Expandable fracture packer for preventing midway setting

An expansion type, halfway seat technology, applied in the directions of sealing/isolation, production fluids, wellbore/well components, etc., can solve the problems of inability to overcome the midway expansion of the rubber tube, the inability to achieve layered fracturing, and the easy damage of the rubber tube. , to achieve the effect of increasing the number of fracturing, long life and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

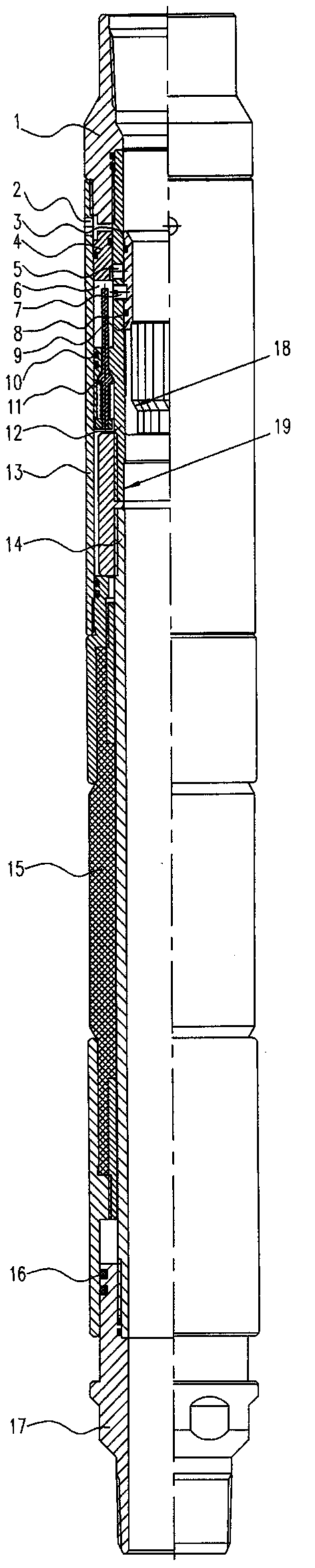

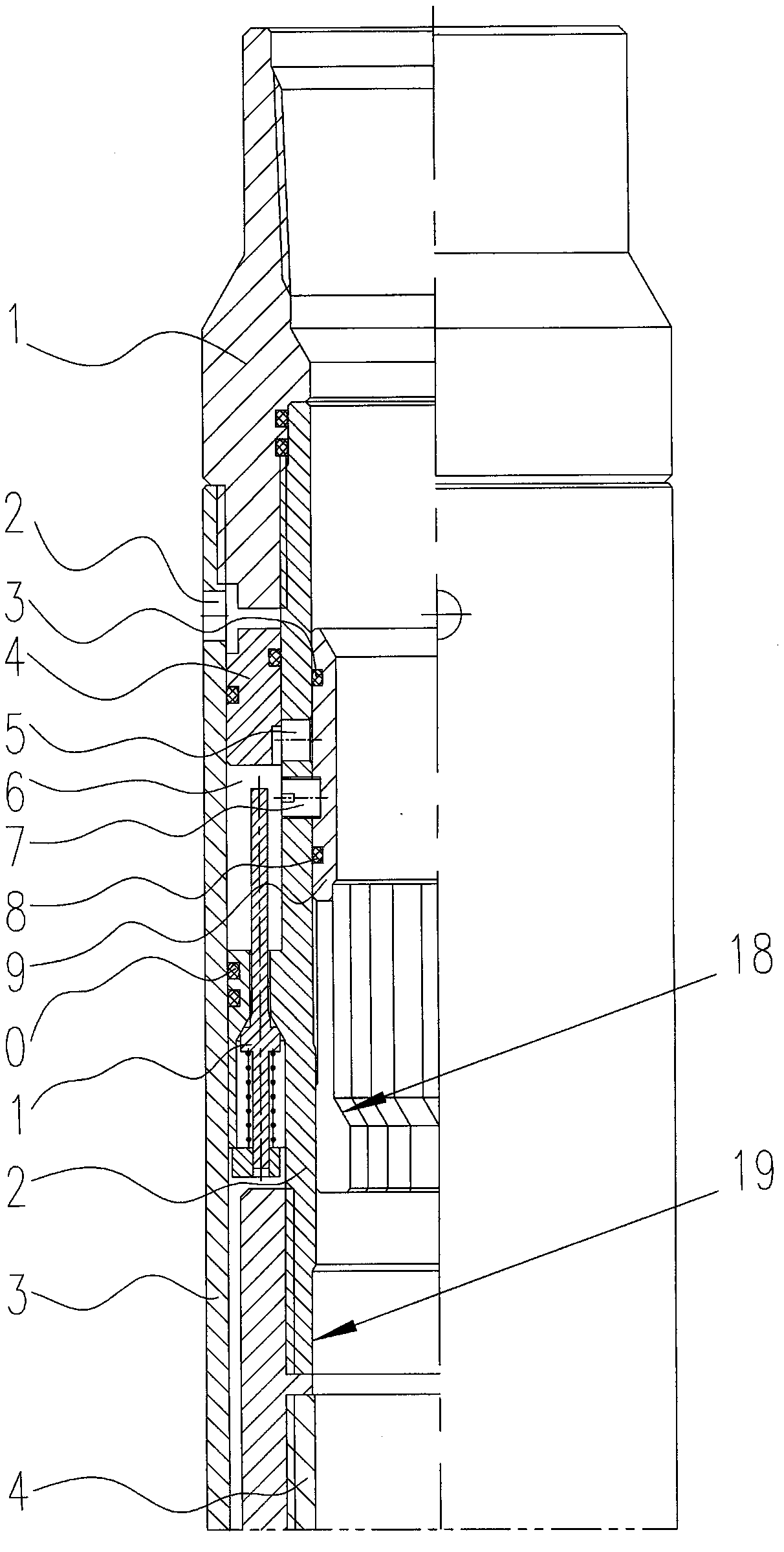

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] The embodiment of the present invention includes an upper joint 1, a sliding sleeve upper sealing ring 3, a piston 4, a control pin 7, a sliding sleeve lower sealing ring 8, a sliding sleeve 9, an upper sealing ring 10, a one-way valve 11, a valve body 12, a seal Sealing cylinder 13, inner pipe 14, rubber cartridge 15, lower sealing ring 16, lower joint 17, the lower part of the valve body 12 is connected with the upper part of the inner pipe 14, and the valve body 12 has an inline through hole 5 on the lower side of the valve body 12 A one-way valve 11 is provided. The one-way valve 11 is a trigger-type one-way valve, which can prevent the lower fluid from flowing upwards. The lower fluid can only flow upwards after being triggered by the upper part. The piston 4 is set outside the valve body 12, and the piston 4 is in the Above the inline thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com