Patents

Literature

582 results about "Galvanic corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

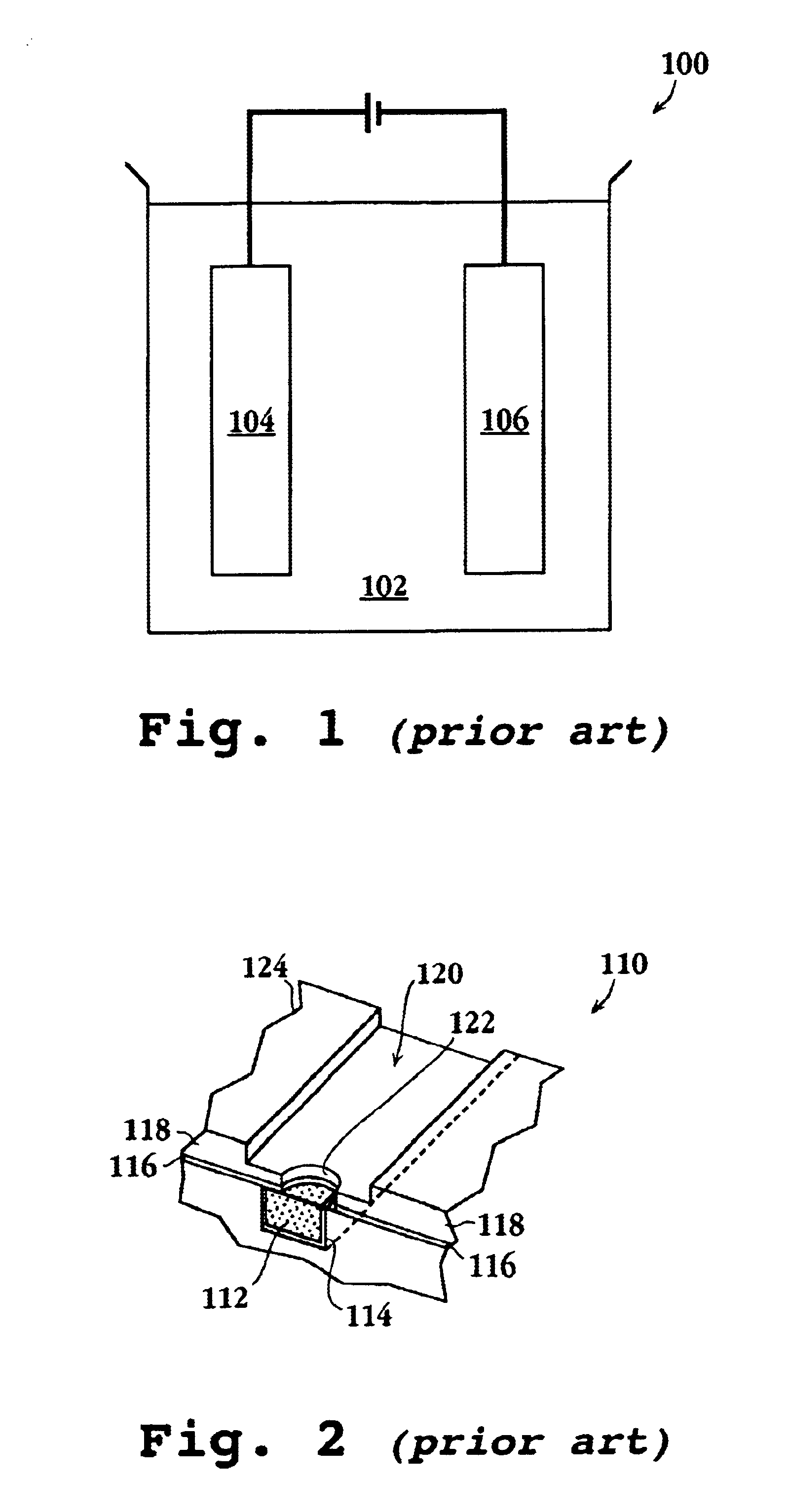

Galvanic corrosion (also called bimetallic corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. A similar galvanic reaction is exploited in primary cells to generate a useful electrical voltage to power portable devices.

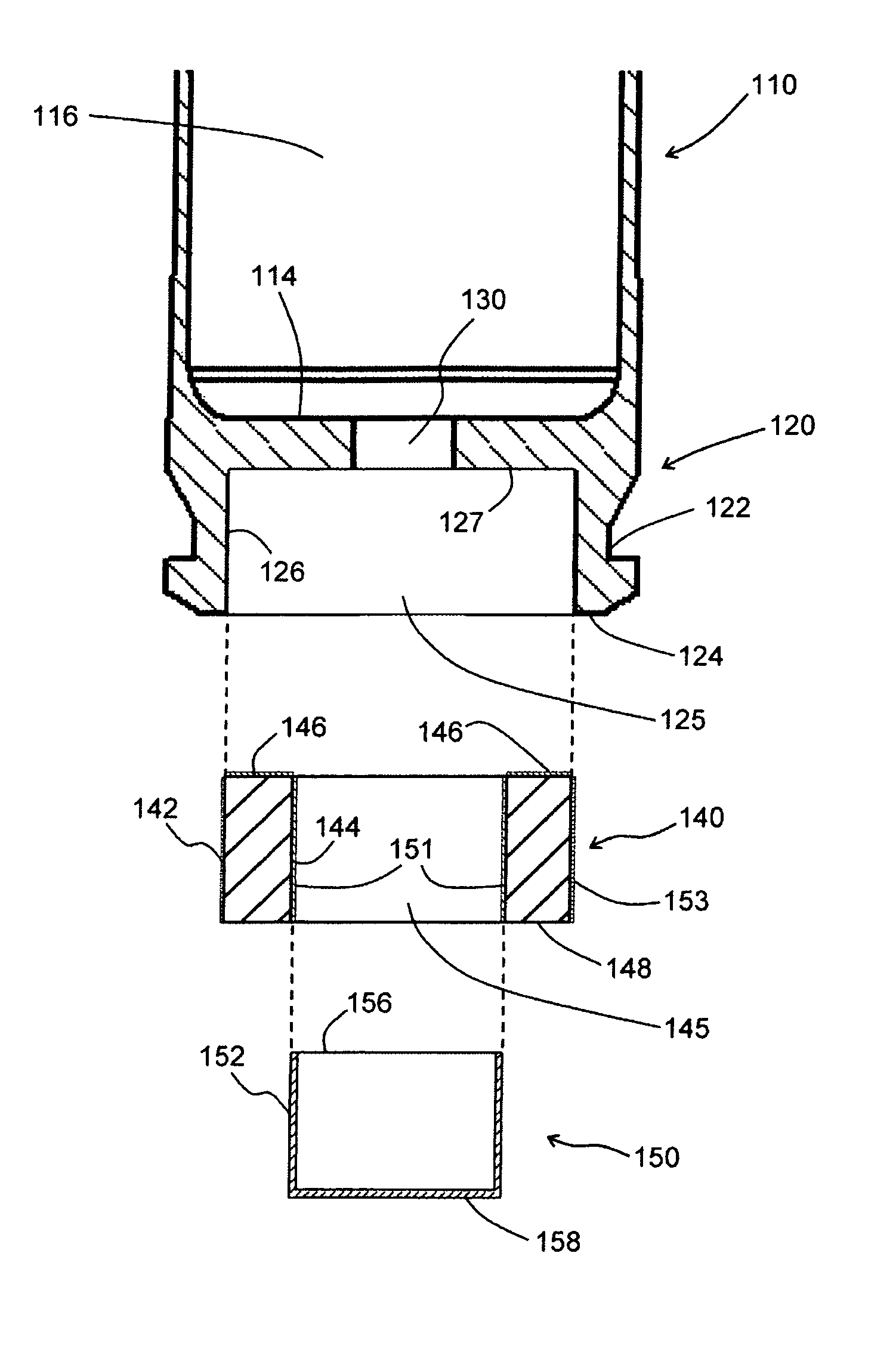

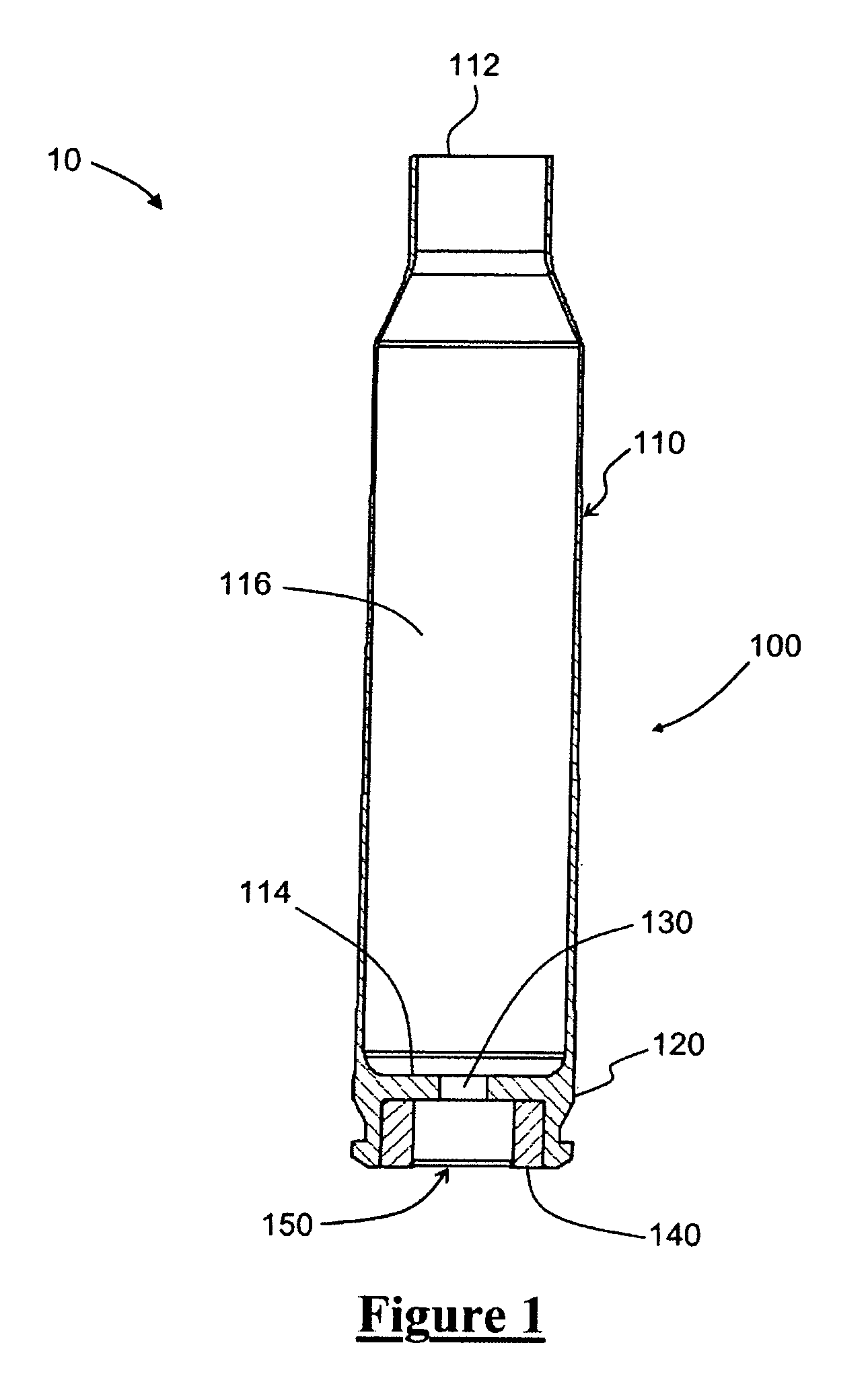

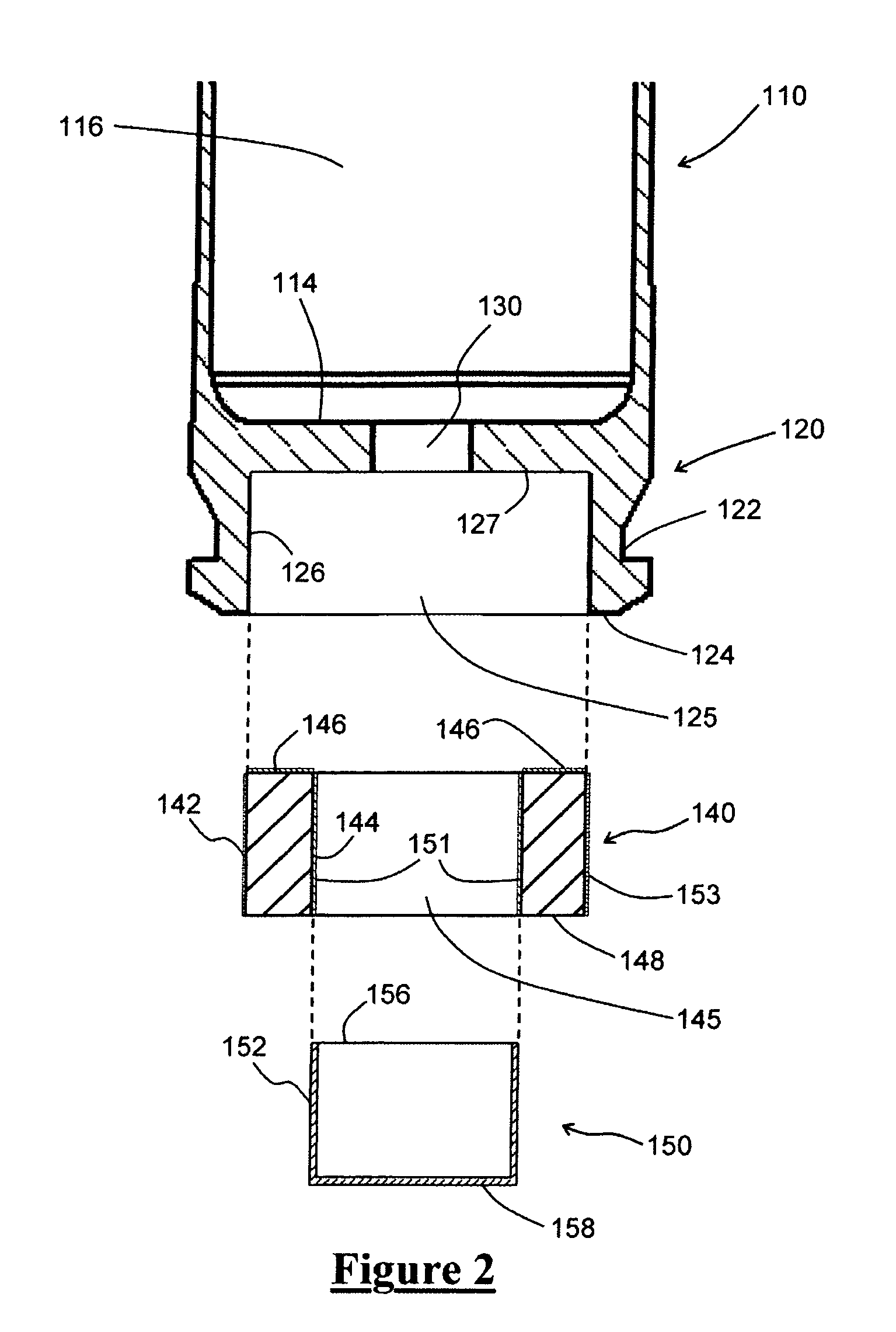

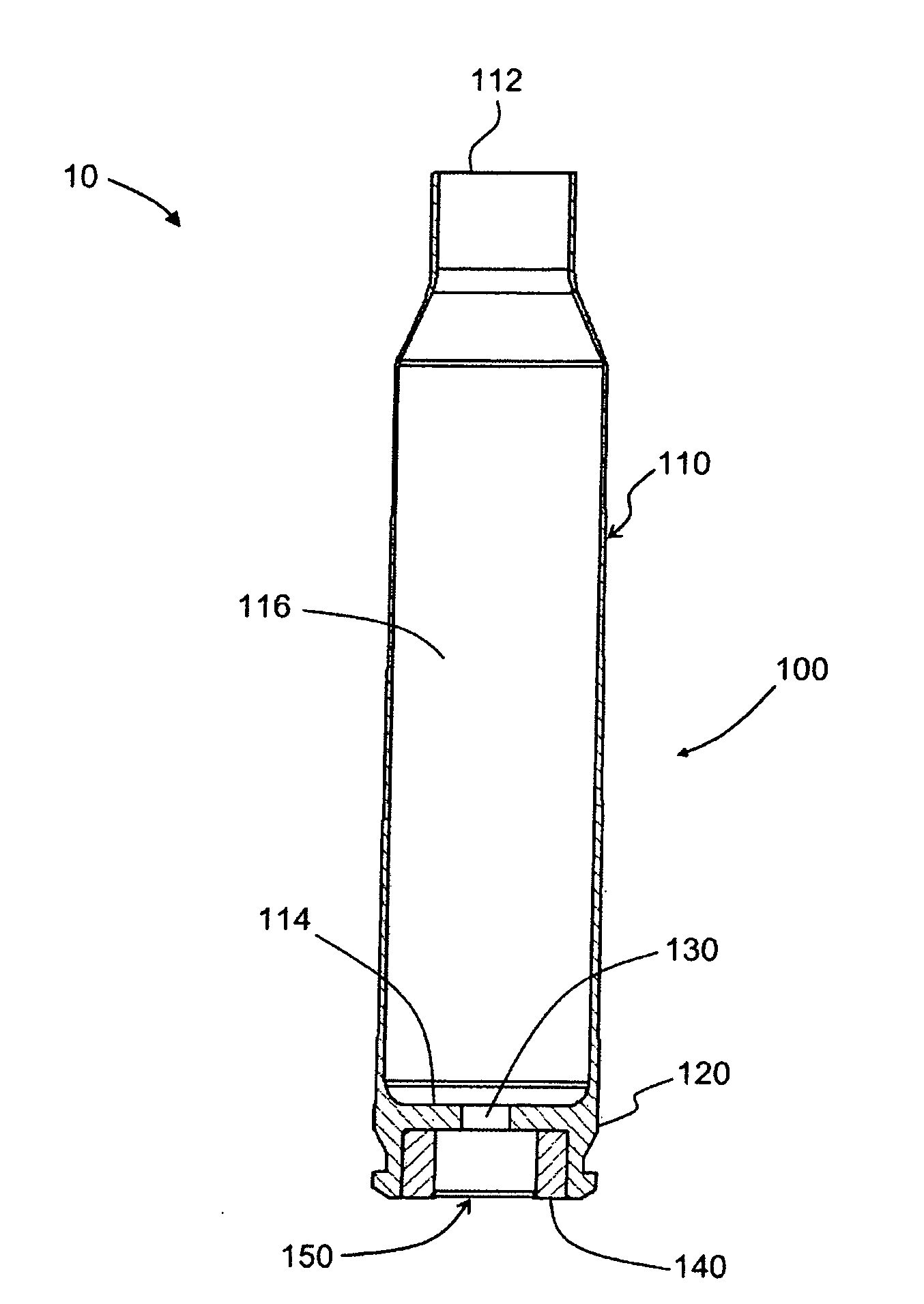

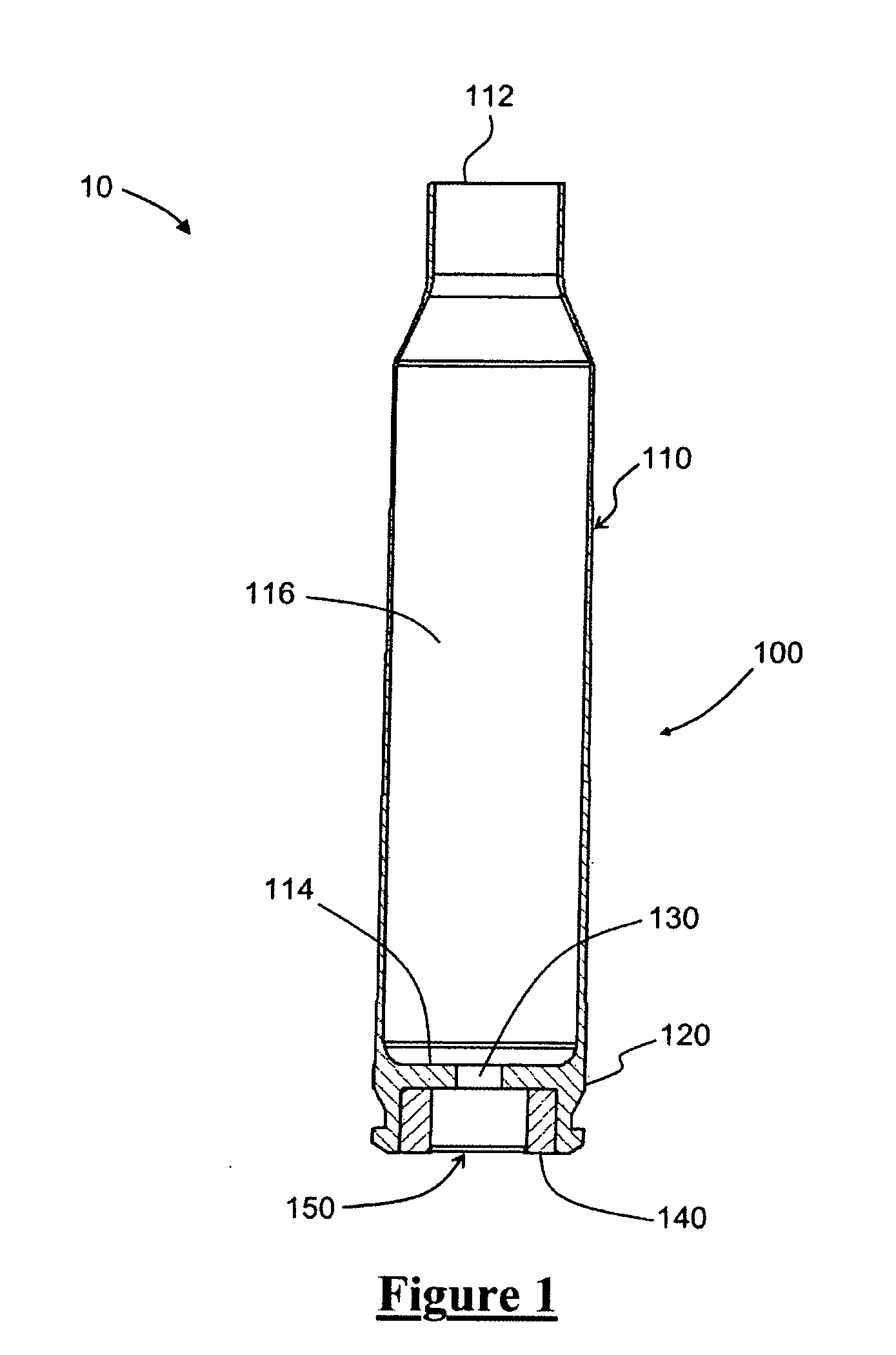

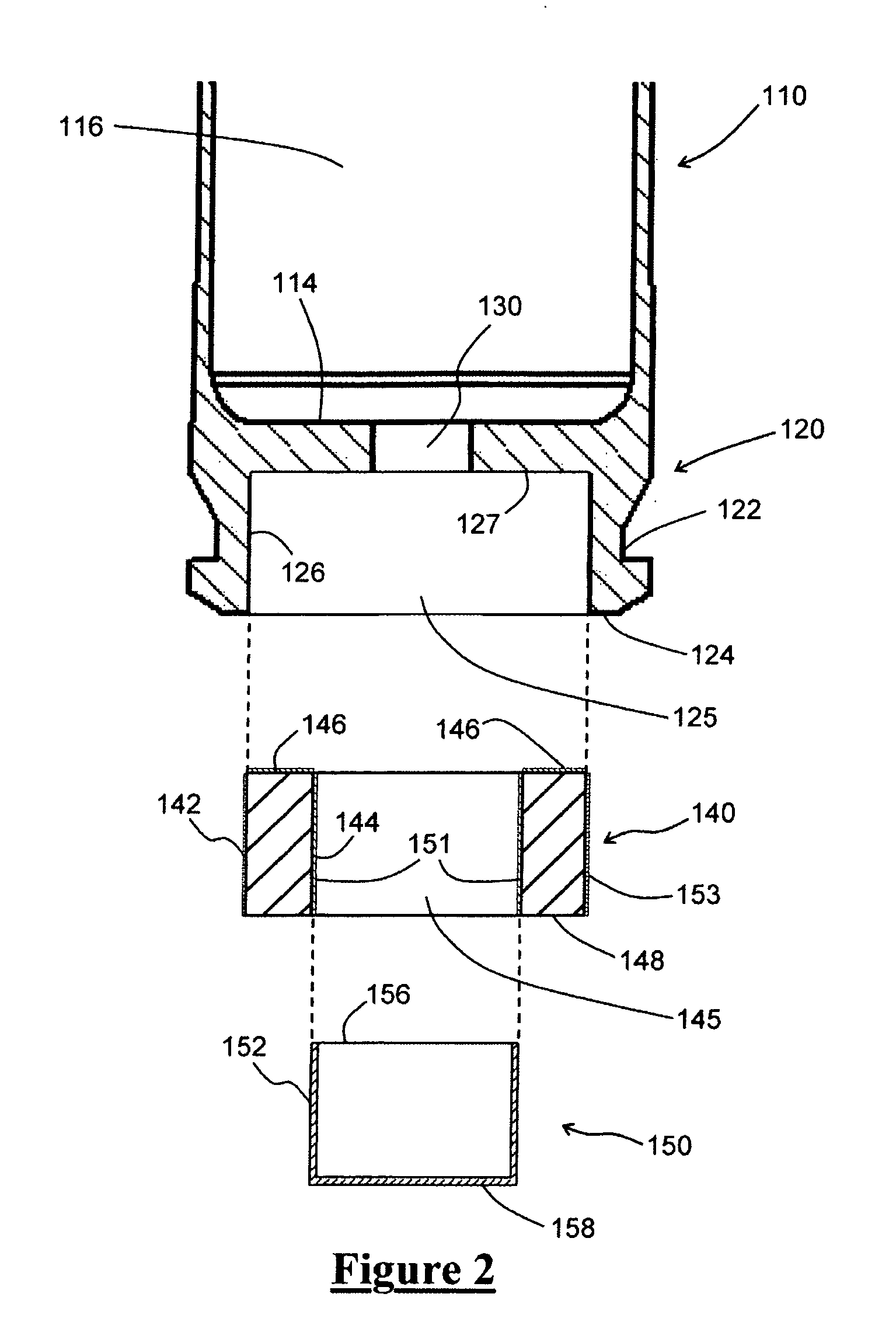

Lightweight cartridge case

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

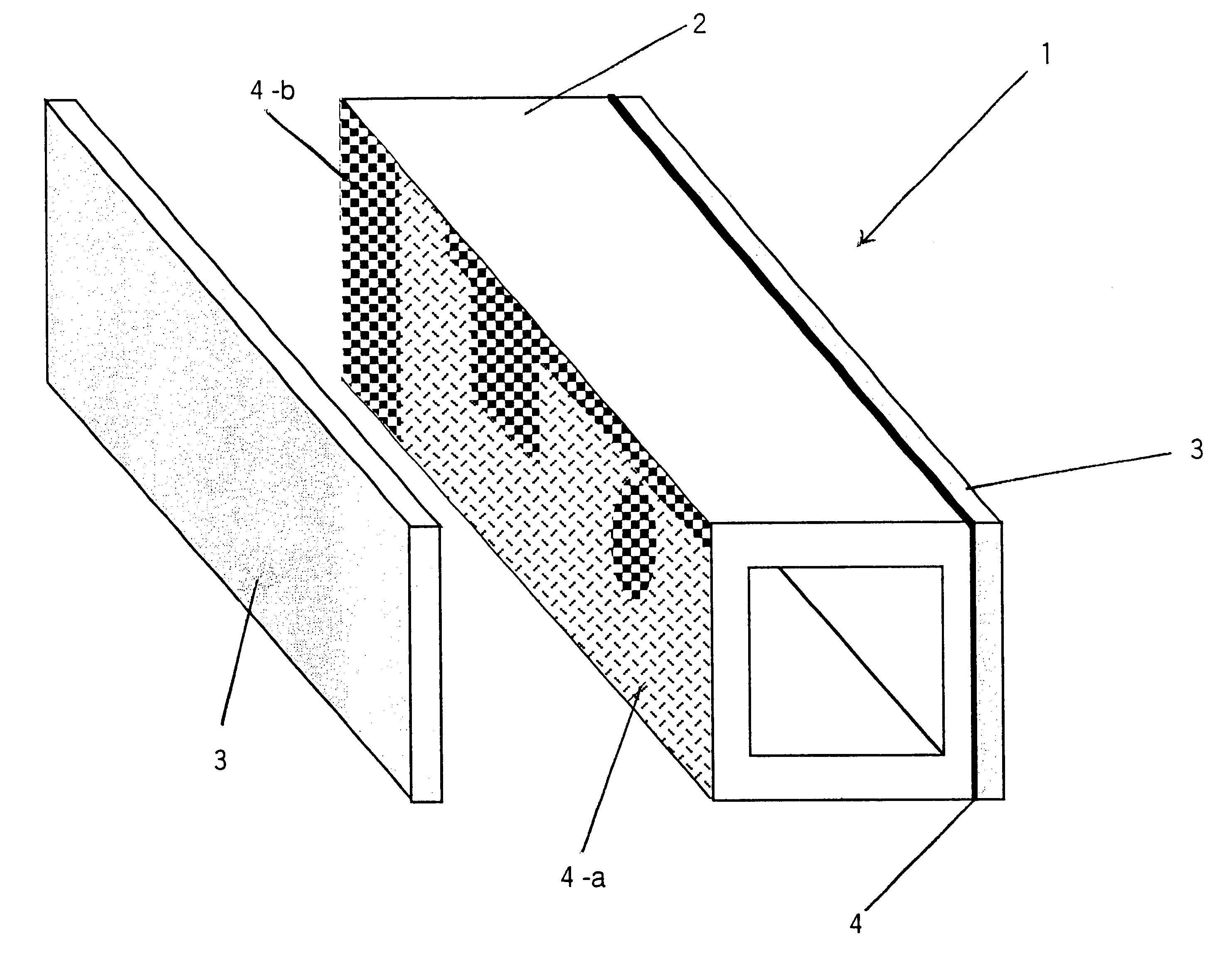

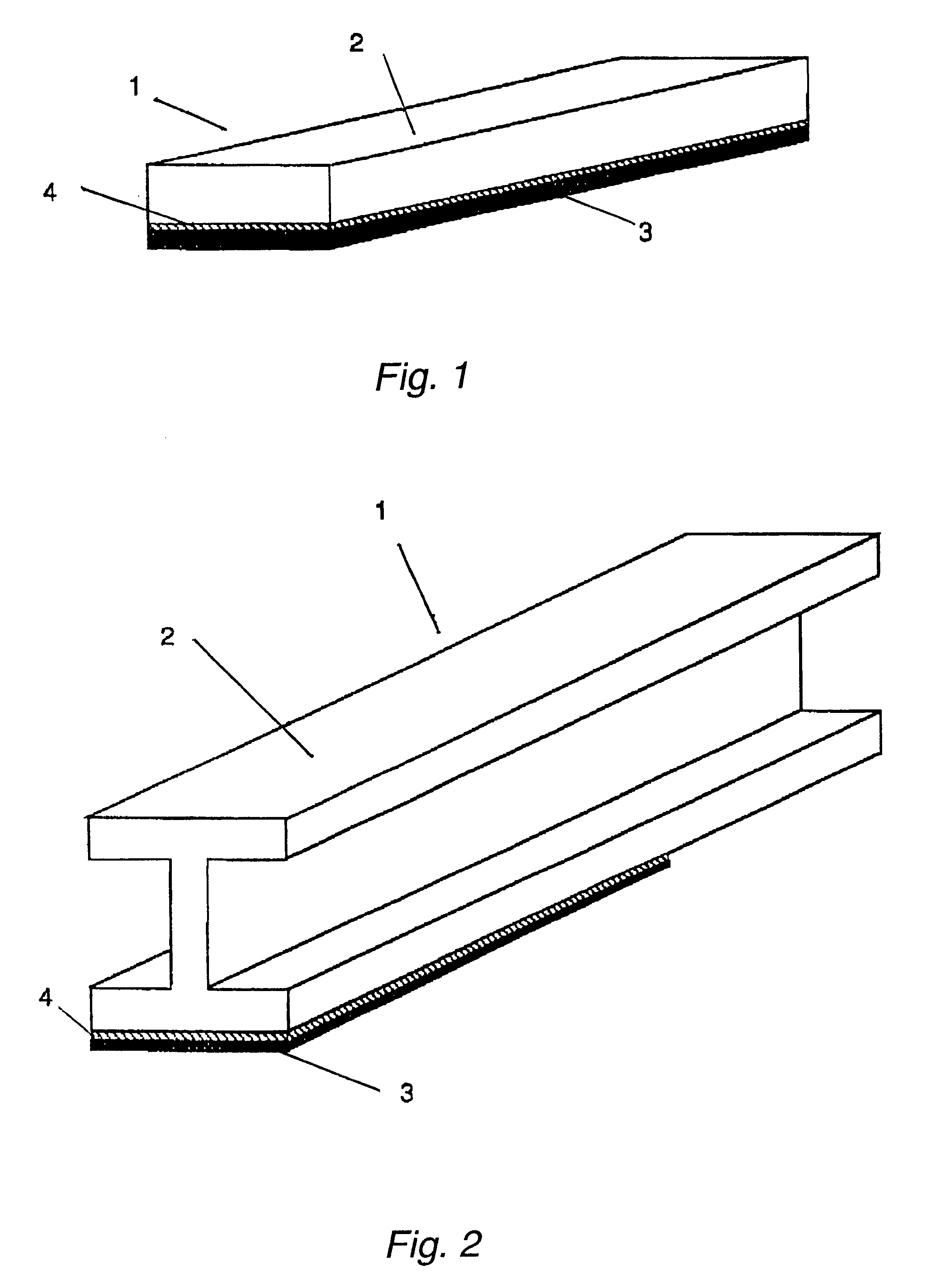

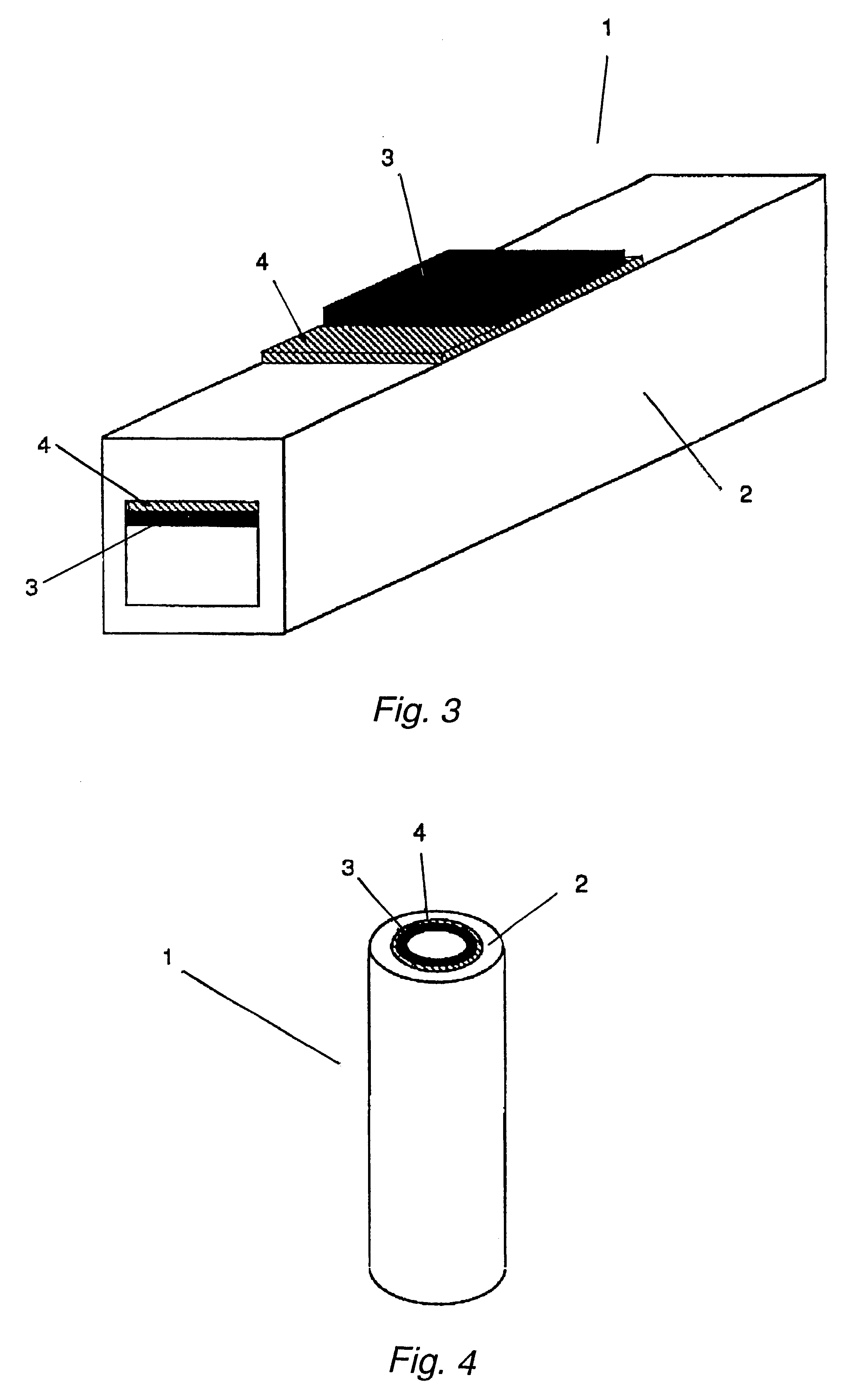

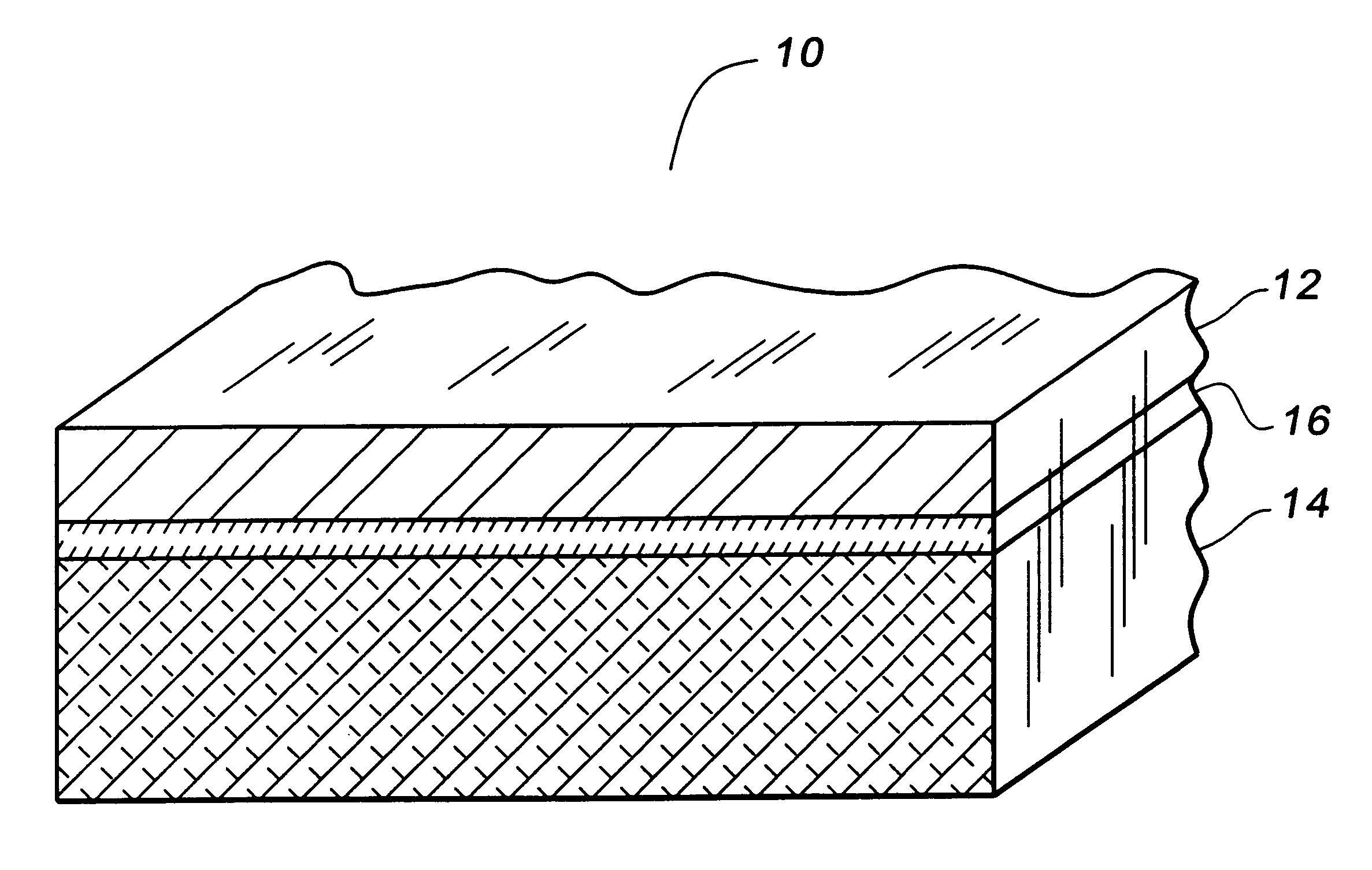

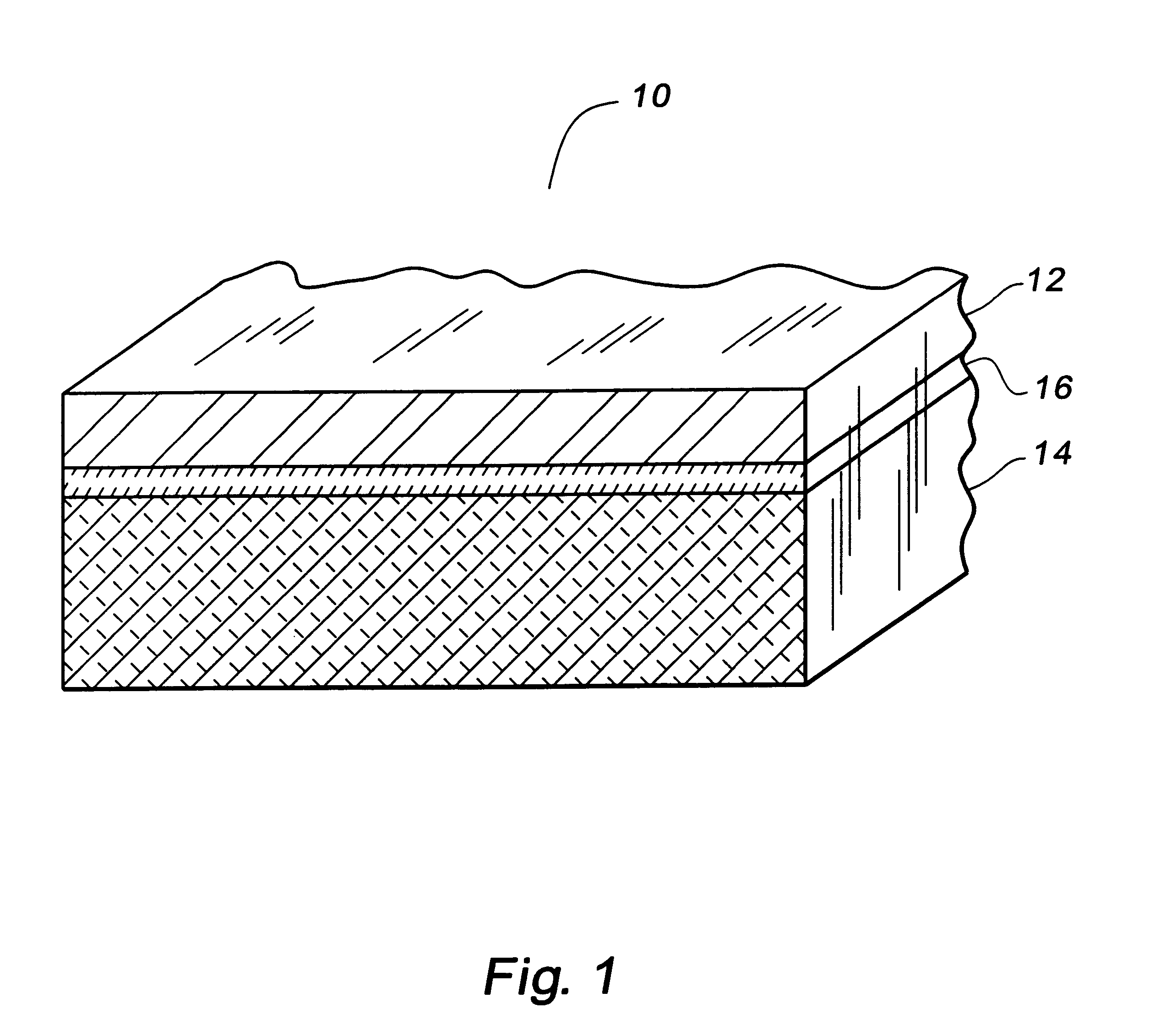

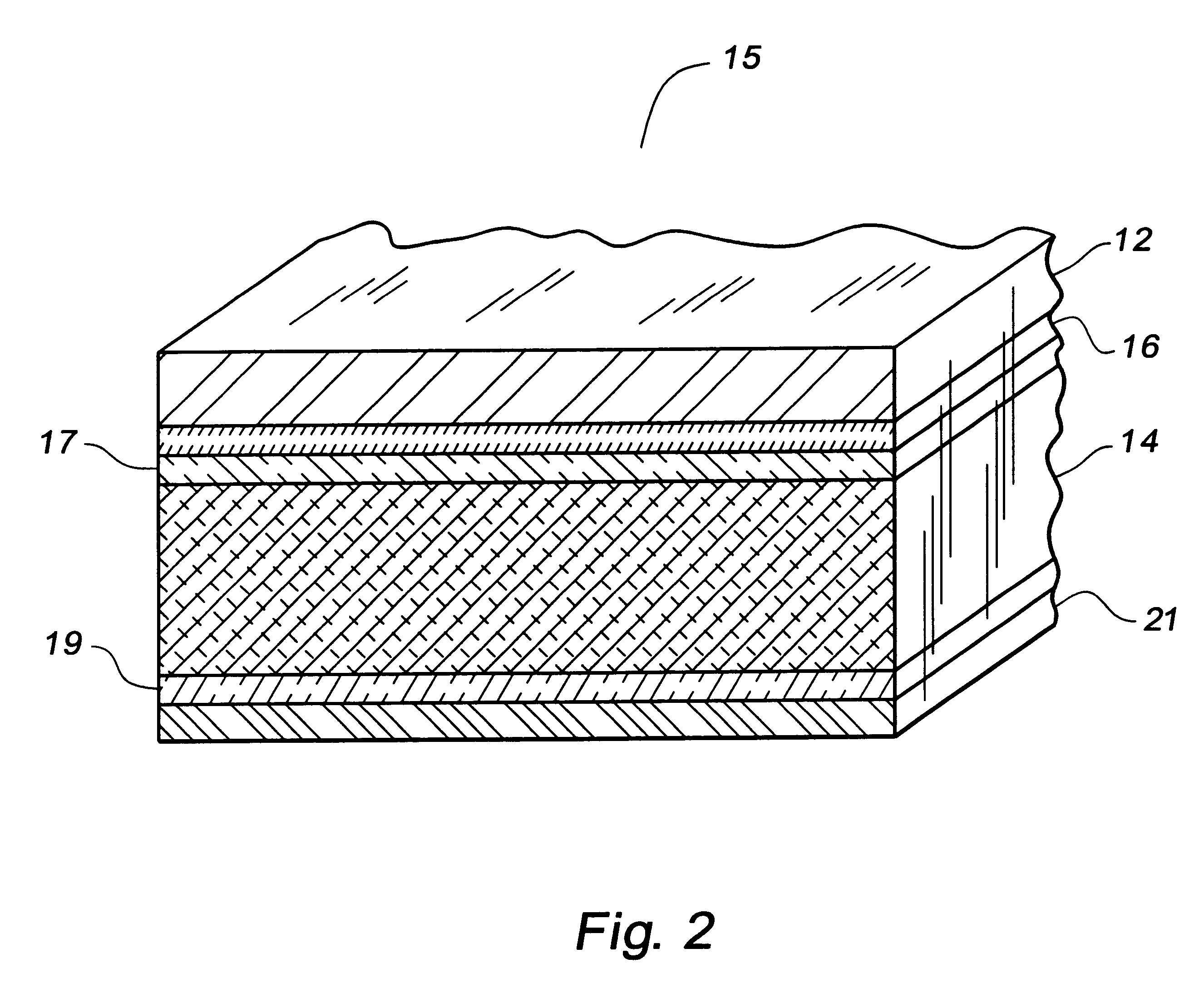

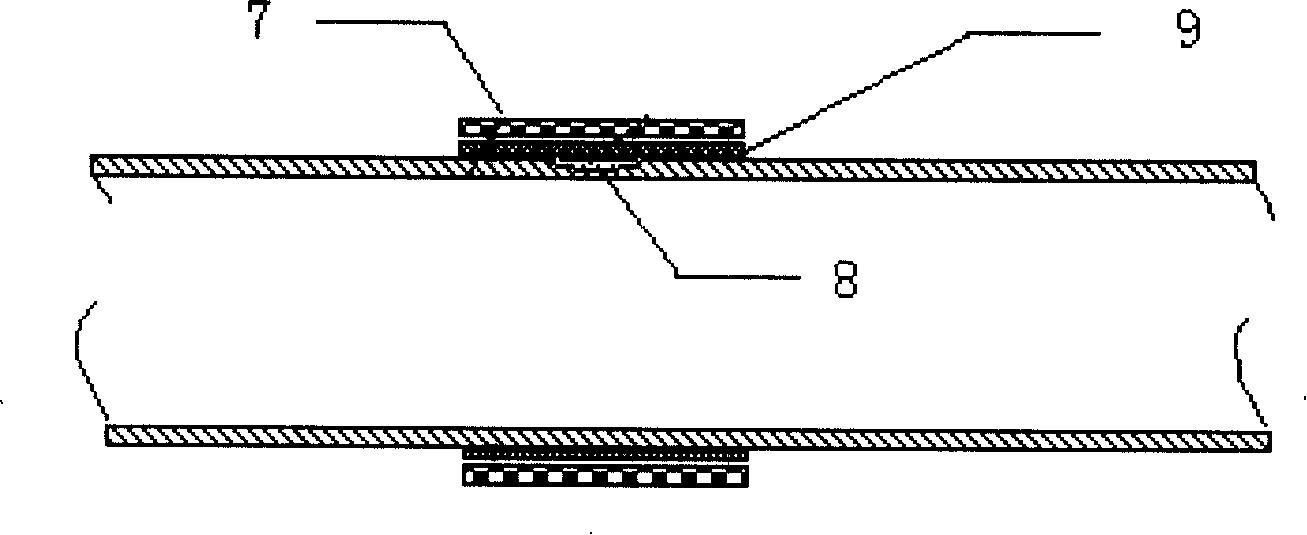

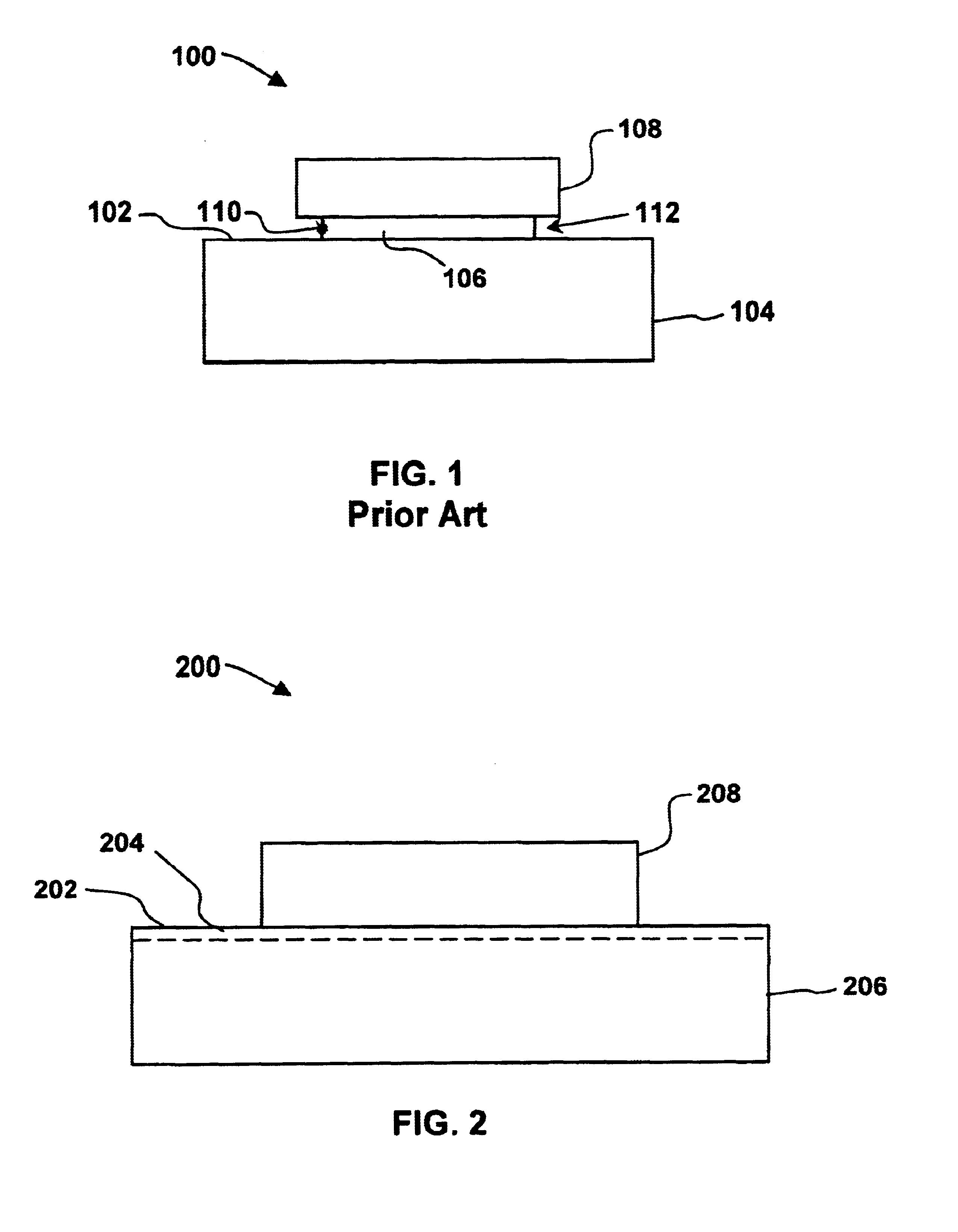

Light metal/CFRP structural member

InactiveUS6468613B1Prevent galvanic corrosionHigh structural reliabilitySynthetic resin layered productsCeramic shaping apparatusMetallic materialsRoom temperature

Light metal / CFRP-made structural members which are characterized in that they are structural materials in which a CFRP material is stuck to the surface of a light metal material via an adhesive agent layer of thickness at least 10 mum and up to 500 mum, and the volume resistivity of the adhesive agent layer between said metal material and said CFRP material is at least 1x1013 OMEGA.cm and, furthermore, the adhesive strength at room temperature is at least 15 MPa. In accordance with the present invention, since conventional light metal / CFRP structural materials can be made lighter and, furthermore, since the resistance to galvanic corrosion is outstanding and it is possible to markedly enhance the strength and the impact energy absorption performance, the development of applications and large-scale expansion into new fields becomes possible. Weight reduction and enhancing the durability and reliability of structures also makes a considerable contribution in terms of environmental protection.

Owner:TORAY IND INC

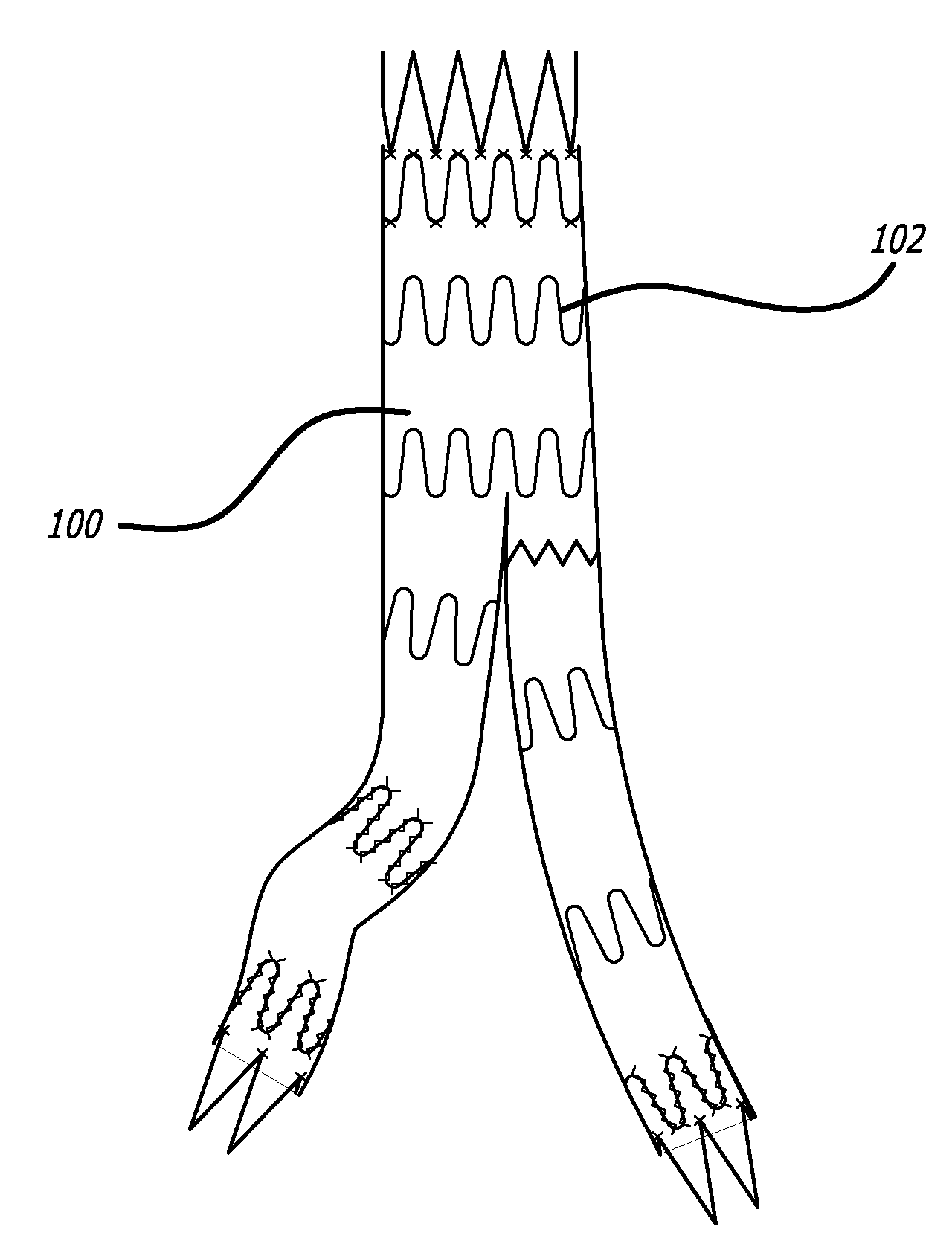

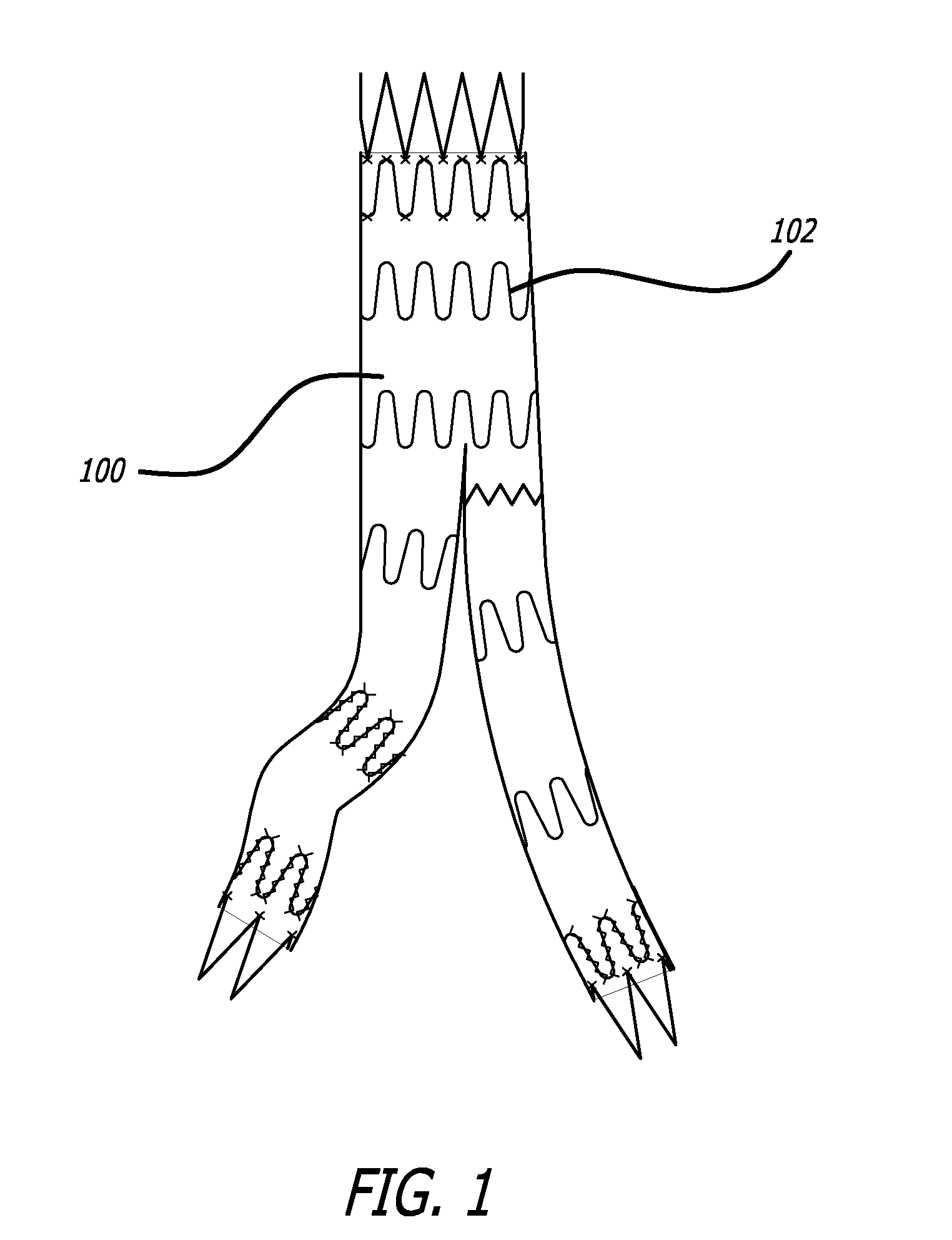

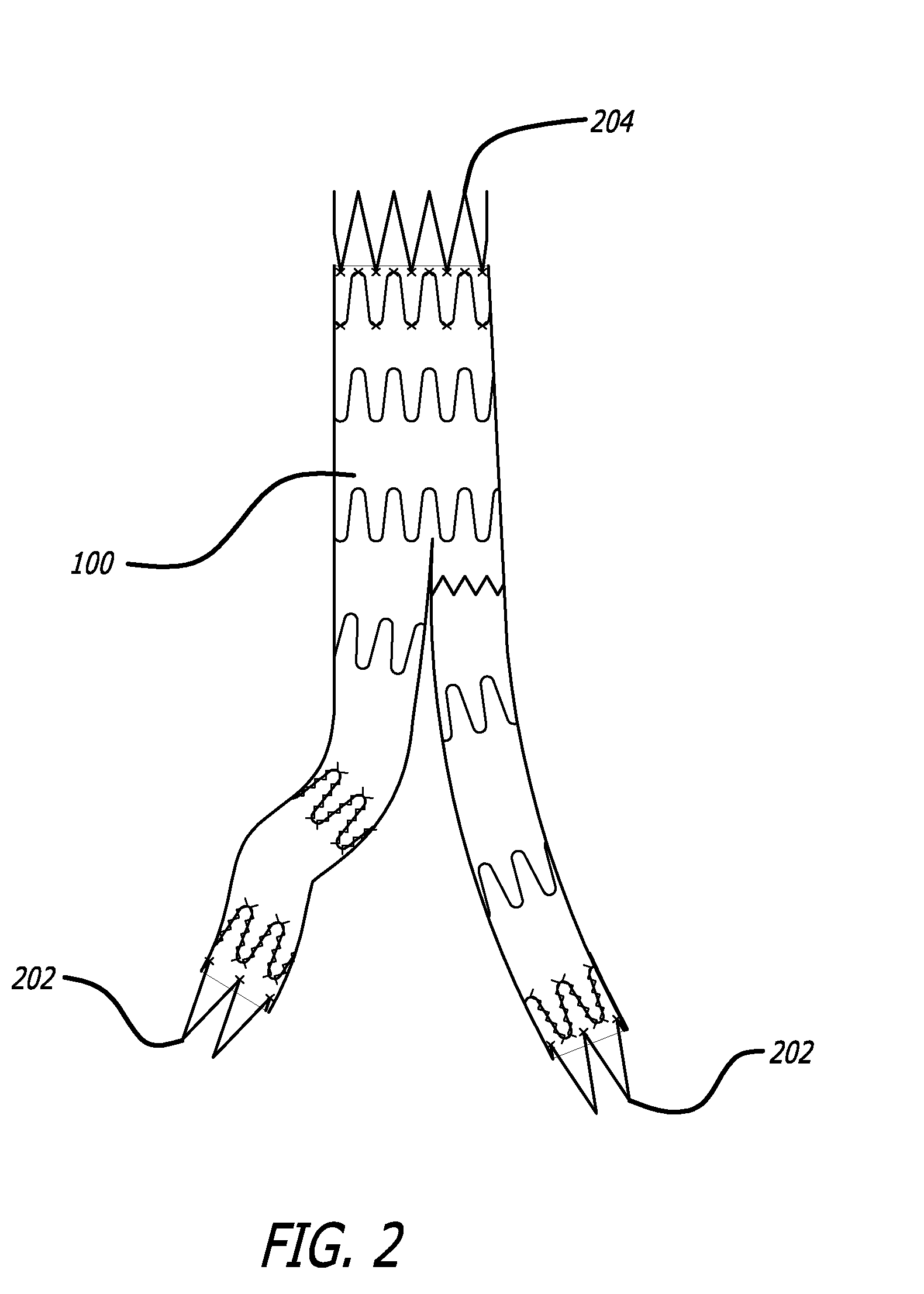

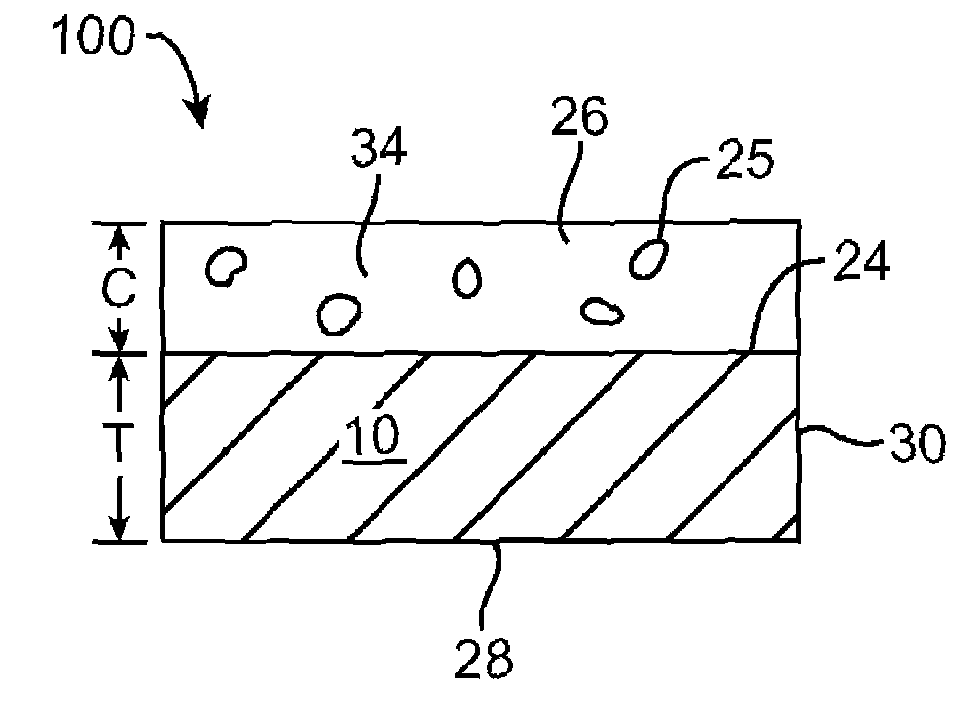

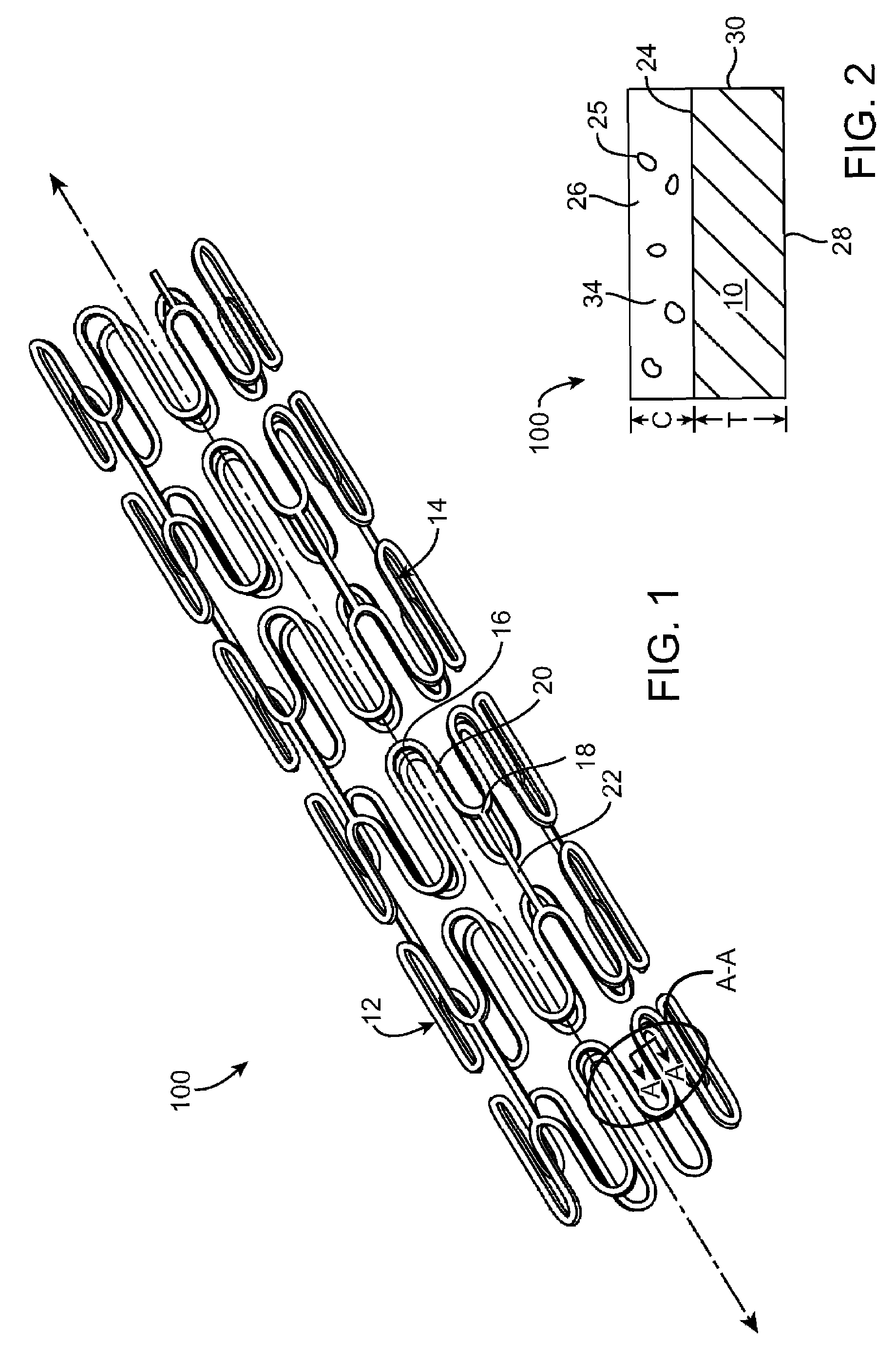

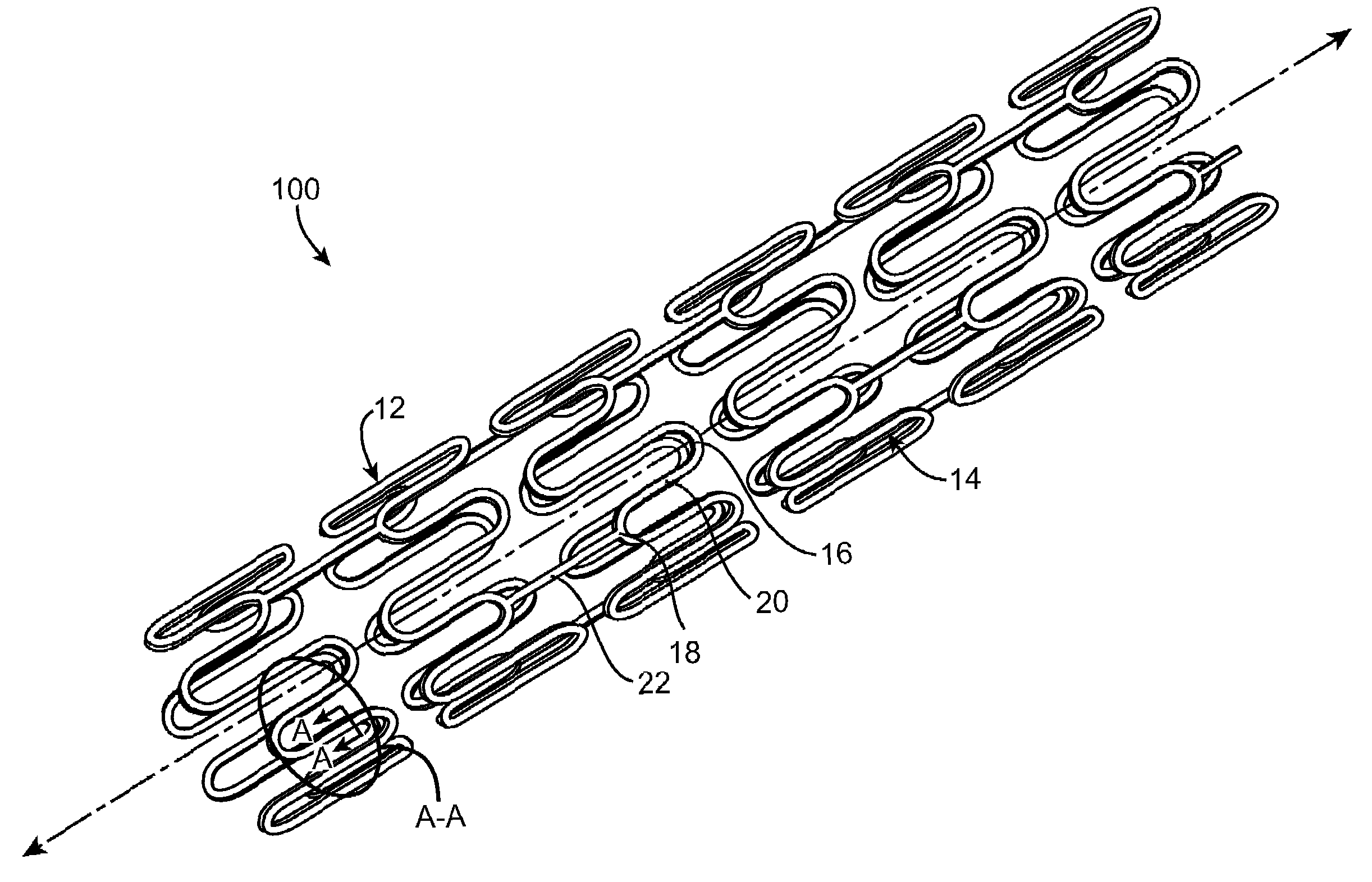

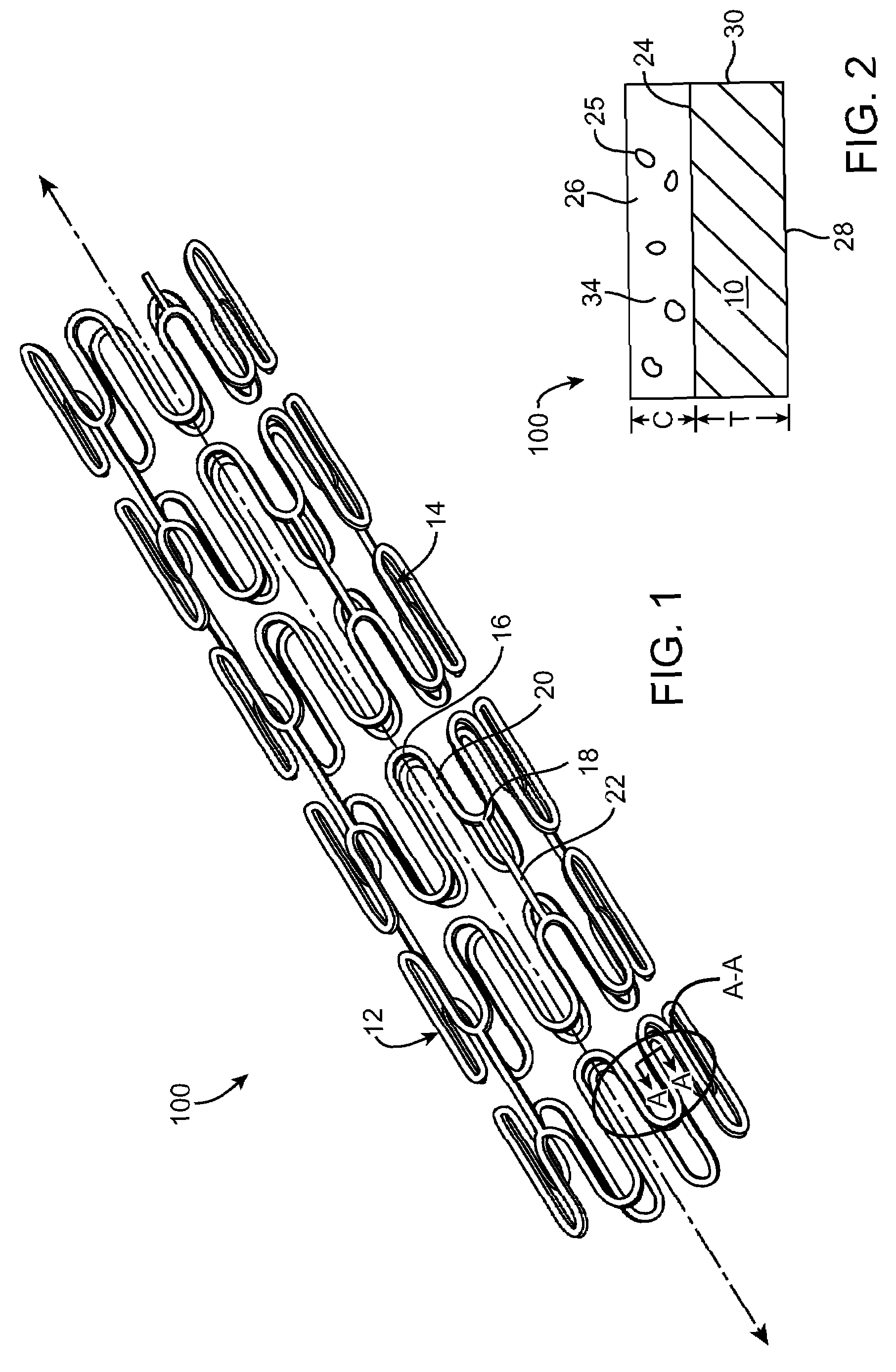

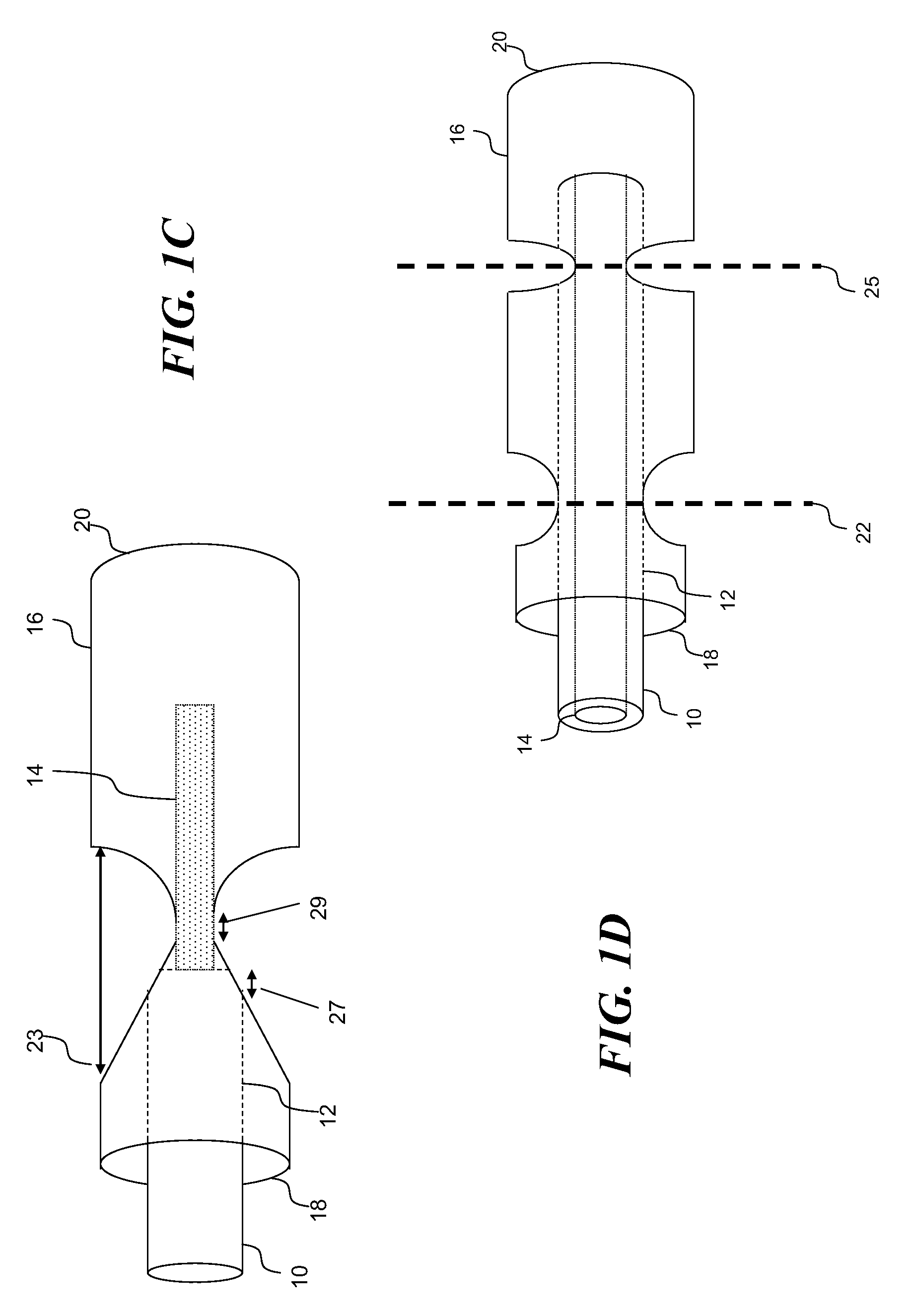

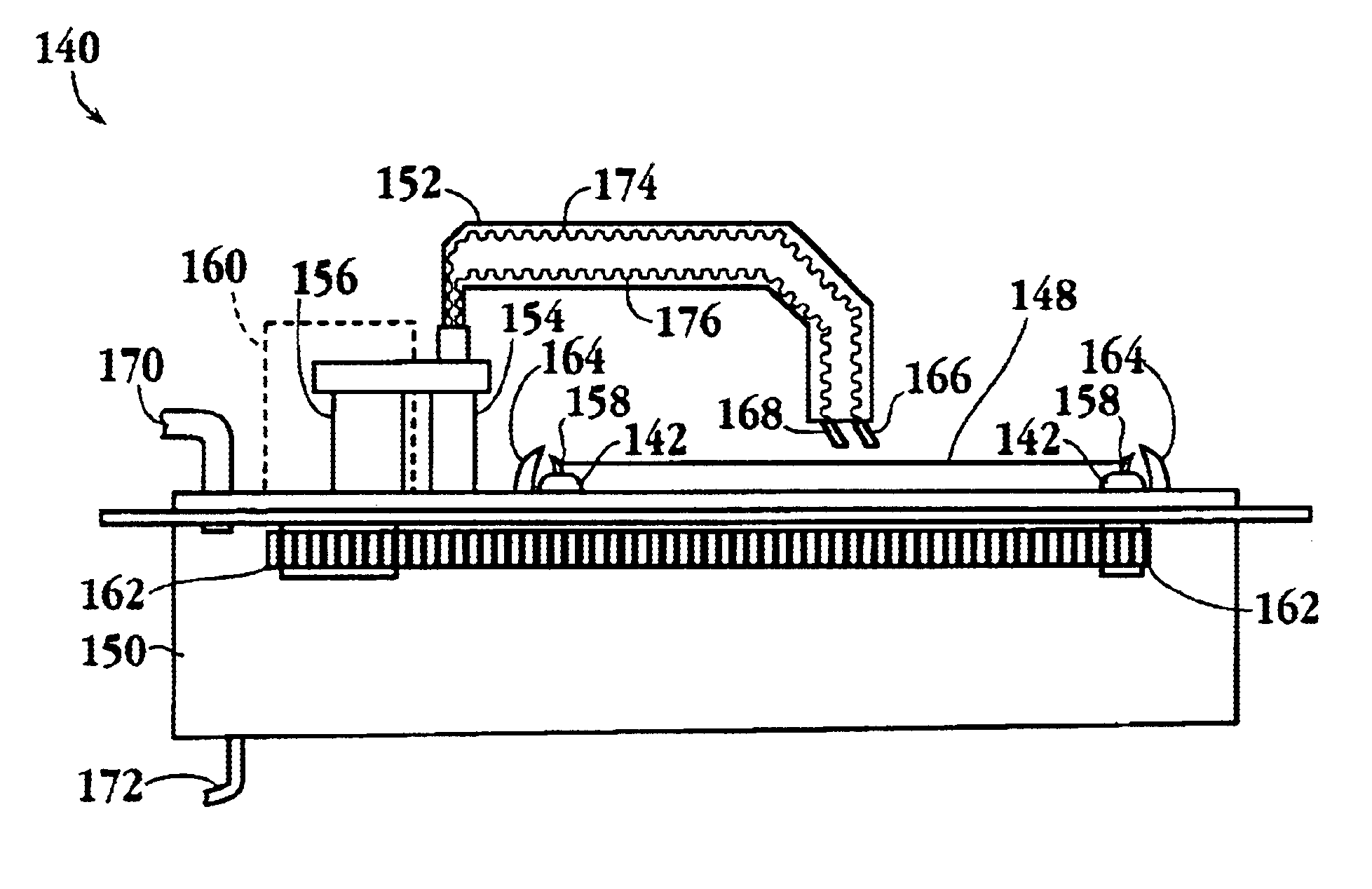

Galvanic Corrosion Methods and Devices for Fixation of Stent Grafts

Methods and devices are provided to contribute to improved stent graft fixation within vessels at treatment sites. Improved stent graft fixation within vessels at treatment sites is provided by providing stent grafts and methods of making and using stent grafts having structural scaffoldings which undergo controlled galvanic corrosion in situ. Other embodiments include stent grafts having galvanic cells attached to the vessel luminal wall-contacting sides. Still other embodiments include stent grafts that undergo controlled galvanic corrosion and include at least one additional cell growth promoting factor.

Owner:MEDTRONIC VASCULAR INC

Degradable medical device

An implantable medical device is provided that degrades upon contact with body fluids so as to limit its residence time within the body. The device is formed of a porous corrodible metal to simultaneously provide high strength and an accelerated corrosion rate. The corrosion rate of a device formed of metal subject to self-dissolution or of a combination of metals subject to galvanic corrosion is accelerated by its porous structure. Coating the corrodible metallic device with a degradable polymer serves to delay the onset of corrosion of the underlying metallic structure.

Owner:KLEINE KLAUS +1

Lightweight cartridge case

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

Aluminum laminate

InactiveUS6235409B1Light weightHigh strengthHot-dipping/immersion processesAdhesive processesAlloy substrateAlclad

A bright finish aluminum alloy on high strength aluminum or aluminum alloy lamination is disclosed including a bright finish top sheet, a high strength aluminum or aluminum alloy substrate, and an adhesive bonding the bright finish metal top sheet to the high strength aluminum or aluminum alloy substrate to provide a bright finish aluminum on high strength aluminum or aluminum alloy lamination product having brighter finish than a sheet product of said high strength aluminum or aluminum alloy and higher strength than a sheet product of said bright finish aluminum of the same thickness as said lamination product, wherein said lamination product withstands galvanic corrosion. In one aspect, the bright finish metal top sheet is 5657 aluminum foil. In one aspect, the high strength aluminum alloy is 5182 alloy sheet.

Owner:ARCONIC INC

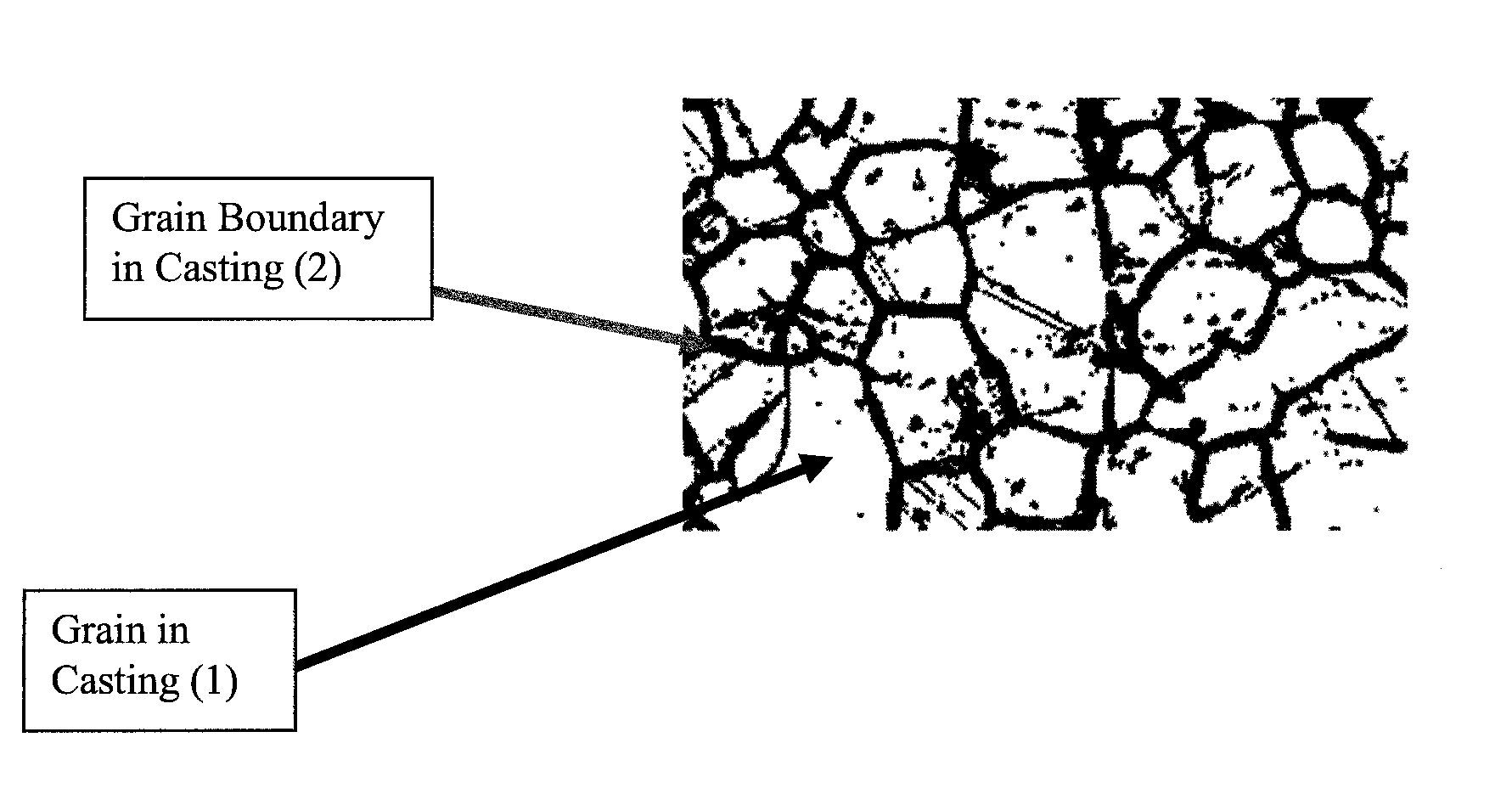

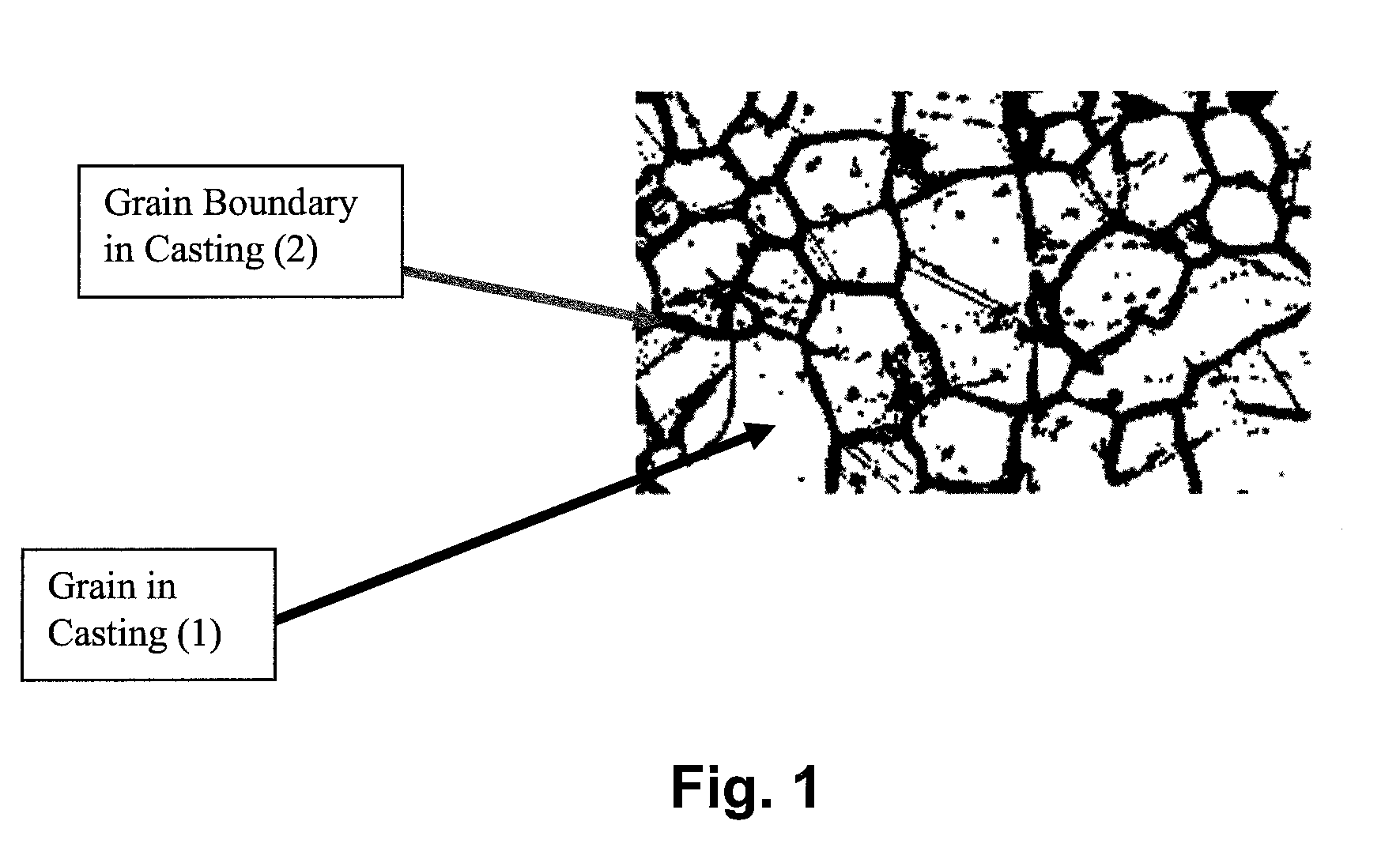

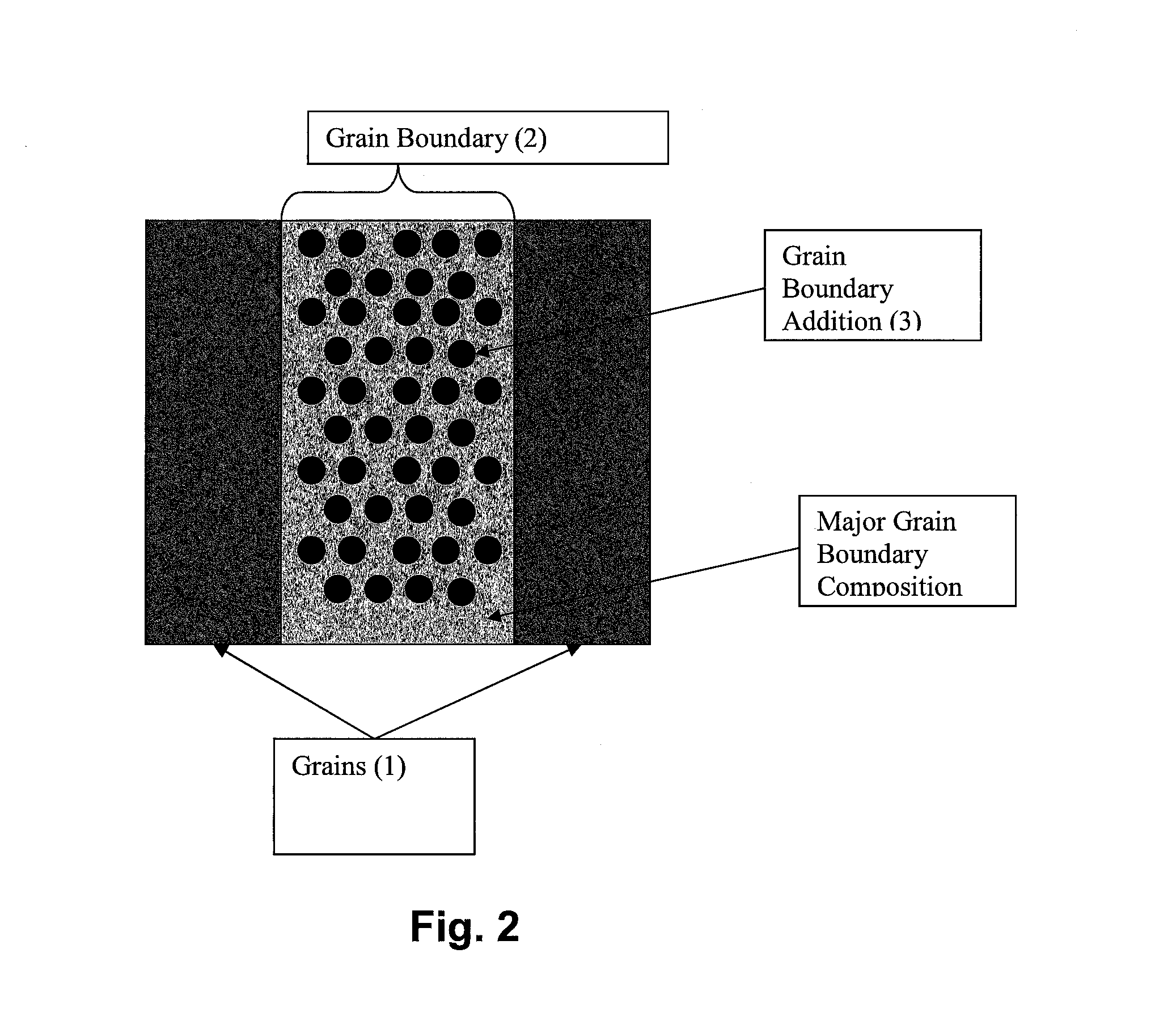

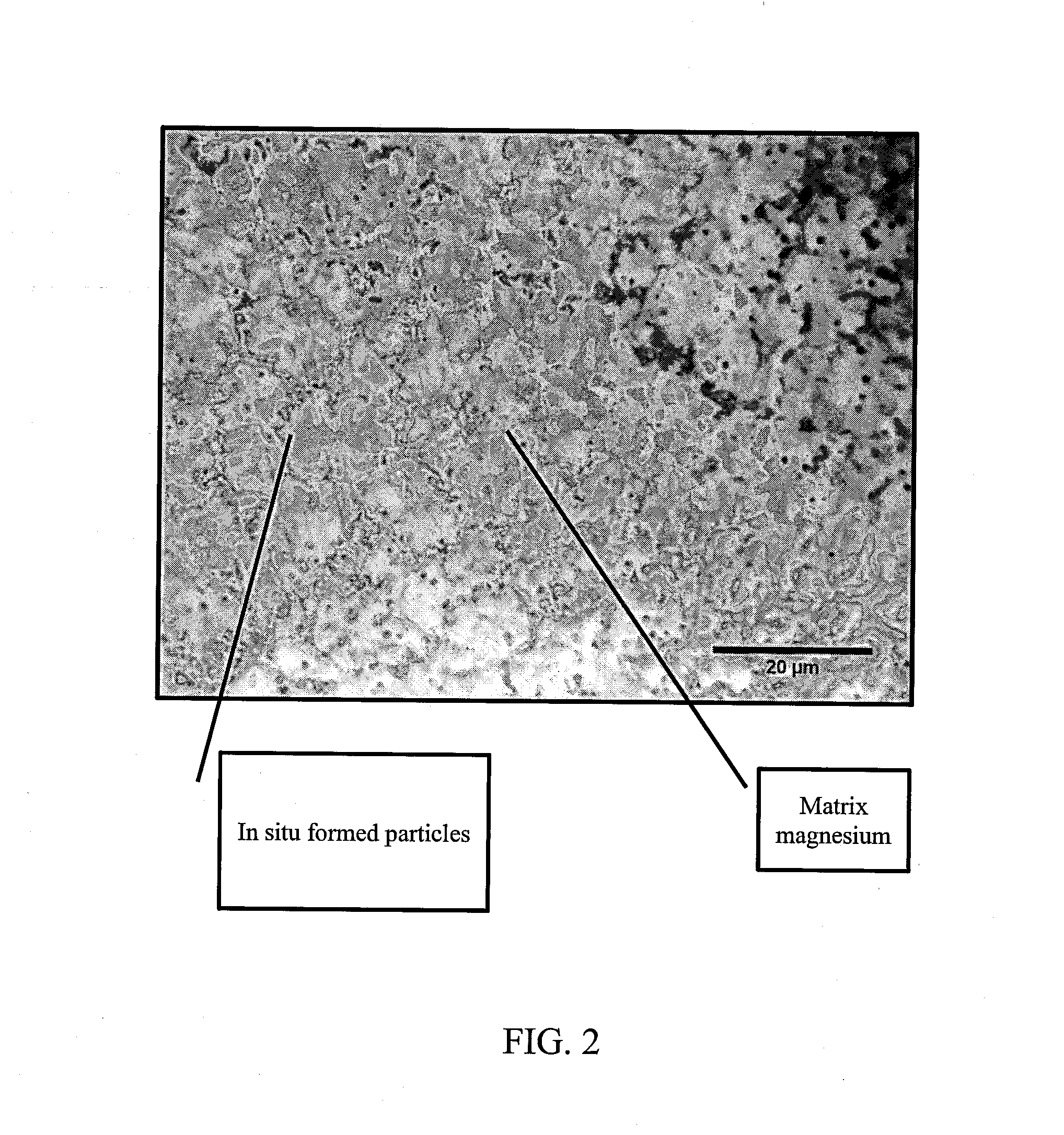

Manufacture of Controlled Rate Dissolving Materials

ActiveUS20150240337A1Improve ductilityImprove propertiesTransportation and packagingMetal-working apparatusAlloyBase metal alloy

A castable, moldable, or extrudable structure using a metallic base metal or base metal alloy. One or more insoluble additives are added to the metallic base metal or base metal alloy so that the grain boundaries of the castable, moldable, or extrudable structure includes a composition and morphology to achieve a specific galvanic corrosion rates partially or throughout the structure or along the grain boundaries of the structure. The insoluble additives can be used to enhance the mechanical properties of the structure, such as ductility and / or tensile strength. The insoluble particles generally have a submicron particle size. The final structure can be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final structure as compared to the non-enhanced structure.

Owner:TERVES

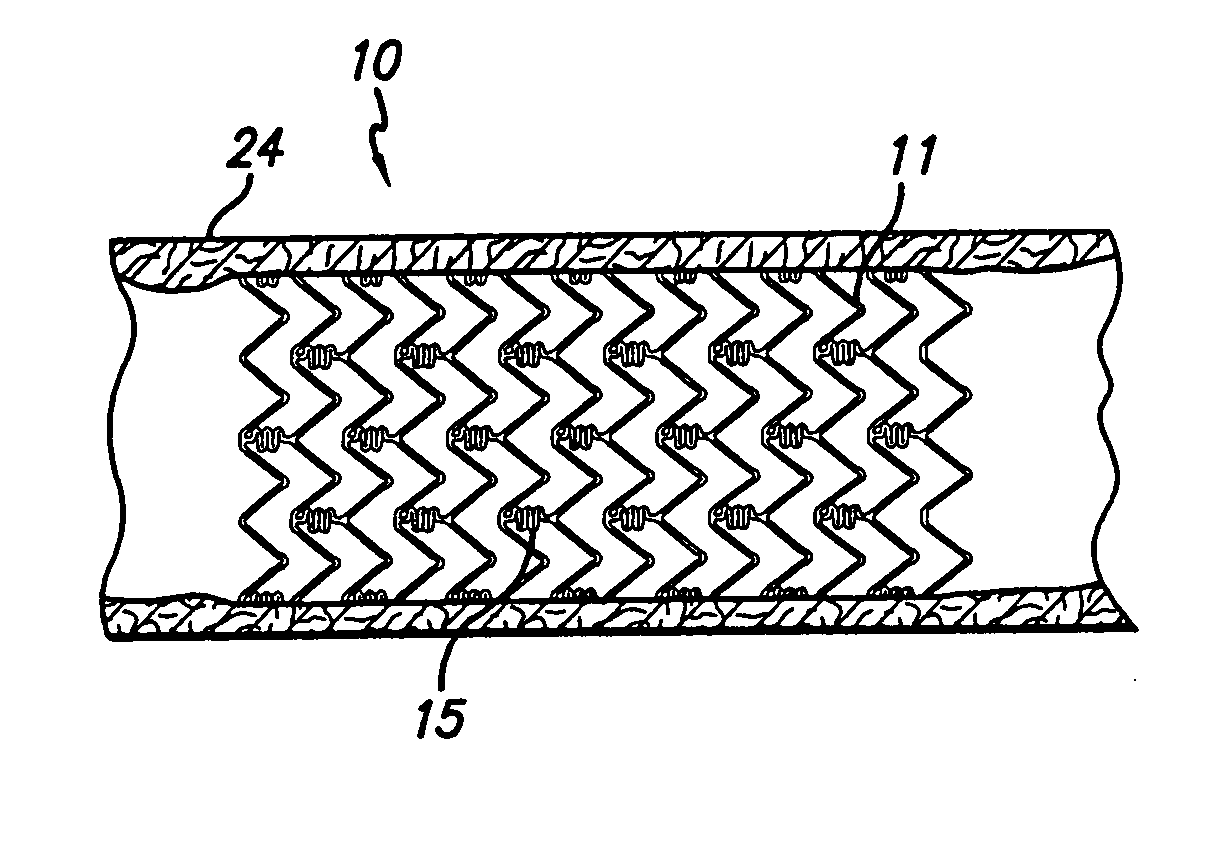

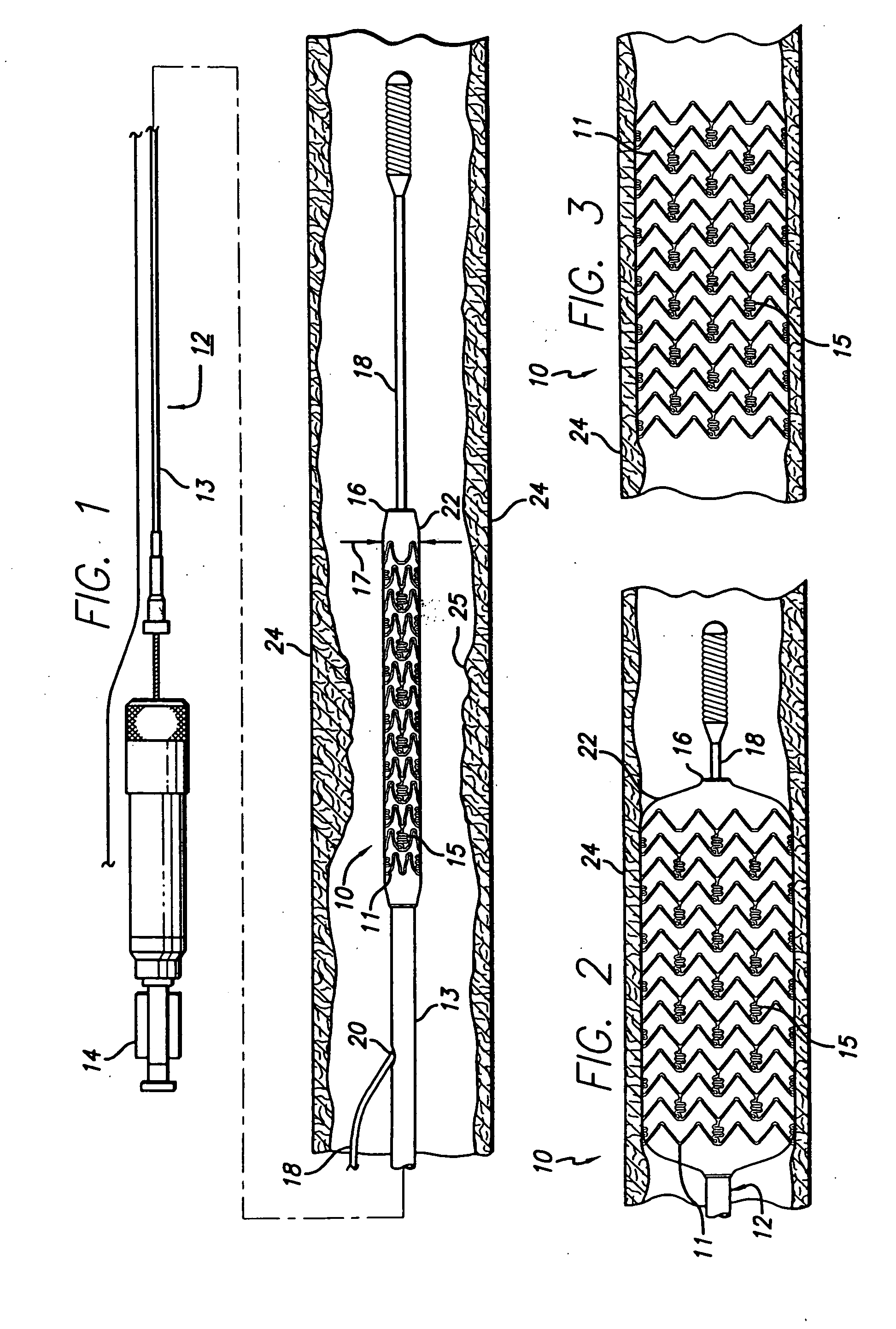

Bioresorbable stent

A bioresorbable endoluminal prosthesis for placement in a body lumen having a stent substrate of a first metallic material that has a lower electrical potential than a standard reference electrode. The stent substrate is coated with a biodegradable polymer having a second metallic material dispersed therein, wherein the second metallic material has a higher electrical potential than the standard reference electrode. After implantation of the stent within the body lumen, the second metallic material is present in the polymeric coating in a sufficient concentration to cause galvanic corrosion of the first metallic material such that over time the stent substrate is bioresorbed.

Owner:MEDTRONIC VASCULAR INC

Bioresorbable Stent

A bioresorbable endoluminal prosthesis for placement in a body lumen having a stent substrate of a first metallic material that has a lower electrical potential than a standard reference electrode. The stent substrate is coated with a biodegradable polymer having a second metallic material dispersed therein, wherein the second metallic material has a higher electrical potential than the standard reference electrode. After implantation of the stent within the body lumen, the second metallic material is present in the polymeric coating in a sufficient concentration to cause galvanic corrosion of the first metallic material such that over time the stent substrate is bioresorbed.

Owner:MEDTRONIC VASCULAR INC

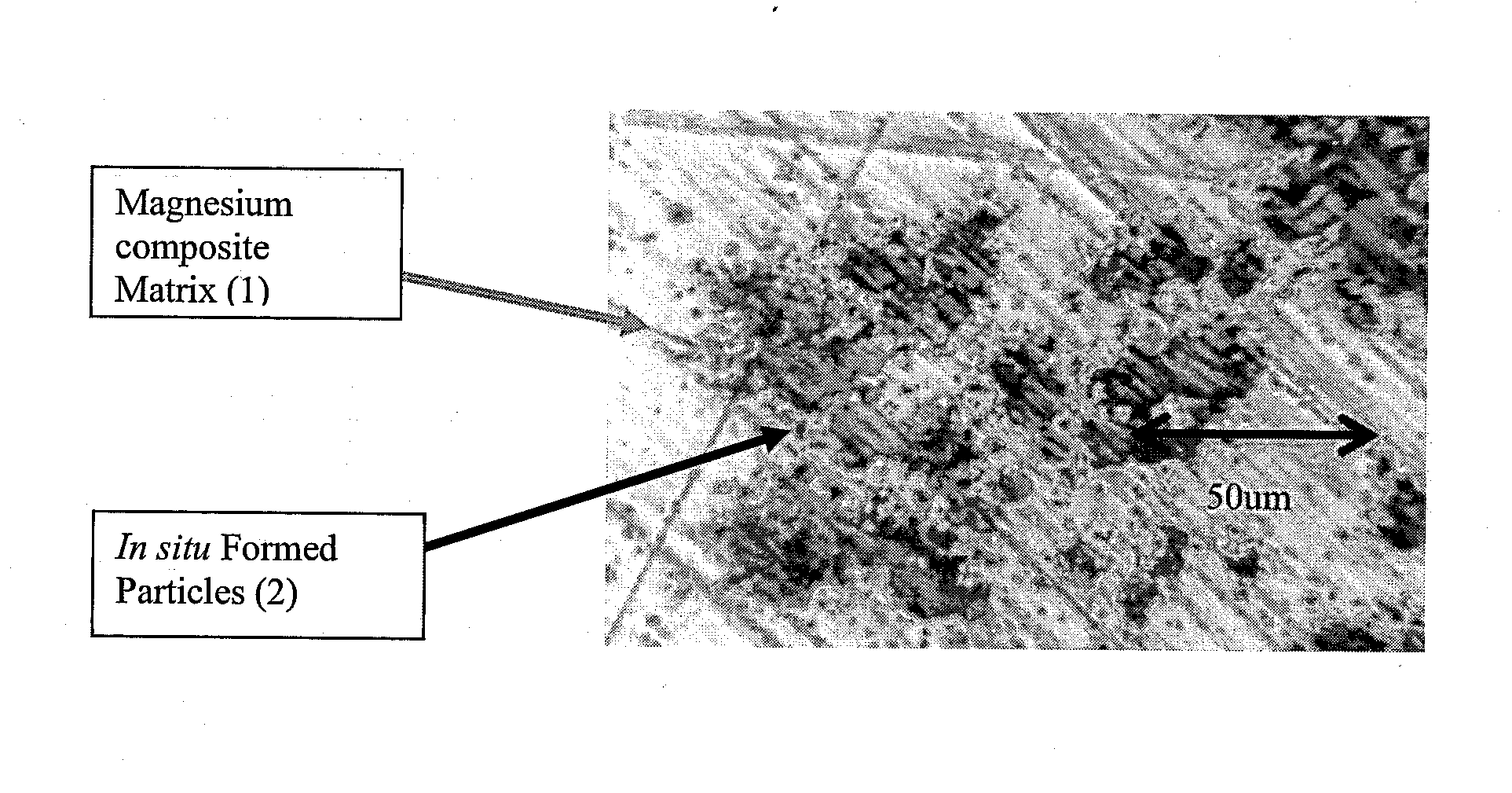

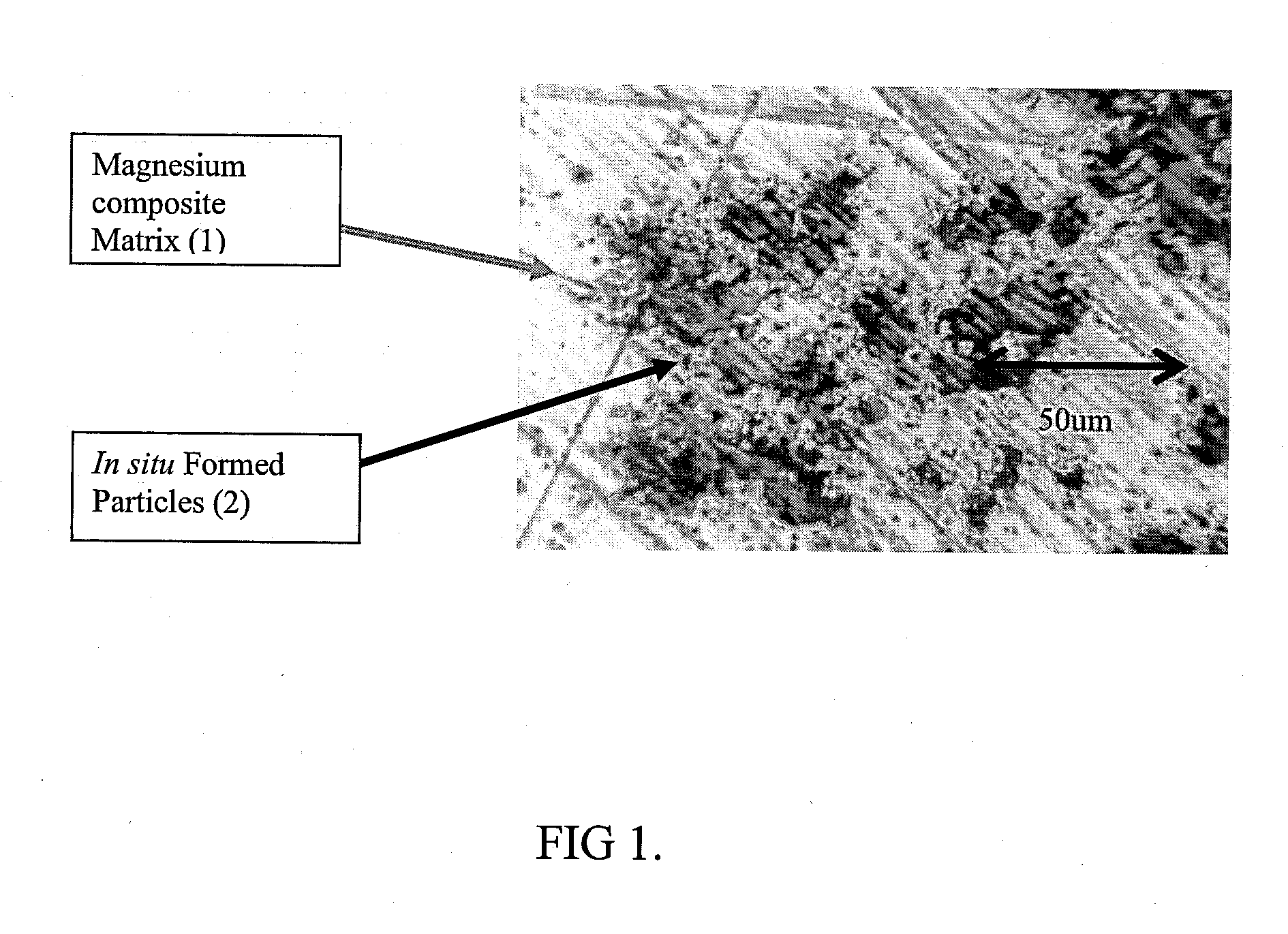

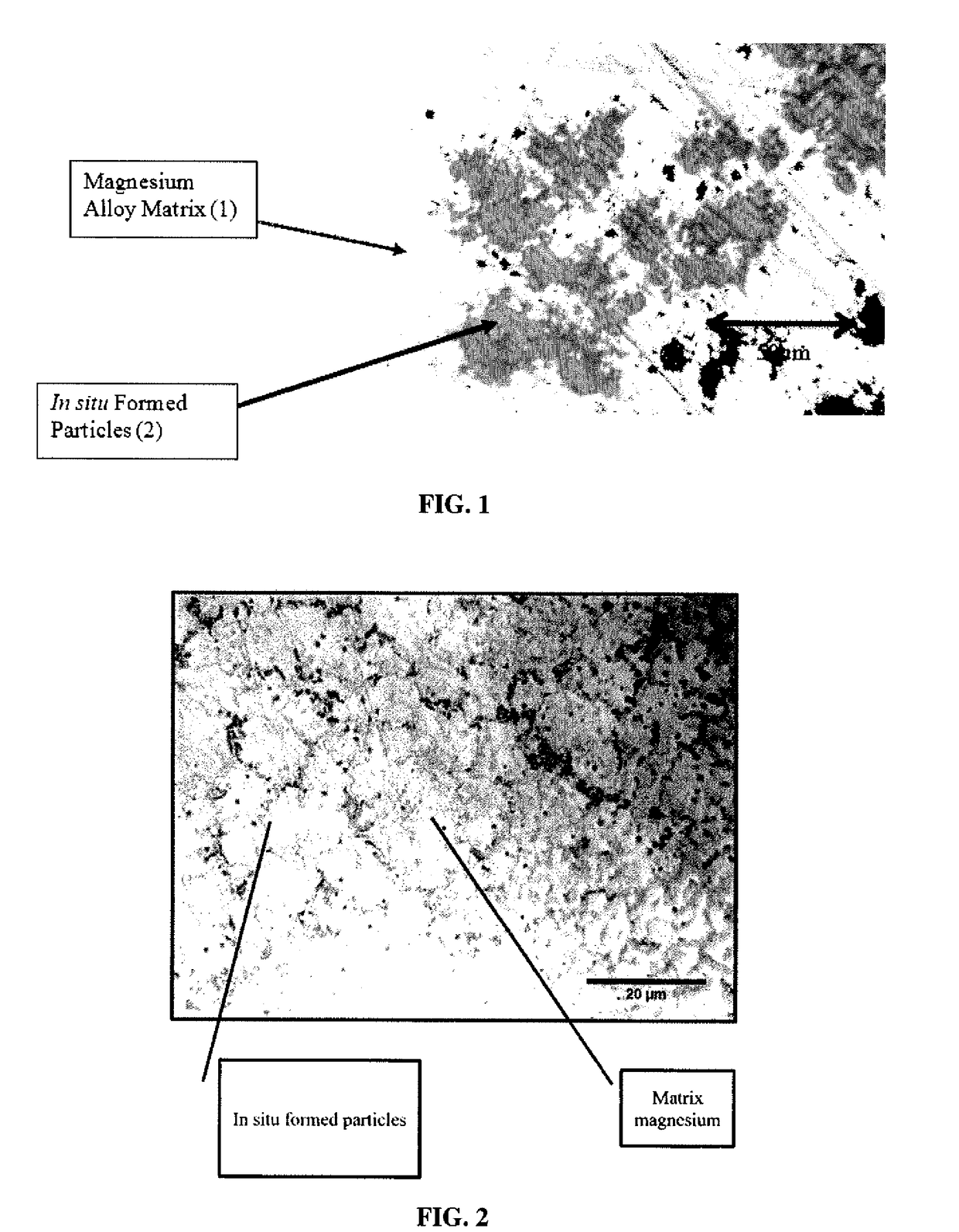

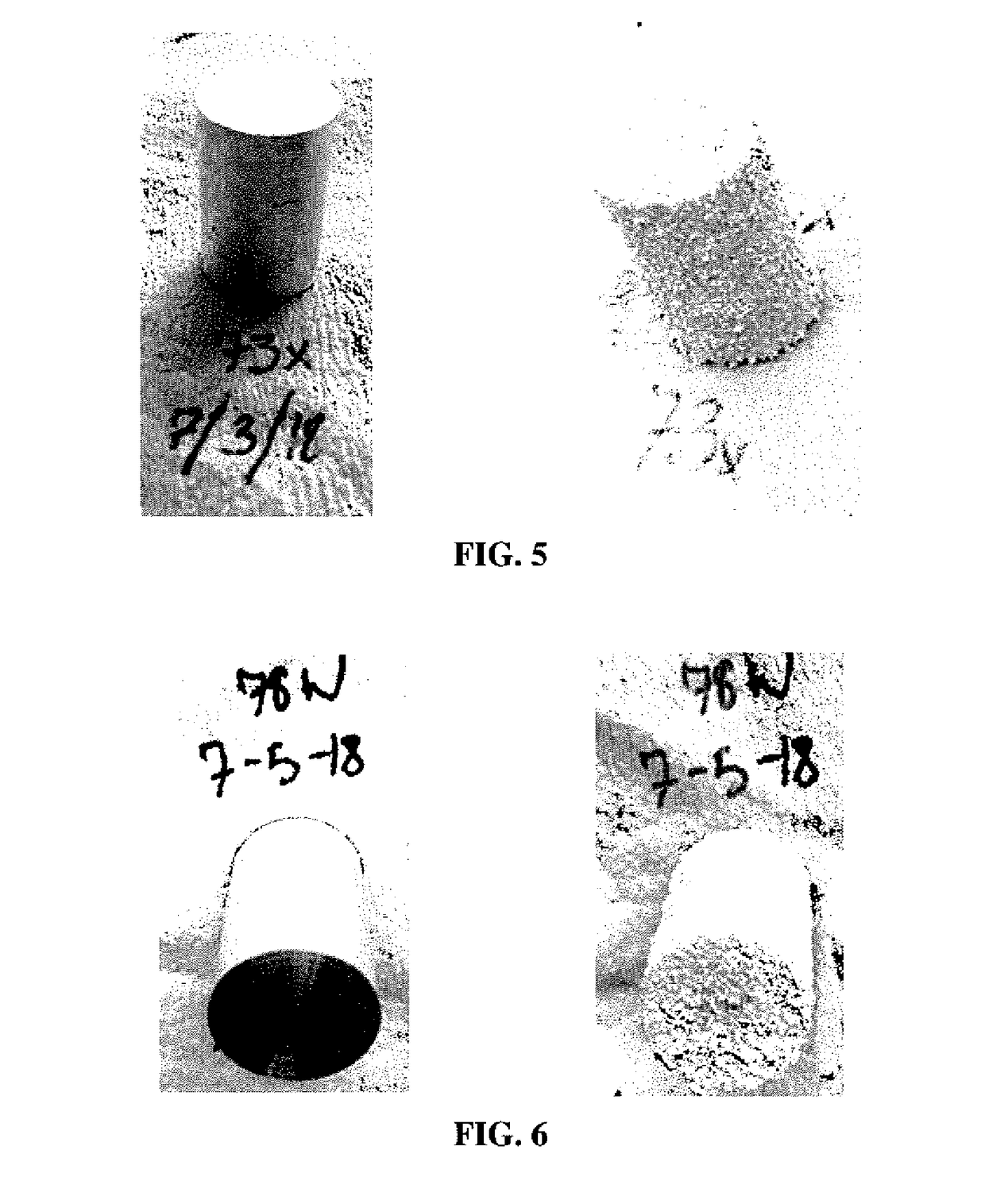

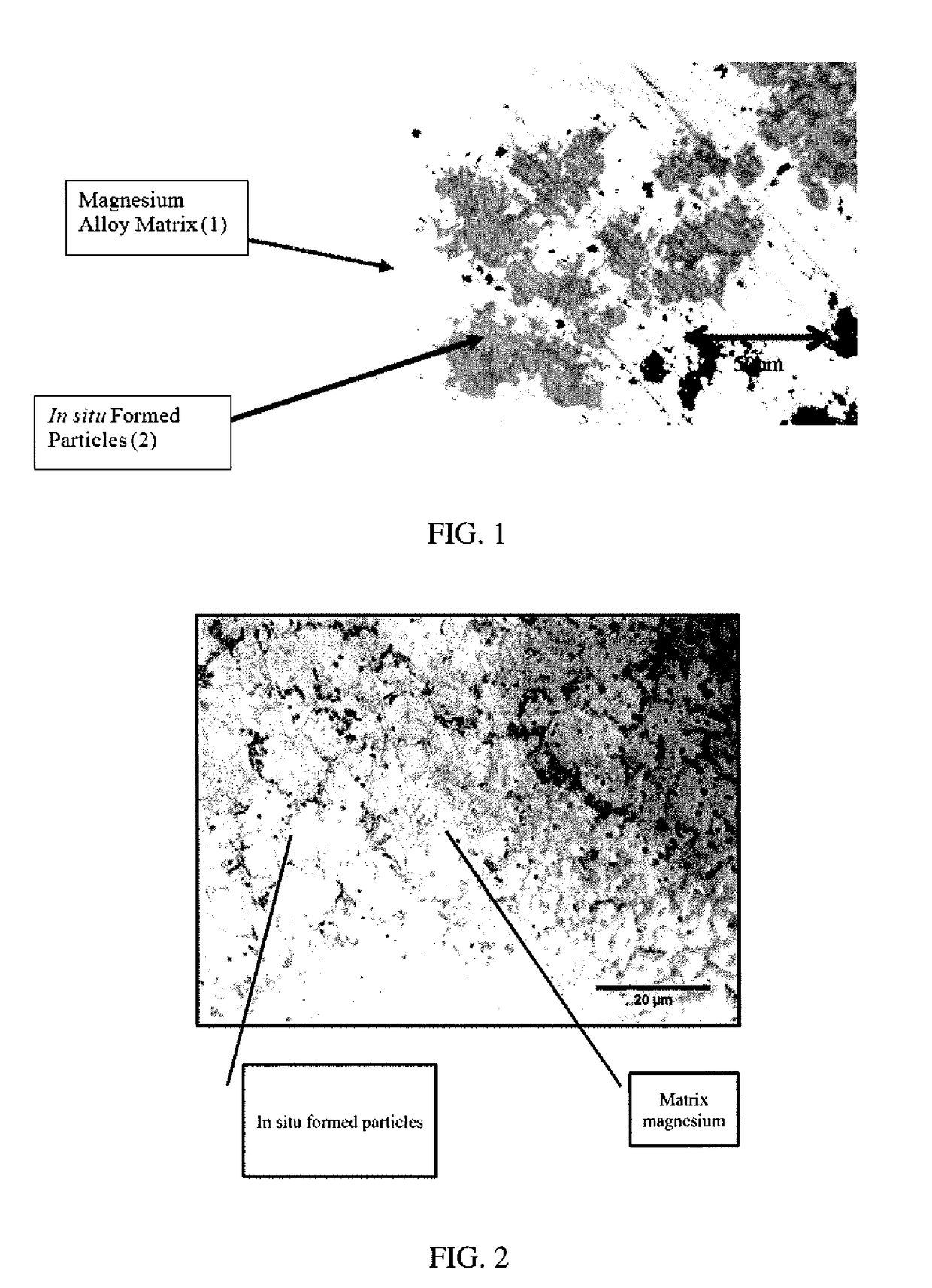

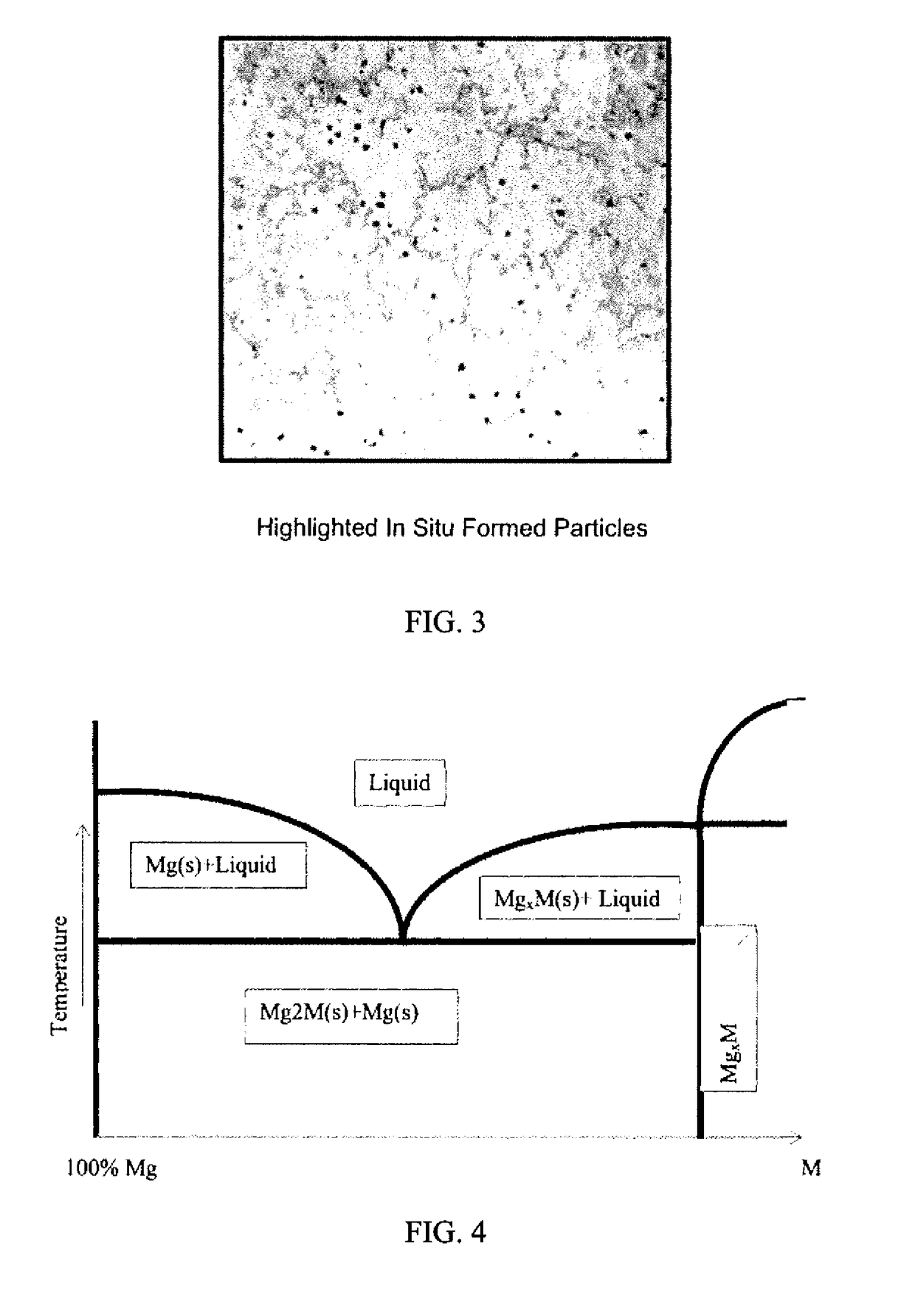

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

A castable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contain an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

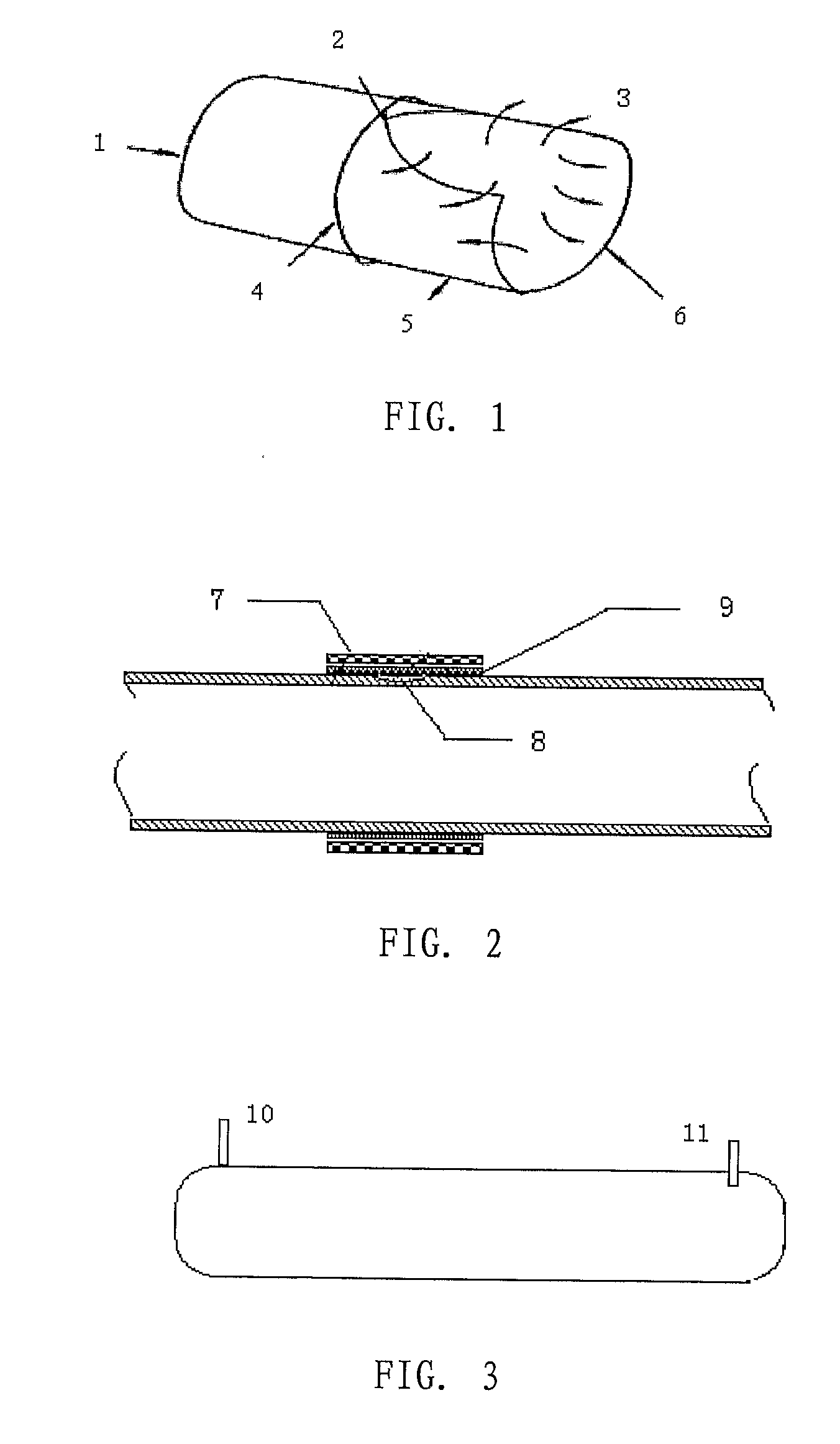

Renovation reinforcement, reinforced and/or crack arrest technique for pipe

The invention relate to a method applicable to pipeline, in particular to a method of repairing reinforcing and / or strengthening a metallic pipe and a pipe crack arrest method, which is characterized in that: a part of a pipe needing repairing reinforcing and / or strengthening or needing crack arrest is firstly coated with insulating material, and then high strength fiber composite material is applied. As the materials used in the invention and the material used in the metallic pipe body portion a similar elastic modulus, the materials used in the invention can be integrated with the pipe body to bear pressure in the pipe together and finally form a bearing capacity required by the composite pipe, such as the original maximum working pressure of the pipe restored; furthermore, the materials used in the invention have good crack arrest function in case of a pipe burst accident. In addition, the insulating material used in the bottom layer completely removes the possibility of galvanic corrosion between the pipe and the reinforcing material. The method provided by the invention which has simple construction without fire work not only facilitates the close attaching between the reinforcing material and the pipe body and between reinforcing layers, but also enables repairing reinforcing and strengthening operations on pipelines in active service.

Owner:BEIJING SAFETECH PIPELINE

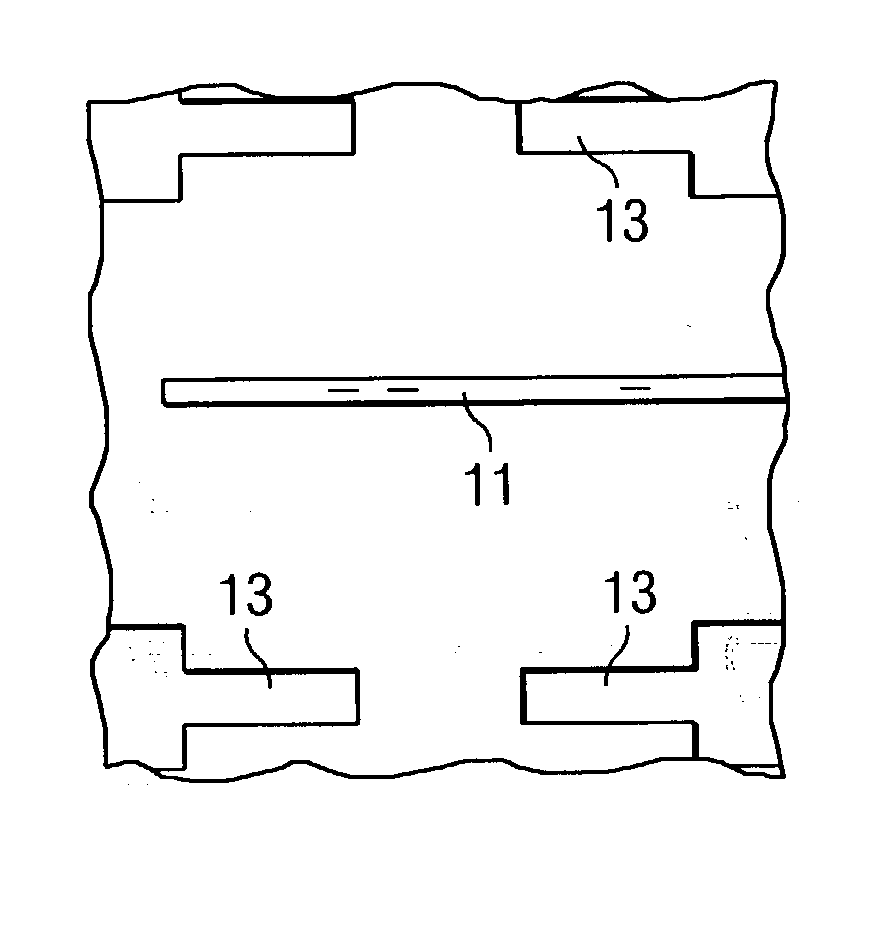

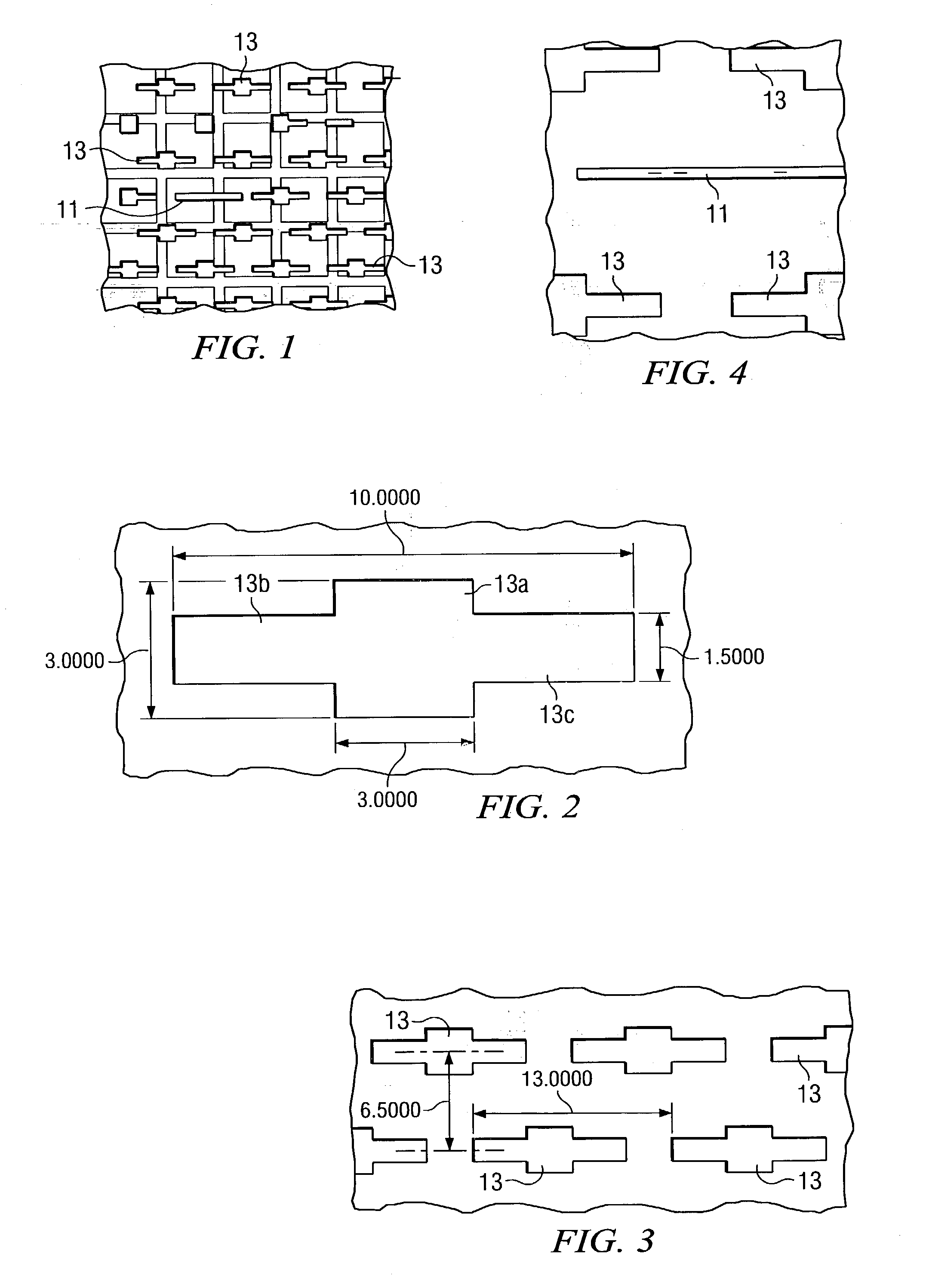

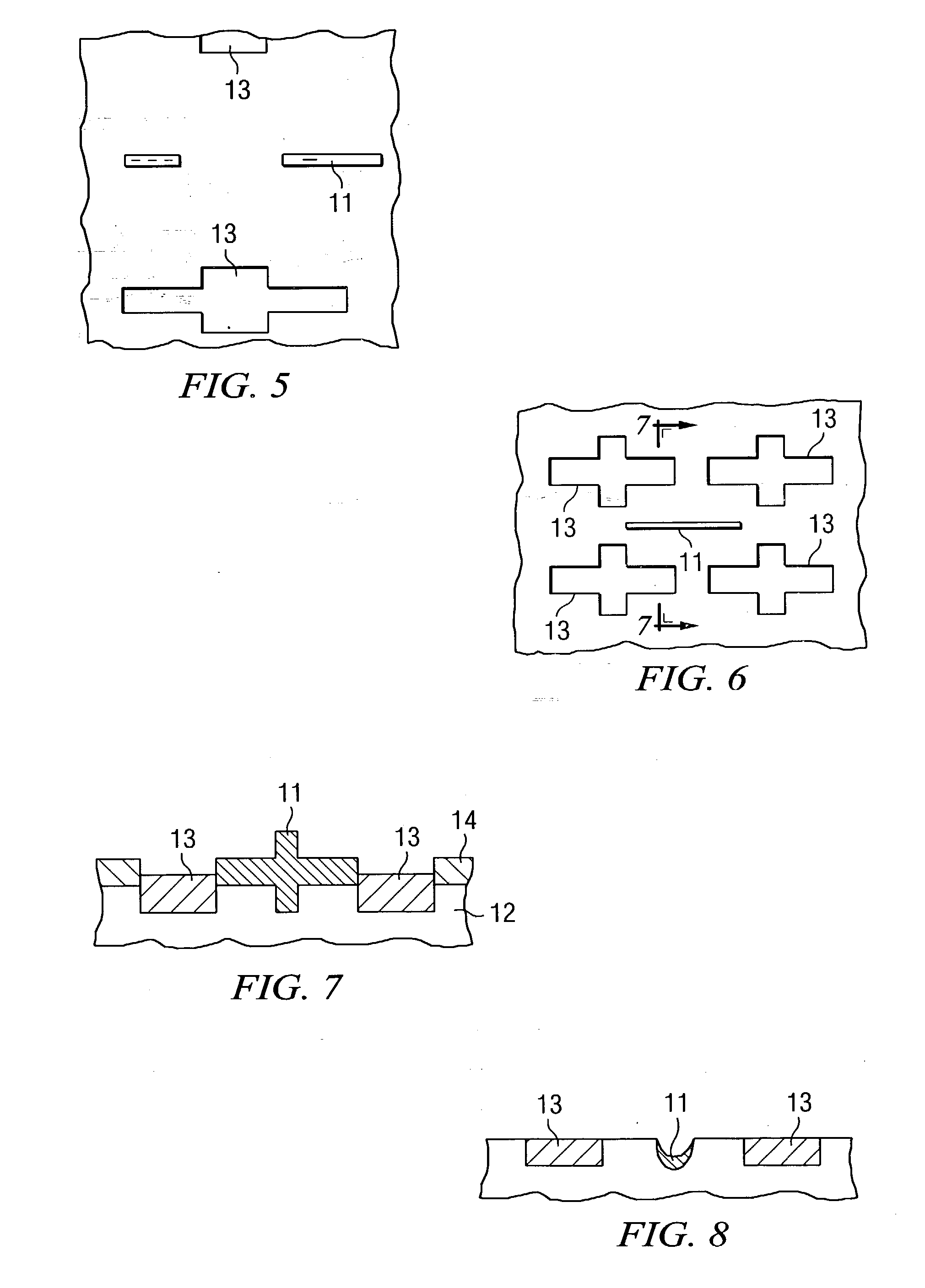

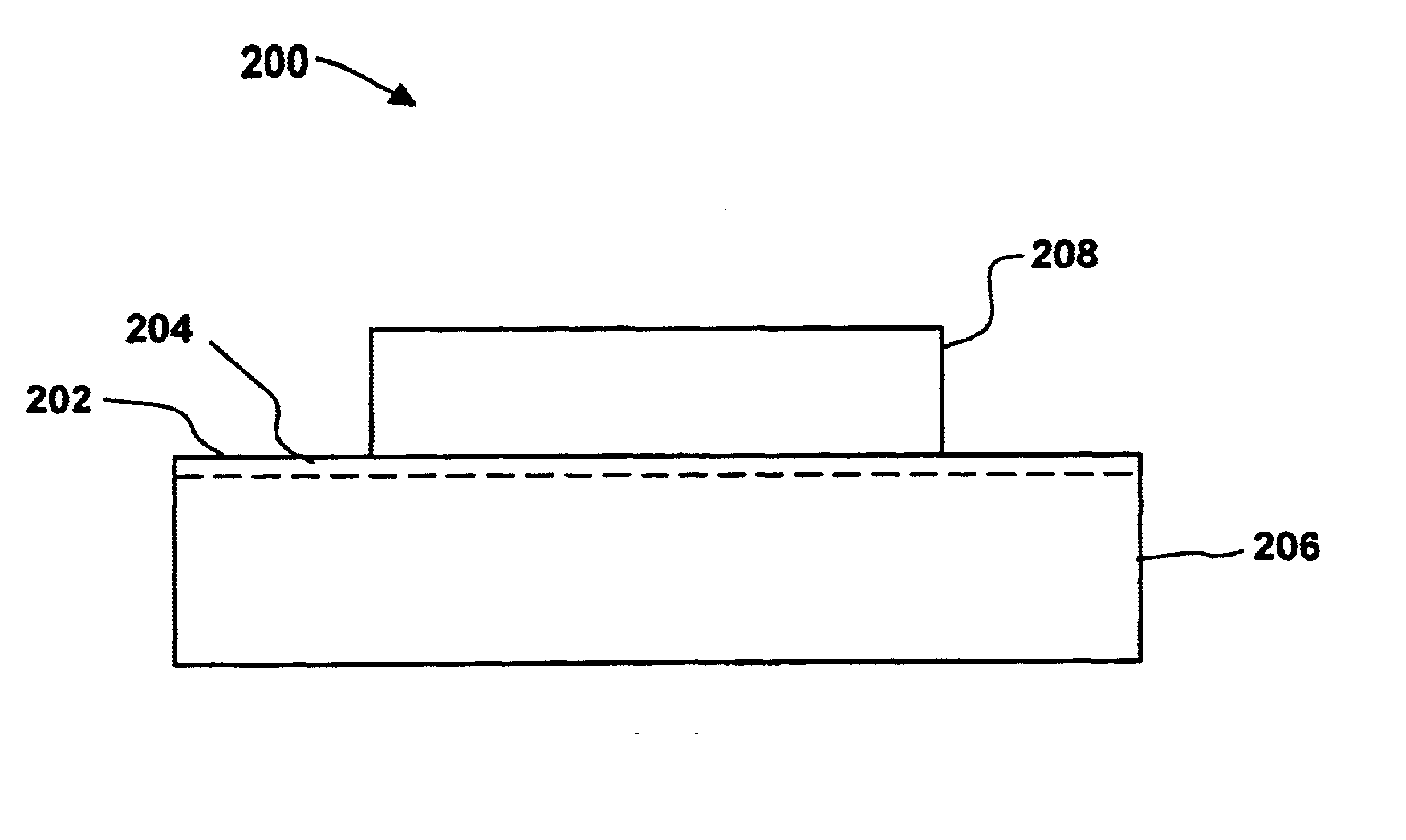

Method of preventing seam defects in isolated lines

InactiveUS20030199150A1Prevents seam defectUniform rateSemiconductor/solid-state device manufacturingElectroplatingMetal

A method of preventing seam defects on narrow, isolated lines of 0.3 micron or less during CMP process is provided. The solution is to change the size of features of dummy metal structures on the same layer as the metal layer to have a width that is about 0.6 micron or less so that during the electroplating the deposition rate in the features is similar to the narrow, isolated lines. The density, shape, and proximity of the dummy metal structures further prevents the seam defects during CMP processing by preventing Galvanic corrosion.

Owner:TEXAS INSTR INC

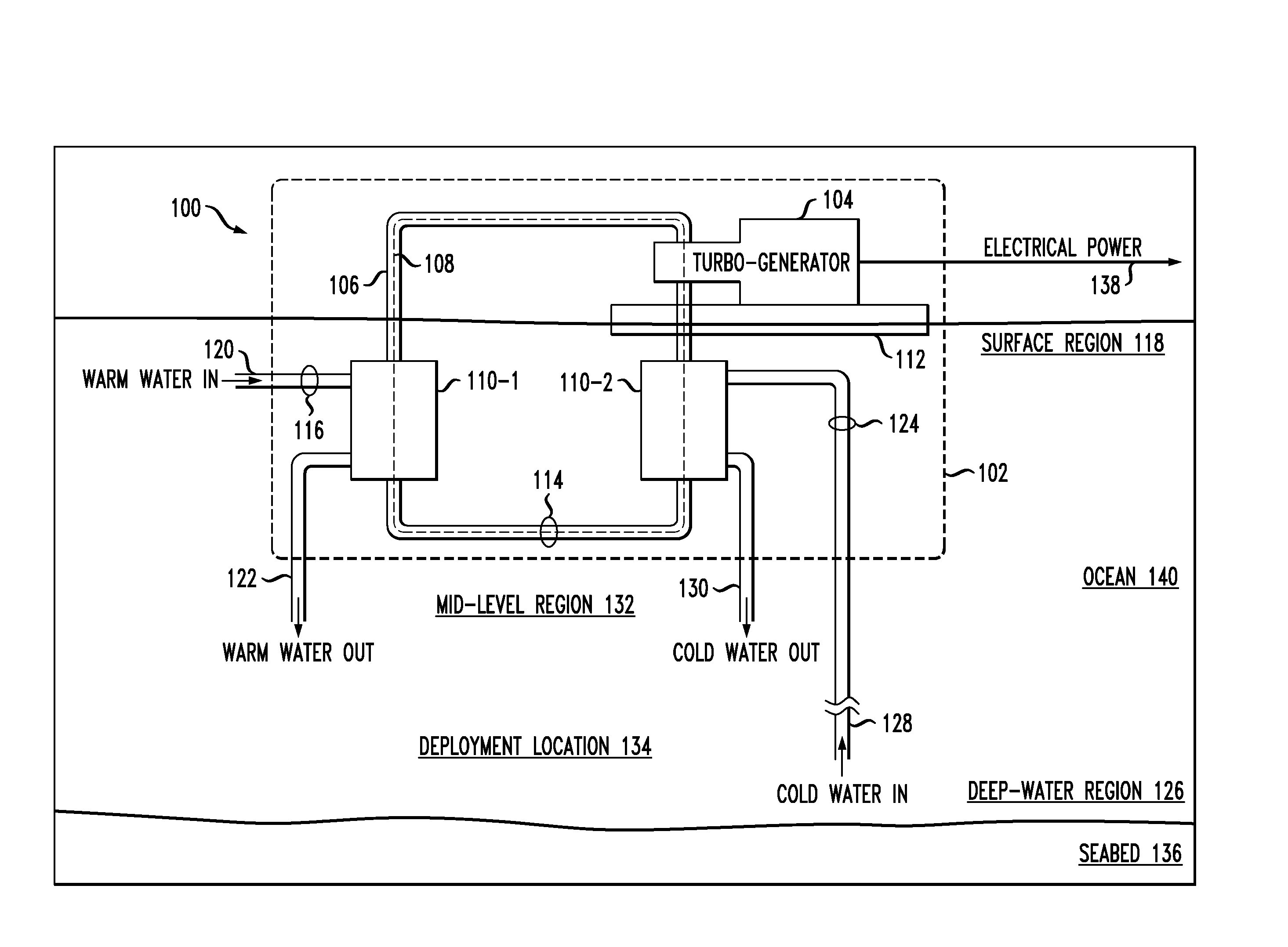

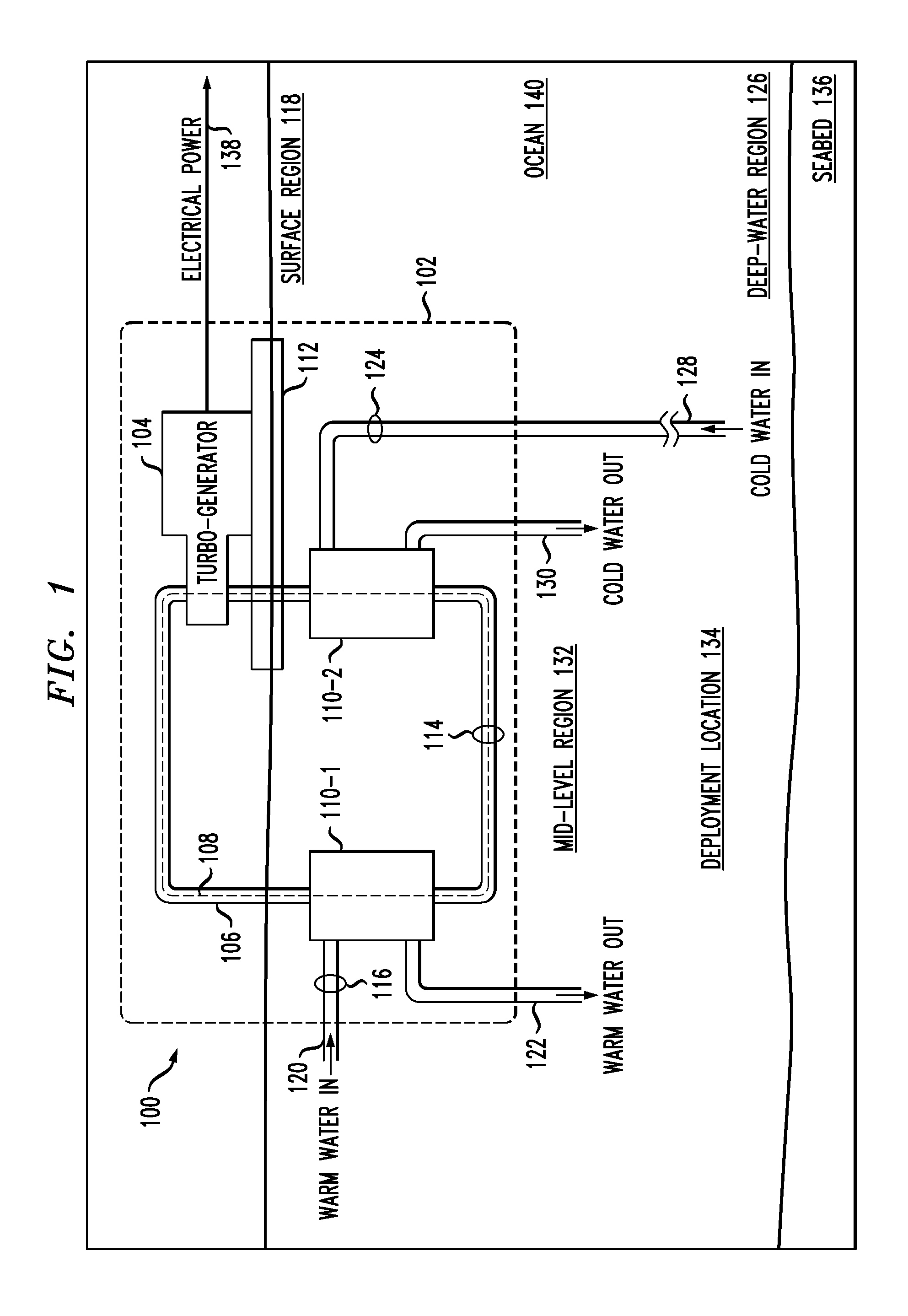

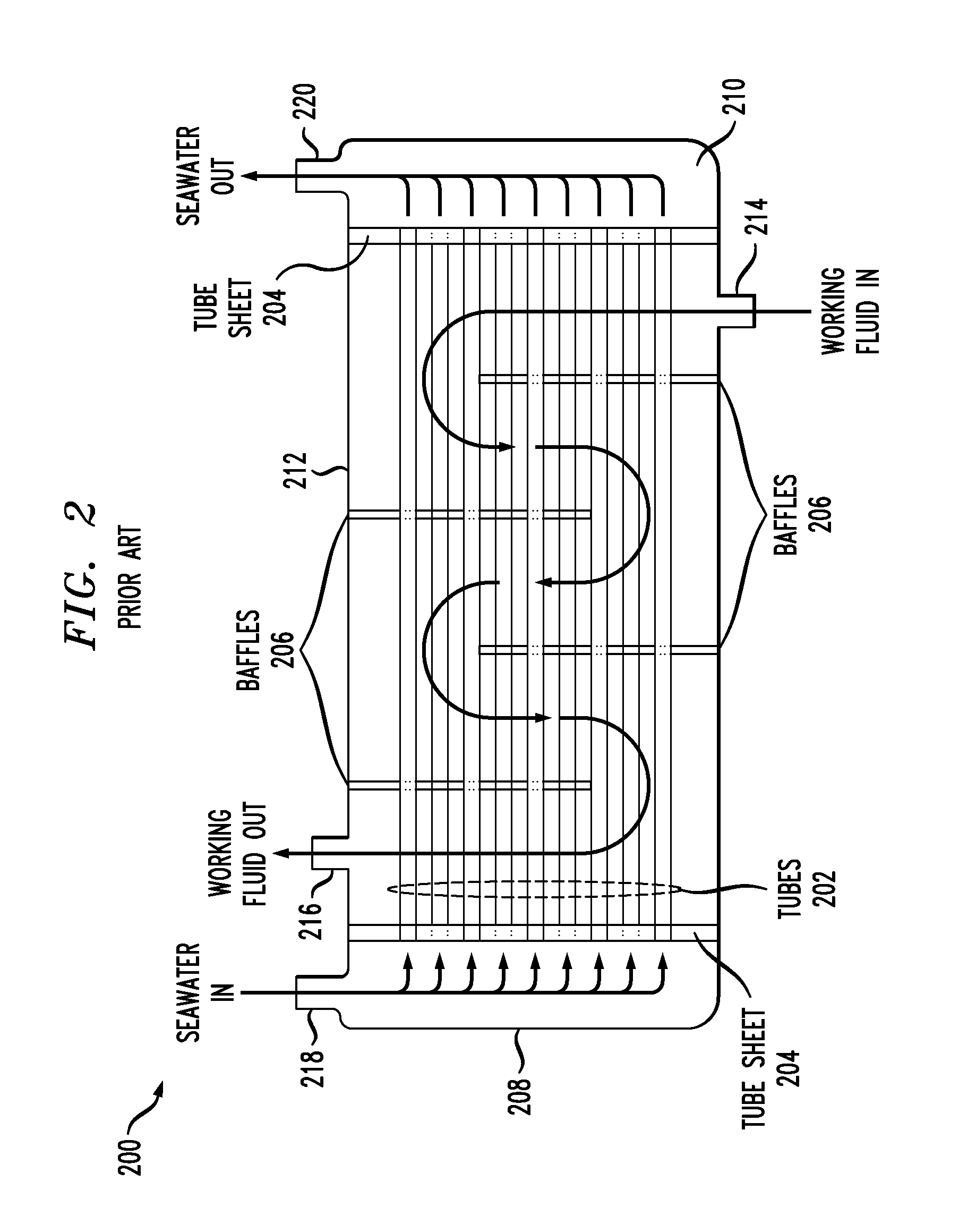

Helical Tube Bundle Arrangements for Heat Exchangers

A heat exchanger comprising helically wound tube bundles is disclosed. The helically wound tube bundles are joined with tube sheets to define a primary working fluid system that is fluidically isolated from a secondary working fluid system. The tube sheets and tubes are formed of the same material, which facilitates their joining by means of joints that are substantially galvanic corrosion-resistant joints.

Owner:LOCKHEED MARTIN CORP

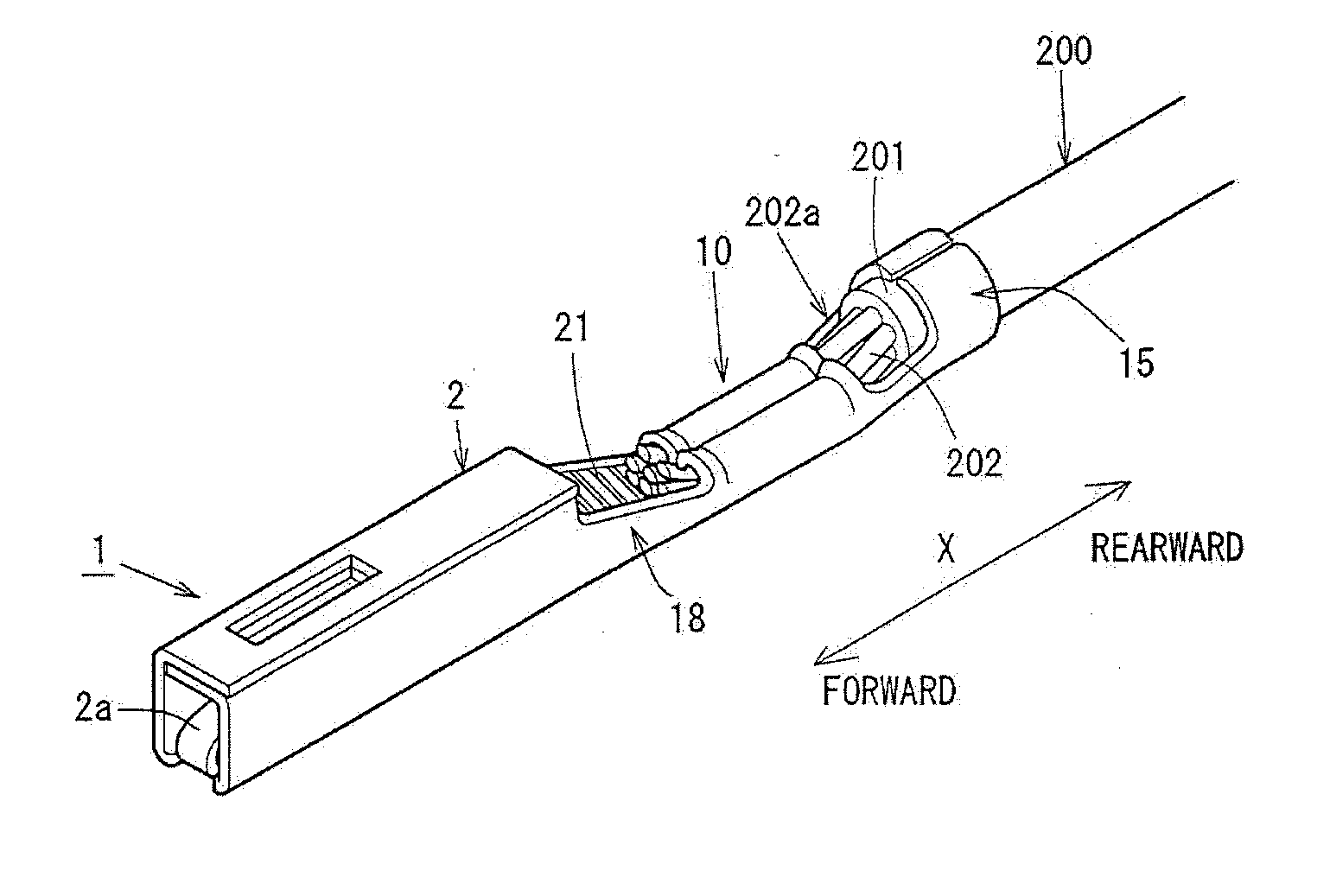

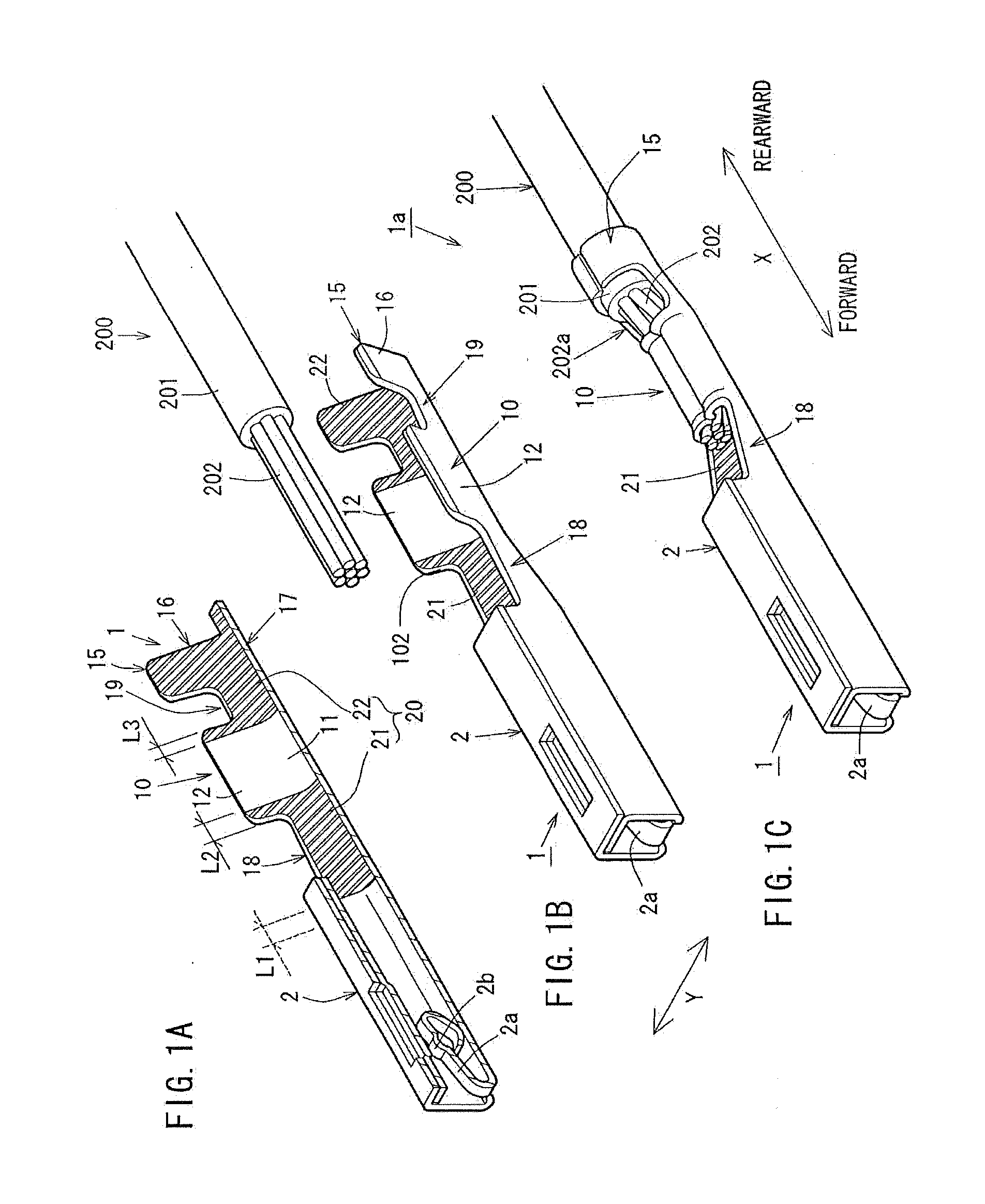

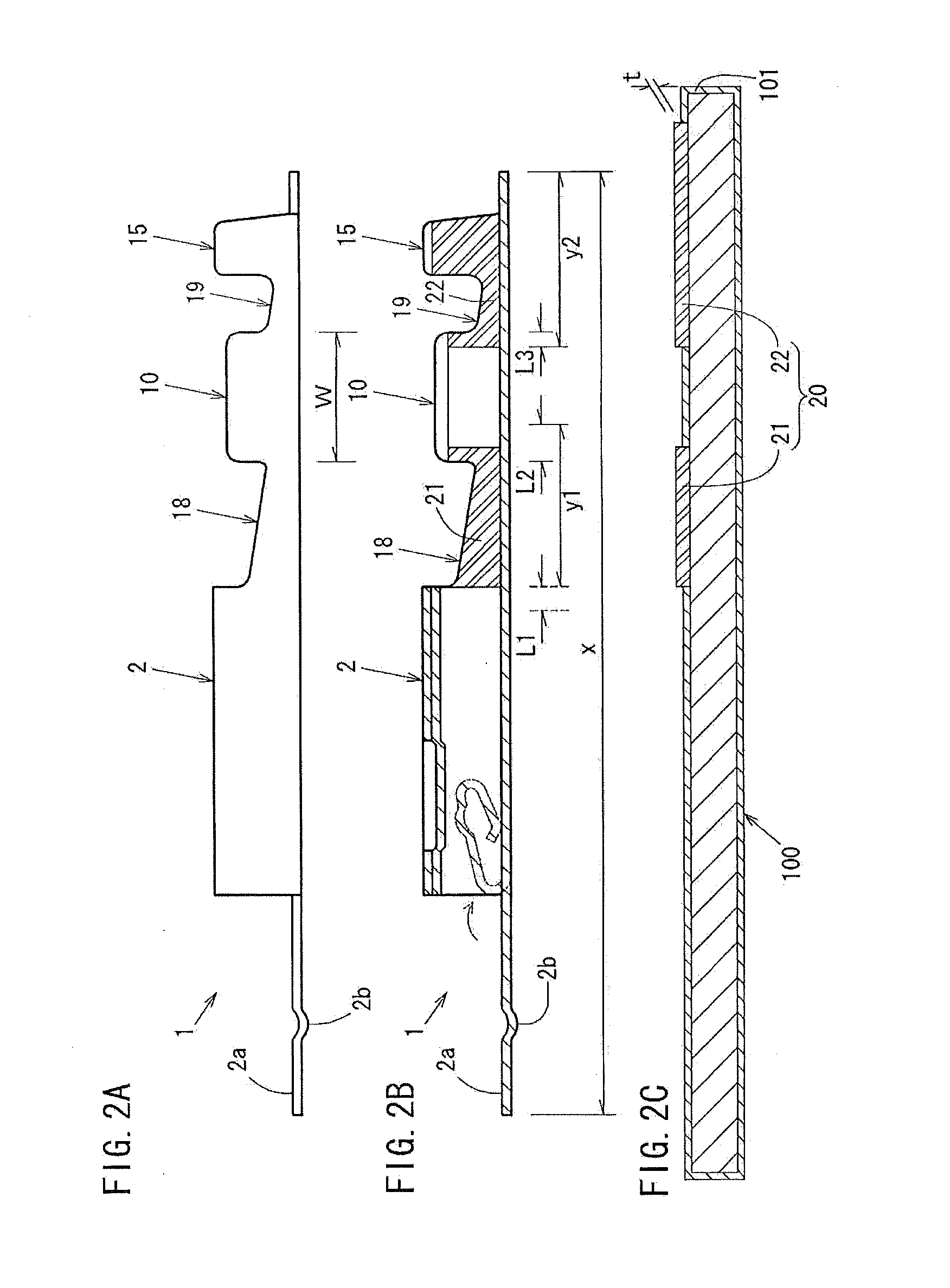

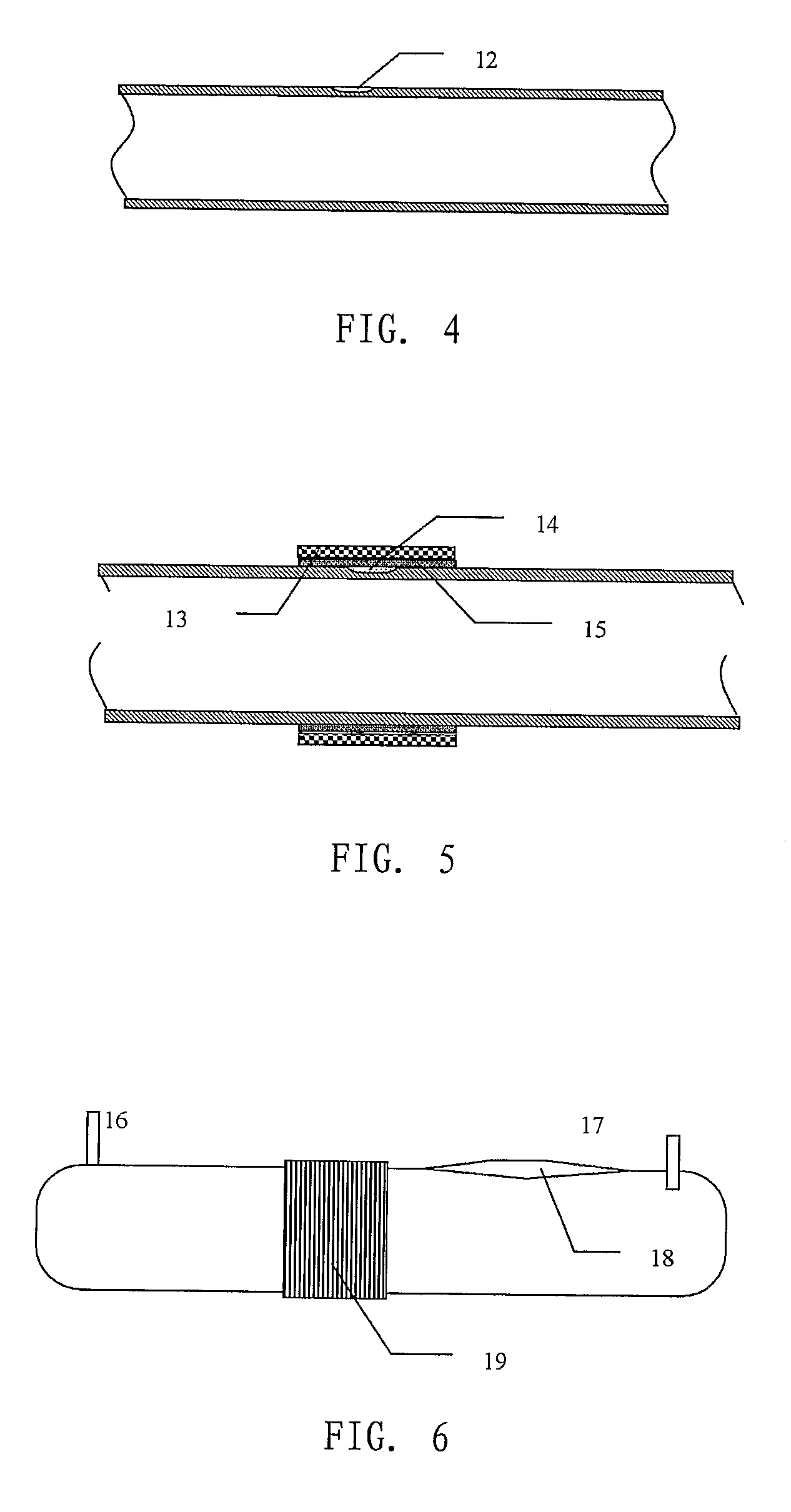

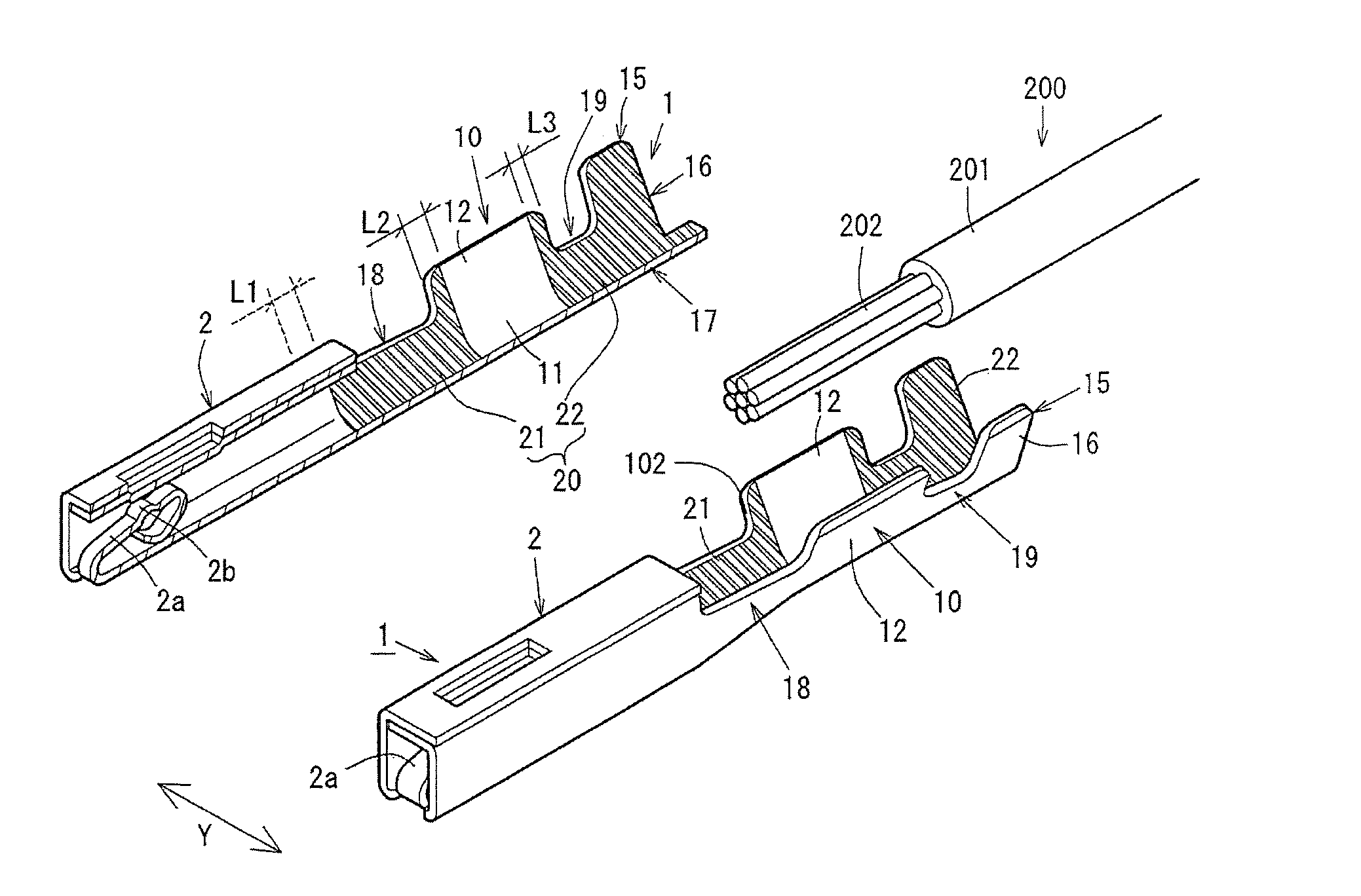

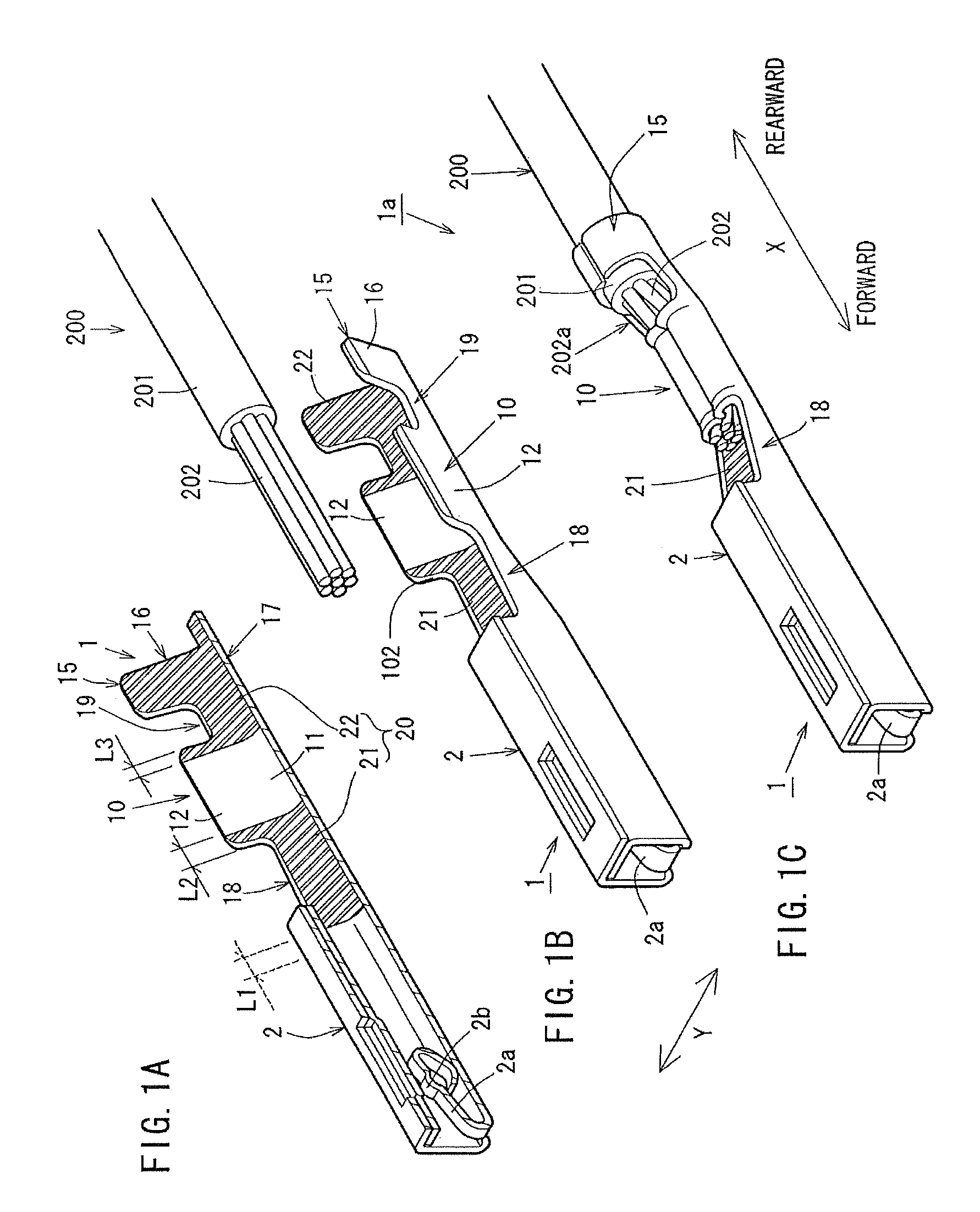

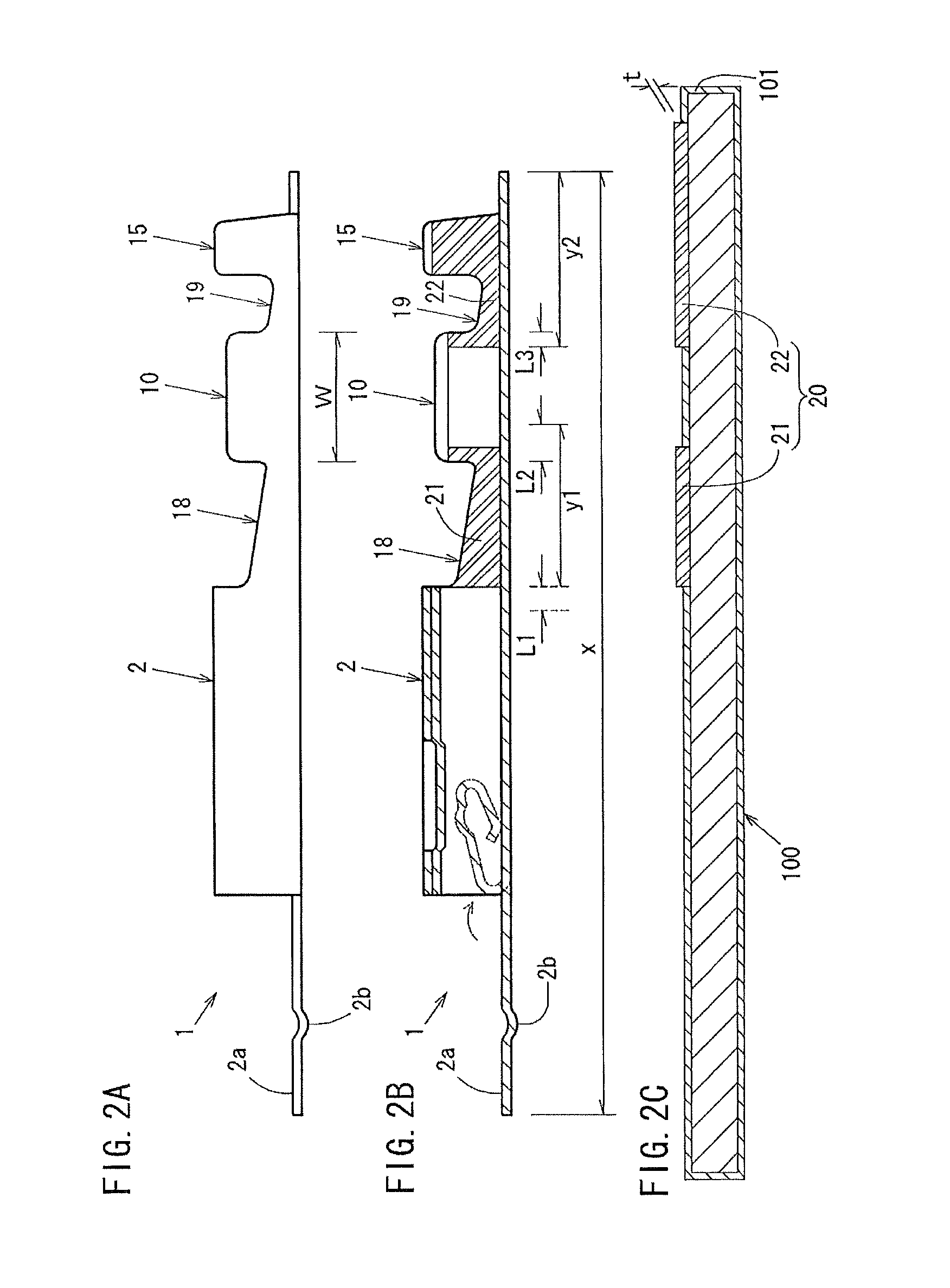

Crimp terminal, connection structural body and method for producing the crimp terminal

ActiveUS20130040509A1Conducting functionImprove batch productivityContact member manufacturingCoupling contact membersMetallic materialsEngineering

Has an object of providing a crimp terminal, a connection structural body, and a method for producing the crimp terminal, which has a conducting function with certainty, with no galvanic corrosion occurring due to an electric wire and the terminal formed of different metal materials. A crimp terminal 1 includes a box section, and a pressure-bonding section including a wire barrel section and an insulation barrel section, which are provided in this order. The crimp terminal is formed of a metal plate which is formed of a copper alloy having a higher potential than aluminum used to form core wires of an insulated wire which is to be pressure-bonded by the pressure-bonding section. The crimp terminal 1 includes, in at least a part thereof, a resin cover section for covering a surface of the metal plate with a resin.

Owner:FURUKAWA ELECTRIC CO LTD +1

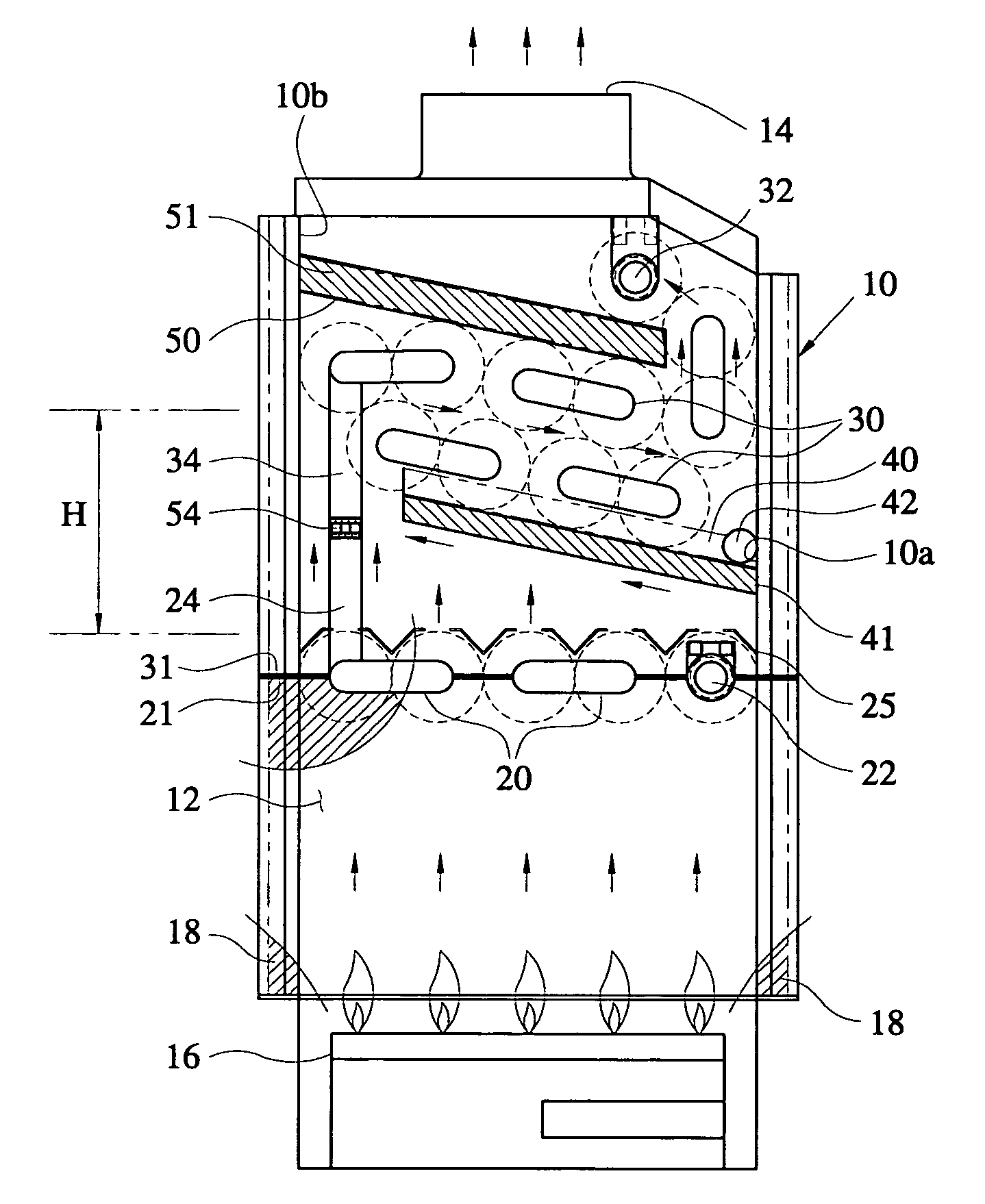

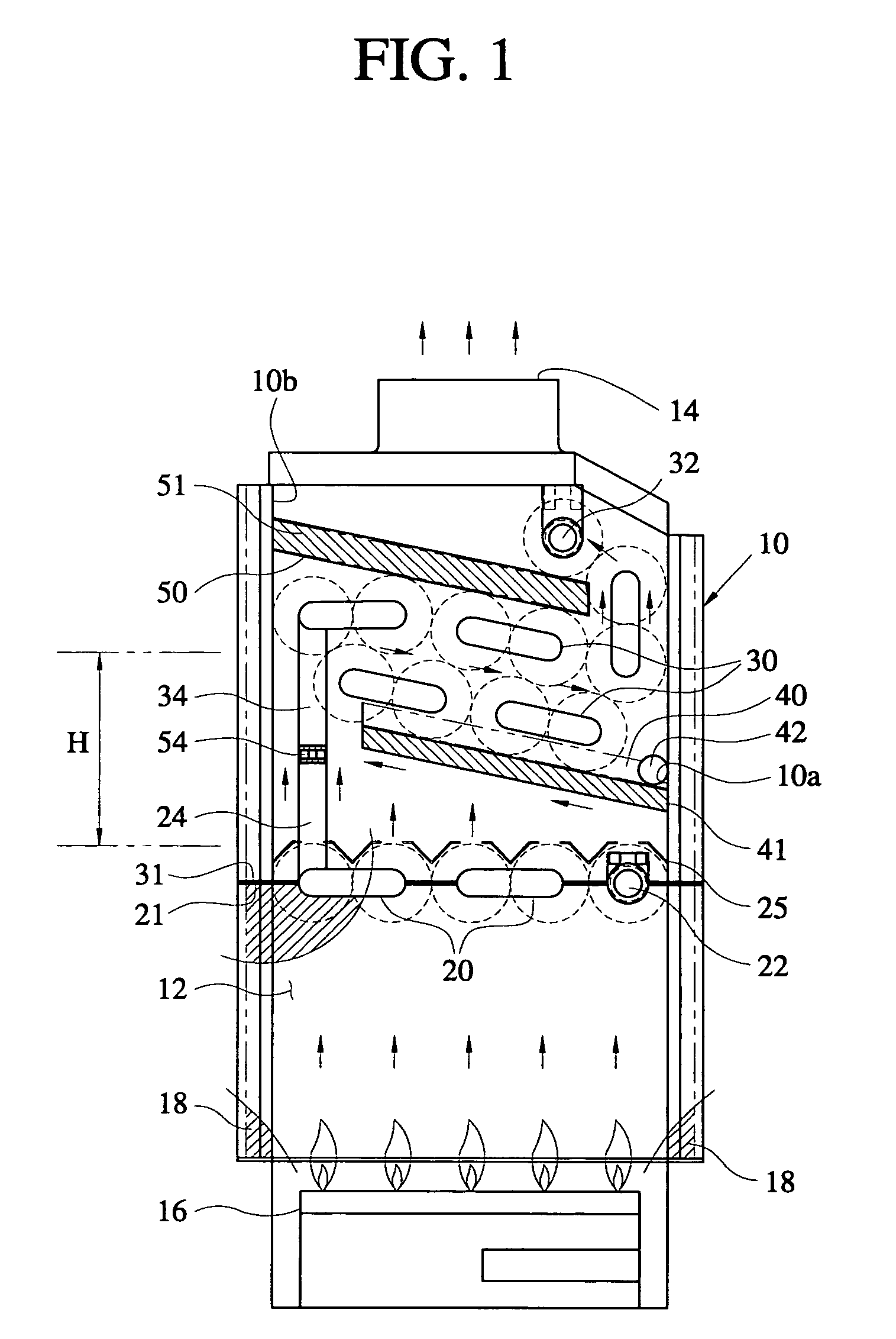

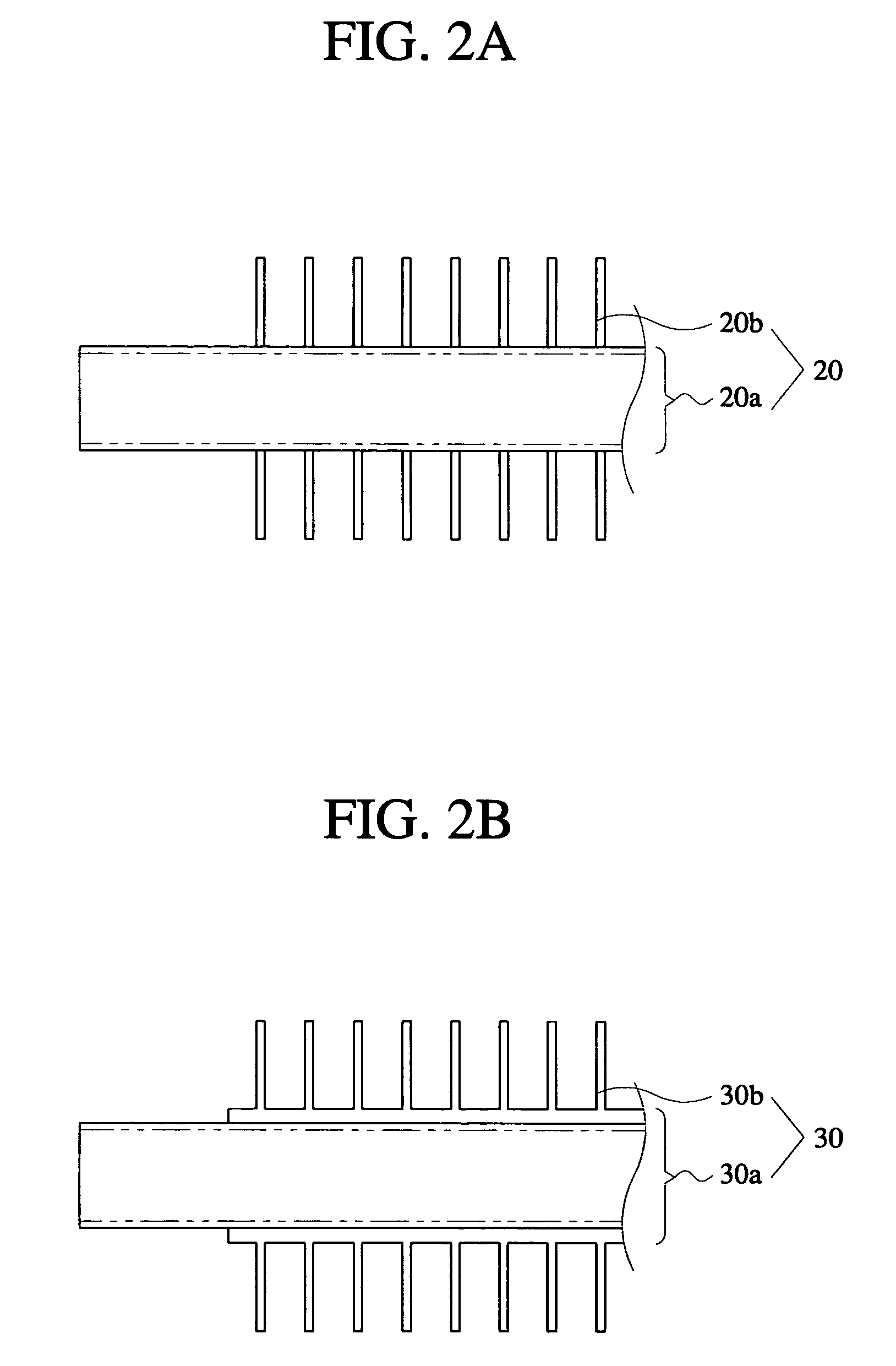

Condensing gas boiler having structure of preventing corrosion caused by using heterogeneous metal

InactiveUS6907846B2Increased durabilityImprove product reliabilityMechanical apparatusEnergy efficient heating/coolingElectricityCombustion chamber

Owner:KYUNGDONG NAVIEN

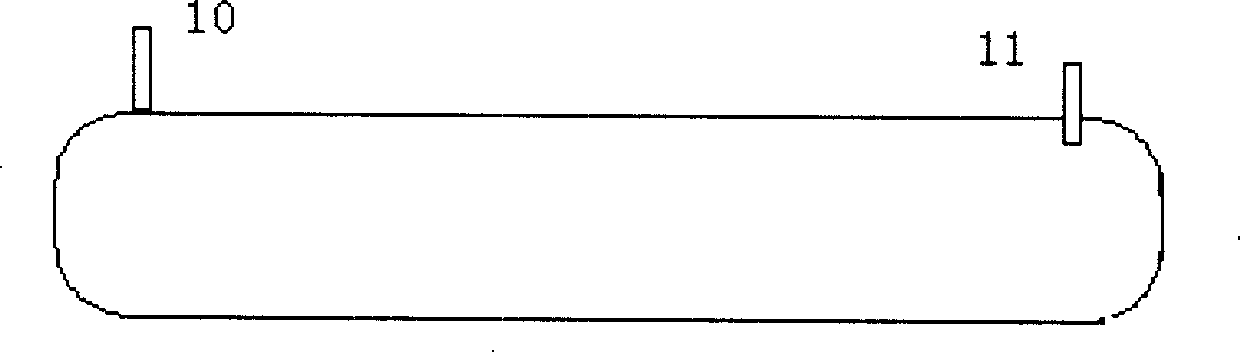

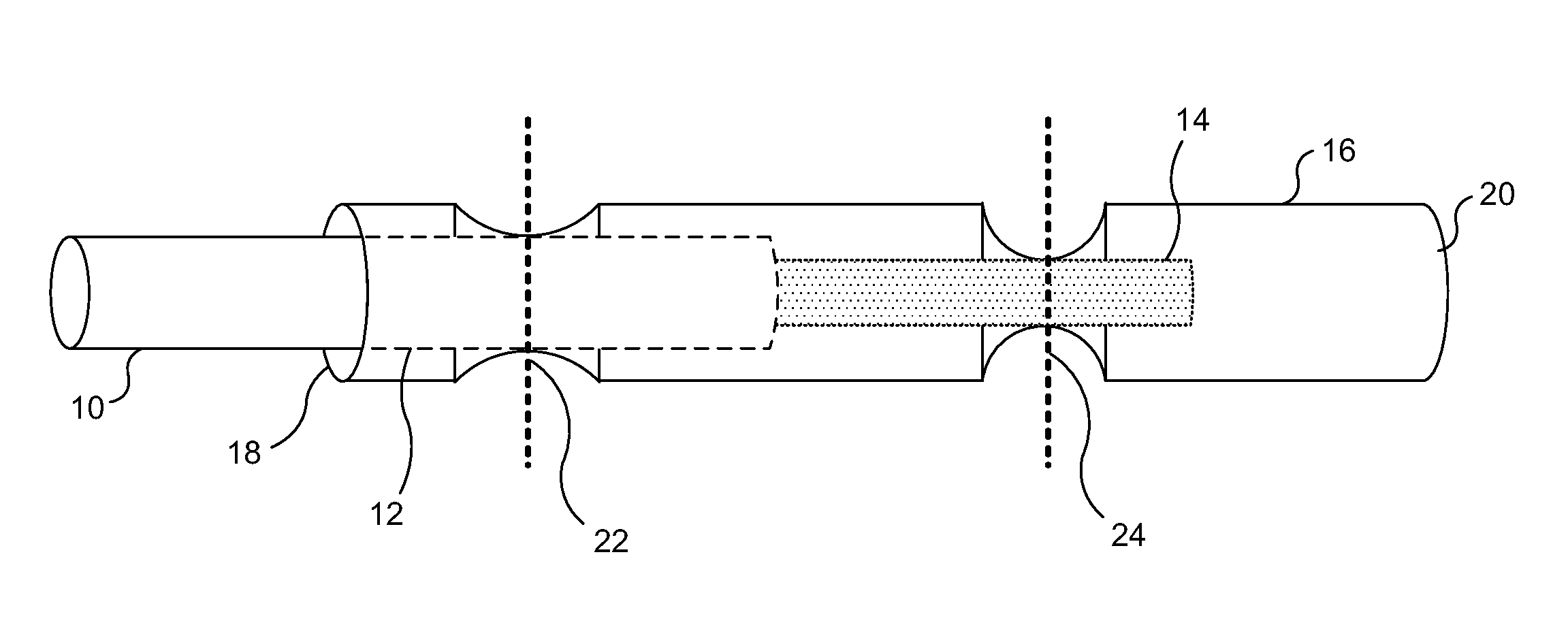

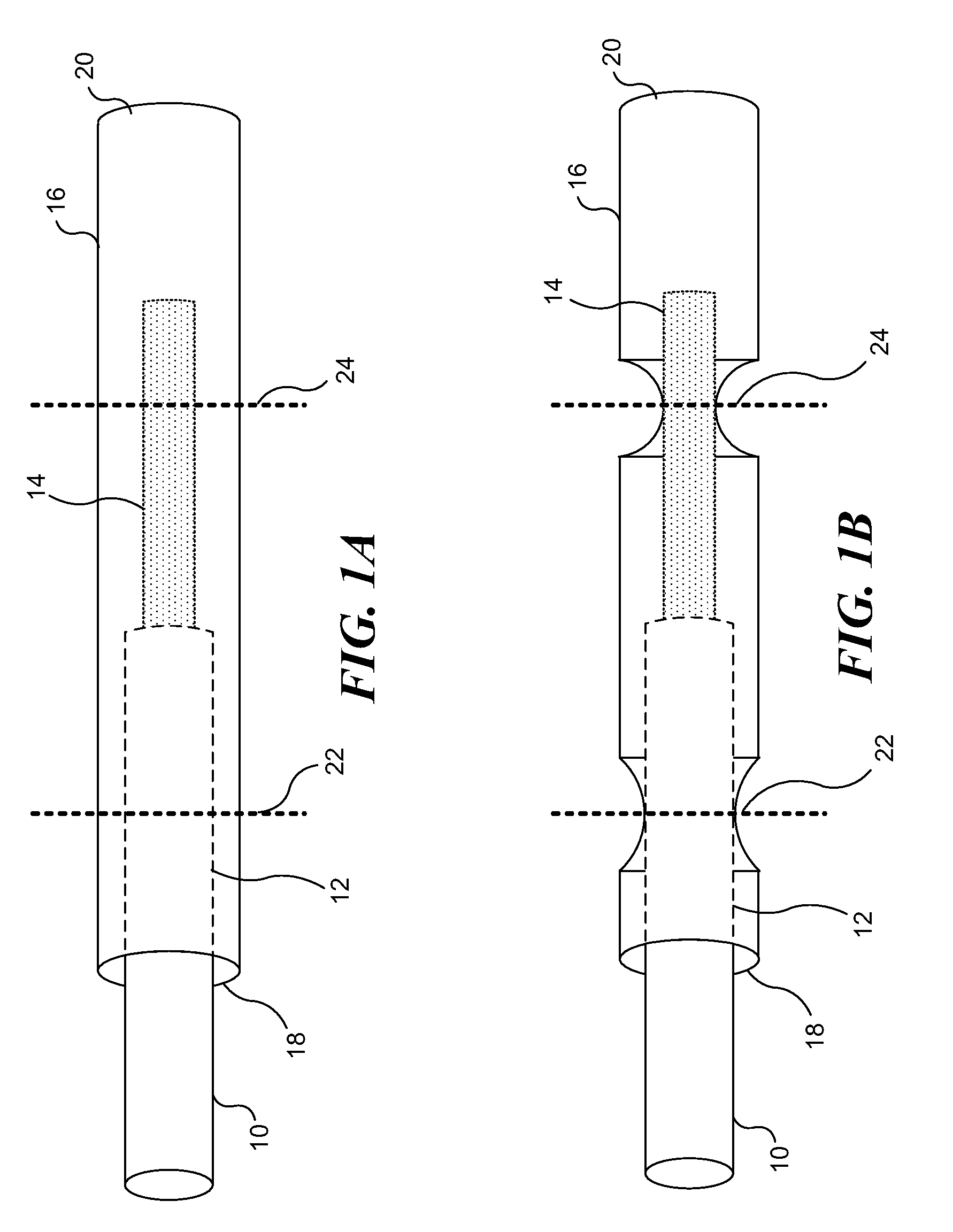

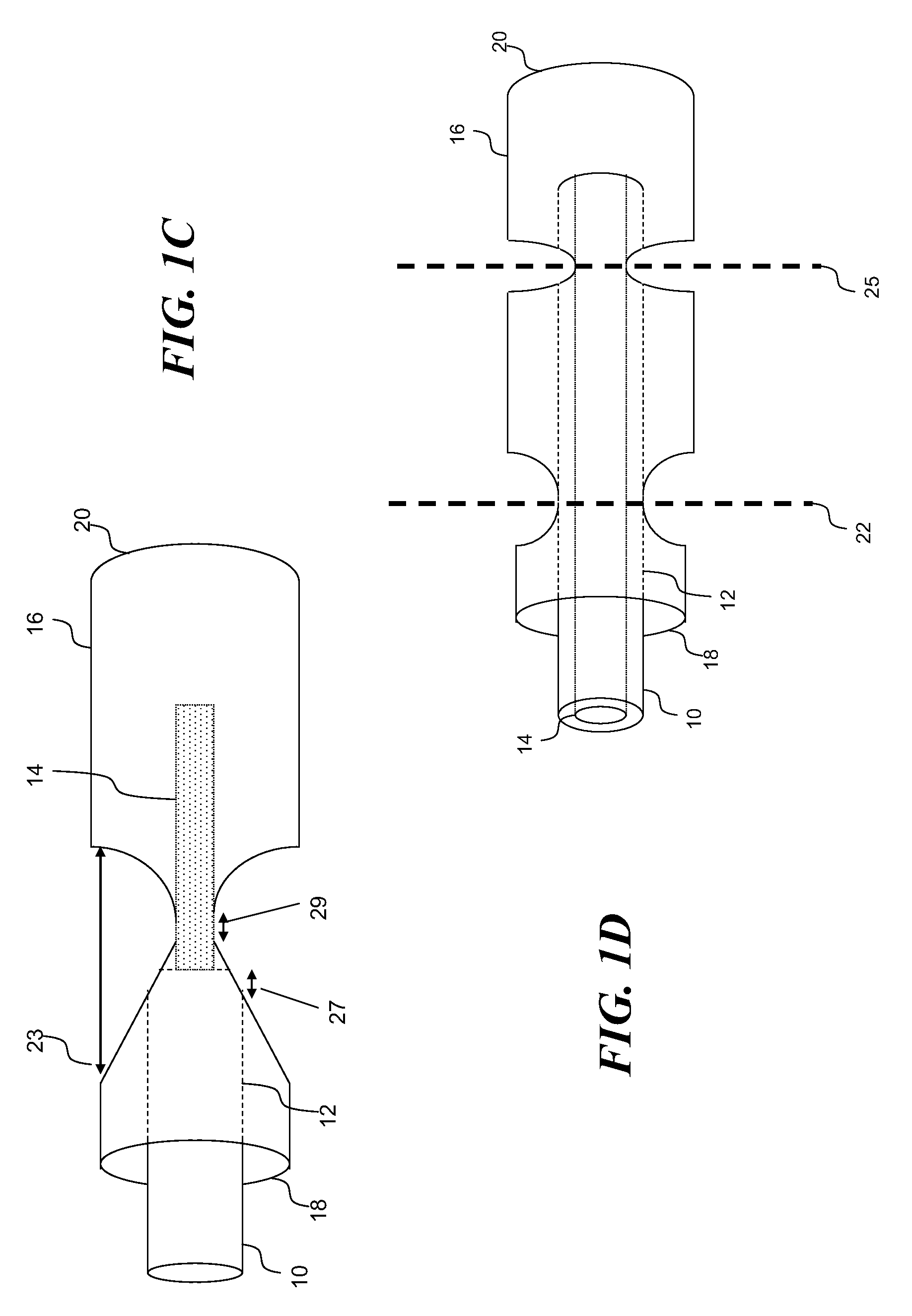

Medical Lead Termination Sleeve for Implantable Medical Devices

ActiveUS20100179627A1RobustEliminate riskBioelectric signal measurementInternal electrodesElectricityElectrical connection

A wire and electrode combination suitable for use with implanted medical devices, and a method for coupling the wire and electrode to achieve a robust electrical connection suitable for use with such medical devices are disclosed. The apparatus employs a wire that is optimized for strength, an electrode optimized for biocompatibility, and a termination sleeve with a closed distal end for coupling the wire to the electrode, while eliminating the potential for galvanic corrosion, enhancing weld quality, and facilitating manufacture of the apparatus. The method involves compressing the sleeve to engage the wire at two locations, where contact between the sleeve and wire at the first location seals the interior of the sleeve, and contact between the sleeve and wire at the second location electrically couples the wire to the sleeve. The sleeve, which is easier to manipulate than the wire, is then spot welded to the electrode.

Owner:CYBERONICS INC

Technique for repairing, strengthening and crack arrest of pipe

InactiveUS20100147409A1High strengthLow costThermal insulationLayered productsFiberInternal pressure

A method for repairing / strengthening and crack arrest of pipe, especially metal pipe, in which, first, to cover an insulated material on the position needing repairing / strengthening and crack arrest, then to lay a high strength fiber composite material. The modulus of elasticity of the material used in the invention is close to the metal pipe's, it can be integrated with the pipe and bear the internal pressure with the pipe, thus the final composite pipe reaches required bear capacity, such as, the original most operation pressure of pipe can be recovered; and it can take effect for crack arrest of pipes when pipes happen burst accident. Otherwise, because of the insulated material is used on the bottom layer, it prevent thoroughly from galvanic corrosion between pipe and strengthening material. The method can be implemented simply and without fire, it is advantageous to tight joint between strengthening material and pipe, and between strengthening layers, and it can be used to repair and enhance the pipeline in use.

Owner:BEIJING SAFETECH PIPELINE

Crimp terminal, connection structural body and method for producing the crimp terminal

ActiveUS8641461B2Mass-productivity is highContact member manufacturingSecuring/insulating coupling contact membersMetallic materialsEngineering

Has an object of providing a crimp terminal, a connection structural body, and a method for producing the crimp terminal, which has a conducting function with certainty, with no galvanic corrosion occurring due to an electric wire and the terminal formed of different metal materials. A crimp terminal 1 includes a box section, and a pressure-bonding section including a wire barrel section and an insulation barrel section, which are provided in this order. The crimp terminal is formed of a metal plate which is formed of a copper alloy having a higher potential than aluminum used to form core wires of an insulated wire which is to be pressure-bonded by the pressure-bonding section. The crimp terminal 1 includes, in at least a part thereof, a resin cover section for covering a surface of the metal plate with a resin.

Owner:FURUKAWA ELECTRIC CO LTD +1

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

A castable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contains an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

Degradable Mg-Zn-Y-Ca intravascular stent material and preparation method thereof

The invention relates to a degradable Mg-Zn-Y-Ca intravascular stent material and a preparation method thereof, which belong to the fields of design and manufacture of metal materials. The intravascular stent material is characterized by comprising the following chemical components in percentage by weight (wt%): Zn 1.00 to 4.00, Y 0.10 to 1.00, Ca 0.01 to 0.50 and the balance of Mg; the chemical components are subjected to sub-rapid solidification at (200+ / -10) K / S and heat treatment of heating at 320 to 420 DEG C and heat preservation for 20 to 30h; and the texture characteristic of the intravascular stent material is that: even and fine spherical quasicrystalline phases Mg3YZn6 are dispersed and distributed on an alpha-Mg matrix. The potential difference between the spherical quasicrystalline phases Mg3YZn6 and magnesium is lower so that the formation of a galvanic cell is restrained and galvanic corrosion is alleviated; the sphericity quasicrystal Mg3YZn6 has good corrosion resistance and can obviously enhance the corrosion resistant performance of magnesium alloy; and at the same time, the quasicrystal also has the characteristics of high hardness, low friction coefficient, low interface energy and the like and can greatly enhance the mechanical performance of the magnesium alloy.

Owner:TAIYUAN UNIV OF TECH

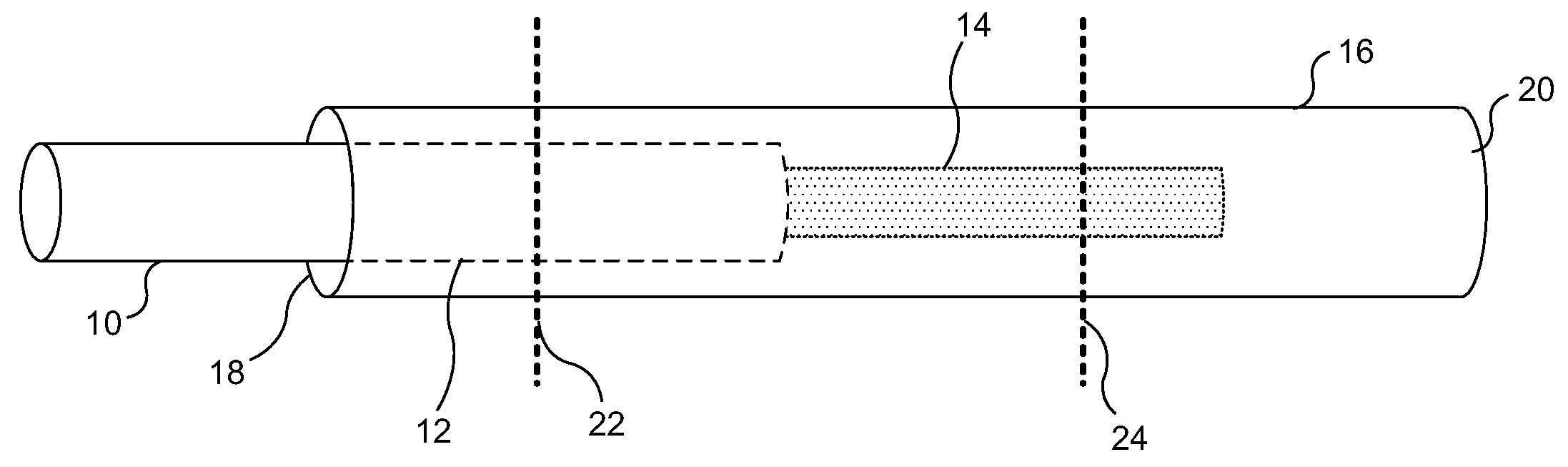

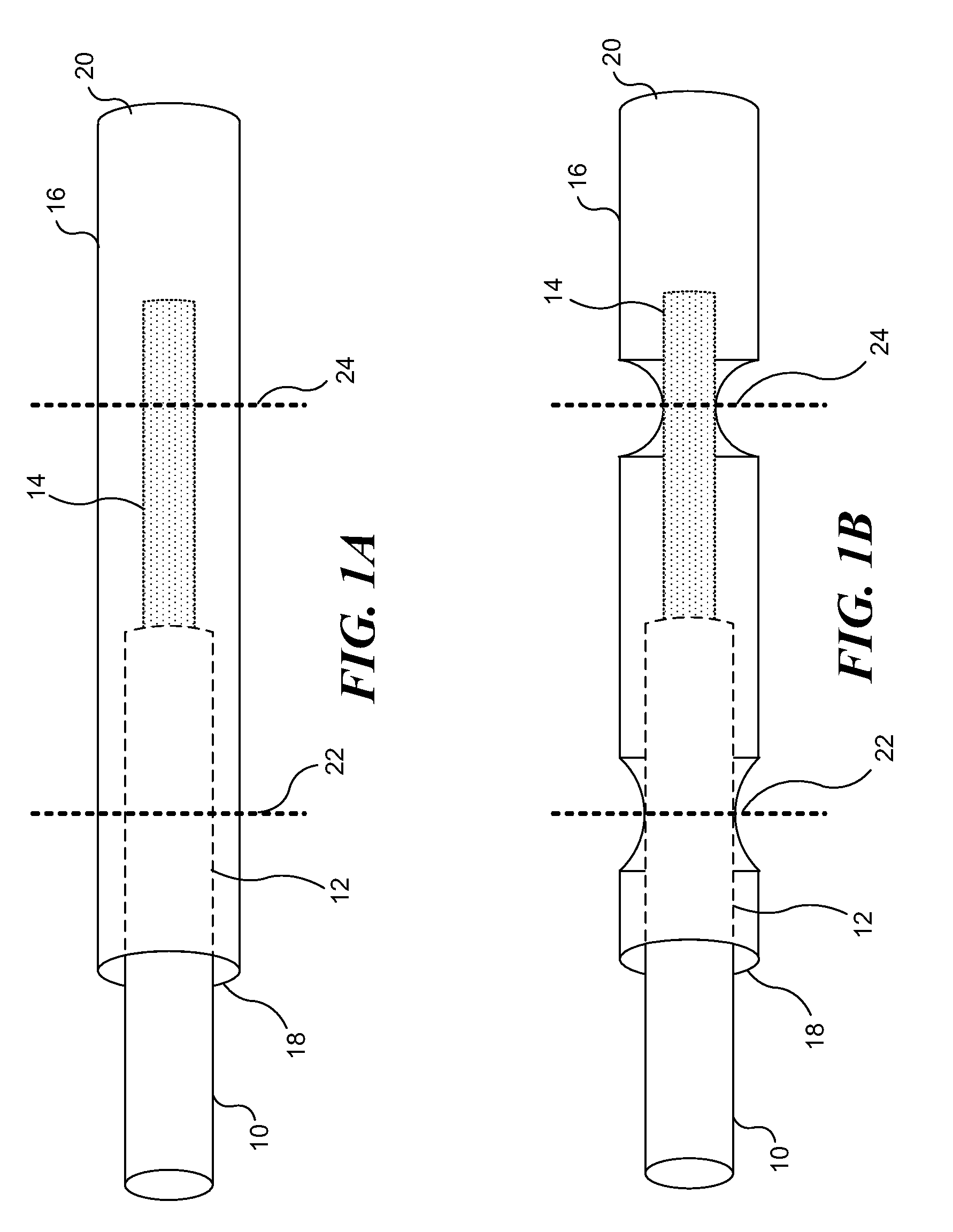

Medical lead termination sleeve for implantable medical devices

ActiveUS8588933B2Eliminate riskEasy to operateBioelectric signal measurementInternal electrodesElectricityElectrical connection

A wire and electrode combination suitable for use with implanted medical devices, and a method for coupling the wire and electrode to achieve a robust electrical connection suitable for use with such medical devices are disclosed. The apparatus employs a wire that is optimized for strength, an electrode optimized for biocompatibility, and a termination sleeve with a closed distal end for coupling the wire to the electrode, while eliminating the potential for galvanic corrosion, enhancing weld quality, and facilitating manufacture of the apparatus. The method involves compressing the sleeve to engage the wire at two locations, where contact between the sleeve and wire at the first location seals the interior of the sleeve, and contact between the sleeve and wire at the second location electrically couples the wire to the sleeve. The sleeve, which is easier to manipulate than the wire, is then spot welded to the electrode.

Owner:CYBERONICS INC

Adherent all-gold electrode structure for lithium niobate based devices and the method of fabrication

InactiveUS6867134B2Improve adhesionImprove performanceSemiconductor/solid-state device manufacturingNon-linear opticsGold layerLithium niobate

An electrode structure wherein galvanic corrosion at adhesion layers formed between electrodes and electronic or electro-optic substrates is eliminated. The electrode structure includes an electro-optic crystalline substrate, an amorphous layer disposed on the crystalline substrate, the amorphous layer having a composition substantially similar to a composition of the crystalline substrate, and a gold layer disposed directly on the amorphous layer. The amorphous layer is created using ion sputtering etching techniques that clean and activate the surface of the crystalline substrate such that the gold layer is able to adhere to it.

Owner:LUMENTUM OPERATIONS LLC

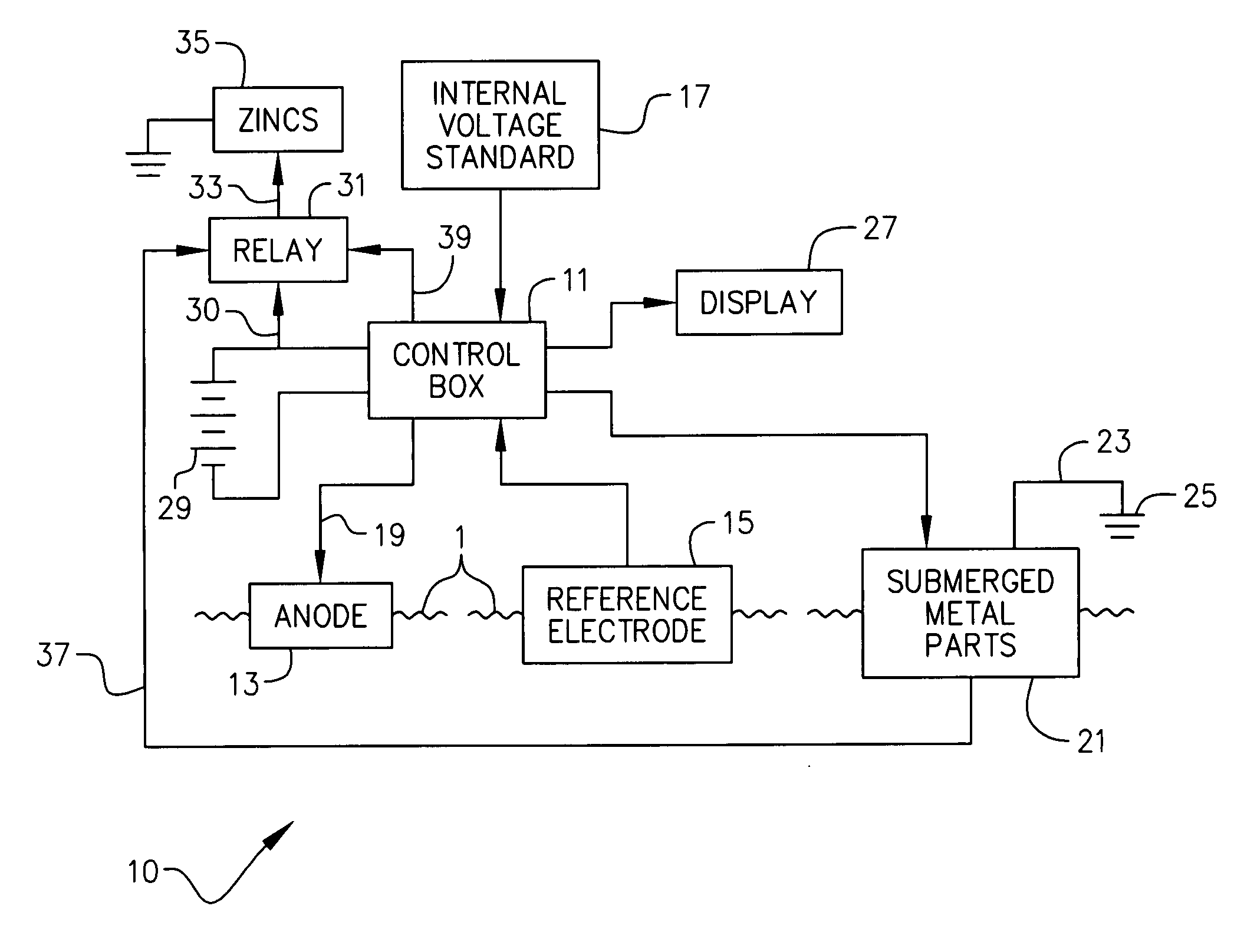

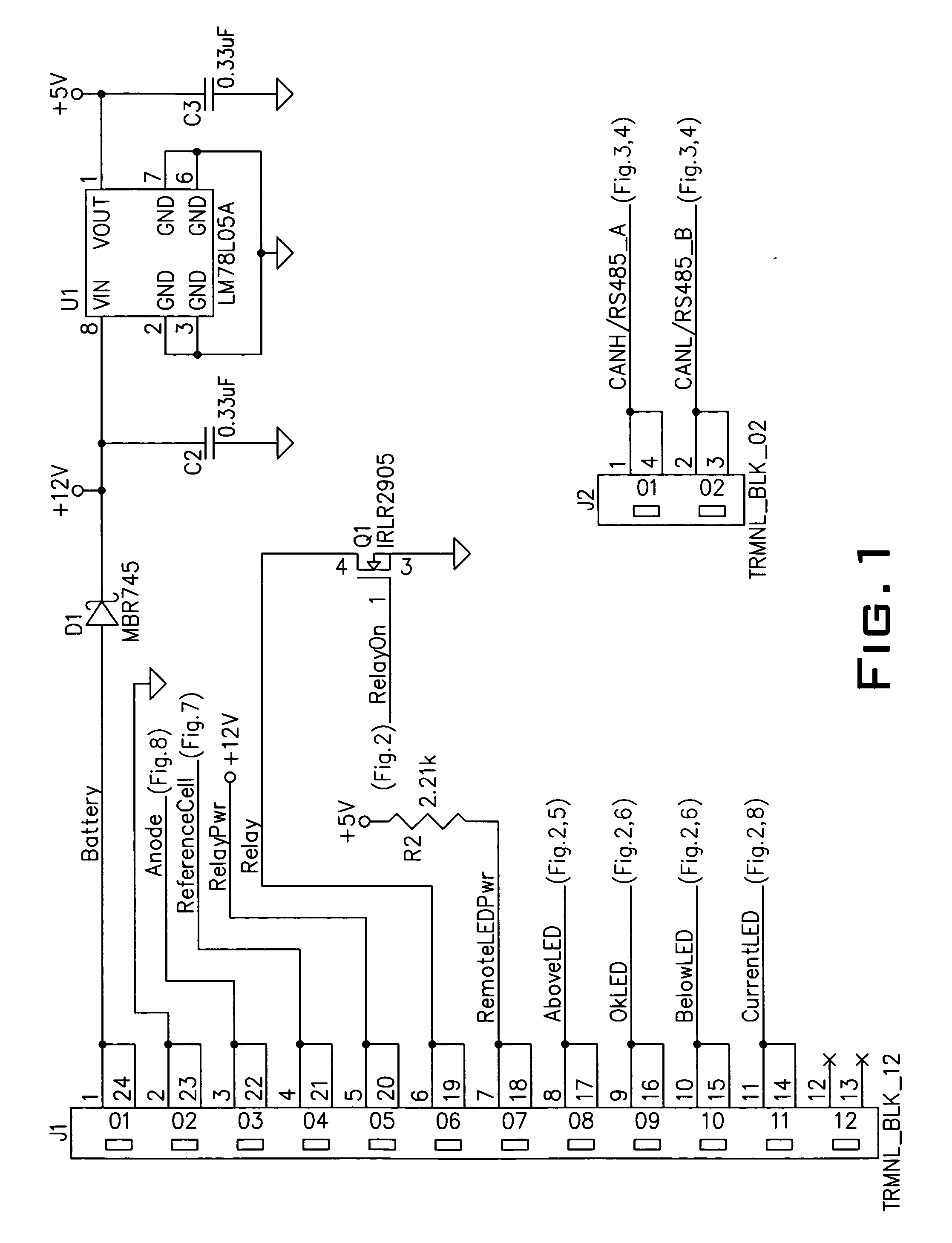

Marine vessel corrosion control system

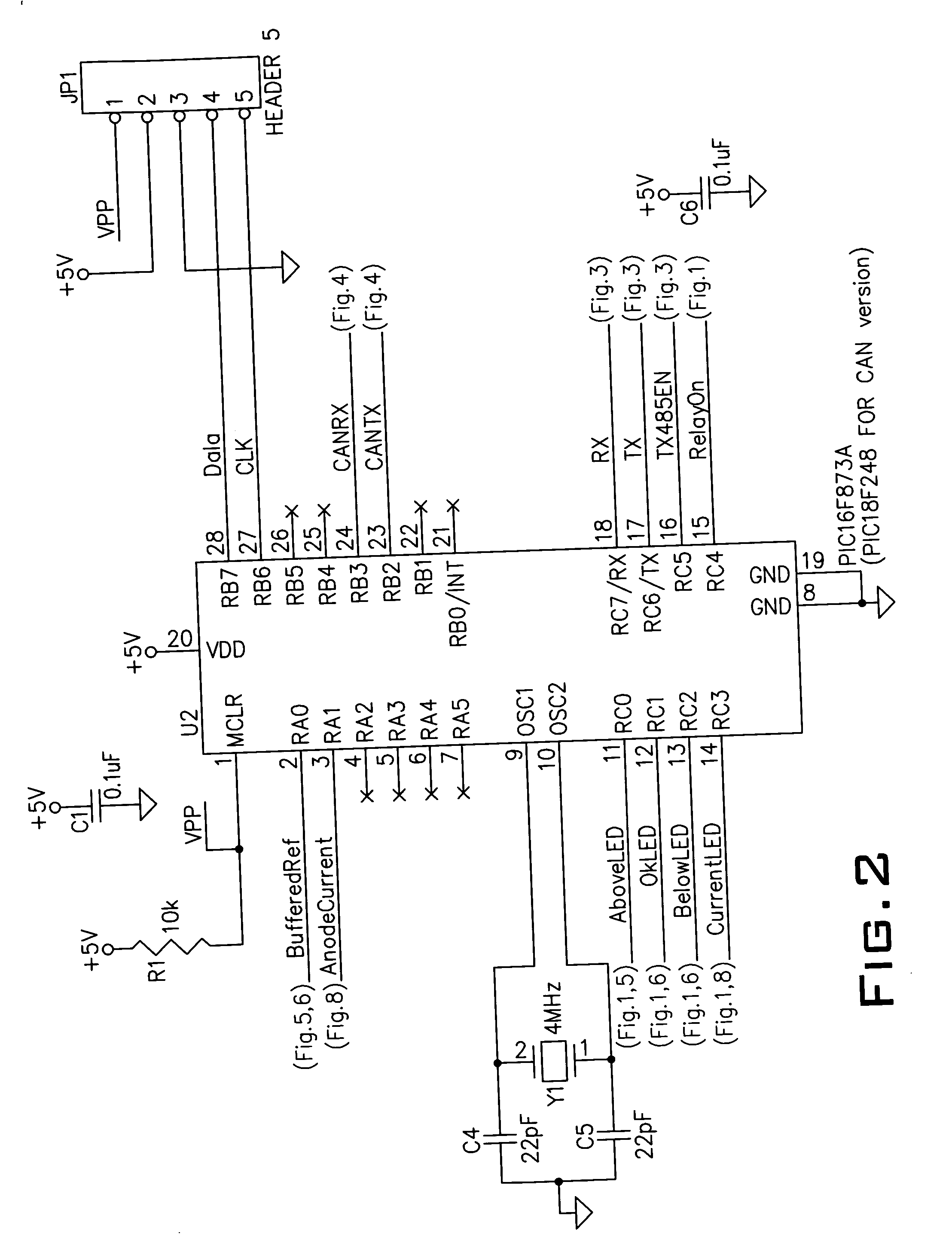

A marine vessel corrosion control system contemplates redundant protection for a marine vessel against the effects of galvanic corrosion. The vessel is equipped with typical zinc anodes interconnected together and attached to metallic components to be protected from galvanic corrosion. A reference electrode immersed in the water provides signals to a control box representative of electrode voltage as compared to an internal stabilized voltage standard. The control box compares the reference electrode voltage with the internal stabilized voltage standard and feeds current through a hull mounted anode into the water and through the submerged metal parts of the vessel. A relay allows selective interruption of the connection between the passive zincs and the vessel ground and selective closing of that circuit. The relay is connected to the control box and when the control box fails in any way, this failure is sensed and results in deactivation of the normally closed relay to electrically interconnect the passive zincs to the vessel ground until the active galvanic corrosion control system is repaired.

Owner:SICA JOSEPH D +1

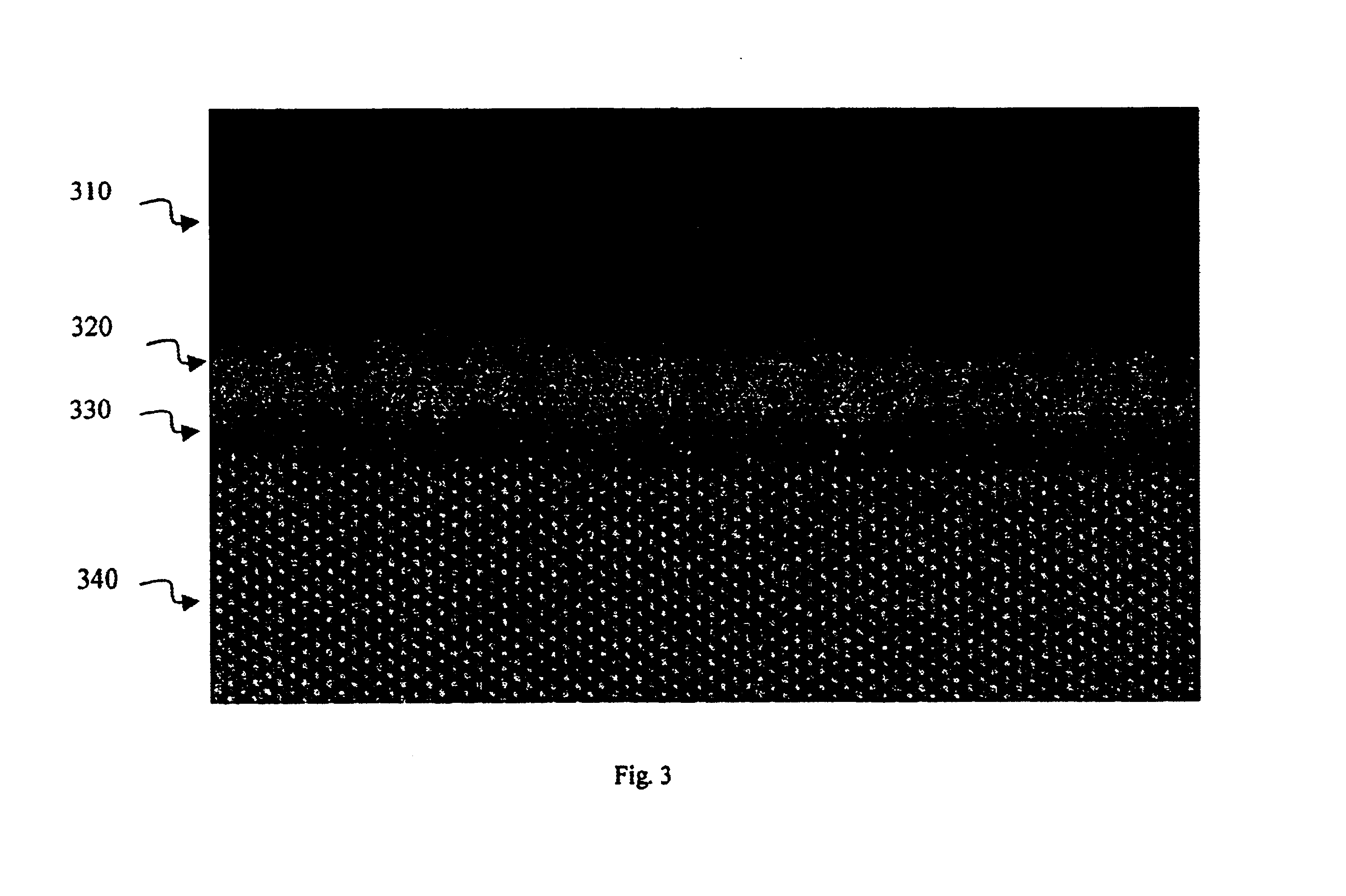

Method for controlling galvanic corrosion effects on a single-wafer cleaning system

InactiveUS6858091B2Reduce exposureEfficient removalSemiconductor/solid-state device manufacturingCleaning using toolsEngineeringConcentration gradient

A method for minimizing galvanic corrosion effects in a single-wafer cleaning system is provided. The method initiates with spraying a cleaning chemistry containing corrosion inhibitors onto a surface of a wafer. Then, the surface of the wafer is exposed to the cleaning chemistry for a period of time. Next, a concentration gradient at an interface of the cleaning chemistry and the surface of the wafer is refreshed. Then, a rinsing agent and a drying agent are applied simultaneously to remove the cleaning chemistry, wherein the drying agent dries the surface of the wafer prior to a concentration of the corrosion inhibitors being diluted to a level insufficient to provide corrosion protection.

Owner:LAM RES CORP

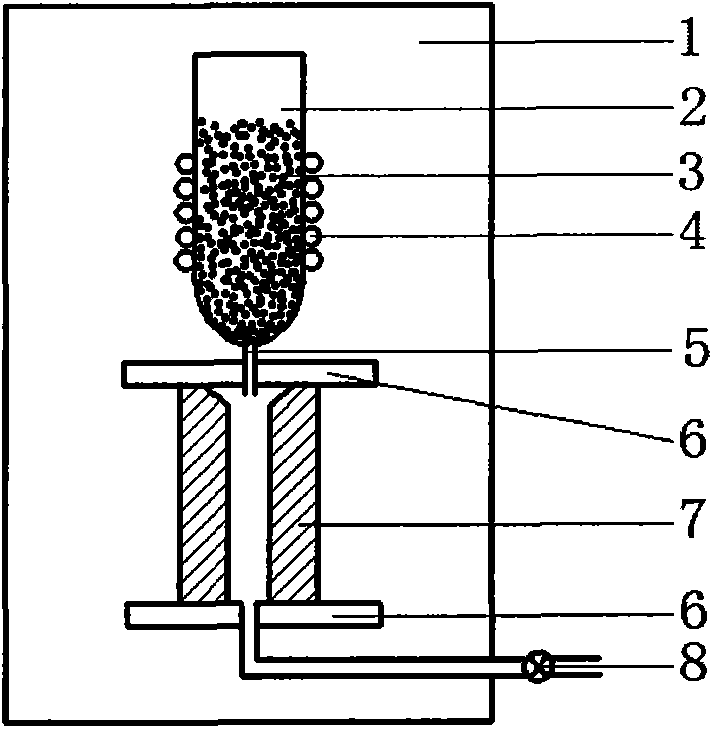

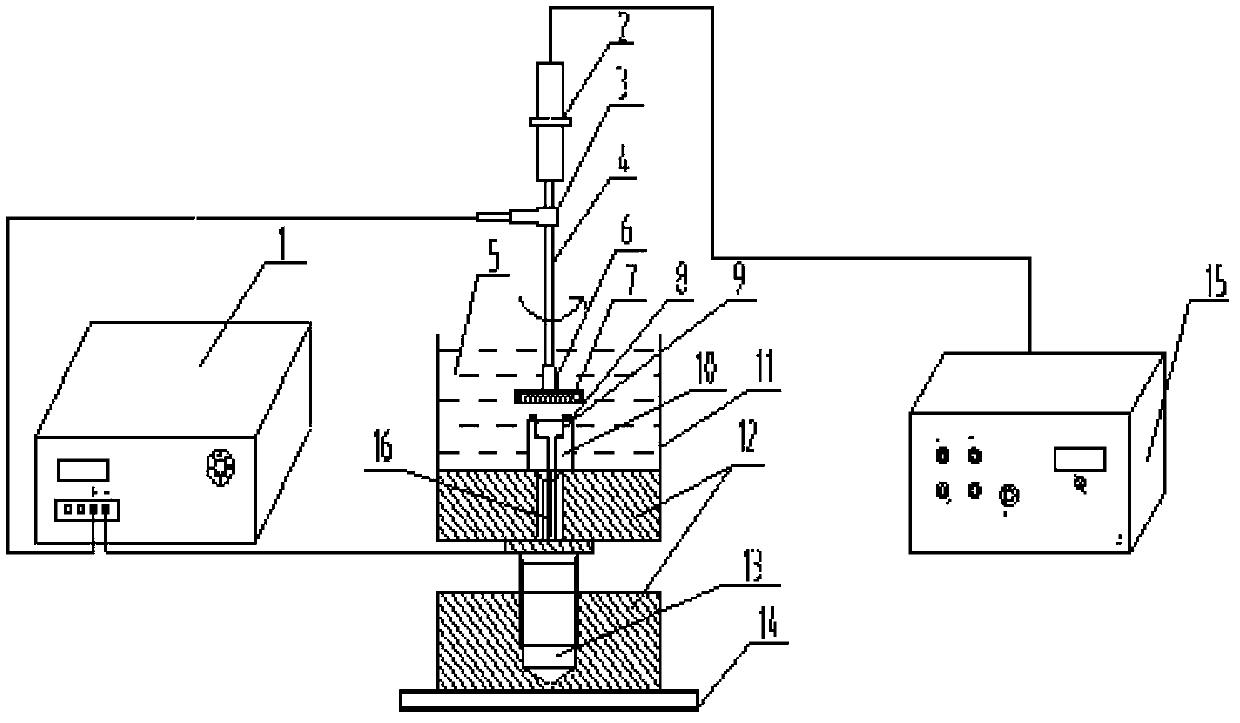

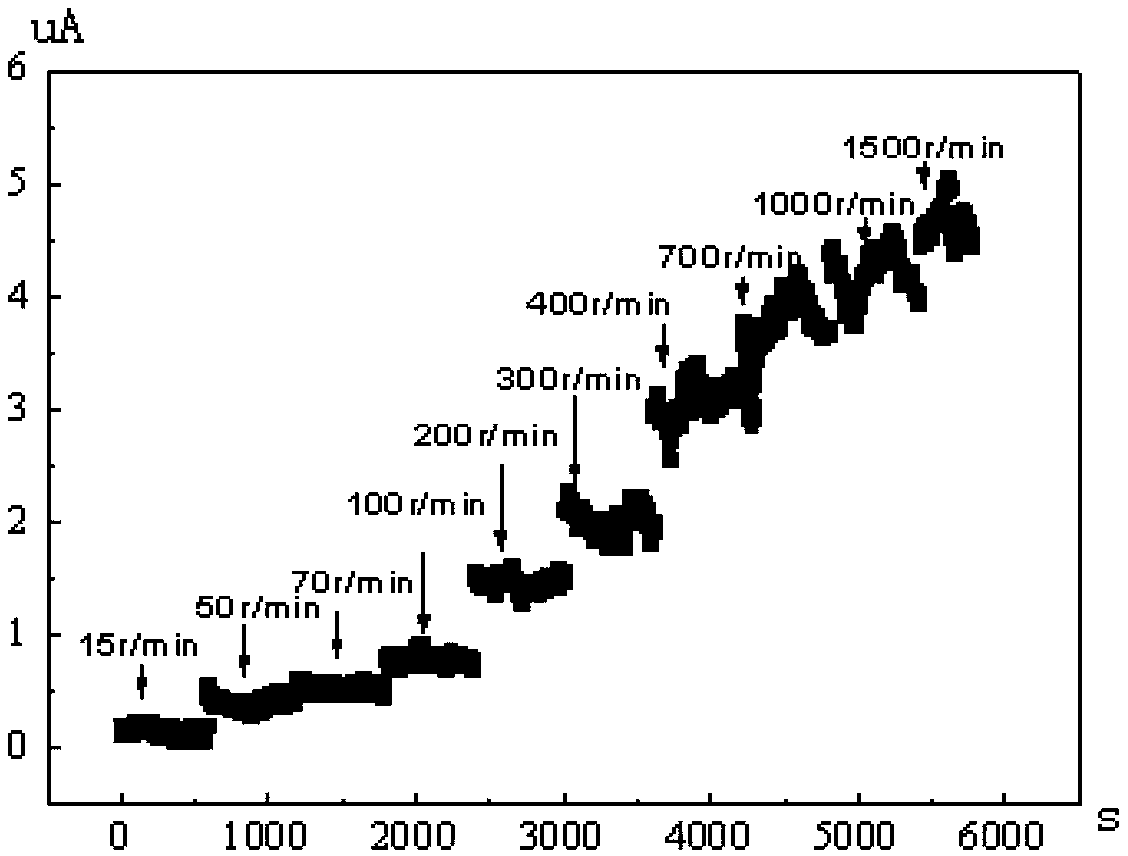

Testing apparatus for dynamic galvanic corrosion

InactiveCN103389263ACorrosion research toolsSimple structureWeather/light/corrosion resistanceElectricityEngineering

The invention belongs to the technical field of corrosion testes of metal materials, and relates to a testing apparatus for dynamic galvanic corrosion. A rotary electrode sample is embedded in a rotary electrode embedded seat; a non-testing surface of the rotary electrode sample is provided with a threaded hole to realize threaded connection with a rotary shaft; a positive electrode of a galvanic corrosion measurement instrument is connected with the rotary electrode sample through an electric brush; a carborundum grinding column is fixed on two sides of a fixed electrode; a channel is disposed between a fixed electrode embedded seat and a support with adjustable height; the fixed electrode and a cooper conductor are electrically connected through a spring; a negative electrode of the galvanic corrosion measurement instrument is directly connected to the fixed electrode; and the support with adjustable height and the fixed electrode embedded seat are connected by a screw with high dense threads. A testing method comprises three steps of installing the testing apparatus; setting testing conditions and controlling rotating speed; and recording data. The testing apparatus is simple in structure and convenient for operation; the testing method is reliable in principle and strong in practicability; the testing conditions can be realized easily; cost is low; testing efficiency is high; and the testing apparatus is environment-friendly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

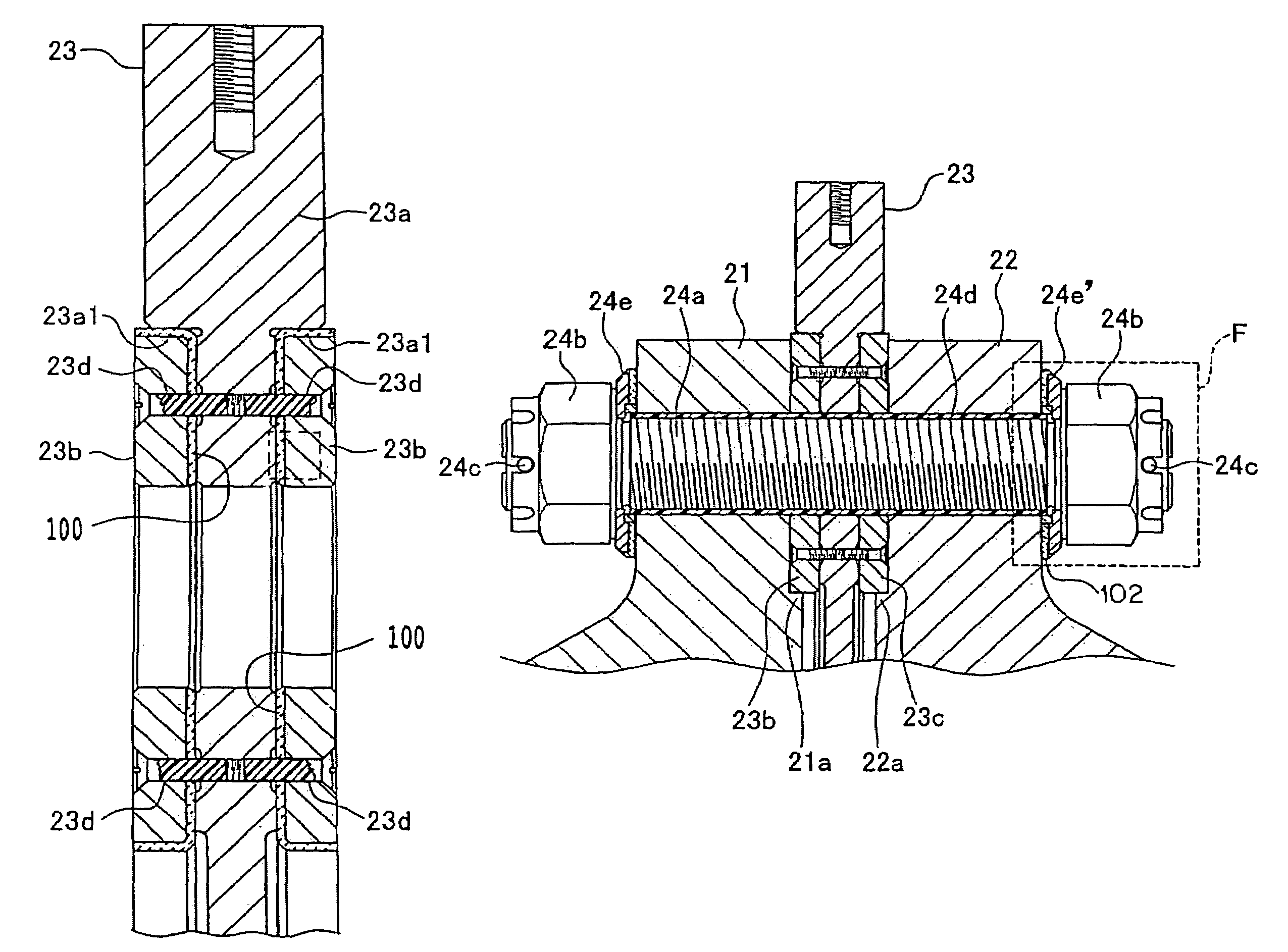

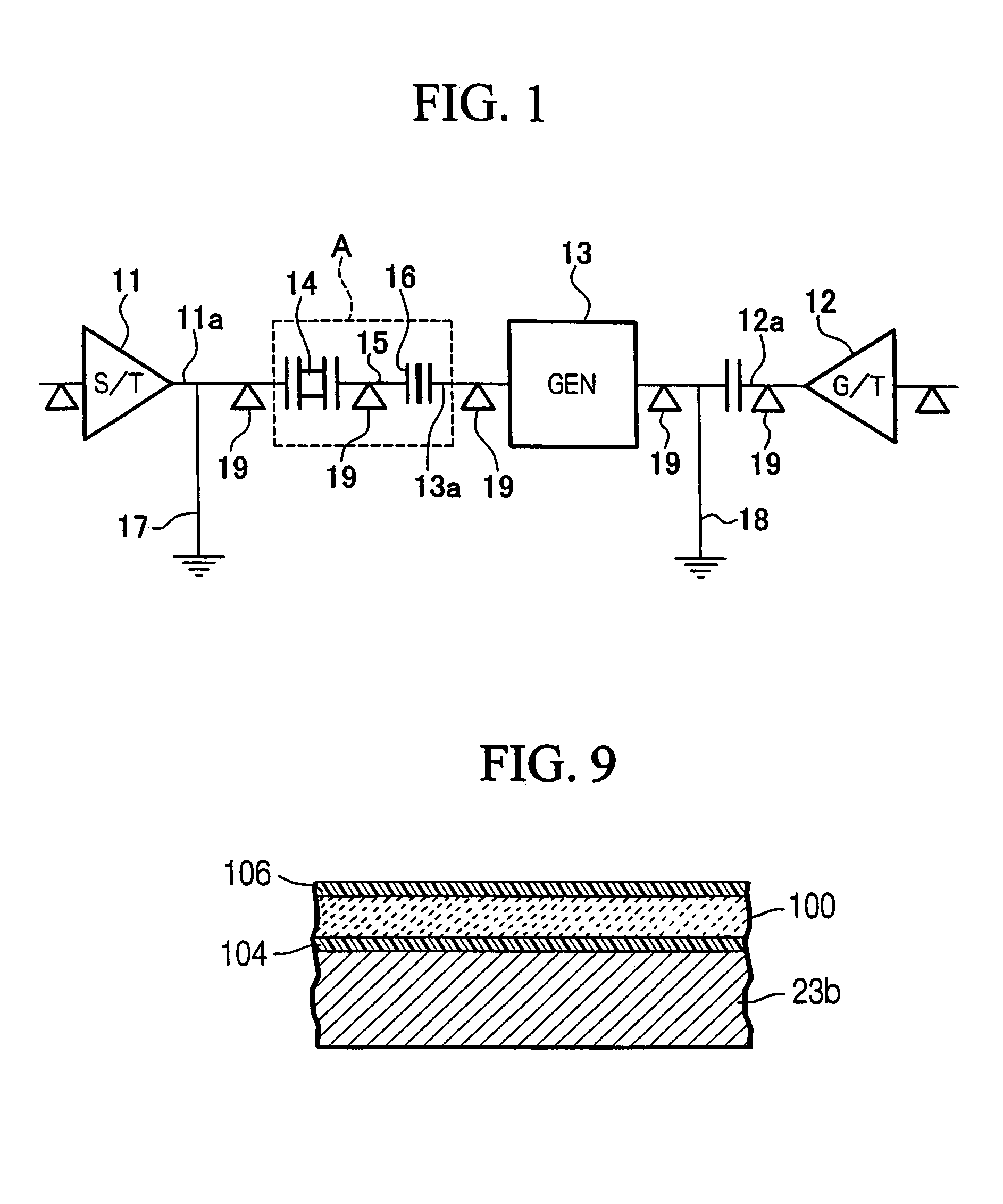

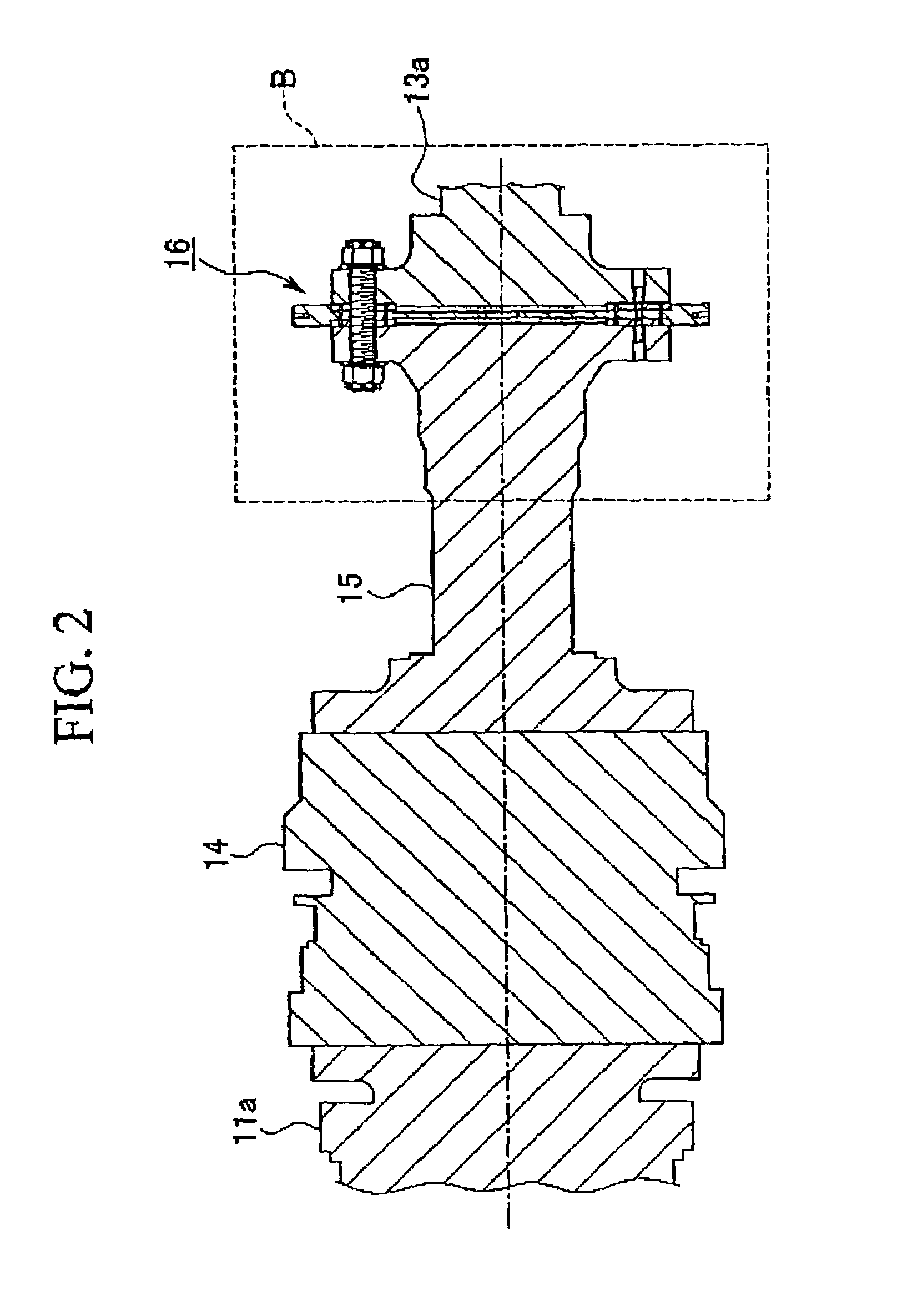

Rotor coupling having insulated structure

InactiveUS7530757B2Prevent galvanic corrosionPotential of each rotor can be reducedMolten spray coatingCombination enginesElectricityCoupling

A rotor coupling having insulated structure which can assuredly prevent galvanic corrosion of beating members, rotors and the like which is caused by shaft voltage, is provided in a shaft system that requires insulation. A generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine. The rotor coupling having insulated structure is employed in power generating equipment in which a generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine, a generator rotor and a rotating machinery rotor are connected, a first grounding electrode is provided to the steam turbine rotor, and a second grounding electrode is provided to the generator rotor, wherein both the rotors between the generator and the steam turbine are connected in an electrically insulated state.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Preparation process of inorganic copper imitation coating and process for replacing protective and decorative copper layer of metal surface with inorganic copper imitation coating

InactiveCN103665973AGood protection and decorationImprove bindingAlkali metal silicate coatingsPretreated surfacesCopper coatingAdhesive

The invention provides a preparation process of an inorganic copper imitation coating and a process for replacing a protective and decorative copper layer of a metal surface with the inorganic copper imitation coating, and belongs to the field of metal protection and decoration. The preparation process of the inorganic copper imitation coating comprises the following steps of: by taking potassium silicate and silica sol as adhesives of the coating, adding fumed silica as filler of the coating to a mixed solution of potassium silicate and silica sol; then adding a silane coupling agent and a wetting dispersant as assistants used for improving the coating performance; finally adding antique brass pigment fillers to obtain the copper imitated inorganic silicate coating. The coating prepared by the method can replace the protective and decorative copper layer of the metal surface, and is applicable to the field of metal protection and decoration. The inorganic copper imitation coating prepared by the method is high in protection and decoration performance, avoids galvanic corrosion caused by the copper layer, saves the protection cost, has performance superior to a copper coating, and also has the advantages of being low in cost, environment-friendly, high in corrosion resistance, high in cohesion, etc.

Owner:HARBIN INST OF TECH

Galvanically-Active In Situ Formed Particles for Controlled Rate Dissolving Tools

ActiveUS20190054523A1High incipient melting pointIncrease corrosion rateTransportation and packagingMetal-working apparatusAlloyElectrochemistry

A tastable, moldable, and / or extrudable structure using a metallic primary alloy. One or more additives are added to the metallic primary alloy so that in situ galvanically-active reinforcement particles are formed in the melt or on cooling from the melt. The composite contains an optimal composition and morphology to achieve a specific galvanic corrosion rate in the entire composite. The in situ formed galvanically-active particles can be used to enhance mechanical properties of the composite, such as ductility and / or tensile strength. The final casting can also be enhanced by heat treatment, as well as deformation processing such as extrusion, forging, or rolling, to further improve the strength of the final composite over the as-cast material.

Owner:TERVES

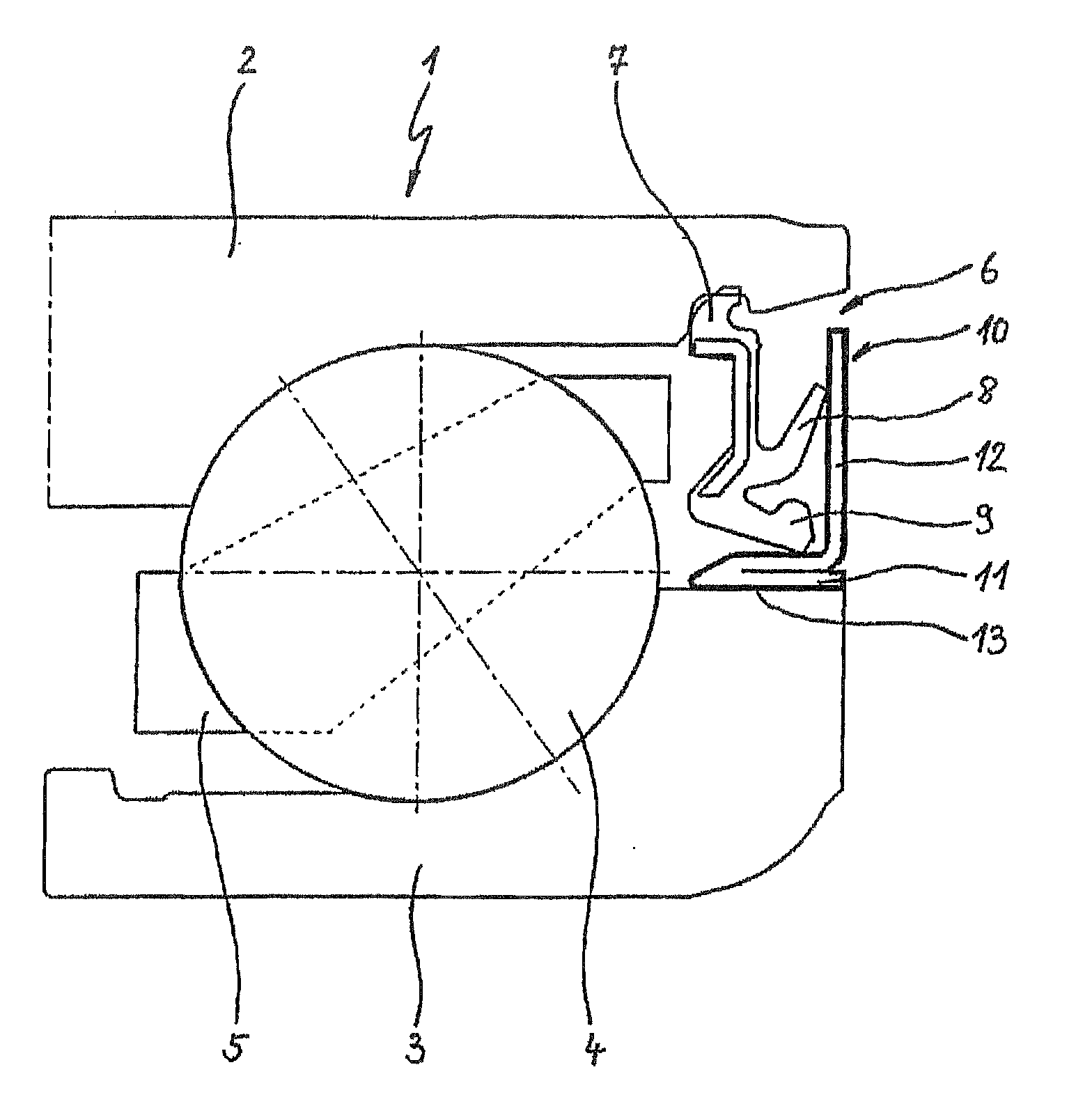

Sealed Radial Rolling Bearing, In Particular Wheel Bearing For a Motor Vehicle

InactiveUS20080187262A1Easy to shapeCost-effective materialEngine sealsRolling contact bearingsRolling-element bearingEngineering

The invention relates to a sealed radial rolling bearing, in particular a wheel bearing for a motor vehicle, which substantially comprises an outer bearing ring and an inner bearing ring and a plurality of rolling bodies which roll between the bearing rings and are held with uniform spacing relative to one another by means of a bearing cage. Here, in each case one radially arranged sealing element extends between the bearing rings at each side at a distance axially from the rolling bodies, said sealing element having one or more sealing lips which are connected to the outer bearing ring and some into contact with a centrifugal ring which is connected by means of a press fit to the inner bearing ring. According to the invention, the centrifugal ring of the sealing element is composed of a simple cold-formable steel sheet and has a galvanic corrosion prevention coating with zinc-containing constituents, the cathodic protective action of which can prevent both rust infiltration at the press fit between the centrifugal ring and the inner bearing ring and the onset of corrosion in the region of contact between the sealing lips and the centrifugal ring.

Owner:SCHAEFFLER KG

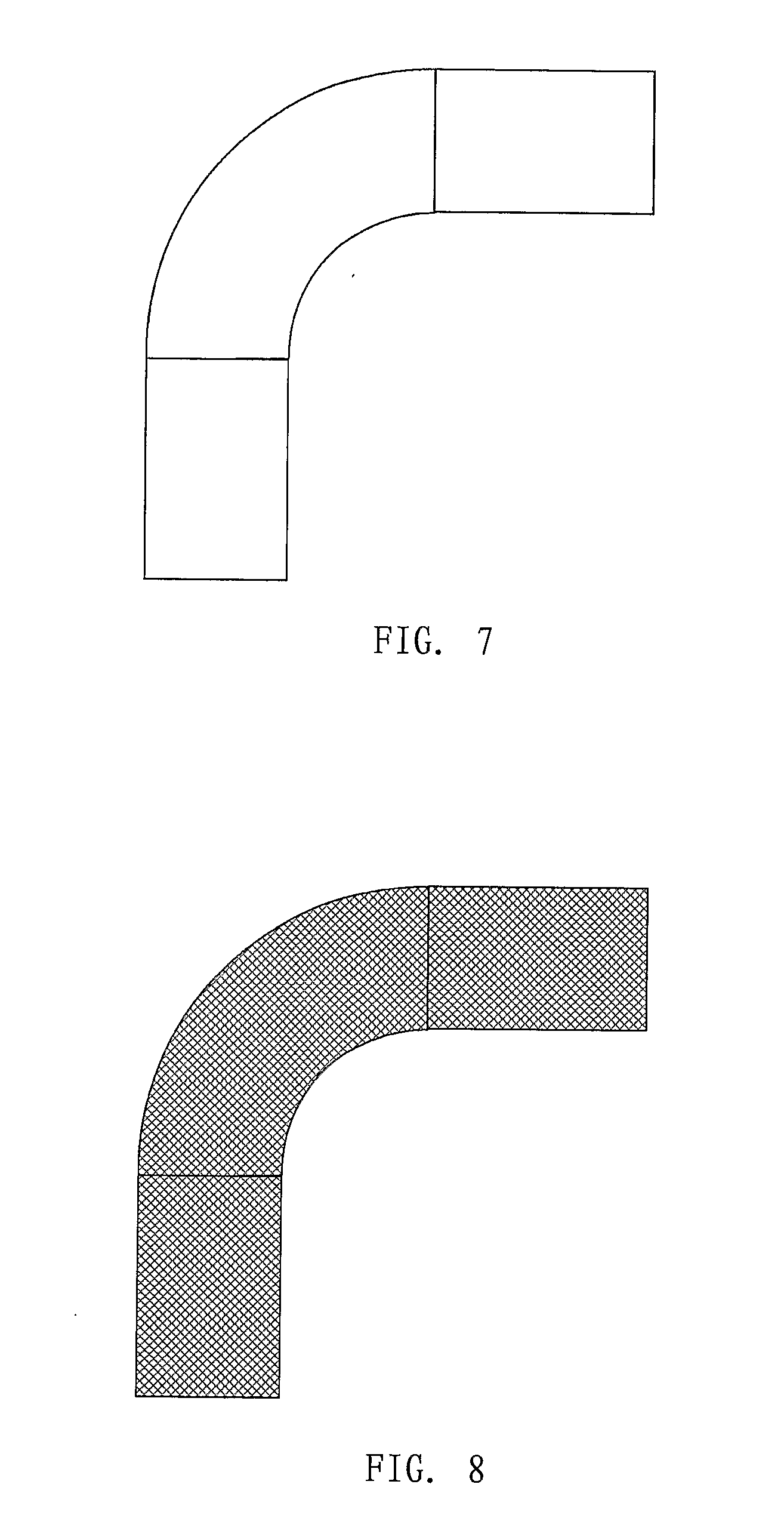

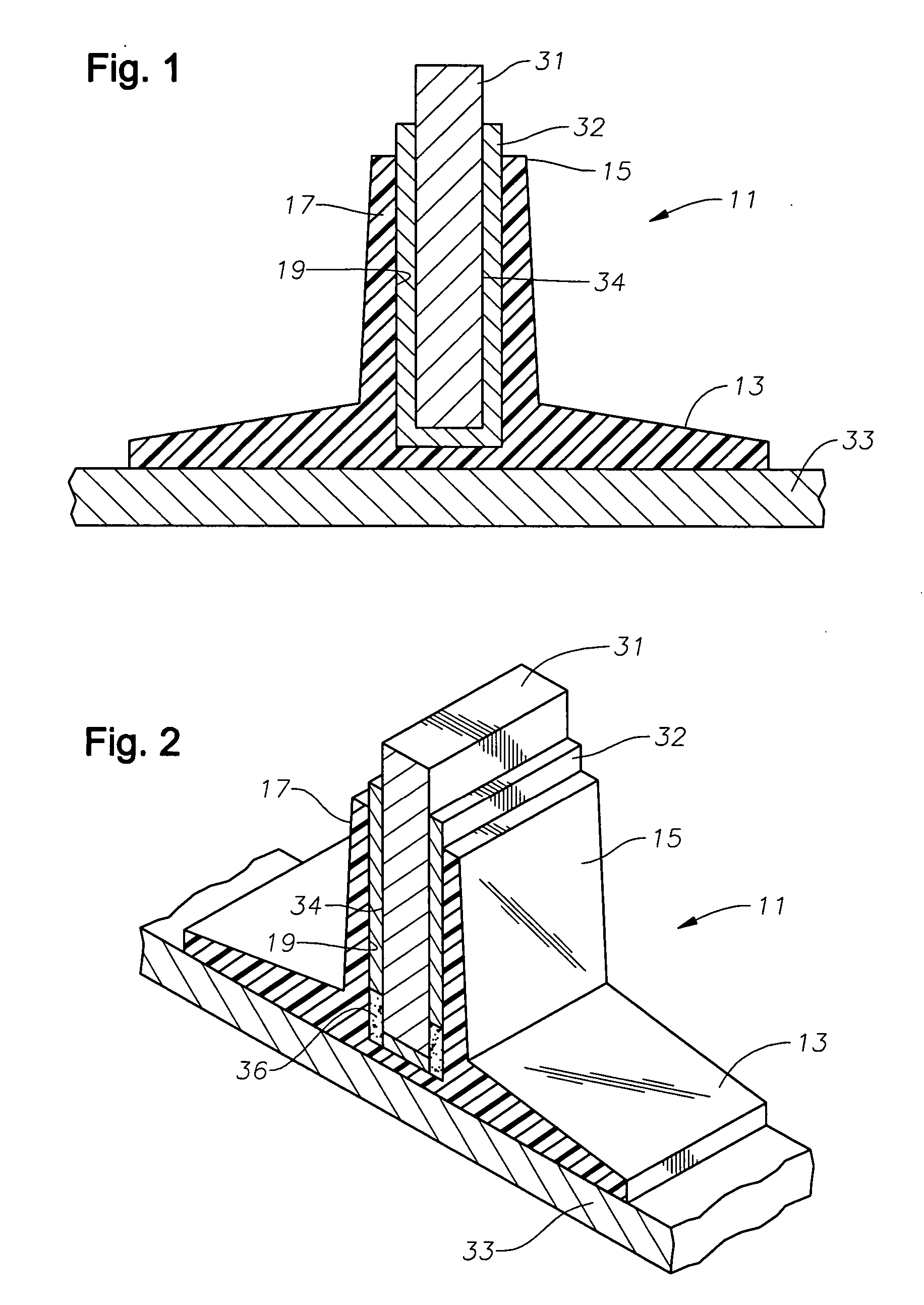

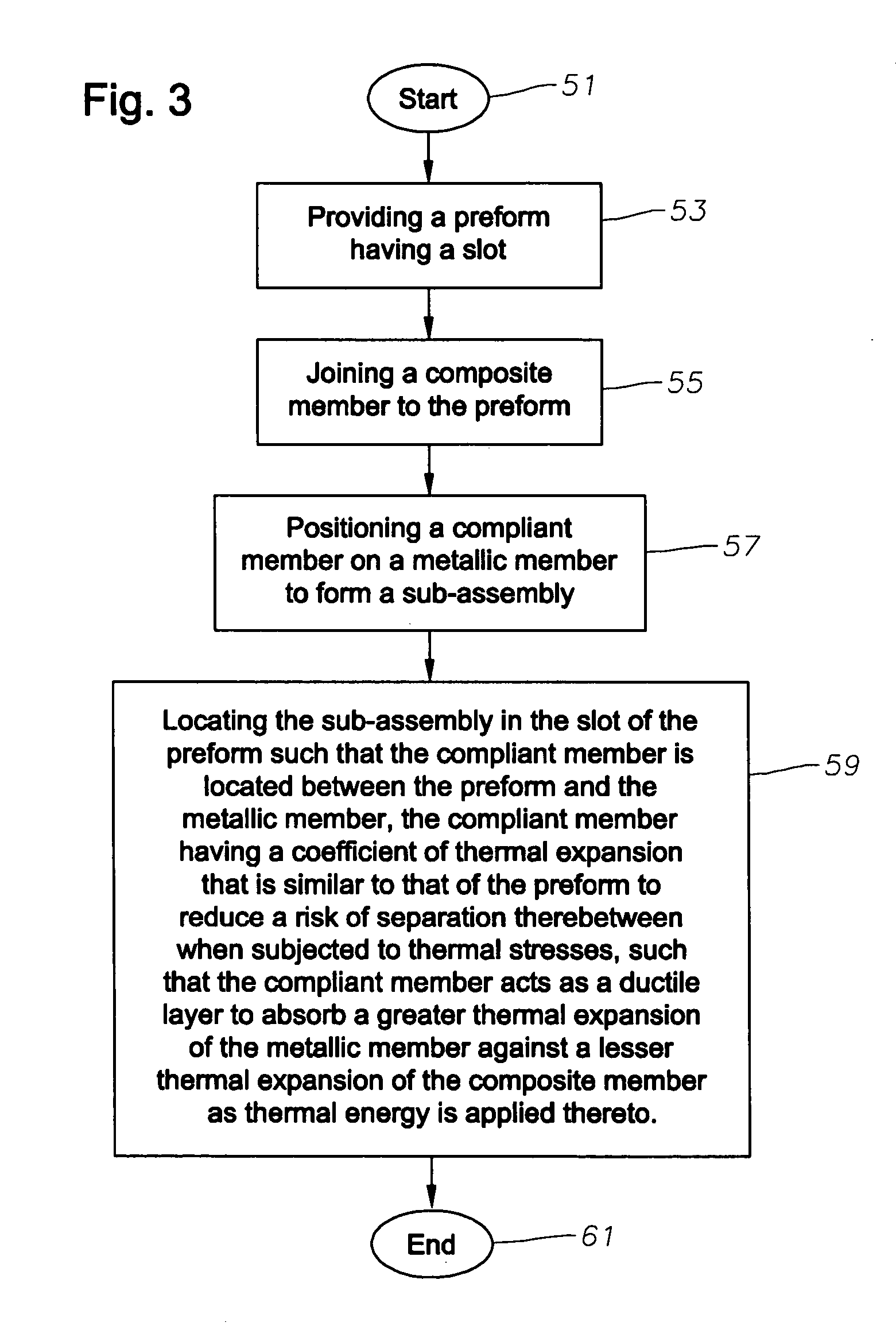

System, method, and apparatus for metallic-composite joint with compliant, non-corrosive interface

ActiveUS20070175966A1Reduce riskBarrier to galvanic corrosionAircraft stabilisationLayered productsFiberCarbon fibers

A metallic-composite joint is formed by inserting a metallic member into a slot of a pi-shaped composite preform. The preform is formed from woven carbon fiber in a binder of resin and may or may not be cured prior to assembly. An inert compliant layer is located between the legs of the preform and the metallic member. The resin binder or an adhesive is used to bond the compliant layer to the preform. The compliant layer has a coefficient of thermal expansion that more closely matches that of the preform. The properties of the compliant layer also avoid galvanic corrosion between the carbon in the preform and the metallic member.

Owner:LOCKHEED MARTIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com