Patents

Literature

1471results about How to "Undamaged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of dried beef

InactiveCN1817229AGreat tastePlay a role in health carePackaging under vacuum/special atmosphereFood preparationChemistryNutrient content

A process for preparing the dried beef includes such steps as washing, shaping, salting, stewing in the soup prepared from more than 20 flavourings and Chinese-medicinal materials, frying in the mixture of oil and water for controlling the temp of oil, parching, vacuum packaging and microwave sterilizing. Its advantages are good enjoyment to eat it, good taste and durable chewing.

Owner:王艺龙

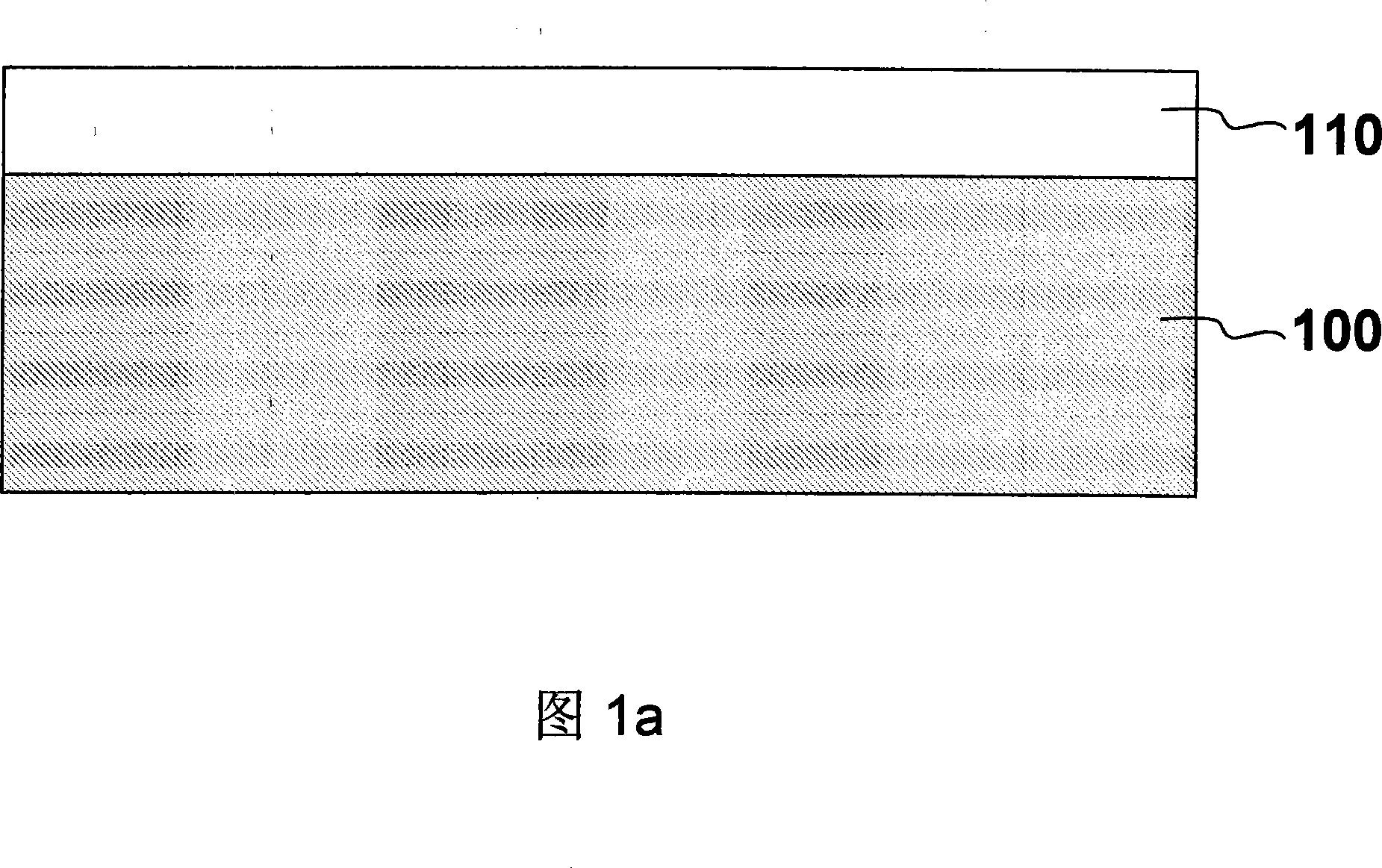

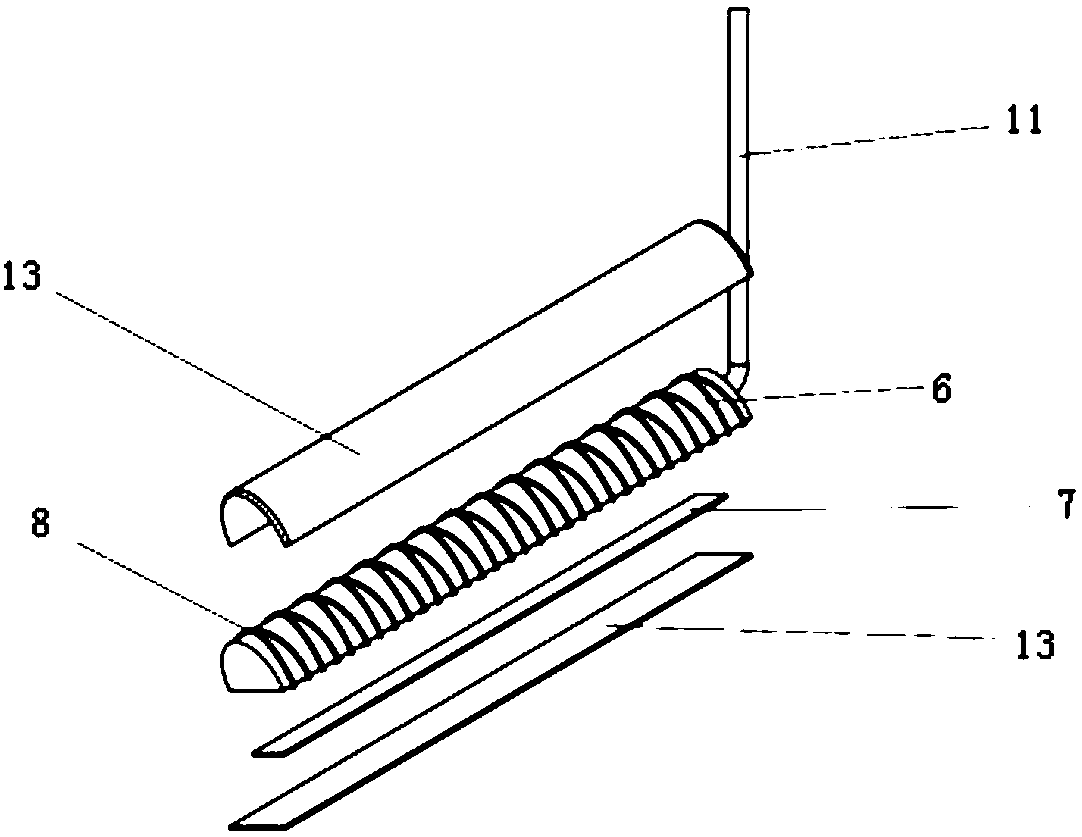

Method for supplementing lithium powder to lithium-ion battery negative plate

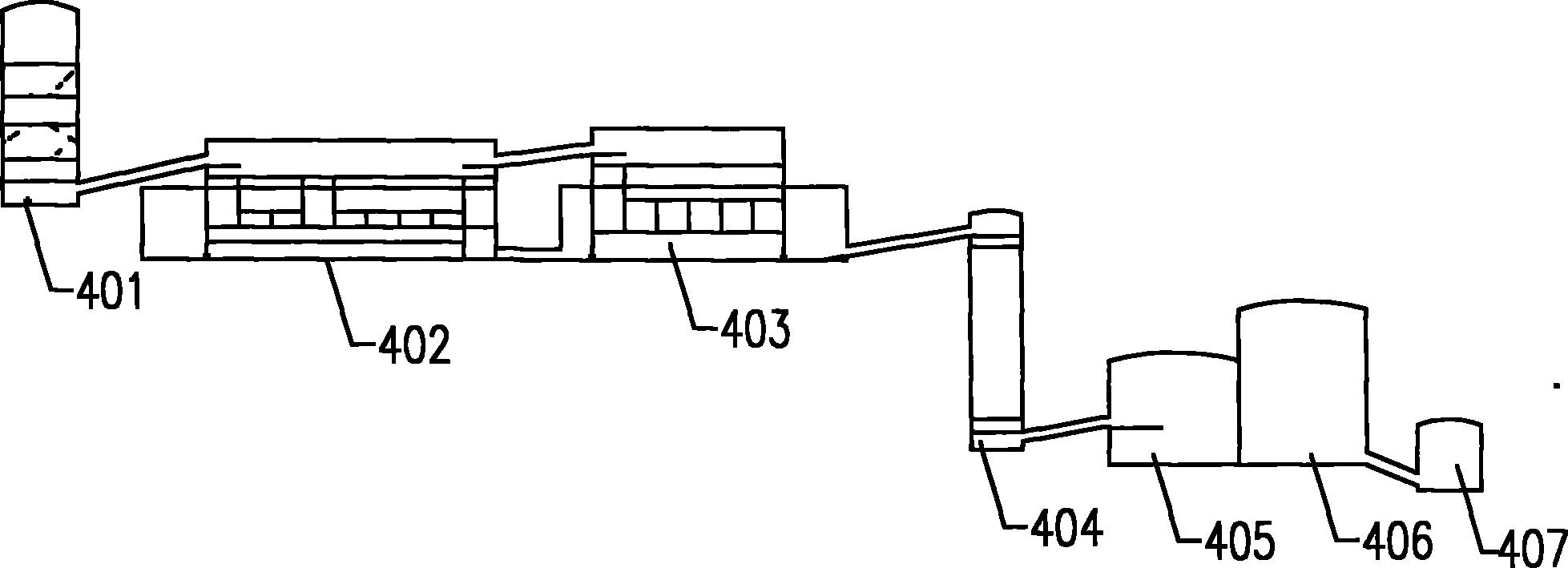

ActiveCN102779975AImprove first-time efficiencyIncrease battery capacityElectrode manufacturing processesElectric fieldLithium electrode

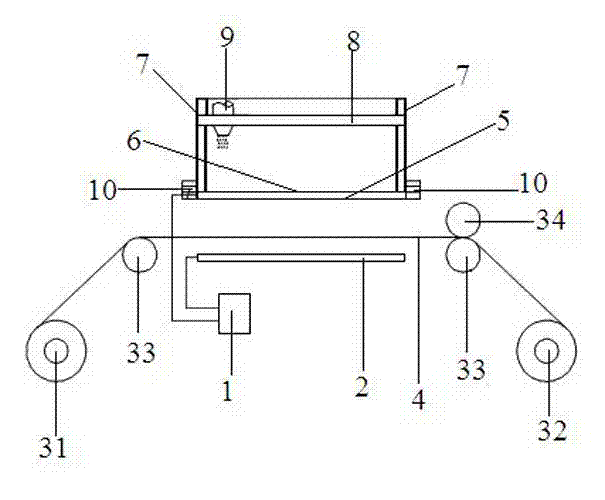

The invention belongs to the technical field of lithium-ion battery, and in particular relates to a method for supplementing lithium powder to a lithium-ion battery negative plate. The method comprises the following steps: a first step, putting the cold-pressed negative plate on an unwinding and rewinding mechanism, and putting lithium powder to a feeding mechanism above the negative plate; a second step, adding electric fields and opening the feeding mechanism, so that the lithium powder is adsorbed on the surface of the negative plate under the action of the electric fields; and a third step, rolling the negative plate adsorbed with the lithium powder. Compared with the prior art, the method can control the movement of the lithium powder to overcome the flotation of metal lithium powder in air through electrostatic effect provided by the electric fields, and can simultaneously control the addition of the lithium powder and the dispersion degree of the lithium powder on the negative plate, thereby uniformly, quantitatively and precisely dispersing the lithium powder on the surface of the negative plate. Besides, the whole process provided in the invention is only needed to be carried out in a drying environment without adding the lithium powder in a process of preparing slurry, has a simple manufacture process and low cost, and is suitable for large-scale production.

Owner:NINGDE AMPEREX TECH

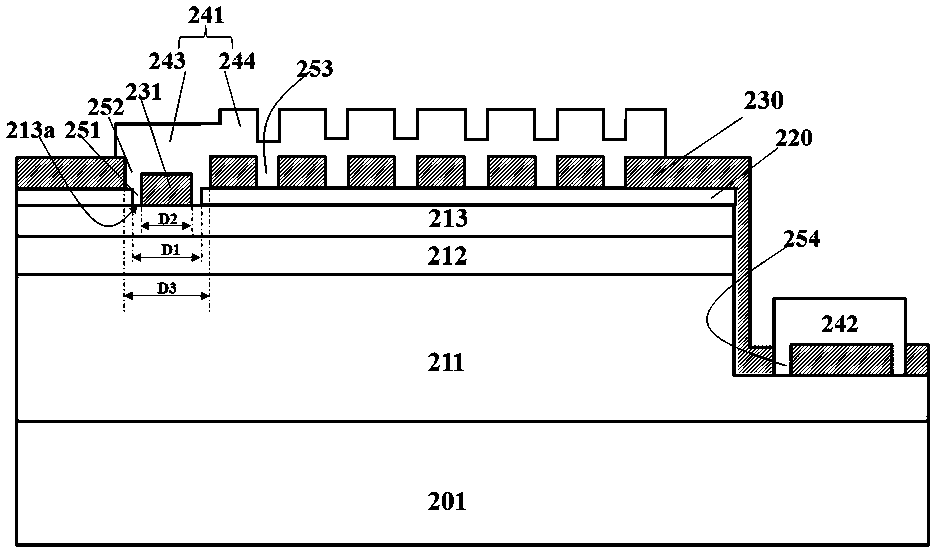

Chip, data communication method for chip, consumable container and imaging equipment

InactiveCN102231054AImprove reliabilityAvoid crackingElectrographic process apparatusPrintingExternal dataStructure of Management Information

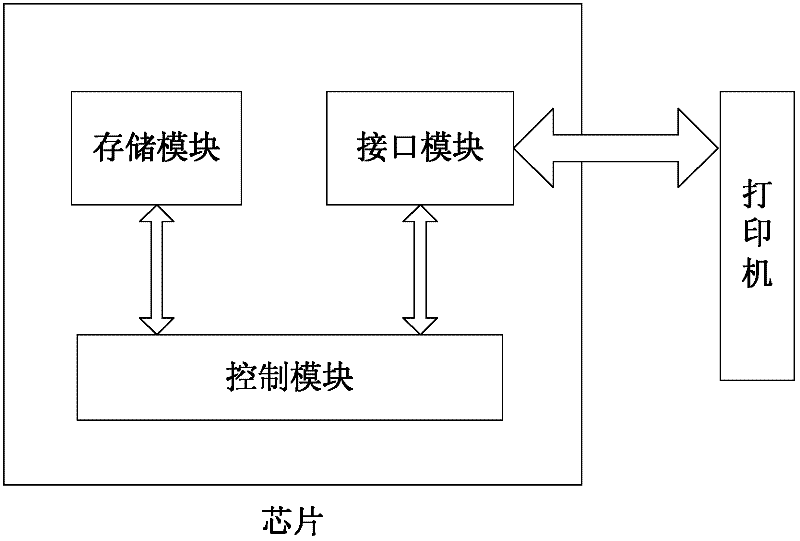

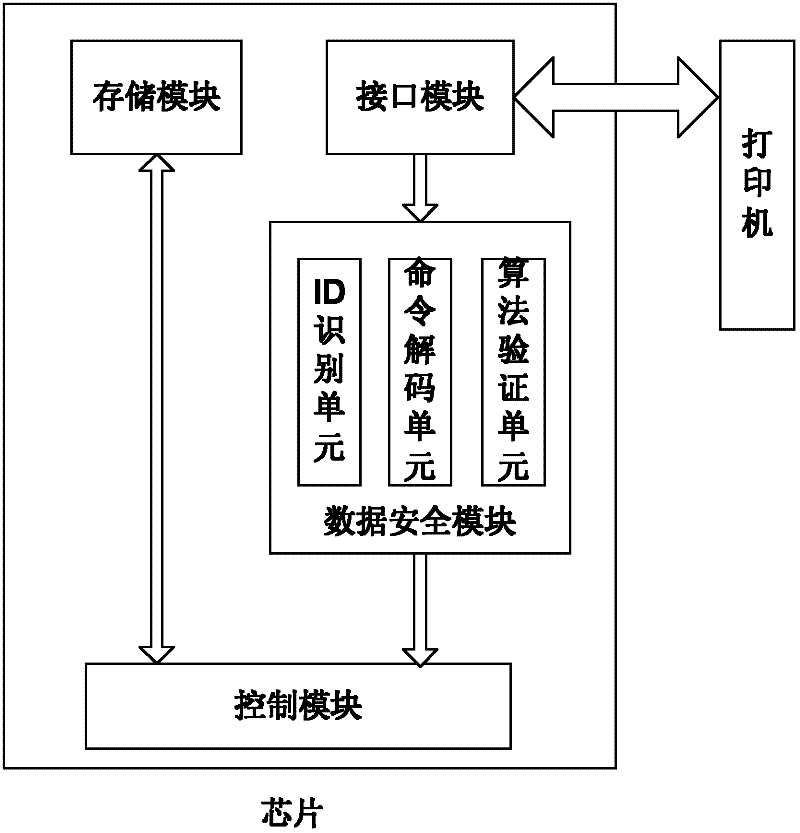

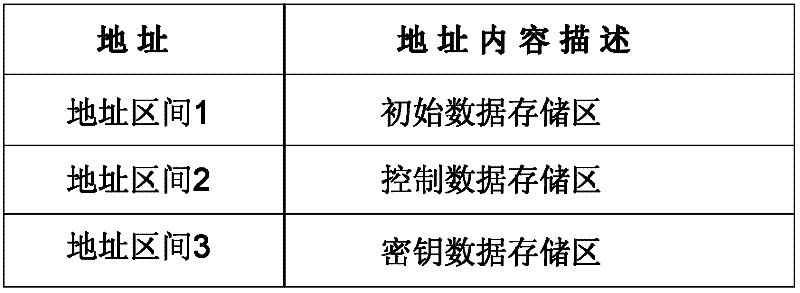

The invention provides a chip of a consumable container, which comprises a storage module, a control module, an interface module and a data safety module. The storage module is used for storing initial data, printing data, control data and key data; the interface module is used for realizing data communication between the storage module and the control module; the data safety module is respectively connected with the interface module and the control module, and is used for identifying a type and a content of data communicated between a printer and the chip, encrypting matched data in a selected safe mode and decrypting the data; the control module is connected with the storage module and is used for controlling data communication between the chip and the printer and the access operation of the data of the storage module and external data and sending a corresponding control command to the chip according to a safety module processing result so as to realize data communication; and the same keys are stored in the printer and the chip. The invention also provides a data communication method for the chip, the consumable container with the chip structure, and imaging equipment with the consumable container. The safety of the communication data of the chip can be protected.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

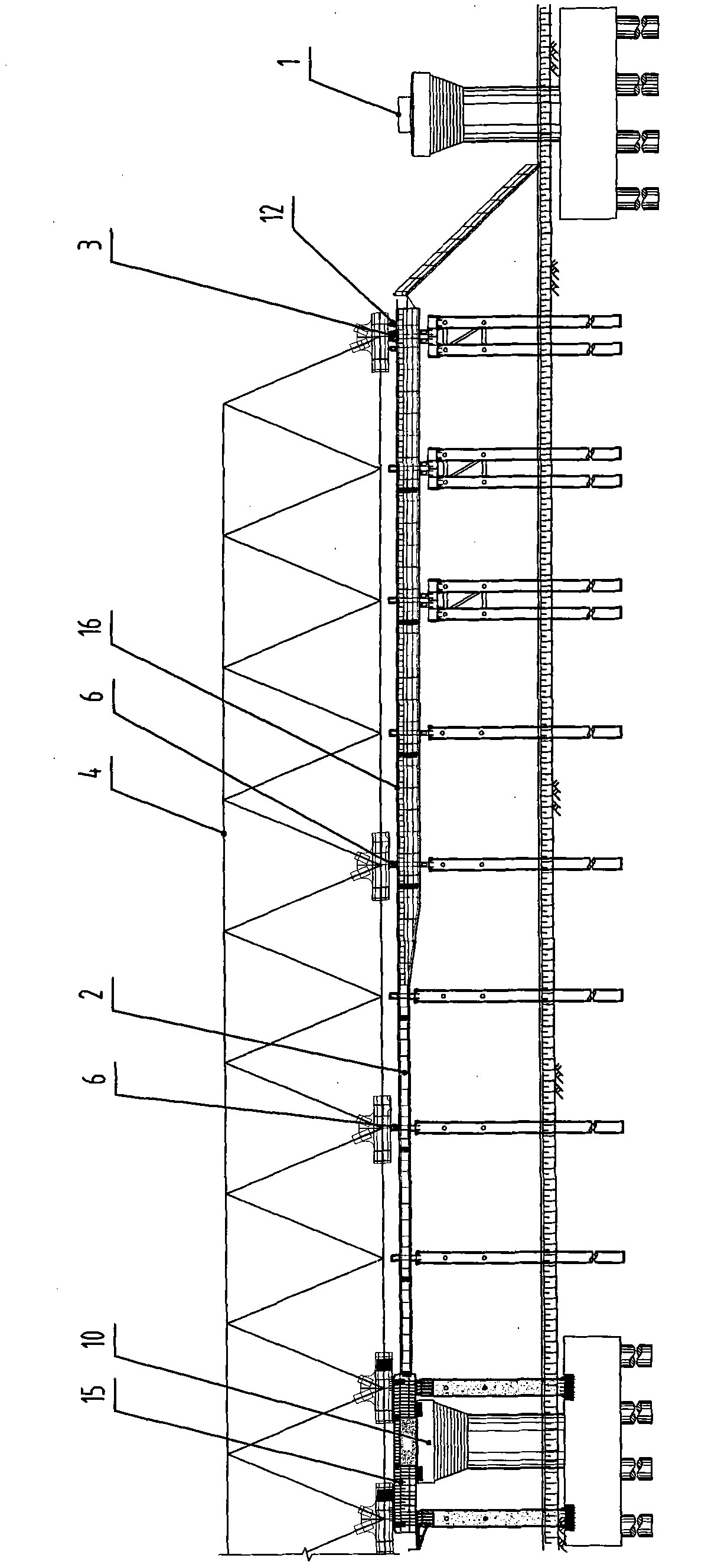

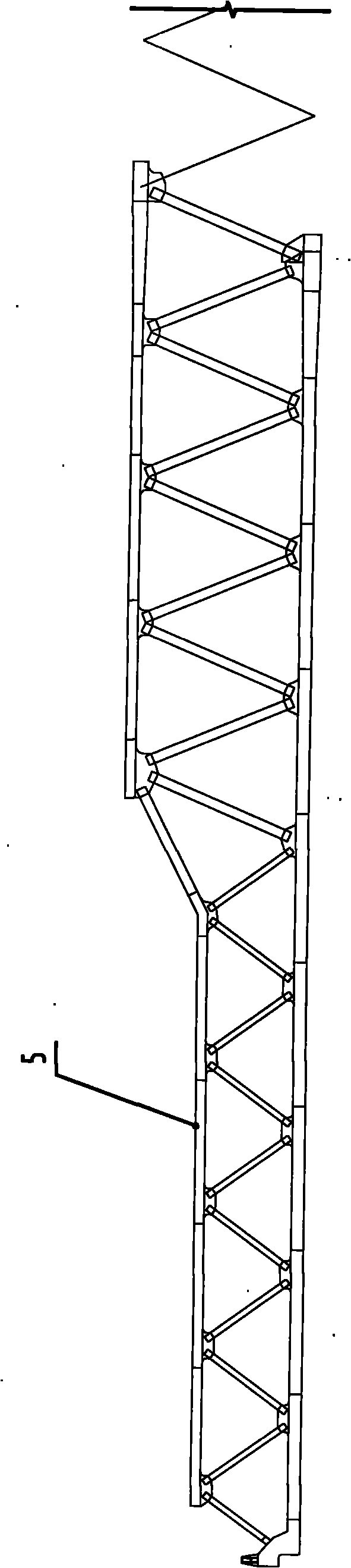

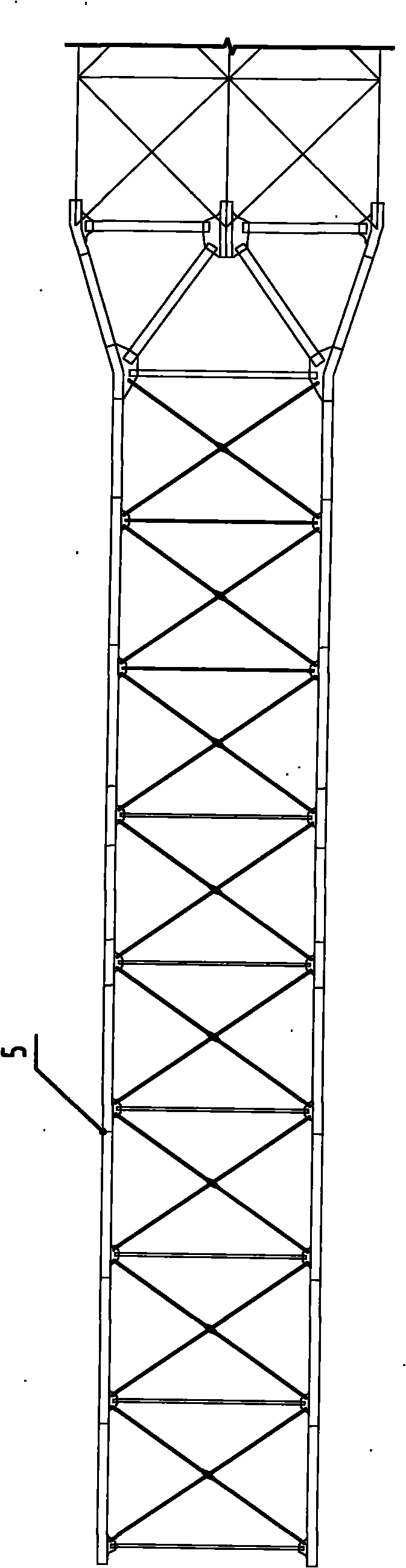

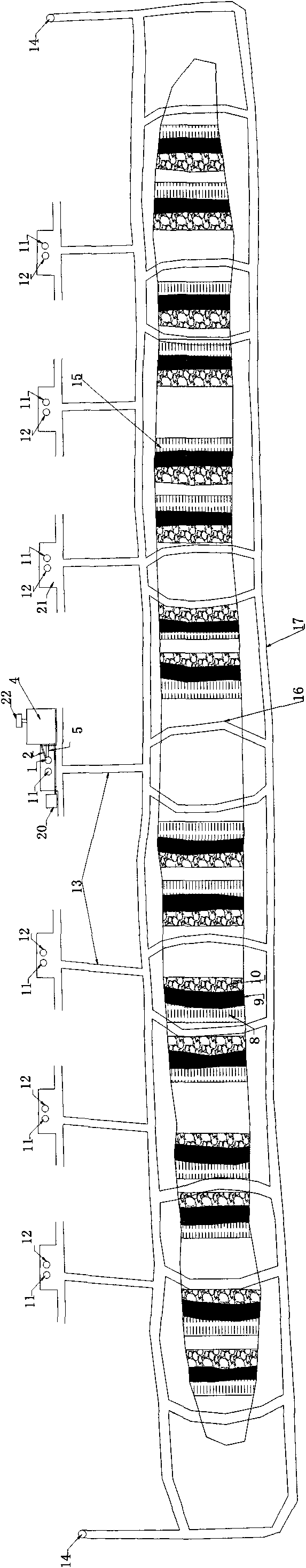

Multipoint synchronous push construction method for porous large-span continuous steel truss girder

ActiveCN101831874AEasy constructionReduce labor intensityBridge erection/assemblyControl systemEngineering

The invention discloses a multipoint synchronous push construction method for a porous large-span continuous steel truss girder, which comprises the following steps of: (1) assembling a steel truss girder assembling platform and a push slideway in a shoreside bridge pier position; (2) assembling a section of steel truss girder and a guide girder on the steel truss girder assembling platform; (3) installing a vertical jack for carrying out support conversion on the steel truss girder and then installing a continuous push jack, a steel strand and an electrohydraulic integrated control system; (4) operating the electrohydraulic integrated control system for carrying out push operation on the steel truss girder; and (5) after the push operation of the section of steel truss girder is finished, continuously assembling the steel truss girder on the steel truss girder assembling platform, carrying out next push operation, repeating the step for circulating operation and finishing the push construction of the porous large-span steel truss girder. The invention has the advantages of short construction period, safe construction, quality guarantee, low cost, and the like, realizes the push operation of the large-span steel truss girder, saves the construction cost, and reduces the pollution to a river channel.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

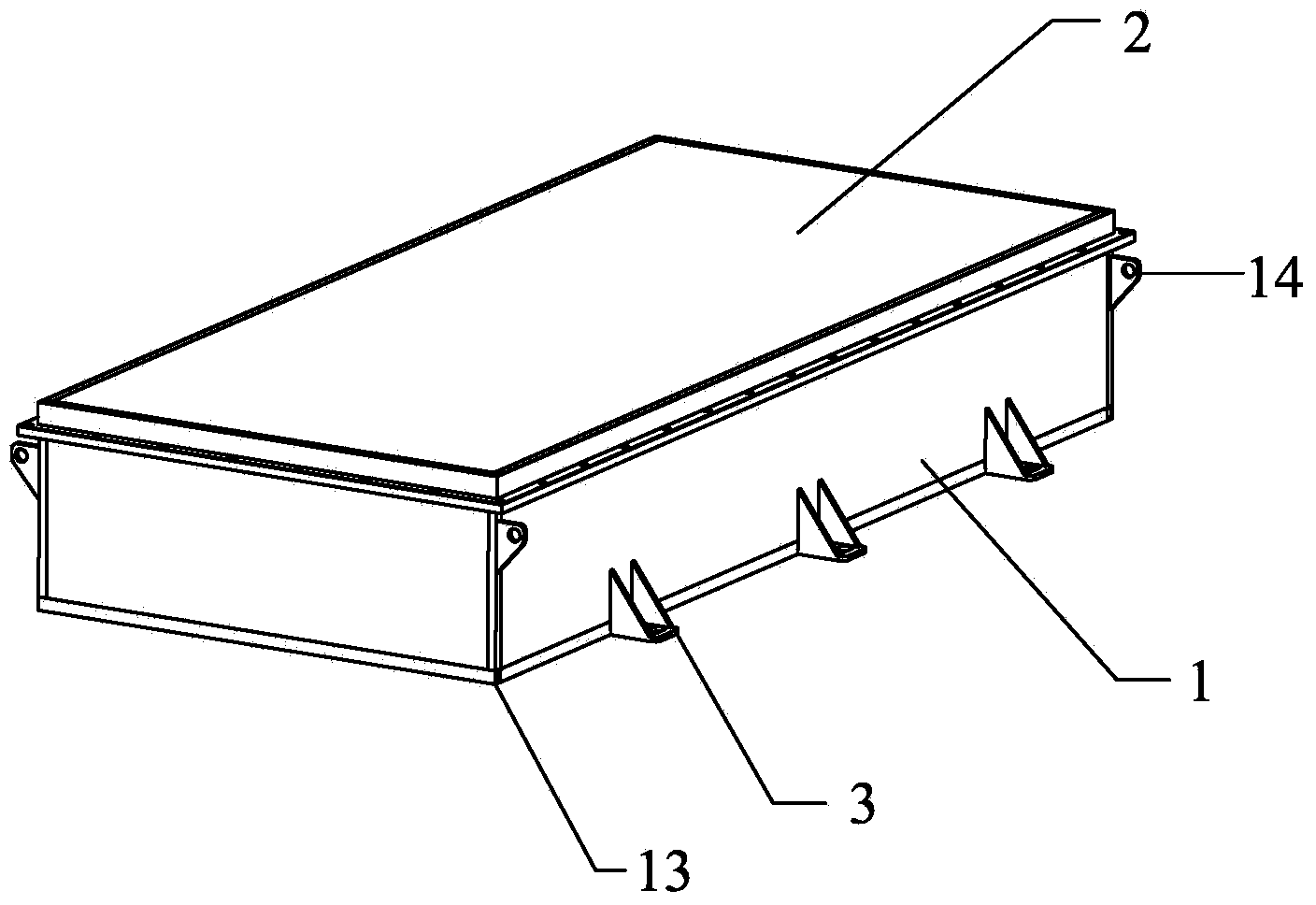

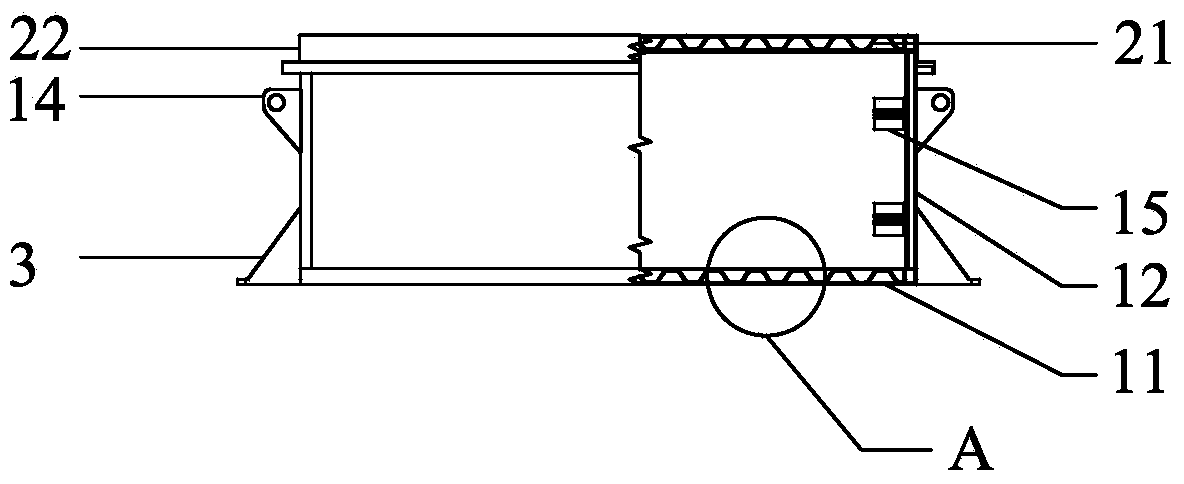

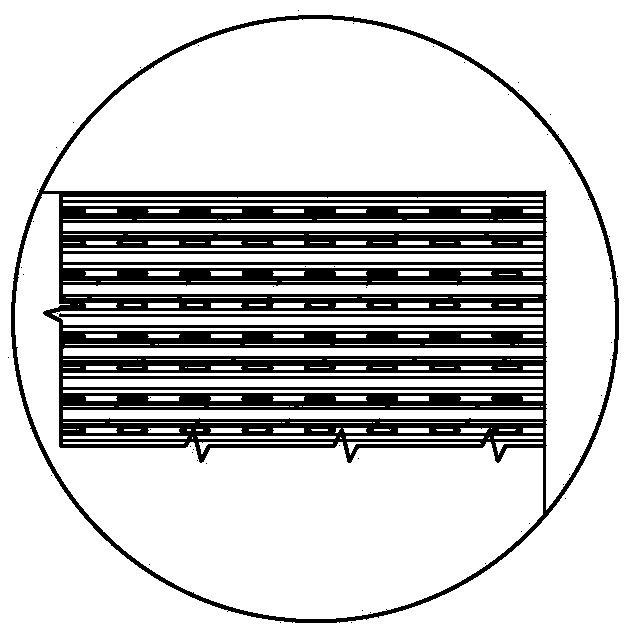

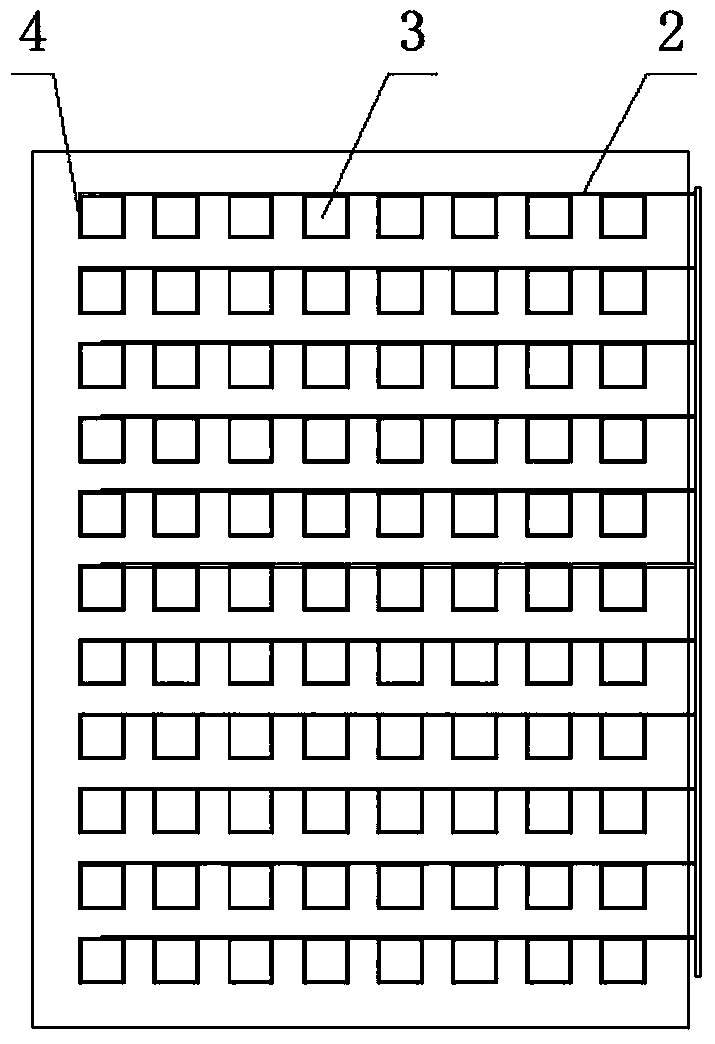

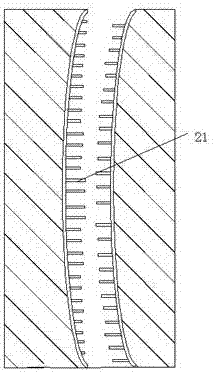

Corrugated sandwich protective structure of battery box of electric vehicle

InactiveCN103730616AUndamagedFree from destructionElectric propulsion mountingVehicle sub-unit featuresAutomotive batteryEngineering

The invention discloses a corrugated sandwich protective structure of a battery box of an electric vehicle. The protective structure comprises a box body and a box cover, wherein the box body is not closed at top, is composed of a baseplate and a baseplate wallboard fixed around the baseplate and is used for accommodating batteries; the box cover comprises a top plate and a top-plate wallboard fixed around the top plate, and the box cover and the box body are buckled so as to form a closed space. The protective structure is characterized in that the baseplate and the baseplate wallboard are respectively made of a corrugated sandwich protective plate. According to the invention, the box body and the box cover are made of the corrugated sandwich protective plates, so that the batteries can be prevented from being damaged; the corrugated sandwich protective structure has the advantages of high specific stiffness, high specific strength, high fatigue life, strong impact resistance and shock resistance, good impacting energy absorption property, light weight, and the like, thereby facilitating the promotion and application of electric vehicles and passenger cars.

Owner:DALIAN UNIV OF TECH

Method for improving solid content of catalytic cracking catalyst slurry

ActiveCN101134906ASimple structureHigh solid contentCatalytic crackingCatalyst activation/preparationMolecular sieveColloid

The present invention is method of raising solid content in catalytic cracking catalyst slurry. The method includes mixing clay, molecular sieve slurry, aluminum-containing binder, pseudo boehmite and inorganic acid to form catalyst slurry and the subsequent spray drying. It features that the addition of inorganic acid before adding pseudo boehmite and the molecular sieve, and the addition of inorganic acid after adding kaolin and aluminum-containing binder or into the aluminum-containing binder. The present invention can raise the solid content in catalyst slurry to over 40 % to short the colloid forming time greatly, raise the catalyst producing efficiency and lower catalyst producing cost while ensuring the wear strength of catalyst. At the same time, the catalyst has great pore volume, high micro reaction activity and improved comprehensive reaction performance.

Owner:PETROCHINA CO LTD

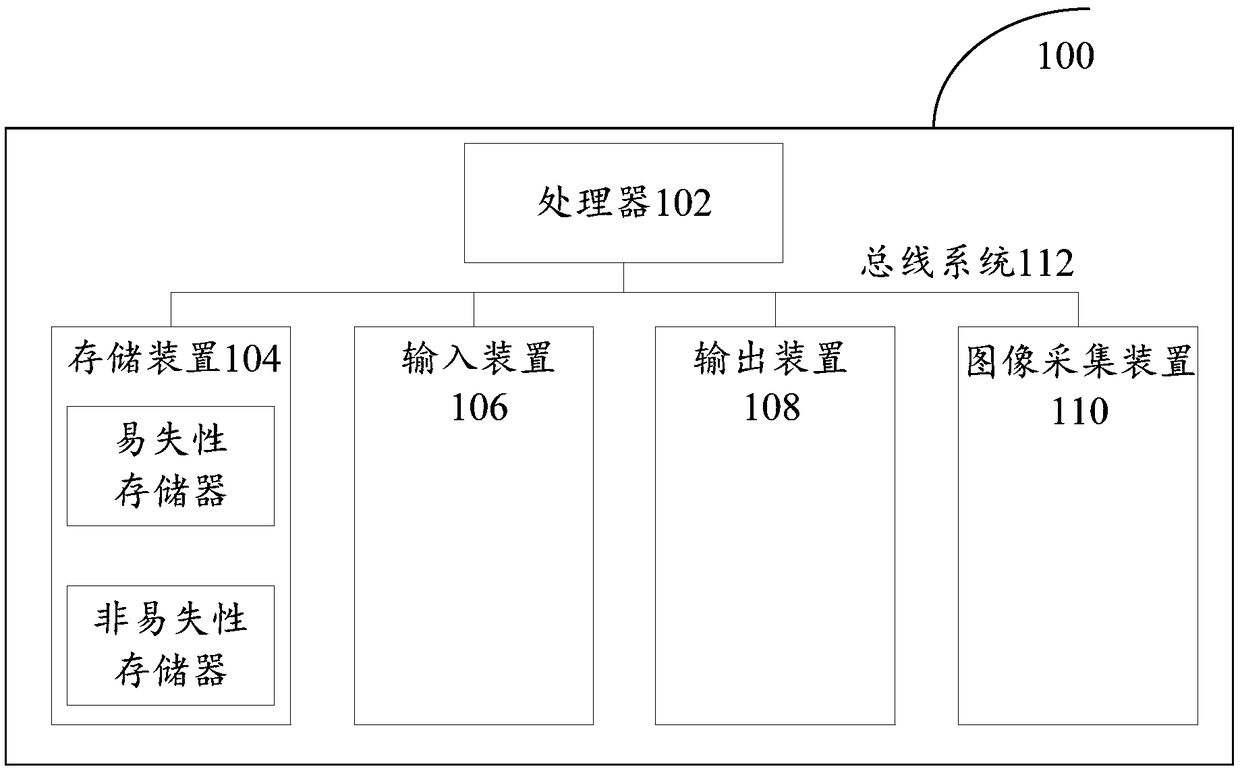

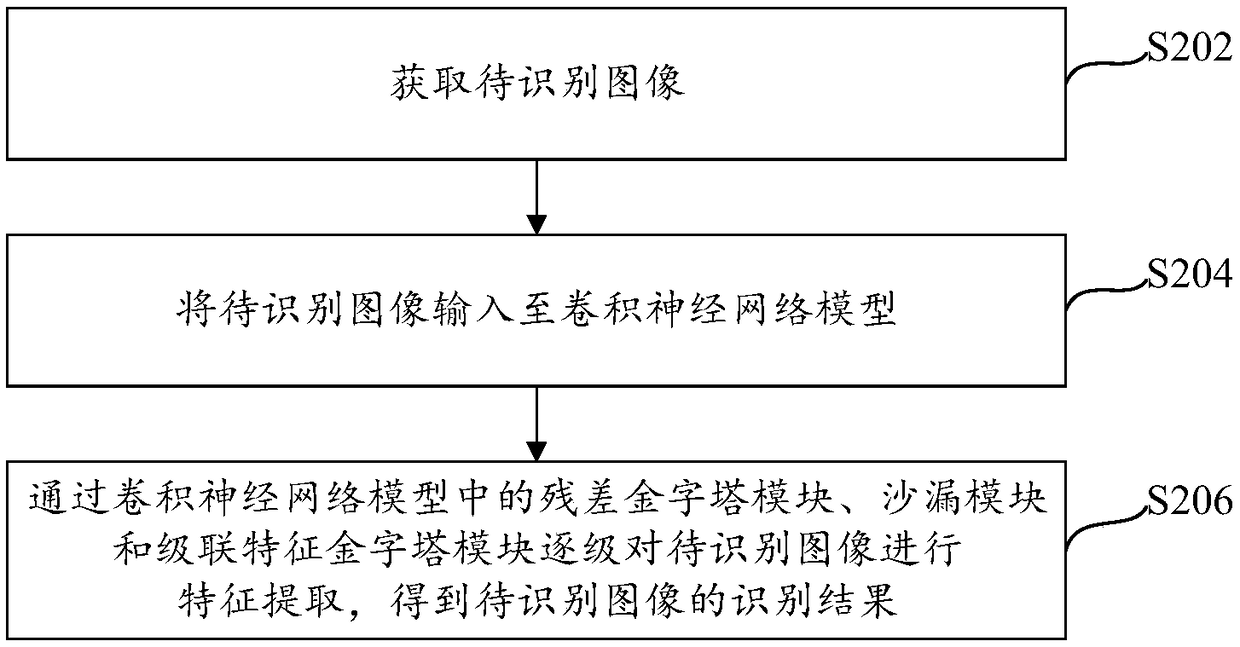

Image recognition method, device and system

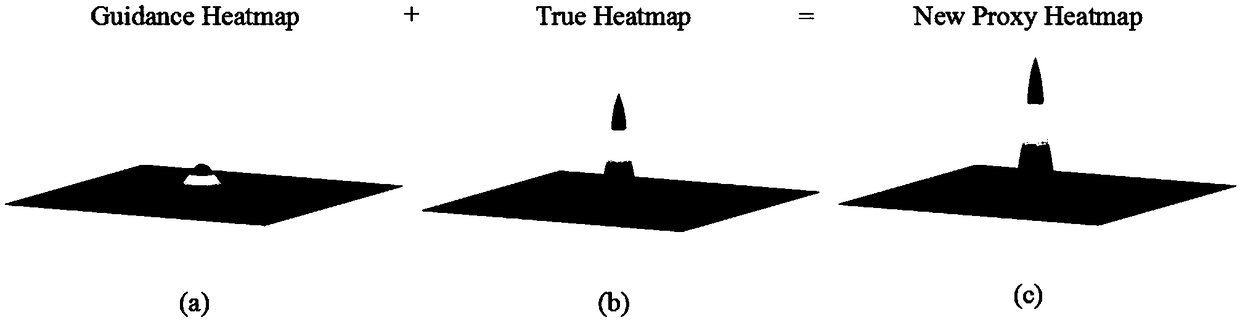

ActiveCN108764133AImprove accuracyUndamagedCharacter and pattern recognitionFeature extractionNetwork model

The invention provides an image recognition method, device and system, and relates to the technical field of image recognition. The method includes the step of acquiring an image to be recognized; inputting the image to be recognized into a convolution neural network model, wherein the convolution neural network model includes a translation invariance pyramid residual module, a hourglass module and a cascaded pyramid network; extracting the features of the image to be recognized step by step by the translation invariance pyramid residual module, the hourglass module and the cascaded pyramid network of the convolution neural network model to obtain the recognition result of the image to be recognized, wherein the identification result includes a position of at least one target point. The invention can recognize based on the image taken by the monocular camera, and can improve the accuracy of image recognition.

Owner:BEIJING KUANGSHI TECH

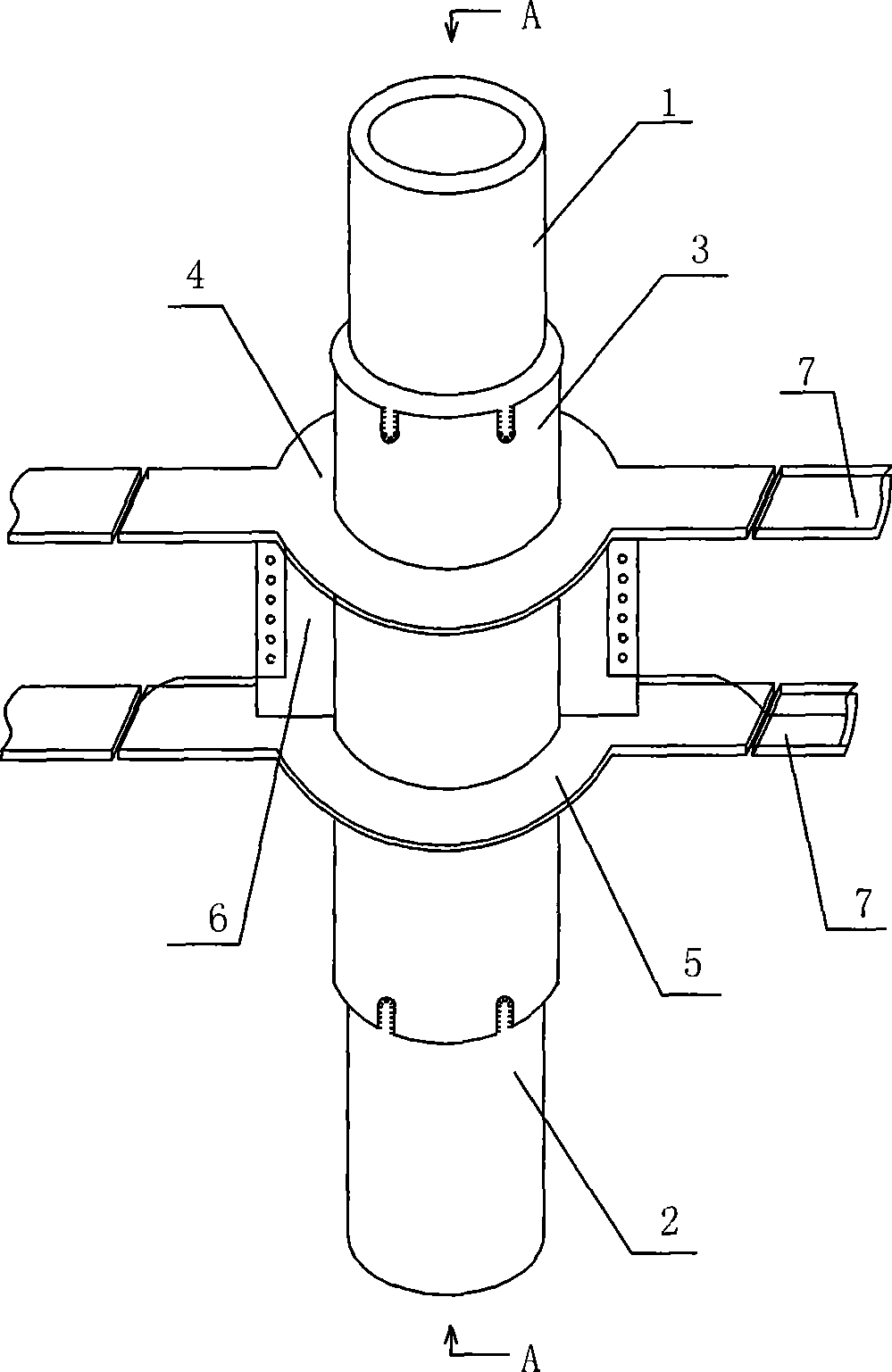

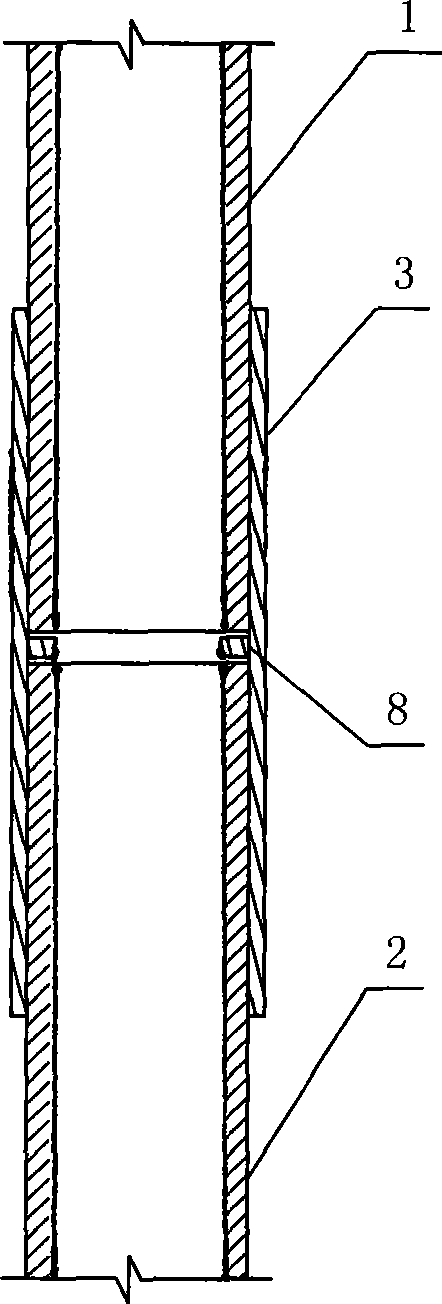

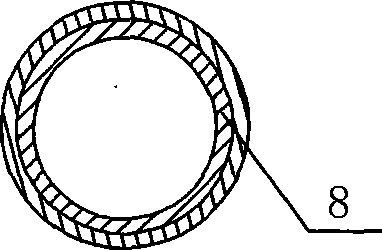

Steel pipe concrete segment type coat node and its construction method

InactiveCN101476348AMeet the needs of strong nodes and weak membersIncrease stiffnessBuilding constructionsUltimate tensile strengthMechanical property

The invention relates to a concrete-filled steel tube sectional type sleeve gusset and a construction method thereof, which relate to a connecting gusset for connecting a concrete-filled steel tube column and a girder in civil engineering and a construction method thereof. The concrete-filled steel tube sectional type sleeve gusset comprises the concrete-filled steel tube column and the steel girder which is connected with the column, wherein the concrete-filled steel tube column is formed by filling concrete into a steel tube; the steel tube is formed by connecting an upper column steel tube and a lower column steel tube through a connecting sleeve; the connecting sleeve and the lower column steel tube are in split type; an upper reinforcement ring plate and a lower reinforcement ring plate are arranged outside the connecting sleeve; and a vertical connecting plate is arranged between the upper reinforcement ring plate and the lower reinforcement ring plate. The connecting sleeve and the lower column steel tube in the concrete-filled steel tube sectional type sleeve gusset are in split type, so that the concrete casting strength of the lower column steel tube and the upper column steel tube can be different under the condition of construction, thereby the requirement of strong gussets and weak members can be met. Moreover, the concrete-filled steel tube sectional type sleeve gusset has the advantages of concise and definite force transferring path, large gusset rigidity, high bearing capacity, superior mechanical property, good anti-seismic performance and simple and convenient processing and manufacture.

Owner:DAQING GASOLINEEUM INST

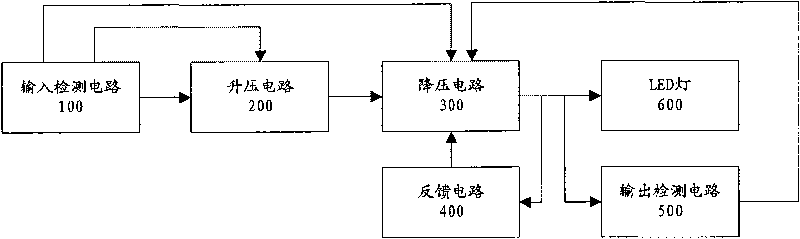

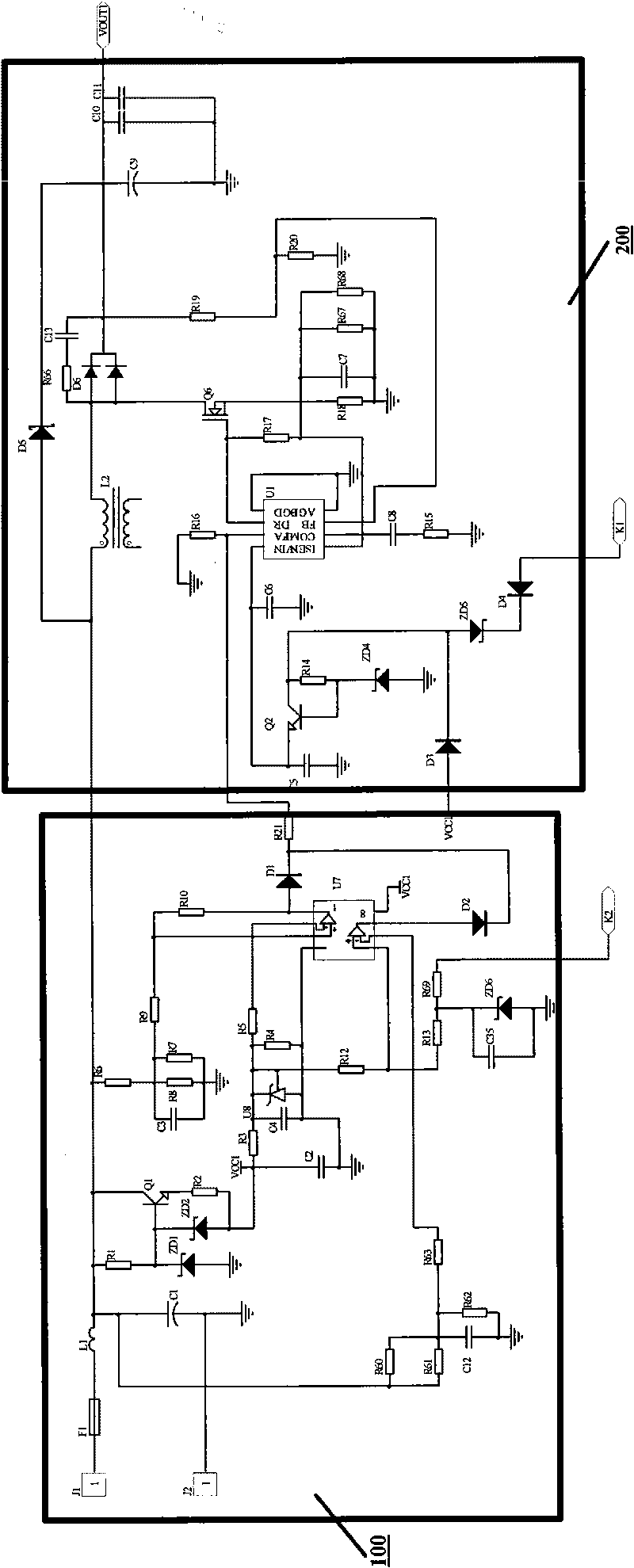

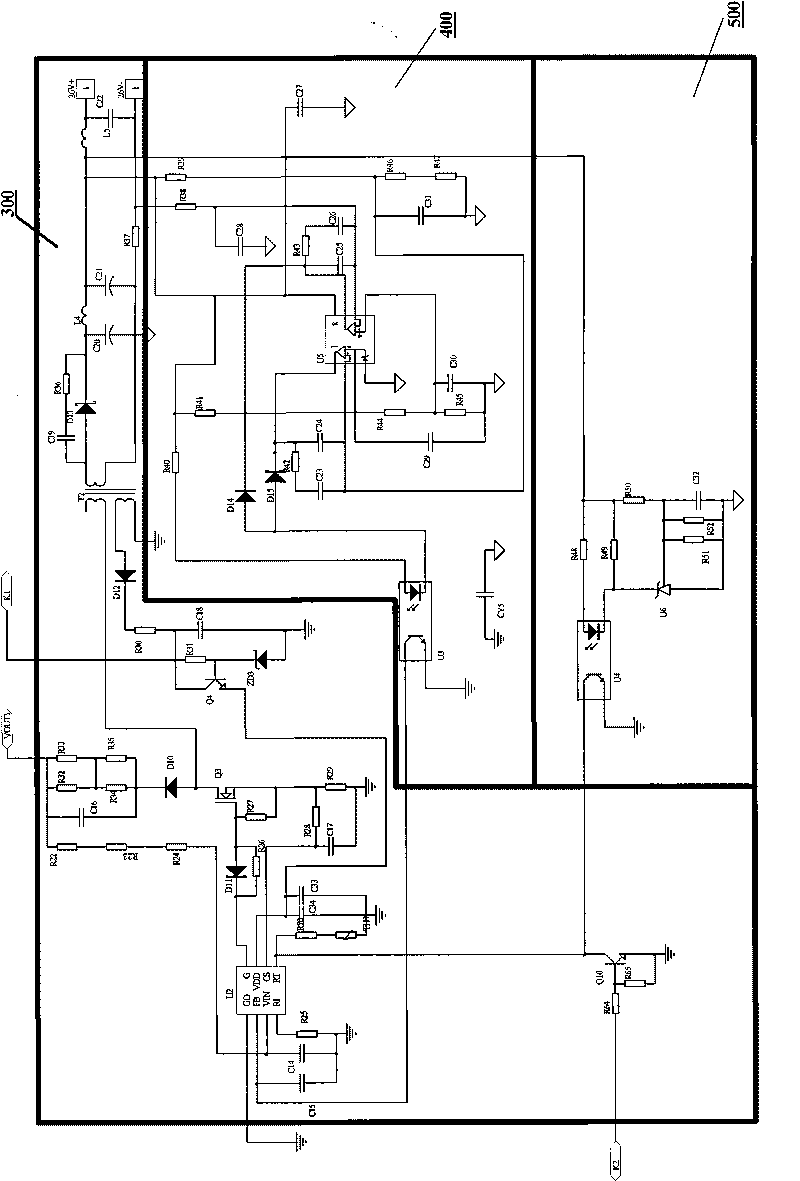

LED direct-current input control circuit

InactiveCN101711070AAvoid being damagedUndamagedApparatus without intermediate ac conversionElectric light circuit arrangementInput controlFeedback circuits

The invention relates to an LED direct-current input control circuit which comprises an input detecting circuit, a voltage increasing circuit and a voltage decreasing circuit which are connected in sequence and also comprises a feedback circuit. The voltage increasing circuit and the voltage decreasing circuit are used for increasing and decreasing the voltage of an inputted direct-current signaland outputting the voltage to supply power to an LED lamp, and the feedback circuit is connected with the voltage decreasing circuit and is used for controlling the constant voltage and the constant current of an output signal. After detecting that the inputted direct-current signal has overvoltage, the input detecting circuit outputs a first overvoltage shutting-off signal to the voltage increasing circuit so as to directly output the inputted direct-current signal to the voltage decreasing circuit to decrease the voltage and supply power to the LED lamp, and after detecting that the inputted direct-current signal has undervoltage, the input detecting circuit outputs an undervoltage shutting-off signal to the voltage increasing circuit and the voltage decreasing circuit so as to shut offthe voltage increasing circuit and the voltage decreasing circuit and carry out undervoltage protection to the voltage increasing circuit and the voltage decreasing circuit. The LED direct-current input control circuit can realize the direct-current input of low voltage and wide range and has the input undervoltage and overvoltage function, the constant current outputting function and the output overvoltage protection function.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Method for preparing fresh grosvener siraitia freeze-dried superfine powder

InactiveCN101720894AIncrease profitPreserve active ingredientsFood shapingFood preparationFreeze-dryingPre treatment

The invention discloses a method for preparing fresh grosvener siraitia freeze-dried superfine powder, relates to processing technology for fruits and vegetables, and provides a method for preparing fresh grosvener siraitia freeze-dried superfine powder, which combines vacuum freeze drying technology with superfine grinding technology to protect effective components of the grosvener siraitia and realize full utilization of the grosvener siraitia. The method comprises the following steps: carrying out pretreatments such as selecting, cleaning, sterilization and the like on the fresh grosvener siraitia; putting the grosvener siraitia on a tray for prefreezing after crushing; putting the prefreezed grosvener siraitia in a vacuum environment for heating and drying at the temperature of between 40 and 120 DEG C; controlling the moisture content of the freeze-dried product to less than 6 percent; and finally, grinding the dried grosvener siraitia until the particle size of the powder reaches 10 to 40 meshes, and then carrying out superfine grinding on the powder by a superfine grinding machine until the particle size of the powder reaches less than 40 microns. Because the product is superfine powder, thus, the fresh grosvener siraitia freeze-dried superfine powder has the advantages of small powder particle, big surface area, delicate taste, quicker absorption and wider application, the superfine powder can be eaten directly, and can also be used as the raw materials of other foods, health-care products, medicaments and cosmetics.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

Method for cleaning glass substrate for coating

ActiveCN102649625AEfficient removalHighly activated atomic activityVacuum evaporation coatingSputtering coatingCooking & bakingStrong acids

The invention discloses a method for cleaning a glass substrate for coating and belongs to the technical field of preparation methods of materials. According to the cleaning method, the cleaning is realized by hydrogen peroxide ultrasound, ultrapure water ultrasound, acetone ultrasound, ethanol ultrasound, drying, wiping, baking and plasma cleaner; a cleaned glass substrate is obtained; and finally, the surface of the glass substrate can be coated. According to the cleaning method provided by the invention, no strong acid or alkali is used, so that the damage to the surface of the glass can be avoided. The cleaning method is simple in operation and is lower in flow; no great cleaning device or much cleaning liquid is needed; and the space can be effectively saved and the cost, energy sources and the time can be saved.

Owner:北京鼎臣世纪超导科技有限公司

Artificial cultivation method of Collybia albuminosa

ActiveCN104255297AAchieving large-scale plantingIncrease productionCultivating equipmentsMushroom cultivationNutritive valuesFlavor

The invention discloses an artificial cultivation method of Collybia albuminosa and belongs to the technical field of artificial cultivation of wild fungi. The artificial cultivation method of Collybia albuminosa includes steps of termites farming, Collybia albuminosa breeding, Collybia albuminosa planting, fertilizer and water management and harvesting. The artificial cultivation method of Collybia albuminosa achieves large-scale cultivation of Collybia albuminosa by selecting high-quality breeds, simulating the wild conditions of Collybia albuminosa and making full use of the symbiotic relationship of Collybia albuminosa and termites. Under scientific management, the output is greatly improved, the quality is stable and unified, the cultivated Collybia albuminosa approaches those growing in the wild environment in terms of the nutritive value, the medicinal value, taste and flavor, protects the unique biological resource while meeting partial requirements of the market, and prevents the wild Collybia albuminosa from dying out due to over exploitation.

Owner:兴义市太阳雨食用菌栽培农民专业合作社

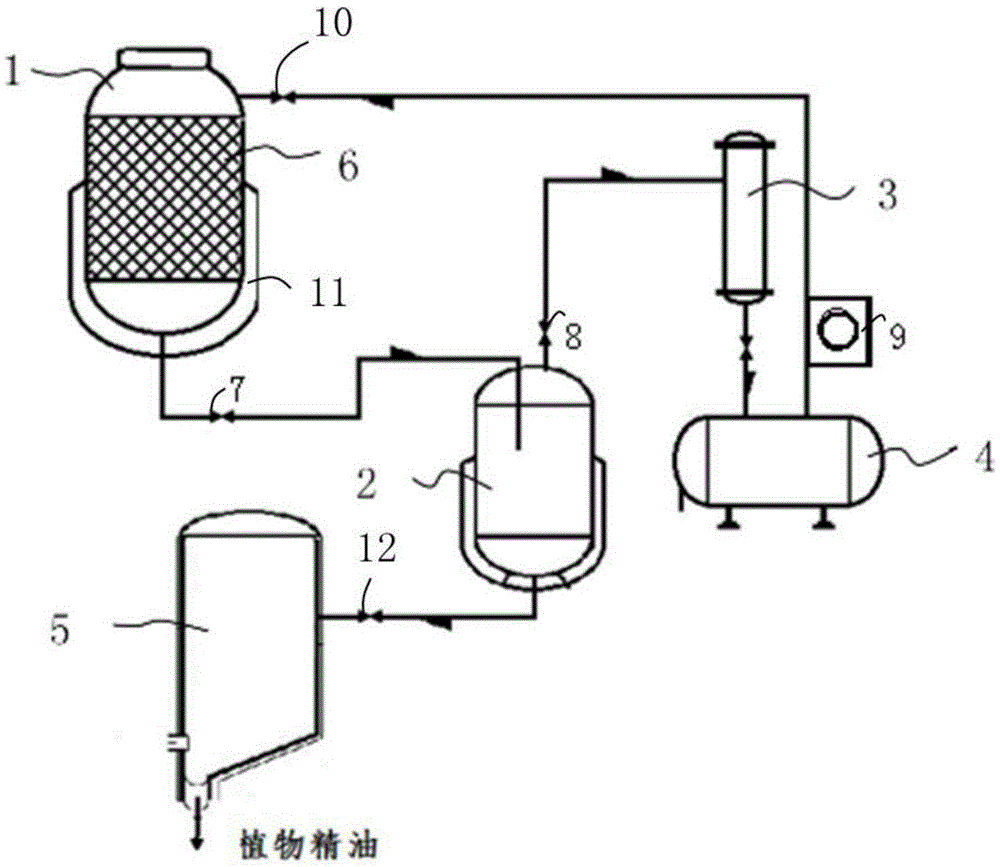

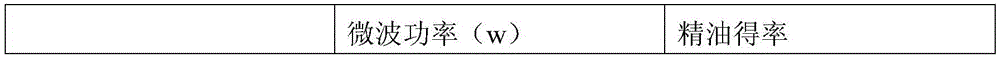

Microwave-assisted subcritical essential oil extracting method

InactiveCN105482897AUndamagedFast extraction rateEssential-oils/perfumesDistillation1,1,1,2-Tetrafluoroethane

The invention discloses a microwave-assisted subcritical essential oil extracting method. The microwave-assisted subcritical essential oil extracting method includes the steps that fresh plant tissues are frozen and then are smashed; 1,1,1,2-tetrafluoroethane is used as an extraction solvent and is led into the smashed plant tissues to perform microwave extraction; during microwave extraction, the extraction temperature is controlled to be 8-12 DEG C, the extraction pressure is controlled to be 0.8-6 Mpa, the microwave frequency is controlled to be 300-2400 MHZ, and the power is controlled to be 200-1200w; after a liquid phase in the system is separated out and microwave extraction is completed, the 1,1,1,2-tetrafluoroethane is recovered from the liquid phase, and the rest of the liquid phase is an essential oil stock solution; the essential oil stock solution is subjected to molecular distillation to obtain essential oil. By the adoption of the microwave-assisted subcritical essential oil extracting method, the essential oil free of any residual solvent can be obtained at lower temperature, the effective ingredients of the essential oil are not destroyed, and the natural quality of the essential oil can be kept to the most degree.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

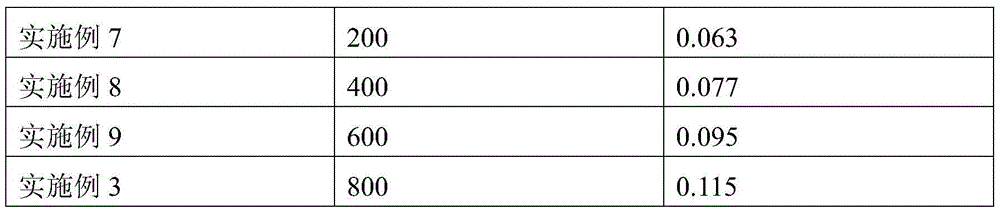

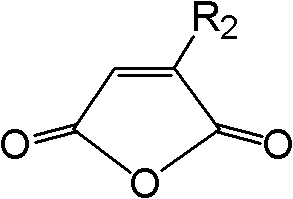

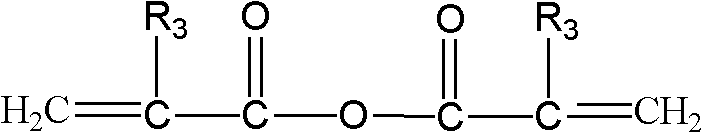

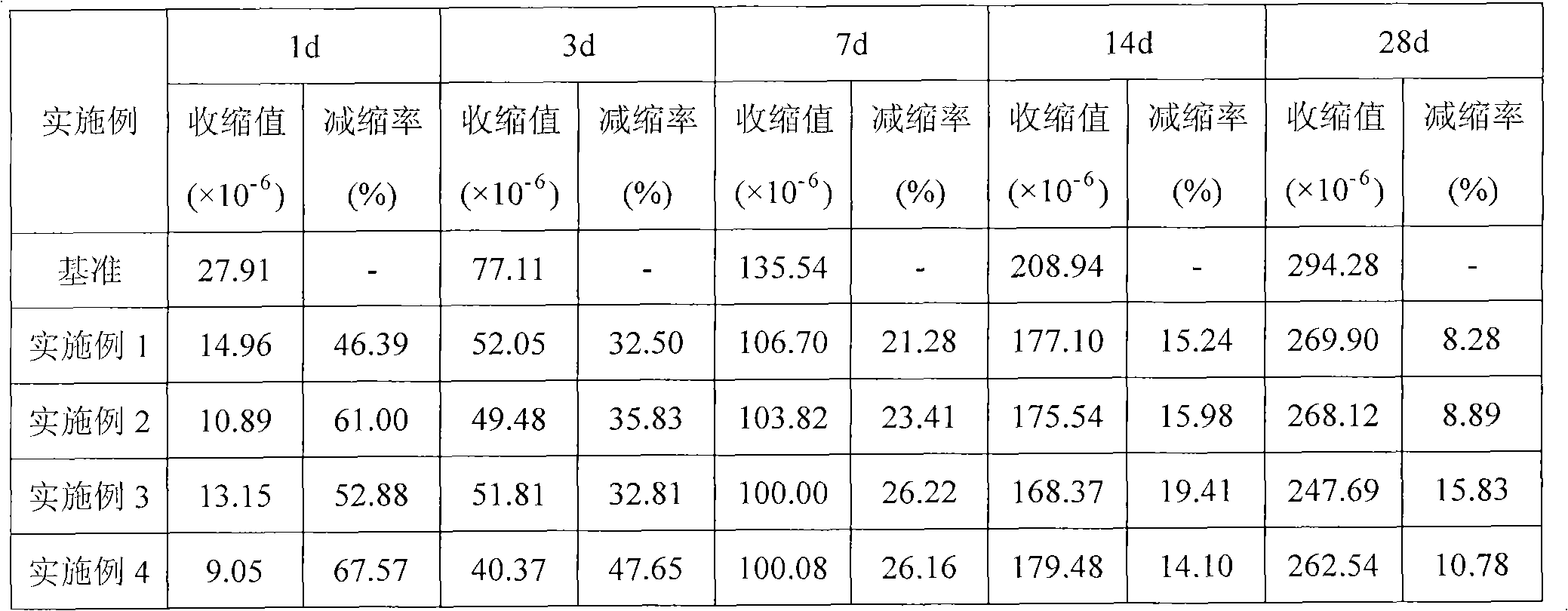

Method for preparing amide/imide type high-concentration polycarboxylic acid high-performance water reducer

The invention discloses a method for preparing an amide / imide type high-concentration polycarboxylic acid high-performance water reducer, which comprises the following: (1) a step of acylation reaction, which is to react unsaturated anhydride and monohydric alcohol amine to obtain an acylated product A; (2) a step of esterification, which is to perform the catalytic esterification of polyoxyalkylene glycol monoalkyl ether and unsaturated acid (anhydride) to obtain an esterified product B; (3) a step of copolymerization, which is to subject the acylated product A, the esterified product B and a sulfonic acid small monomer C to free radical copolymerization under the action of an initiator and a copolymerization regulator to obtain a copolymerized product at a concentration of 70 to 85 percent; and (4) a step of neutralization reaction, which is to regulate the pH value of the copolymerized product to 6 to 7 to obtain the polycarboxylic acid high-performance water reducer at a concentration of 70 to 85 percent. The method can regulate the performance of the product by controlling the structure of the product, avoid using solvent in a reaction process, and is safe, pollution-free andenvironmentally-friendly, and the obtained product is stable in performance and has high slump keeping performance and water reducing performance.

Owner:FUJIAN KZJ NEW MATERIALS CO LTD +1

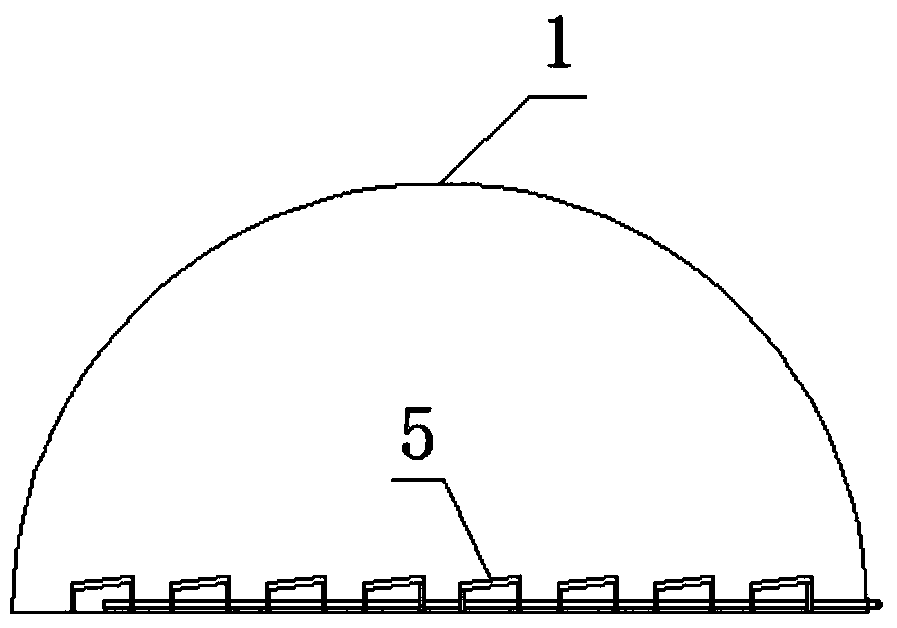

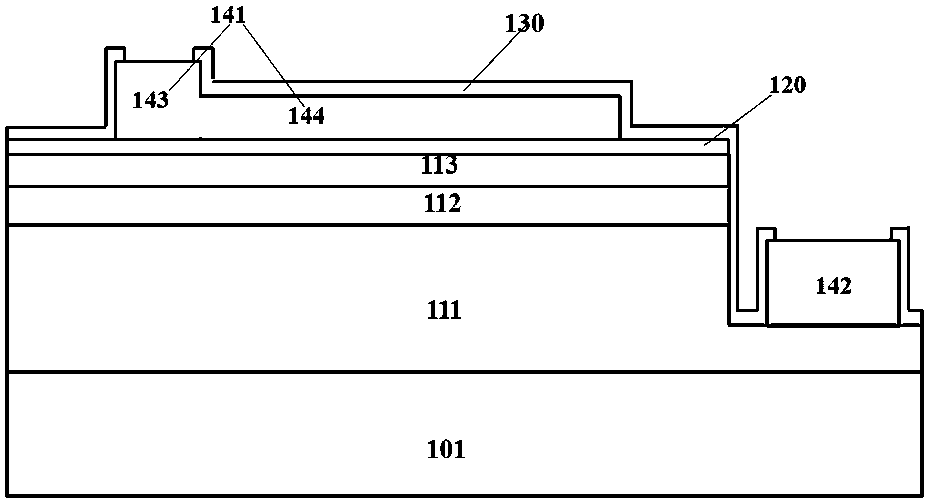

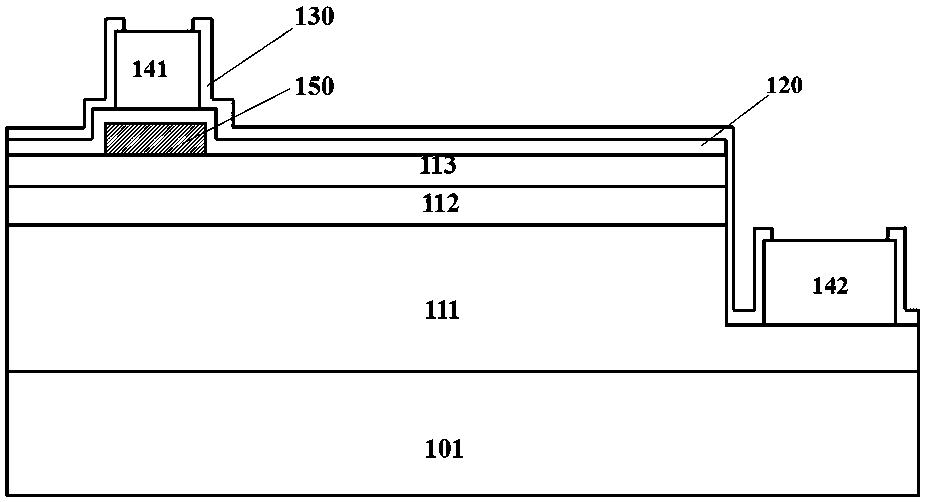

Light-emitting diode and manufacturing method thereof

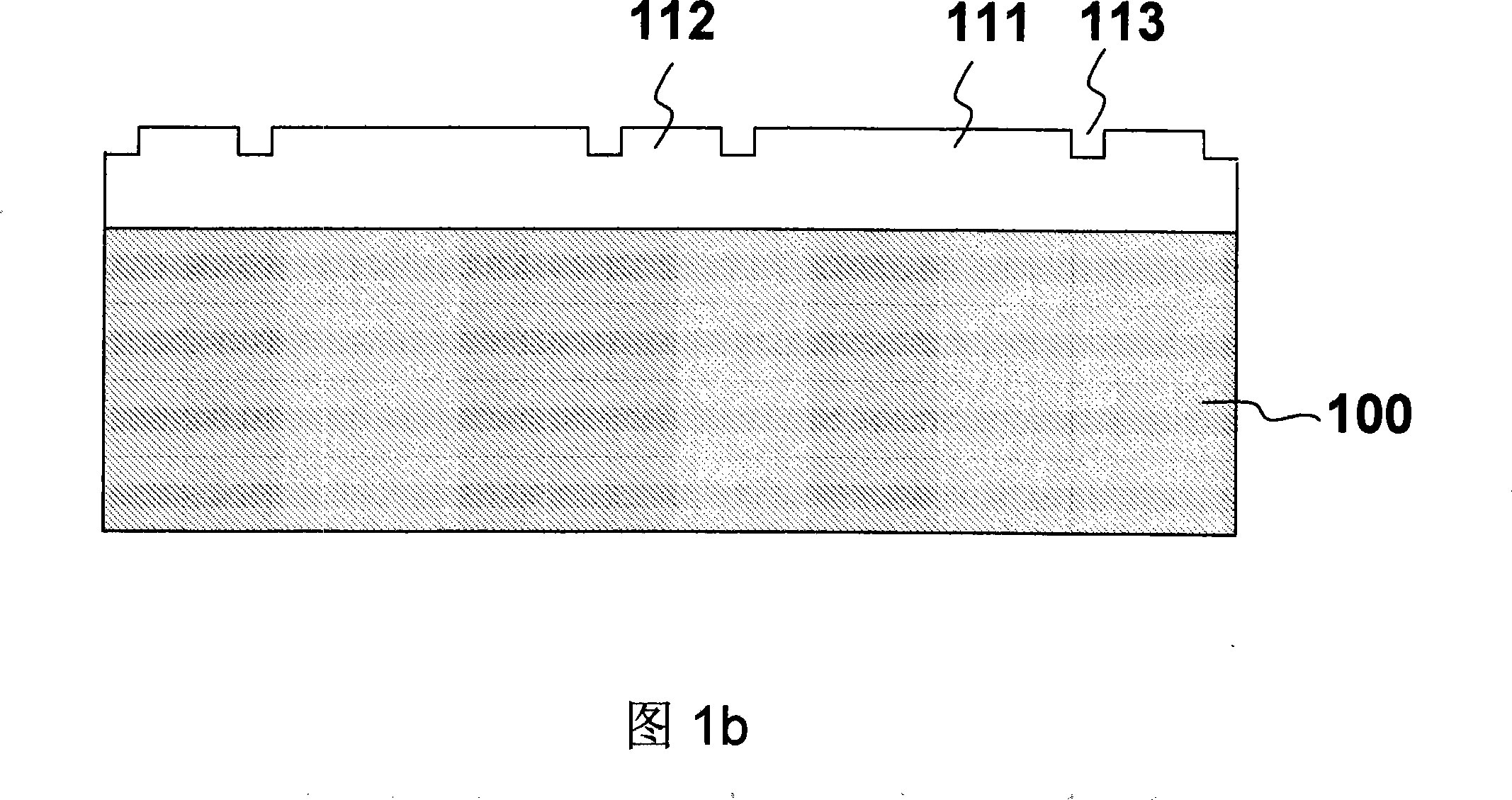

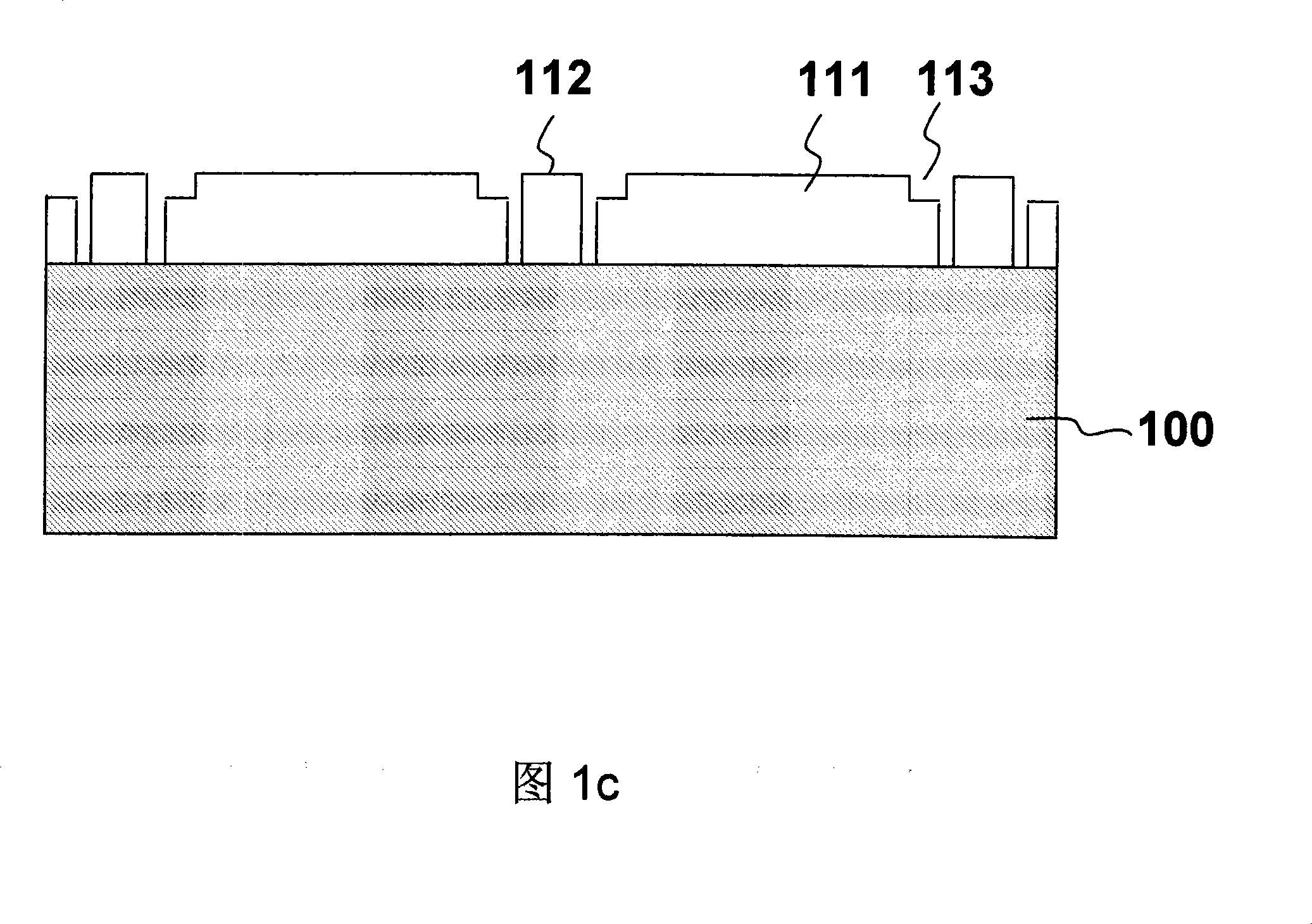

PendingCN107681032AUndamagedIncrease current spreadingSolid-state devicesSemiconductor devicesElectrical conductorProtection layer

The invention discloses a light-emitting diode and a manufacturing method thereof. The light-emitting diode comprises a light-emitting epitaxial layer, a transparent conductive layer, a protection layer and a first electrode, wherein the light-emitting epitaxial layer sequentially comprises a first semiconductor layer, a light-emitting layer and a second semiconductor layer from top to bottom; a first electrode area is arranged on the upper surface of the light-emitting epitaxial layer; the first electrode area comprises a bonding pad area and an expansion area; the transparent conductive layer is formed on the surface of the first semiconductor layer of the light-emitting epitaxial layer, a first opening is formed in the bonding pad area, and the surface, in the bonding pad area, of the first semiconductor layer is exposed; the protection layer is formed on the surface of the transparent conductive layer, a second opening and a third opening are formed in the bonding pad area and theexpansion area of the first electrode area separately, and the surface, in the bonding pad area, of the first semiconductor layer and the surface, in the expansion area, of the transparent conductivelayer are exposed; and the first electrode is formed on the protection layer, and is in direct contact with the first semiconductor layer of the bonding pad area through the first opening and the second opening.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

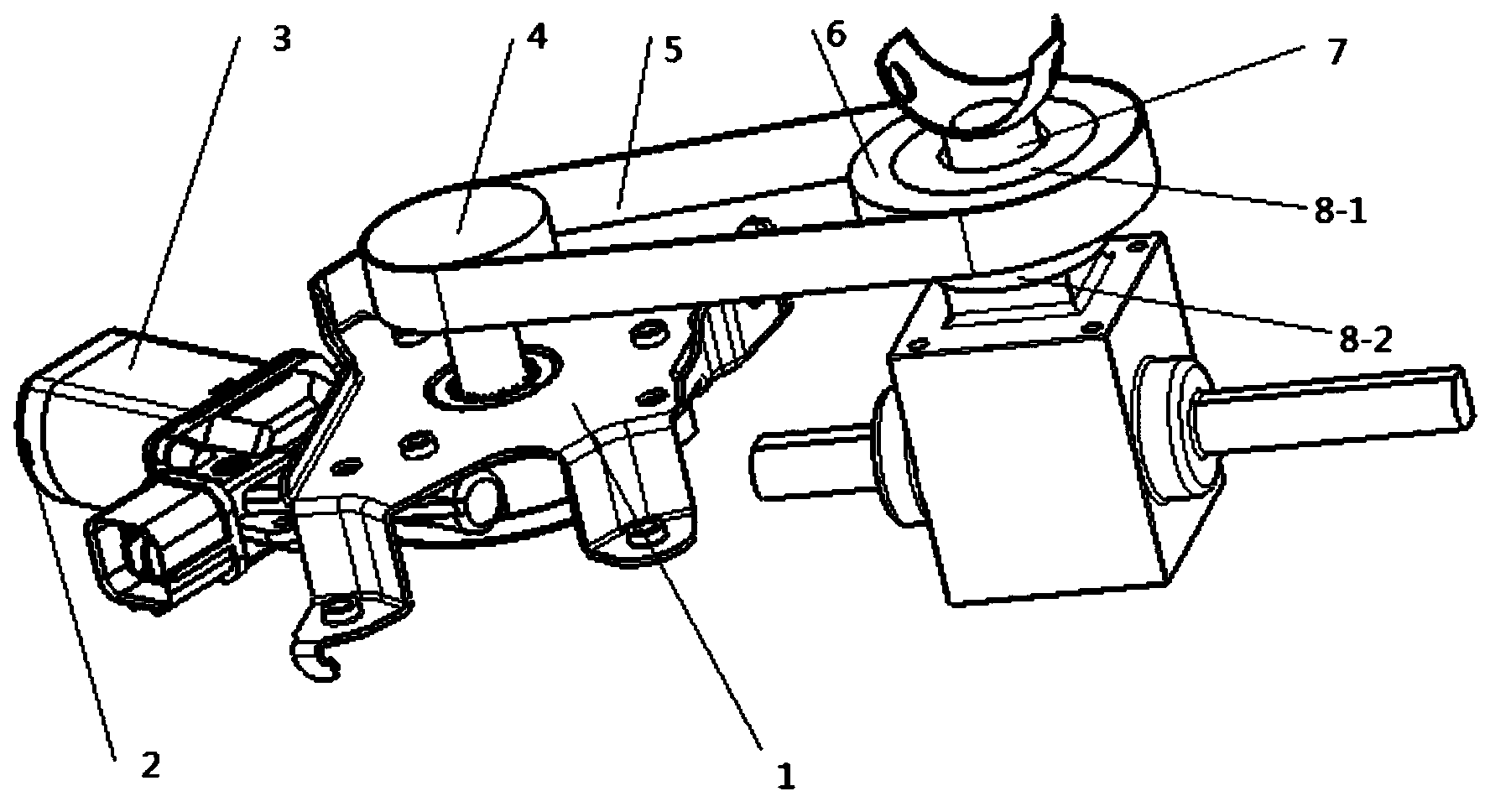

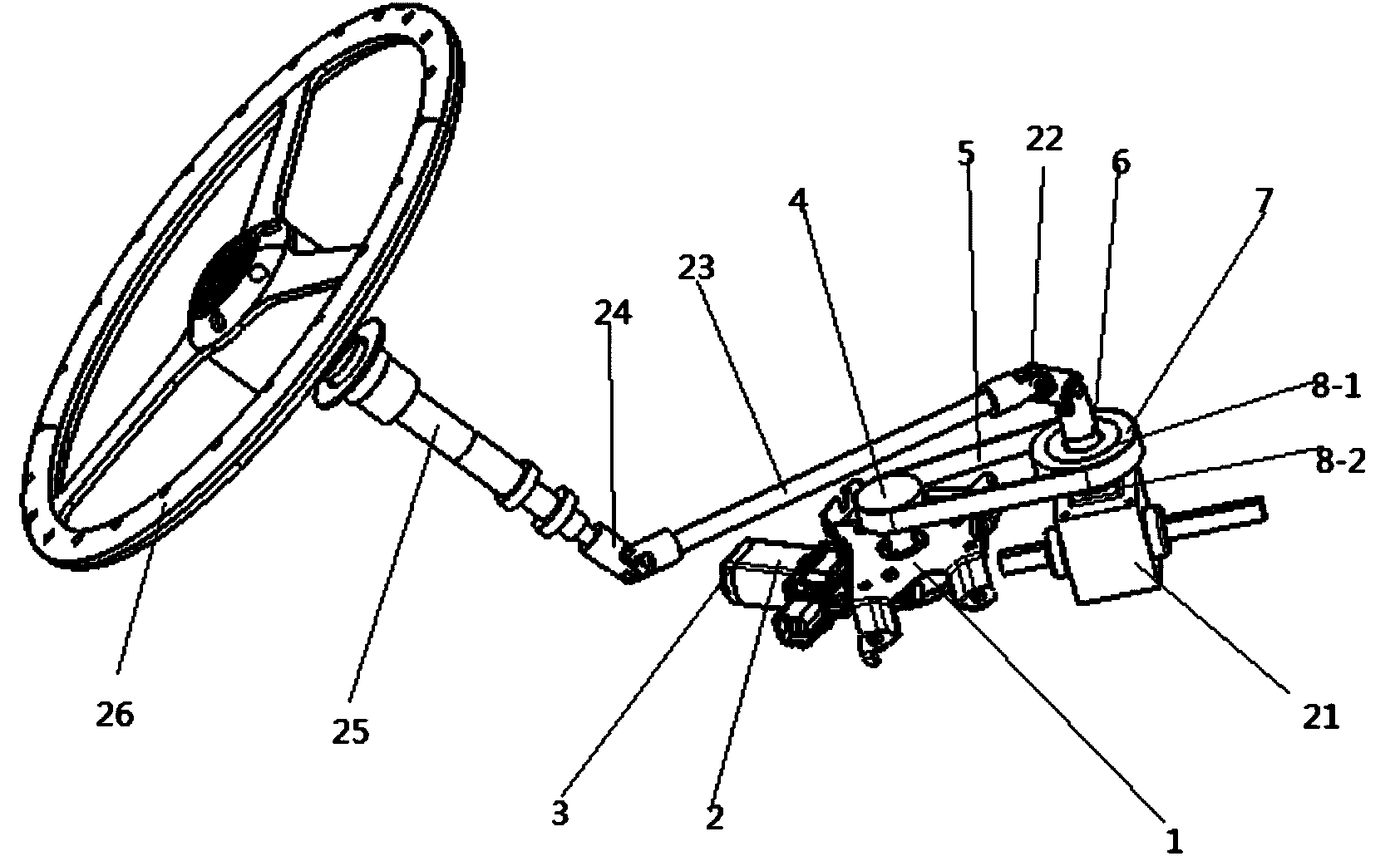

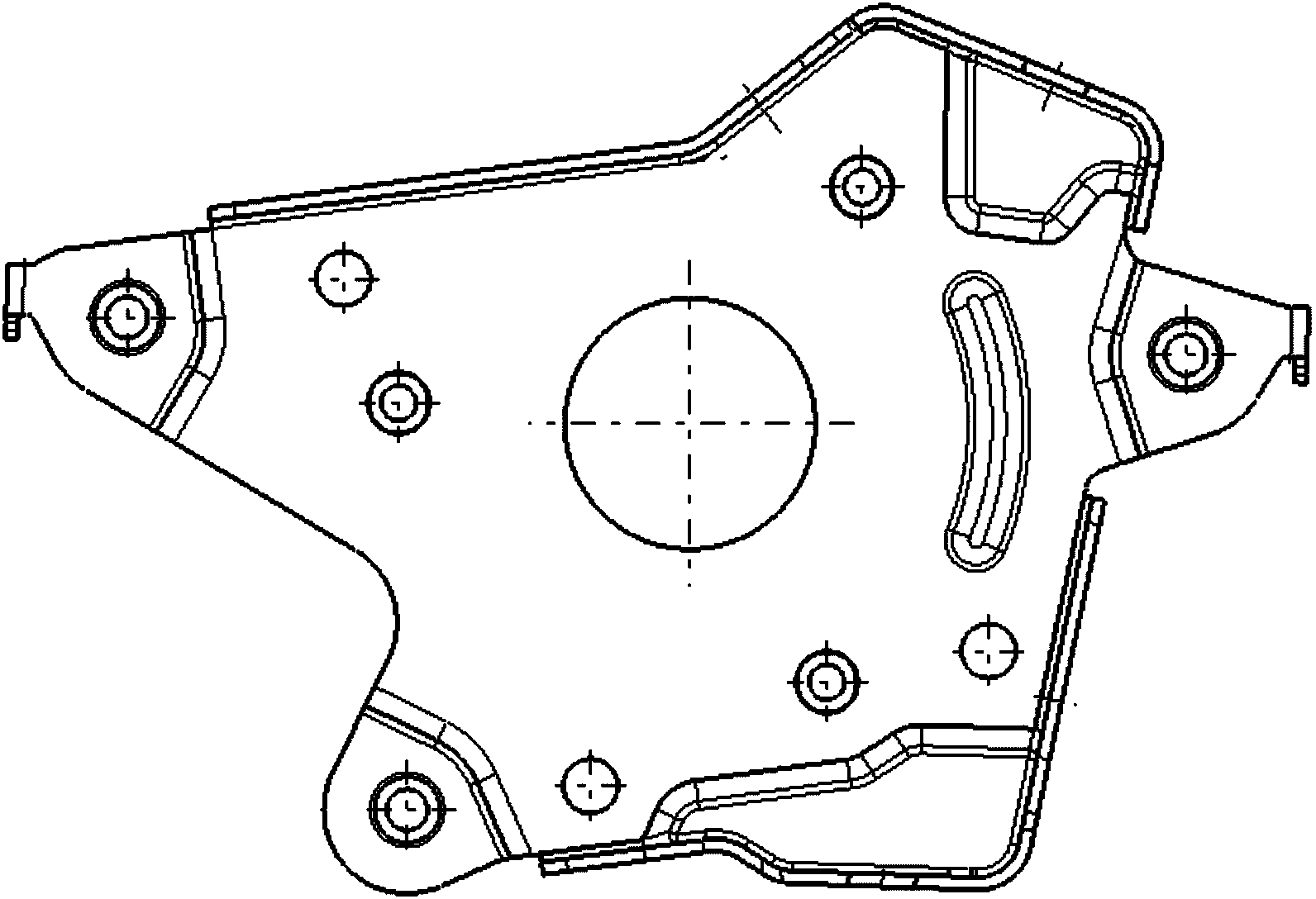

Steering device of intelligent vehicle and control method thereof

ActiveCN104002861ACompact structureLow costSteering linkagesMechanical steering gearsAutomatic steeringVehicle frame

The invention discloses a steering device of an intelligent unmanned vehicle and a control method. The steering device comprises a worm and gear reducer motor, a support, an encoder, a synchronous belt wheel transmission mechanism, an electromagnetic clutch, a non-contact type zero detection mechanism and a limiting device, wherein the worm and gear reducer motor serves as a steering drive mechanism; the support is used for fixing the worm and gear reducer motor to a front vehicle frame of the vehicle and keeping an output shaft of the worm and gear reducer motor parallel to a steering gear input shaft; the encoder is connected with the output shaft at the rear end of the worm and gear reducer motor; the synchronous pulley transmission mechanism comprises a driving pulley and a driven pulley; the driving pulley is fixedly connected to the output shaft of the worm and gear reducer motor; the driving end of the electromagnetic clutch is fixedly connected with the driven pulley, and the driven end of the electromagnetic clutch is fixedly connected with the steering gear input shaft. The steering device can control automatic steering of the intelligent unmanned vehicle, automatic steering and manual steering are executed synchronously during work, and the automatic steering mode and the manual steering mode can be freely switched and do not affect each other.

Owner:WUHAN UNIV OF TECH

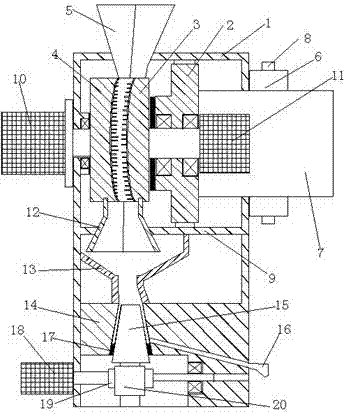

Multistage type traditional Chinese medicine smashing machine

InactiveCN107309057AGuaranteed crushing effectPracticalCocoaGrain treatmentsPulverizerChinese herbology

The invention discloses a multi-stage traditional Chinese medicine pulverizer. The invention adopts two stages of crushing. Firstly, a convex roller and a concave roller are used for primary crushing, and then a millstone is used to grind it to a required particle size. The method can make the Chinese medicine will not be subjected to excessive extrusion force every time it is crushed, so as to ensure that the molecular structure of the Chinese medicine is not damaged, and the efficacy of the Chinese medicine is guaranteed. In addition, the present invention is set as the center of the feeding port of the primary crushing component. The axial direction is perpendicular to the central rotation axis direction of the primary convex roller, and the central axis direction of the feed port of the secondary crushing assembly is parallel to the central axis of the secondary rotating grinding disc of the secondary crushing assembly, which can make the medicine from different Feeding at an angle ensures the crushing effect of the medicine. The distance between the first-stage crushing components of the present invention is adjustable, which can adapt to the crushing of different traditional Chinese medicines and has strong practicability.

Owner:王建梅

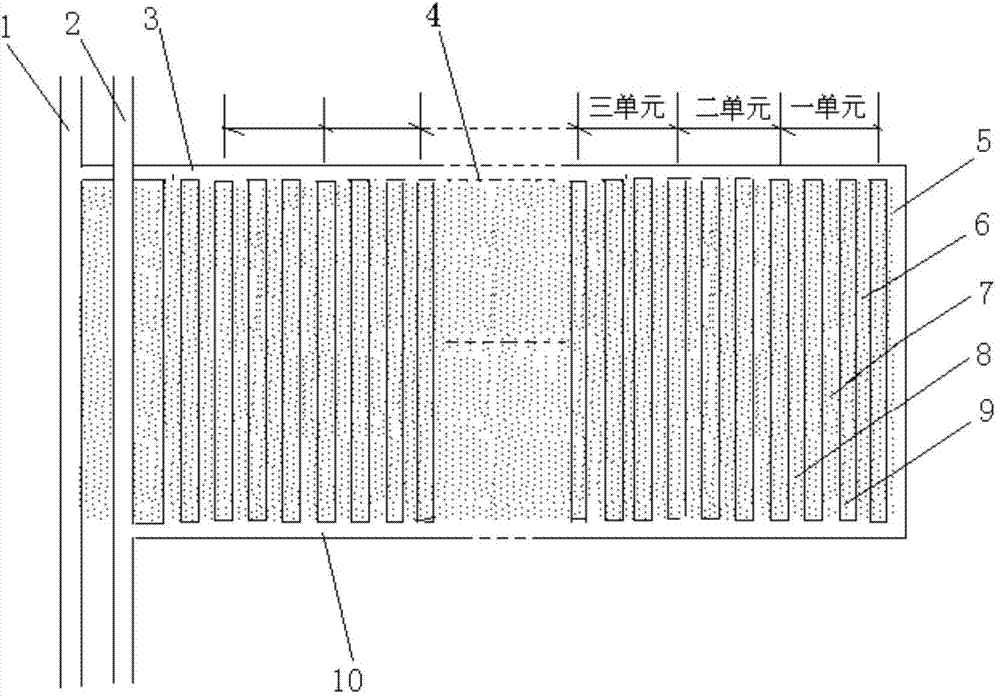

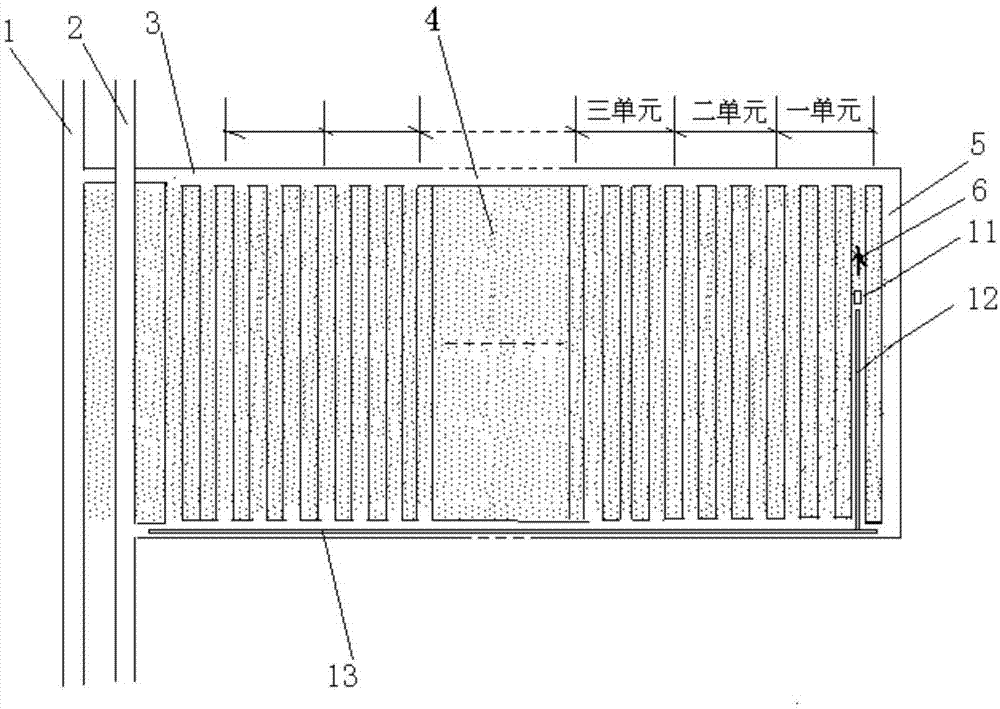

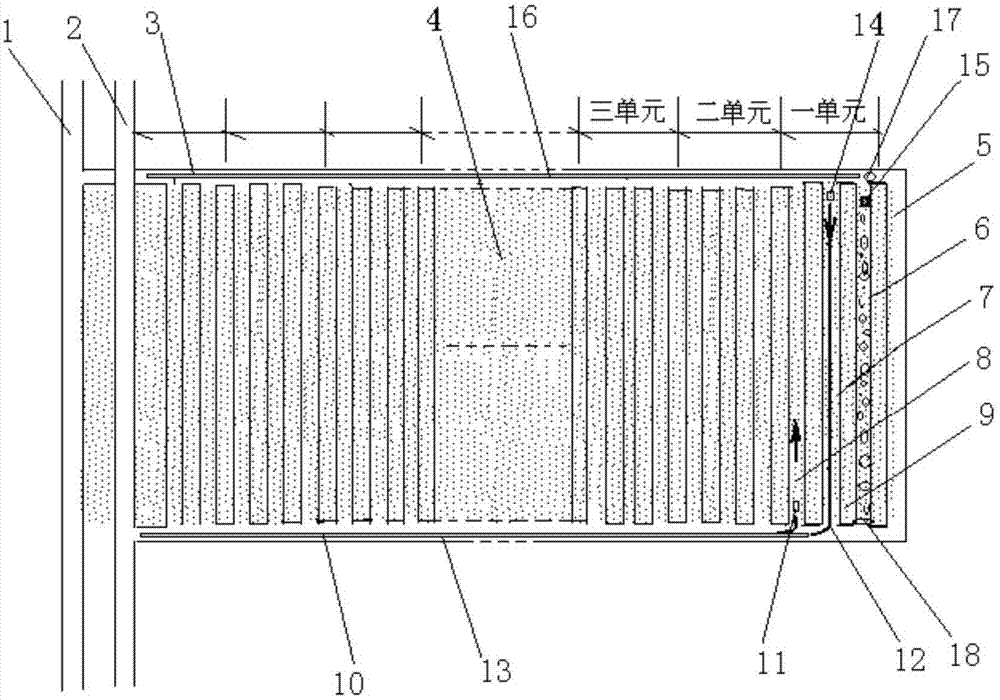

All-negative pressure continuous-mining continuous-filling step-by-step replacement mining method for coal underneath cities and towns, industrial buildings, railways and other buildings

ActiveCN104775817AImprove securityClear division of laborUnderground miningTunnel/mines ventillationCoal miningEngineering

The invention discloses an all-negative pressure continuous-mining continuous-filling step-by-step replacement mining method for coal underneath cities and towns, industrial buildings, railways and other buildings. The main points of the invention are as follows: the whole coal mining zone is divided into a plurality of production units, each production unit is composed of three branch roadway working faces, and branch roadways enable conveyor gateways and air return ways to be communicated; a jump mining sequence is employed, i.e., mining is started from unit 1 and then carried out according to a sequence of unit 1, unit 3, unit 5 ...and so on, and then mining is restarted from unit 2 and then carried out according to a sequence of unit 2, unit 4, unit 8 ... and so on until extraction and filling of all the production units in the whole zone are finished. According to the invention, digging, extraction and filling are spatially assigned to different branch roadways, so the above-mentioned three procedures are effectively isolated and do not influence each other, and the degree of safety is substantially improved; A gangue filling belt conveyor and a gangue conveyor are employed for filling in branch roadways where extraction is finished, so parallel extraction and filling is realized.

Owner:路彬 +1

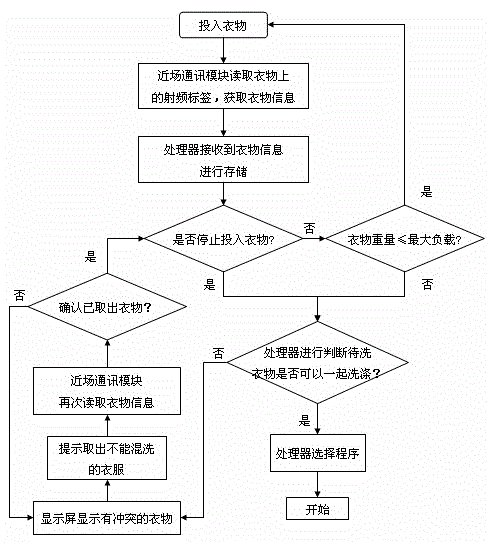

Method for automatically identifying clothes of washing machine

InactiveCN102747584AFew partsLow costControl devices for washing apparatusTextiles and paperComputer moduleEngineering

Owner:NANJING LG PANDA APPLIANCES

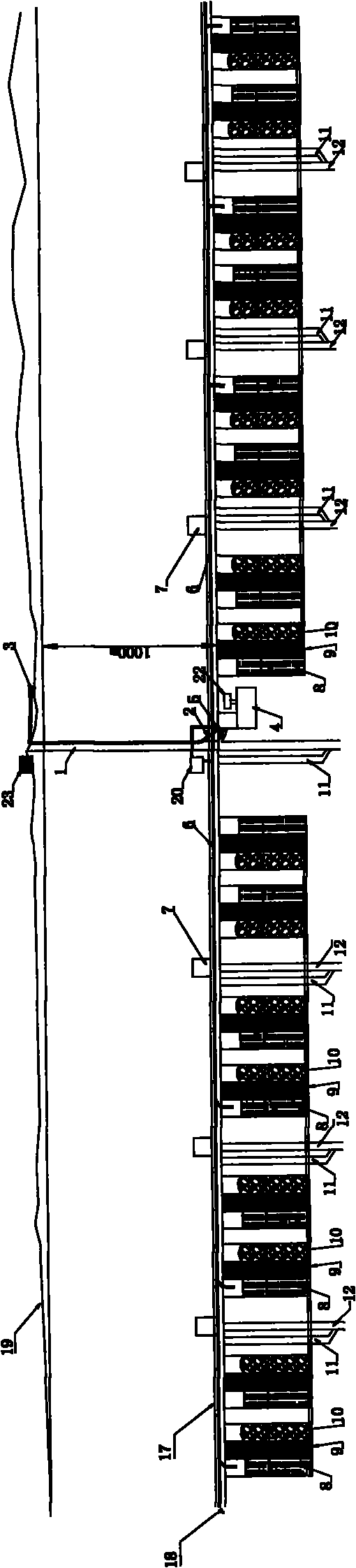

Deeply buried iron mineral resource underground mining and concentrating integration system

ActiveCN101775985AReduce the amount of excavationAchieve short-distance liftsUnderground chambersUnderground miningEcological environmentMineral Sources

The invention relates to a deeply buried iron mineral resource underground mining and concentrating integration system, which is characterized in that only one main hoisting shaft is arranged, positions adjacent to the main hoisting shaft are provided with an underground concentrating mill, an underground filling station and an underground water sump; the left side and the right side of the main hoisting shaft are uniformly provided with at least one blind shaft, and positions adjacent to the main hoisting shaft and the blind shaft are both provided with a main orepass; the footwall side of the top of an ore body is provided with a main horizontal haulage roadway, and both ends of the roadway are provided with air shafts; and the underground concentrating mill comprises a cycle chamber, a conical chamber, a screening chamber, a powder ore chamber, a grinding chamber, a sorting chamber and a product delivery chamber. The invention has the main characteristics that the concentrating mill, the underground filling station and the under water sump are arranged underground so as to realize short-distance hoisting of mined deeply buried mineral resources, the concentrated tailings and waste rocks are directly used underground, the overall mining cost can be reduced by 10 to 30 percent without damaging the earth surface, environment pollution is reduced, and the ecological environment is protected.

Owner:NORTHEASTERN UNIV

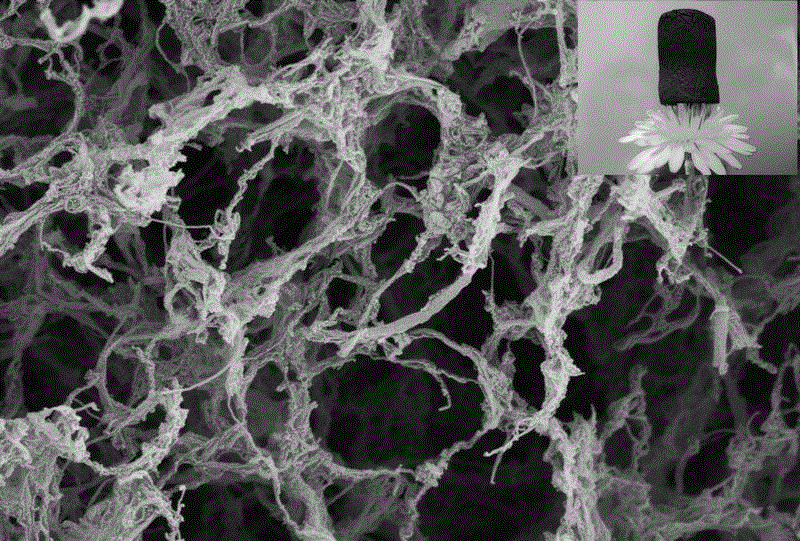

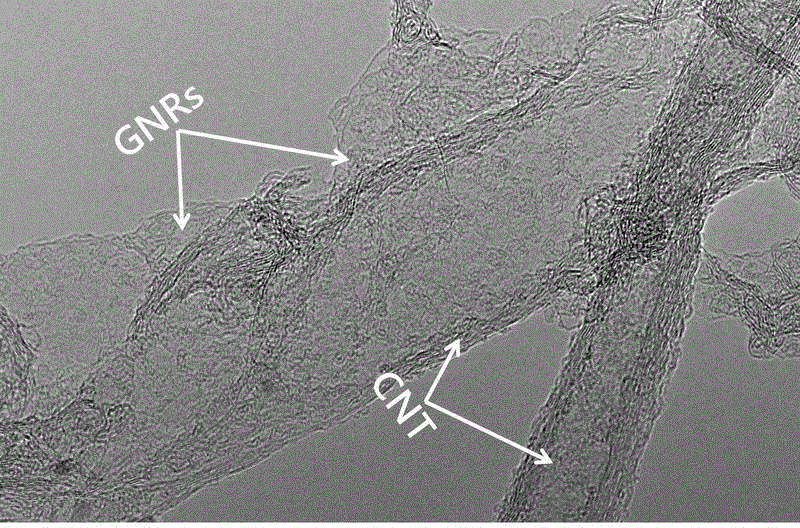

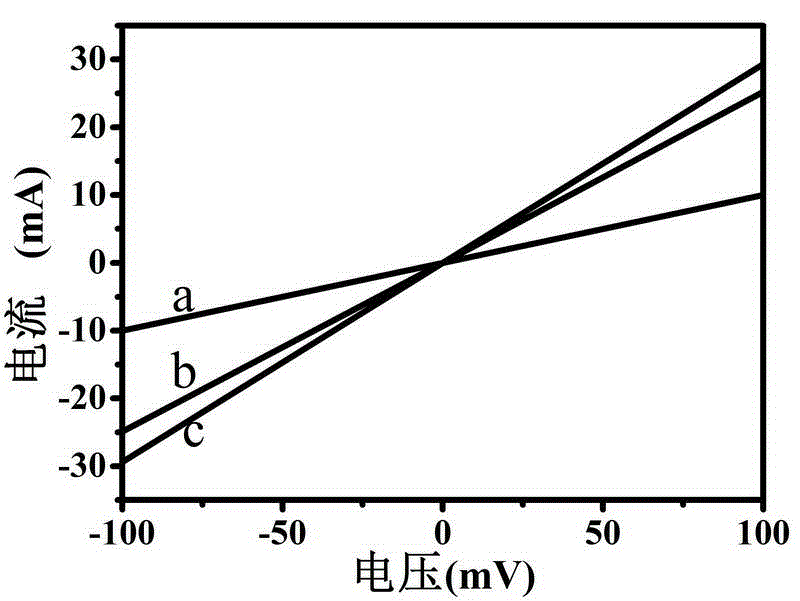

Heteroatom doped leaf-shaped carbon nanometer aerogel material and preparation method and application thereof

InactiveCN104437278AIncrease the areaUndamagedCell electrodesGel preparationCarbon nanotubeStructural unit

The invention belongs to the technical field of nanometer materials and particularly relates to a heteroatom doped leaf-shaped carbon nanometer aerogel material and a preparation method and an application of the heteroatom doped leaf-shaped carbon nanometer aerogel material. The carbon nanometer leaf is a biomimetic concept, a carbon nanometer tube is used for simulating the leaf vein of the leaf, a graphene nanoribbon is used for simulating the leaf, and the carbon nanometer leaf is a seamless bridged hybrid structure of the carbon nanometer tube and the grapheme nanoribbon. The aerogel is assembled by adopting the carbon nanometer leaves as basic structural units, and then a heteroatom doped three-dimensional net structure is realized. The preparation method of the aerogel comprises the following steps: preparing a carbon nanometer leaf solution, adding moderate amount of soluble dopants to the solution, and then carrying out hydrothermal to obtain uniform hydrogel, and then drying and charring to obtain the heteroatom doped carbon nanometer leaf aerogel. The aerogel can be used as a cathode catalyst of the fuel cell, and has a catalytic performance better than that of the commercial Pt / C and the potential application prospect.

Owner:FUDAN UNIV

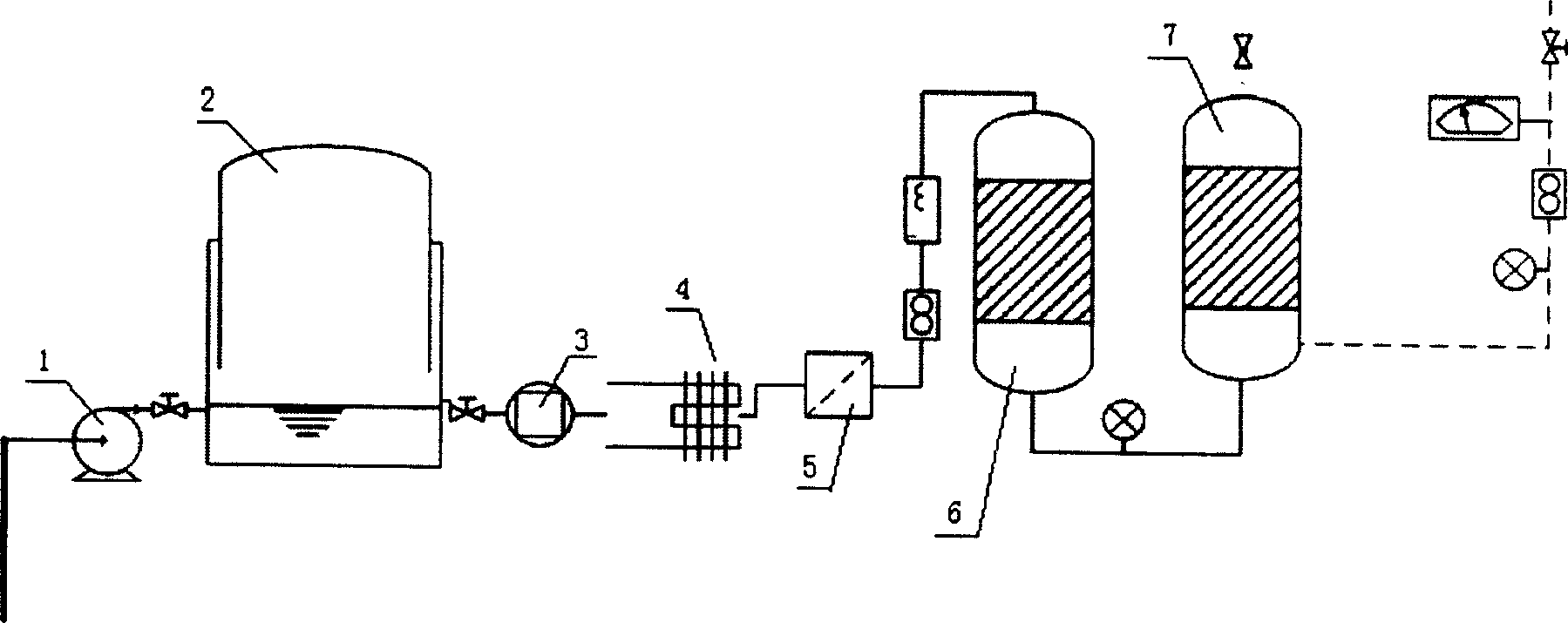

Production and apparatus for producing methane from refuse embedded gas

ActiveCN1680222ASimple and fast operationLess investmentSolid waste disposalAdsorption purification/separationCompressed natural gasFreeze-drying

Production of methane from land-filled garbage gas and its apparatus are disclosed. It is carried out by pressing the abstracted land-filled garbage gas, freezing drying, multi-stage filtering, pretreatment process of adsorption drying, high-pressure adsorbing, co-current pressure equalizing, constant-pressure recovering, and pressure varied adsorption circulating. The apparatus consists of compressors connected orderly, freezing direr, filter, drying tower and pressure varied adsorption circulating system with 2-6 parallel adsorbing columns. Its advantages include simple apparatus and operation, low cost and good flexibility.

Owner:TSINGHUA UNIV

Ecological Liancheng white duck raising method

InactiveCN102652503ARich food chainRealize scientific feedingClimate change adaptationHorticultureGrazingWoodlot

The invention belongs to the technical field of the animal husbandry, and particularly relates to an ecological Liancheng white duck raising method. The white duck raising fields are hillsides and forest lands, such as the mountain stream, the sloping field, the paddy field and the fishpond. The mountain stream penetrates the sloping field to enter the paddy field, and then flows towards the fishpond, and a duck coop is built next to the fishpond. The periphery of the raising field is planted with tall and dense rank vegetation to form biological rails, and the different functional regions are divided by the biological rails. The region with the same function comprises a lawn grazing district, a paddy field grazing district and a fishpond grazing district. The quality of the white ducks produced by the method is better, and the ecology and the water resources can be prevented from being damaged. Different small ecological environments of the functional regions of the white duck raising fields have own characteristics, are intimately connected and mutually supported, and provide favorable ecological environment and abundant food chains for the growth of the white ducks. The method realizes the scientific raising of the white duck, high production quality, zero emission of sewage and dirt; and the ecological raising of the white duct can sustainably develop and create more obvious economic, social and ecological benefits.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

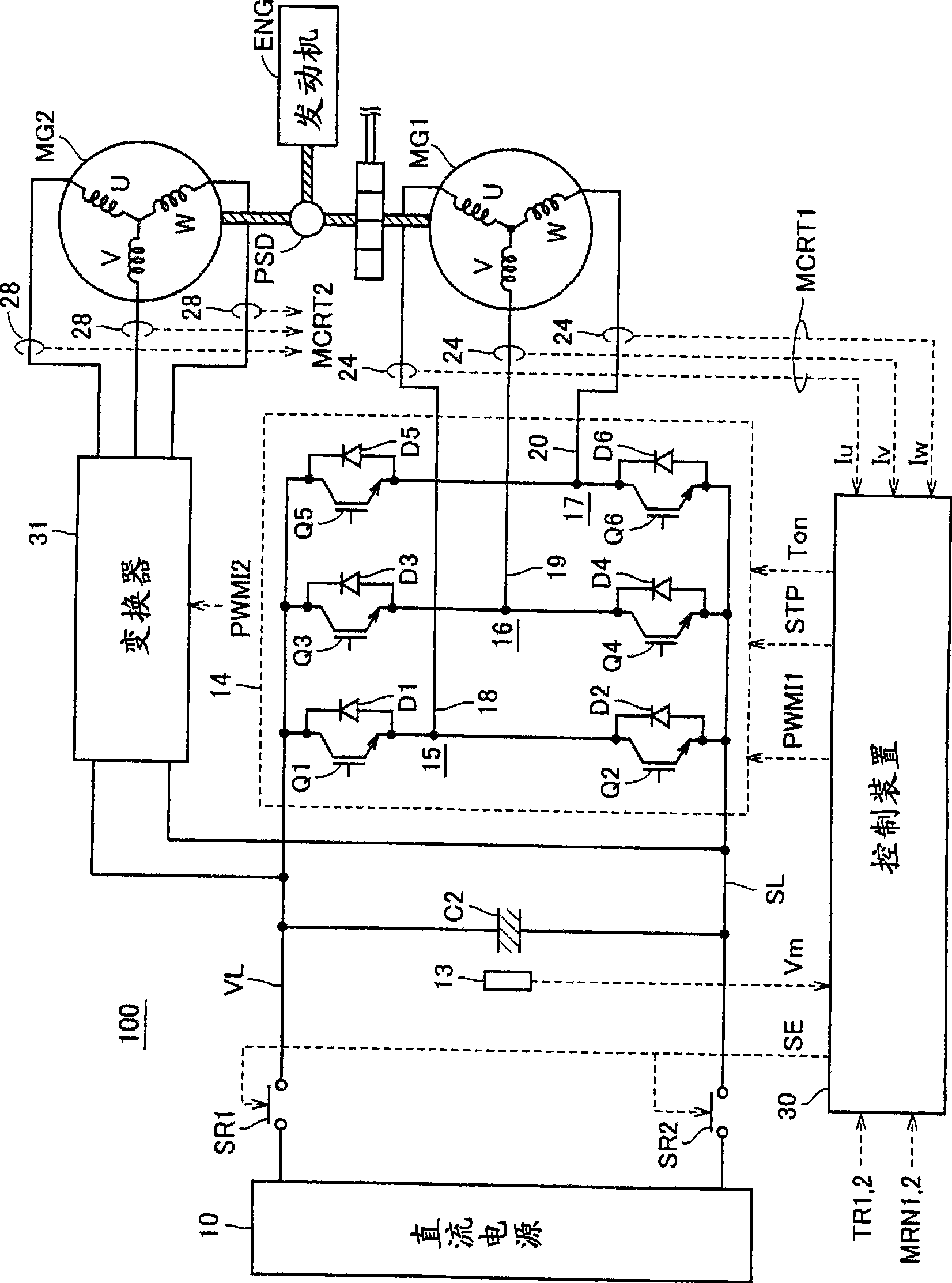

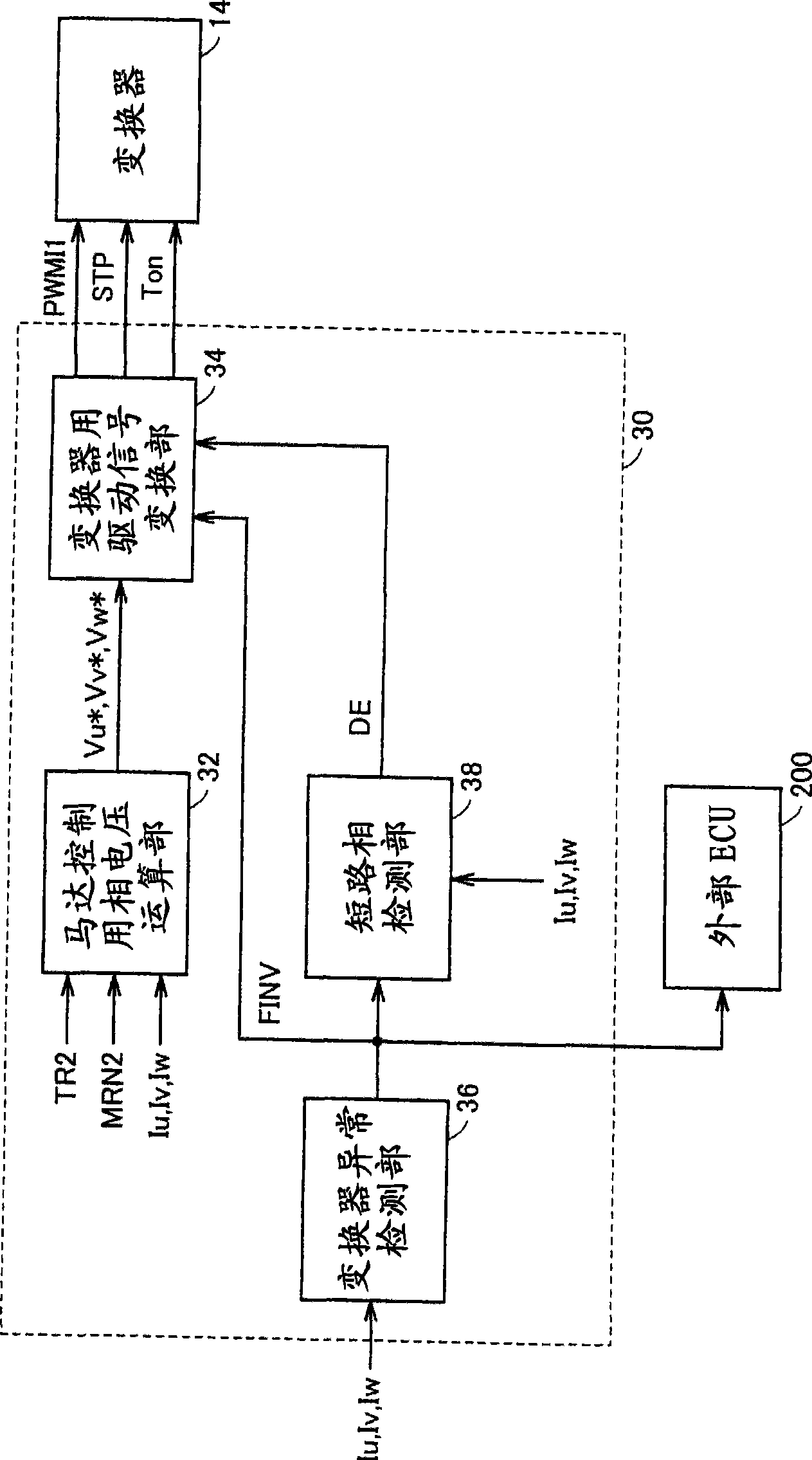

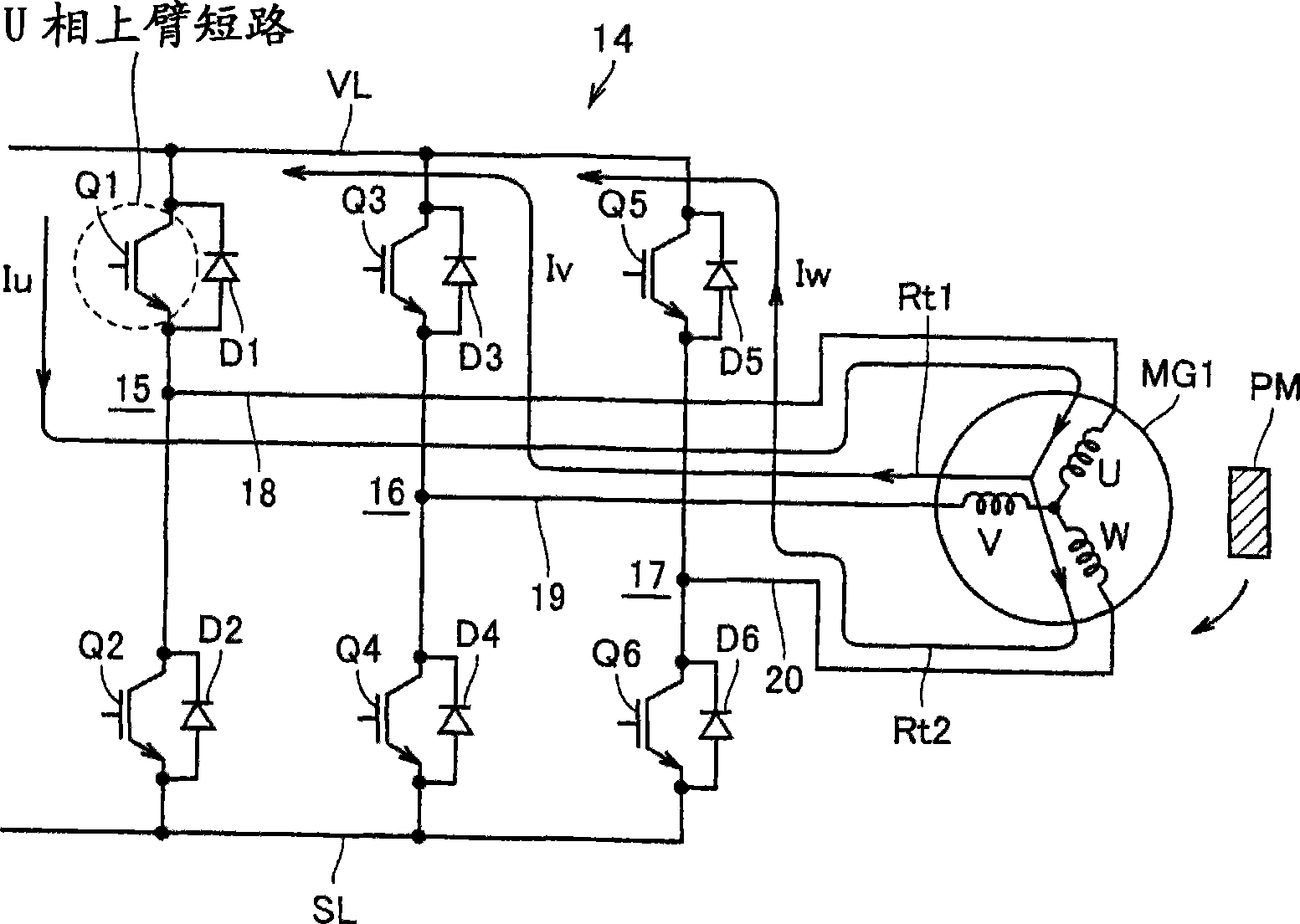

Motor drive device

A control device (30) judges that an inverter (14) has failed upon detection of an overcurrent in any one of the IGBT elements of the inverter (14) during drive of a motor generator (MG1). The control device (30) stops operation of the inverter (14) in response to the failure judgment and identifies a shortcircuit phase according to a motor current (MCRT1) from the current sensor (24). The control device (30) simultaneously turns ON two IGBT elements constituting an upper and a lower arm of the shortcircuit phase in a discharge process of a capacitor (C2) executed upon stop control of a vehicle. Thus, the two IGBT elements receive excessive shortcircuit current to suddenly increase the thermal loss, which causes a shortcircuit failure. This suppresses the overcurrent of the inverter and the power supply line caused by the electromotive force generated in the motor generator (MG1) when towing a vehicle.

Owner:TOYOTA JIDOSHA KK

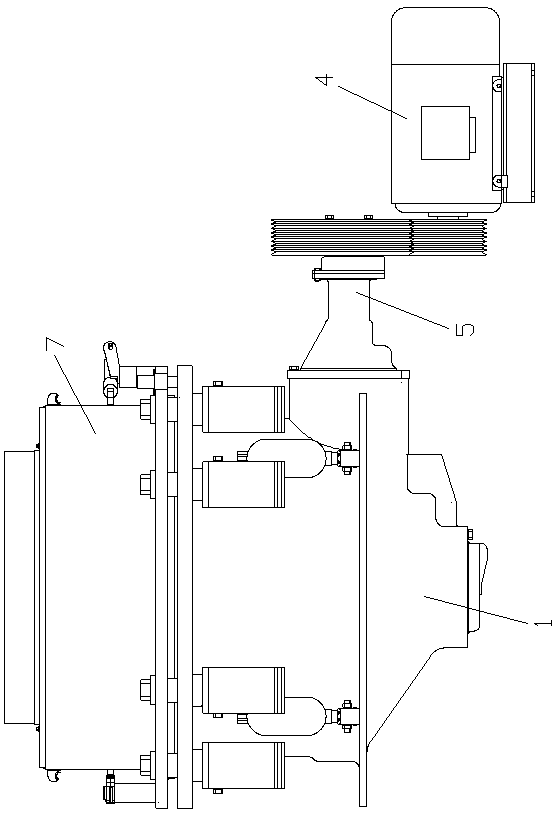

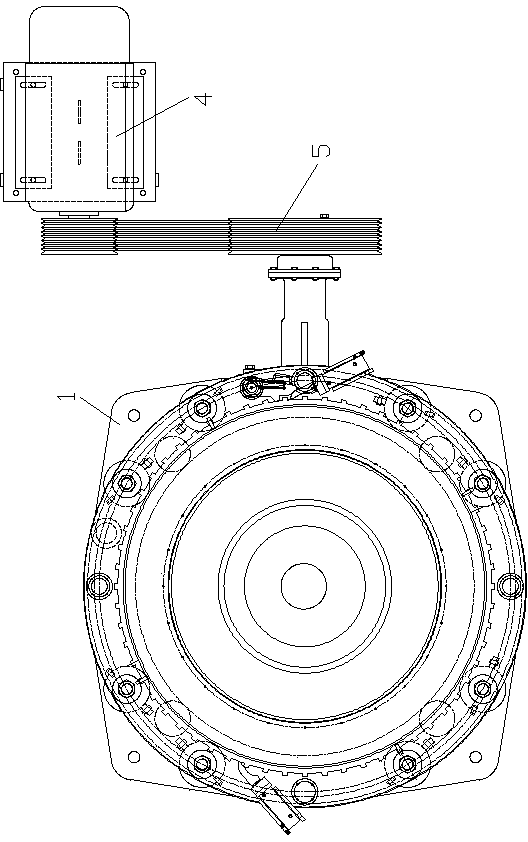

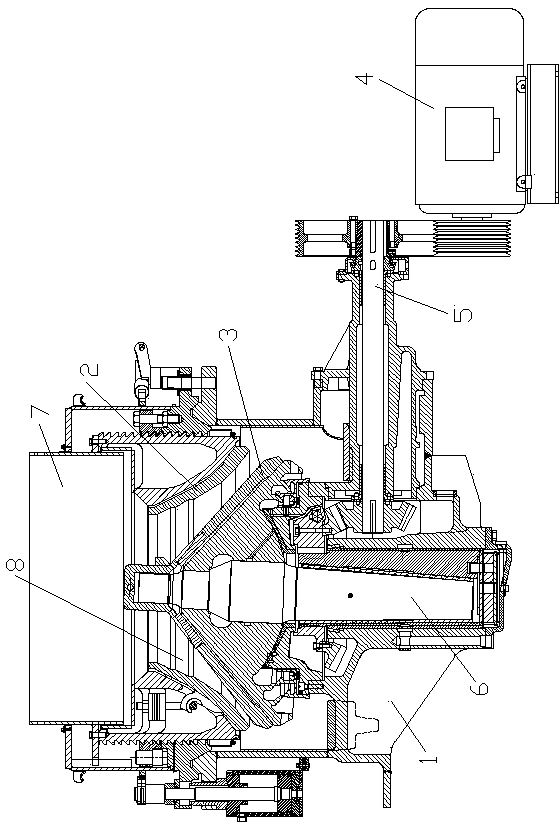

Large-scale energy-efficient high-efficiency cone crusher

The invention relates to a large-scale energy-efficient high-efficiency cone crusher, which comprises a rack, an upper lining plate, a lower lining plate, an electromotor, a transmission device, a crushing cone mechanism and a crushing cavity control mechanism, and is characterized in that the crushing cavity control mechanism consists of a feed hopper, a supporting sleeve, an adjusting sleeve, an outer gear ring, a push cylinder, a locking ring, 16 locking cylinders, 8 hydraulic cylinders and 4 jacks, wherein the supporting sleeve is movably connected to the rack, the adjusting sleeve is in threaded connection into the locking ring and the supporting sleeve, the 16 locking cylinders are all arranged on the supporting sleeve, the feed hopper is fixedly arranged on the adjusting sleeve, the outer gear ring is fixedly arranged on the feed hopper, and the push cylinder and the outer gear ring are matched; lifting ends of the 4 jacks are all supported against the bottom surface of a flange ring of the supporting sleeve; the crushing cone mechanism consists of an eccentric sleeve, a cone gear, an eccentric shaft, a crushing cone, a bowl-shaped bearing and a bowl-shaped bearing sealing ring. According to the large-scale energy-efficient high-efficiency cone crusher, the size of a crushing cavity and the size of a throat can be adjusted, and the cavity cleaning operation is convenient.

Owner:海盐机械厂 +1

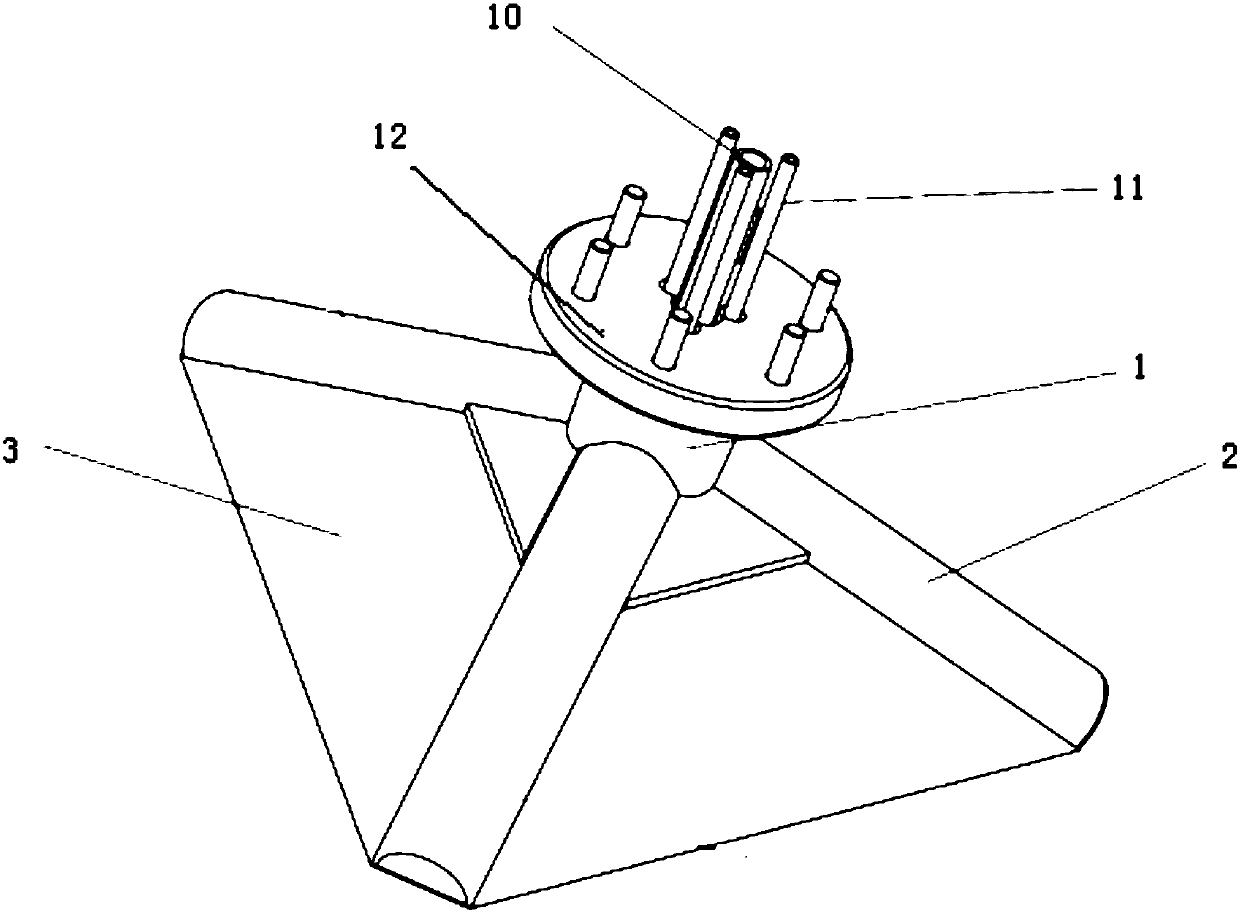

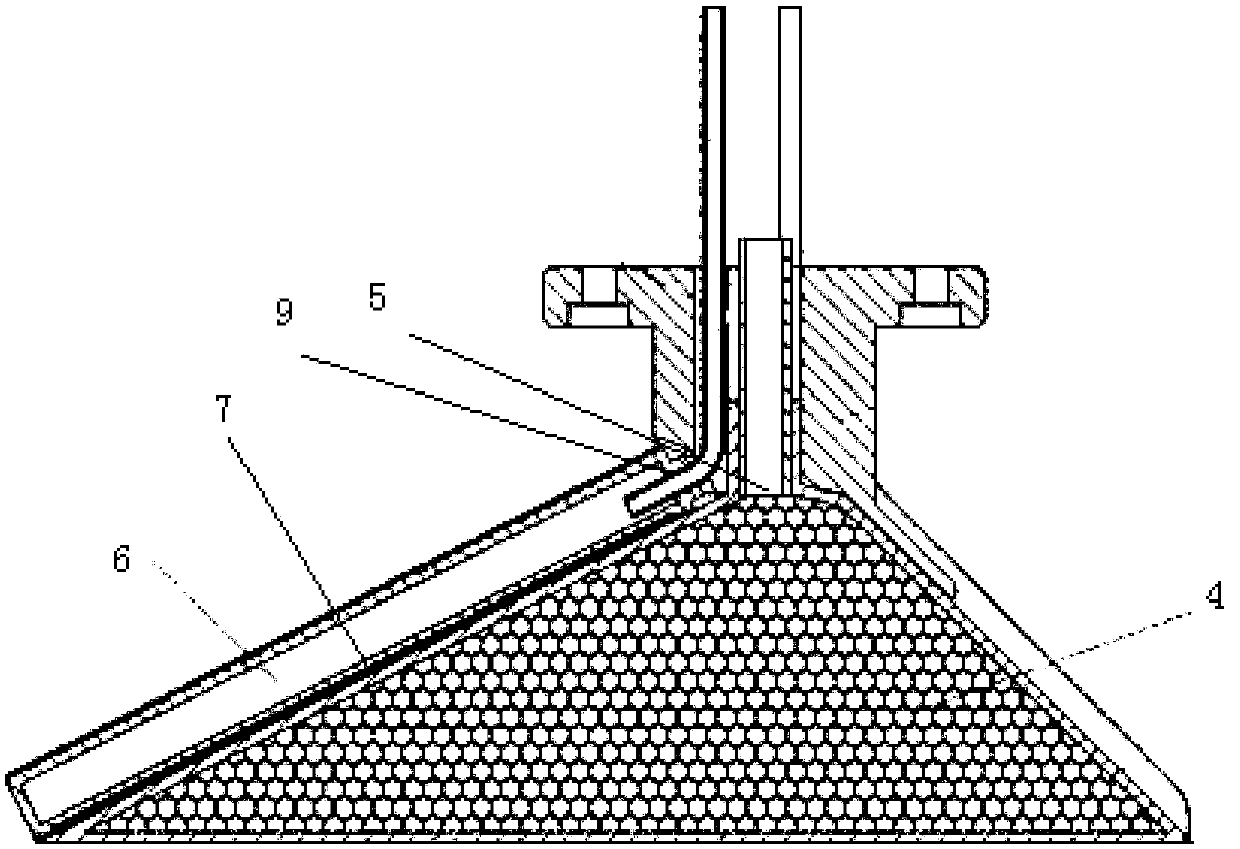

A luminescent part for laser GaN base peeling based on compound separation method and its making method

A laser stripping GaN base illuminating device which is disclosed in the invention and is applied with a synthesizing separating method and the manufacturing method adopt the synthesizing separating method for separating each unit GaN base illuminating device, combining the method for eliminating partial GaN base epitaxial layer and laser-gashing the GaN base epitaxial layer with the dry method, the absolute separating between each unit GaN base illuminating devices can be guaranteed, the creation rate of the slit in the laser stripping process is reduced, and the capability of the device can be protected from being damaged in the laser insulating process; an area is preserved between each of unit GaN base illuminating devices as a laser stripping sacrificial area and is insulated from the unit illuminating device to avoid the extending of the fracture and the illuminating device damage generated by the overlapping irradiation of the laser beam in the laser stripping process and increase the finished product rate of the illuminating device after laser stripping; the laser stripping sacrificial area is surrounded by a metal ring and after laser stripping the residue of epitaxial layer in the sacrificial area can be easily removed along with the etching of the metal ring.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Active adaptation flexible mechanical gripper with variable rigidity

The invention discloses an active adaption flexible mechanical gripper with variable rigidity. The active adaption flexible mechanical gripper with variable rigidity comprises a gripper base, a plurality of gripper fingers capable of being controlled to bend, and a gripping bag used for adaptively attaching and tightly clamping the surface of an object to be gripped; the interior of the gripping bag is filled with particulate matters; a first air port, used for controlling the vacuum degree inside the gripping bag and further controlling overall shaping of the particulate matters, and adaptively clamping the object to be gripped, is formed in the gripping bag; the gripper fingers are fixed on the gripper base; the gripping bag is positioned inside a space formed by the gripper fingers, andthe outer wall of the gripping bag is fixedly attached with the bent inner side walls of the gripper fingers; the active adaptation flexible mechanical gripper can carry out self active adjustment, can improve the adaptation and the flexibility of an actuator at the tail end of a robot to a great extent, can greatly improve gripping performance, is high in gripping load and excellent in stability, and has a wide application scope.

Owner:CHONGQING UNIV

Floating body material and manufacturing technique thereof

The invention relates to a floating body material, in particular to a floating body material and a manufacturing technique thereof for an observation platform at the bottom of the sea. The floating body material comprises bisphenol A type epoxy resin, modified acrylonitrile-butadiene rubber latex, hollow glass microsphere, polyether amine, gamma-glycidoxypropyltrimethoxysilane, a silane coupling agent and polyvinyl alcohol fiber; and the floating body material comprises the following components in parts by weight: 100 parts of bisphenol A type epoxy resin, 0-10 parts of modified acrylonitrile-butadiene rubber latex, 12-18 parts of hollow glass microsphere, 15-20 parts of polyether amine, 2-3 parts of gamma-glycidoxypropyltrimethoxysilane, 1-2 parts of silane coupling agent and 2 parts of polyvinyl alcohol fiber. The invention provides the floating body material and the manufacturing technique thereof for the observation platform at the bottom of the sea; and the observation platform adopting the floating body material can be soaked in the seawater for use in a long term.

Owner:SECOND INST OF OCEANOGRAPHY MNR

Multifunctional anti-leakage shrinkage type concrete surface layer reinforcer

The invention relates to a multifunctional anti-leakage shrinkage type concrete surface layer reinforcer which is prepared from the following components in percentage by weight: 10-20 percent of high polymer, 1-7 percent of film forming aided compound, 5-10 percent of surface layer active agent compound, 1-4 percent of leakage aided compound, 1.5-4.5 percent of active compound and the balance of water. The invention has good concrete surface layer enhancement effect, can obviously reduce the shrinkage of surface layer concrete, obviously improves the carbonization resistance and the medium leakage resistance of surface layer concrete, has convenient construction and obvious economic benefit and can be widely applied to the strengthening treatment operations on the surface layers of cement and concrete pouring components, concrete components under corrosion environment conditions such as piers, dams, and the like and deformed concrete components difficult to be strengthened by adopting a conventional method.

Owner:湖州苏博特新材料有限公司

Preparation method of heat-insulating ceramic phenolic resin-based gradient composite material

The invention discloses a preparation method of a heat-insulating ceramic phenolic resin-based gradient composite material. Fiber cloth is used as a reinforcing phase, and the fiber cloth is respectively dipped in different gum dipping solutions with the phenolic resin as a matrix and contents of ceramic components and hollow microbeads in gradient distribution to prepare a prepreg; laminating, die pressing and thermal curing molding at 150-200 DEG C to obtain the gradient composite material comprising a heat-proof layer, a gradient transition layer and a heat-insulating layer. When the temperature of the gradient composite material is as high as 1000 DEG C, the heat-proof layer can be converted into a ceramic phase with higher strength and can resist heat flow erosion; the gradient transition layer can relieve stress concentration and reduce stress; and hollow microspheres are added to guarantee that the heat-insulating layer has good thermal matching performance.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com