Method of Determining Optimal Amount of Emulsified Asphalt in Emulsified Asphalt Mixture

A technology for emulsified asphalt and mixture, which is used in measuring devices, analytical materials, material inspection products, etc., can solve the problem of not considering the influence of the uniformity of asphalt coating of the mixture, the strength of the emulsified asphalt mixture and the low asphalt coating rate, It is impossible to ensure that the emulsified asphalt is fully spread and dispersed, so as to eliminate the difference in dryness and wetness, reduce test errors, and achieve high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

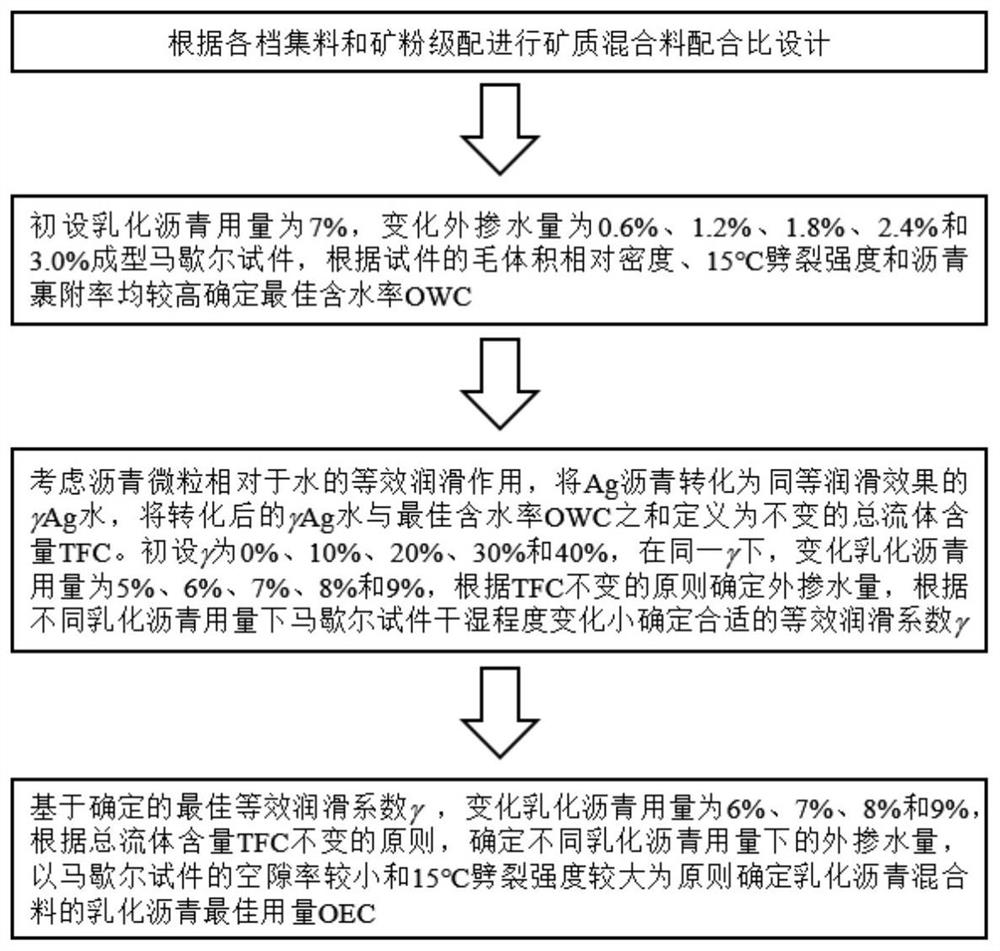

[0060] like figure 1 As shown, the method for determining the optimal amount of emulsified asphalt in the emulsified asphalt mixture of the present embodiment includes the following steps:

[0061] (1) Proportion design of mineral mixture:

[0062] Sieve limestone aggregates and limestone slag with a particle size of 0-3mm, 3-5mm, 4.75-9.5mm, 9.5-13.2mm, and 15-25mm. F41-2008) recommended medium-grain gradation type for mix ratio design, and the design synthesis gradation results are shown in Table 1.

[0063] Table 1 Synthetic gradation of emulsified asphalt mixture

[0064] Sieve hole(mm) The passing range of each sieve hole of the medium grain type (%) Design synthesis gradation passing rate (%) 26.5 100 100 19 90-100 94.1 13.2 - 83.3 9.5 60-80 64.4 4.75 35-65 40.1 2.36 20-50 25.3 0.3 3-21 7.6 0.075 2-8 5.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com