Laminated type lithium battery core body with extremely high bearing capacity and packaging technique

A pressure-bearing capacity, lithium battery technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problem of being blocked in certain parts of the battery core, failing to meet the vacuum degree requirements, and battery cycle Shortened service life and other problems, to achieve the effect of convenient operation and easy control, simple manufacturing method, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

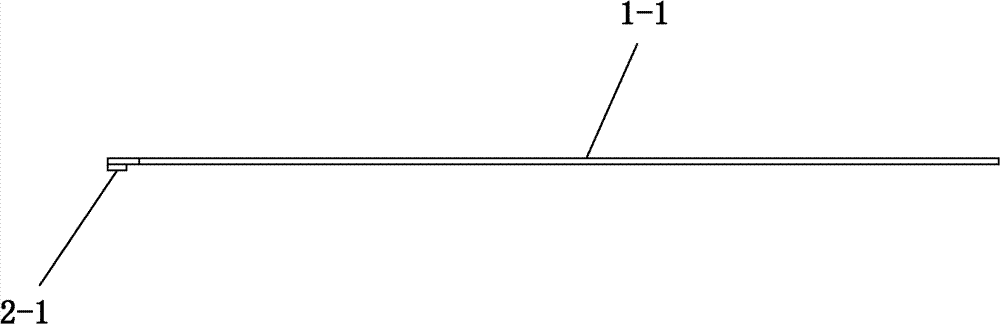

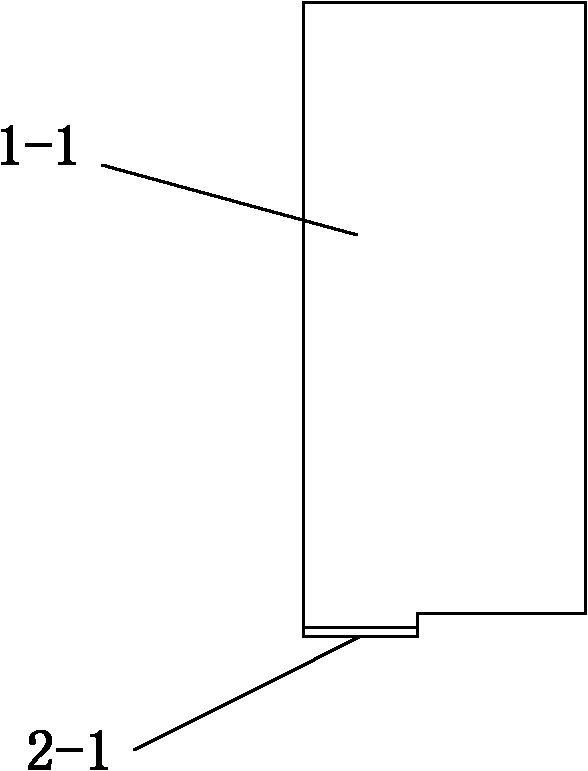

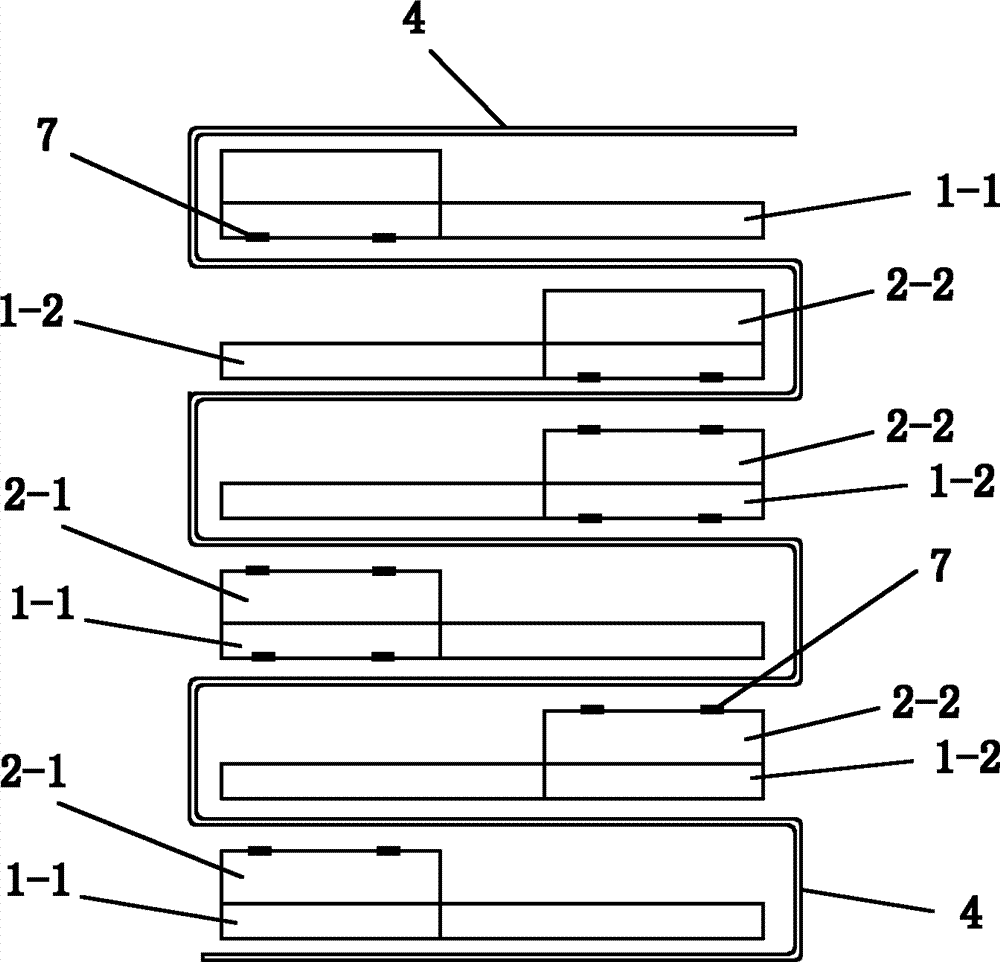

[0062] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the laminated lithium battery core with extremely high pressure bearing capacity described in the present invention includes two tabs, multiple structures that are all the same, and are all pressed and formed by rolling equipment under a pressure of 10MPa to 120MPa. The pole piece of the battery cell and the conductive gasket respectively welded and fixed on the upper side or the lower side of one end of each pole piece of the battery cell, and each pole piece of the battery cell and the conductive gasket arranged on it constitute an electrode chip. A plurality of the electrode chips are stacked side by side from top to bottom and compacted in the vertical direction of the electrode chips by pressing equipment from top to bottom to form a battery core, and the gap between two adjacent electrode chips is Isolation is carried out by a layer of cell diaphragm 4, and the pressing pressure during the pressing an...

Embodiment 2

[0102] like Figure 8 , Figure 9 As shown, in this embodiment, the structure of the laminated lithium battery core with extremely high pressure bearing capacity is different from that of Example 1 in that: the two tabs are respectively arranged on the left and right sides of the battery core On both sides, the conductive pads B2-2 welded on the plurality of cell pole pieces B1-2 are arranged on the other end of the lithium battery core to be made, that is to say, the conductive pads A2-1 and the conductive pads Sheets B2-2 are respectively arranged on the opposite sides of the battery core, so that the Figure 9 The shown lithium battery with the tabs located on opposite sides; in addition, the multi-layer cell diaphragm 4 is composed of multiple cell diaphragms 4, and each layer of cell diaphragm 4 corresponds to a cell diaphragm 4, and each layer The structure and size of the cell separator 4 are the same as those of the cell pole pieces. In this embodiment, the rest of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com