Patents

Literature

124results about How to "Good heat matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

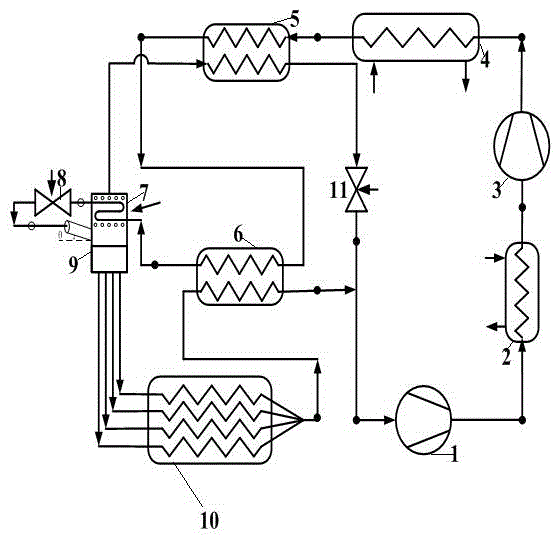

Combined cycle thermoelectric conversion system utilizing multi-grade waste heat of internal combustion engine

ActiveCN103352772ARealize comprehensive utilizationImprove fuel economyInternal combustion piston enginesEngine componentsOrganic Rankine cycleExhaust gas recirculation

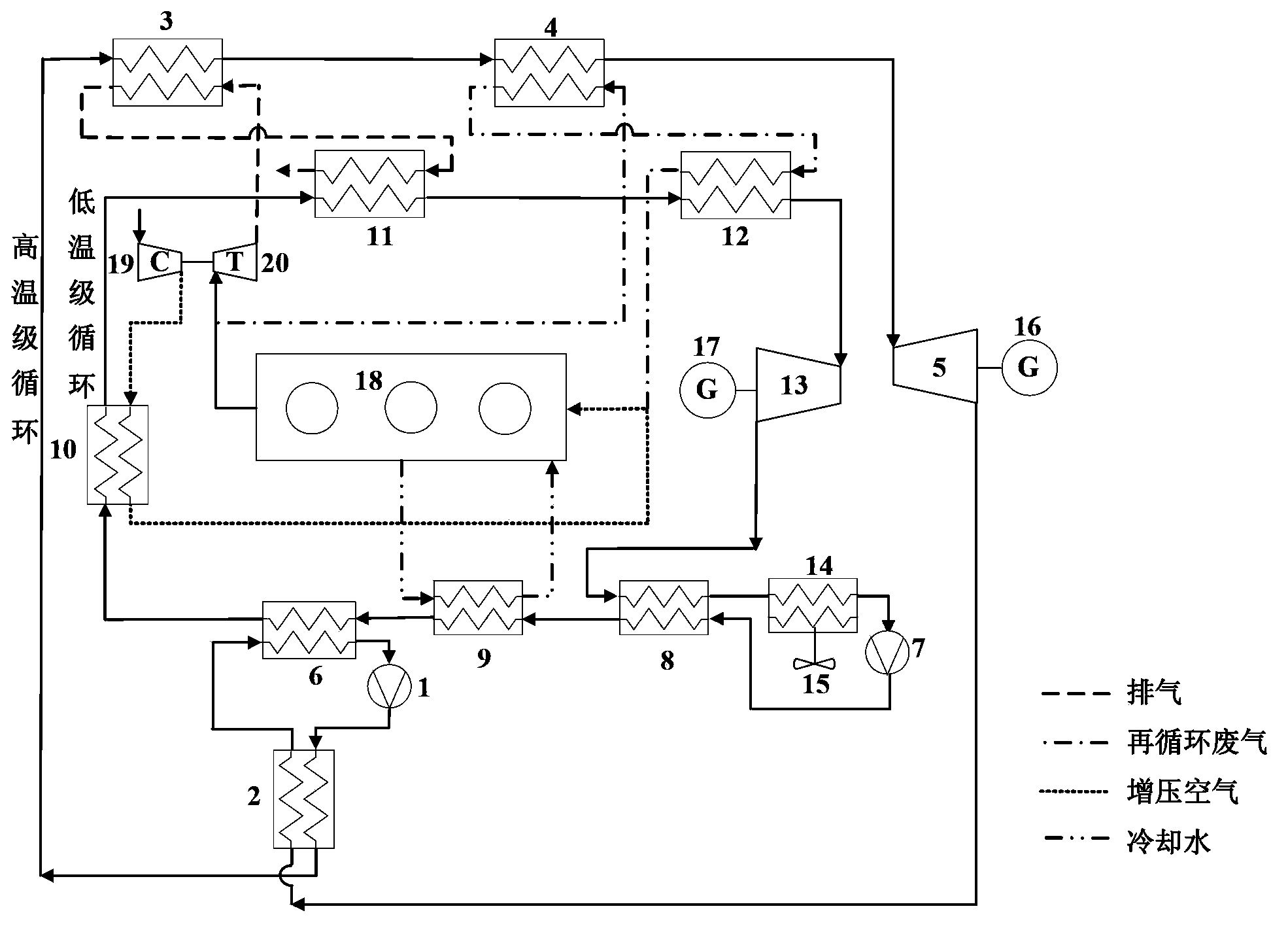

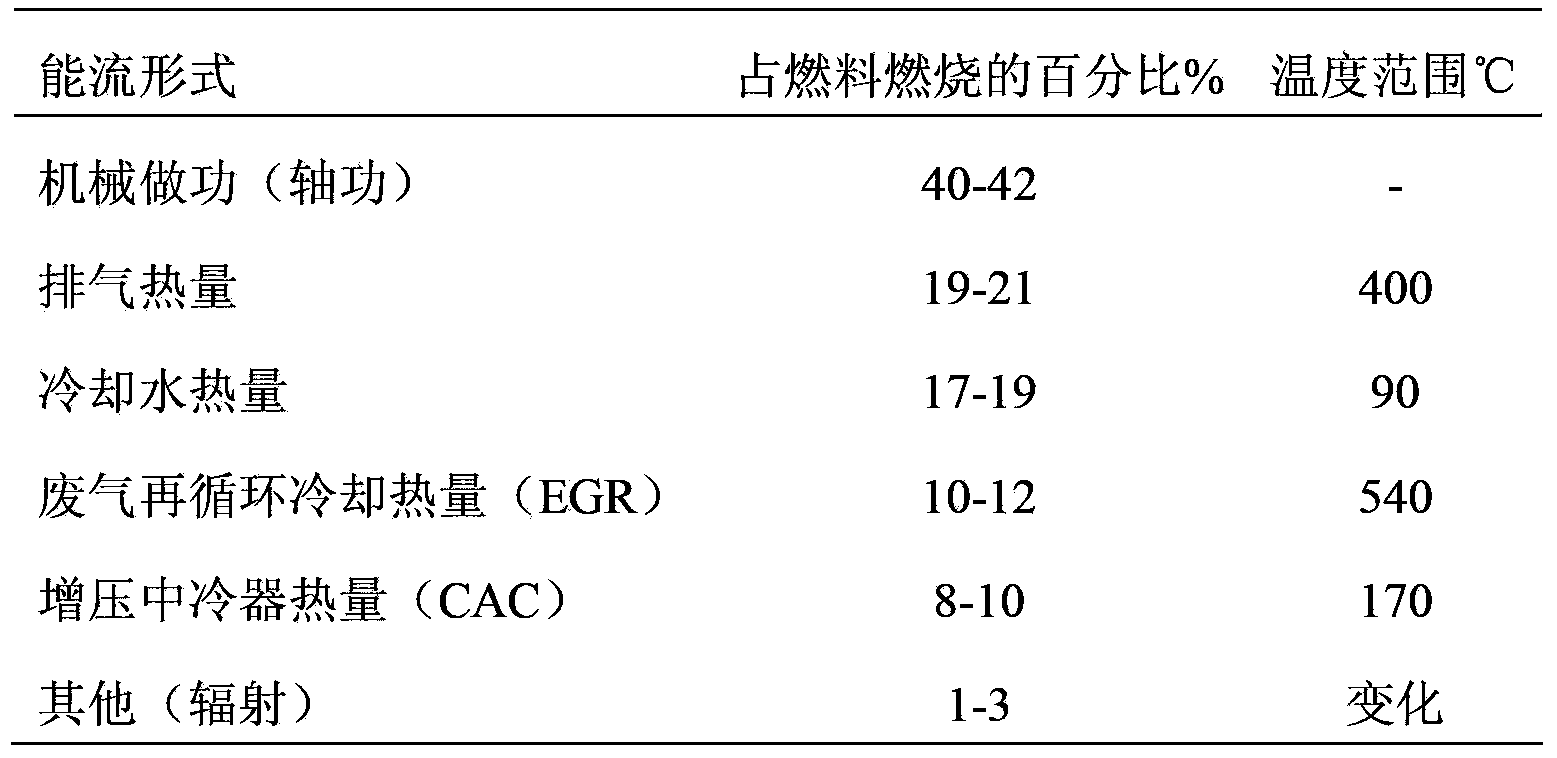

The invention provides a combined cycle thermoelectric conversion system utilizing multi-grade waste heat of an internal combustion engine. According to the system, combined organic Rankine cycle is formed by high-temperature grade cycle and low-temperature grade cycle, heat is supplied by exhaust waste heat of the internal combustion engine, supercharged and mid-cooling waste heat, exhaust gas recirculation waste heat and cooling water waste heat, a cooling quantity is provided by cold wind, and the system comprises a high-temperature grade working medium pump, a high-temperature grade heat regenerator, a high-temperature grade exhaust heater, a high-temperature grade EGR (exhaust gas recirculation) heater, a high-temperature grade expansion engine, a high-temperature grade condenser, a low-temperature grade working medium pump, a low-temperature grade heat regenerator, a low-temperature grade cooling water heater, a low-temperature grade supercharged air heater, a low-temperature grade exhaust heater, a low-temperature grade EGR heater, a low-temperature grade expansion engine, a low-temperature grade condenser, a low-temperature grade condenser fan and a power generator. According to the combined cycle thermoelectric conversion system utilizing multi-grade waste heat of the internal combustion engine, comprehensive and efficient utilization of multi-grade waste heat of the internal combustion engine can be achieved, further, irreversible loss is smaller when both the high temperature and the low temperature adopt supercritical expanding cycle, and the integral efficiency of the internal combustion engine can be effectively improved.

Owner:TIANJIN UNIV

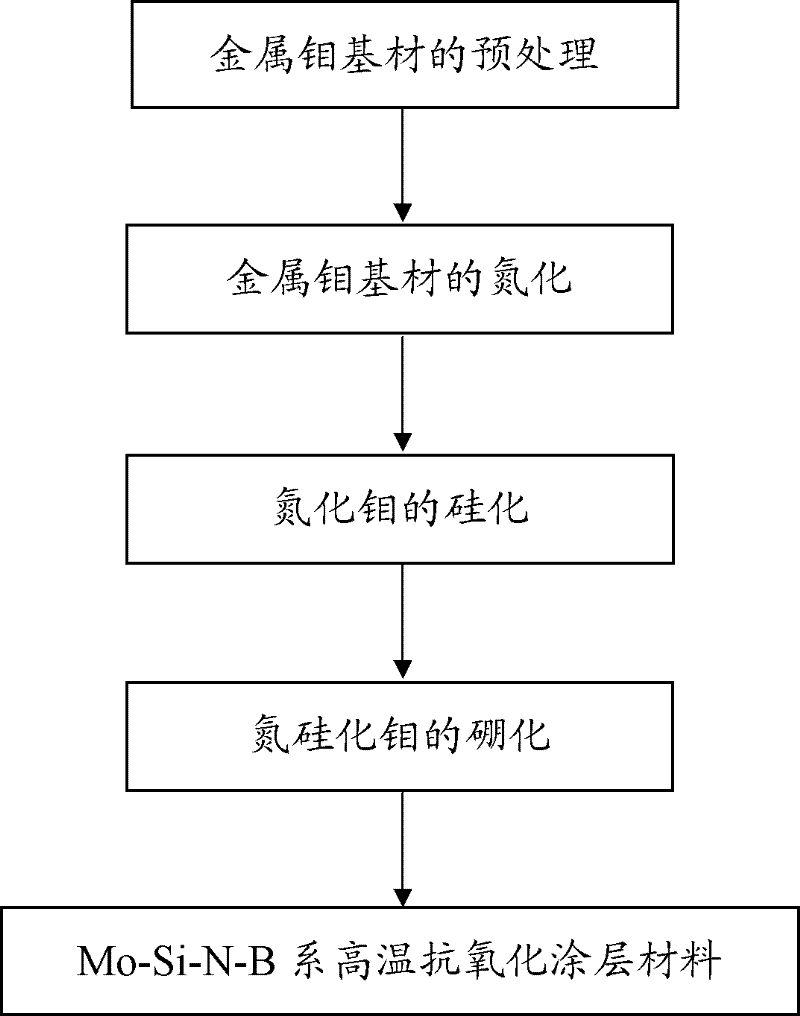

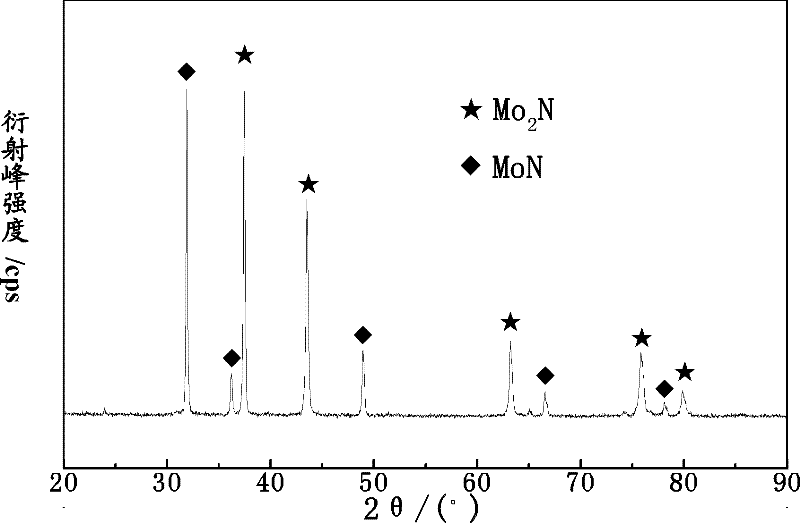

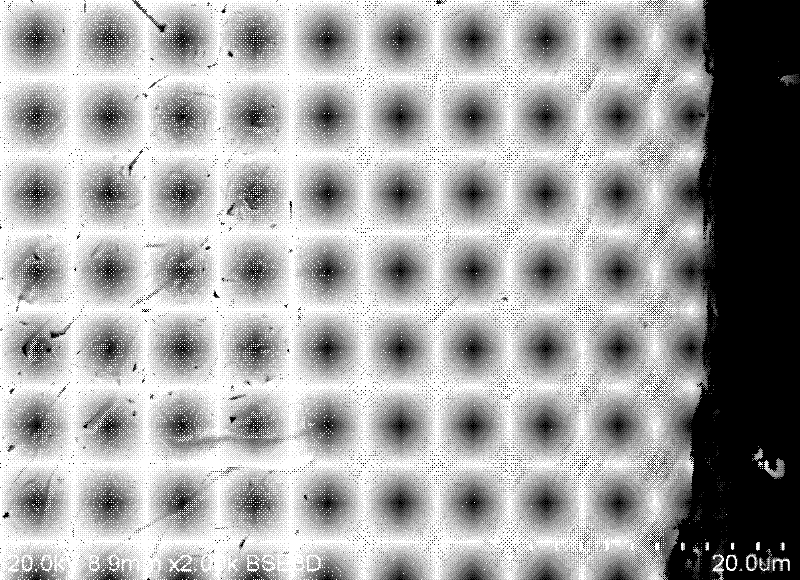

High temperature anti-oxidation coating molybdenum material and preparation method thereof

ActiveCN102534469AImprove compactnessGood heat matchingSolid state diffusion coatingSynthesis methodsSlurry

The invention discloses a high temperature anti-oxidation coating molybdenum material and a preparation method thereof. The surface of a product is provided with a Mo-N-Si-B anti-oxidation coating which is synthesized by adopting a three-step in situ synthesis method. Compared with the prior art, the product has good high temperature anti-oxidation performance and is good in material compactness, and hot matching performance between the coating and a base body is good. The preparation method does not need expensive devices such as plasma spraying, chemical vapor deposition or infiltration, avoids a complex process of a slurry method and is simple in preparation process, low in production cost and easy in controlling of coating structures and phase states.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD +1

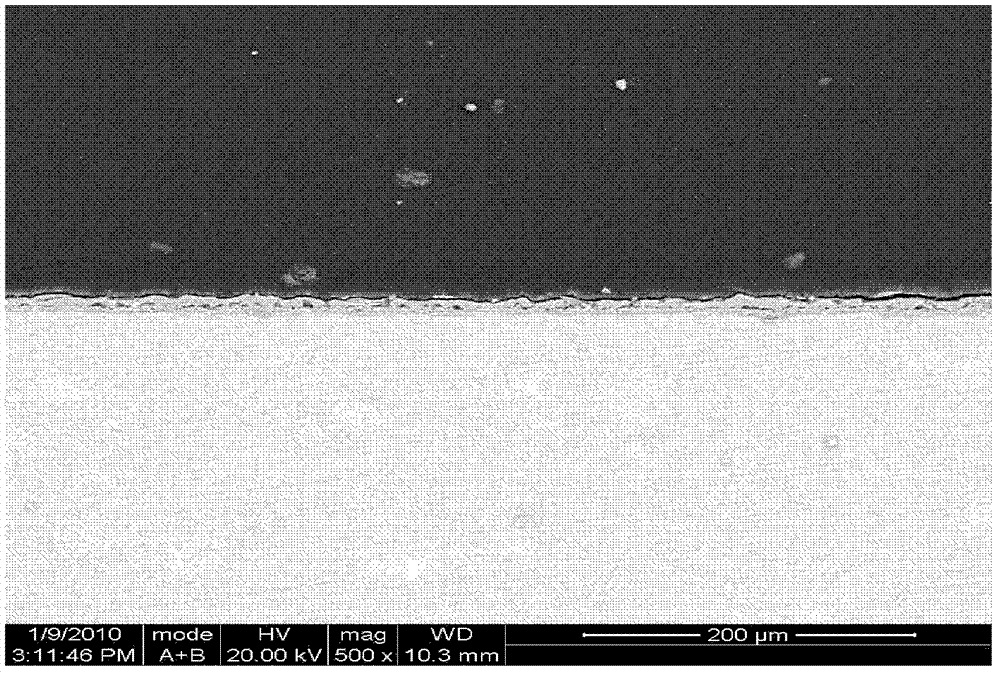

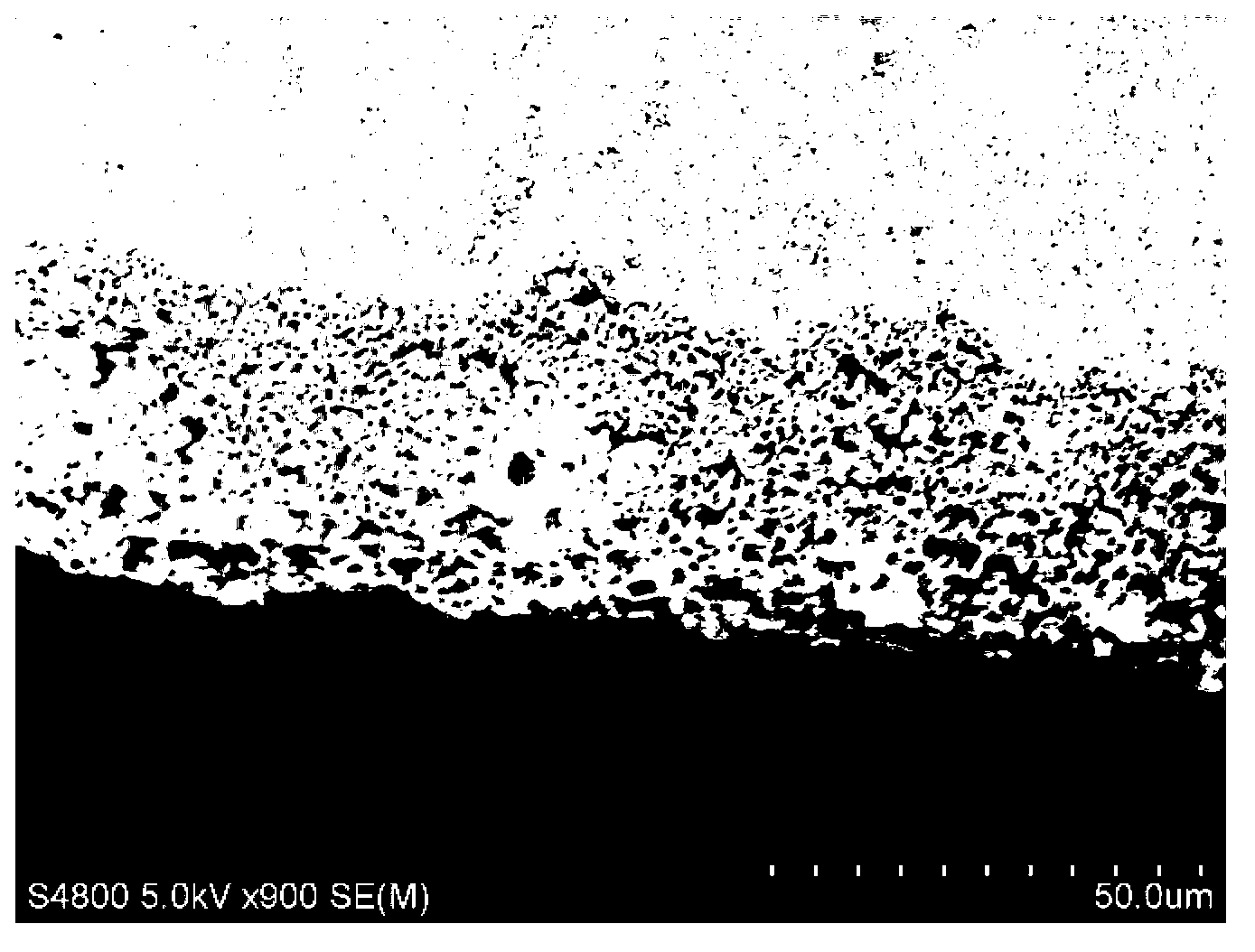

Magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and preparation method thereof

InactiveCN103085379AAchieving densification and sealingReduce defectsAnodisationCeramic layered productsCross-linkMicro arc oxidation

The present invention discloses a magnesium alloy surface micro-arc oxidation nanometer self-assembly metal ceramic coating and a preparation method thereof. The coating comprises a micro-arc oxidation ceramic layer, a self-assembly nanometer film and an inorganic metal ceramic coating, wherein the micro-arc oxidation ceramic layer, the self-assembly nanometer film and the inorganic metal ceramic coating are sequentially attached on the magnesium alloy surface. The preparation method comprises: carrying out plasma electrolysis oxidation on the surface of a magnesium alloy substrate to form a micro-arc oxidation ceramic coating, then carrying out dipping or high pressure spraying of a self-assembly nanometer film as a connection layer on the surface of the ceramic layer, and adopting a low temperature sintering method to prepare an inorganic metal ceramic coating on the surface of the self-assembly nanometer film. According to the present invention, the head group of the self-assembly nanometer film and the micro-arc oxidation bottom layer ceramic layer form chemical bonding, and a sealing treatment is performed on micro-pores of the micro-arc oxidation film; a high density cross-linking effect on active function groups in the inorganic metal ceramic coating by the self-assembly nanometer film is achieved through the end group; and the magnesium alloy surface composite protection coating prepared by using the method has characteristics of good bonding strength, corrosion resistance, scratching resistance and high hardness.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of heat-insulating ceramic phenolic resin-based gradient composite material

The invention discloses a preparation method of a heat-insulating ceramic phenolic resin-based gradient composite material. Fiber cloth is used as a reinforcing phase, and the fiber cloth is respectively dipped in different gum dipping solutions with the phenolic resin as a matrix and contents of ceramic components and hollow microbeads in gradient distribution to prepare a prepreg; laminating, die pressing and thermal curing molding at 150-200 DEG C to obtain the gradient composite material comprising a heat-proof layer, a gradient transition layer and a heat-insulating layer. When the temperature of the gradient composite material is as high as 1000 DEG C, the heat-proof layer can be converted into a ceramic phase with higher strength and can resist heat flow erosion; the gradient transition layer can relieve stress concentration and reduce stress; and hollow microspheres are added to guarantee that the heat-insulating layer has good thermal matching performance.

Owner:WUHAN UNIV OF TECH

High temperature conductive binding material for aluminium electrolysis

InactiveCN1552788AHigh bonding strengthImprove conductivityElectrically-conducting adhesivesAluminium electrolysisElectrical conductor

An electric conducting refractory adhesive for the aluminium electrolysis, especially for carbon anode, carbon cathode, inertial anode and wettable TiB2 cathode, is prepared from electric conducting powder, resin adhesive, solidifying agent, solvent, reinforcing agent and additives. It has high adhesion, electric conductivity, heat shock resistance and high-temp mechanical performance.

Owner:CENT SOUTH UNIV +1

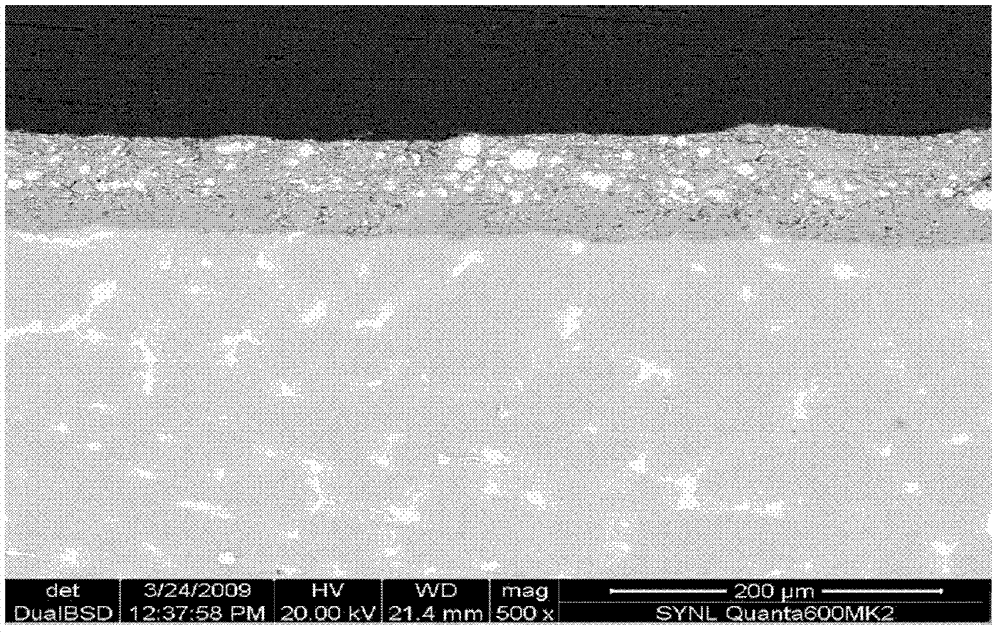

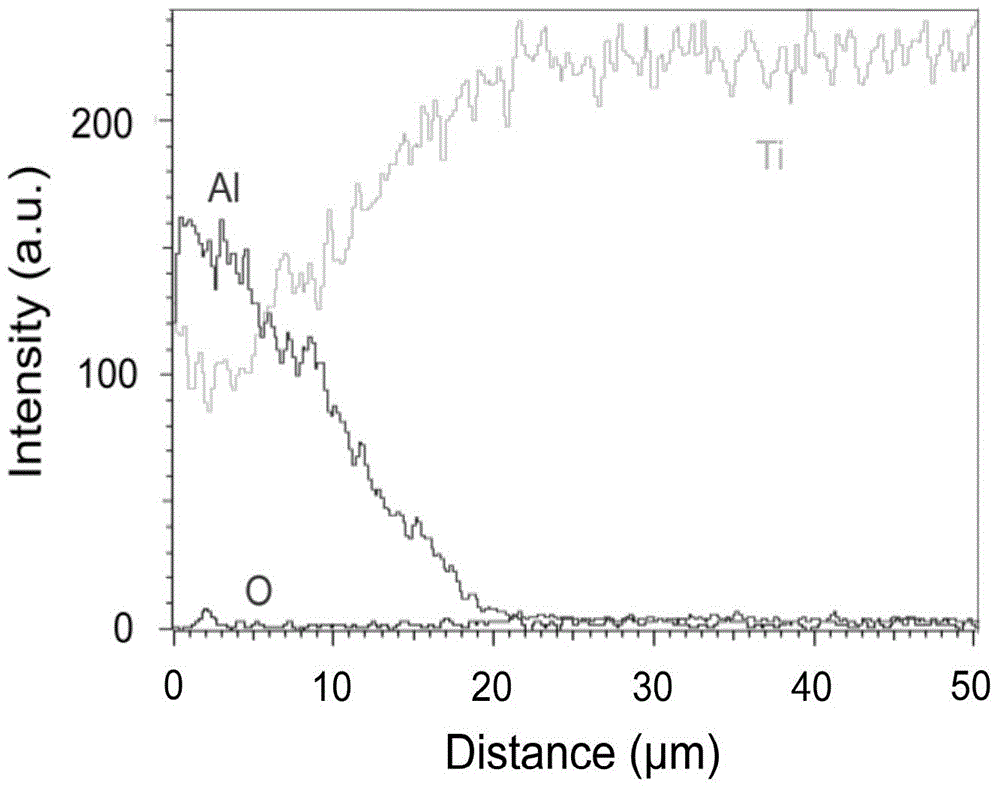

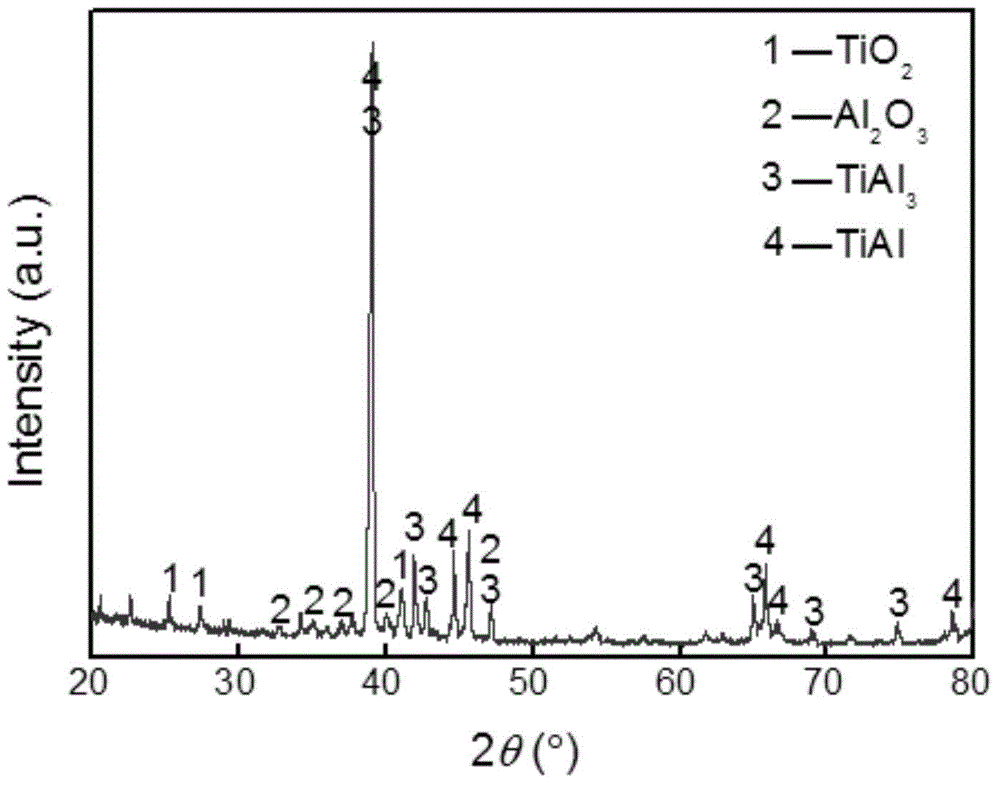

Preparation method of titanium substrate surface high-temperature antioxidant composite coating

ActiveCN104674218AImprove high temperature oxidation resistanceContinuous and dense structureVacuum evaporation coatingSurface reaction electrolytic coatingOxide ceramicsOxidation resistant

The invention discloses a preparation method of a titanium substrate surface high-temperature antioxidant composite coating. The preparation method comprises the following steps: I, carrying out the surface polishing treatment for a titanium substrate, oxidizing the titanium substrate subjected to the surface polishing treatment to obtain a titanium substrate with a titanium dioxide ceramic layer on the surface, and depositing metal aluminum on the titanium dioxide ceramic layer to obtain the titanium substrate with a titanium dioxide ceramic layer and an aluminum coating on the surface; and II, carrying out the vacuum heat treatment for the titanium substrate with the titanium dioxide ceramic layer and the aluminum coating on the surface, and obtaining a high-temperature antioxidant composite coating on the surface of the titanium substrate. The high-temperature antioxidant composite coating consisting of Ti and Al intermetallic compounds and oxide ceramics can be prepared on the surface of the titanium substrate, and the high-temperature antioxidant composite coating structure is continuous and compact and has no hole defect; moreover, the surface of the high temperature antioxidant composite coating is provided with an Al2O3 membrane, the Al2O3 membrane can prevent an oxygen element from diffusing into the titanium substrate, and the high temperature antioxidant capability of the titanium substrate can be improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

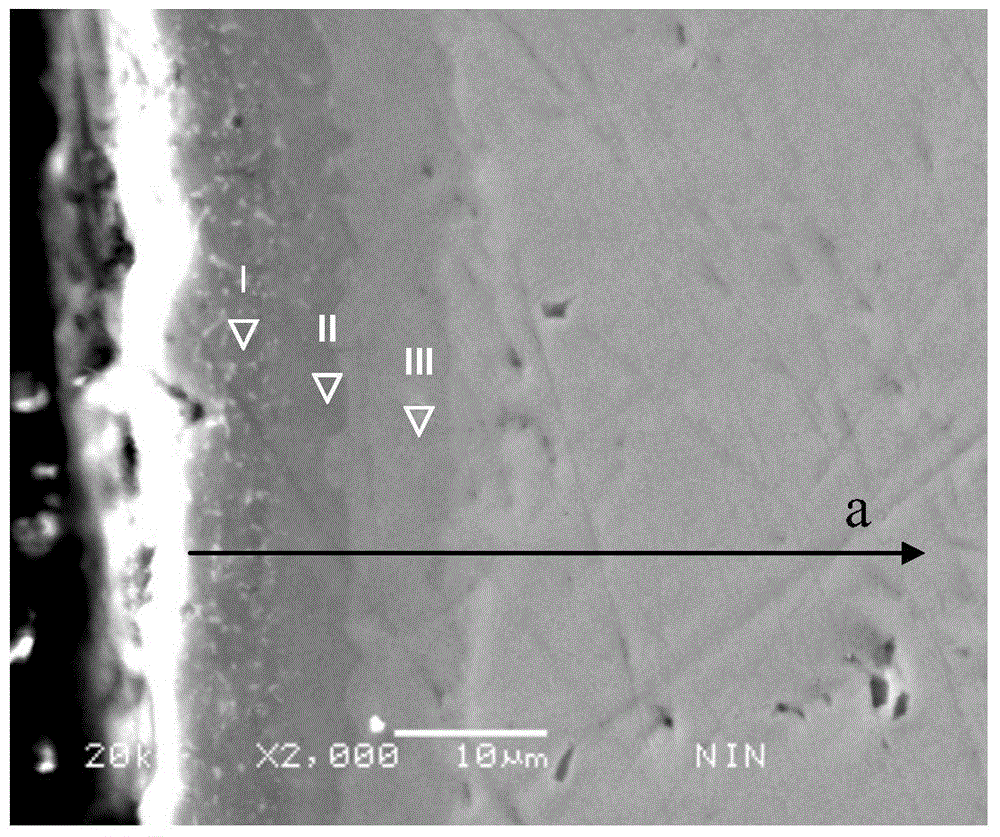

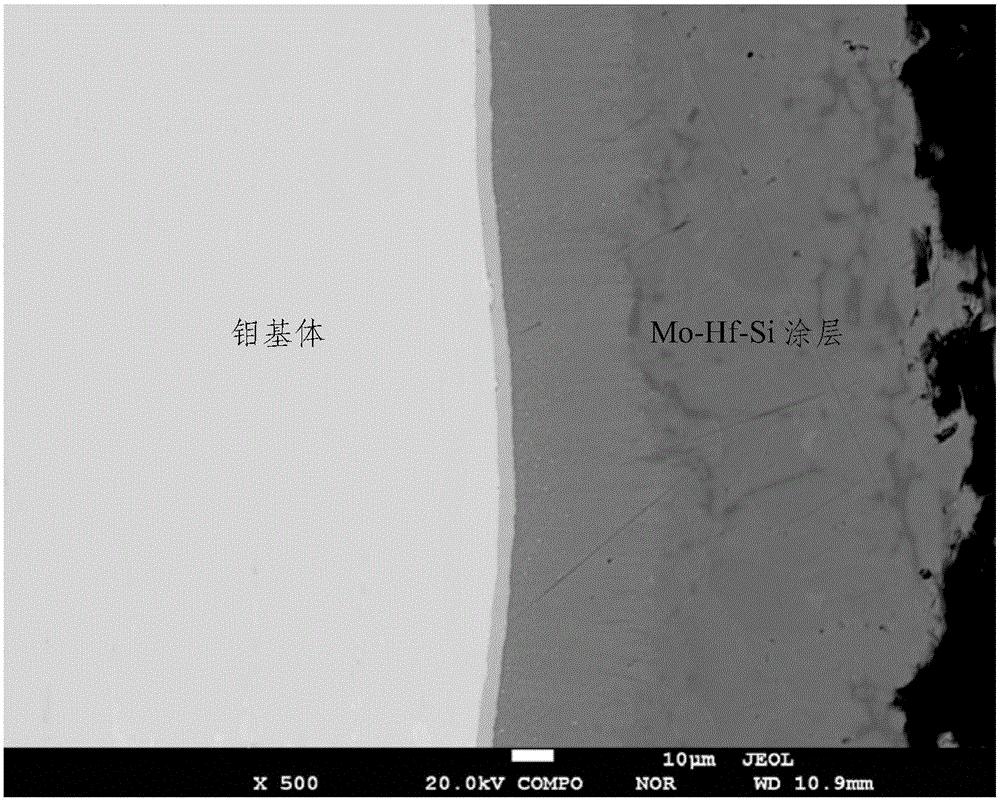

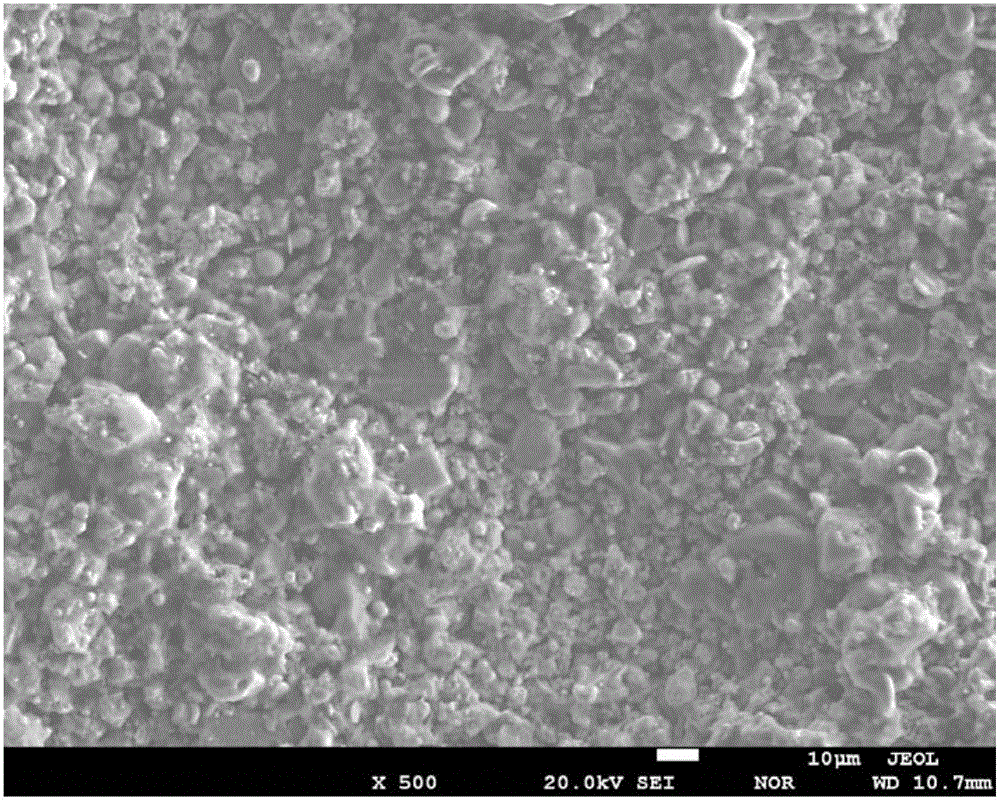

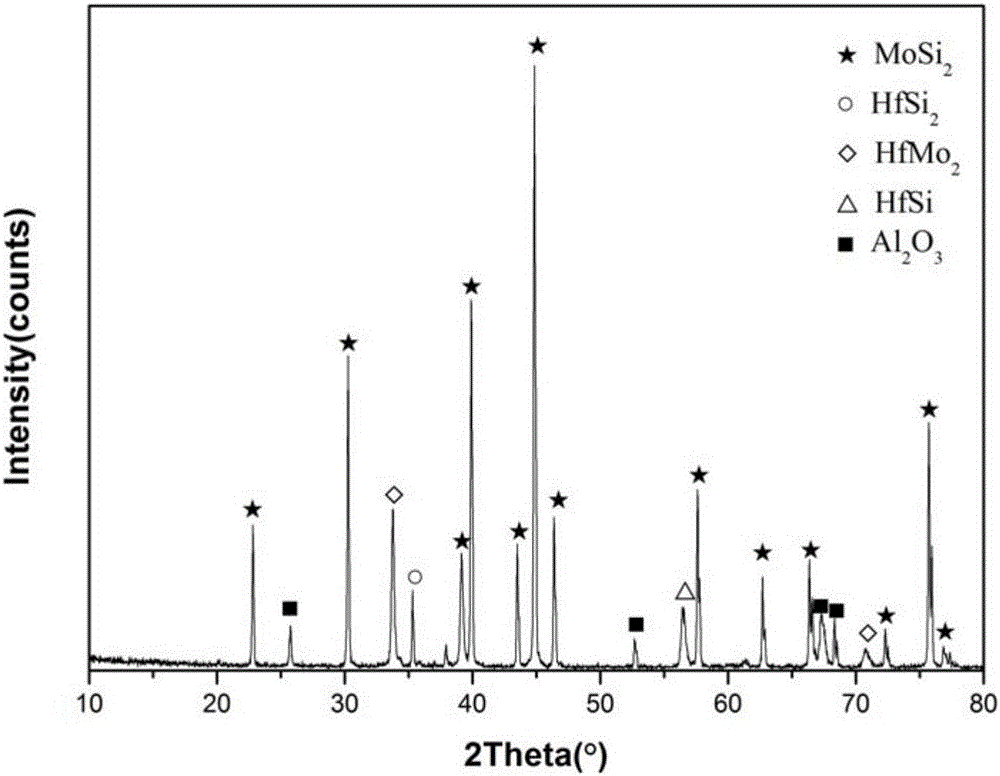

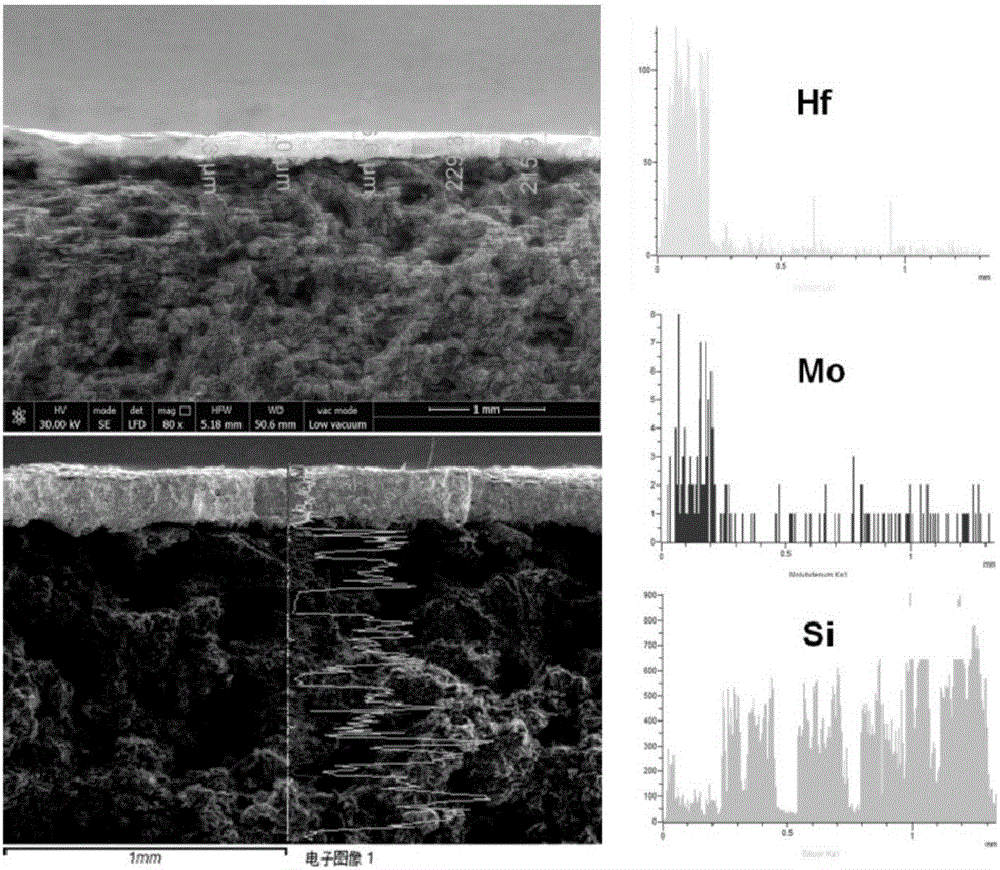

Molybdenum alloy high-temperature anti-oxidation Mo-Hf-Si coating and preparation method thereof

ActiveCN106119829AHigh bonding strengthGood high temperature oxidation resistanceHeat inorganic powder coatingSpray coatingThermal expansion

The invention relates to a molybdenum alloy high-temperature anti-oxidation Mo-Hf-Si coating and a preparation method of the molybdenum alloy high-temperature anti-oxidation Mo-Hf-Si coating and belongs to the field of preparation of high-temperature anti-oxidation coatings. The coating is composed of, by mole ratio, 15-25% of Mo, 8-15% of Hf, 65-75% of Si and 2-5% of an additive. According to the molybdenum alloy high-temperature anti-oxidation Mo-Hf-Si coating and the preparation method, the coating is prepared through a slurry sintering method, a molybdenum alloy is polished, cleaned and dried, the raw materials of the coating are allocated and taken according to the design components and are ball-milled, and slurry is prepared; the surface of the molybdenum alloy is evenly coated with the slurry in a spray coating manner or dip coating manner, vacuum sintering is conducted for 20 minutes to 40 minutes at the temperature of 1,450 DEG C to 1,550 DEG C, and the coating is prepared; and the preparation process is simple, the coating is dense and even, the thermal expansion coefficient of the coating is matched with that of a molybdenum base body, and the high-temperature anti-oxidation performance of the molybdenum alloy can be improved effectively.

Owner:CENT SOUTH UNIV

Yttrium modified chromium aluminium carbonitride/silicon nitride nano composite coating and deposition method thereof

ActiveCN103436841AHigh bonding strengthGood heat matchingLayered productsVacuum evaporation coatingRare-earth elementAlloy

The invention relates to a yttrium modified chromium aluminium carbonitride / silicon nitride nano composite coating and a deposition method thereof. Chromium aluminium carbonitride and silicon nitride are subjected to nano composite design to form a nano composite structure with nanocrystal chromium aluminium carbonitride implanted into amorphous silicon nitride, so that the rigidity of the coating is improved; the toughness of the coating and bonding strength of the coating and a matrix are both considered; a rare earth element Y is introduced simultaneously, so that the mechanical property and high-temperature oxidation resistance of the coating are further improved; and the nano composite coating which is strong in bonding force, high in rigidity, good in toughness, low in friction coefficient and prominent in thermostability and is used for high-speed steel and hard alloy cutters and molds is obtained. The coating comprises a chromium-aluminum-yttrium bonding layer, a chromium-aluminum-yttrium nitride transition layer and a nano composite layer; the membrane / matrix bonding strength of the obtained coating reaches 40-90N; the surface composite strength under 10g load reaches 40-65 GPa; and the friction coefficient is 0.2-0.5 when matched with GCr15.

Owner:JIANGXI SCI & TECH NORMAL UNIV

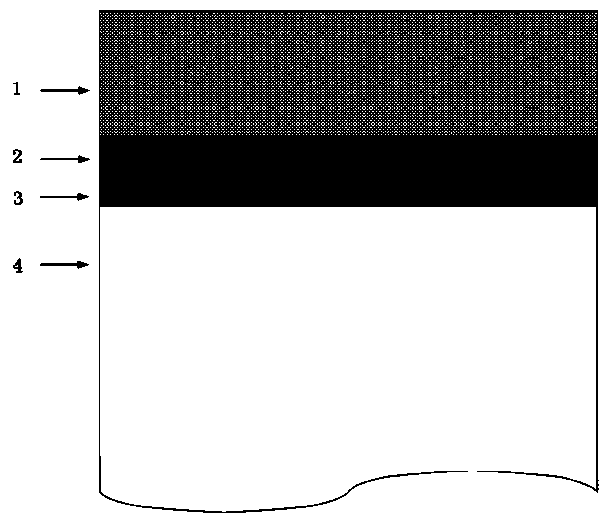

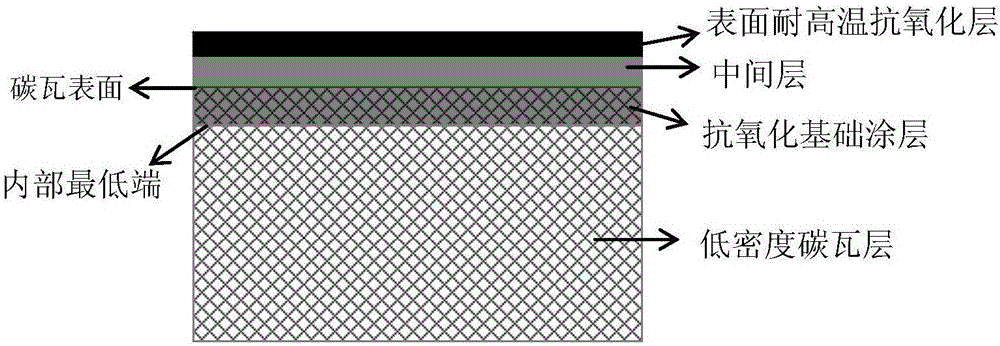

Low-density carbon-tile surface oxidation-resistant coating capable of resisting temperature of 1700 DEG C and preparation method thereof

The invention relates to a low-density carbon-tile surface oxidation-resistant coating capable of resisting the temperature of 1700 DEG C and a preparation method thereof, and belongs to the technical field of heat protective materials. For the requirement of heat protective systems of novel near-space aerocrafts and reusable launch vehicles for the heat protective materials with integrated functions of high-temperature resistance, light weight and heat insulation, the invention provides a low-density carbon-tile surface oxidation-resistant coating system capable of resisting the temperature of 1700 DEG C and a preparation method thereof. The coating is a composite coating with a gradient transition structure. The composite coating comprises an oxidation-resistant layer and a surface high-temperature-resistant oxidation-resistant layer, wherein the oxidation-resistant layer is formed by doping oxidation-resistant components such as Si, B, C and O and the like in a porous carbon-fiber skeleton; and the surface high-temperature-resistant oxidation-resistant layer is composed of compact M(M is Hf, Zr)B2-MoSi2 ultrahigh-temperature ceramic components.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

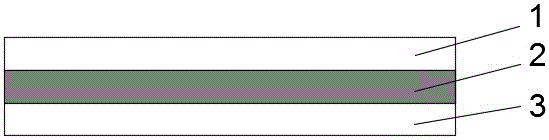

Ceramic metal composite substrate and production method thereof

The invention relates to a ceramic metal composite substrate and a production method thereof. The substrate mainly comprises an ultrathin ceramic sheet, a heat conduction glue and a metal substrate; the ceramic powder of the ultrathin ceramic sheet is a micropowder and a nanopowder mixture, and the volume proportion of nanopowder in the ceramic powder is 15-25%; and the heat conduction glue comprises, by volume, 20-30% of a one-dimensional high heat conduction material. The production method mainly comprises the following steps: making the ultrathin ceramic sheet; carrying out surface treatment on the metal substrate, coating the metal substrate with the heat conduction glue through a coating technology, and carrying out drying semi-solidification; and carrying out hot pressing on the ultrathin ceramic sheet and the glued metal substrate. The ceramic metal composite substrate has a good heat conduction performance, and has a good heat matching performance with chips, and the method has a high production efficiency, and is in favor of realizing development of the substrate to a small, light and thin direction. Tape casting makes the production efficiency of the ultrathin ceramic sheet be high; and the heat conduction glue comprises the one-dimensional high heat conduction material, so thermal resistance between the ultrathin ceramic sheet and the metal substrate is reduced.

Owner:SHANTOU UNIV

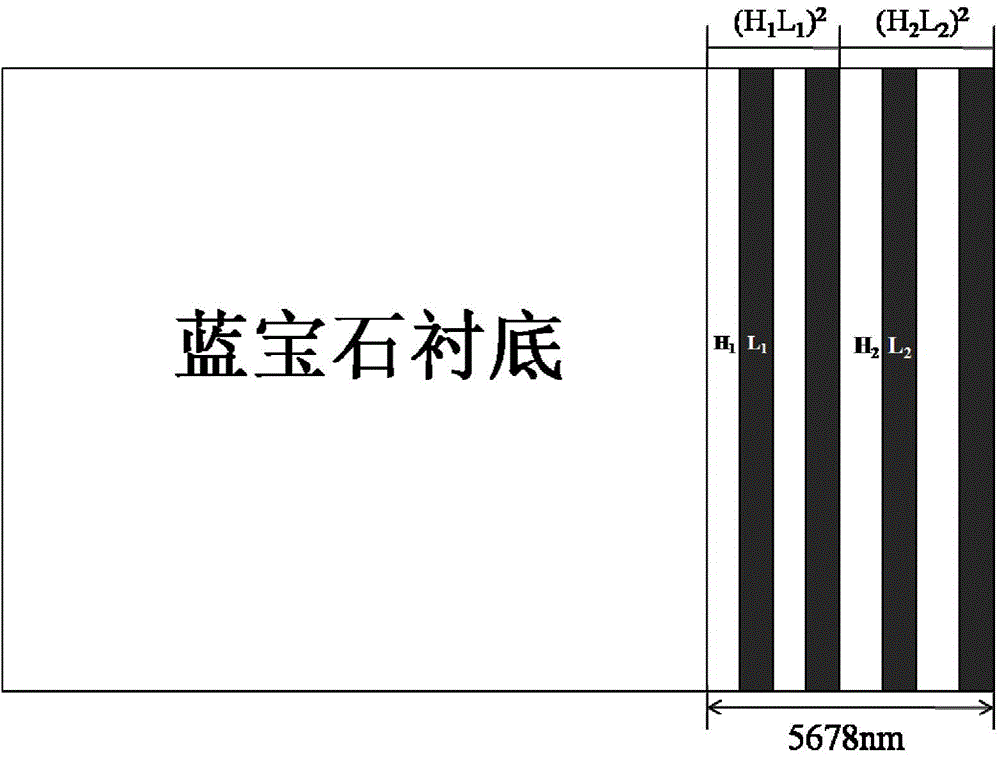

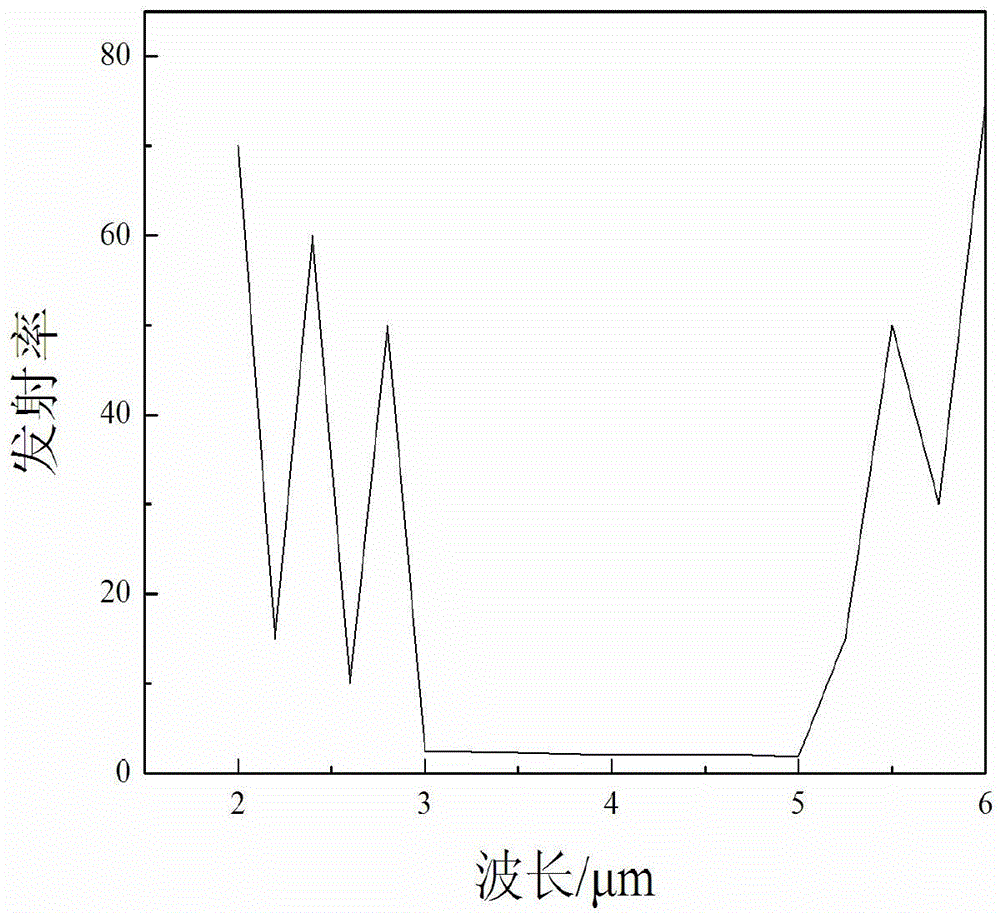

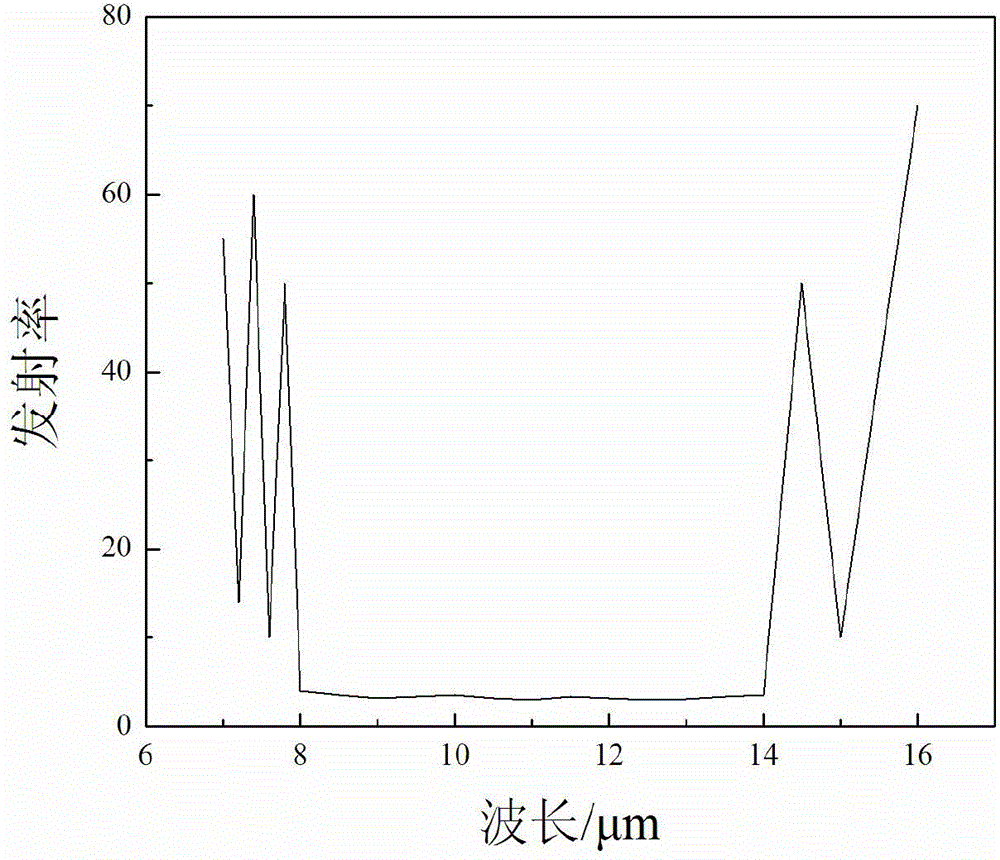

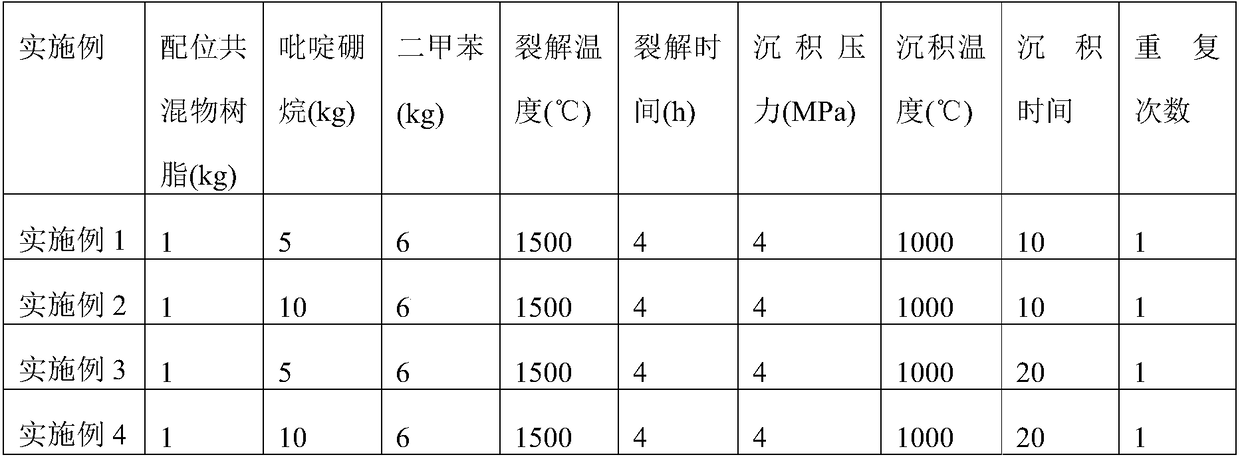

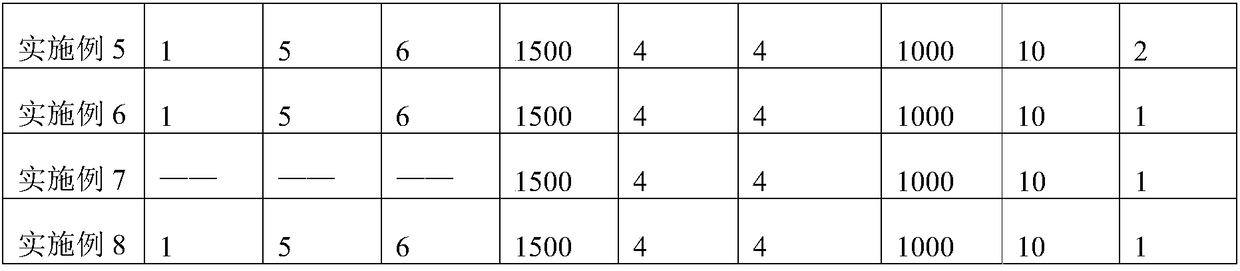

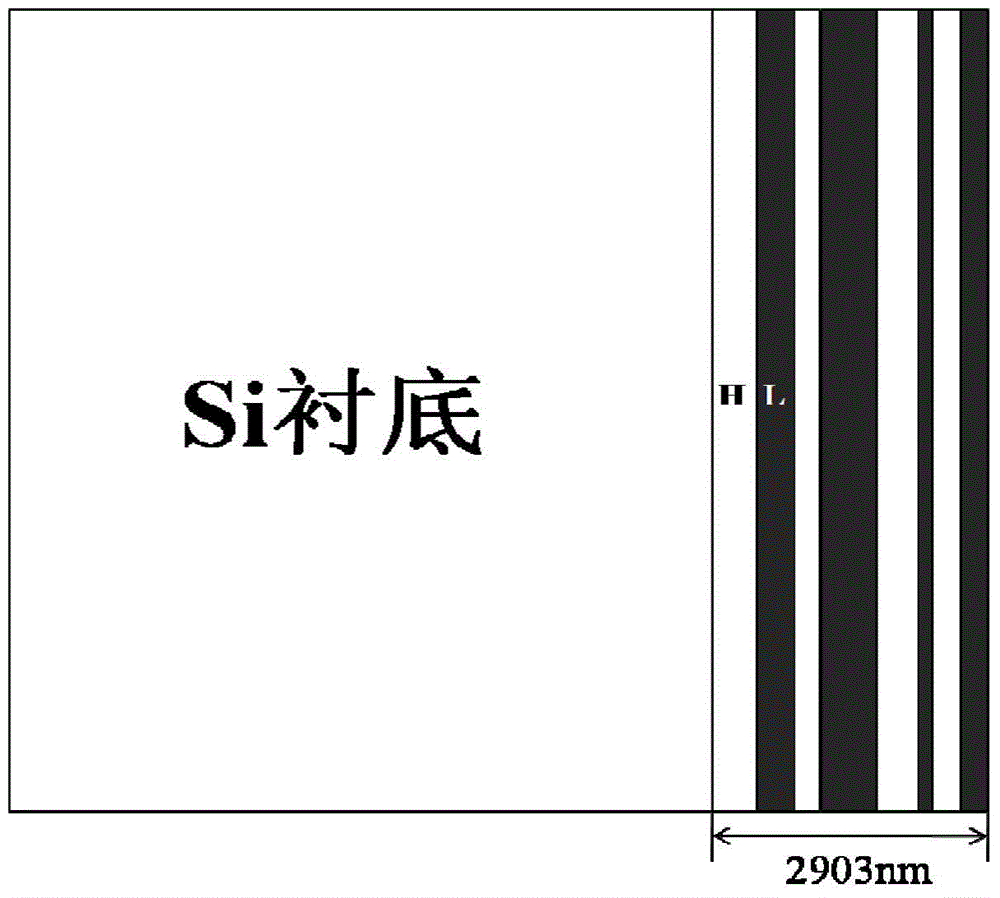

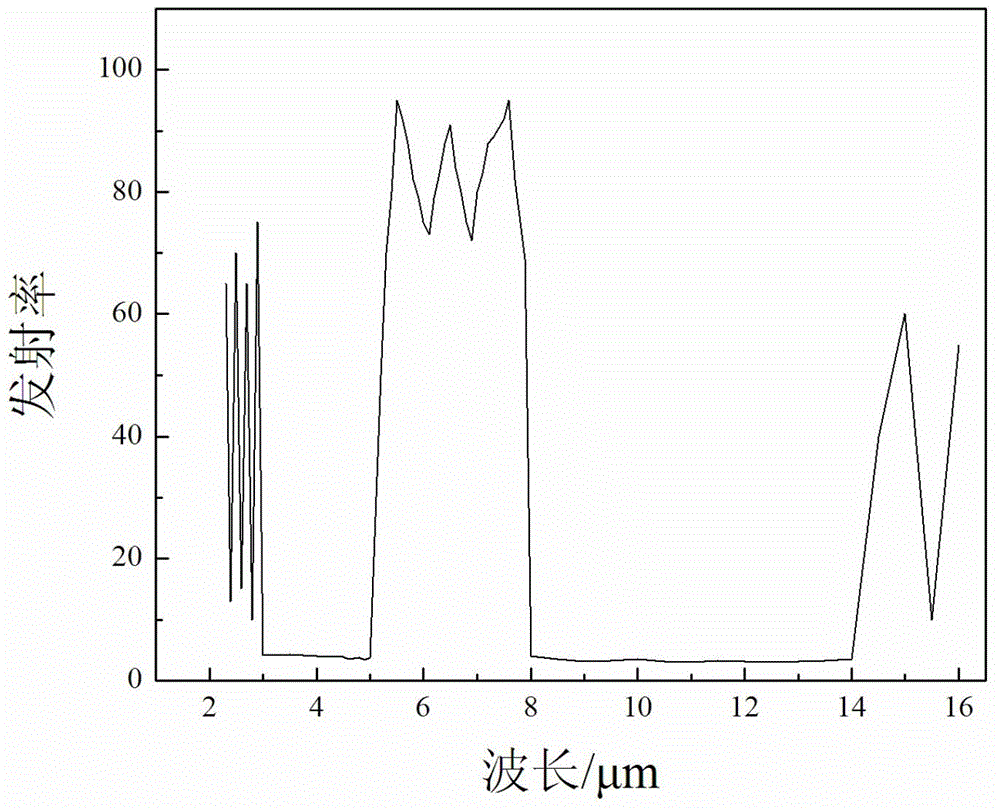

Infrared stealth thin film with spectral selectivity and low emission rate and preparation method of infrared stealth thin film

ActiveCN104865618ANot easy to fall offGood heat matchingVacuum evaporation coatingSputtering coatingEmissivityRadio frequency magnetron sputtering

The invention relates to an infrared stealth thin film with spectral selectivity and low emission rate. The infrared stealth thin film is of a multi-layer superimposed structure; the multi-layer superimposed structure contains a periodically-laminated structure which is formed by alternately superimposing high-refractive index material layers and low-refractive index material layers; and the periodically-laminated structure includes a first multilayer structure and a second multilayer structure of which the center wavelengths are lambda 1 and lambda 2 respectively, wherein the first multilayer structure and the second multilayer structure are superimposed in a complex manner, the lambda 1 satisfies the expression that 3.0 microns<=lambda 1<= 5.0 microns, and the lambda 2 satisfies the expression that 8.0 microns<=lambda 2<=14.0 microns. The preparation method of the infrared stealth thin film includes the steps that: a substrate is cleaned; a Si thin film is plated on the substrate by means of sputtering and through adopting a radio frequency magnetron sputtering method, and a ZnS thin film is plated on the high-refractive index material layer by means of sputtering and through adopting a radio frequency magnetron sputtering method; the previous steps are repeated for a plurality of periods, and alternate control on designed thicknesses is utilized in combination, and therefore, the infrared stealth thin film with spectral selectivity and low emission rate can be obtained. The preparation method of the infrared stealth thin film of the invention has the advantages of simple preparation process, high repeatability, low equipment requirements, excellent product performance and favorable application effect.

Owner:NAT UNIV OF DEFENSE TECH

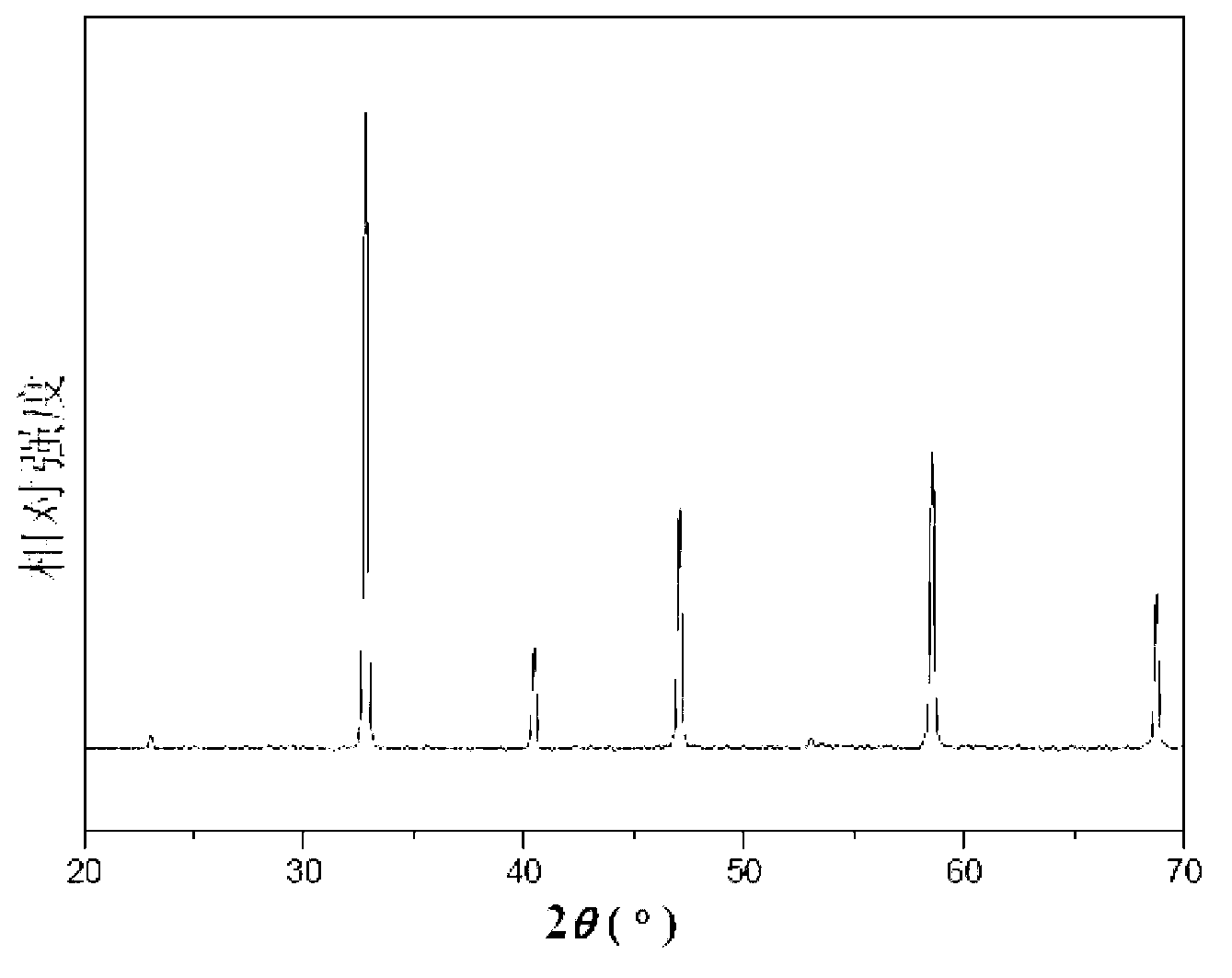

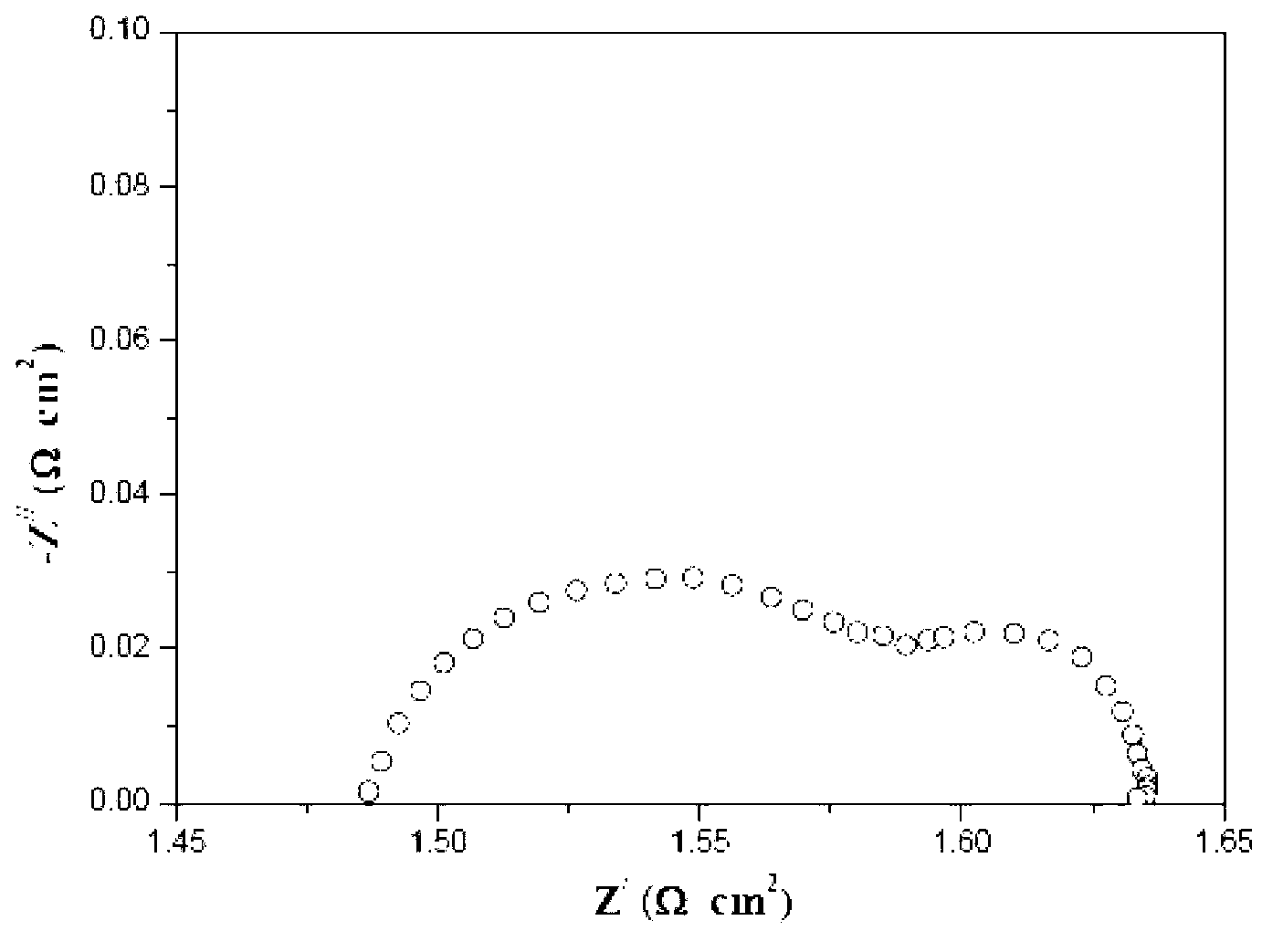

Intermediate temperature solid oxide fuel cell cathode material with perovskite structure and preparation method thereof

InactiveCN102842723AHigh oxygen permeabilityImprove thermal stabilityCell electrodesSpontaneous combustionNitrate

An intermediate temperature solid oxide fuel cell cathode material with a perovskite structure and a preparation method thereof relate to a cell cathode material and a preparation method thereof. The invention solves the problem that under the intermediate-temperature working conditions, existing cathode materials difficultly satisfy the requirements of the intermediate temperature solid oxide fuel cell for the cathode material because existing materials do not have the characteristics of low polarization resistance and overpotential, and high mixed conductivity, oxygen permeability, thermal stability and chemical stability. The intermediate temperature solid oxide fuel cell cathode material with the perovskite structure disclosed by the invention has the general formula of AFe1-xMxO3, wherein A is Ca, Sr or Ba, M is Cu, Co or Ni, x is greater than 0.1 and smaller than 1.0. The preparation method comprises the following steps: preparing nitrate and glycine mixed liquor, heating the mixed liquor until spontaneous combustion, and then sintering to obtain the AFe1-xMxO3. The AFe1-xMxO3 prepared by the invention has good performance. The cathode material and the method disclosed by the invention are suitable for the intermediate temperature solid oxide fuel cell cathode material and the preparation thereof.

Owner:HEILONGJIANG UNIV

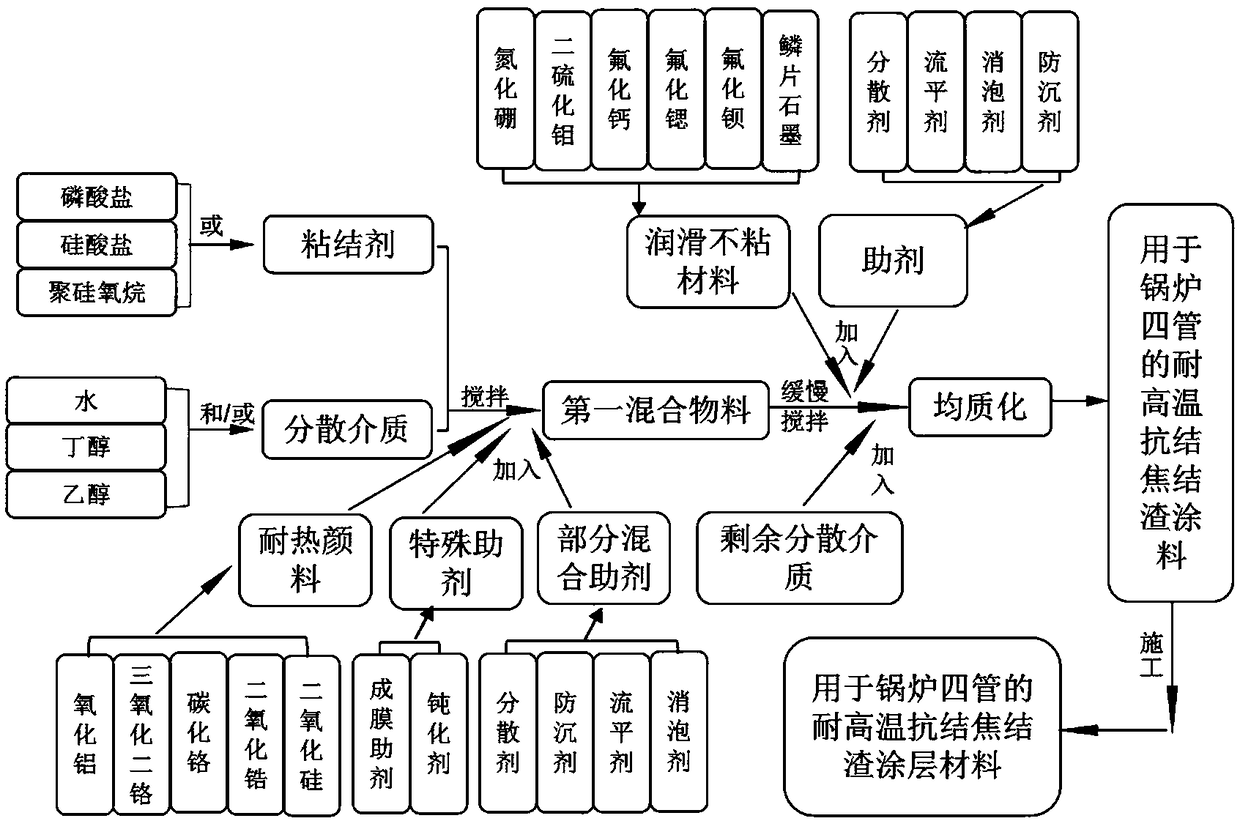

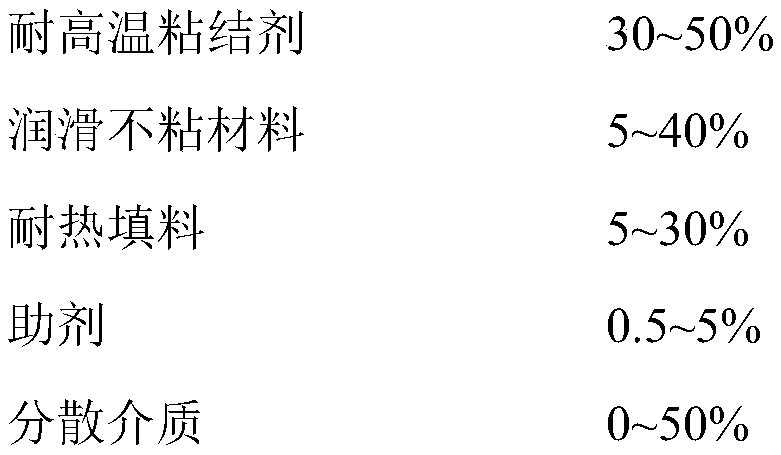

Anti-coking and anti-slagging coating material for four tubes of boiler and preparation method of anti-coking and anti-slagging coating material

InactiveCN109486414AEasy constructionSmall amount of workFireproof paintsAlkali metal silicate coatingsHeat resistanceMaterials science

The invention discloses an anti-coking and anti-slagging coating material for four tubes of a boiler as well as a preparation method and a construction process of the anti-coking and anti-slagging coating material. The anti-coking and anti-slagging coating material comprises the components in percentage by mass: 30-50% of high-temperature-resistant binder, 5-40% of lubricating nonstick material, 5-30% of heat-resistant filler, 0.5-5% of auxiliaries and 0-50% of dispersion medium. The coating material is prepared by using a special preparation method and is better in homogenization and stable in storage. The coating material is not only good in anti-coking and anti-slagging properties, good in long-term heat resistance and good in heat matching property with a substrate, but also good in binding adhesion for a metal substrate.

Owner:深圳陶金材料科技有限公司

Tamping paste for aluminum electrolytic cell and use method of tamping paste

The invention discloses tamping paste for an aluminum electrolytic cell and a use method of the tamping paste. The tamping paste mainly comprises carbonaceous aggregate, a binder, metal powder, an expansion agent and a curing agent. Normal-temperature tamping connection is conducted through the high-expansion high-conductivity tamping paste, and assembly is completed through the working procedures of paste preparation, cleaning of a dovetail groove and a cathode steel bar, laying of the thin-layer tamping paste on the bottom face of the dovetail groove, placing of the cathode steel bar, filling and tamping of the tamping paste, normal-temperature curing and the like. Compared with existing tamping paste and a use method of the existing tamping paste, the tamping paste for the aluminum electrolytic cell and the use method of the tamping paste have the beneficial effects that operation under the normal temperature is easy, and expansion and conductivity are high; the property of conduction between the cathode steel bar and a carbon block and the conductive property of the steel bar paste are improved, the aluminum electrolytic cell cathode voltage drop is reduced, the aluminum electrolysis energy consumption is saved, and the service life of an aluminum electrolytic cathode is prolonged.

Owner:CENT SOUTH UNIV

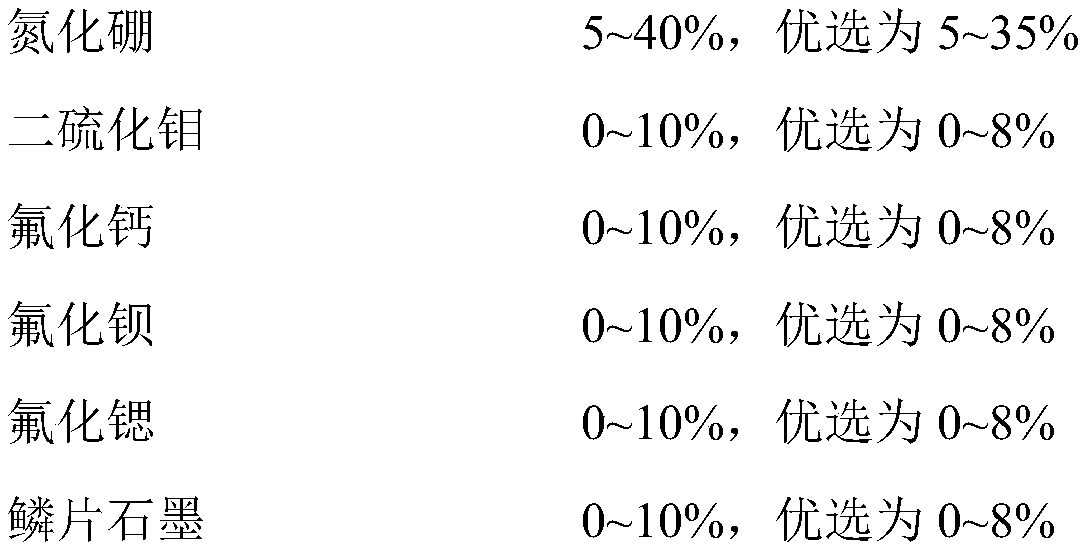

High-toughness ultrahigh-temperature ceramic-based composite material and preparation method thereof

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-strength and high-toughness ultrahigh-temperature ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: alternately depositing two coatings on the surface of the carbon fiber material by adopting a chemical vapor deposition method to obtain the carbon fiber material with the multilayer CVD composite coating, wherein the two coatings are one of a pyrolytic carbon layer or a layered ceramic coating and an ultrahigh-temperature ceramic coating; adopting a phenolic resin / epoxy resin solution and ceramic powder to form ceramic slurry, coating the CVD composite coating carbon fiber material with the ceramic slurry, performing alternately staggered stacking and needling to obtain a stacked fiber felt, and after vacuum drying, performing warm-pressing curing and carbonization treatment, and obtaining a porous prefabricated body; and finally, carrying out densification treatment to obtain the ceramic-based composite material. The material has high strength, high fracture toughness, oxidation resistance, ablation resistance and corrosion resistance, and can be applied to high-temperature and ultrahigh-temperature structural materials, oxidation-resistant and corrosion-resistant materials and aerospace ablation-resistant materials.

Owner:湖南兴晟新材料科技有限公司

Preparation method for metal ceramic composite coating on surface of aluminum alloy

InactiveCN102534720AHigh hardnessImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMechanical property

The invention discloses a metal ceramic film obtained from the surface of the aluminum alloy and a preparation method thereof. The preparation method of the film includes the steps: polishing an aluminum alloy surface, removing impurities of greasy dirt, dust and the like on the surface, conducting microarc oxidation treatment to the surface of the aluminum alloy; and then adopting a high current pulse electron beam to conduct of bombardment processing on the microarc oxidation surface for a plurality of times to prepare the metal ceramic reinforcing film. The preparation method can prepare a high-hardness abrasion-resistant coating on the surface of the aluminum alloy, can greatly improve combination strength of the coating by introducing a metal phase from a base body, improves toughness of ceramic layers, and obtains a metal ceramic coating with good mechanical property.

Owner:SHENYANG LIGONG UNIV

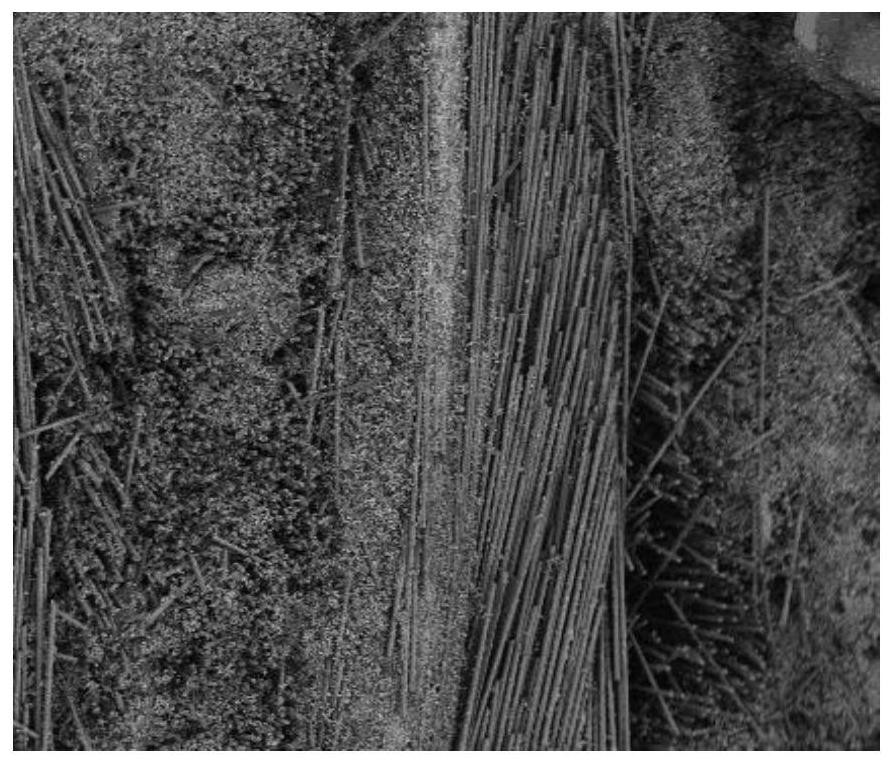

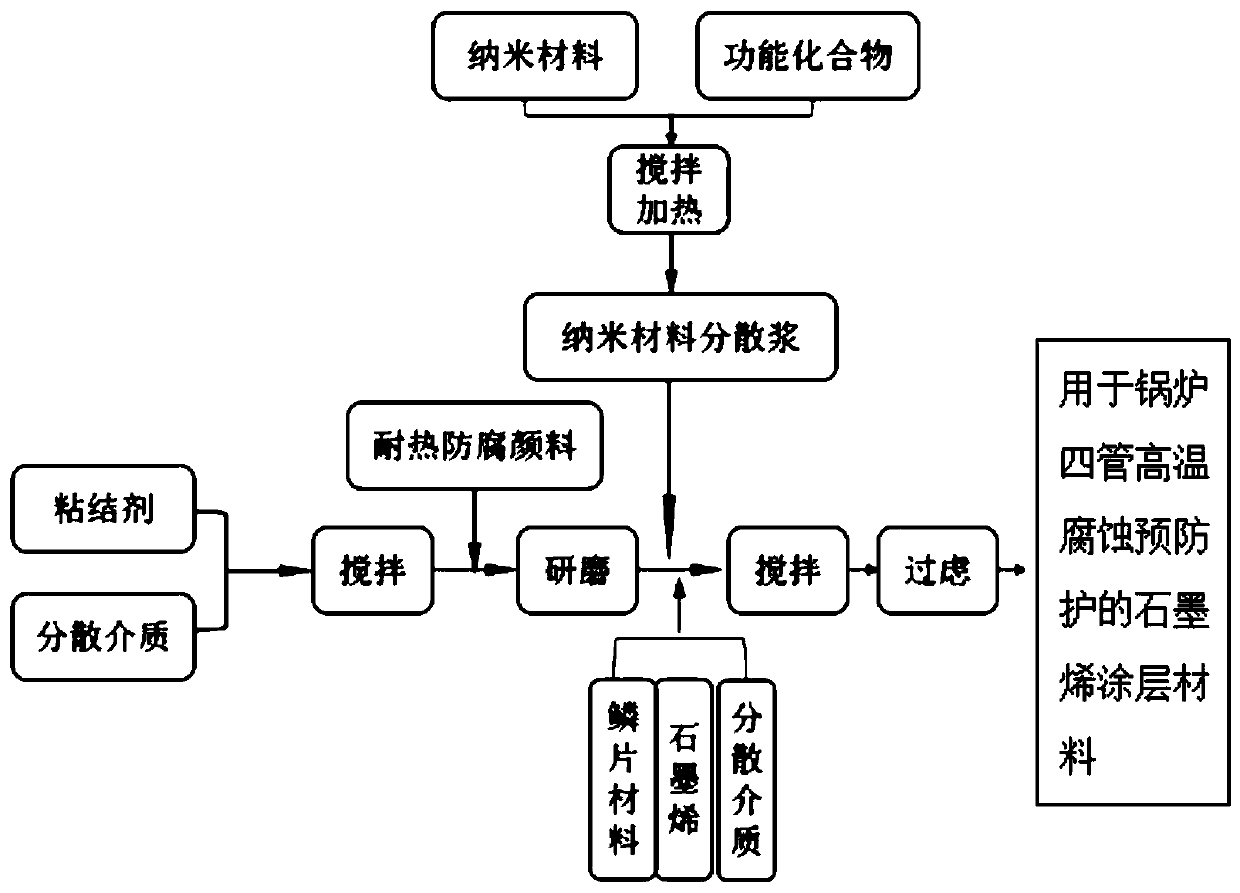

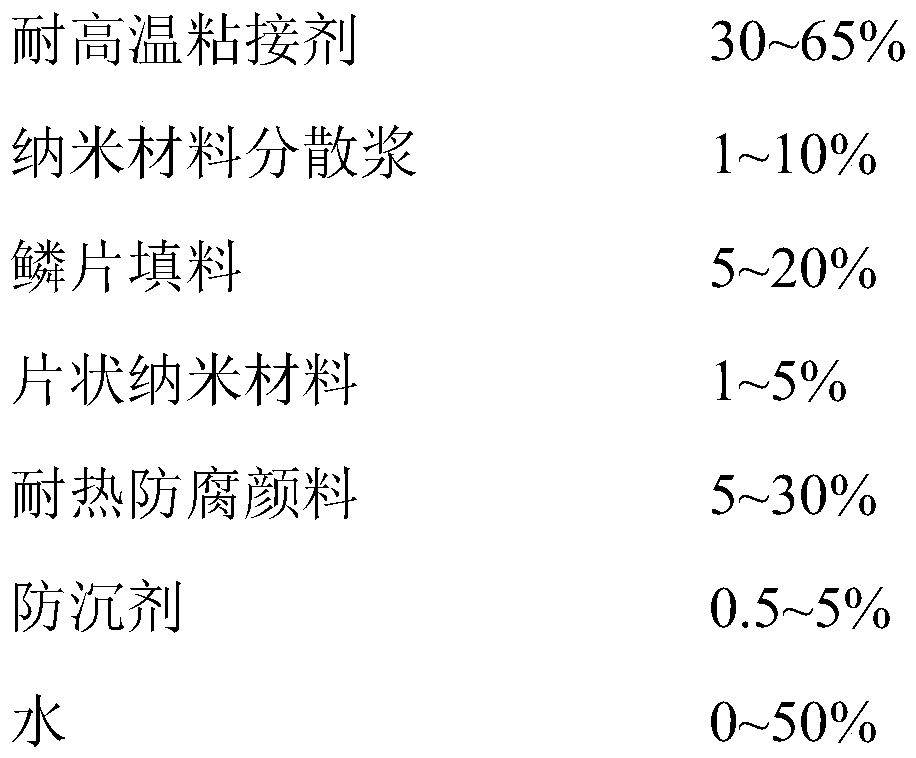

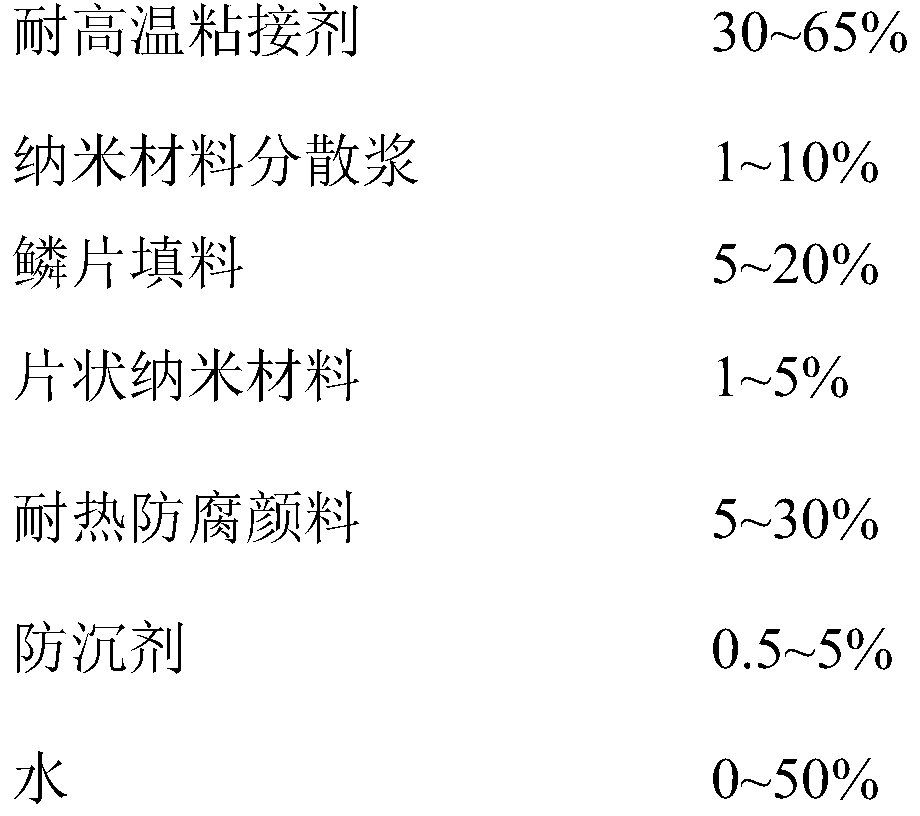

Graphene coating material used for prevention of boiler four tube high temperature corrosion, and preparation method thereof

InactiveCN109897532ASimple and fast operationReduce energy consumptionAlkali metal silicate coatingsAnti-corrosive paintsAdhesiveSlurry

The invention discloses a graphene coating material used for prevention of boiler four tube high temperature corrosion, and a preparation method thereof. The graphene coating material used for prevention of boiler four tube high temperature corrosion comprises, by mass, 30-65% of a high temperature resistant adhesive, 1-10% of a nanometer material dispersed slurry, 5-20% of a scale filler, 1-5% ofa sheet-shaped nanometer material, 5-30% of a heat resistant anticorrosive pigment, 0.5-5% of an anti-settling agent, and 0-50% of water. The graphene coating material is prepared using a special preparation method, homogenization effect is better, and storage is stable; the graphene coating material is excellent in high temperature resistance, is compact, possesses excellent corrosion resistancein corrosive atmosphere, and good adhesion on metal substrate; and in addition, the construction method of the graphene coating material is simple and rapid, and the engineering cost can be greatly reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

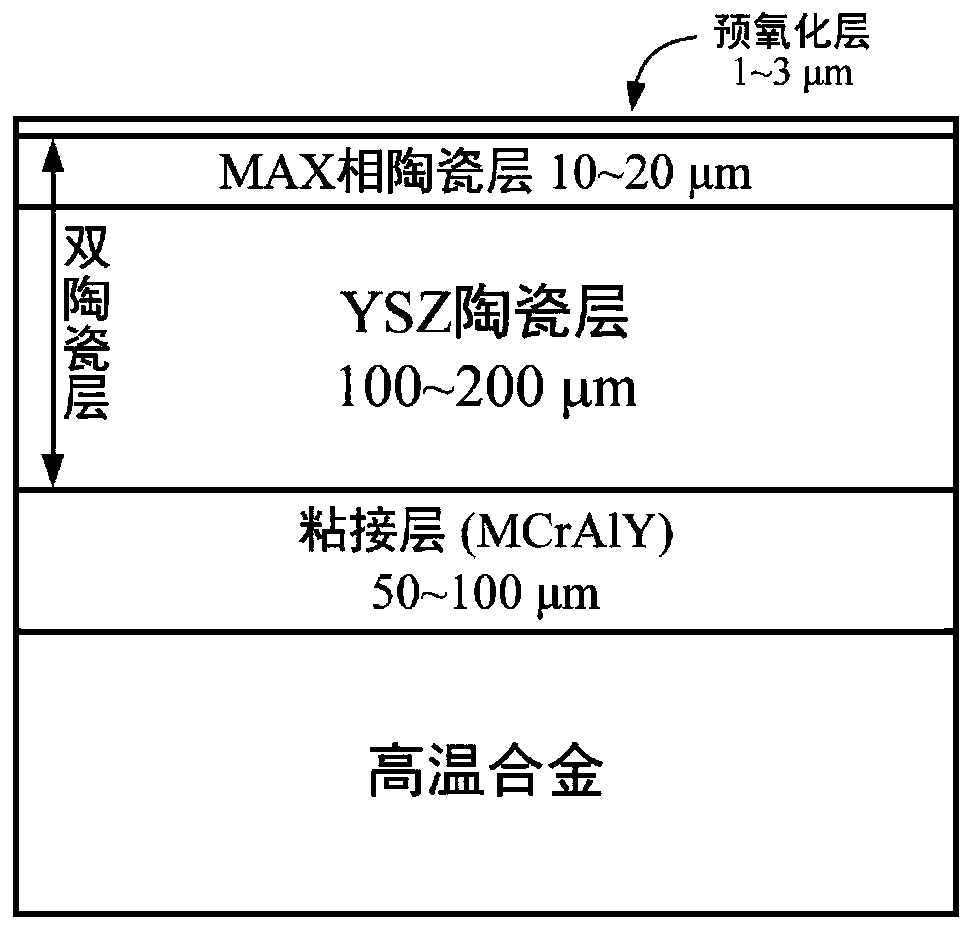

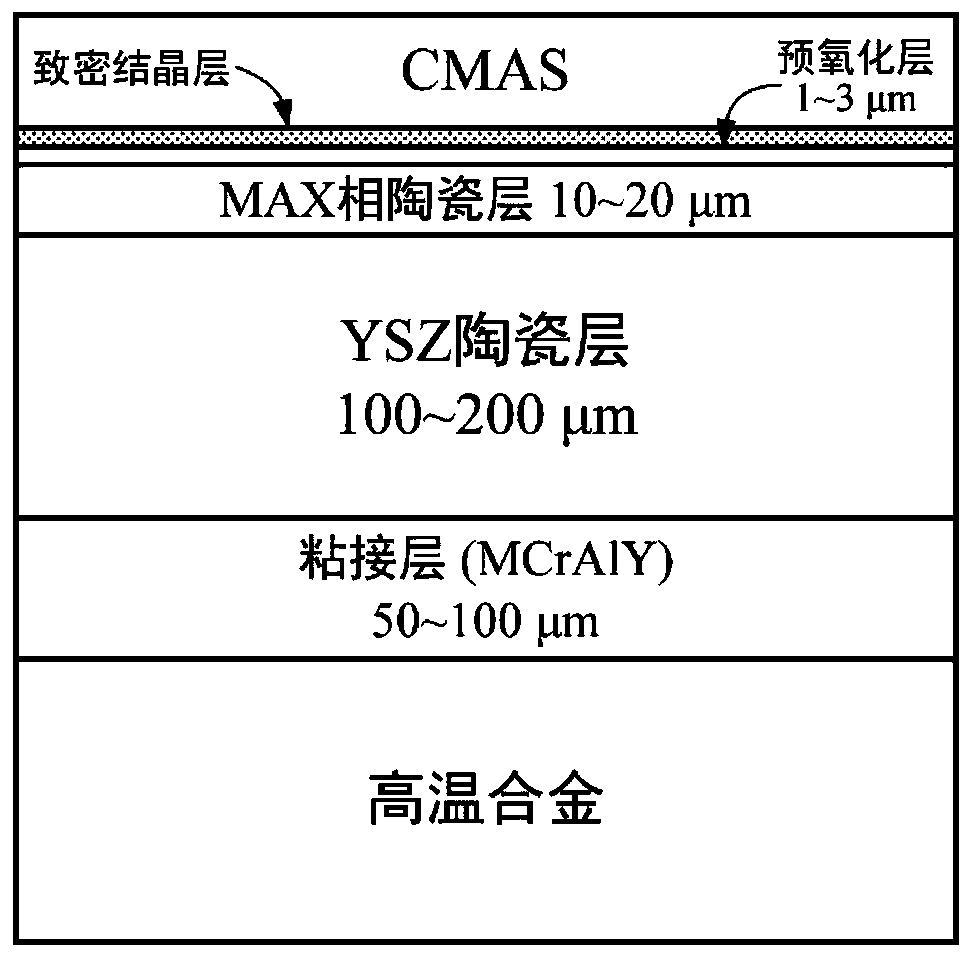

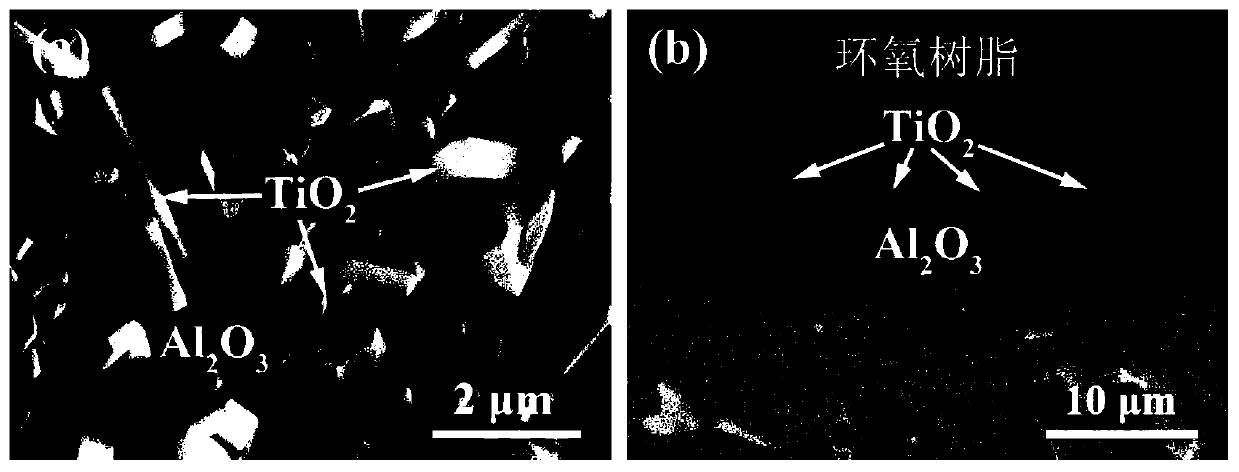

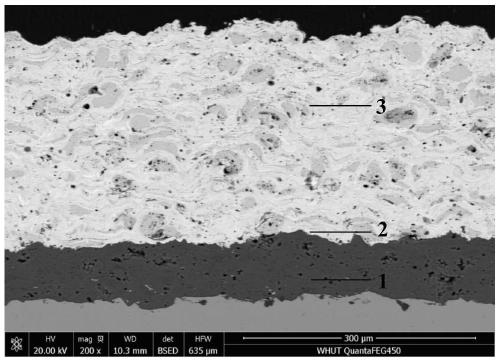

MAX phase coating for resisting molten CMAS corrosion of thermal barrier coating and thermal spraying preparation method

ActiveCN111004990AImprove adaptabilityExcellent anti-CMAS corrosion performanceMolten spray coatingEfficient propulsion technologiesCorrosionMAX phases

The invention relates to an MAX phase coating for resisting molten CMAS corrosion of a thermal barrier coating and a thermal spraying preparation method. The thermal barrier coating system adopting the MAX phase ceramic coating as a corrosion protection layer comprises an alloy matrix, a bonding layer, a YSZ ceramic layer, an MAX phase ceramic layer and a pre-oxidation layer. The method comprisesthe steps that firstly, MAX phase Ti2AlC or Ti3AlC2 powder or suspension for thermal spraying is prepared, the particle size of the powder is 10-100 microns, and the suspension is a water base or an ethanol base and is neutral or acidic; then, a hypersonic flame spraying method or a suspension plasma spraying method or a plasma spraying-physical vapor deposition method is adopted for preparation;and heat treatment is carried out to form a pre-oxidation layer on the surface. The thickness of the prepared ceramic layer is 10-20[mu]m, and the porosity is 3-10%. The thermal barrier coating, whichcomprises the MAX phase coating and is resistant to molten CMAS corrosion, is used for surface protection of aero-engine hot-end components, and the adaptability of the hot-end components in severe high-temperature and corrosive environments can be effectively improved.

Owner:TIANJIN UNIV

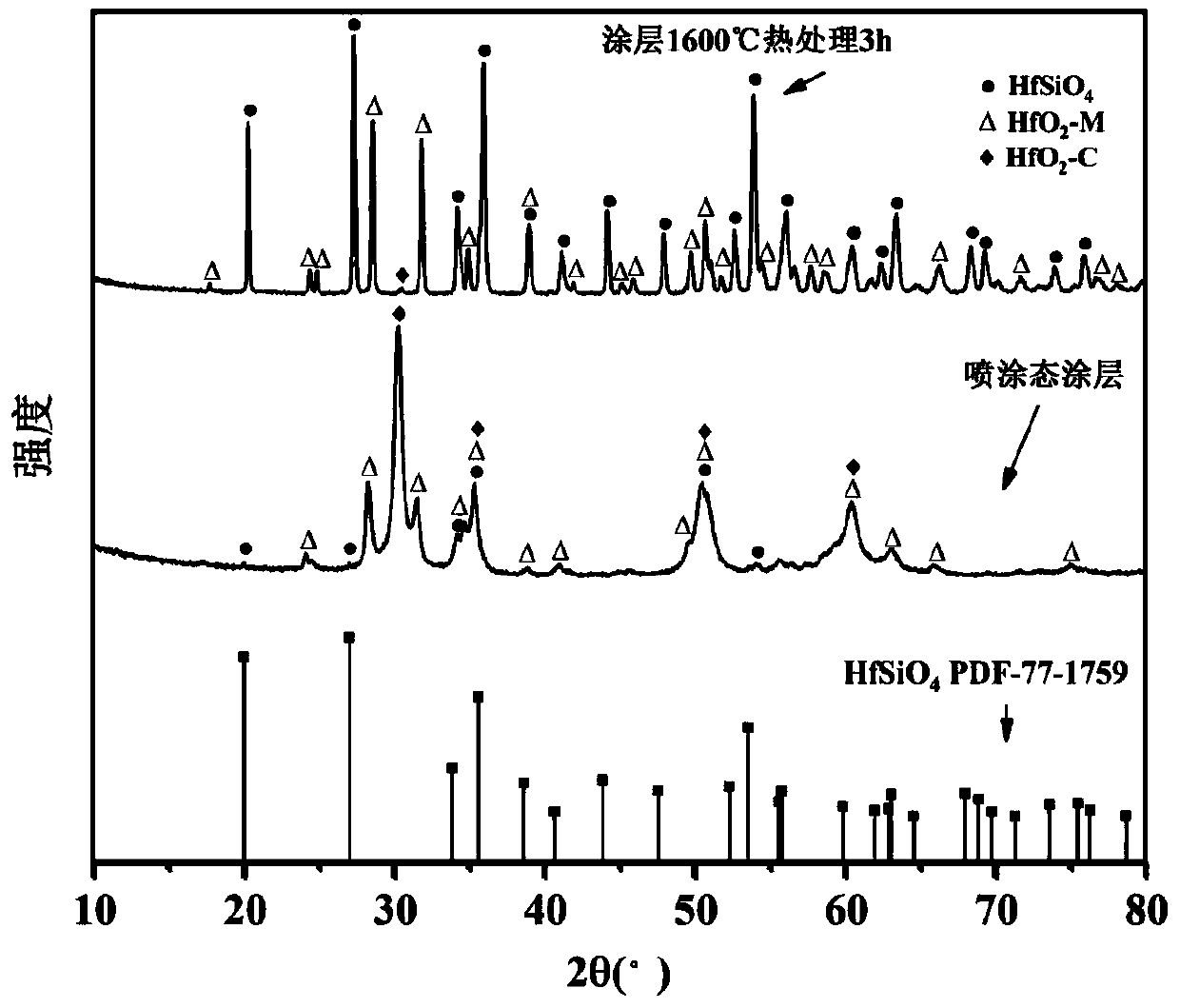

Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

The invention provides a hafnium silicate environment barrier coating for a ceramic-based composite material matrix and a preparation method thereof. The preparation method comprises the following steps: (1) mixing HfO2 and SiO2, carrying out wet mixing and ball milling on a ball mill, drying, grinding, sieving, sintering, and carrying out a high-temperature solid-phase reaction; (2) after the high-temperature solid-phase reaction is finished, adding deionized water for slurry preparation, then performing ball milling, and performing spray granulation to obtain an HfSiO4 powder material; (3) firstly spraying a Si layer on the surface of a ceramic-based composite matrix as a priming coat, and then spraying the HfSiO4 powder material on the surface of the priming coat as a surface layer to form a multi-layer coating; and (4) carrying out a heat treatment on the multi-layer coating to obtain the environmental barrier coating. Due to the added heat treatment, the crystallinity of the HfSiO4 surface layer is improved, the binding force of each layer of the coating is better, the stability is higher, and the water and oxygen resistance of the environment barrier coating is greatly improved. The provided preparation method is simple and easy to control, and is easy for industrial production and application.

Owner:WUHAN UNIV OF TECH

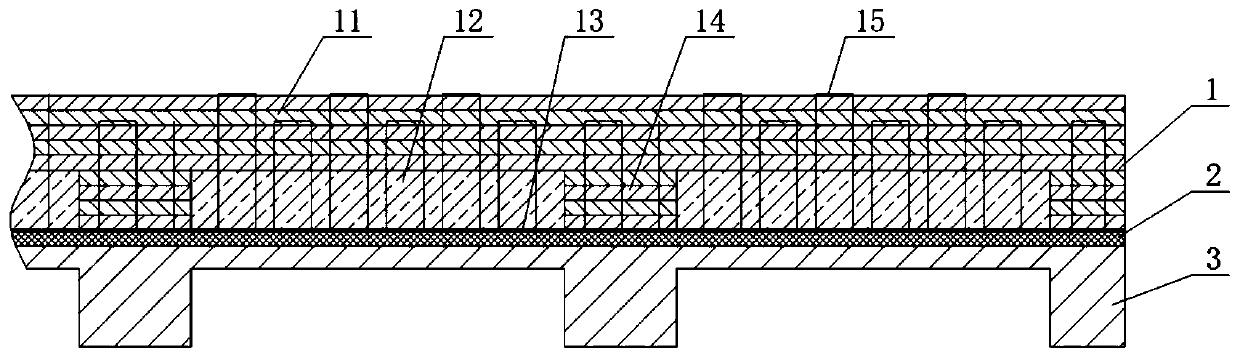

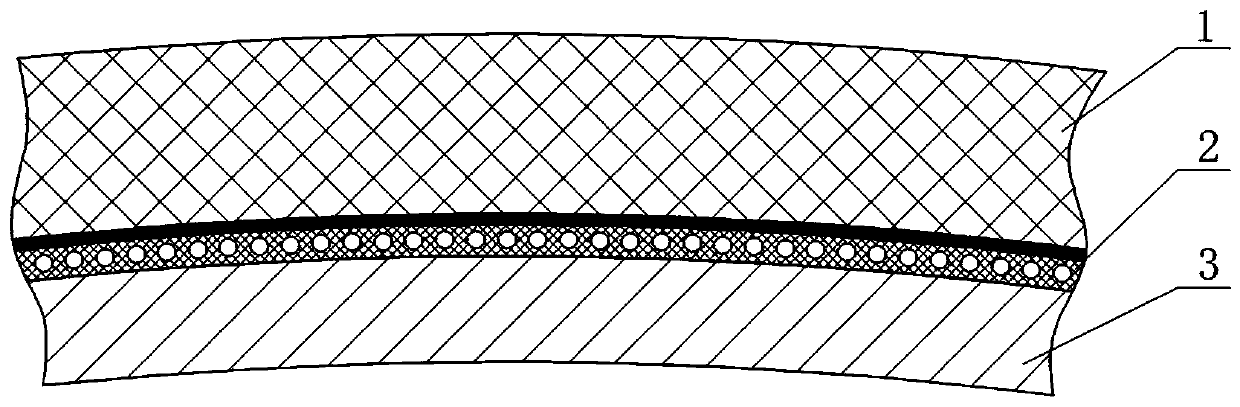

Heat preventing and insulating integrated thermal protection structure suitable for negative curvature shape

ActiveCN110524974AImprove resistance to damageSolve problems prone to separationSynthetic resin layered productsFuselage insulationAdhesiveNear space vehicle

The invention discloses a heat preventing and insulating integrated thermal protection structure suitable for a negative curvature shape, and belongs to the technical field of thermal protection of hypersonic-speed near space aircrafts. The thermal protection structure includes a force bearing shell and a thermal protection layer; the thermal protection layer includes a heat insulating layer and aheat preventing layer, the inner wall of the heat preventing layer is provided with grid-like heat-preventing layer reinforcement ribs, the heat insulating layer is arranged in the grids of the heat-preventing layer reinforcement ribs, and the surface of the heat insulating layer is provided with a heat insulating layer covering skin; the heat preventing layer, the heat insulating layer coveringskin, and the heat-preventing layer reinforcing ribs are sewed together with the heat insulating layer through a sewing line in a prepreg state, and the whole is subjected to high-temperature curing to form the heat preventing and insulating integrated structure; and an adhesive layer is located between the force bearing shell and the thermal protection layer, and the adhesive layer is an adhesivewith high-temperature resistance and heat matching performance. The thermal protection structure provided by the invention adopts the heat preventing and insulating integrated thermal protection layer, and the thermal protection layer is bonded to the force bearing shell by using the high-temperature-resistant adhesive, so that interface separation at the negative curvature part of the thermal protection structure of an aircraft can be avoided.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

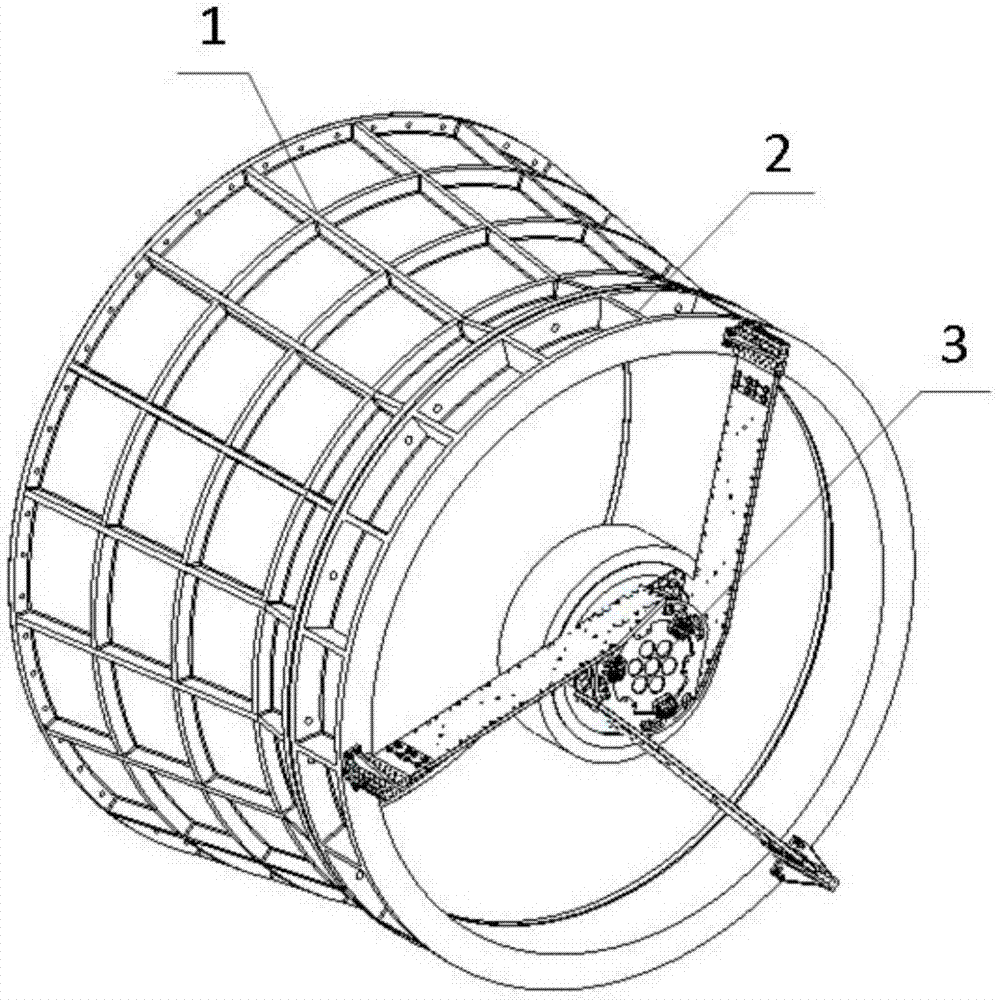

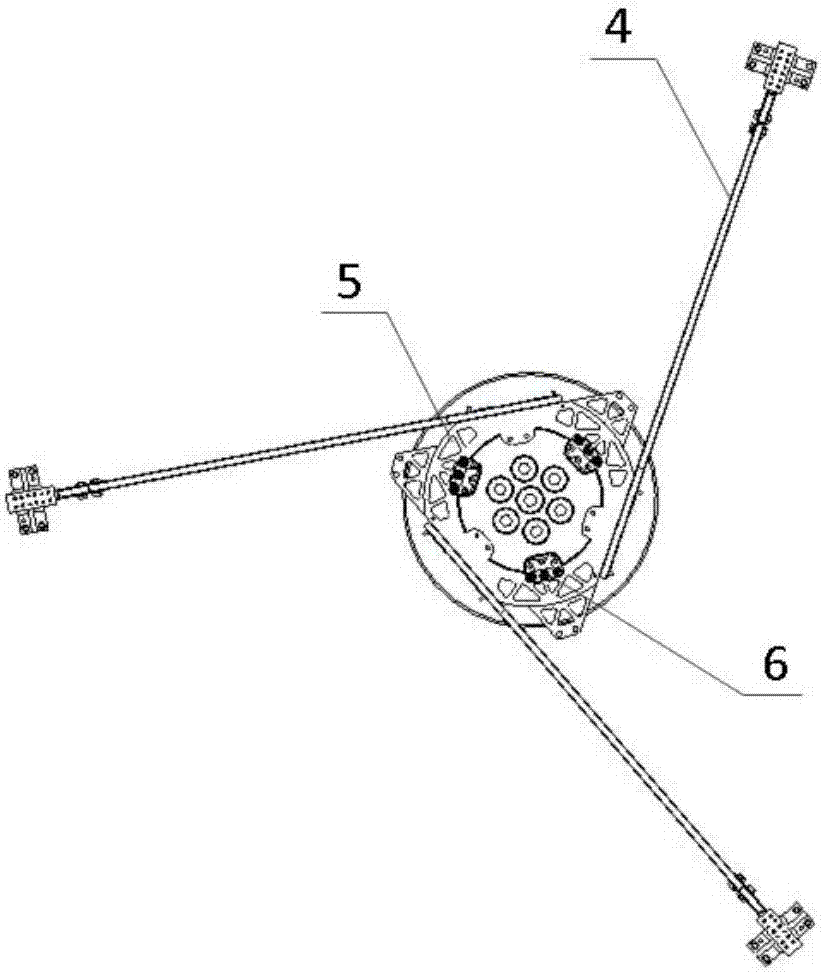

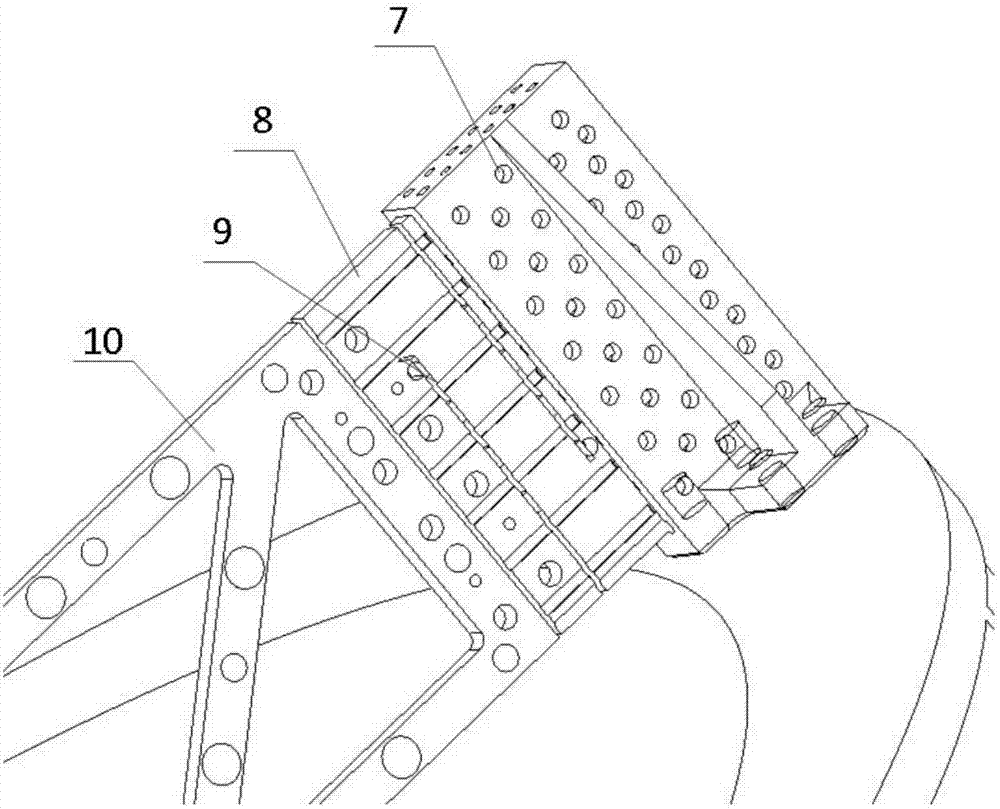

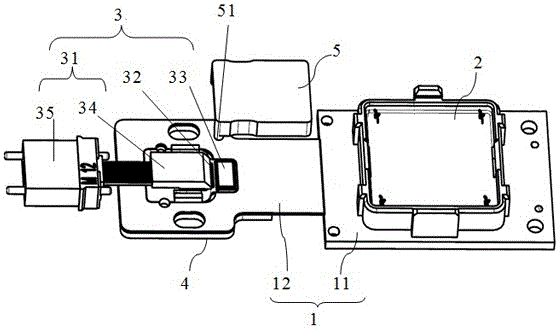

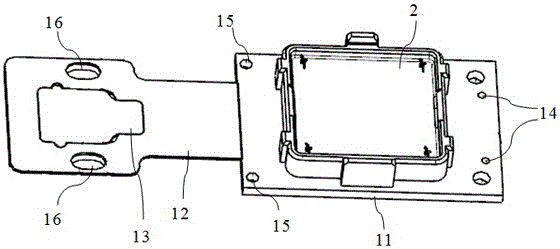

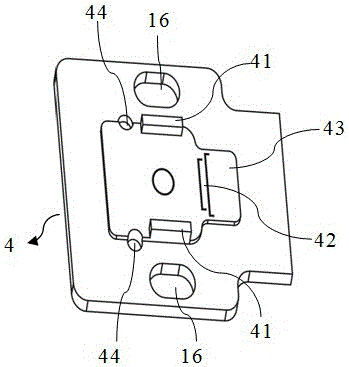

Sectional-type secondary mirror high-stability support structure

ActiveCN107037566APrecise and stable supportGuaranteed image qualityMountingsEngineeringSecondary mirror

Provided is a sectional-type secondary mirror high-stability support structure, which comprises a first front lens cone (1), a second front lens cone (2) and a secondary mirror support assembly (3). The secondary mirror support assembly (3) comprises spoke plate assemblies (4) and a secondary mirror frame (5). Each spoke plate assembly (4) comprises a spoke plate (10) and a spoke plate base. One end of the spoke plate (10) is connected with the spoke plate base, and the other end thereof is connected with the secondary mirror frame (5) and is tangent to the circular secondary mirror frame (5); each spoke plate base is fixedly arranged at one end of the second front lens cone (2); and the other end of the second front lens cone (2) is connected with the first front lens cone (1). The support structure realizes high-stability secondary mirror support through the composite-material lens cones and a flexible spoke plate structure; and the support structure also adopts the spoke plate structure in a three-layer sandwich structure, so that weight is reduced, structure rigidity is improved, and thermal stress is unloaded to some extent.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

C/SiC composite material, oxidation resistant coating for C/SiC composite material and preparation method thereof

The invention relates to a C / SiC composite material, an oxidation resistant coating for the C / SiC composite material and a preparation method thereof. The oxidation resistant coating is used for alternatively forming an HfB2 coating and a SiC coating on a C / SiC composite base material. The preparation method comprises the following steps: coating a layer of HfB2 ceramic precursor solution on the surface of the C / SiC composite base material; forming the HfB2 coating after splitting decomposition; depositing the SiC coating, thereby acquiring an HfB2-SiC compound coating. The invention relates to the C / SiC composite material prepared according to the preparation method. The preparation method is simple in process, low in preparation cost, capable of solving the problems of uniform distribution of HfB2 and SiC and combination with a substrate and promoting the ablation resistance and oxidation resistance of the C / SiC composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Parallel optical assembly

ActiveCN106125215AQuick assemblyImprove assembly efficiency and assembly accuracyCoupling light guidesFibre transmissionElectricityEngineering

The invention discloses a parallel optical assembly. The PCB of the parallel optical assembly comprises a rigid PCB part and a flexible PCB part; the flexible PCB part can be folded or bended; an optical connector is arranged on a metal reinforcement plate in fixed connection with the flexible PCB part. In a packaging process, the optical connector and the metal reinforcement plate can bend or fold with the flexible PCB part, allowing the optical connector of an optical port packaging part to arrive at a most convenient assembling angle and position so as to realize rapid assembling, meanwhile helping reducing a packaging dimension, facilitating component high density distribution, and enhancing an adaptive capacity to environment. The parallel optical assembly can utilize the bending characteristic of the flexible PCB part to realize the overlapping installation of the parallel optical assembly, and guarantee optical connector and electric connector assembling precision so as to realize a compact structure of the parallel optical assembly; the packaging dimension is small, thereby facilitating the application of a parallel optical assembly high density integration communication system.

Owner:HISENSE & JONHON OPTICAL ELECTRICAL TECH CO LTD

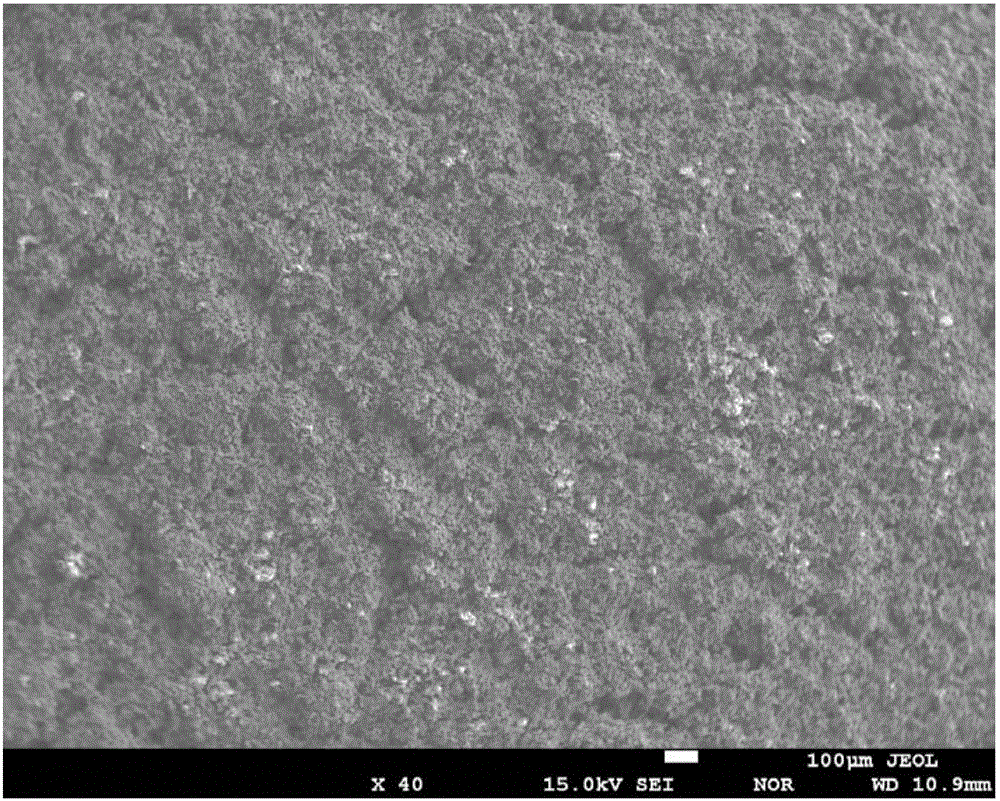

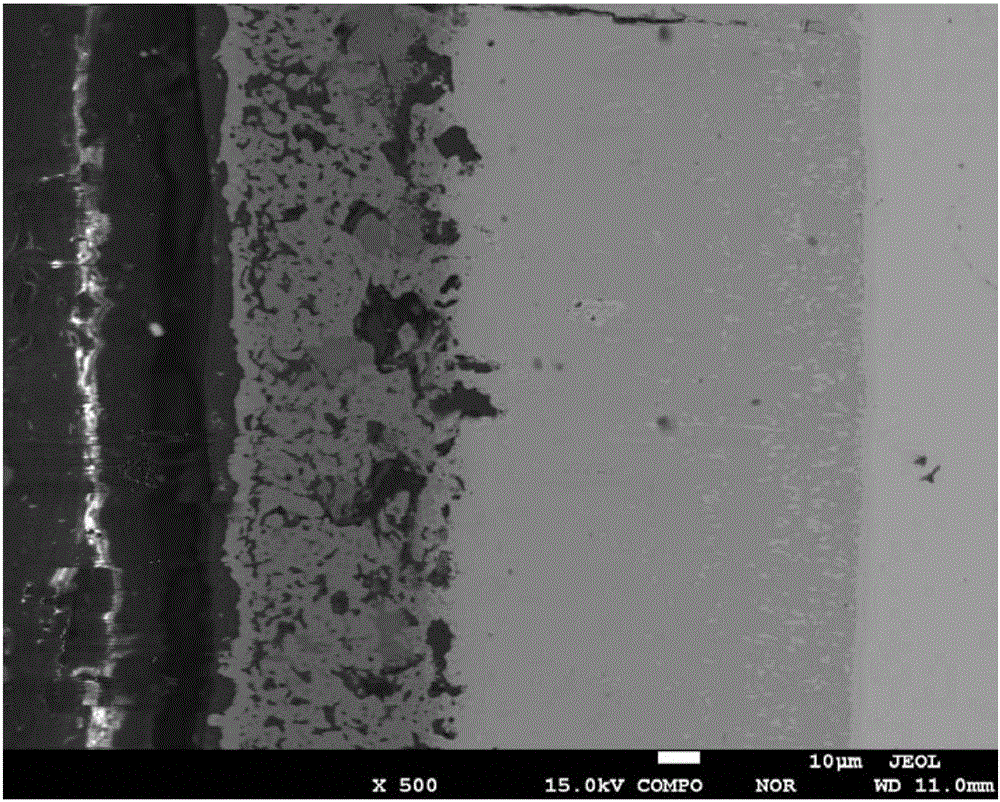

Zirconia-based NOx sensor and preparation method thereof

InactiveCN103884740AConsistent coefficient of thermal expansionGood heat matchingMaterial analysis by electric/magnetic meansWhole bodyResource saving

The invention provides a sensor for measuring the concentration of NOx through measuring the alternating current (AC) impedance, and a preparation method thereof. The preparation method comprises the following steps: adopting an alumina cast sheet forming technology to laminate and burn multiple layers of heating units into a whole body so as to form an authentic direct heating structure; covering the surface of the alumina heating body with a Pt wire and a sensitive body, wherein the sensitive body is arranged on an insulation layer and is composed of a Pt wire, a zirconia layer, and (LaSr<1-x>)MnO3(LSM) and the x is in a range of 1 to 0. When the zirconia-based NOx sensor is in a normal work state, the work voltage (VW) is 10 to 50 mV, and the heating voltage (VH) is 12 V. The detectable range of NOx concentration is 0 to 500 ppm, the response time is less than 2 seconds, and the sensor is suitable for detecting NOx with a low concentration. The sensor can detect NOx with a lower concentration, and has the advantages of simple preparation technology, reduction on production cost, and resource saving.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Preparation method for veneering porcelain used for alumina all-ceramic crown

The invention relates to the technical field of preparation of rare metal materials, specifically to a preparation method for veneering porcelain used for an alumina all-ceramic crown. The preparation method comprises the following steps: weighing a variety of compounds by using an electronic balance and respectively converting the amounts of desired B2O3, K2O, Na2O and CaO into the amounts of H3BO3, K2CO3, Na2CO3 and CaCO3; adding raw materials into deionized water and carrying out ball milling; drying slurry, putting dried slurry into an alumina crucible, delivering the alumina crucible into an electric furnace, carrying out heating, taking out a melt and pouring the melt into cold water for cold quenching; grounding glassy mass obtained after quenching and carrying out sieving with sieve with a bore diameter of 61 [mu]mm so as to obtain baked porcelain powder; weighing 0.2 g of the baked porcelain powder, uniformly blending the baked porcelain powder with deionized water, smearing an alumina ceramic bottom crown with the obtained mixture, delivering the alumina ceramic bottom crown to the electric furnace for heating and carrying out cooling to room temperature in the furnace; and carrying out sintering so as to form the veneering porcelain with a thickness of about 1.5 mm. The microstructure of the baked porcelain powder obtained after sintering is microcrystalline glass, and the thermal expansion coefficient of the baked porcelain powder is 7.2 * 10 <-6> / K. The baked porcelain powder and alumina ceramic have good thermal matching performance; and thermal shock resistance temperature reaches 240 DEG C.

Owner:SHAANXI SHENGMAI PETROLEUM

Aggregation-type composite powder for high-temperature abradable seal coating layer and preparing method of aggregation-type composite powder

The invention relates to aggregation-type composite powder for a high-temperature abradable seal coating layer and a preparing method of the aggregation-type composite powder. The aggregation-type composite powder which has good spraying technology adaptability is prepared through the method of mechanical milling, room-temperature binding and aggregation. The powder comprises MCrAlY alloy powder, alloy powder with beta-NiAl intermetallic compounds as a main phase, polybenzoate powder, boron nitride, binding agents and the like. Raw materials can be the combination of the materials, and the binding agents can be inorganic matter or organic matter. The powder comprises beta-NiAl intermetallic compound high-temperature-resisting components, heat-resisting temperature of an existing metal-based seal coating layer can be raised, and compared with a ceramic seal coating layer, the coating layer has great thermal shock resistance and can be used under the working condition of the high temperature of 1000 DEG C for a long time. The powder has wide application in gas channel sealing of a combustion gas turbine high-temperature part, especially of a high-pressure turbine.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

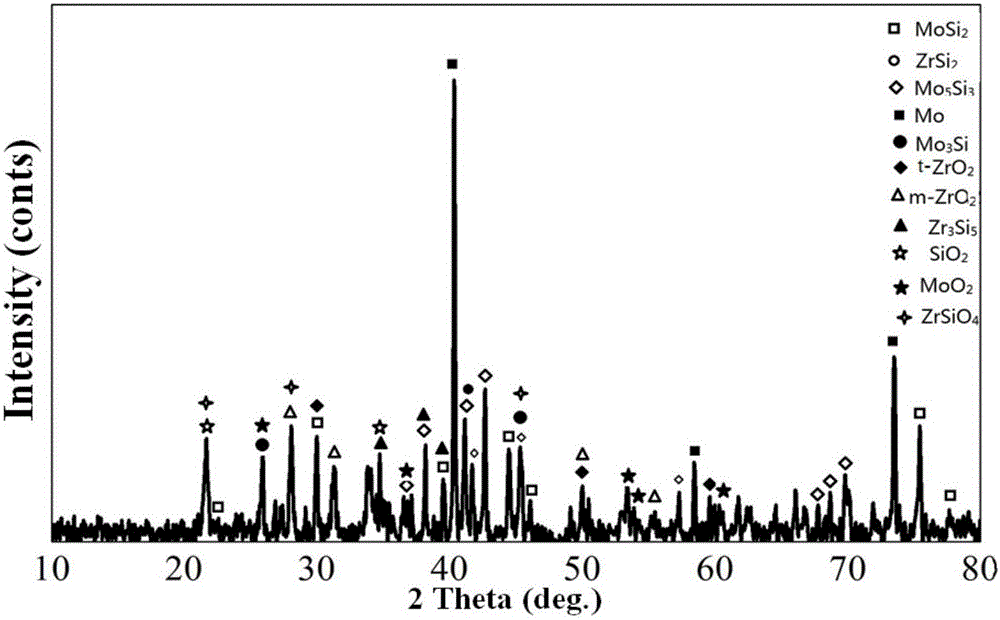

Molybdenum-alloy MoSi2-ZrO2-Y2O3 coating, preparation method therefor and application of molybdenum-alloy MoSi2-ZrO2-Y2O3 coating

The invention relates to a molybdenum-alloy-material MoSi2-ZrO2-Y2O3 coating, a preparation method therefor and an application of the molybdenum-alloy-material MoSi2-ZrO2-Y2O3 coating and belongs to the technical field of preparation of ultrahigh-temperature oxidation-resistant coatings. The coating disclosed by the invention contains the following ingredients in percentage by mass: 60% to 80% of MoSi2, 10% to 30% of ZrO2, 5% to 10% of Y2O3 and 1% to 3% of additive, wherein the additive is at least one selected from Si powder and SiC powder. The preparation method comprises the steps: weighing the raw materials according to the designed ingredients, then, carrying out wet-process ball-milling so as to prepare slurry; and then, coating the surface of molybdenum alloy with the slurry, and carrying out vacuum sintering for 40 to 100 minutes at the temperature of 1,550 DEG C to 1,650 DEG C, thereby preparing the coating. According to the coating disclosed by the invention, the ingredient design is reasonable, the preparation process is simple, the production cost is low, the coating is dense and uniform and has high bonding strength with the molybdenum alloy and a coefficient of thermal expansion matched with the molybdenum alloy, and thus the ultrahigh-temperature oxidation resistance of the molybdenum alloy can be effectively improved.

Owner:CENT SOUTH UNIV

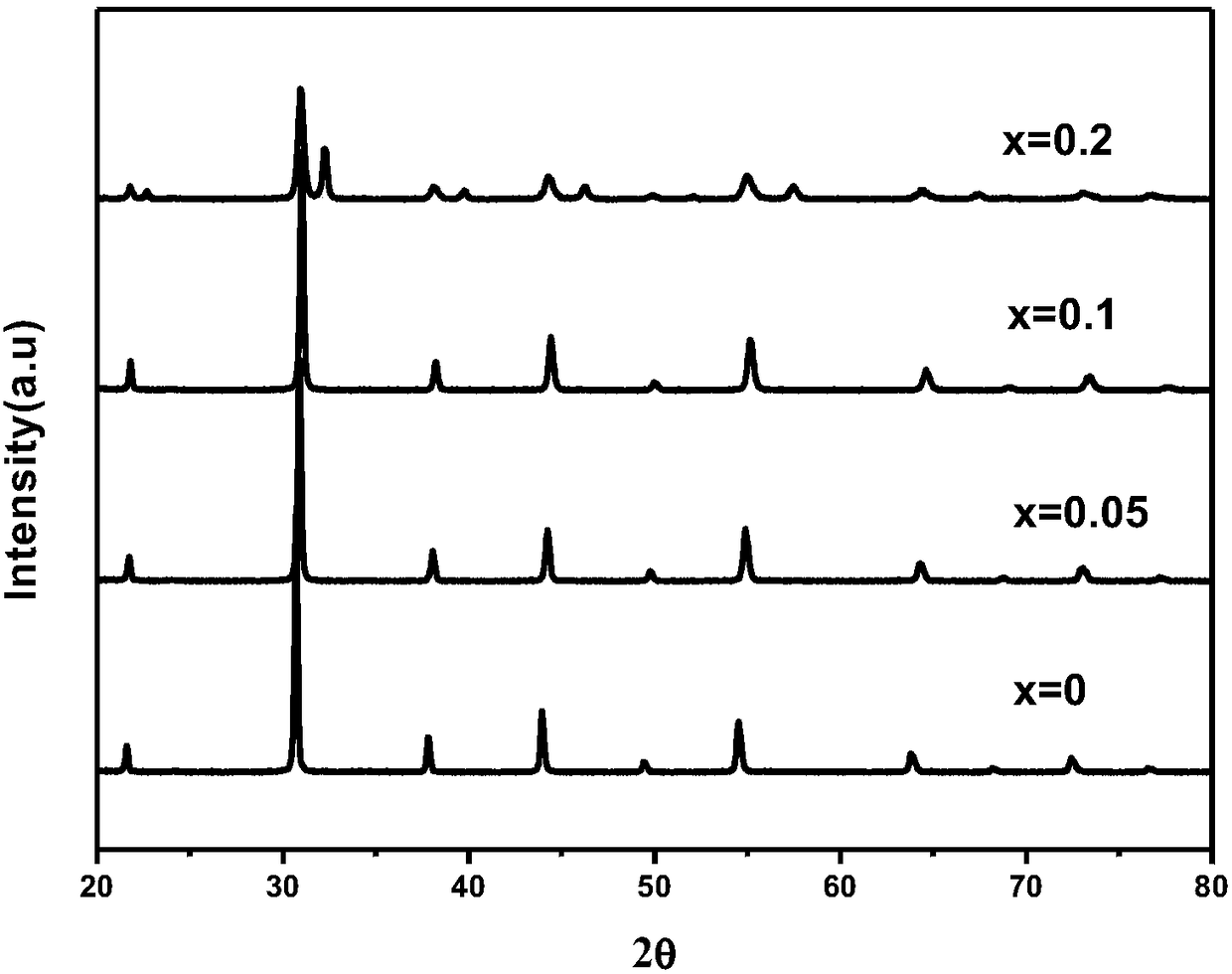

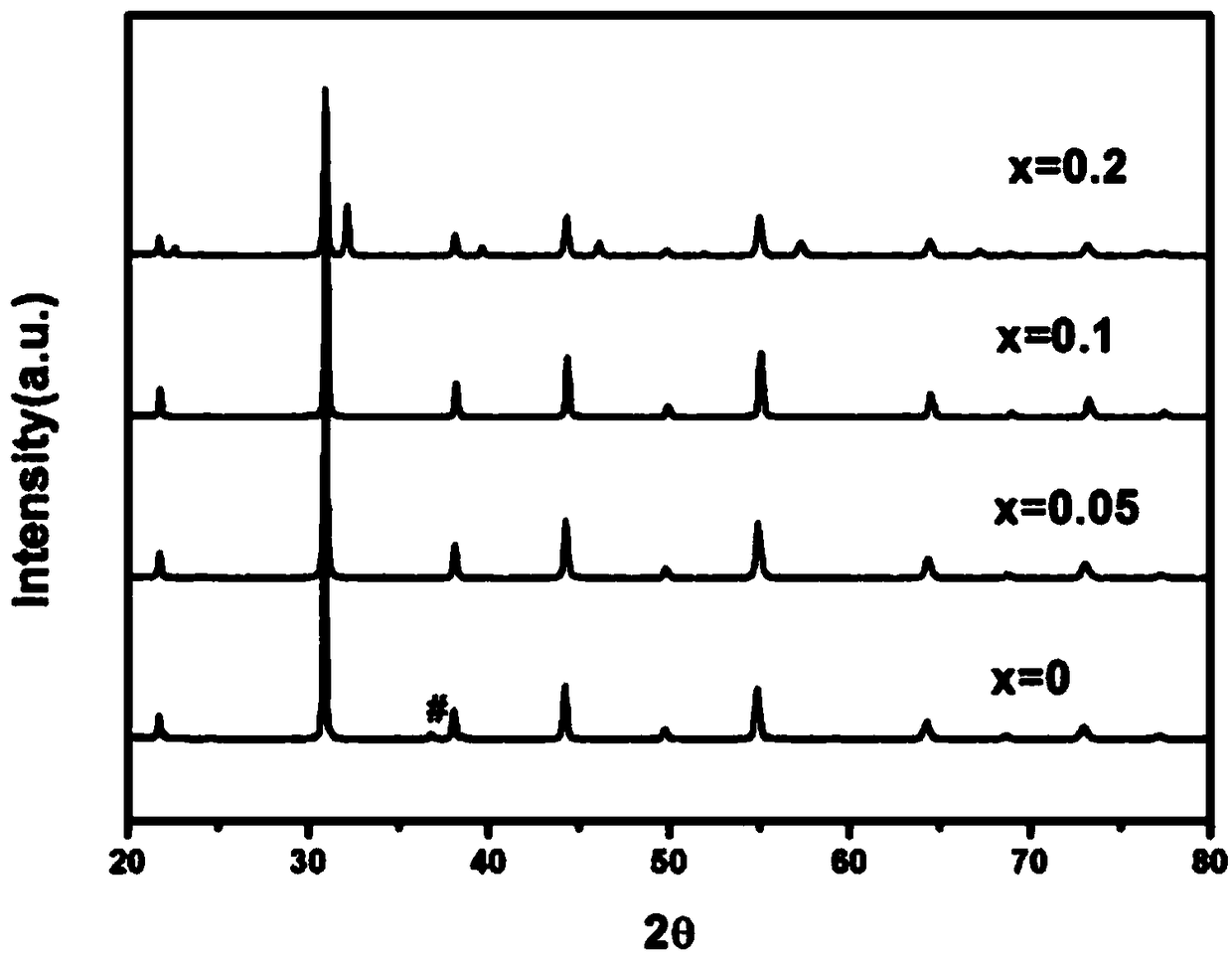

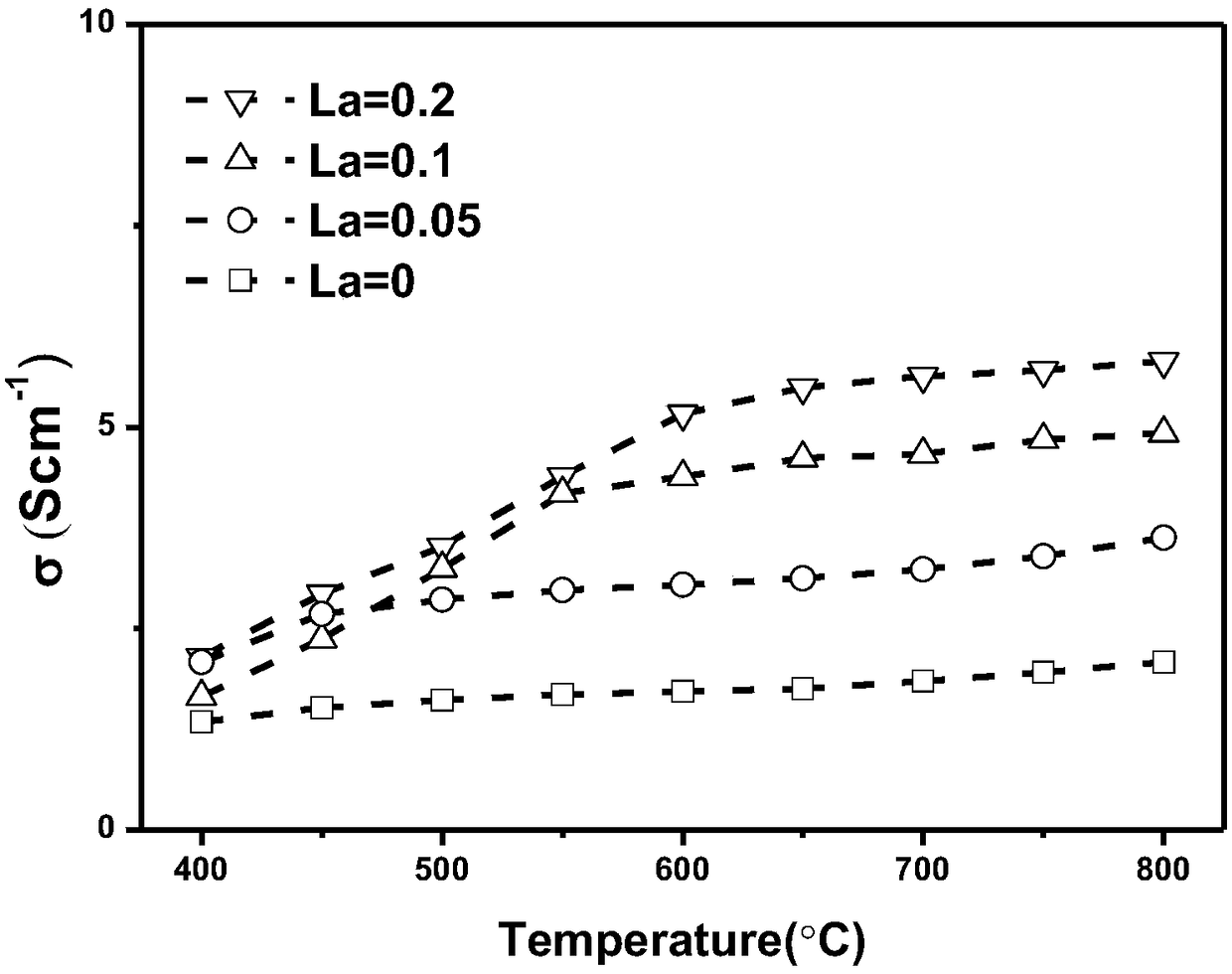

Cathode material for proton conductor SOFC (solid oxide fuel cell) and preparation method

The invention provides a cathode material for a proton conductor SOFC (solid oxide fuel cell) and a preparation method and belongs to the field of SOFCs. According to the material, BaCo(1-y)FeyO(3-delta) with high catalytic activity is selected, material stability is improved by doping the position A with trivalent oxygen ions La<3+>, the electronic structure of transition metal ions Co / Fe is adjusted by introducing Zr<4+> and Y<3+> in the position B, thermal matching with a proton conductor electrolyte is increased, and a single-phase cathode material is obtained. The method comprises steps as follows: preparing powder with an improved citric acid combustion method, weighing chemical raw materials corresponding to the elements in a molar ratio of Ba, La, Co, Fe, Zr and Y being (1-x):x:0.4:0.4:0.1:0.1, adding two complexing agents including citric acid and EDTA, dissolving the two complexing agents with nitric acid and ammonium hydroxide, adjusting PH to be approximately equal to 7, preparing primary powder by sintering, and pre-sintering the primary powder for 3 h at 1000 DEG C to prepare cathode powder. The cathode material has advantages that excellent electrocatalytic activityis kept, cathode oxygen vacancy solubility, material stability and low-temperature performance are increased, and better thermal matching with the proton conductor electrolyte material is achieved, sothat the proton conductor SOFC is endowed with excellent low-temperature performance and stability.

Owner:CHINA UNIV OF MINING & TECH

Dual-stage compression refrigeration circulating system for cooling flashing gas bypass in stepped mode

InactiveCN105650921AImprove efficiencySmall pressure lossMechanical apparatusCompression machines with non-reversible cycleDual stageGas passing

The invention discloses a dual-stage compression refrigeration circulating system for cooling a flashing gas bypass in a stepped mode. High-temperature gas refrigerant discharged by a high-pressure compressor enters a gas cooler to be primarily cooled, then gas refrigerant sequentially passes a flashing gas bypass external heat exchanger, an internal heat exchanger and a flashing gas bypass internal heat exchanger to be sufficiently cooled, and finally refrigerant gas passing through the flashing gas bypass external heat exchanger and refrigerant gas passing through the internal heat exchanger are input to a low-pressure compressor after being mixed. The key problems that CO2 refrigeration circulating throttling loss is large and circulating efficiency is low are solved, the efficiency of the CO2 trans-critical refrigeration circulating system is greatly improved, and the use range of the system is widened.

Owner:TIANJIN UNIV OF COMMERCE

Infrared stealth thin film with spectral selectivity and low emission rate and preparation method of infrared stealth thin film

ActiveCN104865617ANot easy to fall offGood heat matchingVacuum evaporation coatingSputtering coatingInfrared windowRefractive index

The invention relates to an infrared stealth thin film with spectral selectivity and low emission rate. The infrared stealth thin film is of a multi-layer superimposed structure; the multi-layer superimposed structure contains a periodically-laminated structure which is formed by alternately superimposing high-refractive index material layers and low-refractive index material layers; the thicknesses of the film layers in the multi-layer superimposed structure are randomly distributed between 100 and 900nm; and the optical thicknesses of a certain number of film layers in the multi-layer superimposed structure are approximate to lambda / 4, wherein lambda is an arbitrarily wavelength in infrared window bands. The preparation method of the thin film includes the following steps that: a substrate is cleaned; a Ge thin film is plated on the substrate by means of sputtering and through adopting a radio frequency magnetron sputtering method; and a MgF2 thin film is plated on the high-refractive index material layer by means of sputtering and through adopting a radio frequency magnetron sputtering method; the previous steps are repeated for a plurality of periods, and alternate control on designed thicknesses is utilized in combination, and therefore, the infrared stealth thin film with spectral selectivity and low emission rate can be obtained. The preparation method of the infrared stealth thin film of the invention has the advantages of simple preparation process, high repeatability, low equipment requirements, excellent product performance and favorable application effect.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com