Patents

Literature

74results about How to "Avoid brittle break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness ultrahigh-temperature ceramic-based composite material and preparation method thereof

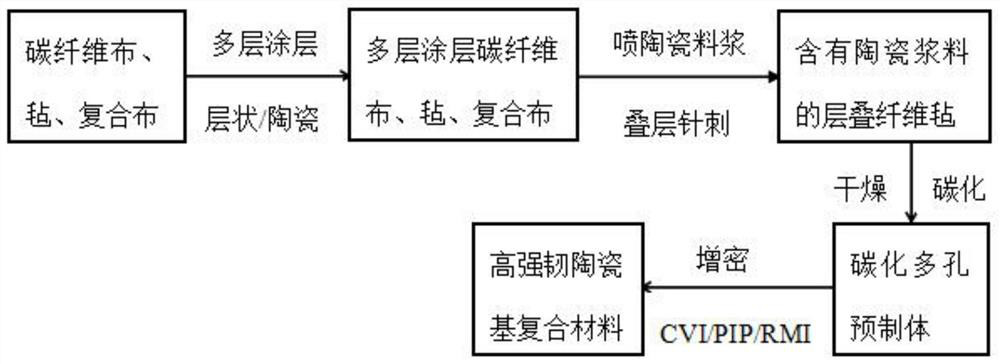

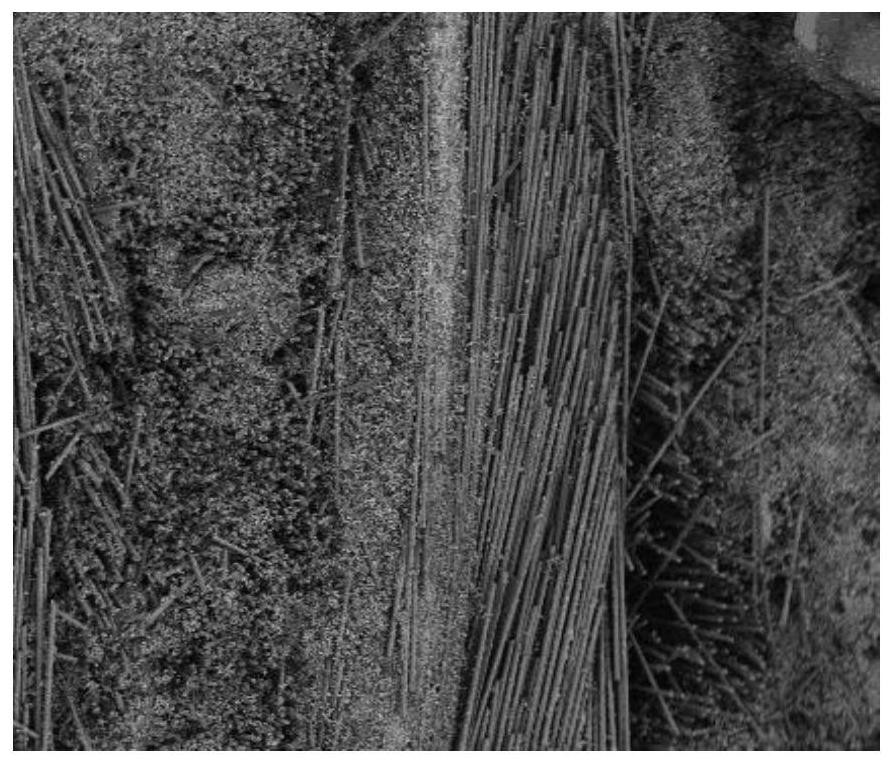

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-strength and high-toughness ultrahigh-temperature ceramic matrix composite material and a preparation method thereof. The preparation method comprises the following steps: alternately depositing two coatings on the surface of the carbon fiber material by adopting a chemical vapor deposition method to obtain the carbon fiber material with the multilayer CVD composite coating, wherein the two coatings are one of a pyrolytic carbon layer or a layered ceramic coating and an ultrahigh-temperature ceramic coating; adopting a phenolic resin / epoxy resin solution and ceramic powder to form ceramic slurry, coating the CVD composite coating carbon fiber material with the ceramic slurry, performing alternately staggered stacking and needling to obtain a stacked fiber felt, and after vacuum drying, performing warm-pressing curing and carbonization treatment, and obtaining a porous prefabricated body; and finally, carrying out densification treatment to obtain the ceramic-based composite material. The material has high strength, high fracture toughness, oxidation resistance, ablation resistance and corrosion resistance, and can be applied to high-temperature and ultrahigh-temperature structural materials, oxidation-resistant and corrosion-resistant materials and aerospace ablation-resistant materials.

Owner:湖南兴晟新材料科技有限公司

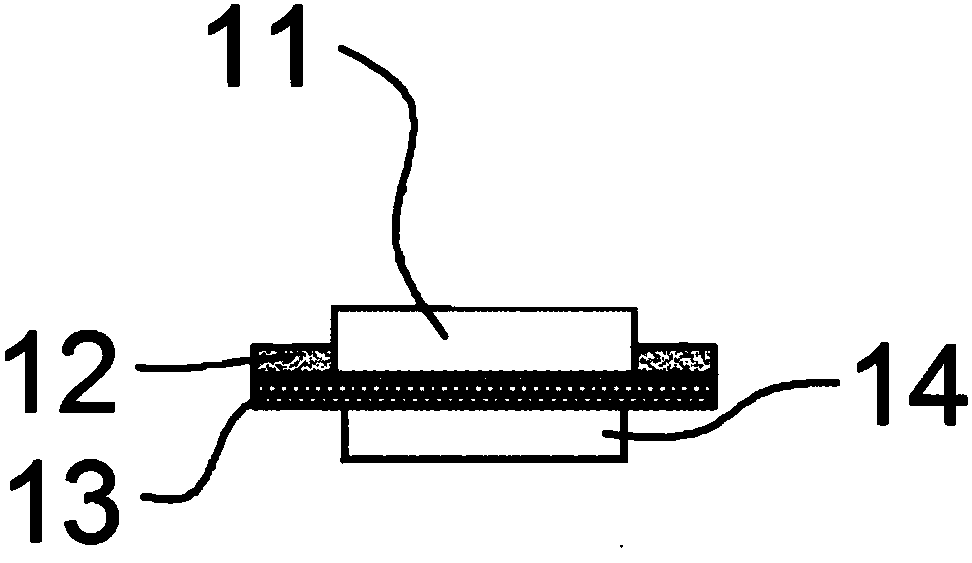

Flexible positive electrode of lithium-ion battery, preparation method of flexible positive electrode and super-flexible lithium-ion all-battery

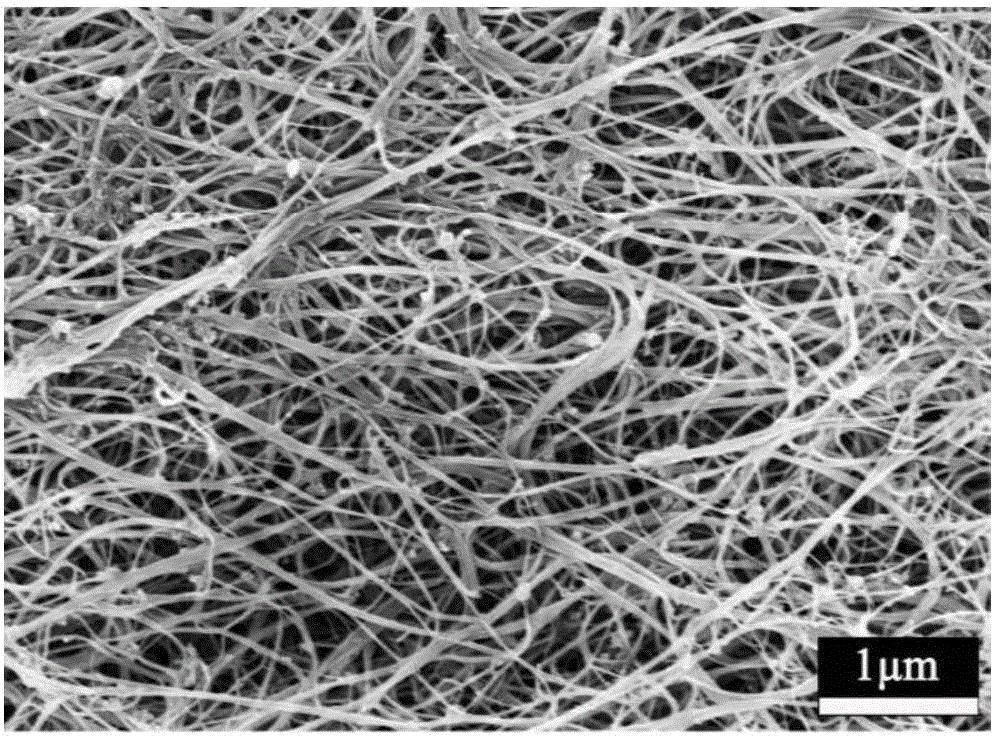

InactiveCN106207091AAvoid brittle breakAttached tightlyElectrode carriers/collectorsSecondary cellsManganateMolten salt

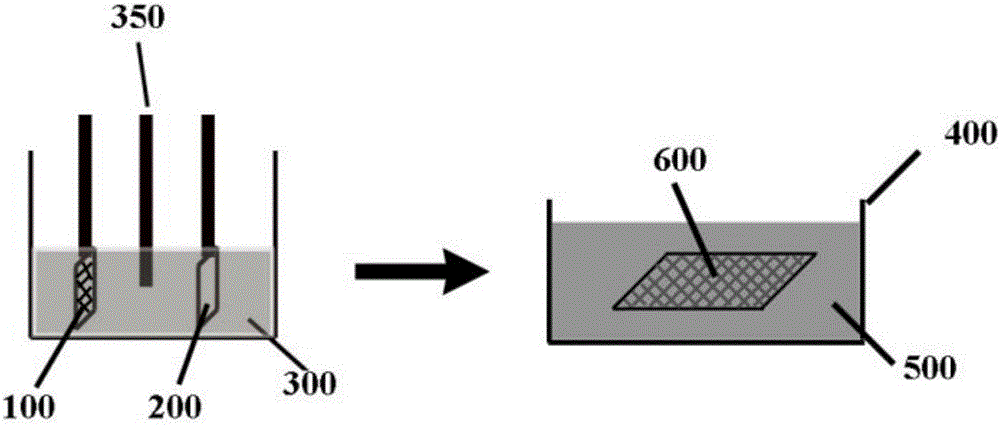

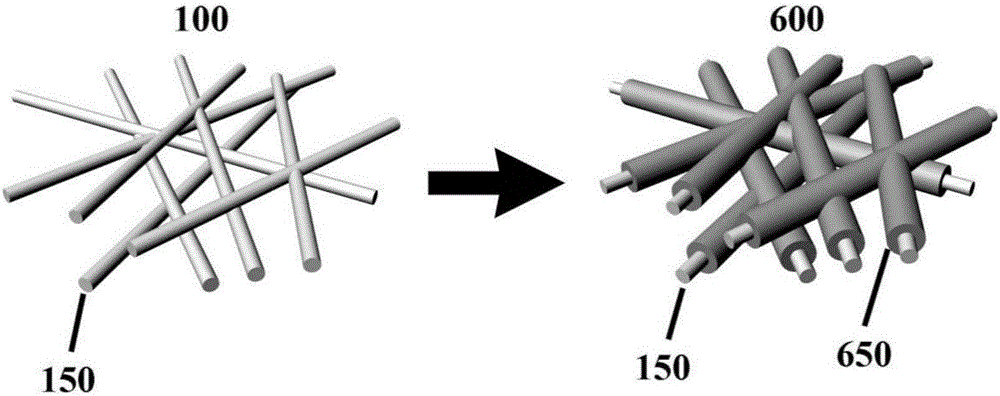

The invention provides a flexible positive electrode of a lithium-ion battery, a preparation method of the flexible positive electrode and a super-flexible lithium-ion all-battery. The flexible positive electrode of the lithium-ion battery is an integrated monolithic electrode formed by a positive electrode material lithium manganate (650) of the lithium-ion battery and a flexible skeleton (150). The preparation method of the flexible positive electrode comprises the following two steps of (1) selecting the flexible skeleton and depositing an oxygen manganese hydroxide material on the flexible skeleton in an electroplating manner; and (2) carrying out lithiation treatment on the electrodeposited oxygen manganese hydroxide material in a low-melting-point fused salt containing lithium ions to form the positive electrode material lithium manganate of the lithium-ion battery growing on the flexible skeleton in a conformal (conformal) manner. The flexible positive electrode of the lithium-ion battery has the technical effect that a three-dimensional flexible network or a bracket is utilized as a substrate, so that the flexible substrate can accept large deformation in the bending process.

Owner:NANJING UNIV

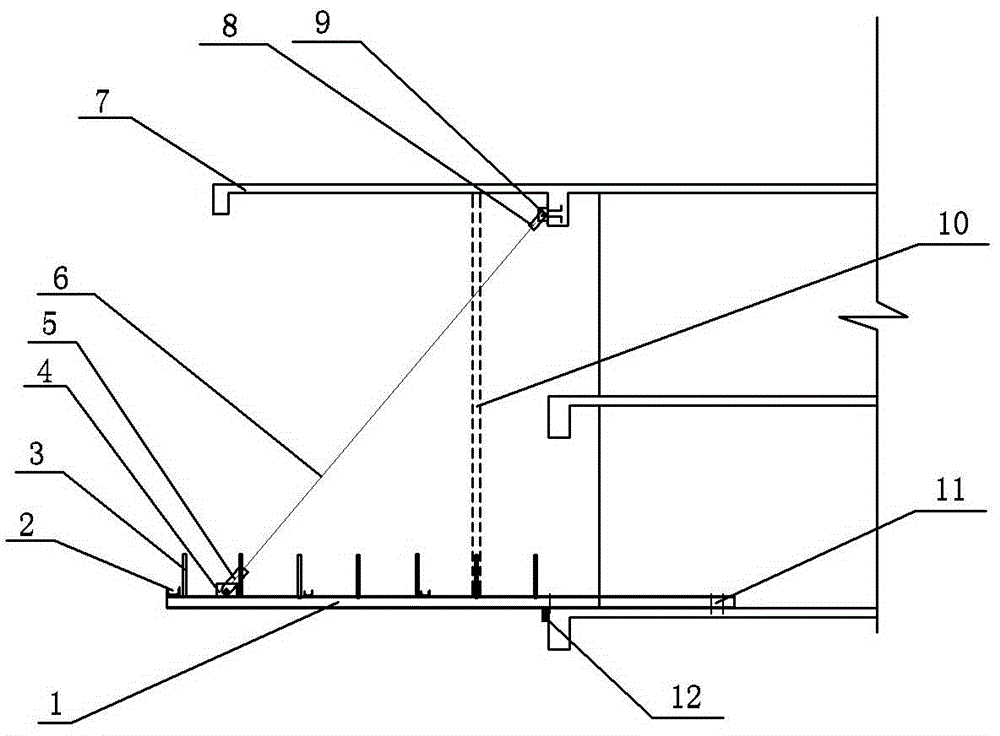

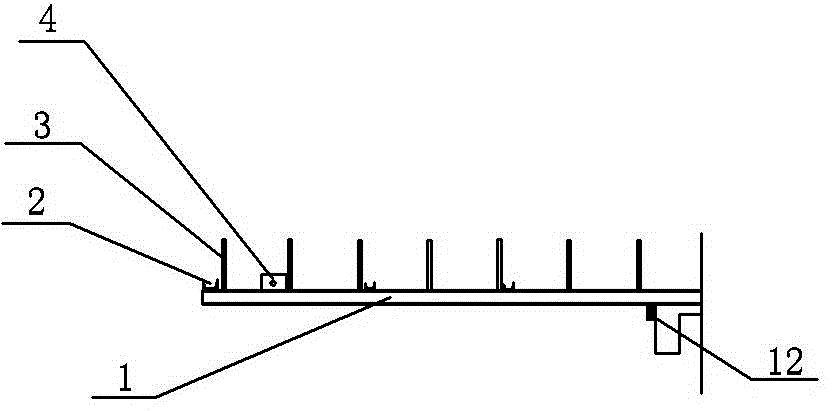

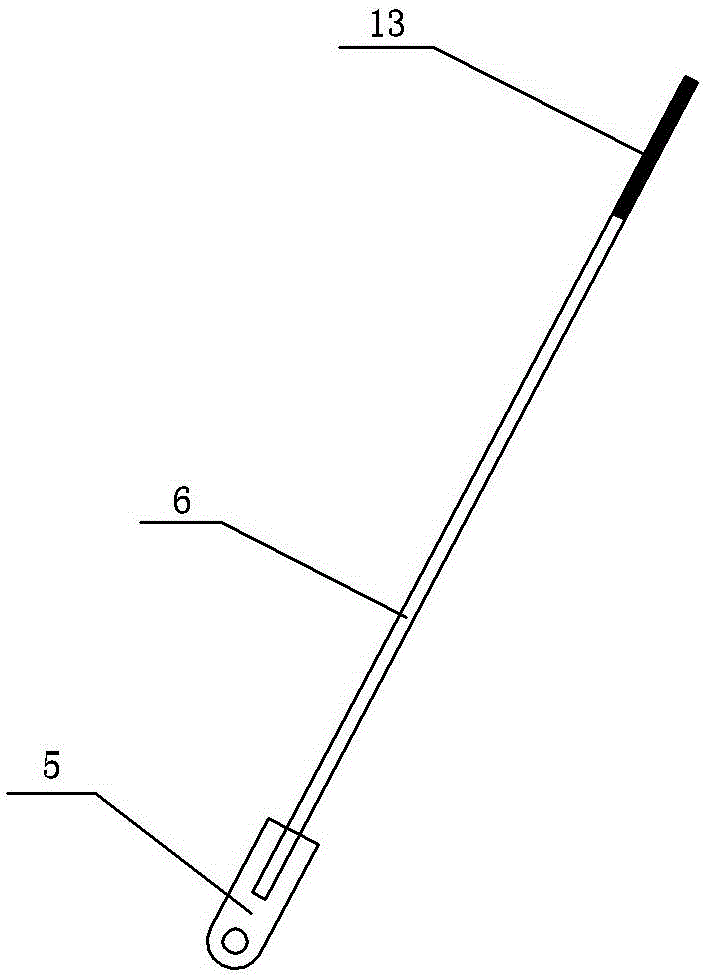

Forming method of upward pull type overhanging joist steel moudle frame stressing platform

InactiveCN102720358AEasy to operateReduce construction difficultyForms/shuttering/falseworksSteel barBolt connection

The invention relates to a forming method of an upward pull type overhanging joist steel moudle frame stressing platform. The forming method comprises the following steps: enabling an overhanging joist steel to weld a connecting plate pull knot on a pre-burying otic placode of a floor structure through an inclined pull round steel, and realizing a pull connection main stress; adopting two bolted connections on a joist steel direction which is perpendicular to the upper surface of the middle of the overhanging joist steel, enabling a channel steel to be as a pull knot rod piece, adopting one bolted connection on the joist steel direction which is perpendicular to the upper surface of the end part of the overhanging joist steel, utilizing the channel steel to strengthen the end part of the overhanging joist steel, and connecting each overhanging joist steel and the channel steel so as to form a whole well-shaped combination stress platform; and welding a vertical rod bearing insertion steel bar head on the overhanging joist steel based on the vertical rod position supported by a moudle frame, welding a steel baffle plate on the edge beam position of the overhanging joist steel and the floor structure, wherein the steel baffle plate is used for generating horizontal thrust after balanced construction stress. The forming method provided by the invention simplifies the construction procedures, reduces construction difficulty, and simultaneously ensures construction safety; and the stress of the stress platform overall structure is reasonable, and the stress platform overall structure is safe and reliable.

Owner:HENAN NO 1 CONSTR ENG GRP

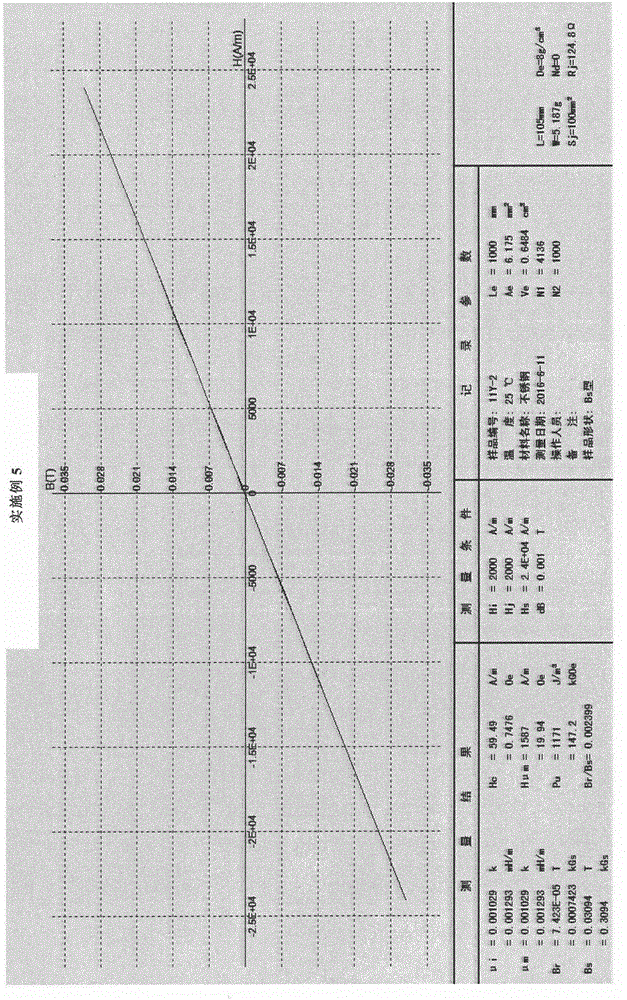

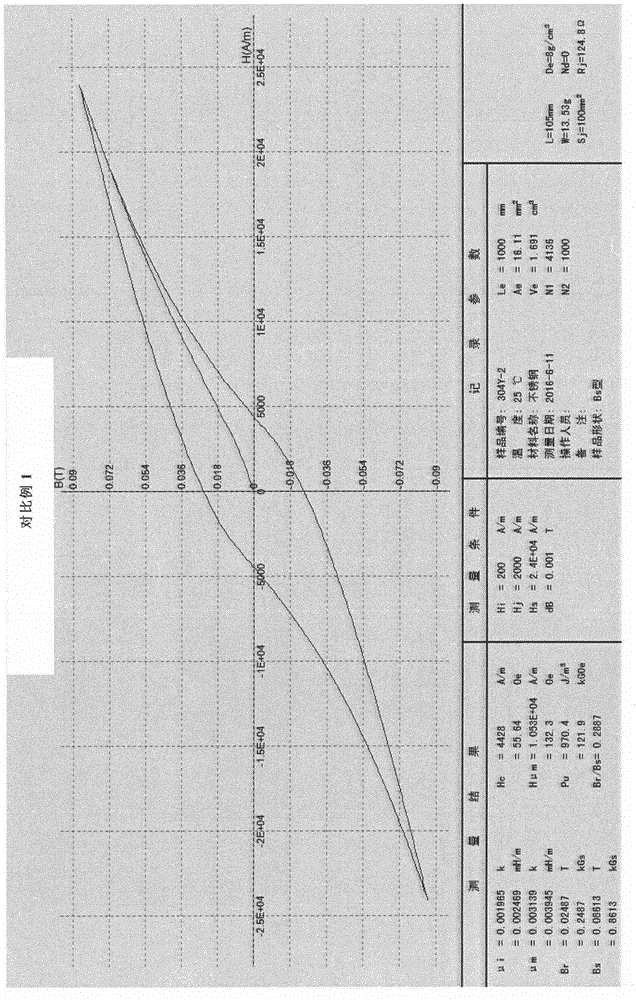

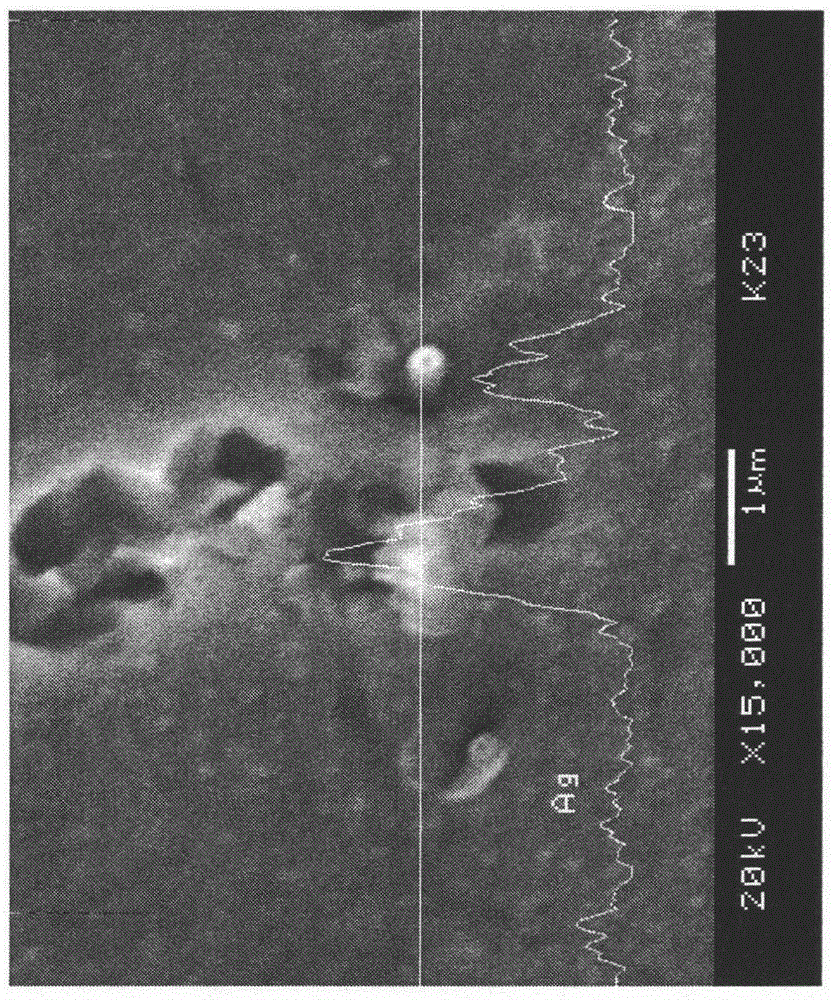

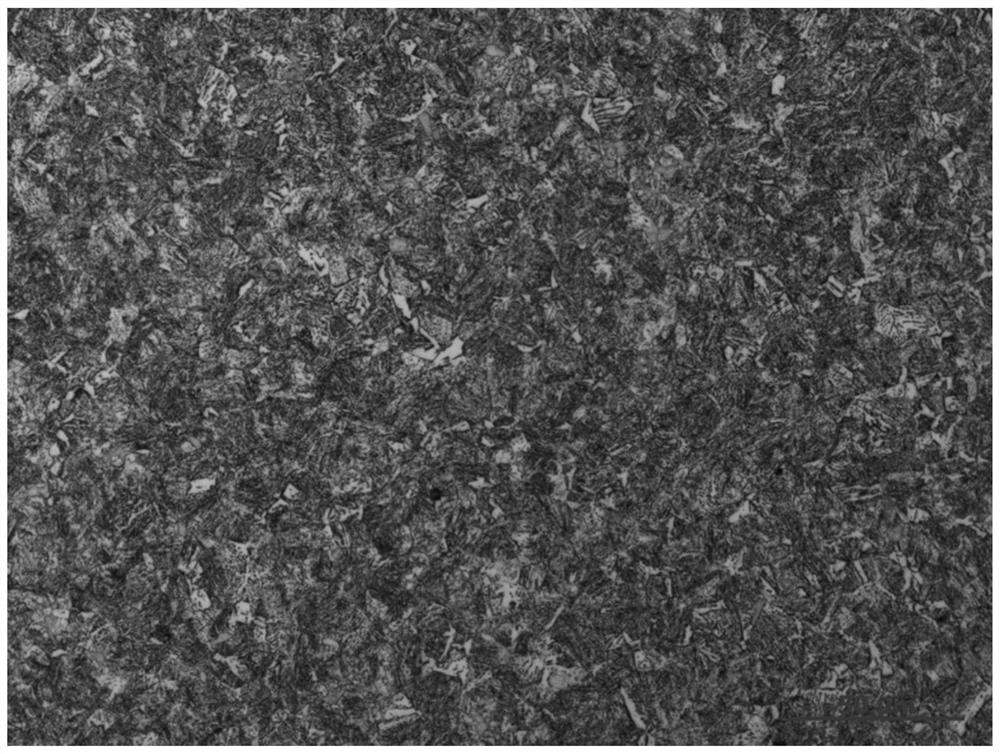

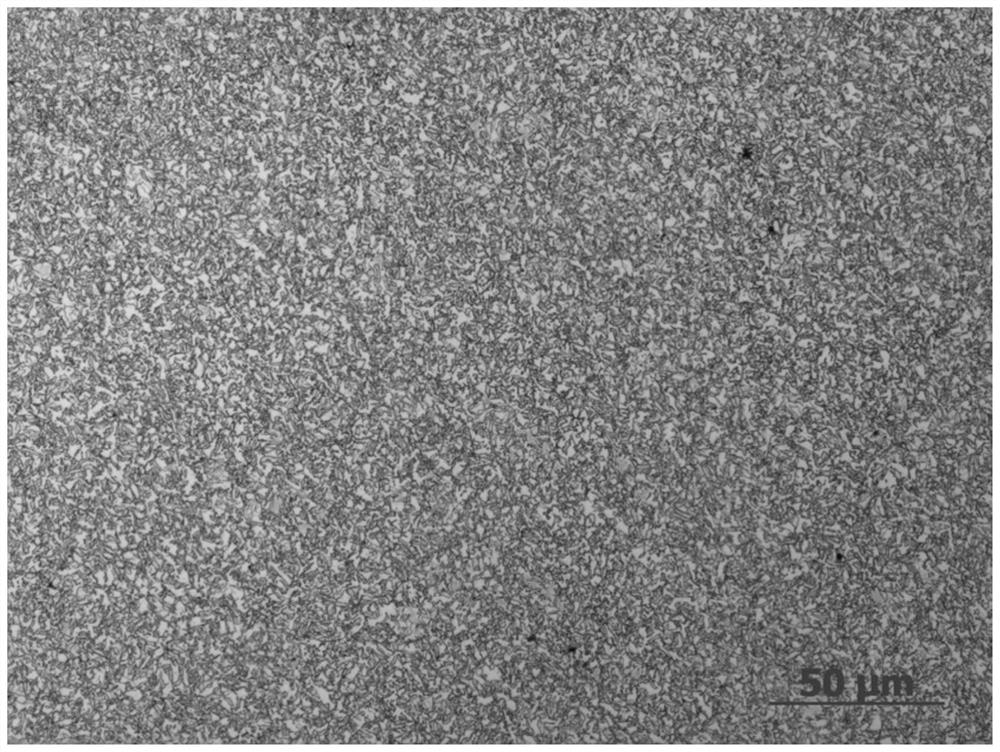

Non-magnetic stainless steel for medical apparatuses and instruments and manufacturing method of non-magnetic stainless steel

ActiveCN106048410AImprove antibacterial propertiesAvoid the risk of infectionChemical compositionMagnetic phase

The invention discloses non-magnetic stainless steel for medical apparatuses and instruments and a manufacturing method of the non-magnetic stainless steel. The non-magnetic stainless steel is prepared from the following chemical components in percentage by weight: 0.005-0.05% of C, 0.2-1.0% of Si, 4.0-6.0% of Mn, 18.0-20.0% of Cr, 0.20-0.40% of Ag, 0.002-0.006% of O and the balance of F and unavoidable impurities; in addition, the chemical components meet the follow relational expression: Ag :Cu=0.15, Ag :(10*O) is equal to or greater than 4.5, (Nb+V): C is equal to or greater than 10.0, (Cr+Mo+1.5Si) / (Ni+30N+30C+0.25Cu+0.5Mn) is equal to or less than 1.30, Cr+3.3Mo+30N-Mn is equal to or greater than 22.0, and 580-520C-2Si-16Mn-23Ni-300N-26Cu-10Mo is equal to or lower than minus 110 DEG C. For the application requirements of non-blade medical apparatuses such as pincers in the department of orthopaedics, the hardness of the non-magnetic stainless steel can reach HV 450-505 degrees at the room temperature and meets the abrasion resistant requirement; the impact value AKV of the non-magnetic stainless steel is equal to or greater than 45 J at the room temperature and meets the tenacity requirement during clamping; the magnetic phase content of the non-magnetic stainless steel is equal to or less than 0.20% and meets the requirement of non-interference to a magnetic resonance system during an operation; and the antibiosis rate of the non-magnetic stainless steel to staphylococcus and escherichia coli is equal to or greater than 98%, so that cross infection during, before and after an operation is effectively avoided.

Owner:上海落日新材料科技有限公司

Cooling control process for preventing decarbonization of small-size spring steel

ActiveCN102962267AAvoid brittle breakImprove cooling effectWork treatment devicesMetal rolling arrangementsSpring steelDecarburization

The invention relates to a cooling control process in the field of metallurgy and a cooling control process for preventing decarbonization of small-size spring steel. The cooling control process comprises the following steps of: respectively controlling the finishing temperature and the spinning process within 800+ / -10DEG C; after spinning, closing all Stelmor fans and covers; meanwhile, setting operation speeds of Stelmor air-cooled roller tables; setting the rotating speed of a first roller table of the Stelmor air-cooled roller tables at 15-20rpm; setting the rotating speeds of roller tables on even number sections as 110 percent of the rotating speed of the first roller table; setting the rotating speeds of roller tables on odd number sections as 100 percent of the rotating speed of the first roller table; and controlling the temperature of the cover below 450DEG C to ensure that all phase changes of a pony roll in the air-cooled roller table are finished. According to the cooling control process disclosed by the invention, various part tissues in a finished product can be uniform, the structure segregation is avoided and the brittle failure of the small-size spring steel in the drawing process is prevented.

Owner:NANJING IRON & STEEL CO LTD

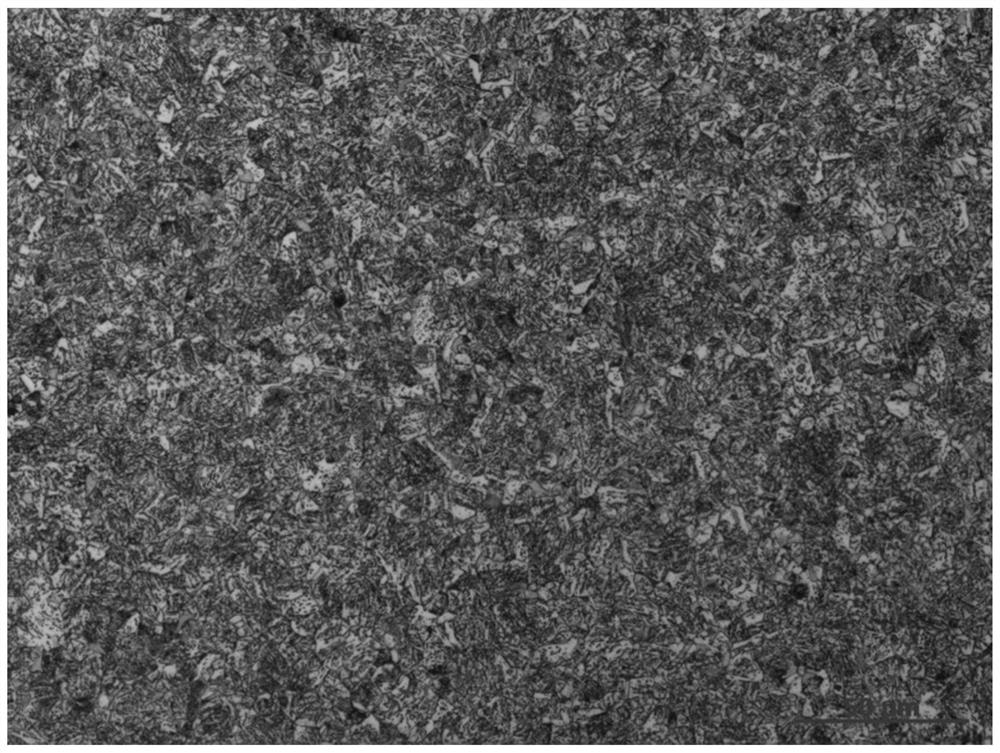

Controlled rolling and controlled cooling method for reducing martensite in microstructure of high-alloy steel hot-rolled wire rod

InactiveCN112239803AEasy to changeShorten transition timeFurnace typesHeat treatment furnacesWire rodTemperature control

The invention belongs to the technical field of steel rolling, and particularly relates to a controlled rolling and controlled cooling method for reducing martensite in a microstructure of a high-alloy steel hot-rolled wire rod. After being heated, a steel billet is subjected to rough, medium and pre-finish rolling deformation; the water flow of a water tank is adjusted, so that the temperature ofthe steel billet reaching a finish rolling mill is controlled to be 750-800 DEG C, and low-temperature controlled rolling is achieved; the flow of the water tank is adjusted after rolling, so that the spinning temperature is controlled to be 780-820 DEG C; a Stelmor fan is started so that the temperature of a wire rod is quickly reduced, and then the wire rod immediately enters an insulation cover to continue the organizational transformation; the speed of a Stelmor roller way is set to be 3-5 m / min, so that the transformation time of a bainite structure is prolonged, and the effect that onlya very small number of martensite structures are contained in the microstructure of the high-alloy steel hot-rolled wire rod is ensured; and therefore, the strength is reduced, the plasticity is improved, and it is ensured that the high-alloy steel hot-rolled wire rod has good drawing performance. By means of the controlled rolling and controlled cooling method for reducing martensite in the microstructure of the high-alloy steel hot-rolled wire rod, the martensite content in the microstructure of the obtained high-alloy steel hot-rolled wire rod is less that 2%, and the drawing performance is extremely good.

Owner:ZENITH STEEL GROUP CORP +1

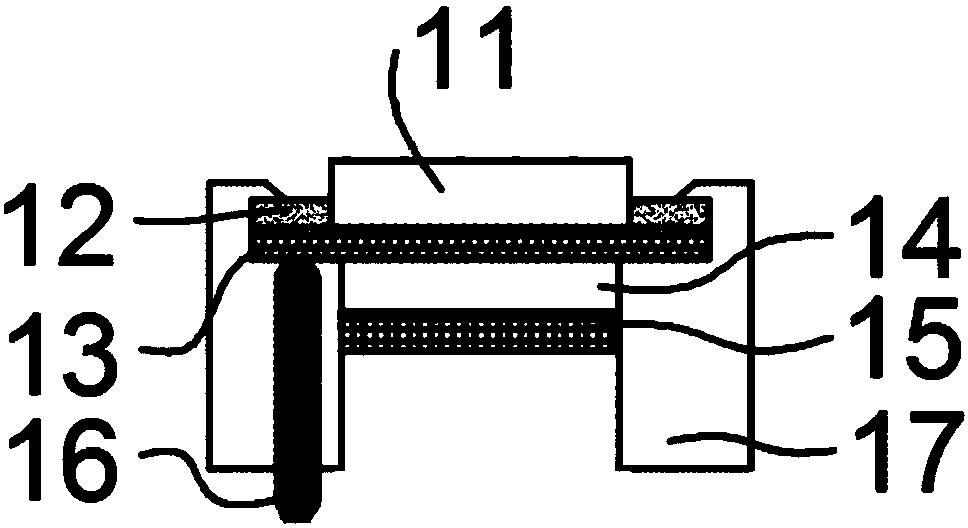

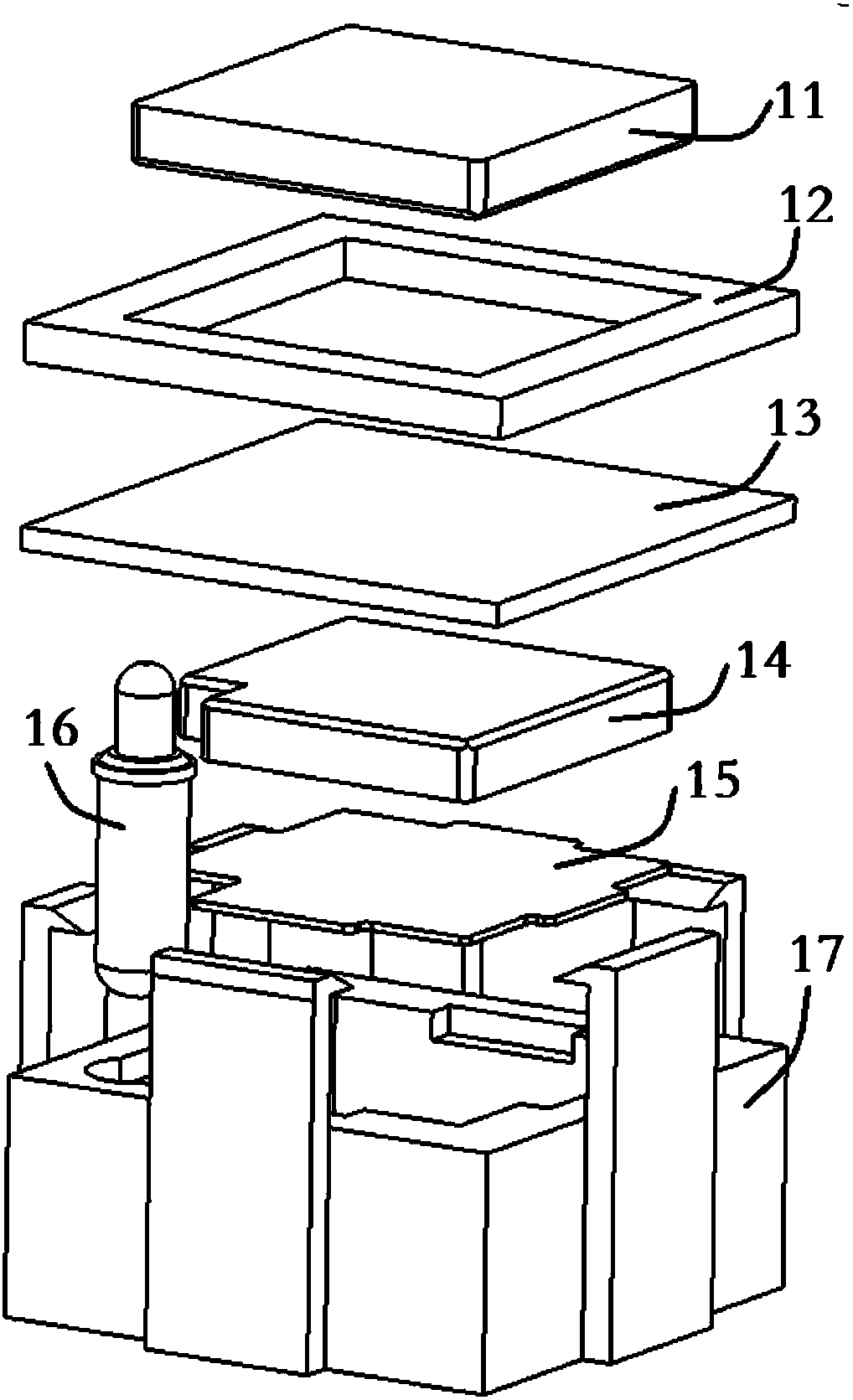

Power semiconductor device packaging structure and packaging method

ActiveCN108231706AImprove reliabilityLess bendingSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceMetal sheet

The embodiment of the invention provides a power semiconductor device packaging structure and a power semiconductor device packaging method. The power semiconductor device packaging structure comprises at least one packaging submodule, wherein the packaging submodule comprises an upper metal sheet, a positioning frame, a power chip and a lower metal sheet; the power chip is arranged on the lower metal sheet; the upper metal sheet is clamped into the positioning frame, and the upper metal sheet and the positioning frame are jointly arranged on the power chip; the size of the upper metal sheet is not smaller than that of the lower metal sheet, and difference between the size of the upper metal sheet and the size of the lower metal sheet is smaller than a preset difference, so that the uppermetal sheet and the lower metal sheet have equivalent area, and thus bending of the chip in a power semiconductor device is effectively reduced, invalidation of the chip due to cracking or even brittle fracture is prevented and the reliability of the power semiconductor device is improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

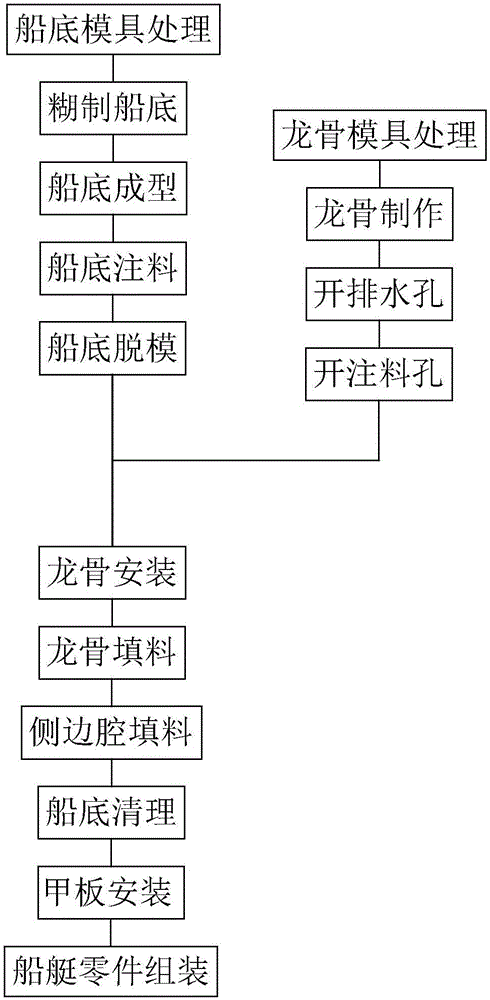

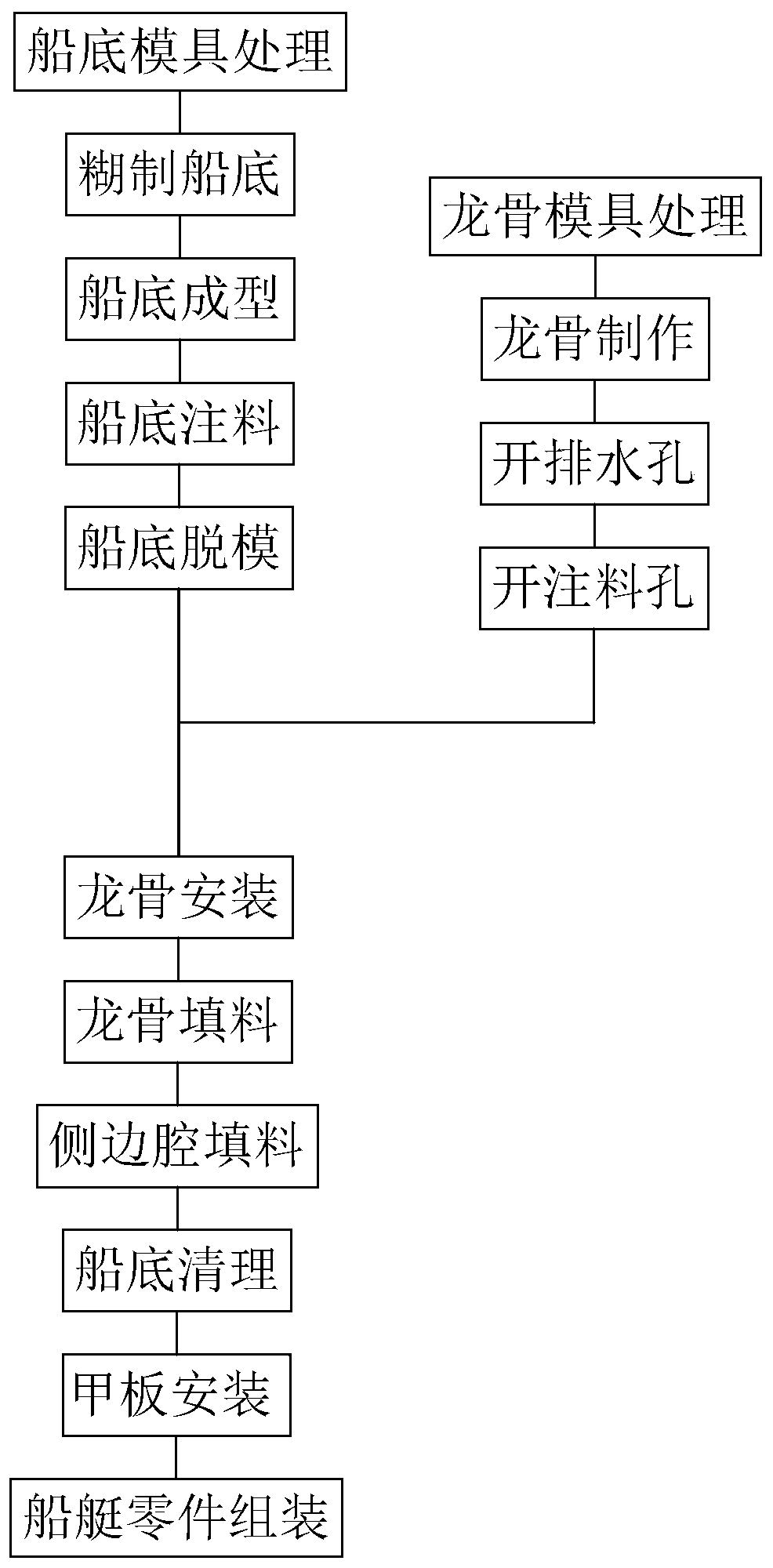

Manufacturing process for anti-sinking fiber reinforced plastic ship

ActiveCN106585873AGood weather resistanceReduce structural strengthNon-magnetic metal hullsVessel partsFiberAdhesive

The invention discloses a manufacturing process for an anti-sinking fiber reinforced plastic ship. The process comprises a series of process steps of mold treatment, ship bottom pasting, ship bottom molding, ship bottom material injection, ship bottom demolding, keel mounting, keel packing, ship bottom side edge packing, ship bottom cleaning, deck mounting and ship part assembling. The ship manufactured through the process has the following advantages that firstly, a keel structure is low in weight and high in strength, the safety is improved while the weight of a ship body is lowered; secondly, corrosion of moisture to the keel structure can be resisted, and the service life is prolonged; and thirdly, due to the fact that a ship bottom and the keel structure are bound firmly through a structural adhesive, decks with foaming fillers can be used as temporary first-aid tools after the ship body is fractured and scattered and replace life rings, and persons falling into water are prevented from drowning.

Owner:山东双一游艇有限公司

Fully sealed gas taking device for gas relay

InactiveCN104458359AAvoid brittle breakGood sealingComponent separationWithdrawing sample devicesSyringeInjector

The invention provides a fully sealed gas taking device for a gas relay and belongs to the technical field of free gas chromatographic analysis in the gas relay. The problems that the head of an injector is easy to break and a gas sample easily escapes from a three-way valve or atmosphere is sucked are mainly solved. The device comprises an injector, a three-way valve, a hose and a gas relay gas outlet, wherein one end of the hose is connected with the gas relay gas outlet, and the other end of the hose is connected with one end of the outlet of two opposite ends of the three-way valve; the diameter of the middle outlet of the three-way valve is consistent with the diameter of the outlet of the injector; the device is characterized by also comprising a two-way joint; and one end of the two-way joint is connected with the other end of the outlet of two opposite ends of the three-way valve, and the other end of the two-way joint is connected with the outlet of the injector. The gas taking efficiency is high, and the utilization of gas samples and oil is increased; and moreover, the working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +1

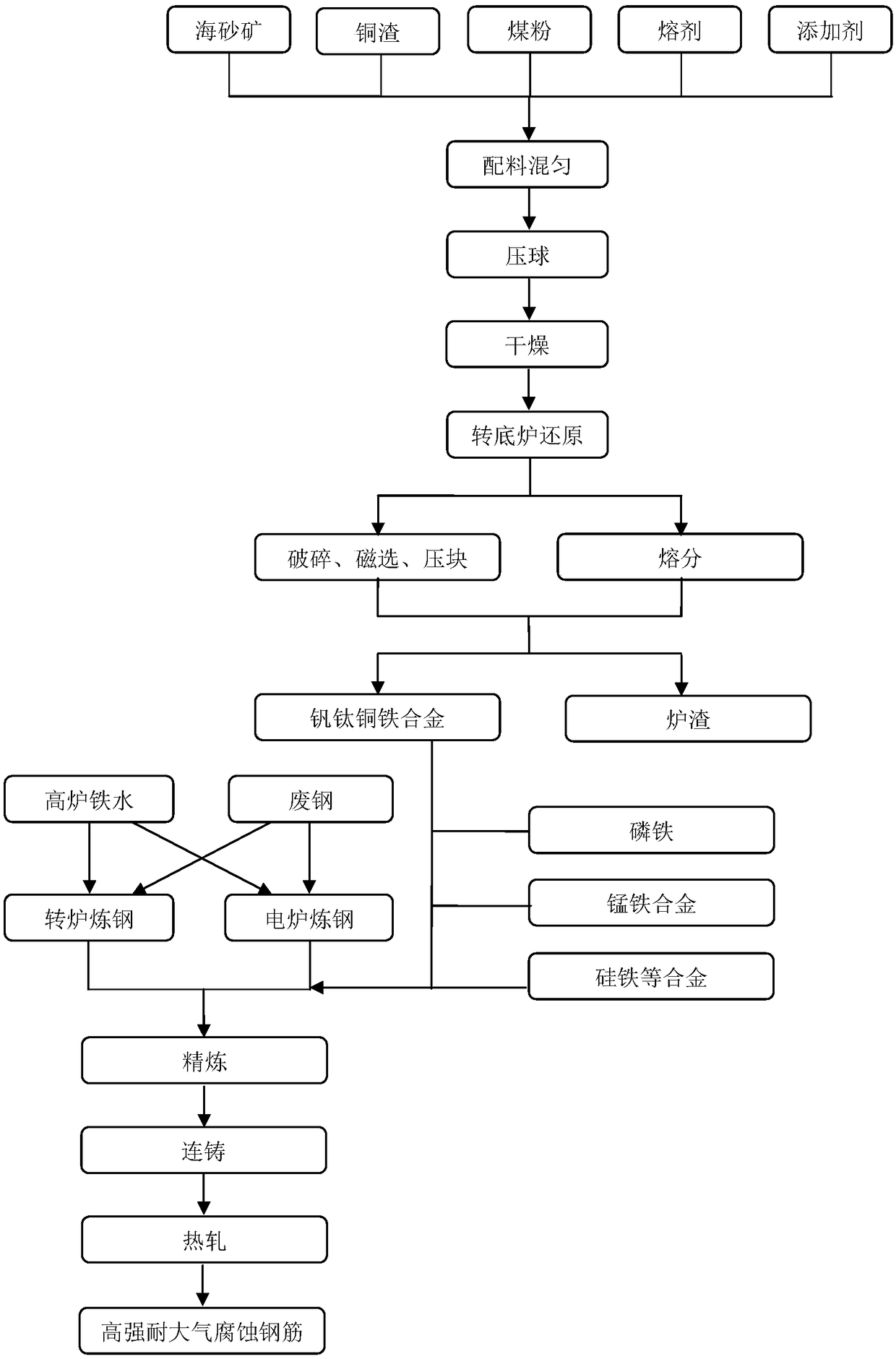

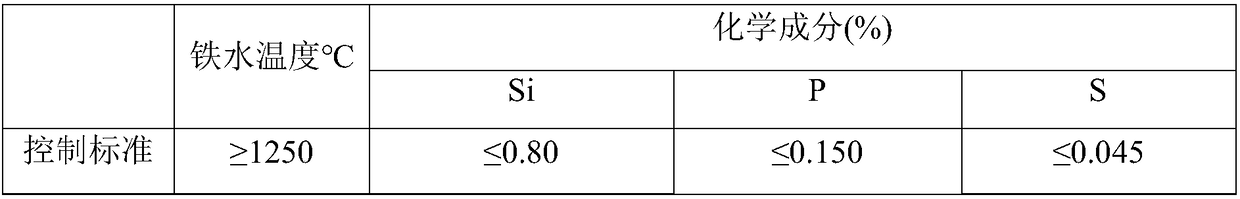

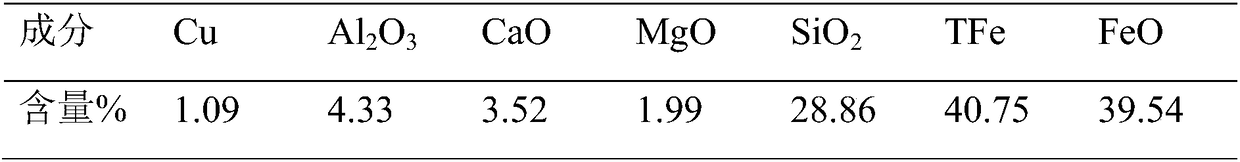

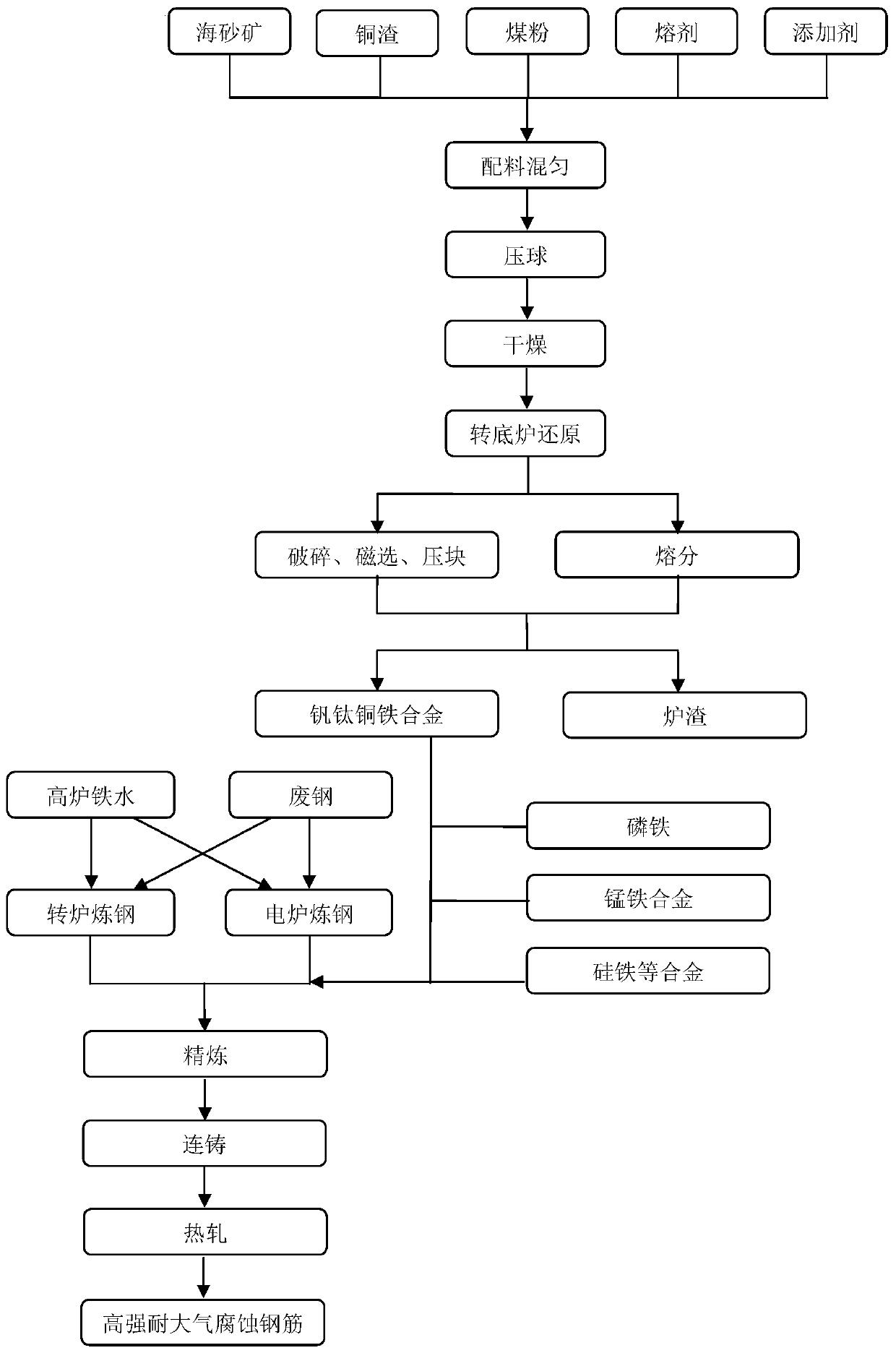

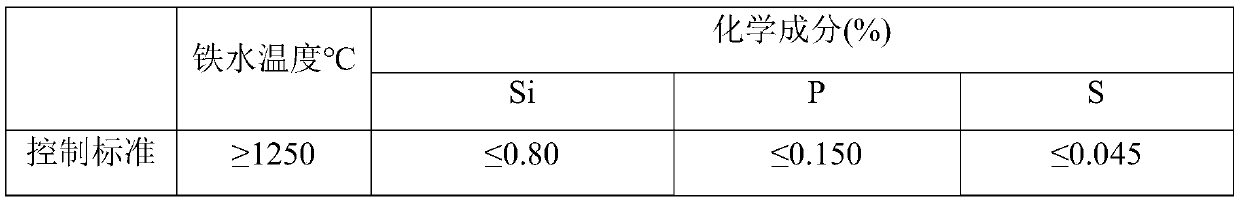

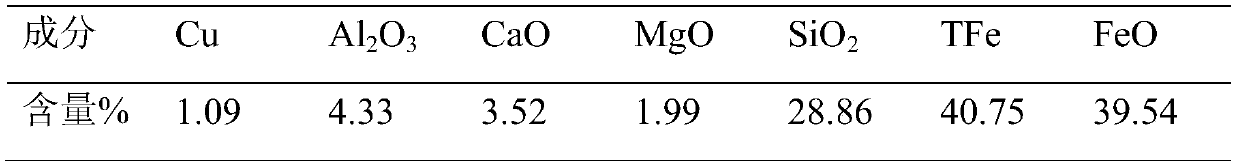

High-strength atmospheric-corrosion-resistant steel bar and preparation method thereof

The invention discloses a high-strength atmospheric-corrosion-resistant steel bar and a preparation method thereof, and belongs to the technical field of steel preparation. According to the preparation method, the problems that in the prior art, high-priced ore concentrates are adopted in the alloy preparation process, iron is wasted in the preparation process and the whole preparation process ofthe high-strength atmospheric-corrosion-resistant steel bar is tedious and high in cost are solved. The preparation method comprises the following steps that 1, marine sand ore, copper slag and coal powder are pretreated and uniformly mixed, so that a raw material mixture is obtained; 2, hydrated lime flux and a syrup additive are added into the raw material mixture, so that a to-be-reduced material is obtained; 3, the to-be-reduced material is pressed into a ball and dried, so that a pellet is obtained; 4, reduction and posttreatment are carried out on the pellet, so that a vanadium-titanium-copper-iron alloy is obtained; and 5, molten steel smelting is carried out through a converter or an electric furnace, the vanadium-titanium-copper-iron alloy and ferrophosphorus are added in the tapping process of molten steel, refining, continuous casting and hot rolling are carried out, so that the high-strength atmospheric-corrosion-resistant steel bar is obtained. The preparation method can be used for preparing the high-strength atmospheric-corrosion-resistant steel bar.

Owner:钢研晟华科技股份有限公司

Resin base composite material dowel pin for dental surgery

InactiveCN1545986AAvoid brittle breakHigh degree of automationImpression capsTeeth fillingChemistryResin matrix

The invention discloses a dentist's resin based composite material dowel pins and the process for preparation, which comprises, (1) preparing acetone solution or alcohol solution with coupling agent, charging nano particles into the acetone solution or alcohol solution for ultrasonic wave decentralized processing, (2) charging the nano particles treated by the solution of the coupling agent into the resin matrix, (3) using the long fiber as reinforced material, making the matrix of the resin fully infiltrate the long fiber, (4) configuring the long fiber along the axis of the dowel pins, performing press forming and hardening on the molding press, cooling down and demoulding, process till the required shape and length are achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

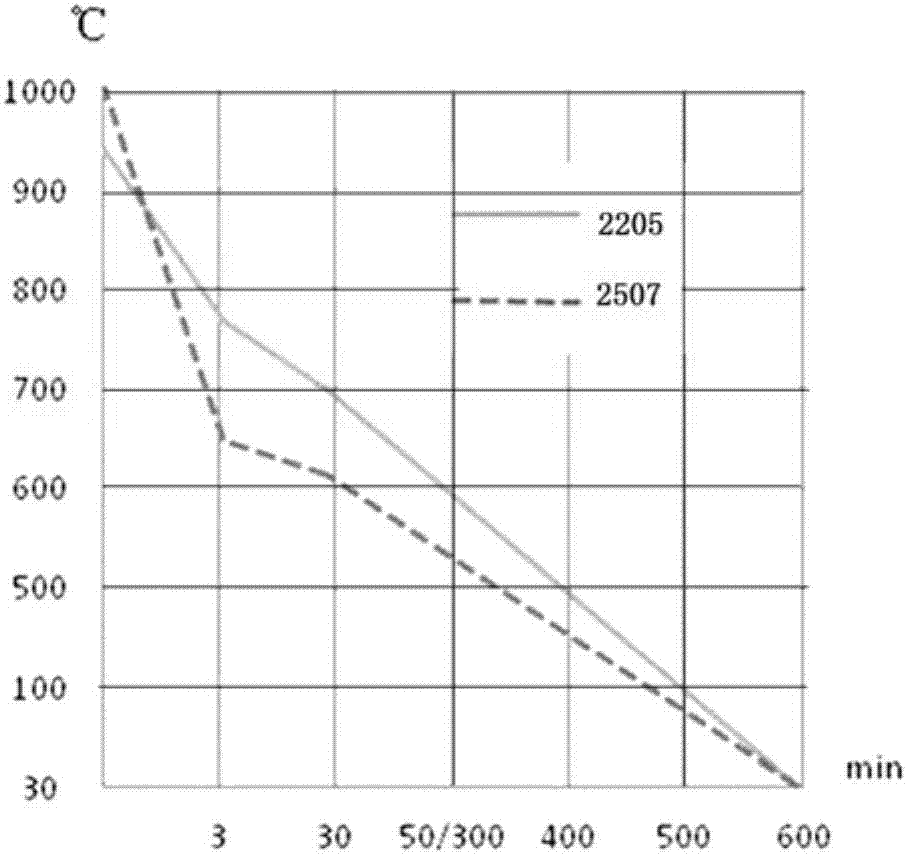

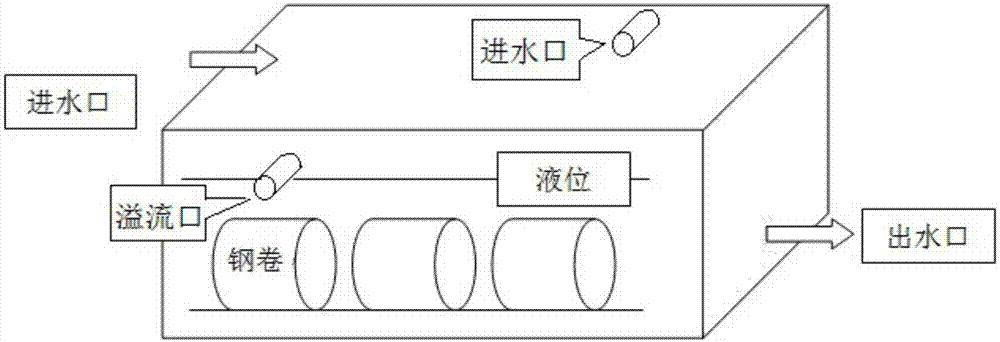

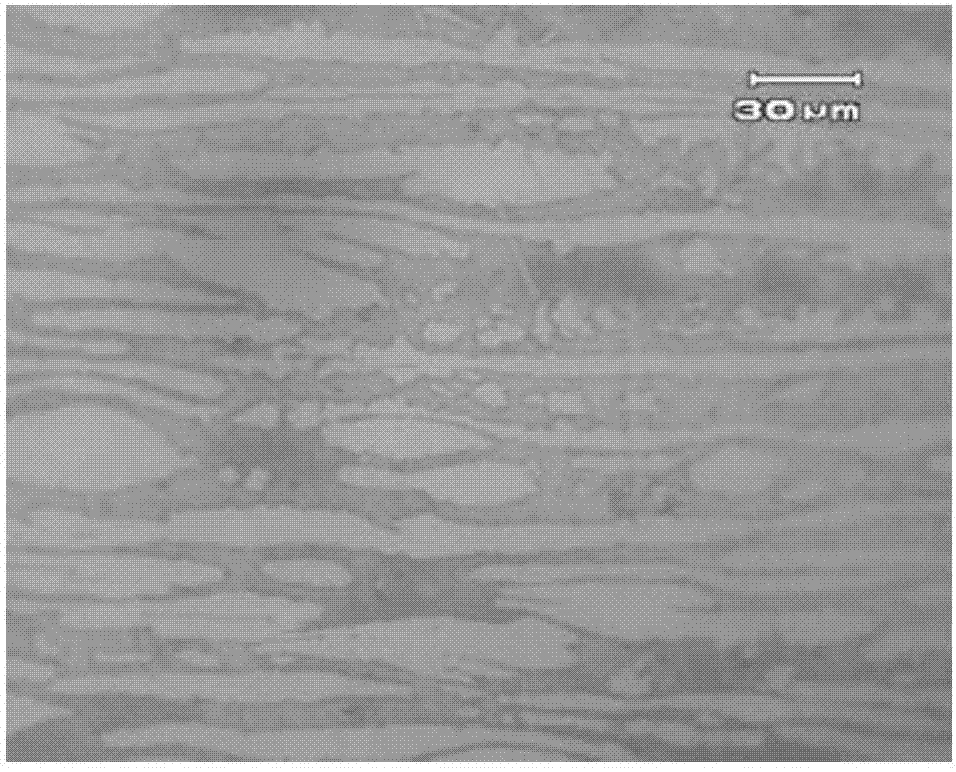

Coiling method for stainless steel dual-phase steel

InactiveCN107470373AControl end temperatureNo σ phase precipitationTemperature control deviceFurnace temperatureLaminar cooling

The invention provides a coiling method for stainless steel dual-phase steel. The coiling method comprises the following steps: placing a roughly-rolled dual-phase steel plate blank in a coiling furnace of a fine rolling machine and carrying out fine rolling calendering to obtain dual-phase steel strip steel subjected to the fine rolling calendering; sequentially carrying out laminar cooling, coiling and water-cooling pool cooling on the dual-phase steel strip steel subjected to the fine rolling calendering; and cooling the dual-phase steel strip steel to achieve room temperature and then obtaining a dual-phase steel product, wherein the furnace temperature of the coiling furnace of the fine rolling machine is 1000-1050 DEG C, and the coiling temperature is 450-750 DEG C. The dual-phase steel plate blank comprises 2205 steel grade or 2507 steel grade, wherein the coiling temperature of the 2205 steel grade is 600-750 DEG C; and the coiling temperature of the 2507 steel grade is 450-700 DEG C.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

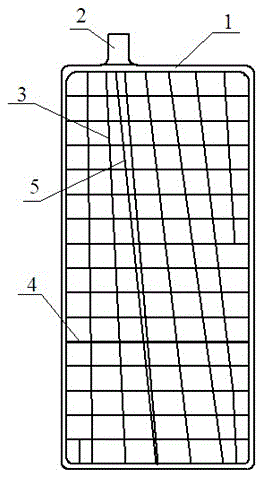

Grid of pole plate

InactiveCN105655594AIncrease the total conductive areaLower internal resistanceElectrode carriers/collectorsCell component detailsLarge ribsEngineering

The invention discloses a grid of pole plate. The grid comprises a pole plate grid body, which comprises a rectangular deck frame, wherein the rectangular deck frame is formed by enclosing a large rib. Non-rectangular net-like grids composed of multiple horizontal ribs and oblique ribs are arranged in the frame; the diagonal positions in the frame are provided with reinforcing ribs; and a position, which is close to the middle part, of the external side of one side of the frame is provided with a rectangular tab. According to the technical scheme mentioned above, the number of vertical ribs of the pole plate grid is increased; the vertical ribs are obliquely arranged, the total conductive area is increased, the battery internal resistance is reduced, the utilization rate of lead paste is guaranteed; moreover, the grid will not be broken off by the expansion or creep deformation of lead paste during the application process, the service life of pole plate grid is guaranteed; the designed structure can improve the conductive performance of grid, is beneficial for large current discharge and fixation of active substances in grid, and disperses the expansion stress of lead paste, thus expansion and creep deformation of lead paste are avoided during the application process, the moulding of grid skeleton is enhanced; the force bearing strength of six surfaces of grid is reinforced, and the comprehensive performance of grid is improved.

Owner:ANHUI YONGHENG STORAGE BATTERY

Light pitched roof waterproof tile and preparation method thereof

ActiveCN105971200AImprove waterproof performanceHigh strengthRoof covering using tiles/slatesLayered productsCardboardGlass fiber

The invention relates to a light pitched roof waterproof tile comprising a first fiber layer, a composite layer and a second fiber layer which are fixedly connected in sequence from the bottom layer to the top layer. The composite layer comprises a reinforcing layer. The first fiber layer and the second fiber layer are each prepared from basic fiber, reinforced fiber and a paper board water repellent agent. The reinforcing layer is a cotton and bast fiber layer or a glass fiber layer, a metal wire layer or a wool fabric material layer. The first fiber layer, the composite layer and the second filter layer are steeped with modified asphalt. The pitched roof waterproof tile has high strength, toughness and impact resistance, not probe to cracking or damage in the installation and using process, good in waterproof effect, not prone to color fading or losing, and capable of being decomposed, recycled and repeatedly used. The invention further relates to a preparation method of the light pitched roof waterproof tile. The preparation method comprises the steps of raw material preparation, body material manufacturing, body material shaping and body material steeping. The method is high in production efficiency, safe in production process and suitable for batch production.

Owner:李淑董

Deburring equipment of hose surface of glass fiber machine and processing method thereof

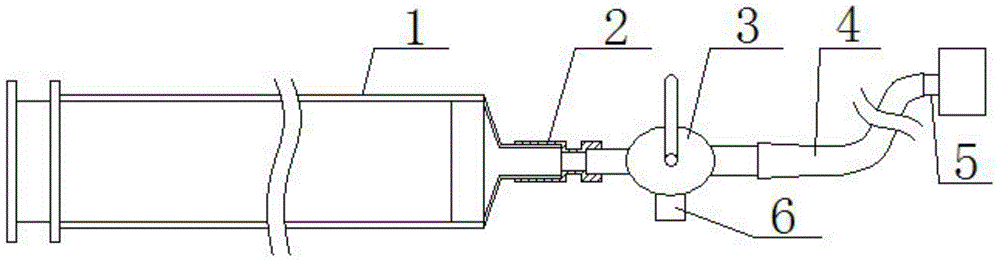

ActiveCN102926160AImprove the safety of useImprove electrical breakdown resistanceSingeingGlass fiberCombustion chamber

The invention relates to deburring equipment of a hose surface of a glass fiber machine and a processing method of the deburring equipment of the hose surface of the glass fiber machine. The deburring equipment of the hose surface of the glass fiber machine comprises a base, a pay-off rack and a take-up rack, and is characterized in that a combusting device and a melting device are sequentially arranged between the pay-off rack and the take-up rack. The combusting device and the melting device are both arranged on the base, and are of the same height. Two ends of an inlet and an outlet of the combusting device and two ends of an inlet and an outlet of the melting device are respectively provided with a hose expanding device, and the four hose expanding devices are arranged coaxially and are matched with the height of the combusting device and the melting device. At least two air inlets are arranged inside a combusting chamber of the combusting device, and the melting device adopts non-contact heat source melting. The deburring equipment of the hose surface of the glass fiber machine and the processing method of the deburring equipment of the hose surface of the glass fiber machine are reasonable in structure, safe and energy-saving, convenient to operate and obvious in deburring effect.

Owner:浙江博菲电气股份有限公司

PVC channel board for displaying auto spare parts, and good in toughness and strong in bearing capability

The invention discloses a PVC channel board for displaying auto spare parts, and good in toughness and strong in bearing capability. The PVC channel board comprises the following raw materials in parts by weight: 20-40 parts of polyvinyl chloride, 10-20 parts of polytetrafluoroethylene, 0.5-1.5 parts of butyl benzyl phthalate, 1-2 parts of polyphenylene sulfide, 1-2 parts of acrylic resin, 1-2 parts of magnesium stearate, 0.5-1.2 parts of foaming agent, 0.5-1.5 parts of stabilizing agent, 5-15 parts of modified potato starch, 10-20 parts of sepiolite powder, 5-12 parts of cyclodextrin, 0.2-1.5 parts of maleic anhydride, 0.5-1.2 parts of gamma-(ethylenediamine) propyl methyl dimethoxy silane, 0.5-1.2 parts of tetraisopropyl di(dilauryl phosphite) titanate, 1-2 parts of 2, 5-dimethyl-2, 5-di-tert-butyl peroxide hexane, and 1-2 parts of 2, 4-DCBP. The PVC channel board is excellent in abrasion resistance, good in high temperature resistance, excellent in stability, good in toughness and strong in bearing force. Meanwhile, the brittle fracture of the PVC channel board can be avoided.

Owner:安徽优丽普科技有限公司

A kind of preparation method of al2o3p/mo alloy

The invention relates to a preparation method for Al2O3p / Mo alloy. The preparation method for the Al2O3p / Mo alloy comprises the steps that calcination is conducted on ammonium molybdate to prepare MoO3 powder, dry grinding is conducted, and the MoO3 powder is prepared to be used; soluble aluminum salt and urea are taken as raw materials, and A1OOH nano particle turbid liquid is prepared through a hydrothermal reaction; the A1OOH nano particle turbid liquid and the dry-grinded MoO3 powder are taken according to proportioning to conduct wet-grinding, drying is conducted, and composite powder is prepared; reduction is conducted on the composite powder at a hydrogen atmosphere, and composite molybdenum powder is obtained; and the composite molybdenum powder is subjected to pressing and sintering, and molybdenum alloy is prepared. According to the preparation method for the A12O3p / Mo alloy, the composite powder is prepared by adopting solid-liquid adulteration and combining ball-milling, the adulteration efficiency is high, the adulteration effect is good, the quality and the stability of the composite powder are good, and the composite powder is easy to collect, and suitable for mass production; and then the molybdenum alloy is prepared through hydrogen reduction, pressing and sintering, ceramic phase A12O3 nano particles are highly dispersed and distributed in a molybdenum matrix, and the wear resistance performance and the anti-electric-arc-erosion performance of the molybdenum alloy are improved.

Owner:HENAN UNIV OF SCI & TECH

A kind of high-strength atmospheric corrosion-resistant steel bar and preparation method thereof

The invention discloses a high-strength atmospheric-corrosion-resistant steel bar and a preparation method thereof, and belongs to the technical field of steel preparation. According to the preparation method, the problems that in the prior art, high-priced ore concentrates are adopted in the alloy preparation process, iron is wasted in the preparation process and the whole preparation process ofthe high-strength atmospheric-corrosion-resistant steel bar is tedious and high in cost are solved. The preparation method comprises the following steps that 1, marine sand ore, copper slag and coal powder are pretreated and uniformly mixed, so that a raw material mixture is obtained; 2, hydrated lime flux and a syrup additive are added into the raw material mixture, so that a to-be-reduced material is obtained; 3, the to-be-reduced material is pressed into a ball and dried, so that a pellet is obtained; 4, reduction and posttreatment are carried out on the pellet, so that a vanadium-titanium-copper-iron alloy is obtained; and 5, molten steel smelting is carried out through a converter or an electric furnace, the vanadium-titanium-copper-iron alloy and ferrophosphorus are added in the tapping process of molten steel, refining, continuous casting and hot rolling are carried out, so that the high-strength atmospheric-corrosion-resistant steel bar is obtained. The preparation method can be used for preparing the high-strength atmospheric-corrosion-resistant steel bar.

Owner:钢研晟华科技股份有限公司

Preparation method for Al2O3p / Mo alloy

The invention relates to a preparation method for Al2O3p / Mo alloy. The preparation method for the Al2O3p / Mo alloy comprises the steps that calcination is conducted on ammonium molybdate to prepare MoO3 powder, dry grinding is conducted, and the MoO3 powder is prepared to be used; soluble aluminum salt and urea are taken as raw materials, and A1OOH nano particle turbid liquid is prepared through a hydrothermal reaction; the A1OOH nano particle turbid liquid and the dry-grinded MoO3 powder are taken according to proportioning to conduct wet-grinding, drying is conducted, and composite powder is prepared; reduction is conducted on the composite powder at a hydrogen atmosphere, and composite molybdenum powder is obtained; and the composite molybdenum powder is subjected to pressing and sintering, and molybdenum alloy is prepared. According to the preparation method for the A12O3p / Mo alloy, the composite powder is prepared by adopting solid-liquid adulteration and combining ball-milling, the adulteration efficiency is high, the adulteration effect is good, the quality and the stability of the composite powder are good, and the composite powder is easy to collect, and suitable for mass production; and then the molybdenum alloy is prepared through hydrogen reduction, pressing and sintering, ceramic phase A12O3 nano particles are highly dispersed and distributed in a molybdenum matrix, and the wear resistance performance and the anti-electric-arc-erosion performance of the molybdenum alloy are improved.

Owner:HENAN UNIV OF SCI & TECH

Special feed for antelopes

InactiveCN106721169AMeet the nutritional requirements for growthPromote digestion and absorptionFood processingAnimal feeding stuffBiotechnologyPhytase

The invention discloses special feed for antelopes. The special feed is prepared from raw materials in parts by weight as follows: 15-35 parts of potato powder, 2-12 parts of bean worm powder, 2-8 parts of meat and bone meal, 5-12 parts of sesame seed meal, 4-12 parts of fish meal, 1-6 parts of full-fat rice bran, 2-8 parts of high-gluten flour, 1-6 parts of sargassum, 2-6 parts of watermelon peels, 1-2 parts of potato protein powder, 0.5-1 part of beta-glucan, 2-8 parts of precipitated calcium carbonate, 0.5-2.5 parts of bentonite, 1-2 parts of choline chloride, 0.5-1.5 parts of monocalcium phosphate, 2-6 parts of glutamic acid modified gelatin, 1-2 parts of decavitamin, 0.01-0.05 parts of high-temperature-resistant phytase, 1-2 parts of soybean phospholipid oil and 1-4 parts of Chinese herbal medicines.

Owner:马加友

Milk and tencel fiber denim and production process thereof

InactiveCN104975406AMeet comfort requirementsGood moisture absorption and moisture conductivitySingeingWarping machinesFiberEnvironmentally friendly

The invention provides milk and tencel fiber denim. The milk and tencel fiber denim is characterized in that the blending proportion of milk fiber and tencel fiber is 40:60 by weight. A production process of the milk and tencel fiber denim is characterized in that the production process includes the following steps of spooling, warping, sizing dyeing, drafting, weaving, running repair, singeing and packaging and warehousing. Compared with the prior art, the grade of the denim is enhanced, high technical content is given to traditional denim, the denim is soft, comfortable and smooth in touch feeling like cashmere, the fiber looks white, has natural gloss like silk and is elegant in appearance and the like, and spinnability is excellent; products developed through the process accord with the environmentally-friendly dressing idea of people and meet the fashion demands of people for nature, comfort and beautiful appearance, and the milk and tencel fiber denim and the production process have good market prospects.

Owner:JIANGSU DELIHENG COTTON

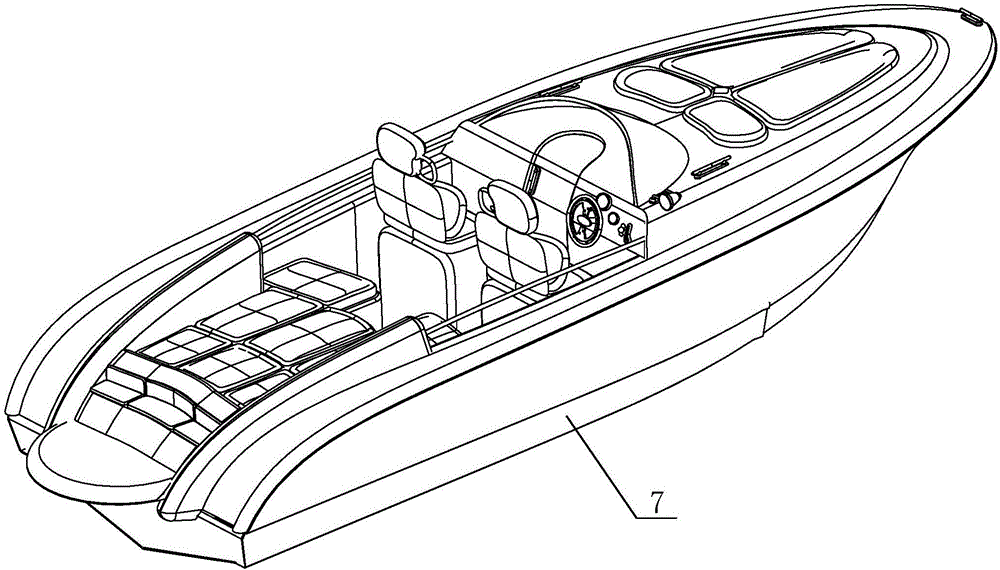

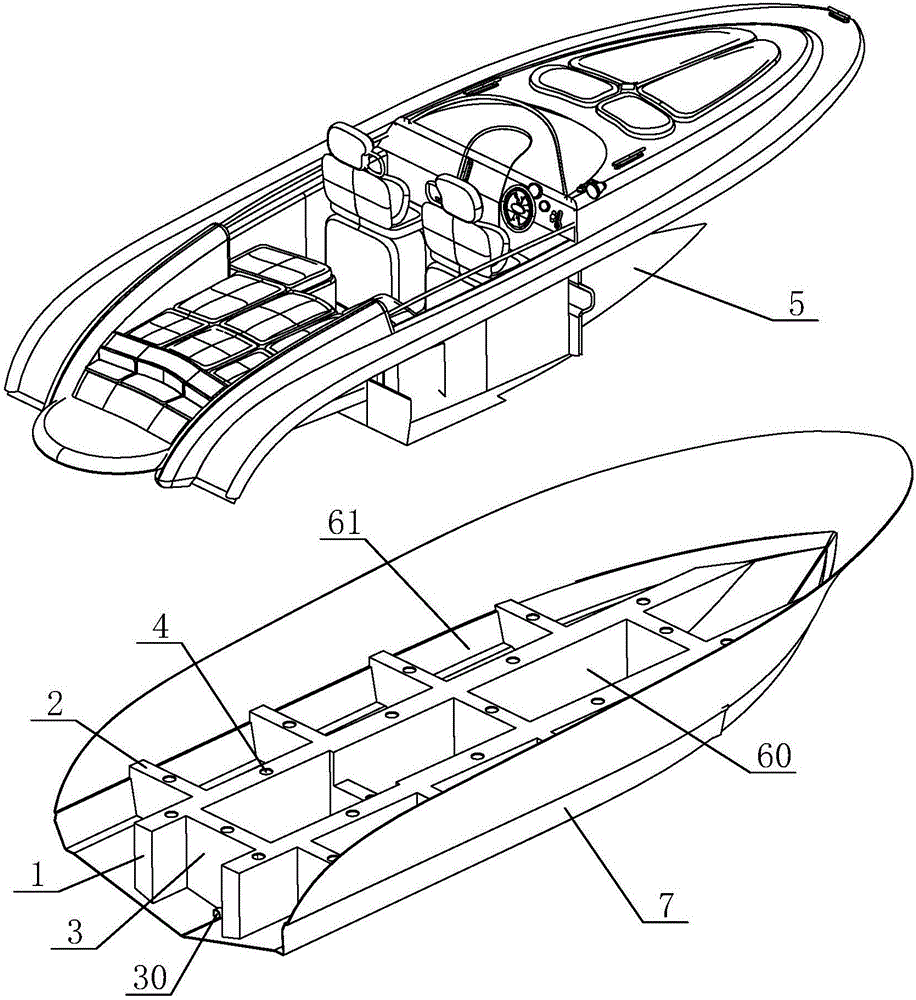

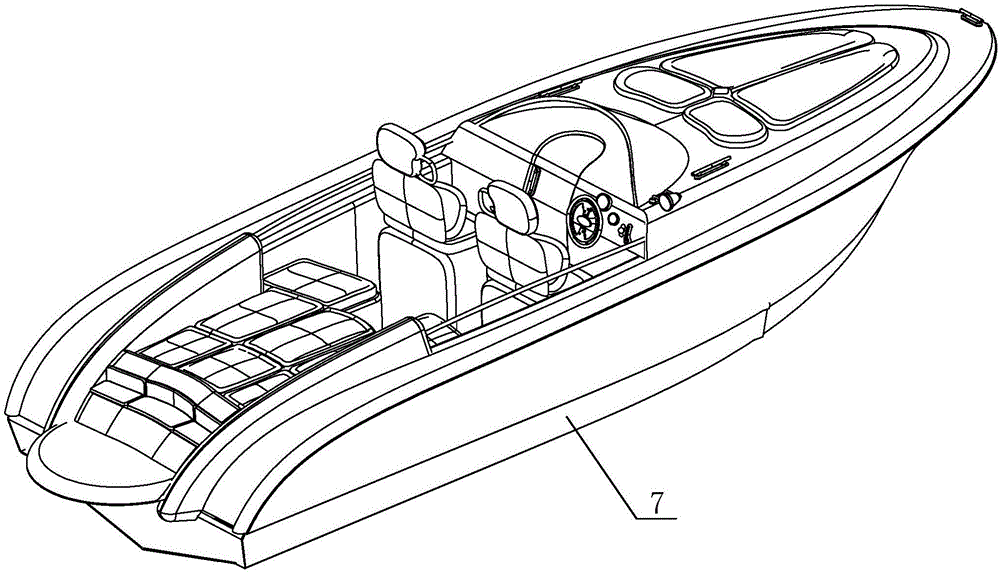

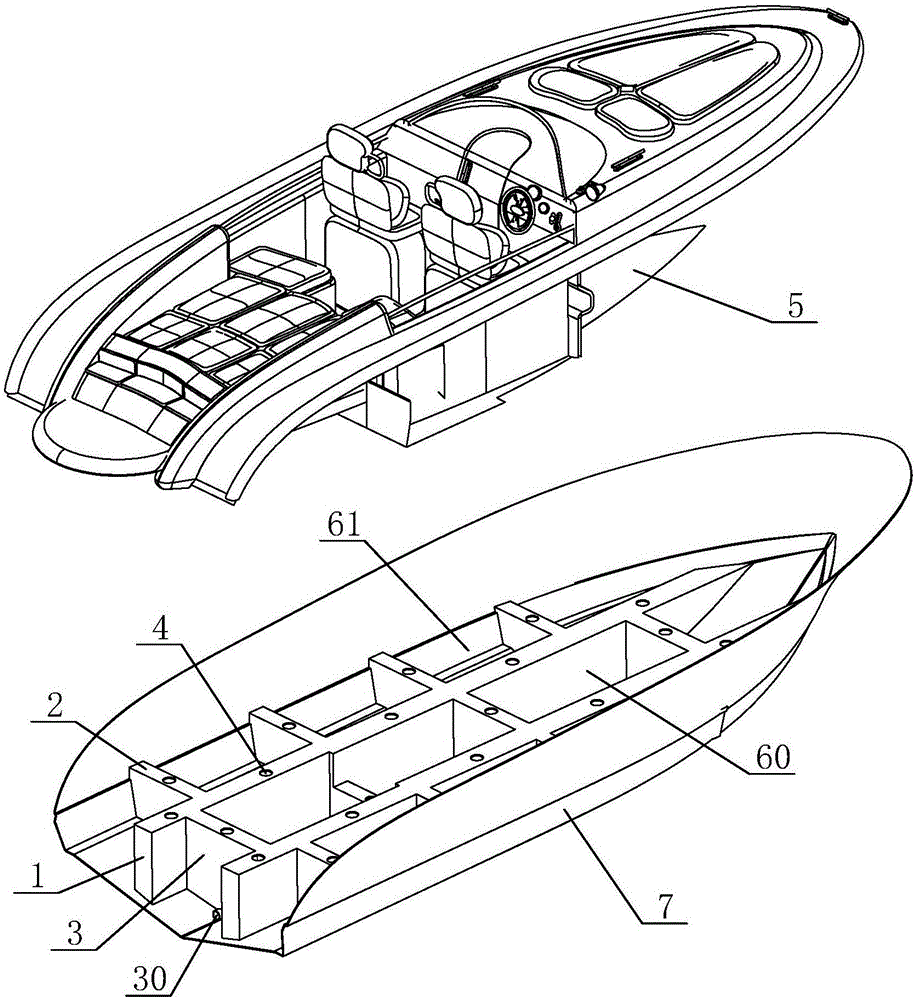

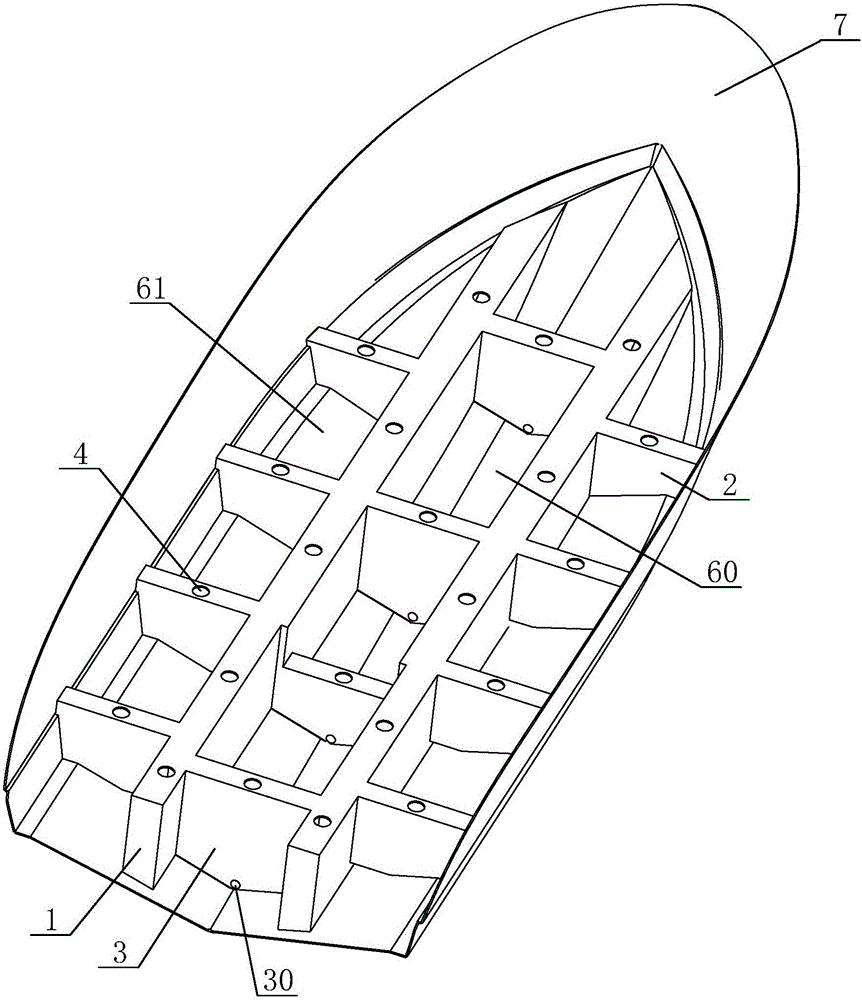

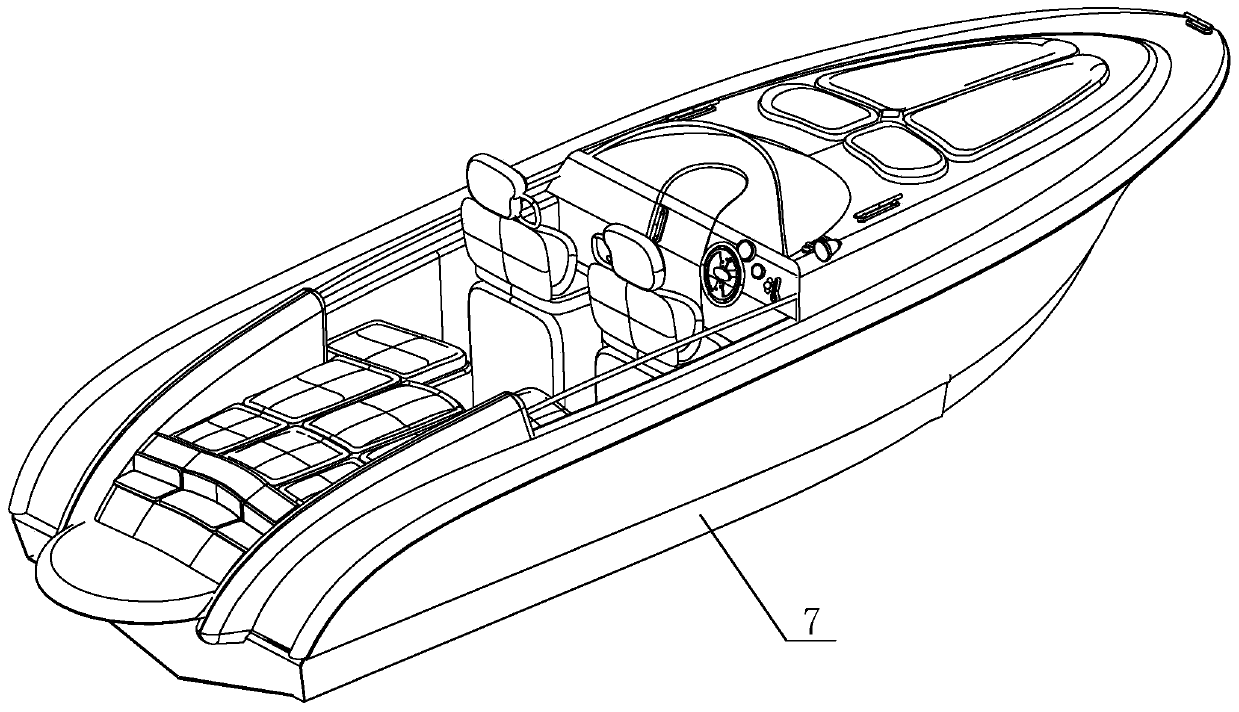

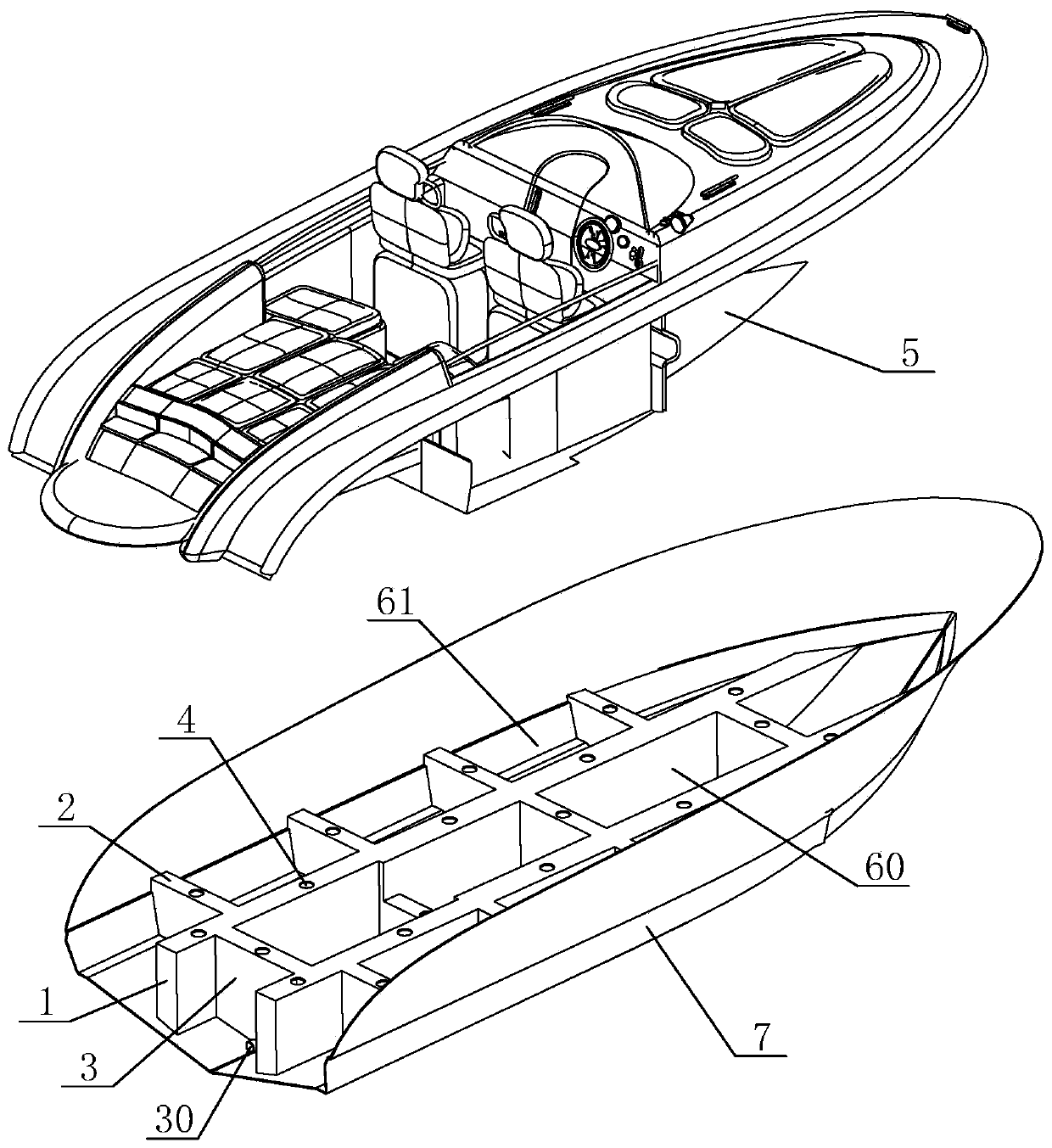

Anti-sedimentation glass fiber reinforced plastic yacht

InactiveCN106697185AGood weather resistanceReduce structural strengthNon-magnetic metal hullsHull keelsGlass fiberWater vapor

The invention discloses an anti-sedimentation glass fiber reinforced plastic yacht which comprises a keel structure, a deck and a hull bottom. The keel structure comprises a plurality of keels and ribs which are integrated into a framework shell, the framework shell is made of hydrophobic hard materials, a cavity is formed in the framework shell and is fully filled with hard foamed plastics, the keel structure is adhered on the inner surface of the hull bottom through structural adhesive, and the deck is fixed above the keel structure to form an anti-sedimentation hull. The hull has the advantages that the keel structure is light and high in strength, hull weight is reduced, safety is improved, corrosion of water vapor for the keel structure can be resisted, service life is prolonged, the hull bottom and the keel structure are firmly bonded through structural adhesive, scattered foamed fillers of the deck can serve as temporary first-aid tools after the hull fractures and replace life buoys, and drowning is avoided.

Owner:浙江澳托美克船业有限公司

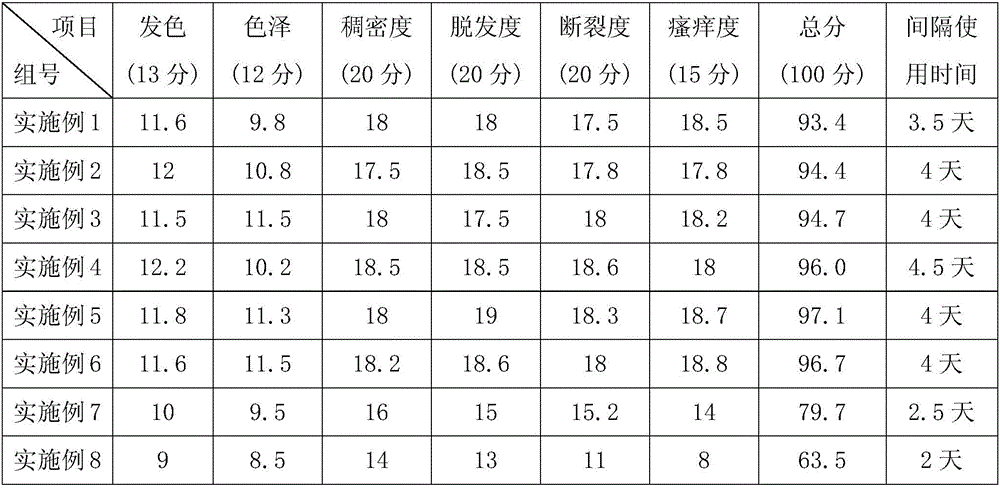

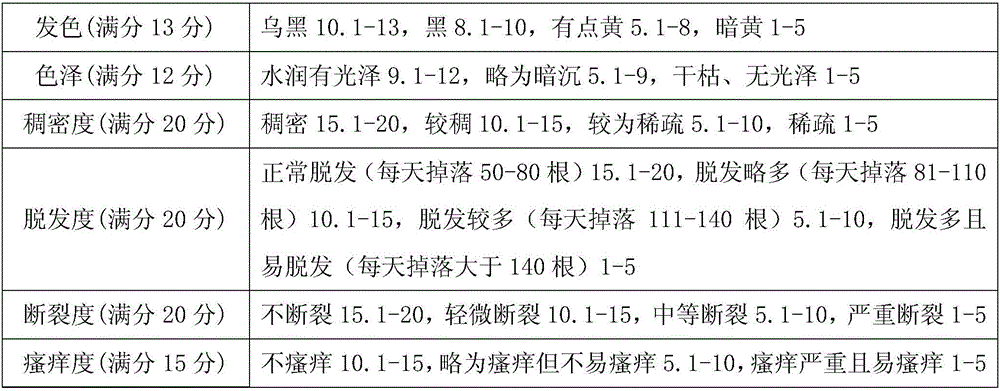

Hair care cosmetics and its manufacturing method

A hair protecting product belonging cosmetics with high hair blackening effect is prepared from 9 Chinese-medicinal materials including biota tops, fleece flower root, Chinese angelica root, ginger, etc.

Owner:田钚

Hair conditioner and preparation method thereof

InactiveCN107737079AHelps healthImprove the environmentCosmetic preparationsHair cosmeticsSide effectMedicine

The invention discloses a hair conditioner and a preparation method thereof. The hair conditioner is prepared from the following substances in parts by weight: fructus ligustri lucidi, liquorice root,aloe, radix polygoni multiflori, pearl powder, old ginger, radix ginseng, peppermint oil, and the rest of water. The invention provides a hair conditioner having obvious hair care effect, high nutrition, natural materials, low cost, safety, and no side effects and the preparation method thereof.

Owner:GUANGXI UNIV FOR NATITIES

High-strength single-body type hanging PVC trough plate

The invention discloses a high-strength single-body type hanging PVC trough plate. The trough plate is prepared from, by weight, 30-60 parts of polyvinyl chloride, 10-20 parts of polyamide, 25-45 parts of polycarbonate, 0.3-0.9 part of di-2,4-dichlorobenzoyl peroxide, 0.3-0.7 part of 2-ethyl-4-methyl imidazole, 1.5-2.5 parts of diethylamino propylamine, 1-2 parts of gamma-(ethylenediamine)propyl methyl dimethoxy silane, 1-2 parts of maleic anhydride, 2-3 parts of butyl titanate, 15-25 parts of ground calcium carbonate, 10-20 parts of graphene, 10-20 parts of mica plate, 14-18 parts of hard clay, 6-12 parts of clay, 0.3-0.7 part of polybenzoate, 0.3-0.9 part of foaming agent, 0.4-1.2 parts of stabilizer, 0.6-1.2 parts of epoxidized soybean oil, 0.6-1.2 parts of disproportionated rosin and 1.5-2.5 parts of magnesium stearate.

Owner:安徽优丽普科技有限公司

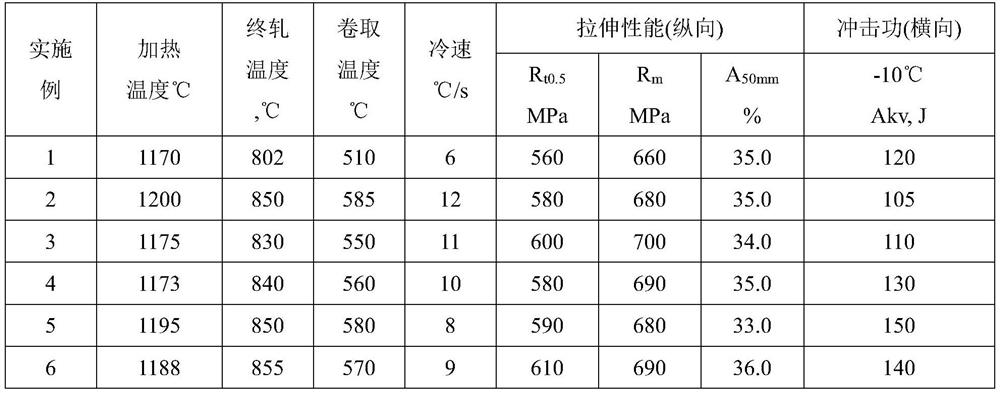

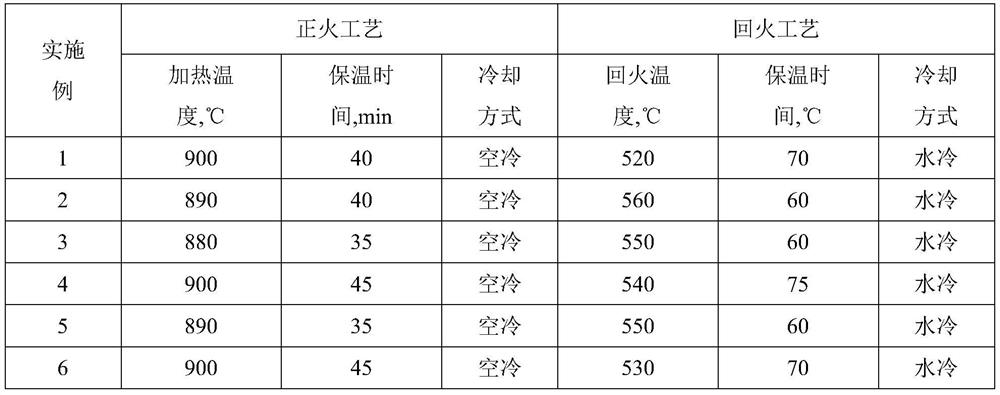

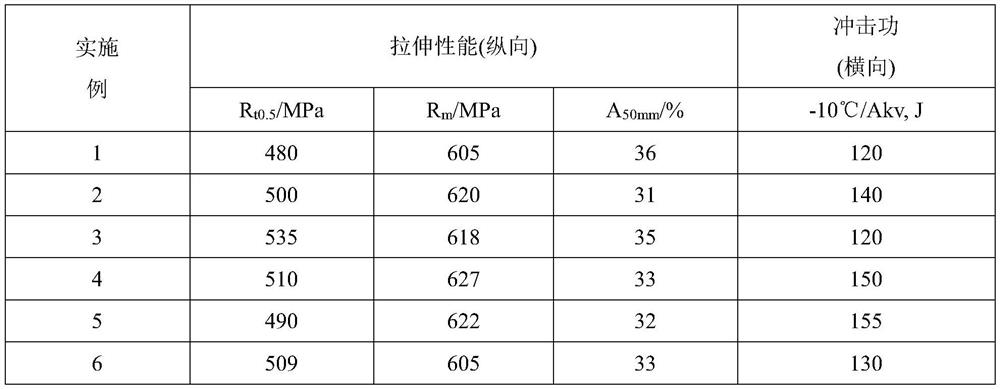

M65-grade electric resistance welding oil casing pipe and manufacturing method thereof

ActiveCN113416894AGuaranteed StrengthImprove impact toughnessDrilling rodsFurnace typesTemperingHeat conservation

The invention relates to the technical field of oil casing pipes, in particular to an M65-grade electric resistance welding oil casing pipe and a manufacturing method thereof. The M65-grade electric resistance welding oil casing pipe comprises the following chemical components in percentage by weight: 0.19%-0.23% of C, 0.15%-0.30% of Si, 1.30%-1.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.008% of S, 0.05%-0.08% of Ti, 0.03%-0.06% of V, 0.02%-0.05% of Als, less than or equal to 0.008% of N and the balance Fe and inevitable elements. The manufacturing method comprises the steps: 1) a smelting continuous casting technology; 2) a rolling process: heating a continuous casting sheet billet to 1150-1200 DEG C by a heating furnace, and then rolling by adopting hot continuous rolling at the final rolling temperature of 800-860 DEG C; 3) cooling a rolled steel strip at the speed of 6-12 DEG C / s, and coiling the steel strip at the temperature of 500-590 DEG C; 4) welding the steel strip into a steel pipe; (5) carrying out heat treatment on the whole steel pipe: after ERW pipe manufacturing, heating the whole pipe to 870-900 DEG C, and carrying out heat preservation for 30-50 min and air cooling; and then tempering the whole pipe, wherrin the tempering temperature is 500-560 DEG C, heat preservation is conducted for 60-80 min, and then water cooling is conducted. The heat treatment process is simplified, it is guaranteed that the steel pipe has better weldability and impact toughness, brittle failure of an oil well pipe can be prevented, and higher safety is achieved.

Owner:ANGANG STEEL CO LTD

Tea bran soap and preparation method thereof

InactiveCN106167747AImprove sustainabilityImprove efficacySoap detergents with organic compounding agentsHair cosmeticsHerbAnti inflammation

The invention provides a kind of tea dead soap and a preparation method thereof, which belong to the field of washing. The tea dead soap uses tea dead and rice as the main raw materials, takes vegetable oil as the carrier, and adds glycerin, mugwort leaf extract, horsetail paste, rose twig and white perilla oil and other Chinese herbal medicines, so that the prepared tea withered soap has the effects of penetrating anti-inflammatory, sterilizing, antipruritic, anti-hair loss, hair care, hair growth, black hair and decontamination, and can improve the efficacy of tea withered soap continuity. The preparation method is simple, without any chemical additives, and has high safety.

Owner:杨秀元

Manufacturing process of anti-sinking fiberglass boat

ActiveCN106585873BGood weather resistanceReduce structural strengthNon-magnetic metal hullsVessel partsGlass fiberFiber

The invention discloses a manufacturing process for an anti-sinking fiber reinforced plastic ship. The process comprises a series of process steps of mold treatment, ship bottom pasting, ship bottom molding, ship bottom material injection, ship bottom demolding, keel mounting, keel packing, ship bottom side edge packing, ship bottom cleaning, deck mounting and ship part assembling. The ship manufactured through the process has the following advantages that firstly, a keel structure is low in weight and high in strength, the safety is improved while the weight of a ship body is lowered; secondly, corrosion of moisture to the keel structure can be resisted, and the service life is prolonged; and thirdly, due to the fact that a ship bottom and the keel structure are bound firmly through a structural adhesive, decks with foaming fillers can be used as temporary first-aid tools after the ship body is fractured and scattered and replace life rings, and persons falling into water are prevented from drowning.

Owner:山东双一游艇有限公司

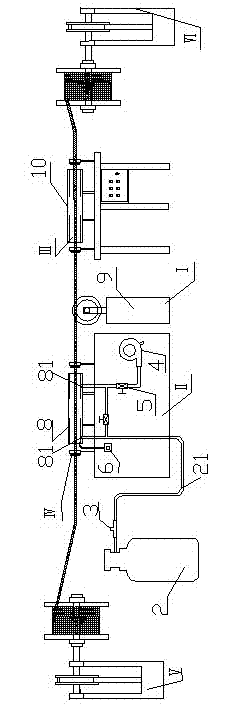

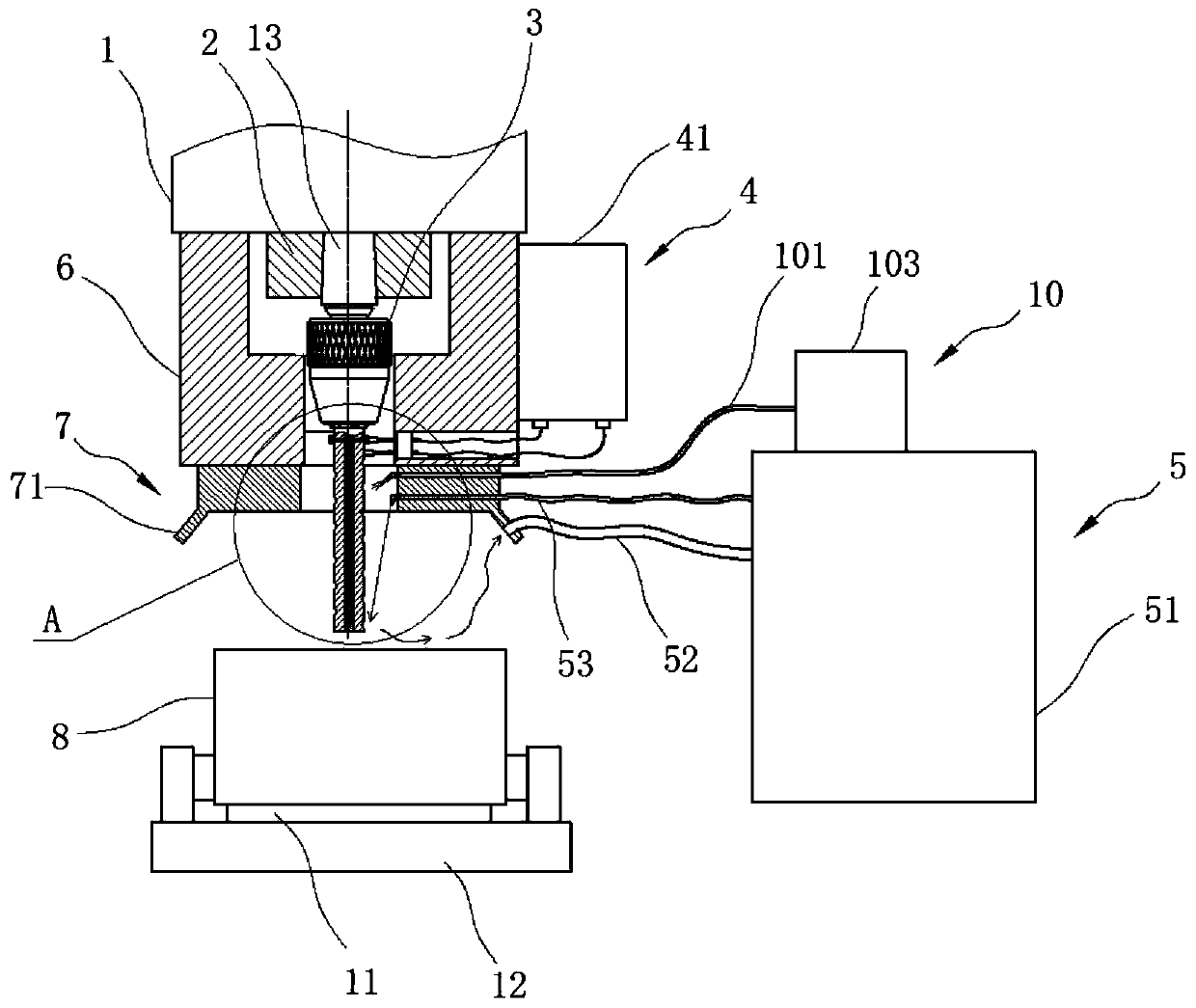

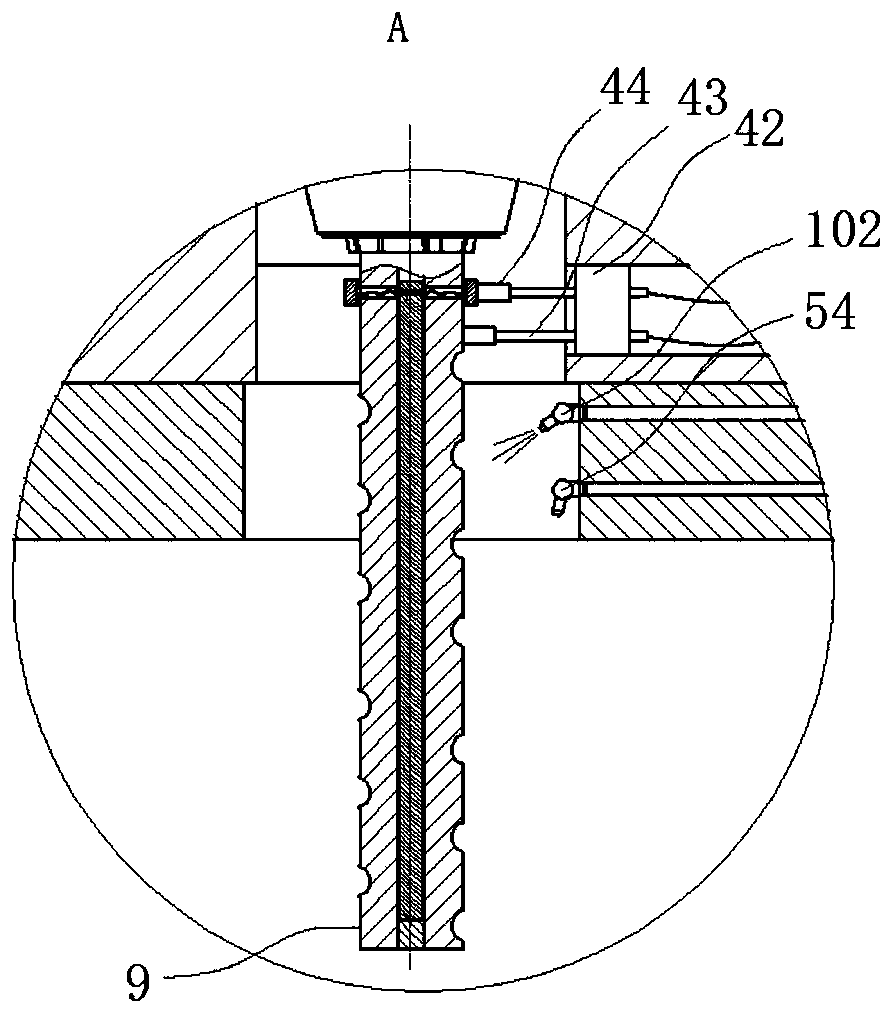

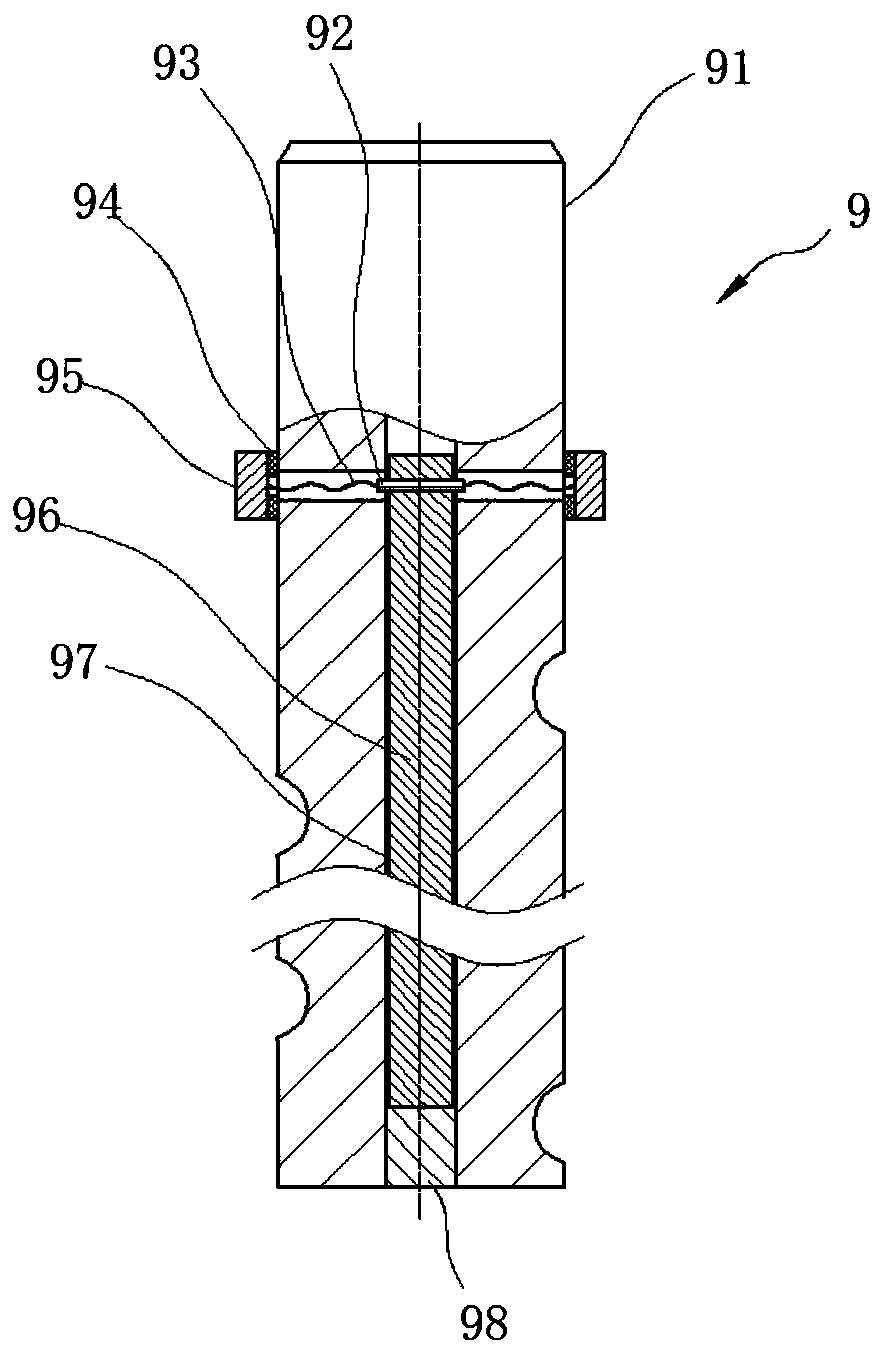

Low-energy-consumption long-service-life liquid nitrogen cooling machining device

PendingCN111002099AReduce energy consumptionExtended service lifeMilling cuttersMilling equipment detailsMilling cutterLiquid nitrogen cooling

The invention relates to the technical field of metal cutting machining, in particular to a low-energy-consumption long-service-life liquid nitrogen cooling machining device. In the case of current liquid nitrogen cutting, local low temperature can be generated on a cutter, so that brittle fracture is caused, the service life of the cutter is relatively short, and the production cost is increased;and meanwhile, liquid nitrogen is rapidly vaporized after being sprayed, and then is dissipated into an external environment, so that the nitrogen loss is relatively large, and the energy consumptionof liquid nitrogen preparation is relatively high. According to the low-energy-consumption long-service-life liquid nitrogen cooling machining device, a liquid nitrogen spraying device is arranged onone side of a machine tool spindle seat and is connected with a collection disc to spray the liquid nitrogen to the lower end of a milling cutter assembly and recover nitrogen at the same time, a heating assembly is arranged in an inner hole of the milling cutter assembly, the heating assembly communicates with a power supply device for heating so that the nitrogen with the relatively low temperature can be recovered by the liquid nitrogen spraying device, the milling cutter assembly can be heated to prevent the brittle fracture, then the service life of the cutter is effectively prolonged, and the energy consumption of the liquid nitrogen preparation is reduced. The low-energy-consumption long-service-life liquid nitrogen cooling machining device is mainly used in the field of liquid nitrogen cooling machining devices.

Owner:付炜亮

Feed with function of promoting absorption of antelopes

InactiveCN106721170AMeet the nutritional requirements for growthPromote digestion and absorptionAnimal feeding stuffAccessory food factorsAnimal sciencePhytase

The invention discloses feed with a function of promoting absorption of antelopes. The feed is prepared from raw materials in parts by weight as follows: 10-16 parts of sunflower seed meal, 5-10 parts of fish meal, 6-18 parts of earthworm powder, 20-40 parts of carrot meal, 6-12 parts of oat bran, 8-14 parts of potato powder, 6-14 parts of radish leaves, 4-10 parts of water hyacinth, 8-18 parts of shrimp head powder, 9-13 parts of oyster powder, 1-2 parts of monocalcium phosphate, 2-4 parts of montmorillonite, 2-4 parts of soybean protein powder, 2-4 parts of choline chloride, 1-2 parts of glycine betaine, 2-4 parts of soybean phospholipid oil, 4-8 parts of glutamic acid modified gelatin, 0.03-0.07 parts of high-temperature-resistant phytase, 1.5-2.5 parts of multivitamins and 3-6 parts of Chinese herbal medicine. The feed is low in raw material cost and has overall and balanced nutrition, digestive absorption of the antelopes is good, the antelopes grow fast, and nutritional requirements of antelope growth can be met.

Owner:马加友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com