Patents

Literature

84results about How to "Won't shrink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified cement-based self-leveling mortar and preparation method and application thereof

The invention relates to improved cement-based self-leveling mortar and a preparation method and application thereof. The improved cement-based self-leveling mortar comprises the following components in percentage by weight: 50%-70% of aggregate, 31%-40% of cement, 13%-15% of anhydrite, 5%-15% of ground calcium carbonate, 0.05%-0.3% of water-retaining agent, 0.05%-0.2% of carbonate, 0.4%-0.9% of retarder, 0.3%-0.9% of lignocellulose, 0.2%-0.3% of antifoaming agent, 0.6%-0.9% of water reducer and 1.5%-4.5% of pure acrylic emulsion powder. The invention has the advantages of simple preparation and application methods, good construction peaceability, good waterproofness, greatly reduced microcracks, high mechanical physics property, good self-leveling performance and impact resistance, and excellent flexibility; no cracking and shrinkage occur to constructed ground; and in addition, the invention can effectively solve the problems of complex site operation process, unstable mortar performance, environmental pollution and the like of the existing dual-component cement-based self-leveling mortar, thus the self-leveling mortar is a green building material because no toxic and harmful matter is contained.

Owner:北京天维宝辰化学产品有限公司

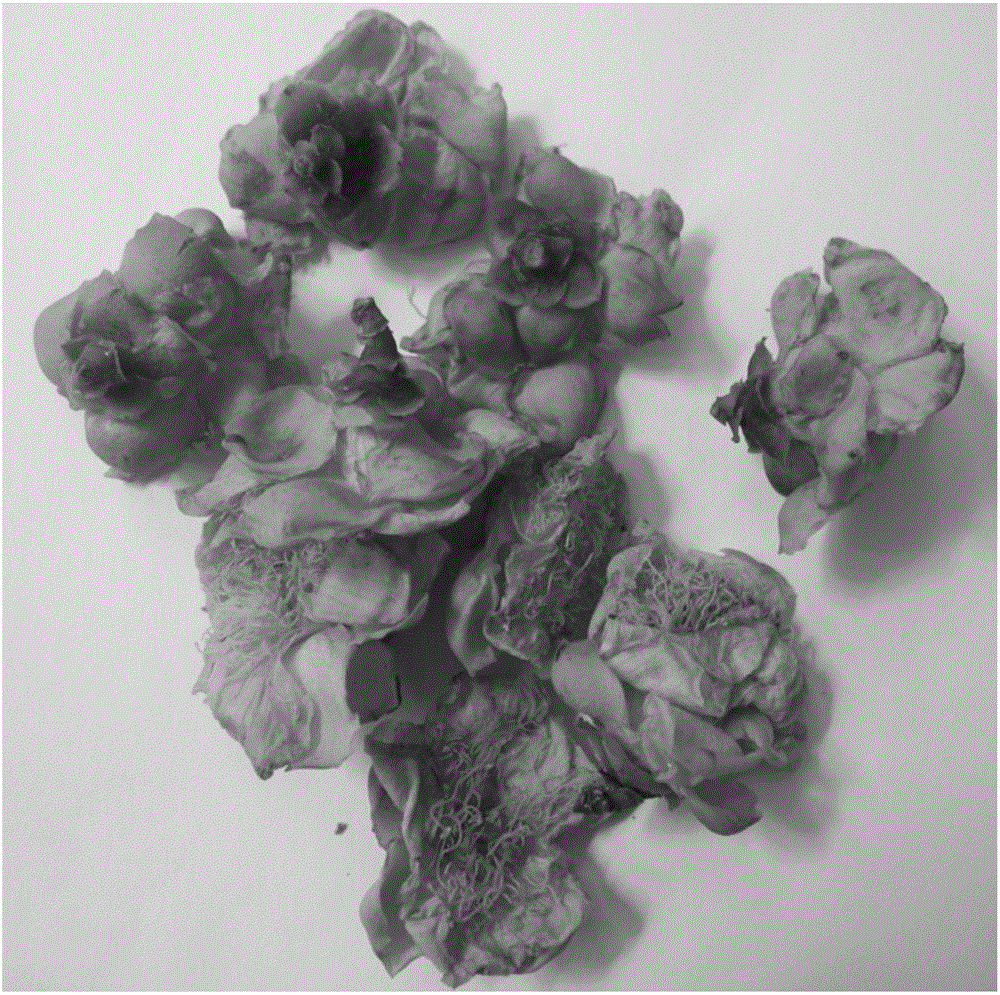

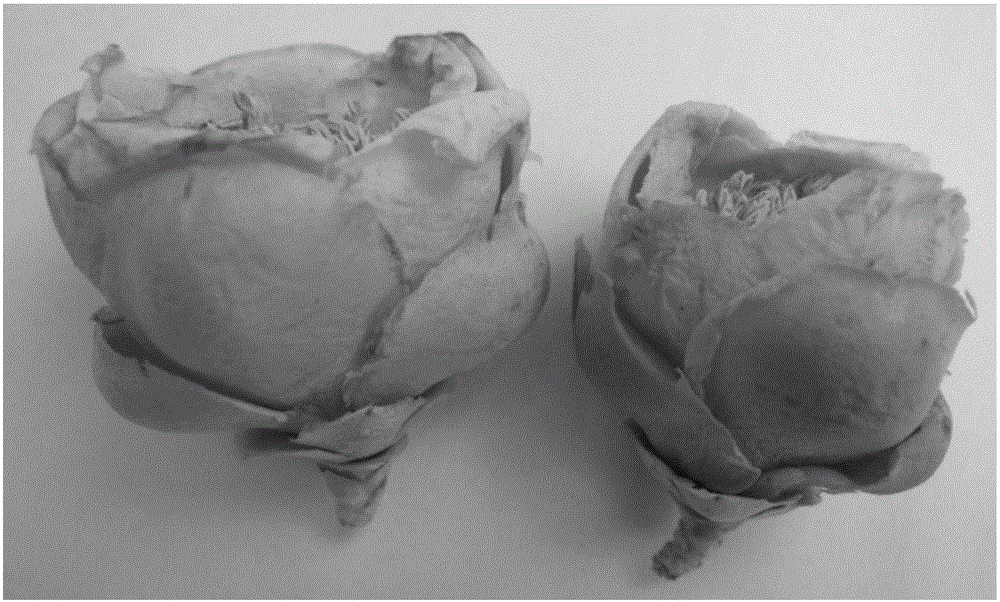

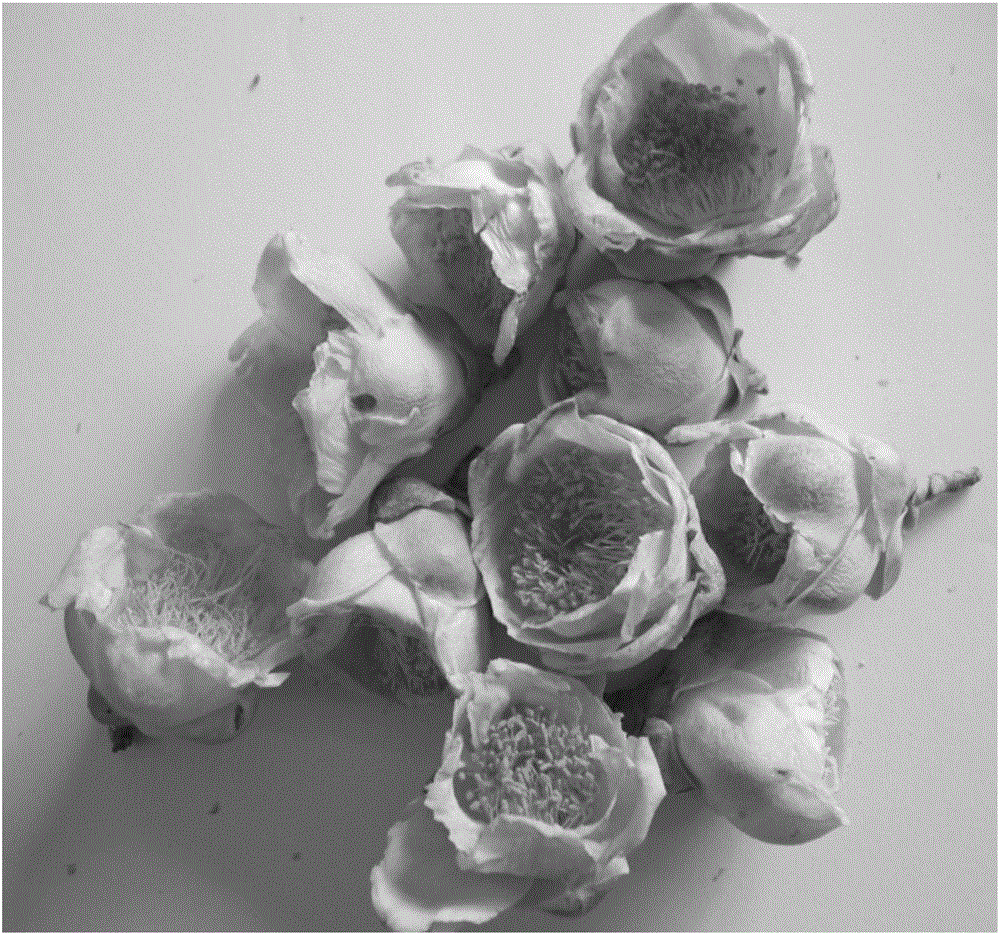

Processing method of tea flowers

The invention discloses a processing method of tea flowers, relating to the technical field of processing. The processing method comprises the following steps: harvesting tea flower buds from the middle ten days of October to the first ten days of December; wiping out receptacles, spreading on a water sieve; freezing the buds in a gauze bag at a temperature of being less than 20 DEG C, freezing for 12-14h; freeze-drying the buds in a vacuum dryer, vacuumizing when the temperature is lower than -20 DEG C, starting an oil heating system when the pressure is vacuumized to -0.1 Mpa, continuously drying for 24-26h by heating until the content of water in the buds is not greater than 4 percent; and baking the buds in a baking machine at a temperature of 90-100 DEG C for 15-20min. According to the processing method, the problem that the quality is not favorably improved because the plumpness is poor, the appearance is unattractive, the color is not fresh and alive, the fragrance is not pure, the color is slightly yellow and not bright, and the like is solved.

Owner:葛智文 +3

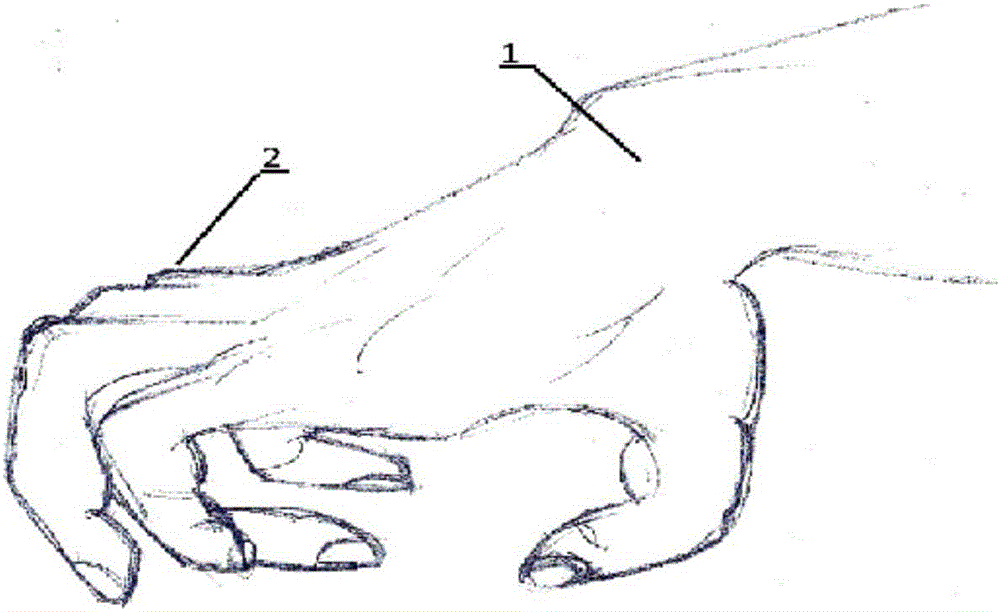

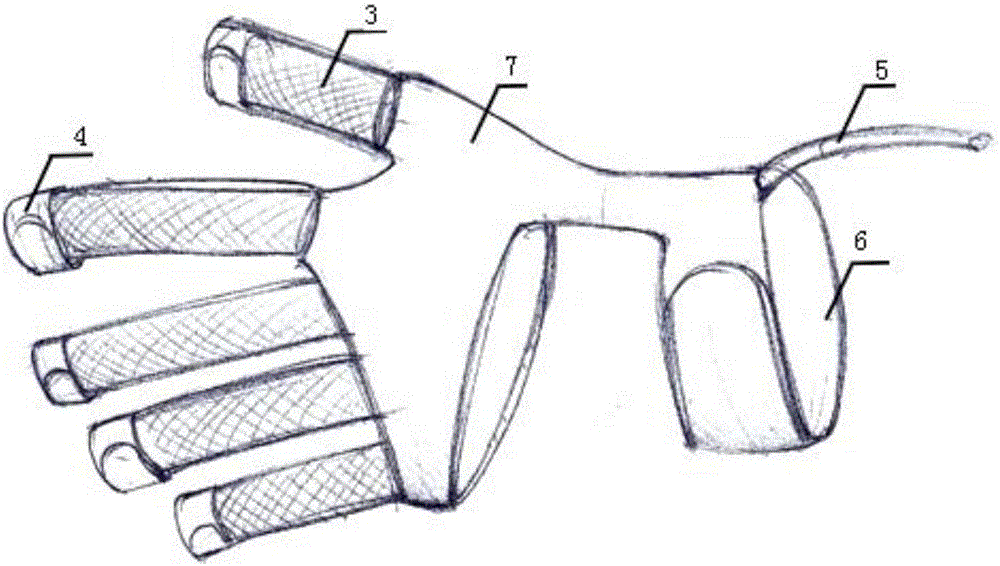

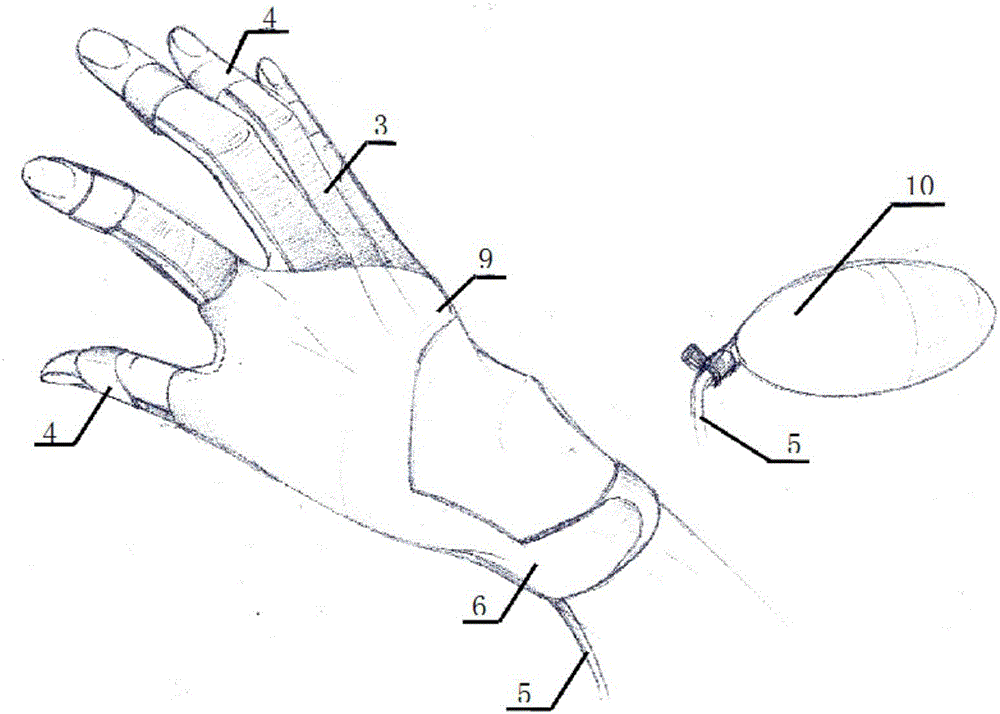

Flexible rehabilitation training glove for stroke patients

The invention discloses a flexible rehabilitation training glove for stroke patients, which comprises a flexible retractable finger traction component and a driving component, and there are five flexible retractable finger traction components arranged in a hand shape. All flexible retractable finger traction components are connected with the driving component, and are stretched under the drive of the driving component; all flexible retractable finger traction components are provided with finger band and / or finger stall. According to the flexible rehabilitation training glove, stroke patients can carry out rehabilitation training for hands, stimulate the reestablishment of neural pathways, prevent the adhesion of soft tissue, prevent muscle atrophy, and avoid the ossification of hand tissue due to calcification, so as to promote the rehabilitation of stroke.

Owner:EDINBURGH NANJING OPTO ELECTRONICS EQUIP CO LTD

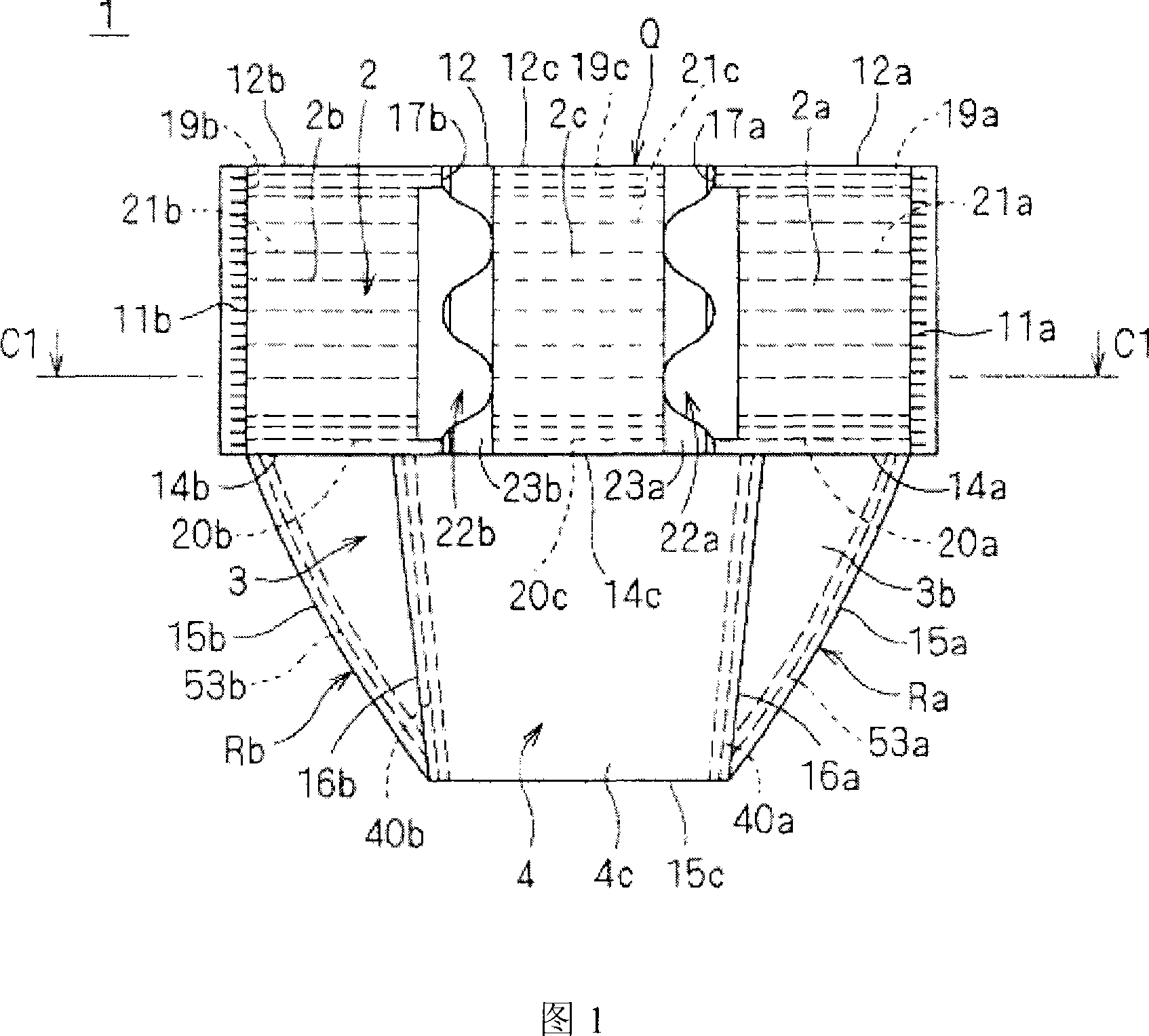

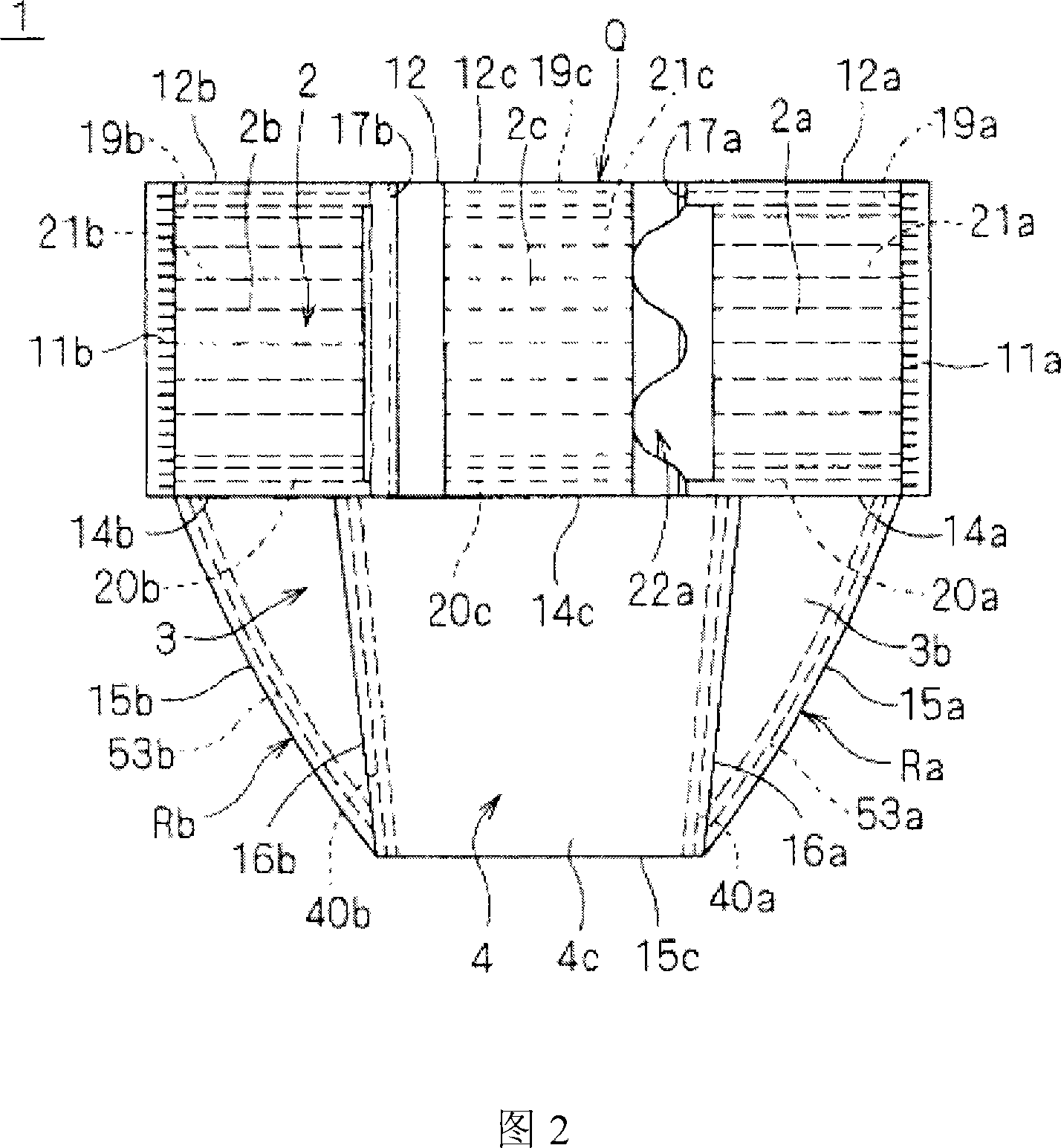

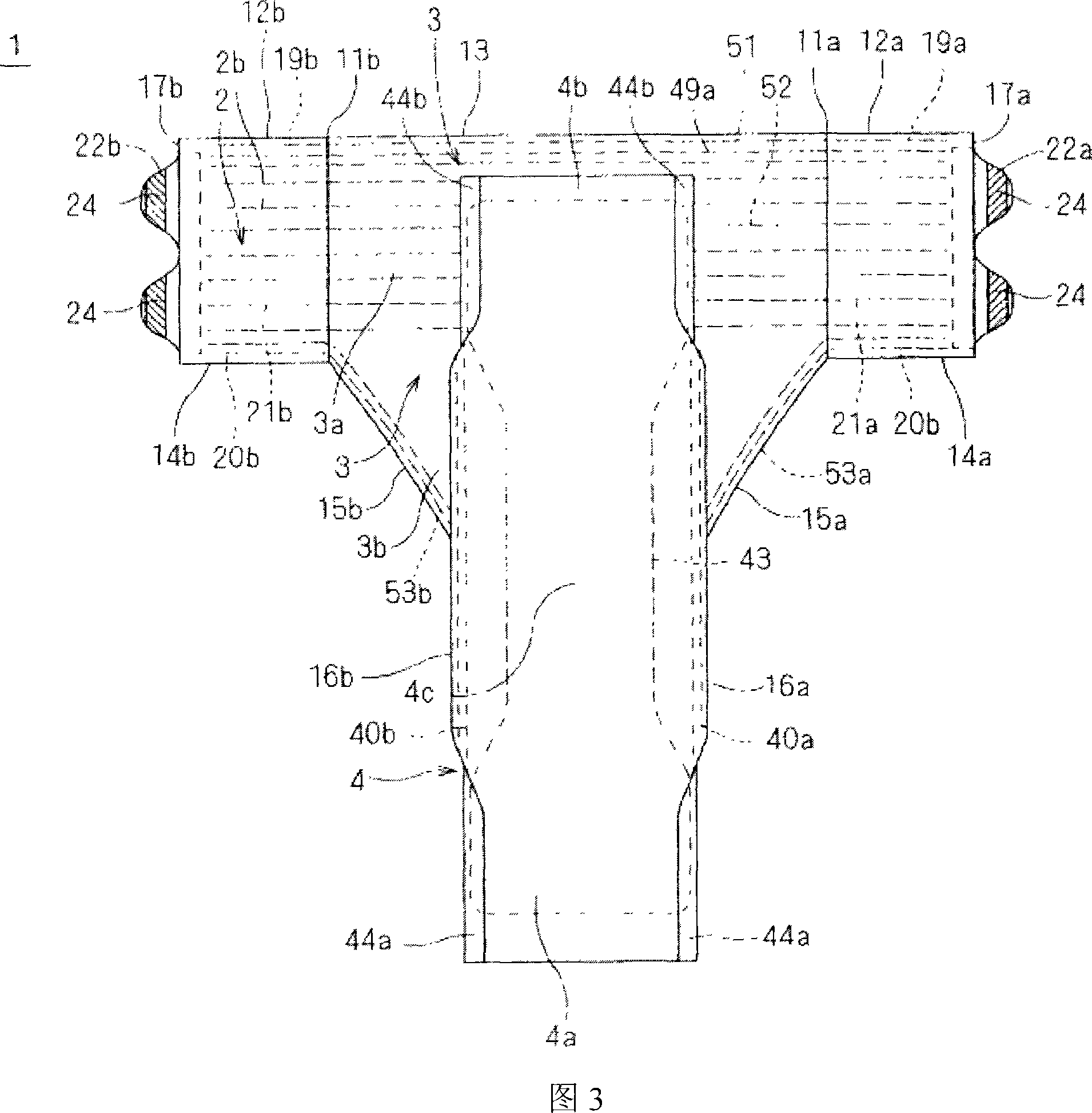

Disposable pants

InactiveCN101065089AClosely connectedGuaranteed scalabilityHandkerchiefsAbsorbent padsCrotchGeneral surgery

Owner:LIVEDO CORP

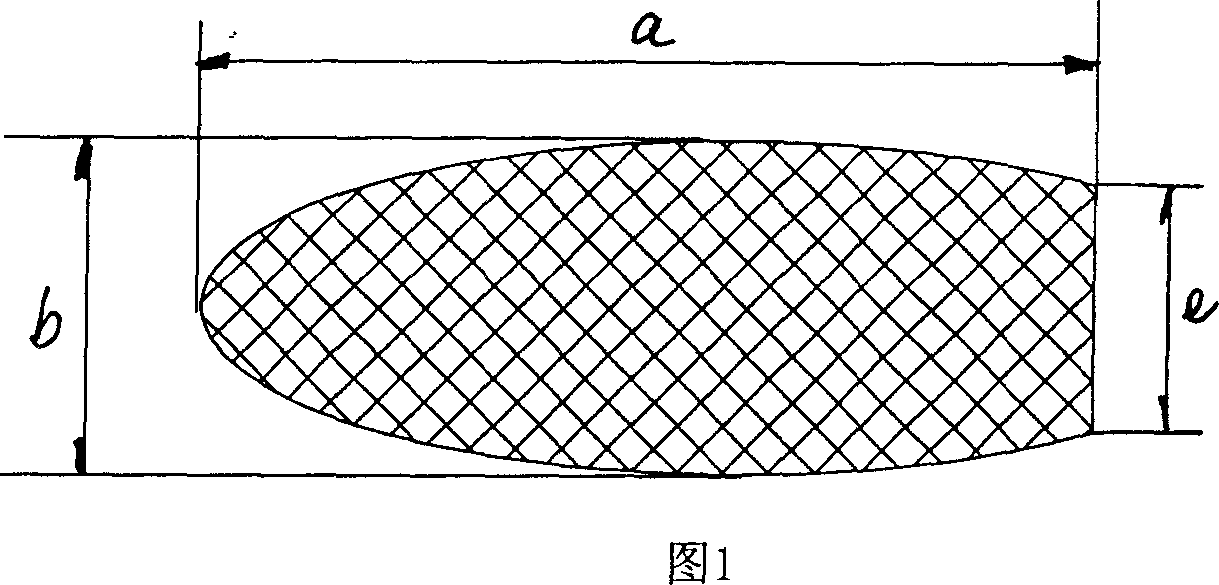

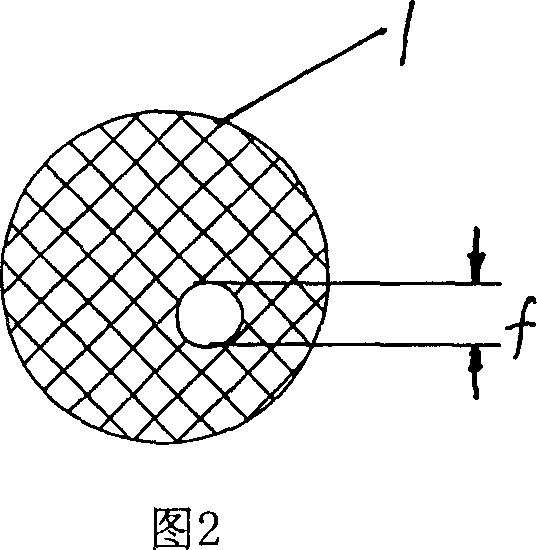

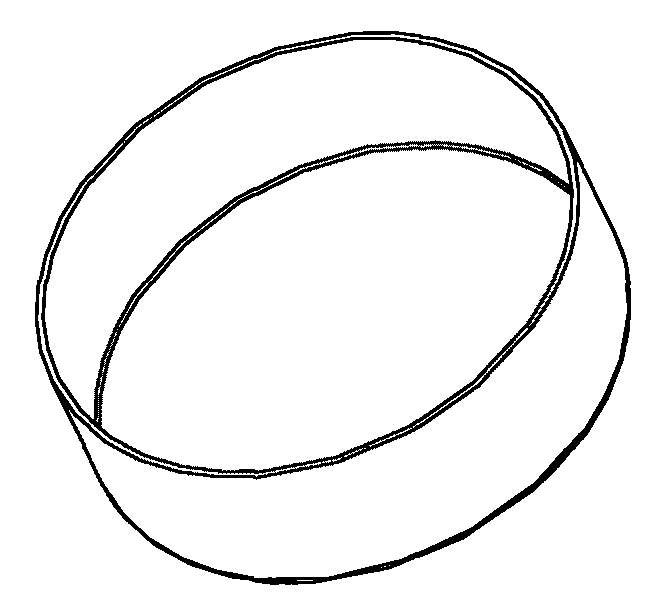

Bracket of vitreous body cavity for curing retina disease, and manufacturing method

A supporting frame of vitreous body cavity for treating retinopathy is a Rugby football-shaped single-layer netted structure with a front opening (1.0-2.2 mm in diameter) and a rear yellow spot hole (0.5-1.5 mm in diameter). Said netted structure is made of Ni-Ti marmem. Its preparing method is also disclosed.

Owner:ZHENGZHOU UNIV

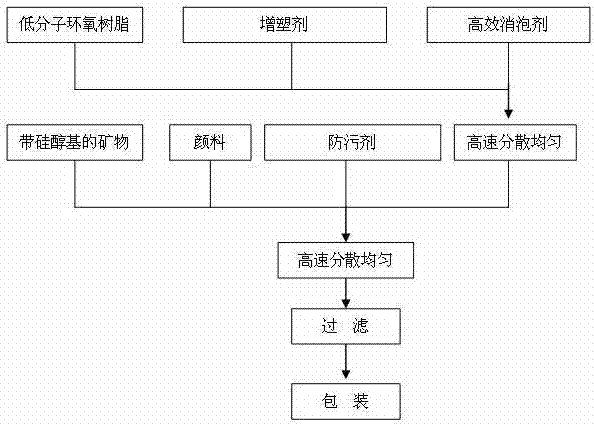

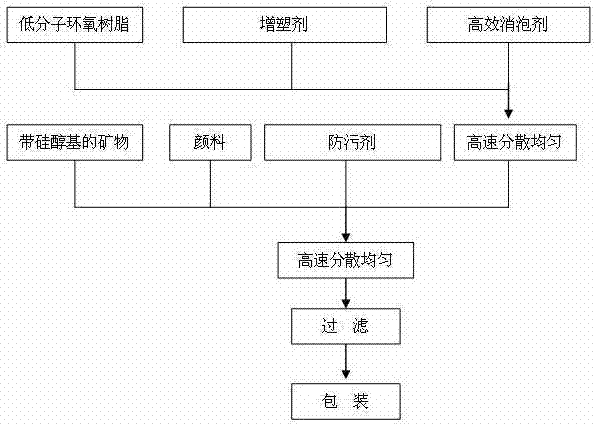

Antifouling paint for underwater coating construction

ActiveCN102363688AGood construction performanceSave resourcesAntifouling/underwater paintsPaints with biocidesEpoxyOyster

The invention discloses an antifouling paint for the underwater coating construction. The antifouling paint comprises a component A and a component B, wherein the component A comprises 20-50 parts of a low molecular epoxy resin, 5-20 parts of a plasticizer, 0.05-1 part of an antifoaming agent, 10-25 parts of silicate mineral powder, 15-40 parts of a broad spectrum antifouling agent, 3-15 parts ofan auxiliary antifouling agent, 0.5-5 parts of a pigment, and 0.5-5 parts of a thixotroping assistant; and the component B is a curing agent which is a Mannich base curing agent, and the mass of the curing agent accounts for 10-30% of the mass of the component A. According to the invention, the antifouling paint is an environmentally friendly resource conserving paint; the coating construction performance is good; the antifouling paint which allows the coating antifouling performance to be improved has a score of more than 85 when the coating is subjected to shallow sea hanging for six monthsin Xiamen seas; the underwater coating construction can be carried out through the antifouling paint; the antifouling paint has an antifouling effect on animal sea creatures of barnacle, oyster and mussel, and botanical algae; and the antifouling paint can be brush-coated, scrape-coated, and roll-coated during underwater coating, the paint cannot be scattered, and the coating does not contract after curing.

Owner:XIAMEN SUNRUI SHIP COATING

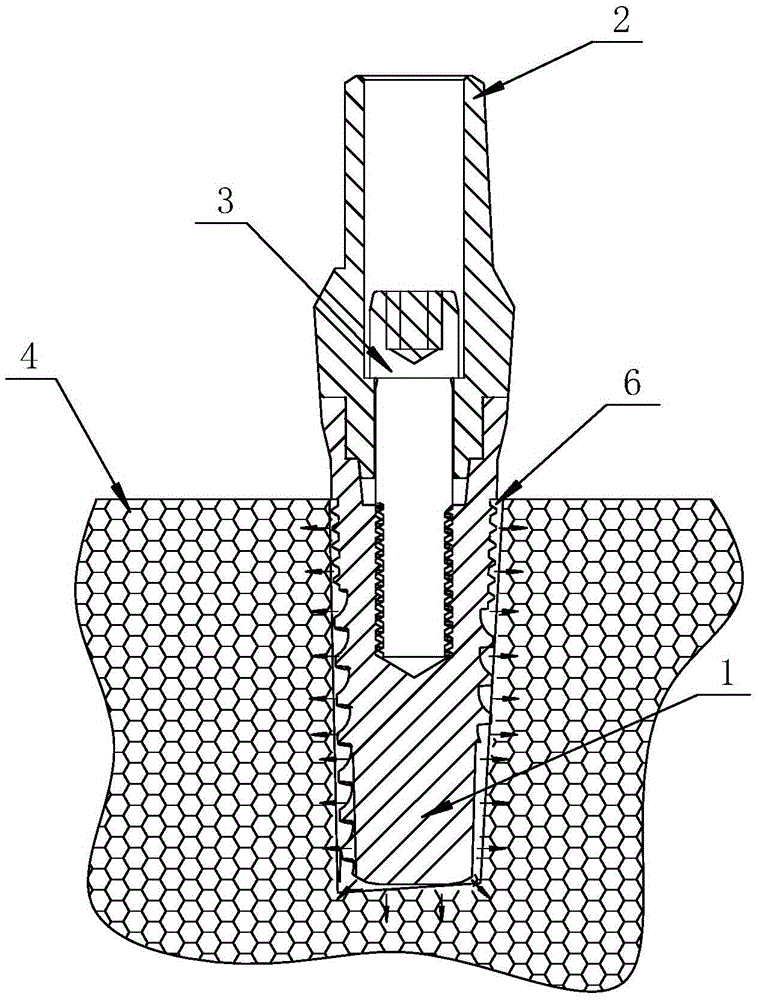

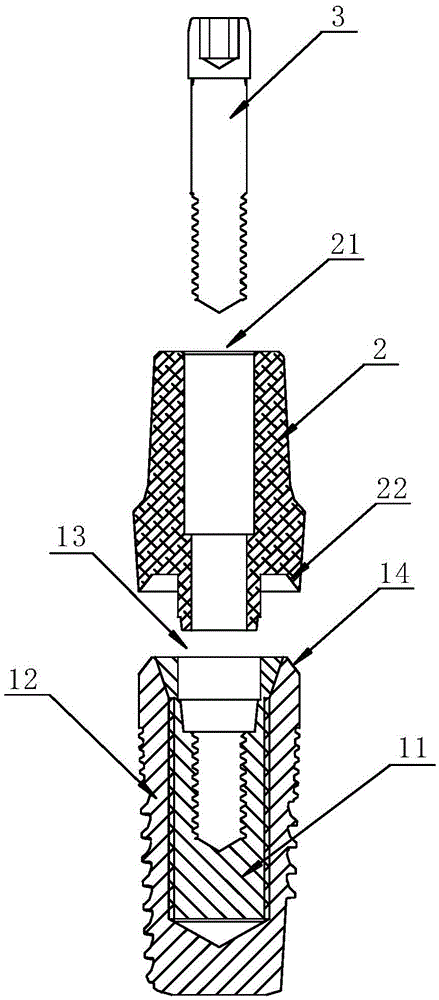

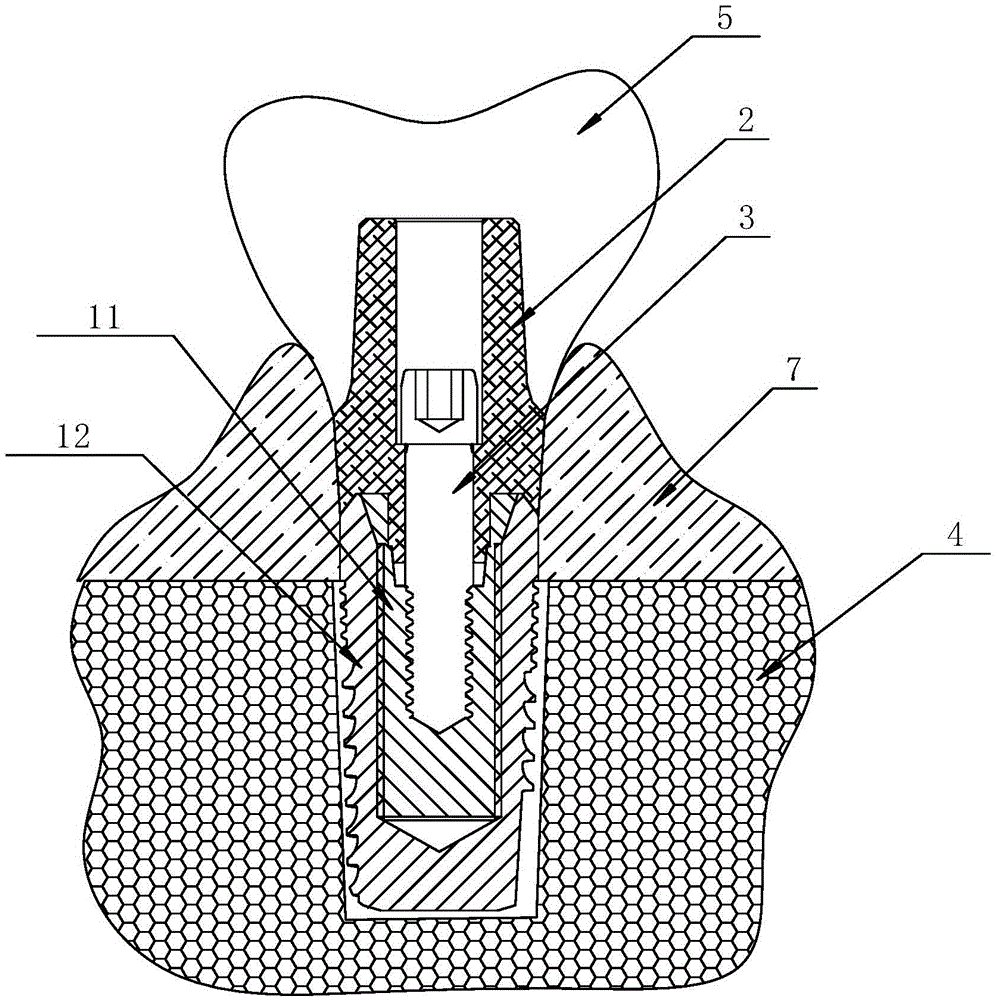

Stable and lasting dental implant structure

InactiveCN105596099AGood biocompatibilityPrevent falling offDental implantsTitaniumBiomedical engineering

The invention relates to a dental implant, and aims at providing a stable and lasting dental implant structure. The dental implant structure comprises an implant, a base station and a central bolt; the upper portion of the implant is located in the gingival, the lower portion of the implant is implanted into the alveolar bone, the lower end of the base station is inserted into an installing hole formed in the upper portion of the implant, the base station is provided with a communicated stepped inner hole, the central bolt fixes the base station into the installing hole through the stepped inner hole formed in the base station, and the base station is used for installing a dental crown; the implant comprises an inner sleeve and an outer sleeve which are coaxially arranged; the installing hole is located at the upper end of the inner sleeve, the outer wall of the inner sleeve is provided with an outer thread, the inner wall of the outer sleeve is provided with a matched inner thread, and the inner sleeve is in threaded connection with the outer sleeve; the outer sleeve is made of pure titanium, the outer surface of the outer sleeve is provided with an outer thread, the outer sleeve is subjected to surface treatment to be in anchor combination with the alveolar bone, and the inner sleeve is made of titanium alloy. The dental implant is good in durability and stable and reliable in performance.

Owner:CHENGDU BESMILE MEDICAL EQUIP CO LTD

Instant medlar juice solid beverage and processing method thereof

The invention discloses an instant medlar juice solid beverage and a processing method thereof, belonging to the field of instant beverage; the beverage comprises the following constituents by weight parts: 10-50 parts of medlar jelly dry powder, 5-30 parts of lyophilized Honey power, 10-50 parts of non-dairy creamers and 3-10 parts of plant flower dry powder. All constituents of the instant medlar juice solid beverage are produced by low temperature freezing below -20 DEG C and at the vacuum condition, the inherent shape can not be contracted, thermal sensitivity substances are not damaged, aromatic substances can not be diffused and readily oxidizable substances are not be oxidized, therefore, the shape, color, taste and nutrition of the substances are like that of fresh products after being processed, and the water-based rehabilitation is good, and large-scale production can be carried out easily; in addition, the solid beverage contains essential amino acids for human body, multiple trace elements and mineral elements, and can increase hematopoiesis function and immunity of human body, and is a new generation nutritional health beverage which has rapid usage and convenient carrying.

Owner:艾志毅 +1

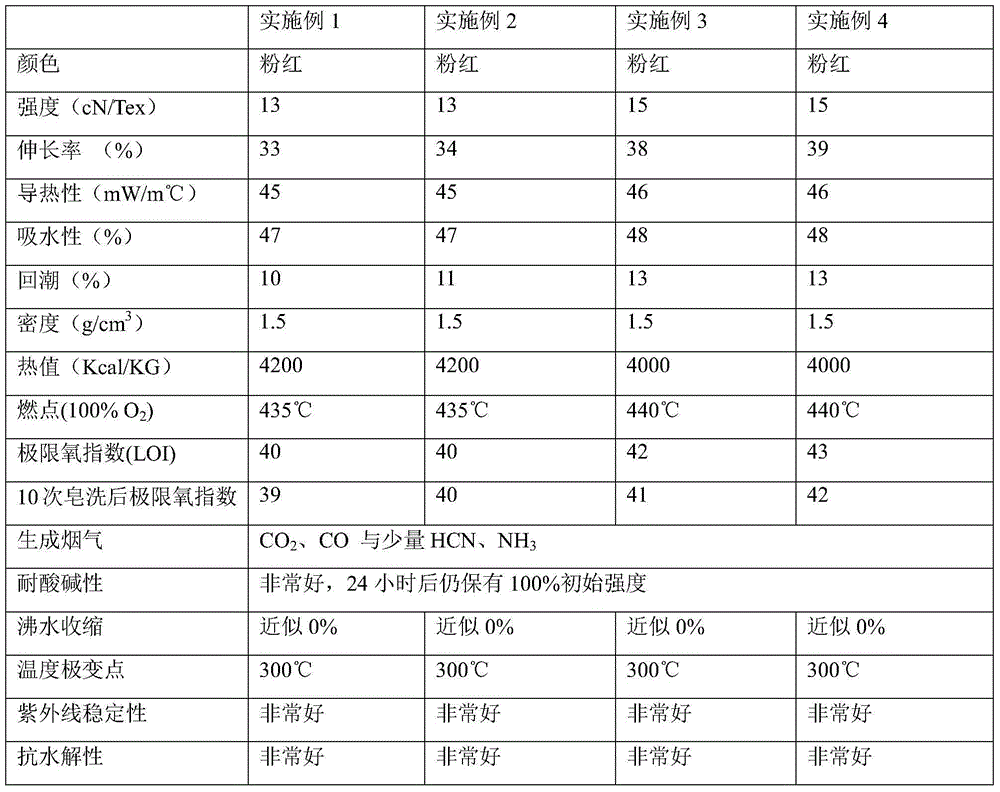

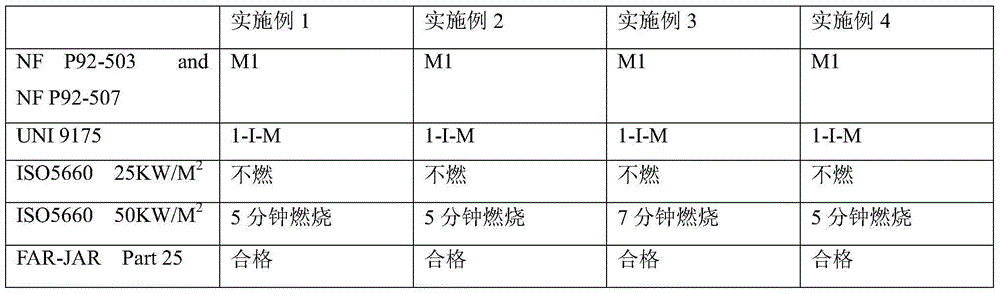

High temperature-resistant flame retardation polyacrylonitrile fiber and production method thereof

ActiveCN105986474AHigh limiting oxygen indexWon't meltFibre typesDyeing processPolymer scienceMoisture regain

The invention relates to a polyacrylonitrile fiber, and concretely relates to a high temperature-resistant flame retardation polyacrylonitrile fiber and a production method thereof. The method concretely comprises the following steps: processing a polyacrylonitrile fiber in a hydrazine solution with the concentration of 7-20wt%, processing the hydrazine processed fiber in an alkaline solution with the concentration of 3-10wt%, washing the alkali processed fiber with water until the fiber is neutral, processing the neutral fiber in an aqueous metal ion salt solution with the concentration of 3-10wt%, oiling the metal salt processed fiber, dehydrating the oiled fiber, and drying the dehydrated fiber to obtain the high temperature-resistant flame retardation polyacrylonitrile fiber. The flame retardation performance LOI of the flame retardation fiber obtained in the invention can reach 40-45, the flame retardation grade is M1, and the amount of smoke generated in the combustion process is very small, the grade of toxic gases is FO, and the smoke amount of the flame retardation fiber in the invention is lower than that of other flame retardation fibers. The flame retardation fiber in the invention has the advantages of high moisture regain rate, high water absorption rate, good dyeability and low shrinkage in boiling water.

Owner:JILIN ACRYLIC FIBERS CO LTD

Novel sound absorbing and insulating and heat insulating material and application thereof

InactiveCN101693415AGood sound and heat insulationMeet the requirements of "three defenses"Thermal insulationLayered productsEngineeringSilicon rubber

The invention discloses a novel sound absorbing and insulating and heat insulating material which can be formed by sound absorbing and insulating cotton felt and can be also compounded by the sound absorbing and insulating cotton felt and an elastic sponge body through damp compound viscose. The sound absorbing and insulating cotton felt is made of interposition aramid fiber 1313; the elastic sponge body is a silicon rubber sheet with the thickness of 0.2-0.3 mm; and the hydrophobic property of the sound absorbing and insulating and heat insulating material is 95 percent. The novel sound absorbing and insulating and heat insulating material is environment friendly and incombustible, has no pollution, long using time and good hydrophobic property, can resist high temperature and can be used as the sound absorbing and insulating and heat insulating material for aerospace vehicles and various vehicle wall plates and acoustic decoration material for halls and stadiums.

Owner:NANJING CHANGRONG ACOUSTIC INC

Camellia nitidissima tea and processing technology thereof

The invention provides camellia nitidissima tea and a processing technology thereof and relates to the technical field of tea. The processing technology of camellia nitidissima tea comprises steps as follows: fresh flowers of camellia nitidissima are withered and subjected to microwave fixation under 2,400-2,500 MHz till the water content is 70wt%-75wt%; the flowers are precooled at the temperature of subzero 20 DEG C-subzero 15 DEG C for 3-5 h and dried under the conditions of minus 0.12-minus 0.08 MPa and the temperature of 35-45 DEG C till the water content of the flowers is 11wt%-15wt%; the flowers are dried at 95-105 DEG C for 10-15 min. By means of the processing technology of camellia nitidissima tea, the shape and the color of camellia nitidissima flowers can be kept, and the astringent taste of the camellia nitidissima tea is effectively reduced.

Owner:GUANGXI GUILIN TEA RES INST

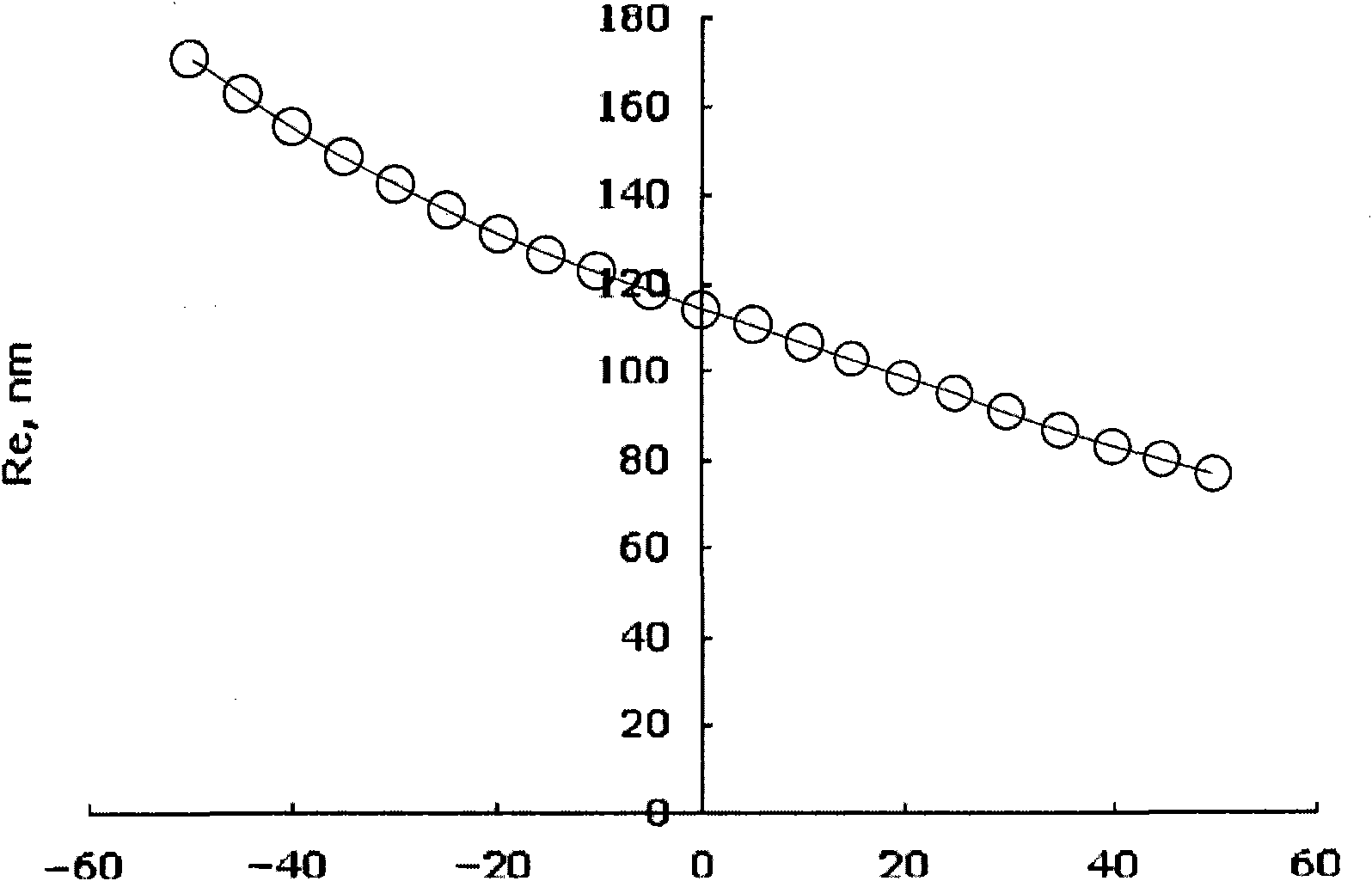

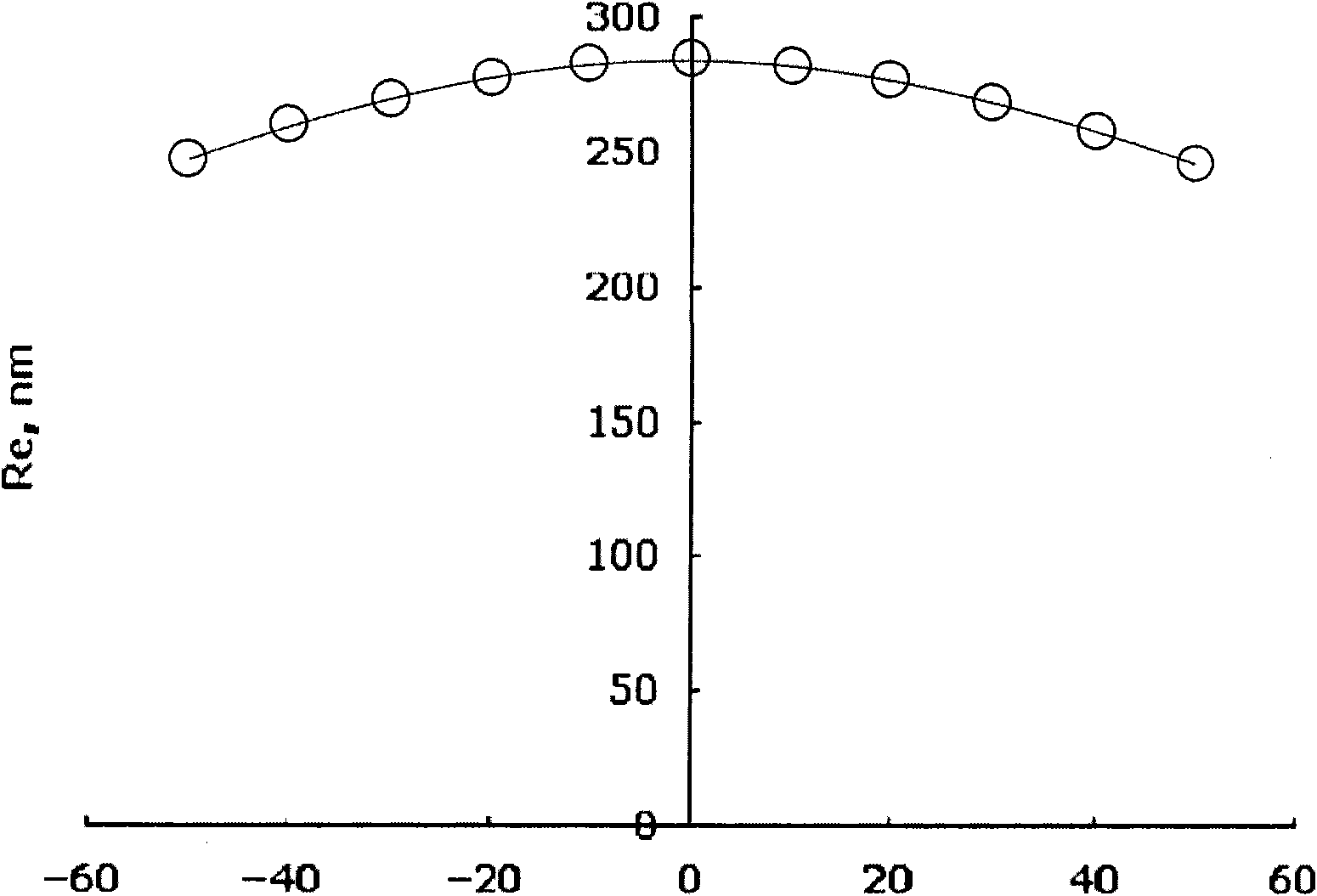

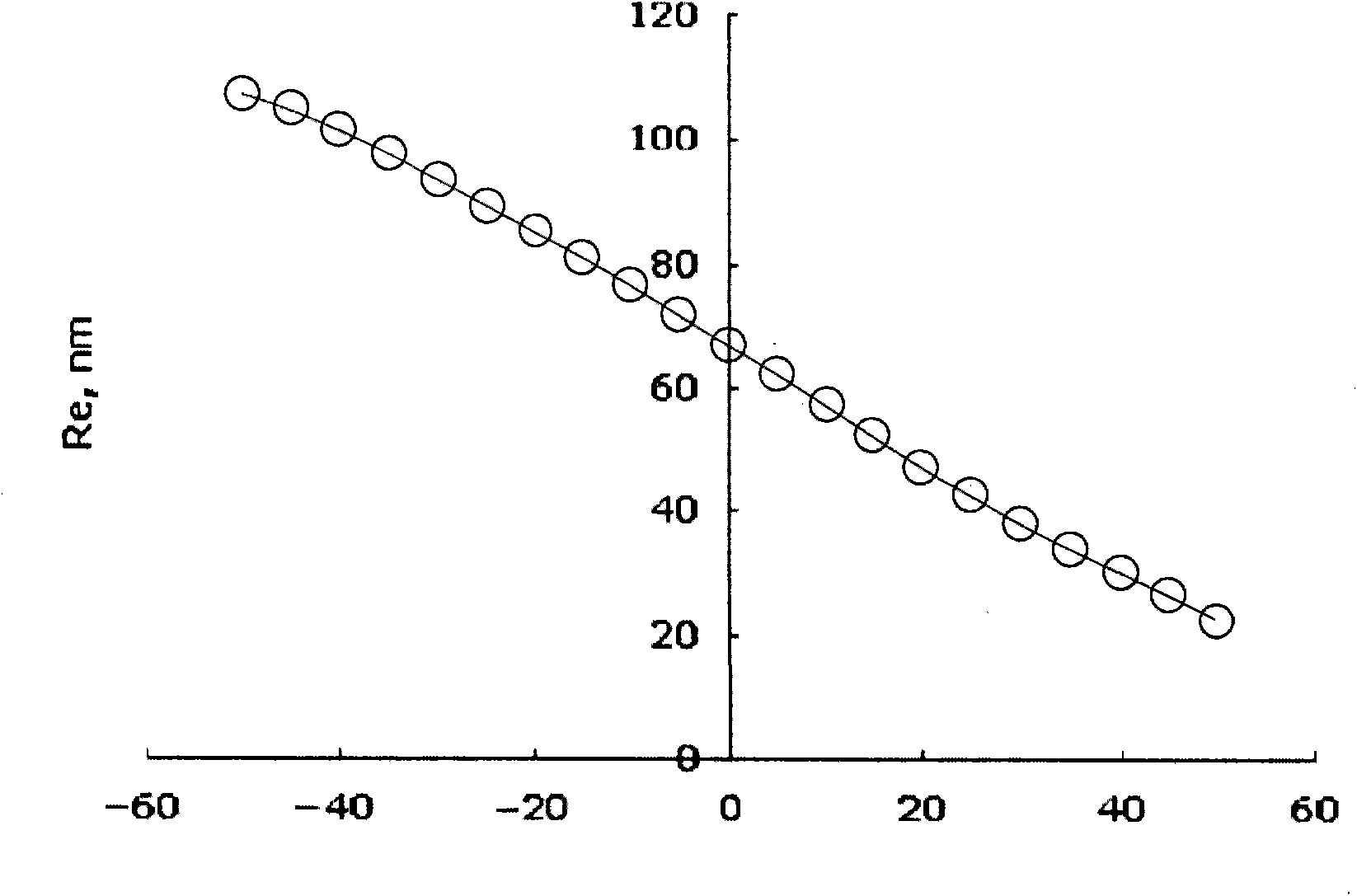

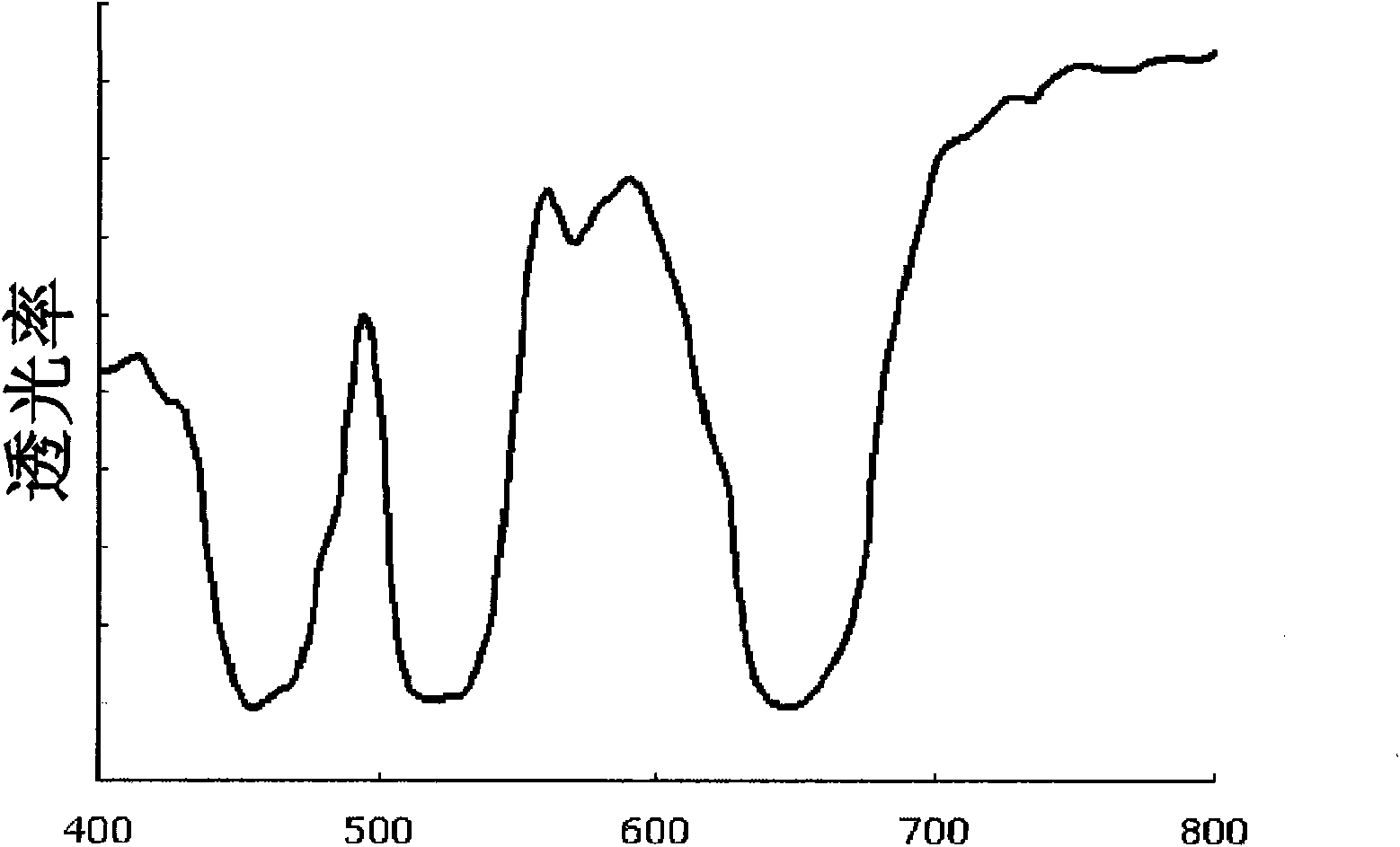

Optical film, preparation method of the same, and liquid crystal display comprising the same

ActiveCN101918886AImprove adhesion strengthIncreased durabilitySynthetic resin layered productsElectrical equipmentCrystallographyLiquid-crystal display

The present invention relates to a composition for liquid crystal alignment layer, a preparation method of liquid crystal alignment layer using the same, and an optical film comprising the liquid crystal alignment layer. More particularly, the composition for liquid crystal alignment layer according to the present invention includes crosslinkable functional monomers as well as a photoreactive polymer, thereby improving thermal stability and durability of the liquid crystal alignment layer that is prepared by using the composition for liquid crystal alignment layer. In addition, when the liquid crystal alignment layer is used to produce an optical film, adhesive strength between substrate and liquid crystal alignment layer and between liquid crystal alignment layer and liquid crystal film can be improved.

Owner:LG CHEM LTD

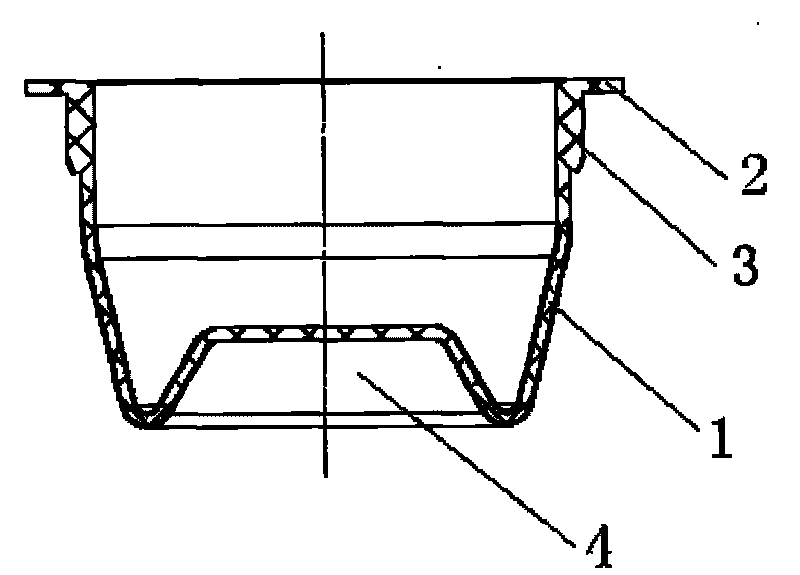

Hemostasis composition containing batroxobin and preparation method thereof

InactiveCN101797378AReduce the chance of infectionAvoid bleeding symptomsPeptide/protein ingredientsAluminium/calcium/magnesium active ingredientsThrombin activityBatroxobin

The invention provides a novel hemostasis composition which comprises fibrinogen or hemaleucin, and batroxobin, wherein the ratio of the batroxobin to the fibrinogen or hemaleucin is 0.01:100IU:1mg. Because a clot formed by the batroxobin can not cause contraction, and the batroxobin can not cause crossimmunity reaction, the hemostasis composition can overcome multiple defects existing in hemostasis products containing thrombin or prothrombin.

Owner:BEIJING SAISHENG PHARMA

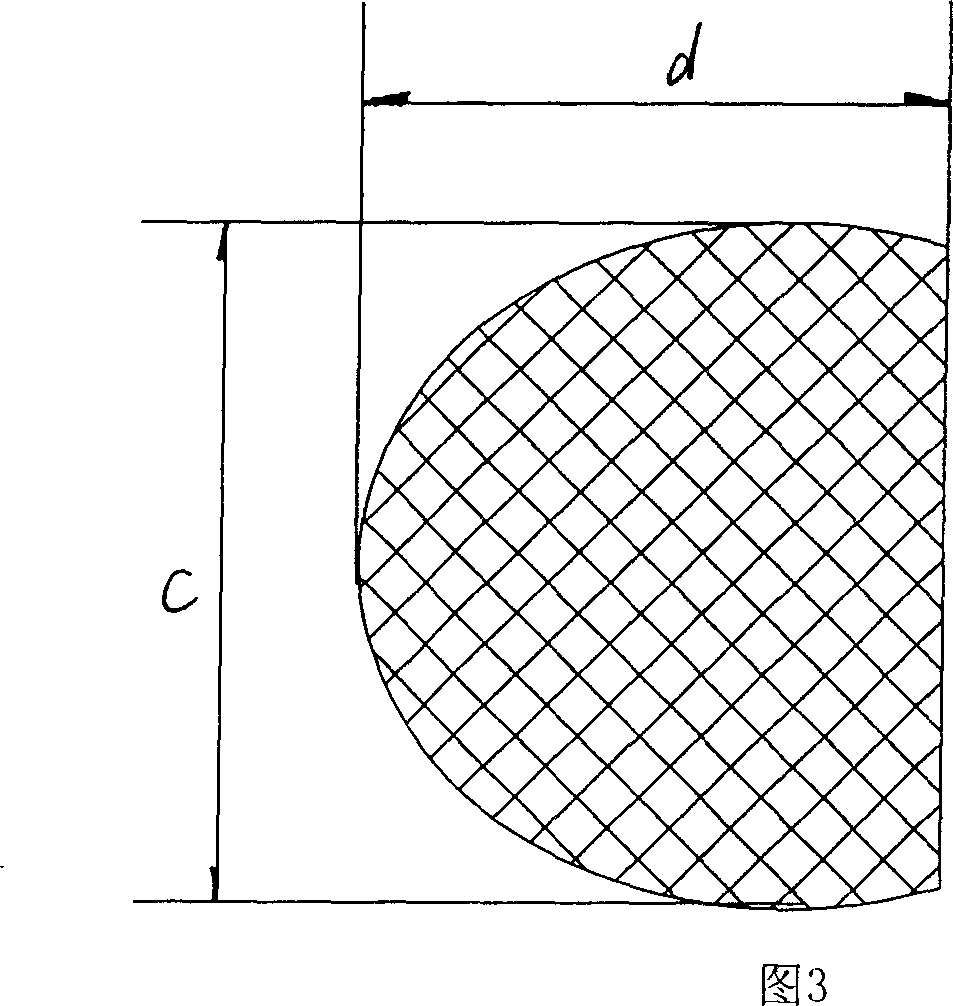

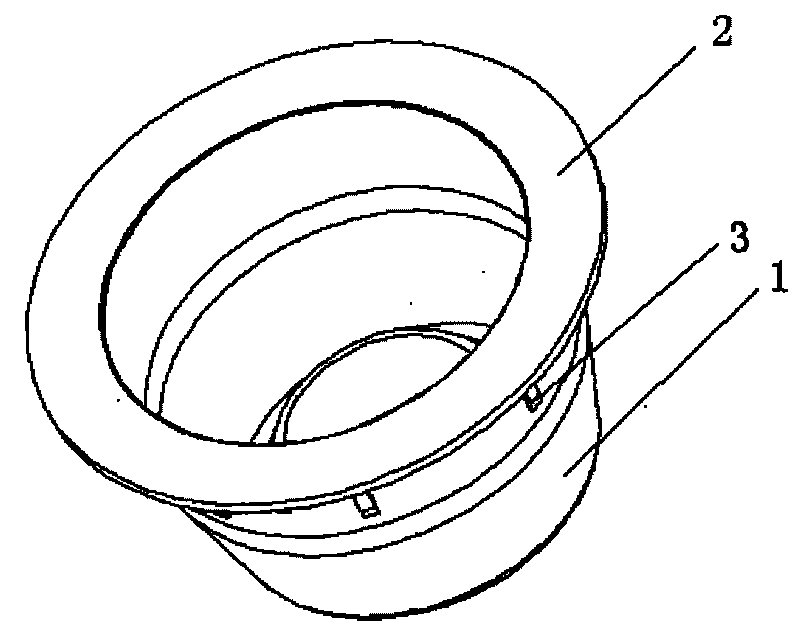

Treatment method suitable for carrying and storing plastic-lined steel pipes

The invention provides a treatment method suitable for carrying and storing plastic-lined steel pipes. Inwards concave pipe caps are inserted at two ends of the plastic-lined steel pipes, the pipe cap is bowl-shaped and comprises an inwards concave bowl body and a thin ring outer edge positioned at the part of a bowl opening, the external surface of the bowl body is approximately in fit with the pipe diameter of the plastic-lined steel pipe, and the thin ring outer edge covers the end face of the plastic-lined steel pipe. The treatment method effectively prevents ports of the plastic-lined steel pipes from being layered, overcomes the potential safety hazard in a process of carrying products and inconvenience in the operation, and improves the quality of the product and work efficiency.

Owner:GUANGDONG LIANSU TECH INDAL

Optical film, preparation method of the same, and liquid crystal display comprising the same

ActiveCN101918885AImprove adhesion strengthIncreased durabilityNon-linear opticsCrystallographyLiquid-crystal display

The present invention relates to a composition for liquid crystal alignment layer, a preparation method of liquid crystal alignment layer using the same, and an optical film comprising the liquid crystal alignment layer. More particularly, the composition for liquid crystal alignment layer according to the present invention includes crosslinkable functional monomers as well as a photoreactive polymer, thereby improving thermal stability and durability of the liquid crystal alignment layer that is prepared by using the composition for liquid crystal alignment layer. In addition, when the liquid crystal alignment layer is used to produce an optical film, adhesive strength between substrate and liquid crystal alignment layer and between liquid crystal alignment layer and liquid crystal film can be improved.

Owner:LG CHEM LTD

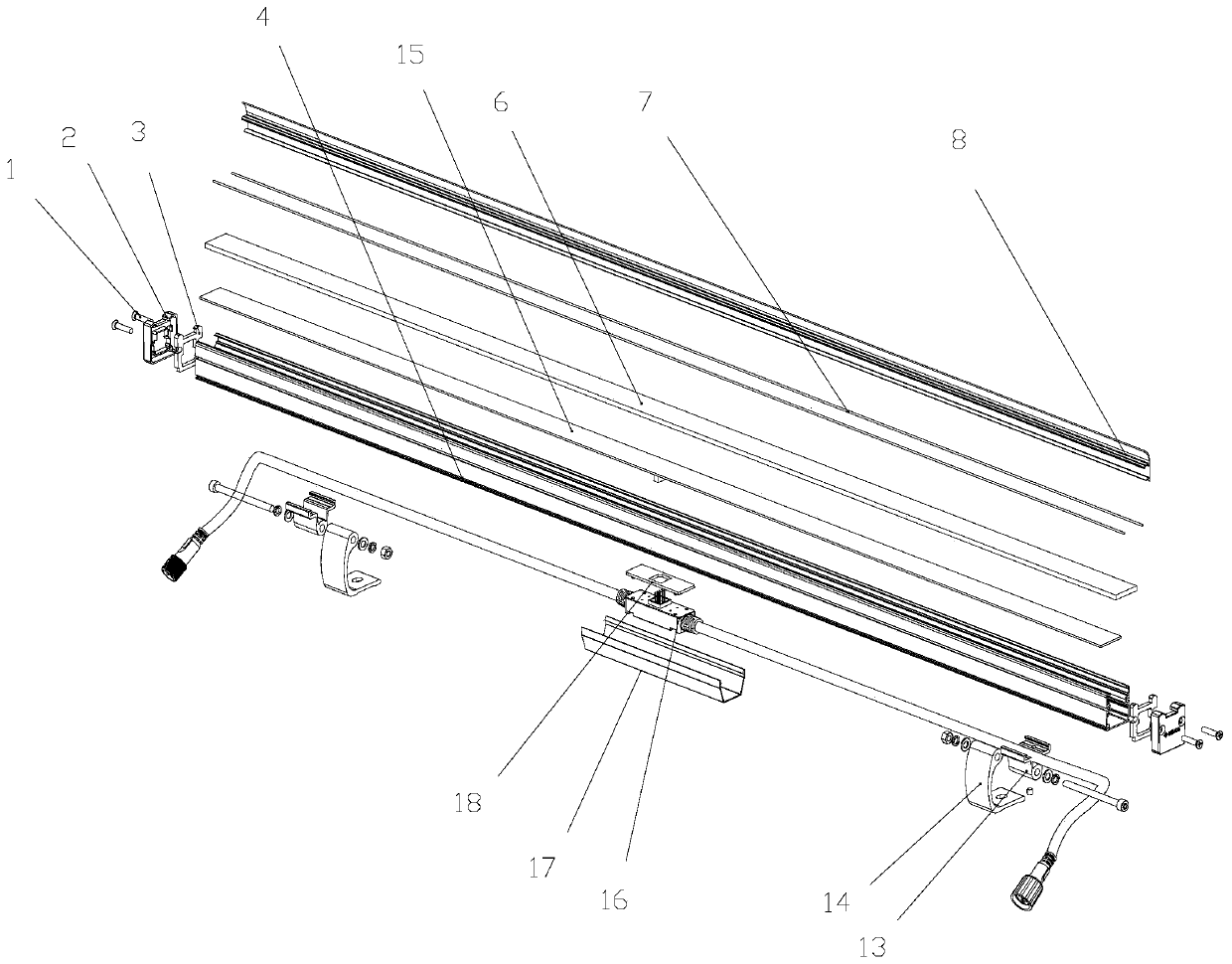

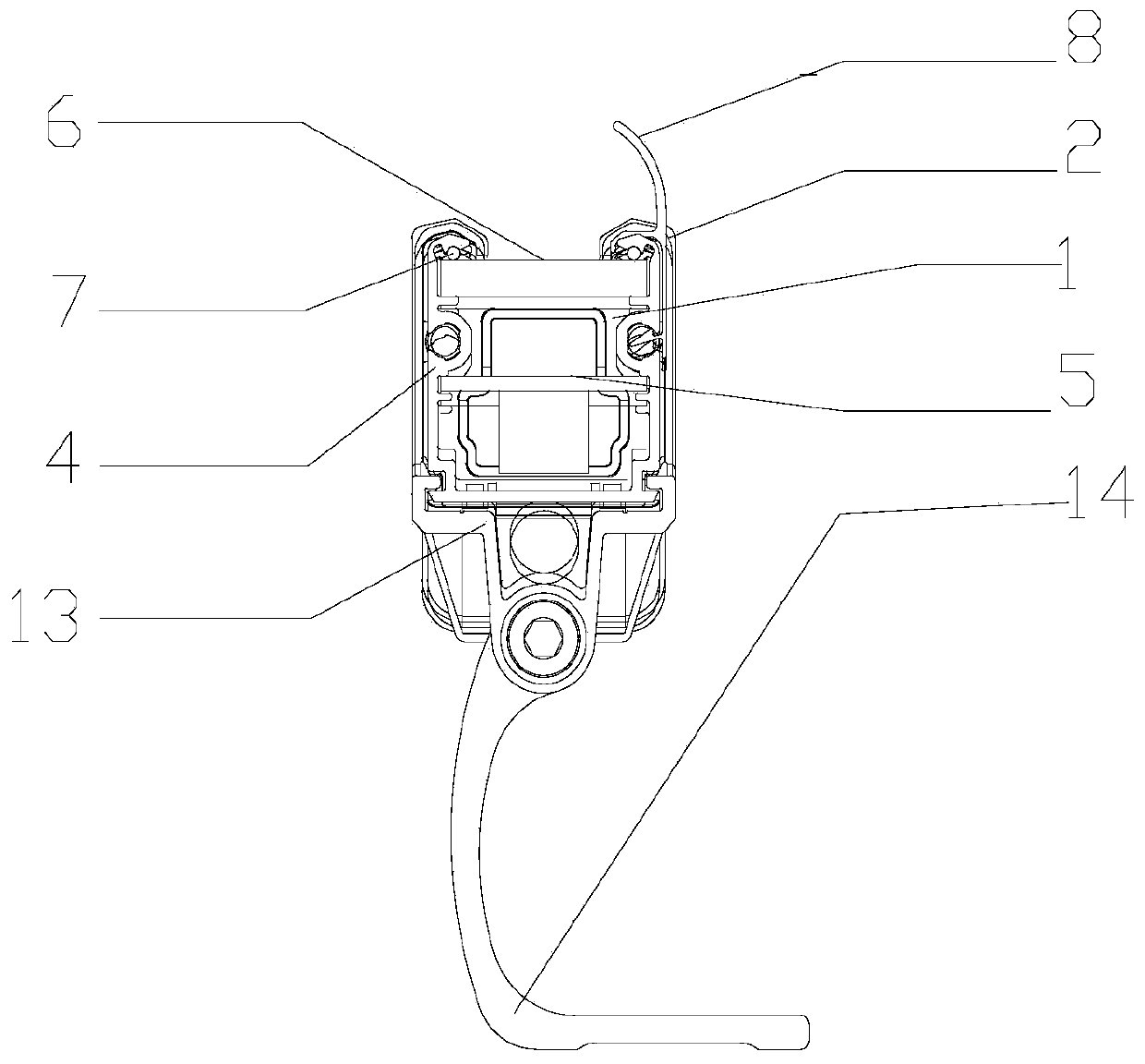

Wall washing lamp and assembly method thereof

PendingCN110594637ASimple structurePractical structureElectric circuit arrangementsGas-tight/water-tight arrangementsEngineeringLight source

The invention relates to the technical field of lamps, and specifically discloses a wall washing lamp. The lamp comprises a lamp body; the lamp body is a strip-shaped lamp body with the U-shaped ends;light-transmitting glass is arranged at the upper portion of the lamp body; a light source assembly is arranged in the lamp body; the two ends of the lamp body are connected with end covers; the lampbody in the U shape is an integrally formed aluminum profile; the light source assembly in the lamp body is connected with an external junction box through a pin type terminal; a waterproof structureis arranged at the upper portion of the light-transmitting glass; and the end covers at the two ends are of tapping hole-free screw connecting structures. The whole structure is simple and practical,the product production cost is reduced, and the assembly processes can be greatly reduced; and due to the structure, an assembly method is simple, the assembly efficiency is improved, and disassemblyis facilitated.

Owner:GUANGDONG DELOS LIGHTING IND

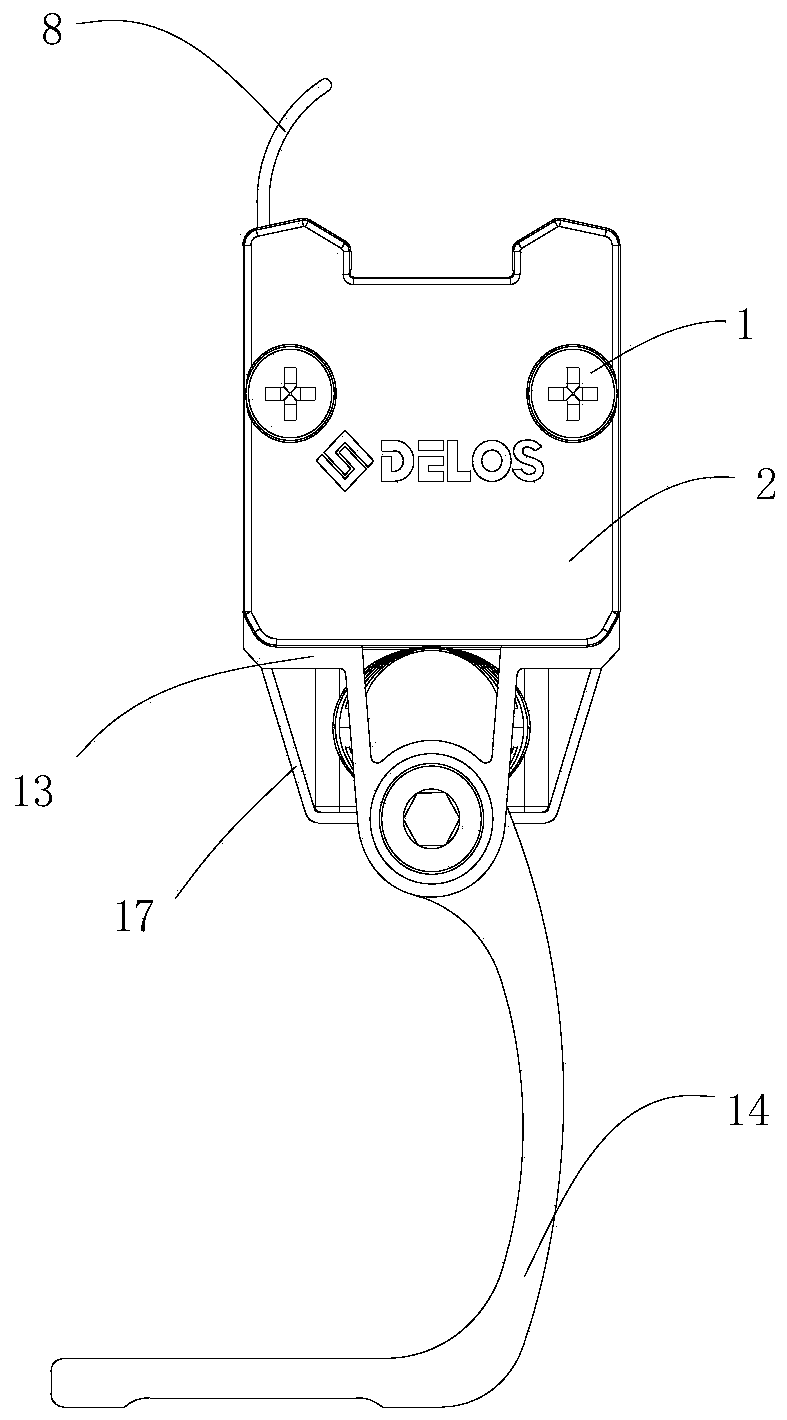

Preparation method of betamethasone sodium phosphate freeze-dried powder injection

ActiveCN105796509AShorten production timeSave energyPowder deliveryOrganic active ingredientsBetamethasone Sodium PhosphateMedicine

The invention relates to a preparation method of a cortical hormone preparation, and concretely relates to a preparation method of a betamethasone sodium phosphate freeze-dried powder injection. The method comprises the following steps: dissolving betamethasone sodium phosphate and auxiliary materials in injection, filling the obtained solution, and freeze-drying the filled solution, wherein nitrogen is introduced in the whole sublimation drying stage and desorption drying stage of freeze-drying. The method solves the problem of increase of the content of impurities in the storage process in the prior art, substantially improves the stability of the betamethasone sodium phosphate freeze-dried powder, and also solves the problem of low production efficiency in the prior art.

Owner:ZHEJIANG XIANJU PHARMA

Processing method of dehydrated vegetables

InactiveCN104222260AWon't be lostWill not oxidizeFruit and vegetables preservationAdditive ingredientSpins

The invention provides a processing method of dehydrated vegetables, belonging to the technical field of food processing. The processing method is realized by adopting the following technical scheme comprising the following steps: blanching by adopting hot water of 80-100 DEG C for multiple seconds to multiple minutes, immediately cooling after blanching; spin-drying cooled vegetables, rapidly freezing the spin-dried materials at a freezing temperature of below minus 30 DEG C; placing the frozen vegetables in a vacuum container, reducing the pressure to below a three-phase point by means of a vacuum system, and supplying heat to the materials by virtue of a heating system to ensure that water in the materials is evaporated until the materials are dried to a water end point. According to the processing method of the dehydrated vegetables, provided by the invention, the dehydrated vegetables are produced under the conditions of low-temperature freezing and vacuum oxygen deficiency, the inherent shapes of the vegetables can not contract, thermosensitive substances can not be damaged, aromatic substances can not dissipate, readily oxidizable substances can not be oxidized, and thus the shapes, colors, tastes and nutritional ingredients of the dehydrated vegetables are basically consistent with those of fresh vegetables, and the reconstitution properties are specially good.

Owner:许姗姗

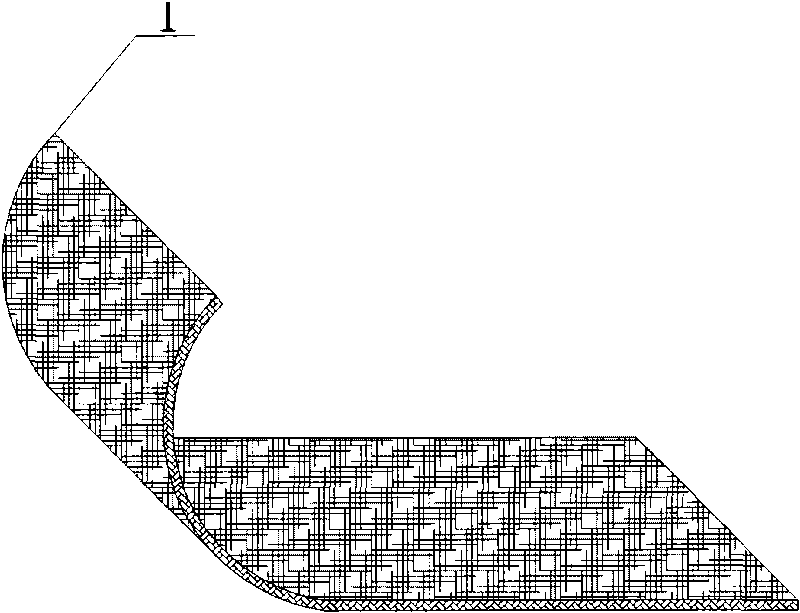

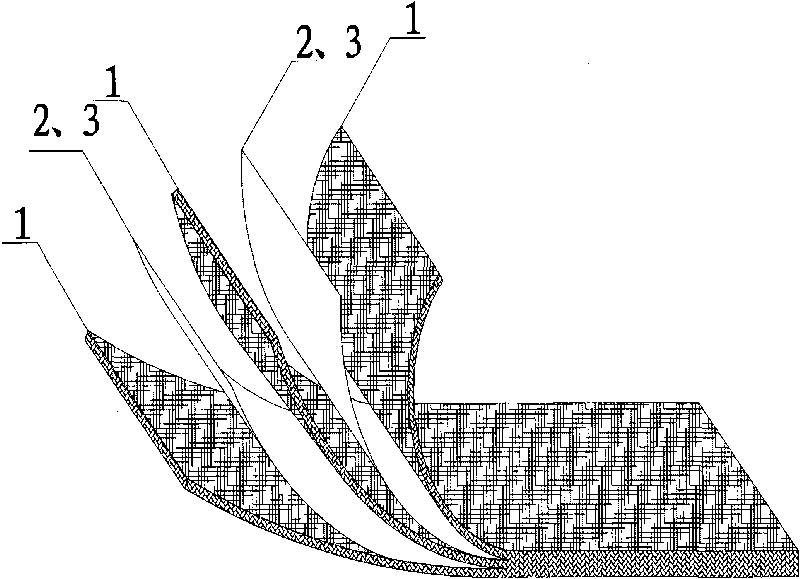

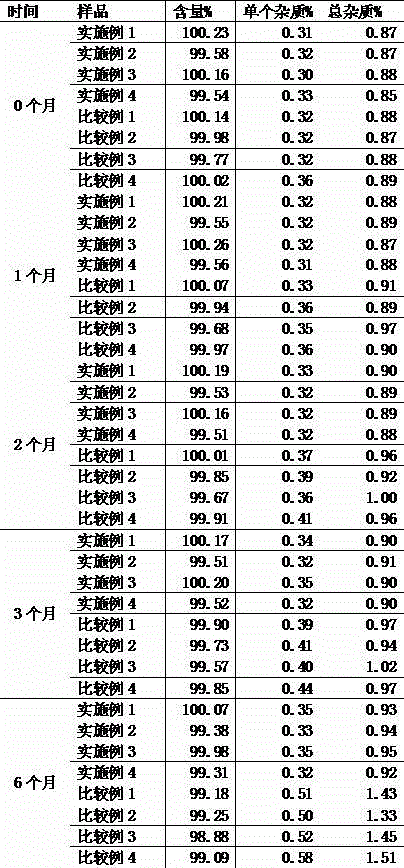

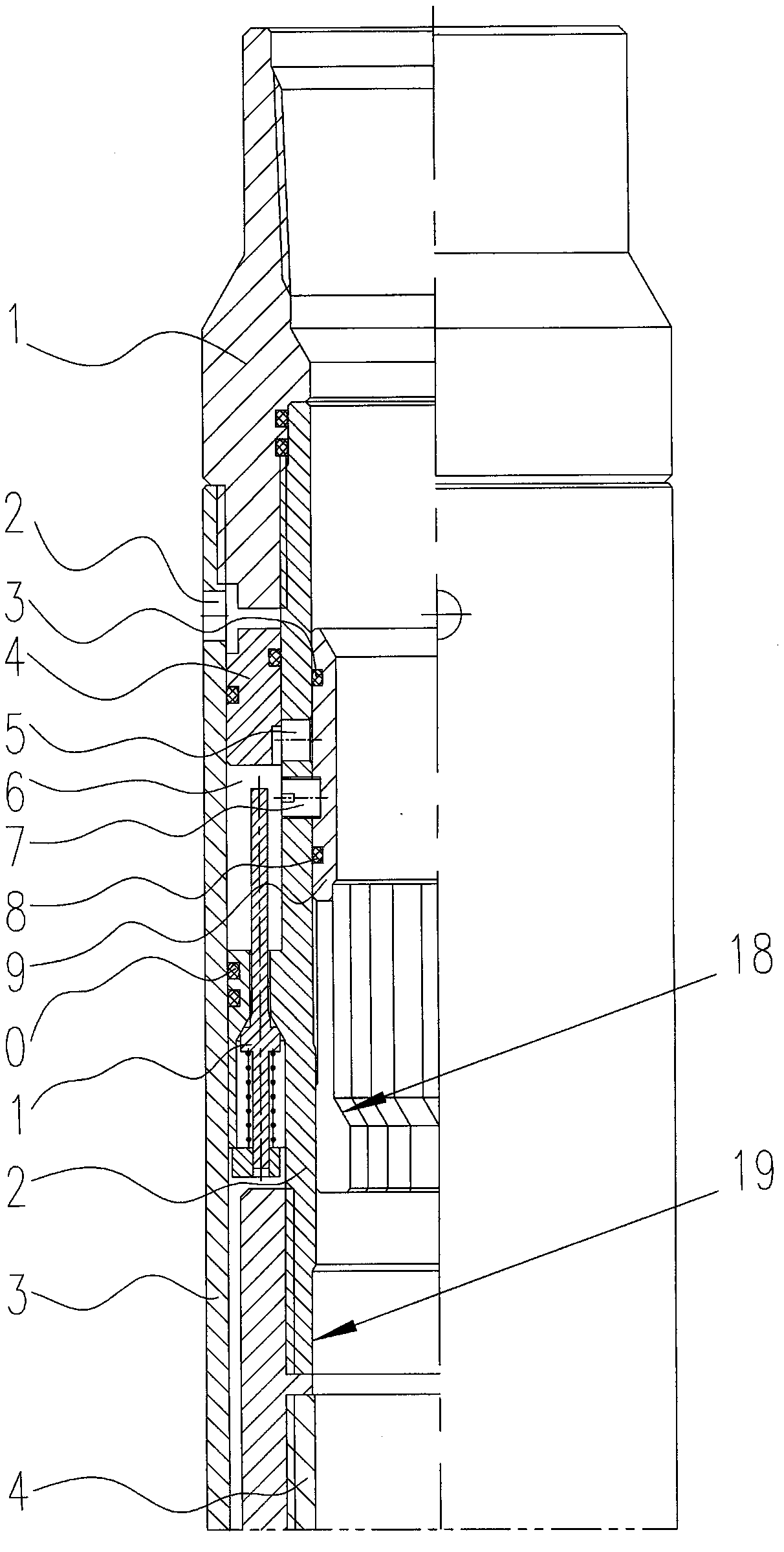

Expandable fracture packer for preventing midway setting

InactiveCN105507846ASo as not to damageWon't shrinkFluid removalSealing/packingEconomic benefitsEngineering

The invention discloses an expandable fracture packer for preventing midway setting. The expandable fracture packer comprises an upper connector, an upper sealing ring of a slide bushing, a piston, a control dowel, a lower sealing ring of the slide bushing, the slide bushing, an upper sealing ring, a check valve, a valve, a sealing barrel, an inner pipe, a rubber barrel, a lower sealing ring and a lower connector. The slide bushing covers an inner joint through hole in the valve, and a gap between the slide bushing and the valve is sealed by the upper sealing ring of the slide bushing and the lower sealing ring of the slide bushing. The expandable fracture packer has the advantages that water impact pressures generated due to excessively high speeds during descending can be prevented from being transmitted into the rubber barrel, accordingly, the problem of damage to an existing rubber barrel due to midway setting can be solved, and problems at present can be solved; shrinkage of the rubber barrel and releasing of the packer can be prevented when fracture is stopped, repeated shrinkage and expansion of the rubber barrel can be prevented, accordingly, the rubber barrel can be prevented from being damaged, the packer is long in service life, the fracture frequencies can be increased, successful separate-layer fracture can be guaranteed, and economic benefits can be increased.

Owner:东营市兆鑫工贸有限责任公司

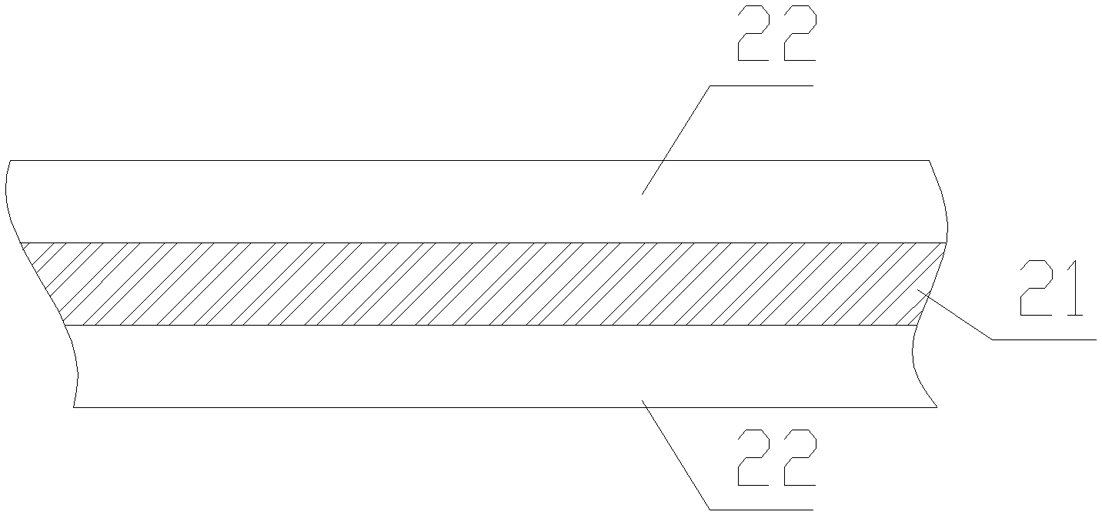

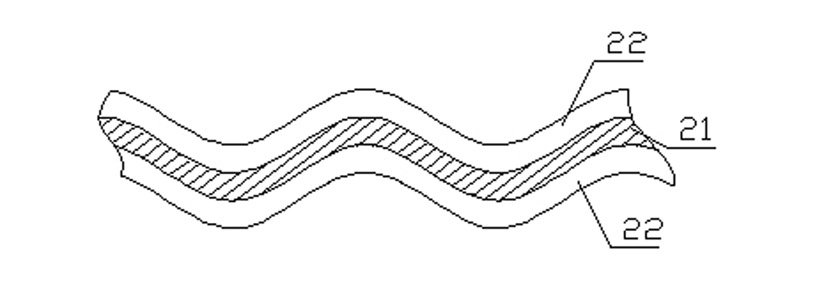

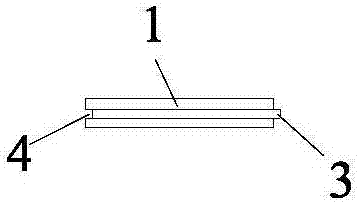

Novel plastic filler

InactiveCN101940907APromotes even distributionIncrease the gas-liquid contact areaChemical/physical/physico-chemical processesPolymer sciencePolymer chemistry

The invention discloses a filler sheet. The filler sheet comprises a strength support layer and is characterized by further comprising a hydrophilic layer which is compounded on the surface of the strength support layer. The filler sheet has the advantages of high uniform distributivity of liquid on the surface of a filler, larger gas-liquid contact area and improvement on mass transfer efficiency due to the hydrophilic layer on the surface of the filler sheet. The invention also discloses the filler made of the filler sheet.

Owner:BEIJING SINOREFINE AIR CONDITIONING TECH

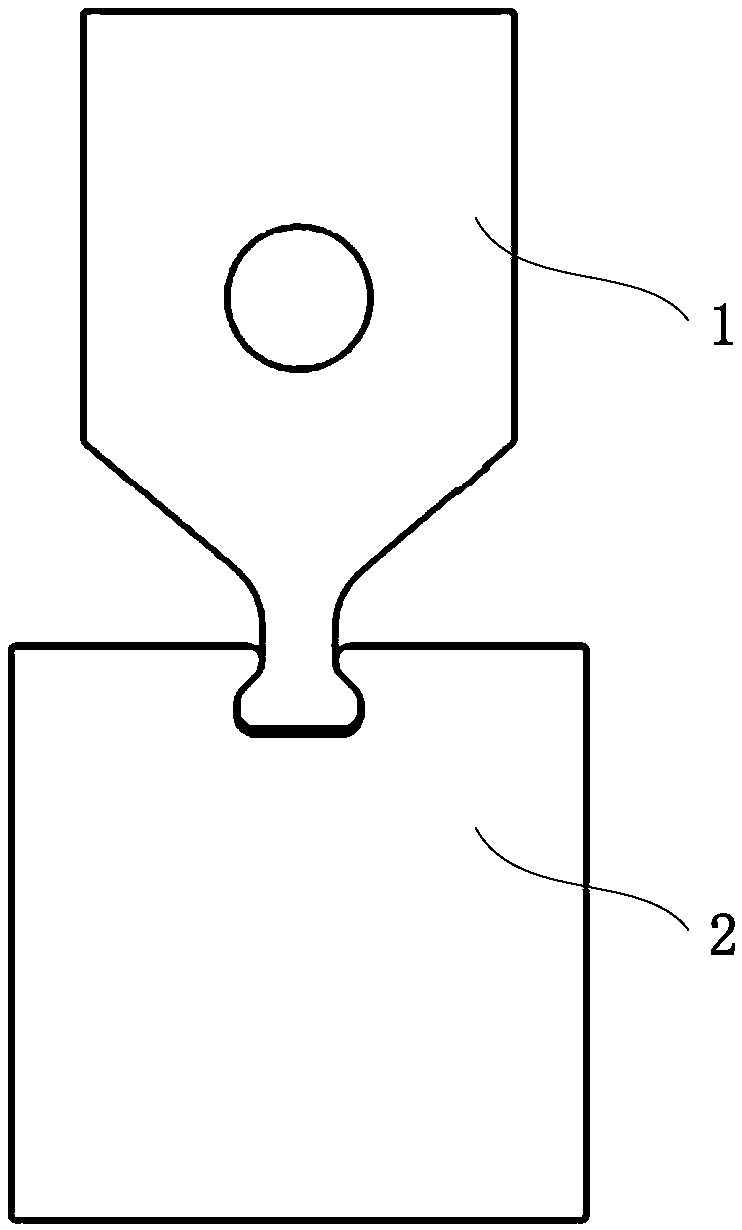

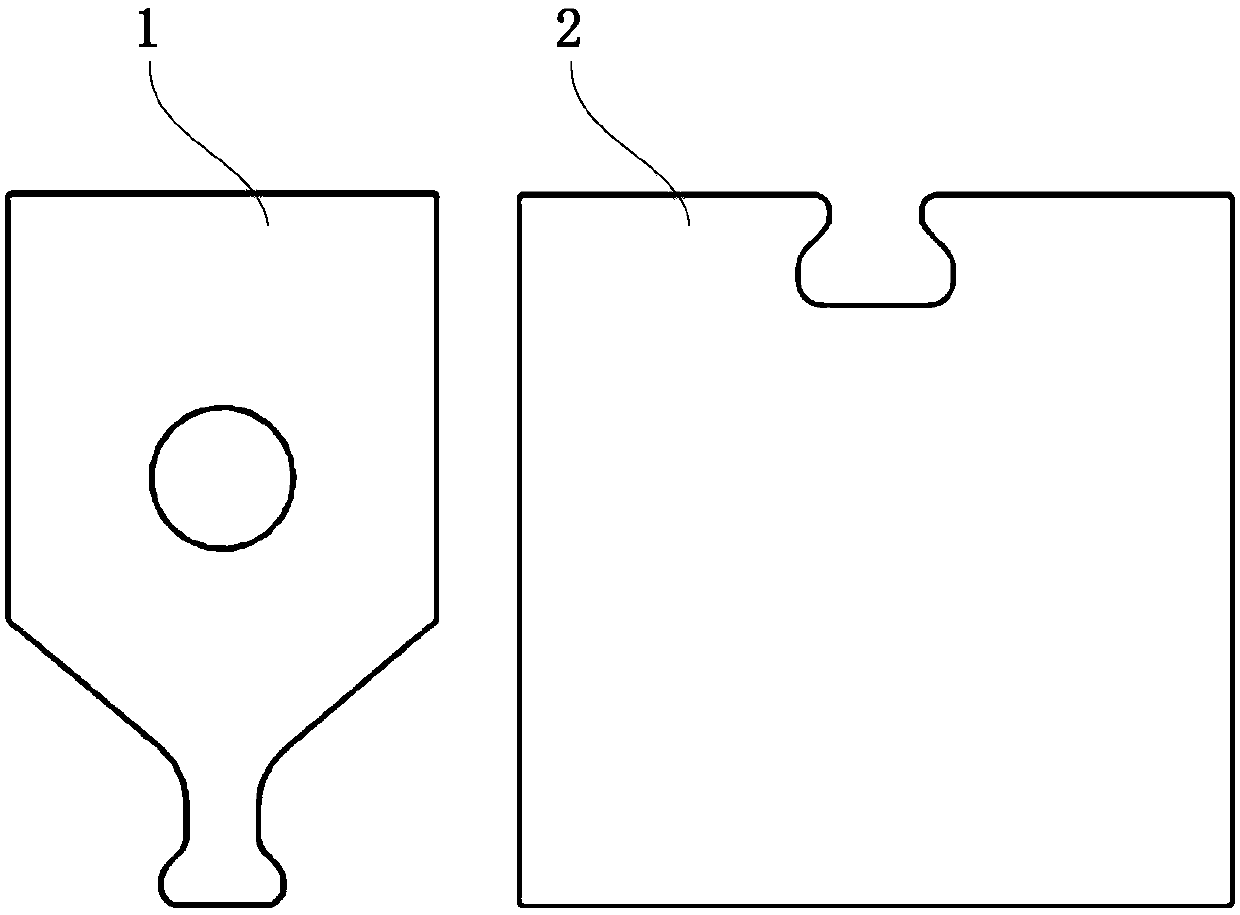

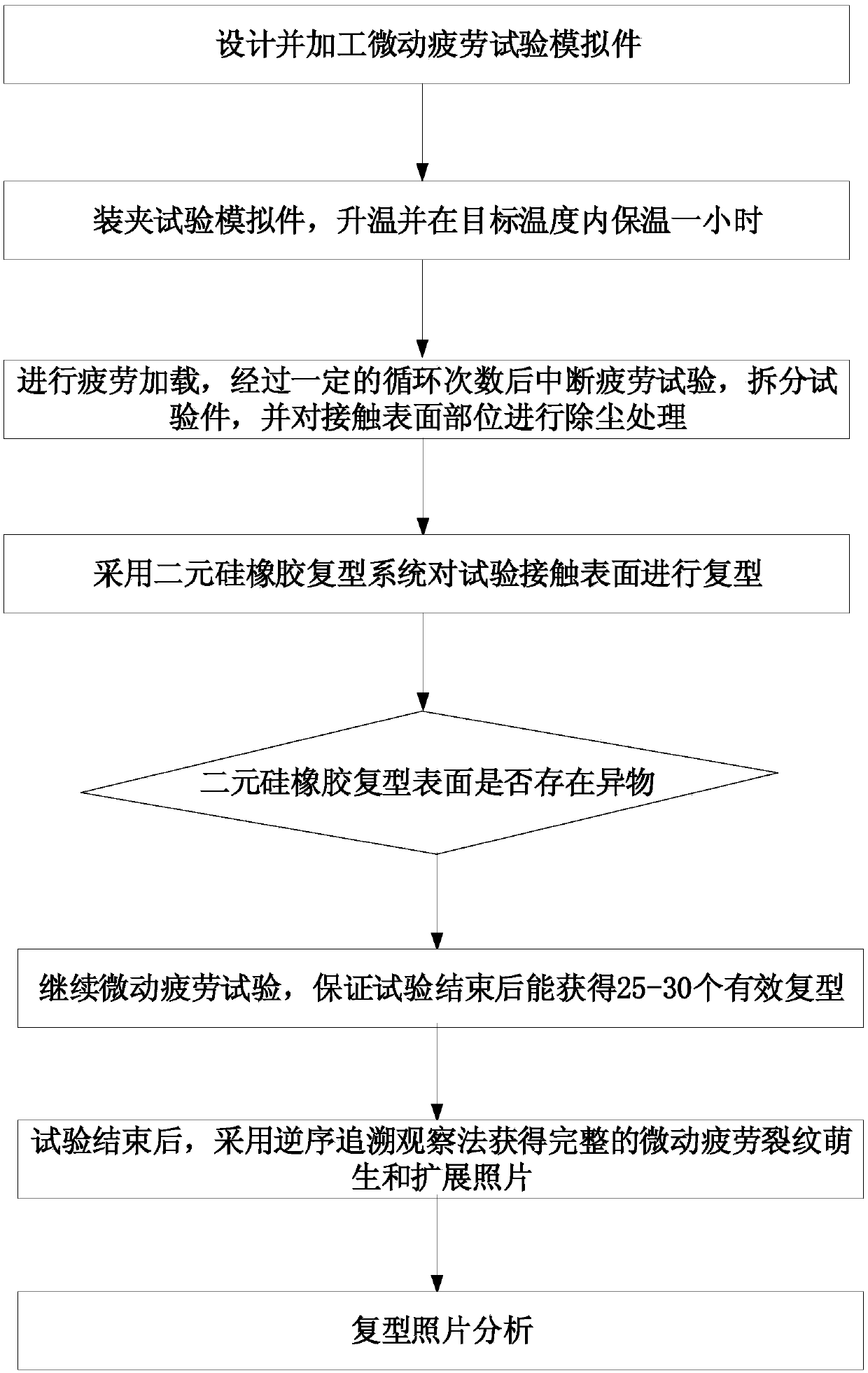

Fretting fatigue surface crack detection method and system

PendingCN110926972AAccurately reflect the crackShorten drying timeMachine part testingMaterial strength using repeated/pulsating forcesFatigue loadingCrazing

The invention discloses a fretting fatigue surface crack detection method and system, relates to the field of fatigue crack monitoring, and is used for simply and conveniently observing fatigue crackinitiation and small crack propagation of a fatigue sample. The method comprises the following steps: carrying out fatigue loading on a first part and a second part which are matched with each other for set times; separating the two first parts and the second part; laminating the mutual contact parts of the first part and the second part with binary silicone rubber to obtain a to-be-observed diaphragm; and repeating the steps until the fretting fatigue test is finished so as to obtain all to-be-observed diaphragms for fretting fatigue analysis. According to the technical scheme, the mutual contact parts of the first part and the second part are respectively laminated by adopting binary silicon rubber; binary silicone rubber laminating is adopted, the curing time is short, shrinkage is avoided after curing, and it is guaranteed that the laminated sheet can accurately reflect cracks on a test; and the method has no influence on the fatigue life of the sample.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

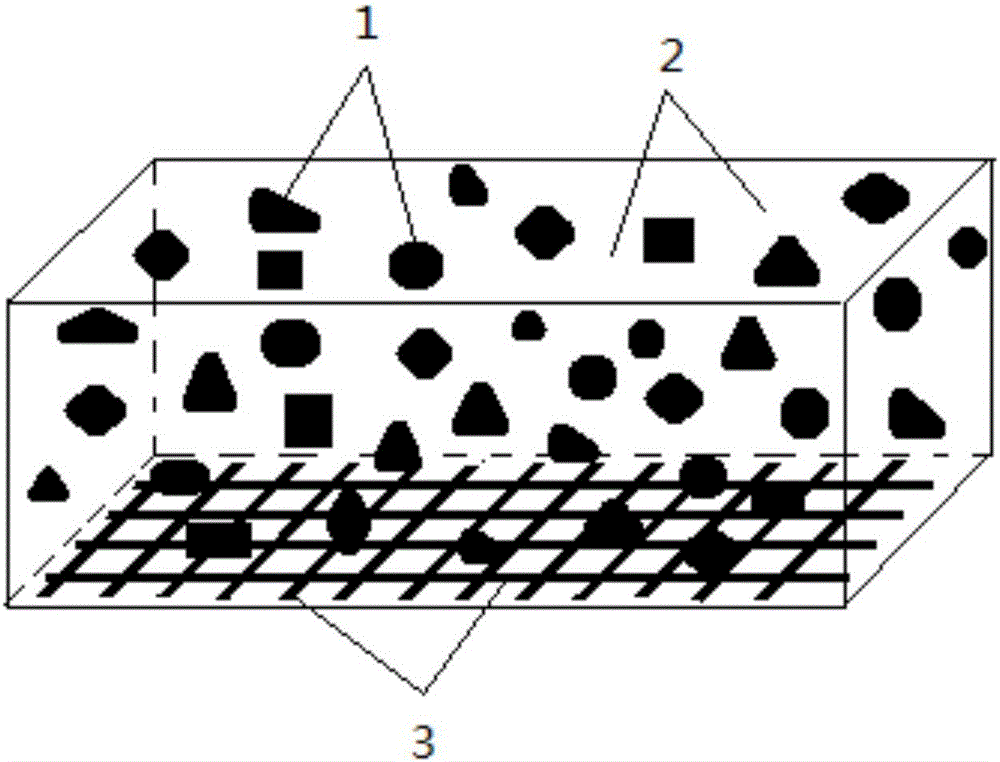

Flexible sound-insulation composite material and preparation method thereof

The invention provides a flexible sound-insulation composite material. The composite material is mainly composed of high-density particles, a viscoelastic thermoplastic material and a flexible framework which is easy to bent and can resist stretching and shearing damages. The composite material prepared by the invention has excellent properties of high strength, high density, fire resistance, no toxin and environment friendliness, corrosion resistance and good sound-insulation effect and can be widely applied to industries including highway traffic, urban rail transit, machinery equipment, house building, ships, home decoration, industrial product packaging and the like. Furthermore, the invention also provides a preparation method of the flexible sound-insulation composite material. A sheet material with low odor, low VOC (Volatile Organic Compound) content, low volatile matter content and good mechanical property indexes of the product is obtained through strictly controlling the extruding temperature and the post-period heating temperature to reduce decomposition and molecular migration of the material, and is an environment-friendly material.

Owner:秦耀东

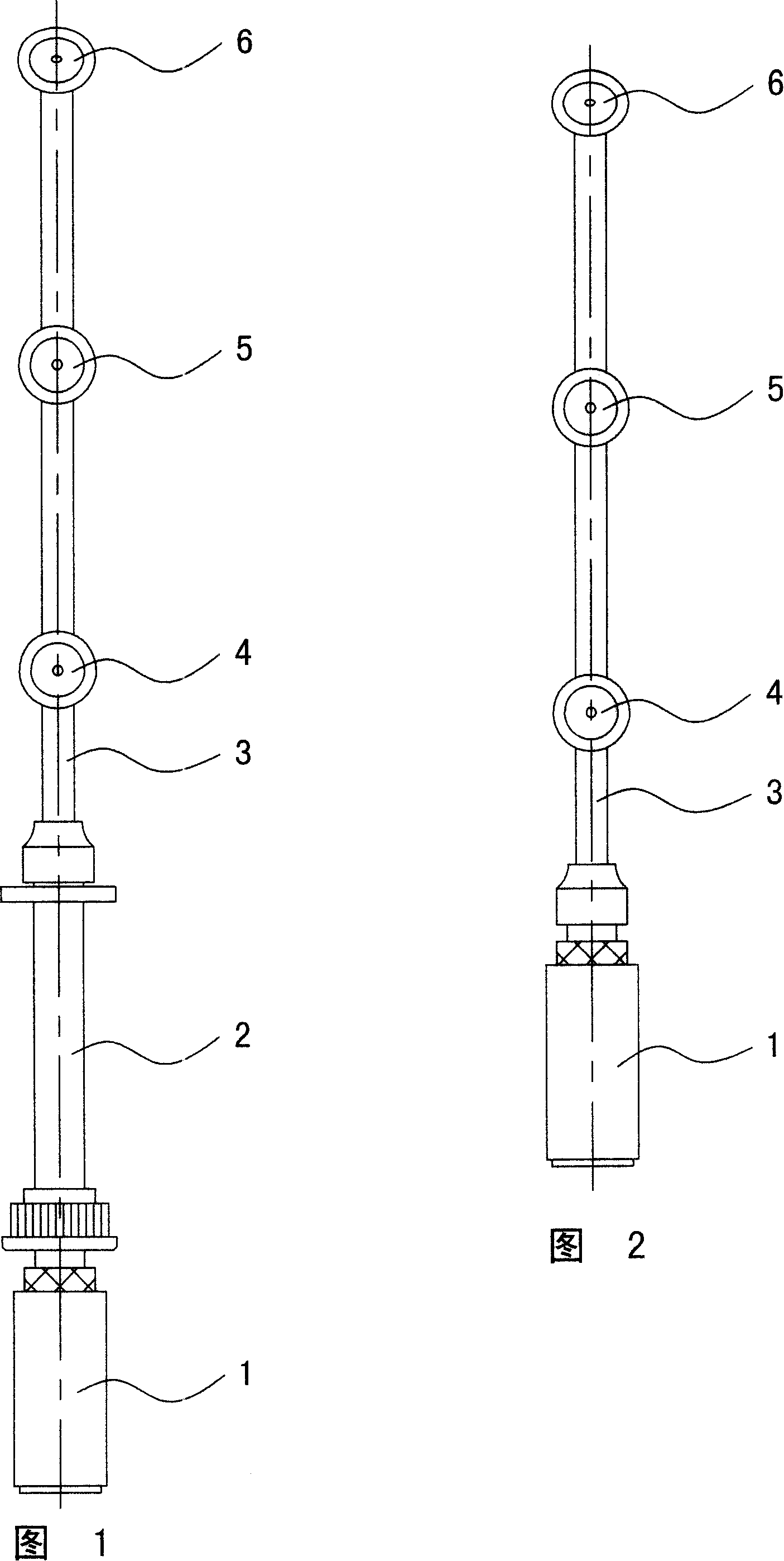

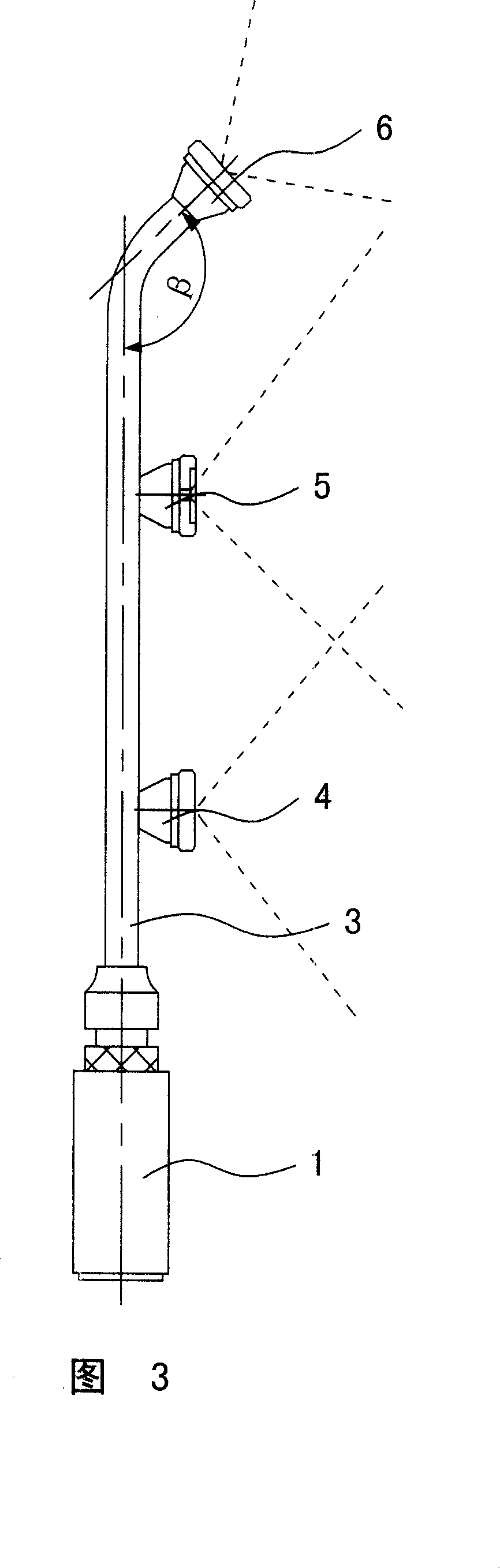

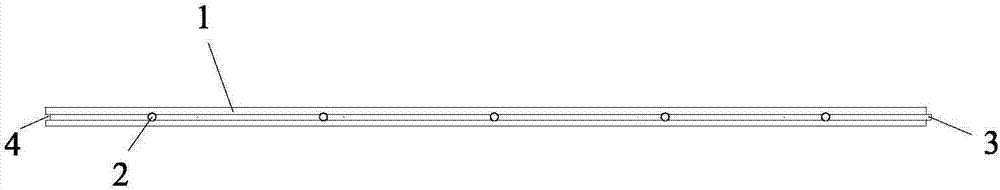

Multiple-nozzle chips connected in series multiple-segment spray lance of the vaporizer

The invention relates to a sprayer with multiple serial nozzles and multiple booms. A handle of a sprayer is connected with a boom, and the boom is provided with a nozzle. The invention is characterized in that at least two nozzles can be arranged on the boom at the same direction, and at least a lengthen boom can be arranged between the boom and the handle. The two nozzles arranged at the same direction of the boom increases the spraying area of the foggy liquid medicine, and more than two nozzles have a larger spraying area; the nozzles at the same direction mean spraying at the same plane, thereby improving the work efficiency exponentially; if the nozzles are at different directions, multiple nozzles do not always improve work efficiency. The boom of the sprayer can be lengthen or shorten by the lengthen boom arranged between the boom and the handle according to the practical situation. Each lengthen boom can be connected by screws, and the application effect is reliable.

Owner:梁小恩

Solid wood floor and preparation method thereof

The invention relates to a solid wood floor comprising a floor body. Holes extending in the width direction of the floor body are formed inside the floor body, and the solid wood floor further comprises pin columns inserted in the holes. According to the solid wood floor, the holes extending in the width direction of the floor body are formed inside the floor body, the pin columns are inserted in the holes, and due to existence of the pin columns, the solid wood floor does not crack, deform and shrink due to pulling force of the pin columns in the width direction of the floor. The solid wood floor is used for underfloor heating and does not crack, deform and shrink.

Owner:MAC DOUGLAS WOOD FLOORING SUZHOU

High-strength nano water plugging agent and preparation method thereof

The invention discloses a high-strength nano water plugging agent. The high-strength nano water plugging agent comprises the following raw materials in parts by weight: 20 to 35 parts of nanometer silicon oxide; 15-30 parts of nano iron oxide; 30-40 parts of nano calcium carbonate; 25-30 parts of nano aluminum oxide; 20-35 parts of nano cement; 5-10 parts of triethanolamine; 10-15 parts of acrylamide; 3-10 parts of methyl methacrylate; 8-15 parts of cyclohexane; 2-8 parts of a surfactant; 12-30 parts of a flame retardant; and 30-50 parts of deionized water. The invention discloses a preparation method of the high-strength nano water plugging agent. The preparation method comprises the following step of: 1) putting nano silicon oxide, nano iron oxide, nano calcium carbonate, nano aluminum oxide and nano cement into a dryer, and drying the raw material to remove moisture. By adding acrylamide, the water plugging agent does not shrink when being cured, so that the plugging rate of the water plugging agent is increased; by adding the nano silicon oxide, nano iron oxide, nano calcium carbonate, nano aluminum oxide and nano cement, the plugging rate of the water plugging agent is furthergreatly increased, and the strength of the water plugging agent is improved.

Owner:SHANDONG BOSAITE PETROLEUM TECH CO LTD +1

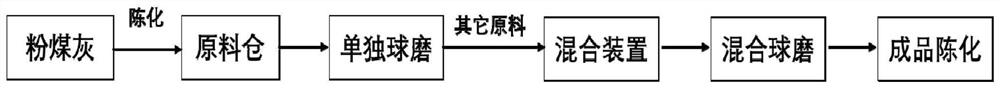

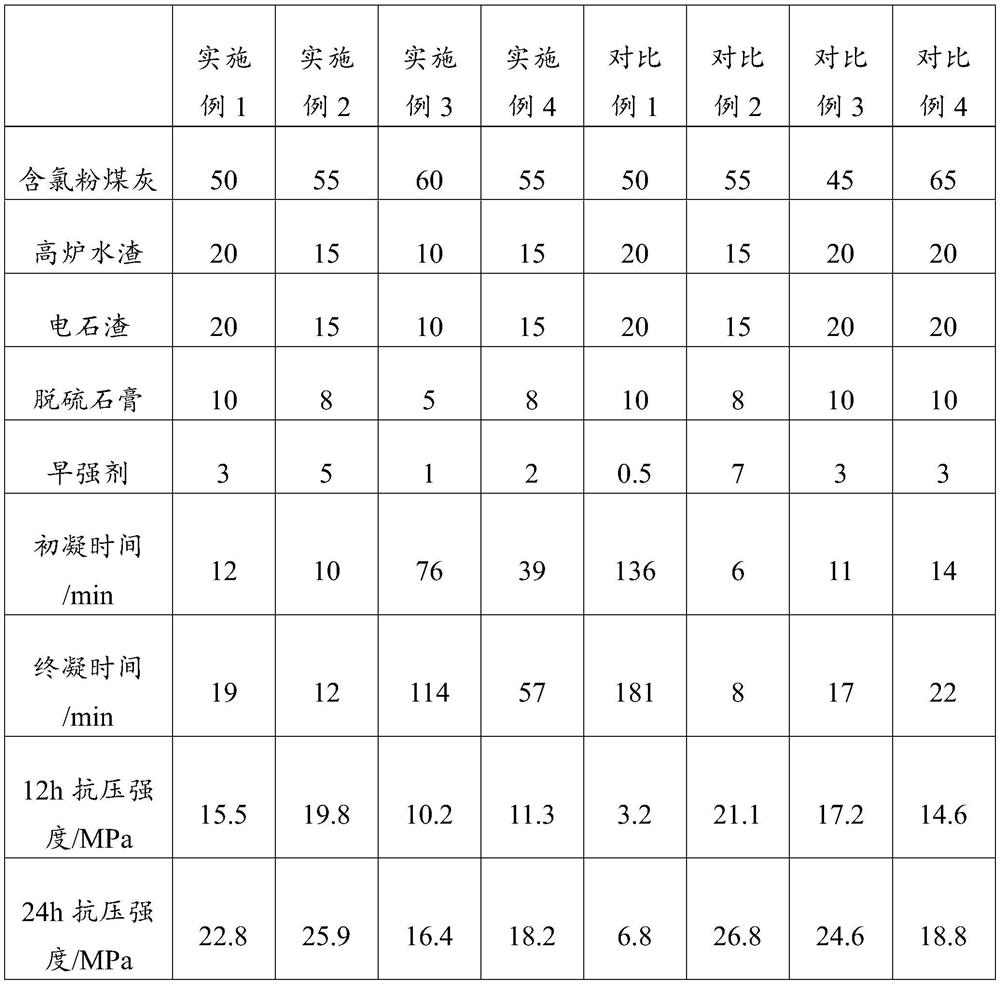

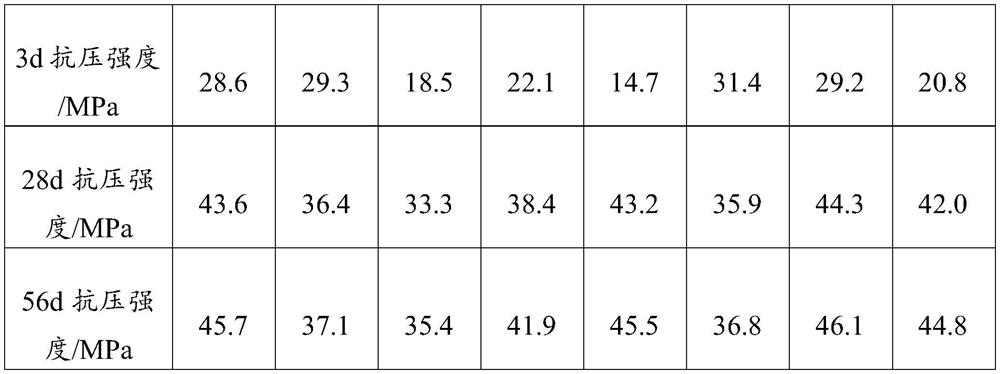

Cementing material and preparation method thereof

The invention discloses a cementing material and a preparation method thereof, and belongs to the field of building materials. The cementing material comprises the following components in parts by weight: 50-60 parts of chlorine-containing fly ash, 10-20 parts of blast furnace granulated slag, 10-20 parts of carbide slag, 5-10 parts of desulfurized gypsum and 1-5 parts of an early strength agent. The cementing material disclosed by the invention does not need additional cement, the setting speed is relatively high, the compatibility of the early strength agent and the cementing material is good, the early strength of the cementing material can be improved, and the cementing material does not shrink in the later stage; meanwhile, chloride ions in the fly ash are changed into waste, and the rapid curing effect of the chloride ions is brought into play; the fly ash is excited in a ball milling and chemical excitation combined mode, and the obtained cementing material is better in performance.

Owner:广东能源集团科学技术研究院有限公司 +1

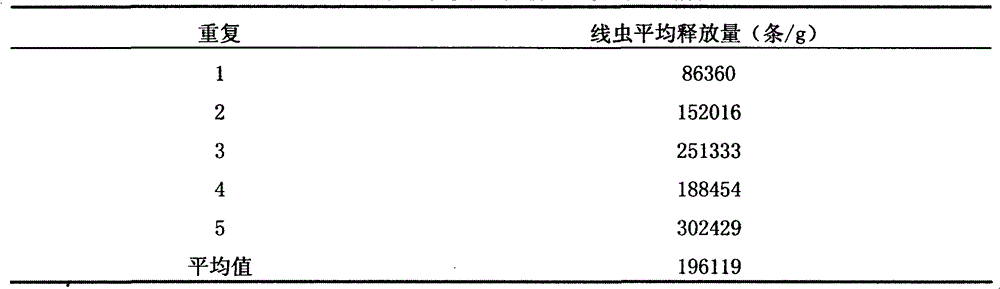

Antibacterial, anti-dry and anti-adhesion method of dead insects infected by entomopathogenetic nematodes

InactiveCN103053619ASufficient oxygenExtended use timeBiocideAnimal repellantsEntomopathogenic nematodePigment

The method performs surface treatment on dead insects resulted from infection of entomopathogenetic nematodes (entomopathogenetic nematodes and insect complexes) through a three-step method. Firstly, anti-dry and antibacterial treatment is performed on the insect complexes infected by the entomopathogenetic nematodes; the insect complexes infected by the entomopathogenetic nematodes are immersed in a mixed solution of kaolin, glycerin soil and water; then further surface treatment is carried out in mixed powder of kaolin starch and vermiculite; and finally, edible pigment is sprayed to make the surface treated dead insects infected by the entomopathogenetic nematodes red color. The surface treated dead insects infected by the entomopathogenetic nematodes can release the entomopathogenetic nematodes normally. Surface treated dead insect agents solve the problems of adhesion and decay during a transport process and guarantees release rate of the entomopathogenetic nematodes. The method is simple and practical, is helpful for large-scale application of the dead insects infected by the entomopathogenetic nematodes.

Owner:NANKAI UNIV

Manufacture method of foaming ball

The invention relates to the technical field of manufacture methods of foaming balls, in particular to a method for manufacturing a foaming ball from acrylic-based resin. The method comprises the following steps of (1) injection moulding, wherein the acrylic-based resin and a foaming additive are added into an injection moulding machine, and are extruded through a screw rod; and then an injection moulded foaming ball intermediate is obtained through the steps of mould clamping, adhesive injecting, pressure maintaining, cooling and mould opening; (2) cooling and foaming, wherein the foaming ball intermediate obtained in the step 1 is taken out of a mould, and is placed in cooling water for cooling and foaming so as to obtain the required foaming ball; the foaming additive is gasified into a low molecule organic matter in a heating condition, and is decomposed to generate a large amount of gas, so that molten solid acrylic-based resin contains a great number of bubbles; the foaming ball is enabled to enter a forming mould for forming, and then is placed in cooling water for cooling; the surface of the foaming ball is sized rapidly in the cooling water; and waste heat exists in the internal part of the foaming ball intermediate, and the acrylic-based resin in the inner part is subjected to cooling shrinkage so as to extrude the bubbles therein, and uniform and beautiful bubbles are generated.

Owner:东莞市协宏塑胶制品科技有限公司

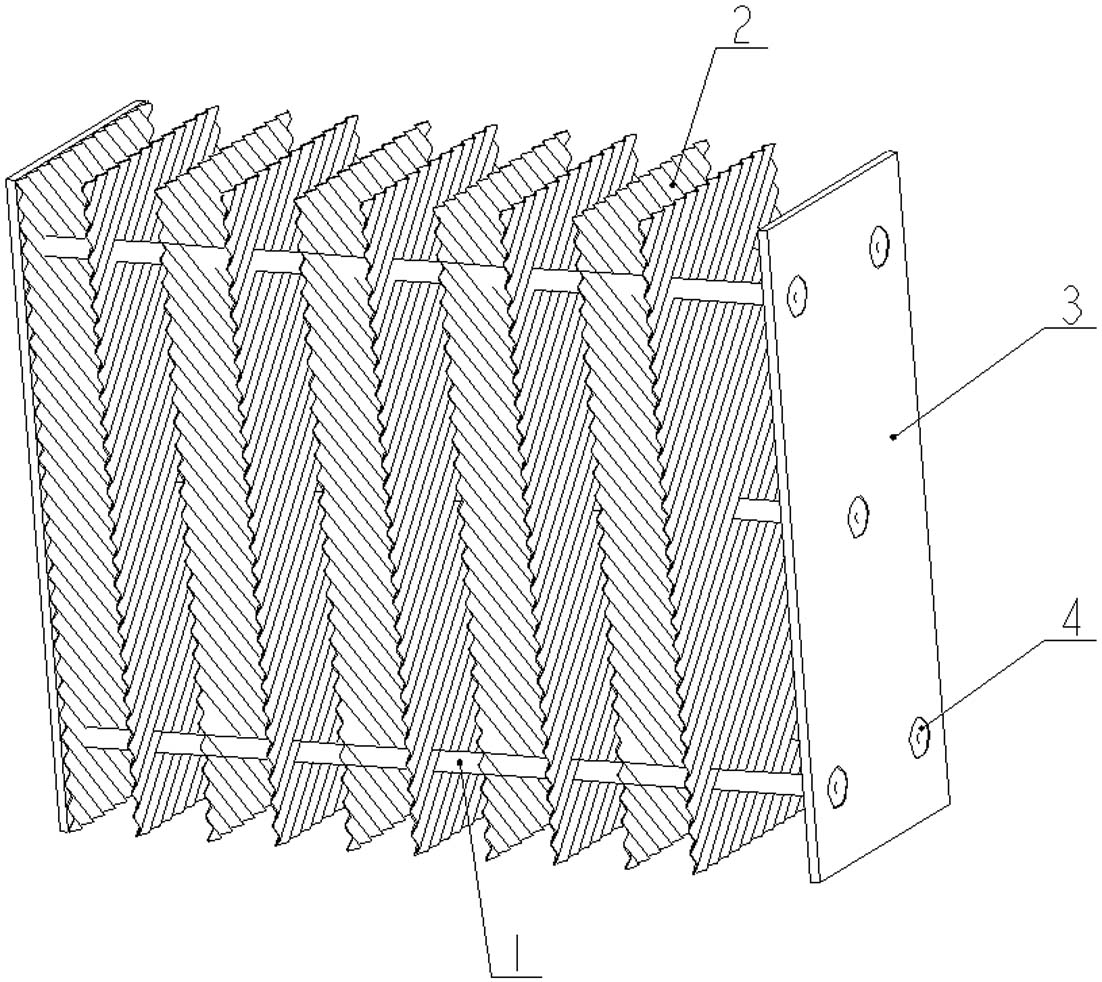

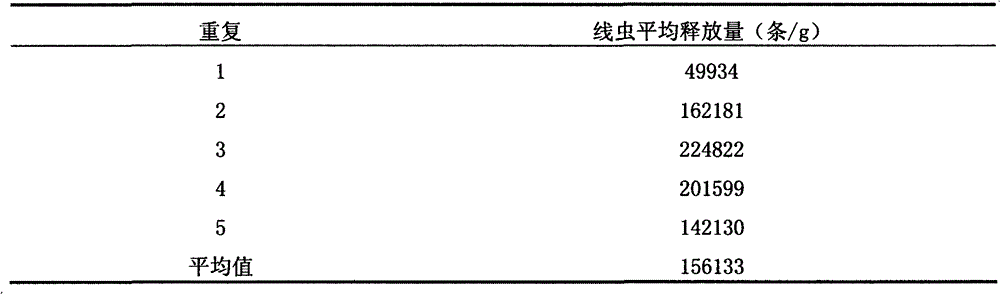

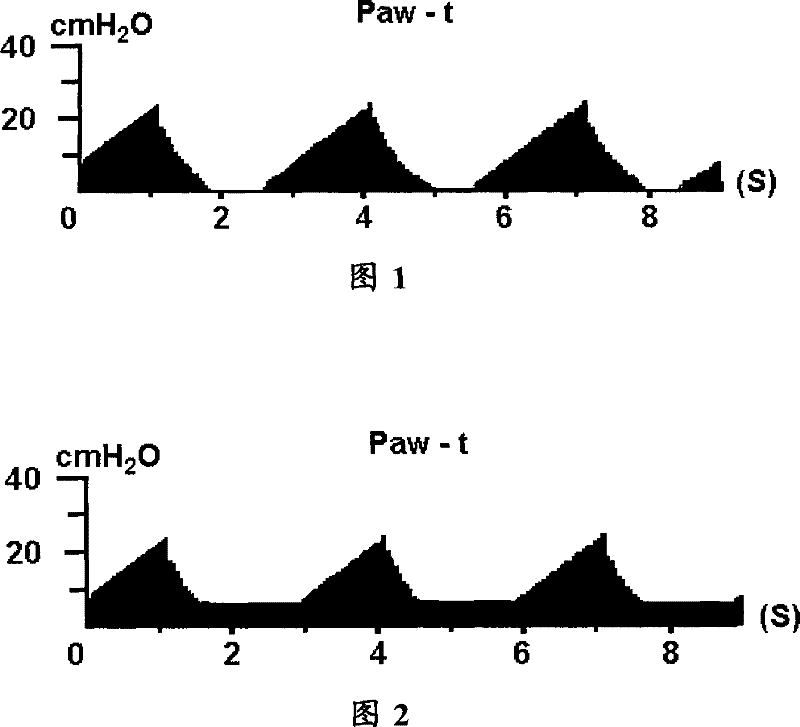

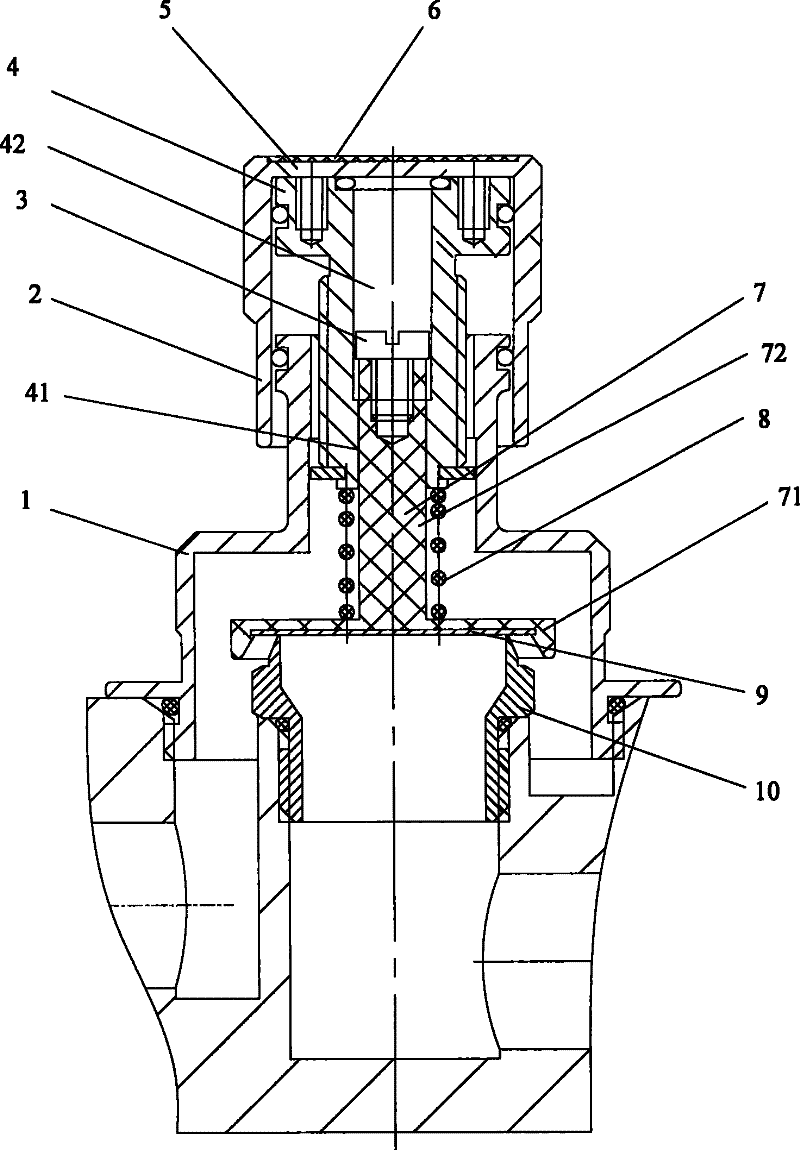

Mechanical PEEP valve

The present invention discloses a mechanical PEEP (Positive End-Expiratory Pressure) valve, and mainly relates to a medical positive end-expiratory pressure device which is adjusted manually. The mechanical PEEP valve of the invention mainly comprises a valve body (1), a connecting component (4), a guiding component (7) and a spring (8), wherein the valve body (1) and the connecting component (4)are connected by screw. The spring (8) is sleeved on the guiding component (7) and is positioned between the connecting component (4) and the guiding component (7). The connecting component (4) is sleeved on the guiding component (7). The connecting component and the guiding component (7) are in clearance fit. The mechanical PEEP valve with the structure can use the spring (8) for realizing the adjustment to PEEP value. The adjusting range is between 0 and 20cmH2O thereby adapting the requirement of patients with different states. Furthermore the gravity force exerted on the diaphragm (9) satisfies the opening pressure requirement of EN740 when the spring pressure is zero.

Owner:BEIJING AEONMED

Processing method of tea tree flowers

The invention discloses a method for processing tea tree flowers, relating to the technical field of processing, comprising the following steps: harvesting tea tree flower buds from mid-October to early December; cutting off the receptacles and spreading them on a water sieve; Freeze inside, the temperature is lower than minus 20°C, and freeze for 12-14 hours; then put the flower buds into a vacuum dryer for freeze drying, when the temperature is lower than minus 20°C, vacuumize until the pressure is -0.1Mpa, turn on the oil Heating system, the heating temperature is 50°C~52°C, continue heating and drying for 24~26 hours, until the water content of the flower buds is ≤4%; put the flower buds into the baking machine for baking, the temperature is 90°C~100°C, and the time is 15~ 20 minutes. The invention solves the problems that the tea tree flower processed products are not full in appearance, not beautiful, not fresh in color, low in aroma and not pure, yellowish in color and not bright in soup, which are not conducive to quality improvement.

Owner:葛智文 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com