Patents

Literature

542 results about "Shaft voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shaft voltage occurs in electric motors and generators due to leakage, induction, or capacitive coupling with the windings of the motor. It can occur in motors powered by variable-frequency drives, as often used in heating, ventilation, air conditioning and refrigeration systems. DC machines may have leakage current from the armature windings that energizes the shaft. Currents due to shaft voltage causes deterioration of motor bearings, but can be prevented with a grounding brush on the shaft, grounding of the motor frame, insulation of the bearing supports, or shielding.

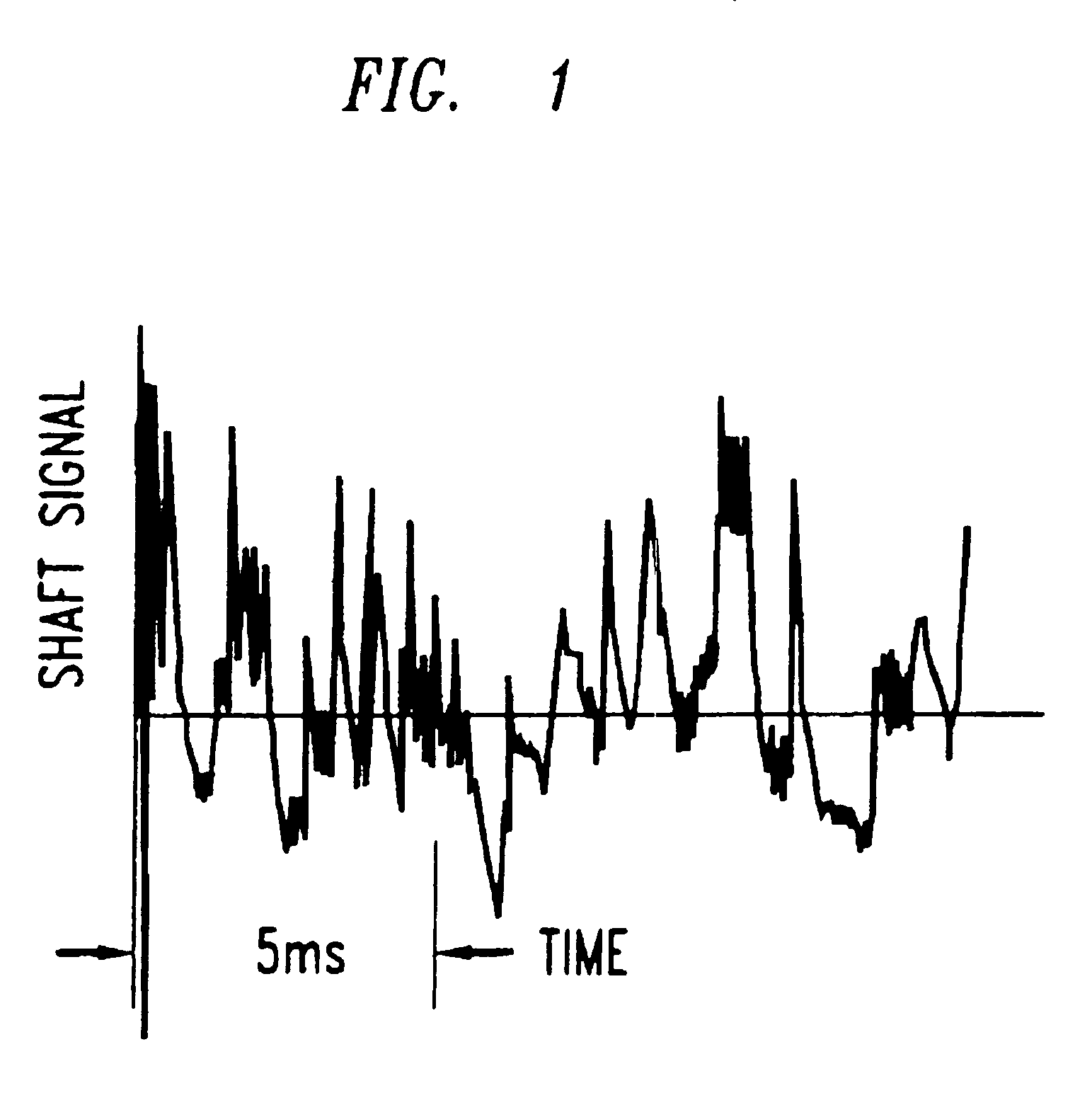

Method and apparatus for detection of brush sparking and spark erosion on electrical machines

InactiveUS20050184751A1Low costSensitive highTesting dielectric strengthAlarmsElectric machineEngineering

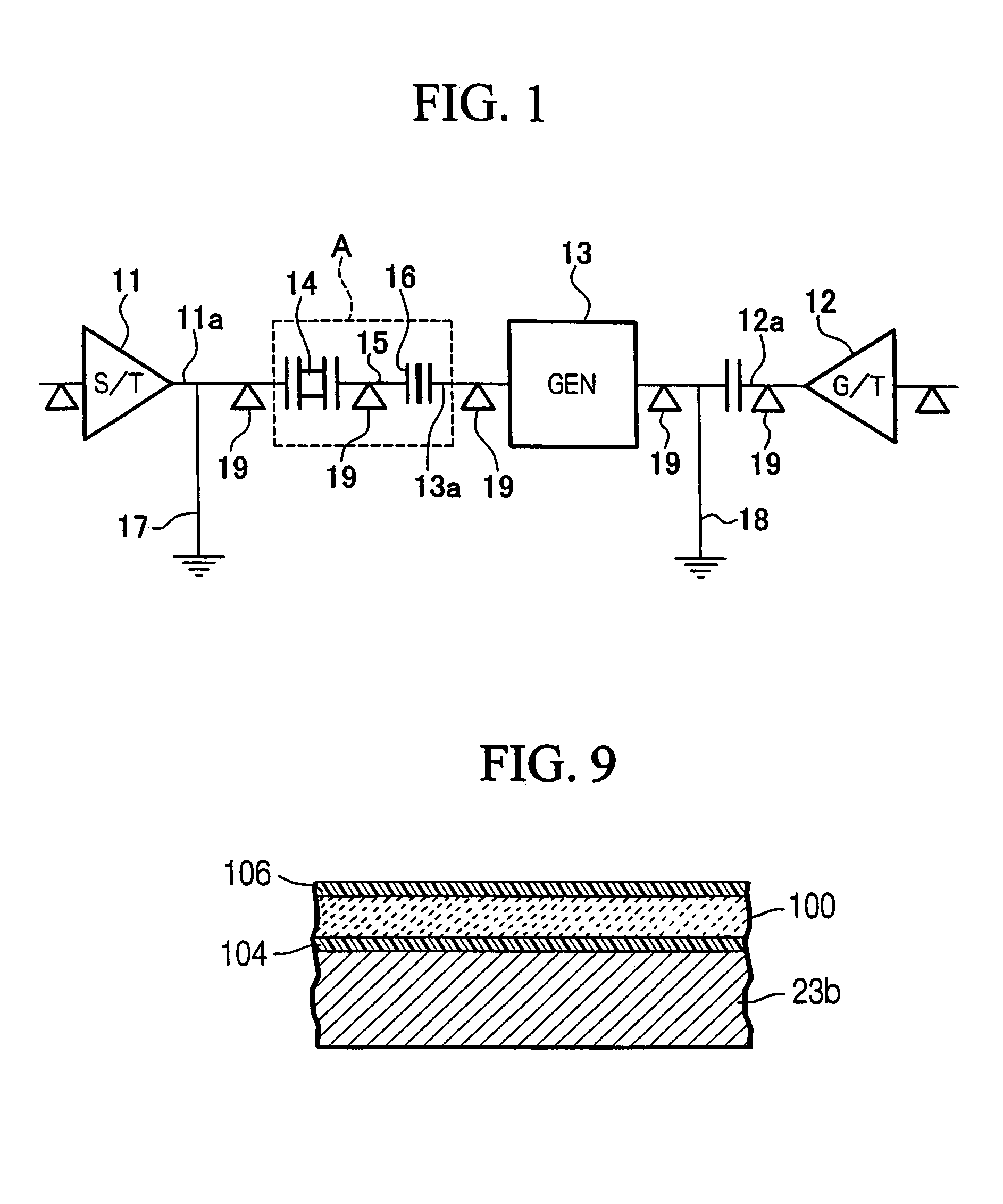

A method and apparatus for detection of spark activity in an electrical machine having a shaft, wherein at least one of the shaft voltage and the shaft current is measured and analyzed for components which are characteristic of spark activity. The method uses the shaft voltages and / or shaft currents which are normally generally regarded only as being damaging has been found to be accurate and to be suitable for long-term monitoring of spark activities such as brush sparking, spark erosion, spark flashovers between parts of the shaft bearings and can be implemented physically very easily and in a reliable manner, since the existing grounding devices are used.

Owner:GENERAL ELECTRIC TECH GMBH

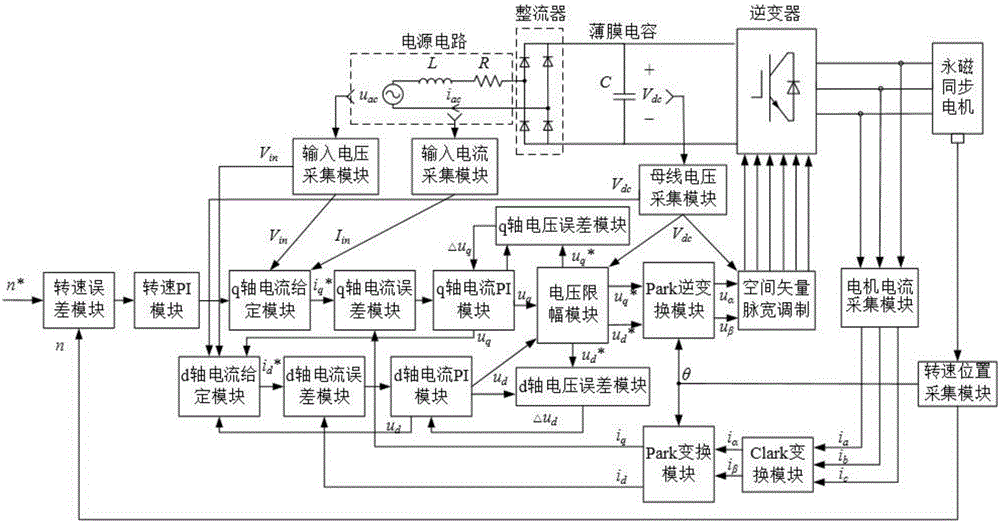

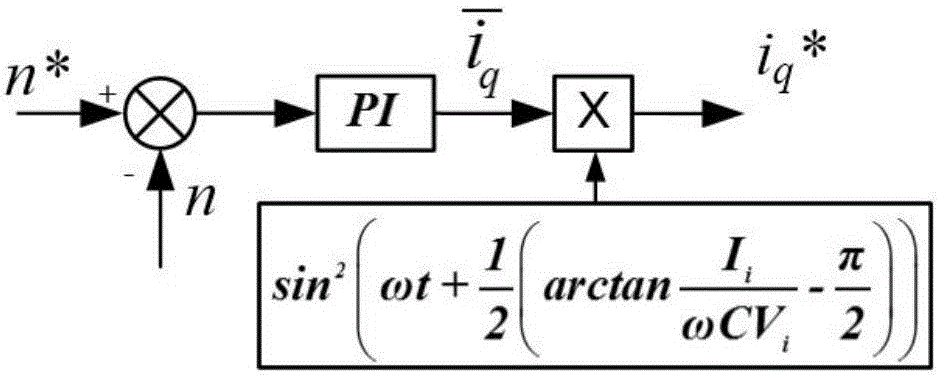

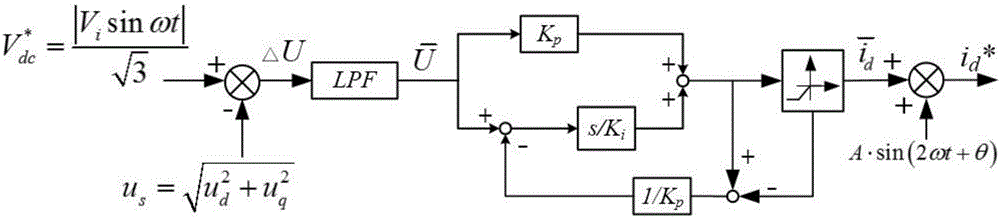

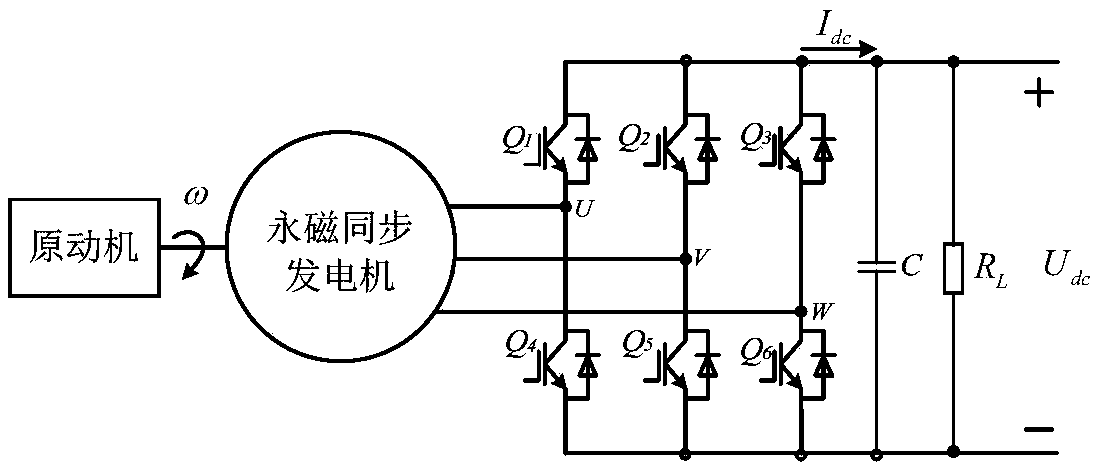

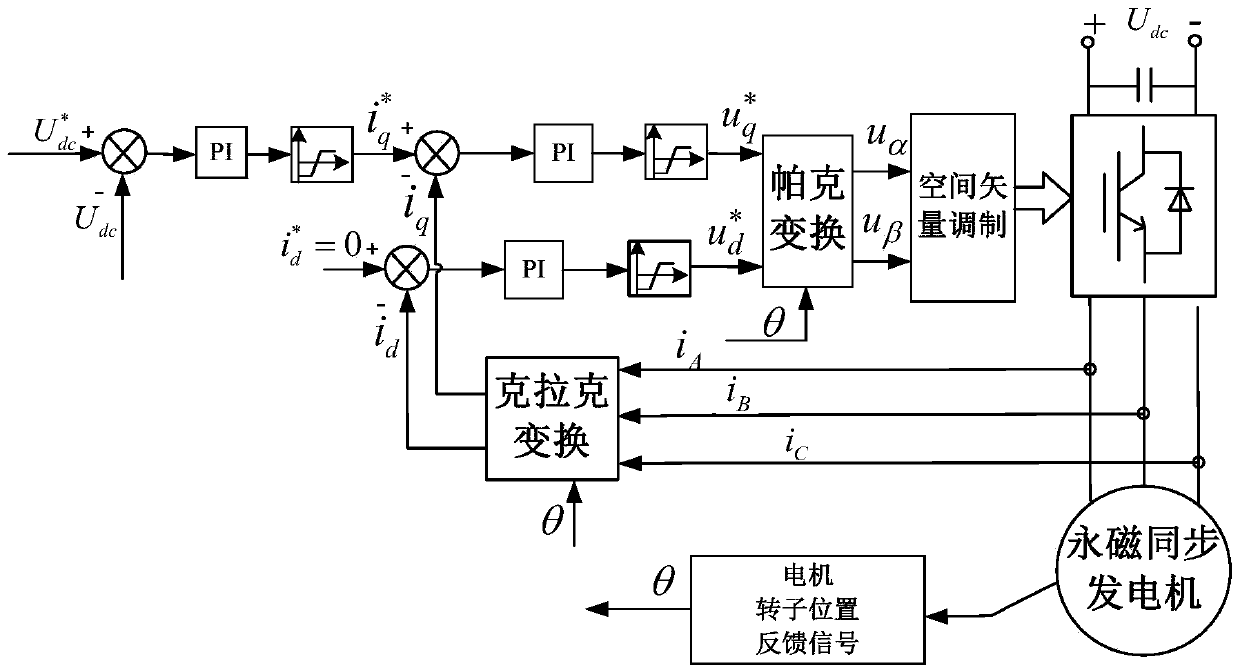

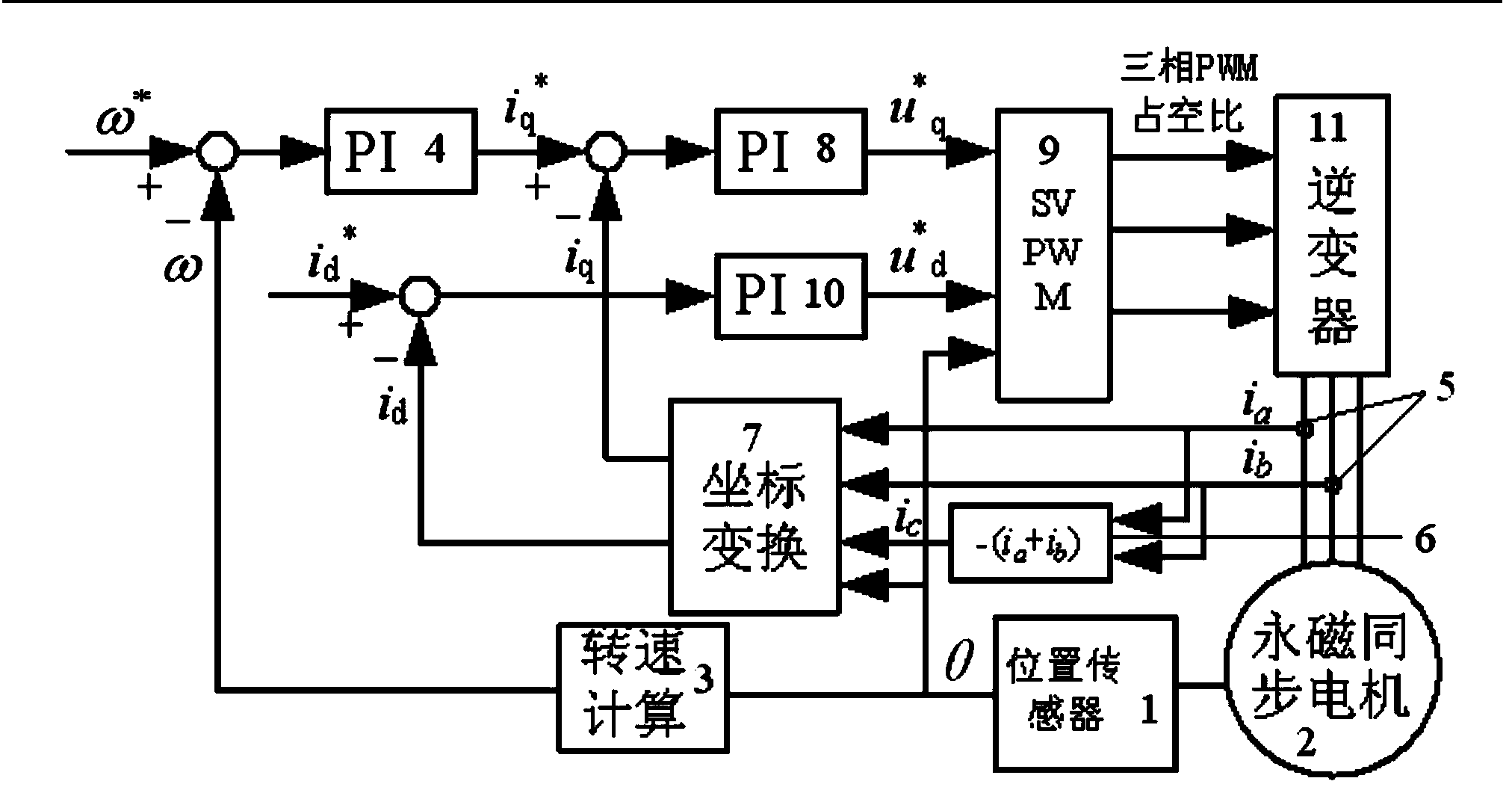

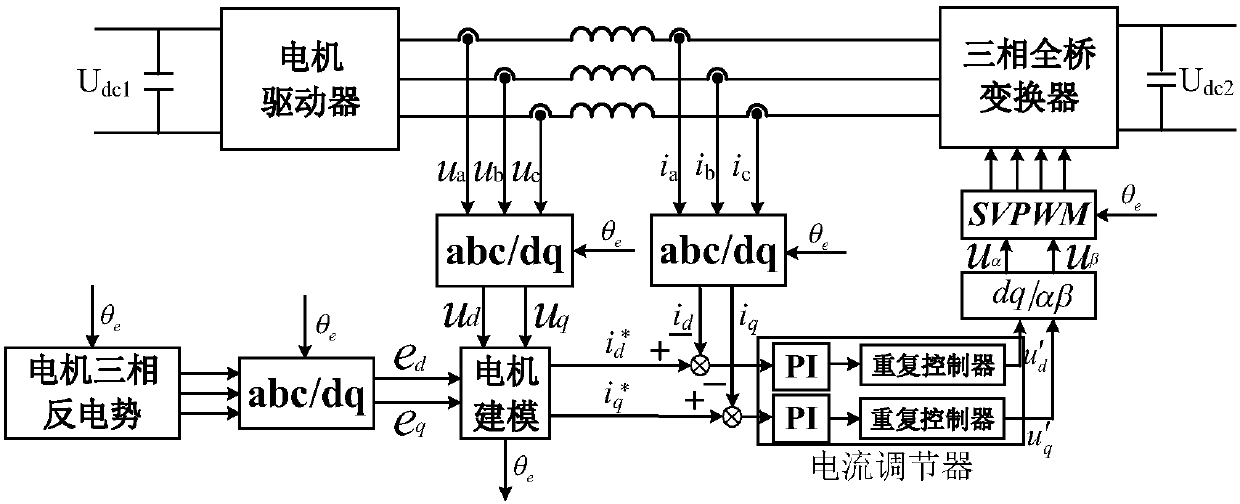

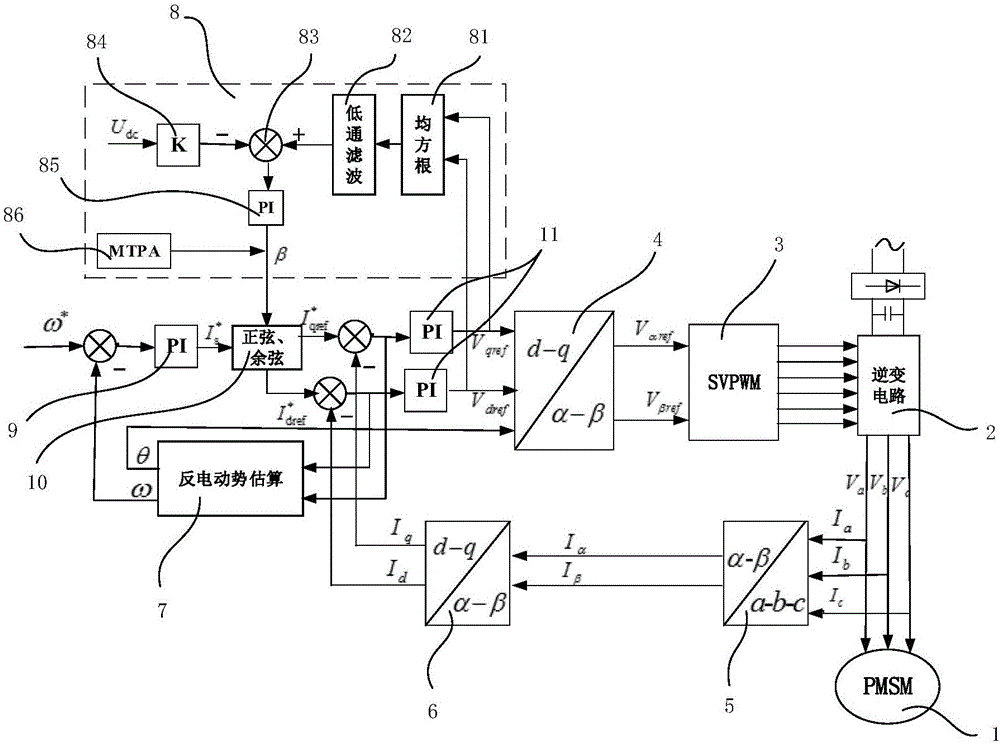

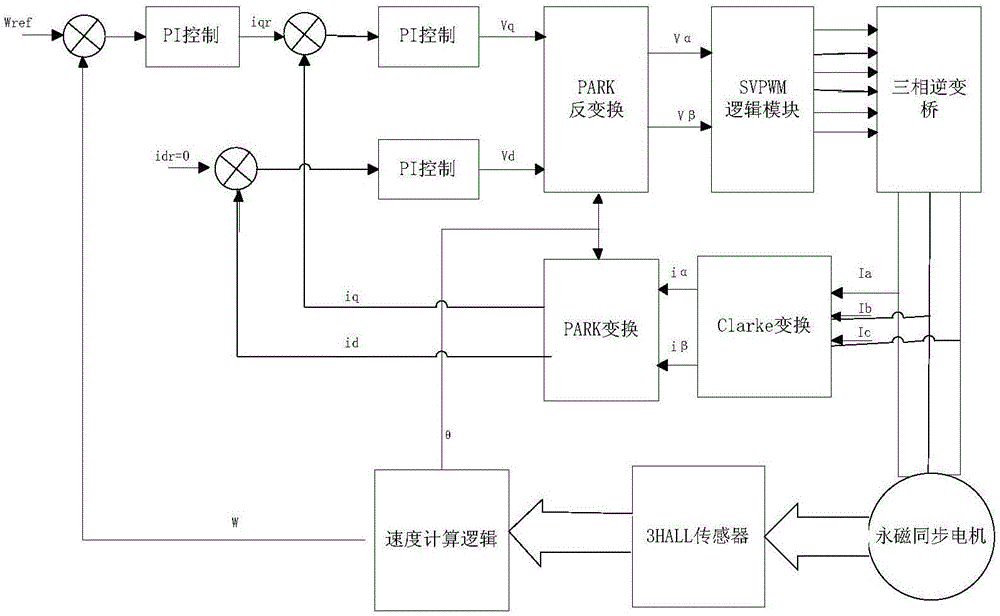

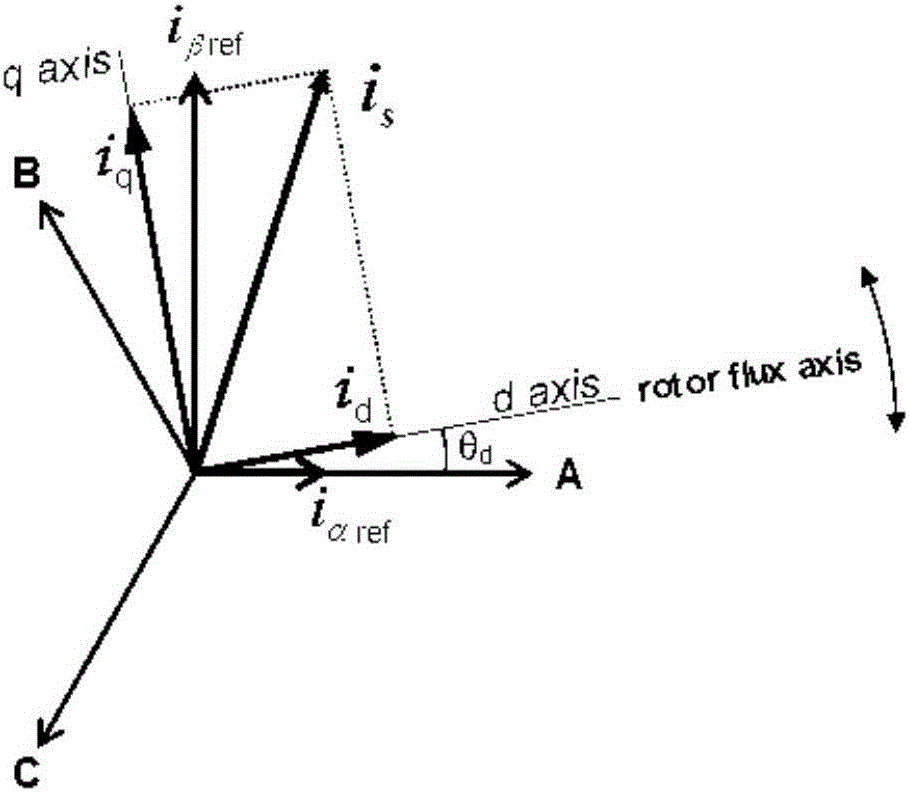

Frequency conversion driving control system and method based on electrolysis-free capacitive inverter

ActiveCN106788115ASimplify a given calculationLimit the actual stator voltageElectronic commutation motor controlAC motor controlCapacitancePhase currents

The invention discloses a frequency conversion driving control system and method based on an electrolysis-free capacitive inverter. The method comprises the following steps: detecting system input voltage current, bus voltage, motor phase current and rotating speed; carrying out Clark and Park conversion on three-phase current to obtain d and q axis current; carrying out error adjustment on a given rotating speed and an actual rotating speed; calculating q axis given current according to input voltage current, speed ring output and capacitance; calculating d axis given current according to voltage; calculating d and q axis error current and carrying out PI adjustment to obtain d and q axis actual voltage; limiting amplitude of actual voltage to obtain d and q axis calculated voltage; carrying out error adjustment on the actual voltage and the calculated voltage and taking the result as current ring feedback; carrying out Park inverse conversion on the d and q axis calculated voltage to obtain alpha and beta axis voltage; and modulating the inverter to control a motor. By the frequency conversion driving control system and method based on the electrolysis-free capacitive inverter, the motor can run at high speed in a flux weakening region, a network side high power factor is obtained, a control structure is simplified, and the reliability of the system is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

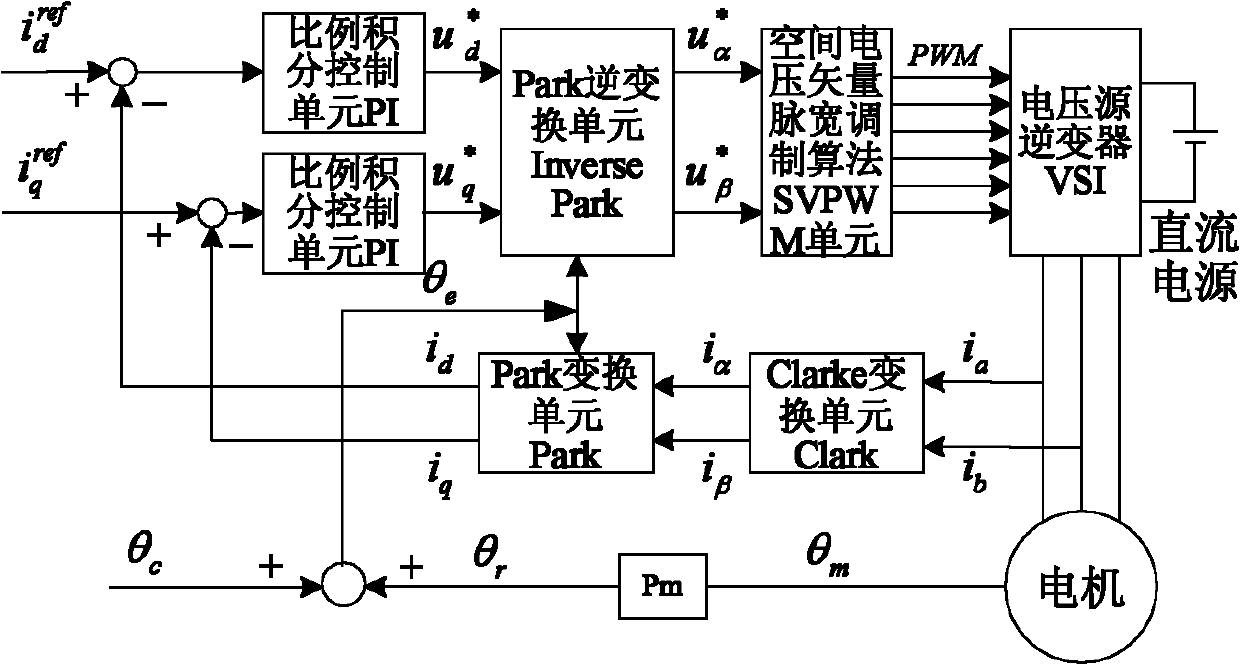

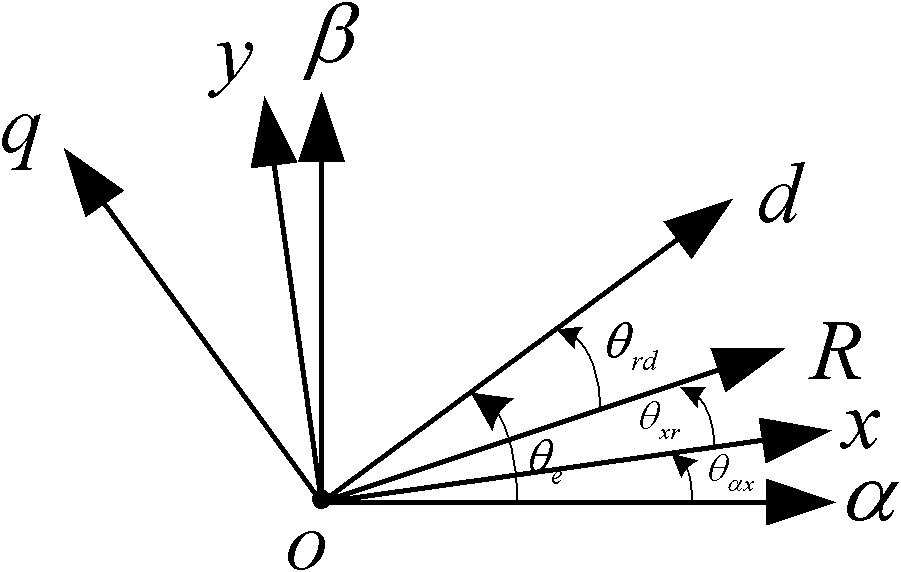

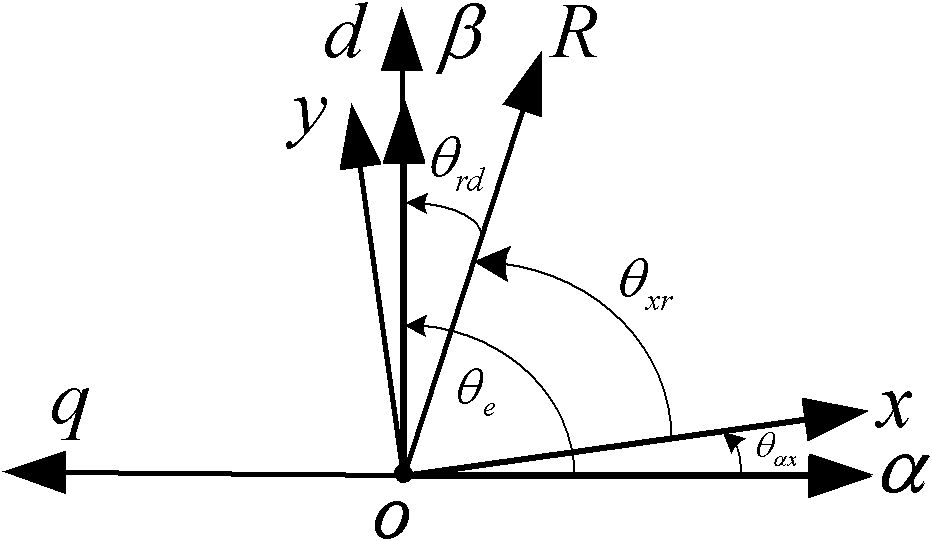

Method and system for measuring position compensation angles of permanent magnet synchronous motor rotor

ActiveCN102097988ALow costImprove reliabilityVector control systemsDynamo-electric converter controlVoltage vectorPermanent magnet synchronous motor

The invention provides a method and device for measuring position compensation angles of a permanent magnet synchronous motor rotor, wherein the method comprises the following steps: setting a forcible magnetic field directional angle Theta Force; setting component instruction value of a d shaft voltage as u*d=0; inputting the component instruction value u*q of a q shaft voltage which can enable the permanent magnet synchronous motor to enter into a zero speed shaft locking state; according to the forcible magnetic field directional angle Theta Force, obtaining voltage vectors by virtue of PARK inverse transformation of u*d and u*q; generating a power device pulse-width signal needed by a voltage source inverter by a space vector pulse width modulation (SVPWM) algorithm; driving the permanent magnet synchronous motor to rote to a position of ThetaForcee+90 DEG by the voltage source inverter; obtaining the angle Theta xr read by an absolute encoder mounted on the rotor; and calculating the compensation angle that Theta c= Theta Force+ 90 DEG-Theta xr. The method provided by the invention can be simply, conveniently and easily realized; a current sensor is unnecessary to work, and the flitter is not existed during initial location.

Owner:北京和利时电机技术有限公司

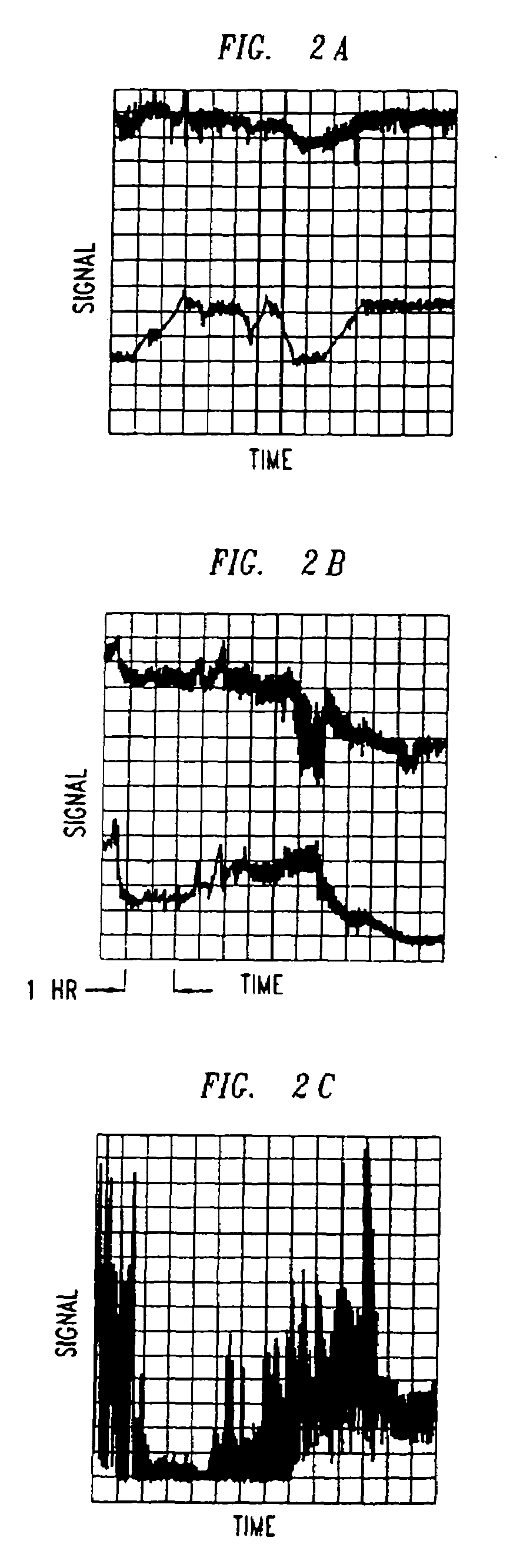

Early warning and problem detection in rotating machinery by monitoring shaft voltage and/or grounding current

A rotating machinery monitor provides a warning that is indicative of a developing problem with the rotating machinery. The rotating machinery monitor has at least one current sensor for detecting shaft grounding current and / or at least one voltage sensor for detecting shaft voltage in the rotating machinery; a monitoring device for monitoring real-time shaft grounding current values and / or real-time shaft voltage values over time; a detector for determining the change and / or determining the rate of change, in the shaft grounding current and / or in the shaft voltage; an evaluation system for producing a warning as a function of the change and / or rate of change, in the shaft grounding current and / or the shaft voltage wherein the warning generated is indicative of a developing problem with the rotating machinery.

Owner:BRITTINGHAM PAMELA J

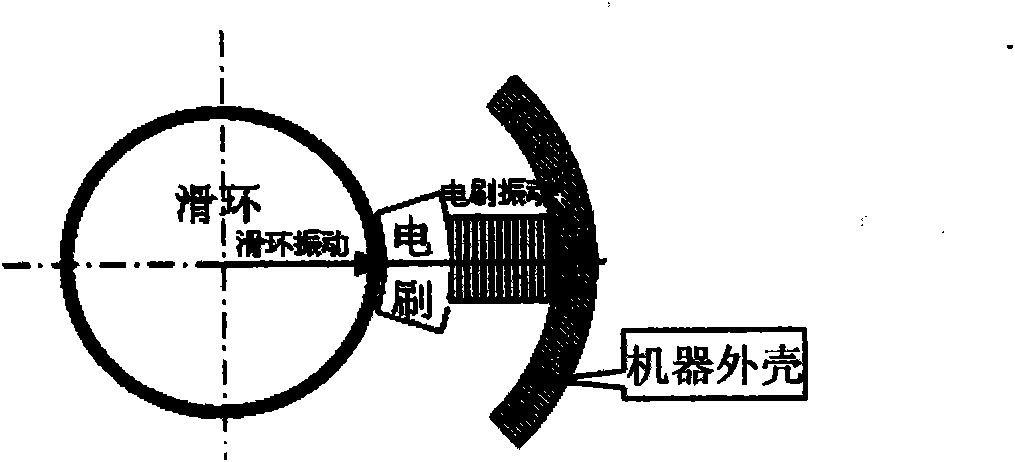

Device for fault diagnosis of electric brush slip ring and method for mechanism diagnosis and maintenance and design

ActiveCN101588112ALow failure rateRepair in timeMachine part testingUsing subsonic/sonic/ultrasonic vibration meansResonanceVibration detection

A device for fault diagnosis of electric brush slip ring and method for mechanism diagnosis and maintenance and design are provided. The device for fault diagnosis of electric brush slip ring comprises at least one or more vibration shock sensors and / or shaft voltage detection sensors fixed on the machine casing of the electric brush, and a vibration and resonance demodulation fault diagnostic apparatus having diagnostic software for fault of electric brush slip ring and connected with the vibration shock sensors and / or shaft voltage detection sensors; the diagnostic software for fault of electric brush slip ring is used for analyzing the signals obtained by the vibration shock sensors and identifying the fault of the electric brush slip ring; and the vibration and resonance demodulation fault diagnostic apparatus has a vibration detection channel, a resonance demodulation detection channel and a computer having an AD converting acquitter and diagnostic software, wherein the detection signals of the vibration shock sensors and / or shaft voltage detection sensors are connected to the output end of the vibration detection channel and resonance demodulation detection channel; the output vibration and shock signals of the vibration detection channel and resonance demodulation detection channel are connected to the AD input end of the computer having an AD converting acquitter and diagnostic software; and the diagnostic software of the computer is for diagnosing fault, analyzing fault mechanism and determining maintenance and improved design for the acquired information.

Owner:北京唐智科技发展有限公司

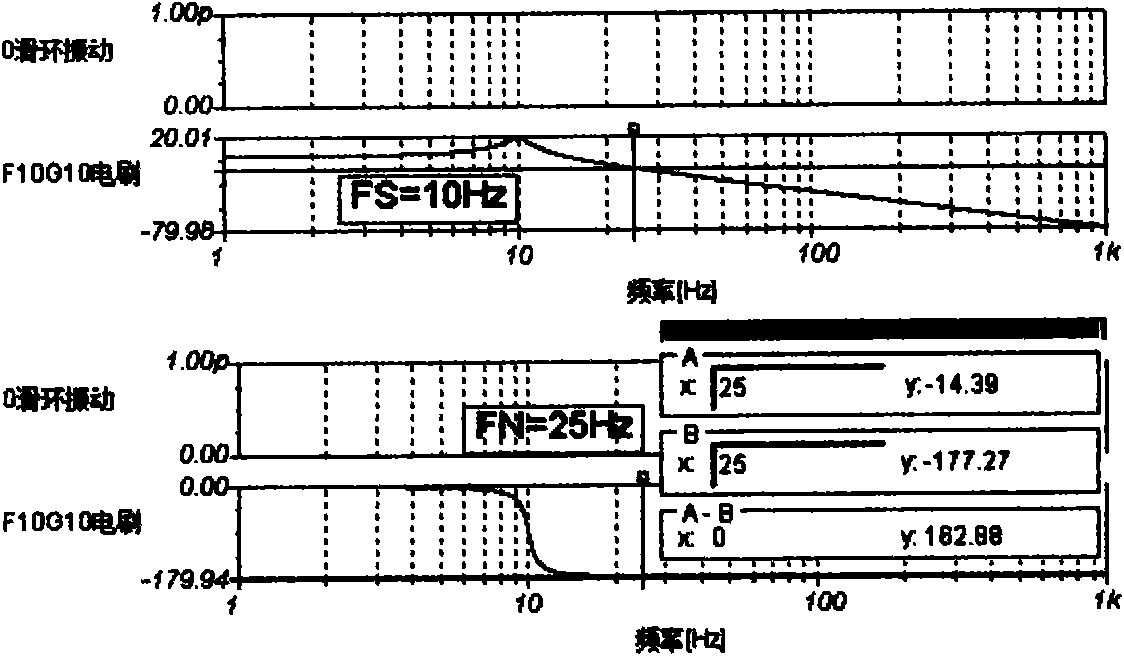

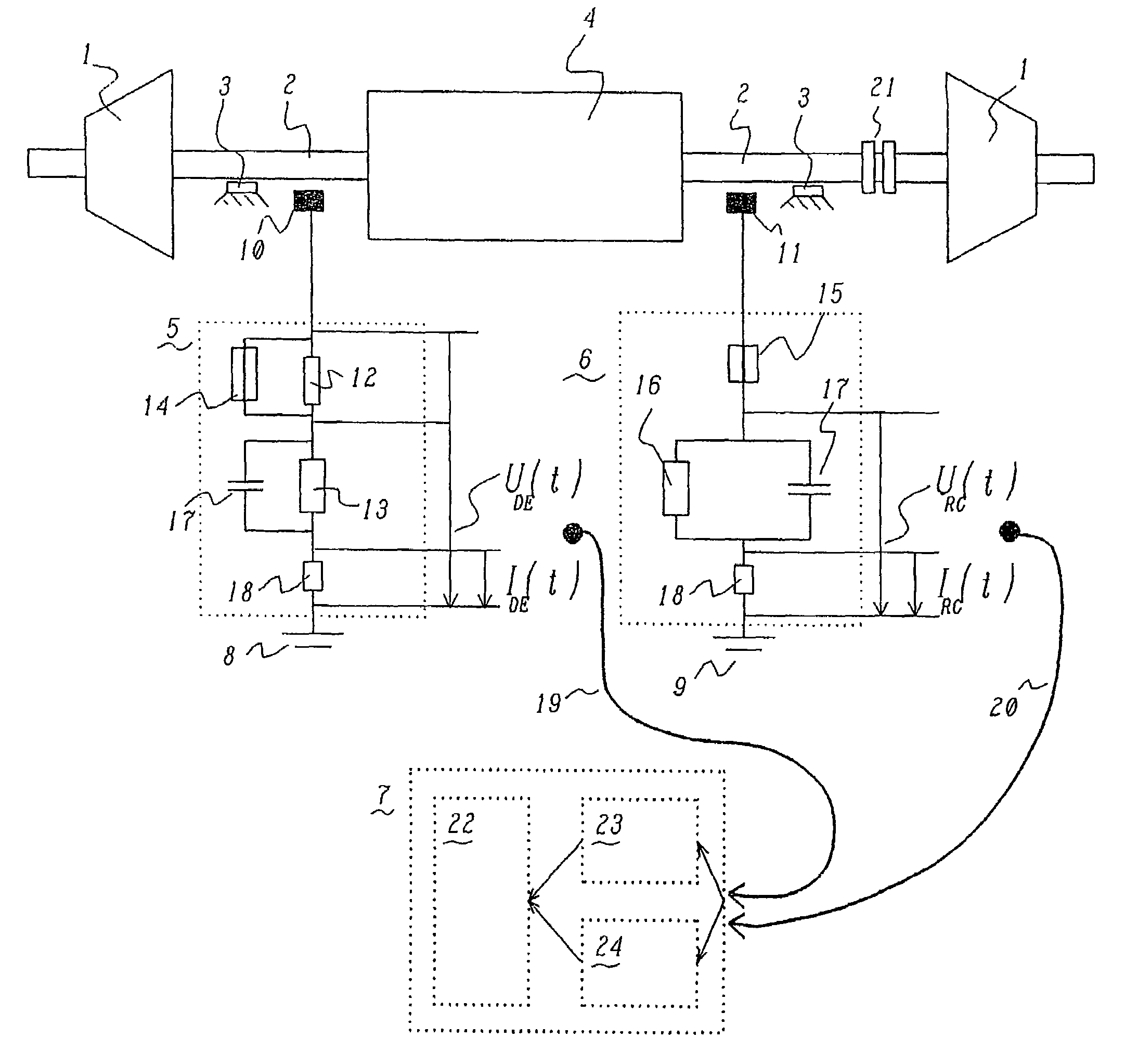

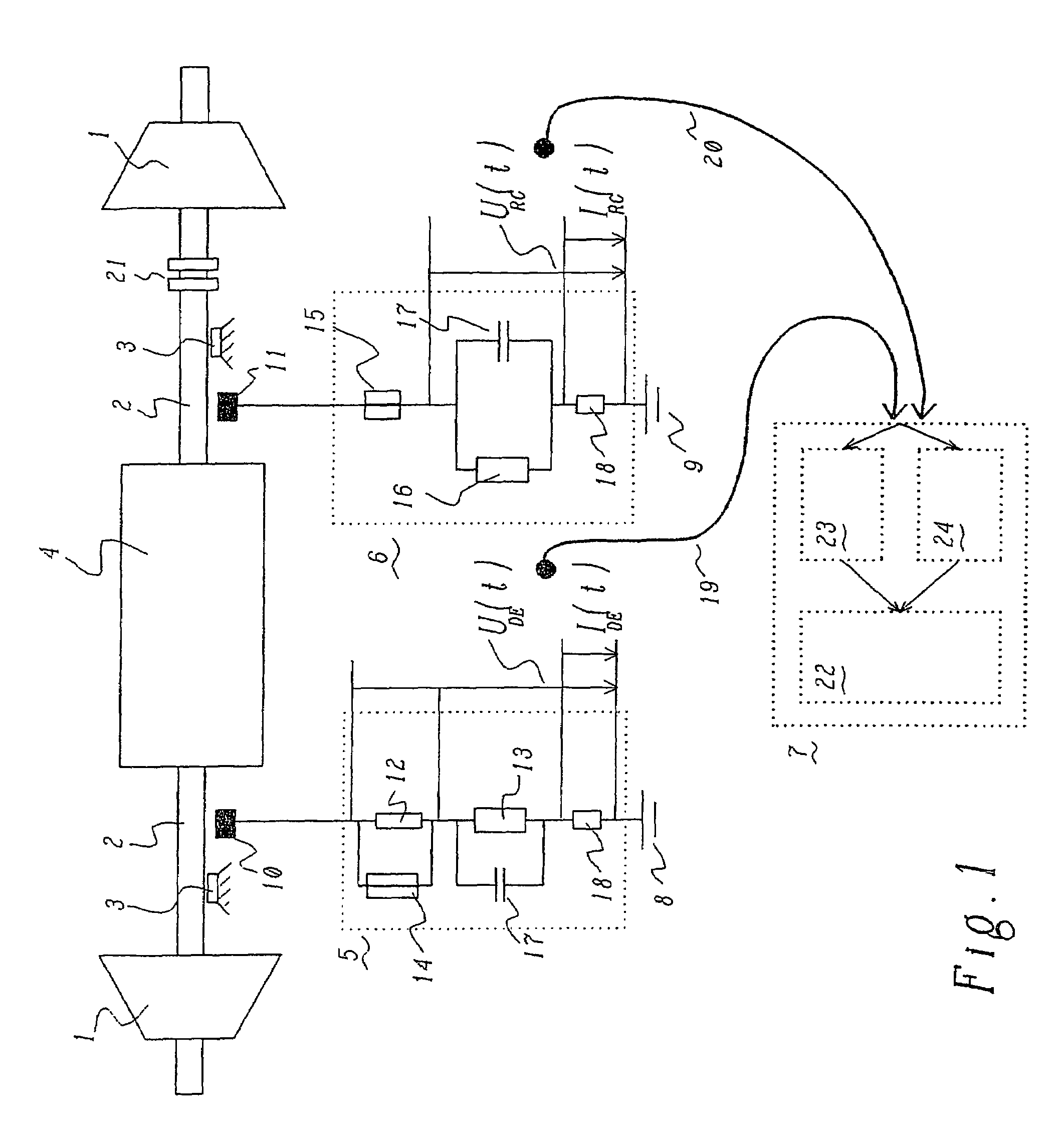

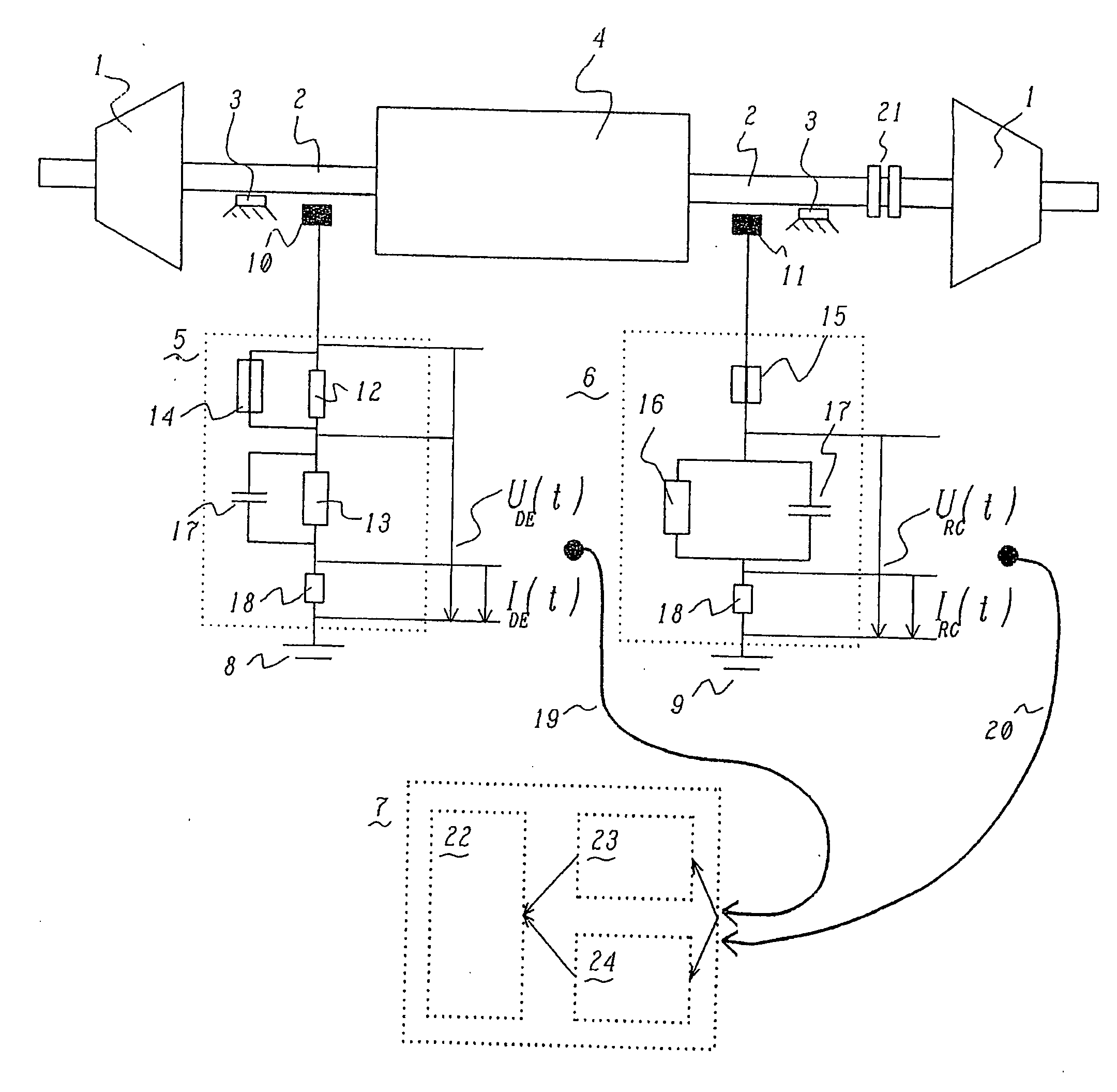

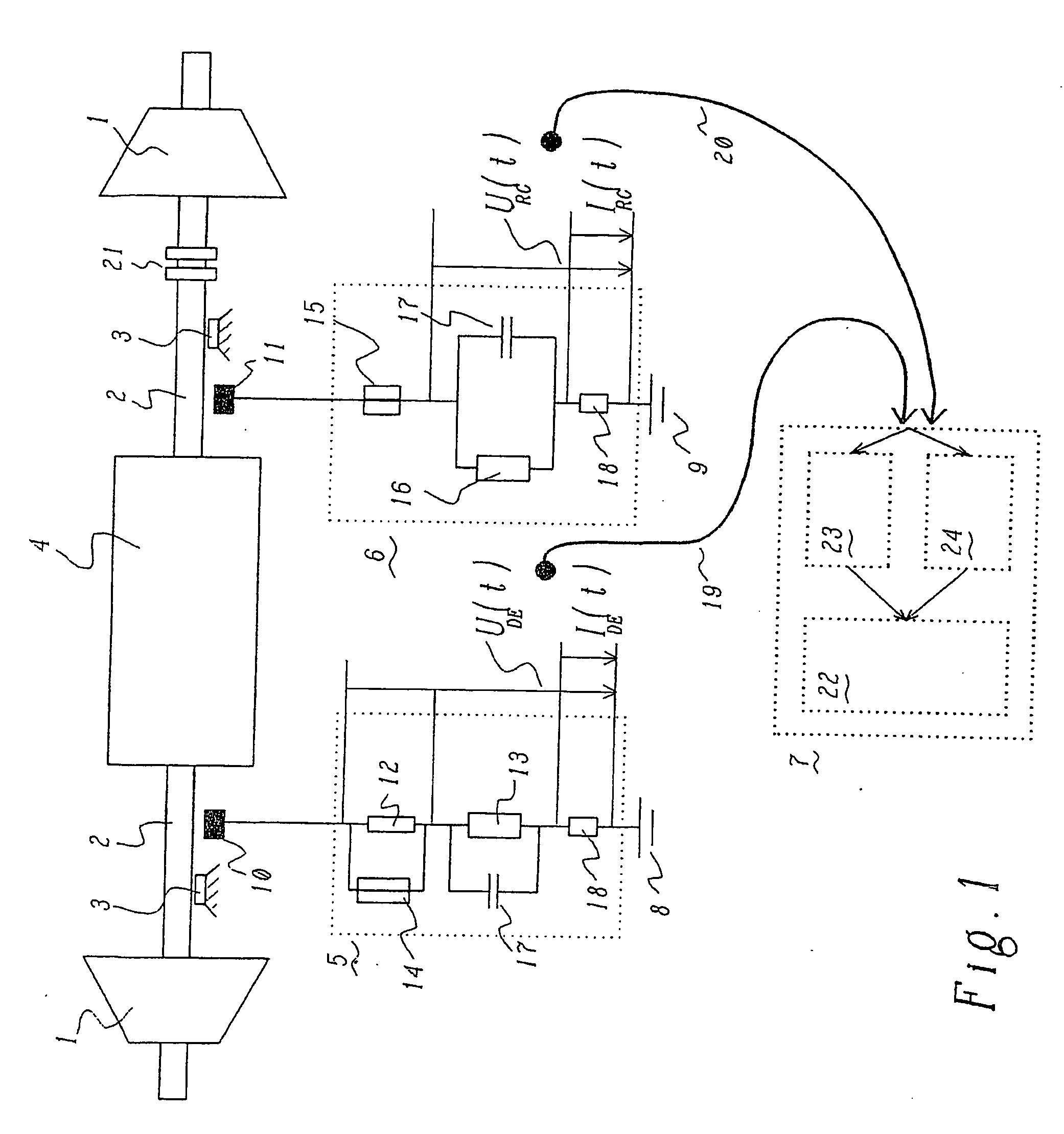

Apparatus and method for monitoring and/or analysis of electrical machines during operation

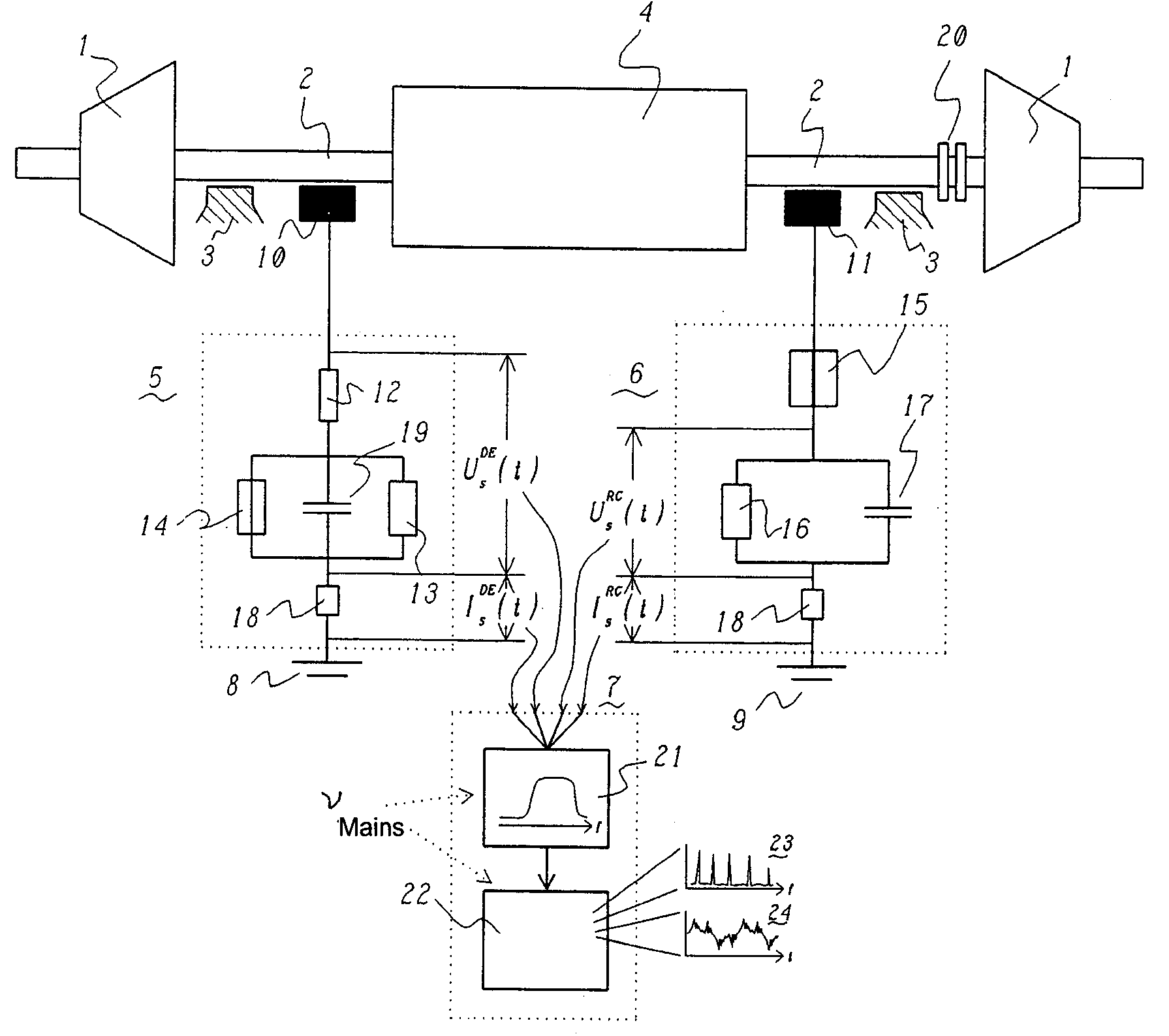

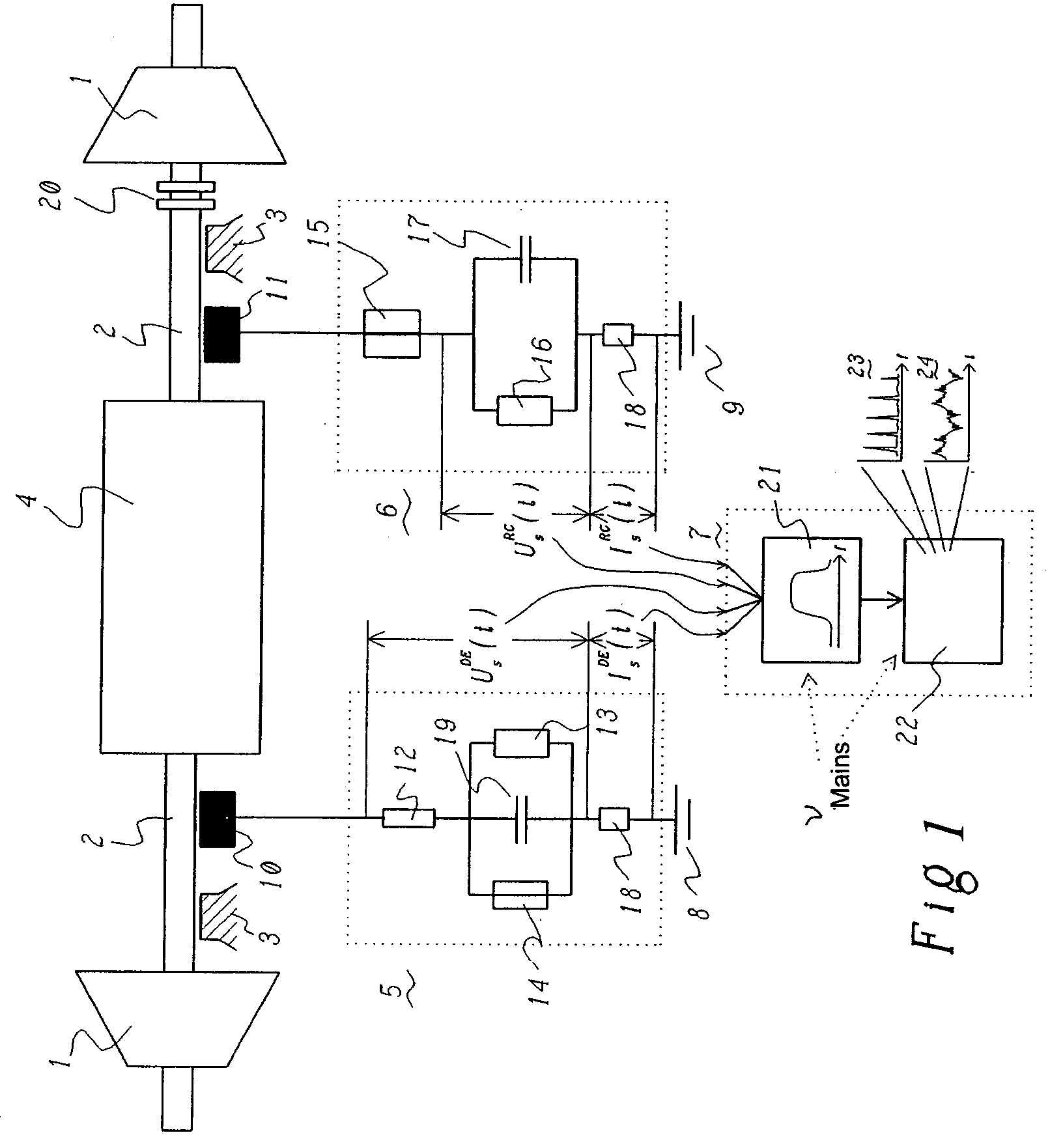

InactiveUS7102379B2Sufficiently accuratePhysically simpleMaterial analysis using sonic/ultrasonic/infrasonic wavesMechanical energy handlingElectric machineEngineering

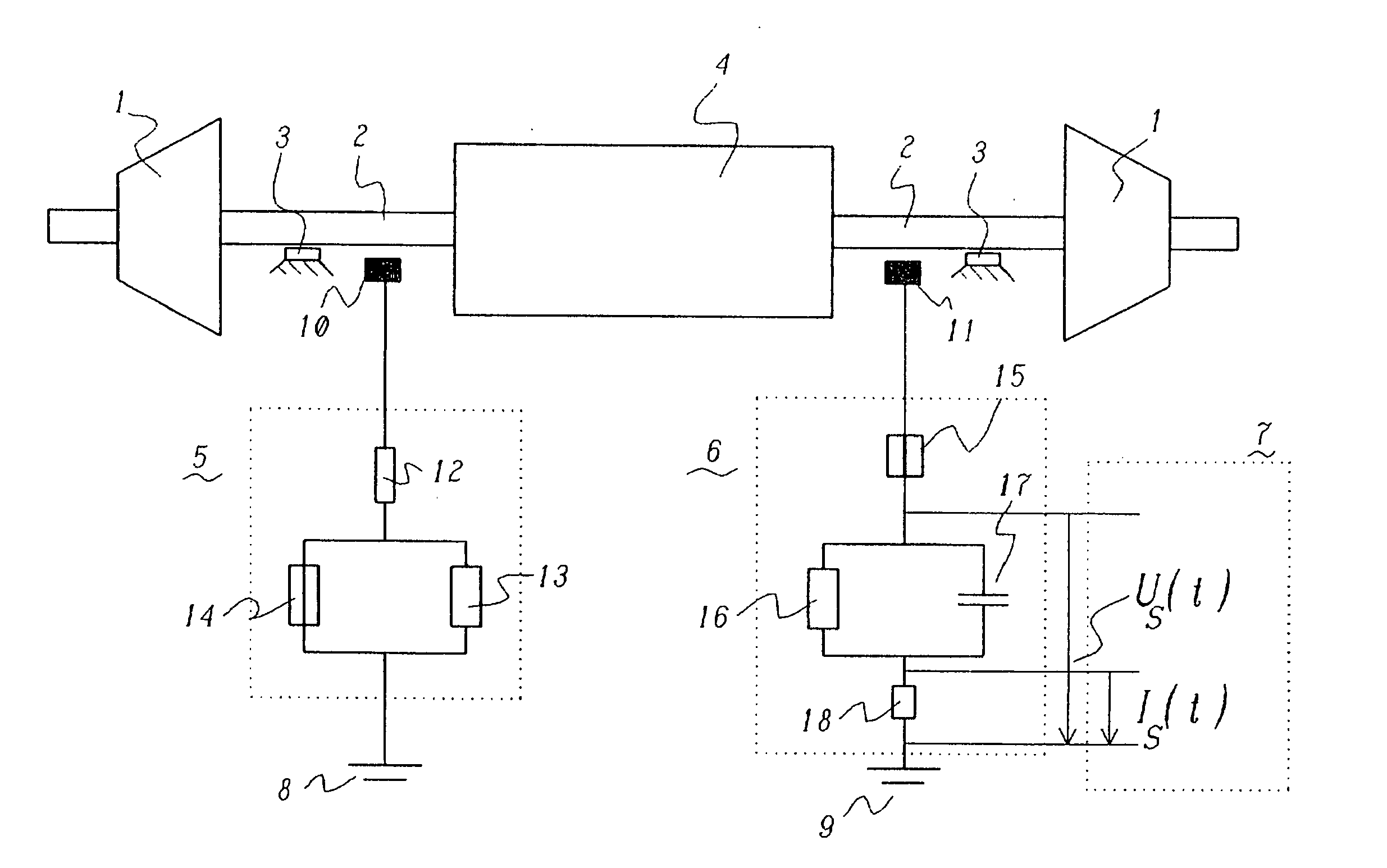

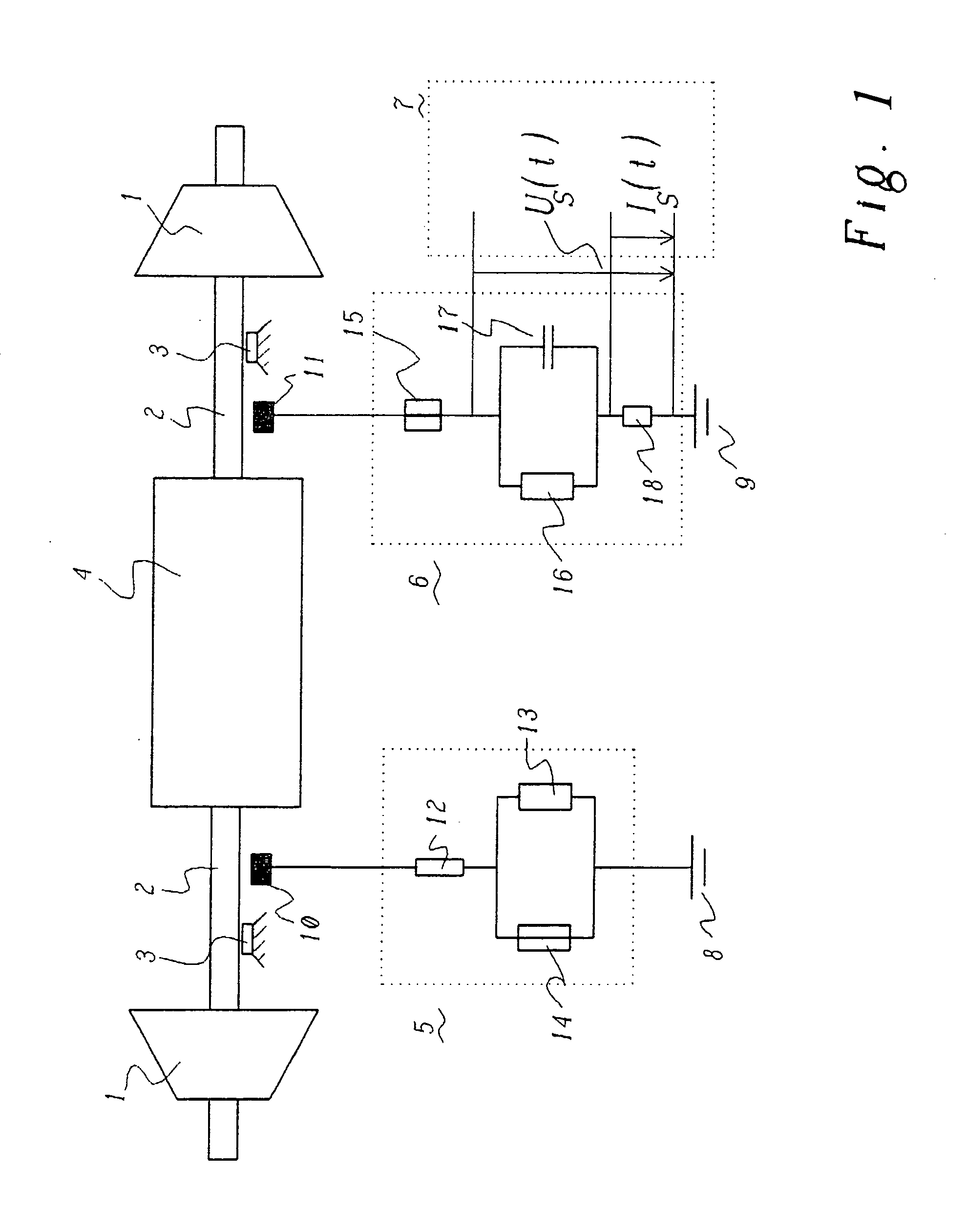

An apparatus and a method for monitoring and / or analysis of electrical machines during operation, wherein the electrical machine has at least one generator with a shaft and drive means for driving this shaft, wherein the shaft is grounded at the first end of the generator, and wherein a measurement unit for measurement of shaft voltage and / or shaft current as a function of time is provided on the shaft at the second end of the generator. An apparatus such as this allows the combined and simultaneous measurement of various fault states by supplying signals for the shaft voltage and / or the shaft current to an analysis unit, wherein the analysis unit allows combined and simultaneous analysis of at least two potential fault states of the electrical machine. Simultaneous cross-relationships between the individual measurement results of individual fault states may be provided so as to allow a clearer and more reliable diagnosis of critical states, not possible when individual phenomena are considered separately.

Owner:GENERAL ELECTRIC TECH GMBH

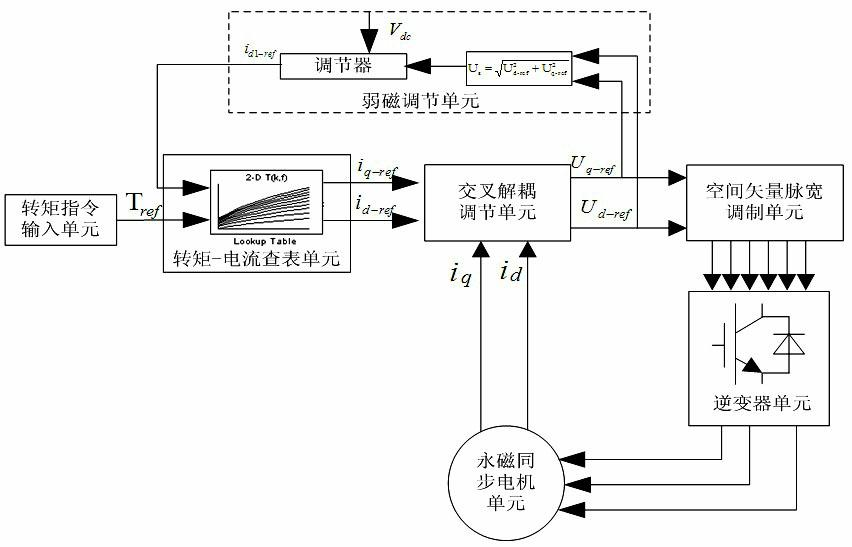

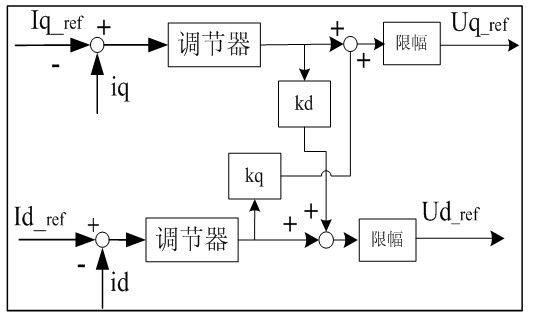

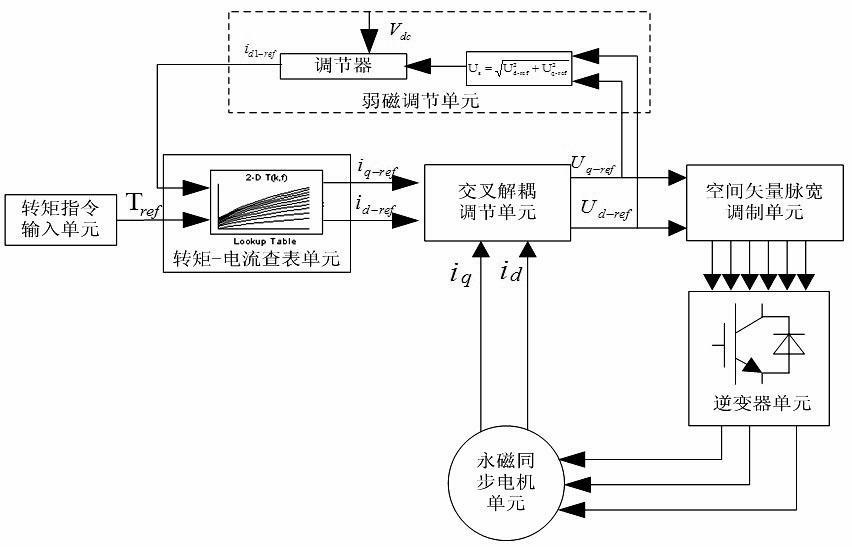

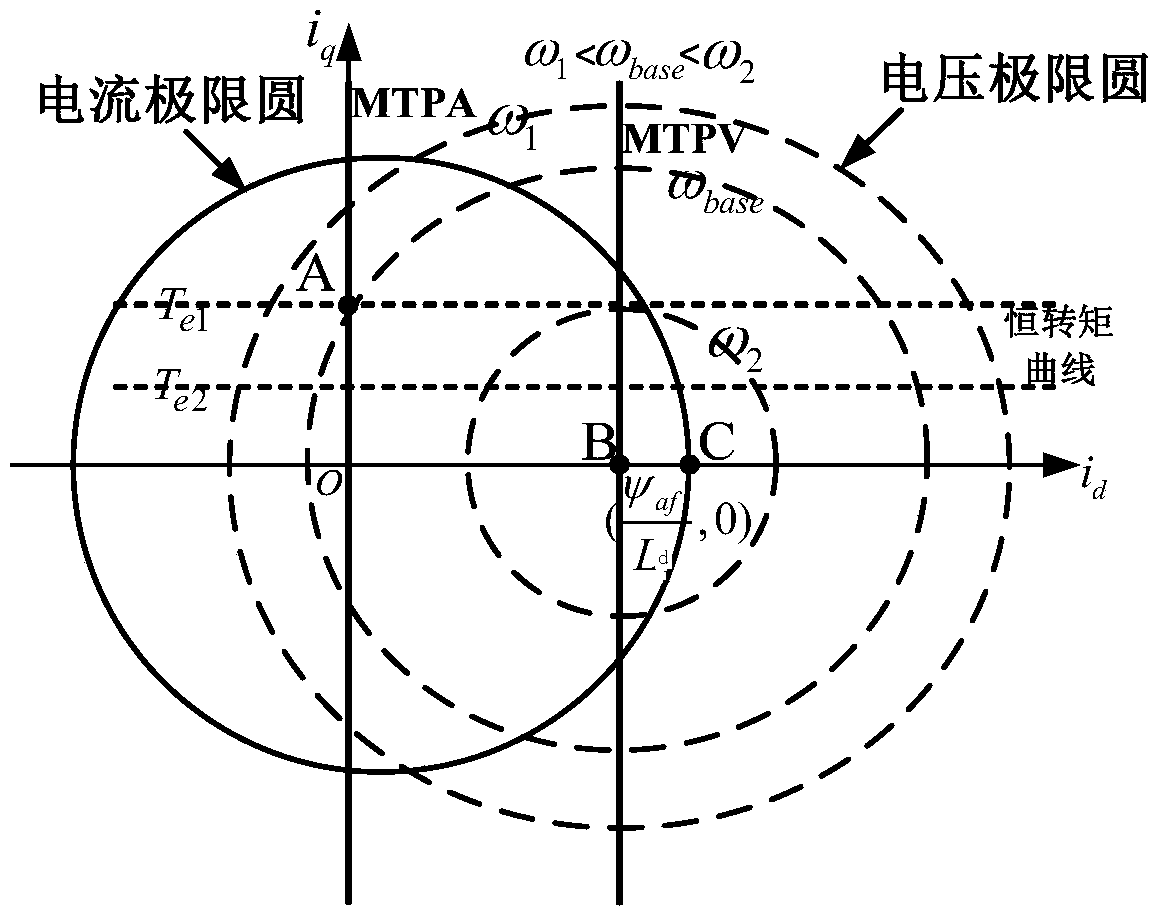

Car permanent magnet synchronous motor control system and method

ActiveCN102324877AIncreased RPM operating rangeImprove securityVector control systemsSingle motor speed/torque controlMotor speedVoltage vector

The invention provides a brand new permanent magnet synchronous motor control method. A control system applied by the method comprises a torque command input unit, a torque-current lookup unit, a cross decoupling regulation unit, a space vector pulse width modulation unit, an inverter unit, a weak magnetic regulation unit and a permanent magnet synchronous motor unit, wherein the torque-current lookup unit performs analysis according to the output result of current weak magnetic regulation and a torque command and acquires an AC-DC shaft current command through lookup, and the lookup manner is irrelevant to the rotating speed so as to improve the convenience and the accuracy of torque lookup; meanwhile, the cross decoupling regulation unit performs cross PI (Proportional-Integral) regulation on the difference between the AC-DC shaft current command and actual current feedback so as to reduce the influence of cross coupling of the motor per se at high speed and improve the high-speed stability of the motor; and the weak magnetic regulation unit calculates the amplitude of voltage vector according to the current AC-DC shaft voltage reference command, performs PI regulation on the amplitude and the maximum available voltage vector amplitude in the current busbar voltage and automatically outputs a weak magnetic reference current command to conveniently enlarge the motor speed regulation range.

Owner:深蓝汽车科技有限公司

Surface-mounted permanent magnet synchronous generator flux weakening control method

ActiveCN105515479ARealize intersection operationGood dynamic responseElectronic commutation motor controlVector control systemsSurface mountingElectric machine

The invention discloses a surface-mounted permanent magnet synchronous generator flux weakening control method, belonging to the PMSM control technical field. The method employs a current regulator to provide a direct-axis voltage when a motor rotating speed is higher than a base speed, thereby allowing a motor to move along the intersection between a voltage horicycle and a constant torque curve. The method allows a current locus to meet a torque curve, and meanwhile to meet voltage and current restriction; an output direct current voltage can rapidly recover stability after short fluctuation, and possesses sound dynamic response.

Owner:SUZHOU SEIDAL INTELLIGENT TECH CO LTD

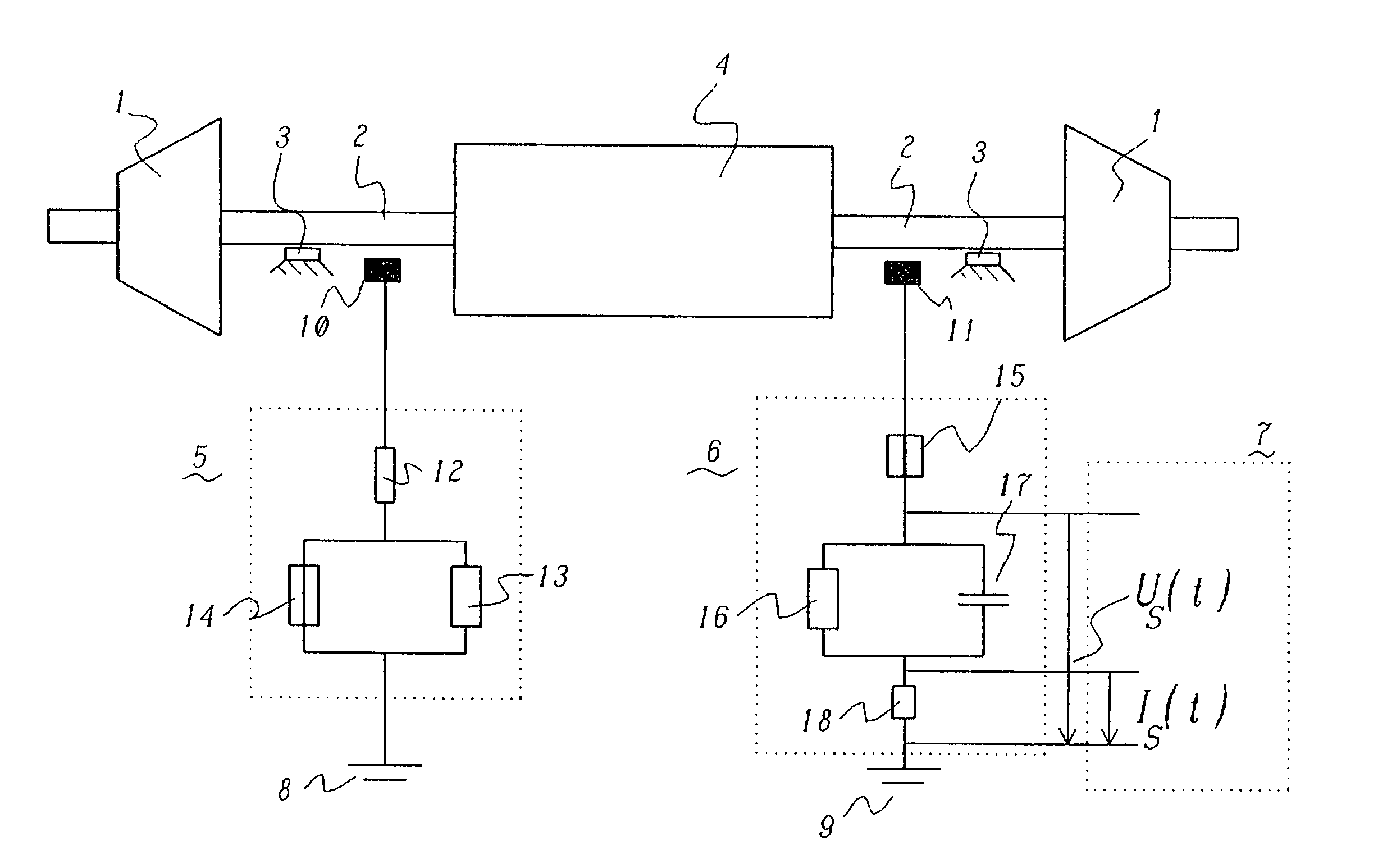

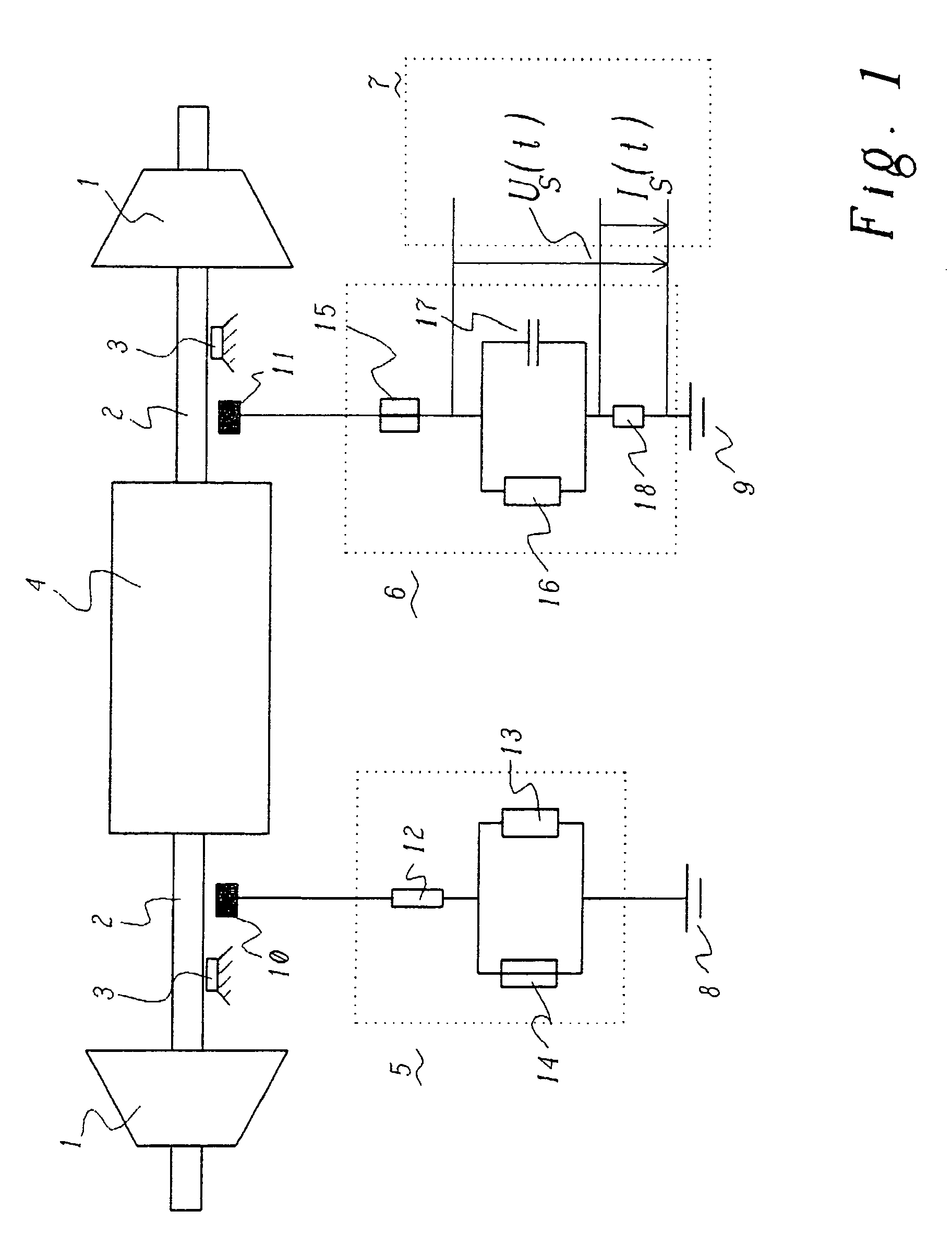

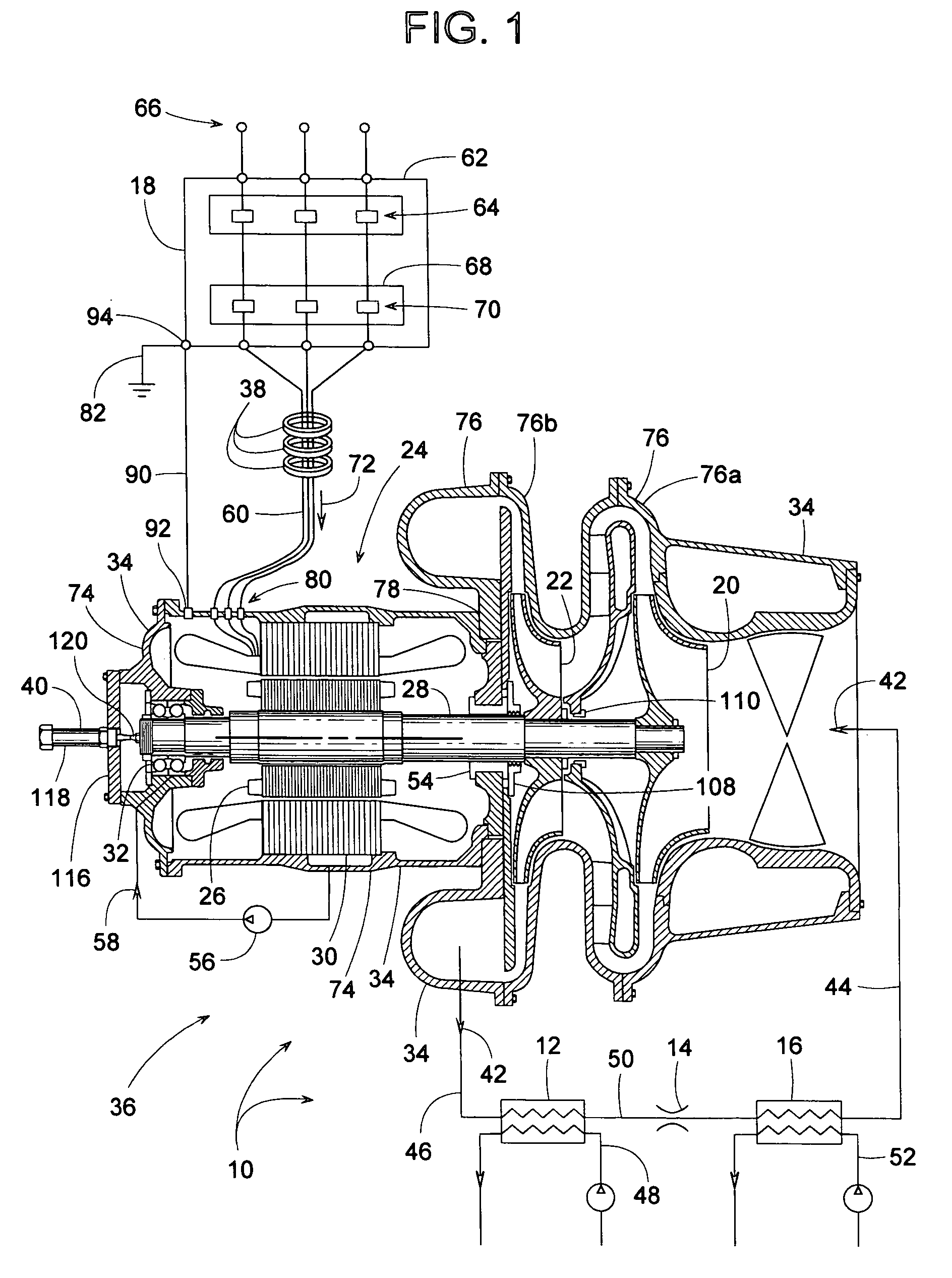

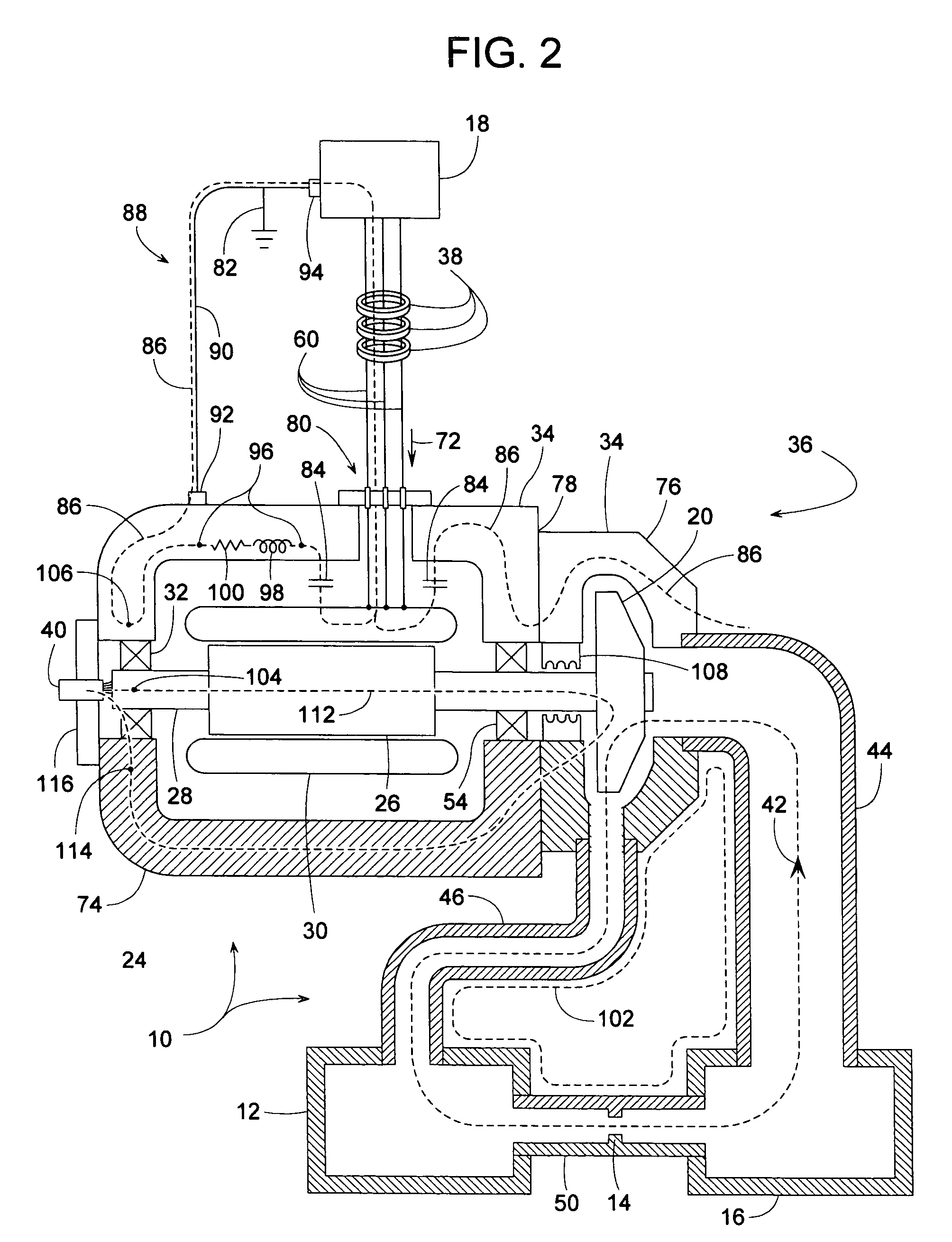

Apparatus and method for monitoring and/or analysis of electrical machines during operation

InactiveUS20050200378A1Sufficiently accuratePhysically simpleMaterial analysis using sonic/ultrasonic/infrasonic wavesMechanical energy handlingElectric machineEngineering

An apparatus and a method for monitoring and / or analysis of electrical machines during operation, wherein the electrical machine has at least one generator with a shaft and drive means for driving this shaft, wherein the shaft is grounded at the first end of the generator, and wherein a measurement unit for measurement of shaft voltage and / or shaft current as a function of time is provided on the shaft at the second end of the generator. An apparatus such as this allows the combined and simultaneous measurement of various fault states by supplying signals for the shaft voltage and / or the shaft current to an analysis unit, wherein the analysis unit allows combined and simultaneous analysis of at least two potential fault states of the electrical machine. Simultaneous cross-relationships between the individual measurement results of individual fault states may be provided so as to allow a clearer and more reliable diagnosis of critical states, not possible when individual phenomena are considered separately.

Owner:GENERAL ELECTRIC TECH GMBH

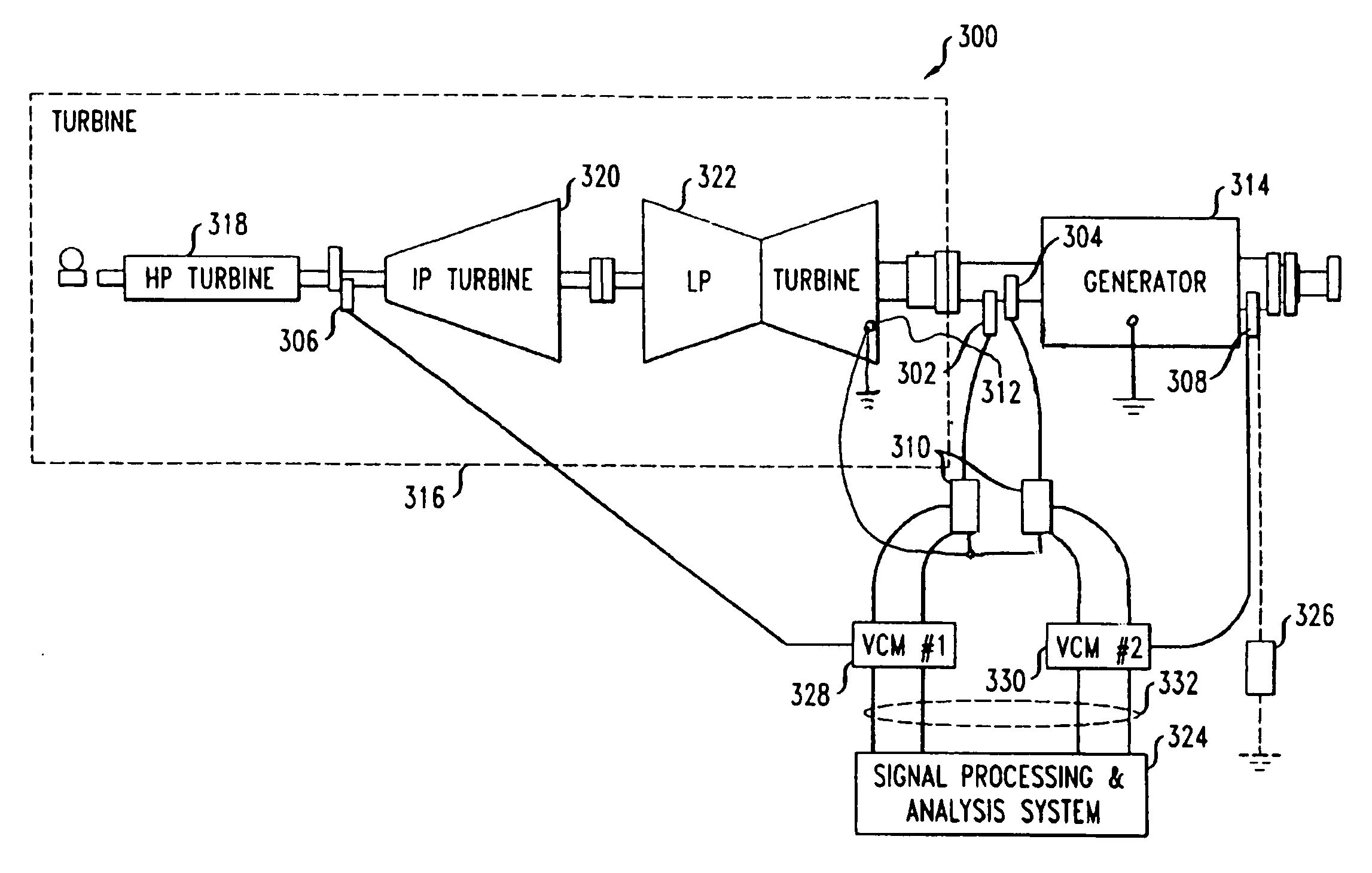

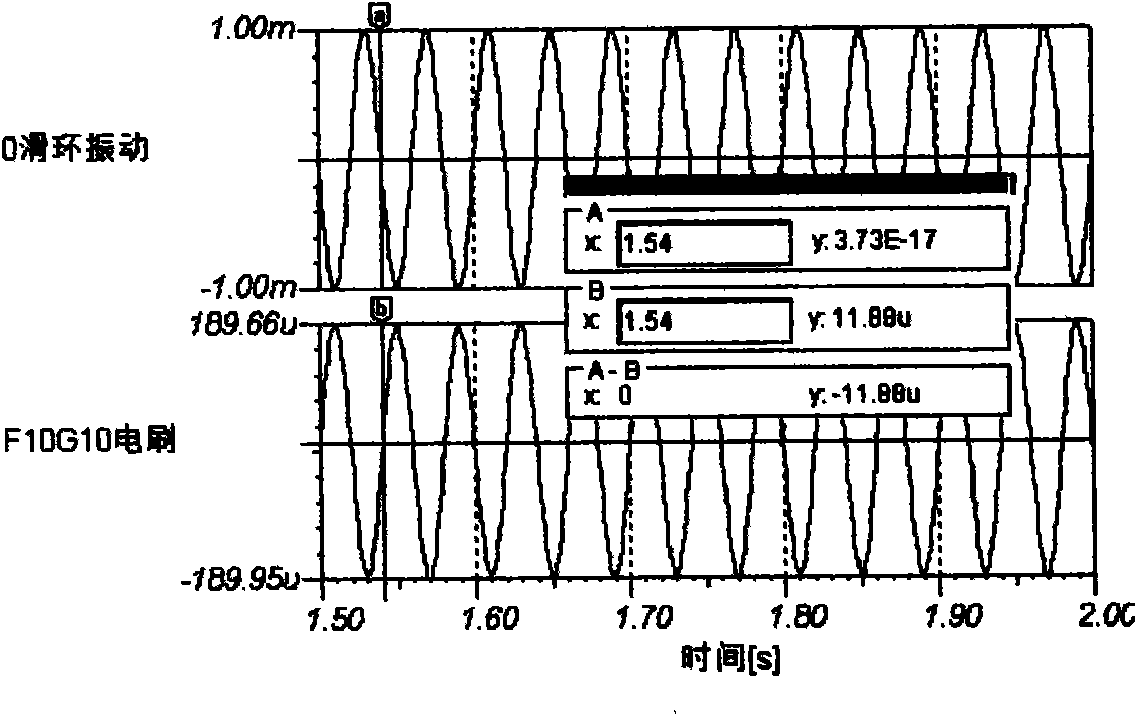

Apparatus and method for detecting vibrations of the shaft assembly in an electrical machine

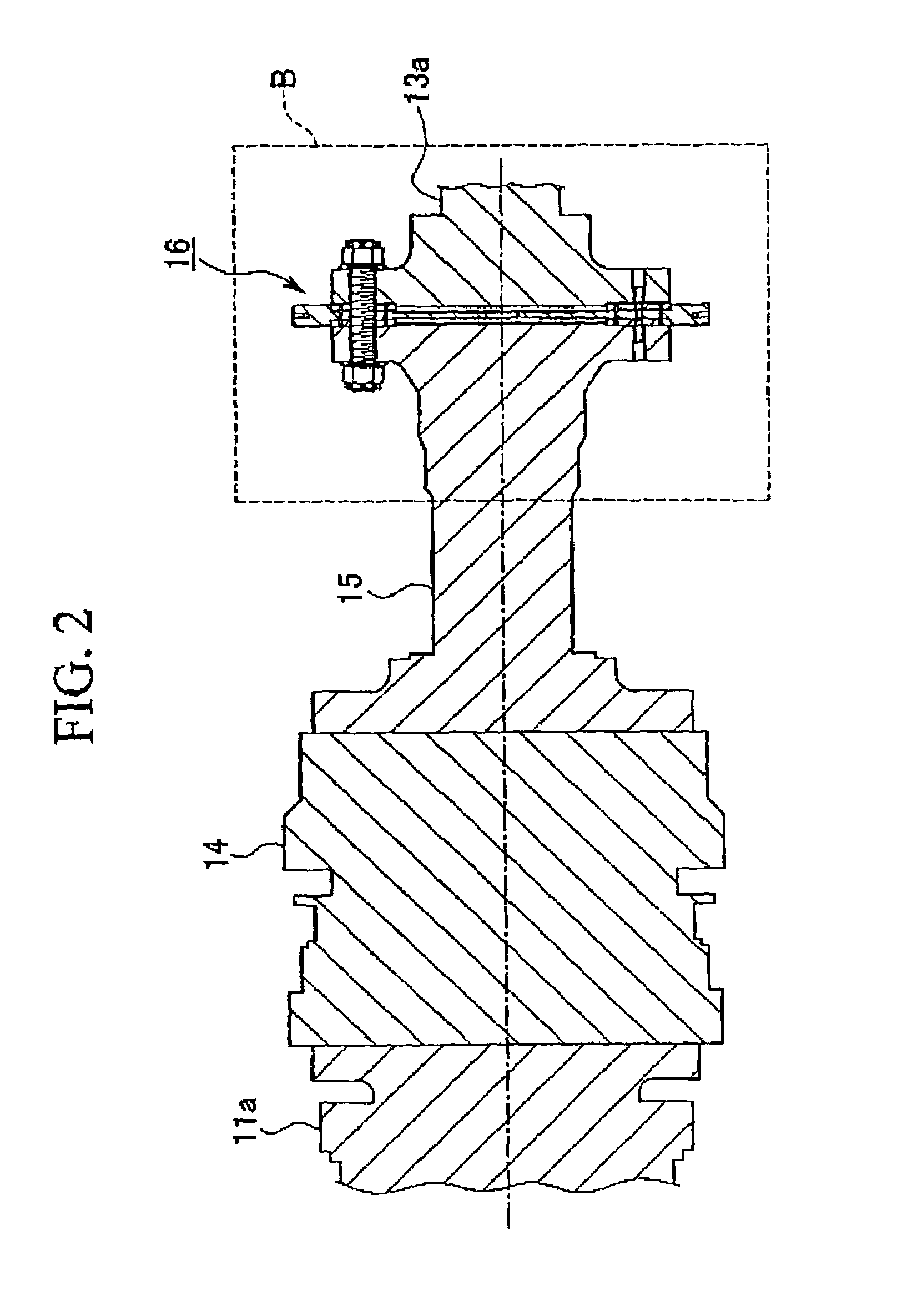

InactiveUS20050183504A1Firmly connectedIntuitive visualizationVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectric machineControl theory

A method for detecting vibrations of a shaft of an electrical machine includes measuring at least one of a shaft voltage and a shaft current and analyzing the measured at least one of the shaft voltage and the shaft current so as to determine the vibrations. In addition, an apparatus for detecting vibrations of a shaft of an electrical machine includes a first grounding device disposed at a first point on the shaft on a first side of the electrical machine and a second grounding device disposed at a second point of the shaft on a second side of the electrical machine. The second grounding device is configured to measure at least one of a shaft voltage and a shaft current.

Owner:GENERAL ELECTRIC TECH GMBH

Timing control system and method for non-salient pole permanent magnet synchronous motor

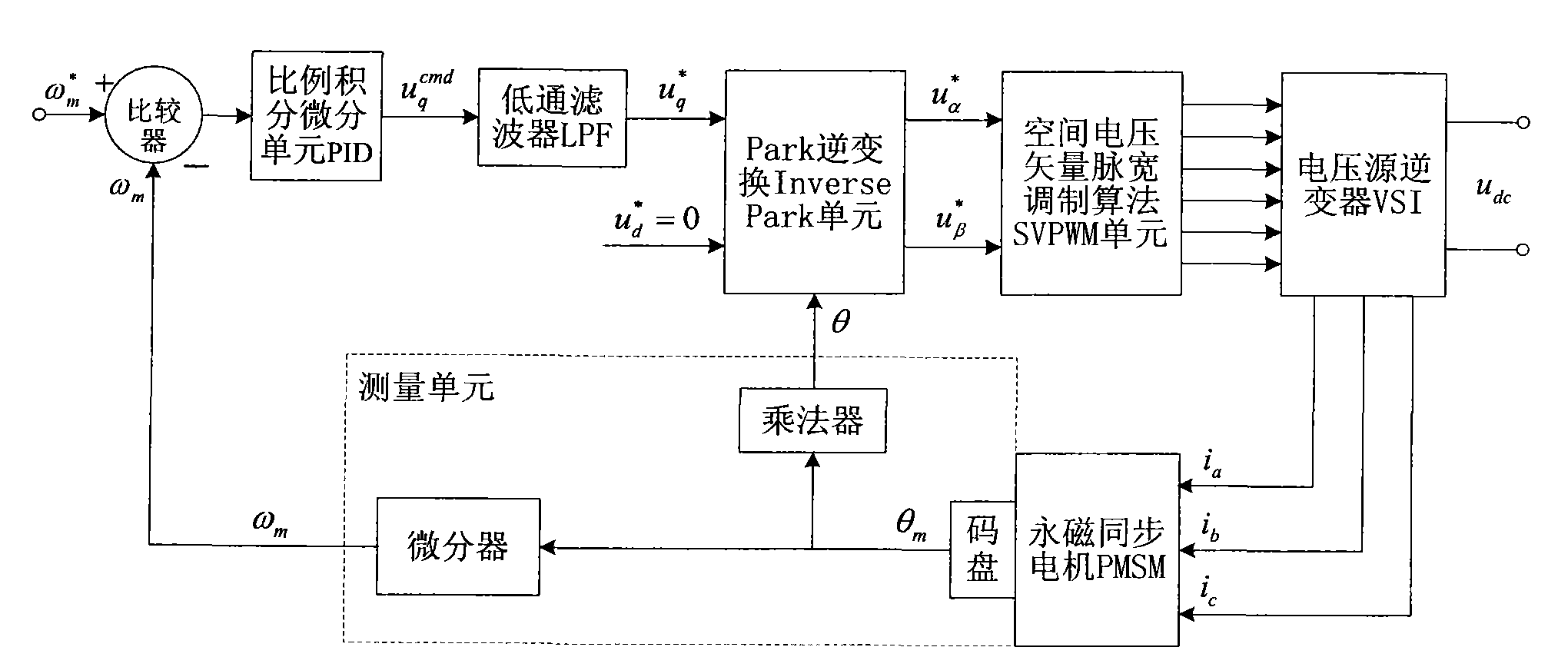

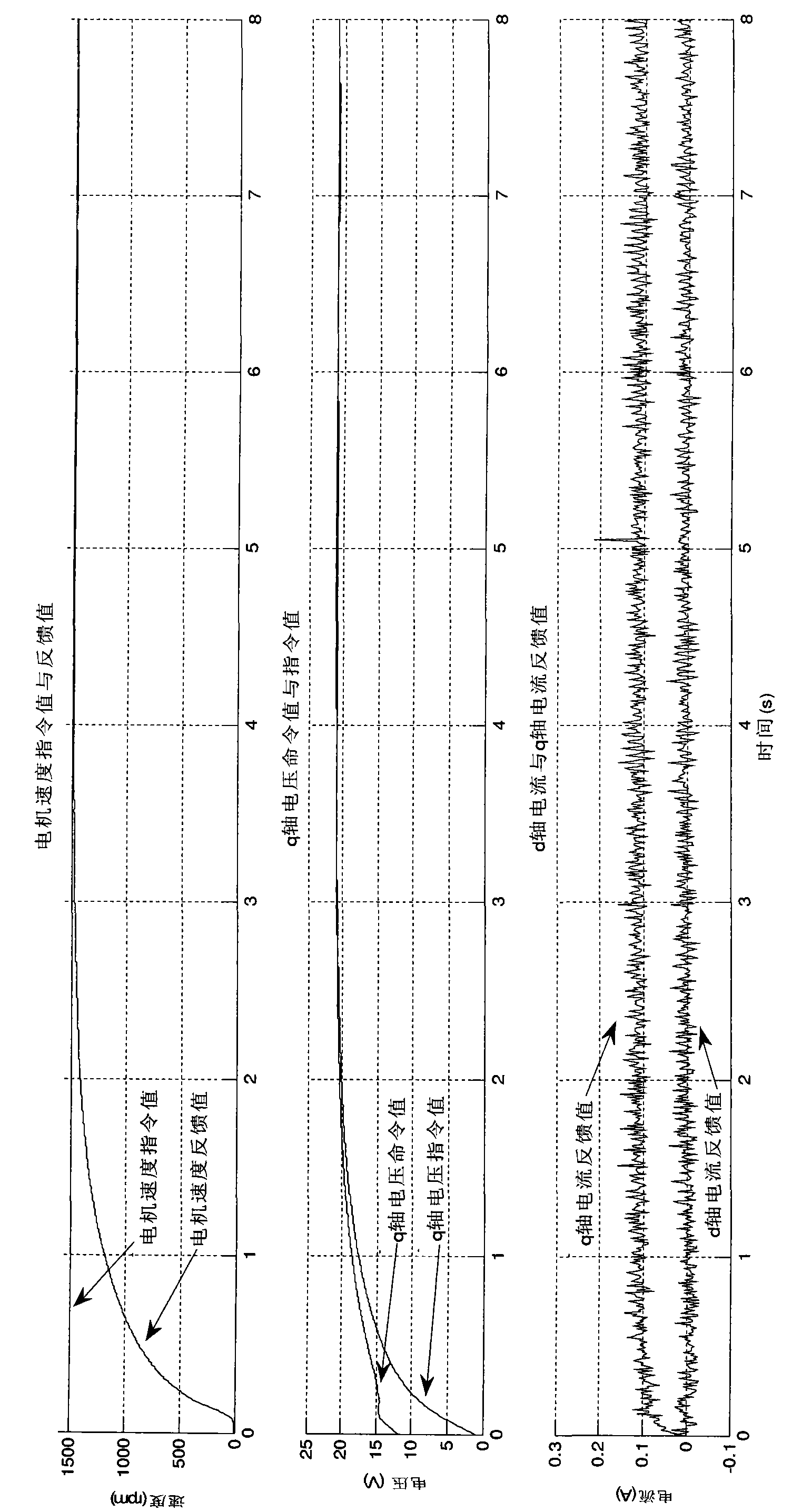

ActiveCN101615876AGuaranteed uptimeReduce current noiseAC motor controlVector control systemsVoltage vectorPermanent magnet synchronous motor

The invention discloses a timing control system and a method for a non-salient pole permanent magnet synchronous motor. The method comprises the following steps: the electrical angle position theta and the mechanical rotational speed omegam of a motor of a non-salient pole permanent magnet synchronous motor rotor are measured; the difference of a preset target rotational speed omegam<*> and omegam is obtained; the difference is performed with scale, integration and differential operation to obtain component instruction value uq<*> of q shaft voltage; voltage vectors ualpha<*> and ubeta<*> on a static coordinate system can be obtained by PARK inverse transformation of ud<*> and uq<*> by theta, wherein, ud<*> is zero; according to ualpha<*> and ubeta<*> of the voltage vector, a power device pulse-width signal can be generated by a space vector pulse width modulation (SVPWM) algorithm; according to the power device pulse-width signal, three-phase winding current is generated and is sent to the non-salient pole permanent magnet synchronous motor. The invention can realize speed loop no-current sensor vector control of the non-salient pole permanent magnet synchronous motor and lower hardware cost for timing.

Owner:北京和利时电机技术有限公司

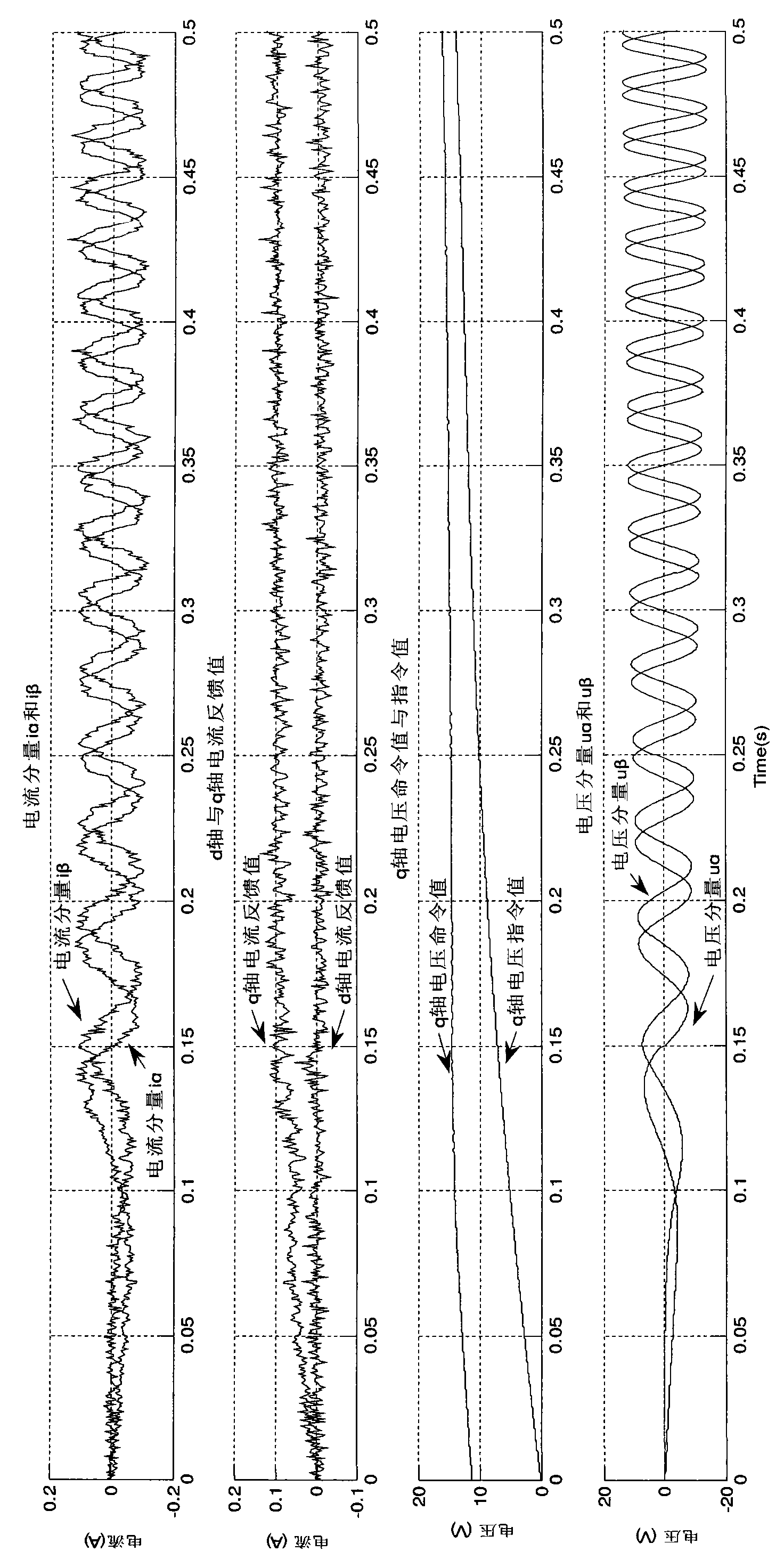

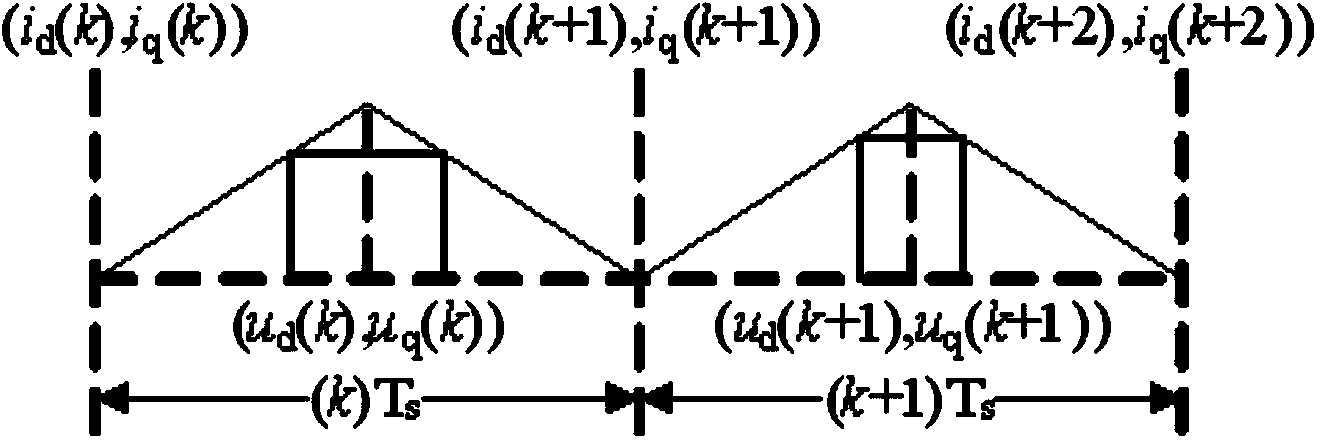

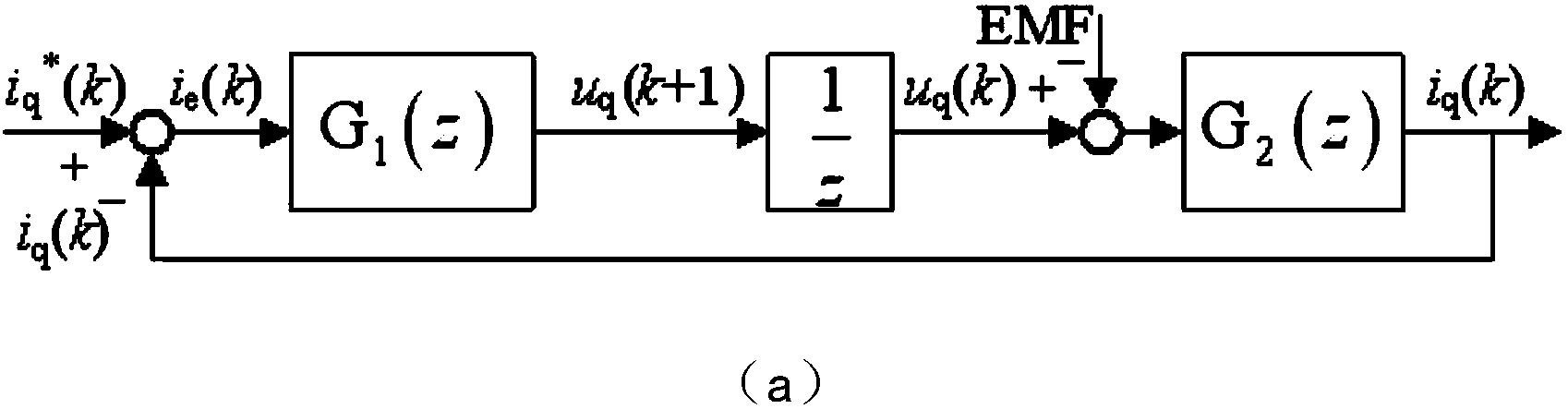

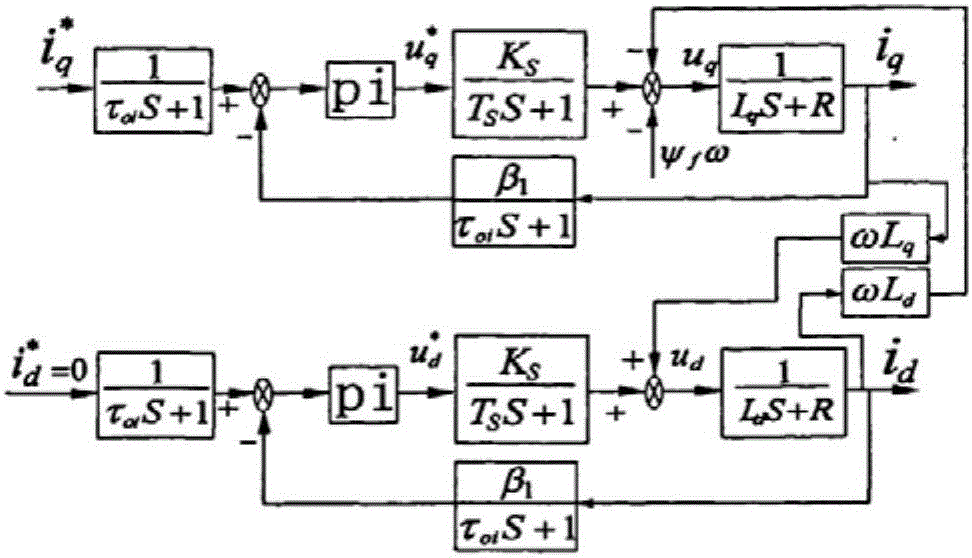

Permanent magnet synchronous motor current increment prediction algorithm

ActiveCN103516284AImprove current dynamic performanceImprove current dynamic response speedElectronic commutation motor controlVector control systemsPrediction algorithmsPermanent magnet synchronous motor

The invention relates to a permanent magnet synchronous motor current increment prediction algorithm which comprises the following steps: (1) a stator d shaft voltage equation and a stator q shaft voltage equation of a permanent magnet synchronous motor in a synchronous rotating reference frame are established; (2) according to the stator q shaft voltage equation in the step (1), discrete voltage equations of the permanent magnet synchronous motor are established in the current period and the previous period respectively; (3) changes in voltage items relevant to rotating speed are ignored, and the discrete voltage equations of the permanent magnet synchronous motor are subtracted to obtain a current increment formula of the permanent magnet synchronous motor; (4) a pulse transfer function between a current predicted value and a current detected value in the current period is obtained according to a transfer function of the permanent magnet synchronous motor and the current increment formula of the permanent magnet synchronous motor; (5) a closed loop pulse transfer function of a q shaft current loop by means of the current increment prediction algorithm is obtained according to the pulse transfer function, a pulse transfer function of a traditional current loop PI regulator, and the transfer function of the permanent magnet synchronous motor. The permanent magnet synchronous motor current increment prediction algorithm can be widely applied to the field of permanent magnet synchronous motor servo control.

Owner:TSINGHUA UNIV

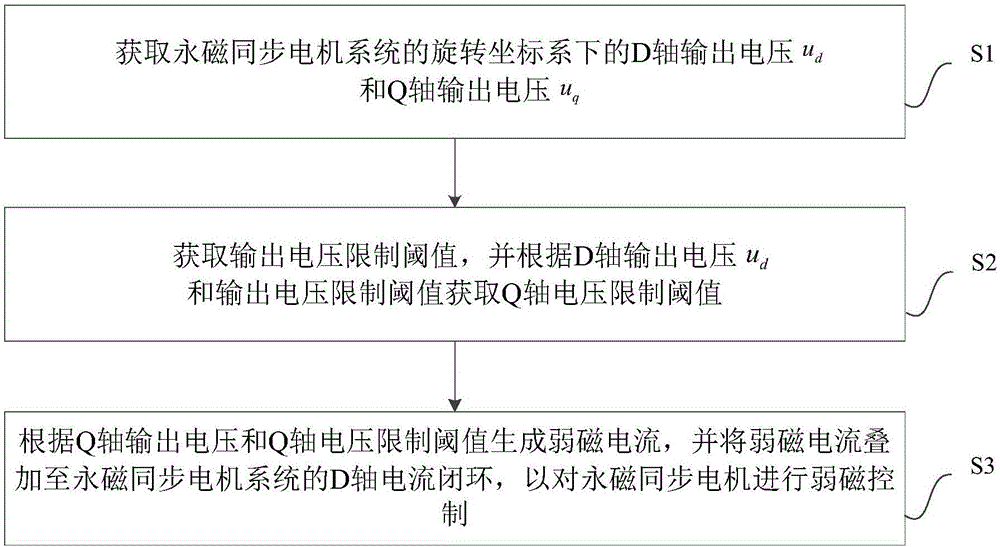

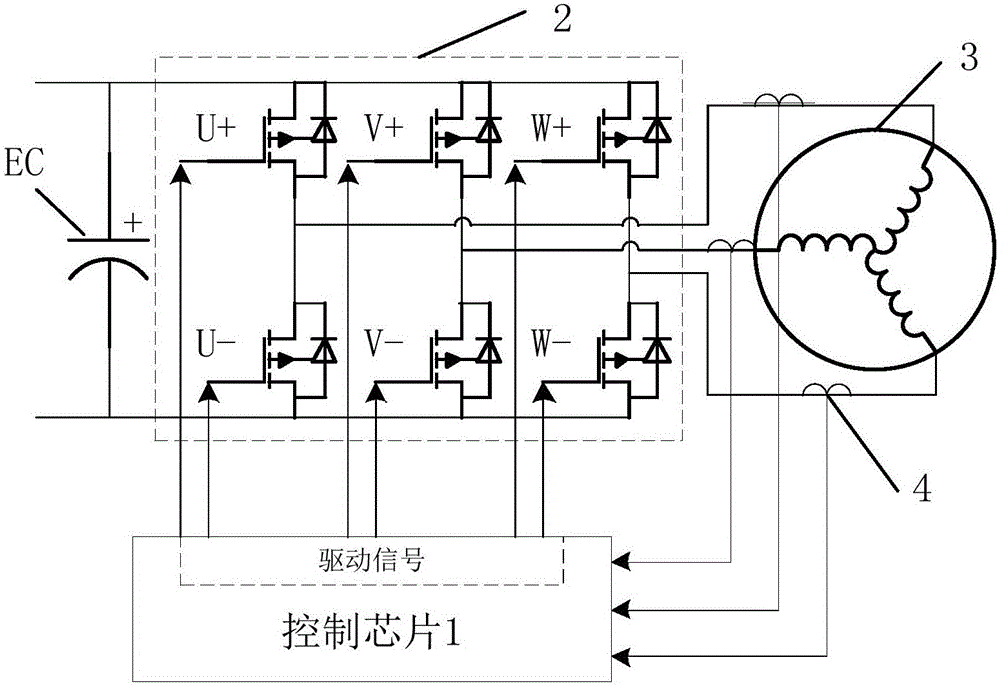

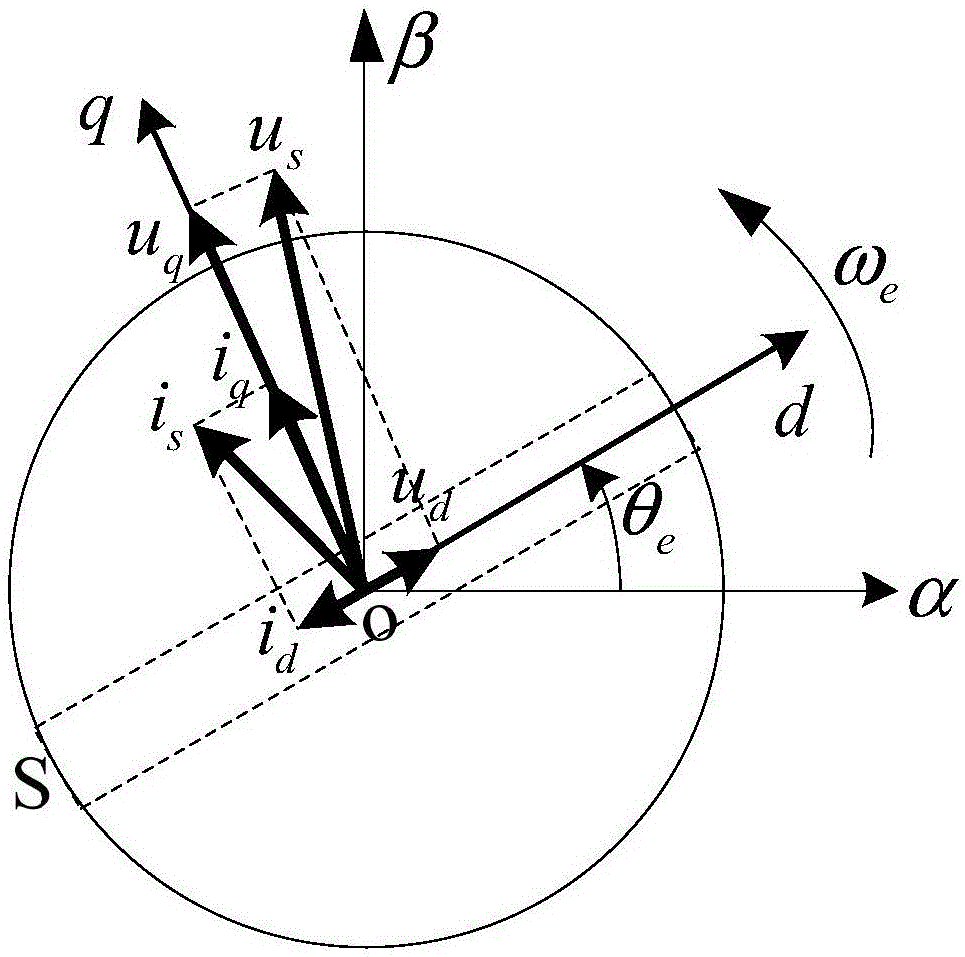

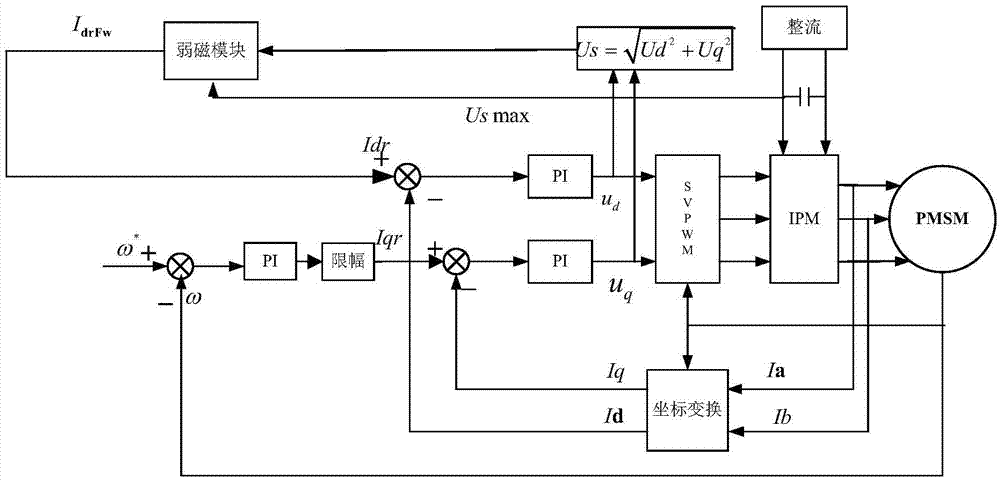

Permanent magnet synchronous motor system, field weakening control method and device thereof

ActiveCN106712631AAvoid instabilityImprove performanceElectronic commutation motor controlAC motor controlField weakeningInstability

The present invention discloses a permanent magnet synchronous motor system, a field weakening control method and device thereof. The method comprises the following steps that: the D-axis output voltage ud and Q-axis output voltage uq of the permanent magnet synchronous motor system under a rotating coordinate system are acquired; an output voltage limit threshold value is acquired, and a Q-axis voltage limit threshold value is acquired according to the D-axis output voltage and the output voltage limit threshold value; and field weakening current is generated according to the Q-axis output voltage uq and the Q-axis voltage limit threshold value, and the field weakening current is superimposed onto the D-axis current closed loop of the permanent magnet synchronous motor system, so that field weakening control can be performed on the permanent magnet synchronous motor. Since field weakening control fed-back by the closed-loop is performed through using Q-axis voltage error, and the full tracking of the D-axis current is maintained, the instability of the D-axis current under a condition of input alternating-current voltage periodic fluctuation and load fluctuation can be avoided, and field weakening control performance can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

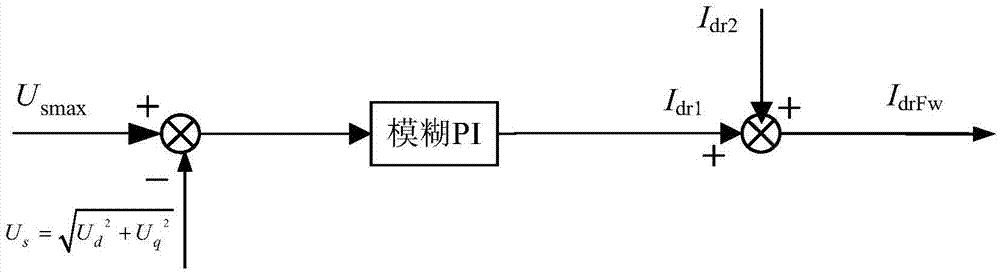

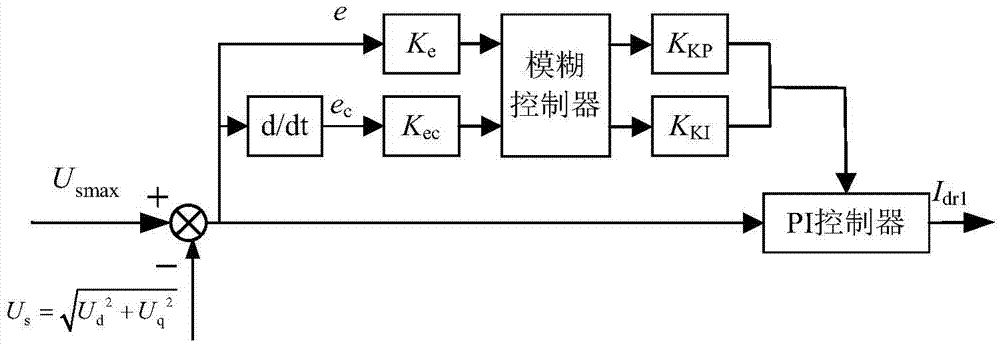

Motor flux-weakening control method

ActiveCN105450121AImproved field weakening performanceAvoid the effects of driftElectronic commutation motor controlElectric motor controlTerminal voltagePermanent magnet synchronous generator

The invention discloses a motor flux-weakening control method and relates to a feedforward control-based voltage feedback compensation method. The motor flux-weakening control method comprises the following steps: determining a flux-weakening limiting voltage Usmax according to the DC bus voltage of a permanent magnet synchronous motor, and calculating through d and q shaft voltages to obtain a terminal voltage Us; designing a PI regulator according to the flux-weakening limiting voltage Usmax and the terminal voltage Us so as to obtain a flux-weakening regulation current Odr1; considering the parameter perturbation of inductance and permanent magnet flux linkage, and calculating on the basis of a theoretical formula to obtain a flux-weakening feedforward current Idr2; and finally superposing the flux-weakening regulation current Idr1 and the flux-weakening feedforward current Idr2 to obtain a straight shaft compensation current IdrFW of a flux-weakening algorithm. According to the motor flux-weakening control method, the flux-weakening control performance of the permanent magnet synchronous motor can be effectively enhanced and the problems that the parameters are difficult to regulate and the dynamic property is not ideal in the prior art are effectively solved.

Owner:NANJING ESTUN AUTOMATION CO LTD

Apparatus and method for detecting vibrations of the shaft assembly in an electrical machine

InactiveUS7117744B2Firmly connectedIntuitive visualizationVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectric machineControl theory

A method for detecting vibrations of a shaft of an electrical machine includes measuring at least one of a shaft voltage and a shaft current and analyzing the measured at least one of the shaft voltage and the shaft current so as to determine the vibrations. In addition, an apparatus for detecting vibrations of a shaft of an electrical machine includes a first grounding device disposed at a first point on the shaft on a first side of the electrical machine and a second grounding device disposed at a second point of the shaft on a second side of the electrical machine. The second grounding device is configured to measure at least one of a shaft voltage and a shaft current.

Owner:GENERAL ELECTRIC TECH GMBH

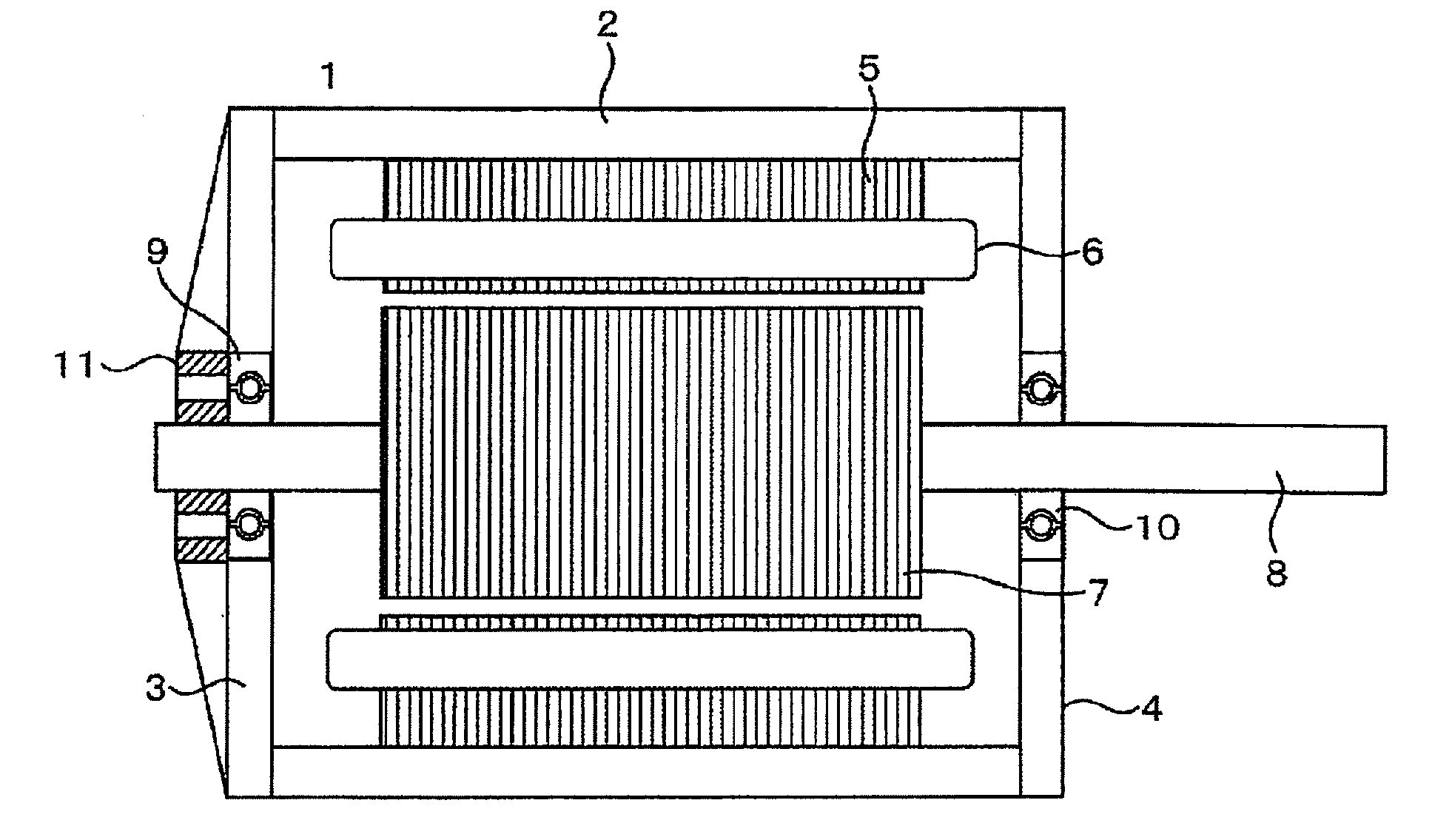

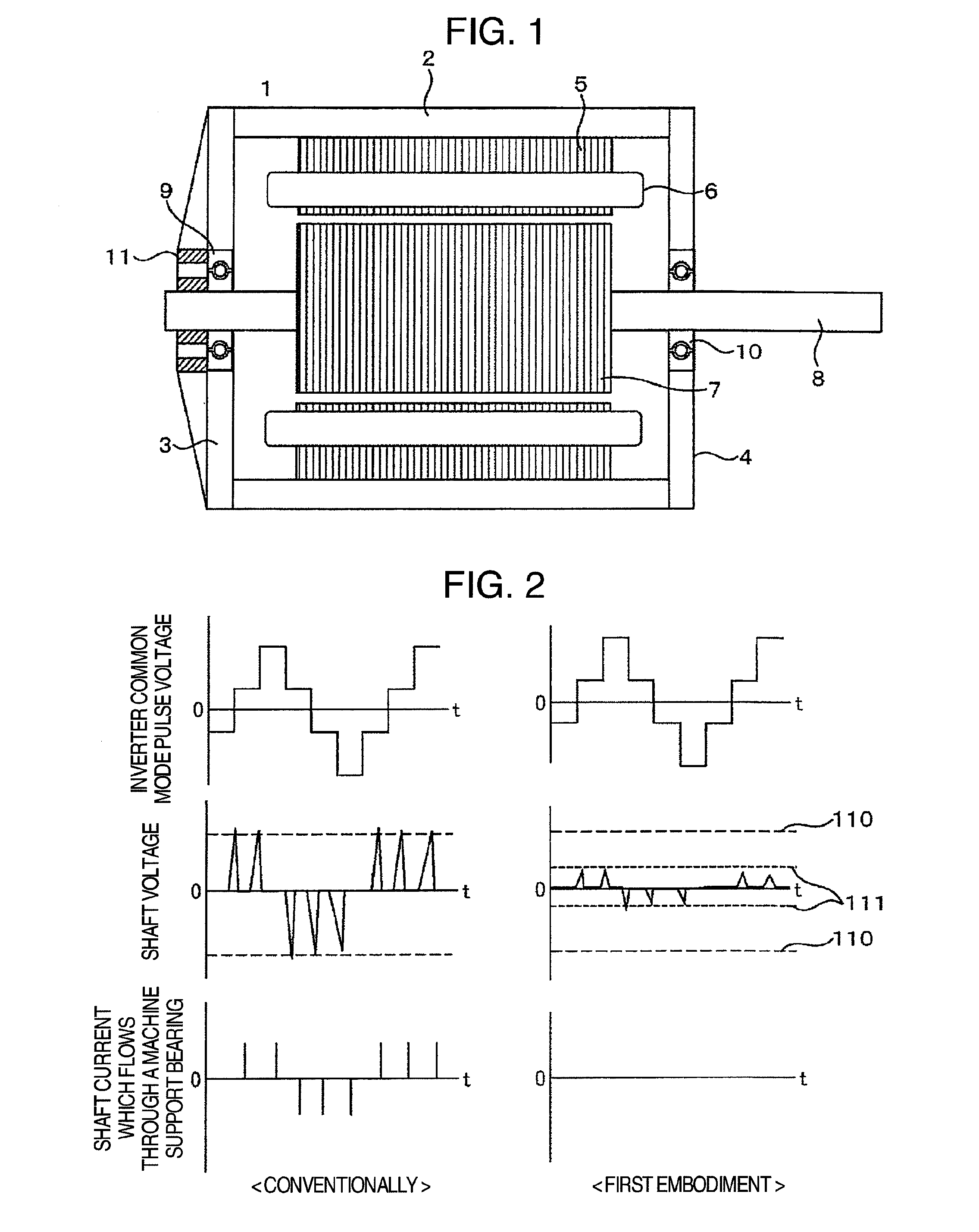

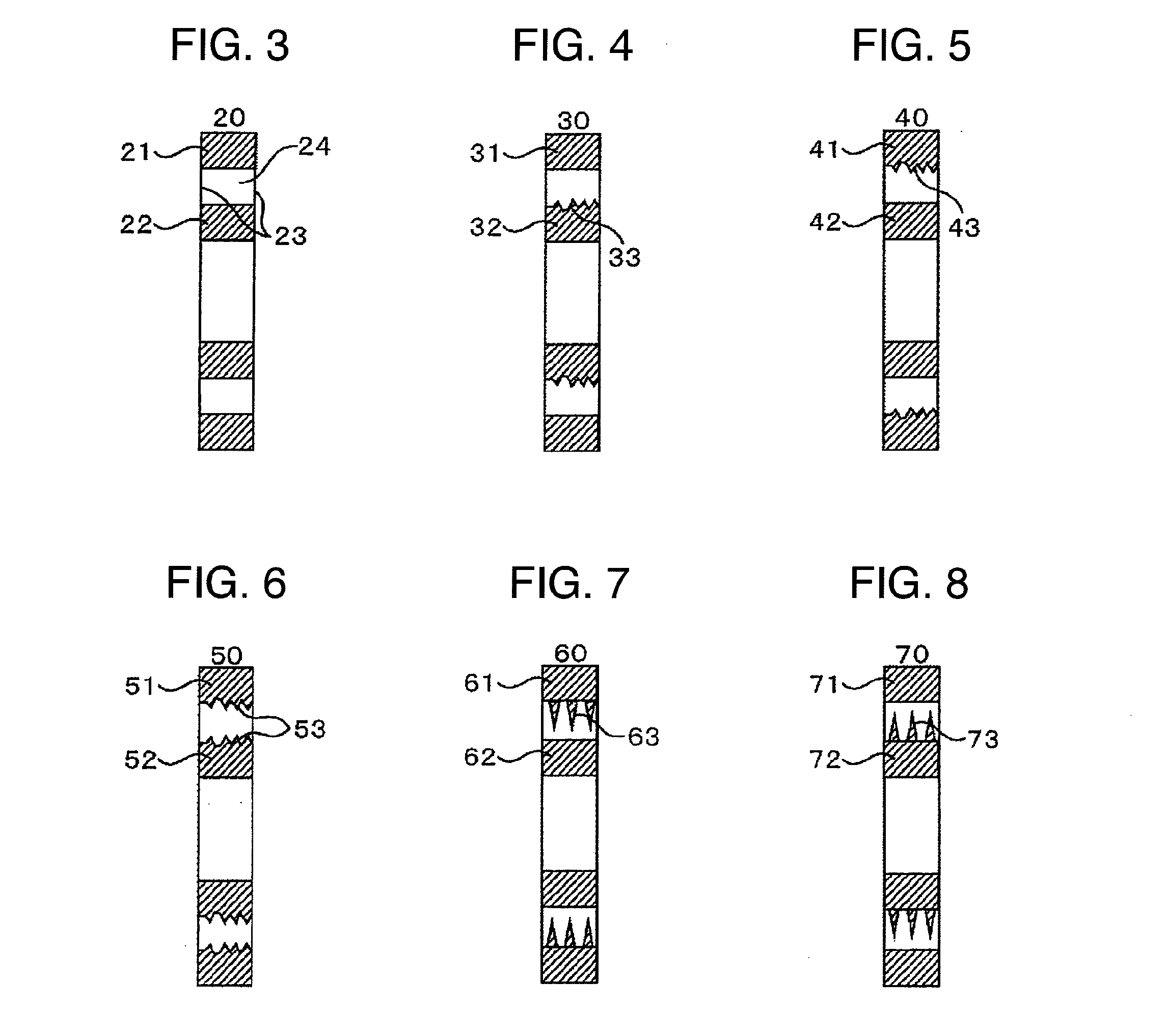

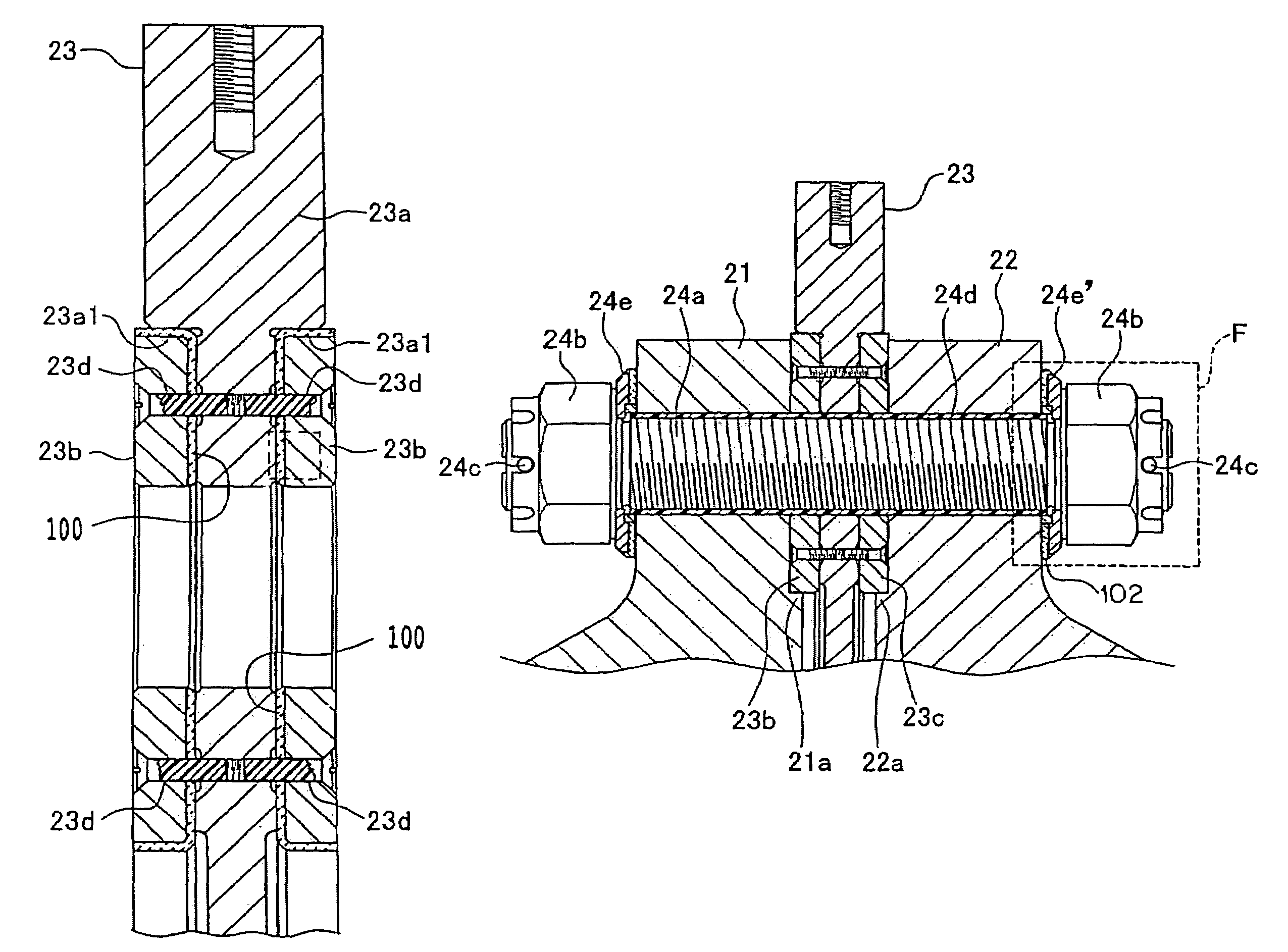

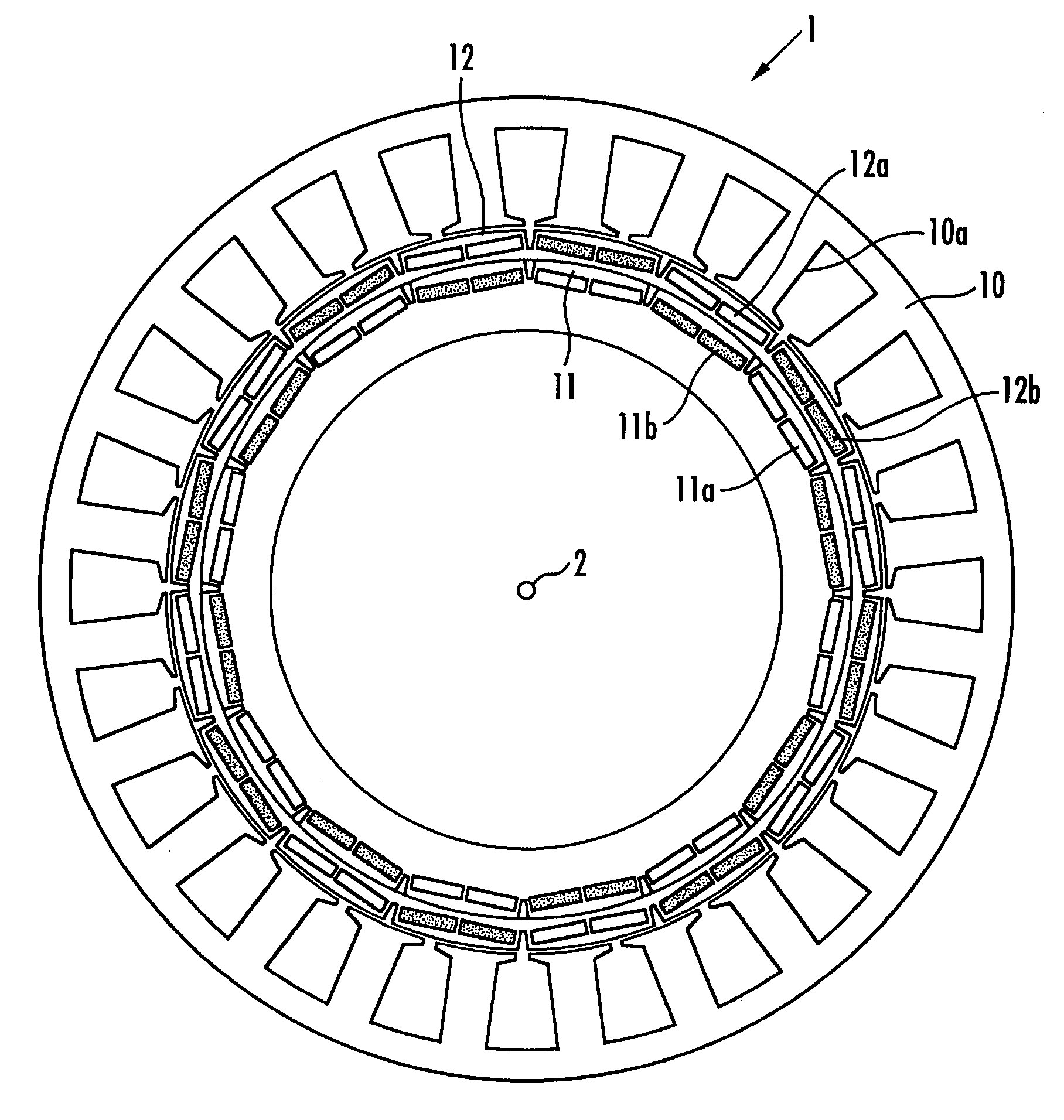

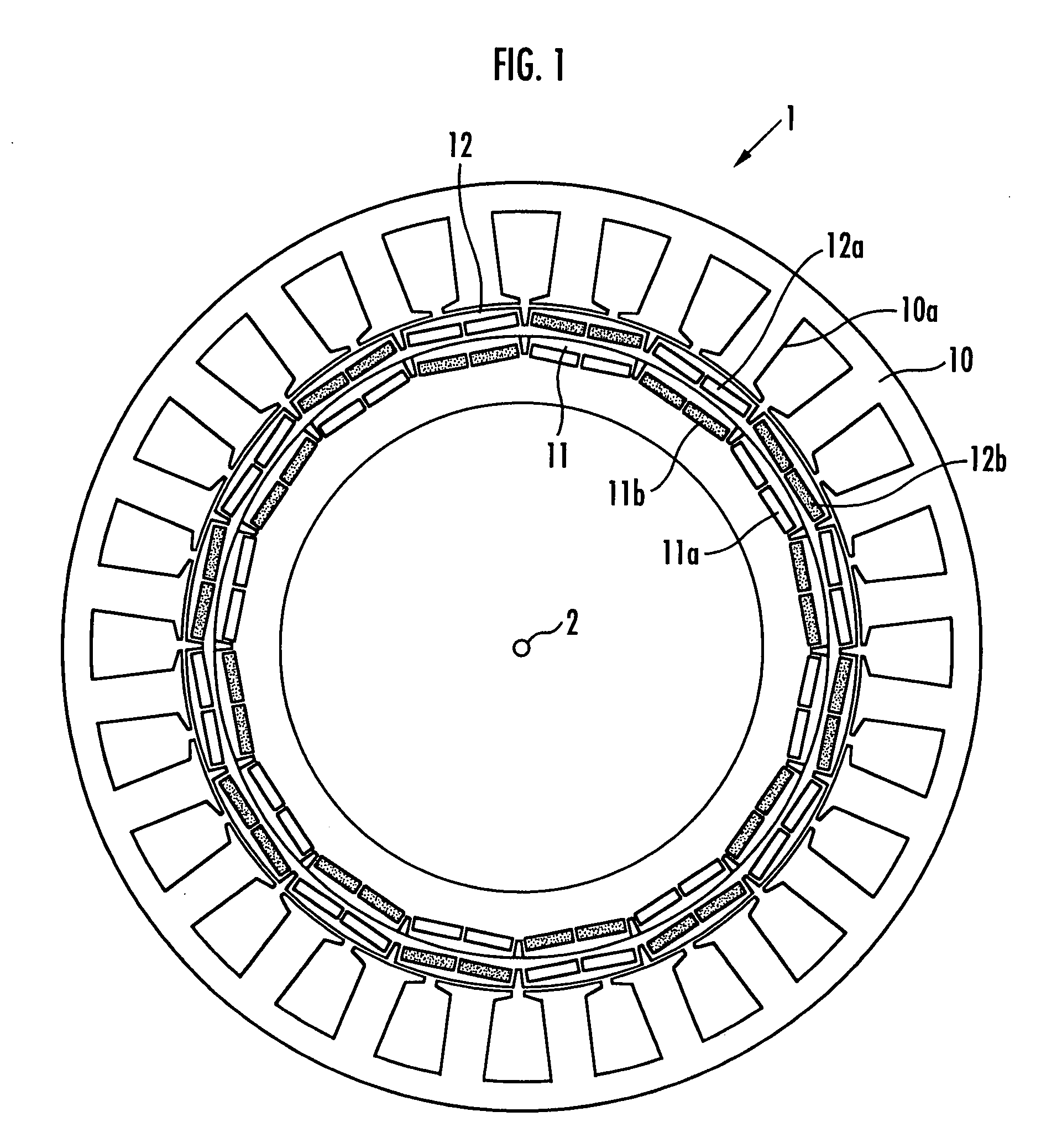

Inverter-driven dynamo electric machine and system, bearing, and end bracket for same

InactiveUS20130038182A1Improve reliabilityImprove efficiencyRotary combination bearingsAssociation with grounding devicesPower inverterShaft voltage

The purpose of the invention is to provide an inverter-driven dynamo electric machine and system for the same having high reliability and high efficiency such that even in the case of inverter pulse voltages having high dv / dt, generation of shaft voltages and generation of shaft currents causing electric corrosion of a bearing with the generation of the shaft voltages are suppressed, thereby keeping the bearing free of electric corrosion.The purpose of the invention is achieved by the following method. That is, the purpose is achieved by an inverter-driven dynamo electric machine and system for the same including at least one machine support bearing which supports a shaft of a rotor, and one electric discharge bearing which discharges the voltage generated in the shaft of the rotor, wherein a bearing having a lower dielectric breakdown voltage between an inner ring and an outer ring than that of the machine support bearing is used as the electric discharge bearing.Accordingly, this can provide an inverter-driven dynamo electric machine and system for the same having high reliability and high efficiency such that the bearing is not electrically corroded with respect to the inverter pulse voltage.

Owner:HITACHI LTD

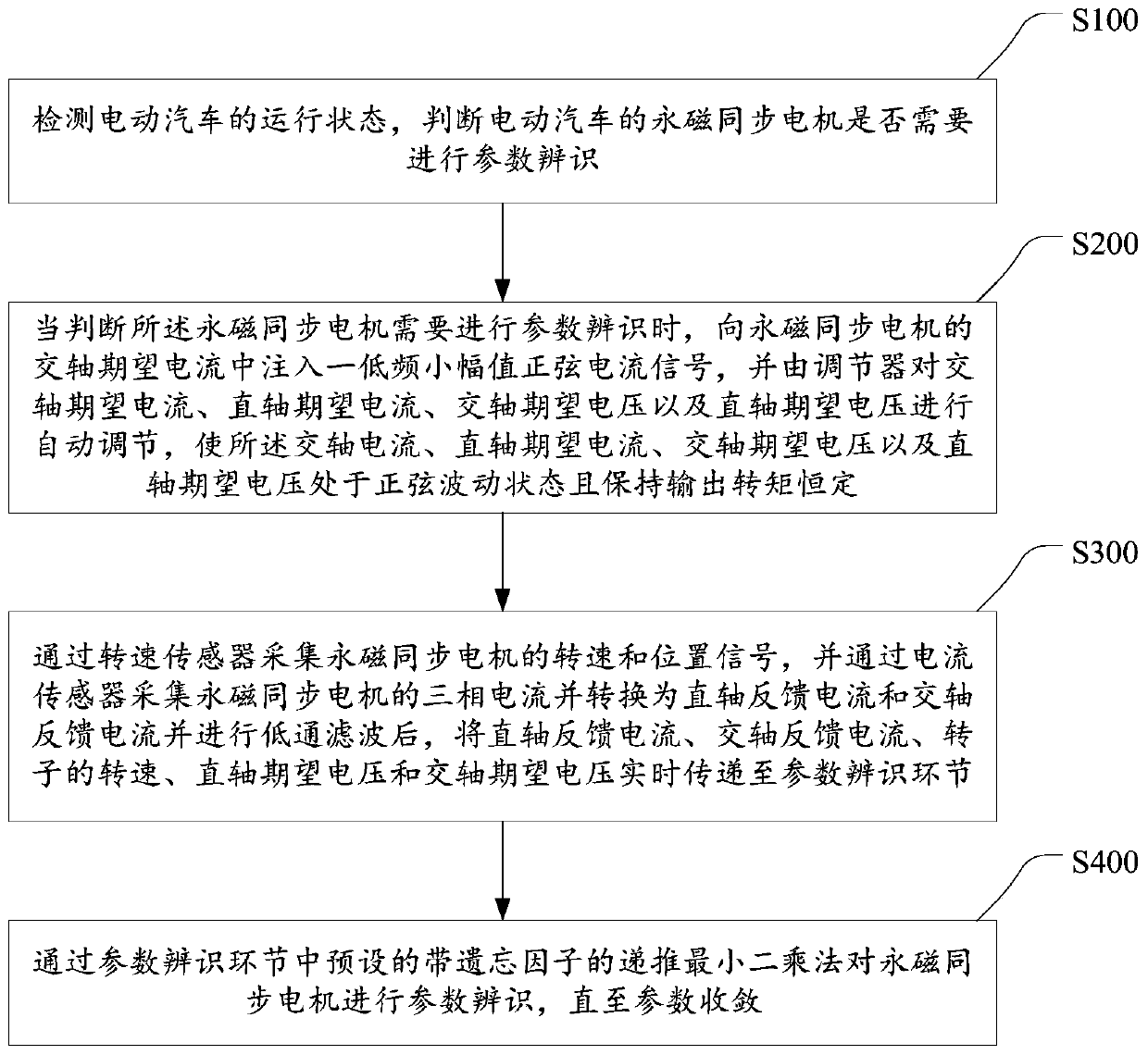

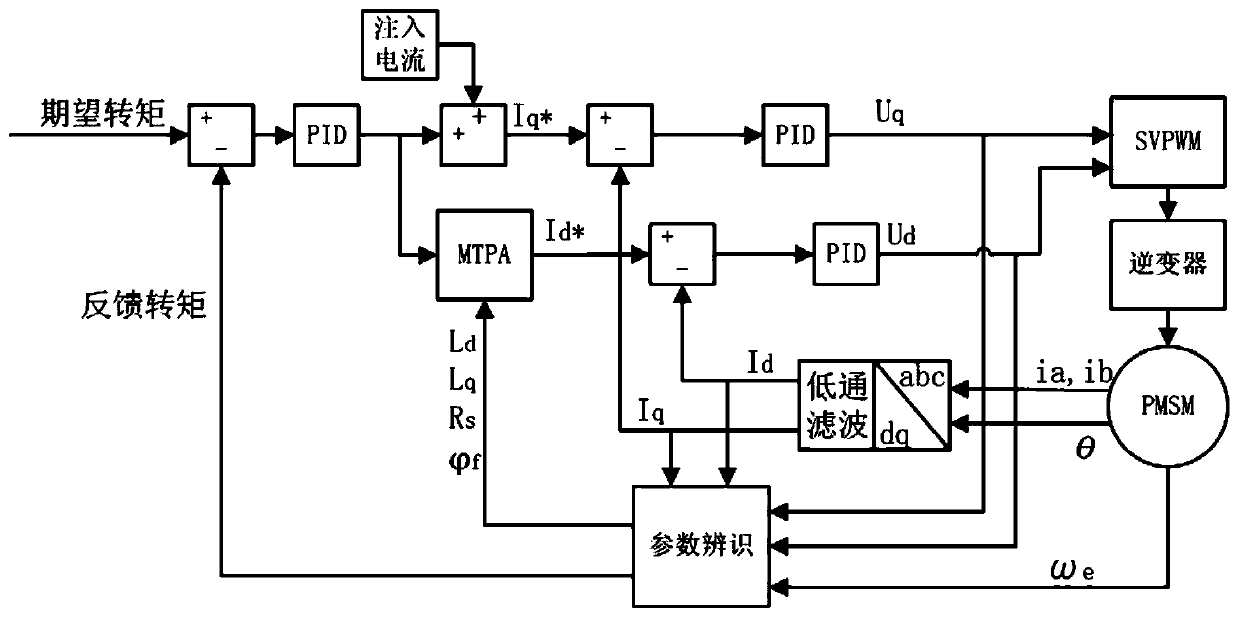

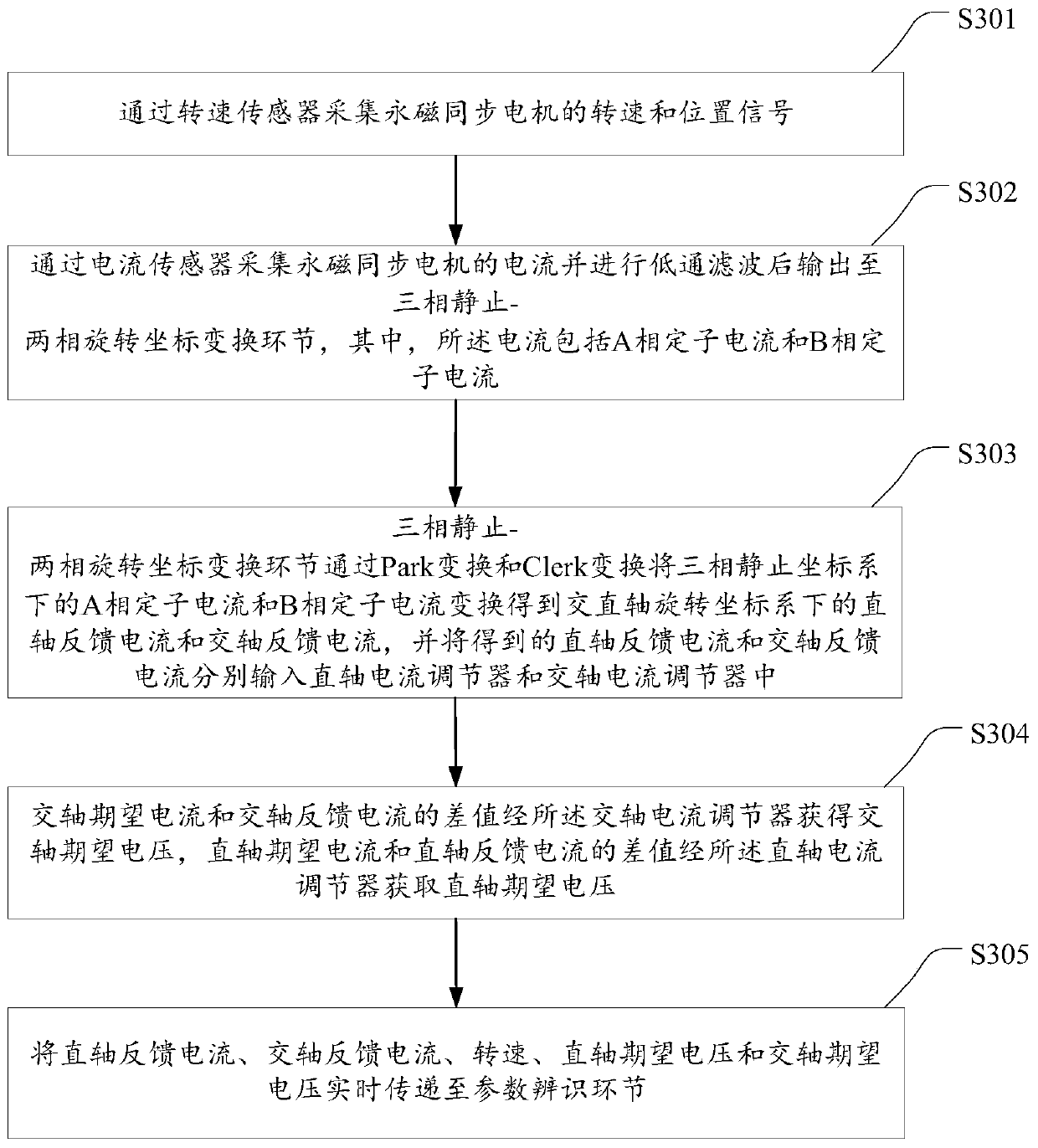

Parameter recognition method for permanent magnet synchronous motor of electric vehicle

InactiveCN110890855AMeet control requirementsAccurate identificationElectronic commutation motor controlAC motor controlElectric machinePermanent magnet synchronous motor

The invention discloses a parameter recognition method for a permanent magnet synchronous motor of an electric vehicle. The method comprises the steps of judging whether the permanent magnet synchronous motor of the electric vehicle needs parameter recognition or not; when parameter recognition needs to be carried out, injecting a low-frequency small-amplitude sinusoidal current signal into quadrature-axis expected current of the permanent magnet synchronous motor, and automatically adjusting the quadrature-axis expected current, direct-axis expected current, quadrature-axis voltage and direct-axis voltage by an adjuster; the rotating speed and position signals of the permanent magnet synchronous motor are measured through a rotating speed sensor, three-phase current of the permanent magnet synchronous motor is collected through a current sensor and converted into direct-axis feedback current and quadrature-axis feedback current, and data are transmitted to a parameter recognition linkin real time; and performing parameter recognition on the permanent magnet synchronous motor through the parameter recognition link until the parameters converge. According to the method, parameter recognition can be carried out under any operation state of the motor, the control requirements of the permanent magnet synchronous motors with different structures can be well met, the identified parameters are accurate, and the application range is wide.

Owner:WUHAN UNIV OF TECH

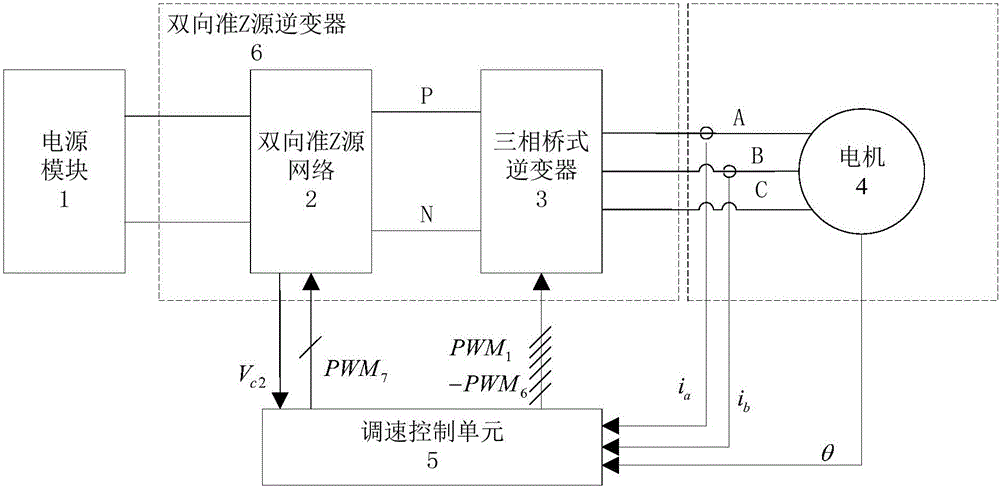

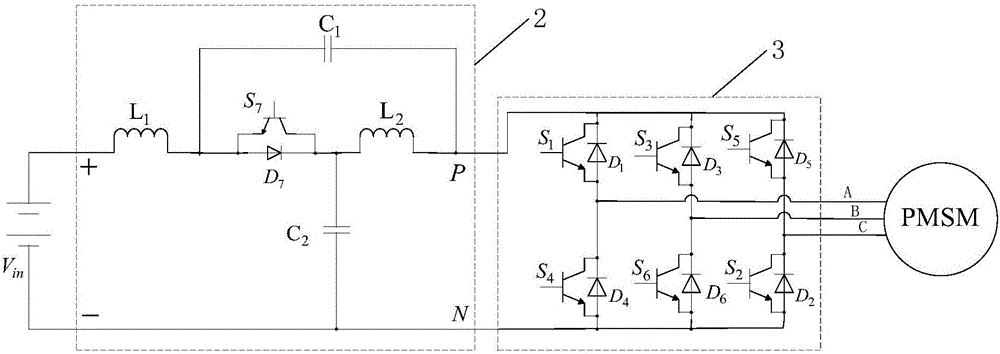

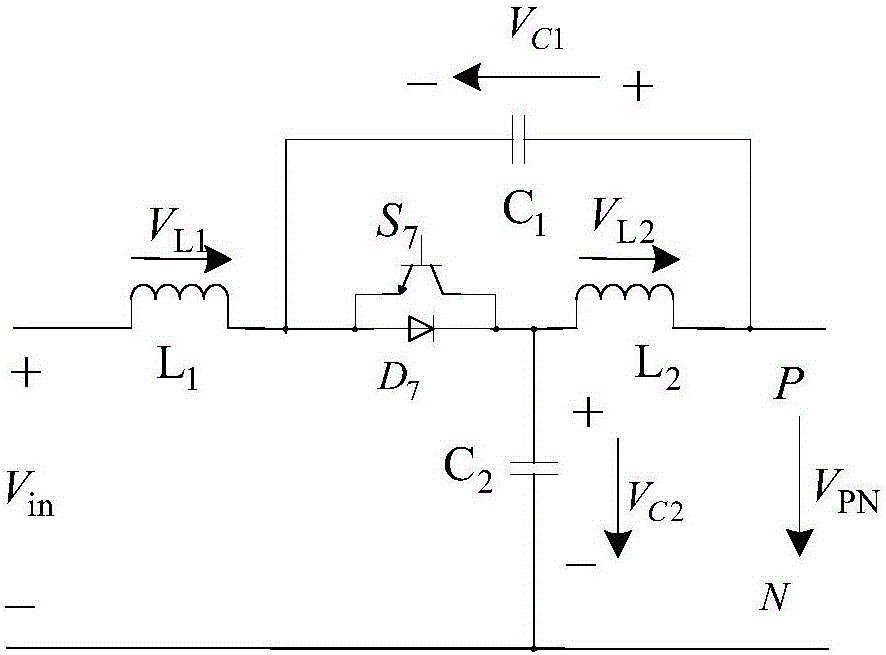

Control method for bidirectional quasi-Z-source inversion type motor driving system

ActiveCN105897099AAchieving two-way flowCapable of boostingElectronic commutation motor controlAC motor controlCapacitanceLoop control

The invention relates to a control method for a bidirectional quasi-Z-source inversion type motor driving system. The control method comprises the following steps of collecting the voltage of a capacitor C2 and the current of a permanent magnet synchronous motor; obtaining voltage components of a d axis and a q axis; obtaining a direct-connection duty ratio; carrying out an SVPWM (space vector pulse width modulation) algorithm by inserting the direct-connection duty ratio according to the voltage components of the d axis and the q axis and the direct-through duty ratio to obtain six paths of PWM control signals for controlling the on and off of three-phase bridge arms of a three-phase bridge type inverter; and carrying out logic calculation on the six paths of PWM control signals to output a PWM control signal for controlling the on and off of an IGBT switch tube S7. Compared with the prior art, the average direct-connection duty ratio and the capacitor voltage closed loop control closed loop policy are added to the conventional SVPWM control method, so that the direct current side voltage has the voltage boosting capability; and on the basis, the power switch S7 which is complementary with the direct-connection state is further designed, so that the bidirectional flow of energy can be realized.

Owner:TONGJI UNIV

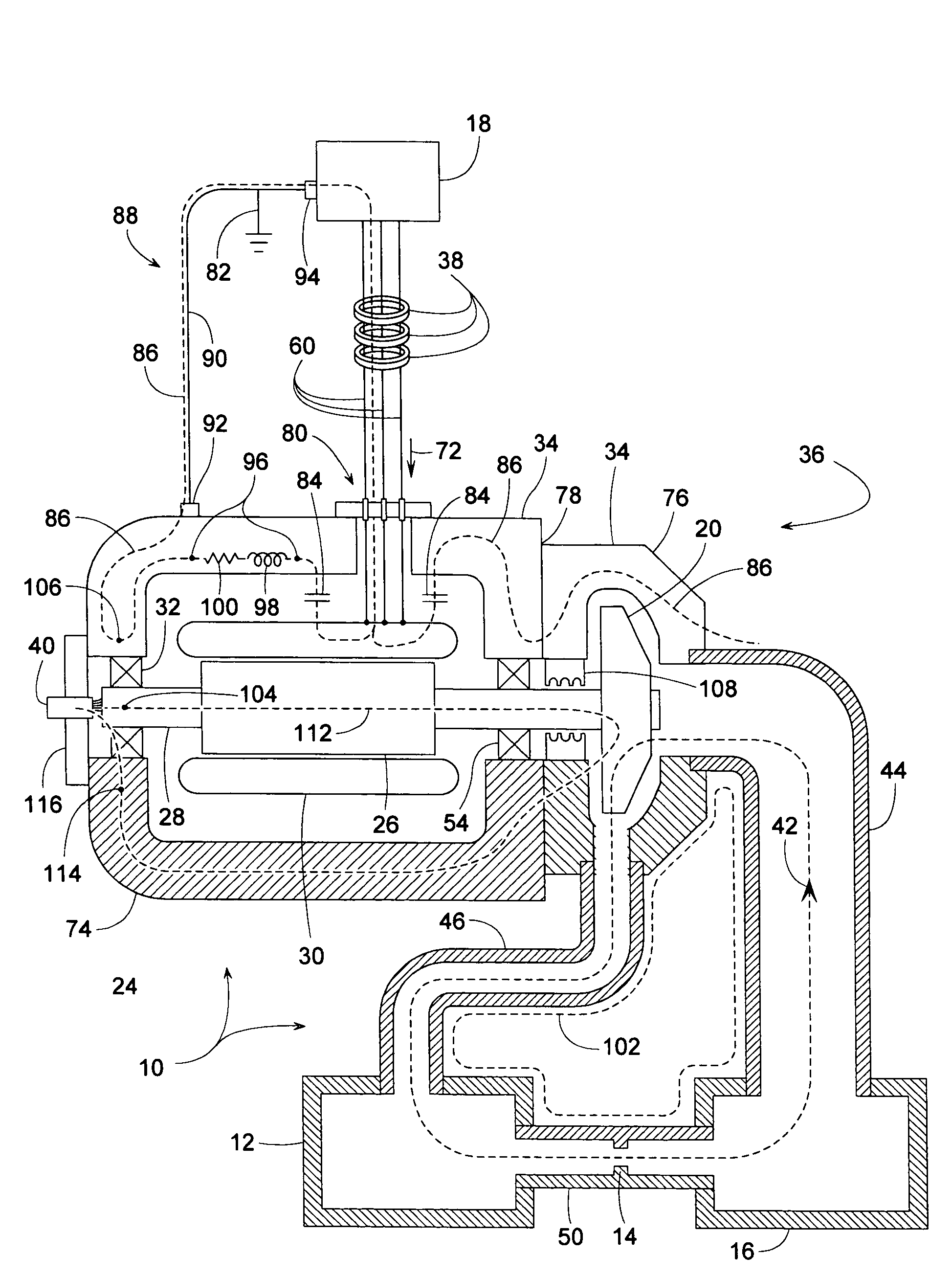

System for protecting bearings and seals of a refrigerant compressor

ActiveUS20080166246A1Reduce shaft voltageReduce frequencyCompressorAC motor controlFrequency changerGround contact

To protect the bearings, lubricant and seals of a refrigerant compressor, the compressor includes one or more inductors for mitigating a high frequency common mode current that produces a high frequency shaft voltage. Each inductor is a ring of magnetic material encircling three insulated cables that convey three-phase power from an adjustable frequency drive to the compressor's motor. Without the inductors, the high frequency shaft voltage can become damagingly high due to the length of a cast iron housing that can be particularly long if the housing contains both a motor and several centrifugal impellers. The high frequency shaft voltage is just one component of a composite adverse shaft voltage. Another component, known as an operationally induced shaft voltage, can be reduced by a grounding contact, so instead of using just an inductor or just a contact, both can be used to provide a total solution to the problem.

Owner:TRANE INT INC

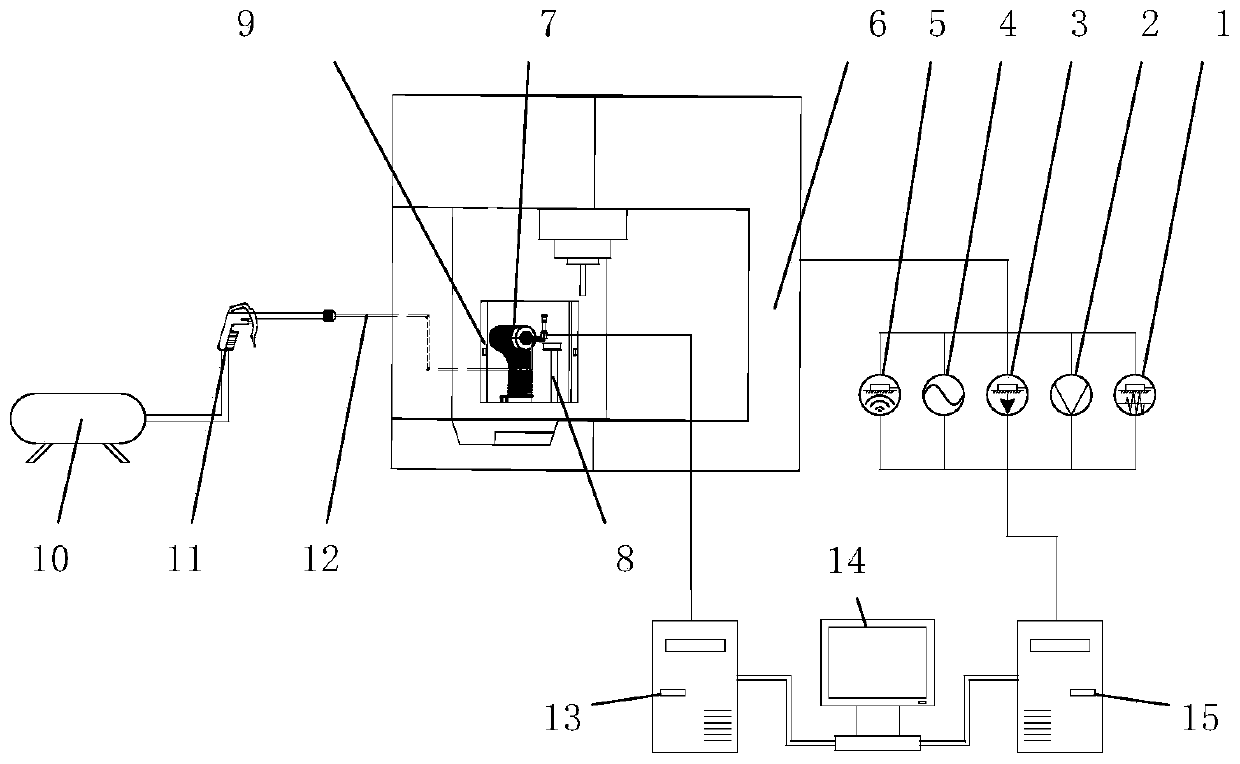

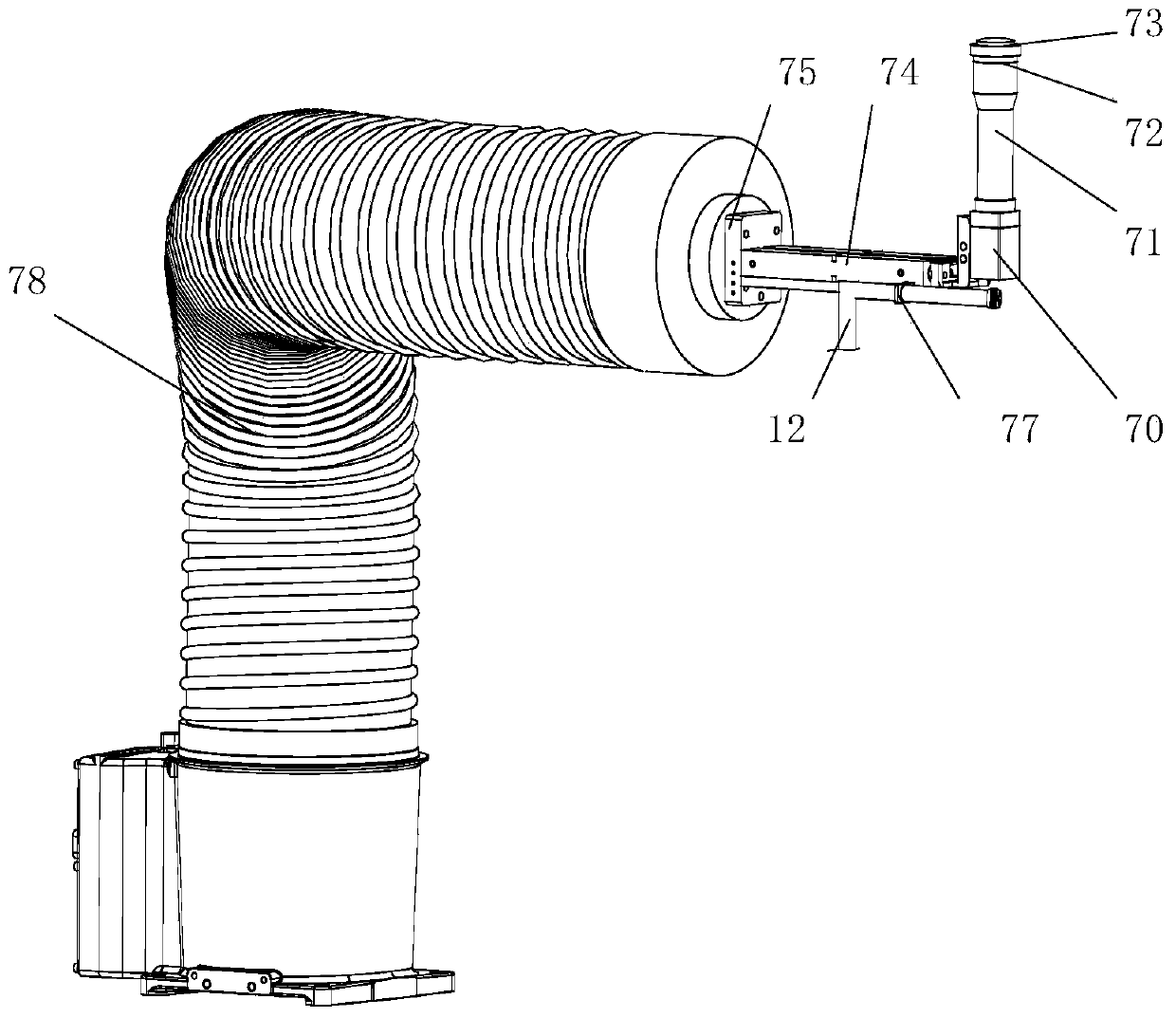

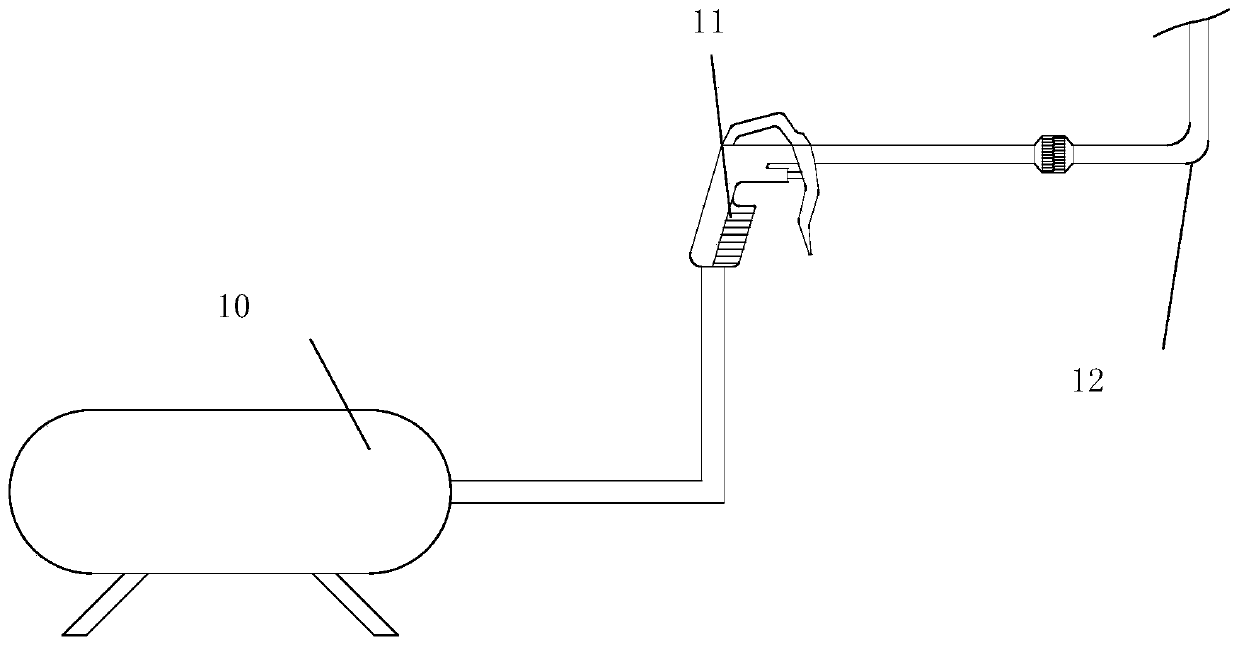

Tool damage online and in-situ detection system in clean cutting environment and method

PendingCN110340733ALong trouble-free uptimeImprove production efficiencyMeasurement/indication equipmentsMaintainance and safety accessoriesShaft voltageFrequency domain

The invention discloses a tool damage online and in-situ detection system in a clean cutting environment and a method. The system comprises an on-line pre-judgment and recognition system, an in-situ detection system, a cleaning system for cleaning a tool, and a computer, wherein the on-line pre-judgment and recognition system is used for measuring the vibration amount of a cutting position in realtime, the change value of a main shaft voltage and the current, the change value of the cutting force and a sound signal, the in-site detection system is used for acquiring a side edge image and a bottom edge image of the tool in-site, and the computer is used for carrying out time domain feature and frequency domain feature extraction and data fusion on signals collected by the on-line pre-judgment and recognition system; whether the data are abnormal or not is judged primarily; and the image is further processed to judge the damage type and damage degree of the tool. According to the method, the tool damage is preliminarily judged through the on-line pre-judgment and recognition system, then the damage type and damage degree of the tool are judged, so that accurate detection of tool abrasion is realized.

Owner:NANJING UNIV OF SCI & TECH

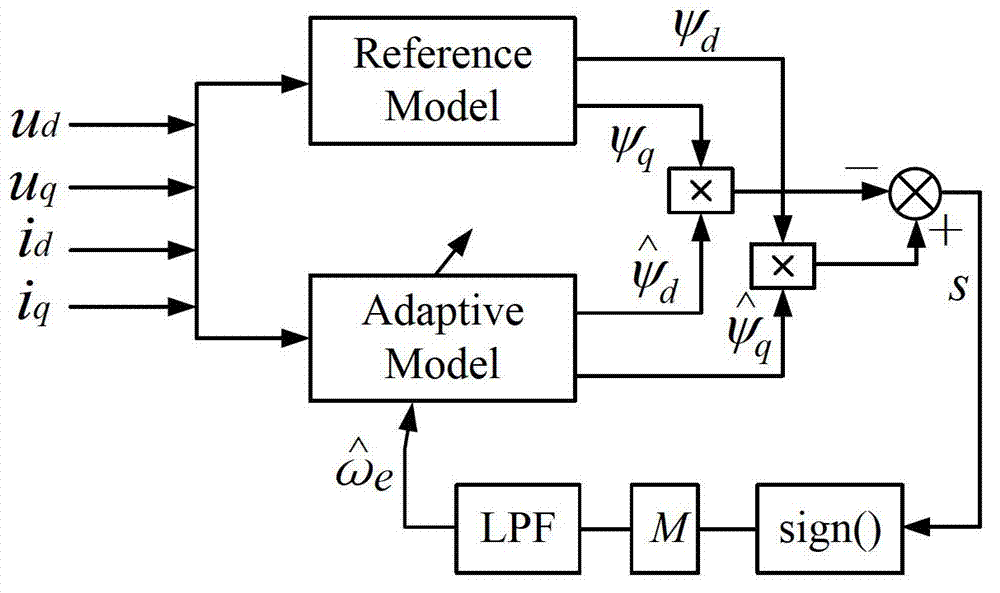

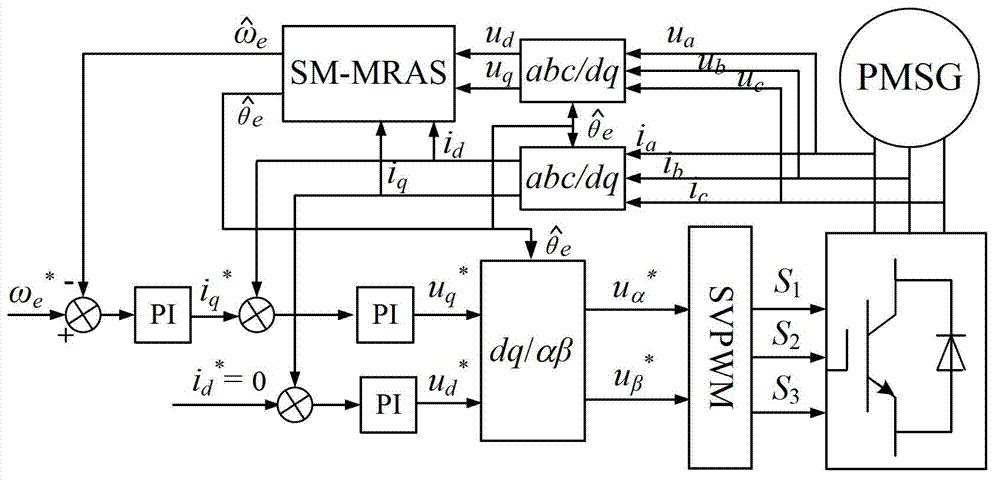

Permanent magnet synchronous motor unposition sensor control method

InactiveCN103051271ALow costSimple control strategyElectronic commutation motor controlVector control systemsControl vectorPower flow

The invention discloses a permanent magnet synchronous motor unposition sensor control method, which concretely comprises the following steps of: step 10, collecting three-phase voltage of a permanent magnet synchronous motor, switching the three-phase voltage to a dd coordinate system, and obtaining voltage ud and uq in a dq axis; step 20, collecting three-phase current of the permanent magnet synchronous motor, switching the three-phase current to a dq coordinate system, and obtaining current id and iq in the dq axis; step 30, adopting a sliding mode variable structure model reference adaptive system-based algorithm to obtain a rotor estimated electric angle speed and a rotor position of the permanent magnet synchronous motor; and step 40, according to the rotor estimated electric angle speed and the rotor position obtained in the step 30, realizing unposition sensor rotation speed close-loop vector control of the motor. The permanent magnet synchronous motor unposition sensor control method has the advantages of low cost, simple control algorithm, high rotation speed and position estimation speed, high estimation accuracy, and the like.

Owner:SOUTHEAST UNIV

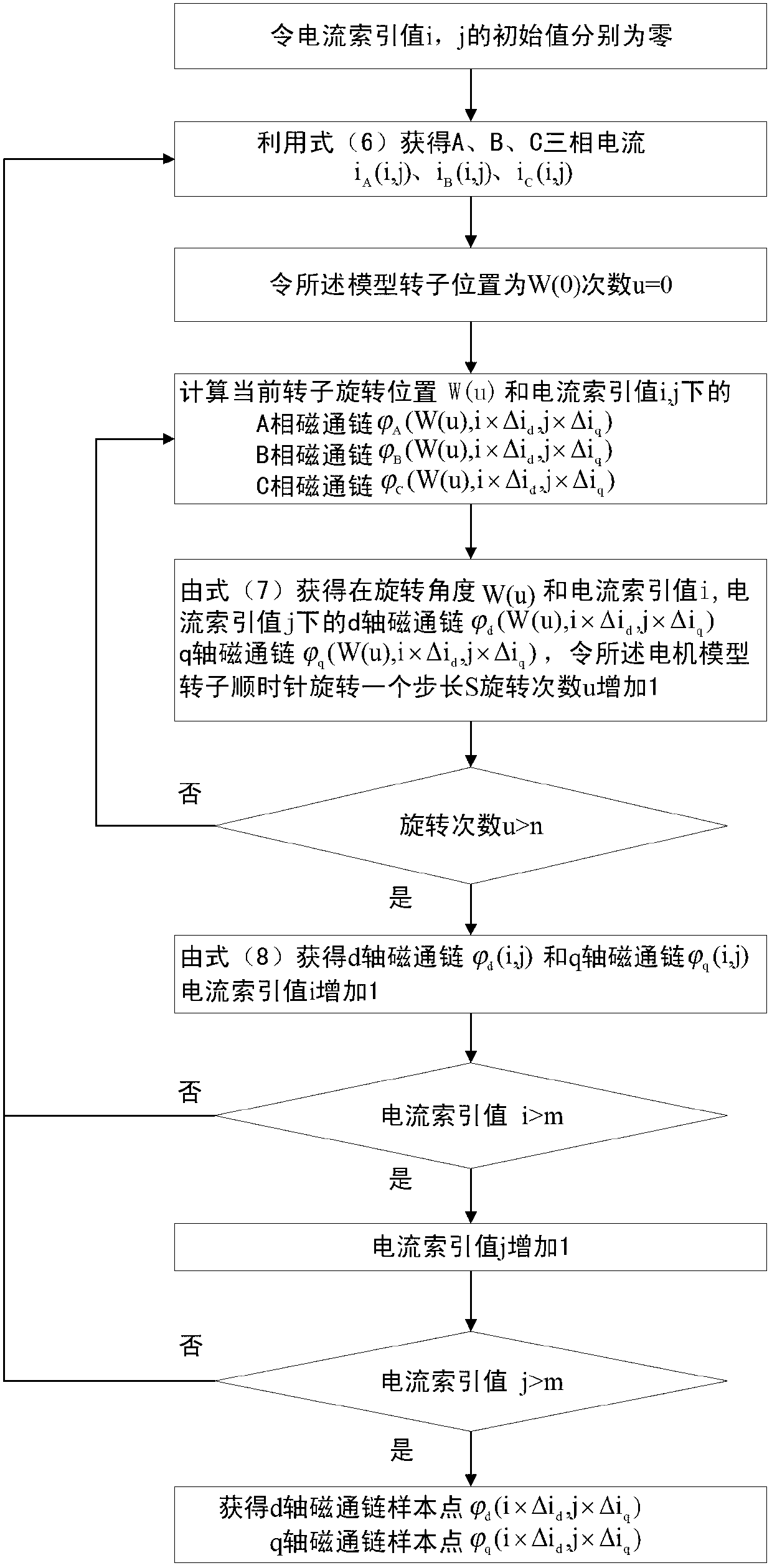

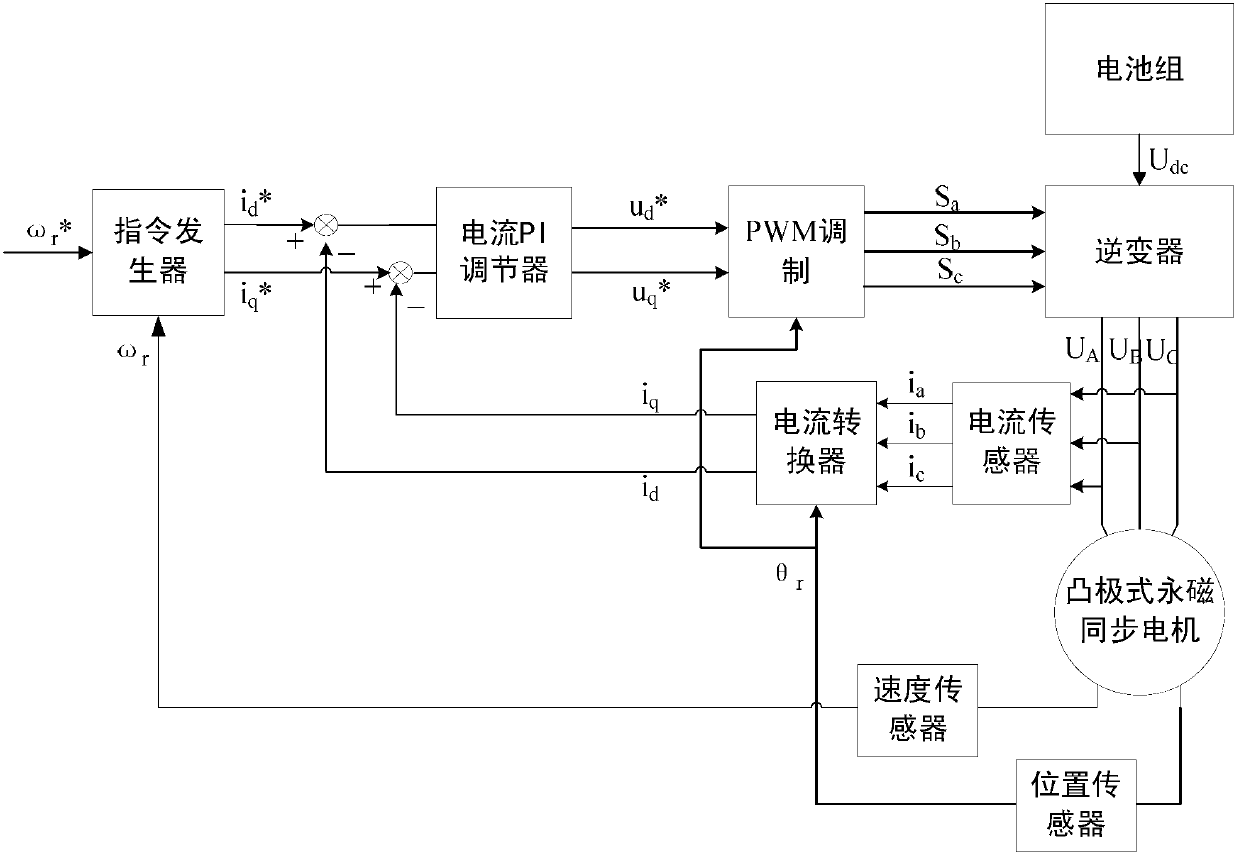

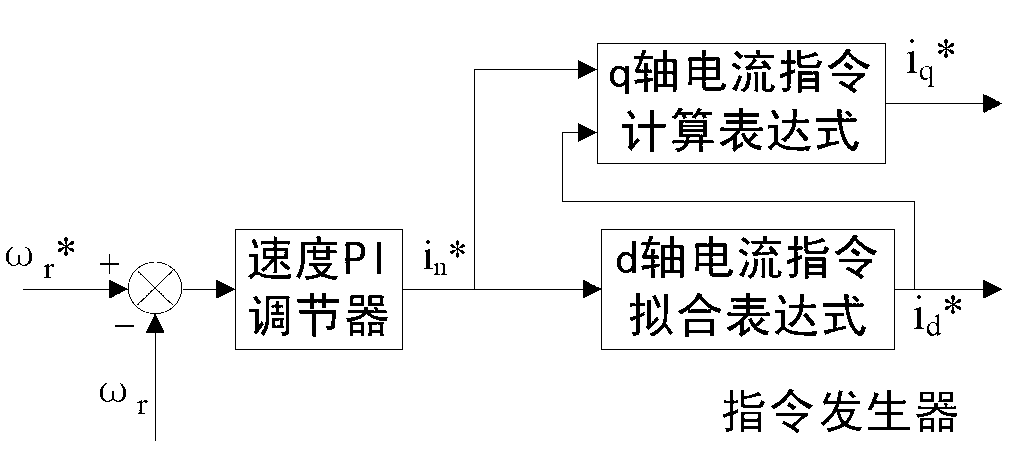

Control method of drive system of salient pole type permanent magnet synchronous motor

ActiveCN102710210AAvoid controlImprove controlElectronic commutation motor controlVector control systemsPhase currentsPosition angle

The invention discloses a control method of a drive system of a salient pole type permanent magnet synchronous motor. The control method is characterized by comprising the steps of: acquiring a d-shaft current instruction fitting expression and a q-shaft current instruction computation expression of an instruction generator by adopting a motor electric magnetic field finite element analysis method according to detected stator a-phase current ia, stator b-phase current ib, stator c-phase current ic, rotor actual position angle theta r, and actual speed omega r, producing a d-shaft stator current instruction id<*> and a q-shaft stator current instruction iq<*> by the instruction generator, acquiring a stator d-shaft voltage instruction ud<*> and a stator q-shaft voltage instruction uq<*> via a current PI (Proportional-Integral) regulator, obtaining three control signals including Sa, Sb and Sc of an inerter by a PWM (Pulse Width Modulation) module according to the acquired instructions, converting voltage udc supplied by a battery pack into control voltages UA, UB and UC of the salient pole type permanent magnet synchronous motor via the inverter by using the three control signals Sa, Sb and Sc, thereby realizing the control of the permanent magnet synchronous motor. The control method disclosed by the invention can be used for effectively increasing the torque output of the permanent magnet synchronous motor under the same current, thereby increasing the control performance of the drive system of the permanent magnet synchronous motor.

Owner:HEFEI UNIV OF TECH

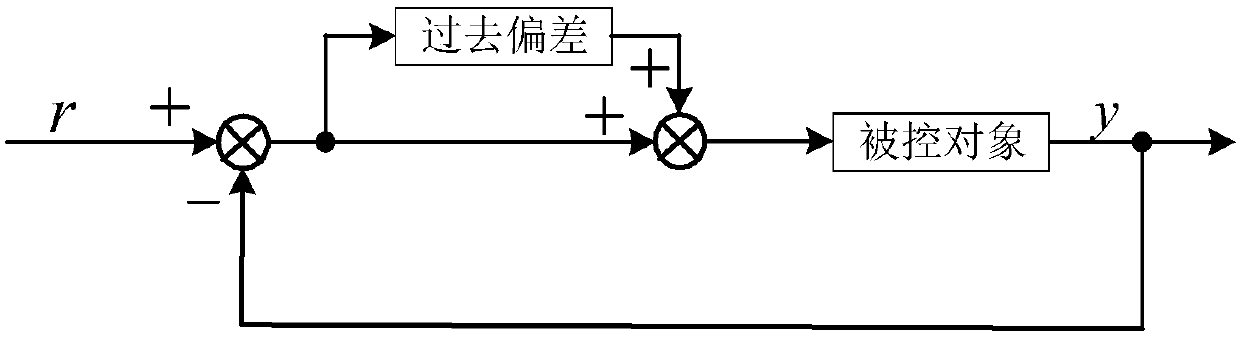

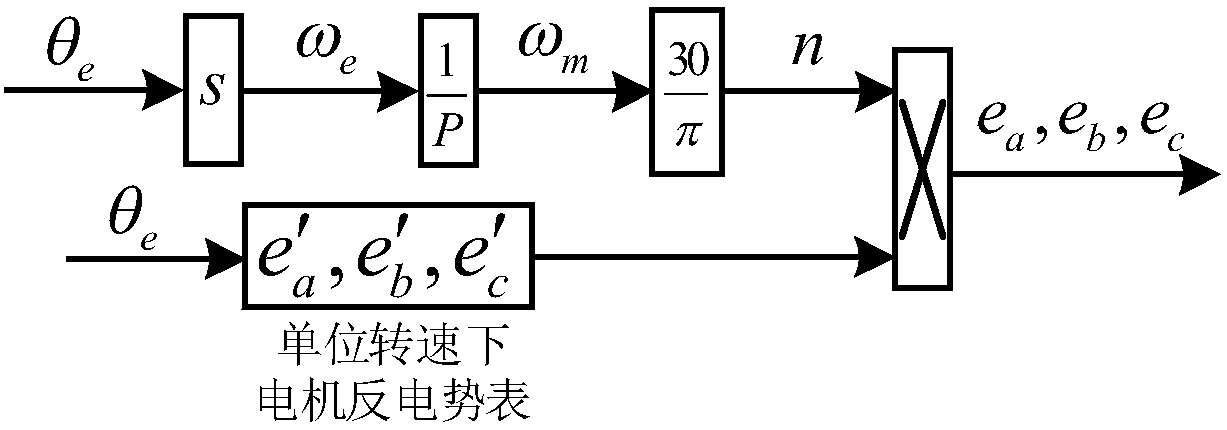

Permanent magnet synchronous motor simulator considering nonlinear characteristics and control method thereof

ActiveCN107943121ARealize static error-free trackingDynamo-electric machine testingSpeed/accelaration control using electric meansMathematical modelAngular velocity

The invention discloses a permanent magnet synchronous motor simulator considering nonlinear characteristics and a control method thereof. The method includes the steps of outputting three-phase voltages and currents, and obtaining q-axis and d-axis voltage and current components respectively through coordinate transformation and combined with a current cycle electrical angle; obtaining q-axis andd-axis counter electromotive force (EMF) components; establishing a nonlinear permanent magnet synchronous motor mathematical model, taking the q-axis and d-axis voltages and q-axis and d-axis counter EMF as the input to calculate the mechanical angular velocity, electrical angle, motor rotation speed, and q-axis and d-axis currents of a next cycle, and taking the q-axis and d-axis currents as command currents for the closed-loop control of the next cycle; and regulating differences between the command currents and the q-axis and d-axis current components by using a current regulator, and connecting the reference voltage obtained after the inverse Park transformation of the results to an SVPWM modulation module such that a three-phase full-bridge converter actually outputs the command currents. According to the invention, the operation characteristics of various working conditions under the condition of non-linear counter EMF can be effectively simulated, and the tracking without static error of high frequency signals contained in the higher harmonic currents can be achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM

Rotor coupling having insulated structure

InactiveUS7530757B2Prevent galvanic corrosionPotential of each rotor can be reducedMolten spray coatingCombination enginesElectricityCoupling

A rotor coupling having insulated structure which can assuredly prevent galvanic corrosion of beating members, rotors and the like which is caused by shaft voltage, is provided in a shaft system that requires insulation. A generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine. The rotor coupling having insulated structure is employed in power generating equipment in which a generator is disposed in between a steam turbine and a gas turbine or a rotating machinery such as another steam turbine, a generator rotor and a rotating machinery rotor are connected, a first grounding electrode is provided to the steam turbine rotor, and a second grounding electrode is provided to the generator rotor, wherein both the rotors between the generator and the steam turbine are connected in an electrically insulated state.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

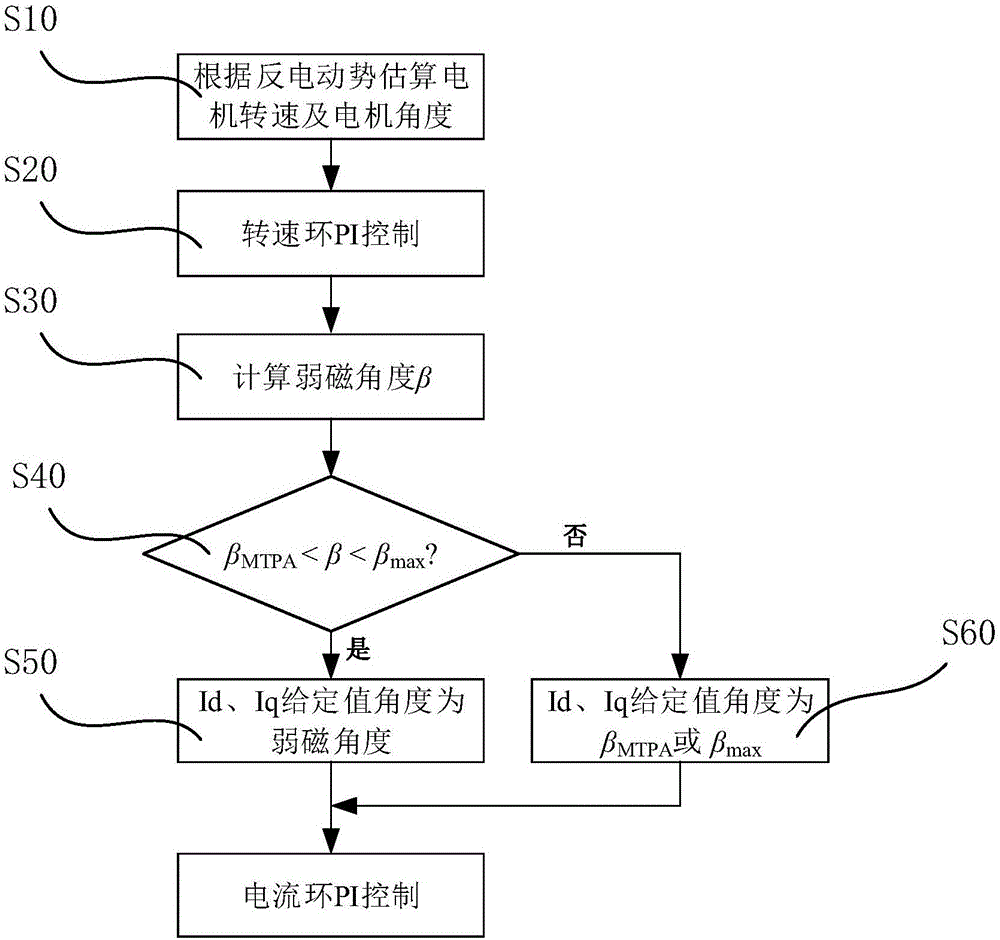

Field weakening control system and method for PMSM, refrigerator controller and refrigerator

ActiveCN106452243AReduce speed fluctuationSmall fluctuationElectronic commutation motor controlVector control systemsControl vectorControl system

The invention provides a field weakening control system and method for a PMSM (Permanent Magnet Synchronous Motor). The field weakening control system and method for a PMSM are used for performing vector control on the PMSM. The field weakening control system includes a rotating speed loop and an electric current loop, wherein output of the rotating speed loop is the given input of the electric current loop; and output of the electric current loop is a d shaft voltage given value Vdref and a q shaft voltage given value Vqref. The field weakening control system also includes a filed weakening angle loop, wherein the field weakening angle loop calculates a field weakening angle Beta according to the output of the electric current loop and a field weakening gain K, and determines the angle of a motor d shaft current given value I*dref and the angle of a q shaft current given value I*qref according to the field weakening angle Beta. The field weakening control system and method for a PMSM can reduce the fluctuation of rotating speed of the PMSM at frequency points opening field weakening. The invention also provides a refrigerator controller and a refrigerator.

Owner:GREE ELECTRIC APPLIANCES INC

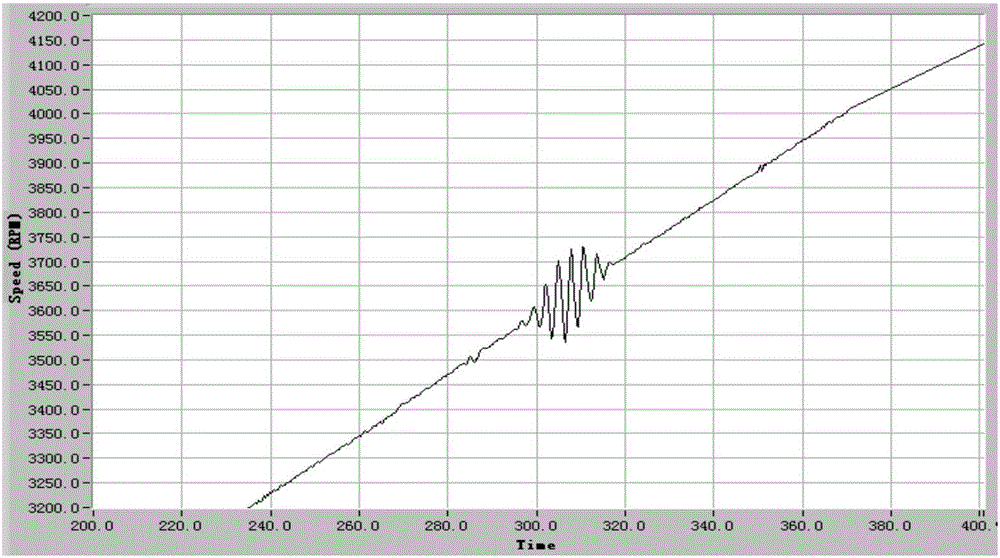

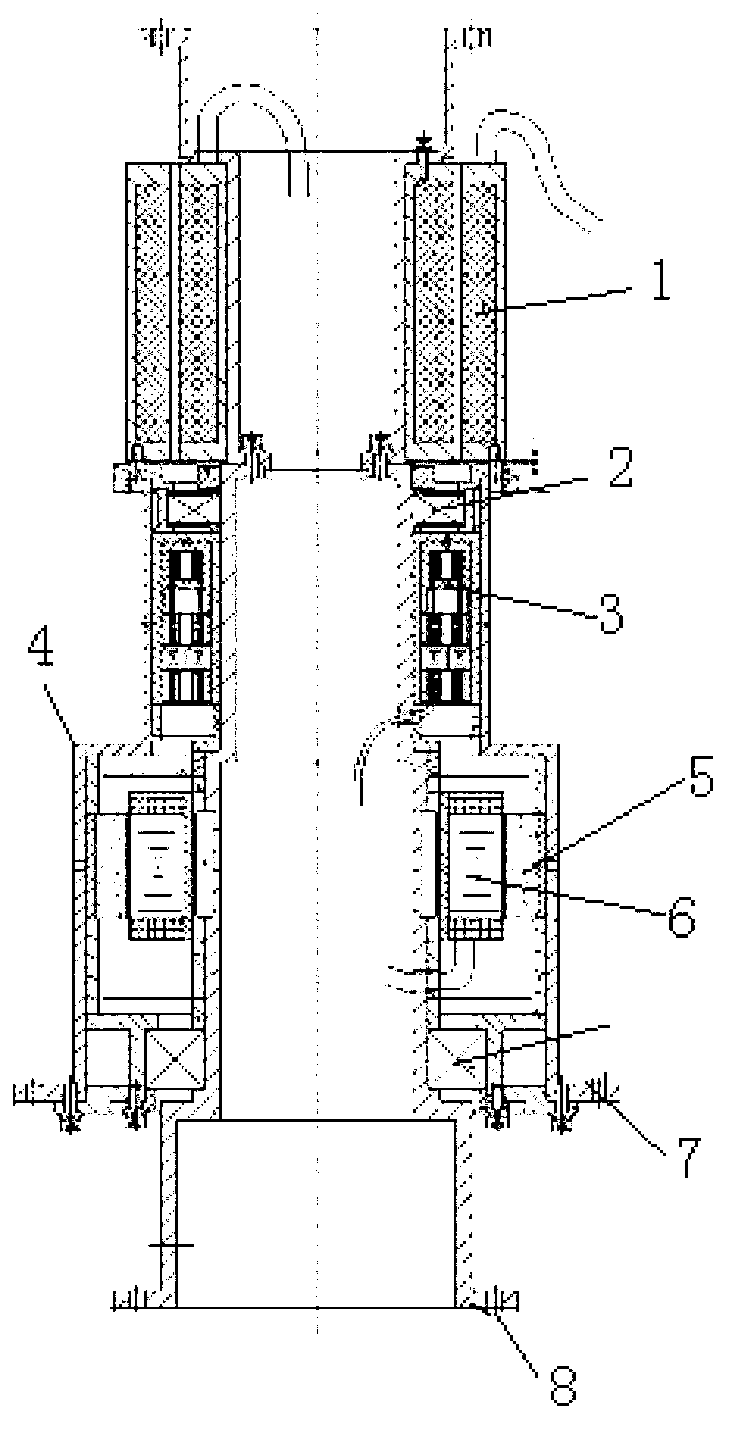

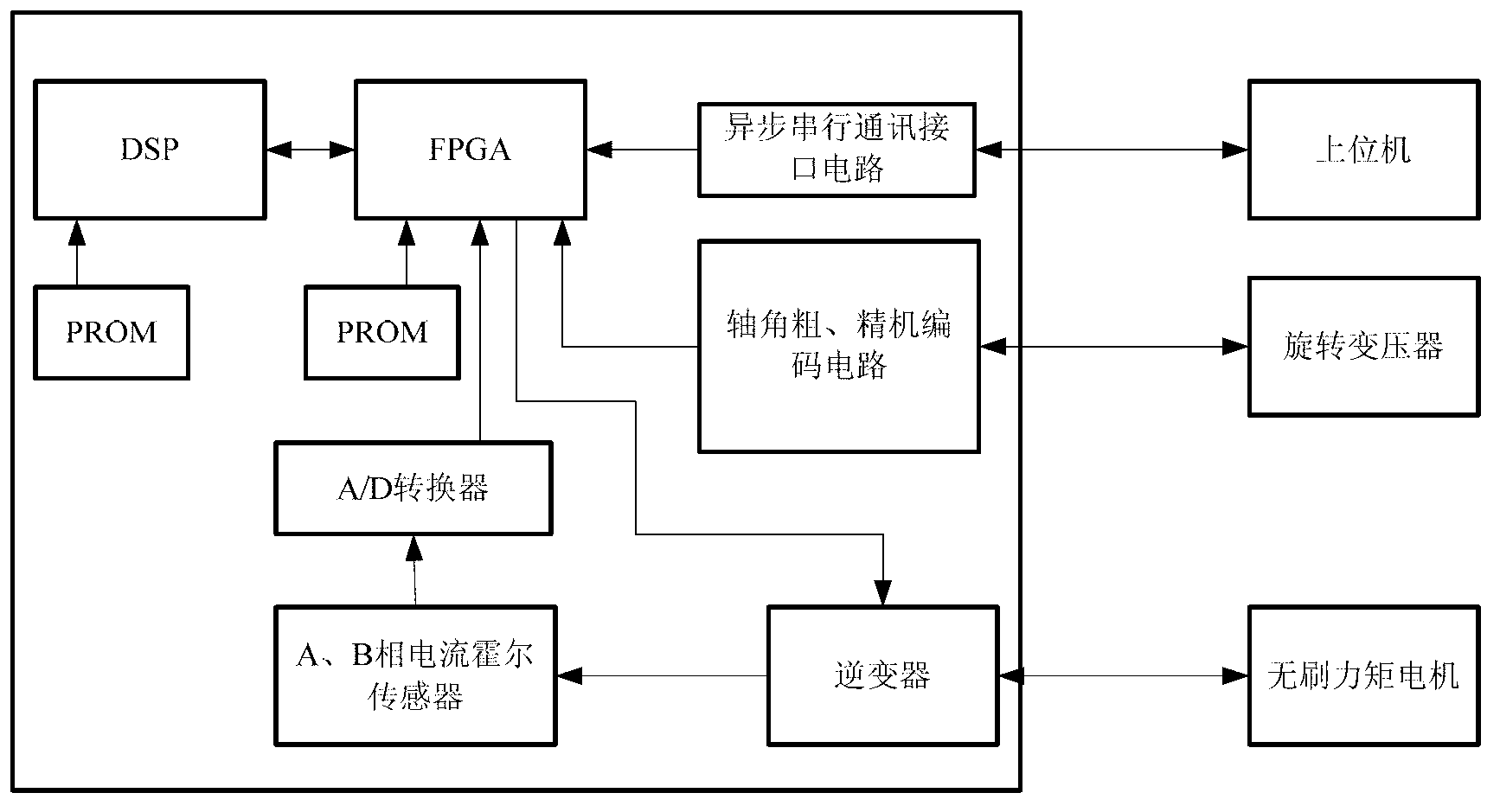

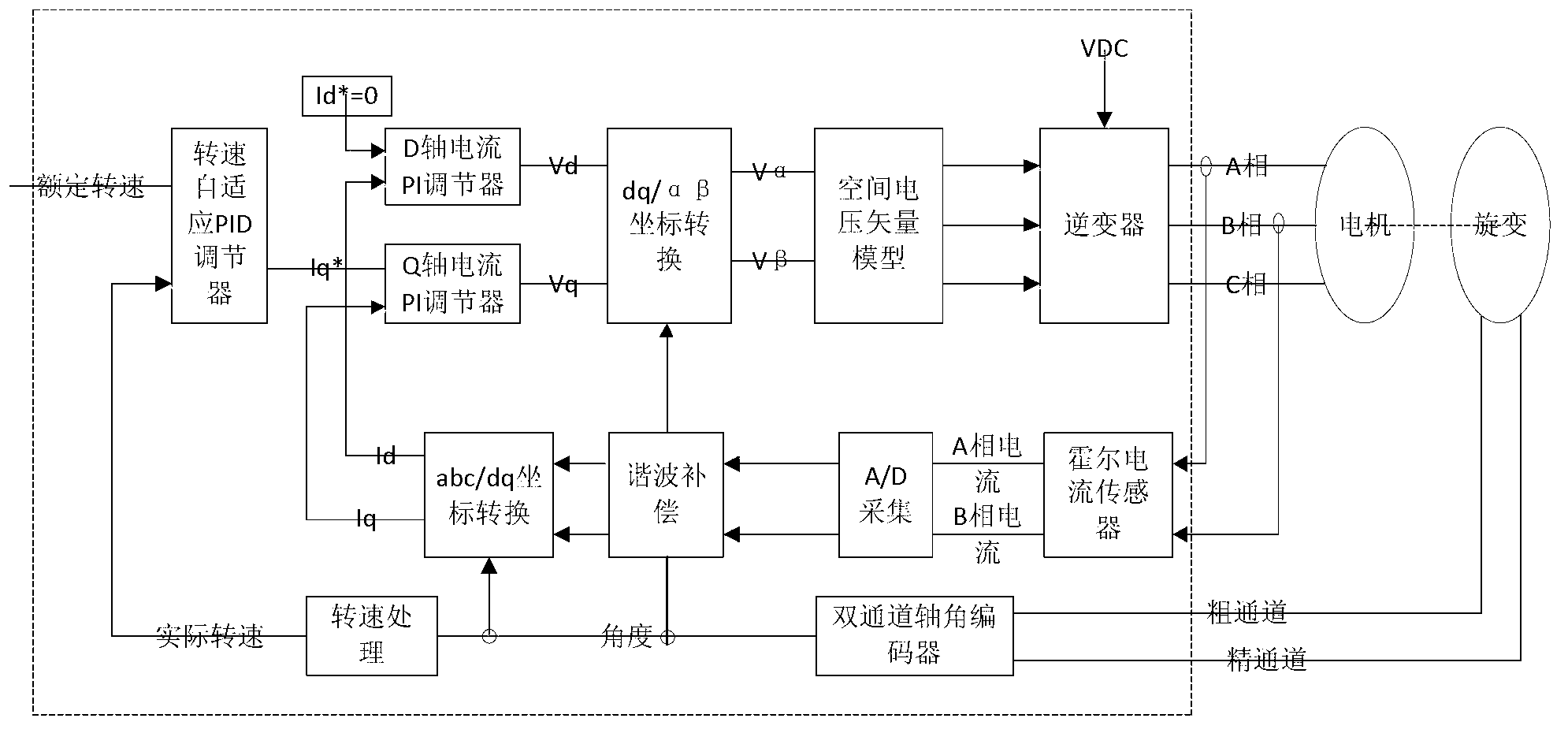

High speed stabilizing drive control method of satellite-borne large inertia load mechanism

ActiveCN103269200AIncrease profitReduced torque harmonic componentsElectronic commutation motor controlAC motor controlFrequency spectrumPhase difference

A high speed stabilizing drive control method of a satellite-borne large inertia load mechanism includes the following steps: (1) powering direct currents on a motor and calculating the phase difference of the motor and a rotary transformer after the load mechanism is stabilized; (2) collecting the current rotating speed of the motor at the current speed ring sampling instant and calculating torque electric currents; (3) collecting the electric currents iA and the electric currents iB of the motor at the current speed ring sampling instant to obtain the harmonic frequency spectrum, the amplitude and the phase of the iA and the iB; (4) conducting harmonic compensation on the iA and the iB; (5) converting the A-phase winding currents and the B-phase winding currents of the motor after compensation under a rotor coordinate system; (6) calculating the two-shaft voltage of the rotor coordinate system; (7) determining the three-phase time value of a PWM waveform generator, wherein a SVPWM waveform generator generates voltage waves according to the three-phase time value, and the voltage waves are loaded on a motor winding to control the motor; (8) entering the next current ring sampling instant, and switching to the step (3) to execute repeatedly; (9) entering the next current ring sampling instant, and switching to the step (2) to execute repeatedly.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Parameter identification method for permanent magnet synchronous motor in steady-state operation mode

ActiveCN111030534AResolve changeImprove recognition accuracyElectronic commutation motor controlAC motor controlPhase currentsPermanent magnet synchronous motor

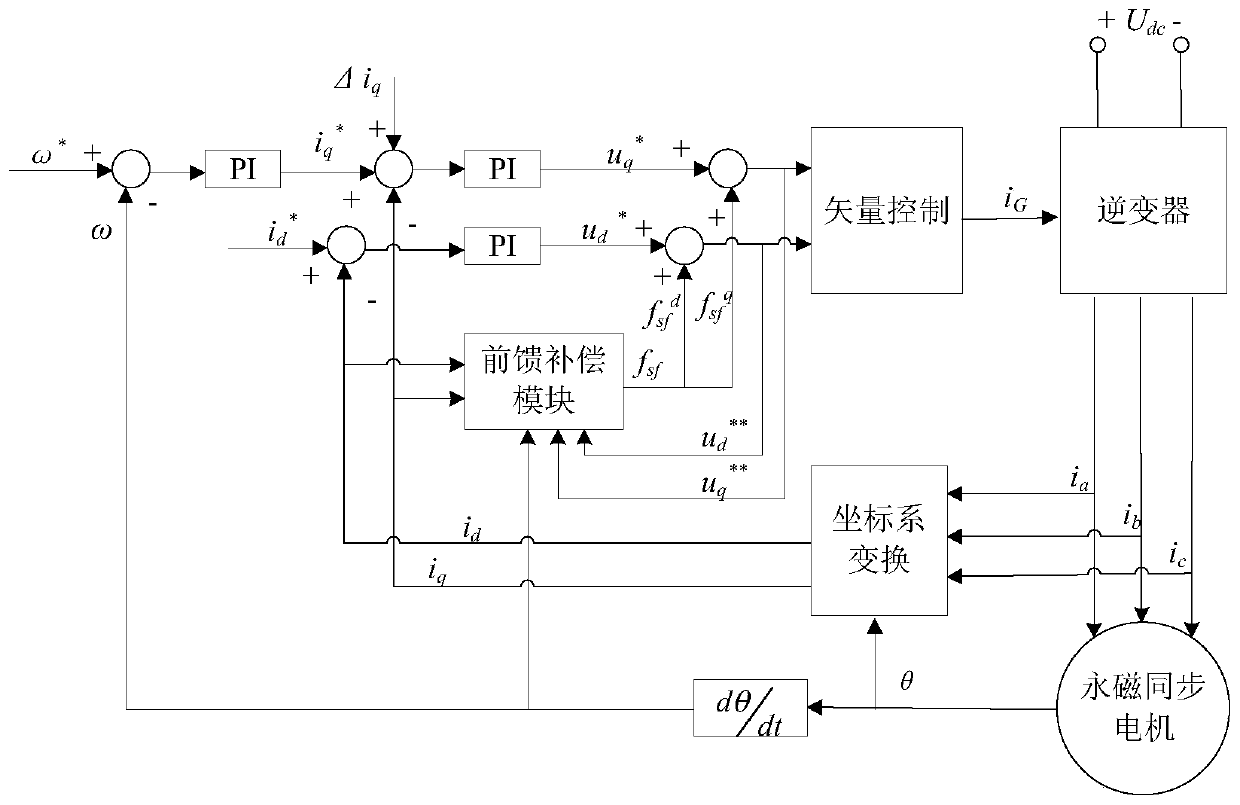

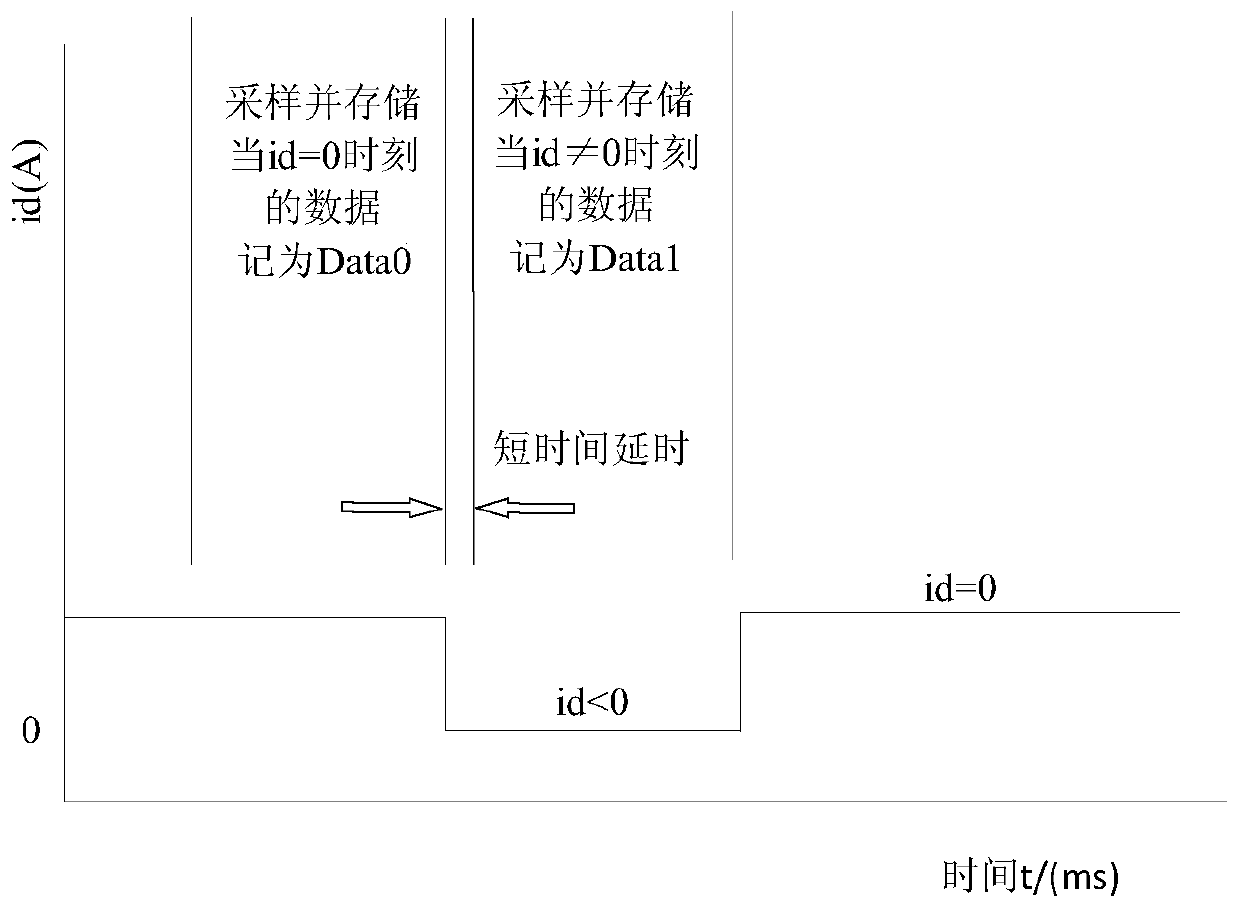

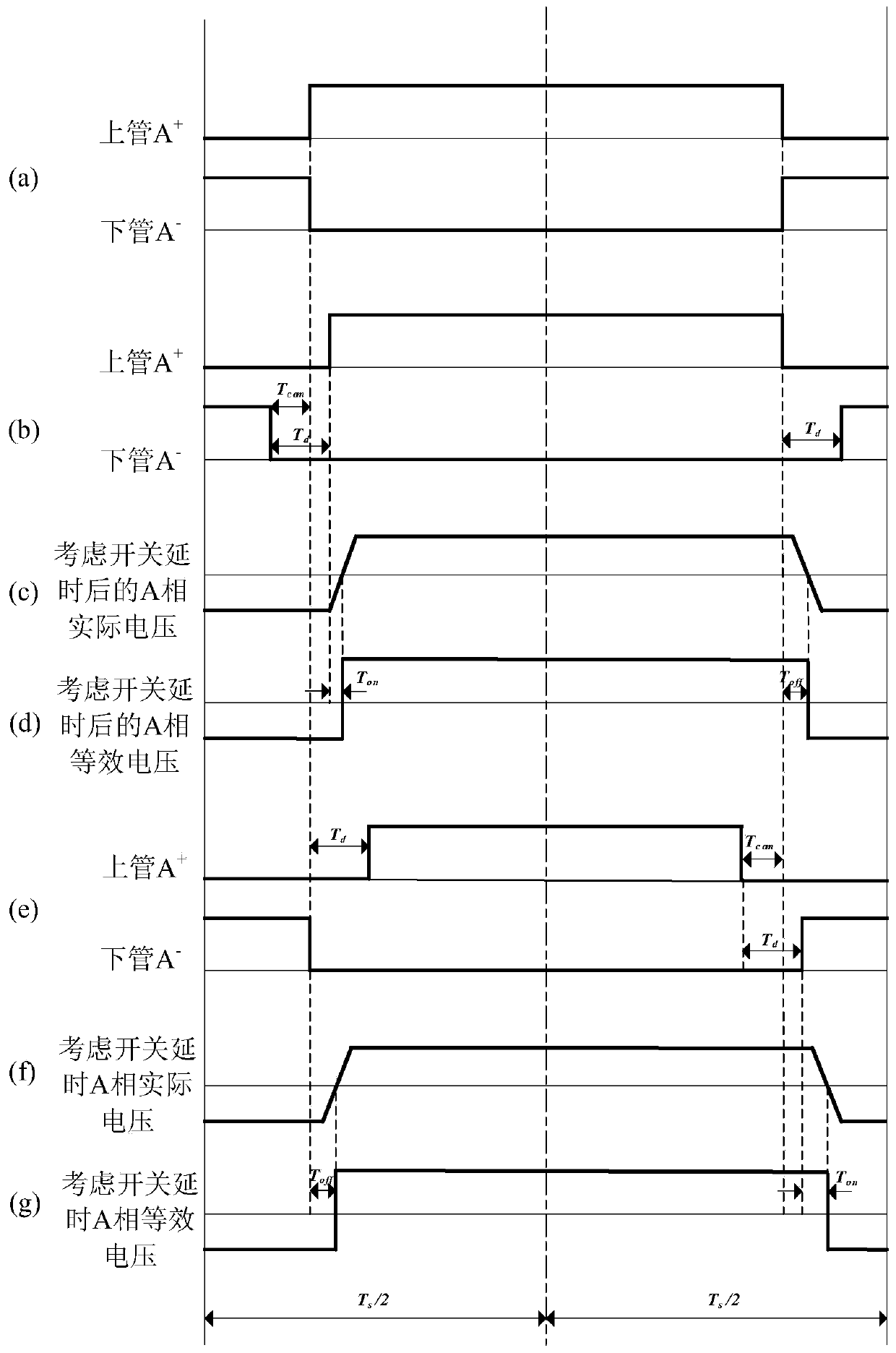

The invention discloses a parameter identification method for a permanent magnet synchronous motor in a steady-state operation mode. The method comprises the steps of: firstly carrying out sampling when the motor is in a steady-state operation state to obtain a direct-axis voltage, a quadrature-axis voltage, a direct-axis current, a quadrature-axis current and an electromechanical angular speed; after short-time current is injected into the direct axis, extracting the five variables again to construct a parameter identification equation; then, analyzing voltage error and three-phase current harmonic problems caused by nonlinearity of an inverter; setting the compensation time to adjust the on-off of a switch tube, reducing the nonlinear influence of the inverter, and improving the overallparameter identification precision; and finally, since the identification result of inductance depends on the direct-axis voltage to a great extent, further improving the identification precision of the inductance through a feedforward compensation algorithm. According to the method, the voltage error caused by the nonlinearity of the inverter can be effectively compensated, the content of the fifth and seventh harmonics of the three-phase current is obviously reduced, the resistance, inductance and permanent magnet flux linkage values can be identified more quickly and precisely, and the control performance of the permanent magnet synchronous motor is improved.

Owner:SOUTHEAST UNIV

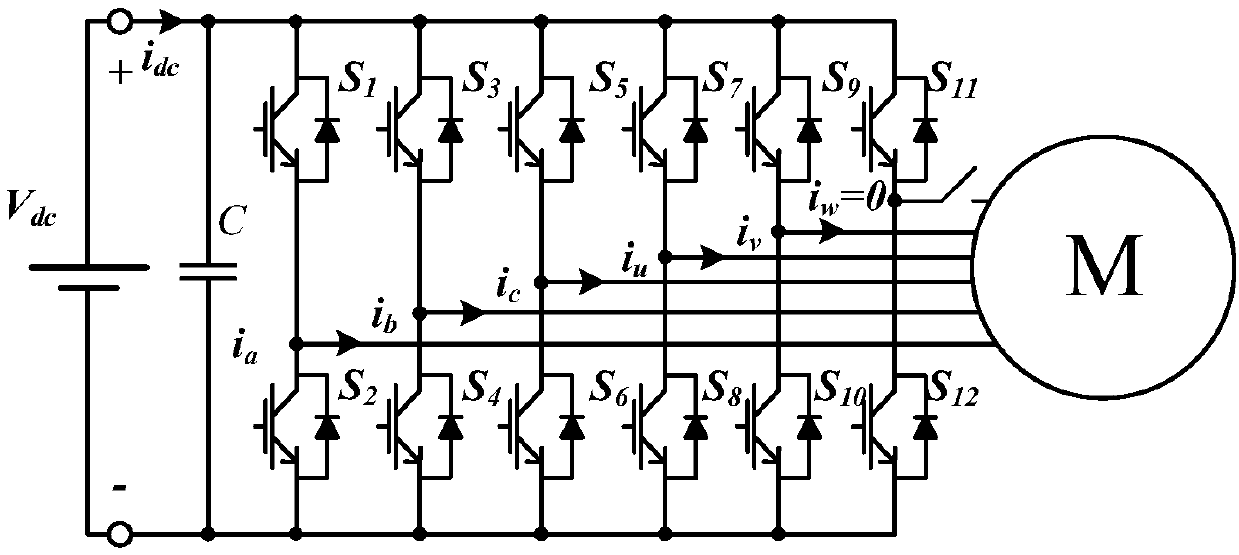

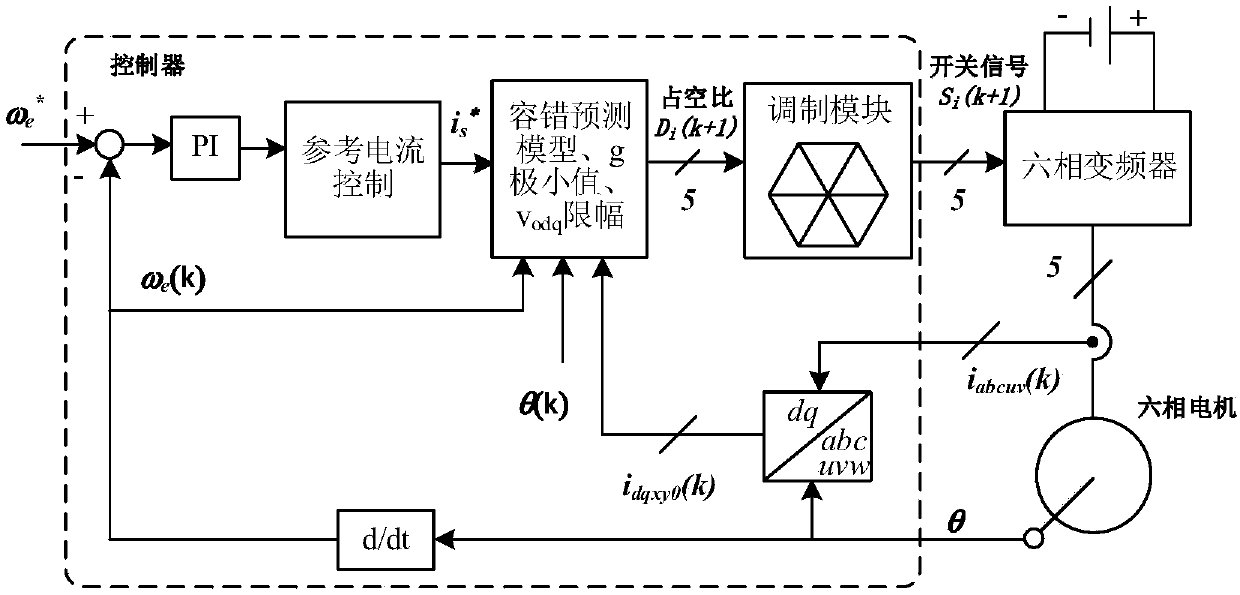

Motor fault-tolerant control method and device

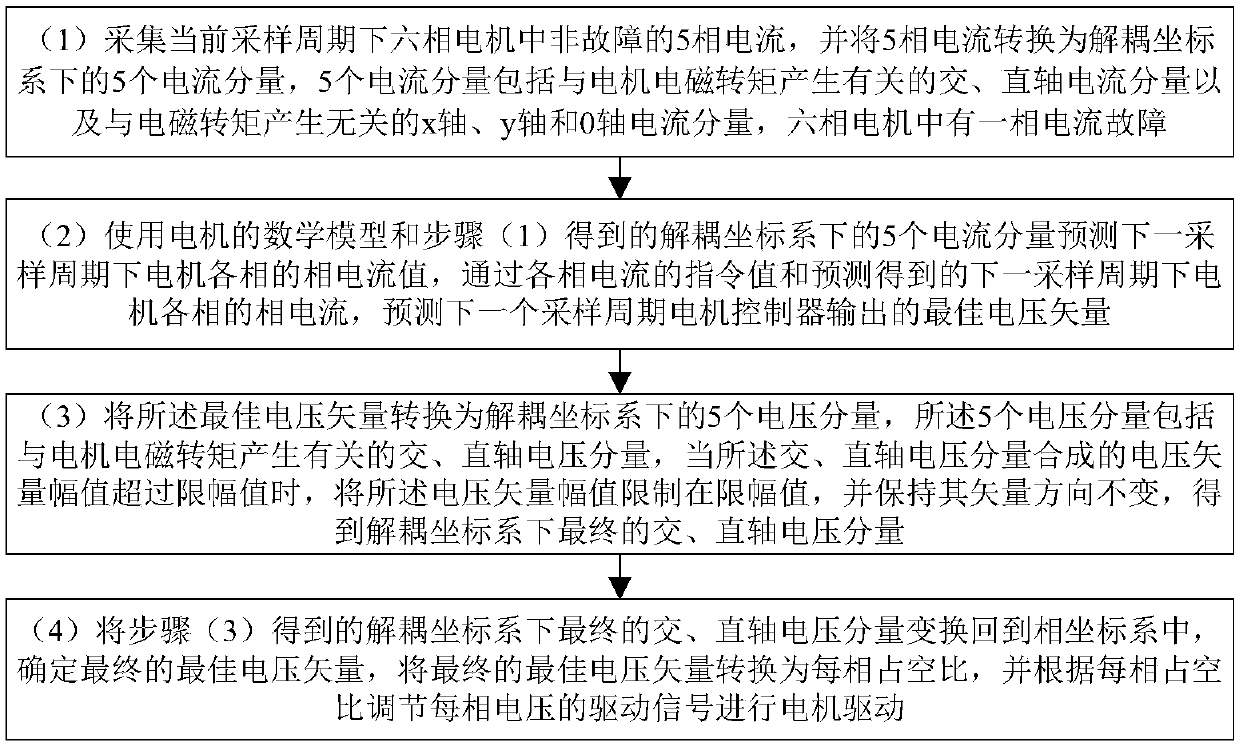

InactiveCN107623479AReduce harmonic contentTo overcome the large amount of calculationElectronic commutation motor controlAC motor controlPhase currentsFault tolerance

The invention discloses a motor fault-tolerant control method and device. The method includes the following steps: collecting non-fault five phases of currents of a six-phase motor in a current sampling period, and converting the five phases of currents into five current components under a decoupled coordinate system; using a mathematical model of the motor and the five current components to predict the phase current value of each phase of the motor in the next sampling period, and predicting the optimal voltage vector output by a motor controller in the next sampling period according to the instruction value of each phase of current; converting the optimal voltage vector into five voltage components under the decoupled coordinate system, and limiting the amplitude of a voltage vector synthesized from a-axis and d-axis voltage components; and transmitting the a-axis and d-axis voltage components after amplitude limiting back to a phase coordinate system, converting the final optimal voltage vector into the duty ratio per phase, and adjusting the drive signal of each phase of voltage according to the duty ratio per phase to drive the motor. The phase current harmonic of the six-phase motor under the open-circuit fault tolerance condition of one phase of winding is significantly reduced while the dynamic performance of the motor is not affected.

Owner:HUAZHONG UNIV OF SCI & TECH

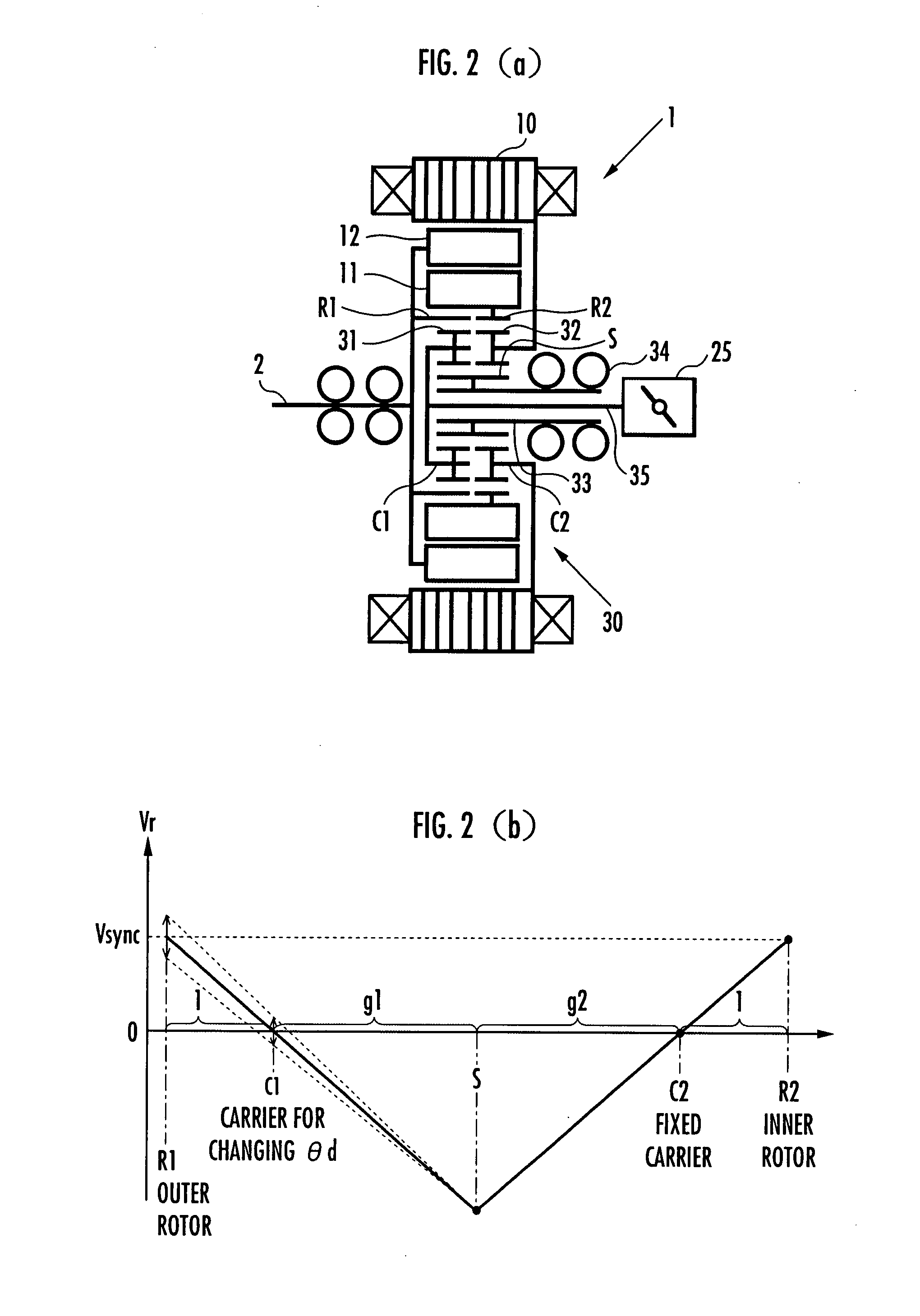

Controller for motor

InactiveUS20070222405A1Short response timeReduce powerMotor/generator/converter stoppersAC motor controlConvertersRotational axis

A controller for a motor permits efficient energization control according to an operating condition of a motor without depending on a number of revolutions of the motor when operating a motor having two rotors disposed around a rotating shaft. The controller includes a voltage-between-terminals increaser which carries out at least one of first processing for increasing a voltage between terminals in which a rotor phase difference is changed by an actuator in a direction for reducing the magnetic fluxes of fields of the motor, second processing for increasing a voltage between terminals in which an output voltage of a DC power source is increased by a DC / DC converter, and third processing for increasing a voltage between terminals in which d-axis current is increased in the case where the magnitude of a resultant vector of a command value of a d-axis voltage and a command value of a q-axis voltage in the motor exceeds the radius of a target voltage circle.

Owner:HONDA MOTOR CO LTD

Permanent magnet brushless DC motor driver control method

ActiveCN106533303AImprove control accuracyImprove dynamic response performanceElectronic commutation motor controlVector control systemsBrushless motorsAnti jamming

The invention discloses a permanent magnet brushless DC motor driver control method. The method is used for control of a motor drive servo control system. The system has relatively good control accuracy and dynamic response performance. The method comprises the steps of firstly reading values of three commutation HALLs through software to obtain an actual position of a rotor when a motor is started, detecting an angular position omega<ref> of the rotor through a rotor position sensor after starting, and simultaneously calculating a speed n of the rotor; detecting a stator current FOC control algorithm to obtain detection values i<d> and i<q>; outputting AC / DC shaft voltage values u<d> and u<q> through a PI adjuster separately, generating voltage values u<alpha> and u<beta> after coordinate transformation to obtain an SVPWM drive signal; and finally outputting sixth paths of control pulse signals and driving six MOSs to drive the motor. The permanent magnet brushless DC motor driver control method is suitable for control of an intelligent obstacle avoidance robot and is achieved by adopting a DSP processor; the control process is achieved through a vector control strategy of which direct axis current is zero; the contradiction between overshoot and the rapidity is solved; the anti-jamming capability of the system is improved; and the high-performance requirement is met.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com