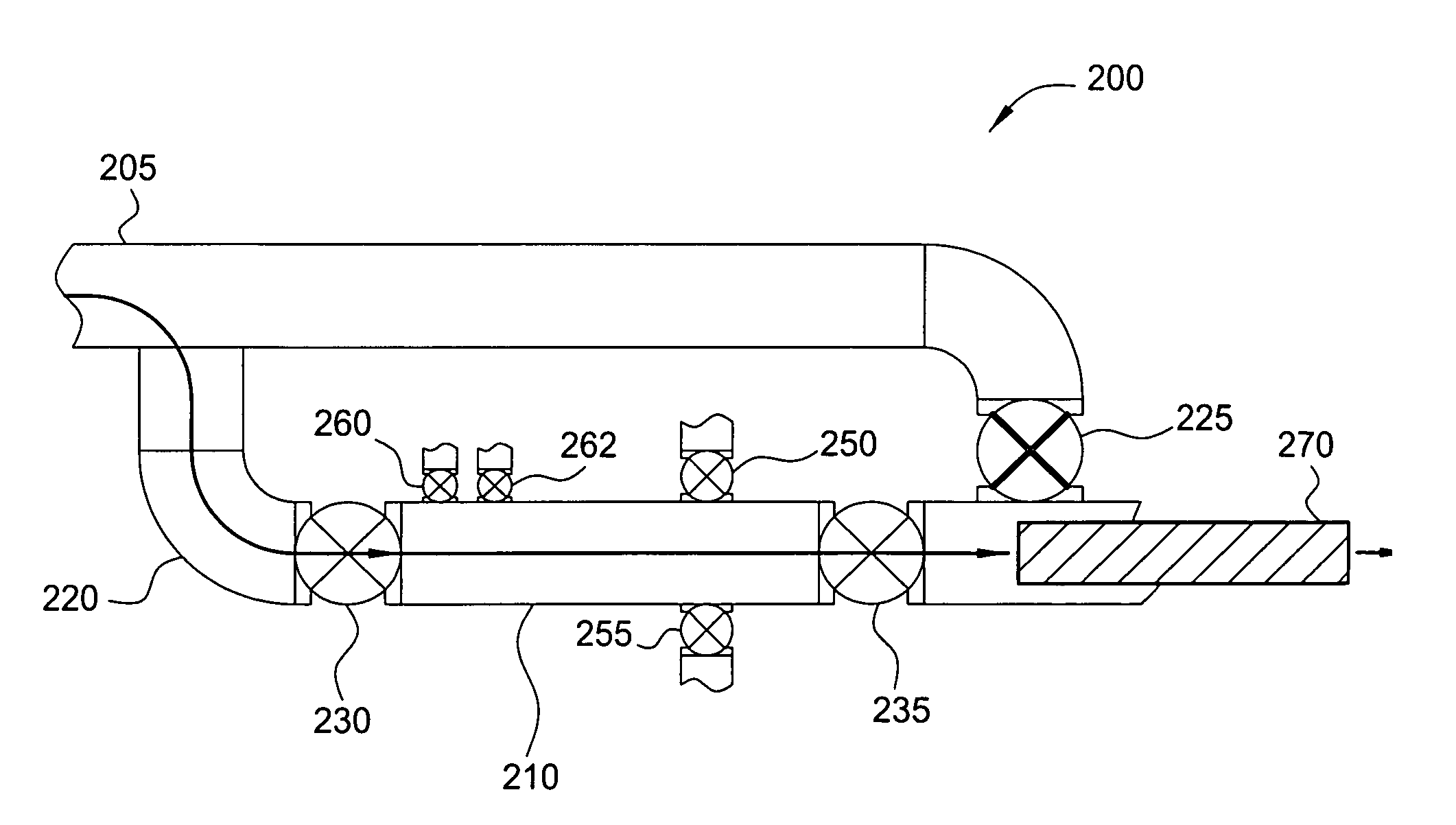

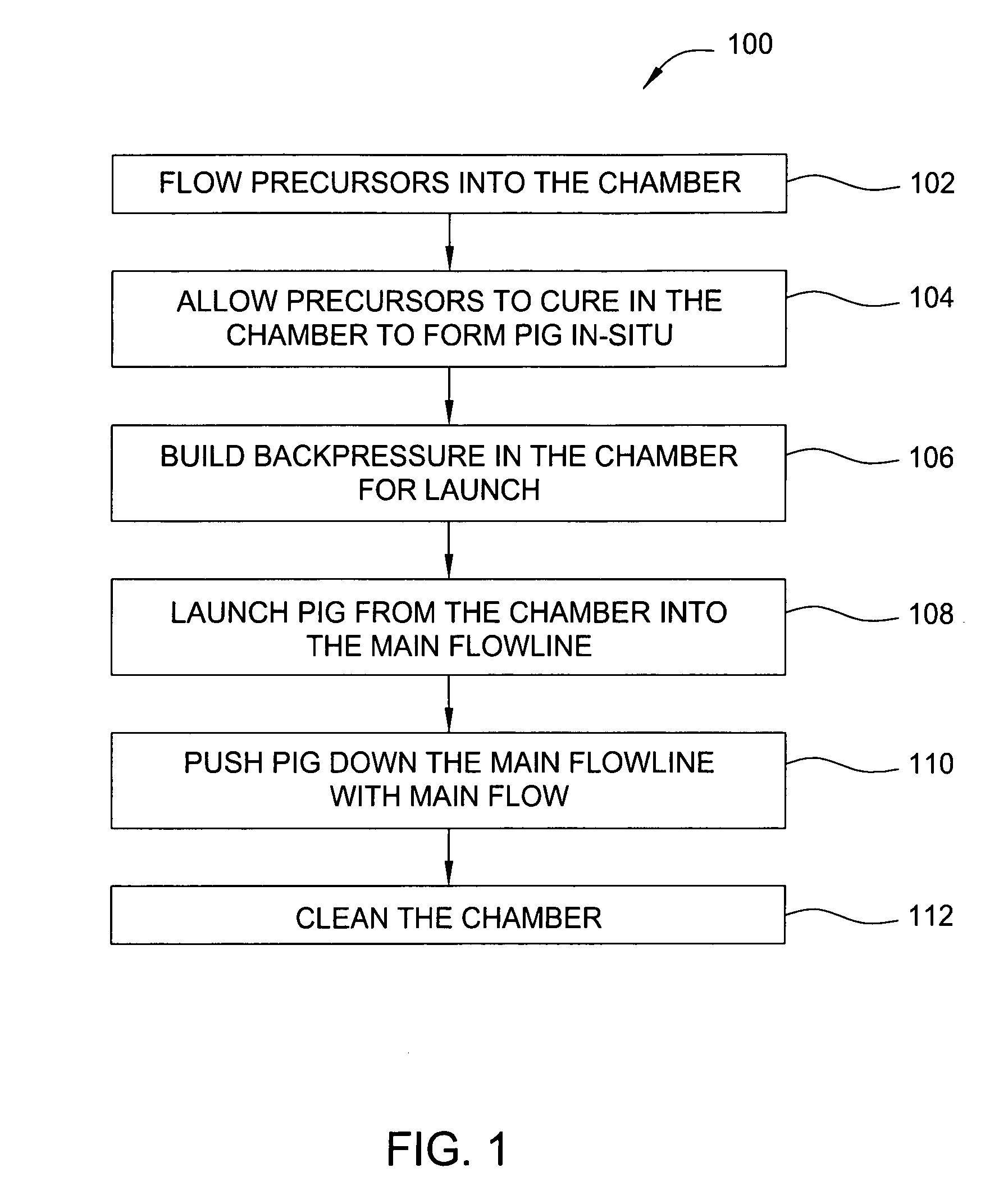

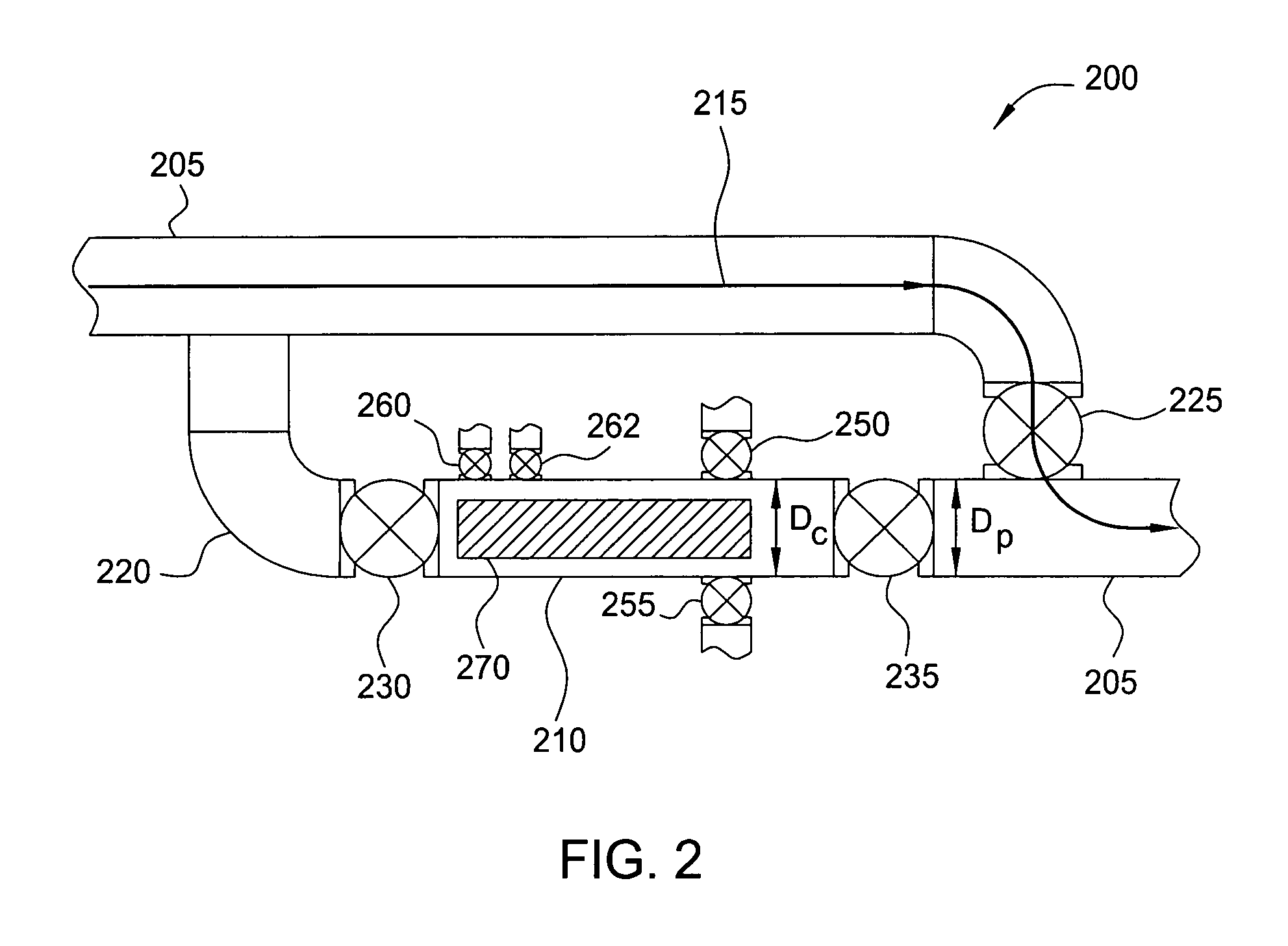

Pigging Of Flowlines By In-Situ Generated Foam Pigs

Methods and apparatus utilized to form foam pigs in-situ are provided. The in-situ generated foam pigs may be used for a number of purposes, including, but not limited to, commissioning or operational pigging. Further, the in-situ generated foam pigs may be used in a variety of type flowlines, including, but not limited to production or transportation pipelines used to carry hydrocarbons from subsea wells over long distances.

Owner:NORMAN DAVID A

Pigging ball valve

A pigging ball valve with a housing and ball core supported for rotation within the housing. The ball core sits on a valve seat, which is supported by a seat carrier. The valve seat carrier has three distinct diameters that locate the seat in the housing and thus provides an anti-cocking feature. A seat insert has a pressure sealing surface and wiper lip on the outer diameter of the pressure sealing surface. An internal seat deflector ring is provided inside of the pressure sealing surface. The seat carrier is spring loaded.

Owner:ARGUS MACHINE

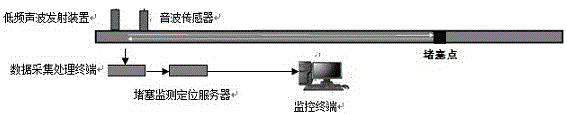

Pipe cleaning ball positioning system for oil and gas pipeline

A pigging ball positioning system for oil and gas pipelines, mainly composed of a low-frequency acoustic wave emitting device, an acoustic wave sensor, a data acquisition and processing terminal, a blockage monitoring and positioning server, and a monitoring terminal, characterized in that: the low-frequency acoustic wave emitting device generates a selectable frequency with high intensity The low-frequency sound wave is transmitted into the pipeline to be detected, and the sound wave signal is sensed by the sound wave sensor installed on the pipeline, and the sound wave signal in the pipeline is converted into an electrical signal in real time and transmitted to the front-end processing module; then, the data acquisition and processing terminal The sound wave signal collected by the received sound wave sensor is preprocessed and amplified, converted into a multi-channel sound wave signal in the digital domain and sent to the blockage monitoring and positioning server.

Owner:北京华科合创科技发展有限公司

Crude-oil pipeline wax deposit pigging simulation experiment method

PendingCN110208500AAchieving on-site pigging conditionsReal-time monitoring of pressure changesWeighing by removing componentHollow article cleaningPiggingEngineering

The invention discloses a crude-oil pipeline wax deposit pigging simulation experiment method. By controlling the temperature difference between an oil flow and a pipe wall, a wax deposition experiment is carried out in a wax removal testing pipe section; after a preset deposition time arrives, pressure at two ends is measured through pressure sensors at two ends, the thickness of the deposition layer is further obtained in the wax removal testing section, a pigging process is then carried out, a pig is sent by a launcher, pigging operation is carried out in the wax removal testing stage underpushing by the oil flow, the process of pushing ball ahead wax blocking or oil wax slurry by the pig is observed through a transparent testing section, the quality before wax deposition and after waxremoval in the wax removal testing stage is obtained, and the wax removal efficiency during a one-time pigging process is measured. Through analyzing the thickness of the deposition layer in the waxremoval testing stage and the wax removal efficiency of different pigs during the one-time pigging process, teh wax removal mechanism in the actual pigging process is studied, the problems of ball clamping, wax blocking and the like during the actual pipeline ball passing wax removal process are solved, and more scientific guidance is provided for actual pigging operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent speed-control blade type pipe cleaner

PendingCN109226128AEnsure pigging efficiencyOvercome the stuck problemHollow article cleaningPiggingMotor control

The invention relates to an intelligent speed-control blade type pipe cleaner which is mainly composed of a plurality of steel blades, a plurality of mileage wheels, a mandrel, a motor, a single-chipmicrocomputer, a drainage device and other components. A plurality of steel blades are designed, a plurality of blade layers are arranged around the mandrel, the blade layers are closely attached to apipe wall for scraping and cleaning a pipe under the preset pressure of springs, and blockage can be avoided through the retraction capacity of the blades under resistance; meanwhile, the mileage wheels are arranged around the mandrel and record displacement, the displacement is converted into speed signals through a speed sensor, the speed signals are transmitted to the single-chip microcomputer, the single-chip microcomputer controls the motor to act, the motor controls a drainage baffle to rotate, and therefore the front-back pressure difference of the pipe cleaner is adjusted, and the speed is reduced. Compared with an existing conventional pipe cleaner, the intelligent speed-control blade type pipe cleaner is lower in price, it is ensured that the pipe cleaning efficiency is higher,and the pipe explosion caused when the pipe cleaner gets stuck and the pipe cleaning speed is too high is effectively avoided.

Owner:SOUTHWEST PETROLEUM UNIV

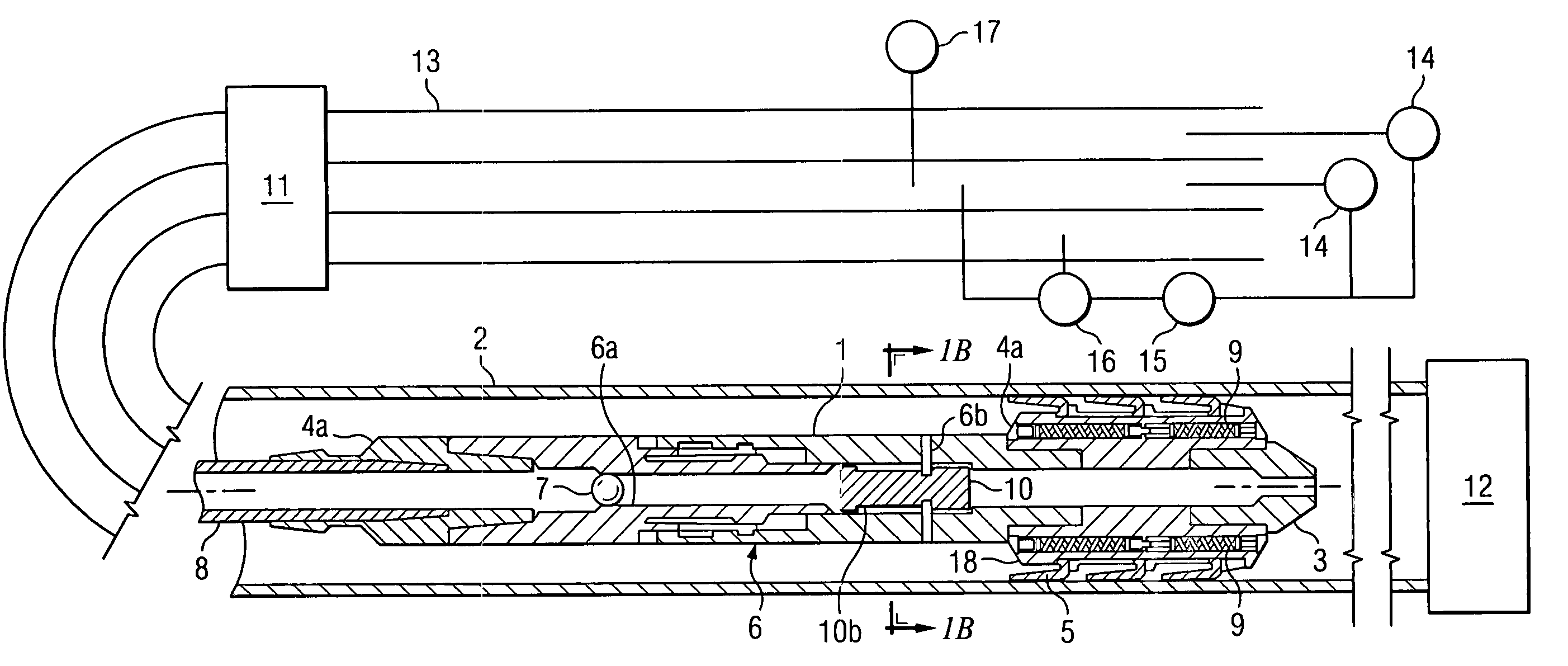

Thruster pig

ActiveUS7406738B2Uniform sectionCable can be longHollow article cleaningCleaning using toolsLine tubingDifferential pressure

A thruster pig for sending through a pipe from an entrance facility to a receiving location, for servicing or monitoring, by pumping a thrusting fluid into the pipe to force the pig forward is disclosed. The thruster pig includes a body having a front end and a back end, where the back end includes a reaction surface to which said the thrusting fluid applies a motive force. The body is slightly smaller in diameter than the inner diameter of the pipe. The pig also includes a seal circumferentially arranged on the pig to seal between said body and said pipe. A desired differential pressure is maintained over the pig to urge said pig forward through the pipe by pumping a fluid into the annulus between the pipe and the return flow line while returning fluid through said return flow line utilizing connected servicing or monitoring equipment. A connector releasably connects a return flow line to the pig. The connector includes a shifting mandrel that may be activated to open the connector by a ball pumped through the return flow line, where the ball is retained in the return flow line after releasing the connector. A blanking device is then provided to blank the bore within the pig that is left after the return flow line is disconnected.

Owner:DEN NORSKE STATS OLJESELSKAP AS +1

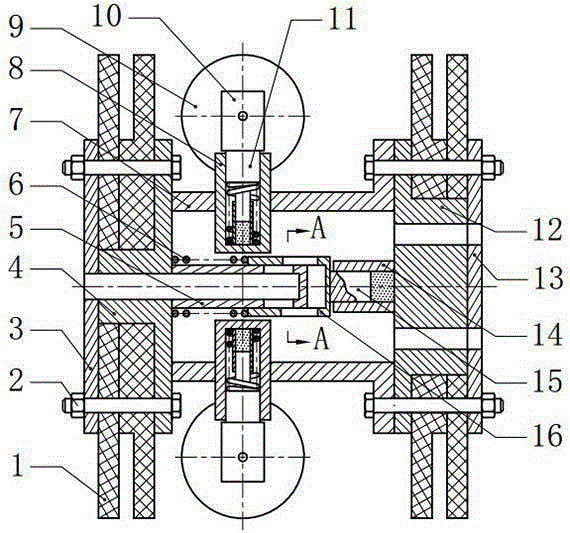

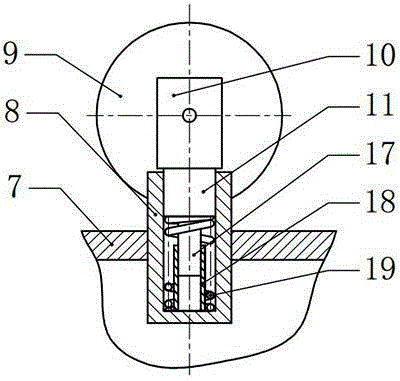

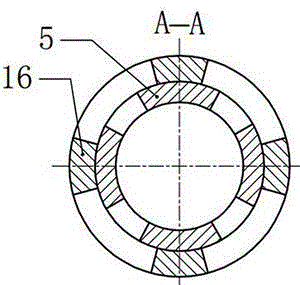

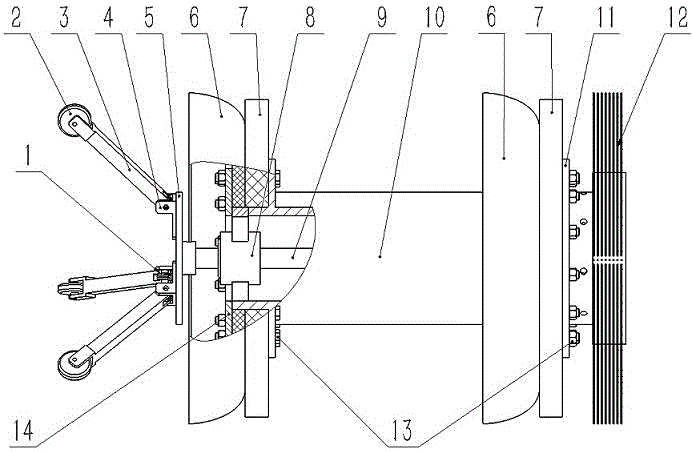

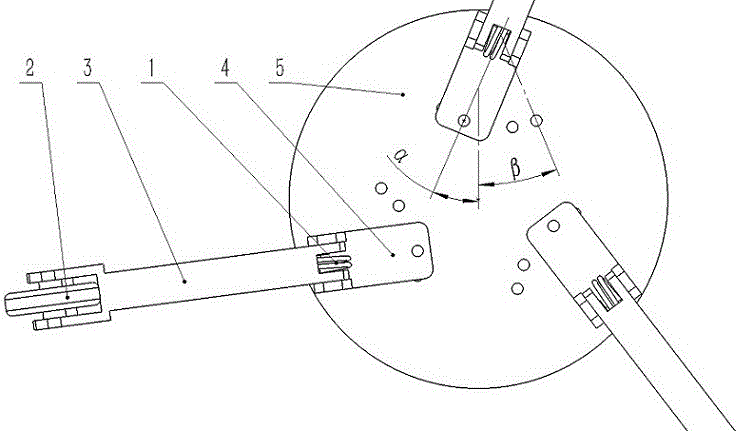

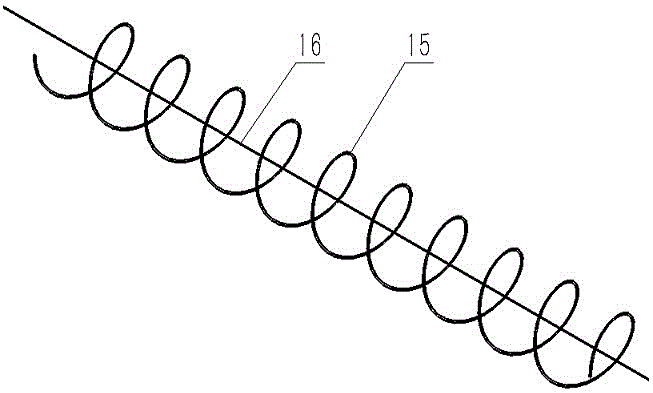

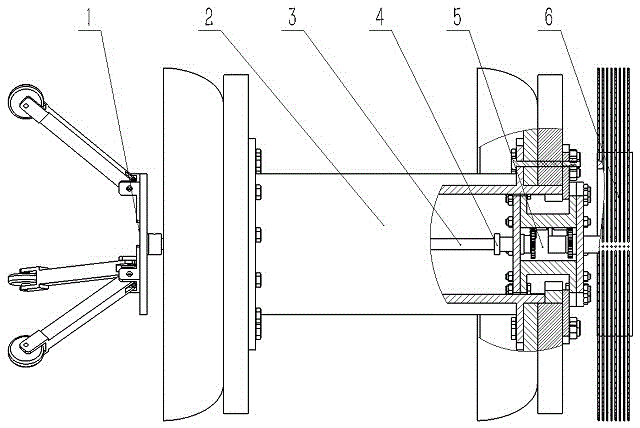

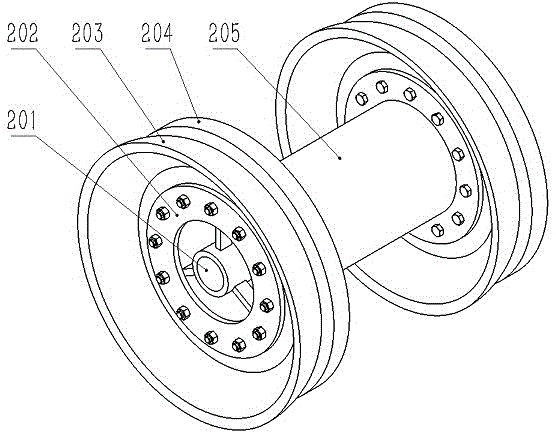

Pipe cleaner adopting revolving brush

The invention discloses a pipe cleaner adopting a revolving brush, and the pipe cleaner is used for pipe cleaning of petroleum and natural gas pipelines. The pipe cleaner adopting the revolving brush consists of a pipe cleaner main body, a cleaning brush and a rotary mechanism, wherein a rotary shaft is mounted in the middle of the pipe cleaner main body; the cleaning brush is mounted at the front end of the pipe cleaner main body, and is connected to the front end of the rotary shaft; and the rotary mechanism is mounted at the rear end of the pipe cleaner main body, and is connected to the rear end of the rotary shaft. The end surface of a pressing wheel on the rotary mechanism and a pipeline axis have certain included angle; when the pipe cleaner moves, the pressing wheel 2 spirally moves in the pipeline, so that the rotary mechanism is driven to rotate; and the rotary mechanism drives the cleaning brush 12 to rotate through the rotary shaft 9. The cleaning brush rotates while moving forwards along with the pipe cleaner, and spirally moves in the pipeline to form a longer cleaning path, so that the pipe cleaning is more complete. Meanwhile, the cleaning brush rotates for stirring cleaned-down attachments, so that the cleaned-down attachment particles are smaller, are mixed with a fluid more sufficiently, and flow out along with the fluid easier.

Owner:XIHUA UNIV

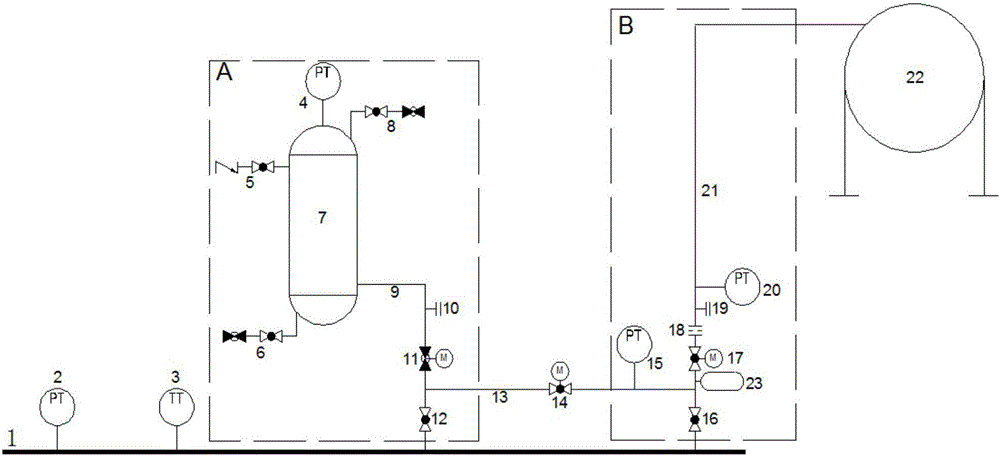

Pipeline pressure-stabilizing system and method used after liquefied petroleum gas out-conveying pipeline stops conveying

ActiveCN105864639AStable pressureEliminate Intensity EffectsPipeline systemsGround temperaturePressure stabilization

The invention discloses a pipeline pressure-stabilizing system and method used after a liquefied petroleum gas out-conveying pipeline stops conveying. The pipeline pressure-stabilizing system comprises a temperature sensor, a pressure sensor, a first-stage pressure-stabilizing device and a second-stage pressure-stabilizing device. The temperature sensor and the pressure sensor are arranged on a main pipeline short section, and the first-stage pressure-stabilizing device and the second-stage pressure-stabilizing device are connected with the main pipeline short section. The first-stage pressure-stabilizing device comprises a first block valve, a stop valve and a pressure buffering tank which are sequentially connected with the main pipeline short section. A second block valve is arranged between the first-stage pressure-stabilizing device and the second-stage pressure-stabilizing device. The second-stage pressure-stabilizing device comprises a third block valve, a pressure buffer, a pressure regulating device and a liquefied petroleum gas storage tank which are sequentially connected with the main pipeline short section. The temperature detection result obtained when conveying is stopped is compared with the ground temperature, the pressure change in the pipeline after a certain period is calculated, and the first-stage pressure-stabilizing device is used for carrying out pressure supplementation on the pipeline according to the analysis result, or the first-stage pressure-stabilizing device and the second-stage pressure-stabilizing device are used for releasing the pressure of the pipeline to achieve pressure stabilization of the pipeline after conveying is stopped, the system safety is guaranteed, and pigging and emptying of the whole line are avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

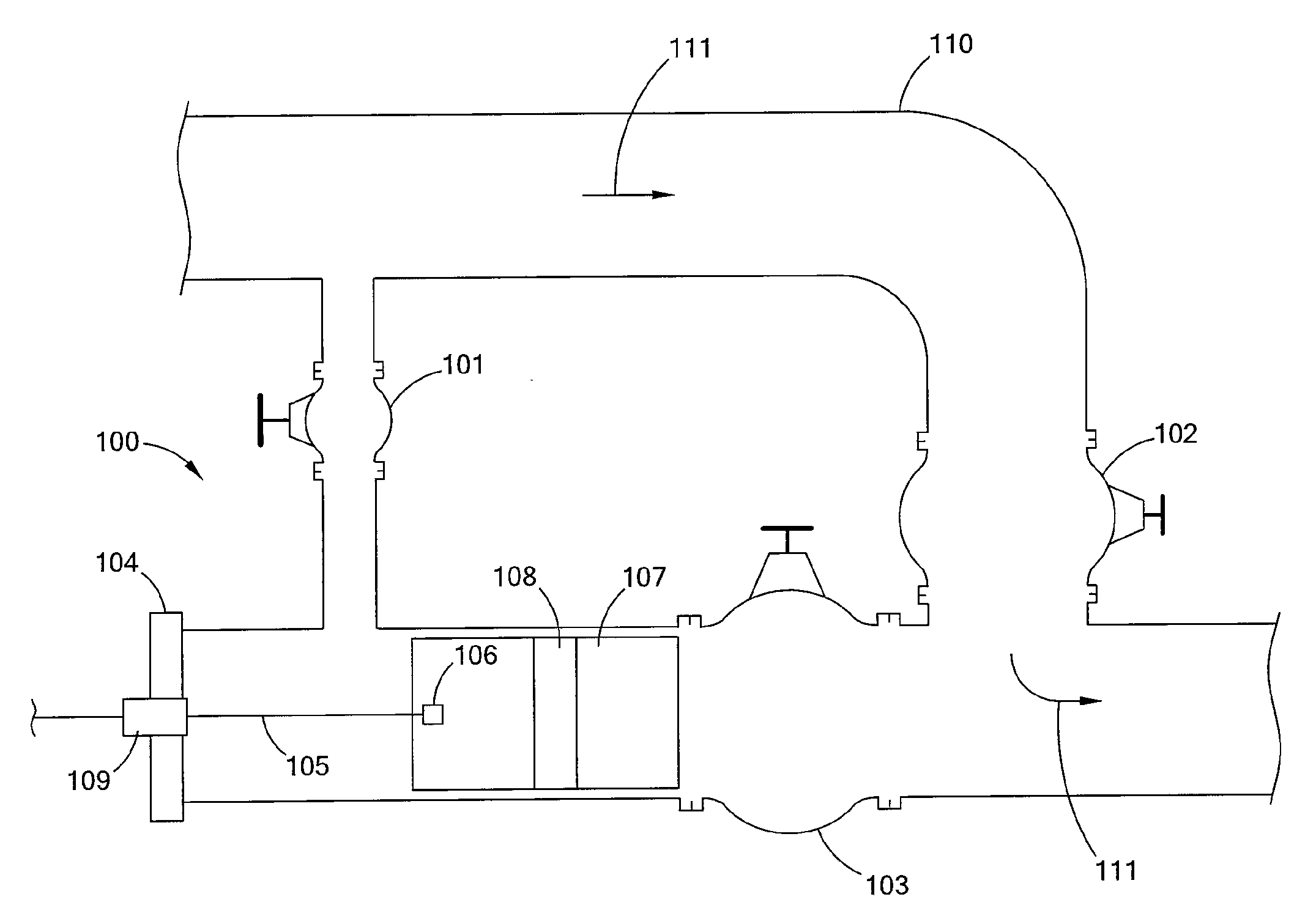

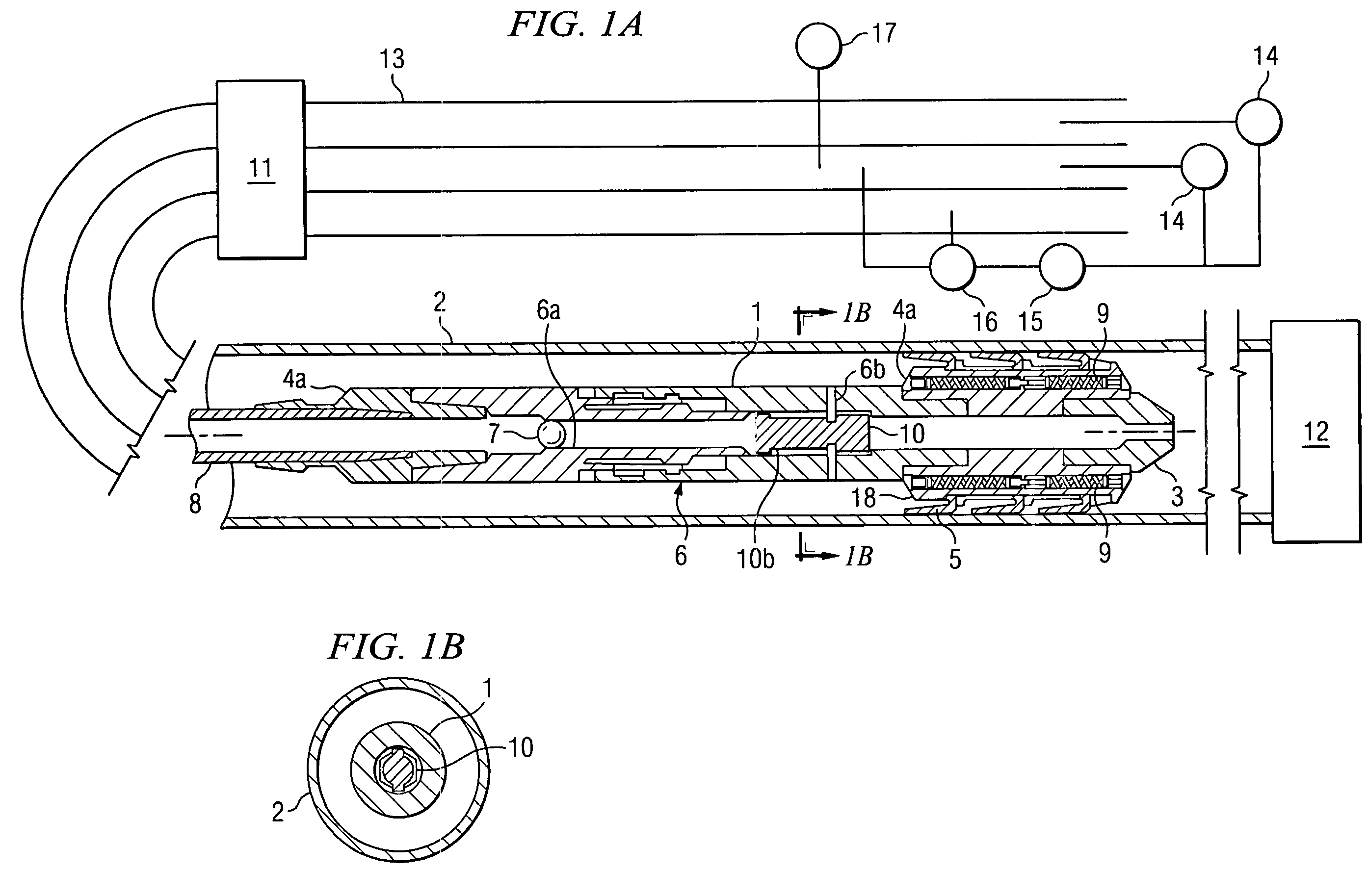

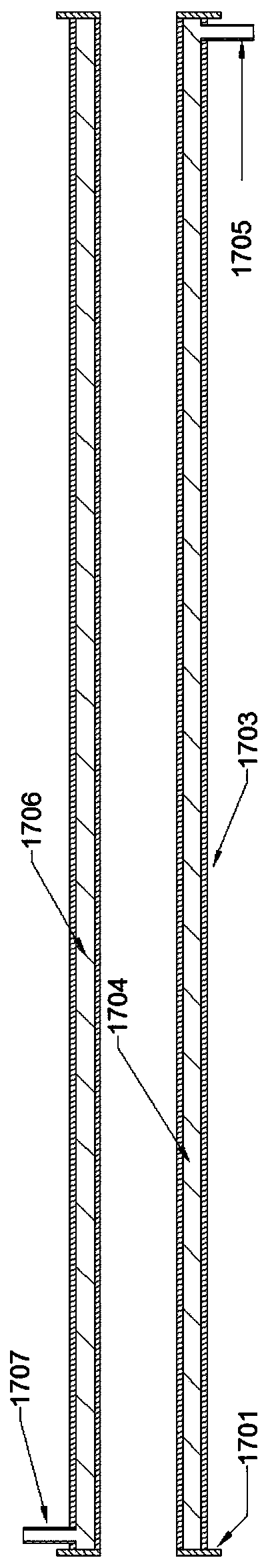

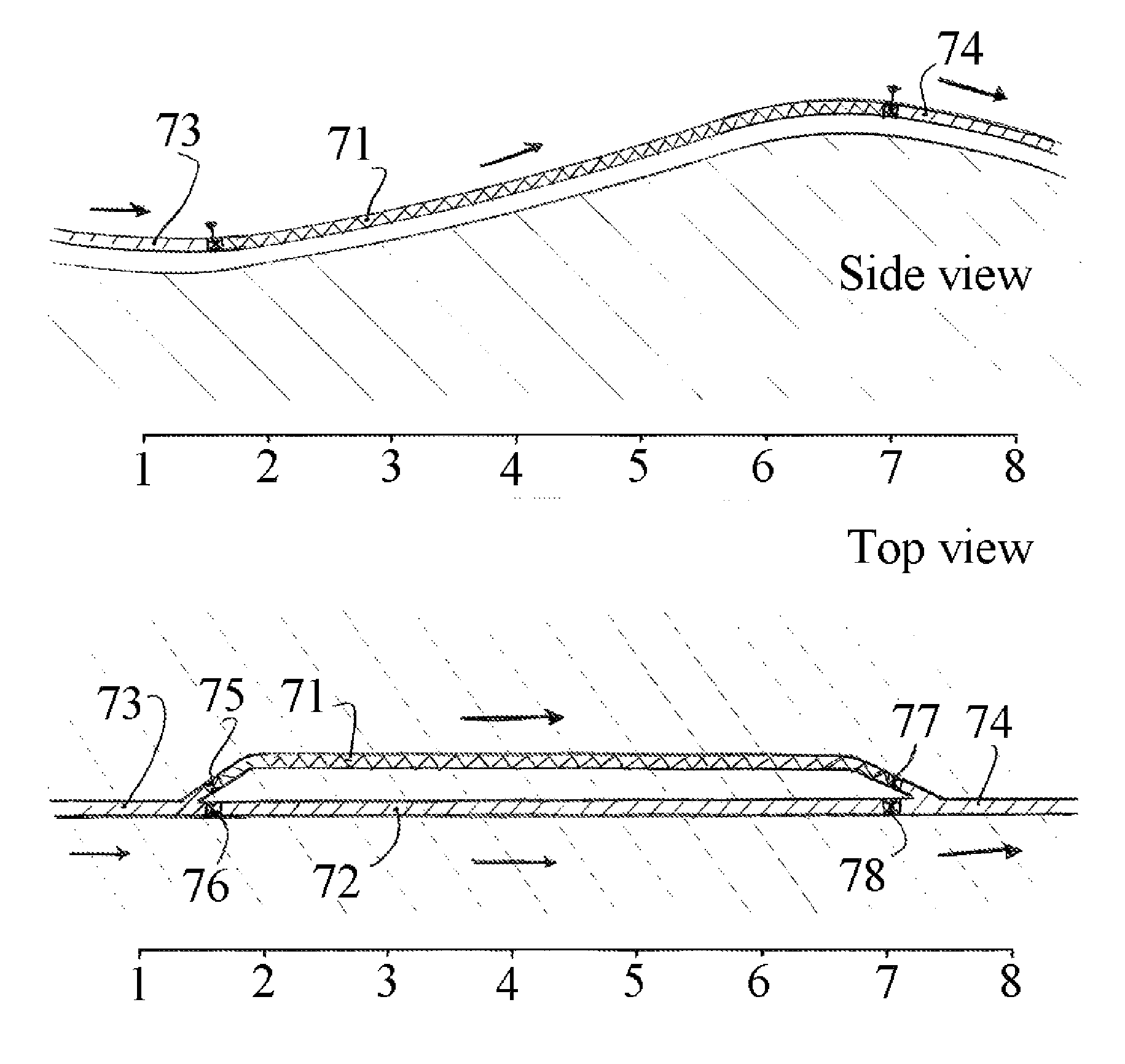

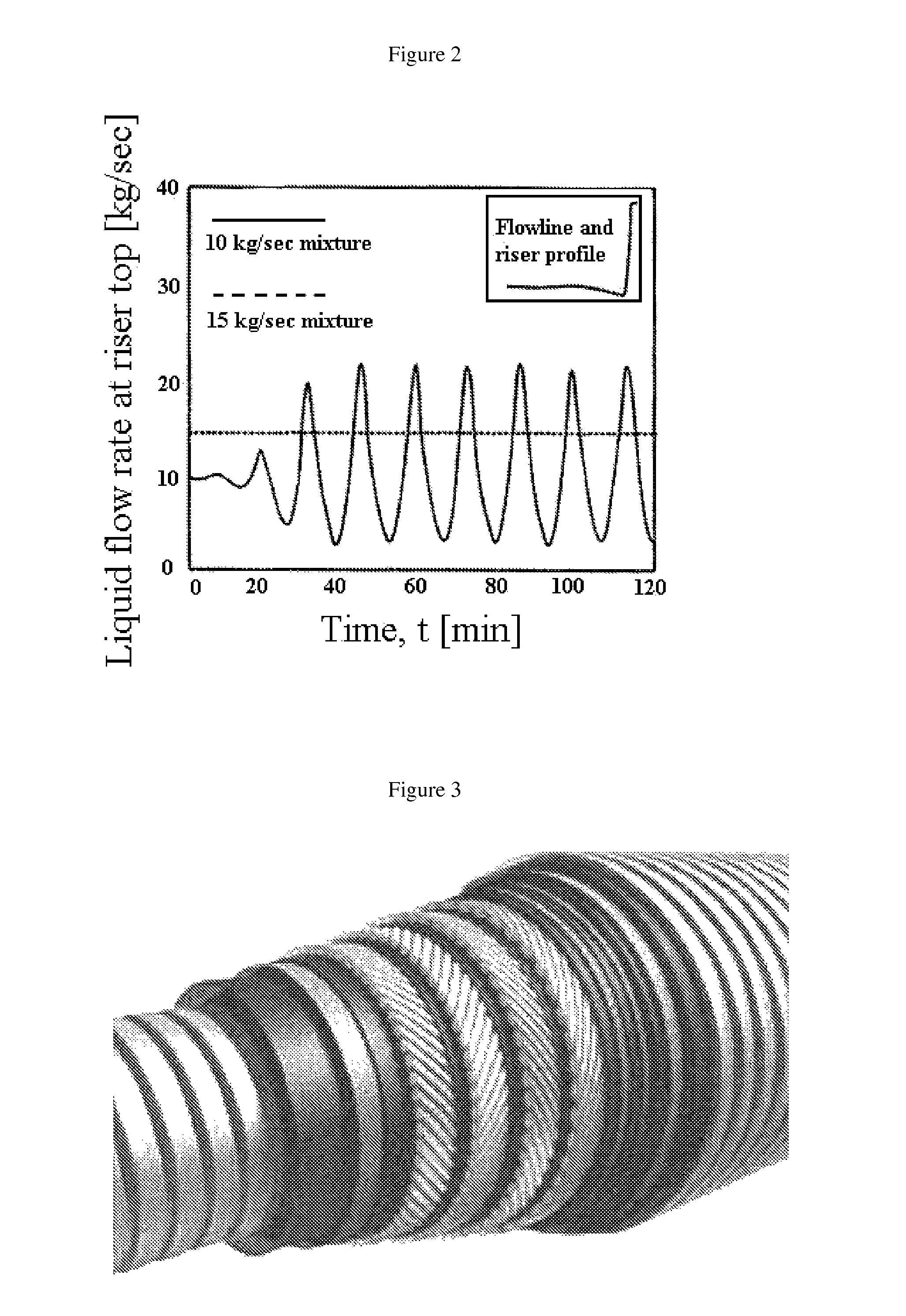

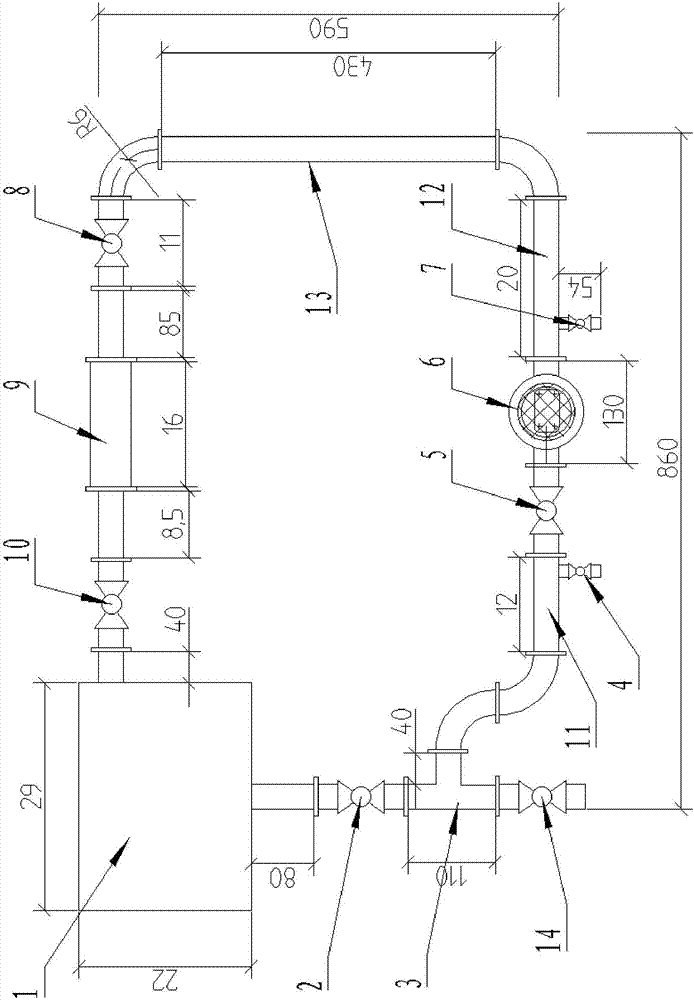

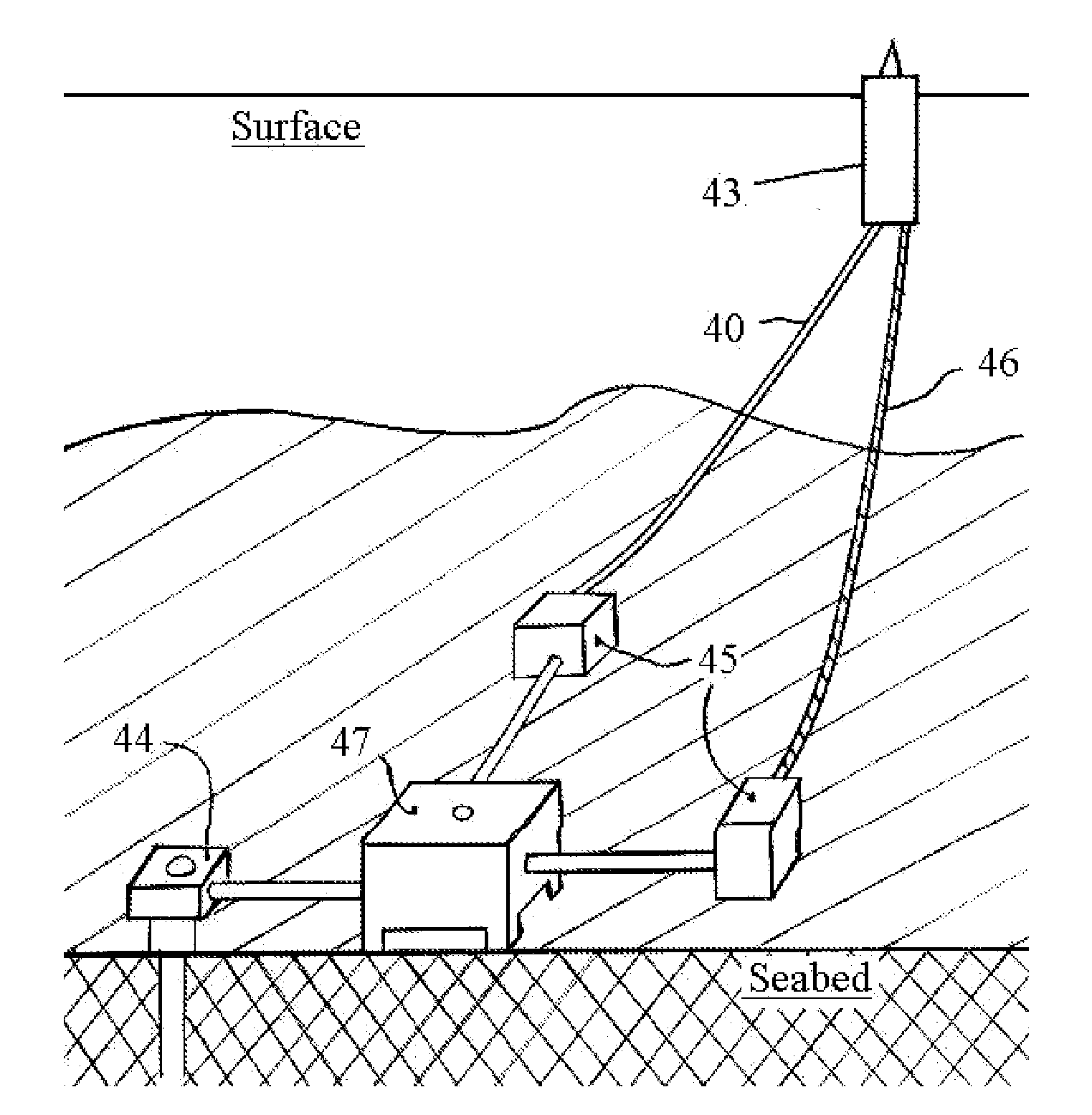

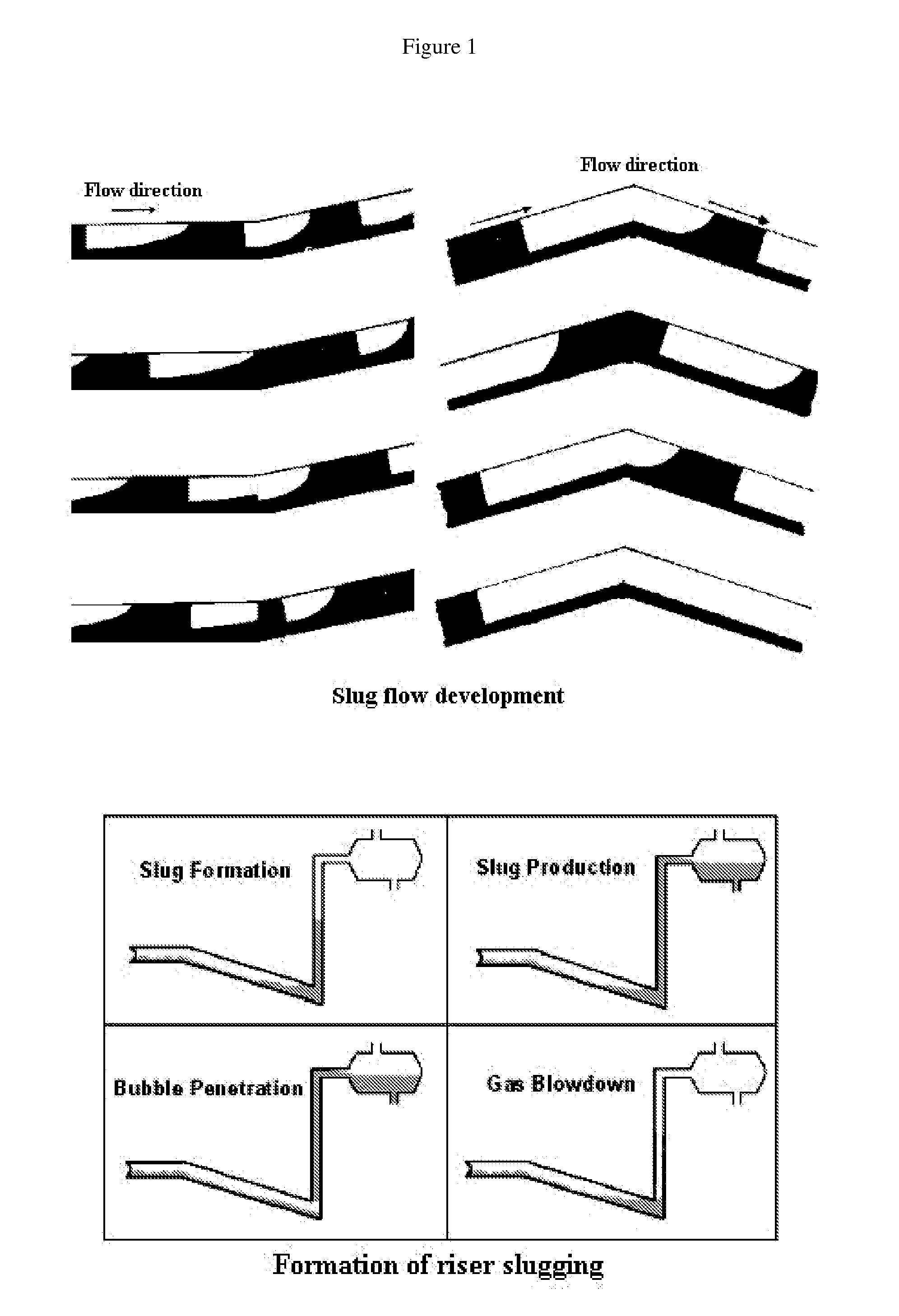

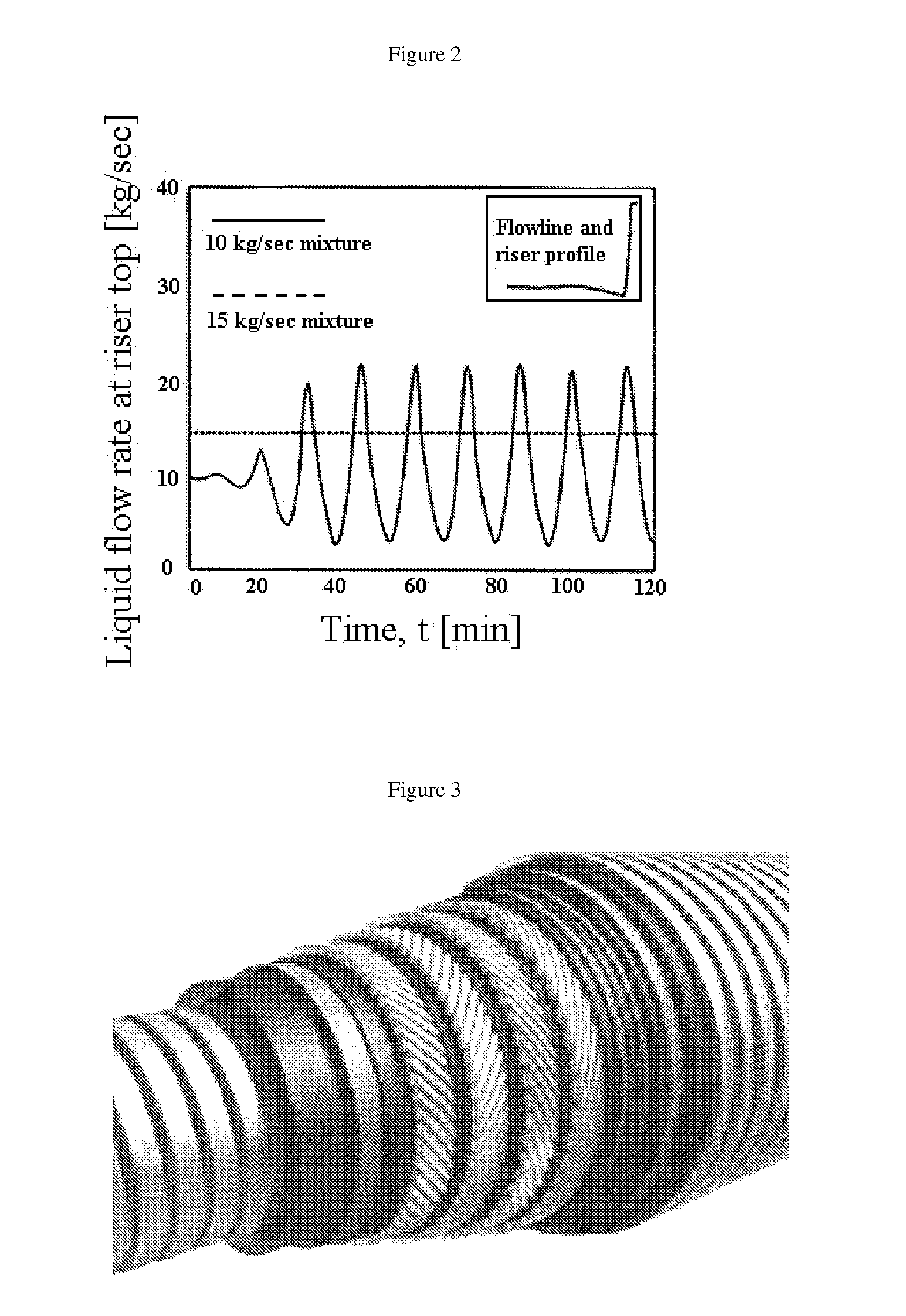

Dual pathway riser and its use for production of petroleum products in multi-phase fluid pipelines

ActiveUS8555978B2Managing/improving the fluid flow characteristicsEfficient transportDrilling rodsFluid removalTerrainPetroleum product

Disclosed is a tubing system for transporting a gas-liquid flow from a well to a production platform or processing facility. It includes a dual pathway section between the well and the production point having a first tubing portion and a second tubing portion. The second tubing portion includes a plurality of parallel channels so as to divide the multi-phase flow into a plurality of flows through individual channels. This is done to reduce flow slippage of the lower viscosity portion of the flow, which may lead to inefficiencies in flow characteristics, and often, undesirable cyclical variations in pressure and fluid volume. This is especially useful in inclined portions of the petroleum flow pipe system and along hilly terrain. The first round tubing portion is used for transporting the gas-liquid flow as well as for maintenance purposes, such as for pigging, fishing or coiled tubing operations.

Owner:TECH COMMLIZATION

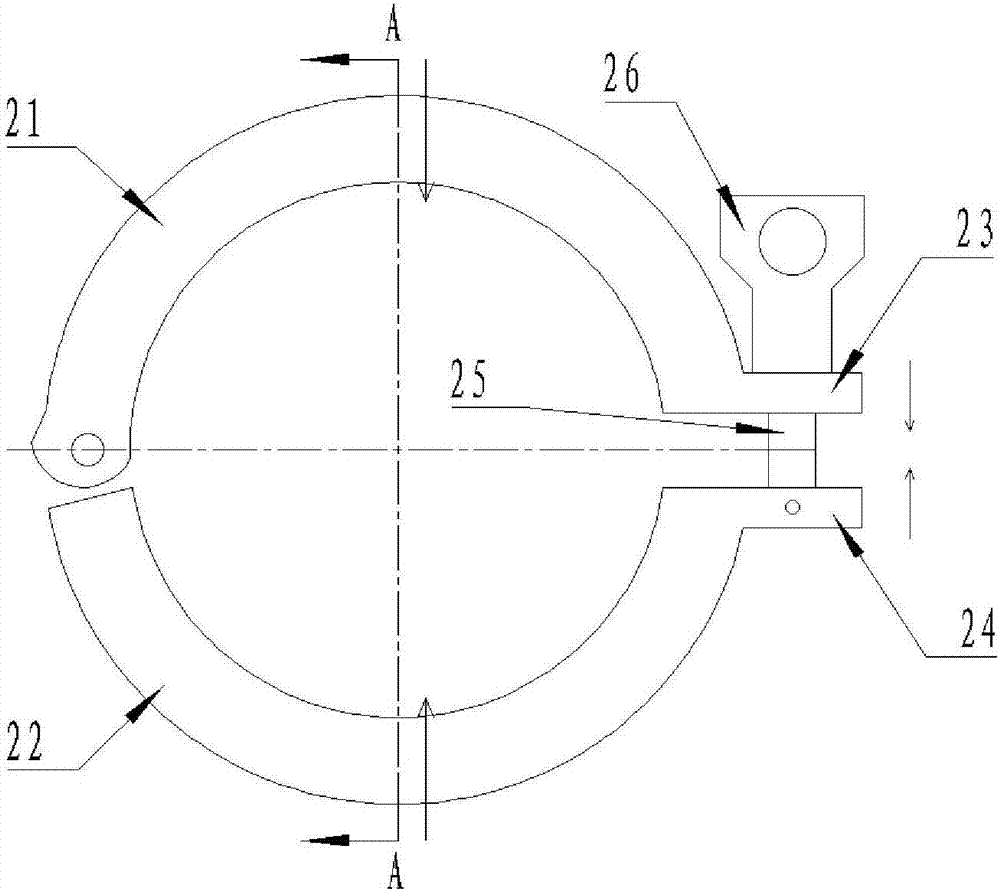

Pipe cleaning experimental facility suite for crude oil pipeline

The invention provides a pipe cleaning experimental facility suite for a crude oil pipeline. The pipe cleaning experimental facility suite comprises a circuit system and a pipe cleaning experimental system, wherein the circuit system includes an oil tank (1), a wax deposition pipe section (9) and a gear oil pump (6), which are connected into a closed loop in sequence; the wax deposition pipe section (9) can simulate a wax deposition process of crude oil in a transportation process; the wax deposition pipe section (9) can be demounted; the pipe cleaning experimental system can measure the strength and the wax cleaning resistance of a wax deposit on the inner wall of the wax deposition pipe section (9). According to the pipe cleaning experimental facility suite for the crude oil pipeline, the true wax deposit in an oil conveying pipeline is obtained by adopting the circuit system; the indoor simulation of the ball running wax cleaning of the crude oil pipeline is carried out by adopting the pipe cleaning experimental system. A wax deposition law of wax-containing crude oil in a pipe conveying condition, the property of a wax layer and a failure law of the wax layer in a pipe cleaning process can be researched; further, the internal relation among the pipe cleaning process, the wax deposition process and the property of the wax deposit is explored.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

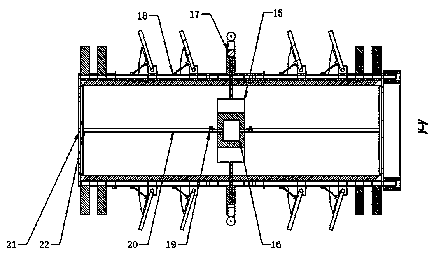

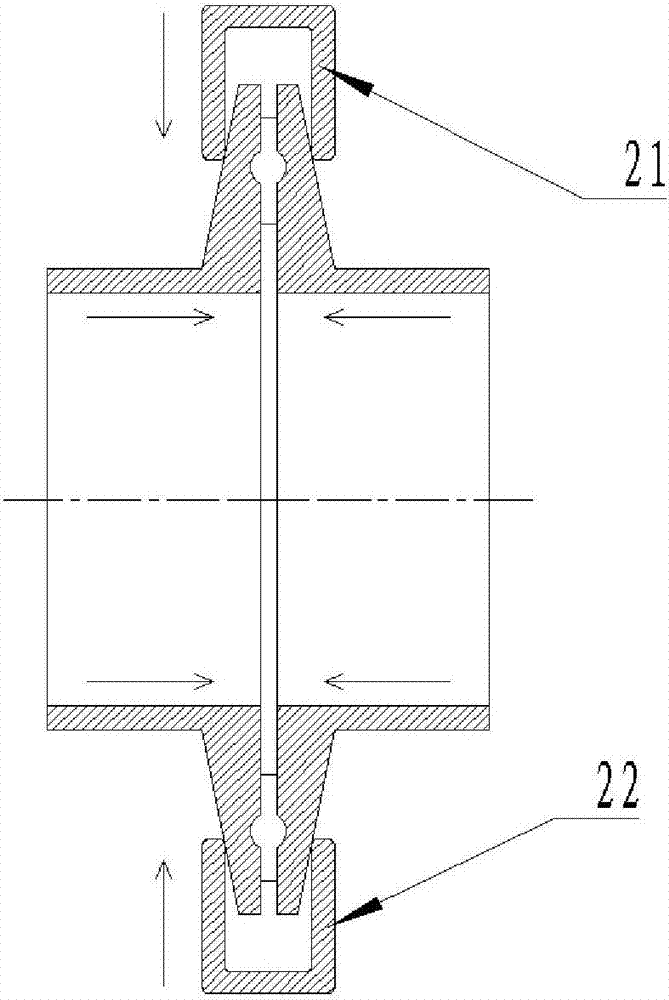

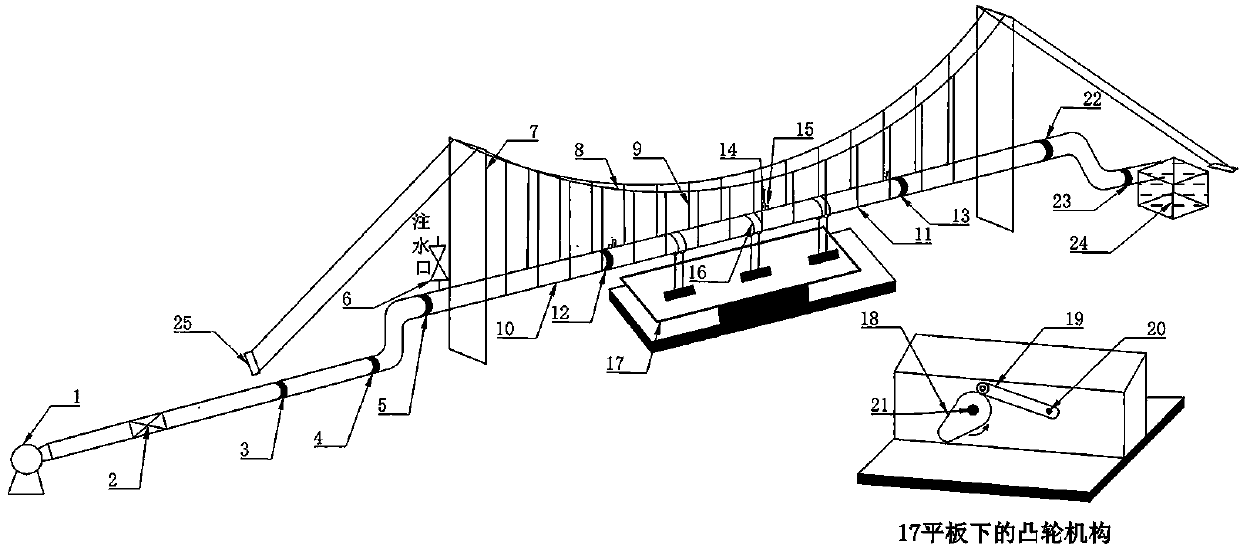

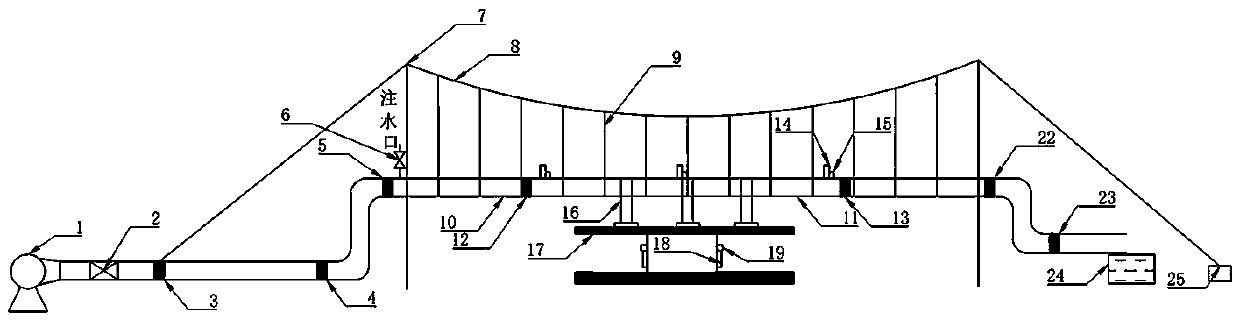

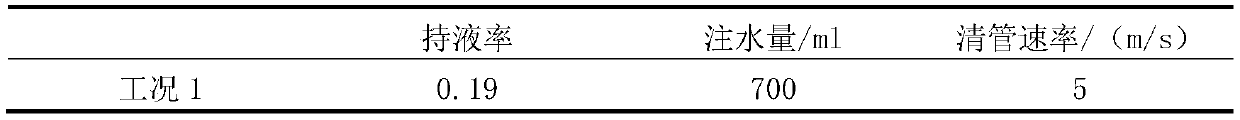

Device for carrying out pigging dynamic response experiment on natural gas pipeline cable-suspension structure

ActiveCN110726529AChange running speedGuaranteed vibration accelerationHydrodynamic testingVibration testingVibration accelerationPigging

The invention provides a device for carrying out a pigging dynamic response experiment on a natural gas pipeline cable-suspension structure. A transparent toughened glass pipe is connected with seamless steel pipes through flanges; a main cable is connected with towers as a main bearing component; fixing brackets can be used for fixing the seamless steel pipes, and are placed on a flat plate; a connecting rod can be driven to move up and down through the rotation of a cam below the flat plate in order to drive the flat plate to move up and down, thereby realizing upward and downward vibrationof a pipeline; and an acceleration sensor and a displacement sensor of a signal testing device can be arranged at corresponding positions of the seamless steel pipes according to testing needs. The device is mainly designed for researching the dynamic response and the influence on the two-phase flow of pigging during pigging of the natural gas pipeline cable-suspension structure, and can acquire the vibration acceleration, vibration displacement and the like of the pipeline cable-suspension structure under different pigging conditions, and simulate the influences of the pipeline on the two-phase flow pattern of pigging under different vibration conditions.

Owner:SOUTHWEST PETROLEUM UNIV

Dual pathway riser and its use for production of petroleum products in multi-phase fluid pipelines

ActiveUS20110127029A1Efficient transportImprove flow characteristicsDrilling rodsFluid removalTerrainPetroleum product

Disclosed is a tubing system for transporting a gas-liquid flow from a well to a production platform or processing facility. It includes a dual pathway section between the well and the production point having a first tubing portion and a second tubing portion. The second tubing portion includes a plurality of parallel channels so as to divide the multi-phase flow into a plurality of flows through individual channels. This is done to reduce flow slippage of the lower viscosity portion of the flow, which may lead to inefficiencies in flow characteristics, and often, undesirable cyclical variations in pressure and fluid volume. This is especially useful in inclined portions of the petroleum flow pipe system and along hilly terrain. The first round tubing portion is used for transporting the gas-liquid flow as well as for maintenance purposes, such as for pigging, fishing or coiled tubing operations.

Owner:TECH COMMLIZATION

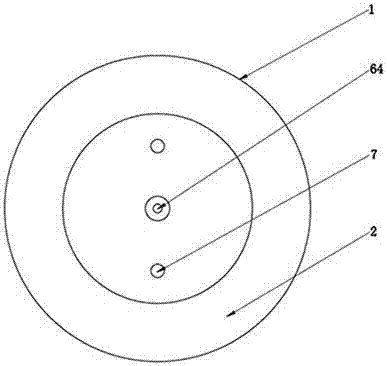

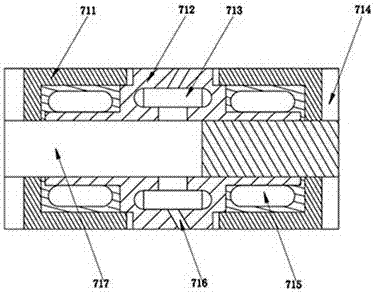

High-speed rotating brush pipe cleaner

A high-speed rotating brush pipe cleaner is used for cleaning petroleum and natural gas pipelines. The high-speed rotating brush pipe cleaner is composed of a pipe cleaner supporting body, a cleaning brush, a rotating mechanism and a planetary gear transmission, wherein the rotating mechanism is installed at the rear end of the pipe cleaner supporting body; the cleaning brush is installed at the front end of the pipe cleaner supporting body; the planetary gear transmission is installed in the pipe cleaner supporting body; the rotating mechanism, a rotating shaft, the planetary gear transmission and the cleaning brush are sequentially connected. When the pipe cleaner runs, the rotating mechanism is driven to rotate, the cleaning brush is driven to rotate at a high speed after rotation of the rotating mechanism is transmitted to the planetary gear transmission through the rotating shaft, and therefore the cleaning brush can form a longer cleaning path in a pipeline; meanwhile, the cleaning brush rotates at a high speed so that attachments which are cleared away can be stirred, attachment particles which are cleared away are finer and fully mixed with fluid, and the attachment particles which are cleared away can be discharged along with the fluid more easily.

Owner:XIHUA UNIV

Subsea Manifold System

An improved subsea manifold system that is capable of being used in an early production system for producing hydrocarbons from a plurality of wells from a common riser system. The subsea manifold is able to control the fluid from a multiple of subsea wet-tree wells while at the same time giving the operator the option to isolate production from a single subsea well for production evaluation. The subsea manifold also includes a pigging loop which enables efficient pigging of the flowline(s) of the early production system.

Owner:CHEVROU USA INC +1

Self-deblocking pipe cleaner provided with rotary heads and gas throttling preventing device

ActiveCN106903121ARealize automatic unblockingIncrease path lengthHollow article cleaningPiggingEddy current effect

The invention relates to a self-deblocking pipe cleaner provided with rotary heads and a gas throttling preventing device. The self-deblocking pipe cleaner integrates multiple functions of two-times pipe cleaning through the rotary heads, automatic deblocking and preventing of ice blockage of bypass holes by hydrates generated by gas throttling. The two rotary heads are designed and can automatically rotate, and ejected high-speed gas is used for conducting comprehensive flushing on the inner wall of a pipeline. The gas throttling preventing device is used for heating gas which flows through the bypass holes through the eddy current effect, and the gas is prevented from blocking a flow channel through ice blockage due to the throttling effect. An automatic deblocking device is designed, and when a speed sensing ball detects that the operation speed of the pipe cleaner is zero, namely blockage occurs, an executing mechanism adjusts a three-way ball valve, and the gas is concentrated at the front end of the de-blocked flow channel to be ejected out at a high speed so as to remove blockage matter in front. The self-deblocking pipe cleaner provided with the rotary heads and the gas throttling preventing device can ideally clean pipes, remove blockage and protect the bypass holes against ice blockage by hydrates generated by gas throttling.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com