High-toughness ultrahigh-temperature ceramic-based composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, applied in the field of high-strength and tough ultra-high-temperature ceramic matrix composite materials and their preparation, can solve the problems of no interface protection of carbon fibers, shortened preparation time, complicated densification process, etc., and is beneficial to subsequent densification. , Good ablation resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

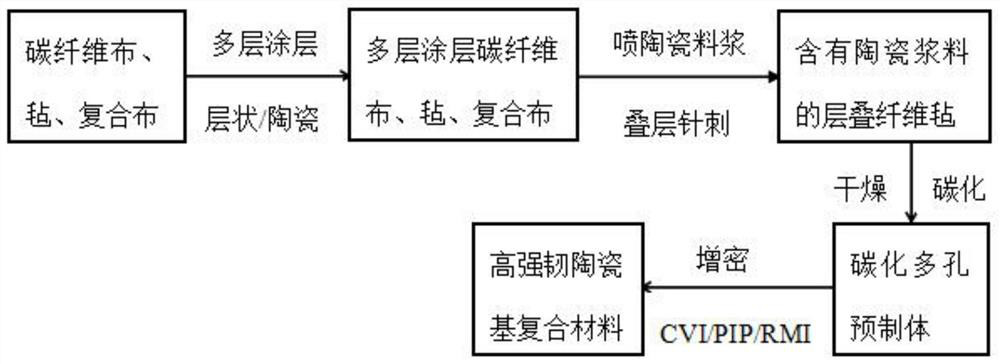

[0044] This embodiment provides a method for preparing a high-strength ultra-high temperature ceramic matrix composite material, including the following steps:

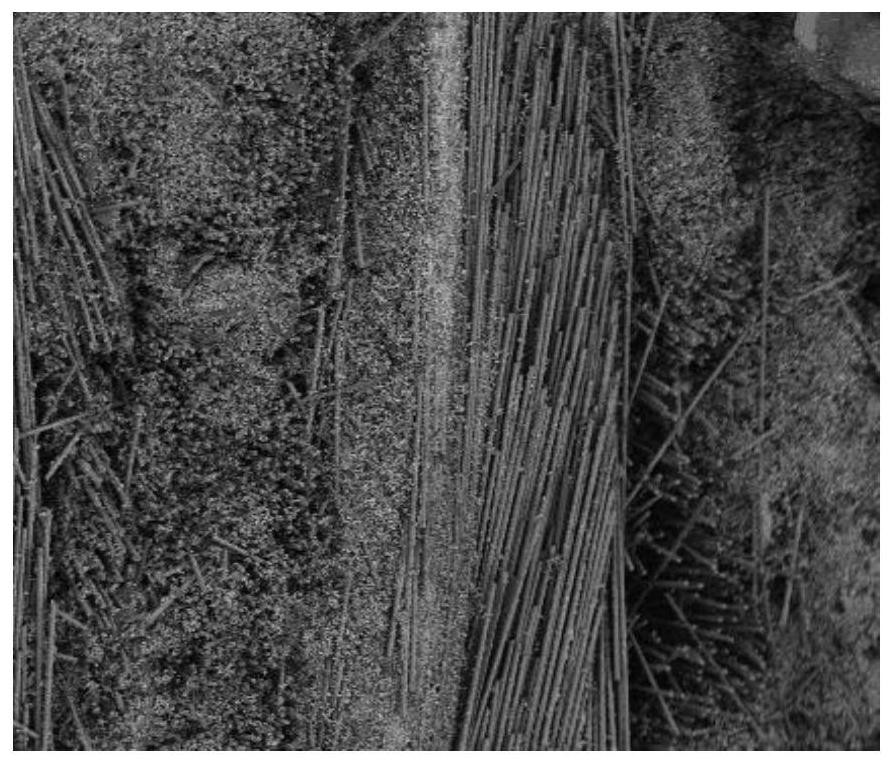

[0045] Preparation of CVD coating on carbon fiber surface: PyC / TaC / PyC / TaC multi-layer composite coating alternately deposited on the surface of carbon fiber cloth, mesh tire or carbon fiber composite cloth by chemical vapor deposition of pyrolytic carbon (PyC) and TaC coating, each The thickness of the layer coating is 0.1-0.2 μm.

[0046] Preparation of laminated fiber mat: Weigh alcohol-soluble phenolic resin / epoxy resin, use absolute ethanol as solvent, prepare a phenolic resin / epoxy resin alcohol solution with a concentration of 10wt% to 15wt%, and mix ZrB 2 (10μm), natural flake graphite powder (800 mesh) according to ZrB 2 : C = 4:1 (volume ratio) mixed to obtain ceramic powder, the weighed ceramic powder and phenolic resin / epoxy resin alcohol solution with a volume ratio of 1:10 to prepare a ceramic alcohol-b...

Embodiment 2

[0052] This embodiment provides a method for preparing a high-strength ultra-high temperature ceramic matrix composite material, including the following steps:

[0053]Preparation of CVD coating on carbon fiber surface: PyC / TiC / PyC / TiC multi-layer composite coating PyC / TiC / PyC / TiC alternately deposited on the surface of carbon fiber cloth, mesh tire or carbon fiber composite cloth by chemical vapor deposition pyrolytic carbon (PyC) and TiC coating, each The thickness of the layer coating is 0.1-0.3 μm.

[0054] Preparation of laminated fiber mat: Weigh alcohol-soluble phenolic resin / epoxy resin, use absolute ethanol as solvent, prepare a phenolic resin / epoxy resin alcohol solution with a concentration of 10wt% to 15wt%, and mix HfB 2 (10μm), natural flake graphite powder (800 mesh) according to HfB 2 :C=20:1 mixed to obtain ceramic powder, the weighed ceramic powder and phenolic resin / epoxy resin alcohol solution were prepared into ceramic alcohol-based slurry with a volume r...

Embodiment 3

[0060] This embodiment provides a method for preparing a high-strength ultra-high temperature ceramic matrix composite material, including the following steps:

[0061] Preparation of CVD coating on carbon fiber surface: four-layer composite coating PyC / TiC / PyC / TiC alternately deposited on the surface of carbon fiber cloth, mesh tire or carbon fiber composite cloth by chemical vapor deposition of pyrolytic carbon (PyC) and TiC coating, each The thickness of the layer coating is 0.1-0.3 μm.

[0062] Preparation of laminated fiber mat: Weigh alcohol-soluble epoxy resin, use absolute ethanol as solvent, prepare epoxy resin alcohol solution with concentration of 15wt%, and ZrB 2 (10μm), ZrC (15μm), natural flake graphite powder (800 mesh) according to ZrB 2 :ZrC:C=4:1:1 (volume ratio) mixed to obtain ceramic powder, the weighed ceramic powder and phenolic resin / epoxy resin alcohol solution were prepared into a ceramic alcohol-based slurry with a volume ratio of 9:50, mechanically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com