Device for fault diagnosis of electric brush slip ring and method for mechanism diagnosis and maintenance and design

A technology of brush slip ring and diagnostic device, which is applied in the direction of electromechanical devices, measuring devices, manufacturing motor generators, etc., to achieve the effect of reducing failure rate and preventing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

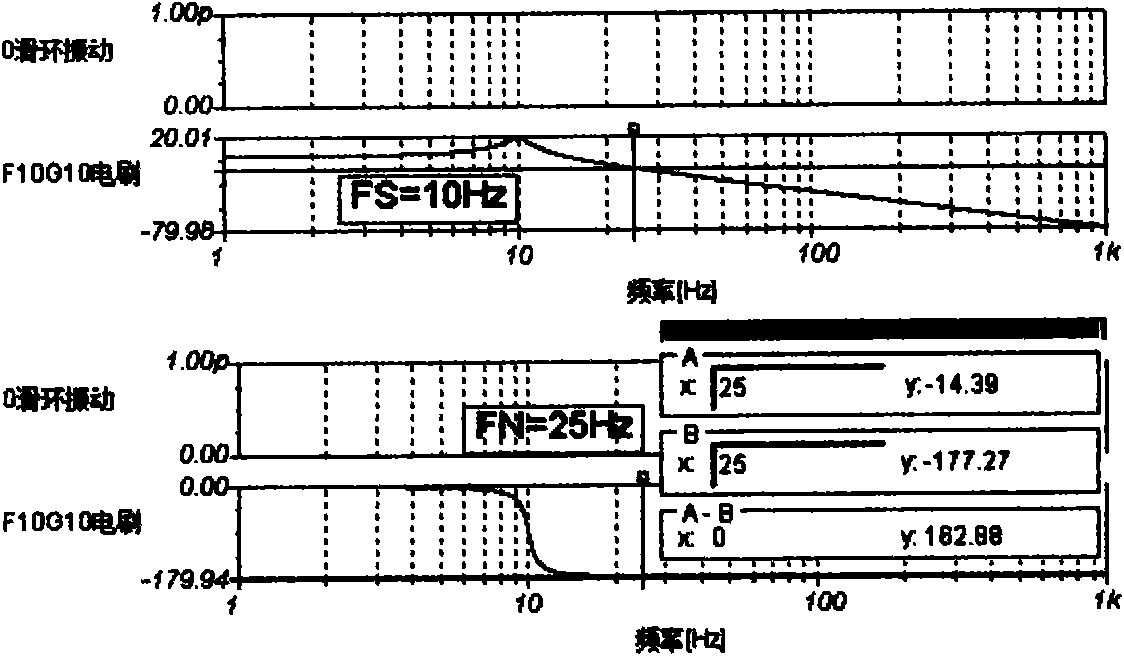

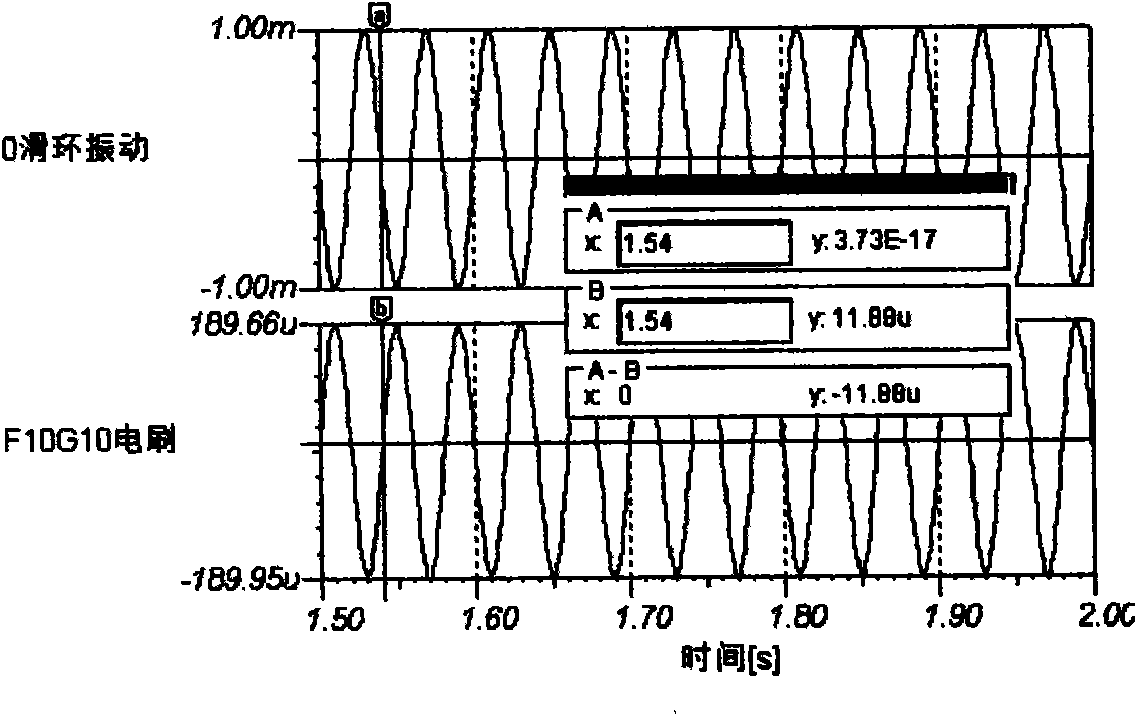

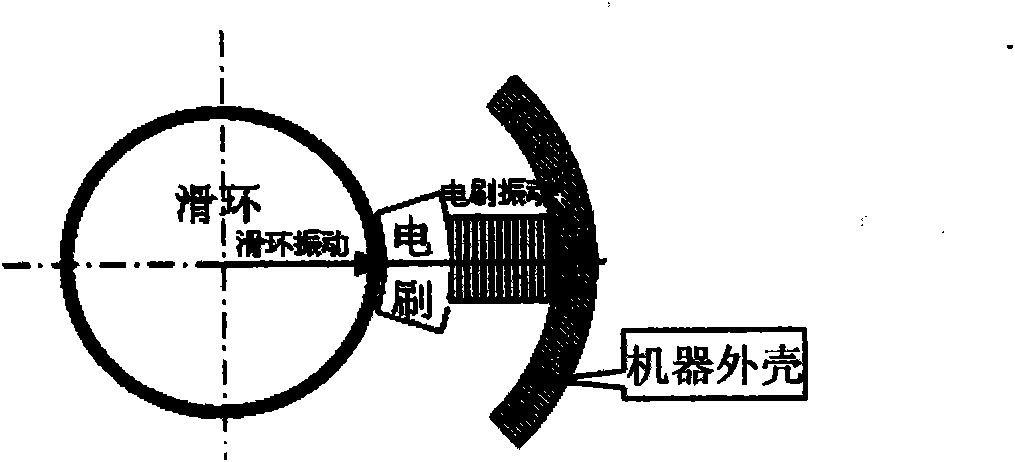

[0081] In this technical solution, the resonant frequency FS of the brush is designed to be greater than the highest excitation frequency FNH of the slip ring. If it is reversed, it will cause a strong impact. The simulation analysis is as follows:

[0082] like Figure 6 It is a mechanical model simulation diagram for analyzing the interaction between slip ring vibration and FS=10Hz brush vibration, and Figure 4 The main difference is that the resonant frequency of the brush is changed from 100Hz to 10Hz, and "F10G10 brush" is used instead of "F100G10 brush". The resonant frequency of the described brush is FS=10Hz, the resonant gain G=10, and the forcing effect of the slip ring on the brush is 1mm. The opening amount of switches SW1~SW3 is 10n, and the closing amount is 0; the opening amount of switches SW4~SW6 is -10n, and the closing amount is 0; The "ring drive brush" impact when the positive vibration of the slip ring has a greater tendency than the positive vibrati...

Embodiment 2

[0112] Example 2: Uniformly distributed brushes and a non-faulty slip ring produce an impact equal to the number of brushes S = 6 times the frequency under the excitation of the first-order vibration frequency FN of the slip ring

[0113] Figure 12-1 It is a schematic diagram of the brush distribution structure of the AS19 wind turbine. The brush slip ring is not known to have failed. According to the fault diagnosis method of this patent technology, it is speculated that the brush should have an S-order prominent shock spectrum of the rotational speed frequency FN. Detected with the vibration and resonance demodulation fault diagnosis instrument 2 with brush slip ring fault diagnosis software manufactured according to this patented technology, it is found as follows:

[0114] One of the obtained data and the spectrum obtained from the analysis is as follows: Figure 12-2 , there are 6 clusters of shock pulses in one rotation cycle. The prominent spectral line frequency F...

Embodiment 3

[0118] A shaft voltage detection sensor 3 for detecting the failure of the brush slip ring in this scheme is a "shaft voltage pulse signal detection sensor" that detects the appearance of the insulated bearing seat of the shaft where the slip ring is located relative to the machine shell to which the brush is connected. Its feature is that it contains the signal line 3-1 connected to the bearing seat and the ground line 3-2 connected to the machine shell, such as Figure 13 "Schematic diagram of shaft voltage detection", and resistors R12~R15, capacitor C11, diodes SD1, SD2 and power supply VDD, NGND, signal line 3-1 is connected to one end of resistor R12, and the other end of R12 is connected to resistor R13 One end of C11 and the negative end of C11, the positive end of C11 is connected to one end of the resistor R15 and the negative end of the diode SD1, the positive end of SD2 and the other end of the resistor R15 are connected to the power supply VDD, and the positive end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com