Light-emitting diode and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which can be applied to semiconductor devices, electrical components, circuits, etc., and can solve problems such as low carrier mobility and current congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

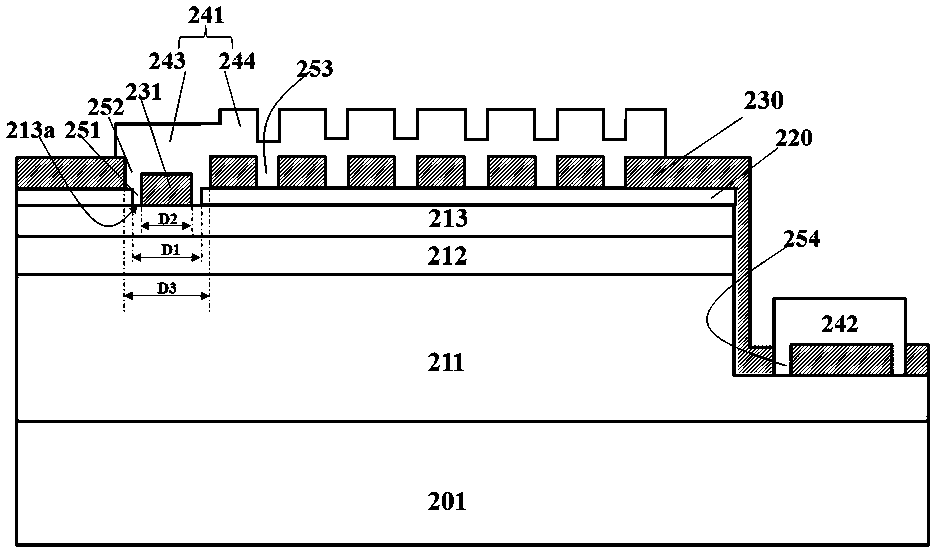

[0130] Such as image 3 As shown, a light-emitting diode includes: a substrate 201 , an N-type layer 211 , a light-emitting layer 212 , a P-type layer 213 , a transparent conductive layer 220 , a semiconductor protection layer 230 , a first electrode 241 , and a second electrode 242 .

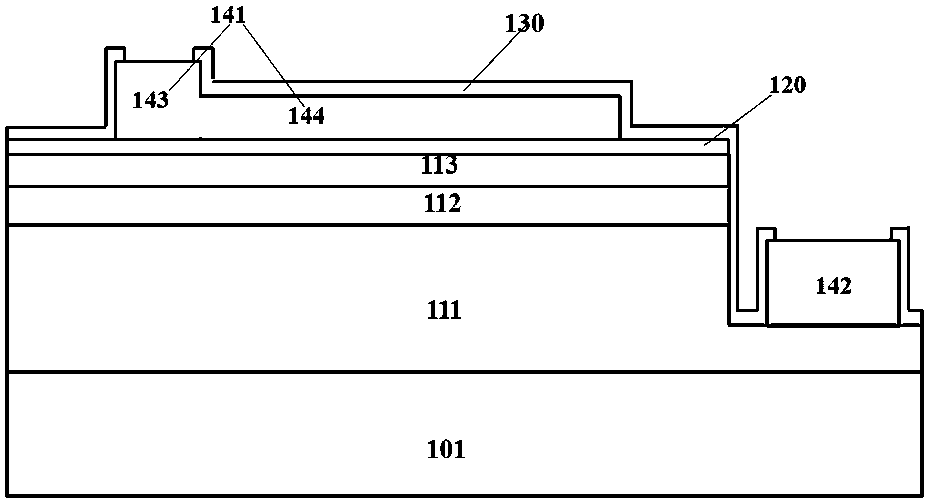

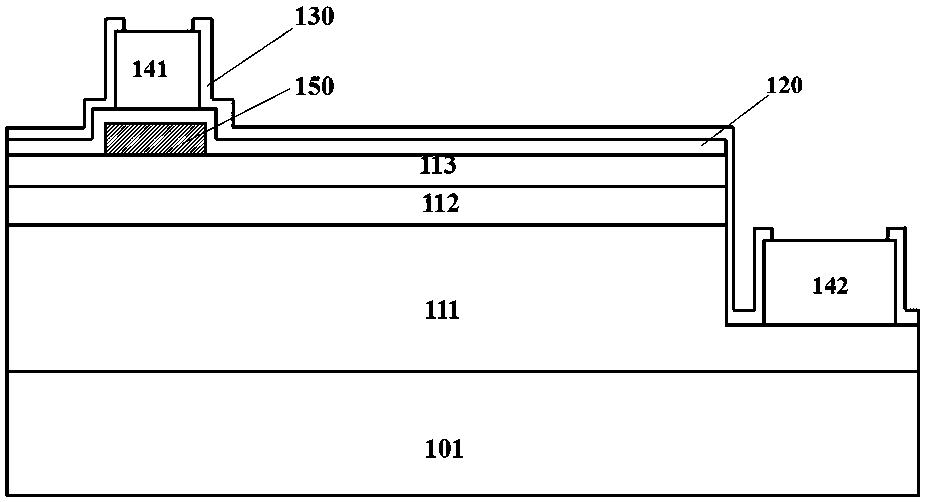

[0131] Specifically, the substrate 201 includes but is not limited to sapphire, aluminum nitride, gallium nitride, silicon, and silicon carbide, and its surface structure can be a planar structure or a patterned pattern structure; the N-type layer 211 is formed on the sapphire substrate 201 on; the light-emitting layer 212 is formed on the N-type layer 211; the P-type layer 213 is formed on the light-emitting layer 212; the transparent conductive layer 220 is formed on the P-type layer 213; the semiconductor protection layer 230 is formed on the transparent conductive layer 220; the first The electrode 241 and the second electrode 242 are formed on the semiconductor protection layer 230 . Fig...

Embodiment 2

[0138] This embodiment discloses a method for manufacturing a light-emitting diode, which mainly includes four processes of mesa etching (MESA), making a transparent conductive layer, making a semiconductor protective layer, and making an electrode. Figure 5 It is shown that the four processes involve respective corresponding mask patterns. Combine below Figure 5-8 Give a brief explanation.

[0139] First, a light-emitting epitaxial layer structure is provided, which generally includes a substrate 201 , an N-type layer 211 , a light-emitting layer 212 , and a P-type layer 213 .

[0140] Next, refer to Figure 5The pattern shown in (a) defines the first electrode region and the second electrode region on the surface of the light-emitting epitaxial layer, removes the hole region, forms the mesa 210 of the second electrode and a series of through holes 256, as Figure 6 shown;

[0141] Next, refer to Figure 5 In the pattern shown in (b), a transparent conductive layer 220...

Embodiment 3

[0146] Figure 9 A schematic diagram showing the structure of another light-emitting diode. The difference from Embodiment 1 is that in the light-emitting diode structure described in this embodiment, the diameter D1 of the second opening 252 is greater than or equal to the diameter D1 of the first opening. At this time, there is no The semiconductor protection layer is in direct contact with the P-type layer 213. At this time, the pad part of the first electrode is in direct contact with the semiconductor, and the adhesion between the electrode and the GaN interface is good, which can reduce the risk of detachment between the first electrode and the adhesion interface of the wire bonding .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com