Diagnosis method for fault position and performance degradation degree of rolling bearing

A rolling bearing and degradation degree technology, which is applied in the field of diagnosis of rolling bearing fault location and performance degradation degree, can solve the problems of low diagnostic accuracy and high training time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

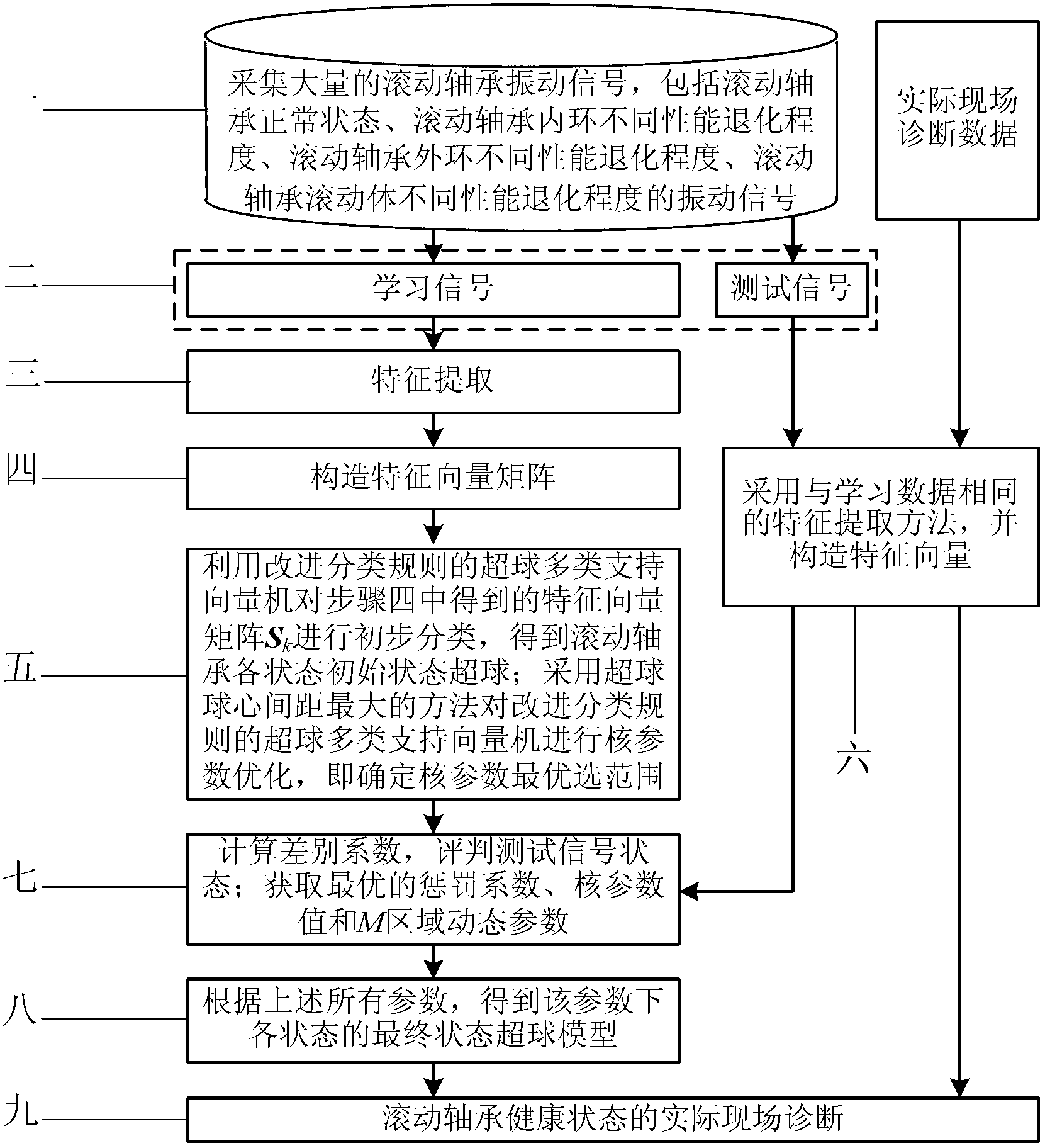

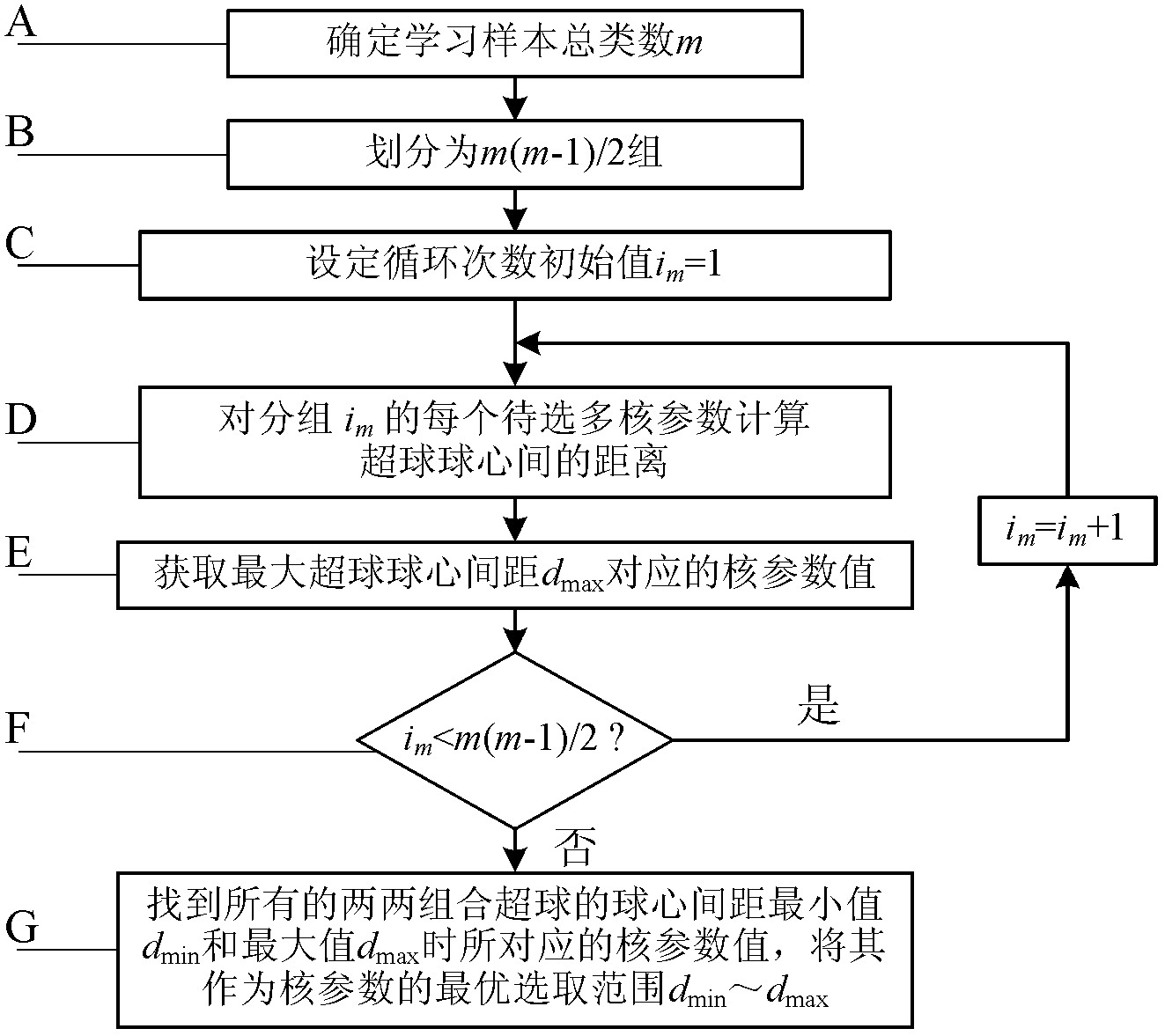

[0055] Specific implementation mode one: as Figure 1~2 As shown, a rolling bearing fault location and performance degradation degree diagnosis method described in this embodiment is implemented according to the following steps:

[0056] Step 1. Collect a large number of vibration signals (data) of rolling bearings, including vibration signals of normal state of rolling bearings, vibration signals of different performance degradation degrees of rolling bearing inner rings, vibration signals of different performance degradation degrees of rolling bearing outer rings, and different performance degradation degrees of rolling bearing rolling bodies vibration signal;

[0057] Step 2, divide the above-mentioned vibration signals in various states into a learning part signal and a test part signal according to the x-fold cross-validation method;

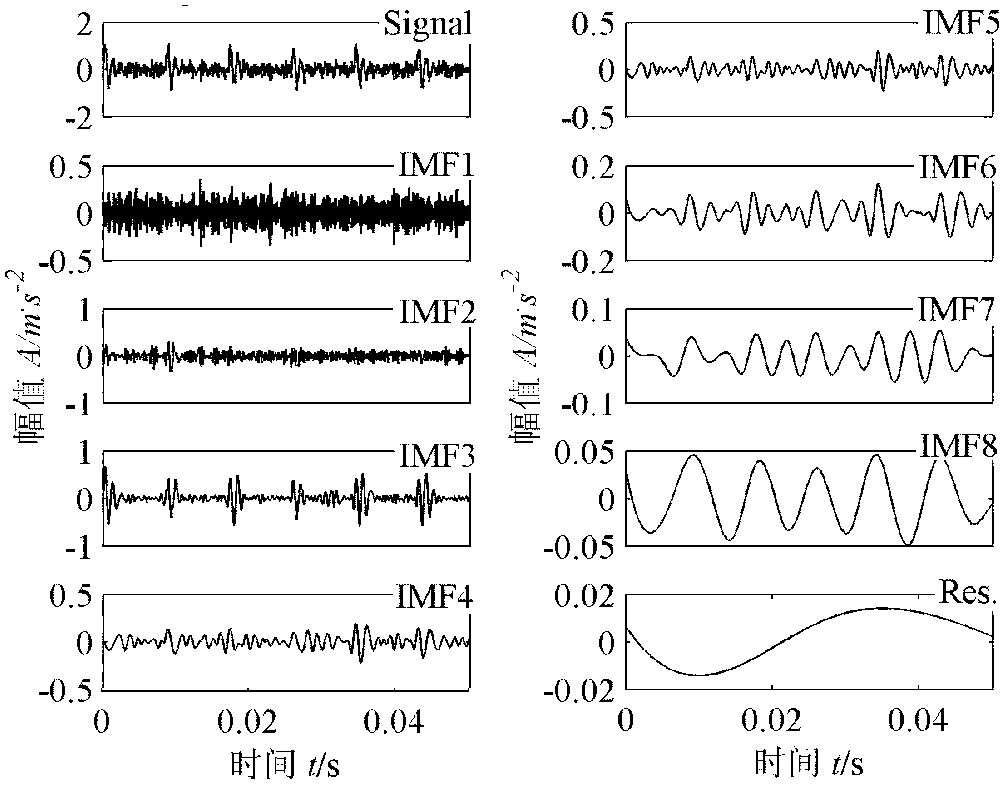

[0058] Step 3. Feature extraction: Use the method of EEMD with optimized parameters combined with SVD to extract features from the learni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com