Pipe cleaner adopting revolving brush

A technology of pigs and rotary brushes, which is applied in natural gas pipeline pigging, fluid conveying pipelines, and petroleum fields. The effect of pipe quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

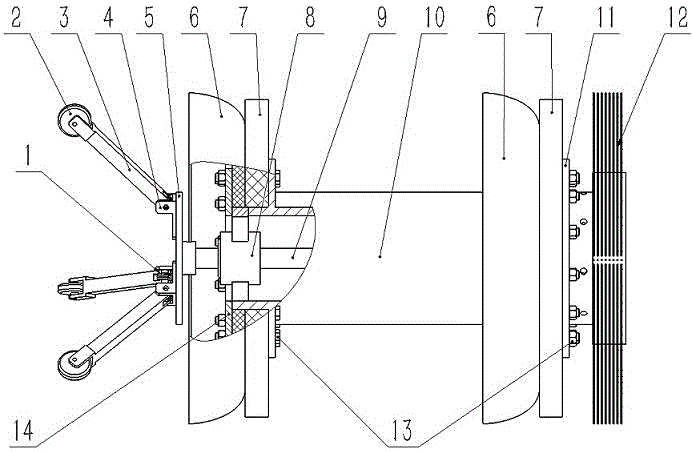

[0016] Such as figure 1 As shown, the rear end of the frame 10 is equipped with a sealing cup 6 and a guide cup 7, and the flange 14 is used to connect and fix the frame 10 through bolts 13. 11 is connected and fixed by bolt 13. Skeleton 10 inside is equipped with rotating shaft 9, cooperates with the rotating shaft installation frame 8 of skeleton 10 front and rear two ends, and skeleton 10 centerline coincides with rotating shaft 9 centerlines.

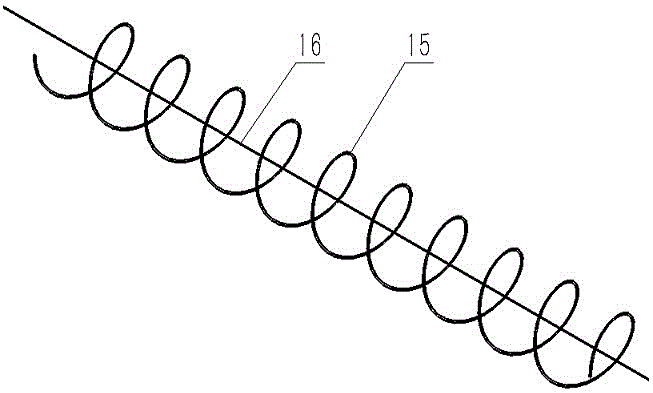

[0017] Rotating shaft front end is fixed with cleaning brush 12, and cleaning brush 12 can rotate together with rotating shaft 9, and cleaning brush 12 will guarantee enough long, makes cleaning brush 12 have enough friction to pipeline inwall all the time.

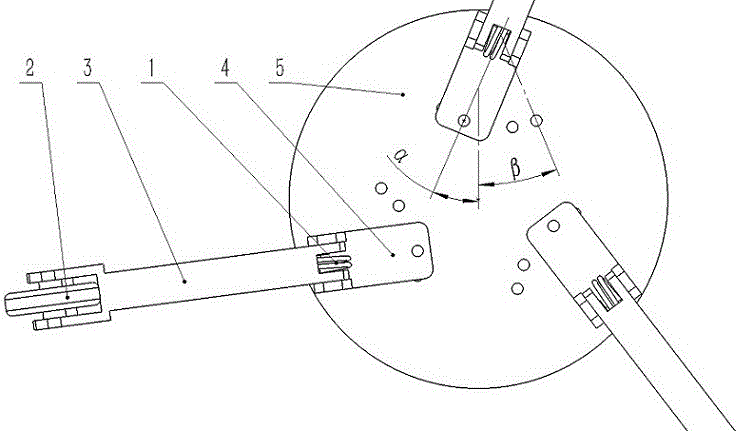

[0018] The rotating mechanism is installed on the rear end of the rotating shaft 9 and can drive the rotating shaft 9 to rotate. Such as figure 2 As shown, the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com