Patents

Literature

5051 results about "Diagnosis methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The four methods of diagnosis consist of observation, auscultation and olfaction, interrogation, pulse taking and palpation. Observation indicates that doctors directly watch the outward appearance to know a patient's condition.

Methods for the diagnosis of fetal abnormalities

ActiveUS8137912B2Accurate and reliable diagnosisSugar derivativesMicrobiological testing/measurementDiseaseFetal abnormality

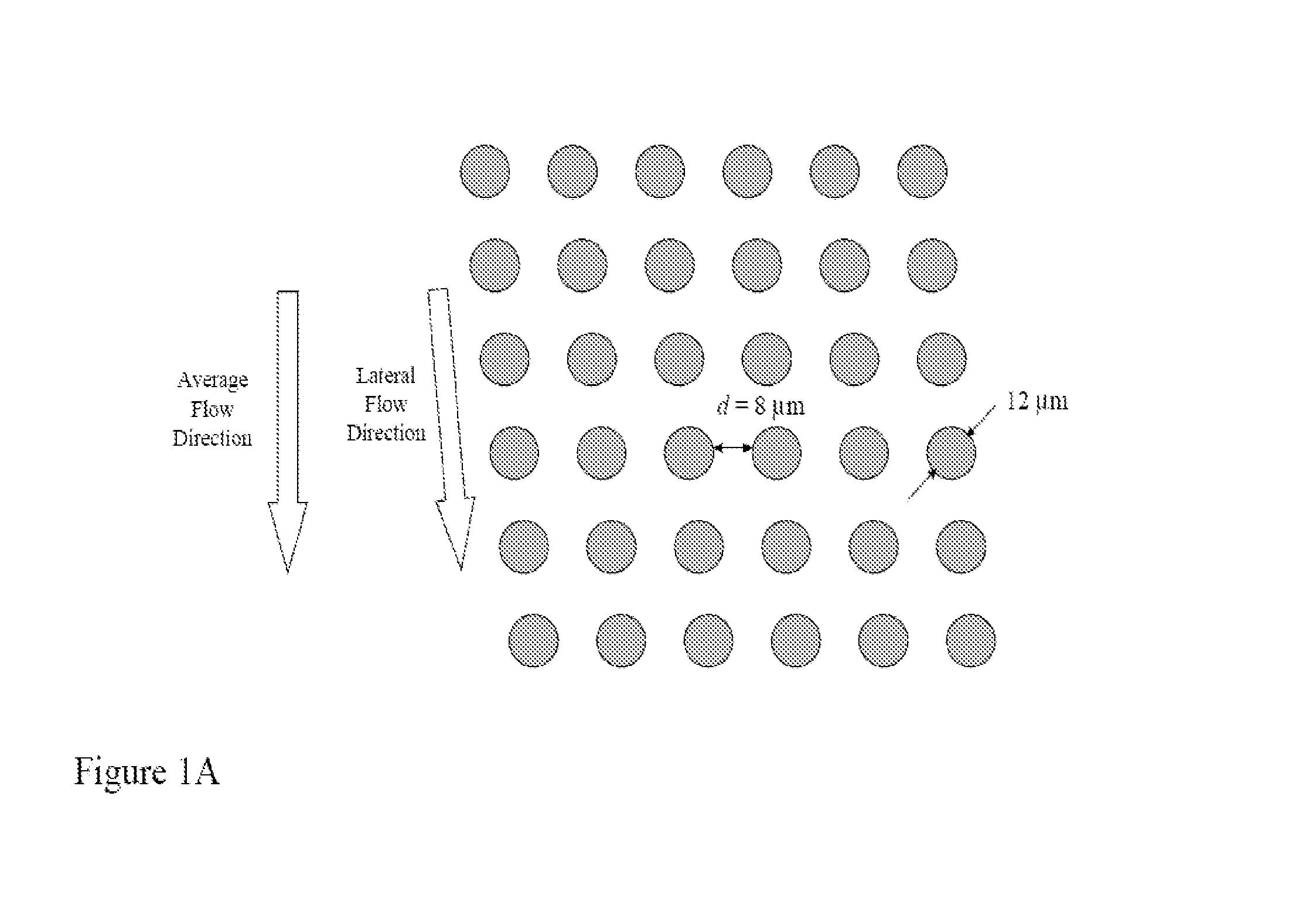

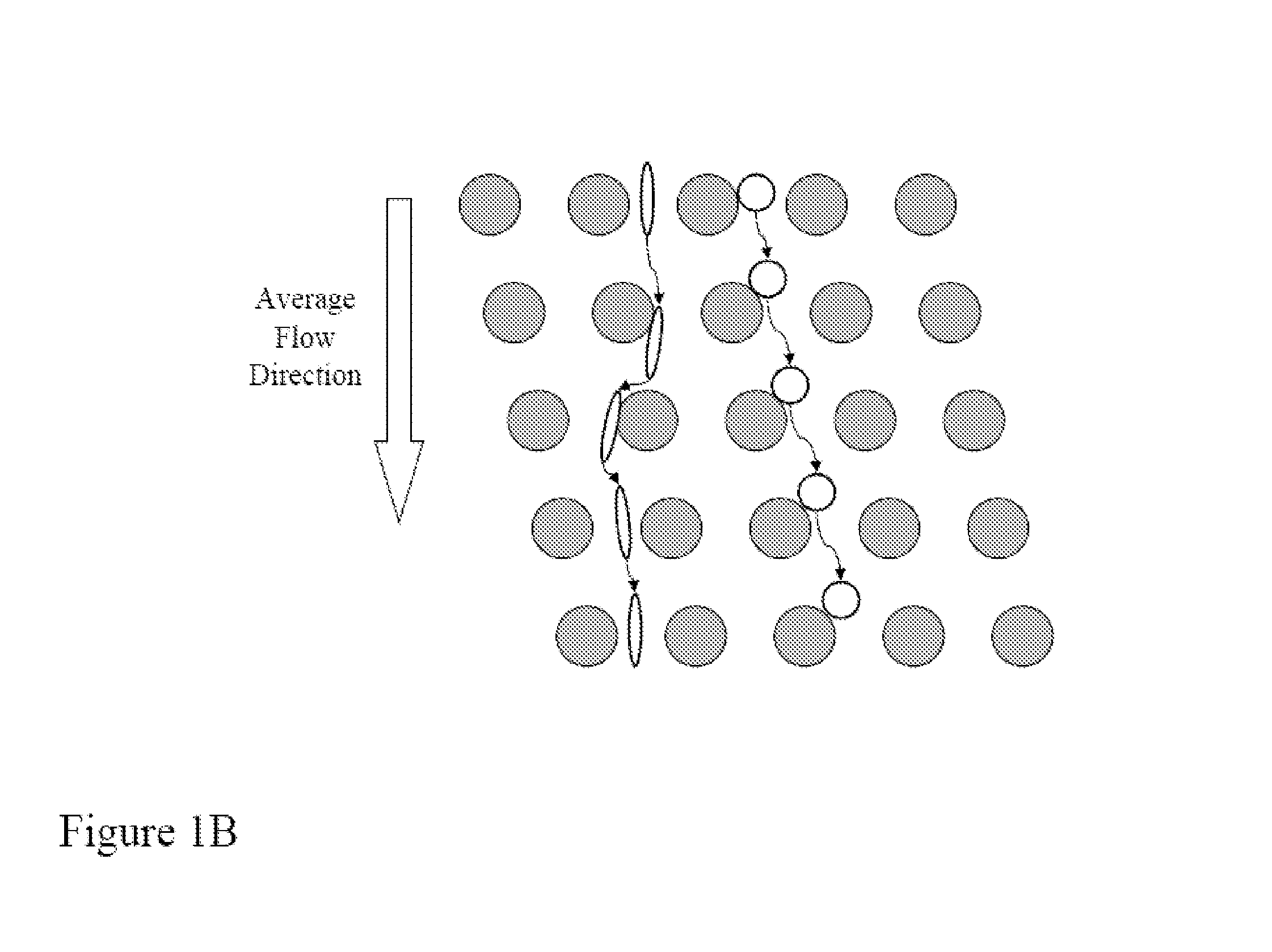

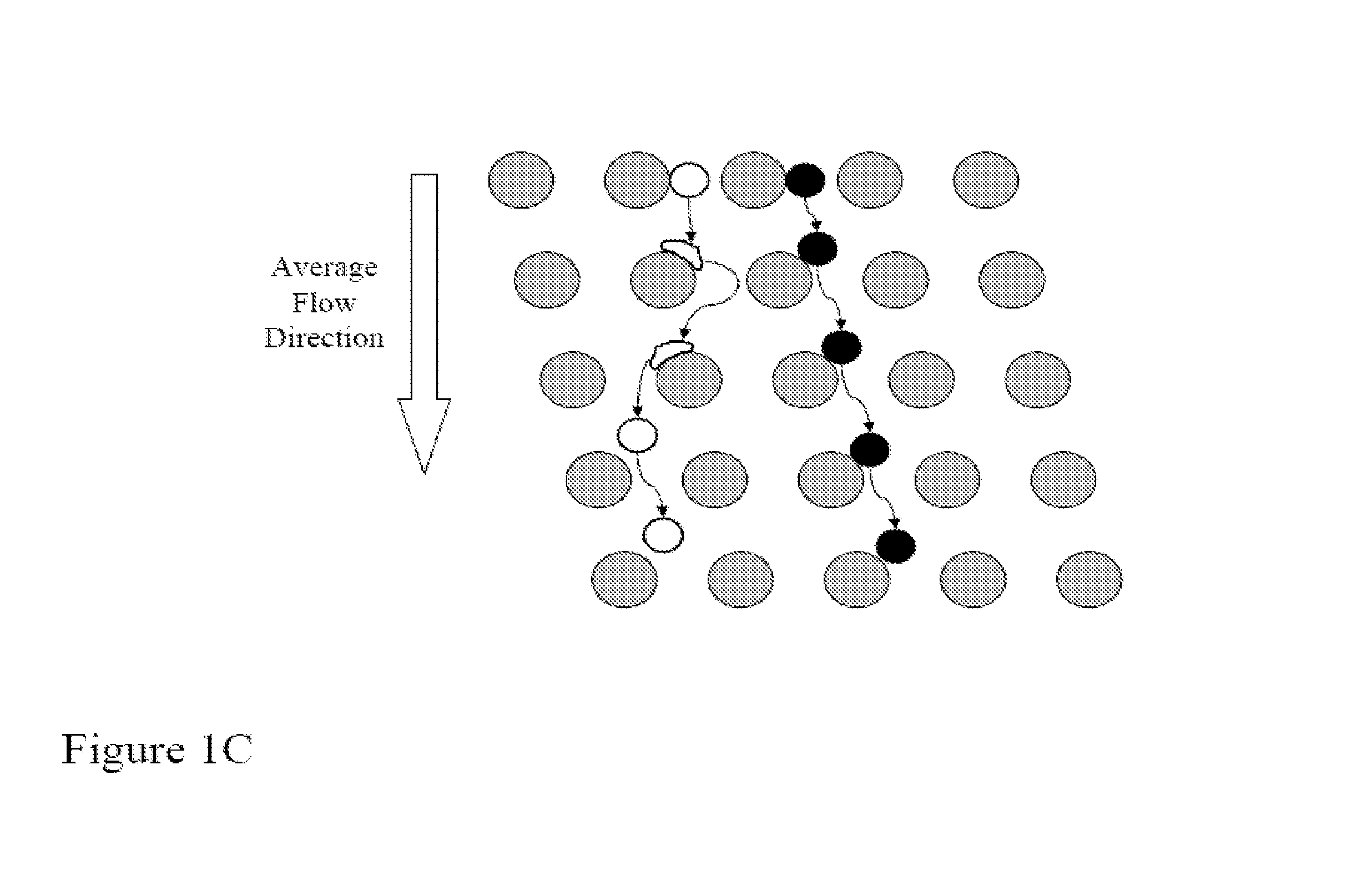

The present invention relates to methods for detecting, enriching, and analyzing rare cells that are present in the blood, e.g. fetal cells. The invention further features methods of analyzing rare cell(s) to determine the presence of an abnormality, disease or condition in a subject, e.g. a fetus by analyzing a cellular sample from the subject.

Owner:VERINATA HEALTH INC +2

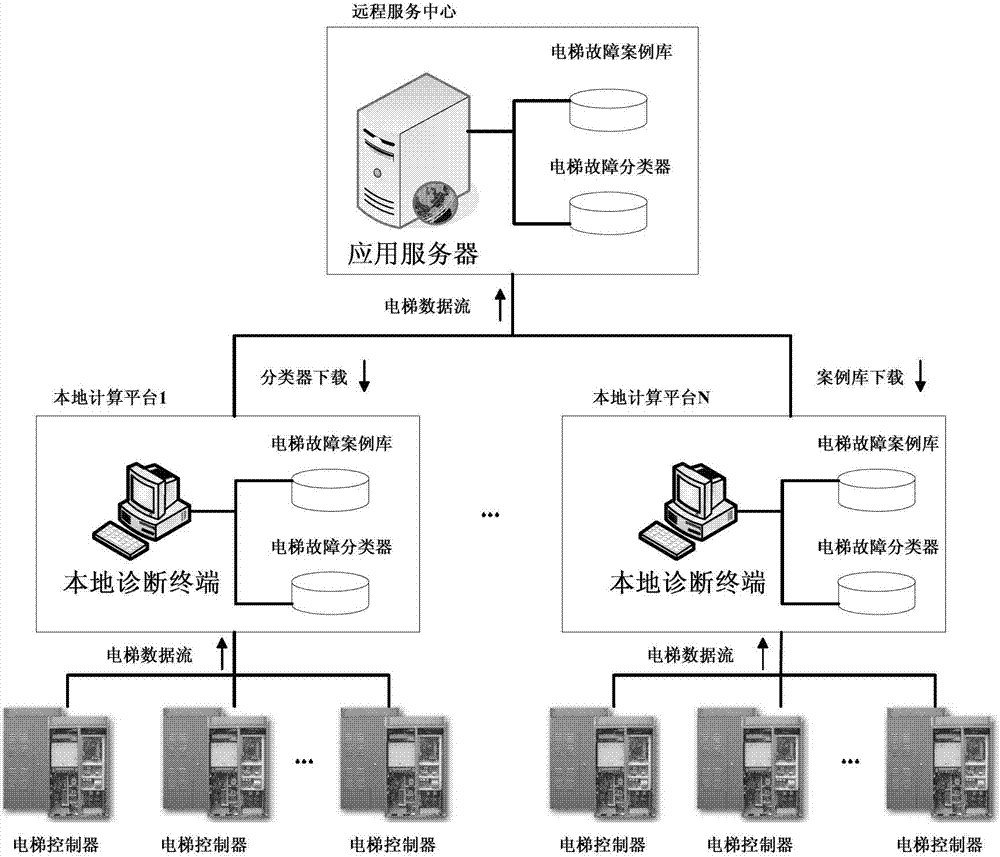

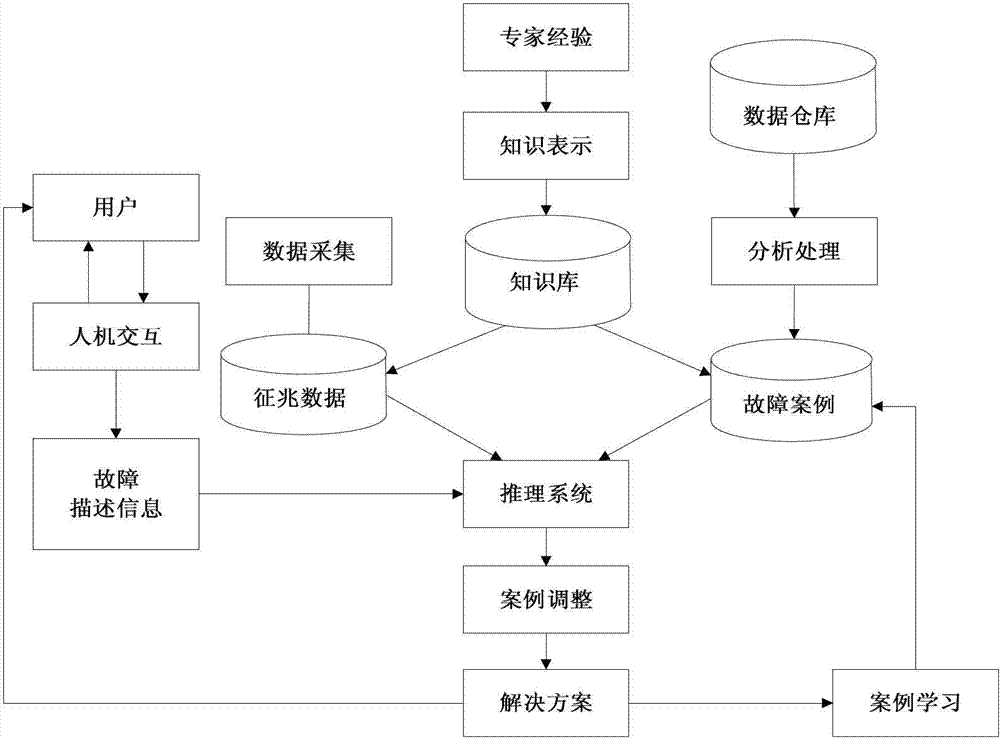

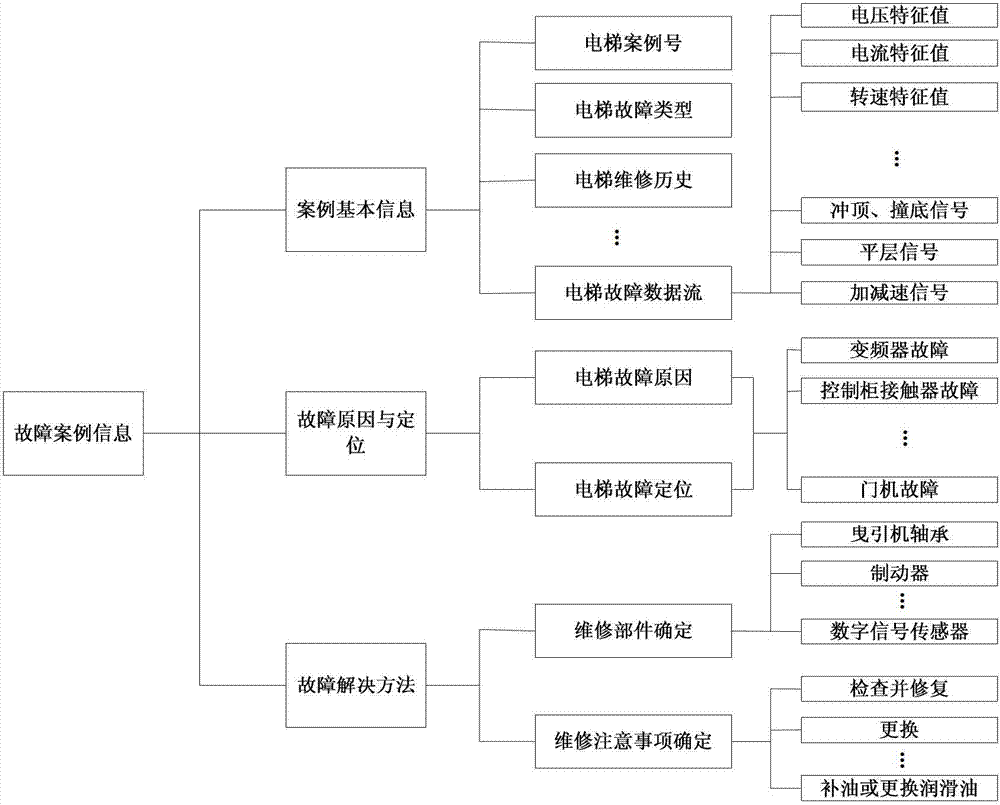

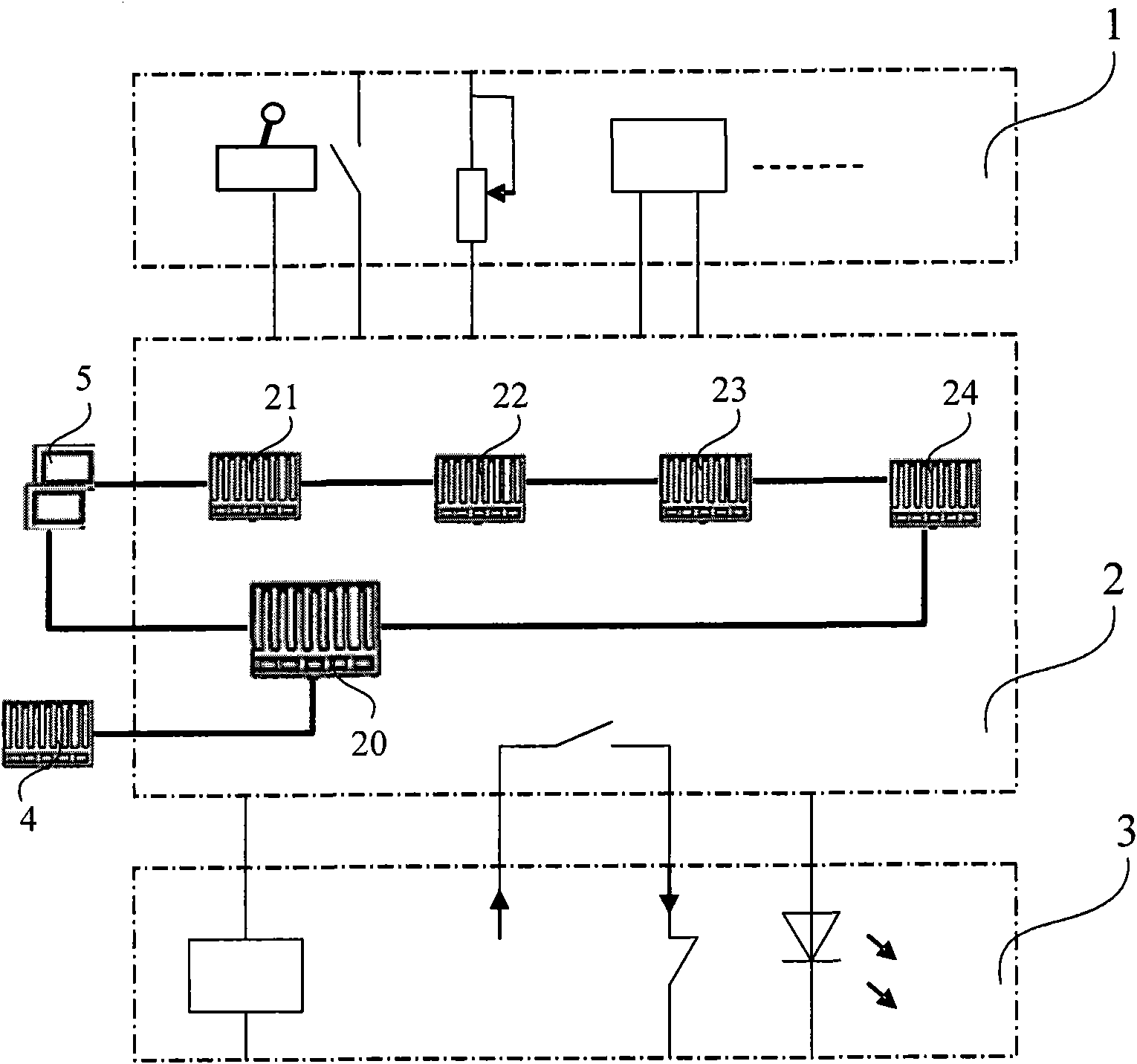

Elevator fault diagnosis and early-warning method based on data drive

InactiveCN102765643AAutomatic acquisitionImprove diagnostic efficiencyElevatorsData streamReliability engineering

The invention relates to the field of elevators. In order to early discover and diagnose A elevator fault, the invention adopts the technical scheme that an elevator fault diagnosis and early-warning method based on data drive is achieved by means of a remote service center, a fault diagnosis and prediction terminal and an elevator controller, and the method comprises the steps as follows: firstly, elevator fault data are mined to obtain characteristic information in an elevator fault data stream, and the mined result is stored in an elevator fault case base of the fault diagnosis and prediction terminal; secondly, an elevator fault knowledge base on the fault diagnosis and prediction terminal is updated by the elevator fault case base; thirdly, the case retrieval is carried out on the characteristic of a new elevator fault problem, and the fault diagnosis is carried out on the elevator system by adopting the fault diagnosis method based on the case-base reasoning; and finally information with the characteristic that is most similar with that of the new elevator fault problem is acquired through retrieval of the knowledge or the case in the elevator fault knowledge base to solve the diagnosis problem. The method is mainly suitable for manufacturing and designing image sensors.

Owner:TIANJIN UNIV

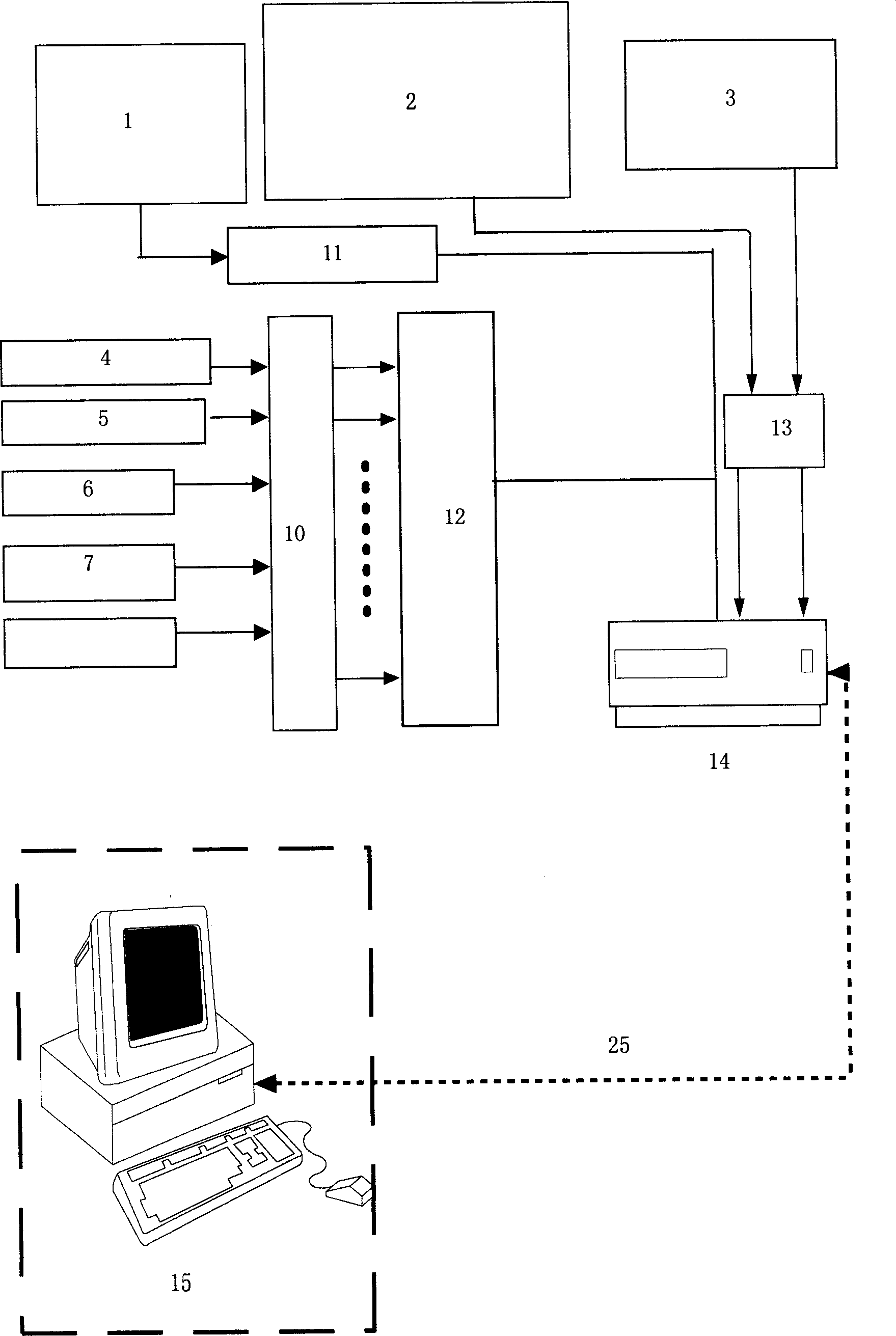

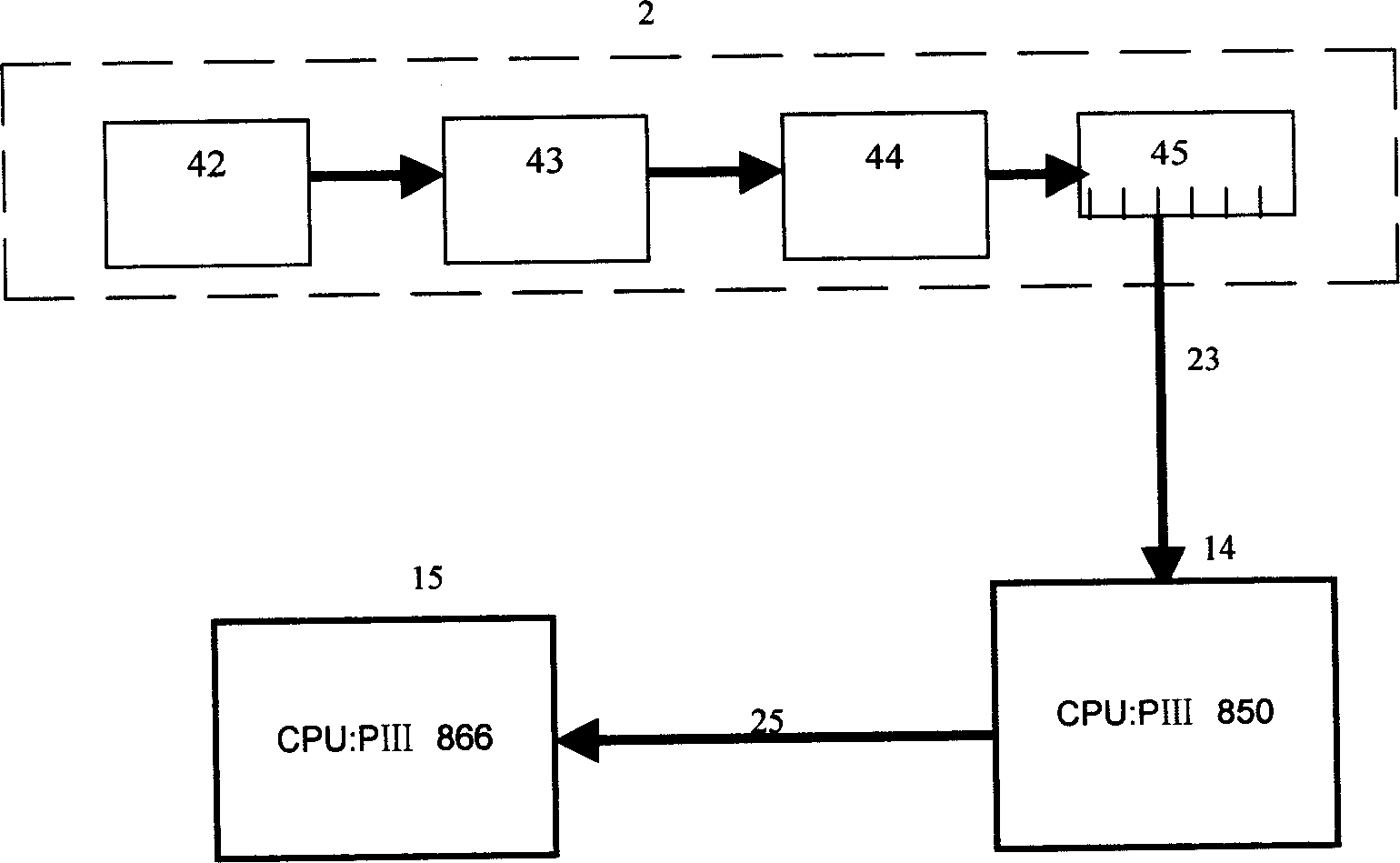

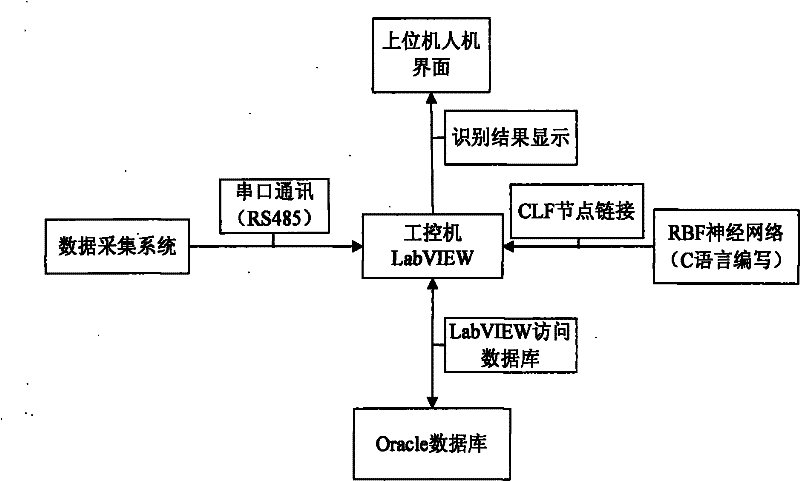

On-line intelligent monitoring system for transformer and intelligent analysis diagnosis method thereof

InactiveCN1484034AGuaranteed uptimeImprove the level of auxiliary diagnosisElectrical testingAudio power amplifierTransformer

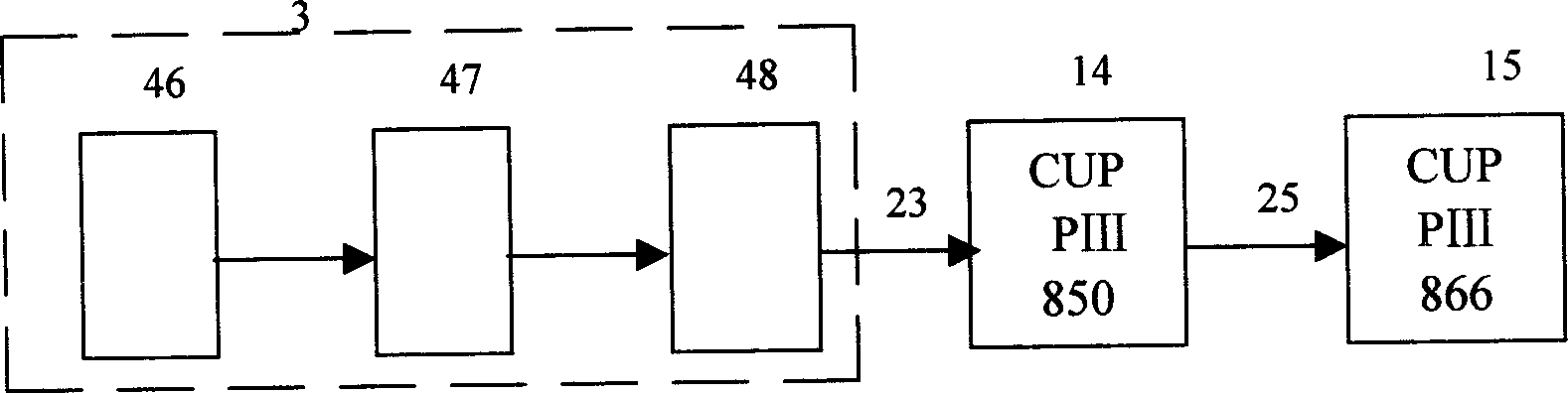

The invention refers to a transformer on-line intelligent monitoring system and its intelligent diagnosis method. It includes all kinds of sensors for the transformer's dynamic capability monitoring device, some electric signals collected by the sensors connected with A / D converting circuit through the amplifier and regulating circuit, some ones connected with industrial computer through A / D collecting card or interface circuit to be processed by the foreground computer, then transmitted into the background CPU transformer fault diagnosis system for diagnosis and analysis, to obtain the monitoring results. The method: inputting various signal data into the computer, making the computer combined with the stored information database to carry out on-line real-time diagnosis and alarm on the abnormal condition.

Owner:TEBIAN ELECTRIC APP CO LTD

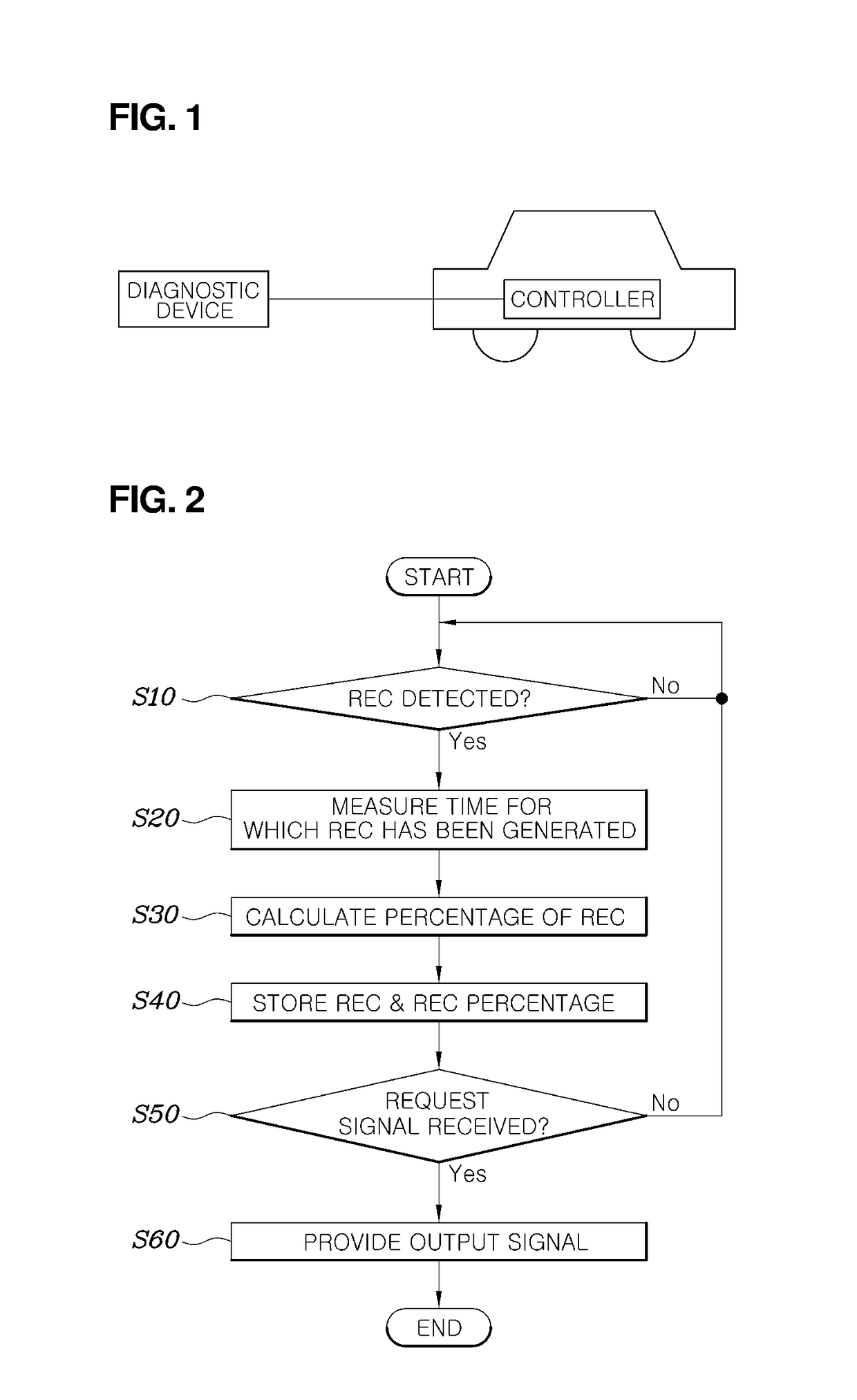

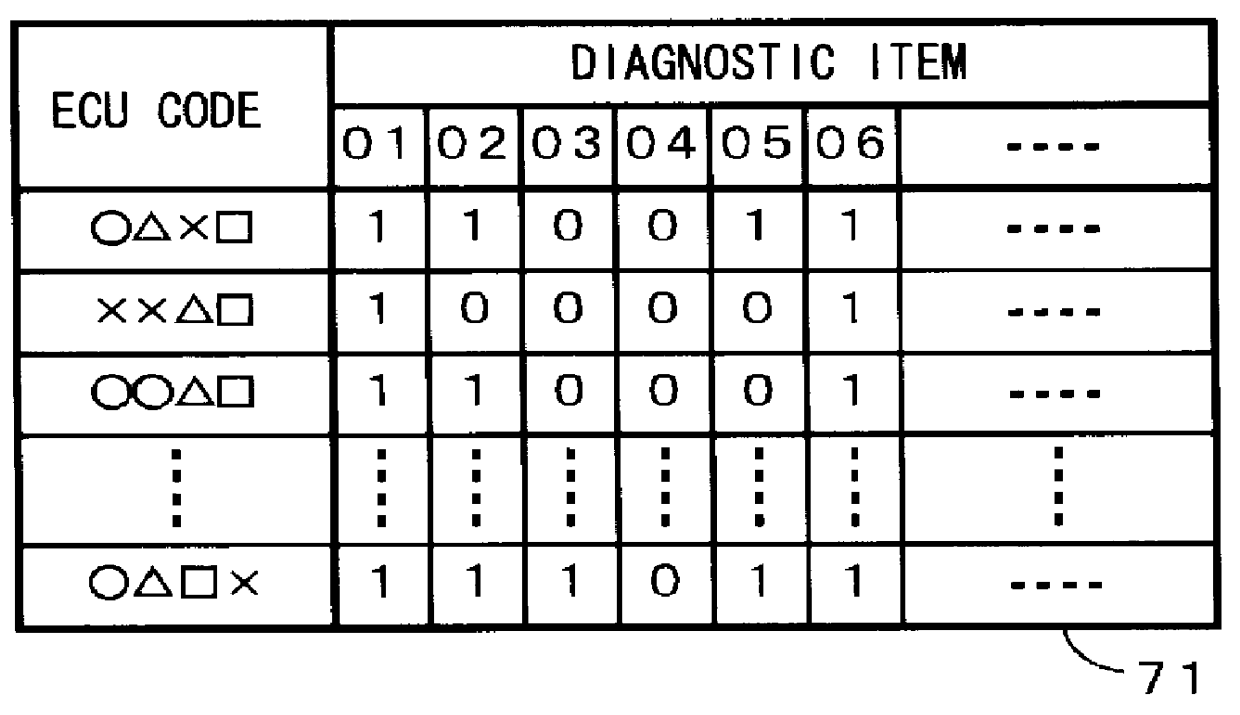

Fault diagnosis method for vehicle

InactiveUS20170154479A1Easy maintenanceImprove usabilityProgramme controlVehicle testingDiagnosis methodsSoftware engineering

A fault diagnosis method for a vehicle includes steps of: detecting, by a controller, whether a reference engineering code (REC) has been generated; if the reference engineering code (REC) has been generated as a result of performing the detecting step, measuring, by the controller, a time for which the reference engineering code (REC) has been generated; after the measuring step, calculating, by the controller, a percentage of the reference engineering code (REC), based on both the time for which the reference engineering code (REC) has been generated and a preset time; after the calculating step, storing, by the controller, the reference engineering code (REC) and the percentage of the REC; and after the storing step, when a request signal is received from a diagnostic device, providing, by the controller, an output signal that includes the reference engineering code (REC) and the percentage of the REC to the diagnostic device.

Owner:HYUNDAI MOTOR CO LTD

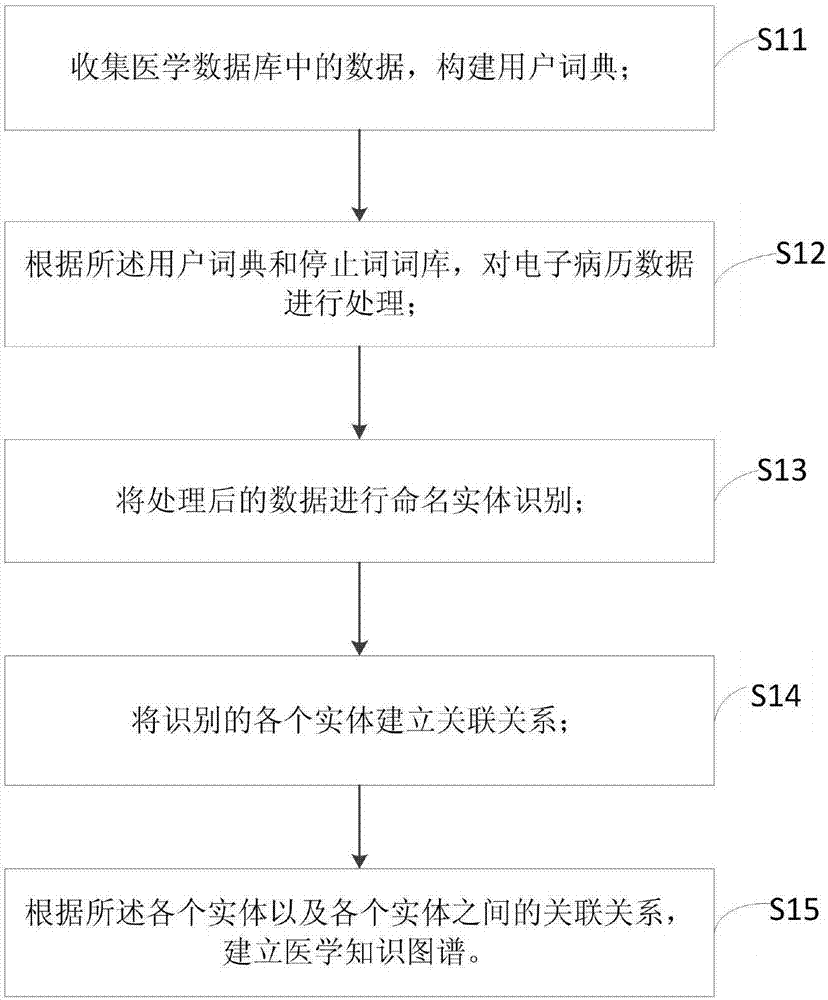

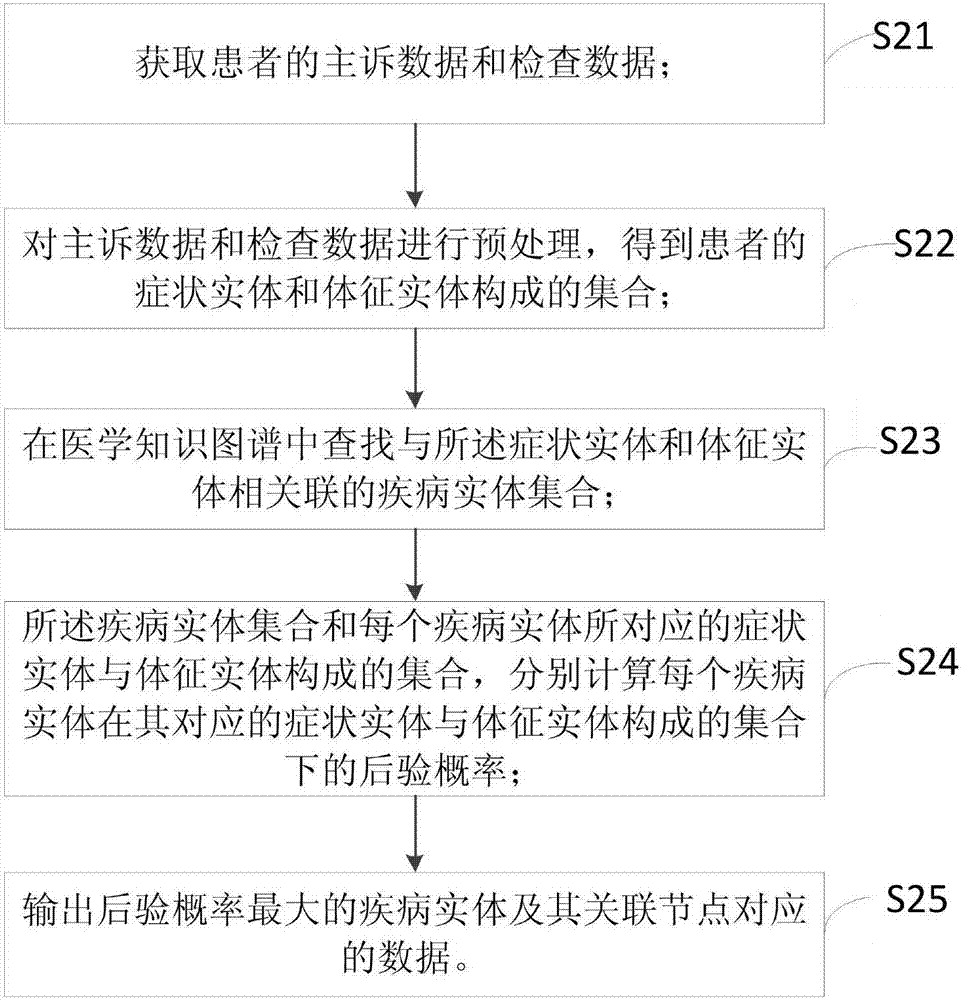

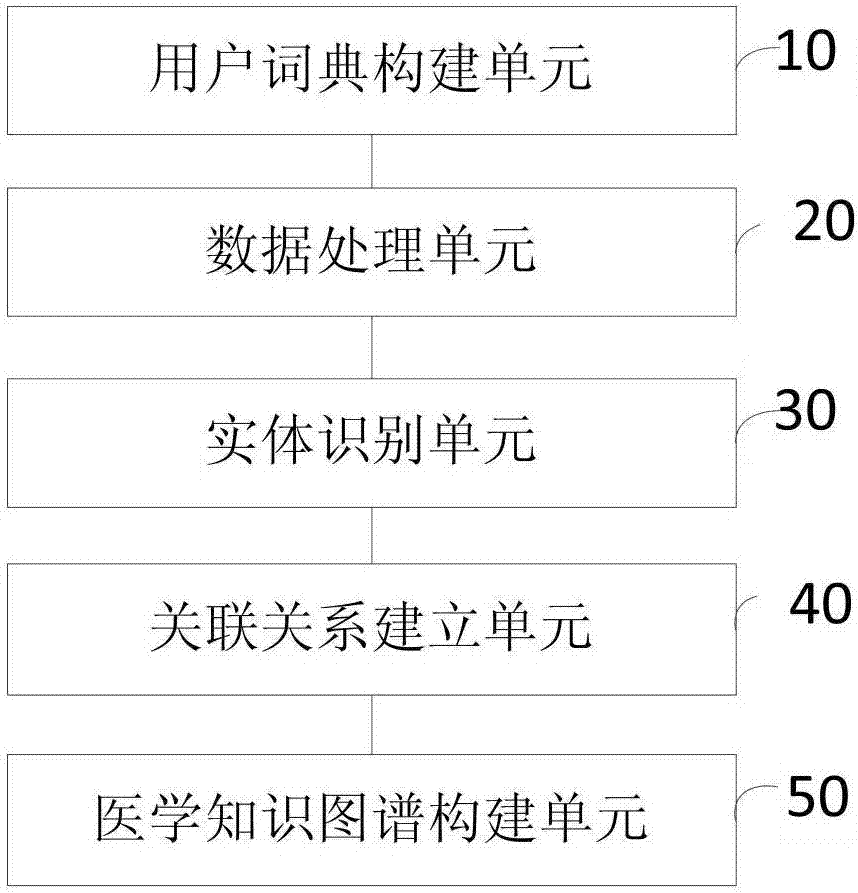

Method and device for establishing medical knowledge graph, and auxiliary diagnosis method

ActiveCN107145744AReduce workloadRelieve medical stressMedical data miningMedical automated diagnosisMedical recordNODAL

The invention discloses a method and device for establishing a medical knowledge graph, and an auxiliary diagnosis method. The method for establishing the medical knowledge graph comprises the steps that a user dictionary is established according to a medical database; electronic medical record data is processed, and named entity recognition is conducted; correlation relations are established for each recognized entity; and the medical knowledge graph is established according to the correlation relations. The auxiliary diagnosis method based on the medical knowledge graph comprises the steps that a patient's chief complaint data and inspection data are acquired and processed, so that a symptom entity and a sign entity of the patient can be obtained; a disease entity correlated with the symptom entity and the sign entity is searched in the medical knowledge graph, and a posterior probability of each disease entity in a set composed of the corresponding symptom entity and the sign entity is computed respectively; and the disease entity with the maximum posterior probability and data corresponding to correlated nodes of the disease entity are output. According to the invention, intelligent auxiliary diagnosis is provided for clinical medical science, so that working burdens of medical workers are relieved; medical stress is relieved; and occurrence rate of medical accidents is reduced.

Owner:HEFEI UNIV OF TECH

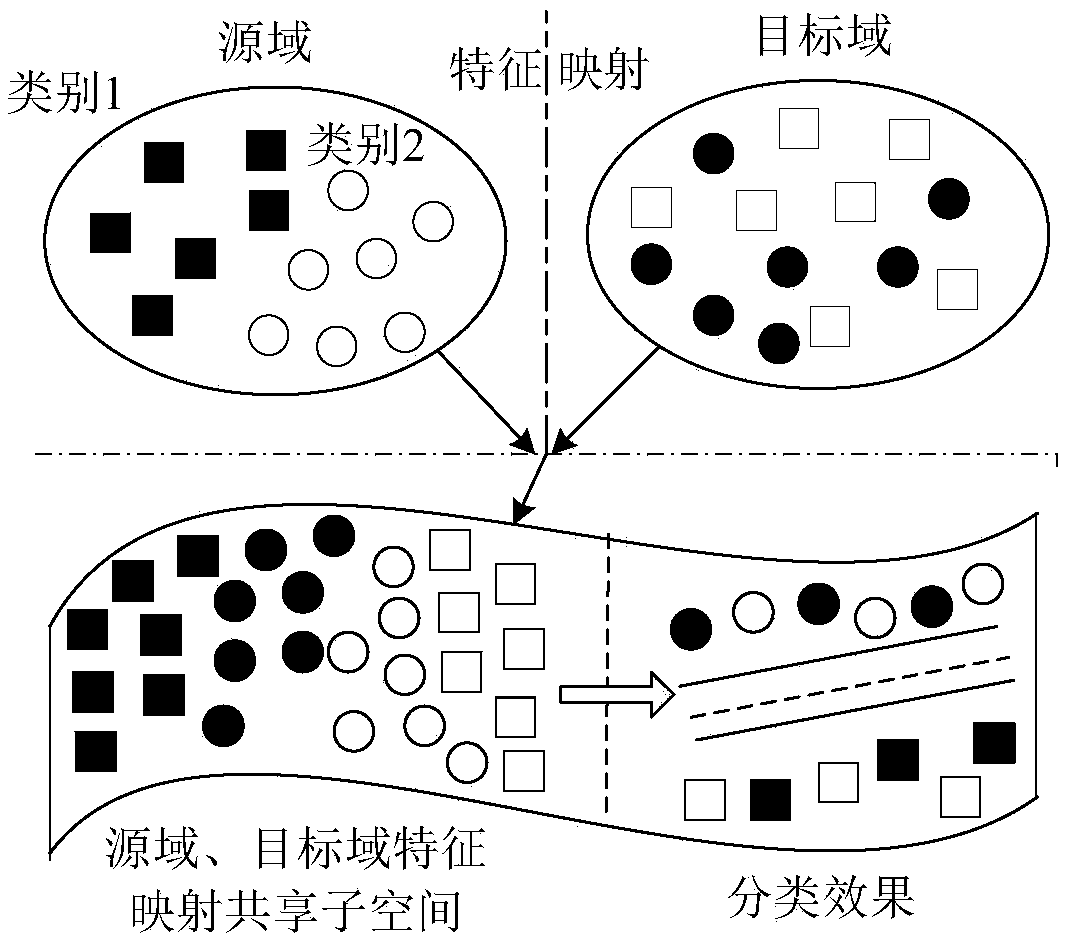

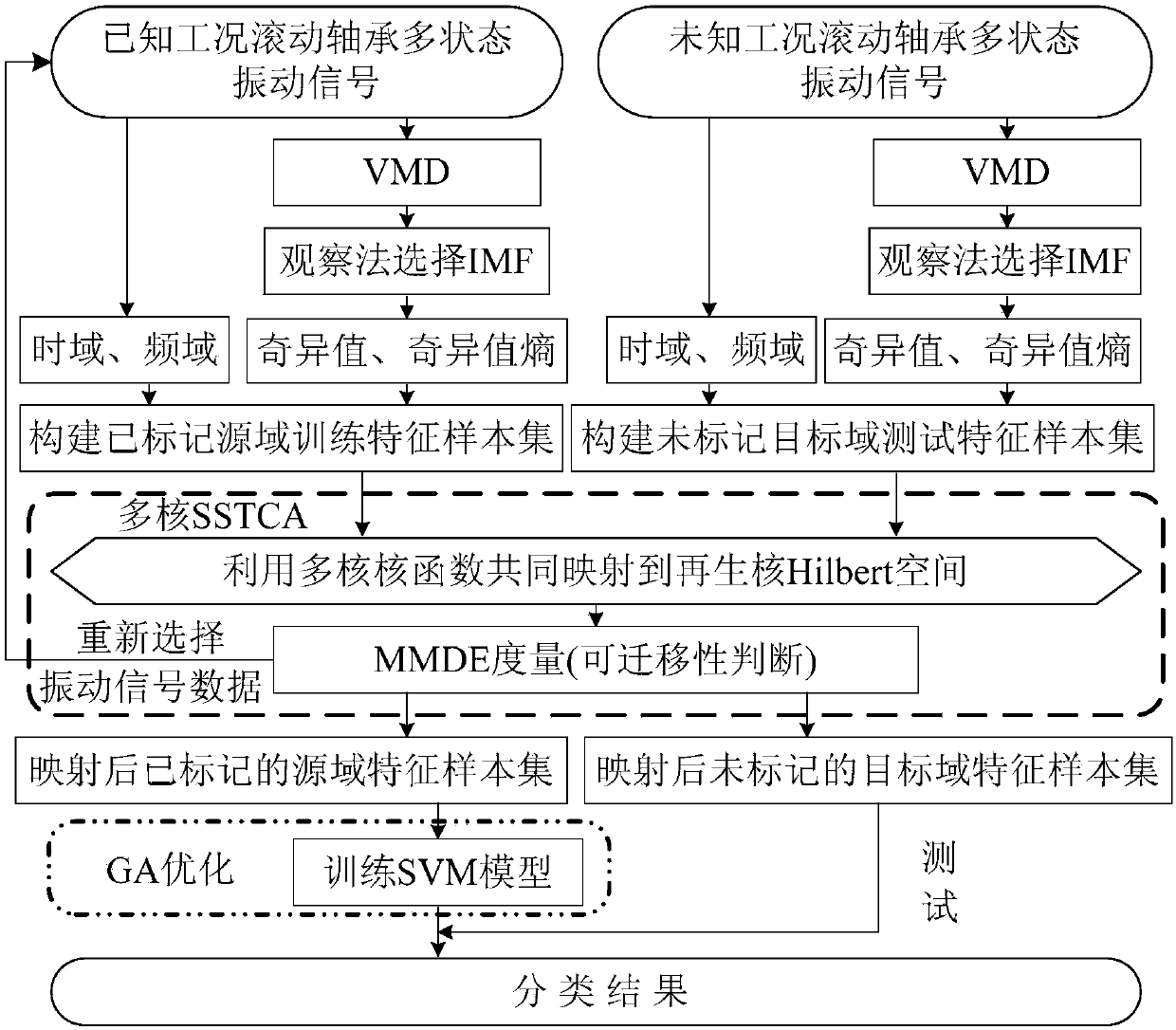

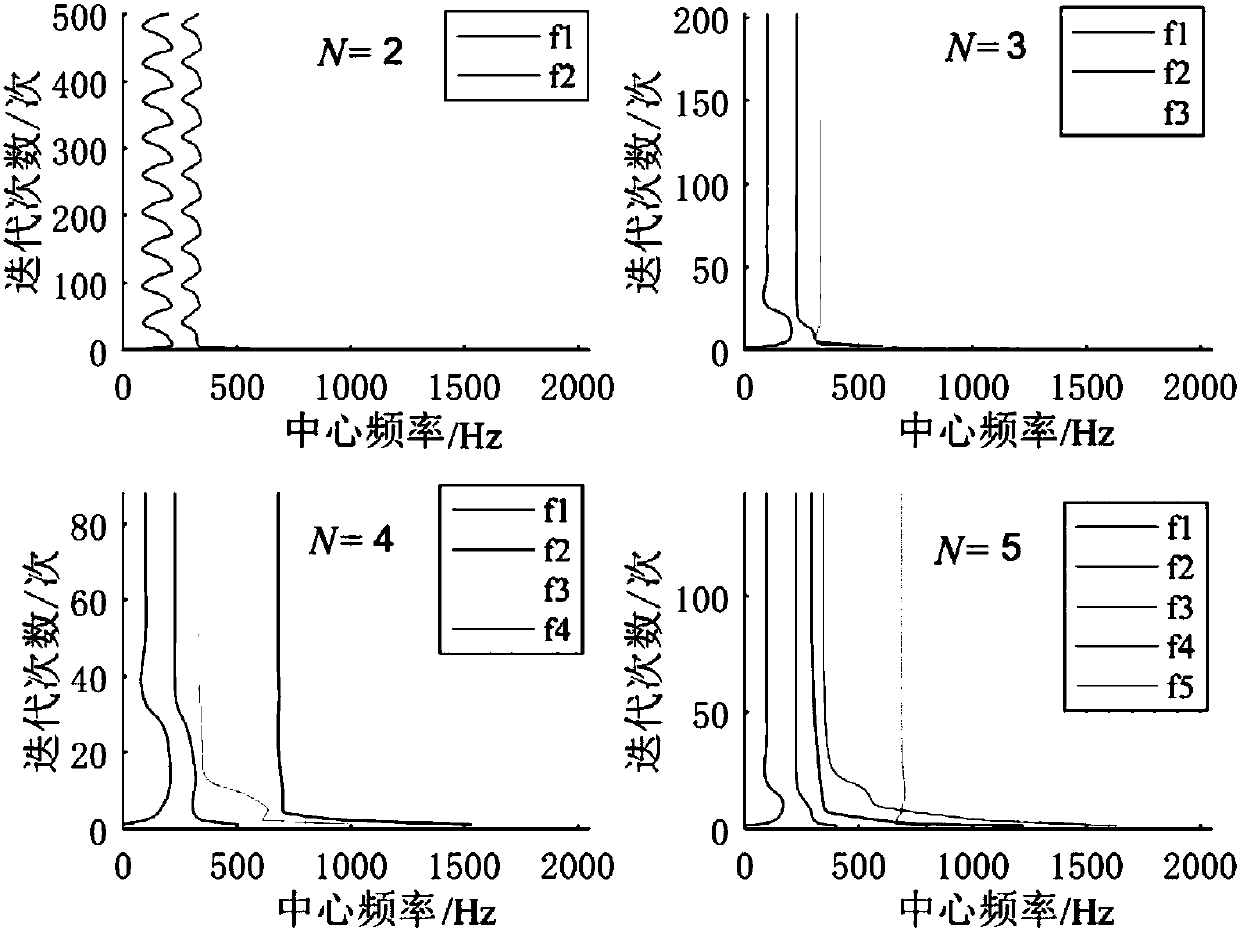

Rolling bearing fault diagnosis method in various working conditions based on feature transfer learning

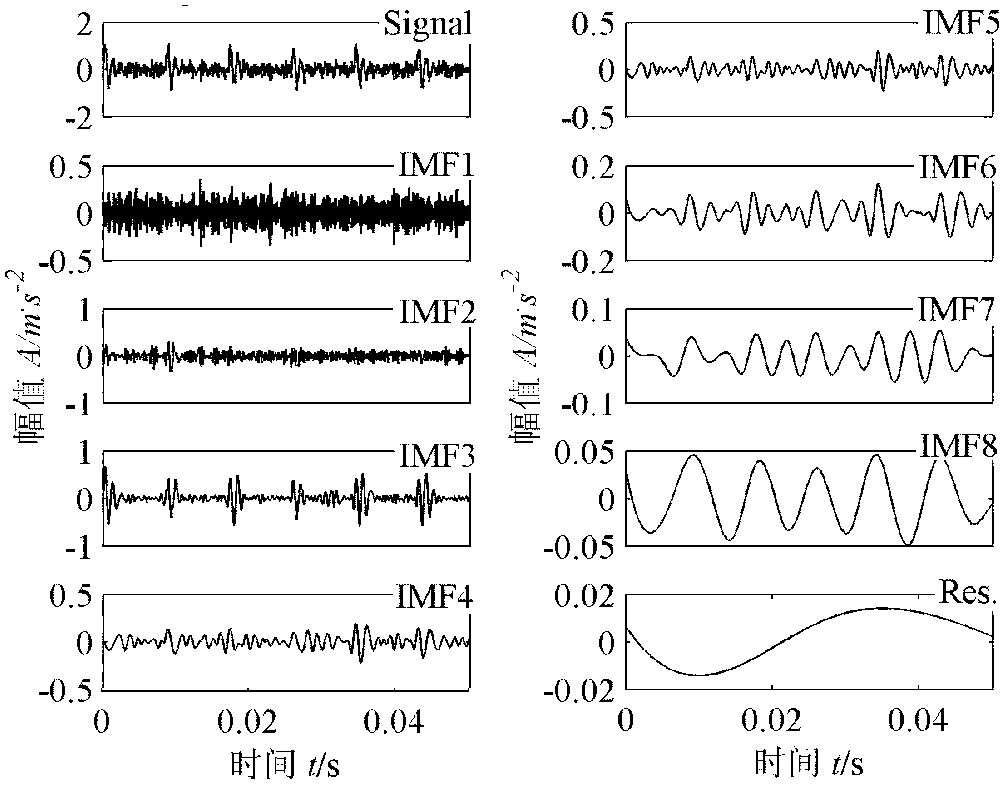

ActiveCN108414226ABest mapped kernel matrixImprove accuracyMachine bearings testingSingular value decompositionDecomposition

The present invention provides a rolling bearing fault diagnosis method in various working conditions based on feature transfer learning, and relates to the field of fault diagnosis. The objective ofthe invention is to solve the problem that a rolling bearing, especially to various working conditions, is low in accuracy of diagnosis. The method comprise the steps of: employing a VMD (VariationalMode Decomposition) to perform decomposition of vibration signals of a rolling bearing in each state to obtain a series of intrinsic mode functions, performing singular value decomposition of a matrixformed by the intrinsic mode functions to solve a singular value or a singular value entropy, combining time domain features and frequency domain features of the vibration signals to construct a multi-feature set; introducing a semisupervised transfer component analysis method to perform multinuclear construction of a kernel function thereof, sample features of different working conditions are commonly mapped to a shared reproducing kernel Hilbert space so as to improve the data intra-class compactness and the inter-class differentiation; and employing the maximum mean discrepancy embedding to select more efficient data as a source domain, inputting source domain feature samples into a SVM (Support Vector Machine) for training, and testing target domain feature samples after mapping. Therolling bearing fault diagnosis method in various working conditions has higher accuracy in the rolling bearing multi-state classification in various working conditions.

Owner:HARBIN UNIV OF SCI & TECH

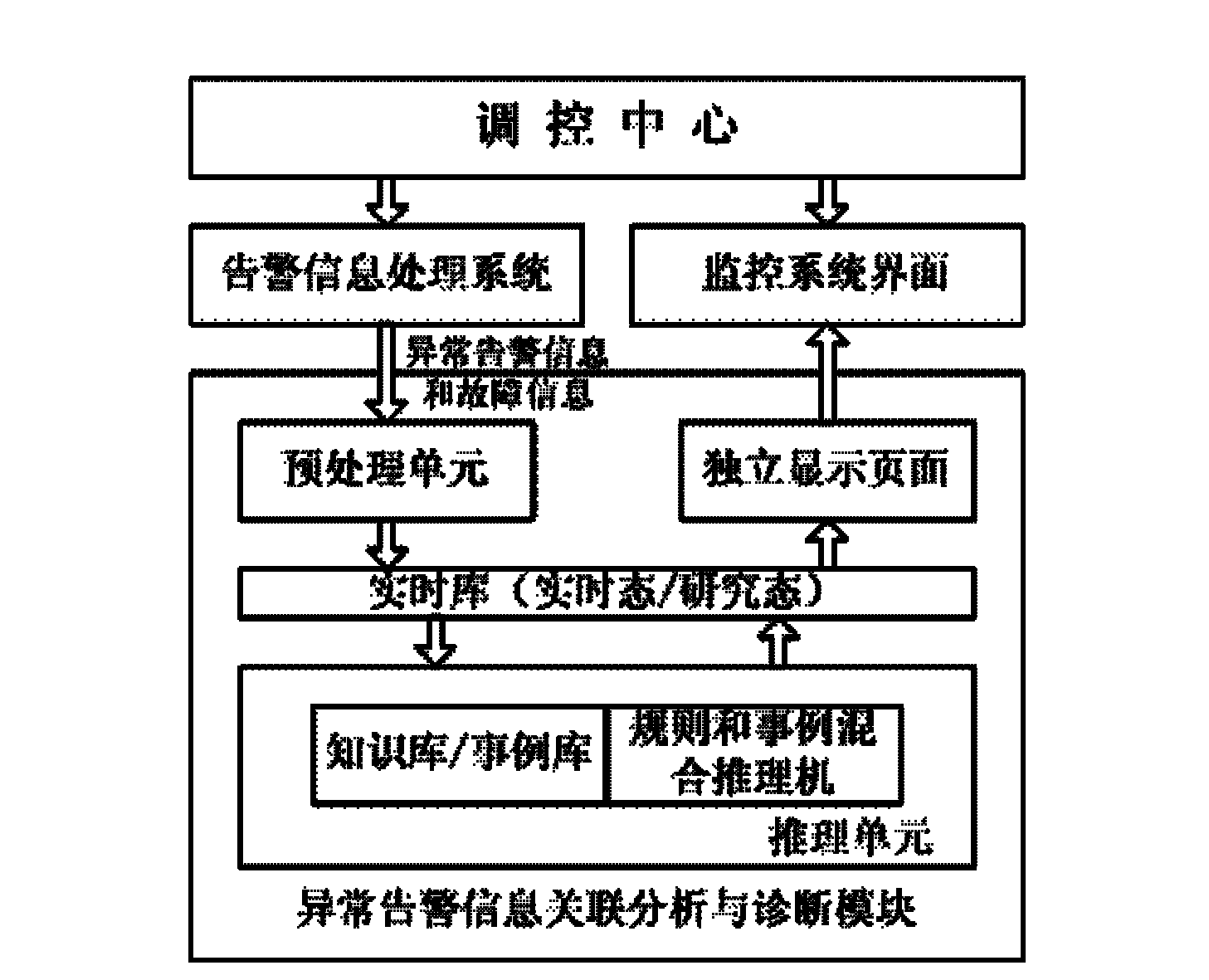

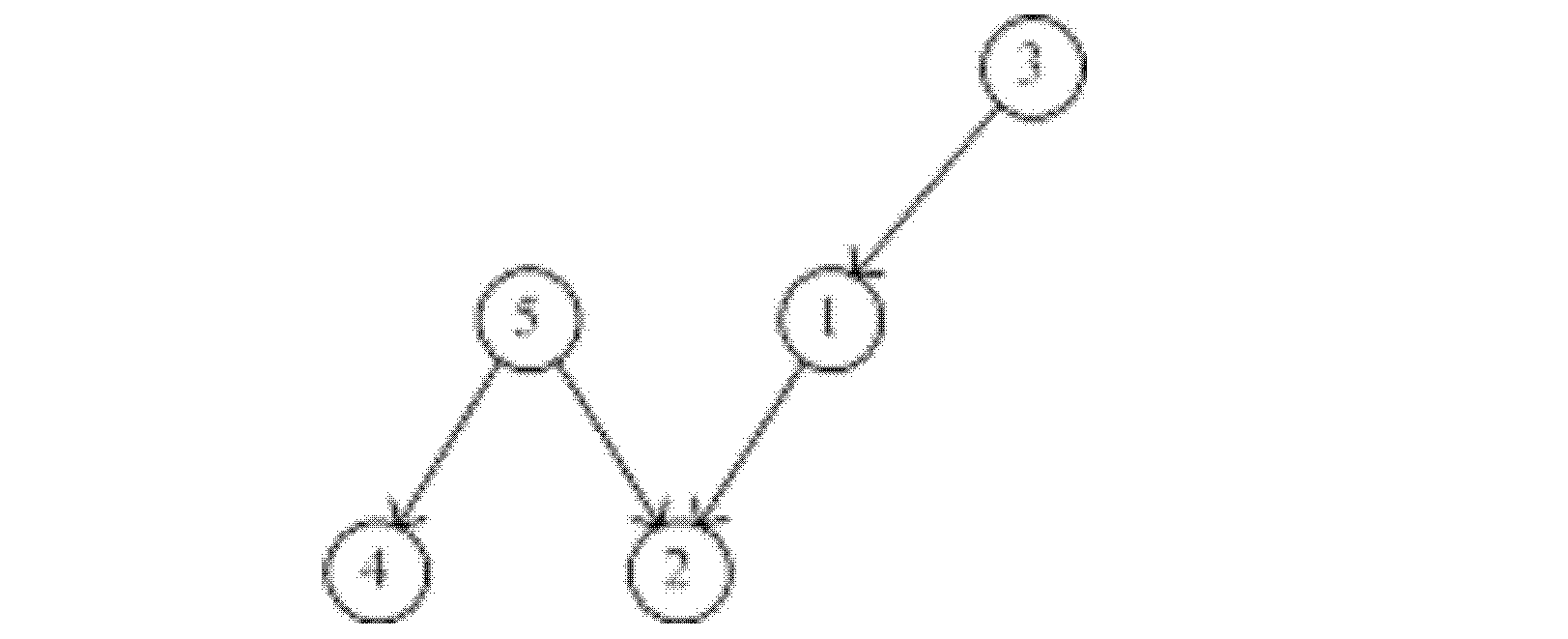

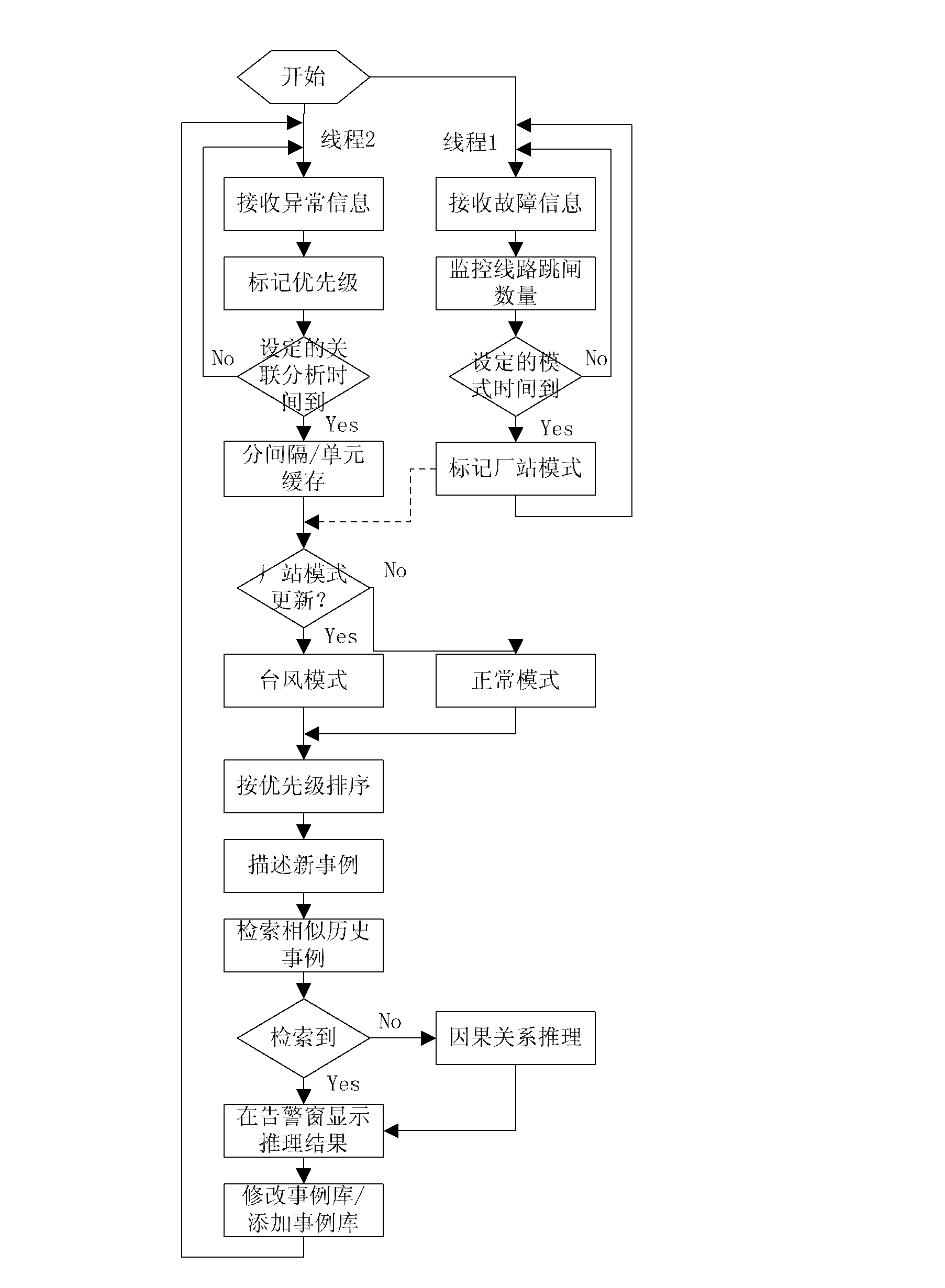

District power network equipment abnormal alarm signal association analysis and diagnosis method

InactiveCN102638100AIntegrity guaranteedGuarantee authenticityCircuit arrangementsInformation processingPower system scheduling

The invention discloses a district power network equipment abnormal alarm signal association analysis and diagnosis method in the field of automation of scheduling of electric power systems. According to the method disclosed by the invention, the weather situation of a plant station region at which abnormal alarm information is located can be automatically identified so as to determine the information processing mode. The method disclosed by the invention has the beneficial effects that by realizing intelligent association analysis and auxiliary decision making of the equipment abnormal alarm information under the real-time state, and performing playback on historical alarm information and performing real-time treatment on manual set information under the research state, the abnormal treatment time is greatly reduced, the incidence of accidents is reduced, a real-time, rich and intelligent auxiliary decision-making support is provided for regulation and control staff, and the safe, high-quality, economical and stable operation of an electric fence is further ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

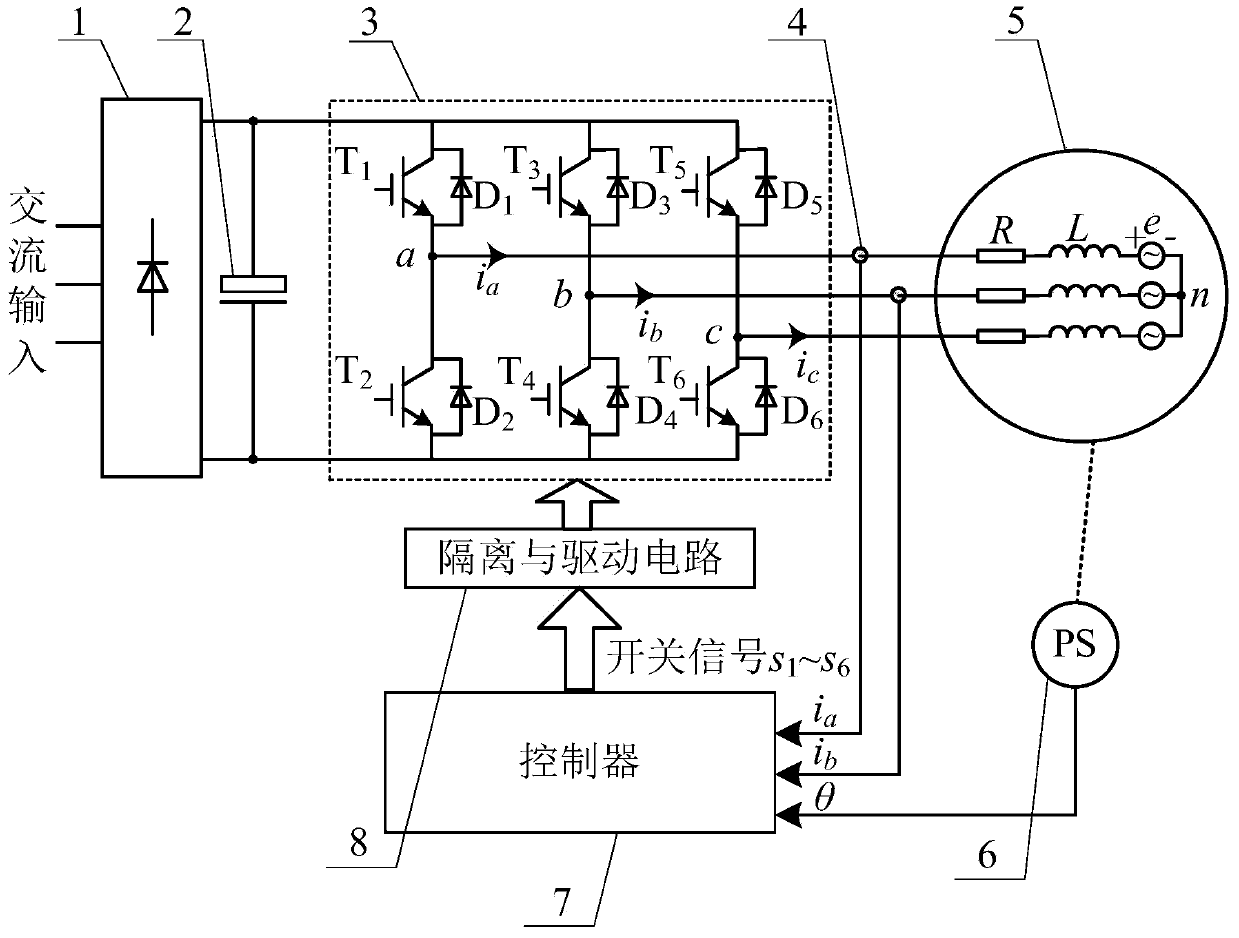

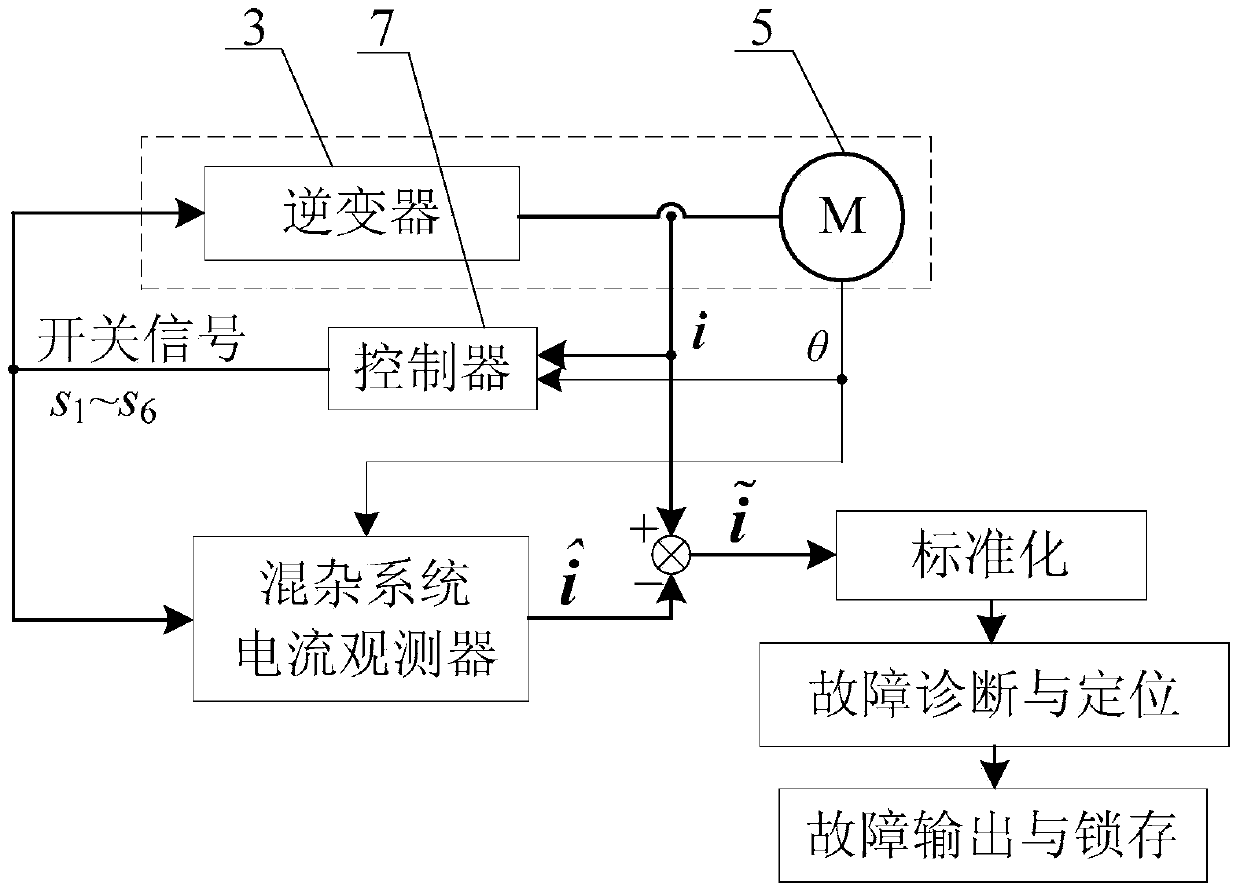

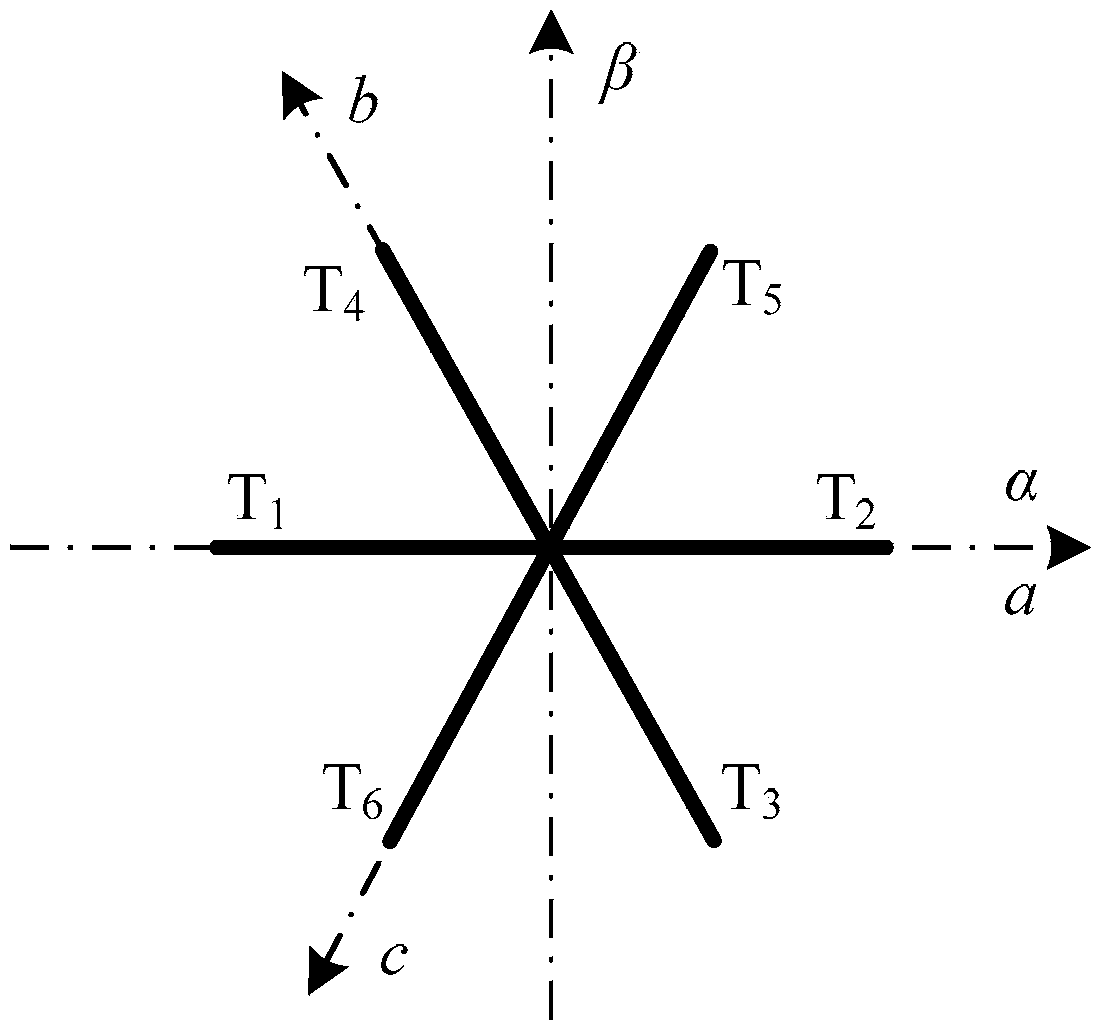

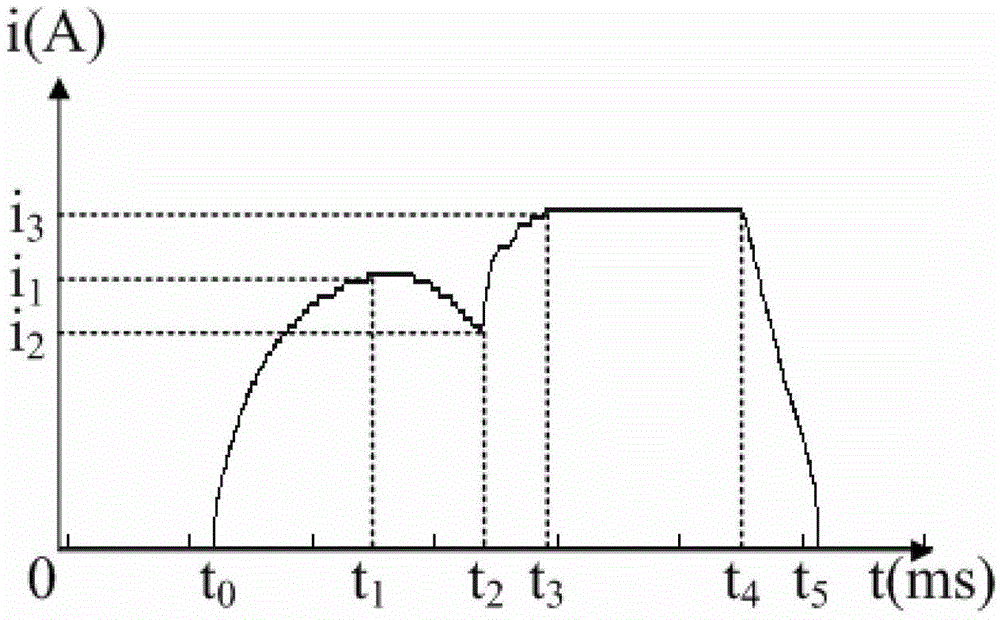

Current-magnitude-based open-circuit failure online-diagnosis method for power tube of inverter

InactiveCN103701394AImprove robustnessElectronic commutation motor controlVector control systemsObservational errorLoop control

The invention discloses a current-magnitude-based open-circuit failure online-diagnosis method for a power tube of an inverter, belongs to the field of motor control, and aims to solve the problem of poor robustness of a current-magnitude-based open-circuit failure diagnosis technology for the power tube of the inverter. The method comprises the following steps of establishing a current observer model of a permanent magnet synchronous motor driving system in a failure-free state, comparing an observed current value with detection current to obtain a three-phase current residual, converting the three-phase current residual to a two-phase coordinate system in a coordinate conversion way to obtain a current residual vector, standardizing the current residual vector, and diagnosing and positioning an open-circuit failure of the power tube of the inverter according to the amplitude and the phase of the standardized current residual vector. The current-magnitude-based open-circuit failure online-diagnosis method for the power tube of the inverter is free of influence of a system closed-loop control algorithm and insensitive to loads, and has higher robustness to parameter errors, measurement errors, system disturbance and the like.

Owner:HARBIN INST OF TECH

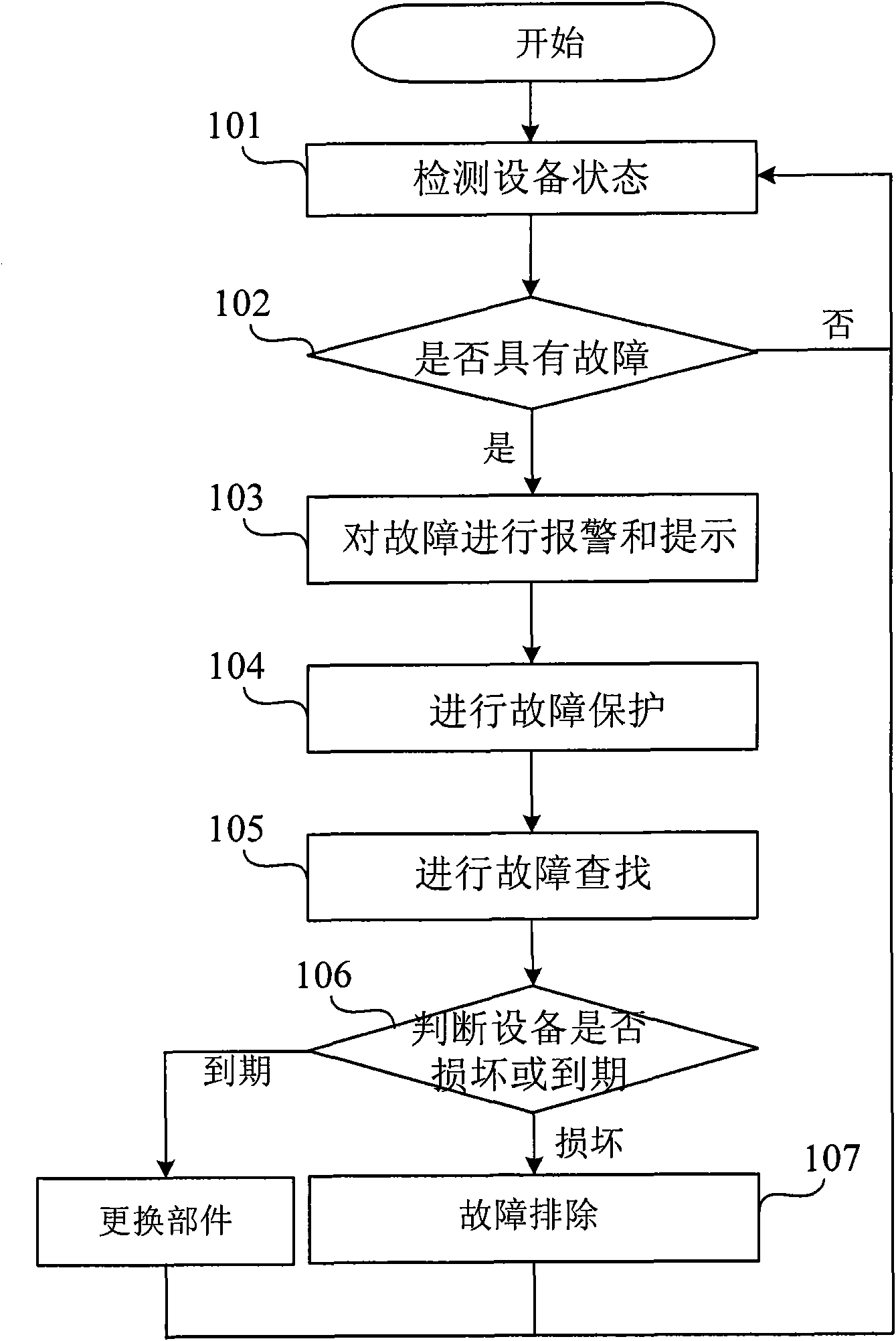

Locomotive fault diagnosis method and system

InactiveCN102042909APerfect fault diagnosis functionRailway vehicle testingDiagnosis methodsComputer science

The invention discloses a locomotive fault diagnosis method and system. The method comprises the following steps: obtaining monitored data acquired when a sampling device monitors locomotive equipment; comparing the monitored data with an equipment variable state or a data threshold in the fault information of the locomotive equipment in a database; if the variable state of the monitored data is abnormal or a sampling value exceeds a fault data threshold, calling fault prompting information of the fault information of the locomotive equipment from the database and displaying the fault prompting information; storing the fault information and monitored data of the locomotive equipment in storage equipment of a locomotive control unit; and carrying out fault handling on the locomotive equipment according to the fault prompting information of the locomotive equipment. Therefore, by utilizing the locomotive fault diagnosis method and system provided by the invention, all equipment of the whole locomotive can be monitored, the fault handling is carried out on the locomotive equipment with faults, and the fault information is stored, therefore, a set of complete locomotive fault diagnosis method and system is established, so that the function for locomotive fault diagnosis is more perfected.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

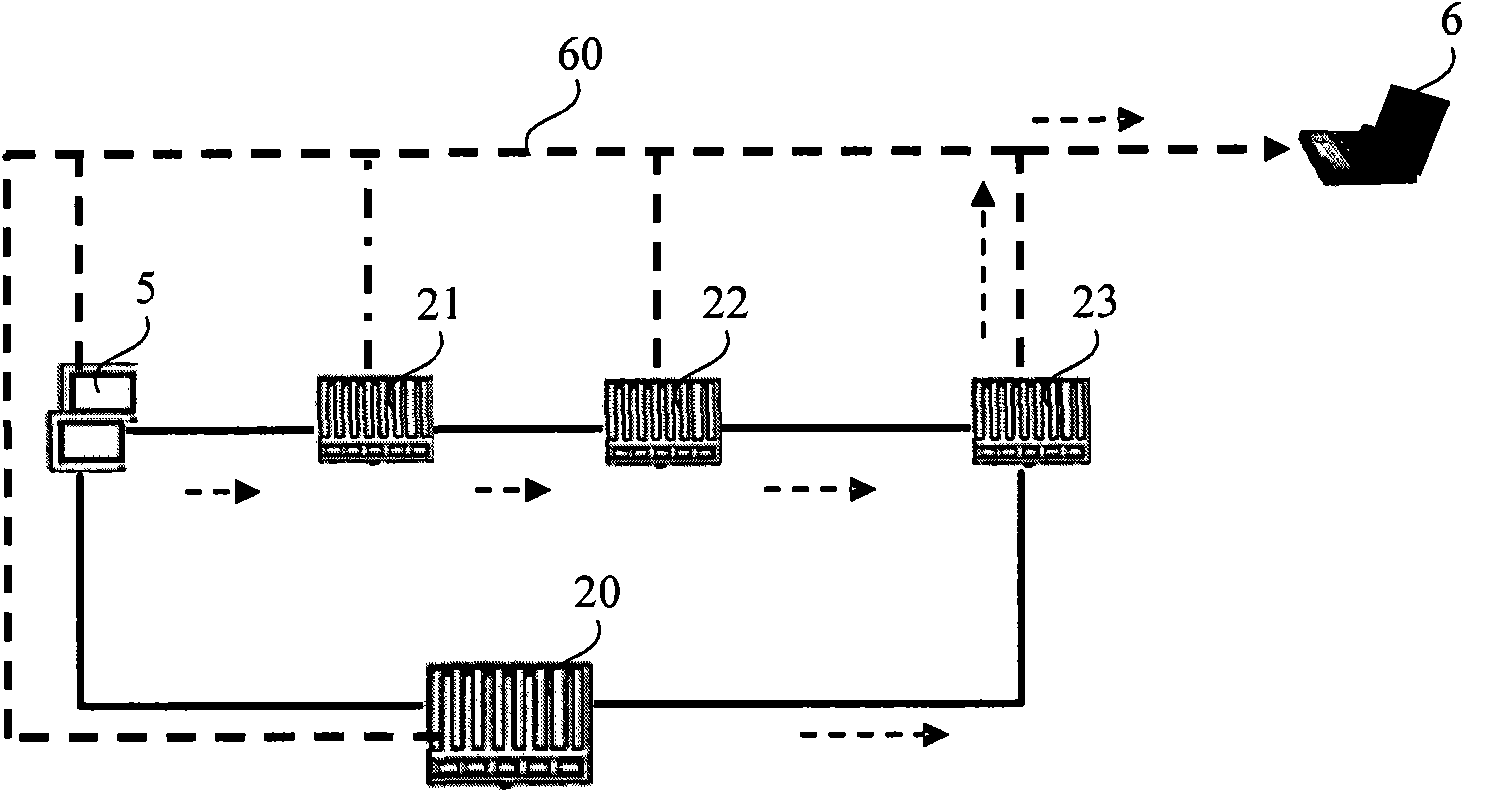

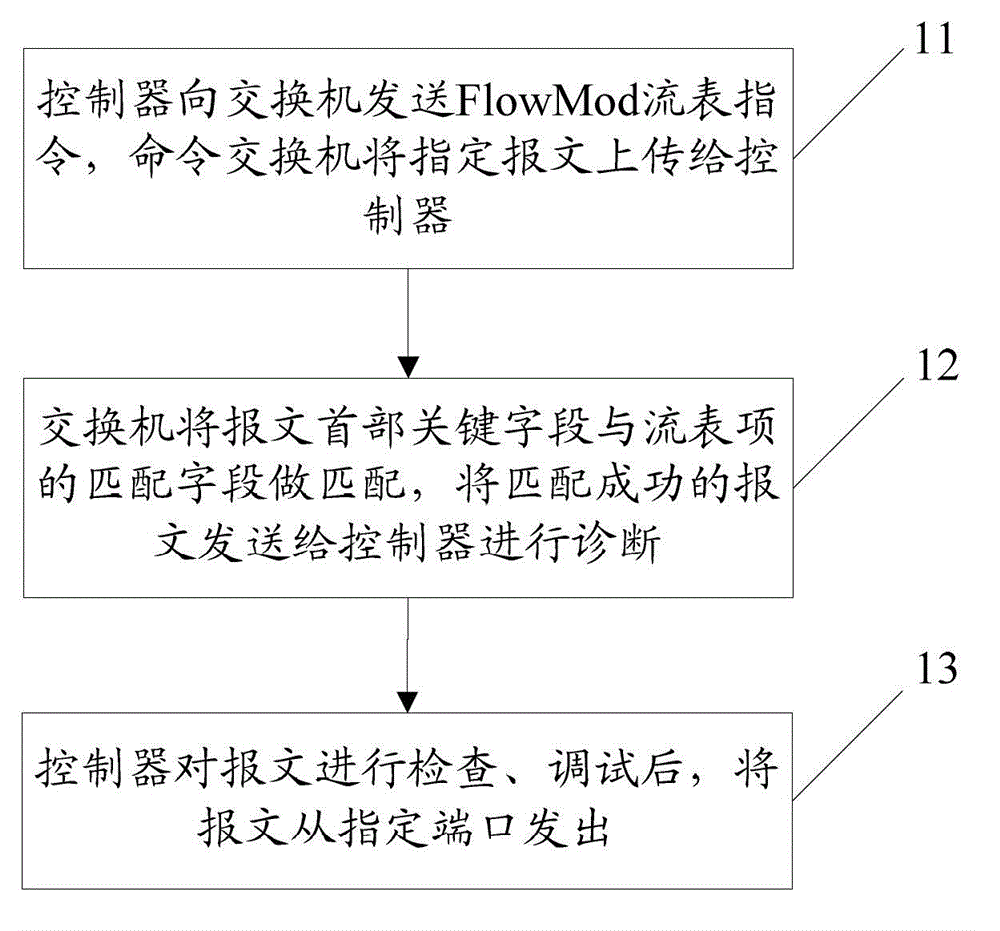

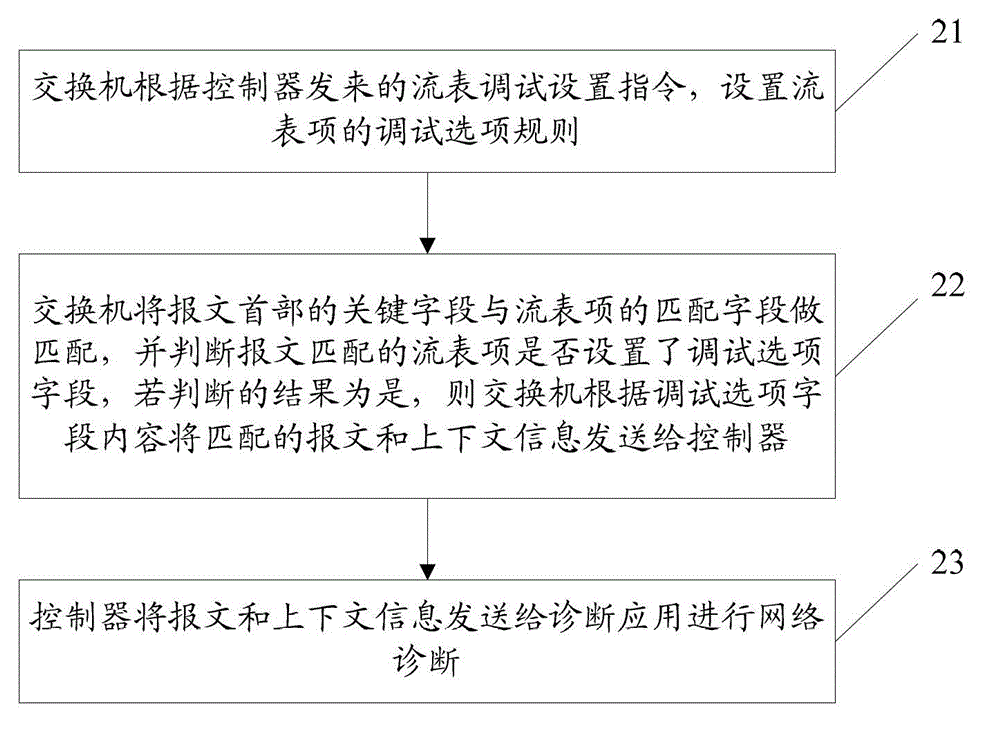

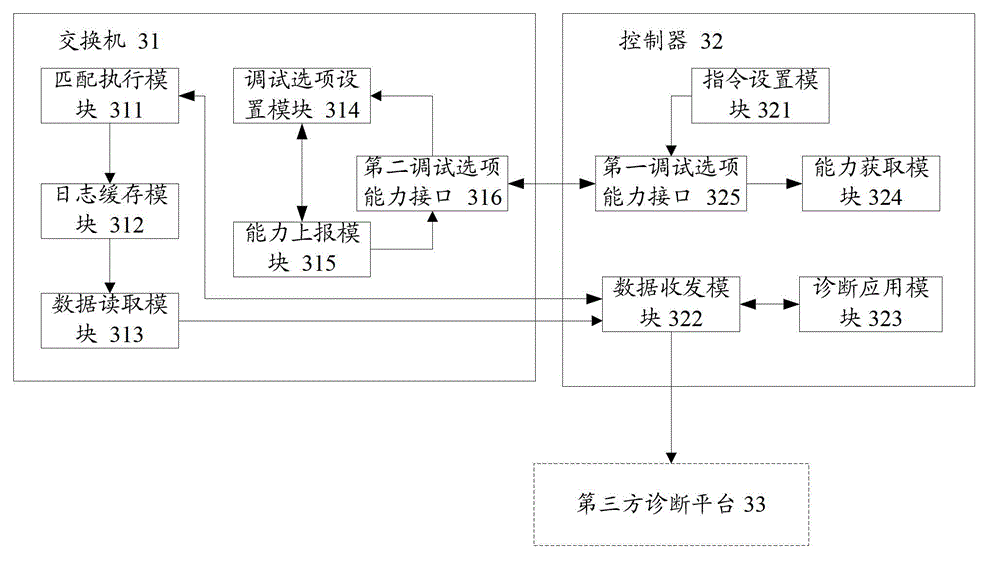

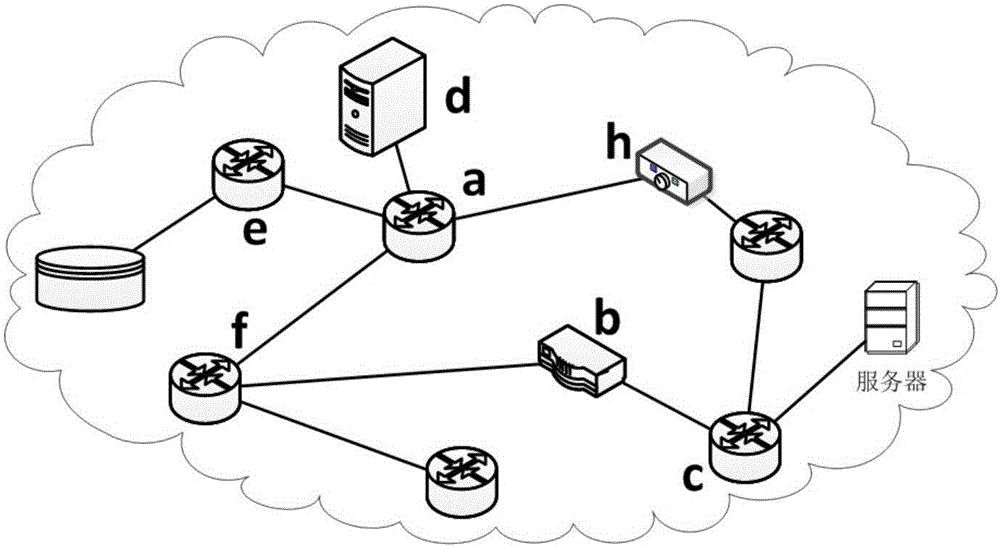

Network diagnosis method, system and equipment based on software defined network

ActiveCN102946325ASpeed up the positioning cycleQuality improvementData switching networksDiagnosis methodsNetwork tomography

The invention discloses a network diagnosis method based on a software defined network (SDN). The method includes the steps that a switchboard sets the rule of debug option of a flow table item according to a flow table debug setting command sent by a controller; the switchboard matches the key field of the message heading with the matching field of the flow table item, and judges whether the flow table item matched with the message is set up with a debug option field or not; if yes, the switchboard executes relevant debugging operations according to the content of the debug option field, and the operations include, but not limited to, sending the matching message and the contextual information to the controller; and the controller proceeds network diagnosis according to the message and the contextual information. The invention further discloses a network diagnosis system and equipment based on the SDN. With the technical scheme provided by the invention, the cycle for positioning a network problem is accelerated, the quality of the network is improved, and the operating maintenance cost of the network is reduced.

Owner:ZTE CORP

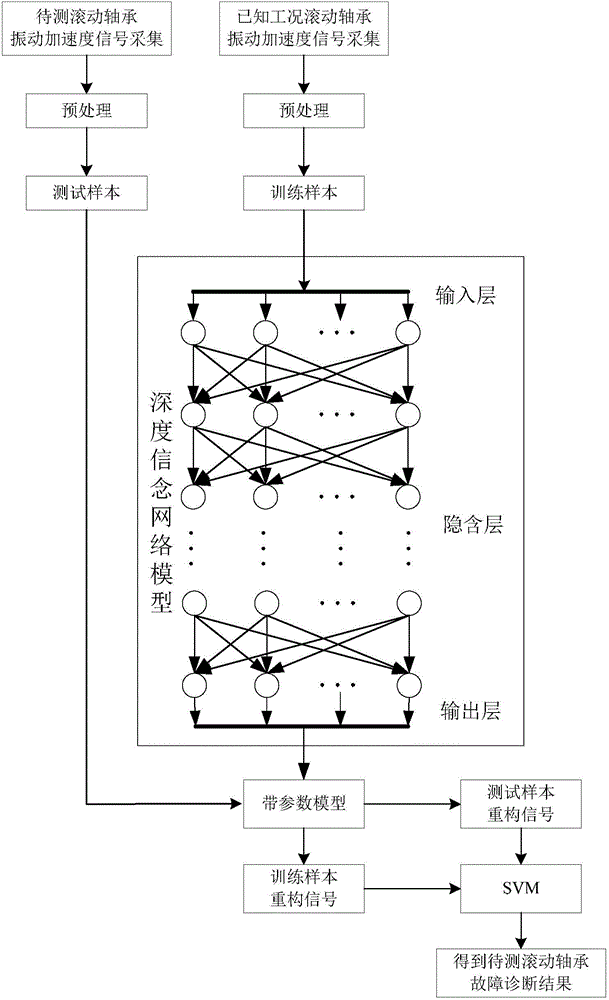

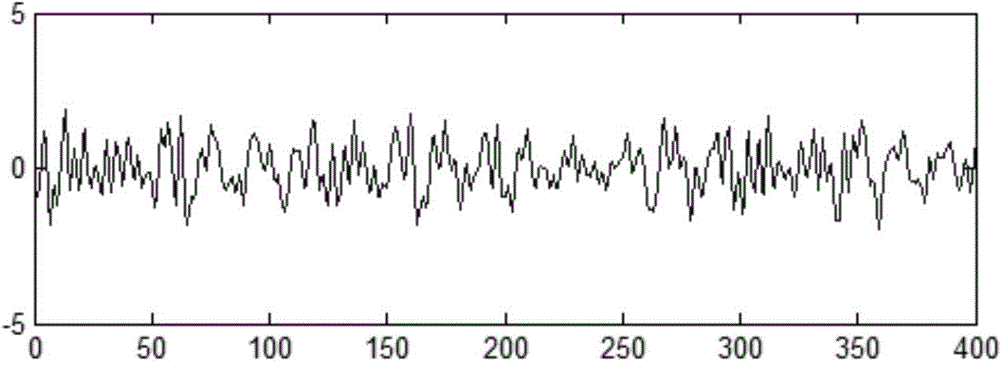

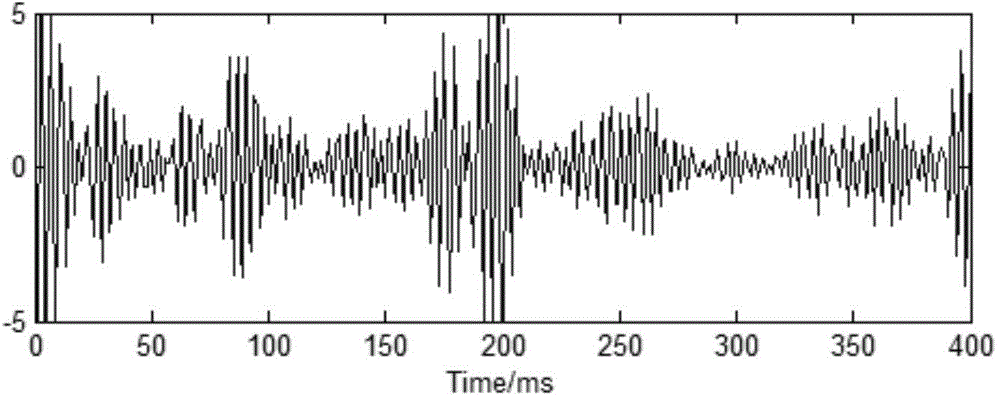

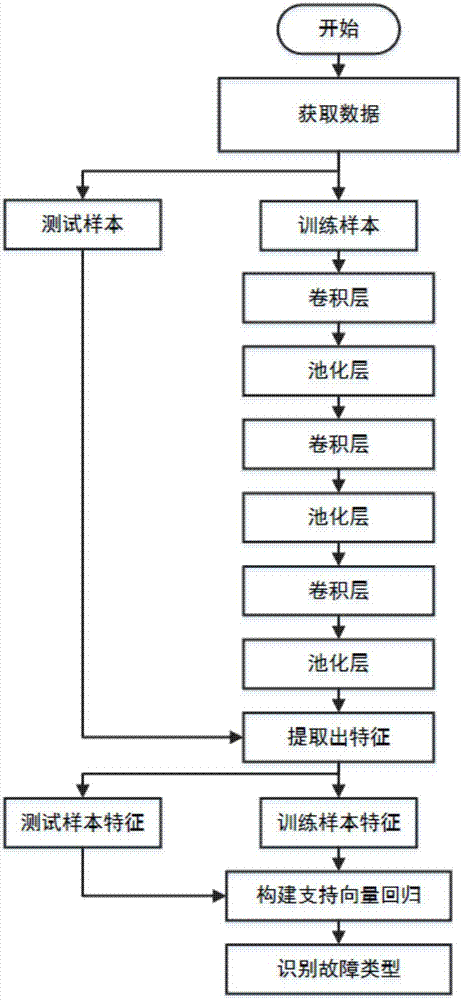

Fault diagnosis method for rolling bearing based on deep learning and SVM (Support Vector Machine)

InactiveCN104616033ASave human effortSolve the problem of local optimum solutionCharacter and pattern recognitionAviationDeep belief network

The invention provides a fault diagnosis method for a rolling bearing based on a deep learning and SVM (Support Vector Machine). The method comprises using a manure learning algorithm in a deep belief network theory to complete a characteristic extraction task needed by fault diagnosis; automatically extracting the substantive characteristics of data input independent of manual selection from simple to complicate, from low to high, and automatically digging abundant information concealed in known data; in addition, classifying and identifying a test sample by adopting an SVM classification method, seeking and finding a global minimum of a target function through an effective method previously designed, so as to solve the problem that a deep belief network may be trapped into a locally optimal solution. According to the fault diagnosis method for the rolling bearing based on the deep learning and SVM provided by the invention, the accuracy and effectiveness of the fault diagnosis method for a rolling bearing can be improved, and a new effective way can be provided to solve the accuracy and effectiveness of the fault diagnosis method, therefore the fault diagnosis method can be extensively applied complex systems in chemistry, metallurgy, electric power, aviation fields and the like.

Owner:CHONGQING UNIV

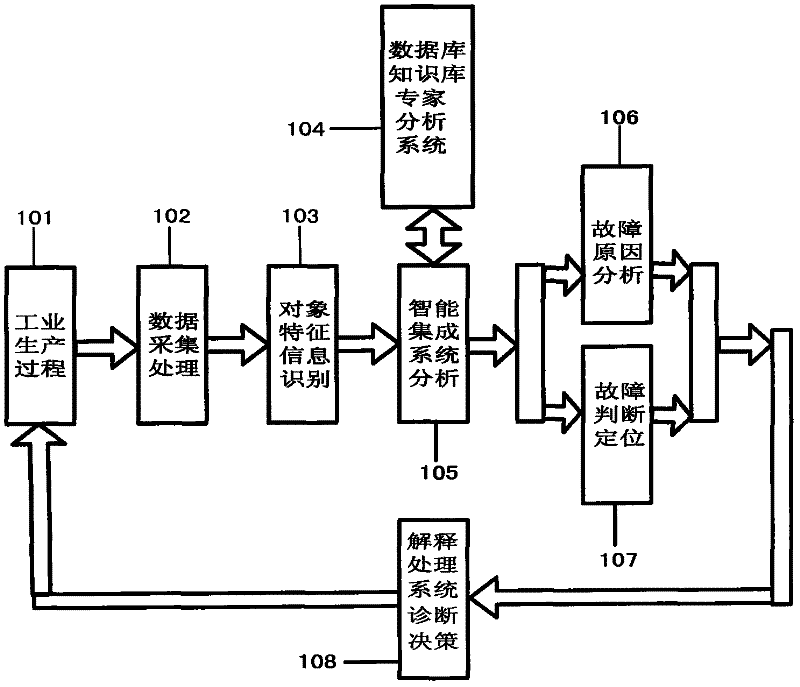

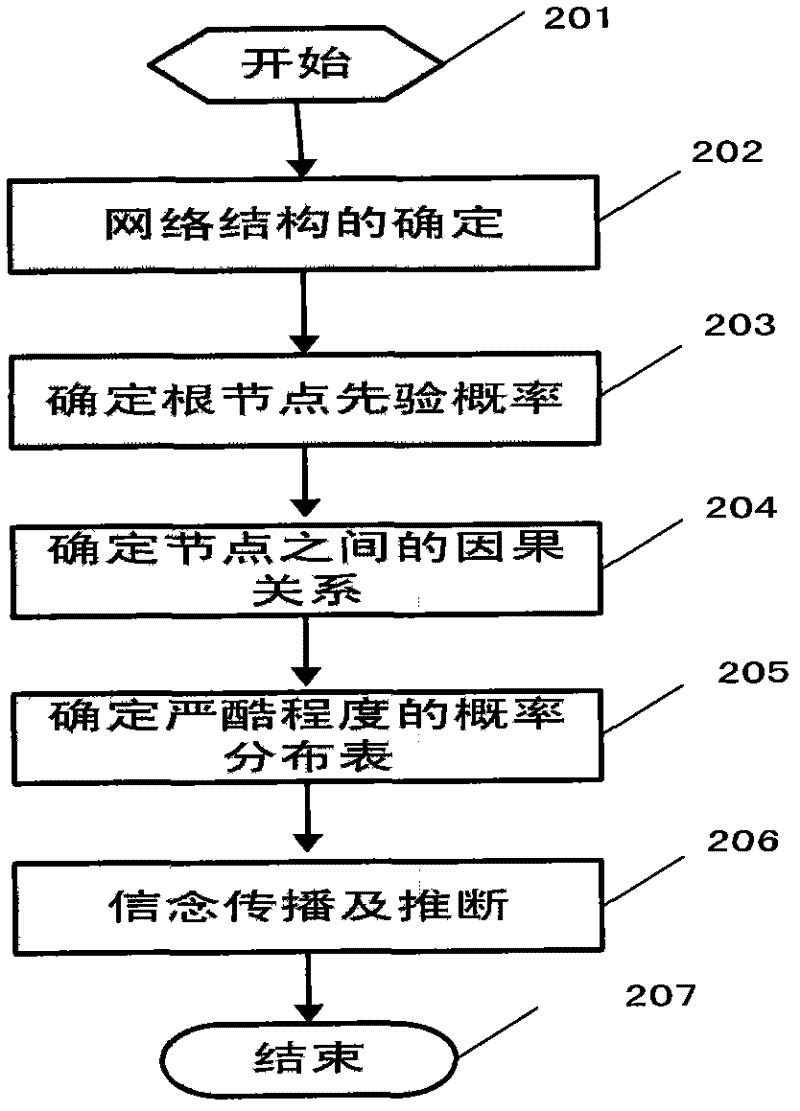

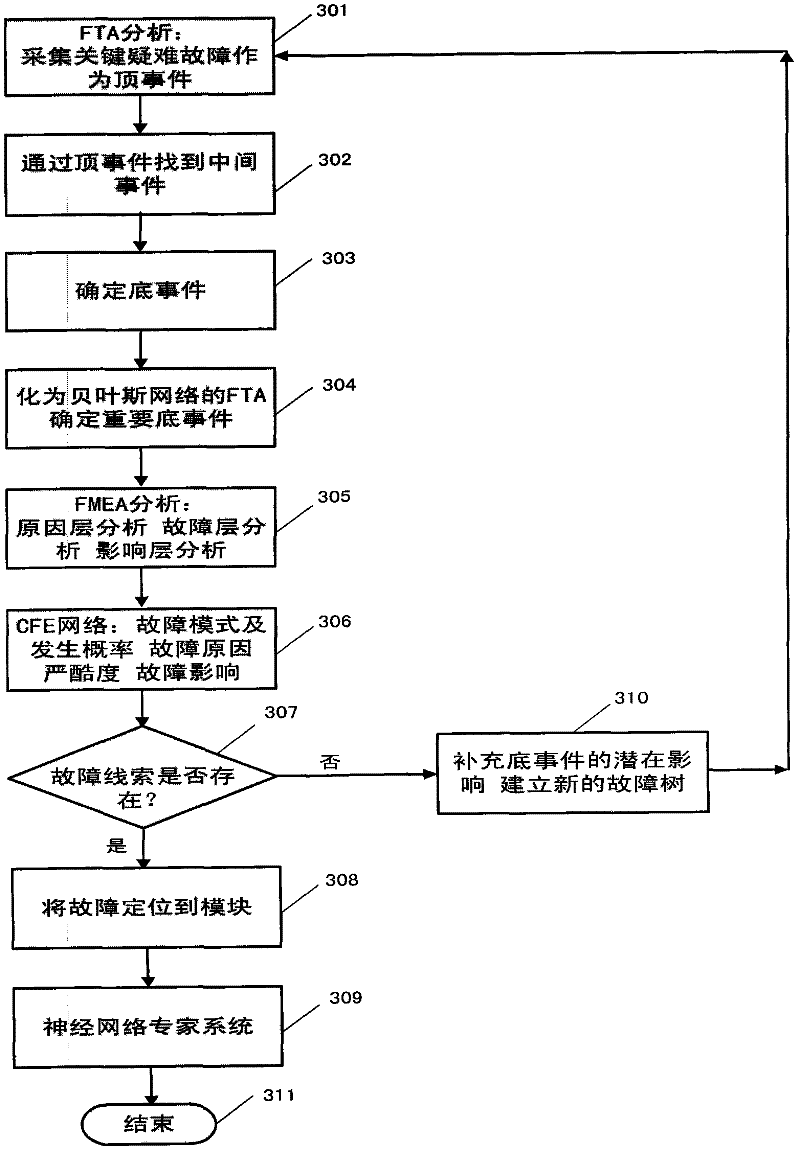

Intelligent integrated fault diagnosis method and device in industrial production process

InactiveCN102637019AEffective regulationIndustrial production process goes smoothlyTotal factory controlProgramme total factory controlDiagnosis methodsFailure diagnosis

The invention relates to an intelligent integrated fault diagnosis method in an industrial production process. The intelligent integrated fault diagnosis method is characterized by comprising the following steps of: acquiring data in the industrial production process; analyzing and processing object characteristics according to an acquired signal; combining expert knowledge according to an intelligent integration method to carry out blast-furnace fault diagnosis analysis so as to identify a fault and find out a reason of the fault, carrying out fault exact location and diagnosis policy, and effectively regulating a production process so that the industrial production process can regularly carry out, wherein the intelligent integration method comprises the following steps of: establishing a Bayesian network model; comprehensively analyzing and processing FTA (full type approval) and FMEA (failure mode and effect analysis) models; and carrying out nerve net expert system fault diagnosis analysis and process. Simultaneously, the invention further relates to an intelligent integrated fault diagnosis device in the industrial production process, and the device is used for realizing the fault diagnosis method. According to the intelligent integrated fault diagnosis method in the industrial production process, disclosed by the invention, various information is fused, ratiocination is carried out under a complex situation, comprehensive diagnosis can be effectively carried out on the fault of the industrial production process, the integration, intelligence, accuracy and effectiveness of the fault diagnosis system are improved, and the production process is ensured to be performed smoothly.

Owner:WUHAN UNIV OF SCI & TECH

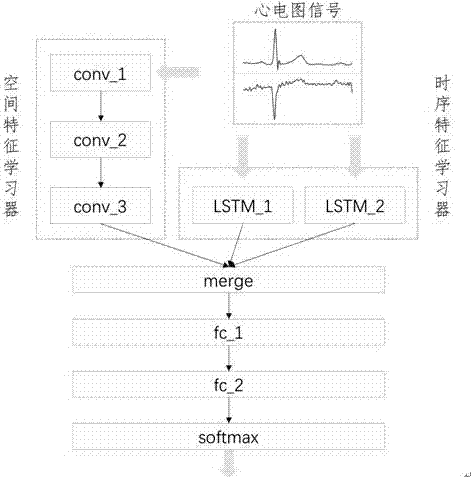

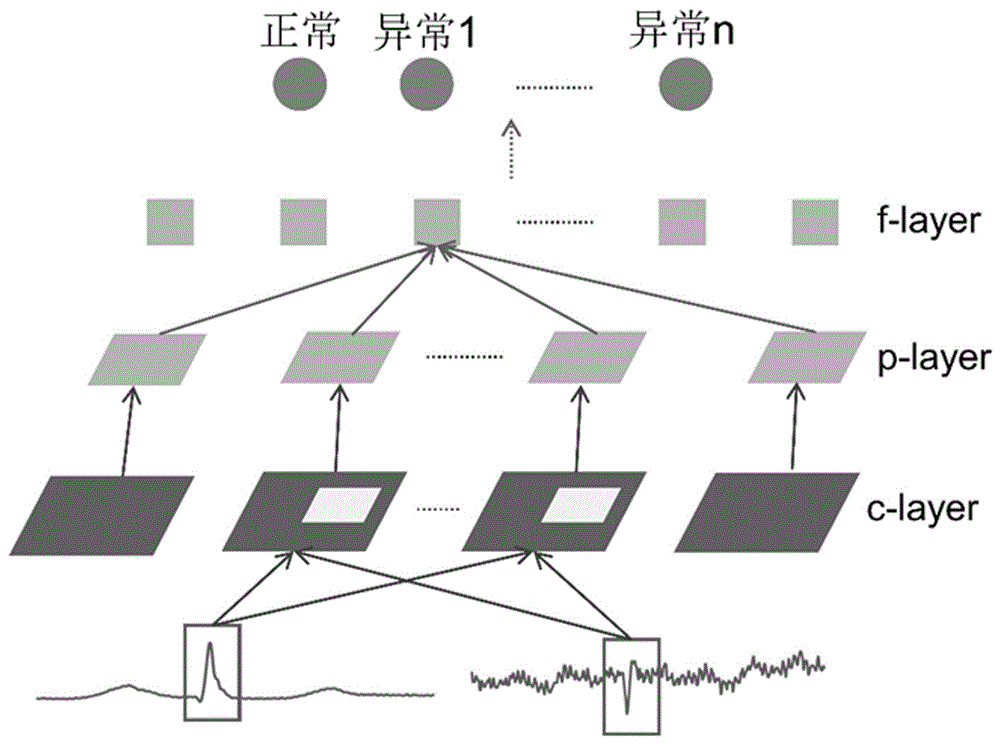

Automatic diagnosis method for electrocardiographic abnormality

InactiveCN106901723AImprove the effect of automatic diagnosisImprove accuracyDiagnostic recording/measuringSensorsAbnormal vectorcardiogramDiagnosis methods

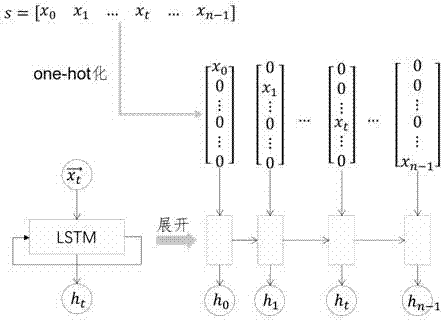

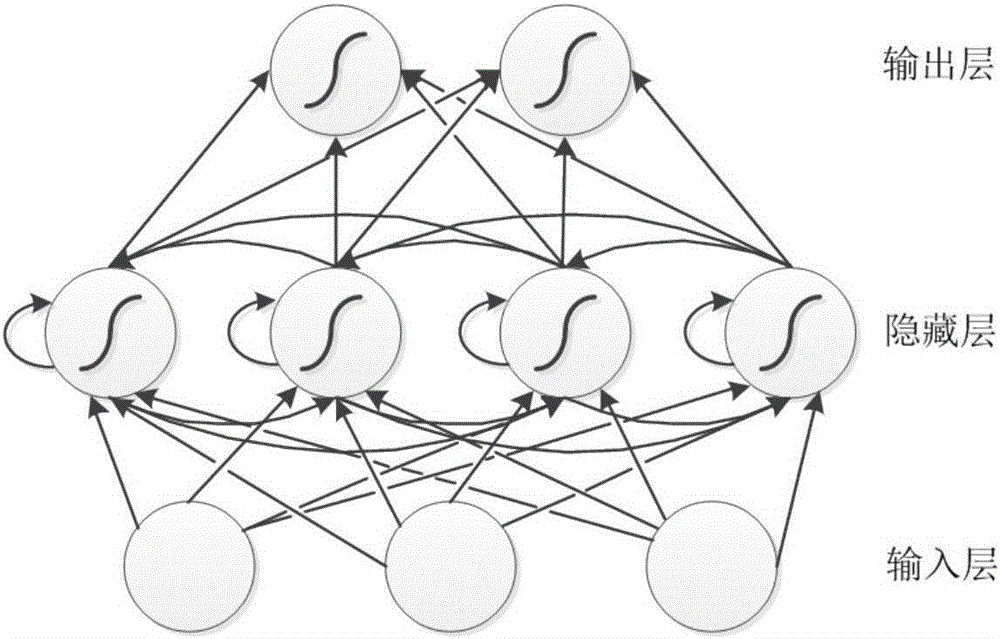

The invention discloses an automatic diagnosis method for electrocardiographic abnormality and relates to the technical field of automatic diagnosis of electrocardiographic abnormality. The learning capacity of an RNN neural network to a time sequence and the learning capability of CNN to spatial features are combined to learn features of the electrocardiographic biological signal, and abnormal electrocardiographs of different types are automatically characterized. Then, a deep neural network based classifier is constructed, which is trained using an electrocardiograph with type annotations to improve the accuracy of classification, and automatic classification of different arrhythmia types is achieved. According to the invention, the process of manually extracting features is avoided; then, time sequence features and spatial features of the electrocardiographs are learned using RNN and CNN to form the classifier, and the classifier is trained through supervised learning so that the classifier can automatically diagnose abnormal electrocardiographs. As a result, the accuracy of automatic diagnosis and classification of electrocardiographic abnormality is improved.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

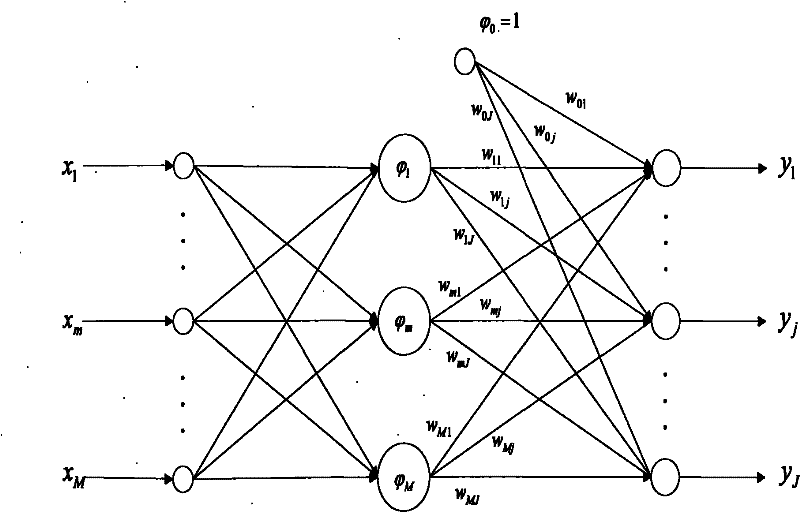

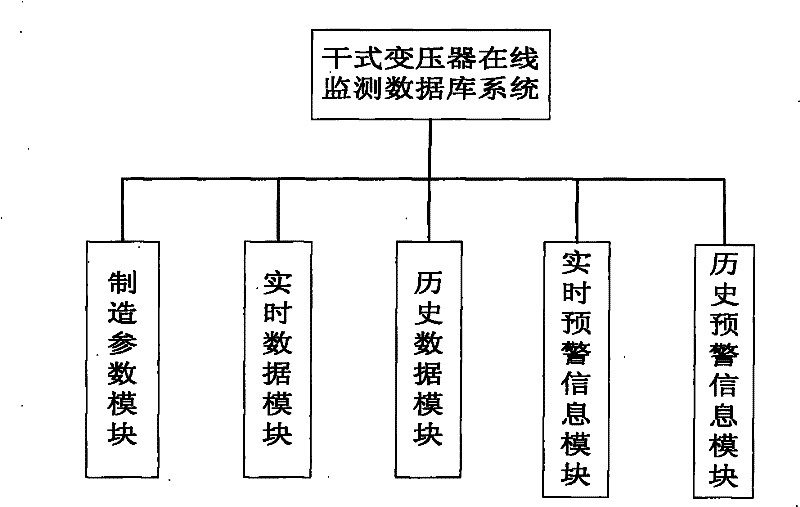

Fault on-line diagnosis and early warning method of flameproof dry-type transformer for mine

ActiveCN102221651ARealize online diagnosisRealize early warningElectrical testingNeural learning methodsNerve networkTransformer

The invention provides a fault on-line diagnosis and early warning method of a flameproof dry-type transformer for mine in order to raise the accuracy and rapidity of fault diagnosis. The method comprises the following steps: determining monitoring quantity; extracting characteristic values: extracting a three-dimensional spectra parameter and two-dimensional statistical parameter in a partial discharge signal as characteristic quantities, with regard to operation voltage, current and iron core leakage current, extracting effective values of the operation voltage, the current and the iron core leakage current as characteristic values, and taking real-time values of a temperature parameter as characteristic quantities; using a normalization method to calculate a corresponding value of each characteristic quantity and taking the corresponding value as an input parameter of an intelligent diagnosis system; collecting values of each monitoring quantity under different environment, and obtaining training and testing samples of a nerve network under corresponding environment; establishing a nerve network: selecting a generalized RBF nerve network intelligent diagnosis method to establish a nerve network; utilizing a sample data training nerve network and forming a fault diagnosis tool; establishing a database; storing collected real time data and the above diagnosis result into a ground server real-time database and a real-time early warning information table, and carrying out diagnosis and early warning through an expert system.

Owner:TAIYUAN UNIV OF TECH

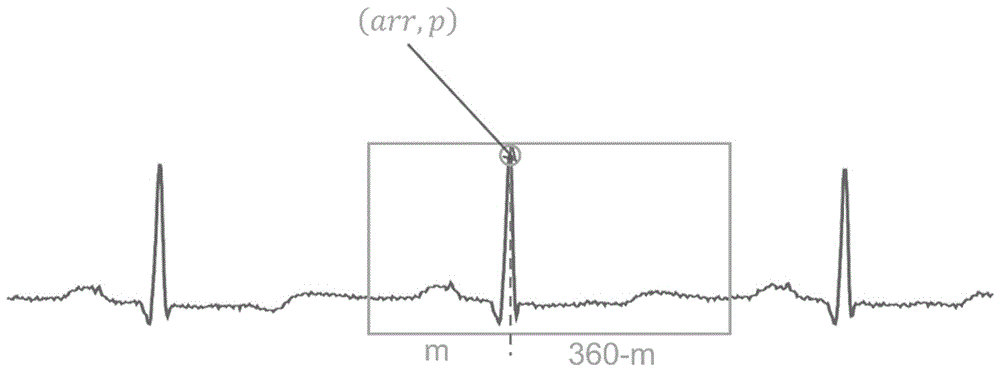

Intelligent arrhythmia diagnosis method based on multiple-lead and convolutional neural network

InactiveCN105748063AImprove learning efficiencyHigh precisionMedical automated diagnosisSensorsDiagnosis methodsCardiac arrhythmia

The invention provides an intelligent arrhythmia diagnosis method based on multiple-lead and a convolutional neural network. The method includes the steps that 1, data samples are selected; 2, arrhythmia types are labeled; 3, led heartbeat signals are intercepted; 4, a normalized heartbeat set is obtained; 5, a concealed layer and an output layer are constructed; 6, a target function is set; 7, sample training is conducted; 8, arrhythmias classification is applied. According to the intelligent arrhythmia diagnosis method, network learning efficiency and precision of automatic arrhythmia diagnosis can be improved by training the convolutional neural network (CNN) through multiple-lead electrocardiogram data, a universal frame and a specific method for training the CNN through the multiple-lead electrocardiogram data with arrhythmia type labels are achieved, the arrhythmia types of electrocardiosignals to be diagnosed can be accurately judged, and the arrhythmia types can serve as diagnosis results or as reference of doctors.

Owner:SHANDONG UNIV QILU HOSPITAL +1

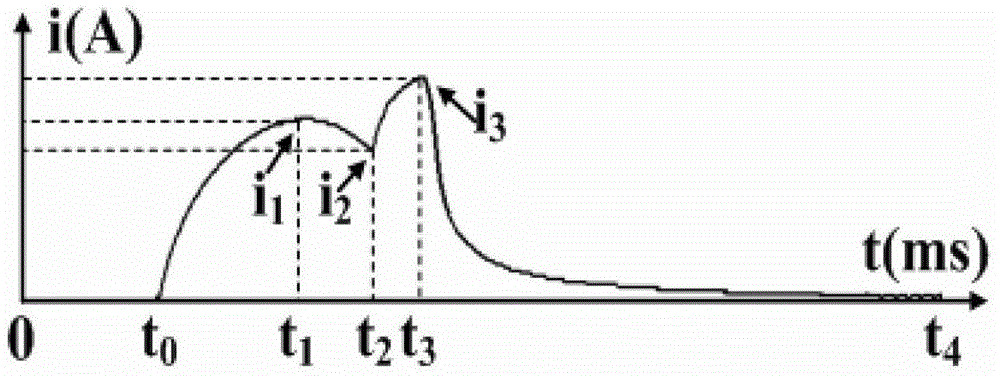

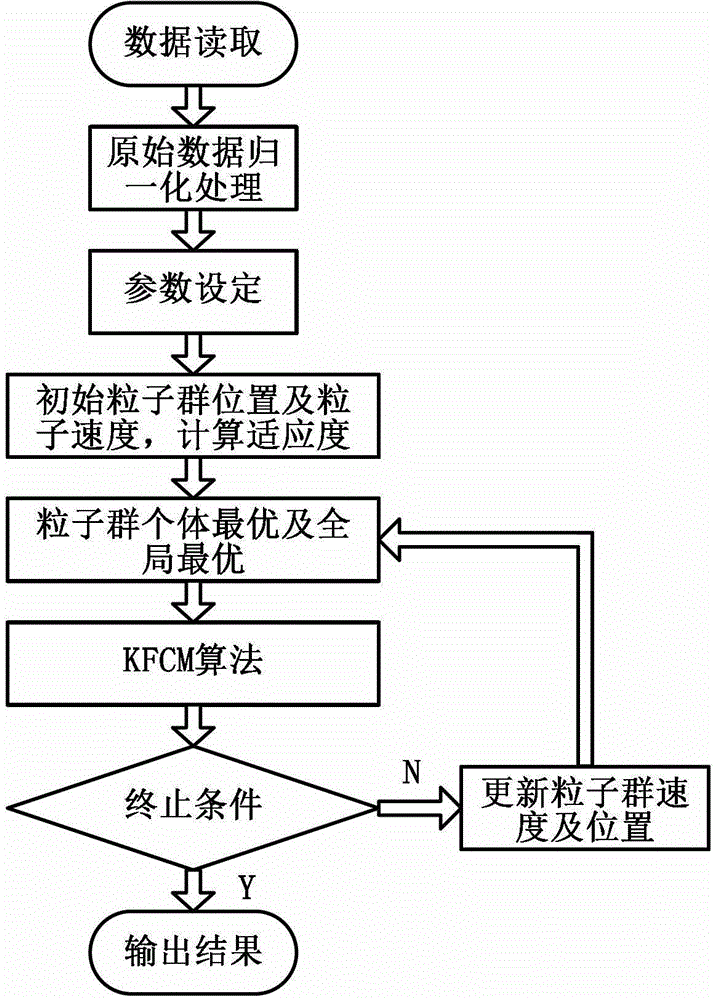

Breaker fault diagnosis method based on separating/closing coil current signals

ActiveCN103336243ARealize online self-testAvoid local optimum problemsCircuit interrupters testingPattern recognitionData set

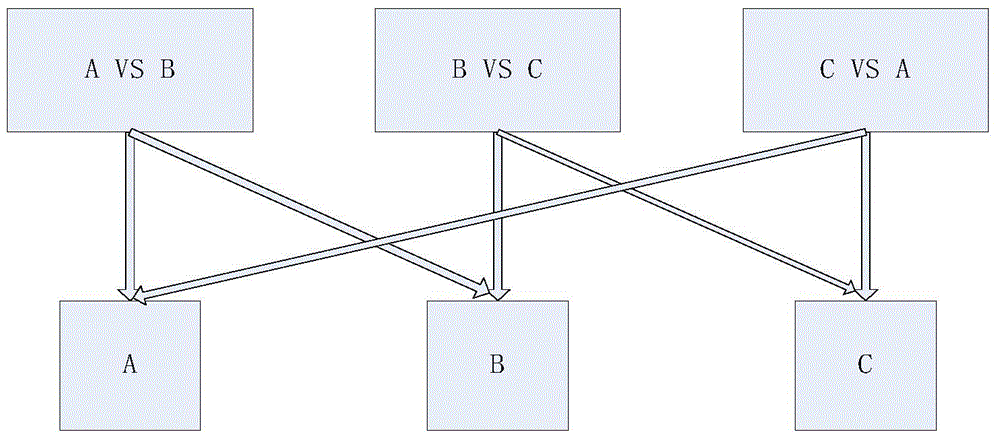

The invention relates to a breaker fault diagnosis method based on separating / closing coil current signals, which includes the following steps: 1, collecting a primary fault dataset and performing normalization processing to the collected data; 2, adopting the algorithm P-KFCM combined by the algorithm PSO (particle swarm optimization) and the algorithm KFCM (kernel fuzzy C-mean clustering) to classify the data set, so as to obtain a primary fault sample membership matrix and classifying the dataset into C types according to the degree of membership; 3, verifying the cluster number C through the cluster effectiveness index MPC, and setting the cluster number C corresponding to the maximum value of MPC as the optimal cluster number; 4, building an SVM predicating trainer through data samples of every two types in the optimal classification, so as to obtain C*(C-1) / 2 SVM training models; 5, inputting the collected test samples in the SVM training models, and obtaining the primary testing results; 6, obtaining the final fault diagnosis by combining all the testing results. Through the adoption of the method, the accuracy of fault classification can be improved, and the on-line detection on fault types of breakers can be realized.

Owner:SOUTHEAST UNIV

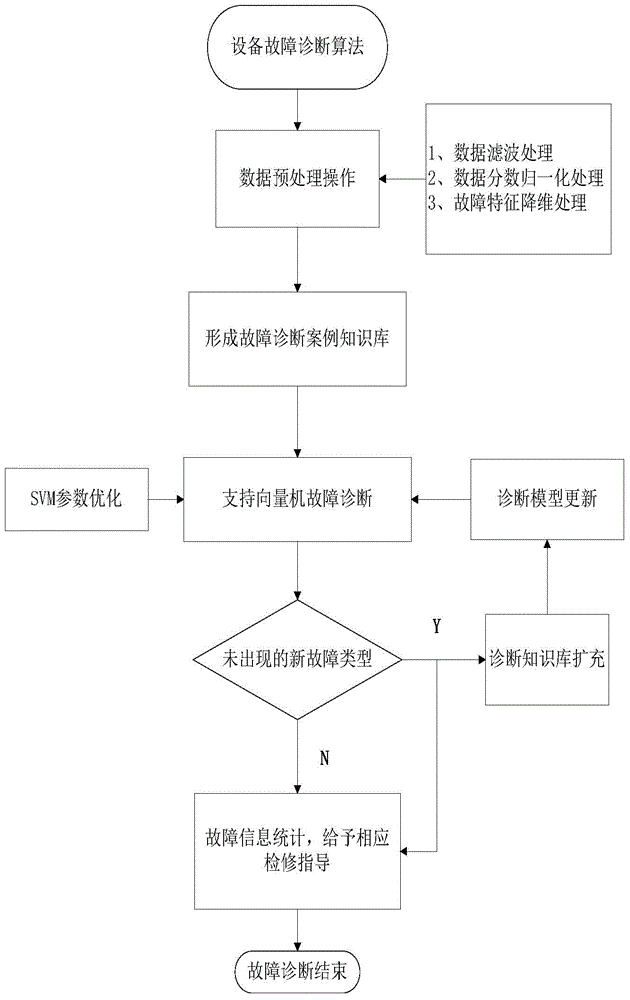

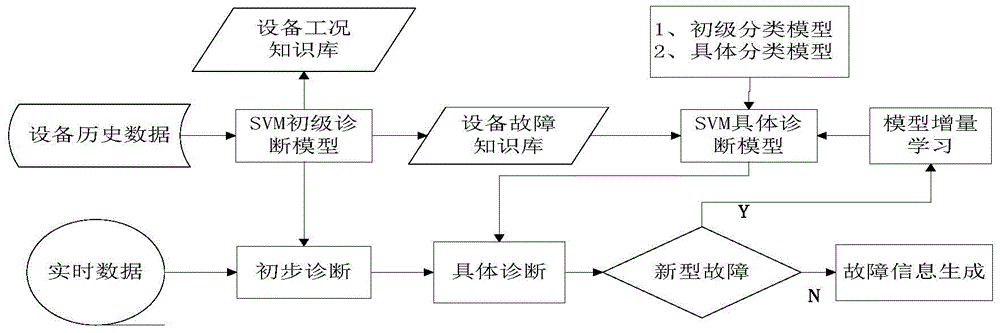

SVM classification model-based equipment fault diagnosing method

ActiveCN104573740AHigh speedHigh precisionDetecting faulty computer hardwareCharacter and pattern recognitionSupport vector machineDiagnosis methods

The invention discloses an SVM classification model-based equipment fault diagnosing method. The method comprises the following steps: performing a preprocessing operation on equipment data; constructing a fault diagnosis case knowledge base; performing fault diagnosis on a support vector machine on the basis of an SVM classification model; acquiring fault information and performing maintenance guide. According to the support vector machine-based intelligent equipment fault diagnosis method, the fault features of equipment are highlighted to the maximum degree; the situations that the equipment data are incomplete and inaccurate are reduced; the possibility is provided for constructing an accurate and reliable fault diagnosis model; the problem that the diagnosis model ages along with the operating time of the equipment is solved; the misdiagnosis rate of the fault diagnosis is reduced; the accuracy and the speed of the equipment fault diagnosis are greatly improved.

Owner:SHANDONG LUNENG SOFTWARE TECH

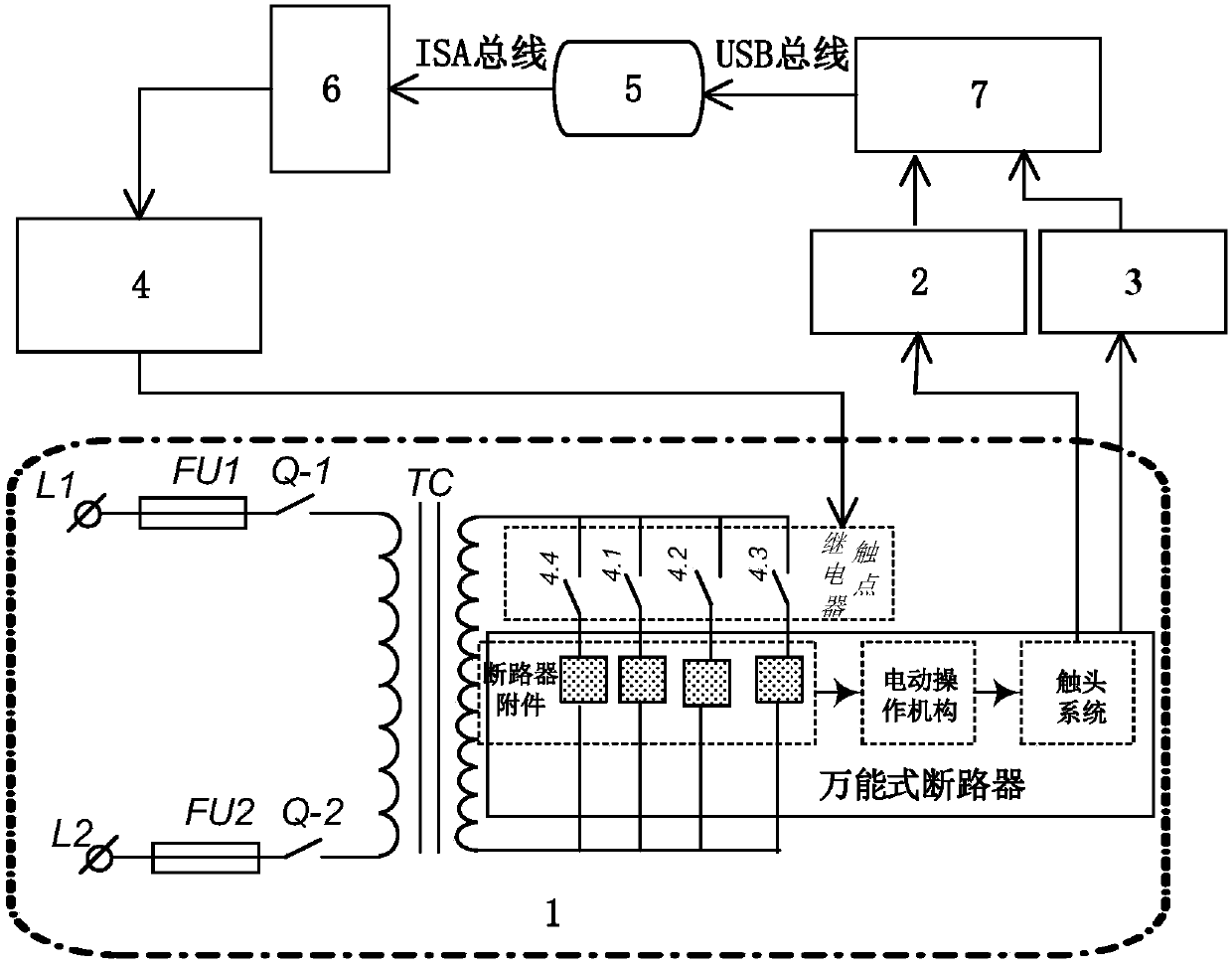

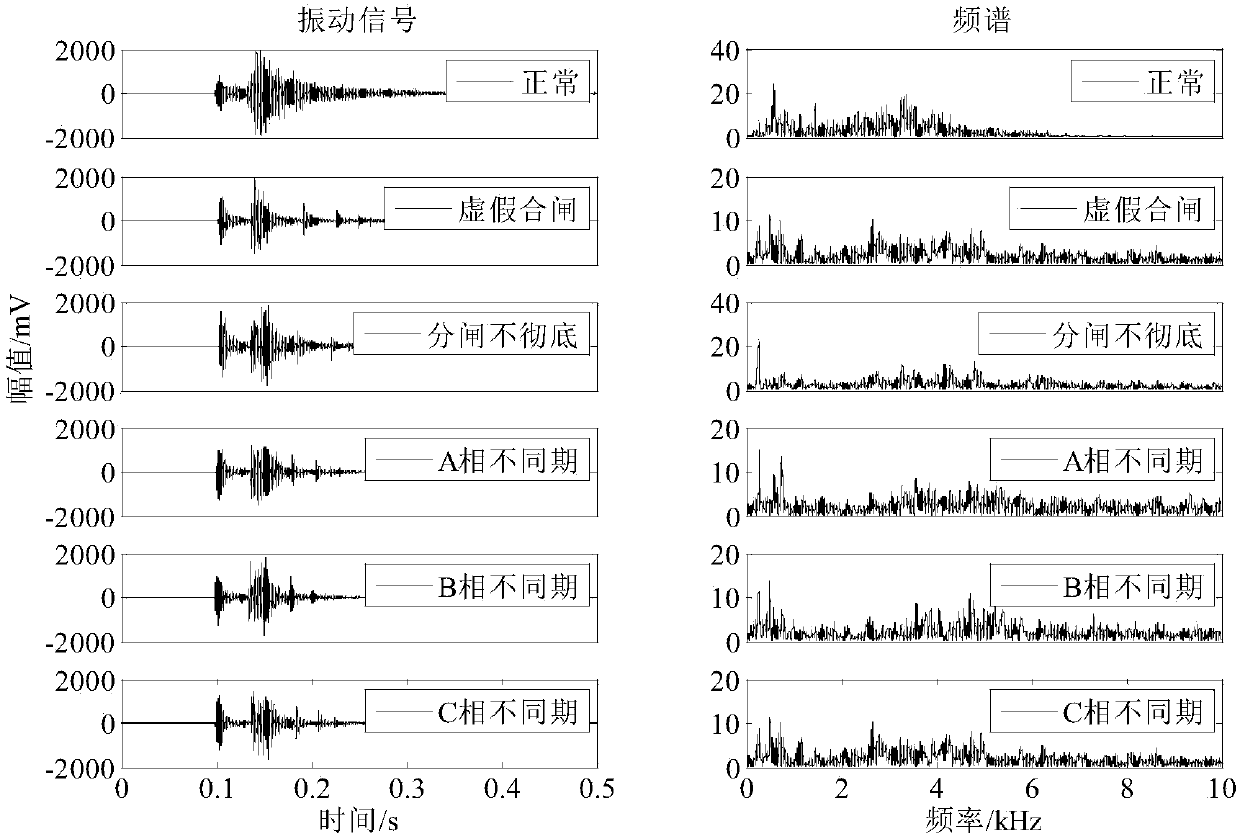

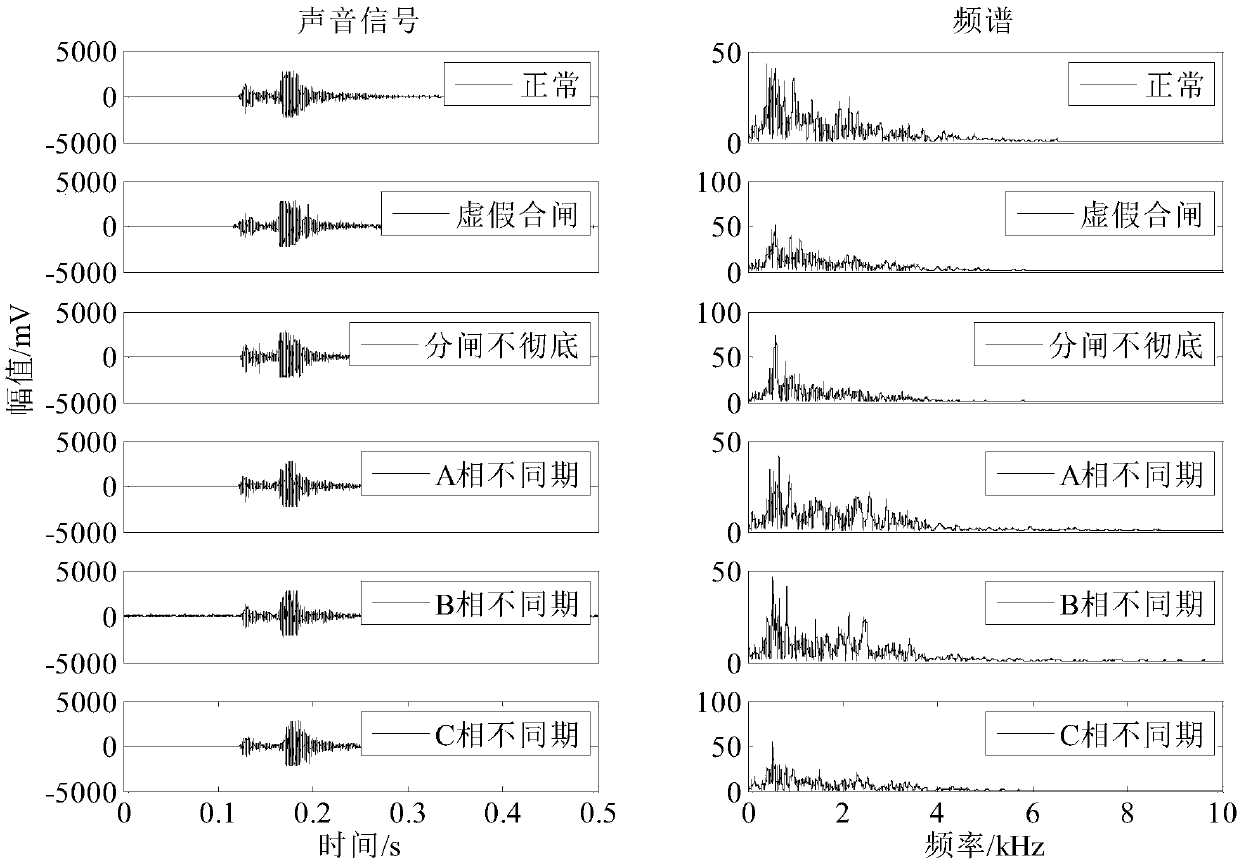

Universal circuit breaker mechanical fault diagnosis method based on feature fusion of vibration and sound signals

InactiveCN106017879AImprove reliabilityThe detection method is simpleMachine part testingCircuit interrupters testingDiagnostic Radiology ModalityMachining vibrations

The invention provides a universal circuit breaker mechanical fault diagnosis method based on feature fusion of vibration and sound signals. The method includes steps of 1, collecting machine vibration signals and machine sound signals during an engaging and disengaging process of a universal circuit breaker; 2, adopting an improved wavelet packet threshold value denoising algorithm for denoising; 3, adopting a complementary total average empirical mode decomposition algorithm for extracting a plurality of solid mode function components reflecting state information of engagement and disengagement actions of the circuit breaker from the denoising signals; 4, determining the number Z of the solid mode function components; 5, calculating the energy ratio, the sample ratio and the power spectrum entropy as three types of features; 6, adopting a combination core principal component analysis method for performing dimension reduction on a feature sample with unified three types of features of the vibration and the sound signals and obtaining M principle components; 7, establishing a related vector machine based sequence binary tree multiple classifier model.

Owner:HEBEI UNIV OF TECH

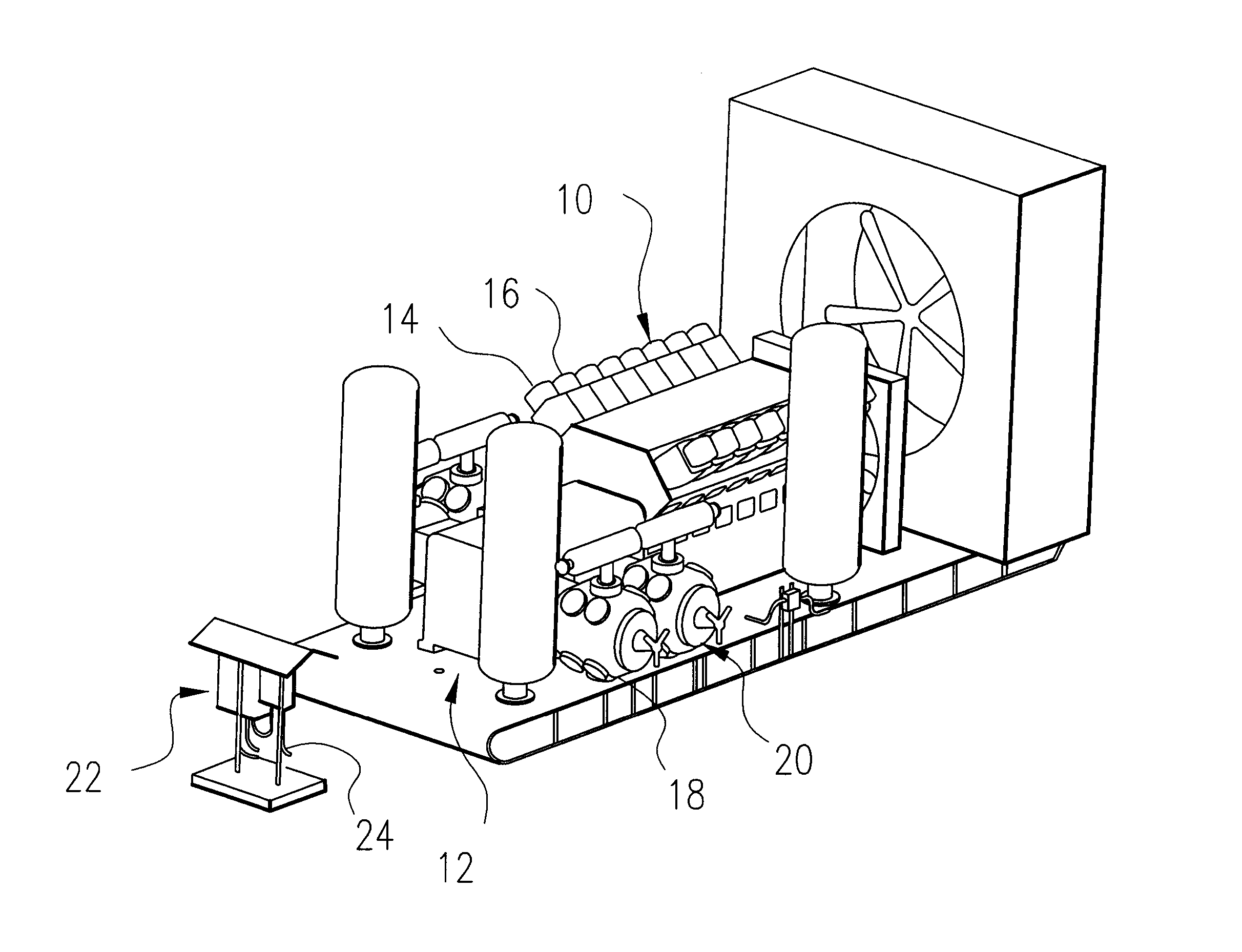

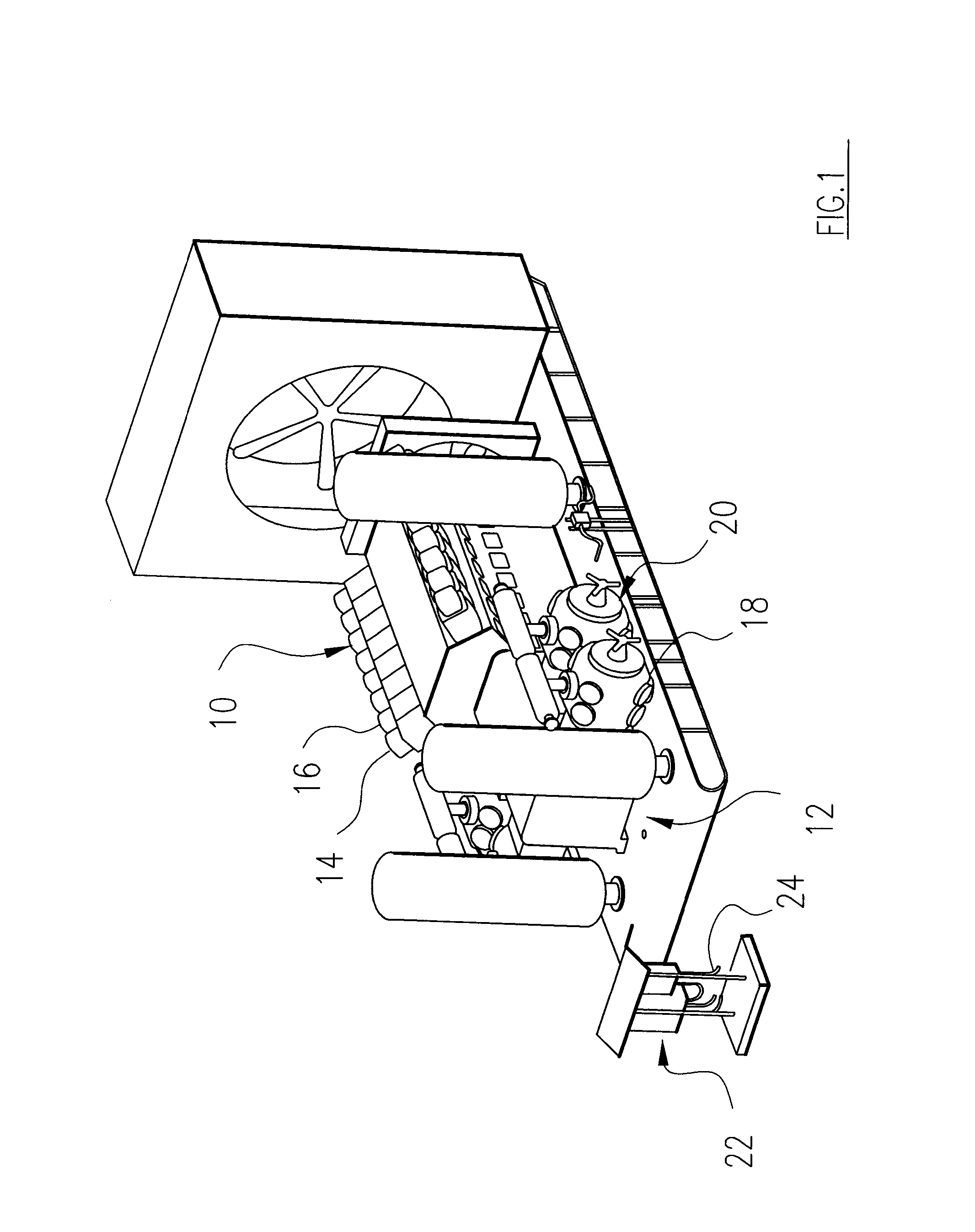

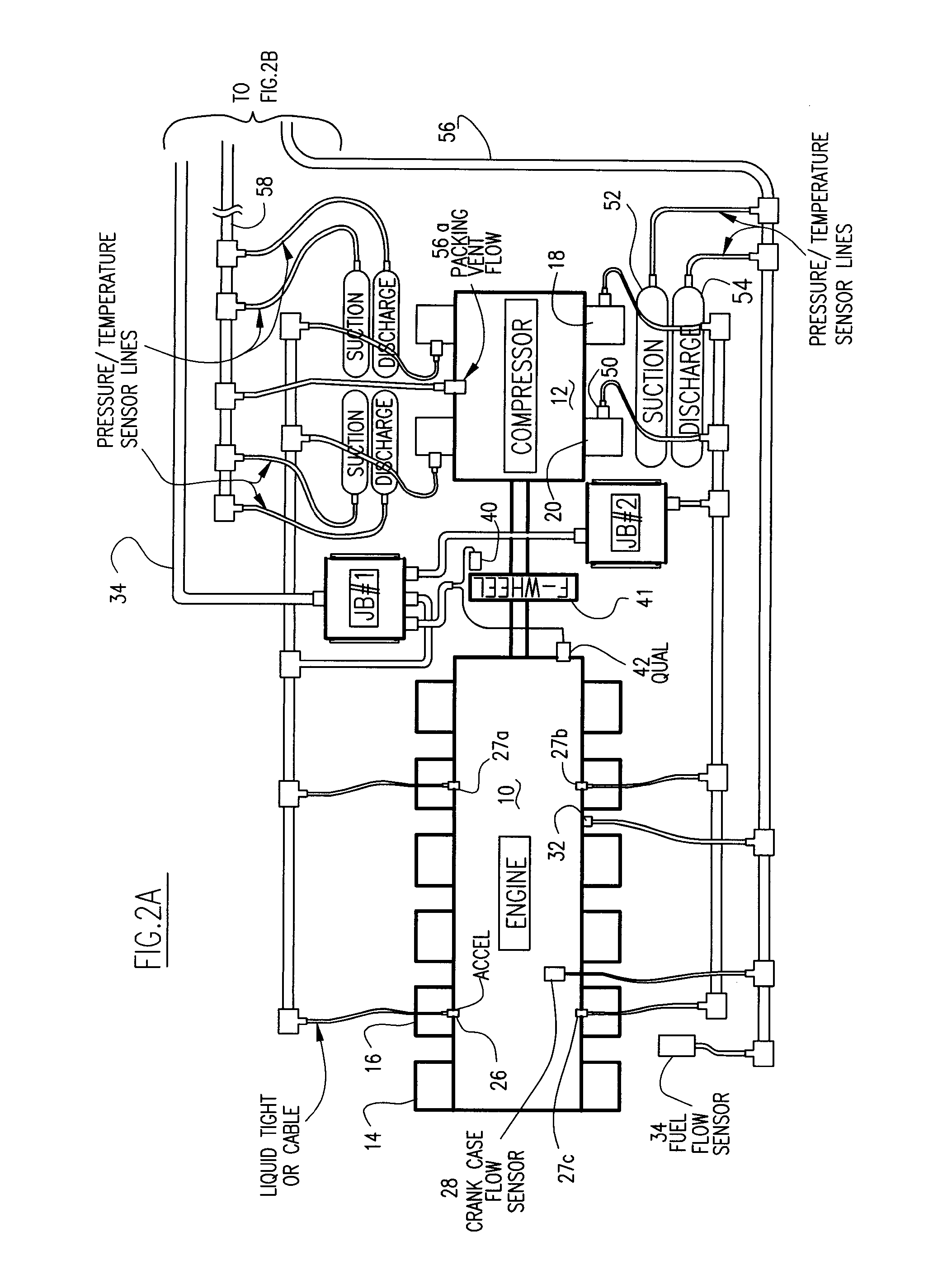

Automated fault diagnosis method and system for engine-compressor sets

InactiveUS7403850B1Improve economic performanceIncrease fuel consumptionInternal-combustion engine testingAutomatic initiationsBaseline dataData acquisition

The automated fault diagnostic system operates on engine-compressor sets with one vibration sensor per sub-group of engine cylinders and one sensor per compressor cylinder. Vibration signals linked to crankshaft phase angle windows (“VT”) mark various engine events and compressor events. In data-acquisition-learning mode, VT is stored for each engine and compressor event per operating load condition, statistical process control (SPC) theory identifies alarm threshold bands. Operator input-overrides are permitted. If no baseline data is stored, the system automatically enters the learn mode. To monitor, current VT are obtained and current load condition is matched to the earlier load set and alarms issue linking predetermined engine or compressor event to the over-under VT. Baseline data, SPC analysis, alarms and monitoring are set for crankcase flow, engine cylinder exhaust temperatures, ignition system diagnostic messages. Compressor performance alarms use suction and discharge temperatures and pressures.

Owner:WINDROCK

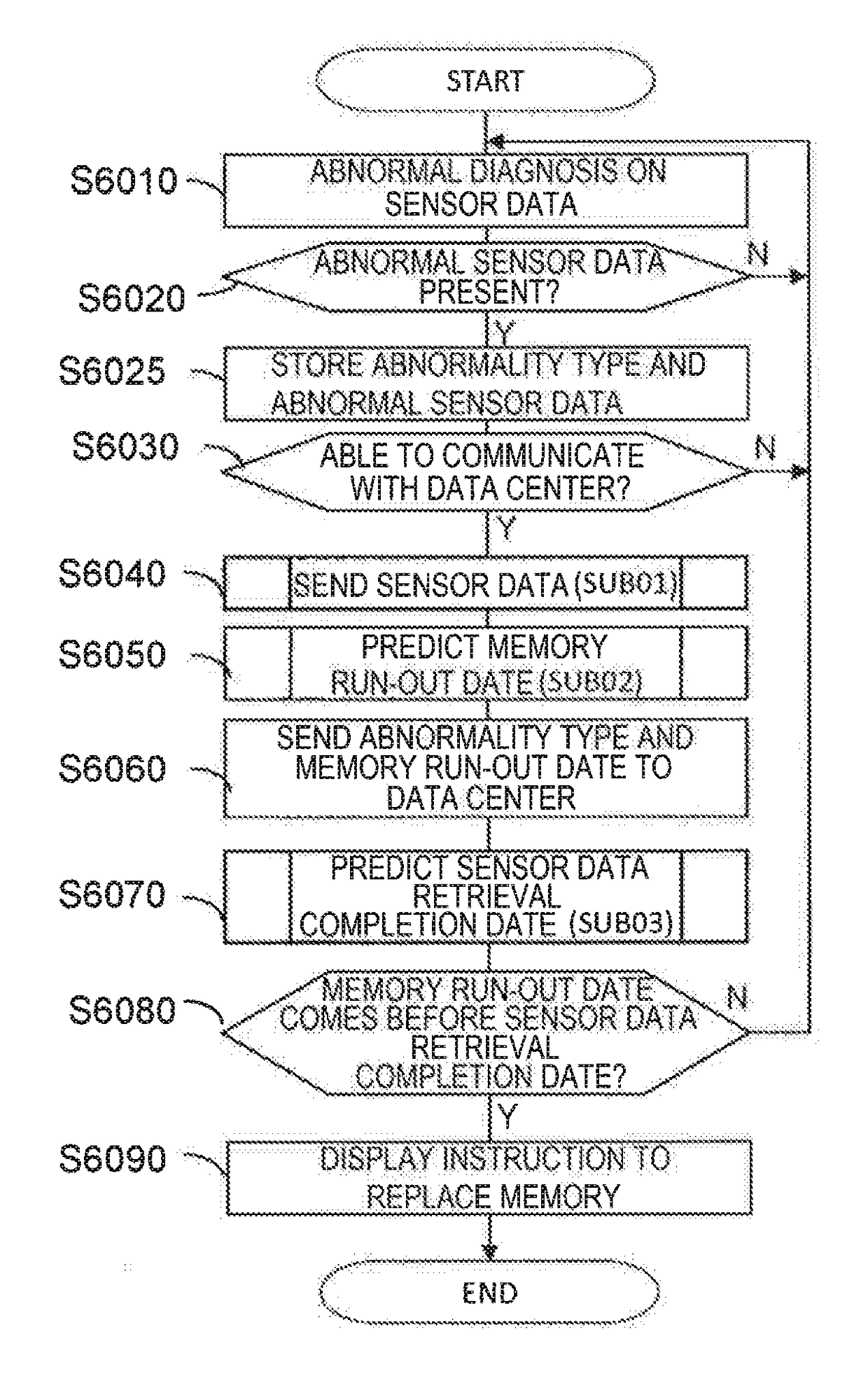

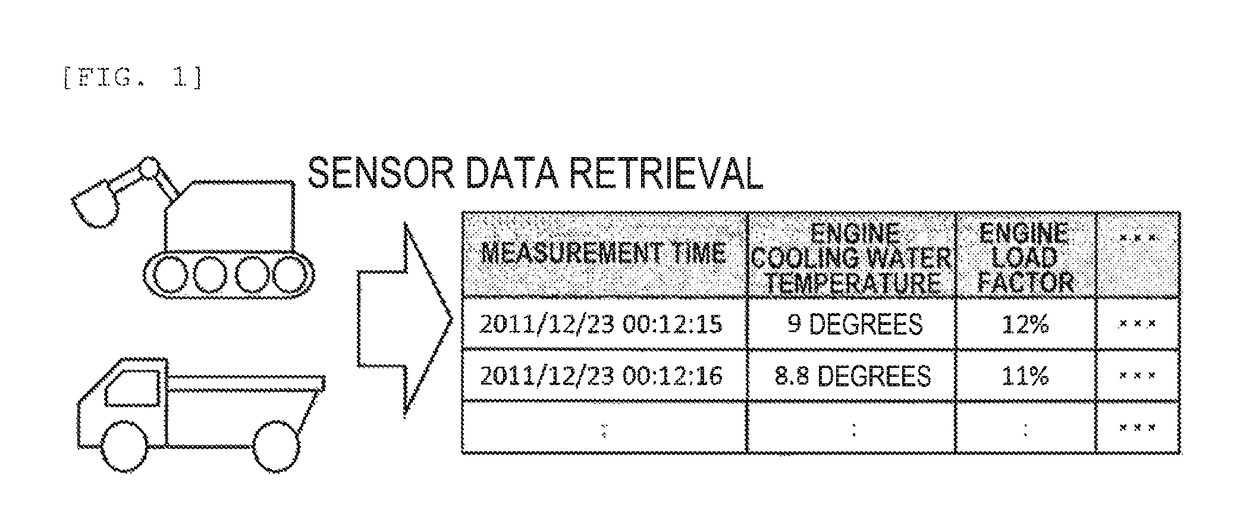

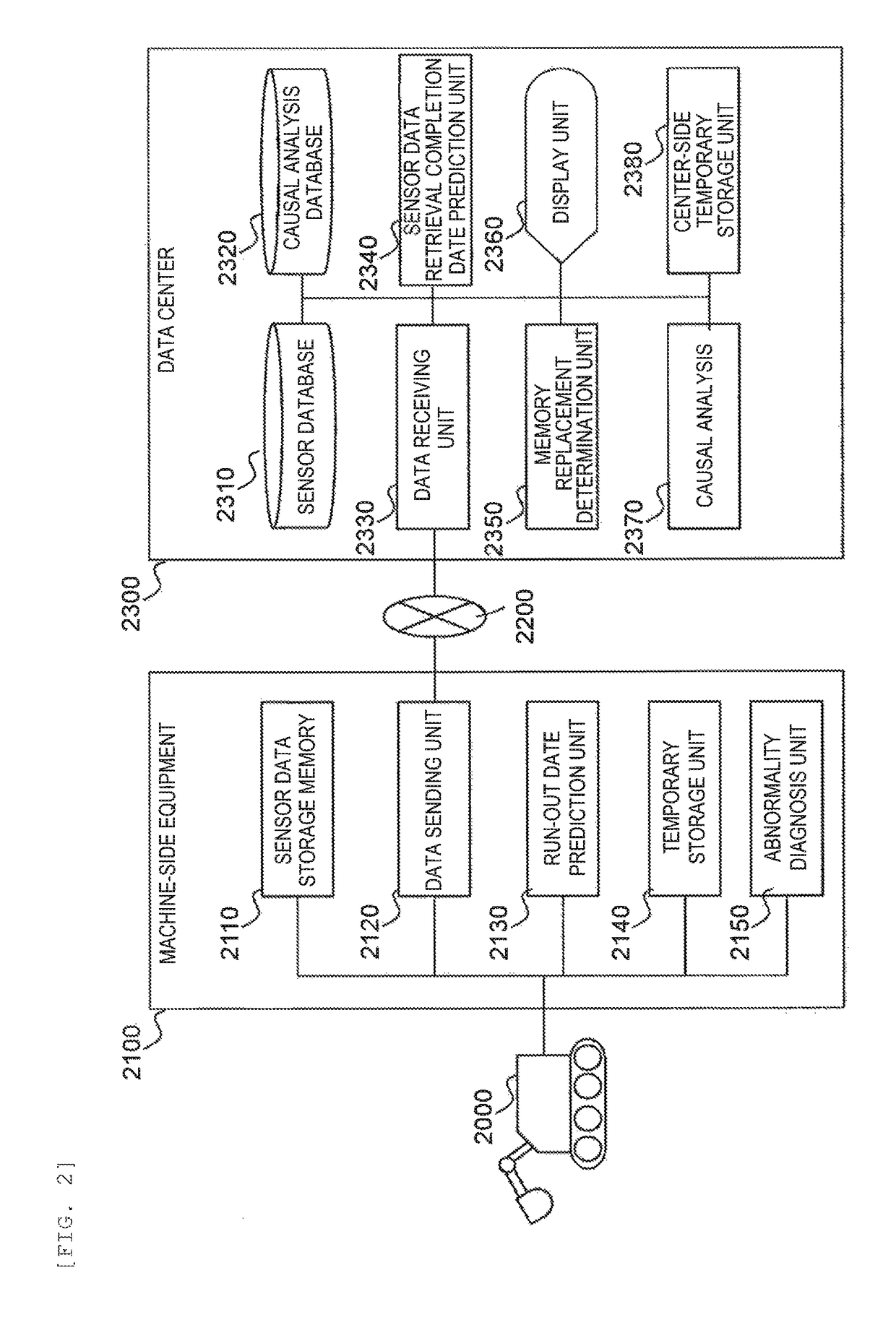

Abnormality diagnosis method and device therefor

ActiveUS10073447B2Detected as abnormalityProgramme controlRegistering/indicating working of vehiclesMechanical AbnormalityDiagnosis methods

In industrial machine abnormality diagnosis, if the machine is diagnosed to have abnormality, then sensor data from the machine needs to be sent to a management center for causal analysis. However, since machines operated at a remote site cannot always communicate with a management center, it has been found that, in some cases, sensor data that has failed to be sent from a machine remains in the memory of the machine, resulting in lack of available memory capacity. In view of this, the present invention determines beforehand whether the diagnosed machine will run out of available memory capacity before the completion of sending the amount of sensor data required for causal analysis for the machine, and instructs a maintenance person to recover memory. This determination as to whether the machine will run out of available memory capacity before the completion of sending the amount of sensor data required for the causal analysis for the machine, is made as follows: (1) first, the machine predicts the run-out date on which the machine will run out of memory capacity for storing sensor data generated in the machine, and sends a notification of the predicted run-out date to the management center for the machine; and (2) next, from the amount of sensor data required for the causal analysis and the reception rate of sensor data, the management center calculates the number of days required to retrieve the necessary data for the causal analysis and determines whether the management center can retrieve the data by the predicted run-out date.

Owner:HITACHI LTD

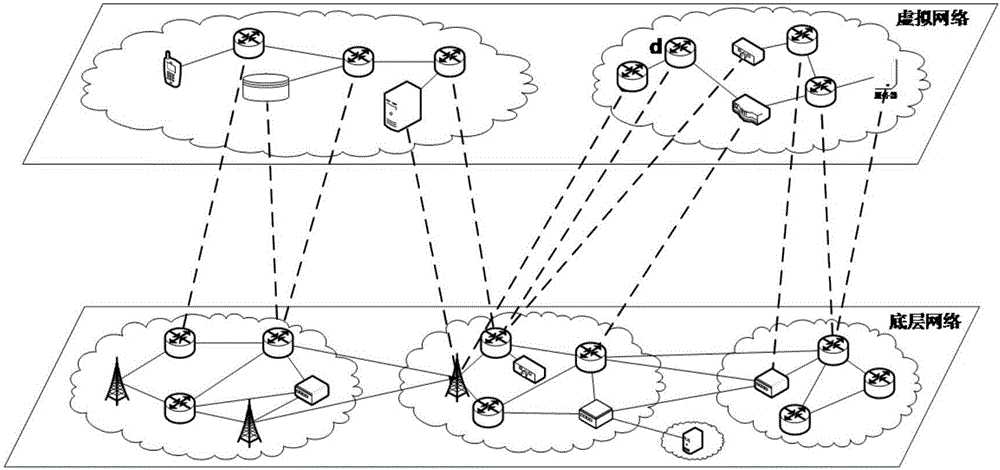

Network fault diagnosis method based on deep learning in virtual network environment

InactiveCN106603293ATo achieve the purpose of failure early warningData switching networksFault severityEngineering

The invention discloses a network fault diagnosis method based on deep learning in a network virtualization environment. The network fault diagnosis method comprises the steps of: dividing a network into a physical network and a virtual network, combining the characteristics of occurrence of network faults, considering the time influencing factor, network topological connection characteristics and a mapping relation between the virtual network and the physical network, and comprehensively evaluating the network faults by means of a fault severity grading probability; regarding network characteristic parameters with influence degrees as a model learning resource, paying attention to the correspondence between variation trend of network historical data and fault tags, establishing a network fault diagnosis model with multiple fault grading probabilities in the network virtualization environment based on a viewing angle of deep learning, and training network parameters by using the network fault diagnosis model; and adjusting a fault prediction model in the training process, and utilizing an optimized and adjusted deep learning network to realize fault diagnosis in the network virtualization environment. The network fault diagnosis method can carry out deep analysis on the network parameters in the network virtualization environment, therefore the network fault diagnosis method has higher precision in predicting the network faults.

Owner:NANJING UNIV OF POSTS & TELECOMM

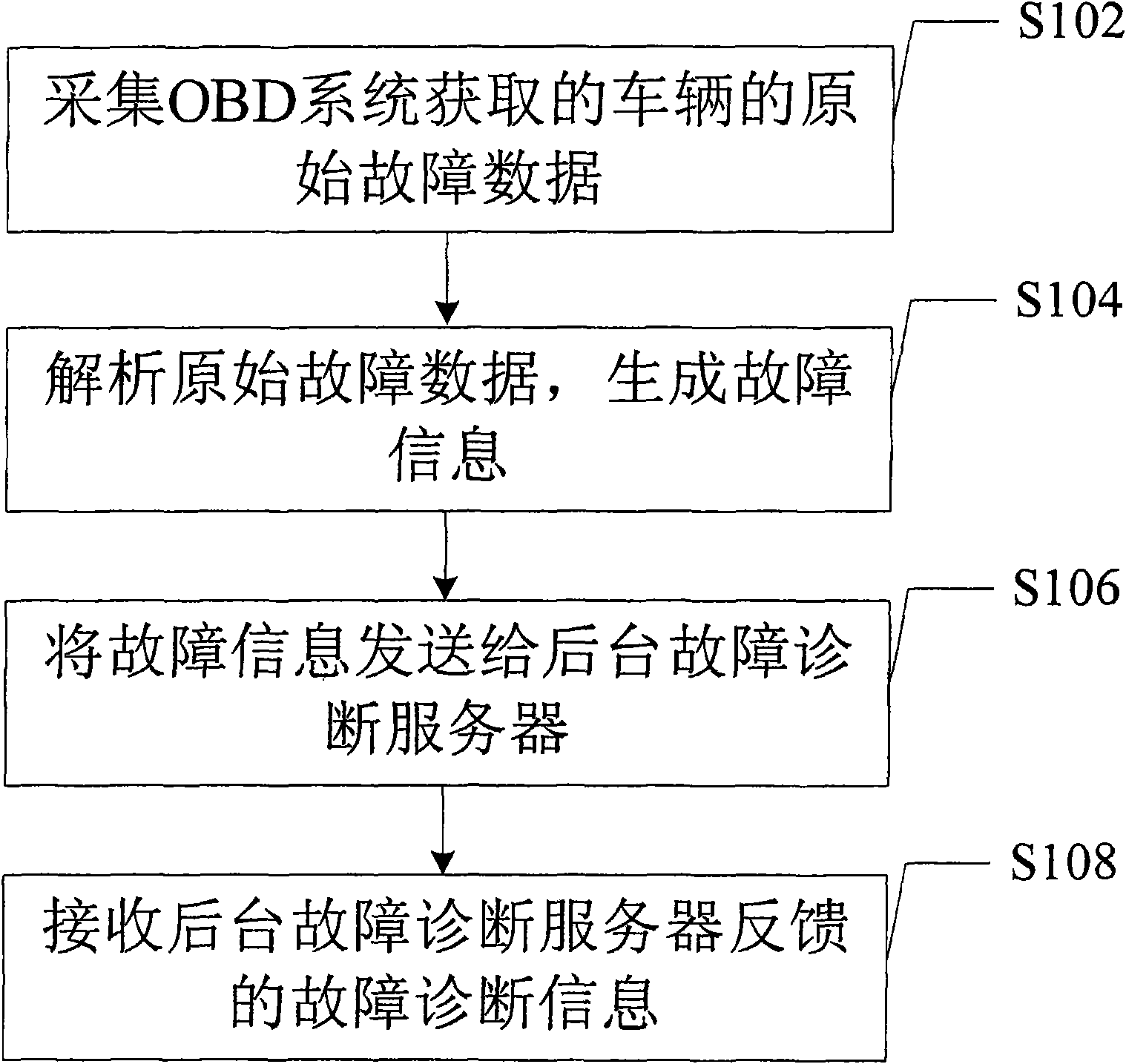

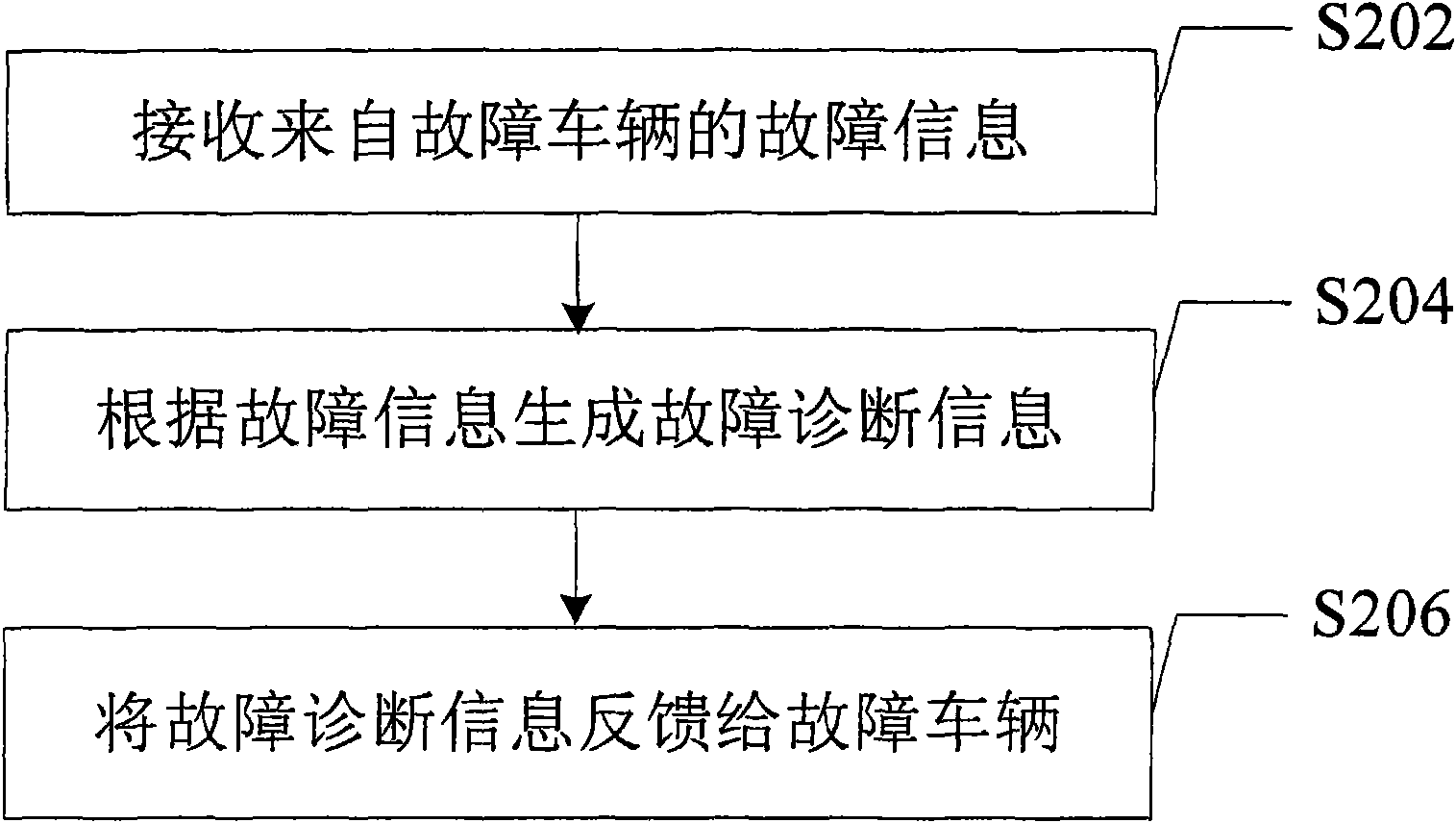

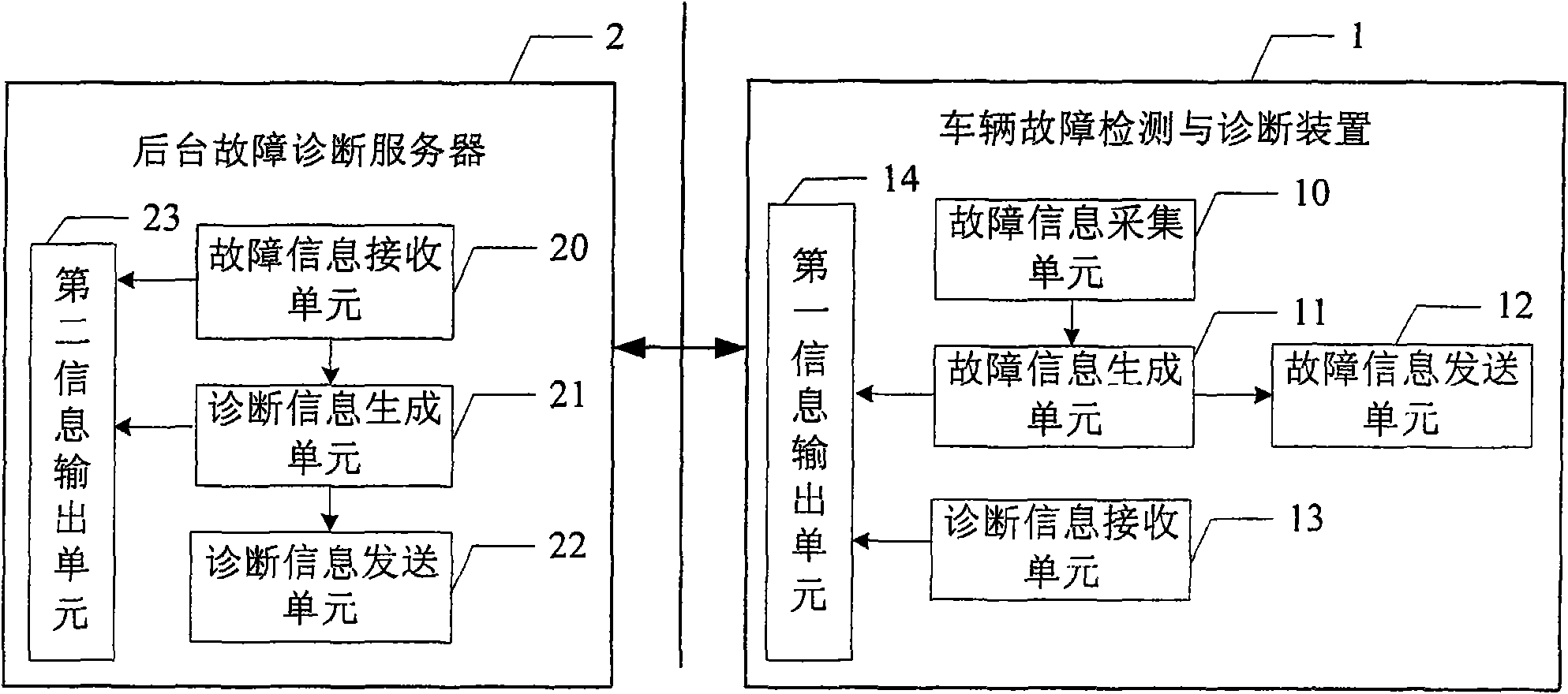

Fault diagnosis server, method, device and system for detecting and diagnosing vehicle fault

InactiveCN101625570AAvoid failureEasy to receiveVehicle testingElectric testing/monitoringDiagnosis methodsDiagnostic system

The invention provides a fault diagnosis server, a method, a device and a system for detecting and diagnosing vehicle faults. The device for detecting and diagnosing vehicle faults comprises a fault information acquisition unit, a fault information generation unit, a fault information transmitting unit, a diagnosis information receiving unit and an information output unit, wherein the fault information acquisition unit is used for acquiring original vehicle fault data from a vehicle-mounted on-line diagnosis system; the fault information generation unit is used for generating fault information after analyzing the original fault data; the fault information transmitting unit is used for transmitting the fault information to the background fault diagnosis server; the diagnosis information receiving unit is used for receiving fault diagnosis information which is fed back by the background fault diagnosis server; and the information output unit is used for outputting the fault information and / or the fault diagnosis information. Through the invention, a user can conveniently receive diagnosis information provided by a 4S shop according to fault information in time, thereby solving vehicle faults.

Owner:北京易行出行旅游有限公司

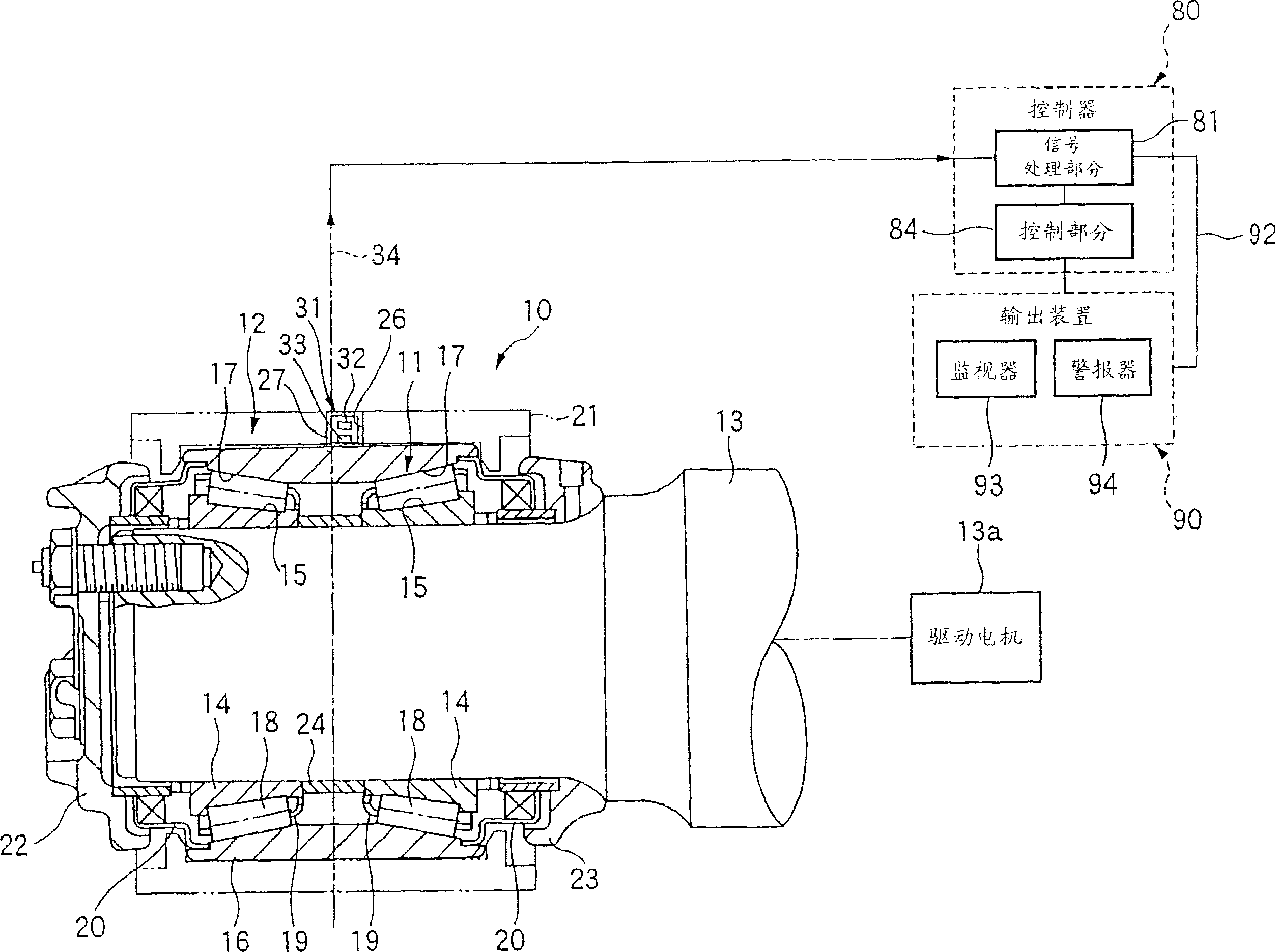

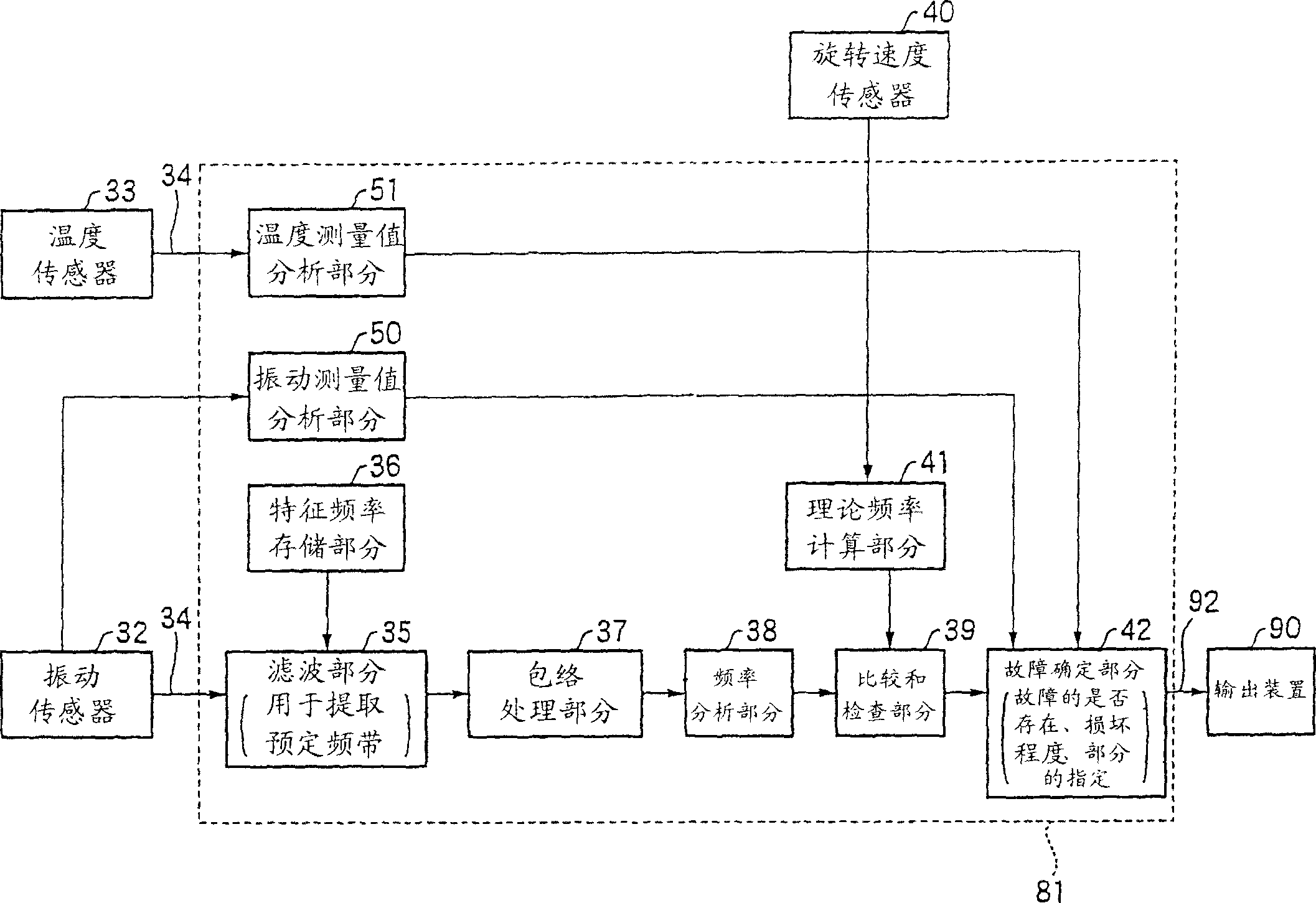

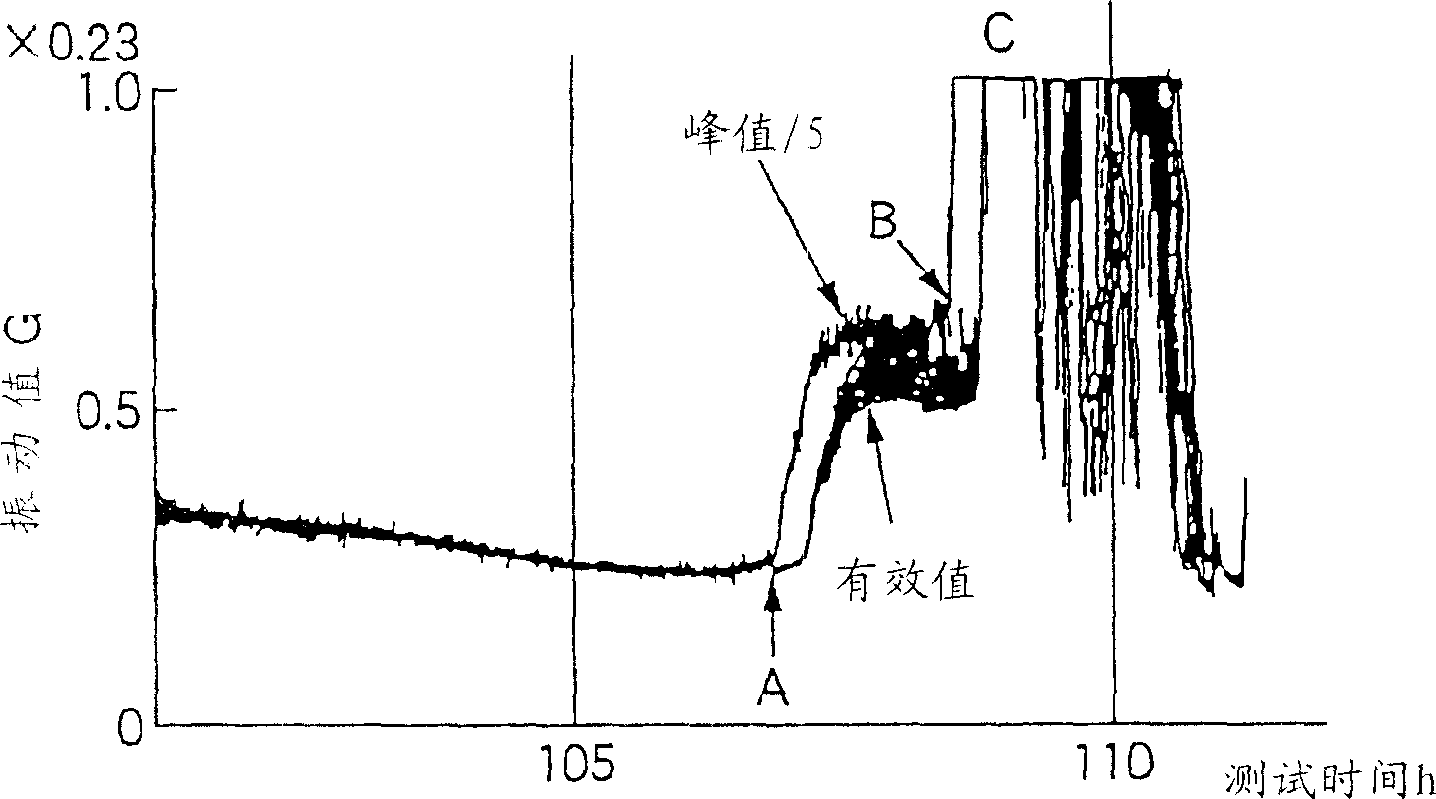

Abnormality diagnosis device and abnormality diagnosis method

InactiveCN1906473AImprove reliabilityEffective maintenanceRolling contact bearingsSubsonic/sonic/ultrasonic wave measurementDiagnosis methodsBiomedical engineering

An abnormality diagnosis device used for a machine apparatus having a part rotating and sliding relative to a stationary member is provided with a detection section (31) and a signal processing section (81). The detection section (31) is fixed to the part rotating or sliding or to the stationary member and has a vibration sensor (32) and a temperature sensor (33). The signal processing section (81) determines the condition of the part based on a signal detected and outputted by the detection section (31). The signal processing section (81) determines whether there is an abnormality in the part, or whether there is an abnormality in the part and the degree of damage of the part.

Owner:NSK LTD

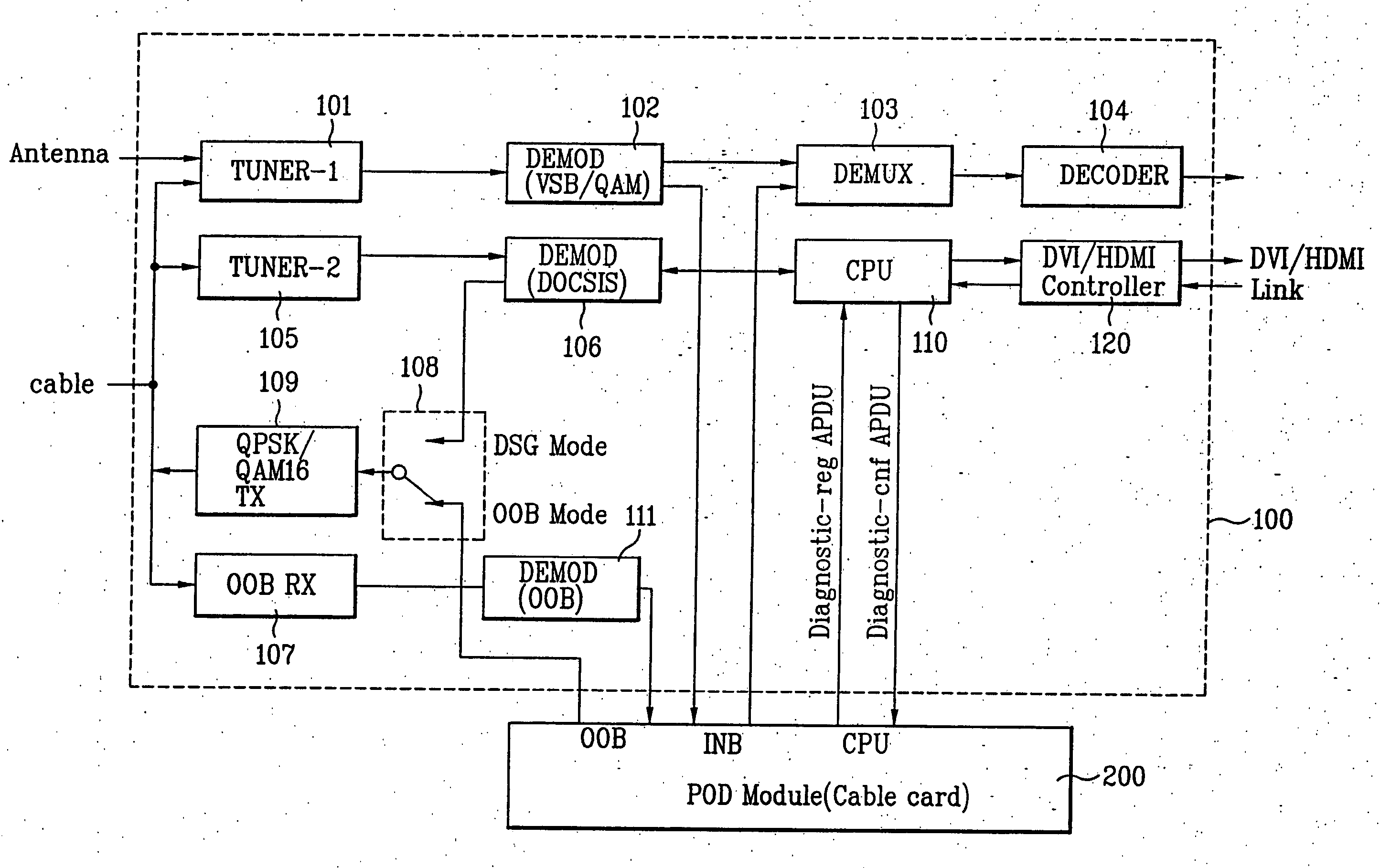

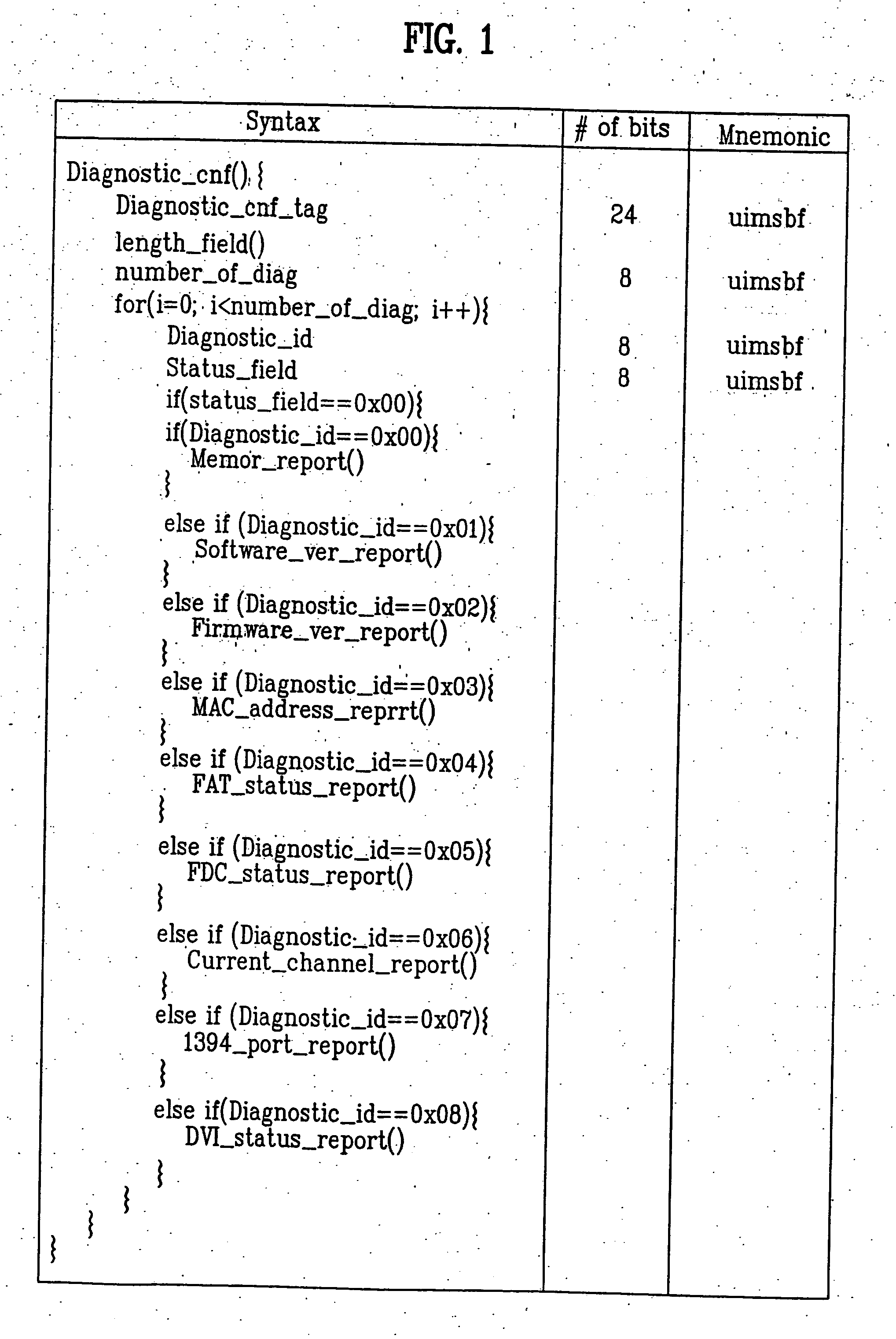

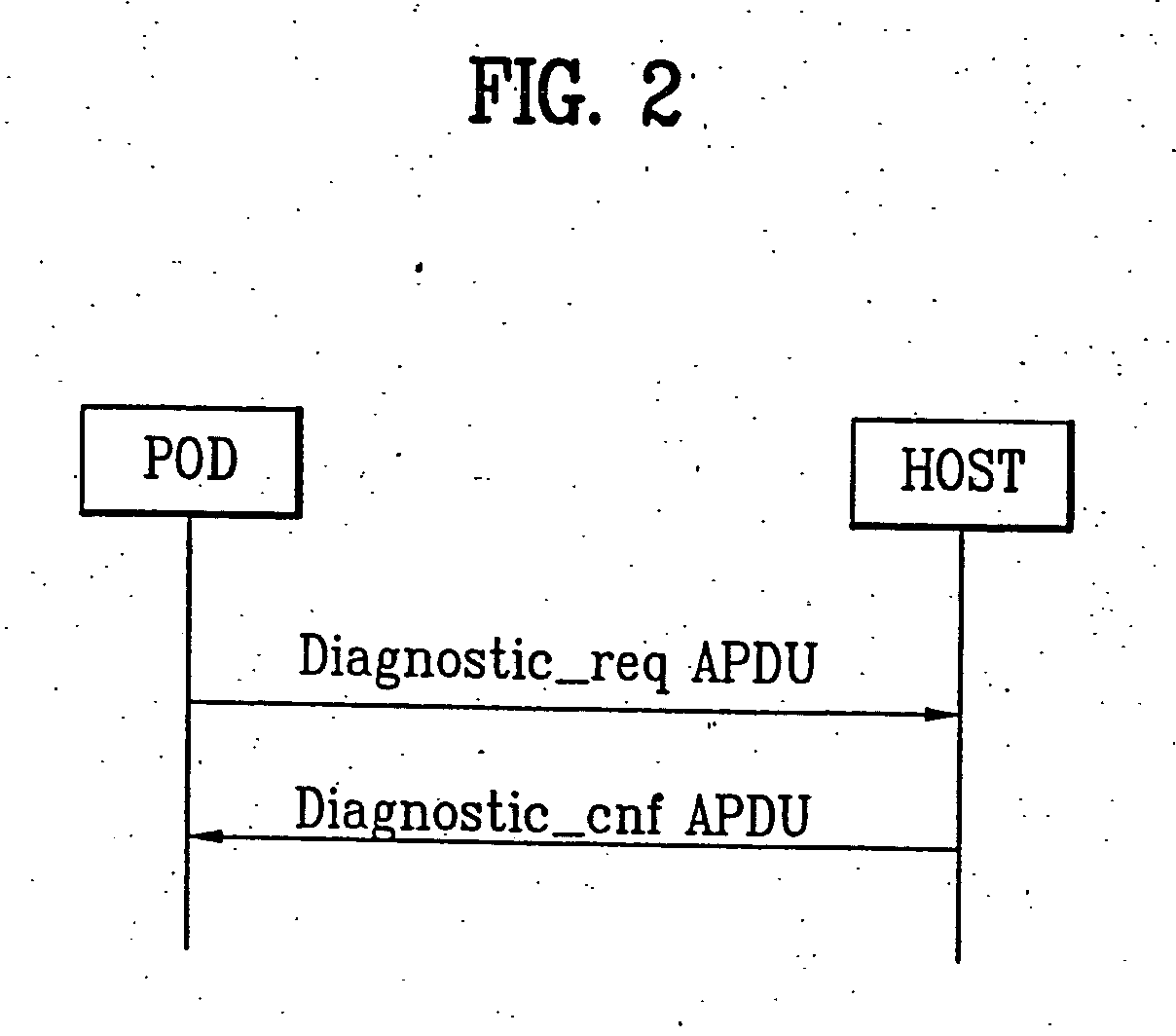

Digital cable TV receiver, diagnosis method for the same, and data structure of HDMI status report

ActiveUS20070056012A1Television system detailsPulse modulation television signal transmissionComputer networkDiagnosis methods

A host includes at least one High-Definition Multimedia Interface (HDMI) port. A controller is configured to receive a request from a source external to the host. The controller is further configured to collect HDMI status information associated with the HDMI port in response to the request.

Owner:LG ELECTRONICS INC

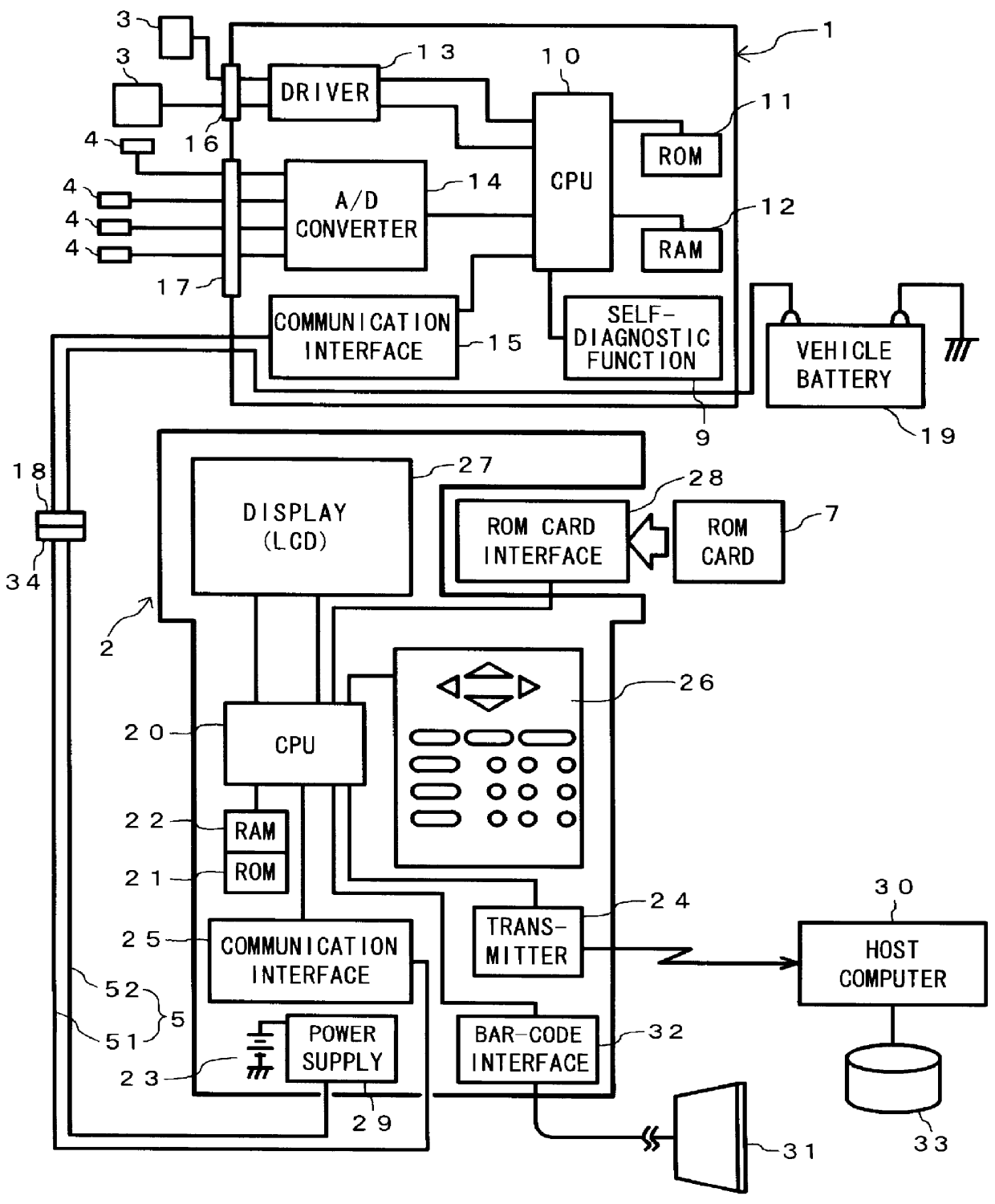

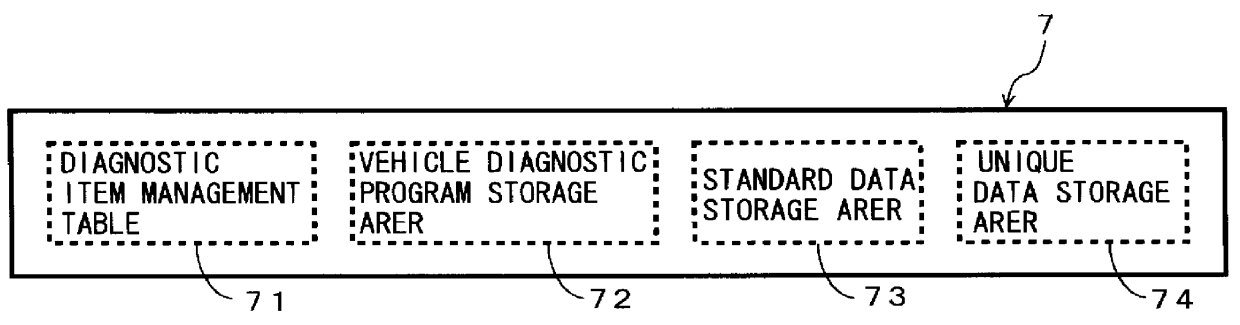

Method and device for diagnosis for vehicle

InactiveUS6134488AThe solution result is accurateVehicle testingElectrical controlDiagnosis methodsEngineering

PCT No. PCT / JP98 / 00975 Sec. 371 Date Oct. 16, 1998 Sec. 102(e) Date Oct. 16, 1998 PCT Filed Mar. 10, 1998 PCT Pub. No. WO98 / 40715 PCT Pub. Date Sep. 17, 1998Forced activation signal supplier 550 supplies a forced activation signal Sx to a diagnostic target part 101 related to a diagnostic item requiring a forced activation signal. Vehicle-state detector 552 detects a current state of the diagnostic target part 101 through an ECU 1. Diagnostic element 553 compares the currently detected state of the diagnostic target part 101 with a state predicted when the forced activation signal Sx is given to diagnose the diagnostic target part 101. When the forced activation signal Sx is supplied to the part of the vehicle, self-diagnosis stopping element 554 gives an instruction to stop a self diagnosis for at least an item the diagnostic result of which may vary under the influence of the forced activation signal Sx, or to invalidate the diagnostic result.

Owner:HONDA MOTOR CO LTD

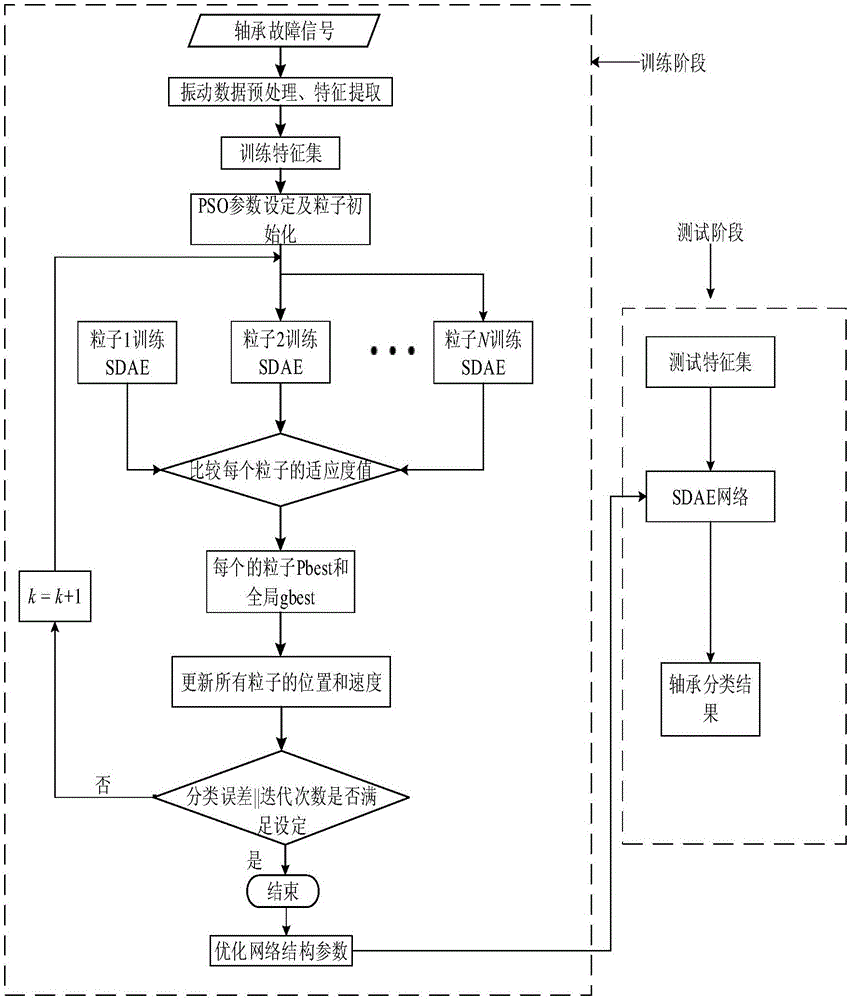

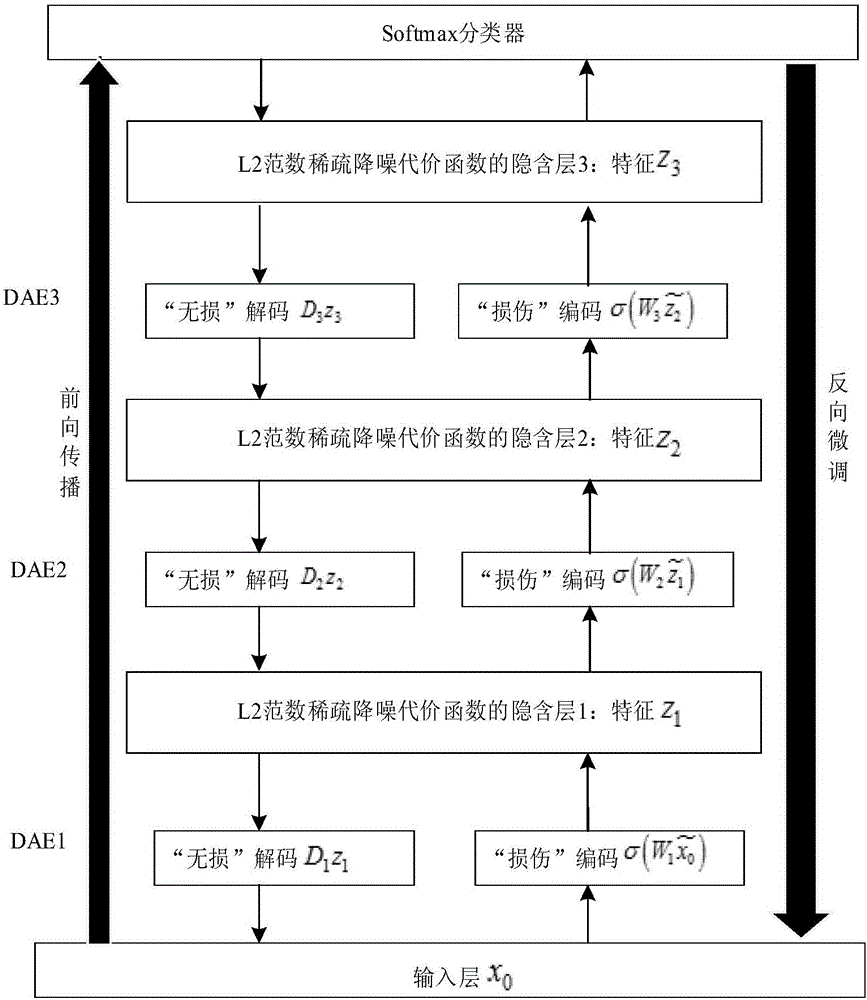

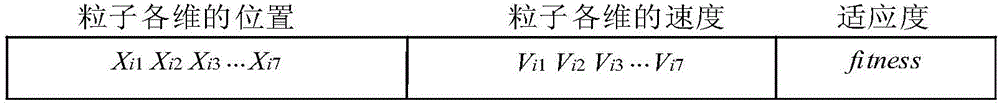

Pile-up noise reduction own coding network bearing fault diagnosis method based on particle swarm optimization

ActiveCN106682688ARobustGood feature learning abilityMachine bearings testingCharacter and pattern recognitionHidden layerDiagnosis methods

The invention discloses a pile-up noise reduction own coding network bearing fault diagnosis method based on particle swarm optimization. The bearing fault diagnosis method provides an improved pile-up noise reduction own coding network SADE bearing fault diagnosis method, SDAE network hyper-parameters, such as cyber hidden layer nodes, sparse parameters, input data random zero setting ratio, are selected adaptively by particle swarm optimization PSO, a SADE network structure is determined, top character representation of malfunction inputting a soft-max classifier is obtained and a classification of defects is discerned. The bearing fault diagnosis method has better feature in learning capacity and more robustness than feature of learning of ordinary sparse own coding device, and builds a SDAE diagnostic model having multi-hidden layer by optimizing the hyper-parameters of noise reduction own coding network deepness network structure with the particle swarm optimization, accuracy of the classification of defects is improved at last.

Owner:SOUTH CHINA UNIV OF TECH

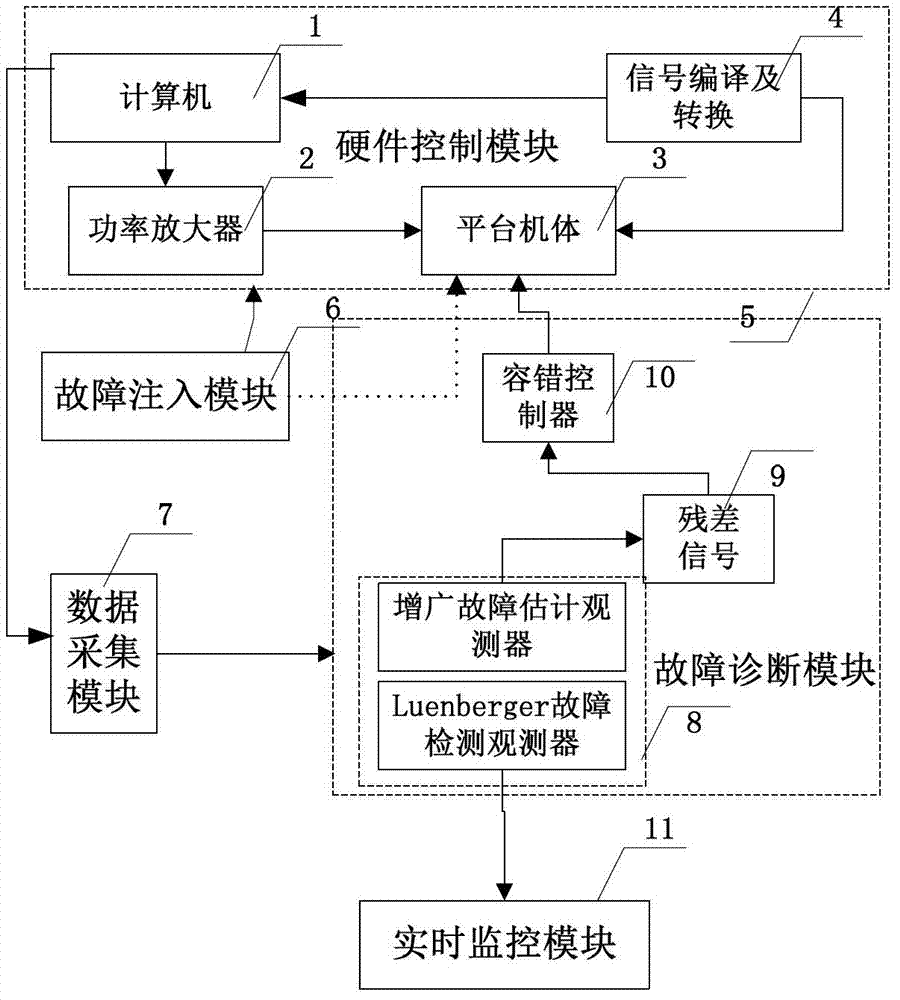

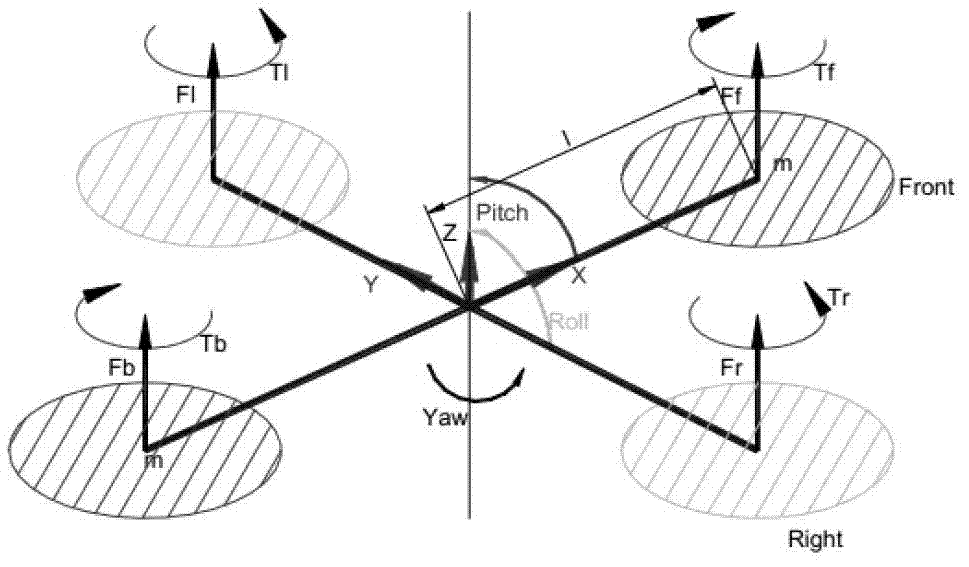

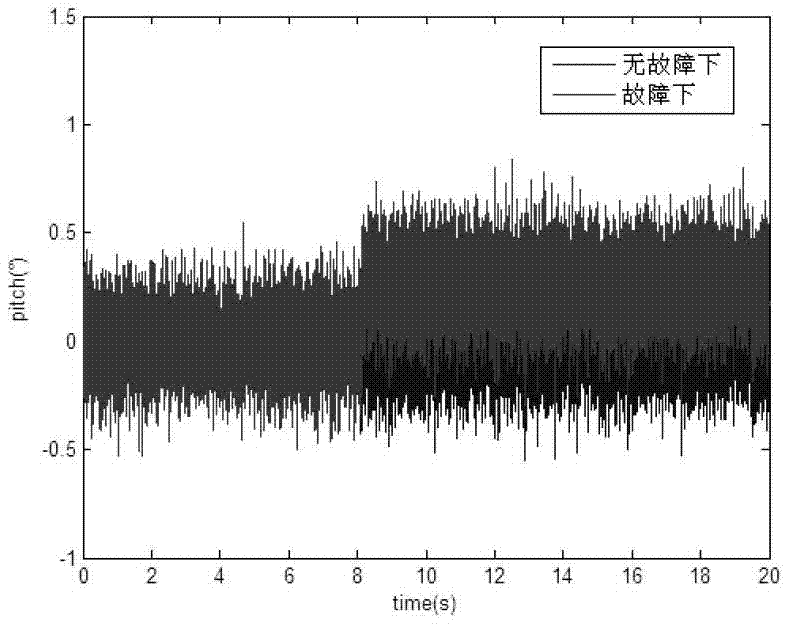

A plurality of united observer based fault diagnosis and fault-tolerant control device and method

ActiveCN102854874AAvoid serious coupling problemsAvoid errorsElectric testing/monitoringAviationDiagnosis methods

The invention discloses a plurality of united observer based fault diagnosis and fault-tolerant control device and a method and belongs to the field of aerospace. The plurality of united observer based fault diagnosis and fault-tolerant control device comprises following modules of a fault injection module, a fault diagnosis module, a real time monitoring module and a hardware control module. According to the method, the problem that traditional observer based fault diagnosis methods are limited by conditions is mainly solved, the operation is simple, the implementability is high, and the method can be used for diagnosing faults of actuating mechanisms of a four rotor wing helicopter and verifying feasibility of state monitoring.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

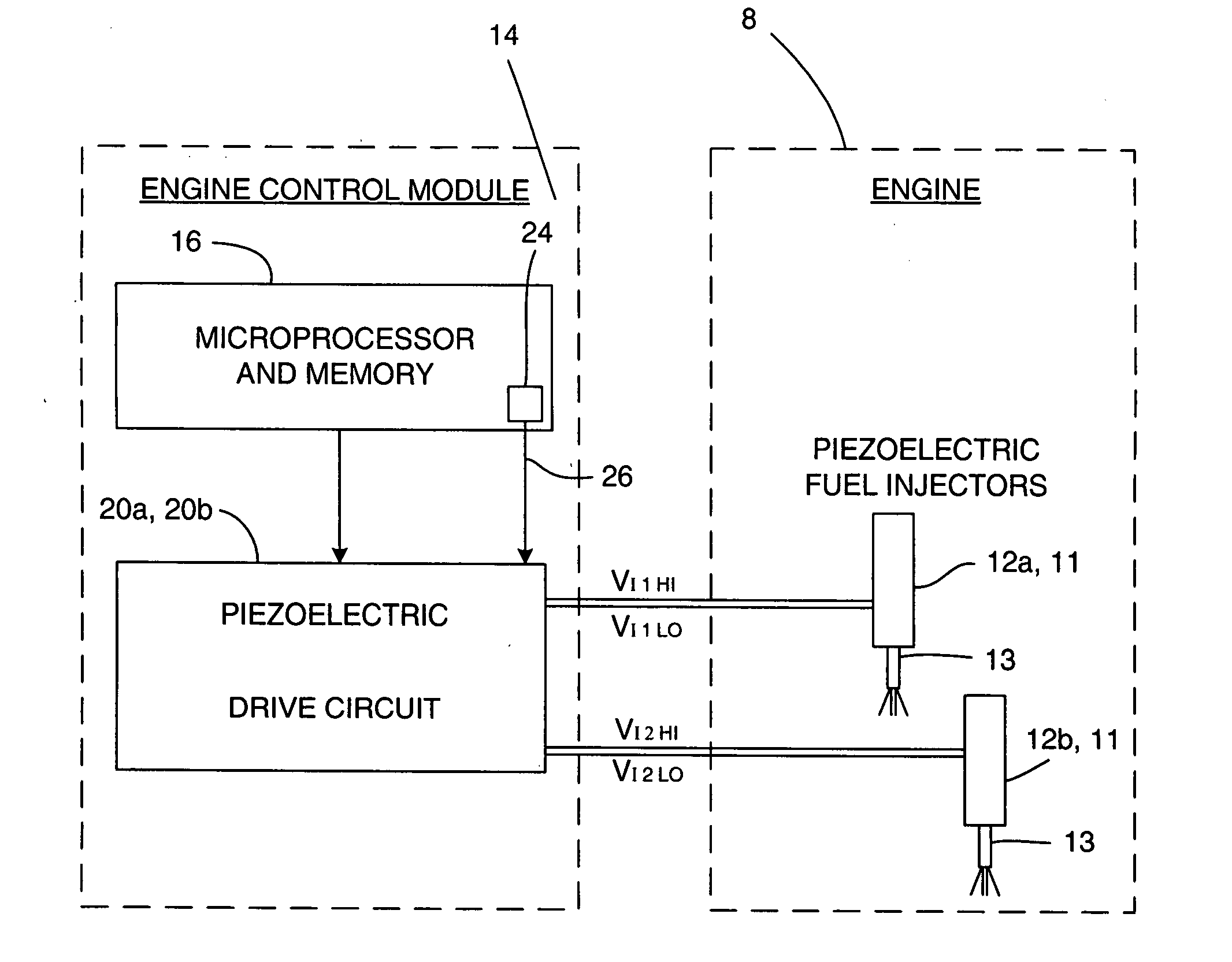

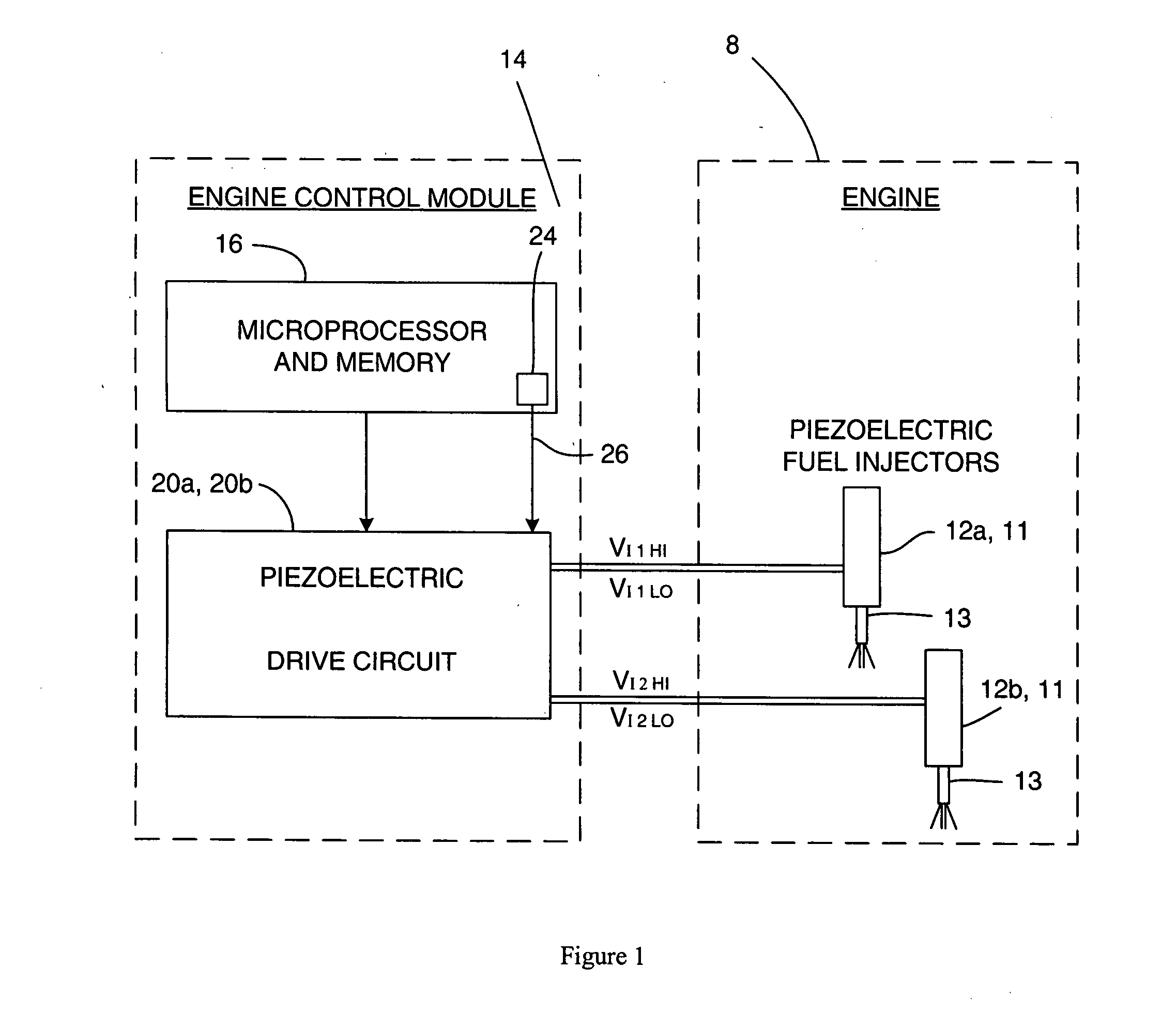

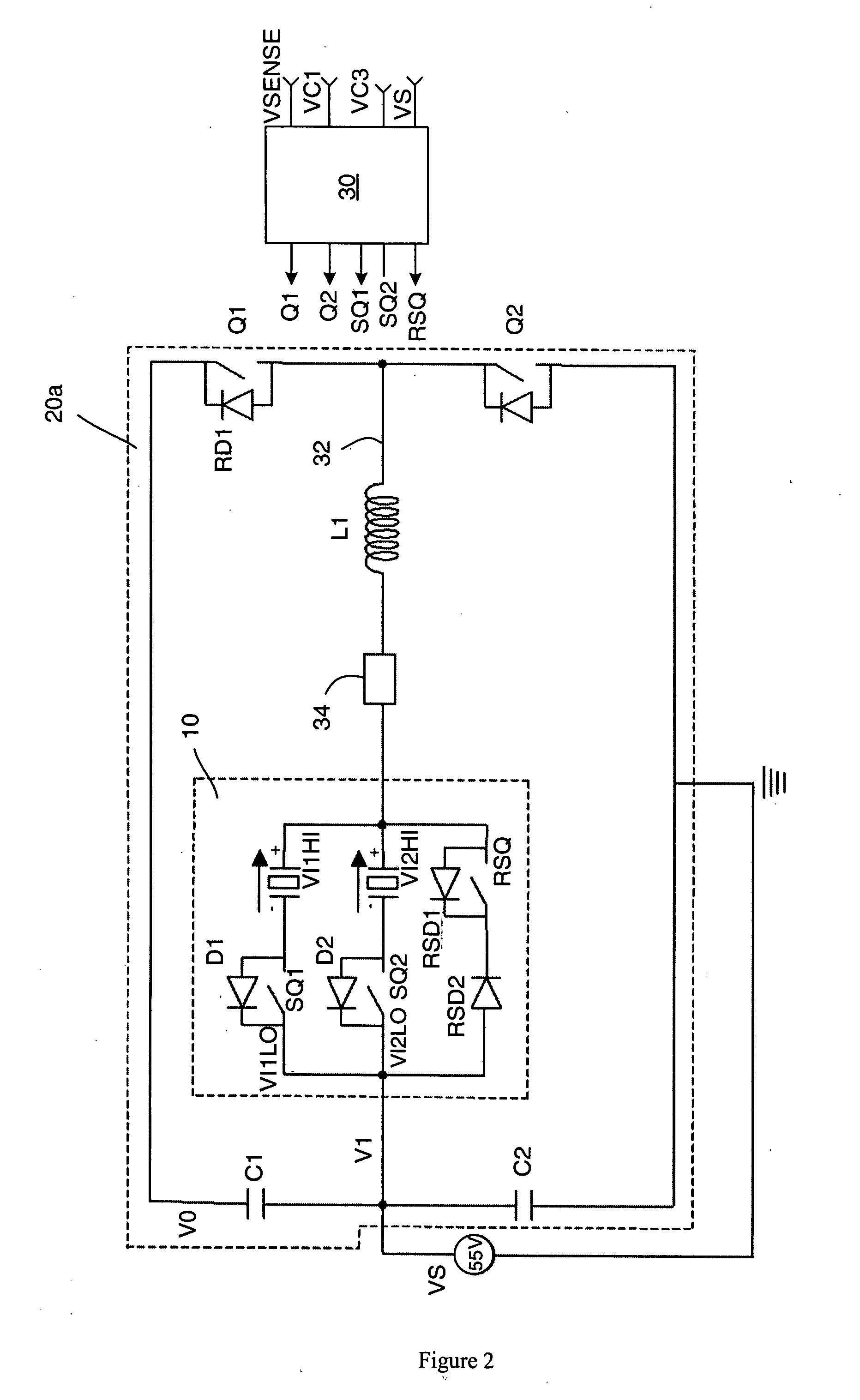

Drive circuit for an injector arrangement and a diagnostic method

ActiveUS20070227506A1Avoid failureCritical failure modeAnalogue computers for vehiclesElectrical controlSignal onDiagnosis methods

The invention relates to a drive circuit for an injector arrangement comprising a fuel injector, and method of detecting faults in the drive circuit. The drive circuit comprises diagnostic means (RH, RL) that is operable to sense a measured voltage (VBIAS) between the injector and a known voltage level (VBAT, VGND). The measured voltage (VBIAS) is biased with respect to the known voltage (VBAT, VGND) to a predicted voltage (VPinjN, VBcalc) unless the drive circuit has a fault. A fault signal is provided on sensing of a measured voltage (VBIAS) that differs from the predicted voltage (VPinjN, VBcalc). The drive circuit may additionally, or alternatively, comprise diagnostic means (RF). The diagnostic means (RF) is operable to sense a detected current (Idect) and to provide a fault signal on detection of a fault, when the detected current (Idect) is at variance from a threshold current (Itrip).

Owner:DELPHI TECH IP LTD

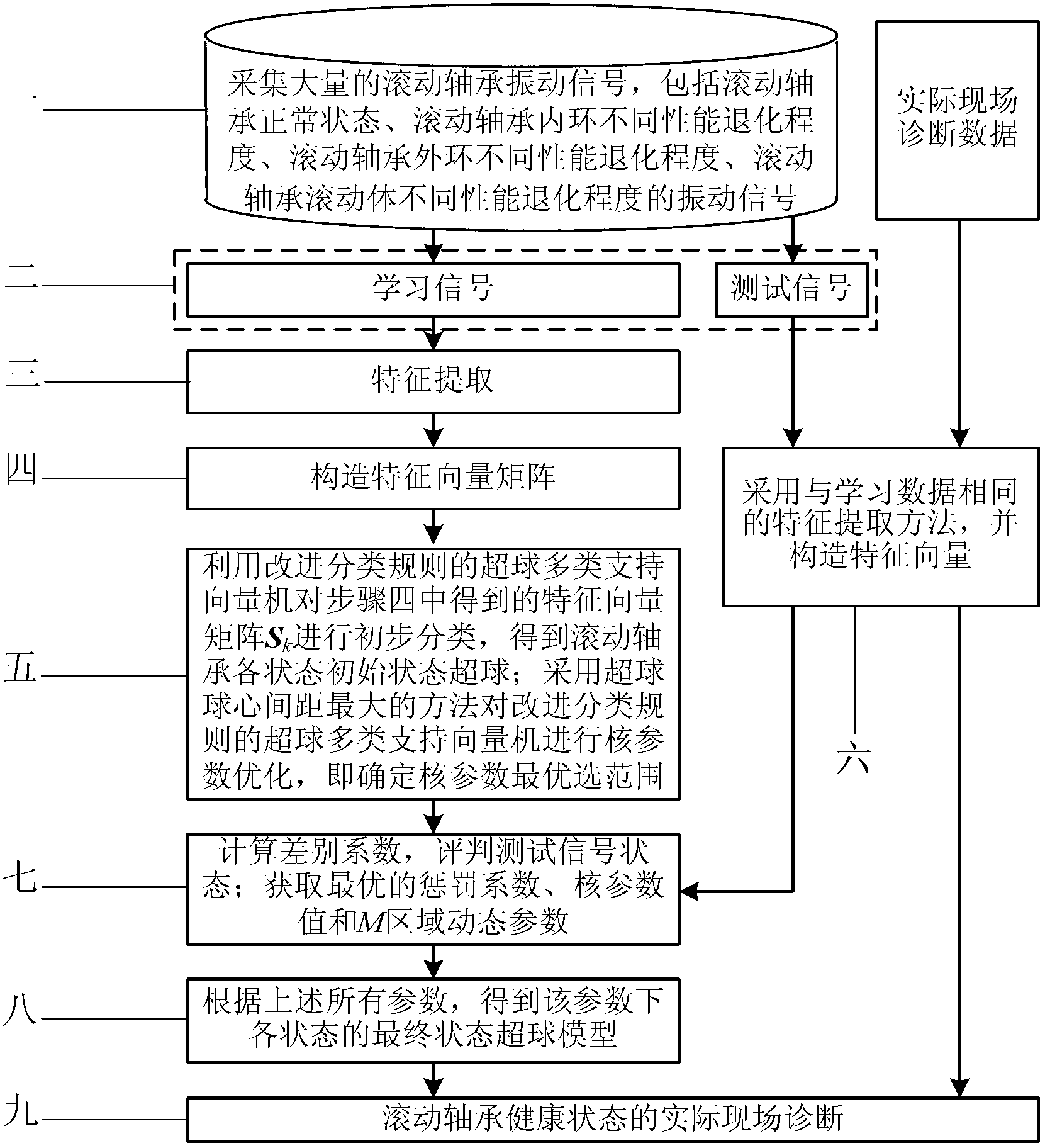

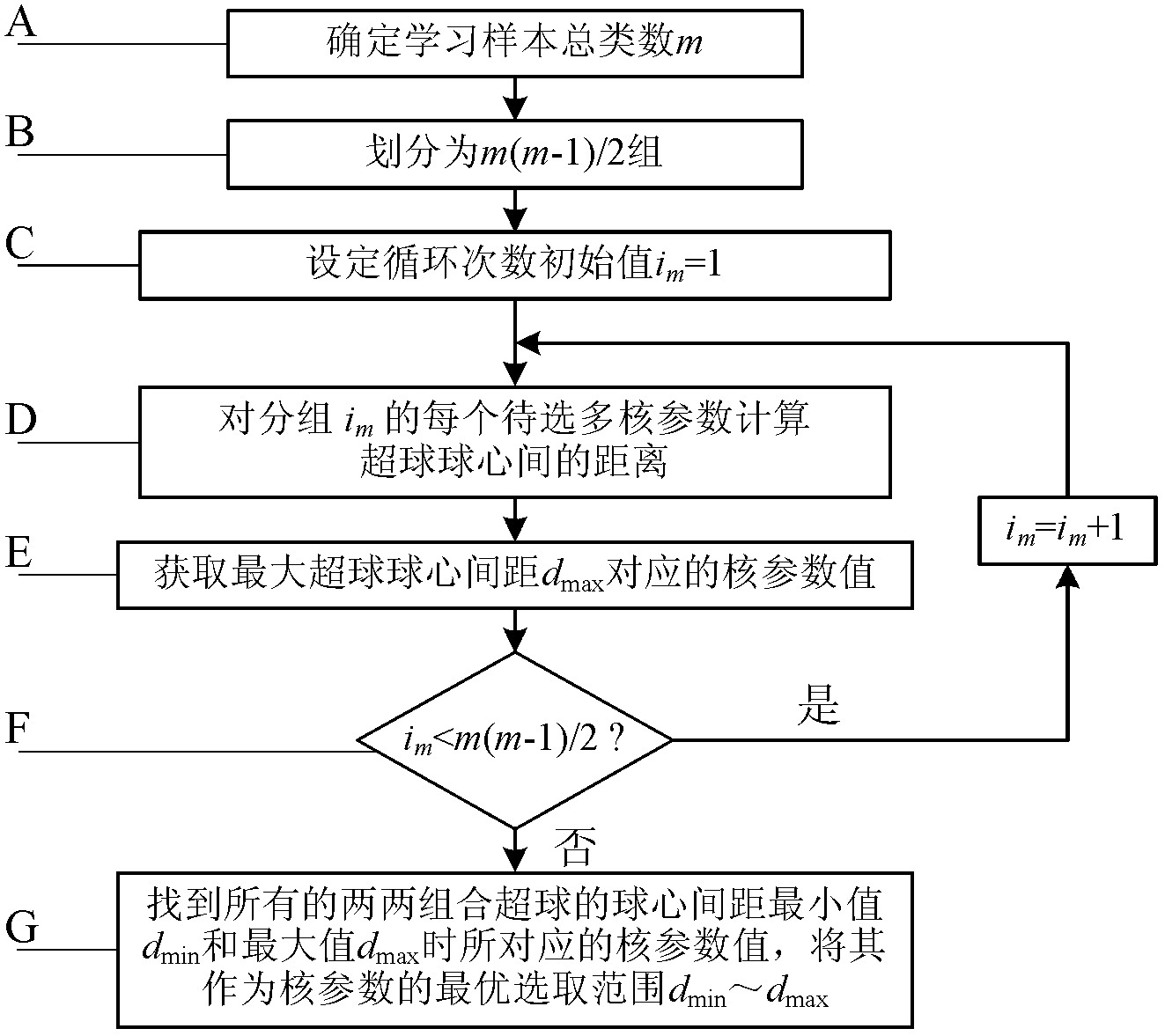

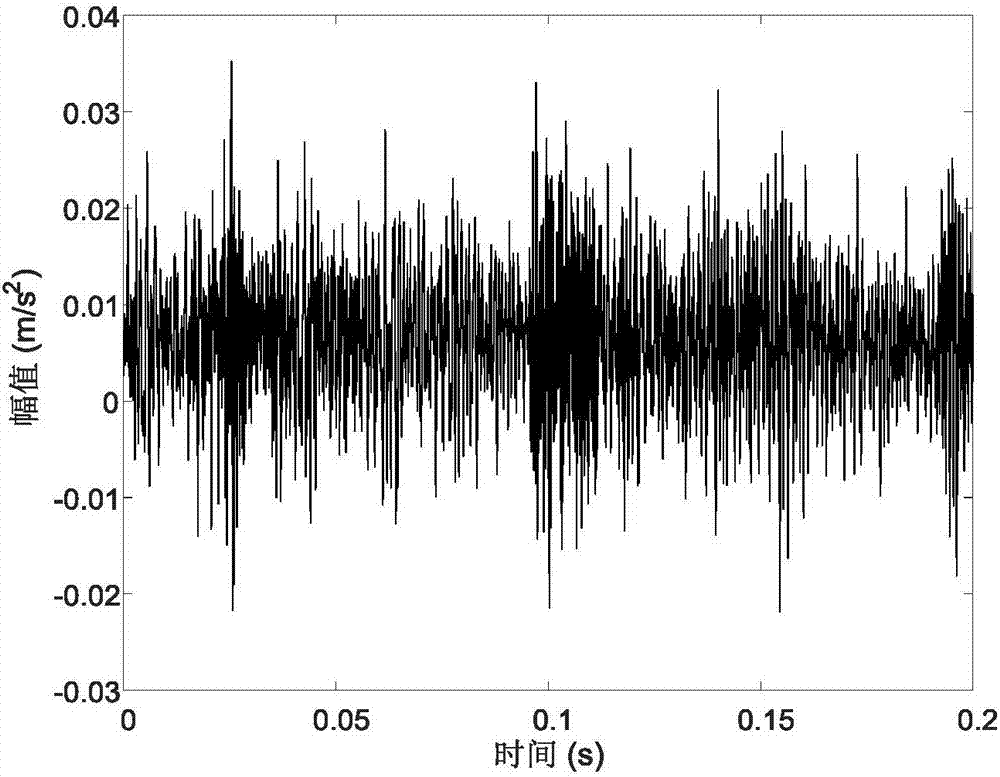

Diagnosis method for fault position and performance degradation degree of rolling bearing

InactiveCN102854015AOptimization determination methodReduce consumptionMachine bearings testingSingular value decompositionSupport vector machine

The invention discloses a diagnosis method for the fault position and the performance degradation degree of a rolling bearing, belonging to the technical field of fault diagnosis for bearings, and solving the problems of low accuracy of diagnosis for fault position and performance degradation degree, and high time consumption of training existing in an intelligent diagnosis method for a rolling bearing in the prior art. A white noise criterion is added in the disclosed integrated empirical mode decomposition method, so that artificial determination for decomposition parameters can be avoided, and the decomposition efficiency can be increased; and via the disclosed nuclear parameter optimization method based on a hypersphere centre distance, the small and effective search region of nuclear parameters in a multi-classification condition can be determined, so that training time is reduced, and the final state hypersphere model of a classifier is given. The intelligent diagnosis method based on parameter-optimized integrated empirical mode decomposition and singular value decomposition, and combined with a nuclear parameter-optimized hypersphere multi-class support vector machine based on the hypersphere centre distance is higher in identification rate compared with the existing diagnosis method. The diagnosis method disclosed by the invention is mainly applied to intelligent diagnosis on the fault position and the performance degradation degree of the rolling bearing.

Owner:HARBIN UNIV OF SCI & TECH

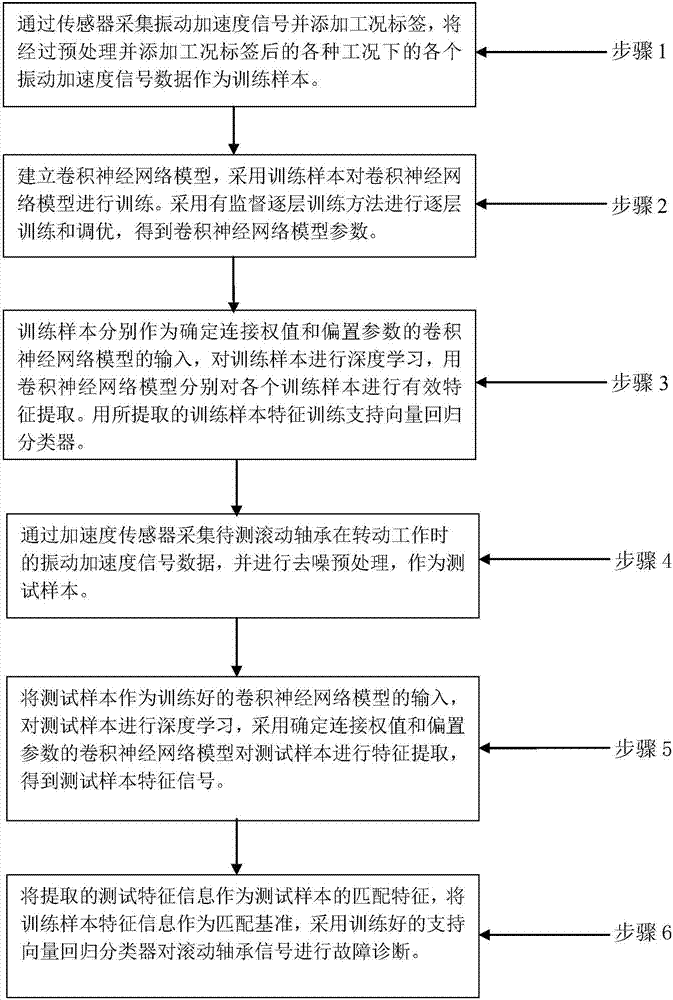

Rolling bearing fault diagnosis method

InactiveCN106874957AGet rid of dependenceSave labor timeMachine bearings testingCharacter and pattern recognitionAviationChemical industry

The invention relates to a rolling bearing fault diagnosis method. The method uses a learning algorithm of a CNN (Convolutional Neural Network) theory to complete a feature extraction task needed by fault diagnosis, and does not rely one manual selection, intrinsic features of input data are extracted automatically from simple to complex and from low-level to high-level, and abundant information hidden in known data can be dug out automatically; and a support vector regression method is used to identity a test sample in a classifying manner, support vector regression with a high generalization capability can be used to identity an unknown new sample in higher precision, and the disadvantage that a default classifier of deep learning tends to be low in the generalization capability can be overcome when support vector regression serves as a classifier to identify samples in the classified manner. The rolling bearing fault diagnosis accuracy and validity can be improved, a new effective approach is provided for solving problems in rolling bearing fault diagnosis, and the method of the invention can be widely applied to fault analysis of complex mechanical systems in the fields of chemical industry, metallurgy, electric power, aviation and the like.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com